IBM IC35L036UCDY10, Ultrastar 146Z10, IC35L036UWDY10, IC35L073UWDY10, IC35L073UCDY10 Specifications

...Page 1

IBM storage products

Hard disk drive specifications

Ultrastar 146Z10

3.5 inch SCSI hard disk drive

ibm

ibm

ibmibm

Models:

Revision 2.2 02 February 2002

IC35L018UWDY10

IC35L018UCDY10

IC35L036UWDY10

IC35L036UCDY10

IC35L073UWDY10

IC35L073UCDY10

IC35L146UWDY10

IC35L146UCDY10

S07N9742-03 Publication number 3630

Page 2

This page intentionally left blank.

Page 3

IBM storage products

Hard disk drive specifications

Ultrastar 146Z10

3.5 inch SCSI hard disk drive

ibm

ibm

ibmibm

Models:

Revision 2.2 02 February 2002

IC35L018UWDY10

IC35L018UCDY10

IC35L036UWDY10

IC35L036UCDY10

IC35L073UWDY10

IC35L073UCDY10

IC35L146UWDY10

IC35L146UCDY10

S07N9742-03 Publication number 3630

Page 4

1st Edition (Rev. 2.0) S07N9742-01 (31 January 2002)

2nd Edition (Rev. 2.1) S07N9742-02 (01 February 2002)

3rd Edition (Rev. 2.2) S07N9742-03 (02 February 2002)

The following paragraph does not apply to the United Kingdom or any country where such provisions are

inconsistent with local law: INTERNATIONAL BUSINESS MACHINES CORPORATION PROVIDES THIS

PUBLICATION “AS IS” WITHOUT WARRANTY OF ANY KIND, EI THER EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS

FOR A PARTICULAR PURPOSE. Some states do not allow disclaimer or express or implied warranties in certain

transactions, therefore, this statement may not apply to you.

This publication could include technical inaccuracies or typographical errors. Changes are periodically made to the

information herein; these changes will be incorporated in new editions of the publication. IBM may make improvements and/or changes in the product(s) and/or the program(s) described in this publication at any time.

It is possible that this publication may contain reference to, or information about, IBM products (machines and

programs), programming, or services that are not announced in your country. Such references or information must

not be construed to mean that IBM intends to announce such IBM products, programming, or services in your

country.

Technical information about this product is available by contacting your local IBM representative or the following:

Internet: http://www.ibm.com/harddrive

IBM may have patents or pending patent applications covering subject matter in this document. The furnishing of

this document does not give you any license to these patents. You can send license inquiries, in writing, to the IBM

Director of Commercial Relations, IBM Corporation, Armonk, NY 10577.

©Copyright International Business Machines Corporation 2002. All rights reserved.

Note to U.S. Government Users —Documentation related to restricted rights —Use, duplication or disclosure is

subject to restrictions set forth in GSA ADP Schedule Contract with IBM Corp.

Page 5

Table of contents

ixFigures ...........................................................................

11.0 General .......................................................................

11.1 Introduction ....................................................................

11.2 Glossary .......................................................................

21.3 General caution .................................................................

32.0 Outline of the drive .............................................................

5Part 1. Functional specification .....................................................

73.0 Fixed disk subsystem description ...............................................

73.1 Control electronics ..............................................................

73.2 Head disk assembly .............................................................

73.3 Actuator .......................................................................

94.0 Drive characteristics ...........................................................

94.1 Formatted capacity ..............................................................

94.2 Data sheet .....................................................................

104.3 Inquiry Information .............................................................

104.3.1 Product ID ...............................................................

104.3.2 World Wide ID - Block assignment ...........................................

114.4 Cylinder allocation ..............................................................

124.5 Performance characteristics .....................................................

124.5.1 Command overhead .......................................................

134.5.2 Mechanical positioning .....................................................

144.5.3 Drive ready time ..........................................................

144.5.4 Spindle stop time .........................................................

154.5.5 Data transfer speed .......................................................

154.5.6 Buffering operation (read ahead/write cache) .................................

164.5.7 Throughput ..............................................................

175.0 Data integrity .................................................................

175.1 Equipment status ..............................................................

175.2 Error recovery procedure ........................................................

196.0 Physical format ...............................................................

196.1 Shipped format (P-List) .........................................................

196.2 Reassigned format (G-List) ......................................................

217.0 Specification .................................................................

217.1 Electrical interface specification ..................................................

217.1.1 Power connector ..........................................................

227.1.2 SCSI bus connector .......................................................

247.1.3 SCSI cable ...............................................................

247.1.4 SCSI bus terminator .......................................................

247.1.5 Hot plug/unplug ...........................................................

247.1.6 SCSI bus electrical characteristics ...........................................

257.1.7 Auxiliary connector on 68-pin model .........................................

267.2 Option jumper block ............................................................

277.2.1 Jumper signal description on J6 .............................................

287.2.2 Jumper signal description on J4 .............................................

307.3 Environment ...................................................................

307.3.1 Corrosion test ............................................................

317.4 Cooling requirements ...........................................................

327.5 DC power requirements .........................................................

327.5.1 Input voltage .............................................................

Ultrastar 146Z10 hard disk drive specifications

iii

Page 6

Ultrastar 146Z10 hard disk drive specifications

iv

327.5.2 Power supply current ......................................................

337.5.3 Ripple voltage ............................................................

337.5.4 Power consumption efficiency index .........................................

347.6 Reliability .....................................................................

347.6.1 Start/stop cycles ..........................................................

347.6.2 Data reliability ............................................................

347.6.3 Seek/ID miscompare errors ................................................

347.6.4 Equipment errors .........................................................

347.6.5 Failure prediction (PFA/S.M.A.R.T.) .........................................

347.6.6 Preventive maintenance ...................................................

357.6.7 Temperature Warning .....................................................

367.7 Mechanical specifications .......................................................

367.7.1 Outline ..................................................................

377.7.2 Mechanical dimensions ....................................................

387.7.3 Interface connector ........................................................

397.7.4 Mounting positions and tappings ............................................

407.7.5 Heads unload and actuator lock .............................................

407.7.6 Breather hole .............................................................

417.8 Vibration and shock ............................................................

417.8.1 Operating vibration ........................................................

417.8.2 Non-operating vibrations ...................................................

427.8.3 Operating shock ..........................................................

427.8.4 Non-operating shock ......................................................

437.9 Acoustics .....................................................................

447.10 Identification labels ............................................................

457.11 Electromagnetic compatibility ...................................................

457.11.1 CE Mark ................................................................

457.11.2 C-Tick Mark .............................................................

457.11.3 BSMI Mark ..............................................................

467.12 Safety .......................................................................

467.12.1 UL and CSA standard conformity ..........................................

467.12.2 European Standards Compliance ..........................................

467.12.3 German Safety Mark .....................................................

467.12.4 Flammability ............................................................

47Part 2. Interface specification .....................................................

498.0 SCSI Command Set ...........................................................

508.1 SCSI Control Byte ..............................................................

508.2 Abbreviations ..................................................................

508.3 Byte ordering conventions .......................................................

518.4 FORMAT UNIT (04h) ...........................................................

528.4.1 Defect list ................................................................

538.4.2 Defect descriptor .........................................................

558.5 INQUIRY (12h) ................................................................

578.5.1 Inquiry DATA .............................................................

648.6 LOG SELECT (4Ch) ............................................................

658.7 LOG SENSE (4Dh) .............................................................

668.7.1 Log Page parameters .....................................................

678.7.2 Log Sense Page 0 ........................................................

688.7.3 Log Sense Page 2 ........................................................

708.7.4 Log Sense Page 3 ........................................................

728.7.5 Log Sense Page 5 ........................................................

738.7.6 Log Sense Page 6 ........................................................

748.7.7 Log Sense Page D ........................................................

758.7.8 Log Sense Page E ........................................................

Page 7

768.7.9 Log Sense Page F ........................................................

778.7.10 Log Sense Page 10 ......................................................

798.7.11 Log Sense Page 2F ......................................................

808.8 MODE SENSE (6) (1A) .........................................................

818.8.1 Mode Parameter List ......................................................

858.8.2 Mode Page 0 (Vendor Unique Parameters) ...................................

888.8.3 Mode Page 1 (Read/Write Error Recovery Parameters) ........................

928.8.4 Mode Page 2 (Disconnect/Reconnect Parameters) ............................

948.8.5 Mode Page 3 (Format Device Parameters) ...................................

968.8.6 Mode Page 4 (Rigid Disk Drive Geometry Parameters) .........................

978.8.7 Mode Page 7 (Verify Error Recovery Parameters) .............................

988.8.8 Mode Page 8 (Caching Parameters) .........................................

1008.8.9 Mode Page A (Control Mode Page Parameters) ..............................

1028.8.10 Mode Page 0C (Notch Parameters) .......................................

1048.8.11 Mode Page 19 (Port Control) .............................................

1108.8.12 Mode Page 1A (Power Control Parameters) ................................

1118.8.13 Mode Page 1C (Informational Exceptions Control) ...........................

1138.9 MODE SENSE (10) (5Ah) ......................................................

1148.10 MODE SELECT (6) (15h) .....................................................

1158.11 MODE SELECT (10) (55h) ....................................................

1168.12 PERSISTENT RESERVE IN (5Eh) .............................................

1168.12.1 Service Action ..........................................................

1178.12.2 Parameter data for Read Keys ............................................

1178.12.3 Parameter data for Read Reservations .....................................

1188.12.4 Parameter data for Read Reservation Descriptor ............................

1198.13 PERSISTENT RESERVE OUT (5Fh) ...........................................

1208.13.1 Service Action .........................................................

1228.13.2 Scope .................................................................

1228.13.3 Type ..................................................................

1248.13.4 Parameter list ..........................................................

1248.13.5 Summary ..............................................................

1268.14 PRE-FETCH (34h) ...........................................................

1278.15 READ (6) (08h) ..............................................................

1288.16 READ (10) (28h) .............................................................

1298.17 READ BUFFER (ACH) ........................................................

1308.17.1 Combined Header And Data (Mode 0000b) .................................

1308.17.2 Read Data (Mode 0010b) ................................................

1308.17.3 Descriptor (Mode 0011b) ................................................

1318.17.4 Read Data from Echo Buffer (Mode 1010b) .................................

1318.17.5 Echo Buffer Descriptor (Mode 1011b) ......................................

1328.18 READ CAPACITY (25h) .......................................................

1348.19 READ DEFECT DATA (10) (37h) ...............................................

1358.19.1 Defect List Header ......................................................

1358.19.2 Bytes from Index Format (100b) ..........................................

1368.19.3 Physical Sector Format (101b) ............................................

1378.20 READ DEFECT DATA (12) (B7h) ..............................................

1388.20.1 Defect List Header ......................................................

1388.20.2 Bytes from Index Format (100b) ..........................................

1398.20.3 Physical Sector Format (101b) ............................................

1408.21 READ LONG (3Eh) ...........................................................

1418.22 REASSIGN BLOCKS (07h) ....................................................

1438.23 RECEIVE DIAGNOSTICS RESULTS (1Ch) ......................................

1438.23.1 Receive Diagnostic Results Page 0 ........................................

Ultrastar 146Z10 hard disk drive specifications

v

Page 8

1448.23.2 Receive Diagnostic Results Page 40 ......................................

1458.23.3 Receive Diagnostic Results Page 80 ......................................

1468.24 RELEASE (6) (17h) ..........................................................

1478.25 RELEASE (10) (57h) .........................................................

1488.26 REPORT DEVICE IDENTIFIER (A3h) ...........................................

1508.27 REPORT LUN (A0h) .........................................................

1518.28 REQUEST SENSE (03h) ......................................................

1528.29 RESERVE (6) (16h) ..........................................................

1538.30 RESERVE (10) (56h) .........................................................

1548.31 REZERO UNIT (01h) .........................................................

1558.32 SEEK (6) (0Bh) ..............................................................

1568.33 SEEK EXTENDED (10) (2Bh) ..................................................

1578.34 SEND DIAGNOSTIC (1Dh) ....................................................

1598.34.1 Send Diagnostic Page 0 .................................................

1598.34.2 Send Diagnostic Page 40 ................................................

1608.34.3 Send Diagnostic Page 80 ................................................

1618.35 SET DEVICE IDENTIFIER (A4h) ...............................................

1628.36 START STOP Unit (1Bh) ......................................................

1638.37 SYNCHRONIZE CACHE (35h) .................................................

1648.38 TEST UNIT READY (00h) .....................................................

1658.39 VERIFY (2Fh) ...............................................................

1668.40 WRITE (6) (0Ah) .............................................................

1678.41 WRITE (10) (2Ah) ............................................................

1688.42 WRITE AND VERIFY (2Eh) ...................................................

1698.43 WRITE BUFFER (3Bh) .......................................................

1708.43.1 Combined Header And Data (Mode 0000b) .................................

1708.43.2 Write Data (Mode 0010b) ................................................

1718.43.3 Download Microcode (Mode 0100b) .......................................

1718.43.4 Download Microcode and Save (Mode 0101b) ..............................

1728.43.5 Download Microcode and Save (Mode 0111b) ..............................

1728.43.6 Write Data to Echo Buffer (Mode 1010b) ...................................

1738.44 WRITE LONG (3Fh) ..........................................................

1748.45 WRITE SAME (41h) ..........................................................

1759.0 SCSI Status Byte .............................................................

17710.0 SCSI Message System .......................................................

17710.1 Supported Messages .........................................................

17810.1.1 TASK COMPLETE (00h) .................................................

17810.1.2 SYNCHRONOUS DATA TRANSFER REQUEST (010301H) ..................

18110.1.3 WIDE DATA TRANSFER REQUEST (010203H) ............................

18310.1.4 PARALLEL PROTOCOL REQUEST (01,06,04H) ............................

18510.1.5 SAVE DATA POINTER (02h) .............................................

18510.1.6 RESTORE POINTERS (03h) .............................................

18510.1.7 DISCONNECT (04h) ....................................................

18510.1.8 INITIATOR DETECTED ERROR (05h) .....................................

18610.1.9 ABORT (06h) ..........................................................

18610.1.10 MESSAGE REJECT (07h) ..............................................

18610.1.11 NO OPERATION (08h) .................................................

18610.1.12 MESSAGE PARITY ERROR (09h) .......................................

18610.1.13 LINKED COMMAND COMPLETE (0Ah) ..................................

18710.1.14 LINKED COMMAND COMPLETE WITH FLAG (0Bh) .......................

18710.1.15 TARGET RESET (0Ch) .................................................

18710.1.16 ABORT TAG (0Dh) ....................................................

18710.1.17 CLEAR QUEUE TAG (0Eh) .............................................

Ultrastar 146Z10 hard disk drive specifications

vi

Page 9

18710.1.18 QUEUE TAG MESSAGES (20xxh, 21xxh, 22xxh) ..........................

18810.1.19 IGNORE WIDE RESIDUE (2301h) .......................................

18810.1.20 IDENTIFY (80 - FFh) ...................................................

18910.2 Supported Message Functions .................................................

19010.3 Attention Condition ...........................................................

19110.4 SCSI Bus Related Error Handling Protocol .......................................

19110.4.1 Unexpected BUS FREE Phase Error Condition .............................

19110.4.2 MESSAGE OUT Phase Parity Error .......................................

19110.4.3 MESSAGE IN Phase Parity Error (Message Parity Error) .....................

19110.4.4 COMMAND Phase Parity Error ...........................................

19110.4.5 DATA OUT Phase Parity Error ............................................

19210.4.6 INITIATOR DETECTED ERROR Message .................................

19210.4.7 MESSAGE REJECT Message ............................................

19311.0 Additional information ......................................................

19311.1 SCSI Protocol ...............................................................

19311.1.1 Priority of SCSI Status Byte Reporting .....................................

19411.1.2 Invalid LUN in Identify Message ...........................................

19411.1.3 Incorrect Initiator Connection .............................................

19411.1.4 Command Processing during execution of active I/O process .................

19611.1.5 Unit Attention Condition ..................................................

19711.1.6 Command Processing During Startup and Format Operations .................

19711.1.7 Deferred Error ..........................................................

19711.1.8 Degraded Mode ........................................................

20311.1.9 Command processing while reserved ......................................

20411.2 Priority commands ...........................................................

20411.3 Command queuing ...........................................................

20511.3.1 Queue depth ...........................................................

20511.3.2 Tagged queuing ........................................................

20511.3.3 Untagged queuing ......................................................

20511.3.4 Command queuing rule ..................................................

20511.3.5 Queue Full status .......................................................

20511.3.6 Device behavior on Command queuing ....................................

20611.4 Command reordering .........................................................

20611.5 Concurrent I/O Process .......................................................

20611.6 Back to Back Write ...........................................................

20711.7 Write Cache .................................................................

20711.8 Automatic Defect Reallocation .................................................

20811.9 Segmented Caching ..........................................................

20811.10 Reselection Timeout ........................................................

20811.11 Single Initiator Selection .....................................................

20811.12 Non-arbitrating systems ......................................................

20811.13 Selection without ATN .......................................................

20911.14 Multiple Initiator Environment .................................................

20911.14.1 Initiator Sense Data ....................................................

20911.14.2 Initiator Mode Select/Mode Sense Parameters .............................

20911.14.3 Initiator Data Transfer Mode Parameter ...................................

20911.15 Contingent Allegiance Condition ..............................................

21011.16 Reset .....................................................................

21011.16.1 Reset Sources ........................................................

21011.16.2 Power On Reset .......................................................

21111.16.3 SCSI Bus Reset and TARGET RESET Message ...........................

21111.16.4 Self-initiated Reset .....................................................

21211.17 Diagnostics ................................................................

Ultrastar 146Z10 hard disk drive specifications

vii

Page 10

21211.17.1 Power on Diagnostics ..................................................

21211.17.2 Self-test by Send Diagnostic Command ...................................

21411.18 Idle Time Function ..........................................................

21411.19 Information Unit Support .....................................................

21512.0 SCSI Sense Data ............................................................

21512.1 SCSI Sense Data Format .....................................................

21612.2 Sense Data Description .......................................................

21612.2.1 Valid (Bit 7 of byte 0) ....................................................

21612.2.2 Error Code (Bit 6 - 0 of byte 0) ............................................

21612.2.3 ILI: Incorrect Length Indicator (Bit 5 of byte 2) ...............................

21612.2.4 Sense Key (Bit 3 - 0 of byte 2) ............................................

21712.2.5 Information Bytes (Byte 3 through 6) .......................................

21712.2.6 Additional Sense Length (Byte 7) ..........................................

21712.2.7 Command Specific Information (Byte 8 through 11) ..........................

21812.2.8 Additional Sense Code/Qualifier (Byte 12 and 13) ...........................

22212.2.9 FRU : Field Replaceable Unit (Byte 14) ....................................

22212.2.10 Sense Key Specific (Byte 15 through 17) ..................................

22412.2.11 Vendor Unique Error Information (Byte 18 through 19) ......................

22512.2.12 Vendor unique error information (Byte 20 through 23) .......................

23012.2.13 Physical Error Record (Byte 24 thru 29) ...................................

23012.2.14 Reserved (Byte 30 through 31) ..........................................

231Index ...........................................................................

Ultrastar 146Z10 hard disk drive specifications

viii

Page 11

Figures

Figure 19. Table of signals

..........................................................

9Figure 1. Formatted capacity .........................................................

9Figure 2. Data sheet ................................................................

10Figure 3. Product ID in Inquiry Command .............................................

10Figure 4. Block assignment of World Wide ID in Inquiry Command ........................

11Figure 5. Cylinder allocation .........................................................

12Figure 6. Command overhead .......................................................

13Figure 7. Mechanical positioning performance .........................................

13Figure 8. Full stroke seek time ......................................................

14Figure 9. Cylinder Skew ............................................................

14Figure 10. Head skew ..............................................................

14Figure 11. Latency time ............................................................

14Figure 12. Drive ready time .........................................................

14Figure 13. Spindle stop time ........................................................

15Figure 14. Data transfer speed (sector size 512 bytes case) .............................

16Figure 15. Simple sequential access performance (sector size 512 byte case) .............

16Figure 16. Random access performance (sector size 512 bytes case) ....................

19Figure 17. P-List physical format ....................................................

21Figure 18. Power connector pin assignments ..........................................

22

23Figure 20. Table of signals ..........................................................

25Figure 21. Auxiliary connector .......................................................

26Figure 22. Jumper pins .............................................................

27Figure 23. Auto Start Delay & Delay Start 6/12 drive behavior ............................

28Figure 24. LED circuit ..............................................................

29Figure 25. SCSI device ID ..........................................................

30Figure 26. Operating and non-operating conditions .....................................

30Figure 27. Temperature and relative humidity ..........................................

31Figure 28. Maximum allowable module surface temperature .............................

31Figure 29. Module location ..........................................................

32Figure 30. Input voltage ............................................................

32Figure 31. Power supply current of 146-GB models ....................................

32Figure 32. Power supply current of 73-GB models ......................................

33Figure 32. Power supply current of 36-GB models ......................................

33Figure 33. Power supply current of 18-GB models ......................................

33Figure 34. Power supply generated ripple at drive power connector .......................

33Figure 35. Power consumption efficiency index ........................................

36Figure 36. Outline of the 68-pin model ................................................

36Figure 37. Outline of the 80-pin model ................................................

37Figure 38. Physical dimensions ......................................................

37Figure 39. Mechanical dimensions ...................................................

38Figure 40. Interface connector for 68-pin models .......................................

38Figure 41. Interface connector for 80-pin models .......................................

39Figure 42. Mounting positions and tappings ...........................................

40Figure 43. Breather hole location ....................................................

41Figure 44. Random vibration PSD profile breakpoints (operating) .........................

41Figure 45. Random vibration PSD profile breakpoints (non-operating) .....................

43Figure 46. A-weighted sound power levels ............................................

44Figure 47. Interface definition mark, SCSI LVD/SE multimode ............................

49Figure 48. Supported SCSI commands ...............................................

50Figure 49. SCSI Control Byte ........................................................

Ultrastar 146Z10 hard disk drive specifications

ix

Page 12

51Figure 50. FORMAT UNIT (04h) .....................................................

52Figure 51. Format of Defect List Header ...............................................

53Figure 52. Defect descriptor - Block format. ...........................................

54Figure 53. Defect descriptor - Bytes from Index format. .................................

54Figure 54. Defect descriptor - Physical Sector format. ..................................

55Figure 55. INQUIRY (12) ............................................................

56Figure 56. Page code descriptions ....................................................

57Figure 57. INQUIRY Data - CmdDt = 0EVPD = 0 .......................................

59Figure 58. Command support data format .............................................

60Figure 59. SUPPORT values and meanings ...........................................

61Figure 60. INQUIRY DATA - EVPD = 1 (Page Code = 00) ...............................

62Figure 61. INQUIRY DATA - EVPD = 1 (Page Code = 80h) ..............................

63Figure 62. INQUIRY DATA - EVPD = 1 (Page Code = 83h) ..............................

64Figure 63. LOG SELECT (4C) .......................................................

65Figure 64. LOG SENSE .............................................................

67Figure 65. Log Sense Page 0 ........................................................

68Figure 66. Log Sense Page 2 (part 1 of 2) .............................................

69Figure 67. Log Sense Page 2 (part 2 of 2) .............................................

70Figure 68. Log Sense Page 3 (part 1 of 2) .............................................

71Figure 69. Log Sense Page 3 (part 2 of 2) .............................................

72Figure 70. Log Sense Page 5 (part 1 of 2) .............................................

73Figure 71. Log Sense Page 5 (part 2 0f 2) .............................................

73Figure 72. Log Sense Page 6 ........................................................

74Figure 73. Log Sense Page D ........................................................

75Figure 74. Log Sense Page E ........................................................

76Figure 75. Log Sense Page F Application Client Log ....................................

77Figure 76. Log Sense Page 10, Self-Test Results .......................................

78Figure 77. Log Sense Page 10 Self-Test Results .......................................

79Figure 78. Log Sense Page 10 Extended Segment Number ..............................

79Figure 79. Log Sense Page 2F .......................................................

80Figure 80. MODE SENSE (1A) .......................................................

81Figure 81. Page Code Usage ........................................................

81Figure 82. Mode parameter header (6) ................................................

82Figure 83. Mode parameter header (10) ...............................................

83Figure 84. MODE Parameter Block Descriptor .........................................

84Figure 85. MODE Parameter Page Format ............................................

84Figure 86. Page Code Usage ........................................................

85Figure 87. Vendor Unique Parameters - Page 0 ........................................

88Figure 88. Mode Page 1 (Vendor Unique Parameters ) ..................................

92Figure 89. Mode Page 2 (Disconnect/Reconnect Parameters ) ...........................

94Figure 90. Mode Page 3 (Format Device Parameters) ...................................

96Figure 91. Mode Page 4 (Rigid Disk Drive Geometry Parameters) ........................

97Figure 92. Mode Page 7 (Verify Error Recovery Parameters) .............................

98Figure 93. Page 8 (Caching Parameters) ..............................................

100Figure 94. Page A (Control Mode Page Parameters) ...................................

102Figure 95. Page 0C (Notch Parameters) ..............................................

104Figure 96. Page 19 (Port Control parameters) Short format .............................

105Figure 97. Page 19 (Port Control Parameters) Long Format .............................

106Figure 98. Margin Control Subpage ..................................................

107Figure 99. Saved Training Configuration Subpage .....................................

108Figure 100. Negotiated Settings Subpage ............................................

109Figure 101. Report Transfer Capabilities Subpage .....................................

110Figure 102. Page 1A (Power Control) ................................................

111Figure 103. Page 1C (Informational Exceptions Control) ................................

Ultrastar 146Z10 hard disk drive specifications

x

Page 13

113Figure 104. MODE SENSE (10) .....................................................

114Figure 105. MODE SELECT (6) .....................................................

115Figure 106. MODE SELECT (10) ....................................................

116Figure 107. Persistent Reserve In ...................................................

116Figure 108. Persistent Reserve In Service Action Codes ................................

117Figure 109. PERSISTENT RESERVE IN parameter data for Read Keys ..................

117Figure 110. PERSISTENT RESERVE IN parameter data for Read Reservations ...........

118Figure 111. PERSISTENT RESERVE IN Read Reservation Descriptor ...................

119Figure 112. Persistent Reserve Out (5F) .............................................

120Figure 113. Persistent Reservation Service Action Code ................................

122Figure 114. Persistent Reservation Scope Code .......................................

122Figure 115. Persistent Reservation Type Code ........................................

123Figure 116. Conflict between new and existing PERSISTENT RESERVATION .............

124Figure 117. PERSISTENT RESERVATION OUT parameter list ..........................

124Figure 118. Service Action and parameters and generation counter ......................

125Figure 119. APTPL and information held by a drive ....................................

126Figure 120. Pre-Fetch .............................................................

127Figure 121. READ (6) ..............................................................

128Figure 122. READ (10) ............................................................

129Figure 123. READ BUFFER ........................................................

130Figure 124. READ BUFFER Header .................................................

131Figure 125. Read Buffer Descriptor ..................................................

131Figure 126. Echo Buffer Descriptor ..................................................

132Figure 127. READ CAPACITY ......................................................

133Figure 128. Format of READ CAPACITY command reply ...............................

134Figure 129. Read Defect Data (10) ..................................................

135Figure 130. Defect List Header ......................................................

135Figure 131. Defect Descriptors of Bytes from Index Format .............................

136Figure 132. Defect Descriptors of Physical Sector Format ...............................

137Figure 133. Read Defect Data (12) ..................................................

138Figure 134. Defect List Header ......................................................

138Figure 135. Defect Descriptors of Bytes from Index Format .............................

139Figure 136. Defect Descriptors of Physical Sector Format ...............................

140Figure 137. READ LONG ..........................................................

141Figure 138. REASSIGN BLOCKS ...................................................

142Figure 139. Format of REASSIGN BLOCKS data ......................................

143Figure 140. RECEIVE DIAGNOSTIC ................................................

143Figure 141. Receive Diagnostic Results Page 0 .......................................

144Figure 142. Receive Diagnostic Results Page 40 ......................................

145Figure 143. Translated address .....................................................

145Figure 144. Receive Diagnostic Results Page 80 .....................................

146Figure 145. RELEASE (6) ..........................................................

147Figure 146. RELEASE (10) .........................................................

148Figure 147. REPORT DEVICE IDENTIFIER ..........................................

149Figure 148. REPORT DEVICE IDENTIFIER parameter list ..............................

150Figure 149. REPORT LUN .........................................................

150Figure 150. LUN Reporting Parameter List Format .....................................

151Figure 151. REQUEST SENSE .....................................................

152Figure 152. RESERVE (6) ..........................................................

153Figure 153. RESERVE (10) ........................................................

154Figure 154. REZERO UNIT .........................................................

155Figure 155. SEEK (6) ..............................................................

156Figure 156. SEEK (10) .............................................................

157Figure 157. SEND DIAGNOSTIC ....................................................

Ultrastar 146Z10 hard disk drive specifications

xi

Page 14

Figure 195. Spindle Motor Degraded Mode - Spindle Stopped by Start Stop Unit

Command ....................................................................

158Figure 158. SEND DIAGNOSTIC (1D) ...............................................

159Figure 159. Diagnostic Page 0 ......................................................

159Figure 160. Diagnostic Page 40 .....................................................

160Figure 161. Address to translate ....................................................

160Figure 162. Send Diagnostic Page 80 ................................................

161Figure 163. SET DEVICE IDENTIFIER ...............................................

161Figure 164. SET DEVICE IDENTIFIER Parameter List .................................

162Figure 165. START STOP Unit ......................................................

163Figure 166. SYNCHRONIZE CACHE ................................................

164Figure 167. TEST UNIT READY ....................................................

165Figure 168. VERIFY ...............................................................

166Figure 169. WRITE (6) .............................................................

167Figure 170. WRITE (10) ............................................................

168Figure 171. WRITE AND VERIFY ...................................................

169Figure 172. WRITE BUFFER (3B) ...................................................

170Figure 173. WRITE BUFFER Header ................................................

173Figure 174. WRITE LONG .........................................................

174Figure 175. WRITE SAME (41) .....................................................

175Figure 176. SCSI Status Byte. Format of the SCSI STATUS byte. .......................

177Figure 177. Supported Messages ...................................................

178Figure 178. Synchronous Data Transfer Request. .....................................

179Figure 179. Initiator Request/Drive Response (LVD mode) ..............................

179Figure 180. Initiator Request/Drive Response (SE mode) ...............................

180Figure 181. Target Response to Initiator's Transfer Period (LVD mode) ...................

180Figure 182. Drive Response to Initiator's Transfer Period (SE mode) .....................

181Figure 183. Wide Data Transfer Request. ............................................

181Figure 184. Initiator Request/Target Response ........................................

182Figure 185. Target Request to Initiator ...............................................

183Figure 186. Parallel Protocol Request. ...............................................

183Figure 187. Initiator Request/Target Response (DT_REQ = 1, IU_REQ = 1) ...............

184Figure 188. Initiator Request/Target Response (DT_REQ = 1, IU_REQ = 0 ................

184Figure 189. Initiator Request/Target Response (DT_REQ = 0, IU_REQ = 0 ................

187Figure 190. Queue Tag Messages ...................................................

188Figure 191. Ignore Wide Residue Message Format ....................................

198Figure 192. Spindle Motor Degraded Mode - Disable Auto Start .........................

199Figure 193. Spindle Motor Degraded Mode - Auto Start Delay/Spinning Up ................

200Figure 194. Spindle Motor Degraded Mode - Spindle Start Failure ........................

201

202Figure 196. Self Configuration Failure Degraded Mode .................................

203Figure 197. Format Command Failure Degraded Mode .................................

213Figure 198. Self-test menu for SEND DIAGNOSTIC command ..........................

215Figure 199. Format of Sense Data. ..................................................

218Figure 200. Sense Key / Sense Code / Qualifier combinations (1 of 4) ....................

219Figure 201. Sense Key / Sense Code / Qualifier combinations (2 of 4) ....................

220Figure 202. Sense Key / Sense Code / Qualifier combinations (3 of 4) ....................

221Figure 203. Sense Key / Sense Code / Qualifier combinations (4 of 4) ...................

222Figure 204. Field Pointer Bytes .....................................................

223Figure 205. Actual Retry Count .....................................................

223Figure 206. Progress Indication .....................................................

224Figure 207. Sense Data Byte 18 for Error Information ..................................

225Figure 208. Sense Data Byte 20 for POR Step .......................................

225Figure 209. Sense Data Byte 21 for POR Step ........................................

226Figure 210. Sense Data Byte 22 POR Error ...........................................

Ultrastar 146Z10 hard disk drive specifications

xii

Page 15

227Figure 211. Sense Data Byte 23 for POR Error ........................................

228Figure 212. Sense Data Byte 20 for Read/Write Error ..................................

228Figure 213. Sense Data Byte 21 for Read/Write Error ..................................

229Figure 214. Sense Data Byte 22 for Read/Write Error ..................................

229Figure 215. Sense Data Byte 23 for Read/Write Error ..................................

230Figure 216. Sense Data Byte 21 for SMART Alert Reason Code .........................

Ultrastar 146Z10 hard disk drive specifications

xiii

Page 16

Ultrastar 146Z10 hard disk drive specifications

xiv

Page 17

1.0 General

1.1 Introduction

This document describes the specifications of the following IBM 3.5-inch SCSI drives:

! IC35L018UWDY10 (68 pin)

! IC35L018UCDY10 (80 pin)

! IC35L036UWDY10 (68 pin)

! IC35L036UCDY10 (80 pin)

! IC35L073UWDY10 (68 pin)

! IC35L073UCDY10 (80 pin)

! IC35L146UWDY10 (68 pin)

! IC35L146UCDY10 (80 pin)

The specifications in this document are subject to change without notice.

1.2 Glossary

Word

Kb

Kbpi

Mb

Mbps

GB

MB

KB

TPI

MLC

PFA

S.M.A.R.T.

ADM

SE

LVD

FC-AL

Meaning

Kilobit

Kilobits per inch

Megabit

Megabits per second

Gigabyte

Megabyte

Kilobyte

Tracks per inch

Machine Level Control

Predictive Failure Analysis (Trademark of IBM Corp.)

Self-Monitoring Analysis and Reporting Technology

Automatic Drive Maintenance

Single Ended SCSI

Low Voltage Differential SCSI

Fibre Channel - Arbitrated Loop

Ultrastar 146Z10 hard disk drive specifications

1

Page 18

1.3 General caution

This drive can be damaged by ESD (Electric Static Discharge). Any damages incurred to the drive after

its removal from the shipping package and the ESD protective bag are the responsibility of the user.

Ultrastar 146Z10 hard disk drive specifications

2

Page 19

2.0 Outline of the drive

! Storage capacities of 146.8 GB, 73.4 GB, 36.7 GB, and 18.3 GB

! Ultra 320 and Ultra 160

! Interleave factor 1:1

! Variable Sector Size (512-528 bytes/sector)

! Tagged Command Queuing support

! Automatic read/write data transfer

! 8 MB segmented sector buffer (from 1 through 256)

! 4.7 ms seek time in read operation

! Adaptive read ahead algorithm

! Write Cache

! Back to back write

! ECC on the fly

! Automatic defect reallocation

! Self diagnostics at power on

! Closed loop actuator servo

! High level of integration of the electronics

! Non head disk contact start stop

! Spindle rotation of 10,000 RPM

! Automatic actuator lock

! PFA (SMART)

! Glass substrate disks

NOTE: PFA (Predictive Failure Analysis) is a trademark of the IBM Corporation

Ultrastar 146Z10 hard disk drive specifications

3

Page 20

This page intentionally left blank.

Page 21

Part 1. Functional specification

Ultrastar 146Z10 hard disk drive specifications

5

Page 22

This page intentionally left blank.

Page 23

3.0 Fixed disk subsystem description

3.1 Control electronics

The drive is electronically controlled by a microprocessor, logic modules, digital/analogue modules, and

various drivers and receivers. The control electronics perform the following major functions:

! Perform self-checkout (diagnostics).

! Conduct a power-up sequence and calibrate the servo.

! Monitor various timers for head settling, servo failure, etc.

! Analyze servo signals to provide closed loop control. These include position error signal and

estimated velocity.

! Control the voice coil motor driver to align the actuator onto a desired position.

! Monitor the actuator position and determine the target track for a seek operation.

! Constantly monitor error conditions of the servo and take corresponding action if an error occurs.

! Control starting, stopping, and rotating speed of the spindle.

! Control and interpret all interface signals between the host controller and the drive.

! Control read write accessing of the disk media, including defect management and error recovery.

3.2 Head disk assembly

The head disk assembly (HDA) is assembled in a clean room environment and contains disks, a spindle

motor, actuator assembly, and voice coil motor. Air is constantly circulated and filtered when the drive is

operational. Venting of the HDA is accomplished via a breather filter.

The spindle is driven directly by a brushless, sensorless DC drive motor. Dynamic braking is used to stop

the spindle quickly.

3.3 Actuator

The read/write heads are mounted in the actuator. The actuator is a swing-arm assembly driven by a

voice coil motor. A closed-loop positioning servo controls the movement of the actuator. An embedded

servo pattern supplies feedback to the positioning servo to keep the read/write heads centered over the

desired track.

The actuator assembly is balanced to allow vertical or horizontal mounting without adjustment.

When the drive is powered off, the actuator automatically moves the head to aparking position outside of

the disk, where the actuator is locked.

Ultrastar 146Z10 hard disk drive specifications

7

Page 24

This page intentionally left blank.

Page 25

4.0 Drive characteristics

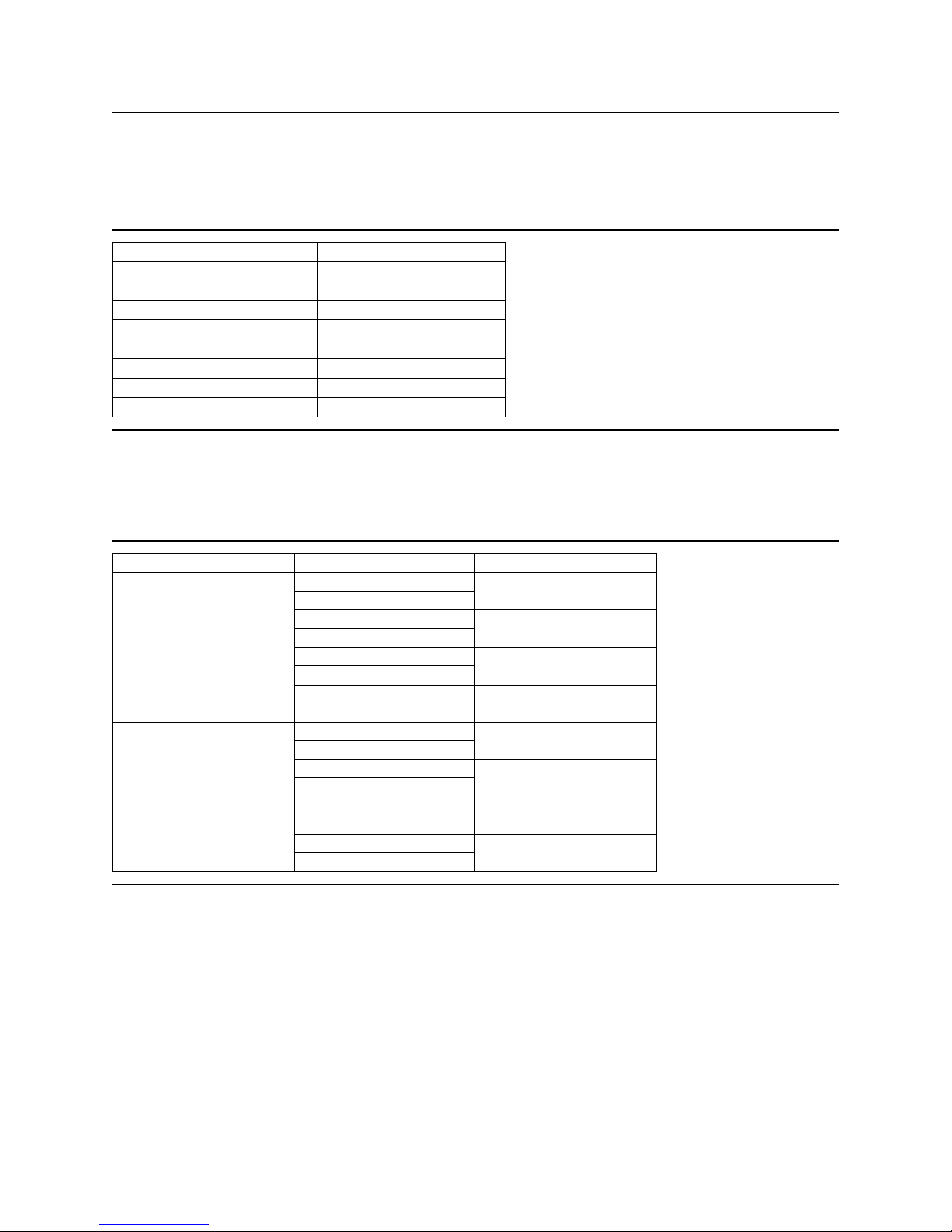

4.1 Formatted capacity

Description

Total data bytes

(512 bytes/sector)

Total logical data

blocks

Figure 1. Formatted capacity

IC35L146UWDY10

IC35L146UCDY10

286,749,610

(111773AAh)

4.2 Data sheet

Host to/from buffer (interface transfer rate)

[MB/sec]

IC35L073UWDY10

IC35L073UCDY10

143,374,805

(88BB9D5h

433 - 825 MbpsBuffer to/from media [Mb/sec]

320

8192 KB Data buffer size

1 - 256Number of buffer segments

10,000Rotational speed [RPM]

548Recording density [Kbpi] (Max)

47.9Track density [TPI] (average)

26,263Areal density [Mb/sq.in.]

15Data zone

IC35L036UWDY10

IC35L036UCDY10

71,687,340

(445DCACh)

IC35L018UWDY10

IC35L018UCDY10

18.35 GB36.7 GB73.4 GB146.8 GBLabel capacity

23612Number of heads

1236Number of disks

18,351,959,04036,703,918,08073,407,900,160146,815,800,320

35,843,670

(222EE56h)

Figure 2. Data sheet

NOTE: KB = 1,024 bytes

Ultrastar 146Z10 hard disk drive specifications

9

Page 26

4.3 Inquiry Information

4.3.1 Product ID

Product ID in Section 8.5.1, "Inquiry data format - CmdDt = 0 EVPD = 0" on page 57 is as follows.

DescriptionProduct ID

IC35L018UWDY10-0

IC35L018UCDY10-0

IC35L036UWDY10-0

IC35L036UCDY10-0

IC35L073UWDY10-0

IC35L073UCDY10-0

IC35L146UWDY10-0

IC35L146UCDY10-0

Figure 3. Product ID in Inquiry Command

4.3.2 World Wide ID - Block assignment

Block assignment of World Wide ID in 8.5.1.5 on Page 63 is as follows.

SFV, Hungary

Singapore

18.3 GB, 68 pin

18.3 GB, 80 pin

36.7 GB, 68 pin

36.7 GB, 80 pin

73.4 GB, 68 pin

73.4 GB, 80 pin

146.8 GB, 68 pin

146.8 GB, 80 pin

IC35L018UWDY10-0

IC35L018UCDY10-0

IC35L036UWDY10-0

IC35L036UCDY10-0

IC35L073UWDY10-0

IC35L073UCDY10-0

IC35L146UWDY10-0

IC35L146UCDY10-0

IC35L018UWDY10-0

IC35L018UCDY10-0

IC35L036UWDY10-0

IC35L036UCDY10-0

IC35L073UWDY10-0

IC35L073UCDY10-0

IC35L146UWDY10-0

IC35L146UCDY10-0

Block assignmentProductManufacturing site

212h, 213h

214h, 215h

216h, 217h

218h, 219h, 21Ah

716h, 717h

718h, 719h

71Ch, 71Dh

71Eh, 71Fh, 720h

Figure 4. Block assignment of World Wide ID in INQUIRY Command

Ultrastar 146Z10 hard disk drive specifications

10

Page 27

4.4 Cylinder allocation

Sectors/TrackPhysical CylindersZone

864 0 - 383Data Zone 0

840 384 - 3967Data Zone 1

8003968 - 5631Data Zone 2

7805632 - 6527Data Zone 3

7686528 - 8703Data Zone 4

720 8704 - 15359Data Zone 5

67215360 - 18047Data Zone 6

66018048 - 19199Data Zone 7

64019200 - 21503Data Zone 8

600 21504 - 24959Data Zone 9

560 24960 - 27775Data Zone 10

540 27776 - 29183Data Zone 11

520 29184 - 30719Data Zone 12

480 30720 - 35199Data Zone 13

440 35200 - 36735Data Zone 14

Figure 5. Cylinder allocation

NOTE: Mode Page 3 (Format Device Parameters) on page 94 and Mode Page 0C (Notch Parameters) on

page 102 provide methods to determine medium format and zone parameters.

Ultrastar 146Z10 hard disk drive specifications

11

Page 28

4.5 Performance characteristics

The performance of a drive is characterized by the following parameters:

! Command overhead

! Mechanical head positioning

- Seek time

- Latency

! Data transfer speed

! Buffering operation (read ahead/write cache)

NOTE: All the above parameters contribute to drive performance. There are other parameters that contribute to the performance of the actual system. This specification tries to define the bare drive characteristics, not the system throughput, which depends on the system and the application.

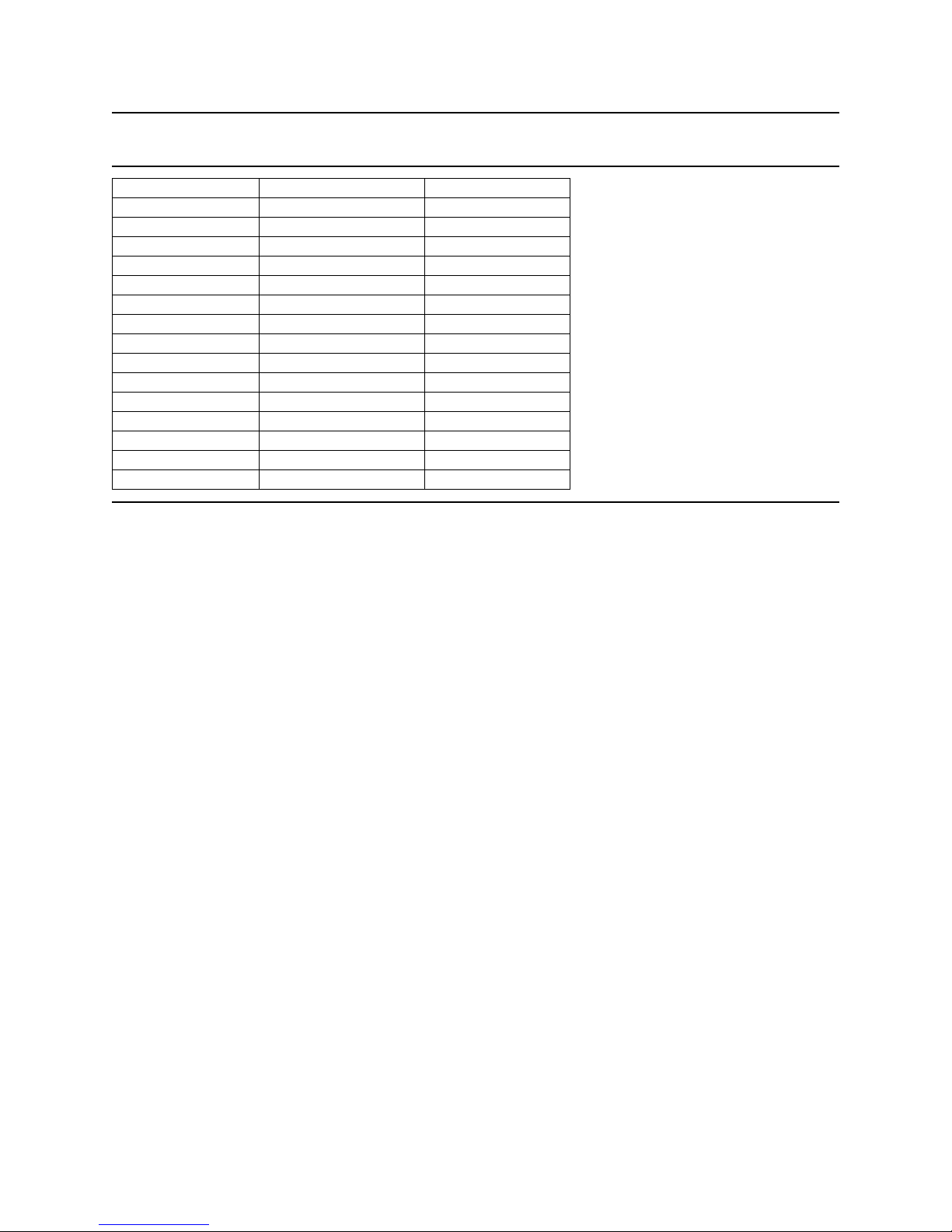

4.5.1 Command overhead

Command overhead is defined as the time required:

! from last byte of command phase

! to the first byte of data phase

! excluding

- Physical seek time

- Latency time

- Initiator delay with reconnections

Cache Not Hit

Cache Hit

Figure 6. Command overhead

TimeRead Command Case (Drive is in quiescent state)

<400 µs

<30 µs

Ultrastar 146Z10 hard disk drive specifications

12

Page 29

4.5.2 Mechanical positioning

4.5.2.1 Average seek time (including settling)

Max (ms)Typical (ms)Command Type

Read

Write

Figure 7. Mechanical positioning performance

“Typical” and “Max” are given throughout the performance specification by:

Typical Average of the drive population tested at nominal environmental and voltage conditions.

Max Maximum value measured on any one drive over the full range of the environmental and

voltage conditions. (See Section 7.3, "Environment" on page 30 and Section 7.5,

"DC power requirements" on page 32 for ranges.)

The seek time is measured from the start of the actuator's motion to the start of a reliable read or write

operation. “Reliable read or write” implies that error correction or recovery is not used to correct arrival

problems. The average seek time is measured as the weighted average of all possible seek combinations.

5.94.7146 GB model

5.74.7all other models

6.95.9146 GB model

6.95.3all other models

max

Sum

(max+1-n) (Tn.in+Tn.out)

Weighted average =

n=1

(max+1) (m ax)

Where

max = Maximum seek length

n = Seek length (1 to max)

Tn.in = Inward measured seek time for an n track seek

Tn.out = Outward measured seek time for an n track seek

4.5.2.2 Full stroke seek time

Maximum (ms)Typical (ms)Function

11.510.5Read

12.511.5Write

Figure 8. Full stroke seek time

Full stroke seek is measured as the average of 1000 full stroke seeks with a random head switch from

both directions (inward and outward).

Ultrastar 146Z10 hard disk drive specifications

13

Page 30

4.5.2.3 Cylinder switch time (cylinder skew)

Typical (ms)

0.70Cylinder skew

Figure 9. Cylinder Skew

A cylinder switch time is defined as the amount of time required by the fixed disk to access the next

sequential block after reading the last sector in the current cylinder.

4.5.2.4 Head switch time (head skew)

Typical (ms)

0.63Head skew

Figure 10. Head skew

A head switch time is defined as the amount of time required by the fixed disk to access the next

sequential block after reading the last sector in the current track.

4.5.2.5 Average latency

Rotation

Figure 11. Latency time

Time for a revolution

4.5.3 Drive ready time

Figure 12. Drive ready time

4.5.4 Spindle stop time

(ms)

Average Latency

(ms)

3.06.010,000 RPM

Maximum (sec)Typical (sec)Model

29.918.0146-GB Model

29.915.0 73-GB Model

29.912.0 36-GB Model

29.911.0 18-GB Model

Maximum (sec)Typical (sec)Model

3020146-GB Model

301473-GB Model

301436-GB Model

301418-GB Model

Figure 13. Spindle stop time

The period from power off to complete stop of spindle is categorized as operating, and Operating Shock

criteria are applied until complete stop of spindle. Refer to Section 7.8.3, "Operating Shock" on page 42.

Ultrastar 146Z10 hard disk drive specifications

14

Page 31

4.5.5 Data transfer speed

Typical (Mbyte/s)Description

Disk-Buffer Transfer (Zone 0)

All models 73.7Instantaneous

146-GB Model 66.7

Sustained

Disk-Buffer Transfer (Zone 16)

Sustained

Buffer-Host

Figure 14. Data transfer speed (sector size 512 bytes case)

! Instantaneous disk-buffer transfer rate is derived by

(Number of sectors on a track)*512*(revolution/sec)

NOTE: The number of sectors per track varies because of the linear density recording.

73-GB Model 66.6

36-GB Model 66.4

18-GB Model 66.2

All models 37.5Instantaneous

146-GB Model 33.9

73-GB Model 33.9

36-GB Model 33.8

18-GB Model 45.9

32068/80pin Ultra 320

! Sustained disk-buffer transfer rate is defined by considering head/cylinder change time. This gives a

local average data transfer rate. It is derived by

(Sustained Transfer Rate) = A/(B +C)

A = (Number of data sectors per cylinder) * 512

B = Average track change time

C = (# of Surface) * (One revolution time)

! Buffer-host transfer rate defines the maximum data transfer rate on SCSI Bus. It also depends on the

speed of the host.

4.5.6 Buffering operation (read ahead/write cache)

This hard disk drive has a buffer for read ahead and write caching. For details, refer to the SCSI interface

specification.

Ultrastar 146Z10 hard disk drive specifications

15

Page 32

4.5.7 Throughput

4.5.7.1 Simple sequential access

Max (ms)Typical (ms)Operation

Sequential read/write

Figure 15. Simple sequential access performance (sector size 512 byte case)

The above table gives the time required to read/write for a total of 8000x consecutive blocks

(16,777,216 bytes) accessed by 128 read/write commands. Typical and Max values are given by 100%

and 110% of T respectively throughput the following performance description.

NOTE: It is asumed that a host system responds instantaneously.

T = A + B + C + 16,777,216/D

where

T = Calculated Time

A = Command Overhead (Cache No Hit)

B = Average Seek Time

C = Average Latency

D = Sustained Disk-Buffer Transfer Rate

Zone 0 <260

Zone 14 <510

Zone 0 <290

Zone 11 <560

4.5.7.2 Random access

Maximum (sec) Typical (sec)Operation

3734Random read

4138Random write

Figure 16. Random access performance (sector size 512 bytes case)

The above table gives the time required to execute a total of 1000x read/write commands which access a

random LBA.

T = (A + B + C) * 4096

Where

T = Calculated Time

A = Command Overhead (Cache No Hit)

B = Average Seek Time

C = Average Latency

Ultrastar 146Z10 hard disk drive specifications

16

Page 33

5.0 Data integrity

The drive retains recorded information under all non-write operations.

No more than one sector will be lost by power down during write operation while write cache is disabled.

If power down occurs before completion of data transfer from write cache to disk while write cache is

enabled, the data remaining in write cache will be lost. To prevent this data loss at power off, the following

action is recommended:

! Confirm successful completion of SYNCHRONIZE CACHE (35h) command.

5.1 Equipment status

Equipment status is available to the host system any time the drive is not ready to read, write, or seek.

This status normally exists at power-on time and will be maintained until the following conditions are

satisfied:

! Access recalibration/tuning is complete.

! Spindle speed meets requirements for reliable operations.

! Self-check of drive is complete.

Appropriate error status is made available to the host system if any of the following condition occurs after

the drive has become ready:

! Spindle speed goes outside of requirements for reliable operation.

! “Write fault” is detected.

5.2 Error recovery procedure

Errors occurring with the drive are handled by the error recovery procedure.

Errors that are uncorrectable after application of the error recovery procedures are reported to the host

system as non-recoverable errors.

Ultrastar 146Z10 hard disk drive specifications

17

Page 34

This page intentionally left blank.

Page 35

6.0 Physical format

Media defects are remapped to the next available sector during the Format Process in manufacturing. The

mapping from LBA to the physical locations is calculated by an internally maintained table.

6.1 Shipped format (P-List)

! Data areas are optimally used

! No extra sector is wasted as a spare throughout user data areas

! All pushes generated by defects are absorbed by spare tracks of the inner zone

Figure 17. P-List physical format

NOTE: Defects are skipped without any constraint, such as track or cylinder boundary. The calculation

from LBA to physical is done automatically by internal table.

6.2 Reassigned format (G-List)

! G-List is prepared for 1078 LBAs

! Multiple reassignment of the same LBA does not increase G-List entry

! A cylinder for spare sectors is prepared every 512 physical cylinders

NOTE: G-List entries are part of the normal maintenance work of hard disk drives. G-List entries are

possible during early drive usage and are caused mainly by handling.

Ultrastar 146Z10 hard disk drive specifications

19

Page 36

This page intentionally left blank.

Page 37

7.0 Specification

7.1 Electrical interface specification

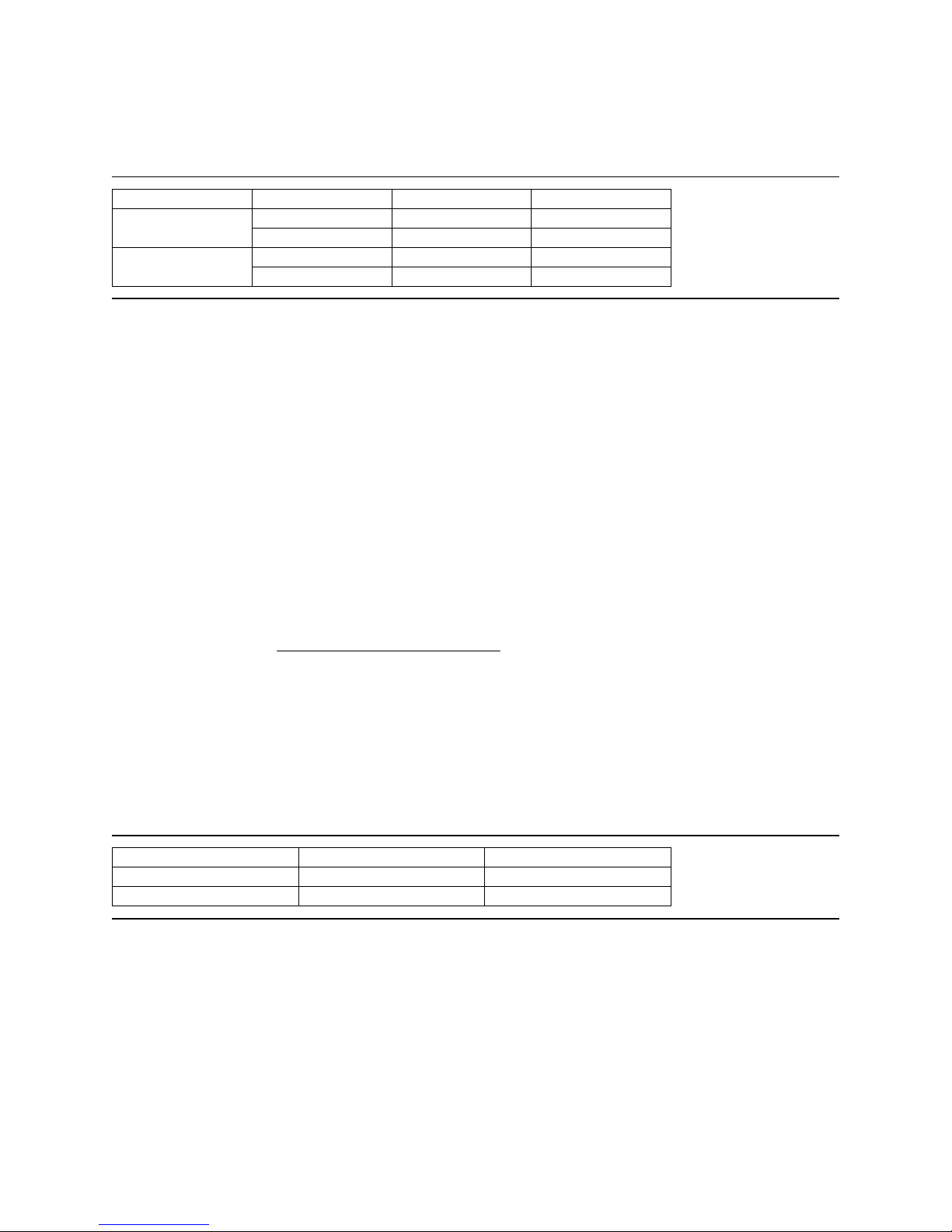

7.1.1 Power connector

The power connector of 68-pin models complies with the SFF-8009 Rev. 4.2. Power pin assignment of

68-pin models is as shown below.

Pin Voltage

4 3 2 1

Figure 18. Power connector pin assignments

Eighty-pin SCA-2 models use a DDK connector (PN HD2-PA080-A14B) or equivalent, which is compatible

with the Specification of “Single Attachment for Small SCSI Disk Drives” SPI-3 document, Annex C.

Power pin assignment of the 80-pin (SCA-2) model is shown in Section 7.1.2.1 on page 22.

1 +12 V

2GND

3GND

4+5V

Ultrastar 146Z10 hard disk drive specifications

21

Page 38

7.1.2 SCSI bus connector

The Ultrastar 146Z10 has 68-pin models and 80-pin SCA-2 models.

7.1.2.1 SCSI signal connector (68-pin model)

The pin assignments of the interface signals conform to SPI-4 as shown in the table below.

Connector contact

number

01

02

03

04

05

06

07

08

09

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

Signal name

+DB(12)

+DB(13)

+DB(14)

+DB(15)

+DB(P1)

+DB(0)

+DB(1)

+DB(2)

+DB(3)

+DB(4)

+DB(5)

+DB(6)

+DB(7)

+P_CRCA

Ground

DIFFSENS(*2)

TERMPWR(*1)

TERMPWR(*1)

Reserved

Ground

+ATN

Ground

+BSY

+ACK

+RST

+MSG

+SEL

+C/D

+REQ

+I/O

+DB(8)

+DB(9)

+DB(10)

+DB(11)

Connector contact

number

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

Signal name

-DB(12)

-DB(13)

-DB(14)

-DB(15)

-DB(P1)

-DB(0)

-DB(1)

-DB(2)

-DB(3)

-DB(4)

-DB(5)

-DB(6)

-DB(7)

-P_CRCA

Ground

Ground

TERMPWR(*1)

TERMPWR(*1)

Reserved

Ground

-ATN

Ground

-BSY

-ACK

-RST

-MSG

-SEL

-C/D

-REQ

-I/O

-DB(8)

-DB(9)

-DB(10)

-DB(11)

Figure 19. Table of signals

NOTES: *1 TERMPWR can be disabled.

*2 HVD is not supported.

Ultrastar 146Z10 hard disk drive specifications

22

Page 39

7.1.2.2 SCSI signal connector (80 pin SCA-2 model)

The 80-pin SCA-2 model uses a DDK connector which is compatible with SPI-4.

Connector contact

number

01

02

03

04

05

06

07

08

09

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

Signal name

12 Volt Charge

12 Volt

12 Volt

12 Volt

Opt 3.3 V/NC

Opt 3.3 V/NC

-DB(11)

-DB(10)

-DB(9)

-DB(8)

-I/O

-REQ

-C/D

-SEL

-MSG

-RST

-ACK

-BSY

-ATN

-P_CRCA

-DB(7)

-DB(6)

-DB(5)

-DB(4)

-DB(3)

-DB(2)

-DB(1)

-DB(0)

-DB(P1)

-DB(15)

-DB(14)

-DB(13)

-DB(12)

5 Volt

5 Volt

5 Volt Charge

Spindle Sync/NC

RMT START

SCSI ID (0)

SCSI ID (2)

Connector contact

number

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

Signal name

12V Ground

12V Ground

12V Ground

MATED 1

Opt 3.3 V charge/NC

DIFFSENS(*1)

+DB(11)

+DB(10)

+DB(9)

+DB(8)

+I/O

+REQ

+C/D

+SEL

+MSG

+RST

+ACK

+BSY

+ATN

+P_CRCA

+DB(7)

+DB(6)

+DB(5)

+DB(4)

+DB(3)

+DB(2)

+DB(1)

-DB(0)

+DB(P1)

+DB(15)

+DB(14)

+DB(13)

+DB(12)

MATED 2

5V Ground

5V Ground

ACTIVE LED OUT

DELAYED START

SCSI ID (1)

SCSI ID (3)

Figure 20. Table of signals

NOTE*1: HVD is not supported.

NOTE: SCA-2 connector is not mechanically compatible with the 68 pin “P” connector as defined in the

ANSI SCSI standard. The connector is intended for direct back plane attachment and is not intended to

be cable attached to the bus.

Eight-bit devices which connect to the SCA-2 connector should have the following signals inactive (high):

-DB(8), -DB(9), -DB(10), -DB(11), -DB(12), -DB(13), -DB(14), -DB(15), -DB(P1). All other signals shall be

connected as defined.

Ultrastar 146Z10 hard disk drive specifications

23

Page 40

7.1.3 SCSI cable

Refer to ANSI SPI-4.

7.1.4 SCSI bus terminator

Onboard SCSI active termination feature is not supported. The using system is responsible for making

sure that all required signals are terminated at both ends of the bus cable.

Terminator power

Termination power can be provided by the drive 5V supply through the current limiter and Schottky diode.

This function can be selected by jumper.

The 80-pin SCA-2 models do not support SCSI bus termination power.

7.1.5 Hot plug/unplug

The term 'Hot Plug' refers to the action of mechanically engaging a device to the power and/or bus when

other devices may be active on the same bus. A comprehensive classification of the state of the SCSI bus

during this event is located in the SCSI-3 Parallel Interface Standard.

While every effort was made to design the drive not to influence the SCSI bus during these events, it is the

responsibility of the system to insure voltage regulation and conformance to operational and nonoperational shock limits. During Hot Plug events the non-operational shock levels should not be exceeded. The operational shock levels of adjacent drives should also not be exceeded. The recommended

procedure is to prohibit write operations to adjacent drives during Hot Plug and Hot Unplug actions.

During Hot Unplug the operational shock limit specifications should not be exceeded. If this cannot be

guaranteed, the drive should be issued a SCSI Stop Unit command that is allowed to complete before

unplugging. The basic requirement is that while the drive is operational or spinning down the operational

shock limits are in effect. When the drive has completely stopped, the non-operational shock limits are in

effect. The recommended procedure is to allow the unplugged drive to rest in the drive bay for a minimum

of 15 seconds and then complete the removal. During Hot Plug or Unplug events the power supply ripple

on adjacent operational drives should not be outside the ±5 % regulation tolerance. It is recommended

that the system have current limiter for in-rush current as described in ANSI SPI-4.

Hot plugging/unplugging the 68-pin model drive to the power supply or to SCSI bus connector is not

allowed since provisions are not available to determine which electrical contact is made first. It may cause

glitches on the system SCSI bus and/or electrical over stress that may result in permanent damage of

electrical components of the drive. It is the responsibility of the system to protect the drive from these

situations when the 68-pin model is connected to the power supply or to SCSI bus.

7.1.6 SCSI bus electrical characteristics

Refer to ANSI SPI-4 for bus electrical characteristics.

NOTE: If the drive is connected to an HVD bus, the drive I/O will be permanently damaged.

Ultrastar 146Z10 hard disk drive specifications

24

Page 41

7.1.7 Auxiliary connector on 68-pin model

D

In addition to the Option Jumper Block the 68-pin models have an Auxiliary Connector between the power

connector and the 68-pin SCSI connector. The settings at the Option Jumper Block and the Auxiliary

Connector work as a logical OR. The drive conforms SFF-8009, Rev 4.2.

! Pin #1,3,5,7 specify SCSI-ID as -DAS0, 1 ,2, 3. Tie-down to the ground is to assert

! Pin #2,4,6,12 are reserved and should be open

! Pin #8 is for external LED cathode

34

68

+5V

(Reserved)

LED cathode

Ground

1

35

NC

911

12 10 8 6 4 2

1357

Bit 3

Bit 2

Bit 1

Bit 0

(Reserved)

(Reserved)

(Reserved)

SCSI I

Figure 21. Auxiliary connector

Ultrastar 146Z10 hard disk drive specifications

25

Page 42

7.2 Option jumper block

(

V+5V

Two jumper blocks, J4 and J6, are located on the card of 68- and 80-pin models as shown in the figure

below.

J4 has 14 positions numbered #1 - #14 and controls Terminator Power supply.

As described in Section 7.1.7, "Auxiliary connector on 68-pin model" on page 25, some of the jumper pins

on J4 of the 68-pin models can also be controlled through the Auxiliary Connector. These controls work

as logical OR between the Option Jumper Block and the Auxiliary Connector.

As described in Section 7.1.2.2, "SCSI signal connector (80-pin SCA-2 model)" on page 23 some of the

jumper pins on J4 of the 80-pin models can also be controlled through the 80 pin SCA-2 connector. These

controls work as a logical OR between the Option Jumper Block the SCA-2 connector.

J6 has 14 positions numbered #1 - #14.

+5

Connected to 5V via Polyswitch for 68-pin an d

Resistor

150 ohms)

NC for 80-pin models.

J4

J6

To

transistor