Page 1

BladeCenterEType8677and1881

Hardw are Maintenance Man ual and

Troubleshooting Guide

Page 2

Page 3

BladeCenterEType8677and1881

Hardw are Maintenance Man ual and

Troubleshooting Guide

Page 4

Note

Before using this information and the product it supports, be sure to read the information in Appendix C, “Notices,” on page

131, and the IBM Safety Information and IBM Systems Environmental Notices and User Guide documents on the IBM

Documentation CD.

The most recent version of this document is available at http://www.ibm.com/systems/support/.

18th Edition (June 2011)

© Copyright IBM Corporation 2011.

US Government Users Restricted Rights – Use, duplication or disclosure restricted by GSA ADP Schedule Contract

with IBM Corp.

Page 5

Contents

About this manual .......................vii

Important safety information ....................vii

Online support .........................viii

Support telephone numbers ....................viii

Chapter 1. General information...................1

The IBM Documentation CD ....................3

Hardware and software requirements ................3

Using the Documentation Browser .................3

Related publications .......................4

Notices and statements used in this book ...............5

Features and specifications.....................5

Major components of the BladeCenter Type 8677 and 1881 unit .......8

Front view ..........................9

Rear view ..........................10

BladeCenter unit power, controls, and indicators.............11

Starting the BladeCenter unit ...................11

Shutting down the BladeCenter unit ................12

BladeCenter components, controls, and LEDs ............13

Setting up the BladeCenter unit ...................17

Connecting to the default IP address on a new BladeCenter .......19

Registering and profiling the BladeCenter products ..........19

Chapter 2. Configuring your BladeCenter unit ............21

BladeCenter unit power requirement .................22

BladeCenter power configuration ..................22

Firmware updates ........................22

Configuring the BladeCenter unit ..................23

Configuring the management module................23

Communicating with the IBM Director software ............23

Configuring I/O modules ....................24

Configuring blade servers ....................24

Using IBM Director .......................24

About the wizard .......................25

Starting the wizard ......................25

Using Remote Deployment Manager Version 4.1 or later .........26

BladeCenter networking guidelines .................26

Chapter 3. Diagnostics .....................29

Diagnostic tools overview .....................29

Identifying problems using the Light Path Diagnostics feature ........29

Chapter 4. Installing options ...................31

Installing the BladeCenter unit in a rack................31

Installation guidelines ......................31

System reliability considerations .................32

Handling static-sensitive devices .................32

Installing and removing modules ..................33

The BladeCenter modules....................33

Installing a module ......................37

Removing a module ......................38

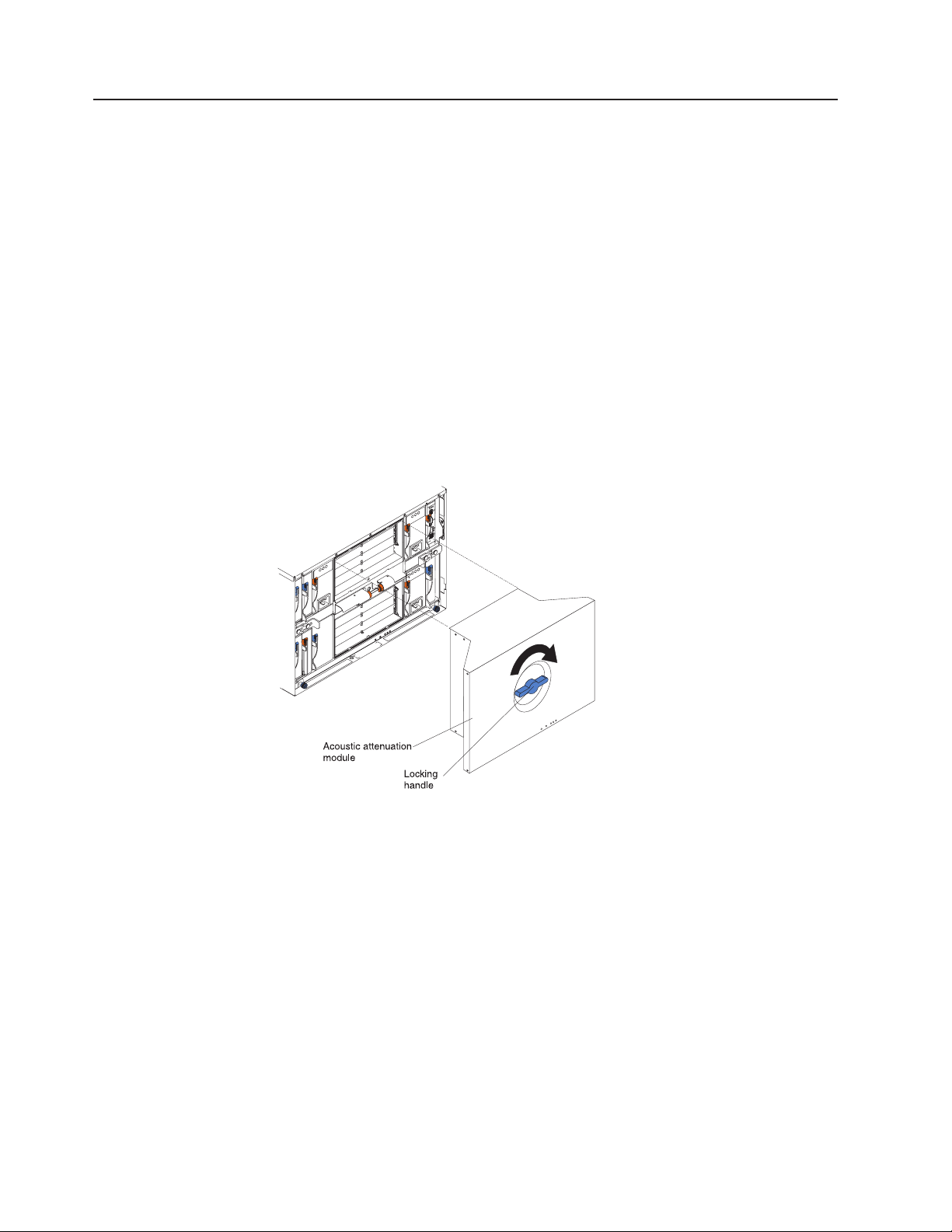

Installing and removing the acoustic module option ...........40

Installing the acoustic module option ................40

© Copyright IBM Corp. 2011 iii

Page 6

Removing the acoustic module option ...............41

Installing and removing blade servers ................41

Blade server expansion options ..................41

Installing a blade server ....................43

Removing a blade server ....................45

Completing the installation.....................46

Input/output connectors ......................46

Chapter 5. Service replaceable units ................47

Replacing a blower module ....................47

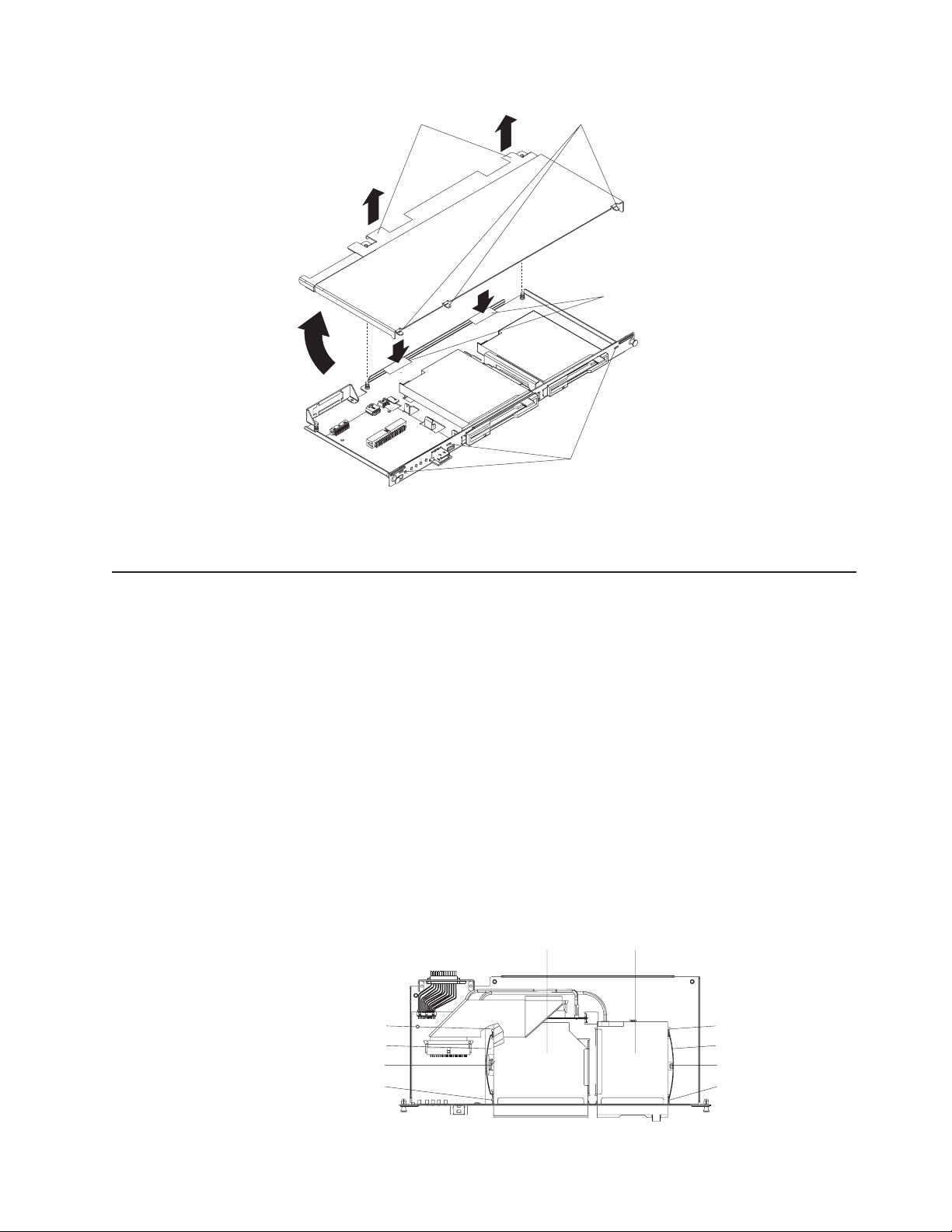

Media tray ..........................48

Removing the media tray ....................48

Removing the media-tray cover ..................48

Optical or diskette drive......................49

Installing SuSE to a SCSI drive ...................50

Customer interface card and USB connector ..............50

CD interposer board .......................51

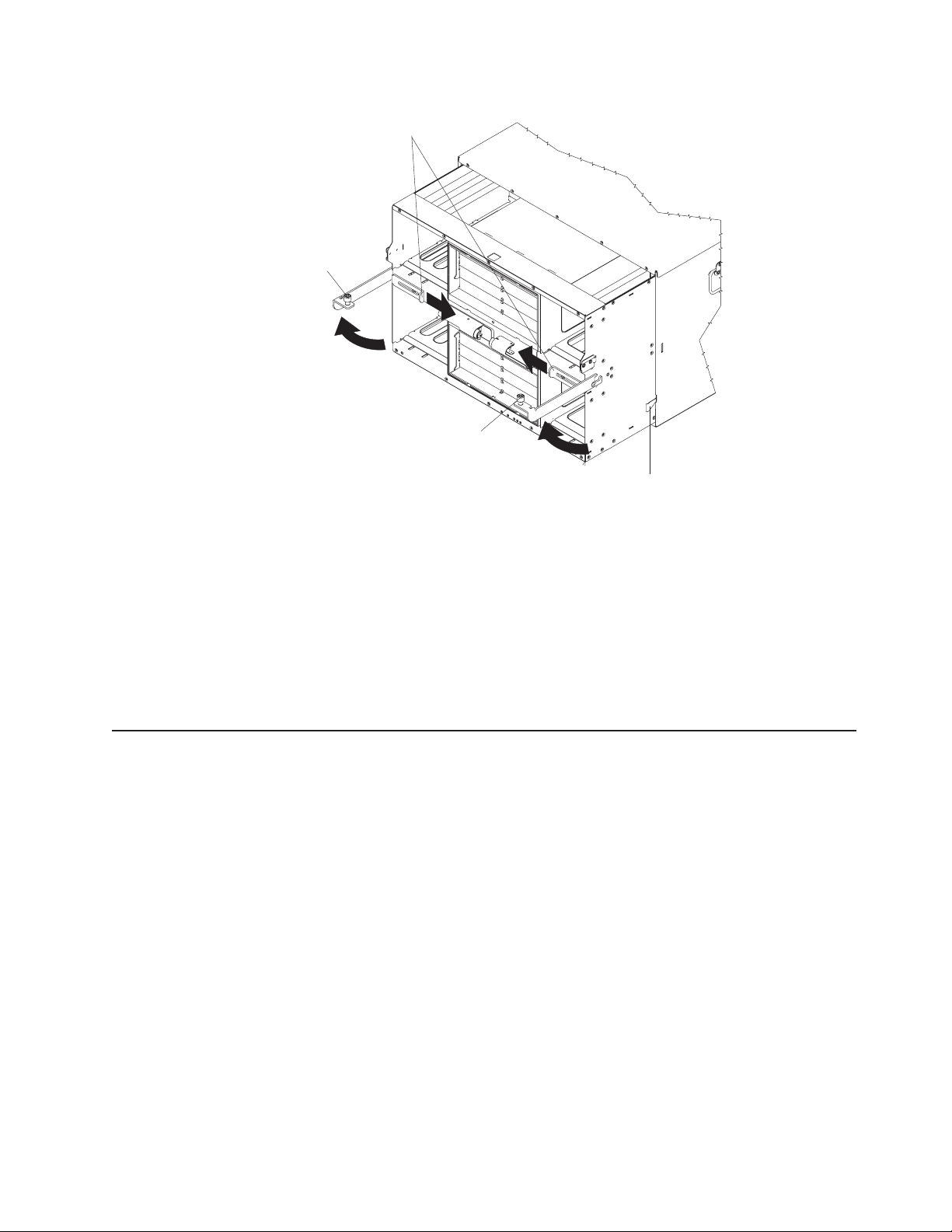

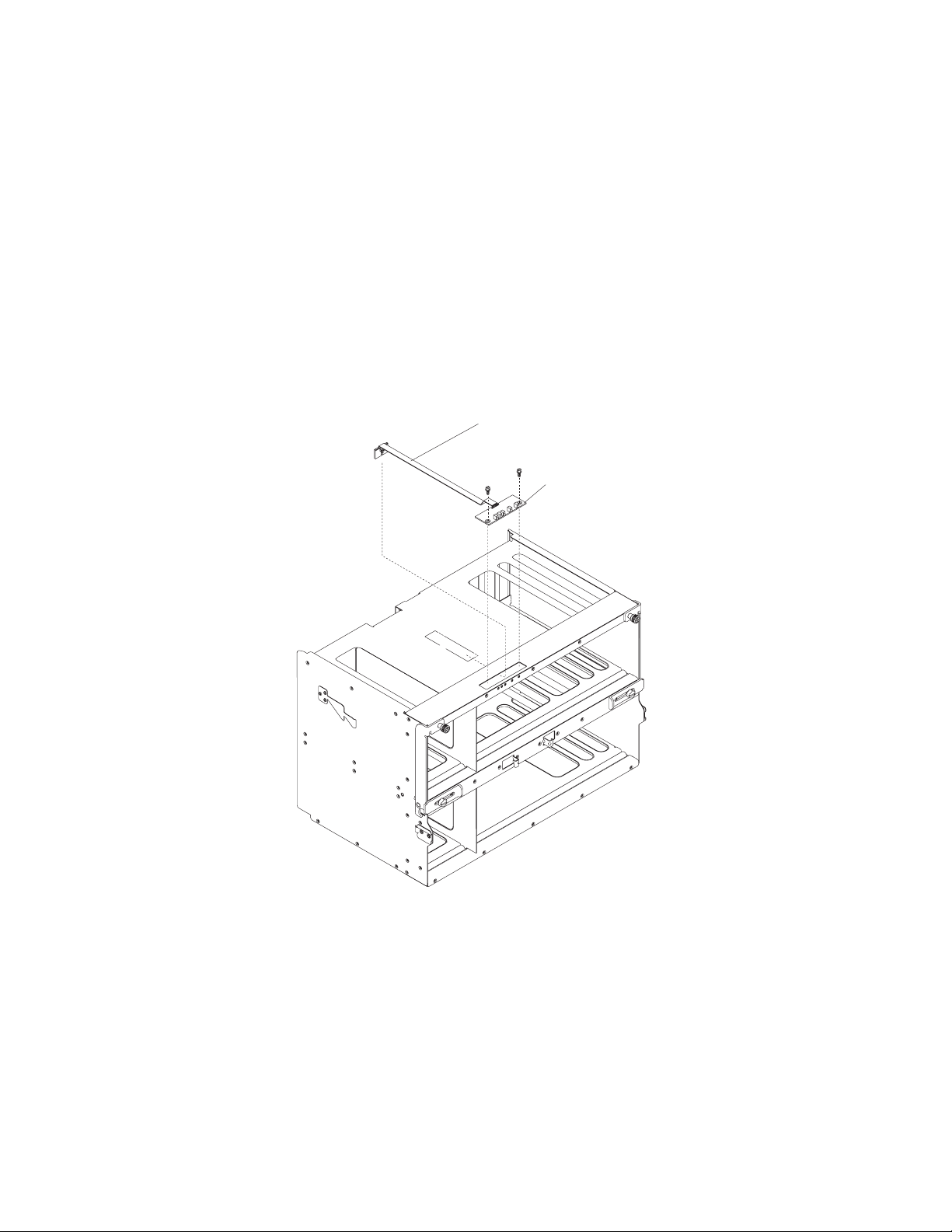

Switch, power, and cooling (SPC) chassis ...............52

Media-cable tray ........................53

Midplane ...........................55

System LED panel .......................55

Front system LED panel ....................56

Rear system-LED panel ....................57

Chapter 6. Symptom-to-FRU index .................59

Error symptoms ........................59

Light Path Diagnostics table ....................71

Temperature error messages ....................72

Blower error messages ......................72

Power error messages ......................73

Blade server error messages....................74

KVM error message .......................74

I/O module error messages ....................74

Management-module error messages ................75

Bus error messages .......................76

Undetermined problems .....................77

Problem determination tips ....................78

Chapter 7. Parts listing, BladeCenter Type 8677 and 1881 ........79

Front view ..........................79

Rear view ...........................81

Appendix A. Getting help and technical assistance ..........85

Before you call .........................85

Using the documentation .....................85

Getting help and information from the World Wide Web ..........85

Software service and support ...................86

Hardware service and support ...................86

IBM Taiwan product service ....................86

Appendix B. Related service information ..............87

Safety information ........................87

General safety ........................87

Electrical safety........................88

Safety inspection guide .....................89

Handling electrostatic discharge-sensitive devices ...........90

iv BladeCenter E Type 8677 and 1881: Hardware Maintenance Manual and Troubleshooting Guide

Page 7

Grounding requirements ....................91

Safety notices (multi-lingual translations) ..............91

Appendix C. Notices ......................131

Trademarks..........................131

Important notes ........................132

Electronic emission notices ....................133

Federal Communications Commission (FCC) statement ........133

Industry Canada Class A emission compliance statement ........133

Avis de conformité à la réglementation d'Industrie Canada .......133

Australia and New Zealand Class A statement ............133

United Kingdom telecommunications safety requirement ........133

European Union EMC Directive conformance statement ........133

Taiwanese Class A warning statement ...............134

Chinese Class A warning statement ................134

Japanese Voluntary Control Council for Interference (VCCI) statement 134

Korean Class A warning statement ................134

Power cords .........................135

Index ............................137

Contents v

Page 8

vi BladeCenter E Type 8677 and 1881: Hardware Maintenance Manual and Troubleshooting Guide

Page 9

About this manual

This manual contains diagnostic information, a Symptom-to-FRU index, service

information, error codes, error messages, and configuration information for the

BladeCenter

Important safety information

Be sure to read all caution and danger statements in this book before performing

any of the instructions. See “Safety information” on page 87.

Lea todas as instruções de cuidado e perigo antes de executar qualquer operação.

®

E Type 8677 and 1881 unit.

Prenez connaissance de toutes les consignes de type Attention et Danger avant de

procéder aux opérations décrites par les instructions.

Lesen Sie alle Sicherheitshinweise, bevor Sie eine Anweisung ausführen.

Accertarsi di leggere tutti gli avvisi di attenzione e di pericolo prima di effettuare

qualsiasi operazione.

© Copyright IBM Corp. 2011 vii

Page 10

Lea atentamente todas las declaraciones de precaución y peligro ante de llevar a

cabo cualquier operación.

Online support

You can download the most current diagnostic, H8 flash, and device driver files

from http://www.ibm.com/systems/support on the World Wide Web.

Support telephone numbers

View support telephone numbers at http://www.ibm.com/planetwide/ on the World

Wide Web.

viii BladeCenter E Type 8677 and 1881: Hardware Maintenance Manual and Troubleshooting Guide

Page 11

Chapter 1. General information

The IBM®BladeCenter E Type 8677 and 1881 unit is a high-density,

high-performance rack-mounted system developed for medium-to-large businesses.

It supports up to 14 blade servers, making it ideally suited for networking

environments that require a large number of high-performance servers in a small

amount of space. The BladeCenter system provides common resources that are

shared by the blade servers, such as power, cooling, system management, network

connections, and input/output (I/O) ports (diskette drive, optical drive, ports for USB,

keyboard, video, mouse, and network interfaces). The use of common resources

enables small blade server size, minimizes the cabling required in a working

configuration, and eliminates resources sitting idle.

Performance, ease of use, reliability, and expansion capabilities were key

considerations during the design of your BladeCenter system. These design

features make it possible for you to customize the system hardware to meet your

needs today, while providing flexible expansion capabilities for the future.

Notes:

1. Current BladeCenter E models do not have a diskette drive in the media tray.

Older BladeCenter E models do have a diskette drive in the media tray. In this

document, this difference is noted, when necessary, to describe differences that

exist between current and older model offerings.

2. The illustrations in this document might differ slightly from your actual hardware:

the illustrations do not depict a particular model offering unless noted in text.

3. Throughout this document, the terms I/O module and switch module are used to

refer to switch modules and all other types of I/O module.

This Hardware Maintenance Manual and Troubleshooting Guide provides

information to troubleshoot your BladeCenter unit and replace damaged parts.

This Hardware Maintenance Manual and Troubleshooting Guide and other

publications that provide detailed information about your BladeCenter unit are

provided in Portable Document Format (PDF) on the IBM BladeCenter

Documentation CD.

The latest version of this publication is available from the IBM support Web site at

http://www.ibm.com/systems/support.

If you have access to the World Wide Web, you can obtain up-to-date information

about your BladeCenter model and other IBM server products at

http://www.ibm.com/eserver/xseries/ on the World Wide Web.

You can register the BladeCenter unit and blade servers on the World Wide Web.

To register, go to http://www.ibm.com/support/mysupport/ on the World Wide Web.

© Copyright IBM Corp. 2011 1

Page 12

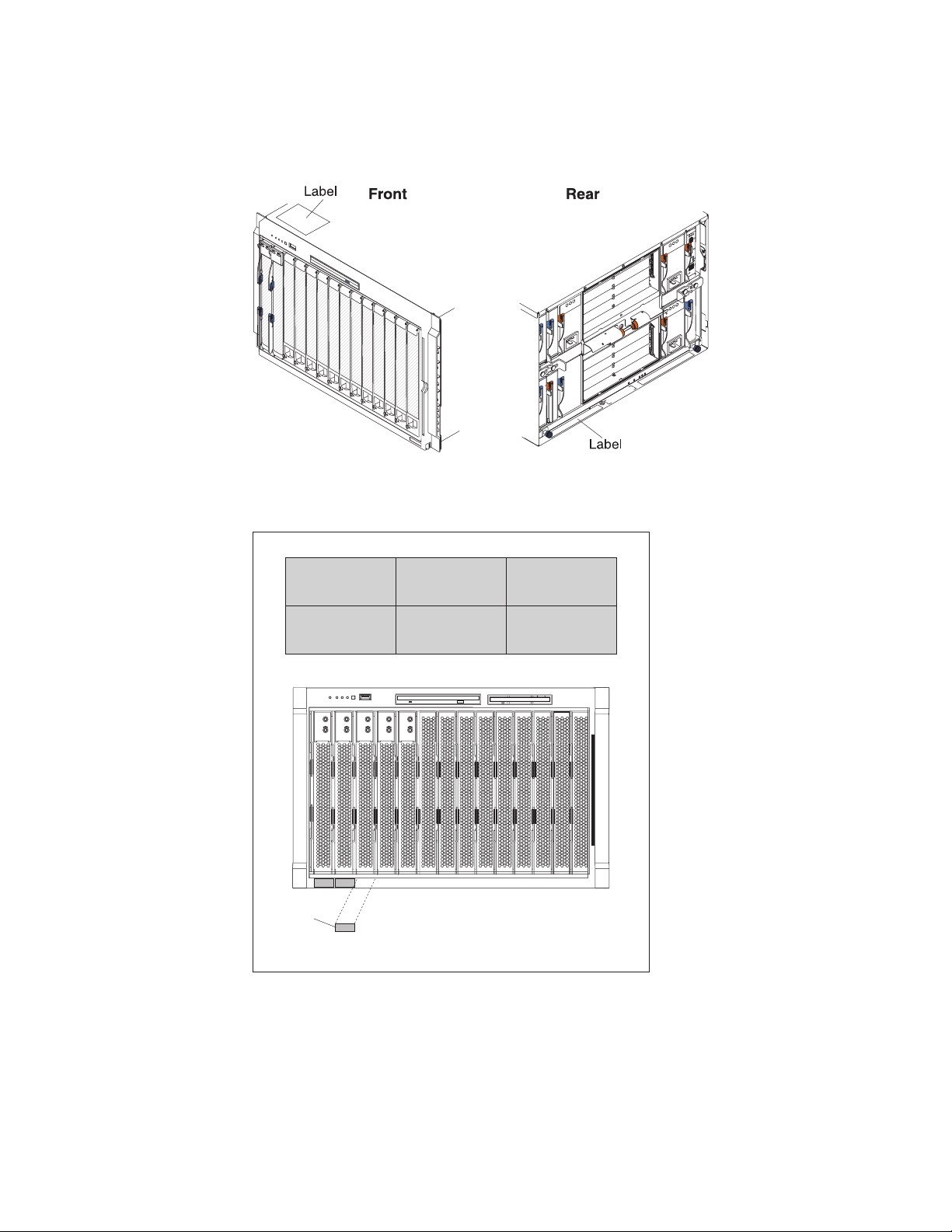

The serial number and model number are on labels on the top, front, and rear of

the chassis, as shown in the following illustration.

Note: The illustrations in this document might differ slightly from your hardware.

A set of user labels comes with each blade server. Write whatever identifying

information you want on a label, and place it on the BladeCenter bezel just below

the blade server, as shown in the following illustration.

User

label

Important: Do not place the label on the blade server itself or in any way block the

ventilation holes on the blade server.

2 BladeCenter E Type 8677 and 1881: Hardware Maintenance Manual and Troubleshooting Guide

Page 13

The IBM Documentation CD

Use the IBM Documentation CD to access the blade server documentation in PDF

format.

You can run the IBM Documentation CD on any personal computer that meets the

hardware and software requirements.

The IBM Documentation CD contains documentation for your blade server in

Portable Document Format (PDF) and includes the IBM Documentation Browser to

help you find information quickly.

Hardware and software requirements

Use this information to determine the minimum hardware and software requirements

for the blade server.

The IBM Documentation CD requires the following minimum hardware and

software:

v Microsoft Windows XP, Windows 2000, or Red Hat Enterprise Linux 5 Server

v 100 MHz microprocessor

v 32 MB of RAM

v Adobe Acrobat Reader 3.0 (or later) or xpdf, which comes with Linux operating

systems

Using the Documentation Browser

Use these instructions to start the Documentation Browser.

Use the Documentation Browser to browse the contents of the CD, read brief

descriptions of the documents, and view documents, using Adobe Acrobat Reader

or xpdf. The Documentation Browser automatically detects the regional settings in

use in your system and displays the documents in the language for that region (if

available). If a document is not available in the language for that region, the

English-language version is displayed.

Use one of the following procedures to start the Documentation Browser:

v If Autostart is enabled, insert the CD into the CD drive. The Documentation

Browser starts automatically.

v If Autostart is disabled or is not enabled for all users, use one of the following

procedures:

– If you are using a Windows operating system, insert the CD into the CD or

DVD drive and click Start → Run.IntheOpen field, type

e:\win32.bat

where e is the drive letter of the CD or DVD drive, and click OK.

– If you are using Red Hat Linux, insert the CD into the CD or DVD drive; then,

run the following command from the /mnt/cdrom directory:

sh runlinux.sh

Select your blade server from the Product menu. The Available Topics list

displays all the documents for your blade server. Some documents might be in

folders. A plus sign (+) indicates each folder or document that has additional

documents under it. Click the plus sign to display the additional documents.

Chapter 1. General information 3

Page 14

When you select a document, a description of the document is displayed under

Topic Description. To select more than one document, press and hold the Ctrl key

while you select the documents. Click View Book to view the selected document or

documents in Acrobat Reader or xpdf. If you selected more than one document, all

the selected documents are opened in Acrobat Reader or xpdf.

To search all the documents, type a word or word string in the Search field and

click Search. The documents in which the word or word string appears are listed in

order of the most occurrences. Click a document to view it, and press Crtl+F to use

the Acrobat search function, or press Alt+F to use the xpdf search function within

the document.

Click Help for detailed information about using the Documentation Browser.

Related publications

This Hardware Maintenance Manual and Troubleshooting Guide is provided in

Portable Document Format (PDF). It contains information to help you solve the

problem yourself or to provide helpful information to a service technician.

In addition to this Hardware Maintenance Manual and Troubleshooting Guide, the

following IBM BladeCenter Type 8677 Documentation is provided with the unit:

v Safety Information: This document contains translated caution and danger

statements. Each caution and danger statement that appears in the

documentation has a number that you can use to locate the corresponding

statement in your language in the Safety Information book.

v BladeCenter Type 8677 Rack Installation Instructions: This document contains

instructions for installing the BladeCenter unit in a rack.

v BladeCenter Management Module Installation Guide: This document contains

instructions for installing the management module in a BladeCenter unit and

creating the initial configuration. There is a unique Installation Guide for each

management module type.

v BladeCenter Management Module User’s Guide: This document provides general

information about the management module for your BladeCenter unit, including

information about features, how to configure the management module, and how

to get help. There is a unique User's Guide for each management module type.

v BladeCenter Management Module Command-Line Interface Reference Guide:

This document explains how to use the management-module command-line

interface to directly access BladeCenter management functions as an alternative

to using the Web-based user interface. The command-line interface also provides

access to the text-console command prompt on each blade server through a

serial over LAN (SOL) connection. There is a unique Command-Line Interface

Reference Guide for each management module type.

Additional publications might be included on the IBM BladeCenter E Type 8677

Documentation CD.

4 BladeCenter E Type 8677 and 1881: Hardware Maintenance Manual and Troubleshooting Guide

Page 15

Notices and statements used in this book

The caution and danger statements used in this book also appear in the multilingual

Safety Information book provided on the IBM BladeCenter Documentation CD. Each

caution and danger statement is numbered for easy reference to the corresponding

statements in the safety book.

The following types of notices and statements are used in this book:

v Note: These notices provide important tips, guidance, or advice.

v Important: These notices provide information or advice that might help you avoid

inconvenient or problem situations.

v Attention: These notices indicate possible damage to programs, devices, or

data. An attention notice is placed just before the instruction or situation in which

damage could occur.

v Caution: These statements indicate situations that can be potentially hazardous

to you. A caution statement is placed just before the description of a potentially

hazardous procedure step or situation.

v Danger: These statements indicate situations that can be potentially lethal or

extremely hazardous to you. A danger statement is placed just before the

description of a potentially lethal or extremely hazardous procedure step or

situation.

Features and specifications

Current BladeCenter E models do not have a diskette drive in the media tray. Older

BladeCenter E models do have a diskette drive in the media tray. A separate

features and specifications table is provided for each of these model types.

Notes:

1. For information about which types of I/O modules can be installed in which

I/O-module bays, see “I/O (switch) modules” on page 34.

2. The operating system in the blade server must provide USB support for the

blade server to recognize and use the keyboard, mouse, and optical drive. The

BladeCenter unit uses USB for internal communication with these devices.

Chapter 1. General information 5

Page 16

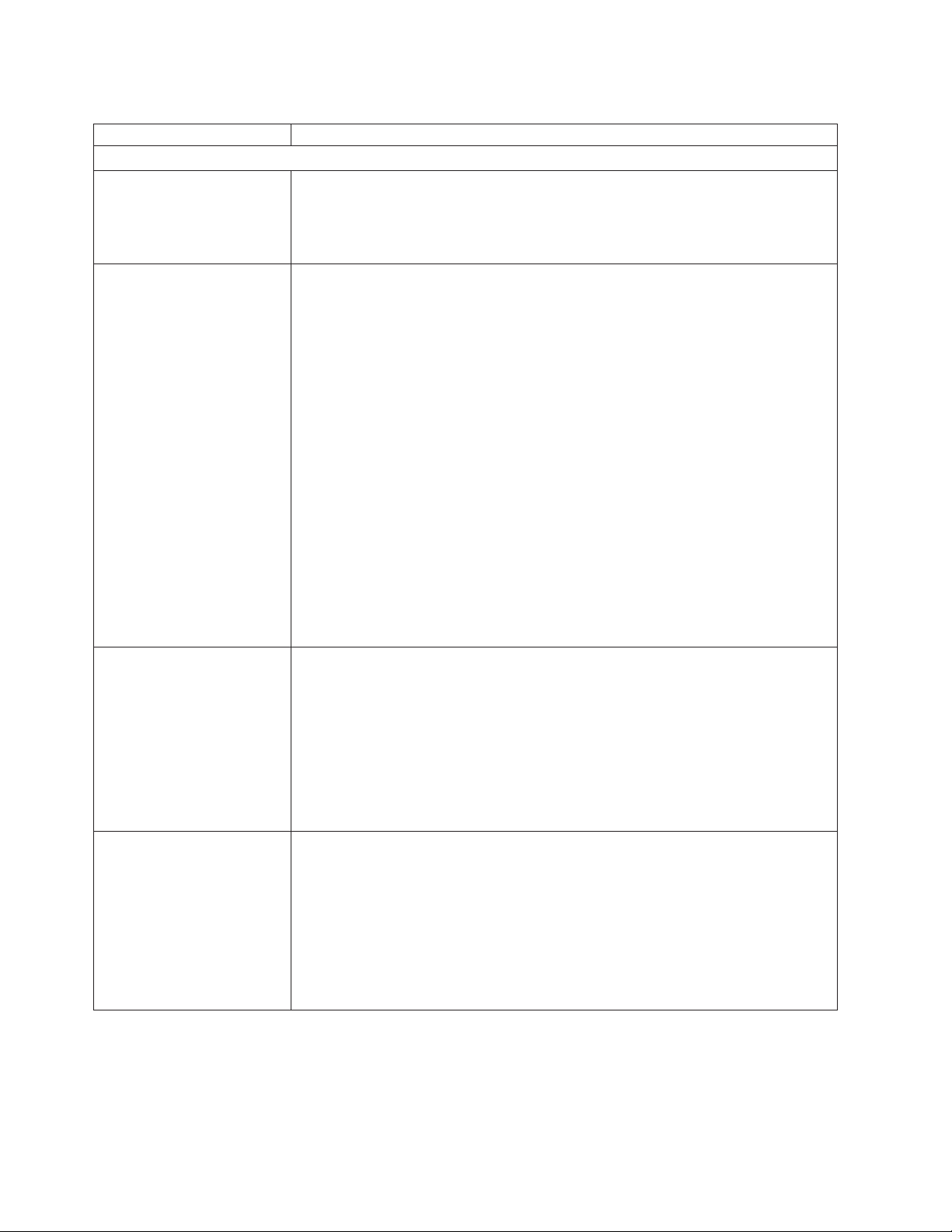

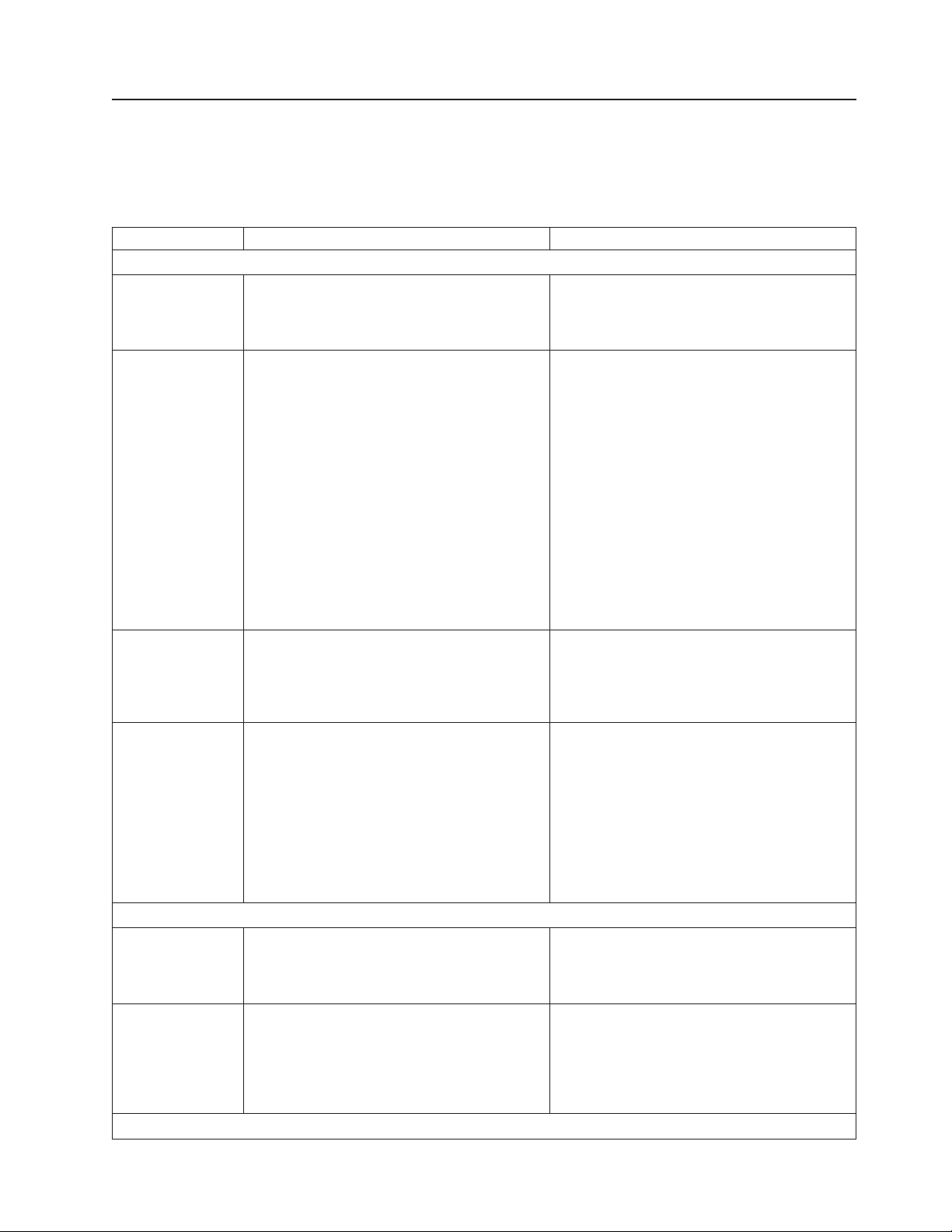

The following table provides a summary of the features and specifications for a

BladeCenter unit that does not have a diskette drive bay in the media tray.

Media tray (on front):

v SATA CD/DVD drive

v USB v2.0 port

v Front system LED panel

Module bays (on rear):

v Four hot-swap power-module bays

v Two hot-swap management-module

bays

v Four hot-swap I/O-module bays

v Two hot-swap blower bays

Blade-server bays (on front):

14 hot-swap blade-server bays

Redundant cooling:

Two variable-speed hot-swap blowers

Power modules:

v Minimum: Two 2000-watt or greater

hot-swap power modules

– Both power modules supply power

to all modules and to blade-server

bays 1 through 6.

– Both power modules provide

redundancy to each other.

v Maximum: Four

– Power modules 1 and 2 supply

power to all modules and to

blade-server bays 1 through 6.

– Power modules 3 and 4 supply

power to blade-server bays 7

through 14.

– Power modules 1 and 2 provide

redundancy to each other.

– Power modules 3 and 4 provide

redundancy to each other.

I/O modules:

v Minimum: One

v Maximum: Four

Management module:

v Minimum: One hot-swap advanced

management module providing the

following features:

– System-management functions for

the BladeCenter unit

– Video port (analog)

– Two USB ports for keyboard and

mouse

– Serial management connection

– 10/100 Mb Ethernet remote

management connection

v Maximum: Two hot-swap advanced

management modules: one active, one

redundant

Upgradeable microcode:

v Management-module firmware

v I/O-module firmware (some I/O module

types)

v Blade-server firmware

Security features:

v Login password for remote connection.

v Secure Socket Layer (SSL) security for

Web interface access, Secure Shell

(SSH) for remote command-line access,

and Lightweight Directory Access

Protocol (LDAP) and role-based security

for user authentication and

authorization.

Size (7 U):

v Height: 304.2 mm (12 in. or 7 U)

v Depth: 711.2 mm (28 in.)

v Width: 444 mm (17.5 in.)

v Weight:

– Fully configured with modules and

blade servers: Approximately 102 kg

(225 lb)

– Fully configured without modules and

blade servers: Approximately 38.6 kg

(85 lb)

Acoustical noise emissions:

v Without acoustic attenuation module: Sound

power, operating, and idle: 7.4 bels

v With acoustic attenuation module: Sound

power, idle, and operating: 6.9 bels

Environment:

v Air temperature:

– On:

- Altitude: 0 to 914 m (3000 ft) - 10° to

35°C (50° to 95°F)

- Altitude: 914 m to 2134 m (3000 ft to

7000 ft) - 10° to 32°C (50° to 89.6°F)

– Off: -40° to 60°C (-40° to 140°F).

v Humidity: 8% to 80%

Electrical input:

v Sine-wave input (50-60 Hz single-phase)

required

v Input voltage:

– Minimum: 200 V ac

– Maximum: 240 V ac

Heat output:

Approximate heat output in British thermal

units (Btu) per hour:

v Minimum configuration: 1365 Btu/hour (400

watts)

v Maximum configuration: Varies depending

on the type of power modules installed.

– Four 2000-watt power modules: 20 094

Btu/hour (5889 watts)

– Four 2320-watt power modules: 23 672

Btu/hour (6938 watts)

6 BladeCenter E Type 8677 and 1881: Hardware Maintenance Manual and Troubleshooting Guide

Page 17

The following table provides a summary of the features and specifications for a

BladeCenter unit that has a diskette drive bay in the media tray.

Media tray (on front):

v Diskette drive: 1.44 MB

v IDE CD or DVD

v USB v1.1 port

v Front system LED panel

Module bays (on rear):

v Four hot-swap power-module bays

v Two hot-swap management-module

bays

v Four hot-swap I/O-module bays

v Two hot-swap blower bays

Blade-server bays (on front):

14 hot-swap blade-server bays

Redundant cooling:

Two variable-speed hot-swap blowers

Power modules:

v Minimum: Two hot-swap power

modules

– Both power modules supply power

to all modules and to blade-server

bays 1 through 6.

– Both power modules provide

redundancy to each other.

v Maximum: Four

– Power modules 1 and 2 supply

power to all modules and to

blade-server bays 1 through 6.

– Power modules 3 and 4 supply

power to blade-server bays 7

through 14.

– Power modules 1 and 2 provide

redundancy to each other.

– Power modules 3 and 4 provide

redundancy to each other.

I/O modules:

v Minimum: One

v Maximum: Four

Management module:

v Minimum: One hot-swap management

module providing the following features:

– System-management functions for

the BladeCenter unit

– Video port (analog)

– Keyboard connection (PS/2 port or

USB port depending on the

management module-type)

– Mouse connection (PS/2 port or USB

port depending on the management

module type)

– Serial management connection

(advanced management module

only)

– 10/100 Mb Ethernet remote

management connection

v Maximum: Two hot-swap management

modules: one active, one redundant

Upgradeable microcode:

v Management-module firmware

v I/O-module firmware (some I/O module

types)

v Blade-server firmware

Security features:

v Login password for remote connection.

v Secure Socket Layer (SSL) security for

Web interface access, Secure Shell

(SSH) for remote command-line access,

and Lightweight Directory Access

Protocol (LDAP) and role-based security

for user authentication and

authorization.

Size (7 U):

v Height: 304.2 mm (12 in. or 7 U)

v Depth: 711.2 mm (28 in.)

v Width: 444 mm (17.5 in.)

v Weight:

– Fully configured with modules and

blade servers: Approximately 102 kg

(225 lb)

– Fully configured without modules and

blade servers: Approximately 38.6 kg

(85 lb)

Acoustical noise emissions:

v Without acoustic attenuation module: Sound

power, operating, and idle: 7.4 bels

v With acoustic attenuation module: Sound

power, idle, and operating: 6.9 bels

Environment:

v Air temperature:

– On:

- Altitude: 0 to 914 m (3000 ft) - 10° to

35°C (50° to 95°F)

- Altitude: 914 m to 2134 m (3000 ft to

7000 ft) - 10° to 32°C (50° to 89.6°F)

– Off: -40° to 60°C (-40° to 140°F).

v Humidity: 8% to 80%

Electrical input:

v Sine-wave input (50-60 Hz single-phase)

required

v Input voltage:

– Minimum: 200 V ac

– Maximum: 240 V ac

Heat output:

Approximate heat output in British thermal

units (Btu) per hour:

v Minimum configuration: 1365 Btu/hour (400

watts)

v Maximum configuration: Varies depending

on the type of power modules installed.

– Four 1200-watt power modules: 9622

Btu/hour (2820 watts)

– Four 1400-watt power modules: 11 111

Btu/hour (3256 watts)

– Four 1800-watt power modules: 13 650

Btu/hour (4000 watts)

– Four 2000-watt power modules (for use

with a Gigabit Ethernet expansion card):

18 425 Btu/hour (5400 watts)

Chapter 1. General information

7

Page 18

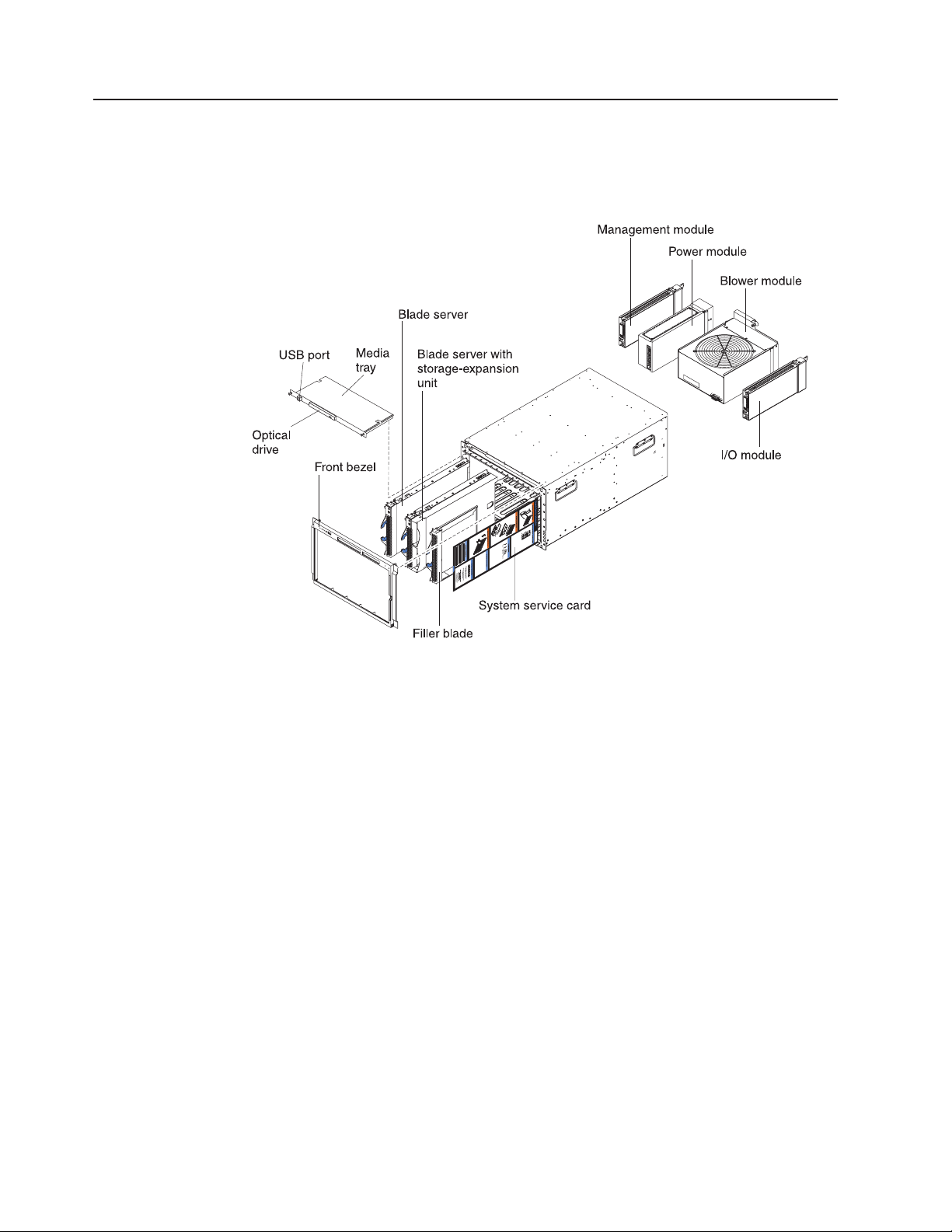

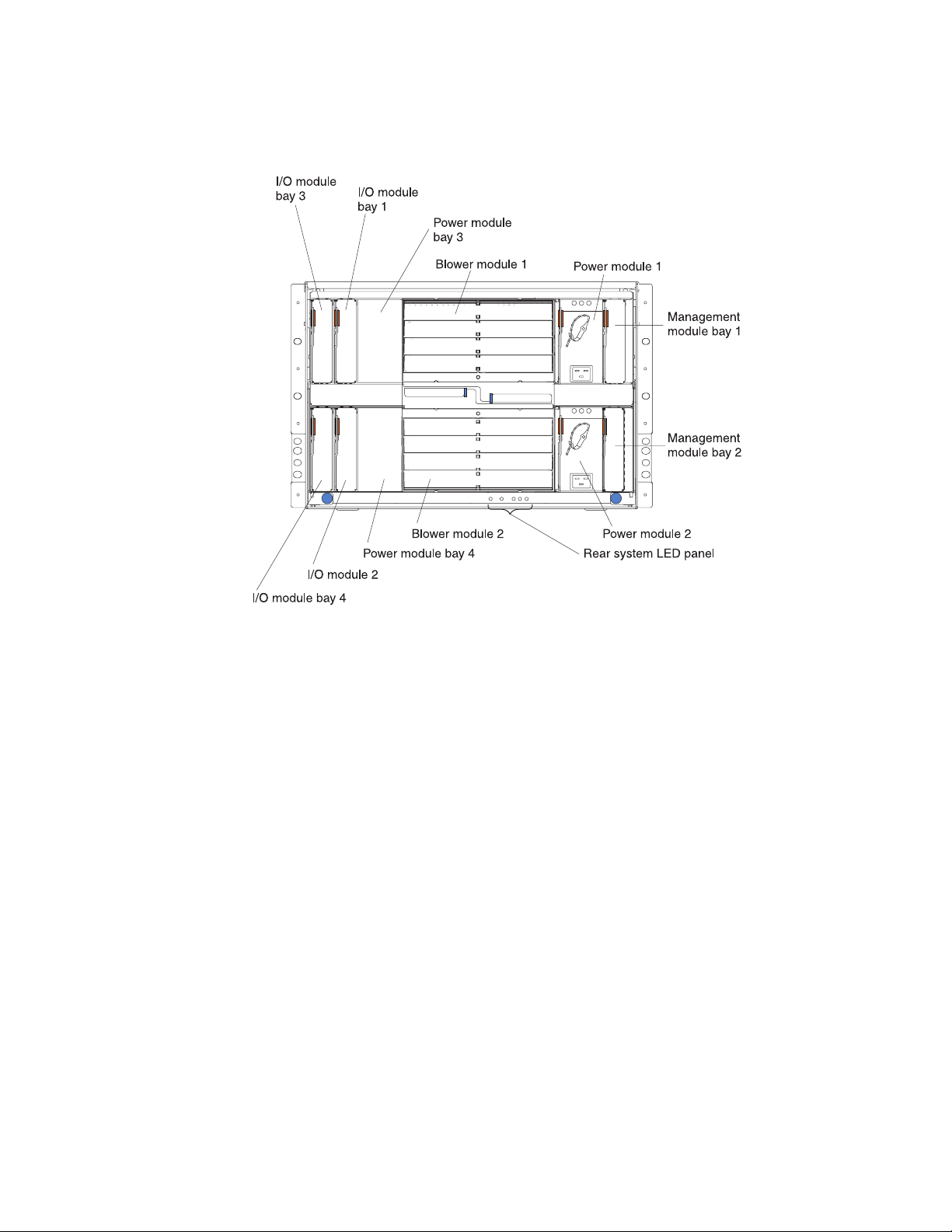

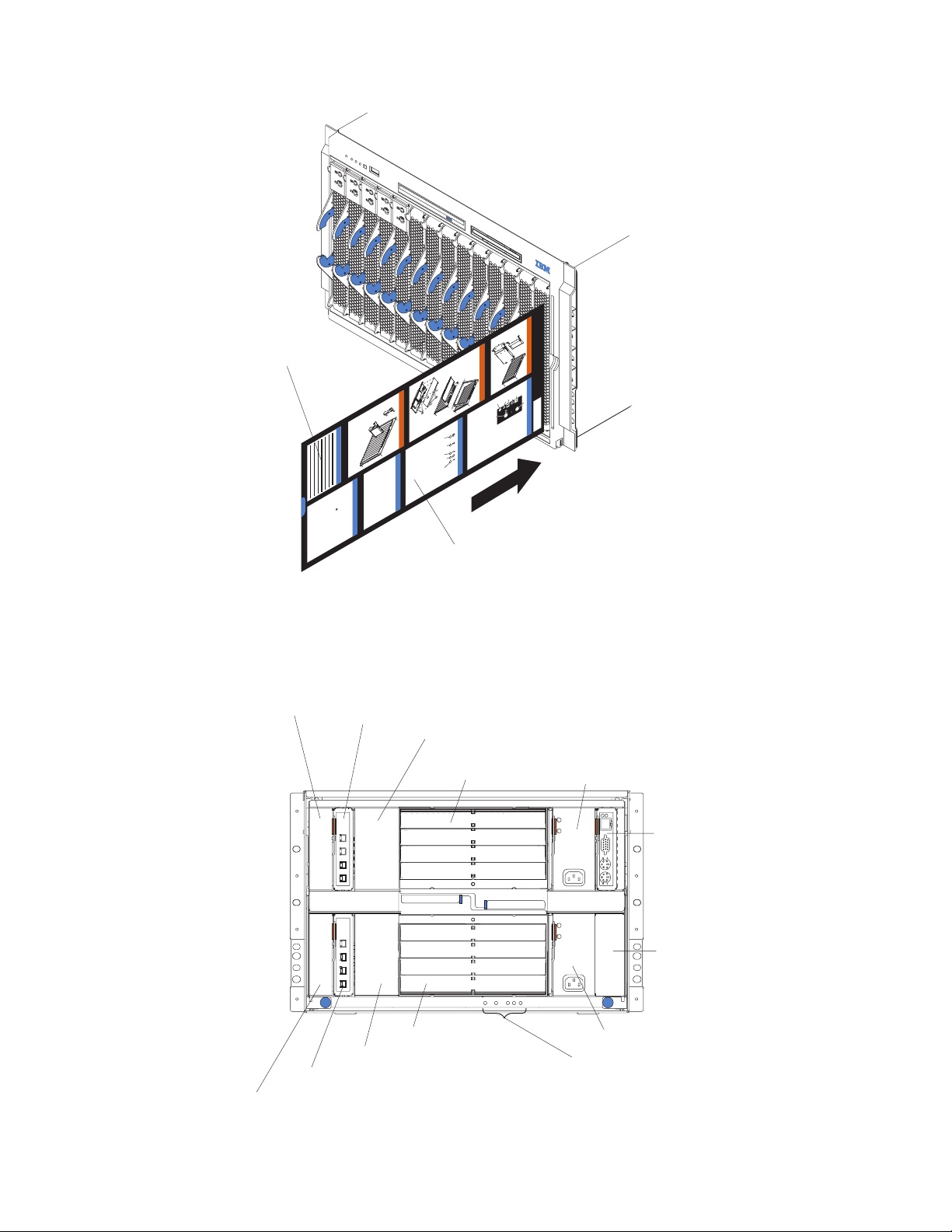

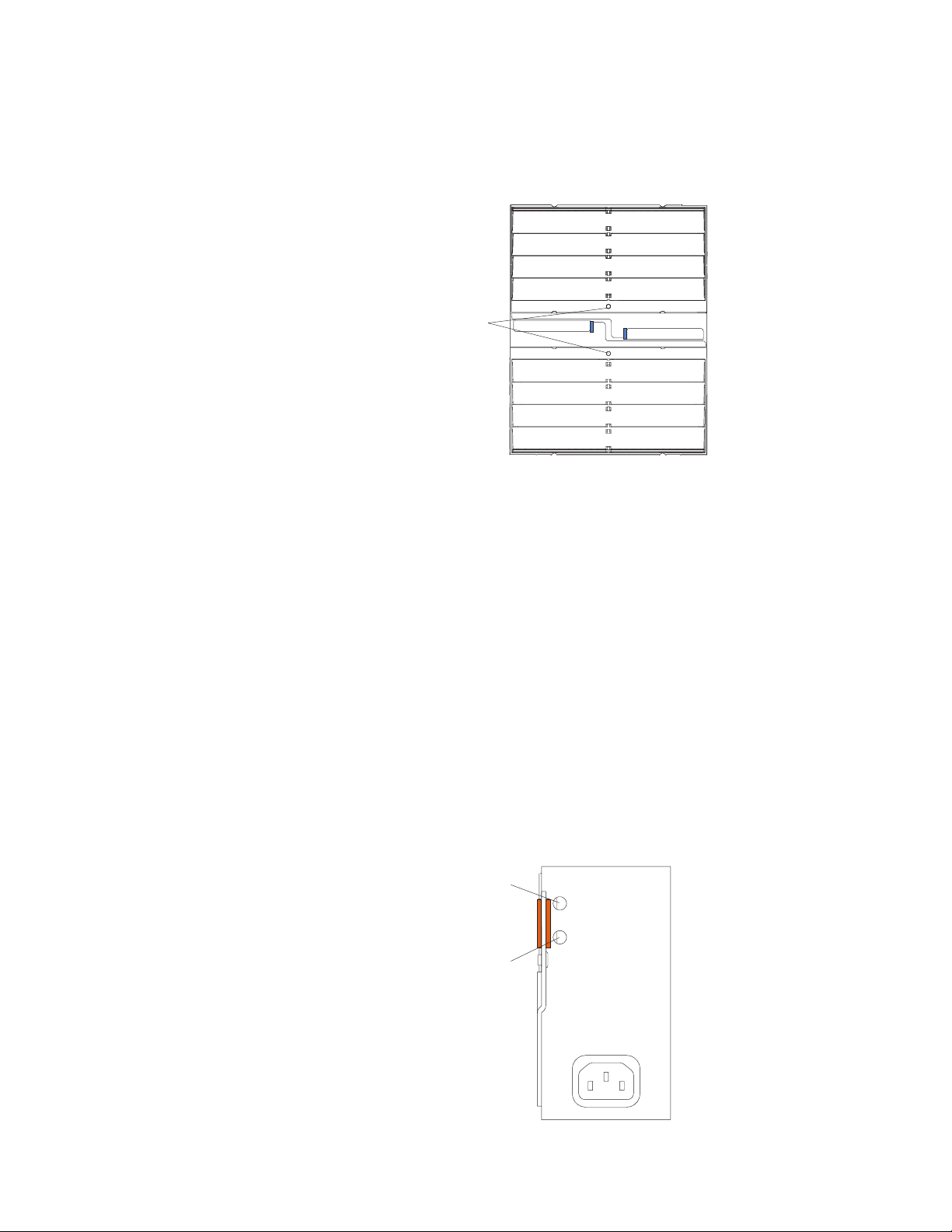

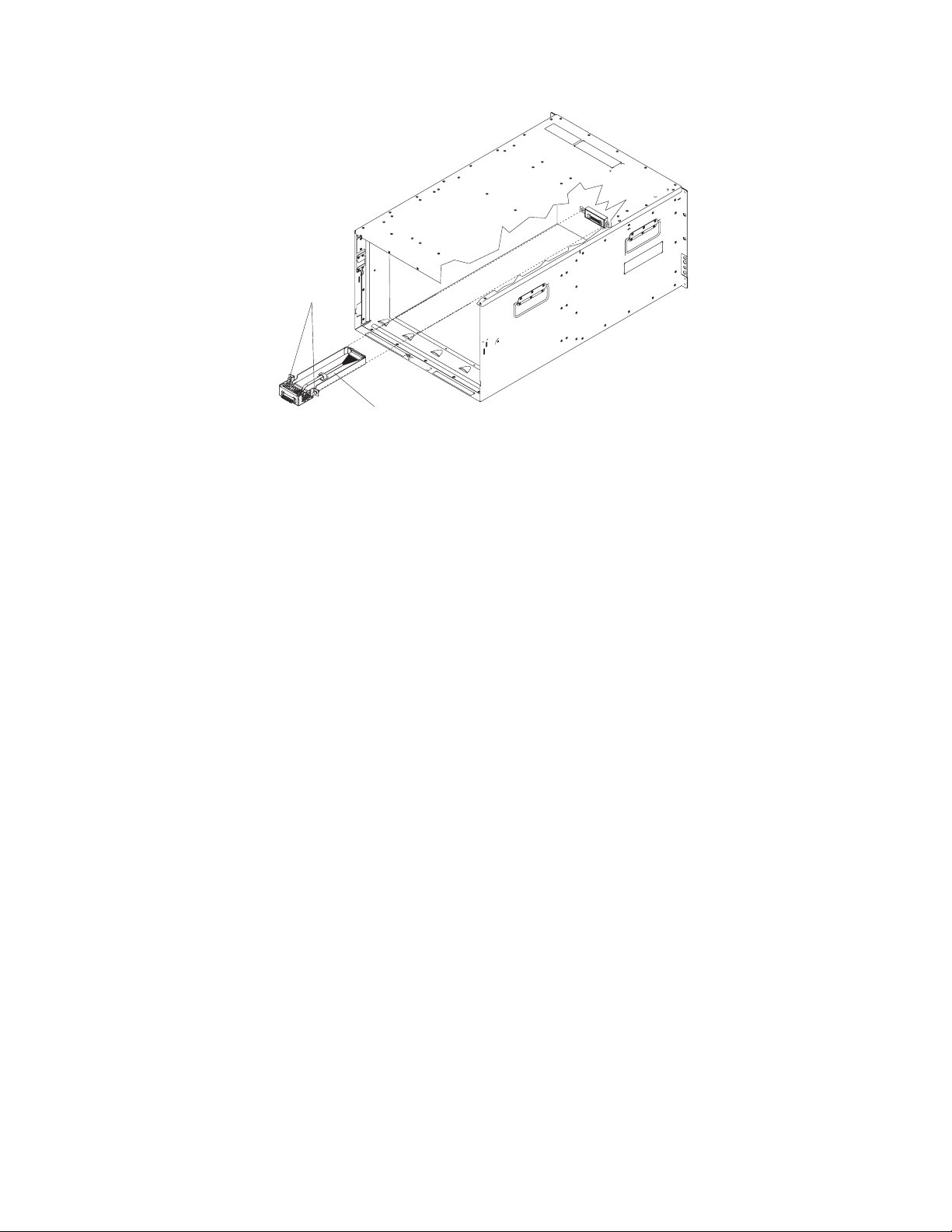

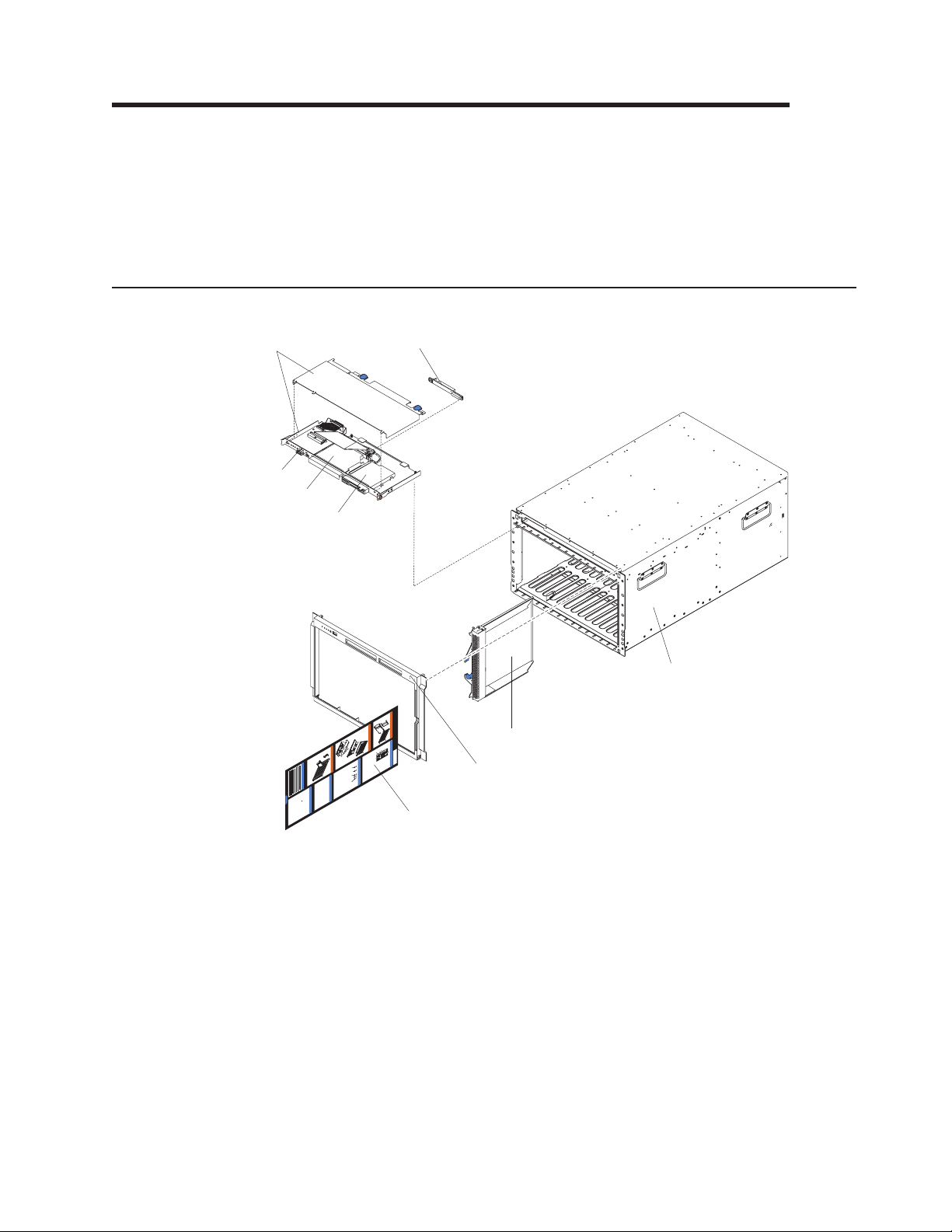

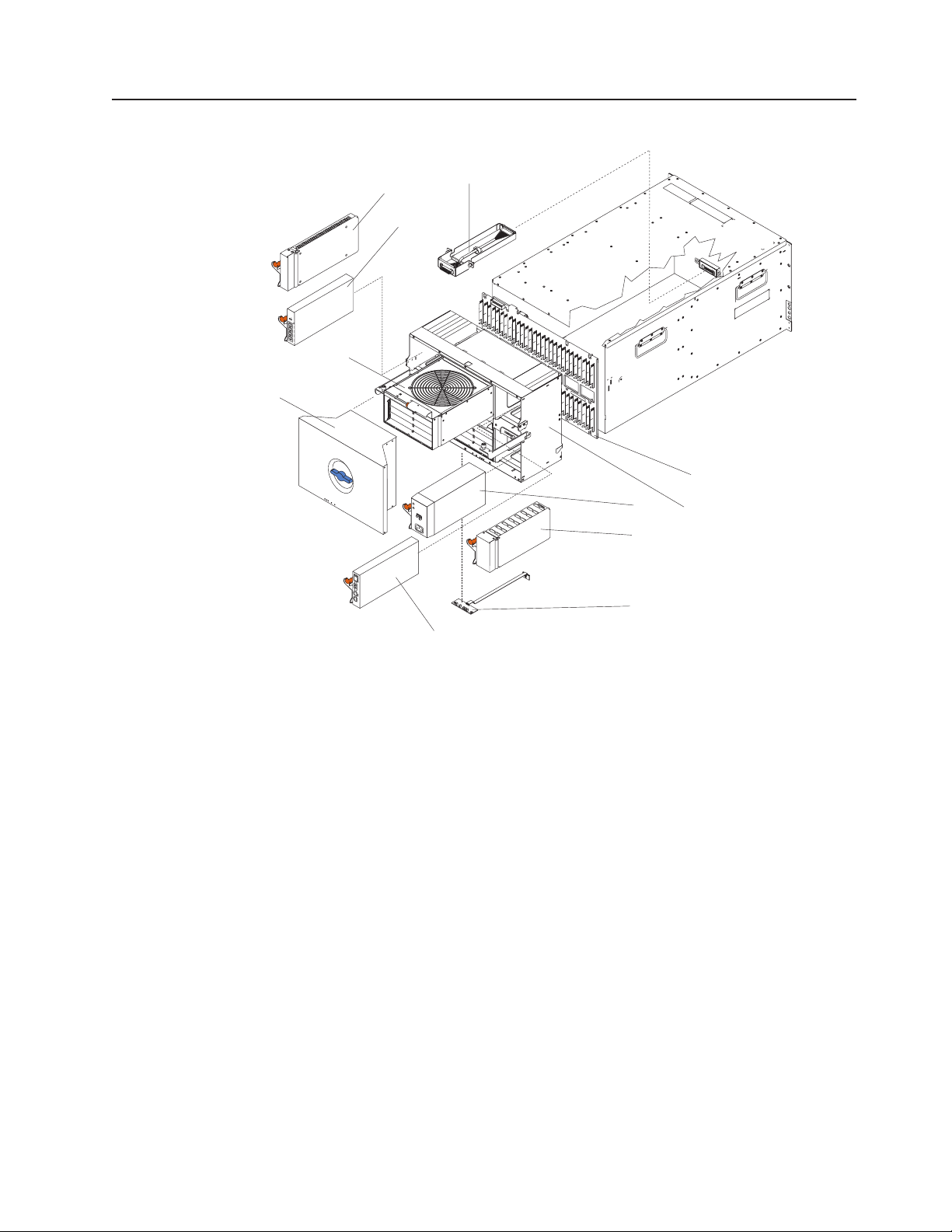

Major components of the BladeCenter Type 8677 and 1881 unit

The following illustration shows the locations of major components in your

BladeCenter unit.

Note: The illustrations in this document might differ slightly from your hardware.

Attention: To maintain proper system cooling, each module bay must contain

either a module or a filler module; each blade bay must contain either a blade

server or a filler blade.

8 BladeCenter E Type 8677 and 1881: Hardware Maintenance Manual and Troubleshooting Guide

Page 19

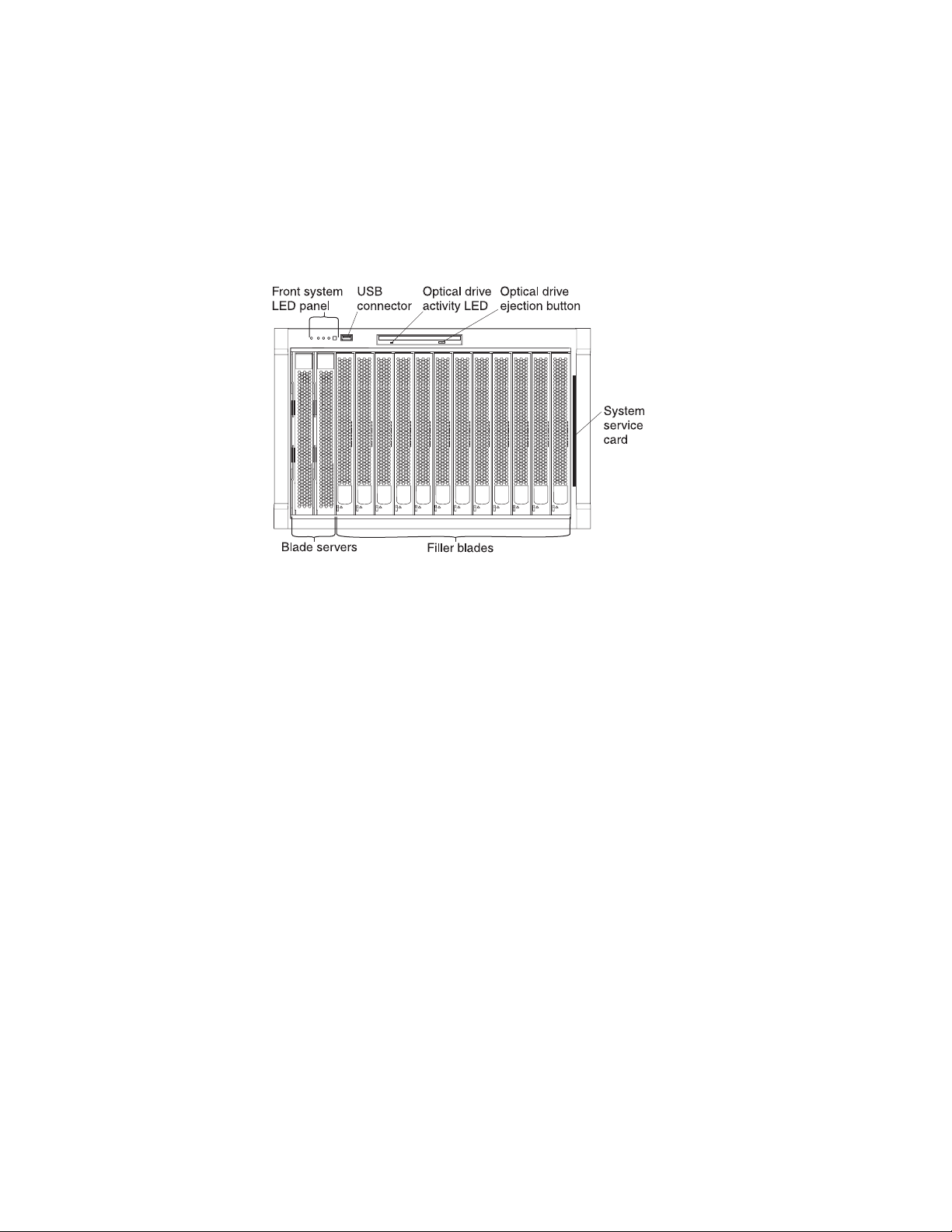

Front view

The following illustration shows the locations of components and indicators on the

front of the BladeCenter Type 8677 and 1881 unit.

See “BladeCenter components, controls, and LEDs” on page 13 for details about

these components and indicators.

Chapter 1. General information 9

Page 20

Rear view

The following illustration shows the locations of components and indicators on the

rear of the BladeCenter Type 8677 and 1881 unit.

See “BladeCenter components, controls, and LEDs” on page 13 for details about

these components and indicators.

10 BladeCenter E Type 8677 and 1881: Hardware Maintenance Manual and Troubleshooting Guide

Page 21

BladeCenter unit power, controls, and indicators

This section describes the controls and light-emitting diodes (LEDs) and how to

start and shut down the BladeCenter unit.

Notes:

1. The removable media drives, keyboard, and mouse in the BladeCenter unit are

viewed as USB devices by the blade server operating system.

2. Local media tray support can be turned off preventing the blade servers from

accessing the removable media drives.

3. Local KVM switching support can be turned off preventing the blade servers

form accessing the keyboard, video, and mouse.

Press keyboard keys in the following sequence to switch KVM control between

blade servers:

NumLock <blade server number> Enter

Where <blade server number> is the two-digit number for the blade bay in which

the blade server is installed.

You will need to press the Shift key to switch KVM control when using the 28L3644

(37L0888) keyboard. If pressing the Shift key does not switch KVM control,

complete the following steps:

1. Press and hold the Shift key.

2. Press keyboard keys in the following sequence:

NumLock <blade server number> Enter

3. Release the Shift key.

Starting the BladeCenter unit

Important: For the LEDs on each system LED panel to function correctly, be sure

to install the management module before turning on the BladeCenter unit. See

Chapter 4, “Installing options,” on page 31 for instructions for installing the

management module.

To start the BladeCenter unit, plug one end of each power cord into a power

module on the rear of the BladeCenter unit and the other end of each power cord

into a 220-volt power distribution unit (PDU) that is plugged into an appropriate

electrical outlet.

After you start the BladeCenter unit, it has dc power. The blade servers in the

BladeCenter unit are connected to dc power but are not turned on. Press the

power-control button on the front of each blade server to obtain full power for the

blade server and start its operating system (see the documentation that comes with

your blade server for information about turning on the blade server).

Note: If a power failure occurs, the BladeCenter unit restarts automatically when

power is restored.

Chapter 1. General information 11

Page 22

Shutting down the BladeCenter unit

You can shut down the BladeCenter unit by turning off the blade servers and

disconnecting the BladeCenter unit from the power source.

Complete the following steps to shut down the BladeCenter unit:

1. Refer to your blade server operating-system documentation for the proper

procedure to shut down the operating system in the blade servers; then, shut

down each operating system.

Statement 5:

CAUTION:

The power control button on the device and the power switch on the

power supply do not turn off the electrical current supplied to the device.

The device also might have more than one power cord. To remove all

electrical current from the device, ensure that all power cords are

disconnected from the power source.

2

1

2. Press the power-control button on the front of each blade server. Wait at least

30 seconds for the blade server drives to stop spinning.

3. Disconnect all power cords on the BladeCenter unit from all the power modules.

Note: After you disconnect the BladeCenter unit from power, wait at least 5

seconds before you connect the BladeCenter unit to power again.

12 BladeCenter E Type 8677 and 1881: Hardware Maintenance Manual and Troubleshooting Guide

Page 23

BladeCenter components, controls, and LEDs

This section identifies the components, controls, and LEDs on the front and rear of

your BladeCenter unit.

Note: The illustrations in this document might differ slightly from your hardware.

Front view

This section identifies the components, controls, and LEDs on the front of your

BladeCenter unit.

Front system LED panel: The LEDs on this panel provide status information for

your BladeCenter unit. See “System LED panel” on page 17 for more information.

USB port: Use this port to attach an external USB device.

Optical-drive activity LED: When this LED is lit, it indicates that the optical drive is

in use.

Optical-drive eject button: Press this button to release a CD or DVD from the

optical drive.

Diskette-drive activity LED (not shown in illustration): For media trays that have a

diskette drive, when this LED is lit, it indicates that the diskette drive is in use.

Diskette-drive eject button (not shown in illustration): For media trays that have a

diskette drive, press this button to release a diskette from the drive.

Blade control panel: This panel contains indicators and controls for the blade

server. See the documentation that comes with your blade server for information

about the blade control panel.

System service card: This card contains system service instructions and a writable

area for your use.

Chapter 1. General information 13

Page 24

Chassis Service Information

H

o

t-P

lu

g

P

r

o

c

e

s

s

o

Writeable

area

H

o

t-P

lu

g

M

e

d

ia

T

ra

H

o

t-S

w

a

p

H

a

r

d

D

is

k

D

riv

C

u

s

to

m

e

r In

fo

r

m

a

tio

n

D

h

p

o

ttp

ro

w

n

file

h

://w

lo

ttp

a

s

d

, a

w

://w

file

n

h

IB

w

d

ttp

s

.ib

M

fre

w

, h

w

://w

h

m

q

in

.ib

ttp

u

server x

.c

ts

e

w

&

n

o

m

://w

C

tly

w

m

tip

o

.c

.ib

m

a

/p

o

w

s

IB

p

s

S

m

c

, c

m

x

k

w

a

e

h

/s

M

e

tib

s

/e

r

.ib

re

.c

ttp

d

ie

e

S

u

q

ility

s

a

o

rie

s

p

m

e

e

te

://w

u

h

m

p

r

r

e

in

ve

.c

c

s

IB

o

v

o

/p

s

/s

m

u

e

o

r

tio

rG

f

M

w

o

c

s

t

r/x

e

m

e

r

to

S

/u

n

w

p

u

m

r

s

/p

id

m

v

s

.ib

e

a

s

a

e

r

e

e

g

c

/c

tio

ve

r

h

e

r

m

/w

g

ie

o

n

r h

o

u

.c

m

w

m

s

id

o

o

p

/e

e

m

e

m

p

a

s

e

t/

a

/s

e

p

g

r

e

e

a

v

r

g

e

v

e

r/

e

r

s

e

s

C

o

m

m

o

n

C

h

a

s

s

is

F

F

o

R

r M

U

s

o

r

e

In

fo

r

m

a

tio

n

y

O

p

Powe

e

ra

r-o

n

to

L

o

c

r P

a

tio

O

n

v

a

e

r-te

n

e

m

In

p

l

f

e

o

r

r

a

m

tu

a

re

tio

n

S

y

s

te

m

e

rro

r

r B

la

d

e

P

r

o

c

e

s

s

o

r B

la

C

d

D

e

O

p

e

ra

to

r P

a

n

e

l

System service card

Rear view

This section identifies the components and indicators on the rear of your

BladeCenter unit.

Switch module

bay 3

Switch module 1

Power module

bay 3

Blower module 1

Blower module 2

Power module bay 4

Power module 1

AC

DC

AC

DC

Power module 2

Rear system LED panel

Switch module 2

Switch module bay 4

14 BladeCenter E Type 8677 and 1881: Hardware Maintenance Manual and Troubleshooting Guide

Management

module

Reserved

Page 25

Rear system LED panel: The LEDs on this panel provide status information for

your BladeCenter unit. These LEDs duplicate the LEDs in the front system LED

panel, see “System LED panel” on page 17 for more information about these LEDs.

Blower module:

Blower error

LEDs

Important: If the ambient temperature is 72° F or below, the BladeCenter blowers

will run at 30% of their maximum rotational speed, increasing their speed as

required to control internal BladeCenter temperature. If ambient temperature is

above 72° F, the blowers will run at 80% of their maximum rotational speed

increasing their speed as required to control internal BladeCenter temperature.

Blower error LEDs: The amber LED on each blower is lit and stays lit when an

error has been detected in the blower. The system-error LED on the BladeCenter

system LED panels is also lit. For additional information, see “Identifying problems

using the Light Path Diagnostics feature” on page 29.

I/O (switch) module: See the documentation that comes with each I/O module for

a description of the LEDs on the I/O module.

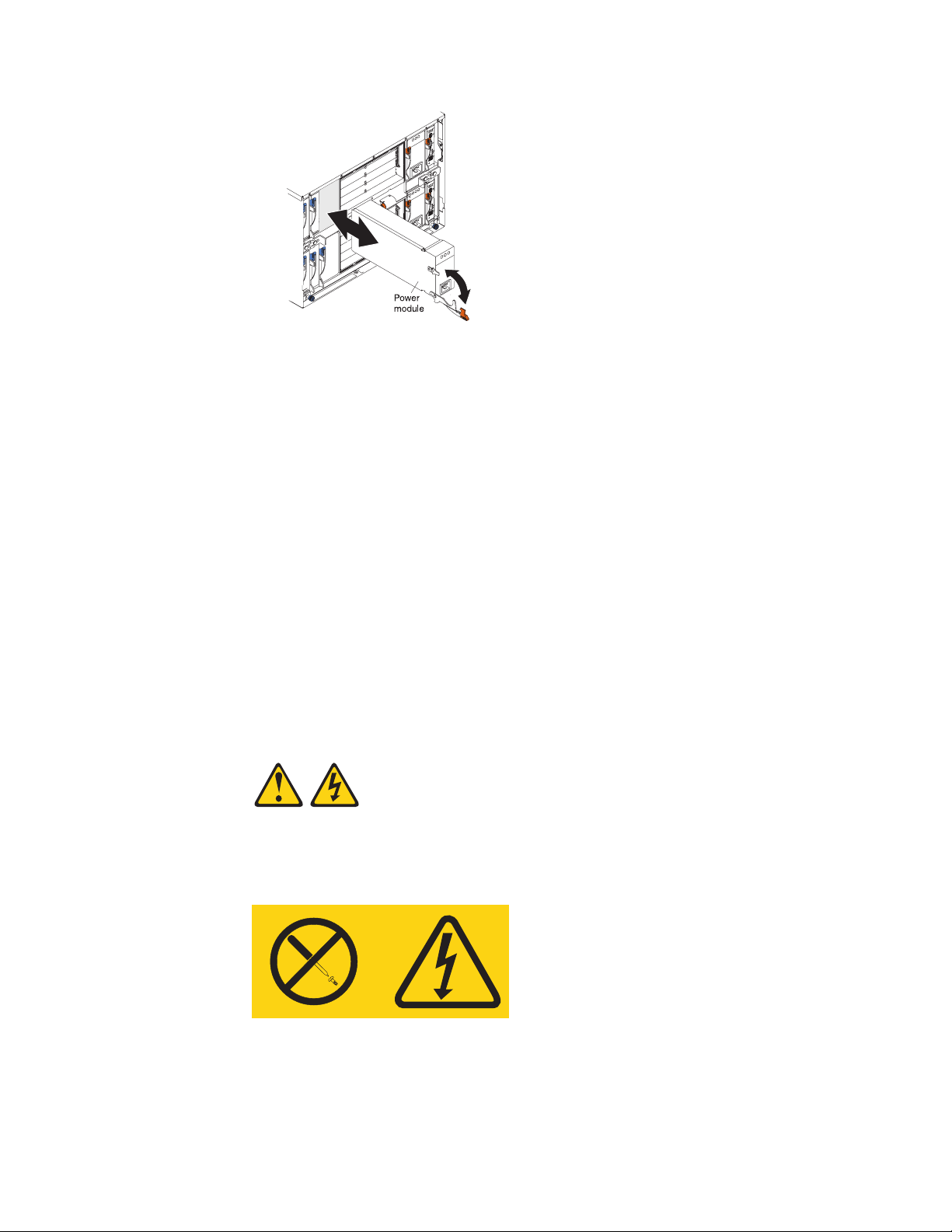

Power module: Several types of power module, with different wattage ratings, can

be used in the BladeCenter E unit.

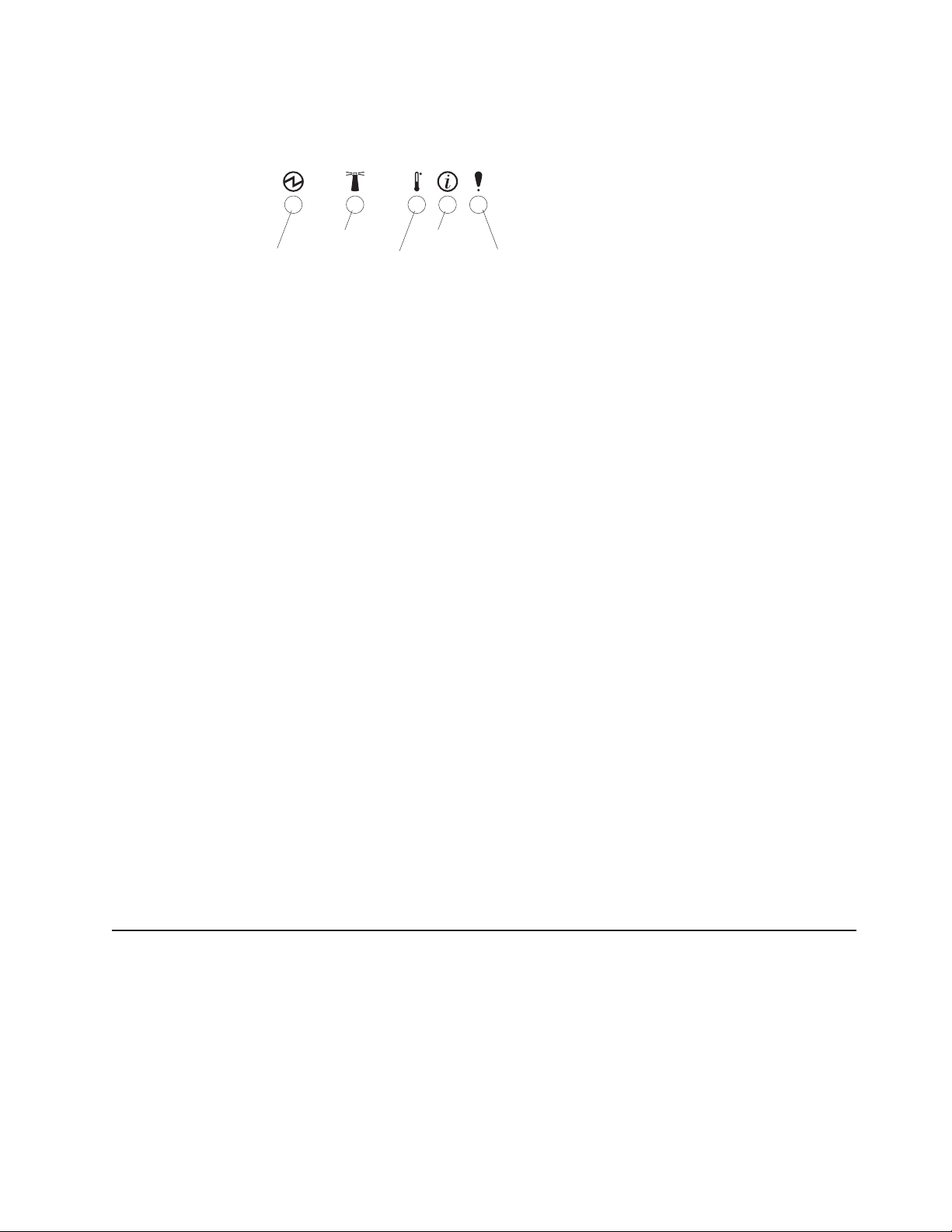

The following illustration shows the rear view for older power modules.

Note: The illustrations might differ slightly from your hardware.

AC power

AC

DC

DC power

Chapter 1. General information 15

Page 26

The following illustration shows the rear view for the currently available power

modules.

Power module LEDs: These LEDs indicate the condition of the power module. For

additional information, see “Identifying problems using the Light Path Diagnostics

feature” on page 29.

v AC power: When this green LED is lit, ac input to the power module is present

and within specifications. During typical operation, both the ac and dc power

LEDs are lit. For any other combination of LEDs, see “Identifying problems using

the Light Path Diagnostics feature” on page 29.

v DC power: When this green LED is lit, the dc output from the power module to

the other components and blade servers is present and within specifications.

During typical operation, both the ac and dc power LEDs are lit. For any other

combination of LEDs, see “Identifying problems using the Light Path Diagnostics

feature” on page 29.

v Power module error LED (2320-watt power modules only): When this amber

LED is lit, it indicates that an error has been detected in the power module.

When this LED is lit, the BladeCenter unit system error LED is also lit.

Management module: The type of management module that is installed in your

BladeCenter unit depends on the BladeCenter unit model and devices that are

installed.

v A BladeCenter unit that has a media tray with a diskette drive can use either a

management module or an advanced management module, depending on which

devices are installed in the BladeCenter unit.

v A BladeCenter unit that has a media tray without a diskette drive must use an

advanced management module.

v If 2320-watt power modules are installed in the BladeCenter unit, you must use

an advanced management module.

v See the documentation that comes with your BladeCenter device to determine if

a specific management module type is required to support the device.

See the documentation for your management module for additional information and

instructions.

16 BladeCenter E Type 8677 and 1881: Hardware Maintenance Manual and Troubleshooting Guide

Page 27

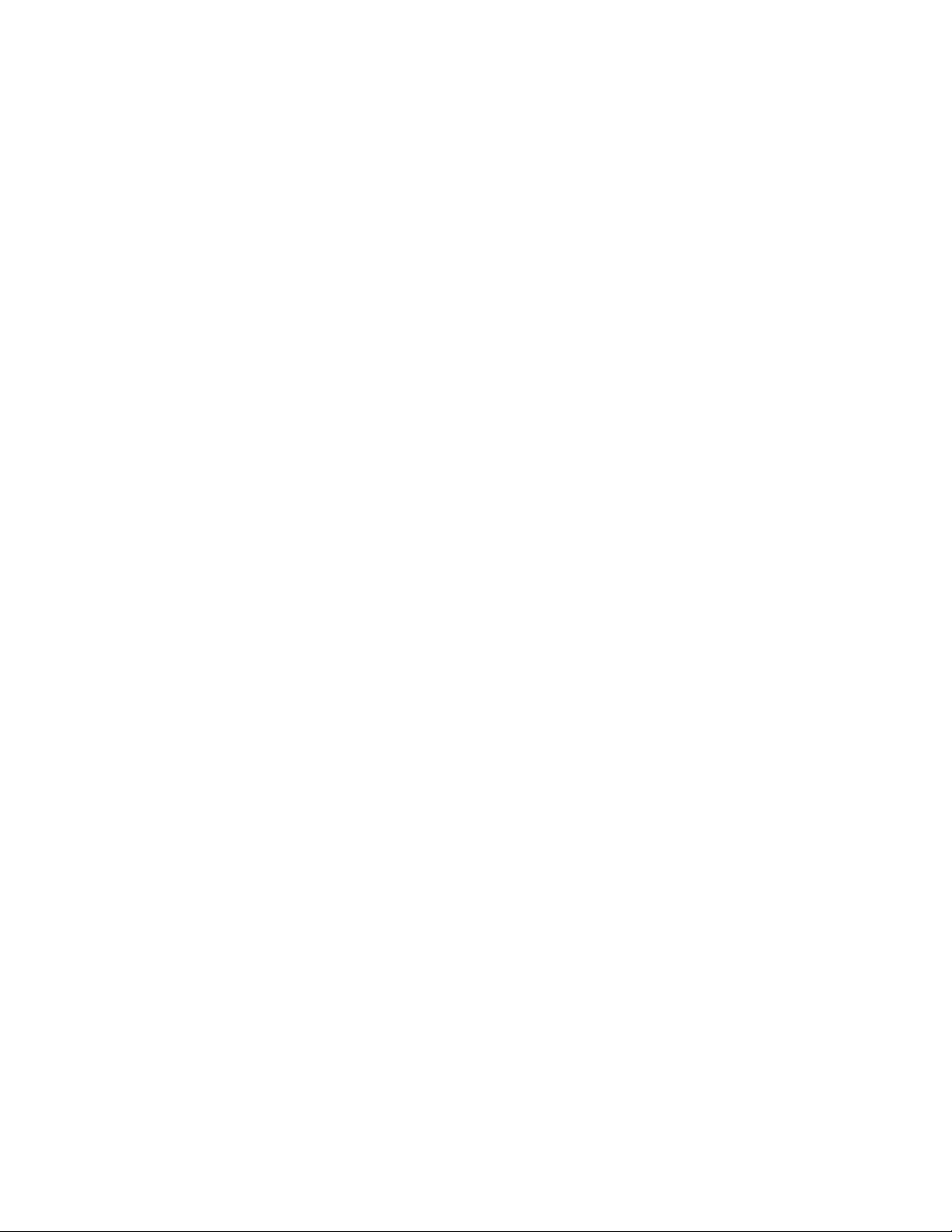

System LED panel

The following illustration shows the status LEDs on the system LED panels on the

front and rear of the BladeCenter unit.

Power-on

Location

Over-temperature

Information

System error

Attention: If the power-on LED is off, it does not mean there is no electrical

current present in the BladeCenter unit. The LED might be burned out. To remove

all electrical current from the BladeCenter unit, you must unplug all power cords

from all power modules.

Note: You can turn off the location LED and the information LED through the Web

interface or the IBM Director console.

Power-on: When this green LED is lit, power is present in the BladeCenter unit.

When this LED is off, the power subsystem, the ac power, or the LED has

failed, or the management module is not present or not functioning.

Location: When this blue LED is lit or flashing, it has been turned on by the

system administrator to aid in visually locating the BladeCenter unit. If a blade

server requires attention, the location LED on the blade server usually will also

be lit. After the BladeCenter unit has been located, you can have the system

administrator turn off the location LED.

Over-temperature: When this amber LED is lit, the temperature in the

BladeCenter unit exceeds the temperature limits, or a blade server has reported

an over-temperature condition. The BladeCenter unit might have already taken

corrective action, such as increasing the blower speed. This LED turns off

automatically when there is no longer an over-temperature condition.

Information: When this amber LED is lit, a noncritical event has occurred that

requires attention, such as the wrong I/O module inserted in a bay or power

demands that exceed the capacity of power modules currently installed. The

event is recorded in the event log. Check the LEDs on the BladeCenter unit and

the blade servers to isolate the component. After the situation is handled, have

the system administrator turn off the information LED.

Note: The information LED will also light if the system error log is 75% full.

System-error: When this amber LED is lit, it indicates that a system error has

occurred, such as a failed module or a system error in a blade server. An LED

on one of the components or on a blade server is also lit to further isolate the

error. (For more information, see “Identifying problems using the Light Path

Diagnostics feature” on page 29.)

Setting up the BladeCenter unit

This section briefly discusses considerations for the setup of your BladeCenter unit.

v Blade bays must be occupied at all times.

To help ensure proper cooling, performance, and system reliability, make sure

that each of the blade bays on the front of the BladeCenter unit has a blade

server, expansion unit, or filler blade installed.

Important: When replacing a blade server or installing an expansion option, do

not operate the BladeCenter unit for more than one minute without either a blade

server, an expansion option, or a filler blade installed in each blade bay.

Chapter 1. General information 17

Page 28

v Module bays must be occupied at all times.

To help ensure proper cooling, performance, and system reliability, make sure

that each of the module bays on the rear of the BladeCenter unit has a module

or filler module installed.

Important: When replacing a module, do not operate the BladeCenter unit for

more than one minute without either a module or a filler module installed in each

module bay.

v There is no power switch on the BladeCenter unit.

The BladeCenter unit does not have a power switch. Plugging the power cords

into the power modules and a 220 V ac power source (rack-mounted 220-volt

PDU) starts the BladeCenter unit (the management module, I/O modules, and

blowers start running).

Each blade server in the BladeCenter unit has an individual power-control button

behind the control-panel door on the blade front that turns on or turns off the

blade server. Be sure to shut down the operating system before turning off the

blade server, to avoid damaging the hard disk drives.

Notes:

1. The blade server power button turns on or turns off the blade server if local

power control has not been disabled through the management module.

2. The blade server power button turns on the blade server only if the green

power light on the blade server is flashing slowly. If the light flashes rapidly,

the blade server has not yet synchronized with the management module, and

the power button will have no effect.

See the IBM BladeCenter Type 8677 Installation and User’s Guide for more

information about the BladeCenter unit. See the Installation and User’s Guide for

your blade server for more information about the blade server power controls and

turning on or turning off the blade server.

v The removable media drives are detected as a Universal Serial Bus (USB)

device

The removable media drives in the BladeCenter unit are viewed as a USB

devices by the operating system in the blade server. Make sure that your

operating system provides USB support.

v Hot-swap capabilities

The front bays on the BladeCenter unit are hot-swap blade bays; the rear bays

on the BladeCenter unit are hot-swap module bays. You can add, remove, or

replace blade servers or management, I/O, power, or blower modules in

hot-swap bays without removing power from the BladeCenter unit.

Attention: To maintain proper system cooling, each unoccupied bay must

contain a filler blade and an expansion or filler module. When replacing a blade

server or installing an expansion option, do not operate the BladeCenter unit for

more than one minute without either a blade server, an expansion option, or a

filler blade installed in each blade bay or without a module or filler installed in

each rear bay.

18 BladeCenter E Type 8677 and 1881: Hardware Maintenance Manual and Troubleshooting Guide

Page 29

Connecting to the default IP address on a new BladeCenter

A newly-installed (out-of-the-box) BladeCenter unit tries to locate a DHCP server on

the network before it will default to the factory-configured static IP address in the

management module. This is the initial configuration setting. When there is no

DHCP server on the network the BladeCenter unit is connected to, it can take

several minutes before the management module uses the default (static) IP

address. When the DHCP search times out and the management module uses the

static IP address, you can change the management module configuration so that it

will not attempt to locate a DHCP server.

See the Installation Guide and User's Guide or Command-Line Interface Reference

Guide for your management module type for information about connecting to and

configuring the BladeCenter management module.

Registering and profiling the BladeCenter products

You can register and profile the BladeCenter unit and blade servers on the World

Wide Web.

v To register, go to: http://www.ibm.com/support/mysupport/

v To profile, go to: http://www.ibm.com/systems/support/

Important:

1. Do not switch control of a shared removable media drive to another blade

server until the activity lights on the drive is off, indicating that no read or write

operations are in progress. Before you remove a hot-swap blade server from

the BladeCenter unit, you must shut down the operating system and turn off the

blade server. You do not have to shut down the BladeCenter unit itself.

2. It can take approximately 20 seconds for the operating system in the

switched-to blade server to recognize the removable media drives and USB port

or the keyboard, video, and mouse.

a. The system-error LED might light, and a KVM allocation error might be

logged if the change in ownership for the removable media drives and USB

port or the keyboard, video, and mouse takes more than 8 seconds. The

system-error LED will go off after the ownership change is complete.

b. It can take up to 48 seconds after a blade server is initially turned on before

you can attempt to switch KVM control to that blade server.

Chapter 1. General information 19

Page 30

20 BladeCenter E Type 8677 and 1881: Hardware Maintenance Manual and Troubleshooting Guide

Page 31

Chapter 2. Configuring your BladeCenter unit

The BladeCenter unit automatically detects the modules and blade servers that are

installed and stores the vital product data (VPD) information. When the BladeCenter

unit is started, it automatically configures the remote-management port on the

management module, so that you can configure and manage the BladeCenter unit

and blade servers. You configure and manage the BladeCenter unit remotely

through the management module using the Web-based user interface.

Note: You can also configure the I/O modules directly through an external

I/O-module port using a Telnet interface or a Web browser. See the documentation

that comes with the I/O module for more information.

For the management module to communicate with the blade servers in the

BladeCenter unit, you will need to configure the IP addresses for the following

internal and external ports:

v The external Ethernet (remote management) port on the management module

(see the User's Guide or Command-Line Interface Reference Guide for your

management module type for instructions). The initial management-module

autoconfiguration enables the network-management station to connect to the

management module to configure the port completely and to configure the rest of

the BladeCenter unit.

v The internal Ethernet port on the management module for communication with

the I/O modules (see the User's Guide or Command-Line Interface Reference

Guide for your management module type for instructions).

v The internal Ethernet management port on each I/O module for communication

with the management module. You configure this port by configuring the IP

address for the I/O module (see the User's Guide or Command-Line Interface

Reference Guide for your management module type for instructions).

Note: Pass-thru modules have no internal Ethernet port.

To communicate with the blade servers for functions such as deploying an operating

system or application program, you also will need to configure at least one external

(in-band) port on an Ethernet switch module. See the BladeCenter Management

Module User’s Guide or the BladeCenter Management Module Command-Line

Interface Reference Guide for information about configuring external ports on I/O

modules.

Note: If a pass-thru module is installed in I/O-module bay 1 or 2 (instead of an

Ethernet switch module), you will need to configure a port on the network switch to

which the pass-thru module is connected.

Management module and advanced management modules support different types

of remote access. See the documentation for your management module type for

information and instructions.

The Web-based user interface and command-line interface communicate with the

management and configuration programs that are part of the firmware that comes

with the management module. You can use these programs to perform tasks such

as:

v Defining the login IDs and passwords

v Selecting recipients for alert notification of specific events

© Copyright IBM Corp. 2011 21

Page 32

v Monitoring the status of the BladeCenter unit and blade servers

v Controlling the BladeCenter unit and blade servers

v Accessing the I/O modules to configure them

v Changing the drive startup sequence in a blade server

v Setting the date and time

v Using a remote console for the blade servers

v Changing ownership of the keyboard, video, and mouse

v Changing ownership of the optical drive, and USB port. (The optical drive in the

BladeCenter unit is viewed as a USB device by the blade server operating

system.)

Note: The IBM Director program is a system-management tool that comes with the

BladeCenter unit. To configure the remote alert recipients for IBM Director over

LAN, the remote alert recipient must be an IBM Director-enabled server.

You also can use the management and configuration programs to view some of the

blade server configuration settings. See the User's Guide or Command-Line

Interface Reference Guide for your management module type for more information.

BladeCenter unit power requirement

The power supply modules in the BladeCenter unit must be connected to 220 V ac

power only. The BladeCenter unit comes with two power cords to connect the

BladeCenter unit to the power distribution unit (PDU).

BladeCenter power configuration

The power modules in power bays 1 and 2 provide power to blade bays 1 through

6 and to common components in the BladeCenter unit. The power modules in

power bays 3 and 4 provide power to blade bays 7 through 14. Power modules

must always be present in power bays 1 and 2.

Attention:

Non-redundant power is not supported by the BladeCenter E unit. Power modules

must always be present in power bays 1 and 2. When any blade server or option is

in blade bay 7 through 14, power modules must be present in power bays 1 and 2,

and power modules must be present in power bays 3 and 4.

If a power module fails or an ac power failure occurs, a BladeCenter unit configured

for redundant power operation will operate in a nonredundant mode, and the blower

modules will run at full speed. You must replace the failing power module or restore

ac power as soon as possible to regain redundant power operation and to reset the

blower modules to their normal operating speed.

See the IBM BladeCenter Power Supply Modules option documentation and the

BladeCenter Type 8677 Installation and User’s Guide for more information.

Firmware updates

The firmware for the management module and other BladeCenter components is

periodically updated and is available for download on the Web. Go to

http://www.ibm.com/support/ to get the latest level of firmware, such as BIOS code

and device drivers.

22 BladeCenter E Type 8677 and 1881: Hardware Maintenance Manual and Troubleshooting Guide

Page 33

Important: Some cluster solutions require specific code levels or coordinated code

updates. If the device is part of a cluster solution, verify that the latest level of code

is supported for the cluster solution before you update the code.

Note: When replacing BladeCenter components, you might have to update the

management module or other components with the latest version of firmware.

Configuring the BladeCenter unit

General configuration of the BladeCenter unit and installed components is

performed through the management module. See the BladeCenter Management

Module User’s Guide and the BladeCenter Management Module Command-Line

Interface Reference Guide for information and instructions. Some devices in the

BladeCenter unit, such as I/O modules and blade servers, might also require

additional configuration. See the documentation that comes with each device for

information and instructions.

Configuring the management module

All management modules are preconfigured with the same static IP address. You

can use the management module to assign a new static IP address. To establish

connectivity, the management module attempts to use Dynamic Host Control

Protocol (DHCP) to acquire its initial IP address for the management-module

Ethernet port. If DHCP is not installed or is enabled and fails, the management

module uses the static IP address. Use the management module to configure other

BladeCenter component settings such as user accounts, DHCP, or Wake on LAN.

See the BladeCenter Management Module User’s Guide and the BladeCenter

Management Module Command-Line Interface Reference Guide for instructions.

Communicating with the IBM Director software

Notes:

1. See the illustration on page 27 for an example of a typical network

configuration. See the IBM BladeCenter Planning and Installation Guide for

more examples of network configurations. You can obtain the planning guide

from http://www.ibm.com/systems/support/.

2. The IBM Director CD comes with the BladeCenter unit.

To communicate with the BladeCenter unit, the IBM Director software needs a

managed object (in the Group Contents pane of the IBM Director Management

Console main window) that represents the BladeCenter unit. If the BladeCenter

management module IP address is known, the network administrator can create an

IBM Director managed object for the unit. If the IP address is not known, the IBM

Director software can automatically discover the BladeCenter unit (out-of-band,

using the Ethernet port on the BladeCenter management module) and create a

managed object for the unit.

For the IBM Director software to discover the BladeCenter unit, your network must

initially provide connectivity from the IBM Director server to the BladeCenter

management-module Ethernet port. To establish connectivity, the management

module attempts to use DHCP to acquire its initial IP address for the Ethernet port.

If the DHCP request fails, the management module uses a static IP address.

Therefore, the DHCP server (if used) must be on the management LAN for your

BladeCenter unit.

Chapter 2. Configuring your BladeCenter unit 23

Page 34

Notes:

1. All management modules are preconfigured with the same static IP address.

You can use the management-module Web interface or command-line interface

to assign a new static IP address for each BladeCenter unit. If DHCP is not

used and you do not assign a new static IP address for each BladeCenter unit

before attempting to communicate with the IBM Director software, only one

BladeCenter unit at a time can be added to the network for discovery. Adding

multiple units to the network without a unique IP address assignment for each

BladeCenter unit results in IP address conflicts.

2. For I/O-module communication with the IBM Director server through the

management-module external Ethernet port, the I/O module internal network

interface and the management-module internal and external interfaces must be

on the same subnet.

Configuring I/O modules

You must install and configure at least one external (in-band) port on an Ethernet

switch module in I/O-module bay 1 to communicate with the Ethernet controllers

that are integrated in each blade server. See the BladeCenter Management Module

User’s Guide and the BladeCenter Management Module Command-Line Interface

Reference Guide for information about configuring external ports on I/O modules.

For I/O-device settings, see the documentation that comes with your I/O device.

See “I/O (switch) modules” on page 34 for information about the location and

purpose of each I/O module.

Notes:

1. If a pass-thru module is installed in I/O-module bay 1, you must configure the

network switch that the pass-thru module is connected to; see the

documentation that comes with the network switch.

2. You can set up Ethernet failover by installing an Ethernet switch module in

I/O-module bay 2.

Configuring blade servers

To achieve communication redundancy on a blade server, you must configure the

Ethernet controllers on the blade servers for failover. When failover occurs on a

blade server, the secondary Ethernet controller takes over network communications,

using the I/O module that is associated with that controller. Install a pair of Ethernet

switches in I/O-module bays 1 and 2; then, configure them and your network

infrastructure so that they can direct traffic to the same destinations. You can also

install a pass-thru module that is connected to an external Ethernet switch in either

or both of these I/O-module bays. See the documentation that comes with your

blade server and operating system for instructions.

Using IBM Director

The IBM Director program is a system-management product that comes with the

BladeCenter unit. Through the remote connection on the management module, you

can use the IBM Director software at the IBM Director console to configure the

BladeCenter unit, modify the configuration, and set up more advanced features.

Notes:

1. Some tasks, such as software distribution, require an in-band connection from

the Director server through a campus (public) LAN to an I/O module port.

2. To manage BladeCenter redundant management modules with the IBM Director

software, IBM Director version 4.1.01 or greater is required.

24 BladeCenter E Type 8677 and 1881: Hardware Maintenance Manual and Troubleshooting Guide

Page 35

The IBM Director software includes the IBM BladeCenter Deployment Wizard.

About the wizard

The BladeCenter Deployment Wizard is integrated into the IBM Director

management software. The wizard walks you through initial startup and

configuration of one or more BladeCenter units.

In addition to performing initial configuration on BladeCenter units, you can use the

built-in IBM Director tasks in the wizard to modify the configuration and to set up

more advanced features.

You can also create a reusable profile in the wizard for configuring or reconfiguring

BladeCenter units. The profile is a noninteractive script that can run as scheduled

or as part of an Event Action Plan. With this feature you can define policies to

reconfigure a BladeCenter unit on demand, responding to hardware failures or other

IBM Director events.

Specifically, you can use the BladeCenter Deployment wizard to perform the

following tasks:

v Perform all initial network configuration, including configuring IP addresses for the

v Set up the initial security profile for the BladeCenter unit, including user names,

v Optionally configure external switch module ports for multi-port link aggregation

management module and the I/O-module internal configuration ports.

passwords, enablement or disablement of management services, and so forth.

(trunking).

Starting the wizard

Start the wizard from the IBM Director Management Console on the Director server.

1. Select one or more BladeCenter units from the middle (contents) pane of the

console window.

Note: A lock icon beside a newly discovered BladeCenter unit indicates that the

Director server cannot log into the management module for that BladeCenter

unit, which can mean that the management module has not been configured

yet. You might want to select that BladeCenter unit for initial configuration

through the wizard.

2. Perform either of the following actions:

v Right-click the selected BladeCenter units (managed objects).

v Drag the wizard task from the right-most pane (under BladeCenter in the task

The wizard starts, and guides you through the login and configuration tasks

needed.

The following illustration shows the main window on the BladeCenter Deployment

wizard.

list) to any of the selected BladeCenter units (managed objects).

Chapter 2. Configuring your BladeCenter unit 25

Page 36

Using Remote Deployment Manager Version 4.1 or later

You can use the Remote Deployment Manager (RDM) Version 4.1 (or later)

program to install a supported Microsoft Windows operating system or a BIOS

update onto a blade server. Follow the instructions in the documentation that comes

with the RDM program to log into the BladeCenter system and install a supported

Microsoft Windows operating system or BIOS update.

Go to http://www-03.ibm.com/systems/management/director/about/director52/

extensions/rdm.html on the World Wide Web for updated information about the

RDM program and to download the software:

BladeCenter networking guidelines

Your networking administrator should assist in the configuration of the network

infrastructure prior to connecting the BladeCenter unit to the LAN switch or similar

network device. This section provides additional guidelines that might be useful in

setting up your system.

A BladeCenter chassis with two Ethernet switch modules and one management

module has the following internal configuration:

26 BladeCenter E Type 8677 and 1881: Hardware Maintenance Manual and Troubleshooting Guide

Page 37

1 Gbps links

1 Gbps or

100 Mbps links

Switch A

1234

MAC MAC MAC

1a 2a 3a

1b 2b 3b

Note: 2nd switch module is optional

5678910

1 Gbps links

11 121314

Mgmt

Mod

Switch B

10/100 Mbps

100 Mbps

links

Each blade server has two independent Ethernet controllers, each with its own

MAC address and a dedicated 1000-Mbps link to one of the I/O modules (Controller

1 to Switch A and Controller 2 to Switch B in this diagram). In this configuration (the

default), the blade servers share access to four external ports on each I/O module.

There is no internal data path between the two switches within the BladeCenter

chassis; an external network device is required for data packets to flow from one

internal switch to the other.

The management module has a separate internal 100-Mbps link to each switch.

These links are for internal management and control only. No data packets are

allowed to flow from application programs on the blade servers to the management

module over this path. A separate, nonswitched path (not shown) is used for

communication between the management module and a service processor on each

blade server.

A typical, preferred BladeCenter network topology is shown in the following

illustration. See the IBM BladeCenter Planning and Installation Guide for more

information and other topologies and guidelines.

Chapter 2. Configuring your BladeCenter unit 27

Page 38

1234

1234

5678910

5678910

11 121314

11 121314

Switch A

Mgmt

Mod

Switch B

Switch A

Mgmt

Mod

Multiport aggregation group

1 Gbps or 100 Mbps links

L2 Switch

10/100 Mbps

management

links

IBM Director

- Chassis management

- Application deployment

L2+ Switch

- Internal switches

Dual

external

switches

Establishment

backbone

1234

5678910

11 121314

Switch B

Switch A

Mgmt

Mod

L2+ Switch

Network administrator

- Infrastructure

management

Switch B

- Network hardware

and software

In this configuration, each BladeCenter unit contains two Ethernet switch modules

and one management module. The external ports on the switch modules are

configured for multi-port link aggregation groups, or trunks, as are the

corresponding ports on the attaching external LAN switches. Additionally, every port

in the switch module in I/O-module bay 1 (switch A in this illustration) in the

BladeCenter units is connected to the same external LAN switch and every port in

the switch module in I/O-module bay 2 (switch B in this illustration) in the

BladeCenter units is connected to the second external LAN switch.

Observe the following guidelines when creating this topology:

1. The external ports on the BladeCenter switch modules are designed for

point-to-point, full-duplex operation to a compatible LAN switch or router.

Configure a corresponding multi-port link aggregation group, or trunk, in both

the switch module and the attaching LAN switch prior to installing the cables.

The connection options are as follows, in order of preference:

v Multi-port Link Aggregation Group or Trunk, 1 Gbps (1000 Mbps) per port

v Single-uplink port, 1 Gbps

v Multi-port Link Aggregation Group or Trunk, 100 Mbps per port

2. Connect the management module 10/100 Mbps Ethernet port to a separate

Layer 2 network if possible, for the best security. If a separate network is not

available, you can attach the Ethernet ports of the management module and

switch modules to the same Layer 2 network.

3. Avoid network configurations that could lead to data loops, if possible. Loops

will be created if you connect multiple ports from the same switch module to the

same Layer 2 network device without first enabling link aggregation. If you

implement configurations that include data loops, it is essential that you enable

Spanning Tree Protocol on the I/O module external ports.

28 BladeCenter E Type 8677 and 1881: Hardware Maintenance Manual and Troubleshooting Guide

Page 39

Chapter 3. Diagnostics

This section provides basic troubleshooting information to help you resolve some

common problems that might occur with your BladeCenter unit.

If you cannot locate and correct the problem using the information in this section,

see Appendix A, “Getting help and technical assistance,” on page 85 for more

information.

Diagnostic tools overview

The following tools are available to help you identify and solve hardware-related

problems:

v Troubleshooting charts

These charts list problem symptoms and steps to correct the problems. See the

Chapter 6, “Symptom-to-FRU index,” on page 59 for more information.

v Diagnostic programs and error messages

The built-in self-test (BIST) program checks the BladeCenter unit during startup

and generates error messages if problems are found.

The system diagnostic program, Real Time Diagnostics Version 1.3, tests the

major components of your BladeCenter unit. The Real Time Diagnostics software

is available from the IBM Support Web site at http://www.ibm.com/systems/

support. It is run from the IBM Director Management Console window (under the

BladeCenter task in the Task panel).

To obtain the Real Time Diagnostics program, go to the following Web site:

http://www.ibm.com/systems/support.

1. Select Servers from the list at the left of the window.

2. Select Downloadable files from the list at the left of the window.

3. In the Downloadable files by category list, select Diagnostic.

4. Click the entry for Real Time Diagnostics and follow the instructions on that

page.

v Light Path Diagnostics feature

Use the Light Path Diagnostics feature to identify system errors quickly. On the

BladeCenter unit, the Light Path Diagnostics feature consists of the LEDs on the

front and rear of the BladeCenter unit and on the front of the modules and blade

servers.

Identifying problems using the Light Path Diagnostics feature

If the system-error LED on the system LED panel on the front or rear of the

BladeCenter unit is lit, one or more error LEDs on the BladeCenter components

also might be on. These LEDs help identify the cause of the problem.

This section provides the information to identify problems that might arise during

installation using the Light Path Diagnostics feature.

© Copyright IBM Corp. 2011 29

Page 40

To locate the actual component that caused the error, you must locate the lit error

LED on that component.

For example:

A system error has occurred, and you have noted that the BladeCenter

system-error LED is lit on the system LED panel. You then locate the module or

blade server that also has an error LED lit (see “BladeCenter unit power, controls,

and indicators” on page 11 for the location of error LEDs; see the documentation

that comes with your blade server for the location of error LEDs on the blade). If the

component is a module, replace the module. If the component is a blade server

with its system-error LED lit, follow the instructions in the documentation that comes

with the blade server to isolate and correct the problem.

30 BladeCenter E Type 8677 and 1881: Hardware Maintenance Manual and Troubleshooting Guide

Page 41

Chapter 4. Installing options

This chapter provides instructions for adding options to your BladeCenter unit.

Some option-removal instructions are provided in case you need to remove one

option to install another.

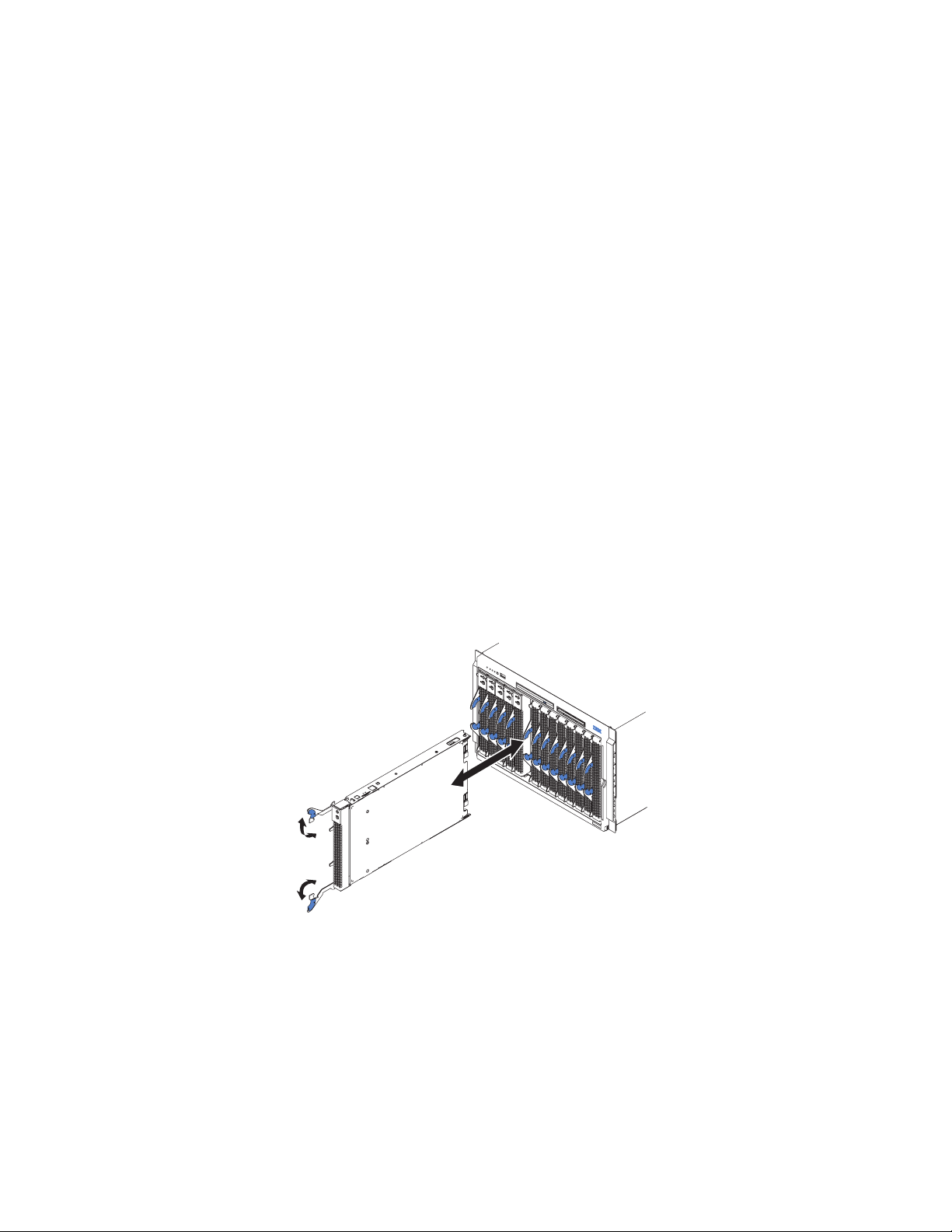

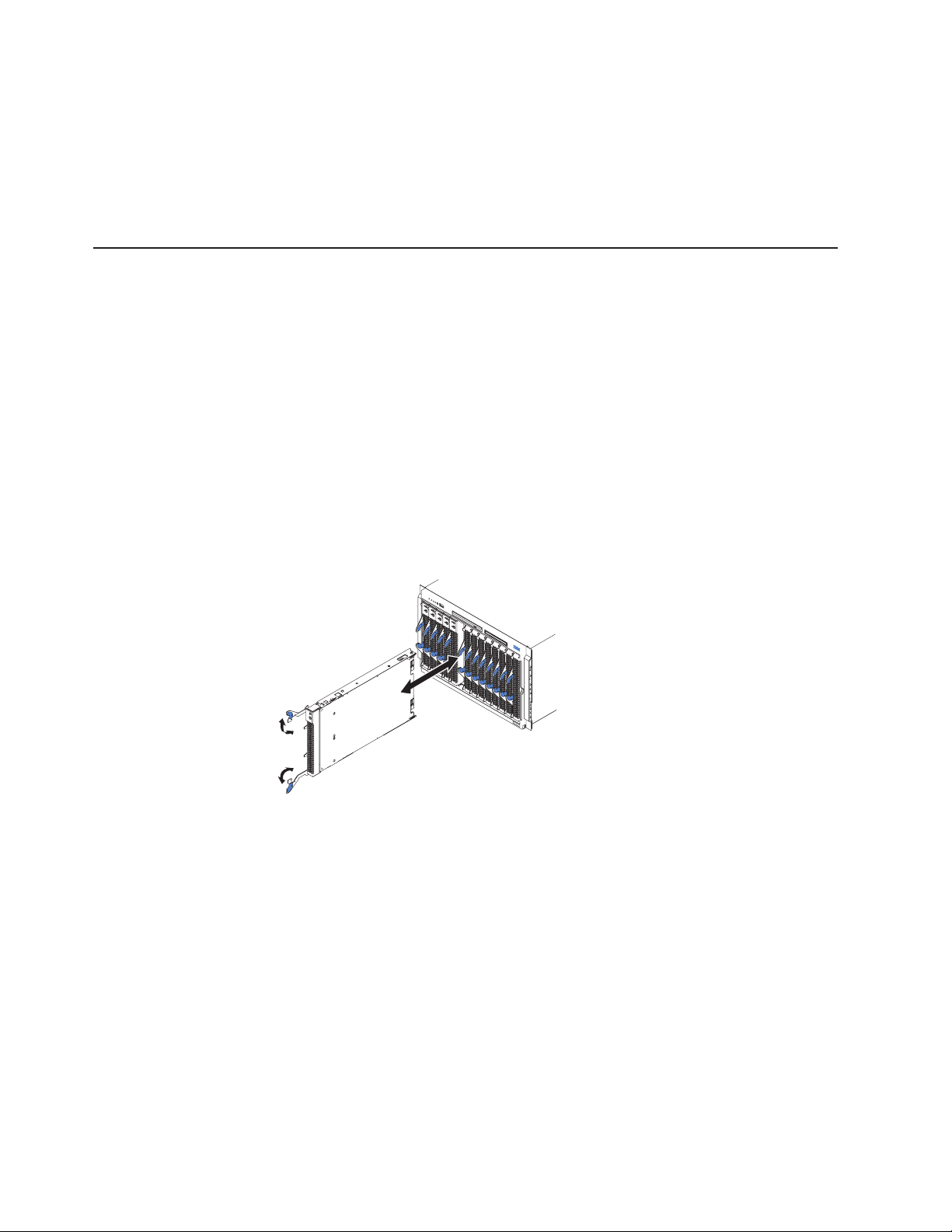

Installing the BladeCenter unit in a rack

Statement 20:

CAUTION:

To avoid personal injury, before lifting the unit, remove all the blades to

reduce the weight.

Statement 4:

≥ 18 kg (39.7 lb) ≥ 32 kg (70.5 lb) ≥ 55 kg (121.2 lb)

CAUTION:

Use safe practices when lifting.

Install the BladeCenter unit in a rack before installing any blade servers in the

BladeCenter unit. If your BladeCenter unit has blade servers already installed,

remove them first. Blade servers are installed from the front of the BladeCenter unit,

without sliding the BladeCenter unit into or out of the rack. Detailed instructions for

installing a BladeCenter unit in a rack are in the Rack Installation Instructions that

come with your BladeCenter unit.

Installation guidelines

Before you begin to install options in your BladeCenter unit, read the following

information:

v Read the “Important safety information” on page vii and the guidelines in

“Handling electrostatic discharge-sensitive devices” on page 90. This information

will help you work safely with your BladeCenter unit and options.

v The orange color on components and labels in your BladeCenter unit identifies

hot-swap components. You can install or remove hot-swap modules and, with

© Copyright IBM Corp. 2011 31

Page 42

some restrictions, hot-swap blade servers while the BladeCenter unit is running.

For complete details about installing or removing a hot-swap component, see the

detailed information in this chapter.

v The blue color on components and labels identifies touch points where you can

grip a component, move a latch, and so on.

v You do not need to disconnect the BladeCenter unit from power to install or

replace any of the hot-swap modules on the rear of the BladeCenter unit. You

need to shut down the operating system and turn off a hot-swap blade server on

the front of the BladeCenter unit before removing the blade server, but you do

not need to shut down the BladeCenter unit itself.

v For a list of supported options for your BladeCenter unit, go to