Page 1

BladeCenter T Ty pe 8720 and 8730

Hardw are Maintenance Manual an d

Troubleshooting Guide

Page 2

Page 3

BladeCenter T Ty p e 8720 and 8730

Hardw are Maintenance Manual an d

Troubleshooting Guide

Page 4

Note

Before using this information and the product it supports, be sure to read Appendix C, “Notices,” on page 157.

Sixth Edition (August 2006)

© Copyright International Business Machines Corporation 2004. All rights reserved.

US Government Users Restricted Rights – Use, duplication or disclosure restricted by GSA ADP Schedule Contract

with IBM Corp.

Page 5

About this manual

This manual contains diagnostic information, a Symptom-to-FRU index, service

information, error codes, error messages, and configuration information for the

BladeCenter

Important safety information

Be sure to read all caution and danger statements in this book before performing

any of the instructions. See “Safety information” on page 113.

Lea todas as instruções de cuidado e perigo antes de executar qualquer operação.

®

Type 8720 and 8730.

Prenez connaissance de toutes les consignes de type Attention et Danger avant de

procéder aux opérations décrites par les instructions.

Lesen Sie alle Sicherheitshinweise, bevor Sie eine Anweisung ausführen.

Accertarsi di leggere tutti gli avvisi di attenzione e di pericolo prima di effettuare

qualsiasi operazione.

© Copyright IBM Corp. 2004 iii

Page 6

Lea atentamente todas las declaraciones de precaución y peligro ante de llevar a

cabo cualquier operación.

Online support

You can download the most current diagnostic, H8 flash, and device driver files

from http://www.ibm.com/pc/support on the World Wide Web.

Support telephone numbers

View support telephone numbers at http://www.ibm.com/planetwide/ on the World

Wide Web.

iv BladeCenter T Type 8720 and 8730: Hardware Maintenance Manual and Troubleshooting Guide

Page 7

Contents

About this manual . . . . . . . . . . . . . . . . . . . . . . . iii

Important safety information . . . . . . . . . . . . . . . . . . . . iii

Online support . . . . . . . . . . . . . . . . . . . . . . . . .iv

Support telephone numbers . . . . . . . . . . . . . . . . . . . .iv

Chapter 1. General information . . . . . . . . . . . . . . . . . . .1

Related publications . . . . . . . . . . . . . . . . . . . . . . .3

Notices and statements used in this book . . . . . . . . . . . . . . .4

Features and specifications for the BladeCenter T Type 8720 unit . . . . . .5

Features and specifications for the BladeCenter T Type 8730 unit . . . . . .7

Major components of the BladeCenter T Types 8720 and 8730 unit . . . . . .9

Front view . . . . . . . . . . . . . . . . . . . . . . . . . .9

Rear view . . . . . . . . . . . . . . . . . . . . . . . . . .15

BladeCenter T unit power, controls, and indicators . . . . . . . . . . . .19

Starting the BladeCenter T unit . . . . . . . . . . . . . . . . . .19

Shutting down the BladeCenter T unit . . . . . . . . . . . . . . .21

Chapter 2. Configuring the BladeCenter T unit . . . . . . . . . . . .23

Setting up the remote connection . . . . . . . . . . . . . . . . . .25

Cabling the Ethernet port . . . . . . . . . . . . . . . . . . . .25

Management and configuration program . . . . . . . . . . . . . . .26

Setting up the management and configuration program . . . . . . . . .26

Starting the management and configuration program . . . . . . . . . .27

Setting management and configuration program options . . . . . . . . .28

Saving and restoring the configuration file . . . . . . . . . . . . . .29

Configuring an I/O module . . . . . . . . . . . . . . . . . . . . .29

What to configure . . . . . . . . . . . . . . . . . . . . . . .29

Supporting Ethernet failover . . . . . . . . . . . . . . . . . . .30

Configuring the Ethernet controllers in the blade servers . . . . . . . .30

BladeCenter T networking guidelines . . . . . . . . . . . . . . . . .31

Using Remote Deployment Manager Version 4.11 Update 3 or later . . . . .33

Using IBM Director . . . . . . . . . . . . . . . . . . . . . . .33

Communicating with the IBM Director software . . . . . . . . . . . .33

Chapter 3. Diagnostics . . . . . . . . . . . . . . . . . . . . .35

Diagnostic tools overview . . . . . . . . . . . . . . . . . . . . .35

Identifying problems using the Light Path Diagnostics feature . . . . . . . .35

Chapter 4. Setting up the BladeCenter T hardware . . . . . . . . . .37

Setting up the BladeCenter T unit . . . . . . . . . . . . . . . . . .37

Installation guidelines . . . . . . . . . . . . . . . . . . . . . .37

Preparing for system power . . . . . . . . . . . . . . . . . . .38

System reliability considerations . . . . . . . . . . . . . . . . .39

Handling static-sensitive devices . . . . . . . . . . . . . . . . .40

Preinstallation steps . . . . . . . . . . . . . . . . . . . . . . .42

Removing and installing the bezel assembly . . . . . . . . . . . . . .43

Removing the bezel assembly . . . . . . . . . . . . . . . . . .43

Installing the bezel assembly . . . . . . . . . . . . . . . . . . .44

Removing and installing the bezel air filter . . . . . . . . . . . . . . .44

Removing and installing power modules . . . . . . . . . . . . . . .46

Removing a power module . . . . . . . . . . . . . . . . . . .47

Installing a power module . . . . . . . . . . . . . . . . . . . .48

Removing and installing the media tray . . . . . . . . . . . . . . . .49

© Copyright IBM Corp. 2004 v

Page 8

Removing the media tray . . . . . . . . . . . . . . . . . . . .50

Installing the media tray . . . . . . . . . . . . . . . . . . . .50

Removing and installing management modules . . . . . . . . . . . . .51

Removing a management module . . . . . . . . . . . . . . . . .52

Installing a management module . . . . . . . . . . . . . . . . .53

Removing and installing blower modules . . . . . . . . . . . . . . .54

Removing a blower module . . . . . . . . . . . . . . . . . . .55

Installing a blower module . . . . . . . . . . . . . . . . . . . .55

Removing and installing the KVM (keyboard, video, mouse) module . . . . .56

Removing the KVM module . . . . . . . . . . . . . . . . . . .57

Installing the KVM module . . . . . . . . . . . . . . . . . . . .57

Removing and installing the LAN module . . . . . . . . . . . . . . .58

Removing the LAN module . . . . . . . . . . . . . . . . . . .59

Installing the LAN module . . . . . . . . . . . . . . . . . . . .59

Removing and installing I/O modules . . . . . . . . . . . . . . . . .60

Removing an I/O module . . . . . . . . . . . . . . . . . . . .62

Installing an I/O module . . . . . . . . . . . . . . . . . . . .62

Blade servers . . . . . . . . . . . . . . . . . . . . . . . . .63

Blade server expansion options . . . . . . . . . . . . . . . . . .63

Removing and installing a blade server or filler module . . . . . . . . .64

Completing the installation . . . . . . . . . . . . . . . . . . . . .66

Chapter 5. Service replaceable units . . . . . . . . . . . . . . . .67

DC terminal cover with fasteners . . . . . . . . . . . . . . . . . .68

AC rear panel . . . . . . . . . . . . . . . . . . . . . . . . .69

DC Rear Panel . . . . . . . . . . . . . . . . . . . . . . . . .70

Upper flex circuit assembly . . . . . . . . . . . . . . . . . . . .71

Lower flex circuit assembly . . . . . . . . . . . . . . . . . . . .72

Docking board/blower housing assembly - (dc Type 8720 and ac Type 8730) 75

Rear chassis stiffener bracket . . . . . . . . . . . . . . . . . . .77

Backplane . . . . . . . . . . . . . . . . . . . . . . . . . .79

Backplane insulator . . . . . . . . . . . . . . . . . . . . . . .81

Air damper . . . . . . . . . . . . . . . . . . . . . . . . . .82

Mechanical chassis . . . . . . . . . . . . . . . . . . . . . . .85

Chapter 6. Symptom-to-FRU index . . . . . . . . . . . . . . . . .89

Error symptoms . . . . . . . . . . . . . . . . . . . . . . . .89

Light path diagnostics LEDs . . . . . . . . . . . . . . . . . . . .98

Temperature error messages . . . . . . . . . . . . . . . . . . . 100

Blower error messages . . . . . . . . . . . . . . . . . . . . . 100

Power error messages . . . . . . . . . . . . . . . . . . . . . 100

Blade server error messages . . . . . . . . . . . . . . . . . . . 101

KVM error message . . . . . . . . . . . . . . . . . . . . . . 102

Switch error messages . . . . . . . . . . . . . . . . . . . . . 102

Management-module error messages . . . . . . . . . . . . . . . . 103

Bus error messages . . . . . . . . . . . . . . . . . . . . . . 104

Undetermined problems . . . . . . . . . . . . . . . . . . . . . 104

Problem determination tips . . . . . . . . . . . . . . . . . . . . 105

Chapter 7. Parts listing, BladeCenter T Type 8720 and 8730 . . . . . . 107

Type 8720 and 8730 - Front view . . . . . . . . . . . . . . . . . 107

Type 8720 and 8730 - Rear view . . . . . . . . . . . . . . . . . . 108

Appendix A. Getting help and technical assistance . . . . . . . . . . 111

Before you call . . . . . . . . . . . . . . . . . . . . . . . . 111

Using the documentation . . . . . . . . . . . . . . . . . . . . . 111

vi BladeCenter T Type 8720 and 8730: Hardware Maintenance Manual and Troubleshooting Guide

Page 9

Getting help and information from the World Wide Web . . . . . . . . . 111

Software service and support . . . . . . . . . . . . . . . . . . .112

Hardware service and support . . . . . . . . . . . . . . . . . . .112

Appendix B. Related service information . . . . . . . . . . . . . .113

Safety information . . . . . . . . . . . . . . . . . . . . . . .113

General safety . . . . . . . . . . . . . . . . . . . . . . . .113

Electrical safety . . . . . . . . . . . . . . . . . . . . . . .114

Safety inspection guide . . . . . . . . . . . . . . . . . . . .115

Handling electrostatic discharge-sensitive devices . . . . . . . . . .116

Grounding requirements . . . . . . . . . . . . . . . . . . . .117

Safety notices (multi-lingual translations) . . . . . . . . . . . . . .117

Appendix C. Notices . . . . . . . . . . . . . . . . . . . . . . 157

Edition notice . . . . . . . . . . . . . . . . . . . . . . . . . 157

Trademarks . . . . . . . . . . . . . . . . . . . . . . . . . . 158

Important notes . . . . . . . . . . . . . . . . . . . . . . . . 158

Product recycling and disposal . . . . . . . . . . . . . . . . . . 159

Battery return program . . . . . . . . . . . . . . . . . . . . . 159

Electronic emission notices . . . . . . . . . . . . . . . . . . . . 160

Federal Communications Commission (FCC) statement . . . . . . . . 160

Industry Canada Class A emission compliance statement . . . . . . . . 160

Australia and New Zealand Class A statement . . . . . . . . . . . . 160

United Kingdom telecommunications safety requirement . . . . . . . . 160

European Union EMC Directive conformance statement . . . . . . . . 161

Taiwanese Class A warning statement . . . . . . . . . . . . . . . 161

Chinese Class A warning statement . . . . . . . . . . . . . . . . 161

Japanese Voluntary Control Council for Interference (VCCI) statement 161

Power cords . . . . . . . . . . . . . . . . . . . . . . . . . 162

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

Contents vii

Page 10

viii BladeCenter T Type 8720 and 8730: Hardware Maintenance Manual and Troubleshooting Guide

Page 11

Chapter 1. General information

®

The IBM

high-density, high-performance blade server systems developed for

telecommunications network applications and other applications requiring physical

robustness.

The BladeCenter T unit uses blade servers, switches, and other components that

are common to the IBM BladeCenter product line. This common component

strategy makes it ideal for applications in telecommunications networks that need

high levels of computing power and access to common off-the-shelf middleware

packages that are used in IT data centers. The BladeCenter T unit supports up to

eight blade servers and four I/O modules, making it ideally suited for networking

environments that require a large number of high-performance servers in a small

amount of space. The BladeCenter T unit provides common resources that are

shared by the blade servers, such as power, cooling, system management, network

connections, backplane, and I/O (CD-ROM drive and connectors for USB, network

interfaces, and – for blade servers that support the KVM function – keyboard, video,

and mouse).

Performance, ease of use, reliability (NEBS/ETSI compliance), and expansion

capabilities were key considerations during the design of the BladeCenter T system.

These design features make it possible for you to customize the system hardware

to meet your needs today, while providing flexible expansion capabilities for the

future.

BladeCenter®T Types 8720 and 8730 units are rack-mounted,

This Hardware Maintenance and Troubleshooting Guide provides information to:

v Set up and cable a BladeCenter T unit

v Start and configure a BladeCenter T unit

v Install and remove modules, options, and blades

v Replace field replaceable units

v Perform troubleshooting and servicing of the BladeCenter T unit

Packaged

with the Hardware Maintenance and Troubleshooting Guide are software

CDs that help you to configure and manage the BladeCenter T unit.

This Hardware Maintenance and Troubleshooting Guide and other publications that

provide detailed information about your BladeCenter T unit are provided in Portable

Document Format (PDF) on the IBM BladeCenter T Documentation CD.

You can register the BladeCenter T unit and blade servers on the World Wide Web.

To register, go to: http://www.ibm.com/pc/register/.

© Copyright IBM Corp. 2004 1

Page 12

Record information about your BladeCenter T unit in the following table. Yo u will

need this information when you register your BladeCenter T unit with IBM.

Product name IBM Eserver BladeCenter T

Machine type (8720 or 8730) _________________________________________

Model number _________________________________________

Serial number _________________________________________

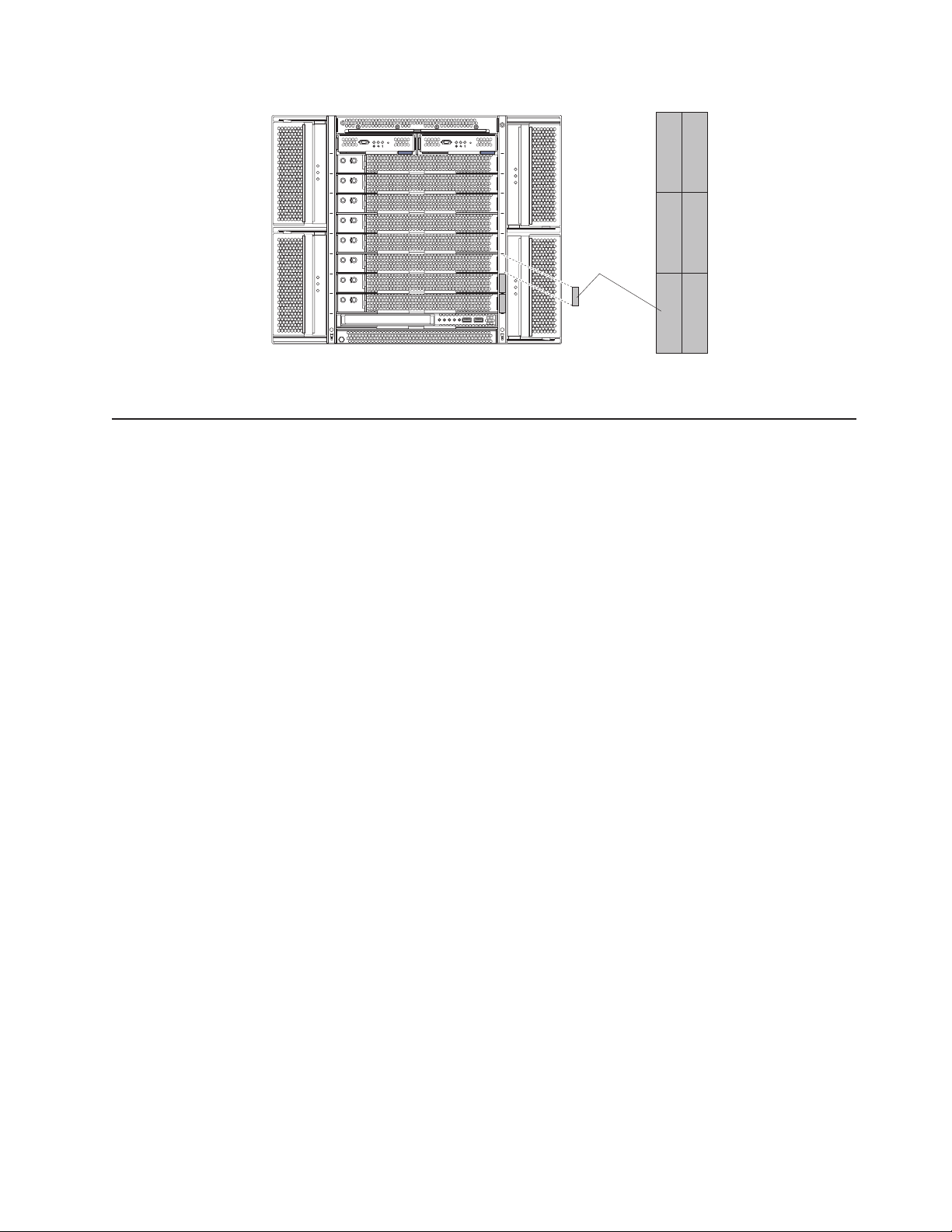

The serial number and model number are located in three places on the

BladeCenter T unit:

v To p of the BladeCenter T unit.

v Front of the bezel assembly.

v Front of the BladeCenter T unit.

labels on the top and the front of the bezel assembly of the BladeCenter T unit

The

are shown in the following illustration.

Information label

C

M

M

1

C

M

M

2

E

S

D

Serial number label

A set of user labels comes with each blade server. When you install a blade server

in the BladeCenter T unit, write identifying information on a label and place the label

on the BladeCenter T unit bezel.

The following illustration shows the placement of the label, to the side of the blade

server, on the BladeCenter T unit.

2 BladeCenter T Type 8720 and 8730: Hardware Maintenance Manual and Troubleshooting Guide

Page 13

Important: Do not place the label on the blade server itself or in any way block the

ventilation holes on the blade server.

Related publications

This Hardware Maintenance and Troubleshooting Guide is provided in Portable

Document Format (PDF). It contains information to help you solve the problem

yourself or to provide helpful information to a service technician.

In addition to this Hardware Maintenance and Troubleshooting Guide, the following

documentation is provided in PDF on the IBM BladeCenter T Documentation CD

that comes with your BladeCenter T unit:

v Safety Information: This document contains translated caution and danger

statements. Each caution and danger statement that appears in the

documentation has a number that you can use to locate the corresponding

statement in your language in the Safety Information document.

v Installation and User’s Guide This publication provides general information about

the server, including information about features, how to configure the server, and

how to get help.

v BladeCenter T rack installation instructions

These documents contain instructions for installing the BladeCenter T unit in a

4-post and 2-post rack.

CMM

1

CMM

2

User

label

Note: The BladeCenter T can also be installed in some xSeries and pSeries

racks, such as the IBM Netbay42 Enterprise Rack Model 9308. See the

installation instructions that come with those racks.

v BladeCenter T Management Module Installation Guide

This document contains instructions for installing an IBM BladeCenter T

management module option in a BladeCenter T unit and creating the initial

configuration.

v BladeCenter T Management Module User’s Guide

This document contains instructions for using the Web interface to configure the

management modules in a BladeCenter T unit.

Additional publications might be included on the IBM BladeCenter T Documentation

CD.

Chapter 1. General information 3

Page 14

Notices and statements used in this book

The caution and danger statements that appear in this book are also in the

multilingual Safety Information book, which is on the IBM BladeCenter T

Documentation CD. Each statement is numbered for reference to the corresponding

statement in the Safety Information book.

The following notices and statements are used in the documentation:

v Note: These notices provide important tips, guidance, or advice.

v Important: These notices provide information or advice that might help you avoid

inconvenient or problem situations.

v Attention: These notices indicate possible damage to programs, devices, or

data. An attention notice is placed just before the instruction or situation in which

damage could occur.

v Caution: These statements indicate situations that can be potentially hazardous

to you. A caution statement is placed just before the description of a potentially

hazardous procedure step or situation.

v Danger: These statements indicate situations that can be potentially lethal or

extremely hazardous to you. A danger statement is placed just before the

description of a potentially lethal or extremely hazardous procedure step or

situation.

4 BladeCenter T Type 8720 and 8730: Hardware Maintenance Manual and Troubleshooting Guide

Page 15

Features and specifications for the BladeCenter T Type 8720 unit

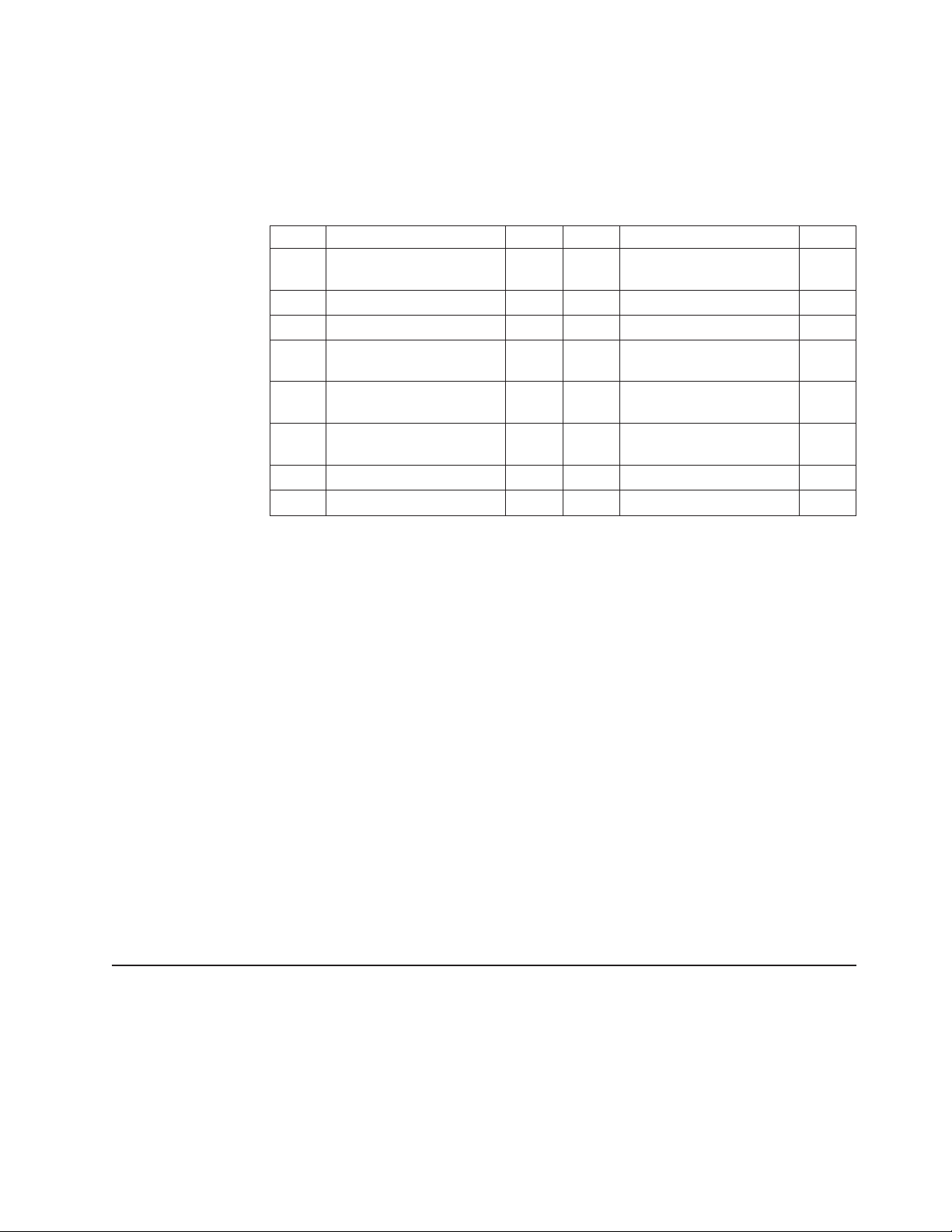

The following table provides a summary of the features and specifications of the

BladeCenter T Type 8720 unit.

Table 1. BladeCenter T Type 8720 features and specifications

Media tray (on front):

v DVD/CD-RW drive: slim IDE

v Two Universal Serial Bus (USB) v2.0

full speed ports

v System-status panel

bays (on front):

Module

v Eight hot-swap blade bays

v Four hot-swap power-module bays

v Two hot-swap management module

bays

Module bays (on rear):

v Four hot-swap I/O module bays

v Four hot-swap blower bays

v One hot-swap KVM (keyboard, video,

mouse) module

v One hot-swap LAN module

modules:

Power

v Standard: Two 1300-watt or greater

hot-swap -48 V dc (-40 to -60 V dc)

power modules

– Power modules 1 and 2 supply

power to:

- Blade bays 1 through 4

- Management modules 1 and 2

- I/O modules 1 and 2

- Media tray

- All KVM, LAN, and alarm

interfaces

- All four blower modules

Power modules 1 and 2 provide

–

redundancy to each other

Maximum: Four 1300-watt or greater

v

hot-swap -48 V dc (-40 to -60 V dc)

power modules

– Power modules 3 and 4 supply

power to:

- Blade bays 5 through 8

- I/O modules 3 and 4

– Power modules 3 and 4 provide

redundancy to each other

– Blowers are powered by all four

power modules

LAN module:

v Two 10/100 Mb Ethernet remote

management connections

v One DSUB 15P alarm connector

module:

KVM

v Video port (analog)

v PS/2 keyboard port

v PS/2 mouse port

v System-status panel

I/O modules:

v Standard: None

v Maximum: Four

– Two hot-swap 1 Gb Ethernet

four-port switch modules

– Two hot-swap switch modules of

another network-communication

standard, such as Fibre Channel

Management

module:

v Standard: One hot-swap management

module providing system-management

functions for the BladeCenter T unit

v Maximum: Two hot-swap management

modules (one active, one redundant)

Redundant

cooling:

Four variable-speed hot-swap blowers

Front bezel with changeable filter

Upgradeable microcode:

v management module firmware

v I/O-module firmware (not all I/O module

types)

v Blade server service processor firmware

(BIOS, service processor)

(8 U):

Size

v Height: 349.25 mm (13.75 in. or 8 U)

v Depth: 508 mm (20 in.) from front of

chassis to rear I/O connector plane

Maximum depth: 600 mm (23.62 in.)

including bezel, handles, and cable

bend radius.

v Width: 442 mm (17.4 in.)

v Weight:

– Fully configured with modules and

blade servers: Approx. 100.2 kg (221

lb)

– Fully configured without blade

servers: Approx. 61.7 kg (136 lb)

Security

features:

v Login password for remote connection

v Lightweight Directory Access Protocol

(LDAP) and role based security for user

authentication and authorization

v Secure Shell (SSH) for remote

command-line interface

v Secure socket layer (SSL) security for

remote Web interface access

®

Predictive Failure Analysis

(PFA)

alerts:

v Blowers

v Blade-dependent features

v Power supplies

Declared acoustical noise emission levels

for normal operations:

v Sound-power levels (upper-limit): 7.8 bels

v Sound-pressure levels (average), for four

one-meter bystander positions: 63 dBA

noise emission levels stated are the

The

declared upper limit sound-power levels, in

bels, for a random sample of machines. All

measurements made in accordance with ISO

7779 and reported in conformance with ISO

9296.

Environment:

v Air temperature:

– Altitude: -60 to 1800 m (-197 ft to 6000

ft)

- BladeCenter T on: 5° to 40°C (41° to

104°F)

- BladeCenter T on (short term): -5° to

55°C (23° to 131°F)

Altitude: 1800 m to 4000 m (6000 ft to

–

13000 ft)

- BladeCenter T on: 5° to 30°C (41° to

86°F)

- BladeCenter T on (short term): -5° to

45°C (23° to 113°F)

– System unit off: uncontrolled

Rate of temperature change: 30°C/hour

v

(54°F/hour)

v Humidity:

– BladeCenter T on: 5% to 85%

– BladeCenter T on (short term): 5% to

90% not to exceed 0.024 water/kg of dry

air

– BladeCenter T off: uncontrolled

Electrical

input:

v dc power

v Input voltage: -48 V dc (-38 V dc to -75 V

dc)

v Input current:

– Chassis: 70 amp maximum

– Single power-supply feed: 70 amp

maximum

Input connector type: Two (2) four post DC

v

terminals, rated at 70 amps each.

output:

Heat

v Input kilovolt-amperes (kVA) approx.

– Minimum configuration: 0.2 kVA

Maximum configuration: 3.7 kVA

–

v BTU output

– Ship configuration:

673 Btu/hour (197 watts)

– Full configuration:

12640 Btu/hour (3707 watts)

Chapter 1. General information 5

Page 16

Notes:

1. For details about the BladeCenter T unit port specifications, see “BladeCenter T

unit power, controls, and indicators” on page 19.

2. For information about which types of I/O modules can be installed in which

I/O-module bays, see “I/O modules” on page 19.

3. The operating system in the blade server must provide USB support for the

blade server to recognize and use the keyboard, mouse, and CD-ROM drive.

The BladeCenter T unit uses USB for internal communication with these

devices.

6 BladeCenter T Type 8720 and 8730: Hardware Maintenance Manual and Troubleshooting Guide

Page 17

Features and specifications for the BladeCenter T Type 8730 unit

The following table provides a summary of the features and specifications of the

BladeCenter T Type 8730 unit.

Table 2. BladeCenter T Type 8730 features and specifications

Media tray (on front):

v DVD/CD-RW drive: slim IDE

v Two Universal Serial Bus (USB) v2.0

full speed ports

v System-status panel

bays (on front):

Module

v Eight hot-swap blade bays

v Four hot-swap power-module bays

v Two hot-swap management module

bays

Module bays (on rear):

v Four hot-swap I/O module bays

v Four hot-swap blower bays

v One hot-swap KVM (keyboard, video,

mouse) module

v One hot-swap LAN module

modules:

Power

v Standard: Two 1300-watt or greater

220-volt (200-240 V ac) hot-swap

power modules

– Power modules 1 and 2 supply

power to:

- Blade bays 1 through 4

- Management modules 1 and 2

- I/O modules 1 and 2

- Media tray

- All KVM, LAN, and alarm

interfaces

- All four blower modules

Power modules 1 and 2 provide

–

redundancy to each other

Maximum: Four 1300-watt or greater

v

220-volt (200-240 V ac) hot-swap

power modules

– Power modules 3 and 4 supply

power to:

- Blade bays 5 through 8

- I/O modules 3 and 4

– Power modules 3 and 4 provide

redundancy to each other

– Blowers are powered by all four

power modules

LAN module:

v Two 10/100 Mb Ethernet remote

management connections

v One DSUB 15P alarm connector

module:

KVM

v Video port (analog)

v PS/2 keyboard port

v PS/2 mouse port

v System-status panel

I/O modules:

v Standard: None

v Maximum: Four

– Two hot-swap 1 Gb Ethernet

four-port switch modules

– Two hot-swap switch modules of

another network-communication

standard, such as Fibre Channel

Management

module:

v Standard: One hot-swap management

module providing system-management

functions for the BladeCenter T unit

v Maximum: Two hot-swap management

modules (one active, one redundant)

Redundant

cooling:

Four variable-speed hot-swap blowers

Front bezel with changeable filter

Upgradeable microcode:

v management module firmware

v I/O-module firmware (not all I/O module

types)

v Blade server service processor firmware

(BIOS, service processor)

(8 U):

Size

v Height: 349.25 mm (13.75 in. or 8 U)

v Depth: 508 mm (20 in.) from front of

chassis to rear I/O connector plane

Maximum depth: 600 mm (23.62 in.)

including bezel, handles, and cable

bend radius.

v Width: 442 mm (17.4 in.)

v Weight:

– Fully configured with modules and

blade servers: Approx. 100.2 kg (221

lb)

– Fully configured without blade

servers: Approx. 61.7 kg (136 lb)

Security

features:

v Login password for remote connection

v Secure Shell (SSH) for command-line

interface

v Secure socket layer (SSL) security for

remote Web management access

Predictive

Failure Analysis (PFA) alerts:

v Blowers

v Blade-dependent features

v Power supplies

Declared acoustical noise emission levels

for normal operations:

v Sound-power levels (upper-limit):7.8 bels

v Sound-pressure levels (average), for four

one-meter bystander positions: 63 dBA

noise emission levels stated are the

The

declared upper limit sound-power levels, in

bels, for a random sample of machines. All

measurements made in accordance with ISO

7779 and reported in conformance with ISO

9296.

Environment:

v Air temperature:

– BladeCenter T on: 10° to 35°C (50° to

95°F). Altitude: 0 to 914 m (2998.69 ft).

– BladeCenter T on: 10° to 32°C (50° to

89.6°F). Altitude: 914 m to 2134 m

(2998.69 ft to 7000 ft).

– BladeCenter T off: -40° to 60° C (-40° to

140°).

v Humidity:

– Server on: 8% to 80%

– Server off: 8% to 80%

Electrical

input:

v Sine-wave input (50 or 60 Hz single-phase)

required

v Input voltage:

– Minimum: 200 V ac

– Maximum: 240 V ac

Input current:

v

– Chassis: 18 amp maximum @ 208 V ac

– Single power-supply feed: 9 amp

maximum

Input connector type: Four (4) C13 inputs,

v

rated at 8 amps each

output:

Heat

v Input kilovolt-amperes (kVA) approx.

– Minimum configuration: 0.2 kVA

– Maximum configuration: 3.5 kVA

BTU output

v

– Ship configuration:

673 Btu/hour (197 watts)

– Full configuration:

11900 Btu/hour (3490 watts)

Chapter 1. General information 7

Page 18

Notes:

1. For details about the BladeCenter T unit port specifications, see “BladeCenter T

unit power, controls, and indicators” on page 19.

2. For information about which types of I/O modules can be installed in which

I/O-module bays, see “I/O modules” on page 19.

3. The operating system in the blade server must provide USB support for the

blade server to recognize and use the keyboard, mouse, and CD-ROM drive.

The BladeCenter T unit uses USB for internal communication with these

devices.

8 BladeCenter T Type 8720 and 8730: Hardware Maintenance Manual and Troubleshooting Guide

Page 19

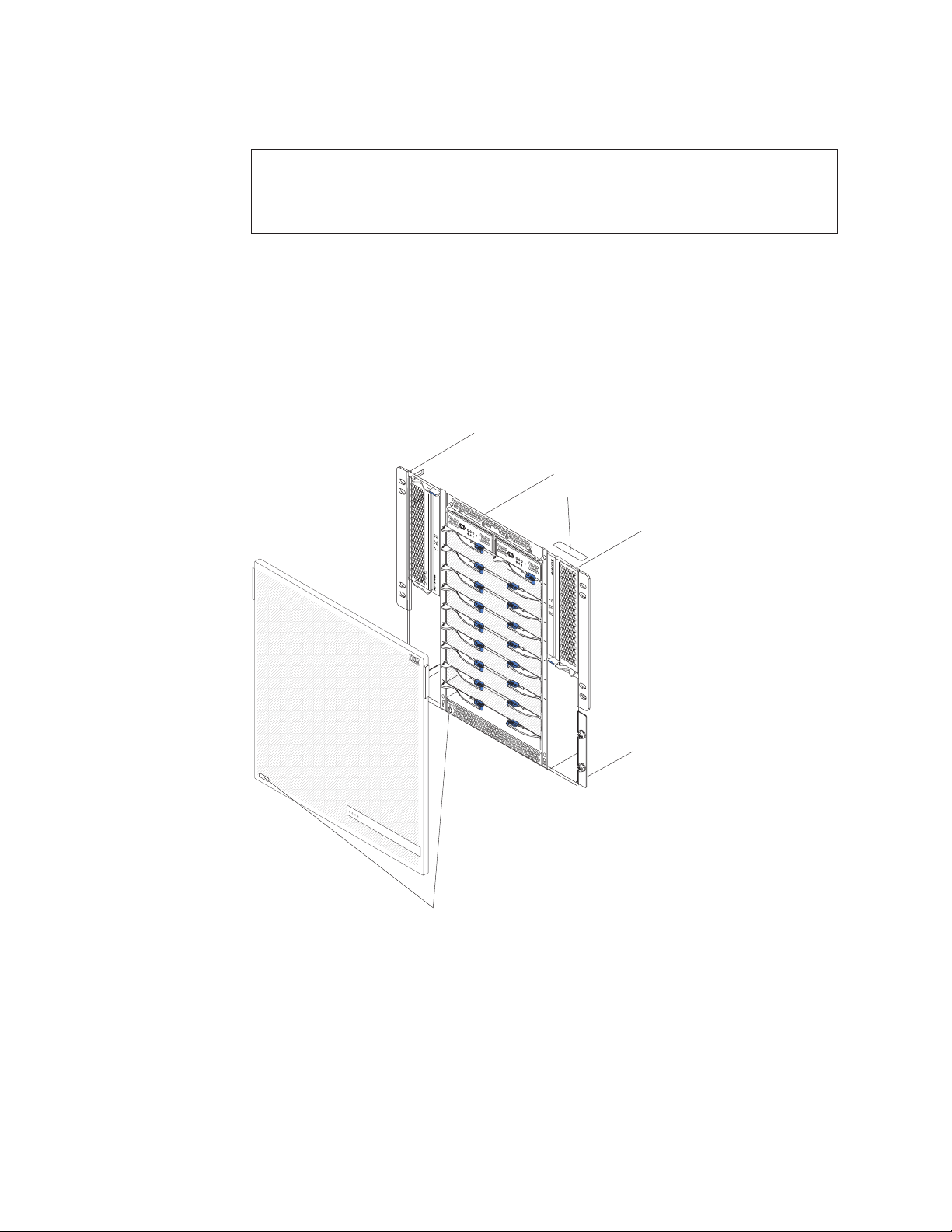

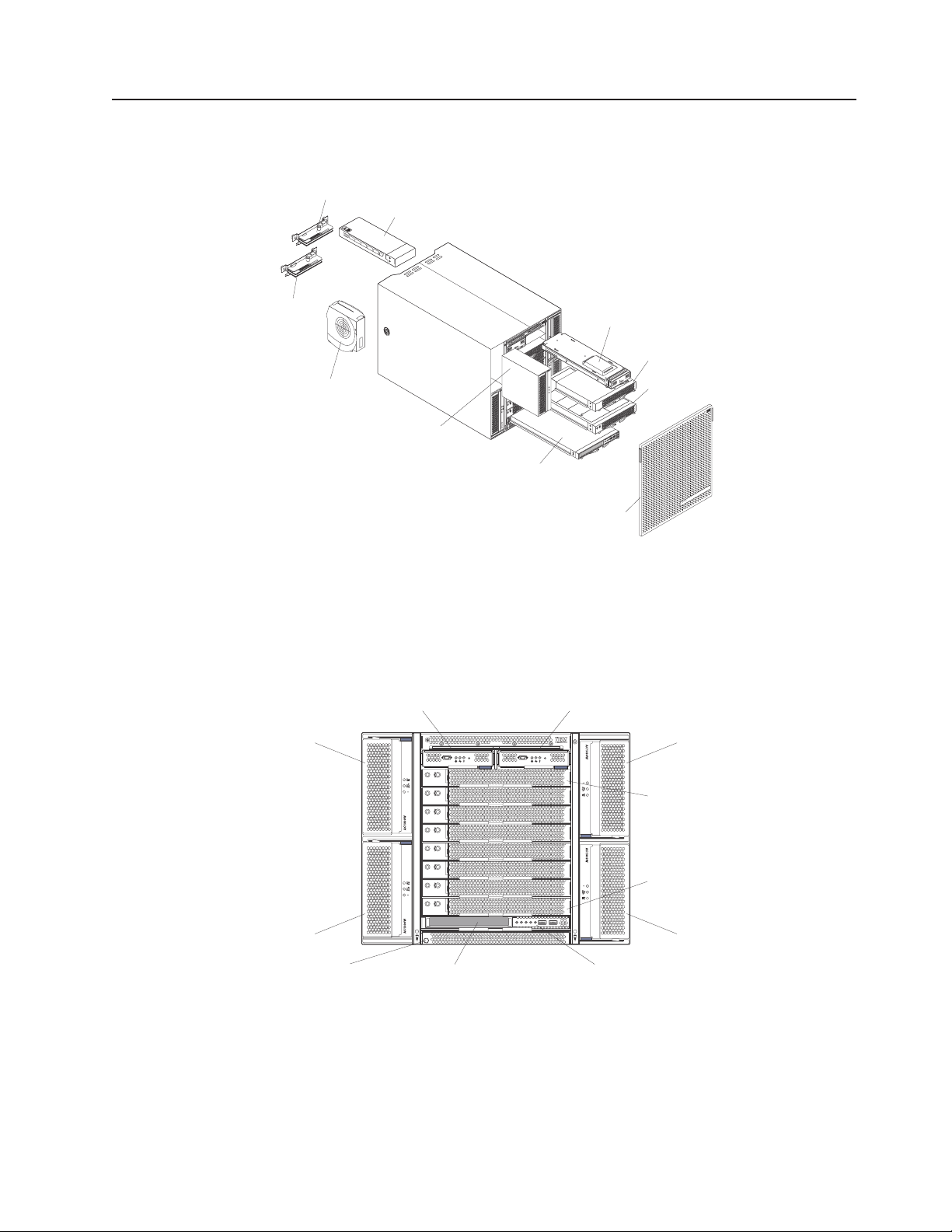

Major components of the BladeCenter T Types 8720 and 8730 unit

The following illustration shows the locations of major components in your

BladeCenter T unit.

KVM module

I/O module

Front view

LAN

module

A

C

1

3

0

0

W

O

D

C

U

T

A

I

C

N

Management module

Filler blade

Blower module

(4 units)

Power module

I

A

T

U

C

D

O

!

W

0

0

3

1

C

A

D

S

E

Blade server

!

O

D

C

U

T

A

I

C

N

N

C

Media tray

Bezel assembly

Attention: To maintain proper system cooling, each module bay must contain

either a module or a filler module; each blade bay must contain either a blade

server or a filler blade.

This section identifies the components, controls, and LEDs on the front of your

BladeCenter T unit.

Power module 1

Management-module bay 1

CMM

1

Management-module bay 2

Power module 2

CMM

2

Power module 3

ESD connector

Blade server 1

Blade server 8

Power module 4

Front panelMedia tray

Chapter 1. General information 9

Page 20

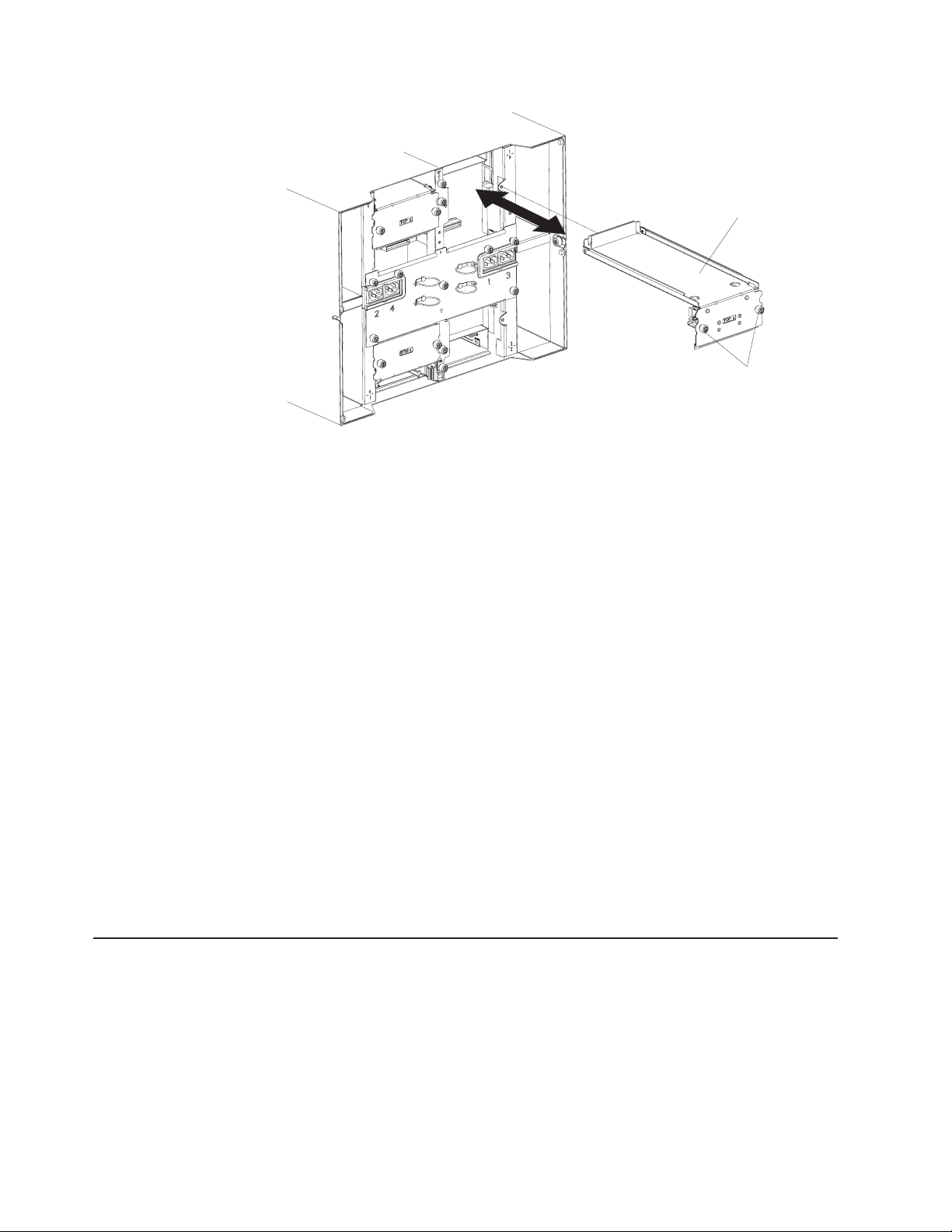

System service cards

These cards contain system service instructions and a writable area for your use.

The cards are located in a slot just above the management-module bays. To access

the service cards, slide out the cards as shown in the following illustration.

System service card

C

MM

1

C

M

M

2

ES

D

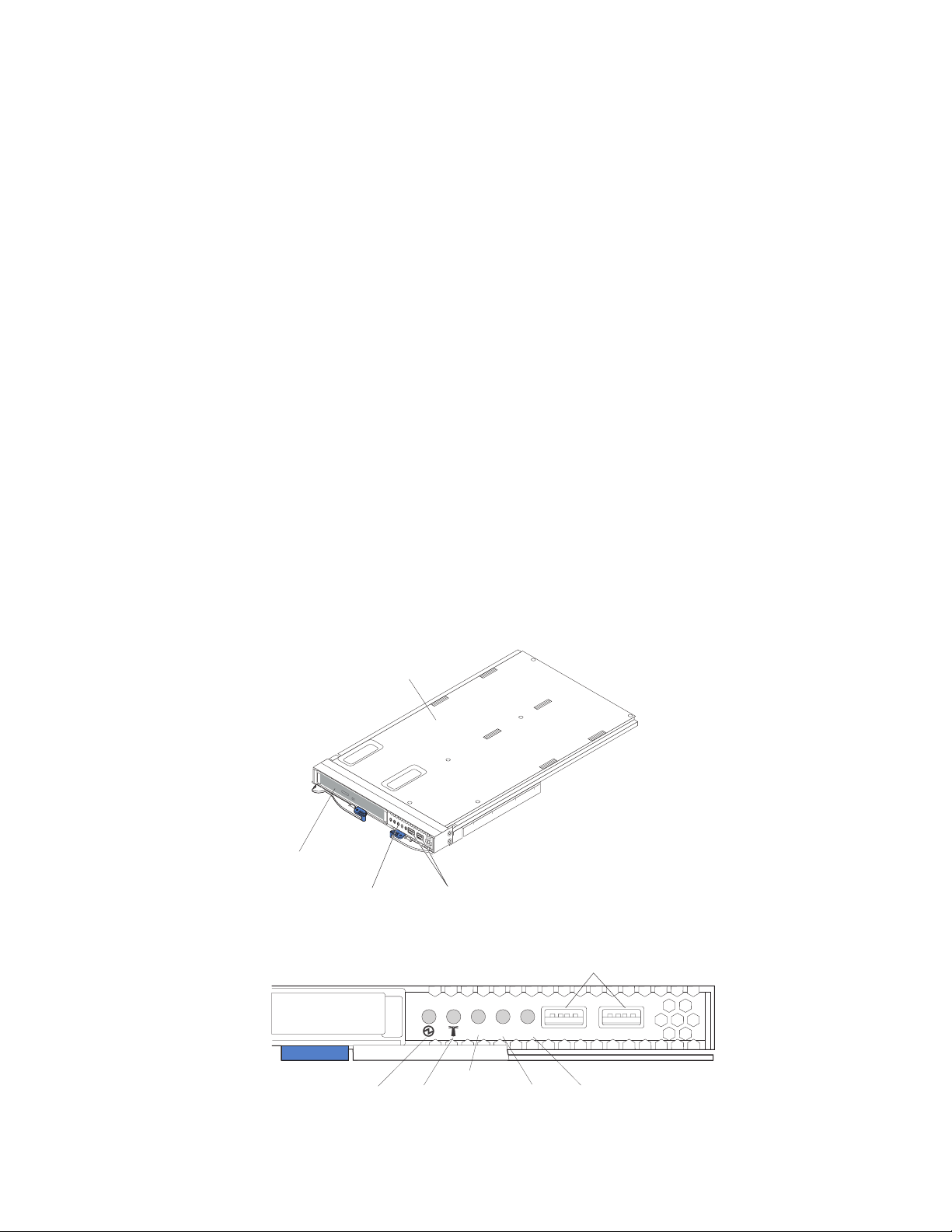

Management module controls and indicators

These management-module controls and indicators provide status information about

the management module and remote management connection. For additional

information, see the Hardware Maintenance Manual and Troubleshooting Guide on

the IBM BladeCenter T Documentation CD.

Serial port

Power LED

Active LED

Management module LEDs: These LEDs provide status information about the

management module and remote management connection.

v Power: When this green LED is lit, it indicates that the management module has

power.

v Active: When this green LED is lit, it indicates that the management module is

actively controlling the BladeCenter T unit. Only one management module

actively controls the BladeCenter T unit. If two management modules are

installed in the BladeCenter T unit, this LED is lit on only one.

Management module

Reset button

Error LED

10 BladeCenter T Type 8720 and 8730: Hardware Maintenance Manual and Troubleshooting Guide

Page 21

v Error: When this amber LED is lit, it indicates that an error has been detected

somewhere on the management module. When this LED is lit, the system error

LED (critical, major, or minor) on each of the BladeCenter T system-status panels

is also lit.

Management

module IP reset button: Do not press this button unless you intend

to erase your configured IP addresses for the management module and lose

connection with the remote management station, the switch modules, and the blade

servers. If you press this button, you will have to reconfigure the management

module settings (see the information beginning with “Setting up the remote

connection” on page 25 for instructions).

Press this recessed button to reset the IP configuration of the management module

network interfaces (Ethernet 1, Ethernet 2, gateway address, and so on) to the

factory defaults and then restart the management module.

Use a straightened paper clip to press the button.

Serial connector: Use this connection for configuring and managing the

BladeCenter components over a serial line through the command-line interface

(CLI) user-interface. This port provides access and redirection to the

serial-over-LAN (SOL) interface of any processor blade server. For example, you

can connect a laptop device to the serial connector and use a terminal-emulator

program to configure the assorted IP addresses, user accounts, and other

management settings through the CLI user-interface.

Media tray

The media tray is a hot-swap unit that is installed on the front of the BladeCenter T

unit and contains the system-status panel, I/O, and CD-ROM drive.

Media tray

CD-ROM drive

System-status panel

USB connectors

The following illustration shows the system-status LEDs on the system-status panel

on the front of the BladeCenter T unit.

Power Location

Media tray

MJR

CRT

Critical

MNR

Major Minor

USB connectors

The system-status panel on the front of the BladeCenter T system has five

system-status LEDs and two USB connectors.

Chapter 1. General information 11

Page 22

System status LEDs: The LEDs on this part of the panel provide status

information for the BladeCenter T unit.

v Power: When continuously lit, this green LED indicates the presence of power in

the BladeCenter T unit. The LED turns off when the power source is interrupted.

Attention: If the power LED is off, it does not mean electrical power is not

present in the BladeCenter T unit. The LED might be burned out. To remove all

electrical power from the BladeCenter T unit, you must disconnect all power

cords from the rear of the BladeCenter T unit.

v Location: This blue LED is for system identification. A system administrator or

servicer uses this LED to locate a specific BladeCenter T unit for service or

repair. You can turn off the location LED through the Web interface or a remote

management console.

Alarm LEDs: These LEDs provide alarm notifications for the BladeCenter T unit.

v CRT (Critical alarm, amber (default) or red): When continuously lit, this LED

indicates the presence of a critical system fault. The system comes with amber

as the default. See the BladeCenter T Management Module User’s Guide for

information on setting the color of this LED.

A critical system fault is an error or event that is unrecoverable. In this case, the

system cannot continue to operate. An example is the loss of a large section of

memory that causes the system to be incapable of operating.

v MJR (Major alarm, amber (default) or red): When continuously lit, this LED

indicates the presence of a major system fault. The system comes with amber as

the default. See the BladeCenter T Management Module User’s Guide for

information on setting the color of this LED.

A major system fault is an error or event that has a discernible impact to system

operation. In this case, the system can continue to operate but with reduced

performance. An example is the loss of one of two mirrored disks.

v MNR (Minor alarm, amber): When continuously lit, this LED indicates the

presence of a minor system fault. A minor system fault is an error or event that

has little impact to system operation. An example is a correctable ECC error.

connectors: There are two USB connectors on the front system-status panel.

USB

You can use these USB connectors to connect two USB peripheral devices without

an external hub. If more devices are required, you can connect an external hub to

any of the built-in connectors.

12 BladeCenter T Type 8720 and 8730: Hardware Maintenance Manual and Troubleshooting Guide

Page 23

Power modules

AC power module DC power module

AC in LED

DC out LED

Error LED

DC in LED

DC out LED

Error LED

Power module LEDs: Each power module has three LEDs to indicate the status of

the power module.

v AC (or DC) in: When continuously lit, this green LED indicates that the input

power source is working. If the LED is not lit, it indicates that the input power

source is not present or is incorrect.

v DC out: When continuously lit, this green LED indicates that the output power is

present. If the LED is not lit, it indicates that the output power is not present.

v ! (Error): When continuously lit, this amber LED indicates that there is a error

condition within the power module.

Table 3. Power module LEDs

! (Error)

DC IN or AC IN DC OUT

(amber) Description and action

On On Off The power module is on and operating

correctly.

On Off Off or On* There is an output power problem. A system

error has shut down the power module.

Actions: Determine the cause of the shutdown

using the diagnostics and replace the failed

component. When the fault has been cleared,

reset the power module in one of the following

ways:

v Issue a power-module reset through the

management module.

v Remove the power module from the unit for

at least 10 seconds.

the problem remains, have the unit serviced.

If

*Error LED will operate only if a redundant

power supply is installed.

Chapter 1. General information 13

Page 24

Table 3. Power module LEDs (continued)

! (Error)

DC IN or AC IN DC OUT

(amber) Description and action

Off Off Off or On* There is an input power problem.

Possible causes:

v There is no power to the power module.

Actions: Make sure that:

1. The power is correctly connected to the

unit.

2. The power is connected to 220 v ac

(8730) or –48 v dc (8720).

3. The power source functions properly.

The power module has failed.

v

Action: Replace the power module.

the problem remains, have the unit serviced.

If

*Error LED will operate only if a redundant

power supply is installed.

On On On There is a fault condition in the power supply.

Possible causes:

v Thermal fault.

Action: Replace the power module.

v 12 v over-voltage power condition or 12 v

under-voltage power condition.

Actions: Determine the cause of shutdown

using diagnostics and replace the failed

component. When the fault has ben

cleared, reset the power module.

– Issue a power-module reset through the

management module.

– Remove the power module from the unit

for at least 10 seconds.

14 BladeCenter T Type 8720 and 8730: Hardware Maintenance Manual and Troubleshooting Guide

Page 25

Rear view

This section identifies the components and indicators on the rear of the

BladeCenter T unit.

I/O module 2 I/O module 1

KVM module

Blower module 2

Blower module 4

I/O module 4

TOP

24

BTM

D

CRT

MNR

MJR

E

TOP

2

1

BTM

ESD connector

D

Alarms

13

E

I/O module 3

LAN module

Blower module 1

Blower module 3

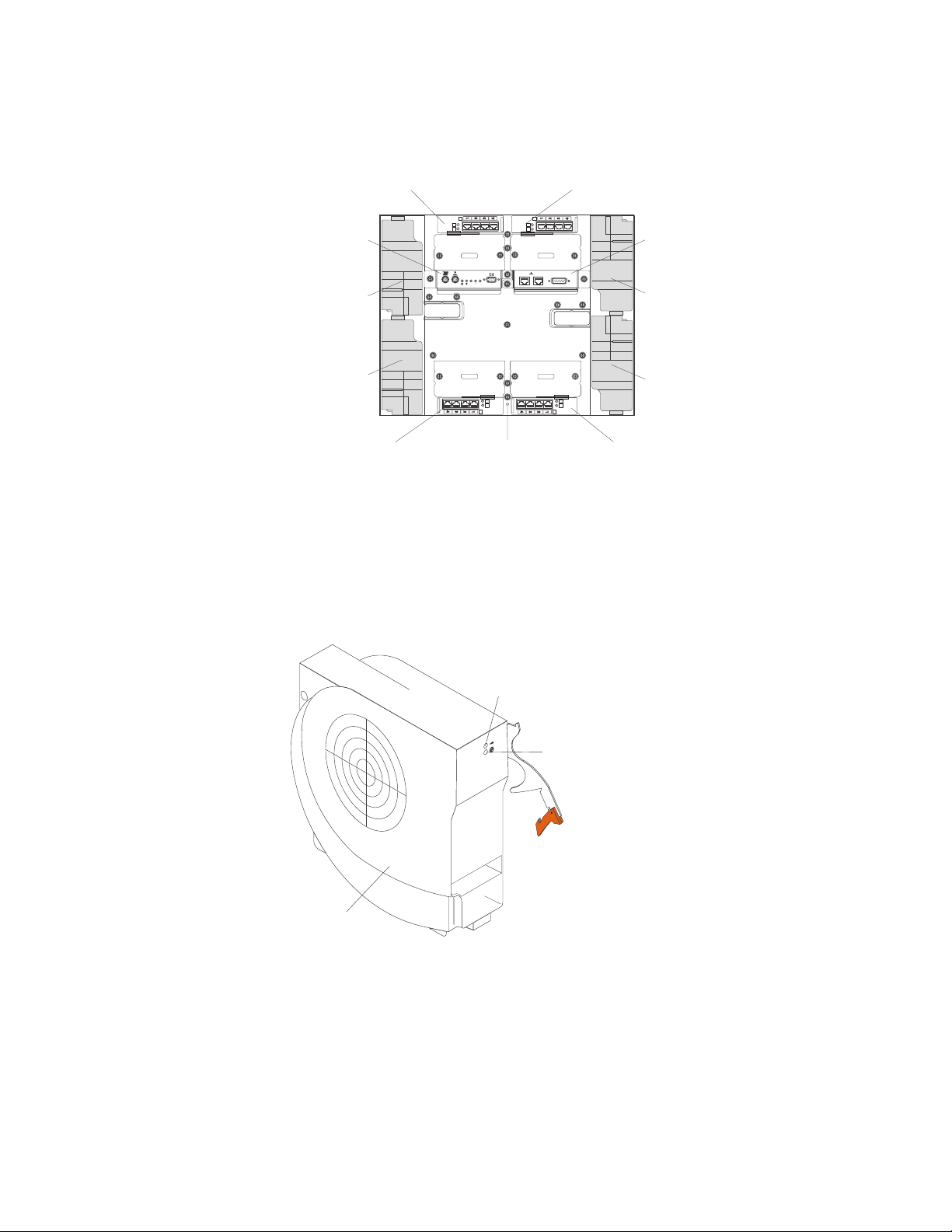

Blower modules

The blower modules are hot-swap units that are installed into the rear of the

system. The BladeCenter T unit comes with four blowers that are in a 3+1

redundancy configuration. All the cooling requirements are met if one blower fails.

All blowers contain a backflow device that prevents the system from drawing air into

the exhaust port of a failed blower. The management module in the BladeCenter T

unit controls the blower speed and detects blower failures.

Error LED

Power LED

Blower

Blower LEDs: The LEDs on each blower provide status information about the

blower.

v Power: When this green LED is lit, it indicates that the blower module has

power.

v Error: This amber LED is lit and stays lit when an error has been detected in the

blower. The system error LED on the BladeCenter system-status panels is also

lit.

Chapter 1. General information 15

Page 26

KVM (keyboard, video, mouse) module indicators and input/output connectors

The KVM module is a hot-swap module that is installed on the rear of the

BladeCenter T unit and is held in place by captive thumbscrews. This module

contains two PS/2 connectors for the keyboard and mouse, a system-status panel,

and an HD-15 video connector.

Thumbscrew

Keyboard

Mouse

Major (MJR) alarm LED

Minor (MNR) alarm LED

CRT

MNR

MJR

Power LED

Critical (CRT) alarm LED

Location LED

Video

System-status LEDs: These LEDs provide status information for the BladeCenter

T unit.

v Power: When continuously lit, this green LED indicates the presence of power in

the BladeCenter T unit. The LED turns off when the power source is interrupted.

Attention: If the power LED is off, it does not mean electrical power is not

present in the BladeCenter T unit. The LED might be burned out. To remove all

electrical power from the BladeCenter T unit, you must disconnect all power

cords from the rear of the BladeCenter T unit.

v Location: This blue LED is for system identification. A system administrator or

servicer uses this LED to locate a specific BladeCenter T unit for service or

repair. You can turn off the location LED through the Web interface or a remote

management console.

Alarm LEDs: These LEDs provide alarm notifications for the BladeCenter T unit.

v CRT (Critical alarm, amber (default) or red): When continuously lit, this LED

indicates the presence of a critical system fault. The system comes with amber

as the default. See the BladeCenter T Management Module User’s Guide for

information on setting the color of this LED.

A critical system fault is an error or event that is unrecoverable. In this case, the

system cannot continue to operate. An example is the loss of a large section of

memory that causes the system to be incapable of operating.

v MJR (Major alarm, amber (default) or red): When continuously lit, this LED

indicates the presence of a major system fault. The system comes with amber as

the default. See the BladeCenter T Management Module User’s Guide for

information on setting the color of this LED.

A major system fault is an error or event that has a discernible impact to system

operation. In this case, the system can continue to operate but with reduced

performance. An example is the loss of one of two mirrored disks.

v MNR (Minor alarm, amber): When continuously lit, this LED indicates the

presence of a minor system fault. A minor system fault is an error or event that

has little impact to system operation. An example is a correctable ECC error.

16 BladeCenter T Type 8720 and 8730: Hardware Maintenance Manual and Troubleshooting Guide

Page 27

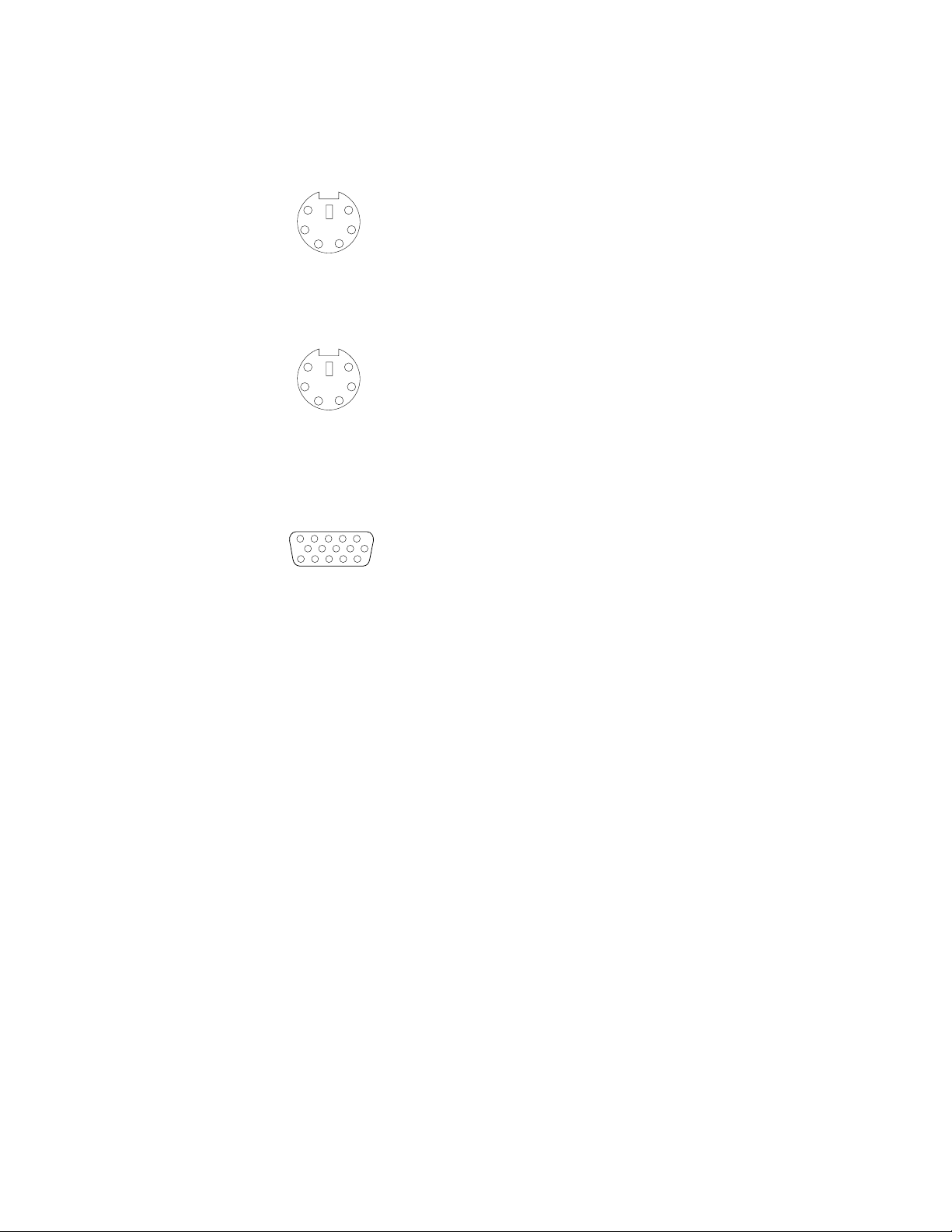

Connectors: The KVM module has the following I/O connectors:

v Keyboard connector: The BladeCenter T KVM module contains one PS/2-style

keyboard connector.

Use this connector to connect a PS/2 keyboard to the BladeCenter T unit.

6

4

2

5

3

1

v Mouse connector: The BladeCenter T KVM module contains one PS/2-style

mouse connector.

Use this connector to connect a PS/2 mouse to the BladeCenter T unit.

6

4

2

5

3

1

v Video connector: The BladeCenter T KVM module contains one standard video

connector. The integrated video controller on each blade server is compatible

with SVGA and VGA and communicates through this video port.

Use this connector to connect a video monitor to the BladeCenter T unit.

5

1

1115

Chapter 1. General information 17

Page 28

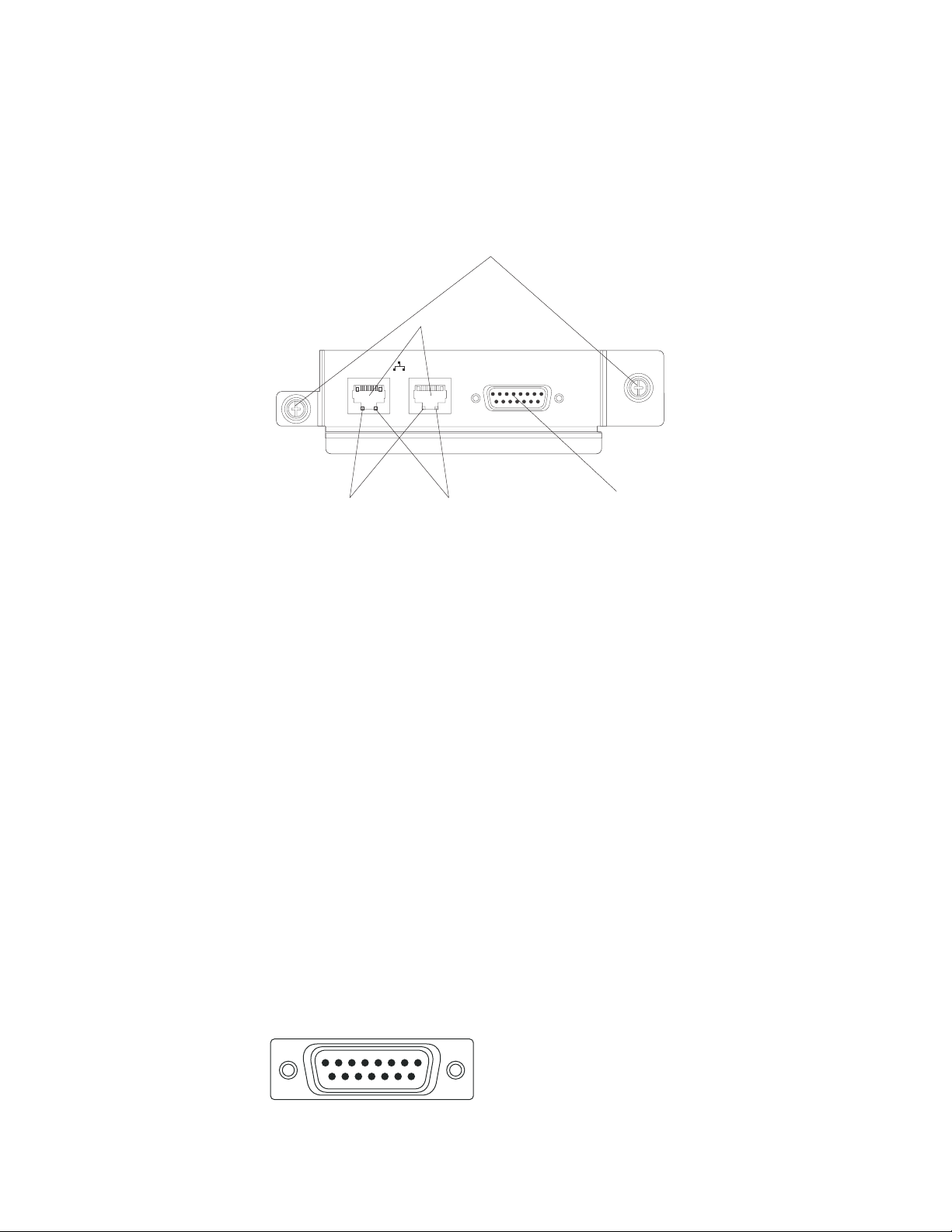

LAN-module indicators and input/output connectors

The LAN module is a hot-swap module that is installed on the rear of the

BladeCenter T unit and is held in place by captive thumbscrews. The LAN module

provides the electrical and mechanical interface to the BladeCenter T unit for the

two local area network (Ethernet) connections, as driven from each management

module, and the telco external alarms. This module contains two RJ-45 connectors

with LEDs and one DSUB 15P telco alarm connector.

Thumbscrews

Remote management

and console (Ethernet)

Ethernet link LED

2

1

Ethernet activity LED

Alarms

Alarms connector

LAN-module LEDs: These LEDs provide status information about the LAN

connection:

v Ethernet link: When this green LED is lit, there is an active connection through

the port to the network.

Ethernet activity: When this green LED is flashing, it indicates that there is

v

activity through the port over the network link.

LAN-module

connectors:

v Remote management and console (Ethernet) connectors: The LAN module

provides two Ethernet RJ-45 connectors.

The BladeCenter T LAN module contains two 10/100 Mb Ethernet connectors

that provide the remote connections, driven from each management module, to

the network management station on the network.

Use these ports for remote management and remote console.

The network management station, through these connectors, can access control

functions running in the management module, the service processor on each

blade server, or within each switch module. However, it cannot use these ports to

communicate with application programs running in the blade servers. The

network management station must direct those communications through a

network connected to the external ports in the I/O modules in the BladeCenter T

unit.

v Alarms connector: The LAN module provides one telco DB15 alarms connector

(male) for critical, major, and minor telco alarms. Each of the alarms has a relay

that enables multiple system alarm indicators to be daisy-chained together.

Table 4 on page 19 shows the pinouts for the telco alarms connector.

Alarms

18

915

18 BladeCenter T Type 8720 and 8730: Hardware Maintenance Manual and Troubleshooting Guide

Page 29

Note: The service processor, management module, or systems-management

function must monitor the alarm reset inputs to maintain the fault condition

that you set for the unit. The alarm reset inputs can be voltages in excess

of standard logic levels, so you must electrically or optically isolate them

from the monitoring logic.

Table 4. Alarms connector pinout

Pin # Description I/O Pin # Description I/O

1 Minor alarm reset + I 9 Minor alarm normally

closed

2 Minor alarm reset - I 10 Minor alarm common O

3 Major alarm reset + I 11 Major alarm normally open O

4 Major alarm reset - I 12 Major alarm normally

closed

5 Critical alarm normally

open

6 Critical alarm normally

closed

7 Critical alarm common O 15 Reserved O

8 Minor alarm normally open O

O 13 Major alarm common O

O 14 Reserved O

O

O

The electrical specifications for the alarms connector are as follows:

– Outputs

- Voltage range: 0 V dc to -100 V dc (maximum current 0.3 A at 100 V dc)

- Current range: 0 A to 1 A (maximum voltage 30 V dc at 1 A)

- Worst-case VA: 1 A at -30 V dc (30 VA maximum) indefinitely

– Inputs

- Voltage range: 0 V dc to -100 V dc (including transients)

- Differential input voltage: 3 V dc to 72 V dc

Reset input activation

–

Pulse width: 200 ms (minimum) to 300 ms

I/O modules

You can install a maximum of four I/O modules at the rear of the system (a

maximum of four Gbit Ethernet switches, or a maximum of two Gbit Ethernet

switches and two Fibre Channel switches). The minimum system configuration

requires one Gbit Ethernet switch or pass-thru module. The I/O switch modules

provide high-performance connectivity between the blade servers.

See the documentation that comes with each I/O module for a description of the

LEDs and connectors on the I/O module.

BladeCenter T unit power, controls, and indicators

This section describes the controls and light-emitting diodes (LEDs) and how to

start and shut down the BladeCenter T unit.

Starting the BladeCenter T unit

Complete the following steps to start the BladeCenter T unit:

1. Read the information in “System reliability considerations” on page 39.

Chapter 1. General information 19

Page 30

2. Reinstall the four blowers into the rear of the BladeCenter T unit if you have not

done so already. See “Removing and installing blower modules” on page 54 for

detailed instructions.

Note: The blowers will not start until the power modules are installed.

3. When the power connections are in place, you can reinstall the power modules

in the BladeCenter T unit. After you connect power to the BladeCenter T unit, all

the power-module bays receive power. To start the BladeCenter T unit, install

power modules in all four power-module bays or install power modules in

power-module bays 1 and 2 and filler modules in bays 3 and 4. See “Installing a

power module” on page 48 for detailed instructions.

AC power module DC power module

AC in LED

DC out LED

Error LED

DC in LED

DC out LED

Error LED

Make sure that the LEDs on the power modules indicate that they are operating

correctly. Make sure that the input and output power LEDs on each power

module are lit, and the error LEDs are not lit.

4. Before proceeding, make sure that the LEDs on the blower modules indicate

that they are operating correctly. Make sure that the power LED on each blower

is lit, and the error LEDs are not lit.

5. Make sure that the following BladeCenter T modules are installed correctly. See

“Media tray” on page 11 for the location of the LEDs on these modules.

v Media tray

v KVM module

v LAN module

v Management module

v I/O modules

Install the blade servers or filler modules in all of the blade server bays before

6.

you power on any of the blade servers. See “Removing and installing a blade

server or filler module” on page 64 for detailed instructions. Make sure that the

power LED on each blade server is flashing.

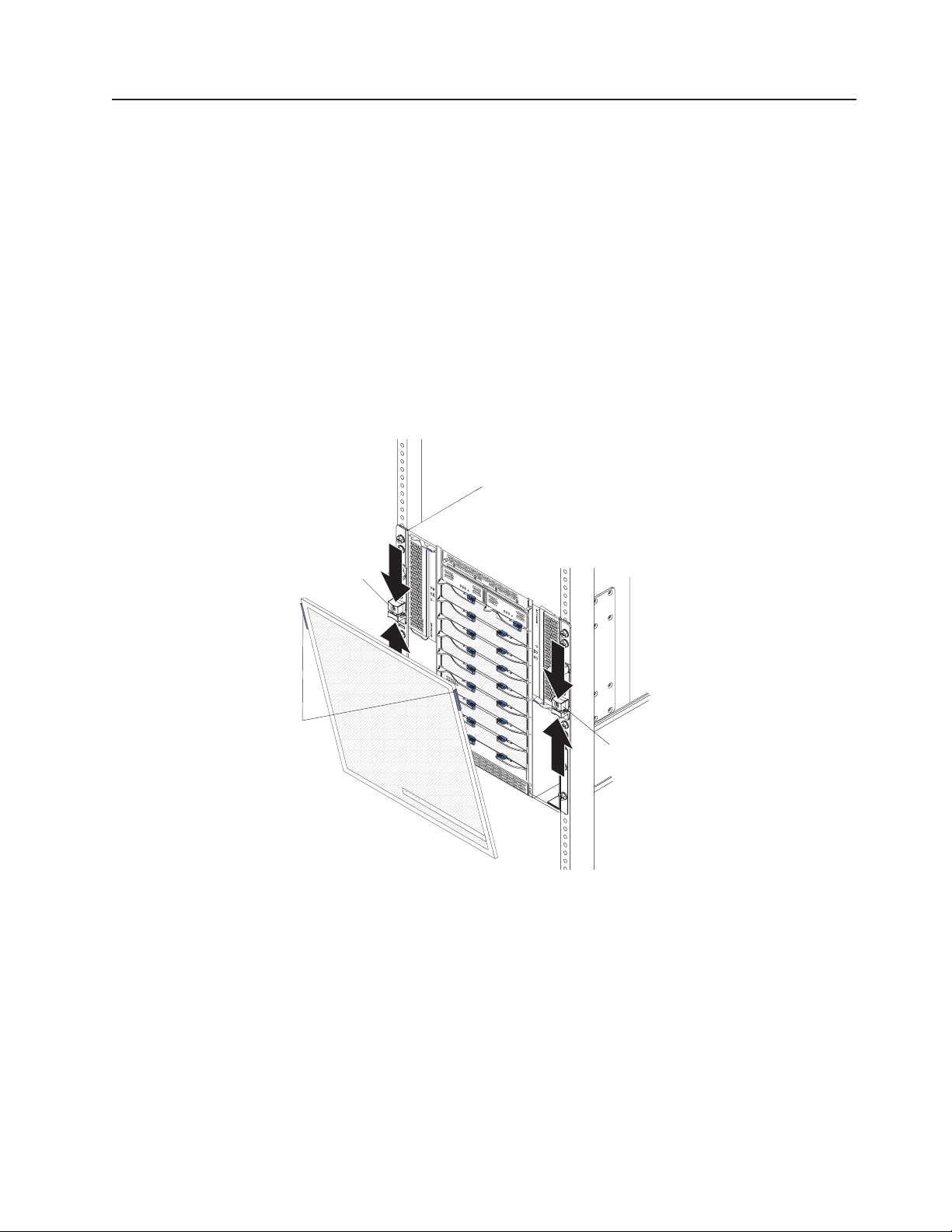

7. Install the bezel assembly on the front of the BladeCenter T unit by inserting the

bottom bezel hooks into the bezel slots at the bottom of the BladeCenter T unit.

Push in the bottom and the top of the bezel assembly until they both lock firmly

into place.

20 BladeCenter T Type 8720 and 8730: Hardware Maintenance Manual and Troubleshooting Guide

Page 31

Notes:

1. Within 2 minutes after power has been connected to the BladeCenter T unit, the

management module applies power to the I/O modules.

2. If a power failure occurs, the BladeCenter T unit restarts automatically when

power is restored.

3. The blade-server power button turns on or turns off the blade server if local

power control has not been disabled through the management module.

4. The blade-server power button turns on the blade server only if the green power

light on the blade server is flashing slowly. If the light flashes rapidly, the blade

server has not yet synchronized with the management module, and pressing the

power button will have no effect. See “Media tray” on page 11 for more

information about the controls and indicators on the BladeCenter T unit

modules.

the Installation and User’s Guide for your blade server on the IBM

See

Documentation CD that comes with the blade server for the location of the blade

server LEDs.

Shutting down the BladeCenter T unit

You can shut down the BladeCenter T unit by turning off the blade servers and

disconnecting the BladeCenter T unit from the power source.

Complete the following steps to shut down the BladeCenter T unit.

1. See your blade server operating-system documentation for the procedure to

shut down the operating system in the blade servers; then, shut down each

operating system.

2. Press the power-control button on the front of each blade server. Wait until the

solid green power LED on the blade server goes to a slow flash indicating that

the blade server drives have stopped spinning.

Statement 5:

CAUTION:

The power control button on the device and the power switch on the

power supply do not turn off the electrical current supplied to the device.

The device also might have more than one power cord. To remove all

electrical current from the device, ensure that all power cords are

disconnected from the power source.

1 2

Note: The BladeCenter T Type 8720 and 8730 units do not have a power

switch. The units also have more than one connection to power. To

remove all electrical current from the unit, make sure that all connections

to input power are disconnected at the power input terminals or

connectors.

3. If you have a BladeCenter T Type 8720 (dc-power) unit, disconnect the unit

from the input power at the dc power distribution panel by switching the circuit

Chapter 1. General information 21

Page 32

breakers to the Off position or removing the fuses as applicable. Make sure that

both circuits are disconnected or turned off.

If you have a BladeCenter T Type 8730 (ac-power) unit, disconnect all power

cords on the BladeCenter T unit from the ac power distribution unit (PDU).

Note: After you disconnect the BladeCenter T unit from power, wait at least 5

seconds before you connect the BladeCenter T unit to power again.

22 BladeCenter T Type 8720 and 8730: Hardware Maintenance Manual and Troubleshooting Guide

Page 33

Chapter 2. Configuring the BladeCenter T unit

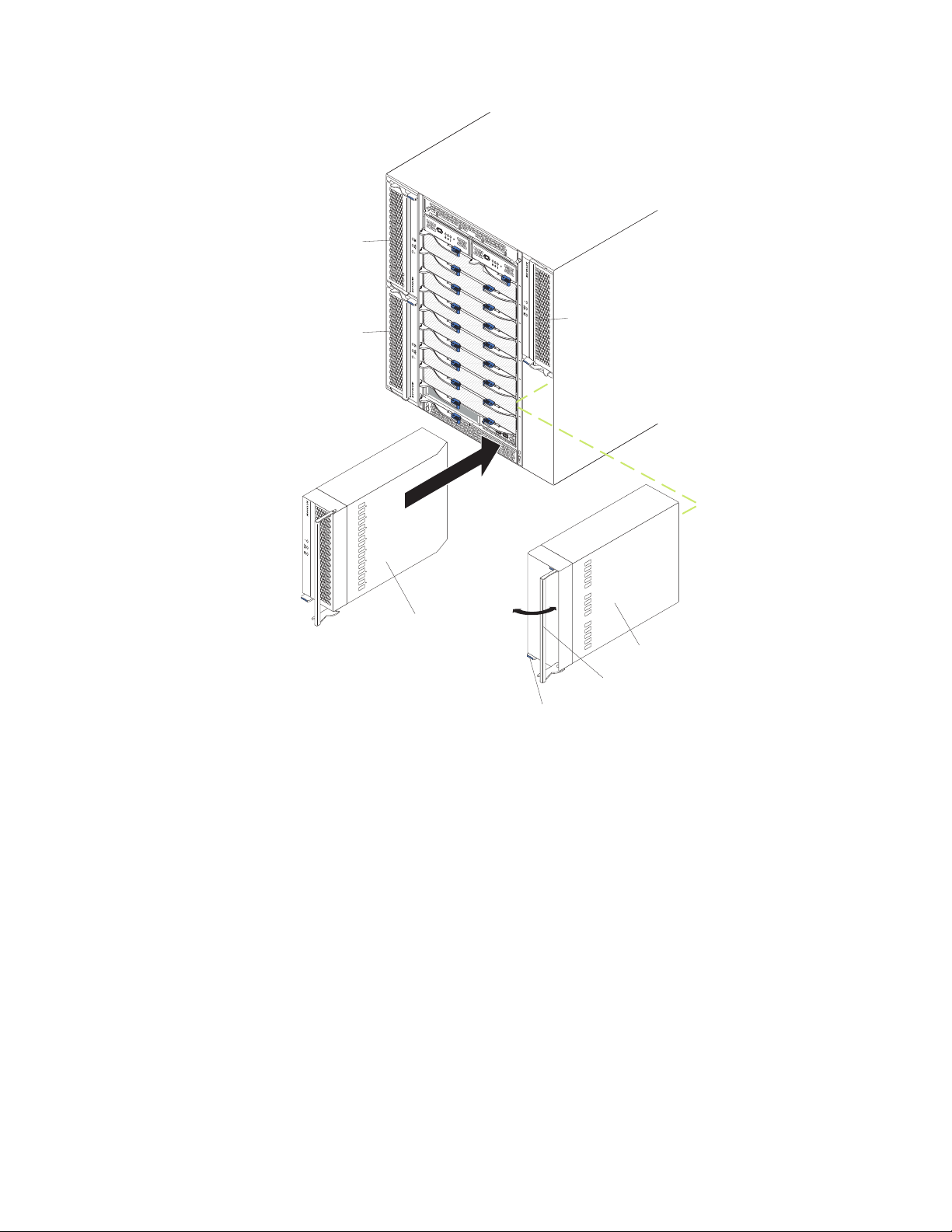

The BladeCenter T unit automatically detects the modules and blade servers that

are installed and stores the vital product data (VPD). When the BladeCenter T unit

is started, the management module automatically configures the remote

management port on the management module, accessed through the LAN module

on the rear of the BladeCenter T unit, so that you can configure and manage the

BladeCenter T unit and blade servers. Yo u configure and manage the BladeCenter

T unit remotely, through the management module, using the Web-based user

interface.

Note: There are two ways to configure the switch modules; through the

management-module Web interface, or through an external switch-module

port enabled through the management module, using a Telnet interface or a

Web browser. See the documentation that comes with the switch module for

more information.

For the active management module to communicate with the I/O modules in the

BladeCenter T unit, you must configure the IP addresses for the following internal

and external ports:

v The external Ethernet (remote management) port on the management module,

accessed through the LAN module on the rear of the BladeCenter T unit (see

“Configuring the external Ethernet port” on page 28 for instructions). The initial

management module autoconfiguration enables the network management station

to connect to the management module to configure the port completely and to

configure the rest of the BladeCenter T unit.

v The internal Ethernet port on the management module for communication with

the I/O modules (see “Configuring the internal Ethernet port” on page 29 for

instructions).

v The management port on each switch module provides for communication with

the management module. You configure this port by configuring the IP address

for the switch module (see “Configuring management ports on I/O modules” on

page 29 for instructions).

Note: Some types of I/O modules, such as the pass-thru module, have no

management port.

the documentation that comes with the I/O module to determine what else you

See

must configure in the I/O module.

To communicate with the blade servers for functions such as deploying an operating

system or application program over the network, you must also configure at least

one external (in-band) port on an Ethernet switch module in I/O-module bay 1 or 2.

See “What to configure” on page 29 for information about configuring external ports

on Ethernet switch modules.

The management module supports the following Web browsers for remote access.

The Web browser that you use must be Java™-enabled, must support JavaScript

™

1.2 or later, and must have the Java Virtual Machine (JVM) 1.4.1 or later Plug-in

installed. The JVM Plug-in is available at the Java Web site at http://www.java.com/.

®

v Microsoft

Internet Explorer 5.5 (with latest Service Pack installed), or later

v Netscape Navigator 4.72, or later (version 6 is not supported)

v Mozilla version 1.3, or later

© Copyright IBM Corp. 2004 23

Page 34

For best results when using the Web browser, set the monitor to 256 colors. Use

only the video resolutions and refresh rates given in the following table. These are

the only video resolution and refresh rate combinations that are supported for all

system configurations.

Resolution Refresh rate

640 x 480 60 Hz

640 x 480 72 Hz

640 x 480 75 Hz

640 x 480 85 Hz

800 x 600 60 Hz

800 x 600 72 Hz

800 x 600 75 Hz

800 x 600 85 Hz

1024 x 768 60 Hz

1024 x 768 75 Hz

The Web interface does not support the double-byte character set (DBCS)

languages.

The Web-based user interface communicates with the management and

configuration program that is part of the firmware that comes with the management

module. You can use this program to perform the following tasks:

v Defining the login IDs and passwords.

v Selecting recipients for alert notification of specific events.

v Monitoring the status of the BladeCenter T unit and blade servers.

v Controlling the BladeCenter T unit and blade servers.

v Accessing the I/O modules to configure them.

v Changing the startup sequence in a blade server.

v Setting the date and time.

v Using a remote console for the blade servers.

v Changing ownership of the keyboard, video, and mouse.

Note: Some blade server models do not support the keyboard, video, and

mouse feature. Ownership of the keyboard, video, and mouse cannot be

transferred to those blade servers.

v Changing ownership of the CD-ROM drive and USB ports. (The CD-ROM drive

in the BladeCenter T unit is viewed as a USB device by the blade server

operating system.)

v Activating On Demand blade servers.

v Setting the active color of the critical (CRT) and major (MJR) alarm LEDs

also can use the management and configuration program to view some of the

You

blade server configuration settings. See “Management and configuration program”

on page 26 for more information.

24 BladeCenter T Type 8720 and 8730: Hardware Maintenance Manual and Troubleshooting Guide

Page 35

Setting up the remote connection

To configure and manage the BladeCenter T unit and blade servers, you must first

set up the remote connection through an Ethernet port on the LAN module. The

LAN module is on the rear of the BladeCenter T unit at the top-right side.

KVM module

Cabling the Ethernet port

You can connect to an Ethernet port directly from a personal computer (PC) using a

cross-over cable, or you can make the connection through an Ethernet switch.

The right Ethernet port on the LAN module is driven by management module 1, and

the left Ethernet port of the LAN module is driven by management module 2.

Rear of BladeCenter T type 8730 unit

TOP

D

24

BTM

E

TOP

24

D

CRT

MNR

MJR

BTM

E

TOP

D

2

1

Alarms

13

BTM

E

192.168.70.125

LAN module

TOP

D

2

1

Alarms

13

BTM

E

LAN module

RJ-45

connector

192.168.70.155

192.168.70.135

Standard

Ethernet

cables

Cross-over

Ethernet cable

Connect directly to PC

Ethernet switch

Connect through an Ethernet switch

Chapter 2. Configuring the BladeCenter T unit 25

Page 36

Complete the following steps to connect the Ethernet cable to the management

module.

1. Connect one end of a Category 5 or higher Ethernet cable to an Ethernet

connector on the LAN module. Connect the other end of an Ethernet cable to

the network.

2. Check the Ethernet LEDs to make sure that the network connection is working.

The following illustration shows the locations of the Ethernet LEDs on the LAN

module.

2

Ethernet link Ethernet activity

1

Alarms

Ethernet link LED

When this green LED is lit, there is an active connection through the

port to the network.

Ethernet activity LED

When this green LED is flashing, it indicates that there is activity

through the port over the network link.

Management and configuration program

This section provides the instructions for setting up and using the management and

configuration program in the management module.

Setting up the management and configuration program

Complete the following steps to set up the management and configuration program:

1. Connect a PC to the BladeCenter T management network.

2. At initial power-on, the management module configures the Ethernet port

connection in one of the following ways:

v If you have an accessible, active, and configured dynamic host configuration

protocol (DHCP) server on the network, the host name, IP address, gateway

address, subnet mask, and DNS server IP address are set automatically.

v If the DHCP server does not respond within 2 minutes after the port is

connected, the management module uses a default IP address of

192.168.70.125 and subnet mask of 255.255.255.0.

Either of these actions enables the Ethernet to assign a connection.

If you cannot communicate with a replacement management module through

the Web interface. Press the IP reset button on the front of the management

module to set the management module to the factory default IP addresses;

then, access the management module using the factory IP address (see

“Setting up the management and configuration program” for the factory IP

addresses) and configure the management module.

Note: If the IP configuration is assigned by the DHCP server, the network

administrator can query the MAC address of the management-module

network interface on the DHCP server to determine what IP address and

host name are assigned.

26 BladeCenter T Type 8720 and 8730: Hardware Maintenance Manual and Troubleshooting Guide

Page 37

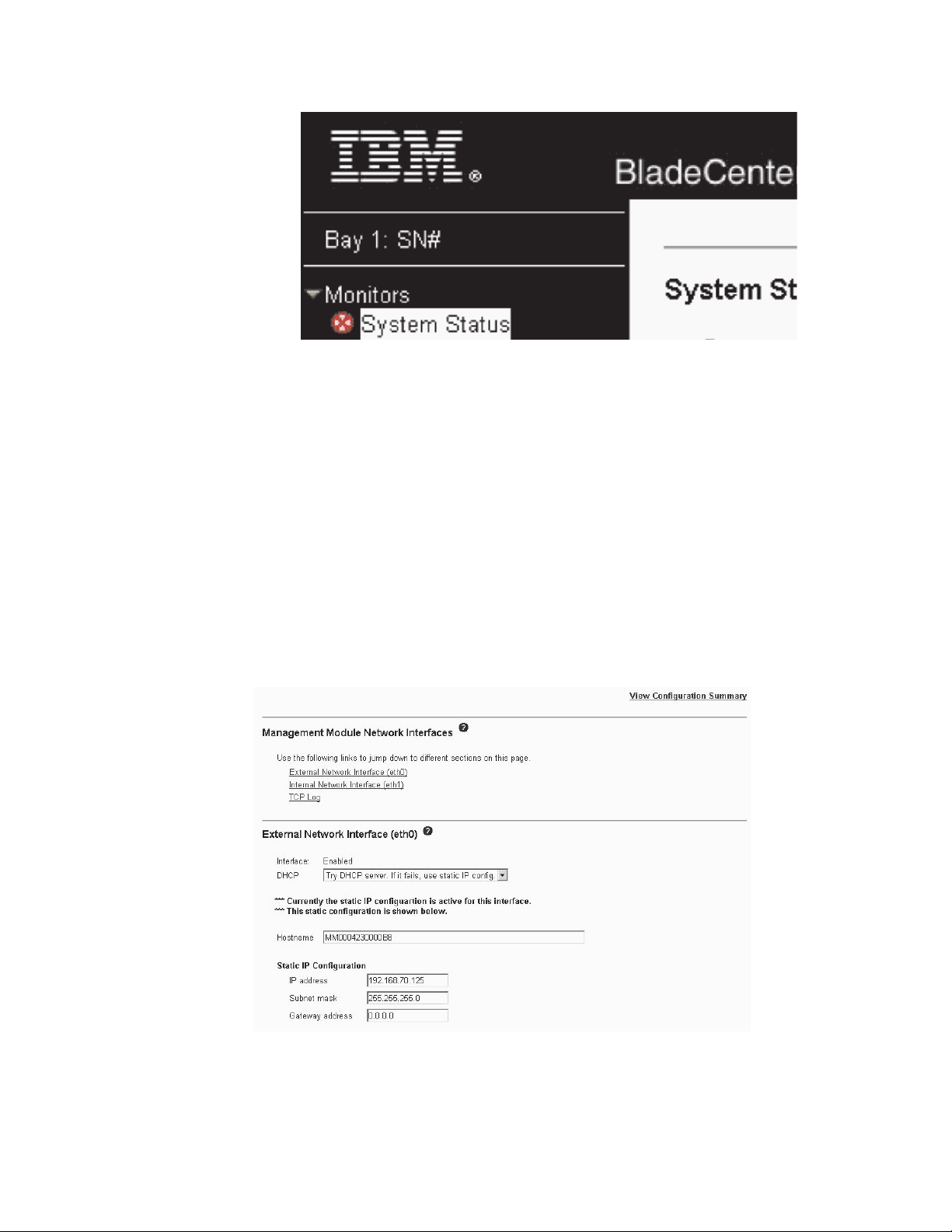

Starting the management and configuration program

Complete the following steps to start the management and configuration program:

1. Open a Web browser. In the address or URL field, type the IP address or host

name that is defined for the management-module remote connection (see

“Setting up the management and configuration program” on page 26 for more

details).

The Enter Network Password window opens.

2. Type your user name and password. If you are logging in to the management

module for the first time, you can obtain your user name and password from

your system administrator. All login attempts are documented in the event log.

Note: The initial user ID and password for the management module are as

follows:

v User ID: USERID (all capital letters)

v Password: PASSW0RD (note the zero, not O, in PASSW0RD)

3. Follow the instructions that appear on the screen. Be sure to set the timeout

value that you want for your Web session.

BladeCenter T management and configuration window opens.

The

Note: The upper left corner of the management and configuration window shows

the location and identity of the active management module.

Chapter 2. Configuring the BladeCenter T unit 27

Page 38

Setting management and configuration program options

From the management and configuration program main menu, you can select

settings that you want to view or change.

The navigation pane (on the left side of the management module window) contains

navigational links that you use to manage the BladeCenter T unit and check the

status of the components (modules and blade servers). The following information

describes the choices that you have to configure the external Ethernet port on the

management module, the internal Ethernet port on the management module, and

the external management port on each I/O module. See the BladeCenter T

Management Module User’s Guide on the BladeCenter T Documentation CD that

comes with the BladeCenter T unit for a description of all the navigational links.

Configuring the external Ethernet port

Under MM Control, click Network Interfaces ” External Network Interface (eth0).

This is the interface for the remote management and console port.

v Set Interface to Enabled to use the Ethernet connection.

v If you plan to use redundant management modules and want both to use the

same IP address, disable DHCP and configure and use a static IP address (the

IP configuration information will be transferred to the redundant management

28 BladeCenter T Type 8720 and 8730: Hardware Maintenance Manual and Troubleshooting Guide

Page 39

module automatically when needed). Otherwise, configure the DHCP setting as

you prefer. You must configure the static IP address only if DHCP is disabled.

– IP address - The IP address for the management module. The IP address

must contain four integers from 0 through 255, separated by periods, with no

spaces or consecutive periods. The default setting is 192.168.70.125.

– Subnet mask - The subnet mask must contain four integers from 0 to 255,

separated by periods, with no spaces. The default setting is 255.255.255.0

– Gateway address - The IP address for your network gateway router. The

gateway address must contain four integers from 0 through 255, separated by

periods, with no spaces.

Configuring the internal Ethernet port

Under MM Control, click Network Interfaces ” Internal Network Interface (eth1).

This interface communicates with the network-interface I/O modules, such as the

Ethernet switch module or the Fibre Channel switch module.

v Specify the IP address to use for this interface. The IP addresses for the internal

Ethernet port (eth1) and external Ethernet port (eth0) must be on the same

subnet.

v (Optional) Configure the locally-administered MAC address for this interface; the

other fields (data rate, duplex mode, maximum transmission unit (MTU), and

burned-in MAC address) are read-only.

Configuring management ports on I/O modules

Under I/O Module Tasks, click Management; then, click the bay number that

corresponds to the I/O module that you are configuring.

v In the New Static IP address fields, specify the IP address to use for this

interface. The new static IP address must be on the same subnet as the internal

network interface (eth1).

v Click Advanced Management ” Advanced setup. Enable the external ports.

v Click Advanced Management ” Advanced setup. (Optional) Enable external

management.

Saving and restoring the configuration file

After you have configured the management module, you can save the configuration

file to a drive attached to the system running the management-module Web

interface. Then, if the configuration in the management module becomes damaged

or if the management module is replaced, you can restore the saved configuration

file to the management module. Use the management-module Web interface to

save and restore the configuration file (MM Control ” Configuration File).

Configuring an I/O module

To connect any of the blade servers to the network, you must have an Ethernet

switch module installed in I/O-module bay 1 or 2, or a pass-thru module in

I/O-module bay 1 or 2 connected to an external Ethernet switch. If you have an I/O

expansion option installed on one or more blade servers, you must have compatible

I/O modules (switch modules or other compatible modules) in I/O module bays 3 or

4. See “Removing and installing I/O modules” on page 60 for information about the

location and purpose of each I/O module.

What to configure

You must configure switch-module IP addresses and subnet masks through the

management-module Web interface to communicate with the management module

Chapter 2. Configuring the BladeCenter T unit 29

Page 40

and remote management station. This is in addition to the IP addresses that are

configured on the management module. You might also have to use the user

interface on the switch module to configure the switch external ports to operate in

the correct link aggregation (trunking) mode, or to configure any VLANs or other

special conditions.

To allow blade servers to communicate with the network, make sure that the

External ports configuration item in the management module is set to Enabled. In

the management-module Web interface, under I/O Module Tasks, click

Management ” Bay n ” Advanced Management ” Advanced Setup and enable

the item (where n is the number of the I/O bay).

To access the user interface using external ports on the switch module, make sure

that the External management over all ports configuration item is set to enabled.

See your network administrator before enabling this feature.

Because all blade servers in the BladeCenter T unit share access to the external

LAN through the switch ports, you can configure the ports on a switch module to

operate together as an aggregate link, or trunk. An aggregate link provides more

bandwidth than a single link to the attached LAN.

Notes:

1. The attaching LAN switch must have a compatible multiport trunk configuration.

2. Configure link aggregation before you attach cables between the external ports

and your LAN equipment.

Configure

the switch through the user interface on the switch module, which you

can access through the Web interface to the management module (click I/O

Module Tasks ” Management ” Advanced Management ” Start Telnet/Web

Session in the navigation pane).

Important: For a remote management station, such as a management server, to

communicate with the switch modules in the BladeCenter T unit, the management

port of the switch module must be on the same subnet as the management module.

Supporting Ethernet failover

To have the BladeCenter T unit support Ethernet failover on the blade servers, set

up the BladeCenter T unit and blade servers as follows:

1. Configure the Ethernet controllers in one or more blade servers for failover (see

the blade server documentation and the operating-system documentation for

information). When failover occurs on a blade server, the secondary Ethernet

controller takes over network communication, using the I/O module associated

with that controller.

2. Install a switch module or a pass-thru module that is connected to external

Ethernet switches in both I/O-module bays 1 and 2.

3. Configure the Ethernet switch modules and your network infrastructure so that

they can direct traffic to the same destinations.

Configuring the Ethernet controllers in the blade servers

Note: The BladeCenter T unit does not include an Ethernet switch module; this is

an optional feature that must be purchased separately. An Ethernet switch

module or a pass-thru module is connected to an external Ethernet switch

30 BladeCenter T Type 8720 and 8730: Hardware Maintenance Manual and Troubleshooting Guide

Page 41

must be installed in the BladeCenter T unit in I/O-module bay 1 or 2, or both,

before the integrated Ethernet controllers on each blade server system board

can be used.

The Ethernet controllers are integrated on each blade server system board. The

Ethernet controllers provide 1-Gbps full-duplex capability only, which enables

simultaneous transmission and reception of data to the external ports on the

Ethernet switches. You do not need to set any jumpers or configure the controller

for the blade server operating system. However, you must install a device driver on

the blade server to enable the blade server operating system to address the

Ethernet controller. For blade server device drivers and information about

configuring the Ethernet controllers, see the Ethernet software CD that comes with

your blade server.

BladeCenter T networking guidelines

Your networking administrator should assist in the configuration of the network

infrastructure before you connect the BladeCenter T unit to a LAN switch or similar

network device. This section provides additional guidelines that might be useful in

setting up your system.

A BladeCenter T unit with two Ethernet switch modules and one management

module has the internal configuration that is shown in the following illustration:

MAC

1a

1b

2a

2b

3a

3b

4a

4b

5a

5b

6a

6b

7a

7b

8a

8b

1

2

3

4

5

6

7

8

1 Gbps links

1 Gbps or

100 Mbps links

Switch A

10/100 Mbps

Mgmt

Mod

100 Mbps links

Switch B

1 Gbps links

Note: 2nd switch module is optional

Each blade server has two independent Ethernet controllers, each with its own

MAC address and a dedicated 1 Gbps link to one of the switch modules in I/O