Page 1

IBM TS3100 Tape Library and TS3200 Tape Library

Setup, Operator, and Service Guide

Machine Type 3573

IBM

Page 2

Page 3

Important

Before using this information and the product it supports, read the information in “Notices” on page 325. To ensure

you have the latest publications, visit the web at http://www.ibm.com/storage/lto.

This edition applies to the IBM TS3100 Tape Library and TS3200 Tape Library Setup, Operator, and Service

Guide, GA32-0545-17, and to the subsequent releases and modifications until otherwise indicated in new

editions.

© Copyright IBM Corporation 2007, 2018.

US Government Users Restricted Rights – Use, duplication or disclosure restricted by GSA ADP Schedule

Contract with IBM Corp.

© Copyright IBM Corp. 2007, 2018 iii

Page 4

iv IBM TS3100 Tape Library and TS3200 Tape Library: Setup, Operator, and Service Guide Machine Type 3573

Page 5

Read this first

This product might not be certified in your country for connection by any means whatsoever to

interfaces of public telecommunications networks. Further certification might be required by law

before making any such connection. Contact IBM®for information.

Minimum firmware levels for common library features

Table 1. Minimum firmware levels for common library features

Feature Minimum Firmware Levels

Internet Protocol Security (IPSec) Library firmware must be greater than A.40.

Feature Codes 8049, 8148, and 8149 (LTO HH Tape

Drives)

LTO 8 Tape Drive Library firmware must be at E.80 or greater to support

LTO M8 media Library Firmware must be at F.00 or greater to support

|

|

|

|

|

LTO 7 Tape Drive Library firmware must be at D.00 or greater to support

LTO 6 Tape Drive Library firmware must be at B.50 or greater to support

LTO 5 Tape Drive Library firmware must be at 9.00, or greater, to support

Library BCR (Bar Code Reader) Libraries that are manufactured after May 2010 might

Dedicated Cleaning Slot removal Library firmware level must be greater than 1.95.

Library firmware level must be at A.40, or greater, to

support Feature Codes 8049, 8148, and 8149 (LTO HH

Tape Drives).

the Ultrium 8 drives. Ensure that the minimum version

to support Ultrium 8 tape drives are installed on the

host. Ensure that any host applications and software that

use their own device drivers are at the minimum level to

support Ultrium 8 tape drives.

the M8 media feature. Drive firmware must be at HB82

or greater to support the M8 media feature. Ensure that

any IBM device drivers are at the minimum level that is

required to support the TS3100/TS3200 library.

the Ultrium 7 drives. Ensure that the minimum version

to support Ultrium 7 tape drives are installed on the

host. Ensure that any host applications and software that

use their own device drivers are at the minimum level to

support Ultrium 7 tape drives.

the Ultrium 6 drives. Ensure that the minimum version

to support Ultrium 6 tape drives are installed on the

host. Ensure that any host applications and software that

use their own device drivers are at the minimum level to

support Ultrium 6 tape drives.

the Ultrium 5 drives. If the IBM Tape Device Driver or

ITDT (IBM Tape Diagnostic Tool) is used, ensure that the

minimum version to support Ultrium 5 tape drives are

installed on the host. Ensure that any host applications

and software that use their own device drivers are at the

minimum level to support Ultrium 5 tape drives.

have a BCR that requires a minimum level of library

firmware. The minimum level of firmware for these

libraries is 9.00. Attempts to downlevel these libraries

below 9.00 is blocked by the library.

© Copyright IBM Corp. 2007, 2018 v

Page 6

Table 1. Minimum firmware levels for common library features (continued)

Feature Minimum Firmware Levels

Encryption Library firmware level must be 4.0 or greater.

Drive firmware level must be 74H4 or greater.

Key Path Diagnostics Library firmware level must be greater than 6.3.

Path Failover (for one activation key for both Control

Path Failover and Data Path Failover)

Secure Socket Layer (SSL) over Encryption Key Manager

(EKM)

LTO 3 Tape Drives: Drive firmware must be greater than

73P5.

Library firmware levels greater than 1.95, but not greater

than 8.xx support Path Failover on the TS3200

(3573-L4U) and Full Height drives. Library firmware

levels greater than 8.xx support Path Failover on the

TS3100 and TS3200 (3573-L2U and 3573-L4U) for both

Full Height and Half Height drives.

Library firmware must be 6.3 or higher.

Accessing online technical support

For online Technical Support for your library, visit http://www.ibm.com/support/

Registering for My Notification

My Notification registration provides email notification when new firmware levels are updated and

available for download and installation. To register for My Notification:

1. Visit the web at http://www-01.ibm.com/software/support/einfo.html.

2. Click My Notifications.

Note: Library firmware and tape drive firmware are verified and released together. When you are

updating to the latest firmware, verify that all installed components such as tape drives and library

firmware are at the latest levels noted on the Support website. Mixing different levels of library and tape

drive firmware is not supported and might cause unpredictable results.

Sending us your comments

Your feedback is important in helping IBM provide accurate and useful information. If you have

comments or suggestions for improving this publication, send your comments by:

v Emailing IBM:

– Internet or IBMLink from US: starpubs@us.ibm.com

– IBMLink from Canada: STARPUBS at TORIBM

Include the following information in your email:

– Exact publication title

– Form number (for example, GA32–1234–02) or part number (on the back cover of the publication)

– Page, table, or illustration numbers that you are commenting on

– A detailed description of any information that should be changed

vi IBM TS3100 Tape Library and TS3200 Tape Library: Setup, Operator, and Service Guide Machine Type 3573

Page 7

Contacting IBM technical support

In the US: Call 1-800-IBM_SERV (1-800-426-7378).

Note: Before calling, complete all the steps in "Contacting IBM Technical Support" in chapter 9.

All other Countries/Regions: Visit http://www.ibm.com.

To open a Service Request online: Under Support & downloads, click Open a service request.

Read this first vii

Page 8

viii IBM TS3100 Tape Library and TS3200 Tape Library: Setup, Operator, and Service Guide Machine Type 3573

Page 9

Summary of changes

|

Table 2. Information added to the GA32-0545-17 edition.

|

v Support for LTO M8 media

|

– Support for LTO8 Type M Cartridge (M8)

|

|

|

|

|

- Description and support for M8 media

v 9 TB data capacity

v 22.5 TB data capacity with 2.5:1 compression

Table 3. Information added to the GA32-0545-16 edition.

v Support for LTO 8

– Specifications for Ultrium 8 half-height drives

– Full support of Ultrium 8 media

- 12 TB data capacity

- 30 TB data capacity with 2.5:1 compression

Table 4. Information added to the GA32-0545-15 edition.

v Feature codes and part numbers are added for Mini-SAS HD 1x and 2x cables.

v Added a section about uploading and configuring the User Defined Certificate.

Table 5. Information added to the GA32-0545-14 edition.

v Support for LTO 7

– Specifications for Ultrium 7 drives

© Copyright IBM Corp. 2007, 2018 ix

Page 10

x IBM TS3100 Tape Library and TS3200 Tape Library: Setup, Operator, and Service Guide Machine Type 3573

Page 11

Contents

Important .............. iii

Read this first ............ v

Minimum firmware levels for common library

features ................ v

Accessing online technical support ....... vi

Registering for My Notification ........ vi

Sending us your comments ......... vi

Contacting IBM technical support ....... vii

Summary of changes......... ix

Figures .............. xv

Tables ............... xix

Safety and environmental notices ... xxi

Safety notices ............. xxi

Possible safety hazards .......... xxii

Class I laser product ........... xxii

Performing the safety inspection procedure ... xxiii

Rack safety .............. xxiii

Power Cords ............. xxv

Cautions and regulatory compliance statements for

NEBS ................ xxv

Preface ............. xxvii

Product description.......... 1

Front panel ............... 1

Rear panel ............... 3

Bar code reader ............. 6

Encryption ............... 6

Supported Internet Protocols ......... 6

SNMP messaging ............. 7

SNMP traps ............. 7

Maximum library storage capacity and data transfer

rate ................. 7

Ultrium tape drives ............ 9

Speed matching ............ 11

Channel calibration ........... 11

Power management........... 11

Media ................ 11

Library specifications ........... 12

Product environment ........... 15

Supported servers, operating systems, and software 15

Supported device drivers .......... 16

User interfaces ........... 19

Operator Control Panel .......... 19

Operator Control Panel philosophy ..... 19

Power-ON display ........... 20

Note about the front panel LEDs ...... 20

Input modes ............. 21

Selecting predefined values ....... 21

Toggling values ........... 21

Entering numerical values ....... 22

Power ON/OFF ............ 22

Web User Interface ............ 22

Login ............... 22

System status............. 23

Web User Interface Help pages ....... 25

Logging out of the Web User Interface .... 25

Installation planning ......... 27

Determining the number of logical libraries

(partitions) .............. 27

Basic guidelines ............ 27

Library sharing ............ 27

Multiple logical libraries for library sharing .. 27

Multiple control paths ........... 28

Multiple control paths for System i, iSeries, and

AS/400 attachment ........... 28

Multiple control paths for path failover .... 28

Library partitioning and element addressing ... 29

Persistent binding to ensure SCSI ID assignment 32

Logical unit number (LUN) scanning ...... 33

Host interfaces ............. 33

SCSI interface ............ 33

Physical characteristics of the SCSI interface 34

Multiple SCSI buses ......... 34

Terminating the bus ......... 35

SCSI connectors and adapters ...... 35

SCSI differential - LVD ........ 35

SAS interface ............. 35

Fibre Channel interface ......... 36

Cables and speeds .......... 36

Zoning to isolate devices and enhance security 36

Fibre Channel host environment ..... 37

Sharing on a storage area network (SAN) .. 37

Installation and configuration ..... 39

The Library Configuration Form ....... 39

Installing your library ........... 39

Acclimation ............. 39

||

Choosing a location .......... 40

Unpacking the library .......... 41

Verifying the shipment ......... 41

Installing the library foot pads (desktop

installation) ............. 42

Removing and storing the shipping lock.... 43

Rackmounting the library (rack installation) .. 45

Attaching the library to a server ..... 53

Connecting the host interface cable ..... 53

Installing a Fibre Channel interposer (feature

code 5096) ............. 55

Connecting a power cord ......... 56

Configuring your library .......... 56

© Copyright IBM Corp. 2007, 2018 xi

Page 12

Choosing your configuration method ..... 57

Choosing factory defaults for your library

configuration ............. 57

Configuring your library with the Web User

Interface .............. 57

Establishing remote access to your library .. 58

Logging on to the Web User Interface ... 59

Verifying/updating firmware ...... 60

Choosing general library settings ..... 61

Choosing the number of logical libraries for

your library ............ 62

Entering Path failover feature activation key 63

Setting up encryption ......... 64

Choosing drive interface identification/

settings .............. 66

Entering library network settings ..... 66

Entering user access information with the Web

User Interface ........... 68

Entering date and time ........ 69

Configuring logs and traces ....... 70

Entering email notification ....... 71

Configuring SNMP settings ....... 71

Testing encryption configuration for Library

Managed encryption ......... 73

Restoring factory default settings ..... 73

Logging out of the Web User Interface ... 73

Configuring your library with the Operator

Control Panel............. 73

Preparing the host ............ 74

Verifying the connection .......... 74

Cartridge magazines ........... 74

Populating the library with data cartridges ... 79

Inserting the cleaning cartridge ....... 79

Registering for My Notification ........ 80

Operations ............. 81

Operator Control Panel navigation ...... 87

Operator Control Panel menu tree ....... 89

Monitor menu ............ 90

Monitor: Library........... 90

Monitor: Drive ........... 92

Monitor: Inventory .......... 94

Control menu ............ 96

Control: Open I/O Station ....... 96

Control: Move Cartridges........ 97

Control: Magazine .......... 97

Control: Re-Inventory ......... 98

Configure menu ............ 98

Configure: Logical Libraries ....... 98

Configure: Library.......... 100

Configure: Drive .......... 102

Configure: Network ......... 103

Configure: Set Access PIN ....... 104

Setting the Operator Control Panel Access

PIN ............. 104

Configure: Save/Restore........ 105

Configure: Set Date and Time ...... 107

Configure: Path Failover........ 107

Service menu ............ 108

Service: Library Verify ........ 108

Service: Run Tests .......... 109

Service: Service (Drives) ........ 109

Service: Display Contrast ....... 110

Service: Telnet service port ....... 110

Web User Interface menus ......... 110

Monitor Library menu ......... 111

Monitor Library: Library Identity ..... 112

Monitor Library: Drive Identity ..... 113

Monitor Library: Library Status ..... 116

Monitor Library: Drive Status ...... 117

Monitor Library: Inventory ....... 119

Manage Library menu ......... 121

Manage Library: Move media ...... 121

Manage Library: Perform inventory .... 122

Manage Library: Release Magazine .... 122

Configure Library menu......... 123

Configure Library: General ....... 123

Configure Library: Logical Libraries .... 124

Configure Library: Path Failover ..... 125

Configure Library: Encryption ...... 125

Configure Library: Drives ....... 127

Configure Library: Network ...... 129

Configure Library: User-Defined Certificate 131

Configure Library: IPSec........ 135

Configure Library: User Access ..... 145

Configure Library: Date & Time ..... 147

Configure Library: Logs & Traces..... 147

Configure Library: Event Notification ... 148

Configure Library: SNMP ....... 149

Configure Library: Save/Restore ..... 150

Service Library menu.......... 151

Service Library: Clean Drive ...... 151

Service Library: Advanced Diagnostics (for

Service Personnel Only) ........ 152

Service Library: View Library Logs .... 152

Service Library: Save Library Dump .... 153

Service Library: View Drive Logs..... 153

Service Library: Save Drive Dump .... 154

Service Library: Perform Diagnostics ... 154

Service Library: Key Path Diagnostics ... 155

Service Library: Upgrade Firmware .... 156

Service Library: Reboot ........ 158

Import and export media during normal library

operation ............... 159

Configuring I/O stations and reserving slots ... 160

Ultrium media ........... 163

Data cartridges ............. 163

Cartridge compatibility ......... 165

LTO 8 Type M Cartridge (M8) ....... 166

||

Capacity scaling ........... 166

WORM (Write Once, Read Many) cartridges ... 167

WORM media ............ 167

Data security on WORM media ...... 167

WORM media errors .......... 167

WORM requirements.......... 167

Cleaning cartridge............ 168

Cartridge memory chip (LTO-CM) ...... 168

Bar code label ............. 168

Guidelines for bar code labels ....... 170

Write-Protect switch ........... 170

Handling the cartridges .......... 171

xii IBM TS3100 Tape Library and TS3200 Tape Library: Setup, Operator, and Service Guide Machine Type 3573

Page 13

Providing training ........... 171

Ensuring proper packaging ........ 171

Proper acclimation and environmental

conditions ............. 172

Completing a thorough inspection ..... 173

Handling the cartridge carefully ...... 174

Examples of cartridge problems ...... 174

Repositioning or reattaching a leader pin .... 174

Repositioning a leader pin ........ 174

Reattaching a Leader Pin ........ 176

Environmental and shipping specifications for tape

cartridges .............. 180

Disposing of tape cartridges ........ 181

Ordering media supplies ......... 182

Ordering bar code labels ........ 185

Troubleshooting .......... 187

Installation problems ........... 193

Library recovery problem determination .... 193

Procedures for isolating CRU problems..... 194

Isolating a power supply problem ..... 194

Isolating drive sled problems ....... 196

Isolating a library controller card versus

accessor enclosure problem ........ 197

Isolating Web User Interface problems .... 198

Isolating accessor scanner problems ..... 198

Isolating host attachment interface problems .. 199

Identifying a suspect cartridge........ 199

Error codes ............ 201

Service procedures ......... 215

Removing cartridges from magazine slots .... 215

Releasing the magazines manually ...... 215

IBM Tape Diagnostic tool (ITDT) ....... 218

Contacting IBM technical support ...... 219

Check, adjust, remove, and replace 221

Tools required ............. 221

Electrostatic discharge .......... 221

Relocating your library .......... 221

Removing/installing/adding a tape drive sled .. 223

Removing a tape drive sled ....... 224

Installing a tape drive sled ........ 226

Adding a tape drive sled ........ 228

Configuring the tape drive ....... 229

Removing the slot blocker - 2U library ..... 229

Replacing a power supply ......... 231

Replacing a library controller card ...... 231

Replacing cartridge magazines ....... 233

Replacing magazine fiducials ........ 233

Replacing the library enclosure ....... 234

Preparing the defective library for replacement 235

Unpacking and preparing the replacement

library enclosure ........... 235

Installing your drive in the replacement library

enclosure .............. 238

Swapping power supplies ........ 240

Swapping library controller cards ..... 241

Swapping cartridge magazines ...... 243

Installing the replacement library enclosure .. 245

Completing the installation of the replacement

library enclosure ........... 247

Returning the defective library enclosure ... 247

Optional features, replacement parts,

and power cords .......... 249

Appendix A. Information for trained

service personnel ......... 259

Internal view of library .......... 259

Manual cartridge removal procedure ..... 260

Recommended tools ........... 260

Before you begin ............ 260

Beginning procedure ........... 261

Removing the drive brick from the sled ... 261

Removing the drive cover ........ 264

Full height drive: Tape spooled off supply reel .. 265

Half height drive: Tape spooled off supply reel 266

Full height drive: Tape pulled from or broken near

leader pin .............. 268

Half height drive: Tape pulled from or broken

near leader pin ............ 270

Full height drive: Tape broken in mid-tape ... 271

Half height drive: Tape broken in mid-tape .. 272

Full height drive: Tape tangled along tape path .. 273

Half height drive: Tape tangled along tape path 276

Full height drive: No apparent failure or damage

to tape ............... 277

Half height drive: No apparent failure or

damage to tape ............ 280

Ending procedure ............ 283

Accessing the library with Telnet ....... 283

Appendix B. SCSI element types, SCSI

addresses, and physical

configurations ........... 285

2U library I/O slot, storage slots, drive slot

element addresses, and physical locations .... 285

4U library I/O slots, storage slots, drive slots

element addresses, and physical locations .... 286

Library partitioning and element addressing ... 287

Appendix C. TapeAlert flags ..... 291

TapeAlert flags supported by the library .... 291

TapeAlert flags supported by the drive ..... 293

Appendix D. Sense data ....... 297

Library sense data ............ 297

Drive sense data ............ 303

Appendix E. Message retrieval at the

host ............... 313

Retrieving from an IBM System p or IBM Power

system with AIX ............ 313

SCSI sense data definition ........ 314

SCSI sense data - library error ....... 314

SCSI sense data - drive error ....... 315

Contents xiii

Page 14

Retrieving from a Sun system ........ 316

Retrieving from an HP-UX system ...... 316

Retrieving from an IBM System i or IBM Power

system with IBM i OS .......... 317

Appendix F. SNMP status MIB

variables and traps ......... 319

Appendix G. Library Configuration

Form ............... 321

Appendix H. Accessibility ...... 323

Notices .............. 325

Trademarks .............. 327

Class A Notices............. 327

Industry Canada Compliance Statement ... 327

European Community and Morocco Notice .. 328

German Notice ............ 328

Japan VCCI Notice .......... 329

Japan JEITA Notice .......... 329

Korea Notice ............ 330

People's Republic of China Notice ..... 330

Taiwan Notice ............ 330

IBM Taiwan Contact Information ...... 330

Russia Notice ............ 331

United States Federal Communications

Commission (FCC) Notice ........ 331

Glossary ............. 333

Index ............... 351

xiv IBM TS3100 Tape Library and TS3200 Tape Library: Setup, Operator, and Service Guide Machine Type 3573

Page 15

Figures

1. Front panel of a 2U library ........ 1

2. Front panel of a 4U library ........ 1

3. Rear panel (drive sled only) of a half height

Fibre Channel drive .......... 3

4. Rear panel of a 4U library with full height Fibre

Channel drive and half height SAS drives... 3

5. Rear panel of a 2U library with a full height

dual port SAS drive .......... 4

6. Library drive sled without ESD springs (SCSI

sled shown) ............ 10

7. Library drive sled with ESD springs [1] (SAS

sled shown) ............ 10

8. Power-ON screens .......... 20

9. Web User Interface login page ...... 23

10. 2U library System status screen ...... 23

11. 4U library System status screen ...... 24

12. 4U library System status screen that is

showing media attention status ...... 24

13. 4U library System status screen that is

showing a power supply failure...... 25

14. Configuration of a one - partition system 30

15. Configuration of a two - partition system 30

16. Configuration of a three - partition system 31

17. Configuration of a four - partition system 31

18. Examples of SCSI element addressing .... 32

19. Installing foot pads on the bottom of the

library enclosure ........... 43

20. Shipping lock and label ........ 44

21. Library shipping lock and label storage

location .............. 44

22. Rack Kit A mounting hardware ...... 45

23. Rack Kit B mounting hardware ...... 46

24. Examples of EIA units for round hole and

square hole installations ........ 47

25. Rear view of Rack Kit A, which shows the

narrow part of the rail at the rear of the rack. . 48

26. Rear view of Rack Kit B shows a different

mounting method .......... 48

27. Kit A (top picture with circles) showing rails

installed. Rack Kit B is below showing the

front view of this kit installed. ...... 49

28. 2U library rack anchors and mounting brackets 50

29. Close-up view of mounting of the anchors on

both sides of the library ........ 50

30. 2U library side screws to remove ..... 51

31. Sliding the 2U library into the rack .... 51

32. Sliding the 4U library into the rack .... 52

33. Securing the 2U library to the rack ..... 52

34. Securing the 4U library to the rack ..... 53

35. Attaching a SCSI host interface cable to the 2U

library .............. 54

36. Attaching host interface cables to the 4U

library .............. 54

37. Attaching a SAS interface cable to the 2U

library .............. 54

38. Interposer installation ......... 55

39. Removing the protective label from the power

receptacle ............. 56

40. Log in screen on the Web User Interface 60

41. The 2U library Configure Library: General

screen .............. 62

42. Example - The 4U library Configure Library:

General screen ........... 62

43. The 4U library Configure Library: Logical

Libraries page............ 63

44. The Configure Library: Path failover feature

activation screen ........... 63

45. Feature key verification screen ...... 64

46. Feature activation key screen....... 64

47. Configure Library: Encryption Activation

screen .............. 65

48. The Configure Library: Drives screen .... 66

49. Configure Library: Network page ..... 67

50. Warning screen ........... 68

51. The Configure Library: User Access screen 69

52. The Configure Library: Date and Time screen 70

53. The Configure Library: Logs and Traces screen 70

54. The Configure Library: Email notification

screen .............. 71

55. Configure Library: SNMP page ...... 72

56. 2U library left magazine ........ 75

57. 2U library right magazine........ 76

58. 2U library I/O station in the left magazine 76

59. 4U library left magazines ........ 77

60. 4U library right magazines ....... 77

61. 4U library I/O station in the lower left

magazine ............. 78

62. Finger Holes on back side of 4U Library I/O

station .............. 78

63. 2U library control keys ......... 88

64. 4U library control keys ......... 88

65. Operator Control Panel menu tree ..... 90

66. Monitor: Library menu......... 91

67. Monitor: Drive menu ......... 93

68. Example of a 4U Monitor: Inventory menu 95

69. Overview of inventoried cartridges: Left

magazines of a 4U Library ....... 95

70. Detailed information on cartridges residing in

a magazine............. 96

71. Control: I/O station menu ....... 96

72. Control: Move Cartridges menu...... 97

73. Control: Magazine menu ........ 97

74. Control: Re-Inventory menu ....... 98

75. Configure: Logical Libraries menu ..... 99

76. Configure: Library menu........ 100

77. Configure: Drive menu ........ 102

78. Configure: Network menu ....... 103

79. Configure: Set Access PIN menu ..... 104

80. Pound sign (#) shows accessible menus when

access PIN is enabled but before it is entered . 105

81. Configure: Save/Restore menu...... 105

82. Configure: Set Date and Time menu .... 107

© Copyright IBM Corp. 2007, 2018 xv

Page 16

83. Configure: Path failover ........ 108

84. Service: Library Verify menu ...... 108

85. Service: Run Tests menu ........ 109

86. Service: Service menu ......... 109

87. Service: Display Contrast menu ..... 110

88. The 4U library Monitor Library: Library

Identity page............ 113

89. The 4U library Monitor Library: Drive

Identity page, showing one V2 HH (Half

Height) SAS (#1), one HH (Half Height) SCSI

drive (#2), and one TD (Full Height) Fibre

Channel drive (#3) .......... 115

90. The 2U library Monitor Library: Drive

Identity page, showing one Ultrium 3 HH

SAS drive (#1) and one Ultrium 4 HH SAS

drive (#2). Version 2 information displayed

for drive #1 identifies the drive as a V2 drive

(Feature Code 8049 - Ultrium 3 HH SAS

Drive V2).............. 116

91. The 4U library Monitor Library: Library

Status page ............ 117

92. The 4U library Monitor Library: Drive Status

page .............. 119

93. The 2U library Monitor Library: Inventory

page .............. 120

94. The 4U library Monitor Library: Inventory

page (Right Magazines) ........ 121

95. Manage Library: move media page .... 122

96. Manage Library: Perform inventory page 122

97. Manage Library: Release Magazine page 122

98. The 4U library Configure Library: General

and Extended page ......... 124

99. The 4U library Configure Library: Logical

Libraries page ........... 125

100. The 4U library Configure Library: Path

Failover page ........... 125

101. Path Failover license verification page 125

102. Feature Activation Key screen ...... 126

103. Configure Library: Encryption feature

configuration screen ......... 126

104. The Configure Library: Drives page for a 2U

library .............. 128

105. The Configure Library: Drives page for a 4U

library .............. 129

106. Configure Library: Network page ..... 129

107. Warning screen ........... 130

108. Generate Certificate Request ...... 132

109. Warning screen ........... 132

110. Certificate request .......... 133

111. Signed certificate .......... 134

112. Reboot .............. 134

113. Configure the certificate ........ 135

114. Configure Library: IPSec The Policy setting

page .............. 136

115. Generic IPSec settings......... 136

116. IPSec Policy editing ......... 137

117. Policy editing ........... 138

118. Overview of the policy configuration page 138

119. General Policy settings ........ 138

120. IKE settings ............ 141

121. Certificate Upload .......... 143

122. Security Association settings ...... 143

123. Policy slot setup after one policy is saved 145

124. Configure Library: User Access page 146

125. The Configure Library: Date & Time page 147

126. Configure Library: Logs & Traces page 148

127. Configure Library: Event Notification page 148

128. Configure Library: SNMP page ..... 149

129. Configure Library: Save/Restore page 151

130. No Cleaning Required ........ 151

131. No cleaning cartridge in library ..... 151

132. Service Library: Clean Drive page..... 152

133. Service Library: View Library Logs page 153

134. Service: Save Library Dump ...... 153

135. Service Library: View Drive Logs screen 154

136. Service: Save Drive Dump ....... 154

137. Service Library: Perform Diagnostics page 155

138. Service Library: Perform Key Path

Diagnostics page .......... 156

139. The 2U library Service Library: Upgrade

Firmware page, showing one Ultrium 3 SAS

Half Height V2 drive and one Ultrium 4 SAS

Half Height drive. .......... 157

140. The 4U library Service Library: Upgrade

Firmware page ........... 158

141. The 2U library Monitor Library: Drive

Identity page, showing one Ultrium 3 HH

SAS drive (#1) and one Ultrium 4 HH SAS

drive (#2). Version 2 information displayed

for drive #1 identifies the drive as a V2 drive

(Feature Code 8049 - Ultrium 3 HH SAS

Drive V2). ............ 158

142. Service Library: Reboot page ...... 159

143. The IBM LTO Ultrium data cartridge 163

144. Ultrium Data and WORM Tape Cartridges 167

145. Sample bar code label on the LTO 8 Tape

Cartridge ............. 170

146. Setting the write-protect switch ..... 171

147. Tape cartridges in a Turtlecase ...... 172

148. Double-boxing tape cartridges for shipping 172

149. Checking for gaps in the seams of a cartridge 173

150. Leader pin in the incorrect and correct

positions ............. 175

151. Placing the dislodged leader pin into the

correct position ........... 176

152. Rewinding the tape into the cartridge 176

153. Leader Pin Reattachment Kit ...... 177

154. Attaching the leader pin attach tool to the

cartridge ............. 178

155. Winding the tape out of the cartridge 178

156. Removing the C-clip from the leader pin 179

157. Attaching the leader pin to the tape .... 180

158. A 250w power supply with LEDs ..... 194

159. A 80w power supply without LEDs .... 195

160. Access holes for the left magazine .... 216

161. Access holes for the right magazine .... 217

162. Left magazine pulled out of the 2U library 218

163. Left Magazines pulled out of the 4U Library 218

164. ESD label ............. 221

165. Shipping lock and label storage location 222

166. Shipping lock and label ........ 222

xvi IBM TS3100 Tape Library and TS3200 Tape Library: Setup, Operator, and Service Guide Machine Type 3573

Page 17

167. Library drive sled without ElectroStatic

Discharge (ESD) springs (SCSI sled shown) . 223

168. Library drive sled with ESD springs [1] (SAS

sled shown) ............ 224

169. Drive sled components (full height fibre drive

in top position, half height SCSI drive in

middle position, half height SAS drive in

bottom position) on back panel of a 4U

library .............. 225

170. Pulling the drive sled out of the library (drive

sled without ESD springs shown) ..... 226

171. Pushing the drive sled into the library (drive

sled without ESD springs shown) ..... 227

172. Diagrams for applying conductive tape for

ESD protection to the back of a drive sled

installed in a 2U or 4U library ...... 227

173. 2U magazine with slot blocker ...... 230

174. Popping the slot blocker out of the cell 230

175. A power supply removed from a 2U library 231

176. A library controller card that is removed from

the library ............ 232

177. Magazine fiducial .......... 234

178. Removing the two mounting bracket screws

anchoring the library to the rack (one screw

on each side of the library) ....... 235

179. Foot pads that are installed on the bottom of

the library enclosure ......... 236

180. Removing the shipping label and lock from

the top of the library and storing on the rear

panel .............. 237

181. Library shipping lock and label storage

location on the real panel of the library ... 237

182. Removing a drive sled from the library (drive

sled without ESD springs shown) ..... 238

183. Drive sled taping diagrams ....... 239

184. A power supply that is removed from a

library .............. 240

185. Removing a library controller card from the

library .............. 242

186. Library front panel LEDs ....... 243

187. Access hole for the left magazine (facing rear

of library)............. 243

188. Access hole for the right magazine (facing

rear of library) ........... 244

189. Left magazines pulled out of a 4U library

(facing front of library) ........ 245

190. Mounting brackets and anchors for securing

the library in a rack (one bracket and anchor

on each side of the library) ....... 246

191. Front view of a rack, showing the rails

installed ............. 246

192. Proper placement of the Repair Identification

(RID) Tag ............. 247

193. Types of receptacles ......... 257

194. Internal view of the library ....... 259

195. Drive connection card, showing screws and

plastic cover ............ 262

196. Half height drive with the connection card

moved to the side, showing the screws ... 263

197. The drive brick, showing the cables to be

unplugged ............ 263

198. Removing the bezel and the cover from the

4U internal drive .......... 264

199. Removing the bezel and the cover from the

half height internal drive........ 265

200. The hex wrench rewinds tape into cartridge 266

201. Rewinding tape into cartridge ...... 267

202. Drive with cover removed to reveal gear

train. .............. 268

203. Leader Block Assembly (LBA) ...... 269

204. Drive with cover removed to reveal gear

train. .............. 270

205. Leader Block Assembly (LBA) ...... 271

206. The hex wrench rewinds tape into cartridge 272

207. Rewinding tape into cartridge ...... 273

208. The hex wrench rewinds tape into cartridge 274

209. Drive with cover removed to reveal gear

train. .............. 275

210. Leader Block Assembly (LBA) ...... 276

211. Rewinding tape into cartridge ...... 277

212. The hex wrench rewinds tape into cartridge 278

213. Drive with cover removed to reveal gear

train. .............. 279

214. Leader Block Assembly (LBA) ...... 280

215. Rewinding tape into cartridge ...... 281

216. Drive with cover removed to reveal gear

train. .............. 282

217. Leader Block Assembly (LBA) ...... 282

218. Configuration of a one - partition system 288

219. Configuration of a two - partition system 288

220. Configuration of a three - partition system 289

221. Configuration of a four - partition system 289

222. Examples of SCSI element addressing 290

223. AIX ERRPT Library Error Log Example 315

224. AIX ERRPT Library Error Log Example 316

Figures xvii

Page 18

xviii IBM TS3100 Tape Library and TS3200 Tape Library: Setup, Operator, and Service Guide Machine Type 3573

Page 19

Tables

1. Minimum firmware levels for common library

features .............. v

|

2. Information added to the GA32-0545-17

||

edition. .............. ix

3. Information added to the GA32-0545-16

edition. .............. ix

4. Information added to the GA32-0545-15

edition. .............. ix

5. Information added to the GA32-0545-14

edition. .............. ix

6. 2U library and 4U library front panel

descriptions ............. 2

7. 2U library and 4U library rear panel

descriptions ............. 5

8. Tape drive model and host interface type 7

9. Library storage capacity and data transfer rate 8

10. Physical specifications ......... 12

11. Power specifications ......... 12

12. Operation specifications: Ultrium 8..... 12

13. Operation specifications: Ultrium 7..... 13

14. Operation specifications: Ultrium 6..... 13

15. Operation specifications: Ultrium 5..... 14

16. Operation specifications: Ultrium 4..... 14

17. Operation specifications: Ultrium 3..... 14

18. Environmental specifications ....... 15

19. Host drive interface support ....... 33

20. Maximum bus length between terminators 34

21. Recommended maximum quantity of drives

per SCSI bus ............ 34

22. Location criteria ........... 40

23. Menu navigation shortcuts ....... 81

24. Library control keys.......... 88

25. Detailed information on cartridges residing in

a magazine............. 96

26. Factory default settings ........ 106

27. Web User Interface menus ....... 110

28. Library Identity page elements ...... 112

29. Drive Identity page elements ...... 113

30. Library Status page elements ...... 116

31. Drive Status page elements ....... 117

32. Configure Library: General page elements 123

33. Configure Library: Specific page elements 123

34. Drive Identity page elements ...... 128

35. Generic IPSec settings......... 137

36. General Policy settings ........ 139

37. IKE settings ............ 141

38. Security Association settings ...... 143

39. Cartridge types and colors ....... 163

40. Cartridge data capacity and recording formats 164

41. Nominal cartridge life: Load/unload cycles 165

42. Ultrium data cartridge compatibility with

Ultrium tape drive .......... 165

||

43. LTO 7 and LTO 8 Cartridge Types .... 166

44. Bar code label requirements for LTO tape

drives and libraries ......... 168

45. Cartridges and VOLSERs compatible with the

LTO Tape Drives .......... 169

46. Location of the write-protect switch .... 171

47. Environment for operating, storing, and

shipping the LTO Ultrium Tape Cartridge .. 181

48. Media supplies ........... 182

49. Authorized suppliers of custom bar code

labels .............. 185

50. Troubleshooting table ......... 187

51. Power supply LED meanings ...... 195

52. Main Error Codes .......... 202

53. Sub error codes ........... 207

54. Warning events ........... 211

55. Shipping lock/Shipping label ...... 222

56. Optional features .......... 249

57. Replacement parts .......... 250

58. Power cords ............ 253

59. Internal view description ....... 259

60. 2U library SCSI element types and element

addresses ............. 285

61. 4U library SCSI element types and element

addresses ............. 285

62. 2U library SCSI element addresses for storage

slots and drive slot (one logical partition with

one drive)............. 286

63. 4U library SCSI element addresses for storage

slots and drive slot (one logical partition with

drives in slot 1 and slot 2) ....... 286

64. TapeAlert flags supported by the Ultrium

tape drive............. 293

65. Library Sense Keys, ASC and ASCQ .... 297

66. LTO Tape Drive Sense Data ....... 303

67. AIX ERRPT library sense data ...... 315

68. AIX ERRPT drive sense data ...... 316

69. SNMP status events ......... 319

© Copyright IBM Corp. 2007, 2018 xix

Page 20

xx IBM TS3100 Tape Library and TS3200 Tape Library: Setup, Operator, and Service Guide Machine Type 3573

Page 21

Safety and environmental notices

When this product is used, observe the danger, caution, and attention notices that are contained in this

guide. The notices are accompanied by symbols that represent the severity of the safety condition.

Most danger or caution notices contain a reference number (Dxxxx or Cxxxx). Use the reference number

to check the translation in the IBM Systems Safety Information (G229-9054) publication included in your

ship group.

The sections that follow define each type of safety notice and give examples.

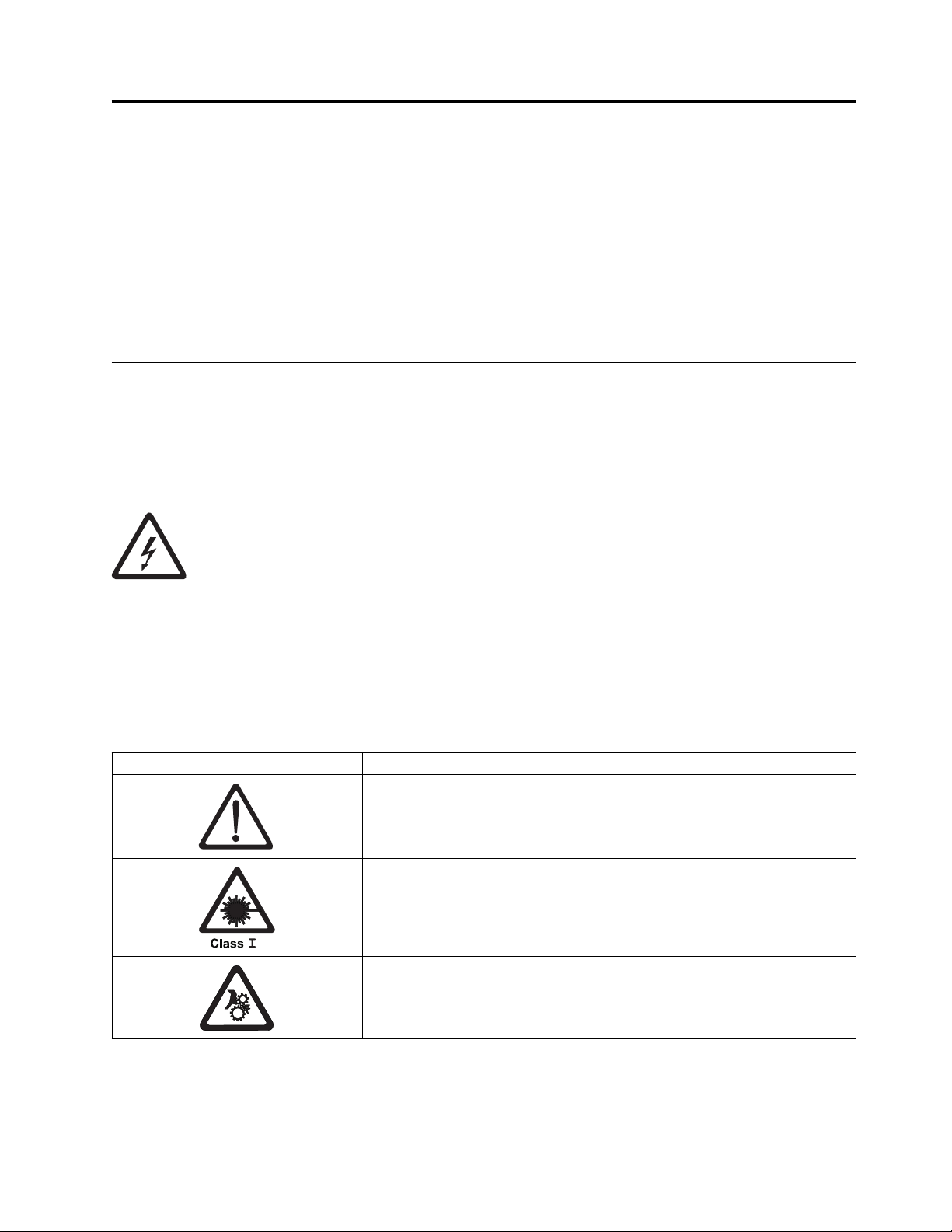

Safety notices

Danger notice

A danger notice calls attention to a situation that is potentially lethal or extremely hazardous to people. A

lightning bolt symbol always accompanies a danger notice to represent a dangerous electrical condition.

A sample danger notice follows:

An electrical outlet that is not correctly wired could place hazardous voltage

on metal parts of the system or the devices that attach to the system. It is the

responsibility of the customer to ensure that the outlet is correctly wired and

grounded to prevent an electrical shock. A lightning bolt symbol always

accompanies a danger notice to represent a dangerous electrical

condition.(D004)

Caution notice

A caution notice calls attention to a situation that is potentially hazardous to people because of some

existing condition, or to a potentially dangerous situation that might develop because of some unsafe

practice. A caution notice can be accompanied by one of several symbols:

If the symbol is... It means...

A generally hazardous condition not represented by other safety symbols.

A hazardous condition due to the use of a laser in the product. Laser

symbols are always accompanied by the classification of the laser as defined

by the U. S. Department of Health and Human Services (for example, Class

I, Class II, and so forth).

A hazardous condition due to mechanical movement in or around the

product.

© Copyright IBM Corp. 2007, 2018 xxi

Page 22

If the symbol is... It means...

svc00168

32-55kg(70.5-121.2lbs)

A hazardous condition due to the weight of the unit. Weight symbols are

accompanied by an approximation of the product's weight.

A hazardous condition due to the unit's susceptibility to electrostatic

discharge.

Sample caution notices follow:

Caution

The battery is a lithium ion battery. To avoid possible explosion, do not burn. Exchange only with

the IBM-approved part. Recycle or discard the battery as instructed by local regulations. In the

United States, IBM has a process for the collection of this battery. For information, call

1-800-426-4333. Have the IBM part number for the battery unit available when you call. (C007)

Caution

The system contains circuit cards, assemblies, or both that contain lead solder. To avoid the

release of lead (Pb) into the environment, do not burn. Discard the circuit card as instructed by

local regulations. (C014)

Caution

When removing the Modular Refrigeration Unit (MRU), immediately remove any oil residue

from the MRU support shelf, floor, and any other area to prevent injuries because of slips or falls.

Do not use refrigerant lines or connectors to lift, move, or remove the MRU. Use handholds as

instructed by service procedures. (C016)

Caution

Do not connect an IBM control unit directly to a public optical network. The customer must use

an additional connectivity device between an IBM control unit optical adapter (that is, fibre,

ESCON, FICON®) and an external public network . Use a device such as a patch panel, a router,

or a switch. You do not need an additional connectivity device for optical fibre connectivity that

does not pass through a public network.

Possible safety hazards

Possible safety hazards to the operation of this product are:

Electrical

An electrically charged frame can cause serious electrical shock.

Mechanical

Hazards (for example, a safety cover missing) are potentially harmful to people.

Chemical

Do not use solvents, cleaners, or other chemicals that are not approved for use on this product.

Before the library is used, repair any of the preceding problems.

Class I laser product

Before the library is used, review the following laser safety information.

xxii IBM TS3100 Tape Library and TS3200 Tape Library: Setup, Operator, and Service Guide Machine Type 3573

Page 23

The product might contain a laser assembly that complies with the performance standards set by the US

Food and Drug Administration for a Class I laser product. Class I laser products do not emit hazardous

laser radiation. The product has the necessary protective housing and scanning safeguards to ensure that

laser radiation is inaccessible during operation or is within Class I limits. External safety agencies

reviewed the product and obtained approvals to the latest standards as they apply.

Performing the safety inspection procedure

Before you service the unit, complete the following safety inspection procedure.

1. Stop all activities between the host and the library’s tape drives.

2. Turn off the power to the library by pushing in the Power button on the rear of the tape library for 4

seconds.

3. If the drives are SCSI attached, disconnect the SCSI cable and check the SCSI bus terminator for

damage.

4. Unplug the library’s power cord from the electrical outlet and the library’s power supply unit.

5. Check the library’s power cords for damage, such as a pinched, cut, or frayed cord.

6. If drives are SCSI attached, check the tape drive's SCSI bus (signal) cable for damage.

7. If drives are FC/SAS attached, check the tape drive's FC/SAS cable for damage.

8. Check the cover of the library for sharp edges, damage, or alterations that expose its internal parts.

9. Check the cover of the library for proper fit. It should be in place and secure.

10. Check the product label at the rear of the library to make sure that it matches the voltage at your

outlet.

Rack safety

The following general safety information must be used for all rack mounted devices.

DANGER

v Always lower the leveling pads on the rack cabinet.

v Always install stabilizer brackets on the rack cabinet.

v To avoid hazardous conditions because of uneven mechanical loading, always install the heaviest

devices in the bottom of the rack cabinet. Always install servers and optional devices, starting from the

bottom of the rack cabinet.

v Rack mounted devices are not to be used as a shelf or workspace. Do not place any object on top of

rack mounted devices.

v Each rack cabinet might have more than one power cord. Be sure to disconnect all power cords in the

rack cabinet before you service any device in the rack cabinet.

v Connect all devices that are installed in a rack cabinet to power devices installed in the same rack

cabinet. Do not plug a power cord from a device that is installed in one rack cabinet into a power

device that is installed in a different rack cabinet.

v An electrical outlet that is not correctly wired might place hazardous voltage on the metal parts of the

system or the devices that attach to the system. It is the responsibility of the customer to ensure that

the outlet is correctly wired and grounded to prevent an electrical shock.

Safety and environmental notices xxiii

Page 24

Caution

v Do not install a unit in a rack where the internal rack ambient temperatures might exceed the

manufacturer's recommended ambient temperature for all your rack mounted devices.

v Do not install a unit in a rack where the air flow is compromised. Ensure that air flow is not blocked

or reduced on any side, front, or back of a unit that is used for air flow through the unit.

v Consideration must be given to the connection of the equipment to the supply circuit so that

overloading of the circuits does not compromise the supply wiring or overcurrent protection. To

provide the correct power connection to a rack, refer to the rating labels on the equipment in the rack

to determine the total power requirement of the supply circuit.

v (For sliding drawers) Do not pull out or install any drawer or feature if the rack stabilizer brackets are

not attached to the rack. Do not pull out more than one drawer at a time. The rack might become

unstable if you pull out more than one drawer at a time.

v (For fixed drawers) This drawer is a fixed drawer and must not be moved for servicing unless

specified by the manufacturer. Attempting to move the drawer partially or out of the rack might cause

the rack to become unstable or cause the drawer to fall out of the rack.

(R001)

Caution

Removing components from the upper positions in the rack cabinet improves rack stability during

relocation. Follow these general guidelines whenever you relocate a populated rack cabinet within a room

or building:

v Reduce the weight of the rack cabinet by removing equipment, starting at the top of the rack cabinet.

When possible, restore the rack cabinet to the configuration of the rack cabinet as you received it. If

this configuration is not known, you must do the following:

– Remove all devices in the 32U position and above.

– Ensure that the heaviest devices are installed in the bottom of the rack cabinet.

– Ensure that there are no empty U-levels between devices that are installed in the rack cabinet below

the 32U level.

v If the rack cabinet you are relocating is part of a suite of rack cabinets, detach the rack cabinet from the

suite.

v Inspect the route that you plan to take to eliminate potential hazards.

v Verify that the route that you choose can support the weight of the loaded rack cabinet. Refer to the

documentation that comes with your rack cabinet for the weight of a loaded rack cabinet.

v Verify that all door openings are at least 760 x 2032 mm (30 x 80 in.).

v Ensure that all devices, shelves, drawers, doors, and cables are secure.

v Ensure that the four leveling pads are raised to their highest position.

v Ensure that there is no stabilizer bracket that is installed on the rack cabinet during movement.

v Do not use a ramp that is inclined at more than 10 degrees.

v When the rack cabinet is in the new location:

xxiv IBM TS3100 Tape Library and TS3200 Tape Library: Setup, Operator, and Service Guide Machine Type 3573

Page 25

– Lower the four leveling pads.

– Install stabilizer brackets on the rack cabinet.

– If you removed any devices from the rack cabinet, repopulate the rack cabinet from the lowest

position to the highest position.

v If a long-distance relocation is required, restore the rack cabinet to the configuration of the rack cabinet

as you received it. Pack the rack cabinet in the original packaging material, or equivalent. Also, lower

the leveling pads to raise the casters off the pallet and bolt the rack cabinet to the pallet.

(R002)

Power Cords

For your safety, IBM provides a power cord with a grounded attachment plug to use with this IBM

product. To avoid electrical shock, always use the power cord and plug with a properly grounded outlet.

IBM power cords used in the United States and Canada are listed by Underwriter’s Laboratories (UL)

and certified by the Canadian Standards Association (CSA).

For units intended to be operated at 115 volts: Use a UL-listed and CSA-certified cord set consisting of a

minimum 18 AWG, Type SVT or SJT, three-conductor cord, a maximum of 15 feet in length and a parallel

blade, grounding-type attachment plug rated 15 amperes, 125 volts.

For units intended to be operated at 230 volts (U.S. use): Use a UL-listed and CSA-certified cord set

consisting of a minimum 18 AWG, Type SVT or SJT, three-conductor cord, a maximum of 15 feet in

length and a tandem blade, grounding-type attachment plug rated 15 amperes, 250 volts.

For units intended to be operated at 230 volts (outside the U.S.): Use a cord set with a grounding-type

attachment plug. The cord set should have the appropriate safety approvals for the country in which the

equipment will be installed.

IBM power cords for a specific country or region are usually available only in that country or region.

Cautions and regulatory compliance statements for NEBS

This library is NEBS certified. This section includes the cautions and regulatory compliance statements for

the Network Equipment-Building System (NEBS) certification from the Telcordia Electromagnetic

Compatibility and Electrical Safety - Generic Criteria for Network Telecommunications Equipment (A

Module of LSSGR, FR-64; TSGR, FR-440; and NEBSFR, FR-2063) Telcordia Technologies Generic

Requirements, GR-1089-CORE, Issue 4, June 2006.

NEBS Compliance Statements

CAUTION:

To comply with the Telcordia GR-1089-CORE standard for electromagnetic compatibility and safety,

for Ethernet RJ-45 ports, use only shielded Ethernet cables that are grounded on both ends. In a NEBS

installation, all Ethernet ports are limited to intra-building wiring.

Safety and environmental notices xxv

Page 26

CAUTION:

The intra-building ports of the equipment or subassembly are only suitable for connection to

intra-building or unexposed wiring or cabling. The intra-building ports of the equipment or

subassembly must NOT be metallically connected to interfaces that connect to the OSP or its wiring.

These interfaces are designed for use only as intra-building interfaces (Type 2 or Type 4 ports as

described in GR-1089-CORE, Issue 4), and require isolation from the exposed OSP cabling. The

addition of primary protectors is not sufficient protection in order to connect these interfaces

metallically to OSP wiring.

An external Surge Protective Device (SPD) is not required for operating this library.

This product can be installed in a network telecommunication facility or location where the NEC applies.

xxvi IBM TS3100 Tape Library and TS3200 Tape Library: Setup, Operator, and Service Guide Machine Type 3573

Page 27

Preface

This manual contains information and instructions necessary for the installation, operation, and service of

the IBM TS3100 Tape Library and TS3200 Tape Library.

Note: The IBM TS3100 Tape Library and TS3200 Tape Library is a customer installed unit. The customer

is responsible for the setup and maintenance of the tape library. The customer is charged for service if a

service contract is not in place.

Related Publications

Refer to the following publications for more information.To ensure that you have the latest publications,

visit the web at http://www.ibm.com/storage/.

v IBM TS3100 Tape Library and TS3200 Tape Library Getting Started Guide (GA32-0546) provides installation

information.

v IBM TS3100 Tape Library and TS3200 Tape Library SCSI Reference (GA32-0547) provides supported SCSI

commands and protocol that governs the behavior of SCSI interface.

v IBM LTO Ultrium Tape Drive SCSI Reference (GA32-0450) provides supported SCSI commands and

protocol that governs the behavior of SCSI interface for the tape drive.

v IBM Tape Device Driver Installation and User's Guide (GC27-2130) provides instructions for attaching

IBM-supported hardware to open-systems operating systems. It indicates what devices and levels of

operating systems are supported. It also gives requirements for adapter cards, and tells how to

configure hosts to use the device driver. All of the above are with the Ultrium family of devices.

v IBM Tape Device Driver Programming Reference (GA32-0566) supplies information to application owners

who want to integrate their open-systems applications with IBM-supported Ultrium hardware. The

reference contains information about the application programming interfaces (APIs) for each of the

various supported operating-system environments.

v IBM Environmental Notices and User Guide (ENUG) (z125-5823), which is at ftp://public.dhe.ibm.com/

systems/support/warranty/envnotices/environmental_notices_and_user_guide.pdf.

v IBM Security Key Lifecycle Manager Knowledge Center, which is at http://www-01.ibm.com/support/

knowledgecenter/SSWPVP/welcome?lang=en, contains information to help you install, configure, and

use the IBM Security Key Lifecycle Manager.

v IBM Tivoli®Key Lifecycle Manager V1.0 (English) publications can be downloaded from the following

website: http://www.ibm.com/software/tivoli/library.

– IBM Tivoli®Key Lifecycle Manager Quick Start Guide (GI11-8738)

– IBM Tivoli®Key Lifecycle Manager Installation and Configuration Guide (SC23-9977)

v The IBM Publications Center: http://www.ibm.com/shop/publications/order. The Publications Center

is a worldwide central repository for IBM product publications and marketing material with a catalog

of 70,000 items. Extensive search facilities are provided. Payment options for orders are with credit card

(in the US) or customer number for 20 countries. Many publications are available online in various file

formats, and they can all be downloaded by all countries, free of charge.

© Copyright IBM Corp. 2007, 2018 xxvii

Page 28

xxviii IBM TS3100 Tape Library and TS3200 Tape Library: Setup, Operator, and Service Guide Machine Type 3573

Page 29

Product description

a77ug006

3

1 2

3

44

5

7

8

6

a77ug115

1 2

33

4

5

7 6

8

The IBM TS3100 Tape Library (2U library) and the IBM TS3200 Tape Library (4U library) provide

compact, high-capacity, low-cost solutions for simple, unattended data backup. The 4U library houses up

to 48 tape cartridges (or 45 and an elective 3-slot I/O station) in a compact 4U form factor with easy

access to cartridges by way of four removable magazines. The 2U library houses up to 24 tape cartridges

(or 23 and an elective 1-slot I/O station) in a compact 2U form factor with easy access to cartridges by

way of two removable magazines.

The eighth generation of the Ultrium series of products is available with interfaces to suit your needs: a

Fibre Channel interface (FC), or Serial Attached SCSI interface (SAS), for 2U and 4U libraries. LTO 8

half-height drives are supported.

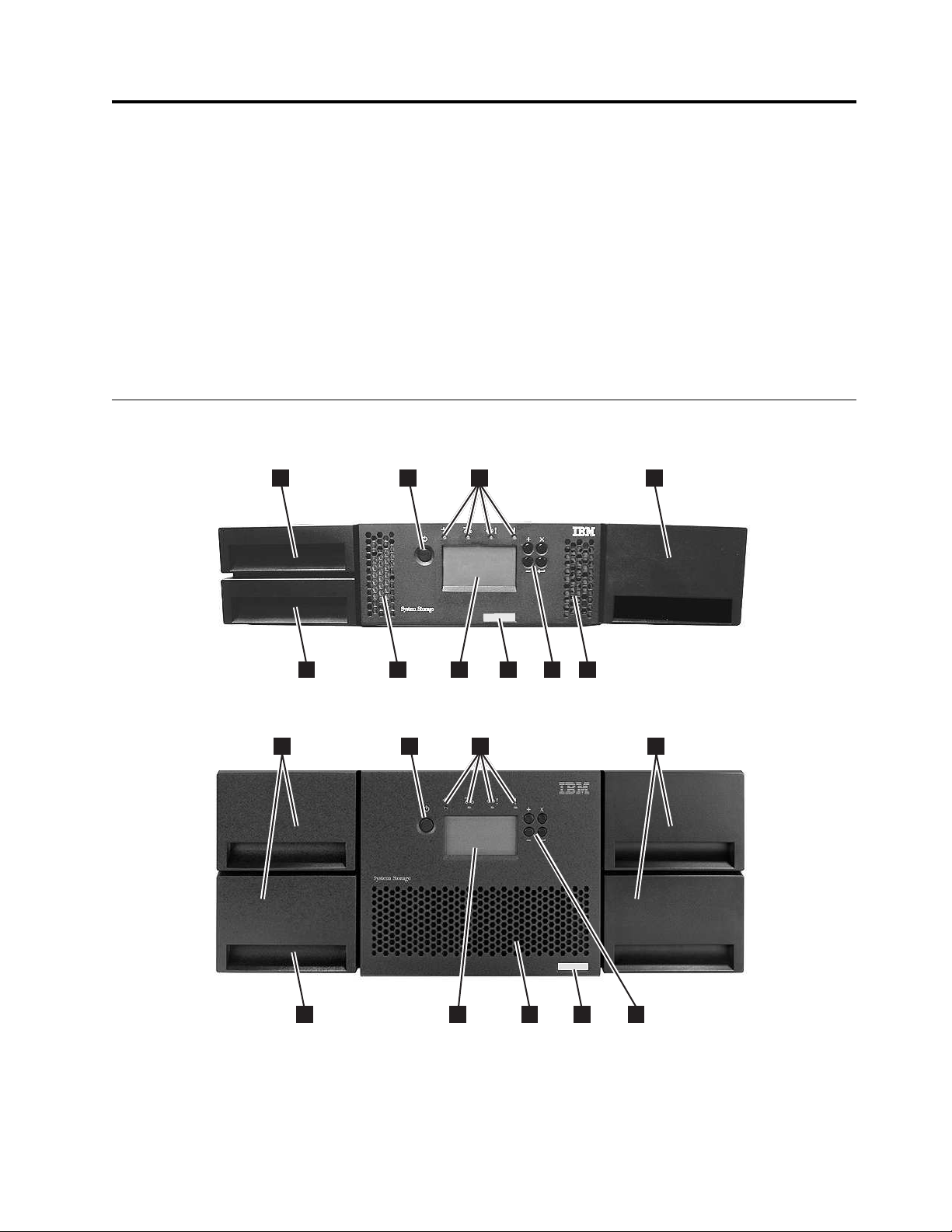

Front panel

Figure 1. Front panel of a 2U library

Figure 2. Front panel of a 4U library

Table 6 on page 2 contains front panel descriptions for both the 2U library in Figure 1 and the 4U library

in Figure 2.

© Copyright IBM Corp. 2007, 2018 1

Page 30

Table 6. 2U library and 4U library front panel descriptions

Number Item Description

▌1▐ Power button Pressing this button powers ON the library. Pressing and

holding this button for 4 seconds powers OFF the unit

(soft power down). No power switch or button is found on

the back panel of the library.

▌2▐ Front panel LEDs (left to right)

▌3▐ Cartridge magazines

▌4▐ Air vents These vents draw cooler air into the library enclosure and

▌5▐ Control keys

▌6▐ Machine type, Model number,

and Serial Number label

v Ready/Activity (Green LED) - It is illuminated any time

that the unit is powered ON and able to function. It

flashes whenever there is library or drive activity, or

when the library is powering up.

v Clean Drive (Amber LED) - It is illuminated when the

drive must be cleaned. The LED is turned OFF after the

drive is cleaned successfully.

v Attention (Amber LED) - It is illuminated when there is

a failure that indicates a piece of media is bad, marginal,

or invalid. It is cleared when all invalid cartridges are

exported from the library. The amber LED might also be

lit because a power supply or a power supply fan is

failing, or a drive sled is defective, missing, or replaced

by a different drive type.

v Error (Amber LED) - It is illuminated when there is an

unrecoverable library or drive failure. A message is

displayed at the same time on the Operator Control

Panel display.

v The 2U library contains two cartridge magazines.

– The left magazine can hold up to 12 cartridges (or 11

data cartridges and the elective 1-slot I/O station.)

– The right magazine can hold up to 12 cartridges.

v The 4U library contains four cartridge magazines.

– The upper left magazine can hold up to 12 cartridges.

– The lower left magazine can hold up to 12 cartridges

(or 9 data cartridges and the elective 3-slot I/O

station.)

– The upper right magazine can hold up to 12

cartridges.

– The lower right magazine can hold up to 12

cartridges.

allow warm air to escape, which helps keep the library at a

normal operating temperature.

v UP (+) - The upper left button is used to scroll upward

through menu items.

v DOWN (-) - The lower left button is used to scroll

downward through menu items.

v CANCEL (X) - The upper right button is used to cancel

a user action and return to the previous menu screen.

v SELECT - The lower right button is used to display a

submenu or force an accessor action.

The machine type, model number, and serial number of

the library are on this label. This serial number is the

number that links the library to your warranty.

2 IBM TS3100 Tape Library and TS3200 Tape Library: Setup, Operator, and Service Guide Machine Type 3573

Page 31

Table 6. 2U library and 4U library front panel descriptions (continued)

1

2

3

a77ug300

a77ug233

1

3

4

12

5

6

7

8

10

2

11

9

Number Item Description

▌7▐ Operator Control Panel display This component is a 128 X 64 monochrome graphic

display.

▌8▐ I/O station The input/output (I/O) station is used to import and

export cartridges into and out of the library.

v The 2U library has an elective 1-slot I/O station.

v The 4U library has an elective 3-slot I/O station.

Rear panel

Figure 3. Rear panel (drive sled only) of a half height Fibre Channel drive

Figure 4. Rear panel of a 4U library with full height Fibre Channel drive and half height SAS drives.

Product description 3

Page 32

a77ug234

1

3

4

5

7

8

9

2

10

11

12

6

Figure 5. Rear panel of a 2U library with a full height dual port SAS drive

4 IBM TS3100 Tape Library and TS3200 Tape Library: Setup, Operator, and Service Guide Machine Type 3573

Page 33

Table 7. 2U library and 4U library rear panel descriptions

Number Item Description

▌1▐ Power connector Both libraries require a 110/220 volt AC power connection.

v The 2U library has one power supply.

v The 4U library has a minimum of one power supply, but is capable of adding a

redundant power supply.

▌2▐ Host interface

connectors

The library has one or more of the following host interface connectors on the drive

sled:

v Fibre Channel connector

v SFF-8088 mini-SAS connector

▌3▐ Tape drive sled This library supports the Ultrium 3, 4, 5, 6, and 7 tape drive. The tape drive in the

library is packaged in a container that is called a drive sled. Drive sleds come in

full height or half height configurations. The drive sled is a customer replaceable

unit (CRU), and is hot-pluggable, which is designed for easy removal and

replacement.

▌4▐ Shipping lock and

label storage

location

The shipping lock, which secures the accessor during shipping, and associated

label are stored on the rear panel of the library for future use. See “Removing and

storing the shipping lock” on page 43.

Note: The shipping lock must be removed before the library is powered ON to

allow the accessor to function properly.

▌5▐ USB port Saves/restores library configuration information about a USB device. Used by

Service.

▌6▐ Library Control

An LED showing the status of the Library Control Board

Board (LCC) LED

LED flashing (1 flash per second) - normal operation

▌7▐ Serial port This port is used to communicate serially with the library with an RJ-11 connector.

For use by IBM Service Personnel.

▌8▐ Ethernet port This port is used to connect the library to a network.

LED

v 10/100 Link

– Description: Green: Link Integrity

– Flashing: Network synchronization/negotiation

– Steady (On): Good connection

– Off: No connection between NIC and hub

v Activity

– Description: Amber: Port traffic indicator

– Flashing: Network traffic present

– Steady (On): Heavy network traffic

– Off: No traffic

▌9▐ Tape drive LED This LED indicates the status of the drive. When the LED is green, it indicates

normal drive activity.

▌10▐ Machine type,

Model number, and

Serial Number

The machine type, model number, and serial number of the library are on this

pull-out label. This serial number is the number that links the library to your

warranty.

pull-out label

▌11▐ Fan vents These vents allow air to escape from the power supply and tape drive sled.

▌12▐ ESD label The Electrostatic Discharge label is a reminder that some of the components of this

library are susceptible to electrostatic discharge. See “Electrostatic discharge” on

page 221.

Product description 5

Page 34

Bar code reader

The bar code reader is a part of the library accessor. The bar code reader provides inventory feedback to

the host application, Operator Control Panel display, and Web User Interface by reading cartridge bar

code labels. The library stores the customized inventory data in memory.

Library firmware supports a 6 or 8 character volume serial number (VOLSER) on the bar code label on

the tape cartridge.

Encryption

The LTO Ultrium 4, 5, and 6 Tape Drives support host Application Managed Encryption (AME), Library

Managed Encryption (LME), and System Managed Encryption (SME). Ultrium 7 and later drives support

AME and LME. These drives support T10 Standards Encryption and IBM Proprietary Encryption, for SAS

and Fibre Channel drives only. Data encryption is supported by LTO Ultrium 4 and later Data Cartridges

only. Encryption is also supported by library firmware version 4.0 or higher.

The encryption enabled drive contains the necessary hardware and firmware to encrypt and decrypt host

tape application data. Encryption policy and encryption keys are provided by the host application or host

server. A drive digital certificate is installed at manufacturing time. Each drive receives a unique serial

number and certificate. The T10 application might validate each drive instance by checking the drive's

digital certificate.

The LTO Ultrium encryption environment is complex and requires knowledge beyond that of product

trained Service Support Representatives (SSRs). The Encryption function on tape drives (desktop,

stand-alone, and within libraries) is configured and managed by the customer. In some instances, SSRs

are required to enable encryption at a hardware level when service access or service password controlled

access is required. Customer setup support is by Field Technical Sales Support (FTSS), customer

documentation, and software support for encryption software problems. Customer 'how to' support is

also provided by support line contract.

The library firmware allows the user to select None or Application Managed Encryption from the Web

User Interface, if there is at least one encryption capable drive in the logical library. If a valid Transparent

Encryption license key is previously entered, System Managed Encryption or Library Managed

Encryption can be selected. The factory default is None.

Note: The optional Transparent Encryption Key feature that enables System Managed Encryption and

Library Managed Encryption is not available on TS3200 and TS3100 models that are purchased through

High Volume (HVEC) channels.

Note: All encryption settings must be configured or reverified in the drive after any library or drive

reset. This is because a new drive might be added or an existing drive might be swapped with another

drive.

For details, see the IBM Tape Device Drivers documentation, and the IBM LTO Ultrium Tape Drive SCSI

Reference documentation. See "Related Publications" in the Preface.

Supported Internet Protocols

The library supports the following Internet Protocols:

v IPv4

v IPv6

To learn more about Internet Protocols, visit http://www.iana.org/.

6 IBM TS3100 Tape Library and TS3200 Tape Library: Setup, Operator, and Service Guide Machine Type 3573

Page 35

SNMP messaging

Occasionally, the library might encounter a situation that you want to know about, such as an open

magazine or a fault that causes the library to stop. The library provides a standard TCP/IP protocol

called Simple Network Management Protocol (SNMP). SNMP sends alerts about conditions (such as need

for operator intervention) over a TCP/IP LAN network to an SNMP monitoring station. These alerts are

called SNMP traps. Using the information that is supplied in each SNMP trap, the monitoring station

(together with customer-supplied software) alerts operations personnel of possible problems or operator

interventions that occur.

All of the IBM automation products support SNMP (Simple Network Management Protocol) and all of

them support SNMP read and write capability.

The new SNMP Query Configuration capability provides a common Management Information Base (MIB)

across all of the IBM tape libraries. This capability allows a product administrator to audit the settings of

all of their IBM tape libraries to ensure that they comply with their own policies.

SNMP traps

SNMP traps are alerts or status messages that are collected, monitored, and used to proactively manage

attached libraries with SNMP protocol with the host servers. In summary, each trap provides the

following information:

v Product Identification such as product name, description, manufacturer, model number, firmware

level, and the URL that the trap is designated for.

v Product Status such as the severity of the trap, status (current and previous) and the time the trap

occurred.

v Library State (physical device status) such as identification and status of devices that is monitored. It

would include enclosure, power supply, controller, magazine status, drive count, cartridge slot count,

and I/O station count. Also included are certain library statistics, and where appropriate, the fault FSC

(fault symptom code) including the severity and description of that fault.

v Drive Status such as the identification of each drive in the library, firmware level, serial number, and

other address and status information.

v Trap Definitions such as library status change, open magazine, I/O accessed, hard fault information,

drive cleaning requests, excessive retries, and library that is returning to normal operations. For

information, refer to Appendix G. "SNMP Status MIB Variables and Traps" on page G-1.

v SNMP MIBs: The library's Management Information Base (MIB) contains units of information that

specifically describe an aspect of the system, such as the system name, hardware number, or

communications configuration. Status and error data is also gathered by MIBs and sent to one or more

IP addresses that are defined during the SNMP configuration operation. Download the SNMP MIB file

for this library from http://www.ibm.com/storage/support.

Maximum library storage capacity and data transfer rate

Table 8. Tape drive model and host interface type

Tape Drive Model Host Interface

Ultrium 8 Half Height drives

Ultrium 7 Full Height and Half

Height drives

Ultrium 6 Full Height and Half

Height drives

v 8 Gb/s Fibre Channel - single port

v 6 Gb/s Serial Attached SCSI (SAS) - dual port

v 8 Gb/s Fibre Channel - single port (Full and Half Height)

v 6 Gb/s Serial Attached SCSI (SAS) - dual port (Half Height only)

v 8 Gb/s Fibre Channel - single port (Full and Half Height)

v 6 Gb/s Serial Attached SCSI (SAS) - dual port (Half Height only)

Product description 7

Page 36

Table 8. Tape drive model and host interface type (continued)

Tape Drive Model Host Interface

Ultrium 5 Full Height and Half

Height drives

Ultrium 4 Full Height drives

Ultrium 4 Half Height V2 drives

Ultrium 4 Half Height drives

Ultrium 3 Full Height drives

Ultrium 3 Half Height V2 drives

Ultrium 3 Half Height drives

Table 9. Library storage capacity and data transfer rate