Page 1

IBM TotalStorage Ultrium Tape Drive 3580

Models L23 and H23

Setup and Operator Guide

GA32-0460-00

Page 2

Page 3

IBM TotalStorage Ultrium Tape Drive 3580

Models L23 and H23

Setup and Operator Guide

GA32-0460-00

Page 4

Note!

Before using this information and the product it supports, read the information in “Safety and Environmental Notices” on

page ix and “Notices” on page 111.

To ensure that you have the latest publications, visit the web at http://www.ibm.com/storage/lto.

First Edition (February 2003)

This edition applies to the IBM TotalStorage Ultrium Tape Drive 3580 Models L23 and H23 Setup and Operator Guide

and to all subsequent releases and modifications until otherwise indicated in new editions.

© Copyright International Business Machines Corporation 2003. All rights reserved.

US Government Users Restricted Rights – Use, duplication or disclosure restricted by GSA ADP Schedule Contract

with IBM Corp.

Page 5

Contents

Figures ...............v

Tables ...............vii

Safety and Environmental Notices . . . ix

Danger Notice .............ix

Caution Notice .............ix

Attention Notice .............xi

Performing the Safety Inspection Procedure....xi

End of Life (EOL) Plan...........xi

Preface ..............xiii

Related Publications ...........xiv

Chapter 1. Introduction ........1

Drive Performance ............2

Supported Servers and Operating Systems ....3

Supported Device Drivers ..........3

TapeAlert Support ............4

Specifications ..............4

Chapter 2. Installing the 3580 Ultrium 2

Tape Drive..............5

Step 1. Unpacking the Tape Drive .......5

Step 2. Using the Inventory Checklist ......6

Step 3. Installing the Rackmount Kit ......6

Step 4. Inspecting the Power Cord and Outlet . . . 6

Step 5. Setting the SCSI ID..........8

Step 6. Positioning the Tape Drive .......8

Step 7. Connecting Power ..........9

Step 8. Running the Fast Read/Write Test ....9

Step 9. Installing the SCSI Host Adapter Card (if

required) ...............12

Step 10. Installing Device Drivers .......12

Step 11. Connecting the SCSI Bus Cable .....13

Step 12. Configuring the 3580 Ultrium 2 Tape Drive

to the Server ..............15

Chapter 3. Operating the 3580 Ultrium 2

Tape Drive .............17

Power Switch..............17

Unload Button .............18

Status Light ..............19

Message Display.............20

Single-Character Display ..........20

Inserting a Tape Cartridge .........20

Removing a Tape Cartridge .........21

Performing Diagnostic and Maintenance Functions 22

Updating the Drive Firmware ........22

Cleaning the Drive Head ..........22

Cleaning the 3580 Ultrium 2 Tape Drive .....23

Chapter 4. Using Ultrium Media ....25

Data Cartridge .............26

Cleaning Cartridge ............27

Bar Code Label .............28

Guidelines for Using Bar Code Labels ....29

Setting the Write-Protect Switch .......30

Handling the Cartridges ..........30

Provide Training............30

Ensure Proper Packaging .........31

Provide Proper Acclimation and Environmental

Conditions..............32

Perform a Thorough Inspection.......32

Handle the Cartridge Carefully .......33

Examples of Cartridge Problems ......34

Repositioning or Reattaching a Leader Pin ....35

Repositioning a Leader Pin ........35

Reattaching a Leader Pin .........37

Environmental and Shipping Specifications for Tape

Cartridges ...............42

Disposing of Tape Cartridges ........43

Ordering Media Supplies..........43

Ordering Bar Code Labels ........45

Chapter 5. Troubleshooting ......47

Procedure 1 ..............48

Procedure 2 ..............49

Procedure 3 ..............49

Procedure 4 ..............50

Pre-Call Checklist ............50

Replacing the Tape Drive..........52

Appendix A. Codes on the

Single-Character Display .......55

Appendix B. Performing Diagnostic and

Maintenance Functions .......59

Placing the Tape Drive in Maintenance Mode . . . 61

Performing a Diagnostic or Maintenance Function 62

Function Code 1: Run Tape Drive Diagnostics . . 62

Function Code 2: Update Tape Drive Firmware

fromFMRTape............64

Function Code 3: Create FMR Tape .....65

Function Code 4: Force a Drive Dump ....67

Function Code 5: Copy the Drive Dump to Tape

(at Beginning of Tape) ..........68

Function Code 6: Run SCSI Wrap Test ....69

Function Code 7: Run RS-422 Wrap Test ....72

Function Code 8: Unmake FMR Tape.....72

Function Code 9: Display Error Code Log . . . 73

Function Code A: Clear Error Code Log ....74

Function Code C: Insert Cartridge into Tape

Drive ...............75

Function Code E: Test Cartridge & Media . . . 75

Function Code F: Fast Read/Write Test ....77

Function Code H: Test Head........79

Function Code P: Enable Post Error Reporting. . 81

© Copyright IBM Corp. 2003 iii

Page 6

Function Code U: Disable Post Error Reporting 81

Function Code 0: Exit Maintenance Mode . . . 81

Appendix C. Manually Removing a

Tape Cartridge ...........83

Required Tools .............83

Performing the Removal ..........83

Rewinding the Tape into the Cartridge ....85

Disengaging the Leader Pin from the Leader

Block ...............87

Unloading the Cartridge from the Drive....88

Fixing a Jammed, Broken, or Detached Tape . . . 89

Removing the Internal Drive .......89

Removing the Cover of the Internal Drive . . . 93

Fixing the Problem ...........93

Removing the Cartridge from the Drive ....95

Appendix D. Installing a Tape Drive into

a Rack ...............97

Safety Considerations ...........97

Installation ..............98

Removing the Shelf from the Rack ......101

Types of Receptacles ..........107

Appendix G. Parts List .......109

Parts for 3580 Ultrium 2 Tape Drive Model L23 109

Parts for 3580 Ultrium 2 Tape Drive Model H23 110

Notices ..............111

How to Send Your Comments ........112

Trademarks ..............113

Electronic Emission Notices.........114

Federal Communications Commission (FCC)

Class A Statement ...........114

Industry Canada Class A Emission Compliance

Statement..............114

Avis de conformitéàla réglementation

d’Industrie Canada ..........114

European Union (EU) Electromagnetic

Compatibility Directive .........114

Germany Electromagnetic Compatibility

Directive ..............115

Japan VCCI Class A ITE Electronic Emission

Statement..............115

Taiwan Class A Electronic Emission Statement 115

Appendix E. TapeAlert Flags .....103

Appendix F. Power Cords ......105

Power Cable Information .........105

Glossary .............117

Index ...............125

iv

IBM 3580 Ultrium Tape Drive Setup and Operator Guide

Page 7

Figures

1. The IBM 3580 Ultrium 2 Tape Drive.....1

2. Components of the 3580 Ultrium 2 Tape Drive 7

3. Example of connecting one SCSI device to the

server ..............14

4. Example of connecting multiple SCSI devices

to the server ............15

5. Front view of the 3580 Ultrium 2 Tape Drive 17

6. Inserting a cartridge into the 3580 Ultrium 2

Tape Drive .............21

7. The IBM TotalStorage LTO Ultrium 200 GB

Data Cartridge ...........25

8. Sample bar code label on the LTO Ultrium 2

Tape Cartridge ...........29

9. Setting the write-protect switch ......30

10. Tape cartridges in a Turtlecase ......31

11. Double-boxing tape cartridges for shipping 32

12. Checking for gaps in the seams of a cartridge 33

13. Leader pin in the incorrect and correct

positions .............35

14. Placing the dislodged leader pin into the

correct position ...........36

15. Rewinding the tape into the cartridge ....36

16. Leader Pin Reattachment Kit .......37

17. Attaching the leader pin attach tool to the

cartridge .............38

18. Winding the tape out of the cartridge ....39

19. Removing the C-clip from the leader pin 39

20. Attaching the leader pin to the tape ....40

21. Flowchart for analyzing maintenance problems 47

22. Checking the setting on the SCSI address

switch ..............48

23. Components of the 3580 Ultrium 2 Tape Drive 53

24. Removing the screw from the access hole 85

25. Determining whether the tape is broken 86

26. Moving the leader pin block into the cartridge 87

27. Removing the cover from the 3580 Ultrium 2

Tape Drive .............89

28. Removing the internal drive from the 3580

Ultrium 2 Tape Drive .........90

29. Removing the bezel from the 3580 Ultrium 2

Tape Drive .............91

30. Removing the internal drive from the 3580

Ultrium 2 Tape Drive .........92

31. Removing the cover from the internal drive 93

32. Rewinding the leader pin into the tape

cartridge .............94

33. Guiding the leader pin into the tape cartridge 95

34. Installing a cage nut in the mounting rail 98

35. Attaching the shelf extender brackets ....99

36. Attaching the front of the shelf to the

mounting rails ...........100

37. Attaching the rear of the shelf to the rear

mounting rails ...........100

38. Attaching the front safety bar to the

mounting rails ...........101

39. Types of receptacles .........107

© Copyright IBM Corp. 2003 v

Page 8

vi IBM 3580 Ultrium Tape Drive Setup and Operator Guide

Page 9

Tables

1. 3580 Tape Drive Models.........2

2. Performance characteristics of the Ultrium 2

Tape Drive and the Ultrium 1 Tape Drive . . . 2

3. Specifications for the 3580 Ultrium 2 Tape Drive 4

4. Meaning of Status Light Activity .....19

5. Environment for operating, storing, and

shipping the LTO Ultrium Tape Cartridge . . 42

6. Ordering media supplies for the 3580 Ultrium

2 Tape Drive ............44

7. Authorized suppliers of custom bar code labels 45

8. Codes on the single-character display of the

3580 Ultrium 2 Tape Drive .......55

9. Diagnostic and maintenance functions of the

3580 Ultrium 2 Tape Drive .......59

10. Power cable information ........105

11. Parts for the 3580 Ultrium 2 Tape Drive

Model L23 ............109

12. Parts for the 3580 Ultrium 2 Tape Drive

Model H23 ............110

© Copyright IBM Corp. 2003 vii

Page 10

viii IBM 3580 Ultrium Tape Drive Setup and Operator Guide

Page 11

Safety and Environmental Notices

When using this product, observe the danger, caution, and attention notices

contained in this guide. The notices are accompanied by symbols that represent the

severity of the safety condition.

Danger Notice

Caution Notice

Most danger or caution notices contain a reference number (RSFTDxxx or

RSFTCxxx). Use the reference number to check the translation in IBM

®

Externally

Attached Devices Safety Information, SA26-2004.

The sections that follow define each type of safety notice and give examples.

A danger notice calls attention to a situation that is potentially lethal or extremely

hazardous to people. A lightning bolt symbol always accompanies a danger notice

to represent a dangerous electrical condition. A sample danger notice follows:

DANGER

An electrical outlet that is not correctly wired could place

hazardous voltage on metal parts of the system or the products that

attach to the system. It is the customer’s responsibility to ensure

that the outlet is correctly wired and grounded to prevent an

electrical shock. (RSFTD201)

A caution notice calls attention to a situation that is potentially hazardous to

people because of some existing condition. A caution notice can be accompanied

by one of several symbols:

If the symbol is... It means....

A hazardous electrical condition with less severity than

electrical danger.

A generally hazardous condition not represented by other

safety symbols.

A hazardous condition due to the use of a laser in the

product. Laser symbols are always accompanied by the

classification of the laser as defined by the U. S.

Department of Health and Human Services (for example,

Class I, Class II, and so forth).

© Copyright IBM Corp. 2003 ix

Page 12

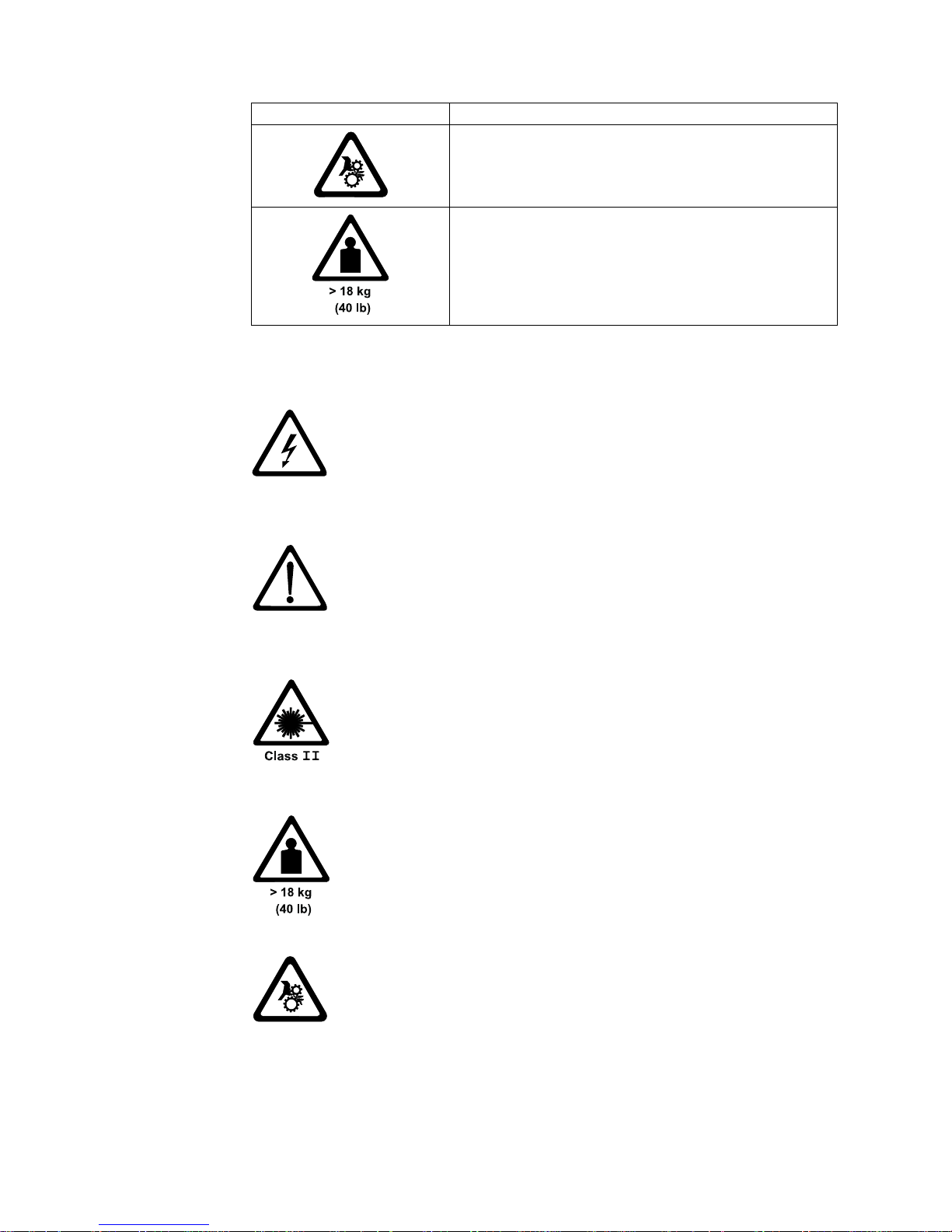

If the symbol is... It means....

A hazardous condition due to mechanical movement in or

around the product.

A hazardous condition due to the weight of the unit.

Weight symbols are accompanied by an approximation of

the product’s weight.

Sample caution notices follow:

CAUTION:

The controller card contains a lithium battery. To avoid possible

explosion, do not burn, exchange, or charge the battery. Discard the

controller card as instructed by local regulations for lithium batteries.

(RSFTC228)

CAUTION:

Do not attempt to use the handle on the module to lift the entire

device (module and enclosure) as a unit. First remove the module;

then, use two hands to lift the enclosure. (72XXC356)

CAUTION:

This product complies with the performance standards set by the U.S.

Food and Drug Administration for a Class II and IEC825 Laser

Product. Avoid prolonged staring into the laser beam.

CAUTION:

The weight of this part or unit is between 18 and 32 kilograms (39.7

and 70.5 pounds). It takes two persons to safely lift this part or unit.

(RSFTC204)

CAUTION:

This assembly contains mechanical moving parts. Use care when

servicing this assembly.

x IBM 3580 Ultrium Tape Drive Setup and Operator Guide

Page 13

Attention Notice

An attention notice indicates the possibility of damage to a program, device, or

system, or to data. An exclamation point symbol may accompany an attention

notice, but is not required. Sample attention notices follow:

Attention: If you use a power screwdriver to perform this

procedure it could destroy the tape.

Attention: Do not operate the 3580 Ultrium 2 Tape Drive in a poor air-quality

environment.

Performing the Safety Inspection Procedure

Before you service the 3580 Ultrium 2 Tape Drive, perform the following safety

inspection procedure:

1. Stop all activity on the SCSI bus.

2. Turn off the power to the tape drive.

3. Disconnect the SCSI cable and check the SCSI bus terminator for damage.

4. Unplug the tape drive’s power cord from the electrical outlet.

5. Check the tape drive’s power cord for damage, such as a pinched, cut, or

frayed cord.

6. Check the tape drive’s SCSI bus (signal) cable for damage.

7. Check the cover of the tape drive for sharp edges, damage, or alterations that

expose its internal parts.

8. Check the cover of the tape drive for proper fit. It should be in place and

secure.

9. Check the product label on the bottom of the tape drive to make sure that it

matches the voltage at your outlet.

End of Life (EOL) Plan

This box is a purchased unit. Therefore, it is the sole responsibility of the purchaser

to dispose of it in accordance with local laws and regulations at the time of

disposal.

This unit contains recyclable materials. The materials should be recycled where

facilities are available and according to local regulations. In some areas IBM may

provide a product take-back program that ensures proper handling of the product.

For more information, contact your IBM representative.

Safety and Environmental Notices xi

Page 14

xii IBM 3580 Ultrium Tape Drive Setup and Operator Guide

Page 15

Preface

This guide describes how to install and use the IBM 3580 Ultrium 2 Tape Drive

Models L23 and H23.

This guide contains the following chapters:

Chapter 1, “Introduction”, on page 1 describes the 3580 Ultrium 2 Tape Drive,

discusses supported servers, operating systems, and device drivers, and lists

hardware specifications.

Chapter 2, “Installing the 3580 Ultrium 2 Tape Drive”, on page 5 tells how to

unpack and set up the 3580 Ultrium 2 Tape Drive.

Chapter 3, “Operating the 3580 Ultrium 2 Tape Drive”, on page 17 describes the

power switch, unload button, and status light on the 3580 Ultrium 2 Tape Drive. It

explains the function of the message display and the single-character display. It

tells how to insert and remove a tape cartridge, describes methods of updating

drive firmware, and explains how to clean the tape drive. It also lists the

diagnostic and maintenance functions that the 3580 Ultrium 2 Tape Drive can

perform.

Chapter 4, “Using Ultrium Media”, on page 25 describes the types of tape

cartridges to use in the 3580 Ultrium 2 Tape Drive and defines the conditions for

storing and shipping them. It also tells how to handle the cartridges, how to set a

cartridge’s write-protect switch, and how to order additional cartridges.

Chapter 5, “Troubleshooting”, on page 47 gives tips for solving problems with the

3580 Ultrium 2 Tape Drive and includes a flowchart that analyzes when the tape

drive requires maintenance.

Appendix A, “Codes on the Single-Character Display”, on page 55 describes the

error and informational codes that appear on the single-character display of the

3580 Ultrium 2 Tape Drive.

Appendix B, “Performing Diagnostic and Maintenance Functions”, on page 59

describes the procedures that you can use to identify and correct problems with

the 3580 Ultrium 2 Tape Drive.

Appendix C, “Manually Removing a Tape Cartridge”, on page 83 gives the

procedure for removing a stuck tape cartridge from the 3580 Ultrium 2 Tape Drive.

Appendix D, “Installing a Tape Drive into a Rack”, on page 97 describes how to

install the 3580 Ultrium 2 Tape Drive into a rack.

Appendix E, “TapeAlert Flags”, on page 103 lists TapeAlert messages that are

supported by the 3580 Ultrium 2 Tape Drive and that may aid during problem

determination.

Appendix F, “Power Cords”, on page 105 provides information about the power

cords that are used in different countries or regions.

© Copyright IBM Corp. 2003 xiii

Page 16

Appendix G, “Parts List”, on page 109 lists parts and supplies that are used by the

3580 Ultrium 2 Tape Drive.

Store this guide with your server’s manuals.

Related Publications

Refer to the following publications for additional information. To ensure that you

have the latest publications, visit the web at http://www.ibm.com/storage/lto.

v IBM TotalStorage

GX35-5068, illustrates how to configure and operate the 3580 Ultrium 2 Tape

Drive.

v IBM TotalStorage LTO Ultrium Tape Drive SCSI Reference, GA32–0450, gives

information about the supported SCSI commands and protocol for the tape

drive.

v IBM Ultrium Device Drivers Installation and User’s Guide, GA32-0430, provides

instructions for attaching IBM-supported hardware to open-systems operating

systems. It indicates what devices and levels of operating systems are supported,

gives the requirements for adapter cards, and tells how to configure servers to

use the device driver with the Ultrium family of devices.

v IBM Ultrium Device Drivers Programming Reference, GC35-0483, supplies

information to application developers who want to integrate their open-systems

applications with IBM-supported Ultrium hardware. The reference contains

information about the application programming interfaces (APIs) for each of the

various supported operating-system environments. You can obtain this reference

via File Transfer Protocol (FTP) at

ftp://ftp.software.ibm.com/storage/devdrvr.

v IBM Externally Attached Devices Safety Information, SA26-2004, provides translation

of danger and caution notices.

™

Ultrium Tape Drive 3580 Models L23 and H23 Quick Reference,

xiv IBM 3580 Ultrium Tape Drive Setup and Operator Guide

Page 17

Chapter 1. Introduction

The IBM 3580 Tape Drive Models L23 and H23 are high-performance,

high-capacity data-storage devices that connect to and provide additional storage

for supported servers. Designed to perform unattended backups as well as to

retrieve and archive files, the IBM 3580 Tape Drive Models L23 and H23 feature:

v Native storage capacity of 200 GB per cartridge (400 GB at 2:1 compression)

v Native sustained data transfer rate of up to 35 MB per second (70 MB per

second at 2:1 compression)

v Burst data transfer rate of 160 MB per second for Model L23

The IBM 3580 Tape Drive Models L23 and H23 are equipped internally with the

IBM Ultrium 2 Tape Drive.

1

2

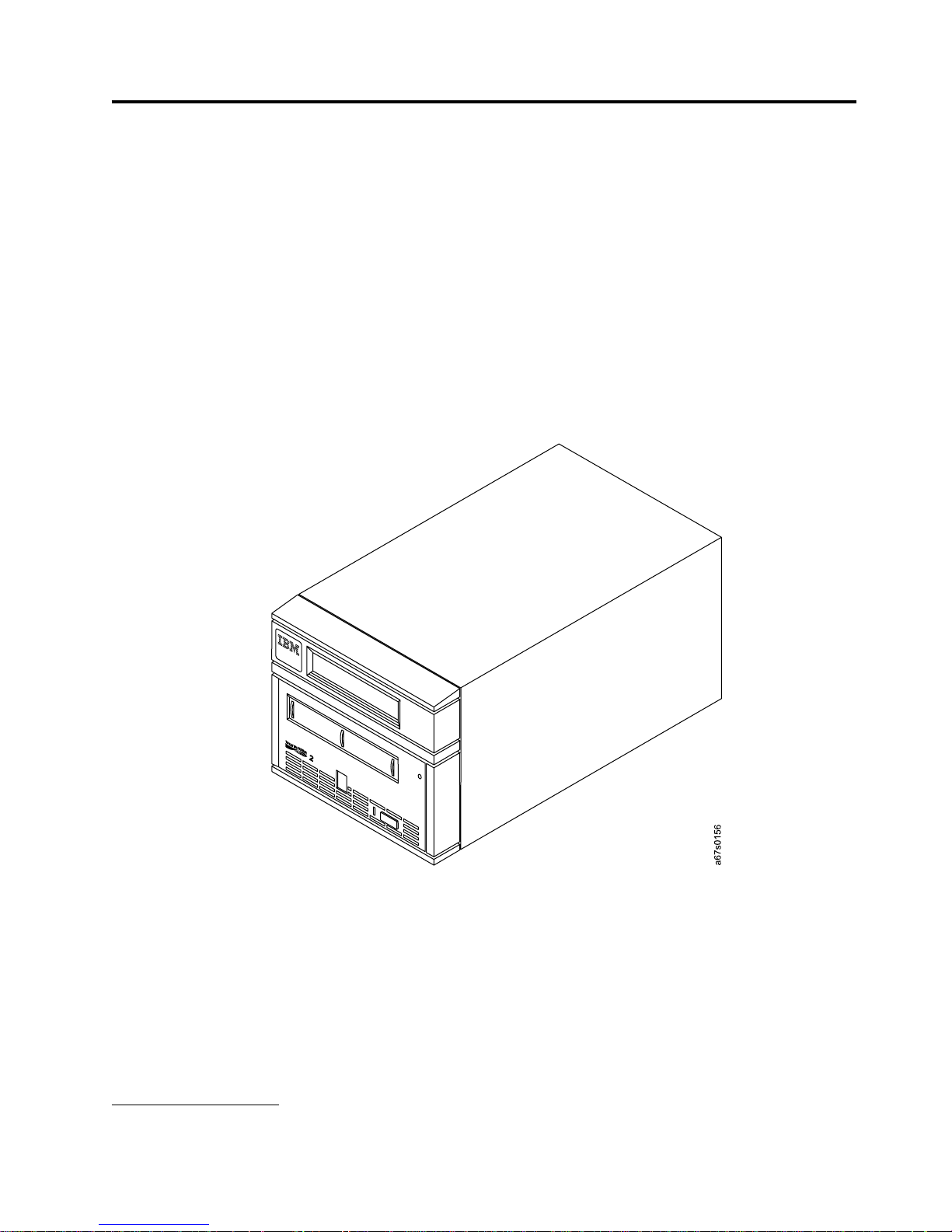

Figure 1. The IBM 3580 Ultrium 2 Tape Drive

For the remainder of this guide, the IBM 3580 Tape Drive Models L23 and H23 will

be referred to as the 3580 Ultrium 2 Tape Drive. Table 1 on page 2 lists the 3580

Tape Drive models. It lists each model’s SCSI attachment, and it shows that Models

L23 and H23 are Ultrium 2 models, while all other models are Ultrium 1 models.

1. 1 GB = one gigabyte or 1 000 000 000 bytes

2. 1 MB = one megabyte or 1 000 000 bytes

© Copyright IBM Corp. 2003 1

Page 18

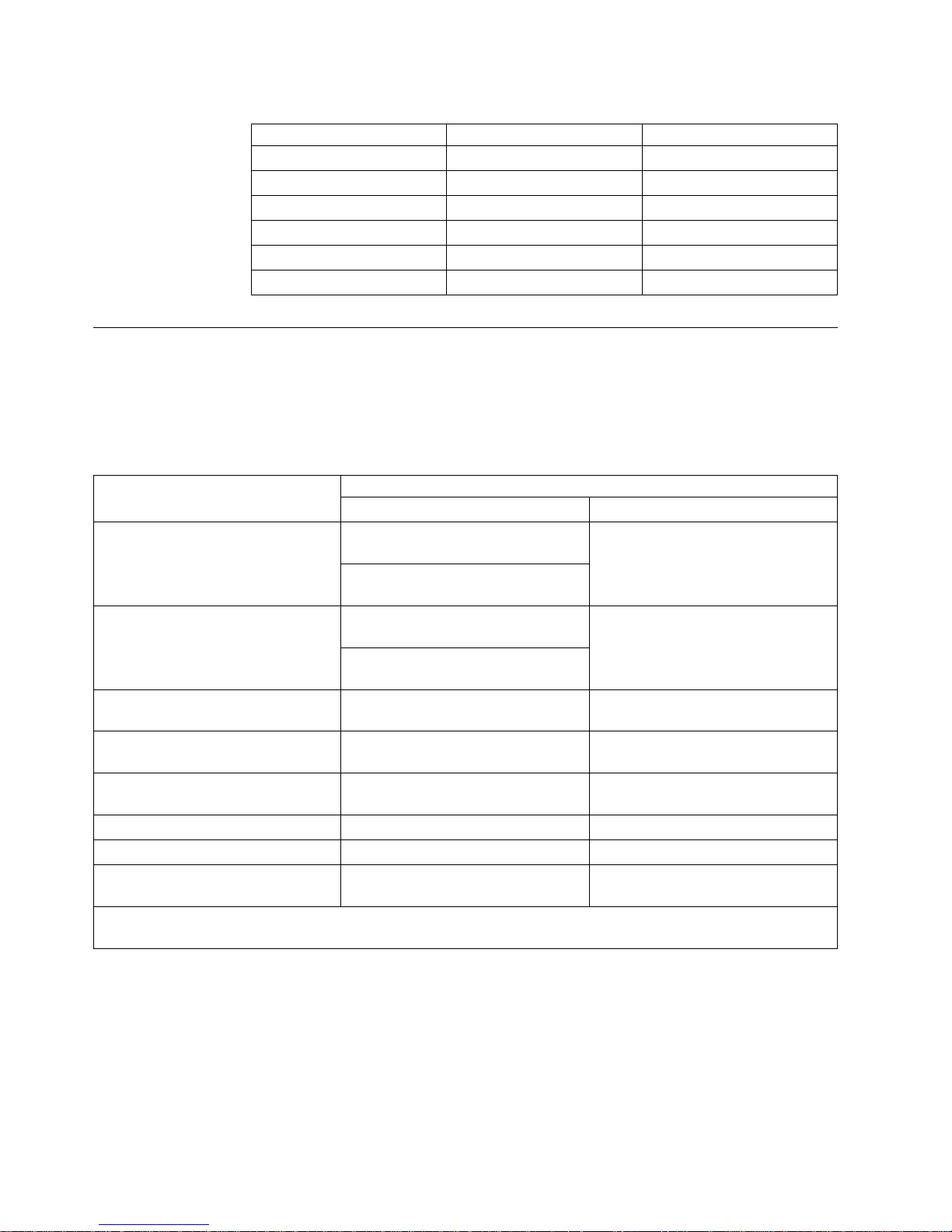

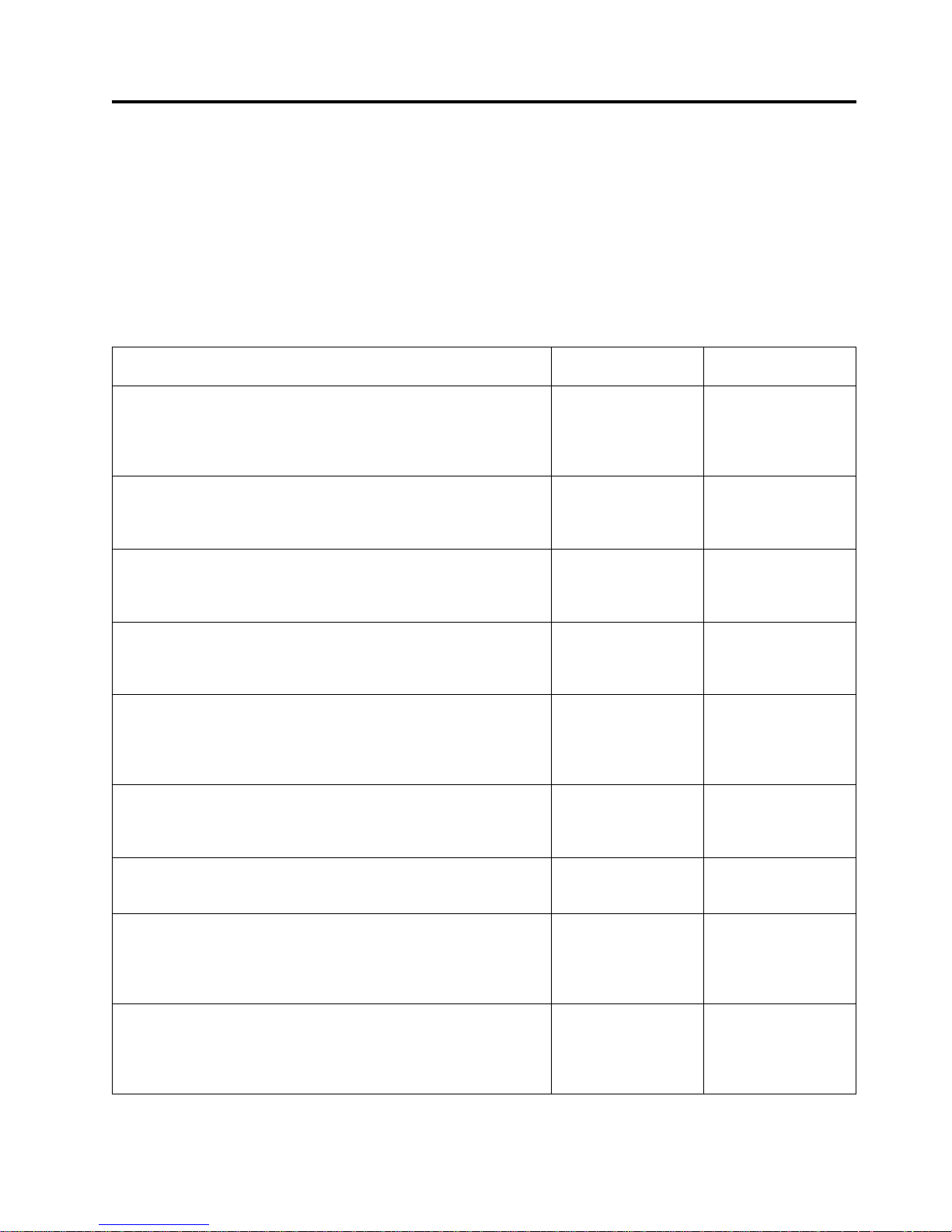

Table 1. 3580 Tape Drive Models

Model SCSI Attachment Ultrium 1 or Ultrium 2

L11 LVD Ultrium 1

L13 LVD Ultrium 1

L23 LVD Ultrium 2

H11 HVD Ultrium 1

H13 HVD Ultrium 1

H23 HVD Ultrium 2

Drive Performance

If you run applications that are highly dependent on tape-processing speed, you

can take advantage of the significant performance improvements provided by the

IBM 3580 Ultrium 2 Tape Drive. Table 2 lists the performance characteristics of

both the Ultrium 2 and Ultrium 1 models.

Table 2. Performance characteristics of the Ultrium 2 Tape Drive and the Ultrium 1 Tape Drive

Performance Characteristic

Native sustained data rate 35 MB/s

Compressed data rate (at 2:1

compression)

Maximum sustained data rate (at

maximum compression)

Burst data rate for Low Voltage

Differential (LVD) SCSI drives

Burst data rate for High Voltage

Differential (HVD) SCSI drives

Nominal load-to-ready time 15 seconds 20 seconds

Nominal unload time 15 seconds 18 seconds

Average search time to first byte of

data

Note: All sustained data rates are dependent on the capabilities of the interconnect (for example, an UltraSCSI bus

is limited to less than 40MB/sec).

Ultrium 2 Tape Drive Ultrium 1 Tape Drive

(with Ultrium 2 media)

20 MB/s

(with Ultrium 1 media)

70 MB/s

(with Ultrium 2 media)

40 MB/s

(with Ultrium 1 media)

107 MB/s (Ultra160) 60 MB/s

160 MB/s (Ultra160) 80 MB/s (Ultra2)

40 MB/s (Ultra) 40 MB/s (Ultra)

49 seconds 73 seconds

Tape Drive

15 MB/s

30 MB/s

By using the built-in data-compression capability of the tape drives, you can

achieve greater data rates than the native data transfer rate. However, the actual

throughput is a function of many components, such as the host system processor,

disk data rate, block size, data compression ratio, SCSI bus capabilities, and system

or application software.

2 IBM 3580 Ultrium Tape Drive Setup and Operator Guide

Page 19

Supported Servers and Operating Systems

The 3580 Ultrium 2 Tape Drive attaches to many servers and many operating

systems. To determine the latest supported attachments, visit the web at

http://www.ibm.com/storage/lto and click on Technical Support or LTO Support.

For specific instructions about attaching the tape drive, see Chapter 2, “Installing

the 3580 Ultrium 2 Tape Drive”, on page 5.

Supported Device Drivers

IBM offers device drivers for the 3580 Ultrium 2 Tape Drive. Device drivers enable

the drive to interact with a variety of servers. To properly install an IBM device

driver (if required), refer to the IBM Ultrium Device Drivers Installation and User’s

Guide. For applications that use other device drivers, see the application’s

documentation to determine which drivers to use.

IBM maintains the latest levels of device drivers and driver documentation for the

IBM TotalStorage Ultrium 2 tape products on the Internet. You can access this

material from your browser or through the IBM FTP site by performing one of the

following procedures. (Note: If you do not have Internet access and you need

information about device drivers, contact your Marketing Representative.)

v Using a browser, type one of the following:

– http://www.ibm.com/storage/lto (select either Technical Support or LTO

Support)

– ftp://ftp.software.ibm.com/storage/devdrvr

– ftp://207.25.253.26/storage/devdrvr

v Using an IBM FTP site, enter the following specifications:

– FTP site: ftp.software.ibm.com

– IP Addr: 207.25.253.26

– Userid: anonymous

– Password: (use your current e-mail address)

– Directory: /storage/devdrvr

IBM provides PostScript- and PDF-formatted versions of its documentation in the

/storage/devdrvr/Doc directory:

v IBM_ultrium_tape_IUG.ps and IBM_ultrium_tape_IUG.pdf contain the current

version of the IBM Ultrium Device Drivers Installation and User’s Guide

v IBM_ultrium_tape_PROGREF.ps and IBM_ultrium_tape_PROGREF.pdf contain

the current version of the IBM Ultrium Device Drivers Programming Reference

Device drivers and utilities for each supported server are beneath

/storage/devdrvr/ in the following directories (the device driver for the iSeries

or AS/400®server is included in the OS/400®operating system):

®

v AIX

v HPUX

v Linux

v Solaris

v Windows

For more information about device drivers, refer to any of the preceding

directories.

™

®

Chapter 1. Introduction 3

Page 20

TapeAlert Support

The 3580 Ultrium 2 Tape Drive is compatible with TapeAlert technology, which

provides error and diagnostic information to the server. For more information, see

Appendix E, “TapeAlert Flags”, on page 103.

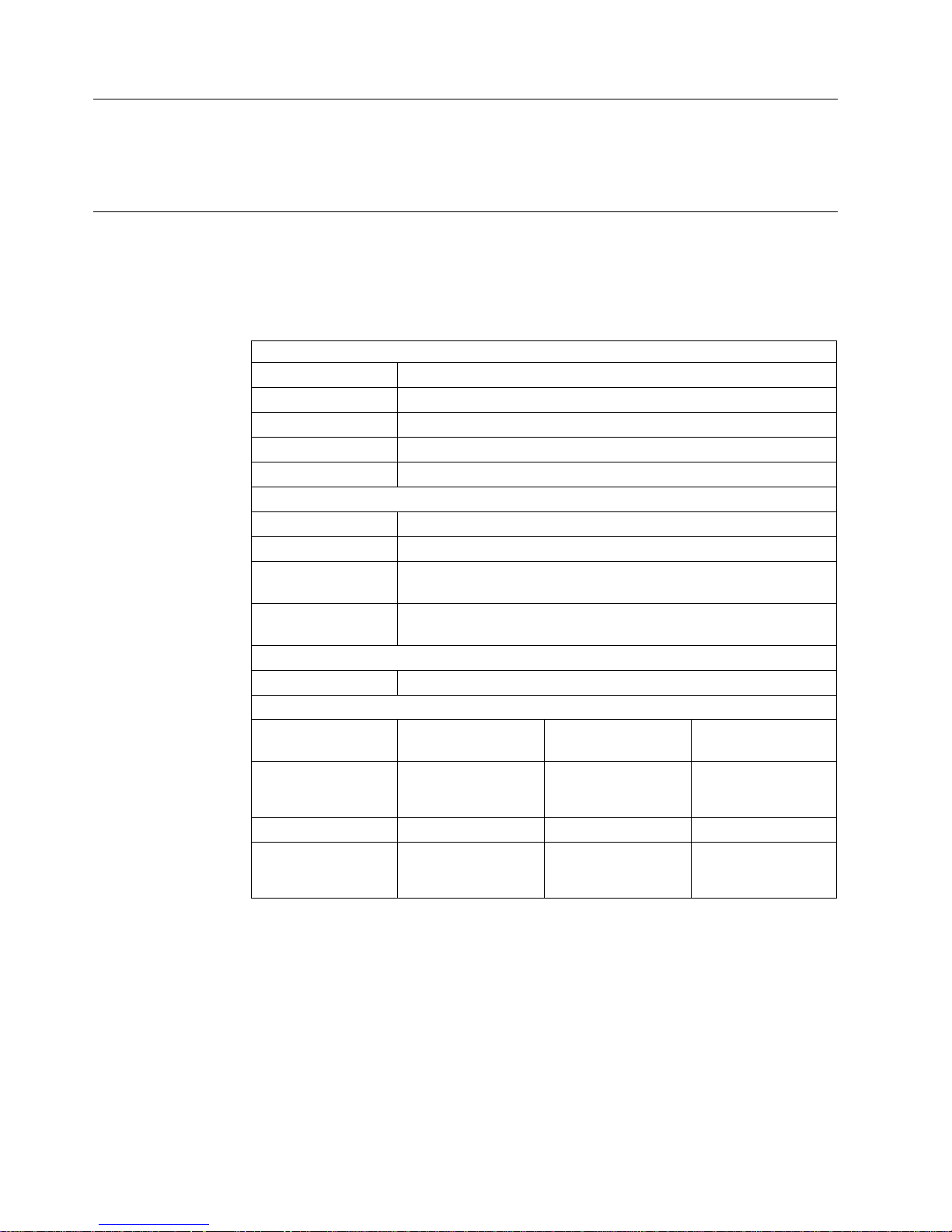

Specifications

The following are specifications for the 3580 Ultrium 2 Tape Drive. Specifications

for tape cartridges are given in “Environmental and Shipping Specifications for

Tape Cartridges” on page 42.

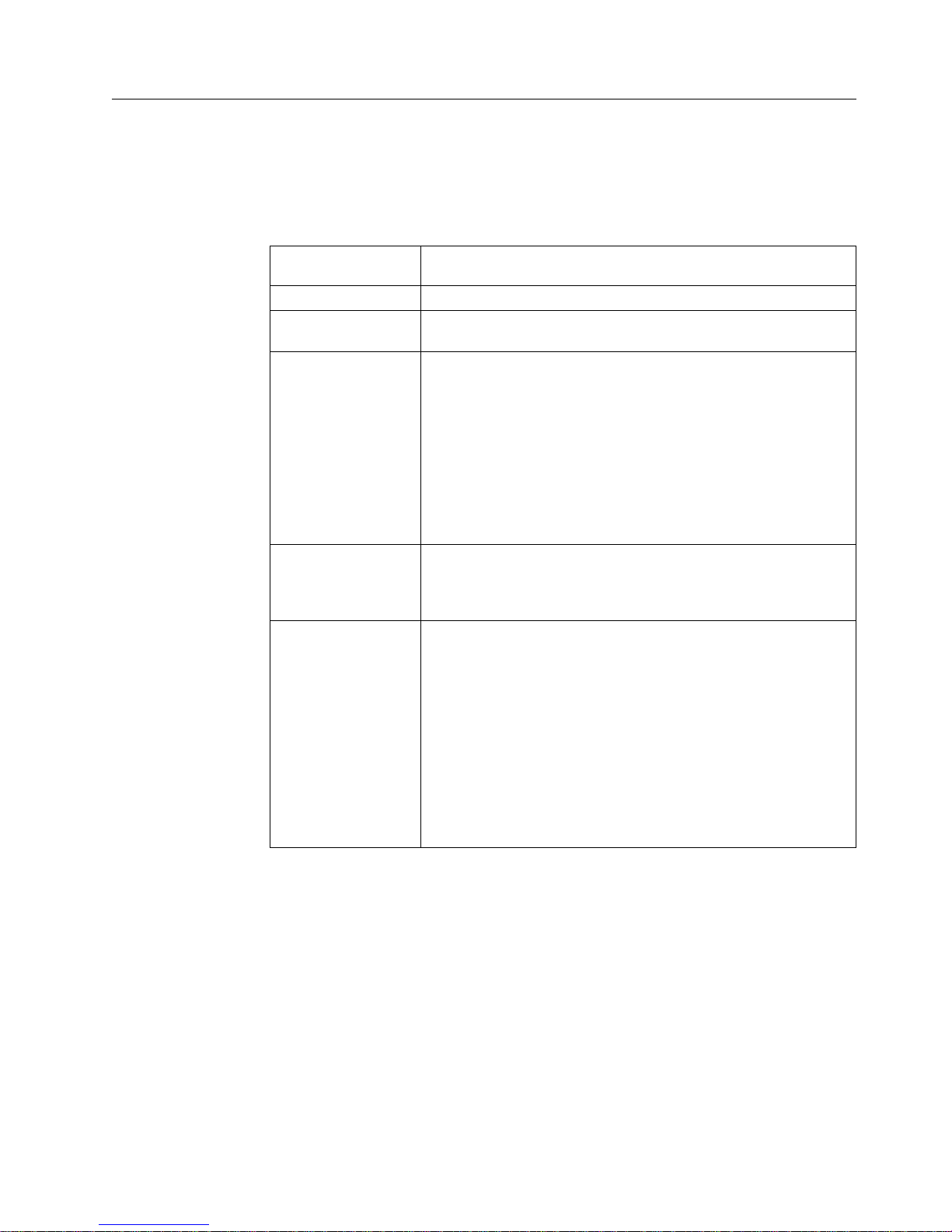

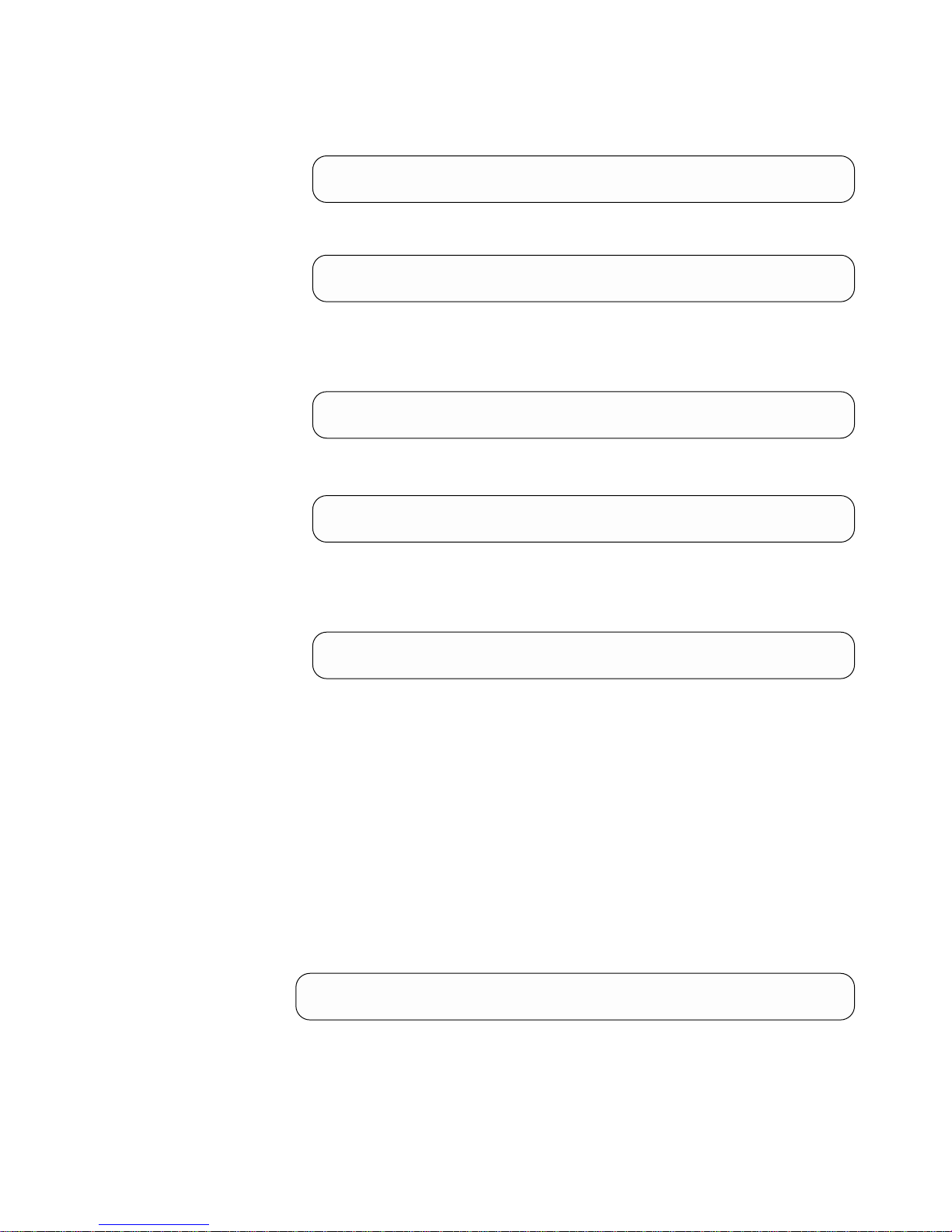

Table 3. Specifications for the 3580 Ultrium 2 Tape Drive

Specification Dimensions

Width 17.1 cm (6.74 in.)

Length 33.3 cm (13.11 in.)

Height 14.6 cm (5.75 in.)

Weight 6.59 kg (14.3 lbs)

AC line voltage 100 to 240 Vac

Line frequency 50 to 60 Hz

Line current at 100

Vac

Line current at 240

Vac

Maximum altitude 2500 m (8202 ft)

Temperature

Relative humidity 20 to 80% 10 to 90% 10 to 90%

Maximum wet bulb

temperature

Environmental

Factor

Physical Specifications

Power Specifications

1.0 A

0.5 A

Other Specifications

Environmental Specifications

Operating Storage Shipping

10 to 38°C

(50 to 100°F)

26°C

(79°F)

−40 to 60°C

(−40 to 140°F)

Noncondensing Noncondensing

−40 to 60°C

(−40 to 140°F)

4 IBM 3580 Ultrium Tape Drive Setup and Operator Guide

Page 21

Chapter 2. Installing the 3580 Ultrium 2 Tape Drive

Attention:

1. The 3580 Ultrium 2 Tape Drive Models L23 and H23 are customer setup units.

It is the customer’s responsibility to install these products.

2. The 3580 Ultrium 2 Tape Drive Models L23 and H23 are supported by

Customer Replaceable Unit (CRU), Courier, or on-site service. Warranty service

may vary by Countries/Regions. Refer to the warranty documentation to

determine the type of warranty service offered in your Countries/Regions.

As with all devices, it is recommended that you download the latest level of

firmware by visiting http://www.ibm.com/storage/lto and clicking on Technical

Support or LTO Support. Be sure to verify that you have the latest firmware

installed on your machine before you contact IBM for any necessary technical

support.

If you choose not to install this product yourself, IBM will install it for a fee. You

can purchase installation services by contacting your local IBM Service office or

your IBM Business Partner.

To install the 3580 Ultrium 2 Tape Drive, complete the following steps.

DANGER

An electrical outlet that is not correctly wired could place hazardous voltage on metal

parts of the system or the products that attach to the system. It is the customer’s

responsibility to ensure that the outlet is correctly wired and grounded to prevent an

electrical shock. (RSFTD201)

Step 1. Unpacking the Tape Drive

__ 1. Unpack the 3580 Ultrium 2 Tape Drive.

__ 2. Inspect the 3580 Ultrium 2 Tape Drive for shipping damage. If there is

damage, do not install the tape drive. Report the damage immediately by

contacting your place of purchase.

__ 3. Tilt the 3580 Ultrium 2 Tape Drive on its side and locate the label that gives

the machine type, model number and serial number of the unit (see 10 in

Figure 2 on page 7). Make a note of these numbers and store them in an

easily accessible place. Should you need to contact IBM Technical Support,

you will be asked for these numbers.

© Copyright IBM Corp. 2003 5

Page 22

Step 2. Using the Inventory Checklist

Ensure that you have received the following items:

__ 1. Power cord (for the appropriate cord for your country or region, see

Appendix F, “Power Cords”, on page 105)

__ 2. IBM LTO Ultrium Data Cartridge

__ 3. IBM TotalStorage LTO Ultrium Cleaning Cartridge

__ 4. Single-connector SCSI wrap tool

__ 5. Device driver kit that includes:

v CD that contains the device drivers, the IBM Ultrium Device Drivers

Installation and User’s Guide, and the IBM Ultrium Device Drivers

Programming Reference

__ 6. A host-to-device SCSI bus (signal) cable and a terminator

__ 7. Optional rackmount kit (if ordered)

__ 8. The IBM TotalStorage Ultrium Tape Drive 3580 Models L23 and H23 Quick

Reference, GX35–5068

__ 9. The IBM TotalStorage Ultrium Tape Drive 3580 Models L23 and H23 Setup and

Operator Guide, GA32–0460 (this guide)

__ 10. The IBM Externally Attached Devices Safety Information manual

Step 3. Installing the Rackmount Kit

If you ordered the optional rackmount kit, refer to Appendix D, “Installing a Tape

Drive into a Rack”, on page 97 for installation instructions. If you did not order the

optional rackmount kit, proceed to “Step 4. Inspecting the Power Cord and

Outlet”.

Step 4. Inspecting the Power Cord and Outlet

__ 1. Inspect the power cord plug to ensure that it matches the power receptacle.

If it does not match, see Appendix F, “Power Cords”, on page 105 to

determine the appropriate power cord.

__ 2. Ensure that the electrical outlets that you use are properly grounded and

that the circuit breaker is turned on.

6 IBM 3580 Ultrium Tape Drive Setup and Operator Guide

Page 23

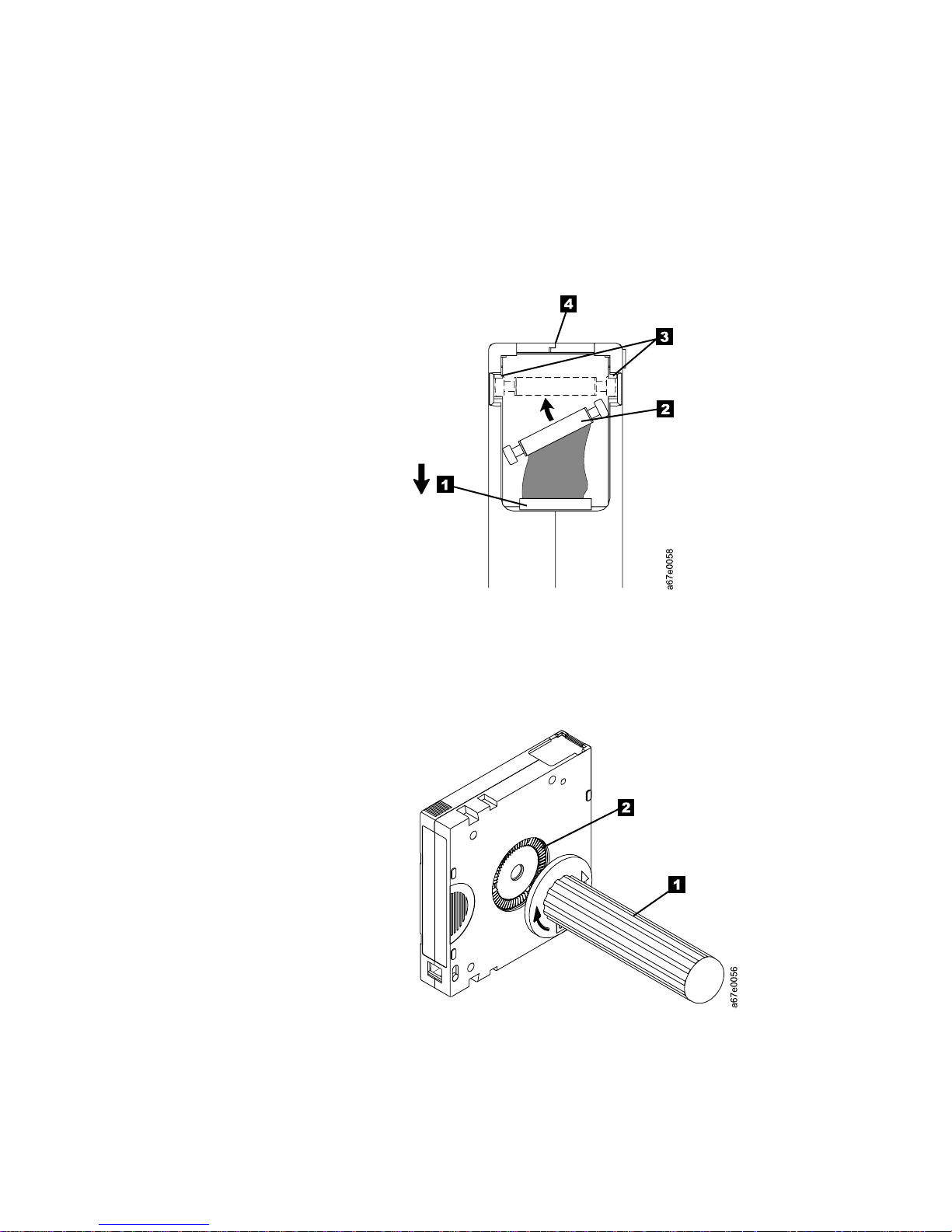

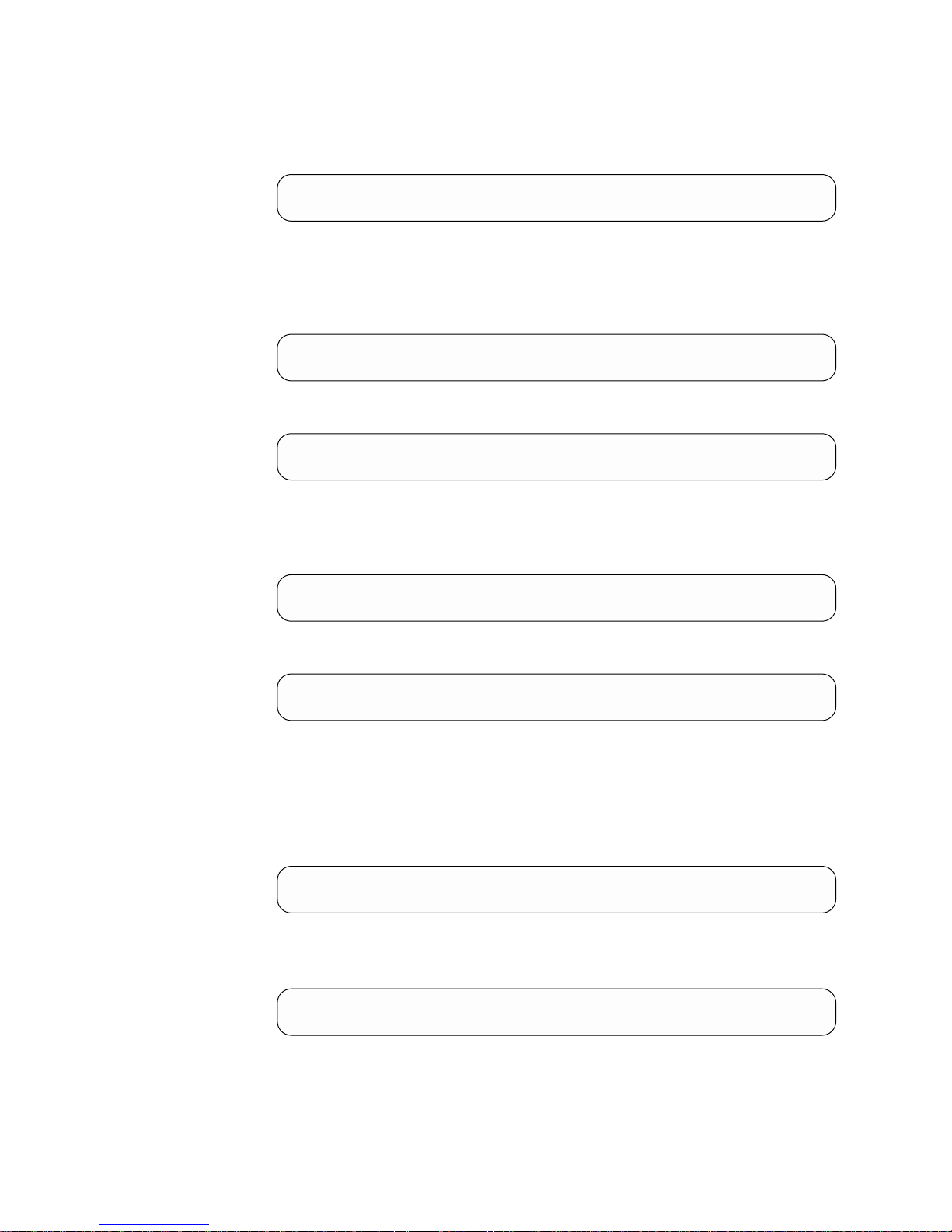

1 Message display 7 Power receptacle

2 Cartridge load compartment 8 Power switch

3 Single-character display 9 SCSI address switch

4 Status light 10 Machine type, model number,

and serial number

5 Unload button 11 IBM Repair Identification Tag

Placeholder

6 External SCSI connectors

Figure 2. Components of the 3580 Ultrium 2 Tape Drive

Chapter 2. Installing 7

Page 24

Step 5. Setting the SCSI ID

The SCSI ID is a unique address that identifies the 3580 Ultrium 2 Tape Drive to

the server. To set the SCSI ID:

__ 1. Refer to the following notes and decide what ID you want to assign to the

3580 Ultrium 2 Tape Drive.

Notes:

a. The range of SCSI IDs is 0 through 15. The priority of SCSI IDs is: 7, 6, 5,

4, 3, 2, 1, 0, 15, 14, 13, 12, 11, 10, 9, 8.

b. Do not select an ID that is already in use by any device on the SCSI bus.

c. Do not select the SCSI ID of the SCSI host adapter card. The priority of

this ID is usually higher than any device on the SCSI bus. Generally, the

SCSI ID for the host adapter is set to 7.

__ 2. Locate the SCSI address switch at the rear of the 3580 Ultrium 2 Tape Drive

(see 9 in Figure 2 on page 7).

__ 3. With a small, pointed object (such as a ballpoint pen), press the + or − push

button until the ID that you want displays on the switch.

Note: If the SCSI ID is changed after installation, cycle the power (turn it off then

on again) to activate the new SCSI ID.

Step 6. Positioning the Tape Drive

Position the 3580 Ultrium 2 Tape Drive anywhere that is convenient to the server.

The only restrictions are the length of the power cord and the length of the SCSI

cable. Recommended locations are:

v Away from high-traffic areas, especially if the floor is carpeted.

v Out of computer rooms to avoid toner and paper dust. Do not store paper

supplies next to any unit.

v Away from moving air, such as doorways, open windows, fans, and air

conditioners.

v Off the floor.

v In a horizontal position.

v Where the tape cartridge can be easily inserted.

The 3580 Ultrium 2 Tape Drive should not be stacked. Do not place anything on

top of the unit. To minimize any contamination from airborne particles, ensure that

the cover is always closed.

8 IBM 3580 Ultrium Tape Drive Setup and Operator Guide

Page 25

Step 7. Connecting Power

__ 1. Ensure that the power switch on the 3580 Ultrium 2 Tape Drive is set to off

by pressing 0 on the switch (see 8 in Figure 2 on page 7).

__ 2. Plug the power cord into the 3580 Ultrium 2 Tape Drive 7, then plug the

other end into a grounded electrical outlet.

__ 3. Because the 3580 Ultrium 2 Tape Drive may not complete the Power-On Self

Test (POST) without SCSI termination, ensure that a terminator (or SCSI bus

with termination) is connected to one of the two SCSI connectors at the rear

of the unit.

Note: LVD and HVD/DIFF terminators cannot be intermixed.

__ 4. Power-on the 3580 Ultrium 2 Tape Drive by pressing | on the power switch.

The tape drive runs the POST, which checks all hardware except the drive

head. During the POST, the Single-Character Display flashes several

segmented characters. Each segmented character respresents a test

performed during the POST. When the POST finishes, the Single-Character

Display momentarily lights all 8 segments and then goes blank. At the

outset of the POST, the following message appears in the message display

for 90 seconds:

Power On Self Test

In Progress

v If the test succeeds, the following message appears in the message display

for 5 seconds:

Drive FW xxxx

Display FW xxxx

followed by:

Ultrium Tape Drive

Drive Empty

v If a failure occurs, the following message appears in the message display:

ERROR!

SELF TEST FAILURE

Step 8. Running the Fast Read/Write Test

The Fast Read/Write Test performs procedures to ensure that the drive can read

from and write to tape. The diagnostic takes approximately 5 minutes to complete

and loops continually until you halt it. To halt the diagnostic, press the unload

button. The diagnostic will continue to the end of its loop and then stop.

Attention: For this test, use only a scratch (blank) data cartridge or a cartridge

that may be overwritten. During the test, the drive overwrites the data on the

cartridge.

__ 1. Make sure that no cartridge is in the drive.

__ 2. Make sure that the following message appears on the message display (you

may need to turn the power off, then on again for the message to appear).

Chapter 2. Installing 9

Page 26

Ultrium Tape Drive

Drive Empty

__ 3. Within two seconds, press the unload button 3 times. The status light

becomes solid amber and the following message displays (indicating that the

tape drive is in maintenance mode):

Maint Mode: Select

Exit Maint Mode

Note: If a cartridge is in the tape drive, it will eject the first time that you

press the unload button and the drive will not be placed in

maintenance mode. To continue placing the drive in maintenance

mode, perform the preceding step.

__ 4. Press the unload button once per second until F appears in the

single-character display and the following message displays. (If you cycle

past the desired code, press the unload button once per second until the

code redisplays.)

Maint Mode: Select

Fast R/W Diagnostic

__ 5. Press and hold the unload button for 2 or more seconds, then release it to

select the function. Immediately after the following message displays, insert

a scratch (blank) data cartridge that is not write-protected (or the tape drive

exits maintenance mode).

Fast R/W Diagnostic

Load Scratch Tape

__ 6. After you insert the scratch data cartridge, the flashing C in the

single-character display changes to F, and one or more of the following

messages display:

Fast R/W Diagnostic

Tape Loading = = = >

Fast R/W Diagnostic

Locating = = = >

Fast R/W Diagnostic

Rewinding = = = >

followed by:

Fast R/W Diagnostic

Writing = = = >

and:

Fast R/W Diagnostic

Reading = = = >

The tape drive runs the tests.

10 IBM 3580 Ultrium Tape Drive Setup and Operator Guide

Page 27

Note: If you inserted an invalid or write-protected tape cartridge, 7 appears

in the single-character display. The 3580 Ultrium 2 Tape Drive

unloads the cartridge and exits maintenance mode.

v If no error is detected, the test will loop and begin again. To stop the

loop, press and hold the unload button for several seconds. When the

loop ends, 0 temporarily appears in the single-character display. The drive

rewinds and unloads the tape, partially ejects the cartridge, then exits

maintenance mode. The solid amber status light turns off and the

following message displays:

Passed!

Tape Unloading

followed by:

Cartridge Unloading

In Progress

then:

Ultrium Tape Drive

Drive Empty

v If an error is detected, the status light flashes amber, a message similar to

the following displays, and the tape drive posts an error code to the

single-character display.

ERROR!

Drive/Media Error

To determine the error, locate the code in Table 8 on page 55. The tape

drive unloads the tape cartridge, exits maintenance mode, and displays

the following message:

Ultrium Tape Drive

Drive Empty

Note: To reset the drive after an error occurs, cycle power (turn it off,

then on again).

__ 7. Power-off the 3580 Ultrium 2 Tape Drive.

Chapter 2. Installing 11

Page 28

Step 9. Installing the SCSI Host Adapter Card (if required)

If there are no other devices attached to your server, you may need to install a

SCSI host adapter card in the server. To determine whether your server needs an

LVD or HVD/DIFF SCSI host adapter card, examine the label between the two

SCSI connectors at the rear of the 3580 Ultrium 2 Tape Drive:

SCSI LVD/SE

v If

v If

appears on the label, your server needs an LVD SCSI host adapter card.

SCSI DIFF

appears on the label, your server needs an HVD/DIFF SCSI host adapter

card.

To install an adapter, refer to the instructions that accompany it, as well as to the

section about SCSI card installation in your server’s documentation. For a list of

supported adapters and required interposers, visit the web at

http://www.ibm.com/storage/lto.

Although the LVD hardware in the 3580 Ultrium 2 Tape Drive Model L23 is

capable of operating in the single-ended (SE) mode, SE operation is not

recommended or supported.

Step 10. Installing Device Drivers

A device driver is firmware that enables the 3580 Ultrium 2 Tape Drive to interact

with a variety of servers. Refer to “Supported Device Drivers” on page 3 for

instructions on downloading the latest device drivers (the CD contains device

drivers current at time of manufacturing). Install device drivers for the 3580

Ultrium 2 Tape Drive as follows:

Note: If you intend to use the 3580 Ultrium 2 Tape Drive with a commercial

software application, IBM recommends that you do not install any device

driver from the CD that was shipped with the tape drive, as conflicts could

occur over which driver controls the drive. Only install a device driver from

the CD if the instructions from your commercial software application tell

you to do so.

v If you intend to use the 3580 Ultrium 2 Tape Drive with an existing or new

commercial software application (such as Tivoli

®

Storage Manager, Computer

Associates ARCserve, VERITAS Backup Exec, or Legato NetWorker), refer to that

application’s installation instructions to install the device driver and configure

the 3580 Ultrium 2 Tape Drive.

v If you do not intend to use the 3580 Ultrium 2 Tape Drive with a commercial

software application, install the device driver from the CD that was shipped

with the drive. Refer to the installation instructions in the IBM Ultrium Device

Drivers Installation and User’s Guide, which is on the CD. The CD contains drivers

and installation instructions for supported operating systems.

12 IBM 3580 Ultrium Tape Drive Setup and Operator Guide

Page 29

Step 11. Connecting the SCSI Bus Cable

For maximum performance, the quantity of tape drives that you can attach to one

SCSI bus is limited, and is based on the type of bus that you have and the amount

of data compression achieved. Ultra SCSI buses have a bandwidth of 40 MB per

second; Ultra2 SCSI buses have a bandwidth of 80 MB per second; Ultra160 SCSI

buses have a bandwidth of 160 MB per second. The 3580 Ultrium 2 Tape Drive is

capable of data transfer rates of up to 35 MB per second with no compression and

70 MB per second at 2:1 compression. For these reasons, you should attach only

one 3580 Ultrium 2 Tape Drive to an Ultra SCSI bus, one or two 3580 Ultrium 2

Tape Drives to an Ultra2 SCSI bus, and one to four 3580 Ultrium 2 Tape Drives to

an Ultra160 SCSI bus.

The SCSI bus cable connects the 3580 Ultrium 2 Tape Drive to the server. You can

connect the SCSI bus cable (and the terminator) to either SCSI connector on the

3580 Ultrium 2 Tape Drive.

__ 1. Ensure that the 3580 Ultrium 2 Tape Drive is powered off and plugged into

the electrical outlet.

__ 2. If the server’s SCSI bus is in operation, stop all activity on the bus that you

are connecting to (for instructions about how to stop SCSI bus activity, see

your server’s documentation).

__ 3. Determine the maximum allowable length of your bus cable. The maximum

allowable length depends on the type of SCSI bus (LVD or HVD) that you

are using and the number of devices on the bus:

v For an LVD bus with a single device, do not use a total cabling length

that exceeds 25 m (82 ft).

v For an LVD bus with multiple devices, do not use a total cabling length

that exceeds 12 m (39 ft).

v For an HVD bus, do not use a total cabling length that exceeds 25 m (82

ft).

To determine whether your drive uses an LVD or HVD SCSI bus, see “Step

9. Installing the SCSI Host Adapter Card (if required)” on page 12.

Attention:

v Do not mix LVD and HVD SCSI host adapters, tape drives, or

terminators on the same bus, as they could become damaged.

v Data transfer protocols for tape and disk drives are very

dissimilar. For that reason, IBM strongly recommends that you

avoid running tape and disk drives on the same host adapter.

A configuration with tape and disk on a single host adapter

gives a slow and unreliable performance.

Chapter 2. Installing 13

Page 30

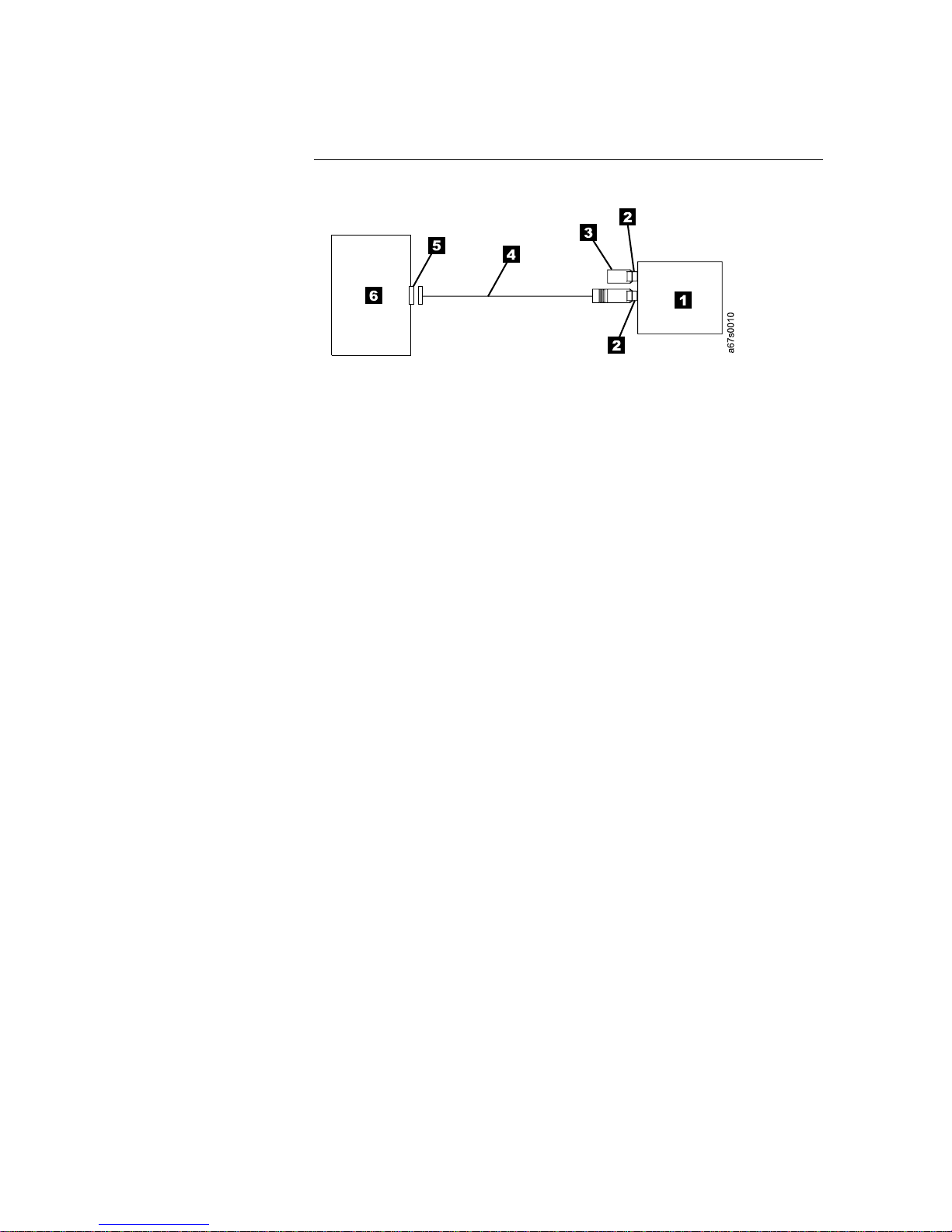

__ 4. Configure your 3580 Ultrium 2 Tape Drive similar to one of the following

examples:

v If the 3580 Ultrium 2 Tape Drive Is the Only Device On the SCSI Bus:

connect the SCSI bus cable to the server (see Figure 3).

Figure 3. Example of connecting one SCSI device to the server. The view is from the top.

1 3580 Ultrium 2 Tape Drive 5 SCSI host adapter card

2 SCSI connectors 6 Server

3 Terminator

4 SCSI bus cable

14 IBM 3580 Ultrium Tape Drive Setup and Operator Guide

Page 31

v If the 3580 Ultrium 2 Tape Drive Is One of Multiple Devices On the

SCSI Bus: connect the SCSI bus cable to the next device on the bus, and

move the terminator to the last device on the bus (see Figure 4). The

maximum allowable length of your bus cable depends on the drive

interface:

– For a drive with an LVD SCSI interface, use a cable with a total length

of 12 m (39 ft) or less.

– For a drive with an HVD/DIFF SCSI interface, use a cable with a total

length of 25 m (82 ft) or less.

To determine whether your drive uses an LVD or HVD/DIFF SCSI

interface, see “Step 9. Installing the SCSI Host Adapter Card (if required)”

on page 12.

Attention: Do not mix LVD and HVD/DIFF SCSI host adapters, tape

drives, or terminators on the same bus, as they could become damaged.

Figure 4. Example of connecting multiple SCSI devices to the server. The view is from the

top.

1 3580 Ultrium 2 Tape Drive 5 SCSI host adapter card

2 SCSI connectors 6 Server

3 Terminator 7 Another tape device

4 SCSI bus cable

Step 12. Configuring the 3580 Ultrium 2 Tape Drive to the Server

__ 1. Power-on the 3580 Ultrium 2 Tape Drive.

__ 2. To configure the 3580 Ultrium 2 Tape Drive for use, refer to the

documentation for your server and application software.

Chapter 2. Installing 15

Page 32

16 IBM 3580 Ultrium Tape Drive Setup and Operator Guide

Page 33

Chapter 3. Operating the 3580 Ultrium 2 Tape Drive

Power Switch

The power switch is a toggle switch that lets you turn the 3580 Ultrium 2 Tape

Drive on or off. The switch is located on the rear panel (see 8 in Figure 2 on

page 7). To power the tape drive on, push the power switch to | ; to power it off,

push the switch to 0. When you place the power switch in the off (0) position, the

primary electrical power within the enclosure is still active. If you do not want

electrical power to be present in the enclosure, unplug the 3580 Ultrium 2 Tape

Drive’s power cord from the receptacle at the rear of the drive (see 7 in Figure 2

on page 7).

When the 3580 Ultrium 2 Tape Drive is powered-on but idle, the status light is off

(see 2 in Figure 5); when the unit is performing a function, the status light is on.

1 Unload button 3 Message display

2 Status light 4 Single-character display

Figure 5. Front view of the 3580 Ultrium 2 Tape Drive

© Copyright IBM Corp. 2003 17

Page 34

Unload Button

The unload push button (1 in Figure 5 on page 17) enables you to perform the

following functions.

v Rewind the tape into the cartridge and eject the cartridge from the tape drive.

v Enter or exit maintenance mode, or perform diagnostic or maintenance

functions. For more information, see “Performing a Diagnostic or Maintenance

Function” on page 62.

v Perform a panic reset of the drive.

Attention: If you press the Unload button during host operation, the 3580

Ultrium 2 Tape Drive ends the command that is being processed, and unloads and

ejects the tape cartridge. Note that (depending on its location on the reel) the tape

may take as much as 20 minutes to completely rewind and eject.

18 IBM 3580 Ultrium Tape Drive Setup and Operator Guide

Page 35

Status Light

The status light (1 in Figure 5 on page 17) is a light-emitting diode (LED) that

provides information about the state of the 3580 Ultrium 2 Tape Drive. The light

can be green or amber, and (when lit) solid or flashing. Table 4 lists the conditions

of the status light and provides an explanation of what each condition means.

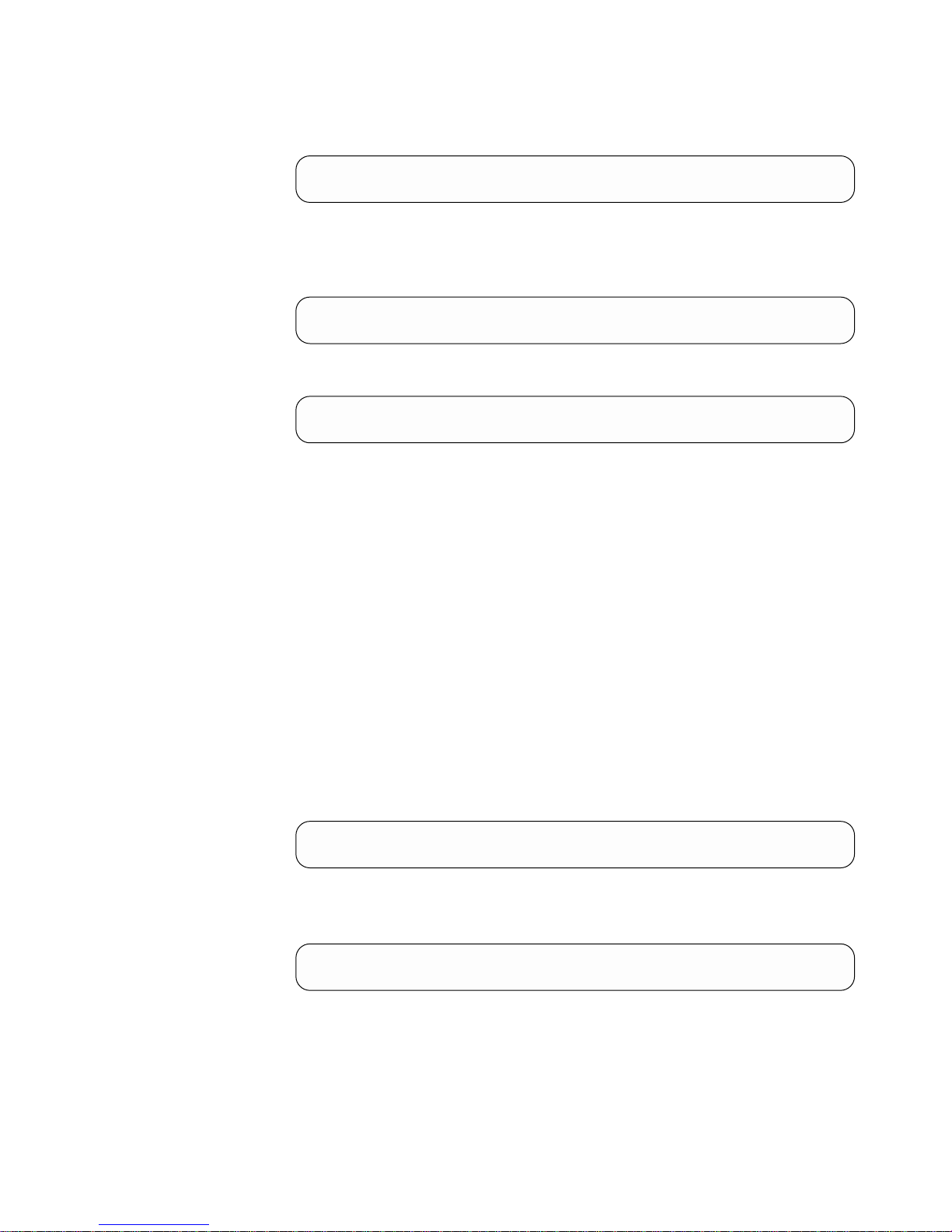

Table 4. Meaning of Status Light Activity

Color and Condition

of Status Light

Off The tape drive has no power or is powered off.

Green/Solid The tape drive is powered on or (if a solid C displays in the

Green/Flashing The tape drive is reading from the tape, writing to the tape,

Amber/Solid The tape drive is powering on or is in maintenance mode. For

Amber/Flashing One of the following applies:

Meaning

single-character display) needs cleaning.

rewinding the tape, locating data on the tape, loading the tape, or

unloading the tape.

The status light also flashes green if the tape drive contains a

cartridge during the power-on cycle. In this case, the drive

completes POST and slowly rewinds the tape (the process may

take approximately 13 minutes). The light stops blinking and

becomes solid when the drive completes the recovery and is ready

for a read or write operation. To eject the cartridge, press the

unload button.

information about the functions that are available when the drive

is in maintenance mode, see “Performing a Diagnostic or

Maintenance Function” on page 62.

v If the light flashes once per second, an error occurred and the

tape drive or media may require service. Note the code on the

single-character display, then go to Table 8 on page 55 to

determine the action that is required. If a solid C appears in the

single-character display, the drive needs cleaning.

v If the light flashes twice per second, the tape drive is updating

firmware. For more information, see “Updating the Drive

Firmware” on page 22.

v If the light flashes once per two seconds, the tape drive detected

an error and is performing a firmware recovery. It resets

automatically.

Chapter 3. Operating 19

Page 36

Message Display

The message display (3 in Figure 5 on page 17) is a liquid crystal display (LCD)

that provides information about the status of the 3580 Ultrium 2 Tape Drive and

any error conditions. The message display consists of two rows, with 20 characters

available in each row. During operation, the message display processor

continuously queries the drive and updates the display with status messages.

When in an idle (non-operating) state, the tape drive displays the following

message:

Ultrium Tape Drive

Drive Empty

If the message display processor loses communication with the 3580 Ultrium 2

Tape Drive, the unit displays the following message (where xxxx equals the

message that was present when the processor lost contact):

xxxx

...

Note: The preceding message may occasionally display during normal processing.

Single-Character Display

The 3580 Ultrium 2 Tape Drive features a light-emitting diode (LED) (4 in

Figure 5 on page 17) that presents a single-character code for:

v Error conditions and informational messages

v Diagnostic or maintenance functions (while in maintenance mode only)

Table 8 on page 55 lists the codes for error conditions and informational messages.

If multiple errors occur, the code with the highest priority (represented by the

lowest number) displays first. When the error is corrected, the code with the next

highest priority displays, and so on until no errors remain.

Table 9 on page 59 lists the single-character codes that represent diagnostic or

maintenance functions. To initiate a function you must be in maintenance mode.

For more information, see Appendix B, “Performing Diagnostic and Maintenance

Functions”, on page 59. While in maintenance mode, the drive may display a single

red dot at the lower-right of the single character display. This indicator is for use

by IBM Support personnel.

The single-character display is blank during normal operation of the 3580 Ultrium

2 Tape Drive.

Inserting a Tape Cartridge

To insert a tape cartridge:

1. Ensure that the 3580 Ultrium 2 Tape Drive is powered-on.

2. Ensure that the write-protect switch (1 in Figure 6 on page 21) is properly set

(see “Setting the Write-Protect Switch” on page 30).

3. Grasp the cartridge so that the write-protect switch faces you.

4. Slide the cartridge into the tape load compartment (see Figure 6 on page 21).

The cartridge loader draws the cartridge into the tape drive and the following

message appears on the message display:

20 IBM 3580 Ultrium Tape Drive Setup and Operator Guide

Page 37

Cartridge Loading In Progress

followed by: (where DC means that drive data compression is enabled)

Volume Loaded DC

Ready...

The status light flashes green, then becomes solid green. The single-character

display remains blank.

Notes:

a. If the cartridge is already in an ejected position and you want to reinsert it,

remove the cartridge then insert it again.

b. If the cartridge is already loaded and you cycle the power (turn it off, then

on), the tape will reload.

c. If you set the write-protect switch so that data cannot be written to it, the

message reads as follows (where WP equals write protect):

Volume Loaded DC WP

Ready...

Figure 6. Inserting a cartridge into the 3580 Ultrium 2 Tape Drive

Removing a Tape Cartridge

Attention: Remove any cartridge from the 3580 Ultrium 2 Tape Drive before

turning off its power. Failure to remove a cartridge may result in damage to the

cartridge or to the tape drive.

To remove a tape cartridge:

1. Ensure that the 3580 Ultrium 2 Tape Drive is powered on.

Note: In the following step, the tape may take as much as 20 minutes to

completely rewind and eject (depending on its location on the reel).

Chapter 3. Operating 21

Page 38

2. Press the unload button. The status light flashes green for approximately 30

seconds while the tape rewinds. The drive then partially ejects the cartridge,

and the status light goes out.

3. After the cartridge partially ejects, grasp the cartridge and remove it.

Performing Diagnostic and Maintenance Functions

The 3580 Ultrium 2 Tape Drive can:

v Run tape drive diagnostics

v Update tape drive firmware from a field microcode replacement (FMR) tape

v Create an FMR tape

v Force a drive dump

v Copy the drive dump to tape

v Run a SCSI wrap test

v Convert an FMR tape to a blank tape

v Display the error code log

v Clear the error code log

v Test the tape cartridge and media

v Test the read/write function

v Test the drive head

To perform the preceding diagnostic and maintenance functions, you must place

the tape drive in maintenance mode. It is recommended that you use a scratch

(blank) data cartridge for diagnostic testing. For complete instructions about

performing each operation, see Appendix B, “Performing Diagnostic and

Maintenance Functions”, on page 59.

Updating the Drive Firmware

Attention: To ensure optimum performance from the 3580 Ultrium 2 Tape Drive,

use the latest level of drive firmware. It is the customer’s responsibility to obtain

and install drive firmware.

You can update the drive firmware in the 3580 Ultrium 2 Tape Drive by:

v Obtaining the new firmware image and downloading it to the tape drive over

the SCSI interface

v Loading the firmware from a field microcode replacement (FMR) tape cartridge

To update the firmware over the SCSI bus, obtain the new firmware image and the

installation instructions by visiting the web at http://www.ibm.com/storage/lto.

For instructions about downloading firmware, see “Procedure 2” on page 49.

To update the firmware by using an FMR tape, visit the web at

http://www.ibm.com/storage/lto.

Cleaning the Drive Head

Attention: When cleaning the drive head in the 3580 Ultrium 2 Tape Drive, use

the IBM TotalStorage LTO Ultrium Cleaning Cartridge (part number 35L2086). You

may use another LTO cleaning cartridge, but it may not meet the standards of

reliability established by IBM.

22 IBM 3580 Ultrium Tape Drive Setup and Operator Guide

Page 39

Clean the drive head in the 3580 Ultrium 2 Tape Drive whenever C displays on the

single-character display and the status light is solid green. IBM does not

recommend that you clean the drive head on a periodic basis; only when C

displays.

To clean the head, insert the cleaning cartridge into the tape load compartment (see

Figure 6 on page 21). The tape drive performs the cleaning automatically. The

cleaning cycle takes less than 2 minutes. When the cleaning is finished, the drive

ejects the cartridge.

Note: If you insert a cleaning cartridge when the drive does not need to be

cleaned or if you insert a cleaning cartridge that has expired, the drive will

automatically eject the cartridge.

The IBM TotalStorage LTO Ultrium Cleaning Cartridge is valid for 50 uses.

Cleaning the 3580 Ultrium 2 Tape Drive

Clean the exterior surface of the 3580 Ultrium 2 Tape Drive with a damp towel. If

you use a liquid all-purpose cleaner, apply it to the towel. Do not spray the

enclosure.

Chapter 3. Operating 23

Page 40

24 IBM 3580 Ultrium Tape Drive Setup and Operator Guide

Page 41

Chapter 4. Using Ultrium Media

The 3580 Ultrium 2 Tape Drive automates the storage and movement of IBM LTO

Ultrium Tape Cartridges. The Ultrium Tape Drive uses the following cartridge

types:

v IBM TotalStorage LTO Ultrium 200 GB Data Cartridge (Ultrium 2)

v IBM LTO Ultrium Data Cartridge (Ultrium 1)

v IBM TotalStorage LTO Ultrium Cleaning Cartridge

v LTO Ultrium Cleaning Cartridge

The 3580 Tape Drive is compatible with the cartridges of its predecessor, the

Ultrium 1 Tape Drive. When labeled according to proper IBM bar code label

specifications (see “Bar Code Label” on page 28), the last character of the

cartridge’s volume serial number (VOLSER) indicates the generation of the media.

For example, a cartridge with a VOLSER of 000764L2 is an Ultrium 2 cartridge; a

cartridge with a VOLSER of 003995L1 is an Ultrium 1 cartridge. Cartridge

compatibility for the 3580 Tape Drive is as follows:

v Reads and writes Ultrium 2 format on Ultrium 2 cartridges

v Reads and writes Ultrium 1 format on Ultrium 1 cartridges

v Does not write Ultrium 2 format on Ultrium 1 cartridges

v Does not write Ultrium 1 format on Ultrium 2 cartridges

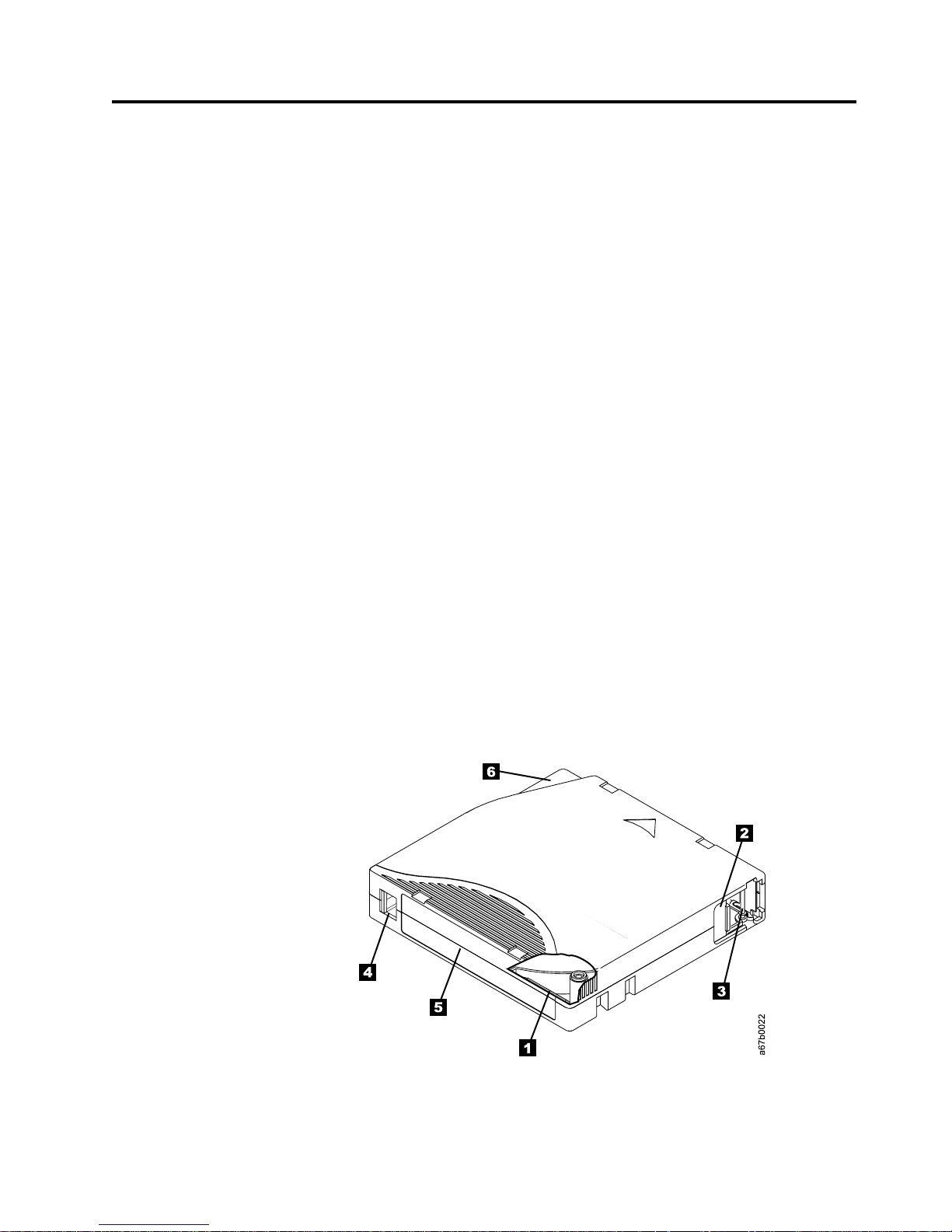

Figure 7 shows the IBM TotalStorage LTO Ultrium 200 GB Data Cartridge and its

components.

1 LTO cartridge memory 4 Write-protect switch

2 Cartridge door 5 Label area

3 Leader pin 6 Insertion guide

Figure 7. The IBM TotalStorage LTO Ultrium 200 GB Data Cartridge

© Copyright IBM Corp. 2003 25

Page 42

Data Cartridge

In addition to using LTO Ultrium 2 Tape Cartridges with up to 200 GB capacity,

the tape drive reads and writes to certified LTO Ultrium Tape Cartridges that have

capacities of 100, 50, 30, and 10 GB. If you want to control the capacity of the

cartridge (for example, if you want to limit the capacity to obtain a faster seek

time) you can do so by issuing the SCSI command SET CAPACITY. For

information about this command, refer to the IBM TotalStorage LTO Ultrium Tape

Drive SCSI Reference.

To ensure that your tape drive conforms to IBM’s specifications for reliability, use

only IBM LTO Ultrium Tape Cartridges. You may use other LTO-certified data

cartridges, but they may not meet the standards of reliability that are established

by IBM. The IBM TotalStorage LTO Ultrium 200 GB Data Cartridge cannot be

interchanged with the media used in other IBM non-LTO Ultrium tape products.

The IBM Ultrium 2 Data Cartridge is purple, and the Ultrium 1 Data Cartridge is

black. Both generations contain 1/2-inch, dual-coat, metal-particle tape. The

Ultrium 1 cartridge has a native data capacity of 100 GB (200 GB at 2:1

compression); the Ultrium 2 cartridge has a native data capacity of 200 GB (400 GB

at 2:1 compression).

When processing tape in the cartridges, the Ultrium Tape Drives use a linear,

serpentine recording format. The Ultrium 1 drive reads and writes data on 384

tracks, eight tracks at a time; the Ultrium 2 drive reads and writes data on 512

tracks, eight tracks at a time The first set of eight tracks is written from near the

beginning of the tape to near the end of the tape. The head then repositions to the

next set of eight tracks for the return pass. This process continues until all tracks

are written and the tape is full, or until all data is written.

Both generations of the IBM LTO Ultrium Data Cartridges include a Linear

Tape-Open Cartridge Memory (LTO-CM) chip (1 in Figure 7 on page 25), that

contains information about the cartridge and the tape (such as the name of the

manufacturer that created the tape), as well as statistical information about the

cartridge’s use. The LTO-CM enhances the efficiency of the cartridge. For example,

the LTO-CM stores the end-of-data location which, when you next insert a

cartridge and issue the Write command, enables the drive to quickly locate the

recording area and begin recording. The LTO-CM also aids in determining the

reliability of the cartridge by storing data about its age, how many times it has

been loaded, and how many errors it has accumulated. Whenever you unload a

tape cartridge, the tape drive writes any pertinent information to the cartridge

memory. The storage capacity of the LTO-CM is 4096 bytes.

The cartridge door 2 protects the tape from contamination when the cartridge is

out of the drive. Behind the door, the tape is attached to a leader pin 3. When

you insert the cartridge into the drive, a threading mechanism pulls the pin (and

tape) out of the cartridge, across the drive head, and onto a non-removable takeup

reel. The head can then read or write data from or to the tape.

The write-protect switch 4 prevents data from being written to the tape

cartridge. On the data cartridge, the switch is red; on the cleaning cartridge, the

switch is gray. The label area 5 provides a location for you to place a label. Affix

only a bar code label. When affixing a label, place it only in the recessed label area.

A label that extends outside of the recessed area can cause loading problems in the

internal drive or in the 3580 Ultrium 2 Tape Drive. The insertion guide 6 is a

large, notched area that prevents you from inserting the cartridge incorrectly.

26 IBM 3580 Ultrium Tape Drive Setup and Operator Guide

Page 43

You can order tape cartridges with the bar code labels included, or you can order

custom labels. To obtain tape cartridges and bar code labels, see “Ordering Media

Supplies” on page 43.

Both generations of the LTO Ultrium Data Cartridge have a nominal cartridge life

of 5000 load and unload cycles.

Cleaning Cartridge

With each 3580 Ultrium 2 Tape Drive, a specially labeled IBM LTO Ultrium

Cleaning Cartridge is supplied to clean the drive heads. The drive itself determines

when a head needs to be cleaned. It alerts you by displaying C on the

single-character display. To clean the head, insert the IBM LTO Cleaning Cartridge

into the tape load compartment (see Figure 6 on page 21). The tape drive performs

the cleaning automatically. When the cleaning is finished, the drive ejects the

cartridge.

Note: If you insert a cleaning cartridge when the drive does not need to be

To remove a cleaning cartridge, see “Removing a Tape Cartridge” on page 21.

The IBM Cleaning Cartridges are valid for 50 uses. The cartridge’s LTO-CM chip

tracks the number of times that the cartridge is used.

cleaned or if you insert a cleaning cartridge that has expired, the drive will

automatically eject the cartridge.

Chapter 4. Using Ultrium Media 27

Page 44

Bar Code Label

The 3580 Ultrium 2 Tape Drive does not require cartridge bar code labels.

However, if you use your data cartridges or cleaning cartridges in an IBM tape

library product, you may need cartridge bar code labels if your tape library

product requires them. A label contains:

v A volume serial number (VOLSER) that you can read

v A bar code that the library can read

When read by the library’s bar code reader, the bar code identifies the cartridge’s

VOLSER to the library. The bar code also tells the library whether the cartridge is a

data cartridge or cleaning cartridge. In addition, the bar code includes the

two-character media-type identifier Lx, where x equals 1 or 2. L identifies the

cartridge as an LTO cartridge. 1 indicates that the cartridge is the first generation

of its type; 2 indicates that the cartridge is the second generation of its type.

Figure 8 on page 29 shows a sample bar code label for the LTO Ultrium Tape

Cartridge.

You can order tape cartridges with the labels included, or you can order custom

labels. To order tape cartridges and bar code labels, see “Ordering Media Supplies”

on page 43. The bar code for usage in IBM tape libraries must meet predefined

specifications. They include (but are not limited to):

v Eight uppercase alphanumeric characters, where the last two characters must be

L1 or L2

v Label and printing to be non-glossy

v Nominal narrow line or space width of 0.423 mm (0.017 in.)

v Wide to narrow ratio of 2.75:1

v Minimum bar length of 11.1 mm (0.44 in.)

To determine the complete specifications of the bar code and the bar code label,

visit the web at http://www.ibm.com/storage/lto (select either Technical Support

or LTO Support), or contact your IBM Sales Representative.

When attaching a bar code label to a tape cartridge, place the label only in the

recessed label area (see 4 in Figure 7 on page 25). A label that extends outside of

the recessed area can cause loading problems in the drive.

Attention: Do not place any type of mark on the white space at either end of the

bar code. A mark in this area may prevent the library from reading the label.

28 IBM 3580 Ultrium Tape Drive Setup and Operator Guide

Page 45

Figure 8. Sample bar code label on the LTO Ultrium 2 Tape Cartridge. The volume serial

number (LTO123) and bar code are printed on the label.

Guidelines for Using Bar Code Labels

Apply the following guidelines whenever you use bar code labels:

v Use only IBM-approved bar code labels if you intend to use the cartridge in an

IBM tape library.

v Do not reuse a label or reapply a used label over an existing label.

v Before you apply a new label, remove the old label by slowly pulling it at a

right angle to the cartridge case.

v Use peel-clean labels that do not leave a residue after they are removed. If there

is glue residue on the cartridge, remove it by gently rubbing it with your finger;

do not use a sharp object, water, or a chemical to clean the label area.

v Examine the label before you apply it to the cartridge. Do not use the label if it

has voids or smears in the printed characters or bar code (a library’s inventory

operation will take much longer if the bar code label is not readable).

v Remove the label from the label sheet carefully. Do not stretch the label or cause

the edges to curl.

v Position the label within the recessed label area (see 5 in Figure 7 on page 25).

v With light finger pressure, smooth the label so that no wrinkles or bubbles exist

on its surface.

v Verify that the label is smooth and parallel, and has no roll-up or roll-over. The

label must be flat to within 0.5 mm (0.02 in.) over the length of the label and

have no folds, missing pieces, or smudges.

v Do not place other machine-readable labels on other surfaces of the cartridge.

They may interfere with the ability of the drive to load the cartridge.

Chapter 4. Using Ultrium Media 29

Page 46

Setting the Write-Protect Switch

The position of the write-protect switch on the tape cartridge (see 1 in Figure 9)

determines whether you can write to the tape:

v If the switch is set to

v If the switch is set to unlocked (black void), data can be written to the tape.

If possible, use your server’s application software to write-protect your cartridges

(rather than manually setting the write-protect switch). This allows the server’s

software to identify a cartridge that no longer contains current data and is eligible

to become a scratch (blank) data cartridge. Do not write-protect scratch (blank)

cartridges; the tape drive will not be able to write new data to them.

If you must manually set the write-protect switch, slide it left or right to the

desired position.

(solid red), data cannot be written to the tape.

Figure 9. Setting the write-protect switch

Handling the Cartridges

Incorrect handling or an incorrect environment can damage the IBM LTO Ultrium

Tape Cartridges or their magnetic tape. To avoid damage to your tape cartridges

and to ensure the continued high reliability of your IBM LTO Ultrium Tape Drives,

use the following guidelines:

Provide Training

v Post procedures that describe proper media handling in places where people

gather.

1

Attention: Do not insert a damaged tape cartridge into your

3580 Ultrium 2 Tape Drive. A damaged cartridge can interfere

with the reliability of a drive and may void the warranties of the

drive and the cartridge. Before inserting a tape cartridge, inspect

the cartridge case, cartridge door, and write-protect switch for

breaks.

A67E0026

30 IBM 3580 Ultrium Tape Drive Setup and Operator Guide

Page 47

v Ensure that anyone who handles tape has been properly trained in handling and

shipping procedures. This includes operators, users, programmers, archival

services, and shipping personnel.

v Ensure that any service or contract personnel who perform archiving are

properly trained in media-handling procedures.

v Include media-handling procedures as part of any services contract.

v Define and make personnel aware of data recovery procedures.

Ensure Proper Packaging

v When you ship a cartridge, ship it in its original or better packaging.

v Always ship or store a cartridge in a jewel case.

v Use only a recommended shipping container that securely holds the cartridge in

its jewel case during transportation. Ultrium Turtlecases (by Perm-A-Store) have

been tested and found to be satisfactory (see Figure 10). They are available at

http://www.turtlecase.com.

Figure 10. Tape cartridges in a Turtlecase

v Never ship a cartridge in a commercial shipping envelope. Always place it in a

box or package.

v If you ship the cartridge in a cardboard box or a box of a sturdy material, ensure

the following:

– Place the cartridge in polyethylene plastic wrap or bags to protect it from

dust, moisture, and other contaminants.

– Pack the cartridge snugly; do not allow it to move around.

– Double-box the cartridge (place it inside a box, then place that box inside the

shipping box) and add padding between the two boxes (see Figure 11 on

page 32).

Chapter 4. Using Ultrium Media 31

Page 48

Figure 11. Double-boxing tape cartridges for shipping

Provide Proper Acclimation and Environmental Conditions

v Before you use a cartridge, let it acclimate to the normal operating environment

for 1 hour. If you see condensation on the cartridge, wait an additional hour.

v Ensure that all surfaces of a cartridge are dry before inserting it.

v Do not expose the cartridge to moisture or direct sunlight.

v Do not expose recorded or blank cartridges to stray magnetic fields of greater

than 100 oersteds (for example, terminals, motors, video equipment, X-ray

equipment, or fields that exist near high-current cables or power supplies). Such

exposure can cause the loss of recorded data or make the blank cartridge

unusable.

v Maintain the conditions that are described in “Environmental and Shipping

Specifications for Tape Cartridges” on page 42.

Perform a Thorough Inspection

After purchasing a cartridge and before using it, perform the following steps:

v Inspect the cartridge’s packaging to determine potential rough handling.

v When inspecting a cartridge, open only the cartridge door. Do not open any

other part of the cartridge case. The upper and lower parts of the case are held

together with screws; separating them destroys the usefulness of the cartridge.

v Inspect the cartridge for damage before using or storing it.

v Inspect the rear of the cartridge (the part that you load first into the tape load

compartment) and ensure that there are no gaps in the seam of the cartridge

case (see 1 in Figure 12 on page 33 and 4 in Figure 14 on page 36). If there

are gaps in the seam (see Figure 12 on page 33), the leader pin may be

dislodged. Go to “Repositioning or Reattaching a Leader Pin” on page 35.

32 IBM 3580 Ultrium Tape Drive Setup and Operator Guide

Page 49

Figure 12. Checking for gaps in the seams of a cartridge

v Check that the leader pin is properly seated (see 2 in Figure 13 on page 35).

v If you suspect that the cartridge has been mishandled but it appears useable,

copy any data onto a good cartridge immediately for possible data recovery.

Discard the mishandled cartridge.

v Review handling and shipping procedures.

Handle the Cartridge Carefully

v Do not drop the cartridge. If the cartridge drops, slide the cartridge door back

and ensure that the leader pin is properly seated in the pin-retaining spring clips

(see 2 in Figure 13 on page 35). If the leader pin has become dislodged, go to

“Repositioning or Reattaching a Leader Pin” on page 35.

v Do not handle tape that is outside the cartridge. Handling the tape can damage

the tape’s surface or edges, which may interfere with read or write reliability.

Pulling on tape that is outside the cartridge can damage the tape and the brake

mechanism in the cartridge.

v Do not stack more than six cartridges.

v Do not degauss a cartridge that you intend to reuse. Degaussing makes the tape

unusable.

Chapter 4. Using Ultrium Media 33

Page 50

Examples of Cartridge Problems

Example: Split Cartridge Case (see Figure 12 on page 33)

The cartridge’s case is damaged. There is a high possibility of media damage and

potential loss. Perform the following steps:

1. Look for cartridge mishandling.

2. Use the IBM Leader Pin Reattachment Kit (part number 08L9129) to correctly

seat the pin (see “Repositioning a Leader Pin” on page 35). Then, immediately

use data recovery procedures to minimize chances of data loss.

3. Review media-handling procedures.

Example: Improper Placement of Leader Pin (see Figure 13 on page 35)

The leader pin is misaligned. Perform the following steps:

1. Look for cartridge damage.

2. Use the IBM Leader Pin Reattachment Kit (part number 08L9129) to correctly

seat the pin (see “Repositioning a Leader Pin” on page 35). Then, immediately

use data recovery procedures to minimize chances of data loss.

34 IBM 3580 Ultrium Tape Drive Setup and Operator Guide

Page 51

Repositioning or Reattaching a Leader Pin