Page 1

IBM TotalStorage SAN32M1 Switch

Installation an d Service Manual

GC26-7665-01

Page 2

Page 3

IBM TotalStorage SAN32M1 Switch

Installation an d Service Manual

GC26-7665-01

Page 4

Second Edition (February 2005)

The following paragraph does not apply to any country (or region) where such provisions are inconsistent with local

law.

INTERNATIONAL BUSINESS MACHINES CORPORATION PROVIDES THIS PUBLICATION “AS IS” WITHOUT

WARRANTY OF ANY KIND, EITHER EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. Some states (or regions) do

not allow disclaimer of express or implied warranties in certain transactions; therefore, this statement may not apply

to you.

Order publications through your IBM

®

representative or the IBM branch office serving your locality.

© Copyright International Business Machines Corporation 2005. All rights reserved.

US Government Users Restricted Rights – Use, duplication or disclosure restricted by GSA ADP Schedule Contract

with IBM Corp.

Page 5

Contents

Chapter 1 General information

Switch description ...............................................................................1

Switch management.....................................................................2

Error-Detection, reporting, and serviceability features...........5

Zoning feature...............................................................................7

Multiswitch fabrics.......................................................................7

Switch specifications ...........................................................................9

Management server....................................................................11

Ethernet hub (optional)..............................................................13

SANpilot interface......................................................................13

Maintenance approach......................................................................14

Remote workstation configurations................................................15

Minimum remote console hardware specifications...............17

Field-replaceable units ......................................................................18

SFP transceivers ..........................................................................20

Cooling fans.................................................................................21

Power supplies............................................................................21

Connectors and indicators................................................................21

Initial Machine load button.......................................................22

Ethernet LAN connector............................................................22

Power and system error LEDs..................................................22

FRU status LEDs.........................................................................23

Maintenance port........................................................................23

Software diagnostic features ............................................................23

SAN management application..................................................24

Element manager description .........................................................25

Using the Element Manager.............................................................28

Using dialog boxes ....................................................................28

Keyboard navigation..................................................................28

Hardware view ...........................................................................29

Window layout and function....................................................29

Closing the Element Manager...................................................44

SANpilot diagnostics .................................................................45

SNMP trap message support ....................................................46

E-Mail and call-home support ..................................................47

Tools and test equipment..................................................................47

Tools supplied with the switch.................................................48

Tools supplied by service personnel........................................49

© Copyright IBM Corp. 2005

iii

Page 6

Chapter 2 Installation tasks

Factory defaults ..........................................................................51

Installation options............................................................................54

Summary of installation tasks..........................................................55

Task 1: Verify installation requirements .........................................56

Task 2: Unpack, inspect, and install the Ethernet hub (optional)57

Unpack and inspect the Ethernet hub .....................................58

Desktop installation ...................................................................58

Rack-Mount installation ............................................................60

Task 3: Unpack, inspect, and install the switch.............................62

Unpack and inspect the switch.................................................62

Desktop installation ...................................................................63

Rack-Mount installation ............................................................64

Task 4: Configure network information .........................................64

Task 5: LAN-Connect the switch.....................................................71

Task 6: Unpack, inspect, and install the management server......71

Task 7: Configure management server password and network

addresses.............................................................................................75

Configure Password...................................................................76

Configure private LAN addresses ...........................................77

Configure public LAN Addresses (optional) .........................78

Task 8: Configure management server information.....................80

Access the management server desktop ................................. 80

Configure management server names.....................................82

Configure gateway and DNS server addresses .....................85

Task 9: Configure Windows 2000 users..........................................88

Change default administrator password ................................89

Add a new user...........................................................................90

Change user properties..............................................................92

Task 10: Set management server date and time ............................94

Task 11: Configure the call-home feature (optional)..................... 96

Task 12: Assign user names and passwords..................................97

Task 13: Configure the switch to the management application 101

Task 14: Record or verify management server restore information

103

Task 15: Verify switch-to-management server communication 105

Task 16: Configure PFE Key (optional).........................................106

Task 17: Configure management server (optional)..................... 109

Configure OSMS.......................................................................109

Installation.................................................................................109

Configure FMS.......................................................................... 110

SANtegrity™binding features................................................ 112

Fabric binding ........................................................................... 112

iv

SAN32M1 Fabric Switch Installation and Service Manual

Page 7

Switch binding...........................................................................113

Flexport..............................................................................................119

Open trunking ..................................................................................119

Open trunking log.....................................................................124

Task 18: Set switch date and time ..................................................124

Set date and time manually.....................................................125

Periodically synchronize date and time ................................126

Task 19: Configure SAN32M1 Element Manager applications 126

Configure switch identification ..............................................127

Task 20: Configure switch operating parameters........................128

Switch parameters.....................................................................129

Task 21: Configure fabric operating parameters..........................131

Fabric parameters......................................................................132

Configure ports (open systems mode)...................................134

Configure ports (FICON mode)..............................................136

Configure port addresses (FICON mode).............................138

Configure SNMP trap message recipients ............................141

Configure and enable E-mail notification .............................142

Configure and enable Ethernet events...................................143

Configure and enable call-home event notification.............144

Configure threshold alerts.......................................................145

Procedures..................................................................................146

Task 22: Configure open trunking .................................................152

Task 23: Test remote notification (optional)..................................152

Task 24: Back up configuration data..............................................153

Task 25: Configure the switch from the SANpilot Interface

(optional) ...........................................................................................157

Configure switch ports.............................................................159

Configure switch identification ..............................................161

Configure date and time..........................................................162

Configure operating parameters.............................................163

Configure fabric parameters....................................................165

Configure Network Information ............................................168

Configure SNMP.......................................................................170

Enable or Disable the CLI ........................................................172

Enable or Disable Host Control ..............................................173

Configure User Rights..............................................................174

Configure Port Binding............................................................176

Configure Switch Binding .......................................................177

Configure Fabric Binding ........................................................178

Enable or Disable Enterprise Fabric Mode............................180

Configure OpenTrunking ........................................................181

Install PFE Keys (Optional) .....................................................184

Contents

v

Page 8

Task 26: Cable Fibre Channel Ports...............................................186

Task 27: Connect Switch to a Fabric Director (Optional)...........187

Chapter 3 Diagnostics

Maintenance analysis procedures.................................................191

Factory defaults ........................................................................191

Quick start .................................................................................191

MAP 0000: Start MAP .....................................................................195

MAP 0100: power distribution analysis.......................................218

MAP 0200: POST, reset, or IPL failure analysis........................... 224

MAP 0300: console application problem determination............226

MAP 0400: loss of console communication..................................235

MAP 0500: fan and CTP card failure analysis............................. 256

MAP 0600: port failure and link incident analysis......................261

MAP 0700: fabric, ISL, and segmented port problem

determination...................................................................................281

MAP 0800: server hardware problem determination................. 297

Chapter 4 Repair inf ormation

Factory defaults ........................................................................305

Procedural notes ..............................................................................306

Using log information.....................................................................307

EFC audit log.............................................................................308

EFC event log ............................................................................308

EFC session log.........................................................................309

EFC product status log ............................................................309

EFC fabric log............................................................................ 310

Audit log.................................................................................... 311

Event log....................................................................................311

Hardware log ............................................................................312

Link incident log.......................................................................314

Threshold alert log ...................................................................315

SANpilot logs............................................................................318

Using views ......................................................................................320

Port list view .............................................................................320

FRU list view ....................................................................................322

Node list view ...........................................................................324

Performance view.....................................................................325

Zone set view ............................................................................325

Performing port diagnostics ..........................................................327

Port LEDs...................................................................................327

vi

SAN32M1 Fabric Switch Installation and Service Manual

Page 9

Hardware view..........................................................................328

Performance view .....................................................................332

Perform loopback tests.............................................................334

Perform channel wrap test.......................................................338

Swapping ports.................................................................................339

Collecting maintenance data ..........................................................340

SANpilot interface ....................................................................341

EFC server..................................................................................343

Clean fiber-optic components ........................................................345

Power-On procedure .......................................................................346

Power-Off procedure .......................................................................347

Reset or IPL the switch....................................................................347

Reset the switch.........................................................................348

IPL the switch............................................................................349

Set the switch online or offline.......................................................349

Set online state...........................................................................350

Set offline state...........................................................................350

Block and unblock ports..................................................................351

Block a port ................................................................................351

Unblock a port...........................................................................352

Manage firmware versions .............................................................353

Determine a switch firmware version....................................353

Add a firmware version...........................................................354

Modify a firmware version description.................................357

Delete a firmware version........................................................358

Download a firmware version to a switch............................358

Manage configuration data.............................................................361

Back up the configuration........................................................362

Restore the configuration.........................................................363

Reset configuration data ..........................................................364

Install or upgrade software.............................................................365

Chapter 5 FRU removal and replacement

Remove and replace FRUs..............................................................369

FRUs............................................................................................369

Procedural notes........................................................................369

RRP: SFP transceiver........................................................................370

Removal......................................................................................370

Replacement...............................................................................371

RRP: power supply ..........................................................................372

Removal......................................................................................372

Replacement...............................................................................373

Contents

vii

Page 10

RRP: cooling fan FRU......................................................................374

Removal .....................................................................................374

Replacement..............................................................................375

RRP: CTP card - switch replacement ............................................376

Replacing a failed switch.........................................................376

Chapter 6 Illustrated parts breakdown

Front-Accessible FRUs....................................................................379

Rear-Accessible FRUs......................................................................380

Power plugs and receptacles..........................................................382

Miscellaneous parts.........................................................................385

Appendix A Messages

Element Manager messages ..........................................................387

A..................................................................................................387

C ..................................................................................................389

D..................................................................................................399

E...................................................................................................400

F...................................................................................................402

I....................................................................................................404

L...................................................................................................410

M .................................................................................................410

N.................................................................................................. 411

O..................................................................................................412

P...................................................................................................412

R ..................................................................................................414

S...................................................................................................414

T...................................................................................................416

U..................................................................................................421

Y ..................................................................................................421

Appendix B Event code tables

System events (000 through 199) ..................................................425

Power supply events (200 through 299) ......................................443

Fan module events (300 through 399) ..........................................448

CTP card events (400 through 499) ..............................................454

Port module events (500 through 599) .........................................468

MPC module events (600 through 699) .......................................489

CMM module events (800 through 899) ......................................495

viii

SAN32M1 Fabric Switch Installation and Service Manual

Page 11

Appendix C Restore EFC servers

Requirements ...................................................................................501

Restore EFC server procedure .......................................................502

Appendix D Consolidating EFC servers in a multiswitch fabric

Overview...........................................................................................506

Required EFC manager version..............................................508

IP address assignment..............................................................509

Consolidating EFC servers .............................................................511

Common steps for all configurations.....................................511

Private LAN connection...........................................................516

Private and public LAN connection.......................................519

Reconfiguring a client PC after an EFC server failure................521

Notices ..........................................................................................................................523

Trademarks........................................................................................524

Electronic emission notices, certifications, other notices (replace

as appropriate-below are typical statements included in most

books).................................................................................................525

Contents

ix

Page 12

x

SAN32M1 Fabric Switch Installation and Service Manual

Page 13

Figures

1 Out-of-Band product management ............................................................... 4

2 Management server ....................................................................................... 12

3 24-Port Ethernet hub ...................................................................................... 13

4 Typical network configuration (one Ethernet connection) ..................... 16

5 Typical network configuration (two Ethernet connections) ................... 17

6 Switch (front view) ....................................................................................... 19

7 Switch (rear view) ......................................................................................... 20

8 Multimode and Singlemode wrap plugs ................................................... 48

9 Fiber-Optic protective plug ........................................................................... 48

10 Null modem cable .......................................................................................... 49

11 Stacked Ethernet hubs ................................................................................... 59

12 Patch cable and MDI selector configuration .............................................. 60

13 Mounting bracket installation (Ethernet hub) ........................................... 61

14 Rack installation (Ethernet hub) ................................................................... 61

15 Connection description dialog box .............................................................. 67

16 Connect to dialog box .................................................................................... 67

17 COMn (COM1 or COM2) dialog box .......................................................... 68

18 Hyperterminal window ................................................................................. 69

19 Disconnect confirmation message box ........................................................ 70

20 Save session device confirmation box ......................................................... 70

21 1U management server connections ............................................................ 73

22 LCD panel during boot sequence ................................................................ 74

23 LCD panel (password entry) ........................................................................ 76

24 LCD panel (new password) .......................................................................... 76

25 LCD panel (save change) .............................................................................. 76

26 LCD panel (password entry) ........................................................................ 77

27 LCD panel (LAN 2 IP address) .................................................................... 77

28 LCD panel (save change) .............................................................................. 77

29 LCD panel (LAN 2 subnet mask) ................................................................. 78

30 LCD panel (save change) .............................................................................. 78

31 LCD panel (password entry) ........................................................................ 78

32 LCD panel (LAN 1 IP address) .................................................................... 79

33 LCD panel (save change) .............................................................................. 79

34 LCD Panel (LAN 1 subnet mask) ................................................................. 79

35 LCD panel (save change) .............................................................................. 79

36 VNC authentication screen ........................................................................... 81

37 Welcome to windows dialog box ................................................................. 81

38 Log on to windows dialog box ..................................................................... 82

39 SANavigator log in or EFCM log in dialog box ......................................... 82

© Copyright IBM Corp. 2005

xi

Page 14

40 Control panel window .................................................................................. 83

41 System properties dialog box (network identification tab) ..................... 84

42 Identification Changes Dialog Box .............................................................. 84

43 Network and dial-up connections window ............................................... 85

44 Local area connection 2 status dialog box .................................................. 86

45 Local area connection 2 properties dialog box .......................................... 86

46 Internet Protocol (TCP/IP) properties dialog box .................................... 87

47 Users and passwords dialog box ................................................................. 88

48 Windows security dialog box ....................................................................... 89

49 Change password dialog box ....................................................................... 90

50 Add new user wizard (first window) ......................................................... 91

51 Add New User Wizard (Second Window) ................................................. 91

52 Add new user wizard (third window) ........................................................ 92

53 EFCSERVER\srvacc properties dialog box (general tab) ........................ 93

54 EFCSERVER\srvacc properties dialog box (group membership tab) ... 93

55 Date/Time properties dialog box ................................................................ 95

56 Date/Time properties dialog box, time zone ............................................. 95

57 Call Home configuration dialog box ........................................................... 97

58 Main window (SANavigator or EFCM) ...................................................... 98

59 SANavigator or EFCM server users dialog box ........................................ 99

60 Add user dialog box ...................................................................................... 99

61 Discover setup dialog box ........................................................................... 101

62 Domain Information Dialog Box (IP Address Page) ............................... 102

63 System properties dialog box (general tab) .............................................. 104

64 Switch hardware view ................................................................................. 106

65 Configure feature key dialog box .............................................................. 107

66 New feature key dialog box ........................................................................ 107

67 Enable feature key dialog box .................................................................... 108

68 Warning dialog box ..................................................................................... 108

69 Configure open systems management server dialog box ...................... 110

70 Configure FICON management server dialog box ................................. 111

71 Switch binding state change dialog box ................................................... 115

72 Switch binding membership list dialog box ............................................ 116

73 Configure open trunking dialog box ......................................................... 120

74 Open trunking log ........................................................................................ 124

75 Configure Date and Time Dialog Box ....................................................... 125

76 Date and Time Synced Dialog Box ............................................................ 126

77 Configure identification dialog box .......................................................... 127

78 Configure switch parameters dialog box ................................................. 129

79 Configure fabric parameters dialog box ................................................... 132

80 Configure ports dialog box (open systems management style) ............ 135

81 Configure ports dialog box (FICON management style) ....................... 137

82 Configure addresses - active dialog box ................................................... 139

xii

SAN32M1 Fabric Switch Installation and Service Manual

Page 15

83 Save address configuration as dialog box ................................................. 140

84 Configure SNMP dialog box ....................................................................... 141

85 Configure E-Mail dialog box ....................................................................... 142

86 Configure Ethernet events dialog box ....................................................... 144

87 Configure call home event notification dialog box ................................. 144

88 Configure threshold alerts dialog box ....................................................... 146

89 New threshold alerts dialog box - first screen .......................................... 147

90 New threshold alerts dialog box - second screen .................................... 148

91 New threshold alerts dialog box - third screen ........................................ 149

92 New threshold alerts dialog box - summary screen ................................ 150

93 Configure threshold alerts dialog box - alerts activated ......................... 150

94 Test remote notification dialog box ........................................................... 153

95 Call-Home Information Dialog Box ........................................................... 153

96 Shut down windows dialog box ................................................................. 155

97 TightVNC network error message ............................................................. 155

98 Enter network password dialog box .......................................................... 158

99 View Panel (Switch Page) ............................................................................ 159

100 Configure panel (ports page) ...................................................................... 160

101 Configure panel (switch page with identification tab) ........................... 162

102 Configure panel (switch page with date/time tab) ................................. 163

103 Configure panel (switch page with parameters tab) ............................... 164

104 Configure panel (switch page with fabric parameters tab) .................... 166

105 Configure Panel (Switch Page with Network Tab) ................................. 169

106 Network Information Message Box ........................................................... 169

107 Configure Panel (Management Page with SNMP Tab) .......................... 171

108 Configure Panel (Management Page with CLI Tab) ............................... 173

109 Configure Panel (Management Page with OSMS Tab) ........................... 174

110 Configure Panel (Security Page with User Rights Tab) .......................... 175

111 Configure Panel (Security Page with Port Binding Tab) ........................ 176

112 Configure Panel (Security Page with Switch Binding Tab) .................... 177

113 Configure Panel (Security Page with Fabric Binding Tab) ..................... 179

114 Configure Panel (Security Page with EFM Tab) ...................................... 181

115 Configure Panel (Performance Page with OpenTrunking Tab) ............ 182

116 Operations Panel (Feature Installation Tab) ............................................. 185

117 Port Properties Dialog Box .......................................................................... 188

118 Shut Down Windows Dialog Box .............................................................. 198

119 LCD panel during boot sequence ............................................................... 199

120 EFC manager product view ........................................................................ 200

121 Port properties dialog box ........................................................................... 204

122 Link incident log ........................................................................................... 206

123 Event log ........................................................................................................ 207

124 Username and Password Required Dialog Box ....................................... 211

125 SANpilot view panel - switch view ........................................................... 212

Figures

xiii

Page 16

126 SANpilot port properties tab ...................................................................... 214

127 Windows Security Dialog Box ................................................................... 226

128 Windows task manager dialog box (applications page) ........................ 227

129 Shut down windows dialog box ................................................................ 228

130 LCD panel during boot sequence .............................................................. 228

131 EFC manager login dialog box ................................................................... 229

132 Dr. Watson for Windows 2000 dialog box ............................................... 232

133 LCD panel during boot sequence .............................................................. 233

134 EFC manager login dialog box ................................................................... 235

135 EFC management services window .......................................................... 237

136 EFC manager login dialog box ................................................................... 238

137 Interconnecting multiple hubs ................................................................... 241

138 LCD panel (LAN 2 IP address) .................................................................. 245

139 Connection description dialog box ............................................................ 246

140 Connect to dialog box .................................................................................. 247

141 COMn dialog box (COM1 or COM2) ........................................................ 247

142 Hyperterminal window - configuration information ............................. 248

143 Disconnect verification message box ........................................................ 249

144 Save session device verification message box .......................................... 249

145 Modify network address dialog box ......................................................... 250

146 New product dialog box ............................................................................. 250

147 Connection description dialog box ............................................................ 253

148 Connect-To dialog box ................................................................................ 254

149 COMn dialog box (COM1 or COM2) ........................................................ 254

150 Hyperterminal window - event log ........................................................... 255

151 Disconnect verification message ................................................................ 256

152 Save session device verification message ................................................. 256

153 Configure ports dialog box ......................................................................... 270

154 Configure fabric parameters dialog box ................................................... 271

155 Fabric binding dialog box (first) ................................................................ 274

156 Switch binding - state change dialog box ................................................. 274

157 Fabric binding dialog box (second) ........................................................... 275

158 Fabric binding dialog box (third) ............................................................... 276

159 Switch binding - membership list dialog box .......................................... 277

160 Clear link incident alert(s) dialog box ....................................................... 278

161 Port properties dialog box .......................................................................... 283

162 Configure fabric parameters dialog box ................................................... 287

163 Configure switch parameters dialog box ................................................. 288

164 Active zone set view .................................................................................... 289

165 Configure fabric parameters dialog box ................................................... 293

166 Windows 2000 task manager dialog box - performance ........................ 299

167 Shut down windows dialog box ................................................................ 300

168 LCD panel during boot sequence .............................................................. 300

xiv

SAN32M1 Fabric Switch Installation and Service Manual

Page 17

169 EFC manager login dialog box ................................................................... 301

170 LCD panel during boot sequence ............................................................... 303

171 EFC event log ............................................................................................... 308

172 Product status log ........................................................................................ 310

173 Event log ....................................................................................................... 311

174 Hardware log ............................................................................................... 313

175 Link incident log .......................................................................................... 314

176 Threshold alert log ....................................................................................... 316

177 Open trunking log ........................................................................................ 318

178 Monitor panel (logs page) ........................................................................... 319

179 Port list view ................................................................................................. 321

180 FRU list view ................................................................................................. 323

181 Node list view .............................................................................................. 324

182 Zone sets view .............................................................................................. 326

183 Hardware view ............................................................................................ 328

184 Port properties dialog box ........................................................................... 329

185 Performance view ........................................................................................ 332

186 Port diagnostics dialog box ........................................................................ 335

187 Channel wrap on for port n dialog box .................................................... 339

188 Swap ports dialog box ................................................................................ 340

189 Operations panel (maintenance page with dump retrieval tab) ........... 341

190 Save as dialog box ........................................................................................ 342

191 Download complete dialog box ................................................................. 343

192 Save data collection dialog box .................................................................. 344

193 Data collection dialog box ........................................................................... 345

194 Clean fiber-optic components ..................................................................... 346

195 Front-Accessible FRUs ................................................................................ 380

196 Rear-Accessible FRUs ................................................................................. 381

197 Power plugs and receptacles ...................................................................... 382

198 Miscellaneous Parts ...................................................................................... 385

199 EFC Server consolidation (private LAN Connection only) ................... 507

200 EFC server consolidation (private and public LAN connections) ........ 508

201 IP addresses in a multiswitch environment ............................................ 510

Figures

xv

Page 18

xvi

SAN32M1 Fabric Switch Installation and Service Manual

Page 19

Tables

1 Status symbols ................................................................................................ 28

2 Operating bar and switch status .................................................................. 43

3 Factory-Set defaults (switch) ........................................................................ 51

4 Factory-Set defaults (management server) ................................................. 51

5 Defaults for reset configuration (switch) .................................................... 52

6 Installation task summary ............................................................................. 55

7 Switch Operational States and Symbols ................................................... 105

8 Factory-Set defaults ...................................................................................... 191

9 MAP summary ............................................................................................. 192

10 Event Codes versus maintenance action ................................................... 192

11 Port operational states and actions (SANpilot) ....................................... 265

12 Port operational and LED states (EFC Server) ......................................... 266

13 Bytes 8 through 11 failure reasons and actions ........................................ 295

14 Factory-Set Defaults ..................................................................................... 306

15 ESD requirements ......................................................................................... 369

16 Front-Accessible FRU parts list .................................................................. 380

17 Rear-Accessible FRU parts list .................................................................... 381

18 Power cord and receptacle list ................................................................... 383

19 Miscellaneous parts list ............................................................................... 385

© Copyright IBM Corp. 2005

xvii

Page 20

xviii

SAN32M1 Fabric Switch Installation and Service Manual

Page 21

Preface

This publication is part of a documentation suite that supports the

IBM TotalStorage SAN32M1 fabric switch.

Who should use this manual

This publication is intended for trained service representatives

experienced with storage area network (SAN) and Fibre Channel

technology.

Organization of this manual

This publication is organized as follows:

Chapter 1, General information. This chapter describes the

maintenance approach to switch problem analysis and repair. The

chapter provides a description of the switches and attached

Enterprise Fabric Connectivity (EFC) Server, specifications,

remote workstation configurations and minimum specifications,

field-replaceable units (FRUs), switches and indicators, software

diagnostic features, and tools and test equipment.

© Copyright IBM Corp. 2005

Chapter 2, Installation tasks. This chapter provides instructions to

install, configure, and verify operation of one or more switches

and the associated EFC Server. The switch can be installed on a

desktop, or mounted in an equipment cabinet or in any standard

equipment rack.

Chapter 3, Diagnostics. This chapter describes maintenance

analysis procedures (MAPs) that assist you in isolating a switch

problem to an individual FRU.

Chapter 4, Repair information. This chapter describes

supplementary diagnostic and repair procedures for a failed

switch. The chapter includes procedures to display and use log

information, perform port diagnostics, save configuration data,

collect maintenance data, power-on, power-off, and IPL the

switch, set the switch online or offline, block ports, manage

firmware, clean fiber optics, and install or upgrade software.

xix

Page 22

Chapter 5, FRU removal and replacement. This chapter describes

procedures to remove and replace the switch FRUs, and the entire

switch when required.

Chapter 6, Illustrated parts breakdown. This chapter illustrates,

describes, and shows the location of all switch FRUs. In addition,

FRUs are cross-referenced to corresponding part numbers.

Appendix A, Messages. This appendix lists user and error

messages that appear in the EFC Manager and IBM TotalStorage

SAN32M1 switch Product Manager applications at the EFC

Server. A description of each message and recommended action

in response to the message are also provided.

Appendix B, Event code tables. This appendix provides an

explanation of event codes that appear at the Product Manager

application. The event severity and a recommended action in

response to each event are also provided.

Appendix C, Restore EFC servers. This appendix provides the

instructions to restore all required switch applications to the EFC

Server in case of a hard drive failure.

Appendix D, Consolidating EFC servers in a multiswitch fabric. This

appendix provides the instructions for consolidating operation

and network addressing of multiple EFC Servers.

Related publications

Other publications that provide additional information about the

switch include:

• IBM TotalStorage Products in a SAN Environment Planning Manual,

• SANpilot User Manual for IBM TotalStorage Products, GC26-7670.

• E/OS SNMP Support Manual for IBM TotalStorage Products,

• Enterprise Operating System Command Line Interface User Manual for

• IBM TotalStorage SANC40M Cabinet Installation and Service Manual,

The defines terms, abbreviations, and acronyms used in the

manual. An Index is also provided.

GC26-7675.

620-000229-000.

IBM Total Storage Products, GC26-7669.

GC26-7746.

xx

SAN32M1 Fabric Switch Installation and Service Manual

Page 23

Ordering manuals

Where to get help

• IBM eServer Safety Notices, G229-9054

To order a printed copy of this publication, contact your IBM Branch

office or you can locate (and purchase) books online at:

http://www.elink.ibmlink.ibm.com/public/applications/publicatio

ns/cgibin/pbi.cgi?

Contact IBM for technical support, which includes hardware support,

all product repairs, and ordering of spare parts, go to:

http://www.ibm.com/servers/storage/support/san/index.html.

You can also contact IBM within the United States at 1-800-IBMSERV

(1-800-426-7378). For support outside the United States, you can find

the service number at

http://www.ibm.com/planetwide/.

How to send your comments

Your feedback is important in helping us provide the most accurate

and high-quality information. If you have comments or suggestions

for improving this document, you can send us comments

electronically by using the following addresses:

• Internet: starpubs@us.ibm.com

• IBMLink™ from U.S.A.: STARPUBS at SJEVM5

• IBMLink from Canada: STARPUBS at TORIBM

• IBM Mail Exchange: USIB3VVD at IBMMAIL

You can also mail your comments by using the Reader Comment

Form in the back of this manual or direct your mail to:

International Business Machine Corporation

Information Development

Department GZW

9000 South Rita Road

Tucson, Arizona 85744-001 U.S.A

Preface

xxi

Page 24

When you send information to IBM, you grant IBM a nonexclusive

right to use or distribute the information in any way it believes

appropriate without incurring any obligation to you.

Safety and Environmental Notices

ATTENTION ! The IBM Total Storage SAN32M1 is not designed to be

installed and serviced by customers. Installation and servicing of the

SAN32M1 should be performed by qualified service representatives only.

Safety Notices and Labels

When using this product, observe the danger, caution, and attention

notices contained in this guide. The notices are accompanied by

symbols that represent the severity of the safety condition. The

danger and caution notices are listed in numerical order based on

their IDs, which are displayed in parentheses, for example (D004), at

the end of each notice. Use this ID to locate the translations of these

danger and caution notices in the IBM eServer Safety Notices

(G229-9054) publication, which is on the CD-ROM that accompanies

this product.

The following notices and statements are used in this document.

They are listed below in order of increasing severity of potential

hazards. Follow the links for more detailed descriptions and

examples of the danger, caution, and attention notices in the sections

that follow.

• Note: These notices provide important tips, guidance, or advice.

• Attention notices: These notices indicate potential damage to

programs, devices, or data.

• Caution notices: These statements indicate situations that can be

potentially hazardous to you.

• Danger notices: These statements indicate situations that can be

potentially lethal or extremely hazardous to you. Safety labels are

also attached directly to products to warn of these situations.

Danger notices A danger notice calls attention to a situation that is potentially lethal

or extremely hazardous to people. A lightning bolt symbol

accompanies a danger notice to represent a dangerous electrical

xxii

SAN32M1 Fabric Switch Installation and Service Manual

Page 25

condition. Read and comply with the following danger notices before

installing or servicing this device.

DANGER

To prevent a possible shock from touching two surfaces with different

protective ground (earth), use one hand, when possible, to connect or

disconnect signal cables.

(D001)

DANGER

Overloading a branch circuit is potentially a fire hazard and a shock

hazard under certain conditions. To avoid these hazards, ensure that

your system electrical requirements do not exceed branch circuit

protection requirements. Refer to the information that is provided

with your device or the power rating label for electrical

specifications.

(D002)

DANGER

If the receptacle has a metal shell, do not touch the shell until you

have completed the voltage and grounding checks. Improper wiring

or grounding could place dangerous voltage on the metal shell. If any

of the conditions are not as described, STOP. Ensure the improper

voltage or impedance conditions are corrected before proceeding.

(D003)

DANGER

An electrical outlet that is not correctly wired could place hazardous

voltage on metal parts of the system or the devices that attach to the

system. It is the responsibility of the customer to ensure that the

outlet is correctly wired and grounded to prevent an electrical shock.

(D004)

Preface

xxiii

Page 26

A comprehensive danger notice provides instructions on how to

avoid shock hazards when servicing equipment. Unless instructed

otherwise, follow the procedures in the following danger notice.

DANGER

Electrical voltage and current from power, telephone, and

communication cables are hazardous. To avoid a shock hazard:

• Do not connect or disconnect any cables or perform installation,

maintenance, or reconfiguration of this product during an

electrical storm.

• Connect all power cords to a properly wired and grounded

electrical outlet. Ensure outlet supplies proper voltage and phase

rotation according to the system rating plate.

• Connect any equipment that will be attached to this product to

properly wired outlets.

• When possible, use one hand only to connect or disconnect signal

cables.

• Never turn on any equipment when there is evidence of fire,

water, or structural damage.

• Disconnect the attached power cords, telecommunications

systems, networks, and modems before you open the device

covers, unless instructed otherwise in the installation and

configuration procedures.

• Connect and disconnect cables as described below when

installing, moving, or opening covers on this product or attached

devices.

To Disconnect:

1. Turn everything OFF (unless instructed otherwise).

2. Remove power cords from the outlet.

3. Remove signal cables from connectors.

4. Remove all cables from devices.

To Connect:

1. Turn everything OFF (unless instructed otherwise).

2. Attach all cables to devices.

3. Attach signal cables to connectors.

4. Attach power cords to outlet.

5. Turn device ON.

(D005)

xxiv

SAN32M1 Fabric Switch Installation and Service Manual

Page 27

Labels As an added precaution, safety labels are often installed directly on

products or product components to warn of potential hazards. These

can be either danger or caution notices, depending upon the level of

the hazard.

The actual product safety labels may differ from these sample safety

labels:

DANGER

Hazardous voltage, current, or energy levels are present inside any

component that has this label attached.

(L001)

DANGER

Rack-mounted devices are not to be used as a shelf or work space.

(L002)

DANGER

Multiple power cords

(L003)

Caution notices A caution notice calls attention to a situation that is potentially

hazardous to people because of some existing condition. A caution

notice can be accompanied by different symbols, as in the examples

below:

Preface

xxv

Page 28

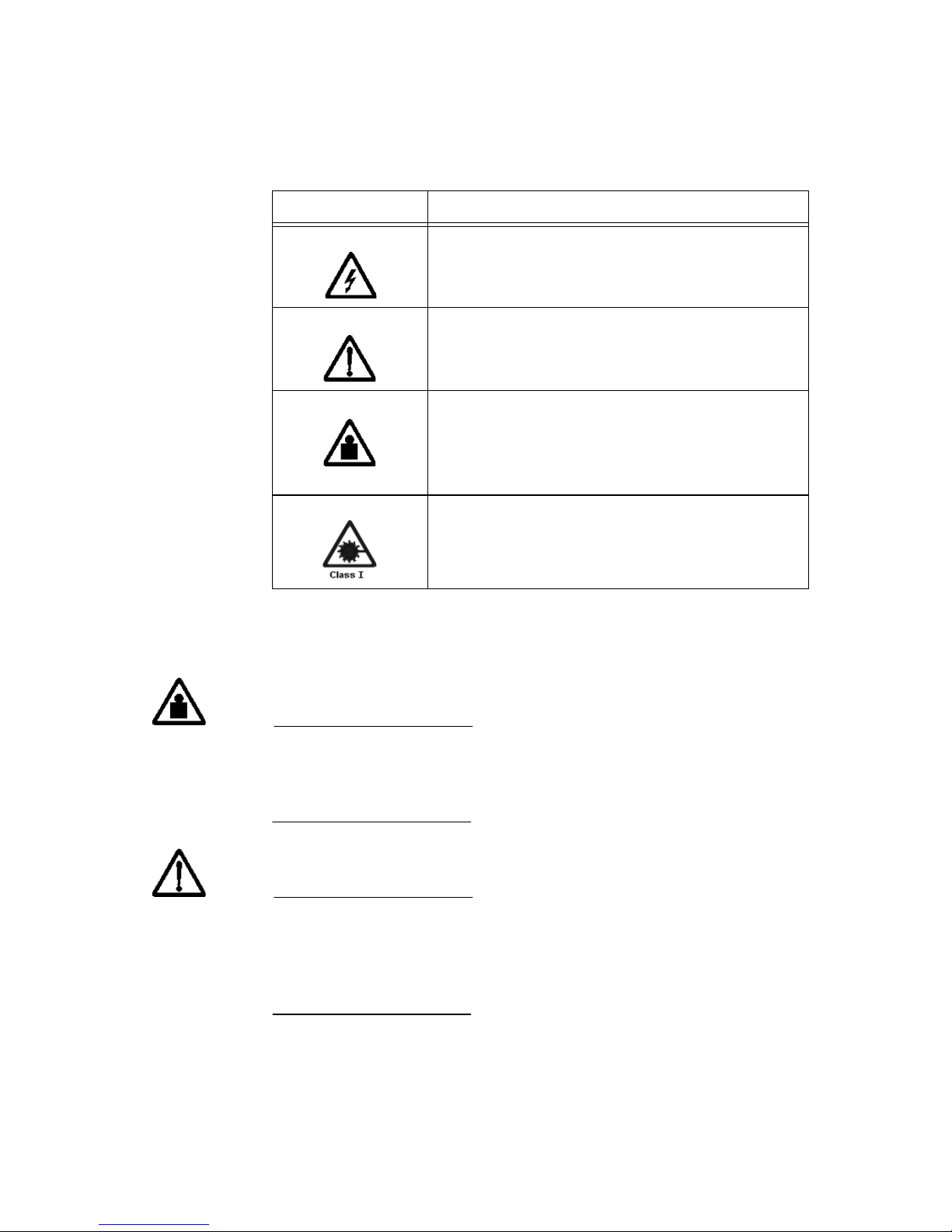

If the symbol is... It means....

A hazardous electrical condition with less severity than electrical

danger.

A generally hazardous condition not represented by other safety

symbols.

A specification of product weight that requires safe lifting

practices. The weight range of the product is listed below the

graphic, and the wording of the caution varies, depending on the

weight of the device.

>18kg (39.7 lb)

A hazardous condition due to the use of a laser in the product.

Laser symbols are always accompanied by the classification of

the laser as defined by the U. S. Department of Health and

Human Services (for example, Class I, Class II, and so forth).

Read and comply with the following caution notices before installing

or servicing this device.

CAUTION

This part or unit is heavy, but has a weight smaller than 18 kg

(39.7 lb.). Use care when lifting, removing, or installing this part or

unit.

(C008)

CAUTION

The doors and covers to the product are to be closed at all times

except for service by trained service personnel. All covers must be

replaced and doors locked at the conclusion of the service

operation.

(C013)

xxvi

SAN32M1 Fabric Switch Installation and Service Manual

Page 29

CAUTION

The system contains circuit cards and/or assemblies that contain

lead solder. To avoid the release of lead (Pb) into the environment,

do not burn. Discard the circuit card as instructed by local

regulations.

(C014)

CAUTION

Ensure the building power circuit breakers are turned off BEFORE

you connect the power cord(s) to the building power.

(C023)

CAUTION

This assembly contains mechanical moving parts. Use care when

servicing this assembly.

(C025)

CAUTION

Servicing of this product or unit is to be performed by trained

service personnel only.

(C032)

Attention notices An attention notice indicates the possibility of damage to a program,

device, or system, or to data. An exclamation point symbol may

accompany an attention notice, but is not required. A sample

attention notice follows:

ATTENTION ! Do not bend a fibre cable to a radius less than 5 cm (2 in.); you

can damage the cable. Tie wraps are not recommended for optical cables

because they can be easily overtightened, causing damage to the cable.

Preface

xxvii

Page 30

Laser safety

This equipment contains Class 1 laser products, and complies with

FDA radiation Performance Standards, 21 CFR Subchapter J and the

international laser safety standard IEC 60825.

CAUTION

This product may contain one or more of the following: CD-ROM,

DVD-ROM, DVD-RAM, or laser module, which are Class 1 laser

products. Please note the following:

• Do not remove the covers. Removing the covers of the laser

product could result in exposure to hazardous laser radiation.

There are no serviceable parts inside the device.

• Use of the controls or adjustments or performance of

procedures other than those specified herein might result in

hazardous radiation exposure.

(C026)

CAUTION

Data processing environments can contain equipment transmitting

on system links with laser modules that operate at greater than

Class 1 power levels. For this reason, never look into the end of an

optical fiber cable or open receptacle.

(C027)

Environmental notices

Product recycling

and disposal

xxvii

SAN32M1 Fabric Switch Installation and Service Manual

This unit contains materials such as circuit boards, cables,

electromagnetic compatibility gaskets and connectors which may

contain lead and copper/beryllium alloys that require special

handling and disposal at end of life. Before this unit is disposed of,

these materials must be removed and recycled or discarded

according to applicable regulations. IBM offers product-return

programs in several countries. Information on product recycling

offerings can be found on IBM’s Internet site at

http://www.ibm.com/ibm/environment/products/prp.shtml

IBM encourages owners of information technology (IT) equipment to

responsibly recycle their equipment when it is no longer needed. IBM

offers a variety of programs and services to assist equipment owners

in recycling their IT products. Information on product recycling

Page 31

offerings can be found on IBM’s Internet site at

http://www.ibm.com/ibm/environment/products/prp.shtml.

Battery return

program

This product may contain sealed lead acid, nickel cadmium, nickel

metal hydride, lithium, or lithium ion battery. Consult your user

manual or service manual for specific battery information. The

battery must be recycled or disposed of properly. Recycling facilities

may not be available in your area. For information on disposal of

batteries outside the United States, go to

http://www.ibm.com/ibm/environment/products/batteryrecycle.s

html or contact your local waste disposal facility.

In the United States, IBM has established a return process for reuse,

recycling, or proper disposal of used IBM sealed lead acid, nickel

cadmium, nickel metal hydride, and other battery packs from IBM

Equipment. For information on proper disposal of these batteries,

contact IBM at 1-800-426-4333. Please have the IBM part number

listed on the battery available prior to your call.

In the Netherlands the following applies:

For Taiwan:

Please recycle batteries.

Preface

xxix

Page 32

Cable Warning

WARNING

Handling the cord on this product or cords associated with

accessories sold with this product, will expose you to lead, a

chemical known to the State of California to cause cancer, and birth

defects or other reproductive harm. Wash hands after handling.

xxx

SAN32M1 Fabric Switch Installation and Service Manual

Page 33

Chapter 1: General information

The IBM TotalStorage SAN32M1 switch (referred to in this

information unit as the SAN32M1) provides dynamically switched

connections between Fibre Channel servers and devices in a storage

area network (SAN) environment. SANs introduce the concept of

server-to-device networking and multiswitch fabrics, eliminate

requirements for dedicated connections, and enable the enterprise to

become data-centric.

A SAN provides speed, high capacity, and flexibility for the

enterprise, and is primarily based upon Fibre Channel architecture.

The SAN32M1 switch implements Fibre Channel technology that

provides a bandwidth of 2.125 gigabits per second ), redundant

switched data paths, a scalable number of active ports, and long

transmission distances (up to 20 kilometers).

This chapter describes the switch and switch management through

the attached Enterprise Fabric Connectivity (EFC) Server. The chapter

specifically discusses:

• Switch management, error-detection and reporting features,

serviceability features, zoning, multiswitch fabrics, and

specifications.

Switch description

• The management server and minimum hardware specifications.

• Remote workstation configurations and hardware specifications.

• Maintenance approach.

• Field-replaceable units (FRUs).

• Connectors and indicators.

• Software diagnostic features.

• Tools and test equipment.

The SAN32M1 switch provides Fibre Channel connectivity through

32 ports. Switch ports operate at 2.125 () gigabits per second (Gbps),

and can be configured as:

• Fabric ports (F_Ports) to provide direct connectivity for up to 24

switched fabric devices.

© Copyright IBM Corp. 2005

1

Page 34

• Expansion ports (E_Ports) to provide interswitch link (ISL)

connectivity to fabric directors and switches.

The switch can be installed on a table or desk top, mounted in an

equipment cabinet or in any standard equipment rack.

Multiple switches and the management server communicate on a

local area network (LAN) through one or more 10/100 Base-T

Ethernet hubs. One or more 24-port Ethernet hubs are optional and

can be ordered with the switch. Up to three hubs are daisy-chained as

required to provide additional Ethernet connections as more switches

(or other IBM managed products) are installed on a customer

network.

The switches provide dynamically switched connections for servers

and devices, supports mainframe and open-systems interconnection

(OSI) computing environments, and provides data transmission and

flow control between device node ports (N_Ports) as dictated by the

Fibre Channel Physical and Signaling Interface (FC-PH 4.3). Through

interswitch links (ISLs), the switch can connect additional switches to

form a Fibre Channel multiswitch fabric.

The switch provides connectivity for devices manufactured by

multiple original equipment manufacturers (OEMs). To determine if

an OEM product can communicate through connections provided by

the switch, or if communication restrictions apply, refer to the

supporting publications for the product or contact your IBM

marketing representative

Switch management

2

SAN32M1 Fabric Switch Installation and Service Manual

Out-of-band (non-Fibre Channel) management access to IBM

products is provided through an Ethernet LAN connection to a

switch front panel. The following out-of-band management access

methods are provided:

• Optional management server with the SAN Management

Application) and Element Manager applications installed. The

management server is a rack-mount unit that provides a central

point of control for up to 48 switches or managed IBM products.

Operators at remote workstations can connect to the management

server through the local SANavigator or EFCM application and

associated Element Manager applications to manage and monitor

switches controlled by the management server. A maximum of

nine concurrent users (including a local user) can log in to the

SANavigator or EFCM application.

Page 35

• Management using simple network management protocol

(SNMP). An SNMP agent is implemented through the

SANavigator or EFCM application that allows administrators on

SNMP management workstations to access product management

information using any standard network management tool.

Administrators can assign Internet Protocol (IP) addresses and

corresponding community names for up to six SNMP

workstations functioning as SNMP trap message recipients.

• Management through the Internet using the SANpilot interface

installed on the director or switch. This interface supports

configuration, statistics monitoring, and basic operation of the

product, but does not offer all the capabilities of the

corresponding Element Manager application. Administrators

launch the SANpilot interface from a remote PC by entering the

product’s IP address as the Internet uniform resource locator

(URL), then entering a user name and password at a login screen.

The PC browser then becomes a management console.

• Management through a customer-supplied remote workstation

communicating with the management server through a corporate

intranet.

• Management through the command line interface (CLI). The CLI

allows you to access many SANavigator or EFCM and Element

Manager applications while entering commands during a telnet

session with the director. The primary purpose of the CLI is to

automate management of a large number of directors using

scripts. The CLI is not an interactive interface; no checking is done

for pre-existing conditions and no prompts display to guide users

through tasks. Refer to the EOS Command Line Interface User

Manual for IBM TotalStorage Products, GC26-7669.

Figure 1 illustrates out-of-band product management. In the figure,

the managed product is a fabric switch.

Chapter 1: General information

3

Page 36

2

3

Remote Computer Running

Client Software

SNMP Management

Workstation(s)

10/100 Mbps Ethernet Hub

1

4

5

8

9

1

2

1

3

1

6

1

7

M

I

D

2

0

2

1

MD

I

X

B

a

P

2

s

4

o

e

r

lin

t

S

e

t

1

1

a

t

0

u

s

/

1

2

00

H

3

u

b

4

5

6

7

C

3

1

o

l

lisio

4

1

n

8

5

1

9

1

0

6

1

1

1

7

1

1

1

2

G

1

8

00

re

1

e

M

9

n

-

1

0

0

2

0

M

,

1

2

Y

ell

o

2

2

w

1

2

0

M

3

,

2

F

l

a

4

s

h

1

-

0

A

M

c

t

i

v

i

t

y

P

o

w

er

®

3

C

1

6

4

1

1

3

S

u

p

e

com

r

S

®

t

a

c

k

3

Internet Connection

1

0

/1

00

3

1

R

S

T

2

9

2

7

2

5

2

3

2

1

1

9

1

7

1

5

1

3

0

3

1

2

8

1

2

6

9

2

4

7

2

2

5

2

0

3

1

8

1

1

6

1

4

P

W

R

1

2

1

0

ER

R

8

6

4

2

0

Switch

or Telnet Session

Figure 1 Out-of-Band product management

The following inband management access methods are provided as

options:

Corporate LAN

10/100 Mbps

Server Platform

SANpilot or CLI

H

D

D

FA

N

L

1

L

2

EN

TE

R

i32M1001

• Management through the product’s open-system management

server (OSMS) that communicates with an application client. The

application resides on an open-systems interconnection (OSI)

device attached to a switch port, and communicates using Fibre

Channel common transport (FC-CT) protocol. Product operation,

port connectivity, zoning, and fabric control are managed through

a device-attached console.

• Management through the product’s Fibre Connection (FICON)

management server (FMS) that communicates with the IBM

System Automation for OS/390 (SA OS/390) operating system.

The operating system resides on an IBM System/390

or zSeries

900 Parallel Enterprise Server attached to a director or switch

port, and communicates through a FICON channel. Control of

connectivity and statistical product monitoring are provided

through a host-attached console.

4

SAN32M1 Fabric Switch Installation and Service Manual

Page 37

Error-Detection, reporting, and serviceabilit y feat ures

The switch provides the following error-detection, reporting, and

serviceability features:

• Light-emitting diodes (LEDs) on switch FRUs and adjacent to

Fibre Channel ports that provide visual indicators of hardware

status or malfunctions.

• System and threshold alerts, event logs, audit logs, link incident

logs, threshold alert logs, and hardware logs that display switch,

Ethernet link, and Fibre Channel link status at the management

server, customer-supplied server (running the EFCM Lite

application), or a remote workstation.

• Diagnostic software that performs power-on self-tests (POSTs)

and port diagnostics (internal loopback, external loopback, and

Fibre Channel (FC) wrap tests). The FC wrap test applies only

when the switch is configured to operate in FICON management

mode.

• Automatic notification of significant system events (to support

personnel or administrators) through e-mail messages or the

call-home feature.

• An external modem for use by support personnel to dial-in to the

management server for event notification and to perform remote

diagnostics.

• An RS-232 maintenance port at the rear of the switch (port access

is password protected) that enables installation or service

personnel to change the switch’s internet protocol (IP) address,

subnet mask, and gateway address; or to run diagnostics and

isolate system problems through a local or remote terminal.

• Redundant FRUs; (small form factor pluggable (SFP)) optical

transceivers, power supplies, and cooling fans that are removed

or replaced without disrupting switch or Fibre Channel link

operation.

• A modular design that enables quick removal and replacement of

FRUs without tools or equipment.

• Concurrent port maintenance. SFPs and Fiber-optic cables are

removed and attached to ports without interrupting other ports

or director operation.

Chapter 1: General information

5

Page 38

• Beaconing to assist service personnel in locating a specific port or