Page 1

IBM TotalStorage SAN140M Director

Installation an d Service Manual

Service information: 2027 / 140

Read Before Using

This product contains software that is licensed under written license agreements. Your use of such software is subject to

the license agreements under which they are provided.

GC26-7664-04

Page 2

Page 3

IBM TotalStorage SAN140M Director

Installation an d Service Manual

Service information: 2027 / 140

GC26-7664-04

Page 4

Note:

Before using this information and the product it supports, read the information in the Notices section.

Fifth Edition (March 2006)

This fifth edition replaces all previous versions. This edition includes information about RoHS compliance and part

numbers.

The following paragraph does not apply to any country (or region) where such provisions are inconsistent with local

law.

INTERNATIONAL BUSINESS MACHINES CORPORATION PROVIDES THIS PUBLICATION “AS IS” WITHOUT

WARRANTY OF ANY KIND, EITHER EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. Some states (or regions) do

not allow disclaimer of express or implied warranties in certain transactions; therefore, this statement may not apply

to you.

Order publications through your IBM

© Copyright International Business Machines Corporation 2004, 2006. All rights reserved.

US Government Users Restricted Rights – Use, duplication or disclosure restricted by GSA ADP Schedule Contract

with IBM Corp.

®

representative or the IBM branch office serving your locality.

Page 5

Contents

Preface.............................................................................................................................xv

Chapter 1 General i nformation

Director description.............................................................................1

Field-replaceable units........................................................................4

Power/system LED assembly.....................................................6

CTP card.........................................................................................6

UPM card.......................................................................................7

XPM card........................................................................................9

SFP and XFP transceivers..........................................................10

Power supply ..............................................................................11

AC module...................................................................................11

Fan module..................................................................................12

SBAR assembly ...........................................................................12

Backplane.....................................................................................12

Error-detection, reporting, and serviceability features ................13

Element Manager status indicators.................................................14

Tools and test equipment..................................................................15

Tools supplied with the director...............................................15

Tools supplied by service personnel........................................17

Director management........................................................................18

Ordering the lift tool..........................................................................19

World Trade locations................................................................19

United States locations...............................................................20

Chapter 2 Installation tasks

© Copyright IBM Corp. 2006

Factory defaults..................................................................................23

Installation task summary ................................................................24

Task 1: Verify installation requirements .........................................26

Task 2: Unpack, inspect, and install the Ethernet hub (optional)26

Unpack and inspect the Ethernet hub .....................................27

Desktop installation....................................................................27

Rack-mount installation.............................................................29

Task 3: Unpack, inspect, and install the director...........................30

Rack-mount installation.............................................................31

Task 4: Configure director at the EFCM Basic Edition interface

(optional).............................................................................................33

iii

Page 6

Configure director identification .............................................34

Configure date and time............................................................35

Configure parameters................................................................36

Configure fabric parameters.....................................................38

Configure network information...............................................39

Configure basic port information.............................................41

Configure port BB_Credit .........................................................42

Configure port NPIV..................................................................42

Configure SNMP ........................................................................43

Enable CLI ...................................................................................44

Enable or disable host control...................................................45

Configure SSL encryption.........................................................46

Install PFE keys (optional) ........................................................47

Configure security......................................................................49

Configure interswitch links.......................................................50

Task 5: Configure director network information (optional)........51

Task 6: Configure server password and network addresses....... 55

Configure password...................................................................55

Configure private LAN addresses...........................................56

Configure public LAN addresses (optional) ..........................56

Task 7: Configure management server information.....................57

Access the management server desktop .................................57

Configure management server names ....................................58

Configure gateway and DNS server addresses .....................59

Task 8: Configure Windows operating system users....................61

Change default administrator password................................61

Add a new user...........................................................................61

Change user properties..............................................................62

Task 9: Set management server date and time ..............................63

Task 10: Configure the call-home feature (optional).....................65

Task 11: Assign user names and passwords ..................................66

Task 12: Configure the director to the management application 67

Task 13: Record or verify server restore information...................68

Task 14: Verify director-to-server communication........................69

Task 15: Configure PFE key (optional) ...........................................70

Task 16: Configure management server (optional).......................72

Task 17: Set director date and time..................................................73

Task 18: Configure the Element Manager application .................74

Configure director identification .............................................75

Configure director parameters.................................................75

Configure fabric parameters.....................................................77

Configure ports...........................................................................79

Configure SNMP ........................................................................80

iv

SAN140M Installation and Service Manual

Page 7

Configure threshold alerts.........................................................81

Enable EFCM Basic Edition and Telnet access .......................84

Configure, enable, and test e-mail notification.......................84

Configure and enable Ethernet events.....................................86

Configure, enable, and test call-home event notification......86

Configure security ......................................................................87

Configure interswitch links.......................................................88

Task 19: Back up configuration data................................................89

Task 20: Cable Fibre Channel ports .................................................91

Task 21: Configure Zoning (Optional) ............................................92

Task 22: Connect director to a fabric element (optional) ..............92

Chapter 3 Maintenance analysis procedures (MAPS)

Factory defaults..................................................................................95

Quick start...........................................................................................95

MAP 0000: Start MAP......................................................................102

MAP 0100: Power distribution analysis........................................107

MAP 0200: POST failure analysis ..................................................110

MAP 0300: Loss of server communication ...................................114

MAP 0400: FRU failure analysis.....................................................124

MAP 0500: Port failure or link incident analysis.........................128

MAP 0600: Fabric or ISL problem analysis...................................141

Chapter 4 Repair information

Factory defaults.........................................................................156

Procedural notes........................................................................156

Obtaining log information..............................................................157

SAN management logs.............................................................157

Element Manager logs..............................................................159

EFCM Basic Edition logs..........................................................162

Obtaining port diagnostic information.........................................165

Port LED diagnostics................................................................165

Element Manager application diagnostics ............................166

EFCM Basic Edition diagnostics.............................................172

Performing loopback tests ..............................................................175

Internal loopback test (Element Manager application).......175

External loopback test (Element Manager application) ......177

Internal loopback test (EFCM Basic Edition) ........................178

External loopback test (EFCM Basic Edition).......................180

Blocking and unblocking ports ......................................................181

Block or unblock a port or port card (Element Manager appli-

Contents

v

Page 8

cation).........................................................................................181

Block or unblock a port (EFCM Basic Edition).....................182

Swapping ports................................................................................183

Performing channel wrap tests (FICON) .....................................185

Collecting maintenance data..........................................................186

Collecting maintenance data (Element Management applica-

tion).............................................................................................186

Collecting maintenance data (EFCM Basic Edit ion) ...........187

Powering the director on or off......................................................188

Power-on procedure ................................................................188

Power-off procedure................................................................189

Setting the director online or offline .............................................190

Set online or offline (Element M anager application) ..........190

Set online or offline (EFCM Basic Edition) ...........................191

IML, IPL, or reset the director........................................................192

IML the director (CTP front panel)........................................192

IPL the director (Element Manager application).................193

Reset the director (CTP front panel).....................................193

Cleaning fiber-optic components..................................................194

Download and install firmware ....................................................195

Download and install firmware to director (Element Manag-

er application) ...........................................................................196

Download and install firmware to director (EFCM Basic Edi-

tion).............................................................................................198

Install or upgrade software............................................................199

Managing configuration data ........................................................202

Back up configuration (Element M anager application)...... 202

Restore configuration (Element Manager application)....... 202

Reset configuration data (Element Manager application)..203

Back up configuration (EFCM Basic Edition).......................205

Restore configuration (EFCM Basic Edition)........................206

Reset configuration data (EFCM Basic Edition)...................206

Chapter 5 Removal and replacement procedures (RRPs)

RRP: CTP card..................................................................................213

RRP: Port module card (UPM and XPM).....................................218

vi

SAN140M Installation and Service Manual

Factory defaults ........................................................................209

Procedural notes.......................................................................209

Removing and replacing FRUs...............................................210

ESD information.......................................................................210

Concurrent FRUs......................................................................212

Nonconcurrent FRU.................................................................212

Page 9

RRP: Optical transceiver (SFP and XFP).......................................223

RRP: Filler panel (UPM and XPM)................................................227

RRP: Power supply ..........................................................................229

RRP: AC module ..............................................................................232

RRP: Fan module..............................................................................235

RRP: Power/system error LED assembly ....................................239

RRP: SBAR assembly.......................................................................241

RRP: Backplane.................................................................................244

Chapter 6 Illustrated parts breakdown

RoHS Information.....................................................................251

Front-accessible FRUs......................................................................253

Rear-accessible FRUs.......................................................................255

Miscellaneous parts .........................................................................258

Power cords and receptacles ..........................................................259

Appendix A Event code tables

System events (000 through 199) ...................................................265

Power supply events (200 through 299) .......................................288

Fan module events (300 through 399) ..........................................292

CTP card events (400 through 499) ...............................................300

Port card (UPM and XPM) events (500 through 599) ................311

SBAR events (600 through 699) .....................................................323

Thermal events (800 through 899) ................................................329

Appendix B Director specifications

Physical characteristics.............................................................335

Power requirements ................................................................335

Heat dissipation .......................................................................335

Cooling airflow clearances (director chassis).....................336

Acoustical noise........................................................................336

Shipping and storage environment........................................336

Operating environment............................................................336

SANC40M equipment cabinet service clearances ......................337

Appendix C Management server and Ethernet hub

Management server description ....................................................339

Ethernet hub description.................................................................339

Appendix D Restore management server

Contents

vii

Page 10

Requirements ...................................................................................341

Restore management server procedure .......................................342

Glossary........................................................................................................................347

Notices .........................................................................................................................373

Trademarks.......................................................................................375

Electronic emission notices.............................................................375

Laser Compliance Statement ..................................................375

Federal Communications Commission (FCC) Class A State-

ment............................................................................................376

Industry Canada Class A Emission Compliance Statement ....

376

Avis de conformité à la réglementation d’Industrie Canada...

376

European Union (EU) Electromagnetic Compatibility Direc-

tive ..............................................................................................376

Germany Electromagnetic Compatibility Directive............377

People’s Republic of China Class A Electronic Emission

Statement...................................................................................378

Korean Class A Electronic Emission Statement...................378

Japan VCCI Class A ITE Electronic Emission Statement.... 378

Index...............................................................................................................................379

viii

SAN140M Installation and Service Manual

Page 11

Figures

1 Cabinet-mounted SAN140M directors and management server .............. 3

2 Director FRUs (front access) ........................................................................... 4

3 Director FRUs (rear access) ............................................................................. 5

4 UPM card LEDs and connectors .................................................................... 8

5 XPM card ........................................................................................................... 9

6 Small form-factor pluggable (SFP) transceiver .......................................... 10

7 Ten Gbps form-factor pluggable (XFP) transceiver .................................. 11

8 Torque tool and hex adapter ........................................................................ 16

9 Door key .......................................................................................................... 16

10 Loopback plug ................................................................................................ 16

11 Fiber-optic protective plug ........................................................................... 17

12 Null modem cable .......................................................................................... 17

13 Patch cable and MDI selector configuration .............................................. 28

14 Mounting bracket installation (Ethernet hub) ........................................... 29

15 AC power connections (director) ................................................................. 32

16 Identification view ......................................................................................... 35

17 Date time view ................................................................................................ 36

18 Parameters view ............................................................................................. 36

19 Fabric parameters view ................................................................................. 38

20 Netw ork view ................................................................................................. 40

21 Basic information view .................................................................................. 42

22 SNMP view ..................................................................................................... 43

23 CLI view .......................................................................................................... 45

24 O SMS view ...................................................................................................... 45

25 SSL view .......................................................................................................... 47

26 Maintenance feature installation view ........................................................ 49

27 Co nnection description dialog box .............................................................. 53

28 Identification changes dialog box ................................................................ 59

29 Internet protocol (TCP/IP) properties dialog bo x ..................................... 60

30 Add new user wizard .................................................................................... 62

31 Pro perties dialog box (General tab) ............................................................. 63

32 Date/time properties dialog box (Time Zone tab) .................................... 64

33 Date/time properties dialog box (Date & Time tab) ................................. 65

34 Add user dialog box ....................................................................................... 66

35 Address properties dialog box (IP Address page) .................................... 68

36 New feature key dialog box .......................................................................... 72

37 Co nfigure date and time dialog box ............................................................ 73

38 Configure identification dialog box ............................................................. 75

39 Co nfigure switch parameters dialog box .................................................... 76

© Copyright IBM Corp. 2006

ix

Page 12

40 Configure fabric parameters dialog box ..................................................... 77

41 Configure ports dialog box ........................................................................... 79

42 Configure SNMP dialog box ........................................................................ 81

43 New threshold alert dialog box (Screen 1) ................................................. 82

44 New threshold alert dialog box (Screen 2) ................................................. 83

45 New threshold alert dialog box (Screen 3) ................................................. 84

46 Email event notification setup dialog box .................................................. 85

47 InCD icon (unformatted CD) ........................................................................ 90

48 Daisy-chained Ethernet hubs ..................................................................... 117

49 UPM (or XPM) card diagram (front) ......................................................... 137

50 UPM (or XPM) card diagram (rear) .......................................................... 138

51 Port list view ................................................................................................. 167

52 Port properties dialog box .......................................................................... 169

53 Port technology dialog box ......................................................................... 171

54 Port list view ................................................................................................. 172

55 Port diagnostics dialog box ........................................................................ 176

56 Diagnostics view .......................................................................................... 179

57 Basic information view ................................................................................ 182

58 Swap ports dialog box ................................................................................. 184

59 Save data collection dialog box .................................................................. 186

60 System files view .......................................................................................... 187

61 Switch view ................................................................................................... 191

62 Clean fiber-optic components .................................................................... 195

63 Firmware library dialog box ....................................................................... 196

64 Firmware upgrade view .............................................................................. 198

65 InstallShield wi zard dialog box ................................................................. 200

66 Address properties dialog box ................................................................... 204

67 Backup configuration view ......................................................................... 205

68 Restore configuration view ......................................................................... 206

69 ESD grounding points ................................................................................. 211

70 CTP card removal and replacement .......................................................... 215

71 UPM (shown) or XPM card removal and replacement .......................... 220

72 SFP (shown) or XFP optical transceiver removal and replacement ..... 225

73 UPM or XPM filler panel removal and replacement ............................. 228

74 Powe r supply removal and replacement .................................................. 230

75 AC module removal and replacement ...................................................... 233

76 Fan module removal and replacement ..................................................... 237

77 Power/System error LED assembly removal and replacement ........... 240

78 SBAR ass embly removal and replacement ............................................... 242

79 Backplane removal and replacement ........................................................ 246

80 Front-accessible FRUs .................................................................................. 253

81 Rear-accessible FRUs (part 1) ..................................................................... 255

82 Rear-accessible FRUs (part 2) ..................................................................... 257

x

SAN140M Installation and Service Manual

Page 13

83 Miscell aneous parts ...................................................................................... 258

84 Power cords and receptacles ....................................................................... 259

85 24-Port Ethernet hub .................................................................................... 340

Figures

xi

Page 14

xii

SAN140M Installation and Service Manual

Page 15

Tables

1 IBM products and SAN management documentation ........................... xvi

2 Element Manager alert symbols, messages, and status ........................... 15

3 Factory-set defaults (director) ...................................................................... 23

4 Installation Task summary ........................................................................... 24

5 Operational states and symbols ................................................................... 70

6 Factory-set defaults ........................................................................................ 95

7 MAP summary ............................................................................................... 95

8 Event codes versus maintenance action ...................................................... 96

9 MAP 100 event codes ................................................................................... 107

10 MAP 200 event codes ................................................................................... 110

11 MAP 200: byte 0 FRU codes ........................................................................ 110

12 MAP 300 error messages ............................................................................. 116

13 MAP 400: Event codes ................................................................................. 124

14 MAP 500: Event codes ................................................................................. 128

15 Lin k incident messages ................................................................................ 129

16 In valid a ttachment reasons and actions .................................................... 130

17 In active port reasons and actions ............................................................... 135

18 MAP 600 event codes ................................................................................... 141

19 E_Port segmentation reasons and actions ................................................ 143

20 Po rt fence codes and actions ....................................................................... 148

21 Fabric merge failure reasons and actions ................................................. 151

22 Facto ry-set defaults ...................................................................................... 156

23 Po rt operational states ................................................................................. 165

24 Facto ry-set defaults ...................................................................................... 209

25 Co ncurrent FRUs .......................................................................................... 212

26 No nconcurrent FRU ..................................................................................... 212

27 Fro nt-accessible FRU parts list ................................................................... 254

28 Rear-accessible FRU parts list (part 1) ....................................................... 256

29 Rear-accessible FRU parts list (part 2) ....................................................... 257

30 Miscellaneous parts ...................................................................................... 258

31 Po wer cord and receptacle list ................................................................... 260

© Copyright IBM Corp. 2006

xiii

Page 16

xiv

SAN140M Installation and Service Manual

Page 17

Preface

This publication is part of a documentation suite that supports the

IBM TotalStorage SAN140M director.

Who should use this manual

This publication is intended for use by installation and service

representatives experienced with the director, storage area network

(SAN) technology , and Fibre Channel technology.

The IBM TotalStorage SAN140M director is to be installed and

serviced by qualified IBM service representatives only. The director

contains no customer-serviceable parts that require internal access to

the product during normal operation or prescribed maintenance

conditions.

Related publications

Other publications that provide additional information about the

director include:

• IBM TotalStorage Products in a SAN Environment Planning Manual,

GC26-7675.

• EFC Manager Software Release 9.0 User Manual, 620-000170.

• Element Manager User Manual, 620-000153.

• EFCM Basic Edition User Manual, 620-000240.

• SNMP Support Manual, 620-000131.

• E/OS Command Line Interface User Manual, 620-000134.

• IBM TotalStorage SANC40M Cabinet Installation andService Manual,

GC26-7746.

• IBM eServer Safety Notices, G229-9054.

© Copyright IBM Corp. 2006

xv

Page 18

IBM and McDATA publications

Some of the documentation that is applicable to IBM TotalStorage

products is provided by McDATA Corporation. The documents often

are identified by a McDATA product name that corresponds to the

IBM product name. Table 1 lists the IBM product name, the

corresponding McDATA product name, the applicable software, and

the documentation that is relevant to the product.

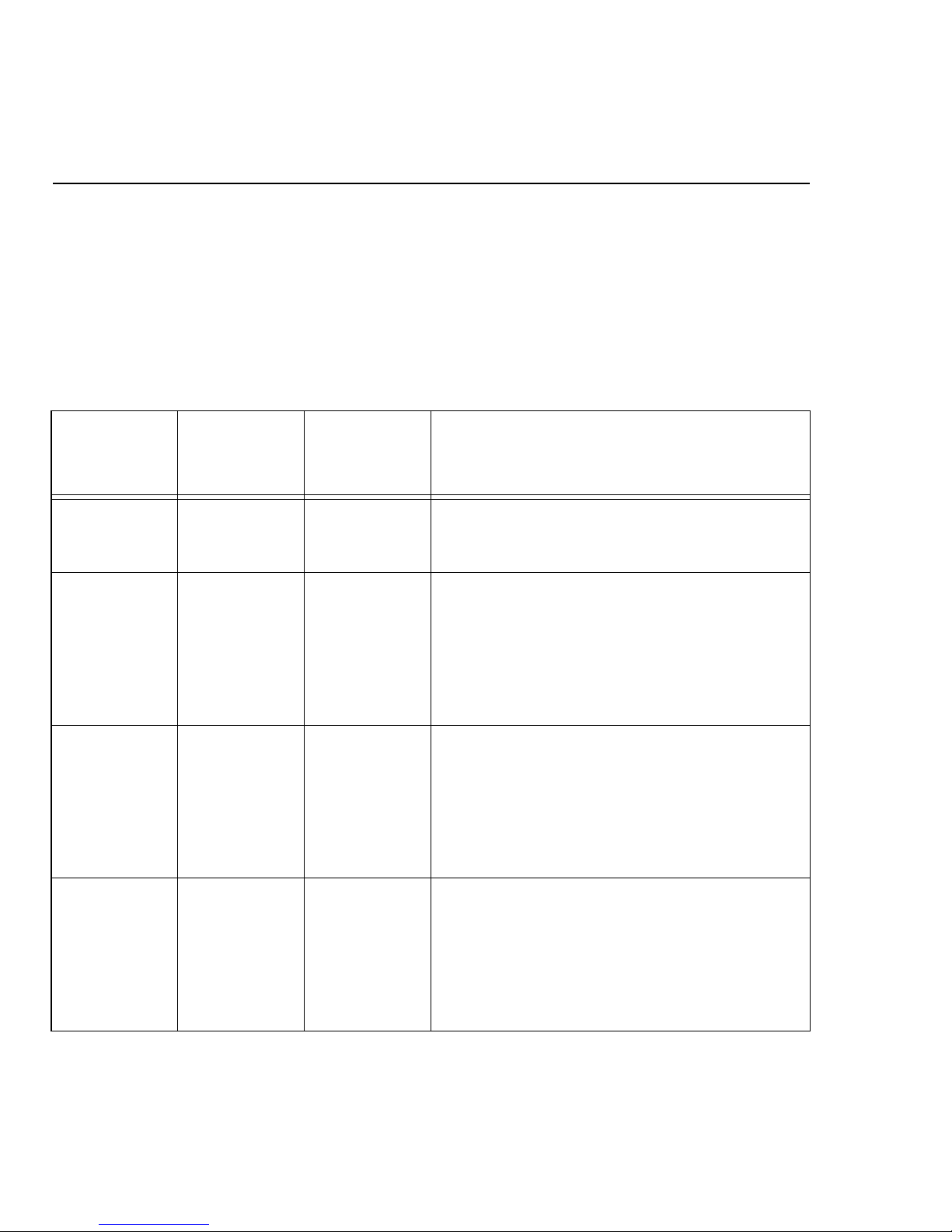

Table 1 IBM products and SAN management documentation

IBM TotalStorage

productname,

and machine type

and model

SAN12M-1 Switch

• 2026-E12

• 2026-12E

SAN24M-1 Switch

• 2026-224

SAN32M-1 Switch

• 2027-232

McDATA product

name

Sphereon 4300

Switch

Sphereon 4500

Switch

Sphereon 3232

Switch

Related firmware

and SAN

management

product

•E/OS

•EFCMBasic

Edition

•E/OS

•EFCM

• Element

Manager

•EFCMBasic

Edition

•E/OS

•EFCM

• Element

Manager

•EFCMBasic

Edition

Relevant documentation

•

EFCM Basic Edition User Manual

•

E/OS SNMP Support Manual

•

E/OS Command Line Interface User Manual

•

EFC Manager Software Release 9.0 User Manual,

620-000170.

•

Sphereon 4500 Switch Element Manager User Manual

(620-000175)

•

EFCM Basic Edition User Manual

•

E/OS SNMP Support Manual

•

E/OS Command Line Interface User Manual

•

EFC Manager Software Release 9.0 User Manual,

620-000170.

•

Sphereon 3032 and 3232 Fabric Switch Element Manager

User Manual

•

EFCM Basic Edition User Manual

•

E/OS SNMP Support Manual

•

E/OS Command Line Interface User Manual

(620-000173)

(620-000240)

(620-000131)

(620-000134)

(620-000240)

(620-000131)

(620-000134)

(620-000240)

(620-000131)

(620-000134)

SAN16M-2 Switch

• 2026-416

• 2026-16E

xvi

SAN140M Installation and Service Manual

Sphereon 4400

Switch

•E/OS

•EFCM

• Element

•EFCMBasic

Manager

Edition

•

EFC Manager Software Release 9.0 User Manual,

620-000170.

•

Sphereon 4400 Switch Element Manager User Manual

(620-000241)

•

EFCM Basic Edition User Manual

•

E/OS SNMP Support Manual

•

E/OS Command Line Interface User Manual

(620-000240)

(620-000131)

(620-000134)

Page 19

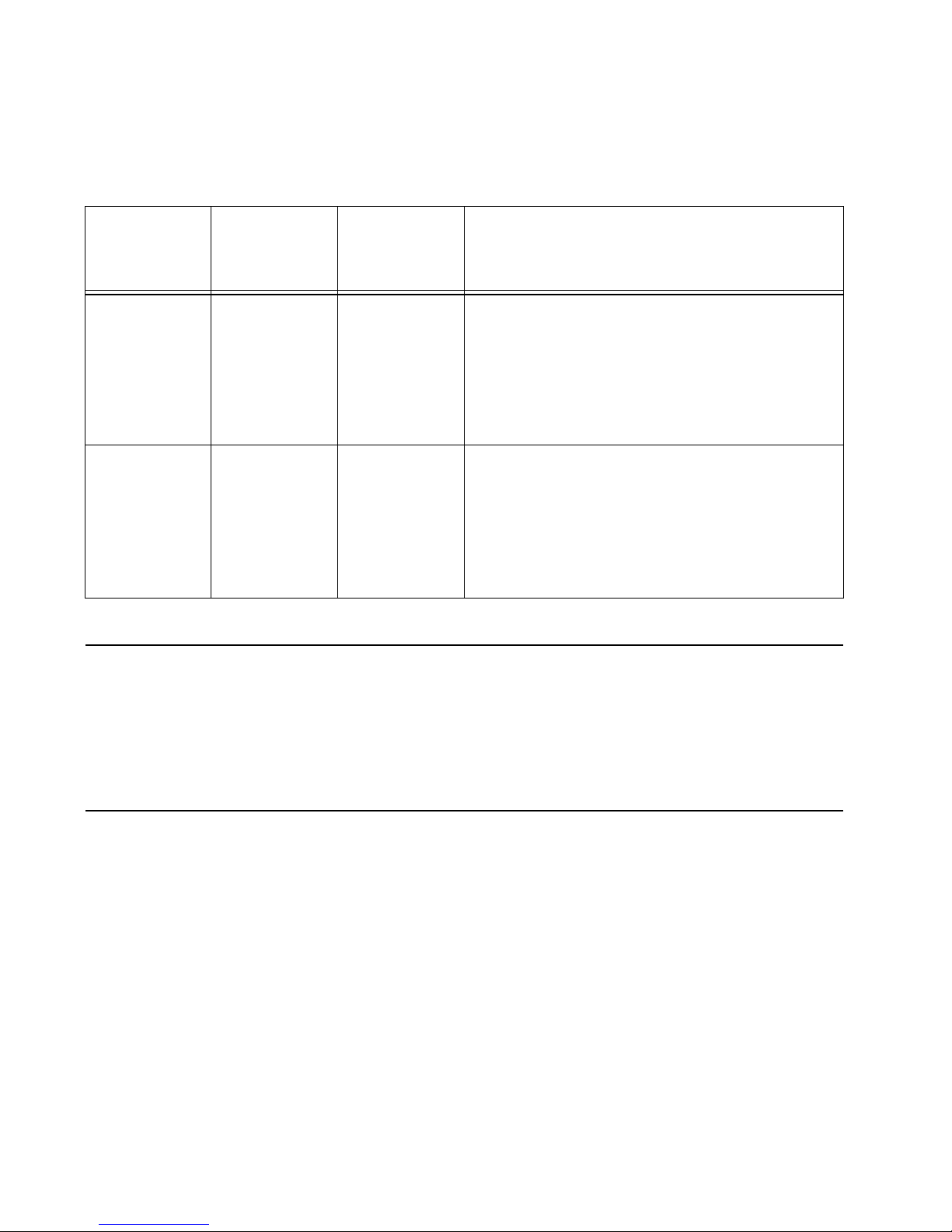

Table 1 IBM products and SAN management documentation (Continued)

IBM TotalStorage

product name,

and machine type

and model

SAN32M-2 Switch

• 2026-432

• 2026-32E

SAN140M director

• 2027-140

McDATA product

name

Sphereon 4700

Switch

Intrepid 6140

director

Related firmware

and SAN

management

product

•E/OS

•EFCM

• Element

Manager

•EFCMBasic

Edition

•E/OS

•EFCM

• Element

Manager

•EFCMBasic

Edition

Ordering printed manuals

Relevant documentation

•

EFC Manager Software Release 9.0 User Manual,

620-000170.

•

Sphereon 4700 Switch Element Manager User Manual

(620-000242)

•

EFCM Basic Edition User Manual

•

E/OS SNMP Support Manual

•

E/OS Command Line Interface User Manual

•

EFC Manager Software Release 9.0 User Manual,

620-000170.

•

Intrepid 6140 and 6064 Directors Element Manager User

Manual

(620-000153)

•

EFCM Basic Edition User Manual

•

E/OS SNMP Support Manual

•

E/OS Command Line Interface User Manual

(620-000240)

(620-000131)

(620-000134)

(620-000240)

(620-000131)

(620-000134)

Where to g et help

To order a printed copy of this publication, contact your IBM Branch

office or you can locate (and purchase) books online at:

http://www.elink.ibmlink.ibm.com/public/applications/publications/cgib

in/pbi.cgi?.

To contact IBM for technical support, which includes hardware

support, all product repairs, and ordering of spare parts, go to:

http://www.ibm.com/servers/storage/support/san/index.html.

You can also contact IBM within the United States at

1-800-IBMSERV (1-800-426-7378). For support outside the United

States, you can find the appropriate service number at

http://www.ibm.com/planetwide/.

Preface

xvii

Page 20

How to send your comments

Your feedback is important in helpin g us provide the most accurate

and high-quality information. If you have comments or suggestions

for improving this document, you can send us comments

electronically by using the following addresses:

• Internet: starpubs@us.ibm.com

• IBMLink™ from U.S.A.: STARPUBS at SJEVM5

• IBMLink from Canada: STARPUBS at TORIBM

• IBM Mail Exchange: USIB3VVD at IBMMAIL

You can also mail your comments by using the Reader Comment

Form in the back of this manual or direct your mail to:

International Business Machine Corporation

Information Development

Department GZW

9000 South Rita Road

Tucson, Arizona 85744-001 U.S.A

When you send information to IBM, you grant IBM a nonexclusive

right to use or distribute the information in any way it believes

appropriate without incurring any obligation to you.

xviii

SAN140M Installation and Service Manual

Page 21

Safety and environmental notices

ATTENTION ! The IBM Total Storage SAN140M director is not designed to

be installed and serviced by customers. Installationand servicing of the

director should be performed only by qualified service representatives.

Safety notices and labels

When using this product, observe the danger, caution, and attention

notices contained in this guide. The notices are accompanied by

symbols that represent the severity of the safety condition. The

danger and caution notices are listed in numerical order based on

theirIDs,whicharedisplayedinparentheses,forexample(D004),at

the end of each notice. Use this ID to locate the translations of these

danger and caution notices in the IBM eServer Safety Notices

(G229-9054) publication, which is on the CD-ROM that accompanies

this product.

The following notices andstatements are used inthis document. They

are listed below in order of increasing severity of potential hazards.

Follow the links for more detailed descriptions and examples of the

danger, caution, and attention notices in the sections that follow.

• Note: These notices provide im portant tips, guidance, or advice.

• Attention notices: These notices indicate potential damage to

programs, devices, or data.

• Caution notices: These statements indicate situations that can be

potentially hazardous to you.

• Danger notices: These statements indicate situations that can be

potentially lethal or extremely hazardous to you. Safety labels are

also attached directly to products to warn of these situations.

Danger notices A danger notice calls attention to a situation that is potentially lethal

or extremely hazardous to people. A lightning bolt symbol

accompanies a danger notice to represent a dangerous electrical

condition. Read and comply with the following danger notices before

installing or servicing this device.

Preface

xix

Page 22

DANGER

To prevent a possibleshock from touching twosurfaces with different

protective ground (earth), use one hand, when possible, to connect or

disconnect signal cables.

(D001)

DANGER

Overloading a branch circuit is potentially a fire hazard and a shock

hazard under certain conditions. To avoid these hazards, ensure that

your system electrical requirements do not exceed branch circuit

protection requirements. Refer to the information that is provided

with your device or the power rating label for electrical

specifications.

(D002)

DANGER

If the receptacle has a metal shell, do not touch the shell until you

have completed the voltage and grounding checks. Improper wiring

or grounding could place dangerous voltage on the metal shell. If any

of the conditions are not as described, STOP. Ensure the improper

voltage or impedance conditions are corrected before proceeding.

(D003)

DANGER

An electrical outlet that is not correctly wired could place hazardous

voltage on metal parts of the system or the devices that attach to the

system. It is the responsibility of the customer to ensure that the

outlet is correctly wired and grounded to prevent an electrical shock.

(D004)

A comprehensive danger notice provides instructions on how to

avoid shock hazards when servicing equipment. Unless instructed

otherwise, follow the procedures in the following danger notice.

xx

SAN140M Installation and Service Manual

Page 23

DANGER

Electrical voltage and current from power, telephone, and

communication cables are hazardous. To avoid a shock hazard:

• Do not connect or disconnect any cables or perform installation,

maintenance, or reconfiguration of this product during an

electrical storm.

• Connect all power cords to a properly wired and grounded

electrical outlet. Ensure outlet supplies proper voltage and phase

rotation according to the system rating plate.

• Connect any equipment that will be attached to this product to

properly wired outlets.

• When possible, use one hand only to connect or disconnect signal

cables.

• Never turnon anyequipment when there isevidence offire, water,

or structural damage.

• Disconnect the attached power cords, telecommunications

systems, networks, and modems before you open the device

covers, unless instructed otherwise in the installation and

configuration procedures.

• Connect and disconnect cables as described below when

installing, moving, or opening covers on this product or attached

devices.

To Disconnect:

1. Turn everything OFF (unless instructed otherwise).

2. Remove power cords from the outlet.

3. Remove signal cables from con necto rs.

4. Remove all cables from devices.

To Connect:

1. Turn everything OFF (unless instructed otherwise).

2. Attach all cables to devices.

3. Attach signal cables to connectors.

4. Attach power cords to outlet.

5. Turn device ON.

(D005)

Labels As an added precaution, safety labels are often installed directly on

products or product components to warn of potential hazards. These

Preface

xxi

Page 24

canbeeitherdangerorcautionnotices,dependinguponthelevelof

the hazard.

The actual product safety labels may differ from these sample safety

labels:

DANGER

Hazardous voltage, current, or energy levels are present inside any

component that has this label attached.

(L001)

DANGER

Rack-mounted devices are not to be used as a shelf or work space.

(L002)

DANGER

Multiple power cords

(L003)

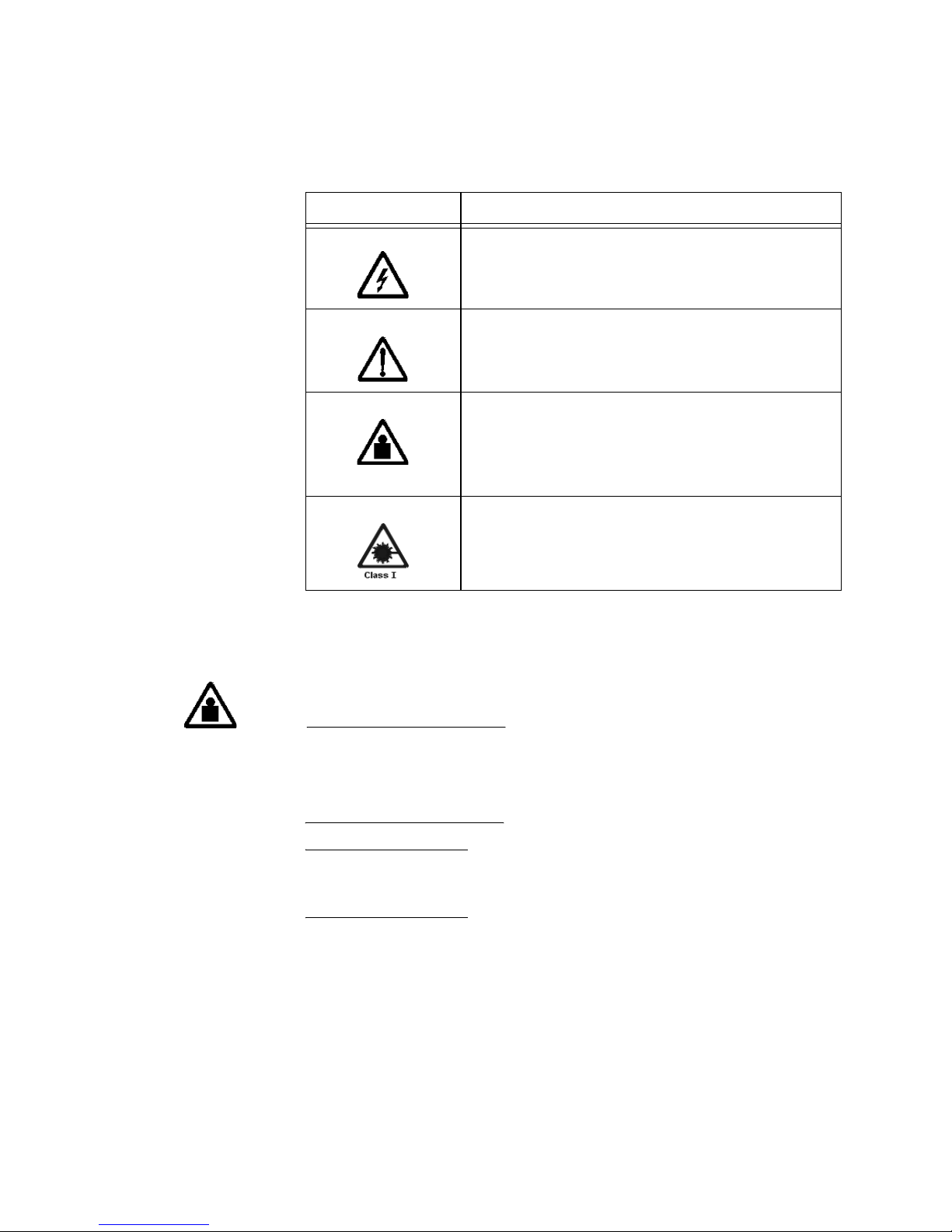

Caution notices A caution notice calls attention to a situation that is potentially

hazardous to people because of some existing condition. A caution

notice can be accompanied by different symbols, as in the examples

below:

xxii

SAN140M Installation and Service Manual

Page 25

If the symbol is... It means....

A hazardous electrical condition with less severity than electrical

danger.

A generally hazardous condition not represented by other safety

symbols.

A specification of product weight that requires safe lifting

practices. The weight range of the product is listed below the

graphic, and thewording of the caution varies,depending on the

weight of the device.

>18 kg (39.7 lb)

A hazardous condition due to the use of a laser in the product.

Laser symbols are always accompanied by the classification of

the laser as defined by the U. S. Department of Health and

Human Services (forexample, Class I, Class II, and so forth).

Read and comply with the following caution notices before installing

or servicing this device.

CAUTION

The weightof this part or unitis more than 55kg (121.2 lb.). It takes

specially-trained persons and/or a lifting device to safely lift this

part or unit.

(C011)

ATTENTION ! Safe installation of the directorrequires the use of a lift tool,

PN 09P2481, and a 24-inch load plate, PN11P4369. S ee Ordering the lift tool on

page 19.

Preface

xxiii

Page 26

CAUTION

The doors and covers to the product are to be closed at all times

except for service by trained service personnel. All covers must be

replaced and doors locked at the conclusion of the service

operation.

(C013)

CAUTION

The system contains circuit cards and/or assemblies that contain

lead solder. To avoidthe release of lead (Pb) into the environment,

do not burn. Discard the circuit card as instructed by local

regulations.

(C014)

CAUTION

Ensure the building power circuit breakers are turned off BEFORE

you connect the power cord(s) to the building power.

(C023)

xxiv

CAUTION

This assembly contains mechanical moving parts. Use care when

servicing this assembly.

(C025)

CAUTION

Servicing of this product or unit is to be performed by trained

service personnel only.

(C032)

SAN140M Installation and Service Manual

Page 27

Rack-mount safety

information

Danger

Always lower the leveling pads on the rack cabinet.

Always install stabilizer brackets on the rack cabinet.

To avoid hazardous conditions due to uneven mechanical

loading, always install the heaviest devices in the bottom of the

rack cabinet. Always install servers and optional devices starting

from the bottom of the rack cabinet.

Rack-mounted devices are not to beused as a shelf or workspace.

Do not place any object on top of rack-mounted devices.

Each rack cabinet might have more than one power cord. Be sure

to disconnect all power cords in the rack cabinet before servicing

any device in the rack cabinet.

Connect all devices installed in a rack cabinet to power devices

installed in the same rack cabinet. Do not plug a power cord from

a device installed in one rack cabinet into a power device installed

in a different rack cabinet.

An electrical outlet that is not correctly wired could place

hazardous voltage on the metal parts of the system or the devices

that attach to the system. It is the responsibility of the customer to

ensure that the outlet is correctly wired and grounded to prevent

an electrical shock.

Caution

Do not install a unit in a rack where the internal rack ambient

temperatures will exceed the manufacturer’s recommended

ambient temperature for all your rack-mounted devices.

Do not install a unit in a rack where the air flow is compromised.

Ensure that air flow is not blocked or reduced on any side, front,

or back of a unit used for air flow through the unit

Consideration should be given to the connection of the

equipment to the supply circuit so that overloading of the circuits

does not compromise the supply wiring or overcurrent

protection. To provide the correct power connection to a rack,

refer to the rating labels located on the equipment in the rack to

determine the total power requirement of the supply circuit.

Preface

xxv

Page 28

(For sliding drawers.) Do not pull out or install any drawer or

feature if the rack stabilizer brackets are not attached to the rack.

Do not pull out more than one drawer at a time. The rack may

become unstable if you pull out more than one drawer at a time.

(For fixed drawers.) This drawer is a fixed drawer and should not

be moved for servicing unless specified by manufacturer.

Attempting to move the drawer partially or completely out of the

rack may cause the rack to become unstable or cause the drawer

to fall out of the rack.

(R001)

Caution

Removing components from the upper positions in the rack cabinet

improves rack stability during relocation. Follow these general

guidelines whenever you relocate a populated rack cabinet within a

room or building:

Reduce the weight of the rack cabinet by removing equipment

starting at the top of the rack cabinet. When possible, restore the

rack cabinet to the configuration of the rack cabin e t as you

received it.

If this configuration is not known, you must do the following:

• Remove all devices in the 32U position and above.

• Ensure that the heaviest devices are installed in the bottom of

the rack cabinet.

• Ensure that there are no empty U-levels between devices

installed in the rack cabinet below the 32U level.

If the rack cabinet you are relocating is part of a suite of rack

cabinets, detach the rack cabinet from the suite.

Inspect the route that you plan to take to eliminate potential

hazards.

Verify that the route that you choose can support the weight of

the loaded rack cabinet. Refer to the documentation that comes

with your rack cabinet for the weight of a loaded rack cabinet.

Verify that all door openings are at least 760 x 230 mm (30 x 80

in.).

xxvi

SAN140M Installation and Service Manual

Page 29

Ensure that all devices, shelves, drawers, doors, and cables are

secure.

Ensure that the four leveling pads are raised to their highest

position.

Ensure that there is no stabilizer bracket installed on the rack

cabinet during movement.

(R002)

Attention notices An attention notice indicates the possibility of damage to a program,

device, or system, or to data. An exclamation point symbol may

accompany an attention notice, but is not required. A sample

attention notice follows:

ATTENTION! Do not bend afibre cable to a radius lessthan 5cm (2 in.); you

candamagethecable.Tiewrapsarenotrecommendedforopticalcables

because they can be easily overtightened, causing damage to the cable.

Laser safety This equipment contains Class 1 laser products, and complies with

FDA radiation Performance Standards, 21 CFR Subchapter J and the

international laser safety standard IEC 60825.

CAUTION

This product may contain one or more of the following: CD-ROM,

DVD-ROM, DVD-RAM, or laser module, which are Class 1 laser

products. Please note the following:

• Do not removethe covers. Removing the covers of the laser

product could result in exposure to hazardous laser radiation.

There are no serviceable parts inside the device.

• Use of the controls or adjustments or performance of

procedures other than those specified herein might result in

hazardous radiation exposure.

(C026)

Preface

xxvii

Page 30

CAUTION

Data processing environments can contain equipmenttransmitting

on system links with laser modules that operate at greater than

Class 1 power levels. For this reason, never look into the end of an

optical fiber cable or open receptacle.

(C027)

Environmental notices

Use the environmental statements and warning in this section to

guide you when using this product and in properly disposing of the

product and its components.

Product recycling

and disposal

This unit must be recycled or discarded according to applicable local

and national regulations. IBM encourages owners of information

technology (IT) equipment to responsibly recycle their equipment

when it is no longer needed. IBM offers a variety of product return

programs and services in several countries to assist equipment

owners in recycling their IT products. Information on IBM product

recycling offerings can be found on IBM’s Internet site at

http://www.ibm.com/ibm/environment/products/prp.shtml

Note: This mark applies only to countries within the European Union

(EU) and Norway.

Appliances are labeled in accordance with European Directive

2002/96/EC concerning waste electrical and electronic equipment

(WEEE). The Directive determines the framework for the return and

recycling of used appliances as applicable throughout the European

Union. This label is applied to various products to indicate that the

product is not to be thrown away, but rather reclaimed upon end of

life per this Directive.

xxvii

SAN140M Installation and Service Manual

Page 31

In accordance with the European WEEE Directive, electrical and

electronic equipment (EEE) is to be collected separately and to be

reused, recycled, or recovered at end of life. Users of EEE with the

WEEE marking per Annex IV of the W EEE Directive, as shown

above, must not dispose of end of life EEE as unsorted municipal

waste, but usethe collection framework available to customers for the

return, recycling and recovery of WEEE. Customer participation is

important to minimize any potential effects of EEE on the

environment and human health due to the potential presence of

hazardous substances in EEE. For proper collection and treatment,

contact your local IBM representative.

Battery return

program

This product may contain sealed lead acid, nickel cadmium, nickel

metal hydride, lithium, or lithium ion battery. Consult your user

manual or service manual for specific battery information. The

battery must be recycled or disposed of properly. Recycling facilities

may not be available in your area. For information on disposal of

batteries outside the United States, go to

http://www.ibm.com/ibm/environment/products/batteryrecycle.s

html or contact your local waste disposal facility.

In the United States, IBM has established a return process for reuse,

recycling, or proper disposal of used IBM sealed lead acid, nickel

cadmium, nickel metal hydride, and other battery packs from IBM

Equipment. For information on proper disposal of these batteries,

contact IBM at 1-800-426-4333. Please have the IBM part number

listed on the battery available prior to your call.

Preface

xxix

Page 32

Cable warning

For Taiwan:

WARNING

Handling the cord on this product or cords associated with

accessories sold with this product, will expose you to lead, a

chemical known to the State of California to cause cancer, and birth

defects or other reproductive harm. Wash hands after handling.

xxx

SAN140M Installation and Service Manual

Page 33

Chapter 1: General information

The IBM®TotalStorage SAN140M directorprovides up to 140ports of

high-performance, dynamic Fibre Channel connectivity for switched

fabric devices in a storage area network (SAN). The director provides

a broad bandwidth (1, 2 or 10 gigabits per second), redundant

switched data paths, and long transmission distances.

This chapter presents information and features of the director and its

management, including:

• Director description.

• Field-replaceable units (FRUs).

• Error detection, reporting, and serviceability features.

• Element Manager status indicators

•Toolsandtestequipment.

• Director management.

Director description

The SAN140M director is a 140-port product that provides dynamic

switched connections between Fibre Chann el servers a nd devices in a

SAN environment. The portsoperate at 1, 2 or 10 gigabits per second

(Gbps). Directors (from one to three) can be configured to order in an

equipment cabinet, which can provide up to 420 ports in a single

cabinet.

The director provides dynamic switched connections for servers and

devices, supports mainframe andopen-systems interconnection (OSI)

computing environments, and provides data transmission and flow

control between device node ports (N_Ports) as dictated by the Fibre

Channel Physical and Signaling Interface (FC-PH 4.3). Through

interswitch links (ISLs), the director can also connect to one or more

additional directors to form a Fibre Channel multiswitch fabric.

The director can be managed through a management server running

a Java™-based SAN management application (Enterprise Fabric

Connectivity Manager (EFCM) and Element Manager applications).

© Copyright IBM Corp. 2006

1

Page 34

Multiple directors and the management server communicate on a

local area network (LAN) through one or more 10/100 Base-T

Ethernet hubs. One or more 24-port Ethernet hubs are optional and

can be ordered with the director. Up to three hubs can be

daisy-chained to provide additional Ethernet connections as more

directors (or other IBM managed products) are installed on a

customer network.

As an option, administrators or operators with a browser-capable PC

and an Internet connection can monitor and manage the director

through the EFCM Basic Edition interface. The interface manages

only a single director, and provides a graphical user interface (GUI)

that supports product configuration, statistics monitoring, and basic

operation. The EFCM Basic Edition interface is opened from a

®

standard web browser running Netscape Navigator

®

Microsoft

Internet Explorer 4.0 or higher.

4.6orhigheror

Figure 1 illustrates an equipment rack with three directors, the

management server, and an Ethernet hub.

2

SAN140M Installation and Service Manual

Page 35

1

2

3

3

H

D

D

FA

N

L

2

L1

ENTER

4

3

4

5

Figure 1 Cabinet-mounted SAN140M directors and management server

Location Description

1Ethernethub

2Director

3 Management server

4Director

5Director

Chapter 1: General information

i140M001

3

Page 36

Field-replaceable units

The director provides a modular design th at enables quick removal

and replacement of FRUs. This section describes director FRUs and

controls, connectors, and indicators associated with the FRUs.

Director FRUs accessed from the front (Figure 2)includethe:

• Universal port module (UPM) cards (2 Gbps).

•10Gbpsportmodule(XPM)cards.

• Control processor (CTP) cards.

1

2

4

3

i140M232

Figure 2 Director FRUs (front access)

Location Description

1XPMcards

2 Power and system error LEDs

3UPMcard

4CTPcards

Director FRUs accessed from the rear (Figure 3)includethe:

•Fanmodules.

4

SAN140M Installation and Service Manual

Page 37

• Universal port module (UPM) cards (2 Gbps).

• 10 Gbps port module (XPM) cards.

• Serial crossbar (SBAR) assemblies.

• Power supplies.

•ACmodules.

• Power/System Error LED Assembly (not shown).

•Backplane(notshown).

1

2

3

4

Figure 3 Director FRUs (rear access)

Location Description

1 Cooling fans

2UPMorXPMCards

3 Maintenance port

4 SBAR assemblies

5 Power supplies

6ACmodules

5

6

i140M003

Chapter 1: General information

5

Page 38

Power/system LED assembly

The bezel at the top front of the director includes an amber system

errorlight-emitting diode (LED)and a greenpower LED. These LEDs

are actuated and controlled by a Power/System LED Assembly

which is accessed from the rear of the director.

The power LED lights up when the director is powered on and

operational. If the LED turns off, a facility power source, alternating

current (AC) power cord, or director power distribution failure is

indicated.

The system error LED lights up when the director detects an event

requiring immediate operator attention, such as a FRU failure. The

LED remains illuminated as long as an event is active. The LED turns

off when the Clear System Error Light function is selected from the

Element Manager application. The LED blinks if unit beaconing is

enabled. A lit system error LED (indicating a failure) takes

precedence over unit beaconing.

CTP card

The director is delivered with two CTP cards. The active CTP card

initializes and configures the director after power on and contains the

microprocessor and associated logic that coordinate director

operation.

The CTP card provides an initial machine load (IML)buttonanda

RESET button (recessed) on the faceplate.

When the IML button is pressed, held for three seconds, and

released,the director performsan IMLthat reloadsthe firmware from

FLASH memory. This operation is not disruptive to Fibre Channel

traffic.

When the RESET button is pressed and held for three seconds, the

director performs a reset. A reset is disruptive and resets the:

• Microprocessor and functional logic for the CTP card and reloads

thefirmwarefromFLASHmemory.

• Ethernet LAN interface, causing the connection to the

management server to drop momentarily until the connection

automatically recovers.

6

SAN140M Installation and Service Manual

Page 39

• Ports, causing all Fibre Channel connections to drop momentarily

until the connections automatically recover. This causes attached

devices to log out and log back in, therefore data frames lost

during director reset must be retransmitted.

A reset should only be performed if a CTP card failure is indicated.

As a precaution, the RESET button is flush mounted to protect

against inadvertent activation.

Each CTP card also provides a 10/100 megabit per second (Mbps)

RJ-45 twisted pair connector on the faceplate that attaches to an

Ethernet local area network (LAN) to communicate with the

management server or a simple network management protocol

(SNMP) management station.

Each CTP card provides system services processor (SSP) and

embedded port (EP) subsystems. The SSP subsystem runs director

applications and the underlying operating system, communicates

with director ports, and controls the RS-232 maintenance port and

10/100 Mbps Ethernet port. The EP subsystem provides Class F and

exception frame processing, and manages frame transmission to

and from the SBAR assembly. In addition, a CTP card provides

nonvolatile memory for s toring firmware, director configuration

information, persistent operating parameters, and memory dump

files. Director firmware isupgraded concurrently (without disrupting

operation).

UPM card

The backup CTP card takes over operation if the active card fails.

Failover from a faulty card to the backup card is transparent to

attached devices.

Each card faceplate contains a green LED that illuminates if the card

is operational and active, and an amber LED that illuminates if the

card fails. Both LEDs are turned off on an operational backup card.

The amber LED blinks if FRU beaconing is enabled.

Each UPM card (Figure 4) provides four full-duplex generic ports

(G_Ports) that transmit or receive data at 2 gigabits per second

(Gbps). G_Port functionality depends on the type of cable

attachment. UPM cards use non-open fiber control (OFC) Class 1

laser transceivers that comply with Section 21 of the Code of Federal

Regulations(CFR),Subpart(J)asofthedateofmanufacture.

The card faceplate contains:

Chapter 1: General information

7

Page 40

• Four duplex LC connectors for attaching fiber-optic cables.

• An amber LED (at the top of the card) that illuminates if any port

fails or blinks if FRU beaconing is enabled.

• A bank of amber and green LEDs above the ports. One amber

LED and one green LED are associated with each port and

indicate port status as follows:

— The green LED illuminates (or blinks if there is active traffic)

and the amber LED turns off to indicate normal port

operation.

— The amber LED illuminates and the green LED turns off to

indicate a port failure.

— Both LEDs turn off to indicate a port is operational but not

communicating with an N_Port (no cable attached, loss of

light, port blocked, or link recovery in process).

— The amber LED flashes and the green LED either remains on,

turns off, or flashes to indicate a port is beaconing or running

online diagnostics.

UPM

Figure 4 UPM card LEDs and connectors

1

2

3

i140M004

8

SAN140M Installation and Service Manual

Page 41

XPM card

Location Description

1 Card LED

2 Port LEDs

3 Port connectors

Each XPM card (Figure 5) provides one full-duplex generic port

(G_Port) that transmits or receives data at 10 gigabits per second

(Gbps). The card faceplate contains:

• One duplex LC connector for attaching fiber-optic cables.

• Amber and green LEDs that indicate port status similar to the

LEDs on the UPM cards (UPM card on page 7).

1

Figure 5 XPM card

Location Description

1XPMcard

i140M229

Chapter 1: General information

9

Page 42

SFP and XFP transceivers

Singlemode or multimode fiber-optic cables attach to director ports

through2 Gbps small form-factor pluggable (SFP, Figure 6 -forUPM

cards) or 10 Gbps form-factor pluggable (XFP, Figure 7 -forXPM

cards) optic transceivers. The fiber-optic transceivers provide duplex

®

connectors and can be detached from director ports for easy

LC

replacement.

NOTE: SFPandXFPtransceiversarenotinterchangeable.

These fiber-optic transceiver types are available:

• Shortwave laser, SFP, 2.125 Gbps

•Shortwavelaser,XFP,10.520Gbps

• Longwavelaser,SFP,2.125Gbps

• Longwavelaser,XFP,10.520Gbps

Figure 6 Small form-factor pluggable (SFP) transceiver

10

SAN140M Installation and Service Manual

i256M066

Page 43

Figure 7 Ten Gbps form-factor pluggable (XFP) transceiver

Power supply

i256M152

Redundant, load-sharing power supplies step down and rectify

facility input power to provide 48-volt direct current (VDC) power to

director FRUs. The power supplies also provide overvoltage and

overcurrent protection. Either power supply can be replaced while

the director is powered on and operational.

Each power supply has a separate backplane connection to allow for

different AC power sources. The power supplies a re in put rated at

180 to 264 volts alternating current (V AC). The faceplate of each

power supply provides the following status LEDs:

• A green AC OK LED illuminates if the power supply is

operational and receiving AC power.

• A green DC OK LED illuminates if the power supply is

operational and producing DC power.

•AredFAULT LED illuminates if the power supply fails.

AC module

The AC module is located at the bottom rearof the director. Either AC

module can be replaced while the director is powered on and

operational. The module provides:

• Two single-phase, 220 VAC, power connectors.

Chapter 1: General information

11

Page 44

Fan module

SBAR assembly

• An input filter and AC system harness (internal to the FRU) that

provides the wiring to connect the AC power connectors to the

power supplies (through the backplane).

Three fan modules, each containing one system fan (three system fans

total), provide cooling for director FRUs, as well as redundancy for

continued operation if a fan fails.

A fan module can be replaced while the director is powered on and

operating, provided the module is replaced within ten minutes (after

which software powers off the director). An amber LED for each fan

module illuminates if one or more fans fail or rotate at insufficient

angular velocity.

The director is delivered with two SBAR assemblies. The active SBAR

isresponsibleforFibreChannelframetransmissionfromanydirector

port to any other director port. Connections are established without

software intervention. The assembly accepts a connection request

from a port, determines if a connection can be established, and

establishes the connection if the destination port is available. The

assembly also stores busy, source connection, and error status for

each director port.

Backplane

12

SAN140M Installation and Service Manual

The backup SBAR takes over operation if the active assembly fails,

and provides the ability to maintain connectivity and data frame

transmission without interruption. Failover tothe backup assembly is

transparent to attached devices.

Each SBARassembly consists of a card and steel carriage that mounts

flushonthebackplane.Thecarriageprovidesprotectionfortheback

of the card, distributes cooling airflow, and assists in aligning the

assembly during installation. The rear of the carriage contains a green

LED that illuminates if the assembly is operational and active, and an

amber LED that illuminates if the assembly fails. Both LEDs are

turned off on an operational backup assembly.The amber LED blinks

if FRU beaconing is enabled.

The backplane provides 48 VDCpower distributionand connections

for all logic cards. The backplane is a nonconcurrent FRU. The

director must be powered off prior to FRU removal and replacement.

Page 45

Error-detection, repor ting, and serviceability features

The director provides the following error detection, reporting, and

serviceability features:

• Light-emitting diodes (LEDs) on director FRUs and the front

bezel that provide visual indicators of hardware status or

malfunctions.

• Redundant FRUs (logic cards, power supplies, and cooling fans)

that are removed or replaced without disrupting director or Fibre

Channel link operation.

• A modular design that enables quick removal and replacement of

FRUs without the use of special tools or equipment.

• System alerts and logs that display director, Ethernet link, and

Fibre Channel link status at the management server (running a

SAN management application), client comm unicating with the

management server, or EFCM Basic Edition interface.

• Diagnostic software that performs power-on self-tests (POSTs)

and port diagnostics (internal loopback, external loopback, and

Fibre Channel (FC) wrap tests). The FC wrap test applies only

when the director isconfigured to operate in FICON management

style.

• An RS-232maintenance port at the rearof the director(port access

is password protected) that enables installation or service

personnel to change the director’s internet protocol (IP) address,

subnet mask, and gateway address; or to run diagnostics and

isolate system problems through a local or remote terminal.

The director parameters can also be changed through a Telnet

session, access for which is providedthrough a local or remotePC

with an Internet connection to the director.

• Data collection through the Element Manager application or the

EFCM Basic Edition interface to help isolate system problems.

The data includes a memory dump file and audit, hardware, and

engineering logs.

• Beaconing to assist service personnel in locating a specific port,

FRU, or director in a multiswitch environment. When port

beaconing is enabled, the amber LED associated with the port

flashes. When FRU beaconing is enabled, the amber (service

Chapter 1: General information

13

Page 46

required) LED on the FRU flashes. When unit beaconing is

enabled, the system error indicator on the front bezel fla shes.

Beaconing does not affect port, FRU, or director operation.

• An internal modem for use by support personnel to dial-in to the

management server for event notification and to perform remote

diagnostics.

• Automatic notification of significant system events (to support

personnel or administrators) through e-mail messages or the

call-home feature.

NOTE: Thecall-homefeatureisnotavailablethroughtheEFCMBasic

Edition interface.

• Concurrent port maintenance. UPM cards are added or replaced

and fiber-optic cables are attached to ports without interrupting

other ports or director operation.

• Status monitoring of redundant FRUs and alternate Fibre

Channel data paths to ensure continued director availability in

case of failover. The SAN management application queries the

status of each backup FRU. A backup FRU failure is indicated by

an illuminated amber LED.

• SNMP management using the Fibre Channel Fabric Element MIB

(Version 1.1), transmission control protocol/internet protocol

(TCP/IP) MIB-II definition (RFC 1157), or a product-specific

private enterprise MIB that runs on each director. Up to six

authorized management workstations can be configured through

the Element Manager application or EFCM Basic Edition interface

to receive unsolicited SNMP trap messages. The trap messages

indicate operational state changes and failure conditions.

• SNMP management using the Fibre Alliance MIB (Version 3.1)

that runs on the management server. Up to 12 authorized

management workstations can be configured through the SAN

management application to receive unsolicited SNMP trap

messages. The trap messages indicate operational state changes

and failure conditions.

Element Manager status indicators

In addition to the visual indicators on the director chassis, the

Element Manager application presents alert symbols and messages

14

SAN140M Installation and Service Manual

Page 47

that describe the condition of the director and its FRUs. These alert

symbols, messages, and a description are summarized in Table 2.

Table 2 Element Manager alert symbols, messages, and status