Page 1

ERserver

7014 Series Model T00 and Model T42 System Rack

Service Guide

SA38-0577-05

Page 2

Page 3

ER s e r v e r

7014 Series Model T00 and Model T42 System Rack

Service Guide

SA38-0577-05

Page 4

A

Sixth Edition (November 2003)

Before using this information and the product it supports, read the information in “Safety Notices” on page v,

Appendix A, “Environmental Notices,” on page 61, and Appendix B, “Notices,” on page 67.

reader’s comment form is provided at the back of this publication. If the form has been removed, address

comments to Information Development, Department H6DS-905-6C006, 11501 Burnet Road, Austin, Texas

78758-3493. To send comments electronically, use this commercial internet address: aix6kpub@austin.ibm.com. Any

information that you supply may be used without incurring any obligation to you.

©International Business Machines Corporation 2000, 2003. All rights reserved.

Note to U.S. Government Users - Documentation related to restricted rights - Use, duplication, or disclosure is

subject to the restrictions set forth in the GSA ADP Schedule Contract with IBM Corp.

Page 5

AC

AC

AC

DC

DC

DC

DC

DC

Contents

Safety Notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .v

Electrical Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .v

Laser Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .vi

Data Integrity and Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

About This Book . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ix

ISO 9000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ix

Highlighting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ix

Accessing Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ix

Related Publications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ix

Trademarks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ix

Chapter 1. Reference Information . . . . . . . . . . . . . . . . . . . . . . . . . .1

Types of Power Distribution . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Rack Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Power Distribution Bus . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Power Distribution Bus Illustration . . . . . . . . . . . . . . . . . . . . . . . .9

External AC Power Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Uninterruptible Power Source . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Rack Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Power Distribution Panel . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Rack Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Power Distribution and Ground Illustration . . . . . . . . . . . . . . . . . . . . .11

Rack Power Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Specifications for 7014 Series Model T00 and Model T42 System Rack Racks . . . . . . . . . .13

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Installation Airflow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Service Inspection Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Chapter 2. Maintenance Analysis Procedures (MAPs) . . . . . . . . . . . . . . . . . .17

MAP 1520: DC Power Distribution Panel - Power MAP . . . . . . . . . . . . . . . . . .17

Purpose of This MAP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Safety Notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

MAP 1522: AC Power Distribution Bus - Power MAP . . . . . . . . . . . . . . . . . . .21

Purpose of This MAP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Safety Notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Chapter 3. Removal and Replacement Procedures . . . . . . . . . . . . . . . . . . .25

Safety Notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Operating System Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Power-On Procedure with the AC Power Distribution Bus . . . . . . . . . . . . . . . . . .25

Power-Off Procedure with the AC Power Distribution Bus . . . . . . . . . . . . . . . . . .27

Power-On Procedure with the DC Power Distribution Panel . . . . . . . . . . . . . . . . .27

Power-Off Procedure with the DC Power Distribution Panel . . . . . . . . . . . . . . . . .29

Removal and Replacement of the AC Power Distribution Bus . . . . . . . . . . . . . . . .29

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Removal and Replacement of the DC Power Distribution Panel . . . . . . . . . . . . . . .31

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

iii

Page 6

iv

Removal and Replacement of the -48 V DC Circuit Breaker . . . . . . . . . . . . . . . . .36

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Removal and Replacement of the Front or Rear Door . . . . . . . . . . . . . . . . . . .39

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Relocating Rack(s) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Chapter 4. Parts Information . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Model T42 To p Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Earthquake Brace . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Blank Fillers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Power Distribution Bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Stabilizers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

Power Distribution Panel Assembly . . . . . . . . . . . . . . . . . . . . . . . . . .49

Power Distribution Panel Interior . . . . . . . . . . . . . . . . . . . . . . . . . . .50

Leveling Feet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Model T42 Brace . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

Rack Beacon Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

Model T42 Kits (For Reference Only) . . . . . . . . . . . . . . . . . . . . . . . . .54

Power Cords . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

Appendix A. Environmental Notices . . . . . . . . . . . . . . . . . . . . . . . . .61

Product Recycling and Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . .61

Environmental Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

Acoustical Noise Emissions . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

Declared Acoustical Noise Emissions . . . . . . . . . . . . . . . . . . . . . . . . .66

Appendix B. Notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

7014 Model T00, and Model T42 Service Guide

Page 7

A

v v v 17 v 21 v 25 A

v v v 15 v 17 v 18 v 25 v 26 v 27 v 29 v 31 v

Safety Notices

danger notice indicates the presence of a hazard that has the potential of causing death or serious

personal injury.

caution notice indicates the presence of a hazard that has the potential of causing moderate or minor

personal injury.

36

Electrical Safety

Observe the following safety instructions any time you are connecting or disconnecting devices attached to

the workstation.

DANGER

electrical outlet that is not correctly wired could place hazardous voltage on metal parts of

An

the system or the devices that attach to the system. It is the responsibility of the customer to

ensure that the outlet is correctly wired and grounded to prevent an electrical shock.

Before installing or removing signal cables, ensure that the power cables for the system unit

and all attached devices are unplugged.

When adding or removing any additional devices to or from the system, ensure that the power

cables for those devices are unplugged before the signal cables are connected. If possible,

disconnect all power cables from the existing system before you add a device.

Use one hand, when possible, to connect or disconnect signal cables to prevent a possible

shock from touching two surfaces with different electrical potentials.

During an electrical storm, do not connect cables for display stations, printers, telephones, or

station protectors for communications lines.

D05

CAUTION:

This product is equipped with a three-wire power cable and plug for the user’s safety. Use this

power cable with a properly grounded electrical outlet to avoid electrical shock.

C01

v

Page 8

A

3B

vi

DANGER

To prevent electrical shock hazard, disconnect all power cables from the electrical outlet before

relocating the system.

D01

CAUTION:

This unit has more than one power supply cord. To reduce the risk of electrical shock, disconnect

two power supply cords before servicing.

C21

Laser Safety Information

The optical drive in this system unit is a laser product. The optical drive has a label that identifies its

classification. The label, located on the drive, is shown below.

CLASS 1 LASER PRODUCT

LASER KLASSE 1

LUOKAN 1 LASERLAITE

APPAREIL A LASER DE CLASSE 1

IEC 825:1984 CENELEC EN 60 825:1991

The optical drive in this system unit is certified in the U.S. to conform to the requirements of the

Department of Health and Human Services 21 Code of Federal Regulations (DHHS 21 CFR) Subchapter J

for Class 1 laser products. Elsewhere, the drive is certified to conform to the requirements of the

International Electrotechnical Commission (IEC) 825 (1st edition 1984) and CENELEC EN 60 825:1991 for

Class 1 laser products.

CAUTION:

class 1 laser is contained in the device. Do not attempt to operate the drive while it is

disassembled. Do not attempt to open the covers of the drive as it is not serviceable and is

replaced as a unit.

C07

Class 1 laser products are not considered to be hazardous. The optical drive contains internally a Class

gallium-arsenide laser that is nominally 30 milliwatts at 830 nanometers. The design incorporates a

combination of enclosures, electronics, and redundant interlocks such that there is no exposure to laser

radiation above a Class 1 level during normal operation, user maintenance, or servicing conditions.

7014 Model T00, and Model T42 Service Guide

Page 9

or

Data Integrity and Verification

IBM computer systems contain mechanisms designed to reduce the possibility of undetected data corruption

loss. This risk, however, cannot be eliminated. Users who experience unplanned outages, system failures,

power fluctuations or outages, or component failures must verify the accuracy of operations performed and

data saved or transmitted by the system at or near the time of the outage or failure. In addition, users must

establish procedures to ensure that there is independent data verification before relying on such data in

sensitive or critical operations. Users should periodically check the IBM support websites for updated

information and fixes applicable to the system and related software.

vii

Page 10

viii

7014 Model T00, and Model T42 Service Guide

Page 11

v

v

v

v

v

v

v

About This Book

This book provides information on how to use diagnostics, use service aids, and verify system operation.

This book also provides information to help you solve some of the simpler problems that might occur.

ISO 9000

ISO 9000 registered quality systems were used in the development and manufacturing of this product.

Highlighting

The following highlighting conventions are used in this book:

Bold

Identifies commands, subroutines, keywords, files, structures, directories, and other items

whose names are predefined by the system. Also identifies graphical objects such as buttons,

labels, and icons that the user selects.

Italics

Monospace

Identifies parameters whose actual names or values are to be supplied by the user.

Identifies examples of specific data values, examples of text similar to what you might see

displayed, examples of portions of program code similar to what you might write as a

programmer, messages from the system, or information you should actually type.

Accessing Information

IBM Eserver pSeries hardware publications are available online. To access the online hardware

publications, see the IBM Eserver pSeries and AIX Information Center at

http://publib16.boulder.ibm.com/pseries/index.htm. Click hardware documentation

Documentation for the AIX operating system is available at the IBM Eserver pSeries and AIX Information

Center at http://publib16.boulder.ibm.com/pseries/index.htm. Click AIX documentation. The AIX

Documentation CD contains the base set of publications for the operating system, including

system-management and end-user documentation.

Related Publications

The following publications are available:

The Diagnostic Information for Multiple Bus Systems, order number SA38-0509, contains diagnostic

information, service request numbers (SRNs), and failing function codes (FFCs).

The Adapters, Devices, and Cable Information for Multiple Bus Systems, order number SA38-0516

contains information about adapters, devices, and cables for your system. This manual is intended to

supplement the service information found in the Diagnostic Information for Multiple Bus Systems.

The Site and Hardware Planning Information, order number SA38-0508, contains specifications to help

you do space and environmental planning before your system is installed.

Trademarks

The following terms are trademarks of International Business Machines Corporation in the United States,

other countries, or both:

AIX

IBM

Eserver

pSeries

ix

Page 12

x

v

RS/6000

company, product, and service names may be trademarks or service marks of others.

Other

7014 Model T00, and Model T42 Service Guide

Page 13

1 DC

4 AC

2

5

3

Chapter 1. Reference Information

This chapter contains information about the locations of rack features, power distribution, and rack

specifications.

Types of Power Distribution

Power is distributed to the devices and drawers in the rack by ac power distribution buses or by a dc

power distribution panel (Model T00 only).

1

5

Power Distribution Panel

Front View of dc Rack

Optional Front Door (Shown for

reference only)

3

2

4

Power Distribution Bus

Rear View of ac Rack

1

Page 14

v

v

to

v

2

AC Rack Information

This section contains information about ac rack components.

AC Power Distribution Bus

There are two types of ac power distribution buses:

Type 6 power distribution buses have six IEC320-C13, 200 V to 240 V ac outlets. An additional two

front outlets have limited access, as shown in the figures on the following pages. The input ac power to

the bus is not switched, so each outlet has a separate circuit breaker to protect against excessive

current (see the schematic on the following pages). The type 6 power distribution bus feature codes are

9171, 9173, 9174, and 6xxx

Type 7 power distribution buses have nine IEC320-C13, 200 V to 240 V ac outlets. The input ac power

the bus is not switched, so each group of three IEC320-C13, 200 V to 240 V ac outlets has a

separate circuit breaker to protect against excessive current (see the schematic on the following pages).

The type 7 power distribution bus feature codes are 9176, 9177, 9178, and 7xxx.

9188/7188 power distribution buses have twelve IEC320-C13, 200 V to 240 V ac outlets. The input ac

power to the bus is not switched, so each group of two IEC320-C13, 200 V to 240 V ac outlets has a

separate circuit breaker to protect against excessive current (See the schematic on the following

pages.).

rack can contain up to four vertically mounted ac power distribution buses. Two additional power

A

distribution buses (each consuming 1 EIA location) can be mounted horizontally in the bottom rear of a

Model T00 rack, and three additional power distribution buses (each consuming 1 EIA location) can be

mounted horizontally in the bottom rear of a Model T42 rack. The four vertical mounting slots will be filled

first before consuming EIA locations in the rack. Type 6 ac power distribution buses contain eight 200 V to

240 V ac outlets to provide power to the devices and drawers. For type 6, the input ac power to the bus is

not switched, so each outlet has a separate circuit breaker to protect against excessive current.

7014 Model T00, and Model T42 Service Guide

Page 15

1

5

of

2

6

3

7

4

8

The following illustration shows the type 6 power distribution bus.

1

3

2

4

R7

CB7

5

R6

CB6

L1

L1

R5

CB5

R4

CB4

R8

CB8

6

7

R3

CB3

R2

CB2

L1

R1

CB1

L1

8

Rear View of the Rack

Reset Buttons (Two Facing the Front

the Rack)

Power Distribution Bus

View of the Power Distribution Bus

Reset Buttons

Outlet for Drawers

(Facing the Rack)

Outlets for Peripherals (Two Facing

the Front of the Rack)

Power Cord (Plug Configuration May

Var y)

Note: Circuit breakers for Type 7 buses are on the back of the bus. To access the circuit breaker, remove

the side cover or remove the bus. For information about removing the side cover, refer to ″Step 6.

Installing Multiple Racks″. For information about removing the bus, refer to “Removal and

Replacement of the AC Power Distribution Bus” on page 29.

Chapter 1. Reference Information

3

Page 16

1

6

2

7

3

8

4

9

5

4

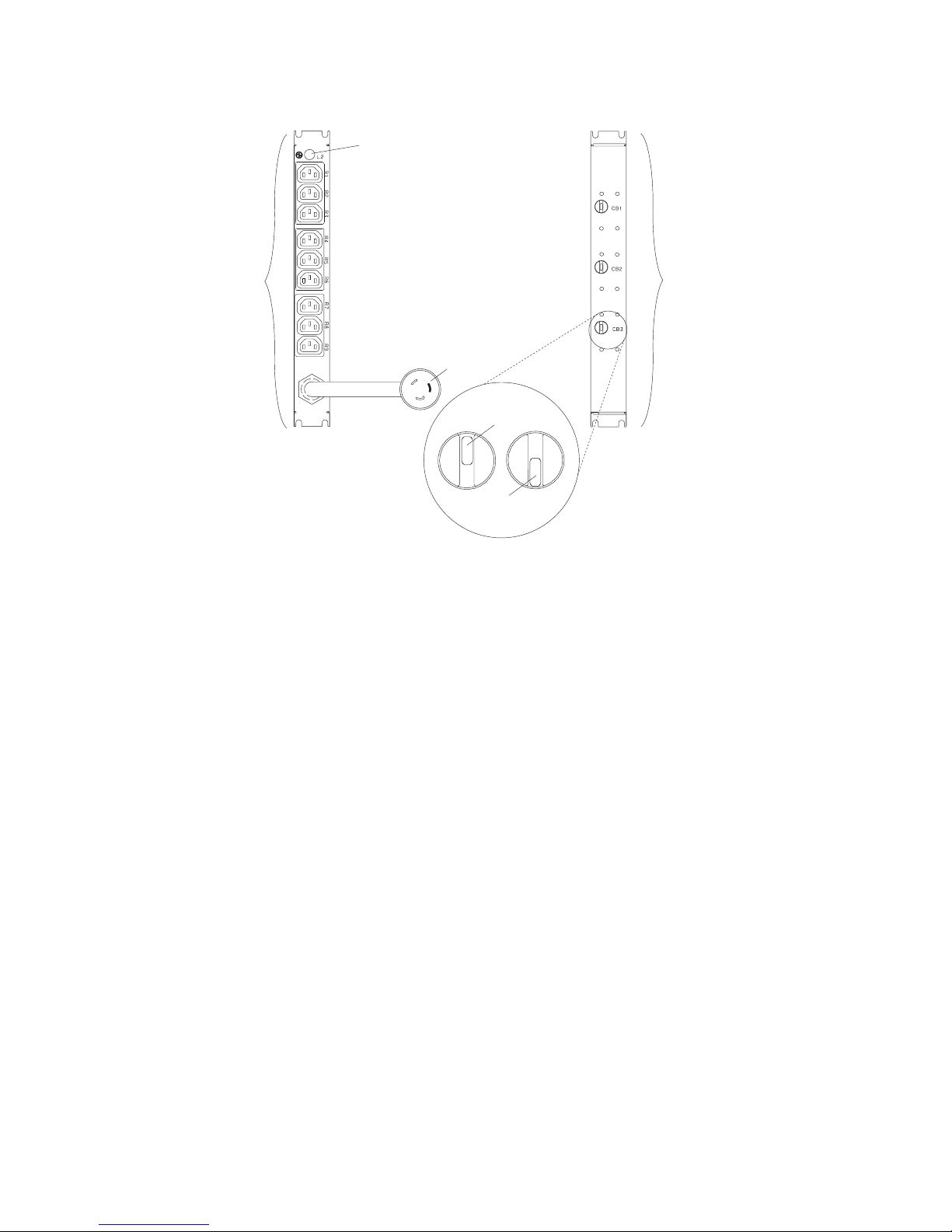

The following illustration shows the type 7 power distribution bus.

7

R1

R2

R3

R4

R5

8

R6

R7

R8

R9

4

5

Off

1

2

9

3

Circuit Breaker 1

Circuit Breaker 2

Circuit Breaker 3

Power Cord (Plug Configuration May

Var y)

Circuit Breaker in Normal Operating

Position

6

Circuit Breaker in Tripped Position

Circuit Breaker Status Lamp

Front of Power Distribution Bus

Rear of Power Distribution Bus

7014 Model T00, and Model T42 Service Guide

Page 17

1a

7a

2a

8a

3a

9 AC

4a

10 AC

5a

11

6a

12 AC

For type 6 buses, the ac power is not switched prior to the individual power outlet circuit breakers.

9

12

1a

2a

3a

4a

5a

6a

1

2

3

10

4

5

6

Reset Circuit Breaker 1

Reset Circuit Breaker 2

Reset Circuit Breaker 3

Reset Circuit Breaker 4

Reset Circuit Breaker 5

Reset Circuit Breaker 6

7a

7

11

8

8a

Reset Circuit Breaker 7

Reset Circuit Breaker 8

Outlets

Outlets Used to Power on

Drawers

Spare Connectors Oulets for

Peripherals (Two Facing Front of

Rack)

Power Plug

Chapter 1. Reference Information

5

Page 18

1a

4 AC

2a

5 AC

3a

6

The following illustration shows the type 7 single phase power distribution bus.

4

1a

5

R1

R2

R3

Circuit Breaker 1 (15 Amp)

Circuit Breaker 2 (15 Amp)

Circuit Breaker 3 (15 Amp)

3a

2a

R4

R5

R6

R7

R8

R9

Power Input

Outlets (quantity 9)

Note: The maximum total amperes is 24 amps.

7014 Model T00, and Model T42 Service Guide

Page 19

1a

6 AC

2a

7 AC

3a

8 AC

4a

9

5a

10 AC

The following illustration shows the type 7 three phase power distribution bus.

Type 7 Three Phase Power Distribution Bus

AC

Power

Input

Phase 1

Phase 2

Phase 3

Neutral

Circuit

Breaker 1

20A

Circuit

Breaker 2

20A

Circuit

Breaker 3

20A

AC

Outlets (11)

R1

R2

R3

R4

R5

R6

R7

Circuit Breaker 1 (20 Amp)

Circuit Breaker 2 (20 Amp)

Circuit Breaker 3 (20 Amp)

Circuit Breaker 4 (20 Amp)

Circuit Breaker 5 (20 Amp)

Circuit

Breaker 4

20A

Circuit

Breaker 5

20A

R8

R9

R10

R11

Power Input (Phase 1)

Power Input (Phase 2)

Power Input (Phase 3)

Neutral Line

Outlets (quantity 11)

Chapter 1. Reference Information

7

Page 20

1a

1f

1b

2 AC

1c

1d

1e

8

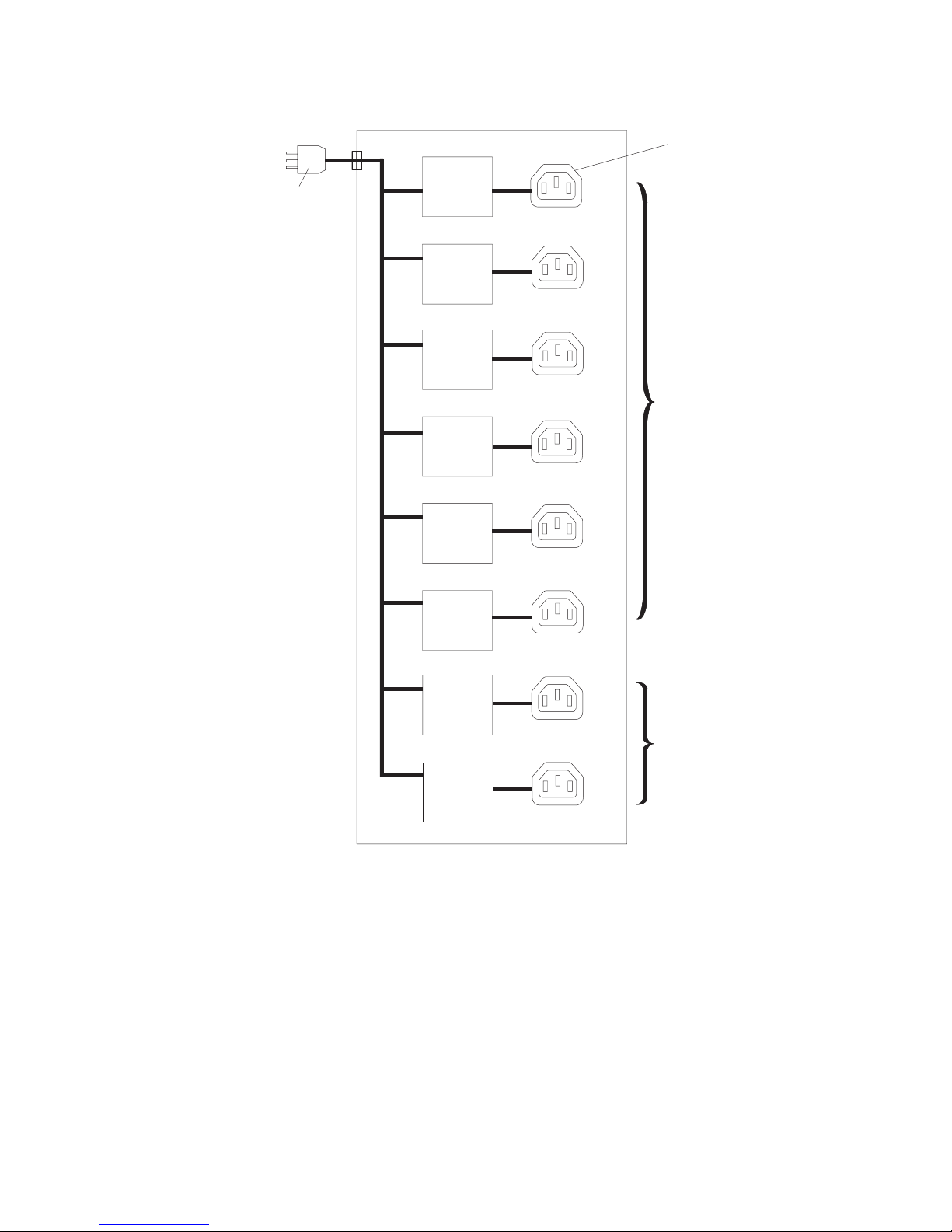

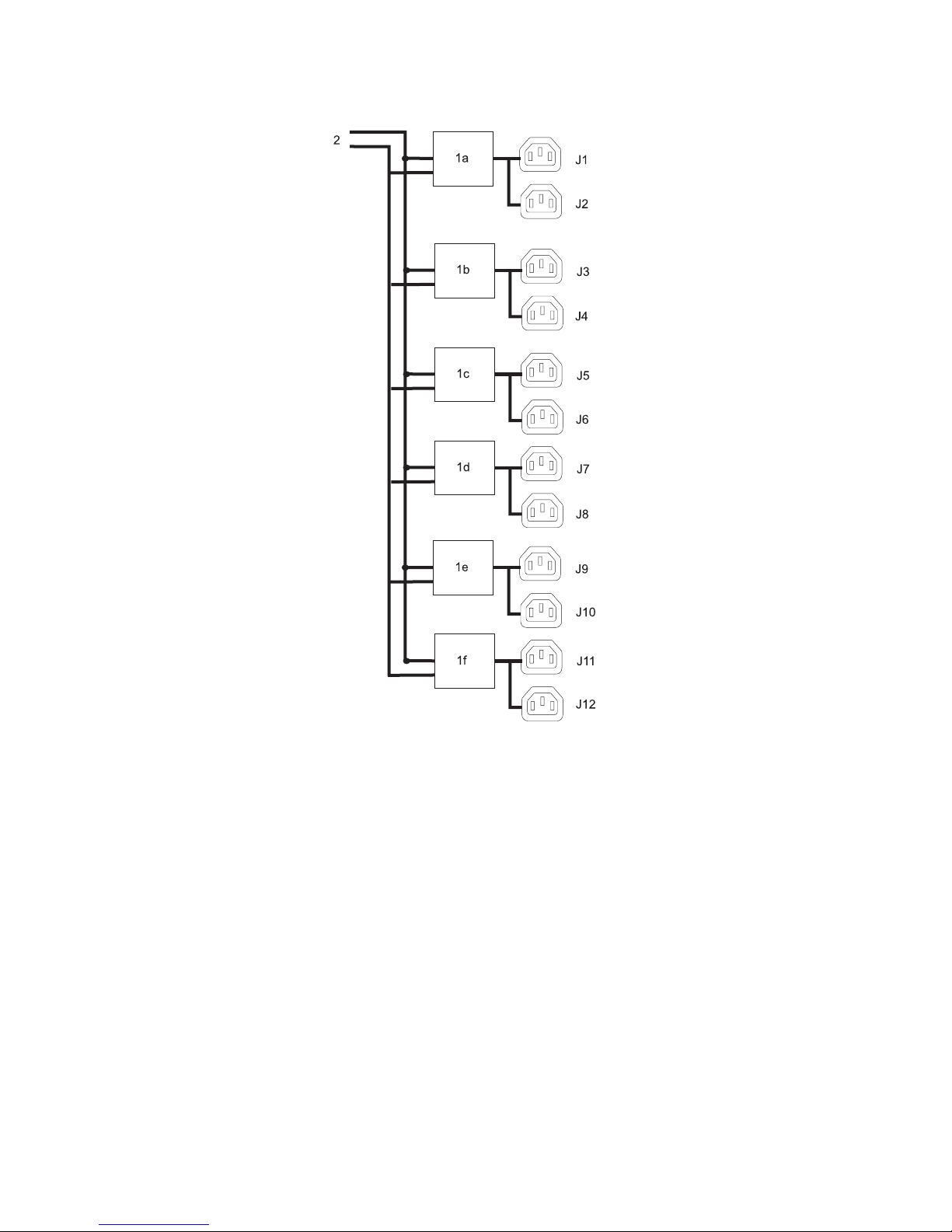

The following illustration shows the 9188/7188 power distribution bus.

Circuit Breaker 1 (20 Amp)

Circuit Breaker 2 (20 Amp)

Circuit Breaker 3 (20 Amp)

Circuit Breaker 4 (20 Amp)

Circuit Breaker 5 (20 Amp)

7014 Model T00, and Model T42 Service Guide

Circuit Breaker 6 (20 Amp)

Power Input

J1–J12 AC Outlets

Page 21

To

v

v

UL

v

An

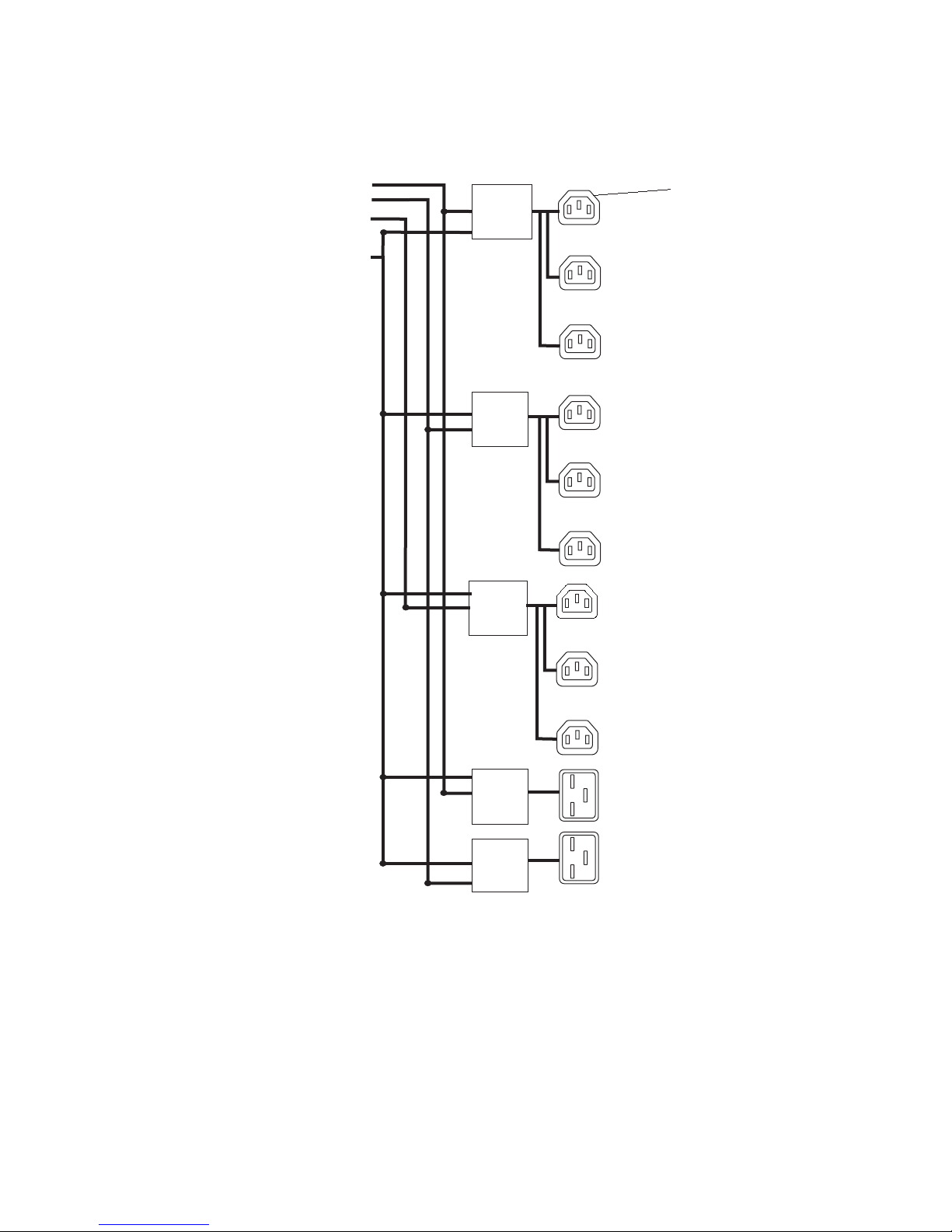

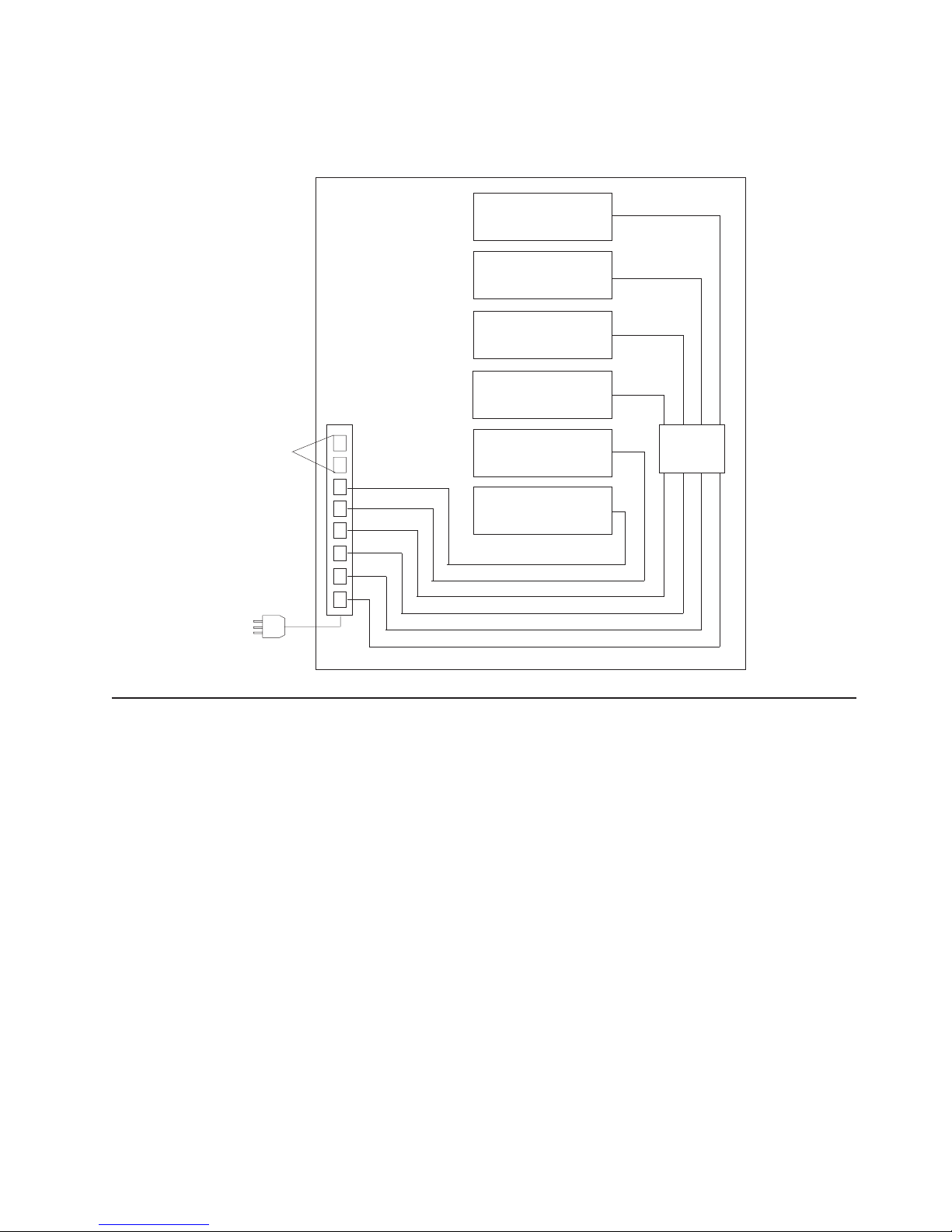

AC Power Distribution Bus Illustration

When the drawer power cords are plugged into the outlets, there should be less than 1 ohm resistance

between the drawer frames or the rack frame.

Outlets for

Peripherals

(Two Facing

Front of Rack)

Power

Distribution

Bus

Main

CPU

Disk Drive

Drawer

Optional Drawer

Disk Drive

Drawer

Optional Drawer

Optional Drawer

Main

Main

Drawer

Power

Cords

External AC Power Cables

avoid electrical shock, the manufacturer provides a power cable with a grounded attachment plug. Use

only properly grounded outlets.

Power cables used in the United States and Canada are listed by Underwriter’s Laboratories (UL) and

certified by the Canadian Standards Association (CSA). These power cords consist of the following:

Electrical cables, type ST

Attachment plugs complying with National Electrical Manufacturers Association (NEMA) as well as other

recognized or UL-listed electrical suppliers.

Appliance couplers complying with IEC Standard 320, Sheets C13, C14 and IEC Standard 309.

find the power cables that are available for the ac rack, refer to “Power Cords” on page 55.

To

Uninterruptible Power Source

uninterruptible power source (UPS) can be installed in the rack that contains an ac power distribution

bus. The uninterruptible power source powers one drawer or device. The uninterruptible power source

contains a power plug (input) and one power outlet (output). IBM offers several UPSs as type 9910 in the

pSeries configurator.

Chapter 1. Reference Information

9

Page 22

A dc

to

1

6

2

7

3

8

4

9

5

10

DC Rack Information

This section contains information about dc rack components.

DC Power Distribution Panel

power distribution panel can be installed on the top of the rack to distribute -48 V dc power to the

drawers and devices in the rack. The dc power distribution panel provides separate circuit breakers to

protect each drawer in the rack from excess current.

The dc power distribution panel configurations shown in this book are for example purposes only. The

actual dc power distribution panel installed in your rack may vary in terms of circuit breaker ratings,

configurations, and connections to the customer’s dc power source.

The power distribution panel contains a connection on the rear of the panel for attaching a

customer-supplied power alarm. This alarm is activated when any circuit breaker is tripped or is switched

the off position.

The circuit breaker is a single pole, single toggle handle unit with stud terminals, UL, CSA and VDE

approved, black with ″on″ and ″off″ markings, and dc with long trip delay. It is on when the handle is up,

and it is off when the handle is down.

The following illustration shows a typical dc power distribution panel (internal view).

1

2

3

4

9

8

5

7

Mounting Screws

To p Cover

Bus Bar Shield (Insulation)

Terminal Block (Both Sides of the

Rear Cover)

Covers for Empty Circuit Breaker

Positions

6

Front Bezel

Bezel Mounting Screws

Circuit Breaker Switches

Circuit Breaker Position Labels

7014 Model T00, and Model T42 Service Guide

Page 23

be

or to

1

3

2

4

DC Rack Configuration

The dc rack must be connected to an external -48 V dc power source. The -48 V dc power source must

electrically isolated from the ac power source. In addition, the -48 V dc source must be grounded.

The dc rack can be connected to one or two -48 V dc power source to provide redundant power backup. If

two power sources are used, one power source is connected to bus bar A and the other to bus bar B.

The circuit breakers in the dc power distribution panel are attached to two dc power bus bars (bus bar A,

and bus bar B). As described above, these bus bars can be connected either to a common power source

separate power sources (redundant power). Typically, a dc power distribution panel contains two

matching banks of circuit breakers. Each bank of circuit breakers is connected to either bus bar A or bus

bar B. The -48 V dc power supply of each drawer is connected to one circuit breaker in each bank of the

-48 V dc power distribution panel. Thus, when one of the -48 V dc power sources fails, the devices in the

rack still receive power from the other source.

The exact configuration of the dc power distribution panel depends on the configuration of drawers and

devices installed in the rack. Illustrations on the following pages show typical examples of power

distribution for a standalone rack containing a CPU drawer and device drawers.

Note: Before you service the dc power distribution panel, use care to first determine the exact power

configuration and distribution.

The following illustration shows a typical dc power distribution panel (external view).

Cable Channel Cover

Terminal Block (Both Sides)

Power Distribution Panel

Front of Rack

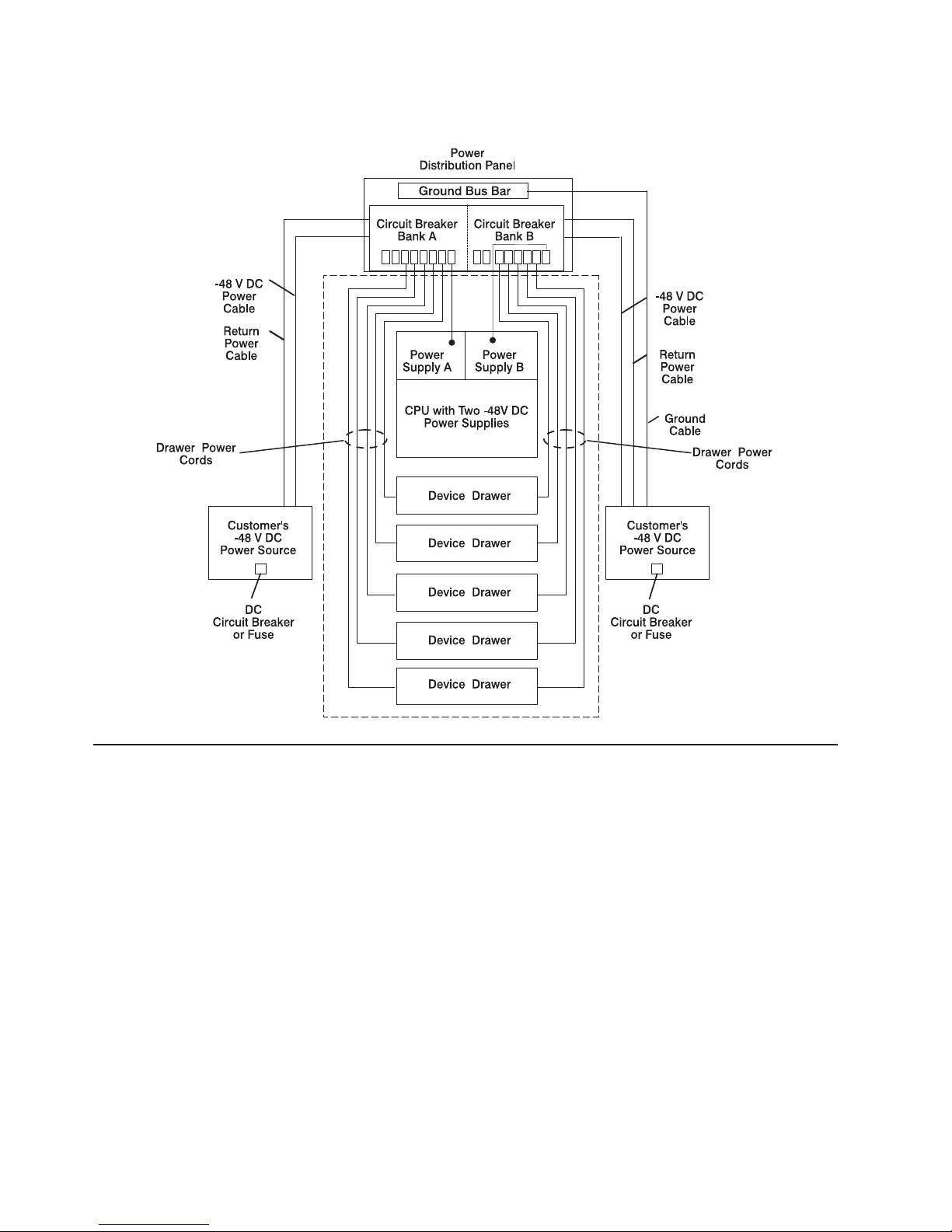

DC Power Distribution and Ground Illustration

The following illustration is for reference only and shows the power distribution in a typical -48 V dc rack

connected to two -48 V dc power sources. Each power supply in the CPU drawer is connected to a

separate circuit breaker in the -48 V dc power distribution panel.

Chapter 1. Reference Information

11

Page 24

v

v

12

When the drawer power cords are connected to the dc power distribution panel, make sure there is less

than 1 ohm resistance between the drawer frames or the rack frame.

DC Rack Power Cables

The customer provides the power cables from the -48 V dc power source to the dc power distribution

panel. The -48 V dc rack must be connected to a -48 V dc power source that is electrically isolated from

the ac power source. In addition, the -48 V dc power source must be reliably grounded.

The -48 V dc rack may be connected to two separate -48 V dc power sources. When the rack is

connected to two power sources, both power sources must be reliably grounded.

Power cables used in the United States and Canada are listed by Underwriter’s Laboratories (UL) and

certified by the Canadian Standards Association (CSA). These power cables have the following

characteristics:

Power cables and ground cables must be a minimum of 6 AWG stranded copper (or equivalent) for

lengths up to 50 feet from the power source.

All connectors must be the copper crimp type (compression). Connector metal must be compatible with

the cable metal.

7014 Model T00, and Model T42 Service Guide

Page 25

v

v

v

v

–

–

–

–

–

–

–

v

v

v

v

v

In

In

Specifications for 7014 Series Model T00 and Model T42 System Rack

Racks

This section contains specifications for the 7014 Series Model T00 and Model T42 System Rack racks.

Dimensions

T00 Height: 1804 mm (71 in)

T00 Height with power distribution panel: 1926 mm (75.8 in)

T42 Height: 2015 mm (79.3 in)

Depth:

T00 and T42 with Rear Door only: 1042 mm (41 in)

T00 with Rear and Front Door: 1098 mm (43.3 in) - Feature 6097 and Feature 6068

T00 with Rear and Front Door: 1147 mm (45.2 in) - Feature 6088

T42 with Rear and Front Door: 1098 mm (43.3 in) - Feature 6083

T42 with Rear and Front Door: 1147 mm (45.2 in) - Feature 6089 and Feature 6069

Width:

v

T00 and T42 without side panels: 623 mm (24.5 in)

T00 and T42 with side panels: 644 mm (25.4 in)

T00 EIA units: 36 EIA units

v

T42 EIA units: 42 EIA units

Weight

T00 Base Empty Rack: 244 kg (535 pounds)

T00 Full Rack: 816 kg (1795 pounds)

T42 Base Empty Rack: 261 kg (575 pounds)

T42 Full Rack: 930 kg (2045 pounds)

Installation Airflow

Rack airflow requirements are a function of the number and type of drawers installed. All rack installations

require careful site and facilities planning designed to address the cumulative drawer heat output and

provide the airflow volume rates necessary to comply with drawer temperature requirements. Refer to the

individual drawer specifications.

Power Requirements

the U.S., each power distribution bus installed in a rack requires a dedicated power line of 200 to 240 V

ac, 30 A.

other countries, input power to each power distribution bus may vary depending upon country

requirements.

Chapter 1. Reference Information

13

Page 26

v

v

v An

v

v

Do

1. If

a.

b.

1

7

2

8

3

9

4

10

5

11

6

12

14

Service Inspection Guide

Perform a service inspection on the rack when any of the following conditions occur:

The rack is inspected under a maintenance agreement.

Service is requested and service has not recently been performed.

alterations-and-attachments review is performed.

Changes have been made to the equipment that might affect the safe operation of the equipment.

External devices with an attached power cord are connected to the rack.

If the inspection indicates an unacceptable safety condition, the condition must be corrected before

representatives service the machine.

Note: The correction of any unsafe condition is the responsibility of the owner of the system.

the following checks:

the rack is bolted down, do the following:

Ensure that the rack is firmly secured to the floor.

Ensure that the four plastic isolator bushings are under the four leveling feet (dc only).

1

2

3

4

5

Rack-Mounting Bolt

Thin Washer

To p Plastic Isolator Bushing

Thick Washer

Spacer

Jam Nut

6

7

8

9

9

10

11

12

Leveling Foot

Lower Plastic Isolator Bushing (Used

only on dc powered systems)

Mounting Plate

Threaded Hole (Used to secure the

rack to mounting plate.)

Anchor Bolt Hole

Traced Pattern (Pattern to be traced

onto the floor using the mounting

plate as a template)

7014 Model T00, and Model T42 Service Guide

Page 27

If

or

1

5

2

6

3

7

4

3.

4.

5.

6.

7.

8.

9.

If

or

2.

the rack is not bolted down, ensure that the stabilizers are firmly attached to both the bottom front

and bottom rear of the rack.

CAUTION:

The stabilizer must be firmly attached to the bottom front of the rack to prevent the rack from

turning over when the drawers are pulled out of the rack. Do not pull out or install any drawer

feature if the stabilizer is not attached to the rack.

C16

1

3

2

Front of Rack

Stabilizer Bar Mounting Screws

Allen Wrench

4

2

3

Stabilizer Bar

Stabilizer Bar Mounting Screws

Mounting Holes

Rear of Rack

Check the covers for sharp edges and for damages or alterations that expose the internal parts of the

rack.

Check the covers for a proper fit to the rack. The covers should be in place and secure.

Open the back door of the rack.

Perform the power-off procedure for the power distribution system installed in your rack. See

″Power-Off Procedure with the AC Power Distribution Bus″ for ac power. See ″Power-Off Procedure

with the DC Power Distribution Panel″ for dc power.

Check for alterations or attachments. If there are any, check for obvious safety hazards such as

broken wires, sharp edges, or broken insulation.

Check the internal cables for damage.

Check for dirt, water, and any other contamination within the rack.

10.

Check the voltage label on the back of the system unit to ensure that it matches the voltage at the

outlet.

11.

Check the external power cable for damage.

12.

your rack is a dc rack, connect the customer’s ground cable to the rack unit and check for 0.1 ohm

less resistance between the metal rack frame and the copper ground strip on the back of the rack.

Chapter 1. Reference Information

15

Page 28

If

a.

1

2

b.

c.

v

v

v

16

13.

your rack is an ac rack, do the following:

With the external power cable connected to the system unit, check for 0.1 ohm or less resistance

between the ground lug on the external power cable plug and the metal frame.

1

L1

2

L1

L1

Rear View of Rack

Ohm Meter

Using the appropriate probe, check for 0.1 ohm or less resistance between the metal frame and

the grounding pin on each of the power outlets on the power distribution bus (check each bus if

there are multiple buses).

Check for the following conditions for each external device that has an attached power cord:

Damage to the power cord.

The correct grounded power cord.

With the external power cord connected to the device, check for 0.1 ohm or less resistance

between the ground lug on the external power cord plug and the metal frame of the device.

14.

Close the rear cover of the rack.

15.

Perform the power-on procedure for the power distribution system installed in your rack. See

“Power-On Procedure with the AC Power Distribution Bus” on page 25 and “Power-On Procedure

with the DC Power Distribution Panel” on page 27.

7014 Model T00, and Model T42 Service Guide

Page 29

If

If

-

Do

NO Go to

Chapter 2. Maintenance Analysis Procedures (MAPs)

This chapter provides diagnostic steps for detecting power problems in the rack. Use these power MAPs

only if you are directed here from a MAP step in the Diagnostic Information for Multiple Bus Systems.

your rack has a power distribution panel, follow the instructions for “MAP 1520: DC Power Distribution

Panel - Power MAP.”

your rack has a power distribution bus, follow the instructions for “MAP 1522: AC Power Distribution Bus

Power MAP” on page 21.

MAP 1520: DC Power Distribution Panel - Power MAP

Purpose of This MAP

This procedure is used to locate power problems in the dc power distribution panel. If a problem is

detected, this procedure helps you isolate the failing field replaceable unit (FRU).

Safety Notices

Observe the following safety notices during service procedures.

DANGER

electrical outlet that is not correctly wired could place hazardous voltage on metal parts of

An

the system or the devices that attach to the system. It is the responsibility of the customer to

ensure that the outlet is correctly wired and grounded to prevent an electrical shock.

Before installing or removing signal cables, ensure that the power cables for the system unit

and all attached devices are unplugged.

When adding or removing any additional devices to or from the system, ensure that the power

cables for those devices are unplugged before the signal cables are connected. If possible,

disconnect all power cables from the existing system before you add a device.

Use one hand, when possible, to connect or disconnect signal cables to prevent a possible

shock from touching two surfaces with different electrical potentials.

During an electrical storm, do not connect cables for display stations, printers, telephones, or

station protectors for communications lines.

D05

CAUTION:

Energy hazard, remove power before servicing. Disconnect two power supply cords.

C23

Step 1520-1

any of the devices in the rack have their power indicator(s) lit? (front operator panel or power

supply LED).

“Step 1520-10” on page 19.

YES Go to “Step 1520-2” on page 18.

17

Page 30

Is

NO Go to

Is

NO

Is

NO Go to

1.

2.

3.

Is

NO

to

NO Go to

Is

NO

18

Step 1520-2

Check the circuit breaker for the drawer that does not have power.

the circuit breaker tripped?

“Step 1520-7.”

YES Reset the circuit breaker by turning the circuit breaker off, then on. Go to “Step 1520-3.”

Step 1520-3

there power to the drawer?

Check the circuit breaker again. Go to “Step 1520-4.”

YES Go to ″MAP 0410: Repair Checkout″ in the Diagnostic Information for Multiple Bus Systems.

Step 1520-4

the circuit breaker tripped again?

“Step 1520-7.”

YES Go to “Step 1520-5.”

Step 1520-5

Set the circuit breaker to the off position.

Disconnect the power cable from the device’s power supply.

Set the circuit breaker to the on position.

the circuit breaker tripped again?

Replace the device power supply. Go to ″MAP 0410: Repair Checkout″ in the Diagnostic

Information for Multiple Bus Systems.

YES Turn circuit breaker off and replace the power cable. Set the circuit breaker to the on position. Go

“Step 1520-6.”

Step 1520-6

Did the circuit breaker trip again?

″MAP 0410: Repair Checkout″ in the Diagnostic Information for Multiple Bus Systems.

YES Replace the circuit breaker. Go to ″MAP 0410: Repair Checkout″ in the Diagnostic Information for

Multiple Bus Systems.

Step 1520-7

there power to the drawer?

Replace the device power supply. Go to “Step 1520-8” on page 19.

YES Go to ″MAP 0410: Repair Checkout″ in the Diagnostic Information for Multiple Bus Systems.

CAUTION:

Energy hazard, remove power before servicing. Disconnect two power supply cords.

C23

7014 Model T00, and Model T42 Service Guide

Page 31

Is

NO Go to

Is

NO Go to

NO

1.

2.

3.

Is

NO Go to

1.

2.

3.

4.

NO

Step 1520-8

there power to the drawer?

“Step 1520-9.”

YES Go to ″MAP 0410: Repair Checkout″ in the Diagnostic Information for Multiple Bus Systems.

Step 1520-9

Set the circuit breaker to the off position, and replace the power cable between the circuit breaker and the

device.

there power to the drawer?

“Step 1520-14” on page 20.

YES Go to ″MAP 0410: Repair Checkout″ in the Diagnostic Information for Multiple Bus Systems.

Step 1520-10

Are all the circuit breakers turned on?

Turn the circuit breakers on. Then go to ″MAP 0410: Repair Checkout″ in the Diagnostic

Information for Multiple Bus Systems.

YES Go to “Step 1520-11.”

Step 1520-11

Set all of the circuit breaker switches to the off position (switches in the down position).

Locate terminal board 2 (TB2) on the outside of the rear cover of the power distribution panel.

Measure for -40 to -60 V dc on terminal board 2 (TB2) between positions one and two (side A circuit

breaker) and between positions five and six (side B circuit breaker).

the voltage between -40 and -60 V dc?

“Step 1520-12.”

YES Go to “Step 1520-13” on page 20.

Step 1520-12

Remove the six screws attaching the top cover of the power distribution panel.

Remove the top cover and then remove the insulator.

Using a multimeter, attach the black multimeter cable lead to the return bus bar (+), and then attach

the red multimeter cable lead to the -48 V dc bus bar (-).

Measure for -40 to -60 V dc between the -48 V dc bus bar (upper bar) and the return bus bar (lower

bar) in the power distribution panel.

Was the correct voltage present?

Ask the customer to check the power source for the correct voltage, and check the external power

cable (from customer’s power source) for continuity.

YES Go to “Step 1520-13” on page 20.

Chapter 2. Maintenance Analysis Procedures

19

Page 32

Do

NO Go to

1.

2.

3.

Is

NO

NO

20

Step 1520-13

Set all of the circuit breaker switches on the power distribution panel to the on position.

all the power supplies on the devices have power?

“Step 1520-14.”

YES Go to ″MAP 0410: Repair Checkout″ in the Diagnostic Information for Multiple Bus Systems.

Step 1520-14

Ensure that the circuit breaker is in the on position.

Using a multimeter, attach the black multimeter cable lead to the return bus bar (+), and then attach

the red multimeter cable lead to the bottom terminal on the circuit breaker.

Measure for -40 to -60 V dc between the -48 V dc circuit breaker and the return bus bar (lower bar) in

the power distribution panel.

the voltage between -40 and -60 V dc?

Replace the circuit breaker. Then go to ″MAP 0410: Repair Checkout″ in the Diagnostic

Information for Multiple Bus Systems.

YES Go to “Step 1520-15.”

Step 1520-15

Has the device power supply previously been replaced?

Replace the power supply. Then go to ″MAP 0410: Repair Checkout″ in the Diagnostic Information

for Multiple Bus Systems.

YES Replace the cable. Then go to ″MAP 0410: Repair Checkout″ in the Diagnostic Information for

Multiple Bus Systems.

7014 Model T00, and Model T42 Service Guide

Page 33

If

to

Is

NO Go to

MAP 1522: AC Power Distribution Bus - Power MAP

Purpose of This MAP

This procedure is used to locate power problems in the power distribution bus. If a problem is detected,

this procedure will help you isolate the failing field replaceable unit (FRU).

the rack contains more than one power distribution bus, use this MAP to test the power distribution bus

that is connected to the failing drawer. If you cannot determine which power distribution bus is connected

the failing drawer, use this MAP to test the first power distribution bus, and then test the other power

distribution bus until the problem is determined.

Safety Notices

Observe the following safety notices during service procedures.

DANGER

electrical outlet that is not correctly wired could place hazardous voltage on metal parts of

An

the system or the devices that attach to the system. It is the responsibility of the customer to

ensure that the outlet is correctly wired and grounded to prevent an electrical shock.

Before installing or removing signal cables, ensure that the power cables for the system unit

and all attached devices are unplugged.

When adding or removing any additional devices to or from the system, ensure that the power

cables for those devices are unplugged before the signal cables are connected. If possible,

disconnect all power cables from the existing system before you add a device.

Use one hand, when possible, to connect or disconnect signal cables to prevent a possible

shock from touching two surfaces with different electrical potentials.

During an electrical storm, do not connect cables for display stations, printers, telephones, or

station protectors for communications lines.

D05

Step 1522-1

uninterruptible power source installed?

“Step 1522-4” on page 22.

YES Go to “Step 1522-2” on page 22.

Chapter 2. Maintenance Analysis Procedures

21

Page 34

If

NO

NO

to

NO If

NO

go to

NO Go to

22

Step 1522-2

the system is not receiving power and the LED on the power distribution bus is off, unplug the

customer’s power cable from the uninterruptible power source, and then plug the customer’s power cable

into the power distribution bus.

The green LEDs located on the power distribution bus indicate that power is supplied from the customer’s

outlet, through the customer’s power cable, and to the power distribution bus.

Are the LEDs on the power distribution bus ON?

Check the customer’s power cable for the proper voltage from the wall outlet to the power

distribution bus or uninterruptible power source. Then go to “Step 1522-3.”

YES Replace the uninterruptible power source if necessary. Refer to the maintenance and diagnostic

information in the service guide for the uninterruptible power source installed in your rack, and

then go to “Step 1522-10” on page 23.

Step 1522-3

Was the voltage correct?

Check the customer’s outlet for the correct voltage. If correct, exchange the power cable. Then go

“Step 1522-10” on page 23.

YES Exchange the power distribution bus, and go to “Step 1522-10” on page 23.

Step 1522-4

Did any of the power lights on the devices come on and stay on?

the LED on the power distribution panel is off, check the customer’s power cable for the proper

voltage from the wall outlet to the power distribution bus and go to “Step 1522-5.”

YES If a single device is not receiving power, go to “Step 1522-6.”

Step 1522-5

Was the voltage correct?

Check the customer’s outlet for the correct voltage. If correct, exchange the power cable and then

“Step 1522-10” on page 23.

YES Exchange the power distribution bus and go to “Step 1522-10” on page 23.

Step 1522-6

Did the drawer power reset circuit breaker on the power distribution bus go to the Off position

(pop out)?

“Step 1522-7” on page 23.

YES Go to “Step 1522-9” on page 23.

7014 Model T00, and Model T42 Service Guide

Page 35

1.

2.

NO Go to

1.

2.

NO

1.

2.

NO

1.

2.

Step 1522-7

Plug the drawer power cable into another outlet on the power distribution bus.

Turn on power to the drawer.

Did the drawer power light come on and stay on?

“Step 1522-8.”

YES The first outlet is defective. Use the second outlet, or exchange the power distribution bus, and

then go to “Step 1522-10.”

Step 1522-8

Plug the power cable of another device or drawer into the same outlet.

Turn on power to the device or drawer.

The green light near the ac plug on the rear of some drawers indicates only that power is reaching the

drawer and not that the power supply is operating.

Did the drawer power light come on and stay on or are the fans operating?

Exchange the power distribution bus, and then go to “Step 1522-10.”

YES The problem is probably located in the original drawer. Go to “MAP 1520: DC Power Distribution

Panel - Power MAP” on page 17 in the service guide for the system installed in your rack.

Step 1522-9

Plug the CPU drawer power cable into another outlet on the power distribution bus.

Set the power button to on (button pushed in).

Did the circuit breaker go to the Off position (pop out)?

The first circuit breaker is probably defective. Use the second outlet, or exchange the power

distribution bus, and then go to “Step 1522-10.”

YES The drawer is overloading the circuit breaker. Exchange the CPU drawer power cable or power

supply. Then go to “Step 1522-10.”

Step 1522-10

Connect all drawer power cables to their original power outlets on the power distribution bus.

This completes the repair. Go to ″MAP 0410: Repair Checkout″ in the Diagnostic Information for

Multiple Bus Systems.

Chapter 2. Maintenance Analysis Procedures

23

Page 36

24

7014 Model T00, and Model T42 Service Guide

Page 37

1.

Chapter 3. Removal and Replacement Procedures

This chapter contains information about powering the rack on and off, and removing and replacing

components.

Use the correct power-on and power-off procedure for the type of power distribution used in your rack.

Safety Notices

This section contains safety notices that apply to all the procedures in this chapter. Review this section

carefully before performing any power-related operations.

DANGER

An electrical outlet that is not correctly wired could place hazardous voltage on metal parts of

the system or the devices that attach to the system. It is the responsibility of the customer to

ensure that the outlet is correctly wired and grounded to prevent an electrical shock.

Before installing or removing signal cables, ensure that the power cables for the system unit

and all attached devices are unplugged.

When adding or removing any additional devices to or from the system, ensure that the power

cables for those devices are unplugged before the signal cables are connected. If possible,

disconnect all power cables from the existing system before you add a device.

Use one hand, when possible, to connect or disconnect signal cables to prevent a possible

shock from touching two surfaces with different electrical potentials.

During an electrical storm, do not connect cables for display stations, printers, telephones, or

station protectors for communications lines.

D05

CAUTION:

This unit has more than one power supply cord. To reduce the risk of electrical shock, disconnect

two power supply cords before servicing.

C21

Operating System Shutdown

Before powering off any drawers or external devices, ask the customer if this rack is used in a

high-availability system. If it is, notify the customer that other attached systems might be affected by this

procedure.

Notify the customer if you are going to turn off power to any drawers that are attached to drawers or

devices in another system.

Before powering off the system unit, you must first shut down the operating system to prevent losing data.

Ask the customer to shut down all programs. Failure to do so can result in the loss of data. See your

operating system documentation for information about the shutdown command.

Power-On Procedure with the AC Power Distribution Bus

This section covers the ac rack power-on procedures.

Plug all drawer power cables into the outlets on the ac power distribution bus or buses.

25

Page 38

If

1

5

of

2

6

3

7

4

8

3.

4.

26

2.

more than one ac power distribution bus is installed in the rack, plug the power cable of each into

the customer’s ac power outlet.

CAUTION:

This product is equipped with a three-wire power cable and plug for the user’s safety. Use this

power cable with a properly grounded electrical outlet to avoid electrical shock.

C01

For illustration purposes, the type 6 power distribution bus is shown. However, this procedure also

applies to the type 7 and 9188/7188 power distribution buses.

1

3

2

4

R7

CB7

5

R6

CB6

L1

L1

R5

CB5

R4

CB4

R8

CB8

6

7

R3

CB3

R2

CB2

L1

R1

CB1

L1

8

Rear View of the Rack

Power Distribution Bus

View of the Power Distribution Bus

(Facing the Rack)

Outlets for Peripherals (Two Facing

the Front of the Rack)

Follow the power-on procedures for the drawers installed in the rack. For more information, refer to the

service guide for the drawers installed in the rack.

Close the rear door of the rack.

7014 Model T00, and Model T42 Service Guide

Reset Buttons (Two Facing the Front

the Rack)

Reset Buttons

Outlet for Drawers

Power Cord (Plug Configuration May

Var y)

Page 39

1. Be

2.

3.

If

4.

5.

6.

It is

dc

1.

1

3

2

4

Power-Off Procedure with the AC Power Distribution Bus

This section covers the ac power-off procedure.

sure the operating system is shut down. See “Operating System Shutdown” on page 25.

Power off each of the drawers installed in the rack. For more information, refer to the service guide for

the drawers installed in the rack.

Note: Because many drawers or devices can be connected to the system unit, it may be impractical

for you to switch off power to all the drawers or devices and unplug their power cables.

Open the rear door of the rack.

Note:

more than one ac power distribution bus is installed in your rack and you are servicing only

one, power off the drawers connected to the ac power distribution bus that you are servicing.

Turn off power to all drawers or devices that are connected to the ac power distribution bus that you

are servicing.

Unplug all the drawer or device power cables from the ac power distribution bus that you are servicing.

Unplug the power cable from the customer’s ac power outlet.

Power-On Procedure with the DC Power Distribution Panel

This section covers the power-on procedure for the dc rack.

CAUTION:

Energy hazard, remove power before servicing. Disconnect two power supply cords.

C23

Note:

Locate terminal board 2 (TB2) on the outside of the dc power distribution panel.

the customer’s responsibility to provide and have a qualified technician properly install both the

power source cables from the customer’s -48 V dc power source to the dc power distribution

panel. The customer is also responsible for connecting the customer-supplied ground cable to the

ground bus bar on the rack frame.

Cable Channel Cover

Terminal Block (Both Sides)

Power Distribution Panel

Front of Rack

Chapter 3. Removal and Replacement

27

Page 40

2

2.

a.

b.

c.

1

2

3 Up

3.

4.

5.

6.

28

2

1

3

1

5

4

6

8

7

2

1 Power Status Connections for Side A Circuit Breaker

Power Status Connections for Side B Circuit Breaker

Using a polarity-sensitive multimeter, ensure that the voltage and polarity are correct at the dc power

distribution panel (check both the -48 V dc bus and the -48 V dc return bus) as follows:

Ensure that all circuit breakers are off (circuit breaker switches in the down position).

Measure for -40 V dc to -60 V dc between position 1 (-) and position 2 (+) on terminal board 2 to

test the power for side A.

Measure for -40 V dc to -60 V dc between position 5 (-) and position 6 (+) on terminal board 2 to

test the power for side B.

The following illustration shows the front view of the power distribution panel (PDP)

A1 B1A2 B2A3 B3

A4 B4A5 B5

1

A7

A6 B6

A8 A9

B7

B8 B9

Plug all externally attached device power cords into customer’s the electrical outlets.

Turn on power to all external devices attached to the system unit. For more information, refer to the

service guide.

Set all the circuit breakers to the on position (up).

Turn on power to all of the devices and drawers connected to the dc power distribution panel.

7014 Model T00, and Model T42 Service Guide

2

3

Circuit Breaker Positions (Not labeled on PDP)

Down Position (Off)

Position (On)

Page 41

1. Be

2.

3.

4.

of

5.

1

2

3 Up

Power-Off Procedure with the DC Power Distribution Panel

This section covers the power-off procedure for the dc rack.

sure the operating system is shut down. See “Operating System Shutdown” on page 25.

Turn off power to all devices and drawers in the rack. For more information, refer to the service guide.

Turn off power to all external devices attached to the system.

Unplug the device power cords from the customer’s electrical outlets.

Note: If drawers in attached racks are connected to circuit breakers in the dc power distribution panel

this rack, power to the drawers in attached racks will be powered off if the circuit breakers in

this rack are set to off.

Except for circuit breakers in this rack that are connected to drawers in another rack, set all circuit

breakers to the off position (down).

CAUTION:

Energy hazard, remove power before servicing. Disconnect two power supply cords.

C23

Note: Because a large number of external devices can be connected to the system unit, it might be

impractical for you to turn off power to all the devices and unplug their power cords.

The following illustration shows the front view of the power distribution panel (PDP)

A1 B1A2 B2A3 B3

A4 B4A5 B5

1

2

Circuit Breaker Positions (Not labeled on PDP)

Down Position (Off)

Position (On)

A7

A6 B6

A8 A9

B7

B8 B9

3

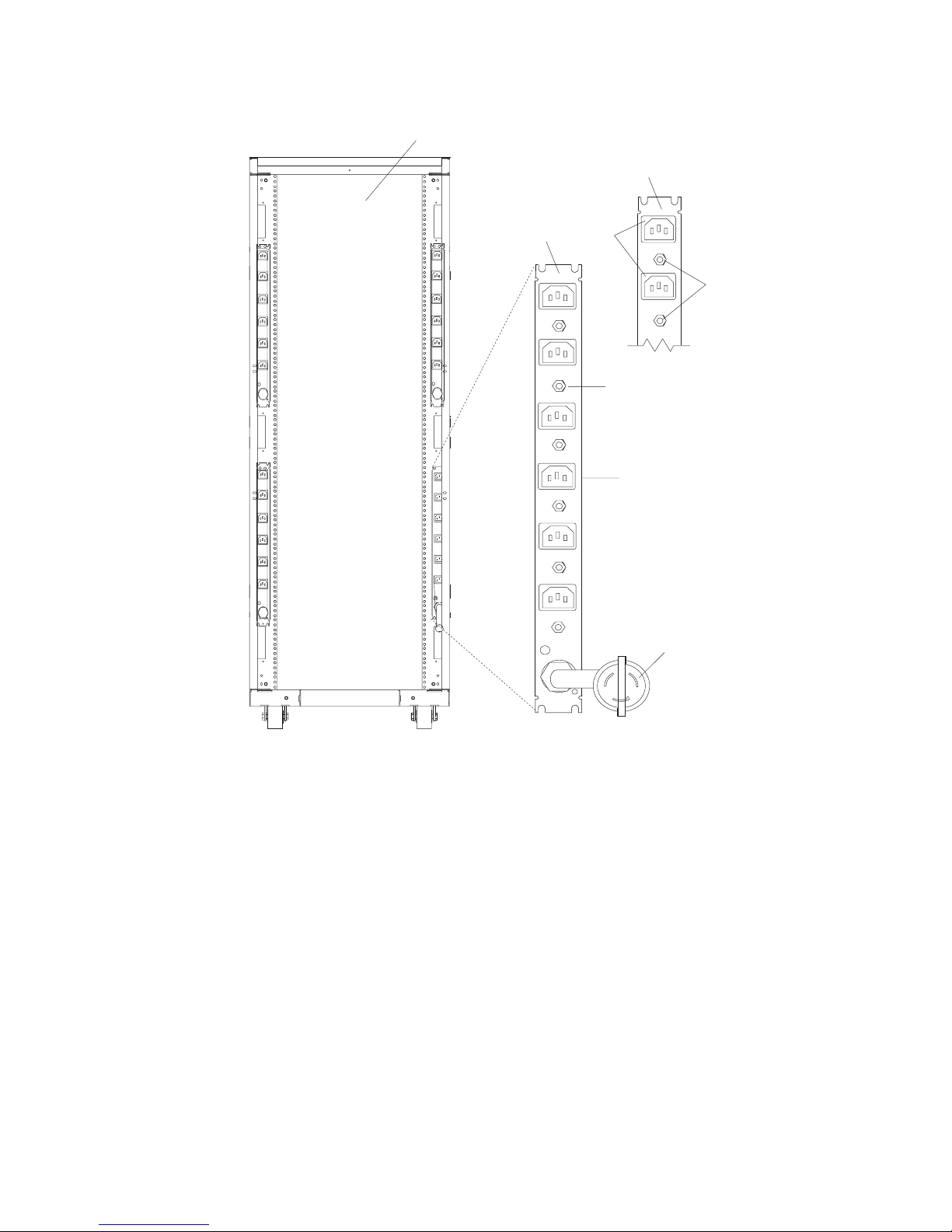

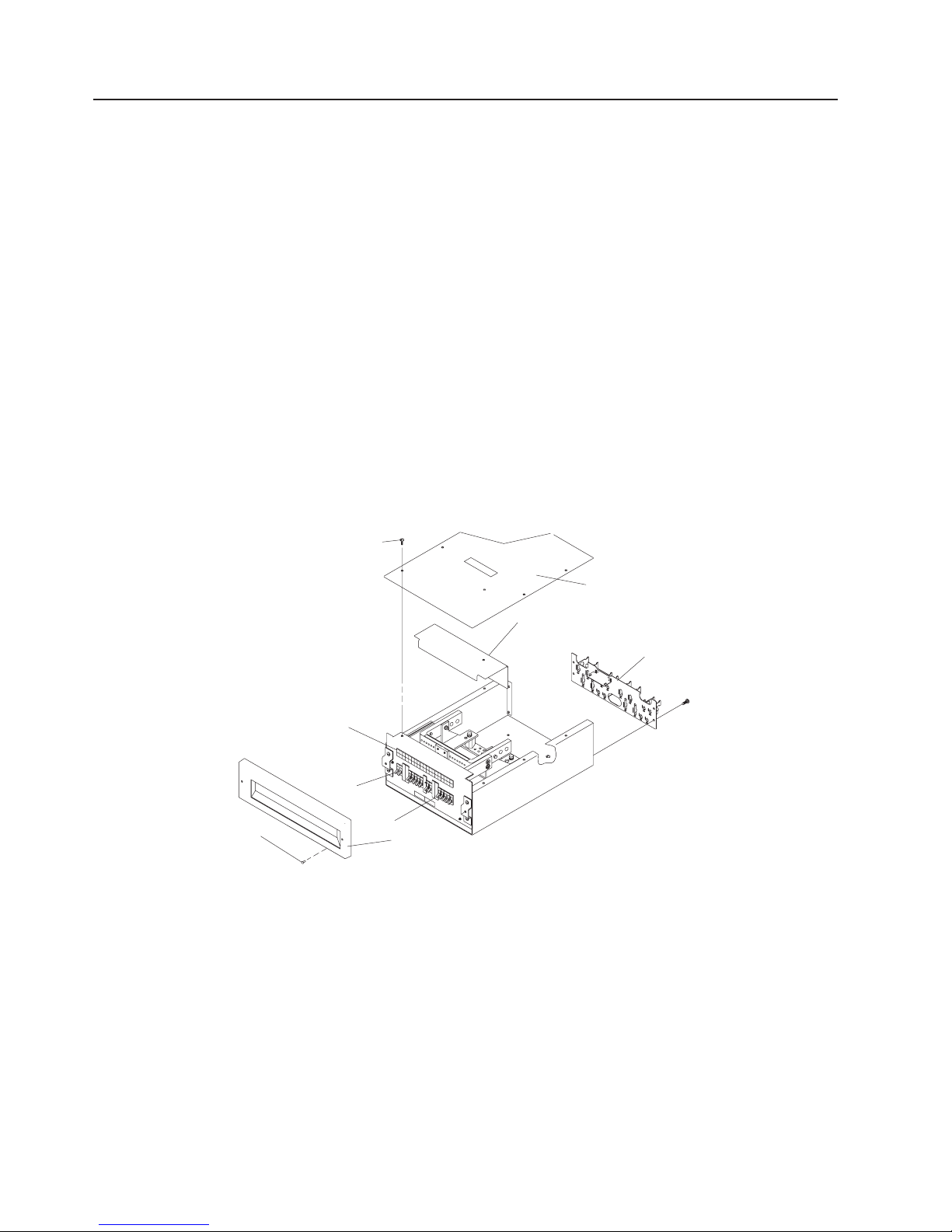

Removal and Replacement of the AC Power Distribution Bus

This section covers the removal and replacement procedures for the ac power distribution bus. The

following illustration shows where the ac power distribution bus might be installed.

Note: If there are more than four power distribution buses in the rack, additional buses may be mounted

horizontally in the rear mounting rails of the rack.

Chapter 3. Removal and Replacement

29

Page 42

to

1

5

of

2

6

3

7

4

8

1.

2.

3.

4.

5.

30

For illustration purposes, the type 6 power distribution bus is shown. However, this procedure also applies

the type 7 and 9188/7188 power distribution buses.

1

3

2

4

R7

CB7

5

R6

CB6

L1

L1

R5

CB5

R4

CB4

R8

CB8

6

7

R3

CB3

R2

CB2

L1

R1

CB1

L1

8

Rear View of the Rack

Power Distribution Bus

View of the Power Distribution Bus

(Facing the Rack)

Outlets for Peripherals (Two Facing

the Front of the Rack)

Removal

This section covers the removal procedure of the ac power distribution bus.

Follow the “Power-Off Procedure with the AC Power Distribution Bus” on page 27.

Turn off power and disconnect the ac power distribution bus from the customer’s ac power outlet.

Record the locations of the drawer ac power cables plugged into the ac power distribution bus.

Unplug the drawer ac power cables from the ac power distribution bus.

Remove the four mounting screws from the ac power distribution bus and, pull the bus toward you to

access the power connectors on the other side of the bus.

Unplug the power cables from the other side of the bus. Remove the ac power distribution bus from

the rack.

7014 Model T00, and Model T42 Service Guide

Reset Buttons (Two Facing the Front

the Rack)

Reset Buttons

Outlet for Drawers

Power Cord (Plug Configuration May

Var y)

Page 43

On

1. On

2.

3.

4.

5.

6.

1.

2.

3.

4.

5.

6. If

6.

9188 or 7188 ac power distribution buses only, remove the top and bottom L-bracket on the PDU

via the two screws per bracket.

Replacement

This section covers the replacement for the ac power distribution bus.

9188 or 7188 ac power distribution buses only, install the top and bottom L-bracket on the PDU via

the two screws per bracket.

Reconnect any power cables that you disconnected from the other side of the ac power distribution

bus.

Slide the ac power distribution bus into position, and install the four mounting screws.

Reconnect any power cables that you disconnected from the ac power distribution bus.

Plug the power cables into the locations that you recorded during the removal procedure.

Follow the steps in “Power-On Procedure with the AC Power Distribution Bus” on page 25.

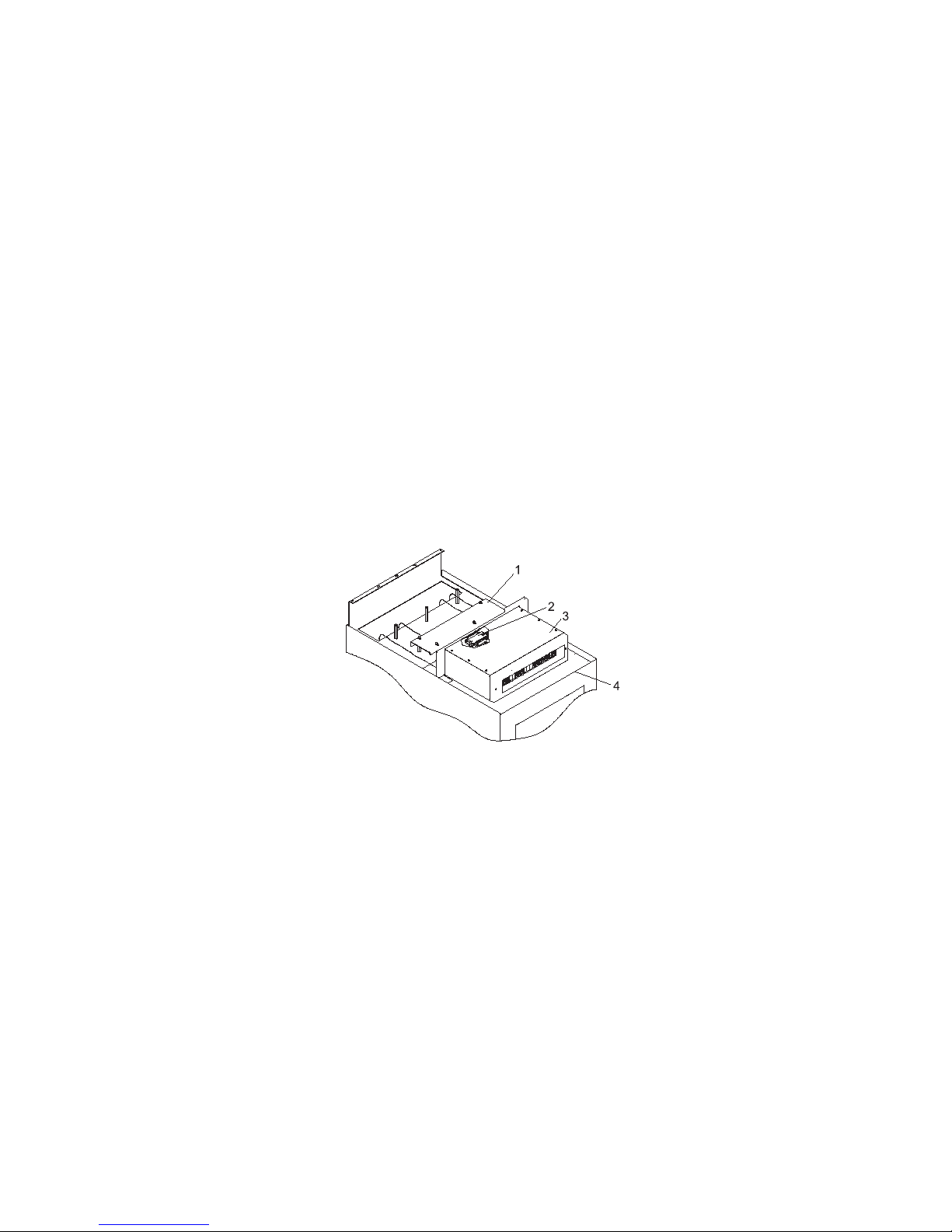

Removal and Replacement of the DC Power Distribution Panel

This section covers the removal and replacement procedure for the dc power distribution panel.

CAUTION:

Energy hazard, remove power before servicing. Disconnect two power supply cords.

C23

Removal

This section covers the removal procedures for the dc power distribution panel.

Follow the steps in “Power-Off Procedure with the DC Power Distribution Panel” on page 29.

Note: Removing power to the dc power distribution panel does not remove power to drawers in this

rack that are powered by the dc power distribution panel in another rack.

Have the customer turn off the dc power source that connects to the dc power distribution panel.

After the customer’s -48 V dc source power is turned off, ensure that a tag or label is positioned over

the power source switches to indicate that the power is intended to be off (lock-out/tag-out).

Remove the six mounting screws from the top cover of the power distribution panel. Then remove the

top cover.

Remove the -48 V dc bus shield (insulation) from the dc power distribution panel.

one is installed, remove the cable channel cover.

Chapter 3. Removal and Replacement

31

Page 44

1

6

2

7

3

8

4

9

5

7.

dc

8.

9.

1

6 B

2 A

7 B

3 A

8 B

4 A

9 B

5 A

32

The following illustration shows a typical dc power distribution panel (internal view).

1

2

3

9

8

5

7

6

4

Mounting Screws

To p Cover

Bus Bar Shield (Insulation)

Terminal Block (Both Sides of the

Front Bezel

Bezel Mounting Screws

Circuit Breaker Switches

Circuit Breaker Position Labels

Rear Cover)

Covers for Empty Circuit Breaker

Positions

With a multimeter, verify that no voltage exists between the two -48 V dc bus bars and the two -48 V

return bus bars.

Ensure that the customer’s service provider completely disconnects the two -48 V dc power source

cables from the -48 V dc bus bars, and the two -48 V dc return ground cables from the -48 V dc

return bus bars.

Record the locations and connection points of all cables.

10.

Disconnect all drawer power cables.

Front of Power Distribution Panel

-48 V dc (-) Bus Bar

-48 V dc (-) Power Cable

Return (-) Bus Bar

Return (-) Power Cable

7014 Model T00, and Model T42 Service Guide

Return (-) Power Cable

-48 V dc (-) Power Cable

Return (-) Bus Bar

-48 V dc (-) Bus Bar

Page 45

1

4

2

5

3

11.

Remove the four mounting screws that attach the dc power distribution panel to the top of the rack,

and remove the panel.

1

2

3

5

Ground Wire with Connector

Mounting Screw (quantity 4)

Power Distribution Panel

4

Ground Wire Connector

Mounting Screw (This screw secures

both the Power Distribution Panel and

the Ground Wire.)

Chapter 3. Removal and Replacement

33

Page 46

1. If it is

2.

3.

4.

5.

6. Be

7.

to

1

6 B

2 A

7 B

3 A

8 B

4 A

9 B

5 A

8.

9.

34

Replacement

This section covers the replacement procedure for the dc power distribution panel.

not already off, remove the top cover of the dc power distribution panel.

Remove the shield.

Place the dc power distribution panel in position on the top of the rack, and install the four mounting

screws.

Route and attach the drawer power cables.

Ensure that all circuit breakers are set to off.

sure that the customer’s dc power source is turned off.

Ensure that the customer’s service provider properly connects the two -48 V dc power source cables

the -48 V dc bus bars, and the two -48 V dc return cables to the -48 V dc return bus bars.

Front of Power Distribution Panel

-48 V dc (-) Bus Bar

-48 V dc (-) Power Cable

Return (-) Bus Bar

Return (-) Power Cable

Replace the -48 V dc bus bar shield (insulation).

Replace the top cover of the dc power distribution panel.

Return (-) Power Cable

-48 V dc (-) Power Cable

Return (-) Bus Bar

-48 V dc (-) Bus Bar

7014 Model T00, and Model T42 Service Guide

Page 47

If

1

4

2

5

3

6

10.

necessary, replace the cable channel cover.

Mounting Screw (quantity 4)

Cable Channel Cover

Mounting Screw (quantity 6)

1

2

3

4

5

6

Shield

Power Distribution Panel (PDP)

Front of Rack

11.

Have the customer turn on the -48 V dc power source.

12.

Follow the steps in “Power-On Procedure with the DC Power Distribution Panel” on page 27.

Chapter 3. Removal and Replacement

35

Page 48

1.

2.

3.

4.

5.

6.

1

6

2

7

3

8

4

9

5

36

Removal and Replacement of the -48 V DC Circuit Breaker

This section covers the removal and replacement procedure for the -48 V dc circuit breaker.

CAUTION:

Energy hazard, remove power before servicing. Disconnect two power supply cords.

C23

Removal

This section covers the removal procedures for the -48 V dc circuit breaker.

Follow the steps in the “Power-Off Procedure with the DC Power Distribution Panel” on page 29.

Have the customer turn off the dc power source that connects to the dc power distribution panel.

After the customer’s -48 V dc source power is turned off, ensure that a tag or label is positioned over

the power source switches to indicate that the power is intended to be off (lock-out/tag-out).

Remove the six mounting screws from the top cover of the power distribution panel, and then remove

the top cover.

Remove the -48 V dc bus shield (insulation).

Remove the bezel from the front of the dc power distribution panel.

1

9

8

5

7

6

Mounting Screws

To p Cover

Bus Bar Shield (Insulation)

Terminal Block (Both Sides of the

Rear Cover)

Covers for Empty Circuit Breaker

Positions

2

3

4

Front Bezel

Bezel Mounting Screws

Circuit Breaker Switches

Circuit Breaker Position Labels

7014 Model T00, and Model T42 Service Guide

Page 49

8.

9.

1 A

8

2 A

9

3 A

10

4 10 mm

11

5 A

12 B

6 B

13 B

7 B

14

7.

Using a multimeter, verify that no voltage exists between the -48 V dc bus bars and the -48 V dc

return bus bars, A and B sides.

Record the locations of all cables or wires connected to the three connector pins on the circuit

breaker that is being removed. Disconnect the wires from the three connector pins and the -48 V dc

power connector.

Disconnect the wire that is attached to the bottom of the circuit breaker.

10.

Disconnect the mounting nut that attaches the rear of the circuit breaker to the dc power bus bar.

13

14

1

2

3

4

12

5

6

7

8

9

-48 V dc (-) Bus Bar

-48 V dc (-) Power Cable

Return (+) Bus Bar

hole, 25.4 mm Spacing

Return (+) Power Cable

Return (+) Power Cable

-48 V dc (-) Power Cable

10

11

Mounting Nut

Three Connector Pins

-48 V dc (-) Power Connector

Connector Nut

Return (+) Bus Bar

-48 V dc (-) Bus Bar

Front of Power Distribution Panel

Chapter 3. Removal and Replacement

37

Page 50

1

2

1.

2.

3.

4.

5.

6.

7.

8.

9. Be

38

11.

Remove the two mounting screws holding the circuit breaker to the panel. Then remove the circuit

breaker from the inside of the panel.

2

1

Front View of Power Distribution Panel (Without Bezel)

Mounting Screws

Note: The PDP shown is for reference only.

Replacement

This section covers the replacement procedures for the -48 V dc circuit breaker.

Mount the circuit breaker to the front of the dc power distribution panel using the two mounting

screws.

Fasten the rear of the circuit breaker to the dc power distribution panel with the mounting nut.

Connect the -48 V dc cable to the circuit breaker using the cable connector nut.

Connect the two wires to the two connector pins on the rear of the circuit breaker.

Replace the front bezel of the dc power distribution panel.

Replace the -48 V dc bus bar shield (insulation).

Replace the top cover of the dc power distribution panel.

Have the customer restore power to the dc power distribution panel.

sure all circuit breakers are set to on.

10.

Follow the steps in “Power-On Procedure with the DC Power Distribution Panel” on page 27.

7014 Model T00, and Model T42 Service Guide

Page 51

It is

1.

2.

1

4

2

5

3

6

3. If

4. If

1.

2.

3.

4.

5.

6.

Removal and Replacement of the Front or Rear Door

possible that inspection or service procedures for certain drawers might require removing the front or

rear door for better access. If this is necessary, follow these instructions.

Removal

This section covers the removal procedure for the front or rear door.

Open the door of the rack.

Remove the door by lifting it up and out.

1

2

6

4

3

5

4

3

Rack Cabinet

Front Rack Door

Door Hinge

Hinge Retaining Screws

Door Latch

Door Latch Mounting Screws

necessary, remove the hinge bracket by removing the mounting screws that attach the bracket to the

rack.

necessary, also remove the latch plate by removing the mounting screws that attach the plate to the

rack.

Replacement

This section covers the replacement procedure for the front or rear door.

Install the hinges on the rack by positioning them on the rack and inserting and securely tightening the

screws.

Install the latch plate.

Install the bottom hinge pin on the door. The bottom hinge pin is the longest of the two hinge pins on

the door.

Install the top hinge pin on the door. The top hinge pin is the shortest of the two hinge pins on the

door.

Position the door at the rack with the hinge pin ends slightly above and adjacent to the hinges on the

rack. Lower the door so the hinge pins slide into the hinges.

Close the door on the rack.

Chapter 3. Removal and Replacement

39

Page 52

To

40

Relocating Rack(s)

relocate a rack refer to step-by-step instructions described in the 7014 Series Model T00 and Model

T42 System Rack Installation Guide, order number SA38-0614.

7014 Model T00, and Model T42 Service Guide

Page 53

1

1

1

1

1

2

2

Chapter 4. Parts Information

This chapter contains detailed drawings, field replaceable unit (FRU) part numbers, and part descriptions

for a 7014 Series Model T00 and T42 rack.

Covers

3

10

1

7

11

12

8

4

2

5

Table 1. Frames, Side Panels, and Top Cover

Index Number

FRU Part Number

05N4868

05N4867

11P0313

11P0314

05N6478

7

11

6

Units Per Assembly

Description

Frame (T00, black, 1.8 m)

Frame (T00, white, 1.8 m)

Frame (T42, black, 2.0 m)

Frame (T42, white, 2.0 m)

Side panel (T00 & T42,

black)

41

Page 54

2

3

1

1

9

11

4

1

1

1

1

1

1

1

1

5

2

5

2

2

6

1

1

7

4

8 2

5

2

6

1

7

4

8

2

42

Table 1. Frames, Side Panels, and Top Cover (continued)

Index Number

FRU Part Number

05N6477

21L4290

21L4277

51H9502

Table 2. Front Door

Index Number

FRU Part Number

Note: See Table 3 for Mounting Hardware for the following:

05N4863

11P0319

12K0456

11P0318

32P1029

45P1429

Note: See Table 4 for Mounting Hardware for the following:

21P4049

21P4729

Units Per Assembly

Units Per Assembly

Description

Side panel (T00 & T42,

white)

To p cover (T00 & T42,

white, T42 cable access)

To p cover (T00 & T42,

black, T42 cable access)

Hook-and-loop fastener

Description

T00, RS/6000, black (55

mm)

T42, RS/6000, black (55

mm)

T00, white (35 mm)

T42, white (35 mm)

T00, High Perforation front

door for 1.8M racks, black

T42, High Perforation front

door for 2M racks, black

T00, (100 mm)

T42, (100 mm)

Table 3. Mounting Hardware for RS/6000 and High Perforation Front Door

Index Number

FRU Part Number

Units Per Assembly

31L7547

09N9686

05N4865

31L7545

05N4866

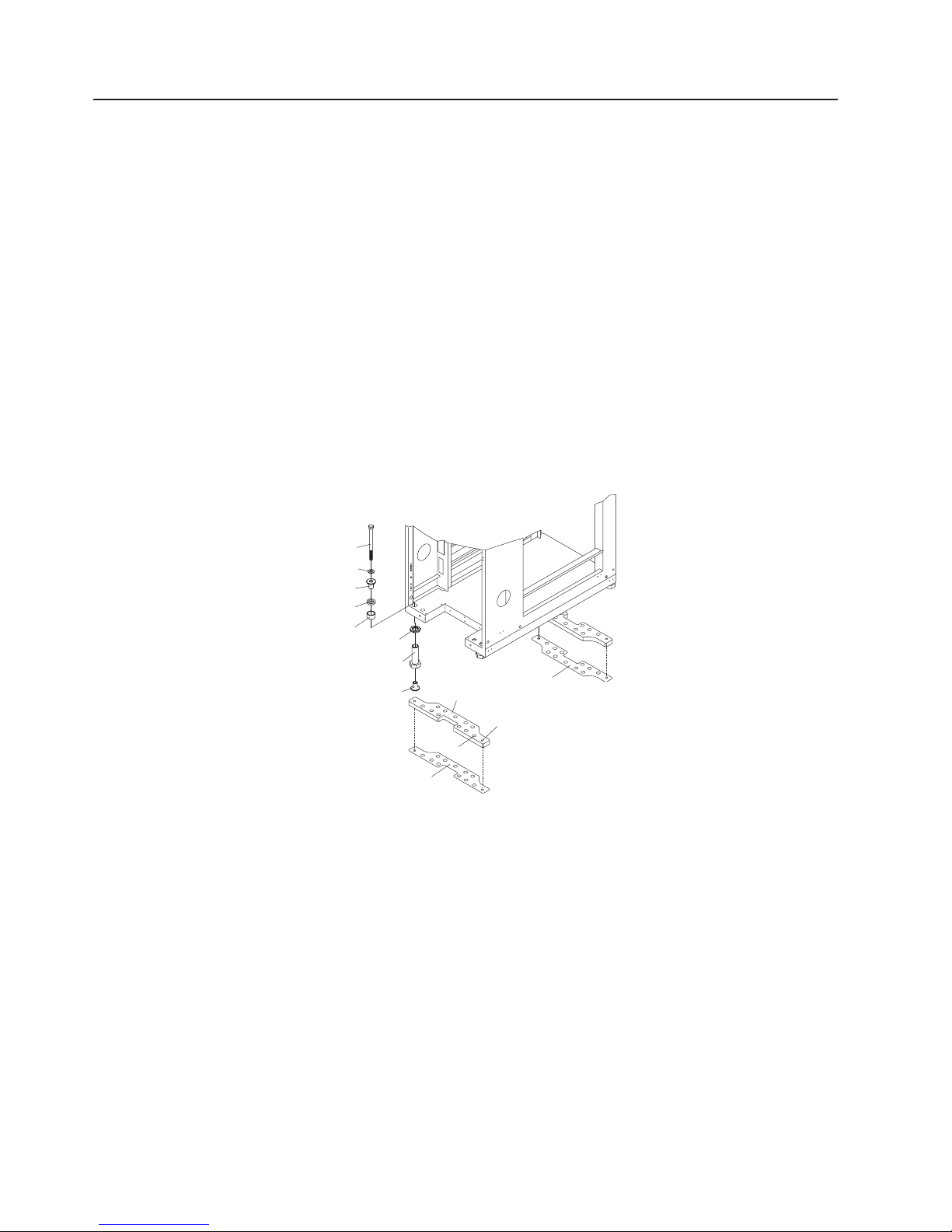

31L8594