Page 1

IBM System x3850 Ty pe 8864

Problem Dete rminatio n and Service Guid e

Page 2

Page 3

IBM System x3850 Ty pe 8864

Problem Dete rminatio n and Service Guid e

Page 4

Note: Before using this information and the product it supports, read the general information in Appendix B, “Notices,” on page

163.

15th Edition (July 2007)

© Copyright International Business Machines Corporation 2006. All rights reserved.

US Government Users Restricted Rights – Use, duplication or disclosure restricted by GSA ADP Schedule Contract

with IBM Corp.

Page 5

Contents

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Guidelines for trained service technicians . . . . . . . . . . . . . . . viii

Inspecting for unsafe conditions . . . . . . . . . . . . . . . . . viii

Guidelines for servicing electrical equipment . . . . . . . . . . . . . viii

Safety statements . . . . . . . . . . . . . . . . . . . . . . . .x

Chapter 1. Introduction . . . . . . . . . . . . . . . . . . . . . .1

Related documentation . . . . . . . . . . . . . . . . . . . . . .1

Notices and statements in this document . . . . . . . . . . . . . . . .2

Features and specifications . . . . . . . . . . . . . . . . . . . . .3

Server controls, LEDs, and connectors . . . . . . . . . . . . . . . .4

Front view . . . . . . . . . . . . . . . . . . . . . . . . . .4

Rear view . . . . . . . . . . . . . . . . . . . . . . . . . .6

System-board layouts . . . . . . . . . . . . . . . . . . . . . . .8

I/O board internal connectors and jumpers . . . . . . . . . . . . . .8

Memory-card connectors . . . . . . . . . . . . . . . . . . . . .9

Memory-card LEDs . . . . . . . . . . . . . . . . . . . . . . .9

Microprocessor-board connectors and LEDs . . . . . . . . . . . . .10

PCI board connectors . . . . . . . . . . . . . . . . . . . . .10

PCI board LEDs . . . . . . . . . . . . . . . . . . . . . . .11

SAS-backplane connectors . . . . . . . . . . . . . . . . . . .11

Chapter 2. Configuration information and instructions . . . . . . . . .13

Updating the firmware . . . . . . . . . . . . . . . . . . . . . .13

Configuring the server . . . . . . . . . . . . . . . . . . . . . .13

Using the ServerGuide Setup and Installation CD . . . . . . . . . . .14

Using the Configuration/Setup Utility program . . . . . . . . . . . .14

Installing and using the baseboard management controller utility programs 19

Using the SAS/SATA Configuration Utility program . . . . . . . . . . .20

Configuring the Ethernet controller . . . . . . . . . . . . . . . . .20

Using the PXE boot agent utility program . . . . . . . . . . . . . .20

Using the ServeRAID configuration programs . . . . . . . . . . . . .21

Chapter 3. Parts listing, Type 8864 . . . . . . . . . . . . . . . . .23

Server replaceable units . . . . . . . . . . . . . . . . . . . . .24

Power cords . . . . . . . . . . . . . . . . . . . . . . . . . .26

Chapter 4. Removing and replacing server components . . . . . . . .29

Installation guidelines . . . . . . . . . . . . . . . . . . . . . .29

System reliability guidelines . . . . . . . . . . . . . . . . . . .30

Working inside the server with the power on . . . . . . . . . . . . .30

Handling static-sensitive devices . . . . . . . . . . . . . . . . .31

Returning a device or component . . . . . . . . . . . . . . . . .31

Removing the cover and bezel . . . . . . . . . . . . . . . . . . .31

Tier 1 CRU information . . . . . . . . . . . . . . . . . . . . . .32

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . .32

DVD Drive . . . . . . . . . . . . . . . . . . . . . . . . .34

Hot-swap fan . . . . . . . . . . . . . . . . . . . . . . . .34

Hot-swap power supply . . . . . . . . . . . . . . . . . . . . .36

Memory module . . . . . . . . . . . . . . . . . . . . . . .38

Tier 2 CRU information . . . . . . . . . . . . . . . . . . . . . .48

Operator information panel assembly . . . . . . . . . . . . . . . .48

I/O board . . . . . . . . . . . . . . . . . . . . . . . . . .49

© Copyright IBM Corp. 2006 iii

Page 6

PCI adapter guide . . . . . . . . . . . . . . . . . . . . . . .50

Power-supply structure . . . . . . . . . . . . . . . . . . . . .51

SAS backplane . . . . . . . . . . . . . . . . . . . . . . . .53

FRU information . . . . . . . . . . . . . . . . . . . . . . . .54

Front-panel assembly . . . . . . . . . . . . . . . . . . . . .54

Microprocessor tray and microprocessor . . . . . . . . . . . . . .54

PCI board assembly . . . . . . . . . . . . . . . . . . . . . .59

PCI switch card assembly . . . . . . . . . . . . . . . . . . . .60

Power backplane . . . . . . . . . . . . . . . . . . . . . . .61

Chapter 5. Diagnostics . . . . . . . . . . . . . . . . . . . . .63

Diagnostic tools . . . . . . . . . . . . . . . . . . . . . . . .63

POST . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

POST beep codes . . . . . . . . . . . . . . . . . . . . . .64

Error logs . . . . . . . . . . . . . . . . . . . . . . . . . .70

POST error codes . . . . . . . . . . . . . . . . . . . . . . .72

Checkout procedure . . . . . . . . . . . . . . . . . . . . . . .86

About the checkout procedure . . . . . . . . . . . . . . . . . .86

Performing the checkout procedure . . . . . . . . . . . . . . . .87

(Trained service technicians only) Checkpoint codes . . . . . . . . . . .88

Problem isolation tables . . . . . . . . . . . . . . . . . . . . .88

CD or DVD drive problems . . . . . . . . . . . . . . . . . . .89

General problems . . . . . . . . . . . . . . . . . . . . . . .89

Hard disk drive problems . . . . . . . . . . . . . . . . . . . .90

Intermittent problems . . . . . . . . . . . . . . . . . . . . . .90

Keyboard, mouse, or pointing-device problems . . . . . . . . . . . .91

USB keyboard, mouse, or pointing-device problems . . . . . . . . . .92

Memory problems . . . . . . . . . . . . . . . . . . . . . . .93

Microprocessor problems . . . . . . . . . . . . . . . . . . . .94

Monitor problems . . . . . . . . . . . . . . . . . . . . . . .94

Optional-device problems . . . . . . . . . . . . . . . . . . . .97

Power problems . . . . . . . . . . . . . . . . . . . . . . .98

Serial port problems . . . . . . . . . . . . . . . . . . . . . .99

ServerGuide problems . . . . . . . . . . . . . . . . . . . . . 100

Software problems . . . . . . . . . . . . . . . . . . . . . . 100

Universal Serial Bus (USB) port problems . . . . . . . . . . . . . 101

Video problems . . . . . . . . . . . . . . . . . . . . . . . 101

Light path diagnostics . . . . . . . . . . . . . . . . . . . . . . 101

Light path diagnostic LEDs . . . . . . . . . . . . . . . . . . . 104

Remind button . . . . . . . . . . . . . . . . . . . . . . . 108

Power-supply LEDs . . . . . . . . . . . . . . . . . . . . . . . 108

Diagnostic programs, messages, and error codes . . . . . . . . . . . .110

Real-time diagnostics . . . . . . . . . . . . . . . . . . . . . 111

Running the on-board diagnostic programs . . . . . . . . . . . . . 111

Diagnostic text messages . . . . . . . . . . . . . . . . . . .112

Viewing the test log . . . . . . . . . . . . . . . . . . . . . .112

Diagnostic error codes . . . . . . . . . . . . . . . . . . . . .112

Recovering from a BIOS update failure . . . . . . . . . . . . . . . 129

System-error log messages . . . . . . . . . . . . . . . . . . . . 130

POST and SMI error messages . . . . . . . . . . . . . . . . . . 142

Solving SCSI problems . . . . . . . . . . . . . . . . . . . . . 154

Solving power problems . . . . . . . . . . . . . . . . . . . . . 155

Solving Ethernet controller problems . . . . . . . . . . . . . . . . 155

Solving undetermined problems . . . . . . . . . . . . . . . . . . 156

Problem determination tips . . . . . . . . . . . . . . . . . . . . 157

Calling IBM for service . . . . . . . . . . . . . . . . . . . . . 158

iv IBM System x3850 Type 8864: Problem Determination and Service Guide

Page 7

Appendix A. Getting help and technical assistance . . . . . . . . . . 161

Before you call . . . . . . . . . . . . . . . . . . . . . . . . 161

Using the documentation . . . . . . . . . . . . . . . . . . . . . 161

Getting help and information from the World Wide Web . . . . . . . . . 162

Software service and support . . . . . . . . . . . . . . . . . . . 162

Hardware service and support . . . . . . . . . . . . . . . . . . . 162

IBM Taiwan product service . . . . . . . . . . . . . . . . . . . . 162

Appendix B. Notices . . . . . . . . . . . . . . . . . . . . . . 163

Trademarks . . . . . . . . . . . . . . . . . . . . . . . . . . 163

Important notes . . . . . . . . . . . . . . . . . . . . . . . . 164

Product recycling and disposal . . . . . . . . . . . . . . . . . . 165

Battery return program . . . . . . . . . . . . . . . . . . . . . 166

Electronic emission notices . . . . . . . . . . . . . . . . . . . . 167

Federal Communications Commission (FCC) statement . . . . . . . . 167

Industry Canada Class A emission compliance statement . . . . . . . . 167

Australia and New Zealand Class A statement . . . . . . . . . . . . 167

United Kingdom telecommunications safety requirement . . . . . . . . 167

European Union EMC Directive conformance statement . . . . . . . . 168

Taiwanese Class A warning statement . . . . . . . . . . . . . . . 168

Chinese Class A warning statement . . . . . . . . . . . . . . . . 168

Japanese Voluntary Control Council for Interference (VCCI) statement 168

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Contents v

Page 8

vi IBM System x3850 Type 8864: Problem Determination and Service Guide

Page 9

Safety

Before installing this product, read the Safety Information.

Antes de instalar este produto, leia as Informações de Segurança.

Pred instalací tohoto produktu si prectete prírucku bezpecnostních instrukcí.

Læs sikkerhedsforskrifterne, før du installerer dette produkt.

Lees voordat u dit product installeert eerst de veiligheidsvoorschriften.

Ennen kuin asennat tämän tuotteen, lue turvaohjeet kohdasta Safety Information.

Avant d’installer ce produit, lisez les consignes de sécurité.

Vor der Installation dieses Produkts die Sicherheitshinweise lesen.

Prima di installare questo prodotto, leggere le Informazioni sulla Sicurezza.

Les sikkerhetsinformasjonen (Safety Information) før du installerer dette produktet.

Antes de instalar este produto, leia as Informações sobre Segurança.

Antes de instalar este producto, lea la información de seguridad.

Läs säkerhetsinformationen innan du installerar den här produkten.

© Copyright IBM Corp. 2006 vii

Page 10

Guidelines for trained service technicians

This section contains information for trained service technicians.

Inspecting for unsafe conditions

Use the information in this section to help you identify potential unsafe conditions in

an IBM product that you are working on. Each IBM product, as it was designed and

manufactured, has required safety items to protect users and service technicians

from injury. The information in this section addresses only those items. Use good

judgment to identify potential unsafe conditions that might be caused by non-IBM

alterations or attachment of non-IBM features or options that are not addressed in

this section. If you identify an unsafe condition, you must determine how serious the

hazard is and whether you must correct the problem before you work on the

product.

Consider the following conditions and the safety hazards that they present:

v Electrical hazards, especially primary power. Primary voltage on the frame can

cause serious or fatal electrical shock.

v Explosive hazards, such as a damaged CRT face or a bulging capacitor.

v Mechanical hazards, such as loose or missing hardware.

inspect the product for potential unsafe conditions, complete the following steps:

To

1. Make sure that the power is off and the power cord is disconnected.

2. Make sure that the exterior cover is not damaged, loose, or broken, and

observe any sharp edges.

3. Check the power cord:

v Make sure that the third-wire ground connector is in good condition. Use a

meter to measure third-wire ground continuity for 0.1 ohm or less between

the external ground pin and the frame ground.

v Make sure that the power cord is the correct type, as specified in “Power

cords” on page 26.

v Make sure that the insulation is not frayed or worn.

Remove the cover.

4.

5. Check for any obvious non-IBM alterations. Use good judgment as to the safety

of any non-IBM alterations.

6. Check inside the server for any obvious unsafe conditions, such as metal filings,

contamination, water or other liquid, or signs of fire or smoke damage.

7. Check for worn, frayed, or pinched cables.

8. Make sure that the power-supply cover fasteners (screws or rivets) have not

been removed or tampered with.

Guidelines for servicing electrical equipment

Observe the following guidelines when servicing electrical equipment:

v Check the area for electrical hazards such as moist floors, nongrounded power

extension cords, power surges, and missing safety grounds.

v Use only approved tools and test equipment. Some hand tools have handles that

are covered with a soft material that does not provide insulation from live

electrical currents.

v Regularly inspect and maintain your electrical hand tools for safe operational

condition. Do not use worn or broken tools or testers.

viii IBM System x3850 Type 8864: Problem Determination and Service Guide

Page 11

v Do not touch the reflective surface of a dental mirror to a live electrical circuit.

The surface is conductive and can cause personal injury or equipment damage if

it touches a live electrical circuit.

v Some rubber floor mats contain small conductive fibers to decrease electrostatic

discharge. Do not use this type of mat to protect yourself from electrical shock.

v Do not work alone under hazardous conditions or near equipment that has

hazardous voltages.

v Locate the emergency power-off (EPO) switch, disconnecting switch, or electrical

outlet so that you can turn off the power quickly in the event of an electrical

accident.

v Disconnect all power before you perform a mechanical inspection, work near

power supplies, or remove or install main units.

v Before you work on the equipment, disconnect the power cord. If you cannot

disconnect the power cord, have the customer power-off the wall box that

supplies power to the equipment and lock the wall box in the off position.

v Never assume that power has been disconnected from a circuit. Check it to

make sure that it has been disconnected.

v If you have to work on equipment that has exposed electrical circuits, observe

the following precautions:

– Make sure that another person who is familiar with the power-off controls is

near you and is available to turn off the power if necessary.

– When you are working with powered-on electrical equipment, use only one

hand. Keep the other hand in your pocket or behind your back to avoid

creating a complete circuit that could cause an electrical shock.

– When using a tester, set the controls correctly and use the approved probe

leads and accessories for that tester.

– Stand on a suitable rubber mat to insulate you from grounds such as metal

floor strips and equipment frames.

Use extreme care when measuring high voltages.

v

v To ensure proper grounding of components such as power supplies, pumps,

blowers, fans, and motor generators, do not service these components outside of

their normal operating locations.

v If an electrical accident occurs, use caution, turn off the power, and send another

person to get medical aid.

Safety ix

Page 12

Safety statements

Important:

Each caution and danger statement in this documentation begins with a number.

This number is used to cross reference an English-language caution or danger

statement with translated versions of the caution or danger statement in the Safety

Information document.

For example, if a caution statement begins with a number 1, translations for that

caution statement appear in the Safety Information document under statement 1.

Be sure to read all caution and danger statements in this documentation before

performing the instructions. Read any additional safety information that comes with

your server or optional device before you install the device.

x IBM System x3850 Type 8864: Problem Determination and Service Guide

Page 13

Statement 1:

DANGER

Electrical

current from power, telephone, and communication cables is

hazardous.

To avoid a shock hazard:

v Do not connect or disconnect any cables or perform installation,

maintenance, or reconfiguration of this product during an electrical

storm.

v Connect all power cords to a properly wired and grounded electrical

outlet.

v Connect to properly wired outlets any equipment that will be attached to

this product.

v When possible, use one hand only to connect or disconnect signal

cables.

v Never turn on any equipment when there is evidence of fire, water, or

structural damage.

v Disconnect the attached power cords, telecommunications systems,

networks, and modems before you open the device covers, unless

instructed otherwise in the installation and configuration procedures.

v Connect and disconnect cables as described in the following table when

installing, moving, or opening covers on this product or attached

devices.

To Connect: To Disconnect:

1. Turn everything OFF.

2. First, attach all cables to devices.

3. Attach signal cables to connectors.

4. Attach power cords to outlet.

1. Turn everything OFF.

2. First, remove power cords from outlet.

3. Remove signal cables from connectors.

4. Remove all cables from devices.

5. Turn device ON.

Safety xi

Page 14

Statement 2:

CAUTION:

When replacing the lithium battery, use only IBM Part Number 33F8354 or an

equivalent type battery recommended by the manufacturer. If your system has

a module containing a lithium battery, replace it only with the same module

type made by the same manufacturer. The battery contains lithium and can

explode if not properly used, handled, or disposed of.

Do not:

v Throw or immerse into water

v Heat to more than 100°C (212°F)

v Repair or disassemble

Dispose

Statement 3:

of the battery as required by local ordinances or regulations.

CAUTION:

When laser products (such as CD-ROMs, DVD drives, fiber optic devices, or

transmitters) are installed, note the following:

v Do not remove the covers. Removing the covers of the laser product could

result in exposure to hazardous laser radiation. There are no serviceable

parts inside the device.

v Use of controls or adjustments or performance of procedures other than

those specified herein might result in hazardous radiation exposure.

DANGER

laser products contain an embedded Class 3A or Class 3B laser

Some

diode. Note the following.

Laser radiation when open. Do not stare into the beam, do not view directly

with optical instruments, and avoid direct exposure to the beam.

xii IBM System x3850 Type 8864: Problem Determination and Service Guide

Page 15

Statement 4:

≥ 18 kg (39.7 lb) ≥ 32 kg (70.5 lb) ≥ 55 kg (121.2 lb)

CAUTION:

Use safe practices when lifting.

Statement 5:

CAUTION:

The power control button on the device and the power switch on the power

supply do not turn off the electrical current supplied to the device. The device

also might have more than one power cord. To remove all electrical current

from the device, ensure that all power cords are disconnected from the power

source.

2

1

Safety xiii

Page 16

Statement 8:

CAUTION:

Never remove the cover on a power supply or any part that has the following

label attached.

Hazardous voltage, current, and energy levels are present inside any

component that has this label attached. There are no serviceable parts inside

these components. If you suspect a problem with one of these parts, contact

a service technician.

Statement 26:

CAUTION:

Do not place any object on top of rack-mounted devices.

xiv IBM System x3850 Type 8864: Problem Determination and Service Guide

Page 17

Chapter 1. Introduction

This Problem Determination and Service Guide contains information to help you

solve problems that might occur in your IBM® System x3850 Type 8864 server. It

describes the diagnostic tools that come with the server, error codes and suggested

actions, and instructions for replacing failing components.

Replaceable components are of three types:

v Tier 1 customer replaceable unit (CRU): Replacement of Tier 1 CRUs is your

responsibility. If IBM installs a Tier 1 CRU at your request, you will be charged for

the installation.

v Tier 2 customer replaceable unit: You may install a Tier 2 CRU yourself or

request IBM to install it, at no additional charge, under the type of warranty

service that is designated for your server.

v Field replaceable unit (FRU): FRUs must be installed only by trained service

technicians.

information about the terms of the warranty and getting service and assistance,

For

see the Warranty and Support Information document.

Related documentation

In addition to this document, the following documentation also comes with the

server:

v Installation Guide

This printed document contains instructions for setting up the server and basic

instructions for installing some optional devices.

v User’s Guide

This document is in Portable Document Format (PDF) on the IBM System x

Documentation CD. It provides general information about the server, including

information about features, and how to configure the server. It also contains

detailed instructions for installing, removing, and connecting optional devices that

the server supports.

v Rack Installation Instructions

This printed document contains instructions for installing the server in a rack.

v Safety Information

This document is in PDF on the IBM System x Documentation CD. It contains

translated caution and danger statements. Each caution and danger statement

that appears in the documentation has a number that you can use to locate the

corresponding statement in your language in the Safety Information document.

v Warranty and Support Information

This document is in PDF on the IBM System x Documentation CD. It contains

information about the terms of the warranty and getting service and assistance.

™

Depending

IBM System x Documentation CD.

The System x and xSeries® Tools Center is an online information center that

contains information about tools for updating, managing, and deploying firmware,

device drivers, and operating systems. The System x and xSeries Tools Center is at

http://publib.boulder.ibm.com/infocenter/toolsctr/v1r0/index.jsp.

© Copyright IBM Corp. 2006 1

on the server model, additional documentation might be included on the

Page 18

The server might have features that are not described in the documentation that

comes with the server. The documentation might be updated occasionally to include

information about those features, or technical updates might be available to provide

additional information that is not included in the server documentation. These

updates are available from the IBM Web site. To check for updated documentation

and technical updates, complete the following steps.

Note: Changes are made periodically to the IBM Web site. The actual procedure

might vary slightly from what is described in this document.

1. Go to http://www.ibm.com/servers/eserver/support/xseries/index.html

2. From the Hardware list, select System x3850 and click Go.

3. Click the Install and use tab.

4. Click Product documentation.

Notices and statements in this document

The caution and danger statements that appear in this document are also in the

multilingual Safety Information document, which is on the IBM System x

Documentation CD. Each statement is numbered for reference to the corresponding

statement in the Safety Information document.

The following notices and statements are used in this document:

v Note: These notices provide important tips, guidance, or advice.

v Important: These notices provide information or advice that might help you avoid

inconvenient or problem situations.

v Attention: These notices indicate potential damage to programs, devices, or

data. An attention notice is placed just before the instruction or situation in which

damage could occur.

v Caution: These statements indicate situations that can be potentially hazardous

to you. A caution statement is placed just before the description of a potentially

hazardous procedure step or situation.

v Danger: These statements indicate situations that can be potentially lethal or

extremely hazardous to you. A danger statement is placed just before the

description of a potentially lethal or extremely hazardous procedure step or

situation.

2 IBM System x3850 Type 8864: Problem Determination and Service Guide

Page 19

Features and specifications

The following information is a summary of the features and specifications of the

server. Depending on the server model, some features might not be available, or

some specifications might not apply.

Table 1. Features and specifications

Microprocessor:

v Intel® Xeon

™

v 1 MB Level-2 cache

v 667 MHz front-side bus (FSB)

v Support for up to four microprocessors

Use the Configuration/Setup Utility

Note:

program to determine the type and speed

of the microprocessors.

Memory:

v Minimum: 2 GB depending on server

model, expandable to 32 GB

v Type: 333 MHz, registered, ECC,

PC2-3200 double data rate (DDR) II,

SDRAM

v Sizes: 1 GB or 2 GB in pairs

v Connectors: Two-way interleaved, four

dual inline memory module (DIMM)

connectors per memory card

v Maximum: Four memory cards, each

card containing two pairs of PC2-3200

DDRII DIMMS

Drives:

v Slim DVD-ROM: IDE

v Serial Attached SCSI (SAS) hard disk

drives

Expansion

bays:

v Six SAS, 2.5-inch bays

v One 12.7-mm removable-media drive

bay (DVD-ROM drive installed)

Expansion

slots:

v Four PCI Express x8 hot-plug slots

v Tw o PCI-X 2.0 hot-plug 266 MHz/64-bit

slots

Upgradeable microcode:

System BIOS, diagnostics, service

processor, BMC, and SAS microcode

Power supply:

v Standard: One dual-rated power supply

– 1300 watts at 220 V ac input

– 650 watts at 11 0 V ac input

Upgradeable to two power supplies

v

(hot-swappable at 220 V ac only)

Size:

v 3U

v Height: 128.35 mm (5.05 in.)

v Depth: 715 mm (28.15 in.)

v Width: 440 mm (17.32 in.)

v Weight: approximately 38.5 kg (85 lb)

when fully configured or 31.75 kg (70

lb) minimum

Racks

of 4.45 cm (1.75 inches). Each increment

is referred to as a unit, or “U.” A 1-U-high

device is 4.45 cm (1.75 inches) tall.

Integrated functions:

v Baseboard management controller

v IBM EXA-32 Chipset with integrated

memory and I/O controller

v Service processor support for Remote

Supervisor Adapter II SlimLine

v Light path diagnostics

v Three Universal Serial Bus (USB) ports

– Tw o on rear of server

– One on front of server

v Broadcom 5704C dual 10/100/1000

Gigabit Ethernet controllers

v AT I 7000-M video

– 16 MB video memory

– SVGA compatible

v Mouse connector

v Keyboard connector

v Serial connector

Acoustical

v Sound power, idle: 6.6 bel declared

v Sound power, operating: 6.6 bel

declared

are marked in vertical increments

noise emissions:

Environment:

v Air temperature:

– Server on:

- 10° to 35°C (50° to 95°F); altitude:

0 to 914 m (3000 ft). If the server

has a dual-core microprocessor, at

maximum power reduce the 35°C

by 1°C per 300 m above sea level,

or the microprocessor might throttle

to remain within the internal thermal

specifications.

- 10° to 32°C (50° to 90°F); altitude:

914 m to 2133 m (7000 ft.)

Humidity:

v

– Server on: 8% to 80%

– Server off: 8% to 80%

Electrical input:

v Sine-wave input (50-60 Hz) required

v Input voltage high range:

– Minimum: 200 V ac

– Maximum: 240 V ac

Approximate input kilovolt-amperes (kVA):

v

– Minimum: 0.08 kVA

– Maximum: 1.6 kVA

Notes:

1. Power consumption and heat output

vary depending on the number and type

of optional features installed and the

power-management optional features in

use.

2. These levels were measured in

controlled acoustical environments

according to the procedures specified by

the American National Standards

Institute (ANSI) S12.10 and ISO 7779

and are reported in accordance with ISO

9296. Actual sound-pressure levels in a

given location might exceed the average

values stated because of room

reflections and other nearby noise

sources. The declared sound-power

levels indicate an upper limit, below

which a large number of computers will

operate.

Chapter 1. Introduction 3

Page 20

Server controls, LEDs, and connectors

This section describes the controls, light-emitting diodes (LEDs), and connectors on

the front and rear of the server.

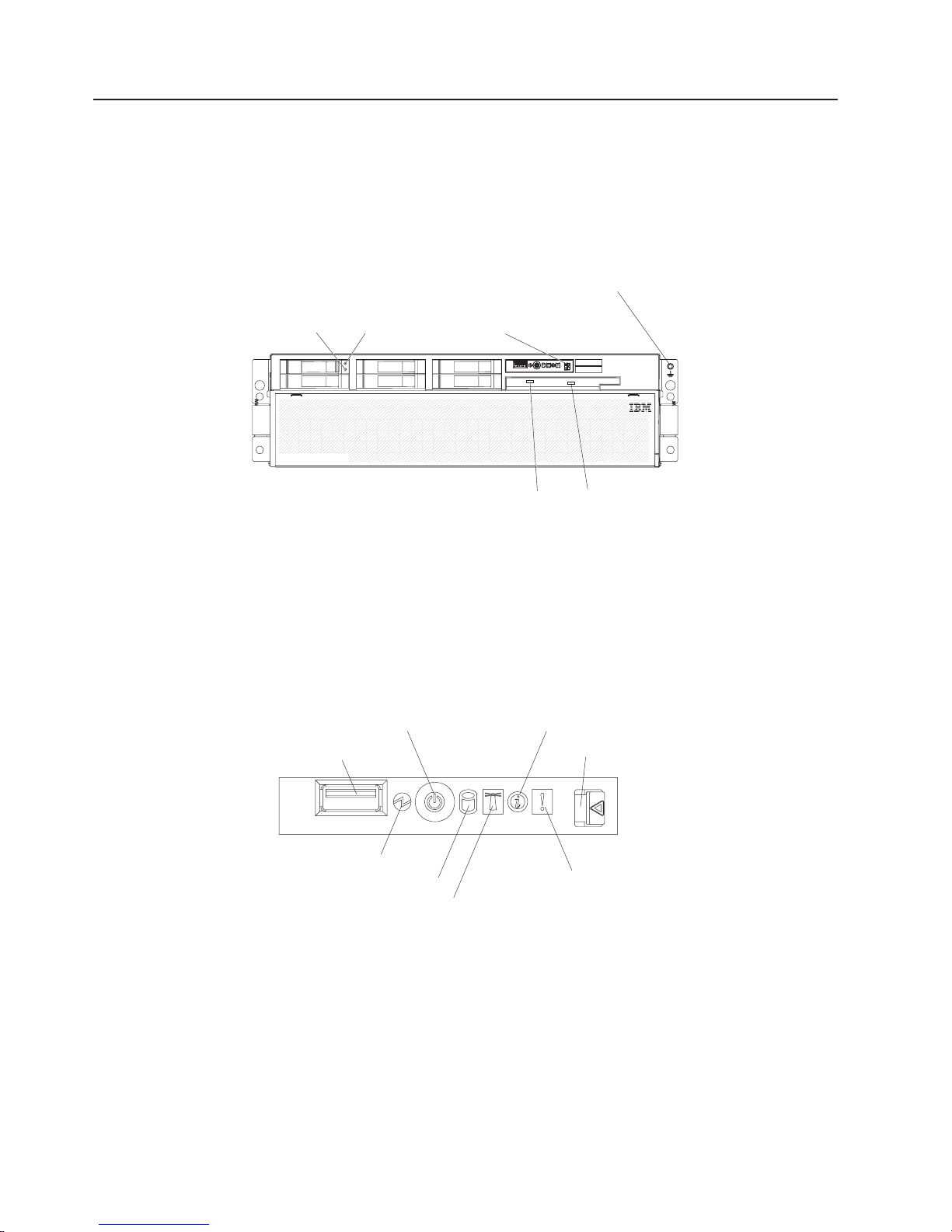

Front view

The following illustration shows the controls, LEDs, and connectors on the front of

the server.

Hard disk drive

status LED

Hard disk drive

activity LED

Electrostatic-discharge

connector

Operator information

panel

DVD-eject button

DVD drive activity LED

Hard disk drive status LED: If a ServeRAID-8i adapter is installed, when this LED

is lit it indicates that the associated hard disk drive has failed. If the LED flashes

slowly (one flash per second), the drive is being rebuilt. If the LED flashes rapidly

(three flashes per second), the controller is identifying the drive.

Hard disk drive activity LED: On some server models, each hot-swap hard disk

drive has an activity LED. When this LED is flashing, it indicates that the drive is in

use.

Operator information panel: This panel contains controls and LEDs. The following

illustration shows the controls and LEDs on the operator information panel.

Power-control button

USB connector

Power-on LED

Hard disk drive activity LED

Locator LED

Information LED

Release latch

System-error LED

The following controls, connectors, and LEDs are on the operator information panel:

v USB connector: Connect a USB device to this connector.

v Power-control button: Press this button to turn the server on and off manually.

A power-control-button shield comes with the server.

v Information LED: When this LED is lit, it indicates that there is a suboptimal

condition in the server and that light path diagnostics will light an additional LED

to help isolate the condition. If the LOG LED on the light path diagnostics panel

is lit, information is available in the baseboard management controller (BMC) log

or in the system-event log about the condition. The condition might be that the

BMC log is full or almost full.

4 IBM System x3850 Type 8864: Problem Determination and Service Guide

Page 21

This LED and LEDs on the light path diagnostics panel remain lit until you

resolve the condition. If the only condition is that the BMC log is full or almost

full, clear the BMC log or the system-event log through the Configuration/Setup

Utility program to turn off the lit LEDs. See the User’s Guide on the IBM System

x Documentation CD for information about clearing the logs. Clear the logs after

you have resolved all conditions.

Important: If the server has a baseboard management controller, clear the BMC

log and system-event log after you resolve all conditions. This will turn off the

information LED and LOG LED, if all conditions are resolved.

v Release latch: Slide this latch to the left to access the light path diagnostics

panel.

v System-error LED: When this LED is lit, it indicates that a system error has

occurred. An LED on the light path diagnostics panel is also lit to help isolate the

error.

v Locator LED: When this LED is lit, it has been lit remotely by the system

administrator to aid in visually locating the server.

v Hard disk drive activity LED: When this LED is flashing, it indicates that a SAS

hard disk drive is in use.

v Power-on LED: When this LED is lit and not flashing, it indicates that the server

is turned on. When this LED is flashing, it indicates that the server is turned off

and still connected to an ac power source. When this LED is off, it indicates that

ac power is not present, or the power supply or the LED itself has failed.

Note: If this LED is off, it does not mean that there is no electrical power in the

server. The LED might be burned out. To remove all electrical power from the

server, you must disconnect the power cords from the electrical outlets.

DVD-eject

button: Press this button to release a CD or DVD from the DVD drive.

DVD drive activity LED: When this LED is lit, it indicates that the DVD drive is in

use.

Electrostatic-discharge connector: Connect an electrostatic-discharge wrist strap

to this connector.

Chapter 1. Introduction 5

Page 22

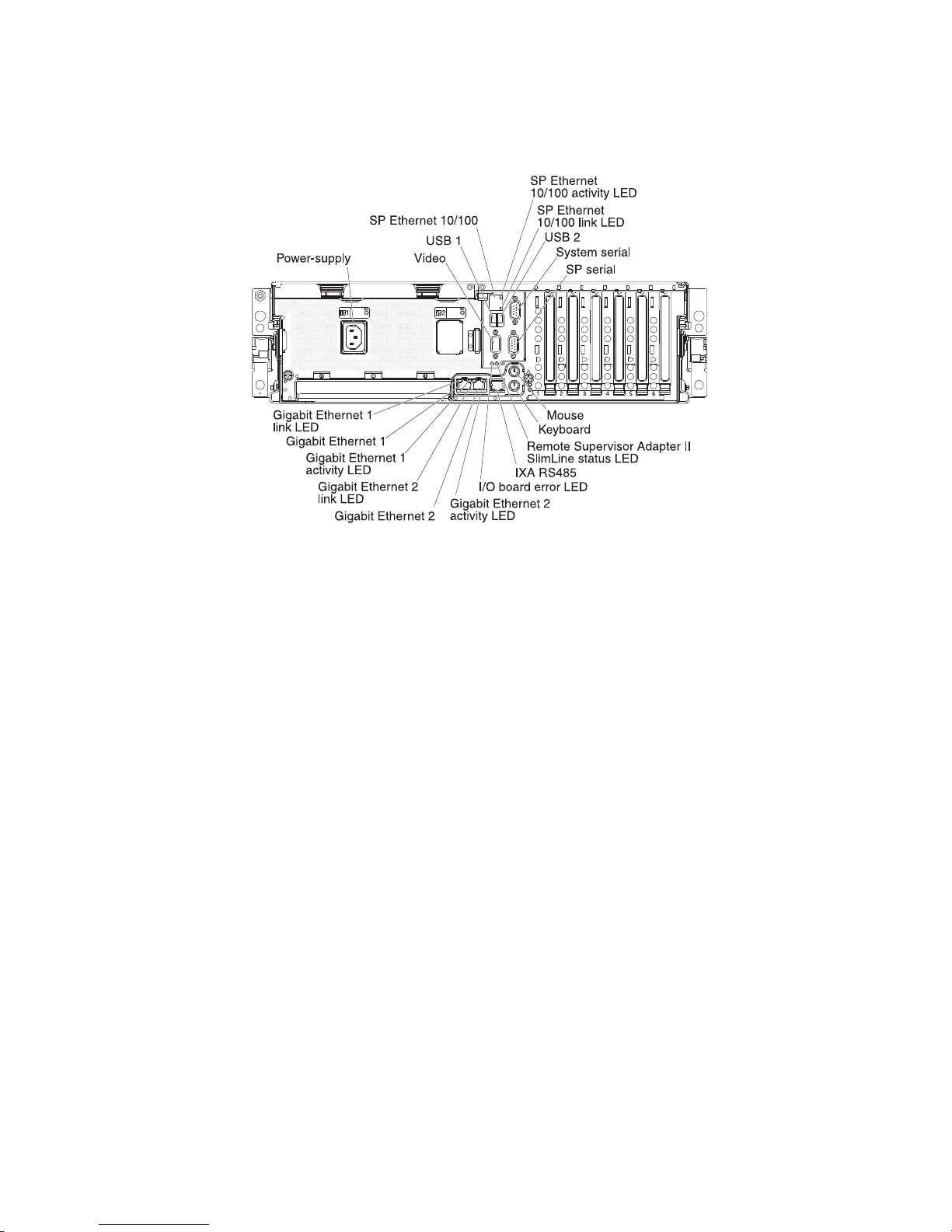

Rear view

The following illustration shows the connectors and LEDs on the rear of the server.

Power-supply connector: Connect the power cord to this connector.

Video connector: Connect a monitor to this connector.

USB 1 connector: Connect a USB device to this connector.

SP Ethernet 10/100 connector: Use this connector to connect the service

processor to a network.

SP Ethernet 10/100 activity LED: This LED is on the SP Ethernet 10/100

connector. When this LED is lit, it indicates that there is activity between the server

and the network.

SP Ethernet 10/100 link LED: This LED is on the SP Ethernet 10/100 connector.

When this LED is lit, it indicates that there is an active connection on the Ethernet

port.

USB 2 connector: Connect a USB device to this connector.

System serial connector: Connect a 9-pin serial device to this connector.

SP Serial connector: Connect a 9-pin serial device to this connector.

Mouse connector: Connect a mouse or other device to this connector.

Keyboard connector: Connect a keyboard to this connector.

Remote Supervisor Adapter II SlimLine status LED: This LED is on the I/O

board and is visible on the rear of the server. When this LED flashes, it indicates

that there is activity on the Remote Supervisor Adapter II SlimLine. When this LED

is lit continuously, it indicates that there is a problem with the Remote Supervisor

Adapter II SlimLine.

6 IBM System x3850 Type 8864: Problem Determination and Service Guide

Page 23

IXA RS485 connector: Use this connector to connect to an iSeries server when an

Integrated xSeries Adapter (IXA) is installed. The cable for this connection comes

with the server.

The optional Integrated xSeries Adapter (IXA) cab be installed only in slot 2. You

must move jumpers J35 and J40 on the IXA. For details about installing the IXA,

see the documentation that comes with the adapter.

I/O board error LED: This LED is on the I/O board and is visible on the rear of the

server. When this LED is lit, it indicates that there is a problem with the I/O board.

Gigabit Ethernet 2 activity LED: This LED is on the Gigabit Ethernet 2 connector.

When this LED flashes, it indicates that there is activity between the server and the

network.

Gigabit Ethernet 2 connector: Use this connector to connect the server to a

network.

Gigabit Ethernet 2 link LED: This LED is on the Gigabit Ethernet 2 connector.

When this LED is lit, it indicates that there is an active connection on the Ethernet

port.

Gigabit Ethernet 1 activity LED: This LED is on the Gigabit Ethernet 1 connector.

When this LED flashes, it indicates that there is activity between the server and the

network.

Gigabit Ethernet 1 connector: Use this connector to connect the server to a

network.

Gigabit Ethernet 1 link LED: This LED is on the Gigabit Ethernet 1 connector.

When this LED is lit, it indicates that there is an active connection on the Ethernet

port.

Chapter 1. Introduction 7

Page 24

System-board layouts

The following illustrations show the connectors, LEDs, and jumpers on the memory

card, microprocessor board, PCI board, SAS backplane, and I/O board. The

illustrations in this document might differ slightly from your hardware.

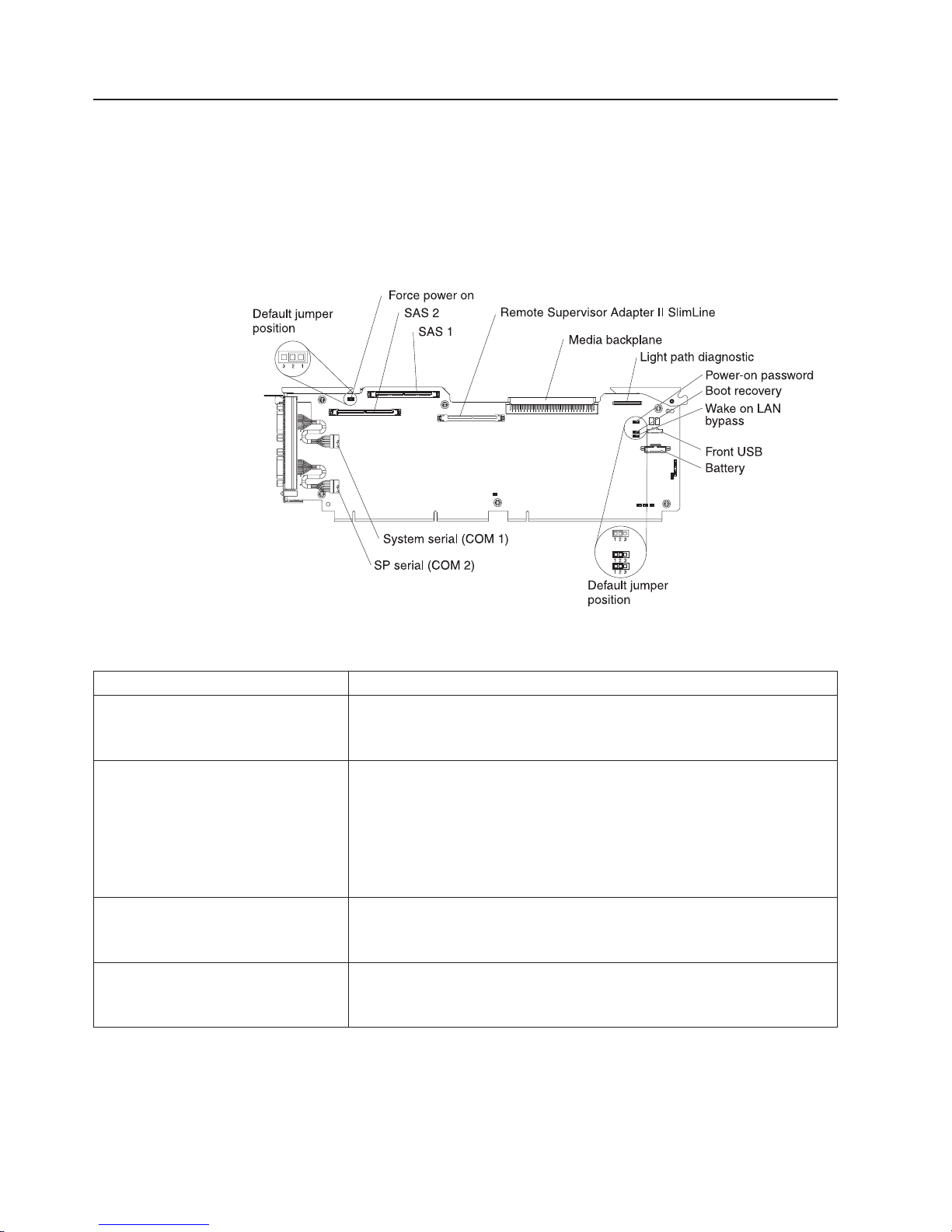

I/O board internal connectors and jumpers

The following illustration shows the internal connectors and jumpers on the I/O

board.

Table 2 describes the function of each three-pin jumper block.

Table 2. I/O board jumper blocks

Jumper name Description

Force power on (J2) The default position is pins 1 and 2. Change the position of this

jumper to pins 2 and 3 to force the server to startup when you

connect the server to ac power.

Power-on password (J9) The default position is pins 1 and 2. Change the position of this

jumper to pins 2 and 3 to bypass the power-on password check.

Changing the position of this jumper does not affect the

administrator password check if an administrator password is set. If

the administrator password is lost, the operator information panel

must be replaced.

Boot recovery (J14) The default position is pins 1 and 2 (use the primary page during

startup). Move the jumper to pins 2 and 3 to use the secondary

page during startup.

Wake on LAN® bypass (J15) The default position is pins 1 and 2. Move the jumper to pins 2 and

3 to prevent a Wake on LAN packet from waking the system when

the system is in the powered-off state.

8 IBM System x3850 Type 8864: Problem Determination and Service Guide

Page 25

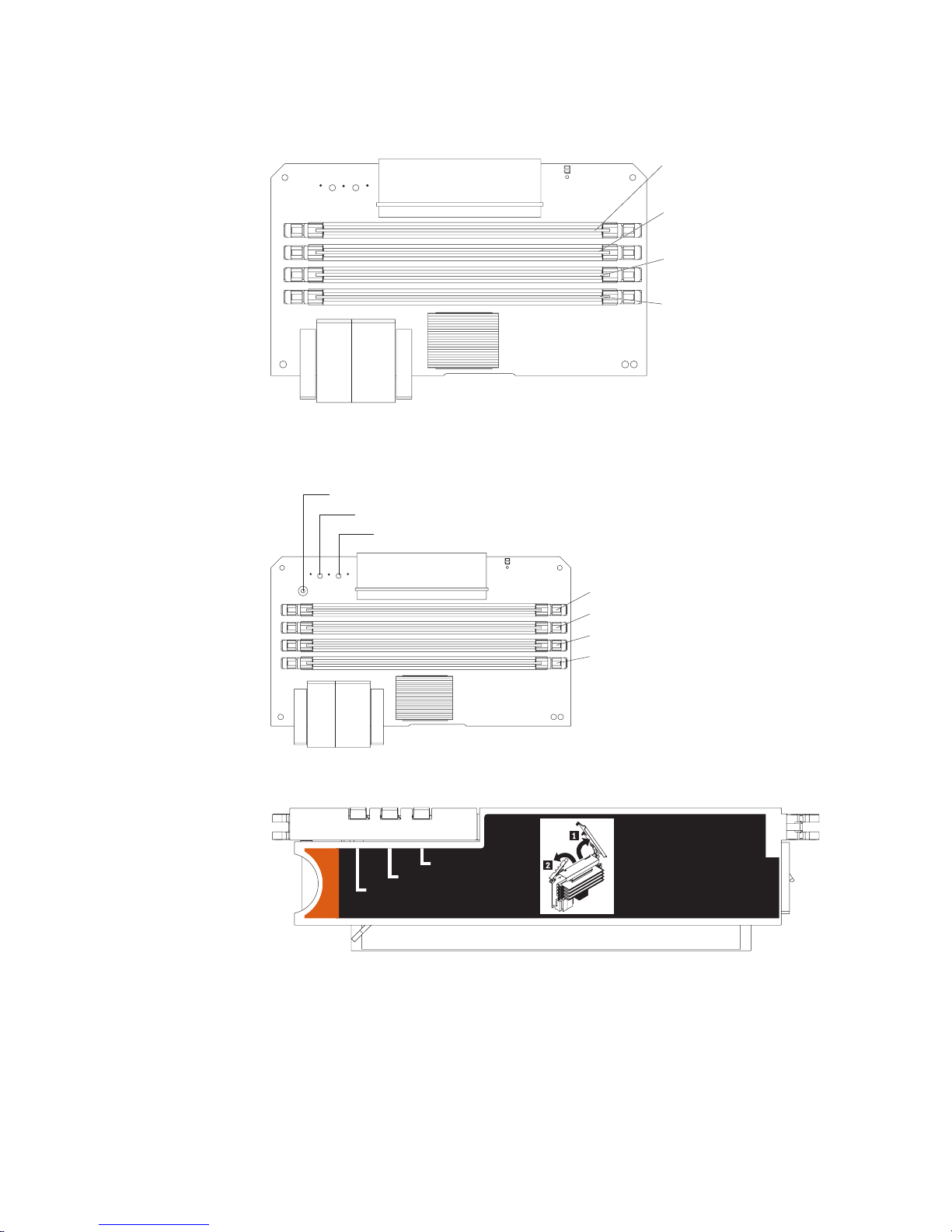

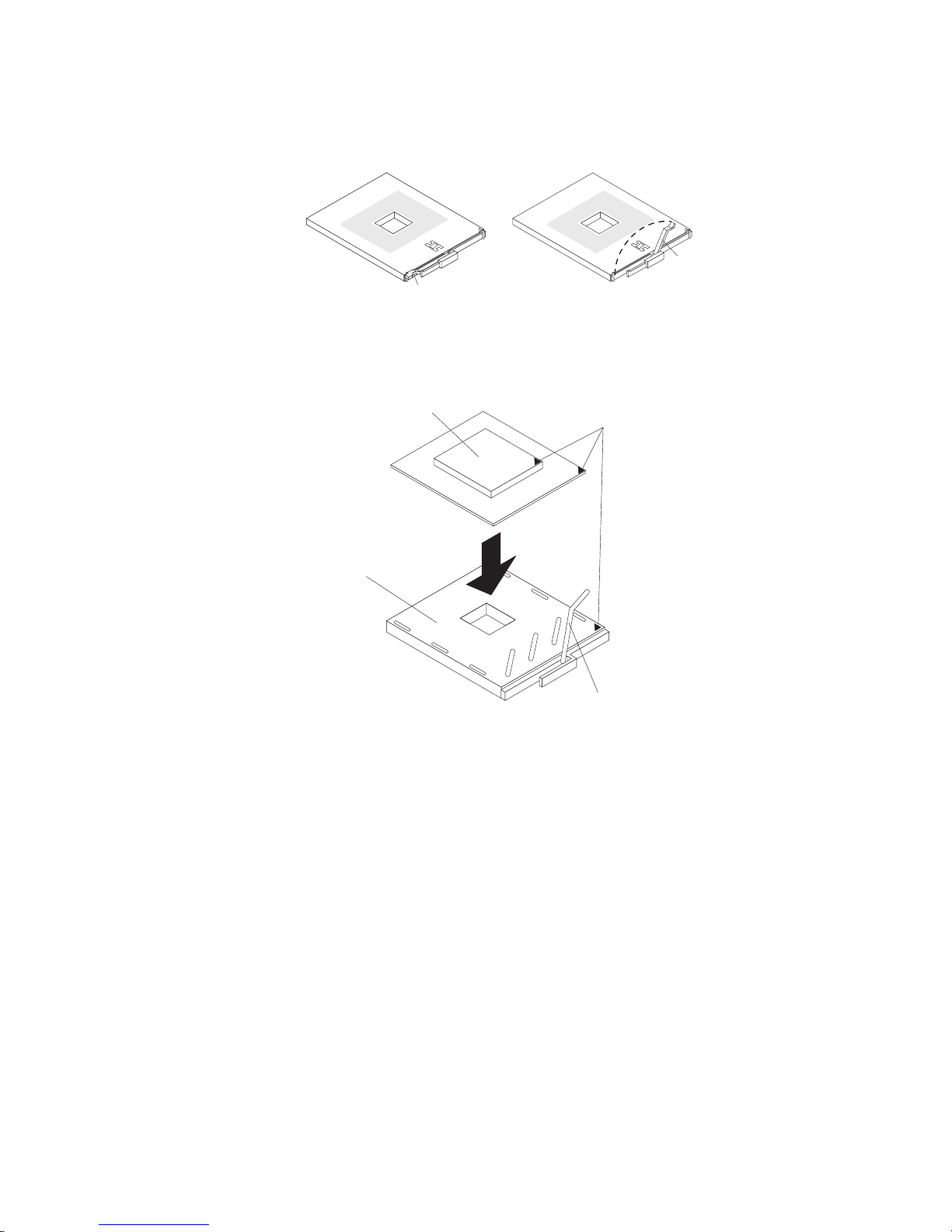

Memory-card connectors

The following illustration shows the connectors on the memory card.

Memory-card LEDs

The following illustration shows the LEDs on the memory card.

Light path diagnostics button

Light path diagnostics button power LED

DIMM 1

DIMM 2

DIMM 3

DIMM 4

Memory card error LED

To p view of the memory card

Memory Port Power

Error

Memory Hot-Swap Enabled

DIMM 1 error LED

DIMM 2 error LED

DIMM 3 error LED

DIMM 4 error LED

Chapter 1. Introduction 9

Page 26

Microprocessor-board connectors and LEDs

The following illustration shows the connectors and LEDs on the microprocessor

board.

Light path diagnostics

button

Fan 6

Fan 2

Memory

card 1

Fan 7

Fan 3

Memory

card 2

Memory

card 3

Fan 8

Microprocessor 1

socket

Microprocessor 2

socket

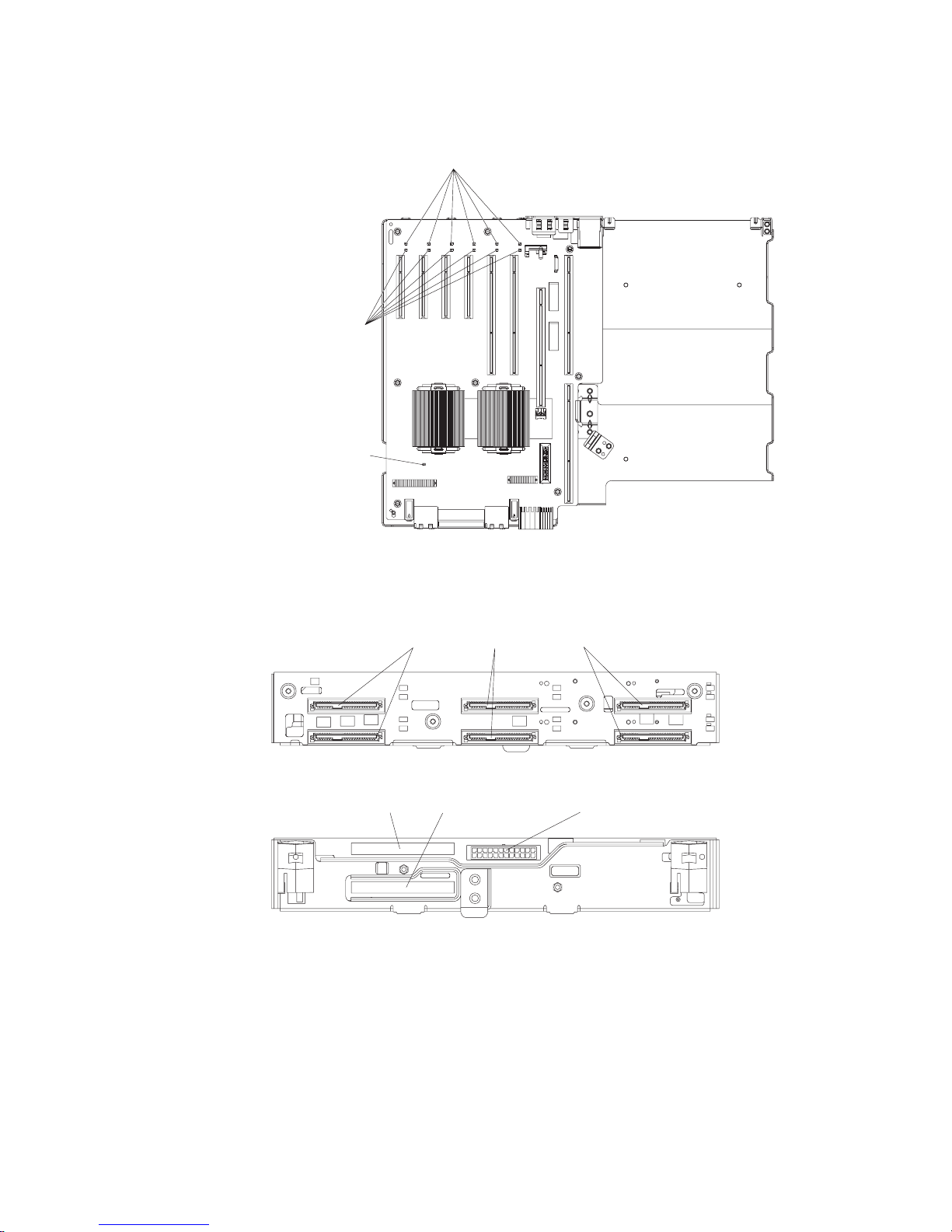

PCI board connectors

The following illustration shows the connectors on the PCI board.

Slot 1 PCI-X

266 MHz/64-bit

Slot 2 PCI-X

266 MHz/64-bit

Fan 5

Fan 1

11 22

Microprocessor 1

error LED

Microprocessor 2

error LED

44

33

Microprocessor 3 error LED

Microprocessor 3 socket

Microprocessor 4 error LED

Microprocessor 4 socket

Attention LED

Power LED

ServeRAID-8i

Active PCI cable

I/O board

Memory

card 4

Microprocessor card

error LED

Fan 4

Microprocessor 3

VRM connector

Microprocessor 4

VRM connector

VRM 4 error LED

VRM 3 error LED

Slot 3 PCI-E x8

Slot 4 PCI-E x8

Slot 5 PCI-E x8

Slot 6 PCI-E x8

10 IBM System x3850 Type 8864: Problem Determination and Service Guide

SAS internal power

cable connector

Page 27

PCI board LEDs

The following illustration shows the LEDs on the PCI board.

PCI power LEDs

Power good LED

PCI attention LEDs

SAS-backplane connectors

The following illustration shows the connectors on the SAS backplane.

Front of SAS backplane

Back of SAS backplane

SAS hard disk drive connectors

2

SAS signal cable 2SAS signal cable 1 SAS power

Chapter 1. Introduction 11

Page 28

12 IBM System x3850 Type 8864: Problem Determination and Service Guide

Page 29

Chapter 2. Configuration information and instructions

This chapter provides information about updating the firmware and using the

configuration utilities.

Updating the firmware

The firmware in your server is periodically updated and is available for download on

the Web. Go to http://www.ibm.com/servers/eserver/support/xseries/index.html to

check for the latest level of firmware, such as BIOS code, vital product data (VPD)

code, device drivers, and service processor firmware.

The UpdateXpress program is available for most IBM System x and xSeries servers

and server options. It detects supported and installed device drivers and firmware in

your server and installs available updates. You can download the UpdateXpress

program from the Web at no additional cost, or you can purchase it on a CD. To

download the program or purchase the CD, go to http://www.ibm.com/servers/

eserver/xseries/systems_management/ibm_director/

extensions/xpress.html.

When replacing devices in the server, you might have to either update the server

with the latest version of the firmware stored on the board or restore the

pre-existing firmware from a diskette or CD image.

v BIOS code and the diagnostics programs are stored in ROM on the

microprocessor board.

v BMC firmware is stored in ROM on the baseboard management controller on the

microprocessor board.

v Ethernet firmware is stored in ROM on the Ethernet controller on the PCI board.

v ServeRAID firmware is stored in ROM on the ServeRAID adapter.

v SAS firmware is stored in ROM on the SAS controller on the I/O board.

v Major components contain VPD code. Yo u can select to update the VPD code

during the BIOS code update procedure.

Configuring the server

The ServerGuide™ Setup and Installation CD provides software setup tools and

installation tools that are specifically designed for your IBM server. Use this CD

during the initial installation of the server to configure basic hardware features and

to simplify the operating-system installation.

In addition to the ServerGuide Setup and Installation CD, you can use the following

configuration programs to customize the server hardware:

v UpdateXpress program

v Configuration/Setup Utility program

v Baseboard management controller utility programs

v Preboot Execution Environment (PXE) boot agent utility program

v SAS/SATA Configuration Utility program

v ServeRAID Manager

© Copyright IBM Corp. 2006 13

Page 30

This section contains basic information about these programs. For detailed

information about these programs, see “Configuring the server” in the User’s Guide

on the IBM System x Documentation CD.

Using the ServerGuide Setup and Installation CD

The ServerGuide Setup and Installation CD provides programs to detect the server

model and installed hardware options, configure the server hardware, provide

device drivers, and help you install the operating system. For information about the

supported operating-system versions, see the label on the CD. If the ServerGuide

Setup and Installation CD did not come with your server, you can download the

latest version from http://www.ibm.com/pc/qtechinfo/MIGR-4ZKPPT.html.

Complete the following steps to start the ServerGuide Setup and Installation CD:

1. Insert the CD, and restart the server.

2. Follow the instructions on the screen to:

a. Select your language.

b. Select your keyboard layout and country.

c. View the overview to learn about ServerGuide features.

d. View the readme file to review installation tips about your operating system

and adapter.

e. Start the setup and hardware configuration programs.

f. Start the operating-system installation. Yo u will need your operating-system

CD.

Using the Configuration/Setup Utility program

Use the Configuration/Setup Utility program to:

v View configuration information

v View and change assignments for devices and I/O ports

v Set the date and time

v Set and change passwords

v Set the startup characteristics of the server and the order of startup devices

v Set and change settings for advanced hardware features

v View and clear error logs

v Change interrupt request (IRQ) settings

v Enable USB legacy keyboard and mouse support

v Resolve configuration conflicts

to http://www.ibm.com/servers/eserver/support/xseries/index.html to check for

Go

the latest version of the BIOS code.

Starting the Configuration/Setup Utility program

To start the Configuration/Setup Utility program, complete the following steps:

1. Turn on the server.

2. When the prompt Press F1 for Configuration/Setup appears, press F1. If you

have set both a power-on password and an administrator password, you must

type the administrator password to access the full Configuration/Setup Utility

menu. If you do not type the administrator password, a limited

Configuration/Setup Utility menu is available.

3. Select settings to view or change.

14 IBM System x3850 Type 8864: Problem Determination and Service Guide

Page 31

Configuration/Setup Utility menu choices

The following choices are on the Configuration/Setup Utility main menu. Depending

on the version of the BIOS code in the server, some menu choices might differ

slightly from these descriptions.

v System Summary

Select this choice to view configuration information, including the type, speed,

and cache sizes of the microprocessors, type and speed of installed USB

devices, and the amount of installed memory. When you make configuration

changes through other options in the Configuration/Setup Utility program, the

changes are reflected in the system summary; you cannot change settings

directly in the system summary.

This choice is on the full and limited Configuration/Setup Utility menu.

v System Information

Select this choice to view information about the server. When you make changes

through other options in the Configuration/Setup Utility program, some of those

changes are reflected in the system information; you cannot change settings

directly in the system information.

This choice is on the full Configuration/Setup Utility menu only.

– Product Data

Select this choice to view the machine type and model of the server, the serial

number, the revision level or issue date of the BIOS and diagnostics code

stored in electrically erasable programmable ROM (EEPROM), and the

revision level of the firmware on the Remote Supervisor Adapter II SlimLine.

– System Card Data

Select this choice to view vital product data (VPD) for some server

components.

v Devices and I/O Ports

Select this choice to view or change assignments for devices and input/output

(I/O) ports.

Select this choice to enable or disable integrated SAS and Ethernet controllers

and all standard ports (such as serial and parallel). Enable is the default setting

for all controllers. If you disable a device, it cannot be configured, and the

operating system will not be able to detect it (this is equivalent to disconnecting

the device). If you disable the integrated Ethernet controller and no Ethernet

adapter is installed, the server will have no Ethernet capability. If you disable the

integrated USB controller, the server will have no USB capability; to maintain

USB capability, make sure that Enabled is selected for the USB Host Controller

and USB BIOS Legacy Support options.

Note: If the USB host controller is disabled, the Remote Supervisor Adapter II

SlimLine remote keyboard, remote mouse, remote disk, OS watchdog, and

in-band management functions are also disabled.

This choice is on the full Configuration/Setup Utility menu only.

v Date and Time

Select this choice to set the date and time in the server, in 24-hour format

(hour:minute:second).

This choice is on the full Configuration/Setup Utility menu only.

v System Security

Select this choice to set passwords. See “Passwords” on page 18 for more

information about passwords. You can also enable the chassis-intrusion detector

to alert you each time the server cover is removed.

Chapter 2. Configuration information and instructions 15

Page 32

This choice is on the full Configuration/Setup Utility menu only.

– Power-on Password

Select this choice to set or change a power-on password. See “Power-on

password” on page 18 for more information.

– Administrator Password

Attention: If you set an administrator password and then forget it, there is

no way to change, override, or remove it. You must replace the I/O board.

Select this choice to set or change an administrator password. An

administrator password is intended to be used by a system administrator; it

limits access to the full Configuration/Setup Utility menu. If an administrator

password is set, the full Configuration/Setup Utility menu is available only if

you type the administrator password at the password prompt. See

“Administrator password” on page 19 for more information.

This choice is on the Configuration/Setup Utility menu only if an IBM Remote

Supervisor Adapter II SlimLine is installed.

Start Options

v

Select this choice to view or change the start options. Changes in the start

options take effect when you restart the server.

You can specify whether the server starts with the keyboard number lock on or

off. Yo u can enable the server to run without a diskette drive, monitor, or

keyboard.

The startup sequence specifies the order in which the server checks devices to

find a boot record. The server starts from the first boot record that it finds. If the

server has Wake on LAN hardware and software and the operating system

supports Wake on LAN functions, you can specify a startup sequence for the

Wake on LAN functions.

If you enable the boot fail count, the BIOS default settings will be restored after

three consecutive failures to find a boot record.

You can enable a virus-detection test that checks for changes in the boot record

when the server starts.

You can enable the use of a USB keyboard in a DOS or System Setup

environment. If a PS/2 keyboard is detected, the USB legacy operation will be

disabled.

This choice is on the full Configuration/Setup Utility menu only.

v Advanced Setup

Select this choice to change settings for advanced hardware features.

Important: The server might malfunction if these options are incorrectly

configured. Follow the instructions on the screen carefully.

This choice is on the full Configuration/Setup Utility menu only.

– System Partition Visibility

Select this choice to specify whether the System Partition is to be visible or

hidden.

– PCI Slot/Device Information

Select this choice to view system resources used by installed PCI devices.

PCI devices are usually configured automatically. This information is saved

when you exit. The Save Settings, Restore Settings, and Load Default

Settings choices on the Configuration/Setup Utility main menu do not save

the PCI Slot/Device Information settings.

This selection is only available when a Remote Supervisor II Adapter SlimLine

is installed in the server.

16 IBM System x3850 Type 8864: Problem Determination and Service Guide

Page 33

– Memory Settings

Select this choice to manually enable a pair of memory connectors. If a

memory error is detected during POST or memory configuration, the server

automatically disables the failing pair of memory connectors and continues

operating with reduced memory. After the problem is corrected, you must

manually enable memory connectors. Use the arrow keys to highlight the pair

of memory connectors that you want to enable, and use the arrow keys to

select Enable.

- Memory hole remapping above 64 GB

Select Disable to prevent memory gap remapping above 64 GB. Enable is

the default setting. Memory gap remapping above 64 GB occurs when 64

GB of system memory is installed. The memory gap created for use by I/O

devices is reclaimed above 64 GB.

CPU Options

–

Select this choice to enable or disable the Hyper-Threading Technology.

– Baseboard management controller (BMC) settings

Select this choice to view information and to change baseboard management

controller (BMC) settings.

- BMC Firmware Ver

This is a nonselectable menu item that displays the BMC firmware version.

- BMC POST Watchdog

Enable or disable the BMC POST watchdog. Disable is the default setting.

- BMC POST Watchdog Timeout

Set the BMC POST watchdog timeout value. 5 minutes is the default

setting.

- System-BMC Serial Port Sharing

Enable or disable the system BMC serial port sharing. Enable is the default

setting.

- BMC Serial Port Access Mode

Share or disable the BMC serial port access mode. Shared is the default

setting.

- Reboot System on NMI

If you enable this option, the server automatically restarts 60 seconds after

the service processor issues a nonmaskable interrupt (NMI) to the server. If

you disable this option, the server does not restart. Enable is the default

setting.

- BMC Network Configuration

Select this choice to view the BMC Network Configuration information.

- BMC System Event Log

To view the BMC System Event Log, which contains all system error and

warning messages that have been generated. Use the arrow keys to move

between pages in the log. If an optional IBM Remote Supervisor Adapter II

SlimLine is installed, the full text of the error messages is displayed;

otherwise, the log contains only numeric error codes. Run the diagnostic

program to get more information about error codes that occur. See

Chapter 5, “Diagnostics,” on page 63 for instructions. Select Clear error

logs to clear the BMC system event log.

v Error Logs

Select this choice to view or clear error logs.

This choice is available on the full Configuration/Setup Utility menu only.

– POST Error Log

Chapter 2. Configuration information and instructions 17

Page 34

Select this choice to view the three most recent error codes and messages

that were generated during POST. Select Clear error logs to clear the POST

error log.

v Save Settings

Select this choice to save the changes you have made in the settings.

v Restore Settings

Select this choice to cancel the changes you have made in the settings and

restore the previous settings.

v Load Default Settings

Select this choice to cancel the changes you have made in the settings and

restore the factory settings.

v Exit Setup

Select this choice to exit from the Configuration/Setup Utility program. If you have

not saved the changes you have made in the settings, you are asked whether

you want to save the changes or exit without saving them.

Passwords

From the System Security choice, you can set, change, and delete a power-on

password and an administrator password. The System Security choice is on the

full Configuration/Setup menu only.

If you set only a power-on password, you must type the power-on password to

complete the system startup, and you have access to the full Configuration/Setup

Utility menu.

An administrator password is intended to be used by a system administrator; it

limits access to the full Configuration/Setup Utility menu. If you set only an

administrator password, you do not have to type a password to complete the

system startup, but you must type the administrator password to access the

Configuration/Setup Utility menu.

If you set a power-on password for a user and an administrator password for a

system administrator, you can type either password to complete the system startup.

A system administrator who types the administrator password has access to the full

Configuration/Setup Utility menu; the system administrator can give the user

authority to set, change, and delete the power-on password. A user who types the

power-on password has access to only the limited Configuration/Setup Utility menu;

the user can set, change, and delete the power-on password, if the system

administrator has given the user that authority.

Power-on password: If a power-on password is set, when you turn on the server,

the system startup will not be completed until you type the power-on password. Yo u

can use any combination of up to seven characters (A–Z, a–z, and 0–9) for the

password.

When a power-on password is set, you can enable the Unattended Start mode, in

which the keyboard and mouse remain locked but the operating system can start.

You can unlock the keyboard and mouse by typing the power-on password.

If you forget the power-on password, you can regain access to the server in any of

the following ways:

v If an administrator password is set, type the administrator password at the

password prompt. Start the Configuration/Setup Utility program and reset the

power-on password.

18 IBM System x3850 Type 8864: Problem Determination and Service Guide

Page 35

v Remove the server battery and then reinstall it. See “Battery” on page 32 for

instructions for removing the battery.

v Change the position of the power-on password override jumper (J9 on the I/O

board) to bypass the power-on password check.

Attention: Before changing any switch settings or moving any jumpers, turn off

the server; then, disconnect all power cords and external cables. See the safety

information beginning on page vii. Do not change settings or move jumpers on

any system-board switch or jumper blocks that are not shown in this document.

The following illustration shows the location of the power-on password override,

boot recovery, and Wake on LAN (WOL) bypass jumpers.

SAS 1

SAS 2

Remote Supervisor Adapter II SlimLine

Media backplane

Light path diagnostic

Power-on password

override

Boot recovery

Wake-on-LAN

bypass

Front USB

Battery

System serial (COM 1)

SP serial (COM 2)

123

123

123

Default jumper

position

While the server is turned off, move the jumper on J9 from pins 1 and 2 to pins 2

and 3. You can then start the Configuration/Setup Utility program and reset the

power-on password. After you reset the password, turn off the server again and

move the jumper back to pins 1 and 2.

The power-on password override switch does not affect the administrator

password.

Administrator

password: If an administrator password is set, you must type the

administrator password for access to the full Configuration/Setup Utility menu. Yo u

can use any combination of up to seven characters (A–Z, a–z, and 0–9) for the

password. The Administrator Password choice is on the Configuration/Setup

Utility menu only if an optional IBM Remote Supervisor Adapter II SlimLine is

installed.

Attention: If you set an administrator password and then forget it, there is no way

to change, override, or remove it. You must replace the I/O board.

Installing and using the baseboard management controller utility

programs

The baseboard management controller provides environmental monitoring for the

server. If environmental conditions exceed thresholds or if system components fail,

the baseboard management controller lights LEDs to help you diagnose the

problem and also records the error in the System Event/Error log.

Also use the baseboard management controller to establish a Serial over LAN

(SOL) connection to manage servers from a remote location. You can remotely view

Chapter 2. Configuration information and instructions 19

Page 36

and change the BIOS settings, restart the server, identify the server, and perform

other management functions. Any standard Telenet client application can access the

SOL connection.

Note: The server Ethernet ports are set to DHCP by default. The BMC MAC

address can be found on a tag on the front of the server. Once you have deployed

the server, remove the BMC MAC address tag so that it does not impede airflow

through the front of the server.

Use the baseboard management controller firmware update utility program to

download a baseboard management controller firmware update. The firmware

update utility program updates the baseboard management controller firmware and

does not affect any device drivers.

Go to http://www.ibm.com/servers/eserver/support/xseries/index.html to download

the utility program; then, copy the Flash.exe file to a firmware update diskette.

Note: To ensure proper server operation, be sure to update the server baseboard

management controller firmware before updating the BIOS code.

Using the SAS/SATA Configuration Utility program

Use the SAS/SATA Configuration Utility program to view or change SAS controller

settings.

Complete the following steps to start the SAS/SATA Configuration Utility program:

1. Turn on the server.

2. When the message Press <CTRL><A> for Adaptec SAS/SATA Configuration

Utility appears, press Ctrl+A. If an administrator password has been set, you

are prompted to type the password.

3. Follow the instructions on the screen to configure the controller settings.

to http://www.ibm.com/servers/eserver/support/xseries/index.html to check for

Go

the latest version of the SAS firmware.

Configuring the Ethernet controller

The Ethernet controller is integrated on the system board. It provides an interface

for connecting to a 10-Mbps, 100-Mbps, or 1-Gbps network and provides full-duplex

(FDX) capability, which enables simultaneous transmission and reception of data on

the network. If the Ethernet ports in the server support auto-negotiation, the

controller detects the data-transfer rate (10BASE-T, 100BASE-TX, or 1000BASE-T)

and duplex mode (full-duplex or half-duplex) of the network and automatically

operates at that rate and mode.

You do not have to set any jumpers or configure the controller. However, you must

install a device driver to enable the operating system to address the controller. For

device drivers and information about configuring the Ethernet controller, see the

Broadcom NetXtreme Gigabit Ethernet Software CD that comes with the server. For

updated information about configuring the controller, go to http://www.ibm.com/

servers/eserver/support/xseries/index.html.

Using the PXE boot agent utility program

The Preboot Execution Environment (PXE) boot agent utility program is part of the

BIOS code. You can use it to specify the startup order of devices and enable or

disable operating-system wake-up support.

20 IBM System x3850 Type 8864: Problem Determination and Service Guide

Page 37

Note: The server does not support changing the network boot protocol or

specifying the startup order of devices through the PXE boot agent utility program.

Complete the following steps to start the PXE boot agent utility program:

1. Turn on the server.

2. When the Initializing Intel (R) Boot Agent Version X.X.XX PXE 2.0 Build

XXX (WfM 2.0) prompt appears, press Ctrl+S. Yo u have 2 seconds (by default)

to press Ctrl+S after the prompt appears. If the prompt does not appear, use the

Configuration/Setup Utility program to enable the Ethernet PXE/DHCP option.

3. Use the arrow keys and press Enter to select a choice from the menu.

4. Follow the instructions on the screen to change the settings of the selected

items; then, press Enter.

Using the ServeRAID configuration programs

A ServeRAID controller enables you to configure multiple physical hard disk drives

to operate as logical drives in a disk array. The controller comes with a CD

containing the ServeRAID Manager program and the ServeRAID Mini-Configuration

program, which you can use to configure the ServeRAID controller. For information

about these programs, see the documentation that comes with the ServeRAID

controller and the User’s Guide on the IBM System x Documentation CD. If your

server comes with an operating system installed, such as Microsoft Windows 2000

Datacenter Server, see the software documentation that comes with the server for

configuration information.

Chapter 2. Configuration information and instructions 21

Page 38

22 IBM System x3850 Type 8864: Problem Determination and Service Guide

Page 39

Chapter 3. Parts listing, Type 8864

The following replaceable components are available for the System x3850 Type

8864 except as specified otherwise in Table 3 on page 24. To check for an updated

parts listing on the Web, complete the following steps:

1. Go to http://www.ibm.com/servers/eserver/support/xseries/index.html.

2. From the Hardware list, select System x3850 and click Go.

3. Click the Install and use tab.

4. Under Technical resources, click Parts information.

1

2

13

20

15

14

FRONT

16

24

23

22

21

19

18

17

26

10

25

3

4

5

6

7

9

8

© Copyright IBM Corp. 2006 23

11

12

x

S

e

r

i

e

r

3

6

5

Page 40

Server replaceable units

Notes:

1. Field replaceable units (FRUs) must be serviced only by trained service

technicians.

2. Customer replaceable units (CRUs) can be replaced by the customer. Tier 1

CRUs and Tier 2 CRUs are described in the IBM “Statement of Limited

Warranty” (at “Part 3 - Warranty Information”), which is in the Warranty and

Support Information document on the IBM System x Documentation CD.

Table 3. Parts listing, Type 8864

CRU No.

Index Description

(Tier 1)

1 To p cover (all models) 26K8947

2 Power supply, 1300 W (all models) 24R2723

3 Power supply structure (all models) 26K8950

4 Power backplane (models 1Rx, 1Tx, 2Rx, 2Tx, 3Rx, 4Rx,

5Rx)

5 PCI board assembly (models 1Rx, 1Tx, 2Rx, 2Tx, 3Rx,

4Rx, 5Rx)

6 PCI switch card assembly (all models) 39M2699

7 Chassis assembly (all models) 42D3935

8 Fan (92 mm) (all models) 39M2694

9 Carrier, LP/media (all models) 42D3936

10 CD drive, 8/24X (primary) (all models) 39M3541

10 CD drive, 8/24X (alternate) (all models) 39M3563

10 CD drive, 24X (optional) 26K5427

10 CD drive, 24X (optional) 39M3559

10 CD drive, 127MM (optional) 39M3529

10 CD drive, 127MM (optional) 39M3567

10 CD-RW drive, 14X (optional) 39M3503

10 DVD drive (optional) 42C0955

11 Microprocessor VRM, 10.2 (optional) 39Y7256

12 Microprocessor tray (all models except 1Tx, 2Tx, EAx,

EBx, EDx)

12 Microprocessor tray (models 1Tx, 2Tx, EAx, EBx, EDx) 44E4281

13 x3850 bezel (all models) 42C2614

14 Microprocessor, 2.5 GHZ (models 1Rx, 1Tx, E1x, E2x) 42D3357

14 Microprocessor, 3.0 GHZ (models 2Rx, 2Tx, E4x) 42D3359

14 Microprocessor, 3.16 GHZ (models 3Rx, E3x) 42D3361

14 Microprocessor, 3.33 GHZ (model 4Rx) 42D3363

14 Microprocessor, 3.5 GHZ (model 5Rx) 43W9473

15 Heat sink (all models) 26K8805

16 Microprocessor baffle (all models) 26K9020

17 Hard disk drive filler (all models) 26K8680

CRU No.

(Tier 2) FRU No.

41Y3188

40K0282

40K2470

24 IBM System x3850 Type 8864: Problem Determination and Service Guide

Page 41

Table 3. Parts listing, Type 8864 (continued)

Index Description

CRU No.

(Tier 1)

CRU No.

(Tier 2) FRU No.

18 Hard disk drive, 36 GB (optional) 39R7364

18 Hard disk drive, 73 GB (optional) 39R7366

19 Memory, 1 GB PC3200 ECC (models (1Rx, 1Tx, 2Rx,

39M5808

2Tx, 3Rx, E1x, E2x, E3x, E4x)

19 Memory, 2 GB PC3200 ECC (model 4Rx, 5Rx) 39M5811

19 Memory, 4 GB PC3200 ECC (optional) 41Y2857

20 Air baffle (all models) 01R1479

21 Memory card (all models) 41Y3153

22 Fan (80 mm) (all models) 39M2693

23 SAS hard disk drive backplane (all models) 41Y3161

24 PCI adapter guide assembly (all models) 26K8951

25 PCI divider (all models) 03K9050

26 I/O board (all models) 41Y3152

AC inlet connector cover (models 1Rx, 1Tx, 2Rx, 2Tx

26K8941

3Rx)

/ Alcohol wipe, Canada 41Y8746

/ Alcohol wipe, Brazil/Mexico 41Y8747

/ Alcohol wipe, Taiwan/Japan 41Y8748

/ Alcohol wipe, China/Malaysia 41Y8749

/ Alcohol wipe, Australia/UK 41Y8750

/ Alcohol wipe, Korea 41Y8751

/ Alcohol wipe, Hungary 41Y8753

/ Alcohol wipe, Latin America 41Y8754

/ Alcohol wipe, China 41Y8757

/ Alcohol wipe, Hong Kong 41Y8758

/ Alcohol wipe, India 41Y8759

/ Alcohol wipe, Singapore 41Y8760

/ Alcohol wipe, other countries 41Y8752

Battery, 3.0 volt (all models) 33F8354

Cable, active PCI (all models) 39M2509

Cable, CD/DVD signal (all models) 25K9626

Cable management arm (all models) 40K6556

Cable, SAS power (all models) 42C2618

Cable, SAS signal (all models) 25K9610

Cable, serial (all models) 39M2641

Cable, USB (all models) 25K9618

Dual port Qlogic adapter 42C1772

DVD/CD bay filler (all models) 26K8938

EIA mounting bracket (all models) 26K8948

Kit, shipping bracket (all models) 40K6592

Chapter 3. Parts listing, Type 8864 25

Page 42

Table 3. Parts listing, Type 8864 (continued)

Index Description

CRU No.

(Tier 1)

CRU No.

(Tier 2) FRU No.

Lift handle kit (all models) 39M2696

Line cord (all models) 39M5377

PCIe 10 GbE PCIe SR server adapter 42C1762

PRO/1000 PT quad port server adapter (optional) 39Y6138

PRO/1000 PF server adapter (optional) 42C1752

Retention module (all models) 26K8836

RSA 2 adapter (standard models 2Rx, 2Tx, 3Rx, 4Rx,

13N0833

5Rx)

Scalability connector filler (all models) 26K8943

ServeRAID-8i card (optional) 39R8731

ServeRAID-8i battery pack (optional) 25R8118

Single port QLogic adapter (optional) 39Y6148

Slide kit (all models) 40K6591

System service label (all models) 42D3933

/ Thermal grease (all models) 41Y9292

Power cords

For your safety, IBM provides a power cord with a grounded attachment plug to use

with this IBM product. To avoid electrical shock, always use the power cord and

plug with a properly grounded outlet.

IBM power cords used in the United States and Canada are listed by Underwriter’s

Laboratories (UL) and certified by the Canadian Standards Association (CSA).

For units intended to be operated at 115 volts: Use a UL-listed and CSA-certified

cord set consisting of a minimum 18 AWG, Type SVT or SJT, three-conductor cord,

a maximum of 15 feet in length and a parallel blade, grounding-type attachment

plug rated 15 amperes, 125 volts.

For units intended to be operated at 230 volts (U.S. use): Use a UL-listed and

CSA-certified cord set consisting of a minimum 18 AWG, Type SVT or SJT,

three-conductor cord, a maximum of 15 feet in length and a tandem blade,

grounding-type attachment plug rated 15 amperes, 250 volts.

For units intended to be operated at 230 volts (outside the U.S.): Use a cord set

with a grounding-type attachment plug. The cord set should have the appropriate

safety approvals for the country in which the equipment will be installed.

IBM power cords for a specific country or region are usually available only in that

country or region.

IBM power cord part

number Used in these countries and regions

02K0546 China

13F9940 Australia, Fiji, Kiribati, Nauru, New Zealand, Papua New Guinea

26 IBM System x3850 Type 8864: Problem Determination and Service Guide

Page 43

IBM power cord part

number Used in these countries and regions

13F9979 Afghanistan, Albania, Algeria, Andorra, Angola, Armenia, Austria,

Azerbaijan, Belarus, Belgium, Benin, Bosnia and Herzegovina,

Bulgaria, Burkina Faso, Burundi, Cambodia, Cameroon, Cape

Verde, Central African Republic, Chad, Comoros, Congo

(Democratic Republic of), Congo (Republic of), Cote D’Ivoire

(Ivory Coast), Croatia (Republic of), Czech Republic, Dahomey,

Djibouti, Egypt, Equatorial Guinea, Eritrea, Estonia, Ethiopia,

Finland, France, French Guyana, French Polynesia, Germany,

Greece, Guadeloupe, Guinea, Guinea Bissau, Hungary, Iceland,

Indonesia, Iran, Kazakhstan, Kyrgyzstan, Laos (People’s

Democratic Republic of), Latvia, Lebanon, Lithuania, Luxembourg,

Macedonia (former Yugoslav Republic of), Madagascar, Mali,

Martinique, Mauritania, Mauritius, Mayotte, Moldova (Republic of),

Monaco, Mongolia, Morocco, Mozambique, Netherlands, New

Caledonia, Niger, Norway, Poland, Portugal, Reunion, Romania,

Russian Federation, Rwanda, Sao Tome and Principe, Saudi

Arabia, Senegal, Serbia, Slovakia, Slovenia (Republic of),

Somalia, Spain, Suriname, Sweden, Syrian Arab Republic,

Tajikistan, Tahiti, Togo, Tunisia, Turkey, Turkmenistan, Ukraine,

Upper Volta, Uzbekistan, Vanuatu, Vietnam, Wallis and Futuna,

Yugoslavia (Federal Republic of), Zaire

13F9997 Denmark

14F0015 Bangladesh, Lesotho, Macao, Maldives, Namibia, Nepal,

Pakistan, Samoa, South Africa, Sri Lanka, Swaziland, Uganda

14F0033 Abu Dhabi, Bahrain, Botswana, Brunei Darussalam, Channel

Islands, China (Hong Kong S.A.R.), Cyprus, Dominica, Gambia,

Ghana, Grenada, Iraq, Ireland, Jordan, Kenya, Kuwait, Liberia,

Malawi, Malaysia, Malta, Myanmar (Burma), Nigeria, Oman,

Polynesia, Qatar, Saint Kitts and Nevis, Saint Lucia, Saint Vincent

and the Grenadines, Seychelles, Sierra Leone, Singapore, Sudan,

Tanzania (United Republic of), Trinidad and Tobago, United Arab

Emirates (Dubai), United Kingdom, Yemen, Zambia, Zimbabwe

14F0051 Liechtenstein, Switzerland

14F0069 Chile, Italy, Libyan Arab Jamahiriya

14F0087 Israel

1838574 Antigua and Barbuda, Aruba, Bahamas, Barbados, Belize,

Bermuda, Bolivia, Brazil, Caicos Islands, Canada, Cayman

Islands, Costa Rica, Colombia, Cuba, Dominican Republic,