Page 1

ERserver

iSeries

Service Functions

Version 5

SY44-5902-05

Page 2

Page 3

ER s e r v e r

iSeries

Service Functions

Version 5

SY44-5902-05

Page 4

Note

Before using this information and the product it supports, be sure to read the information in

“Safety and Environmental Notices” on page vii and Appendix B, “Notices” on page 321.

Sixth Edition (August 2002)

This edition applies to version 5, release 2, modification 0 of Service Functions manual (SY44–5902–05) and to all

subsequent releases and modifications until otherwise indicated in new editions. This edition applies only to

reduced instruction set computer (RISC) systems.

© Copyright International Business Machines Corporation 1997, 2002. All rights reserved.

US Government Users Restricted Rights – Use, duplication or disclosure restricted by GSA ADP Schedule Contract

with IBM Corp.

Page 5

Contents

Safety and Environmental Notices . . . vii

Danger Notices .............vii

Product Recycling and Disposal .......viii

Battery Return Program ..........viii

Environmental Design ..........viii

Caution Notices ............viii

Attention Notices ............ix

Laser Safety Information ..........x

Laser Safety Information (for IBM Fiber Optic

Link Products).............x

About Service Functions (SY44-5902-03) xi

Who should read this book .........xi

Conventions and terminology used in this book . . xi

Prerequisite and related information ......xi

iSeries Navigator ...........xii

How to send your comments ........xii

Chapter 1. Dedicated Service Tools

(DST)................1

Introduction ..............1

DedicatedServiceToolsrequirements.....1

System paging environments .........2

Stand-alone paging (non-paging) ......2

Limited paging ............2

Full paging ..............3

Accessing Dedicated Service Tools .......4

Performing an IPL to DST .........4

Changing a service tools user ID.......5

Resetting QSECOFR service tools user ID ....6

Performing an IPL to DST for secondary partitions 6

Pressing the System Request Key while the system

is operational .............7

Selecting Function 21 while the system Is

operational ..............7

Performing an alternate IPL to DST (type D IPL) . 8

Function keys (in DST) ...........9

Exiting Dedicated Service Tools........10

DSToptions..............10

Installing Licensed Internal Code ......11

Installing the operating system .......11

Perform an IPL ............11

Work with Licensed Internal Code ......11

Workwithdiskunits..........13

Work with Dedicated Service Tools environment 23

Start a service tool ...........28

Perform automatic installation of the operating

system ...............39

Save Licensed Internal Code........40

Work with save storage and restore storage. . . 40

Work with remote service support ......40

Work with system partitions........42

Work with system capacity ........42

Work with system security ........42

Chapter 2. Hardware Service Manager 45

Introduction ..............45

Hardware Service Manager options ......46

Packaging hardware resources .......47

Logicalhardwareresources........49

Locateresourcebyname.........50

Failed and non-reporting resources .....53

System Power Control Network (SPCN) ....55

Battery power unit information .......55

Work with service action log .......56

Displaylabellocationworksheet......58

Device concurrent maintenance .......58

Collecting information and performing functions

from the Hardware Service Manager displays . . . 61

Change resource details .........61

Concurrent maintenance .........63

Createframeinformation.........64

Debugtheresource...........66

Display address ............67

Displayassociatedresources........67

Displaycardgapinformation.......69

Displayfailedresources.........70

Display hardware contained within package . . 70

Displaylocationinformation........71

Display non-reporting resources ......71

DisplayresourcesassociatedwithIOP....72

Displayresourcedetails.........73

Display resources requiring attention .....77

Displayresourcestatus.........78

Display serial/part numbers, logical address, and

status/resourcenameinformation......79

Display system bus resources .......79

Display system information ........82

Displayunresolvedlocations .......82

Print................83

Refreshthedisplay...........83

Remove non-reporting resource information . . 83

Reserve frame space ..........84

Using High-Speed Link (HSL) specific options. . 84

Verify resources ............92

Symbols on the Hardware Service Manager displays 93

Printing the System Configuration List .....93

Verification procedures ..........95

Hardware Service Manager — Verify .....95

Verify optical storage unit ........96

Verify diskette ............96

Verify tape..............96

Verify communications .........97

Chapter 3. Product Activity Log ....99

Introduction ..............99

Product Activity Log (PAL).........100

The Service Action Log (SAL) .......100

Product Activity Log location .......101

© Copyright IBM Corp. 1997, 2002 iii

Page 6

Recovering from Product Activity Log errors

whileinDST............101

Paging environment ...........101

Options and function keys .........102

Analyze log .............102

DisplayorprintbylogID........103

Change Product Activity Log sizes .....104

Work with removable media lifetime statistics 104

Display or print removable media session

statistics ..............105

Sort by ... function...........105

Address information function .......106

View description function ........107

Hexadecimal Product Activity Log data . . . 107

Interpreting Product Activity Log reports ....110

Some considerations when interpreting Product

Activity Log reports ..........110

Resourcename............111

Resourcetype,model,andlocation.....112

Class...............112

System reference code .........113

Multiple SRC entries ..........114

Logical address format .........114

Sequencenumber...........115

Secondary code............115

TableID..............115

IPLsource/state...........115

Hexadecimal report ..........115

Chapter 4. Service Reference

Procedures ............125

Setting the system date and time .......125

Determining the dominant operating system . . . 126

System password ............126

System unique identifier..........127

Determining a primary or alternative console. . . 128

Introduction .............128

Primaryconsolerequirements.......128

Identifying the consoles when the system is

operational .............128

Locating the system’s load source from the system

console...............129

History file ..............130

Continuously Powered Main Storage (CPM) . . . 131

Low-level debug and data collecting procedures 131

Introduction .............131

Getting started ............131

Displaying data for functions 54 through 58, 63,

and 64 (Models 150, 170, 250, 4xx, 50x, 51x, 530,

53S, 6xx, 7xx, SB1, and Sxx) .......131

Displaying data for functions 57, 63, and 64

(Models 270, 8xx, SB2, SB3, and 890) ....132

Changing the address in functions 59 through

61 (Models 150, 170, 250, 4xx, 50x, 51x, 530, 53S,

6xx, 7xx, SB1, and Sxx) .........133

Changing the address in functions 58 through

61 (Models 270, 8xx, SB2, SB3, and 890) . . . 135

Displaying data from function 62......136

Logical partitions ............136

Examples: Missing or non-reporting system bus

resources..............137

Determining the release level of a logical

partition ..............138

Locating a secondary partition’s console . . . 138

Locating a secondary partition’s load source . . 139

Locating a secondary partition’s load source

from the secondary partition’sconsole....139

Locating a secondary partition’s load source

from the primary partition’sconsole.....140

Querying logical partition time and date . . . 141

Converting secondary partition time and date to

primary partition time and date ......141

Finding the SRC history list for a secondary

partition ..............141

Closing related problems in other logical

partitions ..............141

Accessing the panel functions of a logical

partition ..............142

Determining which logical partition owns a

FRU or a system I/O resource.......142

Selecting IPL source and mode for a secondary

partition ..............143

Options on the Work with Partition Status

display..............143

Guest partitions ...........147

IASP/Clustering Service Reference Procedures . . 149

Determining if a tower is configured as

switchable .............149

Determining the power controlling system of a

tower...............150

Determining the resource name and HSL loop

numberofanHSLI/Obridge.......152

Switching ownership of a tower’s switchable

resources..............154

Switching the mode of a tower’s switchable

resources..............156

Chapter 5. Control Panel Functions 159

Values for IPL types, key modes, and speeds . . . 159

Control Panel Functions (Models 150, 170, 250, 4xx,

50x, 51x, 530, 53S, 6xx, 7xx, SB1, and Sxx) ....160

Ways to access the control panel (Models 150,

170, 250, 4xx, 50x, 51x, 530, 53S, 6xx, 7xx, SB1,

and Sxx) ..............162

Control panel function descriptions (Models 150,

170, 250, 4xx, 50x, 51x, 530, 53S, 6xx, 7xx, SB1,

and Sxx) ..............162

Control panel functions (Models 270, 8xx, SB2, SB3,

and 890) ...............174

Ways to access the control panel (Models 270,

8xx, SB2, SB3, and 890) .........175

Control panel function descriptions (Models 270,

8xx, SB2, SB3, and 890) .........177

Chapter 6. System Reference Code

(SRC) Information .........191

Introduction ..............191

SRCformats..............191

Word1-SRCgeneralinformation.....193

Word 2 - System status information .....194

System Reference Codes (SRCs) .......196

iv Service Functions V5R2

Page 7

General system and Unit Reference Code (URC)

information.............196

SPCN informational concurrent maintenance

SRCs ...............201

IPL status SRCs ...........201

General status SRCs ..........214

Chapter 7. Initial Program Load (IPL)

Information ............217

IPLtype,mode,andspeedoptions......217

IPLspeedrecommendations.......217

Methods to perform IPL ..........217

Alternate installation IPL .........218

IPLsequence .............218

Service processor initialization .......218

Licensed Internal Code (LIC) initialization. . . 219

Status SRCs ..............221

Chapter 8. Licensed Internal Code 223

Licensed Internal Code (LIC) introduction ....223

Fixes and cumulative PTF packages ......223

Cumulative PTF packages ........224

PSP listings .............224

Licensed programs ..........224

Displaying Licensed Internal Code fixes ....224

Code naming conventions .........225

Utilities to Install and Restore Licensed Internal

Code ................225

Introduction .............225

Overview of Licensed Internal Code Install and

Restore ..............225

Utility to install Licensed Internal Code . . . 226

Utility to restore Licensed Internal Code . . . 227

Authorized Program Analysis Report (APAR) . . 228

Chapter 9. System Architecture and

Configuration ...........229

Hardwareinformation..........230

System power overview ..........230

Power supply ............230

Battery power unit ..........230

System Power Control Network (SPCN) . . . 231

SPCN menu flow ...........232

System Interconnect ...........241

HighSpeedLink............241

Multi-adapter bridge ...........242

Resourcenames ............242

Hardware configuration restrictions ......244

Communications card, cable, and wrap connector

reference ...............244

Single-port communications adapter card and

TPAC wrap connector .........244

High speed communications card and wrap

connector wiring ...........245

Advanced PCI communications console cable 246

Cryptographic processor card and wrap

connector wiring ...........246

Two-port communications adapter card and

wrap connector wiring .........247

ISDN wrap connector and connector pin . . . 248

Two-port communications adapter cable . . . 249

RJ-45 cable wrap connector ........251

V.24 communications adapter remote power-on

cable...............251

V.24/X.21bis communications adapter cable . . 252

Stage 1 V.24/X.21bis cable wrap connector

wiring ...............253

V.24/X.21bis cable wrap connector wiring . . . 253

EIA 232 advanced PCI communications cable 253

EIA 232 advanced wrap connector wiring . . . 254

Stage 1 EIA-232/X.21bis communications

adapter cable ............254

EIA-232/X.21bis communications adapter cable 255

EIA-232/X.21bis cable wrap connector wiring 255

V.36/EIA 449 high speed communications

adapter cable ............256

V.36/EIA 449 high speed communications

adapter cable wrap connector wiring ....256

Stage 1 V.35 communications adapter cable . . 257

Stage 1 V.35 cable wrap connector wiring . . . 257

V.24 advanced PCI communications cable . . . 257

V.24 advanced wrap connector wiring ....258

V.35 advanced PCI communications cable . . . 258

V.35 advanced wrap connector wiring ....259

V.35 communications adapter cable .....260

V.35 cable wrap connector wiring......260

V.35/High speed communications adapter cable 260

V.35/High speed communications adapter cable

wrap connector wiring .........261

V.36/RS-449 advanced PCI communications

cable...............261

V.36/RS-449 advanced cable wrap connector

wiring ...............262

X.21 communications adapter cable .....263

X.21/High speed communications adapter cable 263

X.21 cable wrap connector wiring .....263

X.21 advanced PCI communications cable . . . 263

X.21 advanced wrap connector wiring ....264

Token-ring communications adapter cable and

cardwrap.............264

Ethernet/IEEE 802.3 transceiver adapter cable

andcardwrap............264

Facsimile adapter cable wrap connector wiring 265

DDI transceiver adapter cable and card wrap 265

PCI communications card wrap connector

wiring ...............266

Communications signal voltage levels .....267

Chapter 10. Working with Storage

Dumps..............269

Main storage dump introduction .......269

Automaticmainstoragedump .......270

Performing a main storage dump to disk (manual

MSD)................271

Copying a main storage dump .......272

Workwithcurrentmainstoragedump....273

Work with copies of main storage dumps . . . 274

Mainstoragedumpstatus.........275

Terminating System Reference Code (SRC) . . 275

Errorrecoveryfordumps.........276

Contents v

Page 8

Determining whether main storage dump data

was written to disk ..........276

Reporting the error ..........276

Additional help ...........277

Performing an IOP storage dump to disk (Models

150, 170, 250, 4xx, 50x, 51x, 530, 53S, 6xx, 7xx, SB1,

S20, S30, and S40) ............277

Performing a service processor storage dump

(Models 270, 8xx, SB2, SB3, and 890) .....277

Copying the IOP storage dump to removable

media (All Models) ...........278

Copying the service processor storage dump to

removable media (Models 270, 8xx, SB2, SB3, and

890) ................278

Performing an IOP dump using hardware service

manager (All Models) ..........279

IOP dump information in the Product Activity Log

(All Models)..............279

Appendix A. OS/400 Operating System 281

DST in OS/400 full paging environment ....281

DST in OS/400 limited paging environment . . . 282

System Service Tools (SST) .........282

Accessing system service tools.......282

SSToptions.............283

Function keys (SST) ..........289

Online problem analysis and resolution ....290

Introduction .............290

System-detected problems ........290

Customer-detected problems .......292

Service support facility .........293

Displaying OS/400 PTFs .........293

OS/400 or LIC APAR information ......293

How to reset an I/O processor card while the

system is up and running .........295

Varying configuration descriptions on and off . . 295

Commonly used OS/400 service commands . . . 296

Work with System Value (WRKSYSVAL)

Command.............298

Service attributes (DSPSRVA or CHGSRVA)

commands .............299

Change Transmit Level (CHGXMTLVL)

command .............301

Work with Hardware Products (WRKHDWPRD)

Command.............302

Verify commands ............308

Commonly used verify commands .....308

Verify communications .........308

Communicationstests..........316

Wireless LAN adapter card indicators ....316

Communications interface trace ......316

Concurrent LPDA-2 tests ........317

Appendix B. Notices ........321

Trademarks..............322

Glossary of Terms and Abbreviations 325

Index ...............331

vi

Service Functions V5R2

Page 9

Safety and Environmental Notices

Danger Notices

A danger notice calls attention to a situation that is potentially lethal or extremely

hazardous to people.

DANGER

To prevent power from switching on automatically during service procedures,

select manual or secure mode on the system unit control panel or disconnect

the cables that connect to J15 and J16 on the frame being serviced.

(RSFTD211)

DANGER

An electrical outlet that is not correctly wired could place hazardous voltage

on metal parts of the system or the products that attach to the system. It is the

customer’s responsibility to ensure that the outlet is correctly wired and

grounded to prevent an electrical shock. (RSFTD201)

DANGER

To prevent a possible electrical shock when installing the system, ensure that

the power cords for all devices are unplugged before installing signal cables.

(RSFTD202)

DANGER

To prevent a possible electrical shock when adding or removing any devices

to or from the system, ensure that the power cords for those devices are

unplugged before the signal cables are connected or disconnected. If possible,

disconnect all power cords from the existing system before you add or

remove a device. (RSFTD203)

DANGER

Use caution when installing or modifying telephone lines. Disconnect the

lines at the network interface before working with telephone wires that are

not insulated. Never install telephone jacks that are not waterproof in wet

locations. Do not install or modify telephone lines or use a telephone (other

than a cordless type) during an electrical storm. Do not use a telephone to

report a gas leak in the area of the leak. (RSFTD213)

DANGER

To prevent a possible electrical shock during an electrical storm, do not

connect or disconnect cables or station protectors for communications lines,

display stations, printers, or telephones. (RSFTD003)

© Copyright IBM Corp. 1997, 2002 vii

Page 10

DANGER

To prevent a possible electrical shock from touching two surfaces with

different electrical grounds, use one hand, when possible, to connect or

disconnect signal cables. (RSFTD004)

DANGER

To prevent a possible electrical shock, do not use the port tester during

electrical storms. (RSFTD006)

Product Recycling and Disposal

Components of the system, such as structural parts and circuit cards, can be

recycled where recycling facilities exist. IBM does not currently collect and recycle

used IBM products from customers in the United States other than those products

that are involved in trade-in programs. Companies are available to disassemble,

reutilize, recycle, or dispose of electronic products. Contact an IBM account

representative for more information.

The system unit contains batteries and circuit boards with lead solder. Before you

dispose of this unit, these batteries and circuit boards must be removed and

discarded according to local regulations or recycled where facilities exist. This book

contains specific information on each battery type where applicable.

Battery Return Program

In the United States, IBM has established a collection process for reuse, recycling,

or proper disposal of used IBM batteries and battery packs. For information on

proper disposal of the batteries in this unit, please contact IBM at 1-800-426-4333.

Please have the IBM part number that is listed on the battery available when you

make your call. For information on battery disposal outside the United States,

contact your local waste disposal facility.

Environmental Design

The environmental efforts that have gone into the design of the system signify

IBM’s commitment to improve the quality of its products and processes. Some of

these accomplishments include the elimination of the use of Class I

ozone-depleting chemicals in the manufacturing process, reductions in

manufacturing wastes, and increased product energy efficiency. For more

information, contact an IBM account representative.

Caution Notices

A caution notice calls attention to a situation that is potentially hazardous to

people because of some existing condition.

CAUTION:

Be careful when removing or installing this part or unit. This part or unit is

heavy, but has a weight smaller than 18 kilograms (39.7 pounds). (RSFTC201)

CAUTION:

The weight of this part or unit is between 18 and 32 kilograms (39.7 and 70.5

pounds). It takes two persons to safely lift this part or unit. (RSFTC204)

viii Service Functions V5R2

Page 11

CAUTION:

The battery is a lead-acid battery. To avoid possible explosion, do not burn.

Exchange only with the IBM-approved part. Recycle or discard the battery as

instructed by local regulations.

In the United States, IBM has a process for the collection of this battery. For

information, call 1-800-426-4333. Have the IBM part number for the battery unit

available when you call. (RSFTC225)

CAUTION:

The circuit card contains lead solder. To avoid the release of lead (Pb) into the

environment, do not burn. Discard the circuit card as instructed by local

regulations. (RSFTC234)

CAUTION:

This assembly has a circuit card that contains lead solder. To avoid the release of

lead (Pb) into the environment, do not burn. Discard the assembly as instructed

by local regulations. (RSFTC235)

CAUTION:

The optical link card contains a laser. To avoid the release of toxic substances

into the environment, do not burn. Discard the optical link as instructed by local

regulations. (RSFTC236)

CAUTION:

The battery is a lithium battery. To avoid possible explosion, do not burn or

charge the battery. Exchange only with the IBM-approved part. Discard the

battery as instructed by local regulations. (RSFTC227)

Attention Notices

An attention notice indicates the possibility of damage to a program, device,

system, or data.

Safety and Environmental Notices ix

Page 12

Laser Safety Information

Laser Safety Information (for IBM Fiber Optic Link Products)

CAUTION:

This system may contain laser products called the IBM Optical Link Module

(OLM), Serial Optical Converter (SOC), or Optical Link Card (OLC). In the

United States, these fiber optic links are certified by IBM as Class I laser

products that conform to the requirements contained in the Department of

Health and Human Services (DHHS) regulation 21 CFR Subchapter J.

Internationally, these fiber optic links are certified as Class 1 laser products that

conform to the requirements contained in the International Electrotechnical

Commission (IEC) standard 825-1 (1993), the CENELEC (European Committee for

Electrotechnical Standardization) European Norm standard EN60825-1 (1994), and

the Verband Deutscher Elektrotechniker (VDE) standard 0837 (1986). The

German testing institute, VDE, has assigned certificate registration number 3642

to all IBM OLM, SOC, and OLC laser products.

The fiber optic links incorporate laser diodes that are either of the gallium

aluminum arsenide (GaAlAs) type that emits in the wavelength range of 770 to

860 nanometers or of the indium gallium arsenide phosphide (InGaAsP) type

that emits in the wavelength range of 1270 to 1355 nanometers. These fiber optic

links incorporate discrete laser diodes that are Class 3B laser products with a

rating of approximately 5.0 milliwatts peak power. Once the lasers are

assembled into the OLM, SOC, or OLC, the automatic laser control safety system

prevents laser emissions from exceeding Class 1 limits during both operation

and service. There are no user maintenance operations or adjustments to be

performed on IBM OLM, SOC, or OLC products. Class 1 laser products are not

considered to be hazardous under any conditions.

The fiber optic links are designed and certified for use in applications with

point-to-point optical links only. Use of these products with multiple input or

multiple output links (for example, star coupler or fiber splitter) is not

compatible with the OLM, SOC, or OLC design and function. In addition, the

fiber optic link products must be connected only to other IBM OLM, SOC, or

OLC (of the same model) or a compatible laser product. This is especially true

for those models that contain both the open link detection safety system called

Open Fiber Control (OFC) and the laser power control safety system. (All OLM,

SOC, and OLC models contain the laser power control safety system. All OLC

models contain OFC, all SOC model have No-OFC, but some OLM models are

available with OFC and some have No-OFC.)

These requirements are necessary for the correct operation of the IBM OLM,

SOC, and OLC products in any optical communication system. Failure to follow

these restrictions could result in the system not operating correctly and the

creation of points of access that emit laser radiation above the Class 1 limit

specified by either the IEC 825-1 (1993) standard internationally or the DHHS

regulation 21 CFR Sub J in the United States. (RSFTC211)

x Service Functions V5R2

Page 13

About Service Functions (SY44-5902-03)

This book provides basic information about iSeries functions that are commonly

used by field hardware service representatives. It provides enough detail for the

hardware service representative to gather information about hardware problems

while under the direction of the next level of support.

The book is meant to assist the hardware service representative in gathering

information about commonly encountered field problems. It does not cover all

service functions available on the iSeries.

Who should read this book

This book is intended for trained iSeries hardware service representatives and

service providers who act as the primary level of field hardware service support

(as opposed to system operators) to help solve and diagnose hardware problems.

Before using this book, you should know how to service (analyze, isolate, report,

and resolve problems, and verify fixes using the iSeries maintenance package) the

iSeries hardware. You must also know how to safely work with electrical

components.

Attention: Some service tools described in this book can be used to change or

erase data, programs, or other objects on the iSeries system. This damage can occur

with the misuse of service tools or with inappropriate security in effect.

Conventions and terminology used in this book

This book contains examples of displays that are illustrated as completely as

possible; however, they may vary from those you actually use.

Before using this information and the product it supports, be sure to read the

general information and danger notices under Appendix B, “Notices” on page 321.

Refer to the Glossary for terms not explained in the text.

Throughout this book, the terms iSeries applies to any iSeries System Model Unit,

unless the reference is to a specific model.

Prerequisite and related information

Use the iSeries Information Center as your starting point for looking up iSeries

technical information. You can access the Information Center from the following

Web site::

http://www.ibm.com/eserver/iseries/infocenter

v

The iSeries Information Center contains advisors and important topics such as CL

commands, system application programming interfaces (APIs), logical partitions,

clustering, Java, TCP/IP, Web serving, and secured networks. It also includes links

to related IBM Redbooks and Internet links to other IBM Web sites such as the

Technical Studio and the IBM home page.

With every new hardware order, you receive the following CD-ROM information:

© Copyright IBM Corp. 1997, 2002 xi

Page 14

v The iSeries Setup and Operations CD-ROM. This CD-ROM contains IBM iSeries

Access for Windows and the EZ-Setup wizard. iSeries Access for Windows offers

a powerful set of client and server capabilities for connecting PCs to iSeries

servers. The EZ-Setup wizard automates many of the iSeries setup tasks.

iSeries Navigator

IBM iSeries Navigator is a powerful graphical interface for managing your iSeries

and AS/400e servers. iSeries Navigator functionality includes system navigation,

configuration, planning capabilities, and online help to guide you through your

tasks. iSeries Navigator makes operation and administration of the server easier

and more productive and is the only user interface to the new, advanced features

of the OS/400 operating system. It also includes Management Central folder within

iSeries Navigator for managing multiple servers from a central server.

For more information on iSeries Navigator, see the iSeries Information Center.

How to send your comments

Your feedback is important in helping to provide the most accurate and

high-quality information. If you have any comments about this book or any other

iSeries documentation, fill out the readers’ comment form at the back of this book.

v If you prefer to send comments by mail, use the readers’ comment form with the

address that is printed on the back. If you are mailing a readers’ comment form

from a country or region other than the United States, you can give the form to

the local IBM branch office or IBM representative for postage-paid mailing.

v If you prefer to send comments by FAX, use either of the following numbers:

– United States, Canada, and Puerto Rico: 1-800-937-3430

– Other countries: 1-507-253-5192

v If you prefer to send comments electronically, use one of these e-mail addresses:

– Comments on books:

RCHCLERK@us.ibm.com

– Comments on the iSeries Information Center:

RCHINFOC@us.ibm.com

xii Service Functions V5R2

Be sure to include the following:

v The name of the book or iSeries Information Center topic.

v The publication number of a book.

v The page number or topic of a book to which your comment applies.

Page 15

Chapter 1. Dedicated Service Tools (DST)

Introduction ..............1

DedicatedServiceToolsrequirements.....1

System paging environments .........2

Stand-alone paging (non-paging) ......2

Limited paging ............2

Full paging ..............3

Accessing Dedicated Service Tools .......4

Performing an IPL to DST .........4

Changing a service tools user ID.......5

Resetting QSECOFR service tools user ID ....6

Performing an IPL to DST for secondary partitions 6

Pressing the System Request Key while the system

is operational .............7

Selecting Function 21 while the system Is

operational ..............7

Performing an alternate IPL to DST (type D IPL) . 8

Function keys (in DST) ...........9

Exiting Dedicated Service Tools........10

DSToptions..............10

Installing Licensed Internal Code ......11

Installing the operating system .......11

Perform an IPL ............11

Work with Licensed Internal Code ......11

Introduction

Dedicated service tools (DST) is used to service Licensed Internal Code (LIC), work

with disk units, work with configuration and resources, verify devices and

communications, and display logs on the system.

Licensed Internal Code general information . 12

Options and function keys .......12

Workwithdiskunits..........13

Options on the Work with Disk Units Display 14

Work with Dedicated Service Tools environment 23

Work with active service tools ......24

Work with system devices .......25

Work with service tools user IDs .....25

Workwithsystemvalues........26

Work with alternate installation device . . . 27

Select DST console mode ........27

Start a service tool ...........28

Options on the Start a Service Tool display . . 28

Perform automatic installation of the operating

system ...............39

Save Licensed Internal Code........40

Work with save storage and restore storage. . . 40

Work with remote service support ......40

Allowing access for remote service support . . 41

Activating remote service support .....41

Work with system partitions........42

Work with system capacity ........42

Work with system security ........42

DST operates in stand-alone, limited, and full paging environments. The DST tools

and functions vary depending on the paging environment and the release level of

the operating system. For more information, see “System paging environments” on

page 2.

System Service Tools (SST) provides a way to access a subset of the service tools

that DST offers without requiring access to DST. SST is available when OS/400 is

operational, and can be accessed using the STRSST CL command.

Dedicated Service Tools requirements

Attention: It is a requirement to change the password the first time anyone signs

on to DST or SST. The customer engineer needs to give the new (changed)

password to the customer or have the customer change the password.

To use DST, you must have the following items:

v The disk that contains the Licensed Internal Code (the load-source disk).

Note: When you perform an alternate initial program load (IPL) to DST, you do

not need the load-source disk.

v An operational workstation on bus 1 as either a primary console or an

operations console.

© Copyright IBM Corp. 1997, 2002 1

Page 16

v One workstation for each system partition.

v A valid service tools user ID and password to sign on to DST. IBM supplies

service tools user IDs that have different levels of privileges. See “Work with

service tools user IDs” on page 25 for more information.

To make a printout, attach the printer to the workstation I/O processor or storage

media unit that is performing the service function. The printer that is used with

DST for service tool output must be an SCS-type data stream printer (for example,

type 5224).

System paging environments

The amount of assistance that software provides for service depends on how you

perform the system IPL. The service tools and functions that are available depend

on how you access DST and which operating system is in use. Service

environments for the system are:

v Stand-alone (also called non-paging)

v Limited paging

v Full paging

Stand-alone paging (non-paging)

You can reach this environment only by performing an alternate IPL to DST (see

“Performing an alternate IPL to DST (type D IPL)” on page 8).

You can access dedicated service tools (DST) while the system is in the stand-alone

paging environment, but not all DST options are available. In this environment, no

operating system is available, and only some functions of Licensed Internal Code

are operational.

The following options are available in the stand-alone environment for all

operating systems:

v Install Licensed Internal Code

v Work with disk units

v Work with DST environment

v Start a service tool

v Work with remote service support

For a description of each option, see “DST options” on page 10.

Attention: Performing an IPL on the primary partition will cause an IPL of all

secondary partitions.

Limited paging

You can reach this environment by performing an IPL to DST (see “Performing an

IPL to DST” on page 4).

The limited paging environment is the first servicing environment you access when

you start to bring up the system in Manual mode. This environment contains all

the functions of the Licensed Internal Code, including storage management.

2 Service Functions V5R2

You can access dedicated service tools (DST) while the system is in the limited

paging environment. This environment accesses the temporary files that are needed

and the Licensed Internal Code on the load-source disk. The operating system is

not available.

Page 17

Attention: For systems with multiple logical partitions, performing an IPL on the

primary partition causes the secondary partitions to be powered down. Failing to

power down these secondary partitions will cause an abnormal power-down on

the secondary partitions and possible loss of data.

The following options are available in the limited paging environment for all

operating systems:

v Perform an IPL

v Install the operating system

v Work with Licensed Internal Code

v Work with disk units

v Work with DST environment

v Start a service tool

v Work with remote service support

v Work with system partitions

v Work with system capacity

v Work with system security

Note: The following options are operating system-dependent. For a list of the

v Perform automatic installation of the operating system

v Save Licensed Internal Code

v Select DST console mode

v Work with save storage and restore storage

For a description of each option, see “DST options” on page 10.

Attention: For systems with logical partitions, performing an IPL on the primary

partition causes the secondary partitions to be powered down. Failing to power

down these secondary partitions will cause an abnormal power down on the

secondary partitions and possible loss of data.

Full paging

The full paging environment is used during normal system operation. The DST

options vary depending on the release level of the operating system. You remain in

this environment when you perform one of the following:

v Function 21 on the control panel or “Work with Partition Status” screen to access

DST (see “Accessing Dedicated Service Tools” on page 4)

This is available only from the primary partition.

v System Request key procedure (see “Accessing Dedicated Service Tools” on

page 4)

v Access system service tools (SST) on a system that uses OS/400

system service tools” on page 282)

®

options available for your IBM

operating system, see “DST in OS/400

limited paging environment” on page 282.

®

(see “Accessing

All disk units, the Licensed Internal Code, and the operating system are available.

Attention: For systems with logical partitions, performing an IPL on the primary

partition causes the secondary partitions to be powered down. Failing to power

down these secondary partitions will cause an abnormal power-down on the

secondary partitions and possible loss of data.

Chapter 1. Dedicated Service Tools (DST) 3

Page 18

The following options are available in the full paging environment for all operating

systems:

v Perform an IPL

v Install the operating system

v Work with Licensed Internal Code

v Work with disk units

v Work with DST environment

v Start a service tool

v Work with remote service support

v Work with system partitions

v Work with system capacity

v Work with system security

Note: The following options are operating system-dependent. For a list of the

options available for your operating system, see “DST in OS/400 full paging

environment” on page 281.

v Select DST console mode

v Resume operating system display

v Perform automatic installation of the operating system

v Save Licensed Internal Code

For a description of each option, see “DST options” on page 10.

Attention: For systems with logical partitions, performing an IPL on the primary

partition causes the secondary partitions to be powered down. Failing to power

down these secondary partitions will cause an abnormal power-down on the

secondary partitions and possible loss of data.

Accessing Dedicated Service Tools

You can start dedicated service tools (DST) in several ways:

v Performing an IPL to DST (see “Performing an IPL to DST”).

v Pressing the System Request key while the system is operational (see “Pressing

the System Request Key while the system is operational” on page 7).

v Selecting function 21 while the system is operational (see “Selecting Function 21

while the system Is operational” on page 7).

This is available from the primary partition only.

v Performing an alternate IPL to DST (type D IPL) (see “Performing an alternate

IPL to DST (type D IPL)” on page 8).

After performing a type D IPL on a primary partition, the first step in DST must

be configuration recovery.

v Using the function key F16 (which is not displayed) while in DST debug mode

during a step-mode IPL.

Performing an IPL to DST

4 Service Functions V5R2

This procedure is for the entire system, or if logical partitions are installed, for the

primary partition. For secondary partitions, see “Performing an IPL to DST for

secondary partitions” on page 6.

Perform the following steps:

Page 19

1. Select a type B IPL in Manual mode.

For information on how to select IPL options, see “IPL type, mode, and speed

options” on page 217.

Attention: For systems with logical partitions, performing an IPL on the

primary partition causes the secondary partitions to be powered down. Failing

to power down these secondary partitions will cause an abnormal power-down

on the secondary partitions and possible loss of data.

2. Perform one of the following:

v If there is a system hang condition after powering on the system, perform

a delayed power-off. (This is the data for problem analysis.) When the

system is off, press the Power button on the control panel to perform an IPL.

Select Function 03 if the delayed power-off takes longer than 40 minutes to

complete. Be careful to realize that performing Function 03 may cause

damage to objects, and it may also cause data loss.

v If there is an attention light after powering on the system, use the

Increment (↑) or Decrement (↓) button to select control panel Function 03.

Press the Enter button on the control panel to perform an IPL.

v When the system is powered off, press the Power button on the control

panel to perform an IPL.

3. The IPL or Install the System display appears on the primary console. Select the

Use Dedicated Service Tools option.

For more information on how to identify the primary console, see Determining

a primary or alternative console.

4. The DST Sign On display appears. Sign on to DST with a valid user ID and

password.

Enter a valid user ID and get the password from the customer. If the customer

has changed the full DST authority, user ID, or password, ask the customer for

the correct values.

Note: If prompted for a password, be sure to give the new (changed) password

to the customer.

Note: You are limited to three sign on attempts to DST. After three

unsuccessful attempts, the service tools user ID will be disabled. A user

ID with a service tool security privilege will need to reset the ID.

5. The Use Dedicated Service Tools (DST) display appears.

The system is in the limited paging environment (see “System paging

environments” on page 2). See “DST options” on page 10 for details on DST

options.

This ends the procedure.

Changing a service tools user ID

Use this procedure to change a service tools user ID:

1. Sign on to DST.

2. Take option 5 on Use Dedicated Service Tools (DST) screen to Work with Dst

Environment.

3. Take option 3 on Work with Dst Environment screen to work with service

tools user IDs.

This ends the procedure.

Chapter 1. Dedicated Service Tools (DST) 5

Page 20

Resetting QSECOFR service tools user ID

Methods to recover from a disabled QSECOFR service tools user ID:

v Sign on with the QSECOFR OS/400 user profile.

v Use the XPF CL command CHGDSTPWD with *DEFAULT as the parameter

value. Executing this command will enable the profile (if disabled), reset the

profile’s password to QSECOFR, and set the password to expired. After using

the CHGDSTPWD command, you can change the password of the QSECOFR

service tools user ID by signing on to DST.

Note: If the system security is set to prevent a service tools user ID with a

default and expired password from changing its own password, then you

will not be able to sign on to SST until you first sign on to DST and

change your password there.

Performing an IPL to DST for secondary partitions

Perform the following steps:

1. Enter STRSST at the OS/400 command line on the system console for the

primary partition. Press Enter.

2. At the Start Service Tools (SST) Sign On display, type in a user ID and

password with QSECOFR service tools user ID authority. Press Enter.

3. At the System Service Tools display, select the Start a service tools option.

4. Select the Work with system partitions option.

5. Select the Work with partition status option.

6. Use the cursor to select the secondary partition you want to IPL.

7. Select option 10 (Mode manual).

8. Select option B (Source B).

9. Select option 1 (Power on). Press Enter.

10. The IPL or Install the System display appears on the secondary partition

console. Select the Use Dedicated Service Tools option.

11. The DST Sign On display appears. Sign on to DST as QSRV.

Type QSRV as the valid user ID and get the password from the customer. If the

customer has changed the full DST authority, user ID, or password, ask the

customer for the correct values.

6 Service Functions V5R2

Note: If prompted for a password, be sure to give the new (changed)

password to the customer.

Note: V5R1 limits you to three sign on attempts to DST. After three

unsuccessful attempts, the service tools user ID will be disabled. The

system administrator with QSECOFR authority will need to reset the

ID.

12. The Use Dedicated Service Tools (DST) display appears.

The system is in the limited paging environment (see “System paging

environments” on page 2). See “DST options” on page 10 for details on DST

options.

This ends the procedure.

Page 21

Pressing the System Request Key while the system is operational

If your system has the OS/400 operating system, you can access DST by using the

following procedure only when the system is in debug mode. Debug mode is an

environment to test programs. It allows you to select a function key and access

DST during the IPL process (see “Perform an IPL” on page 11). For more

information on debug mode, see iSeries Licensed Internal Code Diagnostic Aids -

Volume 1 .

From the console, perform the following steps:

1. Press the System Request Key.

2. Type DST on the system request line.

Note: Ensure that you use capital letters to type the DST command.

3. Sign-on to DST.

Type QSRV as the valid user ID and get the password from the customer. If the

customer has changed the full DST authority user ID or password, ask the

customer for the correct values.

Note: If prompted for a password, be sure to give the new (changed) password

to the customer.

Note: V5R1 limits you to three sign on attempts to DST. After three

unsuccessful attempts, the service tools user ID will be disabled. The

system administrator with QSECOFR authority will need to reset the ID.

4. The Use Dedicated Service Tools (DST) display appears.

See “DST options” on page 10 for details on DST options.

This ends the procedure.

Selecting Function 21 while the system Is operational

Perform the following steps:

1. Select control panel Function 21 (Make DST available).

Select Manual mode, then push the Increment (↑) or Decrement (↓) button on

the control panel until 21 appears in the Function/Data display. Press the Enter

button on the control panel.

Notes:

a. If you enter Function 21 and the primary console is powered off or not

usable, reference code A600 500x appears on the control panel. Enter

Function 21 again to force the DST Sign On display to appear on one of the

alternative consoles.

b. For more information on how to select IPL options, see “IPL type, mode,

and speed options” on page 217.

2. Primary console or alternate console will display the DST sign on.

Note: For more information on how to identify the primary console, see

“Determining a primary or alternative console” on page 128.

3. Sign-on to DST.

Chapter 1. Dedicated Service Tools (DST) 7

Page 22

Type QSRV as the valid user ID and get the password from the customer. If the

customer has changed the full DST authority user ID or password, ask the

customer for the correct values.

Note: If prompted for a password, be sure to give the new (changed) password

to the customer.

Note: V5R1 limits you to three sign on attempts to DST. After three

unsuccessful attempts, the service tools user ID will be disabled. The

system administrator with QSECOFR authority will need to reset the ID.

4. The Use Dedicated Service Tools (DST) display appears.

The system is in the full paging environment (see “System paging

environments” on page 2). See “DST options” on page 10 for details on DST

options.

This ends the procedure.

Performing an alternate IPL to DST (type D IPL)

An alternate IPL to DST is called a type D IPL or a stand-alone IPL by service

representatives. Perform the following steps:

1. To use an alternate installation device, select the DST option to Work with

alternate installation device, see “Work with Dedicated Service Tools

environment” on page 23, “Work with alternate installation device” on

page 27, and Software Installation, SC41-5120-06. This option is available in DST

from control panel function 21 or a type D IPL.

2. Determine the removable media unit or units for an alternate IPL. See the

Alternate IPL Device section in the Problem Analysis information for your

system. Power on the removable media units.

3. Place the media that contains the Licensed Internal Code (first tape of the

customer’s system save, the SAVLIC, ISMD tapes, or optical device) in the

removable media units. Load the media and make the media units ready. See

the device information for instructions on loading the removable media.

4. Power off the system. If the system is running, end all jobs and perform the

power down procedure.

5. Select a type D IPL in Manual mode.

For information on how to select IPL options, see “IPL type, mode, and speed

options” on page 217.

6. Power on the console.

For more information on how to identify the primary console, see

“Determining a primary or alternative console” on page 128.

7. Load the media and make the media unit ready.

Press the Power button to power on the system.

8 Service Functions V5R2

Notes:

a. Some types of removable media units automatically reset. In this

condition, SRC A100 1933 (Media device not ready) may be displayed.

b. If the installation device is an optical device, you may need to IPL the

system again. This action will make the unit ready.

pwrdwnsys restart(*yes) IPL(D)

c. If the installation device is a tape unit, system reference code (SRC)

A1001933 is displayed until the device automatically makes itself ready.

Page 23

d. The removable media becomes active. There is a delay while the system

loads information from the load source. While running a process, the

system continuously updates SRCs on the control panel that show the

status.

8. Wait for the Install Licensed Internal Code display to appear on the console.

The wait varies depending on the speed of the removable media unit and the

processor speed for the specific system model.

Notes:

a. If SRC A600 500x is displayed on the control panel, the system was not

able to locate the console.

Ensure that the console is powered on (repair if necessary). Select Function

21 on the control panel (see “Control panel function descriptions (Models

150, 170, 250, 4xx, 50x, 51x, 530, 53S, 6xx, 7xx, SB1, and Sxx)” on page 162)

to make DST available.

b. If an SRC other than A600 500x is displayed on the control panel, go to

“Starting Point for All Problems” in the Problem Analysis information for

your system.

9. The Install Licensed Internal Code display appears on the console.

v If you want to access DST, select the Work with Dedicated Service Tools (DST)

option and continue to the next step of this procedure.

v If you want to install or restore Licensed Internal Code, select the Install

Licensed Internal Code option and continue with the install or restore

instructions (see “Utility to install Licensed Internal Code” on page 226).

v If you want to define the device from which the system LIC should be

installed, select the Define alternate installation device option. This option also

allows you to enable or disable the alternate installation device.

10. Reapply PTFs.

See the Software Installation manual for information on applying PTFs.

11. Sign on to DST as QSRV.

Type QSRV as the valid user ID and get the password from the customer. If the

customer has changed the full DST authority user ID or password, ask the

customer for the correct values.

Note: If prompted for a password, be sure to give the new (changed)

Note: V5R1 limits you to three sign on attempts to DST. After three

12. The Use Dedicated Service Tools (DST) display appears. Options are limited

because the system is in the stand-alone environment (see “System paging

environments” on page 2). See “DST options” on page 10 for details on DST

options.

This ends the procedure.

Function keys (in DST)

The F3, F12, F16, and System Request function keys perform the following:

password to the customer.

unsuccessful attempts, the service tools user ID will be disabled. The

system administrator with QSECOFR authority will need to reset the

ID.

Chapter 1. Dedicated Service Tools (DST) 9

Page 24

v The F3 function key returns you to the primary menu of the service tool you are

using.

v The F12 function key returns you to the previous DST display.

v The F16 function key returns you to the Use Dedicated Service Tools (DST)

display from the service function you are in. The active service function is not

canceled. To display the service function again, select the Work with DST

environment option.

v The System Request function key returns you to the Use Dedicated Service Tools

(DST) display (on the console). You must type the following on the system

request line:

DST

The active user job is not canceled.

Exiting Dedicated Service Tools

You can exit dedicated service tools (DST) by performing one of the following:

v To exit DST and end all DST functions:

Press F3 (Exit) on the Use Dedicated Service Tools (DST) display. The Exit

Dedicated Service Tools display appears with the following options:

– Exit dedicated service tools (DST)

– Resume dedicated service tools

To exit and end all DST functions, select the Exit dedicated service tools (DST)

option.

v To exit DST and allow the DST functions to remain active, ensure that the

system is operating in debug mode. Select the Select DST console mode option on

the Use Dedicated Service Tools (DST) display. For more information on the DST

console mode, see “Select DST console mode” on page 27

DST options

DST options vary depending on the paging environment and how you access DST.

This section provides information on all DST functions in all paging environments.

For a list of specific options available in each paging environment, see Table 1 or

“System paging environments” on page 2.

For more information on how to access DST, see “Accessing Dedicated Service

Tools” on page 4.

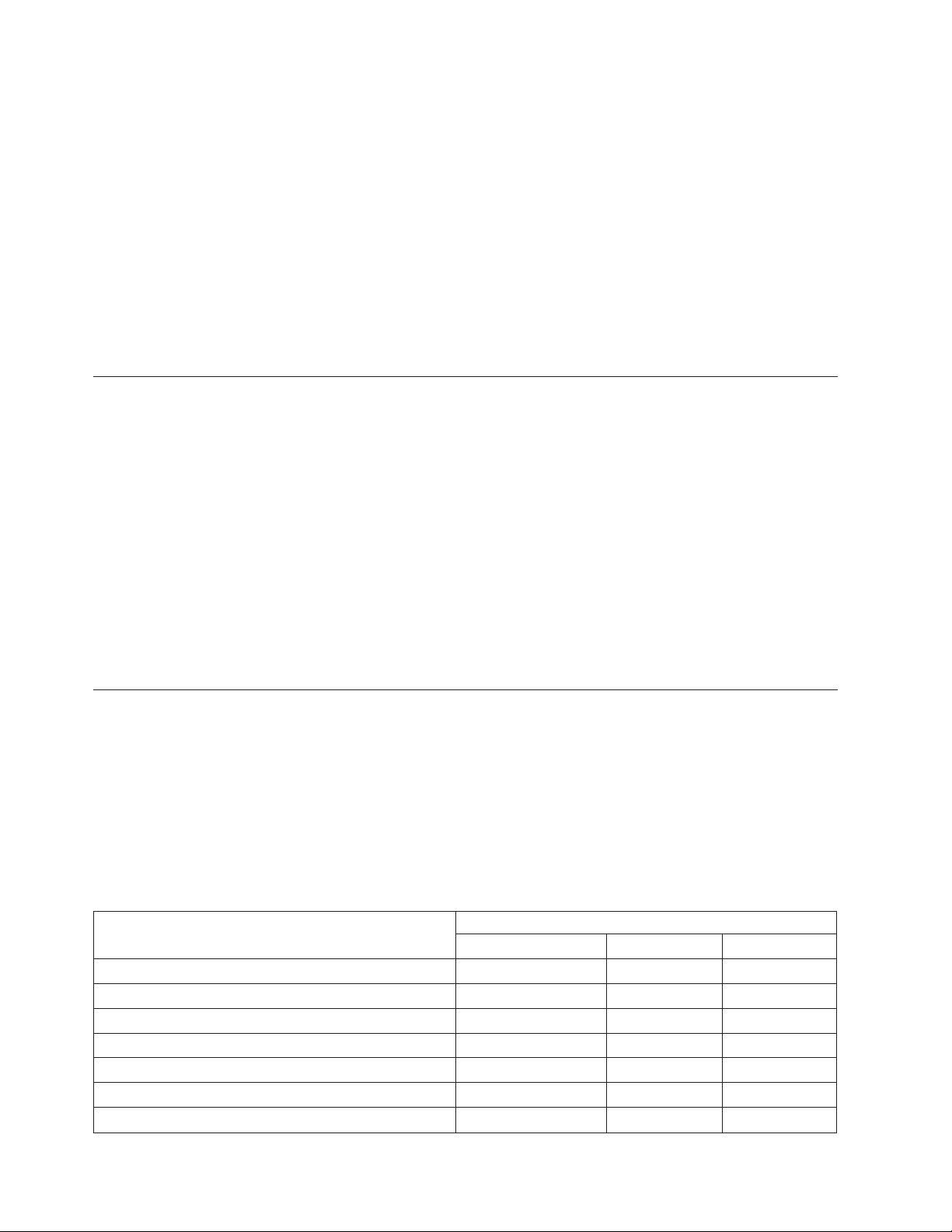

Table 1. DST options

Paging environment

DST options

Install Licensed Internal Code Yes No No

Install the operating system No Yes Yes

Perform an IPL No Yes Yes

Perform automatic installation of the operating system No Yes¹ Ye s

Save Licensed Internal Code No Yes¹ Ye s¹

Select DST console mode No Yes¹ Ye s¹

Start a service tool Yes Yes Yes

D-IPL (non-paging) Limited Full

10 Service Functions V5R2

Page 25

Table 1. DST options (continued)

Paging environment

DST options

Work with disk units Yes Yes Yes

Work with DST environment Yes Yes Yes

Work with Licensed Internal Code No Yes Yes

Work with remote service support Yes Yes Yes

Work with save storage and restore storage No Yes¹ No

Work with system partitions No Yes¹ Ye s¹

Work with system capacity No Yes Yes

Work with system security No Yes Yes

Note: ¹ Indicates that this option is operating system-dependent. It is available only under certain operating

systems (see Appendix A, “OS/400 Operating System” on page 281).

D-IPL (non-paging) Limited Full

Installing Licensed Internal Code

This option allows you to install or restore Licensed Internal Code. For more

information on how to use this option, see “Utilities to Install and Restore Licensed

Internal Code” on page 225.

Attention: Doing this to a system with multiple partitions can cause damage to

the partition configuration and loss of data.

This option is available only in the stand-alone environment.

Installing the operating system

Select the Install the operating system option from the Use Dedicated Service (DST)

Tools display.

This option installs the operating system from removable media (for example,

tape). The present operating system (if any) is replaced. Use this option to install a

new release of the presently installed operating system or to install the operating

system after a failure. You must run this option from the primary console.

This option is not available under basic DST authority. For more information about

authority, see “Work with service tools user IDs” on page 25.

Perform an IPL

Select the Perform an IPL option from the Use Dedicated Service Tools (DST)

display.

This option allows you to load and start the operating system from the disk. If you

have installed the Licensed Internal Code and there is no operating system

installed, load and start the operating system from the same removable media

device as the Licensed Internal Code.

Work with Licensed Internal Code

This option applies PTFs, removes PTFs, or makes PTFs permanent to the system

Licensed Internal Code from removable media when the operating system is not

available. It also allows you to rebuild the Licensed Internal Code, display the

Chapter 1. Dedicated Service Tools (DST) 11

Page 26

Licensed Internal Code information and PTFs, and display free space. Select this

option from the Use Dedicated Service Tools (DST) display. For more information

on Licensed Internal Code fixes and PTFs, see “Licensed Internal Code (LIC)

introduction” on page 223 and the system operation information.

Licensed Internal Code general information

There can be two versions of some Licensed Internal Code modules on the

load-source disk unit. The IPL type (A or B) determines which version of the

modules your system uses. When the system is running on a type A IPL, it uses

the original, permanent version. When a Licensed Internal Code fix (or program

temporary fix (PTF)) is temporarily applied, the system creates a second version of

the module. The system uses this second version when it is running on a type B

IPL.

When the PTF is permanently applied, the side B of the LIC replaces the original

side A version of the LIC module. The system will then use the PTF version of the

LIC module (which is now permanent) when running on a type A IPL.

For PTFs to be activated on each partition, they must be separately applied to each

partition.

To apply a PTF that currently has an earlier version applied temporarily on the

system, be sure you IPL the system from the B side (type B IPL). Then load and

apply the PTF. The existing temporarily applied PTF automatically becomes

permanent as the new PTF is loaded. If you do not want the existing temporarily

applied PTF to become permanent, remove it manually (see the system operation

information).

If you perform the IPL on the B side when you apply PTFs to Licensed Internal

Code, the system applies the PTFs to the active copy of the Licensed Internal Code.

To run the system with the PTFs, you must perform an IPL. For normal operations

use type B IPL. Use type A IPL when the B side is not available or when you want

to remove a PTF.

Note: During and install or upgrade a type A IPL will also be used.

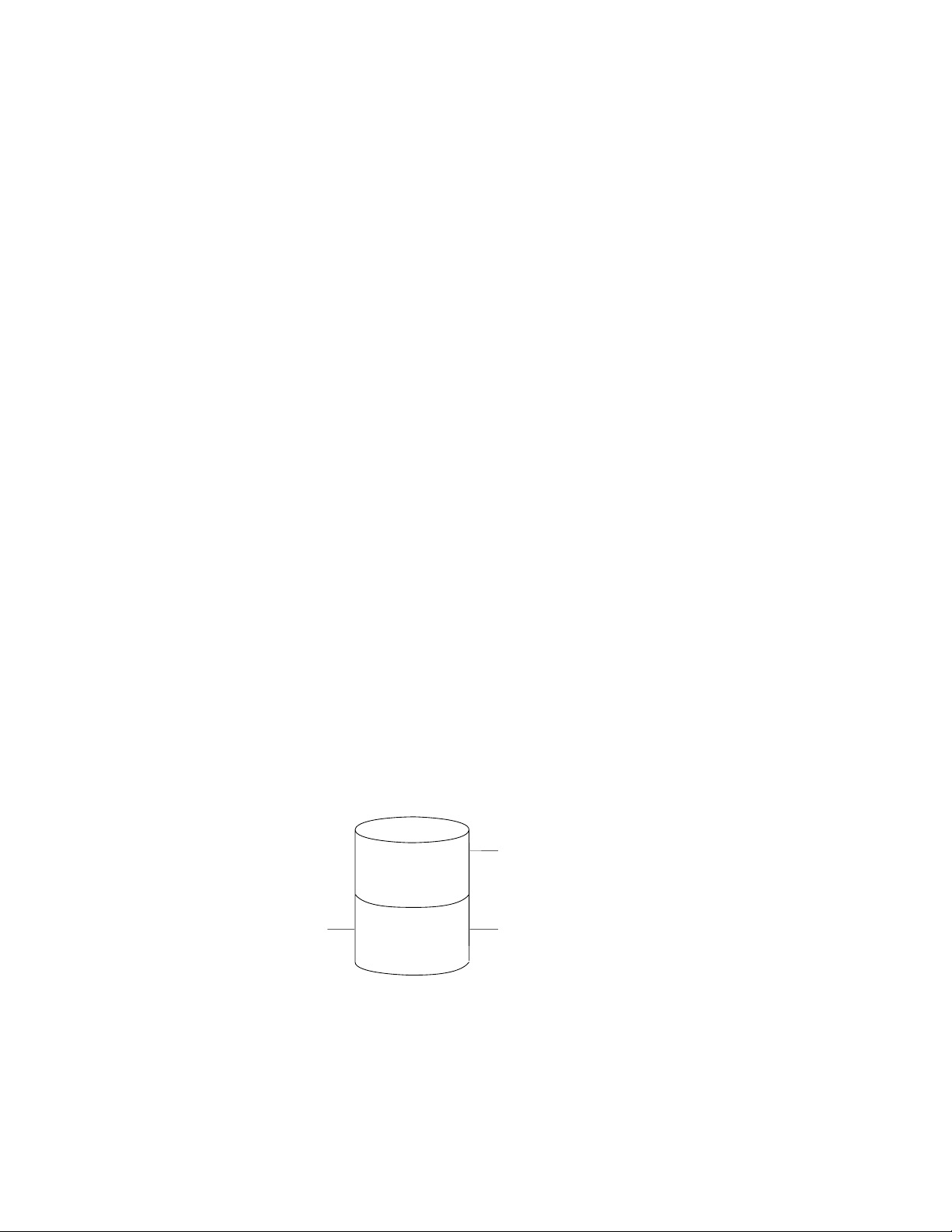

Load-Source Disk Unit

IPL type A uses

A=Permanent

PTF

Temporary

Figure 1. Copies of load-source Licensed Internal Code

B=Temporary

this Licensed

Internal Code

IPL type B uses

this Licensed

Internal Code

RV3B159-0

Options and function keys

v Apply fixes

This option places the fixes into the Licensed Internal Code from removable

media. These PTFs are placed in the inactive (change) copy of the Licensed

Internal Code.

12 Service Functions V5R2

Page 27

Note: There are two copies of some Licensed Internal Code on the load-source

disk unit. It is the IPL type (A or B) that selects the Licensed Internal

Code level with which your system will run.

v Rebuild Licensed Internal Code

This option allows you to rebuild the Licensed Internal Code. On RISC systems,

this means combining free space for all nucleus and service Load IDs.

v Display Licensed Internal Code

This option allows you to display the following:

– Replaceable unit information (code or object modules)

– Fix information

– Product information

The Fix information option allows you to display the status of the Licensed

Internal Code fix (if it is permanently or temporarily applied). For more

information on displaying fixes, see “Displaying Licensed Internal Code fixes”

on page 224.

v Work with free space

This option displays the space available for storing new modules on the system

and allows you to combine the space that is used.

v Remove fixes

To remove Licensed Internal Code fixes, if the PTF is a delayed PTF, the system

must be running on the copy without the changes (type A IPL). Removing these

changes causes the system to load the primary copy over the changes in the

changed copy of Licensed Internal Code.

Immediate LIC PTFs can be removed while running a type B IPL.

v Make fixes permanent

To make Licensed Internal Code fixes permanent, the system must be running

on the copy with the changes. When these changes are made permanent, they

are loaded into the primary copy of the Licensed Internal Code.

v Display status (F6)

Press the F6 function key on the Work with Licensed Internal Code display to

view the history log.

For more information on PTFs, see “Displaying Licensed Internal Code fixes” on

page 224 and the system operation information.

Work with disk units

This option allows you to do the following from the partition from which DST was

entered:

v Work with disk configuration.

– Create and update the disk configuration.

– Display the logical structure (disk unit and auxiliary storage pool (ASP)

information).

v Work with disk unit recovery.

Note: A graphical interface is available for you to use. See Manage disk unit

configuration located in the Systems management, Disk management, Disk

pools, Configure and manage disk pools topic in the Information Center

(http://ibm.com/eserver/iseries/infocenter ).

Chapter 1. Dedicated Service Tools (DST) 13

Page 28

Options on the Work with Disk Units Display

Options and menu flow for the Work with disk units options vary depending on the

system paging environment (see “System paging environments” on page 2). Use

the following table as a reference during problem analysis and system repair.

Select the Work with disk units option on the Use Dedicated Service Tools display.

Options and menu flow for this function vary depending on the paging

environment.

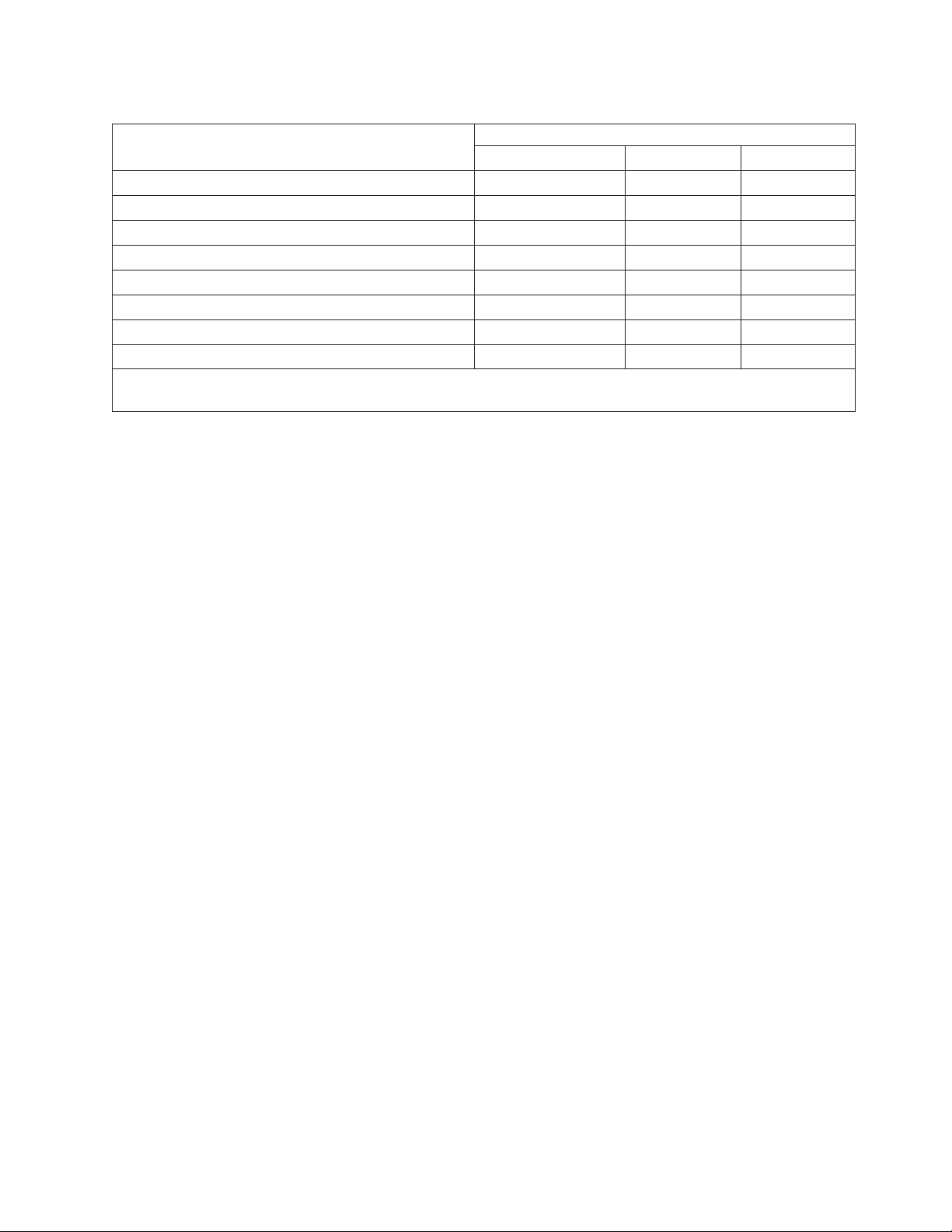

Table 2. Paging environments and the work with disk unit options

Paging environment Work with disk unit options

Stand-alone

1. Save load-source disk unit data

2. Copy load-source disk unit data

3. Display/change page data

4. Analyze disk unit surface

5. Initialize and format disk unit

6. Reclaim IOP cache storage

7. Stop device parity protection

14 Service Functions V5R2

Page 29

Table 2. Paging environments and the work with disk unit options (continued)

Paging environment Work with disk unit options

Limited paging

1. Work with disk configuration

– Display disk configuration

- Display disk configuration status

- Display disk configuration capacity

- Display disk configuration protection

- Display non-configured disk units

- Display device parity status

- Display disk hardware status

- Display disk compression status

– Work with ASP threshold

– Work with ASP configuration

- Display disk configuration capacity

- Delete user ASP

- Add units to ASP

- Delete ASP data

- Change ASP storage threshold

- Move units from one ASP to another

- Remove units from configuration

- Add units to the ASP and balance data

– Work with mirrored protection

- Display disk configuration

- Start mirrored protection

- Stop mirrored protection

- Enable remote load-source mirroring

- Disable remote load-source mirroring

– Work with device parity protection

- Display device parity status

- Start device parity protection

- Stop device parity protection

- Include unit in device parity protection

- Exclude unit in device parity protection

– Work with disk compression

- Display disk compression status

- Start compression on disk units

- Stop compression of disk units

Chapter 1. Dedicated Service Tools (DST) 15

Page 30

Table 2. Paging environments and the work with disk unit options (continued)

Paging environment Work with disk unit options

Limited paging

2. Work with disk unit recovery

– Save disk unit data

– Restore disk unit data

– Replace configured unit

– Assign missing unit

– Recover configuration

– Disk unit problem recovery procedures

- Initialize and format disk units

- Display/change page data

- Analyze disk unit surface

– Suspend mirrored protection

– Resume mirrored protection

– Copy disk unit data

– Delete disk unit data

– Upgrade load-source utility

– Rebuild disk unit data

– Reclaim IOP cache storage

– Correct device parity protection mismatch

– Recover unknown load source

– Recover mirrored load source

– Recover from start compression failure

– Migrate load-source disk unit data

16 Service Functions V5R2

Page 31

Table 2. Paging environments and the work with disk unit options (continued)

Paging environment Work with disk unit options

Full paging

1. Display disk configuration

v Display disk configuration status

v Display disk configuration capacity

v Display disk configuration protection

v Display non-configured units

v Display device parity status

v Display disk hardware status

v Display disk compression status

2. Work with disk configuration

v Display disk configuration

v Add units to ASPs

v Work with ASP threshold

v Include unit in device parity protection

v Enable remote load-source mirroring

v Disable remote load-source mirroring

v Start compression on non-configured units

v Add units to ASPs and balance data

v Start device parity protection

3. Work with disk unit recovery

v Replace configured unit

v Disk unit problem recovery procedures

– Initialize and format disk units

– Display/change page data

– Analyze disk unit surface

v Suspend mirrored protection

v Resume mirrored protection

v Delete disk unit data

v Rebuild disk unit data

v Rebuild IOP cache storage

Work with disk configuration: Options and menu flow for the Work with disk

configuration option vary depending on the system paging environment (see

“System paging environments” on page 2). Options are:

v Display disk configuration

For details on this option, see the main heading “Display disk configuration” on

page 18.

v Add units to ASPs

For details on this option, see the main heading “Work with ASP configuration”

on page 18.

v Add units to ASPs and balance data

For details on this option, see the main heading “Work with ASP configuration”

on page 18.

v Work with ASPs threshold

For details on this option, see the main heading “Work with ASP threshold” on

page 18.

Chapter 1. Dedicated Service Tools (DST) 17

Page 32

v Include unit in device parity protection

This option allows you to add an unprotected disk unit to an existing parity set.

v Enable remote load-source mirroring

For details on this option, see the main heading “Work with ASP threshold”.

v Disable remote load-source mirroring

For details on this option, see the main heading “Work with ASP threshold”.

v Start compression on non-configured disk units

Select this option to increase the effective disk unit capacity of non-configured

disk units.

Display disk configuration: You can select the display disk configuration option

from the main service tools display or the work with disk configuration display

according to the paging environment. From this option, you can display the disk

units that are attached to the ASP and the status and capacity of the system

auxiliary storage pool.

v Display disk configuration status

Select this option to display the status of all ASPs and the disk units that are

configured on the system.

v Display disk configuration capacity

Select this option to display the following for each ASP and the assigned disk

units within each ASP:

– Threshold values

– Overflow values

– Protected storage values

– Unprotected storage values

v Display disk configuration protection

This option allows you to display the type of protection for each ASP and the

assigned disk units within each ASP.

v Display non-configured units

Select this option to display the status of all the disk units that are not

configured.

v Display device parity status

Select this option to display the status of the disk unit subsystems that have

device parity protection on the system. For more information on device parity,

see the main heading “Work with device parity protection” on page 20.

v Disable remote load-source mirroring

For details on this option, see the main heading “Work with ASP threshold”.

v Display disk compression status

This option displays the compression status of compressed disk units.

18 Service Functions V5R2

Work with ASP threshold: Select this option to display or change the threshold

for the system auxiliary storage pool (user ASPs are not supported). The system

issues a notice when it reaches the threshold value.

Work with ASP configuration: The following options appear on the Work with

ASP Configuration display:

v Display disk configuration capacity

Page 33

Select this option to display the threshold and overflow values of the ASP and

the assigned disk units. This display is also available under the Display disk

configuration option (see “Display disk configuration” on page 18).

v Delete user ASP

Select this option to delete a user-defined ASP (ASPs 2 through 16).

v Add units to ASPs

Select this option to add non-configured units to an existing ASP. This increases

the amount of storage that is assigned to the system ASP (ASP 1).

v Add units to ASPs and balance data

Select this option to add disk units to an existing ASP or to create an ASP and

add non-configured disk units to that ASP.

After the disk units are initialized and configured, the data on the other disk

units is moved to equally balance the capacity of all the disk units in the ASP.

v Delete ASP data

Select this option when you want to destroy the data in the ASP.

v Change ASP storage threshold

Select this option to display or change the threshold for the system auxiliary

storage pool (user ASPs are not supported). The system notifies you when the

threshold value is reached.

v Move units from one ASP to another

Select this option to change the assignment of a disk unit to another ASP.

v Remove units from configuration

Select this option to remove a disk unit from the ASP configuration. If the unit

being removed has data and there is space in the ASP, the system copies the

data to other units in the ASP. If there is not enough space in the ASP, the

system prompts you to delete the ASP data before removing the disk unit. The

unit that is removed becomes non-configured.

Attention: This is space-dependent. There must be enough space on the

remaining units to accommodate the data from the unit being removed.

Work with mirrored protection: Select this option to display or change mirrored

protection on the disk units.

v Display disk configuration