Page 1

Customer Engineering

Issued to:

Branch

Department:

Address:

If

this

Office:

__________________

manual

__________________

________________

________________

is

mislaid,

please

Manual

return

it

to

of

Instruction

the

above

_

_

_

_

address.

Selectric

I/O

®

Keyboard Printer

Page 2

PREFACE

This manual has

can

be

incorporated

The

particular

scribed.

This manual covers models

1

620

Mod.

been

model you

I\,

written

in

to

include

the

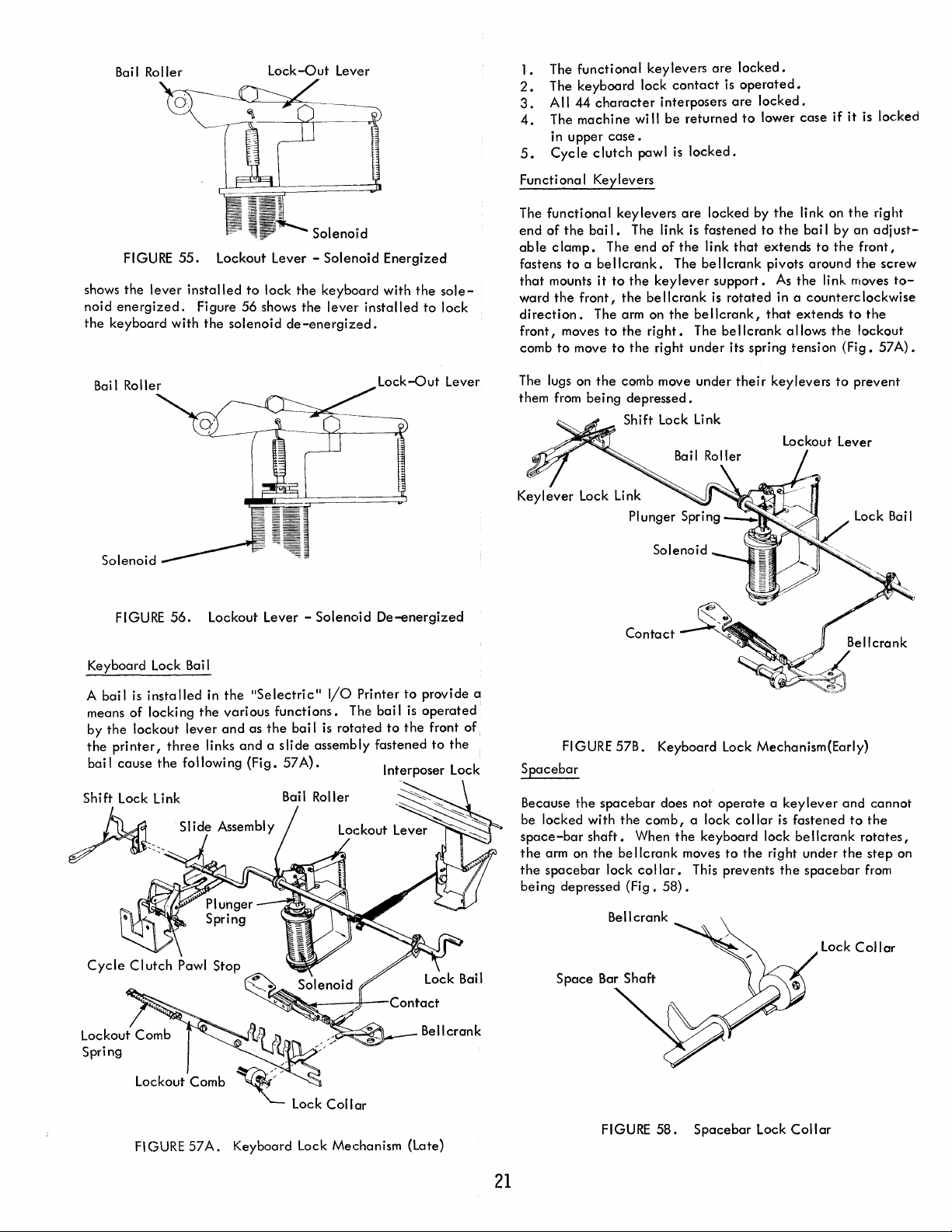

"Selectric"

are

concerned

731, 735, 765, 775,

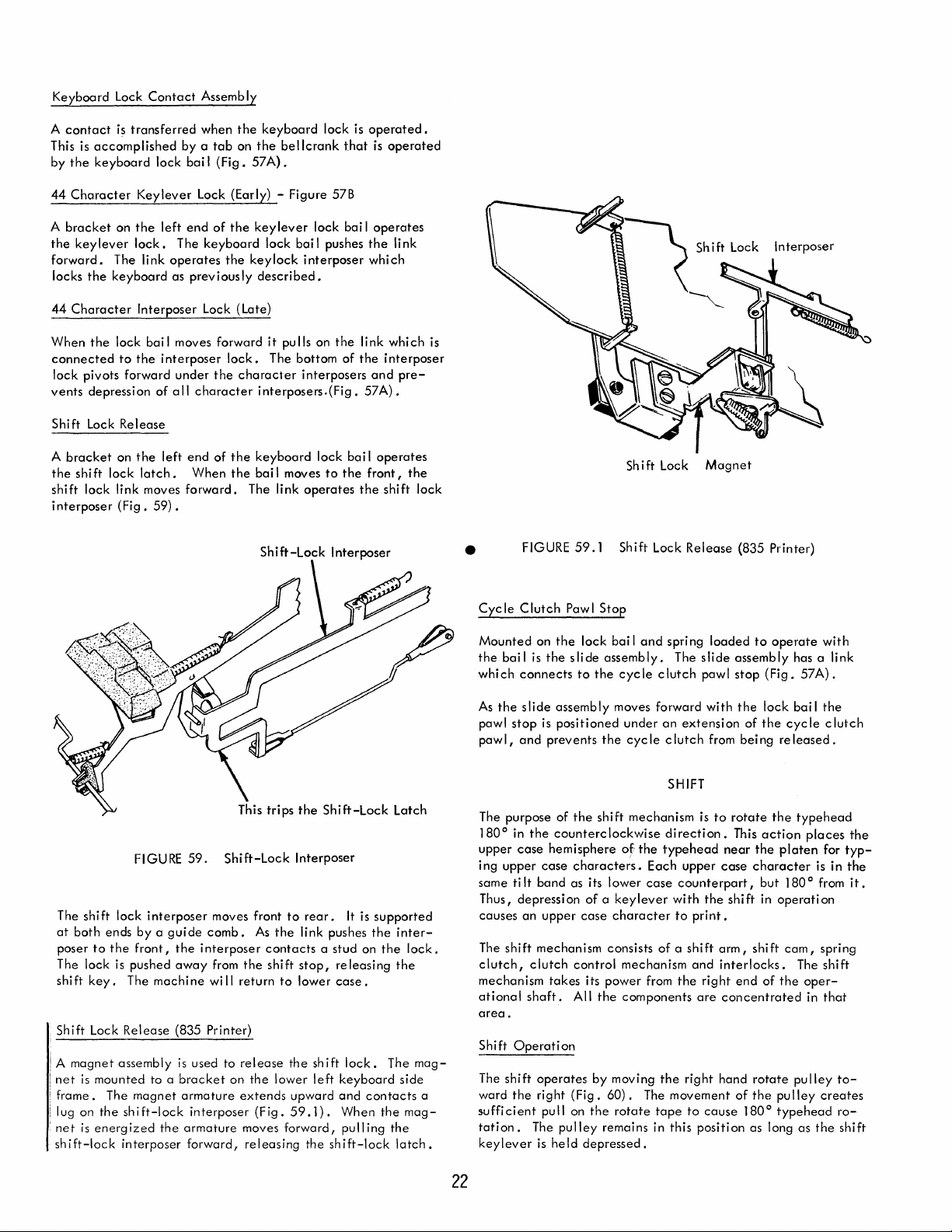

the

I/O

with may not use

maximum hardware or mechanisms

Keyboard

1415,

1014,

Printer

all

of

Sabre,

thru

October

the

mechanisms

Stretch,

7040/44,

that

1964.

de-

All rights

Address comments

IBM

Office

to

reproduce

Products Divi"sion,

this

regarding

material

the

comments

Lexington,

are

reserved

of

this publi

Kentucky

by

IBM.

cation

40507

to:

Page 3

CONTENTS

Motor

Typehead

Tilt

Rotate

Keyboard

Print

Selection

Keyboard

Shift

Cycle Clutch

Alignment

Print

Print

Print

Mainspring

Operational

Operational

Operational

Spacebar.

Spacebar

Carrier

Carrier

Tabulator

Margin

and

Drive

.............................

Mechanism

Mechanism

Section

Selection

Contact

Lock

.........................

.................................

Operation

...........................

Mechanism

Mechanism

Escapement

.....................................•.............................

Cams

Selection

Contact

.. . ........................

Mechanism

Backspace

Indexing

Platen

Paper

Fabric Ribbon

Red Ribbon

Fabric Ribbon

...........................

Return

Return

.......................................•............................

Variabl.e

.............................

Control

Feed

and

(Early

Shift

(Late

...............................................................

"

.......................................

................................................................

..............................................................

and

Character

Unit

.....................

Assembly

.........................................................

(Early

Style)

(Late

Style)

......................•.....................................

and

Control

Unit

Assembly

(Print

(Early

Style)

(Late

Style)

...............................................................

................................................................

Release ME:tchanism

Style)

...............................................................

Style). " .........................................

Selection

.....................................................

........

....................................................

Mechanism

..............

(Late

Escapement)

.....................................................

...............•.....................................

.......................................................

.........................................

"

......................................

"

......................................

"

......................................

','

......................................

:

...........................................

.........................................

','

......................................

Style)

...............•.......................

,

.......................................

..........................................

'

.•.....................................

','

......................................

..............................................

,

...........

1

3

5

8

12

16

18

20

22

28

29

39

41

41.5

44

45

49

50.1

51

54

54.1

55

58.1

59

62

63

69

73

75

79

80

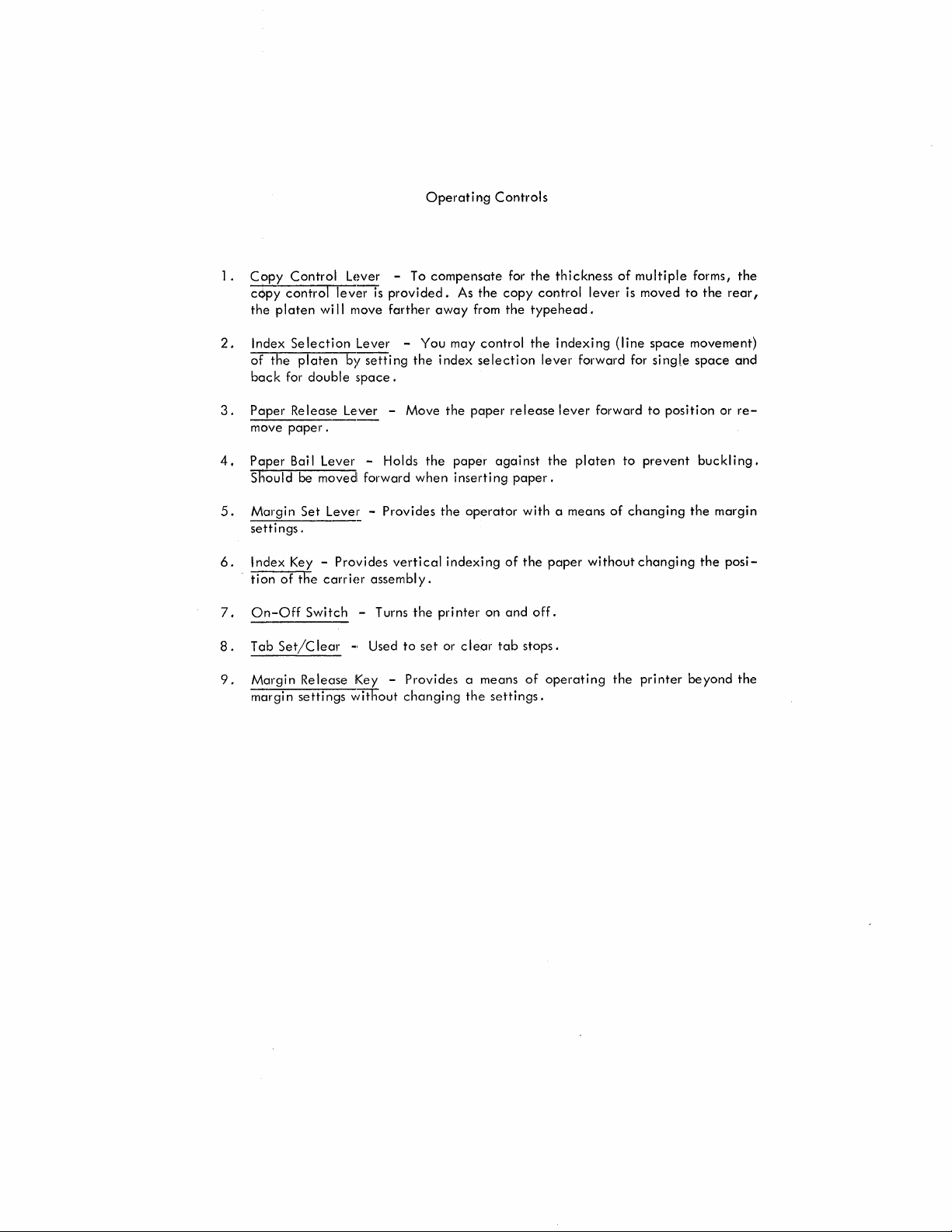

Page 4

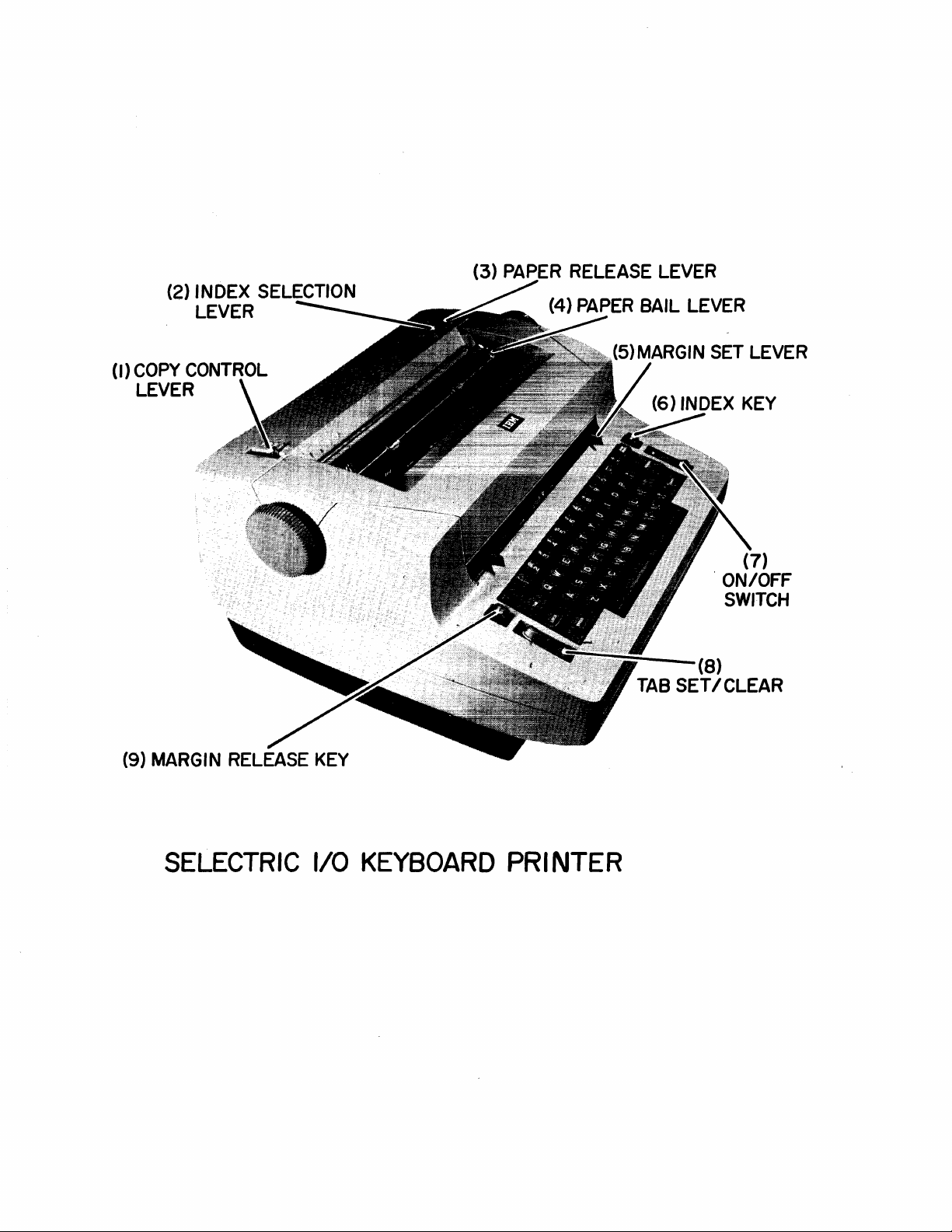

(2) INDEX SELECTION

LEVER

(I) COpy CONTROL

LEVER

(3)

PAPER RELEASE LEVER

(4)

PAPER

BAIL LEVER

TAB

(7)

ON/OFF

SWITCH

(8)

SET/CLEAR

SELECTRIC

1/0

KEYBOARD

PRINTER

Page 5

1.

2.

3.

4.

5.

Copy

Control

copy

control

the

platen

Index

Selection

of

the

back

for

Paper

move

paper.

Paper

Bai I

Should

Margin

settings.

platen

double

Re

lease

be

Set

Lever - To

lever

is

wi

II

move

Lever -You

b)/

setting

space.

Lever -Move

Lever

- Holds

moved

forward

Leve~

-

provided.

farther

the

when

Provides

Operating

compensate

As

the

away

from

may

index

selection

the

paper

the

paper

inserting

the

operator

Controls

for

copy

the

control

release

against

paper.

the

thickness

control

lever

typehead.

the

indexing

lever

forward

lever

forward

the

platen

with a means

of

multiple

is

(line

for

to

of

changing

moved

space

single

to

position

prevent

forms,

to

the

rear,

movement)

space

and

or

buckl

ing.

the

margin

the

re-

6. I ndex

tion

7.

On-Off

8.

Tab

9.

Margin

margin

Key -

of

the

Set/C

Release

settings

Provides

carrier

Switch

lear

assembly.

- Turns

-,

Used

Key -

without

vertical

to

the

set

indexing

pri

nter

or c I

ear

on

Provides a means

changing

the

of

the

and

tab

stops.

of

settings.

paper

off.

operating

without

the

changing

printer

the

beyond

posi-

the

Page 6

Page 7

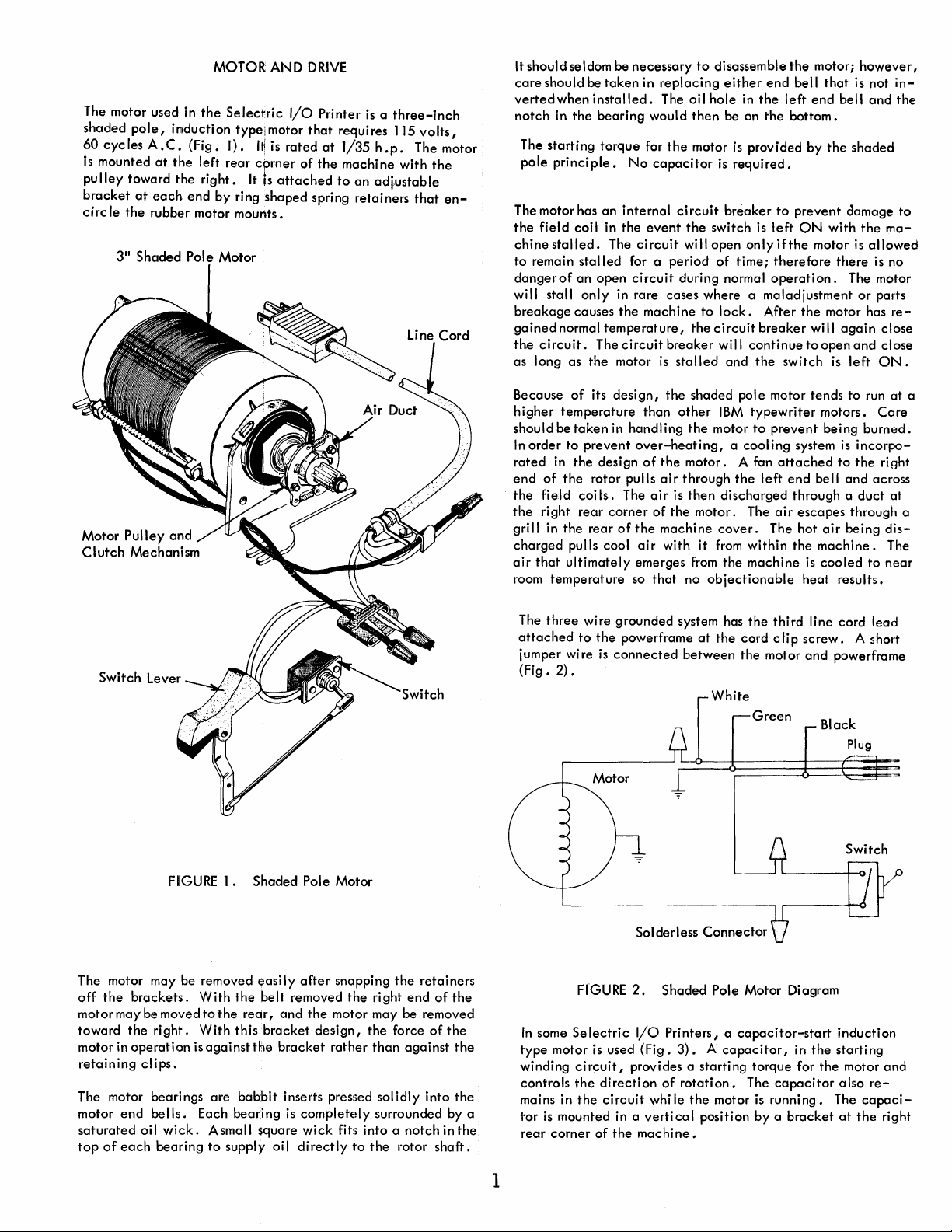

The motor used in

shaded

60

is

pulley

bracket

eirc

pole,

induction

cycles

A.

C.

mounted

at

toward

at

each

Ie

the

rubber motor mounts.

3"

Shaded Pole Motor

the

the

the

(Fig.

left

right.

end

MOTOR

Selectric

type: motor

1).

I~

rear

corner

It

by

ring

AND

I/O

is

rated

is

attached

shaped

DRIVE

Printer

that

of

the

spring

at

is a three-inch

requires 115

1/35 h .p.

machine

to

an

retainers

volts,

The motor

with

the

ad~ustable

that

en-

It should seldom be necessary

care

should be

vertedwhen

notch

in

The

starting

pole

principle.

The motor has

the

field

chine

stalled.

to

remain

dangerof

will stall

breakage

gained

the

circuit.

as long as

the

coil in

stalled

an

only

causes

normal

the

taken

in

replacing

installed.

bearing

torque

an

The

open

temperature,

The

The oil hole in

would

for

the

No

capacitor

internal

the

in rare cases where a maladjustment

the

circuit

motor

circuit

event

circuit

for a period

circuit

machine

breaker

is

stalled

to

disassemble

either

then

be on

motor

is

provided by

is

required.

breaker

the

switch

will

open

only

of

time;

during normal

to

lock.

the

circuit

will

continue

and

the

the

end

bell

the

left

the

bottom.

to

prevent

is

left

if

the

therefore

operation.

After

breaker

switch

end

ON

motor

the

wi

to

motor;

open

however,

that

is

not

bell

and

the

shaded

damage

with

the

is

allowed

there

The motor

or

motor has

II

again

and

is

left

in-

the

to

ma-

is no

parts

reclose

close

ON.

Motor

Clutch

Pulley

and

Mechanism

Because

higher

should be

In

rated

end

the

the

grill in

charged

air

room

The

attached

jumper wire

(Fig.

of

temperature

taken

order

to

in

the

of

the

field coi Is. The

right

the

pulls cool

that

ultimately

temperature

three

2).

its

design,

in handling

prevent

design

rotor pulls

rear

corner

rear

of

wire grounded system has

to

the

is

connected

the

than

other

over-heating,

of

the

air

through

air

is

of

the

the

machine

air

with it

emerges

so

that

powerframe

between

shaded pole motor tends

IBM

the

motor

motor. A fan

then

discharged through a

motor. The

cover.

from

from

no

objectionable

at

the

White

typewriter

to

prevent

a cool ing system is

the

left

The hot

within

the

machine

the

third line cord

cord c

the

motor

Green

attached

end

bell

air

escapes

the

machine.

is

heat

Ii p screw.

and

motors.

air

cooled

Black

to

run

Core

being

burned.

incorpo-

to

the

and

across

duct

through a

being

to

results.

lead

A short

powerframe

Plug

at

right

at

dis-

The

near

a

FIGURE

The motor may be removed easi

off

the

brackets.

motor may be moved

toward

motor in

retaining

The motor bearings

motor

saturated

top

of

end

each

the

right.

operation

cl ips.

bells.

oil

wick.

bearing

1.

Shaded Pole Motor

With

the

to

the

rear,

With

this

is

against

Each

the

are

babbit

bearing

Asmall square

to

supply oil

belt

bracket

Iy

after

snapping

removed

and

bracket

inserts pressed

is

completedy surrounded by a

directly

the

the

motor may be removed

design,

rather

wick

fits

the

right

the

force

than

against

solidly

into a notch

11'0

the

rotor

retainers

end

of

of

into

shaft.

the

the

the

the

inthe

1

Solderless

FIGURE

In

some

Selectric

type

motor is used

winding

controls

mains in

tor

rear

circuit,

the

the

is

mounted in a vel:tical position by a

corner

2.

Shaded Pole Motor Diagram

I/O

Printers, a

(Fig.

3). A capacitor,

provides a starting torque for

direction

circuit

of

the

of

rotation.

whi

Ie

machine.

the

Connector

capacitor-start

The

motor

is

in

the

capacitor

running.

bracket

Switch

induction

starting

the

motor

also

The

at

re-

capaci-

the

right

and

Page 8

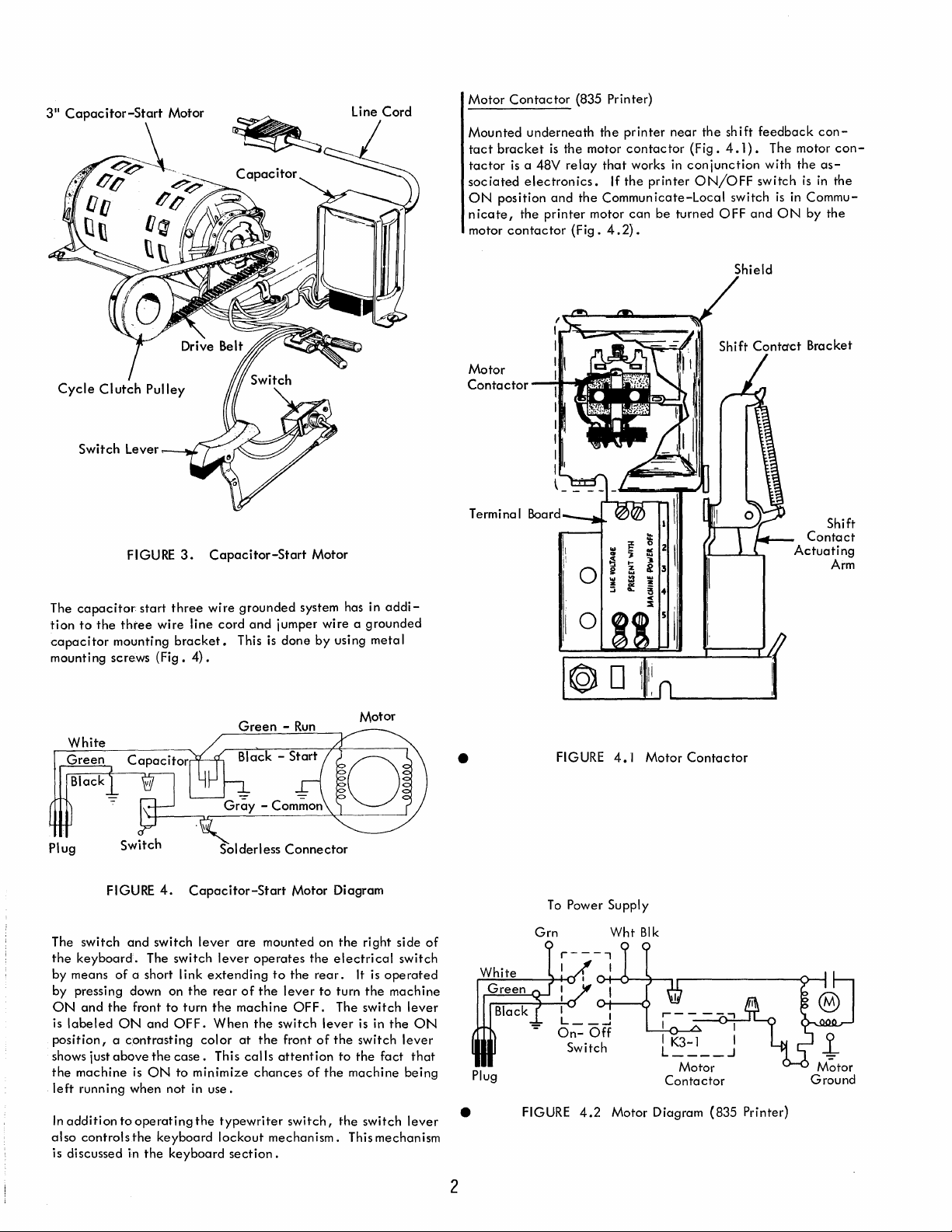

Motor

Contactor

(835 Printer)

FIGURE

The

capacitor

tion

to

capacitor

mounting screws

the

three

mounting

start

three

wire

bracket.

(Fig.

3.

Capacitor-Start

wire

line

cord

4).

grounded

and

jumper

This

is

done

Motor

system has in

wire a grounded

by

using

addi-

metal

Mounted

tact

bracket

tactor

is

sociated

ON

position

nicate,

motor

contactor

Motor

Contactor

Terminal

underneath

is

the motor

a 48V

relay

electronics.

and

the

printer

(Fig.

-lI....,r; •

the

printer

contactor

that

works in

If

the

printer

the

Communicate-Local

motor

can

be

4.2).

...1~

~

...

E

IIC

..

".J

Z \

~

....

~

z

3

2

i

~

:;

$

~

z

§ ..

<

::i

0

near

the

(Fig.

conjunction

ON/OFF

turned

I

I

shift

4.1).

switch

OFF

Shield

feedback

The motor

with

switch

is

and

ON

con-

con-

the

as-

is

in

the

in

Commuby

the

Shift

Contact

Actuating

Arm

Green -Run

White

Green

Black

Plug Solderless

FIGURE

The switch

the

keyboard.

by means

by pressing down on

ON

and

the

is

labeled

position, a contrasting

shows just

the

left

In

also

is discussed in

above

machine

running when

addition

controls

4.

and

switch

The switch

of

a short I ink

front

ON

and

the

is

ON

to

operating

the

keyboard

the

Capacitor-Start

lever

lever

extending

the

rear

to

turn

the

OFF.

When

color

case.

This

to

minimize

not

in

use.

the

typewriter

lockout

keyboard

are

mounted

operates

of

the

machine

the

at

the

calls

chances

section.

mechanism.

Connector

Motor Diagram

on

the

electrical

to

the

rear.

lever

to

turn

OFF.

The switch

switch

lever

front

of

the

attention

of

the

switch,

Motor

the

right side

switch

It

is

operated

the

machine

lever

is in

the

switch

lever

to

the

fact

that

machine

the

This mechanism

switch

being

lever

ON

of

•

•

White

Green

Plug

Black

FIGURE

To

Grn

FIGURE

4.1

Power Supply

Wht

Blk

4.2

Motor Diagram

Motor

Contactor

Contactor

Motor

(835

Printer)

2

Page 9

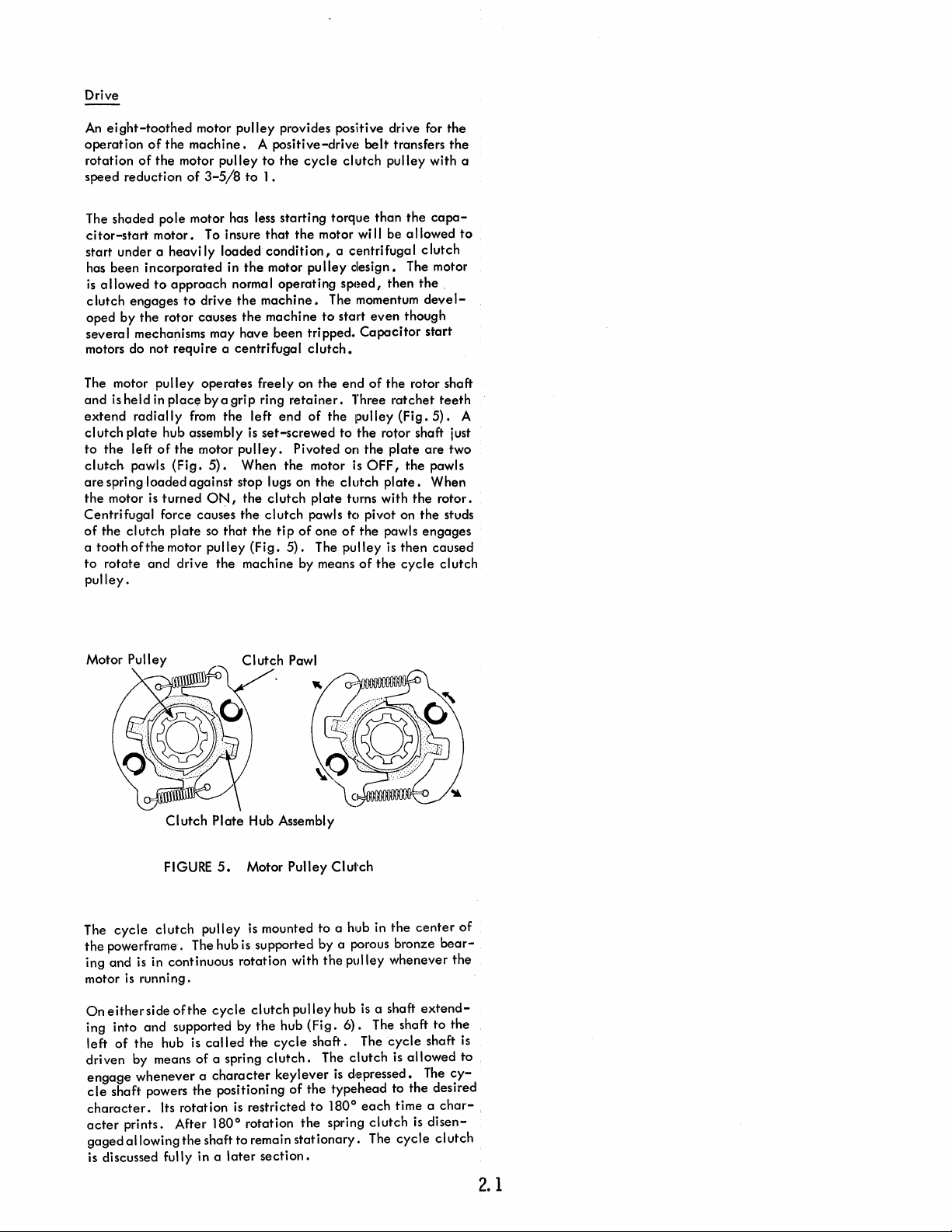

Drive

An

eight-toothed

operation

rotation

of

of

the

the

speed reduction

motor

pulley

provides positive drive for

machine. A positive-drive

motor

pulley

to

the

cycle

of

3-5/8

to

1 .

belt

clutch

transfers

pulley

the

the

with a

The shaded pole motor has less starting torque

ci

tor-start

start under a heavi

has been

is

allowed

clutch

oped by

several

motors do not

The motor

and

extend

clutch

to

the

clutch

are

the

Centrifugal

of

the

a tooth

to

rotate

motor •

incorporated

to

engages

the

To

insure

Iy

loaded conditi

in

approach

to

drive

rotor causes

that

the

motor

normal operating

the

machine.

the

machine

mechanisms may have been tripped.

require a centrifugal

pulley

is

held in

place

radially

plate

hub assembly

left

of

the

pawls

(Fig.

spring loaded

motor

is

turned

force causes

cI

utch

plate

of

the

motor

and

drive

operates

by a grip ring

from

motor

5).

against

ON,

so

pulley

freely on

the

left

end

is

set-screwed

pulley.

When

the

stop lugs on

the

clutch

the

clutch

that

the

ti p

(Fig.

5).

the

machine by means

the

motor

on, a centrifuga I clutch

pulley

design.

speed,

The momentum

to

start

clutch.

the

end

retainer.

of

the

Three

to

pulley

the

Pivoted on

motor is

the

clutch

plate

turns with

pawls

tC)

of

one

of

The

pulley

pulley.

Motor Pulley

than

the

wi

II

be a 1I0wed

The motor

then

even

though

Capacitor

of

the

rotor shaft

ratchet

(Fig.

rotor shaft just

the

plate

OFF,

the

plate.

the

pivot on

the pawls

is

then

of

the

cycle

cape-

the,

devel-

start

teeth

5).

are

two

pawls

When

rotor.

the

studs

engages

caused

clutch

to

A

Clutch

FIGURE

The

cycle

clutch

the

powerframe. The hub

ing and

motor

On

ing into

left

is

in continuous rotation with

is

runn i

eitherside

and

of

the

hub is

driven by means

engage

cle

character.

acter

gaged

whenever a character

shaft powers the positioning

Its rotation

prints. After

allowing

Plate

5.

pulley

ng

.

of

the

cycle

supported by

called

of

a spring

180

the

shaft to remain

is discussed fully in a

Hub Assembly

Motor Pulley

is

mounted to a hub in

is

supported by a porous bronze

clutch

the

hub

the

cycle

clutch.

keylever

is

re$tricted

0

rotation

later

section.

Clutch

the

pulley

hub

(Fig.

shaft.

The

is

of

the

typehead

to

180

the

spring

stationary.

pulley

is

6).

The

clutch

depressed.

0

each

clutch

The

the

center

whenever

a shaft

extend-

The shaft to

cycle

shaft

is

allowed

The

to the desired

time a

is

disen-

cycle

clutch

of

bear-

the

the

is

to

cy-

char-

2.1

Page 10

Print Shaft

lFi I ter

Shaft

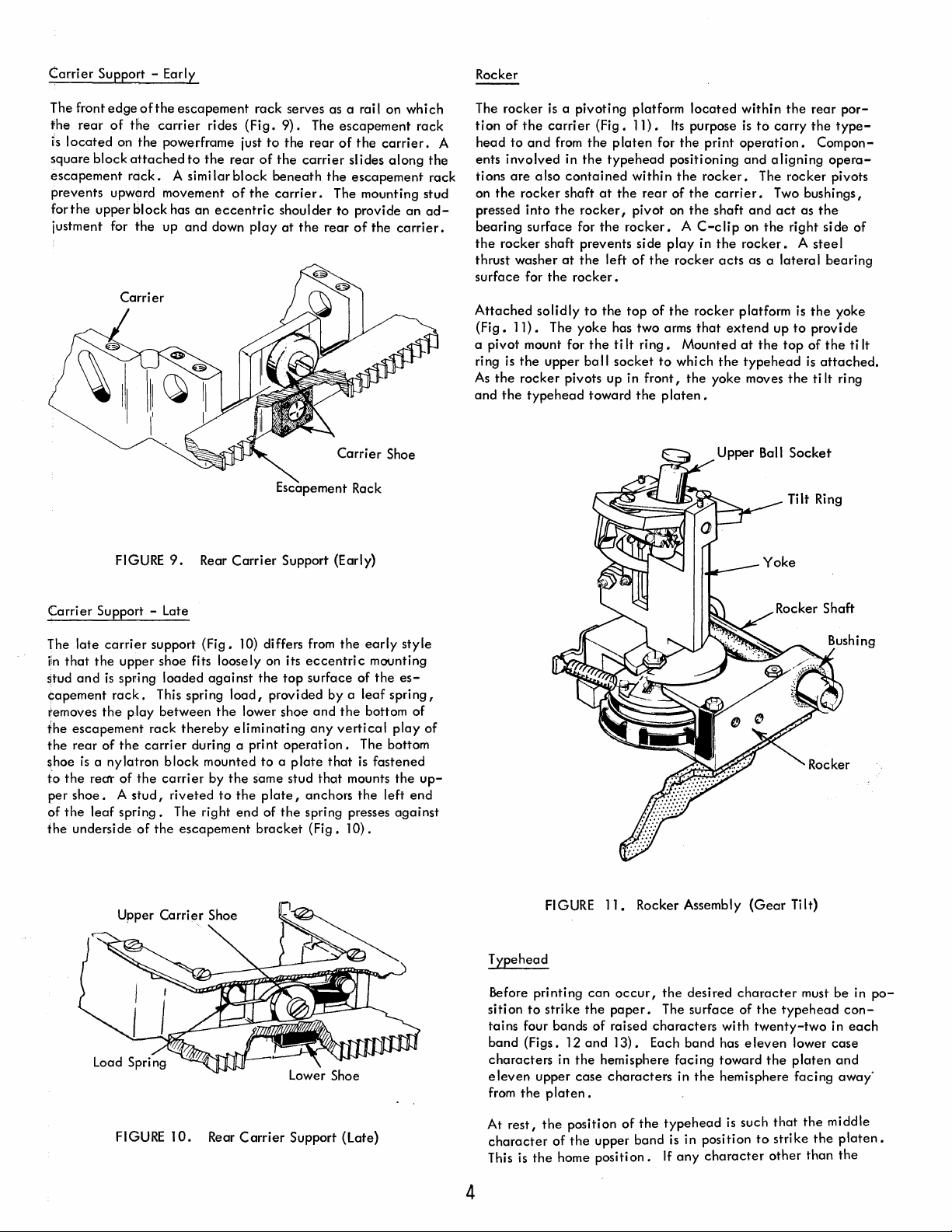

vent

any

noise due

tween

the

cycle

made by two extensions

left

side

of

held

in position

screws. Two nylon inserts fit into

limiter

hub).

tween

Just

clutches

of

their

hub (around

The inserts provide a noiseless driving

the

two hubs.

to

the

and

the

carrier

particular

to

vibration.

clutch

pulley

of

the

the

torque limiter

at

the

extreme

the

extensions

right

of

the

torque limiter hub

two small pinion

return

and

tab

sections.

TYPEHEAD

The driving

hub

hub

hub.

left

gears.

mechanisms

connection

and

the

operational

that

fit into

The torque limiter hub is

end

of

the

of

the

These components

cut-outs

the

shaft by two set

cut-outs

cycle

connection

are

and

are

shsft is

of

the

clutch

three

are

di~ussed

be-

in

the

torque

pulley

be-

spring

part

in

FIGURE

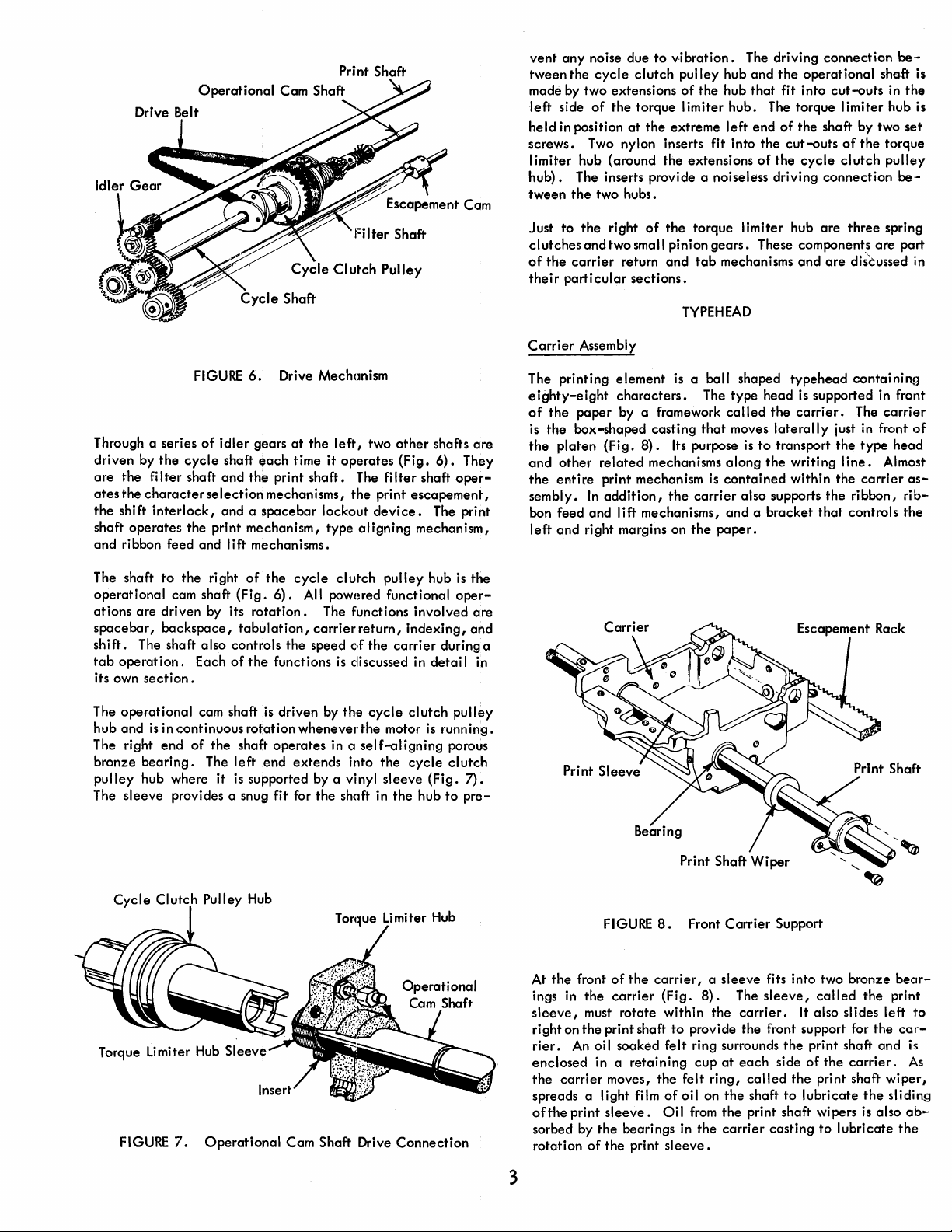

Through a series

driven by

are

ates

the

shaft

and

The shaft

operational

ations

spacebar,

shift.

tab

its own

The

hub and

The right end

bronze

pulley

The

the

cycle

the

filter

shaft

the

characterselectior.l mechanisms,

shift

interlock,

operates

ribbon feed and lift mechanisms.

are

The shaft also controls

operation.

operational

sleeve

the print mechanism, type

to

the

cam shaft

driven by its

backspace,

Each

section.

cam shaft is driven by

isin

continuous rotation

of

bearing.

hub where

provides a snug fit for

of

right

the

The

idler

and

and a

it

6.

gears

shaft

~ach

the

spacebar

of

(Fig.

rotation.

tabulation,

of

the

shaft

left

end

is

supported by a vinyl

Drive Mechanism

at

the

left,

time

it

operates

print

shaft.

the

cycle

6).

All powered functional

the

functions

whenever

operates

extends

The

the

lockout

aligning

clutch

The functions involved

carrier

return,

speed

of

is

discussed in

the

the

in a

self-aligning

into

the

shaft in

two

other

(Fig.

filter

print

device.

pulley

the

carrier

cycle

motor

the

sleeve

the

shafts

6).

They

shaft

oper-

escapement,

The print

mechanism,

hub is

oper-

indexing,

during a

detail

clutch

pulley

is

running.

porous

cycle

c1utclh

(Fig.

7).

hub

to

pre-

are

the

are

and

in

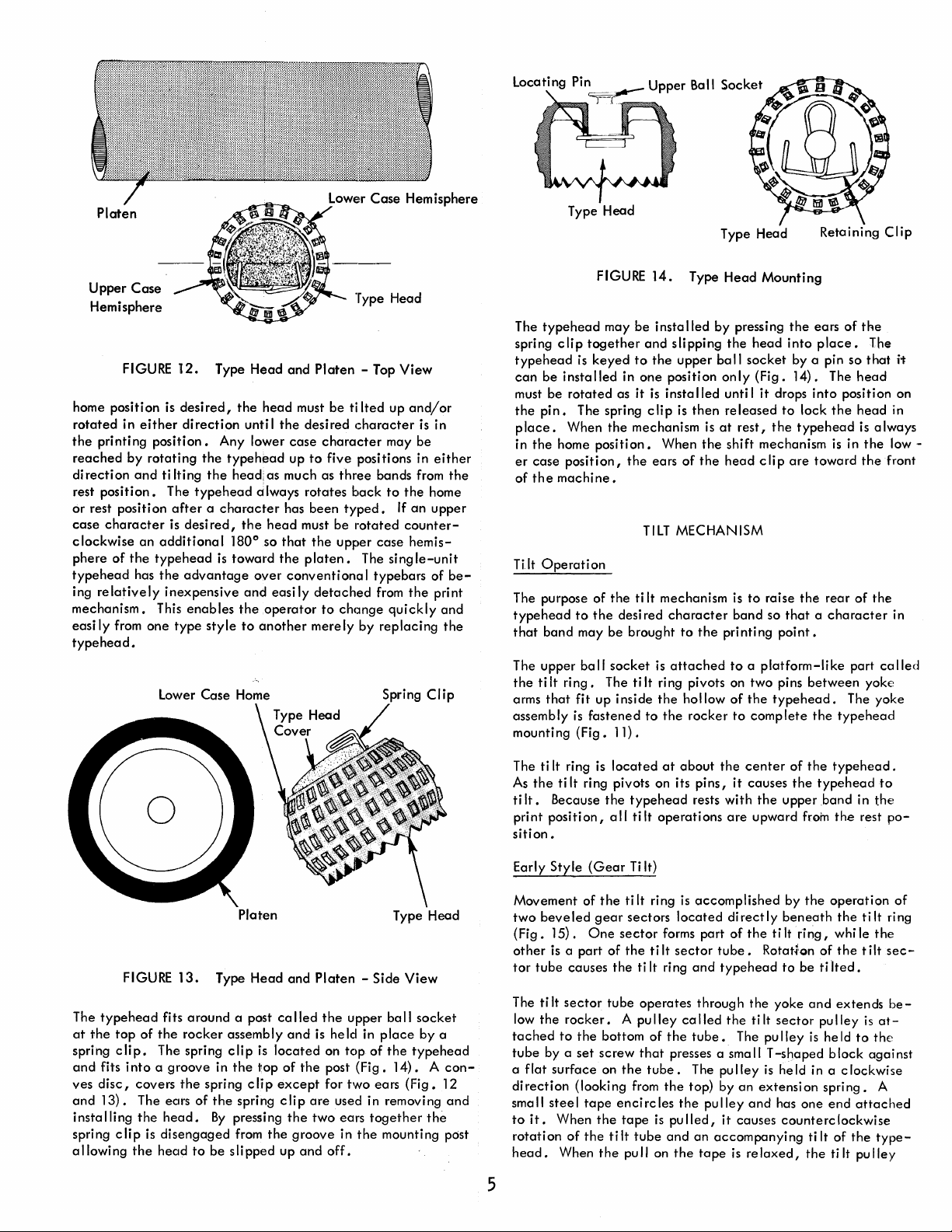

Carrier

The printing

eighty-eight

of

is

the

and

the

sembly.

bon feed and

left

Assembly

the

paper

the

box-shaped

platen

other

related

entire

In

and

right margins on

element

characters.

by a framework

(Fig.

print mechanism

addition,

lift

is a ball shaped

casting

8).

Its purpose

mechanisms

the

mechanisms,

the

The

type

called

that

moves

along

is

contained

carrier

also supports

and a bracket

paper.

is

to

typehead

head

is supported in front

the

carrier.

laterally

transport

the

writing

within

the

that

just in front

the

line.

the

containing

The

carrier

type

head

Almost

carrier

ribbon,

controls

of

asribthe

Cycle

Clutch

Torque Limiter

FIGURE

7.

Pulley

Hub

Hub

Sleeve

Operational

Cam Shaft Drive

Connection

At

the

front

ings in

sleeve,

right on

rier.

enclosed

the

spreads a light film

ofthe

sorbed by

rotation

the

must rotate

the

An

oil soaked

in a

carrier

print

the

of

3

FIGURE

of

the

carrier

print shaft

retaining

moves,

sleeve.

bearings in

the

print

8.

Front

Carrier

carrier, a sleeve

(Fig.

8).

The

within

the

of

Oil

the

to

provide

felt

ring surrounds

cup

felt

ring,

oil

on

from

the

sleeve.

carrier.

the

at

each

called

the

shaft

the

print shaft wipers is also

carrier

Support

fits into two bronze

sleeve,

front support for

It

the

side

of

the

to

lubricate

casting

called

also slides

print shaft

the

the

carrier.

print shaft

the

to

lubricate

the

bear-

print

left

car-

and

wiper,

sliding

the

to

is

As

ab-

Page 11

Carrier

The front

the

is

square block

escapement

prevents upward movement

forthe

Support - Early

edge

rear

of

located

upper block has

justment for

of

the

escapement

the

carrier

on the powerframe just

attached

rack.

the

A simi

up

to

an

and

rides

the

down

rack

(Fig.

rear

of

lar

block

of

the

eccentric

play

serves as a rail on which

9).

The

escapement

to

the

rear

of

the

carrier.

the

carrier

beneath

carrier.

shoulder

at

the

sl

ides

along

the

escapement

The mounting stud

to

provide

rear

of

the

rack

the

rack

an

ad-

carrier.

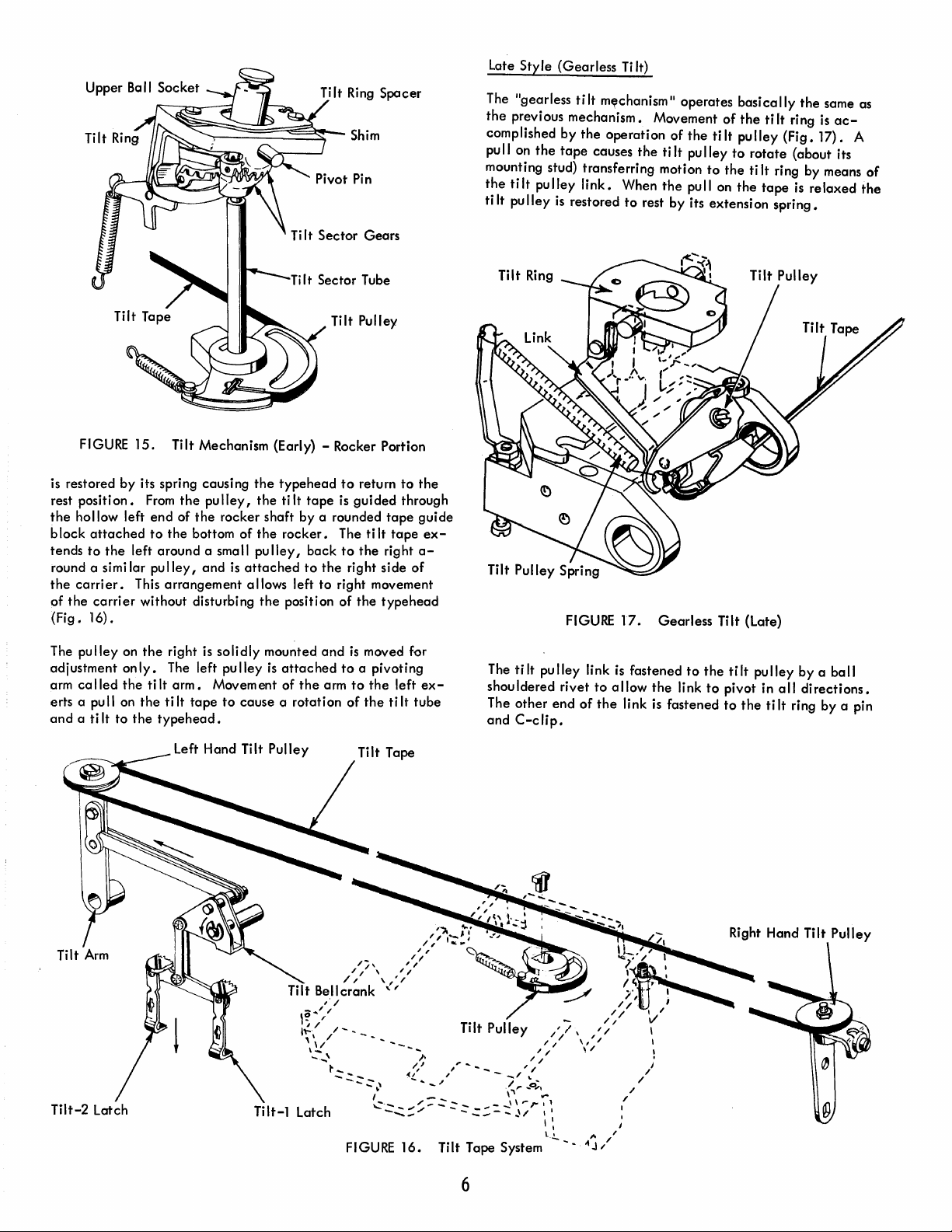

Rocker

The rocker

tion

of

A

head

to

ents

involved

tions

are

the

on

pressed

bearing surface for

the

rocker shaft prevents si de

thrust washer

surface for

is

a pivoting platform

the

carrier

and

from

the

in

the

also

contained

rocker shaft

into

the

rocker,

at

the

the

rocker.

(Fig.

11).

platen

for

type

head

within

at

the

rear

pivot on

the

rocker. A C-clip

left

of

the

located

Its

purpose

the

print

positioning

the

rocker.

of

the

carrier.

the

shaft

play

in

the

rocker

acts

within

the

rear

is

to

carry

the

operation.

and

aligning

The rocker pivots

and

on

the

rocker. A stee

as a

Compon-

Two bushings,

act

as

the

right

latera I bearing

por-

type-

opera-

side

I

of

Carrier

The

iin

stud

capement

removes

the

the

~hoe

to

per

of

the

Support - Late

late

that

the

and

the

escapement

rear of

is

a nylatron

the

rectr of

shoe. A stud,

the

leaf

underside

FIGURE

carrier

upper shoe fits loosely on its

is

spring loaded

rack.

the

spring.

support

This spring

play

rack

carrier

the

of

the

9.

Rear

Carrier

(Fig.

against

load,

between

block

carrier

riveted

the

thereby

The right end of

escapement

eliminating

during a print

mounted

by

the

to

the

10)

the

lower shoe

to a plate

same stud

bracket

Escapement Rack

Support (Early)

differs from

top

provided by a

operation.

plate,

the

the

eccentric

surface

and

the

any

vertical

that

that

anchors

spring presses

(Fig.

early

mounting

of

the

leaf

spring,

bottom of

play

The bottom

is

fastened

mounts

the

left

10).

style

es-

of

the

up-

end

against

Attached

(Fig.

a pivot mount for

ri

ng

As

and

solidly

11).

The yoke has two arms

is

the

upper ba

the

rocker pivots up in

the

typehead

to

the

the

II

toward

top

ti

It

ring.

socket

front,

the

of

the

to

platen.

rocker

that

Mounted

whi ch

the

yoke moves

platform is

extend

at

the

the

type

head

Upper Ball

up

to

top

the

Socket

Tilt Ring

the

yoke

provide

of

the

is

attached.

ti

It

ring

ti

It

FIGURE

10.

Rear

Carrier

Support

(late)

Typehead

Before printing

sition

to

tains four bands

band (Figs. 12

characters

eleven

from

the

At

rest,

character

This

is

the

4

FIGURE

strike

in

upper

platen.

the

of

home

11.

Rocker Assembly

can

occur,

the

paper.

of

raised

and

13).

the

hemisphere facing toward

case

characters

position

the

upper band

position.

the

The

characters

Each band has

of

the

typehead

is

If

desired

in

in position

any

(Gear

character

surface

of

the

with

twenty-two

eleven

the

hemisphere facing

is such

to

character

Tilt)

typehead

lower

the

platen

that

strike

other

must be in

con-

in

each

case

and

away'

the

middle

the

platen.

than

the

po-

Page 12

Platen

Lower

Case

Hemisphere

Type Head

Type Head

Retaining

Clip

Upper

Case

Hemisphere

FIGURE

home position is

rotated

the

reached

di

rest

or rest position

case

clockwise

phere

typehead

ing

mechanism.

easi

typehead.

in

printing

recti

on

position.

character

of

relatively

Iy

from

either

position.

by

rotating

and

ti It'ing

an

additional

the

typehead

has

the

This

one

Lower Case Home

12.

Type

Head

desired,

direction

The

after a character

is

desired,

advantage

inexpensive

enables

type

the

unti I

Any lower

the

typehead

the

headi as much as

typehead

the

180

is

toward

and

the

style

to

0

Type Head

and

Platen

head

must

be

ti Ited up

the

desired

case

up

always

over

rotates

has

head

must be

so

that

the

platen.

conventiona I typebars

easily

operator

another

character

character

to

five positions in

three

back

been

typed.

rotated

the

upper

detached

to

chcmge

merely

- Top

may be

bands from

to

case

The

single-unit

from

quickly

by

replacing

Spring

View

and/or

is

the

home

If

an

counter-

hemis-

the

Clip

in

either

the

upper

of

be-

print

and

the

The

typehead

spring

clip

together

typehead

can

must be

the

place.

in

er

of

Tilt

The purpose of

typehead

that

The

the

arms

assembly

mounting

be

installed

rotated

pin.

When

the

home

case

position,

the

machine.

Operation

to

band

upper

ti

It

ring.

that

fit up inside

is

(Fig.

is

keyed

The spring c lip

the

may be brought

ba

fastened

FIGURE

may

be

to

in

as

it

the

mechanism

position.

the

the

ti

desi red

II

socket

The ti

11).

14.

Type

Head

installed

and

the

one

position

is

insta lied unti I

When

ears

TILT

It

mechanism is

character

is

It

ring pivots on two pins

the

to

the

by

pressing

slipping

upper

is

MECHANISM

to

attached

the

ball

only

then

released

is

at

the

shift mechanism

of

the

head

the

printing

hollow

rocker

rest,

band

to a platform-like

of

to

head

socket

to

the

complete

Mounting

the

ears

into

by a pin so

(Fig.

14). The

it

drops

into

to

lock

the

typehead

clip

are

toward

raise

the

so

that a character

point.

between

typehead.

the

of

place.

position on

the

is

in

rear

part

The yoke

typehead

the

The

that

head

head

is

the

the

of

the

yoke

it

in

always

low -

front

in

ca

lied

FIGURE

The

type

head

at

the

top

spring

clip.

and

fits

into a groove

ves

disc,

and

13). The

insta lIing

spring c lip

a

1I0wi

ng

the

13.

fits a round a post

of

the

rocker

The spring

covers

the

spring c

ears

of

the

head.

is

disengaged

head

to

Platen

Type

assemb I y

clip

in

the

the

spring

By

pressing

from

be s

lipped

Head

and

ca

lied

and

is

located

top

of

Ii p except

clip

the

the

groove

up

Platen

- Side

the

upper ba

is

he

Id

on

top

the

post

(Fig.

for

two

are

used in removing

two

ears

in

the

and

off.

Type Head

View

II

socket

in p

lace

by

of

the

typehead

14). A

ears

(Fig.

together

mounting post

the

a

con-

12

and

The ti

As

the

ti

It.

print

sition.

Early

Movement of

two

(Fig.

other

tor

The

low

tached

tube

a

flat

di

recti

sma

to

it.

rotati

head.

5

It

ring

is

ti

It

ring pivots on its

Because

position,

Style

beveled

15).

is a part

tube

tilt

the

by a

surface

on (looki

II

stee I tape

When

on

the

all

(Gear

the

gear

One

of

causes

sector

tube

rocker. A pulley

to

the

bottom

set

screw

on

the

of

the

ti

When

the

located

typehead

tilt

Ti

It)

ti

It

sectors

sector

the

the

ti

operates

that

the

tube.

ng

from

enci

rc les

tape

It

tube

pu

lion

at

about

pins,

rests

operations

ring

is

accomplished

located

forms part

ti

It

sector

It

ring

and

through

called

of

the

tube.

presses a sma

The

the

top) by

the

is

pulled,

and

an

the

tape

the

center

it

causes

with

the

are

upward from

directly

of

the

tube.

typehead

the

the

tilt

The pu Iley

II T -shaped

pulley

an

extensi on spri

pu lIey

and

it

causes

accompanyi

is

re

laxed,

of

the

typehead.

the

typeheadto

upper

band

the

by

the

operation

beneath

tilt

Rotati'on

to

yoke

sector

is

held in a

has

counterclockwise

ng

ring,

be

and

is

one

ti

the

the

while

of

the

tilted.

extends

pulley

he

Id

block

clockwise

end

It

of

ti

It

in

the

rest

tilt

the

tilt

is

at-

to

the

agai

ng.

A

attached

the

type-

pu

lIey

po-

of

ring

sec-

be-

nst

Page 13

late

Style

(Gearless

Ti

It)

FIGURE

is restored by its spring causing

rest

position.

the

hollow left

b lock

tends

to

round a simi lar

the

carrier.

of

the

(Fig.

15.

attached

the

left around a sma

This

carrier

without disturbing

16).

Tilt Mechanism (Early) - Rocker Portion

From

the

pulley,

end

of

the

rocker

to

the

bottom

pulley,

arrangement

and

of

is

Ti

Tilt Sector Tube

the

type

the

ti

It

shaft

the

rocker.

II

pu

"ey,

attached

allows left

the

position of

Tilt Ring

It

Sector

Tilt

head

to

tape

is

by

a rounded

The

back

to

to

the

right

to

right movement

Spacer

Gears

Pulley

return

guided

tape

ti

It

the

right

side

the

typehead

to

the

through

guide

tape

a-

of

ex-

The "gearless

the

previous mechanism. Movement

complished

pu

II

on

mounting stud) transferring motion

the

tilt

tilt

pulley

by

the

tape

pulley

is

restored

FIGURE 17.

tilt

m~chanism"

the

operation

causes

link.

When

to

the

rest

Gearless

operates

of

ti

It

the

by

the

pu

pull on

its

basically

of

the

ti It

pulley

lIey

to

rotate

to

the

ti It ring by means

the

tape

extension

Tilt

(late)

ti

It

ring is

(Fig.

(about its

spring.

the

is

relaxed

same as

ac-

17).

A

of

the

The

pulley

on

adjustment on

arm

ca

lied

the

erts a

pu

II

on

and

a ti

It

to

Tilt-2

latch

the

right is

Iy.

The left pu Iley

ti

It

arm.

the

ti

It

the

typehead.

left

solidly

Movem ent of

tape

to

cause a rotation

Hand Tilt

mounted

is

attached

Pulley

Tilt-1

the

latch

and

arm

is

moved for

to

a pivoting

to

the

left

of

the

ti It

,

.:~:::

ex-

tube

....

The

ti

It

pu

shouldered

The

other

and

C-clip.

IIey link

rivet

end

of

is

fastened

to

allow

the

link is fastened

the

to

link

the

to

ti

It

pu

pivot in

to

the

Iley

by

all

directions.

tilt

ring by a pin

a ba

II

FIGURE

16.

Tilt Tape System

6

Page 14

Latch Sai I

cycle

The

(Fig.

18).

cams.

pusher

the

motion

paired

to

shaft.

The

later.

shaft

has five

Two

The

to

position the·

operate

5-unit

positive

two

the

latch

and

double

cams,

positive

typehead.

bai I

latch

pusher

lobed cams mounted on

one

5-unit

,:am

and

two

and

one

5-unit

cam provide

The positive cams

located

cams

beneath

wi

1/

be

the

discussed

it

latch

are

cycle

lever

assembly

head

wi

concerned

deal

with rotating

is

referred

If

the

latches remain

pulled

down when

forward,

pulled

down during

od

of

operating

later

secti

II

receive.

with ti Iting

to

later.

it

is

not hooked

ons •

that

determines how much

The first

the

to

the

an

the

various latches forward

and

the

head,

head.

The

the

rear

bail

is

operated.

under

operation

the

tilt

third latches

whi

Ie

the

second

under

of

bai I

the

the

If

plate

latch

latch

plate,

any

and

rotate

to

the

three

on

from

they

latch

and

wi

bail.

is

discussed in

left

the

the

is

II

The

the

right

left

wi

held

not

meth-

are

II

be

be

FIGURE

The

cycle

shaft powers

operating

shaped

Two short arms

on a shaft mounted

bai I

spective

the

rollers

180

and

the

selector

frame

located

of

contains a roller

cyc

Ie

shaft

latch

bai I

applies a constant

0

,

the

is

a 1I0wed

against

bai I

the

is

to

t.....::-----

18.

Cycle

the

positioning

latch

just

beneath

the

frame

extend

to

the

powerframe. Each

that

is

cam.

An

cams.

forced down pivoting

return

Each

to

its upward positi

Positive Cams

Shaft

and

bai I. The

the

forward where

constant

Iy

extension

upward pressure

time

the

LCltch

of

the

latch

cyc

in

spring

cye

about

Latch Bail

Bail

typehead

bai I

Ie

shaft

si

de

contact

at

Ie

shaft

the

on.

by

is a box-

(Fig.

18).

they

pivot

of

the

latch

with its

the

rear of

to

hold

the

operates

bai I shaft

re-

Tilt

Differential

The two

by ball shouldered rivets

shoulders allows

isattachedbyadouble

bellcrankpivotsonastudat

The

lever;

greater

Tilt

tilt

connection

therefore

than

that

Pulley

latches

the

of

the

of

Tilt-2

are

latches

vertical

the

double

leverage

the

Latch

attached

(Fig.

to

pivot in

the

other.

at

each

20).

all

link

to

top

of

the

I ink

is

developed

Tilt Tape

Left Side Frame

Tilt Bel/crank

end

of

a short

The ball shape

directions.

the

tilt

bellcrank.

differential

not in

the

middle

by one

tilt

lever

of

the

The

lever

bracket.

of

latch

Latch

The

the

is

The rear of

the

recesses

latch

bai I

latch

has a lip formed

(Fig.

19).

Five

of

the

POl

Positive Cam

01

the

latch

contain

is a plate

An

extension

selector

Latch Bail

FIGURE

bai I

is

selector

attached

to

the

spring holds

latches

~l

;;==-*

19.

Latch Bail

recessed

latches.

rear

are

at

six

Across

by two

screws.

just under

each

components of

points.

the

Each

the

latch

the

~

o @ 0

\ ,

: 0

\ / ;

"--------<-

-SidE~View

Selector

\1

-~--

Latch Bail

All six

rear

of

selector

bai I

plate

to

the

differential

the

rear.

latch

Plate

of

20.

FIGURE

A horizontal I ink

tilt

arm.

Operation

left

to

exert

a pull on

referred to as

ofthehorizontallinkisincreasedatthepulley

age

deve

The left hand

shouldered pivot

zonta

horizontal

The

tilt

the

left

the

rear,

(Fig.

21).

left

end

the

differential

the'

loped.

regardless

to

prevent

bel/crank

latch

is held

only

the

As

the

of

the

tilt

tilt

screw.

of

is

lever

bracket.

Tilt Differential At

connects

pulley

the

rotated

to

right

latch

the

of

the

bel/crank

the

tilt

multiplying

is

mounted

This allows the

position

the

tilt

by a pull on

the

front whi Ie

latch

pulls down on its

pivots

against

The vertiCal I ink

top

tape.

of

tape

is

7

Rest

of

the

tilt

forces

the

The

tilt

arm

arm,

because

due

to

the

ti It arm on a ball

pulley

the

tilt

arm.

from

coming

the

tilt

the

right

forced down by

attached

a stop lug formed

from

bellcrank

tilt

the movement

to

remain

It

off

latches.

one

the

to

arm

to

is

sometimes

to

the

lever-

hori-

must remain

the

pulley.

When

remains

latch

lever,

out

the

lever

the

the

to

bail

the

from

is

Page 15

\

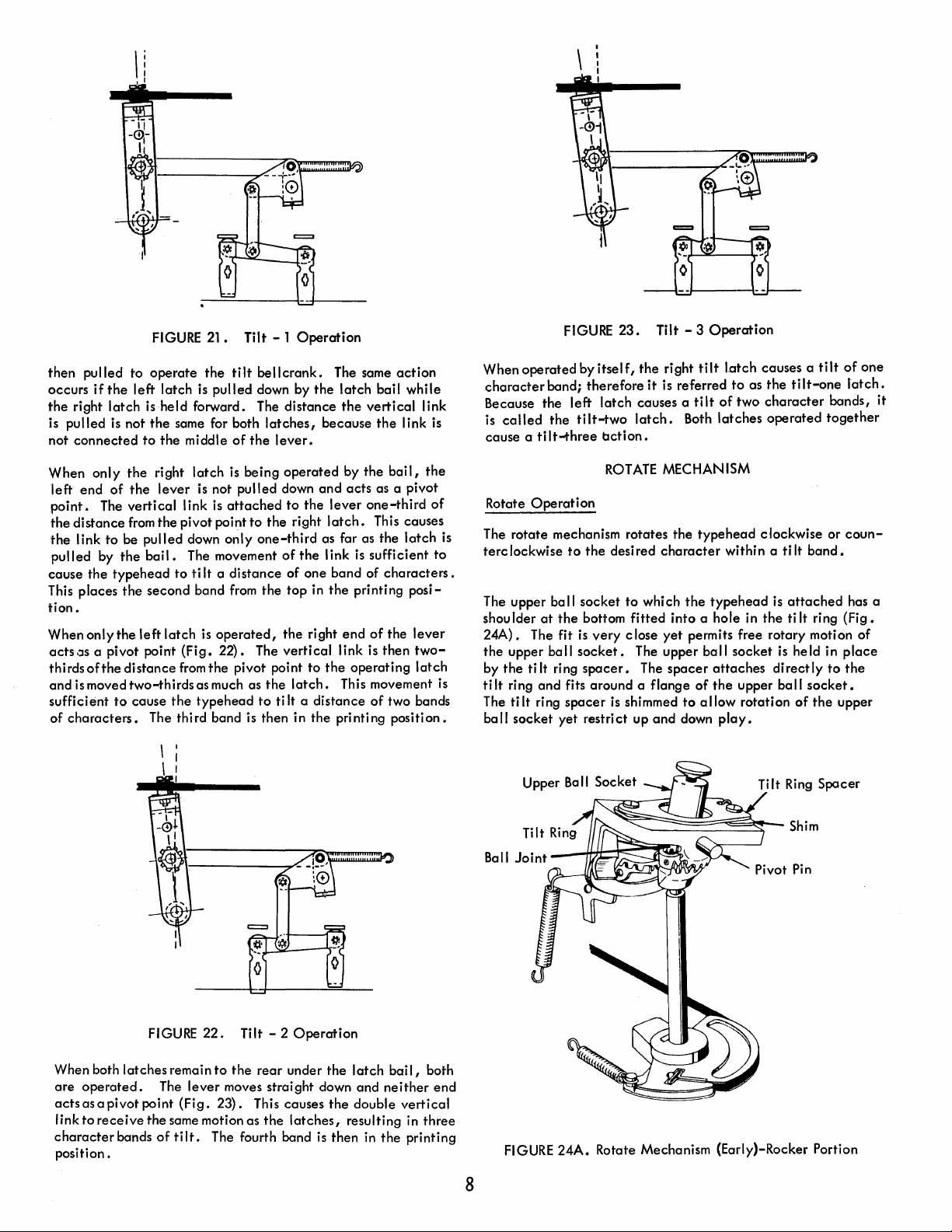

FIGURE

then

pulled to

occurs

if

the

right

pulled is not

is

not

connected

When

only

left

end

point.

the

the

pulled

cause

This places

tion.

When

acts,JS a pivot point

thirds

and

sufficient

of

The

distance

I ink

by

the

only

ofthe

is moved

characters.

operate

the

left

latch

latch

is

held forward. The

the

to

the

the

right

of

the

lever

vertical

from

the

to

be

pulled

the

bail.

typehead

the

second band

the

left

latch

distance

two-thirds

to

cause

The third band is then in

21.

the

tilt

is

pulled

same for both

middle

I ink is

pivot point

down

The movement

to

(Fig.

from

the

of

latch

is

is not

pulled

attached

only

ti

It a distance

from

is

operated,

22).

the

pivot point

as much as

typehead

Tilt - 1

bellcrank.

down by

latches,

the

lever.

being

operated

down

to

the

one-third

of

the

the

The

vertical

the

to

ti

Operation

The same

the

latch

distance

to

right

of one band of

top

latch.

It a distance

the

because

by

and

acts

the

lever

latch.

as far as

the

link is sufficient

in

the

printing

right

end

link is

to

the

operating

This movement is

the

printing

action

bail

while

vertical

the

link is

the

bail,

as a pivot

one-third

This causes

the

latch

characters.

posi-

of

the

lever

then

twolatch

of

two bands

position.

link

the

of

to

When

character

Because

is

cause a tilt-three

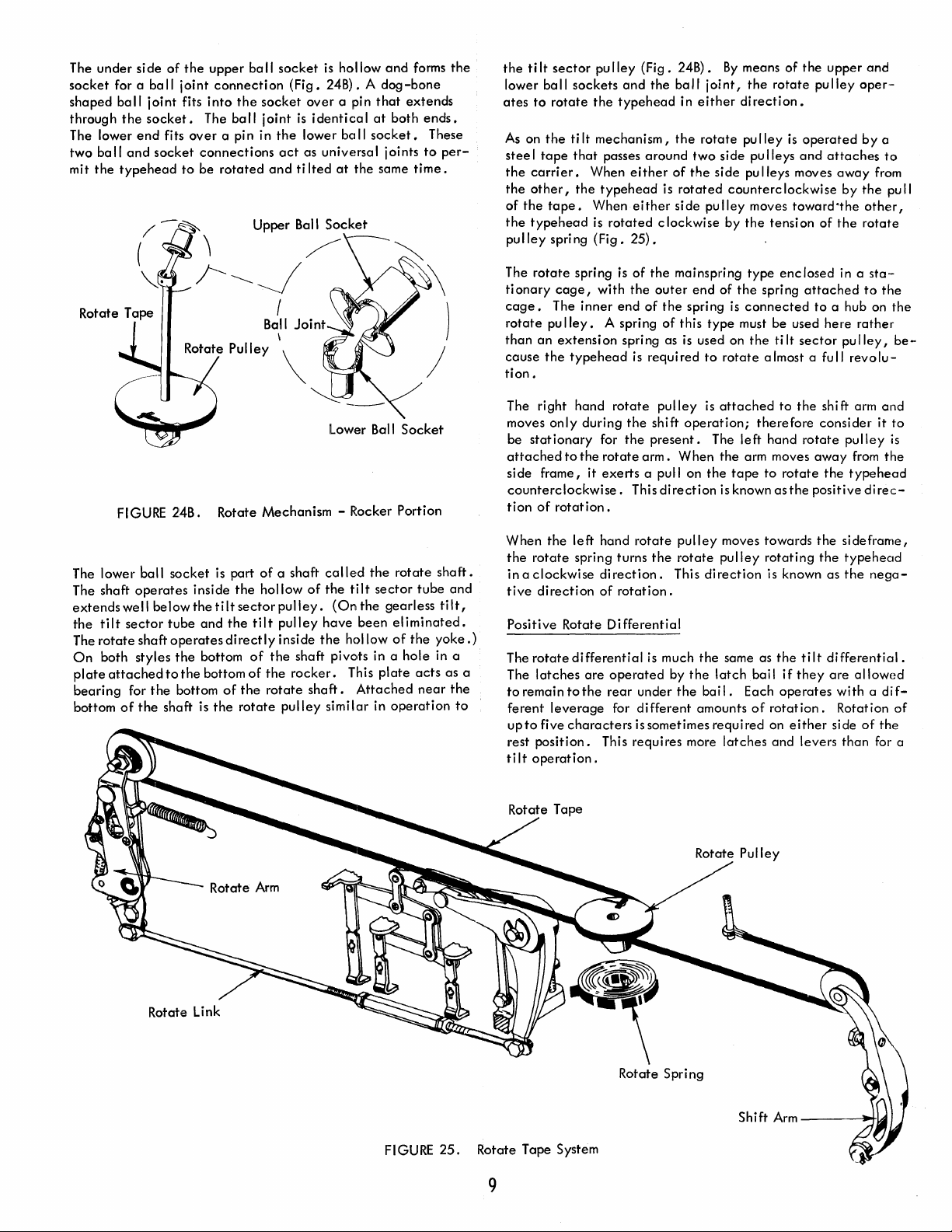

Rotate

The

is

terclockwise

The upper

shou Ider

24A).

the

by

tilt

The

ball

operated

called

Operation

rotate

The fit

upper

the

tilt

ring

tilt

socket

FIGURE

band;

the

left

the

mechanism rotates

to

ball

at

the

ball

ring

and

fits around a flange

ring

spacer

yet

by

itself,

therefore

latch

tilt-two

bction.

ROTATE

the

desired

socket

bottom

is

very

socket.

spacer.

is shimmed

restrict

23.

Tilt - 3

the

right

it

is referred

causes a

latch.

MECHANISM

character

to

which

fitted

c lose

yet

The upper

The

spacer

up

and

Operation

tilt

l.atch causes a

to

as

the

tilt

of

two

character

Both

latches

the

type

the

typehead

into

a hole in

permits free rotary motion of

ball

attaches

of

the

to

allow

down

play.

operated

head

clockwise or

within a

the

socket

upper

rotation

tilt

tilt-one

tilt

band.

is

attached

ti

It

ring

is held in

directly

ball

socket.

of

the

together

to

of

one

latch.

bands, it

coun-

has a

(Fig.

place

the

upper

When both

are

operated.

acts

as a pivot point

link

to

receive

character

position.

latches

the

bands

FIGURE

22.

remain

The

lever

(Fig.

same motion as

of

ti

It.

Ti

It - 2

Operation

to

the

rear

under

the

latch

moves straight down and

23).

This causes

the

The fourth band is then in

the

latches,

double

resulting in

bail,

neither

vertical

the

printing

both

end

three

8

Upper Ball Socket

FIGURE

24A.

Tilt Ring

Rotate Mechanism (Early)-Rocker Portion

Spacer

Page 16

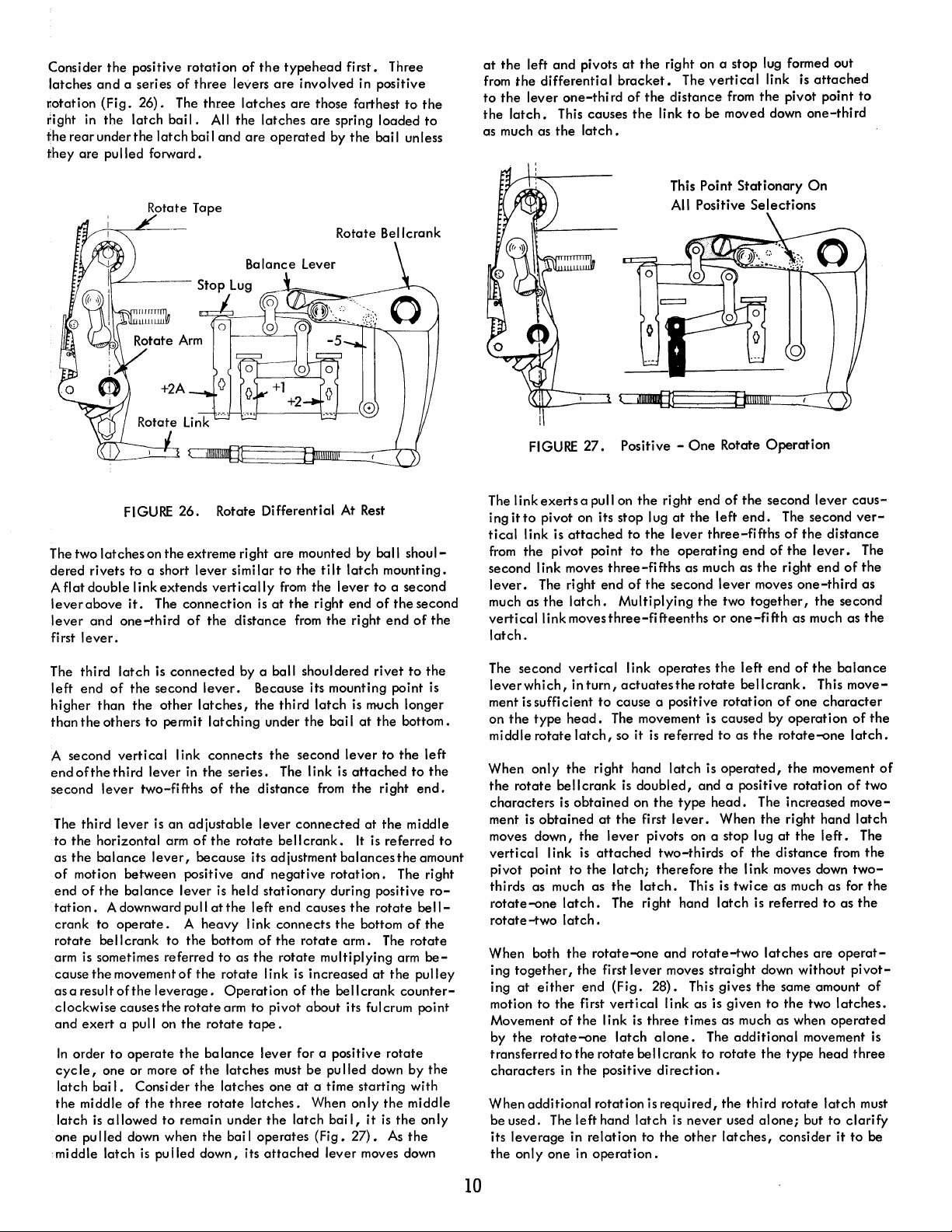

The

under

socket

for a ba

shaped

through

The lower

two

mit

ball

the

ba

the

type

side

II

end

and

(\

"J.

of

the

upper

ball

socket

II

joint

joint

socket.

fits

socket

head

/

--

connection

fits

into

The

over

a pin in

connections

to

be

rotated

~

the

ball

(Fig.

socket

joint

is

the

act

and

ti Ited

Upper Ball

_;--~~I

B~I

Joint

\ )

is

hollow

and

forms

24B). A

over

identical

lower be

as universal joints

Socket

a pin

at

the

dog-bone

that

at

II

socket.

same

extends

both

time.

/\--~

the

ends.

These

to

per-

~

)

the

ti

It

lower ba

ates

to

rotate

As

on

the

stee I tape

the

carrier.

the

other,

of

the

tape.

the

typehead

pulley

spring

The

rotate

ti

onary

cage.

rotate

pulley.

than

an

cause

the

tion.

sector

pu Iley

II

sockets

the

ti

It

mechanism,

that

When

the

When

is

(Fig.

spring

cage,

with

The

inner

extension

typehead

(Fig.

and

typehead

passes

around

either

typehead

either

rotated

25).

is

of

the

end

of

A spring

spring as

is

24B).

the

ba

in

the

of

the

is

rotated

side

clockwise

the

mainspring

outer

the

spring

of

this

is

required

II

j oi

either

rotate

two

side

side

pulley

end

of

type

used on

to

rotate

By

means

nt,

the

rotate

direction.

pu

lIey

pu Ileys

pu

lIeys moves

counterc

moves

by

the

tension

type

the

spri

is

connected

must be used

the

tilt

almost a full

of

the

upper

pu lIey

is

operated

and

attaches

away

lockwise by

toward'the

of

the

enclosed

ng

attached

to

a hub on

here

sector

and

oper-

by

the

other,

rotate

in a

sta-

to

rather

pulley,

revolu-

a

to

from

pu

the

II

the

be-

~--

lower

FIGURE 24B. Rotate Mechanism - Rocker Portion

lower

ball

socket

is part

of

The

The shaft

extends

the

tilt

The

rotate

On

both styles

plate

attached

bearing

bottom

of

operates

well

sector

shaftoperatesdirectly

for

the

inside

the

belowthetiltsectorpulley.

tube

and

the

the

bottom

to

the

bottom

the

bottom

shaft is

of

the

hollow

tilt

of

of

the

the

rotate

a shaft

the

rotate

called

of

the

(On

pulley

have

inside

the

shaft pivots in a

rocker.

shaft.

pulley

similar

Ball

the

tilt

sector

the

been

hollow

This

plate

Attached

in

Socket

rotate

shaft.

tube

gearless

eliminated.

of

the

yoke.)

hole

in a

acts

near

operation

and

tilt,

as a

the

to

The right hand

moves

only

during

be

stationary

attached

side frame, it

counterclockwise.

tion

of

When

the

the

rotate

in a

clockwise

tive

direction

Positive Rotate

The

rotate

The

latches

to

remain

ferent

leverage

upto

five

rest

position.

tilt

operation.

for

to

the

rotate

exerts

rotation.

left

hand

spring turns

direction.

of

differential

are

to

the

characters

This requires more

rotate

pulley

the

shift

the

present.

arm.

a pull on

This

direction

rotate

the

rotation.

Differential

is

much

operated

rear

for

by

under

different

is

sometimes

is

attached

operation;

The

When

the

the

is known

pulley

rotate

pulley

This

direction

the

the

latch

the

bai I. Each

amounts

required

to

the

therefore

left

hand

rotate

arm moves

tape

to

rotate

as

the

moves towards

rotating

is known as

same as

latches

the

bail

of

rotation.

on

and

tilt

if

they

operates

either

levers

shift arm

consider

pulley

away

from

the

typehead

positive

the

direc-

sideframe,

the

typehead

the

differential.

are

allowed

with

Rotation

side

of

than

and

it

the

nega-

a di

the

for a

to

is

fof

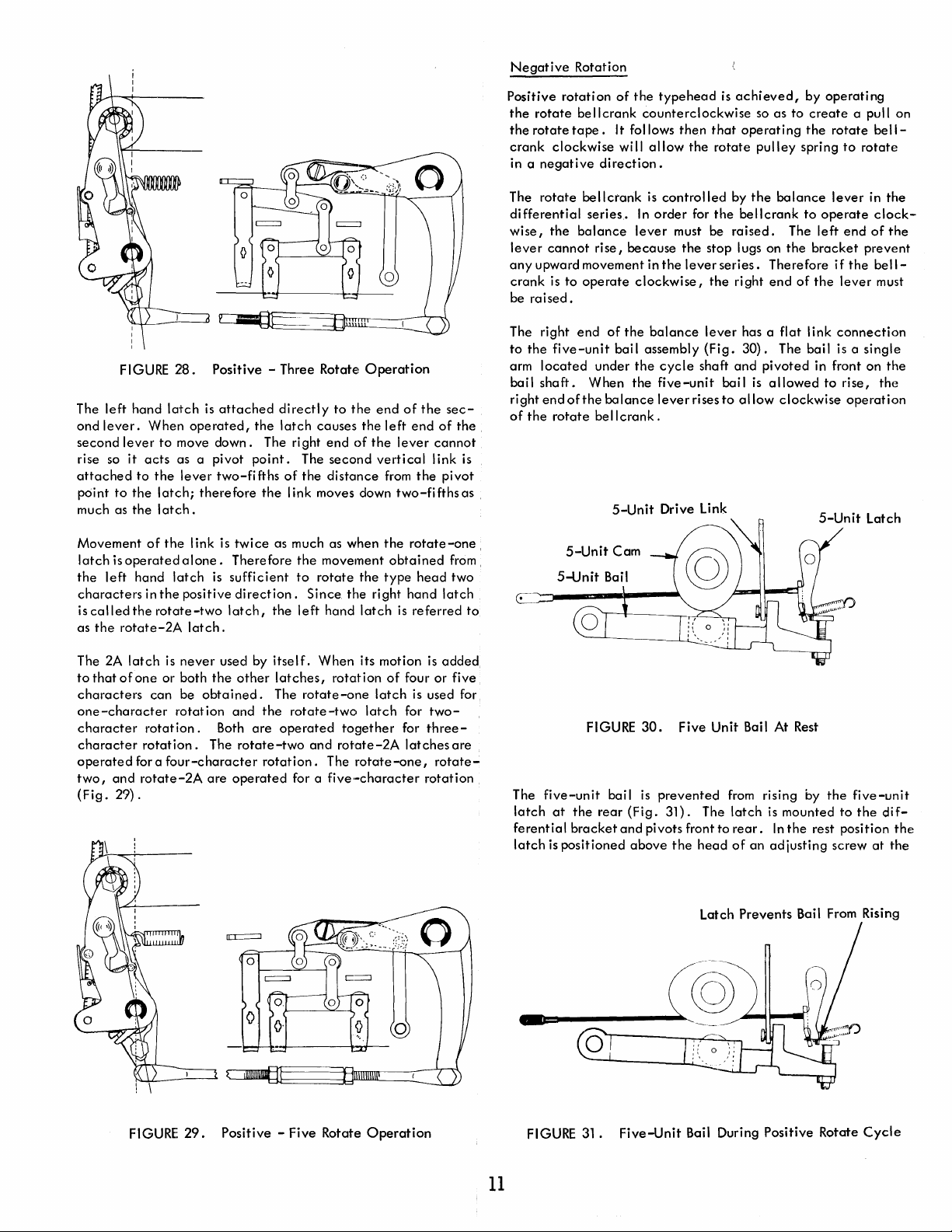

FIGURE

25.

Rotate Tape System

9

Rotate Spring

Shi ft

Arm

---

___

Page 17

Consider

latches

Ilotation

right

in

the

rearunderthe

they

are

the

positive

and

a series of

(Fig.

26).

The

the

latch

bai I. All

latch

pulled forward.

rotation

three

three

bail

and

of

the

levers

latches

the

latches

are

typehead

are

involved in positive

are

operated

first.

those farthest

are

spring loaded

by

the

Three

to

the

to

bail unless

at

the

left

from

the

differential

to

the

lever

the

latch.

as much as

and

pivots

one-thi

This causes

the

latch.

at

the

bracket.

rd

of

the

the

right on a stop lug formed out

The

distance

link

to

vertical

be moved down

from

link is

the

pivot point

attached

one-third

to

FIGURE

The two

dered rivets

A flat double link

lever

'lever

fi

rst I

latches

above

and

ever.

to

it.

one-third

Rotate Tape

26.

on

the

extreme right

a short

extends

The

connection

of

lever

vertically

the

Rotate Bellcrank

Ba

lance

Lever

Rotate Differential At

are

mounted by ball

similar

is

at

distance

to

from

the

from

the

tilt

the

right

the

lever

Rest

latch

end

right

shoul-

mounting.

to

a second

of

the

second

end

of

the

FIGURE

The link

ing it

to

tical

link is

from

the

second link moves

lever.

much as

vertical

latch.

27.

exerts

a pull on

pivot on its stop lug

attached

pivot point to

The right end

the

latch.

link moves

This Point

All Positive

Positive -

the

to

three-fifths

of

Multiplying

three-fifteenths

right end

at

the

lever

the

the

second

One

the

operating

as much as

Stationary

Selections

Rotate

of

the

left

end.

three-fifths

end

lever

the

two

together,

or

one-fifth

Operation

second

The second

of

of

the

the

right

moves

one-third

as much as

On

lever

the

lever.

end

the

caus-

ver-

distance

The

of

the

as

second

the

The third

left

higher

than

A second

endofthethird

second

The third

to

the

as

the

of

end

tation.

crank to

rotate

arm is sometimes referred to as

cause

as a result

clockwise causes

and

In

cyc

latch bai

the

latch

one pulled down when

middle latch

latch

is

connected

end

of

the

second

than

the

the

others to permit

vertical

lever

lever

two-fifths

lever

is an

horizontal arm

balance

motion between positive and'

of

the

be

the

exert

order

Ie,

one or more of

middle of

is

lever,

balance

A downward pull

operate. A heavy

II

crank

movement

of

the

leverage.

a pull on

to

operate

I.

Consider

the

allowed

is

pulled

lever.

other

latches,

latching

I ink

connects

in

the

series.

of

adjustable

of

the

because its ad justment

lever

is held

at

the

to

the

bottom

of

the

rotate

Operation

the

rotate

arm

the

rotate

the

ba

lance

the

latches must be

the

latches one

three

rotate

to

remain under

the

bai I operates (Fig.

down, its

by a ball shouldered

Because its mounting point is

the

third

latch

under

the

the

second

The link is

the

distance

lever

rotate

negative

stationary

left end causes

link

of

the

I ink is increased

to

pivot

tape.

lever for a positive

latches.

the

attached

from

connected

bell

crank.

connects

the

rotate

rotate

multiplying arm

of

the

about

at

a time starting with

When only

latch

lever moves down

rivet

is much longer

bai I

at

the

lever

attached

the

at

It

is referred

balances

rotation.

during positive

the

rotate

the

bottom

arm. The

at

bellcrank

its fulcrum point

pu

lied down by

bail,

it

27).

to

bottom.

to

the

right

the

middle

the

The right

of

the

counter-

rotate

the

middle

is

the

As

the

the

left

to

the

end.

amount

ro-

bell-

the

rotate

be-

pulley

the

only

to

The second

leverwhich,

ment is sufficient

on

the

middle

When

the

rotate

characters

ment is

moves down,

vertical

pivot point

thirds as much as

rotate-one

rotate-two

When both

ing

together,

ing

at

motion to

Movement

by

the

transferred to

characters

When

be used. The left hand

its

leverage

the

only one in

vertical

in

type

head.

rotate

latch,

only

the

bell crank

is

obtained

obtained

the

I ink is

to

latch.

latch.

the

the

either

end

the

first

of

the

rotate-one

the

in

the

additional

in

turn,

to

The movement is caused by

right hand

at

lever

attached

the

latch;

the

The right hand

rotate-one

first

(Fig.

vertical

link is

rotate

positive

rotation is

relation

operation.

link

operates

actuates

cause a positive rotation

so it

is

referred

is

doubled,

on

the

the

first

pivots on a stop lug

two-thirds

therefore

latch.

and

lever

moves straight down without

28).

link as is given

three

latch

alone.

bell

crank

direction.

required,

latch

to

the

the

left

the

rotate

bellcrank.

to

as

the

latch

is

operated,

and a positive rotation

type

head.

lever.

This is

rotate-two

This gives

times as much as when

The

to

is

never

other

The increased

When

the

of

the

the

link moves down

twice

latch

is referred

the

additional

rotate

the

the

third

used

alone;

latches,

end

of

the

This

of

one

character

operation

rotate-one

the

movement

right hand

at

the

left.

distance

as much as for

latches

same amount

to

the

type

rotate

consider

from

to

are

two

operated

movement

head

latch

but

to

balance

move-

of

the

latch.

of

two

move-

latch

The

the

two-

the

as

the

operat-

pivot-

of

latches.

is

three

must

clarify

it

to

be

of

10

Page 18

Negative

Rotation

FIGURE

The

left

hand

ond

lever.

second

lever

rise so

attached

point

much as

Movement

latch

the

characters

iscalledthe

as

it

to

the

the

isoperatedalone.

left

the

rotate-2A

latch

When

to

acts

to

the

latch;

latch.

of

the

hand

in

the

rotate-two

28.

Positive - Three Rotate!

is

attached

operated,

move

as a pivot

lever

therefore

link is

latch

positive

latch.

the

down.

point.

two-fifths

the

twice

Therefore

is

sufficient

direction.

latch,

The right

Operation

directly

latch

of

as much as when

the

to

the

causes

the

end

of

The

second

the

distance

link moves down

the

movement

to

rotate

the

Since

the

left

hand

latch

end

of

the

left

end

the

lever

vertical

from

the

two-fifthsas

the

rotate-one,

obtained

type

head

right hand

is

referred

sec-

of

the.

cannot

link

is

pivot

from,

two

latch

.

to

Positive

the

the

crank

in a

The

differential

wise,

lever

any

crank

be

The right

to

arm

bail

right

of

E--==--m:II-.--~

rotation

rotate

rotate

clockwise

negative

rotate

the

cannot

upward movement in

is

to

raised.

the

five-unit

located

shaft.

end

of

the

rotate

bellcrank

tape.

It follows

direction.

bellcrank

series.

balance

rise,

operate

end

of

bai I assembly

under

When

the

balance

bellcrank.

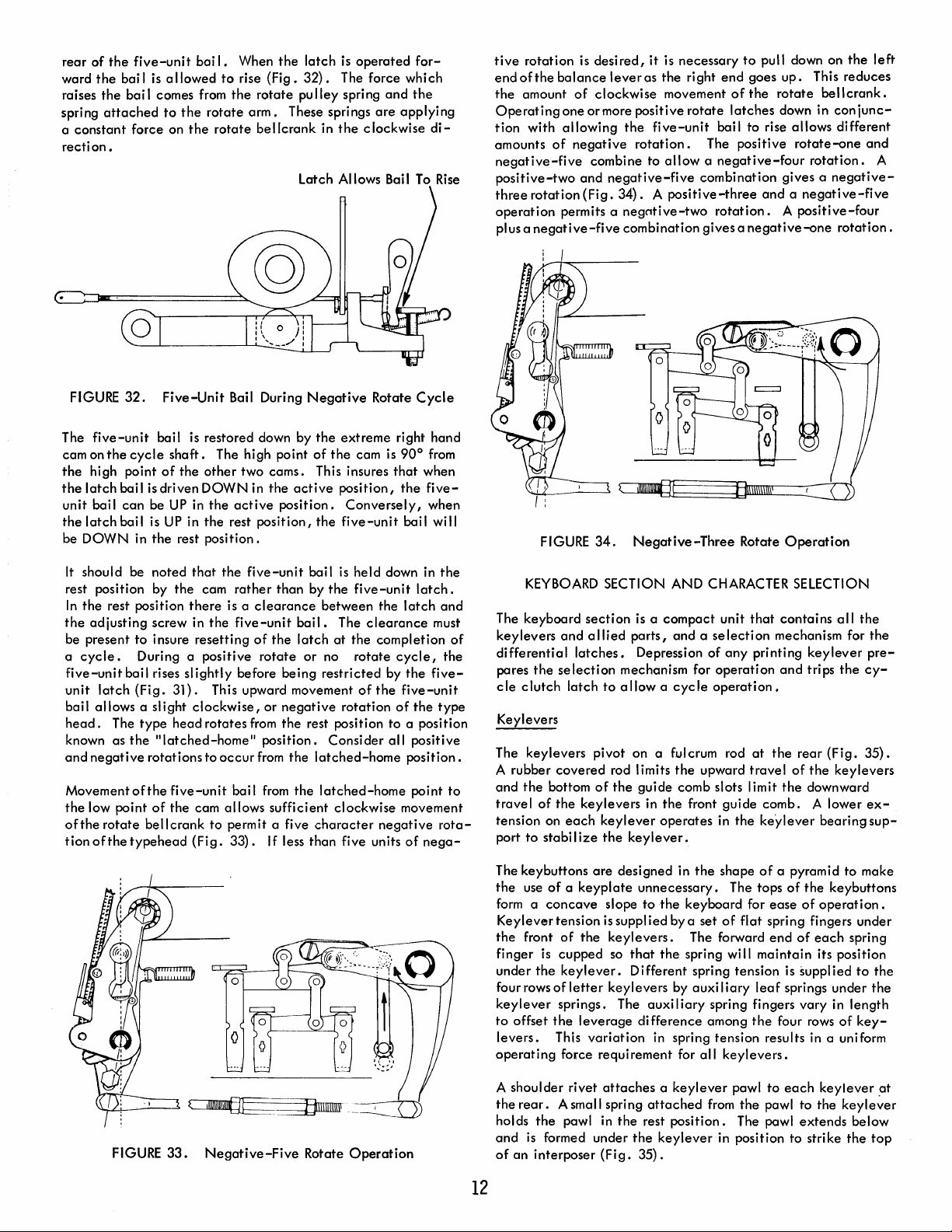

5-Unit

of

the

wi

because

clockwise,

the

the

the

typehead

counterclockwise

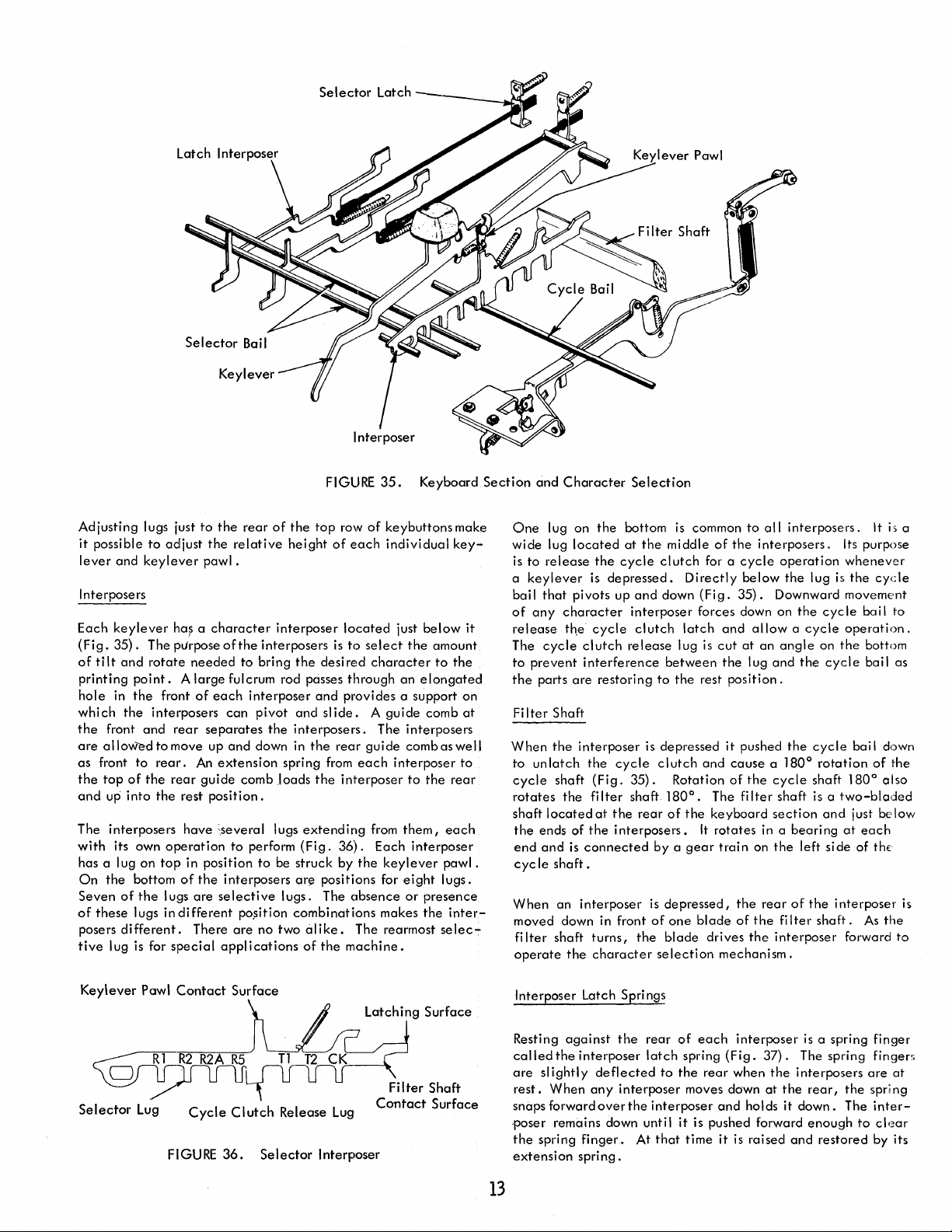

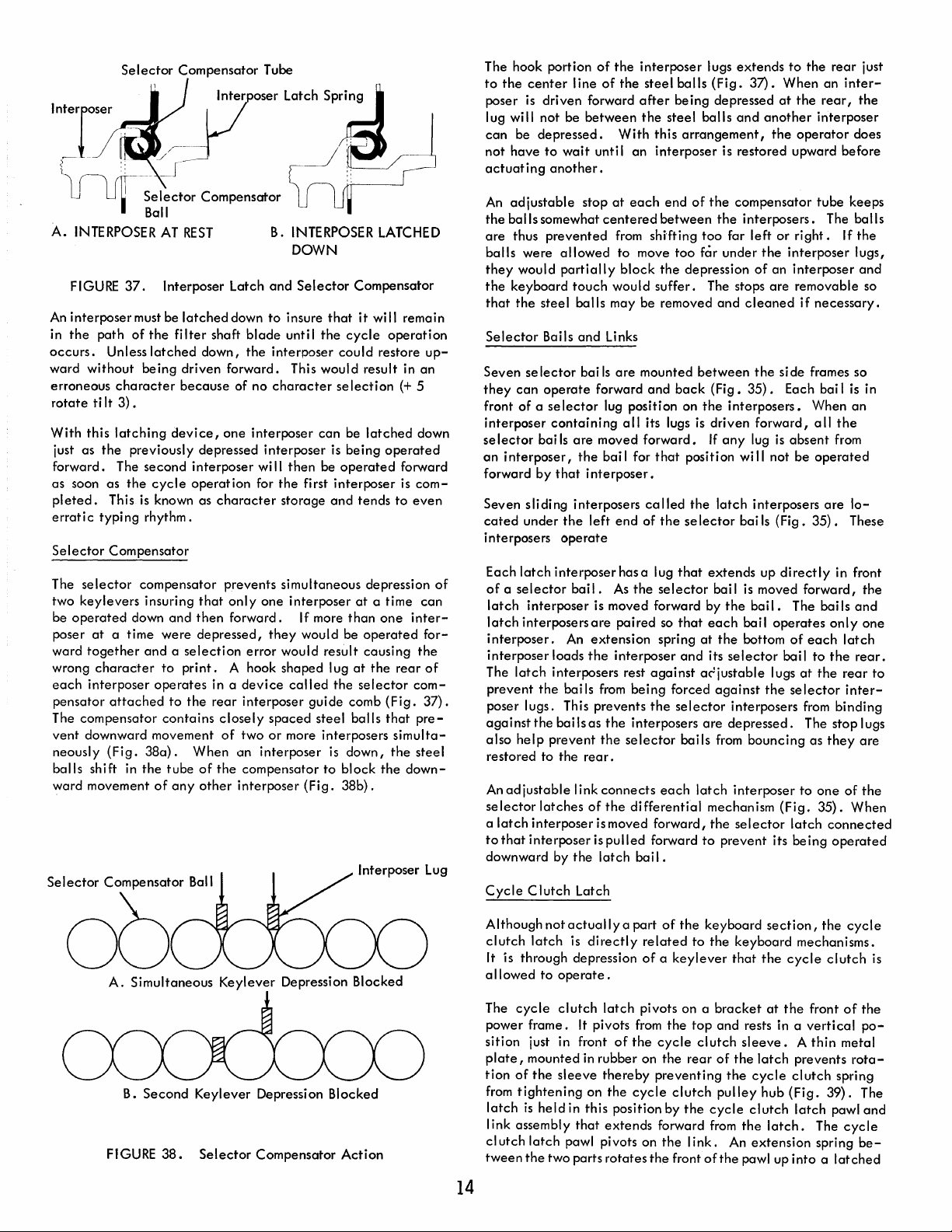

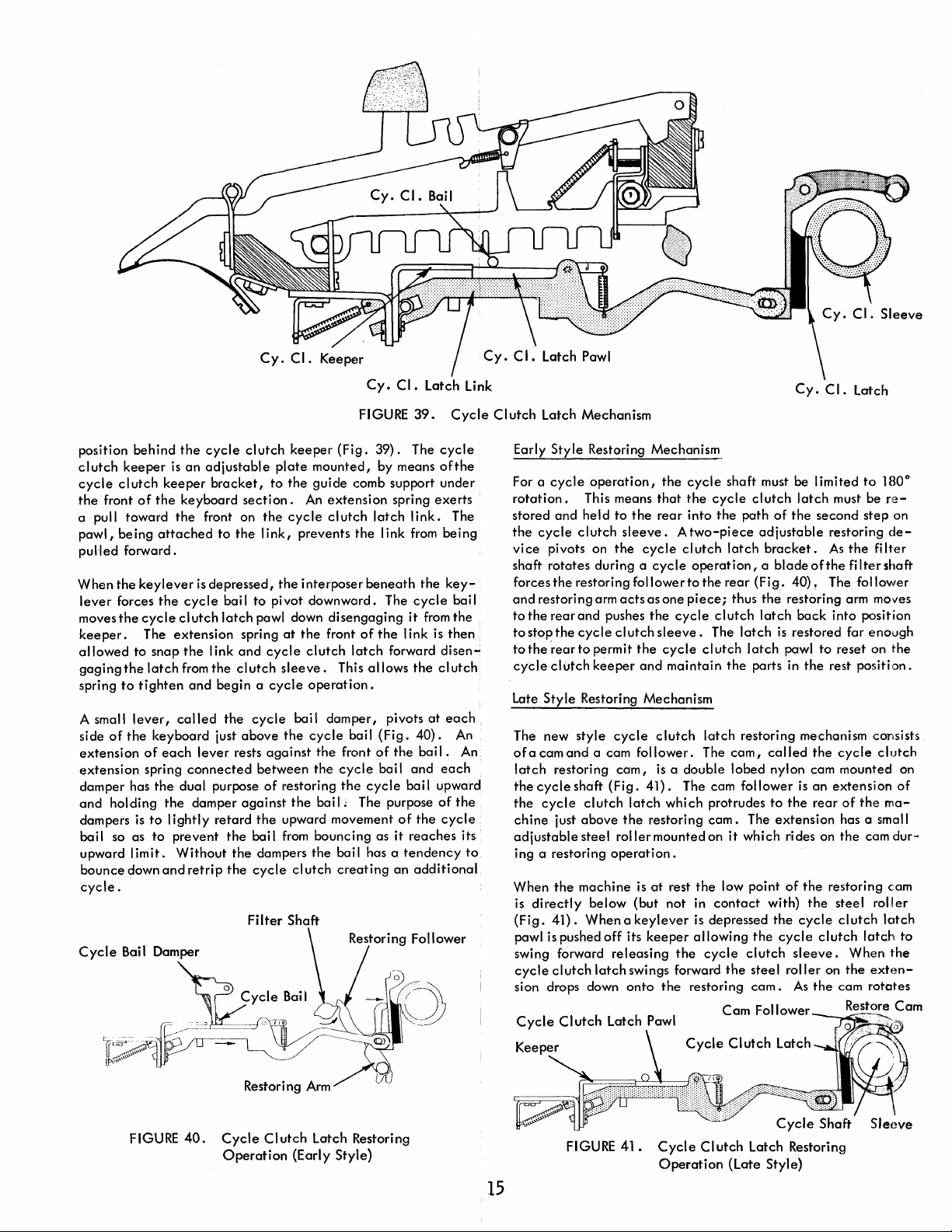

then