Page 1

The

information

programmer

(Form

No.

information

RAMAC®305 REFERENCE SUMMARY

contained

and

operator.

A26-3502).

is

required.

in

this

It

is

Reference

summary

condensed

should

is

from

be

intended

the

made

IBM

to

as

that

an

aid

RAMAC

manual

for

305

the

more

Reference

when

experienced

more

complete

Manual

© 1957, 1958, 1959, 1960 by

International

RAMAC 305

Business

Machines

Corporation

Page 2

Systems

Summary

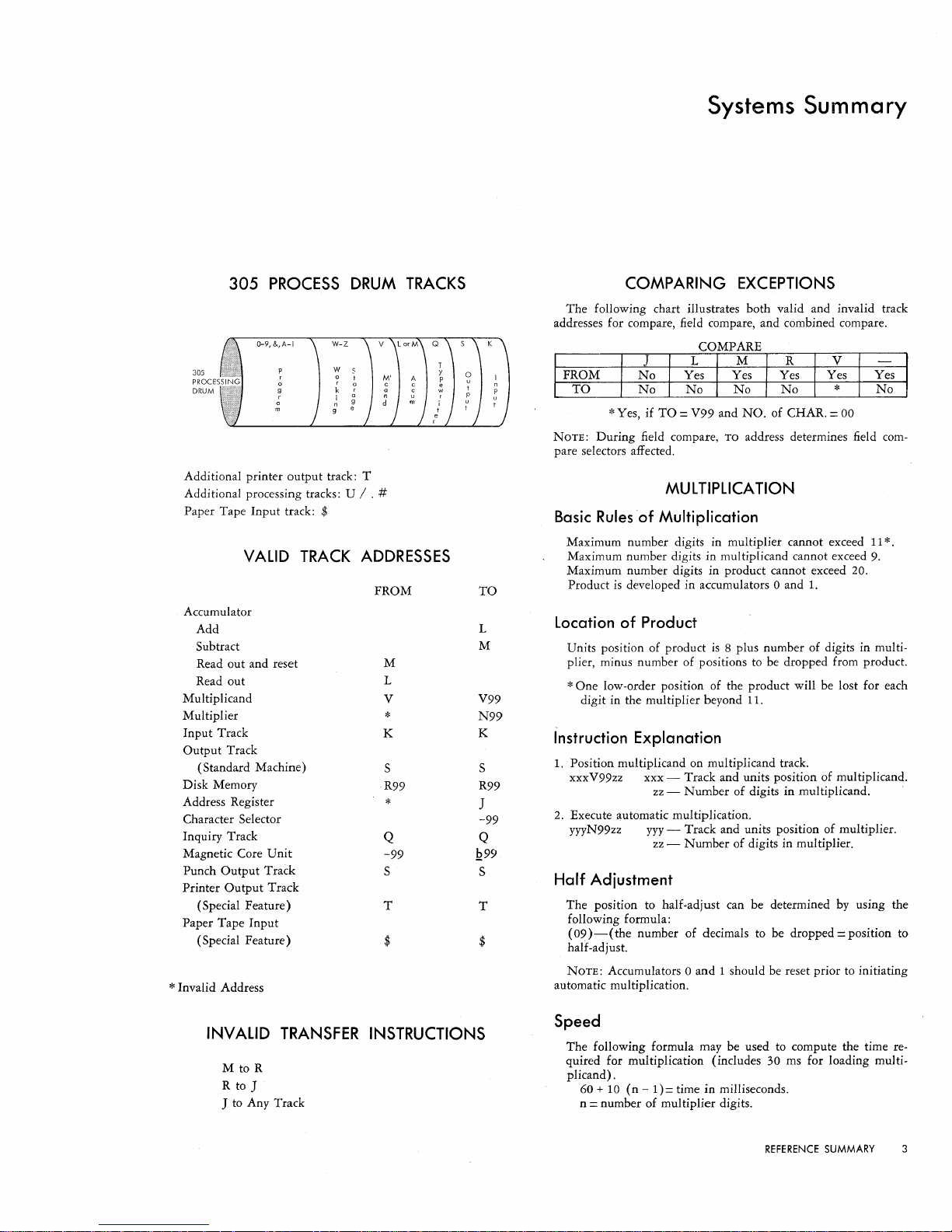

305

PROCESS

305

PROCES

DRUM

Additional printer

Additional processing tracks: U / . #

Paper Tape Input track: $

Accumulator

Add

Subtract

Read out and reset

Read out

Multiplicand

Multiplier

Input

Track

Output

Track

(Standard Machine)

Disk Memory

Address Register

Character Selector

Inquiry Track

Magnetic Core

Punch

Output

Printer

Output

(Special Feature)

Paper Tape

(Special Feature)

VALID

Unit

Track

Track

Input

output

TRACK

track: T

* Invalid Address

DRUM

TRACKS

ADDRESSES

FROM

M

L

V

*

K

S

R99

*

Q

-99

S

T

$

TO

L

M

V99

N99

K

S

R99

J

-99

Q

1299

S

T

$

COMPARING

The

following chart illustrates both valid and invalid track

addresses for compare, field compare, and combined compare.

* Yes, if

NOTE:

During

pare selectors affected.

TO

= V99 and

field compare,

MULTIPLICA

Basic

Rules

of

Multiplication

Maximum number digits in multiplier cannot exceed

Maximum number digits in multiplicand cannot exceed

Maximum number digits in product cannot exceed 20.

Product

is

developed in accumulators 0 and

Location

Units position of product

plier, minus number of positions to be dropped from product.

of

Product

EXCEPTIONS

NO.

of CHAR. = 00

TO

address determines field com-

TION

1.

is

8 plus number of digits in multi-

11

9.

* One low-order position of the product will be lost for each

digit in the multiplier beyond

Instruction Explanation

1.

Position multiplicand on multiplicand track.

xxxV99zz xxx - Track and units position of multiplicand.

2.

Execute automatic multiplication.

yyyN99zz

Half

Adjustment

The

position to half-adjust can be determined by using the

following formula:

(09)

-(

half -ad just.

NOTE:

automatic multiplication.

zz -Number

yyy

- Track and units position of multiplier.

zz -Number

the number of decimals to be dropped = position to

Accumulators 0 and 1 should be reset prior to initiating

11.

of digits in multiplicand.

of digits in multiplier.

*.

INVALID

M to R

R to J

TRANSFER

J to Any Track

INSTRUCTIONS

Speed

The

following formula may be used to compute the time re-

quired for multiplication (includes 30 ms for loading multi-

plicand).

60 +

10

(n

-

1)=

time

in

n

= number of multiplier digits.

milliseconds.

REFERENCE

SUMMARY

3

Page 3

AUTOMATIC DIVISION

Basic

Rules

of

Division

Maximum number digits in dividend cannot exceed 19.

Maximum number digits in divisor cannot exceed

Maximum number digits in quotient cannot exceed 19.

Maximum number digits' in divisor plus maximum number

digits in quotient cannot exceed

20.

9.

OPERATING

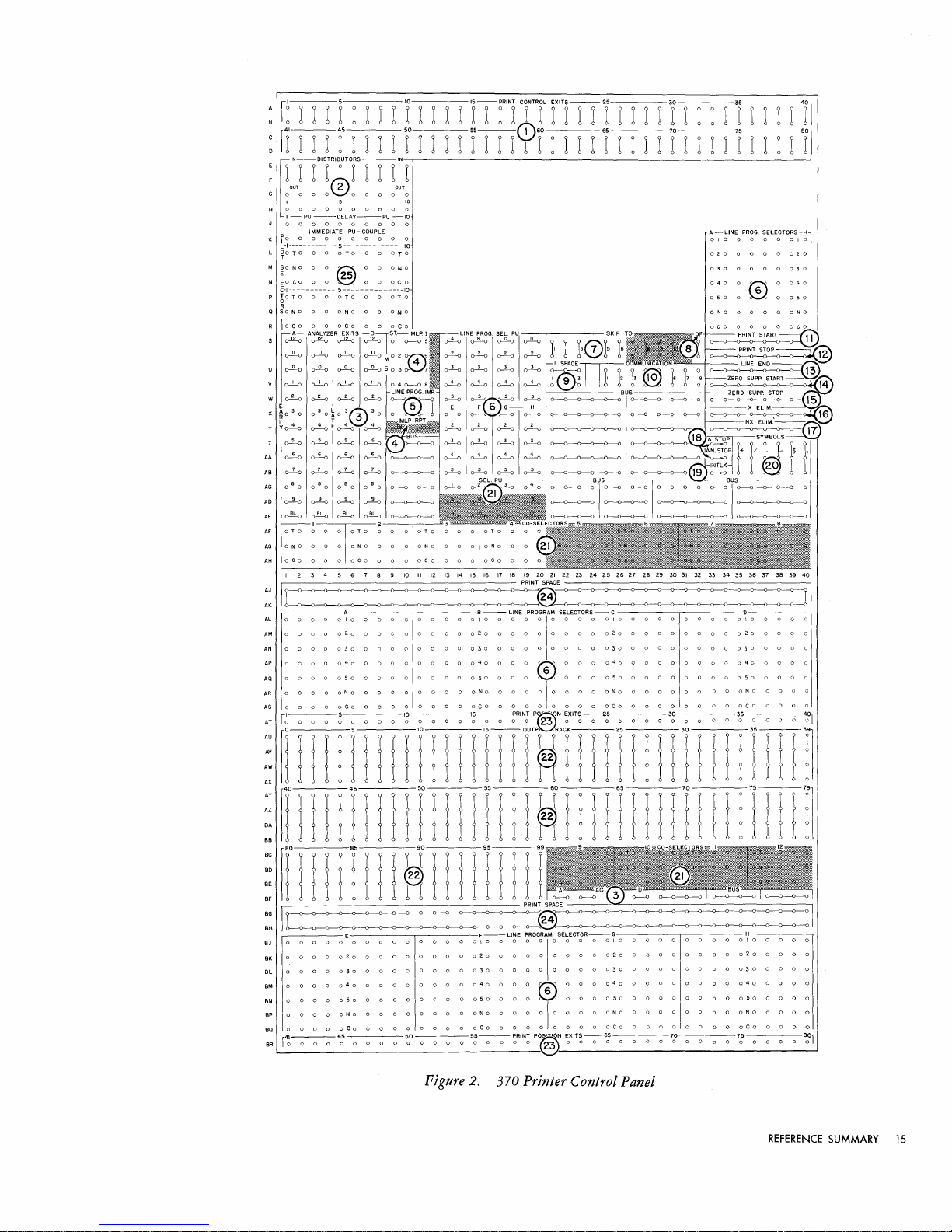

370 Printer Output

80 positions

60 positions

40 positions

20 positions

Punch Output

Card Feed Input

Typewriter Output

Automatic Typing

Manual Typing (average)

Tabulations (average)

Carriage Returns (average)

(29

(36.5

(50

(84

( 100

(125

SPEEDS

LPM)

LPM)

LPM)

LPM)

CPM

max.)

CPM max.)

100

200

300

1000

2050

ms/line

1640

ms/line

1200

ms/line

720

ms/line

600 ms/card

4so

ms/card

ms/

character

ms/

character

ms/tab

ms/

return

Location

Units position of quotient is in 119.

Location

Units position of remainder in L08 minus number of digits in

excess of

of digits in divisor.)

Instruction

1. Position dividend in accumulators 0 and

xxxLyyzzb5 xxx - Track and units position of dividend.

2.

Position divisor on multiplicand track.

xxxV99yy

3. Execute automatic division.

L09P99xx xx - Twice the number of digits in quotient.

Half

Increase the number

(3)

read quotient from position L18. Remainder is also positioned

one position to the left.

sion.)

NOTE:

mum whole number

figures.

of Quotient

of

Remainder

11.

(Number

Explanation

yy

zz -Number

xxx-

yy -Number

Adjustment

above, add 5 to

If

number

of digits in remainder equal number

1.

- Maximum whole number digits

tient plus 8. (Cannot exceed 19.) Maximum whole number digits in quotient is

maximum digits in dividend minus minimum digits in divisor plus one.

Track and units position of divisor.

added zeros.)

quotient exceeds

to right of divisor equal to number in

excess of

instruction.

of

of

of

digits, then additional digits are decimal

of digits in dividend.

of digits in divisor. (Including

If

number of digits of

11, zeros must be added

11

before execution

digits in quotient by one

119

after execution of instruction, and

(Do

not exceed basic rules

digits in quotient desired exceeds maxi-

in

instruction

in

of

of

quo-

this

divi-

Speed

The

following formula may be used to compute the

quired for division (includes

plus

30 ms for loading divisor).

100 + 20

n

(n -1)

= number

= time in milliseconds.

of

quotient digits.

30 ms for positioning dividend

time

re-

Disk

Storage

Seek time disk to disk:

SOo

ms/

Seek time track to track, same disk:

250

ms/max

Seek time record-to-record, same track:

50

ms

Transfer disk

so

ms/max.

Transfer drum to disk:

130 ms/max. 105 ms/avg. 80

Other Operating

Track-to-track transfer

Control panel test additional 20

Record advance additional 30

Skip-to-record additional

Addressing Address Register additional 20

Cycle Delay additional 30

NOTE:

tions which normally require

pleted in

Features of the RAMAC 305 are summarized below.

feature, the table indicates the number

standard machine, the units in which each optional addition may

be made and the maximum available capacity.

305

FEATURES

Character selectors

Distributors

Selectors 10

323

FEATURES

Co-Selectors

Pilot Selectors 0

Digit

Selector 1

Offset Stacker

DPBC

positions 20

FEATURES

370

Co-Selectors

Pilot Selectors

Skip Stops

*One 4S-position character selector standard.

**5-position

t2-position

Timing

max. 600

to

drum track:

ms/

175 ms/avg. 100 ms/min.

55

ms/avg. 30 ms/min.

Speeds

on

If

Program Exit Overlap

30 ms.

FEATURE

Standard

Standard Increment

Standard

avg. 400

drum

50

ms for execution may be com-

ms/

min.

ms/min.

is

installed, certain instruc-

SUMMARY

of

units included in the

Increment

3*

100

()

0

4**

0

6

3

20

,10

4**

5t

1

10

Increment

4**

5t

5

30

30

For

each

Maximum

6

120

40

Maximum

20**

lOt

2

1

80

Maximum

12**

lOt

11

ms

ms

ms

ms

ms

ms

4 IBM RAMAC

305

Page 4

DIGIT

NO

DIGIT

1

2

3

4

5

6

7

8

9

11

12

CONSOLE READING AID

ZONES

CHAR

0

x

•

•

• •

•

• •

•

•

•

•

•

• •

•

•

•

•

•

•

•

•

•

• •

•

•

•

X

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

0

-

&

0

A

J

/

1

B

K

S

2

c

L

T

3

D

M

U

4

E

N

V

5

F

0

W

6

G

p

X

7

H

Q

y

8

I

R

Z

9

$

#

I!

*

%

@

CONSOLE

The

Console

(

On

Left)

operator

decipher

instruction

easi

Iy. It should

following

I.

of

2.

3.

4.

In

the

following

and 4 lights

XOl248

..

Because

the

zone

lights

chart

should

condition.

X

and

0 in

followed

sented,

which

READING AID

Reading

is

designed

the

lights

more

be

manner:

Mentally

arrive

the

numeric

For

example:

1 2 4 8

0.00

.0.0

•••

oooe

Refer

to

the

digit

which

this

sum.

Find

the

proper

opposite

this

Follow

across

letter,

or

represented

example;

are

glowing:

~

6

numeric

opposite

be

checked

The

matching

this

example}

across

to

the

in

this

{left

special

Aid

to

help

binory

quickly

used in

at

the

lights

0

chart

for

corresponds

hand

zone

digit.

to

the

character

by

these

the

lights

total

the

digit 6 on

for a

zone

should

character

case

is

the

coded

and

the

sum

glowing.

the

column}

lights

number,

lights.

X,

6,

matching

pattern

then

repre-

the

to

0,

the

letter

the

READ,

The

the test lock

2,

The

the Test Lock

WRITE,

AND

ALTER

SUMMARY

following diagrams show the sequence of operations

On

or

Off.

Test

Lock

On

1st

~

2nd

~

3rd

I Write I

TesT

Lock

Off

1st

B

2nd

8

3rd

I Write I

TEST

following is a resume

ON

and

LOCK

with

it

to

On

From

To

Parity

From

Q

On

From

Q

Q

Q

Q

Q

To

From

To

[;J

[;J

FUNCTIONS

of

console keyboard operations

OFF.

with

with

Test Lock

Make disk file inquiries during processing

when

{an

be

F.

Make disk file inquiries

Make

drum

Make

track inquiries during processing

drum

track inquiries when

Alter a record in the disk storage file

Alter a

drum

track record

Read from

Correct parity errors

drum

track

________________________________________________

not processing

not

________________________________________

"M"

(clear

____________

________

________

processing

____

____________________

Yes

accumulators) Yes

ON

OFF

No

Yes

No

Yes

No

yes

No

Yes

No No

No

No

No

Yes

NOTE:

Dual

Access

Select

Hubs,

accept

only

RAMAC

RAMAC

during

an

NOTE: Any inquiries directed to the disk storage file

processing will be replied to only as provided for in the program.

CYCLE

exit

Cycles

cycle

CHART

Timing

Chart

Delay

DELAY

Regenerated

Impulses

Emit.Used

to

Return

Stored Prog

or

Select

Access

Arm

EXI

T

REFERENCE

to

during

SUMMARY

5

Page 5

Console

Operating

START-STOP

PROCEDURES

\

Starting the Machine After a

Power-Off

1.

Depress

sole

2. Depress

Hold

3.

and

4. Depress

by

5.

Place

of

6.

Place

reader

7.

If

Load

depress

Restarting the Same Job

To

restart

press

the

Starting or Stopping

To

Start:

1. Set

step.

Set

2.

operation-RUN,

3. Depress

4. Depress

To

Stop:

1.

Set

step.

2. Set

Inquiries-File

When

1.

The

The

2.

3.

Depress

4. Key

Inquiries-File

ITI0ff:

I.

Test

Control

2.

3.

Depress

Inquire

4.

5. Key

ITI0n:

I.

The

2.

The

3.

Depress

Condition

the

lights

the

the

punch

the

Ready

any

the

program.

the

operation.

the

hopper.

a

new

program

button.

the

the

reader

the

Program

the

Control

the

Program

the

Program

the

Control

Not

Test

machine

the

in

the

Lock

Selector

the

light

in

the

Test

Control

the

Power-on

have

printer

Control

Control

desired

If

reader

same

start

Program

key

turned

Start

light

the

key.

Selector switches

Selector switch to

SINGLE

Start.

Selector switches

Selector

at

on,

depress

Start

key.

key

down

is

on.

Impulse

Selector

data

is

job,

switch

or

program

to

be

loaded,

program

Start

key.

place

at

a Specific Program Step

OPERATION,

Set key.

switch

INQUIRIES

Information

Processing

Lock

must

be

must

desired

desired

Information During Processing

must

desired

comes

record

Lock

must

Selector switch

desired

off.

be

reset-depress

Format

five-digit address.

be

off.

switch

should

Format

key.

on

immediately.

address.

be

off.

Format

key.

Procedures

the

console.

until

buttons

is

already

cards

to

to

to

key.

be

should

After

the

Reset

cards

that

to

the

desired

load

depress

in

in

the

the

desired

the

desired

etc.

the

desired

CONTROL

Reset.

set

to

RUN.

be

set

cards

the

feed

to

key.

stop

are

the

machine,

STOP.

RUN.

the

con-

feeding

required

mode

in

the

Program

and

de-

program

mode

program

of

4.

When

the

IN

will

Delay

the

program

hub,

Inquiry

quiry

program

uous

When

5.

address.

Inquiries-Drum

When

Not

1.

The

Test

The

Control

2.

3. Depress

4.

Depress

Processing

Lock

the

the

ALTERATIONS

Altering Part

on

a Drum Track

I.

The

Test

Lock

2.

Depress

Select

3.

character

Depress

4.

Duplicate

5.

by

tion

6.

Type

7. Depress

completed.

8.

Depress

Depress

9.

tion

holding

to

to

the

type

be

the

the

proper

key.

the

the

down

changed.

new

the

the

any

reaches

the

Inquiry

stop.

(The

and

Exit

cycles.)

light

Cycle

turns

Information

may

be

either

Selector

Read

desired

switch

key

(read

character

TO

of

the Information

must

be

on.

Read

key.

track

by

Alter

key

to

on

the

track

information.

Clear

Write

desired

place

Q track.

information

the

DUP

key

after

key.

track

key.

key

the

step

light

will

lights

on,

on

or

is set

on

to

"Q")

key

on

DRUM

depressing

the

keyboard

on

Duplicate

all

alterations

except

which

turn

will

show

key

in

the

off.

RUN.

.

the

keyboard.

TRACKS

the

corresponding

the

typewriter

up

R.

tests

on

and

five-digit

in a condi-

to

the

have

Altering a Complete Drum Track

I.

The

Test

Lock

must

be

on.

2.

Clear

the

ing

this

3.

Depress

tion

Type

4.

5.

Depress

6.

Depress

Select

7.

character

Q track.

the

Read

order.

the

to

type

the

the

the

the

key.

TESTING

key,

Alter

on

desired

Clear

Write

desired

This

may

Space

to

place

Q track.

if

typing

by

depressing

be

bar,

the

key

the

information.

key

key.

track

PROCEDURES

accomplished

and

the

the

keyboard

less

than

100

the

corresponding

by

depress-

Clear

in a condi-

characters.

Testing Typewriter Control Panel Formats

1.

Inquiry

a.

b.

c.

d.

e.

format

Depress

Turn

Depress

Key

in

Depress

of

operation

the

the

the

the

the

Reset

selector

appropriate

desired

Program

on

the

key.

control

switch

Format

file address.

Start

key

typewriter

to

key (1,

one

time

control

FORMAT

2,

or

for

each

panel

program.

the

Inthe

contin-

track

posi-

been

key

TEST.

3) .

cycle

in

6 IBM RAMAC 305

Page 6

2.

Document-printing

a.

Reset

The

Turn

Depress

of

operation

the

test

the

the

b.

c.

d.

process

record

Selector

Program

on

format

must

the

Program Testing

Method I executes a program,

2

executes

stopping.

1.

2.

3.

4.

5.

6.

7.

NOTE:

during

write

File

several

program

The

Test

Lock

The

File

not

is

impossible

the

to

the

program

Interlock

be

plugged.

program

the

first

control

should

it

Turn

spond

place

Place

through a normal

After

the

gram,

TION.

When

will

If

it

and

corresponding

onto

light

processing

turn

the

the

Program

perform

the

operator

is necessary

then

type

Because

this

procedure,

the

disk

will

glow.

one

only

character

the

should

switch

to

destroy

selector

program

selector

load

program

Control

Start

program

wishes

to

out

the

File

each

storage,

Operation

unit.

be

on

Control

Start

typewriter

one

steps

or a complete

METHOD

be

1

off.

on

By

leaving

a file

switches

that

on

cards

in

load

unit

has

Selector

key is

step

to

examine a track

depress

desired

key.

Interlock

time

the

machine

may

the

switch

key

one

control

step

the

process

this

record.

is

CONTROL

the

machine,

routine.

stopped

switch

depressed,

at a time.

the

Keyboard

track

switch

the

program

be

resumed

typewriter

to

FORMAT

time

for

panel

at a time;

routine

control

switch

so

that

to

be

executed,

STOP.

on

the

to

SINGLE

by

depressing

is

not

jack-plugged

will

stop

track.

TEST.

each

cycle

program.

method

before

panel

unplugged,

they

corre-

and

proceed

first

OPERA-

the

machine

at

any

time,

Read

attempts

and

by

depress-

and

pro-

key,

the

the

to

ing

the

Check

next

Start.

Test

File

is

impossible

the

the

the

step

this

have

Because

this

onto

will

Reset

program

Start.

Reset

program

Lock

Interlock

not

be

the

program

to

the

control

processing

first

routine,

of

the

point,

been

This

may

Read

key

the

procedure,

the

disk

glow.

key,

to.

the

Program

1.

The

2.

The

should

it

3.

Turn

spond

place

4.

After

of

first

5.

At

that

order.

board

NOTE:

during

write

File

light

the

Check

the

next

Program

Track Clearing

Clearing a track

can

be

accomplished

1.

Turn

the

Test

2.

Depress

track.

tracks

propriate

To

reset

Read

The Q track

(e.g.,

track

character

the

accumulator

key,

setting

step,

should

switch

plugged.

to

destroy

selector

first

program

selector

second

the

operator

affected

be

accomplished

and

File

each

storage,

Operation

setting

step,

to

blanks

by

using

Lock

and

Space.

can

W)

the

depressing

METHOD

be

off.

on

By

leaving

a file

switches

on

unit

has

place

the

routine.

to

determine

selecting

Interlock

time

the

may

the

program

depressing

or

the

the

on.

This

now

by

depressing

key

(W

track,

program

Program

2

the

process

this

record.

that

is

to

CONTROL

stopped

program

can

investigate

by

the

proper

switch

the

program

machine

be

resumed

Program

accumulator

console

writes

be

used

in

this

depress

selector

Set,

control

switch

so

that

be

executed,

STOP.

on

the

selector

if

everything

depressing

track.

is

not

will

stop

by

selector

Set,

track

keyboard

blanks

to

blank

Write

case) .

Read

and

switches

and

then

panel

unplugged,

they

corre-

and

initial

step

on

the

the

tracks

is

the

Key-

jackplugged

attempts

and

the

depressing

switches

and

then

to

zero

as follows:

on

the

out

other

and

the

ap-

M.

in

to

to

Q

REFERENCE

SUMMARY

7

Page 7

Error Correction Procedures

PROCESSING

Parity

Console Indication:

Cause:

Restart

cycle,

the

Clock

Console Indication:

Cause:

Restart Procedure:

Check

1.

Processing

Parity

2.

Improper

PTOcedure:

1.

If

the

the

machine

on.

depressing

possible

and

2.

If

the

chine

Check

sary

tion

accumulator

data

used

necessary

struction

If

an

indication

To

correct

providing

following

a.

Depress

b.

Read

100

contains

c.

After

key.

page

d.

Type

e.

Depress

been

f.

Depress

Depress

g.

3.

If

the

will

Reset

a

read-in

tion

core

the

comparing

tion

sible,

step

tion

Error

I.

Processing

CLOCK

2.

Some

phase

1.

Make

NOTE:

light

character

parity

The

operator

because

the

records

parity

will

Reset

unless

is

involved.

is

retained

as

an

so

error

an

procedure

the

characters

the

This

and

any

completed.

parity

stop

and

has

occurred,

unit.

core

unit.

and

the

where

can

be

ligh t on.

a.

note

The

stops

on.

Check

stop

and

an

aid

to

that

persists

that

an

the

an

full

will

stop

the

the

program

check

with

Program

to

an

Depress

the

the

program

the

started

Stop

Stops

of

console

Stop

(Red

transfer

check

occurred

will

stop

may

Reset

no

information

in

the

check

occurred

with

the

Program

accumulator

If

read-out

has

been

in

the

to

reconstruction.

restart

the

the

accumulation

on a track

the

source

invalid

accumulator

may

Check

track

that

on

the

error,

it

track

cause

under

corrections

clear

write

key.

start.

occurred

the

TO

Start

accumulator

transferred

Check

It

may

accumulator

source

record.

should

accumulator

over

(Red

machine

of

the

program

may

character

Reset

key

CYCLE

be

timing

ERRORS

Stop

light

within

on

with

the

INSTRUCTION

attempt

and

then

machine

FROM

reset

will

has

the

Stop

has

have

on

the

CYCLE

Start

may

read-out

and

to

zero.

magnetic-core

program

to

data

is

occurring

operation

be

used:

key.

contains

track

are

be

automatically

been

typed,

typewriter

the

first

invalid

that

are

after

the

on

the

light

is

all

that

is

involved.

data

Reset

and

possible

data

However,

be

restarted

is

reset

again.

light

is

out

step

not

indicate

on)

.

the

processing

the

INSTRUCTION

the

transfer

Program

actually

not

FROM

light

be

all

and

reset

has

The

unit

It

will

at

some

can

be

track

transfer,

incorrect.

is

the

parity

typed,

depress

to

character.

required.

last

TO

cycle,

on.

Depressing

is

necessary

If

is

in

make

to

correct

with

the

if

at

and

on)

.

of

step.

involved.

the

CYCLE

Start.

transferred

been

CYCLE,

on.

Depressing

that

reset

occurred,

accumulator

and

normally

previous

built

on

not

and

if

underlined.

space

correction

the

an

the

an

the

core

this

some

the

error,

unit.

cycle,

light

again

This

affected.

the

ma-

is neces-

instruc-

can

up

again.

it

is

the

FROM

involved,

error.

the

track

the

alter

across

machine

Check

unless

accumula-

magnetic-

inquiry

error

informa-

is

not

pos-

previous

accumula-

until

by

is

the

be

be

in-

an

All

the

has

of

by

the

following

must

dicated

2.

Depress

3.

Investigate

and

written

4.

If

tions,

program

mulation

5.

Investigate

cuted

duplicated.

punch a card,

Set

6.

and

Start

7.

File

Check

include

preceding

either

it

to

the

press

the

program

and

the

Reset

the

in

the

or

both

may

where

can

the

insure

For

Program

program

program

Stop

Console Indication:

1.

Processing

File

2.

Check

Stops

light

Cause:

Record

just

data

on

NOTE:

and

will

the

process

on

every

Restart

1.

Depress

2.

Depress

3.

If

typing

that

the

re-entered

at

storage.

Feed

stored

drum.

Accumulator

always

panel

file

write

Procedure:

Check

Program

the

error

out

is

the

source

error

condition

on

an

instruction

Check

cause a File

persists,

the

Stop

Console Indication:

1.

Processing

2.

Feed

Check

Stops

light

Cause:

Misfeed

leave

should

Restart

1.

2.

3.

4.

5.

6.

Read

in

and

arrive

affect

Procedure:

Depress

Remove

Remove

Run

out

Process

Runout

Restart

by

card

failed

unit)

in

processed.

Depress

Check

the

only

Reader

the

any

the

placing

to

front

the

Stop

Console Indication:

1.

Processing

2.

Read

Stops

Check

step.

at

also

program

wrong

be

begin

etc.

are

operation.

Reset.

the

card

at

one

cards

jammed

remaining

feed

Reader

light

Therefore,

least

the

the

preceding

key,

not

TO

address

place.

of

these

necessary

the

accumulator

again.

program

that

information

example, a slide

Selector

set.

by

depressing

(Red

Stop

on.

on

disk

read-out

not

wired, a File

Start.

the

disk

storage

of

the

has

drum

that

will

(Red

Light

on.

reader. A check

each

feed

card

that

Stop.

from

cards

key.

the

last

from

of

the

remaining

Start

(Red

Stop

on.

step

on

step.

the

Check

track

step

to

steps

are

to

restart

steps

which

to

start

light

file

does

and

reset

Check

stop.

information

record

record

being

been

corrected,

track

and

transfer

on)

station.

has

not

the

feed

from

cards

by

three

the

feed

key

to

light

the

restart

which

Reset.

of

both

be

sure

accumulator

at a position

is

reset

are

will

not

operation,

at

the

Program

on)

.

not

agree

to

the

If

the

Check

can

and

the

transferred.

the

the

program

the

.

is

made

Therefore,

been

hopper.

the

feed.

depressing

cards

(two

hopper

cards

run

the

on)

.

procedure

the

error

the

error

data

was

and

the

to

be

re-exe-

be

lost

feed a card,

restart

Start.

with

file is

invalid

FILE

hubs

stop

will

be

retained

drum

data

can

restarted

record

to

as

the

any

processed.

the

cards

into

the

that

are

cards

in.

is

in-

step

not

opera-

in

the

accu-

or

point,

source

on

occur

by

track

After

be

disk

cards

jam

Non-

if

the

feed

to

be

8 IBM RAMAC

305

Page 8

Cause:

An

error

in

Restart

1.

Depress

2.

Remove

3.

Depress

NOTE:

of

4.

The

not

of

depress

reader.

reading

Procedure:

Reader

the

Non-Process

The

the

deck

last

three

processed;

the

remaining

the

cards

card

in

the

therefore,

Reader

or

Stop.

in

error

stacker,

cards

cards

recoding

from

Runout

to

Start

the

is

the

after

run

place

that

feed

are

Key

the

to

third

the

out

these

input

hopper.

clear

cards

of

to

to

run

the

card

the

three

be

processed.

Interlocked Track (Input or Output)

Console

Cause:

track

it

Restart

Indication:

1.

Processing

Interlock

2.

3. Select

Punch

Programming

before

has

called

Print

or

Procedure:

1.

Determine

cards

depress

2.

If

the

dition:

a.

Depress

interlocked

b.

Process

ure

Stops

light

light

for

or

Type)

has

the

last

for a transfer

Punch

operation

if

or

paper.

the

corresponding

interlock

the

through a normal

as

described

PRINTER

(Red

on.

interlock

.

called

for a transfer

feed

operation

to

is

the

interlock

If

so,

replenish

is

due

to

console

instruction.

Check

in

Console

Stop

light

device

the

output

completed.

is

due

input

an

input

Reset

track

Operating

ERRORS

on)

.

on

(Reader,

to

has

been

track

to

running

the

cards

or

output

or

output

key

investigation

card.

feed

from

the

are

run

machine

cards

in

cards

into

or

from

completed,

before

or

paper

Start

error

to

drop

Procedures.

station.

back

out.

were

front

Then

the

Printer,

the

or

the

last

out

of

and

key.

con-

out

the

proced-

a.

Try

2.

Repeat

NOTE:

Print

of

b.

If

track

c.

If

line

during

may

line

NOTE:

instances

A-N.

a.

At

for

sary.

b.

The

set

printing

the

the

the

may

have

typing.

Stop.

the

deltas,

Check

key

the

Switch.

If

the

Repeat

printer

switch

MLP.

error

appears

(see Console

document

be

crossed

future

use

to

be

Reprocessing

because

end

of

the

and

make

light

on

the

printer

line

must

Operating

is

for

out

of

the

redone

of

run,

manual

will

again

is

in

again,

internal

or

document.

either

will

file

updating.

examine

remain

is

depressed.

by

depressing

an

MLP

be

depressed

investigate

Procedures).

all

delta

by

not

be

the

corrections

on

operation,

for

the

purposes,

lines

disregarded

Other

practical

output

where

the

documents

documents

Check

reprocessing

until

the

each

output

the

in

Print

line

error

or

off-

most

neces-

Re-

the

Form Light

K

Console

Printer

Cause:

Restart

Indication:

1.

Processing

tion

(Red

2.

Interlock

3. Select

Printer

Indication:

Form

light

Botton

of

Procedure:

1. Successive

the

printer

the

last

2.

Insert

new

3.

Depress

stops

Stop

light

light

on.

last

form

depressions

to

print

form.

forms

the

printer

on

light

on.

is I

and

the

next

on)

on.

Y2

of

another

align

Start

transfer-to-Qutput

.

inches

from

the

printer

line

in

to

first

key.

print

Start

order

printing

key

to

stick.

will

complete

line.

instruc-

cause

Print Check Error (Parity or Print Setup Error)

Console

Printer

Cause:

Restart

Indication:

Depends

1. A

-N.

~2.

A

-Stop

a.

Processing

struction

b.

Interlock

c. Select

Indication:

1.

A-N.

a.

Check

b.

Delta

c.

Printer

2.

A-Stop.

a.

Check

b.

Delta

c.

Printing

3.

Stop:

1. A parity

output

2.

The

print

Procedure:

1.

A-Stop

on

Stop:

or

Stop.

Same

track

and

printer

No

Stop.

stops

(Red

light

Printer

light

printed

continues

light

printed

stops

as

error

to

stick

Stop.

control

console

on

Stop

on.

light

on.

in

the

on.

in

the

after

A-Stop,

was

sensed

the

may

Depress

panel

indication.

the

light

on.

left

to

print.

left

the

but

printer.

not

have

wiring.

next

transfer-to-output

on)

.

margin

margin

error

line

no

delta

during

the

been

Printer

of

the

of

the

is

is

printed.

transfer

set

Check

line

in

line

in

completed.

from

up

properly.

Reset

error.

error.

key.

in-

the

PUNCH

Punch-Parity Error Stop

Console

Punch

Cause:

cluding

check.

Restart

again.

cedures

Restart

Indication:

1.

Processing

tion

2.

Interlock

3. Select

Indication:

1.

Punch

Parity

2.

One

or

those

Procedures:

In

general,

If

may

Without

1.

Depress

2.

Read

track

will

3.

Depress

stops

(Red

Stop

light

Punch

stops

light

more

of

not

the

the

error

be

used.

the

the

output

are

typed,

be

automatically

Program

on

light

on.

light

on.

at

the

on.

the

100

being

operator

continues,

Clearing

380

Console

track.

and,

Start.

the

on)

end

positions

punched)

should

the

All

if

underlined.

ERRORS

next

transfer-to-output

.

of

the

punch

of

the

failed

try

either

of

Feed - Correct

Check

Reset

100

characters

the

track

contains

REFERENCE

cycle.

-output

to

to

punch

the

key.

track

pass

the

the

following

Later

on

the

an

SUMMARY

instruc-

parity

card

pro-

output

error,

(in-

it

9

Page 9

4.

Remove

finding

Reset

stacker

manually.

Correct

1.

Depress

Read

2.

3.

After

4.

Type

5.

Depress

completed.

6.

Depress

7.

Depress

8.

Remove

press

cards

9.

Remove

into

lO.

Place

input

first

output

programming

Punch

Console

1.

Processing

tion

Interlock

2.

3. Select

Punch

Feed

Cause:

Full

Restart

A.

Empty

I.

Place

stacker.

2.

Depress

B.

Feed

1.

Remove

2.

Depress

3.

Remove

will

this

4.

Replace

sary, a

5.

Depress

C.

Feed

I.

Remove

2.

Remove

the

cards

the

error

and

Start

is

the

the

Error,

then

the

380

the

output

the

full

track

any

corrections

the

Clear

the

Write

Program

the

cards

the

Punch

out

of

the

the

error

the

stacker.

the

last

deck

if

card

in

on a run-in

track

information

proceeds.

Feed-Check

Indication:

stops

(Red

Stop

light

Punch

light

Indication:

Check

light

stacker,

an

empty

Procedures:

Hopper

cards

in

the

Punch

Failure-Misfeed

cards

Start

key

the

be

card

Failure -to

last

repunched

is

retained

the

unpunched

gangpunch

the

Start

the

cards

any

damaged

from

the

card,

and

keys.

in

The

error,

card

Restart

Console

track.

has

been

that

key

after

key.

Start.

from

the

Check

Reset

machine

card,

which

correct

gangpunched

punched

is

Stop

on

the

next

light

on)

on.

on.

on.

hopper,

or

Full

Stacker.

the

hopper

Start

from

from

hopper.

to

clear

punched

because

on

the

master

key.

Feed

Into

from

cards

punch

depress

second

and

it

Check

Reset

typed,

depress

are

required.

the

last

323

Punch

key.

with

the

will

card

data

must

not

punched.)

punches

.

key.

cards

card

the

into a new

transfer-to-output

or a feed

or

remove

Hopper.

feed.

card.

The

the

information

output

in

the

precedes

Punch

Brush

hopper.

and

clear

stacker

the

punch

card

to

may

be

key.

the

correction

hopper,

Run

the

Start

key.

be

the

in

front

be

saved.

The

failure.

cards

last

punched

track.

hopper.

these

Station.

the

to

facilitate

Check

reach

corrected

Alter

has

been

and

remaining

second

of

(The

corrected

card

instruc-

from

concerning

If

neces-

cards.

feed.

the

key.

de-

card

the

and

the

card

3.

Remove

aged

because

on

4.

Replace

punch

5.

Depress

DPBC

Console

1.

Processing

tion

Interlock

2.

3. Select

Punch

DP & BC

the

card) . The

the

the

output

the

master

the

Error

Stop

Indication:

stops

(Red

Stop

light

Punch

Indication:

light.

information

Start

Cause:

Either a double-punch

has

occurred.

in

error

indicate

an

error

Restart

If

the

reconstruct

been

replaced

This

can

processing

In

some

the

output

cycle.

and

correct

If

the

must

be

Two

are:

No

Gangpunched

I.

Depress

2.

Depress

be

depressing

corrected

Gangpunched

1.

Remove

2.

Depress

3.

Depress

into

ually.

punched

4.

Place

master

with

When

has

passed

that

either

occurred

Procedures:

output

the

on

usually

drum

cases

it

data

Then

the

the

DPBC

cleared

methods

the

the

resumed.

Field

the

Check

the

the

stacker

The

on

the

gangpunch

the

Start

punching

output

the

be

tracks,

may

on a working

operator

card

stop

and

for

punch

the

manually.

second

last

last

punched

last

track.

cards

card

key.

on

light

on.

light

this

the

the

in a gangpunched

output

accomplished

be

manually.

was

the

restarting

Fields

punch

The

Start

Checked

cards

Reset.

Start

is

the

run-in.

correct

key.

card

punched

concerning

in

the

hopper.

precedes

the

next

on)

.

on.

or a blank-column

type

of

punch

brush

output

punching

is

at

because

or

fault,

the

track

by

checking

desirable

track

can

investigate

caused

operation

the

METHOD

Checked

Check

Reset

Start

key.

first

card

key is

the

METHOD

for

from

the

key

to

clear

in

error

card

and

is

not

card

information)

The

first

(this

may

card

will

be

this

card

If

these

transfer-to-output

error

with

by

I

for

to

necessary, a

cards.

is

signaled,

station.

is

incorrect,

field.

it

may

information

the

by

succeeding

investigating

the

printed

to

carry,

for

punch

in

one

additional

the

gangpunching,

restarted.

after a DPBC

DPBC

key.

Continuous

reach

the

card

in

error.

error

The

be

working

operation

2

DPBC

feed

hopper

the

feed.

error,

and

in

The

be

corrected

but

of

the

run

is

not

in

card

must

in

front

be

the

repunched

is

retained

instruc-

(or

the

error

necessary

in

error

the

document.

the

program,

the

stacker

It

must

and

stacker.

first

will

deck

the

cards

punched.

dam-

gang-

both)

card

can

or

that

to

has

record.

file

or

punch

track

feed

stop

will

after

be

card

man-

be

re-

(for

in

10

IBM RAMAC

305

Page 10

Control Panel Summary

EACH

under

SECTION

which

of the control panels is assigned a number

the

hubs are briefly described. Shaded areas indicate

special features.

Process Control Panel (Figure 1)

1.

Program

corresponding program exit occurs

is used to make tests on the control panel, and to transfer

program control to the first step

When

and

must

pulsing

When

lower exit hubs

hub

was impulsed last.

2.

Dual

Dual

Access operation.

to the SEL (select) hub, the access arms operate

sequence mode.

o

(zero)

Delay

or

CI

(control

switch.

Record Advances, Skip-To-Record, and R instructions until the

other

access

wired

to

function

DPIS

3.

hub

of

it

suspends the interlock

until the arm

address.

panel, it suspends the interlock for both systems; however, only

the system initiating the suspension can re-establish

by impulsing

tems, the

When

instruction causes a file check. A light on the console

system indicates

4.

ALC

plugged

and

the last card has passed the second reading

card reader

key, and feed

depresses the Start key, the last card selector transfers.

If

the ALC switch is plugged, the card reader

for one additional cycle before stopping.

cycle the last card selector transfers,

that

have been programmed utilizing the last card selector can be

completed.

ing

the

Inquire.

5.

jackplugged if manual inquiries to the disk records are to be

allowed

The

console to take control

not

countermand the stored program instructions.

interlock is

Exits. These hubs emit an impulse whenever the

in

an instruction.

of

one

of

these hubs emits, the program sequence is halted,

a new sequence

The

of

instructions.

be restarted by impulsing program advance

program entries.

Program Exit Split

of a group

is

installed, either the upper

will emit depending on which control

Access. These hubs provide control over the mode of

When

the C

(common)

With

the C

hub

or

1 hub may be impulsed from a Program Exit, Cycle

any

other

impulse originating on the 305 panel, except

impulses),

The

corresponding access

unit

hub

access

of

the

is impulsed.

unit

Process

the

other

PU

hub

either

as

a single access system using this unit.

(Dual

DPIS

is impulsed by either system

When

wired to the SEL hub, either the

and the

upper

unit

If·

(0

the C

or

Suspend).

hub

Interlock

that

prevents reading

system has moved from this same

is impulsed on one process control

hub is not wired

in

the automatic

hub

of

the Inquiry

will then accept all

hub

1)

is permanently

the system will then

When

in

Dual

System Control,

or

writing

the

the

DO hub.

DO

hub

on both process control panels must be impulsed.

a system impulses

when

(Automatic

(when

the cards have

If

PU

has been impulsed

PU,

it

cannot write in the file; a write

on

the interlock is suspended for that system.

Last

Card).

If

run

the ALC switch is

out

of

the card reader hopper,

brushes),

will

stop.

The

operator may depress the Reader Start

the

last cards to the stacker.

Just

after the operator

will

During

this additional

and

any last-card routines

The

cards may then be fed into the stacker by depress-

Reader Start key.

The

pair

of

during

processing.

IN-OUT

hubs form an interlock

hubs marked

of

the access arm

ON

form a switch that is

that

is wired to allow the

at

a time

when

The

wired

in

the program

at a point

where

the

impulse

or

by im-

or

ON

the

PU

a record

interlock

both sys-

of

each

not

the

feed cards

it

will

inquire

access arm

has completed its use

moved by the program, no harm will be done

of

the record.

If

the arm is about to be

if

moves the access arm to some other record to make an inquiry.

When

the record has been obtained

for

the operator, the stored

program resumes control and moves the arm to the next record

required.

A

program

from

sole

or

the

OUT

6.

to make inquiries to the disk records

typewriter may also be used as a secondary

dressing the

control panel (see item

the

OUT

is

delayed

hub

ITI

(Inquiry-Type

output

exit

wired

into

the

IN

hub

is

if

if

wired

no

inquiry

an

inquiry

to

initiate

Interlock).

has

is

the

hub

been

set

The

as

record to Q track and impulsing

33).

If

both

of

emerges

set

up

up.

The

next

impulse

program

typewriter may be used

described in item 5.

output

these uses occur in the

same program, the inquiry-type interlock must be jackplugged to

prevent an inquiry from taking place while the typewriter is under

program control.

7.

File

grams may be tested

disks.

When

to allow

writing

A write operation

J,

8.

Accumulator

Interlock.

the

on the disks may be performed

This interlock is provided so that

without

changing the information

a program has been checked out, this switch is wired

disk records to be changed. All operations except

with

will

cause a file check.

the interlock off.

Sign. Each accumulator has an associated

selector that shows its sign. By using a program exit impulse, a

test may be made to determine

at zero,

or

is negative.

Accumulator

9.

Overflow.

if

an accumulator is positive, stands

Whenever

an accumulator over-

flows (tries to accumulate a number beyond its capacity), a

is established between each

remain set

out

IN

dropped

of

up

until

by impulsing DO. A normal

hub and the corresponding

out

or

when no overflow has occurred.

Character

10.

Selectors

analyzing any character on a

analyzed is entered into this

(-99)

as

the

TO

address. Any character entered establishes test

paths between each

IN

hub

the

accumulator overflow selector is dropped

..

IN

hub

and its YES hub.

path

is established between the

NO

hubs

when

The

character selectors provide a way

drum

track.

unit

by an instruction

The

and the exit hubs corresponding to

the character entered.

Four

distinct

paths

are set

up

on the basic machine.

the paths are arranged so that a test impulse entered into

hub

emerges from

of

the character being tested.

into the

IN

the

specific letters, numbers, and special characters

blank).

The

the

hubs corresponding to the

In

hub

emerges from one

the fourth path, an impulse wired

of

the 48 exit hubs representing

test paths remain set up until another character is

addressed to the unit.

The

special feature X

analysis

for

the presence

no-X

or

and 0 no-O

absence

of

these bits

bit

selectors provide

in

sent to the character selector.

Blank

11.

struction causes

NO

condition.

during

selector

the

380 Console will be

ferred

Transmission.

the

If

the information transferred

the execution of the instruction is all zeros

will

transfer to a YES condition and the

and

the

light

will remain on until another instruction

A 6

in

the tenth position

Blank Transmission selector to reset to a

from

the core storage

turned

on.

The

selector will remain trans-

BLANK

a 6 is read.

the operator

immediately

at

the

con-

from

step.

The

printer

by ad-

TYPE

on the

new

pro-

on

the

path

These

paths

the selector is

position to be

with

hyphen

Three

of

the

IBM

IN

card code

(including

the character

of

an

in-

or

blanks, the

light

on

with

REFERENCE

SUMMARY

11

Page 11

T

: I I I I I I I I

c~~~~~~~~~~~

: ;

;~;

F 8

; ;

tIl

I I i I

;~;

; ;

;'~;

! ;

;~;

(T11J

; ;

r I I I I I I ! I i I

;:~;-~"':'

I':;

! !

I':;

! !

Iii

I:;

; ;

I i I

,

;:;

: I 101 I I 101 I I 101 I I 101 I I 101 I 101 I I 101 I I 101 I I 101 I

: I

I-I

I I

I-I

III

I-I

I I

I-I

AO/FLOW

LOIN

1

M

NO

N 9

P I I I

YES

Q

r

I 2

0 0 I

(bI

0---0-------0-0---0-------0--

G H I J K L M

0 0 0 0 0 0 0

N 0 P Q R S T

ooooooo~o--:---o:::Nt::D-'-'-<)()--"-<)

u v w x y z

0 0 0 0 0 0

'0·

I 2 3 4 5 6

0 0 0 0 0 0 0

I r l-I I I

12

()-'-=-(J

11

o-f!-o

o--!-o

o-!!:-o

4

Q---'--O

5

~

0--1-0

I-I

CHARACTER

o--!!!-o

12

0--.:-=-0

II

0

o---!-o

I I

o-!b..o

4

0--'-0

5

10

o-!-o

o-l-o o-l-o

I-I

SELECTORS

o--!!io

12

~

II

0--2-0

o.!ho

4

Q--'-O

5

o--!-o

o-I-o

I I

I-I

I I

I-I

I I

[~

1101 I

I-I

I

I 2 3 4 5 6 7 8 9

:

f!

: : :

~~!,:

AM

10

0 0 0 0 0 0 0

41_45-IN

::

1111111111

1

AQ

0 a 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

AR

10--0------0----

::

IillrTITI I I I I I 9rill

8M

10

II

12

13

14 15 16

17

18 19

20

21

22

23

24 25

26

27 28

29

30

31

32 33

: : : :

0ffiit0

26

OUT OUT

I

0------0--0----

OUT

'!~!m~'"r:

0 0 0 0 0

55-DISTRIBUTORS-65

GOO

: : :

'!

0 0 0

0tf1t0

: : : :

'f~

0 0 0 0 0 0 0 0 0 0 0 0 0 0

26

70-IN

111111111111111 111111111111

I

~

I I I I

I

0----0------0-0

1

0------0-0-----1

34

35

36

J,:

: : ! : I

37 38

39

40

B~

8R

Figure

12

IBM RAMAC

305

1.

305 Process Control Panel

Page 12

12. Last Card. This selector is used to control machine opera-

tion on the run-out. Normally, a path exists between each

and the

NO

hub beneath it.

When

the cards have

run

IN

hub

out of the

card reader hopper, and the last card has passed the second reading brushes,·

depress the Reader

After the

if

no more cards are to be entered, the operator may

Start key and feed the last cards to the stacker.

Start key has been depressed to initiate an additional

feed cycle, the last card selector transfers. The program control

may be wired through this selector to control the last card routine.

13. Compare. This selector stores the result of the last programmed comparison. A path

the

=

(equal)

hub beneath it whenever the two fields are exactly

equal, and between the

is

set up between each

IN

hubs and their

=I=-

(not

equal) hubs

IN

hub and

when the two fields fail to compare. These paths remain set up

until another programmed comparison is made.

14.

Field

allow,

with

one instruction, from one to ten fields on the track

specified by the

the fields of a track specified by the

may refer to a process drum track, a disk track,

Compare.

The

TO

address may specify any process drum track other than

the accumulator track. Neither the core

be used

as

the

TO

of the instruction to cause automatic field comparing.

The

field compare device is provided to

FROM

address to be individually compared

TO

address.

The

FROM

or

the core unit.

unit

nor the disk file may

with

address

address. A 2 code is placed in the tenth position

The

results

of a field comparison will be indicated in the ten selectors associated with the field compare device.

15. Communication. These hubs are connected to the cor-

respondingly numbered hubs of the communication section on

the printer, console

(TW),

and punch control panels, they allow

for signal communication between the machine units.

16. Start.

When

the first input card after any run-out except

non-process run-out has been read and checked, an impulse

emitted from this hub. This impulse is used

in

the same manner

as a Program Exit impulse to start the stored program at the desired instruction.

17.

CI

(Control

Impulse).

Two buttons are provided on the

operator's panel at the console to allow a control impulse to be

emitted on the control panel. This allows the operator to pick up

or

drop out selectors,

or

initiate other functions from the console.

These impulses are emitted from the correspondingly numbered

CI

hubs on the control panel.

18. Skip-To-Record.

When

one of the numbered hubs associated with Skip-To-Record is impulsed, the access arm remains on

the same disk and track,

so

that the units position of the disk address corresponds to the

but

the disk address register

is

advanced

number of the hub impulsed.

After the corresponding address has been

register, the

OUT

hub emits.

This

impulse

set

up in the address

is

wired to restart the

program. Normally, this device will be used in conjunction with

field compare.

19. Copy.

automatically transfers the contents of the

of

the program storage tracks.

instructions, this records instructions

hub

may be impulsed from the

When

an impulse that

Usually

20.

group

21.

When

the

copy

IN

hub is impulsed, the machine

If

the

input

190-197

START

hub.

the transfer to track I is completed, the

is

wired to start the stored program at any step.

it

is wired to start the program

Reset.

When

impulsed, this hub causes the corresponding

of

ten selectors to be dropped out.

Alteration.

A row of switches on the operator's panel at

at

input

track to track I

card is punched with

on

track

I.

The

OUT

hub emits

step 190.

IN

the console is provided to allow various changes to be made in

the program setup by changing the settings of the switches.

On

the control panel, these switches are wired in a manner similar to

selectors. Program exit impulses wired into the

from the

responding toggle switch

from the

may be used for control functions, such

of selectors.

from the

N

(normal)

T (transferred) hub if the toggle switch is transferred.

22.

Cycle Delay. These units provide a delayed impulse that

hub

of

the same vertical row

is

in

the normal position. They emerge

as

An

impulse wired into the cycle delay

OUT

hub thirty milliseconds later, where

IN

the pickup and dropout

IN

up or drop out selectors after the control impulse has ended.

Whenever Cycle Delay

vanced by the delayed

hubs may be located at

is

impulsed, programming must be ad-

OUT

impulse. Additional Cycle Delay

AF-AH,

6-20

if

Input

Analysis selectors

are not installed.

23. Analysis Selectors. These selectors analyze designated

input card columns for specific codes. Two

to each selector.

One

PU

hub

is

PU

hubs are connected

wired from the

Control Exit to be tested for the code; and the other hub

wired from the CARD CODE to be detected.

When

receive the same digit impulse, the selector transfers and remains

transferred until the next feed card instruction. A blank column

PU

can be detected by wiring both

TRACK

CONTROL

EXIT;

transmission of any card code causes the

hubs from the same

selector to transfer.

24.

Selectors. Latch-type selectors are furnished to provide for

storage and control of operations. Each selector position has a

COMMON,

connected to the

impulsing the

to the

Group

Selectors and Isolators are

is

address register one sector per impulse. This feature

NORMAL,

TRANSFERRED

D selectors may be added at BG-BR, 11-20 if

25.

Record Advance. These hubs advance the address in the

NORMAL

PICKUP

and

TRANSFERRED

hub until the selector

hub.

Then

the

hub until the