Page 1

BladeCenter QS22 Ty pe 0793

Problem Dete rminatio n and Service Guid e

Page 2

Page 3

BladeCenter QS22 Ty pe 0793

Problem Dete rminatio n and Service Guid e

Page 4

Note

Before using this information and the product it supports, read the general information in Appendix C, “Notices,” on page 127

and the Warranty and Support Information on the Documentation CD.

Fourth Edition (October 2008)

© Copyright International Business Machines Corporation 2006, 2008.

US Government Users Restricted Rights – Use, duplication or disclosure restricted by GSA ADP Schedule Contract

with IBM Corp.

Page 5

Contents

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Chapter 1. Introduction . . . . . . . . . . . . . . . . . . . . . .1

Related documentation . . . . . . . . . . . . . . . . . . . . . .1

Notices and statements used in this document . . . . . . . . . . . . . .2

Features and specifications . . . . . . . . . . . . . . . . . . . . .2

Support for storage . . . . . . . . . . . . . . . . . . . . . . . .3

Turning on the blade server . . . . . . . . . . . . . . . . . . . . .4

Turning off the blade server . . . . . . . . . . . . . . . . . . . . .4

Blade server controls and LEDs . . . . . . . . . . . . . . . . . . .5

System board LEDs . . . . . . . . . . . . . . . . . . . . . . .6

System board internal and expansion card connectors . . . . . . . . . . .7

Chapter 2. Configuring the blade server . . . . . . . . . . . . . . .9

Communicating with the blade server . . . . . . . . . . . . . . . . .9

Using the Advanced Management Module . . . . . . . . . . . . . .9

Using the Web interface . . . . . . . . . . . . . . . . . . .10

Using the command-line interface . . . . . . . . . . . . . . . .10

Using Serial over LAN . . . . . . . . . . . . . . . . . . . . .10

Using the serial interface . . . . . . . . . . . . . . . . . . . .11

Using the SMS utility program . . . . . . . . . . . . . . . . . .11

Starting SMS . . . . . . . . . . . . . . . . . . . . . . .11

Viewing FRU information . . . . . . . . . . . . . . . . . . .12

Adding FRU information . . . . . . . . . . . . . . . . . .13

Updating the system and BMC firmware . . . . . . . . . . . . . . .15

Updating steps . . . . . . . . . . . . . . . . . . . . . . . .16

Determining current blade server firmware levels . . . . . . . . . . .16

Updating the BMC firmware . . . . . . . . . . . . . . . . . . .17

Using the BMC update package . . . . . . . . . . . . . . . .18

Using the Advanced Management Module . . . . . . . . . . . . .18

Installing the system firmware . . . . . . . . . . . . . . . . . .20

The firmware update package . . . . . . . . . . . . . . . . . .20

Using the package . . . . . . . . . . . . . . . . . . . . .21

Updating the system firmware automatically . . . . . . . . . . . .21

Installing the firmware manually . . . . . . . . . . . . . . . . . .21

Updating the system firmware images . . . . . . . . . . . . . . .22

Updating the optional expansion card firmware . . . . . . . . . . . . .23

Integrating the Gigabit Ethernet controller into the BladeCenter . . . . . . .23

Updating the Ethernet controller firmware . . . . . . . . . . . . . . .23

Using the update package . . . . . . . . . . . . . . . . . . . .24

Firmware update steps . . . . . . . . . . . . . . . . . . . . .24

Blade server Ethernet controller enumeration . . . . . . . . . . . . . .25

Chapter 3. Parts listing . . . . . . . . . . . . . . . . . . . . .27

Replaceable components . . . . . . . . . . . . . . . . . . . . .27

Consumable parts . . . . . . . . . . . . . . . . . . . . . . . .28

Chapter 4. Installing and removing replaceable units . . . . . . . . .29

Installation guidelines . . . . . . . . . . . . . . . . . . . . . .29

System reliability guidelines . . . . . . . . . . . . . . . . . . .30

Handling static-sensitive devices . . . . . . . . . . . . . . . . .30

Removing the blade server from the BladeCenter unit . . . . . . . . . .30

Opening and removing the blade server cover . . . . . . . . . . . . .31

© Copyright IBM Corp. 2006, 2008 iii

Page 6

Removing the BladeCenter PCI Express I/O Expansion Unit . . . . . . . .32

Removing the blade-server front bezel assembly . . . . . . . . . . . .33

Installing the optional modular flash drive . . . . . . . . . . . . . . .34

Removing the optional modular flash drive . . . . . . . . . . . . . . .35

Installing an optional high-speed expansion card . . . . . . . . . . . .36

Removing an optional high-speed expansion card . . . . . . . . . . . .38

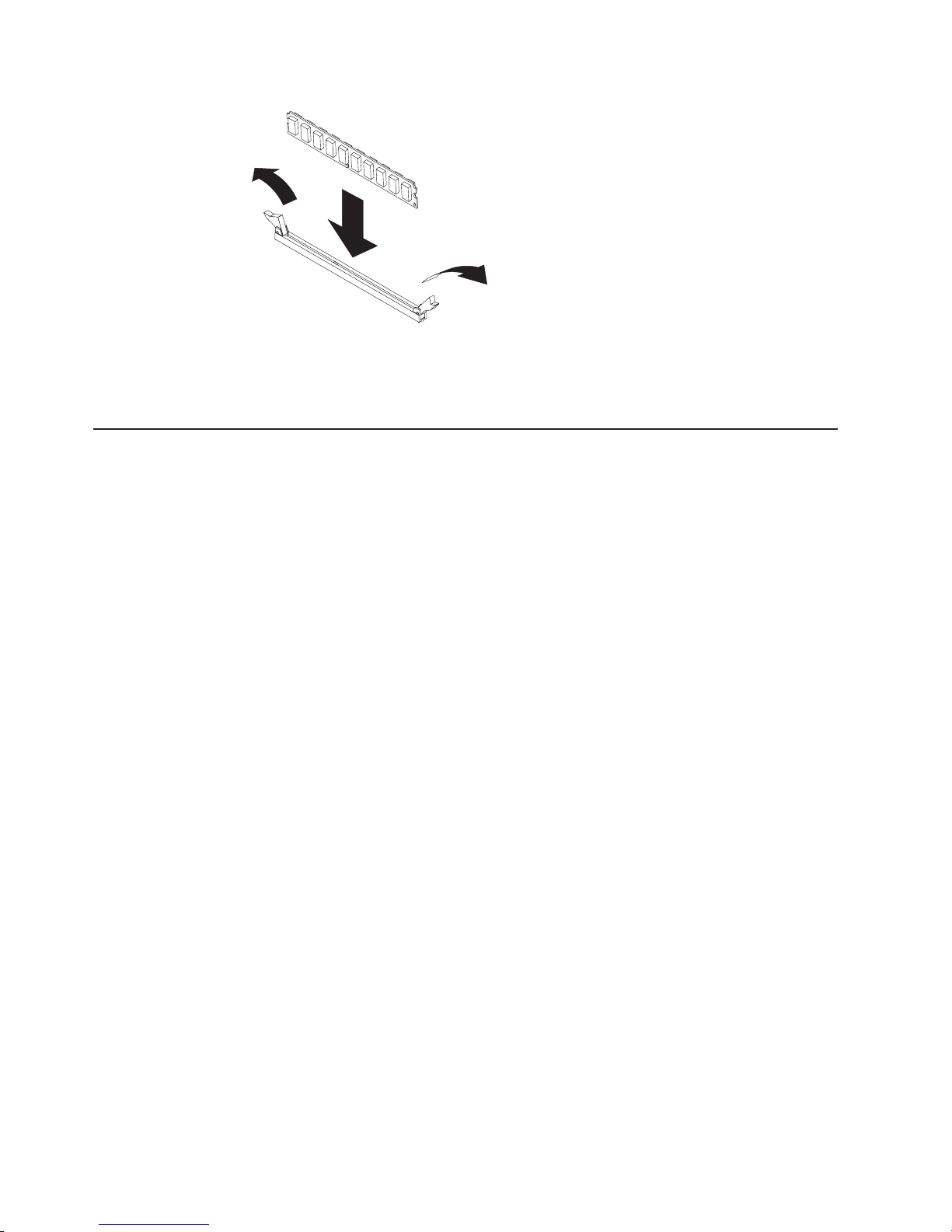

Adding or changing system memory . . . . . . . . . . . . . . . . .39

Adding or changing I/O buffer DDR2 memory modules . . . . . . . . . .41

Replacing DIMM fillers . . . . . . . . . . . . . . . . . . . . . .42

Installing the optional SAS expansion card . . . . . . . . . . . . . . .43

Installing the BladeCenter PCI Express I/O Expansion Unit . . . . . . . .44

Replacing the system board base and planar . . . . . . . . . . . . . .45

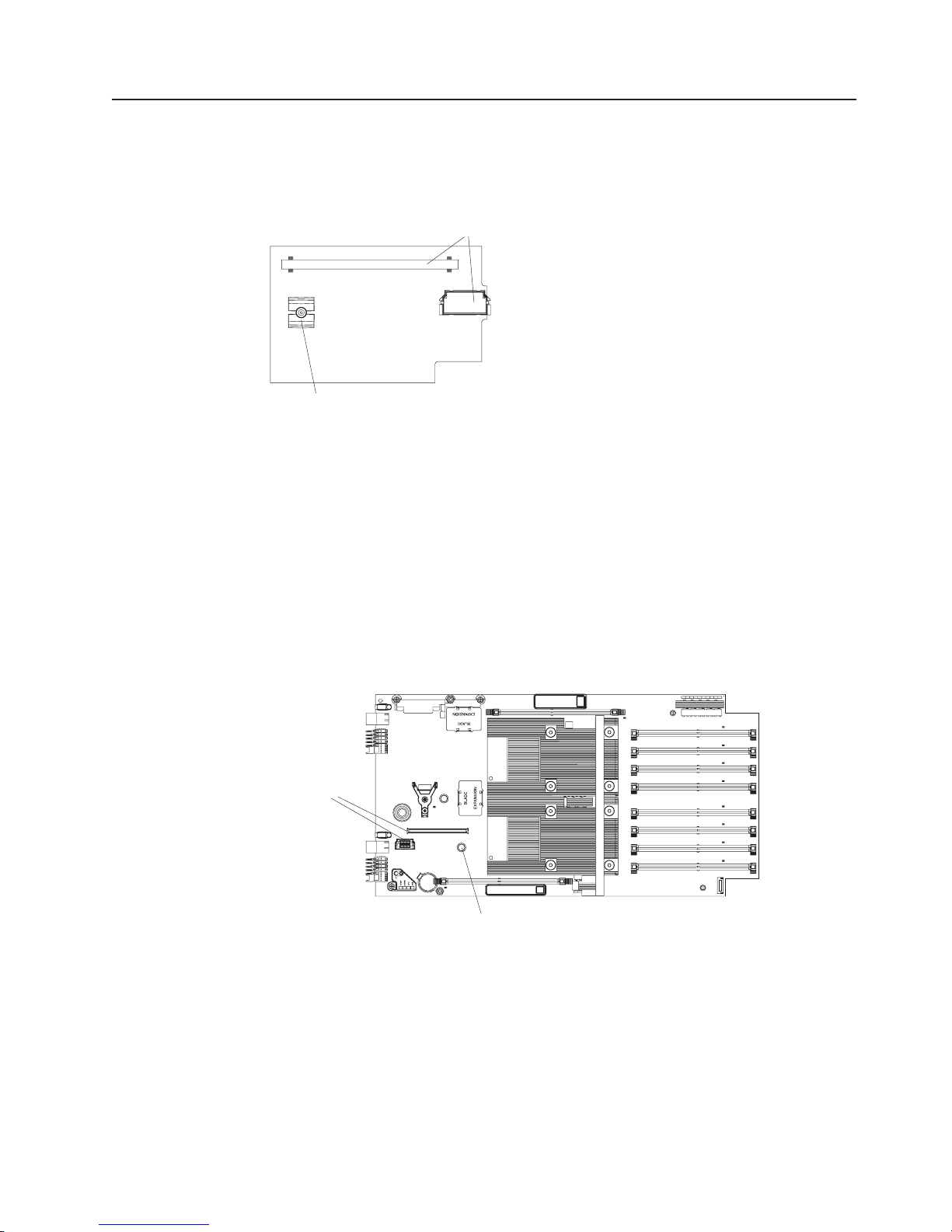

Replacing the battery . . . . . . . . . . . . . . . . . . . . . .46

Replacing the retention clip for the modular flash drive . . . . . . . . . .48

Using the miscellaneous parts kit . . . . . . . . . . . . . . . . . .49

Replacing the ball studs . . . . . . . . . . . . . . . . . . . .50

Finishing the installation . . . . . . . . . . . . . . . . . . . . .50

Installing the front bezel assembly . . . . . . . . . . . . . . . . .51

Closing the blade server cover . . . . . . . . . . . . . . . . . .52

Input/output connectors and devices . . . . . . . . . . . . . . . . .53

Chapter 5. Diagnostics and troubleshooting . . . . . . . . . . . . .55

Prerequisites . . . . . . . . . . . . . . . . . . . . . . . . . .55

Basic checks . . . . . . . . . . . . . . . . . . . . . . . . .55

Finding troubleshooting information . . . . . . . . . . . . . . . . .56

Troubleshooting charts . . . . . . . . . . . . . . . . . . . . . .56

Problems indicated by the front panel LEDs . . . . . . . . . . . . .57

Problems indicated by the system board LEDs . . . . . . . . . . . .58

Power problems . . . . . . . . . . . . . . . . . . . . . . .62

Power throttling . . . . . . . . . . . . . . . . . . . . . . .62

Network connection problems . . . . . . . . . . . . . . . . . .62

Service processor problems . . . . . . . . . . . . . . . . . . .63

Software problems . . . . . . . . . . . . . . . . . . . . . .63

Recovering the system firmware code . . . . . . . . . . . . . . . .64

Checking the boot image . . . . . . . . . . . . . . . . . . . .64

Booting from the TEMP image . . . . . . . . . . . . . . . . . .64

Recovering the TEMP image from the PERM image . . . . . . . . . .64

Supported boot media . . . . . . . . . . . . . . . . . . . . . .65

Booting the system . . . . . . . . . . . . . . . . . . . . . . .65

Diagnostic programs and messages . . . . . . . . . . . . . . . . .67

Running diagnostics and preboot DSA . . . . . . . . . . . . . . .67

Diagnostic text messages . . . . . . . . . . . . . . . . . . . .68

Viewing the test log . . . . . . . . . . . . . . . . . . . . . .68

DSA error messages . . . . . . . . . . . . . . . . . . . . . .69

CPU test results . . . . . . . . . . . . . . . . . . . . . . .69

BMC test results . . . . . . . . . . . . . . . . . . . . . . .69

Memory tests . . . . . . . . . . . . . . . . . . . . . . . .75

System firmware startup messages . . . . . . . . . . . . . . . . .76

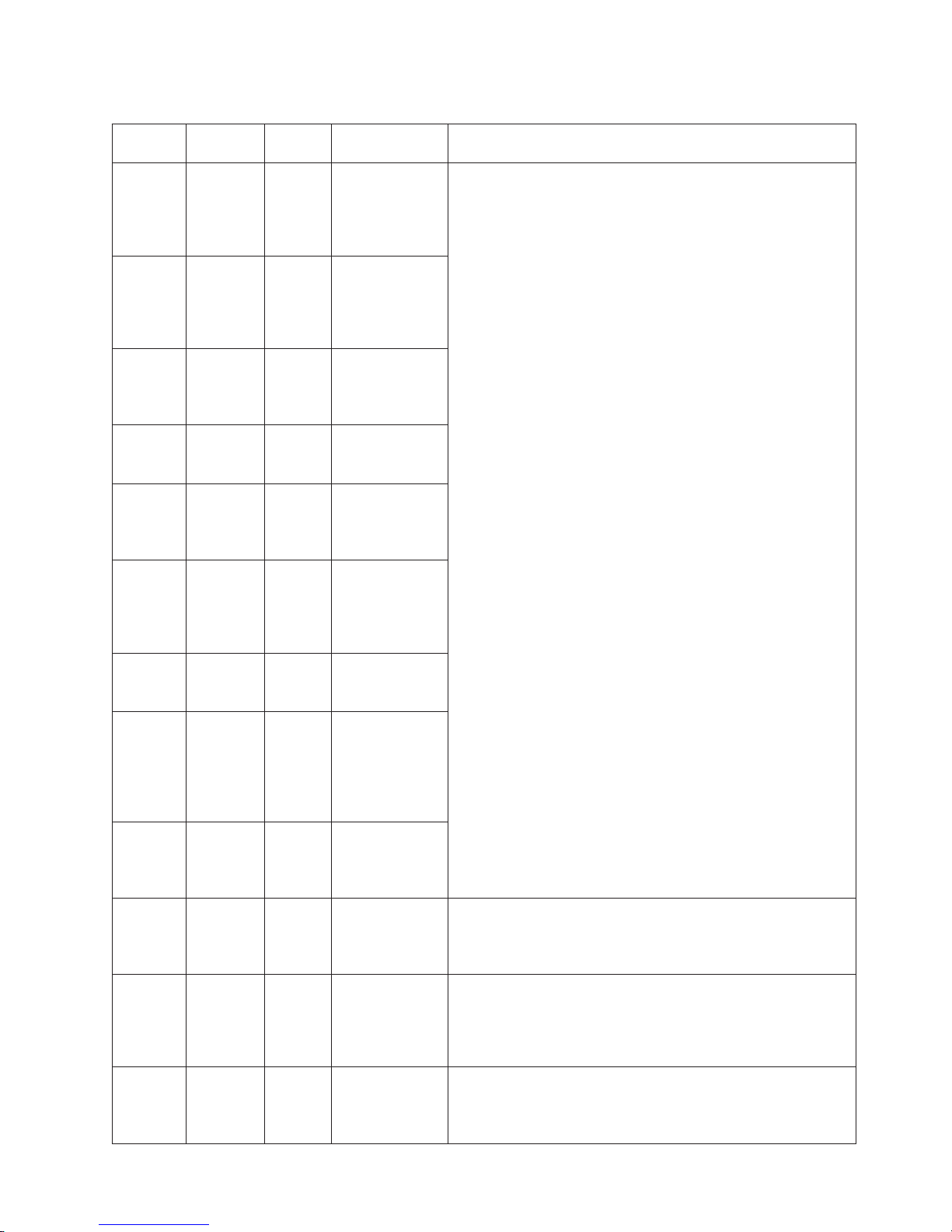

Checkpoints . . . . . . . . . . . . . . . . . . . . . . . . . .77

Boot errors and handling . . . . . . . . . . . . . . . . . . . . .77

Boot list . . . . . . . . . . . . . . . . . . . . . . . . . .77

System firmware update errors . . . . . . . . . . . . . . . . . .79

System memory errors . . . . . . . . . . . . . . . . . . . . .80

USB errors . . . . . . . . . . . . . . . . . . . . . . . . .83

Network boot errors . . . . . . . . . . . . . . . . . . . . . .84

SAS boot errors . . . . . . . . . . . . . . . . . . . . . . .86

iv BladeCenter QS22 Type 0793: Problem Determination and Service Guide

Page 7

I/O DIMM boot-time errors . . . . . . . . . . . . . . . . . . . .97

Other error messages . . . . . . . . . . . . . . . . . . . . .99

BMC firmware messages . . . . . . . . . . . . . . . . . . . . . 100

NMI error messages . . . . . . . . . . . . . . . . . . . . . 107

Problem reporting . . . . . . . . . . . . . . . . . . . . . . . 108

Problem description . . . . . . . . . . . . . . . . . . . . . . . 108

Solving undetermined problems . . . . . . . . . . . . . . . . . . 108

Calling IBM for service . . . . . . . . . . . . . . . . . . . . . 109

Appendix A. Using the SMS utility . . . . . . . . . . . . . . . . 111

Starting the SMS utility . . . . . . . . . . . . . . . . . . . . . 111

The SMS utility menu . . . . . . . . . . . . . . . . . . . . . . 111

Select Language . . . . . . . . . . . . . . . . . . . . . . .112

Setup Remote IPL (Initial Program Load) . . . . . . . . . . . . . .112

IP Parameters . . . . . . . . . . . . . . . . . . . . . . .113

Adapter Configuration . . . . . . . . . . . . . . . . . . . . .114

Ping Test . . . . . . . . . . . . . . . . . . . . . . . . . .115

Advanced Setup: DHCP . . . . . . . . . . . . . . . . . . . .115

Change SCSI Settings . . . . . . . . . . . . . . . . . . . . .115

Select Console . . . . . . . . . . . . . . . . . . . . . . .115

Select Boot Options . . . . . . . . . . . . . . . . . . . . . .116

Firmware Boot Side Options . . . . . . . . . . . . . . . . . .118

Progress Indicator History . . . . . . . . . . . . . . . . . . .118

FRU information . . . . . . . . . . . . . . . . . . . . . . .119

Adding FRU information . . . . . . . . . . . . . . . . . . . 120

SAS Settings . . . . . . . . . . . . . . . . . . . . . . . . 122

Appendix B. Getting help and technical assistance . . . . . . . . . . 125

Before you call . . . . . . . . . . . . . . . . . . . . . . . . 125

Using the documentation . . . . . . . . . . . . . . . . . . . . . 125

Getting help and information from the World Wide Web . . . . . . . . . 125

Software service and support . . . . . . . . . . . . . . . . . . . 126

Hardware service and support . . . . . . . . . . . . . . . . . . . 126

Appendix C. Notices . . . . . . . . . . . . . . . . . . . . . . 127

Trademarks . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Important notes . . . . . . . . . . . . . . . . . . . . . . . . 128

Product recycling and disposal . . . . . . . . . . . . . . . . . . 129

Battery return program . . . . . . . . . . . . . . . . . . . . . 130

Electronic emission notices . . . . . . . . . . . . . . . . . . . . 132

Federal Communications Commission (FCC) statement . . . . . . . . 132

Industry Canada Class A emission compliance statement . . . . . . . . 132

Avis de conformité à la réglementation d’Industrie Canada . . . . . . . 132

Australia and New Zealand Class A statement . . . . . . . . . . . . 132

United Kingdom telecommunications safety requirement . . . . . . . . 132

Deutschsprachiger EU Hinweis: Hinweis für Geräte der Klasse A

EU-Richtlinie zur Elektromagnetischen Verträglichkeit . . . . . . . . 132

Deutschland: Einhaltung des Gesetzes über die elektromagnetische

Verträglichkeit von Geräten . . . . . . . . . . . . . . . . . 133

Zulassungsbescheinigung laut dem Deutschen Gesetz über die

elektromagnetische Verträglichkeit von Geräten (EMVG) (bzw. der EMC

EG Richtlinie 2004/108/EG) für Geräte der Klasse A . . . . . . . . 133

European Union EMC Directive conformance statement . . . . . . . . 133

Taiwanese Class A warning statement . . . . . . . . . . . . . . . 134

Japanese Voluntary Control Council for Interference (VCCI) statement 134

Korean Class A warning statement . . . . . . . . . . . . . . . . 134

Contents v

Page 8

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

vi BladeCenter QS22 Type 0793: Problem Determination and Service Guide

Page 9

Safety

Before installing this product, read the Safety Information.

Antes de instalar este produto, leia as Informações de Segurança.

Pred instalací tohoto produktu si prectete prírucku bezpecnostních instrukcí.

Læs sikkerhedsforskrifterne, før du installerer dette produkt.

Lees voordat u dit product installeert eerst de veiligheidsvoorschriften.

Ennen kuin asennat tämän tuotteen, lue turvaohjeet kohdasta Safety Information.

Avant d’installer ce produit, lisez les consignes de sécurité.

Vor der Installation dieses Produkts die Sicherheitshinweise lesen.

Prima di installare questo prodotto, leggere le Informazioni sulla Sicurezza.

Les sikkerhetsinformasjonen (Safety Information) før du installerer dette produktet.

Antes de instalar este produto, leia as Informações sobre Segurança.

© Copyright IBM Corp. 2006, 2008 vii

Page 10

Antes de instalar este producto, lea la información de seguridad.

Läs säkerhetsinformationen innan du installerar den här produkten.

Guidelines for trained service technicians:

This section contains information for trained service technicians.

Inspecting for unsafe conditions:

Use the information in this section to help you identify potential unsafe conditions in

an IBM product that you are working on. Each IBM product, as it was designed and

manufactured, has required safety items to protect users and service technicians

from injury. The information in this section addresses only those items. Use good

judgment to identify potential unsafe conditions that might be caused by non-IBM

alterations or attachment of non-IBM features or options that are not addressed in

this section. If you identify an unsafe condition, you must determine how serious the

hazard is and whether you must correct the problem before you work on the

product.

Consider the following conditions and the safety hazards that they present:

v Electrical hazards, especially primary power.

v Primary voltage on the frame can cause serious or fatal electrical shock.

v Explosive hazards, such as a damaged CRT face or a bulging capacitor.

v Mechanical hazards, such as loose or missing hardware.

inspect the product for potential unsafe conditions, complete the following steps:

To

1. Make sure that the power is off and the power cord is disconnected.

2. Make sure that the exterior cover is not damaged, loose, or broken, and

observe any sharp edges.

3. Check the power cord:

v Make sure that the third-wire ground connector is in good condition. Use a

meter to measure third-wire ground continuity for 0.1 ohm or less between

the external ground pin and the frame ground.

v Make sure that the power cord is the correct type, as specified in the

documentation for your BladeCenter unit type.

v Make sure that the insulation is not frayed or worn.

Remove the cover.

4.

5. Check for any obvious non-IBM alterations. Use good judgment as to the safety

of any non-IBM alterations.

6. Check inside the blade server for any obvious unsafe conditions, such as metal

filings, contamination, water or other liquid, or signs of fire or smoke damage.

7. Check for worn, frayed, or pinched cables.

8. Make sure that the power-supply cover fasteners (screws or rivets) have not

been removed or tampered with.

Guidelines for servicing electrical equipment:

Observe the following guidelines when servicing electrical equipment:

v Check the area for electrical hazards such as moist floors, nongrounded power

extension cords, and missing safety grounds.

viii BladeCenter QS22 Type 0793: Problem Determination and Service Guide

Page 11

v Use only approved tools and test equipment. Some hand tools have handles that

are covered with a soft material that does not provide insulation from live

electrical current.

v Regularly inspect and maintain your electrical hand tools for safe operational

condition. Do not use worn or broken tools or testers.

v Do not touch the reflective surface of a dental mirror to a live electrical circuit.

The surface is conductive and can cause personal injury or equipment damage if

it touches a live electrical circuit.

v Some rubber floor mats contain small conductive fibers to decrease electrostatic

discharge. Do not use this type of mat to protect yourself from electrical shock.

v Do not work alone under hazardous conditions or near equipment that has

hazardous voltages.

v Locate the emergency power-off (EPO) switch, disconnecting switch, or electrical

outlet so that you can turn off the power quickly in the event of an electrical

accident.

v Disconnect all power before you perform a mechanical inspection, work near

power supplies, or remove or install main units.

v Before you work on the equipment, disconnect the power cord. If you cannot

disconnect the power cord, have the customer power-off the wall box that

supplies power to the equipment and lock the wall box in the off position.

v Never assume that power has been disconnected from a circuit. Check it to

make sure that it has been disconnected.

v If you have to work on equipment that has exposed electrical circuits, observe

the following precautions:

– Make sure that another person who is familiar with the power-off controls is

near you and is available to turn off the power if necessary.

– When you are working with powered-on electrical equipment, use only one

hand. Keep the other hand in your pocket or behind your back to avoid

creating a complete circuit that could cause an electrical shock.

– When using a tester, set the controls correctly and use the approved probe

leads and accessories for that tester.

– Stand on a suitable rubber mat to insulate you from grounds such as metal

floor strips and equipment frames.

Use extreme care when measuring high voltages.

v

v To ensure proper grounding of components such as power supplies, pumps,

blowers, fans, and motor generators, do not service these components outside of

their normal operating locations.

v If an electrical accident occurs, use caution, turn off the power, and send another

person to get medical aid.

Important:

All caution and danger statements in this documentation begin with a

number. This number is used to cross reference an English caution or

danger statement with translated versions of the caution or danger

statement in the IBM Safety Information book.

For example, if a caution statement begins with a number 1,

translations for that caution statement appear in the IBM Safety

Information book under statement 1.

Safety ix

Page 12

Be sure to read all caution and danger statements in this

documentation before performing the instructions. Read any additional

safety information that comes with the blade server or optional device

before you install the device.

x BladeCenter QS22 Type 0793: Problem Determination and Service Guide

Page 13

Statement 1:

DANGER

Electrical

current from power, telephone, and communication cables is

hazardous.

To avoid a shock hazard:

v Do not connect or disconnect any cables or perform installation,

maintenance, or reconfiguration of this product during an electrical

storm.

v Connect all power cords to a properly wired and grounded electrical

outlet.

v Connect to properly wired outlets any equipment that will be attached to

this product.

v When possible, use one hand only to connect or disconnect signal

cables.

v Never turn on any equipment when there is evidence of fire, water, or

structural damage.

v Disconnect the attached power cords, telecommunications systems,

networks, and modems before you open the device covers, unless

instructed otherwise in the installation and configuration procedures.

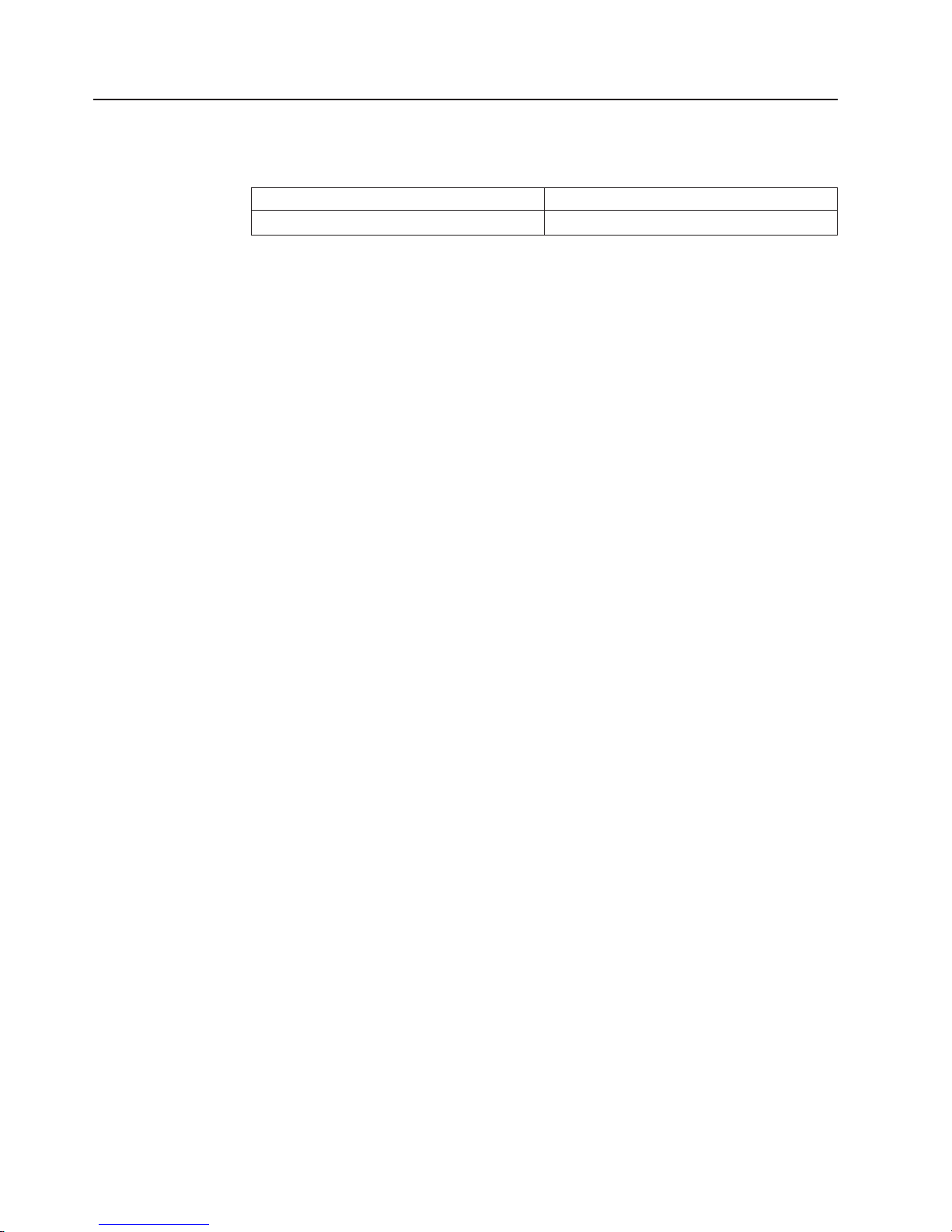

v Connect and disconnect cables as described in the following table when

installing, moving, or opening covers on this product or attached

devices.

To Connect: To Disconnect:

1. Turn everything OFF.

2. First, attach all cables to devices.

3. Attach signal cables to connectors.

4. Attach power cords to outlet.

1. Turn everything OFF.

2. First, remove power cords from outlet.

3. Remove signal cables from connectors.

4. Remove all cables from devices.

5. Turn device ON.

Safety xi

Page 14

Statement 2:

CAUTION:

When replacing the lithium battery, use only IBM Part Number 43W9859 or

03N2449 or an equivalent type battery recommended by the manufacturer. If

your system has a module containing a lithium battery, replace it only with

the same module type made by the same manufacturer. The battery contains

lithium and can explode if not properly used, handled, or disposed of.

Do not:

v Throw or immerse into water

v Heat to more than 100°C (212°F)

v Repair or disassemble

Dispose

of the battery as required by local ordinances or regulations.

xii BladeCenter QS22 Type 0793: Problem Determination and Service Guide

Page 15

Statement 3:

CAUTION:

When laser products (such as CD-ROMs, DVD drives, fiber optic devices, or

transmitters) are installed, note the following:

v Do not remove the covers. Removing the covers of the laser product could

result in exposure to hazardous laser radiation. There are no serviceable

parts inside the device.

v Use of controls or adjustments or performance of procedures other than

those specified herein might result in hazardous radiation exposure.

DANGER

laser products contain an embedded Class 3A or Class 3B laser

Some

diode. Note the following.

Laser radiation when open. Do not stare into the beam, do not view directly

with optical instruments, and avoid direct exposure to the beam.

Class 1 Laser Product

Laser Klasse 1

Laser Klass 1

Luokan 1 Laserlaite

Appareil A Laser de Classe 1

`

Safety xiii

Page 16

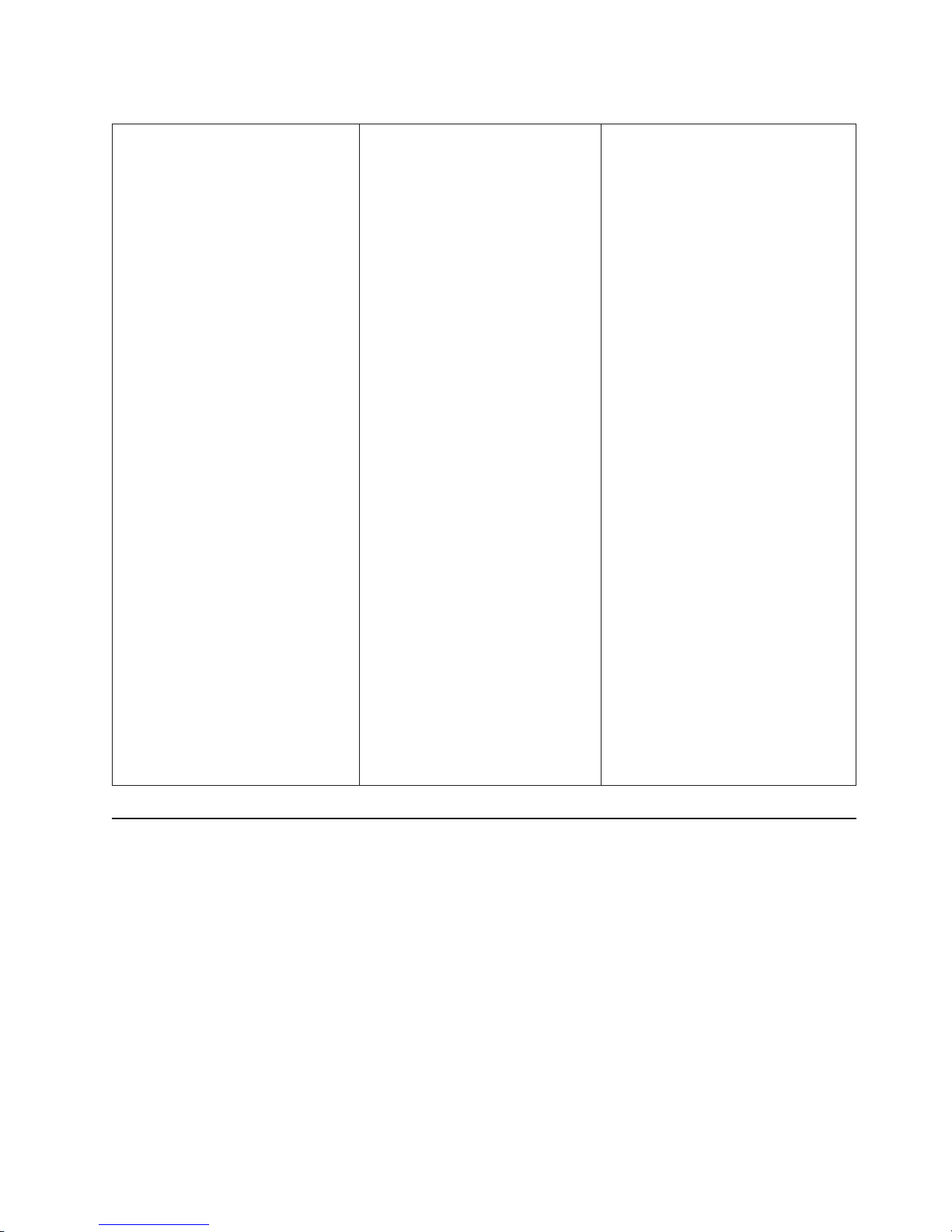

Statement 4:

≥ 18 kg (39.7 lb) ≥ 32 kg (70.5 lb) ≥ 55 kg (121.2 lb)

CAUTION:

Use safe practices when lifting.

Statement 5:

CAUTION:

The power control button on the device and the power switch on the power

supply do not turn off the electrical current supplied to the device. The device

also might have more than one power cord. To remove all electrical current

from the device, ensure that all power cords are disconnected from the power

source.

2

1

xiv BladeCenter QS22 Type 0793: Problem Determination and Service Guide

Page 17

Statement 8:

CAUTION:

Never remove the cover on a power supply or any part that has the following

label attached.

Hazardous voltage, current, and energy levels are present inside any

component that has this label attached. There are no serviceable parts inside

these components. If you suspect a problem with one of these parts, contact

a service technician.

Statement 13:

DANGER

Overloading a branch circuit is potentially a fire hazard and a shock hazard

under certain conditions. To avoid these hazards, ensure that your system

electrical requirements do not exceed branch circuit protection

requirements. Refer to the information that is provided with your device for

electrical specifications.

Statement 21:

CAUTION:

Hazardous energy is present when the blade is connected to the power

source. Always replace the blade cover before installing the blade.

Safety xv

Page 18

WARNING: Handling the cord on this product or cords associated with accessories

sold with this product, will expose you to lead, a chemical known to the State of

California to cause cancer, and birth defects or other reproductive harm. Wash

hands after handling.

ADVERTENCIA: El contacto con el cable de este producto o con cables de

accesorios que se venden junto con este producto, pueden exponerle al plomo, un

elemento químico que en el estado de California de los Estados Unidos está

considerado como un causante de cancer y de defectos congénitos, además de

otros riesgos reproductivos. Lávese las manos después de usar el producto.

xvi BladeCenter QS22 Type 0793: Problem Determination and Service Guide

Page 19

Chapter 1. Introduction

This Problem Determination and Service Guide contains information to help you

solve problems that might occur when installing and using your IBM® BladeCenter®.

It describes the diagnostic tools that come with the BladeCenter QS22, error codes

and suggested actions. It also describes how to replace failing components.

Replaceable components are of three types:

v Tier 1 customer replaceable unit (CRU): Replacement of Tier 1 CRUs is your

responsibility. If IBM installs a Tier 1 CRU at your request, you will be charged for

the installation.

v Tier 2 CRU: You may install a Tier 2 CRU yourself or request IBM to install it, at

no additional charge, under the type of warranty service that is designated for

your server.

v Field replaceable unit (FRU): FRUs must be installed only by trained service

technicians.

information about the terms of the warranty and getting service and assistance,

For

see Warranty and Support Information.

The illustrations in this document might differ slightly from your hardware.

Note:

Related documentation

In addition to this document, the following documentation also comes with the

server:

v Installation and User’s Guide

This document is available in Portable Document Format (PDF) on the

Documentation CD. It contains general information about the blade server,

including how to install supported options and how to configure the blade server.

v Safety Information

This document is on the Documentation CD. It contains translated caution and

danger statements. Each caution and danger statement that appears in the

documentation has a number that you can use to locate the corresponding

statement in your language in the Safety Information document.

v Warranty and Support Information

This document is in PDF on the Documentation CD. It contains information about

the terms of the warranty and about service and assistance.

Depending

Documentation CD.

The blade server may have features that are not described in the documentation

that comes with the server. The documentation might be updated occasionally to

include information about those features, or technical updates might be available to

provide additional information that is not included in the blade server

documentation. The most recent versions of all BladeCenter documentation are at

http://www.ibm.com/support/us/en/.

on the server model, additional documentation might be included on the

In addition to the documentation in this library, be sure to review the planning and

installation documents for your BladeCenter hardware available at

http://www.ibm.com/support/us/en/.

© Copyright IBM Corp. 2006, 2008 1

Page 20

The IBM Software Development Kit for Multicore Acceleration documentation can be

downloaded from http://www.ibm.com/developerworks/power/cell/. This contains

information about how to install the operating system and how to program

applications for the blade server.

Updates may be available for this and other BladeCenter documents. You can

check for the most recent versions at http://www.ibm.com/support/us/en/ or on the

BladeCenter Information center at http://publib.boulder.ibm.com/infocenter/systems/.

Notices and statements used in this document

The caution and danger statements that appear in this document are also in the

multilingual Safety Information document, which is on the Documentation CD. Each

statement is numbered for reference to the corresponding statement in the Safety

Information document.

The following notices and statements are used in this document:

v Notes: These notices provide important tips, guidance, or advice.

v Important: These notices provide information or advice that might help you avoid

inconvenient or problem situations.

v Attention: These notices indicate potential damage to programs, devices, or

data. An attention notice is placed just before the instruction or situation in which

damage could occur.

v Caution: These statements indicate situations that can be potentially hazardous

to you. A caution statement is placed just before the description of a potentially

hazardous procedure step or situation.

v Danger: These statements indicate situations that can be potentially lethal or

extremely hazardous to you. A danger statement is placed just before the

description of a potentially lethal or extremely hazardous procedure step or

situation.

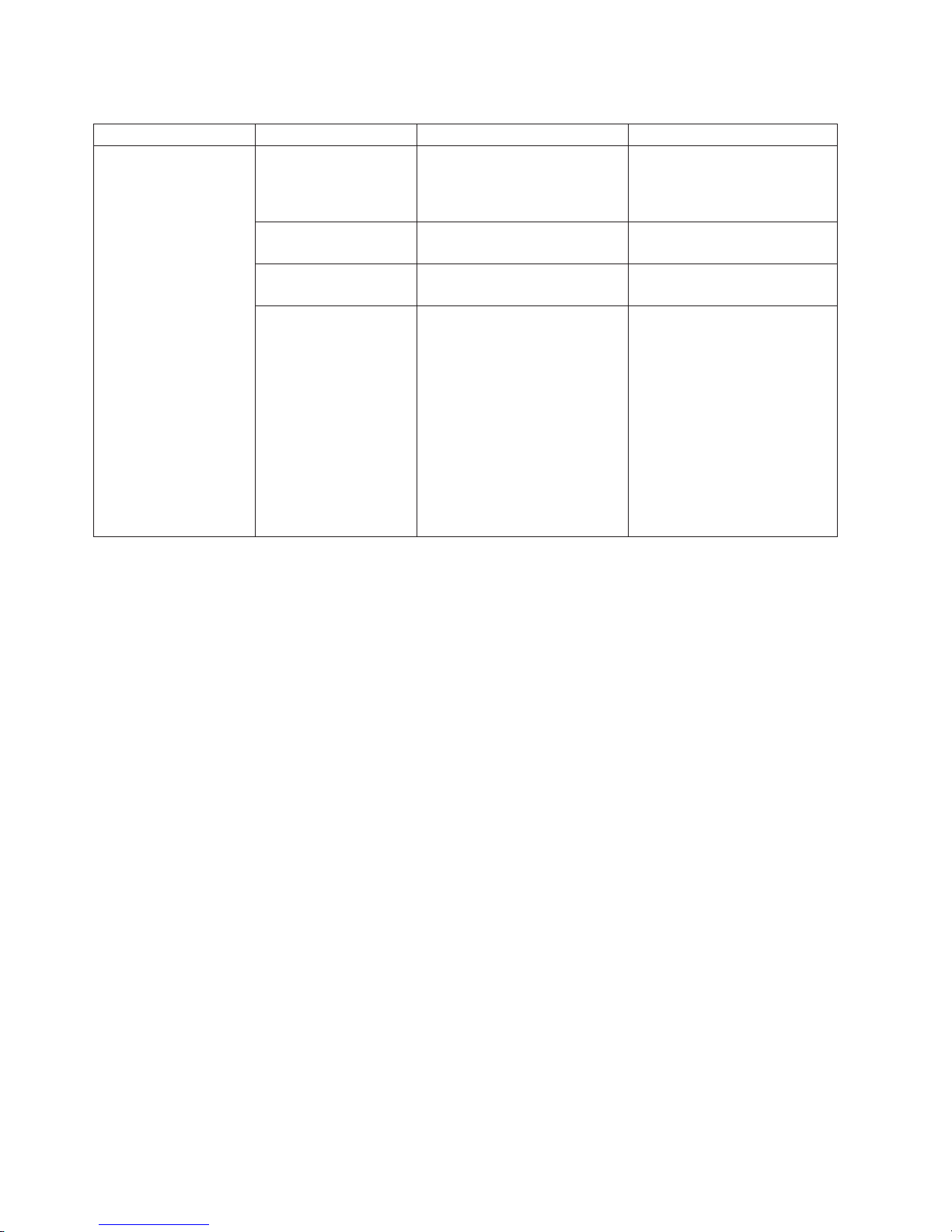

Features and specifications

The following table provides a summary of the features and specifications of the

BladeCenter QS22.

Through the BladeCenter Advanced Management Module, you can view the blade

server firmware code and other hardware configuration information.

The QS22 blade server is supported in the IBM BladeCenter H unit, the IBM

BladeCenter HT unit, and the IBM BladeCenter S (non RAID type only) unit.

Providing it is supported by the BladeCenter unit, you can install and operate any

other model of blade server in the same BladeCenter unit as a BladeCenter QS22.

Note: Power, cooling, removable-media drives, external ports, and advanced

system management are provided by the IBM BladeCenter unit. For more

information, see the Planning and Installation Guide for your BladeCenter

unit.

2 BladeCenter QS22 Type 0793: Problem Determination and Service Guide

Page 21

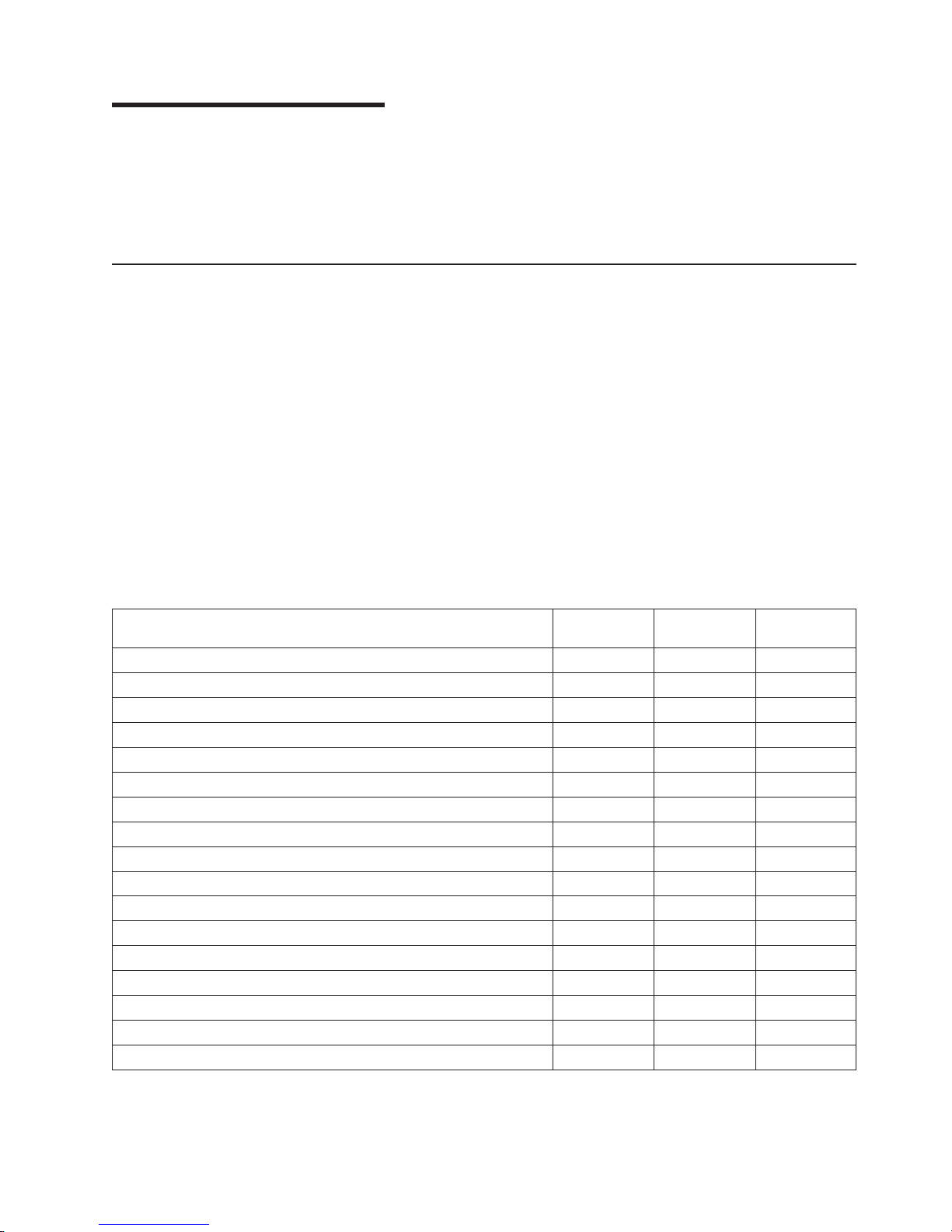

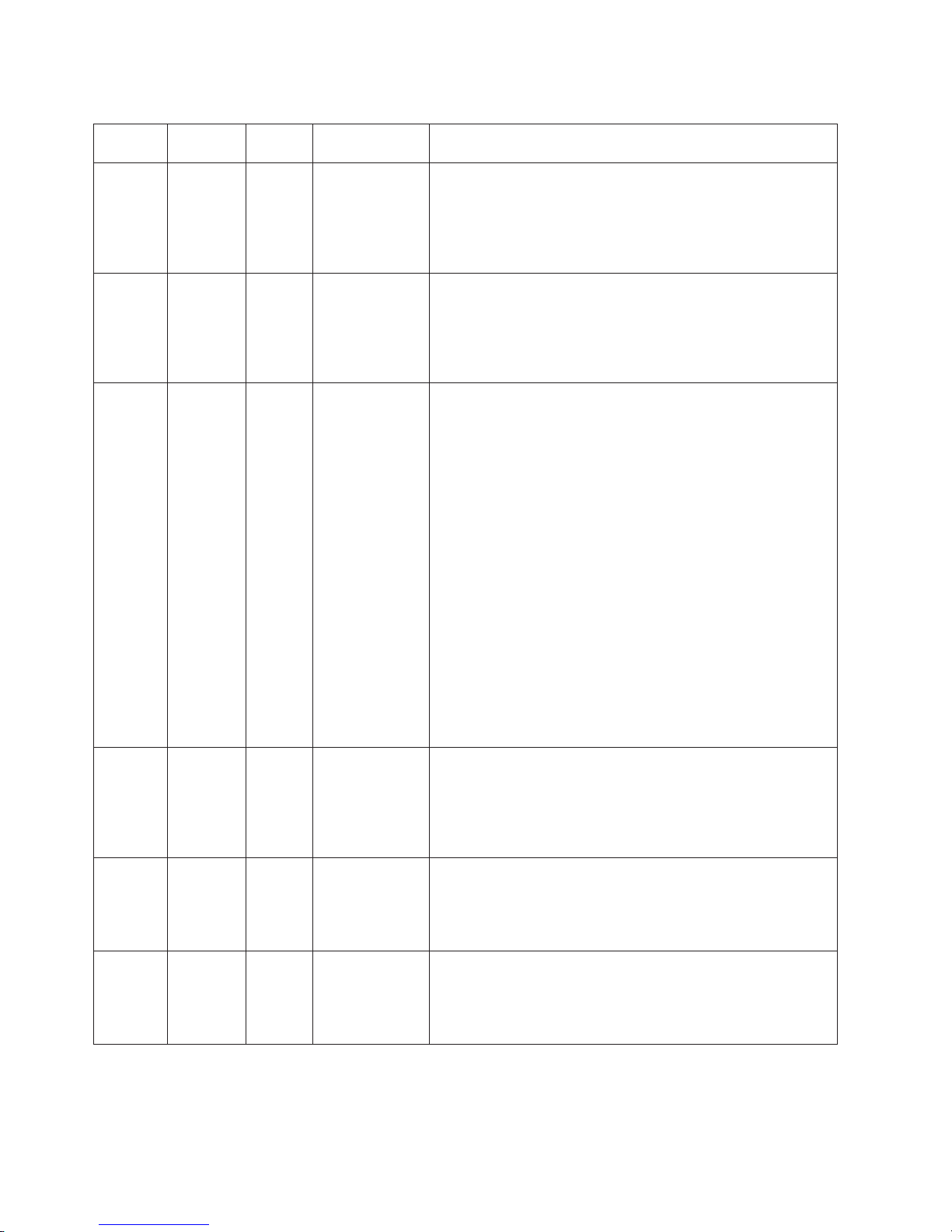

Table 1. Blade server features and specifications

Microprocessor:

Integrated functions:

Two IBM® PowerXCell™ 8i 64-bit

architecture processors w/VMX with 8

Synergistic Processor Units (SPU),

512 KB L2 cache, 256 KB on each

Synergistic Processing Engine (SPE)

v One dual-port 1 Gigabit Ethernet

controller

v Local service processor

v 2 IBM PowerXCell 8i companion

chips each providing a PCIe and

Memory: Minimum 4GB DDR2

memory. 2 GB per IBM PowerXCell 8i

processor. Maximum system memory

32 GB.

Supports 1 GB and 4 GB DDR2-800

VLP DIMMs. 2 GB DIMM support

depends on firmware level.

a single PCI-X interface

v RS-485 interface for

communication with BladeCenter

Management Module

v USB Controller

Supported

v Serial attached SCSI (SAS)

expansion card

v High-Speed InfiniBand Card,

IB-4x

v BladeCenter PCI Express I/O

Expansion Unit

v System memory 1 GB DDR2-800

VLP DIMM, total 4 GB per IBM

PowerXCell 8i processor

v System memory 2 GB DDR2-800

VLP DIMM, total 8 GB per IBM

PowerXCell 8i processor

v System memory 4 GB DDR2-800

VLP DIMM, total 16 GB per IBM

PowerXCell 8i processor

v I/O Buffer DIMM VLP DDR2 1GB,

total 1 GB per IBM PowerXCell 8i

companion chip

v 8 GB IBM Modular Solid State

Disk

v 8 GB Modular Flash Drive

Options:

Environment:

v Ambient temperature:

– Operating temperature: 10°C to

35°C (50°F to 95°F). Altitude: 0

to 2133 m (0 to 7000 ft)

v

Humidity:

– Operating temperature: 8% to

80%

Size:

v Height: 24.5 cm (9.7 inches)

v Depth: 44.6 cm (17.6 inches)

v Width: 2.9 cm (1.14 inches)

v Maximum weight: 5 kg (13.2 lb)

Electrical

input:

v Power provided to the blade server

by the BladeCenter unit: 12 V dc

Support for storage

The BladeCenter provides two options for storage:

SAS solution for storage

Onboard USB attached modular flash drive

SAS storage can be available through the following components: a SAS

Expansion Card attached to the blade server, one or two SAS connectivity

modules in the rear of the BladeCenter unit, and various options to attach

the IBM BladeCenter Boot Disk System to the SAS connectivity modules.

An optional SAS Expansion Card is available for the BladeCenter QS22.

If your QS22 blade server is installed in an IBM BladeCenter S unit, local

SAS drives of the BladeCenter S unit, if present, are also available as

storage.

This option provides a modular flash drive for system boot or local storage.

Chapter 1. Introduction 3

Page 22

Turning on the blade server

The QS22 blade server is hot-swappable and can be inserted into the BladeCenter

unit when the unit is already powered up. However, it can only be powered on by

one of the methods described in this section. While the blade server is powering up,

the power-on LED on the front of the server is lit. See “Blade server controls and

LEDs” on page 5 for the power-on LED states.

After you have installed the blade server into a powered up BladeCenter unit, wait

until the power on LED on the blade server flashes slowly before turning on the

blade server.

You can turn on the blade server in any of the following ways:

Using the power-control button

Providing local power control is enabled, you can press the power-control

button (see Figure 1) which is behind the control-panel door on the front of

the blade server. Local power control is enabled or disabled through the

Advanced Management Module Web interface.

Figure 1. Blade server power-control button

Using the BladeCenter Advanced Management Module

You can use the Advanced Management Module Web interface to turn on

the blade server remotely.

Using the Wake on LAN® feature:

If you want to use the Wake on LAN feature, you must enable it through the

operating system. Note that Wake on LAN does not operate if it has been

disabled through the Advanced Management Module.

In the event of a power failure the BladeCenter unit and then the blade server can

start automatically when power is restored. You must configure this through the

BladeCenter Advanced Management Module. See the BladeCenter Management

Module User's Guide for further information about this feature.

Turning off the blade server

When you turn off the blade server, it is still connected to power through the

BladeCenter unit and can continue to respond to requests from the service

processor, including remote requests to turn the blade server on. To remove all

power from the blade server, you must physically remove it from the BladeCenter

unit or power off the BladeCenter unit.

Power-on

LED

Power-control

button

4 BladeCenter QS22 Type 0793: Problem Determination and Service Guide

Page 23

To avoid loss of data, shut down the Linux® operating system before you turn off the

blade server. Shut down the operating system by entering the shutdown -h now

command at the command prompt or by choosing shutdown if you are using a

graphical user interface (GUI). See your operating system documentation for

additional information about shutting down the operating system.

If the BladeCenter unit has not been turned off, the blade server can be turned off

in any of the following ways:

Using the power-control button

Press the power-control button behind the control-panel door on the front

panel of the blade server. This starts an orderly shutdown of the operating

system if it has not been shut down already, providing your operating

system supports this feature, before turning off the blade server. If the

operating system stops functioning, pressing and holding the power-control

button for more than 4 seconds turns off the blade server.

Using the BladeCenter Advanced Management Module

You can use the Advanced Management Module Web interface to turn off

the blade server remotely. Yo u can also configure the Advanced

Management Module to turn off the blade server automatically if the system

is not operating correctly.

Note: After turning off the blade server, wait at least 5 seconds before turning it on

again.

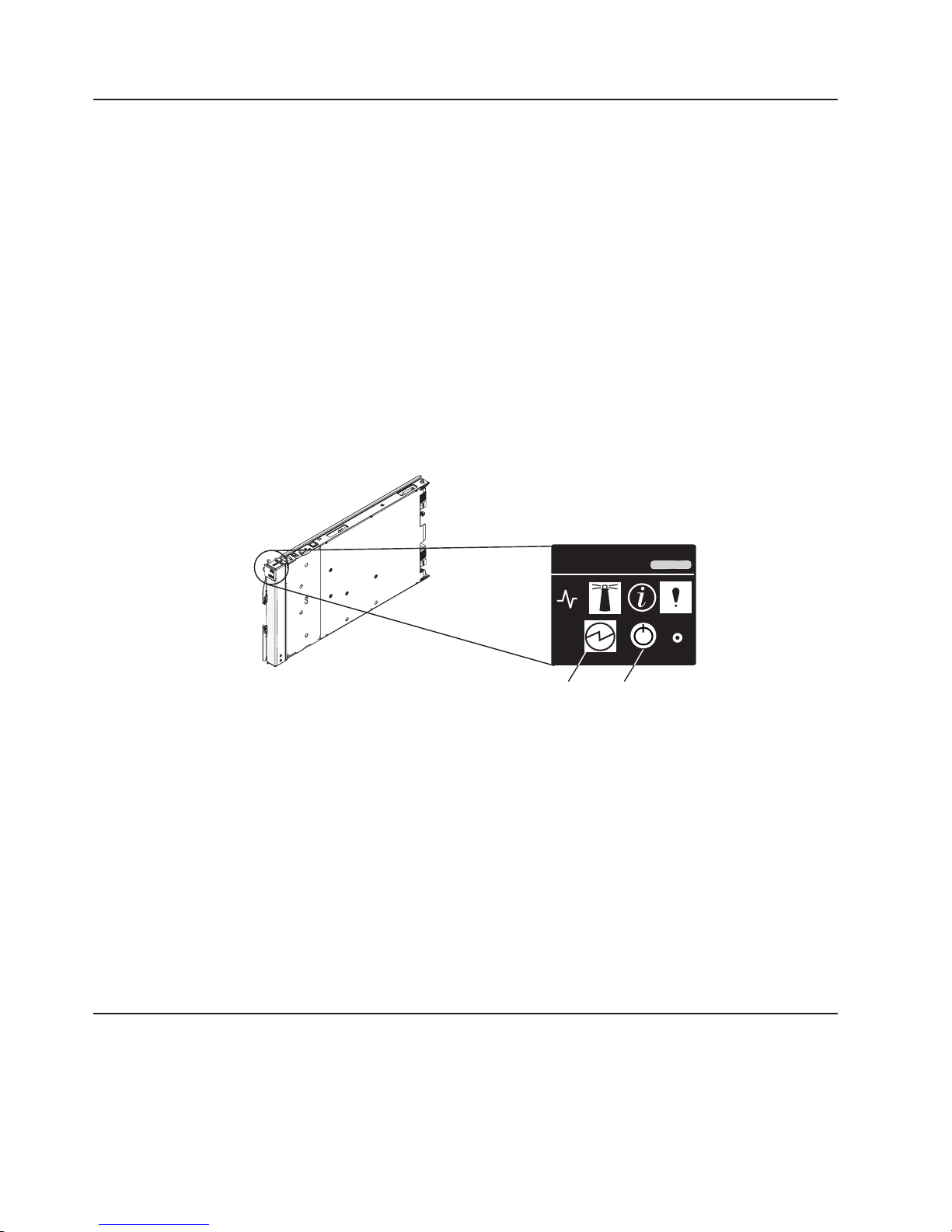

Blade server controls and LEDs

This section describes the controls and LEDs on the front panel of the blade server.

For further information about the LEDs and how they can be used to assist in

troubleshooting, see “Problems indicated by the front panel LEDs” on page 57.

Location

LED

Activity

LED

Information

LED

Power-on

LED

Media-tray

select button

Power-control

button

CD

Blade-error

LED

NMI

reset-button

Figure 2. Power-control button and LEDs

Note: The control panel door which normally covers the LEDs and power-control

button is omitted for reasons of clarity.

Activity LED:

This green LED lights when there is network activity.

Chapter 1. Introduction 5

Page 24

Location LED:

This blue LED is turned on remotely by the system administrator to assist in

locating the blade server. The location LED on the BladeCenter unit lights

at the same time.

Information LED:

This amber LED lights to indicate that information about a system event has

been placed in the Advanced Management Module Event Log. The

information LED remains on until turned off by Advanced Management

Module or through IBM Director Console.

Blade error LED:

This amber LED lights when a system error has occurred in the blade

server.

Power-control button:

Press this button to turn the blade server on or off. The power-control

button only has effect if local power control is enabled for the blade server.

Local power control is enabled and disabled through the BladeCenter

Advanced Management Module Web interface.

Media tray select button:

This button associates the shared BladeCenter unit media tray (DVD/CD

drive and USB ports) with the blade server. The LED on the button flashes

while the request is being processed, then lights when the ownership of the

media tray has been transferred to the blade server.

Power on LED:

reset button

NMI

The blade error LED, information LED, and location LED can be turned off through

the Advanced Management Module Web interface.

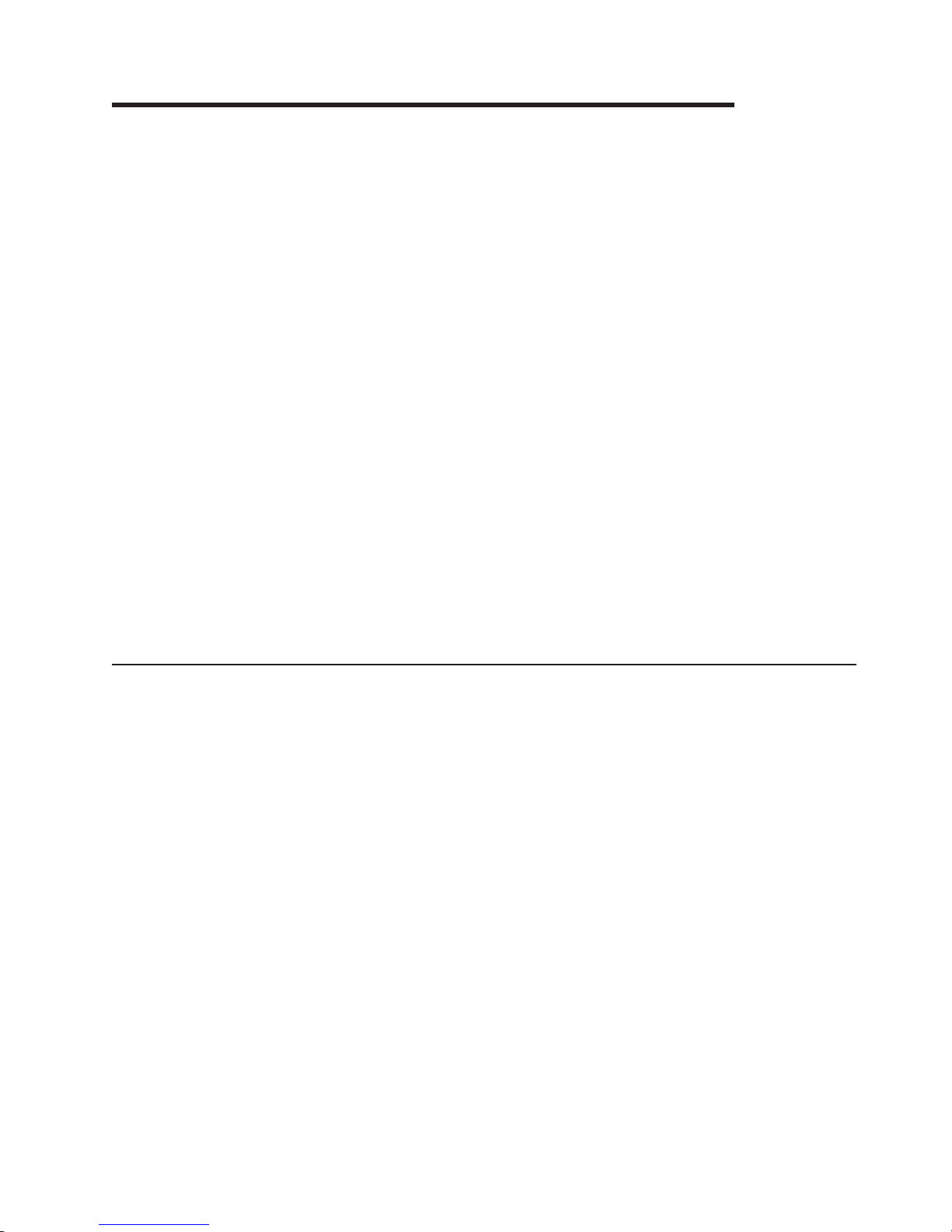

System board LEDs

The QS22 blade server has status LEDs on the system board to indicate the health

of various components. Some are within the light box while others are in different

locations. A lit LEDs indicates an error condition. Complete information about the

LEDs can be found in “Troubleshooting charts” on page 56.

It can take approximately 20 seconds for the operating system on the blade

server to recognize the media tray.

This green LED indicates the power status of the blade server as follows:

v Flashing rapidly - The service processor on the blade server is

communicating with the BladeCenter Advanced Management Module.

v Flashing slowly - The blade server has power but is not turned on.

v Lit continuously (steady) - The blade server has power and is turned on.

v Not lit. Either the BladeCenter unit is powered off, or a power failure has

occurred on the blade server or the BladeCenter unit.

If the operating system has been installed, pressing the button with a paper

clip or pin causes the operating system to call the Linux kernel debugger.

To find out what if any errors have occurred on the system board, you must:

1. Remove the blade server from the BladeCenter unit

2. Open the cover

3. Press the light path diagnostics switch

6 BladeCenter QS22 Type 0793: Problem Determination and Service Guide

Page 25

This lights any error LEDs that were turned on during processing. It also lights a

green LED to indicate the capacitor is charged and the light path diagnostics

system is operating.

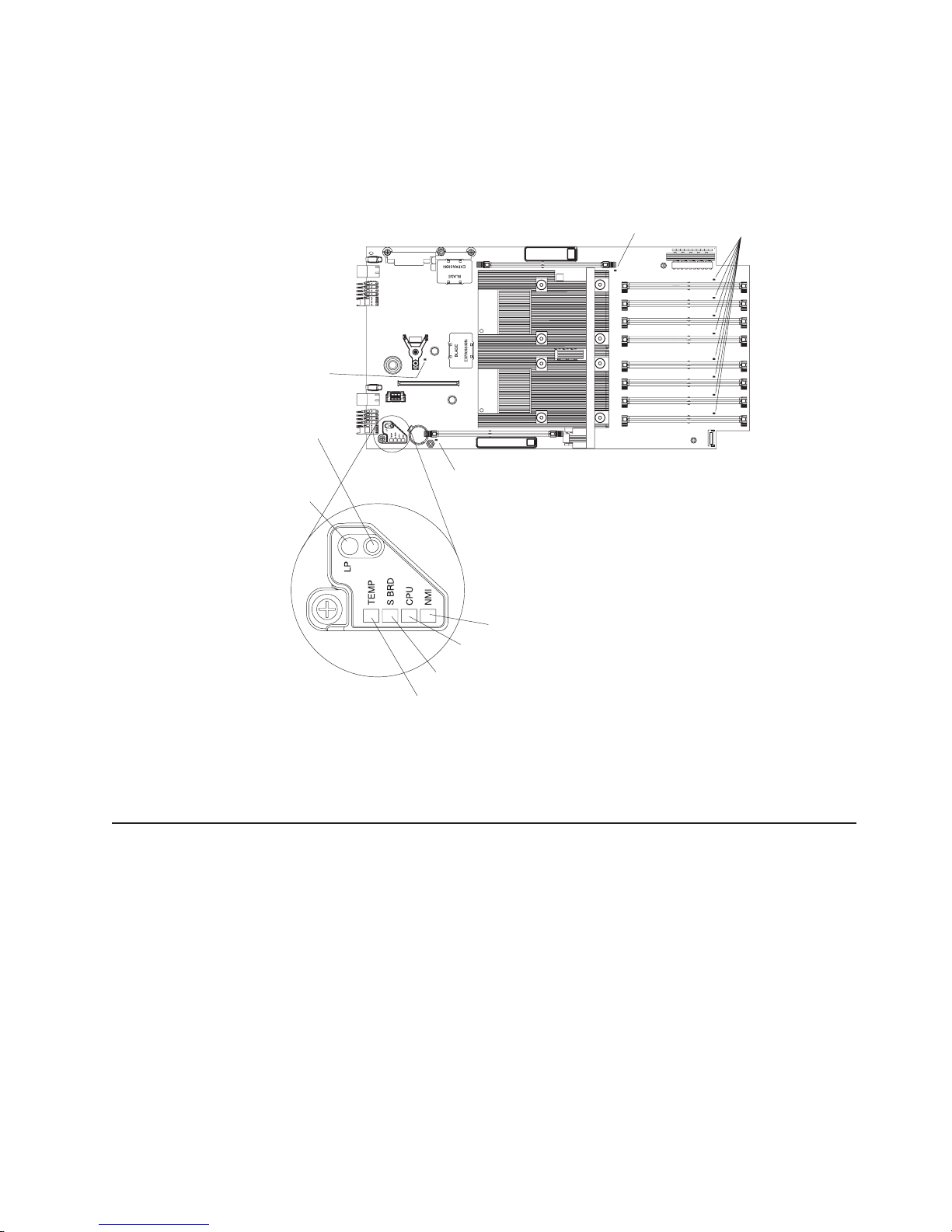

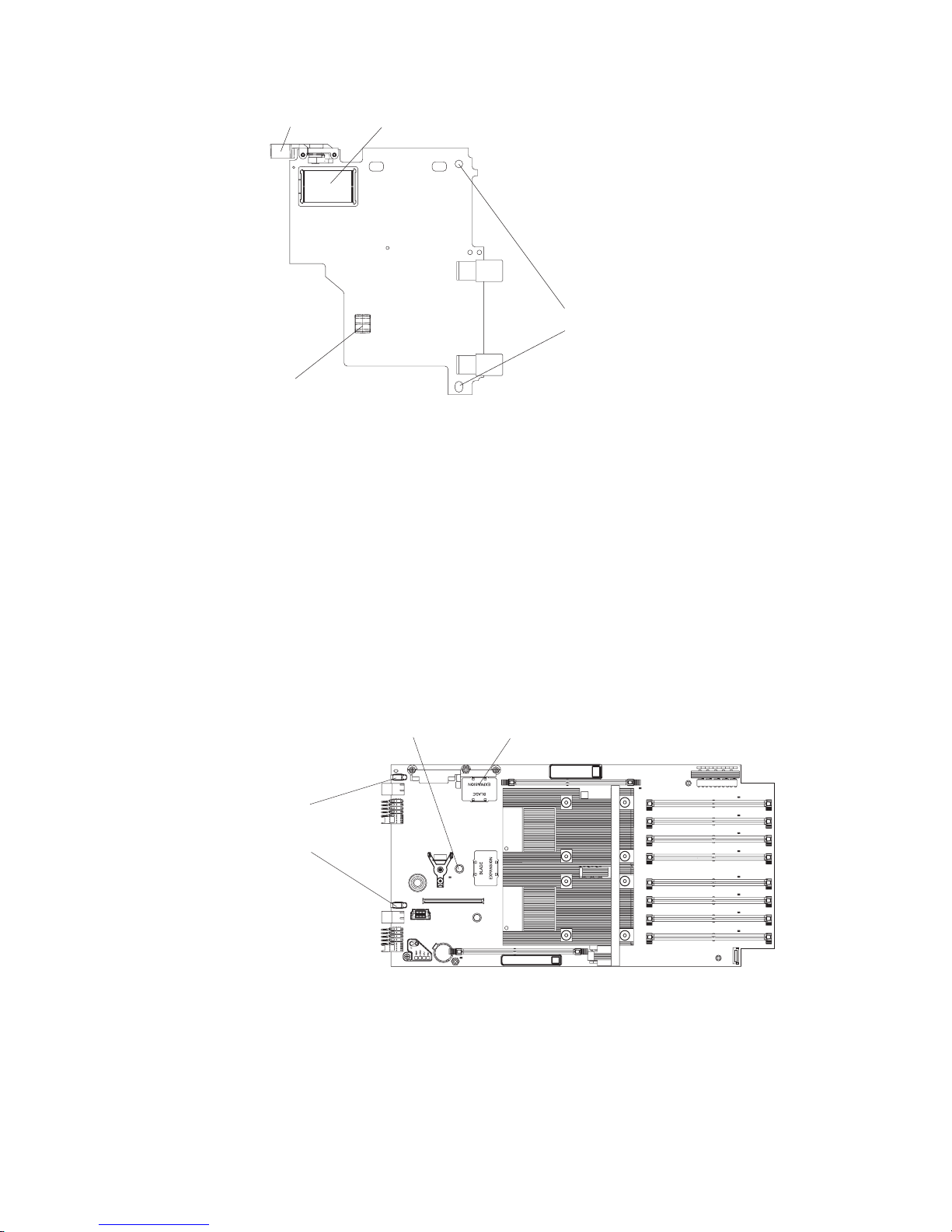

Figure 3 shows the location of the light path LEDs and the diagnostics switch.

Modular

flash drive

error LED

I/O buffer DIMM error LED

System memory DIMM

error LEDs

Light path

diagnosis

1

switch

Light path

diagnosis

I/O buffer DIMM error LED

LED

1

NMI error LED

CPU fail LED

System board LED

Temperature fault LED

Figure 3. System-board LEDs

Pressing the light path diagnostics switch lights the appropriate LED to indicate

where an error has occurred.

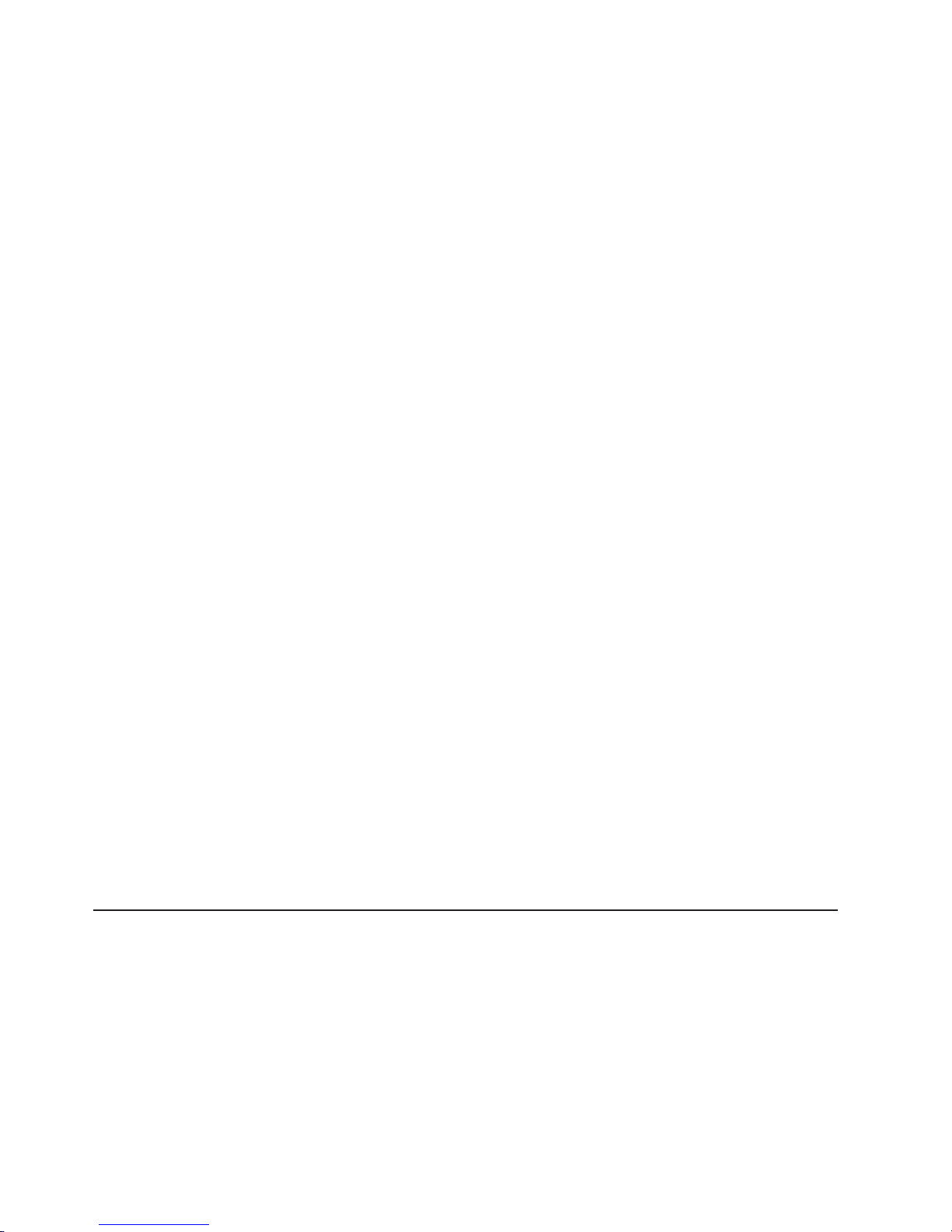

System board internal and expansion card connectors

The following illustration shows the location of the connectors for user-installable

options.

Chapter 1. Introduction 7

Page 26

PCIe high-speed

connector

Reserved

Flash drive connector

PCI-X expansion

connectors

IOBUF 2 DIMM slot

1

DIMM 8 slot

DIMM 7 slot

DIMM 6 slot

DIMM 5 slot

Battery

IOBUF 1 DIMM slot

DIMM 4 slot

DIMM 3 slot

DIMM 2 slot

DIMM 1 slot

Figure 4. Locations of the expansion option connectors on the system board

Control panel

connector

8 BladeCenter QS22 Type 0793: Problem Determination and Service Guide

Page 27

Chapter 2. Configuring the blade server

This chapter describes how to:

v Communicate with a blade server.

v Use System Management Services (SMS) to view and update the system

firmware revision number. This does not require the operating system to be

installed.

v Update the baseboard management controller (BMC) firmware using the update

package and the Advanced Management Module.

v Update the system firmware using the command-line utility.

v Configure the Ethernet Gigabit dual-port controller in preparation for a network

installation of the operating system.

You can update the BMC firmware through the Advanced Management

Note:

Module Web interface without booting the operating system. However, to

update the BMC using the update package or system firmware you must

boot the operating system first.

Communicating with the blade server

You do not have to boot the operating system before you can communicate with the

QS22 blade server. You can access it through:

Advanced Management Module

The Web-based management and configuration program. This is your main

access method to the blade server.

The command-line interface

See “Using the command-line interface” on page 10 for further information.

Serial over LAN (SOL)

This is similar to the serial interface, but allows you to connect to the blade

server over the network. See “Using Serial over LAN” on page 10 for further

information.

The serial interface

You can connect a PC or compatible terminal directly to the BladeCenter

unit. For BladeCenter H and BladeCenter HT you make this direct

connection using a special cable, for BladeCenter S you use a special

module. See “Using the serial interface” on page 11 for further information.

The BladeCenter unit Serial Breakout cable (or module for

Note:

BladeCenter S) is not supplied with the unit and must be ordered

separately.

System

Management Services (SMS)

The SMS utility allows you to view and update the VPD, change the boot

device and set network parameters. See “Using the SMS utility program” on

page 11 for further information.

Using the Advanced Management Module

The Advanced Management Module is the main means of administering the

BladeCenter system. Use the Advanced Management Module Web-based

management and configuration program to:

v Configure the BladeCenter unit

© Copyright IBM Corp. 2006, 2008 9

Page 28

v Update and configure BladeCenter components including the QS22 blade server

v Monitor the current system status

v Check the event log for system and other errors

Using the Web interface

Complete the following steps to start the Web-based management and configuration

program:

1. Open a Web browser. In the address or URL field, type the Internet protocol (IP)

address or host name that is assigned for the Management Module remote

connection. The default IP address is:

192.168.70.125

The Enter Network Password window opens.

2. Type your user name and password. Before you log in to the Advanced

Management Module for the first time, contact your system administrator

regarding whether your organization has assigned a user name and password

to you. Use the initial (default) user name and password the first time that you

log in to the Advanced Management Module. If you have an assigned user

name and password, use them for all subsequent logins. All login attempts are

documented in the event log.

The initial user ID and password for the Advanced Management Module are:

User ID

Password

Follow the instructions that appear on the screen. Be sure to set the timeout

3.

value that you want for your Web session.

BladeCenter management and configuration window opens.

The

For additional information, see the IBM BladeCenter Advanced Management

Module User's Guide.

Using the command-line interface

The IBM BladeCenter Advanced Management Module also provides a

command-line interface to provide direct access to BladeCenter management

functions. Yo u can use this as an alternative to using the BladeCenter Management

Module Web interface.

Through the command-line interface, you can issue commands to control the power

and configuration of the blade server and other components in the BladeCenter

unit. For information and instructions, see the IBM BladeCenter Management

Module Command-Line Interface Reference Guide.

Using Serial over LAN

To establish a Serial over LAN (SOL) connection to the blade server, you must

configure the SOL feature for the blade server and start an SOL session as

described in theIBM BladeCenter Serial over LAN Setup Guide. In addition, the

Advanced Management Module must be configured as described in the IBM

BladeCenter Management Module User’s Guide, and the BladeCenter unit must be

configured as described in the IBM BladeCenter Serial over LAN Setup Guide.

USERID (all capital letters)

PASSW0RD (note the number zero, not the letter O, in PASSW0RD)

10 BladeCenter QS22 Type 0793: Problem Determination and Service Guide

Page 29

Using the serial interface

Use the serial interface to:

v Observe firmware progress.

v Run the SMS Utility program

v Access the Linux terminal in order to configure Linux.

can connect a PC serially through the BladeCenter unit using a specific UART

You

cable. To connect to the serial console, plug the serial cable into the BladeCenter

unit and connect the other end to a serial device or computer with a serial port. For

more information, see the Installation and User's Guide for your BladeCenter unit.

Set the following parameters for the serial connection on the terminal client:

v 115200 baud

v 8 data bits

v No parity

v One stop bit

v No flow control

default, the blade server sends output over SOL and to the serial port on the

By

BladeCenter unit. However, the default for input is to use SOL. If you wish to use a

device connected to the serial port for input you must press any key on that device

while the blade server boots.

Using the SMS utility program

The Advanced Management Module is the main means of administering the

BladeCenter unit and the blade servers. However, another utility is provided which

in some cases can give more information than that displayed in the Advanced

Management Module. This is the System Management Services (SMS) utility

program.

The SMS utility program allows you to view and update the VPD, change the boot

list and set network parameters.

Starting SMS

Complete the following steps to start SMS:

1. Using a Telnet or SSH client, connect to the Advanced Management Module

external Ethernet interface IP address.

2. When prompted, enter a valid user ID and password. The default management

module user ID is USERID, and the default password is PASSW0RD, where the

0 is a zero.

Note: The user ID and password may have been changed. If so, check with the

system administrator for a valid id and password.

3. Power cycle the blade server and start an SOL console session by using the

power -cycle -c command.

For example, to power cycle and start an SOL remote text console with a blade

server that is in the first bay of the BladeCenter unit, issue the command:

power -cycle -c -T system:blade[1]

To open a console session with a blade that is already powered on, use the

command:

console -T system:blade[1]

Chapter 2. Configuring the blade server 11

Page 30

4. After approximately 30 seconds, you see a sequence of checkpoint codes

displayed on the console. These codes are generated by the Power On Self

Test (POST).

5. When the POST menu and indicators displays a screen similar to:

QS22 Firmware Starting

Check ROM = OK

Build Date = Jan 4 2008 11:31:29

FW Version = "QD-1.26.0-0"

Press "F1" to enter Boot Configuration (SMS)

Press "F2" to boot once from CD/DVD

Press F1 to display the SMS menu.

Viewing FRU information

The VPD on each blade server contains details about the machine type or model,

serial number and the universal unique ID.

Complete the following steps to see this information:

1. Start SMS by completing the steps in “Starting SMS” on page 11. The SMS

menu appears:

PowerPC Firmware

Version QD0123000

SLOF-SMS 1.1 (c) Copyright IBM Corp. 2007 All rights reserved.

--------------------------------------------------------------------------------

Main Menu

1. Select Language

2. Setup Remote IPL (Initial Program Load)

3. Change SCSI Settings

4. Select Console

5. Select Boot Options

6. Firmware Boot Side Options

7. Progress Indicator History

8. FRU Information

9. Change SAS Boot Device

--------------------------------------------------------------------------------

Navigation Keys:

X = eXit System Management Services

---------------------------------------------------------------------------

Type menu item number and press Enter or select Navigation key:

---------------------------------------------------------------------------

2. Type 8 to select FRU Information. A screen similar to the following appears:

12 BladeCenter QS22 Type 0793: Problem Determination and Service Guide

Page 31

PowerPC Firmware

Version QD0123000

SLOF-SMS 1.1 (c) Copyright IBM Corp. 2007 All rights reserved.

--------------------------------------------------------------------------------

FRU Information

Machine Type and Model: 079338x

Machine Serial Number: ABCDEFG

Universal Unique ID: 12345678-1234-1234-1234-123456789ABC

--------------------------------------------------------------------------------

Navigation Keys:

M = return to Main Menu

ESC key = return to previous screen X = eXit System Management Services

--------------------------------------------------------------------------------

Select Navigation key :

Note: You cannot change the FRU information from this screen, only view it.

Adding

FRU information: When you replace a FRU details are not recorded in

the VPD. Yo u must enter them manually through SMS.

When the system firmware detects an FRU replacement part during boot the

process stops to allow you to enter the machine type or model and serial number.

Boot does not continue until the information is provided.

To enter new FRU information, complete the following steps:

1. Using a Telnet or SSH client, connect to the Advanced Management Module

external Ethernet interface IP address.

2. When prompted, enter a valid user ID and password. The default management

module user ID is USERID, and the default password is PASSW0RD, where the

0 is a zero.

Note: The userid and password may have been changed. If so, check with the

system administrator for a valid user id and password.

3. Power cycle the blade and start an SOL console by using the power -cycle -c

command. See “Using the SMS utility program” on page 11 for further

information.

4. The following screen appears:

Chapter 2. Configuring the blade server 13

Page 32

PowerPC Firmware

Version QD0123000

SLOF-SMS 1.1 (c) Copyright IBM Corp. 2007 All rights reserved.

--------------------------------------------------------------------------------

Enter Type Model Number

(Must be 7 characters, only A-Z, a-z, 0-9 allowed. Press Esc to skip)

Enter Type Model Number :

Type the model number according to the instructions on the screen and press

Enter to continue.

5. You must confirm the model number:

PowerPC Firmware

Version QD0123000

SLOF-SMS 1.1 (c) Copyright IBM Corp. 2007 All rights reserved.

--------------------------------------------------------------------------------

Number entered is: 1234567

Accept number?

(Enter ’y’ or ’Y’ to accept or ’n’ or ’N’ to decline)

Select Navigation key :

Type y or Y and press Enter to confirm the number.

6. At the following screen, type the serial number:

14 BladeCenter QS22 Type 0793: Problem Determination and Service Guide

Page 33

PowerPC Firmware

Version QD0123000

SLOF-SMS 1.1 (c) Copyright IBM Corp. 2007 All rights reserved.

--------------------------------------------------------------------------------

Enter Serial Number

(Must be 7 characters, only A-Z, a-z, 0-9 allowed)

Enter Serial Number :

---------------------------------------------------------------------------------

Press Enter to continue.

7. You must now confirm the serial number:

PowerPC Firmware

Version QD0123000

SLOF-SMS 1.1 (c) Copyright IBM Corp. 2007 All rights reserved.

--------------------------------------------------------------------------------

Number entered is: ABCDEFG

Accept number?

(Enter ’y’ or ’Y’ to accept or ’n’ or ’N’ to decline)

Select Navigation key :

---------------------------------------------------------------------------------

Type y or Y and press Enter to confirm the number.

This completes the process and the blade server continues to boot as normal.

Updating the system and BMC firmware

The firmware consists of two distinct packages:

v A firmware package for the baseboard management controller (BMC). This is

referred to as the BMC firmware.

v A firmware package for the basic input/output system (BIOS) which runs on the

IBM PowerXCell 8i processor. This is referred to as system firmware.

Chapter 2. Configuring the blade server 15

Page 34

Note: The user and operating system interfaces of the system firmware are

based on the Open Firmware standard. Detailed system information is

provided through the Open Firmware device tree. You can use the client

interface and Run-Time Abstraction Services (RTAS) to run management

functions.

firmware

BMC

v Communicates with advanced management module

v Controls power on

v Initializes the board, including the IBM PowerXCell 8i processors and

clock chips

v Monitors the physical board environment

Updating steps

System

firmware

v Takes over when the BMC has successfully initialized the board

v Acts as the basic input/output system (BIOS)

v Includes boot-time diagnostics and power-on self test

v Prepares the system for the operating system boot

packages are delivered separately and do not follow the same versioning

The

scheme.

IBM periodically makes updates to both BMC and system firmware. These may be

downloaded from http://www.ibm.com/support/us/en/.

Note: To avoid problems and to maintain proper system performance, always make

sure that both the BMC firmware and the system firmware are at the same

level for all QS22 blade servers within the BladeCenter unit.

Complete the following steps to update the BMC and system firmware images:

1. Check the revision level of the firmware on the blade server and the level of the

updates on http://www.ibm.com/support/us/en/. If the level on the Web site is

higher than the version currently installed, continue with the updating steps.

2. Download the firmware updates.

3. Power off the blade server you wish to update.

4. Update the BMC firmware using the BMC update package or the Advanced

Management Module. See “Updating the BMC firmware” on page 17 for further

information.

5. Power on the blade server. This boots it with the new BMC firmware.

6. Update the system firmware image. See “Installing the system firmware” on

page 20 for further information.

7. The system reboots. This boots the blade server with the new system firmware.

8. Shut down the blade server.

There may be instances where you must update the BMC firmware before

Note:

updating the system firmware. Check the readme file that comes with each

firmware package for more information.

Determining current blade server firmware levels

Complete the following steps to view the current firmware code levels for both the

BMC and the system firmware:

16 BladeCenter QS22 Type 0793: Problem Determination and Service Guide

Page 35

1. To check the BMC firmware level, access and log on to the Advanced

Management Module Web interface as described in the Management Module

User's Guide.

2. From the Monitors menu section, select Firmware VPD:

The Blade Server Firmware Vital Product Data (VPD) window shows the build

identifier, release, and revision level of both the system firmware/BIOS and the

BMC firmware. In the example above, the system firmware or BIOS version is

QB01020000 and the BMC firmware is BLBT06b.

Compare this information to the firmware information provided at

http://www.ibm.com/support/us/en/. If the two match, then the blade server has the

latest firmware. If not, download the firmware package from the IBM Support Web

site. See “Updating the BMC firmware” or the IBM Support Web site for installation

instructions.

You can also view the system firmware level from within the operating system by

using the following command:

xxd /proc/device-tree/openprom/ibm,fw-vernum_encoded

Output is similar to:

0000000: 5142 3031 3031 3030 3000 00 QB0101000..

where QB0101000 is the system firmware version.

Note: The system firmware version displayed by the BladeCenter Advanced

Management Module might be different from the version displayed by your

operating system. Cross-reference information is given in the firmware

information at http://www.ibm.com/support/us/en/, and in the readme file

which comes with the firmware image.

Updating the BMC firmware

You can update the BMC firmware from the Linux prompt using the update package

or from the Advanced Management Module.

Chapter 2. Configuring the blade server 17

Page 36

Using the BMC update package

Complete the following steps to update the BMC firmware from the Linux command

prompt:

1. Check the README that comes with the BMC firmware as it contains specific

information about that particular firmware release.

2. Boot the blade server and the operating system.

3. Download the package from the IBM support site at http://www.ibm.com/support/

us/en/. The update package has a .sh extension.

4. Change to the directory where you have downloaded the package.

5. Run the package using the -s option.

6. Reboot the blade server.

Using the Advanced Management Module

Complete the following steps to update the BMC firmware:

1. Download the BMC firmware image file from http://www.ibm.com/support/us/en/

to a suitable location on a server that is accessible on the network.

2. Uncompress the .zip file. The BMC firmware image file name has the format

BLBT<version number>.zip.

3. Power off the blade you want to update.

4. Log in to the Advanced Management Module Web interface.

5. Click Firmware Update from the Blade Tasks submenu at the left of your

screen. The following screen appears:

6. Choose the blade you want to update (target) and browse to the firmware

image file.

7. Click on Update.

8. The validity of the image is checked, then the following screen appears:

18 BladeCenter QS22 Type 0793: Problem Determination and Service Guide

Page 37

Click Continue.

9. The next screen shows the firmware update progress:

When the update is finished, a confirmation message appears and an entry is

placed in the Advanced Management Module log.

10. Power up and boot the blade server.

Chapter 2. Configuring the blade server 19

Page 38

Note: QS22 firmware contains a proprietary implementation of Cell Broadband

Engine™ hardware initialization code.

Installing the system firmware

System firmware can only be installed after the operating system has booted. If the

operating system is not installed or cannot boot, then no upgrade or recovery is

possible. See the other sections of the manual Chapter 5, “Diagnostics and

troubleshooting,” on page 55 for further information about troubleshooting the QS22

blade server.

You can update the system firmware:

v Through IBM Director. See the IBM Director documentation on the IBM Director

CD for further information.

v Using the update package available from http://www.ibm.com/support/us/en/. See

“Updating the system firmware automatically” on page 21 for further information

on how to perform an update.

v Using the update_flash script available on supported Linux operating systems.

This requires the system firmware image file. See “The firmware update

package” for information about how to extract the file.

v Updating the firmware manually. See “Installing the firmware manually” on page

21 for further information.

all the above options Linux needs to have a current version of rtas_flash

For

device driver installed. This is normally installed with the operating system. If it is

not, see the installation guide for the Software Development Kit for Multicore

Acceleration for instructions about how to get this device driver and install it.

Note: You may have to update the BMC before updating the system firmware. See

the README file that comes with the package.

The firmware update package

You can now update firmware using the update packages available from

http://www.ibm.com/support/us/en/. These can be installed either through IBM

Director or by executing the .sh file contained in the package. This section

describes how to use the update package to install the firmware update or extract

the firmware image for manual installation.

To install the firmware package using IBM Director, see the documentation on the

IBM Director CD.

Note: The blade server must be configured and have a running Linux operating

system before the package can be extracted or installed.

The update package consists of 4 files:

v A file containing the change history for the QS22 system firmware. This has a

.chg extension.

v A file containing the update package. This has an .sh extension.

v A readme file for the update package. This contains specific installation and

configuration information.

v An XML file. This file is for use by IBM Systems Management tools, including

IBM Director Update Manager, UpdateXpress CD, and UpdateXpress System

Pack Installer.

20 BladeCenter QS22 Type 0793: Problem Determination and Service Guide

Page 39

Using the package

The package consists of an file with a .sh extension that runs from the Linux

prompt. It has a number of options. To see what options are available, run the

package without any options or with the -h switch:

# ./ibm_fw_bios_qb-1.9.1-2_linux-pq_cell.sh

In this example, ibm_fw_bios_qb-1.9.1-3_linux-pq_cell.sh is the name of the

firmware update package. The file name changes according to the version of the

firmware.

A screen similar to the following appears:

Usage:

-x /someDirectory - Extract the payload to <some directory>

-xr /someDirectory - Extract the payload plus PkgSdk files to <some directory>

-xd /dev/fd0 - Create a DOS bootable diskette - Internel floppy drive

-xd /dev/sda - Create a DOS bootable diskette - External USB floppy drive

-u - Perform update unattended

-h - Display this help screen

++debug - Display helpful debug information

Note:

All other command line arguments are passed to the

payload executable

The -xd options are not supported on the QS22 blade server.

The -x option

This enables to extract another executable file, in this example

ibm_fw_bios_qb-1.9.1-2.sh which in turn may be run to create the .bin file

required if you wish to update the firmware manually. See “Installing the

firmware manually” for further information.

The -u option

This performs an unattended and automatic update of the system firmware.

The blade server reboots automatically as part of the update process.

Updating the system firmware automatically

Complete the following steps to update the firmware automatically using the update

package:

1. Check the README before attempting to update the system firmware as it

contains specific information about the particular firmware release.

2. Download the update package from http://www.ibm.com/support/us/en/. The

update package has a .sh extension.

3. Change to the directory where you have downloaded the package.

4. Run the package with the -u option. Using the example from above, at the

command prompt enter:

./ibm_fw_bios_qb-1.9.1-2_linux-pq_cell.sh -u

5. Check the system firmware images to confirm the update has succeeded. See

“Determining current blade server firmware levels” on page 16 for instructions.

Installing the firmware manually

If you cannot update the firmware using the update_flash script, it is possible to

update the firmware manually. Yo u can use rtas_flash over /proc.

Complete the following steps to install the firmware manually:

1. Download the update package from http://www.ibm.com/support/us/en/.

Chapter 2. Configuring the blade server 21

Page 40

2. Extract the system firmware image package. At the command prompt enter:

./<update package> -x <target directory>

For example, to extract the image package ibm_fw_bios_qb-1.9.1-2.sh from

ibm_fw_bios_qb-1.9.1-2_linux-pq_cell.sh in the directory /temp/fwimage

enter:

./ibm_fw_bios_qb-1.9.1-2_linux-pq_cell.sh -x /temp/fwimage

If the directory does not exist the firmware package creates it.

3. Change to the directory containing the firmware image package.

4. Extract the firmware image. At the command prompt enter:

./<image package> -x

For example, to extract the image file QB-1.9.1-2-boot_rom.bin from

ibm_fw_bios_qb-1.9.1-2.sh enter:

./ibm_fw_bios_qb-1.9.1-2.sh -x

5. Ensure the rtas_flash driver is loaded. To do this, run lsmod.

6. If the module is not yet in the kernel, invoke the following to load it:

modprobe rtas_flash

7. To update your current firmware, copy the image file to /proc/ppc64/rtas/

firmware_update and reboot manually:

cp <image-file> /proc/ppc64/rtas/firmware_update

shutdown —r now

For example, to copy the image file cp QB-1.9.1-2-boot_rom.bin to

/proc/ppc64/rtas/firmware_update enter:

cp QB-1.9.1-2-boot_rom.bin /proc/ppc64/rtas/firmware_update

shutdown —r now

8. Once the system reboots, update the system firmware images. See “Updating

the system firmware images” for instructions.

Updating the system firmware images

Once the system firmware is updated, the QS22 blade server boots from the new

firmware. However, there are always two copies of the system firmware image on

the blade server:

TEMP This is the firmware image normally used in the boot process. When the

firmware is updated, it is the TEMP image that is replaced.

PERM This is a backup copy of the system firmware boot image. The blade server

only boots from this image if the TEMP image is corrupt. See “Recovering

the system firmware code” on page 64 for further information about how to

recover from a corrupt TEMP image.

you have updated the system firmware and booted the blade server, you

Once

should copy the TEMP image to the PERM image. This ensures that the PERM and

TEMP images are at the same revision level. The TEMP and PERM images should

always be at the same revision level.

There are two commands you can use to update an old image on PERM.

v From the Linux prompt issue the following command:

update_flash -c

22 BladeCenter QS22 Type 0793: Problem Determination and Service Guide

Page 41

Note: The script checks whether the board has booted from the TEMP image. If

not, the script does not complete.

v From the Linux prompt issue the following command:

echo 0 > /proc/rtas/manage_flash

For more information on booting from the TEMP or PERM images, see “Recovering

the system firmware code” on page 64.

Updating the optional expansion card firmware

If you have installed the SAS optional expansion card or a high-speed expansion

card, for example the InfiniBand card, you may have to update the firmware. See

the documentation that comes with the components for instructions about how to

update the firmware.

IBM periodically makes updates available for both SAS and high-speed expansion

cards. These may be downloaded from http://www.ibm.com/support/us/en/.

Integrating the Gigabit Ethernet controller into the BladeCenter

One dual-port Gigabit Ethernet controller is integrated on the blade server system

board. Each controller port provides a 1000-Mbps full-duplex interface connecting to

one of the Ethernet Switch Modules in I/O bays 1 and 2 of the BladeCenter unit,

which enables simultaneous transmission and reception of data on the Ethernet

local area network (LAN).

Each Ethernet-controller port on the system board is routed to a different switch

module in I/O bay 1 or bay 2. The routing from the Ethernet-controller port to the

I/O bay varies according to whether an Ethernet adapter is enabled and the

operating system that is installed. See “Blade server Ethernet controller

enumeration” on page 25 for information about how to determine the routing from

the Ethernet-controller ports to I/O bays for your blade server.

You do not have to set any jumpers or configure the controller for the blade server

operating system. However, you must install a device driver to enable the blade

server operating system to address the Ethernet-controller ports. For device drivers

and information about configuring your Ethernet controller ports, see the Ethernet

software documentation that comes with your blade server, or contact your IBM

marketing representative or authorized reseller. For updated information about

configuring the controllers, go to the Barcelona Computing Centre Web site at

http://www.bsc.es/projects/deepcomputing/linuxoncell/.

If your blade server contains a different type of optional Ethernet-compatible

Note:

switch module in I/O bay 1 than the switch modules that are mentioned in

this section, see the documentation that comes with the Ethernet switch

module that you are using.

Updating the Ethernet controller firmware

To update the Ethernet controller firmware, you must download an update package

from http://www.ibm.com/support/us/en/. This section describes how to use the

update package to install the firmware update.

The update package consists of four files:

Chapter 2. Configuring the blade server 23

Page 42

v A file containing the change history for the QS22 Ethernet Controller firmware.

This has a .chg extension.

v A file containing the update package. This has an .sh extension.

v A readme file for the update package. This contains specific installation and

configuration information.

v An XML file. This file is for use by IBM Systems Management tools, including

IBM Director Update Manager, UpdateXpress CD, and UpdateXpress System

Pack Installer.

Using the update package

The package consists of an file with a .sh extension that runs from the Linux

prompt. It has a number of options. To see what options are available, run the

package without any options or with the -h switch:

# ./brcm_fw_nic_2.0.3-e-1_rhel5_cell.sh

In the example shown above, brcm_fw_nic_2.0.3-e-1_rhel5_cell.sh is the name

of the firmware update package. The file name changes according to the version of

the firmware.

A screen similar to the following appears:

Usage:

-x /someDirectory - Extract the payload to <some directory>

-xr /someDirectory - Extract the payload plus PkgSdk files to <some directory>

-xd /dev/fd0 - Create a DOS bootable diskette - Internel floppy drive

-xd /dev/sda - Create a DOS bootable diskette - External USB floppy drive

-u - Perform update unattended

-h - Display this help screen

++debug - Display helpful debug information

The -xd and -x options are not supported on QS22.

The -u option performs an unattended and automatic update of the firmware. The

blade server reboots automatically as part of the update process.

Firmware update steps

Complete the following steps to update the firmware automatically:

1. Check the README before attempting to update the system firmware as it

contains specific information about the particular firmware release.

2. Download the update package from http://www.ibm.com/support/us/en/. The

update package has a .sh extension.

3. Change to the directory where you have downloaded the package.

4. Run the package with the -u option. Using the example from above, at the

command prompt enter:

./ brcm_fw_nic_2.0.3-e-1_rhel5_cell.sh -u

During the update process, messages similar to the following appear on the

console:

24 BladeCenter QS22 Type 0793: Problem Determination and Service Guide

Page 43

[root@c4b14 brcm-2.0.3-ppc]# ./ brcm_fw_nic_2.0.3-e-1_rhel5_cell.sh -u

IBM Ethernet Firmware Update Tool, Version 1.0.2

Warning. No Broadcom NetXtreme II adapters found.

ADAPTER MAC BOOT IPMI ASF PXE UMP

------------------- ---- ---- --- --- --001A640E030C (5704s) 3.21 2.20 NA NA NA

001A640E030D (5704s) NA NA NA NA NA

Updating Broadcom NetXtreme adapters.

Updating 001A640E030C using file 16A8bc.bin ---> Update successful

Updating 001A640E030C using file 16A8ipmi.bin ---> Update successful

Error! Firmware not detected on device 001A640E030D.

Warning. No Broadcom NetXtreme II adapters found.

ADAPTER MAC BOOT IPMI ASF PXE UMP

------------------- ---- ---- --- --- --001A640E030C (5704s) 3.38 2.47 NA NA NA

001A640E030D (5704s) NA NA NA NA NA

One or more errors occurred during the firmware update process. See /var

Note: The error message shown above is correct as it refers to an adapter not

available on QS22.