Page 1

pSeries 7311 Model D10 and Model D20

Service Guide

SA38-0627-01

ERserver

Page 2

Page 3

pSeries 7311 Model D10 and Model D20

Service Guide

SA38-0627-01

ER s e r v e r

Page 4

Second Edition (May 2003)

Before using this information and the product it supports, read the information in “Safety Notices” on page vii,

Appendix A, “Environmental Notices,” on page 177, and Appendix B, “Notices,” on page 183.

A reader’s comment form is provided at the back of this publication. If the form has been removed, address

comments to Information Development, Department H6DS-905-6C006, 11501 Burnet Road, Austin, Texas

78758-3493. To send comments electronically, use this commercial internet address: aix6kpub@austin.ibm.com. Any

information that you supply may be used without incurring any obligation to you.

© International Business Machines Corporation, 2002, 2003. All rights reserved.

Note to U.S. Government Users -- Documentation related to restricted rights -- Use, duplication or disclosure is

subject to restrictions set forth is GSA ADP Schedule Contract with IBM Corp.

Page 5

Contents

Safety Notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Rack Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Electrical Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . viii

Laser Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ix

Laser Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ix

Data Integrity and Verification . . . . . . . . . . . . . . . . . . . . . . . . . . .xi

About This Book . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

ISO 9000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

Highlighting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

Accessing Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

References to AIX Operating System . . . . . . . . . . . . . . . . . . . . . . . . . xiii

Related Publications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

Ergonomic Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

Trademarks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

Chapter 1. Reference Information . . . . . . . . . . . . . . . . . . . . . . . . . .1

pSeries 7311 Model D10 Overview . . . . . . . . . . . . . . . . . . . . . . . . . .1

Model D10 I/O Subsystem Features . . . . . . . . . . . . . . . . . . . . . . . . . .1

I/O Subsystem PCI-X Slot LED Definitions . . . . . . . . . . . . . . . . . . . . . . .2

D10 Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Subsystem Positioning and Cabling . . . . . . . . . . . . . . . . . . . . . . . . .6

Model D10 I/O Subsystem Locations . . . . . . . . . . . . . . . . . . . . . . . . .10

7311 Model D10 I/O Subsystem Front Locations . . . . . . . . . . . . . . . . . . . .10

7311 Model D10 I/O Subsystem Rear Locations . . . . . . . . . . . . . . . . . . . .11

Model D10 I/O Backplane Locations . . . . . . . . . . . . . . . . . . . . . . . .12

Model D10 I/O Subsystem PHB . . . . . . . . . . . . . . . . . . . . . . . . . .13

Model D10 Location Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

AIX and Physical Location Code Table . . . . . . . . . . . . . . . . . . . . . . . .14

7311 Model D10 I/O Subsystem Location Code Table . . . . . . . . . . . . . . . . . .15

pSeries 7311 Model D20 Overview . . . . . . . . . . . . . . . . . . . . . . . . . .16

Model D20 I/O Subsystem Features . . . . . . . . . . . . . . . . . . . . . . . . .16

Model D20 PCI-X Slots . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Model D20 Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Model D20 Location Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

AIX and Physical Location Code Table . . . . . . . . . . . . . . . . . . . . . . . .31

Model D20 Location Code Table . . . . . . . . . . . . . . . . . . . . . . . . . .32

Powering the System On and Off . . . . . . . . . . . . . . . . . . . . . . . . . .34

Power-On Self-Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Model D10 and Model D20 Specifications . . . . . . . . . . . . . . . . . . . . . . .35

Model D10 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Model D20 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

External AC Power Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Service Inspection Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Chapter 2. Diagnostics and Maintenance Procedures . . . . . . . . . . . . . . . . . .39

Power and Attention LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Component LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Resetting the LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Checkpoints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

FRU Isolation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Maintenance Analysis Procedures (MAPs) . . . . . . . . . . . . . . . . . . . . . . .40

iii

Page 6

Checkpoints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Error Code to FRU Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Using the Service Processor . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Using System Management Services . . . . . . . . . . . . . . . . . . . . . . . . .40

Chapter 3. Removal and Replacement Procedures . . . . . . . . . . . . . . . . . . .41

Safety Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Handling Static-Sensitive Devices . . . . . . . . . . . . . . . . . . . . . . . . . .42

Stopping and Starting the System . . . . . . . . . . . . . . . . . . . . . . . . . .42

Removal and Replacement Procedures for the Model D10 I/O Subsystem . . . . . . . . . . .42

Model D10 FRU Replacement Procedure List . . . . . . . . . . . . . . . . . . . . .42

D10 Service Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

D10 Operating Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

D10 Front Bezel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

D10 Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

PCI Adapters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

D10 Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

D10 RIO Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

D10 RIO Bus Adapter Assembly . . . . . . . . . . . . . . . . . . . . . . . . . 109

D10 I/O Backplane Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . .110

D10 Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Removal and Replacement Procedures for the Model D20 I/O Subsystem . . . . . . . . . . .112

Model D20 FRU Replacement Procedure List . . . . . . . . . . . . . . . . . . . . .112

D20 Service Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .113

D20 Operating Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . .114

D20 Service Access Cover . . . . . . . . . . . . . . . . . . . . . . . . . . .115

D20 Front Bezel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .116

D20 Operator Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .117

D20 Blowers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .119

D20 Cooling Blower Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

D20 RIO Bus Adapter Assembly . . . . . . . . . . . . . . . . . . . . . . . . . 124

D20 PCI Adapters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

D20 Hot-Plug Disk Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

D20 Disk Drive Cage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

D20 Disk Drive Backplane . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

D20 Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

D20 Power Supply Bulkhead . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

D20 I/O Backplane Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Chapter 4. Parts Information . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

7311 Model D10 I/O Subsystem . . . . . . . . . . . . . . . . . . . . . . . . . . 161

D10 I/O Subsystems Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

D10 I/O Subsystem Parts (continued) . . . . . . . . . . . . . . . . . . . . . . . 163

D10 SPCN, RIO, and Rack Beacon Cables (These parts are not shown.) . . . . . . . . . . 165

D10 Rack Mounting Enclosure (These parts are not shown.) . . . . . . . . . . . . . . . 165

Model D20 I/O Subsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

D20 I/O Backplane and Cabling . . . . . . . . . . . . . . . . . . . . . . . . . . 166

D20 PCI Slots . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

D20 Power, RIO Adapter, Cabling . . . . . . . . . . . . . . . . . . . . . . . . . 168

D20 Operator Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

D20 Fans and Disk Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

D20 Covers and Brackets . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

D20 RIO, SPCN, and Rack Beacon Cables . . . . . . . . . . . . . . . . . . . . . 171

Power Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

Chapter 5. Fault and Attention LEDs . . . . . . . . . . . . . . . . . . . . . . . . 173

iv Eserver pSeries 7311 Model D10 and Model D20 Service Guide

Page 7

Component LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

Resetting the LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

Appendix A. Environmental Notices . . . . . . . . . . . . . . . . . . . . . . . . 177

Product Recycling and Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

Environmental Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

Acoustical Noise Emissions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

pSeries 7311 Model D10 Declared Acoustical Noise Emissions . . . . . . . . . . . . . . 182

pSeries 7311 Model D20 Declared Acoustical Noise Emissions . . . . . . . . . . . . . . 182

Appendix B. Notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

Product Recycling and Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

Battery Return Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

Contents v

Page 8

vi Eserver pSeries 7311 Model D10 and Model D20 Service Guide

Page 9

Safety Notices

A danger notice indicates the presence of a hazard that has the potential of causing death or serious

personal injury. Danger notices appear on the following pages:

v viii

v 41

v 150

A caution notice indicates the presence of a hazard that has the potential of causing moderate or minor

personal injury. Caution notices appear on the following pages:

v viii

v viii

v 41

v 41

v ix

Note:

For a translation of these notices, see System Unit Safety Information, order number SA23-2652.

Rack Safety Instructions

v Do not install this unit in a rack where the internal rack ambient temperatures will exceed 35 degrees C.

v Do not install this unit in a rack where the air flow is compromised. Any side, front or back of the unit

used for air flow through the unit must not be in direct contact with the rack.

v Care should be taken to ensure that a hazardous condition is not created due to uneven mechanical

loading when installing this unit in a rack. If the rack has a stabilizer it must be firmly attached before

installing or removing this unit.

v Consideration should be given to the connection of the equipment to the supply circuit so that

overloading of circuits does not compromise the supply wiring or overcurrent protection. To provide the

correct power connection to the rack, refer to the rating labels located on the equipment in the rack to

determine the total power requirement for the supply circuit.

v An electrical outlet that is not correctly wired could place hazardous voltage on the metal parts of the

system or the devices that attach to the system. It is the responsibility of the customer to ensure that

the outlet is correctly wired and grounded to prevent an electrical shock.

vii

Page 10

Electrical Safety

Observe the following safety instructions any time you are connecting or disconnecting devices attached to

the workstation.

In the system you are about to setup or service:

v The ac power interface connector is considered the main power disconnect device.

v This system has redundant power supply capabilities, meaning that it has the ability to have two power

supplies running simultaneously in the same system unit. When instructed to disconnect the power

source, ensure that all power cables have been unplugged.

DANGER

An electrical outlet that is not correctly wired could place hazardous voltage on metal parts of

the system or the devices that attach to the system. It is the responsibility of the customer to

ensure that the outlet is correctly wired and grounded to prevent an electrical shock.

Before installing or removing signal cables, ensure that the power cables for the system unit

and all attached devices are unplugged.

When adding or removing any additional devices to or from the system, ensure that the power

cables for those devices are unplugged before the signal cables are connected. If possible,

disconnect all power cables from the existing system before you add a device.

Use one hand, when possible, to connect or disconnect signal cables to prevent a possible

shock from touching two surfaces with different electrical potentials.

During an electrical storm, do not connect cables for display stations, printers, telephones, or

station protectors for communications lines.

D05

CAUTION:

This product is equipped with a three-wire power cable and plug for the user’s safety. Use this

power cable with a properly grounded electrical outlet to avoid electrical shock.

C01

CAUTION:

This unit has more than one power supply cord. To reduce the risk of electrical shock, disconnect

two power supply cords before servicing.

C21

viii Eserver pSeries 7311 Model D10 and Model D20 Service Guide

Page 11

Laser Safety Information

CAUTION:

This product may contain a CD-ROM, DVD-ROM, or laser module on a PCI card, which are class 1

laser products.

C30

Laser Compliance

All lasers are certified in the U.S. to conform to the requirements of DHHS 21 CFR Subchapter J for class

1 laser products. Outside the U.S., they are certified to be in compliance with the IEC 825 (first edition

1984) as a class 1 laser product. Consult the label on each part for laser certification numbers and

approval information.

CAUTION:

All IBM laser modules are designed so that there is never any human access to laser radiation

above a class 1 level during normal operation, user maintenance, or prescribed service conditions.

Data processing environments can contain equipment transmitting on system links with laser

modules that operate at greater than class 1 power levels. For this reason, never look into the end

of an optical fiber cable or open receptacle. Only trained service personnel should perform the

inspection or repair of optical fiber cable assemblies and receptacles.

C25,

C26

Safety Notices ix

Page 12

x Eserver pSeries 7311 Model D10 and Model D20 Service Guide

Page 13

Data Integrity and Verification

IBM computer systems contain mechanisms designed to reduce the possibility of undetected data corruption

or loss. This risk, however, cannot be eliminated. Users who experience unplanned outages, system failures,

power fluctuations or outages, or component failures must verify the accuracy of operations performed and

data saved or transmitted by the system at or near the time of the outage or failure. In addition, users must

establish procedures to ensure that there is independent data verification before relying on such data in

sensitive or critical operations. Users should periodically check the IBM support websites for updated

information and fixes applicable to the system and related software.

xi

Page 14

xii Eserver pSeries 7311 Model D10 and Model D20 Service Guide

Page 15

About This Book

This book provides maintenance information that is specific to the pSeries 7311 Model D10 and Model

D20 I/O subsystems, as well as adapters and attached devices that do not have their own service

information. In this book, the I/O subsystems are referred to as the Model D10 I/O subsystem or the Model

D20 I/O subsystem.

MAPs that are common to all systems are contained in the RS/6000 Eserver pSeries Diagnostic

Information for Multiple Bus Systems.

This book is used by the service representative to repair system failures. This book assumes that the

service representative has had training on the processor subsystem to which an I/O subsystem is

attached, in addition to training on the I/O subsystem drawer.

ISO 9000

ISO 9000 registered quality systems were used in the development and manufacturing of this product.

Highlighting

The following highlighting conventions are used in this book:

Bold Identifies commands, subroutines, keywords, files, structures, directories, and other items

whose names are predefined by the system. Also identifies graphical objects such as buttons,

labels, and icons that the user selects.

Italics Identifies parameters whose actual names or values are to be supplied by the user.

Monospace Identifies examples of specific data values, examples of text similar to what you might see

displayed, examples of portions of program code similar to what you might write as a

programmer, messages from the system, or information you should actually type.

Accessing Information

IBM Eserver pSeries hardware publications are available online. To access the online hardware

publications, see the IBM Eserver pSeries and AIX Information Center at

http://publib16.boulder.ibm.com/pseries/index.htm. Click hardware documentation

Documentation for the AIX operating system is available at the IBM Eserver pSeries and AIX Information

Center at http://publib16.boulder.ibm.com/pseries/index.htm. Click AIX documentation. The AIX

Documentation CD contains the base set of publications for the operating system, including

system-management and end-user documentation.

References to AIX Operating System

This document may contain references to the AIX operating system. If you are using another operating

system, consult the appropriate documentation for that operating system.

This document may describe hardware features and functions. While the hardware supports them, the

realization of these features and functions depends upon support from the operating system. AIX provides

this support. If you are using another operating system, consult the appropriate documentation for that

operating system regarding support for those features and functions.

xiii

Page 16

Related Publications

The following publications provide additional information about your system:

v The D10 I/O Drawer Installation Guide, order number SA23-1295, contains information on how to install

the Model D10 I/O subsystem.

v The D20 I/O Drawer Installation Guide, order number SA23-1296, contains information on how to install

the Model D20 I/O subsystem.

v The Eserver pSeries 630 Model 6C4 and Model 6E4 User’s Guide, order number SA38-0606, contains

information to help users use the system, use the service aids, and solve minor problems.

v The RS/6000 Eserver pSeries Diagnostic Information for Multiple Bus Systems, order number

SA38-0509, contains diagnostic information, service request numbers (SRNs), and failing function codes

(FFCs).

v The RS/6000 Eserver pSeries Adapters, Devices, and Cable Information for Multiple Bus Systems,

order number SA38-0516, contains information about adapters, devices, and cables for your system.

This manual is intended to supplement the service information found in the RS/6000 Eserver pSeries

Diagnostic Information for Multiple Bus Systems.

v The Site and Hardware Planning Guide, order number SA38-0508, contains information to help you plan

your installation.

v The System Unit Safety Information, order number SA23-2652, contains translations of safety

information used throughout this book.

v The PCI Adapter Placement Reference, order number SA38-0538, contains information regarding slot

restrictions for adapters that can be used in this system.

Ergonomic Information

After you have set up your system, we encourage you to visit the Healthy Computing Web site. Good

ergonomic practice is important to get the most from your workstation and to avoid discomfort. This means

that the equipment and the workplace should be arranged to suit your individual needs and the kind of

work you do.

The Healthy Computing Web site gives ergonomic guidelines to help you understand the ergonomic

considerations that you should know when working at a computer workstation. The address is:

http://www.us.pc.ibm.com/healthycomputing

Trademarks

The following terms are trademarks of International Business Machines Corporation in the United States,

other countries, or both:

v AIX

v Electronic Service Agent

v Eserver

v IBM

v LANstreamer

v PowerPC

v pSeries

v RS/6000

Other

company, product, and service names may be trademarks or service marks of others.

xiv Eserver pSeries 7311 Model D10 and Model D20 Service Guide

Page 17

Chapter 1. Reference Information

This chapter provides reference information for the Model D10 and Model D20 I/O subsystems.

pSeries 7311 Model D10 Overview

The Model D10 is a 19-inch, rack-mountable I/O subsystem that is attached to a processor subsystem

drawer to extend the system’s capacity for I/O adapters. The I/O drawer includes redundant concurrently

maintainable power and cooling.

Five PCI-X slots and one PCI slot are available for PCI adapters. PCI adapters are installed through the

rear of the I/O subsystem using PCI adapter cassettes. Because the PCI slots support hot-pluggable

adapters, the I/O subsystem can have adapters installed without turning off power or removing covers. The

Model D10 is 4 EIA units high. Two Model D10s can be installed side-by-side in a 19-inch rack enclosure.

Model D10 I/O Subsystem Features

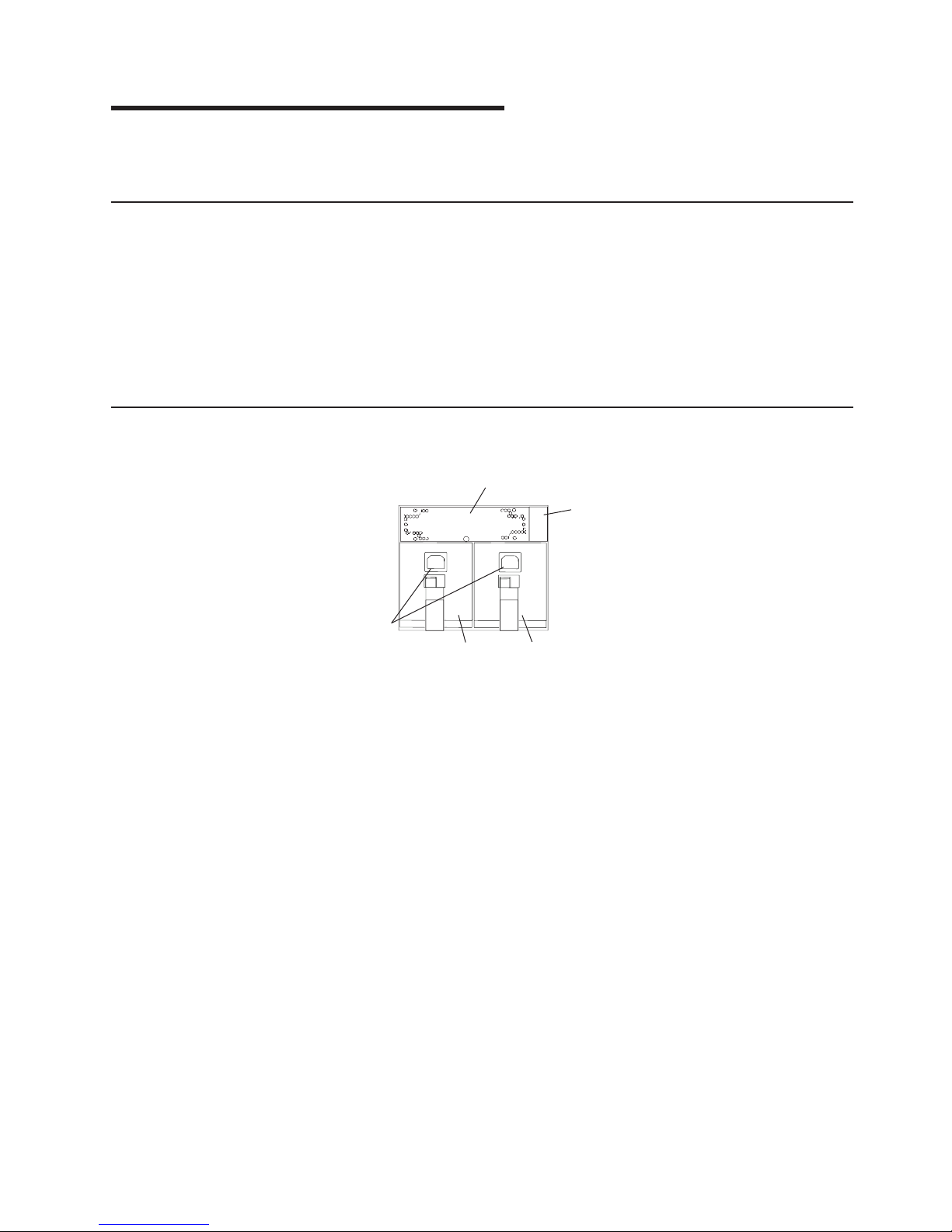

The following figure shows the front view of I/O subsystem.

2

3

1

5

4

1 Cooling Fan 4 Power Supply 1

2 Power cord channel 5 Power cord receptacles

3 Power Supply 2

1

Page 18

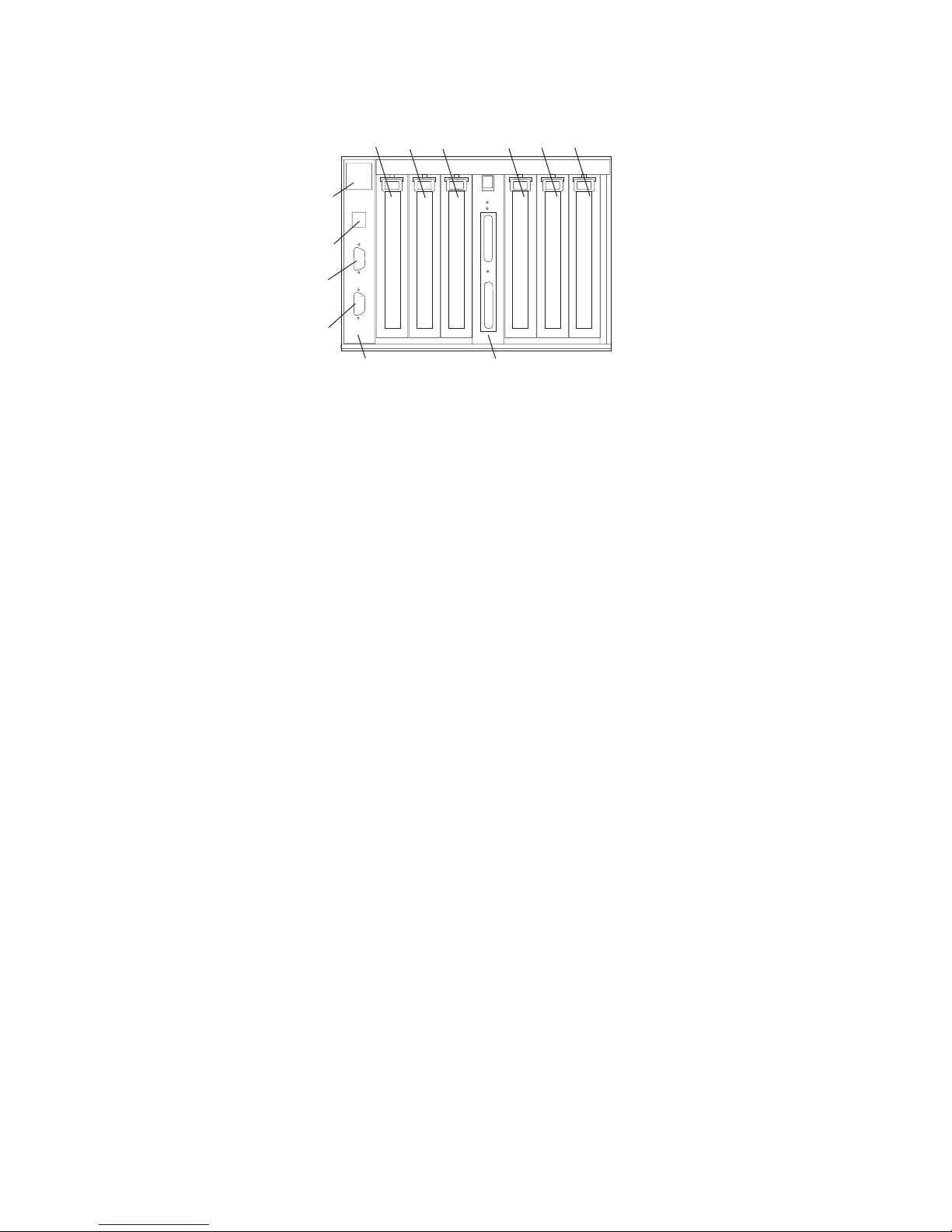

The following figure shows the rear view of the I/O subsystem.

1

23 456

1

23

4

56

78

9

11

10

12

1 PCI adapter slot 1 7 RIO bus adapter card

Upper connector 0

Lower connector 1

2 PCI-X adapter slot 2 8 SPCN connector card

3 PCI-X adapter slot 3 9 Lower SPCN connector J16

4 PCI-X adapter slot 4 10 Upper SPCN connector J15

5 PCI-X adapter slot 5 11 Rack beacon connector

6 PCI-X adapter slot 6 12 Power cord channel

D10 Operator Indicators

LEDs are used on the Model D10 as operator indicators. LEDs can be found on or near the following

FRUs:

v LED indicators visible on each PCI adapter cassette

v LED indicators on the I/O subsystem backplane

v Attention/Identify LEDs for power supplies and fans

For more information on LEDs and their definitions, see Chapter 5, “Fault and Attention LEDs,” on page

173.

D10 PCI-X Slots

The Model D10 has five PCI-X slots and one PCI slot. Adapters are installed and removed using a PCI

adapter cassette, which allows adapters to be installed without turning off the power or opening the I/O

subsystem covers.

PCI adapters are installed using an adapter cassette, each adapter cassette shows two LEDs for each

adapter. There is a green power indicator LED (upper) and an amber fault/identify LED (lower). The slots

are numbered on the rear of the chassis from left to right 1 through 6. Slot 1 is a 5V PCI slot. Slots 2

through 6 are 3.3V PCI-X.

I/O Subsystem PCI-X Slot LED Definitions

The green and amber LEDs (viewed on the rear of the PCI adapter cassette when installed) are used to

indicate the state of the PCI slot during removal and replacement of an adapter. The following table

describes the LED states and their definitions.

2 Eserver pSeries 7311 Model D10 and Model D20 Service Guide

Page 19

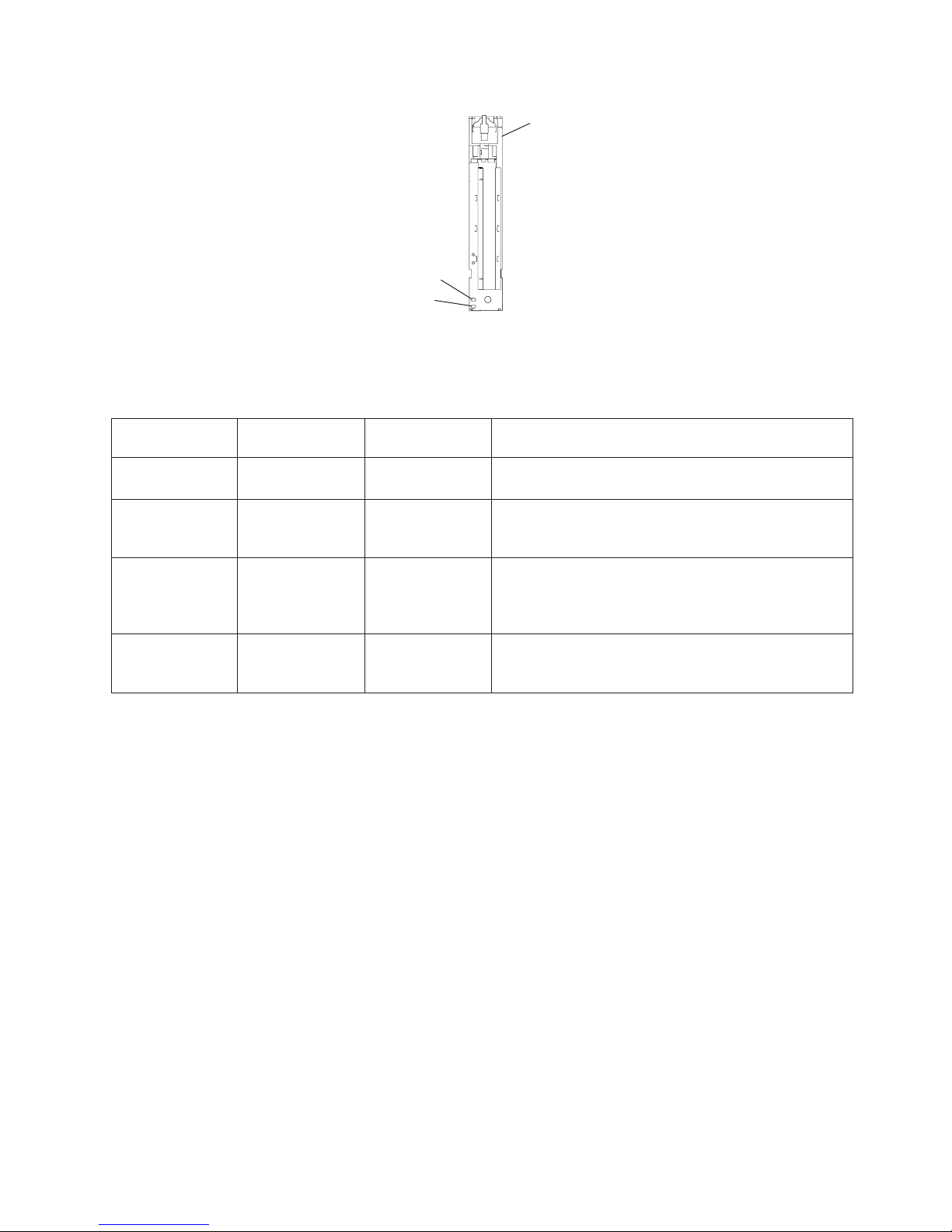

3

2

1

1 PCI Adapter Cassette

2 Power LED (Green )

3 Fault/Identify LED (Amber)

Green PCI Slot

LED Indication

Amber PCI Slot

LED

PCI Slot

Power/Status

Definition

On Off On/No action The PCI slot power is on and the slot is operational. Do

not remove or install adapters.

On Flashing On/Identify The PCI slot power is on, and the slot has been

identified by the software or firmware. Do not remove or

install adapters.

Off Flashing Off/Action The PCI slot power is off, and the slot has been

identified by the software or firmware. If directed by the

PCI hot-plug procedures, perform PCI adapter removal,

replacement, or installation.

Off Off Off/No power The PCI slot power is off. If the system power is off,

perform non-hot-plug PCI adapter removal, replacement,

or installation procedures.

Chapter 1. Reference Information 3

Page 20

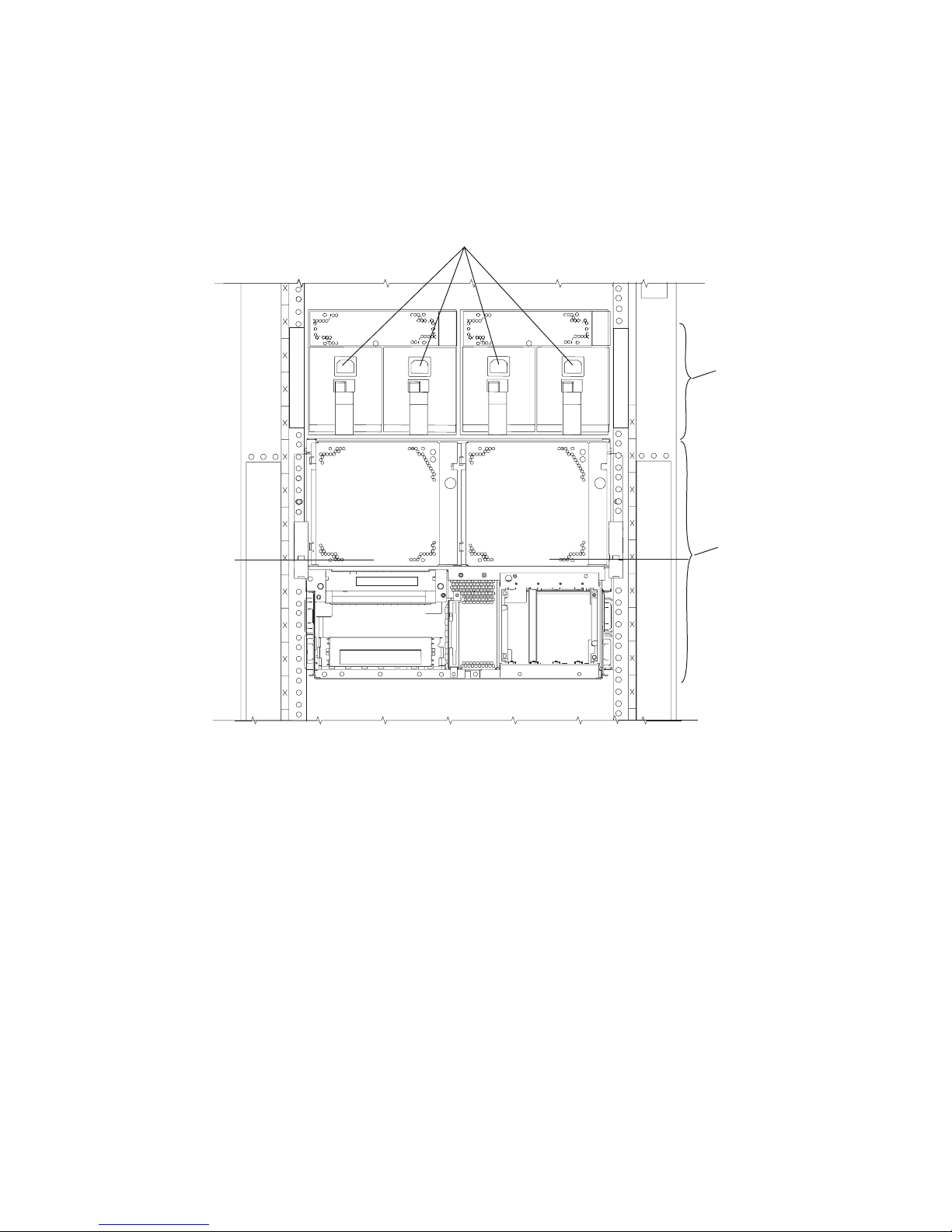

D10 Power

The following figure shows the front view of the pocessor subsystem and two I/O subsystems. Each unit

has two power supplies and two power cords for redundancy. Connect the power cords from one side of

the system to one power distribution bus in the rack. Connect the power cords from the other side of the

system to a different power distribution bus in the rack. To ensure that the systems in a rack keep running

if power is interrupted, a separate branch power line for each side of the rack must be used.

1

1

2

1

3

1 Power supplies, power receptacles

2 Two Model D10 I/O subsystems mounted side-by-side.

3 One 7038 Model 6M2 processor subsystem

The Model D10 I/O subsystem has two power supplies. Either power supply is capable of providing the

necessary voltages and currents, independent of the other power supply. Each power supply provides 5V

dc, 3.3V dc, -12V dc, and 5V dc standby. The power supplies are hot-pluggable and may be changed one

at a time while the system is operational.

4 Eserver pSeries 7311 Model D10 and Model D20 Service Guide

Page 21

The following figure shows the rear view of the processor subsystem and two I/O subsystems.

1 Model D10 I/O subsystem 3 Processor subsystem power supplies,

power receptacles

2 7038 Model 6M2 processor

subsystem

4 I/O backplane power (green) and

fault/identify (amber) LEDs

D10 Cooling

Fans mounted inside each I/O subsystem power supply and an additional fan mounted on the front of the

subsystem provide cooling. The power supplies and the fan can be removed and replaced with the power

turned on, as long as only one fan is removed from the I/O subsystem at a time.

D10 Input/Output Ports

The connector ports on the rear of the Model D10 I/O subsystem are used to connect the RIO-2 cables,

the SPCN cables, and the rack-beacon LED.

Chapter 1. Reference Information 5

Page 22

Subsystem Positioning and Cabling

I/O subsystems can be installed in a standard 19-inch EIA rack in any location. The cables that connect

the subsystems allow some flexibility in drawer placement, but the I/O subsystems should be located

above the processor subsystem to which they are connected in the same rack.

Up to eight I/O subsystems can be connected to a processor subsystem. Use the following guidelines:

v Each I/O subsystem connects to the processor subsystem using one system power control network

(SPCN) cable loop.

v Each I/O subsystem connects to the processor subsystem using one or more remote I/O (RIO) cable

loops.

v Lowest cost configurations allow up to four I/O subsystems connected to the processor subsystem using

a single RIO loop.

v Optimum performance is achieved when each I/O drawer is connected to the processor subsystem

through its own RIO loop.

Note:

The cabling illustrations in this section show examples of how the cabling between a processor

subsystem and connected I/O subsystems can be done. The example illustrations show the logical

connections of SPCN and RIO cables. Your system’s cables might be physically connected in a

different way from these examples.

SPCN Cabling

I/O subsystem SPCN cables are connected to the processor subsystem unit in a loop configuration. The

SPCN cables are connected in a loop so that the system has two paths to each I/O subsystem. Up to

eight I/O subsystems are supported on one SPCN loop.

One I/O Subsystem, Two I/O Subsystems: The illustrations on the left show one I/O subsystem

connected to the processor subsystem. The illustrations on the right show two I/O subsystems connected

to the processor subsystem using one SPCN loop.

Processor Subsystem Connected to One or Two Model D10 I/O Subsystems:

1 Processor Subsystem

2 I/O Subsystem

6 Eserver pSeries 7311 Model D10 and Model D20 Service Guide

Page 23

Four I/O Subsystems, Eight I/O Subsystems: The illustration on the left shows four I/O subsystems

connected to the processor subsystem using one SPCN loop. The illustration on the right shows eight I/O

subsystems connected to the processor subsystem using one SPCN loop.

Processor Subsystem Connected to Four or Eight Model D10 I/O Subsystems:

1 Processor Subsystem

2 I/O Subsystem

RIO Cabling

I/O subsystems are connected to the processor subsystem through remote I/O (RIO) cable loops. The

cable loops are connected to ports that are on the rear of the processor subsystem. The RIO cables are

connected in loops so that the system has two paths to each I/O subsystem when more than one I/O

drawer is in a loop.

If only one I/O subsystem is in a RIO loop and both the processor subsystem and the I/O subsystem are

RIO-2 capable, the RIO-2 cables are used as one two-cable path to the I/O subsystem. In this cable

configuration, the data rate is increased by a factor of 2.

v A maximum of eight Model D10 drawers are supported on one processor subsystem.

v If both D10 I/O drawers are connected to the same processor subsystem, the total number of I/O

subsystems supported is eight.

v The maximum number of I/O subsystems supported on one RIO loop is four.

v The D10 I/O drawers must be on separate RIO loops.

v The speed at which a RIO loop operates is set by the capability of the drawers on the loop. If the

system is capable of operating at RIO-2 speed, but any drawer on the same loop is capable of RIO

speed, the whole loop operates at RIO speed.

The system can have up to four RIO loops. A total of eight I/O drawers can be connected to the processor

subsystem in a variety of cabling configurations. For optimum performance, connect the RIO loops in a

configuration that distributes multiple I/O drawers among as many RIO loops as possible. A dedicated RIO

loop for each I/O drawer can provide optimum performance. Some examples of valid cabling examples

follow.

Chapter 1. Reference Information 7

Page 24

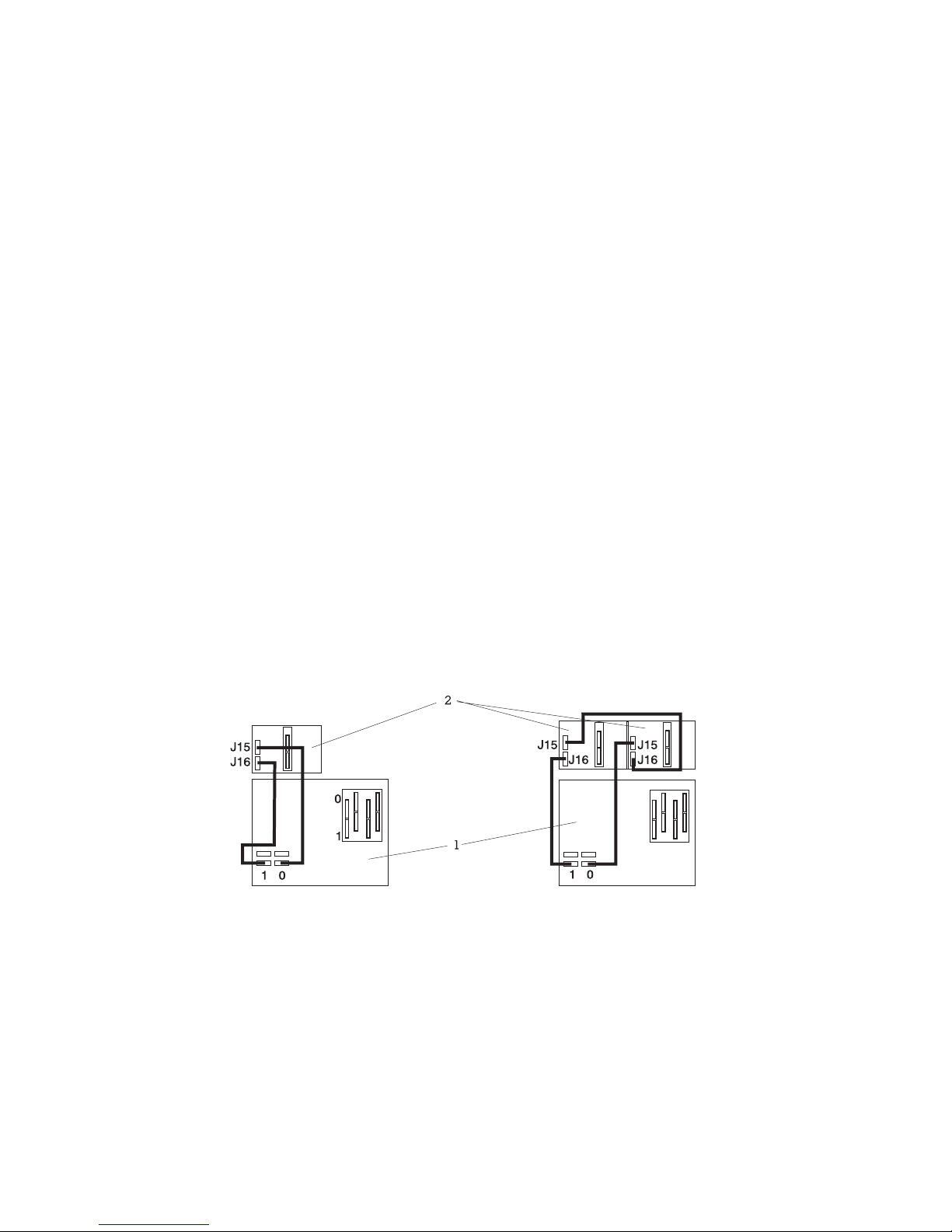

One I/O Subsystem or Two I/O Subsystems: The illustration on the left shows one I/O subsystem

drawer connected to the processor subsystem. The illustration on the right shows two I/O subsystem

drawers connected to the system unit using one RIO loop.

Processor Subsystem Connected to One or Two Model D10 I/O Subsystems:

A0

A0

A1

A1

0

1

1

0

0

1

1

2

1 Processor Subsystem

2 I/O Subsystem

Three I/O Subsystems or Four I/O Subsystems: The illustration on the left shows three I/O subsystem

drawers connected to the system unit using one RIO loop. The illustration on the right shows four I/O

subsystem drawers connected to the system unit using one RIO loop.

Processor Subsystem Connected to Three or Four Model D10 I/O Subsystems:

1 Processor Subsystem

2 I/O Subsystem

Eight I/O Subsystems with Two RIO Loops: The following illustrations show eight I/O subsystem

drawers connected to the processor subsystem unit using two RIO loops.

Processor Subsystem Connected to Eight Model D10 I/O Subsystems:

8 Eserver pSeries 7311 Model D10 and Model D20 Service Guide

Page 25

1 Processor Subsystem

2 I/O Subsystem

Chapter 1. Reference Information 9

Page 26

Model D10 I/O Subsystem Locations

This system uses physical location codes to provide mapping of the failing field replaceable units. The

location codes are produced by the processor subsystem’s firmware and AIX. For information about how to

read a location code, see the service guide for the processor subsystem to which your I/O subsystem is

connected.

7311 Model D10 I/O Subsystem Front Locations

1

2

3

4

1 Cooling fan 3 Power Supply 2

U0.dd-V2

2 Power cord channel 4 Power Supply 1

U0.dd-V1

10 Eserver pSeries 7311 Model D10 and Model D20 Service Guide

Page 27

7311 Model D10 I/O Subsystem Rear Locations

1

23 456

1

23

4

56

78

9

11

10

12

1 PCI adapter slot 1

U0.dd-P1-I1

7 RIO bus adapter card

U0.dd-P1.1

2 PCI-X adapter slot 2

U0.dd-P1-I2

8 SPCN connector card

U0.dd-P1 (part of the I/O backplane

FRU)

3 PCI-X adapter slot 3

U0.dd-P1-I3

9 SPCN Connector 2/J16

U0.ddP1/Q5

4 PCI-X adapter slot 4

U0.dd-P1-I4

10 SPCN Connector 1/J15

U0.ddP1/Q4

5 PCI-X adapter slot 5

U0.dd-P1-I5

11 Rack beacon connector

6 PCI-X adapter slot 6

U0.dd-P1-I6

12 Power cord channel

Note: In the preceding table, dd is equal to the number assigned to each I/O subsystem by the connected

processor subsystem.

Chapter 1. Reference Information 11

Page 28

Model D10 I/O Backplane Locations

The following illustration of the I/O backplane identifies the primary connectors used in your subsystem.

1

2

3

4

5

6

7

8

9

10

11

12

1 PCI adapter connector 1 7 SPCN connector

2 PCI-X adapter connector 2 8 VPD module

3 PCI-X adapter connector 3 9 VPD module pin 1 orientation

4 PCI-X adapter connector 4 10 RIO bus adapter connector

5 PCI-X adapter connector 5 11 Fan connector

6 PCI-X Adapter connector 6 12 Power supply connectors

12 Eserver pSeries 7311 Model D10 and Model D20 Service Guide

Page 29

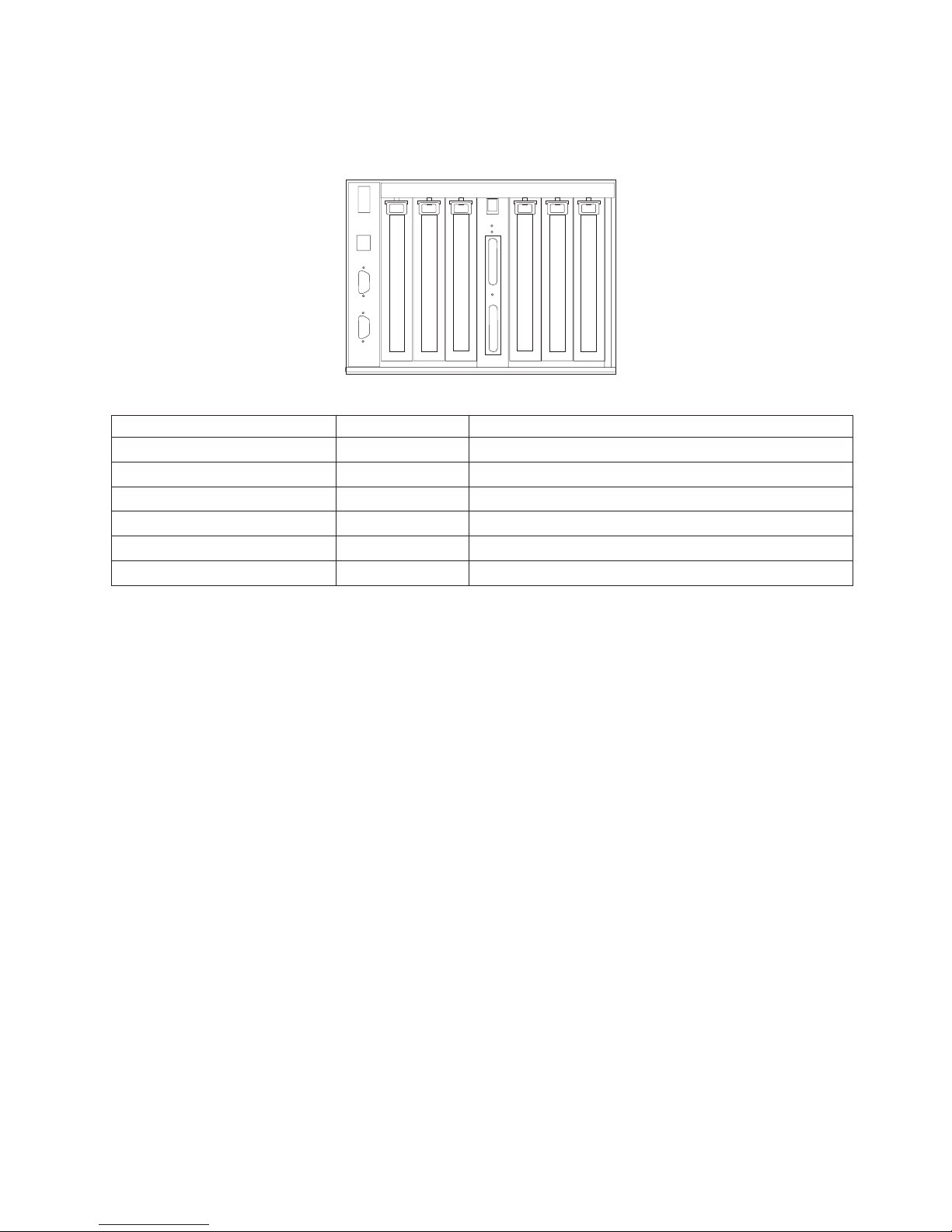

Model D10 I/O Subsystem PHB

Each 7311 Model D10 I/O Subsystem has two PCI host bridges (PHBs) through which the PCI slots are

connected.

1

23 456

Slot PHB Slot Characteristics

1 1 64-bit 5V, 33 MHz

2 1 64-bit 3.3V, 131.5 MHz

3 1 64-bit 3.3V, 131.5 MHz

4 2 64-bit 3.3V, 131.5 MHz

5 2 64-bit 3.3V, 131.5 MHz

6 2 64-bit 3.3V, 131.5 MHz

Chapter 1. Reference Information 13

Page 30

Model D10 Location Codes

This system (processor subsystem and attached I/O subsystems) use physical location codes in

conjunction with AIX location codes to provide mapping of failing field replaceable units (FRUs). The

location codes are produced by the processor subsystem’s firmware and AIX. For information about how to

read a location code, see the service guide for the processor subsystem to which your I/O subsystem is

connected.

AIX and Physical Location Code Table

This section covers the AIX and Physical Location Code tables for the Model D10.

The tables in this section contain the location codes for I/O subsystems when they are attached to the

system unit. In the tables, the location code for the I/O subsystem number is represented by dd. The first

time that an installed system is powered on, the I/O subsystems are numbered. For example, if a system

is first powered on with eight I/O subsystems connected, the dd value for the subsystems should be

numbered from 2 through 9.

Note: If the system was powered on with I/O subsystems connected before delivery to the customer, the

I/O subsystem location codes for the connected I/O subsystems are permanently set.

If at a later time, an I/O subsystem is removed from the system and a different I/O subsystem is

substituted, the substitute is assigned the next higher number available for its value of dd, which in the

earlier example, is 10. If the original I/O subsystem is reinstalled in the system configuration, the system

uses the original dd value for the I/O subsystem.

To keep the system from renumbering the I/O drawer when an I/O backplane is replaced, the VPD module

from the old I/O backplane must be moved over to the new I/O backplane.

The following diagram defines each part of a location code.

Ux.dd-xx-yy

| | | |

| | | |

| | | yy This code is used for the next component (yy, yy, yy, ...)

| | xx This code is used for the next component (Px, Fx, Vx, ...)

| dd This code is the location code for the I/O drawer (2 to 63)

Ux This code normally identifies the rack in which a drawer is installed.

The x will always be zero (0) for this system.

14 Eserver pSeries 7311 Model D10 and Model D20 Service Guide

Page 31

7311 Model D10 I/O Subsystem Location Code Table

The following table lists the location codes for a D10 I/O subsystem. The location code for the I/O

subsystem connected to a system unit is U0.dd (where dd can be any number from 2 through 63).

FRU Name Physical Location Code

Model D10 I/O Drawer U0.dd (dd = any number from 2 through 63)

I/O subsystem 1 drawer U0.dd

I/O backplane U0.dd-P1

RIO connector riser card U0.dd-P1.1

RIO port 0 (upper connector) U0.dd-P1.1/Q1

RIO port 0 cable U0.dd-P1.1/Q1#

RIO port 1 (lower connector) U0.dd-P1.1/Q2

RIO port 1 cable U0.dd-P1.1/Q2#

PHB1 U0.dd-P1

EADS_X under PHB1 U0.dd-P1

PCI slot 1 U0.dd-P1/I1

PCI slot 1 adapter U0.dd-P1-I1

PCI slot 2 U0.dd-P1/I2

PCI slot 2 adapter U0.dd-P1-I2

PCI slot 3 U0.dd-P1/I3

PCI slot 3 adapter U0.dd-P1-I3

PHB2 U0.dd-P1

EADS_X under PHB2 U0.dd-P1

PCI slot 4 U0.dd-P1/I4

PCI slot 4 adapter U0.dd-P1-I4

PCI slot 5 U0.dd-P1/I5

PCI slot 5 adapter U0.dd-P1-I5

PCI slot 6 U0.dd-P1/I6

PCI slot 6 adapter U0.dd-P1-I6

Power supply 1 (with 2 fans) U0.dd-V1

Power supply 2 (with 2 fans) U0.dd-V2

Cooling fan 5 U0.dd-F5

Rack indicator connector (4-pins) U0.dd-P1/Q3

SPCN connector 1/J15 U0.dd-P1/Q4

SPCN connector 2/J16 U0.dd-P1/Q5

Subsystem VPD U0.dd-P1

Chapter 1. Reference Information 15

Page 32

pSeries 7311 Model D20 Overview

The Model D20 is a 19-inch, rack-mountable I/O subsystem that is attached to a processor subsystem to

extend the system’s capacity for I/O adapters and disk drives. The I/O subsystem includes redundant

concurrently maintainable power and cooling.

Seven PCI slots are available for PCI adapters. Because the PCI slots support hot-pluggable adapters, the

I/O subsystem can have adapters installed without turning off power. The Model D20 is 4 EIA units high

and is compatible with 19-inch EIA rack enclosures.

Model D20 I/O Subsystem Features

The features of the Model D20 enable this I/O subsystem to extend the input and output capabilities of the

processor subsystem. Features such as PCI-X adapters and internal SCSI disk drives are supported.

Model D20 Operator Indicators

LEDs are used on the Model D20 as operator indicators. Tables found in “Model D20 PCI-X Slots” and

“Model D20 Power” on page 18 describes the LED states and their definitions. For more information on

LEDs and their definitions, see Chapter 5, “Fault and Attention LEDs,” on page 173. LEDs can be found on

or near the following FRUs:

v LED indicators visible on each PCI adapter light pipe

v LEDs for power on, attention, SCSI activity

v Attention/Identify LEDs

v Rack Beacon

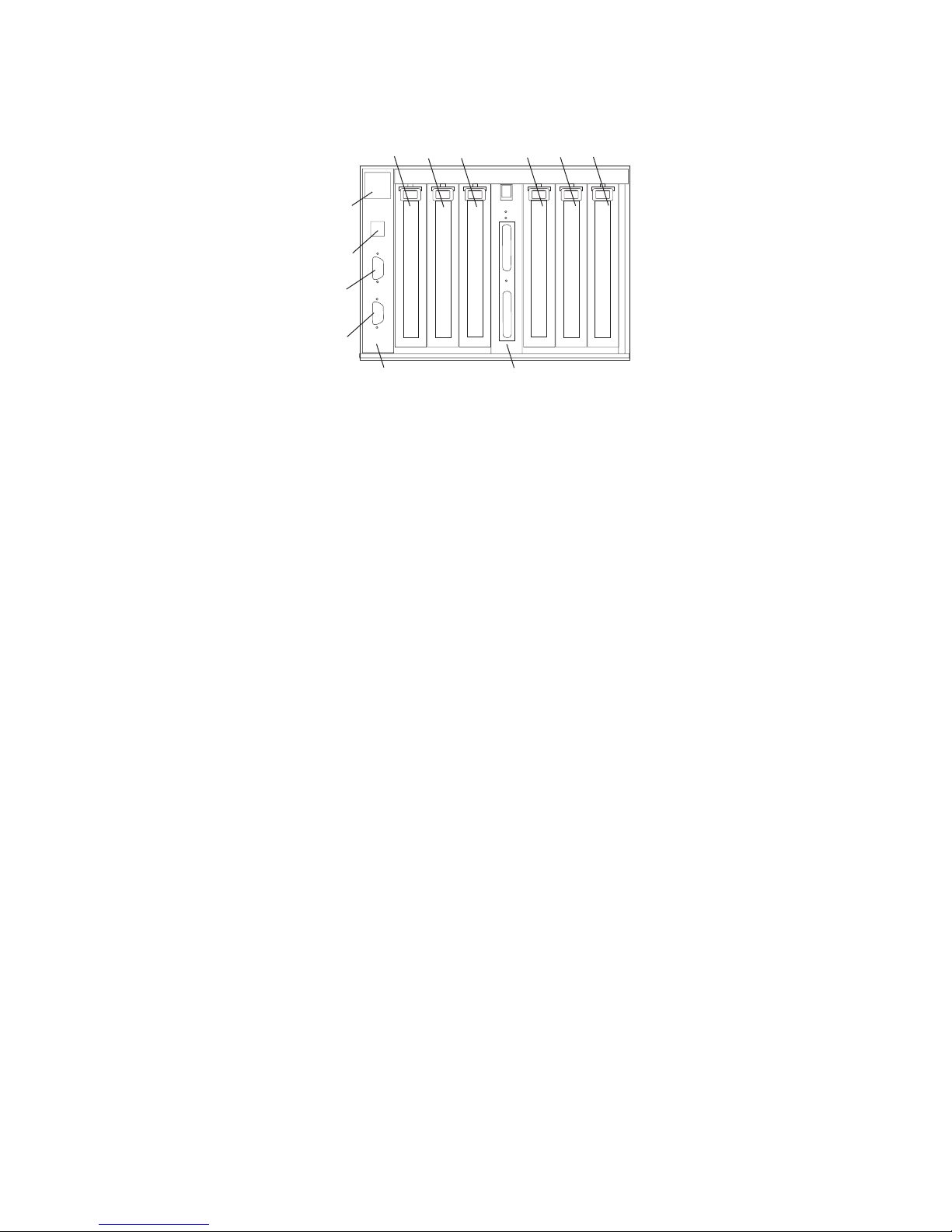

Model D20 PCI-X Slots

Seven PCI-X slots are available. The slots are 64-bit capable at up to 131.5 Mhz, 3.3 volts. The slots are

numbered on the rear of the chassis from left to right 1 through 7. The I/O backplane and each I/O slot

have green power indicator LEDs and amber identify LEDs. The following illustration shows the LED

locations when viewing from the rear of the I/O drawer.

1 PCI-X Expansion Slot 1 6 PCI-X Expansion Slot 6

2 PCI-X Expansion Slot 2 7 PCI-X Expansion Slot 7

3 PCI-X Expansion Slot 3 A Green Power LEDs

4 PCI-X Expansion Slot 4 B Amber Identify LEDs

5 PCI-X Expansion Slot 5

16 Eserver pSeries 7311 Model D10 and Model D20 Service Guide

Page 33

The green LEDs for the PCI-X adapter slots (viewed on the rear of the I/O subsystem) indicate the state of

the PCI slot during removal and replacement of an adapter.

PCI LED (Green) Indication PCI Slot Status Definition

Off Off Slot power is Off. It is safe to remove

or replace adapters.

On (not flashing) On Slot power is On. Do not remove or

replace adapters.

Flashing slowly (one flash per

second)

Slot has been identified by the

software. Do not remove or replace

adapters at this time.

Flashing rapidly (six to eight flashes

per second)

Slot is ready removing or replacing an

adapter.

Model D20 Disk Drives

There are 12 hot-plug disk-drive bays provided. The bays are located behind the Model D20 front bezel.

The Model D20 has from 18.2 GB to 1.7 terabytes of disk storage capacity. The following disk drive sizes

and speeds are available:

v 18.2 GB Ultra3 10K RPM 1 inch

v 36.4 GB Ultra3 10K RPM 1 inch

v 73.4 GB Ultra3 10K RPM 1 inch

v 146.8 GB Ultra3 10K RPM 1 inch

For an updated listing of hot-plug disk-drive sizes, contact your sales representative.

Chapter 1. Reference Information 17

Page 34

Model D20 Power

The Model D20 is standard with one power supply. If the customer wants redundant power in their I/O

subsystem, an optional power supply can be ordered. Either power supply, in a Model D20 that is

configured with two power supplies, can provide the necessary voltages and currents, independent of the

other power supply. The left and right power-supply output voltages are connected and monitored by the

power distribution board contained in the I/O subsystem.

The left and right power supplies are hot-pluggable and may be changed one at a time while the system is

operational. Each power supply is capable of converting available 110/220 V ac to the proper internal

voltages used by the system components. The internal voltage range is 5 volts system standby, 3.3 volts,

5 volts, 12 volts and -12 volts. When operating correctly, each supply will share the current load when

powered on. When in a fault state, the operating power supply will supply standby current to the faulted

supply for the DEVROS module. The following table describes power-related LED indicators that are

available on the Model D20. The operator panel LED referred to in the following table is on the front of the

processor subsystem to which the I/O subsystem is attached.

Status of LED Operator Panel LED (processor subsystem)

Off Power Source not connected

Blinking green LED System power source connected, but power is not turned

on

Blinking green LED, visibly begins to blink faster after the

power-button has been pressed.

System power source connected, the power-on button

has been pressed and power-on initiated

Solid (not blinking) green LED, (There is approximately a

30-second transition period from the time the power on

button is pressed to the time the power LED is on solid.)

System power source connected and turned on

Model D20 Cooling

Four blowers are mounted on the top of the I/O subsystem to provide cooling.

Attention: The four cooling blowers mounted on top of the Model D20 are hot-plug. The one exception

is when your subsystem has only one power supply either installed or functioning, in which case you must

shut down the system and subsystem. Failure to do so will automatically shut down the system.

D20 Input/Output Ports

The connector ports on the rear of the Model D20 I/O subsystem are used to connect the RIO-2 cables,

the SPCN cables, and the rack-beacon LED.

18 Eserver pSeries 7311 Model D10 and Model D20 Service Guide

Page 35

D20 I/O Subsystem Locations

The system uses physical location codes to provide mapping of the failing field replaceable units. The

location codes are produced by the processor subsystem’s firmware and AIX. For information about how to

read a location code, see the service guide for the processor subsystem to which your I/O subsystem is

connected.

Model D20 Front View

1 Serial Number 3 Model D20 Front Bezel

2 Operator Panel 4 Disk Drives (maximum quantity 12 )

Model D20 Rear View

1 PCI-X Expansion Slot 1 9 Primary Power Supply

2 PCI-X Expansion Slot 2 10 Model D20 I/O Drawer

3 PCI-X Expansion Slot 3 11 Connector J11 (Not Used)

4 PCI-X Expansion Slot 4 12 Connector J14 (Not Used)

5 PCI-X Expansion Slot 5 13 Rear Serial Number Label

6 PCI-X Expansion Slot 6 14 Connector J15 (SPCN 3)

7 PCI-X Expansion Slot 7 15 Connector J16 (SPCN 4)

8 Redundant Power Supply Receptacle 16 RIO Connectors

Upper

Connector = 1

Lower Connector = 0

Chapter 1. Reference Information 19

Page 36

Model D20 Power Supply Locations

1

2

3

4

6

5

1 Power Supplies 4 Green AC Power LED

2 Amber Fault/Identify LED 5 Power Supply Filler

3 Green DC Good LED 6 Model D20 I/O Drawer

20 Eserver pSeries 7311 Model D10 and Model D20 Service Guide

Page 37

Model D20 Blower Locations

The following illustration identifies the I/O subsystem cooling blowers. Each blower has a green power

LED and an amber identify LED located on the front blower housing. The green LED indicates that a

blower has power and is operating correctly. The amber LED is in the identify state when blinking.

1 Green LED 4 Blower Connector

2 Amber LED 5 Hot-Plug Blower Assembly

3 Snap Button 6 Docking Connector

Chapter 1. Reference Information 21

Page 38

Model D20 I/O Backplane Locations

The following illustration of the I/O backplane identifies the primary connectors used in your subsystem.

Note:

Before replacing the I/O backplane, note the position of pin 1 on the VPD module.

1 PCI-X Adapter Connector 1 11 Disk Drive Power Connector

2 PCI-X Adapter Connector 2 12 Cooling Blower Connector

3 PCI-X Adapter Connector 3 13 VPD Module

4 PCI-X Adapter Connector 4 14 Redundant Power Supply Connector

5 PCI-X Adapter Connector 5 15 Primary Power Supply Connector

6 PCI-X Adapter Connector 6 16 Connector J11 (Not Used)

7 PCI-X Adapter Connector 7 17 Connector J14 (Not Used)

8 Operator Panel Connector 18 Connector J15 (SPCN 3)

9 RIO Bus Adapter Connector 19 Connector J16 (SPCN 4)

10 Disk Drive System Power Control Network

(SPCN) Connector

20 4-pin Connector, Rack Beacon Connector

22 Eserver pSeries 7311 Model D10 and Model D20 Service Guide

Page 39

Model D20 Reading the Operator Panel and I/O Backplane LEDs

The following illustration shows the component location on the operator panel

1 Power-On LED

2 Attention LED

3 Operator Panel

4 Snap Buttons

The following table defines each LEDs function on the operator panel.

Number Component Name Component Description

1 Green Power LED Standby State - Blinking LED

(System connected to power source but not powered on.)

Powered On - LED is turned on solid (not blinking).

2 Amber Attention LED Normal State - LED is off.

Chapter 1. Reference Information 23

Page 40

Model D20 SCSI IDs and Bay Locations

Index Bay Location Drive Name SCSI Bus ID

8 DB1 D01 Hot-Plug Disk Drive 8 - DB1

9 DB1 D02 Hot-Plug Disk Drive 9 - DB1

A DB1 D03 Hot-Plug Disk Drive A - DB1

B DB1 D04 Hot-Plug Disk Drive B - DB1

C DB1 D05 Hot-Plug Disk Drive C - DB1

D DB1 D06 Hot-Plug Disk Drive D - DB1

8 DB2 D07 Hot-Plug Disk Drive 8 - DB2

9 DB2 D08 Hot-Plug Disk Drive 9 - DB2

A DB2 D09 Hot-Plug Disk Drive A - DB2

B DB2 D10 Hot-Plug Disk Drive B - DB2

C DB2 D11 Hot-Plug Disk Drive C - DB2

D DB2 D12 Hot-Plug Disk Drive D - DB2

Note: The SCSI bus IDs are the recommended values and indicate how the IDs are set when the system

is shipped from the factory. Field installations might not comply with these recommendations.

24 Eserver pSeries 7311 Model D10 and Model D20 Service Guide

Page 41

Cabling the Model D20 to a pSeries 630 Model 6C4

The Model D20 subsystem can be installed in any location in a standard 19-inch EIA rack. The cables that

connect the subsystems allow some flexibility in drawer placement. Up to two Model D20s can be

connected to a pSeries 630 Model 6C4. Each I/O subsystem is connected to the processor subsystem

using a system power control network (SPCN) cable loop and a remote I/O (RIO) cable loop. One SPCN

cable loop is needed to connect the I/O subsystems to one processor subsystem.

Before connecting the RIO-2 and SPCN cables to the model D20, do the following:

1. Ensure that your Model 6C4 is running the latest level firmware. Refer to the ″Firmware Updates″

section of the ″Using the Service Processor″ chapter in the Eserver pSeries 630 Model 6C4 and

Model 6E4Service Guide, order number SA38-0604. For information about checking or upgrading the

firmware level of your Model 6C4.

2. After ensuring that your firmware is at the latest level, turn off the power and disconnect the Model

6C4 power cables from the power source.

3. Attach the RIO-2 and SPCN cables. For cabling diagrams, see “RIO-2 (Remote Input Output) Cabling”

on page 26.

4. After connecting the RIO-2 and SPCN cables from the Model D20 to your system, reconnect the

system’s power cables to the power source and refer to “Stopping and Starting the System” on page

42.

5. Run system verification. Refer to the ″Verifying the Hardware″ chapter in the Eserver pSeries 630

Model 6C4 and Model 6E4 Installation Guide, order number SA38-0604.

Your

Model 6C4 is expandable when connected up to two Model D20 I/O drawers. Each Model D20 can

contain up to 7 I/O PCI adapter slots, and two 6-pack disk drive (DASD) bays.

Chapter 1. Reference Information 25

Page 42

RIO-2 (Remote Input Output) Cabling

The following rules apply to RIO-2 cable connections:

Notes:

1. To connect to a Model D20, you will be using the RIO-2 (Remote Input Output) and SPCN (System

Power Control Network) connectors and cables. The RIO-2 and SPCN cables provide two functions,

remote data bus connection, and power control.

2. The I/O drawers must be connected in a loop for both the RIO-2 and SPCN cables. The loop

connection provides redundant paths so that if a failure occurs in part of a cable, the system will

continue to operate. If a failure does occur, a message is displayed on the system console; however,

the system does continue to operate. See the following illustrations for possible cabling configurations.

To

connect the RIO-2 cables to the rear of the Model 6C4, do the following:

1. Locate the RIO-2 cable-support bracket.

2. Using two M3 x 6 retaining screws, secure the RIO-2 cable-support bracket to the rear of the Model

6C4 chassis. See the following illustration.

1 Model 6C4

2 RIO-2 Cable-Support Bracket

3 M3 x 6 Retaining Screws (Quantity 2)

3. Pull the sliding portion of the RIO-2 cable-support bracket back from the Model 6C4 chassis. The

sliding portion of the cable support bracket will stop before being fully separated.

4. Align the RIO-2 cable connector with the bottom of the sliding portion of the RIO-2 cable support

bracket.

26 Eserver pSeries 7311 Model D10 and Model D20 Service Guide

Page 43

5. Lift the RIO-2 cable and cable connector into the bottom of the RIO-2 cable-support bracket.

1 Model 6C4

2 RIO-2 Cable-Support Bracket

3 Slide Portion of RIO-2 Cable-Support Bracket

4 RIO-2 Connector Support Lever

6. Pull the RIO-2 connector back until the connector is seated against the support hook.

7. Push the RIO-2 connector forward, ensuring that the RIO-2 connector lever slides over the top of the

connector hooks.

8. Slowly push the assembly toward the chassis.

9. Secure the RIO-2 cable-support bracket with the captive thumbscrew, the RIO-2 connector and slide

portion of the RIO-2 support bracket to the back of the Model 6C4 chassis.

1 Captive Thumbscrews

2 RIO-2 Cable and Connector

3 RIO-2 Connector Support Lever

Chapter 1. Reference Information 27

Page 44

Model 6C4 Attached to One I/O Drawer:

1 Model 6C4

2 Model D20

3 Cable from Model 6C4 Connector RIO-2 0 to Model D20 Connector RIO-2 0

4 Cable from Model 6C4 Connector RIO-2 1 to Model D20 Connector RIO-2 1

Model 6C4 Attached to Two I/O Drawers:

1 Model 6C4

2 Model D20 I/O Drawer

3 Model D20 I/O Drawer

4 Cable from Model 6C4 Connector RIO-2 0 to Model D20 Connector RIO-2 0

5 Cable from Model 6C4 Connector RIO-2 1 to Model D20 Connector RIO-2 1

6 Cable from Model D20 Connector RIO-2 1 to Model D20 Connector RIO-2 0

28 Eserver pSeries 7311 Model D10 and Model D20 Service Guide

Page 45

SPCN (System Power Control Network) Cabling

The following figures provide cabling examples for all valid cabling configurations. Match your configuration

to the correct figure and connect your SPCN cables as shown.

Model 6C4 Attached to One I/O Drawer:

1 Model 6C4

2 Model D20

3 Cable from Model 6C4 Connector SPCN 2 to Model D20 Connector SPCN 4 (J16)

4 Cable from Model 6C4 Connector SPCN 1 to Model D20 Connector SPCN 3 (J15)

Model 6C4 Attached to Two I/O Drawers:

1 Model 6C4

2 Model D20 I/O Drawer

3 Model D20 I/O Drawer

4 Cable from Model 6C4 Connector SPCN 1 to Model D20 Connector SPCN 3 (J15)

5 Cable from Model 6C4 Connector SPCN 2 to Model D20 Connector SPCN 4 (J16)

6 Cable from Model D20 Connector SPCN 4 (J16) to Model D20 Connector SPCN 3 (J15)

Chapter 1. Reference Information 29

Page 46

Model D20 Internal Cabling

1 Cooling Blowers (Quantity 4) 6 Disk Drive Power Connector

2 Operator Panel 7 Disk Drive SPCN Connector

3 Disk Drive Backplanes 8 Disk Drive Power/Signal Cable

53P0416

4 Cooling Blower Cable

53P0419

9 Operator Panel Connector

5 Cooling Blower Connector 10 Operator Panel Cable

53P0414

30 Eserver pSeries 7311 Model D10 and Model D20 Service Guide

Page 47

Model D20 Location Codes

This system (processor subsystem and attached I/O subsystems) uses physical location codes in

conjunction with AIX location codes to provide mapping of a failing field replaceable units (FRUs). The

location codes are produced by the processor subsystem’s firmware and AIX. For information about how to

read a location code, see the service guide for the processor subsystem to which your I/O subsystem is

connected.

AIX and Physical Location Code Table

This section covers the AIX and Physical Location Code tables for the Model D20 I/O subsystem.

The tables in this section contain the location codes for I/O subsystems when they are attached to the

system unit. In the tables, the location code for the I/O subsystem number is represented by dd. The first

time that an installed system is powered on, the I/O subsystems are numbered. For example, if a system

is first powered on with two I/O subsystems connected, then the dd value for the connected I/O

subsystems should be numbered from 2 and 3.

Note: If the system was powered on with I/O subsystems connected before delivery to the customer, the

I/O subsystem location codes for the drawers connected at that time are already assigned.

If at a later time, an I/O subsystem is removed from the system and a different I/O subsystem is

substituted, the substitute is assigned the next higher number available for its value of dd, which, in the

earlier example, is 4. If the original I/O subsystem is reinstalled in the system configuration, the system

uses the original dd value for the I/O subsystem.

To keep the system from renumbering the I/O drawer when an I/O backplane is replaced, the VPD module

from the old I/O backplane must be moved over to the new I/O backplane.

The following diagram defines each part of a location code.

Ux.dd-xx-yy

| | | |

| | | |

| | | yy This code is used for the next component (yy, yy, yy, ...)

| | xx This code is used for the next component (Px, Fx, Vx, ...)

| dd This code is the location code for the I/O drawer (2 to 63)

Ux This code normally identifies the rack in which a drawer is installed.

The x will always be zero (0) for this system.

Chapter 1. Reference Information 31

Page 48

Model D20 Location Code Table

The following table lists the location codes for a model D20 I/O subsystem. The location code for the I/O

subsystem connected to a system unit is U0.dd (where dd can be any number from 2 through 63).

FRU Name Physical Location Code

Model D20 I/O Drawer U0.dd (dd = any number from 2 through 63)

Rack frame U0

I/O drawer backplane U0.dd-P1

I/O subsystem drawer U0.dd

RIO Bus Adapter

RIO bus adapter U0.dd-P1.1

RIO port 1 upper connector U0.dd-P1.1/Q1

RIO port 1 cable U0.dd-P1.1/Q1#

RIO port 0 lower connector U0.dd-P1.1/Q2

RIO port 0 cable U0.dd-P1.1/Q2#

PCI Bus Controller

PCI bus controller PHB0 U0.dd-P1

PCI to PCI bridge EADS-X U0.dd-P1

PCI Bus Controller PHB2

PCI bus controller PHB2 U0.dd-P1

PCI to PCI bridge EADS-X U0.dd-P1

Pluggable Adapter Slots

PCI slot 1 U0.dd-P1/I1

PCI card in slot 1 U0.dd-P1-I1

PCI slot 2 U0.dd-P1/I2

PCI card in slot 2 U0.dd-P1-I2

PCI slot 3 U0.dd-P1/I3

PCI card in slot 3 U0.dd-P1-I3

PCI slot 4 U0.dd-P1/I4

PCI card in slot 4 U0.dd-P1-I4

PCI slot 5 U0.dd-P1/I5

PCI card in slot 5 U0.dd-P1/I5

PCI slot 6 U0.dd-P1/I6

PCI card in slot 6 U0.dd-P1/I6

PCI slot 7 U0.dd-P1/I7

PCI card in slot 7 U0.dd-P1/I7

Power Supply

Power supply 1 (no internal blower) U0.dd-V1

Power supply 2 (no internal blower) U0.dd-V2

Cooling Blowers

Cooling blower 1 U0.dd-F1

Cooling blower 2 U0.dd-F2

Cooling blower 3 U0.dd-F3

32 Eserver pSeries 7311 Model D10 and Model D20 Service Guide

Page 49

FRU Name Physical Location Code

Cooling blower 4 U0.dd-F4

SPCN Connectors

SPCN connector 1 U0.dd-P1/Q3

SPCN connector 2 U0.dd-P1/Q4

SPCN connector 3 U0.dd-P1/Q5

SPCN connector 4 U0.dd-P1/Q6

Rack Indicator

Rack beacon (4–pin) U0.dd-P1/Q7

Operator Panel

Operator panel U0.dd-L1

Temperature Sensor

Temperature sensor (on operator panel) U0.dd-L1

Disk Drives Backplanes

Disk drives backplane 1 U0.dd-P3

Disk drives backplane 2 U0.dd-P4

Disk Drive Locations

Hot-swap disk drive bay 1 U0.dd-P1-Ix/Zn-A8

Hot-swap disk drive bay 2 U0.dd-P1-Ix/Zn-A9

Hot-swap disk drive bay 3 U0.dd-P1-Ix/Zn-AA

Hot-swap disk drive bay 4 U0.dd-P1-Ix/Zn-AB

Hot-swap disk drive bay 5 U0.dd-P1-Ix/Zn-AC

Hot-swap disk drive bay 6 U0.dd-P1-Ix/Zn-AD

Hot-swap disk drive bay 7 U0.dd-P1-Iy/Zn-A8

Hot-swap disk drive bay 8 U0.dd-P1-Iy/Zn-A9

Hot-swap disk drive bay 9 U0.dd-P1-Iy/Zn-AA

Hot-swap disk drive bay 10 U0.dd-P1-Iy/Zn-AB

Hot-swap disk drive bay 11 U0.dd-P1-Iy/Zn-AC

Hot-swap disk drive bay 12 U0.dd-P1-Iy/Zn-AD

SCSI

SES0 U0.dd-P1-Ix/Zn-AF

SES1 U0.dd-P1-Iy/Zn-AF

Chapter 1. Reference Information 33

Page 50

Powering the System On and Off

Power for the I/O subsystems is controlled by the attached processor subsystem and the System Power

Control Network (SPCN).

For information about procedures to power the system on and off, refer to the service guide of the

processor subsystem to which the I/O subsystem is attached.

Power-On Self-Test

After power is turned on and before the operating system is loaded, the system does a power-on self-test

(POST). The RIO loop that connects the I/O subsystems to the system unit is tested. Tests are also

performed on the installed adapters and devices in the I/O subsystems. If an error occurs during the

POST, an error code is displayed on the system operator panel LCD that indicates which part is failing and

which subsystem contains the error.

34 Eserver pSeries 7311 Model D10 and Model D20 Service Guide

Page 51

Model D10 and Model D20 Specifications

This section contains system specifications for both the Model D10 and Model D20 I/O subsystems.

Model D10 Specifications

Dimensions 7311-D10 Two 7311-D10s with

Enclosure

Height 170 mm (6.6 in) 178 mm (7.0 in)

Width 220 mm (8.7 in) 445 mm (17.5 in)

Depth 711 mm (28.0 in) 711 mm (28.0 in)

Weight 16.8 kg (37 lbs) 39.1 kg (86 lbs)

Electrical

Power source loading for two 7311-D10 (max.) 0.21 kVA

Voltage range 200 to 240 V ac, (dc not supported)

Frequency 50 or 60 Hz

Thermal output (typical) 461 Btu/hr

Thermal output (max.) 683 Btu/hr

Power requirements (typical) 135 watts

Power requirements for two 7311-D10 (max.) 200 watts

Power factor 0.91

Inrush current² 64 amps

Maximum altitude

3, 4

3048 m (10000 ft.)

Temperature Requirements³ Operating

10 to 38°C

50 to 100°F)

Non-Operating

1 to 60°C

(34 to 140°F)

Storage

1 to 60°C

(34 to 140°F)

Humidity Requirements⁴ Operating Non-Operating Storage

(Noncondensing) 8 to 80% 8 to 80% 8 to 80%

Wet Bulb 23°C (73°F) 27°C (81°F) 29°C (84°F)

Noise Emissions

1, 4

Operating Idle

L

WAd

, one 7311-D10

L

WAd

, two 7311-D10

L

WAd

, four 7311-D10

5.6 bels

5.9 bels

6.2 bels

5.6 bels

5.9 bels

6.2 bels

<LpA>m, one 7311-D10

<L

pA>m

, two 7311-D10

<L

pA>m

, four 7311-D10

40 dBA

43 dBA

46 dBA

40 dBA

43 dBA

46 dBA

Install/Air Flow: Maintaining service clearance allows proper air flow.

Service Clearances: See 7014 Series Model T00 and T42 Rack Installation and Service Guide, order number

SA38-0577 for T00 or T42 rack service clearances.

1. See page 182 for definitions of noise emissions positions. See noise emissions note 4.

2. Inrush currents occur only at initial application of power, no inrush occurs during normal power off-on cycle.

3. The upper limit of the dry bulb temperature must be derated 1°C per 137 m (450 ft.) above 915 m (3000 ft.).

4. The upper limit of the wet bulb temperature must be derated 1°C per 274 m (900 ft. ) above 305 m (1000 ft.).

Chapter 1. Reference Information 35

Page 52

Model D20 Specifications

Dimensions

Height 178 mm (7.0 in)

Width 445 mm (17.5 in)

Depth 610 mm (24.0 in)

Maximum Weight 45.9kg (101 lbs)

Electrical

Power source loading (max.) 0.358 kVA

Voltage range 100 to 240 V ac, V dc not supported

Frequency 50 or 60 Hz

Thermal output (typical) 774 Btu/hr

Thermal output (max.) 1161 Btu/hr

Power requirements (typical) 227 watts

Power requirements for two

7311-D20 (max.)

340 watts

Power factor 0.91

Inrush current² 60 amps

Maximum altitude

3, 4

3048 m (10,000 ft.)

Temperature

Requirements³

Operating

5 to 35°C

41 to 95°F)

Non-Operating

1 to 43°C

(34 to 109°F)

Storage

1 to 60°C

(34 to 140°F)

Humidity Requirements⁴ Operating Non-Operating Storage

(Noncondensing) 8 to 80% 8 to 80% 5 to 80%

Wet Bulb 23°C (73°F) 27°C (81°F) 29°C (84°F)

Noise Emissions

1, 5

Operating Idle

L

WAd

6.1 bels 6.0 bels

<LpA>

m

44 dBA 43 dBA

Install/Air Flow Maintaining service clearance allows proper air flow.

Service Clearances: See 7014 Series Model T00 and T42 Rack Installation and Service Guide, order number

SA38-0577 for T00 or T42 rack service clearances.

1. See 182 for definitions of noise emissions positions. See noise emissions note 4.

2. Inrush currents occur only at initial application of power, no inrush occurs during normal power off-on cycle.

3. The upper limit of the dry bulb temperature must be derated 1 degree C per 137 m (450 ft.) above 915 m (3000

ft.).

4. The upper limit of the wet bulb temperature must be derated 1 degree C per 274 m (900 ft. ) above 305 m (1000

ft.).

36 Eserver pSeries 7311 Model D10 and Model D20 Service Guide

Page 53

External AC Power Cables

To avoid electrical shock, a power cable with a grounded attachment plug is provided. Use only properly

grounded outlets.

Power cables used in the United States and Canada are listed by Underwriter’s Laboratories (UL) and

certified by the Canadian Standards Association (CSA). These power cords consist of the following:

v Electrical cables, Type SVT or SJT.

v Attachment plugs complying with National Electrical Manufacturers Association (NEMA) 5-15P, that is:

″For 115 V operation (Model D20 only), use a UL listed cable set consisting of a minimum 18 AWG, Type

SVT or SJT three-conductor cord a maximum of 15 feet in length and a parallel blade, grounding type

attachment plug rated at 15 A, 125 V.″

″For 230 V operation in the United States use a UL listed cable set consisting of a minimum 18 AWG,

Type SVT or SJT three-conductor cable a maximum of 15 feet in length, and a tandem blade, grounding

type attachment plug rated at 15 A, 250 V.″

v Appliance couplers complying with International Electrotechnical Commission (IEC) Standard 320, Sheet

C13.

Power

cables used in other countries consist of the following:

v Electrical cables, Type HD21.

v Attachment plugs approved by the appropriate testing organization for the specific countries where they

are used.

″For units set at 230 V (outside of U.S.): use a cable set consisting of a minimum 18 AWG cable and

grounding type attachment plug rated 15 A, 250 V. The cable set should have the appropriate safety

approvals for the country in which the equipment will be installed and should be marked `HAR’.″

For information about the power cables that are available, refer to Chapter 4, “Parts Information,” on page

161.

Chapter 1. Reference Information 37

Page 54

Service Inspection Guide

Perform a service inspection on the system (processor subsystem and connected I/O subsystems) when:

v The system is inspected for a maintenance agreement.

v Service is requested and service has not recently been performed.

v An alterations and attachments review is performed.

v Changes have been made to the equipment that may affect the safe operation of the equipment.

v External devices with their own power cables have those cables attached.

If

the inspection indicates an unacceptable safety condition, the condition must be corrected before anyone

can service the machine.

Note: The owner of the system is responsible to correct any unsafe conditions.

Perform the following checks:

1. Check the covers for sharp edges and for damage or alterations that expose the internal parts of the

system.

2. Check the covers for proper fit to the system. They should be in place and secure.

3. Gently rock the system from side to side to determine if it is steady.

4. Set the power button of the system to Off.

5. Remove the covers.

6. Check for alterations or attachments. If there are any, check for obvious safety hazards, such as

broken wires, sharp edges, or broken insulation.

7. Check the internal cables for damage.

8. Check for dirt, water, and any other contamination within the system.

9. Check the voltage label on the back of the system to ensure that it matches the voltage at the outlet.

10. Check the external power cable for damage.

11. With the external power cable connected to the system, check for 0.1 ohm or less resistance between

the ground lug on the external power cable plug and the metal frame.

12. Perform the following checks on each device that has its own power cables:

a. Check for damage to the power cable.

b. Check for the correctly grounded power cable.

c. With the external power cable connected to the device, check for 0.1 ohm or less resistance

between the ground lug on the external power cable plug and the metal frame of the device.

13.

Install the covers.

38 Eserver pSeries 7311 Model D10 and Model D20 Service Guide

Page 55

Chapter 2. Diagnostics and Maintenance Procedures

The system uses an integrated set of software diagnostic procedures to help isolate failing components

and system maintenance. This book, along with the RS/6000 Eserver pSeries Diagnostic Information for

Multiple Bus Systems, is the basis of the diagnostic procedures. Refer to the system service guide when

running diagnostics on your I/O subsystem.

Power and Attention LEDs

The Power and Attention LEDs provide a means to identify failing components in your subsystem. When a

failing component is detected in your system, the system’s Attention LED is turned on.

Component LEDs

To further help you identify the failing component, all system components have individual LEDs that

indicate a failure when lit. The LEDs are either on the component itself or on the carrier of the component

(memory card, fan, memory module, or CPU).

The LEDs are either green or amber in color. A lit green LED indicates that the system or component is

receiving power. A lit amber LED identifies a system or component on the system. The amber LED can

also indicate when a system or component on a system has a problem or fault. For more information on

LEDs and their definitions, see Chapter 5, “Fault and Attention LEDs,” on page 173.

Resetting the LEDs

To reset the LEDs, do the following:

1. Replace the failing component with the new component.

2. Log in as root user.

3. At the command line, type diag.

4. Select Task Selection.

5. Select Log Repair Action.

6. Select the device that was repaired. (If the device is not listed, select sysplanar0.)

Checkpoints

The system uses various types of checkpoints, error codes, and SRNs, which are referred to throughout

your system’s service guide. These codes can appear in the service processor boot progress log, the AIX

error log, and the operator panel display. Understanding the definition and relationships of these codes is

important to the service personnel who are installing or maintaining the system.

Service Request Numbers (SRNs) are listed in the RS/6000 Eserver pSeries Diagnostic Information for

Multiple Bus Systems, order number SA38-0509.

FRU Isolation

For a list of error codes and recommended actions for each code, see your system’s service guide. These

actions can refer to Chapter 4, “Parts Information,” on page 161, “Maintenance Analysis Procedures

(MAPs)” on page 40, or provide informational message and directions. If a replacement part is indicated,

direct reference is made to the part name. The respective AIX and physical location codes are listed for

each occurrence as required. For a list of locations codes, see your system’s service guide.

39

Page 56

Maintenance Analysis Procedures (MAPs)

The maintenance analysis procedures (MAPs) provide the service representative a step-by-step procedure

to analyze a problem with the system and I/O subsystem hardware. Be prepared to record code numbers

and other data while using the MAPs.

Because the Model D10 and Model D20 are subsystems, refer to your system’s service guide. The

system’s service guide contains all of the MAPs needed for servicing the Model D10 and Model D20 I/O

subsystems.

Checkpoints

Checkpoints display on the system operator panel and the virtual terminal while the system unit is

powering on and going through the initial program load (IPL). See the system’s service guide for

descriptive information and a complete listing of all checkpoints used by the Model D10 and Model D20

I/O subsystems.

Error Code to FRU Index

The Error Code to FRU Index lists fault symptoms and possible causes. The most likely cause is listed

first. Use this index to help you decide which FRUs to replace when servicing the Model D10 or Model

D20 I/O subsystem. See your system’s service guide for more information and a complete listing of all

error codes and FRUs used by the Model D10 and Model D20 I/O subsystem.

Using the Service Processor

The service processor is in the processor subsystem to which your I/O subsystem is connected and runs

on its own power boundary. The service processor continually monitors hardware attributes and the

environmental conditions within the system and connected I/O subsystems. The service processor is

controlled by firmware and does not require the operating system to be operational to perform its tasks.

The service processor menus allow you to configure service processor options, as well as enable and

disable functions.

Service processor menus are available using an ASCII terminal or an HMC virtual terminal window when

OK is displayed on the operator panel or when the service processor has detected a system problem (such

as a surveillance failure).

For more information about the service processor for the system to which your I/O subsystem is

connected, see the system’s service guide.

Using System Management Services

Use the system management services menus to view information about the processor subsystem to which

the I/O subsystem is connected. For more information about the service processor, see the service guide

for the attached system.

40 Eserver pSeries 7311 Model D10 and Model D20 Service Guide

Page 57

Chapter 3. Removal and Replacement Procedures

Before performing any of the removal or replacement procedures in this chapter, read the following danger