Page 1

Power Systems

Installing the IBM Power System

S821LC (8001-12C)

IBM

Page 2

Page 3

Power Systems

Installing the IBM Power System

S821LC (8001-12C)

IBM

Page 4

Note

Before using this information and the product it supports, read the information in “Safety notices” on page v, “Notices” on

page 103, the IBM Systems Safety Notices manual, G229-9054, and the IBM Environmental Notices and User Guide, Z125–5823.

This edition applies to IBM Power Systems™servers that contain the POWER8 processor and to all associated

models.

© Copyright IBM Corporation 2016, 2017.

US Government Users Restricted Rights – Use, duplication or disclosure restricted by GSA ADP Schedule Contract

with IBM Corp.

Page 5

Contents

Safety notices ............ v

Installing and configuring POWER8

processor-based systems and system

features ............... 1

Installing the IBM Power System S821LC (8001-12C)

system ................ 1

Prerequisites for installing the rack-mounted

8001-22C system ............ 1

Completing inventory for your system..... 1

Determining and marking the location in the rack

for the 8001-12C system ......... 2

Attaching the rails to the system chassis and to

the rack ............... 3

Installing the system into the rack and connecting

and routing power cables ......... 5

Completing server setup ......... 8

Installing drives in the 8001-12C system ..... 8

Drive installation details for the 8001-12C system 8

Installing a front drive in the 8001-12C system.. 10

Installing a drive on module in the 8001-12C

system ............... 14

Installing a graphics processing unit in the 8001-12C

system ................ 16

Installing memory in the 8001-12C system .... 19

Placement rules for memory in the 8001-12C or

8001-22C system............ 19

Installing memory in the 8001-12C system ... 20

Installing a PCIe adapter in the 8001-12C system .. 23

PCIe adapter placement rules and slot priorities

for the 8001-12C or 8005-12N system ..... 23

PCIe adapter information by feature type for the

8001-12C or 8005-12N .......... 31

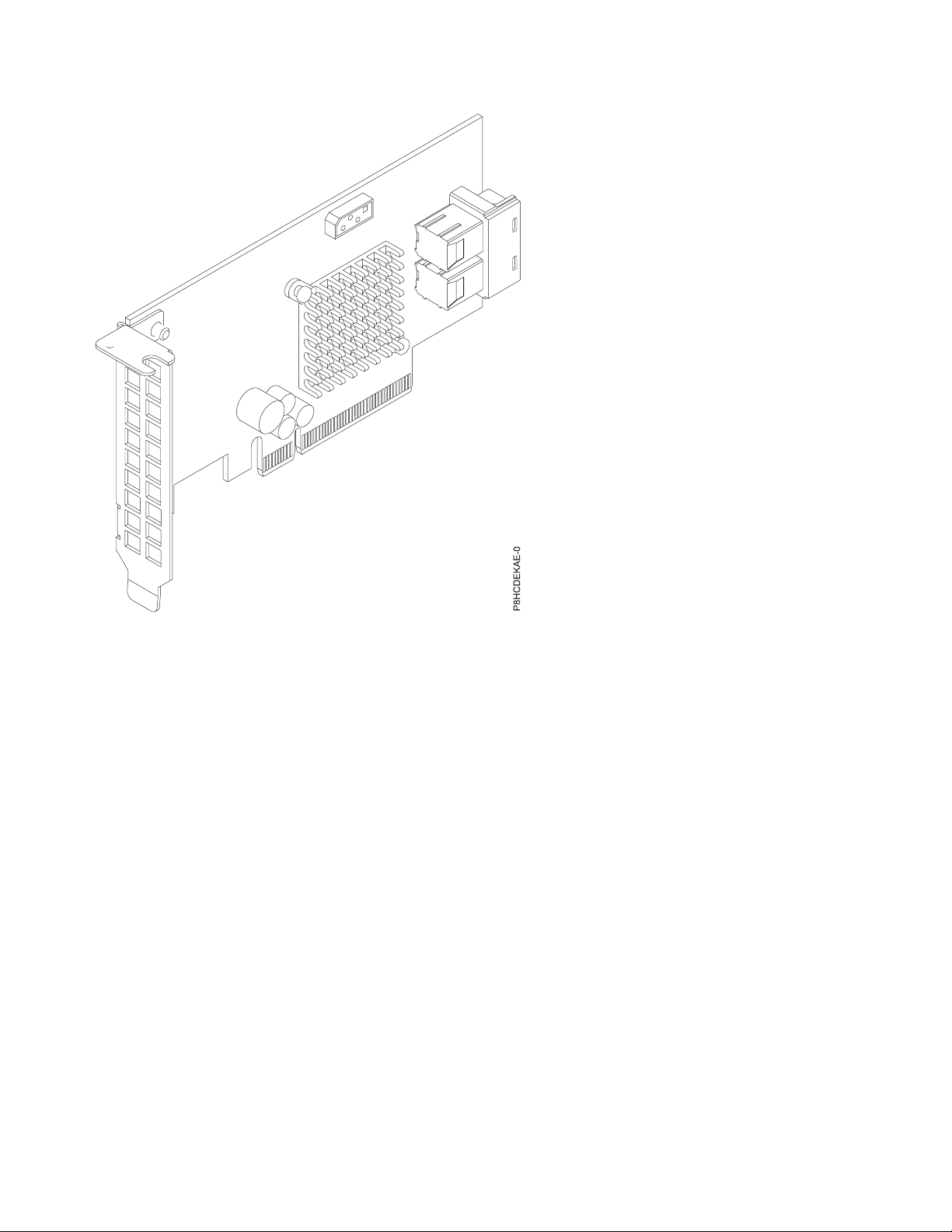

12 Gb/s Eight-Port SAS Internal HBA Adapter

(Adapter FRU number: AOC-S3008L-L8e-P) . 32

PCIe3 x4 Intel x550 10GBase-T Converged

Network Adapter with Dual RJ45 Ports (FC

EKA0) .............. 34

Cavium (Qlogic) BCM57840 4-port SFP+ 10

Gb Ethernet Adapter PCIe3.0 x8 LP (FC

EKA1) .............. 35

Intel 82599ES Ethernet Converged Network

Adapter x520-DA2 Dual-port 10G/1G SFP+

PCIe2.0 x8 LP (FC EKA2) ........ 37

Intel 82575EB dual-port Gigabit Ethernet

Controller PCIe x4.0 LP (FC EKA3) .... 39

Broadcom (LSI) MegaRAID 9361-8i SAS3

Controller with 8 Internal Ports (1 GB Cache)

PCIe3.0 x8 LP with cables (FC EKAA and

EKEA) .............. 41

SMC AOC-K-S3008L-L8i 12 Gbps SAS3/RAID

0,1 and 10 PCIe3.0 x8 LP with cables (FC

EKAB and EKEB) .......... 43

Broadcom (LSI) 9300-8E SAS3 HBA PCIe3.0 x8

LP Adapter (FC EKAD and EKED) .... 45

PCIe3 x8 Dual-port Internal NVMe Host Bus

Adapter (FC EKAE and EKEE) ...... 47

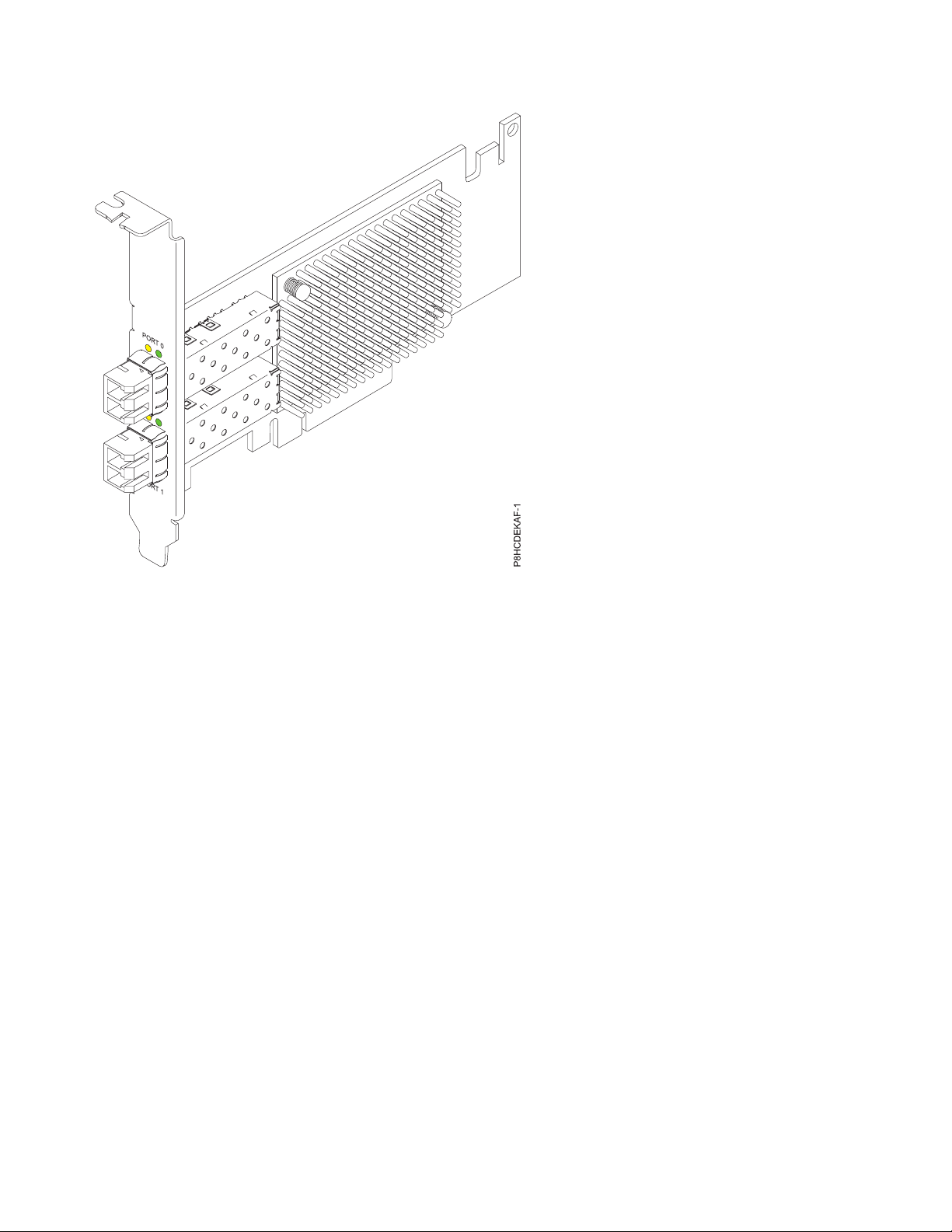

Emulex LPE16002B-M6-O Dual-port 16 Gb

Fibre Channel Card PCIe3.0 x8 LP (FC EKAF) . 49

SMC quad-port NVMe Host Bus Adapter

(PEX9733) PCIe3.0 x8 LP with cables (FC

EKAG and EKEG) .......... 51

Broadcom (LSI) MegaRAID 9361-8i SAS3

Controller with 8 internal ports (2 GB Cache)

PCIe3.0 x8 with cables (FC EKAH and EKEH) . 53

NVIDIA Tesla K80 24 GB GPU Accelerator (FC

EKAJ) .............. 55

Mellanox MCX456A-ECAT ConnectX-4 VPI

EDR IB 100 Gb/s and 100 GbE Dual-port

QSFP28 PCIe3.0 x16 LP (FC EKAL) .... 57

Mellanox MCX415A-CCAT ConnectX-4 EN

100 GbE Single-port QSFP28 PCIe3.0 x16 LP

(FC EKAM) ............ 59

Qlogic QLE2562 Dual-port 8 Gb Fibre Channel

Adapter PCIe x8 LP (FC EKAP) ..... 61

Qlogic QLE2692OP Dual-port 16 Gb Fibre

Channel Adapter PCIe3 x8 LP (FC EKAQ) .. 63

Alpha-data CAPI Adapter: ADM-PCIe KU3

(FC EKAT)............. 65

Mellanox MCX4121A-ACAT ConnectX-4 Lx

EN 25GbE dual-port SFP28 PCIe3.0 x8 LP (FC

EKAU) .............. 67

NVIDIA Tesla P100 16GB PCIe3.0 x16

Dual-slot FHFL with cables (FC EKAZ) ... 69

Intel XL710 Ethernet Converged Network

Adapter Quad-port 10G/1G SFP+ PCIe3.0 x8

LP (FC EKFH) ........... 71

PCIe3 1.6 TB NVMe Flash Adapter (FC EKN2) 73

Installing a PCIe adapter in the 8001-12C system 75

Common procedures for servicing or installing

features in the 8001-12C or 8005-12N ...... 80

Before you begin ........... 80

Identifying the system that contains the part to

replace ............... 83

LEDs on the 8001-12C or 8005-12N system .. 83

Identifying the 8001-12C, 8001-22C, 8005-12N,

or 8005-22N that needs servicing ..... 85

Preparing the 8001-12C or 8005-12N system to

remove and replace internal parts ...... 85

Preparing the 8001-12C or 8005-12N system for

operation after you remove and replace internal

parts................ 87

Starting and stopping the 8001-12C, 8001-22C,

8005-12N, or 8005-22N.......... 88

Starting the 8001-12C, 8001-22C, 8005-12N, or

8005-22N system .......... 88

Stopping the 8001-12C, 8001-22C, 8005-12N, or

8005-22N system .......... 90

Drive commands for 8001-12C, 8001-22C,

8005-12N, or 8005-22N.......... 90

mvCLI commands .......... 90

© Copyright IBM Corp. 2016, 2017 iii

Page 6

StorCLI commands .......... 91

sas3ircu commands .......... 92

NVMe commands .......... 92

Sensor readings GUI display ....... 93

Removing and replacing a power supply in the

8001-12C, 8001-22C, 8005-12N, or 8005-22N ... 93

Removing a power supply from the 8001-12C,

8001-22C, 8005-12N, or 8005-22N ..... 93

Replacing a power supply in the 8001-12C,

8001-22C, 8005-12N, or 8005-22N ..... 95

Removing and replacing covers on an 8001-12C

or 8005-12N system........... 95

Removing the service access cover from an

8001-12C or 8005-12N system ...... 95

Installing the service access cover on an

8001-12C or 8005-12N system ...... 96

Service and operating positions for 8001-12C .. 97

Placing an 8001-12C system into the service

position ............. 97

Placing an 8001-12C system into the operating

position ............. 98

Power cords............. 100

Disconnecting the power cords from an

8001-12C, 8001-22C, 8005-12N, or 8005-22N

system ............. 100

Connecting the power cords to an 8001-12C,

8001-22C, 8005-12N, or 8005-22N system .. 100

Notices .............. 103

Accessibility features for IBM Power Systems

servers ............... 104

Privacy policy considerations ........ 105

Trademarks .............. 106

Electronic emission notices ......... 106

Class A Notices............ 106

Class B Notices ............ 110

Terms and conditions ........... 113

iv Power Systems: Installing the IBM Power System S821LC (8001-12C)

Page 7

Safety notices

Safety notices may be printed throughout this guide:

v DANGER notices call attention to a situation that is potentially lethal or extremely hazardous to

people.

v CAUTION notices call attention to a situation that is potentially hazardous to people because of some

existing condition.

v Attention notices call attention to the possibility of damage to a program, device, system, or data.

World Trade safety information

Several countries require the safety information contained in product publications to be presented in their

national languages. If this requirement applies to your country, safety information documentation is

included in the publications package (such as in printed documentation, on DVD, or as part of the

product) shipped with the product. The documentation contains the safety information in your national

language with references to the U.S. English source. Before using a U.S. English publication to install,

operate, or service this product, you must first become familiar with the related safety information

documentation. You should also refer to the safety information documentation any time you do not

clearly understand any safety information in the U.S. English publications.

Replacement or additional copies of safety information documentation can be obtained by calling the IBM

Hotline at 1-800-300-8751.

German safety information

Das Produkt ist nicht für den Einsatz an Bildschirmarbeitsplätzen im Sinne § 2 der

Bildschirmarbeitsverordnung geeignet.

Laser safety information

IBM®servers can use I/O cards or features that are fiber-optic based and that utilize lasers or LEDs.

Laser compliance

IBM servers may be installed inside or outside of an IT equipment rack.

DANGER: When working on or around the system, observe the following precautions:

Electrical voltage and current from power, telephone, and communication cables are hazardous. To avoid

a shock hazard:

v If IBM supplied the power cord(s), connect power to this unit only with the IBM provided power cord.

Do not use the IBM provided power cord for any other product.

v Do not open or service any power supply assembly.

v Do not connect or disconnect any cables or perform installation, maintenance, or reconfiguration of this

product during an electrical storm.

v The product might be equipped with multiple power cords. To remove all hazardous voltages,

disconnect all power cords.

– For AC power, disconnect all power cords from their AC power source.

– For racks with a DC power distribution panel (PDP), disconnect the customer’s DC power source to

the PDP.

v When connecting power to the product ensure all power cables are properly connected.

© Copyright IBM Corp. 2016, 2017 v

Page 8

– For racks with AC power, connect all power cords to a properly wired and grounded electrical

outlet. Ensure that the outlet supplies proper voltage and phase rotation according to the system

rating plate.

– For racks with a DC power distribution panel (PDP), connect the customer’s DC power source to

the PDP. Ensure that the proper polarity is used when attaching the DC power and DC power

return wiring.

v Connect any equipment that will be attached to this product to properly wired outlets.

v When possible, use one hand only to connect or disconnect signal cables.

v Never turn on any equipment when there is evidence of fire, water, or structural damage.

v Do not attempt to switch on power to the machine until all possible unsafe conditions are corrected.

v Assume that an electrical safety hazard is present. Perform all continuity, grounding, and power checks

specified during the subsystem installation procedures to ensure that the machine meets safety

requirements.

v Do not continue with the inspection if any unsafe conditions are present.

v Before you open the device covers, unless instructed otherwise in the installation and configuration

procedures: Disconnect the attached AC power cords, turn off the applicable circuit breakers located in

the rack power distribution panel (PDP), and disconnect any telecommunications systems, networks,

and modems.

DANGER:

v Connect and disconnect cables as described in the following procedures when installing, moving, or

opening covers on this product or attached devices.

To Disconnect:

1. Turn off everything (unless instructed otherwise).

2. For AC power, remove the power cords from the outlets.

3. For racks with a DC power distribution panel (PDP), turn off the circuit breakers located in the

PDP and remove the power from the Customer's DC power source.

4. Remove the signal cables from the connectors.

5. Remove all cables from the devices.

To Connect:

1. Turn off everything (unless instructed otherwise).

2. Attach all cables to the devices.

3. Attach the signal cables to the connectors.

4. For AC power, attach the power cords to the outlets.

5. For racks with a DC power distribution panel (PDP), restore the power from the Customer's DC

power source and turn on the circuit breakers located in the PDP.

6. Turn on the devices.

Sharp edges, corners and joints may be present in and around the system. Use care when handling

equipment to avoid cuts, scrapes and pinching. (D005)

(R001 part 1 of 2):

DANGER: Observe the following precautions when working on or around your IT rack system:

v Heavy equipment–personal injury or equipment damage might result if mishandled.

v Always lower the leveling pads on the rack cabinet.

v Always install stabilizer brackets on the rack cabinet.

v To avoid hazardous conditions due to uneven mechanical loading, always install the heaviest devices

in the bottom of the rack cabinet. Always install servers and optional devices starting from the bottom

of the rack cabinet.

v Rack-mounted devices are not to be used as shelves or work spaces. Do not place objects on top of

rack-mounted devices. In addition, do not lean on rack mounted devices and do not use them to

stabilize your body position (for example, when working from a ladder).

vi Power Systems: Installing the IBM Power System S821LC (8001-12C)

Page 9

v Each rack cabinet might have more than one power cord.

– For AC powered racks, be sure to disconnect all power cords in the rack cabinet when directed to

disconnect power during servicing.

– For racks with a DC power distribution panel (PDP), turn off the circuit breaker that controls the

power to the system unit(s), or disconnect the customer’s DC power source, when directed to

disconnect power during servicing.

v Connect all devices installed in a rack cabinet to power devices installed in the same rack cabinet. Do

not plug a power cord from a device installed in one rack cabinet into a power device installed in a

different rack cabinet.

v An electrical outlet that is not correctly wired could place hazardous voltage on the metal parts of the

system or the devices that attach to the system. It is the responsibility of the customer to ensure that

the outlet is correctly wired and grounded to prevent an electrical shock.

(R001 part 2 of 2):

CAUTION:

v Do not install a unit in a rack where the internal rack ambient temperatures will exceed the

manufacturer's recommended ambient temperature for all your rack-mounted devices.

v Do not install a unit in a rack where the air flow is compromised. Ensure that air flow is not blocked

or reduced on any side, front, or back of a unit used for air flow through the unit.

v Consideration should be given to the connection of the equipment to the supply circuit so that

overloading of the circuits does not compromise the supply wiring or overcurrent protection. To

provide the correct power connection to a rack, refer to the rating labels located on the equipment in

the rack to determine the total power requirement of the supply circuit.

v (For sliding drawers.) Do not pull out or install any drawer or feature if the rack stabilizer brackets are

not attached to the rack. Do not pull out more than one drawer at a time. The rack might become

unstable if you pull out more than one drawer at a time.

v (For fixed drawers.) This drawer is a fixed drawer and must not be moved for servicing unless specified

by the manufacturer. Attempting to move the drawer partially or completely out of the rack might

cause the rack to become unstable or cause the drawer to fall out of the rack.

Safety notices vii

Page 10

CAUTION:

Removing components from the upper positions in the rack cabinet improves rack stability during

relocation. Follow these general guidelines whenever you relocate a populated rack cabinet within a

room or building.

v Reduce the weight of the rack cabinet by removing equipment starting at the top of the rack

cabinet. When possible, restore the rack cabinet to the configuration of the rack cabinet as you

received it. If this configuration is not known, you must observe the following precautions:

– Remove all devices in the 32U position (compliance ID RACK-001 or 22U (compliance ID RR001)

and above.

– Ensure that the heaviest devices are installed in the bottom of the rack cabinet.

– Ensure that there are little-to-no empty U-levels between devices installed in the rack cabinet

below the 32U (compliance ID RACK-001 or 22U (compliance ID RR001) level, unless the

received configuration specifically allowed it.

v If the rack cabinet you are relocating is part of a suite of rack cabinets, detach the rack cabinet from

the suite.

v If the rack cabinet you are relocating was supplied with removable outriggers they must be

reinstalled before the cabinet is relocated.

v Inspect the route that you plan to take to eliminate potential hazards.

v Verify that the route that you choose can support the weight of the loaded rack cabinet. Refer to the

documentation that comes with your rack cabinet for the weight of a loaded rack cabinet.

v Verify that all door openings are at least 760 x 230 mm (30 x 80 in.).

v Ensure that all devices, shelves, drawers, doors, and cables are secure.

v Ensure that the four leveling pads are raised to their highest position.

v Ensure that there is no stabilizer bracket installed on the rack cabinet during movement.

v Do not use a ramp inclined at more than 10 degrees.

v When the rack cabinet is in the new location, complete the following steps:

– Lower the four leveling pads.

– Install stabilizer brackets on the rack cabinet.

– If you removed any devices from the rack cabinet, repopulate the rack cabinet from the lowest

position to the highest position.

v If a long-distance relocation is required, restore the rack cabinet to the configuration of the rack

cabinet as you received it. Pack the rack cabinet in the original packaging material, or equivalent.

Also lower the leveling pads to raise the casters off of the pallet and bolt the rack cabinet to the

pallet.

(R002)

(L001)

DANGER: Hazardous voltage, current, or energy levels are present inside any component that has this

label attached. Do not open any cover or barrier that contains this label. (L001)

(L002)

viii Power Systems: Installing the IBM Power System S821LC (8001-12C)

Page 11

DANGER: Rack-mounted devices are not to be used as shelves or work spaces. (L002)

1

2

!

1

2

1 2

3

4

(L003)

or

or

or

Safety notices ix

Page 12

1

2

3

4

or

DANGER: Multiple power cords. The product might be equipped with multiple AC power cords or

multiple DC power cables. To remove all hazardous voltages, disconnect all power cords and power

cables. (L003)

(L007)

CAUTION: A hot surface nearby. (L007)

(L008)

x Power Systems: Installing the IBM Power System S821LC (8001-12C)

Page 13

CAUTION: Hazardous moving parts nearby. (L008)

All lasers are certified in the U.S. to conform to the requirements of DHHS 21 CFR Subchapter J for class

1 laser products. Outside the U.S., they are certified to be in compliance with IEC 60825 as a class 1 laser

product. Consult the label on each part for laser certification numbers and approval information.

CAUTION:

This product might contain one or more of the following devices: CD-ROM drive, DVD-ROM drive,

DVD-RAM drive, or laser module, which are Class 1 laser products. Note the following information:

v Do not remove the covers. Removing the covers of the laser product could result in exposure to

hazardous laser radiation. There are no serviceable parts inside the device.

v Use of the controls or adjustments or performance of procedures other than those specified herein

might result in hazardous radiation exposure.

(C026)

CAUTION:

Data processing environments can contain equipment transmitting on system links with laser modules

that operate at greater than Class 1 power levels. For this reason, never look into the end of an optical

fiber cable or open receptacle. Although shining light into one end and looking into the other end of

a disconnected optical fiber to verify the continuity of optic fibers many not injure the eye, this

procedure is potentially dangerous. Therefore, verifying the continuity of optical fibers by shining

light into one end and looking at the other end is not recommended. To verify continuity of a fiber

optic cable, use an optical light source and power meter. (C027)

CAUTION:

This product contains a Class 1M laser. Do not view directly with optical instruments. (C028)

CAUTION:

Some laser products contain an embedded Class 3A or Class 3B laser diode. Note the following

information: laser radiation when open. Do not stare into the beam, do not view directly with optical

instruments, and avoid direct exposure to the beam. (C030)

CAUTION:

The battery contains lithium. To avoid possible explosion, do not burn or charge the battery.

Do Not:

v ___ Throw or immerse into water

v ___ Heat to more than 100°C (212°F)

v ___ Repair or disassemble

Exchange only with the IBM-approved part. Recycle or discard the battery as instructed by local

regulations. In the United States, IBM has a process for the collection of this battery. For information,

call 1-800-426-4333. Have the IBM part number for the battery unit available when you call. (C003)

Safety notices xi

Page 14

CAUTION:

Regarding IBM provided VENDOR LIFT TOOL:

v Operation of LIFT TOOL by authorized personnel only.

v LIFT TOOL intended for use to assist, lift, install, remove units (load) up into rack elevations. It is

not to be used loaded transporting over major ramps nor as a replacement for such designated tools

like pallet jacks, walkies, fork trucks and such related relocation practices. When this is not

practicable, specially trained persons or services must be used (for instance, riggers or movers).

v Read and completely understand the contents of LIFT TOOL operator's manual before using.

Failure to read, understand, obey safety rules, and follow instructions may result in property

damage and/or personal injury. If there are questions, contact the vendor's service and support.

Local paper manual must remain with machine in provided storage sleeve area. Latest revision

manual available on vendor's web site.

v Test verify stabilizer brake function before each use. Do not over-force moving or rolling the LIFT

TOOL with stabilizer brake engaged.

v Do not move LIFT TOOL while platform is raised, except for minor positioning.

v Do not exceed rated load capacity. See LOAD CAPACITY CHART regarding maximum loads at

center versus edge of extended platform.

v Only raise load if properly centered on platform. Do not place more than 200 lb (91 kg) on edge of

sliding platform shelf also considering the load's center of mass/gravity (CoG).

v Do not corner load the platform tilt riser accessory option. Secure platform riser tilt option to main

shelf in all four (4x) locations with provided hardware only, prior to use. Load objects are designed

to slide on/off smooth platforms without appreciable force, so take care not to push or lean. Keep

riser tilt option flat at all times except for final minor adjustment when needed.

v Do not stand under overhanging load.

v Do not use on uneven surface, incline or decline (major ramps).

v Do not stack loads.

v Do not operate while under the influence of drugs or alcohol.

v Do not support ladder against LIFT TOOL.

v Tipping hazard. Do not push or lean against load with raised platform.

v Do not use as a personnel lifting platform or step. No riders.

v Do not stand on any part of lift. Not a step.

v Do not climb on mast.

v Do not operate a damaged or malfunctioning LIFT TOOL machine.

v Crush and pinch point hazard below platform. Only lower load in areas clear of personnel and

obstructions. Keep hands and feet clear during operation.

v No Forks. Never lift or move bare LIFT TOOL MACHINE with pallet truck, jack or fork lift.

v Mast extends higher than platform. Be aware of ceiling height, cable trays, sprinklers, lights, and

other overhead objects.

v Do not leave LIFT TOOL machine unattended with an elevated load.

v Watch and keep hands, fingers, and clothing clear when equipment is in motion.

v Turn Winch with hand power only. If winch handle cannot be cranked easily with one hand, it is

probably over-loaded. Do not continue to turn winch past top or bottom of platform travel.

Excessive unwinding will detach handle and damage cable. Always hold handle when lowering,

unwinding. Always assure self that winch is holding load before releasing winch handle.

v A winch accident could cause serious injury. Not for moving humans. Make certain clicking sound

is heard as the equipment is being raised. Be sure winch is locked in position before releasing

handle. Read instruction page before operating this winch. Never allow winch to unwind freely.

Freewheeling will cause uneven cable wrapping around winch drum, damage cable, and may cause

serious injury. (C048)

Power and cabling information for NEBS (Network Equipment-Building System)

GR-1089-CORE

The following comments apply to the IBM servers that have been designated as conforming to NEBS

(Network Equipment-Building System) GR-1089-CORE:

xii Power Systems: Installing the IBM Power System S821LC (8001-12C)

Page 15

The equipment is suitable for installation in the following:

v Network telecommunications facilities

v Locations where the NEC (National Electrical Code) applies

The intrabuilding ports of this equipment are suitable for connection to intrabuilding or unexposed

wiring or cabling only. The intrabuilding ports of this equipment must not be metallically connected to the

interfaces that connect to the OSP (outside plant) or its wiring. These interfaces are designed for use as

intrabuilding interfaces only (Type 2 or Type 4 ports as described in GR-1089-CORE) and require isolation

from the exposed OSP cabling. The addition of primary protectors is not sufficient protection to connect

these interfaces metallically to OSP wiring.

Note: All Ethernet cables must be shielded and grounded at both ends.

The ac-powered system does not require the use of an external surge protection device (SPD).

The dc-powered system employs an isolated DC return (DC-I) design. The DC battery return terminal

shall not be connected to the chassis or frame ground.

The dc-powered system is intended to be installed in a common bonding network (CBN) as described in

GR-1089-CORE.

Safety notices xiii

Page 16

xiv Power Systems: Installing the IBM Power System S821LC (8001-12C)

Page 17

Installing and configuring POWER8 processor-based systems and system features

Use this information to install and configure POWER8®processor-based systems and to install

customer-installable hardware features. This information also provides removal and replacement

procedures for customer-replaceable hardware features, such as memory modules or fans.

Note: See the International Information Bulletin for Customers - Installation of IBM Machines

(Publication number: SC27-6601-00) that is available from the IBM Publications Center

(http://www-05.ibm.com/e-business/linkweb/publications/servlet/pbi.wss). This bulletin provides a list

of the key IBM system installation activities and a list of activities that might be billable.

Installing the IBM Power System S821LC (8001-12C) system

Learn how to install, cable, and set up your 8001-12C system.

Prerequisites for installing the rack-mounted 8001-22C system

Use the information to understand the prerequisites that are required for installing the system.

About this task

You might need to read the following documents before you install the server:

v The latest version of this document is maintained online, see Installing the IBM Power System

8001-22C (http://www.ibm.com/support/knowledgecenter/POWER8/p8eip/

p8eip_installsys_kickoff.htm).

v To plan your server installation, see Planning for the system (http://www.ibm.com/support/

knowledgecenter/POWER8/p8had/p8had_8xx_kickoff.htm).

Procedure

1. Ensure that you have the following items before starting your installation:

v Phillips screwdriver

v Flat-head screwdriver

v Box cutter

v Electrostatic discharge (ESD) wrist strap

v Rack with two Electronic Industries Association (EIA) units (2U) of space

Note: If you do not have a rack that is installed, install the rack. For instructions, see Racks and rack

features (http://www.ibm.com/support/knowledgecenter/POWER8/p8hbf/p8hbf_8xx_kickoff.htm).

2. If you have already installed a shelf into your rack and plan on installing the system onto the shelf,

an additional 1U of space above the system is required.

Completing inventory for your system

Use this information to complete inventory for your system.

Procedure

1. Verify that you received all the boxes you ordered.

2. Unpack the server components as needed.

3. Complete a parts inventory before you install each server component by following these steps:

© Copyright IBM Corp. 2016, 2017 1

Page 18

a. Locate the inventory list for your server.

b. Ensure that you received all the parts that you ordered.

Note: Your order information is included with your product. You can also obtain order

information from your marketing representative or the IBM Business Partner.

If you have incorrect, missing, or damaged parts, consult any of the following resources:

v Your IBM reseller.

v IBM Rochester manufacturing automated information line at 1-800-300-8751 (United States only).

v The Directory of worldwide contacts website http://www.ibm.com/planetwide. Select your

location to view the service and support contact information.

Determining and marking the location in the rack for the 8001-12C system

You might need to determine where to install the system unit into the rack.

Procedure

1. Read the Rack safety notices (http://www.ibm.com/support/knowledgecenter/POWER8/p8hbf/

racksafety.htm).

2. Determine where to place the system unit in the rack. As you plan for installing the system unit in a

rack, consider the following information:

v Organize larger and heavier units into the lower part of the rack.

v Plan to install units into the lower part of the rack first.

v Record the Electronic Industries Alliance (EIA) locations in your plan.

3. If necessary, remove the filler panels to allow access to the inside of the rack enclosure where you

plan to place the unit, as shown in Figure 1 on page 3.

2 Power Systems: Installing the IBM Power System S821LC (8001-12C)

Page 19

Figure 1. Removing the filler panels

4. Determine to place the system in the rack. Record the EIA location.

5. Facing the front of the rack and working from the right side, use tape, a marker, or pencil to mark

the lower hole of each EIA unit.

6. Repeat step 5 for the corresponding holes located on the left side of the rack.

7. Go to the rear of the rack.

8. On the right side, find the EIA unit that corresponds to the bottom EIA unit marked on the front of

the rack.

9. Mark the bottom EIA unit.

10. Mark the corresponding holes on the left side of the rack.

Attaching the rails to the system chassis and to the rack

You must install the rails onto the chassis and into the rack. Use this procedure to perform this task.

Installing and configuring the system 3

Page 20

About this task

Attention: To avoid rail failure and potential danger to yourself and to the unit, ensure that you have

the correct rails and fittings for your rack. If your rack has square support flange holes or screw-thread

support flange holes, ensure that the rails and fittings match the support flange holes that are used on

your rack. Do not install mismatched hardware by using washers or spacers. If you do not have the

correct rails and fittings for your rack, contact your IBM reseller.

Note: The system requires 1 EIA rack unit (1U) of space.

Ensure that you have the parts you need to install the rails. The following parts are included with the rail

kit:

v Slide rail screws, used to attach the two parts of each slide rail

v Slide rail rack screws, used to secure the rails to the rack

v Rails

v 10-32 x 0.25” screws, used to attach the rails to system chassis

Procedure

1. Remove the rail pieces from the packaging and put them on a work surface.

2. Connect the two parts of each rack slide rail. To connect the two parts of the rack slide rail, perform

the following tasks:

a. Identify the two pieces of the left rack slide rail. Align the short and long pieces (C). Ensure that

the rack rail pins are pointing in the same direction (A) and (D).

b. The shorter piece of the rack slide rail has a metal pin. Insert the pin into the hole in the longer

piece of the rack slide rail (B). Slide the shorter piece of the rack rail into the longer piece of the

rack rail.

c. Align the holes in the two pieces of the rack slide rails. Using a Philips-head screwdriver, attach

the two parts by loosely screwing two rail screws through the holes in the rack slide rail.

Note: Do not tighten the rack slide rail screws.

d. Repeat these steps for the right slide rail.

3. Attach the chassis rails to the system chassis. To attach the chassis rails to the system chassis, perform

the following tasks:

4 Power Systems: Installing the IBM Power System S821LC (8001-12C)

Page 21

a. On the left side of the system, align the metal tabs on the left side of the system chassis with the

square holes on the left chassis slide rail. Slide the chassis slide rail toward the front of the rack

until the chassis slide rail clicks into place.

b. Attach the system chassis slide rail to the system chassis by screwing in the two screws that were

supplied in the rail kit.

c. Repeat these steps for the right system chassis slide rail.

4. Install the rack slide rails into the rack.

a. Move to the front of the rack.

b. Select the left rack slide rail, and locate the EIA unit that you previously marked. Each slide rail is

also marked Back, to designate the rear of the rack. Ensure that you are holding the front end of

the rack slide rail.

c. Extend the rail from the front of the rack to the back of the rack and align the rack slide rail pins

with the holes in the rack flange that you previously marked.

d. Push the rack rail pins into the rear rack flange until the rear rack rail latch clicks into place.

e. Pull the front of the rack rail toward the front of the rack rail flange. Align the slide rail pins with

the holes in the rail flange and pull them until the rail latch clicks into place.

f. Using a screwdriver, Tighten the rail screws that you installed in step 2.

g. Repeat these steps for the right slide rail.

5. Secure the rails to the rack.

a. Move to the rear of the rack.

b. Slide each washer onto to each of the longer screws that is included with the rail kit.

c. Screw a screw and washer through the middle hole of each rail on each side of the rear of the

rack.

Installing the system into the rack and connecting and routing power cables

After you install the system onto the rails in the rack, connect and route power cables.

About this task

CAUTION:

The weight of this part or unit is between 18 and 32 kg (39.7 and 70.5 lb). It takes two persons to

safely lift this part or unit. (C009)

Procedure

1. Remove the protective plastic film from the top of the system chassis.

2. Move to the front of the rack.

3. Using two people, one on each side of the system, lift the system and align the system chassis rails

on each side of the chassis with the rack rails.

4. With each person supporting the weight of the system on each side, gently push the system into the

rack until you hear each rail click into place.

or

or

Installing and configuring the system 5

Page 22

5. Before releasing your hold on the system, ensure that the rails are engaged by sliding the system

forward into service lock position. Check that the rails are properly seated. If the rails are not fully

engaged, the system could drop.

6. Release the rail safety latches and push the system fully into the rack. The safety latches work in

opposite directions; the latch on one side moves up while the latch on the other side moves down.

Figure 2. Placing the system into the operating position

7. Secure the system to the rack by screwing a screw through the handles on each side of the system

chassis.

8. Plug the power cords into the power supplies.

6 Power Systems: Installing the IBM Power System S821LC (8001-12C)

Page 23

Figure 3. Plugging the power cords into the power supplies

9. Attach all cables to the rear of the server.

Figure 4. Rear ports

Table 1. Input and output ports

Identifier Description

1 USB 2.0 used for keyboard and mouse.

Certain USB drives might be too wide to fit properly into

the USB ports on the rear of the system. Test the fit your

USB drive before proceeding.

2 Ethernet Intelligent Platform Management Interface

(IPMI)

3 Serial IPMI

4 Video Graphics Array (VGA) used for monitor. Only the

1024 x 768 at 60 Hz VGA setting is supported. Only up

to a 3-meter cable is supported. Text based capability is

only supported at this time.

10. Plug the system power cords and the power cords for any other attached devices into the alternating

current (AC) power source.

11. Continue with “Completing server setup” on page 8.

Installing and configuring the system 7

Page 24

Completing server setup

Learn how to complete server setup.

Procedure

1. Connect your server to a VGA terminal and keyboard or a console. Only the 1024x768 at 60 Hz VGA

setting is supported. Only up to a 3 meter cable is supported.

2. Go to Getting fixes(http://www.ibm.com/support/knowledgecenter/POWER8/p8ei8/

p8ei8_fixes_kickoff.htm) and update the system firmware with the most recent level of firmware.

3. You can receive important technical information and updates for specific IBM Support tools and

resources by subscribing to receive updates. To subscribe to receive updates, complete the following

steps:

a. Go to the IBM Support Portal.

b. Log in by using your IBM ID and password and click Sign in.

c. Click Support notifications.

d. Click Browse for a product.

e. Select Power > Firmware, find your machine type and model and click Subscribe.

f. Exit the Browse for a product screen.

g. Click Delivery preferences to set email preferences and click Submit.

h. Click Edit to select the types of documentation updates that you want to receive and click Submit.

4. You can install the Linux operating system on bare metal systems, or on non-virtualized systems. For

these systems, the operating system runs directly on the Open Power Abstraction Layer (OPAL)

firmware. For more information about installing the Linux operating system on bare metal systems,

see Installing Linux on bare metal systems(http://www.ibm.com/support/knowledgecenter/

linuxonibm/liabw/liabwkickoff.htm).

Installing drives in the 8001-12C system

Learn how to install storage drives in the IBM Power®System S821LC (8001-12C) system.

About this task

You can install the following types of drives in the system:

v SATA drives connected to the SATA controller ports on the system backplane

v SAS drives connected to a SAS RAID adapter

v NVMe drives connected to an NVMe adapter

v 3.5-inch drives

v 2.5-inch drives by using an adapter

Drive installation details for the 8001-12C system

Find information about the drive installation options for the IBM Power System S821LC (8001-12C)

system.

SATA Drives

The 8001-12C system can support four SATA drives directly connected to the SATA ports and controller

on the system backplane. The SATA drives can be installed into the front drive bay locations. SATA drive

cables connect the disk drive backplane to the SATA sockets on the system backplane.

Use SATA cables to connect the SATA ports on the system backplane to the SATA ports on the disk drive

backplane.

8 Power Systems: Installing the IBM Power System S821LC (8001-12C)

Page 25

You can plug SATA drive on module (DOM) drives directly into the system backplane. Up to two SATA

DOM drives can be installed. Use the two orange SATA connectors.

SAS Drives

With system feature codes EKB1 or EKB2, and by using SATA/SAS RAID adapters, the 8001-12C system

can support up to four SATA/SAS drives. Adapter feature codes EKAA and EKAB each support up to

eight SAS drives, but the system is physically limited to four.

Use SAS cables to connect the SAS ports on the PCIe adapter cards to the SAS ports on the disk drive

backplane.

If you are installing a RAID adapter, see the adapter documentation for information on configuring the

drives.

As an example, consider this configuration:

v Feature code EKAA supporting four front-mounted SATA/SAS drives.

v Two SATA DOMs plugged into the system backplane.

NVMe Enabled System and Drives

When the system has one or more NVMe adapters, feature code EKAE, the system supports NVMe

drives. To support up to two NVMe drives, you need a feature code EKAE PCIe adapter. To support up

to four NVMe drives, you need two EKAE PCIe adapters. Figure 5 shows the adapter positions. The first

EKAE PCIe adapter needs to go in position 2 (UIO Slot1); the second needs to go in position 3 (PLX

Slot1).

Figure 5. 8001-12C PCIe adapter positions

The first two NVMe drives need to be plugged into drive locations 1 and 2 as shown in Figure 6. The

second two NVMe drives need to be plugged into drive locations 3 and 4.

NVMe drives are only supported on host operating systems; NVMe drives are not supported by guest

operating systems. On systems with RHEL 7.3 or later, or Ubuntu 16.04 or later, NVMe drives can be

used as bootable drives. Port 1 of the internal NVMe host bus adapter must be plugged into NVMe port

1 on the disk drive backplane.

Figure 6. NVMe drive locations

As an example, consider this configuration:

v Four NVMe front-mounted drives with two EKAE PCIe adapters.

v Two SATA DOMs plugged into the system backplane.

Installing and configuring the system 9

Page 26

Installing a front drive in the 8001-12C system

Follow these steps to install a front drive in the IBM Power System S821LC (8001-12C) system.

Before you begin

You can install SATA and SAS front drives with the system powered on and running.

When installing NVMe drives, the system needs to be powered down; for instructions, see “Stopping the

8001-12C, 8001-22C, 8005-12N, or 8005-22N system” on page 90.

Procedure

1. Attach the electrostatic discharge (ESD) wrist strap.

Attention:

v Attach an electrostatic discharge (ESD) wrist strap to the front ESD jack, to the rear ESD jack, or to

an unpainted metal surface of your hardware to prevent the electrostatic discharge from damaging

your hardware.

v When you use an ESD wrist strap, follow all electrical safety procedures. An ESD wrist strap is

used for static control. It does not increase or decrease your risk of receiving electric shock when

using or working on electrical equipment.

v If you do not have an ESD wrist strap, just prior to removing the product from ESD packaging

and installing or replacing hardware, touch an unpainted metal surface of the system for a

minimum of 5 seconds.

2. Unlock the drive bay handle (B) by pushing in the handle release (A) as shown in Figure 7. The

handle (B) snaps out towards you. If the handle does not snap out all the way, the drive does not

slide out of the system.

Figure 7. Removing a drive

3. If you are installing more than one drive, remove those drive trays.

10 Power Systems: Installing the IBM Power System S821LC (8001-12C)

Page 27

4. For 3.5-inch drives, remove the plastic filler from the carrier. For 2.5-inch drives in a 3.5-inch

opening, there is a 2.5-inch tool-less drive carrier.

5. Install a drive into the tray. Orient the drive such that the connectors are pointing to the rear of the

drive.

v A 3.5-inch drive fills the tray, as shown in Figure 8. Fasten the drive to the sides of the tray with

four screws (two screws on each side).

Figure 8. Mounting the 3.5-inch drive in the tray

v A 2.5-inch drive slides into the rear of the tool-less drive carrier.

a. Turn the tray upside down as shown in Figure 9 on page 12.

b. Open the retention spring (B) as shown in Figure 10 on page 12.

c. Place the 2.5-inch drive (A) into the tray, aligning the pins with the screw holes in the drive.

d. When the pins are aligned, close the retention spring, allowing the pins to secure the drive in

the tray.

e. Turn the tray right side up.

Installing and configuring the system 11

Page 28

Figure 9. Turning the 2.5-inch tray upside-down

Figure 10. Mounting the 2.5-inch drive in the tray

6. Support the drive by the bottom as you position the drive, and insert it into the drive slot.

Important: Ensure that the drive is fully seated and is all the way into the system.

7. Lock the drive bay handle (A) by pushing in the handle release as shown in Figure 11 on page 13.

12 Power Systems: Installing the IBM Power System S821LC (8001-12C)

Page 29

Figure 11. Disk drive lock detail

8. If you installed an NVMe drive, power the system back on. For instructions, see “Starting the

8001-12C, 8001-22C, 8005-12N, or 8005-22N system” on page 88.

9. Configure the installed drive for your environment.

After you insert the new drive, you need to rescan for the device.

Ubuntu Linux operating system

To run the rescan-scsi-bus command in the Ubuntu Linux operating system, log in to the

system as the root user, and run the following command:

rescan-scsi-bus

The rescan-scsi-bus tool is available in the scsitools package; install the package by using

the following command:

sudo apt-get install scsitools

Red Hat Enterprise Linux (RHEL) version 7.2

To run the rescan command in the REHL version 7.2 operating system, log in to the system

as the root user, and run the command:

rescan-scsi-bus.sh -a

The rescan-scsi-bus tool is available in the sg3_utils package; install the package by using

the following command:

yum install sg3_utils

You can also want to refer to: Adding a Storage Device or Path (https://access.redhat.com/

documentation/en-US/Red_Hat_Enterprise_Linux/7/html/Storage_Administration_Guide/

logical-unit-add-remove.html).

10. Load or restore data from your backup media.

Installing and configuring the system 13

Page 30

Installing a drive on module in the 8001-12C system

Learn how to install a drive on module (DOM) in the IBM Power System S821LC (8001-12C) system.

Before you begin

Power off the system and place it in the service position. For instructions, see “Preparing the 8001-12C or

8005-12N system to remove and replace internal parts” on page 85.

About this task

You can plug SATA drive on module (DOM) drives directly into the system backplane. Up to two SATA

DOM drives can be installed. Use the two orange SATA connectors.

Procedure

1. Attach the electrostatic discharge (ESD) wrist strap.

Attention:

v Attach an electrostatic discharge (ESD) wrist strap to the front ESD jack, to the rear ESD jack, or to

an unpainted metal surface of your hardware to prevent the electrostatic discharge from damaging

your hardware.

v When you use an ESD wrist strap, follow all electrical safety procedures. An ESD wrist strap is

used for static control. It does not increase or decrease your risk of receiving electric shock when

using or working on electrical equipment.

v If you do not have an ESD wrist strap, just prior to removing the product from ESD packaging and

installing or replacing hardware, touch an unpainted metal surface of the system for a minimum of

5 seconds.

2. Install the DOM into the system backplane, in positions (A), as shown in Figure 12 on page 15.

Depending on the DOM model, you may also have to plug in a small power cord for the DOM.

Ensure you plug the connectors in properly.

14 Power Systems: Installing the IBM Power System S821LC (8001-12C)

Page 31

Figure 12. Installing a DOM

3. Prepare the system for operation. For instructions, see “Preparing the 8001-12C or 8005-12N system

for operation after you remove and replace internal parts” on page 87.

4. Configure the installed drive for your environment.

After you insert the new drive, you need to rescan for the device.

Ubuntu Linux operating system

To run the rescan-scsi-bus command in the Ubuntu Linux operating system, log in to the

system as the root user, and run the following command:

rescan-scsi-bus

The rescan-scsi-bus tool is available in the scsitools package; install the package by using

the following command:

sudo apt-get install scsitools

Red Hat Enterprise Linux (RHEL) version 7.2

To run the rescan command in the REHL version 7.2 operating system, log in to the system as

the root user, and run the command:

rescan-scsi-bus.sh -a

The rescan-scsi-bus tool is available in the sg3_utils package; install the package by using the

following command:

yum install sg3_utils

You can also want to refer to: Adding a Storage Device or Path (https://access.redhat.com/

documentation/en-US/Red_Hat_Enterprise_Linux/7/html/Storage_Administration_Guide/

logical-unit-add-remove.html).

5. Load or restore data from your backup media.

Installing and configuring the system 15

Page 32

Installing a graphics processing unit in the 8001-12C system

Follow these steps to install a graphics processing unit in the IBM Power System S821LC (8001-12C)

system.

Before you begin

Power off the system and place it in the service position. For instructions, see “Preparing the 8001-12C or

8005-12N system to remove and replace internal parts” on page 85.

Procedure

1. Attach the electrostatic discharge (ESD) wrist strap.

Attention:

v Attach an electrostatic discharge (ESD) wrist strap to the front ESD jack, to the rear ESD jack, or to

an unpainted metal surface of your hardware to prevent the electrostatic discharge from damaging

your hardware.

v When you use an ESD wrist strap, follow all electrical safety procedures. An ESD wrist strap is

used for static control. It does not increase or decrease your risk of receiving electric shock when

using or working on electrical equipment.

v If you do not have an ESD wrist strap, just prior to removing the product from ESD packaging and

installing or replacing hardware, touch an unpainted metal surface of the system for a minimum of

5 seconds.

2. The GPU can share the PCIe riser card with other PCIe adapters. Label and remove any cables and

plugs that extend out of the adapters.

3. Remove the PCIe riser as shown in Figure 13.

a. Retract the retaining pins (A) so that the arrows on the tabs point to the system.

b. Lift the PCIe riser from the system.

Figure 13. Removing the PCIe riser

16 Power Systems: Installing the IBM Power System S821LC (8001-12C)

Page 33

4. Place the PCIe adapter riser on an ESD surface, with the riser up.

5. Plug the GPU (A) into the PCIe adapter riser (B) as shown in Figure 14. Secure the GPU tailstock with

one or two screws as needed.

Figure 14. Inserting the GPU into the riser

6. Place the PCIe adapter riser and the cards it contains into the system backplane as shown in Figure 15

on page 18.

a. Ensure that the PCIe holder release pins (B) are retracted, so the arrows point into the system.

b. Use the alignment pins (A) and slots to help you properly insert the riser cards and replace the

cover

c. Reset the retaining pins to secure the PCIe cage.

Installing and configuring the system 17

Page 34

Figure 15. Replacing the PCIe riser

7. Using your labels, replace any cables and plugs that you removed from the adapters.

8. Plug the GPU power cable into the system backplane as shown in Figure 16. Ensure that the cable

latch clip snaps into place on the connector.

Figure 16. Plugging the GPU power cable into the system backplane

18 Power Systems: Installing the IBM Power System S821LC (8001-12C)

Page 35

What to do next

Prepare the system for operation. For instructions, see “Preparing the 8001-12C or 8005-12N system for

operation after you remove and replace internal parts” on page 87.

Installing memory in the 8001-12C system

Learn how to install memory in the IBM Power System S821LC (8001-12C) system.

Placement rules for memory in the 8001-12C or 8001-22C system

Learn about the configurations and rules that apply to adding memory to the IBM Power System S821LC

(8001-12C) or the IBM Power System S822LC for Big Data (8001-22C) system.

Table 2 lists the supported memory DIMM feature codes and Table 3 shows the allowable memory

capacity points for the 8001-12C or 8001-22C system.

v Mixing of memory feature codes is not allowed.

v Mixing of memory from different manufacturers is not allowed.

v You must add four memory DIMMs at a time.

v The memory DIMMs need to be added in a sequence. Use Table 4 and Figure 17 on page 20 to

determine the memory placement.

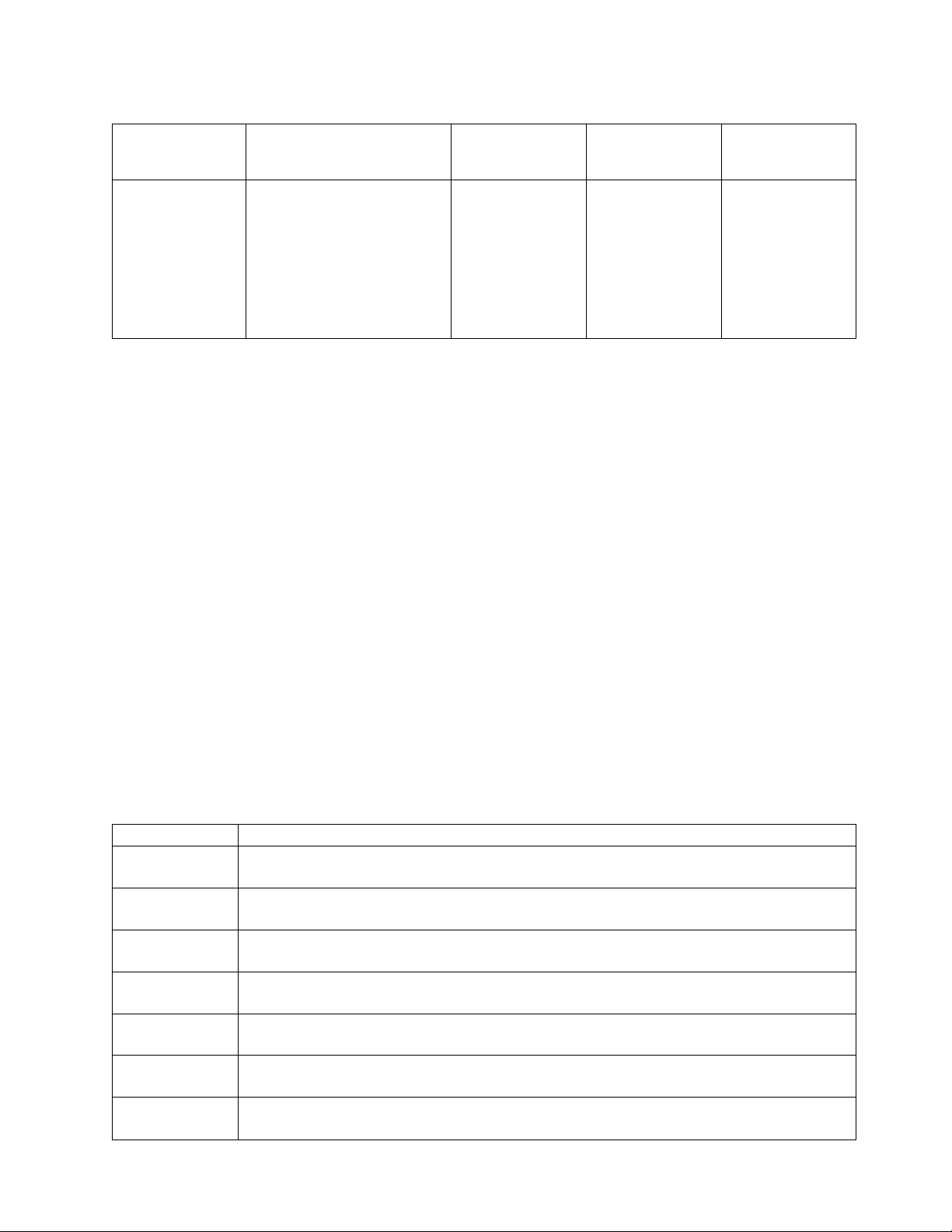

Table 2. Memory DIMM feature codes

Supported feature codes (FC) Size

EMM0 4 GB Memory DDR4 ISRDIMM

EMM1 8 GB Memory DDR4 ISRDIMM

EMM2 16 GB Memory DDR4 ISRDIMM

EMM3 32 GB Memory DDR4 ISRDIMM

Table 3. Memory configuration as a function of the number of DIMMs. You read this table by selecting the individual

DIMM size row in the leftmost column, then move to the right and select the columns for the memory capacity. The

value that is listed is the quantity of the memory feature code that can be ordered, which corresponds to the DIMM

size in the leftmost column.

DIMM

Size DIMMs DIMMs DIMMs DIMMs DIMMs DIMMs DIMMs DIMMs DIMMs DIMMs

Total

Memory 16 GB 32 GB 48 GB 64 GB 96 GB 128 GB 192 GB 256 GB 384 GB 512 GB

4 GB 4

(default)

8 GB 4 8 12 16

16 GB 4 8 12 16

32 GB 4 8 12 16

Table 4. Memory plugging sequence

Slot Location DIMM Quantity Plugging Sequence

P1M1 A and B, P1M2 A and B 4 1

P2M1 A and B, P2M2 A and B 4 2

P1M1 C and D, P1M2 C and D 4 3

P2M1 C and D, P2M2 C and D 4 4

8 12 16

Installing and configuring the system 19

Page 36

Figure 17. Memory slot locations and plugging sequence

Installing memory in the 8001-12C system

Learn how to install memory in the IBM Power System S821LC (8001-12C) system.

Before you begin

Power off the system and place it in the service position. For instructions, see “Preparing the 8001-12C or

8005-12N system to remove and replace internal parts” on page 85.

Procedure

1. Attach the electrostatic discharge (ESD) wrist strap.

Attention:

v Attach an electrostatic discharge (ESD) wrist strap to the front ESD jack, to the rear ESD jack, or to

an unpainted metal surface of your hardware to prevent the electrostatic discharge from damaging

your hardware.

v When you use an ESD wrist strap, follow all electrical safety procedures. An ESD wrist strap is

used for static control. It does not increase or decrease your risk of receiving electric shock when

using or working on electrical equipment.

v If you do not have an ESD wrist strap, just prior to removing the product from ESD packaging and

installing or replacing hardware, touch an unpainted metal surface of the system for a minimum of

5 seconds.

2. Determine the slot in which you want to install the memory. See “Placement rules for memory in the

8001-12C or 8001-22C system” on page 19 to understand the plugging rules and to ensure that you

plug the memory into the system in the correct sequence.

3. Depending on the memory location, you might need to remove the system processor air baffles.

Carefully unsnap and lift the processor air baffle from the system.

20 Power Systems: Installing the IBM Power System S821LC (8001-12C)

Page 37

Figure 18. Removing the processor air baffle

4. Push the DIMM locking tabs away from the socket.

5. Insert the memory DIMM.

a. Grasp the memory DIMM along its edges and align it with the slot on the system backplane.

Attention: Memory is keyed to prevent it from being installed incorrectly. Note the location of

the key tab within the memory connector before you attempt to install it.

b. Press firmly on each side of the memory DIMM until the locking tab locks in place with an

audible click.

Installing and configuring the system 21

Page 38

Figure 19. Inserting the memory DIMM

6. If you removed the system processor air baffle, replace it. Insert the edge of the baffle into the fan

support. Then, carefully press the baffle down into place.

Figure 20. Installing the processor air baffle

22 Power Systems: Installing the IBM Power System S821LC (8001-12C)

Page 39

What to do next

Prepare the system for operation. For instructions, see “Preparing the 8001-12C or 8005-12N system for

operation after you remove and replace internal parts” on page 87.

Installing a PCIe adapter in the 8001-12C system

Learn how to install Peripheral Component Interconnect Express (PCIe) adapters in the IBM Power

System S821LC (8001-12C) system.

About this task

You can install full-length, half-length or short (low-profile) PCIe adapters in the system. If you need to

change the tail-stock of the PCIe adapter from one size to another, so that the adapter fits properly in the

socket, see Removing and replacing the tailstock on a PCIe adapter.

The features listed in Table 5 are electromagnetic compatibility (EMC) Class B features. See the Class B

Notices in the Hardware Notices section.

Table 5. Electromagnetic compatibility (EMC) Class B features

Feature Description

EKAA Broadcom (LSI) MegaRAID 9361-8i SAS3 Controller with 8 Internal Ports (1 GB Cache)

PCIe3.0 x8 LP with cables (Adapter FRU number: AOC-K-9361-8IS-IB001 and

AOC-K-9361-8IB-IB001)

EKAJ NVIDIA Tesla K80 24 GB GPU Accelerator (Adapter FRU number: AOC-KIT-NVK80-

IB001)

EKA3 Intel 82575EB dual-port Gigabit Ethernet Controller PCIe x4.0 LP (Adapter FRU

number: AOC-SG-I2)

EKAT Alpha-data CAPI Adapter: ADM-PCIe KU3 (Adapter FRU Number: ADM-PCIE-KU3)

PCIe adapter placement rules and slot priorities for the 8001-12C or 8005-12N system

Find information about the placement rules and slot priorities for the Peripheral Component Interconnect

Express (PCIe) adapters that are supported for the IBM Power System S821LC (8001-12C) or the IBM

CS821 (8005-12N).

PCIe slot descriptions

The 8001-12C and 8005-12N systems provide PCIe generation 3 slots. Full-length, half-length, or short

(low-profile) adapters can be installed. Figure 21 on page 24 shows the rear view of the system with the

PCIe adapter slots. Table 6 on page 24 lists the PCIe adapter slot locations and details for the 8001-12C or

8005-12N system.

Important: The only two adapters that are currently supported on the 8005-12N are FC EKFH and

AOC-S3008L-L8e-P.

Installing and configuring the system 23

Page 40

Figure 21. Rear view of an 8001-12C or 8005-12N system with PCIe slots indicated

Table 6. PCIe slot locations and descriptions for the 8001-12C or 8005-12N system

Coherent Accelerator

PCI host bridge

Slot Description

1 (UIO Network) 4-ports 10 networking

card, x8

2 (UIO Slot1) PCIe3 x16 Processor Module 1,

3 (PLX Slot1) PCIe3 x8 Processor Module 1,

4 (WIO Slot1) PCIe3 x16 Processor Module 2,

5 (WIO Slot2) PCIe3 x16 Processor Module 2,

(PHB) Adapter size

Processor Module 1,

PHB0

PHB0

PHB0

PHB1

PHB1

Riser No

Half-height,

half-length, internal

Half-height,

half-length

Full-height,

full-length

Full-height,

full-length

Processor Interface

(CAPI)

Yes

No

Yes

Yes

PCIe adapter placement rules

Use this information to select slots for installing PCIe adapters in the 8001-12C or 8005-12N system.

Table 7 provides information about the adapters, the slot priorities in the system they are supported on,

and the maximum number of adapters that can be installed in the supported system. You can click the

link that appears in the feature code column for more technical information specific to the PCIe adapter.

Table 7. PCIe adapters supported in the 8001-12C or 8005-12N system

8001-12C (slot

Feature code Description

EKA0 PCIe3 x4 Intel x550 10GBase-T

Converged Network Adapter

with Dual RJ45 Ports (Adapter

FRU number: AOC-STGS-I2T)

v PCIe2.1 x8

v Short, low-profile

v Direct Cache Access (DCA)

to avoid cache misses

v TCP/UDP Segmentation

Offload

v OS support: Linux

operating systems

priority)

3, 4, 5 NA 3

8005-12N (slot

priority)

Maximum number

of adapters

supported

24 Power Systems: Installing the IBM Power System S821LC (8001-12C)

Page 41

Table 7. PCIe adapters supported in the 8001-12C or 8005-12N system (continued)

Feature code Description

EKA1 Cavium (Qlogic) BCM57840

8001-12C (slot

priority)

3, 4, 5 NA 3

8005-12N (slot

priority)

4-port SFP+ 10 Gb Ethernet

Adapter PCIe3.0 x8 LP

(Adapter FRU number:

AOC-STG-B4S)

v PCIe3 x8

v Short, low-profile

v TCP Offload Engine (TOE)

v VMDq and PC-SIG SR-IOV

for Virtualized

Environments

v OS support: Linux

operating systems

EKA2 Intel 82599ES Ethernet

3, 4, 5 NA 3

Converged Network Adapter

x520-DA2 Dual-port 10G/1G

SFP+ PCIe2.0 x8 LP (Adapter

FRU number: AOC-STGN-I2S)

v PCIe2 x8

v Short, low-profile

v Dual and single SFP+

Connectors

v Load Balancing on Multiple

CPUs

v OS support: Linux

operating systems

EKA3 Intel 82575EB dual-port

3, 4, 5 NA 3

Gigabit Ethernet Controller

PCIe x4.0 LP (Adapter FRU

number: AOC-SG-I2)

v PCIe2 x4

v Short, low-profile

v Intel I/O Acceleration

Technology

v Low-latency interrupts

v OS support: Linux

operating systems

Maximum number

of adapters

supported

Installing and configuring the system 25

Page 42

Table 7. PCIe adapters supported in the 8001-12C or 8005-12N system (continued)

Feature code Description

EKAA Broadcom (LSI) MegaRAID

9361-8i SAS3 Controller with 8

Internal Ports (1 GB Cache)

PCIe3.0 x8 LP with cables

(Adapter FRU number:

AOC-K-9361-8IS-IB001 and

AOC-K-9361-8IB-IB001)

v PCIe3 x8

v Short, low-profile

v Supports 1.5, 3.0, 6.0 and 12

Gb/s SAS and SATA data

transfer rates

v Supports RAID 0, 1, 5, 6, 10,

50, 60

v OS support: Linux

operating systems

EKAB SMC AOC-K-S3008L-L8i 12

Gbps SAS3/RAID 0,1 and 10

PCIe3.0 x8 LP with cables

(Adapter FRU number:

AOC-K-S3008L-L8iS-IB001 and

AOC-K-S3008L-L8iB-IB001)

v PCIe3 x8

v Short, low-profile

v Supports 3.0, 6.0 and 12

Gb/s SAS and SATA data

transfer rates

v Supports MegaRAID

Storage Manager Software

v OS support: Linux

operating systems

EKAD Broadcom (LSI) 9300-8E SAS3

HBA PCIe3.0 x8 LP Adapter

(Adapter FRU number:

AOC-SAS3-9300-8E)

v PCIe3 x8

v Short, low-profile

v Supports 122 devices (HBA

only)

v Port independent

auto-negotiation

v OS support: Linux

operating systems

8001-12C (slot

priority)

2, 3 NA 1

2, 3, 4, 5 NA 1

4, 5 NA 3

8005-12N (slot

priority)

Maximum number

of adapters

supported

26 Power Systems: Installing the IBM Power System S821LC (8001-12C)

Page 43

Table 7. PCIe adapters supported in the 8001-12C or 8005-12N system (continued)

Feature code Description

EKAE PCIe3 x8 Dual-port Internal

8001-12C (slot

priority)

2, 3, 4, 5 NA 2

8005-12N (slot

priority)

NVMe Host Bus Adapter

(Adapter FRU number:

AOC-K-SLG3-2E4S-IB001 and

AOC-K-SLG3-2E4B-IB001)

v PCIe3 x8

v Short, low-profile

v Supports two physical

NVMe Devices

v Four internal lanes per port

with 3.2 GB/s per port

v OS support: Linux

operating systems

EKAF Emulex LPE16002B-M6-O

3, 4, 5 NA 3

Dual-port 16 Gb Fibre Channel

Card PCIe3.0 x8 LP (Adapter

FRU number:

AOC-LPE16002B-M6-Of)

v PCIe3 x8

v Short, low-profile

v Auto-negotiation

v LDAP support

v OS support: Linux

operating systems

EKAG PCIe3 x8 Quad-port Internal

3, 4, 5 NA 3

Host Bus Adapter (Adapter

FRU number:

AOC-K-SLG3-4E2PS)

v PCIe3 x8

v Short, low-profile

v Supports four physical

NVMe Devices

v OS support: Linux

operating systems

Maximum number

of adapters

supported

Installing and configuring the system 27

Page 44

Table 7. PCIe adapters supported in the 8001-12C or 8005-12N system (continued)

Feature code Description

EKAH Broadcom (LSI) MegaRAID

9361-8i SAS3 Controller with 8

internal ports (2 GB Cache)

PCIe3.0 x8 with

cables(Adapter FRU number:

AOC-K-9361-8I2S-IB001 and

AOC-K-9361-8I2B-IB001)

v PCIe3 x8

v Short, low-profile

v Supports 1.5, 3.0, 6.0 and 12

Gb/s SAS and SATA data

transfer rates

v Supports RAID 0, 1, 5, 6, 10,

50, 60

v OS support: Linux

operating systems

EKAJ NVIDIA Tesla K80 24 GB GPU

Accelerator (Adapter FRU

number: AOC-KIT-NVK80IB001)

v PCIe3 x16

v Double-wide, with

full-height tailstock

v Dynamic parallelism

v Hyper-Q and system

monitoring

v OS support: Linux

operating systems

EKAL Mellanox MCX456A-ECAT

ConnectX-4 VPI EDR IB 100

Gb/s and 100 GbE Dual-port

QSFP28 PCIe3.0 x16 LP

(Adapter FRU number:

AOC-MCX456A-ECAT-IB001)

v PCIe3 x16

v Short, with full-height

tailstock

v Virtual Protocol

Interconnect (VPI)

v OS support: Linux

operating systems

8001-12C (slot

priority)

2, 3 NA 1

4-5 NA 1

4, 5 NA 2

8005-12N (slot

priority)

Maximum number

of adapters

supported

28 Power Systems: Installing the IBM Power System S821LC (8001-12C)

Page 45

Table 7. PCIe adapters supported in the 8001-12C or 8005-12N system (continued)

Feature code Description

EKAM Mellanox MCX415A-CCAT

8001-12C (slot

priority)

4, 5 NA 2

8005-12N (slot

priority)

ConnectX-4 EN 100 GbE

Single-port QSFP28 PCIe3.0

x16 LP (Adapter FRU number:

AOC-MCX415A-CCAT-IB001)

v PCIe3 x16

v Short, with full-height

tailstock

v POWER8®CAPI support

v OS support: Linux

operating systems

EKAP Qlogic QLE2562 Dual-port 8

3, 4, 5 NA 3

Gb Fibre Channel Adapter

PCIe x8 LP (Adapter FRU

number: AOC-QLE2562)

v PCIe2 x8

v Short, low-profile

v Auto-negotiation

v StarPower technology

v OS support: Linux

operating systems

EKAQ Qlogic QLE2692OP Dual-port

3, 4, 5 NA 3

16 Gb Fibre Channel Adapter

PCIe3 x8 LP (Adapter FRU

number: AOC-QLE2692OPIB001)

v PCIe2 x8

v Short, low-profile

v Auto-negotiation

v StarPower technology

v OS support: Linux

operating systems

EKAT Alpha-data CAPI Adapter:

4 NA 1

ADM-PCIe KU3 (Adapter FRU

Number: ADM-PCIE-KU3)

v PCIe3 x16

v Short, low-profile

v 1 GB of BPI x16

configuration flash

v Dual QSFP cages for

high-speed optical

communication including 10

and 40-Gigabit Ethernet

v OS support: Linux

operating systems

Maximum number

of adapters

supported

Installing and configuring the system 29

Page 46

Table 7. PCIe adapters supported in the 8001-12C or 8005-12N system (continued)

Feature code Description

EKAU Mellanox MCX4121A-ACAT

ConnectX-4 Lx EN 25GbE

dual-port SFP28 PCIe3.0 x8 LP

(Adapter FRU number:

AOC-MCX4121A-ACAT-IB001)

v PCIe3 x8

v Short, with full-height

tailstock

v POWER8®CAPI support

v End-to-end QoS and

congestion control

v OS support: Linux

operating systems

EKAZ NVIDIA Tesla P100 16GB

PCIe3.0 x16 Dual-slot FHFL

with cables (Adapter FRU

number: AOC-KIT-NVTP100IB001)

v PCIe3 x16

v Double-wide, with

full-height tailstock

v Pascal Architecture

v NVLink

v Kepler GPU Architecture

v OS support: Linux

operating systems

EKFH Intel XL710 Ethernet

Converged Network Adapter

Quad-port 10G/1G SFP+

PCIe3.0 x8 LP (Adapter FRU

number: AOC-STG-I4S)

v Quad SFP+ Connectors

v Small Packet Performance

v Network Virtualization

Offloads including VXLAN

and NVGRE

EKN2 PCIe3 1.6 TB NVMe Flash

Adapter (Adapter FRU

number: HDS-AVMHUSPR3216AHP301)

v PCIe3 x4

v Short, low-profile

v 1.6 TB of low latency flash

memory

v OS support: Linux

operating systems

8001-12C (slot

priority)

3, 4, 5 NA 3

4-5 NA 1

3, 4, 5 4 1

2, 3, 4, 5 NA 4

8005-12N (slot

priority)

Maximum number

of adapters

supported

30 Power Systems: Installing the IBM Power System S821LC (8001-12C)

Page 47

Table 7. PCIe adapters supported in the 8001-12C or 8005-12N system (continued)

Maximum number

Feature code Description

AOC-S3008L-L8e-P 12 Gb/s Eight-Port SAS

Internal HBA Adapter

(Adapter FRU number:

AOC-S3008L-L8e-P)

v PCIe3 x8

v Short, low-profile

v OS support: Linux

operating systems

8001-12C (slot

priority)

NA 2 1

8005-12N (slot

priority)

of adapters

supported

PCIe adapter information by feature type for the 8001-12C or 8005-12N

Find information about the Peripheral Component Interconnect Express (PCIe) adapters that are

supported for the IBM Power System S821LC (8001-12C) or the IBM CS821 (8005-12N).

The table shows the available adapters by feature code (FC), description, adapter FRU number, and

provides a link to more details for each adapter.

Important:

v This document does not replace the latest sales and marketing publications and tools that document

supported features.

v If you are installing a new feature, ensure that you have the software and utilities that are required to

support the new feature and determine whether you must install any adapter firmware updates. The

latest version of adapter firmware and utilities can be downloaded from Fix Central(http://

www.ibm.com/support/fixcentral/).

v For more information regarding PCIe adapter identification and I/O firmware levels for each adapter,

see the IBM Power 8001-12C and 8001-22C I/O Firmware (https://www.ibm.com/developerworks/

community/wikis/home?lang=en_us#!/wiki/W51a7ffcf4dfd_4b40_9d82_446ebc23c550/page/IBM

%20Power%208001-12C%20and%208001-22C%20IO%20Firmware) topic on the Linux on POWER

community wiki.

v The only two adapters that are currently supported on the 8005-12N are FC EKFH and

AOC-S3008L-L8e-P.

®

Table 8. PCIe adapters supported in the 8001-12C or 8005-12N system

Feature code Description

EKA0 PCIe3 x4 Intel x550 10GBase-T Converged Network Adapter with Dual RJ45 Ports (Adapter

FRU number: AOC-STGS-I2T)

EKA1 Cavium (Qlogic) BCM57840 4-port SFP+ 10 Gb Ethernet Adapter PCIe3.0 x8 LP (Adapter FRU

number: AOC-STG-B4S)

EKA2 Intel 82599ES Ethernet Converged Network Adapter x520-DA2 Dual-port 10G/1G SFP+ PCIe2.0

x8 LP (Adapter FRU number: AOC-STGN-I2S)

EKA3 Intel 82575EB dual-port Gigabit Ethernet Controller PCIe x4.0 LP (Adapter FRU number:

AOC-SG-I2)

EKAA Broadcom (LSI) MegaRAID 9361-8i SAS3 Controller with 8 Internal Ports (1 GB Cache) PCIe3.0

x8 LP with cables (Adapter FRU number: AOC-K-9361-8IS-IB001)

EKAB SMC AOC-K-S3008L-L8i 12 Gbps SAS3/RAID 0,1 and 10 PCIe3.0 x8 LP with cables (Adapter

FRU number: AOC-K-S3008L-L8iS-IB001)

EKAD Broadcom (LSI) 9300-8E SAS3 HBA PCIe3.0 x8 LP Adapter (Adapter FRU number:

AOC-SAS3-9300-8E)

Installing and configuring the system 31

Page 48

Table 8. PCIe adapters supported in the 8001-12C or 8005-12N system (continued)

Feature code Description

EKAE PCIe3 x8 Dual-port Internal NVMe Host Bus Adapter (Adapter FRU number:

AOC-K-SLG3-2E4S-IB001)

EKAF Emulex LPE16002B-M6-O Dual-port 16 Gb Fibre Channel Card PCIe3.0 x8 LP (Adapter FRU

number: AOC-LPE16002B-M6-Of)

EKAG SMC quad-port NVMe Host Bus Adapter (PEX9733) PCIe3.0 x8 LP with cables (Adapter FRU

number: AOC-K-SLG3-4E2PS)

EKAH SMC AOC-K-S3008L-L8i 12 Gbps SAS3/RAID 0,1 and 10 PCIe3.0 x8 LP with cables (Adapter

FRU number: AOC-K-9361-8I2S-IB001)

EKAJ NVIDIA Tesla K80 24 GB GPU Accelerator (Adapter FRU number: AOC-KIT-NVK80-IB001)

EKAL Mellanox MCX456A-ECAT ConnectX-4 VPI EDR IB 100 Gb/s and 100 GbE Dual-port QSFP28

PCIe3.0 x16 LP (Adapter FRU number: AOC-MCX456A-ECAT-IB001)

EKAM Mellanox MCX415A-CCAT ConnectX-4 EN 100 GbE Single-port QSFP28 PCIe3.0 x16 LP

(Adapter FRU number: AOC-MCX415A-CCAT-IB001)

EKAP Qlogic QLE2562 Dual-port 8 Gb Fibre Channel Adapter PCIe x8 LP (Adapter FRU number:

AOC-QLE2562)

EKAQ Qlogic QLE2692OP Dual-port 16 Gb Fibre Channel Adapter PCIe3 x8 LP (Adapter FRU number:

AOC-QLE2692OP-IB001)

EKAT Alpha-data CAPI Adapter: ADM-PCIe KU3 (Adapter FRU Number: ADM-PCIE-KU3)

EKAU Mellanox MCX4121A-ACAT ConnectX-4 Lx EN 25GbE dual-port SFP28 PCIe3.0 x8 LP (Adapter

FRU number: AOC-MCX4121A-ACAT-IB001)

EKAZ NVIDIA Tesla P100 16GB PCIe3.0 x16 Dual-slot FHFL with cables (Adapter FRU number:

AOC-KIT-NVTP100-IB001)

1

EKFH

EKN2 PCIe3 1.6 TB NVMe Flash Adapter (Adapter FRU number: HDS-AVM-HUSPR3216AHP301)

AOC-S3008L-L8e-

2

P

1

This adapter is supported on the 8001-12C and 8005-12N.

2

This adapter is only supported on the 8005-12N.

Intel XL710 Ethernet Converged Network Adapter Quad-port 10G/1G SFP+ PCIe3.0 x8 LP

(Adapter FRU number: AOC-STG-I4S)

Note: This adapter must go in WIO Slot1 in the 8005-12N system.

12 Gb/s Eight-Port SAS Internal HBA Adapter (Adapter FRU number: AOC-S3008L-L8e-P)

Note: This adapter must go in UIO Slot1 in the 8005-12N system.