Page 1

User’s Manual

PG-FP3

Flash Memory Programmer

Document No. U13502EJ2V0UM00 (2nd edition)

Date Published July 1999 J CP(K)

1998

1991©

Printed in Japan

Page 2

[MEMO]

2

User's Manual U13502EJ2V0UM00

Page 3

SUMMARY OF CONTENTS

CHAPTER 1 GENERAL .....................................................................................................................................................17

CHAPTER 2 CONFIGURATION.........................................................................................................................................19

CHAPTER 3 STARTING AND STOPPING ........................................................................................................................27

CHAPTER 4 BASIC OPERATING PROCEDURE..............................................................................................................37

CHAPTER 5 COMMAND REFERENCE.............................................................................................................................45

CHAPTER 6 STAND-ALONE FUNCTION .........................................................................................................................67

CHAPTER 7 HARDWARE SPECIFICATIONS...................................................................................................................69

CHAPTER 8 ERROR MESSAGES AND REMEDIAL ACTIONS .......................................................................................87

APPENDIX A NOTES ON DESIGNING A TARGET............................................................................................................91

APPENDIX B REVISION HISTORY.....................................................................................................................................93

User's Manual U13502EJ2V0UM00

3

Page 4

EEPROM is a trademark of NEC Corporation.

PC/AT is a trademark of International Business Machines Corporation.

Windows and Windows NT are either registered trademarks or trademarks of Microsoft Corporation in the United

States and/or other countries.

Pentium is a trademark of Intel Corporation in the United States.

4

User's Manual U13502EJ2V0UM00

Page 5

• The information in this document is subject to change without notice. Before using this document,

please confirm that this is the latest version.

• No part of this document may be copied or reproduced in any form or by any means without the prior written

consent of NEC Corporation. NEC Corporation assumes no responsibility for any errors which may appear in

this document.

• NEC Corporation does not assume any liability for infringement of patents, copyrights or other intellectual

property rights of third parties by or arising from use of a device described herein or any other liability arising

from use of such device. No license, either express, implied or otherwise, is granted under any patents,

copyrights or other intellectual property rights of NEC Corporation or of others.

• Descriptions of circuits, software, and other related information in this document are provided for illustrative

purposes in semiconductor product operation and application examples. The incorporation of these circuits,

software, and information in the design of the customer's equipment shall be done under the full responsibility

of the customer. NEC Corporation assumes no responsibility for any losses incurred by the customer or third

parties arising from the use of these circuits, software, and information.

M7A 98. 8

User's Manual U13502EJ2V0UM00

5

Page 6

Regional Information

Some information contained in this document may vary from country to country. Before using any NEC

product in your application, pIease contact the NEC office in your country to obtain a list of authorized

representatives and distributors. They will verify:

•

Device availability

•

Ordering information

•

Product release schedule

•

Availability of related technical literature

•

Development environment specifications (for example, specifications for third-party tools and

components, host computers, power plugs, AC supply voltages, and so forth)

•

Network requirements

In addition, trademarks, registered trademarks, export restrictions, and other legal issues may also vary

from country to country.

NEC Electronics Inc. (U.S.)

Santa Clara, California

Tel: 408-588-6000

800-366-9782

Fax: 408-588-6130

800-729-9288

NEC Electronics (Germany) GmbH

Duesseldorf, Germany

Tel: 0211-65 03 02

Fax: 0211-65 03 490

NEC Electronics (UK) Ltd.

Milton Keynes, UK

Tel: 01908-691-133

Fax: 01908-670-290

NEC Electronics Italiana s.r.l.

Milano, Italy

Tel: 02-66 75 41

Fax: 02-66 75 42 99

NEC Electronics (Germany) GmbH

Benelux Office

Eindhoven, The Netherlands

Tel: 040-2445845

Fax: 040-2444580

NEC Electronics (France) S.A.

Velizy-Villacoublay, France

Tel: 01-30-67 58 00

Fax: 01-30-67 58 99

NEC Electronics (France) S.A.

Spain Office

Madrid, Spain

Tel: 91-504-2787

Fax: 91-504-2860

NEC Electronics (Germany) GmbH

Scandinavia Office

Taeby, Sweden

Tel: 08-63 80 820

Fax: 08-63 80 388

NEC Electronics Hong Kong Ltd.

Hong Kong

Tel: 2886-9318

Fax: 2886-9022/9044

NEC Electronics Hong Kong Ltd.

Seoul Branch

Seoul, Korea

Tel: 02-528-0303

Fax: 02-528-4411

NEC Electronics Singapore Pte. Ltd.

United Square, Singapore 1130

Tel: 65-253-8311

Fax: 65-250-3583

NEC Electronics Taiwan Ltd.

Taipei, Taiwan

Tel: 02-2719-2377

Fax: 02-2719-5951

NEC do Brasil S.A.

Electron Devices Division

Rodovia Presidente Dutra, Km 214

07210-902-Guarulhos-SP Brasil

Tel: 55-11-6465-6810

Fax: 55-11-6465-6829

J99.1

6

User's Manual U13502EJ2V0UM00

Page 7

Major Revisions in This Edition

Page Description

p.18

p.19

p.20

p.20

p.28

p.30

p.36

p.46

p.50

p.58

p.59

p.61

p.62

p.62

p.65

p.72

p.73

p.77

p.91

p.92

p.93

p.41 in the

first edition

p.46 in the

first edition

p.53 in the

first edition

p.75 in the

first edition

The setting of the baud rate and the c apacity for downloading the user program in

changed.

Figure 2-1

Figure 2-2

The description of EXPANSION CONNECTOR has been deleted from

A description in

A description in

A description has been added to "Option setting" in

A description has been added to

A description in

A description in

A description in

A description in

A description in

A description in

A description in

A description in "Support ed ROM specifications" in

A description has been deleted from

The setting of the baud rate in

Figure A-1

Figure A-2

Appendix B

Section 5.3.2

Section 5.3.7

Section 5.4.6

Section 7.5

has been changed.

has been changed.

Section 3.1

Section 3.2

Section 5.2.2

Section 5.3.2

Section 5.3.3

Section 5.3.4

Section 5.3.5

Section 5.3.6

Section 5.4.3

has been changed.

has been changed.

has been added.

has been deleted.

has been deleted.

has been deleted.

has been deleted.

has been changed.

has been changed.

Section 3.3

Section 5.1.2

has been changed.

has been changed.

has been changed.

has been changed.

has been changed and Caution has been added to

has been changed.

has been changed.

Section 7.3

Table 7-4

.

Section 7.2

.

has been changed.

Section 2.2

.

has been changed.

Table 1-1

.

Section 5.3.5

have been

.

The mark shows major revised points.

User's Manual U13502EJ2V0UM00

7

Page 8

[MEMO]

8

User's Manual U13502EJ2V0UM00

Page 9

PREFACE

Readers of This Manual

Purpose

Organization

How to Read This Manual

This manual is intended for user engineers who use the PG-FP3 to design and develop

systems with an NEC microcontroller with flash memory.

The PG-FP3 enables programs in the NEC microcontroller with flash memory to be

erased, written, or verified with the microcontroller mounted on a user-designed printed

TM

circuit board through simple operations on a Windows

screen.

This manual contains the basic PG-FP3 specifications and explains how to use the

PG-FP3.

This manual contains the following chapters:

General, Configuration, Starting and Stopping, Basic Operating Procedure, Command

Reference, Stand-alone Function, Hardware Specifications, and Error Messages and

Remedial Actions

To understand the basic specifications and operation of the PG-FP3, read this manual

in the order given in the table of contents. Be sure to read

Chapter 3

, which contains

important information on operating the PG-FP3.

It is assumed that the readers of this manual have a basic knowledge of electricity,

logic circuits, and microcontrollers. It is also assumed that, especially in the

description of applications, they have sufficient knowledge of Windows. For

information on using Windows 95 and Windows NTTM and for the related terminology,

refer to the appropriate Windows manual.

Legend Note

Caution

Remark

Numeric notation : Binary..............

: Explanation of the item so marked

: Important information

: Supplementary explanation

××××

Decimal ...........

Hexadecimal....0

User's Manual U13502EJ2V0UM00

××××

××××

or

H or

××××

××××

B

H

9

Page 10

Terminology

PG-FP3 ................................... Flash memory programmer

FLASHPRO3 ........................... Windows application name of PG-FP3

Target ...................................... NEC microcontroller with flash memory or user board

on which such a microcontroller is mounted

Printer interface (IEEE 1284) ... Parallel interface specified by IEEE 1284-1994. Used

by the PG-FP3 as one of the host interfaces.

FA adapter ............................... Adapter board used to write programs to an NEC

microcontroller with flash memory

The FA adapter board is a product of Naito Densei Machida Mfg. Co., Ltd.

Note

Note

<Telephone number>

Naito Densei Machida Mfg. Co., Ltd.: 044-822-3813

10

User's Manual U13502EJ2V0UM00

Page 11

CONTENTS

CHAPTER 1 GENERAL .............................................................................................................................17

CHAPTER 2 CONFIGURATION.................................................................................................................19

2.1 PRODUCT ORGANIZATION.........................................................................................................................19

2.2 NAMES AND FUNCTIONS OF PARTS.........................................................................................................20

2.3 CONNECTIONS OF PARTS..........................................................................................................................22

CHAPTER 3 STARTING AND STOPPING................................................................................................27

3.1 INSTALLING THE APPLICATION.................................................................................................................27

3.2 STARTING THE APPLICATION....................................................................................................................30

3.3 INITIALIZATION AND NOTES ON CORRECT USE.....................................................................................33

3.4 TERMINATING THE APPLICATION.............................................................................................................36

CHAPTER 4 BASIC OPERATING PROCEDURE .....................................................................................37

CHAPTER 5 COMMAND REFERENCE.....................................................................................................45

5.1 File.................................................................................................................................................................45

5.1.1 Load File.............................................................................................................................................45

5.1.2 Save File.............................................................................................................................................46

5.1.3 Load Type...........................................................................................................................................47

5.1.4 Save Type ..........................................................................................................................................48

5.1.5 Exit......................................................................................................................................................48

5.2 Setting...........................................................................................................................................................49

5.2.1 Device.................................................................................................................................................49

5.2.2 Type....................................................................................................................................................50

5.2.3 Voltage ...............................................................................................................................................54

5.2.4 Option.................................................................................................................................................55

5.2.5 Reset..................................................................................................................................................55

5.2.6 Connection Port..................................................................................................................................56

5.3 Procedure......................................................................................................................................................57

5.3.1 Download HEX...................................................................................................................................57

5.3.2 Erase..................................................................................................................................................58

5.3.3 Program..............................................................................................................................................59

5.3.4 Verify ..................................................................................................................................................61

5.3.5 E.P.V. .................................................................................................................................................62

5.3.6 Chip set/Block set/Area set ................................................................................................................62

5.4 Other..............................................................................................................................................................64

5.4.1 Signature............................................................................................................................................64

5.4.2 Status .................................................................................................................................................64

5.4.3 Dump HEX..........................................................................................................................................65

5.4.4 Supply Status .....................................................................................................................................66

5.4.5 PROM Load........................................................................................................................................66

5.5 Help................................................................................................................................................................66

User's Manual U13502EJ2V0UM00

11

Page 12

CHAPTER 6 STAND-ALONE FUNCTION .................................................................................................67

6.1 FUNCTION.....................................................................................................................................................67

6.2 OPERATION ..................................................................................................................................................68

CHAPTER 7 HARDWARE SPECIFICATIONS...........................................................................................69

7.1 PRODUCT CONFIGURATION AND OPERATING ENVIRONMENT.............................................................69

7.2 MASTER ROM SOCKET SPECIFICATIONS ................................................................................................70

7.3 HOST INTERFACE........................................................................................................................................73

7.3.1 Printer Interface Specifications...........................................................................................................73

7.3.2 RS-232C Interface Specifications .......................................................................................................77

7.4 TARGET INTERFACE SPECIFICATIONS ....................................................................................................80

7.4.1 Interface Specifications.......................................................................................................................81

7.4.2 Equivalent Circuit and Load Condition................................................................................................84

CHAPTER 8 ERROR MESSAGES AND REMEDIAL ACTIONS...............................................................87

APPENDIX A NOTES ON DESIGNING A TARGET ..................................................................................91

APPENDIX B REVISION HISTORY............................................................................................................93

12

User's Manual U13502EJ2V0UM00

Page 13

LIST OF FIGURES

Figure No. Title Page

2-1. PG-FP3 System Organization ...........................................................................................................................19

2-2. PG-FP3 Parts and Names.................................................................................................................................20

3-1. FLASHPRO3 Screens.......................................................................................................................................32

3-2. Parameter File Setting Dialog Box.....................................................................................................................33

3-3. TYPE Setting Dialog Box (When the Parameter File Is Loaded).......................................................................34

3-4. TYPE Setting Dialog Box (When the Parameter File Is Not Loaded)................................................................34

4-1. Communication Error Dialog Box ......................................................................................................................38

5-1. File Format Select Dialog Box...........................................................................................................................46

5-2. Mode Screens....................................................................................................................................................63

5-3. Editor Screen.....................................................................................................................................................65

7-1. Pin Configuration (Top View).............................................................................................................................72

7-2. Communication Error Dialog Box ......................................................................................................................77

A-1. Interface Circuit Example for a UART................................................................................................................91

A-2. Interface Circuit Example for SIO......................................................................................................................92

User's Manual U13502EJ2V0UM00

13

Page 14

LIST OF TABLES

Table No. Title Page

1-1. Function Specifications......................................................................................................................................18

2-1. Items in the PG-FP3 Shipping Carton................................................................................................................19

7-1. Product Configuration and Operating Environment...........................................................................................69

7-2. Pin List...............................................................................................................................................................72

7-3. Printer Interface Specifications..........................................................................................................................73

7-4. RS-232C Interface Specifications......................................................................................................................77

7-5. Withstand Voltage of Each Interface Signal.......................................................................................................80

14

User's Manual U13502EJ2V0UM00

Page 15

LIST OF PHOTOGRAPHS

Photo No. Title Page

2-1. Connections (Host, PG-FP3, and Target)..........................................................................................................22

2-2. Connecting the Printer Interface Cable (I/F SELECT Switch Set to PRINTER I/F Position) .............................23

2-3. Connecting RS-232C (I/F SELECT Switch Set to RS-232C Position)...............................................................23

2-4. Connecting the AC Adapter...............................................................................................................................24

2-5. Connecting Target Cable to PG-FP3 <1>..........................................................................................................24

2-6. Connecting Target Cable to User Target...........................................................................................................25

2-7. Connecting Target Cable to PG-FP3 <2>..........................................................................................................25

2-8. Connecting Target Cable to FA Adapter............................................................................................................26

2-9. Directly Connecting FA Adapter to PG-FP3 ......................................................................................................26

3-1. Starting the PG-FP3 ..........................................................................................................................................30

4-1. Connection of Host, PG-FP3, and Target..........................................................................................................37

6-1. Selecting the Command Mode ..........................................................................................................................68

7-1. Mounting the Master ROM.................................................................................................................................70

7-2. Mounting the PROM in the Master ROM Socket...............................................................................................71

7-3. Executing the [PROM Load] Command.............................................................................................................71

User's Manual U13502EJ2V0UM00

15

Page 16

[MEMO]

16

User's Manual U13502EJ2V0UM00

Page 17

CHAPTER 1 GENERAL

The PG-FP3 is a tool for erasing, writing, and verifying programs for an NEC single-chip microcontroller with flash

memory on a user board or FA adapter board.

♦♦♦♦

Features

Supports all NEC microcontrollers with flash memory (as of February 1999)

•

Easy to use in stand-alone mode (with PG-FP3 only) or on Windows 95 or Windows NT using a dedicated

•

application (PG-FP3)

Compact, portable design the size of a sheet of A5 paper

•

Has a printer interface (parallel interface) in addition to the standard RS-232C interface. Downloads user

•

programs quickl y.

Note

Supports high-capacity microcontrollers

•

memory of 2 Mbytes

that are expected to be available in the future as well as flash

Support of microcontrollers developed in the future may require PG-FP3 firmware and application

Note

upgrades.

User's Manual U13502EJ2V0UM00

17

Page 18

CHAPTER 1 GENERAL

♦♦♦♦

Function specifications

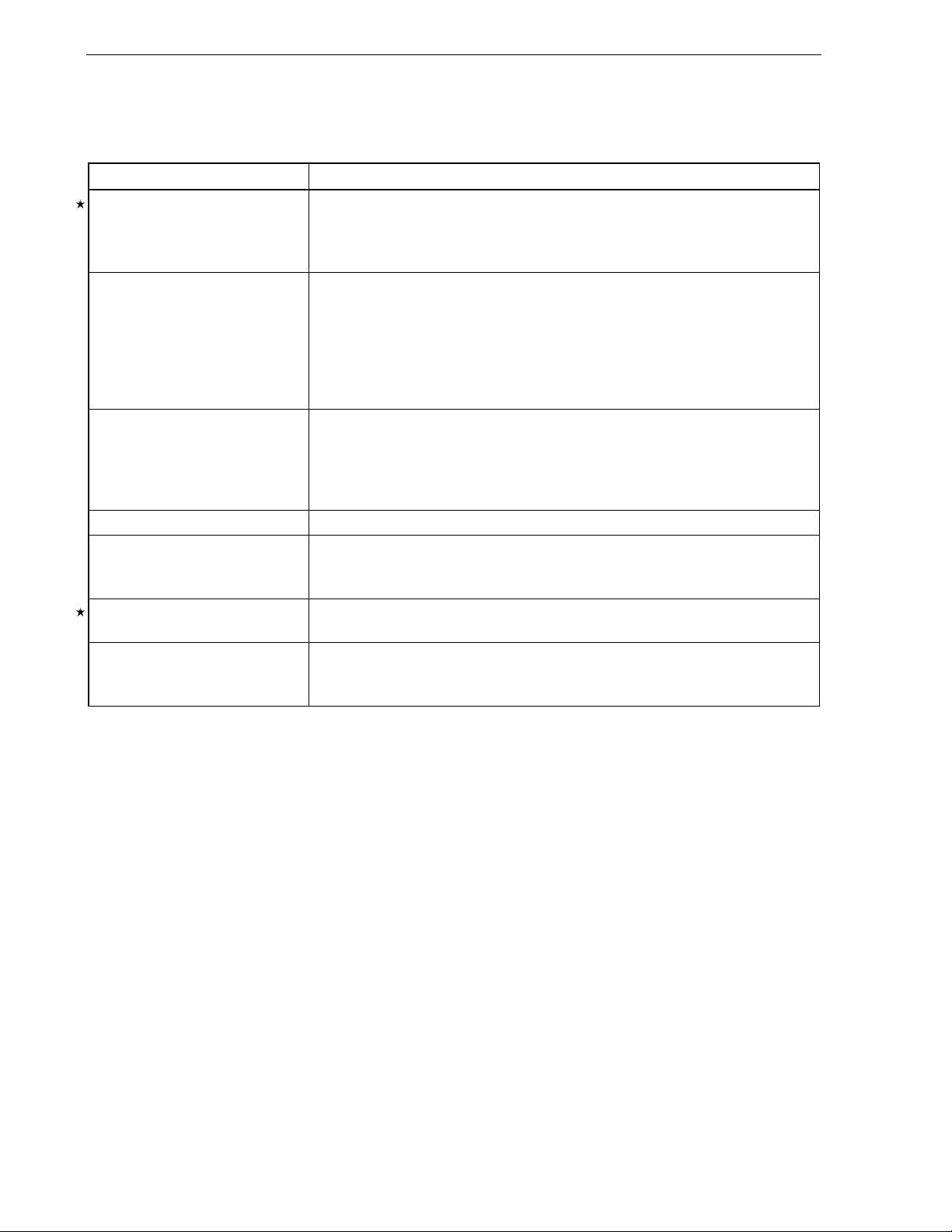

Table 1-1. Function Specifications

Item Specification

Host interface

Target interface

Supply voltage

Note 2

Note 3

Supply voltage input Target VDD supply voltage input: 1.8 to 5.5 V, current consumption: 100 mA max.

CPU clock supply A 16-, 8-, 4-, or 2-MHz clock can be selected as the target CPU clock.

Master ROM A PROM (CMOS, 32-pin) to which the user program is written can be inserted in the

Stand-alone Programming with only the PG-FP3.

RS-232C: D-SUB 25-pin, 9600, 19200, 38400, or 57600 bps

Printer interface

Note 1

: Half-pitch 36-pin conforming to IEEE 1284-1994

(Supports compatible mode and ECP mode.)

The interface can be selected with the I/F SELECT switch.

Connector: D-SUB 9-pin (receptacle)

DD

Level conversion: Within target V

input range (1.8 to 5.5 V)

Protection function: Overvoltage input protection circuit (guaranteed range: 15 V max.)

Supported interface: 3-wi re, 3-wire + handshake (Max. SCK: 2.0 MHz)

Pseudo 3-wire (Max. SCK: 2.0 MHz)

UART (Max. bps: 76800 bps)

IIC (Max. SCK: 50 kHz)

Target VPP supply voltage: 2.7 to 10.3 V, max.: 200 mA

DD

Target V

supply voltage: 1.8 to 6.0 V, max.: 200 mA

Whether power is supplied from the PG-FP3 or from the user target can be selected

DD

with the TARGET V

An overcurrent protection circuit is provided for both V

switch.

PP

and VDD.

The on-board target clock can be also used depending on the application settings.

(PG-FP3-side interface: CMOS level output)

master ROM socket to allow the user program to be downloaded (max.: 500 kbytes).

Functions such as E.P.V., ERASE, PROGRAM, VERIFY, and LOAD can be selected and

executed with the MODE Key.

Notes 1.

18

Only supported for Windows 95.

The maximum communication rate of the interface varies depending on the device used and the

2.

environment.

DD

is supplied to the target system to supply power to the device to which a program is to be written.

V

3.

The power is not enough to operate the target system of the user. Use the power supply on the target

for on-board program writing.

User's Manual U13502EJ2V0UM00

Page 19

CHAPTER 2 CONFIGURATION

2.1 PRODUCT ORGANIZATION

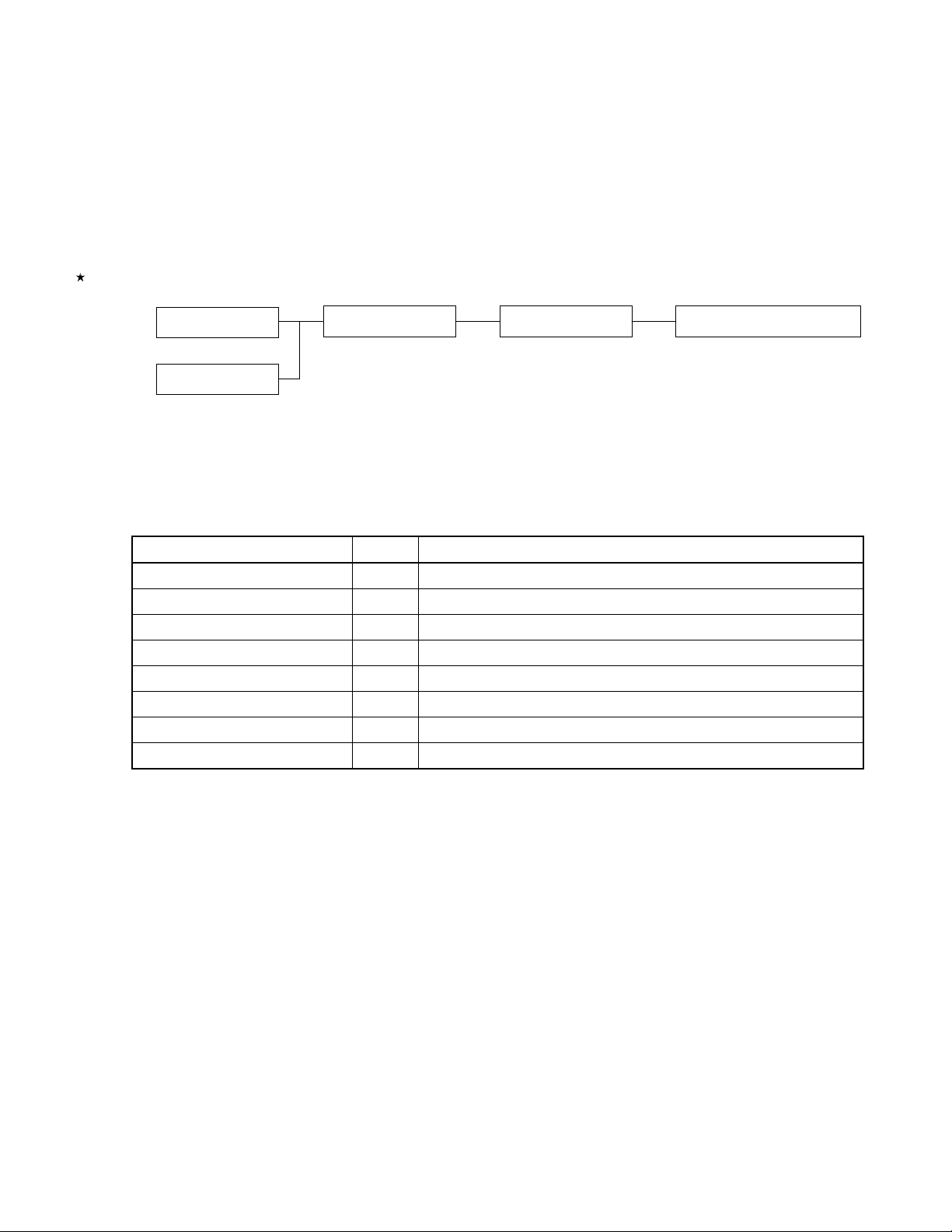

The system configuration of the PG-FP3 is illustrated below.

Figure 2-1. PG-FP3 System Organization

User target

FA adapter

Note

Note

The FA adapter is a product of Naito Densei Machida Mfg. Co., Ltd.

PG-FP3 Host machine Application (FLASHPRO3)

The PG-FP3 shipping carton contains the following items:

Table 2-1. Items in the PG-FP3 Shipping Carton

Item Qty Remarks

PG-FP3 1 PG-FP3

Floppy disk 1 Application software

AC adapter 1 Power supply

Printer cable 2 One for a PC-9800 and one for PC/ATTM or compatible machine

Target cable 2 Type 1 (IC clip) and Type 2 (connector)

User's Manual 1 This manual

Packing list 1 Packing list for this product

Warranty 1

The PG-FP3 is shipped with the above accessories. Make sure that all accessories have been provided by

checking the contents of the box against the above table when you unpack the box. If any part or accessory is missing

or is damaged, notify NEC.

To use RS-232C as the host interface, you will need a commercially available RS-232C straight cable.

User's Manual U13502EJ2V0UM00

19

Page 20

CHAPTER 2 CONFIGURATION

2.2 NAMES AND FUNCTIONS OF P ARTS

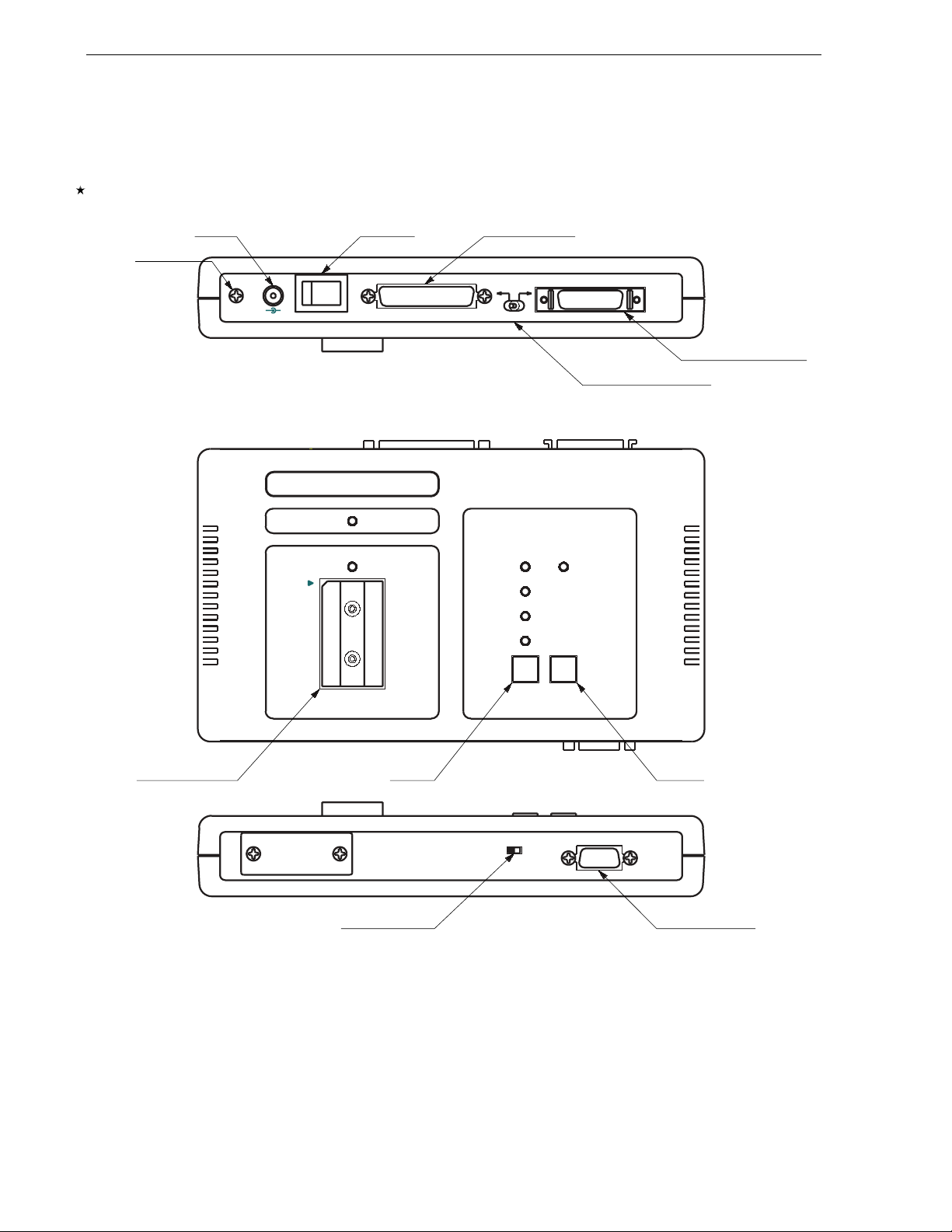

Parts and their names are illustrated bel o w.

Figure 2-2. PG-FP3 Parts and Names

FG TERMI

N

AL

DC JACK

POWER SWITCH

FG

-+

OFF

+

V*IN

9

ON

232

C

-

RS-232-C CONNECTOR

RS-

T

ELE

I/F*S

C

P

RI

NTE

R*I /F

HOST I/F SELE

PRIN

C

TSWITCH

TER I/F CONNE

C

TOR

POWER

ACCESS

E

R

A

E

S

A

M

R

P

R

O

G

R

O

R

R

E

VERIFY

LOAD

E

N

R

E

T

EN

E

TER K

Y

D

D

V

T

I

N

T

E

R

A

T

G

TARGET I/F CONNECTOR

SOCKET OF MASTER ROM

MASTER

ROM

R

EAD ONLY

ODE KEY

M

T

RGET VDD SWITCH

A

MODE

A

T

R

E

G

T

O

U

The following explains the functions of the PG-FP3 parts:

FG TERMINAL

•

The FG terminal is a ground terminal on the PG-FP3. If necessary, ground the terminal using the FG cable

supplied as an accessory.

20

User's Manual U13502EJ2V0UM00

Page 21

CHAPTER 2 CONFIGURATION

DC JACK

•

This is the power supply input jack of the PG-FP3. To supply power to the PG-FP3, use the AC adapter supplied

as an accessory.

POWER SWITCH

•

This switch turns power to the PG-FP3 on or off. Before turning power on, make sure that all required parts are

connected correctly.

RS-232C CONNECTOR

•

This connector is used when RS-232C is used as the host interface. Use a commercially available 25-pin

straight cable to connect the host machine and the PG-FP3.

PRINTER I/F CONNECTOR

•

This connector is used when the printer interface cable supplied as an accessory is used as the host interface.

Connect the host machine and the PG-FP3 with the printer cable. Use only the supplied cable. Another cable

may cause the PG-FP3 to malfunction or to be damaged.

HOST I/F SELECT SWITCH

•

This switch selects whether an RS-232C or the printer interface cable is used as the interface with the host

machine. Select an interface before turning on power to the PG-FP3. The selected interface cannot be changed

after power has been turned on.

SOCKET OF MASTER ROM

•

The master ROM socket is used when a user program is downloaded to the PG-FP3 from a source other than

the host machine. A commercially available EPROM can be used as the master ROM. The user program can

be downloaded from an application or in stand-alone mode.

MODE KEY

•

This key is used to select a command mode when the PG-FP3 is used in stand-alone mode. Each time this key

is pressed, the command mode changes.

ENTER KEY

•

This key is used to execute a command selected by the mode key when the PG-FP3 is in stand-alone mode.

Select the command to be executed with the mode key, and press the ENTER key once to execute the

command.

DD

TARGET V

•

SWITCH

This switch selects whether VDD is supplied from the PG-FP3 or from the target board. Usually, VDD is supplied

from the target board.

DD

Supply V

from the PG-FP3 (TARGET VDD: OUT) only when a writing adapter, such as the FA adapter

used.

TARGET I/F CONNECTOR

•

This connector connects the PG-FP3 and the target board. Use the target interface cable supplied as an

accessory to make the connection.

Note

, is

The FA adapter is a product of Naito Densei Machida Mfg. Co., Ltd.

Note

User's Manual U13502EJ2V0UM00

21

Page 22

CHAPTER 2 CONFIGURATION

2.3 CONNECTIONS OF PARTS

This section explains how to connect the various parts of the PG-FP3.

The PG-FP3 can be used in two ways. It can be connected to a host machine and controlled by application

software or it can be used in stand-alone mode without being connected to a host machine. When using the PG-FP3

without being connected to the host machine (i.e., in stand-alone mode), you may skip the description on connection

with the host machine.

Photo 2-1. Connections (Host, PG-FP3, and Target)

Remark

22

When the PG-FP3 is used in stand-alone mode, interfacing with the target must be specified in advance.

To do so, select the device to be used and the communication mode using the application software on

the host machine. The setting information is recorded in the PG-FP3. In stand-alone mode, the PG-FP3

interfaces with the target based on this information.

User's Manual U13502EJ2V0UM00

Page 23

CHAPTER 2 CONFIGURATION

[Connecting a host machine]

Connection of the host interface cable is illustrated below. Select the host interface before turning on power to

the PG-FP3. The selected host interface cannot be changed after power has been turned on.

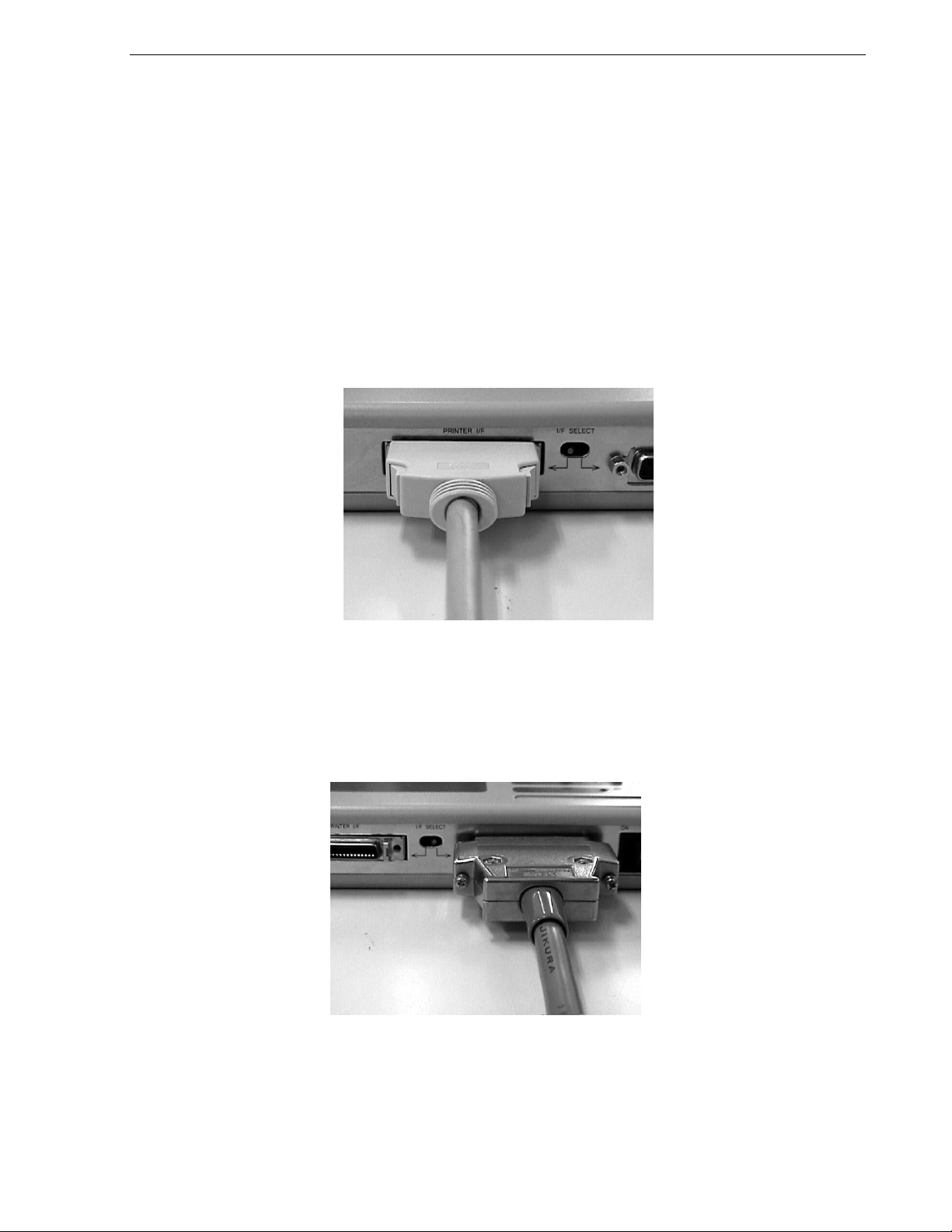

Connecting the printer interface cable

•

Set the interface select switch to the printer interface position. Connect the host machine with the printer

interface cable supplied as an accessory. Use the appropriate interface cable for the type of host machine (PC9800 or PC/AT).

The printer interface cable cannot be used unless the host machine supports bidirectional parallel

communication. Before using this cable, therefore, confirm that the host machine supports bidirectional

communication, compatible mode, and ECP mode.

Photo 2-2. Connecting the Printer Interface Cable (I/F SELECT Switch Set to PRINTER I/F Position)

Connecting the RS-232C interface

•

Set the interface select switch to the RS-232C position, and connect the appropriate RS-232C straight cable to

the RS-232C connector.

Photo 2-3. Connecting RS-232C (I/F SELECT Switch Set to RS-232C Position)

User's Manual U13502EJ2V0UM00

23

Page 24

CHAPTER 2 CONFIGURATION

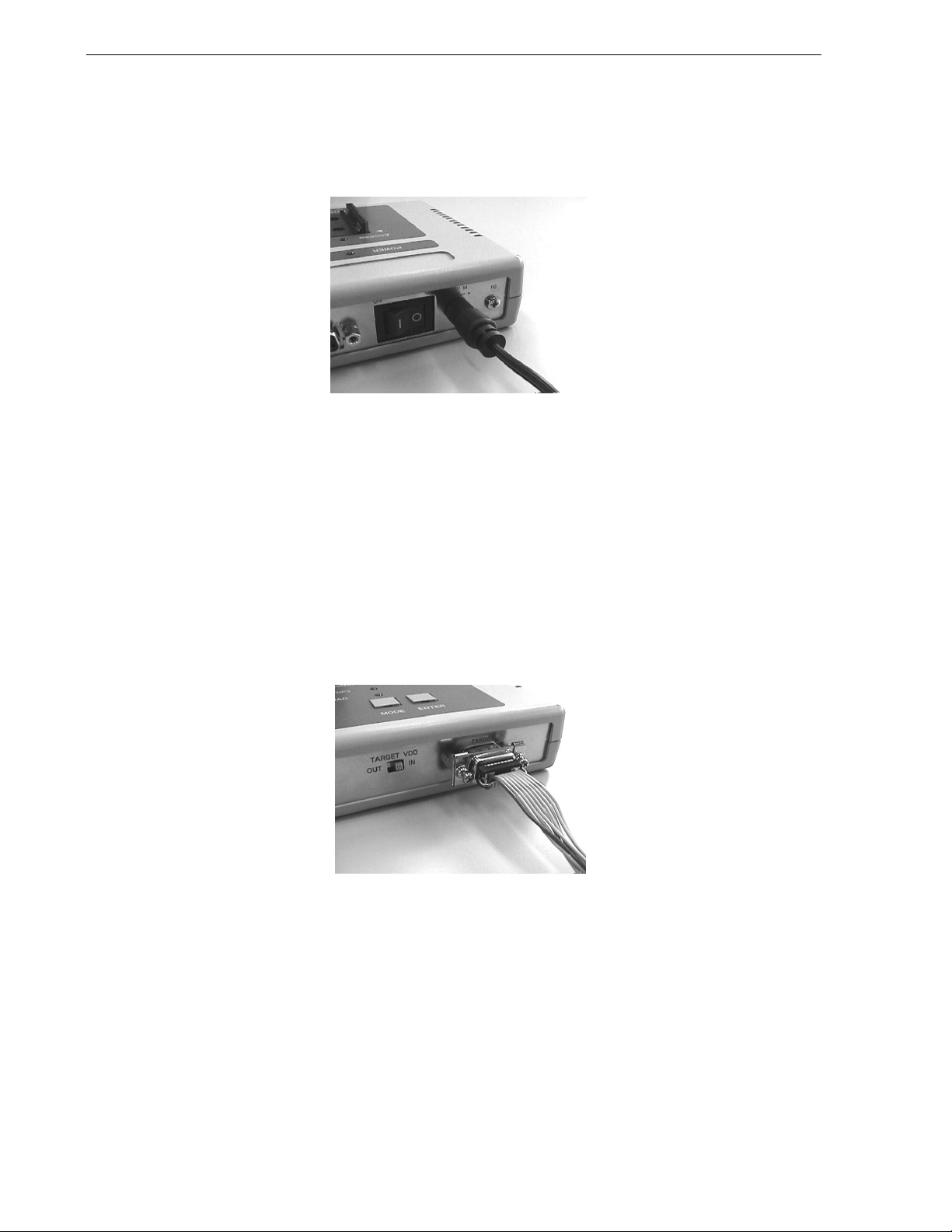

[Connecting the power supply]

With the power switch off, connect the AC adapter supplied as an accessory to the DC jack.

Photo 2-4. Connecting the AC Adapter

[Connecting the target]

Use the target cable supplied as an accessory to connect the target. Whether you use a Type 1 or Type 2 cable

depends on the specifications of the target. If the FA adapter

Note

is used, either use a Type 2 cable, or directly

connect the target to the PG-FP3.

Note

The FA adapter is a product of Naito Densei Machida Mfg. Co., Ltd.

When using a user target

•

Confirm that the target V

DD

switch is set to the IN position and then connect one end of the target cable to the

PG-FP3.

Photo 2-5. Connecting Target Cable to PG-FP3 <1>

Connect the other end of the target cable to the user target (in the example below, an IC clip is used).

24

User's Manual U13502EJ2V0UM00

Page 25

CHAPTER 2 CONFIGURATION

Photo 2-6. Connecting Target Cable to User Target

For the details of interface signal connections, see

When using the FA adapter

•

DD

Make sure that the target V

select switch is set to the OUT position. Connect one end of the Type 2 cable to

Section 7.4

and the manual for the device.

the PG-FP3, and the other end of the cable to the mating connector of the FA adapter. Alternatively, directly

connect the D-SUB connector of the FA adapter to the target interface connector of the PG-FP3.

The FA adapter has a D-SUB connector and a connector supporting the Ty pe 2 cable. Connect the FA adapter

in either of the ways described above. For the wiring of the FA adapter, refer to the FA adapter manual or the

manual for the device.

Photo 2-7. Connecting Target Cable to PG-FP3 <2>

User's Manual U13502EJ2V0UM00

25

Page 26

CHAPTER 2 CONFIGURATION

Photo 2-8. Connecting Target Cable to FA Adapter

The following is an example of directly connecting the FA adapter to the PG-FP3:

Photo 2-9. Directly Connecting FA Adapter to PG-FP3

26

User's Manual U13502EJ2V0UM00

Page 27

CHAPTER 3 STARTING AND STOPPING

This chapter explains how to install, start, and terminate the application. It also contains information on initialization

and on use of the application. Be sure to read this chapter, since it provides very important information about using

the PG-FP3. Unless the information in this chapter is not understood and followed, the PG-FP3 may not operate

correctly.

3.1 INSTALLING THE APPLICATION

This section explains how to install the application program.

Caution Because the program file is stored in compressed form on the floppy disk, it cannot be used

simply by copying the files on the disk to the hard disk. Be sure to install the program correctly

by using the setup program.

Starting the host machine

•

Turn on power to the personal computer, and start Windows 95 or Windows NT.

Host machine: PC-9801 or PC-9821

IBM PC/AT compatible

CPU: Pe ntiu m

RAM: 32 Mbytes or more is recommended.

TM

(100 MHz or higher is recommended.)

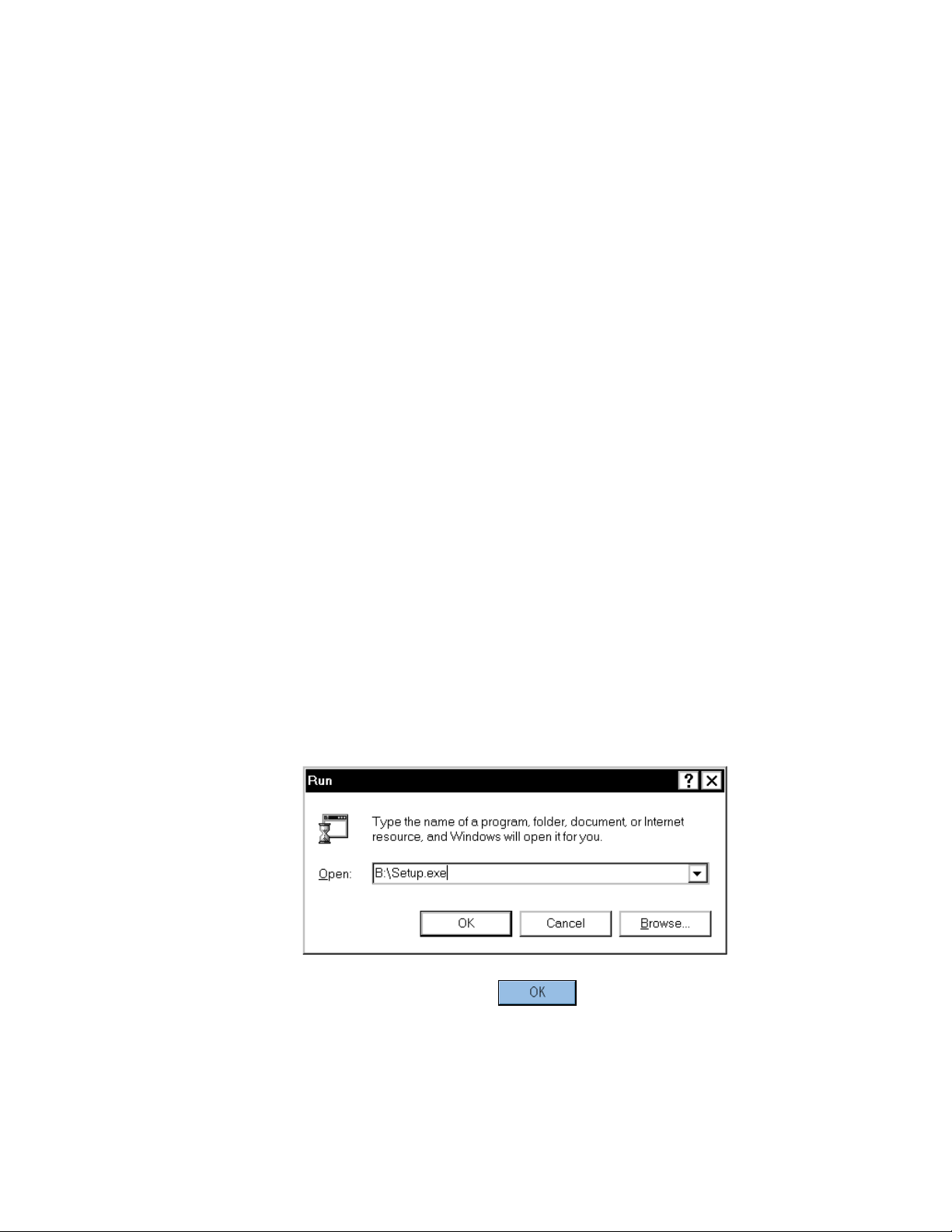

Starting the setup program

•

Select [Run] from the Start menu.

Enter the name of the drive for which [SETUP DISK] has been set and the file name SETUP.EXE in the [Open]

text box in the [Run] dialog box.

Example

When Disk 1 inserted in drive B

After entering the drive name and file name, click the button.

User's Manual U13502EJ2V0UM00

27

Page 28

CHAPTER 3 STARTING AND STOPPING

Starting installation

•

When SETUP.EXE star ts, follow the instructions by the setup program until the setting screen for the installation

directory is displayed. To stop installation partway, click the [Cancel] button.

Specify the installation directory in [Destination Directory] in the Choose Destination Location screen. Then,

click the

Example

Specifying the [\Program Files\Flashpro3] path of drive C

button.

To start the installation, click the [Next] button. When the installation ends, a confirmation message appears as

shown below. Click the [OK] button.

Now, the installation is completed. An English help file is installed as standard. To use a Japanese help file,

copy the flashpro.hlp file from Disk 2 into the installation directory. Note that the English help file is overwritten.

28

User's Manual U13502EJ2V0UM00

Page 29

CHAPTER 3 STARTING AND STOPPING

Uninstalling the program

•

To uninstall the PG-FP3 application, execute [Add/Remove Programs] in [Control Panel], and select

[FLASHPRO3].

Uninstallation will start, and the files copied during installation will be deleted.

Caution Uninstallation erases all installed components. If FLASHPRO3 is required after uninstallation,

reinstall it.

Installing the parameter file

•

The PG-FP3 loads information about the target device as a parameter file and makes the necessary settings for

interfacing.

Caution The PG-FP3 will not operate correctly unless the parameter file of the device to which

programs are to be written has been installed. Be sure to obtain and install the parameter file

when using PG-FP3.

Using Explorer or a similar means, copy the parameter file (XXXXXXX.PRC) to the same location where

FLASHPRO3 has been installed. Unless the file is copied to the same location, FLASHPRO3 will not correctly

recognize the parameter file.

User's Manual U13502EJ2V0UM00

29

Page 30

CHAPTER 3 STARTING AND STOPPING

3.2 STARTING THE APPLICATION

This section explains how to start the application program.

Connection of each unit and applying power

•

For connection of each unit, see

After completing connections, turn on power to the PG-FP3. When the PG-FP3 is operating normally, the

POWER LED lights, the LED on the side of the MODE key blinks, and then the Erase, Program, and Verify LED

indicators light.

Section 2.3

.

Photo 3-1. Starting the PG-FP3

If any of the LEDs mentioned above does not light, the PG-FP3 has probably malfunctioned. If this occurs,

notify NEC.

Starting FLASHPRO3

•

Either select FLASHPRO3 from the Start menu or, if a shortcut has been created, double-click the shortcut to

start FLASHPRO3. If FLASHPRO3 starts correctly, the following screen is displayed.

30

User's Manual U13502EJ2V0UM00

Page 31

CHAPTER 3 STARTING AND STOPPING

If FLASHPRO3 does not start correctly

•

FLASHPRO3 will not start correctly if the communication settings are wrong or if installation has not been

performed correctly.

When FLASHPRO3 starts, connection with the PG-FP3 is checked. If communication is not being performed

normally, the following dialog is displayed.

This dialog is displayed because:

1. The cables are not correctly connected.

Correctly connect the cables. Especially, connect the RS-232C cable correctly because it is a straight

cable.

2. The selected interface is wrong.

Check to see if the setting of the I/F SELECT switch matches the interface used.

3. Setting of Connection Port is wrong.

If the setting of the Port is different from the Port actually being used for the host, set the correct port.

4. A wrong communication rate is set.

The PG-FP3 operates at a communication (baud) rate of 9600 bps on starting if the RS-232C interface is

selected. If a wrong baud rate is set, correct the setting.

There is also a possibility that the communication settings for the RS-232C port are wrong. Also check the

RS-232C port. The correct communication setting is Data: 8 bits, Stop bit: 2 bits, Parity: None, Flow control:

None.

5. Other cases

If all the above are okay but FLASHPRO3 will still not start, either FLASHPRO3 is not correctly installed or

the PG-FP3 is damaged. If FLASHPRO3 will not start after it is installed again, notify NEC.

User's Manual U13502EJ2V0UM00

31

Page 32

CHAPTER 3 STARTING AND STOPPING

FLASHPRO3 screen

•

The FLASHPRO3 screen consists of three subscreens. The operation screen contains command execution

buttons in the for m of a flowchart so that you can perform a series of operations by referring to the flowchart.

The log window screen shows the command flow between the FLASHPRO3 and PG-FP3, the status, and the

progress of command execution. The TYPE screen displays the current TYPE settings, allowing you to check

the current settings without having to open the TYPE setting window.

Figure 3-1. FLASHPRO3 Screens

(a) Operation Screen

(b) Log Window Screen

(c) TYPE Screen

32

User's Manual U13502EJ2V0UM00

Page 33

CHAPTER 3 STARTING AND STOPPING

3.3 INITIALIZATION AND NOTES ON CORRECT USE

Before a target can be accessed with FLASHPRO3, several settings must be perfor med for FLASHPRO3. If these

settings are not done correctly, communication may not be executed correctly or the target may be damaged.

Loading parameter file

•

The parameter file is loaded with the [Setting..Device] command. If the file is not loaded when FLASHPRO3

starts, settings for the target will not be correctly performed. Consequently, communication may fail or the target

may be damaged.

Figure 3-2. Parameter File Setting Dialog Box

When this dialog box is opened, enter the parameter file name in response to Device file name:. Alternatively,

click the button to the right to the text box to display a list of parameter files. Select one and click the [OK]

button. The selected parameter file will be loaded.

User's Manual U13502EJ2V0UM00

33

Page 34

CHAPTER 3 STARTING AND STOPPING

TYPE setting

•

The TYPE setting dialog box is used to set information necessary for communication with the target. Default

information is set when the parameter file is loaded. To change the default setting, either execute the

[Setting..Type] command, or click the [TYPE] button on the screen.

The TYPE setting dialog box below is displayed.

Figure 3-3. TYPE Setting Dialog Box (When the Parameter File Is Loaded)

If the device definition file has not been loaded, the TYPE setting dialog box below is displayed. In this case,

load the file, and then perform TYPE setting.

Figure 3-4. TYPE Setting Dialog Box (When the Parameter File Is Not Loaded)

34

User's Manual U13502EJ2V0UM00

Page 35

CHAPTER 3 STARTING AND STOPPING

In the TYPE setting dialog box, device-specific information is automatically set when the parameter file has been

loaded, and the text box is grayed out. The parameters that can be changed by the user in this dialog box are as

follows:

1. COMM PORT

Selects the communication mode with the target. The communication modes that can be selected depend

on the device. For details, refer to the manual for the device.

The communication rate can be also changed. The communication rate also depends on the function and

the device operating clock. For details, refer to the manual for the device.

2. ROM TYPE

TM

Usually, only FLASH is set. If the device used has an on-chip EEPROM

, however, the internal data of the

EEPROM can be read to the PG-FP3 by selecting EEPROM.

3. CPU CLOCK

Selects the CPU operating clock. When the FA adapter is used, select In Flashpro to choose a clock from

Flashpro Clock. When the user target board is used, select On target board and enter the clock frequency

of the target board in the text box.

Some devices have a multiply circuit. In this case, enter a multiple for Multiple Rate.

Voltage setting

•

Set the operating voltage of the target. When the [Setting..Voltage] command is executed, the following dialog

box opens.

PP

This dialog box is used to set the operating voltage of the target and the V

voltage. If the parameter file has

been loaded, the default voltages are set automatically. Because some devices allow you to select an operating

voltage, set the voltage according to target conditions.

User's Manual U13502EJ2V0UM00

35

Page 36

CHAPTER 3 STARTING AND STOPPING

Option setting

•

The Options dialog box is used for detailed setting of the target and is displayed when the [Setting..Option]

command is executed.

This dialog box is used to set the erase time, write time, and convergence time. These parameters are

automatically set to the default values when the parameter file is loaded.

The new values become valid only when the check box is checked before the [Setting..Option] command is

executed.

Do not change these parameter settings unless it is necessary. Changing any of these parameters may damage

the device.

Because the above settings are necessary for correct interfacing with the target, be sure to perform them when

starting FLASHPRO3. The infor mation set is recorded in the PG-FP3 and is used to interface with the target

when the PG-FP3 is used in stand-alone mode. Any setting that is changed can be saved with the [File..Type

Save] command. To perform setting again, use the [File..Load] command.

Caution Load the parameter file each time FLASHPRO3 is started, even though the file was loaded the

previous time FLASHPRO3 was used. The PG-FP3 updates its settings to prevent a wrong

target from being selected by reloading the parameter file each time FLASHPRO3 has been

started. This is done because the target may be damaged if it is accessed with wrong setting

of the parameter file.

3.4 TERMINATING THE APPLICATION

To terminate the application, execute the [File..Exit] command.

After terminating the application, turn off power to the PG-FP3.

Caution The target may be damaged if power to the PG-FP3 is turned off or if the target is disconnected

while a command is being executed. To end operation of the PG-FP3 while a command is being

executed, execute the [Procedure..Cancel] command to cancel the current processing, then

terminate the application and turn off power to the PG-FP3.

36

User's Manual U13502EJ2V0UM00

Page 37

CHAPTER 4 BASIC OPERATING PROCEDURE

This chapter explains the basic operating procedure, using as an example the µPD78F4216 used as the target.

Specifically, this chapter discusses how to start the system and how to write a program to the target by executing the

E.P.V. command. For the other commands and their usage, see

Chapter 5

[Operating conditions in this example]

The operating conditions for the example used in this chapter are as follows:

HOST I/F : PRINTER I/F

Target :

PD78F4216 (with FA adapter)

µ

Interface : UART 9600 bps

Clock In Flashpro 16 MHz

Mode CHIP

DD

5.0 V

V

PP

10.0 V

V

Command : E.P.V.

(1) Starting the system

.

Connect the PG-FP3 and host.

•

Confirm that the interface select switch is set to the printer interface position.

Connect the PG-FP3 and target (FA adapter).

•

DD

Confirm that the target V

switch is set to the OUT position.

Photo 4-1. Connection of Host, PG-FP3, and Target

User's Manual U13502EJ2V0UM00

37

Page 38

CHAPTER 4 BASIC OPERATING PROCEDURE

Turn on power to the PG-FP3.

•

Confirm that the LED on the PG-FP3 is blinking.

Start FLASHPRO3.

•

If the communication error dialog box opens at this time, check the [Connection Port] setting and

change if necessary.

The example below assumes that the PG-FP3 is connected to LPT1.

Figure 4-1. Communication Error Dialog Box

Open the setting dialog box by clicking [Connection Port].

Change the setting for Connection Port from COM1 to LPT1.

After changing the setting, click the [OK] button.

The error dialog box will be displayed again. Execute [Retry] for reconnection.

38

User's Manual U13502EJ2V0UM00

Page 39

CHAPTER 4 BASIC OPERATING PROCEDURE

When FLASHPRO3 has been started correctly, the following screen is displayed.

User's Manual U13502EJ2V0UM00

39

Page 40

CHAPTER 4 BASIC OPERATING PROCEDURE

(2) Loading the parameter file

Select [Device] from the [Setting] pull-down menu. The dialog box for loading a parameter file will open.

Enter 78F4216.PRC in the box for Device file name: and click the [OK] button.

When the parameter file is read, the PG-FP3 is reset for synchronization, then the parameters are read.

Consequently, immediately after the parameter file is loaded, the initial status is restored, and the CHIP

mode is selected.

The Dump HEX command, Program command, Verify command, and E.P.V. command are dimmed.

Those commands are disabled until a user program is downloaded.

The screen appearing immediately after the parameter file is loaded is as shown below:

40

User's Manual U13502EJ2V0UM00

Page 41

CHAPTER 4 BASIC OPERATING PROCEDURE

(3) TYPE setting

Open the TYPE setting window by selecting [Type] from the [Setting] pull-down menu, or by clicking the

button on the operation screen.

When the window is open, set COMM Port to UART CH-0, and UART bps to 9600 bps. Then click the

[OK] button to accept TYPE setting.

When TYPE setting has been performed, the FLASHPRO3 screen is displayed as follows:

User's Manual U13502EJ2V0UM00

41

Page 42

CHAPTER 4 BASIC OPERATING PROCEDURE

(4) Downloading a user program

Open the dialog box by either selecting [Load File] from the [File] pull-down menu or clicking the

button on the operation screen. Select a HEX file to be downloaded, and load the file into

FLASHPRO3. When the file has been loaded, the FLASHPRO3 screen is displayed as follows:

Next, download the file to the PG-FP3 by either selecting [Download HEX] from the [Procedure] pulldown menu or clicking the

button on the operation screen.

After the file has been downloaded, the FLASHPRO3 screen is displayed as follows:

42

User's Manual U13502EJ2V0UM00

Page 43

CHAPTER 4 BASIC OPERATING PROCEDURE

(5) Executing the E.P.V. command

The E.P.V. command can be executed by selecting [E.P.V.] from the [Procedure] pull-down menu, or by

clicking the

button on the operation screen.

While the E.P.V. command is executed, the progress of execution is displayed in the log window, and a

PG-FP3 LED blinks.

Lighting of LEDs The Erase, Program, and Verify LEDs light, and the LED for the phase under

ex ecut ion blinks.

Erase

Blinks while the program is being erased

Ο ←

Program Ο ← Blinks during programming

Verify

Blinks while the program is being verified

Ο ←

Normal completion of the E.P.V. processing is indicated by the message Ver ify OK!, which is displayed in

the log window.

(6) Verify check

Next, the program is verified independently. This is done by comparing the data stored in the PG-FP3

with the data of the target.

Verification can be executed by either selecting [Verify] from the [Procedure] pull-down menu or clicking

the

button on the operation screen. While verification continues, its progress is displayed

in the log window. In addition, the Verify LED on the PG-FP3 blinks, indicating that the command is

being executed. If verification is completed normally, the message Verify OK! is displayed in the log

window.

(7) Terminating the system

To terminate FLASHPRO3, select [Exit] from the [File] pull-down menu. After terminating FLASHPRO3,

turn off power to the PG-FP3.

This completes the series of operations.

User's Manual U13502EJ2V0UM00

43

Page 44

[MEMO]

44

User's Manual U13502EJ2V0UM00

Page 45

CHAPTER 5 COMMAND REFERENCE

This chapter explains each command. A command can be selected from the pull-down menu on the menu bar or

by clicking the corresponding button on the screen.

5.1 File

When [File] is clicked, the pull-down menu shown below is displayed. This menu lists mostly the commands that

are used to manipulate files.

5.1.1 Load File

The [Load File] command loads the user program into FLASHPRO3. The loaded program can be displayed and

edited with the [Edit] command. Execute the [Load File] command by selecting it from the pull-down menu or by

pressing the

Select the file to be loaded, and click the [Open] button.

button on the screen. When this command has been executed, the window below opens.

Two types of files can be loaded: Intel expansion HEX and Motorola S format files. An Intel expansion HEX file is

recognized as xxxxxx.HEX. A Motorola S format file is recognized as xxxxxx.PRO.

User's Manual U13502EJ2V0UM00

45

Page 46

CHAPTER 5 COMMAND REFERENCE

5.1.2 Save File

The [Save File] command saves the user program loaded into FLASHPRO3 or uploaded from the PG-FP3 to a file.

Execute this command by selecting it from the pull-down menu or by pressing the

button. When

this command has been executed, the window below opens. Enter the name of the file to be saved, and click the

[Save] butto n.

Two types of files can be saved: Intel expansion HEX and Motorola S format files. An Intel expansion HEX file is

recognized as xxxxxx.HEX. A Motorola S format file is recognized as xxxxxx.PRO. For selection of a file format, the

following dialog box is displayed when the [Save File] command has been executed. Click the button corresponding to

the type of file to be saved.

The file format cannot be converted in the file format select dialog box.

Figure 5-1. File Format Select Dialog Box

46

User's Manual U13502EJ2V0UM00

Page 47

CHAPTER 5 COMMAND REFERENCE

5.1.3 Load Type

The [Load Type] command reloads the file (xxxxxx.TYP) in which the information set with [Setting] has been saved

when resetting is required. When the Type File is loaded again, the previously used environment is restored.

Execute the [Load Type] command by clicking [Load Type] on the [File] pull-down menu. When this command has

been executed, the window below opens. Select the Type File to be loaded, and click the [Open] button.

The following information is reset when Type File is reloaded:

Parameter defi nit ion information

•

TYPE setting information

•

Voltage setting information

•

Option setting information

•

User's Manual U13502EJ2V0UM00

47

Page 48

CHAPTER 5 COMMAND REFERENCE

5.1.4 Save Type

The [Save Type] command saves information set with [Setting] to a file (xxxxxx.TYP), so that the information can be

reloaded when resetting is required. When Type File is saved, the previously used environment can be restored at any

time.

Execute the [Save Type] command by clicking [Save Type] on the [File] pull-down menu. When this command has

been executed, the window below opens. Enter the name of the file to be saved and click the [Save] button.

The following information is saved when Type File is saved:

Parameter defi nit ion information

•

TYPE setting information

•

Voltage setting information

•

Option setting information

•

5.1.5 Exit

The [Exit] command terminates FLASHPRO3. Execute this command by clicking [Exit] on the [File] pull-down

menu. You can also terminate FLASHPRO3 by clicking the [×] button on the right of the task bar.

48

User's Manual U13502EJ2V0UM00

Page 49

CHAPTER 5 COMMAND REFERENCE

5.2 Setting

When [Setting] is clicked, the pull-down menu shown below is displayed. This menu lists the commands that are

used to set the FLASHPRO3 operating environment (such as setting of the target interface).

5.2.1 Device

The [Device] command loads information such as information specific to the target device and communication

settings into FLASHPRO3 and the PG-FP3. The information on each target device is supplied to the user in the form

of a parameter file (xxxxxx.PRC). Loading this file automatically sets each parameter. Execute this command by

clicking [Device] on the [Setting] pull-down menu.

When this command is executed, the dialog box below opens. Enter the name of the parameter file for the target to

be used, or select an appropriate parameter file by clicking the button to the right of the text box, and then click the

[OK] button. This completes the setting of the parameters.

Remarks 1.

The information in the parameter file sets infor mation important for interfacing with the target. On

starting FLASHPRO3, therefore, be sure to load the parameter file with [Device].

The parameter file will not be recognized unless it is installed in the same directory as FLASHPRO3.

2.

Install the file correctly b y seeing

If Type information is saved with [Save Type], parameter definition information is also set by loading

3.

Section 3.1

.

Type File with [Load Type]. It is therefore not necessary to load the parameter file again with [Device].

User's Manual U13502EJ2V0UM00

49

Page 50

CHAPTER 5 COMMAND REFERENCE

5.2.2 Type

The [Type] command sets the mode of communication with the target and operating clock. Because the

communication mode and operating clock differ depending on the device used, refer to the manual for the device for

details. Execute the [Type] command by clicking [Type] on the [Setting] pull-down menu or by clicking the

button on the screen.

When this command is executed, the TYPE setting window below opens. After the parameter file has been loaded,

the default values for the information specific to the device is grayed out, and the appropriate default values for the

device are automatically set for the other items. To change a default value, change the contents of the corresponding

item and click the [OK] button. The setting will be changed.

The following describes each parameter in the figure above.

Selecting the device type (DEVICE TYPE)

•

The device type is determined by the information in the parameter file.

Selecting the internal ROM format for the target microcontroller (FLASH, EEPROM)

•

A ROM type cannot be selected for a microcontroller that does not have EEPROM in the parameter definition

information. If a ROM type can be selected, select either of the following ROM types:

FLASH FLASH memory

•

EEPROM EEPROM

•

When FLASH memory is used, the memory cannot be correctly written to unless it has been erased.

The erase command cannot be executed when an EERPOM is used.

Entering the start address (START ADDRESS)

•

The start address is determined by the parameter definition infor mation. It is automatically set in the Block and

Area modes.

50

User's Manual U13502EJ2V0UM00

Page 51

CHAPTER 5 COMMAND REFERENCE

Entering the end address (END ADDRESS)

•

The end address is determined by the parameter definition information. It is automatically set in the Block and

Area modes.

Remark

The end address range that can be specified with the PG-FP3 is 2 Mbytes (1FFFFFH). This is a

hardware specification.

Selective input of serial port (COMM PORT)

•

Select the mode of communication between the PG-FP3 and target device from the modes listed below.

Some of the following communication modes cannot be used with some devices. Select one of the

communication modes listed in the manual for the device. The channel number of some devices starts with ch-

1. In this case, ch-0 is equivalent to ch-1 of the device.

Parameter on screen Description

SIO ch-0 SIO (3-wire clocked communication port) channel 0

•

SIO ch-1 SIO (3-wire clocked communication port) channel 1

•

SIO ch-2 SIO (3-wire clocked communication port) channel 2

•

SIO ch-3 + handshake SIO (3-wire clocked communication port with handshaking)

•

2

I2C ch-0 I

•

I2C ch-1 I

•

I2C ch-2 I

•

I2C ch-3 I

•

UART ch-0 (Async.) UART (asynchronous communication port) channel 0

•

UART ch-1 (Async.) UART (asynchronous communication port) channel 1

•

UART ch-2 (Async.) UART (asynchronous communication port) channel 2

•

UART ch-3 (Async.) UART (asynchronous communication port) channel 3

•

Port A (Pseudo-3 wired) Port (pseudo 3-wire) A

•

Port B (Pseudo-3 wired) Port (pseudo 3-wire) B

•

Port C (Pseudo-3 wired) Port (pseudo 3-wire) C

•

C channel 0

2

C channel 1

2

C channel 2

2

C channel 3

Entering a communication rate for the UART (UART BPS)

•

Select a communication rate from the following if UART is selected for the serial port.

4800 bps

•

9600 bps

•

19200 bps

•

31250 bps

•

38400 bps

•

76800 bps

•

Caution If the targ et CPU clock is slow, use a slow communication rate. If the communication rate is

too fast, communication may not be performed correctly (for details, refer to the target device

specifications).

User's Manual U13502EJ2V0UM00

51

Page 52

CHAPTER 5 COMMAND REFERENCE

Entering a clock frequency in 3-wire or pseudo 3-wire mode (SIO CLOCK)

•

If 3-wire or pseudo 3-wire mode is selected with the serial port, enter a communication rate as a decimal

number. The valid range for communication rates is from 100 Hz to 2.0000 MHz. Be sure to enter the unit also.

Up to six digits can be entered.

Example

100 Hz = 0.1 kHz = 0.0001 MHz

1 MHz = 1000 kHz (1000000 Hz is not recognized because it has 7 digits.)

Caution Generally, high-speed communication cannot be performed in pseudo 3-wire mode. Check the

operation at several hundred Hz and then increase the communication frequency within the

range at which correct operation can be performed. The reason is that it takes a long time to

write or verify programs at a low communication rate.

Some devices do not operate even at the communication rates that can be set for the PG-FP3.

Check the specifications of the device.

Entering a slave address for IIC (SIO CLOCK)

•

If IIC is selected for the serial port, enter a slave address as a hexadecimal number. The valid range is 8 to 77H.

Do not, however, enter the unit. This slave address can take any value within the range, but must not overlap

with the slave address of other devices on IIC.

Entering RAM SIZE

•

This value sets the packet size for communication with the target device and is determined by the parameter

definition information.

Entering the CPU clock source (CPU CLOCK)

•

Selects whether the clock for the target microcontroller is supplied from the PG-FP3.

On target board.......Uses the clock of the target system.

•

The clock is not supplied from the PG-FP3. Open the CLK pin of the target connector.

In Flashpro..............Supplies the clock of the PG-FP3 to the target.

•

Connect the CLK pin of the target connector to the CLK pin of the target microcontroller.

For details of connection, refer to the manual for the device.

Entering the clock frequency of the target system (Target board clock)

•

If [On target board] has been selected when a CPU clock source is being entered, enter a frequency as a

decimal number. The valid range is 1 to 99.999 MHz. Be sure to enter the unit also. Although up to six digits

can be entered, only the first three digits are used.

Example

4.19 MHz = 4190 kHz (4190000 Hz is not recognized because it has seven digits.)

If entered, 3.14159 MHz is recognized as 3.14 MHz.

52

User's Manual U13502EJ2V0UM00

Page 53

CHAPTER 5 COMMAND REFERENCE

Selecting a transmission clock frequency from the PG-FP3 (Flashpro clock)

•

If [In Flashpro] has been selected when a CPU clock source is being entered, select the clock the PG-FP3

transmits from the frequencies listed below. Different devices provide different operating frequency ranges for

the target microcontroller. Select the correct frequency by referring to the manual for the device.

16.0 MHz

•

8.0 MHz

•

4.0 MHz

•

2.0 MHz

•

Caution When the set frequency is changed, execute the [Other-Status] command to check the

contents displayed in the log window.

Setting a multiple for the operating clock (Multiple Rate)

•

If the target has a multiplier circuit and operation will be performed in multiple mode, enter a multiple. Usually,

this parameter is set to 01.00. To operate in multiple mode, enter a multiple.

Example

BLOCK range setting

•

To operate in ×5 mode Enter 05.00.

In block mode, set a range of blocks. In this mode, the [Block/Area] button at the right of the TYPE setting

screen becomes active. When this button is clicked, the dialog box shown below opens. Enter the block range

to be used and click the [OK] button. The block range will be set.

Block: Number of device blocks

(automatically set)

Block Number: Selected blocks

(set by user)

For example, if the block range is specified as 0 to 2 for erasure, Block 0, Block 1, and Block 2 are erased. To

specify only one block, enter the same value as the start block and end block.

Caution To set a block, you must set BLOCK mode by clicking the CHIP/BLOCK/AREA button in the

FLASHPRO3 window or by executing [set block].

For information on changing the mode, see Section 5.3.6.

User's Manual U13502EJ2V0UM00

53

Page 54

CHAPTER 5 COMMAND REFERENCE

AREA setting range

•

In area mode, set an area range. In this mode, the [Block/Area] button at the right of the TYPE setting screen

becomes active. When this button is clicked, the dialog box below opens. Enter the area range to be used and

click the [OK] button. The area range will be set.

Area: Number of device areas

(automatically set)

Area Number: Selected areas

(set by user)

For example, if the area range is specified as 0 to 2 for erasure, Area 0, Area 1, and Area 2 are erased. To

specify only one area, enter the same value as the start area and end area.

Caution To set an area, you must set AREA mode by clicking the CHIP/BLOCK/AREA button in the

FLASHPRO3 window or by executing [set Area].

For information on changing the mode, see Section 5.3.6.

5.2.3 Voltage

DD

[Voltage] sets the voltage at which the target operates. V

and VPP voltages differ depending on the device. The

VDD and VPP voltages are automatically set by loading the parameter file. However, some devices have two supply

voltages, and in this case, the default voltage is automatically set. Change this voltage value, if necessary, depending

on the operating conditions. For information on changing the voltage value, refer to the manual for the device.

When [Voltage...] is selected from [Setting...] on the menu bar, the dialog box below opens. Enter a voltage and

click the [OK] button. The entered voltage will be set.

Setting range

DD

voltage 1.8 to 6.0 V

V

VPP voltage 2.7 to 10.3 V

54

User's Manual U13502EJ2V0UM00

Page 55

CHAPTER 5 COMMAND REFERENCE

5.2.4 Option

[Option] sets detailed conditions for each device, such as erase time, write time, and convergence time. These

conditions are set to the default values when the parameter file is loaded. Unless otherwise specified, use the default

values. If incorrect values are specified, the service life of the device may be shortened or the device may be

damaged.

Click [Options...] on the [Setting] pull-down menu. The dialog box below will open. Change the parameter setting in

this dialog box and click the [OK] button. The setting will be changed.

Erase time: Sets the erase time for the device.

If 0 second is set, erasure processing is not performed.

Write time: Sets the write time for the device.

Convergence time: Sets the time of the function that prevents excessive erasing of the device.

5.2.5 Reset

[Reset] restarts the PG-FP3 system. The PG-FP3 must be restarted if you want to check the firmware version, or if

the system has failed.

Execute this command by selecting [Reset] from the [Setting] pull-down menu. If the PG-FP3 is restarted correctly,

an LED on the PG-FP3 blinks and then LEDs Erase, Program, and Verify light. The firmware version is then displayed

in the log window at the lower left of the screen.

User's Manual U13502EJ2V0UM00

55

Page 56

CHAPTER 5 COMMAND REFERENCE

5.2.6 Connection Port

The [Connection Por t] command sets a port for communication with the PG-FP3. This command is used to change

the baud rate or communication port of the host when RS-232C is used.

Click [Connection Port] on the [Setting] pull-down menu to execute this command. When the command is

executed, the following dialog box opens, allowing you to set a communication port.

If the printer interface was selected when the PG-FP3 started, the communication port setting must be LPTx. A

box for setting a baud rate is displayed in the dialog box, but a setting in this box is ignored.

If a wrong port was specified when FLASHPRO3 started, the error dialog box below is displayed. If this dialog box

is displayed, check the communication setting, and correct as necessary.

When [Connection Port...] in the dialog box is clicked, a dialog box for port setting opens.

56

User's Manual U13502EJ2V0UM00

Page 57

CHAPTER 5 COMMAND REFERENCE

5.3 Procedure

When [Procedure] is clicked, the pull-down menu shown below is displayed. This menu lists commands that

manipulate the target by erasing, programming, or verifying the target.

5.3.1 Download HEX

[Download HEX] downloads the user program loaded into FLASHPRO3 with [Load File] to the PG-FP3. The

progress of downloading is displayed in the log window. While downloading is in progress, the Load LED of the PGFP3 blinks.

Execute this command by selecting [Download HEX] from the [Procedure] pull-down menu or by clicking the

button on the operation screen.

When the user program has been completely downloaded, the buttons such as [Program] and [Verify], which could

not be executed at startup, become active and are ready to be executed.

User's Manual U13502EJ2V0UM00

57

Page 58

CHAPTER 5 COMMAND REFERENCE

5.3.2 Erase

[Erase] erases the flash memory. Use this command to keep the device with the flash memory erased. To program

the flash memory erased by this command, use the [Program] command. A device that has been just delivered to you

is blank and can be programmed without having to be erased.

Execute this command by selecting [Erase] from the [Procedure] pull-down menu or by clicking the

button on the operation screen.

While the device is being erased, the progress of erasure is displayed in the log window, and the Erase LED of the

PG-FP3 blinks.

Caution The typical erase time is set by the device definition information. Do not change the value set as

the erase time except in special circumstances, since the device may be damaged if it is

changed. If the target device is erased repeatedly, further erasing may become difficult, and a

longer erase time may be required.

During erasure, the following messages are displayed in the log window (they are displayed every second if there is

a wait time of second or longer).

NP18 Erase setting xxS

NP1E Erase setting OK

NP30 ROM Erasing now... xxS

If erasure is completed normally

•

NP0E ROM Erase... OK.

In Block mode, this message is displayed.

NP1C ROM Erase... OK. BLOCK x

In Area mode, this message is displayed.

NP1C ROM Erase… OK AREA x

If erasure is not successful

•

ER13 ROM Erase... Failed.

In Block mode, this message is displayed.

ER1C ROM Erase.. Failed. BLOCK x

In Area mode, this message is displayed.

ER5C ROM Erase… Failed. AREA

58

User's Manual U13502EJ2V0UM00

Page 59

CHAPTER 5 COMMAND REFERENCE

5.3.3 Program