Page 1

IBM

Magstar MP 3570 Tape Subsystem

Maintenance Information

C-Series Models

Page 2

Page 3

IBM

Magstar MP 3570 Tape Subsystem

Maintenance Information

C-Series Models

Part Number 08L6250

EC Number F23273

Page 4

Note!

Before using this information and the product it supports, be sure to read the general information under “Notices” on page vii.

Second Edition (October 1998)

The following paragraph does not apply to any country where such provisions are inconsistent with local law.

INTERNATIONAL BUSINESS MACHINES CORPORATION PROVIDES THIS PUBLICATION “AS IS” WITHOUT WARRANTY OF

ANY KIND, EITHER EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. Some states do not allow disclaimer of express or implied

warranties in certain transactions; therefore, this statement may not apply to you.

This edition applies to the initial release of the product and to all subsequent releases and modifications until otherwise indicated in

new editions. Order publications through your IBM representative or the IBM branch office serving your locality. Publications are not

stocked at the address given below.

A readers’ comment form is provided at the back of this publication. Either mail the form or fax it to (520) 799-2230. If the form has

been removed, address your comments about this book to IBM Corporation, Department 63S/031-2, 9000 S. Rita Road, Tucson,

Arizona 85744-0001, U.S.A.

When you send information to IBM, you grant IBM a nonexclusive right to use or distribute the information in any way it believes

appropriate without incurring any obligation to you.

Copyright International Business Machines Corporation 1998. All rights reserved.

Note to U.S. Government Users — Documentation related to restricted rights — Use, duplication or disclosure is subject to

restrictions set forth in GSA ADP Schedule Contract with IBM Corp.

Page 5

Contents

Notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Trademarks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . viii

Communication Statements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

Magstar MP Publications ................................ xi

AS/400 Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

RISC System/6000 Information .......................... xii

9076 SP2 Information ................................ xii

Device Driver Information ............................. xii

Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . START-1

The IBM Magstar MP 3570 Tape Subsystem ................ START-2

Maintenance Starting Point .......................... START-4

| Drive Indicators—Normal Operation for Drive-Only Model C00 .... START-10

FID Entry Point ................................ START-12

Attention Drive Messages .......................... START-24

Attention Library Messages ......................... START-25

MAPs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . MAPS-1

Library Operator Panel Problems ....................... MAPS-3

Library LED Problems .............................. MAPS-5

Drive LED Problems ............................... MAPS-9

Power Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . MAPS-13

Other Obvious Symptom Problems ..................... MAPS-19

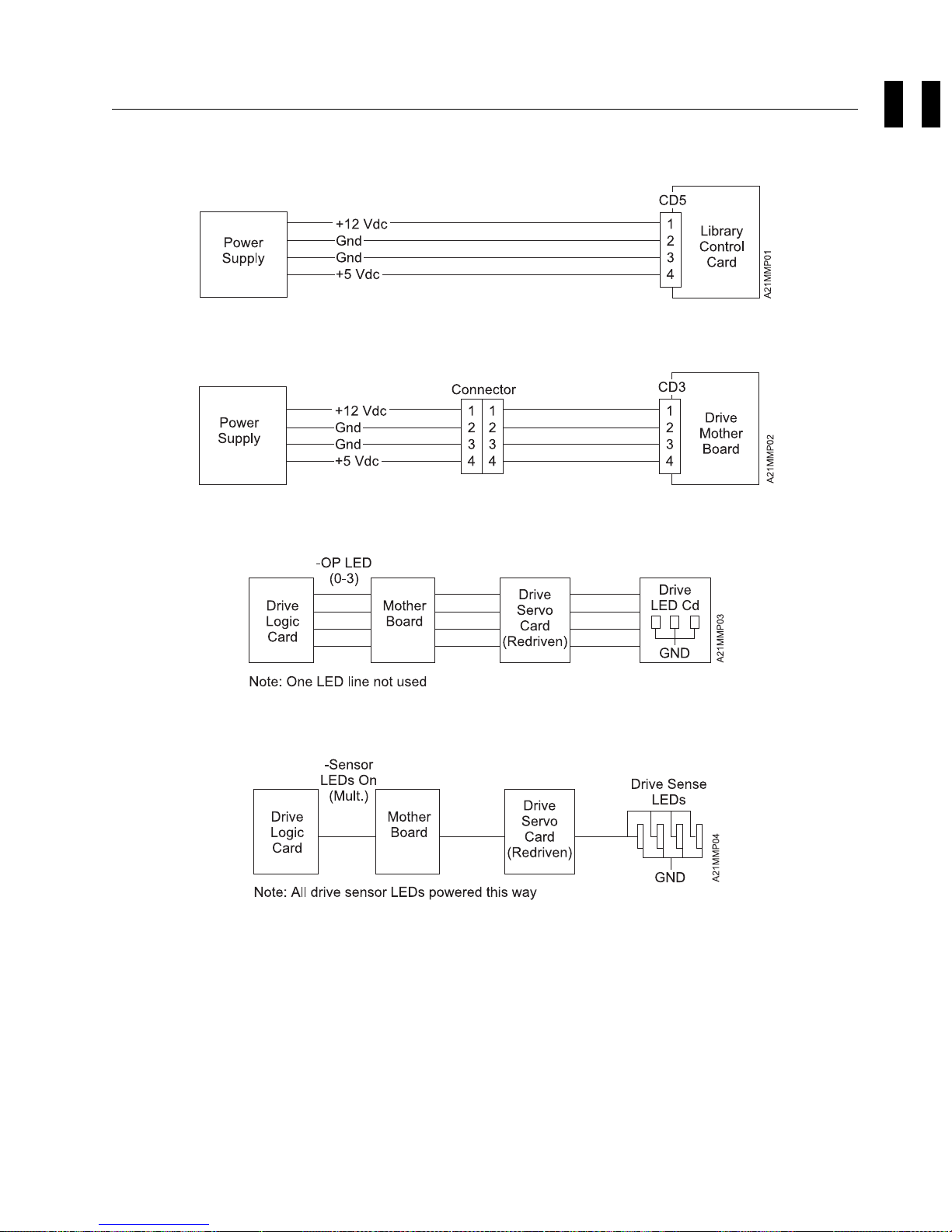

Diagrams Referred to by MAPs ....................... MAPS-27

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . INTRO-1

3570 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . INTRO-3

IBM 3570 Tape Subsystem, C-Series Models ............... INTRO-5

Compatibility with other Magstar MP Tape Subsystems ......... INTRO-6

Operating Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . INTRO-9

SCSI Physical Interface Characteristics ................... INTRO-9

Device Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . INTRO-9

Functional Unit Descriptions ........................ INTRO-14

Library Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . INTRO-22

3570 Media and Cartridge .......................... INTRO-29

| Library Attachment for Models C01, C02, C11, C12, C21 and C22 .. INTRO-31

System Attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . INTRO-34

Drive Indicators and Operator Controls .................. INTRO-39

Library Operator Panel ............................ INTRO-40

Front Panel Overview ............................ INTRO-43

Library . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . LIBRARY-1

Library Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . LIBRARY-2

| Library Attachment for Library Models ................... LIBRARY-2

Library Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . LIBRARY-5

Library Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . LIBRARY-7

SCSI Medium Changer Addressing for Base and Split Configurations LIBRARY-8

Front Panel Overview ............................ LIBRARY-9

Copyright IBM Corp. 1998 iii

Page 6

Library Operator Panel ........................... LIBRARY-11

Front Panel Indicators and Controls ................... LIBRARY-13

Data Flow and Cable Diagram – Library Models ............ LIBRARY-23

Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . MSG-1

Service Information Messages (SIMs) and Media Information Messages

(MIMs) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . MSG-2

Statistical Analysis and Reporting System .................. MSG-3

Obtaining 3570 Drive Error Information at the Host ............. MSG-3

| Error Log Analysis—RS/6000 .......................... MSG-4

Sense Key, ASC and ASCQ Information ................... MSG-13

Using SMIT/ERRPT Commands ........................ MSG-19

| Error Log Analysis—AS/400 .......................... MSG-24

Sun Error Logs .................................. MSG-32

Obtaining Error Information from an HP/UX System ............. MSG-32

Obtaining Error Information from a Windows NT System .......... MSG-32

Operator Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . PANEL-1

Operator Panel Overview ........................... PANEL-3

Status Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . PANEL-5

Intervention Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . PANEL-9

Supplemental Message Screens ...................... PANEL-11

Menu Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . PANEL-11

CE Mode Menus ............................... PANEL-24

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . INSP-1

General Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . INSP-2

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . INSP-3

Sécurité . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . INSP-5

Seguridad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . INSP-9

Segurança . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . INSP-11

Covers and Slides ................................ INSP-13

Completion Report . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . INSP-17

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . INST-1

Applicable Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . INST-2

Pre-Installation Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . INST-2

Drive-Only or Stand-Alone Models ....................... INST-8

| Rack-Mounted Models (Models C11 and C12) ................ INST-14

| Rack-Mounted Models (Models C21 and C22) ................ INST-26

Installation Checkout—Library Models ..................... INST-40

SCSI Attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . INST-43

Post Installation Reporting ........................... INST-65

Removing a 3570 ................................. INST-65

Repack Instructions for the 3570 ........................ INST-67

Common Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . PROC-1

Working with Electrostatic Discharge (ESD) Parts .............. PROC-3

Prepare the Tape Device for Service ..................... PROC-5

Powering Device ON and OFF ......................... PROC-5

FID FF—Operator Action or Host Program Error ............... PROC-6

Suspected Microcode Problem ......................... PROC-6

Verify Fix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . PROC-7

Drive Indicator Decode for Drive-Only Models ................ PROC-8

iv IBM 3570 MI

Page 7

End of Call ................................... PROC-12

Library Sensors Checkout Procedure .................... PROC-13

Cartridge Sensor Pin Locations ........................ PROC-15

Inserting or Removing a Magazine ...................... PROC-15

Removing Tape Cartridge from Drive .................... PROC-18

Inserting or Removing a Cleaning Cartridge ................ PROC-22

Setting Automatic Cleaning .......................... PROC-22

Drive Cleaning Procedure ........................... PROC-22

Cleaning Cartridge Labels ........................... PROC-23

Replacing Cartridge Labels .......................... PROC-23

Resolving Bar Code Reader Problems ................... PROC-24

Initializing the Tape Volume Serial Number ................. PROC-25

Resolving a Mismatch Between the Bar Code Label and VOLSER ... PROC-26

Library Mode Selection ............................ PROC-26

Library Configuration Selection ........................ PROC-27

Pausing the Cartridge Sequence ....................... PROC-27

Resetting the Cartridge Sequence ...................... PROC-28

Clearing Tape Drive Recover Status ..................... PROC-28

Drive Serial Number—Library Models Only ................. PROC-29

Making FMR Tape from Scratch Tape—Library Models ......... PROC-31

Making FMR Tape from Scratch Tape—Drive-Only Models ....... PROC-31

Making Scratch Tape from FMR Tape—Library Models (Unmaking FMR) PROC-32

Making Scratch Tape from FMR Tape—Drive-Only Models (Unmaking

FMR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . PROC-33

Updating Microcode from FMR Cartridge (Library Models) ........ PROC-34

Isolate Drive 1 / Drive 2 Communications Fault .............. PROC-35

Updating Microcode in Drive 2 from FMR Cartridge ............ PROC-36

Updating Microcode from FMR Cartridge (Drive-Only Models) ...... PROC-37

Microcode EC Level History Log ....................... PROC-38

Error Log Analysis Procedure ......................... PROC-39

Set Error Match Trap (To Get a Dump) ................... PROC-44

Remove Error Match Trap ........................... PROC-45

Off-loading Dumps from 3570 to Tape Cartridge (Library Models) .... PROC-47

Off-loading Dumps from 3570 to Tape Cartridge (Drive-Only Models) . PROC-48

Updating Microcode from an AS/400 .................... PROC-49

Off-loading Dumps from 3570 Attached to AS/400 ............ PROC-49

Updating Microcode from RS/6000 by Using TAPEUTIL ......... PROC-50

Off-loading Dumps from 3570 to RS/6000 by Using TAPEUTIL ..... PROC-52

| Updating Microcode from a Sun System by Using TAPEUTIL ...... PROC-54

| Off-loading Dumps from 3570 to a Sun System by Using TAPEUTIL .. PROC-55

| Updating Microcode from a HP-UX System by Using TAPEUTIL .... PROC-56

| Off-loading Dumps from 3570 to a HP-UX System by Using TAPEUTIL PROC-57

| Windows NT Environment ........................... PROC-58

Mapping Element Addresses to Physical Locations ............ PROC-64

Checking the SCSI Attachment in an AS/400 Environment ........ PROC-65

Checking the SCSI Attachment in an AIX Environment .......... PROC-69

Checking the SCSI Attachment in a Sun Environment .......... PROC-73

Checking the SCSI Attachment in a HP-UX Environment ......... PROC-76

Checking the SCSI Attachment in a Windows NT Environment ..... PROC-76

SCSI Port Wrap Test ............................. PROC-77

RS-422 Port Wrap Test ............................ PROC-78

SCSI Bus Problem Determination ...................... PROC-79

FID E5—Microcode Problem ......................... PROC-84

FID E6 or E7—Isolate Fault between Microcode and Hardware ..... PROC-86

Contents v

Page 8

FID FE—Isolate Fault between Media and Hardware ........... PROC-89

No Response from Operator/CE Panel and No Message ......... PROC-91

Checks, Adjustments, Removals, and Replacements .......... CARR-1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . CARR-2

Removal and Replacement Procedures—External Covers ......... CARR-3

| Removal and Replacement Procedures—Drive Pack ............ CARR-7

Removal and Replacement Procedure—Drive Pack Covers ....... CARR-11

Removal and Replacement Procedure—Cooling Pack .......... CARR-12

Removal and Replacement Procedures—Base Drive Components ... CARR-14

Removal and Replacement Procedures for the Library .......... CARR-19

| AppendA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . APPENDA-1

| TAPEUTIL in a Sun (Solaris) System Environment .......... APPENDA-2

| TAPEUTIL in a HP-UX System Environment .............. APPENDA-9

| TAPEUTIL in a Windows NT System Environment ......... APPENDA-15

AppendB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . APPENDB-1

The IBM Magstar MP 3570 Tape Subsystem .............. APPENDB-2

Maintenance Starting Point ........................ APPENDB-4

Drive Indicators—Normal Operation for Drive-Only Models ..... APPENDB-10

| FID Entry Point—EMEA Only ...................... APPENDB-12

Attention Drive Messages—EMEA Only ................ APPENDB-23

Attention Library Messages—EMEA Only ............... APPENDB-24

Appendix C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . APPENDC-1

Library Operator Panel Problems—EMEA Only ............ APPENDC-3

Library LED Problems—EMEA Only ................... APPENDC-5

Drive LED Problems—EMEA Only .................... APPENDC-9

Power Problems—EMEA Only ..................... APPENDC-13

Other Obvious Symptom Problems—EMEA Only .......... APPENDC-21

Diagrams Referred to by MAPs .................... APPENDC-29

Appendix D . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . APPENDD-1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . APPENDD-3

Removal and Replacement Procedures—External Covers ...... APPENDD-4

Removal and Replacement Procedures—Drive Pack ......... APPENDD-7

Removal and Replacement Procedure—Drive Pack Covers .... APPENDD-10

Removal and Replacement Procedure—Cooling Pack ....... APPENDD-11

Removal and Replacement Procedures—Base Drive Components APPENDD-13

Removal and Replacement Procedures for the Library ....... APPENDD-39

Parts Catalog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . PARTS-1

How to Use This Parts Catalog ........................ PARTS-1

Assemblies List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . PARTS-2

Part Number Index ............................. PNindex-1

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Gloss-1

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Index-1

vi IBM 3570 MI

Page 9

Notices

References in this publication to IBM programs or services do not imply that IBM intends to make these

available in all countries in which IBM operates. Any reference to an IBM product, program, or service is

not intended to state or imply that only IBM’s product, program, or service may be used. Any functionally

equivalent product, program, or service that does not infringe any of IBM’s intellectual property rights may

be used instead of the IBM product, program, or service. Evaluation and verification of operation in

conjunction with other products, except those expressly designed by IBM, is the user’s responsibility.

This publication could include technical inaccuracies or typographical errors. Changes are periodically

made to the information herein; these changes will be incorporated in new editions of the publication. IBM

may make improvements and/or changes in the products and/or programs described in this publication at

any time.

This document contains general information, as well as requirements, for use on IBM and third-party

products. IBM makes no warranty, express or implied, as to its completeness or accuracy, and the data

contained herein is current only as of the date of publication. It assumes that the user understands the

relationship among any affected systems, machines, programs, and media.

IBM or third parties may have patents or pending patent applications covering subject matter described in

this document, including appearance design patents or applications. The furnishing of this document does

not constitute or imply a grant of any license under any patents, patent applications, trademarks, copyright,

or other rights of IBM or of any third party, or any right to refer to IBM in any advertising or other

promotional or marketing activities. IBM assumes no responsibility for any infringement of patents or other

rights that may result from use of this document or from the manufacture, use, lease, or sale of apparatus

described herein.

Licenses under IBM’s utility patents are available on reasonable and non-discriminatory terms and

conditions. IBM does not grant licenses under its appearance design patents. You can send license

inquiries, in writing, to the IBM Director of Licensing, IBM Corporation, 500 Columbus Avenue, Thornwood

NY 10594, U.S.A.

For online versions of this book, we authorize you to:

Copy, modify, and print the documentation contained on the media, for use within your enterprise,

provided you reproduce the copyright notice, all warning statements, and other required statements on

each copy or partial copy.

Transfer the original unaltered copy of the documentation when you transfer the related IBM product

(which may be either machines you own, or programs, if the program's license terms permit a

transfer). You must, at the same time, destroy all other copies of the documentation.

You are responsible for payment of any taxes, including personal property taxes, resulting from this

authorization.

THERE ARE NO WARRANTIES, EXPRESS OR IMPLIED, INCLUDING THE WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

Some jurisdictions do not allow the exclusion of implied warranties, so the above exclusion may not apply

to you.

Your failure to comply with the terms above terminates this authorization. Upon termination, you must

destroy your machine readable documentation.

Copyright IBM Corp. 1998 vii

Page 10

Trademarks

The following terms are trademarks of the IBM Corporation in the United States or other countries or both:

9076 SP2 AIX AIX 6000 Application System/400

AS/400 Enterprise System/9000 ES/9000 ESCON

IBM POWERparallel RISC System/6000 RISC/6000

RS/6000 Scalable POWERparallel Systems SP2 System/390

| ADSTAR| Magstar| Netfinity| NetBAY22

The following terms are trademarks of other companies:

Sun, Solaris, and SunOS are registered trademarks of Sun Microsystems, Inc.

HP and HP-UX are trademarks of Hewlett-Packard Company

Windows and Windows NT are trademarks of Microsoft Corporation.

UNIX is a registered trademark in the United States and other countries licensed exclusively through

X/Open Company Limited.

486DX and Pentium are trademarks of Intel Corporation.

viii IBM 3570 MI

Page 11

Communication Statements

Federal Communications Commission (FCC) Statement

Note: This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against

harmful interference when the equipment is operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with

the instruction manual, may cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference, in which case the user will be

required to correct the interference at his own expense.

Properly shielded and grounded cables and connectors must be used in order to meet FCC emission

limits. IBM is not responsible for any radio or television interference caused by using other than

recommended cables and connectors or by unauthorized changes or modifications to this equipment.

Unauthorized changes or modifications could void the user's authority to operate the equipment.

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions:

(1) this device may not cause harmful interference, and (2) this device must accept any interference

received, including interference that may cause undesired operation.

The United Kingdom Telecommunications Act 1984

This apparatus is approved under approval No. NS/G/1234/J/100003 for the indirect connections to the

public telecommunications systems in the United Kingdom.

Industry Canada Compliance Statement

This digital apparatus does not exceed the Class A limits for radio noise emissions from digital apparatus

as set out in the interference-causing equipment standard entitled:

Industry Canada.

Digital Apparatus

, ICES-003 of

Avis de conformité aux normes d'Industrie Canada

Cet appareil numérique respecte les limites de bruits radioélectriques applicables aux appareils

numériques de Classe A prescrites dans la norme sur le matériel brouiller:

NMB-003 édictée par Industrie Canada.

Appareils numériques

,

Notices ix

Page 12

x IBM 3570 MI

Page 13

Preface

| This manual is for use by service personnel who intend to install, remove, diagnose, repair, or test the IBM

| Magstar MP 3570 Tape Subsystem Models C00, C01, C02, C11, C12, C21 and C22.

Part Number 08L6250

Magstar MP Publications

Additional information related to the subsystem is available in the following publications:

IBM Magstar MP 3570 Tape Subsystem Introduction and Planning Guide, C-Series Models

GA32-0392

IBM Magstar MP 3570 Tape Subsystem Operator Guide, C-Series Models

IBM Magstar MP 3570 Tape Subsystem Hardware Reference, C-Series Models

For additional information about the Magstar MP 3575 Tape Library Dataserver, see:

IBM Magstar MP 3575 Tape Library Dataserver, Introduction and Planning Guide

IBM Magstar MP 3575 Tape Library Dataserver, Operator Guide

IBM Magstar MP 3575 Tape Library Dataserver, Hardware Reference

IBM Magstar MP 3575 Tape Library Dataserver, Maintenance Information for Model L06

IBM Magstar MP 3575 Tape Library Dataserver, Maintenance Information for Models L12, L18, L24,

and L32

, PN 05H9581

, GA32-0381

, GA32-0393

, GA32-0394

, GA32-0380

, GA32-0382

, PN 05H9590

AS/400 Information

For additional information about the AS/400 subsystems and software, see:

AS/400 Physical Planning Reference

AS/400 Physical Planning Reference

AS/400 Basic System Operation, Administration and Problem Handling

, SA41-3109 (IMPI)

, SA41-5109 (RISC)

, SC41-5206

,

AS/400 Backup and Recovery

AS/400 CL Reference Guide

AS/400 System API Reference

Hierarchical Storage Management

Automated Tape Library Planning and Management

Automated Tape Library Planning and Management

Backup Recovery and Media Services for AS/400

A Practical Approach to Managing Backup Recovery and Media Services

Copyright IBM Corp. 1998 xi

, SC41-5304

, SC41-5722

, SC41-5801

, SC41-5351

, SC41-3309 (IMPI)

, SC41-5309 (RISC)

, SC41-4345

, SG24-4840

Page 14

RISC System/6000 Information

For additional information about the RISC System/6000 subsystems and software, see:

RISC System/6000 Getting Started: Using RISC System/6000

RISC System/6000 Getting Started: Managing RISC System/6000

RISC System/6000 V4 Problem Solving Guide

RISC System/6000 V4 Message Guide & Reference

RISC System/6000 Problem Solving Guide

RISC System/6000 System Overview and Planning

RISC System/6000 Planning for System Installation

7202 Install and Service Guide

7015 Install and Service Guide

, SA23-2670

, SA23-2628

, SC23-2606

, SC23-2641

, SC23-2204

, GC23-2406

, GC23-2407

, GC23-2521

, GC23-2378

9076 SP2 Information

Scalable POWERparallel Systems: System Planning,

Scalable POWERparallel Systems: Installation Guide,

Scalable POWERparallel Systems: High-Performance Technical Computing Solutions,

Scalable POWERparallel Systems: Business Solutions,

IBM 9076 Scalable POWERparallel Systems: SP2 Administration Guide,

IBM 9076 Scalable POWERparallel Systems: SP2 Diagnosis and Messages,

SC233864 PACKAGE on MKTTOOLS

SH23-3865

GA23-2475

SH26-2486

GH23-2485

SC23-3866

IBM 9076 Scalable POWERparallel Systems: SP2 Command and Technical Reference,

IBM 9076 Scalable POWERparallel Systems: Maintenance Information, Vol. 1,

IBM 9076 Scalable POWERparallel Systems: Maintenance Information, Vol. 2,

SY66-0294

SY66-0295

SC23-3867

Device Driver Information

IBM SCSI tape Drive, Medium Changer, and Library Device Drivers: Installation and User’s Guide

GC35-0154

Additional Information

Automated Tape Library Planning and Management

Backup Recovery Guide—Basic

Backup Recovery Guide—Advanced

Backup Recovery and Media Service/400: Implementation Tips and Techniques

Backup Recovery and Media Service/400

|

Second Edition, October 1998:

| single field replaceable unit (FRU), support for the Model C21 and C22 attached to the IBM Netfinity

| Server and IBM PC Server systems, and the correction of minor errors.

Changes or additions are indicated by a vertical line in the left margin. Editorial changes may not be

indicated.

, SC41-3304

, SC41-3305

, SC41-3345

Improvements and changes include packaging the tape drive as a

, SC41-3309

, GG24-4300

,

xii IBM 3570 MI

Page 15

Start

Contents

The IBM Magstar MP 3570 Tape Subsystem ................ START-2

Drive—Only Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . START-2

Library Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . START-3

Maintenance Starting Point .......................... START-4

Start Here For Drive-Only Models (C00) Without Library Attachments START-4

| Start Here For Library Cxx Models .................... START-5

Start For Library and Drive-Only Common Entries ........... START-7

| Drive Indicators—Normal Operation for Drive-Only Model C00 .... START-10

FID Entry Point ................................ START-12

Attention Drive Messages .......................... START-24

Attention Library Messages ......................... START-25

START

Copyright IBM Corp. 1998 START-1

Page 16

The IBM Magstar MP 3570 Tape Subsystem

Drive—Only Models

The IBM Magstar MP 3570 Tape Subsystem drive-only model is pictured in Figure 1. When procedures

in this manual are unique for this particular model, you will be referred to drive- only or non-library

procedures.

Figure 1. Drive-Only Models

A21M0013

START-2 IBM 3570 MI

Page 17

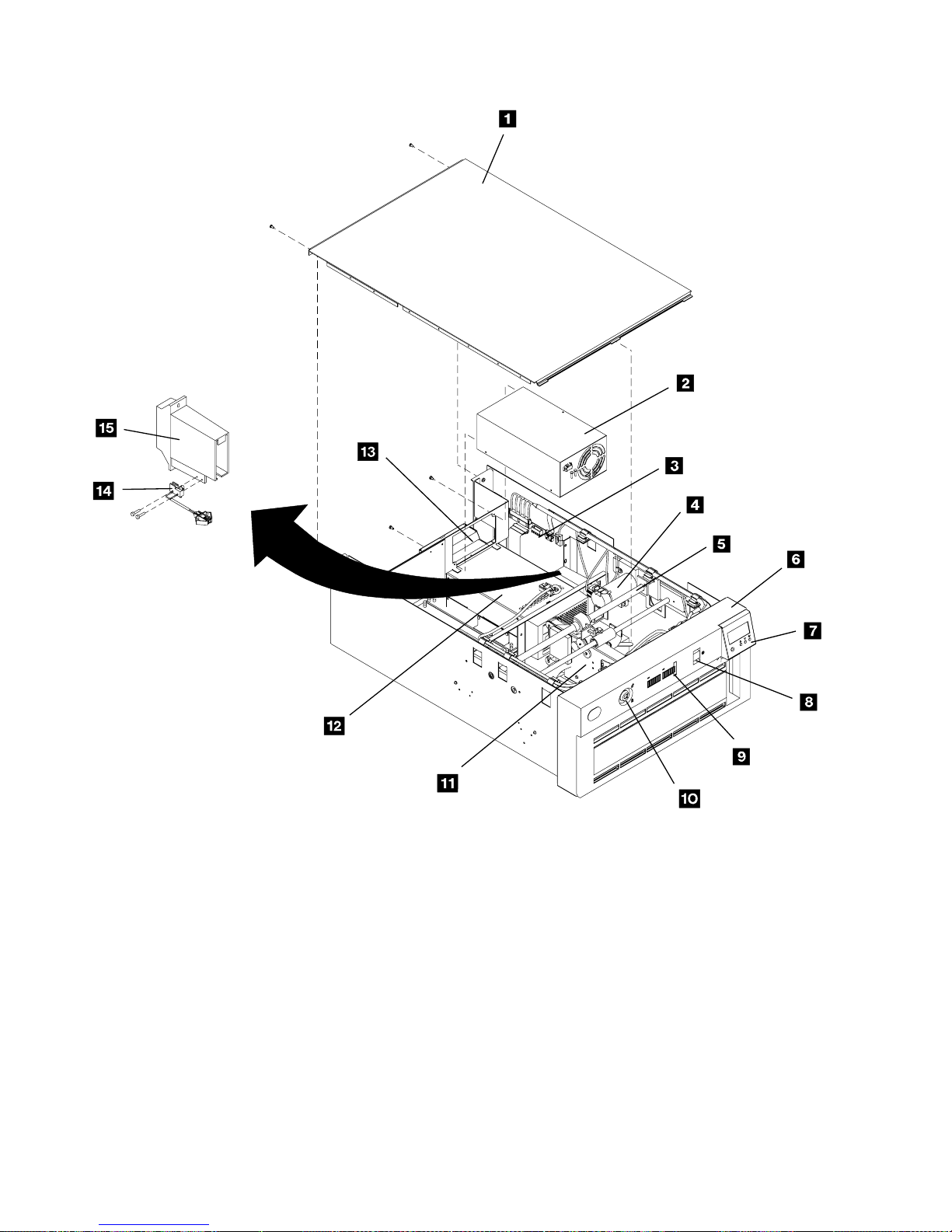

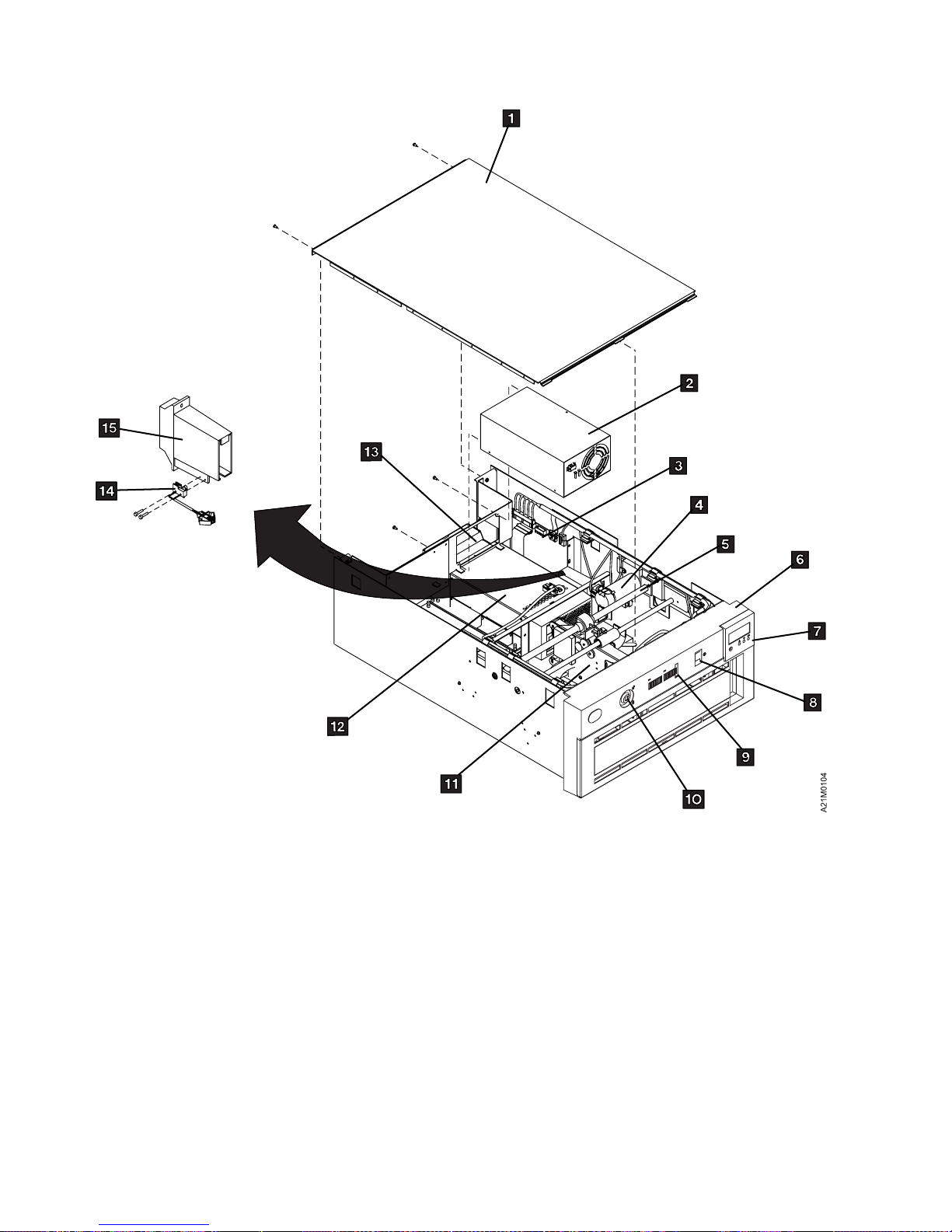

Library Models

The IBM Magstar MP 3570 Tape Subsystem library model is pictured in Figure 2. When procedures in

this manual are unique for library models, you will be referred to library procedures.

Note: In dual drive models, tape drive 1 is on the right and tape drive 2 is on the left, as you face the

front of the library.

START

Figure 2. Library Models

Start START-3

Page 18

Maintenance Starting Point

Begin all maintenance action here.

| Note: In all countries and regions except for EMEA each tape drive in the Model Cxx is treated as a

| single FRU. No diagnosis within the drive is required. Countries and regions within EMEA (Europe,

| Middle East, Asia) must continue to isolate to the failing part within the tape drive. If you are a

| service representative within EMEA, go immediately to “AppendB” on page APPENDB-1

| and start the service call. If you are not in EMEA, start the service call on this page.

Select the table below that best describes the 3570 model that you are here to work on. The two major

model types are shown in Figure 1 on page START-2 and Figure 2 on page START-3. For 3570 drives

without a library, see Figure 3. For 3570 library models, see Figure 4 on page START-5. If you

cannot find the reason you are here in these two tables, see Figure 5 on page START-7 which has other

entries into the Maintenance Information that are common to both the library and drive-only machines.

Find the reason you are here in the left column of the appropriate table and perform the stated action in

the right column.

Notes:

| 1. Be sure that you are working on a 3570 Model Cxx drive. The Model Cxx drives have a green

| UNLOAD button while the Model Bxx drives have a blue UNLOAD button.

| Note: A very few Model Cxx drives were shipped with blue UNLOAD buttons early in the program.

| You can tell if this is a Model Cxx by the level of microcode that is resident in the drive. If your

| microcode level is D1I4_xxx, this is a Model Bxx. If your microcode level is D1I5_xxx, this is a

| Model Cxx.

| If the UNLOAD button is blue, see

|

B—Series Models

Magstar MP 3570 Tape Subsystem Maintenance Information

| 2. The Model Cxx drive pack is a single FRU. It is recommended that when taking any Model Cxx trouble

| call, that the CE take a drive pack to the account. Most failures will occur within the drive pack. If the

| drive pack is not used on this call, it can be returned to stock.

3. If the service call is on a status 3 machine, see “General Instructions” in the INSP section, then return

here to continue the service call.

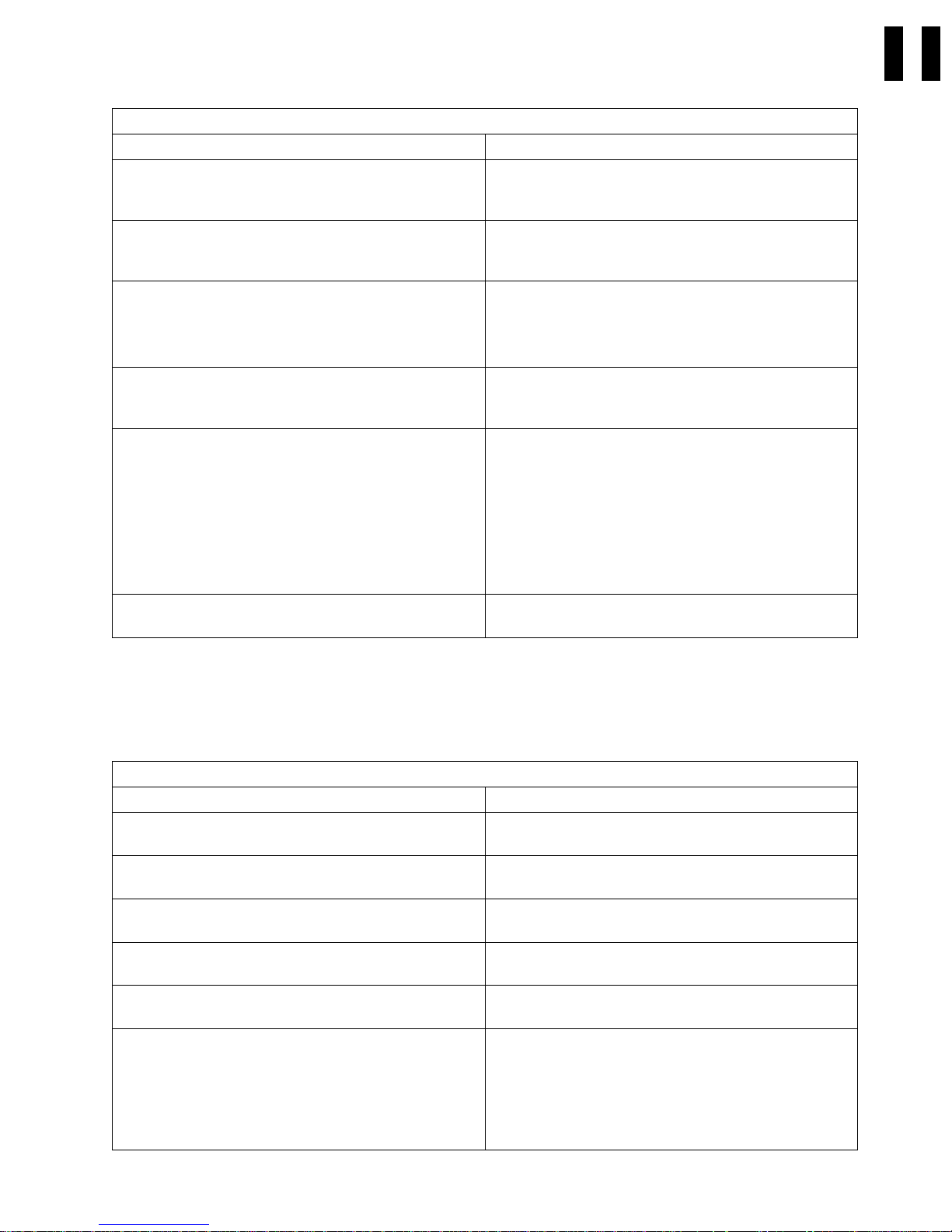

Start Here For Drive-Only Models (C00) Without Library Attachments

Figure 3 (Page 1 of 2). Start—For All Drive-Only Models (C00) Without Library Attachments

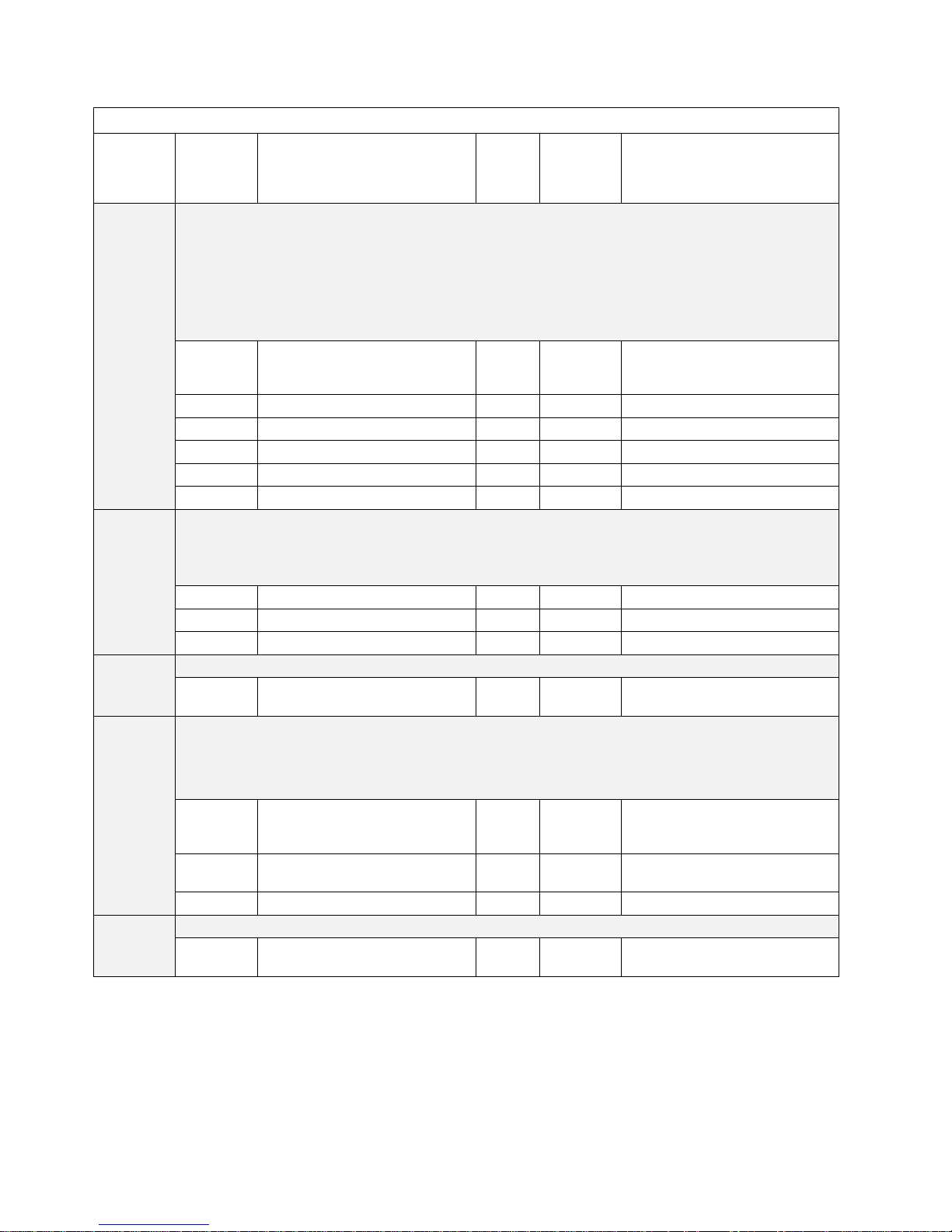

If You Are Here For This Reason Perform This Action

Are you repairing a library model? Go to Figure 4 on page START-5.

FID message from the host. Go to Figure 8 on page START-12 to fix the fault.

No FID message from the host, but the drive

Maintenance, Busy, and Clean indicators are flashing

in an attempt to pass on FID information.

ATTENTION DRIVE message in the host error log or

displayed by LEDs.

Some drive LEDs do light, but the drive Maintenance

LED never cycles on and off at power on. Bring-up

diagnostics are not running.

Go to Figure 7 on page START-11.

Go to “Attention Drive Messages” on page START-24

for further isolation.

Go to “Other Obvious Symptom Problems” on

page MAPS-19 to perform further problem

determination.

START-4 IBM 3570 MI

Page 19

Figure 3 (Page 2 of 2). Start—For All Drive-Only Models (C00) Without Library Attachments

If You Are Here For This Reason Perform This Action

Some LEDs fail to light on the front panel of the drive

during power on or when the drive is in use. The drive

cooling fan is running.

No LED indicators light on the front panel of the drive

during power on. The drive cooling fan is not

running.

The drive hangs with all three LED indicators on solid.

Note: The three LEDs will stay on momentarily during

power on. If it hangs with this condition, the

drive has a problem.

You have no FID number and there are no indicators

lighted to aid in isolation. Looks like power may be

missing from some or all components.

A host or channel detected problem. (No FID

message)

Were you not able to find the reason you are here? Try the Common entry points Figure 5 on

Go to “Drive LED Problems” on page MAPS-9 for

further isolation.

Go to “Power Problems” on page MAPS-13 for further

isolation.

Go to “Other Obvious Symptom Problems” on

page MAPS-19 to perform further problem

determination.

Go to “Power Problems” on page MAPS-13 and

perform further problem determination.

1. Run the Verify Fix diagnostics using a scratch

cartridge to test the Read/Write function. See

“Verify Fix—Drive-Only Models” on page PROC-7.

If Verify Fix fails, use the FID to repair the drive.

2. If you have a SCSI Wrap Tool available, perform

“SCSI Port Wrap Test” on page PROC-77.

3. Verify that the SCSI address is set correctly. See

“Setting the SCSI Address—Drive-Only Model

C00” on page INST-9.

page START-7.

START

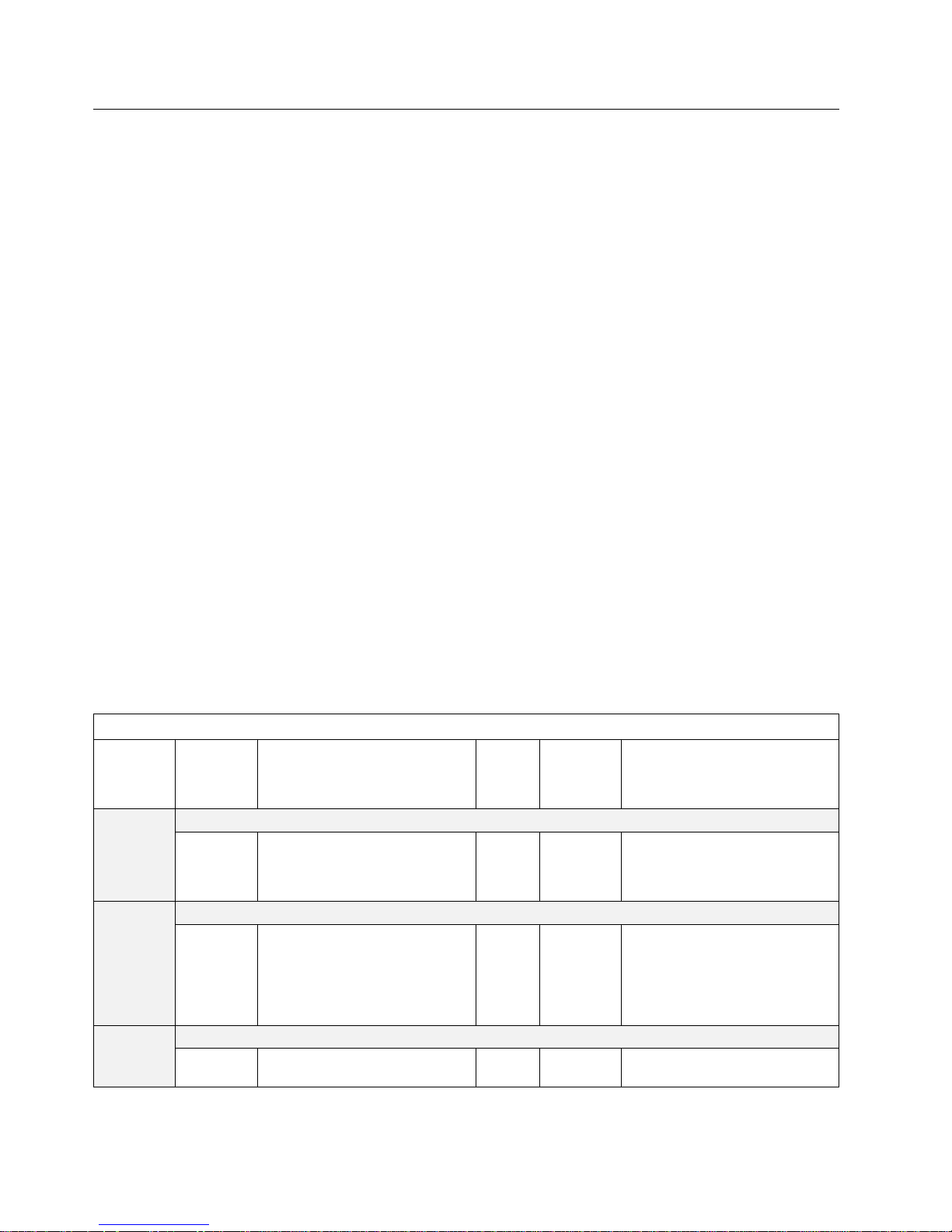

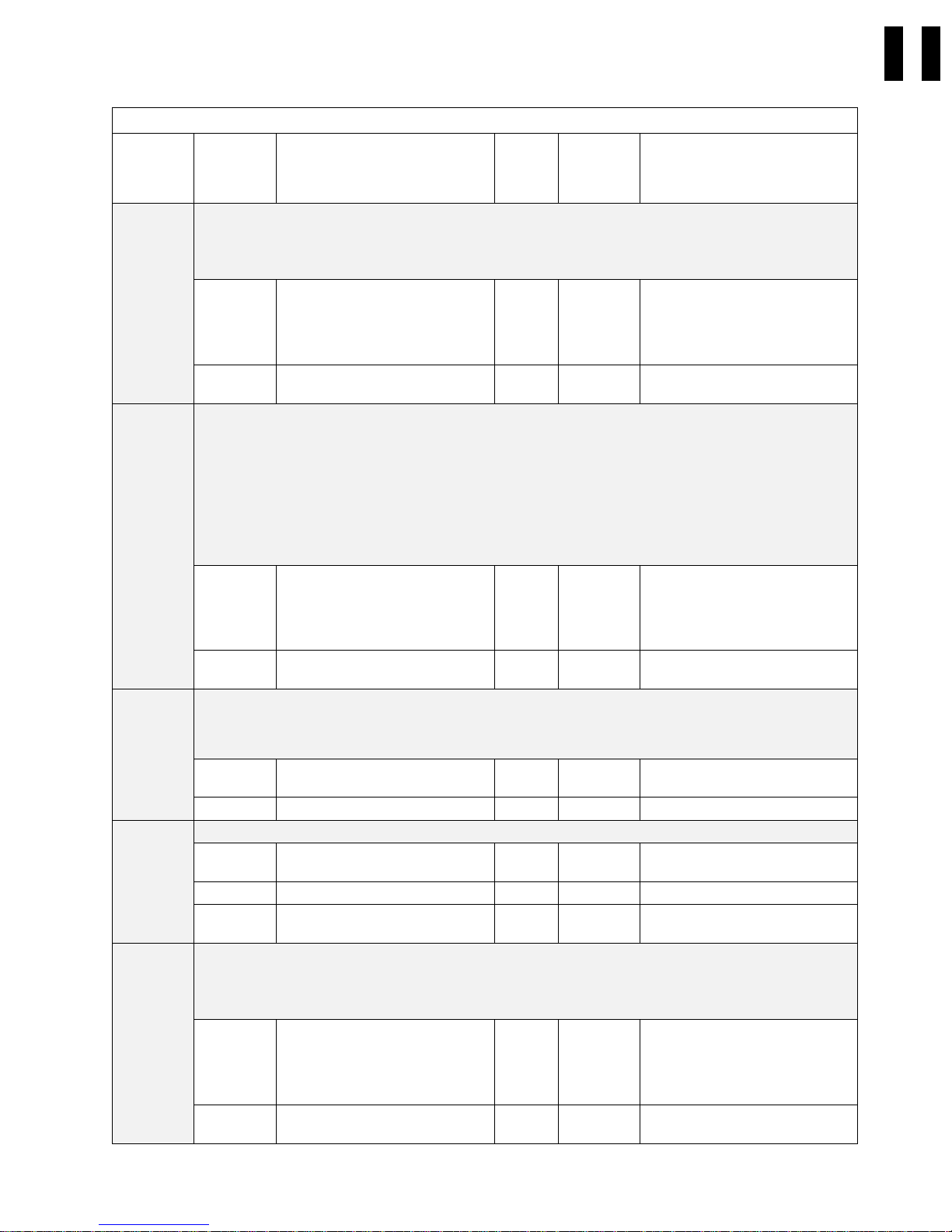

| Start Here For Library Cxx Models

| Note: In Models C02, C12 and C22, (dual drive models) tape drive 1 is on the right and tape drive 2 is

| on the left, when you face the front of the library.

Figure 4 (Page 1 of 2). Start—All Library Models

If You Are Here For This Reason Perform This Action

Are you repairing a drive-only model without a

library?

FID is displayed on the library operator panel display,

in the Error/FID log, or in a host error log entry.

ATTENTION DRIVE message on library operator panel

display or in the error log.

ATTENTION LIBRARY message on library operator

panel display or in the error log.

RECOVER status on library operator panel display. Go to “Clearing Tape Drive Recover Status” on

Library operator panel display hangs with two dark

lines across the display. The library LEDs may or may

not be flashing.

Note: This is normal for the first 30 seconds during

bring-up. If it hangs in this condition, the

machine has a problem.

Go to Figure 3 on page START-4.

Go to Figure 8 on page START-12 to fix the fault.

Go to “Attention Drive Messages” on page START-24

for further isolation.

Go to “Attention Library Messages” on

page START-25 for further isolation.

page PROC-28.

Go to “Other Obvious Symptom Problems” on

page MAPS-19 to perform further problem

determination.

Start START-5

Page 20

Figure 4 (Page 2 of 2). Start—All Library Models

If You Are Here For This Reason Perform This Action

Library operator panel display is blank or partial

characters are indicated.

Some or all the LEDs fail to light on the front panel of

a library machine.

You have no FID number and there are no indicators

lighted. Looks like power is missing from some or all

components.

A host or channel detected problem. (No FID

message)

| You have a dual drive model, and the beginning of line

| Go to “Isolate Drive 1 / Drive 2 Communications Fault”

| three of the library operator panel display indicates an

| on page PROC-35.

| "N", or the library does not recognize that drive 2 is

| installed in the library.

The tape drive status "INIT" is displayed on the

operator panel for more than 5 minutes.

The host displays a message that states:

The cartridge cannot be found.

The Volume ID does not match.

Incorrect volume mounted in drive.

The bar code reader cannot read the label on a tape

cartridge.

The tape drive status indicates "CODE LVL" on the

operator panel display.

Were you not able to find the reason you are here? Try the Common entry points Figure 5 on

Go to “Library Operator Panel Problems” on

page MAPS-3 for further isolation.

Go to “Library LED Problems” on page MAPS-5 for

further isolation.

Go to “Power Problems” on page MAPS-13 and

perform further problem determination.

1. Run the Verify Fix diagnostics using a scratch

cartridge to test the Read/Write function. See “CE

Verify Fix on Library Models” on page PROC-10.

If Verify Fix fails, use the FID to repair the drive.

2. If you have a SCSI Wrap Tool available, perform

“SCSI Port Wrap Test” on page PROC-77.

3. Verify that the SCSI address is set correctly. See

“Setting the SCSI Address and Configuring the

Library” on page INST-43.

Go to “Isolate Drive 1 / Drive 2 Communications Fault”

on page PROC-35.

Go to “Resolving a Mismatch Between the Bar Code

Label and VOLSER” on page PROC-26

Go to “Resolving Bar Code Reader Problems” on

page PROC-24.

Tape drives 1 and 2 have different microcode levels

installed. Update the microcode in the tape drives so

that both drives have the same microcode installed.

Select the appropriate update procedure below:

1. See “Updating Microcode from FMR Cartridge

(Library Models)” on page PROC-34.

2. See “Updating Microcode from an AS/400” on

page PROC-49.

3. See “Updating Microcode from RS/6000 by Using

TAPEUTIL” on page PROC-50.

4. See “Updating Microcode from a Sun System by

Using TAPEUTIL” on page PROC-54.

page START-7.

START-6 IBM 3570 MI

Page 21

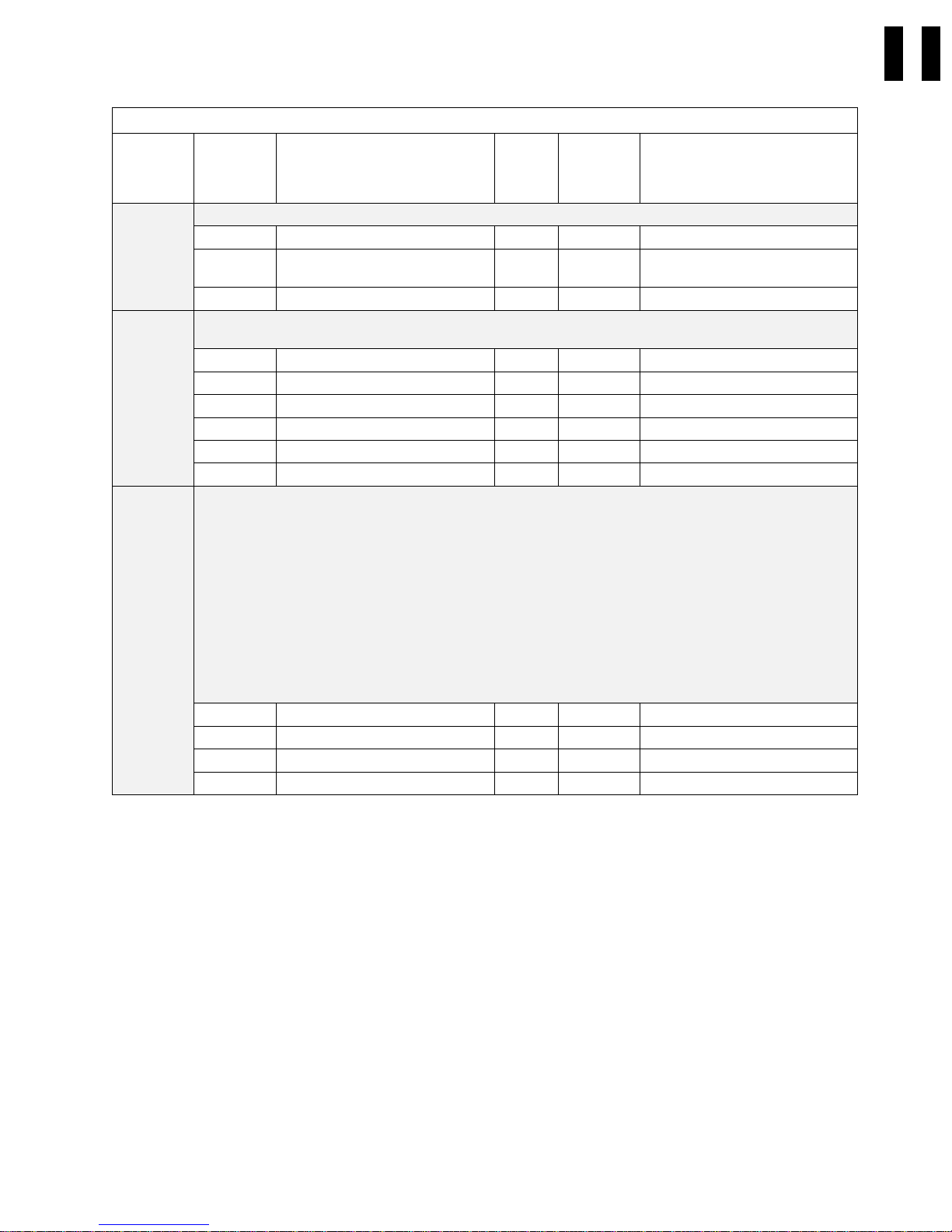

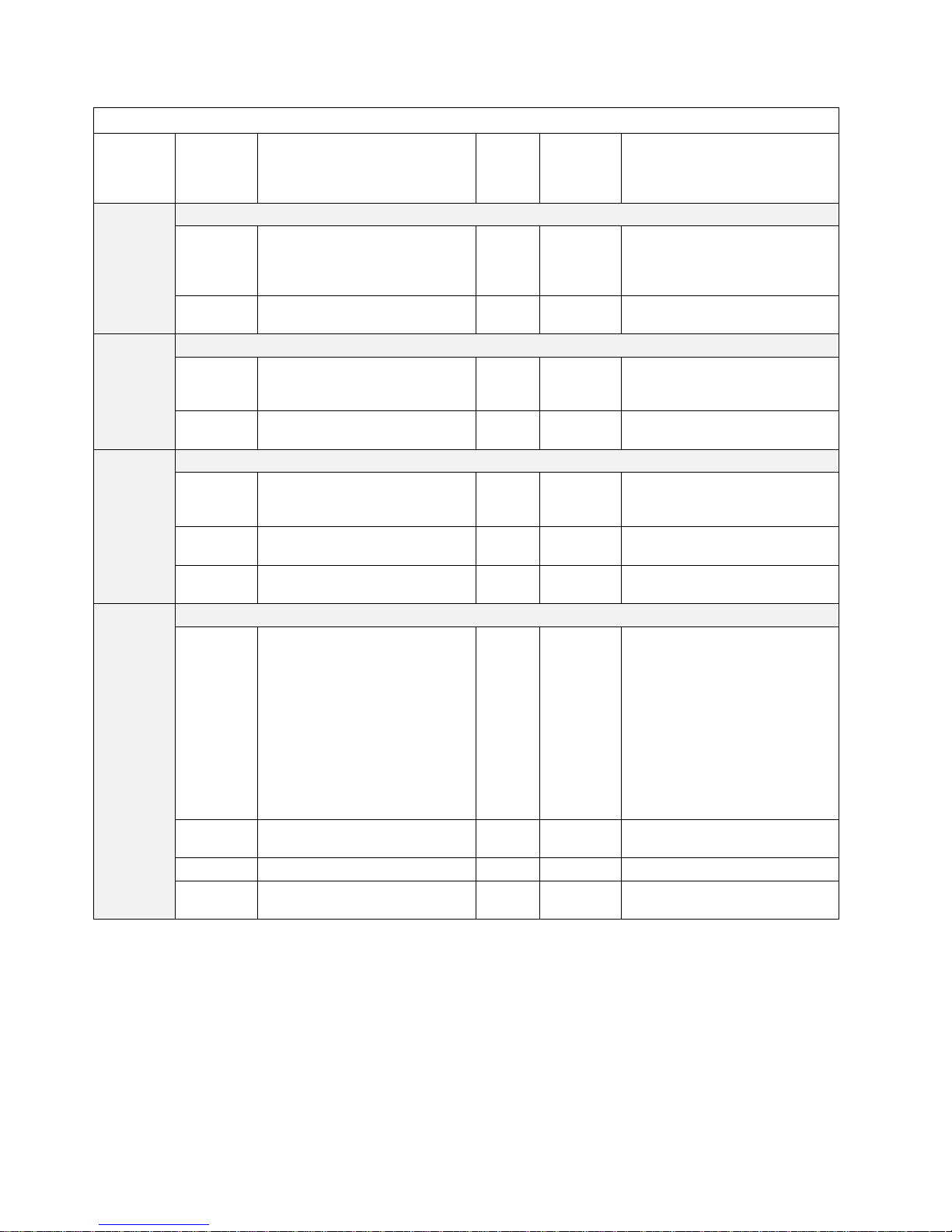

Start For Library and Drive-Only Common Entries

Figure 5 (Page 1 of 3). Start—Here for Common Entries Not Previously Listed

If You Are Here For This Reason Perform This Action

All three drive LED indicators are on solid or library

LEDs flash continuously.

Note: This is normal for a few seconds at power on.

If this condition continues, the machine has a

problem.

Removal of cartridge from loader by hand. Go to “Removing Tape Cartridge from Drive” on

Run verification tests. Go to “Verify Fix” on page PROC-7.

1. Obtain 3570 drive error information at the host

2. Obtain Service Information Message from a

RS/6000.

3. Obtain Service Information Message from an

AS/400.

4. Obtain Service Information Message from a Sun

System.

5. Obtain Error Information from a HP/UX System.

6. Obtain Error Information from a Windows NT

System.

7. Review Service Information Messages in general.

Clean message from the host, the Clean indicator is

on at the drive, or a Clean message is displayed on

the library operator panel display.

1. SCSI problems-AS/400 Environment.

2. SCSI problems-AIX Environment.

3. SCSI problems-Sun Environment.

4. SCSI problems-HP/UX Environment.

5. SCSI problems-Windows NT Environment.

6. SCSI Port Wrap Test.

Go to “Other Obvious Symptom Problems” on

page MAPS-19 to perform further problem

determination.

page PROC-18.

1. See “Obtaining 3570 Drive Error Information at the

Host” on page MSG-3.

2. See “Error Log Analysis—RS/6000” on

page MSG-4.

3. See “Error Log Analysis—AS/400” on

page MSG-24.

4. See “Sun Error Logs” on page MSG-32.

5. See “Obtaining Error Information from an HP/UX

System” on page MSG-32.

6. See “Obtaining Error Information from a Windows

NT System” on page MSG-32.

7. See “Service Information Messages (SIMs) and

Media Information Messages (MIMs)” on

page MSG-2.

See “Drive Cleaning Procedure” on page PROC-22 for

the procedure to use to clean the drive head.

1. Go to “Checking the SCSI Attachment in an

AS/400 Environment” on page PROC-65.

2. Go to “Checking the SCSI Attachment in an AIX

Environment” on page PROC-69.

3. Go to “Checking the SCSI Attachment in a Sun

Environment” on page PROC-73.

4. Go to “Checking the SCSI Attachment in a HP-UX

Environment” on page PROC-76.

5. Go to “Checking the SCSI Attachment in a

Windows NT Environment” on page PROC-76.

6. Go to “SCSI Port Wrap Test” on page PROC-77.

START

Start START-7

Page 22

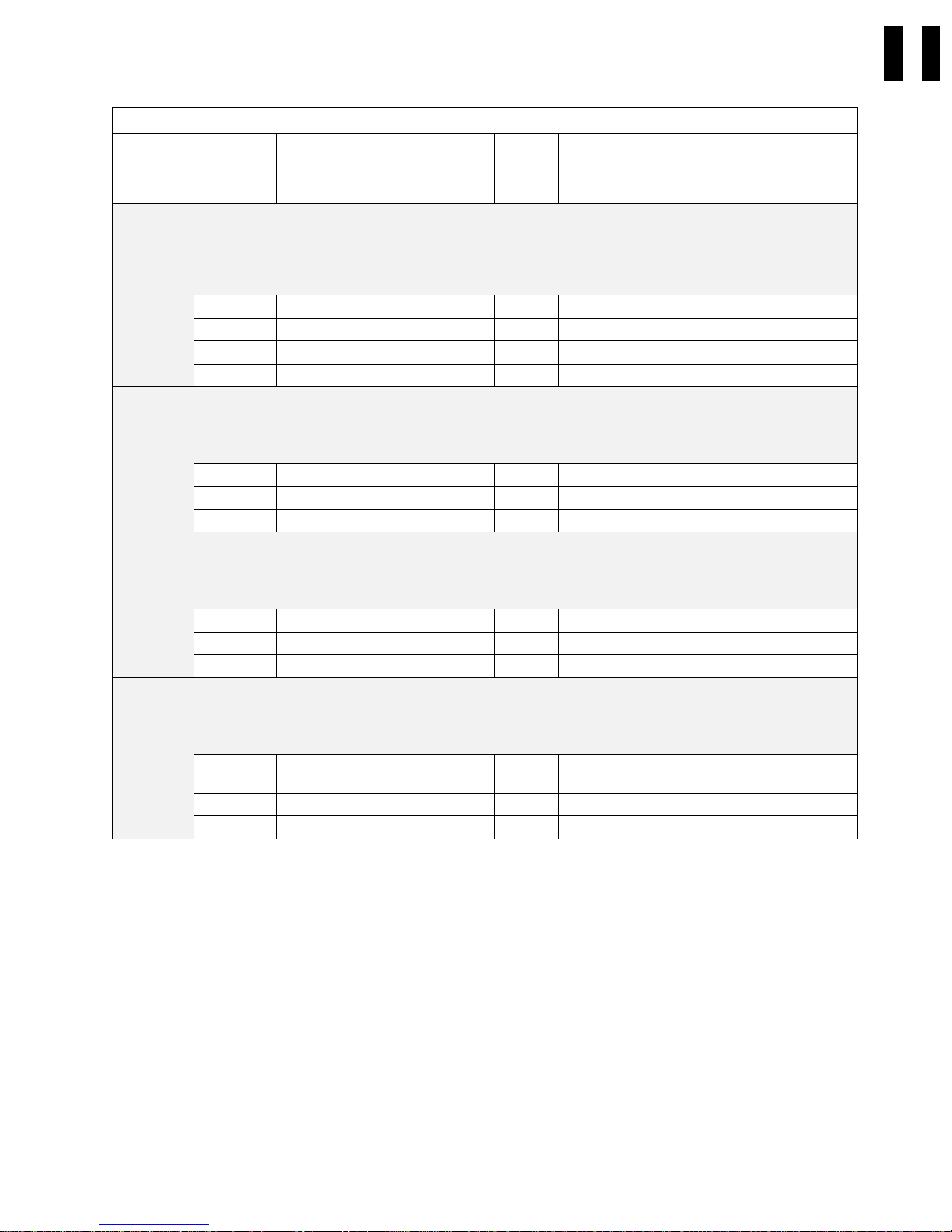

Figure 5 (Page 2 of 3). Start—Here for Common Entries Not Previously Listed

If You Are Here For This Reason Perform This Action

| Tape damage symptoms

| See “FID FE—Isolate Fault between Media and

| Hardware” on page PROC-89.

| Broken tape

| Outbound Reel-to-Reel motor missing tach

| pulses

| Failure of circuitry to detect tack pulses

| Stretched tape

| Outbound Reel-to-Reel motor missing tach

| pulses

| Failure of circuitry to detect tack pulses

| Folded over or wrinkled tape within cartridge

| Inbound Reel-to-Reel motor running away

| Failure of dynamic brake

Installation of a machine. Refer to the INST section.

Remove or relocate a 3570 machine. See “Removing a 3570” on page INST-65.

Inspect a machine. See “General Instructions” on page INSP-2.

1. Microcode update-from FMR cartridge

2. Microcode update-from AS/400

3. Microcode update-from RS/6000

4. Microcode update-from Sun

5. Microcode update-from HP/UX

6. Microcode update-from Windows NT

Update FMR tape with latest microcode. 1. See “Making FMR Tape from Scratch

Making FMR tape from scratch tape. 1. See “Making FMR Tape from Scratch

Making scratch tape from FMR tape. 1. See “Making Scratch Tape from FMR

1. See:

a. “Updating Microcode from FMR Cartridge

(Library Models)” on page PROC-34.

b. “Updating Microcode from FMR Cartridge

(Drive-Only Models)” on page PROC-37.

2. See “Updating Microcode from an AS/400” on

page PROC-49.

3. See “Updating Microcode from RS/6000 by Using

TAPEUTIL” on page PROC-50.

4. See “Updating Microcode from a Sun System by

Using TAPEUTIL” on page PROC-54.

5. See “Updating Microcode from a HP-UX System

by Using TAPEUTIL” on page PROC-56.

6. See “Updating Microcode From a Windows NT

System Using NTUTIL” on page PROC-60.

Tape—Library Models” on page PROC-31.

2. See “Updating Microcode from FMR Cartridge

(Drive-Only Models)” on page PROC-37.

Tape—Library Models” on page PROC-31.

2. See “Updating Microcode from FMR Cartridge

(Drive-Only Models)” on page PROC-37.

Tape—Library Models (Unmaking FMR)” on

page PROC-32.

2. See “Making Scratch Tape from FMR

Tape—Drive-Only Models (Unmaking FMR)” on

page PROC-33.

START-8 IBM 3570 MI

Page 23

Figure 5 (Page 3 of 3). Start—Here for Common Entries Not Previously Listed

If You Are Here For This Reason Perform This Action

1. Perform a microcode dump to tape cartridge.

2. Off-loading dumps from 3570 attached to AS/400.

3. Off-loading dumps from 3570 to RS/6000.

4. Off-loading dumps from 3570 to a Sun System.

5. Off-loading dumps from 3570 to a HP/UX System.

6. Off-loading dumps from 3570 to a Windows NT

System.

Microcode problem (FID E5). See “FID E5—Microcode Problem” on page PROC-84.

You suspect a microcode problem, but no FID E5. See “Suspected Microcode Problem” on

Update or review microcode EC level history log. See “Microcode EC Level History Log” on

Repair a 3570 model without a FID number or

ATTENTION message.

1. See:

a. “Off-loading Dumps from 3570 to Tape

Cartridge (Library Models)” on page PROC-47.

b. “Off-loading Dumps from 3570 to Tape

Cartridge (Drive-Only Models)” on

page PROC-48.

2. See “Off-loading Dumps from 3570 Attached to

AS/400” on page PROC-49.

3. See “Off-loading Dumps from 3570 to RS/6000 by

Using TAPEUTIL” on page PROC-52.

4. See “Off-loading Dumps from 3570 to a Sun

System by Using TAPEUTIL” on page PROC-55.

5. See “Off-loading Dumps from 3570 to a HP-UX

System by Using TAPEUTIL” on page PROC-57.

6. See “Off-loading Dumps to a Windows NT System

Using NTUTIL” on page PROC-61.

page PROC-6.

page PROC-38.

Go to “Other Obvious Symptom Problems” on

page MAPS-19 to perform further problem

determination.

START

Start START-9

Page 24

Drive Indicators—Normal Operation for Drive-Only Model C00

|

For drive-only models without a library attachment, three LEDs indicate operator messages and error

conditions under normal customer operations. Figure 6 shows the location of the operator panel

indicators. See “Drive Indicators and Operator Controls” on page INTRO-39 for a description of the

indicators.

Figure 6. Drive Indicators for Drive-Only Models

Figure 7 on page START-11 shows the combination of the three indicators and their meanings under

normal customer operational conditions. The Note column refers to an operator action or information.

For the meaning of these LEDs when in CE Mode, see Figure 246 on page PROC-9 for FID decode

meanings and Figure 244 on page PROC-7 for meanings when displaying options.

START-10 IBM 3570 MI

Page 25

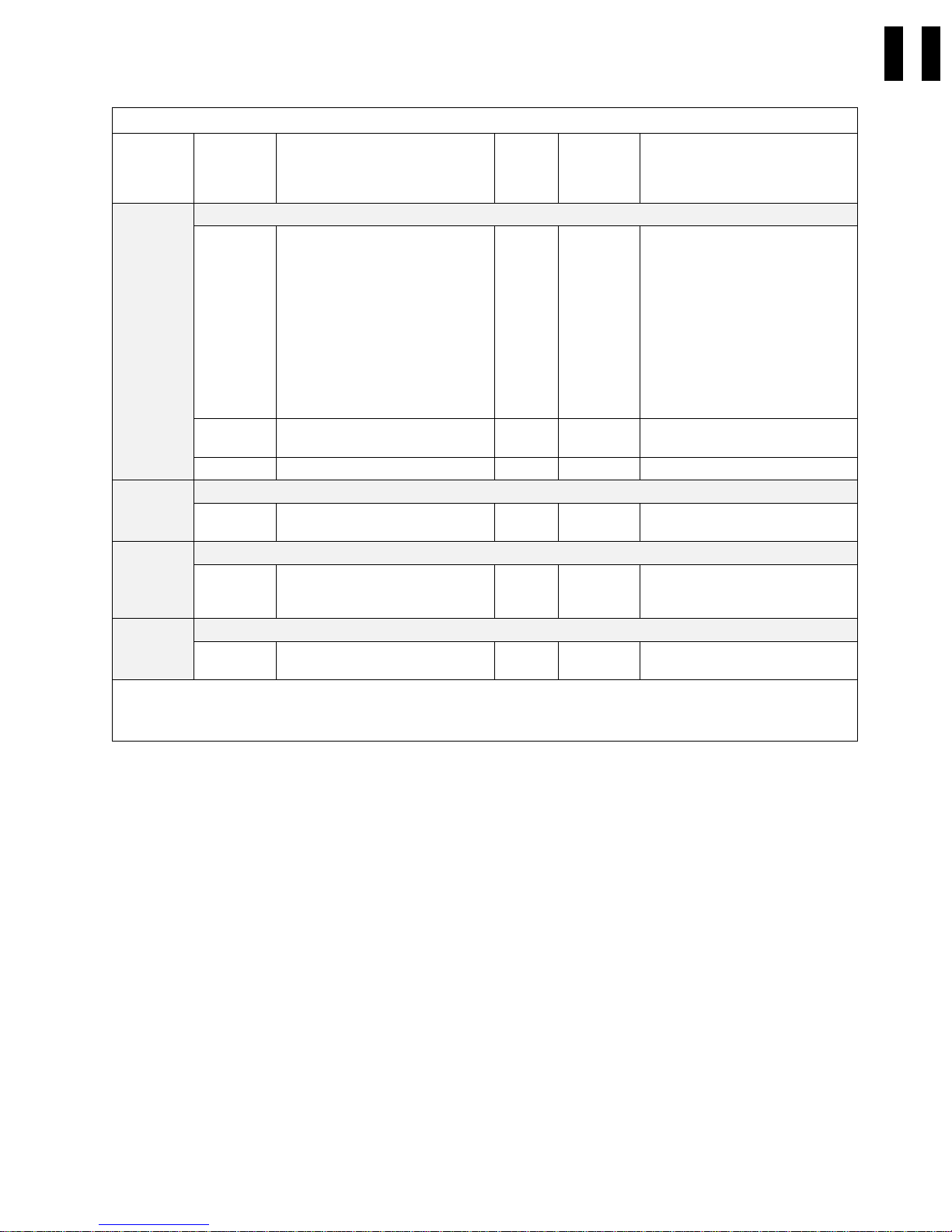

Figure 7. Indicator Meaning During Normal Operational Conditions

Busy 1 Clean 2 Maintenance 3 Note Message

Off Off Off — Inactive

Off Off Flashing 1 POST or write/read diagnostic test running

Off Flashing Off 2 Cleaning is required

Off On Off 2 The drive has been disabled until the Head Cleaning

procedure is performed.

On Off Off 3 Busy, tape in motion for write, read or locate

On On Off — ATTENTION DRIVE message is indicated. See

“Attention Drive Messages” on page START-24.

On On On 4

Flashing Off Off 3 Unloading, rewinding or cleaning

Flashing Flashing Flashing 5 A hard failure on drive

Off Off On 5 A hard failure on drive

Flashing Flashing On 5 A hard failure on drive

Notes:

1. Maintenance indicator flashing: a normal condition that occurs anytime diagnostics are running. The

diagnostics run:

At power-on time.

After a system reset.

When a Send Diagnostic command is sent from the initiator.

When executed by the service representative.

For more information on LED meanings in CE Mode, see Figure 244 on page PROC-7 and Figure 246

on page PROC-9.

2. Clean indicator flashing or ON solid: the 3570 determines that the read/write heads need cleaning.

Note: If the Clean indicator is ON solid, the 3570 drive will be disabled until the cleaning operation has been

performed.

Load the cleaning cartridge into the 3570. See “Drive Cleaning Procedure” on page PROC-22. Cleaning is

automatic: the Busy indicator is lighted and remains ON until the cleaning cartridge is unloaded. If the Clean

indicator remains ON after cleaning or if the Clean indicator comes ON frequently, see “Other Obvious

Symptom Problems” on page MAPS-19 for further isolation.

3. Busy indicator flashing or ON solid: a normal condition that indicates that the drive is executing either a

read/write operation or is locating, rewinding, or unloading.

4. Busy, Clean and Maintenance indicators lighted: the LED test that occurs at power-on time, after a system

reset or during microcode recovery.

5. Two major conditions may occur here:

a. All three indicators flash quickly, then the Maintenance LED stays ON solid while the other two LEDs flash

or stay OFF. This indicates a hard failure on the drive and the drive is sending a coded message of the

associated FID. For more information on LED meanings in CE Mode, see Figure 244 on page PROC-7

and Figure 246 on page PROC-9.

b. All three indicators flash quickly, then all three come ON solid for a time, then the three indicators flash

quickly again. This pattern may repeat as many as four times. This indicates that the microcode has

encountered problems, and is trying to recover. If the microcode fails to recover, it will then flash the

three indicators continuously until the device is powered OFF or reset.

On momentarily as a lamp test during power-on reset

&

or during microcode recovery.

5

START

Start START-11

Page 26

FID Entry Point

Figure 8 lists each FRU identifier (Reported FID) and the field replaceable units (FRUs) to change, or

problem areas to investigate under FRU Name. The figure (beginning with the Third Release) also

contains the Repair Sequence you should follow in performing procedures or FRU replacements. Also

included are page Reference or Instruction to the removal and replacement procedure for the FRU.

Each FRU or problem is identified by name. The technical area code (TAC), provided here and in the

CARR section, is to assist you with call reporting. The Duration in hours is intended to give you some

idea of how long each FRU removal and replacement procedure will take. These numbers, along with the

time it takes to remove and replace decorative covers (see times given for covers in the CARR section)

should give you a ball park estimate of what time you can expect to spend replacing the parts. These

times do not include diagnose and checkout time.

FIDs are displayed on the operator/CE panel in a FID message and in the error log. For example, if the

message is FID1 90, 1 is the severity and 90 is the FID. “Intervention Screens” on page PANEL-9

describes the different types of messages and their impact on 3570 availability. The FID relates to the

FRUs that have the highest probability of causing the problem. Only the reported FID is displayed on the

panel and in the FID log. See Figure 8 for the complete list of FIDs and associated FRUs. Always

replace the FRU or perform the recommended procedure in the order of Repair Sequence which takes

into consideration failure probability.

If the FID has cable FRUs in the FRU list, reseat the cable FRUs before replacing any FRU in the list.

If you are servicing a 3570 model that is Rack installed, two people are required to lift the device from the

rack. Refer to “Installing the 3570 in a Rack (Models C11 and C12 Only)” on page INST-22 for the

procedure to use the hoist in cases where you are alone.

The service information message (SIM) record, which the 3570 sends to the host, also has the reported

FID information. See “Service Information Messages (SIMs) and Media Information Messages (MIMs)” on

page MSG-2.

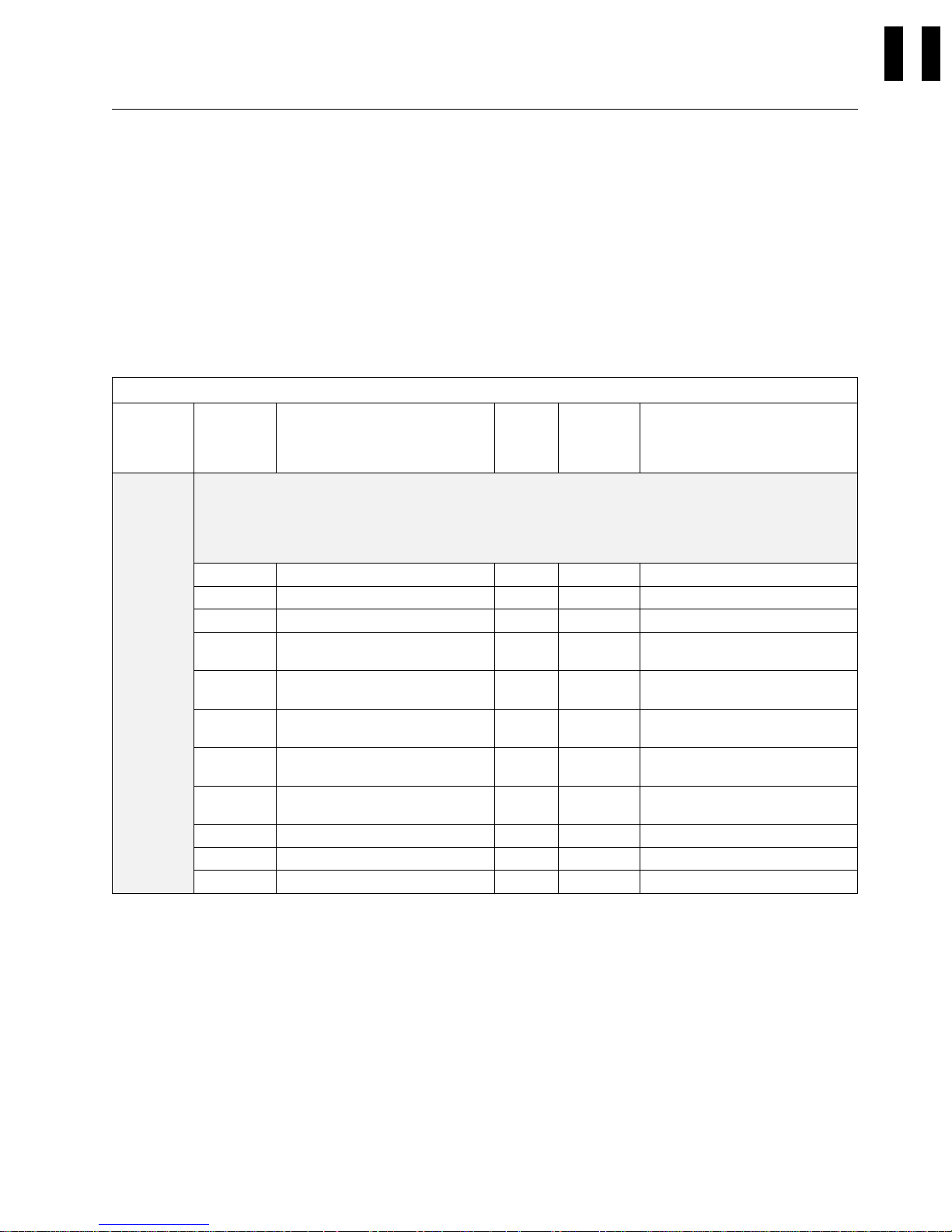

Figure 8 (Page 1 of 12). FIDs, FRUs, and TACs

Reported

FID

00 The drive serial number is the default value

01 The drive logic card serial number is the default value

| procedure is at “Removal and

| Replacement Procedures—Drive

| Pack” on page CARR-7. If this

Repair

Sequence

1 Invalid drive serial number — — Enter valid drive serial number.

1 Invalid drive logic card serial

FRU Name Prob-

ability

— —| Replace the Tape Drive. The

number. This number is set when

the card is built and cannot be

changed in the field.

TAC

Code &

(Duration

in hours)

Page Reference or Instruction

Go to “Drive Serial

Number—Library Models Only” on

page PROC-29.

| does not resolve the problem, call

| for support.

03 Invalid setup detected

1 Configuration problem — — Ensure the config/install options

are correct (library models only).

START-12 IBM 3570 MI

Page 27

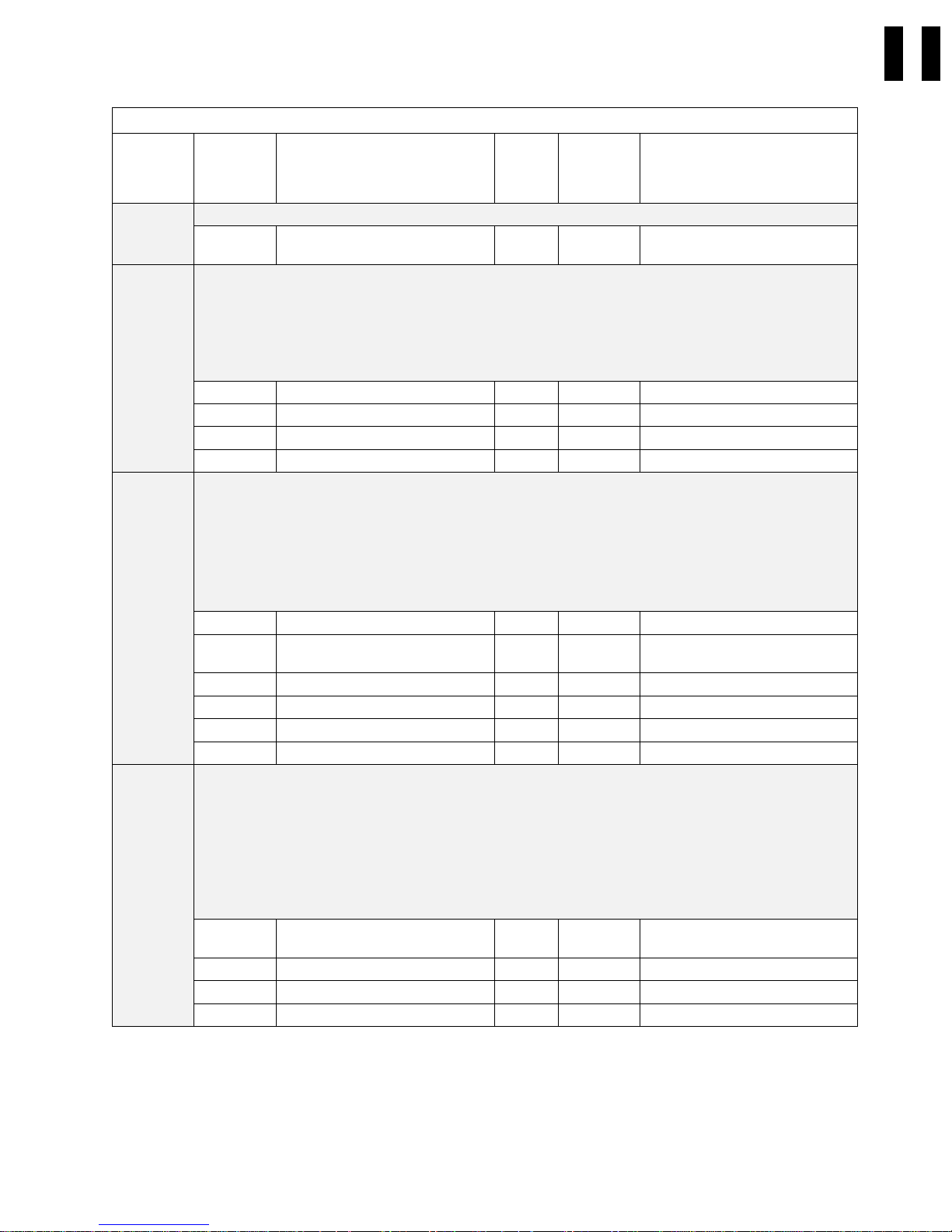

Figure 8 (Page 2 of 12). FIDs, FRUs, and TACs

Reported

FID

90 Electronic fault. See also “Library Operator Panel Problems” on page MAPS-3.

| 2| Library operator panel display

| 40%| T04 (0.1)| CARR-19

| cable

94 Bar code reader failure. Perform the procedure at “Resolving Bar Code Reader Problems” on page PROC-24

| 4| Picker cable| 3%| T04 (0.1)| CARR-23

| 5| Library interface cable| 2%| T04 (0.1)| CARR-32

| 6| Drive pack| 2%| T22 (0.2)| CARR-7

95 Did not detect accessor movement.

Repair

Sequence

1 Library operator panel display 50% L05 (0.2) CARR-19

3 Library control card 10% T15 (0.2) CARR-22

before replacing any of the following FRUs.

1 Bar code reader 70% T18 (0.1) CARR-20

2 Library control card 20% T15 (0.1) CARR-22

3 Picker assembly 3% T12 (0.1) CARR-23

1. Check for anything that might obstruct picker movement.

2. Ensure that cartridges are positioned in the magazines properly. If the picker does not place the cartridges

fully into the magazines, replace the picker assembly before replacing any other FRUs.

3. This failure can also be caused by infrared light reflecting from the picker belts onto the Cartridge Present

sensor. If the picker belts are shiny and you suspect this is the cause, clean the picker belts with alcohol on

a lint-free cloth.

4. If the above checks don't fix the problem, cycle the power off then on to the 3570 and observe the accessor

assembly before replacing FRUs:

a. If the accessor motor assembly can move the picker back and forth, replace the accessor assembly

b. If accessor motor assembly cannot move the picker back and forth, replace the FRUs in the order listed

1 Accessor motor assembly 75% T17 (0.2) CARR-21

2 Library control card 15% T15 (0.1) CARR-22

3 Library sensor cable 5% T04 (0.4) CARR-33

4 Accessor assembly 5% T14 (0.6) CARR-20

FRU Name Prob-

before replacing any of the other FRUs.

below.

ability

TAC

Code &

(Duration

in hours)

Page Reference or Instruction

START

Start START-13

Page 28

Figure 8 (Page 3 of 12). FIDs, FRUs, and TACs

Reported

FID

96 Timeout trying to extract a cartridge from a drive.

Repair

Sequence

1. Before replacing any FRUs below, inspect the cartridge that was being used when the error occurred. Look

for physical defects. Have the customer replace the cartridge if it is damaged.

2. A false 96 error can occur when the library door is opened when the library is attempting to put a cartridge

away as part of the power-up sequence. If you believe this occurred, do not replace FRUs at this time.

3. Before replacing FRUs below, ensure that:

FRU Name Prob-

ability

TAC

Code &

(Duration

in hours)

Page Reference or Instruction

| a. All drive sensors listed on Figure 248 on page PROC-14 are working correctly.

| b. library sensors: Global Interference A & B, Cartridge Present, Pinch 1 & 2 and Limit 1 & 2 are working

| correctly. See Figure 248 on page PROC-14.

| See Figure 128 on page PANEL-26 and select UTILITIES from the CE OPTIONS Menu, then select DISP

| SENSORS from the CE UTILITIES Menu.

4. Ensure that the drive door is not binding or sticking.

| 1| Drive pack| 36%| T45 (0.2)| CARR-7

2 Picker assembly 30% T12 (0.1) CARR-23

3 Drive global sensor pair 10% T31 (0.1) CARR-25

4 Magazine global sensor pair 10% T31 (0.1) CARR-26

| 5| Picker cable| 5%| T04 (0.1)| CARR-23

6 Library control card 5% T15 (0.1) CARR-22

7 Library sensor cable 4% T04 (0.4) CARR-33

97 Electronic-detected fault

1 Library control card 70% T15 (0.1) CARR-22

| 2| Drive pack| 25%| T22 (0.2)| CARR-7

3 Library interface cable 3% C03 (0.1) CARR-32

4 Power supply 2% P04 (0.1) CARR-16

98 Load or unload error while moving cleaner cartridge between the library cleaner cartridge cell and the drive.

Sensor did not change state.

Notes:

1. Check the cleaner cartridge for physical damage.

| 2. Before replacing FRUs below, ensure that:

| a. All drive sensors listed on Figure 248 on page PROC-14 are working correctly.

| b. library sensors: Cleaner Cartridge Present, Global Interference A & B, Pinch 1 & 2 and Limit 1 & 2 are

| working correctly. See Figure 248 on page PROC-14.

| See Figure 128 on page PANEL-26 and select UTILITIES from the CE OPTIONS Menu, then select DISP

| SENSORS from the CE UTILITIES Menu.

1 Picker assembly 60% T12 (0.1) CARR-23

2 Cleaner cartridge-present sensor 15% T31 (0.1) CARR-33

| 3| Drive global sensor pair| 10%| T31 (0.1)| CARR-25

| 4| Magazine global sensor pair| 10%| T31 (0.1)| CARR-26

5 Library control card 4% T15 (0.1) CARR-22

6 Library sensor cable 1% T04 (0.4) CARR-33

START-14 IBM 3570 MI

Page 29

Figure 8 (Page 4 of 12). FIDs, FRUs, and TACs

Reported

FID

| 9A| Library Picker Assembly problem.

| Note: Before replacing FRUs below, ensure that the Cartridge Present, Pinch 1 & 2, and Limit 1 & 2 sensors in

| the library are operating correctly. See Figure 248 on page PROC-14. See Figure 128 on

| page PANEL-26 and select UTILITIES from the CE OPTIONS Menu, then select DISP SENSORS from

| the CE UTILITIES Menu.

| 2| Picker cable| 20%| T04 (0.1)| CARR-23

| 9B| Sensor in an invalid condition.

| Note: Before replacing FRUs below, ensure that the Drive Global Sensor (B) is operating correctly. The sensor

| is shown in Figure 248 on page PROC-14. See Figure 128 on page PANEL-26 and select UTILITIES

| from the CE OPTIONS Menu, then select DISP SENSORS from the CE UTILITIES Menu.

| 1| Drive global sensor pair (B)| 90%| T31 (0.2)| CARR-25

| 9C| Sensor in an invalid condition.

| Note: Before replacing FRUs below, ensure that the Global Interference Sensor A is operating correctly. The

| sensor is shown in Figure 248 on page PROC-14. See Figure 128 on page PANEL-26 and select

| UTILITIES from the CE OPTIONS Menu, then select DISP SENSORS from the CE UTILITIES Menu.

| 1| Magazine global sensor pair (A)| 90%| T31 (0.2)| CARR-26

9E Sensor did not change state.

| Note: Before replacing FRUs below, ensure that the Priority cell cartridge present.sensor is operating correctly.

| The sensor is shown in Figure 248 on page PROC-14. See Figure 128 on page PANEL-26 and select

| UTILITIES from the CE OPTIONS Menu, then select DISP SENSORS from the CE UTILITIES Menu.

Repair

Sequence

1 Picker assembly 70% T12 (0.1) CARR-23

3 Library control card 7% T15 (0.1) CARR-22

4 Library sensor cable 3% T04 (0.4) CARR-33

2 Library control card 9% T15 (0.1) CARR-22

3 Library sensor cable 1% T04 (0.4) CARR-33

2 Library control card 7% T15 (0.1) CARR-22

3 Library sensor cable 3% L01 (0.4) CARR-33

1 Priority cell cartridge-present

2 Library sensor cable 5% L01 (0.4) CARR-33

3 Library control card 5% T15 (0.1) CARR-22

FRU Name Prob-

ability

90% T31 (0.1) CARR-31

sensor

TAC

Code &

(Duration

in hours)

Page Reference or Instruction

START

Start START-15

Page 30

Figure 8 (Page 5 of 12). FIDs, FRUs, and TACs

Reported

FID

9F Load or unload error when moving a cartridge between the drive and the library (a sensor did not change state).

| a. All drive sensors listed on Figure 248 on page PROC-14 are working correctly.

| b. library sensors: Global Interference A & B, Cartridge Present, Pinch 1 & 2 and Limit 1 & 2 are working

| correctly. See Figure 248 on page PROC-14.

| See Figure 128 on page PANEL-26 and select UTILITIES from the CE OPTIONS Menu, then select DISP

| SENSORS from the CE UTILITIES Menu.

| 2| Drive pack| 32%| T45 (0.2)| CARR-7

| 3| Picker cable| 20%| C03 (0.1)| CARR-23

| 4| Library control card| 10%| T15 (0.1)| CARR-22

| 5| Library sensor cable| 4%| T04 (0.4)| CARR-33

| A0| Sensor did not change state.

| Note: Before replacing FRUs below, ensure that the Magazine 2 sensor is operating correctly. The sensor is

| shown on Figure 248 on page PROC-14. See Figure 128 on page PANEL-26 and select UTILITIES

| from the CE OPTIONS Menu, then select DISP SENSORS from the CE UTILITIES Menu.

A1 Sensor did not change state.

| Note: Before replacing FRUs below, ensure that the Magazine 1 sensor is operating correctly. The sensor is

| shown in Figure 248 on page PROC-14. See Figure 128 on page PANEL-26 and select UTILITIES from

| the CE OPTIONS Menu, then select DISP SENSORS from the CE UTILITIES Menu.

A3 Sensor did not change state

| Note: Before replacing FRUs below, ensure that the Cleaner cartridge-present sensor is operating correctly. The

| sensor is shown on Figure 248 on page PROC-14. See Figure 128 on page PANEL-26 and select

| UTILITIES from the CE OPTIONS Menu, then select DISP SENSORS from the CE UTILITIES Menu.

Repair

Sequence

1. Before replacing any FRUs below, inspect the cartridge that was being used when the error occurred. Look

for physical defects. Have the customer replace the cartridge if it is damaged.

2. A false 9F error can occur when the library door is opened when the library is attempting to put a cartridge

away as part of the power-up sequence. If you believe this occurred, do not replace FRUs at this time.

3. Before replacing FRUs below, ensure that:

4. Ensure that the drive door is not binding or sticking.

1 Picker assembly 34% T12 (0.1) CARR-23

1 Magazine 2 sensor 90% T31 (0.2) CARR-32

2 Library control card 7% T15 (0.1) CARR-22

3 Library sensor cable 3% T04 (0.4) CARR-33

1 Magazine 1 sensor 90% T31 (0.1) CARR-32

2 Library control card 7% T15 (0.1) CARR-22

3 Library sensor cable 3% T04 (0.4) CARR-33

1 Cleaner cartridge-present sensor 90% T31 (0.1) CARR-33

2 Library control card 7% T15 (0.1) CARR-22

3 Library sensor cable 3% T04 (0.4) CARR-33

FRU Name Prob-

ability

TAC

Code &

(Duration

in hours)

Page Reference or Instruction

START-16 IBM 3570 MI

Page 31

Figure 8 (Page 6 of 12). FIDs, FRUs, and TACs

Reported

FID

A7 Picker or priority slot error.

| Notes:

| 1. Before replacing any FRUs below, inspect the cartridge that was being used when the error occurred for

| physical defects. Have the customer replace the cartridge if it is damaged.

| 2. Before replacing any FRUs below, check library sensors Priority Slot, Cartridge Present, Global Interference

| B, Pinch 1 & 2, and Limit 1 & 2 sensors to ensure that they are operating correctly. The sensors are shown

| in Figure 248 on page PROC-14.

| 3| Priority cell cartridge-present

| 10%| T31 (0.1)| CARR-31

| sensor

| 4| Magazine global sensor pair| 10%| T31 (0.1)| CARR-26

A8 Picker or magazine error.

| Notes:

| 1. Before replacing any FRUs below, inspect the cartridge that was being used when the error occurred for

| physical defects. Have the customer replace the cartridge if it is damaged.

| 2. Before replacing any FRUs below, check library sensors Magazine 1 Present, Magazine 2 Present, Priority

| Slot, Cartridge Present, Global Interference B, Pinch 1 & 2, and Limit 1 & 2 sensors to ensure that they are

| operating correctly. The sensors are shown in Figure 248 on page PROC-14.

| 1| Library magazine| 30%| Q05 (0.1)| Customer purchase item. Try

| another magazine before

| replacing any FRUs below.

| 2| Picker assembly| 20%| T12 (0.1)| CARR-23

| 3| Magazine 1 sensor| 10%| T31 (0.1)| CARR-32

| 4| Magazine 2 sensor| 10%| T31 (0.1)| CARR-32

| 5| Magazine global sensor pair| 10%| T31 (0.1)| CARR-26

| 6| Priority cell cartridge-present

| 10%| T31 (0.1)| CARR-31

| sensor

Repair

Sequence

1 Library magazine 40% Q05 (0.1) Customer purchase item. Try

2 Picker assembly 30% T12 (0.1) CARR-23

5 Picker cable 5% C03 (0.1) CARR-23

6 Library control card 5% T15 (0.1) CARR-22

7 Picker cable 5% C03 (0.1) CARR-23

8 Library control card 5% T15 (0.1) CARR-22

FRU Name Prob-

ability

TAC

Code &

(Duration

in hours)

Page Reference or Instruction

another magazine before

replacing any FRUs below.

START

Start START-17

Page 32

Figure 8 (Page 7 of 12). FIDs, FRUs, and TACs

Reported

FID

A9 Picker feed error.

| Notes:

| 1. Before replacing any FRUs below, inspect the cartridge that was being used when the error occurred for

| physical defects. Have the customer replace the cartridge if it is damaged.

| 2. Before replacing any FRUs below, check library sensors: Pinch 1 & 2, Limit 1 & 2, Cartridge Present, and

| Global Interference A & B to ensure that they are operating correctly. The sensors are shown in Figure 248

| on page PROC-14.

| 1| Library magazine| 40%| Q05 (0.1)| Customer purchase item. Try

| another magazine before

| replacing any FRUs below.

| 2| Picker assembly| 30%| T12 (0.1)| CARR-23

| 3| Drive global sensor pair| 10%| T31 (0.1)| CARR-25

| 4| Magazine global sensor pair| 10%| T31 (0.1)| CARR-26

AA Library door open sensor

| Note: Before replacing FRUs below, ensure that the Library door open sensor is operating correctly. The sensor

| is shown in Figure 248 on page PROC-14. See Figure 128 on page PANEL-26 and select UTILITIES

| from the CE OPTIONS Menu, then select DISP SENSORS from the CE UTILITIES Menu.

B1 Drive LED fault detected

| 1| Drive pack| 100%| L05 (0.1)| CARR-7 if library installed drive or

| CARR-10 if stand-alone drive.

B9 Cartridge is not fully seated in the loader.

| 2| Drive pack| 35%| T45 (0.2)| CARR-7 if library installed drive or

| CARR-10 if stand-alone drive.

BA Loader asm or servo card

| 1| Drive pack| 100%| T45 (0.2)| CARR-7 if library installed drive or

| CARR-10 if stand-alone drive.

Repair

Sequence

5 Picker cable 5% C03 (0.1) CARR-23

6 Library control card 5% T15 (0.1) CARR-22

1 Library door open sensor 80% T31 (0.2) CARR-34

2 Library control card 14% T15 (0.1) CARR-22

3 Library sensor cable 6% T04 (0.4) CARR-33

Note: This could be an operator problem in drive-only machines without a library.

1. Ensure that the cartridge is not damaged.

2. Ensure that the cartridge is a 3570 type cartridge.

1 Tape cartridge 40% D07 (0.1) Customer item. Inspect for

3 Picker assembly (For library only) 25% T12 (0.1) CARR-23

FRU Name Prob-

ability

TAC

Code &

(Duration

in hours)

Page Reference or Instruction

damage. Try another cartridge

before replacing the FRUs below.

START-18 IBM 3570 MI

Page 33

Figure 8 (Page 8 of 12). FIDs, FRUs, and TACs

Reported

FID

BB Loader asm, servo card, or tape cartridge.

| 1| Tape cartridge (check first)| 20%| D07 (0.1)| Customer item. Inspect for

| damage. Try another cartridge.

| See “FID FE—Isolate Fault

| between Media and Hardware” on

| page PROC-89.

| 2| Drive pack| 80%| T45 (0.2)| CARR-7 if library installed drive or

| CARR-10 if stand-alone drive.

BC Load or unload failure.

| Note: If your drive is at microcode level D1I5_2F1 or lower, this error may be caused by the microcode failing to

| reset an internal counter. Before replacing any hardware, call your next level of support for advice.

| 3. Ensure that all drive sensors are operating correctly. Refer to Figure 248 on page PROC-14 for the drive

| sensors. See Figure 128 on page PANEL-26 and select UTILITIES from the CE OPTIONS Menu, then

| select DISP SENSORS from the CE UTILITIES Menu.

| 1| Tape cartridge (check first)| 20%| D07 (0.1)| Customer item. Inspect for

| damage. Try another cartridge.

| See “FID FE—Isolate Fault

| between Media and Hardware” on

| page PROC-89.

| 2| Drive pack| 80%| T45 (0.2)| CARR-7 if library installed drive or

| CARR-10 if stand-alone drive.

BF Thermal error. The tripped thermal is located on the drive logic card. Causes of a thermal trip can be

| 1| Drive pack| 75%| L01 (0.2)| CARR-7 if library installed drive or

| CARR-10 if stand-alone drive.

| C1| 12 or 36 volts not within specification.

| 1| This FID is also reported when

| | | Power OFF and power back ON.

| the drive detects a power outage.

| 3| Drive pack| 10%| T53 (0.2)| CARR-7 if library installed drive or

| CARR-10 if stand-alone drive.

C5 Tape cartridge or cartridge type sensor

| Note: Before replacing FRUs below, ensure that the Cartridge type sensor is operating correctly. Refer to

| Figure 248 on page PROC-14. See Figure 128 on page PANEL-26 and select UTILITIES from the CE

| OPTIONS Menu, then select DISP SENSORS from the CE UTILITIES Menu.

| 1| Tape cartridge (Check first)| 90%| D07 (0.1)| Customer item. Inspect for

| damage. Try another cartridge.

| Refer to “FID FE—Isolate Fault

| between Media and Hardware” on

| page PROC-89.

| 2| Drive pack| 10%| T53 (0.2)| CARR-7 if library installed drive or

| CARR-10 if stand-alone drive.

Repair

Sequence

1. Before replacing any FRUs below, inspect the cartridge that was being used when the error occurred for

physical defects. Have the customer replace the cartridge if it is damaged.

2. Also ensure that the cartridge is a 3570 type cartridge.

1. Before replacing any FRUs below, inspect the cartridge that was being used when the error occurred for

physical defects. Have the customer replace the cartridge if it is damaged.

2. Ensure that the cartridge is a 3570 type cartridge.

overheating of the logic card circuits, a missing front drive bezel which is needed to deflect airflow to the drive

logic card, a failing drive fan, or blockage of airflow in the fan area. If the cooling system appears to be

adequate, replace the drive pack.

2 Drive cooling fan 25% A03 (0.3) CARR-12

2 Power supply 90% P04 (0.1) CARR-16

FRU Name Prob-

ability

TAC

Code &

(Duration

in hours)

Page Reference or Instruction

START

Start START-19

Page 34

Figure 8 (Page 9 of 12). FIDs, FRUs, and TACs

Reported

FID

CA Sensor failed to change state

| 1| Drive pack| 100%| T31 (0.2)| CARR-7 if library installed drive or

| CARR-10 if stand-alone drive.

CD Sensor failed to change state

| 1| Drive pack| 100%| T31 (0.2)| CARR-7 if library installed drive or

| CARR-10 if stand-alone drive.

D0 Read or write failure, servo error, or IPS calibration error.

| 1| Clean Drive| 80%| D08| See “Drive Cleaning Procedure”

| on page PROC-22.

| 2| Drive pack| 20%| T22 (0.2)| CARR-7 if library installed drive or

| CARR-10 if stand-alone drive.

D1 Calibration error; possible interface problem between the head and the servo card

| 1| Clean Drive| 55%| D08| See “Drive Cleaning Procedure”

| on page PROC-22.

| 2| Drive pack| 45%| T22 (0.2)| CARR-7 if library installed drive or

| CARR-10 if stand-alone drive.

D2 The head did not move. Head asm, servo card, analog card, or mother board

| 1| Clean Drive| 45%| D08| See “Drive Cleaning Procedure”

| on page PROC-22.

| 2| Drive pack| 55%| T22 (0.2)| CARR-7 if library installed drive or

| CARR-10 if stand-alone drive.

| D3| Servo error while moving tape.

| 1| Tape cartridge (check first)| 45%| D07 (0.1)| Customer item. Inspect for

| damage. Try another cartridge.

| Refer to “FID FE—Isolate Fault

| between Media and Hardware” on

| page PROC-89.

| 2| Clean Drive| 20%| D08| See “Drive Cleaning Procedure”

| on page PROC-22.

| 3| Drive pack| 35%| T22 (0.2)| CARR-7 if library installed drive or

| CARR-10 if stand-alone drive.

D8 Read/write error.

| 1| Clean Drive| 36%| D08| See “Drive Cleaning Procedure”

| on page PROC-22.

| 2| Drive pack| 64%| T22 (0.2)| See “Removal and Replacement

| Procedures—Drive Pack” on

| page CARR-7.

| DD| Fault detected in drive loader sensors or the sensors are in an invalid combination.

| 1| Drive pack| 100%| T45 (0.2)| CARR-7 if library installed drive or

| CARR-10 if stand-alone drive.

E0 Tape motion error

| 1| Tape cartridge (check first)| 77%| D07 (0.1)| Customer item. Inspect for

| damage. Try another cartridge.

| Refer to “FID FE—Isolate Fault

| between Media and Hardware” on

| page PROC-89.

| 2| Drive pack| 23%| T45 (0.2)| CARR-7 if library installed drive or

| CARR-10 if stand-alone drive.

Repair

Sequence

FRU Name Prob-

ability

TAC

Code &

(Duration

in hours)

Page Reference or Instruction

START-20 IBM 3570 MI

Page 35

Figure 8 (Page 10 of 12). FIDs, FRUs, and TACs

Reported

FID

E4 Electronic-detected fault

| 1| Drive pack| 92%| L01 (0.2)| CARR-7 if library installed drive or

| CARR-10 if stand-alone drive.

| 2| Power supply| 8%| P04 (0.1)| CARR-16

E5 Microcode detected a fault with the microcode

E6 Timing problem in the microcode or the electronics, or multiple check-1 errors occurred

| 2| Drive pack| 50%| L01 (0.2)| CARR-7 if library installed drive or

| CARR-10 if stand-alone drive.

E7 Timing problem in the microcode or the electronics

| 2| Drive pack| 50%| L01 (0.2)| CARR-7 if library installed drive or

| CARR-10 if stand-alone drive.

E8 Timing problem while writing and/or reading

| EA| Electronic failure-Drive Logic Card

| 1| Drive pack| 90%| L01 (0.2)| CARR-7 if library installed drive or

| CARR-10 if stand-alone drive.

| 2| Power supply| 10%| P04 (0.1)| CARR-16

| EB| Electronic failure-Drive Logic Card

| 1| Drive pack| 90%| T21 (0.2)| CARR-7 if library installed drive or

| CARR-10 if stand-alone drive.

| 2| Power supply| 10%| P04 (0.1)| CARR-16

| EC| Electronic failure-Drive Logic Card

| 1| Drive pack| 90%| T53 (0.2)| CARR-7 if library installed drive or

| CARR-10 if stand-alone drive.

| 2| Power supply| 10%| P04 (0.1)| CARR-16

| ED| Electronic failure

| 1| Drive pack| 100%| L01 (0.2)| CARR-7 if library installed drive or

| CARR-10 if stand-alone drive.

| EE| Electronic failure

| 1| Drive pack| 100%| L01 (0.2)| CARR-7 if library installed drive or

| CARR-10 if stand-alone drive.

| F0| Read error

| 2| Drive pack| 40%| T22 (0.2)| CARR-7 if library installed drive or

| CARR-10 if stand-alone drive.

Repair

Sequence

1 Microcode (known or unknown)

1 Microcode (known or new) (M01 =

1 Microcode (known or new) (M01 =

1 Set a microcode trap based on

1 Tape cartridge 60% D07 (0.1) Customer supply. Refer to “FID

FRU Name Prob-

ability

100% M01/ M02 PROC-84

(M01 = known, M02 = new)

50% M01/M02 PROC-84 and PROC-86

known, M02 = new)

50% M01/ M02 PROC-84 and PROC-86

known, M02 = new)

— — PROC-44

the expert systems data, get a

dump , and contact your next

level of support.

TAC

Code &

(Duration

in hours)

Page Reference or Instruction

FE—Isolate Fault between Media

and Hardware” on

page PROC-89.

START

Start START-21

Page 36

Figure 8 (Page 11 of 12). FIDs, FRUs, and TACs

Reported

FID

| F1| Read error

| 2| Drive pack| 40%| T22 (0.2)| CARR-7 if library installed drive or

| CARR-10 if stand-alone drive.

F2 Read-back check error.

| 2| Drive pack| 40%| T22 (0.2)| CARR-7 if library installed drive or

| CARR-10 if stand-alone drive.

F3 Servo error

| 2| Clean Drive| 15%| D08| See “Drive Cleaning Procedure”

| on page PROC-22.

| 3| Drive pack| 25%| T22 (0.2)| CARR-7 if library installed drive or

| CARR-10 if stand-alone drive.