Page 1

BROOKFIELD R/S RHEOMETER

Operating Instructions

Manual No. M/02-212

Brookfield Engineering Labs., Inc. Page 1 M/02-212

Page 2

Operating Manual for R/S Rheometer

Version 1.10 E,

valid for firmware version 4.02

All rights reserved, the translation included.

Any part of this Operation Manual cannot be reproduced in any form (as printed matter, photocopies,

microfilms or in any other form) or processed, copied or disseminated using electronic system without

written consent of Brookfield Viscometers Ltd.

Brookfield Viscometers Ltd bears no responsibility for any technical or print technical errors or incomplete

information in this Operation Manual.

We reserve the right to change this Operation Manual without previous announcement.

The reproduction of users’ names, trade names, trade marks and so on in this Operation Manual does not

create the necessary prerequisites for their use by anybody; frequently it is a question of protected by law

registered trade marks, even if they are not marked as such.

Copyright 1998 by

Brookfield Viscometers Ltd

1 Whitehall Estate

Flex Meadow

Pinnacles West

Harlow, Essex U.K. CM19 5TJ

MS-WINDOWS - Copyright by Microsoft

IBM, IBM-PC - Registered trade marks of International Business Machines Corporation

All rights reserved

Revision 10/9

Brookfield Engineering Labs., Inc. Page 2 M/02-212

Page 3

CONTENTS

I. GENERAL DESCRIPTION 5

I.1 Use of the Rheometer 5

I.2 Measuring Principle 5

II.

SYSTEM CONFIGURATION 6

II.1 R/S Rheometer 6

II.2 Measuring Devices 8

II.3 Computer System 8

III. INSTRUMENT INSTALLATION 9

III.1 Stand Mounting 9

III.2 Electrical Connections 10

III.2.1 Temperature Sensor Pt100 10

III.2.2 AC-Adaptor 11

III.2.3 Printer Connection 11

III.2.4 Computer Connection 11

III.3 Mounting of temperature controlled measuring devices 12

III.3.1 Mounting of temp control device FTK-CC with and without cooling device KE 12

III.3.2 Mounting of the measuring device ME-CP/PP 14

III.3.3 Mounting of the cooling device KE 17

IV. ENVIRONMENT, HANDLING, CLEANING AND MAINTENANCE 18

IV.1 Operating environment, Storage 18

IV.2 Handling 18

IV.3 Cleaning 18

IV.4 Maintenance 19

V. MEASURING SYSTEMS 20

V.1 Measurement directly in the substance 20

V.2 Measurement with substance in measuring system 21

V.3 Measurement with temperature control device FTK-CC 22

V.4 Measurement with cone/plate and plate/plate measuring systems 23

VI. OPERATION AND MENUE SYSTEM

VI.1 Keyboard 26

VI.2 Menu System of R/S Rheometer 28

VI.3 Selecting from Lists 29

VI.4 Input of numerical values and alphanumeric texts 30

VI.5 Menue entries (MAIN menue) 32

VI.5.1 MAIN-Menue → Run Single 32

VI.5.2 MAIN-Menue → Run Program 34

VI.5.3 MAIN menue → Remote 36

VI.5.4 MAIN menue → Utilities 36

VI.5.5 MAIN menue → Configuration 36

VI.6 Menue entries in the Utilities-Menue 37

VI.6.1Utilities → Zero Calibration 37

VI.6.2 Utilities → Edit Programs 37

VI.6.3 Utilities → Print Programs 41

VI.6.4 Utilities → Measuring systems 41

VI.6.5 Utilities → Print memory 42

VI.6.6 Utilities → Clear memory 43

VI.6.7 Utilities → Measure temperature 43

Brookfield Engineering Labs., Inc. Page 3 M/02-212

25

Page 4

VI.7 Menu entries of the CONFIGURATION menu 44

VI.7.1 Configuration → Set output mode 44

VI.7.2 Configuration → MeasCount mode 45

VI.7.3 Configuration → Reset meascount 45

VI.7.4 Configuration → Set Time/Date 45

VI.7.5 Configuration → Set RS232 Parameter 46

VI.7.6 Configuration → Language 47

VI.7.7 Configuration → Service, Service 2 47

VI.8 Serial Data transfer via Interface RS232 47

VII. MEASUREMENTS 50

VII.1 Measuring in manual mode 50

VII.2 Measuring in Remote-mode 51

VIII. TECHNICAL DATA 52

IX. GUARANTEE 54

APPENDIX

A1 Data sheets of standard measuring systems 55

A2 Error messages 58

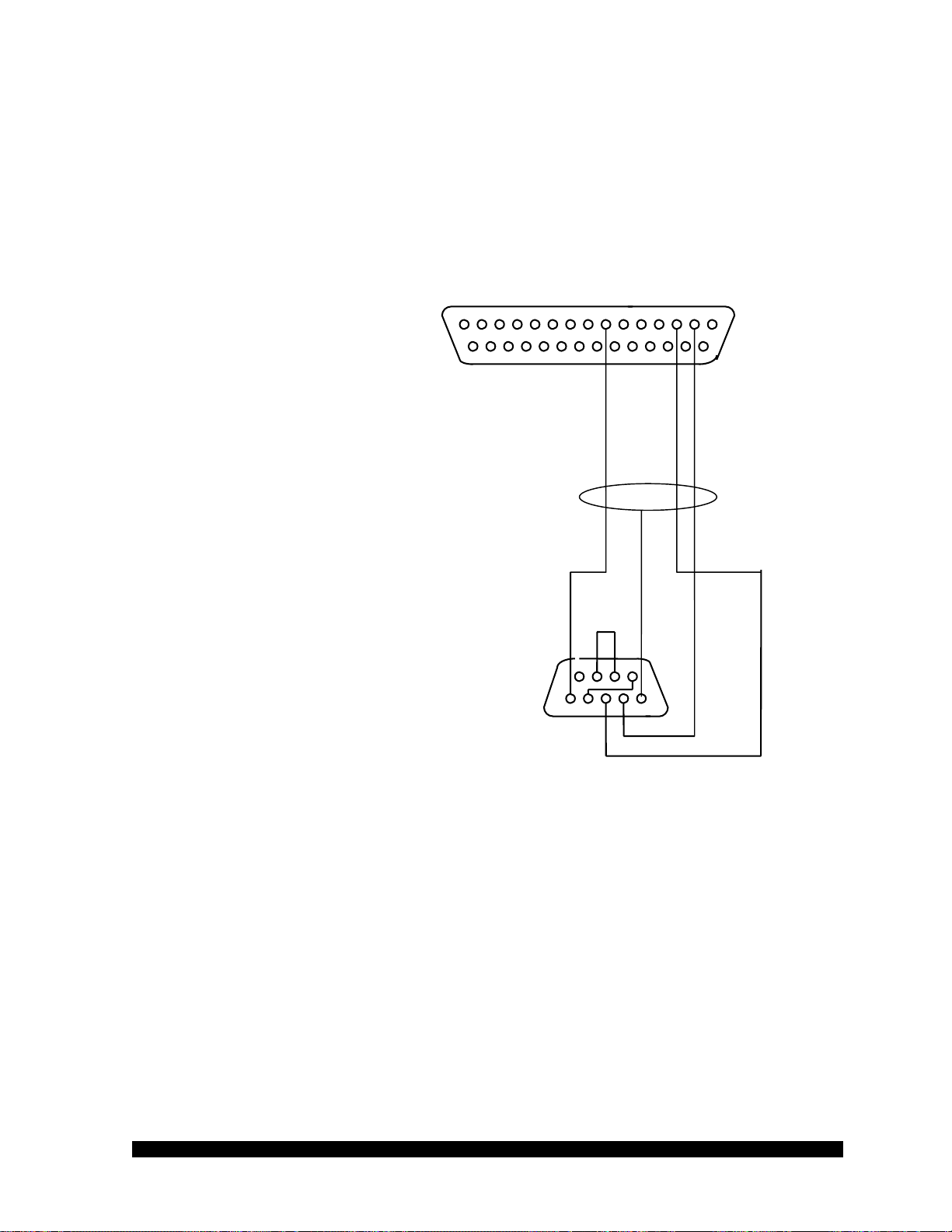

A3 Pin-layout of the serial data cable 61

A4 Requirements to the mains connecting cables 62

A5 Language cross reference 63

Brookfield Engineering Labs., Inc. Page 4 M/02-212

Page 5

I. General Description

In this chapter you get general information concerning use and measurement principle of your R/S

Rheometer.

I.1 Use of the Rheometer

The R/S Rheometer system provides possibility of Newtonian fluids viscosity measurements, recording

of flow curves as well as determination of viscosity functions of non-Newtonian fluids in steady shear

flows. Furthermore, it assures carrying out of measurements in non-stationary shear flows and the

measurements of viscoelastic substances values in creep processes. The R/S Rheometer is used in

quality control, production control and researches

I.2 Measuring Principle

The R/S Rheometer is a rotational-shear rate /shear stress-rheometer.

Concentric cylinders, measuring cones and plates are available as measuring system. The measuringsample is positioned in measuring gap between the stationary measuring cup and the rotating

measuring bob (Searle-principle), respectively between the rotating cone or plate and the stationary

lower plate (cone/plate-, cone/cone-measuring-system).

The measuring drive developed for this instrument operates with a high dynamic precision-drivesystem with optical encoder without gearing and without mechanical force transducers, so torque is

measured without deflection.

The R/S Rheometer measuring drive is applicable for carrying out rotational measurements with pre-set

of speed (shear rate) and pre-set of torque (shear stress).

In case of shear rate pre-set the torque acting on rotating measuring bob/cone/plate by measuring

substance flow resistance is measured (shear stress is measured).

In case of shear stress pre-set resulting speed of rotating measuring bob/cone/plate is measured (shear

rate).

Shear stress measurements can be carried out with R/S Rheometer in order to determine flow behavior

of plastic substances and enables exact measurement of yield point without shearing the measuring

substance.

The types of measurements

- rotation measurement with controlled shear rate (CSR)

- rotation measurement with controlled shear stress (CSS)

can be carried out in manual (without PC support) or in connection with a computer system with the

software RHEO 2000.

The creep measurements requires computer system with software RHEO 2000.

Brookfield Engineering Labs., Inc. Page 5 M/02-212

Page 6

II. System Configuration

In this chapter you get information concerning system configuration, temperature control device,

optional computer system and data- and signal flow of your Rheometer system.

The Rheometer system R/S Rheometer consists of:

- electronic unit with measuring drive integrated in one housing

- stand with working surface

- AC-adaptor

as accessories are supplied:

• printer

• coaxial cylinder measuring system (see Appendix A)

• temperature measuring sensor Pt100

• standard measuring device ME-CP/PP for cone/plate and plate/plate measuring systems

• cone/plate- and plate/plate measuring systems

• temperature control device “FTK-CC“

• cooling device “KE“

• fluids circulation thermostat

• computer system

• software RHEO 2000

bold printed accessories are necessary for minimal configuration

II.1 R/S Rheometer

The Rheometer electronics with measuring drive are built-in in one housing.

The R/S Rheometer system can serve due to consequent use of microelectronics with special

capacities:

⇒ digital control of rotational speed and torque

⇒ automatic matching of control parameters during measurement

⇒ direct indication of measured and calculated values of speed, shear rate, torque, shear stress,

viscosity, temperature, time etc.

⇒ internal measuring values storage

⇒ measuring values output to a printer (parallel centronics)

⇒ user support by dialog mode at LCD-display with clear text output

⇒ built-in system interface with serial standard interface (RS-232-C) for the direct connection of a

computer or other serial data-loggers.

⇒ printing and serial data-transmission while measuring possible

The R/S Rheometer is operated manually using foil keyboard at the front panel or under computer

control. The power supply of the R/S Rheometer with direct current is carried out by AC-adaptor.

Brookfield Engineering Labs., Inc. Page 6 M/02-212

Page 7

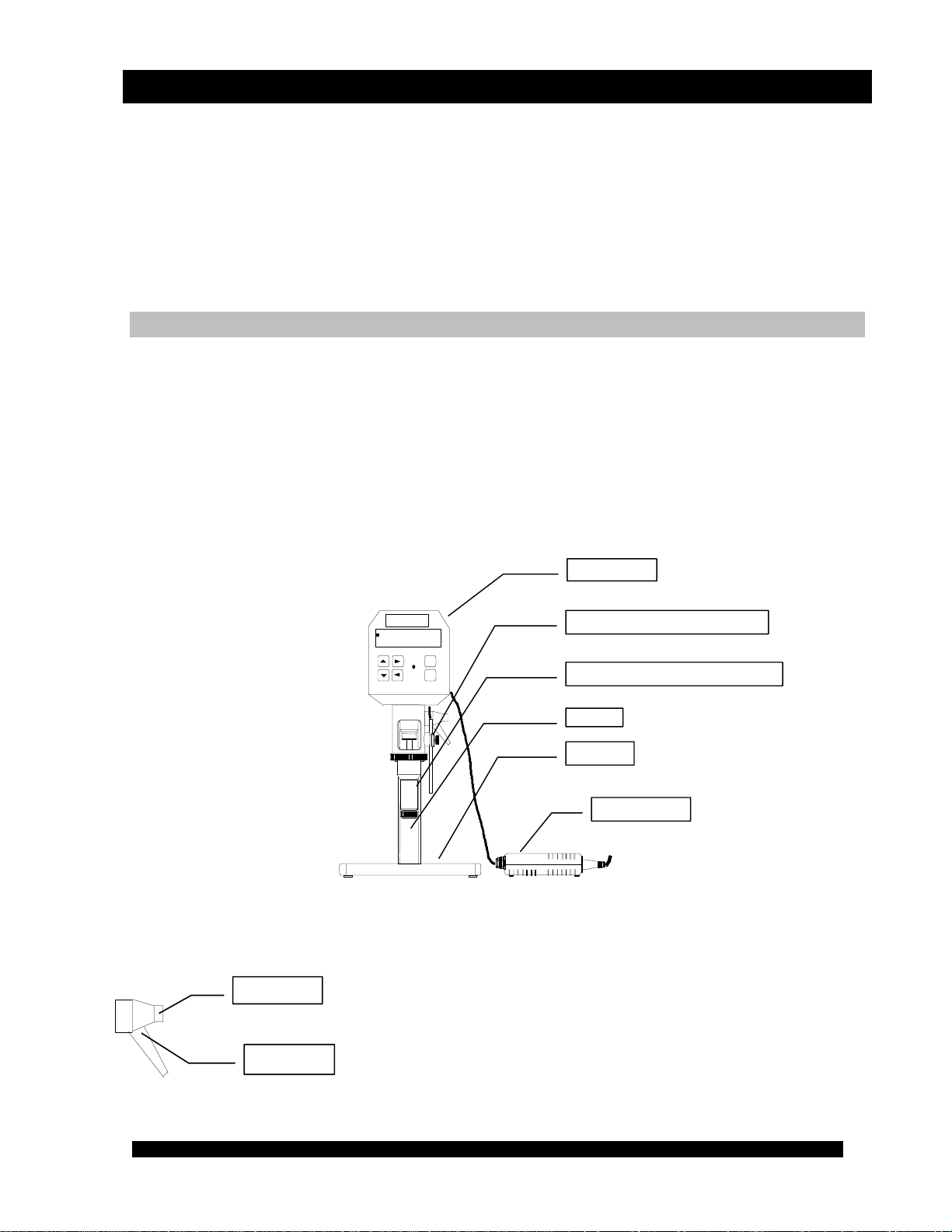

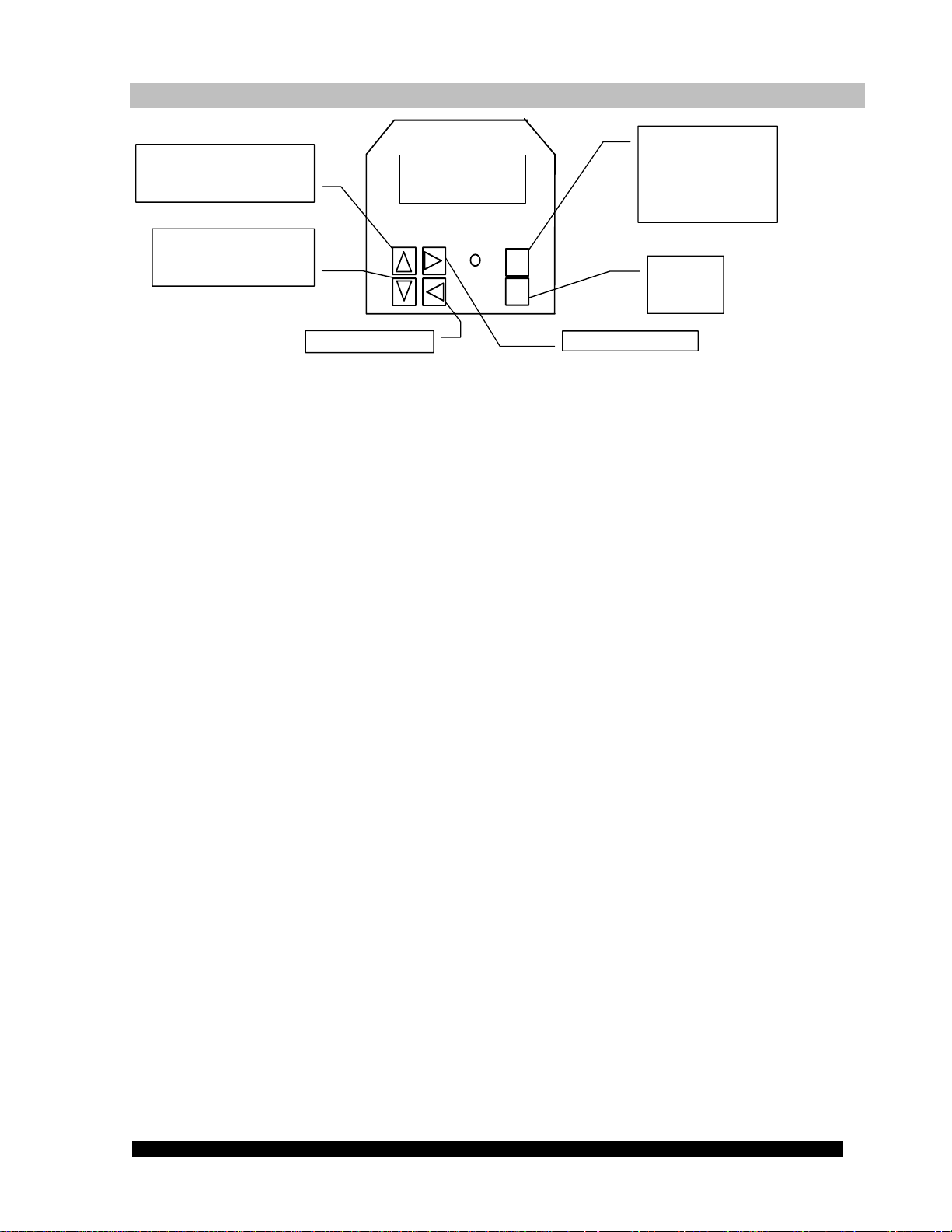

R/S Rheometer main instrument (minimum configuration)

BROOKFIELD

- Run Single

- Run Program

- Remote

6

2

Main-Menue

Power

S T

O K

3

1

14

4

5

7

13

10

12

8

9

11

1 R/S Rheometer

2 Measuring bob coupling

3 Mounting flange

4 Pt100-clamp fixture (accessory)

5 Pt100 (accessory)

6 Standard measuring bob (accessory)

7 Standard measuring cup (accessory)

8 Measuring cup bottom, or thread protection (accessory)

9 Measuring cup screw fitting

10 Stand

11 AC-adaptor

12 Direct current coupling

13 Mains connection cable

14 Data transmission cable (accessory

Brookfield Engineering Labs., Inc. Page 7 M/02-212

Page 8

II.2 Measuring Devices

Measuring devices are not included in the main delivery volume of R/S Rheometer and must be

ordered in accordance with your measuring requirements.

As measuring devices are optional supplied:

• coaxial standard measuring systems for R/S Rheometer (see Appendix A) with and without

built-in temperature sensor Pt100

• temperature control device “FTK-CC“ for use of cylinder measuring system in temperature

range -10°C ... +90°C

• cooling device “KE“ for use of cylinder measuring system in temperature range -20°C ... +180°C

• measuring device “ME-CP/PP“ for use of cone/plate or plate/plate measuring systems (see

Appendix A) in temperature range -10°C ... +90°C

II.3 Computer System

The computer system is optional and provides automatic measuring, graphical representation of

measuring results, printing of report as well as analysis of measuring data and quality control.

The computer system consists of:

• IBM-compatible PC with the following minimal system requirements:

- CPU 486 DX2 66 MHz

- 8 MB RAM (main memory)

- 10 MB free hard disk drive capacity

- operating system Microsoft Windows version 3.x, Microsoft Windows 95

or Microsoft Windows 98

- mouse and keyboard

- VGA-graphic card and monitor

- 1 free serial interface RS-232

• Printer

• user software program package RHEO 2000

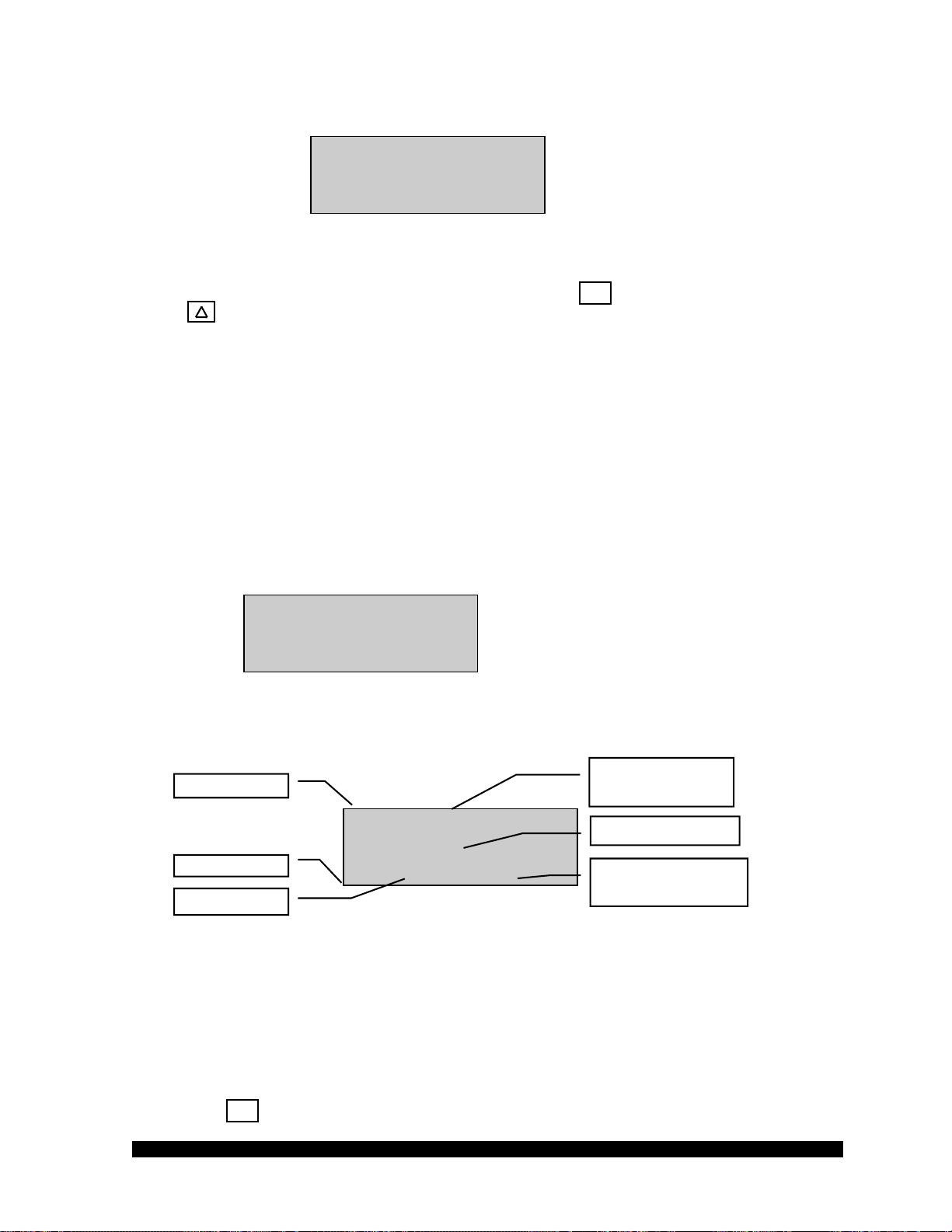

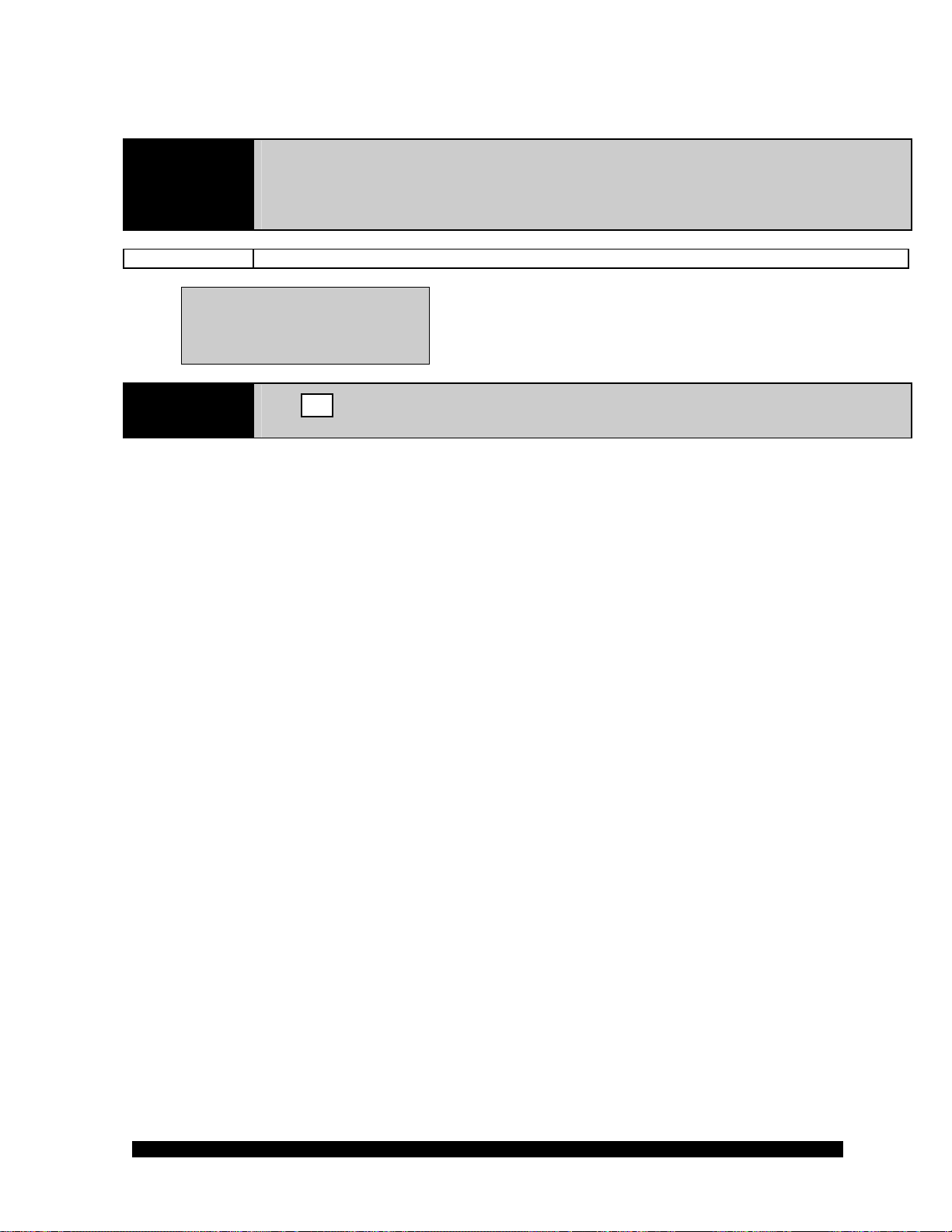

BROOKFIELD

Main-Menue

- Run Single

R/S Rheometer

- Run Program

- Remote

Power

ST

OK

Centronics

Printer when using R/S Rheometer

without Computer

RS232 (Data transmission)

Printer when using R/S Rheometer

PC

Software RHEO 2000

remo te controlled

LPT1

Fig. 1.: Computer system for R/S Rheometer

Brookfield Engineering Labs., Inc. Page 8 M/02-212

Page 9

III. Instrument Installation

In this chapter you will know how to prepare your R/S Rheometer for the first measurements.

You will know particularly,

- how to mount the R/S Rheometer,

- details about the electric connections

- installation of accessories such as temperature control device, cooling device, measuring system

- hose connections.

III.1 Stand Mounting

The stand consists of:

- the stand base plate

- the stand column with Rheometer

- the shelf

Hex-nut wrench size 6 and bolt DIN 912 M8x40 are supplied for mounting.

1. The stand column is joined with the stand base plate by the supplied bolt. It is necessary to check

during this operation that the parallel pin at the down side of the stand column fits into the

corresponding drilled hole at the base plate.

2. Lay the shelf on the stand base plate.

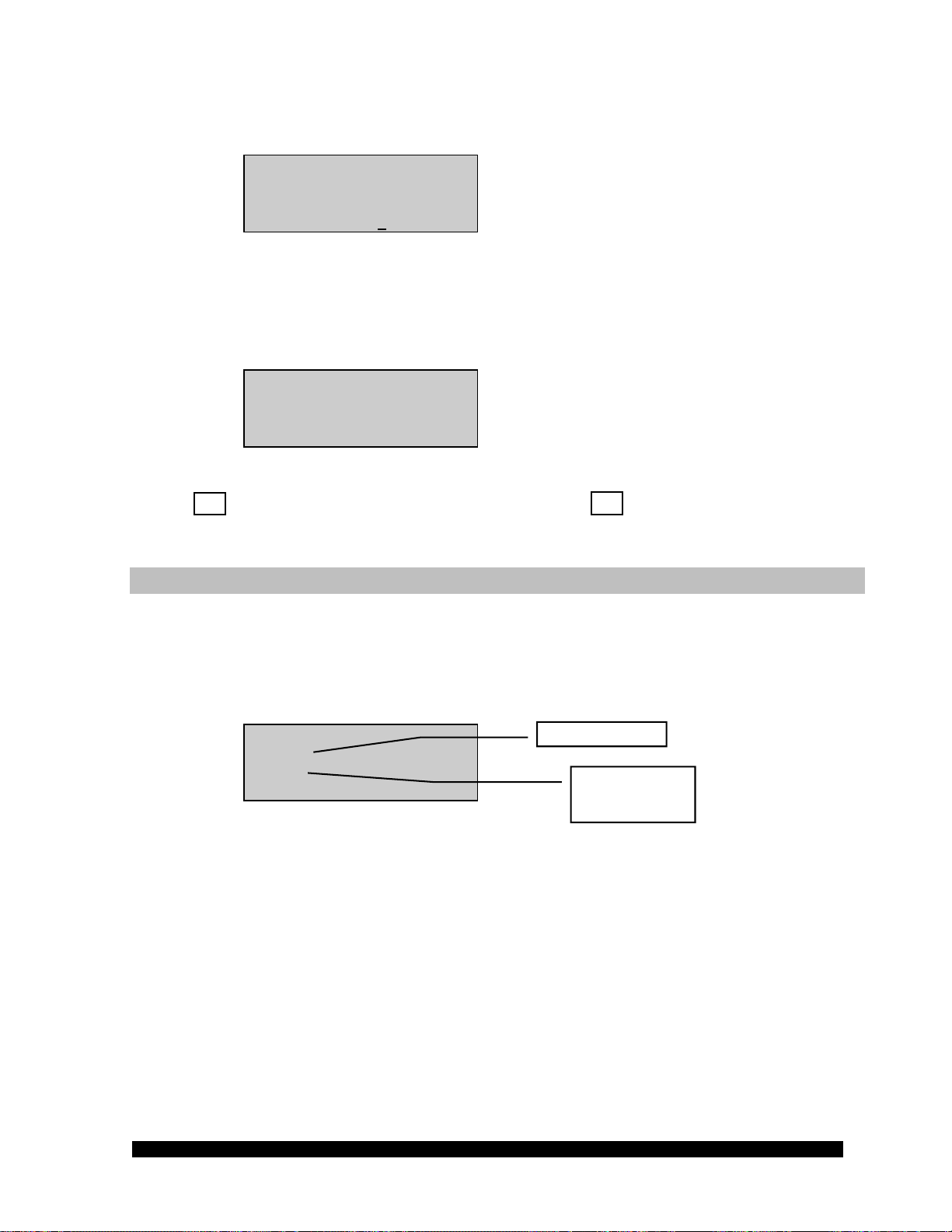

Brookfie ld

Main-Menue

- Run Single

- Run Program

- Remote

ST

OK

Rheometer

Pt100-temperature-sensor

Cylindric measuring system

Shelf

AC-adaptor

Fig. 2.: R/S Rheometer (minimum configuration)

Hints for height adjustment of the stand:

Locking button

In order to change the height adjustment of the stand you must release

the clamp handle and move the stand to the desired height. Caution:

Hold tight the R/S Rheometer as you release the clamp handle!

You can press the locking button to change the clamp handle position

Clamp handle

without screw/unscrew the thread.

After adjustment of the height screw tight the clamp handle thread again

with hand

Brookfield Engineering Labs., Inc. Page 9 M/02-212

Page 10

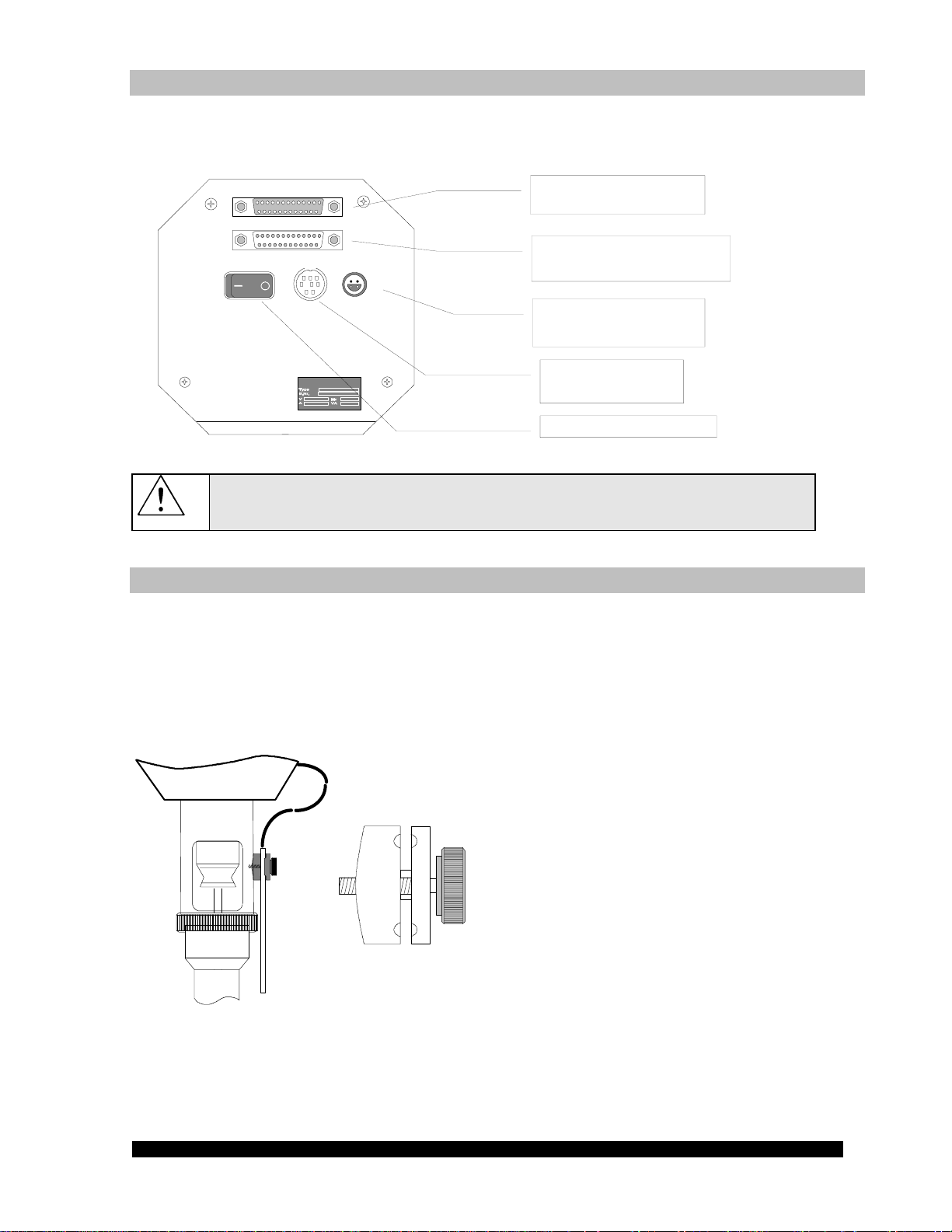

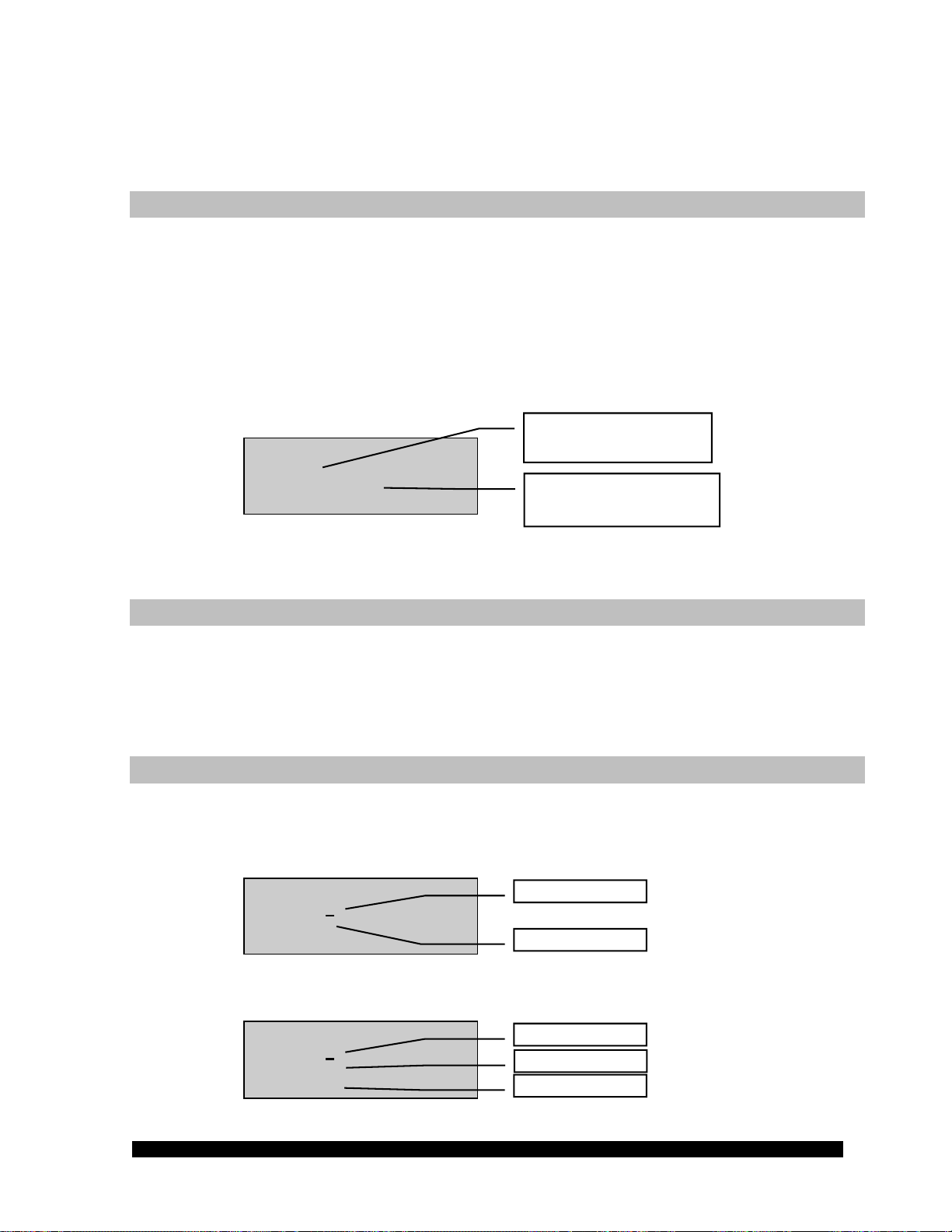

III.2 Electrical Connections

Connections for the electrical components of the R/S Rheometer are located at the instrument back

side:

Socket “Centronics“

parallel Printer interface

Socket “RS232“

serial communication port

Socket “Pt100“

for temperature sensor

Socket “DC“ for ACadaptor connection

Power

Centronics

RS232

DC

Pt 100

Mains switch “POWER“

Any cables from and to R/S Rheometer can be connected or disconnected only

when instrument is switched off!

III.2.1 Temperature Sensor Pt100

The connecting cable of the temperature sensor Pt100 is inserted into connector “Pt100“ at the back

side of the R/S Rheometer.

The Pt100 used is dependent upon measuring system device.

If you use standard cylindric measuring cups (MB-CC45...CC8) for measurements, put the sensor

Pt100 into Pt100 clamp fixture and fix it parallel to the measuring system at mounting flange of the R/S

Rheometer with the help of knurled-head screw.

Fig. 3: Pt100 connection and mounting

Insert the plug of Pt100 temperature sensor into

the connector “Pt100” at the back side of the

Rheometer.

As the viscosity is a function of the temperature, the temperature should be measured preferly in the

measuring substance. For this purpose, the standard measuring systems CC45...CC8 DIN can be

equipped with a Pt100 in measuring cup bottom (only in connection with FTK-CC). If you use a

measuring system with built-in Pt100, insert the cable “VK-MB“ there. With this option you can measure

the substance temperature directly.

Brookfield Engineering Labs., Inc. Page 10 M/02-212

Page 11

III.2.2 AC-Adaptor

The AC adaptor supplies R/S Rheometer with power.

Only the AC-adaptor delivered by BROOKFIELD with your Rheometer may be used for power

supply of R/S Rheometer.

The AC-adaptor may be inserted to the socket with corresponding grounding

only. Connect the AC adaptor only using the plug in a proper way grounded to

avoid electric shocks or damage of the system components. Pay attention also to

“Requirements to the mains cable” (see Appendix).

Connecting the AC-adaptor:

- be sure that R/S Rheometer is switched off (mains switch “POWER” at the back side of the

instrument);

- insert the instrument connector of the mains cable into AC adaptor;

- insert the plug of DC cable into the connector “DC” at the back side of R/S Rheometer;

- insert the mains plug of the mains cable into a grounded socket;

- turn on the R/S Rheometer again.

The AC-adaptor should not remain connected to the mains socket during long time with

disconnected plug of the DC cable from the connector “DC” at the back side.

Before disconnecting R/S Rheometer from mains supply be sure that the Rheometer is switched

off.

III.2.3 Printer Connection

Printer can be connected directly to the interface connector of the R/S Rheometer when measuring

without PC support. You must preset “Printer” as output device to print the measuring values during

measurement (see Chapter 6).

You should use obligatory a printer with parallel “CENTRONICS” interface.

- Turn off the R/S Rheometer with the mains switch “POWER” at the back side.

- Insert the printer connecting cable into the connector “CENTRONICS” at the back side of

rheometer.

- Turn on R/S Rheometer again.

Standard printer cable (Printer ↔ PC) can be used as printer connecting cable. This cable is supplied

with the printer in most cases.

To print data-values from R/S Rheometer all printers can be used which are printing text in ASCII-mode.

III.2.4 Computer Connection

If the R/S Rheometer has to be used in “REMOTE” mode with PC support (Rheo-program package) or

with serial data-terminal for data logging it is necessary to connect the data link with the plug “RS232” at

the instrument back side.

- Turn off the R/S Rheometer with the mains switch “POWER” at the back side.

- Turn off your computer system.

- Insert the data link into the plug “RS232” at the back side of the rheometer.

- Connect the other end of the data link with a free serial interface RS-232 (f.e. “COM2”) of your

computer.

- Turn on the R/S Rheometer and your computer system again.

Use data link cable of BROOKFIELD delivery only!

Brookfield Engineering Labs., Inc. Page 11 M/02-212

Page 12

j

Please read information concerning installation of the computer system in this Operation Manual.

III.3 Mounting of temperature controlled measuring devices

In this chapter you get information concerning mounting and attachment of the following accessories

components:

• FTK-CC temperature control device for use of cylinder measuring system in the

temperature range -10°C...+90°C (liquid’s temperature control)

• KE cooling device in conjunction with FTK-CC temperature control device or ME-CP/PP

measuring device to rise the temperature range up to -20°C...+180°C

• ME-CP/PP measuring device for use of cone/plate and plate/plate measuring system in the

temperature range -10°C...+90°C (liquid’s temperature control)

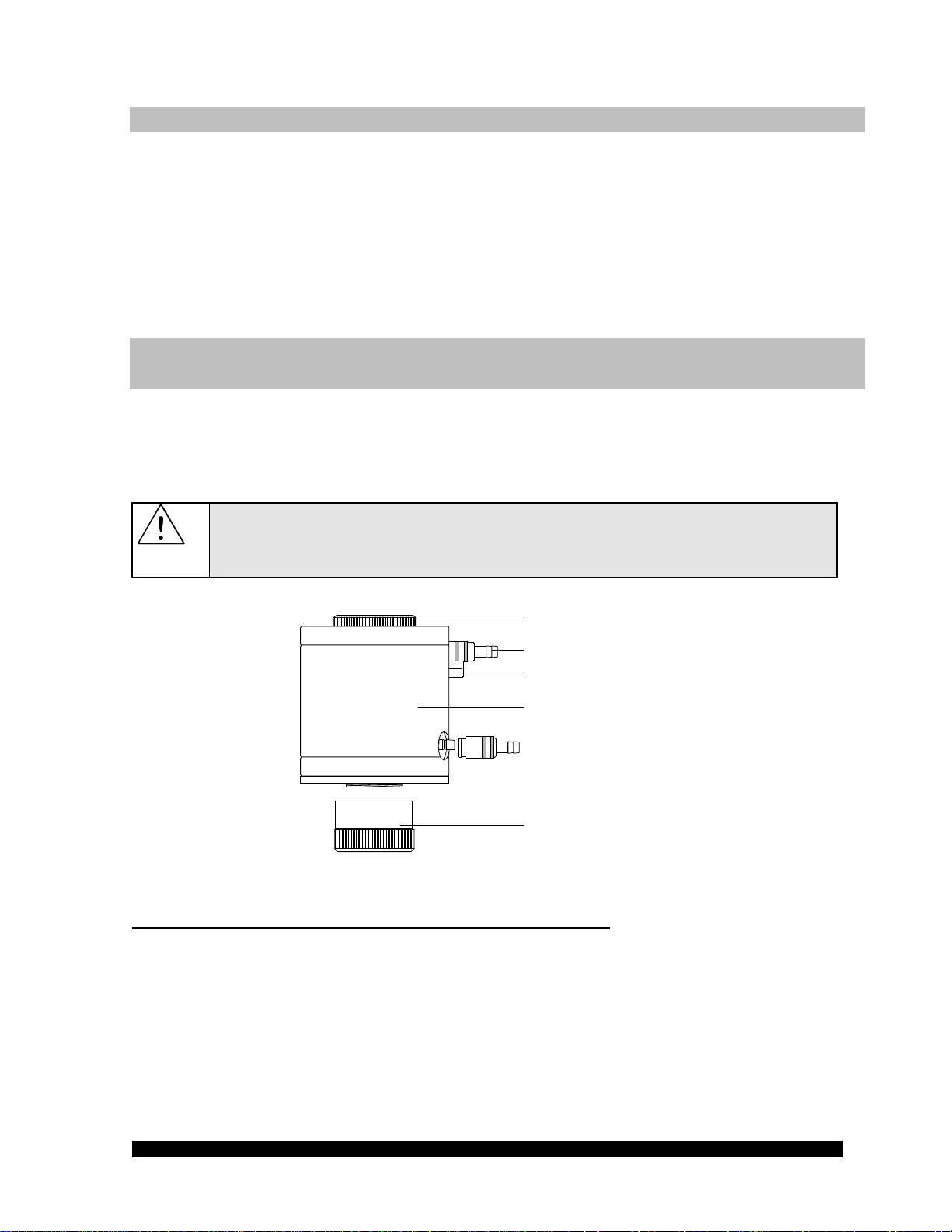

III.3.1 Mounting of temperature control device FTK-CC with and

without cooling device KE

As temperature control device is available optionally:

- FTK-CC

for use of cylinder measuring system in the temperature range -10°C...+90°C (liquid’s temperature

control).

The temperature control device “FTK-CC” should be used only in the temperature

range -10°C ...+90°C.

The cooling device “KE” is necessary additionally for temperature range of 20°C...+180°C!

oint for mounting flange

thread

hose connection of flow output

Pt 100

thermostating chamber

hose connection of flow input

measuring cup screw fitting

Fig.: 4.: Temperature control device FTK-CC

Mounting of the temperature control device “FTK-CC”

- Turn off the R/S Rheometer with the mains switch “POWER” at the instrument back side.

- When using cooling device KE mount cooling device first (see chapter 3.3.3)

- Set the “FTK-CC” from below on the mounting flange of R/S Rheometer and tighten the thread.

- Fix the hoses of liquid circulation thermostat at the “ FTK-CC ” as described below.

- Connect the FTK-CC´s built-in Pt100 cable with the connector “PT100” at the instrument back side

of the R/S Rheometer.

Brookfield Engineering Labs., Inc. Page 12 M/02-212

Page 13

BROOKFIELD

Main-Menue

- Run Single

- Run Program

- Remote

ST

OK

Cooling device KE

Temperature control

device FTK-CC

Built in Pt100

Temperature

control liquid

from / to

thermostatic

device

Connecting

cable Pt100

Fig. 5.: Operation with FTK-CC and cooling device KE

Thermostat connection to temperature control device FTK-CC

Hoses’ connections are necessary to join a liquid circulation thermostat by operation of the R/S

Rheometer with liquid circulation temperature control device “FTK-CC”.

The hoses of liquid circulation thermostat are connected with the help of quick fitting couplings with the

temperature control device “FTK-CC” (below: inlet; above: outlet). For this purpose it is necessary to

move back the coupling’s bush, insert the hose and release the coupling. It fixes the hose (without

screwing or rotation) by groove. Check by pulling gently whether the hoses’ connections are securely

fixed.

The temperature control device “FTK-CC” without cooling device KE must only

be used in the temperature range -10°C ...+90°C.

The temperature control device “FTK-CC” can be used in the temperature range -20°C...+180°C in

case of using optionally obtainable cooling device “KE”.

It is recommended urgently to preset at liquid circulation thermostat the upper temperature

limitation: when using water at 90°C and when using oil at 180°C (only with cooling device KE).

As thermostatic liquids are usually used:

-10 °C to +90 °C water (deionized) - glycol-mixture

Brookfield Engineering Labs., Inc. Page 13 M/02-212

Page 14

-20 °C to +250 °C thermostat oil

Thermostatic fluids can be ordered from BROOKFIELD.

During measurements in the temperature range below -10°C and above +90°C

the temperature control device “FTK-CC” may be put into operation only if the

cooling liquid flows through the “KE” in order to prevent overheat of the

measuring sensor.

III.3.2 Mounting of the measuring device ME-CP/PP

- Turn off the R/S Rheometer with the mains switch “POWER” at the instrument back side.

- When using cooling device KE mount cooling device first (see chapter 3.3.3)

- Set the “ME-CP/PP” from below on the mounting flange of measuring cup and tighten the thread.

Check that before tightening the guide pin of the measuring device must be in the slot of the R/S

Rheometer mounting flange!

- Fix the hoses of liquid circulation thermostat at the “ME-CP/PP” (see below).

- Insert the cable “VK-MB” supplied to the “ME-CP/PP” in the built-in Pt100 and in the connector “PT

100” at the instrument back side of the R/S Rheometer.

- For mounting the cone/plate or plate/plate measuring systems to measuring device refer to chapter

5.

Thermostat connection to temperature control device FTK-CC

Hoses’ connections are necessary to join a liquid circulation thermostat by operation of the R/S

Rheometer with liquid circulation measuring device “ME-CP/PP”.

The hoses of liquid circulation thermostat are connected with the help of quick fitting couplings with the

measuring device “ME-CP/PP” (below: inlet; above: outlet). For this purpose it is necessary to move

back the coupling’s bush, insert the hose and release the coupling. It fixes the hose (without screwing or

rotation) by groove. Check by pulling gently whether the hoses’ connections are securely fixed.

The measuring device “ME-CP/PP” without cooling device KE must only be

used in the temperature range -10°C ...+90°C.

The measuring device “ME-CP/PP” can be used in the temperature range -20°C ... +180°C in case of

using optionally obtainable cooling device “KE”.

It is recommended urgently to preset at liquid circulation thermostat the upper temperature

limitation: when using water at 90°C and when using oil at 180°C (only with cooling device KE).

As thermostatic liquids are usually used:

-10 °C ... +90 °C Water (deionized) - glycol-mixture

-20 °C ... +180 °C Thermostat oil

The proper thermostatic liquids can be ordered from BROOKFIELD.

Brookfield Engineering Labs., Inc. Page 14 M/02-212

Page 15

During measurements in the temperature range below -10°C and above +90°C

the measuring device “ME-CP/PP” may be put into operation only if the cooling

liquid flows through the “KE” in order to prevent overheat of the measuring

sensor.

Brookfield Engineering Labs., Inc. Page 15 M/02-212

Page 16

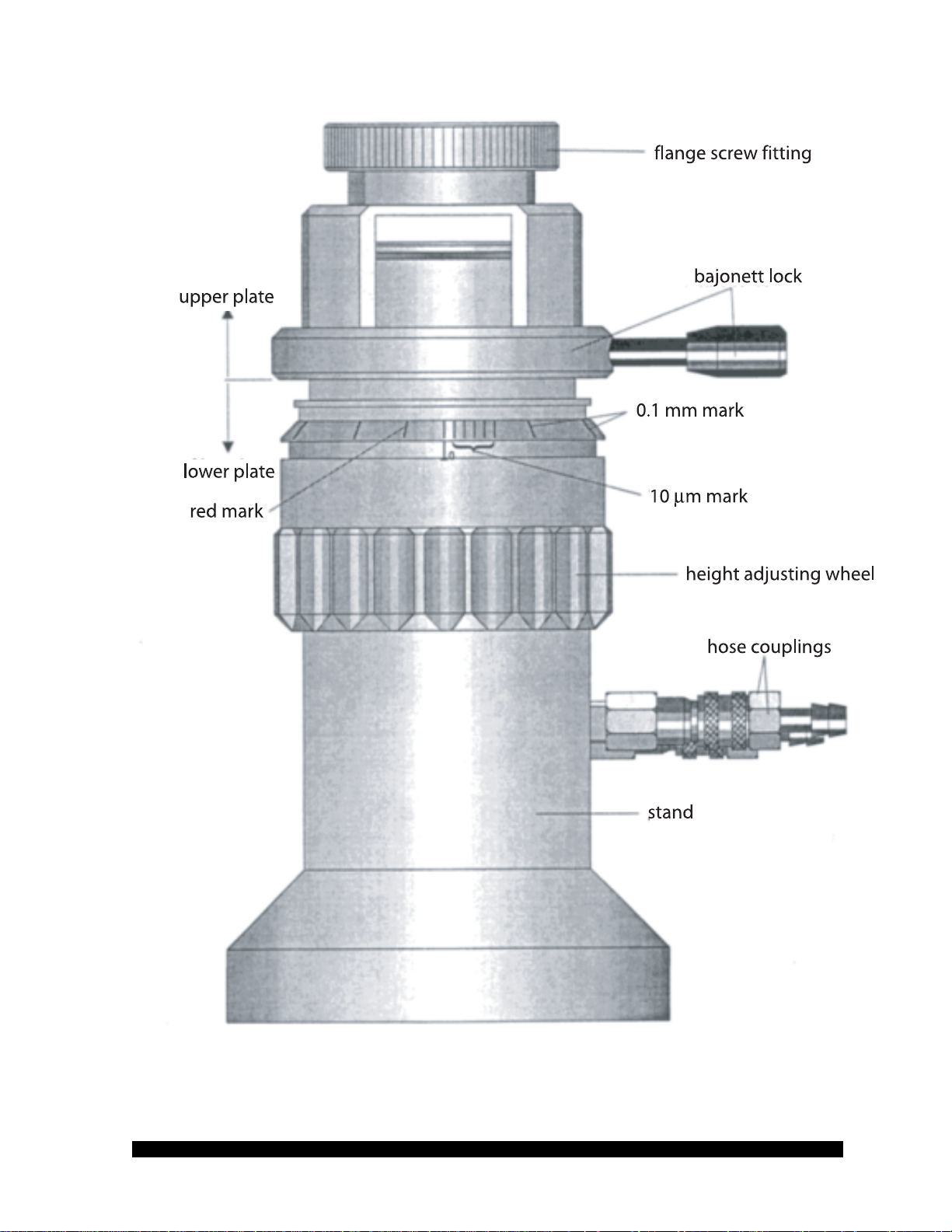

Measuring device for cone/plate and plate/plate measuring systems ME CC/CP

Brookfield Engineering Labs., Inc. Page 16 M/02-212

Page 17

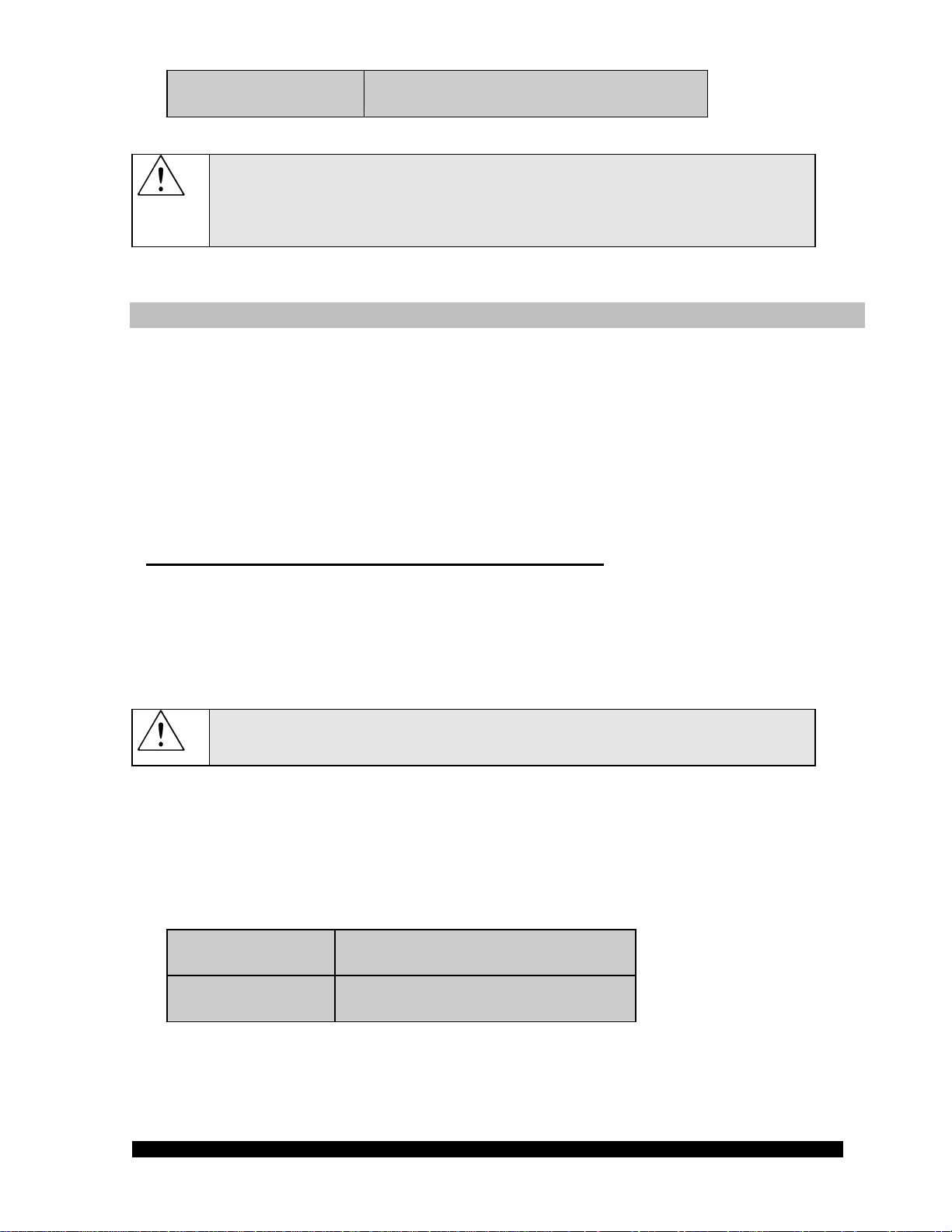

III.3.3 Mounting of the cooling device KE

The optionally supplied cooling device “KE” must be used in case of the R/S Rheometer operation with

the liquid temperature control device “FTK-CC” or measuring device “ME-CP/PP“ in the temperature

range below -10°C and above +90°C. When using cooling device KE temperature range of temperature

control device “FTK-CC“ and measuring device “ME-CP/PP“ is expanded to -20°C... +180°C.

The cooling liquid flows through the cooling channel of the cooling device KE and prevents the heat

transfer from the liquid’s temperated chamber of temperature control device “FTK-CC” or measuring

device “ME-CP/PP“ to the R/S Rheometer.

Mounting

- Turn off the R/S Rheometer with the mains switch “POWER” at the instrument back side.

- Lift the “KE” from below to the R/S Rheometer and tighten the thread.

- Fix the hoses of the cooling loop at the “KE” (see below “Cooling water connection to cooling device

KE”).

Fig. 6: cooling device KE

Cooling water connection to cooling device KE

The hoses of cooling circulation loop are connected with by quick fitting couplings the cooling device

“KE”. For this purpose it is necessary to move back the coupling’s bush, insert the hose and release the

coupling. It fixes the hose (without screwing or rotation) by groove. Check by easy pull if the hoses’

connections are firm.

During measurements in the temperature range below -10°C and above +90°C

the “FTK-CC” / “ME- CP/PP“ may be put into operation only if the cooling liquid

flows through the “KE” in order to prevent overheat of the measuring sensor.

Brookfield Engineering Labs., Inc. Page 17 M/02-212

Page 18

IV. Environment, handling, cleaning and maintenance

In this chapter you get information concerning environment, handling, cleaning and maintenance of your

R/S Rheometer.

IV.1 Operating environment, Storage

Find comfortable, convenient working place where you install your R/S Rheometer. It must be enough

room for installation of the stand, measuring system, measuring substances and peripheral devices (for

example printer, computer and thermostat).

You need a grounded socket for operation of the R/S Rheometer. You need also a socket for

connection of the peripheral devices.

Your operating environment and the place for storage of the R/S Rheometer should not be extremely

hot, extremely cold or moist.

Also avoid places where temperature and air humidity fluctuate strongly.

Moreover check that the R/S Rheometer is not subjected to

• dirt or dust,

• direct sun radiation,

• objects that emit strong heat (e.g. heating radiators),

• objects with strong electromagnetic field (e.g. loudspeakers, motors etc.),

• liquids or corrosive chemicals.

IV.2 Handling

The R/S Rheometer is designed in such way that even by easy kicks or vibrations its’ performance is

failure-free. However, pay attention to absence of strong kicks or falls.

Never lift your R/S Rheometer at the measuring bob coupling or a built-in

measuring bob and avoid everything that could influence free and concentric

rotation of the measuring bob coupling (e.g. a shock).

If the measuring torque is exceeded, e.g. by shut-down of the measuring drive at full load or due to

viscosity raise in solidification process, the safety device in electronic operates and prevents a failure.

The R/S Rheometer could be under the load unlimited time also in such extreme cases.

IV.3 Cleaning

The paint of the R/S Rheometer resists attack by usual solvents and weak acids.

Use dry, clean, soft and nap-free cloth to clean the housing. Use neutral detergent liquids at a soft cloth

in case of severe contamination of the housing.

Do not use any chemical products such as strong solvents or strong acids

to clean the housing, especially the operating fields with the foil keyboard.

Brookfield Engineering Labs., Inc. Page 18 M/02-212

Page 19

Check that any liquid does not penetrate into the housing (e.g. through the

instrument connecting plugs) and into the bearings of the measuring drive. It

results in the instrument damage!

IV.4 Maintenance

The R/S Rheometer is designed for long-term operation.

Nevertheless we recommend a regular maintenance in one-year cycle by a service engineer of

BROOKFIELD or of corresponding representation.

Works on control electronics, all accessories, measuring drive as well as

with the AC-adaptor and all electric circuits and connections may only be

carried out by authorized service personnel trained by us.

Check of the measurements’ accuracy by the customer is possible any time. We recommend the

measurement with the standard oils (normal oils).

Type: standard oil 2000 A, viscosity approx. 1.9 Pas

The measurement is carried out preferably with the temperature control device “FTK-CC” with

measuring system CC25 DIN with Pt100 built-in in the bottom of the measuring cup.

The standard oil is thermostatted for at least 20 minutes at 20°C ± 0.05°C.

Select the appropriate measuring system.

Carry out measurements at the following preset values of shear rates:

10 s-1, 25 s-1, 50 s-1 and 100 s-1.

Print viscosities or read off viscosities from display.

In case of the instrument failure (or severe deviation from the preset value), please, apply to the service

department of BROOKFIELD.

Brookfield Engineering Labs., Inc. Page 19 M/02-212

Page 20

V. Measuring Systems

In this chapter you get information concerning use of the measuring system.

At present the following measuring system types are supplied:

a) Standard measuring systems MS-CC48...CC8 DIN/RC and DG-DIN/RC for measurement without

temperature control device FTK-CC consists of:

- measuring cup for R/S Rheometer (MB-CC48...MB-CC8/RC and MB-DG/RC) depending on

measuring-system

- measuring cup bottom

- measuring bob (MK-CC48...CC8/RC and MK-DG/RC) depending on measuring system

- thread protection

-

b) Standard measuring systems MS-CC48...CC8 DIN/FTK and DG-DIN/FTK for measurement with

temperature control device FTK-CC consists of:

- measuring cup for R/S Rheometer (MB-CC48 ...CC8 DIN/FTK u. MB-DG DIN/FTK)

depending on measuring system

- bottom screw

- measuring bobs (MK-CC48...CC8 DIN and MK-DG DIN) depending on measuring system

- optionally Pt100 temperature sensor in measuring cup bottom or in temperature control

device

c) One-way measuring system EWS-CC48...CC8 DIN/FTK for measurement with temperature control

device FTK-CC consists of:

- measuring cup mounting MBA-CC48...CC8 DIN/FTK depending on measuring system

(holder for disposable one-way cups)

- one-way measuring cup (aluminum) EMB-CC48...CC8 DIN/FTK depending on measuring

system

- measuring cup ejector

- measuring bob (MK-CC48...CC8 DIN)

d) Cone/plate measuring system C25-1...C50-2 for measurement with measuring device ME-CP/PP

consists of:

- measuring cone (C25-1...C50-2) depending on measuring system

e) Plate/plate measuring system P25, P50 for measurement with measuring device SM-KP consists of:

- measuring plate (P25, P50) depending on measuring system

Please select a suitable measuring system for the desired measuring range to carry out measurements.

(for details of measuring systems ranges refer to Appendix A)

V.1 Measurement directly in the substance

If necessary remove in case of measuring systems CC48...CC8-DIN the bottom from measuring cup

and screw on the thread protection.

Attention when using DG-DIN!

When using the measuring system DG-DIN remove very carefully the O-ring seal between the

measuring cup case and inner part. To do this open the measuring system below and take out the inner

part. Take care not to damage or stretch the O-ring seal during removal! Insert the inner part again and

screw the measuring system.

Lift the coupling sleeve of the measuring bob coupling (ring visible).

Brookfield Engineering Labs., Inc. Page 20 M/02-212

Page 21

Insert carefully the measuring bob into the measuring bob coupling. Pay attention to insert the

measuring bob shaft into the measuring bob coupling without impact.

Move down the coupling sleeve of the measuring bob coupling (ring covered).

Fasten the measuring cup at the measuring cup mounting flange with the help of measuring cup thread.

By moving down the stand, immerse the measuring cup into the substance up to the ring mark or up to

the point where diameter of measuring cup increases.

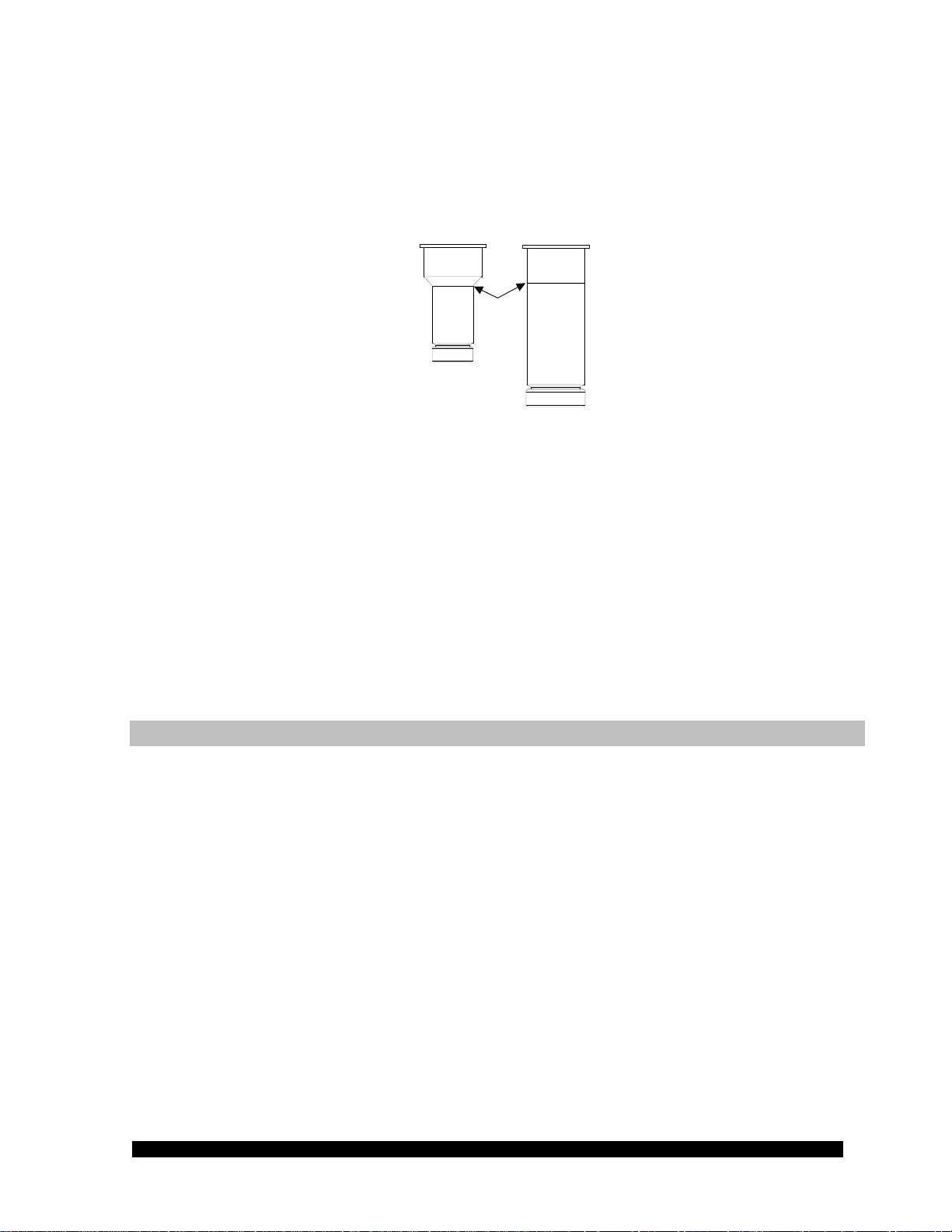

Fig. 7.: Depth of immersion

Pay attention to the fact that any substance or solvent does not ingress into measuring bob

coupling, measuring drive or electronics.

Now the measurement can be carried out.

After the end of measurement unscrew the measuring cup thread and remove measuring cup. Then

open the measuring bob coupling and remove the measuring bob.

Clean measuring cup and measuring bob carefully. Do not use hard objects, always prevent

scratches!

Store measuring bobs on a soft pad. \

V.2 Measurement with substance in measuring system

Fill the measuring cup with substance (sample filling quantity see Appendix A1 “Data sheets of the

standard measuring system”).

Avoid air bubbles when filling in the substance as they result in non-reproducibility of the measured

values.

Place the measuring bob in measuring cup. Lift the coupling sleeve of the measuring bob coupling (ring

visible). Insert the complete measuring system from below into the measuring cup mounting flange and

screw tight using the measuring cup thread. Insert the measuring bob shaft into the measuring bob

coupling without impact. Now insert the measuring bob shaft completely into the measuring bob

coupling and move down the coupling sleeve of the measuring bob coupling (ring is covered).

In this case of measurement the substance temperature control can be carried out by immersing the

measuring system into a thermostat (delivery as special accessory). It is necessary to pay attention to

the immersion depth (Chapter 5.1).

Brookfield Engineering Labs., Inc. Page 21 M/02-212

Page 22

Temperature range max.: 0°C ... +90°C.

The cooling device “KE” is required to expand the temperature range to

-20°C ...+180°C

The temperature sensor Pt100 may be immersed in medium only at 2/3 of

the metal rod length! Cable must be always outside the medium.

If you want to measure with temperature control, the thermostat must be pre-set at the desired

temperature and you should wait till the necessary temperature of the substance is reached (e.g.

temperature measurements through the Pt100 menue point “Utilities → Meas.-Temperature”, see

Chapter 6).

Now the measurement can be carried out.

To remove the measuring system after the measurement first open the measuring bob coupling and

then unscrew the measuring cup thread.

Attention: If you have carried out measurements at higher or very low

temperatures please take care: Some accessible surfaces can become

very hot or cold. Before removing measuring system please wait till the

system-surface-temperature equalized to nearly room temperature and

allows you to touch the system without danger.

When unscrewing the measuring cup, you must hold the measuring

system tightly with one hand! Due to its own weight measuring system

would fall downwards.

Clean measuring cup and measuring bob carefully, do not use hard objects, always prevent scratches!

Store measuring bobs on a soft pad.

V.3 Measurement with temperature control device FTK-CC

In case of one-way measuring systems insert the one-way measuring cup into the measuring cup

mounting.

Fill the measuring cup with substance (sample filling quantity see Appendix A1 “Data sheets of the

standard measuring system”).

Avoid air bubbles when filling in the substance as they result in non-reproducibility of the measured

values.

Place the measuring bob in measuring cup. Lift the coupling sleeve of the measuring bob coupling (ring

visible). Insert the complete measuring system from below into the temperature control device and

screw tight using the measuring cup screw. Insert the measuring bob shaft into the measuring bob

coupling without impact. Now insert the measuring bob shaft completely into the measuring bob

coupling and move down the coupling sleeve of the measuring bob coupling (ring is covered).

The thermostat must now be pre-set at the desired temperature and you should wait till the necessary

temperature of the substance is reached (e.g. temperature measurements through the Pt100 menue

point “Utilities → Meas.-Temperature”, see Chapter 6).

Now the measurement can be carried out.

Brookfield Engineering Labs., Inc. Page 22 M/02-212

Page 23

To remove the measuring system after the measurement first open the measuring bob coupling and

then unscrew the measuring cup screw of temperature control device.

Attention: If you have carried out measurements at higher or very low

temperatures please take care: Some accessible surfaces can become

very hot or cold. Before removing measuring system please wait till the

system-surface-temperature equalized to nearly room temperature and

allows you to touch the system without danger.

When unscrewing the measuring cup, you must hold the measuring

system tightly with one hand! Due to its own weight measuring system

would fall downwards.

In case of one-way measuring cups eject the one-way measuring cup with the measuring cup ejector.

Clean the measuring bob carefully, do not use hard objects, always prevent scratches!

Store measuring bobs on a soft pad.

V.4 Measurement with cone/plate and plate/plate measuring systems

Insert and adjustment of the measuring cone or measuring plate

To install the measuring bob the bayonet lock must be released (position “opened”) and the lower

measuring plate must be displaced down. Caution: during release of the bayonet lock the measuring

device has to be hold tight at height adjustment ring.

Lift the coupling sleeve of the measuring bob coupling (ring visible). Insert the measuring bob (cone or

plate) from below into measuring coupling. Move down the coupling sleeve of the measuring bob

coupling (ring covered).

Loosen the inner hexagon screw at measuring bob shaft.

Press measuring plate upward again and close bayonet lock (position “closed”).

Loosen scale clamp screw at height adjustment ring.

0-/red-position

0

Scale fixing screw

Height adjustment ring

Turn left

lower

Turn right

lift

The upper marker (“0”) and the lower red marker (red mark) are brought into coincidence rotating the

height adjustment ring (=0-/red position, see picture).

Brookfield Engineering Labs., Inc. Page 23 M/02-212

Page 24

In order to avoid thread backlash, the height adjustment ring must be now obligatory turn through to

“0.4” (turn to the right = lift) and then again return back to the 0/red position.

Now screw on the inner hexagon screw at measuring bob shaft finger-tight ; this fixes the measuring

bob in this position.

After rotating the scale mark from 0-/red position to the 0/0 position the cone/plate measuring device is

ready for measurements.

To protect lower plate against accidental turning please fasten scale fixing screw finger-tight .

Open the bayonet lock and lower the lower plate. Apply the desired measuring substance to the lower

plate.

Lift up carefully the lower plate again and fix the bayonet lock.

Caution: Excess of medium at plate edge must be removed (error influence!)

The thermostat must now be pre-set at the desired temperature and you should wait till the necessary

temperature of the substance is reached (e.g. temperature measurements through the Pt100 menue

point “Utilities → Meas.-Temperature”, see Chapter 6).

Brookfield Engineering Labs., Inc. Page 24 M/02-212

Page 25

VI. Operation and Menue System

In the following chapter you will get overview on operations, menue system of R/S Rheometer and

measurements, both in manual and PC controlled modes.

The menue-system of R/S Rheometer (firmware-version 4.02) is a dual-language system. Following

languages are software selectable:

• English

• German

Desired language can be selected via menue item Configuration→Language (if English language is

active) or Konfiguration→Sprache (if German language is active).

More details on language selection see chapter 6.7.6.

The following chapter will describe instrument handling with ENGLISH language active.

After switching on the R/S Rheometer, LCD indicates the following information for few seconds:

* Name of the Rheometer;

* Software firmware-version installed in the instrument (Brand name);

* Serial number of the instrument (xxxxxx);

* Date and time;

Example:

After about 5 sec the instrument checks voltages of the Power Supply Unit. Displayed voltages are to lie

in the range from 14.9 to 16 V. Otherwise, some technical fault has occurred (→ Repairs).

Beispiel:

This message is displayed for about 3 seconds. Then the MAIN menue is displayed.

Before you will get overview of the menue system of R/S Rheometer (Chapter 6.4), at this place it is

worth to make a brief summary on the rheometer keyboard and corresponding rheometer functions.

R/S Rheometer

Ver.: 4.02 #xxxxxx

07.05.98 15.12

© Brookfield

Voltage check:

VCC:15.25 V

Brookfield Engineering Labs., Inc. Page 25 M/02-212

Page 26

K

t

VI.1 Keyboard

START/STOP

- back to parent menue

- break

- st art of measur ement

- break of measurement

- menue: previ ous menue-ent ry

- input:

increment value/ l et t er

BROOKFI ELD

MAIN- men ue

- Run Single

- Run Program

- Remote >

R/S Rheometer

- menue next menue entry

- input:

decr ement val ue/letter

- one digit to the left

ST

O

OK

- enter

- select

- one digit to the righ

All user inputs are made with help of 6 keys located below LCD-Display. Some of the keys are of

multiple use, i.e. their function depends on actual executed operation. The following table shows

detailed overview on keyboard functions.

Brookfield Engineering Labs., Inc. Page 26 M/02-212

Page 27

Key-function dependent to executed operation

key operation Function of key example

Menue goto previous menue-entry „Utilities“ → „Remote“

(above active one)

Value-input increment „8

„A

Selection from List list entry above active Select Meas.system

entry (previous) „CC45“ → „CC48“

Menue goto next menue-entry „Remote“ → „Utilities“

(below active one)

Value-input decrement „5

„F

Selection from List list entry below active Select Meas.system

entry (next) „CC48“ → „CC45“

“ → „9“

“ → „B“

“ → „4“

“ → „G“

Menue goto previous menue-entry „Utilities“-> „Remote“

(above active one)

Value-input one digit to the right „1

00.00“->„100.00“

„Test“->„Test“

Selection from List list entry above active Select Meas.system

entry (previous) „CC45“ -> „CC48“

Menue goto next menue-entry „Remote“->Utilities“

(below active one)

Input one digit to the left „1

00.00“->„100.00“

„Test“->„Test“

Selection from List list entry below active Select Meas.system

entry (next) „CC45“ -> „CC48“

ST

Menue return to parent-menue „UTILITY“->„MAIN“

Value-input Input break

(only if possible)

Selection from List Selection break Select Meas.system

(only if possible) ->back to menue

Messung START and BREAK break while measuring

of measurement Messung

Remote active Break of measurement

Back to MAIN-menue

OK

Menue execute Menue item

(open sub-menue)

Value-input End of input / enter value

Selection from List select active item

A novice might perceive this keyboard layout excessively complicated, however, even after your first

experiments, you will surely come to the conclusion, that you do not need the layout Table for reference

and multi-function keys ensure major simplification of the operations.

Brookfield Engineering Labs., Inc. Page 27 M/02-212

Page 28

g

y

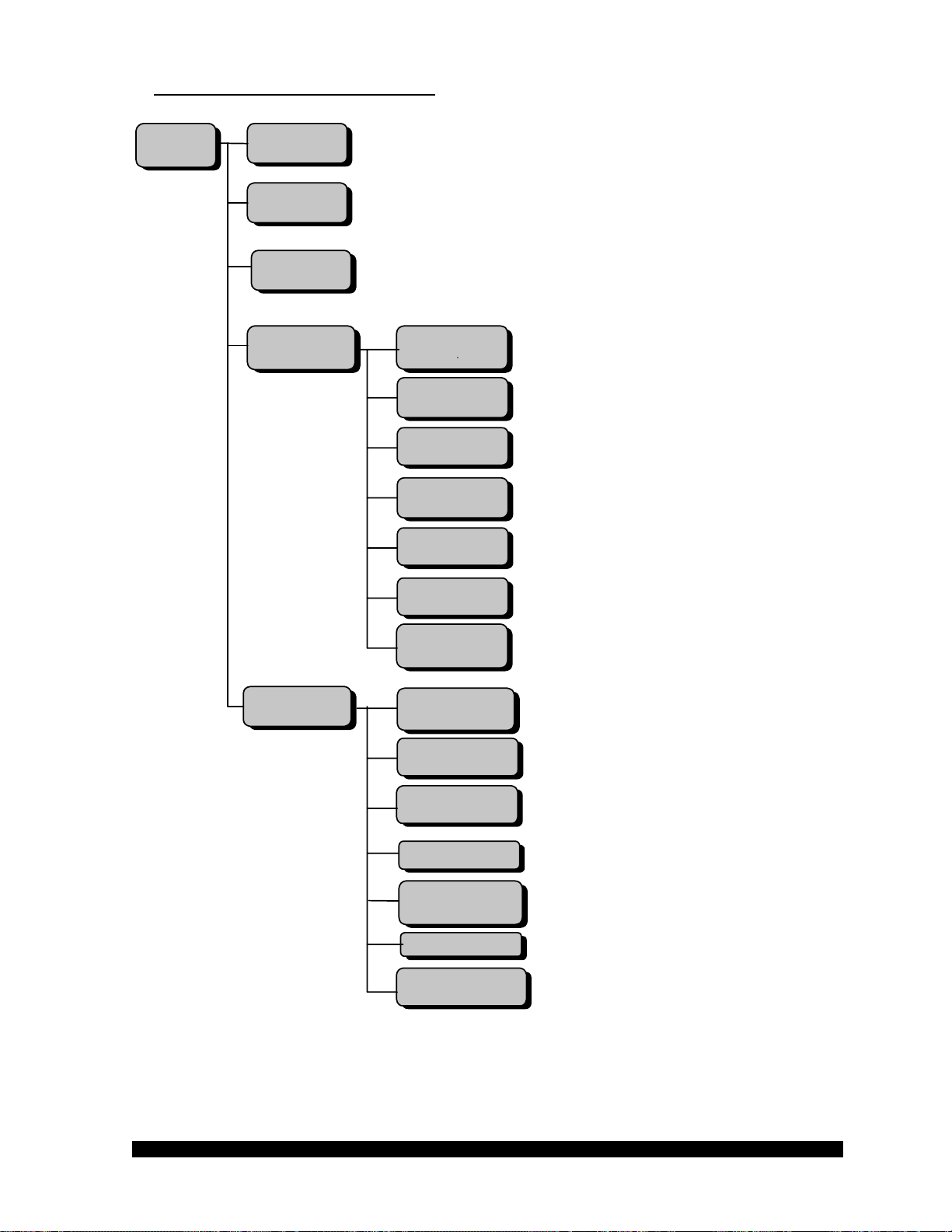

VI.2 Menu System of R/S Rheometer

Main-

This page demonstrates organization of R/S Rheometer menue system.

Run Single

Run

Remote

Utilities

Configuration

Measurement at constant shear rate or shear

stress

Measurement with pre-defined program

Measurement under PC control (remote control)

Zero

Edit

rams

Pro

Print

Measuring-

stems

S

Print

Clear

Measure

Set

-

Set meas-

-

Reset

Set

Set RS232-

Language

Service

Zero-point calibration

Define/edit program

Print programs from memory

Define / edit of measuring systems

Print measuring data from

memory

Clear measuring data in memory

Permanent measuring of

temperature

Selection of output mode for

measuring data (via printer /

Selection of measuring counter

mode

Reset measuring counter

Setting of time and date

Parameter input for serial

communication port (RS232)

Language selection of userlanguage

Only for service personnel!

Brookfield Engineering Labs., Inc. Page 28 M/02-212

Page 29

Menu handling

Because LCD display of R/S Rheometer cannot show simultaneously all menue items, only part of the

menue (three entries) is always displayed. Two arrows “>“ at the right side of display inform you, if there

are still entries in the menue, either above (the arrow in the 2nd line), or below (the arrow in the 4th line).

Currently active (but still not selected) entry is marked by blinking black field (cursor) at the left part of

LCD.

Example:

This entry is preselected and can be

selected by pressing

the “OK“-key

Using and keys you can move cursor upwards and downwards in the menue until desired

menue item is reached.

Note: If there are more menue entries in the menue and you are reaching the end of the display, next

part of menue is opened automatically (scrolling).

You can “start” the pre-set menue entry or open with key.

The major menue (getting active ca. 10 seconds after switching on the instrument) is the MAIN menue.

In the case, you are in a submenue and wish to return to upper menue, press key.

Example:

Press ,you return back to MAIN-menue.

If you push key now, the “Run Single“ function is started.

Before we come to detailed description of this functions like “Run Single“ (see Chapter 6.5), it is worth

to explain, how to input numbers and alphanumeric texts as well as select from a list, because majority

of the Rheometer functions require such actions from the user before execution of a desired function.

ST

OK

MAIN menue

- Run Single

- Run Program

- Remote >

OK

CONFIGURATION-,emie

- Set time/date >

- Set RS232 Param.

- Language

Main-menue

- Run Single

- Run Program

- Remote >

This menue contains

more items below.

ST

Menu has more

entries above.

VI.3 Selecting from Lists

If the Rheometer wants you to select an entry of a list, there are the same rules and functions of LCD

and keyboard as in menue operations.

• Selection from a list is requested, for example at:

• Selection of a measuring system for measurements in “Run Single” or “Edit Program”;

• Selection of pre-set values for measurements in “Run Single” or “Edit Program”;

Brookfield Engineering Labs., Inc. Page 29 M/02-212

Page 30

• Selection of a program or a measuring system you want to edit in “Edit Program” and “Meas.

systems”;

• Answering a request “YES” ↔ “NO”.

• Selection of a program to start in “Run Program”

Keys and move cursor (= pre-selected entry) in the list upwards and downwards.

Key selects the pre-set entry from the list and key interrupts selection from the list (only if

OK

possible).

As well as in the menue, an arrow in the right part of LCD display shows if there are still more elements

of the list above or below the marked element.

Example for selection from a list: Selection of a measuring system.

Select Measuring system:

1) CC48 >

2) DG

3) CC45 >

VI.4 Input of numerical values and alphanumeric texts

Majority of inputs, requested from user, are input of numbers. Pre-set values (e.g. start and end values

of a slope), times, number of measurement points, factors, time, date, etc. are set as numbers with or

without decimal digits.

If LCD display shows the decimal point “.” in a number to be entered, input of floating point number is

requested.

However, number of digits after decimal point is fixed to number of displayed decimal digits, the decimal

point cannot be moved.

Cursor (= the digit to be changed) is here a bar under the digit.

In the following example, the set value for Single Program measurement is to be adjusted by Digit Input.

We want to enter the value 290.00 s-1 for Shear Rate.

Input Values:

Val.[1/s]: 0100.00

Nr. of MP: 010

Time[s]: 0100

The cursor is located under “1” in the value of shear rate to be set (currently 100.00 s

Using and keys one can change “1” (increment or decrement).

We push 1x and get:

Input Values:

Val.[1/s]: 0200.00

Nr. of MP: 010

Time[s]: 0100

Digit to be entered

-1

).

Brookfield Engineering Labs., Inc. Page 30 M/02-212

Page 31

Using and keys you can move cursor leftwards (rightwards). To process the next digit we push

now key and get:

Input Values:

Val.[1/s]: 0200.00

Nr. of MP: 010

Time[s]: 0100

Now we can process the next digit. In order to insert here “9” it’s advisable to decrement once current

“0”, rather than to increment it nine times.

So, we push key and get:

Input Values:

Val.[1/s]: 0290.00

Nr. of MP: 010

Time[s]: 0100

Note:

In the case, you push and hold one of the keys or the cursor-underlined digit will first

increment or decrement for +/- 1 only. However, after short period of time, the digit is automatically

changed. This corresponds to the Repeat Function of the computer keyboard. In our example you

could also push and hold key until “9” will be displayed.

Now, when the desired number is displayed we can enter it by pressing key. In our example cursor

now jumps to the first digit of the next value of user input (here Number of Measpoints).

Input Values:

Val.[1/s]: 0290.00

Nr. of MP: 010

Time[s]: 0100

OK

Alphanumeric inputs

(= text with or without numeric digits) are identical to digit inputs. However, in this case, currently

selected digit could not only be changed from “0” to “9”, but also to “A” to “Z” and to blank symbol “ “.

Selectable values for alphanumeric input digit in order of increase:

“ ABCDEFGHIJKLMNOPQRSTUVWXYZ1234567890”

If for example, your current digit is “B” and you want to input “7”, you have to hold key until desired

“7” will appear at the display.

Alphanumeric inputs are requested for example to give a program, measuring system or measurement

a name.

Brookfield Engineering Labs., Inc. Page 31 M/02-212

Page 32

VI.5 Menue entries (MAIN menue)

Menue entries (see Menue System in Chapter 6.2) may either contain submenues (e.g. “Utilities” or

“Configuration”) or directly executing of one of the Rheometer’s functions.

At Tree Chart in Chapter 6.2 all gray fields without further right branches serve to call functions. Those

ones with right branches are submenues.

Let us remind keyboard layout from Chapter 6.2. Using and keys we move cursor (black

rectangle) upwards and downwards, and with key we start (activate) function (if the current

OK

selection is a submenue, we open it, otherwise the function of the Rheometer starts). Functions of R/S

Rheometer are described in detail elsewhere in this Chapter.

VI.5.1 MAIN-Menue → Run Single

This function carries out a measurement of shear stress or shear rate at constant preset values.

The physical units of preset values may be selected from:

- shear rate D [s-1]

- speed n [rpm]

- shear stress Tau [Pa]

- torque M[‰] [1000 ‰ correspond ca. 50 mNm]

Before you start the measurement itself you have to input the following values:

• Selection of the measuring system used at the instrument (selection from the list, operation see Chapter 6.3)

• Selection of physical units of preset value (see above, selection from the list, operation, see

Chapter 6.3). Here you have to decide, if you want to carry out a shear rate measurement

(shear rate, speed) or a shear stress measurement (shear stress, torque).

• Input of preset values (input of numbers, operation, see Chapter 6.4) D [s-1] The range of the

value depends on the measuring system

• n [rpm] 0.7... 800 rpm (U/min)

• Tau [Pa] The range of the value depends on the measuring system

• M[‰] 0 ... 999 ‰

• Input of desired number of measured points (input of numbers, operation, see Chapter 6.4)

Input of the measurement duration in seconds. Here it is necessary to take into account, that

minimal duration of the measurement depends on kind of the measurement and on number of

desirable measurement points. For minimal duration between 2 measurement points it is valid

• Shear stress measurement t

• Shear rate measurement t

Note: The more is the time period between 2 measured values, the more is the precision of

physical values determined!

(input of numbers, operation, see Chapter 6.4)

• Input of ID (identification text of the measurement). Here you can input textual notes of the

measurement (max. 15 characters). (Alphanumeric input, operation - see Chapter 6.4)

If you have passed these points, before starting a measurement, the Rheometer will indicate, where the

measure points will be written to.

MP

MP

>= 1 s

> =4 s

Brookfield Engineering Labs., Inc. Page 32 M/02-212

Page 33

p

Output of MPs to:

-No output device

-Memory

<^> Menu <ST> Start

At this point you either can start a measurement by pressing key, or return back to Main menue

ST

using key.

In this example, we see that the measurement data will be saved in Memory only. No other output

device is defined. Output devices are printer or serial interface RS232 of the Rheometer. Selection of

these devices is described in Chapter ”Configuration -> Set output mode”.

In case, the Memory is full with measurement data, you have to cancel function Run Single, print out the

measurement data from the memory or send data to a PC via serial interface (see Chapter “Utilities →

Print Memory”) and then delete measurement data from the Memory (see Chapter “Utilities → Delete

Memory”).

However, you can start a measurement even with full Memory, in this case measurement results will be

shown only at LCD display and will be lost after completion of the measurement (because no output

device archives measured data).

If you start the measurement, the instrument shows:

Prog. Running...

Wait for 1.MP

#1

This message will be displayed until the first measurement point is calculated.

First Measure point is displayed like this:

Torque

Actual value of preset

arameter

Duration

Temperature

100.5 ‰ 000.90 1/s

Eta: 1.728 Pas

Tau: 1.572 Pa

04s 20.7 °C #01

Measurement result

Step (in Single meas.

always 01)

If torque is less than 10 ‰

measurement results are often of low precision. In this case, preset values

are to be changed in such a manner, that the torque is higher than 10 ‰.

If the display field for the torque indicates: “M low!”, these values are outside the range of resolution of

the Rheometer.

If the temperature is not to displayed, the measuring sensor is not connected.

At printout, the temperature is printed as 1000.0°C!

The display is updated on every new measure point. Current measurement can be canceled at any time

by pushing key.

Brookfield Engineering Labs., Inc. Page 33 M/02-212

ST

Page 34

A

)

After measurement, or after a break, the display field for Step indicates “END” or “BREAK”.

The Display toggles in intervals of about 4 seconds between last displayed measure point and a

measuring end information like this:

angezeigt:

Break reason

or end

Type / name of

executed progr.

Program end

Single mode

Total time: 100s

Total #MP: 10

Duration until

break or end

Number of measure

points measured

By pressing key you return to the MAIN-Menue.

OK

Note: The last selected program parameters remain nonvolatile in the instrument memory also after

switching off the Rheometer.

VI.5.2 MAIN-Menue → Run Program

This function starts measurements, which were previously defined as a program. Contrary to “Run

Single”, here you can also set values as a linear function of time, for example D[s

to use function Run Program always when you want to carry out repeating measurement series with the

same preset values and with the same measuring system. The second option is used when a user can

carry out measurement without large previous information of rheology. Actually, not every person,

starting a measurement, has unlimited possibilities to determine correct preset values and

measurement system for a medium under study (optimal use of measurement range, irreversible

rheological changes of the substance studied, etc.). 4 standard programs can be defined. How to define

or to edit pragram is described in Chapter “Utilities → Edit Program”.

Function Run Program starts one of the programs defined in memory. If there is no program available,

the following error message is displayed:

No valid program!

Enter program first!

In such a case, you first have to define a program (“Utilities → Edit Program”). Using key you

return back to the Main menue.

However, if programs are available, the list for selection of programs, stored in the memory, appears.

Here you must select the program to start (selection from the list, operation see Chapter 6.3).

Select program

1) Prog xyz

2) Test

3) Prog Öl 2000 >

Press key to select the preselected program (here the program named “Test”), this operation will be

OK

followed by ID input (identification text of the measurement).

You can give your measurement a name (max. 15 characters) (alphanumerical input, operation see

Chapter 6.4).

Measurement

identification

Input measuring id:

ID- number: 125

ID: Ö 2000 040596

utomatic counter of measurement

series MEASCOUNT

(automatic increment at every

measurement

-1

] = f(t). It is advisable

OK

Brookfield Engineering Labs., Inc. Page 34 M/02-212

Page 35

If you have passed these points, before starting a measurement, the Rheometer will indicate, where

the measure points will be written to.

Output of MPs to:

-Printer

-Memory

<^> Menue <ST> Start

At this point you either can start a measurement by pressing key, or return back to Main menue

ST

using key.

In this example we see, that measurement points will be saved in the memory and will be printed at the

printer, so be sure that printer is connected to the Rheometer and ready for operation (=output device).

Output devices are printer or serial interface RS232 of the Rheometer or no device (no output device).

Their preliminary selection is described in Chapter “Configuration → Set Output Mode”.

In case, the Memory is full with measurement data, you have to cancel function Run Single, print out the

measurement data from the memory or send data to a PC via serial interface (see Chapter “Utilities →

Print Memory”) and then delete measurement data from the Memory (see Chapter “Utilities → Delete

Memory”).

However, you can start a measurement even with full Memory, in this case measurement results will be

shown only at LCD display and will be lost after completion of the measurement (because no output

device archives measured data).

If you start the measurement, the instrument shows:

Prog. running...

Wait for 1.MP

#1

This message will be displayed until the first measurement point is calculated.

First Measure point is displayed like this:

Torque

Actual value of

preset parameter

Duration

Temperature

100.5 ‰ 000.90 1/s

Eta: 1.728 Pas

Tau: 1.572 Pa

05s 20.7°C #01

Measurment result

Step (in Run Single

always 01)

If torque is less than 10 ‰

measurement results are often of low precision. In this case, preset values

are to be changed in such a manner, that the torque is higher than 10 ‰.

If the display field for the torque indicates: “M low!”, these values are outside the range of resolution of

the Rheometer.

If the temperature is not to displayed, the measuring sensor is not connected.

At printout, the temperature is printed as 1000.0°C!

The display is updated on every new measure point. Current measurement can be canceled at any time

by pushing key.

ST

Brookfield Engineering Labs., Inc. Page 35 M/02-212

Page 36

After measurement, or after a break, the display field for Step indicates “END” or “BREAK”.

The Display toggles in intervals of about 4 seconds between last displayed measure point and a

measuring end information like this:

Break reason

or end

Type / name of

executed progr.

By pressing key you return to the MAIN-Menue.

OK

Program end

Test

Total time: 200s

Total #MP: 40

Duration until break or

end

Number of measuring

points measured

VI.5.3 MAIN menue → Remote

Function Remote serves measurement under PC control. In this operation mode all functions of the R/S

Rheometer are controlled by a PC. In order to carry out PC-controlled measurements, you need

program package RHEO 2000 for R/S Rheometer. This software operates under operational systems

Microsoft “Windows 3.x and Windows 95 or 98.

More detailed information of RHEO 2000 software you will get from your supplier.

After selection of menue option “Remote”, the Rheometer shows following display:

Remote

Wait for RS232...

<ST>=stop

Now the Rheometer waits for communication with a PC. The data between a PC and the Rheometer is

transferred via serial interface RS232 of the R/S Rheometer.

If you have RHEO program package, you can start now the MEASURE/ANALYSIS program on PC.

At any time you can cancel REMOTE operation with key. But caution: current measurements are

also canceled by key in REMOTE operation.

After completion of communication with the PC, LCD display shows: “Remote done ...” and you can

again return back to the Main menue with key.

During measurement with PC in REMOTE operation LCD display of the Rheometer indicates some of

preset values. These values, however, are not relevant for the user and serve for information in case of

occurring problems.

ST

ST

ST

VI.5.4 MAIN menue → Utilities

Entry to open “Utilities” submenue - see Chapter 6.6.

VI.5.5 MAIN menue → Configuration

Entry to open “Configuration” submenue - see Chapter 6.7.

Brookfield Engineering Labs., Inc. Page 36 M/02-212

Page 37

VI.6 Menue entries in the Utilities-Menue

Utilities menue, as its title presumes, contains several useful functions corresponding to measurements.

The entries:

• Zero Calibration

• Edit Programs

• Print Programs

• Measuring Systems

• Print Memory

• Delete Memory

• Measuring Systems

Chapters below explain these functions more detailed.

Executes zero-calibration of the Rheometer

input and editing of programs (which can be started with Run Program)

prints all parameters of all programs in memory at the printer

input of measuring system’s parameters or generation of new measuring

systems

output of measurement data from memory to the printer or to serial interface

clears measurement data in memory

Measures temperature without rheological measurements

VI.6.1 Utilities → Zero Calibration

The function “Zero calibration” serves to calibrate the Rheometer zero point. This function continues for

approximately 10 minutes and should be done once a week.

Before starting this function, ensure that R/S Rheometer was warmed-up for

not less than 10 minutes and that no measuring system is connected to

RC20´s measuring bob coupling.

The requirement, that a measuring system is removed, is confirmed after checking once more by

OK

OK

ST

ST

pressing key (= start of zero point calibration) or pressing key to return back to Utilities

menue.

Zero point calibration is performed automatically. The progress of calibration is shown as executed step

of total steps to be executed.

In the case of an error message occurs while calibrating you should start zero point calibration again. In

the case, the error message is displayed again, there is a critical system fault (=>Repairs).

After a successful calibration, the message on its completion is displayed and values of the zero point

are saved internally. These values are saved till the next calibration.

Push key to save values or any other key to return back to Utilities menue without saving.

Note:

At any time you can cancel zero point calibration by key. Zero point values, determined up to this

moment will be ignored.

VI.6.2 Utilities → Edit Programs

This function is for input of new or for edition of already existing programs. The programs can be started

after successful installation via the menue entry “Run Program” in the main menue.

The following values are preset in a program:

Brookfield Engineering Labs., Inc. Page 37 M/02-212

Page 38

• measuring system to be used in the measurement

• Number of steps

• start and end value of each step

• Number of measurement points for each step

• Duration of each step

preset value as a function of time:

D[1/s]

100

80

60

40

20

0

0 60 120 180

t[s]

D[1/s]=f(t)

As an example, we would like to consider a standard measurement.

1. Step: shear rate increases within 60 sec from 10.00 to 100.00 s

2. Step: shear rate remains at the level of 100.00 s

-1

for 60 sec.

3. Step: shear rate decreases again within 60 sec from 100.00 to 10.00 s

-1

.

-1

.

This measurement consists of 3 steps.

This example might be used to consider program input.

However, besides the shear rate D [s

-1

] = f(t), preset value can also be defined as:

Speed n[rpm]=f(t)

Torque M[‰]=f(t)

Shear stress Tau[Pa]=f(t)

Slopes and plain parts of the preset values are linear, measurement point is also defined linear, i.e.

there is no possibility to define logarithmic measurements. For logarithmic measurement you need

RHEO program package.

Preset value substeps in a defined step according to the following equation:

∆ Preset Value = End Value - Start Value/(Number of Measuring points - 1)

where ∆ Preset Value is the difference between preset value of measurement point n and

measurement point n+1.

The first preset value (=the first measurement point) is always the start value of the slope, the last

measurement point is determined by the end value. As for our example, in order to reach the values D=

10, 20, 30, ... , 100 [s

-1

] we need ∆ Preset Value of 10 [s-1]. So we need 10 measurement points.

Sample: 100-10/(10-1)=10.

Number of Measurement Points = (End Value - Start Value) / ∆Preset Value)+1

(for slopes only)

Let’s return back to the example.

After selection of the menue point “Edit Program” you will be requested to select a program from the list

of all programs available, which you want to generate or to edit.

Brookfield Engineering Labs., Inc. Page 38 M/02-212

Page 39

Select PROG to edit

1) Prog xyz

2) Test

3) NEW >

Available programs

contain a name

All free (non-defined) programs

are marked as NEW

All free memory parts are marked as NEW. In order to avoid overwriting of already available programs,

please, select a NEW program to be edited.

After selection of the program with key you will be requested to select a measuring system.

OK

Attention: the program has to be executed later with the same measuring system, otherwise senseless

measurement results will be calculated.

Select Meas. system:

3) CC45 >

4) CC25

5) CC14 >

After selection of the measurement system, input of number of steps requested (=number of slopes and

planes of the function).

Nr. of steps : 01

Input number of

steps 1...10

Our example: 03

Number of steps can be from 1 to maximum 10 steps.

In our example we need 3 steps. So, number “01” must be changed to “03”. (Input of numbers - see

Chapter 6.4).

If you try to input numbers <1 or >10, an error message “Range-Error” will appear.

After successful input of number of steps, selection of kind of measurement is carried out:

Select Input-Mode:

-D[1/s]

-n[rpm]

-Tau[Pa] >

Possible types of measurement Range of parameters preset

Shear rate D [s-1] Depending on measuring system

Speed n [rpm] 0.7 ... 800 rpm

Shear stress Tau [Pa] Depending on measuring system

Torque M [‰] 0 ... 999 promille

So selectent (in our example) “D[1/s]” and press key. Now, you have to define each step.

OK

Brookfield Engineering Labs., Inc. Page 39 M/02-212

Page 40

For every step, there are the following inputs:

Input Step Nr 1

Start[1/s]: 0010.00

End[1/s]: 0100.00

Nr of MP: 01

0

Start Value

End Value

Number of MP (measur. points)

(input of numbers: see Chapter 6.4)

Minimum- and maximum-values of start values and end values depend on selected measuring system

for shear rate (D[s-1]) and shear stress (Tau[Pa]). At input the Rheometer checks start and end values

(if these values lie within due range) and indicates error massage “Range-Error” if out of range:

Range-Error

Range-Error

Start-Value:

min: 0.90

max: 1032.80

This message will be indicated, for example, at input of the start value D[s

CC25, which lies outside the range of 0.9 ... 1032.8 s

Name of Value out of range

Allowed mimum-value

Allowed maximum-value

-1

.

-1

] with measuring system

However, in the case, start value, end value and number of measurement points were input correctly,

the request for input of step duration will be indicated:

Input Step Nr. 1

time [s]: 0060

Number of currently editing step

Step duration

Minimum step duration:

D [s-1] tmin = number of measurement points * 4 s

n [rpm] tmin = number of measurement points * 4 s

Tau [Pa] tmin = number of measurement points * 1 s

M [‰] tmin = number of measurement points * 1 s

Maximum step duration allowed is: 3600 s

The duration value is automatically checked for the correct range (dependent on number of meas.

points). At wrong input, the “Range-Error” message will be indicated, accompanied by allowed values.

Attention: The more time between two measuring points, the higher precision of determination

of physical parameters!

This procedure of input Start-, End-Value, Number of MP, time is repeated for each step.

Finally the Program must be named and saved:

Edit PROGRAM name:

TEST

Input name of program

(for input of alpha-numerical texts see Chapter 6.4)

Brookfield Engineering Labs., Inc. Page 40 M/02-212

Page 41

Saving of the Program:

(2) TEST

Press <OK> to save

If you push key now, the Program will be saved. If you push any other key, the entries are

abandoned and previous parameters remain (the current ones, before the edit).

OK

VI.6.3 Utilities → Print Programs

This function prints the parameters of defined programs in memory at the printer. Be sure that printer is

connected to the Rheometer and ready for operation.

In the case, the printer is not ready for operation at launching “Print Programs” function, the error

message will be indicated:

ERROR #1

Printer not ready!

<OK> cont. <ST> stop

In case, this error message appears, please ensure, that the printer is ready and its sheet feeder

contains paper.

Press key to try printing again or push key to return back to the Menue.

OK

ST

VI.6.4 Utilities → Measuring systems

With this function you can create new measuring system or change already defined measuring systems.

Measuring systems are represented by following values. This values might be edited:

• Name of measuring system

• Shear rate factor Kγ [min/s] (k_gamma)

• Shear stress factor τ‰ [Pa] (tau_prom)

Only authorized personnel is permitted to change constants of the measuring

system!

After starting the function you will be prompted to select the measuring system you want to edit. Select

the list item “NEW” to generate a new measuring system.

Select Meas. system:

3) CC45 >

4) CC25

5) CC14 >

Brookfield Engineering Labs., Inc. Page 41 M/02-212

Page 42

After selection of the measuring system, you will be requested to input sequentially: its name, tau_prom

and k_gamma.

Enter Meas. Sys. #4

Name: CP25

tau_prom: 01.1418

k_gamma: 01.2910

The measuring system name is a alpha-numerical entry, factors tau_ prom and k_gamma are input as

numerical entries (see Chapter 6.4).

When done, a security request follows, if you really want to save new parameters.

PRESS <OK> to save

Name: CC25

tau_prom: 01.1418

k_gamma: 01.2990

Using key you can save the changes, otherwise, using key you can return to the Menue,

without saving.

OK

ST

VI.6.5 Utilities → Print memory

This function serves output of measuring values from internal memory to the printer, connected to the

Rheometer, or to the serial interface RS232 of the Rheometer.

First, you will be requested to select the output device, where you want to transfer the measuring values

to.

Sel. Output-device:

- Printer

- RS232

a) Output to printer:

The printer must be connected to the Rheometer and be ready for operation.

b) Output to the serial interface RS232:

Data receiving device (mostly a PC) must be adjusted to same data transfer parameters as R/S