Page 1

LT O Au toloa d er

User’s Guide

IBM

Page 2

Page 3

LT O Au toloa d er

User’s Guide

IBM

Page 4

Note: Before using this information and the product it supports, read the information under Appendix B, ″Product

warranties and notices″ on page B-1.

First Edition (January 2001)

© Copyright International Business Machines Corporation 2000. All rights reserved.

US Government Users Restricted Rights – Use, duplication or disclosure restricted by GSA ADP Schedule Contract

with IBM Corp.

Page 5

Contents

Safety ...............v

Chapter 1. Installation and user’s guide 1

Autoloader features ............1

Before you begin ............1

Autoloader Views ...........2

Product features .............4

Unpacking the autoloader ..........5

Remove the autoloader and its internal packaging 5

Installing the pull-out information tab .....5

Preparing for installation ..........7

Additional preparation ..........7

Installing the autoloader ..........8

Getting started with the autoloader .......9

Selecting the operation mode ........9

Chapter 2. Autoloader operation....13

Using the front panel ...........13

Panel icon messages ..........14

Menu Commands and structures .......14

Menu Command Nesting .........14

Understanding the menu structure .....15

Tape and drive operations .........15

Accessing tapes in the autoloader ......1518

Handling tape cartridges .........19

Chapter 3. Autoloader configuration . . 21

Retrieving autoloader information .......21

Autoloader information .........21

Drive Information ...........21

Configuration Information ........22

Date and time ............22

Firmware revisions ...........22

Running autoloader diagnostics tests ......22

Chapter 4. Autoloader maintenance . . 25

Removing and replacing parts ........25

Removing and replacing the controller card . . 25

Removing and replacing drive modules ....25

Upgrading Firmware ..........28

Moving or shipping the autoloader .....28

Chapter 5. Error messages,

troubleshooting, and problem solving . 31

Understanding error states .........31

Soft (recovered) errors ..........31

Partial availability state .........32

Hard (unrecoverable) errors ........33

Host software and media errors ......35

Finding and identifying error information ....37

Accessing error log files .........37

Using LEDs to determine status ......37

Troubleshooting common problems ......40

Appendix A. Help and service

information.............43

Online technical support ..........43

Telephone technical support .........43

Appendix B. Product warranties and

notices...............45

Warranty Statements ...........45

IBM Statement of Limited Warranty for United

States, Puerto Rico, and Canada (Part 1 - General

Terms) ................45

IBM Statement of Warranty Worldwide except

Canada, Puerto Rico, Turkey, United States (Part 1 -

General Terms) .............48

Part2-Worldwide Country-Unique Terms ....51

Notices ................54

Taiwan Class A warning statement .....55

Trademarks ..............55

Federal Communications Commission (FCC)

statement ...............57

© Copyright IBM Corp. 2000 iii

Page 6

iv LTO Autoloader: User’s Guide

Page 7

Safety

Before installing this product, read the Safety Information.

Antes de instalar este produto, leia as Informações de Segurança.

Pred instalací tohoto produktu si prectete prírucku bezpecnostních instrukcí.

Læs sikkerhedsforskrifterne, før du installerer dette produkt.

Ennen kuin asennat tämän tuotteen, lue turvaohjeet kohdasta Safety Information.

Avant d’installer ce produit, lisez les consignes de sécurité.

Vor der Installation dieses Produkts die Sicherheitshinweise lesen.

Prima di installare questo prodotto, leggere le Informazioni sulla Sicurezza.

Lees voordat u dit product installeert eerst de veiligheidsvoorschriften.

Les sikkerhetsinformasjonen (Safety Information) før du installerer dette produktet.

Antes de instalar este produto, leia as Informações sobre Segurança.

red inštaláciou tohto zariadenia si pečítaje Bezpečnostné predpisy.

Antes de instalar este producto lea la información de seguridad.

Läs säkerhetsinformationen innan du installerar den här produkten.

© Copyright IBM Corp. 2000 v

Page 8

vi LTO Autoloader: User’s Guide

Page 9

Chapter 1. Installation and user’s guide

The IBM®LTO autoloader is an automated storage and retrieval system that comes

with a preinstalled LTO tape drive, three fixed-cartridge slots, and a removable

magazine that can hold six additional tape cartridges. You can connect the

autoloader to a server externally, or you can install the autoloader in a server rack

on a fixed shelf.

The autoloader complies with the ANSI standard for the SCSI-3 LVD (low-voltage

differential) interface and has industry-standard, 68-pin, external SCSI cable

connectors. The tape media format follows ECMA-approved and ANSI-proposed

standards.

Autoloader features

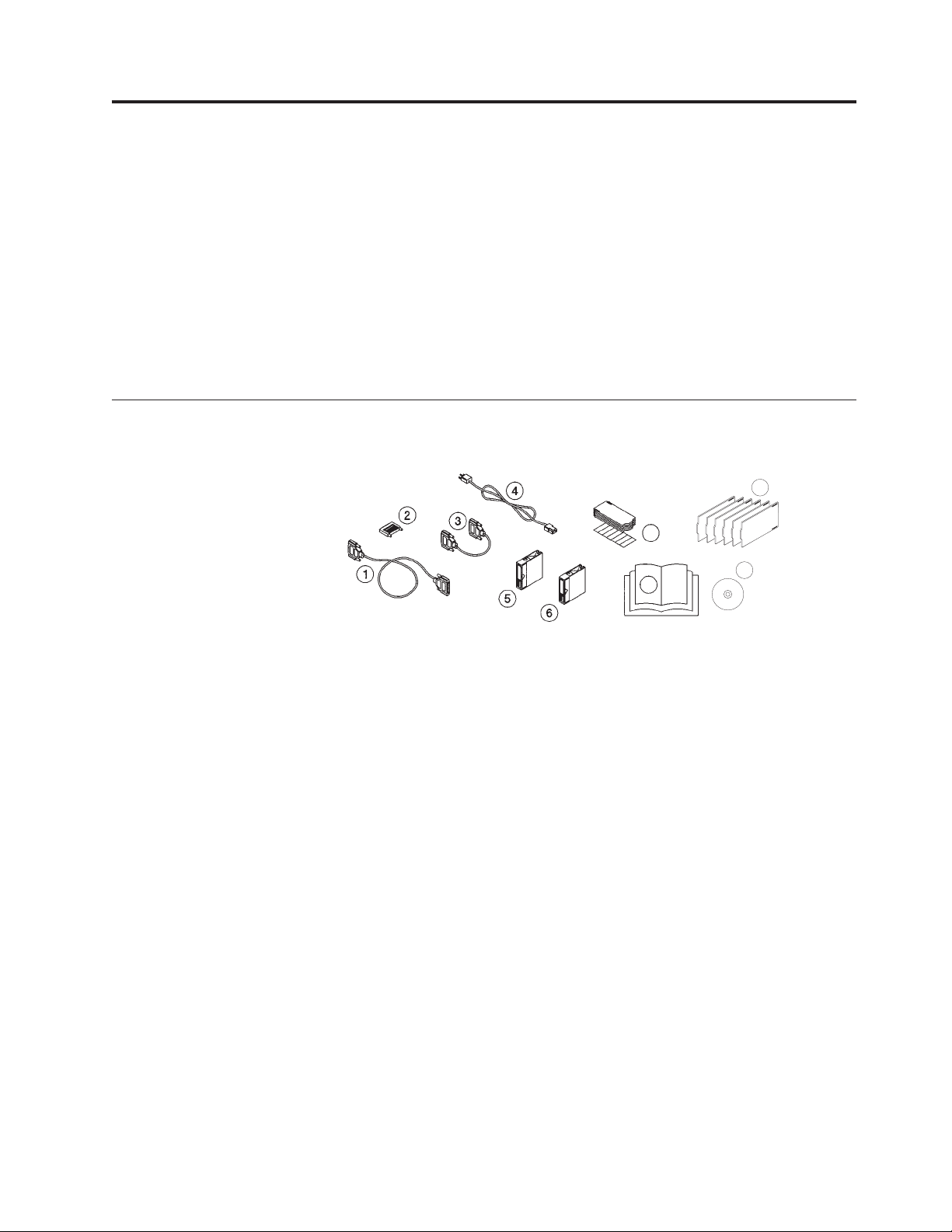

In addition to this book, the option kit includes:

10

8

9

7

CD

«1¬SCSI external cable

«2¬SCSI terminator

«3¬SCSI jumper cable

«4¬AC power cord

«5¬Data cartridge

«6¬Cleaning cartridge

«7¬Quick install guide booklet

«8¬Barcode kit

«9¬Trial software CDs

«10¬Information tabs

Before you begin

The autoloader requires the following environmental conditions:

v AC power voltage: autoswitching 100-127 V or 200-240 V. Line frequency: 50-60

Hz.

v Moderate room temperate between 10-35

v Humidity ranging from 20-80%.

v Standalone configuration includes the base enclosure and feet, and requires the

following clearances:

– Back: 56 cm (22 in.) for cooling and service

– Front: 86 cm (34 in.) for operator access

°

C (50-95°F).

© Copyright IBM Corp. 2000 1

Page 10

v A clean, level surface on which to place the autoloader. The weight of the

autoloader is approximately 22.7 kg (50 lbs.). Be sure that the surface can

support the weight of the autoloader.

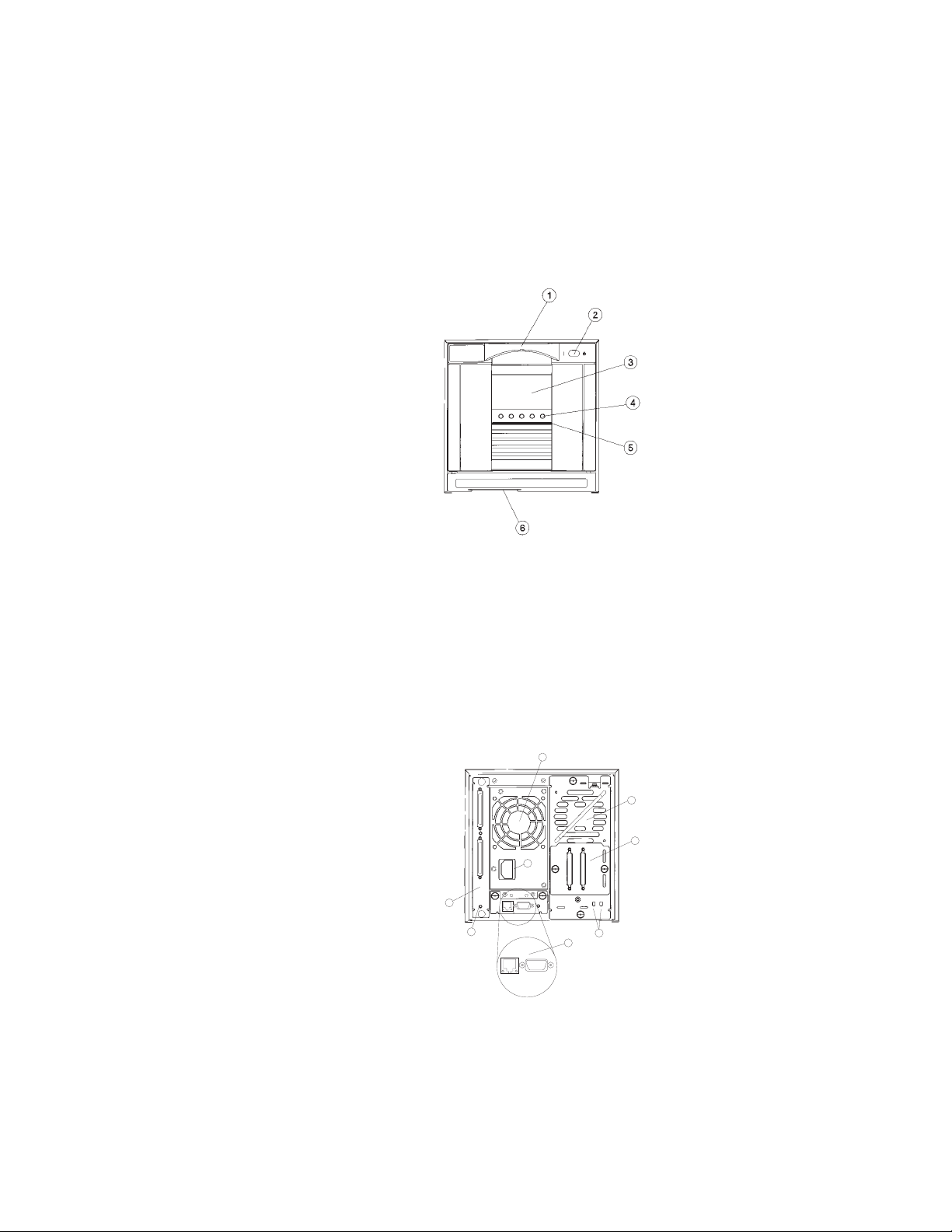

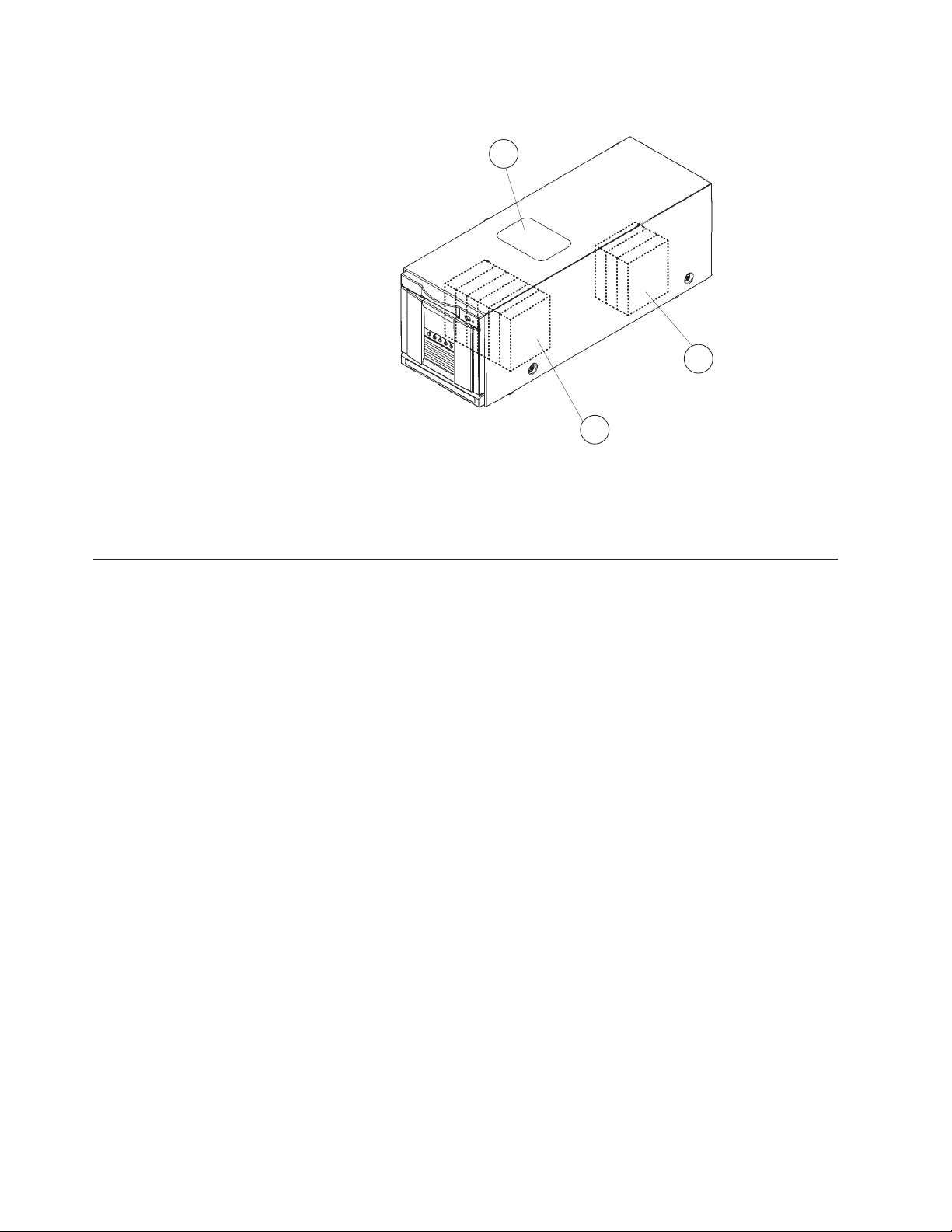

Autoloader Views

The following illustrations and descriptions review the front and back panel views

of the autoloader.

Front panel view

The components shown in the previous illustration include the following.

«1¬Door handle

«2¬Power (standby) switch

«3¬Front panel display

«4¬Soft-button keys

«5¬LED status bar

«6¬Slot for pull-out information tab

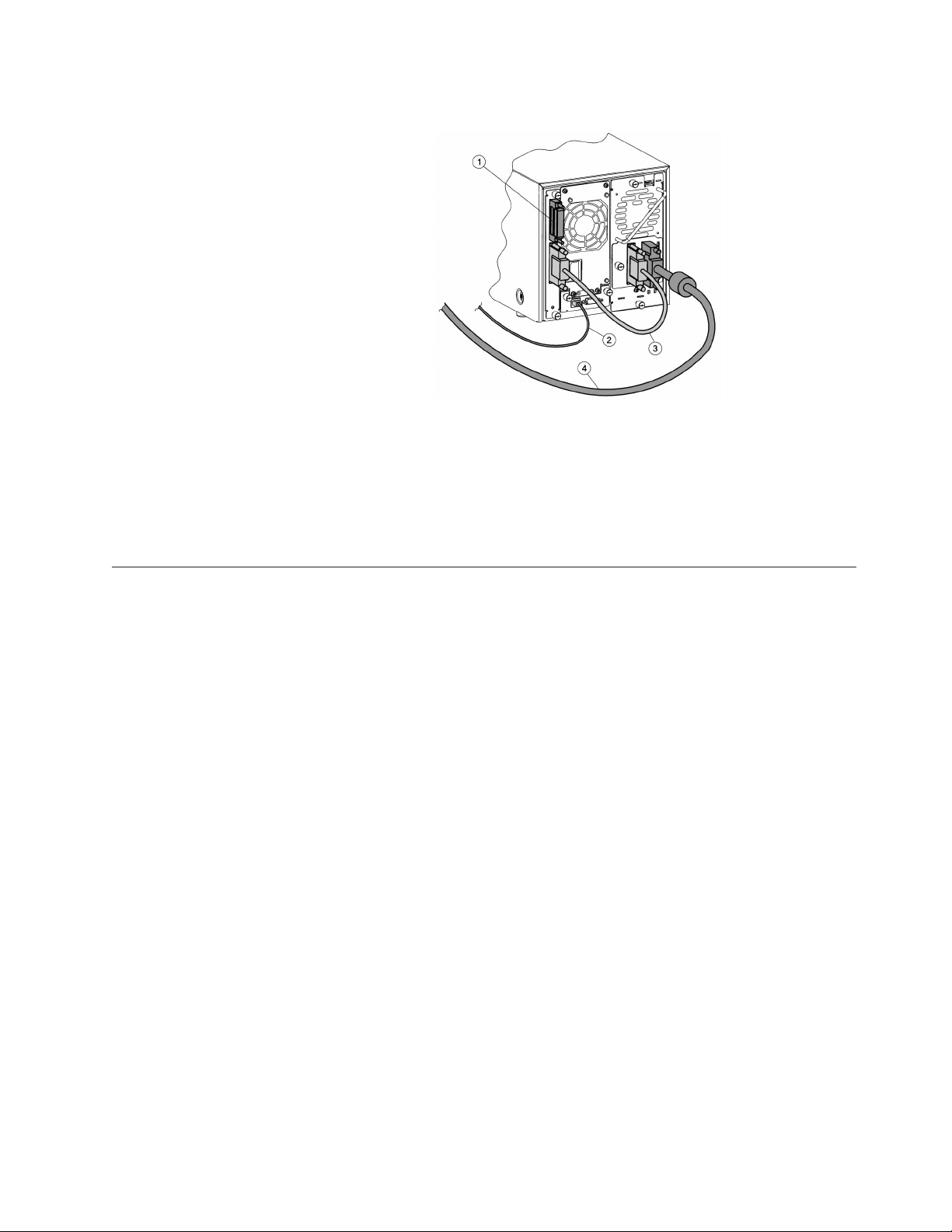

Back panel view

The components shown in the previous illustration include the following.

«1¬autoloader controller card

«2¬Power supply

«3¬Future upgrade

«4¬Drive module

«5¬Status LEDs

2 LTO Autoloader: User’s Guide

2

4

7

6

1

5

5

3

Page 11

«6¬Power cord receptacle

«7¬SCSI connectors

Chapter 1. Installation and user’s guide 3

Page 12

Internal view

2

7

8

9

6

5

4

3

2

1

3

1

The internal components shown in the previous illustration include the following.

1. Removable magazine with slots numbered 1-6

2. Viewing window on the top of the autoloader

3. Internal back storage slots with slots numbered 7-9

Product features

The autoloader provides the following features:

v Automatic tape operations

v Autoloader status display using the operator control panel (OCP), including:

v Mode control features:

v Manual selection of cartridges to be loaded into the tape drive

v SCSI ID selection using the OCP

v Autoloader and tape drive microcode updates using the SCSI bus

v Display of device microcode and hardware revision numbers

v Embedded diagnostic software that displays status for head cleaning, autoloader,

– Tape drive status and activity

– Tape drive error status

– Magazine slot status

– Loaded tape-cartridge conditions

– Automatic random access to all tape cartridges

– Sequential access to tape cartridges in a single cycle

– Sequential access to tape cartridges in circular cycles

– An optional autoclean mode that automatically cleans the drive when

necessary

and tape drive operation and provides test functions to help isolate problems.

4 LTO Autoloader: User’s Guide

Page 13

Unpacking the autoloader

Before taking the autoloader out of its packaging, inspect the carton for damage

that might have occurred during shipment. If you received the autoloader on a

pallet, inspect the pallet for damage. Report any damage to the shipper

immediately. When you unpack the autoloader, place the unit as close to the

installation location as possible.

To prepare the autoloader for installation, remove the internal packaging from the

autoloader and install the pull-out information tabs.

Remove the autoloader and its internal packaging

To unpack the autoloader, follow these steps.

1. If you received the autoloader on a pallet, cut the straps that secure the

shipping carton to the pallet, and then move the carton off of the pallet.

2. Open the top of the shipping carton by carefully cutting the packing tape.

3. Remove the accessories box from the carton.

4. Remove the packing foam from the top of the autoloader.

v Statement 4

22.7 kg (50 lbs)

5. With two people lifting the autoloader, remove it from the shipping carton.

6. Remove the autoloader from the shipping bag.

7. Place the autoloader in the installation location.

8. Remove the internal packaging by opening the autoloader front door and

pulling the foam packaging out from around the magazine.

Note: Do not turn on the autoloader before removing the internal packaging or

a hard error will result.

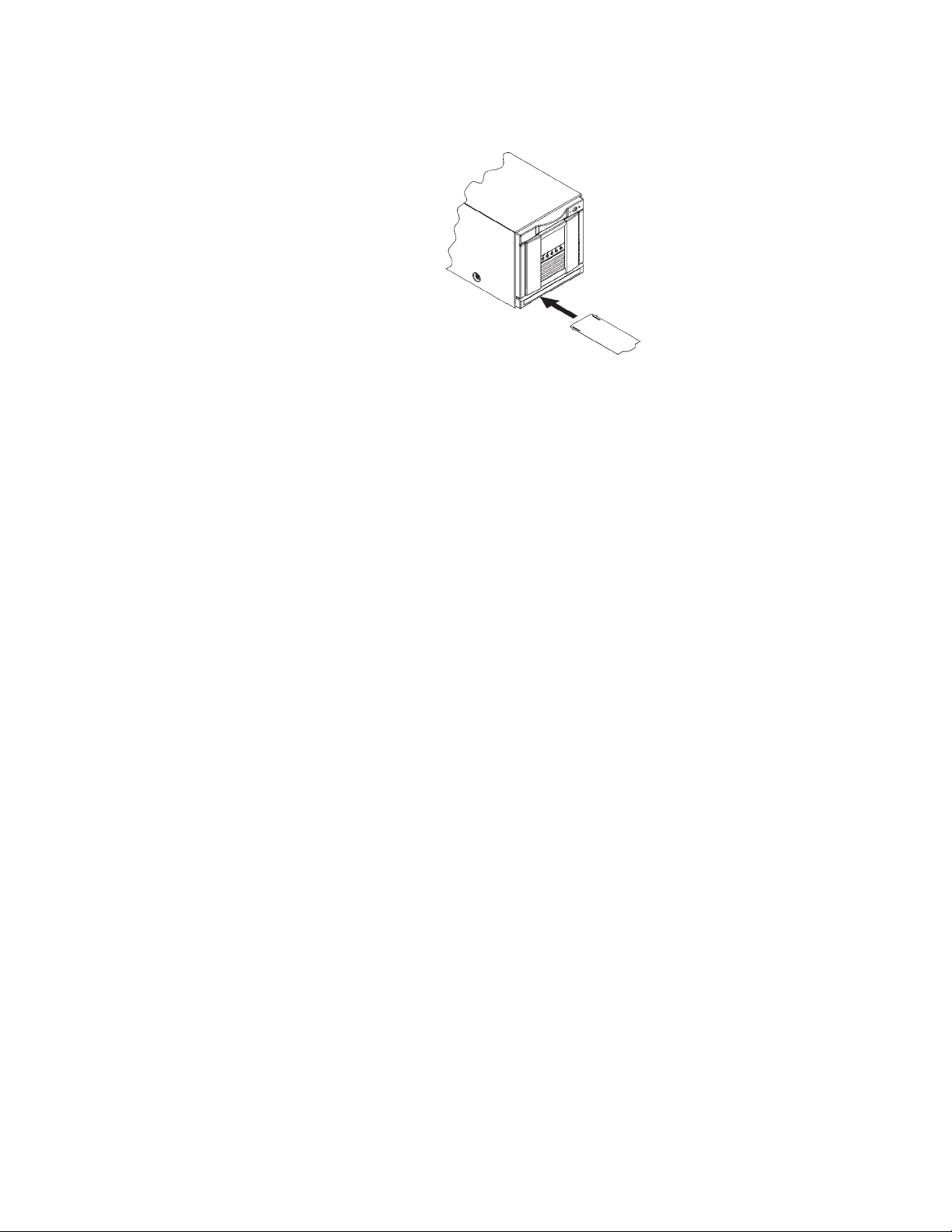

Installing the pull-out information tab

Select the tab in the language that you prefer, (for reference see «10¬ on page 1)

and insert it into the slot on the front of the autoloader, as shown in the following

illustration. The tab snaps into place when you push it to the back of the slot. This

tab contains information on basic autoloader operations.

Chapter 1. Installation and user’s guide 5

Page 14

Note: You might need to forcefully push the tab all the way to the back of the slot

in order for it to click completely into place.

6 LTO Autoloader: User’s Guide

Page 15

Preparing for installation

Before installing the autoloader, read the following safety statements.

v Statement 1

DANGER

Electrical current from power, telephone, and communication cables is hazardous.

To avoid a shock hazard:

— Do not connect or disconnect any cables or perform installation, maintenance, or reconfiguration of this

product during an electrical storm.

— Connect all power cords to a properly wired and grounded electrical outlet.

— Connect to properly wired outlets any equipment that will be attached to this product.

— When possible, use one hand only to connect or disconnect signal cables.

— Never turn on any equipment when there is evidence of fire, water, or structural damage.

— Disconnect the attached power cords, telecommunications systems, networks, and modems before you open

the device covers, unless instructed otherwise in the installation and configuration procedures.

— Connect and disconnect cables as described in the following table when installing, moving, or opening covers

on this product or attached devices.

To connect: To disconnect:

1. Turn everything OFF. 1. Turn everything OFF.

2. First attach all cables to devices. 2. First, remove power cords from outlet.

3. Attach signal cables to connectors. 3. Remove signal cables from connectors.

4. Attach power cords to outlet. 4. Remove all cables from devices.

5. Turn device ON.

Additional preparation

Do the following to prepare the autoloader for installation.

1. Use proper procedures to prevent electrostatic discharge (ESD). Use

wrist-grounding straps and anti-static mats when removing internal

components.

2. If your server does not already have an external SCSI connector, you will have

to install a SCSI host adapter and compatible software and drivers. Refer to the

user manual and installation instructions that came with the SCSI host adaptor.

3. Locate the autoloader in a convenient place or on a fixed rack shelf.

4. Do not connect the autoloader drive to the same SCSI bus as the hard drive,

because it will degrade the autoloader performance.

5. Check for available SCSI IDs if you are installing the autoloader onto the same

SCSI bus as other devices. You might need to use the front-panel buttons to

change the SCSI ID, if you think there will be an ID conflict with other devices.

6. If you have removed the internal packaging and installed the pull-out

information tabs as shown in the section “Installing the pull-out information

tab” on page 5, then the autoloader is ready for installation.

Chapter 1. Installation and user’s guide 7

Page 16

Installing the autoloader

To connect the autoloader, do the following:

Note: Refer to the following illustration.

1. If the host computer is connected to a network, check with the system

administrator before turning off power.

2. Properly turn off all attached devices connected to the host computer.

3. Turn off the host computer.

Note: When installing cables, use care in handling the SCSI pins. These pins

are easily damaged.

4. Install the SCSI jumper cable«3¬from the bottom connector on the autoloader

controller card to the left connector on the drive module.

5. Install the SCSI terminator «1¬to the top connector of the controller card.

6. Install the SCSI cable «4¬ from the SCSI adapter on the host to the remaining

connector on the tape drive module.

7. Connect the power cord,«2¬, from the back of the power supply module to a

properly grounded outlet. See .

Note: Remember to remove the internal packaging before turning on the

autoloader.

8. Go to the front of the autoloader, and turn it on by pressing the power

(standby) switch in the top right corner. After the power-up test completes,

you will see the default Home screen on the front panel display (see “Front

panel view” on page 2).

9. Set the SCSI IDs for the autoloader and drive if there will be a conflict with

the default SCSI IDs.

10. Turn on other devices and then turn on the host.

11. After turning on the autoloader, the following will happen:

v LED bar («5¬ on page 2) flashes solid amber for a few seconds.

v LED bar flashes green during self-test

v LED bar flashes green during calibration.

v LED bar flashes green during inventory of cartridges.

v LED bar is solid green with Home screen displayed on LCD.

12. Verify that the autoloader is installed correctly by looking for the autoloader

and drive devices after turning on the host computer.

v If you are using Microsoft

recognized by clicking Settings-->Control Panel-->SCSI Adapter and

expanding the device tree to view the autoloader SCSI adapter.

v Or, during the boot sequence, you can press Cntrl a during the SCSI

adapter configuration. Select SCSI Select Utilities and then select SCSI

Disk Utilities to have the computer retrieve the SCSI bus and display all of

the attached SCSI devices.

13. If you do not already have backup/restore software installed, you can install

the complementary trial software of your choice by inserting the CD into your

®

Windows NT®, you can see if the autoloader is

8 LTO Autoloader: User’s Guide

Page 17

computer CD-ROM drive and following the onscreen instructions.

«1¬Terminator

«2¬Power cord

«3¬SCSI jumper cable

«4¬SCSI interface cable to host

Getting started with the autoloader

After you install the autoloader, perform the following to begin using the

autoloader.

v Select the operating mode. From the Change Configuration menu, select

Operating Mode. Select one of the following operating modes: stacker, random,

or autodetect.

v Enable the password.

v Set the date and time.

Selecting the operation mode

To select the operation mode, do the following:

v SelectMain-->Administration-->Change Configuration-->Operating Mode.

v When you enter the Operating Mode menu, the front panel indicates the mode

currently selected. To change the operating mode, select one of the following:

– Stacker Mode: Stacker mode enables you to use the autoloader like a

standalone drive, without using special automation software and without

accessing the autoloader with host SCSI commands. The autoloader

automatically unloads and loads tapes from the drive until it unloads the last

tape. With this operating mode, you must also select the following:

- Circular Mode On/Off: If the circular mode option has been selected, the

autoloader will reload the first tape cartridge after unloading the last tape

cartridge. If circular mode is disabled and the last tape cartridge has been

unloaded, the autoloader stops operating until the user loads additional

tape cartridges.

- Autoload On/Off: If the autoload option is selected, the first available tape

loads into the drive at power up. When the host issues a SCSI Unload

Chapter 1. Installation and user’s guide 9

Page 18

command to the drive, the autoloader automatically removes the tape

cartridges from the drive and inserts the next available tape.

If the autoloader encounters a cleaning cartridge during the cycle, it will be

loaded into the drive as normal, but will be automatically unloaded after the

cleaning cycle.

– Random Mode: Random mode provides full autoloader functionality with

special automation software in the host computer. Tapes can only be loaded

to the drive from the front panel, host SCSI commands, or the optional

remote management card. The autoloader will not automatically load tapes as

it will in stacker mode.

– Autodetect Mode (Factory Default): In autodetect mode, the autoloader starts

in Stacker mode until it receives a SCSI “changer” command. The autoloader

then runs in random mode. The “changer” commands include the following:

INITIALIZE ELEMENT STATUS, READ ELEMENT STATUS, POSITION TO

ELEMENT, MOVE MEDIA, and EXCHANGE MEDIA.

With this operating mode, you must also select Circular Mode On/Off.Ifthe

circular mode option is ON, the autoloader will reload the first tape cartridge

after unloading the last tape cartridge. If circular mode is OFF and the last

tape cartridge has been unloaded, the autoloader stops operating until the

user loads additional tape cartridges.

Note: You must set autoload to OFF when in autodetect mode.

Enabling and changing the password

When the autoloader is first installed, the password is inactive. Set a password to

protect the system from unauthorized access.

1. To enable and change the password, select Main Menu--> Administration-->

Change Configuration-->Password.

2. Enter the Password menu. A status screen will indicate if a password is

enabled.

v If the password is turned off, select Set New Password to enter the new

password.

v If the password is enabled, select Change Password to enter the new

password.

v If the password is enabled, select Turn Password Off to clear the password.

Note: The password must be exactly eight digits. If you enter more than eight

digits, the ninth digit becomes the first digit of the new password.

3. Select OK to save your changes and exit or Back to exit without saving your

changes.

Attention: If you forget the password, only a service representative can

restore it to the default settings.

Setting the date and time

When the autoloader is initially set up, you must set the date and time. If the

autoloader has been unplugged for an extended period and the autoloader

displays a partial availability message, you must reset the date and time. To set the

date and time, enter the Administration menu, and then do the following steps:

1. Select Main menu-->Administration-->More-->Set Date and Time.

2. Enter the Set Date & Time menu.

3. Use the [-] or [+] keys to select the year, month, and day. Use the --> to scroll to

the next entry when complete.

10 LTO Autoloader: User’s Guide

Page 19

4. Set the hour and minutes (00:00:00) using [-] or [+] keys. Use the --> key to

scroll over to the next selection. The seconds are automatically set at 00.

5. Use the [-] or [+] keys to substract or add hours for your time zone. (For more

information, see the following table.) ″UTC″ stands for Coordinated Universal

Time.

6. Press OK to save your changes. Press Quit to exit this menu without saving

your changes.

Note: The time does not automatically adjust for time changes, such as

daylight savings time.

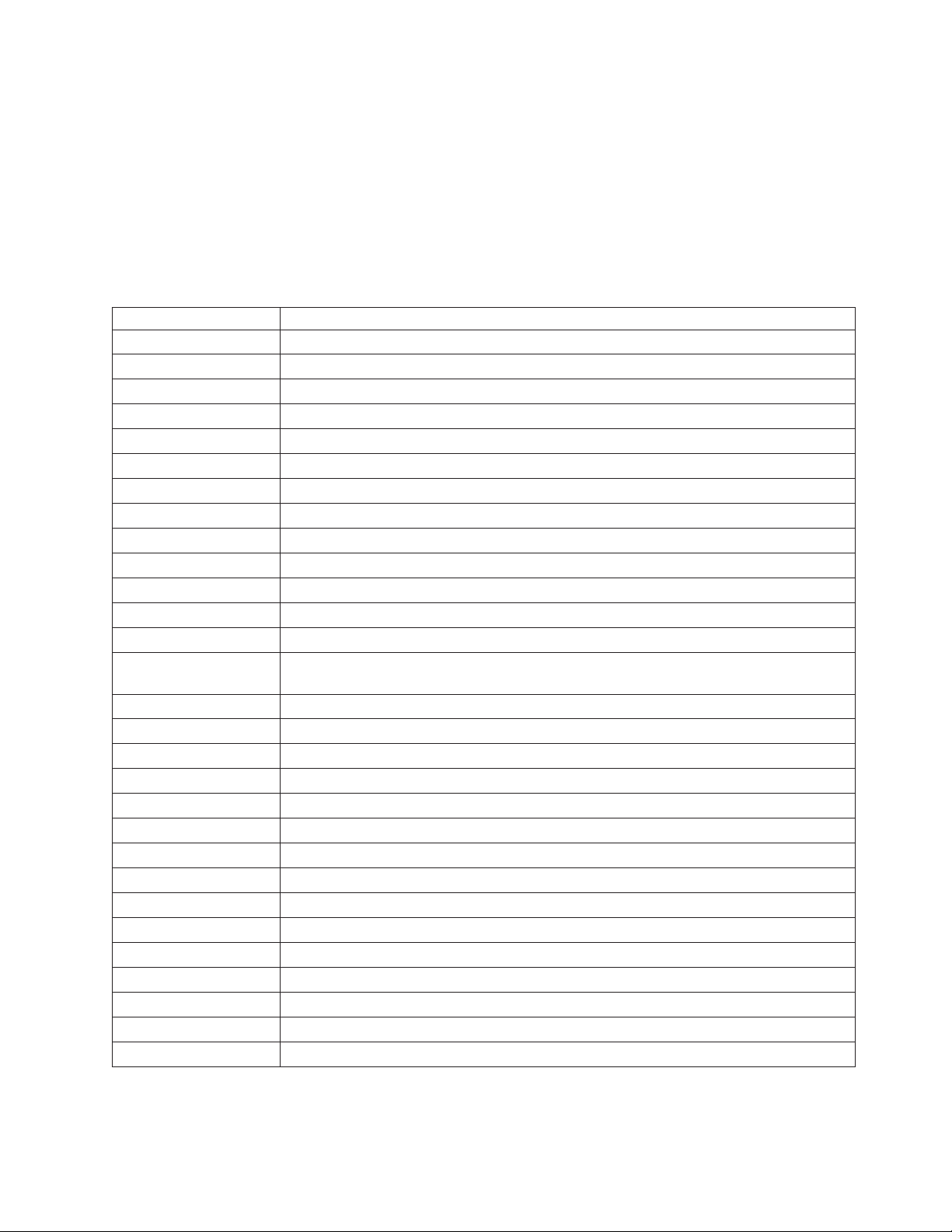

Code Time Zone

UTC -12 Eniwetok, Kwajalein

UTC -11 Midway Island, Samoa

UTC -10 Hawaii

UTC -9 Alaska

UTC -8 Pacific Time (US and Canada), Tijuana

UTC -7 Mountain Time (US and Canada), Arizona

UTC -6 Central Time (US and Canada), Saskatchewan, Mexico City, Tegucigalpa

UTC -5 Eastern Time (US and Canada), Bogota, Lima

UTC -4 Atlantic Time (Canada), Caracas, La Paz

UTC -3 Brasilia, Buenos Aires, Georgetown

UTC -2 Mid-Atlantic

UTC -1 Atlantic Ocean

UTC Great Britain, Lisbon, Monrovia, Casablanca

UTC +1 Berlin, Stockholm, Rome, Bern, Brussels, Vienna, Paris, Madrid, Amsterdam, Prague,

Warsaw, Budapest

UTC +2 Athens, Helsinki, Istanbul, Cairo, Eastern Europe, Harare, Pretoria, Israel

UTC +3 Baghdad, Kuwait, Nairobi, Riyadh, Moscow, St. Petersburg, Kazan, Volgograd

UTC +3:30 Tehran

UTC +4 Abu Dhabi, Muscat, Tbilisi

UTC +4:30 Kabul

UTC +5 Islamabad, Karachi, Ekaterinburg, Tashkent

UTC +5:30 Bombay, Calcutta, Madras, New Delhi, Colombo

UTC +6 Almaty, Dhaka

UTC +7 Bangkok, Jakarta, Hanoi

UTC +8 Beijing, Chongqing, Urumqi, Hong Kong, Perth, Singapore, Taipei

UTC +9 Tokyo, Osaka, Sapporo, Seoul, Yakutsk

UTC +9:30 Adelaide, Darwin

UTC +10 Brisbane, Melbourne, Sydney, Guam, Port Moresby, Vladivostock, Hobart

UTC +11 Magadan, Solomon Is., New Caledonia

UTC +12 Fiji, Kamchatka, Marshall Is., Auckland, Wellington

Chapter 1. Installation and user’s guide 11

Page 20

12 LTO Autoloader: User’s Guide

Page 21

Chapter 2. Autoloader operation

This chapter describes operations of the autoloader.This section describes the

operational processes of the following autoloader components:

v Front panel

v Main menu structure

v Tape and drive operations

Using the front panel

2

This section describes how to use or the purpose of the following autoloader

components:

This LCD display on the control panel provides a drive and autoloader status line

at the top, up to five lines of text, and five buttons under the display. The function

of the buttons varies between screens.

1

2

3

2

4

The display automatically displays to the Home screen. The previous figure shows

a typical view of the Home screen. The Home screen shows the following:

v Statement indicating the general condition of the autoloader«1¬

v Drive and tape status«2¬

v Tape bar codes (if applicable)«3¬

v Slot to display slot status, bar-code information, and tape locations

v Help to display the icons with a description

v An icon, «4¬, that indicates the general status of the autoloader. Press the

corresponding button to obtain more information about the autoloader status

v Door to open the door

v Main to go to the Information, Operations, and Administration menus

© Copyright IBM Corp. 2000 13

Page 22

Panel icon messages

The following illustration shows an example of the LCD display. The following

table shows the available icons that display in the LCD.

Power is off Online

Failed, offline

Needs to be cleaned

Offline

Failed, online

Tape is cleaning a

drive

Tape is write

protected

Empty

Loading a tape

Library status - failed

Library status - healthy

Full and idle

Unloading a tape

Seeking data on a

tape

Writing data to a

tape

Rewinding a tape

Reading a tape

Erasing a tape

Library status partially available

Menu Commands and structures

This section describes the structure of menu commands.

Menu Command Nesting

Each level of the password-protected menus (Administration and Service) includes

all options available in the subordinate menu. For example, all options available in

the Administration Menu are also included in the Service Menu. This

functionality reduces the need to return to the Main Menu or re-enter the

password. The following figure displays the top level menu items and their

corresponding nested submenus.

Note: The front panel display returns to the Home screen if a button is not pressed

for 3 minutes.

14 LTO Autoloader: User’s Guide

Page 23

Understanding the menu structure

The following graphic shows the front panel menu structure.

Tape and drive operations

The following sections describe how to access tapes within the autoloader.

Accessing tapes in the autoloader

Tapes in the autoloader can be accessed from the front magazine or the internal

back slots. To open the door, do the following:

v Select Main-->Operations-->Open Door.

v Pull the door handle down.

Chapter 2. Autoloader operation 15

Page 24

Accessing tapes from the front magazine

Refer to the previous illustration. To access tape cartridges from the front

magazine, do the following.

1. Pull the unlocked door down to access the magazine and tapes.

2. Remove the magazine by fully depressing the release button on the bottom of

the magazine while pulling the magazine out with the tab.

3. Use the magazine carrying handle to lift it out from the autoloader.

4. To remove a tape, grasp the top and bottom corners of the tape, and pull the

tape straight out of the magazine. Do not hold the magazine handle down

when you are removing tapes. When the handle is depressed, the tapes are

locked in place.

5. To insert a tape, slide the cartridge directly into a slot, ensuring the

write-protect switch faces out and at the bottom of the magazine. Push the tape

into the slot until it “clicks” into place.

6. Using the magazine tab, guide the magazine into the back of the autoloader by

sliding it across the inside of the door until it aligns with the guide tracks and

clicks into place. Close the door. The autoloader runs an inventory check.

7. If the tape is not positioned correctly inside the slot, try pushing the tape in

again until it clicks into place.

Accessing tapes from the internal back slots

Refer to the following illustration. To access tape cartridges from the internal back

slots, do the following.

1. Unplug the power cord from the back of the autoloader.

16 LTO Autoloader: User’s Guide

Page 25

2. Follow the steps on the previous page to open the door and remove the front

magazine. If you are loading tapes for the first time, ensure you turn the autoloader

on, wait until the autoloader is ready and then turn it off before loading any tapes.

This procedure moves the transport away from the back slots.

3. Unload tapes from the internal slots by pressing the tape in until it clicks and

releases. Remove the tape after it partially ejects.

Note: Always remove back tapes by first pushing them in until they click and

release. Do not remove back tapes by pulling them straight out.

4. With the write-protect switch facing out of the autoloader and at the bottom,

load the internal slots by pushing the tape in until it clicks into place.

Drive and tape operations

This section contains information about loading and unloading tapes, cleaning the

drive, and moving tapes between slots.

Loading a tape into a drive: To load a tape into a drive, do the following:

1. Select Main-->Operations-->Drive operations--->Load Tape to Drive.

2. Use the [-] or [+] key to select any full slot and then select OK.

3. Select Load to move the tape from a slot to the drive. The drive makes a

clicking noise as the tape is being loaded. A status screen indicates that the tape

is being loaded.

Note: To view the slot numbering scheme on the Home screen see “Using the

front panel” on page 13.

Unloading a tape from the drive: To unload a tape from the drive, do the

following:

1. Select Main-->Operations-->Drive operations--->Unload Tape from Drive to

move the tape from the drive to the original tape location (the location it

occupied before being loaded into the drive). If that slot is occupied, you are

prompted to select another slot location.

The tape automatically rewinds before it is unloaded. A status screen displays

autoloader progress as the tape is relocated.

2. From the Drive and Tape Operations menu, select Menu to return to the

Operations menu.

Cleaning a drive: To clean a drive, do the following:

Chapter 2. Autoloader operation 17

Page 26

Note: As an alternative, you can load a cleaning cartridge into one of the fixed

slots at the back of the autoloader and let the backup software clean the

drive automatically. Refer to the backup software instruction for information

on this automatic cleaning process.

1. Install a cleaning cartridge into any vacant slot, and note the location. See

“Accessing tapes in the autoloader” on page 15 for more information.

2. Select Main-->Operations-->Drive Operations-->Clean Drive.

3. From Choose Cleaning Slot, use the [-] or [+] key to select the slot location of

the cleaning tape. Refer to page 1-6, the label inside the autoloader door, or the

Home screen for a list of slot numbers.

4. Select OK.

5. When the cleaning process is complete, the cleaning tape will be returned to

the original slot location. The screen will display the appropriate status

information.

Moving tapes between slots

To move tapes between slots, do the following:

1. Select Main-->Operations-->Move Tape Slot-to-Slot.

2. Select the slot from which you want to move the tape using the [-] or [+] keys,

and press OK.

3. Select the slot to which you want to move the tape using the [-] or [+] keys,

and then press OK. A message displays if the destination slot chosen is

reserved or is the original “home” slot for a tape in the drive.

4. A status screen indicates the tape is being moved.

18 LTO Autoloader: User’s Guide

Page 27

Handling tape cartridges

When using tapes in the autoloader, you need to ensure that the tape media is

compatible with the drive. You can damage drives if you try to load incompatible

media.

For best results, use IBM brand data and clean cartridges. You can order additional

IBM clean and data cartridges by calling 1-800-IBM-MEDIA.

Note: Although you can use other IBM approved data cartridges, use of non-IBM

brand clean cartridges is not supported and will cause unsupported clean

cartridges to be ejected.

Chapter 2. Autoloader operation 19

Page 28

Write-protecting tape cartridges

The use of the write protect switch ensures data safety for files that have been

previously written to tape by preventing additional files from being written to that

tape.

Labeling tape cartridges

Make it a practice to use bar code labels on your tape cartridges. Your host

software might need to keep track of the following information and the associated

bar code:

v Date of format or initialization

v Cartridge owner (such as group or department)

v Storage purpose

A complementary set of barcode labels is provided with your purchase. The

following illustration shows the proper placement of the barcode label.

24P1913

Maintaining tape cartridges

When maintaining tape cartridges, use the following guidelines.

Do not:

v Expose tape cartridges to magnetic fields.

v Leave cartridges in the drive when autoloader is turned off.

v Expose cartridges to extreme temperatures or humidity. Refer to the

documentation with your tape media for appropriate operating and storage

temperatures.

v Expose cartridges to moisture or direct sunlight.

v Drop the tape cartridges or subject the cartridges to any physical shock.

v Open the tape cartridge lid and expose the tape to possible contamination or

physical damage.

v Touch the tape surface.

v Take the tape cartridges apart.

v Use graphite pencils, water soluble felt pens, or other debris-producing writing

instruments to label tape cartridges.

v Erase a label; replace it instead.

Do:

v Remove dust on the outside of tape cartridges with a damp cloth.

v Store cartridges vertically, not horizontally.

v Store tape cartridges in their plastic containers and in the environmental

conditions recommended in your tape media documentation.

v Use bar code labels.

20 LTO Autoloader: User’s Guide

Page 29

Chapter 3. Autoloader configuration

This chapter describes how to configure the autoloader.

Note: After configuring the autoloader, you might need to turn on and off the host

computer for it to recognize the new configurations. This process causes the

configurations to be saved to permanent memory, which enables the settings

to be recovered if the unit is turned off for more than 8 days.

To change the autoloader’s configuration, select Main -->Administration-->Change

Configuration.

Retrieving autoloader information

The following information is available from the Information and Administration

front panel menus:

v Autoloader information

v Drive information

v Configuration information

v Date and time

v Firmware revisions

Autoloader information

To view information about the autoloader, select Main -->Information-->Loader

Information. Then select one of the options in the following table:

Menu Option Information

Loader Status Displays information about the overall status of the autoloader and any

partial availability flags.

Hard Error Log Displays a history of unrecoverable errors. Returns a message indicating that

there are no hard errors or provides an error entry. Use the Older or Newer

buttons to select an entry.

Recovered (Soft) Error Log Displays a history of recovered errors. Returns a message indicating that

there are no soft entries or supplies an error entry. Use the Older or Newer

buttons to select an entry.

Odometer Displays the number of times tapes have been moved.

Identity Displays the autoloader serial number.

Drive Information

To display drive information, select Main -->Information-->Drive Information.

Then select one of the options in the following table:

© Copyright IBM Corp. 2000 21

Page 30

Menu Option Information

Event Log Displays significant drive events, including drive errors, online and offline

transitions, and drive cleaning. This log is even available after removing

the drive.

Odometer Displays a count of cumulative power-on hours, number of times tapes

have been loaded into the drive, and power-on cycles.

Identity Displays drive type, serial number, and firmware revision.

Configuration Information

To view configuration information select Main -->Information-->View

Configuration. You can then view current information about the drive:

v Password enabled status

v Network access configuration

v Operating mode

v SCSI ID assignments

v Element (drive or slot) reservations

v Other configuration options (prevent media access, restore factory defaults,

report recovered error logs, and diagnostic configurations for service only).

Date and time

To view the date and time, select Main -->Information-->More-->Date and Time.

Access this menu to view the autoloader settings for the date, time, and time zone.

Use the Powered button to display the date and time when the autoloader was last

turned on. See “Setting the date and time” on page 10 for world date and times.

Firmware revisions

To view this menu, select Main menu-->Information-->Firmware Revisions.From

the Firmware Revisions menu, you can view information about the following:

v Autoloader

v Tape drive

Running autoloader diagnostics tests

Use the following procedure to run internal tests of autoloader functions. The

following table describes these tests.

1. Select Main-->Administration-->More-->Run Test .

2. From Run Test, use the [-] or [+] key to view available tests.

3. Select OK to select the test.

4. Select the number of times this test will run (if more than one cycle is available

and desired).

5. Select Run to start the test cycle. The test results will display at the conclusion

of the test cycle.

Note: Select Stop to halt a running test. The current test cycle completes and

the test stops. Stopping the test might take a few minutes.

22 LTO Autoloader: User’s Guide

Page 31

Test Description

Check Inventory Physically scans the entire autoloader to determine the location, status, and

barcode information of tapes.

Recalibrate Loader Performs the power-up self-tests. Each test runs one time per test loop. This

test recalibrates the mechanics and clears hard errors, but not the hard error

log.

Test Lateral Motion Moves the transport assembly to a random slot. No tape is required.

Test Magazine Moves Moves a tape from a random slot to an empty, random slot, and then

returns it to the original location.

Wellness Test Moves a tape from a random slot to an empty drive and back to its original

location.

Rewind Media Attention: Do not run this test if the drive contains a tape that is

receiving data from the host.

Rewinds the tape in the drive.

Lock Transport Locks the transport assembly in place to enable shipping the autoloader.

Note: The only way to unlock the transport after you run this test is to run

the Unlock Transport test or turn the autoloader off and then on.

Unlock Transport Unlocks the transport assembly if you want to unlock the transport without

turning the autoloader off and on. The transport must have already been

locked to use this test.

Test Transport Comm Exercises the internal infrared communications path between the autoloader

controller and the transport microcontroller. Reports the health of this link.

If the test passes, the infrared communication link is good.

Show All Sensors Dynamically displays the state of the door sensor. To toggle the door

sensor, open and close the door

Demonstration Attention: Run an inventory check from the host backup application after

performing this test because the tapes will be in a different order.

Selects a random full storage slot and moves the tape to the drive. The test

locates a full slot, a full drive, an empty slot, and then performs an

exchange.

Additional Tests Available for Service Personnel

Empty Drive Unloads a tape from the drive and returns it to its original location.

Fill Transport Attention: Unload the tape from the transport, and runan inventory check

from the backup software after performing this test.

Moves a tape from a random storage slot into the transport.

Empty Transport Attention: Run an inventory check from the backup software after

performing this test.

Moves the tape in the transport back to the original slot, or a different slot

if the original position is full. The test passes if the transport is successfully

emptied.

Clear Soft Log Clears all historical data from the Soft Error (recoverable error) Log.

Clear Hard Log Clears all historical data from the Hard Error (unrecoverable error) Log.

This test clears any “Hard Error” indicators on the front panel.

Find Plunge Home Moves the transport plunge mechanism to the back of the transport

assembly.

Clear Hard Log Clears all historical data from the Hard Error (unrecoverable error) Log.

This test clears any “Hard Error” indicators on the front panel.

Find Plunge Home Moves the transport plunge mechanism to the back of the transport

assembly.

Find Lateral Home Moves the transport to the extreme front right side of the autoloader and

then locates slot 2.

Test Lateral Encoder Moves the transport to the extreme front right side of the autoloader and

then to the extreme back right to check the distance and verify the

mechanics are moving consistently.

Chapter 3. Autoloader configuration 23

Page 32

24 LTO Autoloader: User’s Guide

Page 33

Chapter 4. Autoloader maintenance

This appendix contains information on how to remove and replace different

components and parts of the autoloader.

Attention: This autoloader contains very sensitive electronic components. It is

important to prevent electrostatic discharge (ESD). Use wrist grounding straps and

anti-static mats when removing and replacing cards and internal assemblies.

Removing and replacing parts

Removing and replacing the controller card

Attention: This autoloader contains very sensitive electronic components. It is

important to prevent electrostatic discharge (ESD). Use wrist grounding straps and

anti-static mats when removing and replacing cards and internal assemblies.

To remove the controller card, do the following:

1. Note the front panel configuration settings so that after you download

firmware, you can reset the autoloader configuration settings (see “Chapter 3.

Autoloader configuration” on page 21.)

2. Note how the autoloader is connected, and remove all external cables attached

to the controller card.

3. Loosen the two thumbscrews at the top of the card with a screwdriver or by

hand.

4. Remove the card by gently pulling it straight out from the autoloader.

To replace the controller card, do the following:

1. Align the top and bottom edges of the card with the recessed slots on the left

side of the autoloader.

2. Gently slide the controller to the back slot, ensuring that the card aligns with

the internal guide tracks.

3. Ensure that the front of the card is flush with the autoloader, and tighten the

thumbscrews.

4. Turn on the autoloader.

5. Download new firmware.

6. Configure the autoloader.

Removing and replacing drive modules

This sections explains how to replace a drive module.

Removing the LTO drive module

This section explains how to remove the LTO drive module.

Note: To preserve SCSI communications, do not loosen or remove the SCSI cable

connected to the outside of the drive module. The connection to be removed

is located inside the drive module.

© Copyright IBM Corp. 2000 25

Page 34

When the drive module has been successfully taken offline, the LED on the back of

the drive will be flashing yellow. To remove the drive module, do the following

steps.

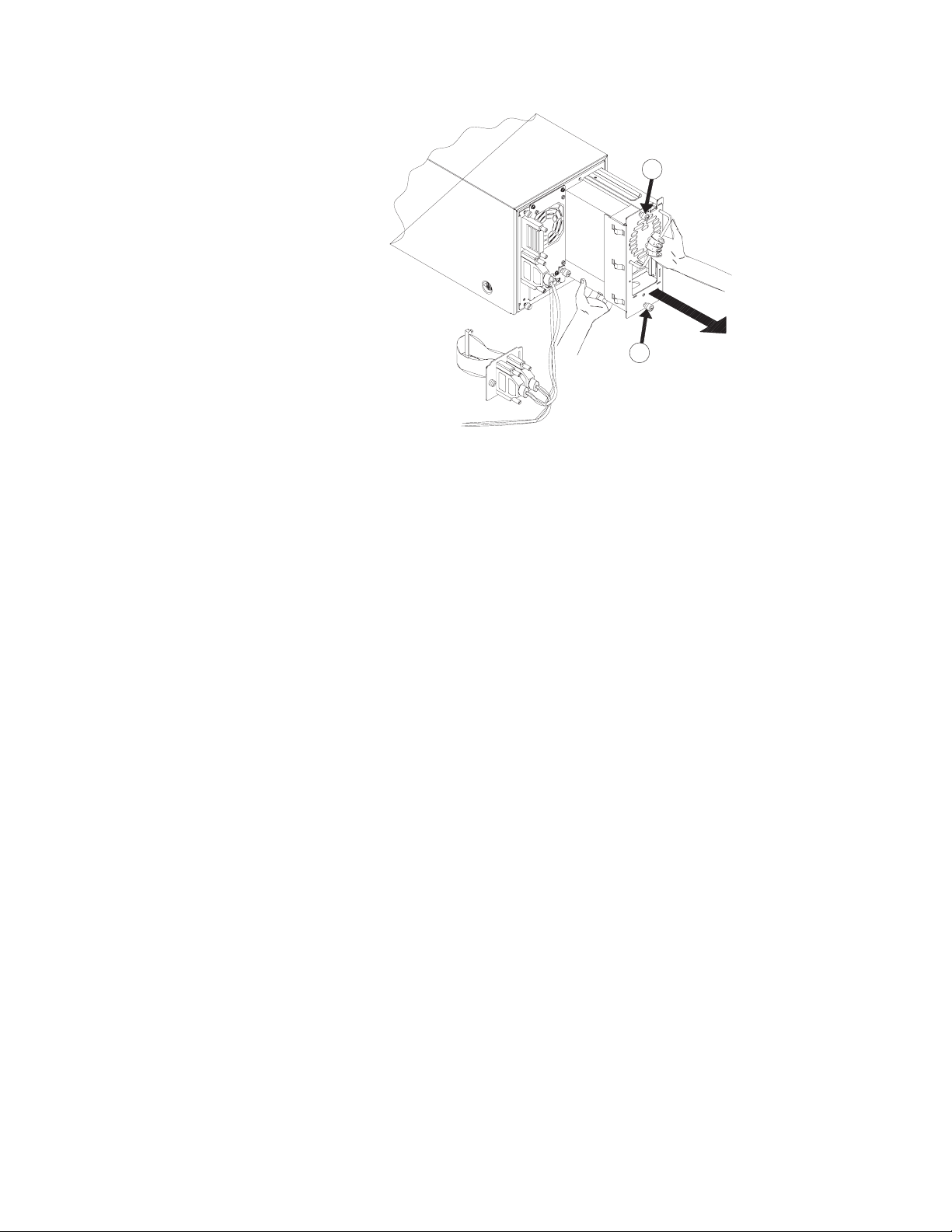

1. Verify that the external SCSI cable is securely fastened to the connector plate.

2. Loosen the thumbscrews on each side of the connector plate located in the

middle of the drive module. See the following illustration. If this is your fist

time loosening the thumbscrews, you may want to use a screwdriver.

3. Gently remove the connector plate and keep the SCSI cable connected.

CAUTION:

Use standard precautions for electro-static discharge (ESD) protection.

4. Grasp the ribbon cable that is plugged into the drive module. Remove the cable

by pulling the connector to the left. See the following illustration.

2

1

5. Lay the connector assembly to the side, allowing the external cables to hang

from the connector. Do not disconnect external cables from the connector plate.

6. Loosen the top and bottom thumbscrews on the drive module. See the

following illustration.

7. Using the handle that is mounted on the back of the drive module, pull the

drive module straight out with one hand while supporting the bottom of the

drive module with the other hand.

CAUTION:

As the drive module is pulled out. support the bottom of the drive module to

avoid dropping or damaging it.

26 LTO Autoloader: User’s Guide

Page 35

3

3

Unloading a tape from a drive

Before replacing a drive, unload any tape from the drive. Do the following steps:

1. Select Main-->Operations-->Drive and tape operation--> Unload tape from

Drive.

2. The tape is automatically rewound before it is unloaded.

Installing a drive module

To install a drive module, do the following:

1. Hold the drive module with one hand on the drive module handle while the

other hand supports the drive.

2. Install the drive by inserting the rail at the top of the drive module into the slot

at the top of the drive module opening. There is some resistance as the drive

connector engages with the connector on the autoloader.

3. Tighten the top and bottom thumbscrews by hand, securing the drive module

into the autoloader.

4. Connect the ribbon connector to the back of the drive module.

5. Gently fold the ribbon cable (attached to the plate and SCSI cable) into the back

of the drive module.

6. Holding the connector plate in place, tighten the thumbscrews by hand.

Chapter 4. Autoloader maintenance 27

Page 36

Upgrading Firmware

This section details the processes for upgrading autoloader and drive firmware.

Some of the processes used for upgrading autoloader firmware are different from

those used to upgrade drive firmware. Use the following steps:

4

3

3

Step1. Checking the Firmware revision

To check your current firmware revisions before downloading new firmware, do

the following:

1. Ensure the autoloader is powered on.

2. Use the Main-->Information-->Firmware Revisions menus on the front panel.

Step 2. Download the new Firmware

To download the new Firmware, do the following:

1. Go to www.ibm.com/pc/support.

2. Select Options.

3. Select Tape Backup.

4. Select Tape Library 3600.

5. Select your model.

6. Select Download Files.

7. Download the latest Firmware file and follow the README installation

instructions.

Moving or shipping the autoloader

To move or ship the autoloader, do the following:

1. Verify that the drive is empty.

2. If the drive contains a tape, unload it. Refer to the backup software

documentation, or use the front panel menu (see “Unloading a tape from the

drive” on page 17).

3. Remove all tapes from the autoloader.

4. When shipping, lock the transport by running the Lock Transport front panel

test to prevent damage.

28 LTO Autoloader: User’s Guide

Page 37

Attention: Do not turn off the autoloader until the interface is inactive.

Removing power from a SCSI peripheral when the bus is active can result in

data loss and indeterminate bus states. If your computer is connected to a

LAN, be sure to check with your system administrator before turning off the

device.

5. Turn off the autoloader. The power “standby” switch is recessed to avoid

accidental power cycles. Disconnect the power cable.

6. To ship the autoloader, remove all external cords, cables, and terminators. For

an internal move, only disconnect the power cable, remote management card

cable, and SCSI cable to the host.

Note: You do not need to remove the SCSI cable that connects the controller to

the drive module unless the autoloader is being shipped.

7. Re-install the internal packaging to secure the magazine inside the autoloader

(see“Remove the autoloader and its internal packaging” on page 5 ).

8. Place the autoloader into the original packaging box. If you no longer have the

original packaging, contact your service representative to purchase the

packaging kit.

Chapter 4. Autoloader maintenance 29

Page 38

30 LTO Autoloader: User’s Guide

Page 39

Chapter 5. Error messages, troubleshooting, and problem solving

This chapter includes information on types of and codes for error messages,

troubleshooting techniques, and solutions for problems you might encounter.

Understanding error states

This section describes the differences between the following types of errors:

v Soft (recovered) errors

v Errors that result in partial availability

v Hard (unrecoverable) errors

v Host software and media errors

Soft (recovered) errors

Soft errors are hardware errors that the autoloader recovered from by retrying the

operation. Although soft errors are often transparent to a user, they are logged in

the soft-error log. To access the error log, select Main menu-->Information--

>Loader Information-->Soft (recovered) errors.

Periodically review the soft error log to monitor and track errors before they

become serious. If you see that a component has many soft errors, it might indicate

an autoloader component that is likely to fail. If the autoloader has a hard error

(see “Hard (unrecoverable) errors” on page 33) and you are unsure what caused it,

you can review the soft error log to help identify problem areas.

You can also use soft errors to identify the reason for backup software timeouts.

The backup software on the host computer allows for only a designated time for

each operation. If the autoloader takes longer than the backup software allows, it

might be due to the autoloader retrying a failed operation.

© Copyright IBM Corp. 2000 31

Page 40

Note: The date and time stamp will help you identify errors.

Monitor and track

components that might

fall.

Review the soft error log

to:

Partial availability state

When the autoloader is in the partial availability state, it is still functional, but has

a condition that needs attention (see “Partial availability conditions”). Partial

availability does not indicate a hardware error. With partial availability, the LED

under the display is solid amber until you correct the problem. A partial

availability state from the default home screen will look similar to the following

example. The front panel uses the term Partly Available because of display size

limitations.

See error history to

determine why other

errors have occurred.

Identify the reason for

backup software

timeouts.

The middle icon button on the Home screen is a shortcut to the Loader Status

menu and partial availability information. To view more information about the

partial availability error, you can also access the log by selecting Main

menu-->Information-->Loader Information-->Loader Status.

Partial availability conditions

The partial availability state is caused by one of the errors described in the

following table.

Displayed error

message

Drive not present Autoloader could not detect

32 LTO Autoloader: User’s Guide

Causes Recovery actions

the drive module.

Chek that the drive is correctly installed and online. See

“Drive and tape operations” on page 17.

Page 41

Displayed error

message

Drive offline The drive was taken offline

Drive online pending Drive is turned on but has

Drive needs cleaning Drive needs cleaning. Clean the drive. See “Cleaning a drive” on page 17.

Drive critical error Critical error occurred on the

Firmware update

needed

Incompatible magazine The magazine is

Fan failure Fan has failed. Turn the autoloader off and then on.

Magazine missing Autoloader could not detect

Door open Front door is open. Close the door.

Remote management

card not present

Front panel not present Autoloader could not detect

Remote management

card failed

Front panel failed Front panel display failed on

Date and time not set The date and time are not set

Causes Recovery actions

Turn the autoloader off and then on. Ensure that the drive

because of the following:

v User took drive offline

using front-panel controls

v Host computer took drive

offline

v Drive failed power-on test

v Drive failed serial

communication with

autoloader

v Drive failed to load or

unload tape

outdated firmware.

drive.

Autoloader component has

incompatible firmware with

the rest of the autoloader.

incompatible with the drive

type.

the magazine.

Autoloader could not detect

the remote management

card.

the front panel display.

Remote management card

failed power-up test.

power-up test.

on the front panel.

is correctly installed and online. Put drive back online

from the front panel. Check the error log from the front

panel or remote management card.

Download new drive firmware. See “Firmware revisions”

on page 22.

Check the drive error logs. See “Accessing error log files”

on page 37.

Download new loader firmware. See “Firmware revisions”

on page 22.

Use the correct magazine for the autoloader drive.

Ensure that the magazine is present and correctly installed.

Check that the remote management card is correctly

installed.

Turn the autoloader off and then on.

Check that the remote management card is correctly

installed.

Turn the autoloader off and then on.

Set the date and time. See “Setting the date and time” on

page 10.

Hard (unrecoverable) errors

Note: The hard error codes are described on the front panel and in this appendix.

When a hard error occurs, the front panel will display Hard Error and the LED bar

will flash amber. The front panel will automatically display information about the

error, shown in the following illustrations. You cannot operate the autoloader until

this error is resolved.

Chapter 5. Error messages, troubleshooting, and problem solving 33

Page 42

Error information includes the following:

v Time stamp of error event

v Error code number

v Autoloader component that might have caused the problem

v Error code description

v Recovery actions

v Error code qualifier that provides more information on the type of error

v Sequence numbers, which are used for factory diagnostics

View the hard error log to see the sequence of error events and more information

on resolving the error condition. To view this log, select Main

menu-->Information-->Loader Information-->Hard Error Log or press the middle

(shortcut) button.

Note: When you are reviewing the error log, select Older to view error history

and Newer to see more recent errors.

Also, the date and time stamp will help you identify errors.

To retrieve more information about an error, follow these steps:

1. From the screen with the initial error message or from the Hard Error Log

screen, select More to retrieve more information about that error, which might

include the following:

2. Record all information from this screen for later reference.

3. Select More. Record the list of recommendations on this and any subsequent

screens. To retrieve the same information after you exit, view the latest entry in

the hard error log.

4. Perform the recovery actions in the order presented. Continue with each

successive action until the problem is isolated.

The front panel might display recovery actions such as the following:

v Turn the autoloader off and then on.

v Remove a tape from the drive.

v Check the autoloader or host configuration.

v Check the cable connections (data or power).

v Run front-panel diagnostic tests. Diagnostic tests are run to help identify and

clear the error condition.

v Reposition a tape or magazine.

v Upgrade firmware.

5. If the problem persists after implementing all of the actions presented on the

front panel display, contact your service representative.

34 LTO Autoloader: User’s Guide

Page 43

Host software and media errors

Verify the

autoloader

hardware is

correctly

operating.

Verify the

software is

supported and

correctly

configured.

Look for

connection

errors with the

host and

network.

Ensure the LED on the front panel is not flashing amber.

Flashing amber indicates a hardware error.Check the hard

and soft error logs.

Ensure the backup software has the Loader Module or

Changer option to communicate with the autoloader robotics or

use the Stacker operating mode from the autoloader front panel

Run a Wellness Test from the autoloader front panel.

Check the software configuration.Ensure the SCSI ID’s are

correct on the backup software application.

Use a different backup software application (if available) and

see if similar errors occurs.

Ensure the host can identify the autoloader and drive.

Ensure the SCSI host bus adaptor card and the drives are

compatible and correctly installed.

Check all cable connections.Ensure the SCSI bus is properly

terminated.

The autoloader depends on several other components to operate correctly. Many

errors that appear to be caused by the autoloader are often a result of errors on the

host, the network, or with the backup software.

When troubleshooting the autoloader, begin by ruling out these other components.

Here are some troubleshooting procedures to help determine if an error is caused

by the autoloader hardware, host, or backup software.

The table that follows describes error code qualifiers.

Chapter 5. Error messages, troubleshooting, and problem solving 35

Page 44

Error code

Qualifiers

0 00H Qualifier code is unknown. Check the error code.

0 0AH Plunge motion system detected

11 0BH Plunge motion system detected

12 0CH Plunge motion system detected

13 0DH Plunge motion system timed

19 13H Translate motion system

20 14H Translate motion system

21 15H Translate motion system

22 16H Translate motion system

26 1AH Translate motion system failed

29 1DH The translate motion system

33 21H Failed to detect a cartridge in

36 24H Drive module failed to eject a

37 25H Failed to detect the drive

42 2AH Drive module is missing or not

47 2FH Drive module fan is not

48 30H Failed to detect that the

50 32H Failed to detect the magazine

54 36H Failed to detect the magazine

56 38H Failed to empty the transport

60 3CH Internal communication on I2C

83 53H Failed during a diagnostic test. Run Recalibrate Loader test, followed by Check

86 56H Timed out on a command sent

87 57H A command to the transport

36 LTO Autoloader: User’s Guide

88 58H Attempted to overlap

Hex error Description Recovery procedure

Check the error code. Clear the transport path.

an over voltage.

Turn off the unit. Clear the transport path. Turn on

an over force.

an error.

out.

detected an unknown error.

detected an over voltage.

detected an over force.

detected an error.

to detect a hardstop or the

edge of the frame.

attempted a move when it was

not ready.

the drive.

tape.

hardstop while loading a tape.

communicating.

working properly.

transport has loaded a tape.

hardstop while loading a tape.

hardstop while removing a

tape.

during an inventory check.

bus has failed.

to the transport controller.

controller was corrupted.

commands to the transport

the unit.

Turn the unit off and then on. Clear the transport

path.

Turn the unit off and then on.

Check the error code. Clear the transport path.

Clear the transport path.

Turn off the unit. Clear the transport path.

Turn the unit off and then on. Clear the transport

path.

Run Recalibrate Loader test. Run Test Lateral

Encoder test.

Run Recalibrate Loader from panel test.

Run Recalibrate Loader test, followed by Check

Inventory test. Turn the unit off and then on.

Take the drive off- and online. Turn the unit off and

then on.

Run Recalibrate Loader test, followed by Check

Inventory test. Turn the unit off and then on.

Check that the drive is installed and online.

Check for obstructions in the drive fan. Try bringing

the drive back online. Replace the drive.

Run Test Lateral Loader test, Recalibrate Loader test,

followed by Check Inventory.

Run Test Lateral Loader test, Recalibrate Loader test,

followed by Check Inventory.

Run Recalibrate Loader test, followed by Check

Inventory test. Turn the unit off and then on.

Ensure there is a vacant slot. Run Recalibrate

Loader test, followed by Check Inventory test.

Run Recalibrate Loader test, followed by Check

Inventory test. Turn the unit off and then on.

Inventory test. Run diagnostic again.

Verify that the transport LEDs are on and green.

Clear any obstructions from the transport path.

Turn the unit off and then on.

Run Recalibrate Loader test. Clear the transport

path. Turn the unit off and then on.

Page 45

Finding and identifying error information

The following sections describe information on accessing log files and using LEDs

to determine status.

Accessing error log files

You can access error log files for the types of errors listed as follows.

v Soft (recovered) errors: Contains a log of minor errors, which is helpful in

identifying errors that might indicate an underlying problem or lead to major

errors. (See “Soft (recovered) errors” on page 31.)

v Partial availability errors: Indicates a current condition that needs attention, but

enables you to still fully operate the autoloader. (See “Partial availability state”

on page 32.)

v Hard (unrecoverable) errors: Contains a log of major errors that needed to be

resolved. (See “Hard (unrecoverable) errors” on page 33.)

v Drive event log: Contains a log of drive errors and events.

Menu paths

Soft (recovered) error log

Main menu-->Information-->Loader Information-->Soft (recovered) error

log

Partial availability

Main menu-->Information-->Loader Information-->Loader Status

Hard (unrecoverable) error log

Main menu-->Information-->Loader Information-->Hard Error Log

Drive event log

Main menu-->Information-->Drive Information-->Event Log

Using LEDs to determine status

LEDs communicate status and errors as they are occurring. Use the following LED

conditions for more information on how the autoloader is functioning.

Front panel LEDs

Color Description

Green The autoloader is ready.

Flashing green The autoloader is active and in

the process of performing a

function.

Solid amber The autoloader is partially

available (the autoloader is not

fully functional, but can still be

used).

Flashing amber A hard error has occurred. You

cannot operate the autoloader

until resolving the error.

Chapter 5. Error messages, troubleshooting, and problem solving 37

Page 46

LVDS library controller card LED

1) Controller LED

Color Description

Flashing green Controller needs boot code.

Yellow In the process of powering up.

Yellow n flashes

Pause

Yellow n flashes

Green Controller passed power-on test.

2) SCSI LED

Color Description

Green No bus connected or low voltage differential SCSI bus

Flashing green Single-ended SCSI bus attached. SCSI performance

Yellow Incorrect SCSI bus type. Single-ended, low-voltage

Controller failed power-on test.

n=1; ROM error

n=3; microprocessor error

n=4; controlled RAM error

n=5; non-volatile RAM error

n=6; volatile RAM error

connected.

may be reduced. SCSI cable length restrictions apply.

terminator attached.

38 LTO Autoloader: User’s Guide

Page 47

Drive module LEDs

1) Yellow 2) Green Description

Off On Drive is online and available.

Flashing Off Drive is offline and can be

replaced without turning off the

autoloader.

On Flashing Drive is being brought online.

Flashing On Drive is offline. Internal

communication to the controller

has been lost.

On On Drive module controller is in

reset.

On Off Power-on test in progress.

Note: Depending on your autoloader drive type, the back of the drive module might look different from the

previous illustration.

Chapter 5. Error messages, troubleshooting, and problem solving 39

Page 48

Troubleshooting common problems

The following table describes how to troubleshoot autoloader problems. For

problems that might be related to the host or application software, refer to the host

system documentation or the application software instructions.

Attention: Consult the system administrator before turning the autoloader off

and then on. Never do this procedure when active devices are connected to the

SCSI bus. Turning the autoloader off and then on when the SCSI bus is active can

cause data loss or cause the host system to stop responding.

40 LTO Autoloader: User’s Guide

Page 49

Problem Recovery actions

Power

Autoloader will not turn on Check the power cord connection. Make sure the power (standby)

switch is on. Make sure there is power to the outlet. Try another

working outlet. Replace the power cord. Check that the LEDs on the

back of the autoloader are on and the fans are turning to ensure the

autoloader is receiving power.

Power-on test failed. An error message on

the front panel is displayed.

Verify that all tapes are fully inserted in the magazine and that athe

magazine is fully installed inside the autoloader. Check that the internal

packaging has been removed. Make sure the door is closed. If the

power-on test fails again, look at the error code and refer to

“Understanding error states” on page 31 for more information.

The autoloader power failed while a tape

was in the drive and did not return to the

Check that the LEDs on the back of the autoloader are on and the fans

are turning. Turn the autoloader off and then on.

ready state after the power came on.

Tape Movement

An error message is displayed after

inserting the magazine or loading tapes.

Verify that the tapes are inserted correctly in the magazine. (See

“Accessing tapes in the autoloader” on page 15.)

Tape stuck in drive. Turn the unit off and then on and retry unloading the tape from the

autoloader front panel. Ensure the backup host software is not reserving

the slot. The backup software needs to cancel the reservation.

Tape stuck in transport. Run the Recalibrate Loader test. Open the door. Remove the magazine

and then gently ease the tape out of the transport. Do not grasp the

back of the transport assembly. Call your service representative.

Tape stuck in back storage slot. Using the front panel display, open the door. Pull the door down, and

remove the magazine. Push the tape into the back slot until it clicks into

the slot. Push the tape in again until it clicks and releases.

Transport will not load or unload a tape. Run the Recalibrate Loader test. Ensure you are using the correct tape

type and magazine for your autoloader drive configurations.

Media

Tapes or cleaning cartridge incompatible

with drive.

Ensure you are using media and a cleaning cartridge that is compatible

with the drive.

Connections

Host does not detect the autoloader. Check that the autoloader is terminated and properly cabled. Ensure the

terminator and host bus adapter card are compatible with the

autoloader and SCSI bus type (HVDS or LVDS). Check that the

autoloader is recognized by the operating system. Check that the SCSI

host bus adapter card and backup software are compatible with the

autoloader.

Backup software application on the host

does not detect the autoloader.

If the backup software detects the drive, but not the autoloader, check

that the Autoloader Module or Changer Option is included with the

backup software. Most software packages require an addtiional module

to communicate with the autoloader robotics. If the backup software

detects the autoloader and not the drive check that you have installed

the correct backup software driver and that there are no conflicting

drivers installed.

Changed drive SCSI ID, but the new ID is

not recognized by the host computer.

Check that all SCSI devices on the same bus have different ID numbers.

Restart the host. If the drive remains at SCSI ID 5, regardless of how it

is set, then the drive is not communicating with the autoloader. Call

your service representative.

Host responds slowly or stops responding

after connecting to the autoloader.

Check the SCSI IDs of all devices on the host to ensure there are no

conflicts. Check that the backup software does not require SCSI IDs to

be in a certain order.

Network Monitoring and Operations

The remote management card interface is

slow in updating the Web pages or does

not display clearing.

Check your computer display settings. For est results, make sure the

display resolution is set to 800 x 600 and the color palette is set to 65535

colors or higher. To speed up the display of pages, be sure to bypass

Chapter 5. Error messages, troubleshooting, and problem solving 41

Page 50

42 LTO Autoloader: User’s Guide

Page 51

Appendix A. Help and service information

This section contains information on how to obtain online and telephone technical

support.

Online technical support

Online technical support is available during the life of your product. Online

assistance can be obtained through the Personal Computing Support Web site and

the IBM Automated Fax System.

Online technical support

IBM Personal Computing Support Web site http://www.ibm.com/pc/support

IBM Automated Fax System 1-800-426-3395 (U.S. and Canada)

During the warranty period, assistance for replacement or exchange of defective

components is available. In addition, if your IBM option is installed in an IBM

computer, you might be entitled to service at your location. Your technical support

representative can help you determine the best alternative.

Telephone technical support

Installation and configuration support through the HelpCenter will be withdrawn

or made available for a fee, at IBM’s discretion, 90 days after the option has been

withdrawn from marketing. Additional support offerings, including step-by-step

installation assistance, are available for a nominal fee.

To assist the technical support representative, have available as much of the

following information as possible:

v Option name

v Option number

v Proof of purchase

v Computer manufacturer, model, serial number (if IBM), and manual

v Exact wording of the error message (if any)

v Description of the problem

v Hardware and software configuration information for your system

If possible, be at your computer. Your technical support representative might want

to walk you through the problem during the call.

For the support telephone number and support hours by country, refer to the

following table or to the enclosed technical support insert. Support phone numbers

are also available by clicking HelpCenter phone list on the IBM support Web page

at

http://www.ibm.com/pc/support

If the number is not provided, contact your IBM reseller or IBM marketing

representative. Response time may vary depending on the number and nature of

the calls received.

© Copyright IBM Corp. 2000 43

Page 52

Support 24 hours a day, 7 days a week

Canada (Toronto only) 416-383-3344

Canada (all other) 1-800-565-3344

U.S.A. and Puerto Rico 1-800-772-2227

44 LTO Autoloader: User’s Guide

Page 53

Appendix B. Product warranties and notices

Warranty Statements

The warranty statements consist of two parts: Part 1 and Part 2. Part 1 varies by

country. Part 2 is the same for both statements. Be sure to read both the Part 1 that

applies to your country and Part 2.

v United States, Puerto Rico, and Canada (Z125-4753-05 11/97) (see “IBM

Statement of Limited Warranty for United States, Puerto Rico, and Canada (Part

1 - General Terms)”)

v Worldwide except Canada, Puerto Rico, Turkey, and United States

(Z125-5697-01 11/97) (see “IBM Statement of Warranty Worldwide except

Canada, Puerto Rico, Turkey, United States (Part 1 - General Terms)” on page 48)

v Worldwide Country-Unique Terms (see “Part2-Worldwide Country-Unique

Terms” on page 51)

IBM Statement of Limited Warranty for United States, Puerto Rico, and Canada (Part 1 - General Terms)

This Statement of Warranty includes Part 1 - General Terms and Part 2 - Country-unique

Terms. The terms of Part 2 may replace or modify those of Part 1. The warranties

provided by IBM in this Statement of Warranty apply only to Machines you purchase for

your use, and not for resale, from IBM or your reseller. The term ″Machine″ means an

IBM machine, its features, conversions, upgrades, elements, or accessories, or any

combination of them. The term ″Machine″ does not include any software programs,

whether pre-loaded with the Machine, installed subsequently or otherwise. Unless IBM

specifies otherwise, the following warranties apply only in the country where you acquire

the Machine. Nothing in this Statement of Warranty affects any statutory rights of

consumers that cannot be waived or limited by contract. If you have any questions, contact

IBM or your reseller.

Machine - LTO Autoloader

Warranty period* - One (1) year

* Contact your place of purchase for warranty service information. Some IBM Machines are eligible for on-site warranty service

depending on the country where service is performed.

The IBM Warranty for Machines

IBM warrants that each Machine 1) is free from defects in materials and

workmanship and 2) conforms to IBM’s Official Published Specifications. The

warranty period for a Machine is a specified, fixed period commencing on its Date

of Installation. The date on your sales receipt is the Date of Installation, unless IBM

or your reseller informs you otherwise.

During the warranty period IBM or your reseller, if approved by IBM to provide

warranty service, will provide repair and exchange service for the Machine,

without charge, under the type of service designated for the Machine and will