Page 1

Basic Purpose Printer

LB20

User’s Guide

Part number: EK-LB20A-UG.001

Page 2

ACKNOWLEDGMENT

IBM, PC, XT, AT, PS/2, Proprinter and 4722 are

registered trademarks of International Business

Machines Corporation

MS-DOS, Windows 3.1x, Windows 95 and

WindowsNT are trademarks of Microsoft

Corporation.

A publication of:

DIGITAL EQUIPMENT BCFI AB

P.O. Box 904

S-175 29 Järfälla, Sweden

Printed in Sweden, March, 1997

© Digital Equipment Corporation, 1997.

All rights reserved

The information in this document is subject to change

without notice and should not be construed as a

commitment by Digital Equipment Corporation.

Digital Equipment Corporation assumes no

responsibility for any error which may appear in this

document.

Digital conducts its business in a manner that

conserves the environment and protects the safety and

health of its employees, customers, and the

community.

Digital, the Digital logo, DECbank and FBS are

trademarks of Digital Equipment Corporation.

Part number: EK-LB20A-UG.001

Page 3

CONTENTS

1 INTRODUCTION 1-1

1.1 Scope 1-1

1.2 Related Documentation 1-1

1.3 Order Process 1-2

1.4 Warnings, Cautions and Notes 1-2

1.5 Manufacturers Declaration 1-3

2 INSTALLATION 2-1

2.1 Preparation 2-1

2.2 Operating Space 2-2

2.3 Removal of transport locks 2-3

2.4 Trapdoor, Lid and Document Guide 2-4

2.5 Connections and Settings 2-5

2.6 Ink Ribbon Cassette 2-6

2.6.1 Power On 2-6

2.6.2 Unpacking the Ink Ribbon Cassette 2-7

2.6.3 Centering the Skid 2-7

2.6.4 Raising the Carrier 2-8

2.6.5 Positioning the Ink Ribbon Cassette 2-8

2.6.6 Installing the Ink Ribbon Cassette 2-9

2.6.7 Installing the Skid 2-9

2.6.8 Removing Slack Ribbon 2-10

2.6.9 Ready to Print 2-10

3 SETUP 3-1

3.1 Introduction 3-1

3.1.1 Setup Functions 3-1

3.1.2 Setup Controls 3-2

3.1.3 Menu’s and Parameters 3-2

3.1.4 Changing or Viewing the Setup 3-3

3.2 Setup Example 3-4

3.2.1 Entering Setup 3-5

3.2.2 Loading a Document 3-6

3.2.3 Moving to VIEW or a Menu 3-7

3.2.4 Printing the Current Settings 3-8

3.2.5 Changing a Setting 3-8

3.2.6 Validating 3-9

3.2.7 Quitting 3-9

Page 4

3.3 Setup Check 3-9

3.4 Performing a Setup 3-10

3.4.1 COM Menu 3-10

3.4.2 IBM Menu 3-10

3.4.3 DOC Menu 3-12

3.4.4 <>DFT Menu 3-18

3.4.5 <>HQD Menu 3-18

4 OPERATION 4-1

4.1 Controls and Indications 4-1

4.1.1 Confidence Test Routine 4-2

4.2 Documents 4-2

4.2.1 New Pages 4-2

4.2.2 Loading a Document 4-3

4.2.3 Stop while printing 4-4

4.2.4 Clearing Document Jams 4-4

5 MAINTENANCE 5-1

5.1 Ink Ribbon Cassette 5-2

5.1.1 Centering the Skid 5-2

5.1.2 Raising the Carrier 5-3

5.1.3 Removing the Skid 5-3

5.1.4 Removing the Old Ink Ribbon Cassette 5-4

5.1.5 Cleaning 5-4

5.1.6 Unpacking the New Ink Ribbon Cassette 5-4

5.1.7 Positioning the New Ink Ribbon Cassette 5-5

5.1.8 Installing the New Ink Ribbon Cassette 5-5

5.1.9 Reinstalling the Skid 5-6

5.1.10 Removing Slack Ribbon 5-6

5.2 Mylar Cassette 5-7

5.2.1 Centering the Skid 5-7

5.2.2 Raising the Carrier 5-8

5.2.3 Removing the Mylar Cassette 5-8

5.2.4 Inspecting the Mylar Edges (Bottom View) 5-9

5.2.5 Checking for Free Movement (Top View) 5-10

5.2.6 Reinstalling the Mylar Cassette 5-10

5.2.7 Positioning the Slider 5-11

Page 5

5.3 Printhead 5-12

5.3.1 Preparation 5-12

5.3.2 Removing the Trapdoor 5-13

5.3.3 Releasing the Printhead 5-13

5.3.4 Lowering the Carrier 5-14

5.3.5 Removing the Printhead 5-14

5.3.6Reinstalling the Printhead 5-15

5.4 Cleaning of Edge Detection Sensor and Mylar Slide Hole 5-16

5.5 Cleaning the Feed Rollers 5-17

5.6 Ready to Print 5-18

6 SPECIFICATIONS 6-1

6.1 Printer Characteristics 6-1

6.2 Serial Interface - RS232C 6-2

6.2.1 Configurable Parameters 6-2

6.2.2 Serial Connector 6-2

6.2.3 Handshaking 6-3

6.3 Parallel Interface - Centronics 6-4

6.4 Documents 6-5

6.4.1 Recommendations and Restrictions 6-7

6.4.2 Passbook Thickness 6-7

6.4.3 Center Outfold Bulge 6-8

6.4.4 Passbook Squareness 6-8

7 GLOSSARY 7-1

Page 6

1 INTRODUCTION

The LB20 Printer is delivered as one of the following:

• 9 pin dot matrix Serial printer (Model: LB20A-AA)

OR

• 9 pin dot matrix Parallel printer (Model: LB20B-AA)

When installed the printer forms an integrated part of a User’s Information System

and provides a printing function in IBM ProprinterIII emulation for the following

types of document:

• Passbooks - vertical or horizontal seam

• Envelopes

• Forms

The printer is simple to install, operate and maintain and provides a guaranteed

Print Quality for documents of thickness 0.0787 in (2 mm) or less.

1.1 Scope

This User Guide contains the following chapters:

• Introduction

• Installation

• Setup

• Operation

• Maintenance

• Specifications

• Glossary

1.2 Related Documentation

• Programmers Reference Guide (EK-LB20A-RG)

• Field Support Manual (EK-LB20A-SM)

• Spare Part Guide (EK-LB20A-PG)

Introduction 1-1

Page 7

1.3 Order Process

Documentation, Accessories and Spare Parts shall be ordered from:

Digital Equipment BCFI AB, Attn. Orderdesk

P.O.Box 904

175 29 Järfälla, Sweden

Telephone: +46 8 759 4600

Facsimile: +46 8 621 1718

1.4 Warnings, Cautions and Notes

WARNING!

This type of safety instruction is used where there is a danger of injury to persons

and/or damage to the equipment or the environment. The symbol inside the triangle

indicates type of danger.

CAUTION!

This type of safety instruction is used where danger of injury to persons and/or

damage to the equipment or the environment can occur, if the instruction is not

followed.

NOTE!

Notes are used to provide important or explanatory information.

Introduction 1-2

Page 8

1.5 Manufacturers Declaration

Document Number: S960242-1

This is to certify that the Digital Equipment BCFI AB, product indicated below

complies with the requirements on the EEC-Directives and/or other Standards as

indicated below and has been officially released for normal delivery to customers

and equipped with the CE-mark.

PRODUCT DESCRIPTION: Terminal Printer

DIGITAL MODEL NUMBER: LB20A-AA, LB20B-AA

This certificate is a confirmation of full compliance with the following regulations:

EEC-directive 89/336/EEC: "Electromagnetic Compatibility"

*EN 50081-1 (Emission EN 55022/1985)

*EN 50082-1 (Emission IEC 801-2, -3, -4)

EEC-Low Voltage Directive (LVD) 73/23/EEC of February 19, 1973

"Safety of Information technology equipment including electrical business

equipment"

*EN60950, 1992 + A1 + A2 + A3

Järfälla, 1996-12-19

Lars-Erik Högquist

Product Safety Manager

Introduction 1-3

Page 9

2 INSTALLATION

Perform the actions described and illustrated under the headings:

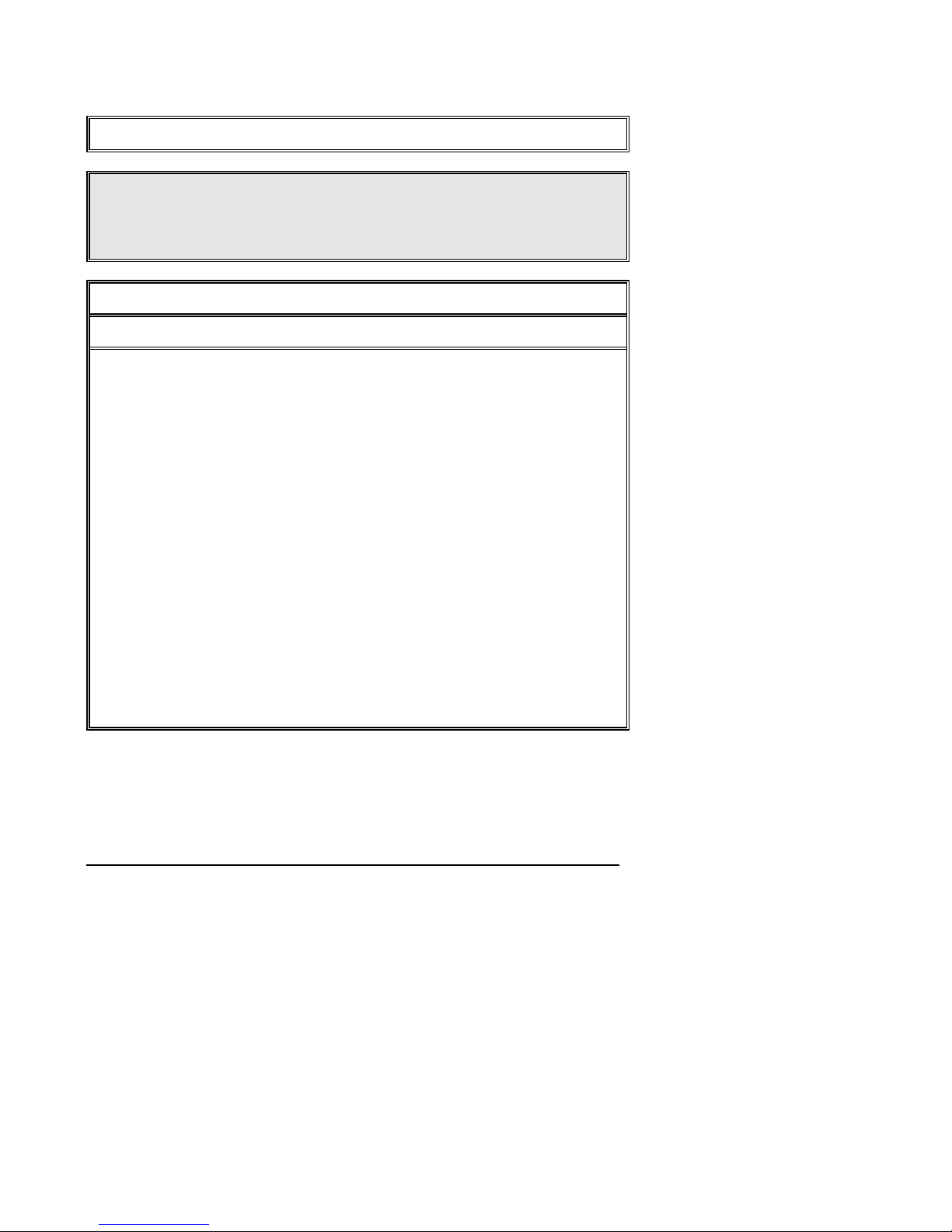

2.1 Preparation

Open the packing carton at one end, pull out the two foam sections and unpack the

following:

1. Mains Power Cable

2. Printer

3. User’s Guide

4. Ribbon Cartridge Box

5. Document Guide

6. Trapdoor

Note: If possible store the packing carton for future use

WARNING !

Make sure that the mains outlet connector in the building is a

Class-1 outlet with protective earth, easily accessible and the fuse

in the building protects against earth fault.

Installation 2-1

Page 10

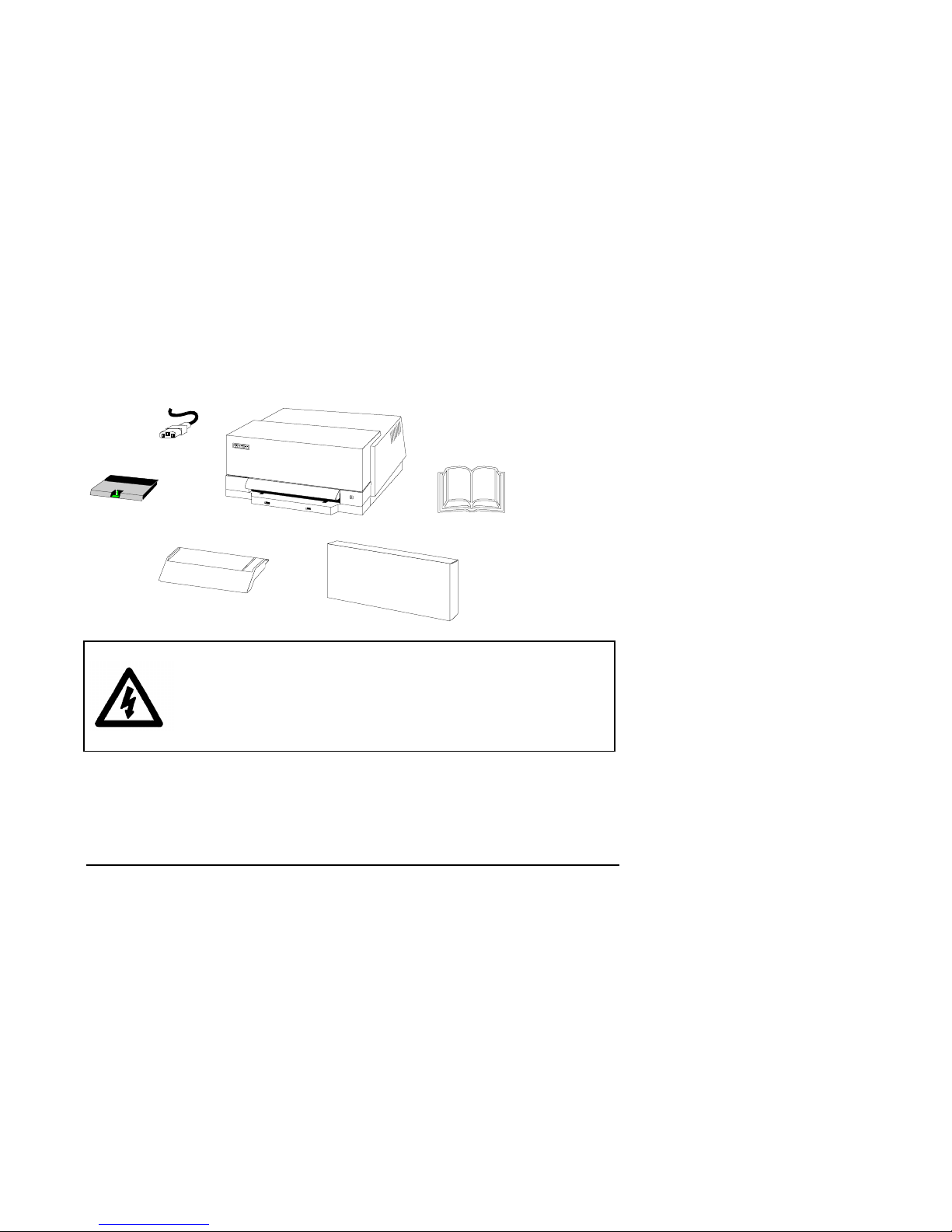

2.2 Operating Space

Place the printer on a flat, horizontal surface in a clear area as follows:

1. Back - 8in (203 mm) for document removal.

2. Sides - 4in (101mm) for air cooling.

3. Front - 10in (254 mm)for document loading.

Note: If necessary, allow further space for power and communication cable routing.

1

2

3

Installation 2-2

Page 11

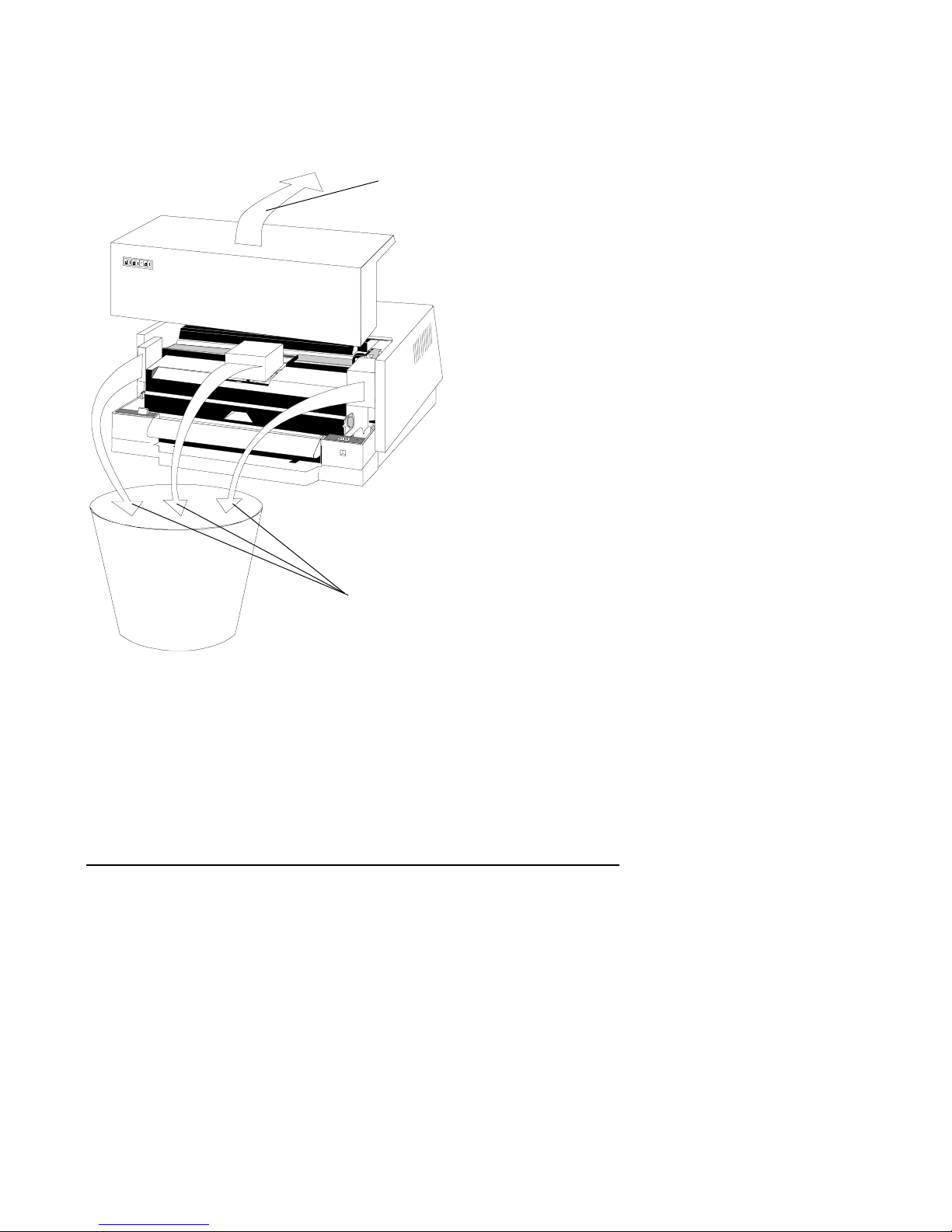

2.3 Removal of transport locks

1. Lid - lift and remove.

2. Packing - remove and discard.

1

2

Installation 2-3

Page 12

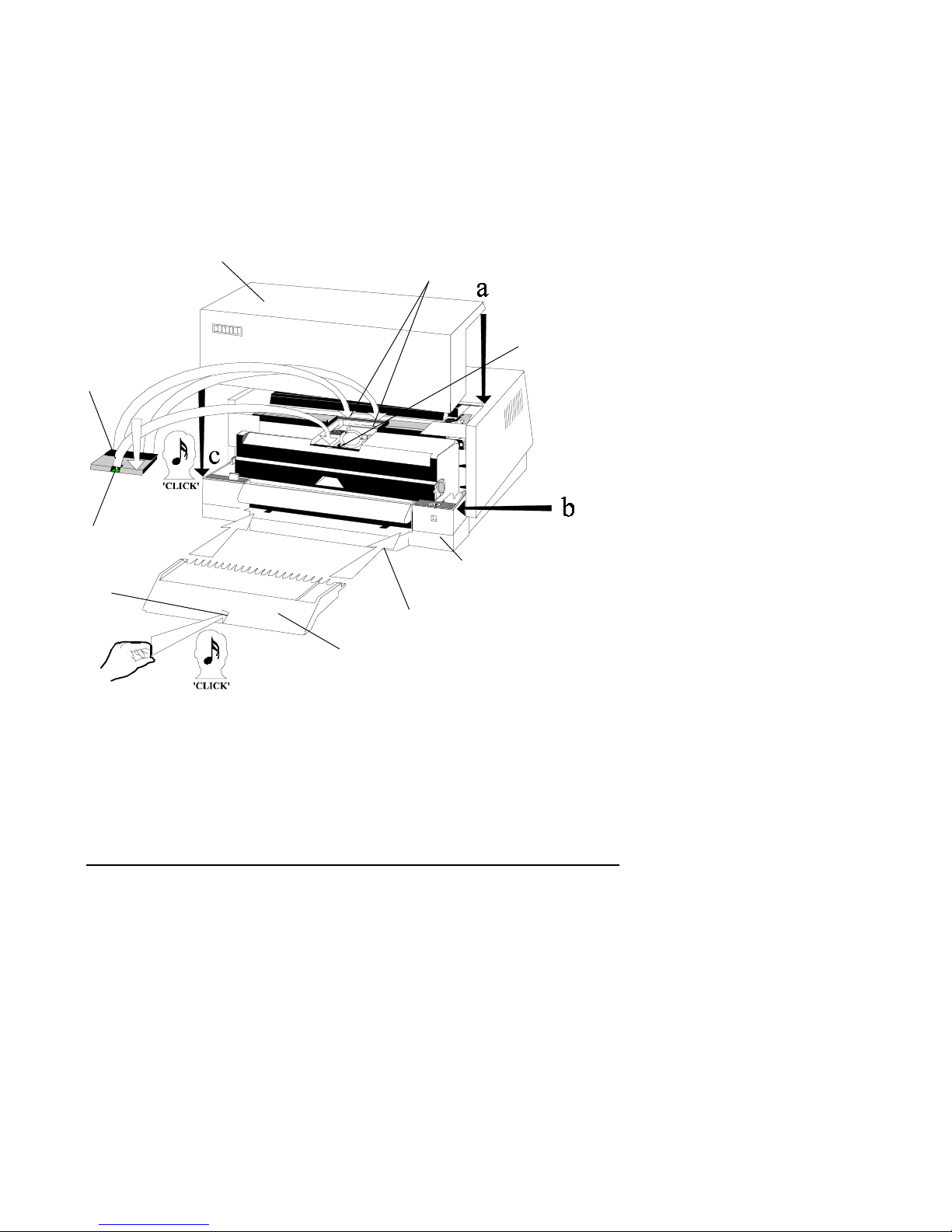

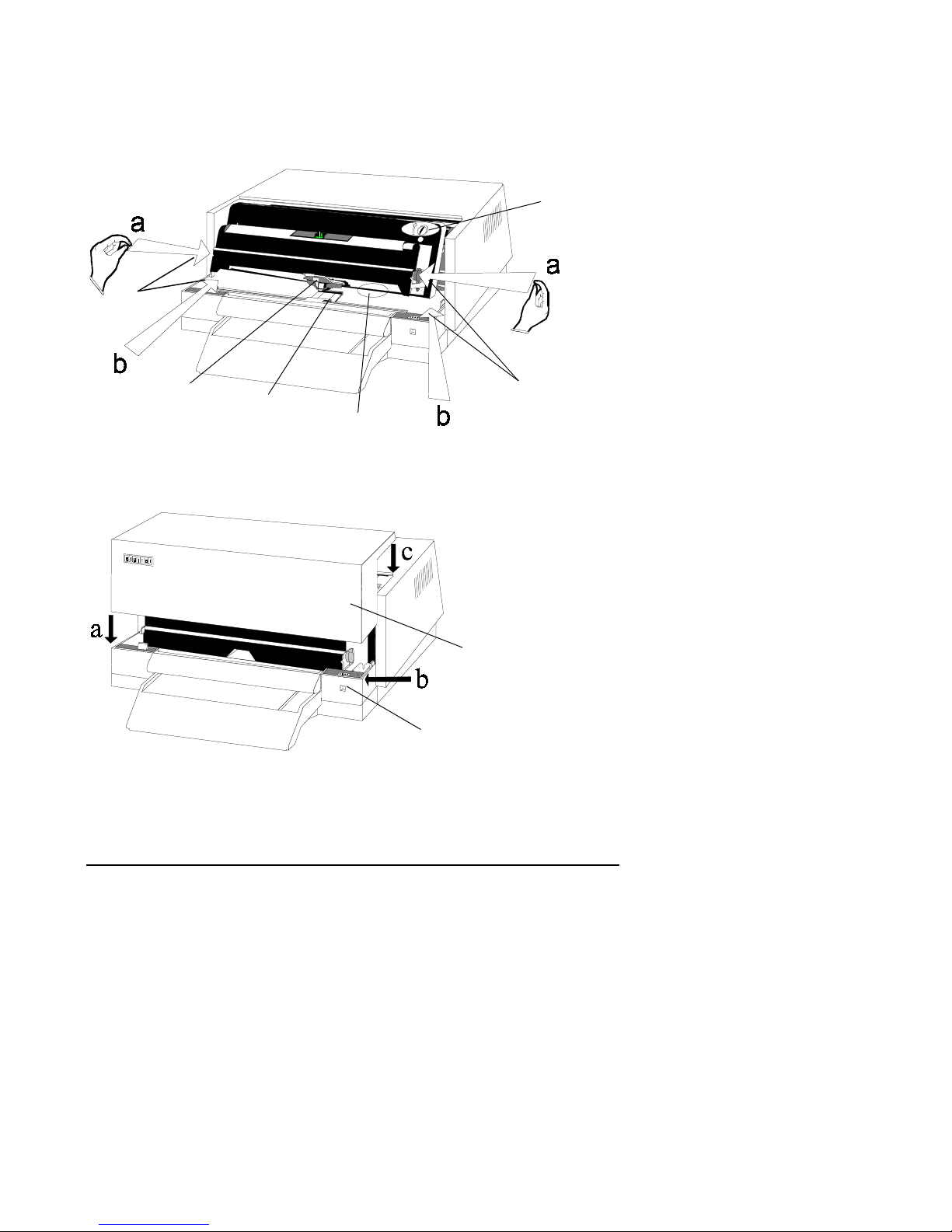

2.4 Trapdoor, Lid and Document Guide

1. Trapdoor - 1) position the two Rear Lugs,

2) lower, the trapdoor to engage

the Front Lock and press until

a ‘CLICK’ is heard.

2. Lid - accurately align at a, b and c.

3. Document Guide - 1) position in the Front Cover,

2) push until a ‘CLICK’ is heard.

2

1

Front Lock

1.1

1.2

Front Cover

3.2

3.1

3

Installation 2-4

Page 13

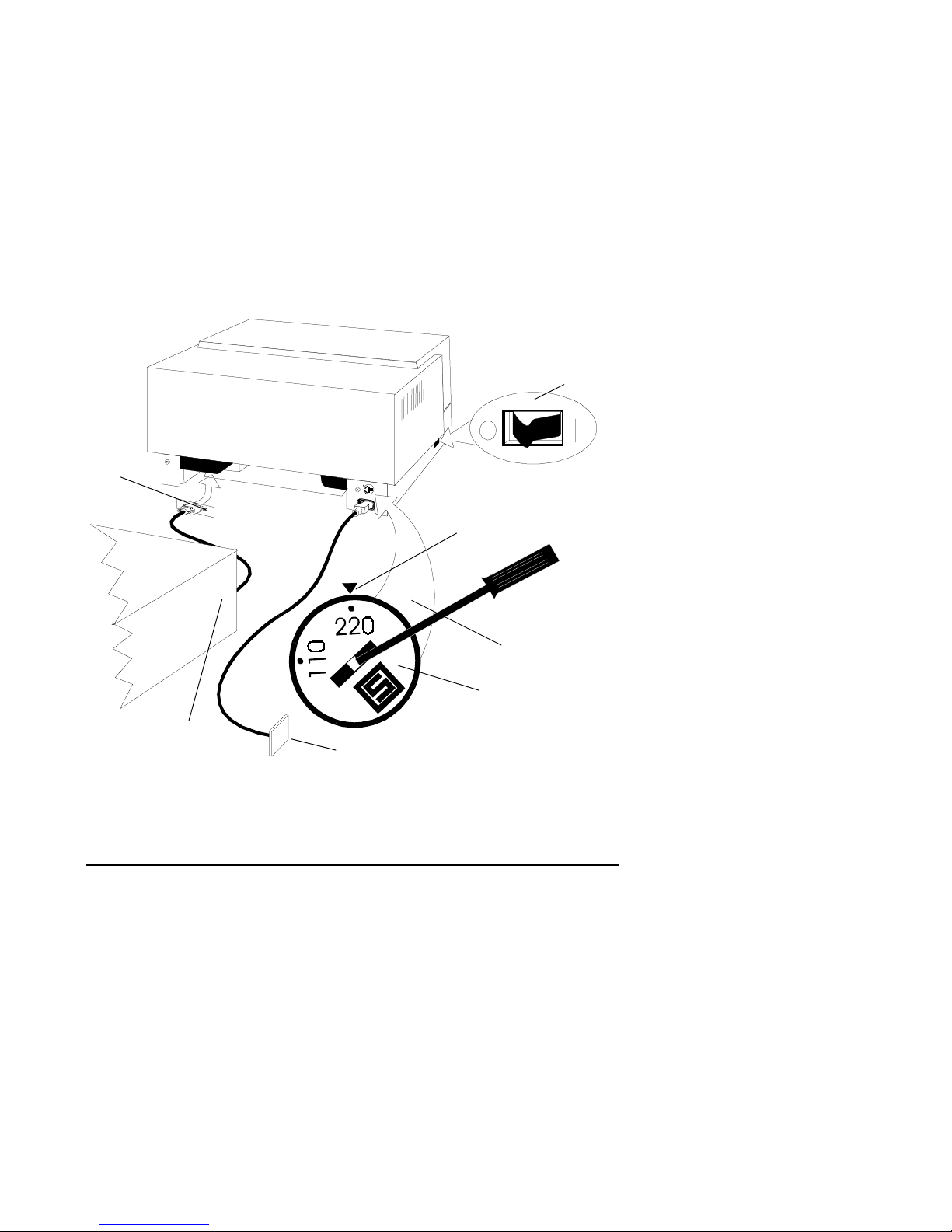

2.5 Connections and Settings

1. Power Switch - set to the OFF position.

2. Power Setting - check the setting: use a screw-

driver to turn the Selector to

the Mains Supply Voltage you

are using.

3. Mains Power Cable - connect to the Printer and the

Mains Supply.

4. Communication Cable - Connect to the Printer and the

Host Computer

Note: The Communication cable is supplied as a separate item.

4

Mains Supply Voltage

Settings

1

2

Host Computer

3

Installation 2-5

Page 14

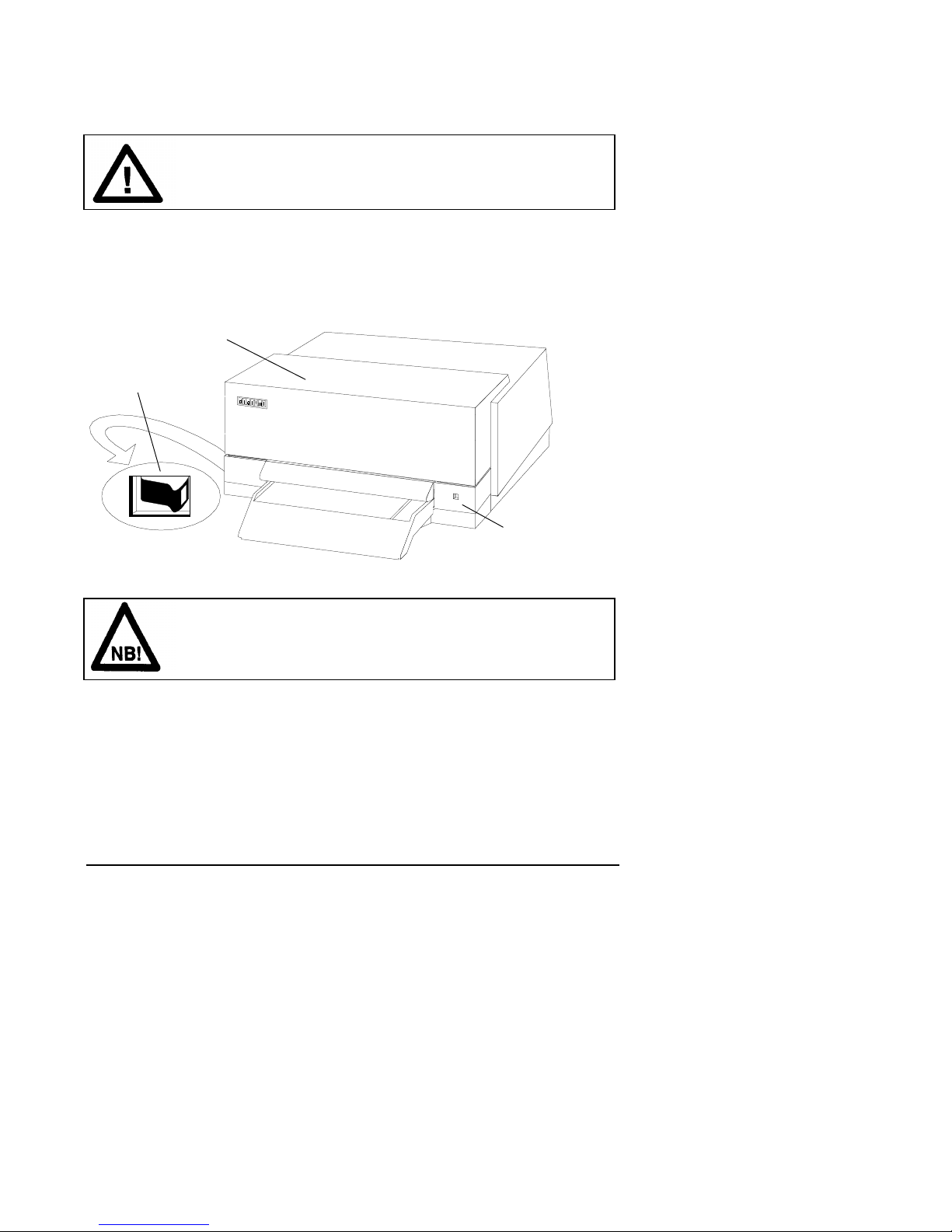

2.6 Ink Ribbon Cassette

Caution!

The printer must be switched ON during this task.

2.6.1 Power On

1. Power Switch - set to the ON position,

• Station LED - shows RED for six seconds and

then changes to GREEN.

Lid

1

Station LED

Note !

If the Station LED ‘BLINKS’ RED check that the Lid is

correctly installed.

Installation 2-6

Page 15

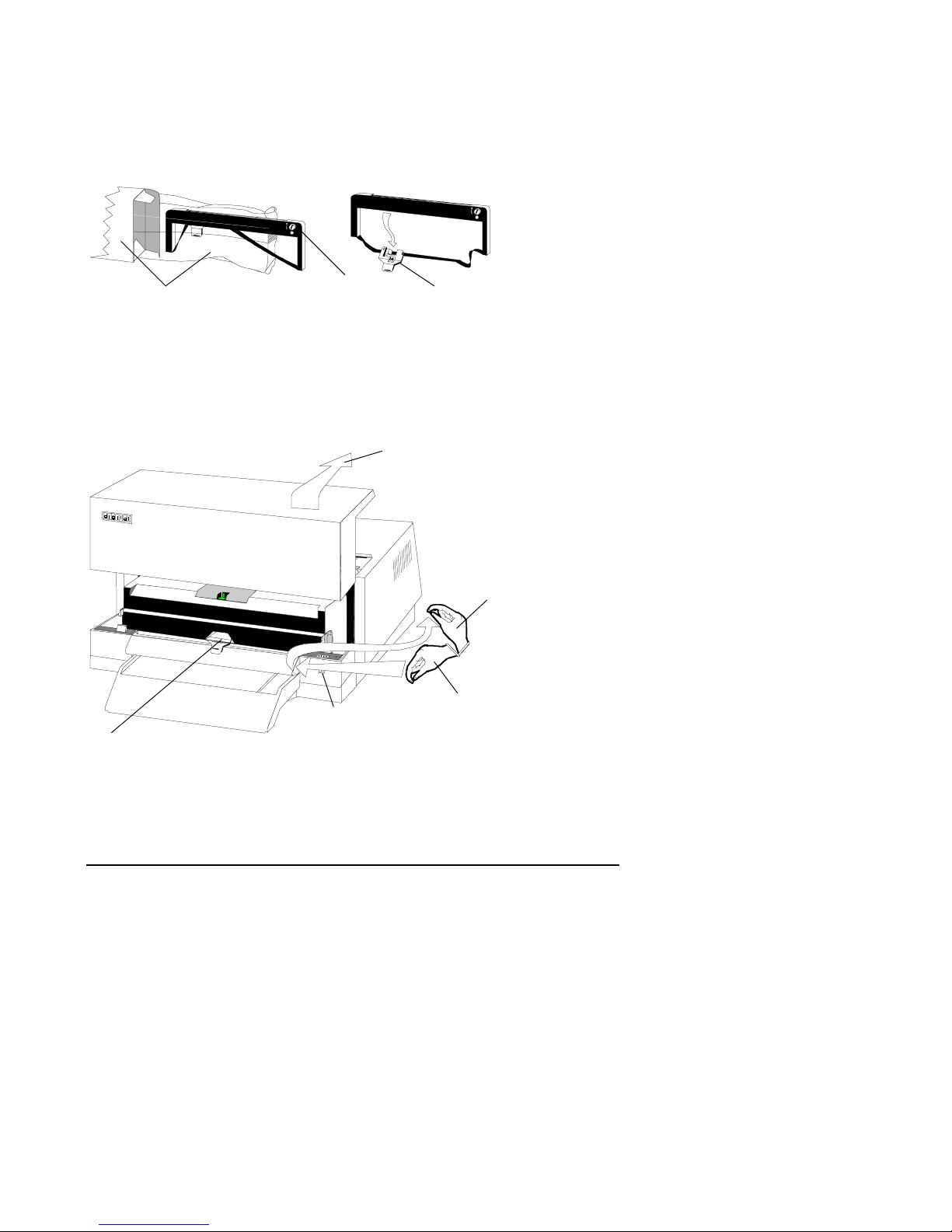

2.6.2 Unpacking the Ink Ribbon Cassette

1. Box and plastic bag - open the packing.

2. Ink Ribbon Cassette - remove from the plastic bag.

3. Skid - unclip from the Cassette.

1

2

3

2.6.3 Centering the Skid

1. Lid - lift and remove,

• Station LED - changes from GREEN to Blinking RED.

2. Button Bar - press and hold down,

• Skid - moves to the center of the Carrier.

3. Button Bar - release.

1

2

Station LED

Skid

3

Installation 2-7

Page 16

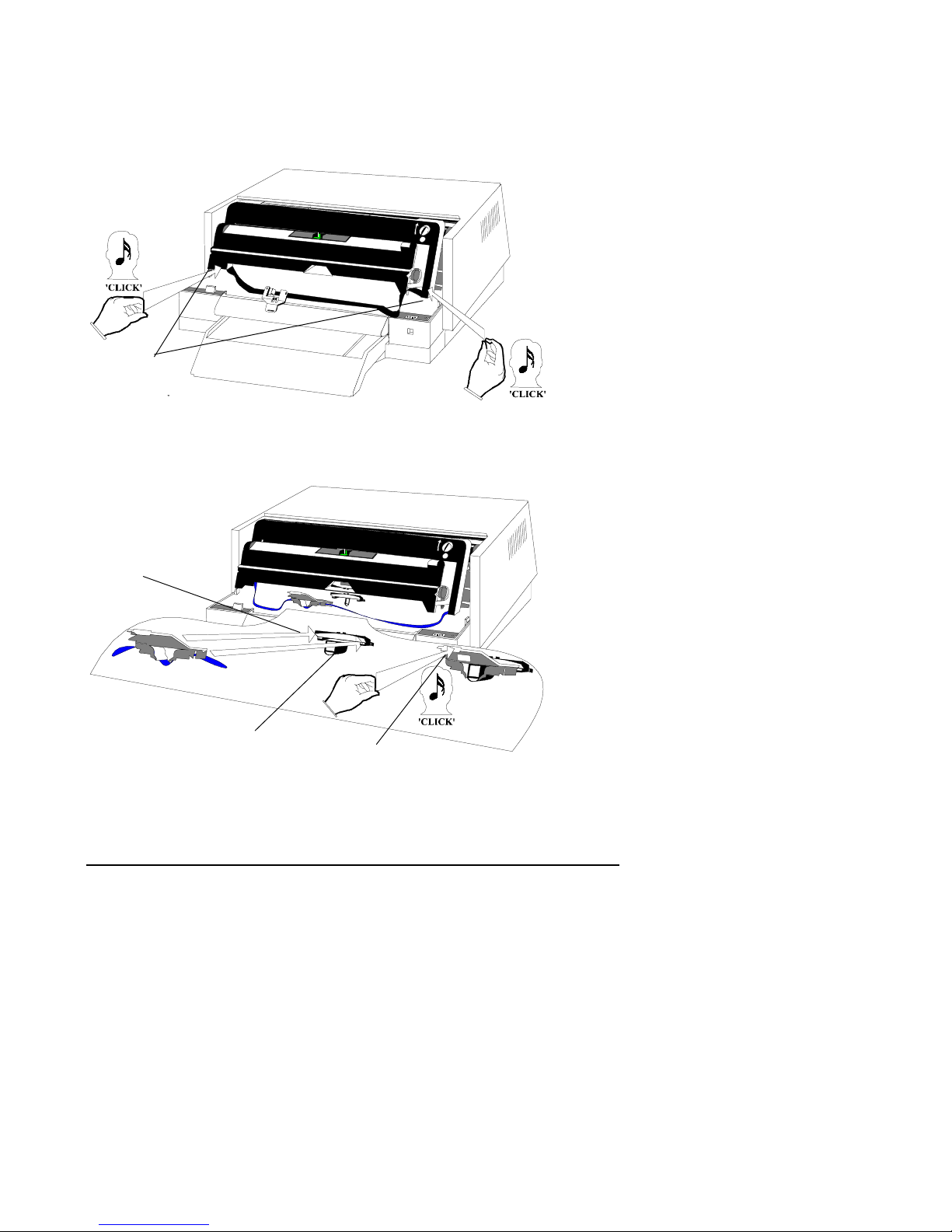

2.6.4 Raising the Carrier

1. Carrier Buttons - press in at a and Lift to b

• the Carrier is now locked in a tilted, raised position.

1

2.6.5 Positioning the Ink Ribbon Cassette

1. Ink Ribbon Cassette - position on the top and sides

of the Carrier.

Carrier

1

Installation 2-8

Page 17

2.6.6 Installing the Ink Ribbon Cassette

1. Ink Ribbon Cassette - push until a ‘CLICK’ is heard at

each side of the Carrier.

1

2.6.7 Installing the Skid

1. Skid - locate in the bottom of the Head Carrier Assembly.

2. Skid - push until a ‘CLICK’ is heard.

1

Head Carrier Assembly

2

Installation 2-9

Page 18

2.6.8 Removing Slack Ribbon

1. Green Wheel - turn until the Ink Ribbon is tight.

2. Carrier - hold at a, lower to b and ensure the

Printhead locates in the Slider.

2

1

Printhead

Slider

Ink Ribbon

2.6.9 Ready to Print

1. Lid - install and align at positions a, b and c,

• Station LED - changes from Blinking RED to GREEN.

1

Station LED

2

Installation 2-10

Page 19

3 SETUP

Setup consists of a number of Menu’s that contain software settings.

It is important that the correct software settings are made in the DOC Menu so that

everyday Customer documents are handled correctly. Document dimensions

determine the DOC Menu software settings. Therefore, when a Customer receives a

new printer, or when a new document is introduced, this Menu’s settings should be

checked and modified as necessary.

The printer does not need to be connected to the Host Computer during Setup.

3.1 Introduction

A Software Setting consists of assigning a value to a parameter where:

• Parameters - are shown vertically under each Menu

• Values - are shown horizontally next to the Parameter.

Software Settings are held in a matrix where:

• Parameters (matrix vertical plane ) are reached using a Setup Function which

advances the document under the printhead

• Values (matrix horizontal plane ) are reached by using a Setup Function which

moves the Printhead along a line.

3.1.1 Setup Functions

These are:

Vertical Tab the document is advanced under the printhead to a new

line when the Button Bar is pressed down and released

after two seconds.

Horizontal Tab the printhead is moved a fixed horizontal distance along a

line when the Button Bar is held down for less than one

second (Hit).

Setup 3-1

Page 20

3.1.2 Setup Controls

These are:

Button Bar providing three functional periods of operation:

• Press down and release in less than one second (Hit)

• Press down and release after two seconds

• Press down and hold down until the engine runs and the document moves,

then release

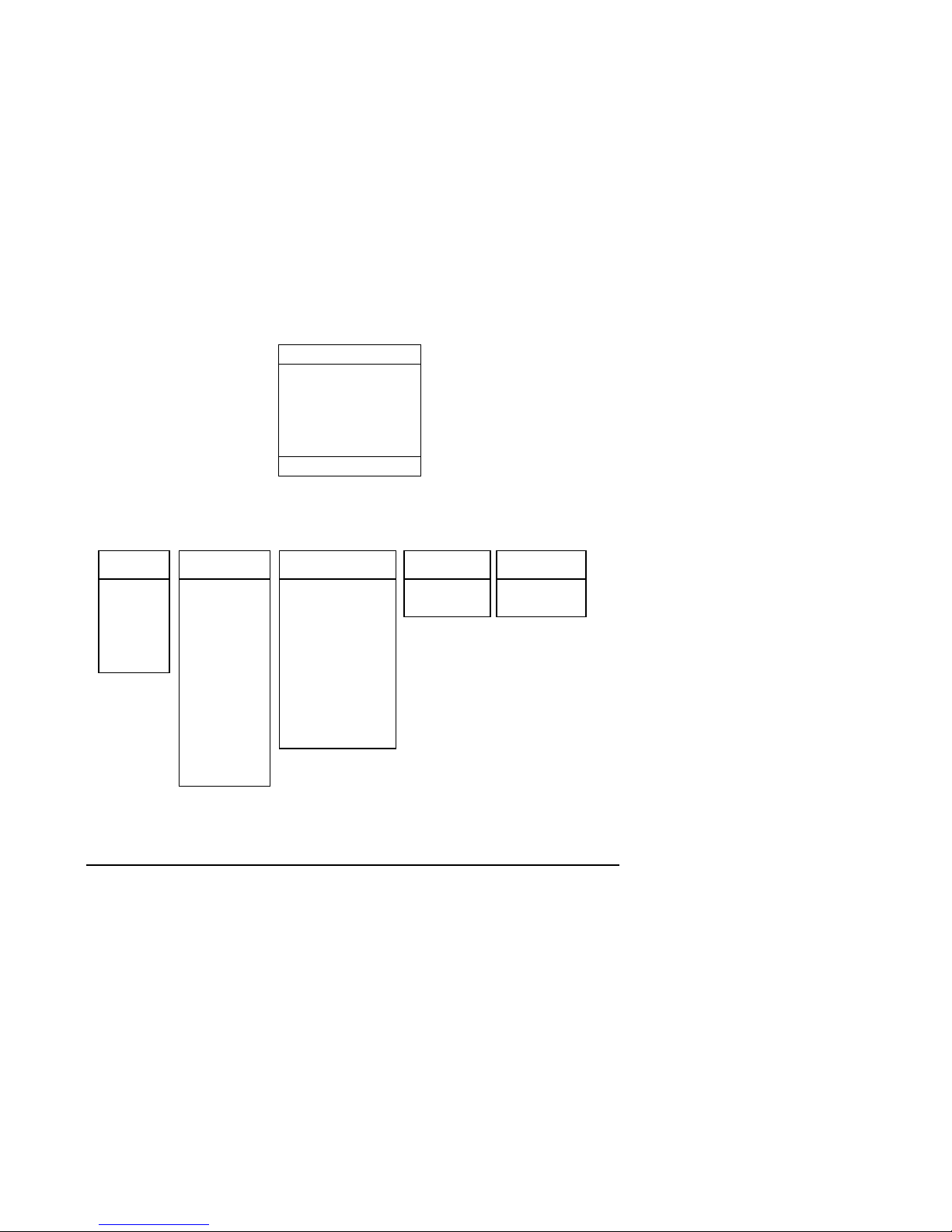

3.1.3 Menu’s and Parameters

On entering Setup, you are prompted to Select a Menu or Quit the Setup. Menu’s

are Selected or Quit from the start and end point, QUIT OR SELECT. Printer

Settings are printed from the VIEW point. Thus, the structure is :

QUIT OR SELECT

COM Menu

IBM Menu

DOC Menu

<>DFT Menu

<>HQD Menu

VIEW

Note: The COM menu is not used or shown in a Parallel Printer.

The Parameter’s in each Menu for a Serial Printer are:

COM IBM DOC <>DFT <>HQD

Baud rate Country Cover offset Draft coarse HQD coarse

Length Set Horz psbk seam Draft fine HQD fine

Stop bits Font Psbk range

Parity CPI Psbk width min.

Flow ctrl LPI Psbk seam type

Condensed Top offset

CR=>LF Psbk smudging

LF/VT=>CR Form smudging

Form Length Print contrast

Zero

Top Margin

Setup 3-2

Page 21

3.1.4 Changing or Viewing the Setup

This involves the following:

• Entering Setup - using a Setup Control

• Loading a Document - a blank document or an existing

document is used

• Moving to VIEW or a Menu - Serial Printer have 5 Menu’s

Parallel Printer have 4 Menu’s

• Printing Current Settings - from the VIEW point

• Changing a Setting - moving to a Menu, a Parameter

and then assigning a new Value

• Validating - printing to check the change or

changes

• Quitting - from the QUIT point

Setup 3-3

Page 22

3.2 Setup Example

The Factory Default Setup is shown below:

The above example was produced by performing the procedure Printing the Printer

Settings.

Setup 3-4

Page 23

3.2.1 Entering Setup

1. Lid - lift and remove.

2. Button Bar - hold down.

3. Power Switch - set to ON,

• Station LED - shows RED.

4. Button Bar - release,

• Station LED - blinks GREEN within 6 seconds.

1

3

Station LED

Note !

If a document is not loaded OR a document is loaded and no

further actions are taken, the print engine will run for 2 minutes,

stop and the Station LED will show RED and BLINK. Setup may

be entered again by pressing the Button Bar down for less than

one second (Hit).

4

2

Setup 3-5

Page 24

3.2.2 Loading a Document

Prerequisite 1 Entering Setup has been performed.

Prerequisite 2 A blank document at least 8in (203mm) but less than 8.5in

(217mm) wide and at least 10in (254mm) long must be used.

1. Document - feed along the Left Edge of the Document

Guide until the document is gripped

Note: If the document covers the Marker, the printer will return the document

forward over the Document Guide.

Left Edge

Marker

Document Guide

1

Setup 3-6

Page 25

3.2.3 Moving to VIEW or a Menu

Prerequisite Loading a Document has been performed

1. Button Bar - press for less than one second (Hit),

• Document - a) advances to the Trailing edge,

b) print of menu’s are performed,

c) returns with the Skid pointing at the

QUIT OR SELECT point.

2. Menu’s and VIEW are visible above the FW Level that’s installed.

3. Button Bar - Tab Horizontally (Hit) until the Skid is

above the selection you require.

Skid

Horizontal Tabs

Number of Hits

2

1, 3

Setup 3-7

Page 26

3.2.4 Printing the Current Settings

This is done from the VIEW point.

Prerequisite 1: Loading a Document has been performed.

Prerequisite 2: Moving to VIEW has been performed.

1. Button Bar - press and hold down until the document

is advanced and printing begins.

Note: When printing has finished the document will be ejected forward over the

Document Guide.

3.2.5 Changing a Setting

In the following example the Print Quality parameter is changed from the factory

default Value of DRAFT to HQD (High Quality Draft).

1. Enter Setup - perform Entering Setup.

2. Load a Blank Document - perform Loading a Blank

Document.

3. Tab Horizontally, TWICE - the Skid points to the IBM Menu.

4. Select IBM - press and hold down the Button

Bar until the engine runs and the

document moves,

• Print functions follow and the list, CURRENT SETTINGS, will be visible.

5. Tab Vertically, 2 TIMES - the FONT values DRAFT and

HQD are visible.

6. Tab Horizontally, 2 TIMES - the Skid points to <>HQD.

LOAD the selection - press and hold down the Button

Bar until the engine runs and

the document moves,

• HQD is printed between FONT and DRAFT and the Skid performs a

vertical tab.

7. Tab Vertically, 8 TIMES - the CONFIRM values, yes and

no are visible.

8. Tab Horizontally, 1 TIME - the Skid points to the ‘yes’ option.

9. Button Bar - press for longer than 2 seconds,

• The new configuration is stored, print functions follow and the document

is returned forward over the document guide.

Setup 3-8

Page 27

3.2.6 Validating

10. Load a Blank Document - perform Loading a Blank

Document with the other side

of the document you have just

used in step 8 above.

11. Print the Settings - perform Printing the Current

Settings,

• the changed parameter will be underlined; Font : HQD

3.2.7 Quitting

12. Load a Blank Document - perform Loading a Blank

Document using the same side

of the document you have just

used in step 11, above.

13. Button Bar - press and hold down until the

document is returned forward

and ejected.

3.3 Setup Check

Prerequisite 1: The Configuration Settings that your department will use.

Prerequisite 2: The printer’s Current Settings. Note: Perform Printing the

Current Settings on page 2-3-8.

1. Compare prerequisite 1 with prerequisite 2

• The Current Settings are the same as the Configuration Settings?

Yes No

The Setup Check is

complete, Go to the

Operations Chapter.

Setup 3-9

Go to Changing a Setting on page 2-3-8

and make the required changes to the

Setup.

Page 28

3.4 Performing a Setup

An Engineer would normally perform this task for you.

Prerequisite 1 All types of Customer Document are available.

Prerequisite 2 A measuring ruler. This may be graduated in Metric or

Imperial units. Note: 1 inch = 25.4 mm.

Move to each of the Menu’s shown below and for each Parameter check or set a

new Value.

3.4.1 COM Menu

This menu is available on Serial Printers only. It is used when changing the

Communication Settings.

The Baud Rate values are:

• 19200, 9600, 4800, 2400 and 1200 Baud

Further Parameters and Values are:

Parameter

Length (bits) Stop Bits (number) Parity Flow Control

Value

Value

Value

7 1 Even RTS-CTS

8 2 Odd XON-XOFF

None

3.4.2 IBM Menu

The standard IBM Proprinter III parameters are used where:

The Country values are:

• USA - Code Page 437 (Factory Default Setting)

• Multi (Latin) - Code Page 850

Note: A Code Page is downloaded from the Host Computer. At Power

ON the option set will be used unless overridden by a download.

Setup 3-10

Page 29

The Set values are:

• Set 1 - [0–31] and [128–159] specify control codes

(Factory Default Setting).

• Set 2 - [03–06], 21 and [128–159] specify printable characters.

Note: The PC Table may be set such that a range of ASCII characters in the

code page are interpreted.

The Font (quality) values are:

• DRAFT (Factory Default Setting)

• HQD (High Quality Draft)

The CPI (Characters Per Inch) values are:

• 10, 12, 17 or 20.

The LPI (Lines Per Inch) values are:

• 5, 6 or 8.

Condensed

• 17 CPI,

The CR =>LF(Auto Line Feed) values are:

• Yes or No

Automatic Line Feed (LF) after each Carriage Return (CR).

The LF/VT =>CR (Auto Carriage Return) values are:

• Yes or No

Automatic Carriage Return (CR) after each Line Feed (LF) or Vertical Tabulation

(VT).

The Form Length values are:

• 11in (279mm) or 12in (305mm)

•

The Zero style values are:

• Normal or Slashed

Setup 3-11

Page 30

The Top Margin values are:

•

1 = 0.1in (2.54mm) (Factory Default Setting)

• 2 = 0.2in (5mm)

• 3 = 0.3in (7.6mm)

• 4 = 0.4in (10mm)

• 5 = 0.5in (13mm)

• 6 = 0.6in (15.mm)

3.4.3 DOC Menu

This Menu is concerned with Documents and the parameter values that must be set

so that documents are handled correctly.

All documents, Form and/or Passbook (Psbk), must be measured. A value for each

of the following parameters must be set:

• Top Offset

• Psbk Seam Type

• Psbk Width min.

• Psbk Range

• Horz Psbk Seam,

• Cover Offset

Setup 3-12

Page 31

The values are shown along the Parameter line in the DOC Menu printout, which

follows:

Setup 3-13

Page 32

The Print Contrast values are:

• 1, 2, 3 (Factory Default Setting), 4 and 5.

The Form Smudging values are:

• 1, 2, 3 (Factory Default Setting), 4, 5 and 6

1 = least smudging (anvil in the lowest position).and

6 = most smudging (anvil in the highest position).

The Psbk Smudging values are:

• 1, 2, 3 (Factory Default Setting) 4, 5 and 6

1 = least smudging (anvil in the lowest position).and

6 = most smudging (anvil in the highest position).

The Top Offset values are:

• 0 = 0.1in (2.54mm) Factory Default Setting

Note: Mechanical Top Margin = Top Offset

• 1 = Up to 0.6in (13.3mm)

• 2 = Up to 1.1in (27.94mm)

• 3 = Up to 1.6in (40.64mm)

• 4 = Up to 2.1in (53.34mm)

The printer uses an Optical Sensor to measure width. During the measuring process,

the sensor must not cross a black area. Therefore, if a Form or Envelope is

preprinted with a black area on the near the top of the document, such as a Logo or

Letter Head, a Top Offset must be set so that the width is measured in an area free

of black.

Measure the Black Border and use one of the values.

Setup 3-14

Page 33

The Psbk seam type values are:

• Horz (Factory Default Setting) for horizontal seam passbooks

• Vert for vertical seam passbooks.

The Psbk width min. values are:

• 3in (76.2mm), 4in (101.6mm), 5in (127mm) Factory default value, 6in

(152.4mm), 7in (177.8mm).

The printer will handle a document as a Passbook only when the width lies within

the [Pbsk width min.] + [Pbsk range].

If your Passbook Types have different widths calculate Psbk range, (see the next

parameter) and then return here.

1. Measure the Passbook Width and use the value which is nearest and less than

Psbk width min.

Setup 3-15

Page 34

The Psbk range values are:

• 0.5in (12.7mm), 1in (25.4mm), 1.5in (38.1mm), 2in (50.8mm),

2.5in (63.5mm) and 3in (76.2mm).

Psbk width + Psbk range must be greater then the highest Psbk width min. value of

any Passbook that is used.

1. Measure all Passbook Widths. Make a note of the maximum width measured.

2. Add an appropriate Psbk range value to the set Psbk width min. value so that all

Passbook Widths measured are in range.

The Horz Psbk Seam values are:

• 2.5in (63.5mm), 3in (76.2mm), 3.5 in (88.9mm), 4 in (101.6mm) and 4.5 in

(114.3mm).

This setting indicates the seam location with respect to the top of the passbook

cover. If the measured result is between two of the following, then select the

smaller.

This parameter is ignored if Psbk seam type is set to vert (vertical).

Setup 3-16

Page 35

The Cover Offset values are:

0 = 0.1in (2.54mm) Factory Default Setting

Mechanical Top Margin = Cover Offset

1 = Up to 0.6in (13.3mm)

2 = Up to 1.1in (27.94mm)

3 = Up to 1.6in (40.64mm)

4 = Up to 2.1in (53.34mm)

This setting defines the location of the top edge of an inside sheets with respect to

the top edge of a Passbook (Psbk).

Printing is unidirectional above a Cover Offset and bi-directional below.

Measure the Cover Offset and use one of the following values:

If the Passbook Seam is horizontal and the Cover Offset is greater than 0, the

printer will smooth the document.

Setup 3-17

Page 36

3.4.4 <>DFT Menu

The Horizontal Alignment of a printed line in bi-directional DRAFT (DFT) can be

adjusted. This is done in two steps, DRAFT COARSE and DRAFT FINE.

1. Print the <>DFT menu settings.

2. Look at the printout and chose the DRAFT COARSE and DRAFT FINE

settings, indicated on the same line in the left most column, where you judge the

character overlap to be the best.

The Draft Coarse values are:

• 1, 2, 3 (Factory Default Setting), 4, 5 and 6.

This define the printing speed in steps.

Draft Fine

• 1 (Factory Default Setting), 2, 3 and 4.

This define the printing speed in firing units.

3.4.5 <>HQD Menu

The Horizontal Alignment of a printed line in bi-directional HIGH QUALITY

DRAFT (HQD) can be adjusted. This is done in two steps, HQD COARSE and

HQD FINE.

Perform the following:

1. Print the <>HQD menu settings.

2. Look at the printout and chose the HQD COARSE and HQD FINE settings,

indicated on the same line in the left most column, where you judge the

character overlap to be the best.

The HQD Coarse values are:

• 1, 2, 3 (Factory Default Setting), 4, 5 and 6.

This define the printing speed in steps:

HQD Fine

• 1 (Factory Default Setting), 2, 3 and 4.

This define the printing speed in firing units:

Setup 3-18

Page 37

4 OPERATION

Normal everyday operation is a simple matter of Loading a Document. Printing is

controlled from the Customer Host System.

4.1 Controls and Indications

1

Power Switch - ON or OFF.

2

Button Bar - having two functional periods:

• Press down and release in less than one second (Hit)

• Press down, hold and release when printer reacts (2 sec.)

3

Lid - Installed or Removed.

4

Four Status LED’s - RED, static indication only.

5

Station LED - RED or GREEN, static and blinking

indications.

6

Document Guide - helps to ensure correct document

loading.

3.

1

4

2

6

Operation 4-1

5

Page 38

4.1.1 Confidence Test Routine

When printer power is switched ON a Confidence Test Routine (CTR) verifies that

all functions are error free. CTR Success or Failure is indicated by the Station LED

as follows:

• Solid or Blinking GREEN - Success

• Solid RED - Fatal Failure, preventing normal

use

• Blinking RED - Non-Fatal Failure, recoverable

errors

CTR Errors are indicated by the Status LED’s as follows:

Status LED’s (x=On) Station Error Corrective

#4 #3 #2 #1 LED Action

x Blink. RED NVM failure Perform setup

x Blink. RED Lid open Install correctly

x RED Initialization Call service

x x RED Motors Call service

x x RED Edge detectors Call service

x x x RED Motors & Edge Call service

RED CPU error Call service

4.2 Documents

When the printer is switched on and the print engine is running, documents fed over

the Document Guide will be gripped and loaded by a process called Automatic

Document Alignment (ADA).

4.2.1 New Pages

Smooth and flatten new pages of passbooks by slightly folding back the spine

before loading.

Operation 4-2

Page 39

4.2.2 Loading a Document

Caution!

Do not load documents that are hole punched, contain staples or

are held together by a paper clip. This will cause paper jams or

damages to the printer.

It is only possible to load a document when the printer have received data from the

host computer, or entering into Setup Mode or the internal Maintenance Tests

Routine.

1

Document - Check the width

• If the document width is less than or equal to 8.7in (221mm), Load

anywhere between Left Edge and the Marker

• If the document width is greater than 8.7in (221mm), ensure it touches the

Left Edge of the Document Guide

2

Insert - when the Station LED blinks GREEN

3

Button bar - hit (for less than 1 sec.) and release

• Document is fed in and the width is measured

• If the document is inserted incorrect, it is ejected out and a new insertion has

do be done aligning to the Left Edge

• If it’s inserted correctly, printing will start

Button bar

Left Edge

Marker

Document Guide

Operation 4-3

Page 40

4.2.3 Stop while printing

To stop the printing, press and hold the Button Bar for more than 10 seconds.

4.2.4 Clearing Document Jams

1

Power - set to OFF

2

Lid - lift and remove

3

Carrier - raise and secure in open position

4

Document - remove by pulling from the front or rear

of the printer

Operation 4-4

Page 41

5 MAINTENANCE

Caution !

Unless otherwise stated, the printer should be switched ON

during all Maintenance Tasks.

This chapter describes how to do if the performance of the printer is not satisfied.

Some actions should be performed to prevent unnecessary wear of the printer, or to

keep up the lifetime.

The following Parts can be replaced. New parts can be ordered from your Supplier.

Part Order Number

Ink Ribbon Cassette 2S-AA374-AA

Mylar Cassette 2S-AA373-AA

Printhead 29-33361-01

Note: All Replacement Parts should be stored at room temperature.

Maintenance 5-1

Page 42

5.1 Ink Ribbon Cassette

These have a maximum storage life of 2 years and should be replaced after printing

approximately 2.5 million characters.

5.1.1 Centering the Skid

1

Lid - lift and remove,

• Status LED’s - LED-1 is ON, others are OFF

• Station LED - changes from GREEN to Blinking RED.

2

Button Bar - press and hold down,

• Skid - moves to the center of the Carrier.

3

Button Bar - release.

1

Status LED’s

3

2

Skid

Maintenance 5-2

Station LED

Page 43

5.1.2 Raising the Carrier

1

Carrier Buttons - press in at (a) and Lift to (b),

• Carrier - is now locked in a tilted, raised position.

1

5.1.3 Removing the Skid

1

Skid - lift until a ‘CLICK’ is heard.

2

Skid - pull forward and remove.

1

2

Maintenance 5-3

Page 44

5.1.4 Removing the Old Ink Ribbon Cassette

1

Skid - position

2

Sides - move forward

3

Ink Ribbon Cassette - remove and discard

2

1

2

3

5.1.5 Cleaning

Perform the following:

• Mylar Cassette slider refer to the procedure on page 4-5-7

• Edge Detection Sensor and Mylar Slide Hole refer to the procedure on page 4-

5-16

5.1.6 Unpacking the New Ink Ribbon Cassette

1. Box and plastic bag - open the packing.

2. Ink Ribbon Cassette - remove from the plastic bag.

3. Skid - unclip from the Cassette.

1 2

Maintenance 5-4

3

Page 45

5.1.7

1

Positioning the New Ink Ribbon Cassette

Ink Ribbon Cassette - position on the top and sides of

the Carrier.

1

5.1.8 Installing the New Ink Ribbon Cassette

1. Ink Ribbon Cassette - Push until a ‘CLICK’ is heard at

each side of the Carrier.

Carrier

1

Maintenance 5-5

Page 46

5.1.9 Reinstalling the Skid

1

Skid - locate in the bottom of the Head Carrier

assembly.

2

Skid - push until a ‘CLICK’ is heard.

1

Head Carrier assembly

5.1.10 Removing Slack Ribbon

1

Green Wheel - turn until the Ink Ribbon is tight .

2

Carrier - hold at a, lower to b and ensure the

Printhead locates in the Slider.

Ink Ribbon

2

Printhead

Maintenance 5-6

Slider

2

1

2

Page 47

5.2 Mylar Cassette

Smooth transport of the document during printing is ensured by separating the

ribbon from the document by a strip of mylar.

The mylar slider should be inspected and cleaned when the Ink Ribbon Cassette is

replaced or when excessive document jams are experienced.

Mylar edges and surfaces may be damaged when in contact with a sharp or hard

object such as a paper clip or staple.

5.2.1 Centering the Skid

1

Lid - lift and remove,

• Station LED - changes from GREEN to Blinking RED.

• Status LED’s - LED-1 is ON, others are OFF

2

Button Bar - press and hold down,

• Skid - moves to the center of the Carrier.

3

Button Bar - release.

1

Station LED

Skid

Station LED

Maintenance 5-7

2

Page 48

5.2.2 Raising the Carrier

1

Carrier Buttons - press in at (a) and Lift to (b),

• the Carrier is now locked in a tilted, raised position.

1

5.2.3 Removing the Mylar Cassette

1

Left and right hand - a) push on each handle using a finger

b) press on the wire with each thumb.

2

Mylar Cassette - remove from the printer

2

1a

Wire

1b

Maintenance 5-8

1a

Page 49

5.2.4 Inspecting the Mylar Edges (Bottom View)

Turn the Mylar Cassette over and inspect the edges for damage as follows:

1

From Cylinder to Cylinder - move the Slider and check for

damage.

2

From Slider to Left Cylinder - move the Slider and check that

the complete edge stays OUT.

3

From Slider to Right Cylinder - move the Slider and check that

the complete edge stays IN.

Left Cylinder

3

1

Slider

Right Cylinder

2

Maintenance 5-9

Page 50

5.2.5 Checking for Free Movement (Top View)

1

Slider - move full left to full right

5.2.6 Reinstalling the Mylar Cassette

1

Left hand and right hand - a) use a Finger to push on the

Handles,

b) use a Thumb to press on the

Wire.

2

Mylar Cassette - install.

1aa

2

Wire

1a

1b

Handles

Maintenance 5-10

Page 51

5.2.7 Positioning the Slider

1

Slider - position under the Printhead.

2

Carrier - hold with each finger and lower the

Carrier from a to b and ensure the

Printhead locates in the center of the

Slider.

2

1

Printhead

2

Maintenance 5-11

Page 52

5.3 Printhead

The result of printing with a damaged Printhead is shown below.

The white space in the characters A,B,C,D and E above indicate a pin in the

Printhead is not operating or is broken. A Pin will be damaged when is strikes a

sharp or hard object such as a paper clips or staple.

Caution !

The Printhead may be hot. Be carefull when touching the

printhead.

5.3.1 Preparation

Perform the following:

• Power Up

• Centering the Skid

• Raising the Carrier

• Removing the Ink Ribbon Cassette

Maintenance 5-12

Page 53

5.3.2 Removing the Trapdoor

1

Carrier - support to keep the Carrier raised.

2

Trapdoor Lock - push in to release the Lock and lift to

remove the Trapdoor.

3

Printhead Tool - position in the Printhead Assembly.

2

1

3

5.3.3 Releasing the Printhead

1

Carrier - support to keep the Carrier raised.

2

Printhead Tool - a) push into the Printhead assembly,

b) squeeze the arms until a ‘CLICK’ is

heard, and then release the arms.

Printhead Assembly

1

Arms

2a

Printhead Assembly

2b2

Maintenance 5-13

Page 54

5.3.4 Lowering the Carrier

1

Carrier - hold at a, lower to b and ensure the

Printhead locates in the Slider.

1

Printhead

Slider

5.3.5 Removing the Printhead

1

Printhead - grip between thumb and finger and remove

1

1

Maintenance 5-14

Page 55

5.3.6 Reinstalling the Printhead

1

Printhead - locate the Clip and Lock Clip in the

Printhead Assembly

2

Printhead - push down until a ‘CLICK’ is heard

Printhead Assembly

Lock Clip

Clip

1

2

Maintenance 5-15

Page 56

5.4 Cleaning of Edge Detection Sensor and Mylar Slide

Hole

These should be cleaned when the Ink Ribbon Cassette is changed.

Note: if pressurized air is not available a Lint Free cloth may be used.

If necessary, refer to the Ink Ribbon Cassette and Mylar Cassette procedure

1

Pressurized Air Can - position the can near the sensor

and release air

2

Pressurized Air Can - position the nozzle near the

Slide Hole and release air

Sensor

1

2

Mylar Slide Hole

Maintenance 5-16

Page 57

5.5 Cleaning the Feed Rollers

These should be cleaned when feeding problems are experienced or when black

vertical lines appear on the document.

1

Lid - Lift and remove

• Station LED - changes from GREEN to Blinking RED,

• Status LED’s - ooox, where x = ON.

2

Button Bar - press for less than one second (Hit),

• Status LED’s - ooxo, where x = ON.

3

Button Bar - press down for longer than 2 sec. and

then release

• Station LED - blinks GREEN

4

Cleaning Sheet - load (see Loading a Document)

5

Button Bar - press until the Station LED shows

GREEN and then release

• Cleaning Sheet - printer runs the Feed rollers some

seconds and then the Cleaning Sheet is

feeded a number of times

• Station LED - blinks RED

6

Cleaning Sheet - remove.

1

Status LEDs

4, 6

Station LED

Maintenance 5-17

2,3, 5

Page 58

5.6 Ready to Print

After completion of Maintenance, the printer must be set back to operational mode Printer is set to On-Line Status - ready for receiving data and printing.

1

If necessary, reinstall the Parts by performing the tasks as described on previous

pages (reverse order).

2

Lid - install and align at positions a, b and c,

• Station LED - changes from Blinking RED to GREEN.

2

Station LED

Maintenance 5-18

Page 59

6 SPECIFICATIONS

These are as follows:

6.1 Printer Characteristics

Width 16.14" (410mm)

Depth w/o Doc. Guide 10.43" (265mm)

Depth with Doc. Guide 13.78" (350mm)

Height 07.48" (190mm)

Weight 19.16 lb. (8.7 kg)

Interface, Serial

Interface, Parallel

Printing Speed 10 CPI draft 200 CPS

Ink Ribbon Color: black. Replacement frequency: Draft

Power Supply

Frequency

Power Consumption

Power Cord Requirements • For 115V operation:- UL listed and CSA

Temperature, Operating and

Non-operating

Rel. Humidity, Operating and

Non-operating

Acoustical Noise Level

ISO779

One RS232C port, 9-pin male connector

One parallel port, 36-pin female connector

Mode - at 30% print contrast signal after

printing 2.5 million characters. Stock shelf life:

2 years max.

100 – 120 V or 200 – 240V

50/60 Hz

120VA(max.) 30VA(idle)

certified type SVT 18/3 AWG, rated minimum

10A, 125V.

• For 230V operation:- Use HAR type

HO5.VVF 3G1.0

13°C – 35°C (55°F – 95°F)

- 4°C – 65°C (- 40°F – 149°F)

10% to 80%

95% max.

Noise power emission: < 6.6 Bells

Sound pressure level: < 65 dB at operator

position

Specifications 6-1

Page 60

6.2 Serial Interface - RS232C

This signal port option is one serial line that conforms to RS232C-EIA standard.

The Printer input buffer size is 4K bytes.

6.2.1 Configurable Parameters

These are as follows, where factory defaults are in Italic:

• Baud Rate - 1200, 2400, 4800, 9600, 19200

• Character length - 7, 8 data bits

• Stop Bits - 1, 2

• Parity - odd, even, none

• Flow Ctrl - RTS/CTS, XON/XOFF

6.2.2 Serial Connector

Located at the rear of the printer is a 9 Pin male DSUB. The pin assignments and

signals between printer - host are as follows:

Printer

Connector

9-pin

1

2

3

4

5

6

7

8

9

Signal Description Source Host

Connector

9pin 25pin

DCD

RXD

TXD

DTR

GND

DSR

RTS

CTS

-

Not Used

Receive Data

Transmit Data

Data Terminal Ready

Signal Ground

Data Set Ready

Request to Send

Clear to Send

Not Used

Host

Printer

Printer

Host

Printer

Host

-

-

3

2

6

5

4

8

7

-

2

3

6

7

20

5

4

-

Specifications 6-2

Page 61

RXD - receives data from the Host. The interface ignores RX Data when DSR

is low.

TXD - when using XON/XOFF, Printer to Host, Clear to Send (CTS) must be

high to enable transmission. The Printer does not transmit any data

when RTS or CTS are high.

DTR - is set and remains ‘HIGH’ while the Printer power is ON and the

interface is operational.

GND - This pin is connected to the logic ground to provide a common

reference for the data and control signals.

DSR - The interface ignores received data unless DSR is ‘HIGH’.

RTS - This signal is set, ‘HIGH’ at power ON. RTS. ‘HIGH’ tells the HOST

that the Printer is busy and cannot receive data.

CTS - The interface monitors this signal which must be. ‘HIGH’ for the

interface to transmit XON and XOFF where:

• XON = DC1, Hexadecimal 11

• XOFF = DC3, Hexadecimal 13.

6.2.3 Handshaking

This is either XON/XOFF or RTS/CTS with the Flow Control according to Setup.

A Buffer full treatment is performed according to Flow Control when the available

space is 10 bytes.

XON/XOFF When this protocol is selected, the Printer sends XON to the Host

when it is able to receive data and XOFF to stop the data flow or

to indicate it is unable to receive any data.

RTS/CTS When the Host wants to send data to the Printer, it must wait for

the Printer RTS line to go ‘HIGH’. If RTS goes ‘LOW’, the Host

must stop transmission and wait for RTS ‘HIGH’ before sending

any data.

Specifications 6-3

Page 62

6.3 Parallel Interface - Centronics

This is an unidirectional interface that transfers 1 byte at a time.

Signal Name Description Pin in Pin out Source

D STROBE

CE DATA 1

CE DATA 2

CE DATA 3

CE DATA 4

CE DATA 5

CE DATA 6

CE DATA 7

CE DATA 8

ACK

BUSY

PE

SELECT OUT

AUTO FEED

NOT USED

SIGNAL GROUND

CHASSIS GND

+5V

GND (1)

GND (2)

GND (3)

GND (4)

GND (5)

GND (6)

GND (7)

GND (8)

GND (9)

GND (10)

GND (11)

GND (31)

INIT

FAULT

GND (36)

NOT USED

NOT USED

SELECT IN

Data Strobe

Data 1

Data 2

Data 3

Data 4

Data 5

Data 6

Data 7

Data 8

Acknowledge

Printer Busy

Paper End

Printer On Line

Not Used

Not Connected

Ground Layer

Not Connected

Pull Up to +5V

Gnd (1)

Gnd (2)

Gnd (3)

Gnd (4)

Gnd (5)

Gnd (6)

Gnd (7)

Gnd (8)

Gnd (9)

Gnd (10)

Gnd (11)

Gnd (31)

Soft Reset

Printer Error

Gnd (36)

Not Connected

Not Connected

Not Used

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

1

2

3

4

5

6

7

8

9

19

20

21

22

23

24

25

26

27

28

29

31

33

Host

Host

Host

Host

Host

Host

Host

Host

Host

Printer

Printer

Printer

Printer

Host

Host

Host

Host

Printer

Host

Host

Host

Host

Host

Host

Host

Host

Host

Host

Host

Host

Host

Printer

Host

Host

Host

Host

Specifications 6-4

Page 63

6.4 Documents

The printer handles two basic document types, forms and passbooks. Forms can be

single-ply or multi-ply or envelopes. Passbooks can have a vertical or a horizontal

seam.

Vertical Seam

Passbooks

Minimum Width 4.0" (101 mm) 4.0" (101 mm)

Maximum Width 7.6" (193 mm) 7.6" (193 mm)

Minimum Length 4.0" (101 mm) 4.0" (101 mm)

Maximum Length 7.6" (193 mm) 7.0" (177 mm)

Minimum Thickness 0.02" (0.5 mm) 0.02" (0.5 mm)

Maximum Thickness 0.08" (2 mm) 0.08" (2 mm)

Top & Bottom, Left &

0.25" (6.35 mm) 0.25" (6.35 mm)

Right Minimum Margin

Minimum Seam Margins 2 x 0.31" (8 mm)* 2 x 0.39" (10 mm)*

Form Sizes and minimum margins are:

Documents

≤ 8.7" (221 mm)

Width 2.5" (63mm) to

8.7" (221mm)

Length 2.5" (63mm) to

14.5" (368mm)

Ratio,Length

Up to 2.5 Up to 2.5

2.5" (63mm) to

9.5" (241mm)

2.5" (63mm) to

14.5" (368mm)

/Width

Left Margin Single-ply 0.10" (2.5mm)

Single-ply 0.10" (2.5mm)

Multi-ply 0.22" (5.5mm)

Multi-ply0.22" (5.5mm)

Right Margin Single-ply 0.10" (2.5mm)

Multi-ply 0.22" (5.5mm)

Single-ply 0.10" (2.5mm) to

0.7" (18mm)*

Multi-ply* 0.10" (2.5mm) to

0.7" (18mm)*

* Depending on document position

Horizontal Seam

Passbooks

Documents

≤ 9.5" (241 mm)

Specifications 6-5

Page 64

The Paper used for a Form should be:

Single-Ply Two-Ply Multi-Ply

Total

Thickness

0.004" to 0.02"

(0.1 to 0.45 mm)

0.004" to 0.02"

(0.1 to 0.45 mm)

0.004" to 0.02"

(0.1 to 0.45

mm)

Max. No. of

1 1 + 1 1 + 3 *

Copies

Top Sheet

Weight

Bottom

Sheet

16 to 32 lb.

(60 to 120 /m

2

)**

14 to 26 lb.

(50 to 100 g/m2)

14 to 26 lb.

(50 to 100 g/m

2

)

11 to 24 lb.

(40 to 90 g/m

22 to 32 lb.

(80 to 120 g/m

2

Weight

Inner sheet

weight

Total weight 16 to 32 lb.

(60 to 120 g/m

2

26 to 52 lb.

)

(100 to 200 g/m2)

11 to 22 lb.

(40 to 80 g/m

2

16 to 77 lb.

(60 to 280 g/m2)

* To handle this number of copies you must use the minimum allowed weight for

each sheet

** To allow for varying paper quality, the recommended minimum weight is

65g/m2

The paper for a Passbook should be:

Maximum Total Thickness 0.08" (2 mm)

Cover Weight 26 to 32 lb. (100 to 120 g/m2)

Cover Thickness 0.008" to 0.02" (0.2 to 0.5 mm)

Inner sheet weight 24 to 32 lb. (90-120g/m2)

)

2

)

)

Specifications 6-6

Page 65

6.4.1 Recommendations and Restrictions

• Transparent documents or documents containing transparent areas cannot be

used. Reflective ink surfaces (i.e. silver, gold) do not cause problems with the

edge detection system.

• Dark areas at the top of a form, close to the Left and Right Margins, i.e. Logo’s

and Letterheads will cause problems unless the TOP OFFSET in SETUP is

correctly set.

• Documents with staples, paper clips, holes or perforations are not permitted.

• Multi-ply forms of different lengths can be handled only if they are aligned at

the top. The shortest form must have a minimum length of 7.3" (185 mm) and

the software must eject the form at the rear of the printer.

• Multi-ply forms can consist of up to 3 copies plus the original.

Multi-ply forms with carbon sheets are not supported.

• The single part sheet and the top sheet of a multi-ply form should be either white

or a light color for maximum print contrast.

• When preprinted lines are required, the preprint must be as thin and fine as

possible to produce legible results.

6.4.2 Passbook Thickness

The maximum thickness of a passbook shall not exceed 0.08" (2.0 mm) when the

print page is opened. The difference between the maximum and the minimum

thickness at the centerfold shall not exceed 0.05" (1.4 mm) except for an end sheet

(vertical seam passbook only).

Specifications 6-7

Page 66

6.4.3 Center Outfold Bulge

When the passbook is opened at the middle page, the height of the bulge at the

center outfold shall not exceed 0.01" (0.3 mm).

6.4.4 Passbook Squareness

When the passbook is closed, the edge of the shorter side must be at a 90° angle to

the longer side.

Specifications 6-8

Page 67

7 GLOSSARY

ASCII American Standard Code for Information Interchange. A

standardized set of machine-readable 7 or 8-bit codes

consisting of control codes and codes representing

alphanumeric characters and symbols.

AWG American Wire Gauge

Bi-directional

printing

Baud rate The speed of data transmission measured in bits per second.

Bit a single character of a language having just two characters,

Byte a group of bits of information.

CPI Character Per Inch - the spacing of characters in a line.

CPS Characters Per Second.

CSA Canadian Standards Association

CTR Confidence Test Routine. Performed by the printer at

CTS See RTS/CTS.

Character Set a table of characters, each associated with an ASCII code,

Ctrl Control

DCD Data Carrier Detect

DPI Dots Per Inch.

Draft printing in single strike mode where one dot impact is

DSR Data Set Ready.

DTR Data Terminal Ready.

Double Height where characters are printed in two passes twice their

Double strike where text is printed in two passes with no horizontal or

Double width See expanded.

where printing occurs from left to right and from right to

left.

binary digits 0 or 1.

Sometimes referred to as 'pitch' or 'density'.

power-on

in a given font that can be printed.

delivered.

normal height.

vertical offset.

EU European Union

EIA Electronic Industries Association. Sets standards for the

Glossary 7-1

Page 68

electrical and functional characteristics of equipment.

Emulation where software allows the printer to imitate another printer.

Emphasized where text is printed in two passes with a horizontal offset.

Expanded where characters are printed in one pass at twice their

normal width.

ESC A single byte ASCII code that initiates an escape sequence.

Corresponding hexadecimal code is <1B>.

Escape Sequence A series of characters beginning with the code ESC which

activates a printer function.

FCC Federal Communications Commission

Flow Control RTS/CTS or XON/XOFF protocol.

Font Quality where characters are printed in Draft or High Quality Draft.

Form a document type defined as single-ply, multi-ply or an

envelope.

HQD High Quality Draft. Two consecutive dot impacts are

delivered (double strike).

Hz Hertz. The measuring unit for frequency (cycles per second)

ISO International Standards Organization

IEC International Electrotechnical Commission

Intercharacter

the space left blank between two consecutive characters.

Spacing

Loadable Character

where resident and/or downloaded characters are used.

Set

LPI Lines Per Inch.

Mechanical Margin defined by the hardware, this is 0.1" (2.5 mm) from the left,

right and top edges of the document.

NVM Non Volatile Memory.

Off-line the state when the communications line between the printer

and the host is not ready for data exchange.

On-line the state when the communications line between the printer

and the host is ready for data exchange.

Overscore To draw a line above printed characters and space.

RAM Random Access Memory.

RS232C serial interface standard used to connect the printer to the

Glossary 7-2

Page 69

host.

RTS/CTS Request To Send / Clear To Send. One of the standards

used by the RS232C protocol for controlling the flow of

data between two communicating devices using handshake

signals. When the host wants to send data to the printer, it

must wait for the printer RTS line to go on. If the printer

RTS line goes off, the host must stop transmission and wait

for it to go on again before sending any data. If the host

input buffer is full, when receiving an incoming message

from the printer, it must turn the printer CTS line off so that

the printer stops transmitting data. To restart

communication, the host turns the printer's CTS line on.

RX Receive

RXD Receive Data

Resident Character

permanently available in the printer.

Set

Reversed where characters are printed in white against black.

Stop bit The bit which signals the end of data.

SVT Standard Voltage Temperature

TX Transmit

TXD Transmit Data

Underscore To draw a line under printed characters and spaces.

UL Underwriters Laboratory

Unidirectional print

where the printer prints from left to right only.

mode

V Volt

VA Volt Ampere

XON/XOFF A software protocol for controlling the flow of data between

two communicating devices. By sending the XON

(Transmit on) code, the receiving device informs the

transmitter that it is ready to receive data. By sending the

XOFF (transmit off) code, the receiver instructs the

transmitter to stop sending data.

Glossary 7-3

Page 70

Printed in Sweden on

Totally Chlorine Free paper (TCF)

Loading...

Loading...