Page 1

InfoPrint 60

3160 Advanced Function Printer

IBM

Introduction and Planning Guide

G544-5242-03

Page 2

Page 3

InfoPrint 60

3160 Advanced Function Printer

Introduction and Planning Guide

IBM

G544-5242-03

Page 4

Note

Before using this information and the product it supports, be sure to read the general information under “Notices” on page vii.

Fourth Edition (June 1998)

This edition, G544-5242-03, applies to the IBM InfoPrint 60 Printer and the 3160 Model 001 Advanced Function Printer.

The following paragraph does not apply to any other country where such provisions are inconsistent with local law.

INTERNATIONAL BUSINESS MACHINES CORPORATION PROVIDES THIS PUBLICATION “AS IS” WITHOUT WARRANTY OF

ANY KIND, EITHER EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO THE IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. Some states do not allow disclaimer of express or implied

warranties in certain transactions; therefore, this statement may not apply to you.

Requests for IBM publications should be made to your IBM representative or to your IBM branch office serving your locality. If you

request publications from the address given below, your order will be delayed because publications are not stocked there.

IBM welcomes your comments. For your convenience, a form for readers' comments is provided at the back of this publication. If

this form is missing, you may write to:

Information Development

IBM Printing Systems Company

Department H7FE Building 003G

P.O. Box 1900

Boulder, CO 80301-9191, U.S.A.

If you prefer to send comments electronically, use one of the following methods:

Fax: 1-800-524-1519

Internet:

printpub@us.ibm.com

Internet

Visit our home page at http://www.printers.ibm.com

When you send information to IBM, you grant a nonexclusive right to use or distribute the information in any way IBM believes

appropriate without incurring any obligation to you.

Copyright International Business Machines Corporation 1995, 1996, 1998. All rights reserved.

Note to U.S. Government Users — Documentation related to restricted rights — Use, duplication or disclosure is subject to

restrictions set forth in GSA ADP Schedule Contract with IBM Corp.

Page 5

Contents

Notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

What's New in This Publication ........................... ix

Communication Statements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

Trademarks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

Related Publications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

Chapter 1. InfoPrint 60 and 3160-001 Printers .................. 1

General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Special Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Host Environments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Application Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Operational Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Data Security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Fonts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Performance and Print Quality ............................. 5

Advanced Function Image and Graphics ....................... 5

Print Material and Paper Handling ........................... 6

Chapter 2. Planning Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Sample Implementation Plan .............................. 8

Additional Planning Tasks ............................... 10

Chapter 3. Preparing the Processing Environment .............. 11

Performance Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Compatibility Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Attachments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Advanced Function Presentation Licensed Programs ............... 13

Installing and Verifying AFP Programs ...................... 13

Conversion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

AS/400 Migration Considerations ........................... 14

Bolding Characters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Enlarge Print Function ............................... 14

Box Draw Function ................................. 14

Chapter 4. Preparing the Physical Environment ................ 15

Environmental Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Temperature and Humidity ............................. 15

Altitude Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Heat and Airflow ................................... 16

Sound Levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Power Dissipation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Physical Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Weight and Dimensions .............................. 18

Service Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Physical Layout and Space Requirements .................... 19

Installation Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Installation Planning Worksheet ........................... 21

Copyright IBM Corp. 1995, 1996, 1998 iii

Page 6

Chapter 5. Configuring the Printer and Its Attachments ........... 23

Printer Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

System Attachment Worksheets ........................... 24

Ethernet TCP/IP Attachment Worksheet ..................... 25

SNA Token-Ring Attachment Worksheet ..................... 26

TCP/IP Token-Ring Attachment Worksheet ................... 29

System/370 Channel Attachment Worksheet .................. 30

Chapter 6. Ordering and Storing Supplies ................... 31

Printer Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

How to Order Supplies ................................. 31

Selecting Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Paper Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Label Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Prepunched Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Preprinted Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Selecting, Testing, and Ordering Paper ....................... 36

Storing Paper and Supplies .............................. 36

Appendix A. 3160 Font Set ............................. 39

IBM Core Interchange Resident Scalable Font Set ................ 39

GCSGID Subsets for IBM Core Interchange Fonts ............... 41

IBM Core Interchange Resident Code Page Set ................ 41

4028 Compatibility Resident Font Set ........................ 45

4028 Compatibility Resident Code Page Set .................. 47

IBM Coordinated Font Set ............................... 48

GCSGID Subsets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

DBCS Resident Raster Font Set ........................... 49

Default Font . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

AS/400 Bolding Function, Native and OfficeVision ................. 52

Appendix B. Software and Hardware Requirements ............. 55

Host Attachments That Support the InfoPrint 60 and the 3160-001 Printer ... 55

Host Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Host/PSF Software Support ............................ 57

PSF Support Notes ................................... 60

PSF/MVS Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

PSF/VSE Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

PSF/VM Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

0S/400 and PSF/400 Support ........................... 61

PSF/2 Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

PSF for AIX Support ................................ 62

System Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Host Software References: .............................. 62

System Attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

SNA or TCP/IP Token Ring ............................ 63

TCP/IP Ethernet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

System/370 Channel Attachment ......................... 65

Attachment Hardware Requirements ......................... 67

Bibliography . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

iv InfoPrint 60 and 3160 Introduction and Planning Guide

Page 7

Acronyms and Abbreviations ............................. 79

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Contents v

Page 8

Figures

1. Power Plug and Connector ........................... 17

2. Service Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3. Prepunched Paper Clearances -- A4, B5, and Letter Size ......... 35

4. Prepunched Paper Clearances -- A3, B4, Legal, and Ledger Size .... 35

5. Preprinted Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6. Parallel Channel Attachment Options (3160-001) .............. 66

vi InfoPrint 60 and 3160 Introduction and Planning Guide

Page 9

Notices

References in this document to IBM products, programs or services do not imply

that IBM intends to make these available in all countries in which IBM operates.

Any reference to an IBM licensed product, program, or service is not intended to

state or imply that only IBM’s product, program, or service may be used. Any

functionally equivalent product, program, or service that does not infringe any of

IBM’s intellectual property rights may be used instead of the IBM product.

Evaluation and verification of operation in conjunction with other products, except

those expressly designated by IBM, is the user’s responsibility.

Any performance data contained in this document was obtained in a controlled

environment based on the use of specific data. The results that may be obtained in

other operating environments may vary significantly. Users of this document should

verify the applicable data in their specific environment. Therefore, such data does

not constitute a performance guarantee or warranty.

IBM may have patents or pending patent applications covering subject matter in

this document. The furnishing of this document does not give you any license to

these patents. You can send license inquiries, in writing, to IBM Corporation, IBM

Director of Licensing, 208 Harbor Drive, Stamford, Connecticut, 06904, United

States of America.

The IBM 3160 Advanced Function Printer and the IBM InfoPrint 60 meet the

requirements of IEC 950, First Edition, Amendments 1 and 2. The laser used in

the 3160 complies with IEC 825 and EN 60825.

Copyright IBM Corp. 1995, 1996, 1998 vii

Page 10

viii InfoPrint 60 and 3160 Introduction and Planning Guide

Page 11

What's New in This Publication

The Attachment Menu for certain InfoPrint 60 printers has been expanded to

include SNA/Token Ring and 370 Parallel Channel. The InfoPrint 60 printers with

the expanded attachment capabilities have serial numbers equal to or higher than

the following numbers, according to region of manufacture:

For North and South America, serial number 01-30400.

For Europe, serial number 01-40200.

For Asia and Pacific areas, serial number 97-00020.

For printers after these serial numbers, attachment choices are the same for the

InfoPrint 60 and the 3160 Advanced Function Printer.

The following machine types and model types are covered in this publication.

Machine Number Machine Type Model Number

3160 3160 Model 001

InfoPrint 60 3160 Model 002

Copyright IBM Corp. 1995, 1996, 1998 ix

Page 12

Communication Statements

Federal Communications Commission (FCC) Statement

Note: This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to Part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This equipment generates,

uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely to cause

harmful interference, in which case the user will be required to correct the

interference at his own expense.

Properly shielded and grounded cables and connectors must be used in order to

meet FCC emission limits. IBM is not responsible for any radio or television

interference caused by using other than recommended cables and connectors or by

unauthorized changes or modifications to this equipment. Unauthorized changes or

modifications could void the user's authority to operate the equipment.

This device complies with Part 15 of the FCC Rules. Operation is subject to the

following two conditions: (1) this device may not cause harmful interference, and

(2) this device must accept any interference received, including interference that

may cause undesired operation.

The United Kingdom Telecommunications Act 1984: This apparatus is approved

under approval No. NS/G/1234/J/100003 for the indirect connections to the public

telecommunications systems in the United Kingdom.

Canadian Department of Communications Compliance Statement: This Class

A digital apparatus meets the requirements of the Canadian Interference-Causing

Equipment Regulations.

Avis de conformité aux normes du ministère des Communications du

Canada: Cet appareil numérique de la classe A respecte toutes les exigences du

Réglement sur le matériel brouilleur du Canada.

German Conformity Statement: Dieses Gerät erfüllt die Bedingungen der EN

55022 Klasse A. Für diese Klasse von Geräten gilt folgende Bestimmung nach

dem EMVG:

Geräte dürfen an Orten, für die sie nicht ausreichend entstört sind, nur mit

besonderer Genehmigung des Bundesminesters für Post und Telekommunikation

oder des Bundesamtes für Post und Telekommunikation betrieben werden. Die

Genehmigung wird erteilt, wenn keine elektromagnetischen Störungen zu erwarten

sind.

(Auszug aus dem EMVG vom 9.Nov.92, Para.3, Abs.4)

European Community (EC) Conformity Statement: This product is in conformity

with the protection requirements of EC Council Directive 89/336/EEC on the

approximation of the laws of the Member States relating to electromagnetic

compatibility. IBM cannot accept responsibility for any failure to satisfy the

protection requirements resulting from a non-recommended modification of the

product, including the fitting of non-IBM option cards.

x InfoPrint 60 and 3160 Introduction and Planning Guide

Page 13

Shielded Cables (European Statement): Properly shielded and grounded cables

and connectors must be used in order to reduce the potential for causing

interference to radio and TV communication and to other electrical or electronic

equipment. Such cables and connectors are available from IBM authorized

dealers. IBM cannot be responsible for any interference caused by using other

than recommended cables and connectors.

Statement for CISPR 22 Edition 2 Compliance: Warning: This is a Class A

product. In a domestic environment this product may cause radio interference, in

which case the user may be required to take adequate measures.

Japanese VCCI

Trademarks

The following terms are trademarks of the IBM Corporation in the United States or

other countries or both:

Advanced Function Presentation

AFP

AIX

AIX/6000

Application System/400

AS/400

Bar Code Object Content Architecture

BCOCA

ES/3090

ES/4381

ES/9000

ES/9370

ESCON

GDDM

IBM

InfoPrint 60

Intelligent Printer Data Stream

IPDS

Micro Channel

MVS/ESA

MVS/SP

MVS/XA

OfficeVision

OfficeVision/400

Operating System/400

OS/2

OS/400

Personal System/2

PrintManager

PS/2

PSF

PSF/6000

RISC System/6000

SAA

System/360

System/370

VSE/ESA

The following terms are trademarks or registered trademarks of other companies:

Trademark Company

HP-PCL5 Hewlett Packard Co.

Lexmark Lexmark International, Inc.

NetWare Novell Inc.

PostScript Adobe Systems, Inc.

What's New in This Publication xi

Page 14

Related Publications

IBM 3160 Advanced Function Printer: User's Guide

operate and maintain the 3160 printer.

, S544-5243, describes how to

IBM InfoPrint 60: User's Guide

the InfoPrint 60 printer.

, S544-5232, describes how to operate and maintain

IBM InfoPrint 60; 3130, 3160, and 3935 Advanced Function Printers: Attachment

Configuration Handbook,

your system for the attachment you use.

S544-3977, provides information to help you configure

System/360, System/370, 4300, 9370, and ES900 Processors Input/Output

Installation Manual–Physical Planning

System/370 parallel channel cables and other installation information.

Important

Before the customer engineer can install the printer, you must complete a

configuration worksheet for the attachment you plan to use. Simplified versions

of these worksheets are available in this book (see “System Attachment

Worksheets” on page 24). However, for detailed worksheets, instructions, and

examples, please refer to the

Function Printer: Attachment Configuration Handbook

have a copy of the handbook, ask your marketing representative to obtain one

for you.

For a list of publications that describe Advanced Function Page Printers and related

printing tools, see “Bibliography” on page 69.

, GC22-7064 provides information about

IBM InfoPrint 60; 3130, 3160, 3935 Advanced

, S544-3977. If you do not

For a more extensive listing of available publications, refer to

Presentation: Printer Information

For more information about Advanced Function Presentation, refer to the

Advanced Function Presentation

Contact your IBM marketing representative for information concerning the InfoPrint

60 and 3160, their documentation, or their associated licensed programs.

, G544-3290.

, G544-3876.

Advanced Function

Guide to

xii InfoPrint 60 and 3160 Introduction and Planning Guide

Page 15

Chapter 1. InfoPrint 60 and 3160-001 Printers

Chapter Overview

This chapter describes the characteristics, functions, features, and components

of the InfoPrint 60 printer and the 3160-001 Advanced Function Printer.

General Description

These printers are cut-sheet, intermediate speed, non-impact, all-pointsaddressable printers. They use low-power laser, electrophotographic print

technology, and are capable of a volume-capacity of up to 750 000 impressions

per month at speeds of up to 60 impressions per minute.

Two models are available, the 3160-001 and the InfoPrint 60. The 3160-001 prints

at a resolution of 240 x 240 picture elements (pels) and the InfoPrint 60 at

600 x 600 pels. Both models can be used for text, graphics, optical character

recognition (OCR), and bar code printing. Text, images, and electronic overlays

can be placed at any defined point on the page areas on which the printer can

print.

Note: In this guide, the unspecified term "printer" refers to

if a statement is made without reference to a particular model, it refers to both

models.

These printers also feature a high-speed RISC/6000-based control unit, which

provides the following benefits:

Special Features

Contact your marketing representative about obtaining these features:

both

models. Likewise,

The ability to process complex print jobs at high speed

Expanded network attachment capability

Improved paper handling

2000-sheet (optional) input tray (adjustable for A4 or letter-size paper)

3000-sheet side stacker (option) with convenience stapler

Additional memory (3160-001: 16 MB or 32 MB increment; InfoPrint 60: 32 MB

or 64 MB increment)

Ethernet Transmission Control Protocol/Internet Protocol (TCP/IP) interfaces:

– 10BaseT (twisted pair)

– 10Base2 (thin)

– 10Base5 (thick) (3160-001)

Token Ring with SNA

Token Ring for Transmission Control Protocol/Internet Protocol (TCP/IP)

System/370 Parallel Channel Attachment

Copyright IBM Corp. 1995, 1996, 1998 1

Page 16

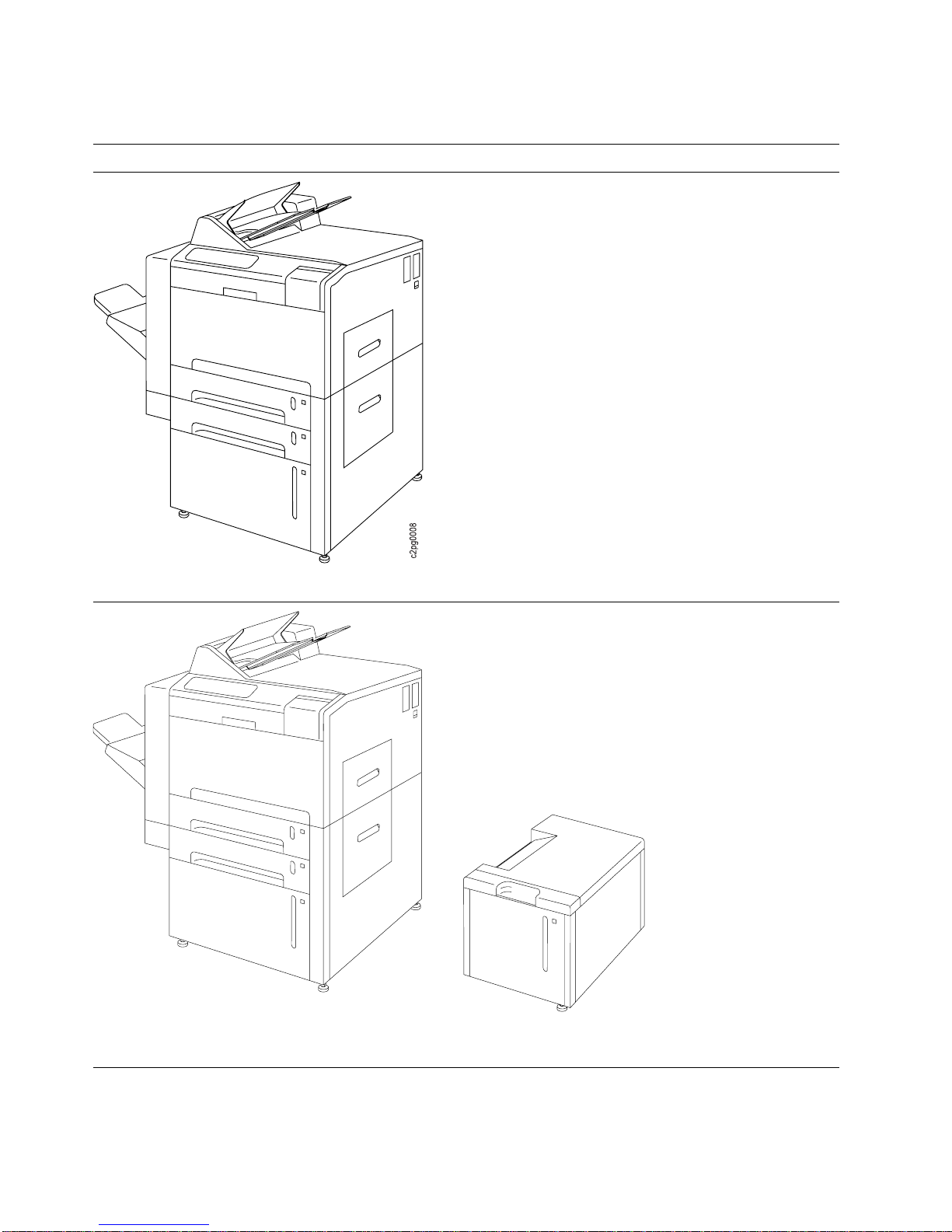

The InfoPrint60 and 3160-001 come with the following:

Machine Comes with This...

One 500-sheet top stacker.

A 1500-sheet side stacker.

Three paper input sources (3000-sheets total).

An optional 2000-sheet tray is available. See

“Special Features” on page 1 and the drawing

at the bottom of this page.

Paper sizes: letter, legal, ledger, A3, A4, B4,

B5.

Advanced function common control unit

(AFCCU) with 32 MB of storage (3160-001) or

64 MB (InfoPrint 60). Additional memory is

available in 16MB increments up to a

maximum of 64MB (3160-001) or 32 MB

increments up to a maximum of 128MB

(InfoPrint 60).

One attachment feature (see “Special

Features” on page 1). You must order at least

one.

Standard Printer

All of the above, plus a 2000-sheet input tray.

C2PG0010

Printer with the Optional 2000-Sheet Input Tray

Feature

2 InfoPrint 60 and 3160 Introduction and Planning Guide

Page 17

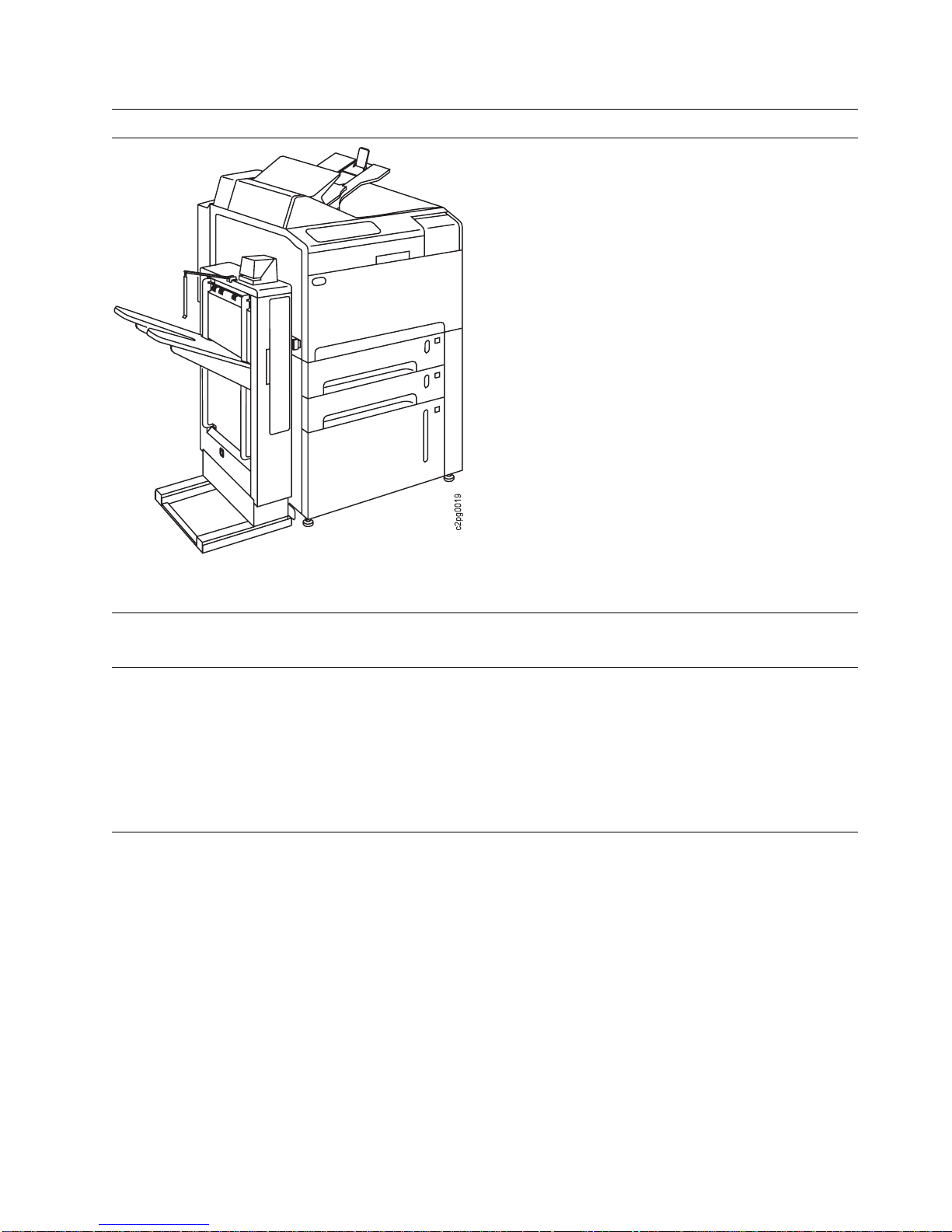

Machine Comes with This...

The standard machine, plus a 3000-sheet

output stacker with convenience stapler.

Printer with the Optional 3000-Sheet Side Stacker

Feature

Host Environments

For a summary of host environments and support, see Appendix B, “Software and

Hardware Requirements” on page 55. For a summary of PSF support and host

software requirements, refer to

Information

S544-3417.

Application Environment

The printer supports IBM Advanced Function Presentation (AFP) software, a

collection of licensed programs that let application developers take advantage of

many special kinds of printing, including bar code and optical character recognition

(OCR) output. Two OCR fonts are available from IBM: OCR-A and OCR-B.

Advanced Function Presentation uses the intelligent printer data stream (IPDS) to

drive the printer. Refer to the

G544-3876, and the

more information.

, G544-3290 and to the

Intelligent Printer Data Stream Reference,

Advanced Function Presentation: Printer

Intelligent Printer Data Stream Reference,

Guide to Advanced Function Presentation

S544-3417, for

,

Chapter 1. InfoPrint 60 and 3160-001 Printers 3

Page 18

Operational Features

The following list summarizes some of the operational features of the printer:

Standalone operation—The printer is designed to operate in an unattended

office environment. It does not require a dedicated operator for normal printing

tasks.

Operator messages and actions— The printer has a 32-character display for

messages, operator instructions, setup options, and host-related status.

Beeper— A beeper can alert operators when the printer requires attention.

Problem indicators— LEDs on a printer icon at the left of the operator panel

indicate where a problem such as a paper jam occurs.

Paper jam auto-eject doors—After a paper jam, you can usually auto-

matically clear the jammed paper by opening one or two doors.

Traces—The printer can perform several kinds of traces, which record details

about printer activities and communications with the control unit and the

controlling computer system, to assist service personnel.

Print samples—Several print sample masters are stored in the printer control

memory. Key operators can print these print samples whenever necessary to

sample print quality and solve problems.

Data Security

Authorization levels—You can have one or more persons designated as a

key operator. The key operator performs tasks such as configuring the printer,

cleaning the printer, adding new toner, and replacing supplies.

Password protection—You can specify that certain operator actions be

password-protected; in other words, only the person who knows the password

can perform certain key operator functions.

Toner cartridge—The printer monitors the toner supply and alerts the operator

when it should be replenished. In addition, automatic toner recycling reduces

the amount of toner the printer uses.

Error log—Sensors and other error-checking hardware detect status in the

printer. Information about errors is displayed to the operator and logged for

use in correcting problems.

The printer has the following data security features:

You cannot read data from the printer back to the controlling computer system.

You cannot print data that remains in memory after a job is finished.

Images on the photoconductor are cleaned and erased after each print.

The control unit accepts commands from the host to erase all residual print

data and fonts from its memory.

Characters stored in memory cannot be easily interpreted because they are

translated into a form different from 8-bit EBCDIC characters.

If many of the printing applications for your company are confidential, consider

placing the printer in a controlled-access area.

4 InfoPrint 60 and 3160 Introduction and Planning Guide

Page 19

Fonts

The printer supports the following:

The IBM strategic font set, which includes:

– The IBM Core Interchange Resident Scalable Font Set

– The 4028 Compatibility Resident Font Set

– The IBM Coordinated Font Set

The DBCS Resident Raster Font Set (as a separately-orderable feature)

For a more detailed description of each font set, see Appendix A, “3160 Font Set”

on page 39.

Performance and Print Quality

The printer prints up to 60 impressions per minute in either simplex or duplex mode

when using long-edge-fed paper; it prints up to 30 impressions per minute for

short-edge-fed paper. Table 1 on page 6 summarizes the types of paper you can

use and the maximum impressions per minute you can print.

Notes:

1. Actual printer performance is affected by a number of factors, including how

you configure the printer, the complexity of the data you print, the performance

of the host-system and the attachment you use, and the amount of available

memory.

2. The quality of printer output is affected by the paper you use and the

composition of the logical pages you print.

Advanced Function Image and Graphics

The printer can directly process advanced Image Object Content Architecture

(IOCA) images and Graphics Object Content Architecture (GOCA) graphics data,

as described in

SC31-6802. This provides the following performance benefits:

The printer can process compressed images and vector graphics data in the

GOCA format, thus reducing demand on attachment data transfer and host

storage.

The printer, rather than the host system, decompresses images and rasterizes

vectors, thus reducing host system processing cycles.

The printer can perform arbitrary scaling operations or resolution correction for

scanned images, which allows some complex jobs to print at greater throughput

by increasing the overall data-processing speed of the printer.

Mixed Object Document Content Architecture Reference

,

Chapter 1. InfoPrint 60 and 3160-001 Printers 5

Page 20

Print Material and Paper Handling

The printer can use paper in a variety of sizes and weights, including preprinted

paper, perforated paper, punched paper, drilled paper, color stock, and adhesive

labels. The printer can accept paper with a basis weight of 64 to 160 grams per

square meter (17 to 42 pounds). Paper is fed automatically from paper trays and,

after printing, is automatically placed in output stackers.

Table 1 summarizes the paper sizes the printer can use and indicates the feed

orientation and the number of impressions per minute for each paper size. See

“Selecting Paper” on page 32 for more information on print materials you can use.

Table 1. Paper Sizes

Paper Size Feed Orientation Impressions per Minute

A4 (210 x 297 mm)

Letter (8.5 x 11 in.)

Legal (8.5 x 14 in.)

B4 (257 x 364 mm)

Ledger (11 x 17 in.)

A3 (297 x 420 mm)

B5 (182 x 257 mm)

Long-edge

Long-edge

Short-edge

Short-edge

Short-edge

Short-edge

Long-edge

60

60

30

30

30

30

60

Note: When the paper (weight) is heavier than 22 pounds (88g/mò), print speed may

be reduced by 17%

Paper input trays provide automatic, printer-controlled paper tray switching so you

can load unused paper trays while the printer is running. Prints are stacked in

output stackers that have offsetting capability.

The duplex mode lets you print both sides of the paper without restacking and

refeeding the sheets.

6 InfoPrint 60 and 3160 Introduction and Planning Guide

Page 21

Chapter 2. Planning Overview

Chapter Overview

This chapter provides an overview of the planning process for installing an

InfoPrint 60 or 3160-001 printer.

There are two basic types of planning required for installing and using the printer:

physical planning and system planning.

Physical planning consists of:

– Determining the location for the printer.

– Preparing a layout plan for the printer

– Making sure all printer environmental, electrical, and space requirements

are met

For more information, see Chapter 4, “Preparing the Physical Environment” on

page 15. In addition, IBM offers special assistance with physical planning.

Contact your IBM branch office for information.

System planning consists of:

– Ordering the Advanced Function Presentation licensed programs and

updates required to use the printer

– Installing and testing the licensed programs and AFP resources

– Verifying that the host operating system is at the correct level

– Incorporating the printer into the system configuration and completing the

configuration worksheets

For more information, see Chapter 3, “Preparing the Processing Environment”

on page 11, and Chapter 5, “Configuring the Printer and Its Attachments” on

page 23 .

Another useful source of information when you are planning to install an IBM

InfoPrint 60 Printer or 3160 Advanced Function Printer is Preventative Service

Planning (PSP) "Buckets," accessible through IBM Link. The correct upgrade name

is PSF Printers, and the subset is 3160. For help accessing this aid, call the IBM

Support Center at 1-800-237-5511.

You can also visit IBM Printer Systems Company on the World Wide Web at

http://www.can.ibm.com/ibmprinters.

Copyright IBM Corp. 1995, 1996, 1998 7

Page 22

Sample Implementation Plan

Note

The following checklist contains many of the major tasks that must be

performed before and during printer installation. Use this checklist as a basis

for developing your own detailed implementation plan.

Also, note that the tasks you need to perform depend on whether or not you are

already running Advanced Function Presentation (AFP) programs.

Step One–Identify Team and Plan Layout

1. Identify the people who can prepare the physical site, identify and test

required software, and configure the host systems. Make sure to plan for

the printer and the attachment you use to connect it to your host system.

2. Order the printer including optional features you require, such as extra

memory.

3. Order any cabling, lines, equipment, or software you require for the

attachment you use to connect the printer to your host system.

4. Order the IBM Advanced Function Presentation licensed programs required

for your system. If you already use IBM Advanced Function Presentation

licensed programs, make sure they are at the service level required to

support the printer.

5. Make sure the host operating system is at the level required to support the

Advanced Function Presentation licensed programs and their updates.

6. Determine which printer resolution will be used and make sure the host

library resources (fonts, page segments, overlays, FORMDEFs, and

PAGEDEFs) are compatible with the printer resolution you select.

7. Prepare a plan for selecting and testing forms for use with the printer.

8. Determine the location for the printer and arrange for any changes to the

site.

9. Identify the internal delivery route for the printer

10. Prepare a space layout plan.

11. Determine who will install the electrical wiring and outlets.

12. Create a conversion plan for line-printer data and electronic overlays.

13. Prepare a plan for creating, converting, and testing applications that will be

used with the printer

Step Two–Review Plans, Order Supplies, and Prepare Site

1. Review installation plans with the IBM installation planning representative.

2. Order initial supplies for the printer.

3. Make sure attachment hardware is on order.

4. Schedule the installation of lines and equipment required for the

attachment.

5. Schedule the installation of electrical wiring and outlets.

8 InfoPrint 60 and 3160 Introduction and Planning Guide

Page 23

6. Make sure required host system updates are installed.

7. Begin installing and testing the Advanced Function Presentation licensed

programs and updates on the host system.

Step Three–Review Progress of Site Preparation

1. Review site-preparation progress with the IBM installation planning

representative.

2. Make sure the electrical wiring and outlets are being installed on schedule.

3. Make sure the attachment lines and equipment are being installed on

schedule.

Step Four–Make sure Site Preparation is Complete

1. Make sure installation and testing of electrical wiring and outlet is complete.

2. Make sure all site preparation activity is complete.

3. Gather information for the configuration worksheets in Chapter 5,

“Configuring the Printer and Its Attachments” on page 23, and schedule an

NCP Generation if needed.

Important

Before the customer engineer can install the printer you must complete

a configuration worksheet for the attachments you plan to use.

Completing the attachment worksheets usually requires input from the

personnel responsible for network and device driver configuration.

Simplified versions of these worksheets are available in this book (see

“System Attachment Worksheets” on page 24). However, for detailed

worksheets, instructions, and examples, please refer to the

IBM

InfoPrint 60; 3130, 3160, and 3935 Advanced Function Printers:

Attachment Configuration Handbook

copy of the handbook, ask your marketing representative to obtain one

for you.

, S544-3977. If you do not have a

Step Five–Arrival of the 3160

1. Contact the customer engineer and arrange to have the printer installed.

2. Arrange to have the printer attached to the host system.

3. Complete tests of the Advanced Function Presentation licensed programs,

including the IBM-supplied installation verification procedures.

Chapter 2. Planning Overview 9

Page 24

Additional Planning Tasks

Here are some other issues to consider before you install the printer

Training—Who will need training on the printer and AFP? Who will conduct

the training sessions? When will training be scheduled?

Implementation—How will the printer be phased into production? Which

applications will use the printer first?

Documentation—Which local procedures need to be changed? Who will be

responsible for changing local procedures? Who will need copies of IBM

hardware and software documents?

Supplies—How large should the initial printer supply order be? What is the

local procedure for ensuring that supplies are kept in stock? What is the

anticipated usage of the printer

10 InfoPrint 60 and 3160 Introduction and Planning Guide

Page 25

Chapter 3. Preparing the Processing Environment

Chapter Overview

This chapter contains information to help system programmers integrate the

printer into the existing processing environment. The basic hardware, software,

and application requirements for the printer are described in “Host

Environments” on page 3 and “Application Environment” on page 3.

Performance Considerations

The quality of printer output is affected by the paper you use and the

composition of the logical pages you print. To ensure printing legibility in your

application, test small (4-point) fonts and special characters such as logos in

your application. Refer to the

Reference for Use with IBM Electrophotographic Printers

information about these considerations.

IBM Advanced Function Printer Cut-Sheet Paper

, G544-3915, for

The following factors affect the performance of the system and directly affect

communication to the printer:

– Speed of the computer system

– Amount of available memory

– Priority of tasks assigned in the system

– Control program used to drive the printer

– Attachment type and line speed

– Workload on the LAN when using a LAN attachment, such as TCP/IP over

Token-Ring or Ethernet

Consider the following when setting up your host-attachment configuration:

– Before attaching the printer to non-IBM equipment, ensure that the

equipment supports the printer. The equipment vendor can answer your

questions about configuration options and other attachment issues.

– High-speed, direct-access storage devices (DASD) are recommended for

spool data sets and library data sets, particularly for printing workloads

consisting of documents with many fonts and images.

– Printer performance is best when high-use devices are used on a separate

attachment from the printer. Printer throughput can be degraded if the

printer is attached with other high-use devices, such as disk units, tape

units, or another printer that prints complex documents.

Printer traces, which you can run to help diagnose problems with the

attachment, the software, or the printer microcode, run in the background while

the printer performs its normal operations, and may reduce throughput.

To minimize the downloading of fonts, consider using printer resident fonts

when possible.

When memory can hold fonts and images for several pages at one time,

performance improves substantially. Complex documents require more

memory and, therefore, can take longer to print.

Copyright IBM Corp. 1995, 1996, 1998 11

Page 26

The printer uses 6 MB of its 32 MB (3160-001) or 64 MB (InfoPrint 60). of

standard memory for downloading fonts, page segments, and overlays. To

determine if this is enough, calculate the total memory you need for fonts and

images on that page.

Depending on the size and number of characters within a font, about 25 kbytes

to 37.5 kbytes of memory are needed for each single-byte font. Additionally, at

least 7.5 kbytes of memory are needed for each square inch of image data

when the resolution is 240 x 240 (3160-001), and 45 kbytes per square inch

when the resolution is 600 x 600 (InfoPrint 60). For better performance within

a job, consider the font and image memory requirements for all of the pages

that comprise the job.

Note: The figures given here reflect memory requirements for normal usage

and are provided only as a guideline. Under unusual circumstances,

there can be additional considerations. For example, there is a limit to

the total number of characters and images that can be stored in

memory.

If you need additional memory, contact your IBM marketing representative.

The 3160-001 can be upgraded with an additional 16 or 32 MB of memory, and

the InfoPrint 60 with 32 or 64 MB.

Compatibility Considerations

Here are some factors to consider if you are sending jobs from other page printers

to the InfoPrint 60 or 3160-001 printer.

The printer supports fonts in the same format as those for the IBM 3130, 3820,

3825, 3827, 3828, 3835, and 3900 printers. User-modified or user-created

3800 printer fonts are not compatible with this printer's fonts.

Although the printer can print edge to edge, consider paper registration and

size variations when defining the margins.

The printer can print to the paper’s edge, but for the best print quality, the

following margins are recommended:

Edges: 2.5 mm (0.1 in.)

Punched holes: 3.0 mm (1.2 in.)

The printer's default point of origin is the top left corner of the short side of the

media.

12 InfoPrint 60 and 3160 Introduction and Planning Guide

Page 27

Attachments

Important

Attaching your printer to your host system requires configuration changes to the

host system. Depending on the type of attachment and the host system you

use, you may need to make some configuration changes before you can install

the printer Several printer configuration parameters require values that match

values in your host system; at the least, you need to be prepared to provide

these values to the customer engineer who installs the printer

See Chapter 5, “Configuring the Printer and Its Attachments” on page 23 for

more details about configuring host systems.

Advanced Function Presentation Licensed Programs

Some Advanced Function Presentation (AFP) licensed programs are required for

the operation of the printer; others are optional. Work with your users to determine

which optional advanced functions they need. For a list of publications that

describe the programs you require for a particular environment, as well as a

summary of Advanced Function Presentation concepts, products, and benefits,

refer to the

Guide to Advanced Function Presentation

, G544-3876.

Installing and Verifying AFP Programs

Install and verify AFP programs before you install the printer. The licensed

programs include verification procedures to help you install the software correctly.

In addition, the system programmer is responsible for:

Creating the resources (page definitions, electronic overlays, form definitions,

and page segments) that the resource libraries will contain, beyond the

resources shipped with the PSF products being used

Creating or modifying the PSF startup procedure to include resource libraries

and attachment information

Enabling printer resident fonts, if necessary

Conversion

If Advanced Function Presentation is on another printer, you may begin the

conversion effort before you install the printer. Some tasks to consider are:

Changing font character sets

Converting line-printer applications to page-printer applications

Converting preprinted forms to electronic overlays

Creating new applications by using electronic overlays

Enhancing existing applications to take advantage of InfoPrint 60 or 3160-001

functions

Investigating applications that have special programming requirements

Chapter 3. Preparing the Processing Environment 13

Page 28

AS/400 Migration Considerations

Here are some things to consider if you migrate your print workload to an InfoPrint

60 or 3160-001 printer attached to an AS/400 operating in the OS/400 environment.

Bolding Characters

Both OfficeVision and Data Description Specification (DDS, the native OS/400 key

word HIGHLIGHT function) enable you to make characters bold by using a font

modification parameter. The printer automatically prints the indicated characters

bold for any font supported by the printer. The printer supports this same function

for the set of fonts resident in the printer that have bold versions.

See “AS/400 Bolding Function, Native and OfficeVision” on page 52 for a list of the

printer fonts and what will occur when the bolding function is invoked.

Important

Bolding may cause changes to line length, and in some cases may cause

information to exceed the page width.

Enlarge Print Function

OfficeVision/400, the Advanced Function Presentation Utilities/400, and the Data

Description Specification (DDS), native OS/400 keyword for CHRSIZ enable you to

direct the printer to enlarge characters. This function is not supported on the

InfoPrint 60 or 3160-001 using fonts selected by FGID (Font Global ID). This

function is supported only under DDS if you use GDDM fonts. GDDM fonts are

selected by name, such as ADMVMOB for Multinational Open Block.

Box Draw Function

OfficeVision lets you draw boxes with the cursor and then print them as drawn.

The printer supports this function if you specify ON for the AS/400 Box Draw

Enhancement printer configuration item. If you specify OFF for the AS/400 Box

Draw Enhancement printer, boxes drawn with OfficeVision will have breaks in them.

Note: To print boxes correctly, the printer substitutes code page 1091 for code

page 259.

14 InfoPrint 60 and 3160 Introduction and Planning Guide

Page 29

Chapter 4. Preparing the Physical Environment

Chapter Overview

This chapter describes the environmental, power, physical, and space

requirements you must meet before you install the printer. It includes an

installation planning worksheet.

Environmental Requirements

Temperature and Humidity

Table 2 lists the permitted temperature and relative humidity values for the printer.

Operating the printer above or below these ranges may result in poor print quality

and degraded paper handling.

Table 2. 3160 Temperature and Humidity Ranges

Temperature (Dry Bulb) Relative Humidity

Power on operations 10 to 32°C (50 to 90°F) 20% to 80%

Power off 10 to 40°C (50 to 104°F) 8% to 80%

Shipping and storage -10 to 40°C (14 to 104°F) 5% to 90%

Altitude Range

Ventilation

The altitude range permitted for printer operation is sea level to 2133 meters (7000

feet).

The printer operates best in an air-conditioned computer room with year-round

humidity control and recirculated, filtered air. Dust and other contamination can

cause machine problems.

To reduce any health risks associated with preprinted forms, follow IBM preprinted

forms recommendations and provide appropriate ventilation to the printer area. The

American Society of Heating, Refrigeration, and Air Conditioning Engineers

(ASHRAE) recommends a minimum of 0.42-0.57 metersó/minute (15-20 ftó/minute)

per person of outdoor air make-up for an office size of 12 ft x 12 ft x 8 ft (32.4

Meteró) during human occupancy (ASHRAE 62-1989).

For information about selecting and safely using preprinted forms, refer to the

Advanced Function Printer: Cut-Sheet Paper Reference for Use with IBM

Electrophotographic Printers

, G544-3915.

IBM

Copyright IBM Corp. 1995, 1996, 1998 15

Page 30

Heat and Airflow

Average heat dissipation of the printer while printing is less than 27 kcal/minute

(107 BTU/minute), based on 1.5 kVA for the printer.

No airflow restrictions apply if the printer is installed according to the guidelines and

floor plans established in this document.

Sound Levels

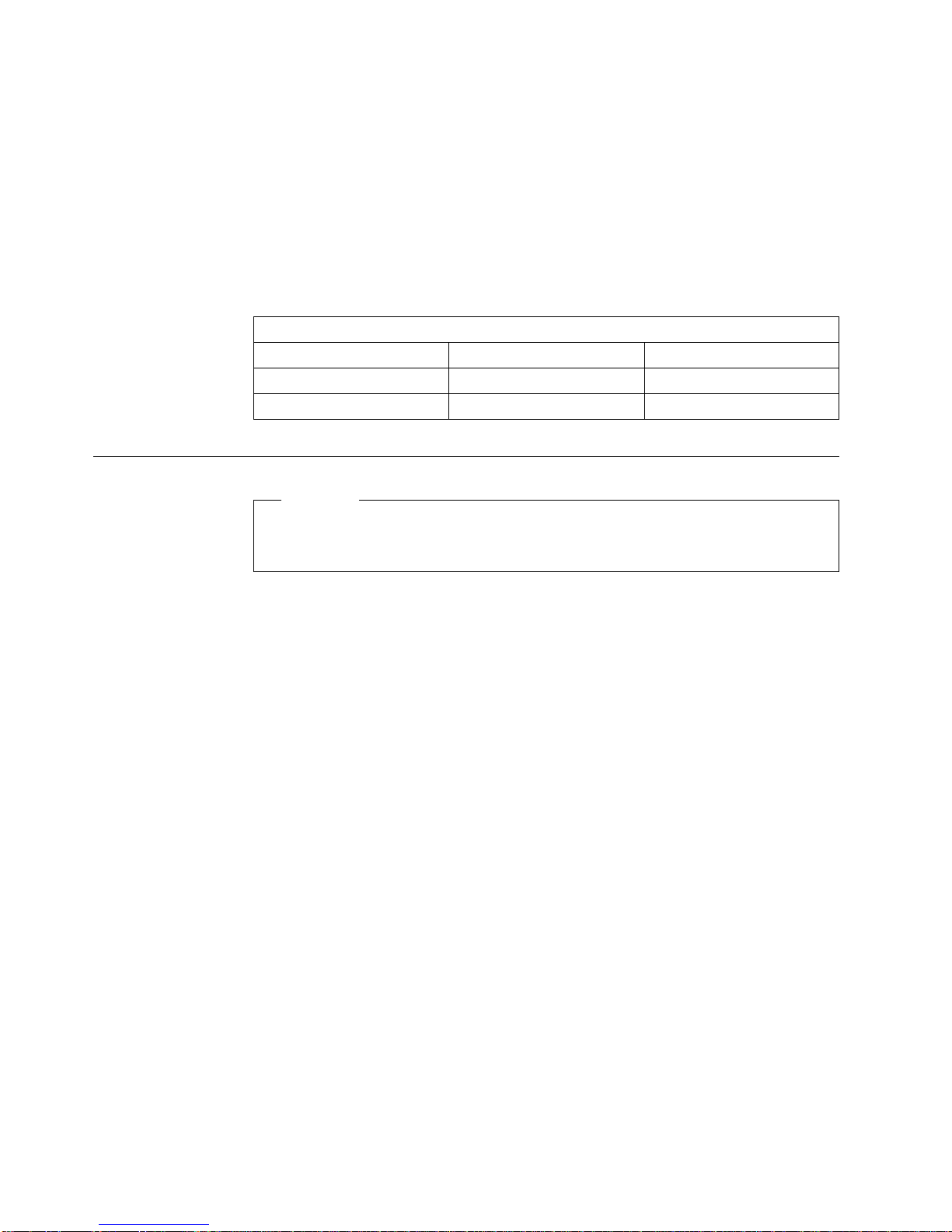

The upper limits for sound level are listed in Table 3.

Table 3. Sound Levels

Printer Condition 3160-001 InfoPrint 60

Idle 6.5 bels (49.6 dBA) 6.5 bels (50.4 dBA)

Operating 7.4 bels (59.2 dBA) 7.5 bels (58.8 dBA)

Power Requirements

Warning

Do not connect the printer to any 380—415 IT power distribution system

(impedance grounded neutral system).

Make sure your installation meets the electrical power requirements listed in

Table 4 on page 17 before the printer is delivered. In addition:

Reserve a dedicated circuit to support the printer and to allow the printer to be

disconnected from power. If you order the 3000-sheet side stacker (option),

reserve another dedicated circuit for it or put it on the same circuit as the

printer. Do not put anything else on the circuits dedicated to the printer, to the

stacker, or to the printer and stacker.

Provide electrical outlets for auxiliary equipment, such as modems or

communication modules. If necessary, make sure a telephone line and jack

are available.

For your safety, the printer is equipped with a plug required and approved by

UL and CSA. Use it in conjunction with a properly grounded receptacle.

16 InfoPrint 60 and 3160 Introduction and Planning Guide

Page 31

Table 4. Power Source Requirements

Item Requirements

Volts ac 200V to 240V ac ±10%, single phase, two wires

plus ground

Nominal frequency 48 to 62 Hz ±1.0%

Input current

Printer

3000-sheet side stacker (option)

Power input

Printer

3000-sheet side stacker (option)

Power cord plug NEMA 6-15R (in-line connector)

Notes:

1. Grounded neutral is required for the 50 Hz, 200-240 volt version of the printer.

2. Non-earthed neutral and impedance grounded neutral are NOT supported by the 50

Hz, 200-240 volt version of the printer and could damage components.

9.0 amperes

0.093 amperes

0.8 kVA (maximum standby)

1.5 kVA (maximum printing)

0.02 kVA (maximum standby)

0.07 kVA (maximum printing)

NEMA 6-15P (plug)

Figure 1. Power Plug and Connector

Power Dissipation

The printer can enter a power-save mode after a specified time has elapsed with

no printer activity. When the printer enters power-save, it removes power from all

printer subsystems. Normal operation resumes when the printer receives a host

command.

Table 5. Power Dissipation

Mode 3160-001 InfoPrint 60

Printing (fuser on) 1200 watts 1300 watts

Standby (fuser off) 340 watts 432 watts

Chapter 4. Preparing the Physical Environment 17

Page 32

Physical Requirements

Weight and Dimensions

Table 6. Weight

Unit Weight (kilograms) Weight (pounds)

3160-001 223 492

InfoPrint 60 227 500

1500-sheet side stacker 13 29

3000-sheet side stacker

(option)

Figure 2 on page 19 shows the dimensions of the printer, except the height, which

is 130 cm (51.2 in.).

Service Clearances

Refer to Figure 2 on page 19.

35 77

18 InfoPrint 60 and 3160 Introduction and Planning Guide

Page 33

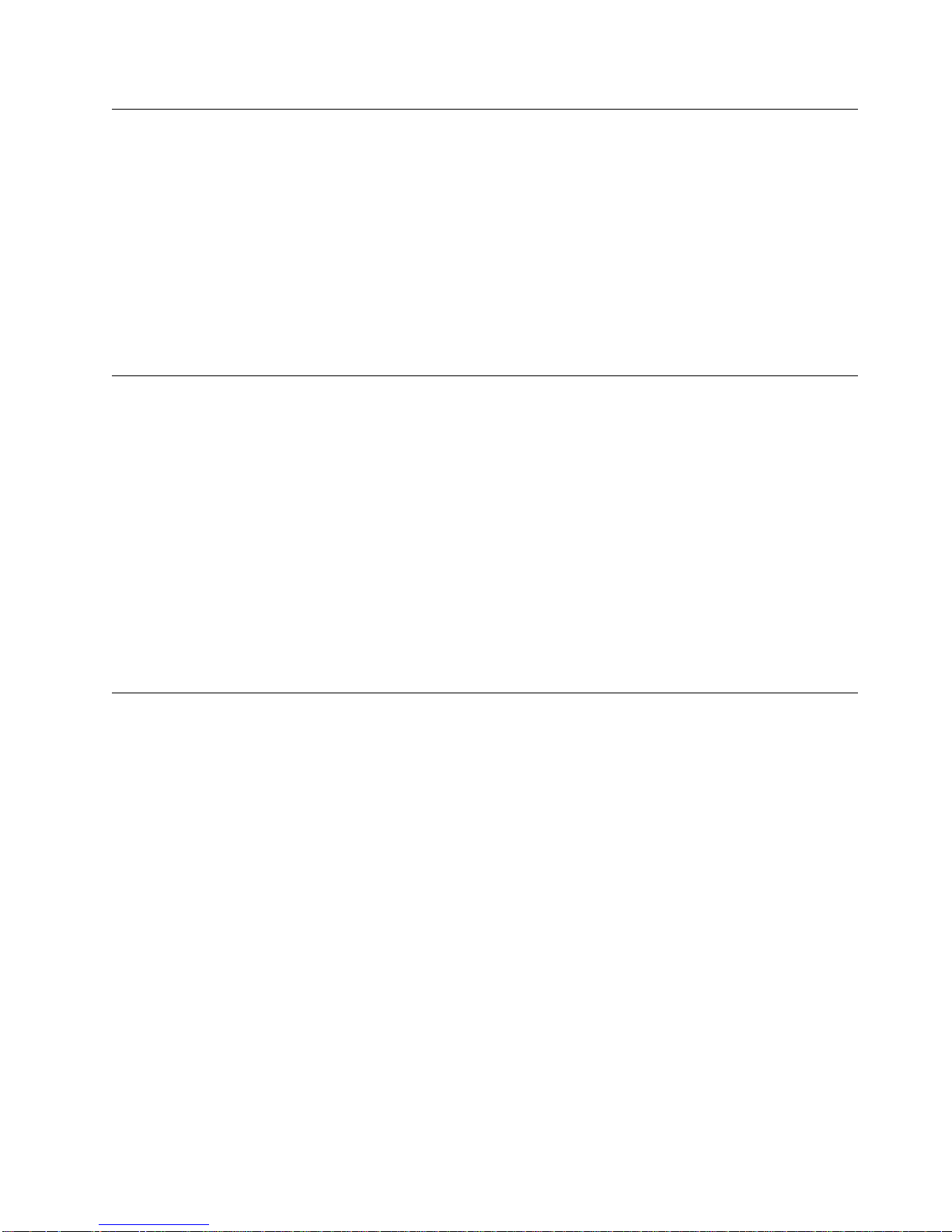

Physical Layout and Space Requirements

Figure 2 shows the space requirements for a permanent installation.

As you plan your physical layout:

Install the printer away from the main traffic pattern. Allow space for key

operators and customer engineers to perform their tasks. This space should

not extend into walkways.

Install the printer in a location that is convenient for the key operator and other

users. For example, consider whether the planned location is close to printer

supply storage areas and to output distribution areas.

Allow 2.1 meters (83 in.) between the floor and the lowest permanently

attached object above the printer, such as a light or a cable rail. This layout

gives printer operators and customer engineers space in which to work.

Check the route that the printer must travel from your loading dock to the

location where it will be installed, to ensure that it fits through the doorways and

halls. When possible, move the printer from the dock to its installation location

on its shipping pallet.

Note: Install the printer permanently in the service position if you attach it to a

System/370 parallel channel (available only with 3160-001).

Figure 2. Service Clearances

Chapter 4. Preparing the Physical Environment 19

Page 34

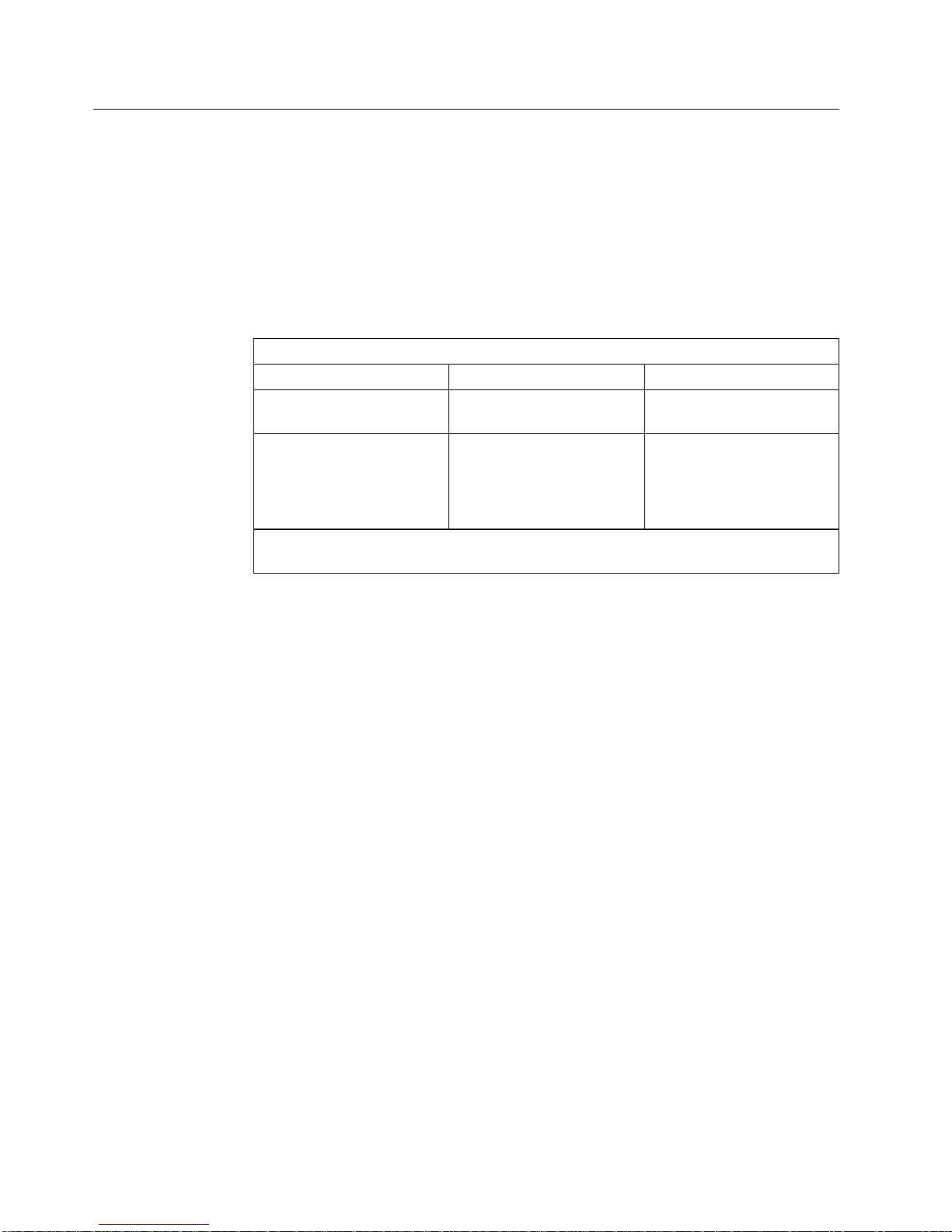

Dimension A Values:

Dimension A Configuration

65 cm (25.6 in.) Base printer without side stacker and 2000-sheet tray

40.5 cm (15.9 in.) Add to base printer for side stacker with short paper

50.2 cm (19.8 in.) Add to base printer for side stacker with long paper (A3 and

46 cm (18 in.) Add to base printer for optional 2000-sheet tray

70.2 cm (27.6 in.) Add to base printer for 3000-sheet side stacker (option).

Dimension B Values:

Dimension B Model

69.5 cm (27.4 in.) 3160-001

77 cm (30.3 in.) InfoPrint 60

Installation Requirements

Procedures for installing the printer are included with the printer and in the

InfoPrint 60; 3160 Advanced Function Printer: Maintenance Information

Although a service person installs the printer, the customer is responsible for the

following pre-installation tasks:

Ledger)

This dimension includes 6 inches of travel when stacker is

pulled away from printer to remove paper jams.

IBM

, 30H7534.

Make sure the environmental, electrical, and space requirements specified in

this chapter are met. Use the “Installation Planning Worksheet” on page 21 to

complete this step.

Make sure the receiving area and internal delivery route contain no obstacles

that might interfere with moving the printer to its planned location:

– Halls and doorways must be large enough for the printer to pass through,

and corners and angles must be large enough to permit the printer to turn.

For example, the minimum doorway opening through which this printer can

pass from a 91.5 cm (36 in.) wide aisle is 75 cm (30 in.).

– Ramps must have no more than 12 degrees, 50 minutes incline to allow

clearance for the lower edge of the printer with its supporting feet retracted.

– Elevators and elevator doorways must be able to accommodate the size

and weight of the printer and the people who are moving it.

– Stairs, sills, and gaps, and carpeting can make rolling the printer difficult.

Do not tilt the printer more than 15°.

Make sure that the floor is level within ±1.5° from earth horizontal in any plane.

Make sure that an approved electrical outlet with correct power is reserved for

the printer (and another for the 3000-sheet stacker (option), if appropriate), and

that it can be reached with the power cable.

If the printer is being installed in an area with a raised floor, make sure the

access hole in the raised floor is large enough for both the communication

attachment cables and the power cable.

20 InfoPrint 60 and 3160 Introduction and Planning Guide

Page 35

Installation Planning Worksheet

Before your printer is delivered, prepare a site installation plan. Use the following

worksheet (Table 7) to ensure that all of the pre-installation requirements are met.

Table 7. Installation Planning Worksheet

Requirements Meets

Requirements

Environmental

Ventilation

Temperature

Relative humidity

Space

Layout

Supplies storage space

Clearances

Delivery route

Electrical

Voltage

Outlets:

– Reached by cables?

– Correctly grounded?

– Meet local and

national codes?

Building branch circuit:

– Correctly grounded?

– Enough power

to meet needs?

– Meets local and

national codes?

Host Attachment

Cables

Lines

Other equipment

Security ________ ________ ________ ________ ________

________

________

________

________

________

________

________

________

________

________

________

________

________

________

________

________

________

Needs

Attention

________

________

________

________

________

________

________

________

________

________

________

________

________

________

________

________

________

Assigned to Date Due Date

Completed

________

________

________

________

________

________

________

________

________

________

________

________

________

________

________

________

________

________

________

________

________

________

________

________

________

________

________

________

________

________

________

________

________

________

________

________

________

________

________

________

________

________

________

________

________

________

________

________

________

________

________

Chapter 4. Preparing the Physical Environment 21

Page 36

22 InfoPrint 60 and 3160 Introduction and Planning Guide

Page 37

Chapter 5. Configuring the Printer and Its Attachments

Chapter Overview

This chapter contains worksheets you can use to configure the printer and the

attachments you use to connect host systems to the printer.

Printer Configuration

Fill in the information on Table 8, and give a copy of the completed form to the

customer engineer when the printer is installed. The customer engineer will use

the worksheet to configure the printer. You can change some of these options

later.

The procedures for configuring the printer are in

Function Printer: Maintenance Information

the configuration are in

Advanced Function Printer: User's Guide

Table 8. Printer Configuration

Item Available Values Selected Value

AUTOSTART YES or NO

DUPLEX ENABLE or DISABLE

DEFAULT FONT Several

AS/400 BOX DRAW ENHANCEMENT ON or OFF

LOGICAL PAGE INCREMENT 0 PELS to +20 PELS

BEEPER ERROR: TIMED, CONTINUOUS, OFF

KEYS: ON or OFF

SLEEP TIME Up to 3 digits (minutes)

LANGUAGE

(For operator panel display only)

3935 EMULATION ON or OFF

OPTICAL DENSITY NORMAL or HIGH

ENGLISH, FRENCH, GERMAN, JAPANESE

(KATAKANA), ITALIAN, SPANISH, DUTCH,

BRAZILIAN PORTUGUESE

IBM InfoPrint 60: User's Guide

, G544-5243.

IBM InfoPrint 60; 3160 Advanced

, 30H7534. The procedures for updating

, G544-5232, and

IBM 3160

Autostart A yes or no indication of whether the printer performs an autostart during power-on.

With autostart, the printer automatically enables the attachment that was enabled at

the time of the last power-off. The printer then makes itself ready.

Note: When

disabled

switch inadvertantly). This results in messages declaring that PSF cannot

communicate with the printer. Therefore, in distributed LAN environments using

TCP/IP protocols, you will probably decide to define

Duplex An indication of whether the printer is enabled for duplex printing

Default font The font that is used when no font is designated by the host. Unless you specify

otherwise, the default font is Courier Roman Medium 12 pitch (10 point) using code

page 500, version 1.

Copyright IBM Corp. 1995, 1996, 1998 23

Autostart

has been defined NO, TCP/IP communication defaults to

after an unexpected shutoff (for example, a power outage, pressing the off

Autostart

YES.

Page 38

AS/400 Box Draw Enhancement

If set ON, the printer can correctly print boxes drawn with OfficeVision. If set to

OFF, boxes drawn with OfficeVision will have breaks in them.

Note: To print boxes correctly, the printer substitutes code page 1091 for code

page 259.

Logical page increment

This number expands the logical page for cases in which the printable page is

larger than the logical page (or printed sheet).

Beeper A beeper sounds when the printer detects an error or when keys are pressed during

menu mode:

You can set the

– Beep until any operator panel key is selected

– Beep for three minutes and then stop

– Never beep at all

You can set the

Sleep time The number of minutes the printer waits before it goes into

Specify a value from 0 to 999. '0' means the printer will never go into power-save

mode.

Language The language used to display operator console text for general users and key

operators. Text for customer engineers is in English only.

3935 Emulation This function is used for AS/400 installations. When it is turned on, the printer

communicates with the host. When it is turned off, the printer responds as an

InfoPrint 60 or 3160 Advanced Function Printer. This emulation is required if the

host system does not support the InfoPrint 60 or 3160-001 printer.

Note: This printer will not emulate 3935 function.

Optical Density This indicates the degree of print darkness of a printed page. You can choose a

lighter print density to add detail to a fine line, or darker print density to enhance

graphics or images. The recommended density is medium. The darker selection

(dark) uses more toner, and the lighter selection (light), less toner.

error

beeper to:

keys

beeper to on or off.

power-save mode

.

System Attachment Worksheets

Important

Appendix B, “Software and Hardware Requirements” on page 55 summarizes the host environments

that support this printer and the attachments than run under each.

Before the customer engineer can install the printer you must complete the appropriate attachment

configuration worksheets. Simplified versions of these worksheets are available in the sections that

follow. For detailed worksheets, instructions, and examples, refer to the

and 3935 Advanced Function Printers: Atttachment Configuration Handbook

have a copy, ask your marketing representative to get you one.

24 InfoPrint 60 and 3160 Introduction and Planning Guide

IBM InfoPrint 60; 3130, 3160,

, S544-3977. If you do not

Page 39

Ethernet TCP/IP Attachment Worksheet

Important

Installing an Ethernet attachment requires changes to your host system configuration. For detailed

worksheets, instructions, and examples, refer to the

Function Printers: Atttachment Configuration Handbook

The printer is connected to a host Ethernet using the Integrated Ethernet LAN adapter contained in the

control unit.

The control unit can be attached directly to standard Thick (10Base5) Ethernet coaxial cable (Feature

Code 4163) (3160-001). The output connector is a thick, 15-pin, D-shell “slide-latch” type that is

compatible with IEEE 802.3 Section 7.6. Connection to thick Ethernet media is through an Ethernet/IEEE

802.3 AUI cable available from OEM vendors. Attachment to thin (10Base2) or twisted-pair (10BaseT)

Ethernet media is through external transceivers.

The coaxial T connector is used in addition to the 10Base2 transceiver to connect to the thin Ethernet

coaxial cable. You should use a customer-supplied RJ45 unshielded twisted-pair cable (must meet IEEE

802.3 requirements) to attach the 10BaseT transceiver to the Ethernet twisted-pair hub.

IBM InfoPrint 60; 3130, 3160, and 3935 Advanced

, S544-3977.

Table 9. Ethernet TCP/IP Configuration

Item Available Values Selected Value

Install Status Installed or Not Installed

TCP Port 5001 to 65536

IP Address X.X.X.X where X <=255

Subnet Mask X.X.X.X where X <=255

Default Gateway Address X.X.X.X where X <=255

Standard MTU Size 60 to 1500 (bytes)

IEEE802.3 MTU Size 60 to 1492 (bytes)

Ethernet Type Standard or IEEE802.3

Alternate Address 0000 0000 0001 to FFFF FFFF FFFE ñ

MAC (Medium Access Control) Read-only field

Note:

ñ Do not enter the spaces shown; they are included here as a visual aid.

Install status An indication of whether the attachment is installed.

TCP port The TCP socket address of the attachment. This value must match the

corresponding host parameter.

IP address The Internet Protocol address of the printer in dotted decimal format.

Subnet mask The mask identifying the local subnet in dotted decimal format. If there is no local

subnet, leave this field blank.

Default gateway address

The IP address of the default gateway in dotted decimal format.

Standard MTU size MTU is an abbreviation for maximum transmission unit. This TCP/IP Ethernet type

ranges from 60 to 1500.

Chapter 5. Configuring the Printer and Its Attachments 25

Page 40

IEEE802.3 MTU size

This TCP/IP Ethernet type ranges from 60 to 1492.

Ethernet type The Ethernet type, either standard or IEEE802.3.

Alternate Address (Local Adapter Address)

The LAN adapter unique address for the printer. The address must be different

from other addresses on the LAN.

MAC (Medium Access Control)

Read-only field.

SNA Token-Ring Attachment Worksheet

Note: SNA token-ring attachment is available on the 3160-001 and the InfoPrint 60.

Important

Installing a token-ring attachment requires changes to your host system configuration. For detailed

worksheets, instructions, and examples, refer to the

Function Printers: Atttachment Configuration Handbook

IBM InfoPrint 60; 3130, 3160, and 3935 Advanced

, S544-3977.

The printer can be attached to a host system using a 4 Mbps or 16 Mbps token-ring local area network

(LAN), with the IBM Token-Ring cabling and Token-Ring High-Performance Adapter contained in the

printer control unit (or Auto Token-Ring LANstreamer adapter contained in the printer control unit for the

InfoPrint 60.

The maximum allowable distance of the printer from the 8228 Multistation Access Unit or 8230 Controlled

Access Unit depends on several factors. In general, a maximum distance of 100 meters (328 feet) is

allowed. However, to calculate the exact maximum distance, refer to

Introduction and Planning Guide

, GA27-3677. An 8219 or 8220 Optical Fiber Repeater can be used to

IBM Token-Ring Network

increase this distance.

Table 10 (Page 1 of 2). SNA Token-Ring Attachment Worksheet

Item Available Values Selected Value

Install Status Installed or Not Installed

XID Number 0000 0000 to FFFF FFFF ó

Remote Network Name Up to 8 characters ñ

SNA Intervention Timer 0 to 99 (Minutes), Default=99

Local LU Name Up to 8 characters ñ

Remote LU Name Up to 8 characters ñ

Mode Name Up to 8 characters ñ or null

Remote Address 4000 0000 0000 to 7FFF FFFF FFFF ó

Local Network Name Up to 8 characters ñ

Control Point Name Up to 8 characters ñ

Alternate Address (Local Adapter

Address)

Ring Speed 4 or 16 (Mbps)

SSCP ID (0500 0000 xxxx) 0000 to FFFF ò

Local LU Address 0 to 255 (0 for Independent LU, 1 to 255 for

Call Type Listen or Call

4000 0000 0000 to 7FFF FFFF FFFF ó

Dependent LU)

26 InfoPrint 60 and 3160 Introduction and Planning Guide

Page 41

Table 10 (Page 2 of 2). SNA Token-Ring Attachment Worksheet

Item Available Values Selected Value

MAC (Medium Access Control) Read-only field

Notes:

ñ Eight characters maximum; 0–9, A–Z, $, #, and @ permitted, but the first character cannot be 0-9.

ò Printer prefixes with 0500 0000.

ó Do not enter the spaces shown; they are included here as a visual aid.

Install status An indication of whether the attachment is installed.

XID number An ID that distinguishes a specific piece of equipment from all other similar pieces

of equipment on the network.

Remote network name

The network name associated with the remote logical unit. The first character of

this name cannot be 0-9.

SNA intervention timer

The amount of time the operator is allowed to correct recovery-required errors (such

as paper jams) before the printer notifies the host that the attachment is not

operating. The timer can be set from 0 to 98 minutes. To turn the timer off, specify

99 (the default value).

Local LU name The name of the local logical unit involved in the session.

Remote LU name The name of the remote logical unit involved in the session. The first character of

this name cannot be 0-9.

Mode name The name of the SNA mode that describes the characteristics of a session. The

first character of this name cannot be 0-9.

Remote address The remote host Token-Ring adapter card address.

Local network name

The name of the network associated with the local logical unit. If you enter a local

network name, you must also enter a control point name. The first character of this

name cannot be 0-9.

Control point name The name of the application control point. The first character of this name cannot

be 0-9.

Alternate address (Local Adapter Address)

The LAN adapter unique address for the printer. The address must be different

from other addresses on the LAN.

Ring speed The ring speed of the network the adapter is attached to. An incorrect value can

cause the network to stop operating.

SSCP ID The ID of the controlling system services control point in the SNA network. The

3160 uses this ID to send information to the host system's Netview programs. If the

host does not use Netview, set SSCP ID to 0000.

Note: Specify SSCP ID as a hexadecimal value. If the corresponding host value is

in decimal, you must convert it to hexadecimal.

Local LU address The destination address used by other systems to send information to the local

logical unit.

Chapter 5. Configuring the Printer and Its Attachments 27

Page 42

Call type An indication of how the printer identifies itself to the host system. LISTEN, the

default value, means that the printer waits until the host asks for (or polls) its

identification. CALL means that the printer identifies itself to the host during printer

initialization.

MAC (Medium Access Control)

Read-only field.

28 InfoPrint 60 and 3160 Introduction and Planning Guide

Page 43

TCP/IP Token-Ring Attachment Worksheet

Important

Installing a token-ring attachment requires changes to your host system configuration. For detailed

worksheets, instructions, and examples, please refer to the

Advanced Function Printers: Atttachment Configuration Handbook

The following table lists the configuration attachment parameters for a TCP/IP Token-Ring attachment:

Table 11. TCP/IP Token-Ring Attachment Worksheet

Item Available Values Selected Value

Install Status Installed or Not Installed

TCP Port 5001 to 65536

IP Address X.X.X.X where X <=255

Subnet Mask X.X.X.X where X <=255

Default Gateway Address X.X.X.X where X <=255

MTU Size 60 to 4096

Ring Speed 4 or 16 (Mbps)

Confine Broadcast Yes or No

Alternate Address 0000 0000 0001 to FFFF FFFF FFFE ñ

MAC (Medium Access Control) Read-only field.

Note:

ñ Do not enter the spaces shown; they are included here as a visual aid.

IBM InfoPrint 60; 3130, 3160, and 3935

, S544-3977.

Install status An indication of whether the attachment is installed.

TCP port The TCP socket address of the attachment. This value must match the

corresponding host parameter.

IP address The Internet protocol (IP) address of the printer in dotted decimal format.

Subnet mask The mask identifying the local subnet in dotted decimal format. If there is no local

subnet, leave this field blank.

Default gateway address

The IP address of the default gateway in dotted decimal format.

MTU size The maximum allowable length of IP packets.

Ring speed The ring speed of the network the adapter attaches to. This value must match the

speed of the network; an incorrect value can cause the network to stop operating.

Confine broadcast A yes or no indication of whether broadcast packets—notably ARP (Address

Resolution Protocol) packets—are enabled to cross bridges to other rings. Specify

NO to allow ARP packets to cross bridges.

Alternate Address (Local Adapter Address)

The LAN adapter unique address for the printer. The address must be different

from other addresses on the LAN.

MAC (Medium Access Control)

Read only field.

Chapter 5. Configuring the Printer and Its Attachments 29

Page 44

System/370 Channel Attachment Worksheet

Note: System/370 channel attachment is available on the 3160-001 and the InfoPrint 60.

Table 12. System/370 (Parallel) Channel Attachment

Item Available Values Selected Value

Channel A Install Status Installed or Not Installed

Device Address X'00' to X'FF'

Data Transfer Protocol Interlocked or Data Streaming

Data Streaming Rate 1.9 MB per second

2.7 MB per second

3.4 MB per second

4.5 MB per second

Channel A Install Status

An indication of whether the attachment is installed.

Device Address Address of the printer. Valid values are X'00' to X'FF'.

Data Transfer Protocol

Either Interlocked or Data Streaming.

Data Streaming Rate

If Data Streaming is selected, this field sets the speed of transfer.

Valid values are:

1.9 MB per second

2.7 MB per second

3.4 MB per second

4.5 MB per second

30 InfoPrint 60 and 3160 Introduction and Planning Guide

Page 45

Chapter 6. Ordering and Storing Supplies

Chapter Overview

This chapter describes how to order and store the supplies that the printer uses.

Printer Supplies

Table 13 lists printer supplies, the part numbers you use to order them, and an

estimate of how often they need to be replaced. The yields listed in the table are

approximations. They are not a warranty or guarantee of minimum life, and are

provided only to assist in supplies planning. Analyze your actual usage figures to

determine how much of each supply item to stock.

Actual supply life varies according to printer usage, toner settings, paper

characteristics, temperature, and humidity. In addition, special applications (such

as adhesive labels, extensive graphics, bar codes, landscape applications, and

pre-printed forms) may significantly reduce supply life.

When the printer runs low on a particular supply, it displays a message on the

operator panel.

Table 13. Printer Supplies

Supply Item Part Number Replace Every...