Page 1

IBM InfoColor 70 and 3170

Print Media Guide

Page 2

Page 3

IBM InfoColor 70 and 3170

Print Media Guide

Page 4

First Edition (June 1998)

The following paragraph does not apply to any other country where such provisions are inconsistent with local law.

INTERNATIONAL BUSINESS MACHINES CORPORATION PROVIDES THIS PUBLICATION “AS IS” WITHOUT

WARRANTY OF ANY KIND, EITHER EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO THE IMPLIED

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. Some states do not allow

disclaimers of express or implied warranties in certain transactions, therefore, this statement may not apply to you.

Order publications through your IBM representative or the IBM br anch office serving your locality. Publications are not

stocked at the address given below.

The IBM Printing Systems Company welcomes your comments. A form for readers’ comments is provided at the back

of this publication. If the form has been removed, you may send your comments to the following address:

IBM Printing Systems Company

Information Development

Department H7FE, Building 003G

P.O. Box 1900

Boulder, CO 80301-9191

U.S.A

If you prefer to send comments electronically, use one of the following methods:

Internet: print_pubs@vnet.ibm.com

Fax: 1-800-524-1519

Visit our home page at

http://www.printers.ibm.com/

.

When you send information to IBM, you grant a nonexclusive right to use or distribute the information in any way IBM

believes appropriate without incurring any obligation to you.

Copyright International Business Machines Corporation 1998 All rights reserved.

Note to U.S. Government Users − Documentation related to restricted rights − Use, duplication or disclosure is subject to restrictions set forth in GSA ADP Schedule Contract with IBM Corp.

Page 5

IBM InfoColor 70 and 3170 Print Media Guide 1

Purpose of this manual 3

Requesting a Print Medium Test 5

Importance of Print Medium Testing ................................................................................................................ 5

Procedures....................................................................................................................................................... 5

Test Results, Medium Performance and Script................................................................................................ 9

Rush Testing.................................................................................................................................................... 9

Basic Paper Types and Their Properties 11

Basic paper types........................................................................................................................................... 11

Uncoated paper ......................................................................................................................................... 11

Coated paper............................................................................................................................................. 12

Speciality paper ......................................................................................................................................... 12

Paper properties............................................................................................................................................. 13

Guidelines for Print Medium Quality Inspection 15

Check Paper Quality ...................................................................................................................................... 15

Guidelines for Print Medium Storage and Handling....................................................................................... 16

Splicing........................................................................................................................................................... 17

Roll inspection................................................................................................................................................ 17

Paper Waste During Printing and Waste Reduction (3.02 code or higher).................................................... 18

Start of a Print Job..................................................................................................................................... 18

Auto Mode............................................................................................................................................. 18

Manual Mode......................................................................................................................................... 18

Finishing the Print Job ............................................................................................................................... 18

Changing the Paper Roll............................................................................................................................ 19

Operator Skills ........................................................................................................................................... 19

Paper Quality............................................................................................................................................. 19

Environment............................................................................................................................................... 19

Artifact Samples 21

Low-density cloudiness.................................................................................................................................. 22

High-density cloudiness ................................................................................................................................. 22

High-frequency cloudiness............................................................................................................................. 23

Periodic low-density bands ............................................................................................................................ 23

Weak cloudiness............................................................................................................................................ 24

Low-density speckles..................................................................................................................................... 24

Low-density spots .......................................................................................................................................... 25

Gloss too low.................................................................................................................................................. 25

GEM hot offset ............................................................................................................................................... 26

Worm like streaks........................................................................................................................................... 26

Wrinkling in the PRS ...................................................................................................................................... 27

Non-uniform transfer quality across the web.................................................................................................. 28

Micro-blistering from the fuser........................................................................................................................ 29

Description of paper-dependent parameters 31

List of IBM Recommended Print Media for IBM 3170 and InfoColor 70 35

© Copyright IBM Corp. 1998

iii

Page 6

iv

IBM InfoColor 70 and 3170 Print Media Guide

Page 7

IBM InfoColor 70 and 3170 Print Media Guide

© Copyright IBM Corp. 1998

1

Page 8

2

IBM InfoColor 70 and 3170 Print Media Guide

Page 9

•

•

•

•

•

•

•

Purpose of this manual

A guide to have print medium tested through a certified agency

To provide information on basic paper quality requirements for the InfoColor 70 Printer.

To provide information on proper paper handling and storage

To provide information about how paper is tested at the certified agency.

To provide information on the basic paper types and properties.

To assist in understanding the media limitations of InfoColor 70 Printer.

To provide Artifact Samples to assist in print quality troubleshooting.

Purpose of this manual

3

Page 10

4

IBM InfoColor 70 and 3170 Print Media Guide

Page 11

•

•

•

•

Requesting a Print Medium Test

Importance of Print Medium Testing

InfoColor 70/3170 Print Medium testing is needed to adjust and optimize a set of control parameters

to obtain the best print quality.

Using a tested and supported print medium offers you the following advantages:

Stable print quality

Minimum quantity of wasted paper

Minimum printing problems, such as paper jams

Minimum contamination of the InfoColor 70/3170 print engine; thereby reducing machine intervention and frequency of service.

Procedures

1. Before considering a print medium test, request the latest IBM InfoColor 70 Print Media List from

your account representative. Make sure that there is not a similar stock on this list before you initiate a request for a test.

2. Make sure there is full support from the Medium Manufacturer.

3. Contact IBM certified Medium Test Agencies

For US region contact RIT (Lisa Ford, Tel: 716-475-5593, Fax: 716-475-5250, Email: LMFASP@RIT.EDU).

For EMEA regions, contact Pira (Mike Chamberlain, Tel: 44-1372-802000, Fax: 44-1372-802238/

46, E-mail: paper@pira.co.uk or printing@pira.co.uk)

4. The test will cost the medium manufacturer or the customer about $240/hour. It usually takes

about 2.5 - 3 hours for one medium test. The turn around time is about 2 to 6 months depending

on the agencies current work load. A paper may also be tested on an emergency basis with a

shorter turn around time for a cost premium.

5. Paper Test Agencies will request the following information from the medium manufacturer through

two different forms as a pre-requisite for testing. The following is a sample of these forms:

Requesting a Print Medium Test

5

Page 12

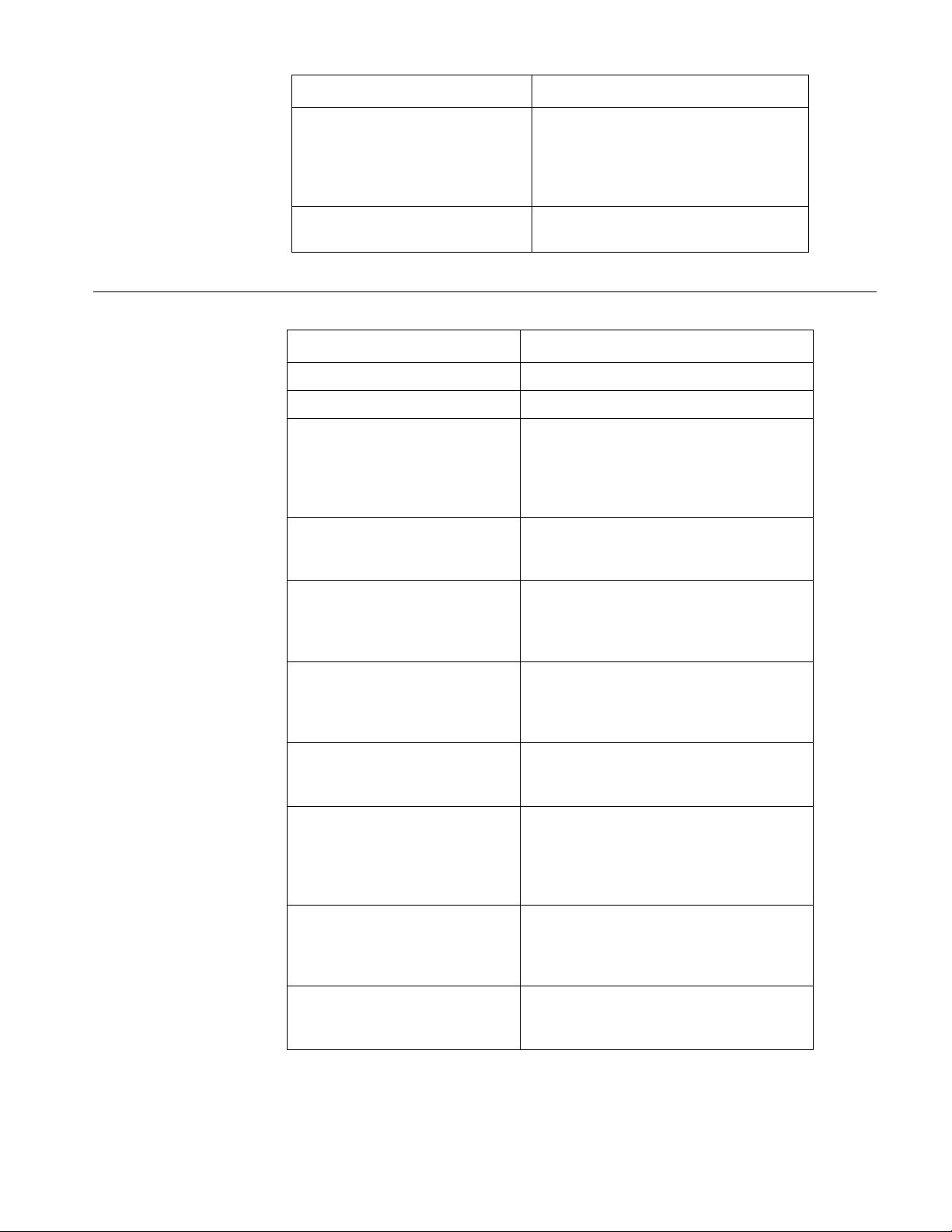

Form 1: Substrate Qualification Data Collection Worksheet

Company Contact

Product Name:

Manufacture:

Name:

Title:

Address:

City:

State:

Country:

Postal Code:

Telephone Number:

Fax Number:

Email:

Paper Classification X

Uncoated Super Calandered

Uncoated Calandered

Uncoated Uncalandered

Uncoated Pigmented

Matt Coated

Satin Coated

Glossy Coated

Single-sided Cast Coated

Recycled Coated

Latex Impregnated Paper

Film

Others (Please specify)

Material Properties (Fill-in or attach

documentation)

Grammage (GSM)

Caliper(micron)

Brightness (ISO%)

Opacity(%)

6

IBM InfoColor 70 and 3170 Print Media Guide

Page 13

Smoothness (PPS micron/Sheffield units)

Moisture Content (% AH)

Certificate of Non-toxicity (Please Attach)

Guarantee Splice Free

Marketing Contact:

Postal Code:

Telephone Number:

Name:

Title:

Address:

City:

State:

Country:

Technical Contact:

Distribution List (Please attach)

Fax Number:

Email:

Name:

Title:

Address:

City:

State:

Country:

Postal Code:

Telephone Number:

Fax Number:

Email:

Requesting a Print Medium Test

7

Page 14

•

) •

•

•

•

•

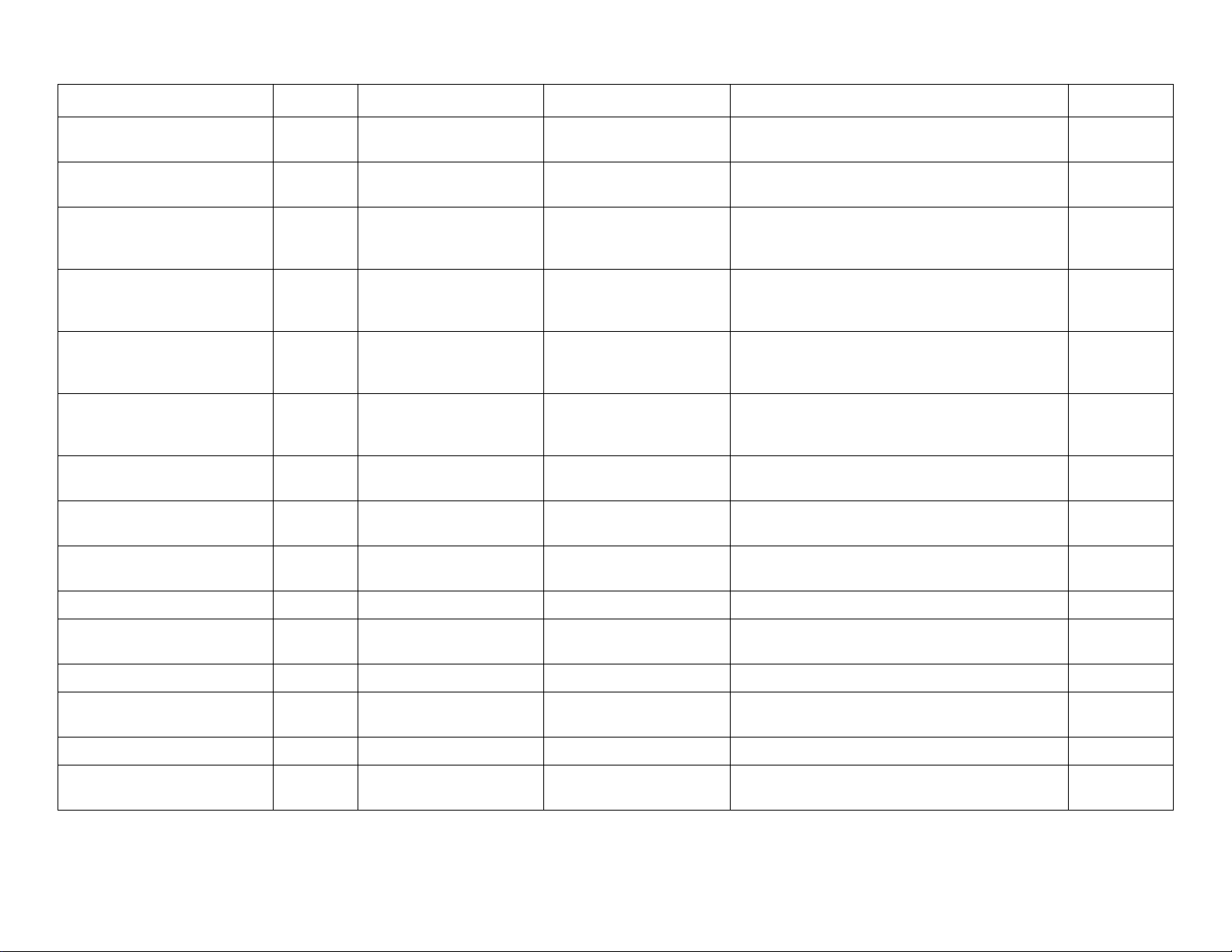

Form 2: Specifications for Print Media Qualification on the IBM InfoColor 70 Print Engine

Roll Dimensions

Description Dimension (USA) Dimension (EU)

Inner Core Diameter 6"-0/+.02 150mm+/-.5

Outer Core Diameter 7.1" 174mm

Maximum Roll Diameter 19.7" 500mm

Typical Roll Diameter 15.75" 400mm

Maximum Roll Weight 88lbs 40kg

Roll Width 12.6" 320mm

Roll Specifications

The paper must be free from splices, tears, dents, holes and other physical defects. The paper

should be flush with the core and must not slide axially over the core.

Paper Weight

60 to 250GSM are specification limits for InfoColor 70 engine.

200GSM and above require GEM unit.

Temperature Resistance

The paper must withstand prolonged (1 hour minimum) heating to 100 ° C and heating to 200 ° C for

5 seconds without physical or chemical degradation. Under these conditions, the paper should not

release any toxic substances.

Demonstrated Paper Properties

The following data must be submitted for each substrate to be tested.

Weight (grams/m

2

Caliper (micron)

Brightness (ISO%)

Opacity (%)

Smoothness (pps/sheffield units)

Moisture Content (%AH)

A certificate of non-toxicity is required. This must contain the following statement: “The print

medium will not release toxic gasses when heated up to 200 ° C during 5 seconds and during

prolonged heating at 100 ° C. ”

Note: The above properties can be tested at the Agencies for a fee.

8

IBM InfoColor 70 and 3170 Print Media Guide

Page 15

Test Results, Medium Performance and Script

Once the print medium is tested, the performance of the medium is reviewed. All the information of

the paper and scripts will be shared information.

The tested print medium will be rated at 1A, 1B, 2, 3 performance lev el. These performance levels are

defined as follows:

1A – Good print quality is easy to obtain and rather stable without any finishing or stacking problems.

1B – Good print quality is not very easy to obtain. It requires close monitoring to maintain good

and stable print quality. No finishing or stacking problems.

2 – Minor print quality problems and/or finishing problems.

3 – Severe print quality and finishing problems.

IBM has chosen to support 1A level media only. IBM allows customer to use 1B level media and a

select few others at their own risk. IBM provides these scripts to its customers through IBM Service

Engineers. They can update the InfoColor 70 with the latest print medium scripts upon your request.

Rush T esting

In a situation where paper needs to be tested in a short period of time, paper test agencies may offer

testing on rush basis for a surcharge. IBM may also offer medium testing under some limitations. To

qualify for testing at IBM, you need to contact y our account manager . Your account manager will need

to petition the marketing organization for an evaluation and approval. IBM marketing will evaluate the

following key areas:

1. Does IBM already provide support for a similar stock?

2. Does this print medium open a new market for InfoColor 70 print business?

3. Does this new print media bring additional IBM sales opportunities?

If you are approved for testing at IBM, you will need to submit the same pre-requisite medium information and prepare a medium sample (3 rolls) just as you would do for certified agencies. The turn

around time at IBM is usually about 3 to 6 weeks depending on work load.

Requesting a Print Medium Test

9

Page 16

10

IBM InfoColor 70 and 3170 Print Media Guide

Page 17

Basic Paper Types and Their Properties

Basic paper types

In order to understand fully what requirements have to be met by the paper, it is important that you

know how paper types are distinguished:

.

Uncalendered

Uncoated paper

Paper, the surface of which is not covered with an additional coating. It is only composed of pulp, containing cellulose fibers, fillers, binders, pigments, etc.. The various types of uncoated paper are listed

in the table below.

Paper types

Uncoated paper

Coated paper

Speciality paper

calendered

Supercalendered

Matt

Satin

Glossy

High-gloss

Embossed

Watermarked

Recycled

Tinted & Colored

Translucent

Parchment

Uncoated paper types Description

Uncalendered paper Paper which was not submitted to the

calendering process. See below.

Calendered paper During the calendering process the paper

passes through a number of calendering rolls

made of steel, in order to make it more compact

and smoother by increasing influences of

temperature and pressure on the paper.

Supercalendered paper During the supercalendering process the paper

passes through a number of calendering rolls

made alternately of steel and cotton, in order to

make it even more compact and smoother.

Basic Paper Types and Their Properties

11

Page 18

Coated paper

Paper, the surface of which is covered with a coating, in order to alter the surface properties of the

original paper such as smoothness, gloss and water resistance.

Gloss property Description

Matt coated paper Coated paper, which was not submitted

to the calendering process, or which

passed through only one pair of

calendars.

Satin coated paper Coated paper, which was submitted to

the calendering process.

Depending on the production method, coated papers can also be divided as follows:

Speciality paper

Paper, which has special properties, intended for special purpose use.

Glossy and high-gloss coated

paper

Coated paper type Description

Machine coated paper Coating is applied by means of a dosing

Cast coated paper The gloss of the coated paper is

Feature Description

Coated paper, which was submitted to

the supercalendering process.

roll and the excess coating is removed

with a scraper. The gloss is achieved b y

calendering.

The coating thickness is variable on the

scale of the paper’s relief.

obtained by passing the paper over a

very smooth chromium roll. This results

in very high-gloss coated paper.

The coating thickness is uniform.

Embossed paper P aper with an amount of relief which is

Recycled paper Paper that is made of pulp containing

Tinted and Colored paper Paper that is made of pulp containing

12

IBM InfoColor 70 and 3170 Print Media Guide

produced by pressing it between a

rotary embosser, i.e. a metal roll

having a embossing pattern.

fibers of paper that has already been

used and to which new fibers are

added. Sometimes all fibers are

recycled.

an amount of colored pigments.

Colored paper has a more saturated

color than tinted paper.

Page 19

Paper properties

Feature Description

Watermarked paper With a roll similar to an embosser,

paper, that is still v ery wet in the paper

machine, is processed. This causes

thickness variations that creates

different transparency levels.

Translucent paper Paper which is highly transparent due

to a special way of crushing the fibers.

Paper property Description

Weight In grams per square meter (g/m

2

).

Caliper Thickness of the paper expressed in µ m.

Absolute moisture content The absolute moisture content is the

ratio between the total amount of water

in the paper and the weight of the paper

(including fibers, fillers, binders and

water).

Relative moisture content The relative moisture content equals the

relative humidity of the surrounding air , in

equilibrium with the paper.

Smoothness A paper property characterized by the

roughness value, i.e. the size of tips and

valleys on the paper’s surface measured

in PPS µ m, Bendtsen, Bekk, or sheffield.

Brightness Total amount of visible light reflected by

the paper. Adequate paper brightness is

necessary to provide high-contrast

images.

Bulk The thickness of paper, in terms of the

number of pages per inch for a given

basis weight.

Formation The formation of paper depends on the

structure of cellulose fibers, which, in

turn, depends on the construction of the

paper machine and the composition of

the pulp.

Opacity Opacity is the opposite of transparency.

The lower the opacity, the more you can

see through the paper. Thin papers

usually have a lower opacity.

Gloss The amount of incident light under a

certain angle that the paper reflects with

the same angle.

Basic Paper Types and Their Properties

13

Page 20

14

IBM InfoColor 70 and 3170 Print Media Guide

Page 21

Guidelines for Print Medium Quality Inspection

Check Paper Quality

1. Compare the manufacturer’s Packaging and Reel Formation information with the Paper Roll specifications listed in the following table.

Roll Dimensions

Description Dimension (USA) Dimension (EU)

Inner Core Diameter 6"-0/+.02 150mm+/-.5

Outer Core Diameter 7.1" 174mm

Maximum Roll Diameter 19.7" 500mm

Typical Roll Diameter 15.75" 400mm

Maximum Roll Weight 88lbs 40kg

Roll Width 12.6" 320mm

Roll Specifications

The paper must be free from splices, tears, dents, holes and other physical defects. The paper

should be flush with the core and must not slide axially over the core.

2. Paper Formation

Good paper formation is very important to obtaining good print and finish quality. A paper with poor

formation quality produces a high degree of uneven print, mottling, and release of fibers. Non-uniform texture affects the uniformity of resistivity, causing uneven toner transfer to the paper.

3. Moisture content

Moisture content should be consistent from roll to roll and also within a roll. Uneven moisture content can cause unstable print quality. Too high a moisture content can cause wrinkling (especially

with thin paper), curling, and poor print quality. See "Artifact Samples" on page 21.

4. Surface smoothness

A smooth paper surface greatly improves print quality because the contact area between the paper and the imaging drum is more uniform.

Guidelines for Print Medium Quality Inspection

15

Page 22

Guidelines for Print Medium Storage and Handling

Print Medium for IBM InfoColor 70 needs to be wrapped moisture tight on a continuous basis (including unused partial roll).

Print Medium for IBM InfoColor 70 needs to be stored on a wood shelf, moisture tight, for 48 hours

or longer to allow the paper to reach equilibrium with the printing room environment prior to printing.

The moisture content of the print medium (especially paper) for the IBM InfoColor 70 should not

be allowed to vary. The variation needs to be within ± 0.1%. If the moisture content varies outside

of this range within the roll or from roll to roll, the paper conditioning script may not work consistently.

•

•

•

A

B

Precaution Reason

Store the rolls in their original package

in the printer room for 48 hours or

longer, depending on the difference

between the ambient temperature

and that of the roll. (A)

During long term storage the paper roll

needs to retain the moisture content

as shipped from the paper mill. If the

paper roll is at a different temperature

from that of the print room while

printing, the paper can lose or absorb

moisture, causing print quality

problems.

Store rolls on a pallet, not on a cold or

warm surface. (B)

A roll containing warmer or colder

areas cannot be conditioned uniformly

in the paper supply (PRS) of the

InfoColor 70.

C

Cold

Moist

Hot

Dry

Store rolls under normal ambient

conditions. Av oid extreme temper ature

and moisture conditions. (C)

Remove the roll from the paper supply

of the machine after printing and wrap

the roll in its original package.

16

IBM InfoColor 70 and 3170 Print Media Guide

If the rolls are stored under extreme

conditions, the paper-dependent

parameters will not match the paper

properties.

Over night the outer windings of a

paper roll may attract or lose a

substantial amount of moisture.

Page 23

Splicing

Always make sure that no adhesive substance is left near the splice on either side of the web.

Apply an additional single-sided tape over the exposed edge if you are making a splice between two

different print media, as shown in the table below. This will minimize jams and broken splices.

Roll inspection

Print medium in paper supply Print medium in engine

label stock any medium

film any medium

any medium film

stiff material (250 g/m

2

paper) any medium

D

C

E

6 in

A

B

15 cm

Core

Wood

screw

Paper

1. Check whether the roll is guaranteed splice free. (A)

a. If there is a factory splice. Stop printing as soon as the splice lies within a few millimeters of the

outer windings.

b. Cut the paper at the splice table and unwind the roll until you can remove the factory splice.

c. Then splice the paper together again using the standard splicing procedure.

2. Check whether the paper is wound around the core tightly to prevent the web from shifting left/

right. (B)

a. If the paper is not tightly wound around the core a wood screw can be used as a “first-aid solu-

tion” to secure the paper to the core. See illustration above.

b. If this situation occurs, contact your paper supplier and report a quality issue.

3. Check for dust on roll sides and surface.

Note: Do Not put the brake onto the roll before you have removed any dust.

a. Remove dust from the sides of the roll using either an adhesive rubber roller or a vacuum clean-

er. (C)

b. Remove dust from the roll surface by removing the first winding of paper. (D)

Guidelines for Print Medium Quality Inspection

17

Page 24

c. If dust appears on the paper surface of the entire roll, contact your paper supplier.

4. Verify that the paper axle mounting flanges are mounted correctly for the current paper roll inner

core diameter. (E)

Paper Waste During Printing and Waste Reduction (3.02 code or higher)

Paper waste is one of the biggest concerns to the press industry. To reduce the amount of paper

waste to minimum levels, you must first understand the causes of paper waste in the IBM

InfoColor 70. This section explains where paper waste occurs when printing with the IBM

InfoColor 70 and how to minimize it.

Start of a Print Job

Whenever you send a job to print, the printer will always respond by cutting one blank page (size v aries). The printer will then stop and wait for the fuser to reach its set point.

Auto Mode

1. Paper conditioning

Normally, you need to run 18 to 25 blank pages minimum of about A4 size to get the paper conditioning system to reach its required criteria. Some paper types may take a longer time (more paper) depending on the quality of the paper. The Gloss Enhancement Module (GEM) also requires

additional time to warm up. It can take 20 to 25 blank pages minimum of about A4 size (depending

on parameters set) to get the GEM to warm from 30°C to 100°C during a typical first run in the

morning. The GEM starts to warm up at the same time the PRS begins to condition the paper.

Usually it takes a little longer to get paper conditioned when you start the machine and print the

first job of the day. Or right after you have changed to a different paper. This is because the machine has not yet determined the conditioning temperature needed for your specific environment,

specific paper and the initial values to be used.

2. Starting the image

Once the paper has reached the proper condition, and the GEM is at the correct temperature, the

printer will begin imaging. After imaging starts, the machine will cut 18 to 20 pages, of about A4

size, plus two blank pages of the job size before your job will appear at the cutter.

Manual Mode

In Manual print mode the number of blanks pages can be either reduced or increased, depending on

the quality of the material, the experience of the operator, the quality requirements for the print job,

and other factors.

Finishing the Print Job

1. At the end of the last job, the printer will cut 2 blank pages of about A4 size.

2. Between jobs, if the 1st and 2nd jobs are both simplex1 (or both duplex2), the printer will output 2

blank pages the size of the second job. Otherwise, it will output 8 A4 size blank pages plus 2 blank

pages the size of the 2nd job.

3. In the situation that the 2nd job has not been completely downloaded to memory (non-collator

models) before the 1st job is completed, the 1st job ends normally and the printer will output blank

pages until the 2nd job is downloaded and begins imaging. The number of blank pages output depends on the timing of when the second job is ready to begin imaging. The collator model is faster

in this regard when compared to the non-collator model.

1.Must be printing from the same tower (either X or Y).

2.Must have image data on both sides of paper for both jobs. If a duplex job does not have an image on one

side it is treated as a simplex job.

18 IBM InfoColor 70 and 3170 Print Media Guide

Page 25

Changing the Paper Roll

1. Paper left over from a previous roll also contributes to paper waste. The Operator needs to replace

the paper roll when receiving the "Paper Low" alarm. Close to the end of the paper roll, the paper

tension is not very stable. This condition can cause a print quality problem. The Operator must

avoid running the end of the paper through the printer. Running the end of the paper through the

printer can cause damage to sensitive parts, taking the printer down for several hours while the

damage is repaired.

2. When a new roll is spliced in, the splice must be completely driven through the printer before starting (or resuming) a print job. The engine will stop driving the paper out at about one meter past

the splice. This can be controlled by the operator or by changing the splice_delay value in the

params.set file. If needed, ask your IBM Customer Engineer to change this value.

Operator Skills

Operator inexperience can cause additional unusable prints and/or blank pages due to (but not limited to):

1. Out of specification densities.

2. Out of specification registration.

3. Dirty corona wires causing print defects.

4. Starting to print before the printer is conditioned to the correct temperature and humidity.

5. Reloading the conditioning script when a new roll of the same media is mounted.

6. The GEM is switched On and Off during printing.

7. The job is sent to print before the heating drum reaches its standby temperature.

8. The job is sent to print in the non-GEM mode before the GEM has cooled.

Paper Quality

Environment

Paper Quality can be aff ected b y improper manufacturing, handling, or storage.This can cause unstable conditioning and registration, contributing to the number of unusable prints or blank pages. You

should always protect stored paper in moisture tight packaging. Do not use the paper before it

reaches the same temperature as the print room.

In a humid print room environment, paper can easily become curled, wavy, or even wrinkled depending on its thickness.These conditions can be minimized by reducing the fusing temperature, GEM

temperature, or possibly the U2 value.

Guidelines for Print Medium Quality Inspection 19

Page 26

20 IBM InfoColor 70 and 3170 Print Media Guide

Page 27

Artifact Samples

There are a number of common artifacts that can be corrected by optimizing parameters. See the

section “Description of paper-dependent parameters” on page 31 for additional information on

machine/paper parameters.

The following artifact samples (and the suggested actions) should not used until the following items

have been addressed.

1. Has periodic maintenance/cleaning been performed?

2. Has the new medium been acclimated (at least 48 hours)?

3. Is current print quality, on a known paper, good?

If you answered No, to any of the above questions Do Not procede until the machine is clean, functioning properly and the new medium has been acclimated.

Artifact Page No.

Low-density cloudiness 22

High-density cloudiness 22

High-frequency cloudiness 23

Periodic low-density bands 23

Weak cloudiness 24

Low-density speckles 24

Low-density spots 25

Gloss too low 25

GEM hot offset 26

Worm like streaks 26

Wrinkling in the PRS 27

Non-uniform transfer quality across the web 28

Micro-blistering from the fuser 29

Note: This book is being distributed in both hard copy and online versions . If you are using the online

version to print a copy, be aware that your choice of paper and the print quality of the printer

that you use to print it on can affect the appearance of the artifact samples. Use a known

paper, that has excellent print quality characteristics on a printer that does not have any print

quality problems.

Artifact Samples 21

Page 28

Low-density cloudiness

Description Cause Solution

Light clouds of 0.5 to 1cm in diameter

in a darker surrounding. They have a

reduced density and occur against a

background of normal density. They

are not clearly edged.

High-density cloudiness

low-density clouds

WEB

Transfer currents too low. Increase transfer currents in

steps of 20%.

Description Cause Solution

Dark clouds of 0.1 to 0.5cm in

diameter in a lighter surrounding,

equivalent to the mottle structure of

the paper. They have a normal

density and appear against a

background of reduced density. They

are clearly edged.

22 IBM InfoColor 70 and 3170 Print Media Guide

high-density clouds

WEB

Transfer currents too high. Decrease transfer currents

in steps of 20%.

Page 29

High-frequency cloudiness

B

Description Cause Solution

Irregular low-density clouds,

especially occurring at the

borders of the web.

Periodic low-density bands

high-frequency clouds

WEB

Duplex currents too high. Decrease positive duplex

currents in steps of 20µA and

negative duplex currents in

steps of 10µA.

low-density band

Description Cause Solution

Low-density bands along the

Duplex currents too low. Increase the positive duplex

web, appearing in duo-color

planes over the whole web

width. They do not occur in

WE

currents in steps of 10µA and

the negative duplex currents in

steps of 5µA.

mono-color planes.

Artifact Samples 23

Page 30

Weak cloudiness

Description Cause Solution

WEB

Small amount of cloudiness. It

is not easy to determine what

type of cloudiness it is.

Low-density speckles

Transfer current too high or too

low.

Duplex currents too high or too

low.

Decrease or increase the

transfer current in steps of

10µA.

Decrease or increase the

duplex current in steps of 10µA

(positive) and 5µA (negative).

Description Cause Solution

Tiny round speckles ranging

from 1 to 2mm in diameter with

reduced density and sharply

outlined.

24 IBM InfoColor 70 and 3170 Print Media Guide

low-density speckles

WEB

Transfer currents too high. First, reduce IPS/U2.N2 in

steps of 20V.

Decrease transfer currents in

steps of 10µA.

Increasing duplex currents may

also be desirable but not

always necessary.

Page 31

Low-density spots

Description Cause Solution

WEB

Gloss too low

Spots having an irregular

shape and not sharply

Paper surface too rough. Owing to the cause, this

artifact cannot be eliminated.

outlined.

Artifact cannot be reproduced in this manual.

Description Cause Solution

The gloss is visibly too low. Temperature set points IFX/

T5.N22 and IFX/T6.N22 are

too low.

Increase temperature set

points IFX/T5.N22 and IFX/

T6.N22 of both roll pairs in

steps of 2˚C.

If IFX/T5.N22 and IFX/T6.N22

are too high, GEM hot offset

will appear. Therefore,

decrease temperature set

points IFX/T5.N22 and IFX/

T6.N22 again by 2˚C until the

lines disappear (see "GEM hot

offset" on page 26.

Artifact Samples 25

Page 32

GEM hot offset

Description Cause Solution

When looking at the gloss of

the image, recurrent very

narrow lines, similar to

scratches or cracks across the

web, are visible.

Worm like streaks

hot offset line

Temperature set points IFX/

T5.N22 and IFX/T6.N22 are

too high.

WEB

Decrease temperature set

points IFX/T5.N22 and IFX/

T6.N22 of both roll pairs in

steps of 2˚C until the offset

lines disappear.

Description Cause Solution

Tiny snakes, especially visible

in duo-colors and on papers

weighing more than 150 g/m2.

26 IBM InfoColor 70 and 3170 Print Media Guide

wormlike streak

WEB

Erase voltage is too high. Consult your service technician

to reduce the erase voltage.

IPS/U2.N2 is too high (if erase

voltage was correct).

To eliminate the worms

completely, reduce IPS/U2.N2

in steps of 20 to 40V

(depending on the quantity and

severity of the worms). Then,

transfer currents must always

be decreased.

Page 33

Wrinkling in the PRS

Description Cause Solution

WEB

wrinkle

Bent and slanted wrinkles

across the whole web on print

media weighing less than

100 g/m2. Since the wrinkles

occur before the paper is

printed, weak transfer occurs in

and around the wrinkles.

Pre-heating roll temperature is

too high, causing temperature

shock.

Decrease paper conductivity

set point IPS/U2.N2 in steps of

20V, so that the pre-heater’s

temperature decreases.

Transfer currents must also be

decreased.

Artifact Samples 27

Page 34

Non-uniform transfer quality across the web

paper too dry or transfer current too low

Description Cause Solution

Either transfer quality is good in

the center of the web, and poor

at the border, or vice v ersa. The

image will always be clouded

either in the center (highdensity clouds because of

transfer current too high) or at

the border (low-density clouds

because of transfer current too

low).

28 IBM InfoColor 70 and 3170 Print Media Guide

paper too wet or transfer current too high

Moisture content of the paper

too high.

Inappropriate storage of paper

reels (more moisture towards

the edges).

Due to the limited drying

capacity of the pre-heater, this

artifact cannot be eliminated.

Paper reel cannot be used.

To prevent this problem, wrap

each reel in a moisture-tight

package.

Page 35

Micro-blistering from the fuser

Description Cause Solution

WEB

Tiny craters are visible (you

can see the underlying toner)

and tangible (the printed

surface is rough and the tops of

the craters can be rubbed

away). Sometimes, only the

underlying toner and small

glossy dots are visible.

Due to the high temperature of

the paper traveling through the

fuser; excess moisture in the

paper erupts like tiny volcanos,

especially in high coverage

areas.

Reduce IFX/T3.N2 in steps of

5˚C until the artifact

disappears.

Artifact Samples 29

Page 36

30 IBM InfoColor 70 and 3170 Print Media Guide

Page 37

Description of paper-dependent parameters

The table below briefly describes the paper-dependent parameters that can be found in XPOSE.

Parameter Description

web

IDR/W2.N2 Web tension set point

paper conditioning

IPS/T2.N2 Temperature set point of the pre-heating roll before printing.

IPS/T2.N40 Temperature set point of the pre-heating roll during standby.

IPS/K2.N2 Fixed power applied to the pre-heating roll during start-up of the web (in

% of the nominal power rating of the heating lamp).

IPS/U1.N4 Time constant of the SW-integrating controller for U1.

Description of paper-dependent parameters 31

Page 38

Parameter Description

IPS/U2.N4 Amplification constant of the SW-proportional-integrating controller for

U2.

IPS/U2.N6 Time constant of the SW-proportional-integrating controller for U2.

IPS/I1.N2 Limitation for the control variable I1 applied during start-up of the U1

controller.

IPS/K3.N6 Time that K2.N2 is applied during start-up of the web.

IPS/U1.N2 Set point for the initial paper charge for the paper conductivity

measurement.

IPS/U2.N2 Set point for the desired conductivity of the paper before printing.

ICN/T9.N8 Amount of water flowing through the radiator of the PRS cooling unit.

duplex/transfer

ITR/I4AA.N1 Current applied to the back of the paper, exerting an electrostatic force

onto the toner. This force holds the toner against the paper when

loosening the paper from the drum.

ITR/I6AA.N1

ITR/I7AA.N1

The positive and negative current respectively, applied to the pair of

duplex coronas positioned between two successive stations. They

inversely charge the toner transferred to the paper by the lower printing

stations.

fuser

IFX/T3.N2 Temperature set point of the web leaving the fuser; when the GEM is

“off”

IFX/T3.N4 Temperature set point of the web leaving fuser; when the GEM is “on”

IFX/T3.N10 Amplification constant of the SW-proportional-integrating controller for

T3.

IFX/T3.N12 Time constant of the SW-proportional-integrating controller for T3.

IFX/T4.N2 Constant A of warm-up temperature of fuser elements (= T3 x T4

dependency).

IFX/T4.N4 Constant B of warm-up temperature of fuser elements (= T4

dependency).

IFX/T3.N6 Constant C of warm-up temperature of fuser elements (= T3

dependency).

IFX/T4.N6 Constant D of warm-up temperature of fuser elements (= constant

term).

Factors A to D are the paper-dependent constants in the formula for the

SW calculation of the warm-up temperature of the fuser elements IFX/

T1.

IFX/T3.B4 Alarm level that triggers an alarm when the paper temperature IFX/T3

exceeds it.

IFX/T1.N12 Temperature set point of the fuser elements during stand-by.

GEM

32 IBM InfoColor 70 and 3170 Print Media Guide

Page 39

Parameter Description

IFX/T7.N4 GEM on/off

IFX/T5.N22 Temperature set point first nip rolls

IFX/T5.N30 Pre-set duty cycle first nip rolls -20˚C

IFX/T5.N32 Pre-set duty cycle first nip rolls -100˚C

IFX/T6.N22 Temperature set point later nip rolls

IFX/T6.N28 Pre-set duty cycle latter nip rolls -20˚C

Description of paper-dependent parameters 33

Page 40

34 IBM InfoColor 70 and 3170 Print Media Guide

Page 41

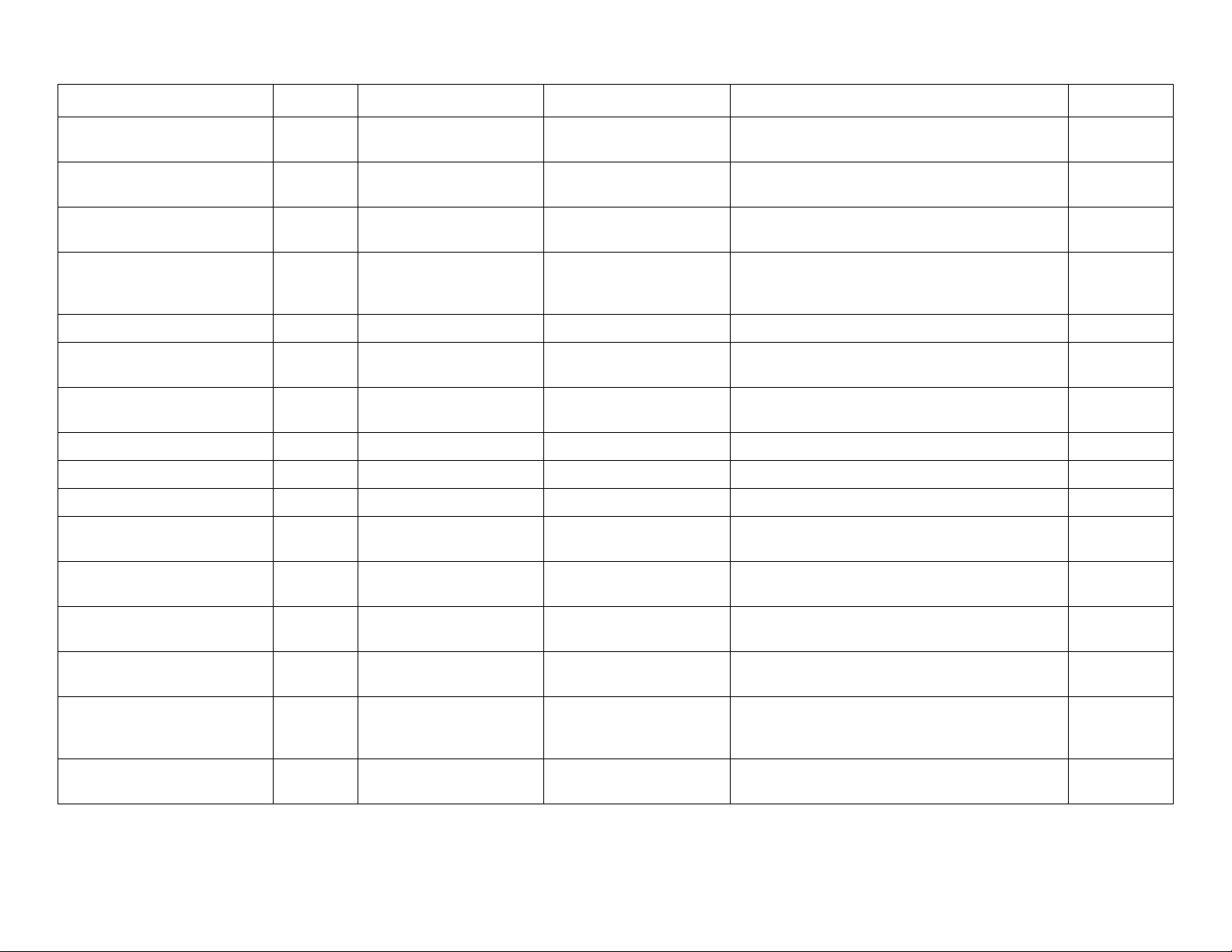

List of IBM Recommended Print Media for IBM 3170 and InfoColor 70

Script names match the May 1998 script release for 3.02PES

Please visit http://www.printers.ibm.com/pbin-psc/go?/manuals/ic70m.html for the latest list.

Uncoated Paper

Paper Script Location: PrintMedia\Paper\

Brand Name Weight Type/Description Manufacture/Distribution Script Performance

DigiSmooth 60 60GSM Uncalendered Enso Group / 201-635-

3530 US

Mitsubishi II 60GSM Contact IBM Japan for

more information

Nopasat/Nopacolor Digiprint/

Nopacolor Gigi 60

Compat Clearbrite 17# 63GSM Translucent uncalen-

Mitsubishi I 64GSM Contact IBM Japan for

Digital Publishing Text 66GSM Calendered Georgia Pacific / 800-

Westminster Trade Book 66GSM Calendered with Vellum

Springhill Incentive 100 DP

50#

4CC New 80 80GSM SuperCalendered Enso Group FACTORY\ UNCOATED\4CCN080 1A

Digisuperior 80 80GSM Calendered Enso Group IBM\ENSO\DISUP080 IG

Hokuetsu 80GSM Contact IBM Japan for

60GSM SuperCalendered Nordland(Kymmene) /

dered

more information

Finish

74GSM Calendered, 100% Recy-

cled

more information

Mitsubishi Japan IBM\JAPAN\JM60G 1G

914-332-4444 US

Nationwide Papers / 800-

323-1003 US

Mitsubishi Japan IBM\JAPAN\JM64G IG

386-8118 US

Georgia Pacific IBM\GPACIFIC\GP66WMTB IG

International Paper /

814-870-6282 US

Hokuetso Japan IBM\JAPAN\JH80G IG

FACTORY\UNCOATED\DIGISM60 1A

FACTORY\ UNCOATED\NOCOD060 1A

IBM\NATIONWD\NW63CB IG

IBM\GPACIFIC\GP66MCDI IG

IBM\INTPAPER\SPIDP074 IG

Lenza-Top-Recycling

*Choose to use it carefully

© Copyright IBM Corp. 1998 35

80GSM Calendered, 100% Recy-

cled, Rough surface.

Lenzing Papier AG / 437672-701-3465 Austria

IBM\LENZING\LENTR080 IG

Page 42

Brand Name Weight Type/Description Manufacture/Distribution Script Performance

Lenza-Top-Recycling-Super

*Choose to use it carefully

Nopasat/Nopacolor Digiprint/

Nopacolor Gigi 80

80GSM Calendered, 100% Recy-

cled, Rough surface.

Lenzing Papier AG / 437672-701-3465 Austria

80GSM SuperCalendered Nordland(Kymmene) /

Russell-Field

Artica Digital Rolls 88 88GSM Calendered Avenor Inc.

905-793-0707 Canada

630-955-4566 US

Artica Digital Rolls Recycled 8888GSM Calendered, Recycled Avenor Inc.

905-793-0707 Canada

630-955-4566 US

Arctica Premium 88 88GSM Calendered Avenor Inc.

905-793-0707 Canada

630-955-4566 US

Arctica Premium Recycled 88 88GSM Calendered, Recycled Avenor Inc.

905-793-0707 Canada

630-955-4566 US

60lb Satin-Kote 89 89GSM Calandered, Pigmented Plainwell Paper Co.

616-685-2553 US

Hamermill Accent Opaque

Luster White 60#

Springhill Opaque Smooth

60#

89GSM Calendered International Paper

814-870-6282 US

89GSM Calendered International Paper

814-870-6282 US

IBM\LENZING\LENTRS080 IG

FACTORY\ UNCOATED\NOCOD080 1A

FACTORY\ UNCOATED\AVEAD088 1A

FACTORY\ UNCOATED\AVEDR088 1A

FACTORY\ UNCOATED\AVEAP088 1A

FACTORY\ UNCOATED\AVEPR088 1A

FACTORY\ UNCOATED\PLSK089 1A

IBM\INTPAPER\HMAOW089 IG

IBM\INTPAPER\SPHOS089 IG

Brazil Chamex Premium 90 90GSM Calendered, Woodfree Champion, Brazil IBM\CHAMPION\CHMEX090 IG

Microprint DCP 90GSM Calendered Georgia Pacific

IBM\GPACIFIC\GP90MDCP IG

800-386-8118 US

Color Copy R 90 90GSM Calendered Neusiedler FACTORY\ UNCOATED\COCOR090 1A

Rolltek Opaque Text 60# 90GSM Uncalendered Rollsource

IBM\ROLLTEK\RT90-OPQ IG

612-331-2900 US

MultiCopy 90 90GSM Calendered Stora Kabel IBM\STORA\STMLC090 IG

Lightening Laser 24# 90GSM Calendered Union Camp

IBM\UNCAMP\UCLL090 IG

804-569-5131 US

IBM InfoColor 70 and 3170 Print Media Guide 36

Page 43

Brand Name Weight Type/Description Manufacture/Distribution Script Performance

IvoLaser 95 95GSM Calendered Steinbach Intermill / Rus-

FACTORY\ UNCOATED\IVOL095 1A

sell-Field

4CC New 100 100GSM SuperCalendered Enso Group

FACTORY\ UNCOATED\4CCN100 1A

201-635-3530 US

Aussedat Rey Zanders Imag-

100GSM Calendered Aussedat Rey Zanders FACTORY\ UNCOATED\ARZIN100 1B

ing Natura 100

Color Copy R 100 100GSM Calendered Neusiedler FACTORY\ UNCOATED\COCOR100 1A

Color Press Smooth Pig-

mented 100 / Anitec Ausedat

100GSM Pigmented Aussedat Rey / Interna-

tional Paper

FACTORY\ UNCOATED\CPSP100 1A

Rey Zanders Satin 100

DCP 100 100GSM Calendered Clairefontaine FACTORY\ UNCOATED\DCP100 1A

Galilei Opal 100 100GSM Calendered Metsä-Serla

FACTORY\ UNCOATED\MSGO100 1A

358-1046-45346 Finland

Mellotex Smooth Brilliant

100GSM Calendered Tullis Russell FACTORY\ UNCOATED\MLSBW100 1A

White 100

MoDo Ebene Satin/Data-

100GSM Calandered MoDo Paper PSM IBM\MODO\MOEBS100 IG

copy Digital 100

Nopasat/Nopacolor Digiprint/

Nopacolor Digi 100

100GSM SuperCalendered Nordland(Kymmene) /

Russell-Field

FACTORY\ UNCOATED\NOCOD100 1A

Presentation 100 100GSM Calendered Federal Tait FACTORY\ UNCOATED\PRESE100 1B

Splendorgel 100 100GSM Calendered Fedrigoni FACTORY\ UNCOATED\SPLEN100 1A

Versoix-Digital ECF 100 100GSM Uncalendered Papeterie de Versoix FACTORY\ UNCOATED\VEDIE100 1A

Versoix-Digital TCF 100 100GSM Uncalendered Papeterie de Versoix FACTORY\ UNCOATED\VEDIT100 1A

Artica Digital Rolls 104 104GSM Calendered Avenor Inc.

FACTORY\ UNCOATED\AVEAD104 1A

905-793-0707 Canada

630-955-4566 US

Artica Digital Rolls Recycled

104GSM Calendered, Recycled Avenor Inc. FACTORY\ UNCOATED\AVEDR104 1A

104

Artica Premium 104 104GSM Calendered Avenor Inc. FACTORY\ UNCOATED\AVEAP104 1A

IBM InfoColor 70 and 3170 Print Media Guide 37

Page 44

Brand Name Weight Type/Description Manufacture/Distribution Script Performance

Artica Premium Recycled

104GSM Calendered, Recycled Avenor Inc. FACTORY\ UNCOATED\AVEPR104 1A

104

Beckett Expression Text

Snow Smooth 70#

Carnival Smooth Text 104 104GSM Calendered Champion International

104GSM Calendered International Paper

814-870-6282 US

IBM\INTPAPER\BKETS104 IG

FACTORY\ UNCOATED\CHACS104 1B

203-358-6931 US

MohawkNavajo Brilliant 104 104GSM Calendered Mohawk Paper Mills

FACTORY\ UNCOATED\MOHNA104 1A

800-843-6455 US

Plainfield Offset Opaque

Plus, Smooth 104

Recycled Super Smooth 70#

104GSM Calendered Domtar Inc.

FACTORY\ UNCOATED\DOPLO104 1A

514-848-5292 Canada

104GSM Uncalendered, Recycled Nationwide Papers IBM\NATIONWD\NW104RSS IG

Text

70lb Text Color Copy 105 105GSM Calendered Wausau Paper Mills

FACTORY\ UNCOATED\WATCC105 1A

715-675-9891 ext.5504

US

Hokuetsu 105GSM Contact IBM Japan for

Hokuetso Japan IBM\JAPAN\JH105G IG

more information

IvoLaser 105 105GSM Calendered Steibach Intermill FACTORY\ UNCOATED\IVOL105 1A

Mitsubishi 106GSM Contact IBM Japan for

Mitsubishi Japan IBM\JAPAN\JM106G IG

more information

Lenza-Plakat

* Choose to use it carefully

110GSM Uncalandered, Rough

surface

Lenzing Papier AG

43-7672-701-3465 Aus-

IBM\LENZING\LENPL110 IG

tria

Esse Text Smooth White 80lb 118GSM Calendered Gilbert Paper

FACTORY\UNCOATED\GILET080 1A

414-729-7734 US

Mohawk Navajo Brillaint

White 118

Mohawk Options 118 118GSM Calendered Mohawk Paper Mills

118GSM Calendered Mohawk Paper Mills

800-843-6455 US

FACTORY\ UNCOATED\MOHNA118 1A

FACTORY\ UNCOATED\MOHOP118 1A

800-843-6455 US

Solar White Classic Crest

80# Text

118GSM Calendered Neenah

800-558-5061 US

IBM\NEENAH\NNSW118 IG

IBM InfoColor 70 and 3170 Print Media Guide 38

Page 45

Brand Name Weight Type/Description Manufacture/Distribution Script Performance

Lightening DCP 73# 118GSM Calendered Union Camp

IBM\UNCAMP\UCLD118 IG

804-569-5131 US

Pageantry Smooth Text 118 118GSM Calendered Champion International

FACTORY\ UNCOATED\CHAPS118 1A

203-358-6931 US

Conqueror CX-22 120 120GSM Calendered Arjo Wiggins

FACTORY\UNCOATED\COCX120 1A

44-1322-397176

England

Galilei Opal 120 120GSM Calendered Metsä-Serla

FACTORY\ UNCOATED\MSGO120 1A

358-1046-45346 Finland

Microprint DCP, Natural Text

120

120GSM Calendered Georgia-Pacific Corp.

800-386-8118 US

FACTORY\UNCOATED\DCPNA118 1B

Presentation 120 120GSM Calendered Federal Tait FACTORY\ UNCOATED\PRESE120 1B

Microprint DCP 120GSM Calendered Georgia Pacific

IBM\GPACIFIC\GP120MDC IG

800-386-8118 US

Color Copy R 120 120GSM Calendered Neusiedler FACTORY\ UNCOATED\COCOR120 1A

Nopasat/Nopacolor Digiprint/

Nopacolor Gigi 120

Color Press Smooth Pig-

mented 130 / Anitec Ausedat

120GSM SuperCalendered Nordland(Kymmene) /

Russell-Field

130GSM Pigmented Aussedat Rey / Interna-

tional Paper

FACTORY\ UNCOATED\NOCOD120 1A

FACTORY\ UNCOATED\CPSP130 1A

Rey Zanders Satin 130

DCP 130 130GSM Calendered Clairefontaine FACTORY\ UNCOATED\DCP130 1A

4CC New 130 130GSM SuperCalendered Enso Group

FACTORY\ UNCOATED\4CCN130 1A

201-635-3530 US

IvoLaser 135 135GSM Calendered Steibach Intermill / Rus-

FACTORY\UNCOATED\IVOL135 1A

sell-Field

Mellotex Smooth Brilliant

135GSM Calendered Tullis Russell FACTORY\UNCOATED\MLSBW135 1A

White 135

Splendorgel 140 140GSM Calendered Fedrigoni FACTORY\UNCOATED\SPLEN140 1A

Pageantry Smooth Text 148 148GSM Calendered Champion International

FACTORY\UNCOATED\CHAPS148 1B

203-358-6931 US

Carnival Smooth Text 148 148GSM Calendered Champion International FACTORY\UNCOATED\CHACS148 1B

IBM InfoColor 70 and 3170 Print Media Guide 39

Page 46

Brand Name Weight Type/Description Manufacture/Distribution Script Performance

Book Design Smooth 150 150GSM Calendered Klippan AB

FACTORY\UNCOATED\KLIBD150 1A

46-478-10600 Sweden

Nopasat/Nopacolor Digiprint/

Nopacolor Gigi 150

4CC New 160 160GSM SuperCalendered Enso Group

150GSM SuperCalendered Nordland(Kymmene) /

Russell-Field

FACTORY\UNCOATED\NOCOD150 1A

FACTORY\UNCOATED\4CCN160 1A

201-635-3530 US

Color Press Smooth Pigmented 160 / Anitec Ausedat

160GSM Pigmented Aussedat Rey / Interna-

tional Paper

FACTORY\UNCOATED\CPSP160 1A

Rey Zanders Satin 160

DCP 160 160GSM Calendered Clairefontaine FACTORY\UNCOATED\DCP160 1A

Galilei Opal 160 160GSM Calendered Metsä-Serla

FACTORY\ UNCOATED\MSGO160 1A

358-1046-45346 Finland

High Tech Special 160 160GSM Calendered Klippan AB

FACTORY\UNCOATED\KLIHT160 1A

46-478-10600 Sweden

Presentation 160 160GSM Calendered Federal Tait FACTORY\UNCOATED\PRESE160 1B

Splendorgel 160 160GSM Calendered Fedrigoni FACTORY\UNCOATED\SPLEN160 1A

Color Copy R 160 160GSM Calendered Neusiedler FACTORY\UNCOATED\COCOR160 1A

IvoLaser 160 160GSM Calendered Steinbach Intermill / Rus-

FACTORY\UNCOATED\IVOL160 1A

sell-Field

Mellotex Smooth Brilliant

160GSM Calendered Tullis Russell FACTORY\UNCOATED\MLSBW160 1A

White 160

110 Index 163GSM Super Calendered, 9pt

Recycled

Microprint DCP 100# Text 163GSM Calendered Georgia Pacific

Dunsirn Industries

800-593-1588 US

IBM\DUNSIRN\DI163IN IG

IBM\GPACIFIC\GP163MDC IG

800-386-8118 US

60lb Cover Color Copy 165 165GSM Calendered Wausau Paper Mills

FACTORY\ UNCOATED\WACCC165 1B

715-675-9891 ext.5504

US

Nopasat/Nopacolor Digiprint/

Nopacolor Gigi 170

170GSM SuperCalendered Nordland(Kymmene) /

Russell-Field

FACTORY\UNCOATED\NOCOD170 1A

IBM InfoColor 70 and 3170 Print Media Guide 40

Page 47

Brand Name Weight Type/Description Manufacture/Distribution Script Performance

Sweprint Digital 170 170GSM Calendered Klippan AB

FACTORY\UNCOATED\KLISD170 1B

46-478-10600 Sweden

Mohawk Options Bright White

176

Mohawk Navajo Brilliant

176GSM Calendered Mohawk Paper Mills

FACTORY\UNCOATED\MOHOP176 1A

800-843-6455 US

176GSM Calendered Mohawk Paper Mills FACTORY\UNCOATED\MOHNA176 1A

White 176

Solar White Classic Crest

65#cvr

Mellotex Smooth Brilliant

176GSM Calendered Neenah

IBM\NEENAH\NNSW176 IG

800-558-5061 US

180GSM Calendered Tullis Russell FACTORY\UNCOATED\MLSBW180 1A

White 180

DCP 190 190GSM Calendered Clairefontaine FACTORY\UNCOATED\DCP190 1A

4CC New 190 190GSM SuperCalendered Enso Group FACTORY\UNCOATED\4CCN190 1A

Nopasat/Nopacolor Digiprint/

Nopacolor Gigi 190

IvoLaser 190 190GSM Calendered Steibach Intermill / Rus-

190GSM SuperCalendered Nordland(Kymmene) /

Russell-Field

FACTORY\UNCOATED\NOCOD190 1A

FACTORY\UNCOATED\IVOL190 1A

sell-Field

Color Press Smooth Pigmented 200 / Anitec Ausedat

200GSM Pigmented Aussedat Rey / Interna-

tional Paper

FACTORY\UNCOATED\CPSP200 1B

Rey Zanders Satin 200

Data Copy Digital 200 200GSM Calendered MoDo Paper PSM FACTORY\ UNCOATED\DACOD200 1A

Color Copy R 200 200GSM Calendered Neusiedler FACTORY\UNCOATED\COCOR200 1A

Mellotex Smooth Brilliant

200GSM Calendered Tullis Russell FACTORY\UNCOATED\MLSBW200 1A

White 200

Mohawk Navajo Brilliant

216GSM Calendered Mohawk Paper Mills FACTORY\UNCOATED\MOHNA216 1B

White 216

4CC New 220

220GSM SuperCalendered Enso Group FACTORY\UNCOATED\4CCN220 2A

* Make sure the stock is manufactured after 08/97

Splendorgel 230 230GSM Calendered Fedrigoni FACTORY\UNCOATED\SPLEN230 2A

IBM InfoColor 70 and 3170 Print Media Guide 41

Page 48

Brand Name Weight Type/Description Manufacture/Distribution Script Performance

Color Press Smooth Pigmented 240 / Anitec Ausedat

240GSM Pigmented Aussedat Rey / Interna-

tioanl Paper

FACTORY\UNCOATED\CPSP240 2A

Rey Zanders Satin 240

IvoLaser 240 240GSM Calendered Steibach Intermill / Rus-

FACTORY\UNCOATED\IVOL240 2A

sell-Field

4CC New 250

250GSM SuperCalendered Enso Group FACTORY\UNCOATED\4CCN250 2B

* Make sure the Stock is

manufactured after 08/97

Data Copy Digital 250 250GSM Calendered MoDo Paper PSM FACTORY\ UNCOATED\DACOD250 2A

Color Copy R 250 250GSM Calendered Neusiedler FACTORY\UNCOATED\COCOR250 2A

Mellotex Smooth Brilliant

250GSM Calendered Tullis Russell FACTORY\UNCOATED\MLSBW250 2B

White 250

IBM InfoColor 70 and 3170 Print Media Guide 42

Page 49

Coated Paper

Paper Script Location: PrintMedia\Paper\

Brand Name Weight Type/Description Manufacture/Distribution Script Performance

Terratec Matt 70 70GSM Matte Stora Kabel FACTORY\COATED_M\TERMA070 1B

HANNO'ART tecgloss 80 80GSM Gloss Sappi Europe FACTORY\COATED_G\HAGLO080 1B

HANNO'ART tecsilk 80 80GSM Matte Sappi Europe FACTORY\COATED_M\HASIL080 1B

Terratec Matt 80 80GSM Matte Stora Kabel FACTORY\COATED_M\TERMA080 1B

60# Semi-gloss CS2 Web 90GSM Gloss, Web Enamel Dunsirn Industries

800-593-1588 US

DigiSilk 90/4CCSilk 90 90GSM Satin Enso Group

201-635-3530 US

DigiArt 90/4CCArt 90 90GSM Gloss Enso Group FACTORY\COATED_G\DIGIA090 1A

HANNO'ART tecgloss 90 90GSM Gloss Sappi Europe FACTORY\COATED_G\HAGLO09 1B

HANNO'ART tecsilk 90 90GSM Matte Sappi Europe FACTORY\COATED_M\HASIL090 1B

Lazulis Brillant 90 90GSM Gloss Smurfit Condat FACTORY\COATED_G\LAZBR090 1A

DigiArt 100/4CCArt 100 100GSM Gloss Enso Group FACTORY\COATED_G\DIGIA100 1A

DigiSilk 100/4CCSilk 100 100GSM Satin Enso Group FACTORY\COATED_S\DIGIS100 1B

Data Copy Option 100 /

MoDo Dian

HANNO'ART tecgloss 100 100GSM Gloss Sappi Europe FACTORY\COATED_G\HAGLO100 1B

HANNO'ART tecsilk 100 100GSM Matte Sappi Europe FACTORY\COATED_M\HASIL100 1B

Lazulis Brillant 100 100GSM Gloss Smurfit Condat FACTORY\COATED_G\LAZBR100 1A

Terratec Matte 100 100GSM Matte Stora Kabel FACTORY\COATED_M\TERMA100 1B

Champion Courtland Matte 105GSM Matte Champion IBM\CHAMPION\CH105CM IG

70# Semi-gloss CS2 Web 105GSM Gloss, Web Enamel Dunsirn Industries

100GSM Matte MoDo Paper PSM / Rus-

sell-Field

800-593-1588 US

IBM\DUNSIRN\DI90SGL IG

FACTORY\COATED_S\DIGIS090 1B

FACTORY\COATED_M\DACOP100 1A

IBM\DUNSIRN\DI105SGL IG

Aussedat Rey Zanders Imaging Matte 115

IBM InfoColor 70 and 3170 Print Media Guide 43

115GSM Matte International Paper

Zanders

FACTORY\COATED_M\ARZIM115 1A

Page 50

Brand Name Weight Type/Description Manufacture/Distribution Script Performance

Aussedat Rey Zanders Imaging Gloss 115

DigiSilk 115/4CCSilk 115 115GSM Satin Enso Group

115GSM Gloss International Paper

Zanders

FACTORY\COATED_M\ARZIG115 1A

FACTORY\COATED_S\DIGIS115 1B

201-635-3530 US

DigiArt 115/4CCArt 115 115GSM Gloss Enso Group FACTORY\COATED_G\DIGIA115 1A

Royal Digital Gloss 115 (ne w)

* Packed in Round Box

Royal Digital Silk 115 (new)

115GSM Gloss KNP Leykam

FACTORY\COATED_G\RDGLS115 1A

32-897-19645 Belgium

115GSM Satin KNP Leykam FACTORY\COATED_S\RDSIL115 1A

* Packed in Round Box

HANNO'ART tecgloss 115 115GSM Gloss Sappi Europe FACTORY\COATED_G\HAGLO115 1B

HANNO'ART tecsilk 115 115GSM Matte Sappi Europe FACTORY\COATED_M\HASIL115 1B

Lazulis Brillant 115 115GSM Gloss Smurfit Condat FACTORY\COATED_G\LAZBR115 1A

80lb Gloss White Text 118 118GSM Gloss Plainwell Paper Com-

FACTORY\COATED_G\PLGWT118 1A

pany

616-685-2553 US

Champion Influence Soft

Gloss 118GSM

118GSM Gloss Champion

203-358-6931 US

IBM\CHAMPION\CH118ISG IG

Champion Influence White 118GSM Gloss Champion IBM\CHAMPION\CH118IW IG

Champion Preference White 118GSM Gloss Champion IBM\CHAMPION\CH118PW IG

Golden Web Gloss 80# Text 118GSM Gloss Nationwide Papers

IBM\NATIONWD\NW118GW IG

800-323-1003 US

Rolltek Gloss Text 118GSM Gloss Rollsource

IBM\ROLLTEK\RT118GLT IG

612-331-2900 US

Rolltek Matte Text 118GSM Matte Rollsource IBM\ROLLTEK\RT118MTT IG

Lustro Web Gloss 80# Text 118GSM Gloss S.D. Warren

IBM\SDWARREN\WA118LWG IG

303-721-7383 US

Champion Courtland Gloss 120GSM Gloss Champion IBM\CHAMPION\CH120CG IG

NopaCoat 120 120GSM Gloss Kymenne Nordland /

IBM\NORDLAND\NOPAC120 IG

Russell-Field

IBM InfoColor 70 and 3170 Print Media Guide 44

Page 51

Brand Name Weight Type/Description Manufacture/Distribution Script Performance

Data Copy Option 120 /

120GSM Matte MoDo Paper PSM FACTORY\COATED_M\DACOP120 1A

MoDo Dian

DigiArt 130/4CCArt 130 130GSM Gloss Enso Group

FACTORY\COATED_G\DIGIA130 1A

201-635-3530 US

DigiSilk 130/4CCSilk 130 130GSM Satin Enso Group FACTORY\COATED_S\DIGIS130 1B

DigiMagic/Magic Gloss 86#

130GSM Gloss Enso Group IBM\ENSO\MG130G IG

Text

Galilei Art Silk 130 130GSM Satin Metsä-Serla, Kangas Mill

FACTORY\COATED_S\MSGAS130 1B

358-1046-45346 Finland

Galilei Art Gloss 130 130GSM Gloss Metsä-Serla, Kangas Mill FACTORY\COATED_S\MSGAG130 1B

MoDo Silverblade Matte 130 130GSM Matte MoDo Paper PSM IBM\MODO\MOSIM130 IG

Silverblade Gloss 130 130GSM Gloss MoDo Paper PSM FACTORY\COATED_G\SILGL130 1A

Aussedat Rey Zanders Imag-

ing Matte 135

Aussedat Rey Zanders Imag-

ing Gloss 135

Color Press Gloss Coated

135GSM Matte International Paper

FACTORY\COATED_M\ARZIM135 1A

Zanders

135GSM Gloss International Paper

FACTORY\COATED_M\ARZIG135 1A

Zanders

135GSM Gloss Aussedat Rey FACTORY\COATED_G\CPGC135 1A

135

Royal Digital Gloss 135 (ne w)

* Packed in round box

135GSM Gloss KNP Leykam

32-897-19645 Belgium

FACTORY\COATED_G\RDGLS135 1A

Royal Digital Silk 135 (new)

135GSM Satin KNP Leykam FACTORY\COATED_S\RDSIL135 1A

* Packed in round box

Data Copy Option 135 /

135GSM Matte MoDo Paper PSM FACTORY\COATED_M\DACOP135 1A

MoDo Dian

Satin Matte 135 135GSM Matte Russell-Field

IBM\RSLFIELD\SATMT135 IG

800-323-1947 US

Satin Gloss 135 135GSM Gloss Russell-Field IBM\RSLFIELD\SATGL135 IG

HANNO'ART tecgloss 135 135GSM Gloss Sappi Europe FACTORY\COATED_G\HAGLO135 1B

HANNO'ART tecsilk 135 135GSM Matte Sappi Europe FACTORY\COATED_M\HASIL135 1B

Lazulis Brillant 135 135GSM Gloss Smurfit Condat FACTORY\COATED_G\LAZBR135 1A

IBM InfoColor 70 and 3170 Print Media Guide 45

Page 52

Brand Name Weight Type/Description Manufacture/Distribution Script Performance

Imaging Digital Matte 135 135GSM Matte Zanders FACTORY\COATED_M\DIMAT135 1B

Rolltek Gloss Text 148GSM Gloss Rollsource IBM\ROLLTEK\RT148GLT IG

Lustro Web Dull 100# Text 148GSM Dull S.D. Warren IBM\SDWARREN\WA148LWD IG

Aussedat Rey Zanders Imag-

ing Matte 150

Aussedat Rey Zanders Imag-

ing Gloss 150

150GSM Matte International Paper

Zanders

150GSM Gloss International Paper

Zanders

FACTORY\COATED_M\ARZIM150 1A

FACTORY\COATED_M\ARZIG150 1A

Digimatt/Matte Art 150GSM Matte Enso Group IBM\ENSO\MA150G IG

DigiSilk 150/4CCSilk 150 150GSM Satin Enso Group FACTORY\COATED_S\DIGIS150 1B

DigiArt 150/4CCArt 150 150GSM Gloss Enso Group FACTORY\COATED_G\DIGIA150 1A

Galilei Art Silk 150 150GSM Satin Metsä-Serla, Kangas Mill

FACTORY\COATED_S\MSGAS150 1B

358-1046-45346 Finland

Royal Digital Gloss 150 (ne w)

150GSM Gloss KNP Leykam FACTORY\COATED_G\RDGLS150 1A

* Packed in round box

Royal Digital Silk 150 (new)

150GSM Satin KNP Leykam FACTORY\COATED_S\RDSIL150 1A

* Packed in round box

Data Copy Option 150 /

150GSM Matte MoDo Paper PSM FACTORY\COATED_M\DACOP150 1A

MoDo Dian

Silverblade Gloss 150 150GSM Gloss MoDo Paper PSM FACTORY\COATED_G\SILGL150 1A

Lazulis Brillant 150 150GSM Gloss Smurfit Condat FACTORY\COATED_G\LAZBR150 1A

Imaging Digital Matte 150 150GSM Matte Zanders FACTORY\COATED_M\DIMAT150 1B

Color Press Gloss Coated

155GSM Gloss Aussedat Rey FACTORY\COATED_G\CPGC155 1B

155

Rolltek Gloss Cover 162GSM Gloss Rollsource

IBM\ROLLTEK\RT162GLC IG

612-331-2900 US

Colorprint Castcote 110# Text 163GSM Castcoate Nationwide Papers

IBM\NATIONWD\NW163CC IG

800-323-1003 US

DigiSilk 170/4CCSilk 170 170GSM Satin Enso Group

FACTORY\COATED_S\DIGIS170 1B

201-635-3530 US

IBM InfoColor 70 and 3170 Print Media Guide 46

Page 53

Brand Name Weight Type/Description Manufacture/Distribution Script Performance

DigiArt 170/4CCArt 170 170GSM Gloss Enso Group FACTORY\COATED_G\DIGIA17 1A

Galilei Art Silk 170 170GSM Satin Metsä-Serla, Kangas Mill

FACTORY\COATED_S\MSGAS170 1B

358-1046-45346 Finland

Galilei Art Gloss 170 170GSM Gloss Metsä-Serla, Kangas Mill FACTORY\COATED_S\MSGAG170 1B

Royal Digital Gloss 170 (ne w)

* Packed in round box

Royal Digital Silk 170 (new)

170GSM Gloss KNP Leykam

FACTORY\COATED_G\RDGLS170 1A

32-897-19645 Belgium

170GSM Satin KNP Leykam FACTORY\COATED_S\RDSIL170 1A

* Packed in round box

Data Copy Option 170 /

MoDo Dian

170GSM Matte MoDo Paper PSM / Rus-

sell-Field

FACTORY\COATED_M\DACOP170 1A

Silverblade Gloss 170 170GSM Gloss MoDo Paper PSM FACTORY\COATED_G\SILGL170 1A

Lazulis Brillant 170 170GSM Gloss Smurfit Condat FACTORY\COATED_G\LAZBR170 1A

Rolltek Matte Cover 7pt. 176GSM Matte Rollsource IBM\ROLLTEK\RT176MTC IG

Aussedat Rey Zanders Imag-

ing Gloss 200

Royal Digital Gloss 200 (ne w)

200GSM Gloss International Paper

FACTORY\COATED_M\ARZIG200 1A

Zanders

200GSM Gloss KNP Leykam FACTORY\COATED_G\RDGLS200 1A

* Packed in round box

Royal Digital Silk 200 (new)

200GSM Satin KNP Leykam FACTORY\COATED_S\RDSIL200 1A

* Packed in round box

***NopaCoat 200 - under

problem checking status

200GSM Gloss Kymenne Nordland /

Russell-Field

IBM\NORDLAND\NOPAC200 IG

Data Copy Option 200 /

MoDo Dian

200GSM Matte MoDo Paper PSM / Rus-

sell-Field

FACTORY\COATED_M\DACOP200 1A

Silverblade Gloss 200 200GSM Gloss MoDo Paper PSM FACTORY\COATED_G\SILGL200 1A

Lazulis Brillant 200 200GSM Gloss Smurfit Condat FACTORY\COATED_G\LAZBR200 1A

Imaging Digital Matte 200 200GSM Matte Zanders FACTORY\COATED_M\DIMAT200 1B

Rolltek Gloss Cover 80# 216GSM Gloss Rollsource IBM\ROLLTEK\RT216GLC 2IG

Lazulis Brillant 225 225GSM Gloss Smurfit Condat FACTORY\COATED_G\LAZBR225 2A

IBM InfoColor 70 and 3170 Print Media Guide 47

Page 54

Brand Name Weight Type/Description Manufacture/Distribution Script Performance

Silverblade Gloss 240 240GSM Gloss MoDo Paper PSM FACTORY\COATED_G\SILGL240 2B

Data Copy Option 250 /

MoDo Dian

250GSM Matte MoDo Paper PSM FACTORY\COATED_M\DACOP250 2A

IBM InfoColor 70 and 3170 Print Media Guide 48

Page 55

Specialty Paper

Paper Script Location: PrintMedia\Paper\

Brand Name Weight Type/Description Manufacture/Distribution Script Performance

Autocopy Laser CF Carbonless Paper Zanders Feinpapiere

49-2202-156565 Germany

Autocopy Laser CFB Carbonless Paper Zanders Feinpapiere FACTORY\SPECIAL\AUTOCFB 1B

Autocopy Laser CB Carbonless Paper Zanders Feinpapiere FACTORY\SPECIAL\AUTOCB 1B

Idem Superior CB 80GSM Carbonless Paper Arjo Wiggins Ltd.

44-1494-652275

England

Idem Superior CFB 80GSM Carbonless Paper Arjo Wiggins Ltd. FACTORY\SPECIAL\AWCFB_080 1A

Copy Fantasy CTM 1500

* Use with understanding

Photo-TransÆ SC

*Use with understanding

Supergloss 80 80GSM Single-side castcoate Zanders FACTORY\SPECIAL\SUGLO080 1A

Classic Laid 90 90GSM Creamy Color Water

Heat Transfer Paper Meserli FACTORY\COPFAN15 May experi-

Heat Transfer Paper Wyndstone

800-395-8870 US

Neenah

Marked Paper with

Parchment Surface

800-558-5061 US

FACTORY\SPECIAL\AUTOCF 1B

FACTORY\SPECIAL\AWCB_080 1B

ence print

quality and

finishing

problem.

IBM\WSTONE\WSPHOTSC Need low

fusing.

Image quality

is moderate

for fabric

IBM\NEENAH\NNCLD090 IG

DigiTerreus 100 100 GSM Embossed Enso Group

201-635-3530 US

Oxford Text White 80lb 118 GSM Uncoated embossed Gilbert Paper

414-729-7734 US

Corolla Book Ivory 120 120 GSM Watermarked Fedrigoni FACTORY\SPECIAL\COBOI120 1A

Pretex Manual 120 120GSM Impregnated, High tear/

fold resistant

IBM InfoColor 70 and 3170 Print Media Guide 49

Papierfabrik Lahnstein,

Holland

FACTORY\SPECIAL\DITER100 1B

FACTORY\SPECIAL\GILOT080 1B

FACTORY\SPECIAL\PRETE120 1B

Page 56

Brand Name Weight Type/Description Manufacture/Distribution Script Performance

ImagEase Ferenze 135 135GSM 1-side Gloss Coated,

Leather Look Finish,

Rexam DSI / RussellField

FACTORY\SPECIAL\IMAFI135 1A

Latex Saturated

ImagEase Linenweave 135 135GSM 1-side Gloss Coated,

Linen finish, Latex Satu-

Rexam DSI / RussellField

FACTORY\SPECIAL\IMALI135 1A

rated

ImagEase Chrome 135 135GSM 1-side Gloss Coated,

Latex Saturated

Rexam DSI / RussellField

FACTORY\SPECIAL\IMACH135 1A

IvoLaser Antique 135 135 GSM Tinted Paper Steinbach Intermills FACTORY\SPECIAL\IVOA135 1A

IvoLaser Antique TM 135 135 GSM Embossed Steinbach Intermills FACTORY\SPECIAL\IVOAT135 1A

Supergloss 135 135GSM Single-side castcoate Zanders FACTORY\SPECIAL\SUGLO135 1A

Conqueror Laid 150 150GSM Watermarked, Uncoated

Calendered

Arjo Wiggins

44-1322-397176

F A CT OR Y\SPECIAL\COLAI150 1A

England

Marina Conchiglia 175 175 GSM Parchment Fedrigoni FACTORY\SPECIAL\MARCO175 1A

Supergloss 180 180GSM Single-side castcoate Zanders FACTORY\SPECIAL\SUGLO180 1A

IvoLaser Antique 190 190 GSM Tinted Paper Steinbach Intermills FACTORY\SPECIAL\IVOA190 1A

IvoLaser Antique TM 190 190 GSM Embossed Steinbach Intermills FACTORY\SPECIAL\IVOAT190 1A

IvoLaser TM 190 190 GSM Embossed Steinbach Intermills FACTORY\SPECIAL\IVOT190 1A

ImagEase 212 Chrome 212 GSM 1-side Gloss Coated,

Rexam / Russell-Field IBM\REXAM\RXIME212 2IG

Latex Saturated

IvoLaser TM 240 240 GSM Embossed Steinbach Intermills FACTORY\SPECIAL\IVOT240 2A

IBM InfoColor 70 and 3170 Print Media Guide 50

Page 57

Label Materials

Paper Script Location: PrintMedia\Label\

Sorted by manufacturer

Brand Name Weight Type/Description Manufacture/Distribution Script Performance

White 2 mil Vinyl Thermal

Transfer Film Label 3690E

5mil Gloss White Acrylate

Thermal Transfer Film Label

3921

1.5mil Gloss Clear Polyester

Press Printable Film Label

7753

Matte White 7mil TeslinTM

Polyolefin Laser Imageable

Label 7841

Fasson Digital Print Media

High Gloss 7250/10112

Fasson Digital Print Media

Uncoated 7251/10111

Fasson Digital Print Media

3.4 mil White Flex Vinyle

7252/73180

Fasson Vellum DI-CP

WA1525 Matte Paper Label

2mil face, 1mil adhesive,

3.2mil paper liner

5mil face, 1mil adhesive,

4.6mil paper liner

1.5mil face, 0.7mil adhesive, 1.5mil polyester film

liner

7mil face, 0.8mil adhesive, 3.2mil paper liner

50# MF

liner

50# MF

liner

78# liner Vinyle Label, Permenant

80 micron

face, 100

micron

liner

Coated Paper Label,

Permenant Adhesive

Uncoated Paper Label,

Permenant Adhesive

Adhesive

Uncoated Paper Label

with Paper Liner

3M

800-328-1681 US

3M IBM\3M\3M3921 IG

3M IBM\3M\3M7753 IG

3M IBM\3M\3M7841 IG

Avery Dennison

800-443-9380 US

Avery Dennison IBM\FASSON\FS7251 IG

Avery Dennison IBM\FASSON\FS7252 IG

Avery Dennison

(Europe)

IBM\3M\3M3690E IG

IBM\FASSON\FS7250 IG

FACTORY\FASVEL 1A

Fasson MCWhite DI-CP

WA1533 Semi-gloss Paper

Label

Fasson HGW DI-CP

WA1541 High-gloss Paper

Label

IBM InfoColor 70 and 3170 Print Media Guide 51

80GSM

face,

100GSM

liner

80GSM

face,

100GSM

liner

Satin Machine Coated

Paper Label with Paper

Liner

High Gloss Cast Coated

Paper Label with Paper

Liner

Avery Dennison

(Europe)

Avery Dennison

(Europe)

FACTORY\FASMCW 1A

FACTORY\FASHGW 1A

Page 58

Brand Name Weight Type/Description Manufacture/Distribution Script Performance

Fasson MCWhite DI-CP WA

1962 Coated Paper Label

80GSM

face,

Semi-gloss Paper Label

with Scored Liner

85GSM

liner

Classic Plus 41405 50# liner 4 mil Vinyl Aggressive, 1

mil Permanent acrylic

adhesive, 3.0 mil paper

liner

IMAGinTM TF6628 50# face,

50# liner

Uncoated paper face,

permanent adhesive,

white Kraft liner

IMAGinTM TF6628PS 50# face,

60# liner

Uncoated paper label

with scored whit Kraft

liner, permanent adhe-

sive

IMAGinTM TF6623 Uncoated opaque paper

label

IMAGinTM TF6627 PS 50# face,

60# liner

White semi-gloss paper

face, permenant adhe-

sive, scored white Kraft

liner

IMAGinTM TF6627 50# face,

50# liner

White semi-gloss paper

face, permenant adhe-

sive, white Kraft liner

Avery Dennison

FACTORY\FASMCWS 1A

(Europe)

Flexcon

IBM\FLEXCON\FL41405 IG

508-885-8420 US

MACtac

FACTORY\TF6628 1B

800-334-7310 US

MACtac FACTORY\TF6628PS 1A

MACtac FACTORY\TF6623 1A

MACtac FACTORY\TF6627PS 1B

MACtac FACTORY\TF6627 1B

IMAGinTM TF6728 PET face with paper liner MACtac FACTORY\TF6728 1A

Digi Vellum Matt coated paper face,

Raflatac FACTORY\RAFDIVEL 1B

permanent adhesive,

scored kraft liner

Digi Castgloss Cast gloss coated paper

Raflatac FACTORY\RAFDICGL 1B

face, permanent adhesive, scored kraft liner

IBM InfoColor 70 and 3170 Print Media Guide 52

Page 59

Film Materials

Paper Script Location: PrintMedia\Film\