Page 1

HTEB1

User manual

Hitachi

H8/Tiny 3664F

LowCost

Evaluation Board

User Manual

Issue 0.2 Page 1 07/2002

Page 2

HTEB1

User manual

PREFACE

Product Warranty

The warranty period against defects in materials and workmanship are as set out in the

accompanying Customer Information sheet.

Limitation of Warranty

The foregoing warranty does not cover damage caused by fair wear and tear, abnormal

storage conditions, incorrect use, accidental misuse, neglect, corruption, misapplication,

addition or modification or by the use with other hardware or software, as the case may

be, with witch the product is incompatible. No warranty of fitness for a particular purpose

is offered. The user assumes the entire risk of using the product. Any liability of embesso

GmbH is limited exclusively to the replacement of defective material or workmanship.

Trademarks

All brand or product names used in this manual are trademarks or registered trademarks

of their respective companies or organisations.

Microsoft is a registered trademark and Windows and Windows NT are trademarks of

Microsoft Corporation. IBM is a registered trademark of International Business Machines

Corporation.

Cautions

This document may be, wholly or partially, subject to change without notice. All rights

reserved. No one is permitted to reproduce or duplicate, in any form, a part or this entire

document without embesso GmbH written permission.

Restrictions

Please refer to the restrictions of all components and tool suppliers.

Hardware Considerations

Grounding: This hardware is designed for use with equipment that is fully grounded.

Ensure that all equipment used is appropriately grounded. Failure to do so could lead to

danger for the operator or damage the equipment.

Electrostatic Discharge Precautions: This hardware contains devices that are sensitive to

electrostatic discharge. Ensure appropriate precautions are observed during handling and

accessing connections. Failure to do so could result in damage to the equipment.

Electromagnetic Compatibility: This product can cause radio frequency noise when used

in the residential area. In such cases the user of the equipment my be required to take

appropriate countermeasures under his responsibility.

Support

Support by embesso GmbH is provided only for the supplied hardware. Any software

tools are supported from their supplier. Please notice that maybe some software tools

coming with this kit are only unsupported freeware and no support will be given.

For embesso support please contact: support@embesso.com

Issue 0.2 Page 2 07/2002

Page 3

HTEB1

User manual

Table of Contents

PREFACE ..............................................................................2

Table of Contents ..................................................................3

1 Overview .........................................................................4

1.1 System Development Kit content.................................... 4

1.2 Hardware description ....................................................4

1.3 Features...................................................................... 5

1.4 Board overview ............................................................ 6

1.5 Jumpers and switches ...................................................7

1.6 Connectors ..................................................................9

1.7 Start-Up instructions..................................................... 12

2 Development Environment ................................................. 15

2.1 Creating a program using IAR-EWH8 ..............................15

2.2 Download the code using FDT ........................................ 23

2.3 Workflow.....................................................................31

3 Examples ......................................................................... 32

3.1 Key’s and LED’s............................................................ 33

3.2 LCD ............................................................................36

3.3 SCI............................................................................. 39

3.4 A/D + PWM .................................................................41

3.5 AT-Keyboard-Interface.................................................. 44

Appendix A: CD-R content ......................................................51

Appendix B: Schematic...........................................................52

Appendix C: Board layout .......................................................53

Issue 0.2 Page 3 07/2002

Page 4

HTEB1

User manual

1 Overview

1.1 System Development Kit content

Thank you for purchasing our product. If you take care on the different

hints in this manual you will have great success in software development

with this microcontroller. Please refer to the documents listed in appendix.

The System Development Kit

contains the following parts:

Evaluation-Board HTEB1

CD-ROM

User manual (this document)

RS232 cable (1.8m, DSub9, malefemale)

4 plastic feet for the HTEB1

Carefully remove the board from the shipping carton. Check first if there

are any damages before power on the evaluation board.

1.2 Hardware description

The Hitachi-Tiny-Eval-Board (HTEB1) is a low cost multifunctional

evaluation board for the Hitachi Tiny H8/3664F microcontroller. It can be

used stand alone for software development and testing or as a simple

target board. You can use the Flash-Download-Tool (FDT) for

programming the target code or work with a debug system (E10T) at the

provided connector. The board allows the designer immediately to start

with the software development before his own final target system is

available.

This eval-kit provides some additional hardware e.g. 8 LED’s, a 2*16

Character LCD, 4 key’s, a PC-AT-keyboard connector, an I2C-connector

and more for hard- and software evaluation. All peripherals are used by

some software application notes. Please refer chapter 3.

Issue 0.2 Page 4 07/2002

Page 5

HTEB1

User manual

1.3 Features

• Contains H8/3664F microcontroller

• In-Circuit serial Flash programming

• All resources available for evaluation

• All pins routed to connectors

• 9.8304 MHz main crystal

• 32.768 kHz sub crystal

• UART interface with MAX232 level converter and SubD-9 (female)

connector

• 8 User LEDs

• 2*16 characters LCD with LED backlight (switchable)

• Additional connector for external LCD

• 4 user keys

• PC-AT-Keyboard interface

• 2 potentiometer connected to A/D-channel 0/1

• Reset button

• 1 switch user/prog(programming)

• E10T-debug-connector

• +5V voltage regulator on board

Issue 0.2 Page 5 07/2002

Page 6

HTEB1

Prog/Run

User manual

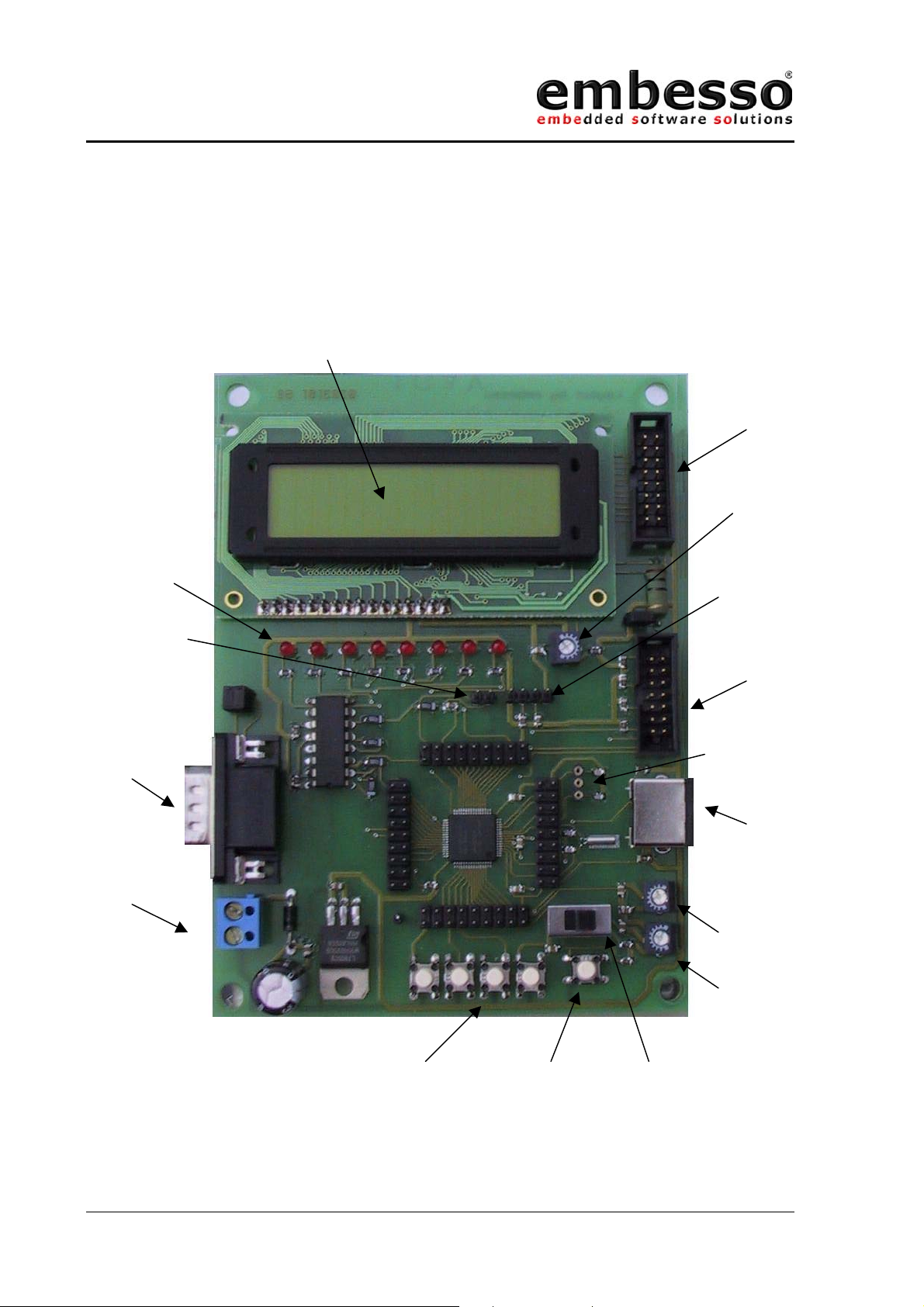

1.4 Board overview

2*16 char LCD with

LED backlight

Ext.-LCD

connector

Contrast

8 user LEDs

DA connector

RS232

connector

SubD0

female

Power 7,5 V9V DC

I2C

connector

E10T

connector

Crystal

socket

AT/PS2

keyboard

connector

+

-

P1 = ADC 0

P2 = ADC 1

4 user keys Reset button

Figure 1 Board overview

Issue 0.2 Page 6 07/2002

switch

Page 7

HTEB1

User manual

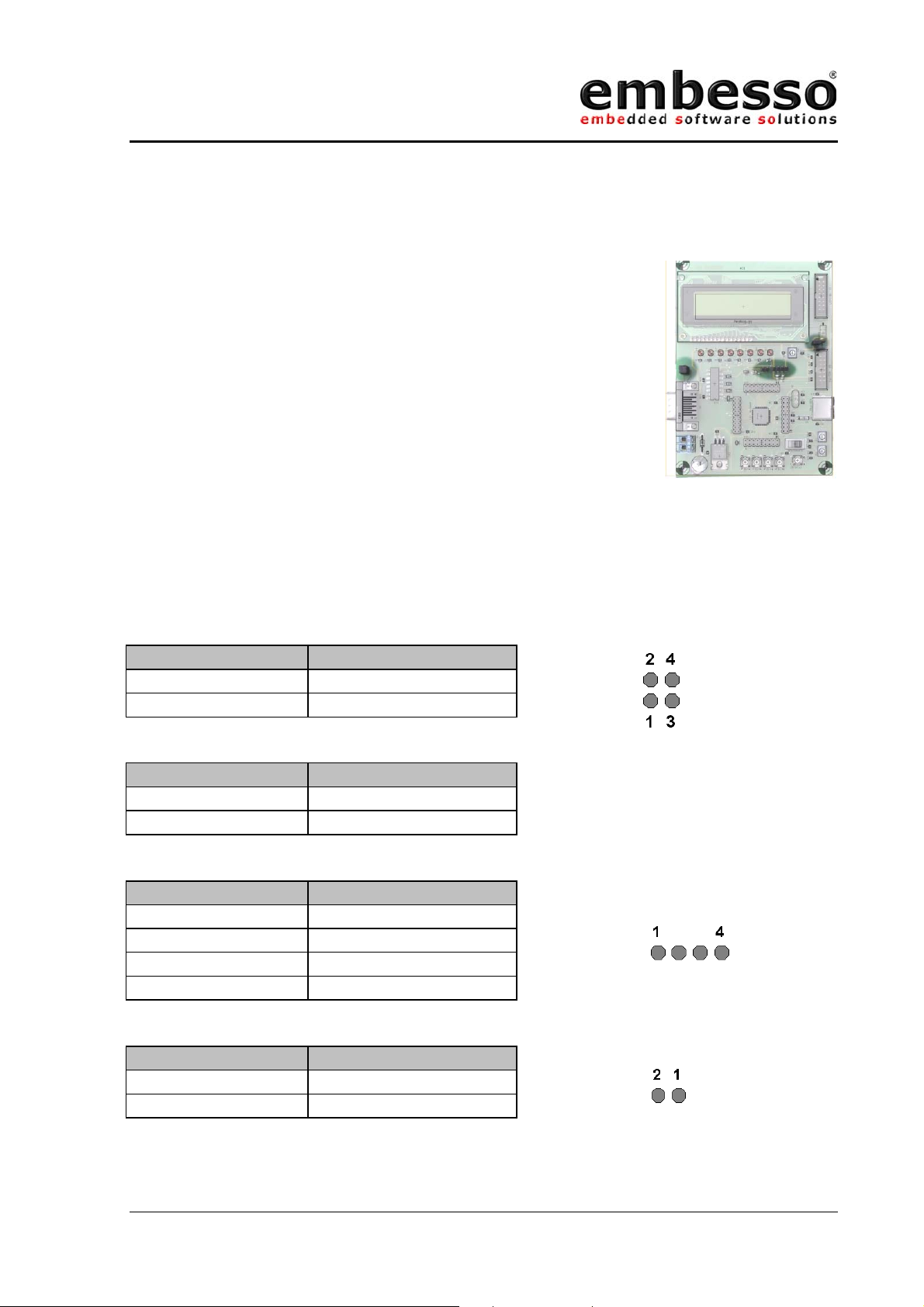

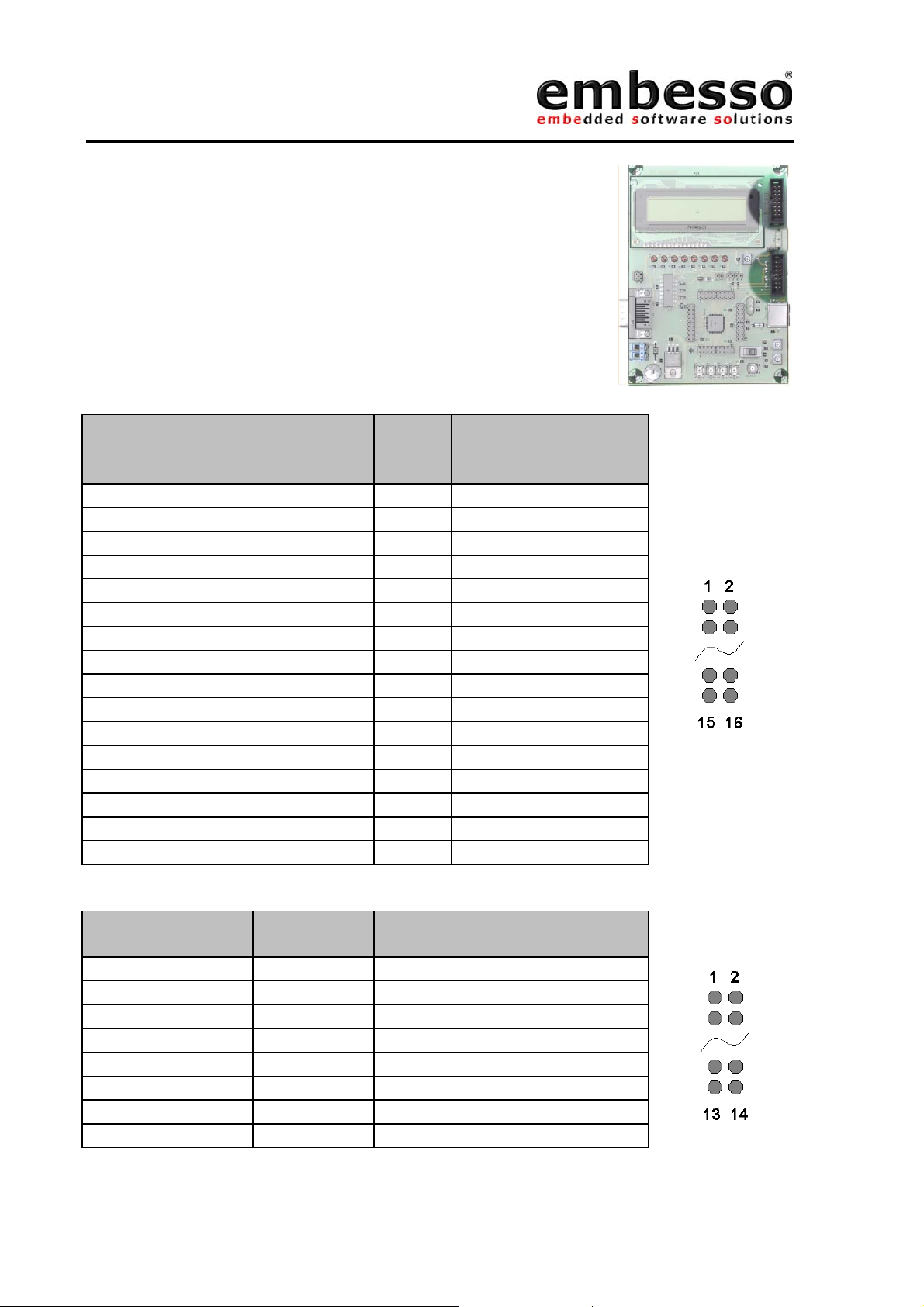

1.5 Jumpers and switches

JP1 is used for switching the serial interface from 1:1

to crossed connection. If you connect a 1:1 cable (like

the cable that comes with the kit) use the default

setting. If you connect a crossed cable set the jumper

to alternate setting.

JP3 is used for the LCD-LED backlight. If the jumper is

closed (1-2) the backlight will be ON. Remove the

jumper (=open) if backlight operation is not

necessary.

JP2 is used for I2C interface

JP4 is used as an output for the DAC or for PWM

JP1 Operation

1-3, 2-4 1:1 operation

1-2, 3-4 Crossed connection

JP3 Operation

Closed LED backlight ON

Open LED backlight OFF

JP2, I2C-CON Operation

1+5V

2SDA

3SCL

4GND

JP4, D/A CON Operation

1 D/A Output (PWM)

2GND

Issue 0.2 Page 7 07/2002

Page 8

HTEB1

User manual

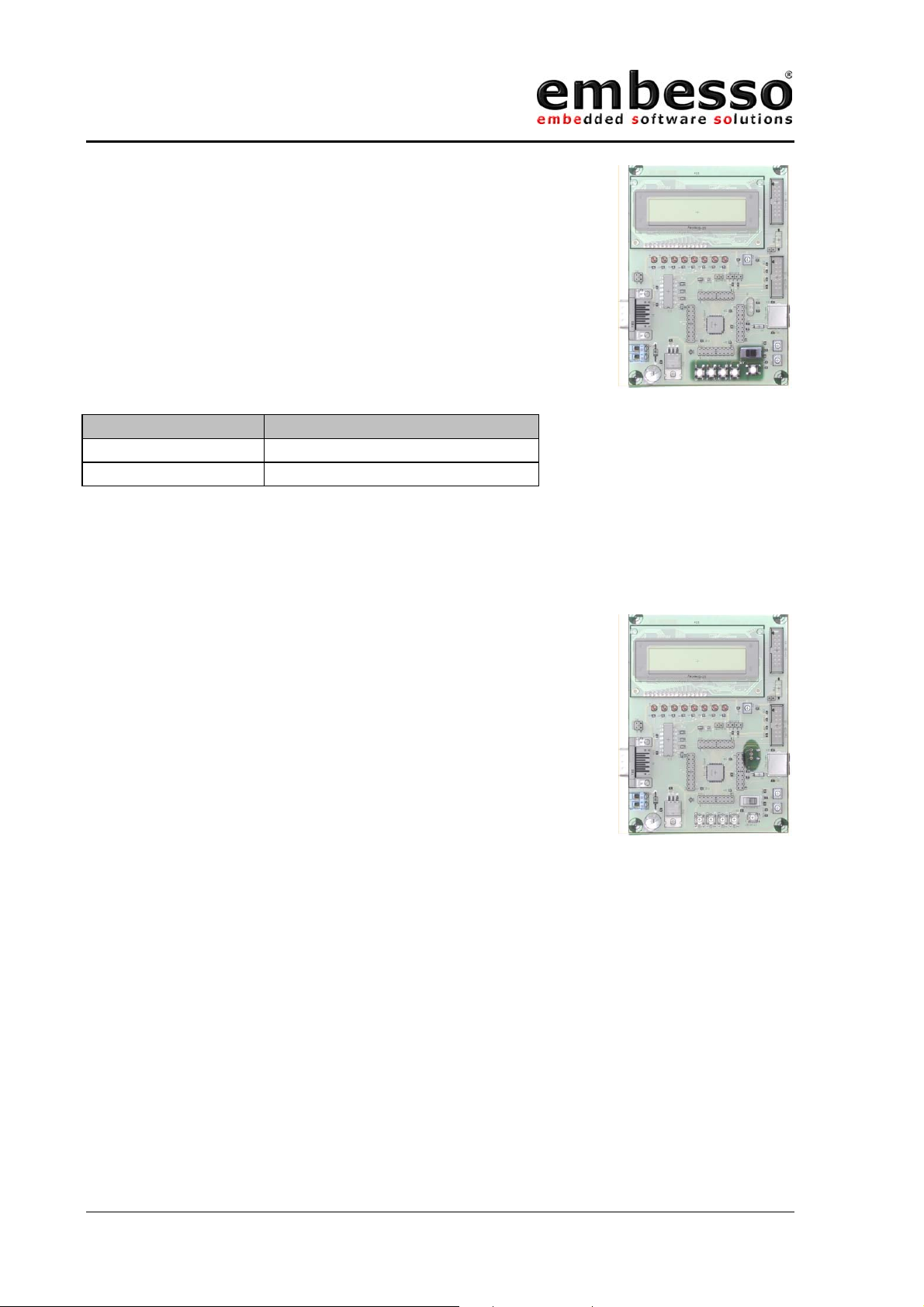

S_PROG/RUN switches between RUN- and

PROG(PROGRAMMING) mode.

KEY_1 (T1) to KEY_4 (T4) are user keys.

RESET_KEY (T7) is for reset.

Orientation Operation

LEFT PROG(programming) mode

RIGHT RUN mode

Main crystal (Q1) can be changed to another

frequency. Therefore a crystal socket is provided.

Please refer to the microcontroller hardware

documentation for recommended devices. The crystal

type should be a HC49 / HC49U type. Eventually

change the capacitors C6/C7 if necessary. If you

change the crystal frequency take care on possible

changes by flash download tool (see FDT manual).

Figure 1.5 crystal socket

Issue 0.2 Page 8 07/2002

Page 9

HTEB1

User manual

1.6 Connectors

X1, Serial communication, SubD-9 female

X2, Power connector, for cable connection

X4, MiniDIN (PS2)

X2, Pin Operation

1GND

2 DC power supply,

7,5 – 9 VDC,

approx. 180mA

with LED backlight

X1 (SubD9), Pin Operation Remark

1 (DTR,DSR, DTS) Connected to X1.4, X1.6

2 TXD Connected to JP1.1

3 RXD Connected to JP1.3

4 DTR Connected to X1.1, X1.6

5GND

6 DSR Connected to X1.1, X1.4

7 RTS Connected to X1.8

8 CTS Connected to X1.7

9 n.c. Not connected

X4 (Mini-Din)

µC-Pin Operation

Pin

1 P17 (can be Data or Clk)

5 P16 (can be Clk or Data)

3GND

4Vcc

2,6 n.c.

Issue 0.2 Page 9 07/2002

Page 10

HTEB1

User manual

OnBoard LCD (IC4)

X3, external LCD-connector (057-016-1)

X5, E10T debug connector (Sys-Con)

LCD Modul

(IC4) pin

X3 (LCD-CON)

(057-016-1)

µCpin

Operation

pin

31 -GND

42 -Vcc

5 3 - contrast (=P3)

6 4 P75 RS (register select)

7 5 P74 R/W (read / write)

8 6 P20 EN (enable)

97 P50D0

10 8 P51 D1

11 9 P52 D2

12 10 P53 D3

13 11 P54 D4

14 12 P55 D5

15 13 P56 D6

16 14 P57 D7

1 15 - Backlight +

216 -GND

X3 pinout

X5 (SYS-CON),

pin

µC-pin Operation

X5 pinout

1 P87 Debug pin

5 P86 Debug pin

7 /NMI /NMI

11 P85 Debug pin

13 /RESET reset control

8Vcc

2,4,6,10,12,14 GND

3,9 n.c. Not connected

Issue 0.2 Page 10 07/2002

Page 11

HTEB1

User manual

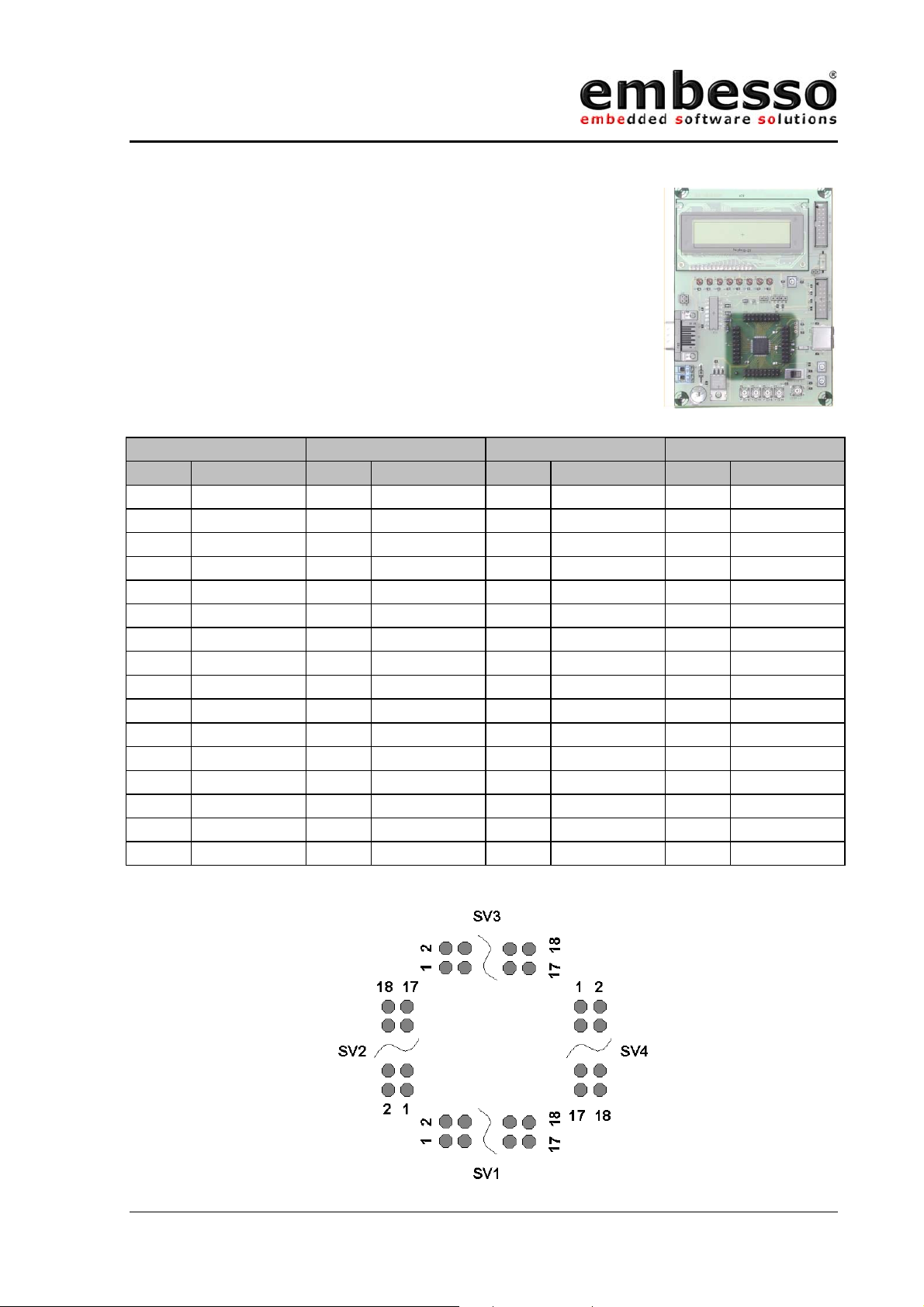

SV1,SV2, SV3,SV4 connectors with microcontroller

signals

SV1 SV2 SV3 SV4

PIN Operation PIN Operation PIN Operation PIN Operation

1,2 GND 1,2 GND 1,2 GND 1,2 GND

3 n.c. 3 n.c. 3 n.c. 3 P51

4 n.c. 4 n.c. 4 n.c. 4 P50

5 P14 5 P22 5 P76 5 n.c.

6 P15 6 P21 6 P75 6 n.c.

7 P16 7 P20 7 P74 7 n.c.

8 P17 8 P87 8 P57 8 n.c.

9AN4 9P86 9P56 9n.c.

10 AN5 10 P85 10 P12 10 n.c.

11 AN6 11 P84 11 P11 11 n.c.

12 AN7 12 P83 12 P10 12 n.c.

13 AN3 13 P82 13 P55 13 GND

14 AN2 14 P81 14 P54 14 /RESET

15 AN1 15 P80 15 P53 15 VCL

16 AN0 16 /NMI 16 P52 16 n.c.

17,18 Vcc 17,18 Vcc 17,18 Vcc 17,18 Vcc

Issue 0.2 Page 11 07/2002

Page 12

HTEB1

User manual

1.7 Start-Up instructions

1.7.1 Installing the HTEB1

Installing the HTEB1 requires a power supply and a serial connection to a

host computer (common PC). The serial communications cable for

connecting the HTEB1 to a host computer is supplied and has 1:1

connectivity.

PC with COM1/2

Power supply

7,5-9V DC

Figure 1.8 shows how to connect the HTEB1 to a PC and to a power supply

1.7.2 Power Supply

The HTEB1 hardware requires a power supply of 7,5V DC at minimum.

Please don’t use a power supply with more the 9V DC because the on

board voltage regulator becomes very hot!

The HTEB1 power consumption is about 180mA with LCD-backlight ON.

Since total power consumption can vary widely due to external

connectors, H8/3664F port state, use a power supply capable of providing

at least 300mA at +7,5V DC.

The design includes circuitry for reversed polarity protection.

Please watch on GND (ground) connection between power supply, evalboard and PC.

Issue 0.2 Page 12 07/2002

Page 13

HTEB1

User manual

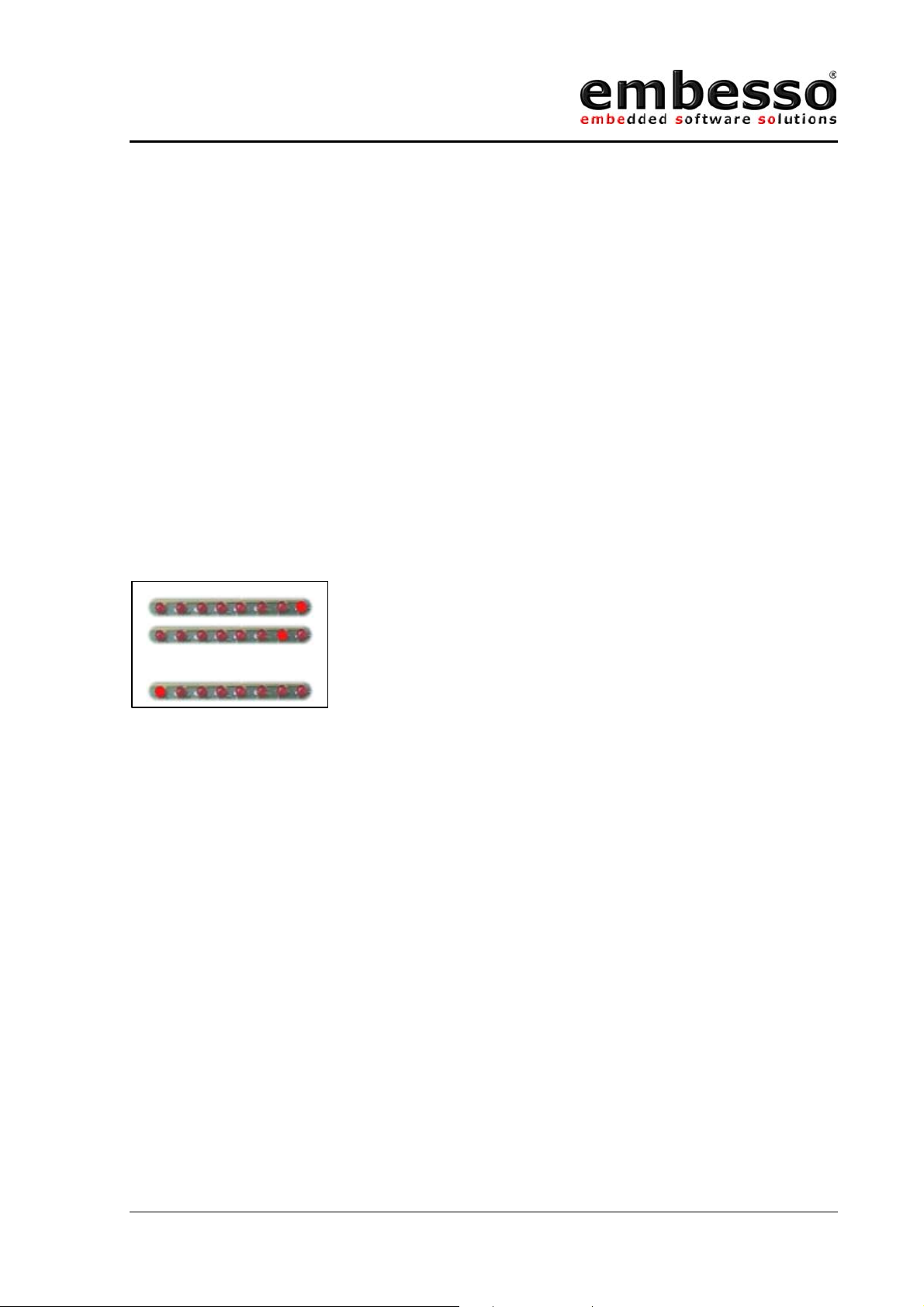

1.7.3 Test program

The HTEB1 is supplied with a short demo application when delivered. If

you power up the eval-board for the first time, you will see a start up

message and some LEDs lighting.

If no message appear, please set the switch “Prog/Run” to “Run-Mode”

(right position) and power up the board or, if already done, press the

reset-button.

The demo application contains a small “Running-Light” application. The

keys can be used for control the state, P2 is used as speed control. First

press the key T3 (RUN) for starting demo application. Then you can check

the functionality by pressing the keys KEY T1 to KEY T4 or change the

value of potentiometer P2.

[…]

Figure of the Demo application. “Running Light”

Any time you want to reset the application press the reset-button. If you

want to reload the demo application later (after reprogrammed the evalboard) you can find the code on CD-R in the directory

“X:\examples\flashdemo\runlight.a37” (For X use the appropriate char

from your CD-ROM).

Issue 0.2 Page 13 07/2002

Page 14

HTEB1

User manual

1.7.4 Software Installation

Software development on embesso-HTEB1 requires some software tools to

be installed on your PC. All tools can be found on CD-R. Some of them

must be installed separately. Please refer on installation / setup

requirements.

You will find the following tools:

EWH8: IAR Embedded Workbench with a limited version of the IAR

C compiler for all Hitachi Tiny controllers, assembler, linker

and library generator

FDT: A powerful freeware flash tool (flash-writer) from HMSE

Installation hints:

EWH8: Install EWH8 by start \programs\iar\autorun.exe . Follow

the instructions in setup and look at the readme.txt file.

FDT: Next install \programs\fdt\ftd15.exe. Then the plugin

fdt3664f.exe must be installed. Follow the setup

instructions. A documentation will be found in fdt_man.pdf.

If you have installed these tools please refer to the next lessons for

workflow.

NOTE: Most freeware tools are unsupported versions! Please refer

to manuals or hints on website for FAQ’s!

It is strongly recommended to refer all additional documents like

H8/3664F hardware manual and H8 programming manual. Please see the

application notes and several readme files on CD-R. Sometimes you

should watch on the Hitachi, HMSE and IAR websites for tool upgrading,

news and latest versions of all tools.

Hitachi: www.hitachi-eu.com/semiconductors

HMSE: www.hmse.com

IAR: www.iar.com

Issue 0.2 Page 14 07/2002

Page 15

HTEB1

User manual

2 Development Environment

2.1 Creating a program using IAR-EWH8

Software development can be done with a integrated embedded

workbench like IAR-EWH8. This software contains an editor, some tools

for organization and a tool chain for compiling, assembling and linking

programs.

Start IAR Embedded Workbench on your PC. The following window will

appear:

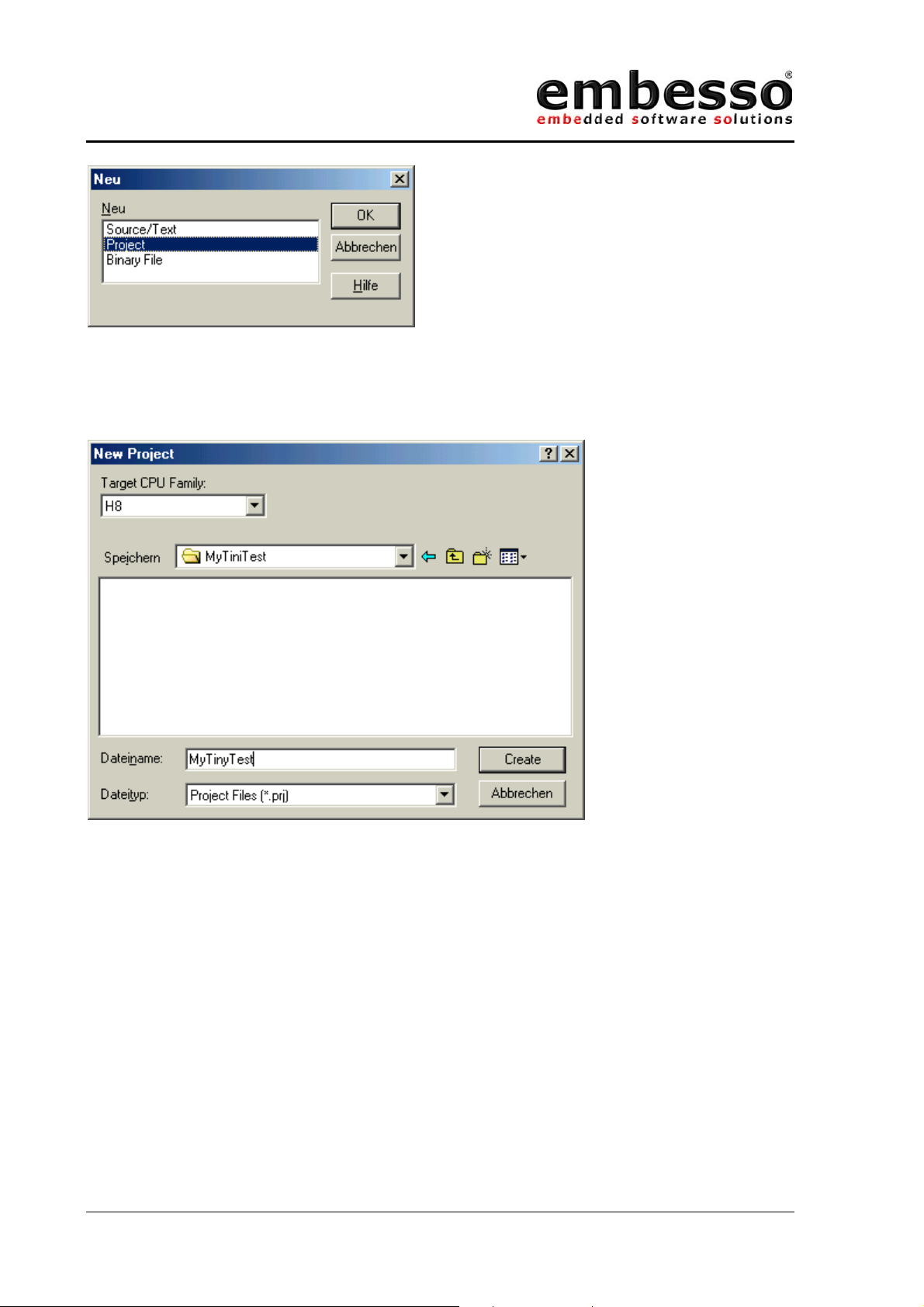

Now select File / New and select “Project”

Issue 0.2 Page 15 07/2002

Page 16

HTEB1

User manual

Press OK and a file window will appear. Here first create a new directory

(e.g. c:\MyTinyTest) and type the project filename “MyTinyTest”. After

that click CREATE.

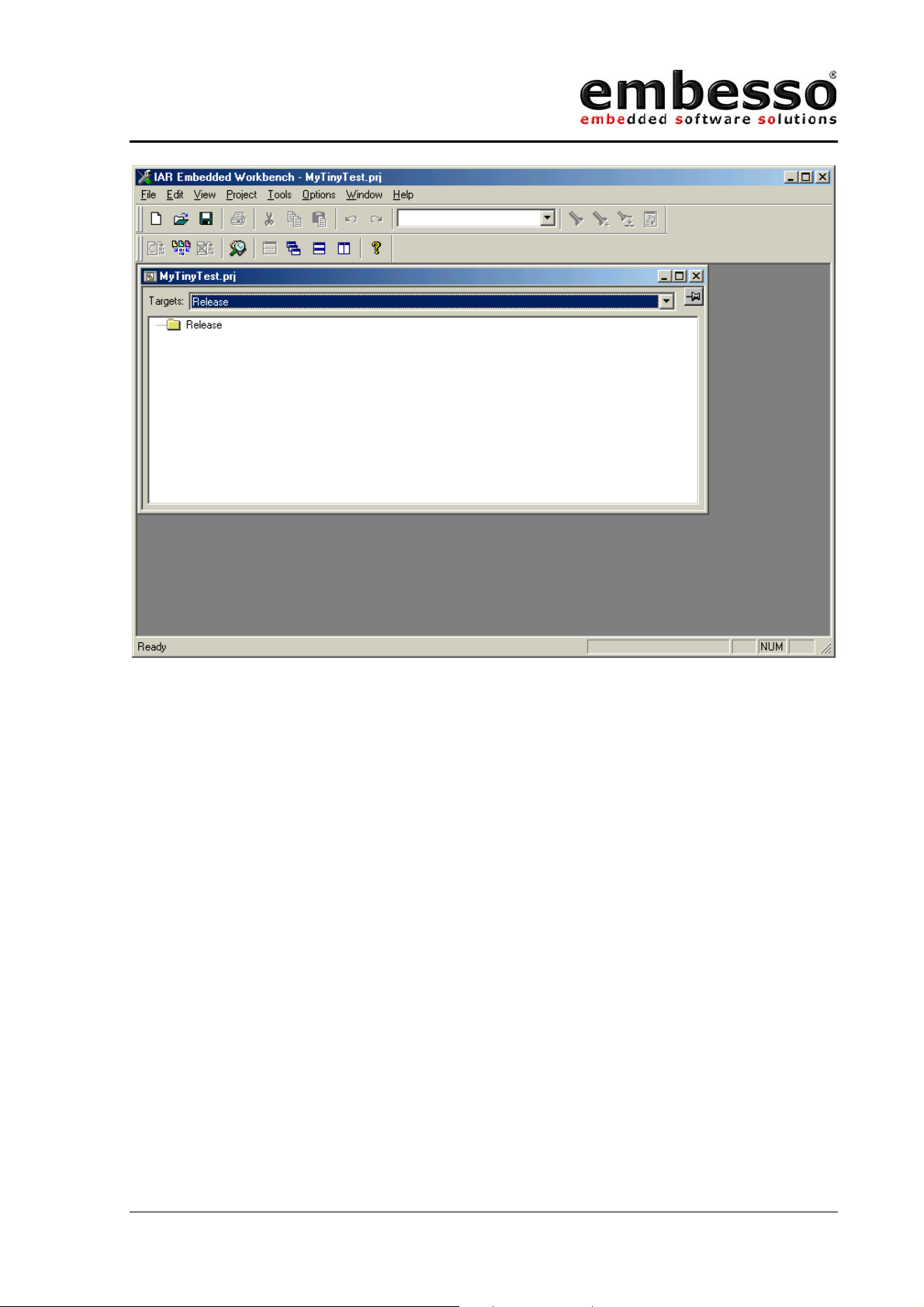

Now a new project is created and we must do some settings. In the

window select under targets: “RELEASE”.

Issue 0.2 Page 16 07/2002

Page 17

HTEB1

User manual

Now select release with the right mouse button. A popup appears. Select

Options… and do the following settings:

In selection ICCH8/List select the List file box.

In section XLINK/Output select under Format “motorola” as the output

format.

Issue 0.2 Page 17 07/2002

Page 18

HTEB1

User manual

On the CD-R you will find a file called “hteb1.xcl”. That file must be used

as the xlink input file. Please copy it to your target directory and select in

section Input/XCL file name the file hteb1.xcl.

Issue 0.2 Page 18 07/2002

Page 19

HTEB1

User manual

All other options can be changed later.

Click on OK.

Now select File/new/source file and type in the following program:

/* MyTinyTest */

#include "ioh83664.h"

void main(void)

{

unsigned int x=0; /* counter */

unsigned char c=0; /* holds port output */

PCR8 = 0xff; /* port is output */

PDR8 = c; /* all LED's on (inverse) */

while (1)

{

while (--x); /* wait ... */

c++; /* increment c */

PDR8 = c; /* to port */

}

}

Issue 0.2 Page 19 07/2002

Page 20

HTEB1

User manual

After that save it under MyTinyTest.c

Now we must add this file to our project. Please select Project/Files and

add the file MyTinyTest.c.

Issue 0.2 Page 20 07/2002

Page 21

HTEB1

User manual

After that click on DONE.

Now you can select Projet/Build ALL (or F9) and all files are compiled and

linked. The message window shows if your project is error free or if there

are any errors.

Issue 0.2 Page 21 07/2002

Page 22

HTEB1

User manual

The target file for download can be found in directory

c:\mytinytest\release\exe\mytinytest.a37.

Please see chapter “FDT” for information about downloading this file to

target system.

Issue 0.2 Page 22 07/2002

Page 23

HTEB1

User manual

2.2 Download the code using FDT

After compiling and linking (error free!), the target code (mytinytest.mot)

should be downloaded to target board. Therefore we use a freeware tool

from HMSE : FDT.

Even FDT must be prepared for a new workspace.

Issue 0.2 Page 23 07/2002

Page 24

HTEB1

User manual

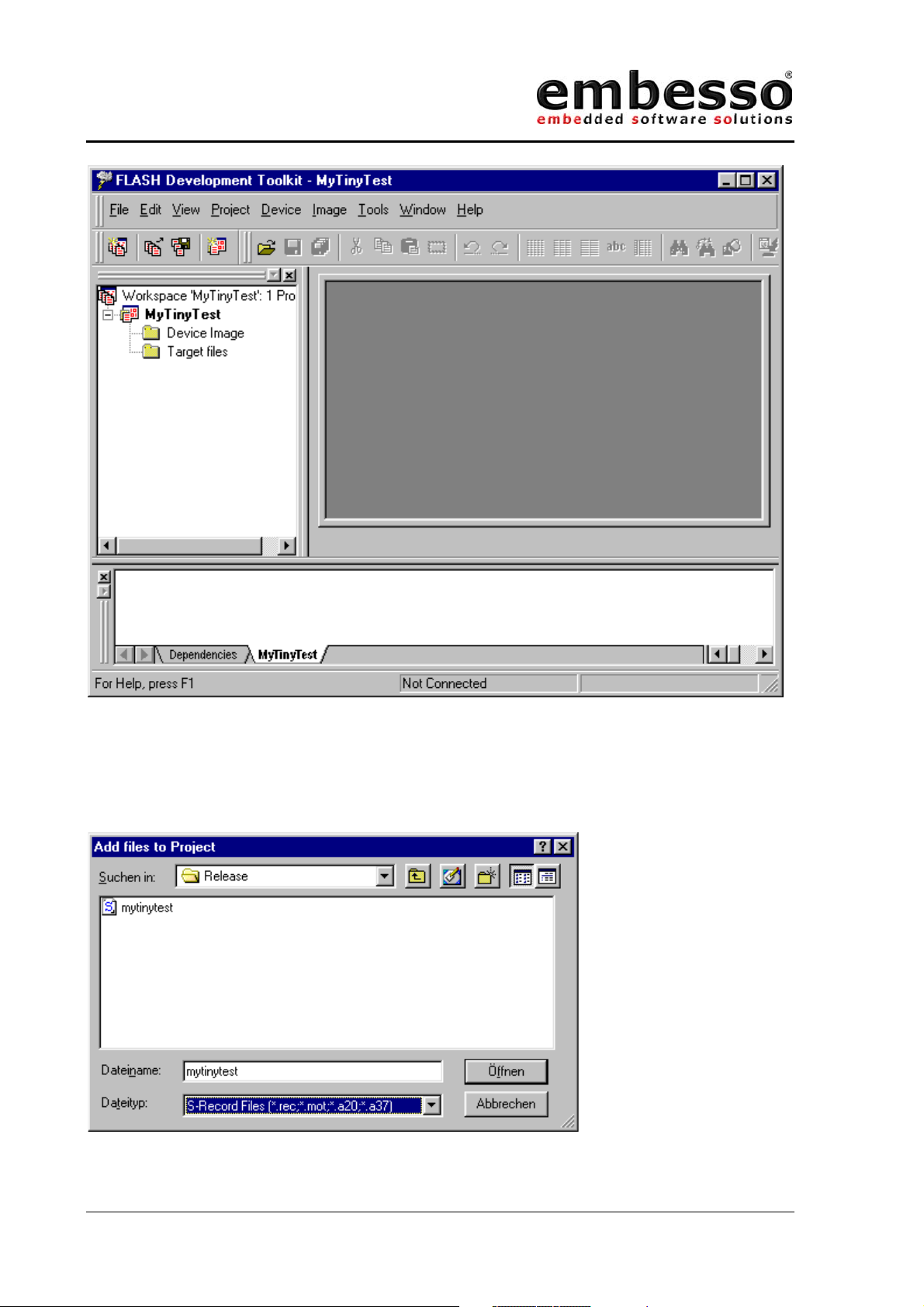

Please start FDT and select „New Workspace“. Here we use the project

name “MyTinyTest”.

You can choose a location for all workspace files. Select on subdirectory

from „MyTinyTest“.

Click ok and a further window will appear:

Select „Yes“

Issue 0.2 Page 24 07/2002

Page 25

HTEB1

User manual

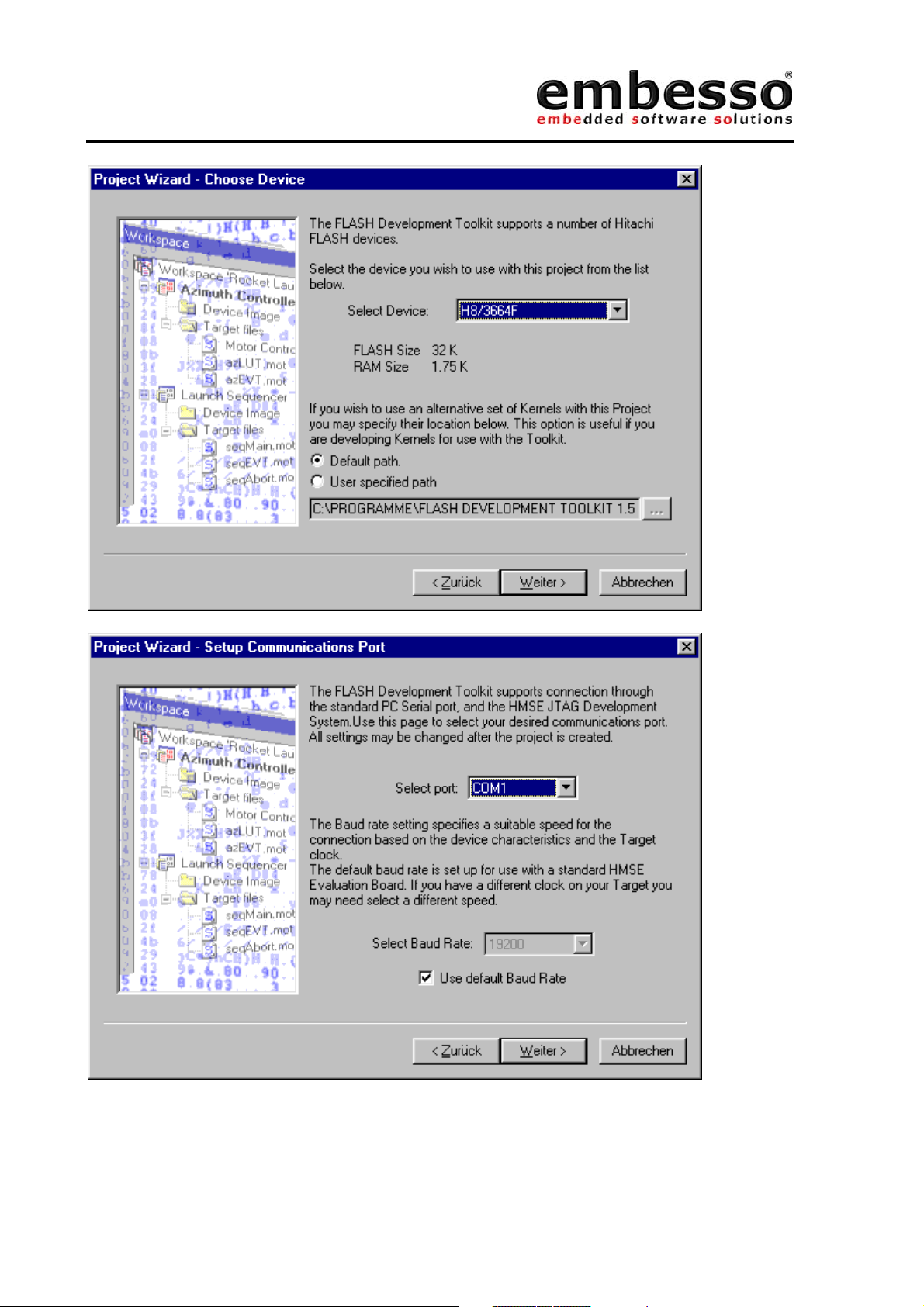

First time users should use the wizard!

Fill in the following things:

Issue 0.2 Page 25 07/2002

Page 26

HTEB1

User manual

Issue 0.2 Page 26 07/2002

Page 27

HTEB1

User manual

Issue 0.2 Page 27 07/2002

Page 28

HTEB1

User manual

Now a workspace is created and you can add your target file to

„TargetFiles“:

Select Project/Add new files to project… and search for file:

c:\hew2\mytinytest\mytinytest\release\mytinytest.mot.

Issue 0.2 Page 28 07/2002

Page 29

HTEB1

User manual

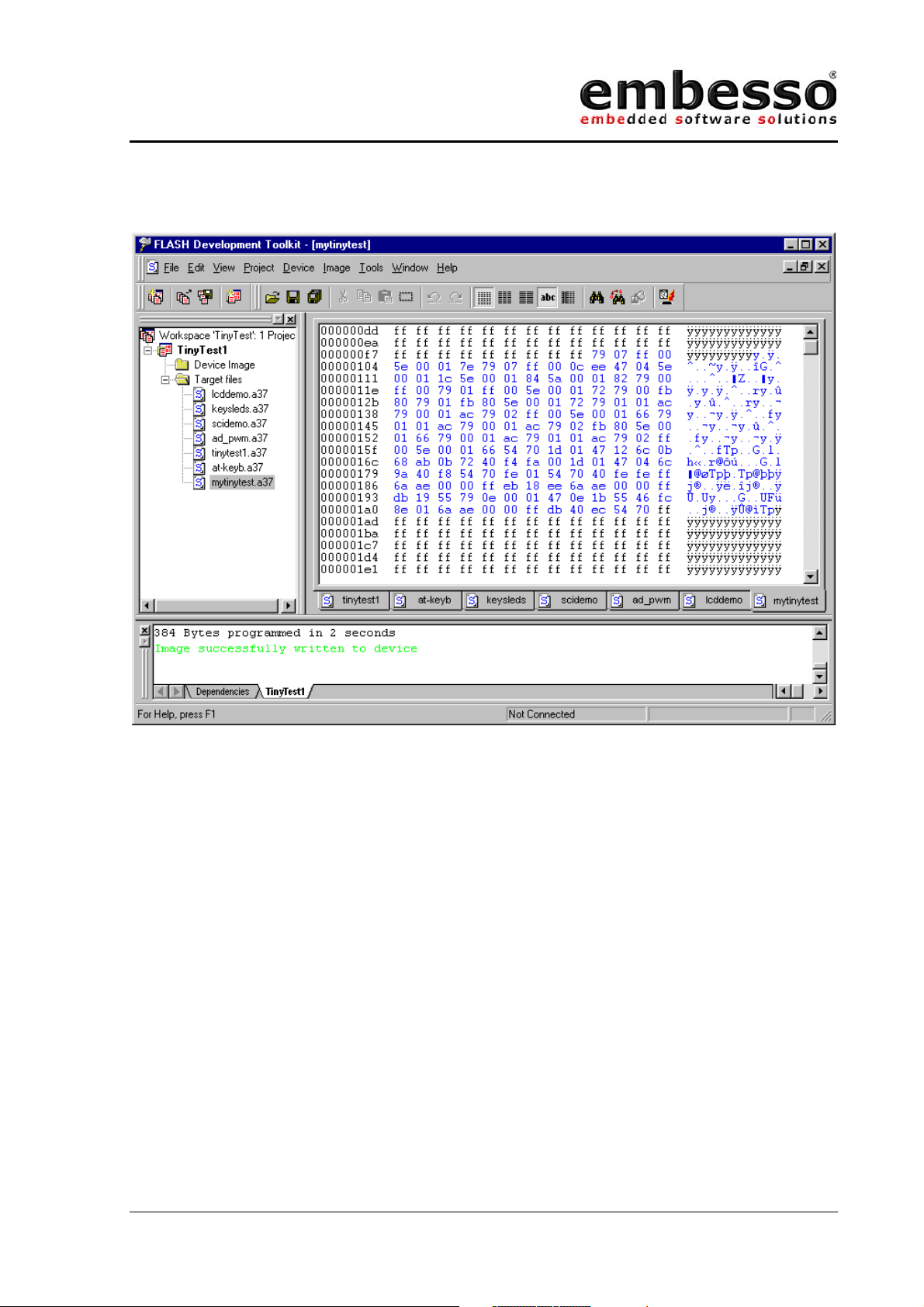

Now make a double click on \targetfiles\mytinytest and the file content of

mytinytest.mot will appear in hex format in the right window.

First press the reset button at the target board, hold it down and move

Prog/Run-switch to prog position (left). After that release the reset button.

With Image/Download image (Ctrl-P) you one can start the connection

setup to target board and start downloading image file.

Now press Ctrl-P (Download) on FDT and the download process will start.

Watch on progress bar while download.

When the download is finished press Alt-C to disconnect the PC

connection.

On target board, move Prog/Run-switch to run position (right) press down

the reset button and release reset button.

Congratulations! Now your first program is running!

You will see the LED’s flickering.

Issue 0.2 Page 29 07/2002

Page 30

HTEB1

User manual

Now you can do some additional functions in HEW. After compiling and

linking only go to FDT, update your download file with the command

Freshen all Target files (Ctrl-T), reconnect the link and repeat the

download process.

Issue 0.2 Page 30 07/2002

Page 31

HTEB1

User manual

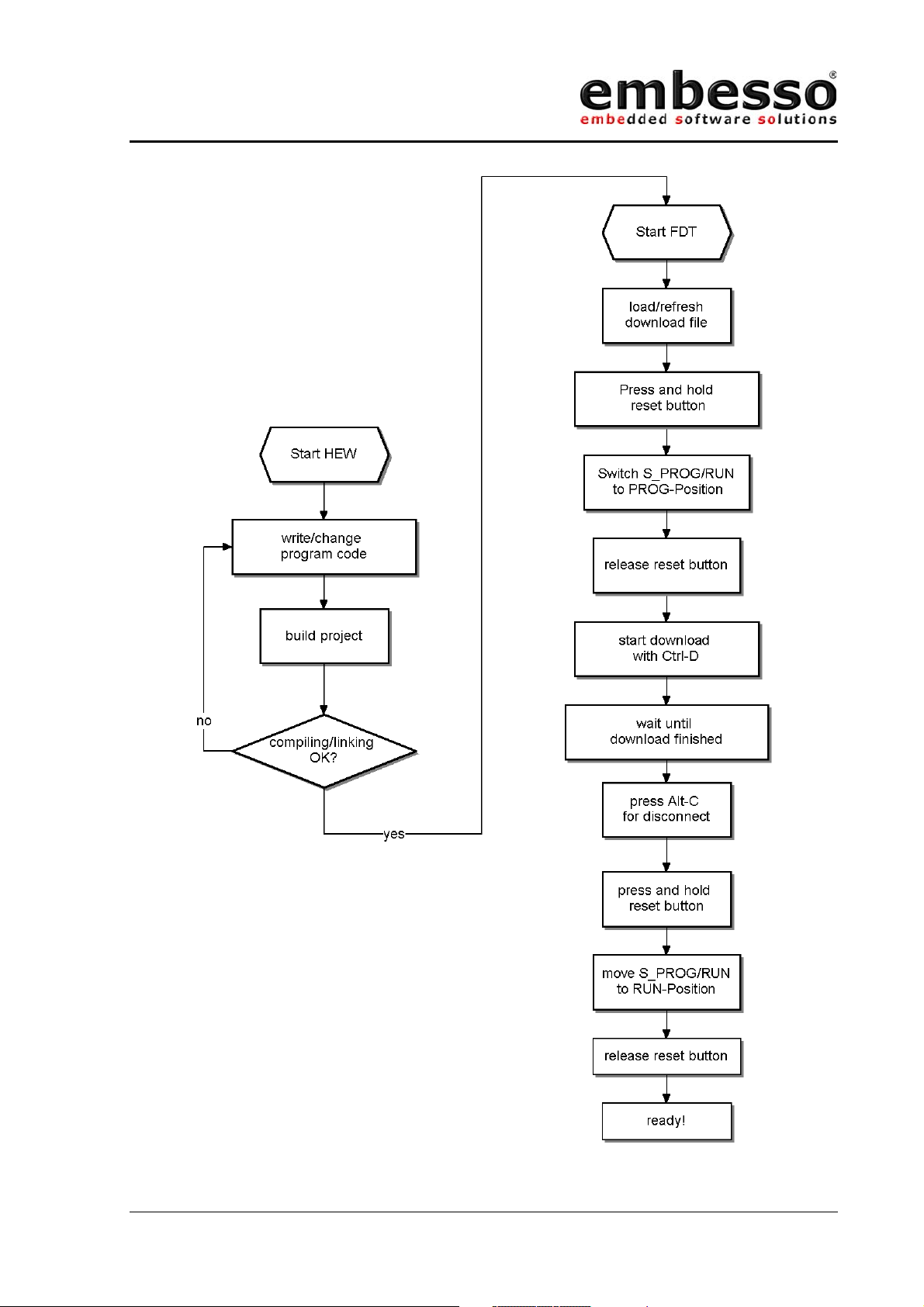

2.3 Workflow

Issue 0.2 Page 31 07/2002

Page 32

HTEB1

User manual

3 Examples

HTEB1 is provided with some demonstration code.

On the supplied CD-R you should find a complete prepared workspace for

IAR-EWH8.

\examples\demoapp\demoapp.prj

Please copy the complete directory to your hard disk in a directory

c:\H8TinyIAR, so you will finally have the following directory (per

example) “c:\H8TinyIAR\examples\demoapp\” with all application notes

included.

Then start IAR-Ewh8 and select “open existing workspace”. Select one of

the projects and do your exercises.

For all projects we need the same header file containing some definitions

and the include file for the target microcontroller H8/3664F. So if you

want to work with these files don’t forget to include the file “mydefs.h”

first in your project file:

#ifndef _MYDEFS_H_

#define _MYDEFS_H_

#include "ioh83664.h" // select processortype here

#include "inh8.h"

#include "icclbutl.h"

#define CPU_CLK 9830400 // select clk for diff. calc.

#ifndef NULL

#define NULL 0x00

#endif

#ifndef FALSE

#define FALSE 0x00

#endif

#ifndef TRUE

#define TRUE 0x01

#endif

typedef unsigned char u8;

typedef unsigned int u16;

#endif

Issue 0.2 Page 32 07/2002

Page 33

HTEB1

User manual

3.1 Key’s and LED’s

The first demo program shows the usage of LEDs and keys on HTEB1. For

time-controlling we use TIMER_A as an periodic interval timer. The

interrupt service routine (isr) is checking the state of the keys, actualising

the LED port and reading out the AD1-channel to determine the running

light speed. If you want to do some experiments, first check out to find if

other LED pattern maybe in form of a table read out or calculate them by

functions developed by yourself. If speed control should be changed, first

change the calculation of the A/D-conversion value to timer ticks.

/*-----------------------------------------------------------------** KeysLEDs.c contains some sample code for using LEDs and Key's

** on TinyEvalBoard

** in addition Timer_A is used for timer tick with irq

**-----------------------------------------------------------------*/

#include "mydefs.h" // for all nec. includes

/* defines */

#define KEY_1 0x10

#define KEY_2 0x20

#define KEY_3 0x04

#define KEY_4 0x02

#define KEY_ALL (KEY_1|KEY_2|KEY_3|KEY_4)

#define KEY_RELEASED 0x40

#define KEY_PROCESSED 0x80

#define LED_SPEED_INIT4 // = 4/32 = 1/8s = 125ms

/* variables */

u8 KeyCode=0;

u8 LED_Out, LED_Dir, LED_Run, LED_Speed;

/* functions */

void KeyCheck(void)

{

if ((PDR1 & KEY_ALL) != KEY_ALL) // is any key pressed ?

{

if (!(PDR1 & KEY_1)) KeyCode = KEY_1;

else if (!(PDR1 & KEY_4)) KeyCode = KEY_4;

else if (!(PDR1 & KEY_3)) KeyCode = KEY_3;

else if (!(PDR1 & KEY_2)) KeyCode = KEY_2;

}

else

{

KeyCode = KEY_RELEASED; // no, mark key_released

}

}

void RunningLightUpdate(void) // check for keypresse

{ // and update LEDs

u8 dummy;

u16 adval;

if (!(KeyCode & KEY_RELEASED))

{

if ((KeyCode & KEY_1)==KEY_1) LED_Dir = 1;

else if ((KeyCode & KEY_4)==KEY_4) LED_Dir = 0;

else if ((KeyCode & KEY_2)==KEY_2) LED_Run = 0;

else if ((KeyCode & KEY_3)==KEY_3) LED_Run = 1;

KeyCode |= KEY_RELEASED;

Issue 0.2 Page 33 07/2002

Page 34

HTEB1

User manual

}

if (LED_Speed) LED_Speed--; // decrement speed counter

if (!LED_Speed) // if zero ...

{

LED_Speed = LED_SPEED_INIT; // re init speed counter

if (LED_Run)

{

}

}

PDR8 = ~LED_Out; // output (invert)

}

void PrepKeyPort(void) // prepare key-port-bits

{

PMR1 &= ~KEY_ALL; // Port1 = I/O (0) for all keys

PCR1 &= ~KEY_ALL; // Port1 = input(0) for all keys

PUCR1 |= KEY_ALL; // PullUps = on for all keys

}

if (LED_Dir) // right

{

LED_Out >>= 1; // shift right

if (!LED_Out) LED_Out = 0x80; // if empty, set to 0x80

}

else

{

LED_Out <<= 1; // shift left

if (!LED_Out) LED_Out = 0x01; // if empty, set to 0x01

}

void RunningLightInit(void) // prepare LED-port and vars

{

PrepKeyPort();

PDR8 = 0xff; // all LED's off

PCR8 = 0xff; // all out's

LED_Out = 0x01; // start value

LED_Run = 0x01; // run

LED_Dir = 0x00; // dir = left

LED_Speed = LED_SPEED_INIT; // start speed

}

/****************************************

TimerA-Interrupt (1s)

increments var c and output

the value of c to LED's (inverted)

****************************************/

interrupt [TIMER_A] void Timer_A_Isr(void)

{

static u8 c;

KeyCheck(); // check for key pressed

RunningLightUpdate();

IRR1 &= ~0x40; // clear irq-flag

}

/****************************************

TimerA-Test

setup : CLK/8 (=1µs @ 8MHz) at P10 (TMOW)

****************************************/

void Timer_A_Init(void)

{

PCR8 = 0xff; // P8 = output

TMA = 0x0c; // Reset PrescalerW

TMA = 0x4b; // CLK/8 on P10, 1/32s-interval (Clk=Prescaler W)

PMR1 |= 0x01; // set TMOW (P10) = Output

IENR1 |= 0x40; // enable TimerA-Interrupt

set_interrupt_mask(0); // enable all interrupts

}

1s-Irq-intervall @ SubClock (32.678 Hz)

void main(void)

{

Issue 0.2 Page 34 07/2002

Page 35

HTEB1

User manual

RunningLightInit(); // Init key's and LEDs

Timer_A_Init(); // init & start timer_A

while(1); // just wait ...

}

Issue 0.2 Page 35 07/2002

Page 36

HTEB1

User manual

3.2 LCD

One of the highlights of the HTEB1 is the 2*16 character LCD with

backlight. Simple functions are provided here to demonstrate the usage of

the LCD. Please refer to the LCD manual for further information (e.g.

commands, other character sets etc.).

The demo source contains some definitions to reset and initialise the

display. Then we make some simple write outs.

/*-----------------------------------------------------------------** LCDDemo shows some funcions of the LCD on the TinyEvalBoard

** Please refer to LCD datasheet for further details

**-----------------------------------------------------------------*/

#include "mydefs.h" // find further includes there!

void wait(u16 wastetime) // local LCD port delay

{

while(wastetime--);

}

/*

LCD-Port / Bits on TinyEvalBoard

RS = P75, R/W = P74, EN = P20, DATA = P5

*/

// some defines for easy access

#define CLEAR_LCD_RS (PDR7 &= ~0x20)

#define SET_LCD_RS (PDR7 |= 0x20)

#define CLEAR_LCD_RW (PDR7 &= ~0x10)

#define SET_LCD_RW (PDR7 |= 0x10)

#define CLEAR_LCD_EN (PDR2 &= ~0x01)

#define SET_LCD_EN (PDR2 |= 0x01)

#define LCD_DATA_PORT (PDR5)

#define LCD_DATA_CTRL (PCR5)

#define LCD_OUT 0xff

#define LCD_IN 0x00

#define LCD_WAIT {wait(100);}

void LCDWriteCmd(u8 cmd) // write cmd to LCD port

{

CLEAR_LCD_RS;

CLEAR_LCD_RW;

SET_LCD_EN;

LCD_DATA_PORT = cmd;

LCD_WAIT;

CLEAR_LCD_EN;

LCD_WAIT;

}

void LCDWriteData(u8 data) // write data to LCD port

{

SET_LCD_RS;

CLEAR_LCD_RW;

SET_LCD_EN;

LCD_DATA_PORT = data;

LCD_WAIT;

CLEAR_LCD_EN;

LCD_WAIT;

}

Issue 0.2 Page 36 07/2002

Page 37

HTEB1

User manual

u8 LCDReadStatus(void) // get the LCD status register

{

u8 status;

CLEAR_LCD_RS;

SET_LCD_RW;

LCD_DATA_CTRL = LCD_IN;

SET_LCD_EN;

status = LCD_DATA_PORT;

CLEAR_LCD_EN;

LCD_DATA_CTRL = LCD_OUT;

return status;

}

void LCDInit(void) // init LCD

{

u16 cnt=0;

CLEAR_LCD_RS;

CLEAR_LCD_RW;

CLEAR_LCD_EN;

PCR7 |= 0x30; // Set RS+RW = Output

PCR2 |= 0x01; // Set EN = Output

LCD_DATA_CTRL = LCD_OUT; // Set DDR to Output

LCDWriteCmd(0x38); // 8Bit-IF, 2 Lines, 5x7 character font

while(--cnt);

LCDWriteCmd(0x38); // 8Bit-IF, 2 Lines, 5x7 character font

while(--cnt);

LCDWriteCmd(0x38); // 8Bit-IF, 2 Lines, 5x7 character font

while(--cnt);

LCDWriteCmd(0x38); // 8Bit-IF, 2 Lines, 5x7 character font

while(--cnt);

// LCDWriteCmd(0x01); // Display Clear

// LCDReadStatus();

// LCDWriteCmd(0x0f); // DisplayOn, CursorOn, BlinkingOn

LCDWriteCmd(0x0c); // DisplayOn, CursorOff, BlinkingOff

LCDReadStatus();

LCDWriteCmd(0x06); // Enter Mode, AutoIncrement

LCDReadStatus();

LCDWriteCmd(0x14); // MoveCursor right

LCDReadStatus();

LCDWriteCmd(0x80); // Set DD RAM Address = 0x00

LCDReadStatus();

}

// writesomedata from 1st position in #line (0/1)

void LCDWriteLine(u8 line, const u8 *data)

{

LCDWriteCmd(0x80 + line*0x40); // select line

while (*data)

{

LCDWriteData(*data);

data++;

}

}

void Delay(void) // "manual" delay

{

long z = 0x200000;

while(--z);

}

const u8 Text1[17] = " embesso ";

const u8 Text2[17] = " presents ";

const u8 Text3[17] = " HITACHI ";

const u8 Text4[17] = " Tiny-H8/3664F ";

const u8 Text5[17] = "LowCostEvalBoard";

Issue 0.2 Page 37 07/2002

Page 38

HTEB1

User manual

void LCDLoopMsg(void)

{

while(1) // do forever...

{

LCDWriteLine(0,&Text1[0]); // display msgs

LCDWriteLine(1,&Text2[0]);

Delay();

LCDWriteLine(0,&Text3[0]);

LCDWriteLine(1,&Text4[0]);

Delay();

LCDWriteLine(0,&Text4[0]);

LCDWriteLine(1,&Text5[0]);

Delay();

}

}

void main(void)

{

LCDInit(); // init ports and LCD

LCDLoopMsg(); // go to LoopMsg

}

Issue 0.2 Page 38 07/2002

Page 39

HTEB1

User manual

3.3 SCI

SCI is used here for a simple RS232 (V24) terminal connection. Please use

a terminal program like HyperTerm (included in Windows), select

Baudrate 9600 Baud, 8 Databits, No Parity and 1 Stopbit (8N1). After

connection and setup, hit some keys and you will see a message

responding on every keycode sent.

/*

**----------------------------------------------------------------------**

** main.c - contains C entry point main()

**

** This file was generated by HEW IAR Icch8 project generator

**

**----------------------------------------------------------------------*/

#include "mydefs.h" // see file for further include

/* some defines */

#define TIE 0x80

#define RIE 0x40

#define TE 0x20

#define RE 0x10

#define MPIE 0x08

#define TEIE 0x04

#define CK_INT 0x00

#define CK_INT_OUT 0x01

#define CK_EXT 0x02

#define IS_SCI_RDF (SSR & 0x40)

#define CLEAR_SCI_RDF SSR = (SSR & ~0x40)

#define IS_SCI_TX_FREE (SSR & 0x80)

#define V24_BRR(x) ((unsigned char)(((CPU_CLK+16*x)/32/x) - 1))

void V24Init (u16 Baudrate)

{

SCR3 = 0x00; // disable all

SSR = 0x00; // clear all errorbits

SMR = 0x00; // 8N1 + /1 clock

BRR = V24_BRR(Baudrate); // set baud

PMR1 |= 0x02; // P22 = TxD Output

SCR3 = (TE|RE|CK_INT); // Ints und Data disabled, internal clock

}

u8 V24NewChar(void) // check for new char on V24

{

if (IS_SCI_RDF) // Receive buffer full?

{

return TRUE;

}

return FALSE;

}

u8 V24GetChar(u8* data) // simple GetChar via V24

{

u8 idx;

if (IS_SCI_RDF) // Receive buffer full?

{

*data = RDR; // yes, get data

CLEAR_SCI_RDF; // clear RDRF-Bit

Issue 0.2 Page 39 07/2002

Page 40

HTEB1

User manual

return TRUE;

}

return FALSE;

}

u8 V24PutChar(u8 c) // simple PutChar via V24

{

if (IS_SCI_TX_FREE) // Tx register free ?

{

TDR = c; // yes, put data in tx register

return TRUE;

}

return FALSE;

}

u8 V24Write(u8 *s) // simple Write(string) via V24

{

while (*s != 0) // while not end of string

{

if (V24PutChar(*s) == TRUE) s++; // PutChar

}

return TRUE;

}

u8 V24WriteLn(u8 *s) // simple WriteLine (string + CR/LF)

{

u8 ret = FALSE;

ret = V24Write(s);

ret |= V24Write("\n\r");

return ret;

}

void ShowUse(void) // simple menu

{

V24WriteLn("\n\n\rV24-DemoProgram");

V24WriteLn("-1- Line 1");

V24WriteLn("-2- Line 2");

V24Write("make your choise :");

}

void main(void)

{

char c;

V24Init(9600); // init sci with 9600Baud, 8N1

ShowUse(); // display start msg

while(1) // loop ...

{

if (V24GetChar(&c)==TRUE)

{

}

}

if (c=='1')

{

V24WriteLn("\n\n\rGreat! This was '1'");

}

else if (c=='2')

{

V24WriteLn("\n\n\rSuper! '2'");

}

else

{

V24WriteLn("\n\n\rSorry! Only '1' or '2' are supported!");

}

ShowUse();

}

Issue 0.2 Page 40 07/2002

Page 41

HTEB1

User manual

3.4 A/D + PWM

This sample shows the usage of the A/D converter. We sample the voltage

of P1/P2, filter it and show the result on the LCD. On D/A-Con you will see

a reversed voltage at P2 – built with a RC-filter from TOW (P76).

/*-----------------------------------------------------------------** AD_PWM Demo shows some funcions of the A/D converter

** and the use of PWM (= inverse output from P2) at D/A-Con

**-----------------------------------------------------------------*/

#include "mydefs.h" // with further includes!

#include "stdlib.h" // for abs()

void wait(u16 wastetime) // local LCD port delay

{

while(wastetime--);

}

/*

LCD-Port / Bits on TinyEvalBoard

RS = P75, R/W = P74, EN = P20, DATA = P5

*/

// some defines for easy access

#define CLEAR_LCD_RS (PDR7 &= ~0x20)

#define SET_LCD_RS (PDR7 |= 0x20)

#define CLEAR_LCD_RW (PDR7 &= ~0x10)

#define SET_LCD_RW (PDR7 |= 0x10)

#define CLEAR_LCD_EN (PDR2 &= ~0x01)

#define SET_LCD_EN (PDR2 |= 0x01)

#define LCD_DATA_PORT (PDR5)

#define LCD_DATA_CTRL (PCR5)

#define LCD_OUT 0xff

#define LCD_IN 0x00

#define LCD_WAIT {wait(100);}

void LCDWriteCmd(u8 cmd) // write cmd to LCD port

{

CLEAR_LCD_RS;

CLEAR_LCD_RW;

SET_LCD_EN;

LCD_DATA_PORT = cmd;

LCD_WAIT;

CLEAR_LCD_EN;

LCD_WAIT;

}

void LCDWriteData(u8 data) // write data to LCD port

{

SET_LCD_RS;

CLEAR_LCD_RW;

SET_LCD_EN;

LCD_DATA_PORT = data;

LCD_WAIT;

CLEAR_LCD_EN;

LCD_WAIT;

}

u8 LCDReadStatus(void) // get the LCD status register

{

u8 status;

CLEAR_LCD_RS;

SET_LCD_RW;

Issue 0.2 Page 41 07/2002

Page 42

HTEB1

User manual

LCD_DATA_CTRL = LCD_IN;

SET_LCD_EN;

status = LCD_DATA_PORT;

CLEAR_LCD_EN;

LCD_DATA_CTRL = LCD_OUT;

return status;

}

void LCDInit(void) // inits the LCD

{

u16 cnt=0;

CLEAR_LCD_RS;

CLEAR_LCD_RW;

CLEAR_LCD_EN;

PCR7 |= 0x30; // Set RS+RW = Output

PCR2 |= 0x01; // Set EN = Output

LCD_DATA_CTRL = LCD_OUT; // Set DDR to Output

// required 3 times pls. ref. data sheet

LCDWriteCmd(0x38); // 8Bit-IF, 2 Lines, 5x7 character font

while(--cnt);

LCDWriteCmd(0x38); // 8Bit-IF, 2 Lines, 5x7 character font

while(--cnt);

LCDWriteCmd(0x38); // 8Bit-IF, 2 Lines, 5x7 character font

while(--cnt);

LCDWriteCmd(0x38); // 8Bit-IF, 2 Lines, 5x7 character font

while(--cnt);

LCDWriteCmd(0x0c); // DisplayOn, CursorOff, BlinkingOff

LCDReadStatus();

LCDWriteCmd(0x06); // Enter Mode, AutoIncrement

LCDReadStatus();

LCDWriteCmd(0x14); // MoveCursor right

LCDReadStatus();

LCDWriteCmd(0x80); // Set DD RAM Address = 0x00

LCDReadStatus();

}

// writesomedata from 1st position in #line (0/1)

void LCDWriteLine(u8 line, u8 *data)

{

LCDWriteCmd(0x80 + line*0x40); // select line

while (*data)

{

LCDWriteData(*data);

data++;

}

}

#define ADDR_A (*(volatile unsigned short *)(0xFFB0))

#define ADDR_B (*(volatile unsigned short *)(0xFFB2))

u16 Read_AD(u8 channel)

{

u8 dummy;

u16 adval;

dummy = ADCSR; // dummy read

ADCSR = 0x00; // reset A/D

ADCSR |= (0x20 + (channel &0x01)); // start A/D, channel 0 or 1

while (!(ADCSR & 0x80)); // wait conversion end

if (channel & 0x01) adval = ADDR_B; // read A/D-value

else adval = ADDR_A;

return adval>>6;

}

u8 Line0[] = " A/D#0=P1=0x \0";

u8 Line1[] = " A/D#1=P2=0x \0";

// convert int to ASCII-HEX

void ShowHexValue(u16 code, u8 line)

Issue 0.2 Page 42 07/2002

Page 43

HTEB1

User manual

{

u8 *data, *text, c,d;

if (line==0) text = &Line0[0]; // last digit = start address

else text = &Line1[0];

data = text+14;

d=3;

while (d)

{

*data = '0'; // default = '0'

c = code & 0x000f; // check digit

if (c) // if > 0 chk for value

{

}

data--; // next digit

code >>= 4;

d--;

}

LCDWriteLine(line,text); // show result

}

void Delay(void) // "manual" delay

{

long z = 0x010000;

while(--z);

}

if (c < 10) *data = '0'+c; // 0..9

else *data = 'A'+c-10; // a..f

u16 oldval[2];

u16 Average(u8 channel, u16 adval) // calculate av of last 15 values

{

if ((abs)(oldval[channel]-adval)>10)

oldval[channel]=adval;

else

oldval[channel] = ((oldval[channel]*15)+adval)>>4;

return oldval[channel];

}

/****************************************

TimerV-Test

setup : CLK/8 (=1µs @ 8MHz)

****************************************/

void Test_Timer_V(void)

{

TCRV0 = 0x08|0x01; // Clear by CompMatchA; IntClk/8

TCRV1 = 0x01; // Clk/2, no external Trigger

TCSRV = 0x08|0x01; // 0=onCompMatchA, 1=onCompMatchB (output on P76)

TCORA = 100; // set periode to 100 => 10.000Hz

TCORB = 75; // set init dutycycle to 75%

}

void main(void)

{

u16 val;

LCDInit(); // init ports and LCD

Test_Timer_V(); // for PWM-Output

while(1) // do forever...

{

val = Average(0,Read_AD(0));

ShowHexValue(val,0);

val = Average(1,Read_AD(1));

ShowHexValue(val,1);

PWM-Output at TMOV (P76)

val /= 10; // max. 1023/10 = 102

TCORB = (unsigned char)(val & 0xff); // set PWM-output

Delay();

}

}

Issue 0.2 Page 43 07/2002

Page 44

HTEB1

User manual

3.5 AT-Keyboard-Interface

This demo shows the usage of the PS2 (mini-DIN) interface on HTEB1.

Please connect an AT-keyboard (MF102) to this port. You will see the

keycodes, provided by the keyboard on the LCD. Please refer to the code

table for keycode translation in your own projects.

/*-----------------------------------------------------------------** AT-Keyb shows the PS2-Interface to an AT-Keyboard

**-----------------------------------------------------------------*/

#include "mydefs.h" // with further includes!

void wait(u16 wastetime) // local LCD port delay

{

while(wastetime--);

}

/*

LCD-Port / Bits on TinyEvalBoard

RS = P75, R/W = P74, EN = P20, DATA = P5

*/

// some defines for easy access

#define CLEAR_LCD_RS (PDR7 &= ~0x20)

#define SET_LCD_RS (PDR7 |= 0x20)

#define CLEAR_LCD_RW (PDR7 &= ~0x10)

#define SET_LCD_RW (PDR7 |= 0x10)

#define CLEAR_LCD_EN (PDR2 &= ~0x01)

#define SET_LCD_EN (PDR2 |= 0x01)

#define LCD_DATA_PORT (PDR5)

#define LCD_DATA_CTRL (PCR5)

#define LCD_OUT 0xff

#define LCD_IN 0x00

#define LCD_WAIT {wait(100);}

void LCDWriteCmd(u8 cmd) // write cmd to LCD port

{

CLEAR_LCD_RS;

CLEAR_LCD_RW;

SET_LCD_EN;

LCD_DATA_PORT = cmd;

LCD_WAIT;

CLEAR_LCD_EN;

LCD_WAIT;

}

void LCDWriteData(u8 data) // write data to LCD port

{

SET_LCD_RS;

CLEAR_LCD_RW;

SET_LCD_EN;

LCD_DATA_PORT = data;

LCD_WAIT;

CLEAR_LCD_EN;

LCD_WAIT;

}

u8 LCDReadStatus(void) // get the LCD status register

{

u8 status;

CLEAR_LCD_RS;

Issue 0.2 Page 44 07/2002

Page 45

HTEB1

User manual

SET_LCD_RW;

LCD_DATA_CTRL = LCD_IN;

SET_LCD_EN;

status = LCD_DATA_PORT;

CLEAR_LCD_EN;

LCD_DATA_CTRL = LCD_OUT;

return status;

}

void LCDInit(void) // inits the LCD

{

u16 cnt=0;

CLEAR_LCD_RS;

CLEAR_LCD_RW;

CLEAR_LCD_EN;

PCR7 |= 0x30; // Set RS+RW = Output

PCR2 |= 0x01; // Set EN = Output

LCD_DATA_CTRL = LCD_OUT; // Set DDR to Output

// required 3 times pls. ref. data sheet

LCDWriteCmd(0x38); // 8Bit-IF, 2 Lines, 5x7 character font

while(--cnt);

LCDWriteCmd(0x38); // 8Bit-IF, 2 Lines, 5x7 character font

while(--cnt);

LCDWriteCmd(0x38); // 8Bit-IF, 2 Lines, 5x7 character font

while(--cnt);

LCDWriteCmd(0x38); // 8Bit-IF, 2 Lines, 5x7 character font

while(--cnt);

LCDWriteCmd(0x0c); // DisplayOn, CursorOff, BlinkingOff

LCDReadStatus();

LCDWriteCmd(0x06); // Enter Mode, AutoIncrement

LCDReadStatus();

LCDWriteCmd(0x14); // MoveCursor right

LCDReadStatus();

LCDWriteCmd(0x80); // Set DD RAM Address = 0x00

LCDReadStatus();

}

// writesomedata from 1st position in #line (0/1)

void LCDWriteLine(u8 line, u8 *data)

{

LCDWriteCmd(0x80 + line*0x40); // select line

while (*data)

{

LCDWriteData(*data);

data++;

}

}

#define cKEYCLK 0x40 // P16 (IRQ_2)

#define cKEYDATA 0x80 // P17

#define cKeyBufSize 16 // input keycode buffsize

u16 KeyCodeBuf[cKeyBufSize]; // input code buffer

u8 keyWriteIndex,keyReadIndex; // buffer write/read index

u16 outval;

u8 outact;

// check for odd parity and stopbit

u8 OddParStopCheck(u16 data)

{

u8 pcnt=0;

u16 mask=0x0080;

if (!(data & 0x0200)) return FALSE; // check for stopbit

while (mask)

{

Issue 0.2 Page 45 07/2002

Page 46

HTEB1

User manual

if (data & mask) pcnt++;

mask >>= 1;

}

if ((pcnt & 0x01) ^ (data & 0x0100)) return TRUE;

return FALSE;

}

interrupt [IRQ_2] void IRQ_2_Isr(void) // irq on key_clk

{

static u8 cnt;

static u16 val;

if (outact) /* do some output? */

{

if (outval & 0x0001) PDR1 |= cKEYDATA;

else PDR1 &= ~cKEYDATA;

outval >>= 1;

if (!outval)

{

PDR1 |= cKEYDATA; // set out=HIGH (1)

PCR1 &= ~cKEYDATA; // set portpin as input (0)

outact=0;

}

}

else // process input data

{

val >>= 1;

if (PDR1 & cKEYDATA) val |= 0x0200;

cnt++;

if (cnt>=11)

{

if (OddParStopCheck(val)==TRUE)

{

KeyCodeBuf[keyWriteIndex] = val;

keyWriteIndex++;

if (keyWriteIndex >= cKeyBufSize) keyWriteIndex = 0;

cnt = 0;

val = 0;

}

}

}

IRR1 &= ~0x04; // clear IRQ-Flag

}

void SendKeyBoard(u8 data) // send data to keyboard

{

u8 pcnt = 0;

u8 mask = 0x80;

outval = data | 0x0600; // stopbit + clkbit(internal)

while (mask) // calculate odd parity

{

if (mask & data) pcnt++;

mask >>= 1;

}

if (!(pcnt & 0x01)) outval |= 0x0100; // set parity bit

PDR1 &= ~cKEYDATA; // set data=LOW

PCR1 |= cKEYDATA; // set as output(1)

outact = 1; // start output action

}

u8 kbhit(void)

{

if (keyReadIndex != keyWriteIndex) return TRUE;

else return FALSE;

}

u16 GetKey(void)

{

u16 KeyCode;

KeyCode = KeyCodeBuf[keyReadIndex];

Issue 0.2 Page 46 07/2002

Page 47

HTEB1

User manual

keyReadIndex++;

if (keyReadIndex >= cKeyBufSize) keyReadIndex = 0;

return KeyCode;

}

u8 buffer[17] = " KeyCode : 0000 \0"; // msg buffer

// convert int to ASCII-HEX

void ShowCode(u16 code)

{

u8 *data, c;

data = &buffer[14]; // last digit = start address

while (code)

{

*data = '0'; // default = '0'

c = code & 0x000f; // check digit

if (c) // if > 0 chk for value

{

}

data--; // next digit

code >>= 4;

}

LCDWriteLine(1,buffer); // show result

}

if (c < 10) *data = '0'+c; // 0..9

else *data = 'A'+c-10; // a..f

void KeyTest(void)

{

u8 c;

u16 KeyCode;

PMR1 |= cKEYCLK; // P16 irq-input

PMR1 &= ~cKEYDATA; // P17 i/o-pin

IEGR1 &= ~0x04; // IRQ_2 on falling edge

IENR1 |= 0x04; // enable IRQ_2

set_interrupt_mask(0); // enable all interrupts

LCDWriteLine(0, "PC-Keyboard-Test");

LCDWriteLine(1, "press any key...");

while (1)

{

if (kbhit()) // if new key ...

{

}

}

}

void main(void)

{

LCDInit(); // init ports and LCD

KeyTest(); // go to keyboard test

}

KeyCode = GetKey(); // get codes

ShowCode(KeyCode); // display code

Issue 0.2 Page 47 07/2002

Page 48

HTEB1

User manual

Tables : Scan-Codes MFII-Keyboard

Numeric

Keypad

Key

Num 45 C5 77 F0-77 76 Make, Break

747C76C F0-6C 6C Make, Break

448C86B F0-6B 6B Make, Break

14FCF69 F0-69 69 Make, Break

/E0-35E0-B5E0-4A E0-F0-4A 77 Make, Break

848C875 F0-75 75 Make, Break

54CCC73 F0-73 73 Make, Break

250D072 F0-72 72 Make, Break

052D270 F0-70 70 Make, Break

*37B77C F0-7C 7E Make, Break

949C97D F0-7D 7D Make, Break

64DCD74 F0-74 74 Make, Break

351D17A F0-7A 7A Make, Break

Del 53 D3 71 F0-71 71 Make, Break

-4ACA7B F0-7B 84 Make, Break

+4ECE79 F0-79 7C Make, Break

Enter E0-1C E0-9C E0-5A E0-F0-5A 79 Typematic

Scan-Code

Set 1

Make-

Code

Break-

Code

Scan-Code

Set 2

Make-

Code

Break-

Code

Scan-Code

Set 3

Code Typ

Issue 0.2 Page 48 07/2002

Page 49

HTEB1

)

)

q

y

p

[

]

g

j

;

\

,

/

User manual

Main-

Keypad

Key

^29A90E F0-0E 0E Typematic

1028216 F0-16 16 Typematic

203831E F0-1E 1E Typematic

3048426 F0-26 26 Typematic

4058525 F0-25 25 Typematic

506862E F0-2E 2E Typematic

6078736 F0-36 36 Typematic

708883D F0-3D 3D Typematic

809893E F0-3E 3E Typematic

90A8A46 F0-46 46 Typematic

00B8B45 F0-45 45 Typematic

-0C8C4E F0-4E 4E Typematic

=0D8D55 F0-55 55 Typematic

<-(Backspace

->| (Tab

w11911D F0-1D 1D Typematic

e129224 F0-25 24 Typematic

r13932D F0-2D 2D Typematic

t14942C F0-2C 2C Typematic

u16963C F0-3C 3C Typematic

i179743 F0-43 43 Typematic

o189844 F0-44 44 Typematic

Return 1C 9C 5A F0-5A 5A Typematic

CAPS-Lock 3A BA 58 F0-58 58 Make, Break

a1E9E1C F0-1C 1C Typematic

s1F9F1B F0-1B 1B Typematic

d20A023 F0-23 23 Typematic

f21A12B F0-2B 2B Typematic

h23A333 F0-33 33 Typematic

k25A542 F0-42 42 Typematic

l26A64B F0-4B 4B Typematic

'28A852 F0-52 52 Typematic

left Shift 2A AA 12 F0-12 12 Make, Break

<56D661 F0-61 13 Typematic

z2CAC1A F0-1A 1A Typematic

x2DAD22 F0-22 22 Typematic

c2EAE21 F0-21 21 Typematic

v2FAF2A F0-2A 2A Typematic

b30B032 F0-32 32 Typematic

n31B131 F0-31 31 Typematic

m32B23A F0-3A 3A Typematic

.34B449 F0-49 49 Typematic

right Shift 36 B6 59 F0-59 59 Make, Break

Ctrl 1D 9D 14 F0-14 11 Make, Break

Left Win 5B DB E0-1F E0-F0-1F E3 Make, Break

Alt 38 B8 11 F0-11 19 Make, Break

Space 39 B9 29 F0-29 29 Typematic

AltGr Strg+Alt Strg+Alt Strg+Alt Strg+Alt Strg+Alt Make, Break

Right Win 5C DC Ê0-27 E0-F0-27 E7 Make, Break

Menu 5D DD E0-2F E0-F0-2F 65 Make, Break

Scan-Code

Set 1

Make-Code

0E 8E 66 F0-66 66 Typematic

0F 8F 0D F0-0D 0D Typematic

10 90 15 F0-16 15 Typematic

15 95 35 F0-36 35 Typematic

19 99 4D F0-4D 4D Typematic

1A 9A 54 F0-55 54 Typematic

1B 9B 5B F0-5B 5B Typematic

22 A2 34 F0-34 34 Typematic

24 A4 3B F0-3B 3B Typematic

27 A7 4C F0-4C 4C Typematic

2B AB 5D F0-5D 5D Typematic

33 B3 41 F0-41 41 Typematic

35 B5 4A F0-4A 4A Typematic

Break-

Code

Scan-Code

Set 2

Make-Code

Break-

Code

Scan-Code

Set 3

Code Typ

Issue 0.2 Page 49 07/2002

Page 50

HTEB1

User manual

Function-

and other

keys

Key

Esc 01 01 76 F0-76 08 Make, Break

F1 3B BB 05 F0-05 07 Make, Break

F2 3C BC 06 F0-06 0F Make, Break

F3 3D BD 04 F0-04 17 Make, Break

F4 3E BE 0C F0-0C 1F Make, Break

F5 3F BF 03 F0-03 27 Make, Break

F6 40 C0 0B F0-0B 2F Make, Break

F7 41 C1 83 F0-83 37 Make, Break

F8 42 C2 0A F0-0A 3F Make, Break

F9 43 C3 01 F0-01 47 Make, Break

F10 44 C4 09 F0-09 AF Make, Break

F11 57 D7 78 F0-78 56 Make, Break

F12 58 D8 07 F0-07 5E Make, Break

Print

Scroll 46 C6 7E F0-7E 5F Make, Break

Pause

Ins E0-52 E0-D2 E0-70 E0-F0-70 67 Make, Break

Del E0-53 E0-D3 E0-71 E0-F0-71 64 Typematic

Pos1 E0-47 E0-C7 E0-6C E0-F0-6C 6E Make, Break

End E0-4F E0-CF E0-69 E0-F0-69 65 Make, Break

PgUp E0-49 E0-C9 E0-7D E0-F0-7D 6F Make, Break

PgDn E0-51 E0-D1 E0-7A E0-F0-7A 6D Make, Break

Arrow left E0-4B E0-CB E0-6B E0-F0-6B 61 Typematic

Arrow up E0-48 E0-C8 E0-75 E0-F0-75 63 Typematic

Arrow down E0-50 E0-D0 E0-72 E0-F0-72 60 Typematic

Arrow right E0-4D E0-CD E0-74 E0-F0-74 6° Typematic

Scan-Code

Set 1

Make-

Code

E0-2A-

E0-37

E1-1D-

45-E1-

9D-C5

Break-

Code

E0-B7-E0-AAE0-12-

available

Not

Scan-Code

Set 2

Make-

Code

E0-7C

E1-1477-E1F0-14-

F0-77

Break-

Code

E0-F0-7C-

E0-F0-12

available

Not

Scan-Code

Set 3

Code Typ

57 Make, Break

62 Make, Break

Issue 0.2 Page 50 07/2002

Page 51

HTEB1

User manual

Appendix A: CD-R content

Programs

IAR-EWH8

\programs\iar\

FDT (flash development toolkit)

\programs\fdt\

Examples

\examples\demoapp\

Demo

\examples\flashdemo\

Datasheets

Tiny Hitachi H8/3664F hardware manual, H8 programming manual,

Tiny Application notes, LCD-Module,

\datasheets\

Documentation

This manual as pdf

\documentation\

HTEB1 board schematic

\documentation\schematic\

Issue 0.2 Page 51 07/2002

Page 52

HTEB1

User manual

Appendix B: Schematic

Issue 0.2 Page 52 07/2002

Page 53

HTEB1

User manual

Appendix C: Board layout

Issue 0.2 Page 53 07/2002

Page 54

HTEB1

User manual

NOTES

Issue 0.2 Page 54 07/2002

Page 55

HTEB1

User manual

NOTES

Issue 0.2 Page 55 07/2002

Page 56

HTEB1

User manual

Issue 0.2 Page 56 07/2002

Loading...

Loading...