Page 1

IBM FlashSystem A9000R

Models 9835-415 and 9837-415

Deployment Guide

IBM

GC27-8565-03

Page 2

Note

Before using this information and the product it supports, read the information in “Safety and environmental notices” on

page xi and “Notices” on page 91.

Edition Notice

Publication number: GC27-8565-03.

This publication applies to IBM FlashSystem A9000R, replacing GC27-8565-02, and shall remain applicable to all

product releases and modifications until replaced by a newer publication.

© Copyright IBM Corporation 2016, 2017.

US Government Users Restricted Rights – Use, duplication or disclosure restricted by GSA ADP Schedule Contract

with IBM Corp.

Page 3

Contents

Figures ................................... vii

Tables .................................... ix

Safety and environmental notices ........................ xi

Safety notices and labels ............................... xi

Special caution and safety notices ............................ xii

Laser safety .................................. xii

Ladder usage ................................. xiii

Fire suppression systems ............................. xiii

Power cables ................................. xiii

Sound pressure ................................. xiv

Leakage current ................................ xiv

Site preparation................................. xiv

Environmental notices ............................... xvi

About this guide ............................... xvii

Who should use this guide.............................. xvii

Roles and responsibilities .............................. xvii

Conventions used in this guide ............................ xviii

Related information and publications .......................... xix

Getting information, help, and service .......................... xx

IBM Publications Center ............................... xx

Sending or posting your comments ........................... xx

Chapter 1. Overview .............................. 1

Chapter 2. System specifications ......................... 5

Chapter 3. Physical configuration options ..................... 9

FlashSystem A9000R grid elements ............................ 9

Components and interconnect ............................. 10

Rack configurations................................. 11

Flash enclosure components and feature codes ....................... 13

Grid controller components and feature codes ........................ 14

Rear-door heat exchanger............................... 15

Weight-reduced shipping option ............................ 17

Height reduced shipping option ............................ 17

Radio frequency identification device option ........................ 18

Chapter 4. Physical installation site requirements ................. 19

Floor and space requirements ............................. 19

Raised or non-raised floor considerations ........................ 20

Floor-load requirements .............................. 21

Rack dimensions and service clearance requirements .................... 22

Preparing for raised-floor installation and cabling ..................... 24

Preparing for non-raised-floor installation and cabling .................... 25

Preparing for the rear-door heat exchanger ........................ 26

Power requirements ................................ 26

Power sources ................................. 27

Power consumption ............................... 27

Input voltages and frequencies ............................ 28

Main power cables specifications ........................... 29

Environmental requirements.............................. 32

© Copyright IBM Corp. 2016, 2017 iii

Page 4

Operating and shipping environment requirements ..................... 32

Air circulation and cooling ............................. 33

Contamination information ............................. 35

Acoustic declaration ............................... 37

Operating vibration requirements ........................... 37

Planning for the rear-door heat exchanger ......................... 38

Rear-door heat exchanger operating specifications ..................... 38

Rear-door heat exchanger performance ......................... 39

Preparing your site to provide water to the rear-door heat exchanger ............... 41

Secondary cooling loop parts and services information .................... 57

Maintenance schedule ............................... 60

Site security considerations .............................. 60

Chapter 5. Network and host connectivity requirements .............. 63

Network connections for management .......................... 63

Management port requirements............................. 64

Network configurations ............................... 66

Host ports configuration .............................. 66

Fibre Channel (FC) network configurations ........................ 67

iSCSI network configurations ............................ 69

Network cable requirements .............................. 71

Network and host connectivity security information ...................... 71

IPv6 addresses ................................. 71

Internet Protocol Security (IPSec) ........................... 71

Authorization rules for managing multiple systems ..................... 72

Lightweight Directory Access Protocol (LDAP) ...................... 72

Chapter 6. Planning for physical shipment .................... 75

Planning to receive delivery .............................. 75

Planning for relocation ............................... 76

Shipment weights and dimensions............................ 76

Chapter 7. Planning for remote support, on-site service, and maintenance ...... 79

Planning for remote support connection .......................... 79

Remote support for severe system conditions ....................... 81

Planning for Call Home ............................... 81

Planning for Call Home Web ............................ 82

Required support information ............................. 84

Support and software maintenance security information .................... 86

Chapter 8. PCI DSS compliance ......................... 89

Notices ................................... 91

Trademarks ................................... 92

Homologation statement ............................... 92

Electronic emission notices .............................. 92

Federal Communications Commission Statement ...................... 92

Industry Canada Compliance Statement ......................... 93

Australia and New Zealand Class A Statement ...................... 93

European Union Electromagnetic Compatibility Directive ................... 93

Germany Electromagnetic Compatibility Directive ..................... 93

People's Republic of China Class A Statement ....................... 95

Taiwan Class A Statement ............................. 95

Taiwan Contact Information ............................. 95

Japan Voluntary Control Council for Interference Class A Statement ............... 95

Japan Electronics and Information Technology Industries Association Statement ........... 96

Korean Communications Commission Class A Statement ................... 96

Russia Electromagnetic Interference Class A Statement .................... 97

iv IBM FlashSystem A9000R Models 9835-415 and 9837-415 Deployment Guide

Page 5

Index .................................... 99

Contents v

Page 6

vi IBM FlashSystem A9000R Models 9835-415 and 9837-415 Deployment Guide

Page 7

Figures

1. IBM FlashSystem A9000R storage system ........................ 1

2. Grid element – 2 grid controllers and 1 flash enclosure ................... 10

3. Fully-populated IBM FlashSystem A9000R ....................... 12

4. Minimally-populated IBM FlashSystem A9000R ..................... 13

5. Front of a flash enclosure ............................. 14

6. Rear of a flash enclosure ............................. 14

7. Front of a grid controller ............................. 15

8. Rear of a grid controller with FC configuration ..................... 15

9. Rear of a grid controller with 10 Gb Ethernet configuration ................. 15

10. Rear-door heat exchanger option kit ......................... 16

11. Clearance requirements for servicing the FlashSystem A9000R rack ............... 23

12. Bottom rack dimensions and castor placements ..................... 24

13. Raised floor requirements ............................. 25

14. Typical performance of a rear-door heat exchanger, 32 kW heat load .............. 40

15. Typical performance of a rear-door heat exchanger, 20 kW heat load .............. 41

16. Cooling distribution unit that uses off-the-shelf supplier solutions ............... 45

17. Cooling distribution unit that uses a water chiller unit to provide conditioned water ......... 46

18. Cooling distribution unit that uses a fabricated facilities solution................ 47

19. Primary and secondary cooling loops ......................... 48

20. Typical central manifold (at a central location for multiple water circuits) ............. 50

21. Typical extended manifold (located along aisles between racks) ................ 50

22. Raised-floor hose management example 1: hose exit through floor tile at the door hinge ........ 52

23. Raised-floor hose management example 2: tile cutout size and position ............. 53

24. Raised-floor and non-raised-floor hose management example 2: loop under the rack with door closed 54

25. Raised floor and non-raised floor hose management example 2: loop under the rack with door open ... 55

26. Non-raised floor hose requirements ......................... 56

27. Eaton-Williams cooling distribution unit features ..................... 59

28. Utility patch panel ............................... 63

29. Crossing Fibre Channel grid controller ports ...................... 67

30. Fibre Channel port numbering on the grid controllers ................... 68

31. iSCSI port numbering on the grid controllers ...................... 69

32. Maximum tilt for a packaged rack is 10 degrees. ..................... 76

33. Remote support components ............................ 80

34. IBM Call Home and Call Home Web ......................... 83

35. Machine type and model, and serial number label on front of rack ............... 85

36. Machine type and model, and serial number on rear of rack ................. 86

© Copyright IBM Corp. 2016, 2017 vii

Page 8

viii IBM FlashSystem A9000R Models 9835-415 and 9837-415 Deployment Guide

Page 9

Tables

1. Components and interconnection options in IBM FlashSystem A9000R .............. 10

2. Feature codes for flash enclosures .......................... 14

3. Feature codes for grid controllers .......................... 15

4. Rear-door heat exchanger features .......................... 17

5. Floor weight-support requirements.......................... 21

6. Rack dimensions and clearance requirements ...................... 22

7. Power consumption ............................... 28

8. Input voltages and frequencies ........................... 28

9. Main power cables ............................... 30

10. Thermal dissipation for FlashSystem A9000R system .................... 34

11. Airflow requirements .............................. 35

12. FlashSystem A9000R system temperature thresholds and events ................ 35

13. Acoustic declaration .............................. 37

14. Vibration levels ................................ 38

15. Random vibration PSD profile breakpoints ....................... 38

16. Operational shock levels ............................. 38

17. Rear-door heat exchanger specifications ........................ 39

18. Miscellaneous secondary loop parts supplier information for customers in North America, Europe, Middle

East, Africa, Asia Pacific ............................. 57

19. Services supplier information for customers in North America, Europe, Middle East, Africa, Asia Pacific 58

20. Cooling distribution unit supplier information for customers in Europe ............. 58

21. Eaton-Williams cooling distribution unit specifications ................... 59

22. Utility patch panel connections ........................... 63

23. Management protocols through TCP/IP ........................ 65

24. Example of recommended fabric zoning ........................ 68

25. Example of recommended switch subnets ....................... 70

26. Required cable types .............................. 71

27. Typical delivery clearance requirements ........................ 76

28. Floor weight-support requirements.......................... 77

29. Call Home configuration information ......................... 82

30. PCI-DSS Support................................ 89

© Copyright IBM Corp. 2016, 2017 ix

Page 10

x IBM FlashSystem A9000R Models 9835-415 and 9837-415 Deployment Guide

Page 11

Safety and environmental notices

Review the safety notices, environmental notices, and electronic emission notices

for this product before you install and use the product.

Safety notices and labels

Review the safety notices and safety information labels before using this product.

IBM Systems safety notices and information

This publication contains the safety notices for the IBM Systems products in

English and other languages. It also contains safety information labels found on

the hardware in English and other languages. Anyone who plans, installs, operates,

or services the system must be familiar with and understand the safety notices.

Read the related safety notices before beginning work.

IBM Systems Safety Notices (ibm.com/shop/publications/order/), G229-9054

The publication is organized into three sections:

Safety notices

Lists the danger and caution notices without labels, organized

alphabetically by language.

The following notices and statements are used in IBM documents. They are

listed in order of decreasing severity of potential hazards.

Danger notice definition

A special note that calls attention to a situation that is potentially

lethal or extremely hazardous to people.

Caution notice definition

A special note that calls attention to a situation that is potentially

hazardous to people because of some existing condition, or to a

potentially dangerous situation that might develop because of

some unsafe practice.

Labels Lists the danger and caution notices that are accompanied with a label,

organized by label reference number.

Text-based labels

Lists the safety information labels that might be attached to the hardware

to warn of potential hazards, organized by label reference number.

Note: This product has been designed, tested, and manufactured to comply with

IEC 60950-1, and where required, to relevant national standards that are based on

IEC 60950-1.

Finding translated notices

Each safety notice contains an identification number. You can use this identification

number to check the safety notice in each language. The list of notices that apply

to this product are listed in the “Special caution and safety notices” on page xii

and “Environmental notices” on page xvi topics of this guide.

© Copyright IBM Corp. 2016, 2017 xi

Page 12

To find the translated text for a caution or danger notice:

1. In the product documentation, look for the identification number at the end of

each caution notice or each danger notice. In the following examples, the

numbers (D002) and (C001) are the identification numbers.

DANGER

A danger notice indicates the presence of a hazard that has the potential

of causing death or serious personal injury. (D002)

CAUTION:

A caution notice indicates the presence of a hazard that has the potential of

causing moderate or minor personal injury. (C001)

2. Open the IBM Systems Safety Notices.

3. Under the language, find the matching identification number. Review the topics

concerning the safety notices to ensure that you are in compliance.

To view a PDF file, you need Adobe Reader. You can download it at no charge

from the Adobe website (get.adobe.com/reader/).

Special caution and safety notices

This information describes special safety notices that apply to the FlashSystem

A9000R. These notices are in addition to the standard safety notices supplied and

address specific issues relevant to the equipment provided.

Laser safety

When using an NVRAM5 or NVRAM6 cluster media converter, the storage system

must be installed in a restricted access location.

CAUTION:

This product contains a Class 1M laser. Do not view directly with optical

instruments. (C028)

This equipment contains Class 1 laser products, and complies with FDA radiation

regulations 21 CFR Subchapter J, international laser safety standard IEC 60825

parts -1 and -2, and relevant national standards based on these.

CAUTION:

Data processing environments can contain equipment transmitting on system

links with laser modules that operate at greater than Class 1 power levels. For

this reason, never look into the end of an optical fiber cable or open receptacle.

(C027)

Attention: In the United States, use only SFP or GBIC optical transceivers that

comply with the FDA laser registration, reporting and accessions per the Center for

Devices and Radiological Health (CDRH) according to 21 CFR Subchapter J.

Internationally, use only SFP or GBIC optical transceivers that comply with IEC

standard 60825–1. Optical products that do not comply with these standards might

produce light that is hazardous to the eyes.

xii IBM FlashSystem A9000R Models 9835-415 and 9837-415 Deployment Guide

Page 13

Usage restrictions: The optical ports of the modules must be terminated with an

optical connector or with a dust plug.

Ladder usage

A step or platform ladder might be necessary to service higher modules.

Use an OSHA/CSA approved non-conductive step or platform ladder specified for

at least a 136.4 kg (300 lb.) load capacity.

Fire suppression systems

A fire suppression system is the responsibility of the customer. The insurance

underwriter, local fire marshal, or a local building inspector, or all three, must be

consulted in selecting a fire suppression system that provides the correct level of

coverage and protection.

IBM®designs and manufactures equipment to internal and external standards that

require certain environments for reliable operation. Because IBM does not test any

equipment for compatibility with fire suppression systems, IBM does not make

compatibility claims of any kind nor does IBM provide recommendations on fire

suppression systems.

Power cables

Use only IBM approved UL power cables.

For your safety, IBM provides a power cable with a grounded attachment plug to

use with this IBM product. To avoid electrical shock, always use the power cable

and plug with a correctly grounded outlet. IBM power cables used in the United

States and Canada are listed by Underwriters Laboratories (UL) and certified by

the Canadian Standards Association (CSA). For units intended to be operated at

115 volts: Use a UL-listed and CSA-certified cable set consisting of a minimum 18

AWG, Type SVT or SJT, three-conductor cable, a maximum of 15 feet in length and

a parallel blade, grounding-type attachment plug rated 15 amperes, 125 volts. For

units intended to be operated at 230 volts (U.S. use), use a UL-listed and

CSA-certified cable set consisting of a minimum 18 AWG, Type SVT or SJT,

three-conductor cable, a maximum of 15 feet in length and a tandem blade,

grounding-type attachment plug rated 15 amperes, 250 volts. For units intended to

be operated at 230 volts (outside the U.S.), use a cable set with a grounding type

attachment plug. The cable set must have the appropriate safety approvals for the

country in which the equipment is to be installed. IBM power cables for a specific

country or region are usually available only in that country or region.

Connect all power cables to a correctly wired and grounded electrical outlet.

Ensure that the outlets supplies correct voltage and phase rotation according to the

system rating plate. Ensure that all customer facility outlets are protected with

circuit breakers rated at maximum for 30 Amps. The power cable plugs operate as

the system main-disconnection method.

Note: For power cables outside of the U.S., IBM provides power cables with no

connector. It is the client's responsibility to install the correct power plug with the

aide of a certified electrician. For power requirements, see “Power requirements”

on page 26.

Safety and environmental notices xiii

Page 14

Sound pressure

Hearing protection must be worn while you service the FlashSystem A9000R

system.

Attention: Depending upon local conditions, the sound pressure might exceed 85

dB(A) during service operations. When working on the FlashSystem A9000R

system while either the front or rear door is in the open position, hearing

protection must be worn.

CAUTION:

Depending upon local conditions, the sound pressure might exceed 85

dB(A) during service operations. Hearing protection must be worn when you are

in a room that has an FlashSystem A9000R system while either the front or rear

door is open or when the front and rear doors are not installed.

Leakage current

The FlashSystem A9000R system incorporates electromagnetic-interference filter

capacitors that are required to prevent electrical noise from penetrating the power

grid. A characteristic of filter capacitors, during normal operation, is a high amount

of leakage current.

Depending on the storage configuration, this leakage current can reach 100 mA.

For the most reliable operation, do not use Ground Fault Circuit Interrupter

(GFCI), Earth Leakage Circuit Breaker (ELCB), and Residual Current Circuit

Breaker (RCCB) type circuit breakers with a FlashSystem A9000R system. The

FlashSystem A9000R system is certified for safe operation and is compliant with

IEC, EN, UL, CSA 60950-1 standards. However, if leakage detection circuit breakers

are required by local electrical practice, the breakers must be sized for a

leakage-current rating of 300 mA or greater to reduce the risk of server outage

caused by erroneous and spurious tripping.

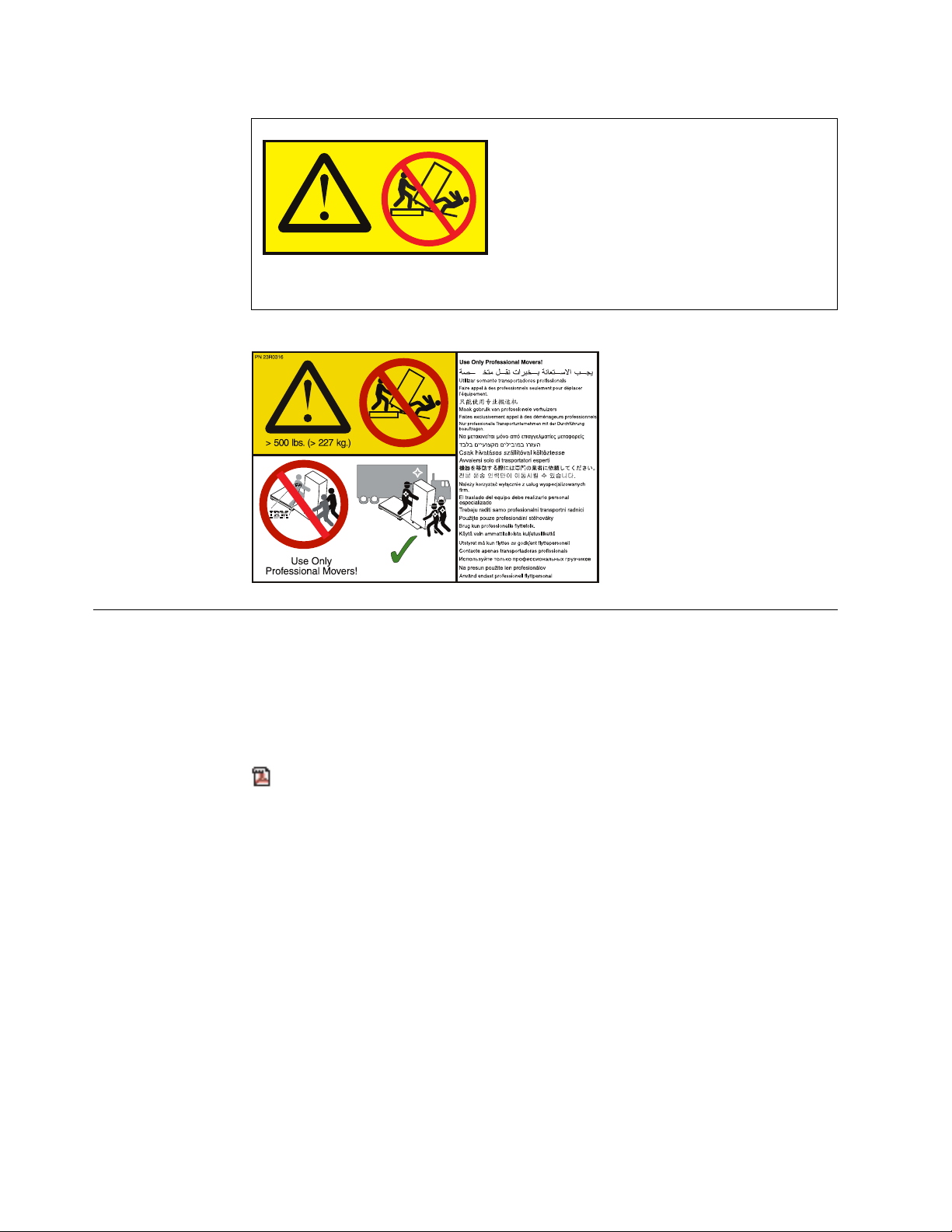

Site preparation

The IBM service representative can only minimally reposition the rack at the

installation site, as needed to service the FlashSystem A9000R system. The

customer is responsible for using professional movers or riggers in the case of

equipment relocation or disposal.

xiv IBM FlashSystem A9000R Models 9835-415 and 9837-415 Deployment Guide

Page 15

Attention: Do not tilt the FlashSystem A9000R system rack more than 10 degrees.

10

fsa9k071

If more clearance is needed for FlashSystem A9000R or racks the height-reduced

shipping (feature code AFR2) should be ordered to reduce the height of the rack.

When the height-reduced feature is ordered, the top cover is removed before the

IBM FlashSystem®A9000R is moved to its final location by professional movers.

The top cover must be installed during the IBM FlashSystem A9000R installation.

If tilting or weight-reduction is needed for IBM FlashSystem A9000R or rack

shipment, the weight-reduced shipping (feature code AFR3) should be ordered to

reduce the weight of the rack.

When the weight-reduced feature is ordered grid controllers and flash enclosures

are shipped separately: this allows the rack to be tilted as much as necessary in

order to fit under low doorways. As a result, these components must be installed

during IBM FlashSystem A9000R installation.

IBM FlashSystem A9000R arrives fully assembled with all components in place,

unless the weight or height reduced shipping options is ordered.

If the site does not meet the delivery clearances and the height-reduced shipping is

ordered, the doors, side panels, and rack top cover of the rack must be removed

before moving to the final location.

Safety and environmental notices xv

Page 16

DANGER

xiv10012

Heavy equipment - personal injury or equipment damage might result if

mishandled. Use only professional movers.

Environmental notices

This publication contains all the required environmental notices for IBM Systems

products in 26 languages. The environmental notices that are included are

limitations, product recycling and disposal, product information, battery return

program, flat panel display, monitors and workstations, refrigeration, and

water-cooling system.

IBM Systems Environmental Notices and User Guide (ftp://

public.dhe.ibm.com/systems/support/warranty/envnotices/

environmental_notices_and_user_guide.pdf), Z125-5823

To view a PDF file, you need Adobe Reader. You can download it at no charge

from the Adobe website (get.adobe.com/reader/).

xvi IBM FlashSystem A9000R Models 9835-415 and 9837-415 Deployment Guide

Page 17

About this guide

This manual defines information regarding the deployment, configuration,

preinstallation requirements for IBM FlashSystem A9000R models 9835-415 and

9837-415. It is important to ensure that you meet all requirements to ensure a fast

and reliable deployment and installation.

If you cannot meet the deployment and installation requirements explained in this

document, notify your IBM representative to devise an alternative solution.

Who should use this guide

This publication is for personnel that are involved in planning. Such personnel

include IT facilities managers, individuals responsible for power, cooling, wiring,

network, and general site environmental planning and setup.

Roles and responsibilities

Both IBM and the customer have roles and responsibilities that they must adhere

to, in order to ensure proper workflow, timely successful installation, properly

configured Call Home and remote support, leading to a superior client experience.

Roles and responsibilities of the customer

v Review the product Deployment Guide

v Enable and work with the Remote Support Center (RSC) remote support in

performing remote data collection and support

v Work with the IBM Planning Representative (IPR), Service Representative (SSR),

Quality Practitioner (QPer), or other IBM personnel to fill out the Technical and

Delivery Assessment (TDA) for accurate and quicker initial installation

v Provide and prepare a rack, adhering to the rack requirements, as specified in

this guide.

v Provide adequate staffing/resources to support this solution.

v Provide sufficient bandwidth and host attachments to support this solution.

v Provide necessary Ethernet cabling

v Provide all initial host Fibre Channel (FC) and iSCSI cabling

v Provide proper power receptacles to match the requirements for the IBM

FlashSystem A9000R ordered

v Provide proper thermal dissipation, airflow and cooling, and environmental

requirements

v Provide proper floor space and clearance

v Provide access for the IBM service representative (SSR), including laptop or

computer access

v Provide access for movers and vehicles

v Allow firewall access to Call Home servers

v Setup IP host network

v Setup SAN host networking

v Download and install appropriate Host Attachment Kit (HAK)

© Copyright IBM Corp. 2016, 2017 xvii

Page 18

v Install the Management Server from Fix Central for IBM Hyper-Scale Manager

UI use

v Perform logical configuration

v Complete the host attachment plan

v Prepare Fibre Channel (FC) connections

v Prepare raised floor, if required

Roles and responsibilities of IBM Service Support

Representatives (SSRs)

v Complete Distant Learning (DL) education and hands-on education course

v Enroll in a hearing conservation program

v Perform product installation

v Configure Call Home and remote support

v Installation of software upgrades

v Installation of hardware Engineering Change Notices (ECA) also known as Field

Bill of Materials (FBM)

v Conduct product relocation, at customer request

v Perform break/fix repairs

v Return of failed parts that are under warranty or have a Certified Spare Parts

Value

v Keep customers informed of service activities

v Arrange time with customer/TA to facilitate upgrades

v Assist with break/fix support as requested by Remote Support Center, Top Gun,

or PFE team member

v Complete accurate Quality Service Activity Reporting (QSAR) reporting

Note: Additional information can be found in your the customer Enterprise Class

Support for Storage document, provided by the IBM Planning Representative (IPR).

Conventions used in this guide

These notices are used to highlight key information.

Tip: These notices provide important tips.

Note: These notices provide important guidance, or advice.

Important: These notices provide information or advice that might help you avoid

inconvenient or difficult situations.

Attention: These notices indicate possible damage to programs, devices, or data.

An attention notice is placed before the instruction or situation in which damage

can occur.

xviii IBM FlashSystem A9000R Models 9835-415 and 9837-415 Deployment Guide

Page 19

CAUTION:

These notices indicate a situation that is potentially hazardous to people

because of some existing condition or where a potentially dangerous situation

might develop because of some unsafe practice.

DANGER

These notices indicate a situation that is potentially lethal or hazardous to

people. For example, after a computer side panel is removed, exposed

high-voltage wires might be lethal.

Related information and publications

You can find additional information and publications related to IBM FlashSystem

A9000R on the following information sources.

v IBM FlashSystem A9000R on IBM Knowledge Center (ibm.com/support/

knowledgecenter/STJKN5) – on which you can find the following related

publications:

– IBM FlashSystem A9000R – Release Notes

– IBM FlashSystem A9000R – Product Overview

– IBM FlashSystem A9000R – Command-Line Interface (CLI) Reference Guide

– IBM FlashSystem A9000 and IBM FlashSystem A9000R – Application

Programming Interface (API) Reference Guide

– IBM Hyper-Scale Manager – Release Notes

– IBM Hyper-Scale Manager – User Guide

– IBM Hyper-Scale Manager – Representational State Transfer (REST) API

Specifications

– IBM XIV Remote Support Proxy – Release Notes

– IBM XIV Remote Support Proxy – Installation and User Guide

v IBM FlashSystem A9000 on IBM Knowledge Center (ibm.com/support/

knowledgecenter/STJKMM) – on which you can find the following related

publications:

– IBM FlashSystem A9000 – Release Notes

– IBM FlashSystem A9000 – Product Overview

– IBM FlashSystem A9000 – Deployment Guide

– IBM FlashSystem A9000 – Command-Line Interface (CLI) Reference Guide

– IBM FlashSystem A9000 and IBM FlashSystem A9000R – Application

Programming Interface (API) Reference Guide

– IBM XIV Remote Support Proxy – Release Notes

– IBM XIV Remote Support Proxy – Installation and User Guide

v IBM Flash Storage and Solutions marketing website (ibm.com/systems/storage/

flash)

v IBM Storage Redbooks®website (redbooks.ibm.com/portals/storage)

About this guide xix

Page 20

Getting information, help, and service

If you need help, service, technical assistance, or want more information about IBM

products, you can find various sources to assist you. You can view the following

websites to get information about IBM products and services and to find the latest

technical information and support.

v IBM website (ibm.com®)

v IBM Support Portal website (www.ibm.com/storage/support)

v IBM Directory of Worldwide Contacts website (www.ibm.com/planetwide)

IBM Publications Center

The IBM Publications Center is a worldwide central repository for IBM product

publications and marketing material.

The IBM Publications Center website (www.ibm.com/shop/publications/order/)

offers customized search functions to help you find the publications that you need.

You can view or download publications at no charge.

Sending or posting your comments

Your feedback is important in helping to provide the most accurate and highest

quality information.

Procedure

To submit any comments about this guide:

v Go to IBM FlashSystem A9000R on IBM Knowledge Center

(ibm.com/support/knowledgecenter/STJKN5), drill down to the relevant page,

and then click the Feedback link that is located at the bottom of the page.

The feedback form is displayed and you can use it to enter and submit your

comments privately.

v You can post a public comment on the Knowledge Center page that you are

viewing, by clicking Add Comment. For this option, you must first log in to

IBM Knowledge Center with your IBM ID.

v You can send your comments by email to starpubs@us.ibm.com. Be sure to

include the following information:

– Exact publication title and product version

– Publication form number (for example: GC01-0001-01)

– Page, table, or illustration numbers that you are commenting on

– A detailed description of any information that should be changed

xx IBM FlashSystem A9000R Models 9835-415 and 9837-415 Deployment Guide

Page 21

Note: When you send information to IBM, you grant IBM a nonexclusive right to

use or distribute the information in any way it believes appropriate without

incurring any obligation to you.

About this guide xxi

Page 22

xxii IBM FlashSystem A9000R Models 9835-415 and 9837-415 Deployment Guide

Page 23

Chapter 1. Overview

IBM FlashSystem A9000R is a grid-scale, all-flash storage platform designed to

drive your business into the cognitive era.

This guide defines deployment, planning, and preinstallation requirements for IBM

FlashSystem A9000R storage systems. It is important to ensure that you meet all

requirements to help achieve a fast and reliable installation.

FlashSystem A9000R provides consistent, extreme performance for dynamic data at

scale. The FlashSystem A9000R storage system integrates the microsecond latency

and high availability of IBM FlashCore®technology with grid architecture,

comprehensive data reduction, and industry leading IBM software.

Figure 1. IBM FlashSystem A9000R storage system

IBM FlashSystem A9000R is an excellent platform for industry leaders with rapidly

growing cloud storage and mixed workload environments. IBM software-defined

storage capabilities and IBM FlashCore technology combine to produce the extreme

performance and scalability required in enterprise-class storage solutions.

The storage system utilizes IBM MicroLatency®modules that leverage

IBM-enhanced MLC flash to provide density, low latency, high I/O, and high

availability. IBM FlashSystem A9000R aggregates grid elements (each containing

two grid controllers and one flash enclosure) within a 42U integrated rack solution.

(For more information about grid elements, see “FlashSystem A9000R grid

elements” on page 9).

Due the combination of grid-scale architecture and flash storage media, the system

delivers predictable high performance and ultra-low latency, even under heavy

workloads with full data reduction enabled. As a result, the grid-scale architecture

© Copyright IBM Corp. 2016, 2017 1

Page 24

maintains this performance by automatically self-optimizing workloads across all

storage resources without manual intervention. Secure multi-tenancy and quality of

service (QoS) features help ensure that tenant service levels are not compromised

within your complex environment.

Advanced management capabilities allow it to integrate easily into your existing

data center infrastructure and with a wide variety of hypervisor and virtualization

software, including VMware, OpenStack, and Microsoft.

For more information regarding the IBM FlashSystem A9000R grid scale

architecture, see Introduction > Architecture in the IBM FlashSystem A9000R Product

Overview (SC27-8559).

Planning best practices and requirements

Good planning is essential for the successful setup and use of your FlashSystem

A9000R. It ensures that you have everything you need and that you meet all the

prerequisites for the storage system. It minimizes errors and helps for a faster

installation process.

Use this planning information to place the FlashSystem A9000R system, plan

power and environmental needs, plan for software and storage needs, and prepare

for unique configurations that are based on how you plan to use the storage

system.

It is imperative that you work with the sales team, IBM Installation Planning

Representative (IPR), and IBM Service Representative (SSR) to capture information

needed to install and configure the storage system. This information is collected

during a Technical and Delivery Assessment (TDA) or Installation planning

meeting. This information must be collected prior to the commencement of the

installation, or delays may occur.

CAUTION:

You must prepare your environment to handle the FlashSystem A9000R

system based on this planning information with assistance from an IBM

installation planning representative (IPR) or an IBM service representative. The

final installation site within the computer room must be prepared before the

equipment is delivered. If the site cannot be prepared before the delivery time,

you must make arrangements to have the professional movers return to finish

the transportation later. Only professional movers can transport the equipment.

The IBM service representative can minimally reposition the rack at the

installation site, as needed to complete required service actions. You are also

responsible for using professional movers in the case of equipment relocation or

disposal.

If you cannot meet any of the installation requirements, notify your IBM service

representative to devise alternative solutions.

2 IBM FlashSystem A9000R Models 9835-415 and 9837-415 Deployment Guide

Page 25

Notes:

v This guide covers planning information for the IBM FlashSystem A9000R

integrated rack storage system.

For planning information for the IBM FlashSystem A9000 pod system, see IBM

FlashSystem A9000 Deployment Guide, GC27-8564 on the IBM FlashSystem A9000

Knowledge Center website (ibm.com/support/knowledgecenter/STJKMM).

v For information regarding management, automation, and access security, see the

following documentation, which can be found on the IBM FlashSystem A9000R

Knowledge Center website (ibm.com/support/knowledgecenter/STJKN5):

– IBM Hyper-Scale Manager User Guide, SC27-8560

– IBM Hyper-Scale Manager Release Notes

– IBM FlashSystem A9000R Command-Line Interface (CLI) Reference Guide,

SC27-8711

– IBM Hyper-Scale Manager REST API Specifications, SC27-6440

Chapter 1. Overview 3

Page 26

4 IBM FlashSystem A9000R Models 9835-415 and 9837-415 Deployment Guide

Page 27

Chapter 2. System specifications

This information compares general properties, performance, physical features, and

host connectivity for the IBM®FlashSystem™A9000R storage system.

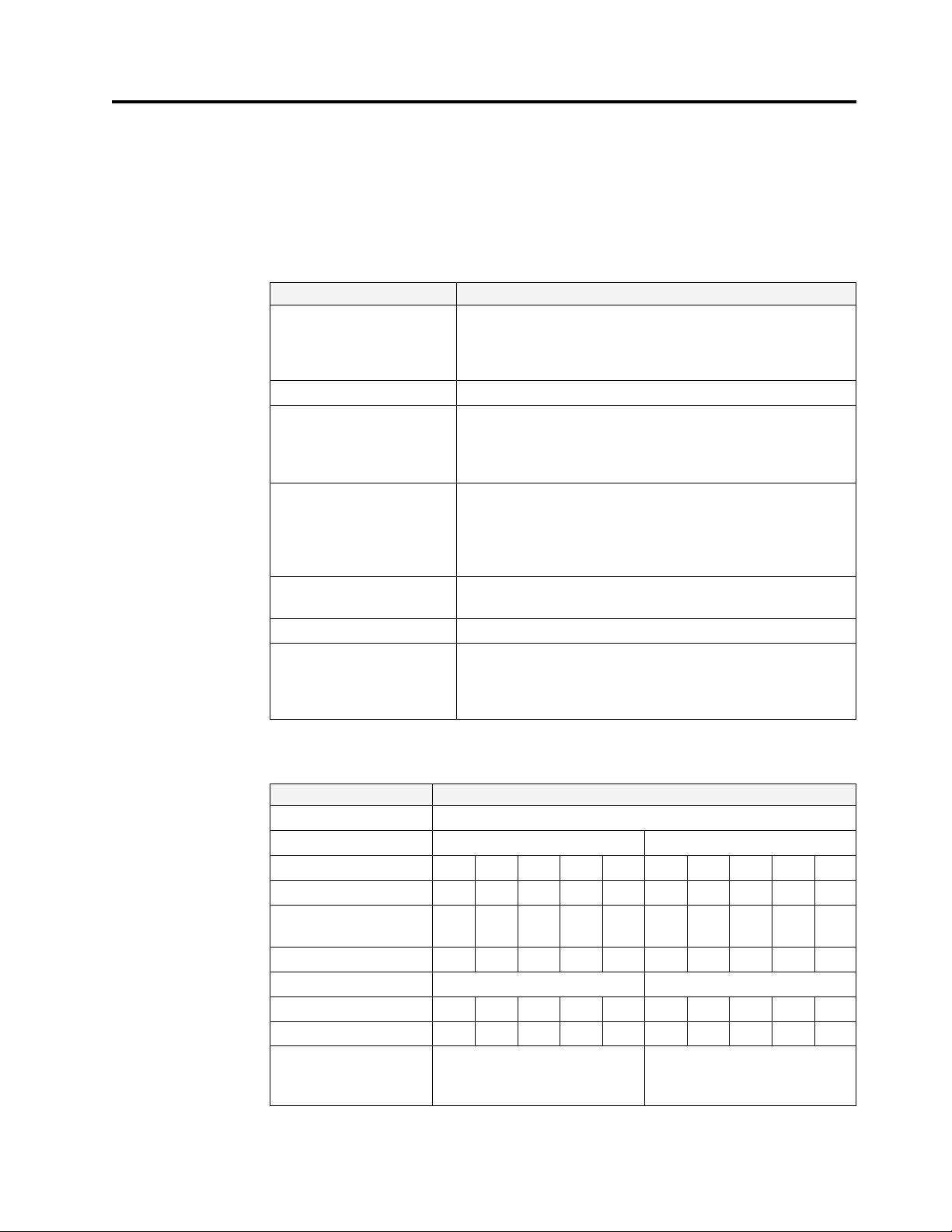

General properties

Specification Details

Controllers Up to 12 active grid controllers, each containing:

v Two Intel Xeon E5 v3 10-core 2.3 GHz processors

v 384 GB DDR4 memory

v Redundant battery backup units and power supply units

Software IBM FlashSystem A9000 and A9000R software v12.0

Models and warranties

Data reduction and

efficiency

Encryption Hardware-based AES-XTS 256-bit with centralized key

Backplane interconnect InfiniBand

Client operating system

support

v 9835-415: 1-year warranty

v 9837-415: 3-year enterprise-class warranty

Warranties include onsite service, same day 24×7

v Pattern removal

v Global, inline deduplication

v Inline compression

v Space-efficient snapshots

v Thin provisioning

management

For a current list of platforms supported, please visit the IBM

System Storage®Interoperation Center (SSIC)

(ibm.com/systems/support/storage/ssic/

interoperability.wss)

Storage capacity features

Specification Details

Flash type IBM-enhanced MLC

900 TB configuration 1.8 PB configuration

Flash enclosures 2 3 4 5 6 2 3 4 5 6

Effective capacity* (TB) 300 450 600 750 900 600 900 1200 1500 1800

Maximum capacity**

(TB)

Raw capacity (TB) 105.6 158.4 211.2 264.0 316.8 211.2 316.8 422.4 528 633.6

Flash enclosure type Flash enclosure-150 Flash enclosure-300

Flash enclosures 2 3 4 5 6 2 3 4 5 6

Grid controllers 4 6 8 10 12 4 6 8 10 12

IBM MicroLatency

modules per flash

enclosure

© Copyright IBM Corp. 2016, 2017 5

1400 2000 2600 3000 3000 1400 2000 2600 3000 3000

12 × 2.9 TB 12 × 5.7 TB

Page 28

Specification Details

*Typical effective capacity is the available capacity after system overhead (including

over-provisioning and RAID protection) and after the data reduction benefits of pattern

removal, deduplication and compression. this assumes data reduction of up to a multiple

of 5.26 to 1.

**Maximum capacity refers to the effective capacity provisioning limit.

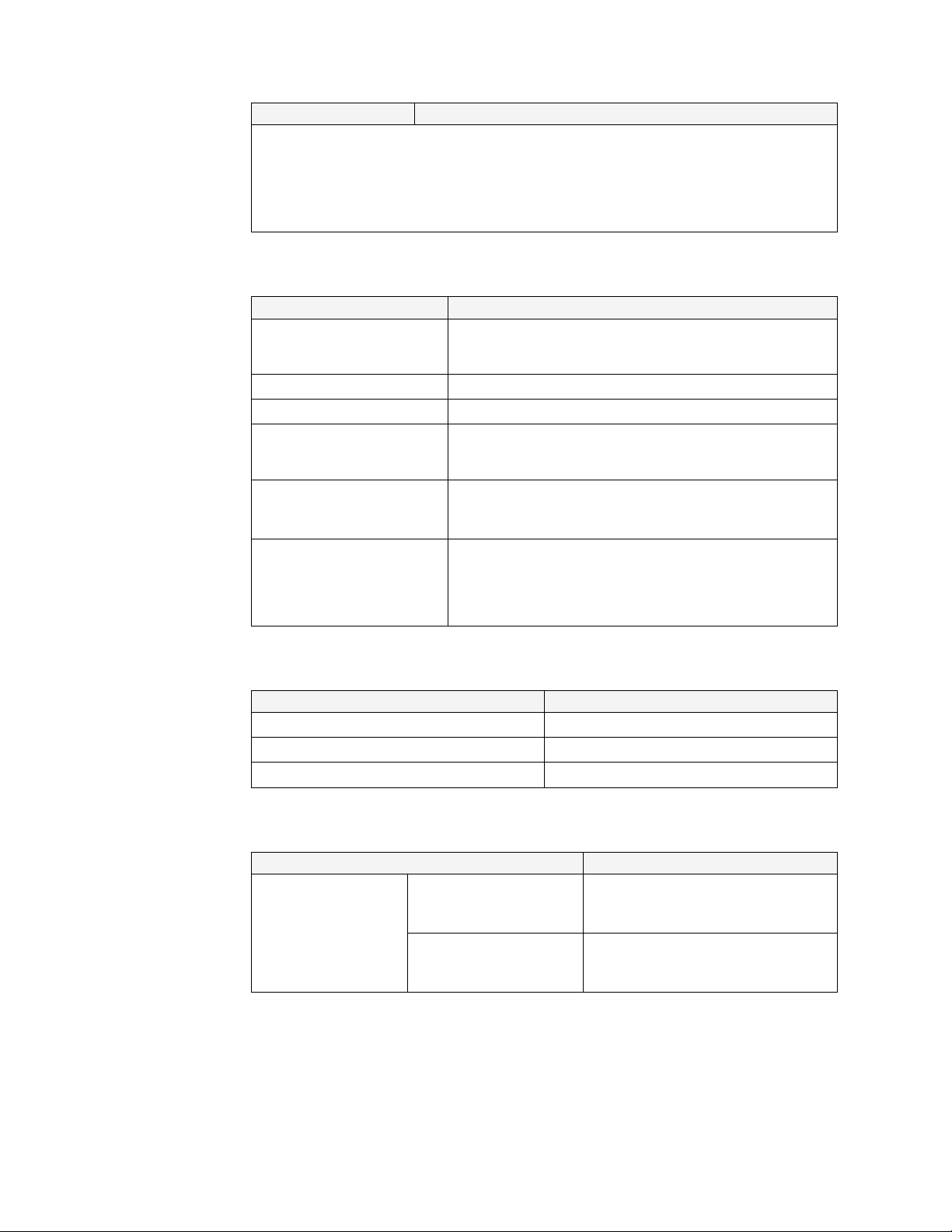

Physical features

Specification Details

Rack dimensions (H × W ×D)201.5 cm (42U) × 66.44 cm × 129.7 cm

(79.3 in. × 25.4 in. × 51.1 in.)

Front clearance 120 cm (47.2 in.)

Rear clearance 100 cm (39.4 in.)

Weight Entry configuration: 666 kg (1468 lb)

986 kg (2174 lbs)

Input voltage 200–240 V AC, 50/60Hz (+/-10% tolerance) via 30A–63A

Note: Dependent on input phase configuration type (single,

delta, or wye)

Power usage Entry configuration: 3.07 KW (typical); 4.82 KW (max)

Maximum configuration: 8.81 KW (typical); 13.91 KW (max)

See “Power consumption” on page 27.

Temperature

Specification Details

Temperature 10 - 35° C (50 - 95° F)

Maximum altitude 2134 m (7000 ft.)

Humidity 25 - 80% non-condensing

Host connectivity

Specification Details

Host system interfaces

(per grid controller)

Storage systems with

Fibre Channel (FC)

capabilities)

Storage systems with

iSCSI (Ethernet)

capabilities only

4 × 16 Gb Fibre Channel + 2 × 10 Gb

iSCSI

4×10 Gb iSCSI

6 IBM FlashSystem A9000R Models 9835-415 and 9837-415 Deployment Guide

Page 29

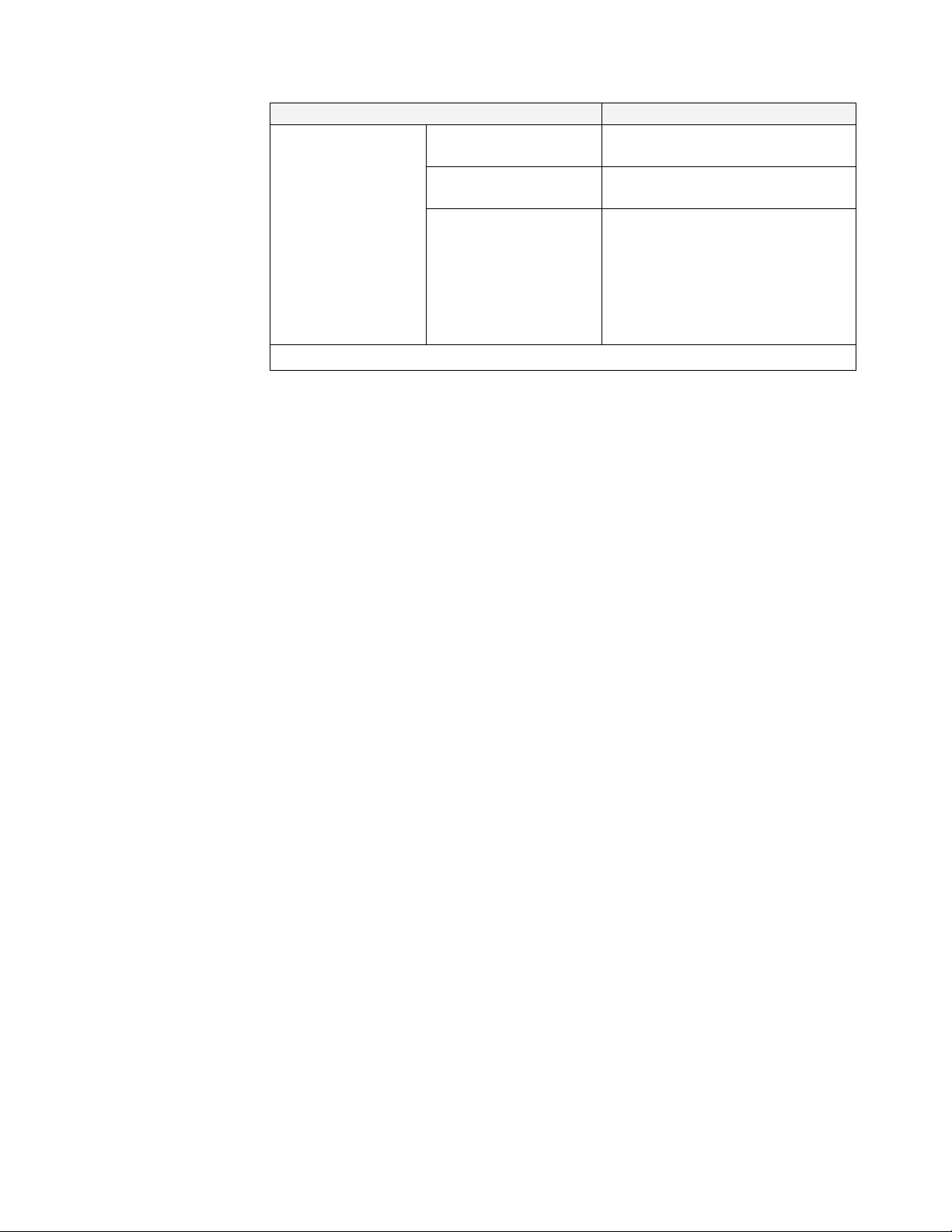

Specification Details

Host connectivity for

mirroring (per system)

Recommended minimum

link bandwidth value

Recommended maximum

50 Mbps

250 ms

round trip latency value

Attaching IBM

FlashSystem A9000 and

A9000R systems for

mirroring

The connection between two

FlashSystem A9000R systems, or

between a FlashSystem A9000R and a

FlashSystem A9000 system, has to

pass through:

v Ethernet LAN for iSCSI connections

v SAN for FC connections

Note: Synchronous remote mirroring is supported by version 12.0.1 and later.

Chapter 2. System specifications 7

Page 30

8 IBM FlashSystem A9000R Models 9835-415 and 9837-415 Deployment Guide

Page 31

Chapter 3. Physical configuration options

Use these general guideline for determining and ordering the feature codes that

you need to customize your IBM FlashSystem A9000R system.

Procedure

Note: Talk to your IBM planning representative (IPR) to help determine which

options are best for your needs.

To determine the required ordering information, answer the following questions:

1. Which model best fits your warranty requirements?

2. What are your capacity needs?

3. What are your performance requirements?

4. What type of host connectivity do you need?

5. What type of power input do you have?

6. Does the installation site meet the physical site requirements for the

FlashSystem A9000R and features that you plan to order? For example:

v Can you space the racks to allow for sufficient floor strength?

v Is there adequate cooling capacity to handle the new equipment?

v Is sufficient power available?

v Do you need 30A or 60A power cables?

v Is water cooling required?

7. Do you require any of the following:

v Any weight or height reduced shipping?

v A radio frequency identification device (RFID) tag?

What to do next

See the following information on the various physical configuration options for

your IBM FlashSystem A9000R storage system.

v “FlashSystem A9000R grid elements”

v “Components and interconnect” on page 10

v “Rack configurations” on page 11

v “Flash enclosure components and feature codes” on page 13

v “Grid controller components and feature codes” on page 14

v “Rear-door heat exchanger” on page 15

v “Weight-reduced shipping option” on page 17

v “Height reduced shipping option” on page 17

v “Radio frequency identification device option” on page 18

FlashSystem A9000R grid elements

A grid element is an orderable bundle that ensures only valid FlashSystem A9000R

rack configurations.

Each grid element contains two grid controllers and one flash enclosure, as shown

in Figure 2 on page 10.

© Copyright IBM Corp. 2016, 2017 9

Page 32

fsa9k145

Figure 2. Grid element – 2 grid controllers and 1 flash enclosure

Grid elements can be ordered according to your performing and capacity needs.

Configurations range between a minimum of two grid elements to a maximum of

six grid elements. Partially populated configurations contain three, four, or five

grid elements.

For more information on rack configurations, see “Rack configurations” on page

11.

All configurations have the same power, floor planning, hardware, and software

configurations as fully populated systems.

Important: Each grid controller in a system rack is equally connected to each flash

enclosure in the system, regardless of how many elements are in the system.

Components and interconnect

This section lists the components and interconnection options that are supplied

with each IBM FlashSystem A9000R integrated rack.

Table 1 breaks down the various components and sub-components of the IBM

FlashSystem A9000R.

Table 1. Components and interconnection options in IBM FlashSystem A9000R

Component Sub-components

IBM T42 rack

4 - 12 grid controllers, depending on

ordered configuration

2 - 6 flash enclosures, depending on

ordered configuration

Two InfiniBand switches

Each grid controller includes:

v Two hot-swappable power supply units (PSUs)

v Two internal battery modules

v Two data reduction hardware acceleration cards

v Two or three dual-ported host adapters,

configuration according to customer request

– Two 16 Gb Fibre Channel dual ports (total

four ports) and a 10 Gb Ethernet (iSCSI) dual

port (total two ports) adapter or

– Two 10 Gb Ethernet (iSCSI) dual port (total

four ports) adapters

v 12 hot-swap 2.9 or 5.7 TB IBM MicroLatency

modules

v Two internal battery modules

10 IBM FlashSystem A9000R Models 9835-415 and 9837-415 Deployment Guide

Page 33

Table 1. Components and interconnection options in IBM FlashSystem A9000R (continued)

Component Sub-components

Two power distribution units (PDUs)

Utility patch panel

Others

Rack configurations

IBM FlashSystem A9000R supports racks that contain a total of two to six grid

elements.

For various configuration feature codes see:

v “Flash enclosure components and feature codes” on page 13

v “Grid controller components and feature codes” on page 14

v “Main power cables specifications” on page 29

Note: An IBM FlashSystem A9000R with less grid controllers also has fewer usable

Fibre Channel and iSCSI ports, as well as less processing power.

v Three management ports

v Two VPN ports

v Maintenance module

v External modem

v Internal cabling

For more information regarding capacity, processors, memory, and connectivity, see

Chapter 2, “System specifications,” on page 5.

Fully populated rack

A fully populated rack contains 12 grid controllers and 6 flash enclosures.

Note: A valid configuration always has two times the amount of grid controllers

than flash enclosures.

Each grid controller contains 384 GB RAM capacity, for a total of 4608 GB RAM for

a fully populated rack.

Each flash enclosure supports RAID 5 (10+1 MicroLatency modules with

distributed parity, in accordance to RAID 5) with one spare MicroLatency module

(total 12 MicroLatency modules). The physical capacity is equal to 10 MicroLatency

modules with 2.9 TB or 5.7 TB, giving a total of either 29 TB or 57 TB per flash

enclosure and 174 TB or 342 TB for a fully populated rack.

Figure 3 on page 12 shows an example the front and back of a fully populated IBM

FlashSystem A9000R.

Chapter 3. Physical configuration options 11

Page 34

Figure 3. Fully-populated IBM FlashSystem A9000R

Minimally populated rack

A minimally populated rack contains four grid controllers and two flash

enclosures.

Each grid controller contains 384 GB RAM, for a total of 1536 GB RAM for a

minimally populated rack.

Each flash enclosure supports RAID 5 (10+1 MicroLatency modules with

distributed parity, in accordance to RAID 5) with one spare MicroLatency module

(total 12 MicroLatency modules). The physical capacity is equal to 10 MicroLatency

12 IBM FlashSystem A9000R Models 9835-415 and 9837-415 Deployment Guide

Page 35

modules with 2.9 TB or 5.7 TB, giving a total of either 29 TB or 57 TB per flash

enclosure and 58 TB or 114 TB for a minimally populated rack.

Figure 4 shows an example of the front and back of a minimally populated IBM

FlashSystem A9000R.

Figure 4. Minimally-populated IBM FlashSystem A9000R

Flash enclosure components and feature codes

Each flash enclosure contains 12 hot-swap 2.9 TB or 5.7 TB IBM MicroLatency

modules. The flash enclosures are used for IBM FlashSystem A9000R storage

functions.

Chapter 3. Physical configuration options 13

Page 36

Each rack unit contains 2 - 6 flash enclosures, according to customer specifications.

Figure 5 and Figure 6 illustrate the front and rear of the flash enclosure.

▌1▐ Battery modules

▌2▐ LED indicator panel

▌3▐ IBM MicroLatency modules

Figure 5. Front of a flash enclosure

▌1▐InfiniBand Adapters (two per canister)

▌2▐Internal interconnect Infiniband ports

▌3▐Canister 1

▌4▐Canister 2

▌5▐Maintenance ports (serial) (IBM technician access)

▌6▐Management ports (Ethernet) (IBM technician access)

Figure 6. Rear of a flash enclosure

Table 2. Feature codes for flash enclosures

Description Feature code

Flash enclosure with 12 x 2.9 TB IBM MicroLatency modules AFE2

Flash enclosure with 12 x 5.7 TB IBM MicroLatency modules AFE3

Grid controller components and feature codes

Each grid controller contains two hard disk drives (HDDs) and two solid state

drives (SSDs) for IBM FlashSystem A9000R performance functions.

Each rack unit contains 4 - 12 grid controllers, according to customer specifications.

Figure 7 on page 15 illustrates the front of the grid controller. Figure 8 on page 15

and Figure 9 on page 15 illustrate the two rear options for the grid controller.

14 IBM FlashSystem A9000R Models 9835-415 and 9837-415 Deployment Guide

Page 37

fsa9k058

4

5

2

1

3

▌1▐HDDs (two per grid controller)

▌2▐SSDs (two per grid controller)

▌3▐Battery modules (two per grid controller)

▌4▐Battery module Fault LED (one per unit)

▌5▐General battery module LEDs

Figure 7. Front of a grid controller

Figure 8. Rear of a grid controller with FC configuration

Figure 9. Rear of a grid controller with 10 Gb Ethernet configuration

Table 3. Feature codes for grid controllers

Description Feature code

Grid controller with four 16 Gb Fibre Channel (FC) + two 10 GbE

iSCSI ports

Grid controller with four 10 GbE iSCSI ports 5002

Rear-door heat exchanger

The rear-door heat exchanger (feature code AFR1) is an optional water-cooled

device that is mounted on the rear of an IBM FlashSystem A9000R system. It cools

the air that is heated and exhausted by devices inside the rack.

A supply hose delivers chilled, conditioned water to the heat exchanger. A return

hose delivers warmed water back to the water pump or chiller (referred to as the

secondary cooling loop).

5001

Chapter 3. Physical configuration options 15

Page 38

The primary cooling loop supplies the building chilled water to secondary cooling

loops and air conditioning units.

Note: The hoses for the secondary cooling loop are not included with this option.

The rack on which you install the heat exchanger can be on a raised floor or a

non-raised floor.

The rear-door heat exchanger option consists of the following components that are

shown in Figure 10.

v Door assembly

v Hinge kit

v Air-purge tool

▌1▐Door assembly

▌2▐Hinge kit

▌3▐Air-purging tool

Figure 10. Rear-door heat exchanger option kit

The following table lists the rear-door heat exchanger feature code for the

FlashSystem A9000R system.

16 IBM FlashSystem A9000R Models 9835-415 and 9837-415 Deployment Guide

Page 39

Table 4. Rear-door heat exchanger features

Feature description Feature code

Rear-door heat exchanger AFR1

See “Preparing for the rear-door heat exchanger” on page 26 for information about

the requirements for preparing the installation site before the rear-door heat

exchanger feature can be installed.

Weight-reduced shipping option

This information describes the Weight Reduction shipping option for the storage

system, feature code AFR3.

IBM offers weight reduced shipping for all IBM FlashSystem A9000R system

configurations. This optional feature provides that the weight of the rack is only

approximately 440 kg (970 lb) for traversal at the delivery site.

This option is ordered for installations where receiving an assembled storage unit,

or ordering feature code AFR2 would be impractical, due to greater weight

limitations.

The unit is delivered fully tested but partially disassembled into several easily

transported subassemblies. This feature allows racks to be safely transported on

lower weight capacity elevators.

At the installation site the system is unpacked by IBM technicians, and the front

door, rear door and side covers are temporarily removed so that the rack assembly

can then be carried up stairs, hoisted via crane through windows, tipped to fit

through low doorways, and rolled through low doorways in the customer's facility.

At the final destination, all devices that were shipped separately can be installed.

A fully configured FlashSystem A9000R system, including packaging, weighs

approximately 986 kg (2174 lbs).

Attention: The storage system must not be tilted more than 10 degrees.

Note: This option greatly increases the system installation time. Onsite

coordination is needed for both the IBM service representative and the professional

movers.

Height reduced shipping option

This information describes the Height Reduction shipping option for IBM

FlashSystem A9000R, feature code AFR2.

If your site does not meet the delivery clearances that are shown in “Rack

dimensions and service clearance requirements” on page 22, the height reduced

shipping option can be ordered to reduce the height of the rack by 30 cm (11.8 in.)

Chapter 3. Physical configuration options 17

Page 40

After the rack is delivered, the IBM service representative removes the rack top

cover so that the rack can be moved to the final location. Only professional movers

can transport the equipment.

After the rack is in its final location, the IBM service representative must return to

complete the installation, including reinstalling the rack top cover.

A fully configured FlashSystem A9000R system, including packaging, weighs

approximately 986 kg (2174 lbs) with dimensions of 66 cm × 118 cm

(26 in. × 46.5 in.).

Attention: The storage system must not be tilted more than 10 degrees.

Note: This option greatly increases the system installation time. Onsite

coordination is needed for both the IBM service representative and the professional

movers.

Radio frequency identification device option

IBM offers an optional radio frequency identification device (RFID) for the storage

system, feature code AFR5.

If you use frequency identification device (RFID) technology to track equipment in

your data centers, you can order the RFID option to attach an RFID tag to system

racks.

This RFID is designed to meet the performance and numbering specification as

outlined by the radio frequency identification specifications. For information about

the specification, see the Financial Services Technology Consortium website

(www.bits.org/?id=29).

Important: This option is applicable only in environments that can use the correct

RFID reading technology. Before you order this option, review the RFID

capabilities with your IBM service representative.

When this option is ordered, IBM attaches one RFID tag per rack. Order one RFID

option for each FlashSystem A9000R that you want to track. This option does not

tag individual components.

This option can be ordered only when a new rack is ordered. The RFID option

cannot be ordered as a miscellaneous equipment specification (MES).

Important: If the tag must be replaced for an IBM FlashSystem A9000R system,

ensure that you update the asset-management database with the new RFID

number for that FlashSystem A9000R.

18 IBM FlashSystem A9000R Models 9835-415 and 9837-415 Deployment Guide

Page 41

Chapter 4. Physical installation site requirements

The location where you plan to install the storage system must meet all

requirements.

Plan your installation site with assistance from an IBM installation planning

representative (IPR) or an IBM service representative.

Prepare the site in advance so that professional movers or riggers can transport the

equipment to the final site within the computer room. If the site cannot be

prepared before the delivery time, you must make arrangements to have the

professional movers return to finish the transportation later.

Attention: Only professional movers can transport the equipment.

An IBM service representative installs the storage system. The IBM service

representative can only minimally reposition the rack within the room, as needed

to complete required service actions.

Professional movers or riggers are required to transport the FlashSystem A9000R

rack as close to the installation site as possible because of its weight.

Note: Professional movers or riggers are also required to relocate or dispose of the

FlashSystem A9000R system.

The physical installation site requirements are listed in the following sections:

v “Floor and space requirements”

v “Power requirements” on page 26

v “Environmental requirements” on page 32

v “Planning for the rear-door heat exchanger” on page 38

v “Site security considerations” on page 60

Floor and space requirements

Ensure that the location of the FlashSystem A9000R system meets floor and space

requirements.

Procedure

Complete the following steps to ensure that the planned installation location meets

space and floor load requirements:

1. Decide whether the FlashSystem A9000R system is to be installed on a raised

floor. See “Raised or non-raised floor considerations” on page 20.

2. Determine whether the floor meets the floor-load requirements for the

FlashSystem A9000R system. See “Floor-load requirements” on page 21.

3. Calculate the amount of space needed for the rack footprint and service

clearance requirements. See “Rack dimensions and service clearance

requirements” on page 22.

© Copyright IBM Corp. 2016, 2017 19

Page 42

4. Determine where to place the rack in the installation site, based on the

floor-load and space requirements.

5. If the location has a raised floor, prepare the raised floor with cable cutouts and

required ventilation. See “Preparing for raised-floor installation and cabling” on

page 24.

6. If the location is not a raised floor, resolve any safety concerns that are caused

by the location of overhead-cable exits and cable routing. See “Preparing for

non-raised-floor installation and cabling” on page 25.

7. Provide your IBM service representative with the following information before

the installation:

a. Whether under-floor or over-head power-cabling scheme is to be used.

b. The distance of the rack from the power receptacles.

8. If a rear-door heat exchanger is being ordered, be sure to follow instructions in

“Preparing for the rear-door heat exchanger” on page 26.

9. If absorbent padding is used where the rack casters (wheels) are located, be

sure to follow instructions in “Bottom rack dimensions” on page 23.

Raised or non-raised floor considerations

The IBM FlashSystem A9000R storage system can be installed on a raised or a

non-raised floor.

Raised floor considerations

Installing the racks on a raised floor provides the following benefits:

v Improves operational efficiency and provides greater flexibility in the

arrangement of equipment.

v Increases air circulation for better cooling.

v Protects the interconnecting cables and power receptacles.

v Prevents tripping hazards because cables can be routed underneath the raised

floor.

When you install on a raised floor, consider the following factors:

v The raised floor must be constructed of fire-resistant or noncombustible material.

v Avoid the exposure of metal or highly conductive material at ground potential

to the walking surface when a metallic raised floor structure is used. Such

exposure is considered an electrical safety hazard.

v The raised floor height must be at least 30.5 cm (12 in.). Clearance must be

adequate to accommodate interconnecting cables, Fibre Channel (FC) cable

raceways, power distribution, and any piping that is present under the floor.

Floors with greater raised floor heights allow for better equipment cooling.

v When a raised floor tile is cut for cable entry or air supply, an extra floor tile

support (pedestal) might be required to restore the structural integrity of the

panel to the previous requirement.

v The use of a protective covering (such as plywood, tempered masonite, or

plyron) is required to prevent damage to floor tiles, carpeting, and panels while

equipment is being moved into or is relocated within the installation site. When

the equipment is moved, the dynamic load on the casters is greater than when

the equipment is stationary.

v Concrete subfloors require treatment to prevent the release of dust.

20 IBM FlashSystem A9000R Models 9835-415 and 9837-415 Deployment Guide

Page 43

v Use noncombustible protective molding to eliminate sharp edges on all floor

cutouts to prevent damage to cables and hoses, and to prevent casters from

rolling into the floor cutout.

v Seal raised-floor cable openings to prevent the escape of chilled air.

v Pedestals must be firmly attached to the structural (concrete) floor by using an

adhesive.

For more information, see “Preparing for raised-floor installation and cabling” on

page 24.

Non-raised floor considerations

Raised floors are preferred because they provide better support for the cabling and

to ensure efficient cooling for the FlashSystem A9000R system; however, overhead

cabling at the rear of the rack is available when the FlashSystem A9000R system is

installed on a non-raised floor.

Unlike raised-floor cabling, the installation planning, cable length, and the rack

location, in relation to the cable opening at the top of the rack, are critical to the

successful installation when using overhead cabling.

For more information, see “Preparing for non-raised-floor installation and cabling”

on page 25.

Floor-load requirements

You must ensure that the floor load rating can support the weight of the

FlashSystem A9000R system.

Floor reinforcement must support the weight of the FlashSystem A9000R system

over a specific area, as shown in Table 5. These measurements are slightly less than

the footprint area of the system, due to the overhang of the door.

To support future scale-out capability (MES) upgrades, the installation site must

provide floor weight-support requirements to support a full rack configuration.

Table 5. Floor weight-support requirements

Grid element configuration Floor reinforcement area Total weight

12 grid controllers and 6 flash

enclosures

10 grid controllers and 5 flash

enclosures

8 grid controllers and 4 flash

enclosures

6 grid controllers and 3 flash

enclosures

4 grid controllers and 2 flash

enclosures

66 cm × 118 cm (26 in. × 46.5 in.) 986 kg (2174 lbs)

66 cm × 118 cm (26 in. × 46.5 in.) 906 kg (1998 lbs)

66 cm × 118 cm (26 in. × 46.5 in.) 826 kg (1821 lbs)

66 cm × 118 cm (26 in. × 46.5 in.) 746 kg (1645 lbs)

66 cm × 118 cm (26 in. × 46.5 in.) 666 kg (1468 lbs)

Note: The same floor-loading requirements apply to partially populated and fully

populated racks.

Chapter 4. Physical installation site requirements 21

Page 44

The rear-door heat exchanger adds more weight to the rack. For information about

the weight of an empty and filled door, see “Rear-door heat exchanger” on page

15.

To ensure that all requirements are met, obtain the service of a qualified structural

engineer to prepare the floor.

Important: If you do not know or are not certain about the floor-load rating of the

installation site, you must check with the building engineer or another appropriate

person.

Rack dimensions and service clearance requirements

The installation site must accommodate the rack dimensions and minimum service

clearance for the FlashSystem A9000R system.

The IBM service representative must have enough space to open the front and rear

covers to service the FlashSystem A9000R system, including removing components

and other assemblies from the FlashSystem A9000R system.

Notes:

v You can position racks no closer than 45 cm (17.7 in.) to a wall.

v You can position racks alongside (next to) other racks.

v Because several rack designs are available from IBM and other vendors, space

between adjacent racks might be required to open the door for service. You must

determine the space requirement at the time of installation.

Table 6 and Figure 11 on page 23 describe dimensions and minimum service

clearance for the FlashSystem A9000R system.

Table 6. Rack dimensions and clearance requirements

Dimension Clearance

Height 201.5 cm (79.3 in.)

Depth 129.7 cm (51.1 in.)

Width 64.4 cm (25.4 in.)

Front clearance 120 cm (47.2 in.)

Rear clearance 100 cm (39.4 in.)

Side (door) clearance 10 cm (3.9 in.)

22 IBM FlashSystem A9000R Models 9835-415 and 9837-415 Deployment Guide

Page 45

Figure 11. Clearance requirements for servicing the FlashSystem A9000R rack

Bottom rack dimensions

When using absorbent padding where the rack casters (wheels) are located, use

this information for proper pad placement.

Figure 12 on page 24 shows the bottom rack dimensions and castor placements.

Chapter 4. Physical installation site requirements 23

Page 46

Figure 12. Bottom rack dimensions and castor placements

Preparing for raised-floor installation and cabling

Prepare the raised floor with cable cutouts, required ventilation, and additional

floor support, if necessary.

Procedure

Complete the following steps to prepare for cabling each FlashSystem A9000R

based on raised floor with 60 × 60 cm (24 × 24 in.) tiles:

1. Based on your planned layout, ensure that the installation site can

accommodate the locations of the cables exiting each FlashSystem A9000R rack.

2. Plan for the FlashSystem A9000R system to be positioned on two tiles, with the

rear of the rack aligned on a floor-tile seam and with two full rows of

24 IBM FlashSystem A9000R Models 9835-415 and 9837-415 Deployment Guide

Page 47

perforated tiles immediately in front of the rack (see Figure 13).

Figure 13. Raised floor requirements

3. Cut a 200 × 200 mm (8 × 8 in.) opening in the rear floor tile for under-floor

cabling and electricity (see Figure 13).

Notes:

v Place the opening under the FlashSystem A9000R system, centered on the back

edge of the tile along the rear of the rack.

v Sizing the cutout correctly is important. An oversized cutout permits excessive

cooling loss and weakens the floor tile. An undersized cutout must be enlarged,

which causes an installation delay while the tile is replaced or the cutout is

enlarged.

4. To allow for ventilation for airflow and support system cooling requirements,

have at least two tiles (and preferably more) in front of the FlashSystem

A9000R system (see Figure 13). These tiles must have a minimum of 40%

perforation.

5. If the rear-door heat exchanger is ordered, see “Raised floor hose requirements

and management” on page 51 for additional floor preparation steps.

Preparing for non-raised-floor installation and cabling

Prepare the installation site to accommodate overhead cabling for mainline-power

cables, customer Fibre Channel (FC) and Ethernet host cables as well as network

Ethernet cables.

Using overhead cabling provides many of the cooling and safety benefits that are

provided by raised flooring in a non-raised floor environment.

Unlike raised-floor cabling, the installation planning, cable length, and the system

location in relation to the cable entry point are critical to the successful installation

of a top cable exit.

Chapter 4. Physical installation site requirements 25

Page 48

Notes:

v Main power cables are routed to the rack by the customer, and internally routed

and connected by an IBM service representative.

v Host-attachment cables are internally routed and connected by either the

customer or by an IBM service representative.

v All remaining cables are internally routed and connected by an IBM service

representative.

If the rear-door heat exchanger is ordered, see “Non-raised floor hose requirements

and management” on page 55 for more floor preparation steps.

Installation and safety requirements

If the cables are too long, there might not be enough room inside of the rack to

handle the extra length and the extra cable might interfere with the servicing tasks,

preventing concurrent repair.

IBM Corporate Safety restricts the servicing of your overhead equipment to a

maximum of 10 feet from the floor. Therefore, your power source must not exceed

10 feet from the floor and must be within 5 feet of the top of the rack.

Servicing any overhead equipment higher than 10 feet requires a special bid

contract. Contact your IBM Representative for more information about special bids.

Preparing for the rear-door heat exchanger

An optional rear-door heat exchanger (feature code AFR1) may be ordered to help

cool your system.

To complete the rear-door heat exchanger site preparation, follow the instructions

in “Planning for the rear-door heat exchanger” on page 38.

Power requirements

Ensure that your operating environment meets the AC-power and voltage

requirements.

The FlashSystem A9000R system is designed with backup battery modules in order

to maintain power to the storage system in the event of an AC-power loss.

The FlashSystem A9000R system has redundant main power cables. For

two-main-power-cable configuration, you must supply power from two

independent sources of electricity.

Consult with an IBM service representative to discuss power source options for the

four-main-power-cable configuration.

Note: Removing all AC power from the FlashSystem A9000R system causes an

emergency shutdown. All modified data is then saved to drives, and the system

turns off within 5 minutes.

26 IBM FlashSystem A9000R Models 9835-415 and 9837-415 Deployment Guide

Page 49

Customer responsibilities

v You must supply enough branch circuits to prevent overloading from the

equipment that you install.

v You must ensure that each electrical outlet is correctly wired and grounded to

prevent an electrical shock.

IBM responsibilities

v The IBM service representative completes several checks, including voltage and

grounding checks before the power to the FlashSystem A9000R system is

connected.

v The IBM service representative connects power to the racks and initially powers

on the equipment.

Power outlet requirements

Ensure that the installation site has the required power outlets.

Two independent power outlets are required for the two main power cords that

are needed by each FlashSystem A9000R system.

Important: To eliminate a single point of failure, the outlets must be independent.

This means that each outlet must use a separate power source and each power

source must have its own wall circuit breaker.

For the most reliable operation, do not use Ground Fault Circuit Interrupter

(GFCI), Earth Leakage Circuit Breaker (ELCB), and Residual Current Circuit

Breaker (RCCB) type circuit breakers with the FlashSystem A9000R system.

The FlashSystem A9000R system is certified for safe operation and is compliant

with IEC, EN, UL, CSA 60950-1 standards. However, if leakage detection circuit

breakers are required by local electrical practice, the breakers must be sized for a

leakage-current rating of 100 mA or greater to reduce the risk of server outage

caused by erroneous and spurious tripping.

Power sources

Several AC power source configurations are available.

v Four 60/63 A, 200-240 V AC, North American, EMEA, and Japan single-phase

receptacles, each connected to a different power source.

v Two 60 A, 200-240 V AC, US and Japan delta three-phase receptacles, each

connected to a different power source.

v Two 30/32 A, 200-240 V AC (Line-to-Neutral [LN]), EMEA WYE three-phase

receptacles, each connected to a different power source

The storage system is protected from a power outage by internal backup battery