Page 1

IBM TotalStorage FAStT600

Fibre Channel Storage Server

Installation and User’s Guide

GC26-7531-01

Page 2

Page 3

IBM TotalStorage FAStT600

Fibre Channel Storage Server

Installation and User’s Guide

GC26-7531-01

Page 4

Note: Before using this information and the product it supports, be sure to read the general information in “Notices” on page 79.

Second Edition (June 2003)

© Copyright International Business Machines Corporation 2003. All rights reserved.

US Government Users Restricted Rights – Use, duplication or disclosure restricted by GSA ADP Schedule Contract

with IBM Corp.

Page 5

Safety

Before installing this product, read the Safety information.

Antes de instalar este produto, leia as Informações de Segurança.

Pred instalací tohoto produktu si prectete prírucku bezpecnostních instrukcí.

Læs sikkerhedsforskrifterne, før du installerer dette produkt.

Lees voordat u dit product installeert eerst de veiligheidsvoorschriften.

Ennen kuin asennat tämän tuotteen, lue turvaohjeet kohdasta Safety Information.

Avant d’installer ce produit, lisez les consignes de sécurité.

Vor der Installation dieses Produkts die Sicherheitshinweise lesen.

Prima di installare questo prodotto, leggere le Informazioni sulla Sicurezza.

Les sikkerhetsinformasjonen (Safety Information) før du installerer dette produktet.

Antes de instalar este produto, leia as Informações sobre Segurança.

© Copyright IBM Corp. 2003 iii

Page 6

Antes de instalar este producto, lea la información de seguridad.

Läs säkerhetsinformationen innan du installerar den här produkten.

The following Caution notices are printed in English throughout this document. For

translations of these notices, refer to IBM Safety Information.

Statement 3

CAUTION:

When laser products (such as CD-ROMs, DVD drives, fiber optic devices, or

transmitters) are installed, note the following:

v Do not remove the covers. Removing the covers of the laser product could result in

exposure to hazardous laser radiation. There are no serviceable parts inside the

device.

v Use of controls or adjustments or performance of procedures other than those

specified herein might result in hazardous radiation exposure.

Danger

Some laser products contain an embedded Class 3A or Class 3B laser diode. Note the

following.

Laser radiation when open. Do not stare into the beam, do not view directly with optical

instruments, and avoid direct exposure to the beam.

Class 1 laser statement

Class 1 Laser Product

Laser Klasse 1

Laser Klass 1

Luokan 1 Laserlaite

Appareil A Laser de Classe 1

`

IEC 825-1:1993 CENELEC EN 60 825

Statement 4

≥18 kg (37 lbs) ≥32 kg (70.5 lbs) ≥55 kg (121.2 lbs)

iv IBM TotalStorage FAStT600 Fibre Channel Storage Server: Installation and User’s Guide

Page 7

Statement 4

CAUTION:

Use safe practices when lifting.

Statement 5

CAUTION:

The power control button on the device and the power supply do not turn off the

electrical current supplied to the device. The device also might have more than one

power cord. To remove all electrical current from the device, ensure that all power

cords are disconnected from the power source.

2

1

Statement 8:

CAUTION:

Never remove the cover on a power supply or any part that has the following

label attached.

Hazardous voltage, current, and energy levels are present inside any

component that has this label attached. There are no serviceable parts inside

these components. If you suspect a problem with one of these parts, contact

a service technician.

Safety v

Page 8

vi IBM TotalStorage FAStT600 Fibre Channel Storage Server: Installation and User’s Guide

Page 9

Contents

||

Safety ............................iii

Figures ............................xi

Tables............................xiii

About this document ......................xv

Who should read this document ...................xv

How this document is organized ..................xv

FAStT installation process overview .................xv

FAStT documentation ......................xvi

FAStT Storage Manager Version 8.3 library .............xvii

FAStT900 Fibre Channel Storage Server library ............xix

FAStT700 Fibre Channel Storage Server library ............xx

FAStT600 Fibre Channel Storage Server library ............xxi

FAStT500 Fibre Channel Storage Server library ...........xxii

FAStT200 Fibre Channel Storage Server library ...........xxiii

FAStT related documents ...................xxiv

Notices used in this document ...................xxiv

Getting information, help, and service ................xxiv

Before you call .......................xxiv

Using the documentation ....................xxv

Web sites .........................xxv

Software service and support ..................xxvi

Hardware service and support ..................xxvi

Fire suppression systems ...................xxvi

How to send your comments ...................xxvi

Chapter 1. Introduction ......................1

Features at a glance .......................1

Clustering support ........................2

Inventory checklist ........................2

Handling static-sensitive devices ...................3

Best practices guidelines......................3

Storage server components.....................4

Front view ..........................4

Back view ..........................6

Interface ports and switches ....................6

Operating specifications ......................8

Heat output, airflow, and cooling ..................8

Chapter 2. Installing and configuring the storage server ........11

Getting started .........................11

Rack mounting template and instructions ...............11

Installing the storage server in a rack ................14

Setting server ID settings .....................18

Configuring the storage subsystem .................19

Storage subsystem management methods ..............19

Fibre Channel connections ...................21

Fibre Channel loop configurations .................22

Redundant host and drive loops ................22

Installing the storage subsystem configuration ...........26

© Copyright IBM Corp. 2003 vii

Page 10

Chapter 3. Cabling the storage server ...............27

Working with SFPs and fiber-optic cables ...............27

Handling fiber-optic cables ...................27

Installing SFP modules .....................28

Removing SFP modules ....................30

Installing fiber-optic cables ...................30

Connecting hosts to the RAID controllers ...............31

Connecting secondary interface cables ................32

||

Power cabling .........................32

Installing the storage-management software ..............34

Connecting additional expansion units ................35

Chapter 4. Operating the storage server...............37

Turning the storage server on and off ................37

Turning on the storage server ..................38

Turning off the storage server ..................39

Restoring power after an unexpected shutdown .............40

Performing an emergency shutdown ................41

Restoring power after an emergency shutdown ............41

Restoring power after an over-temperature shutdown ..........41

Monitoring status through software .................41

Checking the LEDs .......................42

Cache memory and RAID controller battery ..............46

Cache memory ........................46

RAID controller cache battery ..................47

Chapter 5. Installing and replacing components ...........49

Handling static-sensitive devices ..................49

Working with hot-swap drives ...................49

Installing hot-swap drives ....................50

Replacing hot-swap drives....................52

Upgrading drives ........................53

Adding larger-capacity drives...................53

Replacing all drives at the same time ...............54

Replacing the drives one at a time.................56

Working with hot-swap cooling fans .................57

Working with hot-swap power supplies ................59

Removing a hot-swap power supply ................60

Installing a hot-swap power supply ................61

Working with hot-swap RAID controllers................63

Replacing a RAID controller ...................64

Replacing the battery in the RAID controller ..............69

Installing SFPs and fiber-optic cables ................71

Chapter 6. Solving problems ...................73

Troubleshooting ........................74

Appendix. Records .......................77

Identification numbers ......................77

Installed-device records......................77

Notices ...........................79

Trademarks ..........................79

Important notes.........................80

Electronic emission notices ....................80

Federal Communications Commission (FCC) statement .........80

viii IBM TotalStorage FAStT600 Fibre Channel Storage Server: Installation and User’s Guide

Page 11

Chinese class A compliance statement ...............81

Industry Canada Class A emission compliance statement ........81

Australia and New Zealand Class A statement ............81

United Kingdom telecommunications safety requirement .........81

European Union EMC Directive conformance statement .........81

Taiwan electrical emission statement ................82

Japanese Voluntary Control Council for Interference (VCCI) statement . . . 82

Power cords ..........................82

Glossary ...........................85

Index ............................93

Proof of Entitlement ......................97

Contents ix

Page 12

x IBM TotalStorage FAStT600 Fibre Channel Storage Server: Installation and User’s Guide

Page 13

Figures

1. Installation process flow by current publications ...................xvi

2. Front controls and components ..........................5

3. Back view of FAStT600 storage server .......................6

4. Interface ports and switches ...........................7

5. Example of Cold Aisle/Hot Aisle Rack Configuration ..................9

6. Front rack mounting template ..........................12

7. Rear rack mounting template ..........................13

8. RAID controller removal ............................15

9. Hot-swap fan removal .............................15

10. Power supply removal .............................16

11. Hard disk drive removal ............................16

12. Rack nut installation..............................17

13. Rail extension ................................17

14. Rail adjustment screws ............................18

15. Server installation ..............................18

16. Setting the Server ID .............................19

17. Host-agent managed storage subsystems .....................20

18. Direct-managed storage subsystems .......................21

19. Redundant host and drive Fibre Channel loop configurations...............23

20. Example of a single SAN fabric zone configuration ..................24

21. Example of a dual SAN fabric zone configuration ...................24

22. Example of two clusters ............................25

23. Small Form-Factor Pluggable (SFP) Module .....................29

24. Installing an SFP module into the host port .....................29

25. Unlocking the SFP module latch - plastic variety ...................30

26. Unlocking the SFP module latch - wire variety ....................30

27. Removing caps from fiber-optic cables .......................31

28. Connecting cables to the installed SFP.......................31

29. Location of host cables ............................32

30. Ethernet and serial port locations .........................32

||

31. Power cord locations .............................33

||

32. Redundant AC power connections to controllers and drive expansion units .........34

33. Adding an expansion unit............................35

34. Adding a second expansion unit .........................36

35. Storage server LEDs (front) ...........................43

36. RAID controller LEDs .............................44

37. Fan and power supply LEDs ..........................45

38. Cache active LED ..............................47

39. Battery LED.................................47

40. Location of hot-swap drives ...........................50

41. Releasing the drive latch ............................51

42. Drive latch on a hot-swap drive .........................52

43. Fan locations ................................58

44. Removing a fan ...............................58

45. Power supply controls .............................60

46. Lever for power supply removal .........................61

47. Installing a hot-swap power supply ........................62

48. Connecting the power cord to the AC power connector .................63

49. RAID controller levers and labels .........................64

50. Location of SFPs and fiber-optic cables ......................65

51. Unlocking the SFP module latch - plastic variety ...................65

52. Unlocking the SFP module latch - wire variety ....................66

53. Pull-rings for removing a controller ........................66

© Copyright IBM Corp. 2003 xi

Page 14

54. Controller battery-access panel screws.......................67

55. Removing the controller battery .........................67

56. Installing a new RAID controller .........................71

xii IBM TotalStorage FAStT600 Fibre Channel Storage Server: Installation and User’s Guide

Page 15

Tables

1. TotalStorage FAStT Storage Manager Version 8.3 titles by user tasks ...........xvii

2. TotalStorage FAStT900 Fibre Channel Storage Server document titles by user tasks ......xix

3. TotalStorage FAStT700 Fibre Channel Storage Server document titles by user tasks ......xx

4. TotalStorage FAStT600 Fibre Channel Storage Server document titles by user tasks ......xxi

5. TotalStorage FAStT500 and FAStT High Availablity Storage Server document titles by user tasks xxii

6. TotalStorage FAStT200 and FAStT High Availablity Storage Server document titles by user tasks xxiii

7. TotalStorage FAStT related document titles by user tasks ...............xxiv

8. Features at a glance ..............................2

9. FAStT600 storage server operating specifications ...................8

10. Storage server LEDs (front) ...........................43

11. RAID controller LEDs .............................44

12.FanLED..................................46

13. Power supply LEDs ..............................46

14. Storage server troubleshooting ..........................74

© Copyright IBM Corp. 2003 xiii

Page 16

xiv IBM TotalStorage FAStT600 Fibre Channel Storage Server: Installation and User’s Guide

Page 17

About this document

This document provides instructions on how to install the IBM®TotalStorage

FAStT600 Storage Server.

Who should read this document

This document is intended for system operators and service technicians who have

extensive knowledge of Fibre Channel and network technology.

How this document is organized

Chapter 1, “Introduction”, on page 1 describes the storage server. This chapter

includes an overview of the storage server features and components.

Chapter 2, “Installing and configuring the storage server”, on page 11 contains

information about installing the storage subsystem configuration and gives Fibre

Channel loop configuration examples.

Chapter 3, “Cabling the storage server”, on page 27 contains information about

cabling the storage server to other devices.

Chapter 4, “Operating the storage server”, on page 37 describes the tasks that are

required to operate the storage server, including the proper sequences for powering

the storage subsystem on and off.

™

Chapter 5, “Installing and replacing components”, on page 49 contains step-by-step

instructions for installing and removing the storage server components.

Chapter 6, “Solving problems”, on page 73 contains storage server problem

symptoms and possible solutions.

“Records”, on page 77 provides a form on which you can record and update

important information about the storage server, including serial number and device

records. When you add components to the storage server, be sure to update the

information in this appendix.

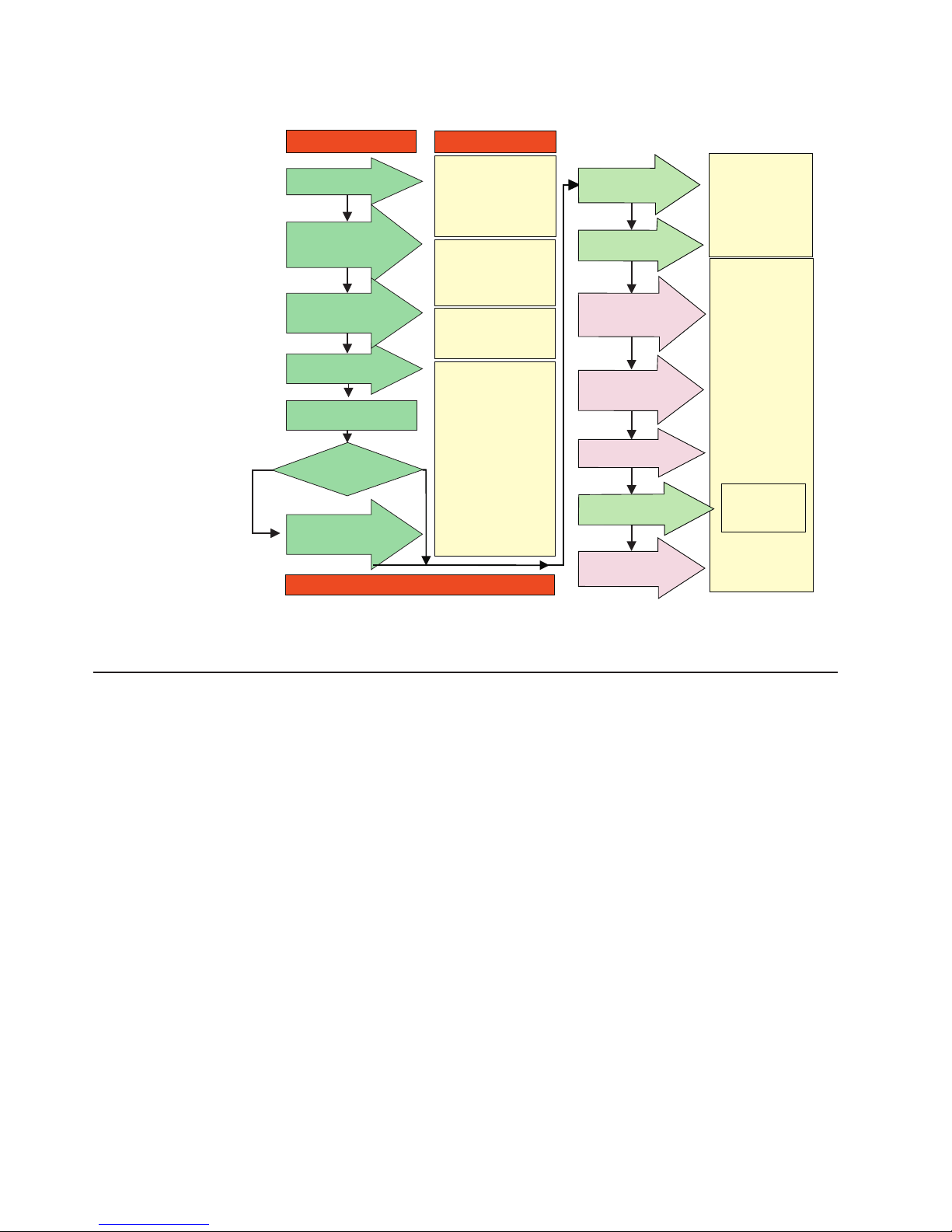

FAStT installation process overview

The following flow chart gives an overview of the FAStT hardware and the FAStT

Storage Manager software installation process. Lined arrows in the flow chart

indicate consecutive steps in the hardware and software installation process.

Labeled arrows indicate which current documents provide detailed information about

© Copyright IBM Corp. 2003 xv

Page 18

those steps.

Install Process

Plan Installation

Install Storage

Server/RAID Controller

Enclosure(s) in Rack

Install Storage

Expansion Unit(s)

Make FC Connections

Set Link Speed

(1 Gb only)

Determine

Management

Method

Out-of-Band

Install Network

Hardware; Prepare

Network Connection

* For pSeries Server and 6227 or 6228 HBA use only

In-Band

Documentation

FC Planning and

*

Integration: User's Guide

and Svc Info

FAStT SM V. 7.10

Concepts Guide

FAStT Storage Svr

Installation Guide

FAStT RAID Controller

Enclosure Unit Install

and User's Guide

FAStT Storage Exp Units

Install and User's Guides

FAStT and HBA Install

and User's Guides

FAStT Fibre Channel

Storage Server

Installation Guides

Fibre Channel Cabling

Instructions

Connect Power and

Start Server

Verify Server

operation w/ LEDs

Prepare for

Installation of

SM Software

Install and Verify SM SW

on Host and

Workstation

Complete SM SW

Installation

Configure Storage

Hardware

Configure Storage

Subsystems on Host

FAStT Storage Server

Installation Guides

Fibre Channel

Hardware Maintenance

and Problem

Determination Guide

FAStT Storage

Manager Installation

and Support

OS Guides

FAStT Remote Mirror

Option Installation

and User's Guide

Online Help

Figure 1. Installation process flow by current publications

FAStT documentation

The following tables present an overview of the FAStT Storage Manager and the

FAStT900, FAStT700, FAStT600, FAStT500, and FAStT200 Fibre Channel Storage

Server product libraries, as well as other related documents. Each table lists

documents that are included in the libraries and what common tasks they address.

Click on active links in the tables to access those documents currently available on

the Internet.

xvi IBM TotalStorage FAStT600 Fibre Channel Storage Server: Installation and User’s Guide

Page 19

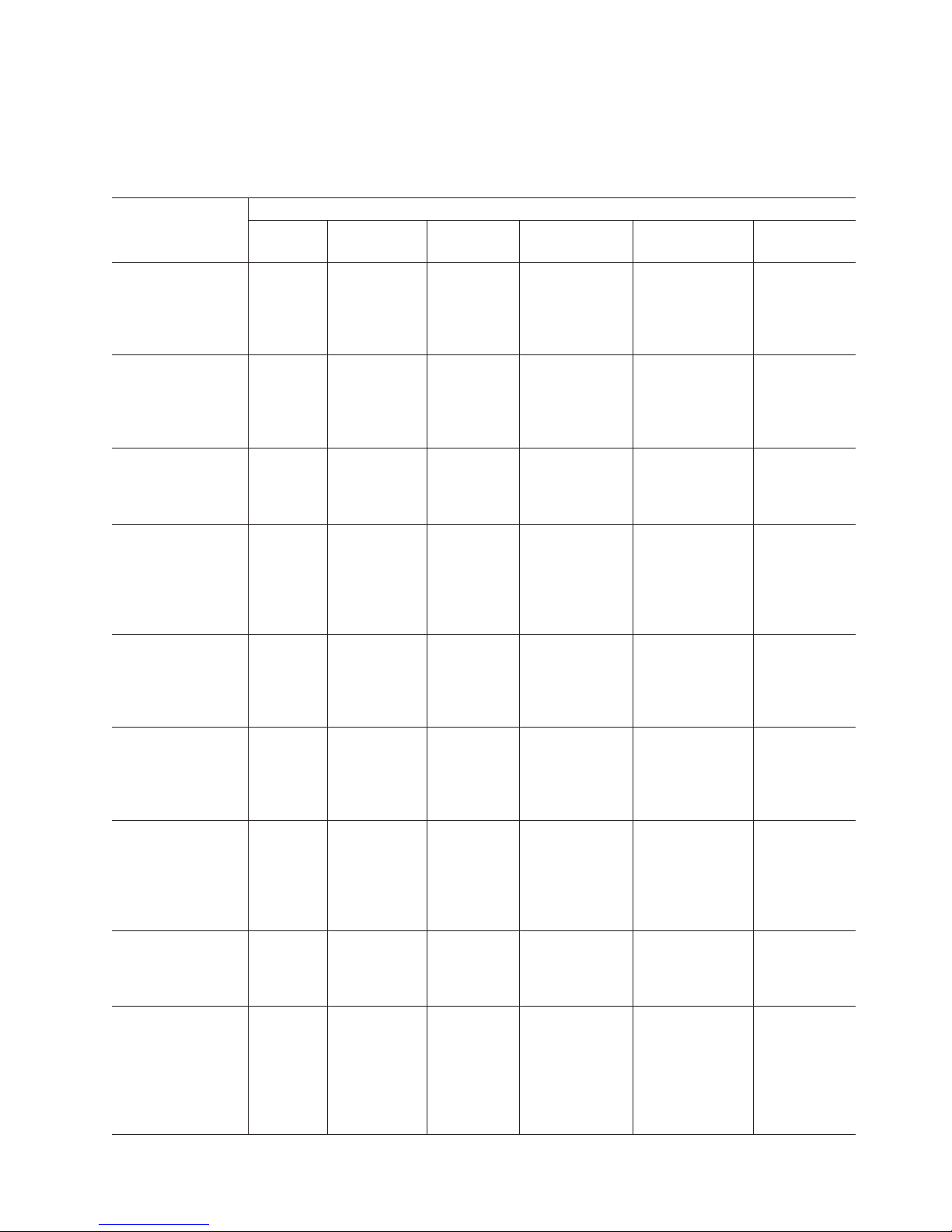

FAStT Storage Manager Version 8.3 library

Table 1 associates each document in the FAStT Storage Manager library with its

related common user tasks.

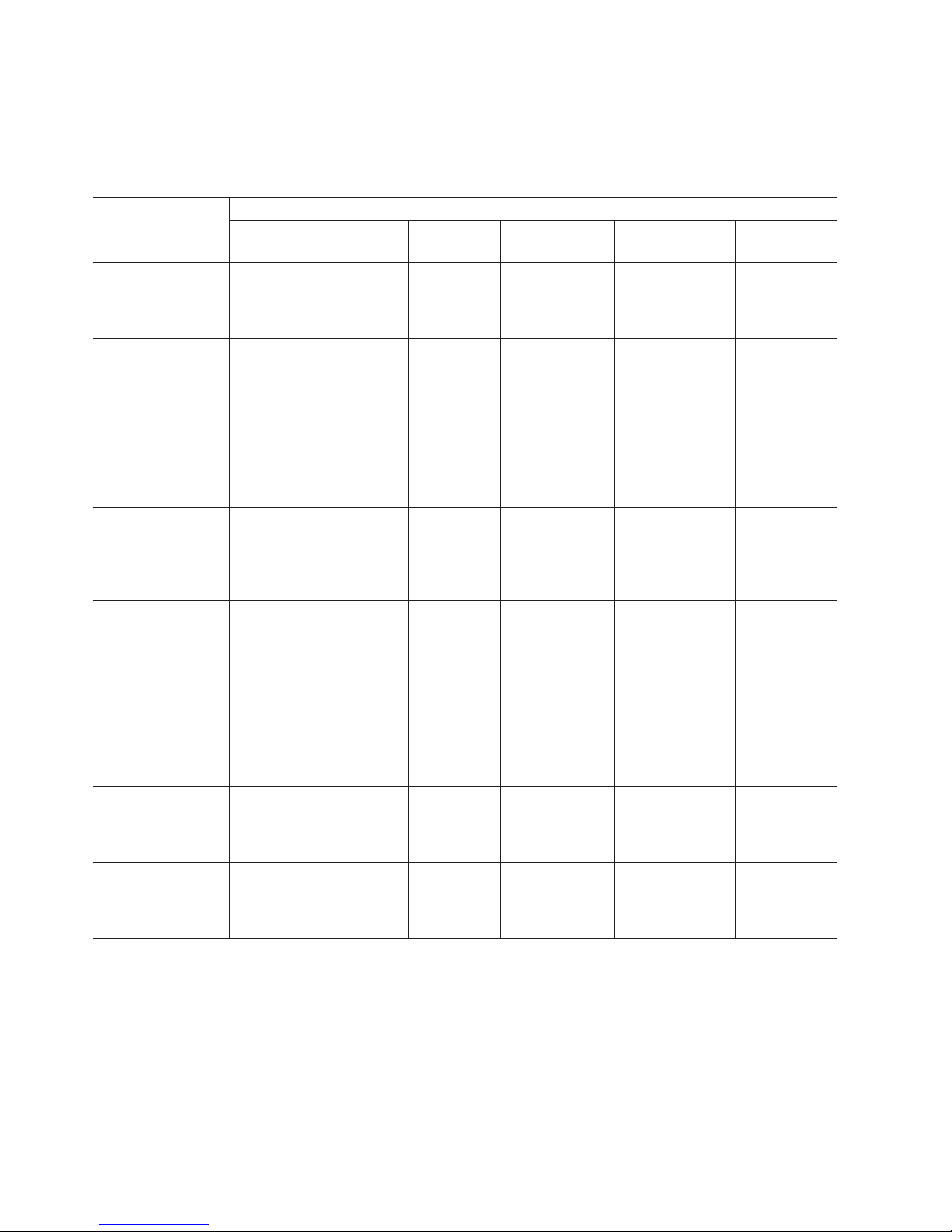

Table 1. TotalStorage FAStT Storage Manager Version 8.3 titles by user tasks

Title User Tasks

IBM TotalStorage

FAStT600 and

Storage Manager

8.3 Library Guide

and Common Index,

GC26-7562

IBM TotalStorage

FAStT Storage

Manager 8.3

Installation and

Support Guide for

Microsoft

NT

®

®

Windows

, Windows 2000,

and Windows Server

2003, GC26-7579

IBM TotalStorage

FAStT Storage

Manager 8.3

Installation and

Support Guide for

Linux, GC26-7519

IBM TotalStorage

FAStT Storage

Manager 8.3

Installation and

Support Guide for

Novell NetWare,

GC26-7520

IBM TotalStorage

FAStT Storage

Manager 8.3

Installation and

Support Guide for

UNIX and

®

Environments,

AIX

GC26-7521

IBM FAStT Remote

Mirror Option

Installation and

User’s Guide,

48P9821

IBM FAStT Storage

Manager Script

Commands (see

product CD)

Planning Hardware

Installation

UU U U U U

UUU

UUU

UUU

UUU

UUUU

Software

Installation

Configuration Operation and

U

Administration

Diagnosis and

Maintenance

About this document xvii

Page 20

Table 1. TotalStorage FAStT Storage Manager Version 8.3 titles by user tasks (continued)

Title User Tasks

IBM FAStT Storage

Manager Version

7.10 Concepts

Guide, 25P1661

Planning Hardware

Installation

UU U U U U

Software

Installation

Configuration Operation and

Administration

Diagnosis and

Maintenance

xviii IBM TotalStorage FAStT600 Fibre Channel Storage Server: Installation and User’s Guide

Page 21

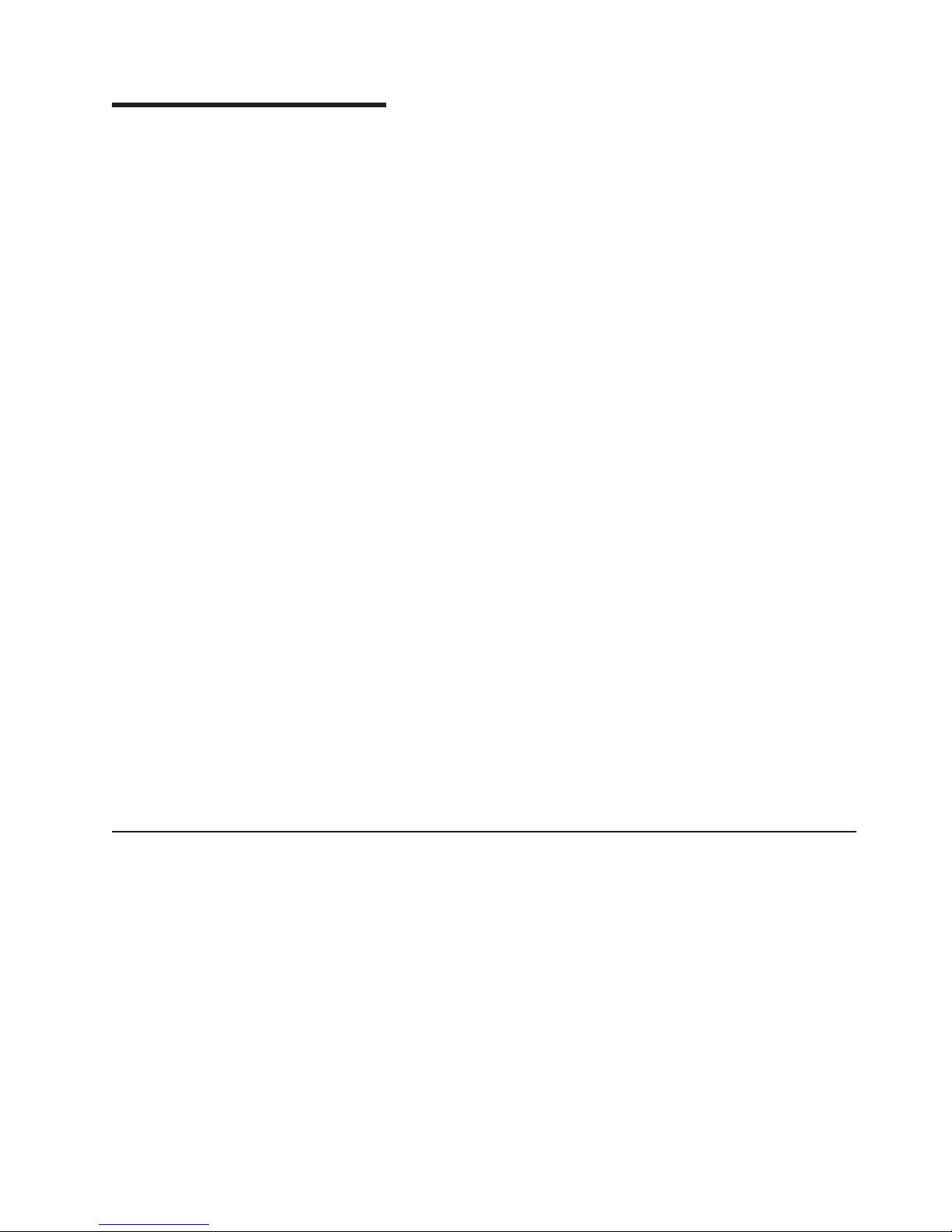

FAStT900 Fibre Channel Storage Server library

Table 2 associates each document in the FAStT900 Fibre Channel Storage Server

library with its related common user tasks.

Table 2. TotalStorage FAStT900 Fibre Channel Storage Server document titles by user tasks

Title User Tasks

IBM TotalStorage

FAStT900

Installation and

Support Guide,

GC26-7530

IBM TotalStorage

FAStT900 Fibre

Channel Cabling

Instructions,

24P8135

IBM TotalStorage

FAStT900 Storage

Server User’s Guide,

GC26-7534

IBM TotalStorage

FAStT FC2-133 Dual

Port Host Bus

Adapter Installation

and User’s Guide,

GC26-7532

IBM FAStT FC2-133

Host Bus Adapter

Installation and

User’s Guide,

48P9823

IBM TotalStorage

FAStT900 Rack

Mounting

Instructions,

19K0900

IBM Fibre Channel

Planning and

Integration: User’s

Guide and Service

Information,

SC23-4329

IBM FAStT

Management Suite

Java User’s Guide,

32P0081

IBM TotalStorage

FAStT Fibre Channel

Hardware

Maintenance Manual

and Problem

Determination

Guide, GC26-7528

Planning Hardware

Installation

UU U

UU

UU

UU

UU

UU U U

Software

Installation

Configuration Operation and

Administration

UUU

Diagnosis and

Maintenance

UU

U

About this document xix

Page 22

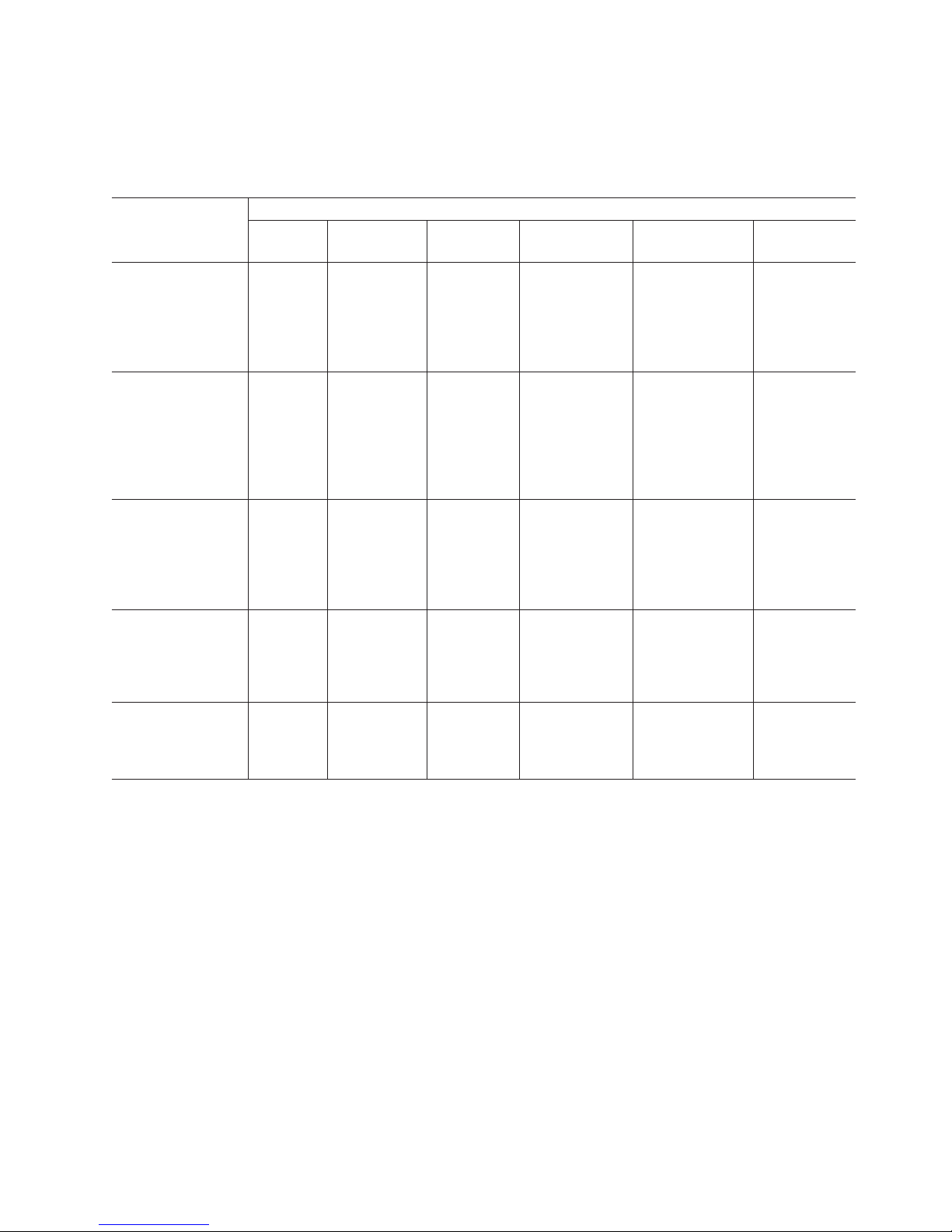

FAStT700 Fibre Channel Storage Server library

Table 3 associates each document in the FAStT700 Fibre Channel Storage Server

library with its related common user tasks.

Table 3. TotalStorage FAStT700 Fibre Channel Storage Server document titles by user tasks

Title User Tasks

IBM FAStT700

Installation and

Support Guide,

32P0171

IBM FAStT700 Fibre

Channel Cabling

Instructions,

32P0343

IBM FAStT700 Fibre

Channel Storage

Server User’s Guide,

32P0341

IBM EXP700

Storage Expansion

Unit Installation and

User’s Guide,

32P0178

IBM FAStT FC2-133

Dual Port Host Bus

Adapter Installation

and User’s Guide,

GC26-7532

IBM TotalStorage

FAStT FC2-133 Host

Bus Adapter

Installation and

User’s Guide,

48P9823

IBM FAStT

Management Suite

Java User’s Guide,

32P0081

IBM Fibre Channel

Hardware

Maintenance

Manual, 19K6130

IBM Fibre Channel

Problem

Determination

Guide, 48P9804

Planning Hardware

Installation

UU U

UU

UU U U U

UU

UU

Software

Installation

Configuration Operation and

Administration

UUU

Diagnosis and

Maintenance

UU

U

U

xx IBM TotalStorage FAStT600 Fibre Channel Storage Server: Installation and User’s Guide

Page 23

FAStT600 Fibre Channel Storage Server library

Table 4 associates each document in the FAStT600 Fibre Channel Storage Server

library with its related common user tasks.

Table 4. TotalStorage FAStT600 Fibre Channel Storage Server document titles by user tasks

Title User Tasks

IBM TotalStorage

FAStT600 Fibre

Channel Storage

Server Installation

and User’s Guide,

GC26-7531

IBM TotalStorage

FAStT Fibre Channel

Hardware

Maintenance Manual

and Problem

Determination

Guide, GC26-7528

IBM TotalStorage

FAStT FC2-133 Dual

Port Host Bus

Adapter Installation

and User’s Guide,

GC26-7532

IBM TotalStorage

FAStT600 Rack

Mounting

Instructions,

24P8125

IBM TotalStorage

FAStT600 Cabling

Instructions,

24P8126

Planning Hardware

Installation

UU U

UU

UU

UU

Software

Installation

Configuration Operation and

Administration

Diagnosis and

Maintenance

U

About this document xxi

Page 24

FAStT500 Fibre Channel Storage Server library

Table 5 associates each document in the FAStT500 Fibre Channel Storage Server

library with its related common user tasks.

Table 5. TotalStorage FAStT500 and FAStT High Availablity Storage Server document titles by user tasks

Title User Tasks

IBM FAStT500 RAID

Controller Enclosure

Unit User’s Guide,

48P9847

IBM FAStT EXP500

Storage Expansion

Unit Installation and

User’s Guide,

59P5637

IBM FAStT500 RAID

Controller Enclosure

Unit Installation

Guide, 59P6244

IBM FAStT FC2-133

Dual Port Host Bus

Adapter Installation

and User’s Guide,

GC26-7532

IBM TotalStorage

FAStT FC2-133 Host

Bus Adapter

Installation and

User’s Guide,

48P9823

IBM FAStT

Management Suite

Java User’s Guide,

32P0081

IBM Fibre Channel

Hardware

Maintenance

Manual, 19K6130

IBM Fibre Channel

Problem

Determination

Guide, 48P9804

Planning Hardware

Installation

UU U U U

UU

UU

UU

Software

Installation

Configuration Operation and

Administration

UUU

UU

Diagnosis and

Maintenance

U

U

xxii IBM TotalStorage FAStT600 Fibre Channel Storage Server: Installation and User’s Guide

Page 25

FAStT200 Fibre Channel Storage Server library

Table 6 associates each document in the FAStT200 Fibre Channel Storage Server

library with its related common user tasks.

Table 6. TotalStorage FAStT200 and FAStT High Availablity Storage Server document titles by user tasks

Title User Tasks

IBM FAStT200 and

FAStT200 HA

Storage Servers

Installation and

User’s Guide,

59P6243

IBM FAStT200 Fibre

Channel Cabling

Instructions,

21P9094

IBM FAStT FC2-133

Dual Port Host Bus

Adapter Installation

and User’s Guide,

GC26-7532

IBM FAStT FC2-133

Host Bus Adapter

Installation and

User’s Guide,

48P9823

IBM FAStT

Management Suite

Java User’s Guide,

32P0081

IBM Fibre Channel

Hardware

Maintenance

Manual, 19K6130

IBM Fibre Channel

Problem

Determination

Guide, 48P9804

Planning Hardware

Installation

UU U U

UU

UU

UU

Software

Installation

Configuration Operation and

Administration

UU

Diagnosis and

Maintenance

U

U

About this document xxiii

Page 26

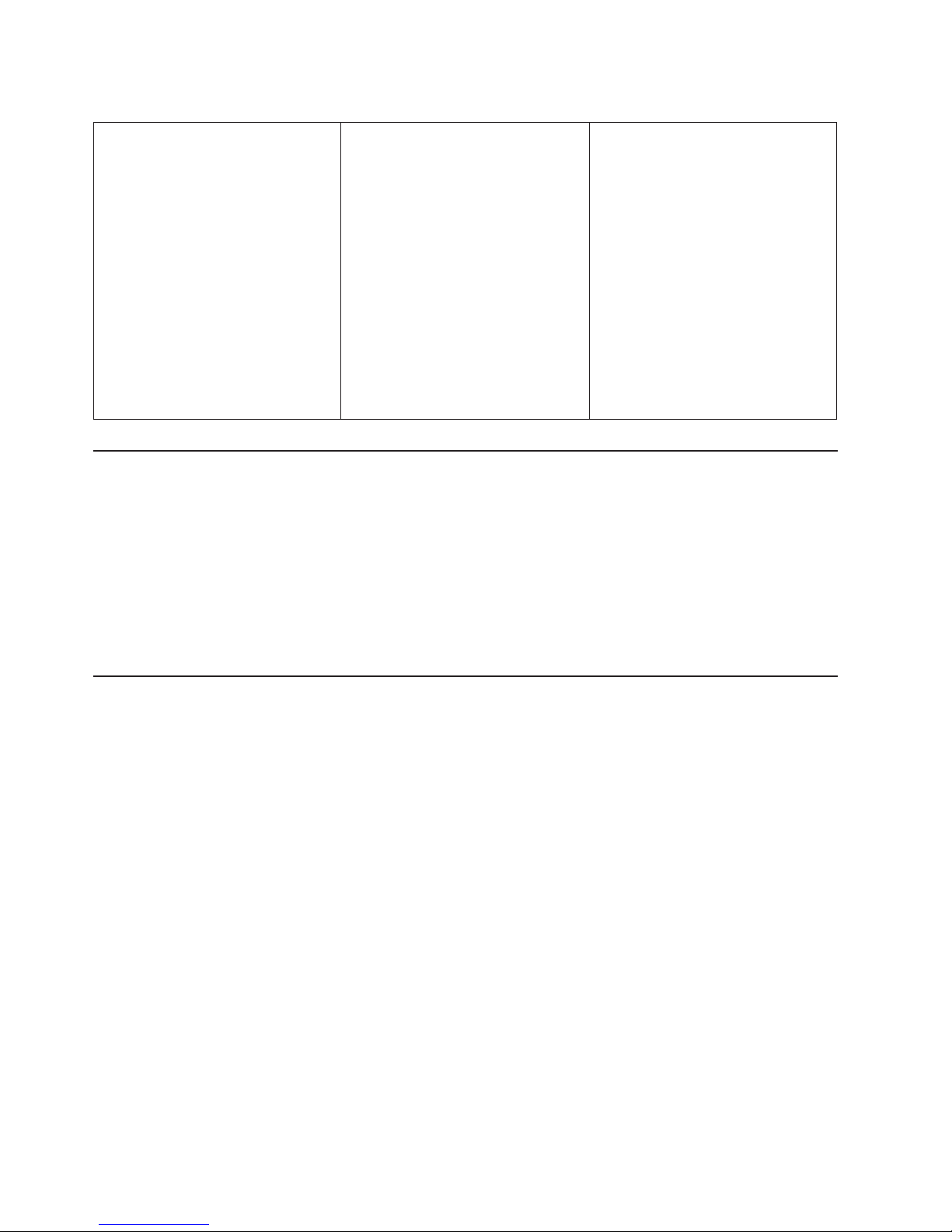

FAStT related documents

Table 7 associates each of the following documents related to FAStT operations

with its related common user tasks.

Table 7. TotalStorage FAStT related document titles by user tasks

Title User Tasks

IBM Safety

Information,

P48P9741

®

IBM Netfinity

Channel Cabling

Instructions,

19K0906

IBM Fibre Channel

SAN Configuration

Setup Guide,

25P2509

Fibre

Planning Hardware

Installation

U

UUUU

Software

Installation

Configuration Operation and

Notices used in this document

This document contains the following notices designed to highlight key information:

v Note: These notices provide important tips, guidance, or advice.

v Important: These notices provide information that might help you avoid

inconvenient or problem situations.

v Attention: These notices indicate possible damage to programs, devices, or

data. An attention notice is placed just before the instruction or situation in which

damage could occur.

v Caution: These statements indicate situations that can be potentially hazardous

to you. A caution statement is placed just before the description of a potentially

hazardous procedure step or situation.

v Danger: These statements indicate situations that can be potentially lethal or

extremely hazardous to you. A danger statement is placed just before the

description of a potentially lethal or extremely hazardous procedure step or

situation.

Administration

U

Diagnosis and

Maintenance

Getting information, help, and service

If you need help, service, or technical assistance or just want more information

about IBM products, you will find a wide variety of sources available from IBM to

assist you. This section contains information about where to go for additional

information about IBM and IBM products, what to do if you experience a problem

with your IBM Eserver xSeries

service, if it is necessary.

Before you call

Before you call, make sure that you have taken these steps to try to solve the

problem yourself:

v Check all cables to make sure that they are connected.

v Check the power switches to make sure that the system is turned on.

xxiv IBM TotalStorage FAStT600 Fibre Channel Storage Server: Installation and User’s Guide

™

or IntelliStation®system, and whom to call for

Page 27

v Use the troubleshooting information in your system documentation and use the

diagnostic tools that come with your system.

v Check for technical information, hints, tips, and new device drivers at the

following Web site:

www.ibm.com/storage/techsup.htm

v Use an IBM discussion forum on the IBM Web site to ask questions.

You can solve many problems without outside assistance by following the

troubleshooting procedures that IBM provides in the online help or in the documents

that are provided with your system and software. The information that comes with

your system also describes the diagnostic tests that you can perform. Most xSeries

and IntelliStation systems, operating systems, and programs come with information

that contains troubleshooting procedures and explanations of error messages and

error codes. If you suspect a software problem, see the information for the

operating system or program.

Using the documentation

Information about the xSeries or IntelliStation system and preinstalled software, if

any, is available in the documents that come with your system. This includes printed

documents, online documents, readme files, and help files. See the troubleshooting

information in your system documentation for instructions for using the diagnostic

programs. The troubleshooting information or the diagnostic programs might tell you

that you need additional or updated device drivers or other software.

Web sites

IBM maintains pages on the World Wide Web where you can get the latest

technical information and download device drivers and updates.

v For FAStT information, go to the following Web site:

www.ibm.com/storage/techsup.htm The support page has many sources of

information and ways for you to solve problems, including:

– Diagnosing problems, using the IBM Online Assistant

– Downloading the latest device drivers and updates for your products

– Viewing frequently asked questions (FAQ)

– Viewing hints and tips to help you solve problems

– Participating in IBM discussion forums

– Setting up e-mail notification of technical updates about your products

v You can order publications through the IBM Publications Ordering System at:

www.elink.ibmlink.ibm.com/public/applications/publications/cgibin/pbi.cgi/

v For the latest information about IBM xSeries products, services, and support, go

to the following Web site:

www.ibm.com/eserver/xseries/

v For the latest information about IBM pSeries products, services, and support, go

to the following Web site:

www.ibm.com/eserver/pseries/

v For the latest information about the IBM IntelliStation information, go to the

following Web site:

www.ibm.com/pc/intellistation/

v For the latest information about operating system and HBA support, clustering

support, SAN fabric support, and Storage Manager feature support, see the

TotalStorage FAStT Interoperability Matrix at the following Web site:

About this document xxv

Page 28

www.storage.ibm.com/disk/fastt/pdf/0217-03.pdf

Software service and support

Through IBM Support Line, for a fee you can get telephone assistance with usage,

configuration, and software problems with xSeries servers, IntelliStation

workstations, and appliances. For information about which products are supported

by Support Line in your country or region, go to the following Web site:

www.ibm.com/services/sl/products/

For more information about the IBM Support Line and other IBM services, go to the

following Web sites:

v www.ibm.com/services/

v www.ibm.com/planetwide/

Hardware service and support

You can receive hardware service through IBM Integrated Technology Services or

through your IBM reseller, if your reseller is authorized by IBM to provide warranty

service. Go to the following Web site for support telephone numbers:

www.ibm.com/planetwide/

In the U.S. and Canada, hardware service and support is available 24 hours a day,

7 days a week. In the U.K., these services are available Monday through Friday,

from 9 a.m. to 6 p.m.

Fire suppression systems

|

|

|

|

|

|

|

|

|

|

A fire suppression system is the responsibility of the customer. The customer’s own

insurance underwriter, local fire marshal, or a local building inspector, or both,

should be consulted in selecting a fire suppression system that provides the correct

level of coverage and protection. IBM designs and manufactures equipment to

internal and external standards that require certain environments for reliable

operation. Because IBM does not test any equipment for compatibility with fire

suppression systems, IBM does not make compatibility claims of any kind nor does

IBM provide recommendations on fire suppression systems.

Table 9 on page 8 lists the environmental specifications for the FAStT600.

How to send your comments

Your feedback is important to help us provide the highest quality information. If you

have any comments about this document, you can submit them in one of the

following ways:

v E-mail

Submit your comments electronically to:

starpubs@us.ibm.com

Be sure to include the name and order number of the document and, if

applicable, the specific location of the text that you are commenting on, such as

a page number or table number.

v Mail or fax

xxvi IBM TotalStorage FAStT600 Fibre Channel Storage Server: Installation and User’s Guide

Page 29

Fill out the Readers’ Comments form (RCF) at the back of this document and

return it by mail or fax (1-800-426-6209) or give it to an IBM representative. If the

RCF has been removed, you can address your comments to:

International Business Machines Corporation

RCF Processing Department

Dept. M86/Bldg. 050-3

5600 Cottle Road

San Jose, CA 95193-0001

U.S.A

When you send information to IBM, you grant IBM a nonexclusive right to use or

distribute the information in any way it believes appropriate without incurring any

obligation to you.

About this document xxvii

Page 30

xxviii IBM TotalStorage FAStT600 Fibre Channel Storage Server: Installation and User’s Guide

Page 31

Chapter 1. Introduction

IBM FAStT (Fibre Array Storage Technology) solutions support the large and

growing data storage requirements of business-critical applications. These scalable

IBM FAStT solutions offer you data access and protection to meet your existing

enterprise storage requirements and prepare for the future.

Fibre channel is a new technology, similar to a high-speed network, that you can

use to connect large amounts of disk storage to a server or cluster of servers. Fibre

Channel technology supports increased performance, scalability, availability, and

distance for attaching storage subsystems to network servers. The storage server

provides for the attachment of Fibre Channel disk drives to give superior

performance and redundancy.

Fibre channel technology supports applications that require large amounts of disk

storage that is shared by two or more servers. With fibre channel, you can see a

higher throughput rate over longer distances than is possible with small computer

system interface (SCSI) or with serial storage architecture (SSA) technology.

The IBM TotalStorage FAStT600 Storage Server (Machine Type 1722, Models 60U

and 60X) comes with two RAID controllers, two power supplies, and two cooling

units and provides dual, redundant controllers, redundant cooling, redundant power,

and battery backup of the RAID controller cache. The FAStT600 Storage Server is

designed to provide maximum host and drive side redundancy. Each RAID

controller supports direct attachment of one host containing one or two host

adapters.

FAStT600 supports up to fourteen internal disk drive modules, supporting over 2

TBs of storage capacity. Additional storage can be added to the FAStT600 with up

to two FAStT EXP700 Expansion Units using optional EXP700 Attachment features

(feature number 7360, or features number 7361 and number 7362). Utilizing these

features, up to 42 disk drives can be attached to the FAStT600 with individual drive

module capacities ranging from 36.4 GB to 146.8 GB.

After you review the introductory information that is provided in this chapter, go to

Chapter 2, “Installing and configuring the storage server”, on page 11 to begin the

installation process.

Features at a glance

Table 8 on page 2 summarizes the features of the storage server. For a list of the

operating specifications, such as weight, height, and heat output, see Table 9 on

page 8.

© Copyright IBM Corp. 2003 1

Page 32

Table 8. Features at a glance

General

v Modular components:

– High-capacity disk drives

– RAID controllers

– Power supplies

– Cooling fans

v Technology:

– Support for disk arrays

– Support for clustering

– Fibre Channel host interface

– Redundant data storage, cooling

system, power system, and RAID

controllers

– Hot-swap technology for drives,

power supplies, fans, and RAID

controllers

Clustering support

Clustering is a means of sharing array groups among controllers to provide

redundancy of controllers and servers. This redundancy is important if a hardware

component fails. If a hardware component failure occurs in a cluster, another server

takes ownership of the array group.

v User interface:

– Built-in power, activity, and fault Light

Emitting Diodes (LEDs)

– Identification labeling on customer

replaceable units (CRUs), rear LEDs,

switches, and connectors

– Easy-to-replace drives, power

supplies, RAID controllers, and fans

Disk drive storage

2Gb Fibre Channel enclosure

Maximum drives per storage server: 14

Attached Expansion Units

Attachment of drive expansion units

(EXP700’s) requires one or more

EXP700 Attachment option (or feature)

upgrades for the FAStT600

2 Gb connection only

RAID controllers

v Technology and interfaces:

– Fibre channel: 40-pin FC disk drives

– Fibre Channel interface: six small

form-factor pluggable (SFP) modules

for incoming and outgoing FC cables

(three SFPs on each RAID

controller)

– Two 2Gb Fibre Channel host side

connections per controller

Clustering requires software specific to your operating system. For more information

about clustering, go to the following Web site:

www.pc.ibm.com/us/compat/nos/cert.shtml

Inventory checklist

After you unpack the storage server, verify that you have the following items:

Hardware

IBM FAStT600 Storage Server comes with the following components:

v Two RAID controllers

v Two fan units

v Two power supplies

v Two power cords

v 14 filler panels

v Rack-mounting hardware kit (1)

– Two rails (right and left assembly)

– Ten M6 screws

– Ten M6 cage nuts

– Ten M6 clip nuts

Software and documentation:

v IBM FAStT Storage Manager Version 8.3 CD including:

– IBM FAStT Storage Manager Version 8.3

2 IBM TotalStorage FAStT600 Fibre Channel Storage Server: Installation and User’s Guide

Page 33

– Publications and online help in Adobe Acrobat Portable Document Format

(PDF)

For a list of available IBM FAStT publications, see “FAStT documentation” on

page xvi.

v Rack Mounting Assembly kit, including:

– Rack mounting installation instructions

– Rack mounting template (for aligning the rails properly)

– White tape dots for marking the holes in the rack

v Fibre Channel cabling instructions

If an item is missing or damaged, contact your IBM reseller or your IBM marketing

representative.

If you have not already done so, record your storage server serial number in the

table in “Records”, on page 77.

Handling static-sensitive devices

Attention: Static electricity can damage electronic devices and your system. To

avoid damage, keep static-sensitive devices in their static-protective package until

you are ready to install them.

To reduce the possibility of electrostatic discharge (ESD), observe the following

precautions:

v Limit your movement. Movement can cause static electricity to build up around

you.

v Handle the device carefully. Hold it by its edges or its frame.

v Do not touch solder joints, pins, or exposed printed circuitry.

v Do not leave the device where others can handle and possibly damage the

device.

v While the device is still in its static-protective package, you should hold the

device and touch an unpainted metal part of the system unit for at least two

seconds. This drains static electricity from the package and from your body.

v Remove the device from its package and install it directly into your system unit

without setting it down. If it is necessary to set the device down, place it in its

static-protective package. Do not place the device on your system unit cover or

on a metal table.

v Take additional care when handling devices during cold weather because heating

reduces indoor humidity and increases static electricity.

Best practices guidelines

|

|

|

|

|

|

|

|

|

To ensure optimal operation of your system, always follow these best practices

guidelines:

v Back up the data on your storage drives periodically.

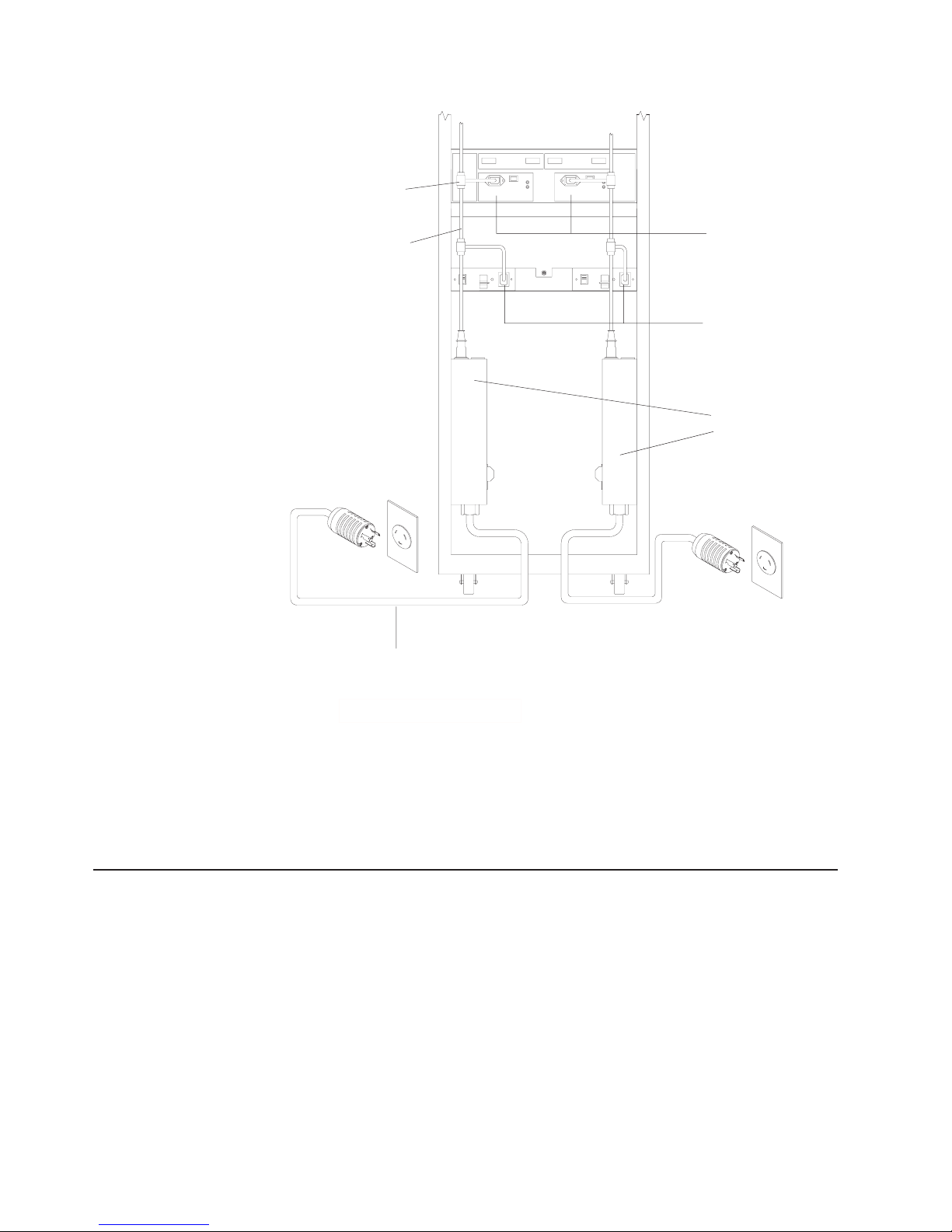

v To maintain power redundancy, plug the FAStT600 Storage Server’s right and the

left power supplies into two independent external power circuits through ac

distribution units inside a rack cabinet or directly into external receptacles.

Similarly, the right and left power supplies of the FAStT drive enclosures attached

to the FAStT600 Storage Server should be plugged into the same two

independent external power circuits as the FAStT600 Storage Server. This

Chapter 1. Introduction 3

Page 34

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ensures that the FAStT600 Storage Server and all its attached drive enclosures

will have power if only one power circuit is available. In addition, having all the

right or all the left power supplies plug into the same power circuit will enable the

components in the storage subsystem to power on simultaneously during an

unattended restoration of power. See Figure 32 on page 34 for an example of

redundant power connections.

v Before any planned system shutdown or after any system changes (additions,

removals, or modifications), save controller subsystem profiles as explained in

the Storage Manager guide for your operating system.

v Ensure that your system is in an optimal state before shutting down. Never turn

the power off if any fault light is lit; be sure to resolve any error conditions before

you shut down the system.

v During any maintenance or attended power-up procedure, carefully follow the

power-up sequence listed in “Turning on the storage server” on page 38. Each

component of the subsystem should be checked that it is powered-on in the

proper order during this entire power-up procedure to ensure the controller will be

able to optimally access all of your storage subsystems.

v The storage subsystem supports simultaneous power-up to the system

components; however, you should always follow the power-up sequence listed in

“Turning on the storage server” on page 38 during any attended power-up

procedure.

v A storage system in an optimal state should recover automatically from an

unexpected shutdown and unattended simultaneous restoration of power to

system components. After power is restored, call IBM support if any of the

following conditions occur:

– The storage subsystem logical drives and arrays are not displayed in the

Storage Manager graphical user interface (GUI).

– The storage subsystem logical drives and arrays do not come online.

– The storage subsystem logical drives and arrays seem to be degraded.

Storage server components

The following sections show the components of the storage server.

The hot-swap features of the storage server enable you to remove and replace hard

disk drives, power supplies, RAID controllers, and fans without turning off the

storage server. Therefore, you can maintain the availability of your system while a

hot-swap device is removed, installed, or replaced.

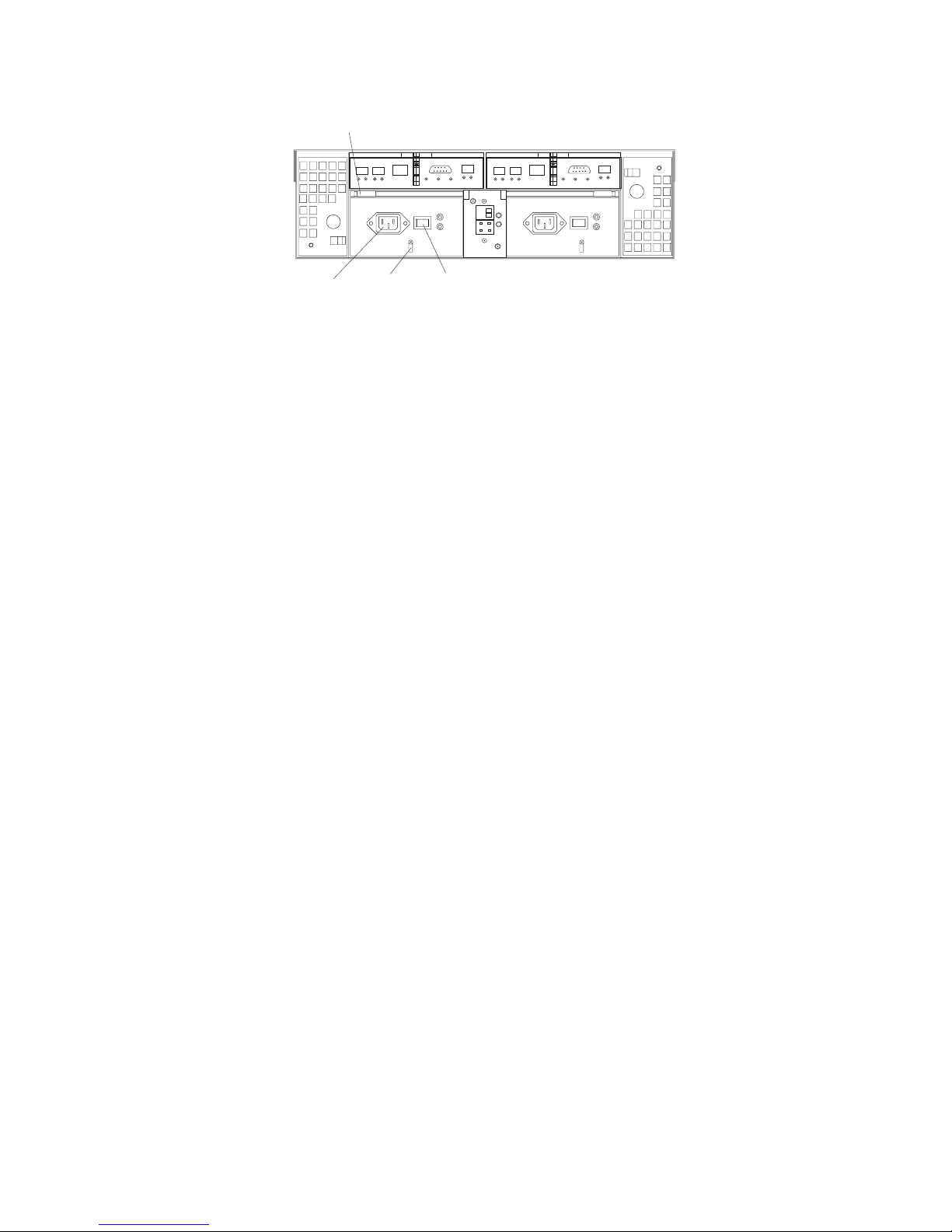

Front view

Figure 2 on page 5 shows the components and controls on the front of the storage

server.

4 IBM TotalStorage FAStT600 Fibre Channel Storage Server: Installation and User’s Guide

Page 35

Power-on LED

General-system-

error LED

Locator LED

Hot-swap

drive CRU

Tray handle

Figure 2. Front controls and components

Latch

Power-on LED

When on, this green light indicates that the unit has good dc power.

General-system-error LED

When on, this amber LED indicates that the storage server has a fault,

such as in a power supply, fan unit, or hard disk drive.

Note: If the General-system-error LED is on continuously (not flashing),

there is a problem with the storage server. Use the

storage-management software to diagnose and repair the problem.

For more information, see “Checking the LEDs” on page 42.

Locator LED

When on, this blue light indicates the storage-management software is

locating the server.

Hot-swap drive CRU

You can install up to 14 hot-swap drive customer replaceable units (CRUs)

in the storage server. Each drive CRU consists of a hard disk drive and

tray.

Drive activity LED

Drive fault LED

Filler panel

Drive activity LED

Drive fault LED

Latch This multipurpose blue latch releases or locks the drive CRU in place.

Tray handle

The storage server comes without drives installed and contains filler panels

in the unused drive bays. Before installing new drives, you must remove the

filler panels and save them. Each of the 14 bays must always contain either

a filler panel or a drive CRU to ensure proper cooling, air ventilation, and

EMI compliance.

Each drive CRU has a green Drive activity LED. When flashing, this green

LED indicates drive activity. When on continuously, this green LED indicates

that the drive is properly installed.

Each drive CRU has an amber Drive fault LED. When on, this amber LED

indicates a drive failure. When flashing, this amber LED indicates that a

drive identify is in progress.

You can use this multipurpose handle to insert and remove a drive CRU in

the bay.

Chapter 1. Introduction 5

Page 36

Back view

For information on how to install and replace drive CRUs, see “Working with

hot-swap drives” on page 49. For more information about the LEDs, see “Checking

the LEDs” on page 42.

Figure 3 shows the components at the back of the storage server.

Hot-swap fan bays

Raid controllers

Hot-swap

power supplies

Figure 3. Back view of FAStT600 storage server

RAID controller

Each RAID controller contains three ports for Small Form-Factor Pluggable

(SFP) modules that connect to the Fibre Channel cables. Two SFPs can

connect to two host systems. The third SFP is used to connect additional

expansion units to the storage server.

Each RAID controller also contains a battery to maintain cache data in the

event of a power failure. For more information, see “Cache memory and

RAID controller battery” on page 46.

Hot-swap fans

The storage server has two interchangeable hot-swap and redundant fan

CRUs. Each fan CRU contains two fans. If one fan CRU fails, the second

fan CRU continues to operate. Both fan CRUs must be installed to maintain

proper cooling within the storage server, even if one fan CRU is not

operational.

Hot-swap power supplies

The storage server comes with two hot-swap power supplies. Both power

supplies must be installed to maintain proper cooling.

Interface ports and switches

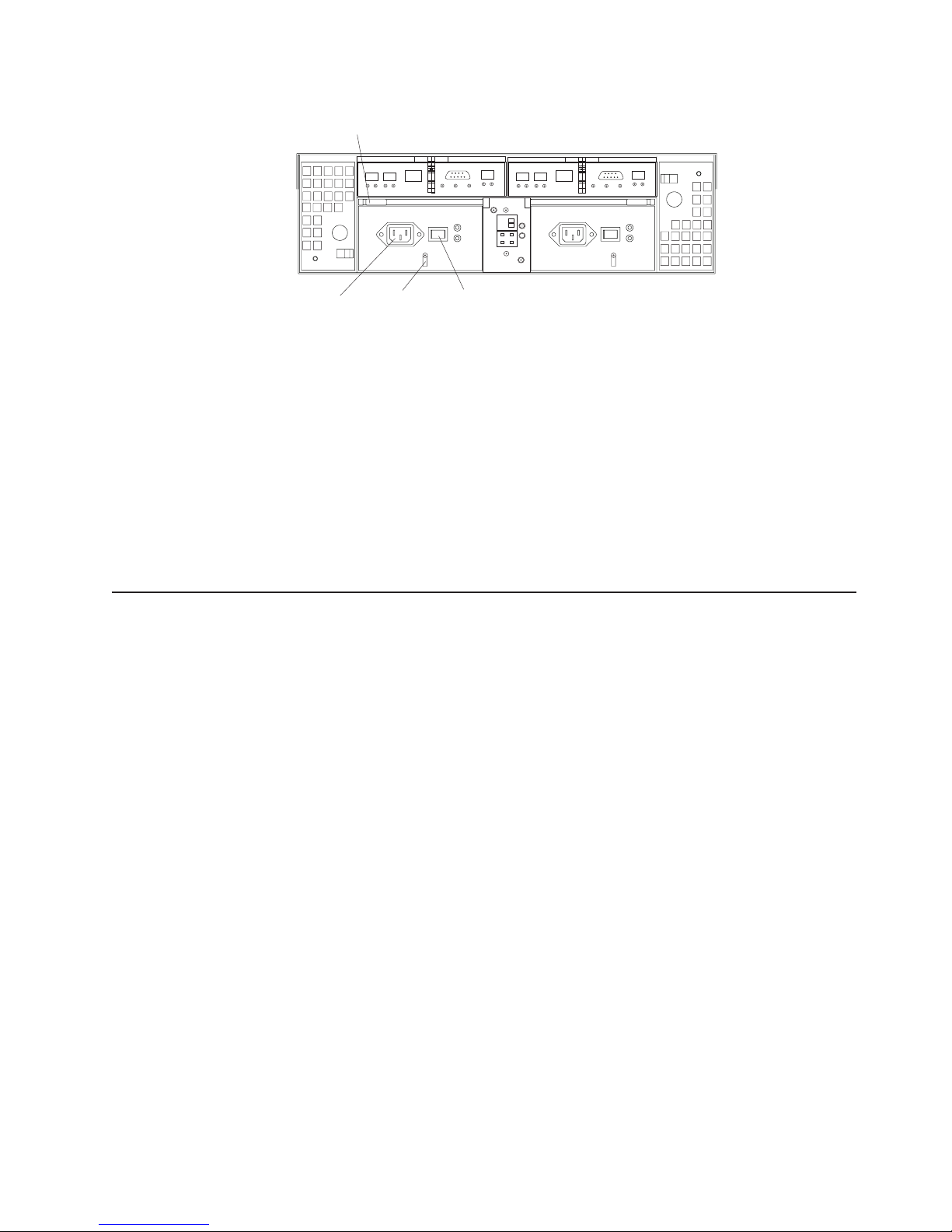

Figure 4 on page 7 shows the ports and switches on the back of the storage server.

6 IBM TotalStorage FAStT600 Fibre Channel Storage Server: Installation and User’s Guide

Page 37

Ethernet

Host port 2

Host port 1

Expansion port

Serial port Serial port

Host port 2

Host port 1

Ethernet

Expansion port

AC power

connector

Figure 4. Interface ports and switches

AC power

switch

Server ID

switch

RAID controller

Each RAID controller contains several connectors and LEDs. Each

controller has two host ports and one expansion port for connecting the

storage server to hosts or expansion units. You first insert SFPs into the

ports and then connect the Fibre Channel cables.

Host ports

The host ports are used to connect a Fibre Channel cable from the host

systems. You first insert an SFP into the port and then connect a Fibre

Channel cable. The two host ports in each controller are independent. They

are not connected in the controller module as they would be in a hub

configuration.

Ethernet port

The Ethernet port is for an RJ-45 10BASE-T or 100BASE-T Ethernet

connection. Use the Ethernet connection to directly manage storage

subsystems.

Expansion port

The expansion port is used to connect additional expansion units to the

RAID controllers. You first insert a SFP into the port and then connect a

fibre channel cable.

AC power

connector

AC power

switch

Serial port

Server ID switch

Note: For controller firmware version 05.33.xx.xx, both host and expansion ports

operate at 2 Gbps only.

Note: You must purchase the option to enable the attachment of up to two

FAStT EXP700 Expansion Units using optional EXP700 Attachment

features (feature number 7360, or features number 7361 and

number 7362).

The serial port is used by service personnel to perform diagnostic

operations on the RAID controllers.

The Server ID switch settings range from 0 through 7, and unique IDs

ranging from 00 through 77 can be set.

Chapter 1. Introduction 7

Page 38

Operating specifications

The following table summarizes the operating specifications of the storage server.

Table 9. FAStT600 storage server operating specifications

Size (with front panel and without

mounting rails)

v Depth: 59.7 cm (23.6 in)

v Height: 13.2 cm (5.2 in)

v Width: 48 cm (18.9 in)

Heat output

v 390 watts (1330 BTU/hr)

Weight

v Standard storage server as shipped:

39.10 kg (86.2 lb)

v Unit weight: 31.48 kg (69.4 lb)

Electrical input

v Sine-wave input (50 to 60 Hz) is

required

v Input voltage:

– Low range:

- Minimum: 90 V ac

- Maximum: 136 V ac

– High range:

- Minimum: 198 V ac

- Maximum: 264 V ac

– Input kilovolt-amperes (kVA)

approximately:

- Minimum configuration: 0.06 kVA

- Maximum configuration: 0.37 kVA

Environment

v Air temperature:

– Storage server on:

10° to 35°C

(50° to 95°F)

Altitude: 0 to 914 m (3000 ft.)

– Storage server on:

10° to 32°C

(50° to 90°F)

Altitude: 914 m (3000 ft.) to 2133 m

(7000 ft.)

v Humidity:

– 8% to 80%

Acoustical noise emissions values For

open bay (0 drives installed) and typical

system configurations (14 hard disk drives

installed).

v Sound power (idling):

– 6.3 bels (open bay)

– 6.5 bels (typical)

v Sound power (operating):

– 6.3 bels (open bay)

– 6.8 bels (typical)

v Sound pressure (idling):

– 47 dBA (open bay)

– 49 dBA (typical)

v Sound pressure (operating):

– 47 dBA (open bay)

– 53 dBA (typical)

These levels are measured in controlled

acoustical environments according ISO

7779 and are reported in accordance with

ISO 9296. The declared sound power

levels indicate an upper limit, below which

a large portion of machines operate.

Sound pressure levels in your location

might exceed the average 1-meter values

stated because of room reflections and

other nearby noise.

Heat output, airflow, and cooling

The maximum heat output of the FAStT600 is 390 watts (1330 BTU/hr). Each

FAStT600 (machine type 1722) and drive expansion (EXP700) rack-mounted unit

requires an airflow of 2.5 m

temperature to all racks is recommended to be in the range 10°C through 35°C

(50°F through 95°F), with a recommended operating temperature of 22°C (72°F).

When racks that contain many 1722 units are to be installed together, the following

requirements must be met to ensure that the 1722 units are adequately cooled:

v Air enters at the front of the rack and leaves at the back. To prevent the air that

is leaving the rack from entering the intake of another piece of equipment, racks

must be positioned in alternate rows, back-to-back and front-to-front. This

arrangement is known as “Cold Aisle / Hot Aisle” and is shown in Figure 5 on

page 9.

v Where racks are in rows, each rack must touch the rack that is next to it to

reduce the amount of hot air that can flow around from the back of the rack into

the intakes of the 1722 units that are in that rack. It is recommended that Suite

Attach Kits be used to completely seal any gaps that remain between the racks.

For details of Suite Attach Kits, contact your marketing representative.

v Where racks are in rows front-to-front or back-to-back, a gap of at least 1220 mm

(48 in.) must separate the rows across the cold aisle.

3

per minute (87 ft3per minute). The input air

8 IBM TotalStorage FAStT600 Fibre Channel Storage Server: Installation and User’s Guide

Page 39

v To ensure correct airflow in each rack, the rack filler plates must be installed in

unused positions. Also, all the gaps in the front of the racks must be sealed,

including the gaps between the 1722 units.

back

T42 racks

front

1220 mm cold

aisle width

Air

Cold aisle

front

T42 racks

back

conditioner

Hot aisle

back

T42 racks

front

Airflow

Figure 5. Example of Cold Aisle/Hot Aisle Rack Configuration

Perforated tiles

or gratings

2440 mm between

center lines of hot

and cold aisle

Chapter 1. Introduction 9

Page 40

10 IBM TotalStorage FAStT600 Fibre Channel Storage Server: Installation and User’s Guide

Page 41

Chapter 2. Installing and configuring the storage server

This chapter contains information about how to prepare, install, and configure the

storage subsystem.

Getting started

Use the following list to prepare a storage server for installation:

1. Prepare the site to meet all area, environmental, power, and site requirements.

For more information, see “Operating specifications” on page 8.

2. Move the storage server and its rack cabinet to the site.

3. Remove the storage server from its shipping container and check the contents

(for a list of items, see “Inventory checklist” on page 2.) If any items are missing,

contact your IBM reseller before you proceed.

4. Assemble the tools and equipment that you will need for installation. These

might include:

v Power cords (come with the storage server)

v Screwdrivers (various sizes)

v Antistatic protection (such as a grounding wrist strap)

v SFPs

v Fibre Channel and Ethernet interface cables and cable straps

v Rack-mounting hardware (comes with the storage server)

v Storage-management software to configure the storage subsystems (comes

with the storage server on the IBM TotalStorage FAStT Storage Manager 8.3

installation CD.)

Rack mounting instructions and a template for aligning the holes in the rails and the

rack come with the storage server. If you have misplaced these items, see “Rack

mounting template and instructions”.

After you install the storage server in the rack and configure the storage server, go

to Chapter 3, “Cabling the storage server”, on page 27.

Rack mounting template and instructions

A rack mounting template and instructions come with the storage server. If you have

misplaced these items, use the following template and instructions.

© Copyright IBM Corp. 2003 11

Page 42

FRONT

Rack Mounting

Template

Bezel

()Front Left

Rail assembly

()Front Left

Figure 6. Front rack mounting template

()Front Right

Bezel

Rail assembly

()Front Right

12 IBM TotalStorage FAStT600 Fibre Channel Storage Server: Installation and User’s Guide

Page 43

REAR

Rack Mounting

Template

Rail assembly

()Rear Left

Figure 7. Rear rack mounting template

Rail assembly

()Rear Right

®

P/N 06P4631

Printed in the U.S.A.

Chapter 2. Installing and configuring the storage server 13

Page 44

Installing the storage server in a rack

Review the documentation that comes with the rack cabinet for safety and cabling

information. When you install the storage server in a rack, consider the following

factors:

v Ensure that the room air temperature is below 35°C (95°F).

v Do not block any air vents. Usually, leaving 15 cm (6 in.) of air space provides

proper airflow.

v Plan the device installation starting from the bottom of the rack.

v Do not extend more than one device out of the rack at the same time.

v Remove the rack doors and side panels to provide easier access during

installation.

v Connect all power cords to properly wired and grounded electrical outlets.

v Take precautions to prevent overloading the power outlets when you install

multiple devices in a rack.

Statement 4:

≥ 18 kg (39.7 lb) ≥ 32 kg (70.5 lb) ≥ 55 kg (121.2 lb)

CAUTION:

Use safe practices when lifting.

You will need a flat-blade and a Phillips screwdriver during the installation. The

following items come with your option. If any items are missing or damaged, contact

your place of purchase.

v Cage nuts (10)

v Clip nuts (10)

v M6 screws (10)

v Side rails (2)

Note: See the storage server documentation for handling guidelines before

removing any ESD-sensitive devices. Perform the following steps to install

the storage server in a rack. The first four steps for the installation procedure

involve removing some components from the storage server in order to

reduce the weight of the storage server for easier installation.

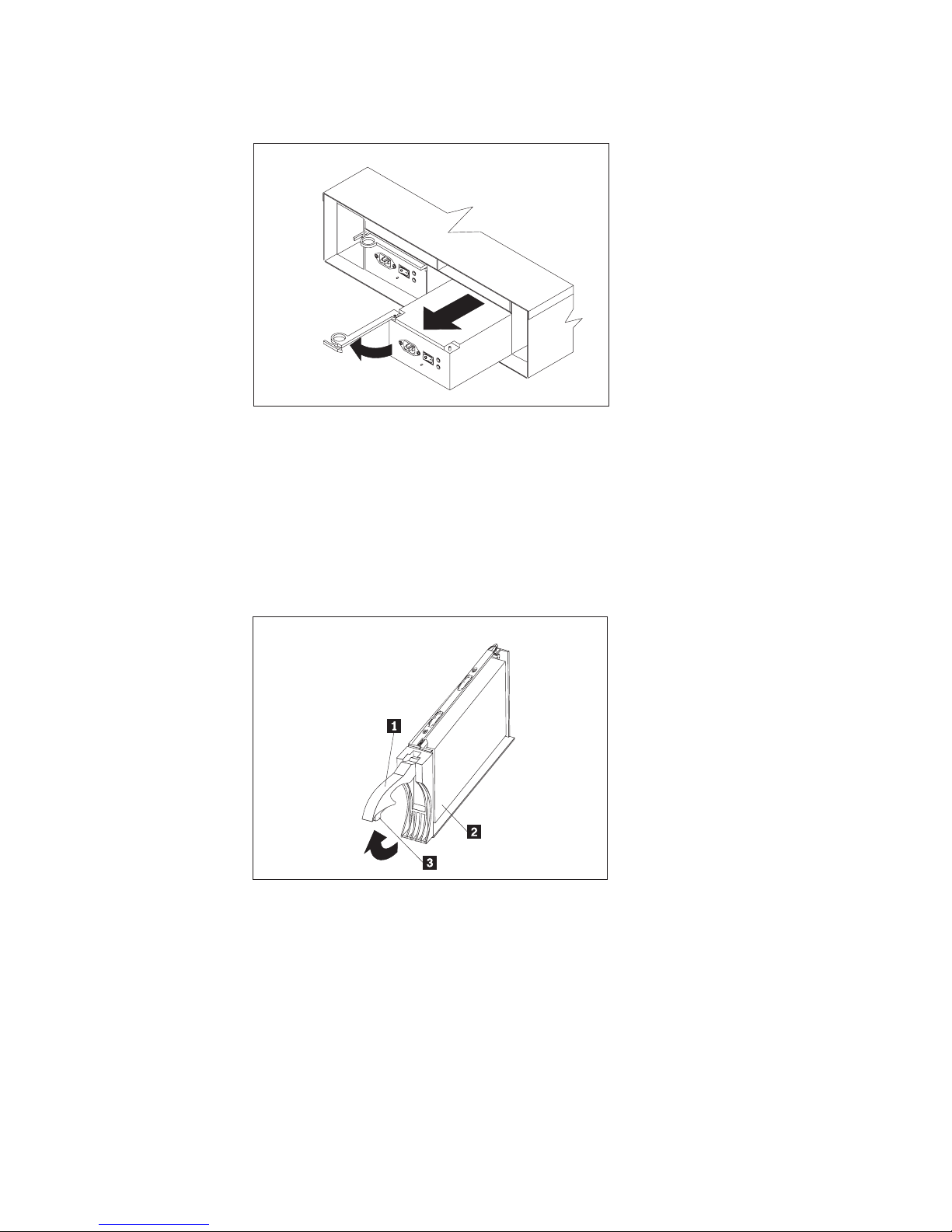

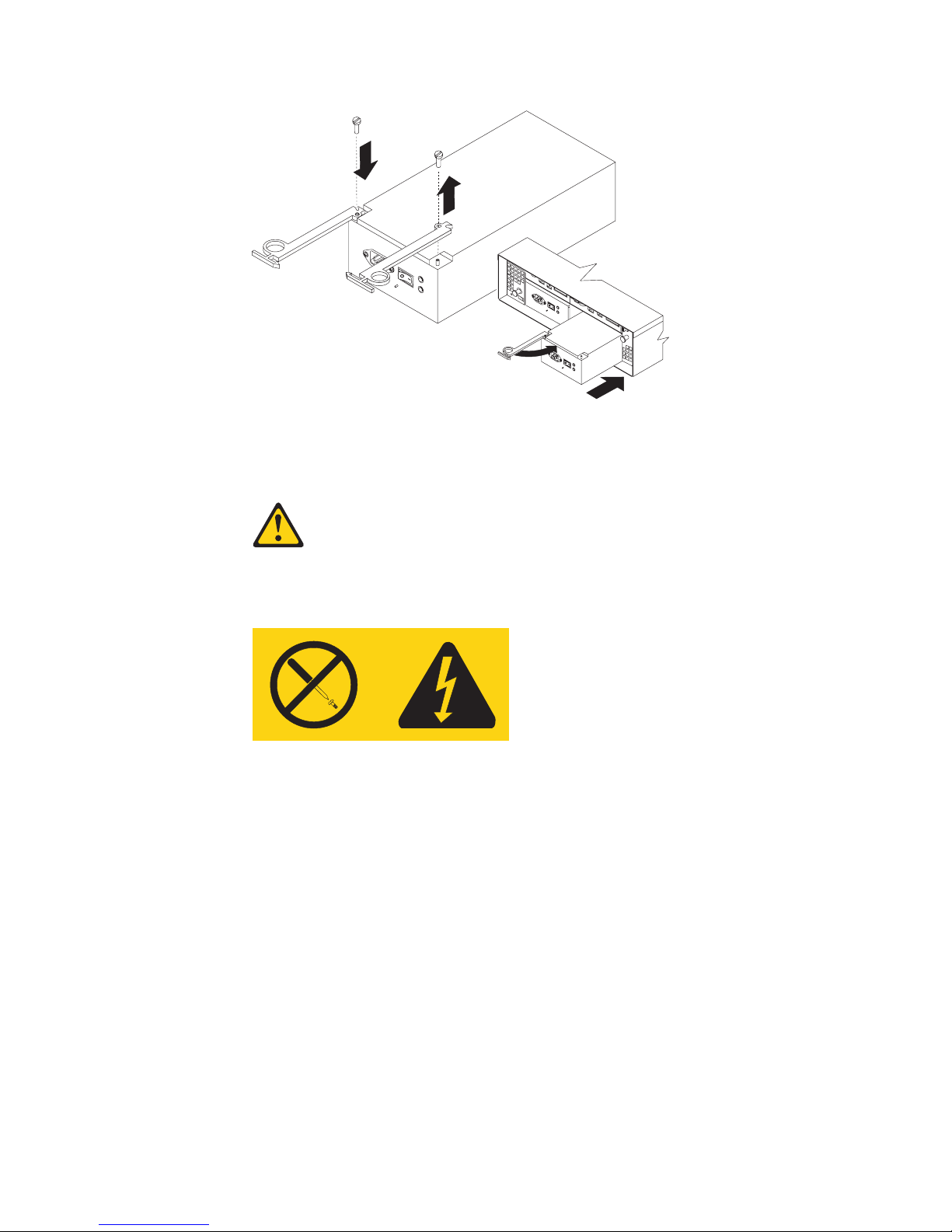

1. To remove a RAID controller, push down on the latch centered on the controller;

then, grasp the pull-rings on the levers and pull them to remove the RAID

controller and set it aside for later installation.

If you have a second RAID controller, repeat this step for the second controller.

14 IBM TotalStorage FAStT600 Fibre Channel Storage Server: Installation and User’s Guide

Page 45

1

1

Figure 8. RAID controller removal

2. To remove a hot-swap fan, slide the latch on the fan to unlock it; then pull the

handle and remove the fan from the storage server.

Repeat this step for the other fan and set both fans aside for later installation.

2

2

Figure 9. Hot-swap fan removal

3. To remove a power supply, grasp the pull-ring on the power supply lever and

squeeze to release it; then pull the lever fully open and remove the power

supply from the storage server.

Repeat this step for the other power supply; then set both power supplies aside

for later installation.

Chapter 2. Installing and configuring the storage server 15

Page 46

thisstepforthesecondcontroller.

3

3

Figure 10. Power supply removal

4. To remove a hard disk drive 2, press the blue latch 3 and pull the handle

1 upwards; then carefully pull the drive from the storage server.

Note: Before you remove any hard disk drives, make sure that you mark their

location so that you can reinstall them in the same location.

Repeat this step for all hard disk drives.

4

Figure 11. Hard disk drive removal

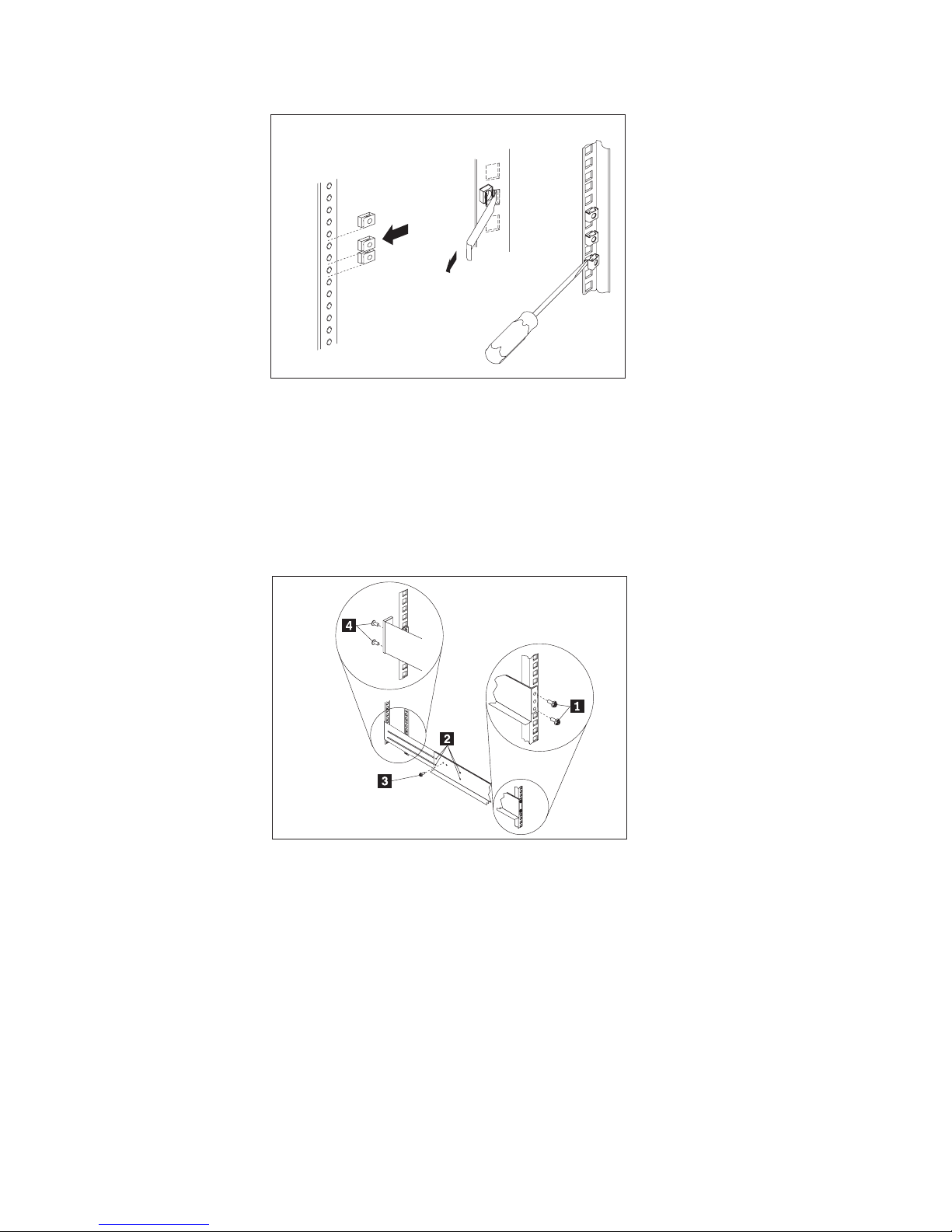

5. Use the attached template and stickers to mark the appropriate holes on the

rack; then install clip nuts or cage nuts as required for the rack cabinet.

Note: Use the cage-nut-insertion tool or a flat-blade screwdriver to install cage

nuts.

16 IBM TotalStorage FAStT600 Fibre Channel Storage Server: Installation and User’s Guide

Page 47

5

5

Cage

Cage

nuts

Clip

Clip

nuts

n uts

n uts

Cage

Cage

nuts

n uts

Figure 12. Rack nut installation

6. On the rail marked R, remove the 6/32 in. screw 3 and loosen the four screws

2; then hold the front of the rail against the outside of the right

rack-mounting-flange and loosely install two M6 screws 1.

Extend the rear of the rail outside of the rear rack-mounting-flange; then install

and tighten two M6 screws 4. Tighten the front screws 1 and repeat this

step for the other rail.

6

6

Figure 13. Rail extension

7. Tighten the rail adjustment screws 1 on both rails.

Chapter 2. Installing and configuring the storage server 17

Page 48

7

7

Figure 14. Rail adjustment screws

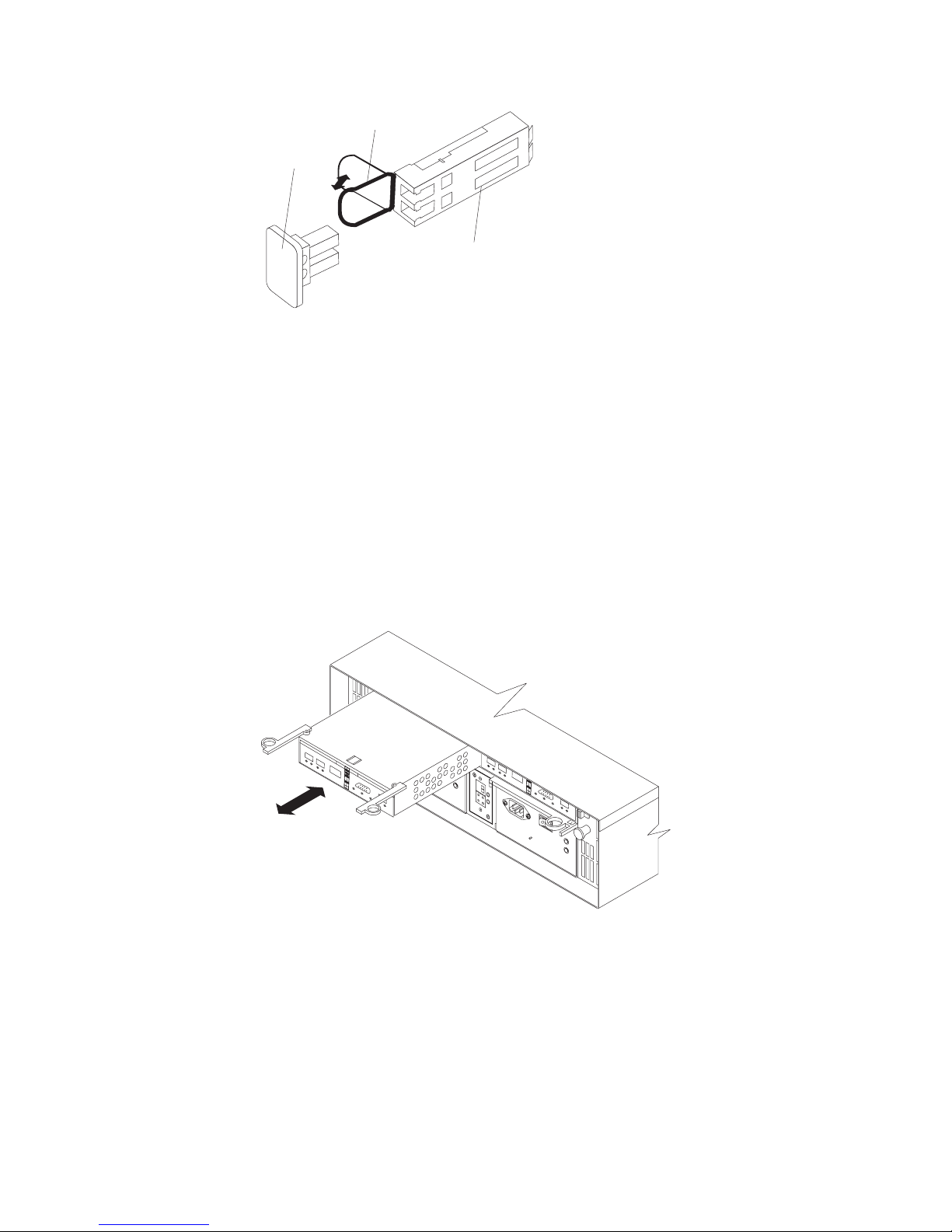

8. Remove the white screws and nuts 1 from the storage server bezel; then slide

the storage server into the rack. Align the bezel locator pins and attach the

bezel with two M6 screws 2; then install and tighten the 6-32 in. screws 3.

8

8

Figure 15. Server installation

9. Reverse step 1 through step 4 to reinstall the components that you removed.

See your storage server documentation to complete your installation. Store this

information with the storage server documentation for future use.

Setting server ID settings

The FAStT600 comes with a server ID switch that is used to identify the FAStT600

on a Fibre Channel loop. The server ID switch is located on the back of the unit, as

shown in Figure 16 on page 19.

18 IBM TotalStorage FAStT600 Fibre Channel Storage Server: Installation and User’s Guide

Page 49

Server ID Switch

Figure 16. Setting the Server ID

Server ID switch settings set the server ID to a value from 00 - 77. Server ID switch

X1 is for setting the ones position, and Server ID switch X10 is for setting the tens

position. The settings of the two server ID switches, when used together, provide a

two-digit ID of the server unit. The storage-management software uses the server

ID to provide a correlation between the storage-management graphics and the

physical storage unit. The ID indicates which physical unit corresponds to the

storage-management software status.

Use Server ID switches X10 and X1 to set the server-unit ID to any value from 0

through 7.

Note: Each server unit should have a unique ID if it is going to be connected to

other drive expansion units through the drive loop ports. The Server ID

setting is only valid for the drive loop. The amber Conflict LED (located on

the right-side of the switch) will be lit if there is another unit in the drive loop

that has the same ID setting as the server ID. See your storage server

documentation for more information.

Configuring the storage subsystem

You must configure the storage subsystem configuration after you install the storage

server in a rack. Use the information in the following sections to configure your

storage subsystem configuration.

Storage subsystem management methods

Before you configure the storage subsystem, determine which method of storage

subsystem management you want to use. You can manage the storage subsystems

in either of two ways: Host-agent management or Direct-management.

Chapter 2. Installing and configuring the storage server 19

Page 50

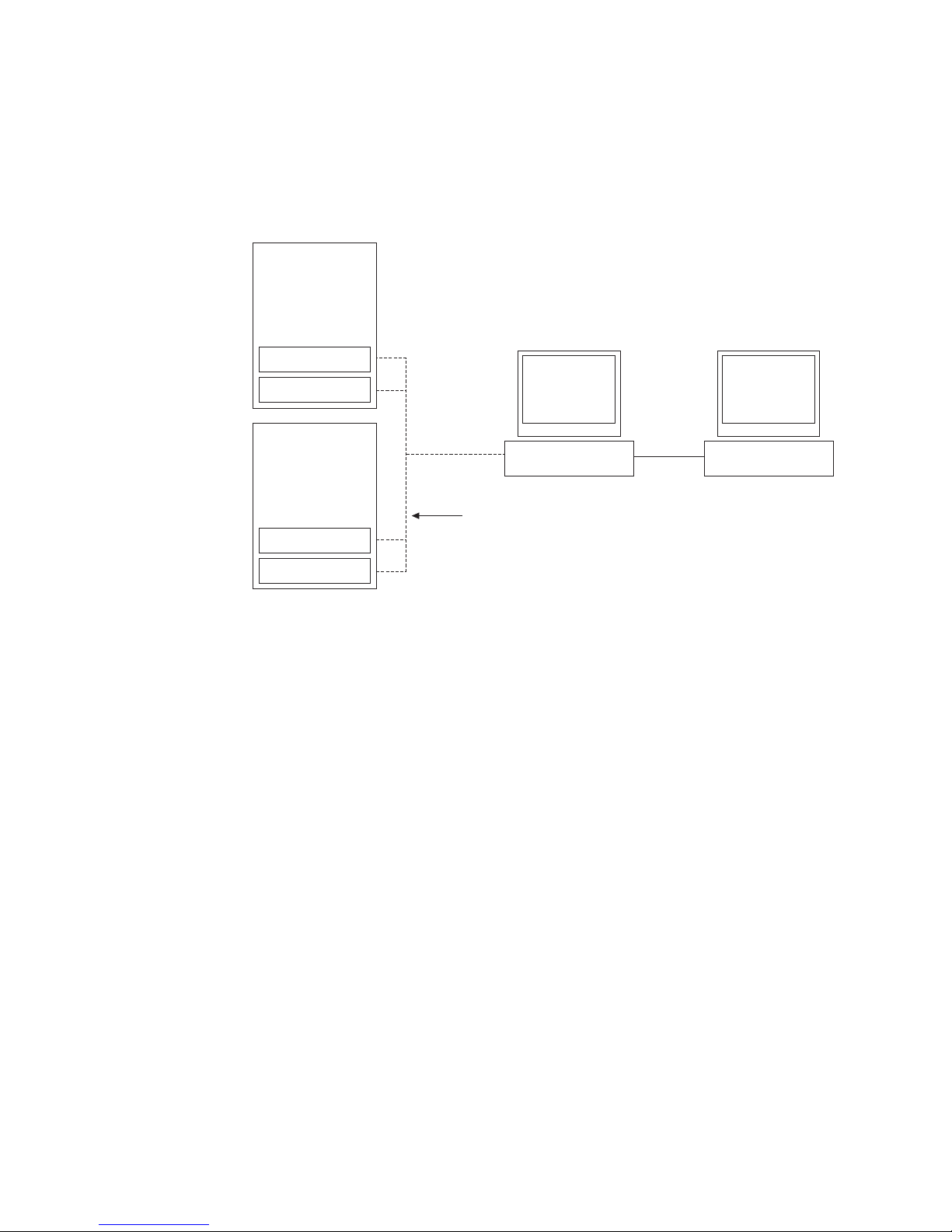

Host-agent management method:

This method uses host-agent software that is installed on the host server. You must

install at least one management station and a software-agent host. The

management station can be the host or a workstation on the Ethernet network. A

management station will have the client software installed. Figure 17 shows the

host-agent management method.

Controller

Controller

Host-agent

software

Fibre Channel

I/O path

Controller

Controller

Figure 17. Host-agent managed storage subsystems

Ethernet

Note: The client software is

Client software

Management station

(one or more)

installed on one or more

management systems,

or on the host computer.

20 IBM TotalStorage FAStT600 Fibre Channel Storage Server: Installation and User’s Guide

Page 51

Direct-management method:

This method uses Ethernet connections from a management station to each

controller. You must install at least one management station. The management

station can be the host or a workstation on the Ethernet network. A management

station will have the client software installed. Attach Ethernet cables to each

management station (one pair per storage server). You will connect the cables to

each controller later when you install the storage server. Figure 18 shows the direct

management method.

Controller

Controller

Host computer

Fibre Channel

I/O path

Controller

Controller

Storage subsystems

Note: The client software is

installed on one or more

management systems,

or on the host computer.

Ethernet

Figure 18. Direct-managed storage subsystems

Fibre Channel connections

The storage server Fibre Channel consists of a host Fibre Channel loop and a drive

Fibre Channel loop. The host Fibre Channel loop provides the fibre path for host

attachment. It can consist of Fibre Channel cables, SFPs, host bus adapters, Fibre

Channel switches, and RAID controllers. The drive Fibre Channel loop provides the

fibre path to the hard disk drives (HDDs). The drive Fibre Channel loop consists of

Fibre Channel HDDs and optional drive expansion units, Fibre Channel cables, and

SFPs.

The FAStT600 Storage Server supports redundant disk-drive-loop configurations.

Each RAID controller has three SFP ports. These SFP ports are labeled ″Host 1″,

″Host 2″, and ″Expansion″. You can build a redundant drive loop by connecting one

or more expansion units to the redundant RAID controllers. Then, use dual

Management station

Chapter 2. Installing and configuring the storage server 21

Page 52

fiber-optic cables to connect one expansion unit to another in a daisy-chain. For

more information about adding expansion units, see “Connecting additional

expansion units” on page 35.

Fibre Channel loop configurations

You must determine how the host systems will connect to the storage server. You

can connect up to two host systems directly to the storage server, or you can

connect more than two hosts to the storage server through switches. The

illustrations in the following sections show common host system configurations.

Note: The default is one partition. Four-partition and eight-partition configurations

are provided as option upgrades, as is the option of additional attachments

to expansion units (EXPs). Contact your IBM resellers or marketing

representatives for more information.

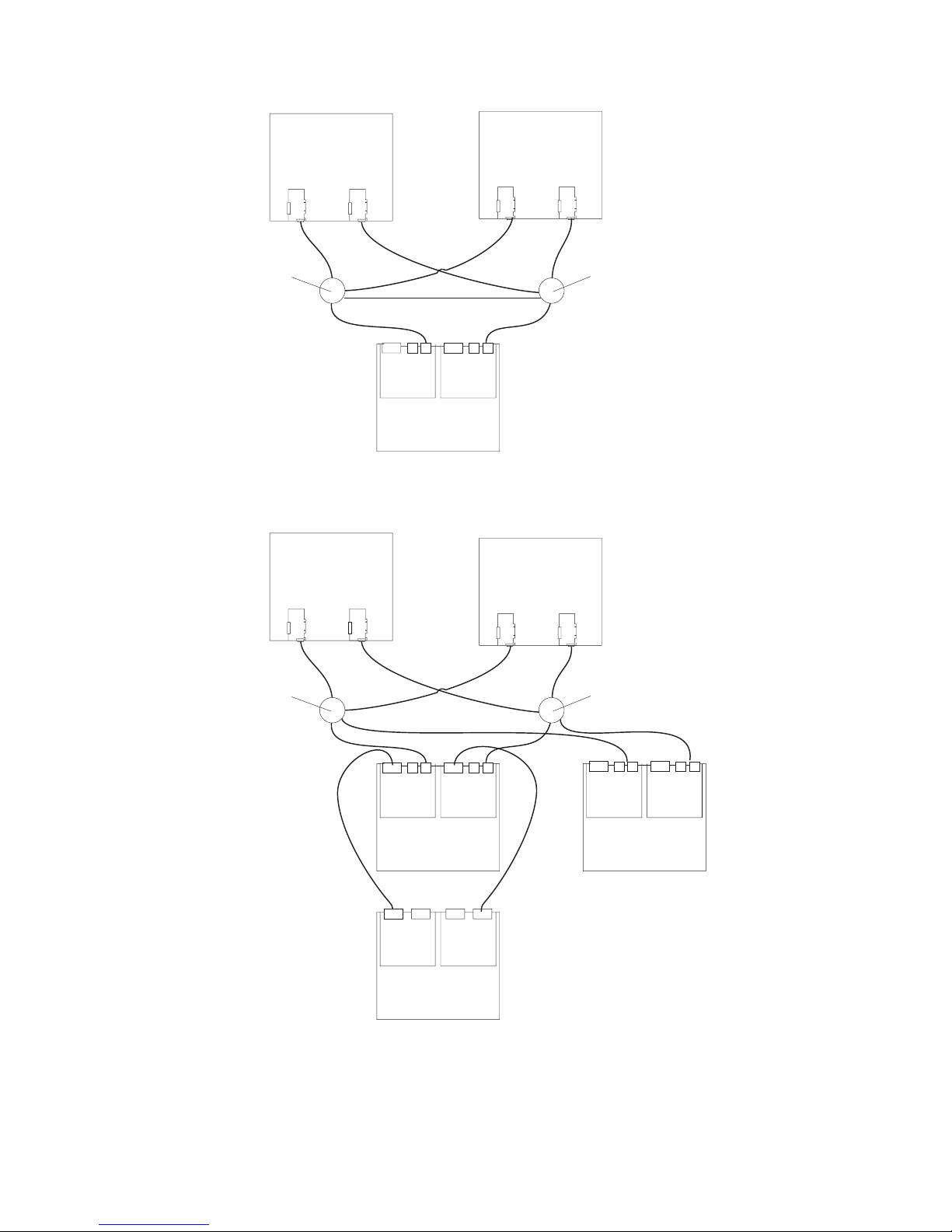

Redundant host and drive loops

This section provides examples of FAStT600 host Fibre Channel configurations,

including:

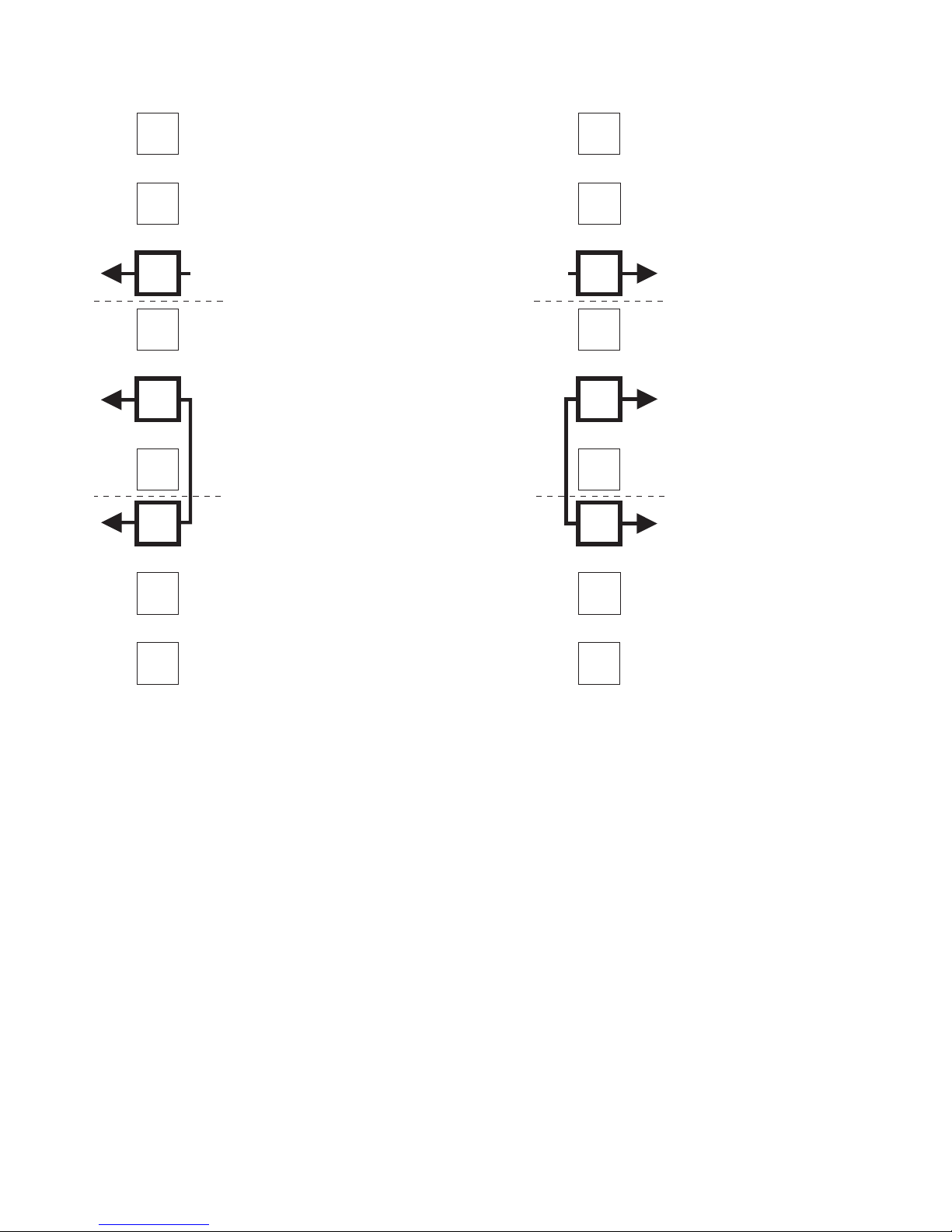

v Redundant host and drive loop Fibre Channel configurations in Figure 19 on

page 23

v Single SAN fabric zone configuration in Figure 20 on page 24

v Dual SAN fabric zone configuration, with an additional FAStT600 storage server

and an EXP expansion unit attached in Figure 21 on page 24

v Two clusters in Figure 22 on page 25

Note: These configurations have host and drive path failover protection and are

recommended for high availability.

22 IBM TotalStorage FAStT600 Fibre Channel Storage Server: Installation and User’s Guide

Page 53

Host system

with two host

adapters

Host system

with two host

adapters

Host system

with two host

adapters

Note: Node level

redundancy with

cluster software.

Switch

FAStT600 FAStT600

Host system

with two host

adapters

Host system

with two host

adapters

Switch

Figure 19. Redundant host and drive Fibre Channel loop configurations

FAStT600

Chapter 2. Installing and configuring the storage server 23

Page 54

Host system

with two host

adapters

Host system

with two host

adapters

Switch

Interswitch link

FAStT600

Switch

Figure 20. Example of a single SAN fabric zone configuration

Host system

with two host

adapters

Switch

Host system

with two host

adapters

Switch

Figure 21. Example of a dual SAN fabric zone configuration

24 IBM TotalStorage FAStT600 Fibre Channel Storage Server: Installation and User’s Guide

FAStT600 FAStT600

EXP700

(Expansion unit)

Page 55

Host system

with two host

adapters

Host system

with two host

adapters

Host system

with two host

adapters

Host system

with two host

adapters

Switch

Switch

Figure 22. Example of two clusters

Switch

FAStT600

Switch

Chapter 2. Installing and configuring the storage server 25

Page 56

Installing the storage subsystem configuration

Using the information gathered in the previous sections, install the host systems

and host adapters.

Notes:

1. See the documentation provided with your host adapters for installation

requirements and procedures.

2. Use the correct host adapter driver. For the latest supported host adapters and

drivers, go to the following Web site:

www.ibm.com/support/

Attach fiber-optic interface cables to each host adapter. You will connect the other

end of the cables to the controller later in the installation process. For more

information about handling fiber-optic cables, see “Installing fiber-optic cables” on

page 30.

Note: Do not install the storage-management software at this time, if it is not

already installed. Install the storage server completely before you install the

software because you cannot test the software installation until the hardware

is connected.

26 IBM TotalStorage FAStT600 Fibre Channel Storage Server: Installation and User’s Guide

Page 57

Chapter 3. Cabling the storage server

This chapter provides Fibre Channel and power cabling information for the storage

server.

After you attach the storage server power cables, use the instructions that are

provided in “Turning the storage server on and off” on page 37 for the initial startup

of the storage server.

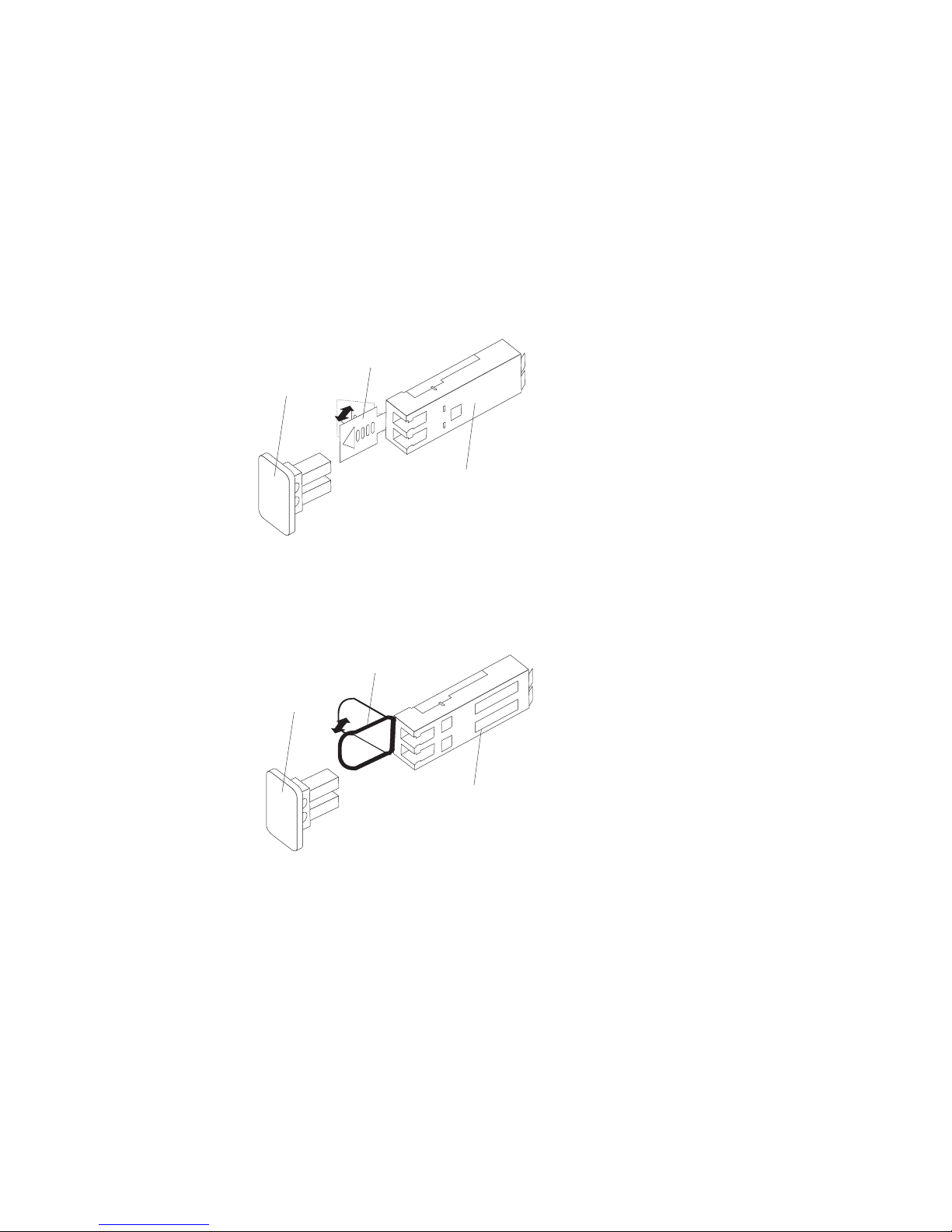

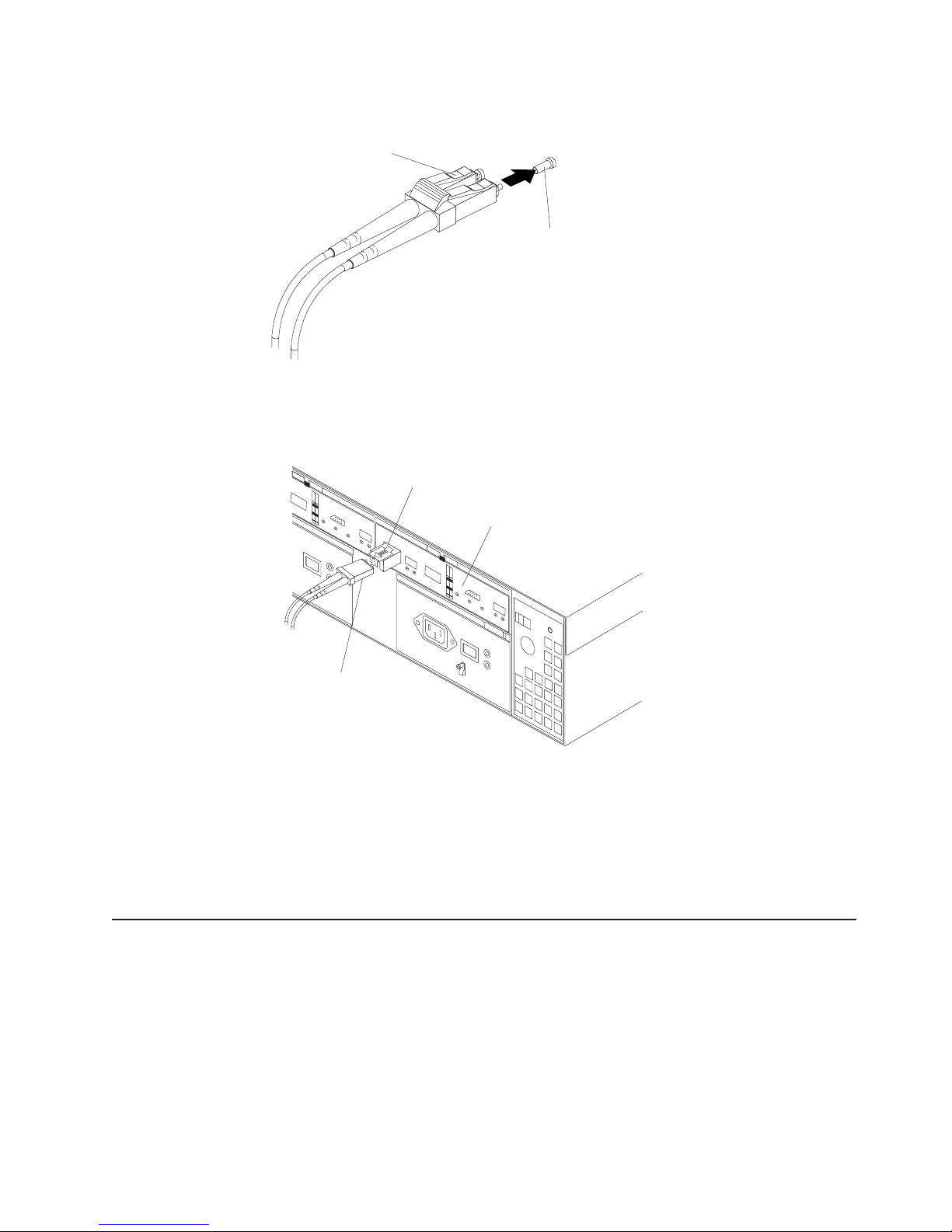

Working with SFPs and fiber-optic cables

Each RAID controller has two host ports and one expansion port. An SFP is used to

connect each host port and expansion port to hosts and expansion units. The SFP

is inserted into the port, and then a fiber-optic cable is inserted into the SFP. The

other end of the fiber-optic cable connects to an external device. SFPs are laser

products.

Statement 3

CAUTION:

When laser products (such as CD-ROMs, DVD drives, fiber optic devices, or

transmitters) are installed, note the following:

v Do not remove the covers. Removing the covers of the laser product could result in

exposure to hazardous laser radiation. There are no serviceable parts inside the

device.

v Use of controls or adjustments or performance of procedures other than those

specified herein might result in hazardous radiation exposure.

Danger

Some laser products contain an embedded Class 3A or Class 3B laser diode. Note the

following.

Laser radiation when open. Do not stare into the beam, do not view directly with optical

instruments, and avoid direct exposure to the beam.

Handling fiber-optic cables

Before using fiber-optic cables, read the following precautions.