Page 1

RS/6000 Enterprise Server Model F80

Eserver

pSeries 620 Models 6F0 and 6F1

Service Gui de

SA38-0568-03

Page 2

Fourth Edition (April 2002)

Before using this information and the product it supports, read the information in “Safety Notices” on page xi,

Appendix A, “Environmental Notices,” on page 389, and on page 0.

A reader’s comment form is provided at the back of this publication. If the form has been removed, address comments

to Information Development, Department H6DS-905-6C006, 11501 Burnet Road, Austin, Texas 78758-3493. To send

comments electronically, use this commercial internet address: aix6kpub@austin.ibm.com. Any information that you

supply may be used without incurring any obligation to you.

© International Business Machines Corporation, 2000, 2002. All rights reserved. Note to U.S. Government Users

-- Documentation related to restricted rights -- Use, duplication or disclosure is subject to restrictions set forth is GSA

ADP Schedule Contract with IBM Corp.

Page 3

Contents

Safety Notices . . . . . . . . . . . . . . . . . . . . . . . .xi

Electrical Safety . . . . . . . . . . . . . . . . . . . . . . . xii

Laser Safety Information . . . . . . . . . . . . . . . . . . . . . xii

Laser Compliance . . . . . . . . . . . . . . . . . . . . . . xii

Data Integrity and Verification . . . . . . . . . . . . . . . . . .xv

About This Book . . . . . . . . . . . . . . . . . . . . . . xvii

ISO 9000 . . . . . . . . . . . . . . . . . . . . . . . . . xvii

Online Publications . . . . . . . . . . . . . . . . . . . . . . xvii

Related Publications . . . . . . . . . . . . . . . . . . . . . . xvii

Trademarks . . . . . . . . . . . . . . . . . . . . . . . . xviii

Chapter 1. Reference Information . . . . . . . . . . . . . . . . .1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . .2

Bus Architecture . . . . . . . . . . . . . . . . . . . . . . .3

Microprocessor . . . . . . . . . . . . . . . . . . . . . . .3

Memory . . . . . . . . . . . . . . . . . . . . . . . . .4

Media Drives . . . . . . . . . . . . . . . . . . . . . . . .4

Internal Hard Disk Drives . . . . . . . . . . . . . . . . . . . .4

Power Supply . . . . . . . . . . . . . . . . . . . . . . .4

Keyboard . . . . . . . . . . . . . . . . . . . . . . . . .4

Mouse . . . . . . . . . . . . . . . . . . . . . . . . . .4

Operator Panel . . . . . . . . . . . . . . . . . . . . . . .5

Input/Output Ports . . . . . . . . . . . . . . . . . . . . . .5

Security Features . . . . . . . . . . . . . . . . . . . . . .5

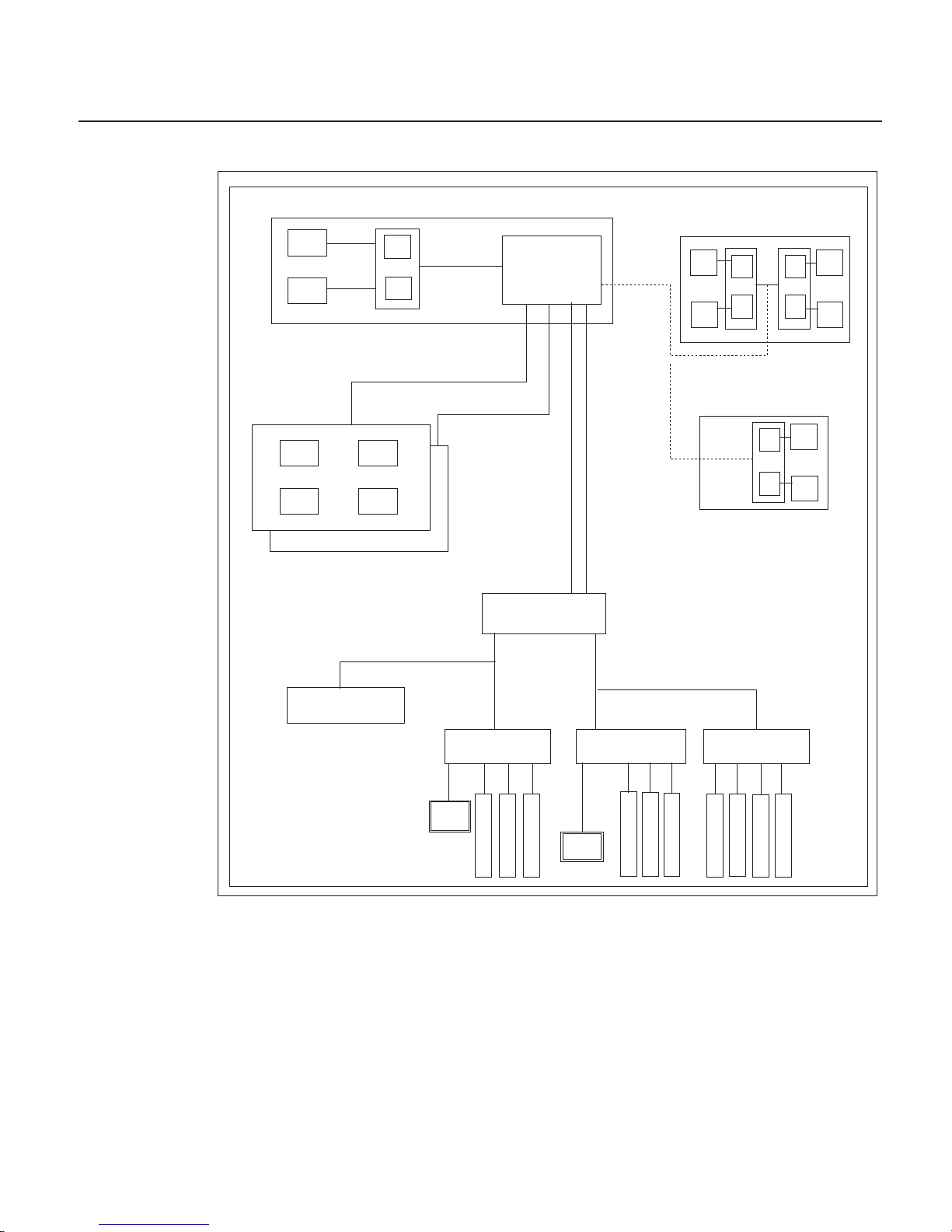

Data Flow with One-Way Processor . . . . . . . . . . . . . . . . .6

Data Flow with Two- to Six-Way Processor . . . . . . . . . . . . . . .7

Power Flow . . . . . . . . . . . . . . . . . . . . . . . . .8

Powering Off and Powering On the System . . . . . . . . . . . . . . .9

Powering Off the System . . . . . . . . . . . . . . . . . . . .9

Powering On the System . . . . . . . . . . . . . . . . . . . .9

Powering Off and Powering On the System Using the Service Processor . . . .9

Console Strategy . . . . . . . . . . . . . . . . . . . . . . .10

Power-On Self-Test . . . . . . . . . . . . . . . . . . . . . .10

POST Indicators . . . . . . . . . . . . . . . . . . . . . . .10

POST Keys . . . . . . . . . . . . . . . . . . . . . . . . .11

1 Key . . . . . . . . . . . . . . . . . . . . . . . . . .11

5 Key . . . . . . . . . . . . . . . . . . . . . . . . . .11

6 Key . . . . . . . . . . . . . . . . . . . . . . . . . .12

8 Key . . . . . . . . . . . . . . . . . . . . . . . . . .12

System Unit Locations . . . . . . . . . . . . . . . . . . . . .13

Front View . . . . . . . . . . . . . . . . . . . . . . . .13

Rear View . . . . . . . . . . . . . . . . . . . . . . . .14

System Board . . . . . . . . . . . . . . . . . . . . . . .15

Operator Panel . . . . . . . . . . . . . . . . . . . . . . .16

System Memory . . . . . . . . . . . . . . . . . . . . . . .16

iii

Page 4

One-Way Processor Memory Placement Rules . . . . . . . . . . . .16

Riser Card Memory Placement Rules . . . . . . . . . . . . . . .17

Logical and Physical Locations . . . . . . . . . . . . . . . . . .17

Physical Location Codes . . . . . . . . . . . . . . . . . . . .17

Location Code Format . . . . . . . . . . . . . . . . . . . .17

Multiple FRU Callout Instructions . . . . . . . . . . . . . . . . .18

AIX Location Codes . . . . . . . . . . . . . . . . . . . . . .19

AIX and Physical Location Code Reference Tables . . . . . . . . . . .21

Memory Riser Card and Memory DIMM Locations . . . . . . . . . . .23

One-Way Processor Card Memory DIMM Locations . . . . . . . . . .24

Specifications . . . . . . . . . . . . . . . . . . . . . . . .30

Dimensions . . . . . . . . . . . . . . . . . . . . . . . .30

Weight . . . . . . . . . . . . . . . . . . . . . . . . .31

Operating Environment . . . . . . . . . . . . . . . . . . . .31

Operating Voltage . . . . . . . . . . . . . . . . . . . . . .31

Heat Output (Maximum) . . . . . . . . . . . . . . . . . . . .31

Acoustics . . . . . . . . . . . . . . . . . . . . . . . .32

External AC Power Cables . . . . . . . . . . . . . . . . . . . .32

Service Inspection Guide . . . . . . . . . . . . . . . . . . . .33

Chapter 2. Diagnostics Overview . . . . . . . . . . . . . . . . .35

Maintenance Analysis Procedures (MAPs) . . . . . . . . . . . . . . .35

Checkpoints . . . . . . . . . . . . . . . . . . . . . . . . .36

FRU Isolation . . . . . . . . . . . . . . . . . . . . . . . .37

Electronic Service Agent for the Eserver pSeries and RS/6000 . . . . . . .37

Using the Service Processor and Electronic Service Agent Features . . . . . .38

Service Processor . . . . . . . . . . . . . . . . . . . . . .38

Electronic Service Agent . . . . . . . . . . . . . . . . . . .39

Chapter 3. Maintenance Analysis Procedures (MAPs) . . . . . . . . . .41

Entry MAP . . . . . . . . . . . . . . . . . . . . . . . . .41

Quick Entry MAP . . . . . . . . . . . . . . . . . . . . . . .42

Quick Entry MAP Table of Contents . . . . . . . . . . . . . . . .42

MAP 1020: Problem Determination . . . . . . . . . . . . . . . . .48

Purpose of this MAP . . . . . . . . . . . . . . . . . . . . .48

MAP 1520: Power . . . . . . . . . . . . . . . . . . . . . . .53

Step 1520-1 . . . . . . . . . . . . . . . . . . . . . . . .53

Step 1520-2 . . . . . . . . . . . . . . . . . . . . . . . .54

Step 1520-3 . . . . . . . . . . . . . . . . . . . . . . . .54

Step 1520-4 . . . . . . . . . . . . . . . . . . . . . . . .55

Step 1520-5 . . . . . . . . . . . . . . . . . . . . . . . .55

Step 1520-6 . . . . . . . . . . . . . . . . . . . . . . . .56

Step 1520-7 . . . . . . . . . . . . . . . . . . . . . . . .56

MAP 1540: Minimum Configuration . . . . . . . . . . . . . . . . .57

Purpose of this MAP . . . . . . . . . . . . . . . . . . . . .57

SSA Maintenance Analysis Procedures (MAPs) . . . . . . . . . . . . .75

Using SSA MAPs . . . . . . . . . . . . . . . . . . . . . .75

MAP 2010: SSA Hot-Swap Disk Drive–Start . . . . . . . . . . . . . .77

Step 2010-1 . . . . . . . . . . . . . . . . . . . . . . . .77

Step 2010-2 . . . . . . . . . . . . . . . . . . . . . . . .77

iv Service Guide

Page 5

Step 2010-3 . . . . . . . . . . . . . . . . . . . . . . . .78

Step 2010-4 . . . . . . . . . . . . . . . . . . . . . . . .78

Step 2010-5 . . . . . . . . . . . . . . . . . . . . . . . .78

Step 2010-6 . . . . . . . . . . . . . . . . . . . . . . . .78

Step 2010-7 . . . . . . . . . . . . . . . . . . . . . . . .78

Step 2010-8 . . . . . . . . . . . . . . . . . . . . . . . .79

Step 2010-9 . . . . . . . . . . . . . . . . . . . . . . . .79

Step 2010-10 . . . . . . . . . . . . . . . . . . . . . . .79

Step 2010-11 . . . . . . . . . . . . . . . . . . . . . . .79

Step 2010-12 . . . . . . . . . . . . . . . . . . . . . . .79

Step 2010-13 . . . . . . . . . . . . . . . . . . . . . . .80

MAP 2323: SSA hot-swap disk drive Intermittent Link Verification . . . . . . .80

Step 2323-1 . . . . . . . . . . . . . . . . . . . . . . . .80

Step 2323-2 . . . . . . . . . . . . . . . . . . . . . . . .80

Step 2323-3 . . . . . . . . . . . . . . . . . . . . . . . .81

MAP 2324: SSA hot-swap disk drive RAID . . . . . . . . . . . . . .81

Chapter 4. Checkpoints . . . . . . . . . . . . . . . . . . . .83

IPL Flow . . . . . . . . . . . . . . . . . . . . . . . . . .83

Service Processor Checkpoints . . . . . . . . . . . . . . . . . .85

Firmware Checkpoints . . . . . . . . . . . . . . . . . . . . .91

Boot Problems and Concerns . . . . . . . . . . . . . . . . . . 102

Step 1 . . . . . . . . . . . . . . . . . . . . . . . . . 102

Step 2 . . . . . . . . . . . . . . . . . . . . . . . . . 102

Step 3 . . . . . . . . . . . . . . . . . . . . . . . . . 103

Step 4 . . . . . . . . . . . . . . . . . . . . . . . . . 103

Step 5 . . . . . . . . . . . . . . . . . . . . . . . . . 104

Chapter 5. Error Code to FRU Index . . . . . . . . . . . . . . . 105

Four-Character Checkpoints . . . . . . . . . . . . . . . . . . . 105

Operator Panel Replacement . . . . . . . . . . . . . . . . . . 105

Replacing the Network Adapter . . . . . . . . . . . . . . . . . . 105

Determining Location Code . . . . . . . . . . . . . . . . . . . 105

Checkpoint and Error Code Index . . . . . . . . . . . . . . . . . 106

Performing Slow Boot . . . . . . . . . . . . . . . . . . . . . 107

Confirming Initial Error Code . . . . . . . . . . . . . . . . . . . 107

Memory-Related Error Codes . . . . . . . . . . . . . . . . . . 108

Operator Panel Error Codes . . . . . . . . . . . . . . . . . . . 109

SPCN Error Codes . . . . . . . . . . . . . . . . . . . . . .110

Firmware Error Codes . . . . . . . . . . . . . . . . . . . . .117

Service Processor Error Codes . . . . . . . . . . . . . . . . . . 138

System Firmware Update Messages . . . . . . . . . . . . . . . . 239

Common Firmware Error Codes . . . . . . . . . . . . . . . . . . 239

Scan Log Dump Progress Codes . . . . . . . . . . . . . . . . . 248

Problem Determination-Generated Error Codes . . . . . . . . . . . . 248

Chapter 6. Loading the System Diagnostics In Service Mode . . . . . . . 251

Default Boot List and Service Mode Bootlist . . . . . . . . . . . . . . 252

Chapter 7. Using the Service Processor . . . . . . . . . . . . . . 253

Contents v

Page 6

Service Processor Menus . . . . . . . . . . . . . . . . . . . . 254

Accessing the Service Processor Menus Locally . . . . . . . . . . . 254

Accessing the Service Processor Menus Remotely . . . . . . . . . . 254

Saving and Restoring Service Processor Settings . . . . . . . . . . . 254

Menu Inactivity . . . . . . . . . . . . . . . . . . . . . . 255

General User Menu . . . . . . . . . . . . . . . . . . . . . . 255

Privileged User Menus . . . . . . . . . . . . . . . . . . . . . 256

Main Menu . . . . . . . . . . . . . . . . . . . . . . . . 256

Service Processor Setup Menu . . . . . . . . . . . . . . . . . 258

Passwords . . . . . . . . . . . . . . . . . . . . . . . . 259

System Power Control Menu . . . . . . . . . . . . . . . . . . 262

System Information Menu . . . . . . . . . . . . . . . . . . . 266

Memory Riser Card 1 Memory DIMM Locations for Service Processor Menus 270

Memory Riser Card 2 Memory DIMM Locations for Service Processor Menus 271

Processor Card Memory DIMM Locations for Service Processor Menus . . . 271

Language Selection Menu . . . . . . . . . . . . . . . . . . 273

Call-In/Call-Out Setup Menu . . . . . . . . . . . . . . . . . . 274

Modem Configuration Menu . . . . . . . . . . . . . . . . . . 275

Serial Port Selection Menu . . . . . . . . . . . . . . . . . . 276

Serial Port Speed Setup Menu . . . . . . . . . . . . . . . . . 276

Telephone Number Setup Menu . . . . . . . . . . . . . . . . . 277

Call-Out Policy Setup Menu . . . . . . . . . . . . . . . . . . 278

Customer Account Setup Menu . . . . . . . . . . . . . . . . . 279

Service Processor Procedures in Service Mode . . . . . . . . . . . . 279

Service Processor Functions . . . . . . . . . . . . . . . . . . . 280

System Power-On Methods . . . . . . . . . . . . . . . . . . . 281

Service Processor Reboot/Restart Recovery . . . . . . . . . . . . . 282

Boot (IPL) Speed . . . . . . . . . . . . . . . . . . . . . 282

Failure During Boot Process . . . . . . . . . . . . . . . . . . 282

Failure During Normal System Operation . . . . . . . . . . . . . . 282

Service Processor Reboot/Restart Policy Controls . . . . . . . . . . . 282

System Firmware Updates . . . . . . . . . . . . . . . . . . . 284

General Information on System Firmware Updates . . . . . . . . . . 284

Determining the Level of Firmware on the System . . . . . . . . . . . 285

System Firmware Update Using a Locally Available Image . . . . . . . . 285

Updating System Firmware From the Service Processor Menus . . . . . . 286

Updating System Firmware from the AIX Service Aids . . . . . . . . . 286

Updating System Firmware from the AIX Command Line . . . . . . . . 286

Recovery Mode . . . . . . . . . . . . . . . . . . . . . . 286

Configuring and Deconfiguring Processors or Memory . . . . . . . . . . 287

Run-Time CPU Deconfiguration (CPU Gard) . . . . . . . . . . . . 288

Service Processor System Monitoring - Surveillance . . . . . . . . . . . 288

System Firmware Surveillance . . . . . . . . . . . . . . . . . 288

Operating System Surveillance . . . . . . . . . . . . . . . . . 288

Call-Out (Call-Home) . . . . . . . . . . . . . . . . . . . . . 289

Console Mirroring . . . . . . . . . . . . . . . . . . . . . . 291

System Configuration . . . . . . . . . . . . . . . . . . . . 291

Service Processor Error Log . . . . . . . . . . . . . . . . . . . 292

LCD Progress Indicator Log . . . . . . . . . . . . . . . . . . . 293

Service Processor Operational Phases . . . . . . . . . . . . . . . 294

vi Service Guide

Page 7

Pre-Standby Phase . . . . . . . . . . . . . . . . . . . . . 294

Standby Phase . . . . . . . . . . . . . . . . . . . . . . 294

Bring-Up Phase . . . . . . . . . . . . . . . . . . . . . . 295

Run-Time Phase . . . . . . . . . . . . . . . . . . . . . . 296

Chapter 8. Using System Management Services . . . . . . . . . . . 297

Password Utilities . . . . . . . . . . . . . . . . . . . . . . 298

Display Error Log . . . . . . . . . . . . . . . . . . . . . . 299

Remote Initial Program Load Setup . . . . . . . . . . . . . . . . 299

IP Parameters . . . . . . . . . . . . . . . . . . . . . . 300

Adapter Parameters . . . . . . . . . . . . . . . . . . . . . 301

Ping . . . . . . . . . . . . . . . . . . . . . . . . . . 302

SCSI Utilities . . . . . . . . . . . . . . . . . . . . . . . . 303

Select Console . . . . . . . . . . . . . . . . . . . . . . . 303

MultiBoot . . . . . . . . . . . . . . . . . . . . . . . . . 304

Select Software . . . . . . . . . . . . . . . . . . . . . . 304

Software Default . . . . . . . . . . . . . . . . . . . . . . 304

Select Install Device . . . . . . . . . . . . . . . . . . . . 304

Select Boot Devices . . . . . . . . . . . . . . . . . . . . 305

OK Prompt . . . . . . . . . . . . . . . . . . . . . . . . 306

Multiboot Startup <OFF> . . . . . . . . . . . . . . . . . . . 306

Select Language . . . . . . . . . . . . . . . . . . . . . . . 307

OK Prompt . . . . . . . . . . . . . . . . . . . . . . . . . 307

Exiting System Management Services . . . . . . . . . . . . . . . . 307

Chapter 9. Removal and Replacement Procedures . . . . . . . . . . 309

Handling Static-Sensitive Devices . . . . . . . . . . . . . . . . . 310

Removal and Replacement Procedures . . . . . . . . . . . . . . . 310

Covers . . . . . . . . . . . . . . . . . . . . . . . . . .311

Removing the Covers . . . . . . . . . . . . . . . . . . . .311

Replacing Covers . . . . . . . . . . . . . . . . . . . . . 314

Removing Processor and Memory Riser Card Cover . . . . . . . . . . . 315

Replacing Processor and Memory Riser Card Cover . . . . . . . . . . 315

Hot-Pluggable FRUs . . . . . . . . . . . . . . . . . . . . . 316

Hot-Pluggable Options . . . . . . . . . . . . . . . . . . . . . 316

Stopping the System Unit . . . . . . . . . . . . . . . . . . . . 316

Disk Drive Options . . . . . . . . . . . . . . . . . . . . . . 317

Disk Drive Slot LED Definitions . . . . . . . . . . . . . . . . . 318

Preinstallation Considerations . . . . . . . . . . . . . . . . . 319

Removing Hot-Plug SCSI Disk Drives . . . . . . . . . . . . . . . 319

Replacing Hot-Plug SCSI Disk Drives . . . . . . . . . . . . . . . 321

Configuring and Deconfiguring SCSI Hot-Swap Disk Drives . . . . . . . 323

Removing Hot-Plug SSA Disk Drives . . . . . . . . . . . . . . . 324

Replacing Hot-Plug SSA Disk Drives . . . . . . . . . . . . . . . 326

PCI Adapter Options . . . . . . . . . . . . . . . . . . . . . 328

PCI Slot LED Definitions . . . . . . . . . . . . . . . . . . . 328

Removing Adapter Cards . . . . . . . . . . . . . . . . . . . . 329

Removing a Non-Hot-Pluggable PCI Adapter . . . . . . . . . . . . 329

Removing a Hot-Pluggable PCI Adapter . . . . . . . . . . . . . . 330

Replacing Adapter Cards . . . . . . . . . . . . . . . . . . . . 332

Contents vii

Page 8

Replacing a Non-Hot-Pluggable PCI Adapter . . . . . . . . . . . . 333

Replacing a Hot-Pluggable PCI Adapter . . . . . . . . . . . . . . 334

PCI Hot-Plug Manager Access . . . . . . . . . . . . . . . . . . 336

Accessing Hot-Plug Management Functions . . . . . . . . . . . . . 336

PCI Hot-Plug Manager Menu . . . . . . . . . . . . . . . . . . 337

Fans and Fan Fillers . . . . . . . . . . . . . . . . . . . . . 338

Removal . . . . . . . . . . . . . . . . . . . . . . . . 338

Replacement . . . . . . . . . . . . . . . . . . . . . . . 338

Power Supplies . . . . . . . . . . . . . . . . . . . . . . . 338

Removal . . . . . . . . . . . . . . . . . . . . . . . . 339

Replacement . . . . . . . . . . . . . . . . . . . . . . . 339

Installing the Redundant Power and Cooling Option . . . . . . . . . . . 339

Installing a Redundant Fan . . . . . . . . . . . . . . . . . . 339

Installing a Redundant Power Supply . . . . . . . . . . . . . . . 340

Memory Riser Card and Processor Card . . . . . . . . . . . . . . . 342

Removing a Memory Riser Card or One-Way Processor Card . . . . . . . 342

Installing a Memory Riser Card or a One-Way Processor Card . . . . . . 343

Memory and Processor Card CEC Assembly . . . . . . . . . . . . . 344

Removal . . . . . . . . . . . . . . . . . . . . . . . . 344

Replacement . . . . . . . . . . . . . . . . . . . . . . . 344

System Memory Options . . . . . . . . . . . . . . . . . . . . 345

Memory Placement with a One-Way Processor Card . . . . . . . . . . 345

Memory Placement for a Memory Riser Card . . . . . . . . . . . . 346

Memory DIMMs . . . . . . . . . . . . . . . . . . . . . . . 346

Removing Memory DIMMs . . . . . . . . . . . . . . . . . . 346

Replacement . . . . . . . . . . . . . . . . . . . . . . . 348

Processor Card . . . . . . . . . . . . . . . . . . . . . . 349

Removal . . . . . . . . . . . . . . . . . . . . . . . . 349

Replacement . . . . . . . . . . . . . . . . . . . . . . . 349

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . 349

Removal . . . . . . . . . . . . . . . . . . . . . . . . 350

Replacement . . . . . . . . . . . . . . . . . . . . . . . 350

Operator Panel . . . . . . . . . . . . . . . . . . . . . . . 351

Removal . . . . . . . . . . . . . . . . . . . . . . . . 351

Operator Panel Cable . . . . . . . . . . . . . . . . . . . . . 353

Removal . . . . . . . . . . . . . . . . . . . . . . . . 353

PCI Adapter Dividers . . . . . . . . . . . . . . . . . . . . . 353

Removal . . . . . . . . . . . . . . . . . . . . . . . . 353

Replacement . . . . . . . . . . . . . . . . . . . . . . . 354

System Board Assembly . . . . . . . . . . . . . . . . . . . . 354

Removal . . . . . . . . . . . . . . . . . . . . . . . . 354

Replacement . . . . . . . . . . . . . . . . . . . . . . . 355

Internal Disk Drive Bays . . . . . . . . . . . . . . . . . . . . 355

Removing a Two-Position SCSI Disk Drive Bay . . . . . . . . . . . 356

Replacing a Two-Position SCSI Disk Drive Bay . . . . . . . . . . . . 357

Removing Six-Position SCSI (SES) or SSA Disk Drive Bays . . . . . . . 358

Replacing Six-Position SCSI (SES) or SSA Disk Drive Bays . . . . . . . 362

SCSI and SSA Cabling Configurations . . . . . . . . . . . . . . . 366

Two-Position SCSI Disk Drive Bay Cabling . . . . . . . . . . . . . 366

First Six-Position SCSI Disk Drive Bay Cabling . . . . . . . . . . . . 367

viii Service Guide

Page 9

Second Six-Position SCSI Disk Drive Bay Cabling . . . . . . . . . . . 368

Two Six-Position SCSI RAID Bays Connected to a Single RAID Adapter . . . 368

One Six-Position SCSI RAID Bay and One Six-Position SSA Bay . . . . . 369

Two Six-Position SSA Bays Connected to the Same SSA Loop . . . . . . 369

Replacing Non-Hot-Plug Drives . . . . . . . . . . . . . . . . . . 370

Removing a Media Drive from the Optional Media Position . . . . . . . . 370

Replacing a Media Drive in the Optional Media Position . . . . . . . . . 371

Removing a Disk Drive from the Two-Position Disk Drive Bay . . . . . . . 371

Replacing a Disk Drive in the Two-Position Disk Drive Bay . . . . . . . . 373

Chapter 10. Parts Information . . . . . . . . . . . . . . . . . . 375

Covers . . . . . . . . . . . . . . . . . . . . . . . . . . 375

Right Side . . . . . . . . . . . . . . . . . . . . . . . . . 376

Left Side . . . . . . . . . . . . . . . . . . . . . . . . . 379

Accessories . . . . . . . . . . . . . . . . . . . . . . . . 382

Power Cords . . . . . . . . . . . . . . . . . . . . . . . 382

Keyboards and Mouse (White) . . . . . . . . . . . . . . . . . 384

Keyboards and Mouse (Black) . . . . . . . . . . . . . . . . . 386

Appendix A. Environmental Notices . . . . . . . . . . . . . . . . 389

Product Recycling and Disposal . . . . . . . . . . . . . . . . . . 389

Environmental Design . . . . . . . . . . . . . . . . . . . . . 393

Acoustical Noise Emissions . . . . . . . . . . . . . . . . . . . 394

Declared Acoustical Noise Emissions . . . . . . . . . . . . . . . . 394

Appendix B. Notices . . . . . . . . . . . . . . . . . . . . . 395

Product Recycling and Disposal . . . . . . . . . . . . . . . . . . 395

Battery Return Program . . . . . . . . . . . . . . . . . . . . 396

Appendix C. Service Processor Setup and Test . . . . . . . . . . . 397

Service Processor Setup Checklist . . . . . . . . . . . . . . . . . 397

Testing the Setup . . . . . . . . . . . . . . . . . . . . . . 398

Testing Call-In . . . . . . . . . . . . . . . . . . . . . . 398

Testing Call-Out . . . . . . . . . . . . . . . . . . . . . . 398

Serial Port Configuration . . . . . . . . . . . . . . . . . . . 399

Appendix D. Modem Configurations . . . . . . . . . . . . . . . 401

Sample Modem Configuration Files . . . . . . . . . . . . . . . . 401

Generic Modem Configuration Files . . . . . . . . . . . . . . . 401

Specific Modem Configuration Files . . . . . . . . . . . . . . . 401

Configuration File Selection . . . . . . . . . . . . . . . . . . . 402

Examples for Using the Generic Sample Modem Configuration Files . . . . 403

Customizing the Modem Configuration Files . . . . . . . . . . . . . 404

IBM 7852-400 DIP Switch Settings . . . . . . . . . . . . . . . . 405

Xon/Xoff Modems . . . . . . . . . . . . . . . . . . . . . 405

Ring Detection . . . . . . . . . . . . . . . . . . . . . . 406

Terminal Emulators . . . . . . . . . . . . . . . . . . . . . 406

Recovery Procedures . . . . . . . . . . . . . . . . . . . . 406

Transfer of a Modem Session . . . . . . . . . . . . . . . . . . 407

Recovery Strategy . . . . . . . . . . . . . . . . . . . . . 408

Contents ix

Page 10

Prevention Strategy . . . . . . . . . . . . . . . . . . . . . 408

Modem Configuration Sample Files . . . . . . . . . . . . . . . . 409

Sample File modem_m0.cfg . . . . . . . . . . . . . . . . . . 409

Sample File modem_m1.cfg . . . . . . . . . . . . . . . . . .411

Sample File modem_z.cfg . . . . . . . . . . . . . . . . . . . 413

Sample File modem_z0.cfg . . . . . . . . . . . . . . . . . . 415

Sample File modem_f.cfg . . . . . . . . . . . . . . . . . . . 417

Sample File modem_f0.cfg . . . . . . . . . . . . . . . . . . 419

Sample File modem_f1.cfg . . . . . . . . . . . . . . . . . . 421

Appendix E. SSA Problem Determination Procedures . . . . . . . . . 425

Disk Drive Module Power-On Self-Tests (POSTs) . . . . . . . . . . . . 425

Adapter Power-On Self-Tests (POSTs) . . . . . . . . . . . . . . . 425

Appendix F. SSA Software and Microcode Errors . . . . . . . . . . . 427

Service Request Numbers (SRNs) . . . . . . . . . . . . . . . . . 427

SRN Table . . . . . . . . . . . . . . . . . . . . . . . . 427

Using the SRN Table . . . . . . . . . . . . . . . . . . . . 427

Software and Microcode Errors . . . . . . . . . . . . . . . . . 428

FRU Names and Abbreviations Used in the SRN Table . . . . . . . . . 428

SSA Loop Configurations That Are Not Valid . . . . . . . . . . . . . 436

SSA Location Code Format . . . . . . . . . . . . . . . . . . . 437

SSA Loops and Links . . . . . . . . . . . . . . . . . . . . . 438

The SSA Adapter . . . . . . . . . . . . . . . . . . . . . 438

Disk Drive Module Strings . . . . . . . . . . . . . . . . . . . 439

Pdisks, Hdisks, and Disk Drive Module Identification . . . . . . . . . . 439

Rules for SSA Loops . . . . . . . . . . . . . . . . . . . . 440

Loops and Data Paths . . . . . . . . . . . . . . . . . . . . 440

Index . . . . . . . . . . . . . . . . . . . . . . . . . . 443

x Service Guide

Page 11

Safety Notices

A danger notice indicates the presence of a hazard that has the potential of causing

death or serious personal injury. Danger notices appear on the following pages:

v xii

v 53

v 309

v 339

A

caution notice indicates the presence of a hazard that has the potential of causing

moderate or minor personal injury. Caution notices appear on the following pages:

v xii

v xii

v 53

v 309

v 370

Note:

For a translation of these notices, see the System Unit Safety Information

manual, order number SA23-2652.

xi

Page 12

Electrical Safety

Observe the following safety instructions any time you are connecting or disconnecting

devices attached to the server.

DANGER

An

electrical outlet that is not correctly wired could place hazardous voltage

on metal parts of the system or the devices that attach to the system. It is the

responsibility of the customer to ensure that the outlet is correctly wired and

grounded to prevent an electrical shock.

Before installing or removing signal cables, ensure that the power cables for

the system unit and all attached devices are unplugged.

When adding or removing any additional devices to or from the system,

ensure that the power cables for those devices are unplugged before the

signal cables are connected. If possible, disconnect all power cables from the

existing system before you add a device.

Use one hand, when possible, to connect or disconnect signal cables to

prevent a possible shock from touching two surfaces with different electrical

potentials.

During an electrical storm, do not connect cables for display stations, printers,

telephones, or station protectors for communications lines.

D05

CAUTION:

This product is equipped with a three-wire power cable and plug for the user’s

safety. Use this power cable with a properly grounded electrical outlet to avoid

electrical shock.

C01

Laser Safety Information

CAUTION:

This product may contain a CD-ROM, DVD-ROM, or laser module on a PCI card,

which are class 1 laser products.

C30

Laser Compliance

All lasers are certified in the U.S. to conform to the requirements of DHHS 21 CFR

Subchapter J for class 1 laser products. Outside the U.S., they are certified to be in

compliance with the IEC 825 (first edition 1984) as a class 1 laser product. Consult the

label on each part for laser certification numbers and approval information.

xii Service Guide

Page 13

CAUTION:

All IBM laser modules are designed so that there is never any human access to

laser radiation above a class 1 level during normal operation, user maintenance,

or prescribed service conditions. Data processing environments can contain

equipment transmitting on system links with laser modules that operate at

greater than class 1 power levels. For this reason, never look into the end of an

optical fiber cable or open receptacle. Only trained service personnel should

perform the inspection or repair of optical fiber cable assemblies and receptacles.

C25,

C26

Preface xiii

Page 14

xiv Service Guide

Page 15

Data Integrity and Verification

IBM computer systems contain mechanisms designed to reduce the possibility of

undetected data corruption or loss. This risk, however, cannot be eliminated. Users who

experience unplanned outages, system failures, power fluctuations or outages, or

component failures must verify the accuracy of operations performed and data saved or

transmitted by the system at or near the time of the outage or failure. In addition, users

must establish procedures to ensure that there is independent data verification before

relying on such data in sensitive or critical operations. Users should periodically check

the IBM support websites for updated information and fixes applicable to the system and

related software.

xv

Page 16

xvi Service Guide

Page 17

About This Book

This book provides maintenance information that is specific to the Enterprise Server

Model F80 and Eserver pSeries 620 Models 6F0 and 6F1, as well as to adapters and

attached devices that do not have their own service information. In this book, the

Enterprise Server Model F80 and Eserver pSeries 620 Models 6F0 and 6F1 are

hereafter referred to as the ″system″ or the ″server.″

This book also contains Maintenance Analysis Procedures (MAPs) that are not common

to other systems. MAPs that are common to all systems are contained in the RS/6000

and Eserver pSeries Diagnostic Information for Multiple Bus Systems.

This book is used by the service technician to repair system failures. This book

assumes that the service technician has had training on the system unit.

ISO 9000

ISO 9000 registered quality systems were used in the development and manufacturing

of this product.

Online Publications

RS/6000 and pSeries publications are available online. To access the online books, visit

our Web site at: http://www.rs6000.ibm.com/resource/hardware_docs/

Related Publications

The following publications are available for purchase:

v The System Unit Safety Information, order number SA23-2652, contains translations

of safety information used throughout this book.

v The RS/6000 Enterprise Server Model F80, Eserver pSeries 620 Models 6F0 and

6F1 User’s Guide, order number SA38-0567, contains information to help users set

up, install options, configure and modify the system, and solve minor problems.

v The RS/6000 and Eserver pSeries Diagnostic Information for Multiple Bus Systems,

order number SA38-0509, contains common diagnostic procedures, error codes,

service request numbers, and failing function codes. This manual is intended for

trained service technicians.

v The PCI Adapter Placement Reference, order number SA38-0538, contains

guidelines for placement of PCI adapters into I/O slots of Models F80, 6F0, and 6F1

systems. This manual is intended to help when planning to install adapters so that

optimum, tested adapter configurations are used.

v The RS/6000 and Eserver pSeries Adapters, Devices, and Cable Information for

Multiple Bus Systems, order number SA38-0516, contains information about

adapters, external devices, and cabling. This manual is intended to supplement

information found in the RS/6000 and Eserver pSeries Diagnostic Information for

Multiple Bus Systems.

xvii

Page 18

v The Site and Hardware Planning Information, order number SA38-0508, contains

information to help you plan your installation.

v SSA Adapters User’s Guide and Maintenance Information, order number SA33-3272,

is intended to help users and service representatives work with and diagnose

problems with SSA adapters and devices.

v RS/6000 SP Systems Service Guide, order number GA22-7442, is intended to help

users and service representatives work with and diagnose problems with SP

systems.

v Clustered Eserver Installation and Service Guide, order number SA22-7863, is

intended to help users and service representatives work with and diagnose problems

with clustered Eserver systems.

Trademarks

The following terms are trademarks of International Business Machines Corporation in

the United States, other countries, or both:

v AIX

v RS/6000

v pSeries

v e (logo)

Other

company, product, and service names may be trademarks or service marks of

others.

xviii Service Guide

Page 19

Chapter 1. Reference Information

This chapter provides an overview of the system, including a logical description and a

physical overview of the system. Additional details pertaining to the system are also

provided. These include:

v Memory overview and placement rules

v General description of the operator panel

v System location rules and descriptions

v Powering on and off the system

v Power flow

v Data flow

1

Page 20

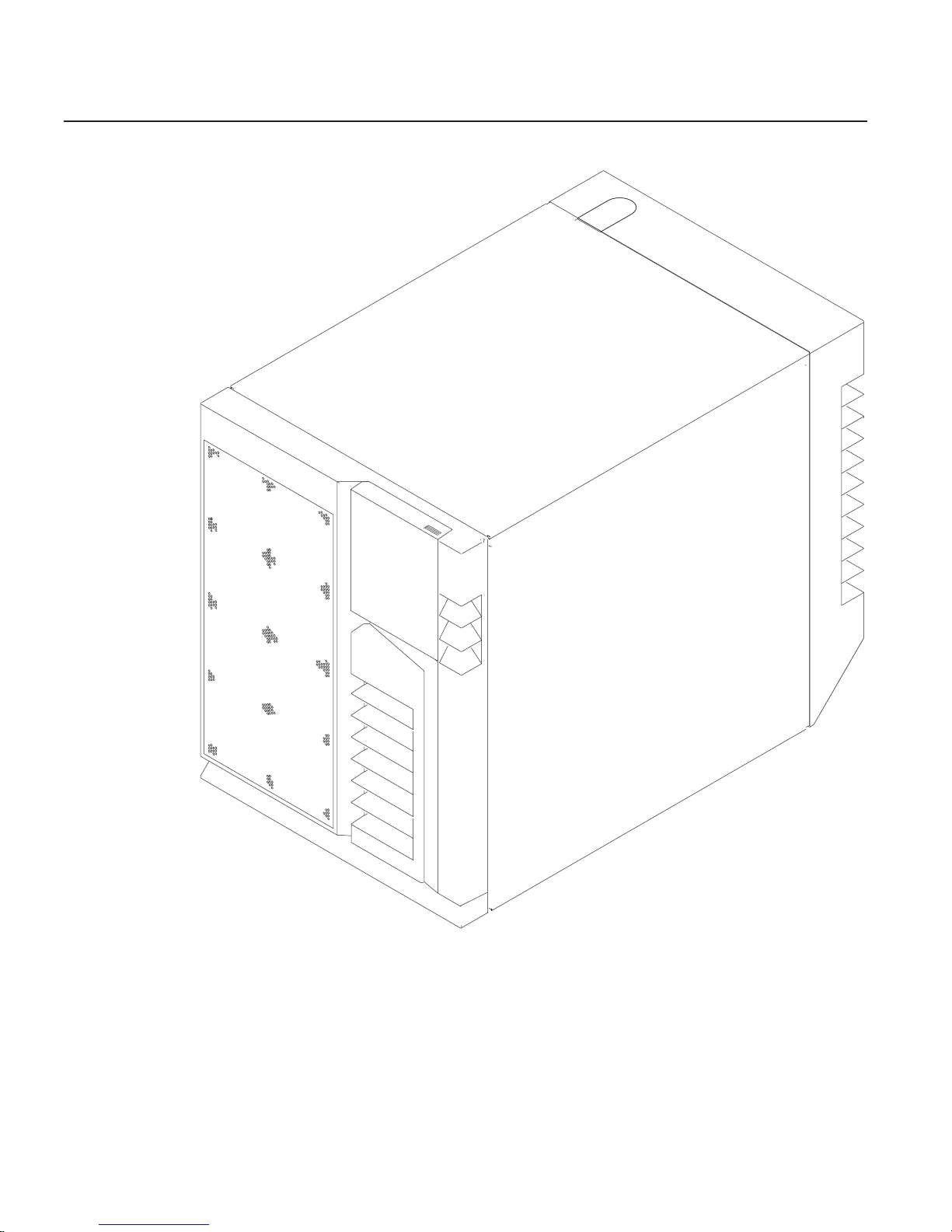

Overview

This system is a high-performance entry server in a deskside system unit. It provides

64-bit symmetric multiprocessing (SMP) with true multithreaded application support in a

double-wide deskside box.

2 Service Guide

Page 21

Bus Architecture

Te n PCI slots are available:

v Six of the slots are 64-bit PCI full-sized slots at 66 MHz, 3.3 volts.

v Four of the slots are 64-bit PCI full-sized slots at 33 MHz, 5 volts.

v

Bus 1 contains:

– PCI slot 3

– PCI slot 4

– PCI slot 5

– Integrated Ultra2 SCSI

v

Bus 2 contains:

– PCI slot 6

– PCI slot 7

– PCI slot 8

– Integrated Ethernet (32-bit)

v

Bus 3 contains:

– PCI slot 9

– PCI slot 10

– PCI slot 11

– PCI slot 12

The PCI buses support both 32-bit and 64-bit adapters. Slots 3, 4, 5, 8, 9, and 10

support adapters running at 3.3 volts at up to 66 MHz. Slots 6, 7, 11, and 12 support

adapters running at 5 volts at 33 MHz. The server data flows are shown in “Data Flow

with One-Way Processor” on page 6 and “Data Flow with Two- to Six-Way Processor”

on page 7.

Microprocessor

The Models F80 and 6F1 can have one to six processors, of either of two processor

types, in various configurations:

v Minimum configuration is one 450 MHz processor, which has 2 MB of L2 cache.

v Two or four 450 MHz processors, each with 4 MB of L2 cache.

v Six 500 MHz processors, each with 4 MB of L2 cache.

OR

v Minimum configuration is either one 600 MHz processor, which has 2 MB of L2

cache, or one 750 MHz processor, which has 8 MB of L2 cache.

v Two or four 600 MHz processors, each with 4 MB of L2 cache.

v Two or four 750 MHz processors, each with 8 MB of L2 cache.

v Six 668 MHz processors, each with 8 MB of L2 cache.

v Six 750 MHz processors, each with 8 MB of L2 cache.

The

Model 6F0 can have one to four processors, of either of two processor types, in

various configurations:

v Minimum configuration is one 450 MHz processor, which has 2 MB of L2 cache.

v Two or four 450 MHz processors, each with 4 MB of L2 cache.

OR

Chapter 1. Reference Information 3

Page 22

v Minimum configuration is either one 600 MHz processor, which has 2 MB of L2

cache, or one 750 MHz processor, which has 8 MB of L2 cache.

v Two or four 600 MHz processors, each with 4 MB of L2 cache.

v Two or four 750 MHz processors, each with 8 MB of L2 cache.

Memory

v 256 MB (minimum) to 32 GB (maximum).

v One or two memory riser cards; each riser card has 16 sockets. 128 MB, 256 MB,

512 MB and 1 GB dual inline memory modules (DIMMs) are available.

v Certain 32 MB DIMMs from older systems can also be used when upgrading the

system memory.

Media Drives

Three media bays are available:

v Optional media bay (D17) that can accommodate 5.25-inch drives such as CD-ROM

drives, tape drives, or other removable media drives

v Standard CD-ROM drive with sliding tray (D16)

v Standard 3.5-inch, 1.44 MB diskette drive (D15)

Internal Hard Disk Drives

Three bays are available to install disk drives, as follows:

v Disk bay 3, a two-position SCSI disk drive bay (D13 and D14)

This bay supports two SCSI disk drives.

v Disk bay 2, a six-position hot-plug disk drive bay (D07 - D12)

This bay can accommodate a six-position SCSI disk drive cage or a six-position SSA

disk drive cage.

v Disk bay 1, a six-position hot-plug disk drive bay (D01 - D06)

This bay can accommodate a six-position SCSI disk drive cage or a six-position SSA

disk drive cage.

Power Supply

v 575-watt power supply (two required), usable with 100-127 V ac (low voltage) or

200-240 V ac (high voltage)

Keyboard

v Standard: 101-key enhanced keyboard

v Optional: 101/102-key or 106-key enhanced keyboard

Mouse

v Three-button

4 Service Guide

Page 23

Operator Panel

v 32-character LED diagnostics display

v Power and Reset buttons

Input/Output Ports

v 25-pin parallel

v 9-pin serial (4)

v Keyboard

v Mouse

v Ultra 2 SCSI LVD

v 10/100BaseT Ethernet

Security Features

v Power-on password

v Privileged-access password

v Unattended start mode

Chapter 1. Reference Information 5

Page 24

Data Flow with One-Way Processor

System Board

L2

Processor Card (1 way only)Processor Card (1 way only)

6XX

Bus 0

P

Memory Card

(1 only is optional)

Memory Card

(1 only is optional)

SMI BUS 0, 1

SMI

SMI

SMI

SMI

SMI

SMI

SMI BUS 2, 3

64-bit

PCI Bus 2

64-bit

PCI Bus 2

RIO

(2)

PCI Host Bridge

Memory

Controller

Memory

Controller

64-bit

PCI Bus 1

64-bit

PCI Bus 1

PCI to PCI

Bridge 3

PCI to PCI

Bridge 3

5V5V

PCI to PCI

Bridge 2

PCI to PCI

Bridge 2

5V5V

3.3

V

3.3

V

3.3V3.3

V

3.3V3.3

V

3.3V3.3

V

3.3V3.3

V

3.3V3.3

V

PCI to PCI

Bridge 1

PCI to PCI

Bridge 1

Converged Support

Processor

Converged Support

Processor

S

L

O

T

3

S

L

O

T

3

S

L

O

T

6

S

L

O

T

6

S

L

O

T

9

S

L

O

T

9

S

L

O

T

4

S

L

O

T

4

S

L

O

T

7

S

L

O

T

7

S

L

O

T

10

S

L

O

T

10

S

L

O

T

5

S

L

O

T

5

S

L

O

T

8

S

L

O

T

8

S

L

O

T

11

S

L

O

T

11

S

L

O

T

12

S

L

O

T

12

SCSI

10/100

E’net

10/100

E’net

256 MB - 16 GB

6 Service Guide

Page 25

Data Flow with Two- to Six-Way Processor

System Board

L2

2-Way System

6XX

Bus 0

L2

P

P

L2

L2

P

6XX

Bus 1

Memory Cards

(1 or 2)

Memory Cards

(1 or 2)

256 MB - 32 GB

SMI BUS 0, 1

SMI

SMI

SMI

SMI

SMI BUS 2, 3

64-bit

PCI Bus 2

64-bit

PCI Bus 2

RIO

(2)

6-Way System

L2

L2

P

4-Way System

OR

L2

L2

P

P P

P

PCI Host Bridge

Memory

Controller

Memory

Controller

64-bit

PCI Bus 1

64-bit

PCI Bus 1

10/100

E’net

10/100

E’net

PCI to PCI

Bridge 3

PCI to PCI

Bridge 3

5V

5V

PCI to PCI

Bridge 2

PCI to PCI

Bridge 2

3.3V3.3

V

5V

5V

3.3

V

3.3

V

3.3V3.3

V

3.3V3.3

V

3.3V3.3

V

3.3V3.3

V

PCI to PCI

Bridge 1

PCI to PCI

Bridge 1

Converged Support

Processor

Converged Support

Processor

S

L

O

T

3

S

L

O

T

3

S

L

O

T

7

S

L

O

T

7

S

L

O

T

6

S

L

O

T

6

S

L

O

T

4

S

L

O

T

4

S

L

O

T

8

S

L

O

T

8

S

L

O

T

10

S

L

O

T

10

S

L

O

T

9

S

L

O

T

9

S

L

O

T

5

S

L

O

T

5

S

L

O

T

11

S

L

O

T

11

S

L

O

T

12

S

L

O

T

12

SCSI

Chapter 1. Reference Information 7

Page 26

Power Flow

The following diagram shows the right side of the system with the cover removed.

1

2

3

45

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

1 110 V ac/220 V ac power into system

board assembly

11 Power 1 to DASD bay 1 (DB1)

2 110 V ac/220 V ac power into power

supply V1

12 Power 1 to DASD bay 2 (DB2)

3 2.5 V dc out of power supply V1 into

system board

13 Power to cooling fans

4 2.5/3.3 V dc out of power supply V1 into

system board

14 Power 2 to DASD bay 2 (DB2)

5 3.3 V dc out of power supply V1 into

system board

15 Signal to diskette drive

6 5 V dc out of power supply V1 into

system board

16 I2C to DASD bay 2 (DB2)

7 Ground out of power supply V1 into

system board

17 Power to diskette drive

8 12 V dc out of power supply V1 into

system board

18 Signal to operator panel

9 I2C to DASD bay 1 (DB1) 19 Power to media drive bay

10 Power 2 to DASD bay 1 (DB1) 20 Power 1 to two-position disk drive bay 3

(DB3)

8 Service Guide

Page 27

Powering Off and Powering On the System

This section provides procedures for powering off and powering on the system.

Powering Off the System

If the system is operating under AIX, type the shutdown command to power off the

system.

If you cannot use this method, you can power off the system by using the following

operator-panel power button procedure:

Attention: Using the operator-panel power button to power off the system might

cause unpredictable results in the data files, and the next IPL will take longer to

complete.

1. Open the access door.

2. Press the power button on the operator panel.

B0FF appears in the operator panel display. The operator panel power LED starts

blinking at a fast rate.

When

the power-off sequence is complete, the system goes into standby power mode,

as evidenced by the following:

v OK displays in the operator panel display.

v The operator panel power LED starts blinking at a slow rate.

Powering On the System

Perform the following steps to power on the system:

1. Open the access door. Look for OK on the operator panel display, which indicates

that the system is in standby mode.

2. Press the power button on the operator panel.

The power LED on the operator panel starts blinking at a fast rate. Checkpoint

codes (9xxx) appear in the operator panel display. For details, see “IPL Flow” on

page 83.

When

the power-on sequence is complete, the power LED on the operator panel stops

blinking and stays on.

Powering Off and Powering On the System Using the Service Processor

The system can be powered off and on using the System Power Control menu, which is

a service processor menu that is available to the privileged user. See “System Power

Control Menu” on page 262.

Chapter 1. Reference Information 9

Page 28

Console Strategy

The firmware starts a console-selection sequence at system boot time if any of the

following is true:

v A console has not yet been selected.

v A previous console selection sequence timed out.

v A change in the system configuration affects the console (keyboard

installed/removed, mouse installed/removed, graphics adapter installed/removed or

moved to another PCI slot).

The

console-selection sequence allows you to select (from the appropriate input device)

one of the available console devices. If no console is selected within approximately 60

seconds, serial port 1 (S1) is selected as the console and the selection sequence times

out.

After a console has been selected, the console-selection sequence is only started at

boot time if there is a change in the system configuration (as described above), or the

contents of the system’s nonvolatile memory (NVRAM) are lost.

Note: Moving an ASCII terminal from one serial port to another (from S1 to S2) cannot

be detected by the firmware, so it does not constitute a configuration change.

You can also initiate a firmware console selection sequence from the System

Management Services (SMS) menus.

Power-On Self-Test

After power is turned on and before the operating system is loaded, the system does a

power-on self-test (POST). This test performs checks to ensure that the hardware is

functioning correctly before the operating system is loaded. During the POST, a POST

screen displays and POST indicators appear on the fimware console (if one is

connected). The next section describes the POST indicators and functions that can be

accessed during the POST.

POST Indicators

POST (power-on self-test) indicators indicate tests that are being performed as the

system is preparing to load the operating system. The POST indicators are words that

display on the system console. Each time that the system starts another step in the

POST, a POST indicator word appears on the console. Each word is an indicator of the

tests that are being performed.

10 Service Guide

Page 29

The POST screen displays the following words:

Memory Memory test

Keyboard Initialize the keyboard and mouse. The window for pressing a key to

access the System Management Services, or to initiate a service

mode boot, is now open. See “POST Keys” for more information.

Network Self-test on network adapters

SCSI Adapters are being initialized

Speaker Sounds an audible tone at the end of POST

POST Keys

The POST keys, if pressed after the keyboard POST indicator displays and before the

last POST indicator (speaker) displays, cause the system to start services or to initiate

service mode boots used for configuring the system and diagnosing problems. The keys

are described below:

Note: The program function keys (F1-F12) on a keyboard attached to the system unit

are no longer used and will be ignored during POST. After the keyboard POST

indicator displays, you must use the numeric number keys to enter input.

1 Key

The numeric 1 key, when pressed during POST, starts the System Management

Services (SMS) interface.

5 Key

The numeric 5 key, when pressed during POST, initiates a system boot in service mode

using the default service mode boot list.

This mode attempts to boot from the first device of each type found in the list. It does

not search for other bootable devices of that type if the first device is not bootable.

Instead, it continues to the next device type in the list. The firmware supports up to five

entries in the boot list.

The default boot sequence is:

1. Diskette

2. CD-ROM

3. Hard file

4. Tape drive (if installed)

5. Network

a. Token ring

b. Ethernet

Chapter 1. Reference Information 11

Page 30

6 Key

The numeric 6 key works like the numeric 5 key, except that firmware uses the

customized service mode bootlist that was set up using the AIX service aids.

8 Key

To enter the open firmware command line, press the numeric 8 key after the word

keyboard displays and before the last word (speaker) displays during startup. After you

press the 8 key, the remaining POST indicators display until initialization completes.

When initialization and POST are complete, the open firmware command line (an OK

prompt) displays.

The open firmware command line should only be used by service personnel to obtain

additional debug information.

To exit from the open firmware command prompt, type reset-all or power off the

system and reboot.

12 Service Guide

Page 31

System Unit Locations

Front View

14

5

6

7

8

4

1

3

2

13

12

11

10

9

1 Media Bay (Optional Drive): Bay D17 -

This position is for installing an optional

media device.

5 & 6 Two-Position SCSI Disk Drive Bay: Bay

D14 (top), Bay D13 (bottom). Bays for

the installation of two SCSI disk drives.

2 CD-ROM Drive: Bay D16 7 & 8 Disk Drive Bay: Bank DB2 (top), Bay

DB1 (bottom) (SES or SSA). Bays for the

installation of SCSI or SSA disk drives or

RAID arrays.

3 Diskette Drive: Bay D15 9 &

10

Disk Drive: Bay D07 (top left), Bay D12

(top right). Bay D01 (bottom left), Bay

D06 (bottom right). Disk drives in a SCSI

or SSA disk drive bay.

4 Operator Panel Display 11 -

14

Fan Positions: Fan F01 (bottom), Fan

F04 (top). Fans F01 and F03 are

required. Fans F02 and F04 are required

only for the redundant power option.

Chapter 1. Reference Information 13

Page 32

Rear View

5

6

7

8

4

1

3

2

10 9

11

12

13

14

12

11

10

09

08

07

06

05

04

03

64-bit 5V Slots

at 33MHz

64-bit 5V Slots

at 33MHz

64-bit 3.3V Slots

at 66MHz

64-bit 3.3V Slots

at 66MHz

1 & 2 Expansion Slots: For adding PCI

adapters.

1 Expansion Slot C12

2 Expansion Slot C3

8 Keyboard Port: For keyboard

connection.

3 Test Port: For testing during

manufacturing.

9 Mouse Port: For mouse connection.

4 Parallel Port: For connecting a parallel

printer or other parallel devices.

10 Power Connector: For connecting the

power cable.

5 External SCSI Port: For connecting

external SCSI devices.

11 &

12

Power Supplies: V1 (bottom), V2

(middle) Power supplies are installed

from the side of the system unit.

6 100BaseT Ethernet Port: For attaching

your computer to an Ethernet/Twisted

pair connection through a 100BaseT

connector.

13 Redundant Power Supply V3

(Optional)

7 9-Pin Serial Ports: For a TTY terminal,

modem, or other serial devices.*

14 Disk Drive Bulkhead Connector: For

attaching internal disk drive bays to an

SSA adapter or connecting internal

hardfiles to the external SCSI port (5) or

a SCSI adapter.

*Serial ports 1 and 2 can only be used for service processor menus. No

″heartbeat-type″ devices can be used on these ports. ″Heartbeat-type″ devices or

cables must be installed on serial port 3 or serial port 4.

14 Service Guide

Page 33

System Board

1

.

.

.

2

5b

4

9

17

12

13

7

5a

10

16

13

14

3

8

6

11

12

15

1 & 2 Expansion Slots: For adding PCI

adapters.

1 Expansion Slot C12

2 Expansion Slot C3

8 11

9-Pin Serial Ports: For a TTY terminal,

modem, or other serial devices.

3 Test Port: For manufacturing use only. 12 Mouse Port

4 Parallel Port 13 Keyboard Port

5 SCSI Port

v 5a Internal Port 1 speed must be set

to fast/wide

v 5b External Port 2 Ultra-2

14 &

15

Memory Riser Card Slots

6 Processor Card Connector 16 Battery

7 100BaseT Ethernet Port 17 Fan Cable Connector

Note: For locations of diskette and operator panel connectors, see “Power Flow” on

page 8. For AIX location codes and physical location codes, see “System Board

Locations” on page 22.

Chapter 1. Reference Information 15

Page 34

Operator Panel

The following diagram shows the locations of the operator panel display and the

operator panel pushbuttons.

R

12 345

8910

11

76

1 Power-On Button 7 Speaker

2 Power-On LED (Green) 8 Serial Number Plate

3 System Attention LED (Yellow) 9 Reset Icon

4 SCSI Activity LED (Green) 10 Reset Button

5 LAN Activity LED (Green) 11 Service Processor Reset Button

6 Operator Panel Display

Note: The service processor reset button must be activated very carefully. An insulated

paper clip is recommended. Unbend the clip so that it has a straight section

about two inches long. Insert the clip straight into the hole, keeping the clip

perpendicular to the plastic bezel. When you engage the reset switch, you

should feel the detent of the switch. After you press the switch, the service

processor resets and then shuts down the system.

System Memory

Two slots are available for memory riser cards. Each riser card had 16 sockets. See

“System Board” on page 15, which illustrates the positions of the memory riser cards in

the system.

Four sizes of DIMMs are available: 128 MB, 256 MB, 512 MB, and 1 GB. Certain 32

MB DIMMs from older RS/6000 systems can also be used when upgrading system

memory.

One-Way Processor Memory Placement Rules

The rules for one-way processor memory are as follows:

v Minimum memory is 1 pair of DIMMs in slots 1 and 8 (see “Processor Card Memory

DIMM Locations for Service Processor Menus” on page 271).

v Maximum memory is 4 DIMM pairs in slots 1 through 8 (see “Processor Card

Memory DIMM Locations for Service Processor Menus” on page 271).

v Each memory riser slot must have a memory filler card installed.

16 Service Guide

Page 35

v When you are installing a memory riser card:

– Memory DIMMs must be moved from the one-way processor card to the memory

riser card.

– The memory riser card must then have a minimum of 1 quad (four DIMMs).

Riser Card Memory Placement Rules

The rules for memory riser cards are as follows:

v Memory quads must contain DIMMs of equal memory size.

v Quad memory size may be mixed on a riser card.

v The minimum memory is four DIMMs, which must occupy quad A, slots 1, 2, 15 and

16 (see “Memory Riser Card and Memory DIMM Locations” on page 23).

v Populate the riser card starting with quad A and continuing with quads B, C, and D

(see “Memory Riser Card and Memory DIMM Locations” on page 23).

Logical and Physical Locations

This system uses physical location codes in conjunction with AIX location codes to

provide mapping of the failing field replaceable units (FRUs). The location codes are

produced by the system unit’s firmware and the AIX operating system.

Physical Location Codes

Physical location codes provide a mapping of logical functions in a platform (or

expansion sites for logical functions, such as connectors or ports) to their specific

locations within the physical structure of the platform.

Location Code Format

The format for the location code is a string of alphanumeric characters separated by a

dash (–), slash (/), pound sign (#) or period (.) character. The base location is all of the

information preceding the slash (/) or pound sign (#). The base location identifies a

device that is connected to or plugged into the parent. Extended location information

follows the slash (/). Extended location information identifies a device that is part of the

parent, a connector, or a cable. Cable information follows the pound sign (#). Cable

information identifies a cable that is connector to parent. The following are examples:

v P1-C1 identifies a processor card C1 plugged into planar P1.

v P1-M1 identifies a memory riser card M1 plugged into planar P1.

v P-1-Z1-A3 identifies a SCSI device with SCSI ID 3 attached to SCSI bus 1 on planar

1.

v P1-K1 identifies a keyboard attached to K1 on planar P1.

v P1/S1 identifies serial port 1 controller on planar P1, the connector for serial port 1,

or the cable attached to serial port 1.

v P1-I2/E3 identifies an Ethernet controller 3, on the card in slot 2 (I2) on planar P1,

the connector for Ethernet controller 3, or the cable attached to Ethernet controller 3.

v P1-I2#E3 identifies the cable attached to Ethernet controller 3 on the card in slot 2

(I2) on planar P1.

Chapter 1. Reference Information 17

Page 36

The period (.) identifies sublocations (DIMMs on a memory riser card, SCSI addresses,

cables). The following are examples:

v P1-M1.4 identifies DIMM 4 on memory riser card 1 plugged into planar P1.

v P1-C1.1 identifies processor 1 on processor card 1 plugged into planar P1.

v P2-Z1-A3.1 identifies a SCSI device with SCSI address of LUN 1 at SCSI ID 3

attached to SCSI bus 1 from planar 2.

v P1-I2#E3.2 identifies the second in a series of cables attached to Ethernet controller

3 on the card in slot 2 (I2) on planar P1.

Depending

on the AIX and firmware levels, AIX diagnostics may include the extended

location information when identifying a planar or card. The extended location

information or cable information is always included when identifying a cable or

connector. Location codes with extended location information that are displayed without

a description identifying the devices always identify the cable attached to the port.

Multiple FRU Callout Instructions

If an eight-digit error code appears in the operator panel display or as described in

Chapter 5, “Error Code to FRU Index,” on page 105, a location code for a failing part

may also be specified. If the location code includes a blank space followed by a

lowercase x followed by a number, this is an error code with multiple FRU callouts. This

error can typically happen with memory DIMMs, memory riser cards, or processors and

may involve mixed types of parts. In this case, check the system’s configuration for

FRU part numbers to determine the appropriate set of FRUs.

For example, if the location code P1-M1.1 x2 was displayed, this indicates memory pair

A (two DIMMs) on the first memory riser card was suspected.

You can determine the FRU part numbers of the electronic assemblies in the system in

two ways:

v Using the service processor menus

From the general user menu, select Read VPD Image from Last System Boot,

then enter 90 to display detailed vital product data (VPD).

v Typing the lscfg -vp | pg command on the AIX command line

Type the following command: lscfg -vp | pg to display the detailed VPD of all

assemblies. Notice that the FRU part number information for processors and memory

DIMMs may be at the bottom of the command output.

18 Service Guide

Page 37

AIX Location Codes

The basic formats of the AIX location codes are as follows:

v For non-SCSI devices/drives:

– AB-CD-EF-GH

v

For SCSI devices/drives:

– AB-CD-EF-G,H

For

planars, cards, and non-SCSI devices, the location code is defined as follows:

AB-CD-EF-GH

| | | |

| | | Device/FRU/Port ID

| | Connector ID

| devfunc Number, Adapter Number or Physical Location

Bus Type or PCI Parent Bus

v The AB value identifies a bus type or PCI parent bus as assigned by the firmware.

v The CD value identifies adapter number, adapter’s devfunc number, or physical

location. The devfunc number is defined as the PCI device number times 8, plus the

function number.

v The EF value identifies a connector.

v The GH value identifies a port, address, device, or FRU.

Adapters

and cards are identified only with AB-CD.

The possible values for CD depend on the adapter/card. For pluggable PCI

adapters/cards, CD is the device’s devfunc number (PCI device number times 8, plus

the function number). The C and D are characters in the range of 0-9, and A-F (hex

numbers). The location codes therefore uniquely identify multiple adapters on individual

PCI cards.

EF is the connector ID, used to identify the adapter’s connector to which a resource is

attached.

GH is used to identify a port, device, or FRU. For example:

v For async devices, GH defines the port on the fanout box. The values are 00 to 15.

v For a diskette drive, H identifies either diskette drive 1 or 2. G is always 0.

v For all other devices, GH is equal to 00.

For

integrated adapter, EF-GH is the same as the definition for a pluggable adapter. For

example, the location code for a diskette drive is 01-D1-00-00. A second diskette drive

is 01-D1-00-01.

Chapter 1. Reference Information 19

Page 38

For SCSI devices, the location code is defined as follows:

AB-CD-EF-G,H

| | | | |

| | | | Logical Unit address of the SCSI Device

| | | Control Unit Address of the SCSI Device

| | Connector ID

| devfunc Number, Adapter Number or Physical Location

Bus Type or PCI Parent Bus

AB-CD-EF are the same as non-SCSI devices.

G defines the control unit address of the device. Values of 0 to 15 are valid.

H defines the logical unit address of the device. Values of 0 to 255 are valid.

A bus location code is also generated as 00-XXXXXXXX, where XXXXXXXX is

equivalent to the node’s unit address.

Examples of physical location codes and AIX location codes are:

v PCI adapter in Slot 1

v Location code P1-I1

v AIX location code 20-58

20 Service Guide

Page 39

AIX and Physical Location Code Reference Tables

The following diagrams identify the physical locations in the system. These locations

correspond to the tables on “System Location Codes” on page 25, which contain

location codes that are used to identify functional units in the system.

The following diagram shows the right side of the system with the cover removed.

Power Supply Locations

AIX

Location

Codes

V3

V2

V1

Physical

Location

Codes

Chapter 1. Reference Information 21

Page 40

System Board Locations

AIX

Location

Codes

P1-I 12

31-08

27-08

P1-I 10

37-08

2D-08

17-08

P1-I 11

34-08

2A-08

P1-I 9

3A-08

14-08

1A-08

P1-I 5

P1-I 7

P1-I 3

P1-I 8

P1-I 4

P1-I 6

Debug

01-R1 P1-R1

11-08 P1-Z1

01-S4 P1-S4

01-S3 P1-S3

01-S1 P1-S1

01-S2 P1-S2

00-00 P1-M1

00-00 P1-M2

Battery

Fan Connector

P1-C1

21-08 P1-E1

01-K1 P1-K1

01-O1 P1-O1

Physical

Location

Codes

Slot

Name

C12

C10

C11

C9

C5

C7

C3

C8

C4

C6

11-09 P1-Z2

Note: See “System Board” on page 15 for descriptions of connectors.

22 Service Guide

Page 41

Memory Riser Card and Memory DIMM Locations

(15) A

(16) A

(14) B

(12) C

(10) D

(8) D

(6) C

(4) B

(2) A

(13) B

(11) C

(9) D

(7) D

(5) C

(3) B

(1) A

Location Code Memory DIMMs

P1-M1.n Memory DIMMs on riser card 1 (n denotes DIMM number)

P1-M2.n Memory DIMMs on riser card 2 (n denotes DIMM number)

P1-M1.1 x4 Memory quad A (DIMMs 1, 2, 15, 16)

P1-M1.3 x4 Memory quad B (DIMMs 3, 4, 13, 14)

P1-M1.5 x4 Memory quad C (DIMMs 5, 6, 11, 12)

P1-M1.7 x4 Memory quad D (DIMMs 7, 8, 9, 10)

P1-M2.1 x2 Memory pair A (DIMMs 1 and 15)

P1-M2.1 x4 Memory quad A (DIMMs 1, 2, 15, 16)

P1-M2.3 x4 Memory quad B (DIMMs 3, 4, 13, 14)

P1-M2.5 x4 Memory quad C (DIMMs 5, 6, 11, 12)

P1-M2.7 x4 Memory quad D (DIMMs 7, 8, 9, 10)

P1-M1.1 x16 All memory DIMMs on riser card 1

P1-M2.1 x16 All memory DIMMs on riser card 2

P1-M1 x2 All memory DIMMs on riser cards 1 and 2

Chapter 1. Reference Information 23

Page 42

One-Way Processor Card Memory DIMM Locations

(8) A

(7) B

(6) C

(5) D

(3) C

(4) D

(2) B

(1) A

Location Code Memory DIMMs

P1-C1-Mn Memory DIMMs on processor card (n denotes DIMM number)

P1-C1-M1 x2 Memory pair A (DIMMs 1 and 8)

P1-C1-M2 x2 Memory pair B (DIMMs 2 and 7)

P1-C1-M3 x2 Memory pair C (DIMMs 3 and 6)

P1-C1-M4 x2 Memory pair D (DIMMs 4 and 5)

P1-C1-M1 x8 All memory DIMMs on processor card

24 Service Guide

Page 43

System Location Codes

If a returned value is not listed in this table, see ″Physical Location Code Standard

Prefixes″ under ″Diagnostic Numbers and Codes″ in RS/6000 and Eserver pSeries

Diagnostic Information for Multiple Bus Systems.

FRU Name Slot

Name

Location

Code

AIX

Location

Code

Physical

Connection

Logical

Connection

System board P1

Processor Card C01 P1-C1

Processor 1 P1-C1 00-00

Processor 2 P1-C1 00-02

Processor 3 P1-C1 00-04

Processor 4 P1-C1 00-06

Processor 5 P1-C1 00-08

Processor 6 P1-C1 00-0A

Memory DIMMs (1-way) P1-C1-M1 to

P1-C1-M8

00-00 See

“One-Way

Processor

Card

Memory

DIMM

Locations”

on page 24

Memory riser card 1 M01 P1-M1 00-00

Memory DIMM 1-16 P1-M1.1 to

P1-M1.16

00-00 See

“Memory

Riser Card

and Memory

DIMM

Locations”

on page 23

Memory riser card 2 M02 P1-M2 00-00

Memory DIMM 1-16 P1-M2.1 to

P1-M2.16

00-00 See

“Memory

Riser Card

and Memory

DIMM

Locations”

on page 23

PCI Host Bridge Bus 1 P1 00-fff7f09000

ISA Bus P1 10-80

PCI to PCI Bridge 1 P1 10-58,

10-5A,

10-5C,

10-5E

Chapter 1. Reference Information 25

Page 44

FRU Name Slot

Name

Location

Code

AIX

Location

Code

Physical

Connection

Logical

Connection

PCI Slot 3 C03 P1/I3 10-5A J10, 64 BIT

See Note 1

on page 30.

PCI to PCI

Bridge 1

PCI Slot 3 Device P1-I3 1A-08 to

1A-0F or

1B-xx or

1C-xx

J10, 64 BIT

See Note 1

on page 30.

PCI to PCI

Bridge 1

PCI Slot 4 C04 P1/I4 10-5C J11, 64 BIT

See Note 1

on page 30.

PCI to PCI

Bridge 1

PCI Slot 4 Device P1-I4 17-08 to

17-0F or

18-xx or

19-xx

J11, 64 BIT

See Note 1

on page 30.

PCI to PCI

Bridge 1

PCI Slot 5 C05 P1/I5 10-5E J12, 64 BIT

See Note 1

on page 30.

PCI to PCI

Bridge 1

PCI Slot 5 Device P1-I5 14-08 to

14-0F or

15-xx or

16-xx

J12, 64 BIT

See Note 1

on page 30.

PCI to PCI

Bridge 1

Internal SCSI controller P1/Z1 11-08 PCI to PCI

Bridge 1

External SCSI controller P1/Z2 11-09 PCI to PCI

Bridge 1

PCI Host Bridge Bus 2 P1 00-fff7f0a000

PCI to PCI Bridge 2 P1 20-58,

20-5A,

20-5B

(unused),

20-5C,

20-5E

PCI Slot 6 C06 P1/I6 20-5A J13, 64 BIT

See Note 1

on page 30.

PCI to PCI

Bridge 2

PCI Slot 6 Device P1-I6 2D-08 to

2D-0F or

2E-xx or

2F-xx

J13, 64 BIT

See Note 1

on page 30.

PCI to PCI

Bridge 2

PCI Slot 7 C07 P1/I7 20-5C J14, 64 BIT

See Note 1

on page 30.

PCI to PCI

Bridge 2

26 Service Guide

Page 45

FRU Name Slot

Name

Location

Code

AIX

Location

Code

Physical

Connection

Logical

Connection

PCI Slot 7 Device P1-I7 2A-08 to

2A-0F or

2B-xx or

2C-xx

J14, 64 BIT

See Note 1

on page 30.

PCI to PCI

Bridge 2

PCI Slot 8 C08 P1/I8 20-5E J14, 64 BIT

See Note 1

on page 30.

PCI to PCI

Bridge 2

PCI Slot 8 Device P1-I8 27-08 to

27-0F or

28-xx or

29-xx

J14, 64 BIT

See Note 1

on page 30.

PCI to PCI

Bridge 2

Integrated Ethernet P1/E1 21-08 PCI to PCI

Bridge 2

PCI to PCI Bridge 3 P1 20-60,

20-62,

20-63,

20-64, 20-65

(unused),

20-66,

PCI Slot 9 C09 P1/I9 20-60 J16, 64 BIT

See Note 1

on page 30.

PCI to PCI

Bridge 3

PCI Slot 9 Device P1-I9 3A-08 to

3A-0F or

3B-xx or

3C-xx

J16, 64 BIT

See Note 1

on page 30.

PCI to PCI

Bridge 3

PCI Slot 10 C10 P1/I10 20-62 J17, 64 BIT

See Note 1

on page 30.

PCI to PCI

Bridge 3

PCI Slot 10 Device P1-I10 37-08 to

37-0F or

38-xx or

39-xx

J17, 64 BIT

See Note 1

on page 30.

PCI to PCI

Bridge 3

PCI Slot 11 C11 P1/I11 20-64 J18, 64 BIT

See Note 1

on page 30.

PCI to PCI

Bridge 3

PCI Slot 11 Device P1-I11 34-08 to

34-0F or

35-xx or

36-xx

J18, 64 BIT

See Note 1

on page 30.

PCI to PCI

Bridge 3

PCI Slot 12 C12 P1/I12 20-66 J19, 64 BIT

See Note 1

on page 30.

PCI to PCI

Bridge 3

Chapter 1. Reference Information 27

Page 46

FRU Name Slot

Name

Location

Code

AIX

Location

Code

Physical

Connection

Logical

Connection

PCI Slot 12 Device P1-I12 31-08 to

31-0F or

32-xx or

33-xx

J19, 64 BIT

See Note 1

on page 30.

PCI to PCI

Bridge 3

Diskette Controller P1/D1 01-D1

Diskette Drive D15 P1-D1 01-D1-00-00

Keyboard Controller/Connector P1/K1 01-K1-00

Keyboard P1-K1 01-K1-00-00

Mouse Controller P1/K1 01-K1-01

Mouse Connnector P1/O1 01-K1-01

Mouse P1-O1 01-K1-01-00

Parallel Port Controller P1/R1 01-R1

Serial Port 1 Controller P1/S1 01-S1

Serial Port 2 Controller P1/S2 01-S2

Serial Port 3 Controller P1/S3 01-S3

Serial Port 4 Controller P1/S4 01-S4

TOD Battery P1-V4

System Firmware P1/Y1

Service Processor Firmware P1/Y2

PRD Code P1/Y2

SPCN Firmware P1/Y3

SPCN VPD P1/Y4

Operator Panel NB1 L1

Operator Panel VPD Module L1-N1

Fan 1 F01 F1

Fan 2 F02 F2

Fan 3 F03 F3

Fan 4 F04 F4

Power Supply 1 V1

Power Supply 2 V2

Power Supply 3 V3

DASD 6-Pack 1 backplane

(SES or SSA)

DB1 B1 SCSI:

xx-xx-0015,0

SSA:

See Note 4

on page 30.

See Note 3

on page 30.

28 Service Guide

Page 47

FRU Name Slot

Name

Location

Code

AIX

Location

Code

Physical

Connection

Logical

Connection

DASD 6-Pack 1, Drive 1 D1 B1.1 SCSI:

xx-xx-00-8,0

SSA: See

Note 4 on

page 30.

DASD 6-Pack 1, Drive 2 D2 B1.2 SCSI:

xx-xx-00-9,0

SSA: See

Note 4 on

page 30.

DASD 6-Pack 1, Drive 3 D3 B1.3 SCSI:

xx-xx-0010,0

SSA:

See Note 4

on page 30.

DASD 6-Pack 1, Drive 4 D4 B1.4 SCSI:

xx-xx-0011,0

SSA:

See Note 4

on page 30.

DASD 6-Pack 1, Drive 5 D5 B1.5 SCSI:

xx-xx-0012,0

SSA:

See Note 4

on page 30.

DASD 6-Pack 1, Drive 6 D6 B1.6 SCSI:

xx-xx-0013,0

SSA:

See Note 4

on page 30.

DASD 6-Pack 2 backplane

(SES or SSA)

DB2 B2 SCSI:

xx-xx-0015,0

SSA:

See Note 4

on page 30.

See Note 3

on page 30.

DASD 6-Pack 2, Drive 1 D7 B2.1 SCSI:

xx-xx-00-8,0

SSA: See

Note 4 on

page 30.

DASD 6-Pack 2, Drive 2 D8 B2.2 SCSI:

xx-xx-00-9,0

SSA: See

Note 4 on

page 30.

Chapter 1. Reference Information 29

Page 48

FRU Name Slot

Name

Location

Code

AIX

Location

Code

Physical

Connection

Logical

Connection

DASD 6-Pack 2, Drive 3 D9 B2.3 SCSI:

xx-xx-0010,0 SSA:

See Note 4.

DASD 6-Pack 2, Drive 4 D10 B2.4 SCSI:

xx-xx-0011,0

SSA:

See Note 4.

DASD 6-Pack 2, Drive 5 D11 B2.5 SCSI:

xx-xx-0012,0

SSA:

See Note 4.

DASD 6-Pack 2, Drive 6 D12 B2.6 SCSI:

xx-xx-0013,0 SSA:

See Note 4.

2-Pack DASD Drive 1 D13 P1-Z1-A4 11-08-00-4,0 See Note 2.

2-Pack DASD Drive 2 D14 P1-Z1-A2 11-08-00-2,0 See Note 2.

Tape Drive D17 P1-Z1-A0 11-08-00-0,0 See Note 2.

CD-ROM Drive D16 P1-Z1-A1 11-08-00-1,0 See Note 2.

Notes:

1. The physical location code for the PCI slots, when empty, uses the P1/Ix notation,

where the ’/’ identifies an integrated device (in this case the empty slot). A PCI

device plugged into the slot uses the P1-Ix notation, where the ’–’ identifies a

plugged device.

2. 11 is for the integrated SCSI device. -4,0 and -2,0 are hardcoded on the DASD

2-pack; -0,0 is the tape drive; -1,0 is the CD-ROM.

3. xx-xx is dependent on which SCSI controller is driving the 6-pack.

4. Use the link verification utility in the SSA service aids under AIX diagnostics to

identify individual SSA drives.

Specifications

This section contains specifications for the system.

The mechanical packaging, cooling, power supply, and environmental requirements for

the system are as follows:

Dimensions

In horizontal orientation, the dimensions are:

v Height - 610 mm (24.0 inches)

v Width - 483 mm (19.0 inches)

30 Service Guide

Page 49

v Depth - 728 mm (28.7 inches)