Page 1

Fibre Channel RAID Storage Server and

Expandable Storage Unit, IBM 2102

ModelF10andModelD00

Service Guide

IBM

SY27-7604-02

Page 2

Page 3

Fibre Channel RAID Storage Server and

Expandable Storage Unit, IBM 2102

ModelF10andModelD00

Service Guide

IBM

SY27-7604-02

Page 4

Take Note!

Before using this information and the product it supports, be sure to read the general information under “Notices” on page xv.

Second Edition (April 1999)

Publications are not stocked at the address given below. If you want additional IBM publications, ask your IBM

representative or write to the IBM branch office serving your locality.

A form for reader’s comments is provided at the back of this publication. If the form has been removed, address your

comments to:

International Business Machines Corporation

RCF Processing Department

Dept G26/Bldg. 050-3

5600 Cottle Road

SAN JOSE, CA 95193-0001

U.S.A.

You can also send your comments electronically to:

When you send information to IBM, you grant IBM a nonexclusive right to use or distribute the information in any

way it believes appropriate without incurring any obligation to you.

© Copyright International Business Machines Corporation 1999. All rights reserved.

US Government Users Restricted Rights – Use duplication or disclosure restricted by GSA ADP Schedule Contract

with IBM Corp.

Page 5

Contents

Figures ........................... xi

Notices ...........................xv

Safety and Environmental Notices .................xv

Safety Notices........................ xv

Environmental Notices and Statements ..............xvi

Electronic Emission Statements ..................xvi

Federal Communications Commission (FCC) Statement ........xvi

Industry Canada Compliance Statement ..............xvii

European Community Compliance Statement ............xvii

Germany Only........................xvii

Japanese Voluntary Control Council for Interference (VCCI) Class A

Statement ........................xviii

Korean Government Ministry of Communication (MOC) Statement ....xviii

Taiwan Class A Compliance Statement...............xviii

Trademarks..........................xviii

IBM License Agreement for Machine Code .............xxi

Statements of Limited Warranty .................xxiii

Production Status .......................xxiii

The IBM Warranty for Machines ..................xxiii

Warranty Service........................xxiv

Extent of Warranty .......................xxiv

Limitation of Liability ......................xxv

About This Book .......................xxvii

Who Should Use This Book....................xxvii

Related Publications ......................xxvii

Web Site...........................xxvii

Part 1. Maintenance Starting Points...................... 1

Chapter 1. Maintenance Starting Points .............. 3

2102 Fibre Channel RAID Storage Server Start Tables .......... 4

Start Table A ........................ 4

Start Table B ........................ 8

Start Table C ........................11

Start Table D ........................13

AIX Error Codes (SRNs) .....................15

The Error Code Table .....................15

Using the Error Code Table ...................15

Location Codes Displayed By Diagnostics .............31

Part 2. Installation and Removal .......................33

Chapter 2. Installation And Removal Guide .............35

Preparatory Tasks .......................35

Tools and Equipment You May Need ...............35

About the Installation Procedure .................35

Preparing the Site .......................36

Floor Space ........................36

© Copyright IBM Corp. 1999 iii

Page 6

Heating and Air Conditioning ..................38

Electrical..........................39

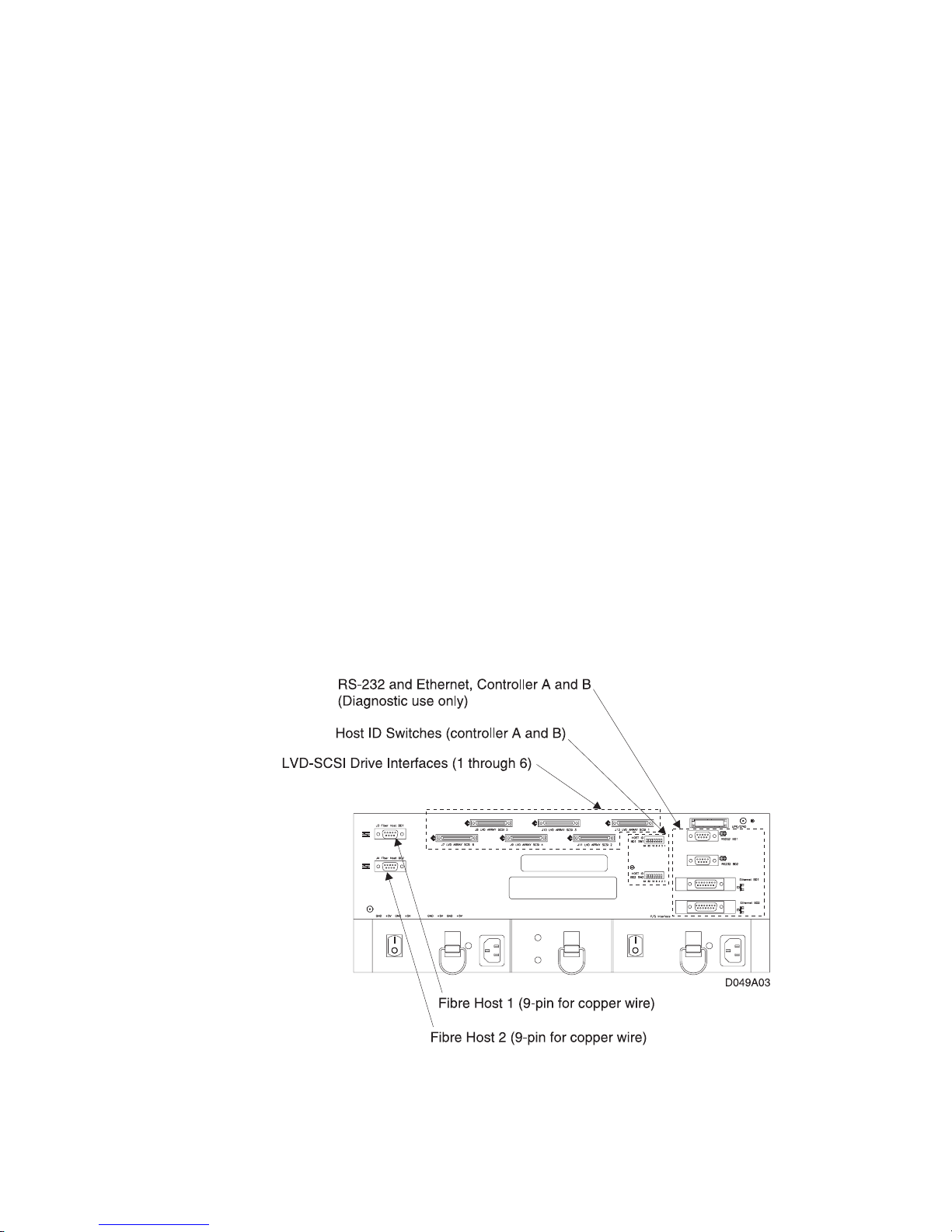

Interface Connectors and Cables .................41

Preparing the Rackmount Cabinet .................43

Cabinet Preparation Task List ..................43

Installing the Support Rails ....................44

About Support Rails......................44

Instructions .........................44

Installing the Controller Module ..................45

Tools and Equipment .....................45

Instructions .........................45

Installing the Drive Module ....................49

Tools and Equipment .....................49

Instructions .........................49

Configuring the Controller Module .................54

Completing the Installation ....................56

Start-up Notes........................56

Configuration Notes......................56

Starting Up the Subsystem ...................56

Verifying the Installation ....................58

Removal ...........................59

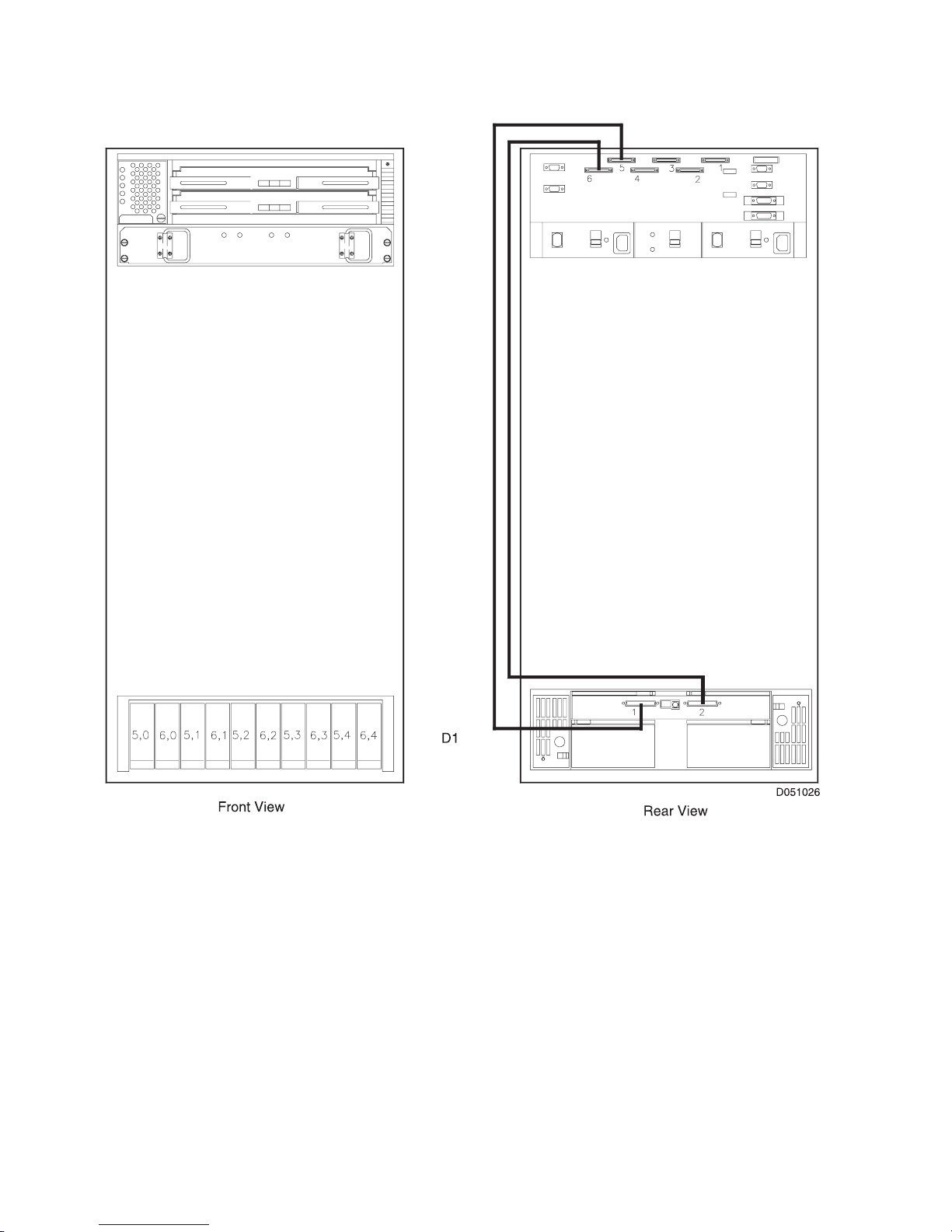

LVD-SCSI Drive Cable Routing Examples ..............59

Drive Cabling Example A....................59

Drive Cabling Example B....................60

Drive Cabling Example C....................61

Drive Cabling Example D....................62

Drive Cabling Example E....................63

Drive Cabling Example F ....................64

Part 3. Controller Module Service Guide ...................67

Chapter 3. Getting Started....................69

Identifying the Parts.......................69

Controller Module Cabinets ...................69

Removable Components ....................69

Internal Components .....................70

Basic Operation ........................72

Gaining Access to the Controls .................72

Turning On the Power .....................72

Turning Off the Power .....................74

Restoring Power .......................74

Using the Status LEDs.....................75

Instructions for Modifying the Controller Module ............78

Preparing to Move the Controller Module ..............79

Removing and Installing FRUs..................79

Removing the Module from the Rackmount Cabinet ..........81

Disassembling and Reassembling the Chassis ............83

Chapter 4. Controllers .....................87

Overview...........................87

General Description......................87

Identifying Interface Problems ...................87

Types of Interface Problems...................87

Hints for Troubleshooting Interface Problems ............88

Controller FRU ........................89

Controller Description .....................89

iv IBM 2102 Model F10 and Model D00 Service Guide

Page 7

Controller Specifications ....................91

Controller Servicing Notes ...................91

Troubleshooting Controller Problems ...............92

Replacing a Failed Controller ..................93

Controller Backpanel ......................96

Controller Backpanel Description .................96

Controller Backpanel Specifications ................97

Controller Backpanel Servicing Notes ...............97

Troubleshooting Controller Backpanel Problems ...........97

Replacing a Failed Controller Backpanel ..............98

Chapter 5. Cooling System ...................101

Overview of Cooling System ...................101

General Description......................101

Servicing the Cooling System ...................101

Preserving Proper Air Flow ...................102

Determining Which Fan Failed ..................102

Controller Fan FRU .......................103

Controller Fan Description ...................103

Controller Fan Specifications ..................104

Controller Fan Servicing Notes..................105

Troubleshooting Controller Fan Problems..............105

Replacing a Failed Controller Fan ................106

Power Supply Fan FRU .....................107

Power Supply Fan Description ..................107

Power Supply Fan ......................108

Power Supply Fan Servicing Notes ................109

Troubleshooting Power Supply Fan Problems ............109

Replacing a Failed Power Supply Fan ...............109

Chapter 6. Power System ....................111

Overview of Power System ....................111

General Description......................111

Servicing the Power System ...................111

Types of Power System Problems ................112

Hardware-Related Problems ..................112

Battery FRU .........................112

Battery Description ......................112

Battery Specifications .....................113

Battery Servicing Notes ....................113

Troubleshooting Battery Problems ................114

Checking the Battery Service Date ................115

Replacing the Battery FRU ...................116

Power Supply FRU .......................118

Power Supply Description ...................118

Power Supply Specifications ..................119

Power Supply Recovery Notes..................119

Troubleshooting Power Supply Problems ..............120

Recovering from a Power Supply Shutdown .............121

Replacing a Failed Power Supply.................122

Battery Harness ........................123

Battery Harness Description...................123

Battery Harness Specifications..................124

Battery Harness Servicing Notes .................124

Troubleshooting Battery Harness Problems .............125

Replacing the Battery Harness..................125

Contents v

Page 8

DC Power Harnesses ......................126

DC Power Harness Description .................126

DC Power Harness Specifications ................127

DC Power Harness Servicing Notes................127

Troubleshooting DC Power Harness Problems ............127

Replacing the DC Power Harnesses................128

Power Interface Board......................130

Power Interface Board Description ................130

Power Interface Specifications ..................130

Power Interface Board Servicing Notes ..............130

Troubleshooting Power Interface Board Problems...........131

Replacing a Controller Module Chassis ..............131

Chapter 7. Reference......................133

Troubleshooting Quick Reference..................133

Controller and Interface Problems ................133

Cooling Problems ......................135

Power Problems .......................136

Part 4. Drive Module Service Guide ......................139

Chapter 8. Getting Started with the Drive Module...........141

What is the Drive Module? ....................141

Basic Components .......................142

Front View .........................142

Back View .........................142

About the Drives ........................143

Front Panel.........................143

Drive FRUs.........................144

Drive Numbering .......................144

Drive Capacities .......................145

About the SCSI Components ...................146

Environmental Services Monitor Board ...............146

Mid-Plane .........................148

Interface Cables .......................149

About the Power System .....................149

Power Supply FRUs .....................149

About the Cooling System ....................151

Fan FRUs .........................151

Moving The Drives .......................151

Chapter 9. Operating the Drive Module...............153

Basic Operation ........................153

Controls on the Front .....................153

Controls on the Back .....................153

Turn On the Power ......................153

Turn Off the Power ......................154

Perform an Emergency Shutdown ................155

Restore Power After an Emergency ................156

Checking the Drive Module ....................156

Status LEDs ........................156

Check the Overall Hardware Status ................156

Chapter 10. Servicing the Drives .................159

Disk Drive Overview ......................159

General Notes........................159

vi IBM 2102 Model F10 and Model D00 Service Guide

Page 9

Drive Failure Notes ......................160

Maintaining the Drives ......................160

Replace a Failed Drive ....................160

Identify Other Drive-Related Problems ...............164

Chapter 11. Servicing the SCSI Components ............167

SCSI Component Overview ....................167

Servicing SCSI Components ..................167

Maintaining the SCSI Components .................168

Types of Interface Problems...................168

Hints for Troubleshooting Interface Problems ............169

Replace a SCSI Interface Cable .................169

Replace a Failed ESM FRU...................170

Replace a Failed MidPlane ...................173

Chapter 12. Servicing the Power System ..............179

Power System Overview .....................179

Power Supply Servicing Notes ..................179

Power Supply Recovery Notes..................179

Maintaining the Power System...................180

Types of Power System Problems ................180

Recover from a Power Supply Shutdown ..............180

Replace a Failed Power Supply .................183

Chapter 13. Servicing the Cooling System .............187

Cooling System Overview ....................187

Fan Servicing Notes .....................187

Maintaining the Cooling Fans ...................187

Replace a Failed Fan .....................188

Chapter 14. Technical Reference .................191

Technical Specifications .....................191

Factory Settings .......................191

Hardware Features ......................192

Software Features ......................192

Interface Connections and Cables .................193

Drive Module Interface Connections................193

Host SCSI Interface Connections.................193

SCSI Cables ........................194

Host SCSI Pin Assignments and Signals ..............194

SCSI Drive Pin Assignments and Signals ..............195

Chapter 15. Quick References ..................197

Drive Module Parts .......................197

Drive Module Troubleshooting Chart.................198

Part 5. Debugging Tools and Procedures ...................203

Chapter 16. RAID Manager for DOS ................205

What is RAID Manager for DOS?..................205

When to Use RAID Manager for DOS ................205

Menu Options Summary .....................206

Task Summary ........................208

PC Requirements and Preparation Tasks ...............208

PC Requirements ......................208

Preparation Tasks ......................209

Contents vii

Page 10

Changing DRM Boot Up Defaults (Floppy Drive and COM Port) ......210

Using DRM with a Monochrome Display ...............210

Connecting to the Controller Locally.................210

Starting DRM .........................211

Verifying the Installation .....................212

Using the Array Configuration Editor (ACE) ..............212

Starting ACE ........................213

The Logical Unit Window ....................214

The Drive Window ......................216

Navigating in ACE ......................221

Identifying Drives and Logical Units ................222

Identify the Controller or Change the Name .............222

Scan the Bus for Array Devices .................222

Using the Array Monitor ....................223

Diagnostics .........................225

Changing the Password ....................226

Display and Set the Battery Age .................226

Checking Array Status.....................226

Chapter 17. Installing the Remote Support Feature ..........229

Remote Support Attachment of the WTI Data Switch and Modem ......229

Remote Support Feature Initial Installation .............229

Chapter 18. Drive Microcode Download ..............239

Downloading Drive Microcode from Windows NT using DriveDload .....239

What is DriveDload? .....................239

When to Use DriveDload ....................239

Installing DriveDload .....................239

Starting DriveDload ......................240

Using DriveDload ......................240

Drive Mode Page Download...................243

Downloading Drive Microcode from HP-UX or SUN Solaris Using drvDLoad . . 244

What is drvDLoad? ......................244

When to Use drvDLoad ....................244

Installing drvDLoad ......................244

Starting drvDLoad ......................245

Using drvDLoad .......................245

Downloading Drive Microcode From An AIX Host ............246

Chapter 19. Controller Debug Shell ................247

Accessing the Controller Debug Shell ................247

Controller Debug Shell Commands .................248

Summary of Common Debug Shell Commands ...........248

Part 6. Appendixes .............................251

Appendix A. AIX Code Information ................253

2102-F10 Error Log Sense Information................253

Field Replaceable Unit (FRU) Codes ................258

Additional FRU Information ....................258

Disk Array Errors........................260

2102 Array Additional Sense Codes And Qualifiers (ASC/ASQ) .......261

Appendix B. Safety Inspection Procedure..............269

Appendix C. Safety Inspection Procedure in German .........273

viii IBM 2102 Model F10 and Model D00 Service Guide

Page 11

Appendix D. Safety Inspection Procedure in Traditional Chinese.....277

Appendix E. Fibre Channel RAID Storage Server and Expandable Storage

Unit Parts Catalog ......................281

2102 Model F10 Controller Module FRUs...............282

2102 Model D00 Drive Module FRUs ................286

Glossary ..........................289

Index ............................291

Readers’ Comments — We’d Like to Hear from You..........309

Contents ix

Page 12

x IBM 2102 Model F10 and Model D00 Service Guide

Page 13

Figures

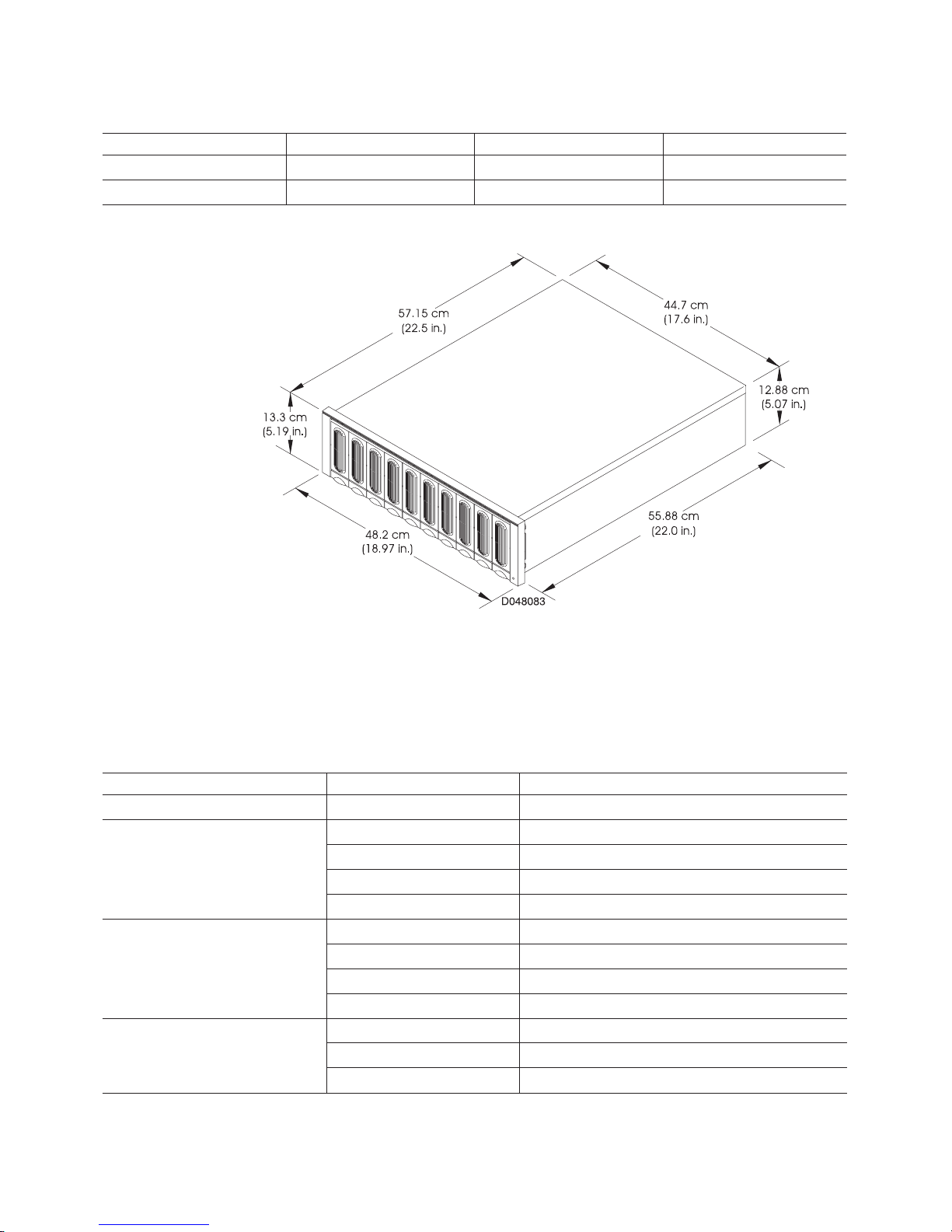

1. Controller Module Dimensions .................37

2. Dimensions of Drive Module..................38

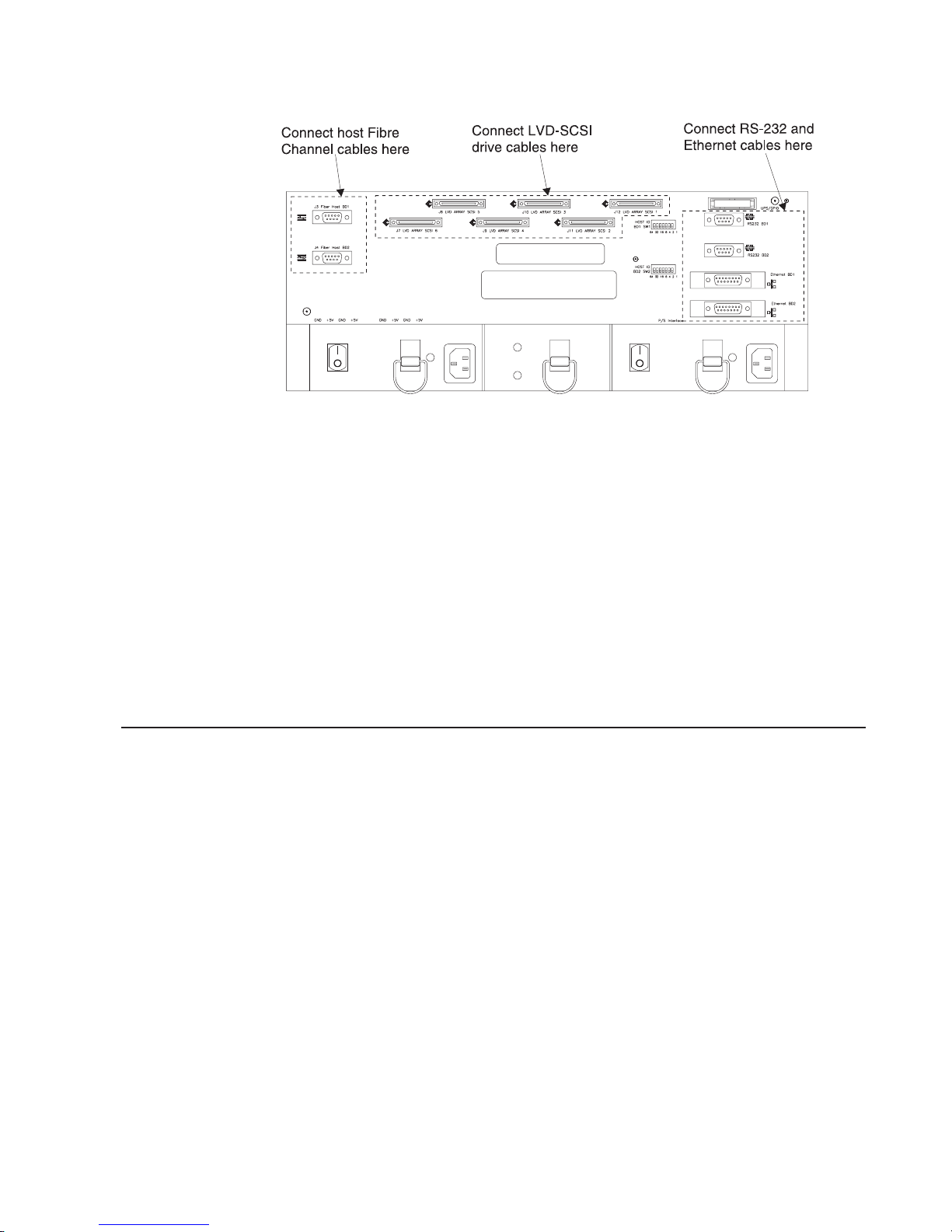

3. Interface Connections on Controller Module ............41

4. Media Interface Adapter (MIA) .................42

5. Rackmount Cabinet .....................43

6. Removable Covers on the Controller Module............46

7. Removing The FRUs ....................46

8. Removing The FRUs – cont...................47

9. Removing The FRUs – cont...................47

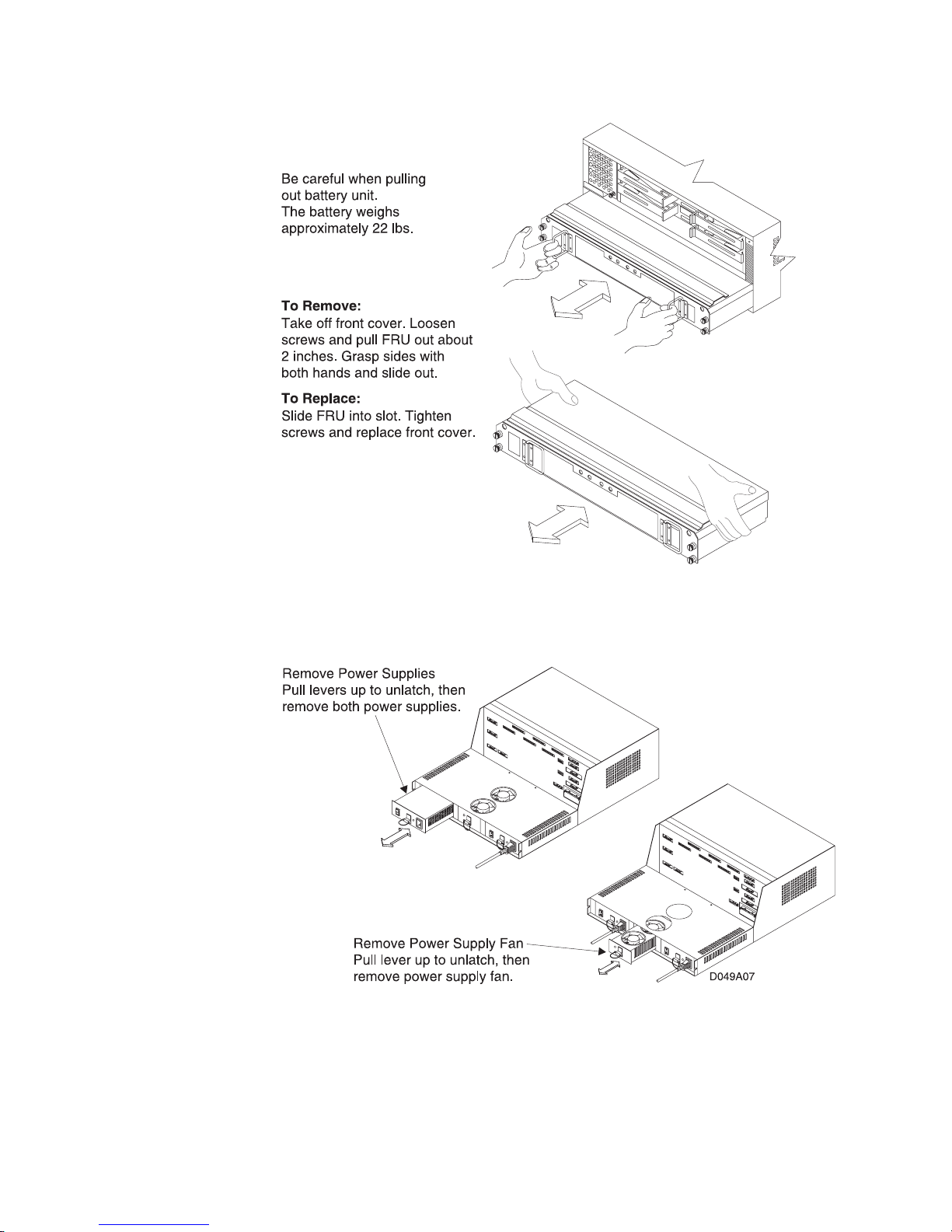

10. Chassis Mounting on Support Rails ...............48

11. Interface Connections on a Rackmount Controller Module .......49

12. Removing the Drive Module FRUs ...............50

13. Removing the Drive Module FRUs – cont..............51

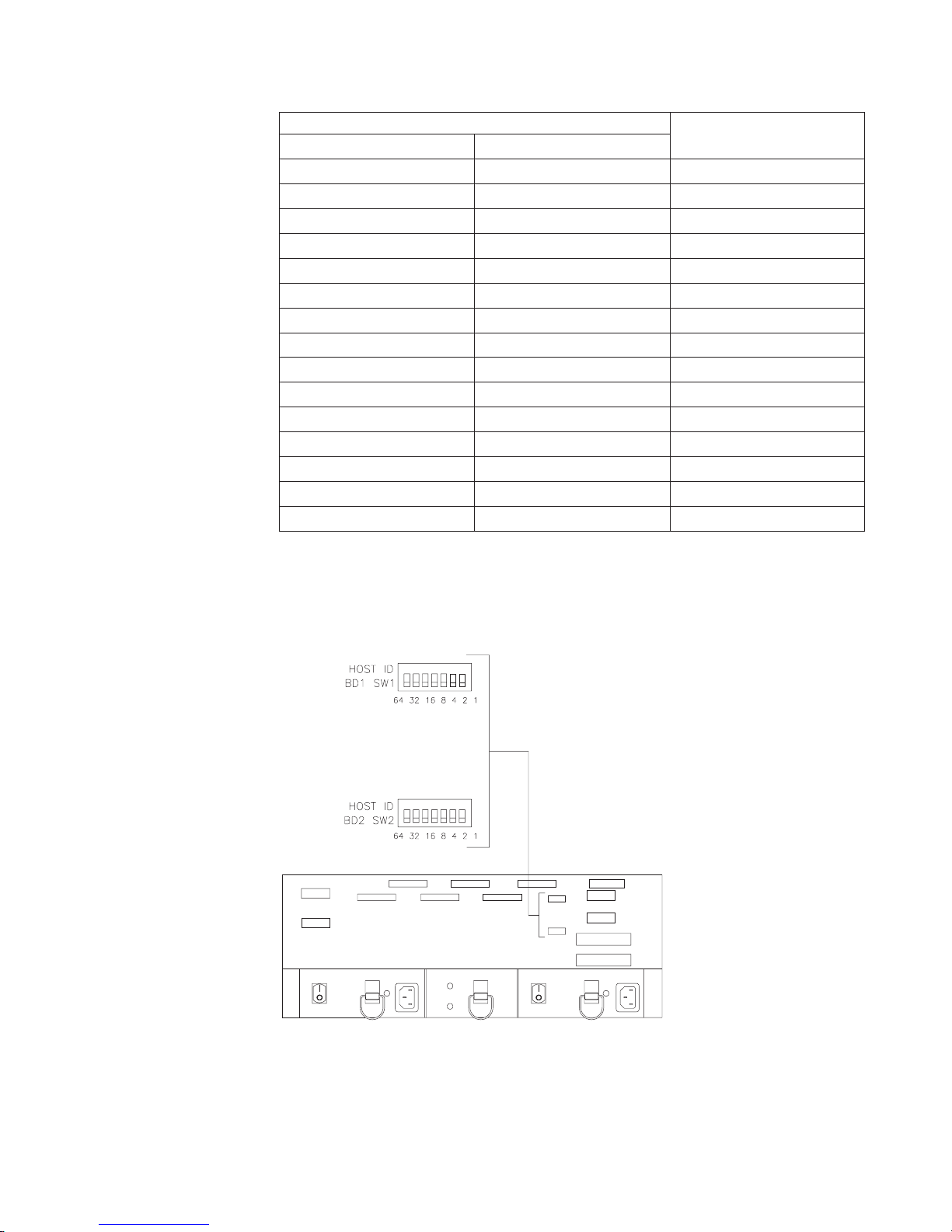

14. Tray ID and Option Switches .................53

15. Connecting Interface Cables and Power Cords ...........54

16. Setting the Fibre Host IDs ..................55

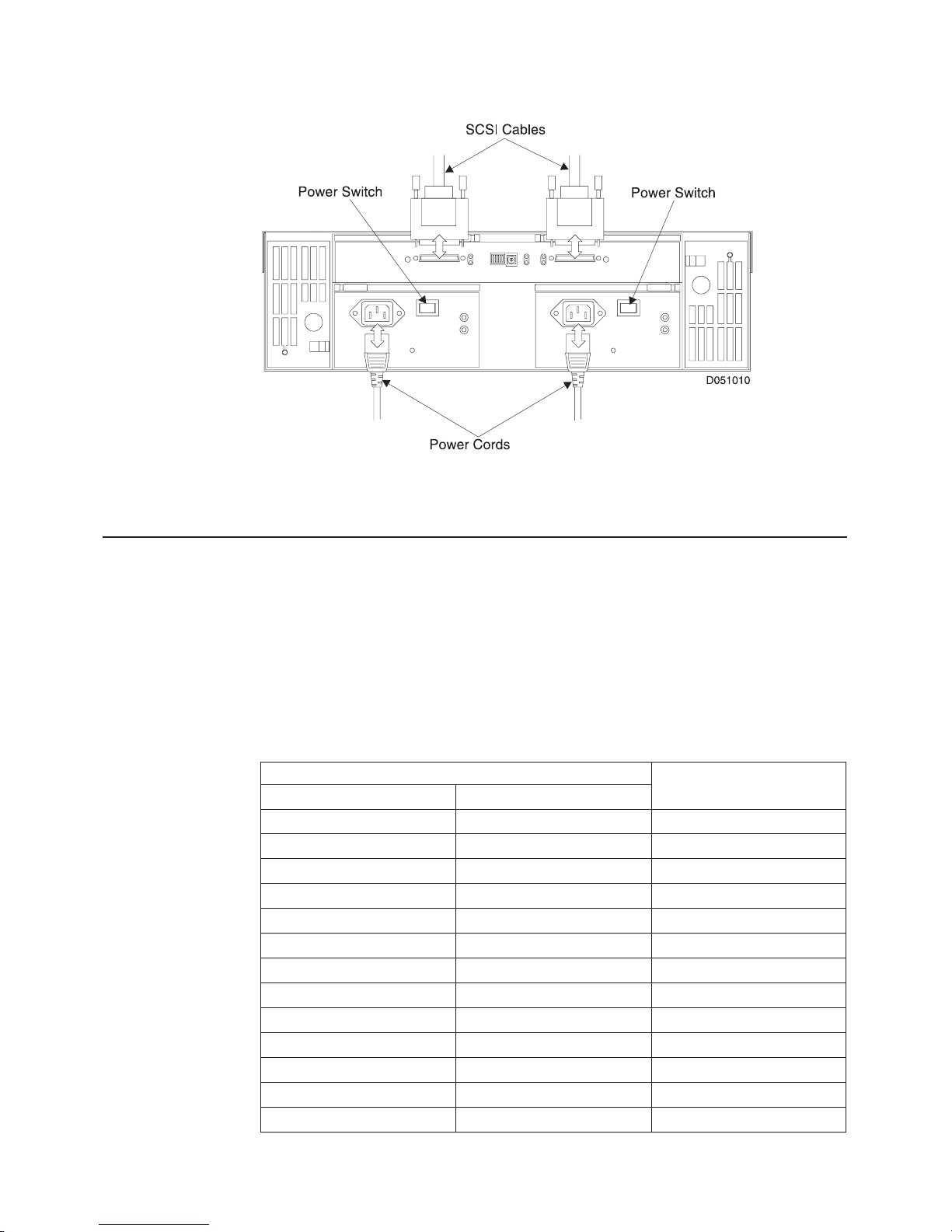

17. Controller Module Power Cords and Power Switches.........57

18. Drive Module Power Switches .................57

19. Rackmount Cabling to One Drive Module .............60

20. Rackmount Cabling to Two Drive Modules ............61

21. Rackmount Cabling to Three Drive Modules ............62

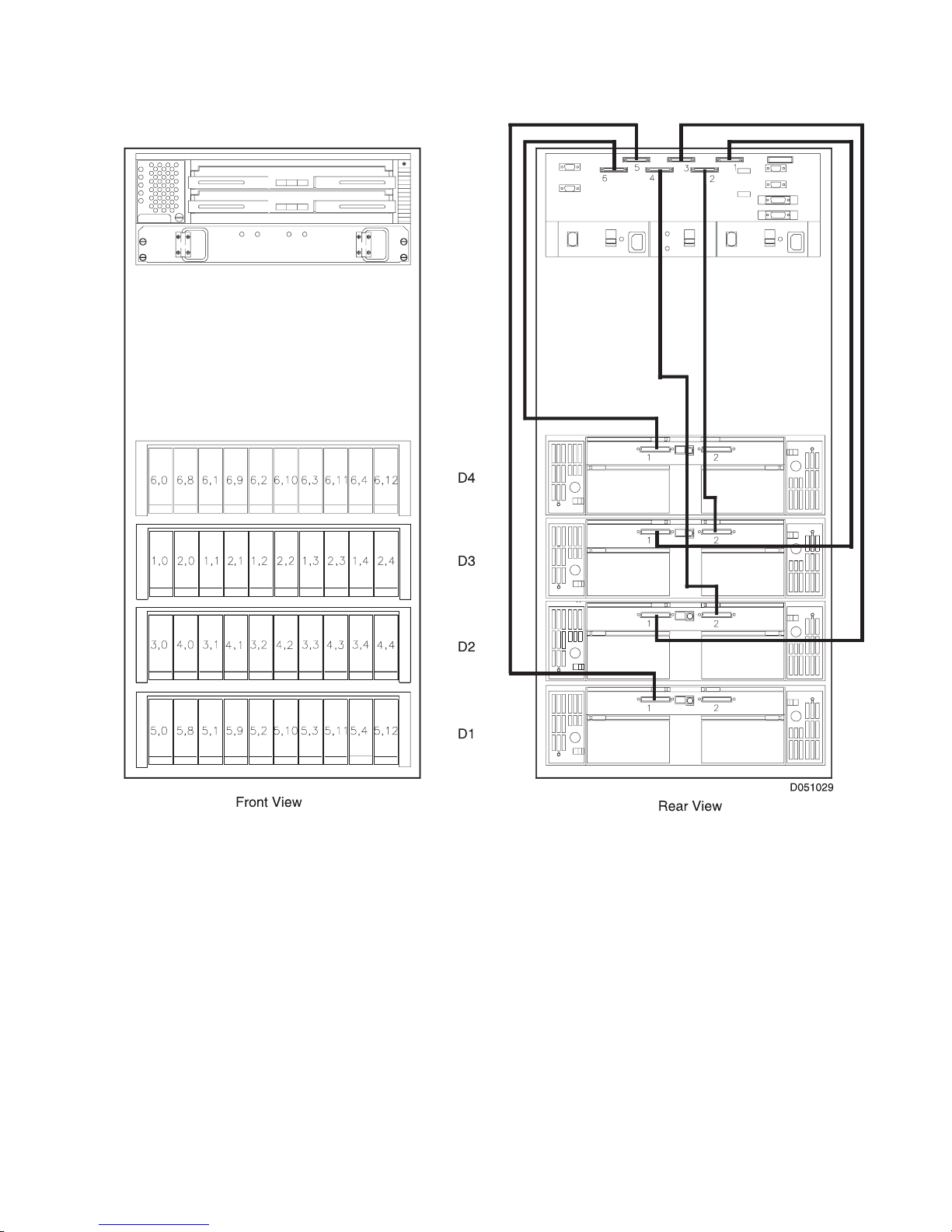

22. Rackmount Cabling to Four Drive Modules ............63

23. Rackmount Cabling to Five Drive Modules ............64

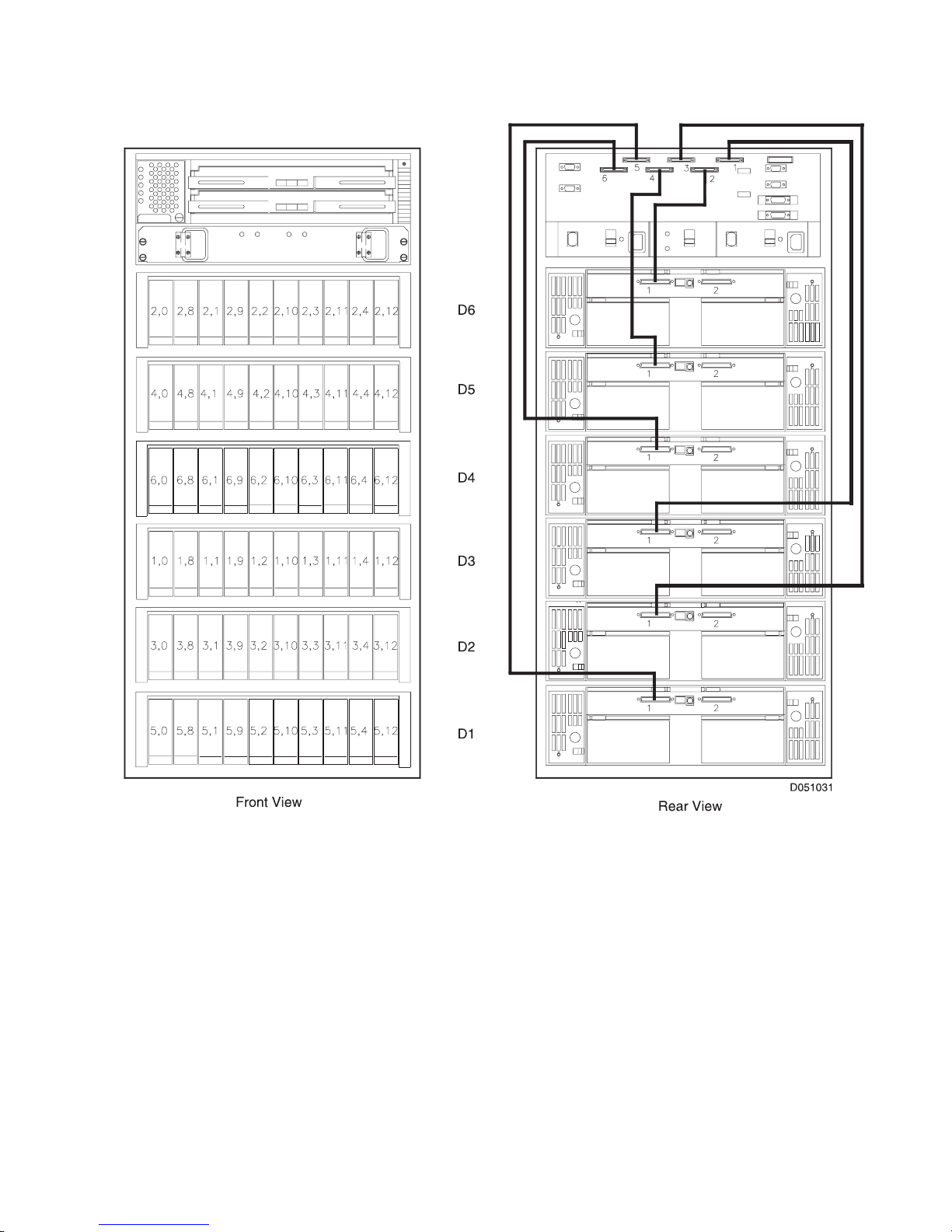

24. Rackmount Cabling to Six Drive Modules .............65

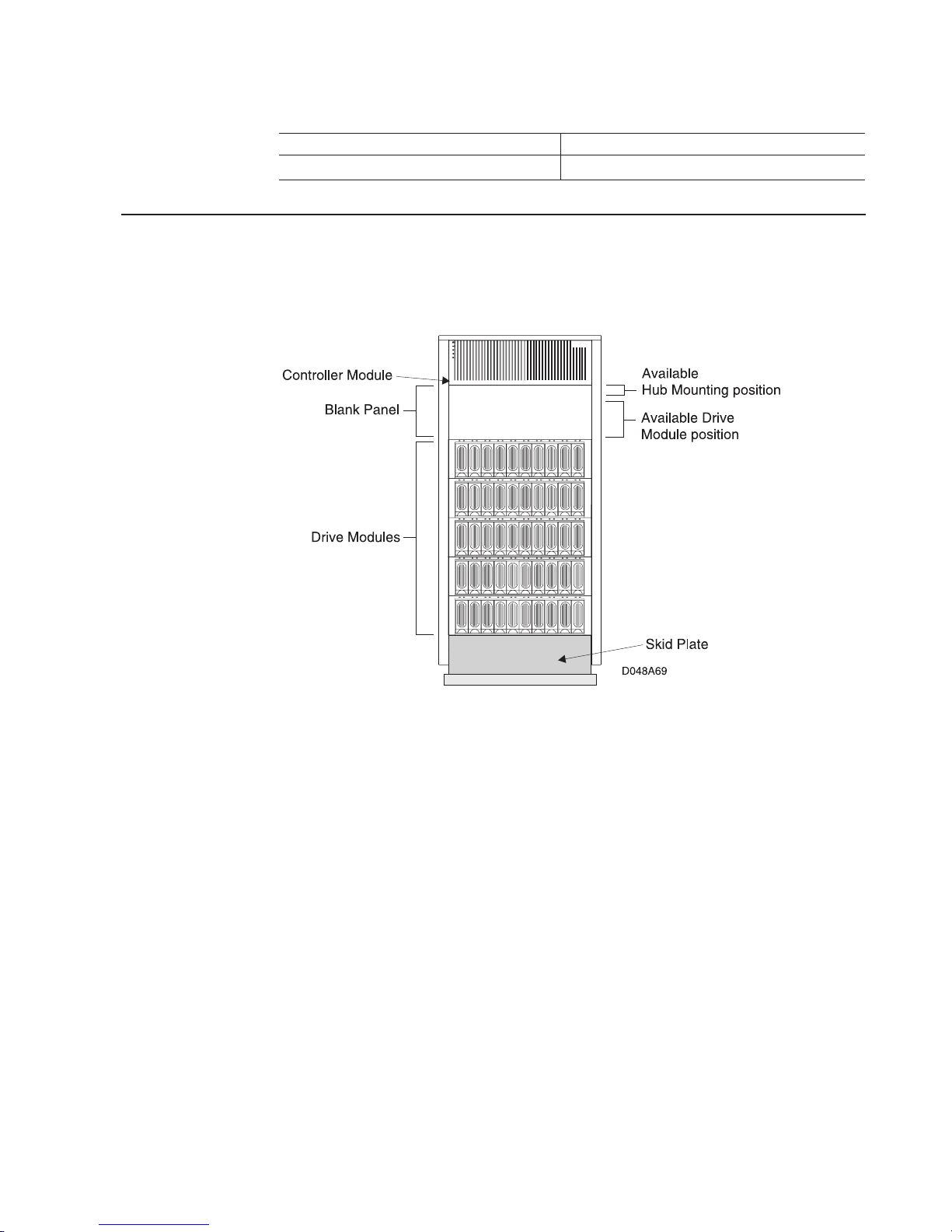

25. Rackmount Cabinet .....................69

26. Front View of Controller Module ................70

27. Back View of Controller Module ................70

28. Internal Components ....................71

29. Internal Components – cont...................71

30. Removable Cover on the Controller Module ............72

31. Controller Module Power Switches ...............73

32. LEDs on the Front .....................76

33. LEDs on the Back .....................78

34. Removing and Installing FRUs .................80

35. Removing and Installing FRUs – cont. ..............80

36. Removing and Installing FRUs – cont. ..............81

37. Disconnecting Interface Cables.................82

38. Removing and Installing the Chassis on Support Rails ........82

39. Removing and Replacing the Cover Plate.............83

40. Removing Screws, Harnesses, and Power Supply Assembly ......84

41. DC Battery and Power Harness Connections ...........85

42. Removing the Controller Card Cage ...............85

43. Controller FRUs in Controller Module ..............87

44. Controller FRU, Slots and LEDs ................89

45. Controller FRU, Slots and LEDs – cont. .............90

46. LEDs on Front Covers ....................93

47. Removing and Installing a Controller FRU.............95

48. Controller Card Cage ....................96

49. Controller Module Cooling System ...............101

50. Air Flow through Chassis ...................102

51. Controller Module Fan Fault LEDs ...............103

52. Controller Fan FRU and Status LEDs ..............104

53. Removing and Installing a Controller Fan .............107

© Copyright IBM Corp. 1999 xi

Page 14

54. Power Supply Fan FRU ...................108

55. Removing and Installing a Power Supply Fan FRU .........110

56. Controller Module Power System FRUs .............111

57. Battery FRU........................113

58. Removing and Replacing a Front Cover .............115

59. Battery FRU Service Label ..................116

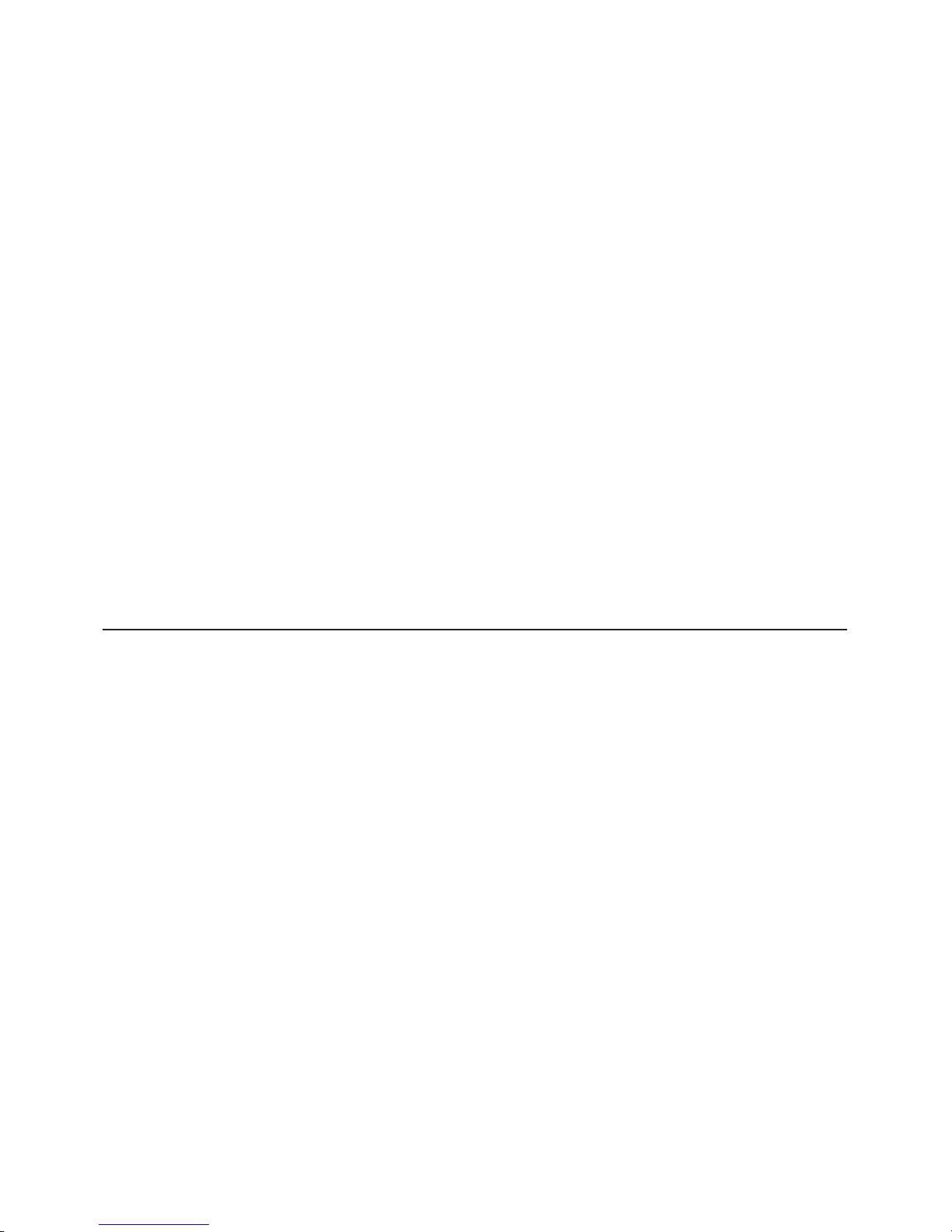

60. Removing and Installing the Battery FRU .............117

61. Power Supply FRU .....................119

62. Fault Indicators for a Failed Power Supply ............122

63. Turning Off the Power and Unplugging the Power Cord........123

64. Removing and Installing a Power Supply FRU ...........123

65. Battery Harness ......................124

66. Removing and Installing a Battery Harness ............126

67. DC Power Harnesses ....................127

68. Reconnecting the DC Power Harnesses .............129

69. Power Supply Assembly ...................130

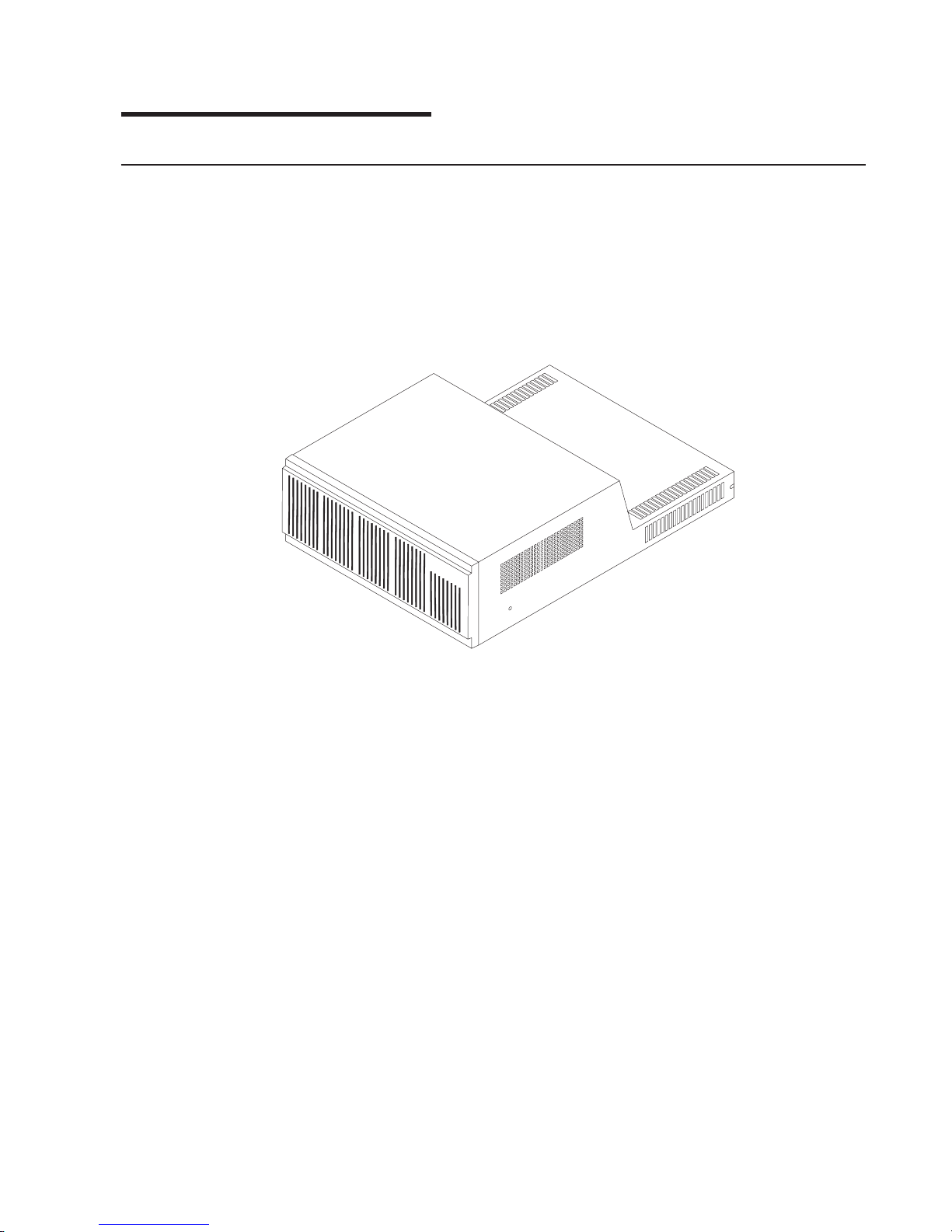

70. Drive Module .......................141

71. Front Views of the Drive Module ................142

72. Back View of the Drive Module.................143

73. Drive LEDs ........................144

74. Drive FRU ........................144

75. Drive Channel and SCSI ID Numbering..............145

76.ESMFRU........................146

77. ESM Board Connectors, Switches, and LEDs ...........147

78. Location of Mid-Plane ....................149

79. Power Supply FRU .....................150

80.FanFRU.........................151

81. Power Cords and Switches ..................154

82. Drive LEDs on the Front Panel.................157

83. LEDs on Drive Module with ESM Board .............158

84. Drive FRU and Front Panel LEDs................162

85. Removing/Installing Drive FRUs ................163

86. Amber Fault LEDs (Rackmount) ................171

87. Power Switches, Power Cords, and SCSI Interface Cables ......172

88. Removing/Installing an ESM FRU................173

89. Power Switches, Power Cords, and SCSI Cables ..........175

90. Removing/Installing Power Supplies and Interface FRUs .......175

91. Removing/Installing Drive and Fan FRUs .............176

92. Rear Mounting Screws ....................177

93. Front Mounting Screws....................177

94. Fault LEDs on the Back of the Drive Module............181

95. Fault LEDs on the Back of the Drive Module............184

96. Power Switches and Power Cords ...............185

97. Removing/Installing a Power Supply FRU .............186

98. Fault LEDs on the Back of the Drive Module............189

99. Removing/Installing a Fan FRU ................190

100. RAID Manager for DOS Main Menu ...............212

101. The Array Configuration Editor (ACE) Display ...........213

102. The Logical Unit window ...................214

103. The Logical Unit Status Display ................215

104. The Drive window .....................217

105. The Drive Matrix ......................218

106. Device Drawer with Single Drive Bus (Bridge Disable OFF) ......218

107. Device Drawer with 2 Drive Buses (Bridge Disable ON)........219

108. Attachment of the Modem and WTI Switch to a IBM 2102 F10 Fibre

Channel Storage Server ...................229

xii IBM 2102 Model F10 and Model D00 Service Guide

Page 15

109. Help Menu. ........................231

110. Port Configuration Menu ...................232

111. Port Configuration Menu ...................233

112. Help Menu. ........................237

113. DriveDload Main Menu....................241

114. 2102 Model F10 Controller Module FRUs .............282

115. 2102 Model F10 Controller Module FRUs – cont. ..........283

116. 2102 Model F10 Controller Module FRUs – cont. ..........284

117. 2102 Model D00 Drive Module FRUs ..............286

Figures xiii

Page 16

xiv IBM 2102 Model F10 and Model D00 Service Guide

Page 17

Notices

References in this publication to IBM products, programs, or services do not imply

that IBM intends to make these available in all countries in which IBM operates. Any

reference to an IBM product, program, or service is not intended to state or imply

that only that IBM product, program, or service may be used. Subject to IBM’s valid

intellectual property or other legally protected rights, any functionally equivalent

product, program, or service, may be used instead of the IBM product, program, or

service. The evaluation and verification of operation in conjunction with other

products, except those expressly designated by IBM, are the responsibility of the

user.

IBM may have patents or pending patent applications covering subject matter in this

document. The furnishing of this document does not give you any license to these

patents. You can send license inquiries, in writing, to:

IBM Director of Licensing

IBM Corporation

North Castle Drive

Armonk, NY 10504-1785

U.S.A.

Read Before Using

IMPORTANT

YOU ACCEPT THE TERMS OF THIS IBM LICENSE AGREEMENT FOR

MACHINE CODE BY YOUR USE OF THE HARDWARE PRODUCT OR

MACHINE CODE. PLEASE READ THE AGREEMENT CONTAINED IN THIS

BOOK BEFORE USING THE HARDWARE PRODUCT. SEE “IBM License

Agreement for Machine Code” on page xxi.

Safety and Environmental Notices

This section contains information about:

v Safety notices used in this guide

v Environmental notices and statements for this product

Safety Notices

Note: For a translation of the danger and caution notices, see

Notices for Open Attachment

Definitions of Safety Notices

DANGER

A danger notice indicates the presence of a hazard that has the potential of

causing death or serious personal injury.

Translated Safety

, GC26-7246.

CAUTION:

A caution notice indicates the presence of a hazard that has the potential of

causing minor or moderate personal injury.

© Copyright IBM Corp. 1999 xv

Page 18

CAUTION:

The drawer weighs approximately 25 kg (55 lb) with no devices installed. Do

not try to lift it by yourself. Ask another service representative for assistance.

CAUTION:

Energy hazard, remove power before servicing.

CAUTION:

This unit weighs between 18 kg (39.7 pounds) and 32 kg (70.5 pounds). Two

persons are required to safely move it. Using less than two persons to move

it can result in injury.

Attention: An attention notice indicates the possibility of damage to a program,

device, system or data.

Translations of the Safety Inspection Procedure

See “Appendix C. Safety Inspection Procedure in German” on page 273 and

“Appendix D. Safety Inspection Procedure in Traditional Chinese” on page 277 for

the German and Chinese translations of “Appendix B. Safety Inspection Procedure”

on page 269.

Environmental Notices and Statements

Product Disposal

This product contains a SEALED LEAD ACID BATTERY. When the battery

assembly is replaced, the used battery assembly must be returned to IBM for

proper disposal.

Product Recycling

This unit contains recyclable materials. These materials should be recycled where

processing sites are available and according to local regulations. In some areas

IBM provides a product take-back program that ensures proper handling of the

product. Contact your IBM representative for more information.

Electronic Emission Statements

This section gives the electronic emission notices or statements for the United

States and other countries.

Federal Communications Commission (FCC) Statement

This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful

interference, in which case the user will be required to correct the interference at

his own expense.

xvi IBM 2102 Model F10 and Model D00 Service Guide

Page 19

Properly shielded and grounded cables and connectors must be used in order to

meet FCC emission limits. IBM is not responsible for any radio or television

interference caused by using other than recommended cables and connectors or by

unauthorized changes or modifications to this equipment. Unauthorized changes or

modifications could void the user’s authority to operate the equipment.

This device complies with Part 15 of the FCC Rules. Operation is subject to the

following two conditions: (1) this device may not cause harmful interference, and (2)

this device must accept any interference received, including interference that may

cause undesired operation.

Industry Canada Compliance Statement

This Class A digital apparatus complies with Canadian ICES-003.

Avis de conformité à la réglementation d’Industrie Canada: Cet appareil

numérique de la classe A est conform à la norme NMB-003 du Canada.

European Community Compliance Statement

This product is in conformity with the protection requirements of EC Council

Directive 89/336/EEC on the approximation of the laws of the Member States

relating to electromagnetic compatibility. IBM cannot accept responsibility for any

failure to satisfy the protection requirements resulting from a non-recommended

modification of the product, including the fitting of non-IBM option cards.

Germany Only

Zulassungsbescheinigung laut Gesetz ueber die elektromagnetische

Vertraeglichkeit von Geraeten (EMVG) vom 30. August 1995.

Dieses Geraet ist berechtigt, in Uebereinstimmung mit dem deutschen EMVG das

EG-Konformitaetszeichen - CE - zu fuehren.

Der Aussteller der Konformitaetserklaeung ist die IBM Deutschland.

Informationen in Hinsicht EMVG Paragraph 3 Abs. (2) 2:

Das Geraet erfuellt die Schutzanforderungen nach EN 50082-1 und

EN 55022 Klasse A.

EN 55022 Klasse A Geraete beduerfen folgender Hinweise:

Nach dem EMVG:

"Geraete duerfen an Orten, fuer die sie

nicht ausreichend entstoert

sind, nur mit besonderer Genehmigung des Bundesministeriums

fuer Post und Telekommunikation oder des Bundesamtes fuer Post und

Telekommunikation

betrieben werden. Die Genehmigung wird erteilt, wenn keine

elektromagnetischen Stoerungen zu erwarten sind." (Auszug aus dem

EMVG, Paragraph 3, Abs.4)

Dieses Genehmigungsverfahren ist nach Paragraph 9 EMVG in Verbindung

mit der entsprechenden Kostenverordnung (Amtsblatt 14/93)

kostenpflichtig.

Nach der EN 55022:

Notices xvii

Page 20

"Dies ist eine Einrichtung der Klasse A. Diese Einrichtung kann im

Wohnbereich Funkstoerungen verursachen. in diesem Fall kann vom

Betreiber verlangt werden, angemessene Massnahmen durchzufuehren

und dafuer aufzukommen."

Anmerkung:

Um die Einhaltung des EMVG sicherzustellen, sind die Geraete wie in den

Handbuechern angegeben zu installieren und zu betreiben.

Japanese Voluntary Control Council for Interference (VCCI) Class A

Statement

Korean Government Ministry of Communication (MOC) Statement

Please note that this device has been approved for business purposes with regard

to electromagnetic interference. If you find this is not suitable for your use, you may

exchange it for one with a non-business purpose.

Taiwan Class A Compliance Statement

Trademarks

The following terms are trademarks of the International Business Machines

Corporation in the United States or other countries or both:

IBM

Seascape

StorWatch

HP-UX and Hewlett-Packard are trademarks of Hewlett-Packard Company.

Sun, SPARC, SunOS, and Solaris, are trademarks of Sun Microsystems, Inc.

xviii IBM 2102 Model F10 and Model D00 Service Guide

Page 21

Windows NT and Alpha Windows NT are trademarks of Microsoft Corporation.

UNIX is a registered trademark in the United States and other countries licensed

exclusively through X/Open Company Limited.

Other company, product, or service names, may be trademarks or service marks of

others.

Notices xix

Page 22

xx IBM 2102 Model F10 and Model D00 Service Guide

Page 23

IBM License Agreement for Machine Code

Regardless of how you acquire (electronically, preloaded, on media or otherwise)

BIOS, Utilities, Diagnostics, Device Drivers or Microcode (collectively called

“Machine Code”), you accept the terms of this Agreement by your initial use of a

Machine or Machine Code. The term “Machine” means an IBM machine, its

features, conversions, upgrades, elements or accessories, or any combination of

them. Acceptance of these license terms authorizes you to use Machine Code with

the specific product for which it is provided.

International Business Machines Corporation or one of its subsidiaries (“IBM”), or an

IBM supplier, owns copyrights in Machine Code.

IBM grants you a nonexclusive license to use Machine Code only in conjunction

with a Machine. As the rightful possessor of a Machine, you may make a

reasonable number of copies of Machine Code as necessary for backup,

configuration, and restoration of the Machine. You must reproduce the copyright

notice and any other legend of ownership on each copy of Machine Code you

make.

You may transfer possession of Machine Code and its media to another party only

with the transfer of the Machine on which the Machine Code is used. If you do so,

you must give the other party a copy of these terms and provide all user

documentation to that party. When you do so, you must destroy all your copies of

Machine Code.

Your license for Machine Code terminates when you no longer rightfully possess the

Machine.

No other rights under this license are granted.

You may not, for example, do any of the following:

1. otherwise copy, display, transfer, adapt, modify, or distribute in any form,

Machine Code, except as IBM may authorize in a Machine’s user

documentation.

2. reverse assemble, reverse compile, or otherwise translate the Machine Code,

unless expressly permitted by applicable law without the possibility of

contractual waiver;

3. sublicense or assign the license for the Machine Code; or

4. lease the Machine Code or any copy of it.

The terms of IBM’s Machine warranty, which is incorporated into this Agreement by

reference, apply to Machine Code. Please refer to that warranty for any questions

or claims regarding performance or liability for Machine Code.

© Copyright IBM Corp. 1999 xxi

Page 24

xxii IBM 2102 Model F10 and Model D00 Service Guide

Page 25

Statements of Limited Warranty

International Business Machines Corporation

Armonk, New York, 10504

The warranties provided by IBM in this Statement of Limited Warranty1apply only to

Machines you originally purchase for your use, and not for resale, from IBM or your

reseller. The term “Machine” means an IBM machine, its features, conversions,

upgrades, elements, or accessories, or any combination of them.

Unless IBM specifies otherwise, the following warranties apply only in the country

where you acquire the Machine. If you have any questions, contact IBM or your

reseller.

Machine: IBM Fibre Channel RAID Storage Server and

Warranty Period: One Year*

* Contact your place of purchase for warranty service information.

Production Status

Each Machine is manufactured from new parts, or new and used parts. In some

cases, the Machine may not be new and may have been previously installed.

Regardless of the Machine’s production status, IBM’s warranty terms apply.

Expandable Storage Unit

2102 Model F10 and 2102 Model D00

The IBM Warranty for Machines

IBM warrants that each Machine 1) is free from defects in materials and

workmanship and 2) conforms to IBM’s Official Published Specifications. The

warranty period for a Machine is a specified, fixed period commencing on its Date

of Installation. The date on your receipt is the Date of Installation, unless IBM or

your reseller informs you otherwise.

During the warranty period IBM or your reseller, if authorized by IBM, will provide

warranty service under the type of service designated for the Machine and will

manage and install engineering changes that apply to the Machine.

For IBM or your reseller to provide warranty service for a feature, conversion, or

upgrade, IBM or your reseller may require that the Machine on which it is installed

be 1) for certain Machines, the designated, serial-numbered Machine and 2) at an

engineering-change level compatible with the feature, conversion, or upgrade. Many

of these transactions involve the removal of parts and their return to IBM. You

represent that all removed parts are genuine and unaltered. A part that replaces a

removed part will assume the warranty service status of the replaced part.

If a Machine does not function as warranted during the warranty period, IBM or your

reseller will repair it or replace it with one that is at least functionally equivalent,

without charge. The replacement may not be new, but will be in good working order.

1. Form Z125-4753

© Copyright IBM Corp. 1999

xxiii

Page 26

If IBM or your reseller is unable to repair or replace the Machine, you may return it

to your place of purchase and your money will be refunded.

If you transfer a Machine to another user, warranty service is available to that user

for the remainder of the warranty period. You should give your proof of purchase

and this Statement to that user. However, for Machines which have a lifetime

warranty, this warranty is not transferable.

Warranty Service

To obtain warranty service for the Machine, you should contact your reseller or call

IBM. In the United States, call IBM at 1-800-IBM-SERV (426-7378) In Canada, call

IBM at 1-800-465-6666. You may be required to present proof of purchase.

IBM or your reseller will provide certain types of repair and exchange service, either

at your location or at IBM’s or your reseller’s service center, to restore a Machine to

good working order.

When a type of service involves the exchange of a Machine or part, the item IBM or

your reseller replaces becomes its property and the replacement becomes yours.

You represent that all removed items are genuine and unaltered. The replacement

may not be new, but will be in good working order and at least functionally

equivalent to the item replaced. The replacement assumes the warranty service

status of the replaced item. Before IBM or your reseller exchanges a Machine or

part, you agree to remove all features, parts, options, alterations, and attachments

not under warranty service. You also agree to ensure that the Machine is free of

any legal obligations or restrictions that prevent its exchange.

You agree to:

1. obtain authorization from the owner to have IBM or your reseller service a

2. where applicable, before service is provided:

IBM is responsible for loss of, or damage to, your Machine while it is 1) in IBM’s

possession or 2) in transit in those cases where IBM is responsible for the

transportation charges.

Extent of Warranty

IBM does not warrant uninterrupted or error-free operation of a Machine.

The warranties may be voided by misuse, accident, modification, unsuitable

physical or operating environment, improper maintenance by you, removal or

alteration of Machine or parts identification labels, or failure caused by a product for

which IBM is not responsible.

THESE WARRANTIES REPLACE ALL OTHER WARRANTIES OR CONDITIONS,

EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED

WARRANTIES OR CONDITIONS OF MERCHANTABILITY AND FITNESS FOR A

Machine that you do not own; and

a. follow the problem determination, problem analysis, and service request

procedures that IBM or your reseller provide,

b. secure all programs, data, and funds contained in a Machine, and

c. inform IBM or your reseller of changes in a Machine’s location.

xxiv IBM 2102 Model F10 and Model D00 Service Guide

Page 27

PARTICULAR PURPOSE. THESE WARRANTIES GIVE YOU SPECIFIC LEGAL

RIGHTS AND YOU MAY ALSO HAVE OTHER RIGHTS WHICH VARY FROM

JURISDICTION TO JURISDICTION. SOME JURISDICTIONS DO NOT ALLOW

THE EXCLUSION OR LIMITATION OF EXPRESS OR IMPLIED WARRANTIES, SO

THE ABOVE EXCLUSION OR LIMITATION MAY NOT APPLY TO YOU. IN THAT

EVENT SUCH WARRANTIES ARE LIMITED IN DURATION TO THE WARRANTY

PERIOD. NO WARRANTIES APPLY AFTER THAT PERIOD.

Limitation of Liability

Circumstances may arise where, because of a default on IBM’s part or other liability

you are entitled to recover damages from IBM. In each such instance, regardless of

the basis on which you are entitled to claim damages from IBM (including

fundamental breach, negligence, misrepresentation, or other contract or tort claim),

IBM is liable only for:

1. damages for bodily injury (including death) and damage to real property and

tangible personal property; and

2. the amount of any other actual direct damages or loss, up to the greater of U.S.

$100,000 or the charges (if recurring, 12 months’ charges apply) for the

Machine that is the subject of the claim.

UNDER NO CIRCUMSTANCES IS IBM LIABLE FOR ANY OF THE FOLLOWING:

1) THIRD-PARTY CLAIMS AGAINST YOU FOR LOSSES OR DAMAGES (OTHER

THAN THOSE UNDER THE FIRST ITEM LISTED ABOVE); 2) LOSS OF, OR

DAMAGE TO, YOUR RECORDS OR DATA; OR 3) SPECIAL, INCIDENTAL, OR

INDIRECT DAMAGES OR FOR ANY ECONOMIC CONSEQUENTIAL DAMAGES

(INCLUDING LOST PROFITS OR SAVINGS), EVEN IF IBM OR YOUR RESELLER

IS INFORMED OF THEIR POSSIBILITY. SOME JURISDICTIONS DO NOT ALLOW

THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL

DAMAGES, SO THE ABOVE EXCLUSION OR LIMITATION MAY NOT APPLY TO

YOU.

Statements of Limited Warranty xxv

Page 28

xxvi IBM 2102 Model F10 and Model D00 Service Guide

Page 29

About This Book

This book provides the information for servicing the IBM Fibre Channel RAID

Storage Server with the Expandable Storage Unit.

Who Should Use This Book

This publication is for Service Representatives who are installing and maintaining

the 2102 subsystem.

Related Publications

Additional information that is related to the subsystem is available in the following

publications:

Seascape Solution Rack, Installation and Service Guide, IBM 2101 Model 100

v

SY27-7606

v

Fibre Channel RAID Storage Server, Introduction and Planning Guide, IBM 2102

GC26-7281

Fibre Channel Storage Manager, Installation Guide for Microsoft Windows NT

v

SC26-7283

v

StorWatch Fibre Channel RAID Specialist, Installation Guide for Microsoft

Windows NT and Windows 95

v

Fibre Channel Storage Manager and StorWatch Fibre Channel RAID Specialist,

User’s Guide

Fibre Channel Storage Manager, Installation Guide for Sun Solaris Operating

v

System

v

Fibre Channel Storage Manager, Installation Guide for Hewlett Packard HP-UX

Operating System

v

Fibre Channel RAID Storage Server and Expandable Storage Unit, User’s Guide,

IBM 2102 Model F10 and Model D00

v

Fibre Channel Storage Hub, Installation, Service, and User’s Guide, IBM 2103

Model H07

v

Fibre Channel Storage Manager, Installation and User’s Guide for the AIX

Operating System

v

Diagnostic Information for Multiple Bus Systems

, SC26-7285

, SC26-7286

, SC26-7289

,

,

,

, SC26-7284

, SC26-7287

, SC26-7288

, SC26-7290

, SA38-0509

Additional publications are available for purchase from IBM. For a list of publications

available in your country:

v In the U.S. and Puerto Rico, call 1–800–426–7282.

v In the United Kingdom, call 01705–565000 or 0161–9056001.

v In Canada, call 1–800–465–1234.

v In other countries, contact the IBM support organization that services your area,

your IBM marketing representative, or your IBM reseller.

Web Site

For more Fibre Channel Storage information, go to

http://www.ibm.com/storage/fcss on the World Wide Web.

© Copyright IBM Corp. 1999 xxvii

Page 30

xxviii IBM 2102 Model F10 and Model D00 Service Guide

Page 31

Part 1. Maintenance Starting Points

© Copyright IBM Corp. 1999 1

Page 32

2 IBM 2102 Model F10 and Model D00 Service Guide

Page 33

Chapter 1. Maintenance Starting Points

The following four tables contain pointers into the 2102 subsystem maintenance

package. Before using the tables, be sure to consult the Installation and/or User’s

Guide for the storage management software specific to the operating system being

used. In many cases, these Guides contain procedures for analyzing and repairing

problems from the host that provide better isolation and the most up-to-date

recovery steps. Throughout this guide, the term ″storage management software″ is

used generically to refer to the Fibre Channel Storage Manager software and its

related components running on a Windows NT, SUN Solaris, HP-UX or AIX host

platform.

v For subsystems attached to a Windows NT host, refer to

Manager and StorWatch Fibre Channel RAID Specialist, User’s Guide

SC26-7285 and

Windows NT

v For subsystems attached to an HP-UX host, refer to

Manager and StorWatch Fibre Channel RAID Specialist, User’s Guide

SC26-7285 and

Packard HP-UX Operating System

v For subsystems attached to a SUN Solaris host, refer to

Manager and StorWatch Fibre Channel RAID Specialist, User’s Guide

SC26-7285 and

Solaris Operating System

v For subsystems attached to an AIX host, refer to

Manager, Installation and User’s Guide for the AIX Operating System

SC26-7290.

v For subsystems using a networked storage management station running

StorWatch Fibre Channel RAID Specialist, refer to

Manager and StorWatch Fibre Channel RAID Specialist, User’s Guide

SC26-7285 and

Microsoft Windows NT and Windows 95

Fibre Channel Storage Manager, Installation Guide for Microsoft

, SC26-7283.

Fibre Channel Storage Manager, Installation Guide for Hewlett

, SC26-7287.

Fibre Channel Storage Manager, Installation Guide for Sun

, SC26-7286.

StorWatch Fibre Channel RAID Specialist, Installation Guide for

Fibre Channel Storage

,

Fibre Channel Storage

,

Fibre Channel Storage

,

Fibre Channel Storage

,

Fibre Channel Storage

,

, SC26-7284.

If you are unable to resolve the problem using the software guides or you cannot

find the appropriate information, then use these START tables. To use the tables,

find the reason you are here in the left column and then perform the action in the

right column.

After completing a recovery procedure (especially hardware replacement), you

should verify the subsystem status using the host software:

v If the subsystem is attached to a Windows NT, SUN, or HP-UX host system

running the Fibre Channel Storage Manager software or a Windows NT or

Windows 95 system running the StorWatch Fibre Channel RAID Specialist

software, then run the Recovery Guru to verify that the subsystem is operating

properly. Refer to

RAID Specialist, User’s Guide

v If the subsystem is attached to an AIX host, then run the Advanced Diagnostics

in System Verification mode from the diagnostic interface (type ″diag″ from the

command prompt) to verify that the subsystem is operating properly. Refer to

Fibre Channel Storage Manager and StorWatch Fibre Channel

, SC26-7285.

Fibre Channel Storage Manager, Installation and User’s Guide for the AIX

Operating System

Systems

customer to normal operation).

© Copyright IBM Corp. 1999 3

, SA38-0509 for more information (refer to MAP 0410 for returning the

, SC26-7290 and

Diagnostic Information for Multiple Bus

Page 34

2102 Fibre Channel RAID Storage Server Start Tables

Start Table A

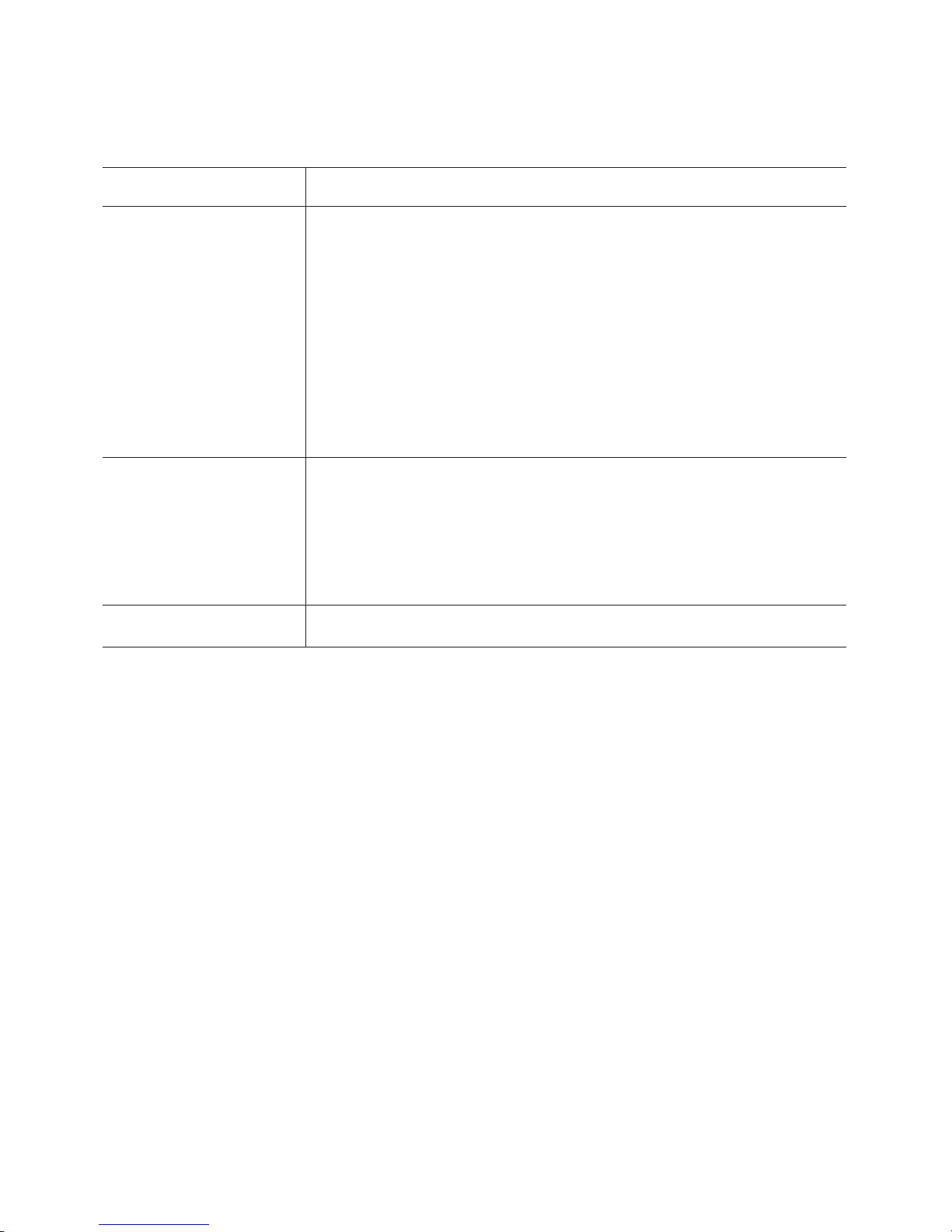

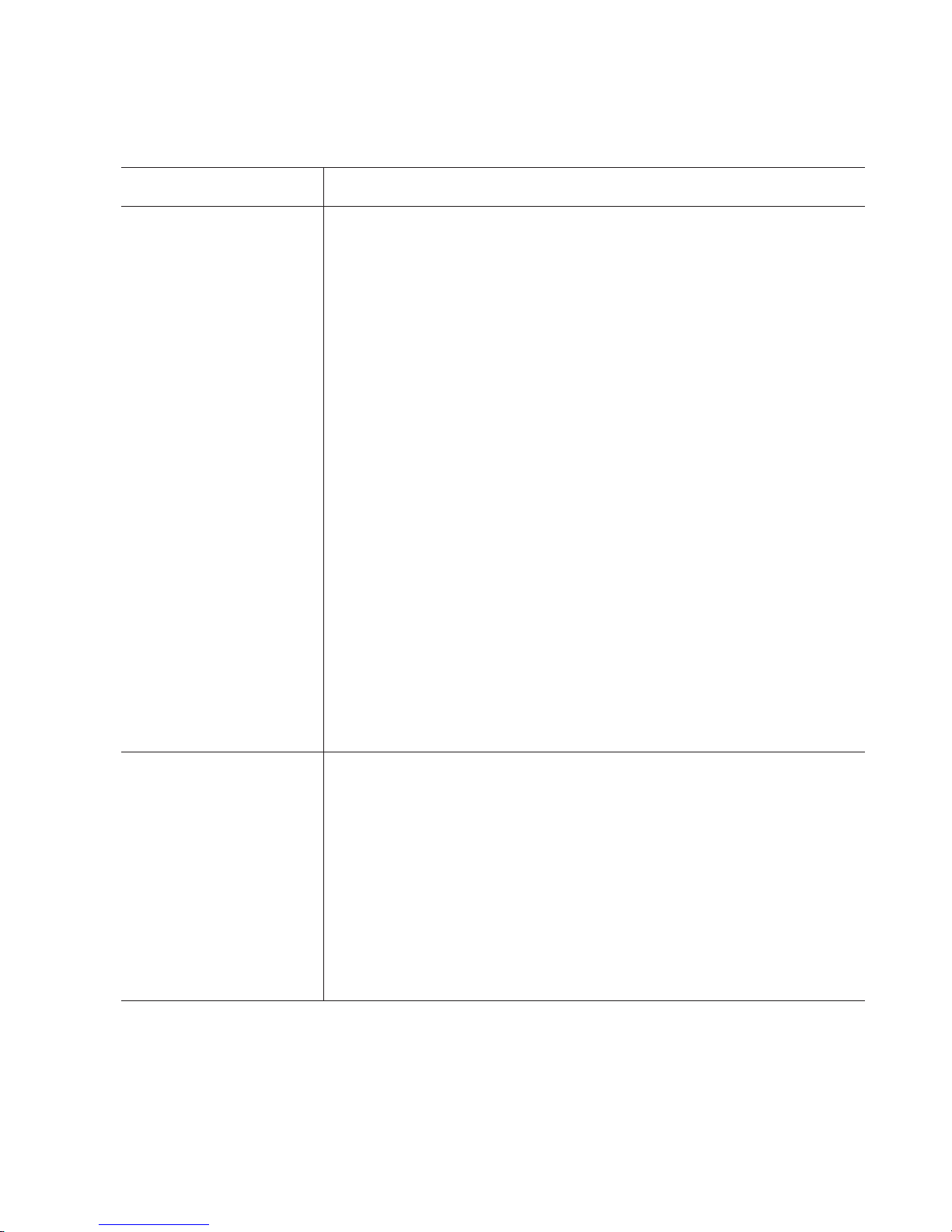

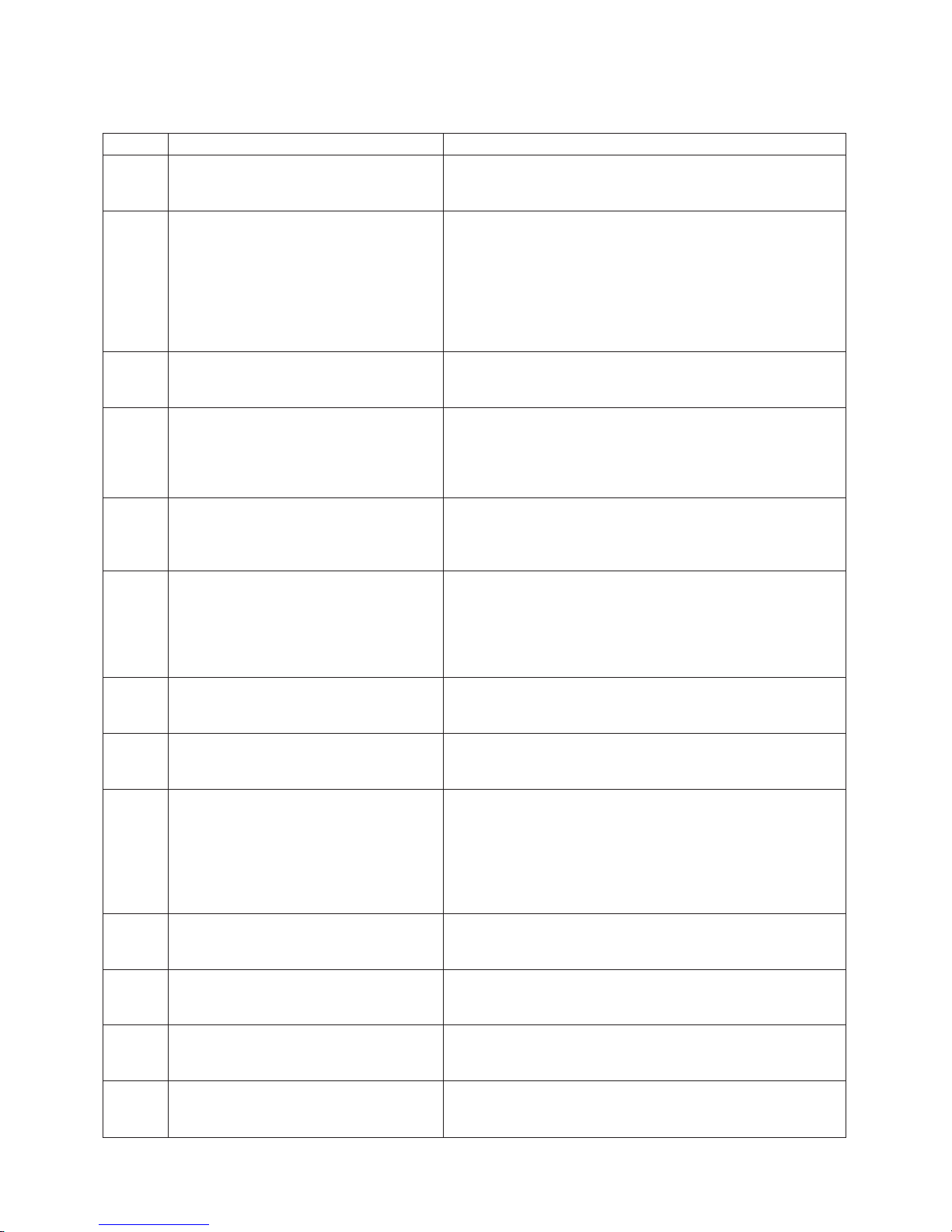

Table 1. 2102 Fibre Channel RAID Storage Server Start Table A

If you are here for this

reason...

Running diagnostics from an

AIX host resulted in a six digit

Service Request Number/Error

Code

...Then perform this action

Go to “AIX Error Codes (SRNs)” on page 15.

4 IBM 2102 Model F10 and Model D00 Service Guide

Page 35

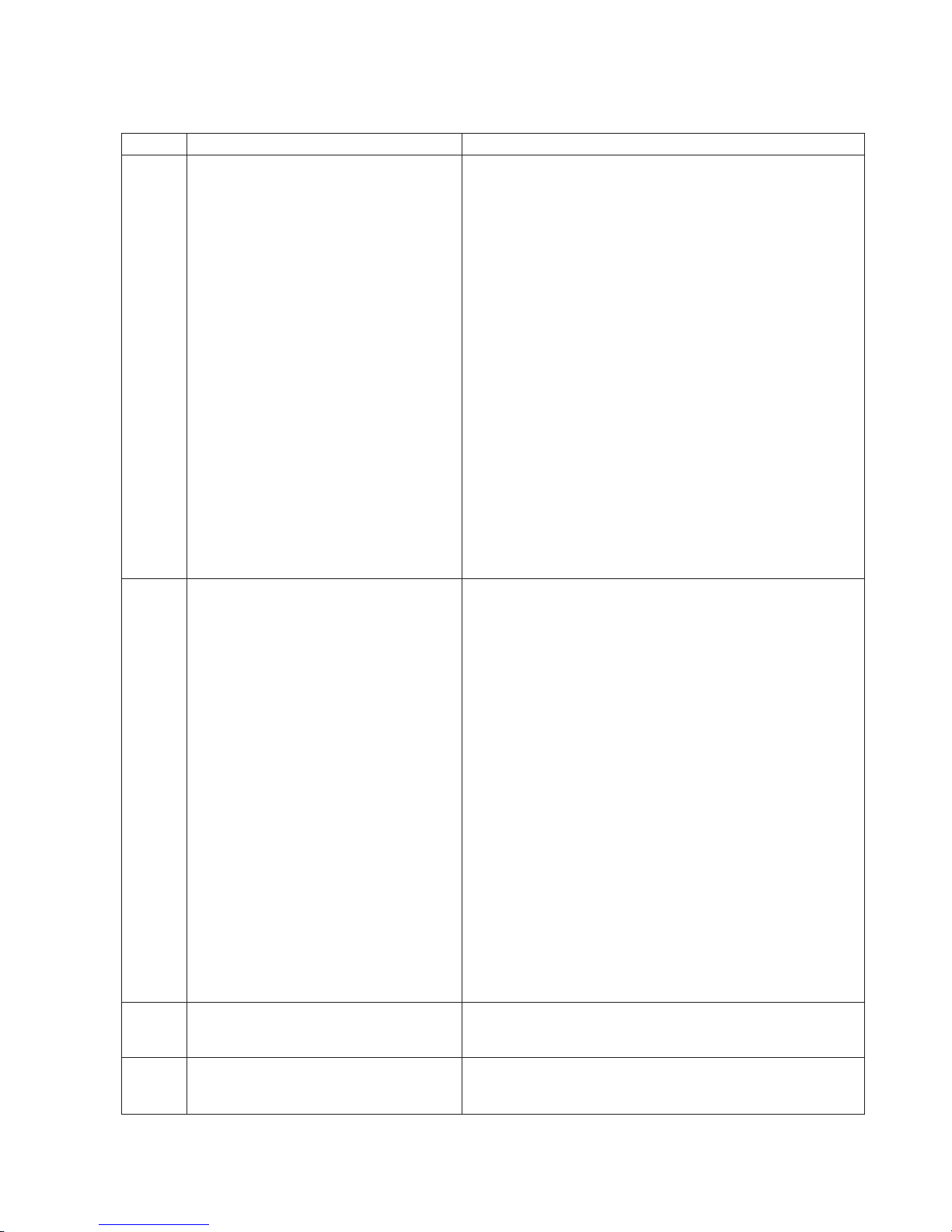

Table 1. 2102 Fibre Channel RAID Storage Server Start Table A (continued)

If you are here for this

...Then perform this action

reason...

v A check light is active on a

subsystem component

v A problem occurred during

an installation procedure

v The host software indicated

that a problem occurred

within the RAID array

subsystem

v The customer observed a

problem that was not

detected or reported by the

host system

v You suspect a problem

within the RAID array

subsystem

Controller:

1. If the subsystem is attached to a Windows NT, SUN, or HP-UX host system

running the

Windows 95 system running the

Fibre Channel Storage Manager

StorWatch Fibre Channel RAID Specialist

software, then run the Recovery Guru from the host system and follow the

recovery procedures given. Refer to

Fibre Channel Storage Manager and

StorWatch Fibre Channel RAID Specialist, User’s Guide

2. If the subsystem is attached to an AIX host, then run Advanced Diagnostics in

Problem Determination mode from the diagnostic interface (type ″diag″ from the

command prompt). If the diagnostics return an error code for the 2102

subsystem, then go to “AIX Error Codes (SRNs)” on page 15 and follow the

instructions for the error code generated. Once the problem has been addressed,

rerun the AIX Advanced Diagnostics in System Verification mode to verify the

repair. Refer to

the AIX Operating System

Bus Systems

Fibre Channel Storage Manager, Installation and User’s Guide for

, SC26-7290 and

, SA38-0509 (MAP 0410) for more information.

3. If you don’t have access to the host system or the host system does not provide

a recovery procedure or error code, then follow these steps in order:

a. Go to “Troubleshooting Controller Problems” on page 92 and follow the

procedure for the matching symptoms. If no symptoms match, go to the next

step.

b. Go to “Troubleshooting Controller Fan Problems” on page 105 and follow the

procedure for the matching symptoms. If no symptoms match, go to the next

step.

c. Go to “Identifying Interface Problems” on page 87 and follow the procedure for

debugging interface problems. If this does not fix the problem, go to the next

step.

d. Go to “Troubleshooting Power Supply Problems” on page 120 and follow the

procedure for the matching symptoms. If no symptoms match, go to the next

step.

e. Go to “Troubleshooting Battery Problems” on page 114 and follow the

procedure for the matching symptoms. If no symptoms match, go to the next

step.

f. Go to “Troubleshooting Controller Backpanel Problems” on page 97 and follow

the procedure for the matching symptoms. If no symptoms match, go to the

next step.

g. Go to “Troubleshooting Battery Harness Problems” on page 125 and follow

the procedure for the matching symptoms. If no symptoms match, go to the

next step.

h. Go to “Troubleshooting DC Power Harness Problems” on page 127 and follow

the procedure for the matching symptoms. If no symptoms match, go to the

next step.

i. Go to “Troubleshooting Power Interface Board Problems” on page 131 and

follow the procedure for the matching symptoms. If no symptoms match, go to

the next step.

j. Call your next level of support.

software or a Windows NT or

, SC26-7285.

Diagnostic Information for Multiple

Chapter 1. Maintenance Starting Points 5

Page 36

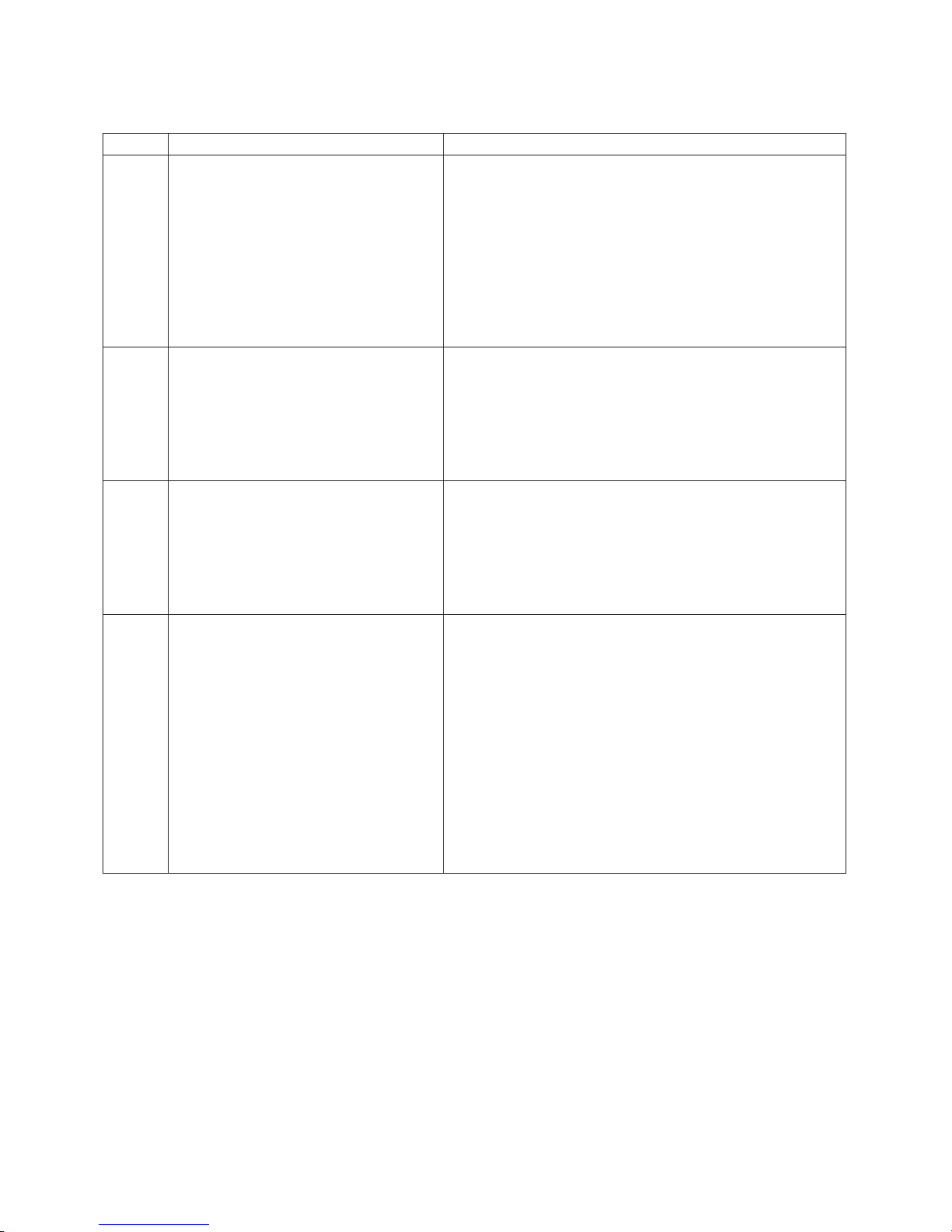

Table 1. 2102 Fibre Channel RAID Storage Server Start Table A (continued)

If you are here for this

reason...

Continued from page 5.

...Then perform this action

Device Drawer:

1. If the subsystem is attached to a Windows NT, SUN, or HP-UX host system

running the

Windows 95 system running the

software, then run the Recovery Guru from the host system and follow the

recovery procedures given. Refer to

Fibre Channel Storage Manager

StorWatch Fibre Channel RAID Specialist

Fibre Channel Storage Manager and

StorWatch Fibre Channel RAID Specialist, User’s Guide

2. If the subsystem is attached to an AIX host, then run Advanced Diagnostics in

Problem Determination mode from the diagnostic interface (type ″diag″ from the

command prompt). If the diagnostics return an error code for the 2102

subsystem, then go to “AIX Error Codes (SRNs)” on page 15 and follow the

instructions for the error code generated. Once the problem has been addressed,

rerun the AIX Advanced Diagnostics in System Verification mode to verify the

repair. Refer to

the AIX Operating System

Bus Systems

3. If you don’t have access to the host system or the host system does not provide

a recovery procedure or error code, then follow these steps in order:

a. Go to “Maintaining the Drives” on page 160 and follow the problem

identification procedures given. If this does not fix the problem, go to the next

step.

b. Go to “Identify Other Drive-Related Problems” on page 164 and follow the

problem identification procedures given. If this does not fix the problem, go to

the next step.

c. Go to “Maintaining the SCSI Components” on page 168 and follow the

problem identification procedures given. If this does not fix the problem, go to

the next step.

d. Go to “Maintaining the Power System” on page 180 and follow the problem

identification procedures given. If this does not fix the problem, go to the next

step.

e. Go to “Drive Module Troubleshooting Chart” on page 198 and follow the

problem identification procedures given. If this does not fix the problem, go to

the next step.

f. Call your next level of support.

Fibre Channel Storage Manager, Installation and User’s Guide for

, SC26-7290 and

, SA38-0509 (MAP 0410) for more information.

software or a Windows NT or

, SC26-7285.

Diagnostic Information for Multiple

6 IBM 2102 Model F10 and Model D00 Service Guide

Page 37

Table 1. 2102 Fibre Channel RAID Storage Server Start Table A (continued)

If you are here for this

reason...

Continued from page 5

. Hub:

...Then perform this action

1. If the subsystem is attached to a Windows NT, SUN, or HP-UX host system

running the

Windows 95 system running the

software, then run the Recovery Guru from the host system and follow the

recovery procedures given. Refer to the

Fibre Channel Storage Manager

StorWatch Fibre Channel RAID Specialist

StorWatch Fibre Channel RAID Specialist, User’s Guide

2. If the subsystem is attached to an AIX host, then run Advanced Diagnostics in

Problem Determination mode from the diagnostic interface (type ″diag″ from the

command prompt). If the diagnostics return an error code for the 2102

subsystem, then go to “AIX Error Codes (SRNs)” on page 15 and follow the

instructions for the error code generated. Once the problem has been addressed,

rerun the AIX Advanced Diagnostics in System Verification mode to verify the

repair. Refer to

the AIX Operating System

Bus Systems

3. If you don’t have access to the host system or the host system does not provide

a recovery procedure or error code, then follow these steps in order:

a. Go to ″Troubleshooting″ in

Fibre Channel Storage Manager, Installation and User’s Guide for

, SC26-7290 and

, SA38-0509 (MAP 0410) for more information.

Fibre Channel Storage Hub, Installation, Service,

and User’s Guide, IBM 2103 Model H07

identification procedures given. If this does not fix the problem, go to the next

step.

b. Go to ″Connect the Cables″ in

Fibre Channel Storage Hub, Installation,

Service, and User’s Guide, IBM 2103 Model H07

problem identification procedures given. If this does not fix the problem, go to

the next step.

c. Call your next level of support.

software or a Windows NT or

Fibre Channel Storage Manager and

, SC26-7285.

Diagnostic Information for Multiple

, SC26-7289 and follow the problem

, SC26-7289 and follow the

Rack:

Go to

Seascape Solution Rack, Installation and Service Guide, IBM 2101 Model 100

SY27-7606 and follow the appropriate procedure for debugging rack problems. If you

cannot fix the problem following the procedures in

Installation and Service Guide, IBM 2101 Model 100

level of support.

Seascape Solution Rack,

, SY27-7606, then call your next

,

Chapter 1. Maintenance Starting Points 7

Page 38

Start Table B

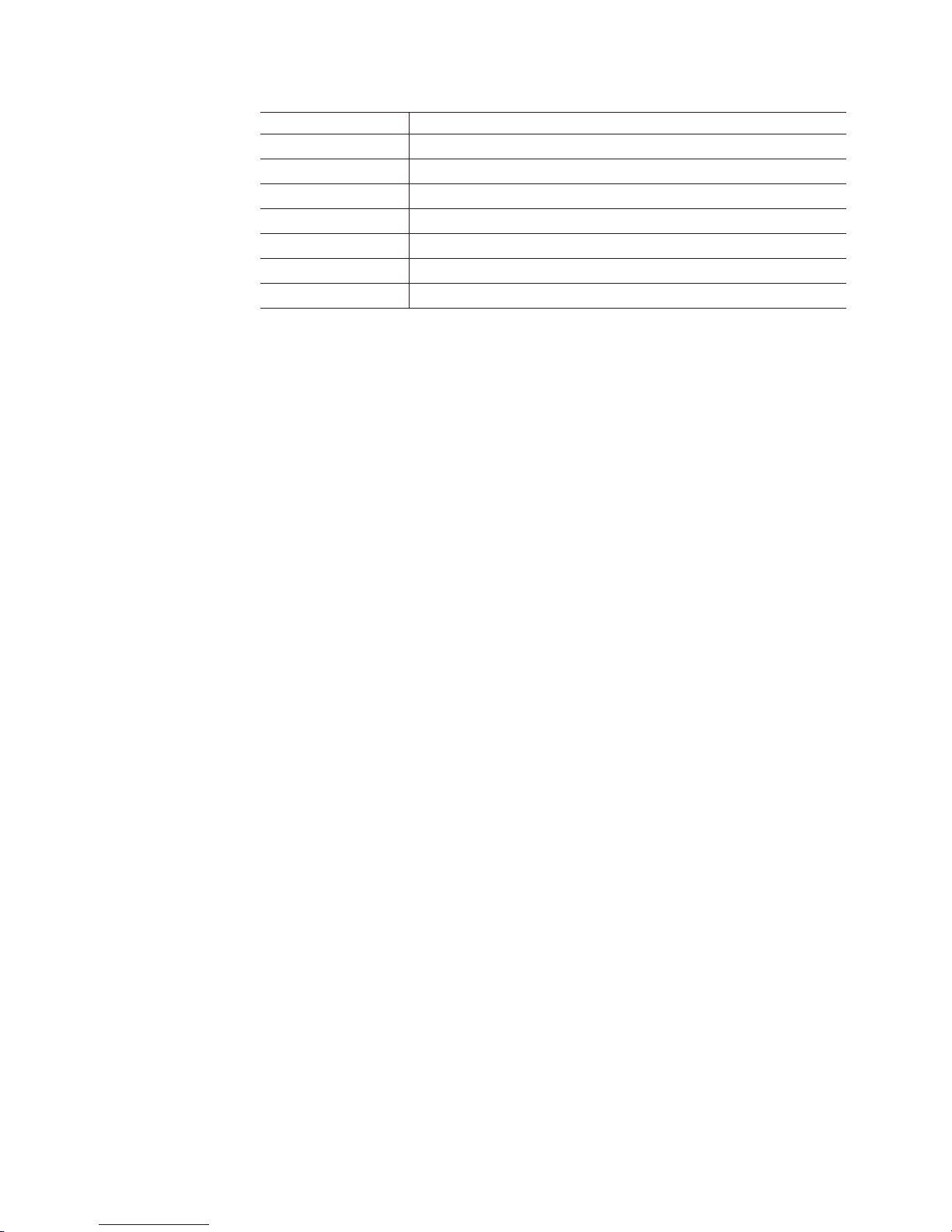

Table 2. 2102 Fibre Channel RAID Storage Server Start Table B

If you are here for this

reason...

Replace FRUs in the Controller

Module

...Then perform this action

Controller Card Go to “Replacing a Failed Controller” on page 93

Battery Go to “Replacing the Battery FRU” on page 116

Backpanel Go to “Replacing a Failed Controller Backpanel”

Controller Fan Go to “Replacing a Failed Controller Fan” on

Power Supply Go to “Replacing a Failed Power Supply” on

Power Supply Fan Go to “Replacing a Failed Power Supply Fan” on

on page 98

page 106

page 122

page 109

Replace FRUs in the Device

Drawer

Replace FRUs in the Fibre

Channel Hub

Drive Go to “Replace a Failed Drive” on page 160

ESM board Go to “Replace a Failed ESM FRU” on page 170

Fan Go to “Replace a Failed Fan” on page 188

Power Supply Go to “Replace a Failed Power Supply” on

page 183

Refer to

2103 Model H07

Fibre Channel Storage Hub, Installation, Service, and User’s Guide, IBM

, SC26-7289.

8 IBM 2102 Model F10 and Model D00 Service Guide

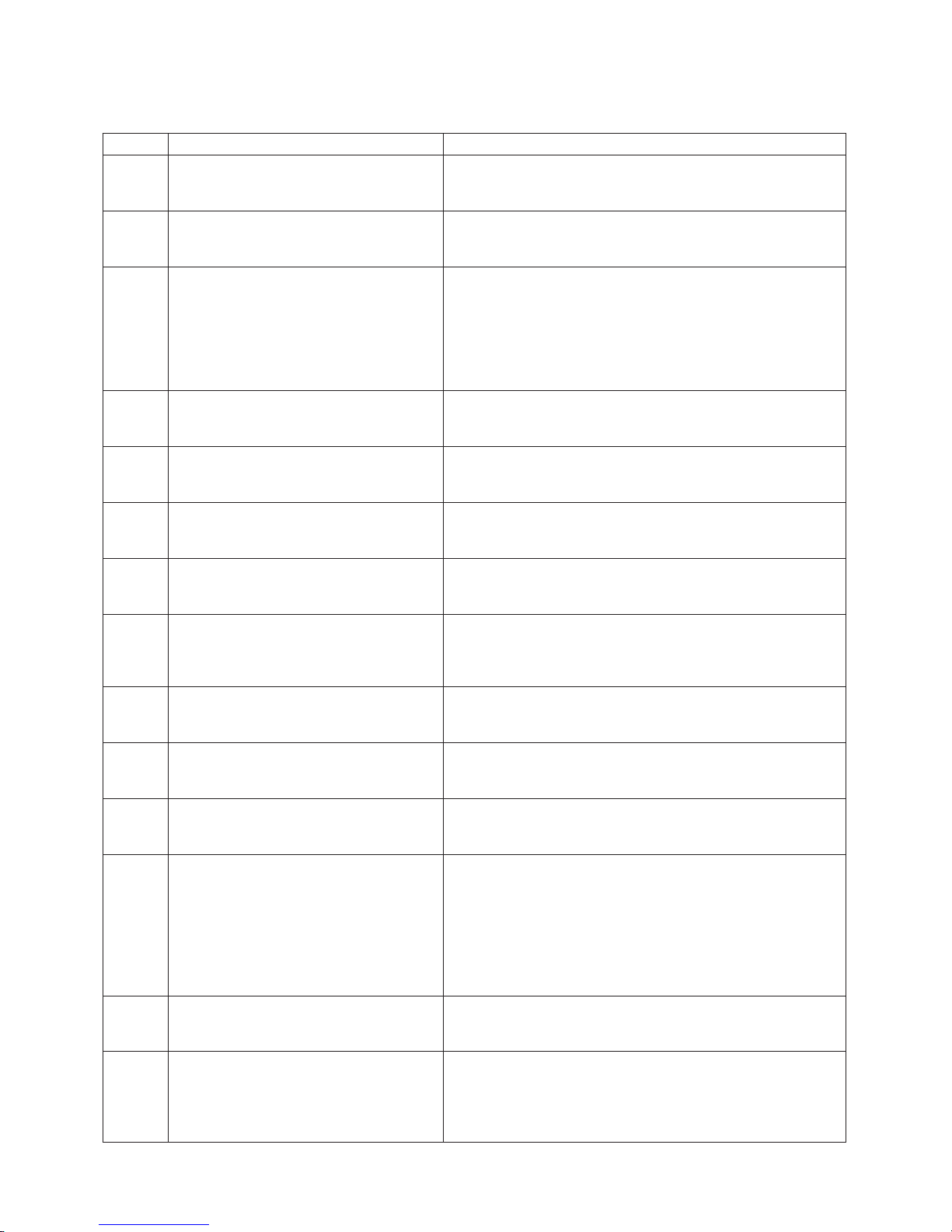

Page 39

Table 2. 2102 Fibre Channel RAID Storage Server Start Table B (continued)

If you are here for this

...Then perform this action

reason...

Power On/Off Subsystem

Components

Note: Subsystem components must be powered up in the correct sequence to

ensure proper operation.

Power Up Sequence:

1. rack (ensure that power for attached subsystem components is off)

2. hub

3. device drawers

4. controller module

5. host (wait until all drives have spun up to speed)

Power Off Sequence:

1. host (if applicable)

2. controller module

3. device drawers

4. hub

5. rack

Component Power On/Off Procedures:

rack Rack power is active when each Power

Distribution Unit (PDU) power cord is plugged in.

A green light on the PDU indicates that power is

active to that PDU. Each PDU should be

powered on before continuing.

hub Hub power is active when the hub power cord is

plugged in.

Device Drawer Wait at least 30 seconds after powering off a

device drawer before turning power back on. Turn

on both power switches on the back of the

drawer. An LED on the back of the ESM board

indicates that power is active. Refer to “Turn On

the Power” on page 153 and “Turn Off the Power”

on page 154 for details.

Controller Module Turn on/off both power switches on the back of

the module. An LED on the front panel indicates

that power is active. Refer to “Turning On the

Power” on page 72 and “Turning Off the Power”

on page 74.

host See your host system documentation

Chapter 1. Maintenance Starting Points 9

Page 40

Table 2. 2102 Fibre Channel RAID Storage Server Start Table B (continued)

If you are here for this

reason...

The host cannot communicate

with one or both of the

controllers, but there is no LED

indication of any subsystem

faults.

...Then perform this action

1. Go to “Identifying Interface Problems” on page 87 and follow the procedure for

the debugging of interface problems. If this fails to solve the problem, then go to

Step 2.

2. Connect a service terminal to the top serial port on the back of the controller

module and start RAID Manager for DOS (DRM). See “Chapter 16. RAID

Manager for DOS” on page 205 for information on setting up and starting DRM.

3. Using DRM, run the Array Monitor utility to check the current status of array

components and verify the communication paths within the array subsystem.

Follow the procedure in “Verifying the Installation” on page 212.

v If the Array Monitor indicates a component failure within the array, then replace

the failed component.

v If the Array Monitor runs without indicating a failure (that is, it displays the

message ″Waiting for Next Polling Period″), then go to Step 4.

4. Using DRM, run the Array Configuration Editor (ACE) to verify the

communications between the controllers and the devices and check the status of

the devices.

a. If ACE indicates that the controller is not communicating over a specific drive

channel (that is, the Drive Window in ACE shows no devices on channel 6,

but there is a SCSI cable connected to channel 6 on the back of the

controller module), then replace the SCSI cable connected to that channel.

b. If ACE indicates that the controller is not communicating with a specific drive

or indicates a failure on a specific drive, then replace the defective drive.

c. If ACE indicates a problem with LUN 0 or LUN 0 is not optimal, then you must

fix the problem with LUN 0 in order to enable communication with the host. If

the problem cannot be fixed by replacing hardware, you may need to delete

and recreate LUN 0. If you do this, all data on LUN 0 will be lost. Make sure

the customer is aware of your actions and call your next level of support for

assistance.

Note: One possible case of an off-line LUN 0 can occur when a drive drawer

containing LUN 0 configuration information is added to an existing subsystem.

In this case, the subsystem has conflicting information about the LUN 0

configuration and you must remove and rebuild the LUN.

d. If ACE does not indicate any failures or communications problems, then go to

Step 5.

5. Repeat steps 2 through 5 using the bottom serial port on the back of the

controller module.

6. There is a problem with the Fibre Channel host adapter or in the fibre channel

path between the host and the subsystem. Perform the following steps:

a. Recheck the fibre channel cables between the host and the controller and

replace if necessary.

b. If there is a hub in the fibre channel path, verify that there are no failures in

the hub. See

Guide, IBM 2103 Model H07

c. Verify that the host fibre channel adapter is configured properly.

d. Verify that the host fibre channel adapter is at the correct firmware level.

e. Verify that the host fibre channel adapter is working properly and replace if

necessary. If the subsystem is attached to a system running AIX, run

diagnostics from the host on the fibre channel adapter to check for problems.

For information on running diagnostics on the adapter refer to

Fibre Channel Storage Hub, Installation, Service, and User’s

, SC26-7289 for details.

Information for Multiple Bus Systems

Diagnostic

, SA38-0509.

10 IBM 2102 Model F10 and Model D00 Service Guide

Page 41

Start Table C

Table 3. 2102 Fibre Channel RAID Storage Server Start Table C

If you are here for this

reason...

Use Fibre Channel Storage

Manager for AIX

Download Controller Firmware The controller firmware download function is provided by the host storage

Update Controller NVSRAM The update controller NVSRAM function is provided by the host storage management

Download Drive Firmware The drive firmware download function is provided by a software utility that runs on

Configure the Subsystem The subsystem configuration functions are provided by the

...Then perform this action

See

Fibre Channel Storage Manager, Installation and User’s Guide for the AIX

Operating System

management software:

v If the subsystem is attached to a Windows NT, SUN, or HP-UX host system

running the

Windows 95 system running the

software, then upgrade the controller firmware using the Maintenance and Tuning

Application. Refer to

Channel RAID Specialist, User’s Guide

v If the subsystem is attached to an AIX host system, then upgrade the controller

firmware using the AIX Diagnostic Service Aids (″Fibre Channel RAID Tasks″).

Refer to the

AIX Operating System

software:

v If the subsystem is attached to a Windows NT, SUN, or HP-UX host system

running the

Windows 95 system running the

software, then update the controller NVSRAM using the Maintenance and Tuning

application. Refer to

Channel RAID Specialist, User’s Guide

v If the subsystem is attached to an AIX host system, then upgrade the controller

firmware using the AIX Diagnostic Service Aids (″Fibre Channel RAID Tasks″).

Refer to

Operating System

the host system:

v For Windows NT host systems, refer to “Downloading Drive Microcode from

Windows NT using DriveDload” on page 239.

v For SUN Solaris or HP-UX host systems, refer to “Downloading Drive Microcode

from HP-UX or SUN Solaris Using drvDLoad” on page 244.

v For AIX host systems, use the AIX Diagnostic Service Aids (″Fibre Channel RAID

Tasks″). Refer to

for the AIX Operating System

, SC26-7290.

Fibre Channel Storage Manager

software or a Windows NT or

StorWatch Fibre Channel RAID Specialist

Fibre Channel Storage Manager and StorWatch Fibre

, SC26-7285.

Fibre Channel Storage Manager, Installation and User’s Guide for the

, SC26-7290.

Fibre Channel Storage Manager

software or a Windows NT or

StorWatch Fibre Channel RAID Specialist

Fibre Channel Storage Manager and StorWatch Fibre

, SC26-7285.

Fibre Channel Storage Manager, Installation and User’s Guide for the AIX

, SC26-7290.

Fibre Channel Storage Manager, Installation and User’s Guide

, SC26-7290.

Fibre Channel Storage

Manager

system for the appropriate procedure.

software running on the host. Refer to the software documentation for your

Chapter 1. Maintenance Starting Points 11

Page 42

Table 3. 2102 Fibre Channel RAID Storage Server Start Table C (continued)

If you are here for this

reason...

Check the Status of Subsystem

Components

...Then perform this action

Subsystem component status can be checked from the host using the status

functions provided by the host storage management software. Component status

may also be checked using a service tool connected to the controller module via the

RS232 port.

v If the subsystem is attached to a Windows NT, SUN, or HP-UX host system

running the

Windows 95 system running the

software, then run the Status application from the host system. Refer to

Fibre Channel Storage Manager

StorWatch Fibre Channel RAID Specialist

Channel Storage Manager and StorWatch Fibre Channel RAID Specialist, User’s

Guide

, SC26-7285.

v If the subsystem is attached to an AIX host system, then follow the procedures in

the

Fibre Channel Storage Manager, Installation and User’s Guide for the AIX

Install the Subsystem or

Subsystem Components

Operating System

v To check the subsystem component status from the service tool, go to “Using the

Array Monitor” on page 223.

subsystem Go to “Chapter 2. Installation And Removal

hub Go to ″Rack Installation″ in

, SC26-7290 for checking the status of subsystem components.

Guide” on page 35.

Storage Hub, Installation, Service, and User’s

Guide, IBM 2103 Model H07

drive modules Go to “Installing the Drive Module” on page 49.

controller module Go to “Installing the Controller Module” on

page 45.

software or a Windows NT or

Fibre

Fibre Channel

, SC26-7289

Use RAID Manager for DOS

(DRM)

Decipher LEDs

Go to “Chapter 16. RAID Manager for DOS” on page 205

hub Go to ″Port Status LEDs″ in

Fibre Channel

Storage Hub, Installation, Service, and User’s

Guide, IBM 2103 Model H07

device drawer and drives Go to “Check the Overall Hardware Status” on

page 156.

controller module Go to “Using the Status LEDs” on page 75.

, SC26-7289

12 IBM 2102 Model F10 and Model D00 Service Guide

Page 43

Start Table D

Table 4. 2102 Fibre Channel RAID Storage Server Start Table D

If you are here for this

reason...

Check Cables Refer to the following sections for cable locations and debug procedures:

...Then perform this action

hub

v For an example of proper GBIC and fiber optic cable installation, see ″Installing

the GBIC″ in

IBM 2103 Model H07

v For an example of a host bus adapter with a GBIC attached, see ″Attaching a

GBIC to Initiators and Targets″ in

and User’s Guide, IBM 2103 Model H07

v For GBIC and cable debug procedures, see ″Troubleshooting″ in

Fibre Channel Storage Hub, Installation, Service, and User’s Guide,

, SC26-7289.

Fibre Channel Storage Hub, Installation, Service,

, SC26-7289.

Fibre Channel

Storage Hub, Installation, Service, and User’s Guide, IBM 2103 Model H07

SC26-7289.

Device Drawer

v For SCSI connector locations on the ESM board, see “Environmental Services

Monitor Board” on page 146.

v For SCSI cable installation and routing information, see “LVD-SCSI Drive Cable

Routing Examples” on page 59.

v For SCSI cable technical information, see “Interface Connections and Cables” on

page 193.

v For SCSI cable troubleshooting procedures, see “Hints for Troubleshooting

Interface Problems” on page 169.

,

Identify Subsystem

Components

Controller Module

v For controller interface connector locations, see “Interface Connectors and Cables”

on page 41

v For cable troubleshooting hints, see “Controller and Interface Problems” on

page 133.

v If the subsystem is attached to a Windows NT, SUN, or HP-UX host system

running the

Windows 95 system running the

software, then you can identify disk drives, drive groups and logical units using the

Configuration application. Refer to

Fibre Channel RAID Specialist, User’s Guide

v If the subsystem is attached to an AIX host system, then follow the procedures in

the ″Problem Determination and Recovery″ chapter of

Manager, Installation and User’s Guide for the AIX Operating System

for identifying subsystem components.

v The disk drives that comprise a particular Logical Unit (LUN) can also be identified

by using a service tool that is connected to the controller module via the RS232

port. See “Identifying Drives and Logical Units” on page 222 for details.

Fibre Channel Storage Manager

StorWatch Fibre Channel RAID Specialist

Fibre Channel Storage Manager and StorWatch

software or a Windows NT or

, SC26-7285.

Fibre Channel Storage

, SC26-7290

Chapter 1. Maintenance Starting Points 13

Page 44

Table 4. 2102 Fibre Channel RAID Storage Server Start Table D (continued)

If you are here for this

reason...

View Message or Error Logs Message and error logs are maintained on the host system. Refer to the host system

Perform a Health Check

Perform a Parity Check/Repair The Parity Check/Repair function scans a logical unit, checks the array parity for

...Then perform this action

documentation for information on accessing and analyzing the system logs.

v The Fibre Channel Storage Manager software for Windows NT, Sun Solaris and

HP-UX, and the StorWatch Fibre Channel RAID Specialist software for Windows

NT or Windows 95 also maintains a separate message log that can be viewed

from within the status application. Refer to

StorWatch Fibre Channel RAID Specialist, User’s Guide

v On AIX host systems, the error and message logging is integrated with operating

system error log. The AIX operating system contain functions for analyzing the

system log and indicating the appropriate recovery actions. Refer to

Storage Manager, Installation and User’s Guide for the AIX Operating System

SC26-7290 and

more information.

v If the subsystem is attached to a Windows NT, SUN, or HP-UX system running the

Fibre Channel Storage Manager software or a Windows NT or Windows 95 system

running the StorWatch Fibre Channel RAID Specialist software, then you can

perform an immediate health check by using the Recovery application. There is

also a background array monitor that checks the subsystem component status at

intervals defined by the operator. Refer to

Diagnostic Information for Multiple Bus Systems

StorWatch Fibre Channel RAID Specialist, User’s Guide

information.

v On subsystems attached to an AIX host, the passive controller health check

provides monitoring capability for testing components that are not actively in use.

The health check frequency can be set from in the Disk Array Router

configuration. Refer to

Fibre Channel Storage Manager, Installation and User’s

Guide for the AIX Operating System

each block in the LUN and repairs any parity errors found.