Page 1

IBM System Storage DS4000 EXP810

Storage Expansion Enclosure

Installation, Us e r’s and M aint enance Guide

GC26-7798-09

Page 2

Page 3

IBM System Storage DS4000 EXP810

Storage Expansion Enclosure

Installation, Us e r’s and M aint enance Guide

GC26-7798-09

Page 4

Note:

Before using this information and the product it supports, be sure to read the general information in the “Safety” on page xi

and “Notices” on page 177 sections.

Ninth Edition (April 2009)

This edition replaces GC26-7798-08 and all previous editions of GC26-7798. This edition also applies to all

subsequent releases and modifications until otherwise indicated in new editions.

© Copyright International Business Machines Corporation 2006, 2009.

US Government Users Restricted Rights – Use, duplication or disclosure restricted by GSA ADP Schedule Contract

with IBM Corp.

Page 5

Contents

Figures ...........................vii

Tables ............................ix

Safety ............................xi

About this document .....................xvii

Who should read this document

How this document is organized

DS4000 and DS5000 Storage Subsystem installation tasks - General overview xviii

Getting information, help, and service

Be

fore you call........................ xxii

Using the documentation .................... xxii

Finding Storage Manager software, controller firmware, and README files xxii

IBM System Storage Productivity Center .............. xxiii

Essential Web sites for DS4000/DS5000 support information

Software service and support ..................xxiv

Hardware service and support .................. xxv

Fire suppression systems ...................xxv

How to send your comments ..................xxv

Chapter 1. Introduction ......................1

Overview ...........................1

Operating system support ....................2

Fibre channel defined ...................... 2

SATA defined ......................... 2

Inventory checklist ........................3

EXP810 components .......................3

Enhanced Disk Drive Modules (E-DDMs)............... 4

Environmental Service Modules (ESMs) ............... 5

Connectors, switch, and enclosure ID ............... 5

Rear drive channel ports .................... 7

The ac power supply and fan units ................. 8

The dc power supply and fan units ................ 10

Small Form-Factor Pluggable (SFP) modules ............ 12

Telco bezel .........................13

Software and hardware compatibility and upgrades ........... 14

Software and firmware support code upgrades ............ 14

EXP810 hardware and software compatibility ............. 15

Determining firmware levels ...................16

Receiving product updates and support notifications .......... 17

Best practices guidelines ....................17

Specifications .........................18

Area requirements ......................19

Dimensions ........................19

Weight .......................... 19

Shipping dimensions ..................... 19

Environmental requirements and specifications ............ 20

Temperature and humidity ................... 20

Altitude .......................... 20

Airflow and heat dissipation

Shock and

Acoustic noise .......................22

vibration requirements ................ 21

..................

..................xvii

................ xxii

...... xxiii

..................21

xvii

© Copyright IBM Corp. 2006, 2009 iii

Page 6

Electrical requirements ..................... 22

Power and site wiring requirements for models with ac power supply and

fan units ........................23

Power and site wiring requirements for models with dc power supply and

fan units ........................23

Heat output, airflow, and cooling ................. 24

Network Equipment-Building System (NEBS) information for applicable Disk

Systems .........................25

Chapter 2. Installing the EXP810..................29

Installation overview ....................... 29

Handling static-sensitive devices .................. 30

Preparing for installation .....................30

Tools and hardware required ................... 31

Preparing the site ....................... 31

Preparing the rack ......................32

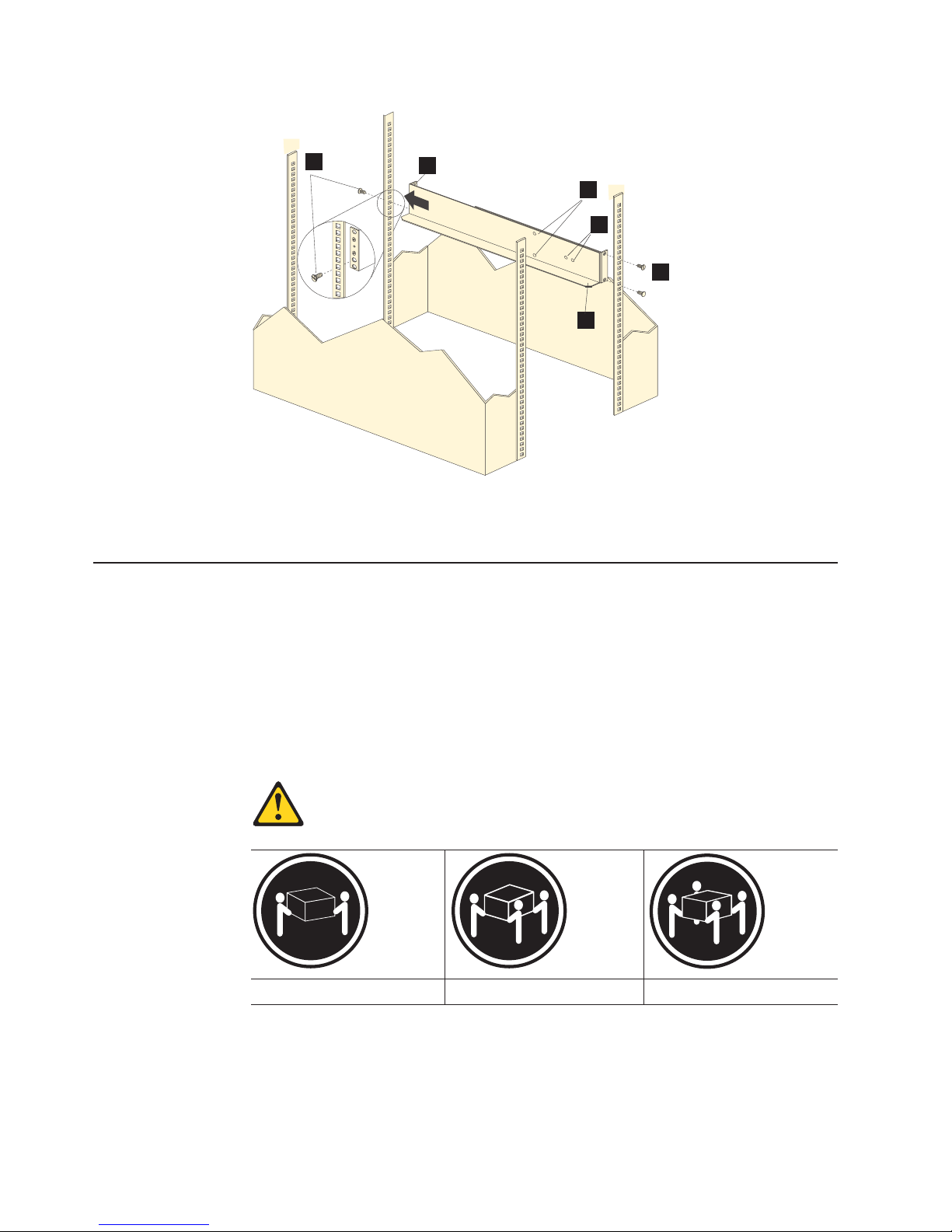

Installing the support rails ..................... 32

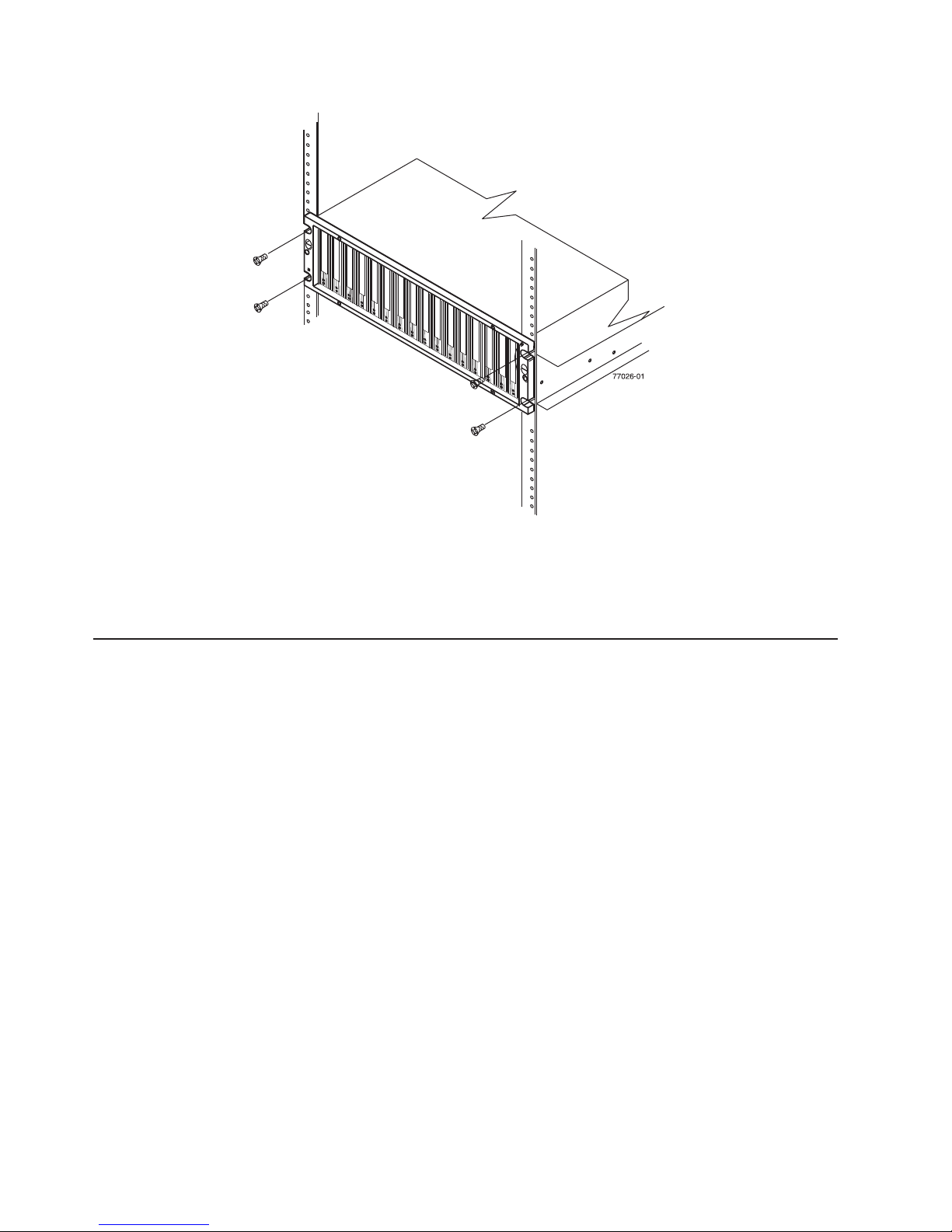

Installing the EXP810 into a rack ..................36

Installing a Telco bezel ......................38

Chapter 3. Cabling the EXP810 ..................41

Enclosure ID settings ......................41

Fibre channel loop and ID settings.................. 42

Cabling the EXP810 ....................... 42

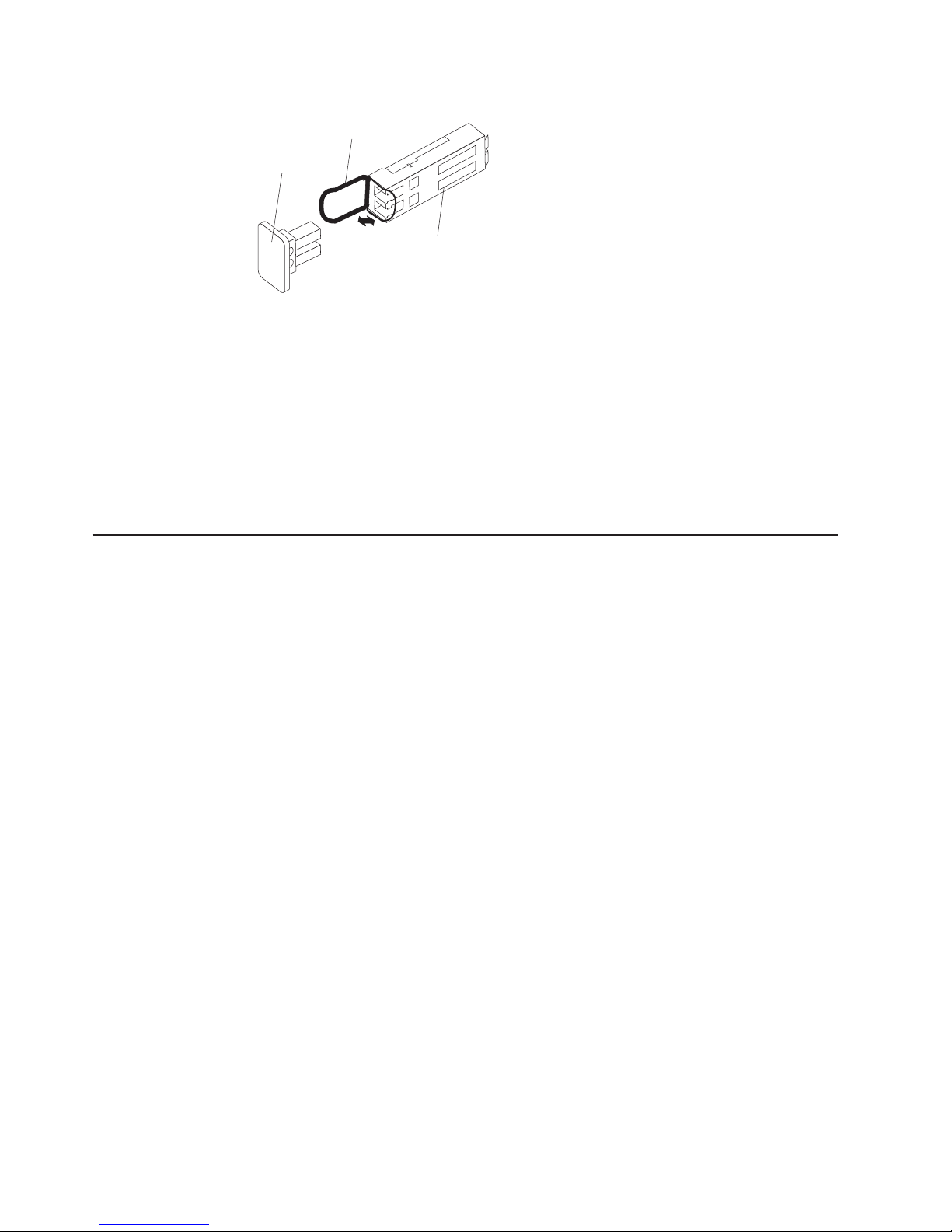

Installing SFP modules ...................... 43

Removing SFP modules .....................45

Handling fibre-optic cables ....................46

Using LC-LC fibre-channel cables .................. 47

Connecting an LC-LC cable to an SFP module ............ 48

Removing an LC-LC fibre-channel cable .............. 49

Cabling rules and recommendations ................. 50

Cabling the EXP810 to a storage subsystem .............. 51

EXP810 loop redundancy ..................... 53

Example of a correct redundant drive loop .............. 54

Intermixing the EXP810, EXP710, and EXP100 in the same drive loop .... 56

Intermixing EXP810s with EXP710s and EXP810s in a DS4700 or DS4800

configuration ......................... 60

Cabling the ac power supply .................... 61

Cabling the dc power supply .................... 62

Single-level redundant dc cabling ................. 63

Dual-level redundant dc cabling .................. 64

Chapter 4. Operating the EXP810 .................67

Performing the DS4000 Health Check process ............. 67

Web pages .........................68

Hardware responsibilities ....................68

Powering on the EXP810 .....................69

Turning on the EXP810 ....................69

Firmware updates ........................ 71

Finding controller, storage expansion enclosure, and drive information .... 72

Troubleshooting the storage expansion enclosure

Checking the LEDs .......................73

The ac power supply and fan unit LEDs............... 73

The dc power supply and fan unit LEDs............... 74

Front LEDs .........................75

Rear LEDs

iv IBM System Storage DS4000 EXP810 Storage Expansion Enclosure: Installation, User’s and Maintenance Guide

............ 72

.........................76

Page 7

Seven-segment numeric display .................77

Powering off the storage expansion enclosure ............. 79

Turning off the EXP810 ..................... 80

Performing an emergency shutdown ................ 82

Restoring power after an unexpected shutdown ............ 83

Recovering from an overheated power supply and fan unit ......... 84

Chapter 5. Installing and replacing components ...........87

Service Action Allowed Status LED ................. 87

Adding the EXP810 to an existing and configured redundant drive channel/loop

pair ............................87

Removing and replacing a bezel ..................90

Replacing a filter and filter retainer ................. 91

Working with hot-swap E-DDMs ..................92

Installing hot-swap hard disk drives ................ 94

Replacing hot-swap hard disk drives ................ 95

Replacing multiple E-DDMs ...................96

Replacing all E-DDMs at the same time.............. 98

Replacing the drives one at a time ............... 100

Verifying the Link Rate setting ..................101

Replacing an ac power supply and fan unit .............. 104

Replacing a dc power supply and fan unit .............. 109

Replacing an Environmental Service Module (ESM) ........... 115

Replacing an SFP module ....................118

Replacing a midplane ...................... 120

Chapter 6. Hardware maintenance ................125

General checkout .......................125

Solving problems .......................125

Parts listing .......................... 131

Appendix A. Upgrading the DS4000 controller firmware ........135

Upgrading the firmware .....................137

Downloading the firmware to controller B ............... 138

Powering up the DS4000 with EXP810 drive enclosures attached ...... 140

Adding and synchronizing the firmware for controller A with the firmware for

controller B ......................... 141

Completing the firmware upgrade procedure ............. 142

Upgrading controller firmware for an existing DS4000 EXP710 configuration to

support EXP810 .......................143

Appendix B. Records .....................147

Identification numbers ...................... 147

Storage subsystem and controller information record .......... 148

Sample information record ...................149

Installed device records .....................150

Appendix C. Rack mounting template ...............151

Appendix D. Power cords ....................155

Appendix E. Additional System Storage DS documentation ......159

DS Storage Manager Version 10 library ............... 159

DS5100 and DS5300 Storage Subsystem library ............

DS4800 Storage Subsystem library ................. 160

DS4700 Storage Subsystem library ................. 162

159

Contents v

Page 8

DS4500 Storage Subsystem library ................. 163

DS4400 Storage Subsystem library ................. 164

DS4300 Storage Subsystem library ................. 165

DS4200 Express Storage Subsystem library ............. 166

DS4100 Storage Subsystem library ................. 167

DS5000 Storage Expansion Enclosure documents ........... 168

DS4000 Storage Expansion Enclosure documents ........... 168

Other DS and DS-related documents ................ 170

Appendix F. Accessibility ....................171

Appendix G. Product Recycling and Disposal ............173

Appendix H. Battery Return Program ...............175

Notices ...........................177

Trademarks.......................... 177

Important notes ........................178

Product recycling and disposal ..................178

Battery return program .....................179

Contact information for IBM Taiwan Product Service ........... 180

Electronic emission notices .................... 180

Federal Communications Commission (FCC) statement ........ 180

Chinese class A compliance statement............... 180

Industry Canada Class A emission compliance statement ........ 181

Australia and New Zealand Class A statement ............ 181

United Kingdom telecommunications safety requirement ........ 181

European Union EMC Directive conformance statement ........ 181

Taiwan Class A warning statement ................ 182

Japanese Voluntary Control Council for Interference (VCCI) statement 182

Glossary ..........................183

Index ............................193

vi IBM System Storage DS4000 EXP810 Storage Expansion Enclosure: Installation, User’s and Maintenance Guide

Page 9

Figures

1. EXP810 hot-swap drive bays ........................... 4

2. Back view; power switch, enclosure ID, and connectors ................. 6

3. Back view; power switch, enclosure ID, and connectors ................. 7

4. Rear view of drive channel ports .........................8

5. Power supply and fan unit components .......................9

6. Power supply and fan unit and airflow .......................10

7. The dc power supply and fan unit components .................... 11

8. The dc power supply and fan unit and airflow .................... 12

9. SFP module and fibre optic cable......................... 13

10. Bezel ...................................13

11. Filter and filter retainer............................. 14

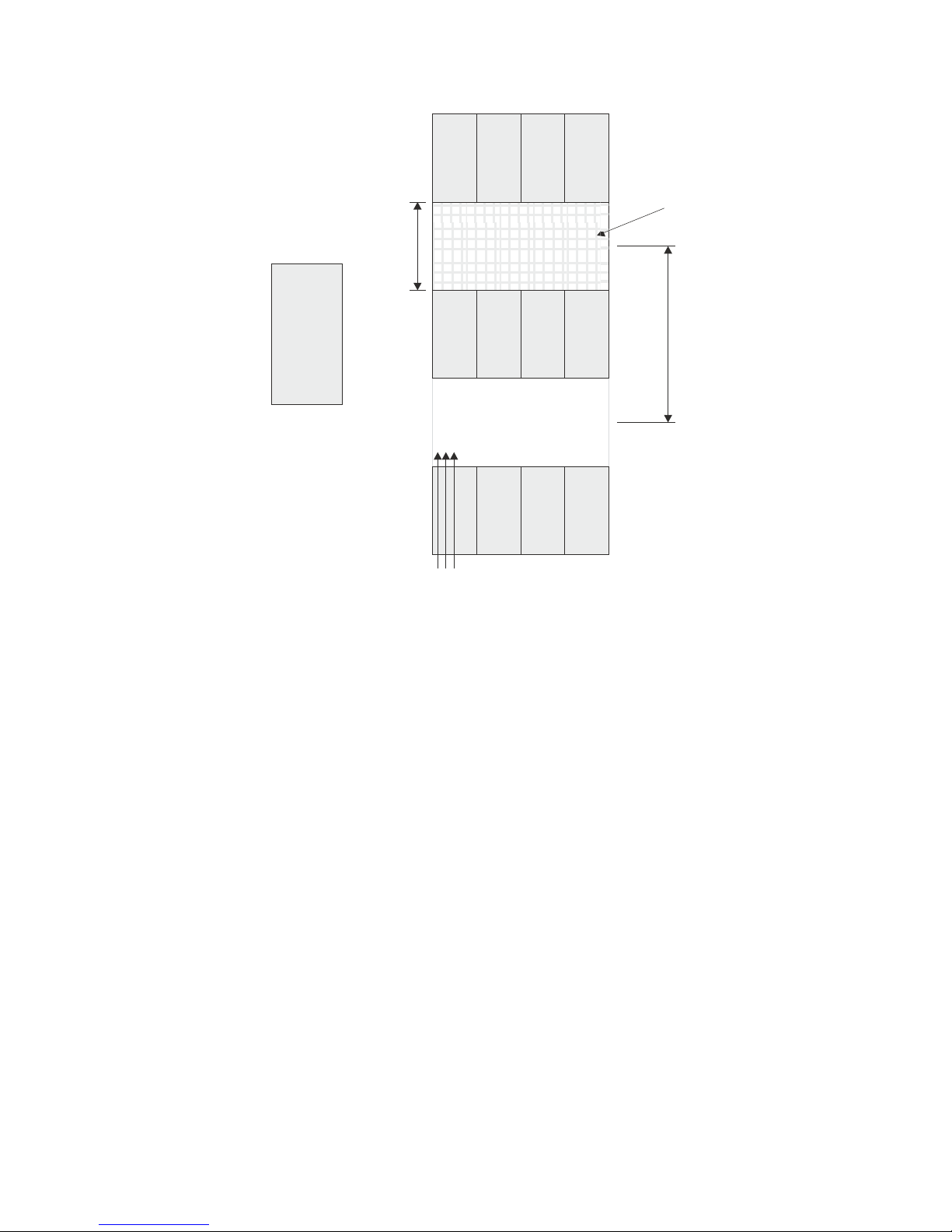

12. EXP810 dimensions .............................19

13. EXP810 airflow ...............................21

14. Example of cold aisle/hot aisle rack configuration ................... 25

15. Front rack mounting template ..........................33

16. Rear rack mounting template ..........................34

17. Installing the support rails ...........................36

18. Installing the EXP810 .............................37

19. Securing the storage expansion enclosure to the rack ................. 38

20. Installing a bezel ............................... 39

21. Storage expansion enclosure seven-segment enclosure ID ............... 42

22. SFP module and protective cap .........................44

23. Installing an SFP module into the host port ..................... 45

24. Unlocking the SFP module latch - plastic variety ................... 45

25. Unlocking the SFP module latch - wire variety .................... 46

26. Recommended bending and looping specifications for fibre-optic cables .......... 47

27. LC-LC fibre-channel cable ...........................47

28. Removing fibre-optic cable protective caps ..................... 48

29. Inserting an LC-LC fibre-channel cable into an SFP module ............... 49

30. LC-LC fibre-channel cable lever and latches..................... 49

31. Removing the LC-LC fibre-channel cable ...................... 50

32. Installing an SFP module and LC-LC cable in a supported DS4000 storage subsystem ..... 53

33. Installing an SFP module and connecting an LC-LC cable to the EXP810 .......... 53

34. Correct EXP810 redundant drive loop configuration .................. 55

35. Intermixing EXP810 and EXP710 in different drive loops ................ 59

36. Intermixing EXP810 and EXP710 by model type behind each controller drive port ....... 59

37. Acceptable EXP710, EXP810 and EXP100 intermix configuration in a DS4700 or DS4800

environment ................................61

38. Cabling variations when intermixing EXP100, EXP710, and EXP810 storage expansion

enclosures behind a DS4800 Storage Subsystem ................... 61

39. The dc power supply and fan unit cabling scheme - single-level redundancy ......... 64

40. The dc power supply and fan unit cabling scheme - dual-level redundancy ......... 65

41. The dc power supply connector - PIN positions.................... 65

42. The dc wiring from EXP810 to disconnect device and dc power source ........... 66

43. The ac power supply and fan unit LEDs ......................74

44. The dc power supply and fan unit LEDs ......................74

45. Front LEDs................................. 76

46. Rear LEDs, controls, and connectors .......................77

47. Numeric display LEDs............................. 78

48. Cabling the EXP810 to an existing and configured drive loop .............. 89

49. Removing and replacing a bezel .........................91

50. Hot-swap E-DDM LEDs ............................94

51. E-DDM CRU handle .............................95

© Copyright IBM Corp. 2006, 2009 vii

Page 10

52. Link rate LEDs ...............................103

53. Link rate switch ............................... 104

54. Replacing a power supply and fan unit ......................108

55. Replacing a dc power supply and fan unit ..................... 114

56. Removing and replacing an Environmental Service Module (ESM) ............ 117

57. Replacing an SFP module ........................... 119

58. Front cage frame screw locations ........................121

59. Screws holding the top and bottom sides of the chassis to the cage frame ......... 122

60. EXP810 storage expansion enclosure parts list ................... 132

61. Only one entry appears in the Directly-Managed Storage Subsystem tree ......... 142

62. Dual entries appear in the Directly-Managed Storage Subsystem tree ........... 143

63. Front rack mounting template .......................... 152

64. Rear rack mounting template .......................... 153

viii IBM System Storage DS4000 EXP810 Storage Expansion Enclosure: Installation, User’s and Maintenance Guide

Page 11

Tables

1. Where to find DS4000 or DS5000 installation and configuration procedures......... xviii

2. Description of Figure 2 on page 6 .........................7

3. Description of Figure 3 on page 7 .........................7

4. Description of Figure 4 on page 8 .........................8

5. Description of Figure 5 on page 9 .........................9

6. Description of Figure 7 on page 11 ........................11

7. Filter and filter retainer description ........................14

8. Software and firmware levels for the EXP810 .................... 14

9. EXP810 hardware and software compatibility .................... 16

10. EXP810 weights ...............................19

11. EXP810 component weights ..........................19

12. EXP810 shipping carton dimensions........................ 20

13. Temperature and humidity requirements for storage expansion enclosure when in storage or in

transit ................................... 20

14. Temperature and humidity requirements for storage expansion enclosure in a typical Information

Technology (IT) or office environment .......................20

15. EXP810 altitude ranges ............................21

16. EXP810 power and heat dissipation........................ 21

17. Random vibration power spectral density ...................... 22

18. EXP810 sound levels .............................22

19. EXP810 ac power requirements .........................22

20. EXP810 dc power requirements .........................23

21. Temperature and humidity requirements for storage expansion enclosure in a Telco/NEBS-3

compliant environment ............................. 26

22. Altitude requirements .............................26

23. Altitude objectives ..............................26

24. Minimum firmware levels required to support the EXP810 ................ 30

25. Firmware levels for intermixing storage servers and expansion enclosures.......... 56

26. Supported EXP810, EXP710, and EXP100 enclosure combinations per redundant drive

channel/loop pair in a DS4800 Storage Subsystem environment ............. 57

27. Possible combinations of 14-drive and 16-drive storage expansion enclosures per drive loop for

DS4300 dual controller Turbo models only ..................... 57

28. Supported EXP810 and EXP710 enclosure combinations per redundant drive channel/loop pair in

a DS4700 Express configuration .........................58

29. The dc power supply connector - PIN descriptions .................. 65

30. The dc power source wiring descriptions ......................66

31. The ac power supply and fan unit LEDs ......................74

32. The dc power supply and fan unit LEDs ......................75

33. Front LEDs and controls ............................76

34. Rear LEDs, controls, and connectors .......................77

35. Numeric display diagnostic codes......................... 79

36. Drive LED activity ..............................93

37. Data transfer rates for drive modules ....................... 102

38. Symptom-to-FRU index............................ 126

39. Parts listing (EXP810 storage expansion enclosure) ................. 132

40. Firmware versions.............................. 136

41. Storage subsystem and controller information record ................. 148

42. Sample information record........................... 149

43. Hard disk drive record ............................150

44. IBM power cords ..............................155

45. DS Storage Manager Version 10 titles by user tasks ................. 159

46. DS5100 and DS5300 Storage Subsystem document titles by user tasks .......... 160

47. DS4800 Storage Subsystem document titles by user tasks ............... 160

© Copyright IBM Corp. 2006, 2009 ix

Page 12

48. DS4700 Storage Subsystem document titles by user tasks ............... 162

49. DS4500 Storage Subsystem document titles by user tasks ............... 163

50. DS4400 Storage Subsystem document titles by user tasks ............... 164

51. DS4300 Storage Subsystem document titles by user tasks ............... 165

52. DS4200 Express Storage Subsystem document titles by user tasks ........... 166

53. DS4100 Storage Subsystem document titles by user tasks ............... 167

54. DS5000 Storage Expansion Enclosure document titles by user tasks ........... 168

55. DS4000 Storage Expansion Enclosure document titles by user tasks ........... 168

56. DS4000 and DS4000–related document titles by user tasks .............. 170

57. DS4000 Storage Manager alternate keyboard operations ............... 171

x IBM System Storage DS4000 EXP810 Storage Expansion Enclosure: Installation, User’s and Maintenance Guide

Page 13

Safety

The caution and danger statements that this document contains can be referenced

in the multilingual IBM

System Storage

®

™

Safety Information document that is provided with your IBM

EXP810 storage expansion enclosure. Each caution and danger

statement is numbered for easy reference to the corresponding statements in the

translated document.

v Danger: These statements indicate situations that can be potentially lethal or

extremely hazardous to you. A danger statement is placed just before the

description of a potentially lethal or extremely hazardous procedure, step, or

situation.

v Caution: These statements indicate situations that can be potentially hazardous

to you. A caution statement is placed just before the description of a potentially

hazardous procedure step or situation.

v Attention: These notices indicate possible damage to programs, devices, or

data. An attention notice is placed just before the instruction or situation in which

damage could occur.

Before installing this product, read the following danger and caution notices.

Statement 1:

© Copyright IBM Corp. 2006, 2009 xi

Page 14

DANGER

Electrical current from power, telephone, and communication cables is

hazardous.

To avoid a shock hazard:

v Do not connect or disconnect any cables or perform installation,

maintenance, or reconfiguration of this product during an electrical

storm.

v Connect all power cords to a properly wired and grounded electrical

outlet.

v Connect to properly wired outlets any equipment that will be attached to

this product.

v When possible, use one hand only to connect or disconnect signal

cables.

v Never turn on any equipment when there is evidence of fire, water, or

structural damage.

v Disconnect the attached power cords, telecommunications systems,

networks, and modems before you open the device covers, unless

instructed otherwise in the installation and configuration procedures.

v Connect and disconnect cables as described in the following table when

installing, moving, or opening covers on this product or attached

devices.

To Connect: To Disconnect:

1. Turn everything OFF.

2. First, attach all cables to devices.

3. Attach signal cables to connectors.

4. Attach power cords to outlet.

5. Turn device ON.

1. Turn everything OFF.

2. First, remove power cords from outlet.

3. Remove signal cables from connectors.

4. Remove all cables from devices.

Statement 2:

CAUTION:

When replacing the lithium battery, use only an equivalent type battery

recommended by the manufacturer. If your system has a module containing a

lithium battery, replace it only with the same module type made by the same

manufacturer. The battery contains lithium and can explode if not properly

used, handled, or disposed of.

Do not:

v Throw or immerse into water

v Heat to more than 100° C (212° F)

v Repair or disassemble

Dispose of the battery as required by local ordinances or regulations.

Statement 3:

xii IBM System Storage DS4000 EXP810 Storage Expansion Enclosure: Installation, User’s and Maintenance Guide

Page 15

CAUTION:

When laser products (such as CD-ROMs, DVD drives, fibre optic devices, or

transmitters) are installed, note the following:

v Do not remove the covers. Removing the covers of the laser product could

result in exposure to hazardous laser radiation. There are no serviceable

parts inside the device.

v Use of controls or adjustments or performance of procedures other than

those specified herein might result in hazardous radiation exposure.

DANGER

Some laser products contain an embedded Class 3A or Class 3B laser

diode. Note the following.

Laser radiation when open. Do not stare into the beam, do not view directly

with optical instruments, and avoid direct exposure to the beam.

Class 1 Laser statement

Class 1 Laser Product

Laser Klasse 1

Laser Klass 1

Luokan 1 Laserlaite

Apparell À Laser de Calsse 1

IEC 825-11993 CENELEC EN 60 825

Statement 4:

≥ 18 kg (39.7 lb) ≥ 32 kg (70.5 lb) ≥ 55 kg (121.2 lb)

CAUTION:

Use safe practices when lifting.

Safety xiii

Page 16

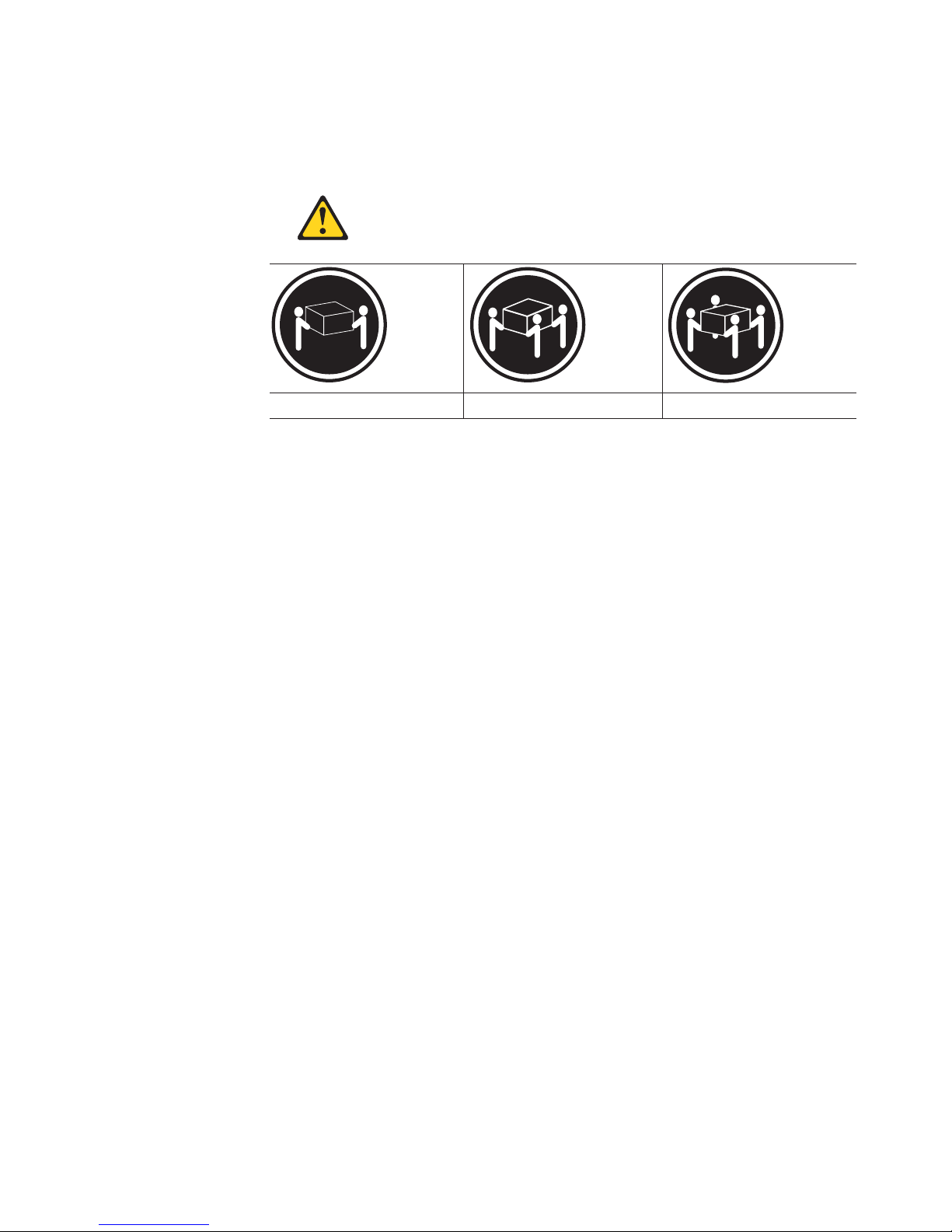

Statement 5:

CAUTION:

The power control button on the device and the power switch on the power

supply do not turn off the electrical current supplied to the device. The device

also might have more than one power cord. To remove all electrical current

from the device, ensure that all power cords are disconnected from the power

source.

2

1

Statement 8:

CAUTION:

Never remove the cover on a power supply or any part that has the following

label attached.

Hazardous voltage, current, and energy levels are present inside any

component that has this label attached. There are no serviceable parts inside

these components. If you suspect a problem with one of these parts, contact

a service technician.

Statement 29:

xiv IBM System Storage DS4000 EXP810 Storage Expansion Enclosure: Installation, User’s and Maintenance Guide

Page 17

CAUTION:

This equipment is designed to permit the connection of the earthed conductor

of the dc supply circuit to the earthing conductor at the equipment.

This equipment is designed to permit the connection of the earthed conductor

of the dc supply circuit to the earthing conductor at the equipment. If this

connection is made, all of the following conditions must be met:

v This equipment shall be connected directly to the dc supply system

earthing electrode conductor or to a bonding jumper from an earthing

terminal bar or bus to which the dc supply system earthing electrode

conductor is connected.

v This equipment shall be located in the same immediate area (such as,

adjacent cabinets) as any other equipment that has a connection between

the earthed conductor of the same dc supply circuit and the earthing

conductor, and also the point of earthing of the dc system. The dc system

shall not be earthed elsewhere.

v The dc supply source shall be located within the same premises as this

equipment.

v Switching or disconnecting devices shall not be in the earthed circuit

conductor between the dc source and the point of connection of the

earthing electrode conductor.

Statement 30:

CAUTION:

To reduce the risk of electric shock or energy hazards:

v This equipment must be installed by trained service personnel in a

restricted-access location, as defined by the NEC and IEC 60950-1, First

Edition, The Standard for Safety of Information Technology Equipment.

v Connect the equipment to a reliably grounded safety extra low voltage

(SELV) source. An SELV source is a secondary circuit that is designed so

that normal and single fault conditions do not cause the voltages to exceed

a safe level (60 V direct current).

v The branch circuit overcurrent protection must be rated 20 A.

v Use 12 American Wire Gauge (AWG) or 2.5 mm2 copper conductor only, not

exceeding 4.5 meters in length.

v Incorporate a readily available approved and rated disconnect device in the

field wiring.

CAUTION:

This unit has more than one power source. To remove all power from the unit,

all dc MAINS must be disconnected.

Safety xv

Page 18

Cable Warning:

WARNING: Handling the cord on this product or cords associated with accessories

sold with this product, will expose you to lead, a chemical known to the State of

California to cause cancer, and birth defects or other reproductive harm. Wash

hands after handling.

xvi IBM System Storage DS4000 EXP810 Storage Expansion Enclosure: Installation, User’s and Maintenance Guide

Page 19

About this document

This document provides instructions for installing and customizing the configuration

of your IBM

provides maintenance procedures and troubleshooting information.

®

System Storage DS4000 EXP810 storage expansion enclosure. It also

Who should read this document

This document is intended for system operators and service technicians who have

extensive knowledge of fibre channel and network technology.

How this document is organized

Chapter 1, “Introduction,” on page 1 describes the IBM System Storage EXP810

storage expansion enclosure. This chapter includes an inventory checklist and an

overview of the storage expansion enclosure features, operating specifications, and

components.

Chapter 2, “Installing the EXP810,” on page 29 contains information on how to

install the EXP810.

Chapter 3, “Cabling the EXP810,” on page 41 contains information on how to cable

the EXP810.

Chapter 4, “Operating the EXP810,” on page 67 contains information on how to

power on and off the storage expansion enclosure, recover from an overheated

power supply and fan unit, troubleshoot the storage expansion enclosure, and

interpret LEDs.

Chapter 5, “Installing and replacing components,” on page 87 contains step-by-step

instructions about how to install or remove customer replaceable units (CRUs), such

as hard disk drives, power supply and fan units, dc power supply and fan units,

bezel, filter and filter retainer, environmental services modules (ESMs), midplane,

and SFP modules.

Chapter 6, “Hardware maintenance,” on page 125 describes problems and

symptoms that are specific to your storage expansion enclosure. It also provides a

parts list for the EXP810.

Appendix A, “Upgrading the DS4000 controller firmware,” on page 135 contains

instructions for how to upgrade the existing EXP810 ESM firmware.

Appendix B, “Records,” on page 147 provides a table that you can use to record

and update important information about your EXP810, including serial number and

device records. Whenever you add options to your EXP810, be sure to update the

information in this table.

Appendix C, “Rack mounting template,” on page 151 provides the rack mounting

templates for installation of the EXP810. If you want to tear out the templates from

the document for use during installation, use these copies of the templates.

Appendix D, “Power cords,” on page 155 lists power cord information for the

EXP810.

© Copyright IBM Corp. 2006, 2009 xvii

Page 20

Appendix E, “Additional System Storage DS documentation,” on page 159 lists

additional DS4000™ documents.

Appendix F, “Accessibility,” on page 171 details accessibility information.

Appendix G, “Product Recycling and Disposal,” on page 173 details the European

directive about product recycling.

DS4000

verview

o

and DS5000 Storage Subsystem installation tasks - General

Table 1 provides a sequential list of many installation and configuration tasks that

are common to most DS4000 and DS5000 configurations. When you install and

configure your DS4000 or DS5000 storage subsystem, refer to this table to find the

documentation that explains how to complete each task.

See also: The DS4000 or DS5000 Quick Start Guides for your storage subsystem

configuration provides an excellent overview of the installation process.

Table 1. Where to find DS4000 or DS5000 installation and configuration procedures

Installation task Where to find information or procedures

1 Plan the installation

v IBM System Storage DS Storage Manager Installation and

Host Support Guide

v IBM System Storage DS Storage Manager Command-line

Programming Guide

v IBM System Storage Quick Start Guide for the following

storage subsystems:

– DS5100/DS5300

– DS4800

– DS4200/DS4700

v IBM System Storage DSxxxx Installation, User’s, and

Maintenance Guide for the following storage subsystems:

– DS5100/DS5300

– DS4800

– DS4700

– DS4500

– DS4400

– DS4300

– DS4200

– DS4100

xviii IBM System Storage DS4000 EXP810 Storage Expansion Enclosure: Installation, User’s and Maintenance Guide

Page 21

Table 1. Where to find DS4000 or DS5000 installation and configuration

procedures (continued)

Installation task Where to find information or procedures

2 Mount the DS4000

or DS5000 storage

subsystem in the

rack

v IBM System Storage Quick Start Guide for the following

storage subsystems:

– DS5100/DS5300

– DS4800

– DS4200/DS4700

v IBM System Storage DSxxxx Installation, User’s, and

Maintenance Guide for the following storage subsystems:

– DS5100/DS5300

– DS4800

– DS4700

– DS4200

– DS4100

v DS4400 and DS4500 Rack Mounting Instructions

v DS4300 Rack Mounting Instructions

3 Mount the DS4000

or DS5000 EXP

storage expansion

unit in the rack

v IBM System Storage Quick Start Guide for the following

storage subsystems:

– DS5100/DS5300

– DS4800

– DS4200/DS4700

v IBM System Storage EXPxxx Installation, User’s, and

Maintenance Guide for the following storage expansion

enclosures:

– EXP5000

– EXP810

– EXP700/EXP710

– EXP500

– EXP420

– EXP100

4 Route the storage

expansion enclosure

Fibre Channel cables

v IBM System Storage Quick Start Guide for the following

storage subsystems:

– DS5100/DS5300

– DS4800

– DS4200/DS4700

v IBM System Storage EXPxxx Installation, User’s, and

Maintenance Guide for the following storage expansion

enclosures:

– EXP5000

– EXP810

– EXP700/EXP710

– EXP500

– EXP420

– EXP100

About this document xix

Page 22

Table 1. Where to find DS4000 or DS5000 installation and configuration

procedures (continued)

Installation task Where to find information or procedures

5 Route the host

server Fibre Channel

cables

6 Power up the

subsystem

7 Configure

DS4000/DS5000

network settings

v IBM System Storage Quick Start Guide for the following

storage subsystems:

– DS5100/DS5300

– DS4800

– DS4200/DS4700

v IBM System Storage DSxxxx Installation, User’s, and

Maintenance Guide for the following storage subsystems:

– DS5100/DS5300

– DS4800

– DS4700

– DS4500

– DS4300

– DS4200

– DS4100

v IBM TotalStorage DS4400 Fibre Channel Cabling Instructions

v IBM System Storage Quick Start Guide for the following

storage subsystems:

– DS5100/DS5300

– DS4800

– DS4200/DS4700

v IBM System Storage DSxxxx Installation, User’s, and

Maintenance Guide for the following storage subsystems:

– DS5100/DS5300

– DS4800

– DS4700

– DS4500

– DS4400

– DS4300

– DS4200

– DS4100

v IBM System Storage DSxxxx Installation, User’s, and

Maintenance Guide for the following storage subsystems:

– DS5100/DS5300

– DS4800

– DS4700

– DS4500

– DS4400

– DS4300

– DS4200

– DS4100

xx IBM System Storage DS4000 EXP810 Storage Expansion Enclosure: Installation, User’s and Maintenance Guide

Page 23

Table 1. Where to find DS4000 or DS5000 installation and configuration

procedures (continued)

Installation task Where to find information or procedures

8 Zone the fabric

switch

(SAN-attached only)

v IBM System Storage DS Storage Manager Installation and

Host Support Guide

v DS Storage Manager Copy Services Guide (describes switch

zoning for the Remote Mirror Option)

v See also the documentation provided by the switch

manufacturer

9 Install DS Storage

Manager software on

the management

station

v IBM System Storage DS Storage Manager Installation and

Host Support Guide

v DS Storage Manager online help (for post-installation tasks)

10 Install host software

(failover drivers) on

host server

11 Start DS Storage

Manager

12 Set the DS Storage

Manager clock

13 Set the DS Storage

Manager host default

type

14 Verify

DS4000/DS5000

subsystem health

v IBM System Storage DSxxxx Installation, User’s, and

Maintenance Guide for the following storage subsystems:

– DS5100/DS5300

– DS4800

– DS4700

– DS4500

– DS4400

– DS4300

– DS4200

– DS4100

15 Enable DS Storage

Manager premium

feature keys

Copy Services premium features

IBM System Storage DS Storage Manager Copy

Services Guide

FC/SATA Intermix premium feature

IBM System Storage DS4000/DS5000 Fibre Channel

and Serial ATA Intermix Premium Feature Installation

Overview

Storage Partitioning (and general premium features

information)

v IBM System Storage DS Storage Manager

Installation and Host Support Guide

About this document xxi

Page 24

Table 1. Where to find DS4000 or DS5000 installation and configuration

procedures (continued)

Installation task Where to find information or procedures

16 Configure arrays and

logical drives

17 Configure host

partitions

18 Verify host access to

DS4000/DS5000

storage

v IBM System Storage DS Storage Manager Installation and

Host Support Guide

v DS4000 or DS5000 Storage Manager online help

Getting information, help, and service

If you need help, service, or technical assistance or just want more information

about IBM products, you will find a wide variety of sources available from IBM to

assist you. This section contains information about where to go for additional

information about IBM and IBM products, what to do if you experience a problem

with your system, and whom to call for service, if it is necessary.

Before you call

Before you call, take these steps to try to solve the problem yourself:

v Check all cables to make sure that they are connected.

v Check the power switches to make sure that the system is turned on.

v Use the troubleshooting information in your system documentation, and use the

diagnostic tools that come with your system.

v Check for technical information, hints, tips, and new device drivers at the IBM

System Storage Disk Support Web site pages that are listed in this section.

v Use an IBM discussion forum on the IBM Web site to ask questions.

You can solve many problems without outside assistance by following the

troubleshooting procedures that IBM provides in the DS Storage Manager online

help or in the documents that are provided with your system and software. The

information that comes with your system also describes the diagnostic tests that

you can perform. Most subsystems, operating systems, and programs come with

information that contains troubleshooting procedures and explanations of error

messages and error codes. If you suspect a software problem, see the information

for the operating system or program.

Using the documentation

Information about your IBM system and preinstalled software, if any, is available in

the documents that come with your system; this includes printed books, online

documents, README files, and help files. See the troubleshooting information in

your system documentation for instructions for using the diagnostic programs. The

troubleshooting information or the diagnostic programs might tell you that you need

additional or updated device drivers or other software.

Finding Storage Manager software, controller firmware, and README

files

DS Storage Manager software and controller firmware versions are available on the

product CD and can also be downloaded from the Web.

xxii IBM System Storage DS4000 EXP810 Storage Expansion Enclosure: Installation, User’s and Maintenance Guide

Page 25

Important: Before you install DS Storage Manager software, consult the README.

Updated README files contain the latest device driver versions,

firmware levels, limitations, and other information not found in this

document.

Storage Manager README files are found on the Web, at the following address:

www.ibm.com/servers/storage/support/disk/

1. On the Support for IBM System Storage and TotalStorage products page,

from the Product family drop-down menu, select Disk systems. From the

Product drop-down menu, select your product (for example, DS5100 Midrange

Disk System). Click Go.

2. In the Support & downloads box, again click Download. The Software and

device drivers page opens.

3. In the Storage Manager section of the table, locate your operating system and

version level (for example, IBM DS5000 Storage Manager v10.xx.xx.xx for

AIX - IBM System Storage), and click on the version link in the right-hand

column. The DS5000 Storage Manager download page opens.

4. On the download page, in the table under File details, click on the *.txt file link,

and the README will open in your Web browser.

IBM System Storage Productivity Center

The IBM System Storage Productivity Center (SSPC) is an integrated hardware and

software solution that provides a single point of entry for managing IBM System

Storage DS4000 systems, DS5000 systems, DS8000 systems, IBM System Storage

SAN Volume Controller clusters, and other components of your data storage

infrastructure. Therefore, you can use the IBM System Storage Productivity Center

to manage multiple IBM System Storage product configurations from a single

management interface.

To learn how to incorporate the DS Storage Manager with the IBM System Storage

Productivity Center, see the IBM System Storage Productivity Center Information

Center at the following Web site:

publib.boulder.ibm.com/infocenter/tivihelp/v4r1/index.jsp

Essential Web sites for DS4000/DS5000 support information

The most up-to-date information about DS4000/DS5000 storage subsystems and

DS Storage Manager, including documentation and the most recent software,

firmware, and NVSRAM downloads, can be found at the following Web sites:

IBM System Storage Disk Storage Systems

Find links to software and firmware downloads, READMEs, and support

pages for all IBM System Storage disk storage systems, including DS5000:

www.ibm.com/systems/support/storage/disk

IBM System Storage Interoperation Center (SSIC)

Find technical support information for your specific DS4000/DS5000 storage

subsystem/host configuration, including the latest recommended firmware

versions for your system, by using this interactive Web-based utility:

www.ibm.com/systems/support/storage/config/ssic/index.jsp

IBM DS3000, DS4000, DS5000, and BladeCenter Premium Feature Activation

Activate a DS5000 premium feature by using this Web-based utility:

About this document xxiii

Page 26

www-912.ibm.com/PremiumFeatures

IBM System Storage Productivity Center

Find the latest documentation supporting the IBM System Storage

Productivity Center, a new system that is designed to provide a central

management console for IBM System Storage DS4000, DS5000, DS8000,

and SAN Volume Controller:

publib.boulder.ibm.com/infocenter/tivihelp/v4r1/index.jsp

IBM System Storage Support

Find the latest support information for host operating systems, HBAs,

clustering, storage area networks (SANs), DS Storage Manager software

and controller firmware:

www.ibm.com/systems/support/storage

Storage Area Network (SAN) Support

Find information about using SAN switches, including links to SAN user

guides and other documents:

www.ibm.com/systems/support/storage/san

Support for IBM System p AIX 5L and Linux servers

Find the latest support information for System p

and i5/OS servers:

www.ibm.com/systems/support/supportsite.wss/

brandmain?brandind=5000025

™

Support for IBM System x

servers

Find the latest support information for System x Intel®- and AMD-based

servers:

www.ibm.com/systems/support/supportsite.wss/

brandmain?brandind=5000008

Eserver System p and AIX Information Center

Find everything you need to know about using AIX with System p and

POWER

™

servers:

publib.boulder.ibm.com/infocenter/pseries/index.jsp?

Fix Central

Find fixes and updates for your system’s software, hardware, and host

operating system:

www.ibm.com/eserver/support/fixes

IBM System Storage products

Find information about all IBM System Storage products:

®

AIX®, Linux®, BladeCenter,

www.ibm.com/systems/storage

IBM Publications Center

Find IBM publications:

www.ibm.com/shop/publications/order/

Software service and support

Through IBM Support Line, for a fee you can get telephone assistance with usage,

configuration, and software problems. For information about which products are

supported by Support Line in your country or region, go to the following Web site:

xxiv IBM System Storage DS4000 EXP810 Storage Expansion Enclosure: Installation, User’s and Maintenance Guide

Page 27

www.ibm.com/services/sl/products

For more information about the IBM Support Line and other IBM services, go to the

following Web sites:

v www.ibm.com/services

v www.ibm.com/planetwide

Hardware service and support

You can receive hardware service through IBM Integrated Technology Services or

through your IBM reseller, if your reseller is authorized by IBM to provide warranty

service. Go to the following Web site for support telephone numbers:

www.ibm.com/planetwide

In the U.S. and Canada, hardware service and support is available 24 hours a day,

7 days a week. In the U.K., these services are available Monday through Friday,

from 9 a.m. to 6 p.m.

Fire suppression systems

A fire suppression system is the responsibility of the customer. The customer’s own

insurance underwriter, local fire marshal, or a local building inspector, or both,

should be consulted in selecting a fire suppression system that provides the correct

level of coverage and protection. IBM designs and manufactures equipment to

internal and external standards that require certain environments for reliable

operation. Because IBM does not test any equipment for compatibility with fire

suppression systems, IBM does not make compatibility claims of any kind nor does

IBM provide recommendations on fire suppression systems.

How to send your comments

Your feedback is important to help us provide the highest quality information. If you

have any comments about this document, you can submit them in one of the

following ways:

E-mail

Submit your comments by e-mail to:

starpubs@us.ibm.com

Be sure to include the name and order number of the document and, if

applicable, the specific location of the text that you are commenting on,

such as a page number or table number.

Mail

Fill out the Readers’ Comments form (RCF) at the back of this document

and return it by mail or give it to an IBM representative.

If the RCF has been removed, send your comments to:

International Business Machines Corporation

Information Development

Department GZW

9000 South Rita Road

Tucson, Arizona

USA

85744-0001

About this document xxv

Page 28

Be sure to include the name and order number of the document and, if

applicable, the specific location of the text that you are commenting on,

such as a page number or table number.

xxvi IBM System Storage DS4000 EXP810 Storage Expansion Enclosure: Installation, User’s and Maintenance Guide

Page 29

Chapter 1. Introduction

This chapter describes the operating specifications, features, and components for

the IBM System Storage EXP810 storage expansion enclosure (hereafter referred

to as EXP810 or storage expansion enclosure). This chapter also includes a list of

hardware that comes with the storage expansion enclosure.

Overview

The IBM System Storage DS4000 EXP810 storage expansion enclosure (Machine

Type 1812, Models 81A, 81H, 81S, and 81T) provides high-capacity, fibre channel

and SATA disk storage. The storage expansion enclosure delivers fast, high-volume

data transfer, retrieval, and storage functions for multiple drives to multiple hosts.

The storage expansion enclosure provides continuous, reliable service, using

hot-swap technology for easy replacement without shutting down the system and

support redundant, dual-loop configurations. External cables and Small Form-Factor

Pluggable (SFP) modules connect the DS4000 storage subsystem to the storage

expansion enclosure.

The EXP810 is a rack-mountable enclosure that supports up to 16 2 or 4 Gbps 300

GB fibre-channel Enhanced Disk Drive Modules (E-DDMs) or 500 GB SATA

E-DDMs, offering up to 4.8 terabytes (TB) of capacity per enclosure when using

300 GB fibre-channel E-DDMs and 8.0 TB when using 500 GB SATA E-DDMs.

Coupled with a DS4000 storage subsystem such as the DS4800, you can configure

RAID-protected storage solutions of up to 67.2 TB, providing economical and

scalable storage for your rapidly growing application needs for limited access, data

reference storage capacity.

The EXP810 uses the latest fibre channel and SATA technology and is designed

with redundant 2 or 4 Gbps fibre channel connections to the DS4000 storage

subsystem offering reliability and performance.

Note: With this release, mixing EXP100, EXP710, and EXP810 with the following

storage servers is supported:

v DS4300

v DS4500

v DS4700

v DS4800

The EXP810 supports redundant, dual drive channel/loop configurations with

DS4000 storage subsystems and other EXP810, EXP100, and EXP710 enclosures.

External cables and small form-factor pluggable (SFP) modules connect the

controller to the storage expansion enclosure. EXP810s attached to supported

DS4000 storage subsystems can be used with storage area networks to satisfy the

needs of various fixed content, data reference applications that require large

amounts of storage capacity but do not have the high utilization and access

characteristics satisfied by fibre channel disk drive storage. The storage expansion

enclosure provides continuous, reliable service and uses hot-swap technology for

easy replacement without the need to shut down the system. Up to seven EXP810

units can be connected together in a redundant fibre-channel drive channel/loop

pair, providing connections to a maximum of 112 hard drives.

© Copyright IBM Corp. 2006, 2009 1

Page 30

Depending on the model, the EXP810 storage expansion enclosure is shipped with

either ac or dc (-48V dc) power supply and fan unit CRUs. In addition, an EXP810

Telco bezel assembly with an integrated air filter can also be purchased for the

operating environments that require it.

The EXP810 storage expansion enclosure with dc power supply and fan units

(1812-81S, 81T) supports both NEBS level 3/Telco operating environments and

standard Information Technology (IT) and office environments. However, not all

EXP810 models with ac power supplies (1812-81A, 81H) support both NEBS level

3/Telco operating environments and standard IT and office environments. EXP810

storage expansion enclosures that shipped before the introduction of the EXP810

models with dc power supply and fan units support standard IT and office operating

environments only. You can identify whether an EXP810 storage expansion

enclosure is NEBS/Telco compliant by checking the serial number. Any EXP810

storage expansion enclosures with serial numbers starting at 136250A and higher

are NEBS level 3/Telco compliant.

Operating system support

For supported operating systems, see the latest DS Storage Manager host software

readme file and the IBM DS4000 series products System Storage Interoperation

Center at the following Web site for additional host operating system support:

www.ibm.com/systems/support/storage/config/ssic/index.jsp

See “Finding Storage Manager software, controller firmware, and README files” on

page xxii to learn how to access the DS4000 readme files on the Web.

Fibre channel defined

Fibre channel technology is outlined in the SCSI-3 Fibre Channel Protocol

(SCSI-FCP) standard. Fibre channel is a high-speed data transport technology that

is used for mass storage and networking.

Using a fibre-channel arbitrated loop (FC-AL), more than 100 fibre-channel devices

can be supported, compared to 15 small computer system interface (SCSI) devices.

The connection from the DS4000 storage subsystem to the EXP810 isa2or4

Gbps fibre-channel device that supports data transfer rates up to 400 MBps

half-duplex and 800 MBps full-duplex on optical interfaces.

SATA defined

The Serial Advanced Technology Attachment (SATA) interface offers increased data

rate performance over Parallel Advanced Technology Attachment (ATA), while

maintaining the benefits of ATA. SATA is designed to overcome the performance

barriers that have been forecasted for current parallel technologies while

maintaining the cost-efficiency of Parallel ATA. SATA specifications allow for thinner,

more flexible cables, and lower pin counts. It also enables easier, more flexible

cable routing management and the use of smaller connectors than is possible with

the existing Parallel ATA technology.

The Serial ATA Working Group introduced the first SATA specification, Serial ATA

1.0, in 2001. See the following Web site:

www.serialata.org

2 IBM System Storage DS4000 EXP810 Storage Expansion Enclosure: Installation, User’s and Maintenance Guide

Page 31

Inventory checklist

The EXP810 ships with the following items:

v Power cables rack jumper line cords (2) (ac models only)

v Two dc power jumper cables (dc models only)

v Rack-mounting hardware kit (1), including:

– Rails (2) (right and left assembly)

– M5 black hex-head slotted screws (12)

– Washers (8)

v Blank trays (16) (Your storage expansion enclosure might come with up to 16

SATA E-DDMs.)

v 4 Gbps SFPs (2) (already installed in the EXP810 ESM ports)

v Box ID labels (used to label the enclosure IDs on the front of the EXP810)

v DS4000 Storage Server Controller Firmware Version 6.16 Support for DS4000

EXP810 Fibre-Channel Storage Expansion Enclosure CD

v (Optional) Telco bezel

A rack mounting template and instructions for installing the support rails and the

storage expansion enclosure are provided in “Installing the support rails” on page

32.

To connect your EXP810 to other devices, use the following options:

v IBM SFP module

v IBM LC-LC fibre-channel cable

Note: You must order these options separately.

EXP810 components

The EXP810 has the following removable components. These components, called

customer replaceable units (CRUs), are accessible from the front or back of the

EXP810.

v Up to 16 2 or 4 Gbps fibre channel or SATA Enhanced Disk Drive Modules

(E-DDMs)

v Two environmental services modules (ESMs)

v Two ac power supply and fan units (Models 81A and 81H)

v Two dc power supply and fan units (Models 81S and 81T)

The hot-swap features of the EXP810 enable you to remove and replace 2 or 4

Gbps fibre-channel or SATA E-DDMs, power supply and fan units, ESMs, and dc

power supply without turning off the storage expansion enclosure. You can maintain

the availability of your system while a hot-swap device is removed, installed, or

replaced.

Chapter 1. Introduction 3

Page 32

Enhanced Disk Drive Modules (E-DDMs)

Attention:

v You cannot mix storage expansion enclosures with different fibre channel speed

settings in the same drive channel/loop. All of the enclosures in a redundant drive

channel/loop pair must have the same enclosure speed setting. In addition, the

enclosure speed setting must be set at the lowest operating enclosure speed.

v E-DDM options and FRUs for the EXP810 and DS4700 Express Storage

Subsystem are not the same as the Enhanced Value Disk Drive Modules

(EV-DDMs) and FRU options for the EXP420 and DS4200 Express Storage

Subsystem. Verify that the E-DDM option and FRU part numbers are correct

before inserting into the EXP810 and DS4700 Express drive slots. The disk drive

module CRUs for EXP420 storage expansion enclosures and DS4200 Express

Storage Subsystems appear as uncertified drives when inserted into EXP810

storage expansion enclosures and DS4700 Express Storage Subsystems and

vice versa.

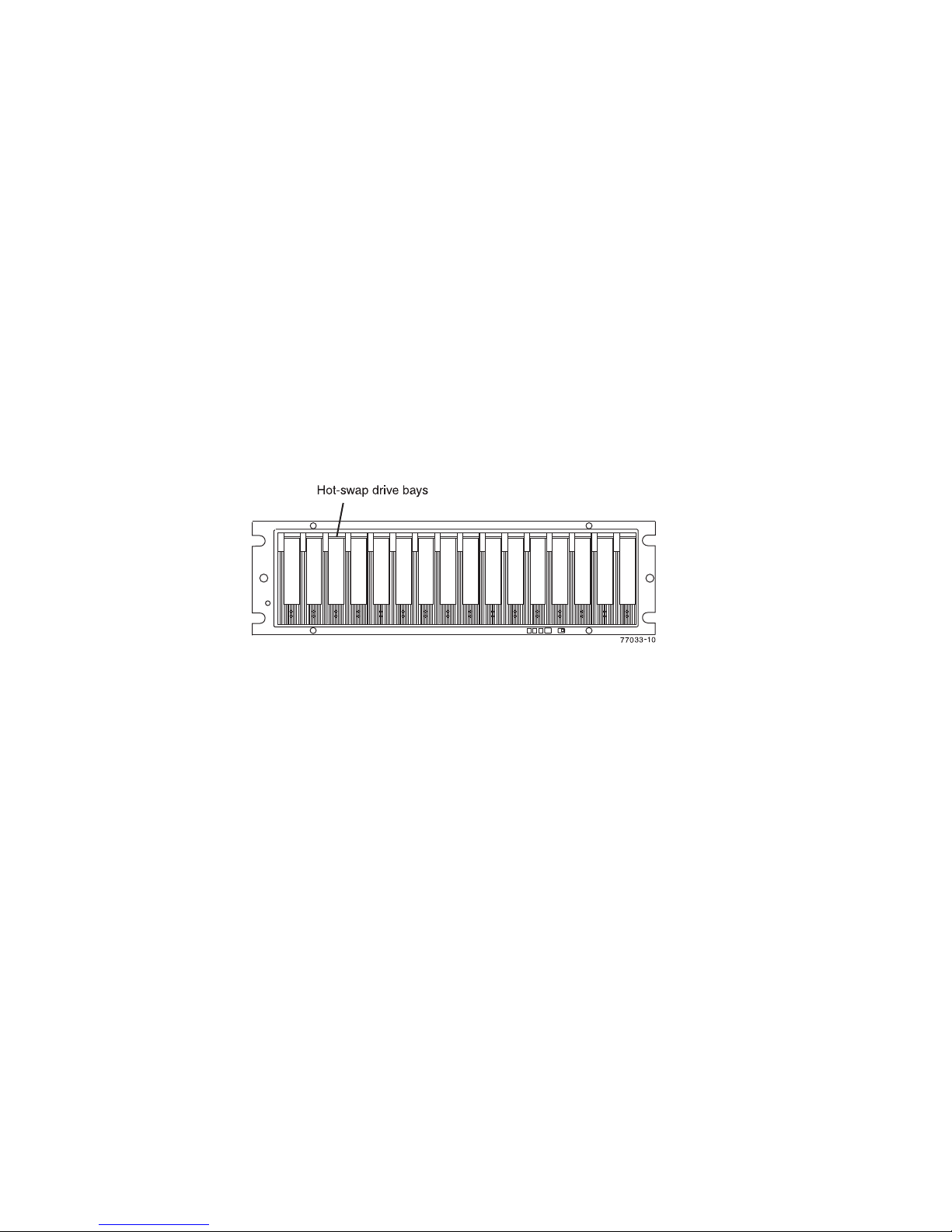

The hot-swap drive bays that are accessible from the front of your storage

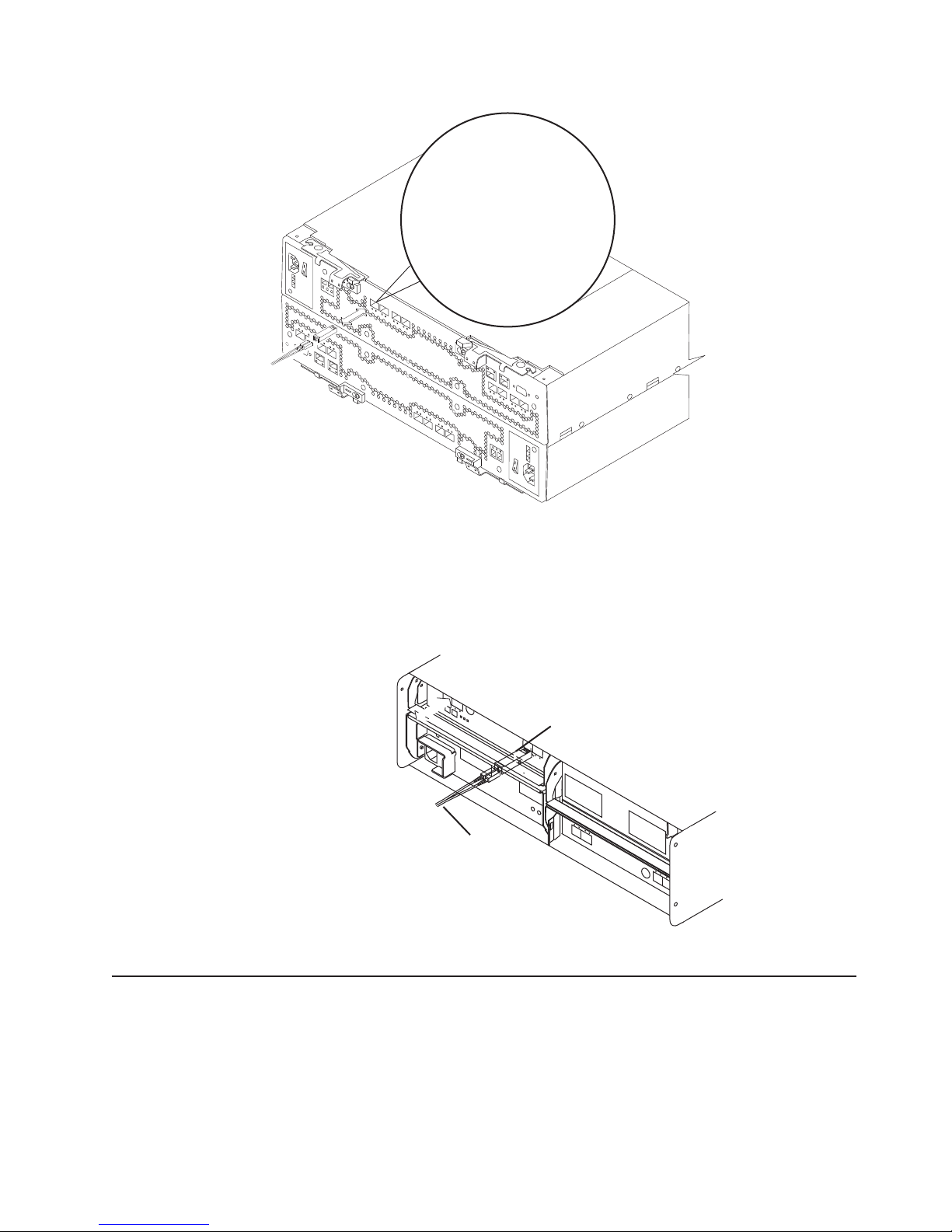

expansion enclosure are shown in Figure 1.

Figure 1. EXP810 hot-swap drive bays

The EXP810 supports up to 16 2 or 4 Gbps fibre channel (FC) or SATA E-DDMs.

The SATA E-DDMs have an ATA translator card that converts the fibre channel

protocol interface of the EXP810 drive channel/loop into the hard drive SATA

protocol interface. It also provides dual paths to the SATA drive for E-DDM CRU

path redundancy. Each SATA hard drive, ATA translator card (also referred to as a

interposer card), and carrier assembly (drive tray) are called SATA E-DDM CRUs.

The fibre channel E-DDMs consisted of the fibre channel and the carrier assembly

(drive tray).

Install E-DDM CRUs in the 16 drive bays on the front of the storage expansion

enclosure from the leftmost (slot 1) to rightmost (slot 16).

The EXP810 storage expansion enclosure drive channel operates at either 2 or 4

Gbps fibre channel interface speed. Ensure that the EXP810 enclosure speed

switch is set correctly for the 2 Gbps or 4 Gbps fibre channel E-DDM CRUs. The

EXP810 SATA E-DDM CRUs have an ATA translator card that converts E-DDM 3

Gbps SATA drive interface protocol to either 2 Gbps or 4 Gbps fibre channel

interface protocol. It is recommended to operate these SATA E-DDMs at 4 Gbps

fibre channel operating speed whenever the configuration allows, for example, when

no 2 Gbps fibre channel devices are in the configuration. The Link Rate setting

speed must be set accordingly. See “Verifying the Link Rate setting ” on page 101

for more information. The enclosure speed of the DS4000 Storage Subsystem that

the EXP810s are connected to must be set to the same fibre channel speed as the

EXP810 enclosure ID speed switch.

4 IBM System Storage DS4000 EXP810 Storage Expansion Enclosure: Installation, User’s and Maintenance Guide

Page 33

There are no serviceable parts in a E-DDM CRU. If it fails, it must be replaced in its

entirety. The EXP810 E-DDM option/FRU is not interchangeable with the drive tray

of other DS4000 storage expansion enclosures such as the EXP100 and EXP710.

When replacing a E-DDM CRU, be sure to order and install the correct E-DDM

CRU.

Attention:

1. After you remove a drive CRU, wait 70 seconds before replacing or reseating

the drive CRU to allow the drive to properly spin down. Failure to do so may

cause undesired events.

2. Never hot-swap a drive CRU when its associated green Activity LED is flashing.

Hot-swap a drive CRU only when its associated amber Fault LED lights is not

flashing or when the drive is inactive and its associated green Activity LED lights

is not flashing.

Note: If the E-DDM you want to remove is not in a failed or bypass state, always

use the DS Storage Manager client program either to place the E-DDM in a

failed state or to place the array that is associated with the E-DDM (or

E-DDMs) in an offline state before you remove it from the enclosure.

Environmental Service Modules (ESMs)

The EXP810 has two hot-swappable and redundant ESM units. The ESMs are

located at the back of the storage expansion enclosure. The left ESM is labeled

ESM A, and the right ESM is labeled ESM B. One ESM will continue to operate if

the other ESM fails.

The ESMs contain the storage expansion enclosure control logic, interface ports,

and LEDs. Each ESM has four SFP module ports that you could use to connect the

storage expansion enclosure to the controller. However, only the two ESM SFP

ports (labeled 1A and 1B) near the center of the storage expansion enclosure are

used. The SFP ports labeled 2A and 2B are reserved for future use.

The EXP810 ESMs support automatic ESM firmware synchronization. This function

allows a new ESM with a different level of ESM firmware to be automatically

synchronized with the ESM firmware version in the existing ESM in the EXP810

chassis. To enable automatic ESM firmware synchronization:

1. Verify that the DS Storage Manager Event Monitor is installed and running.

2. Verify that the DS4000 storage subsystem that the EXP810 is attached to is

defined in the Enterprise Management window of the DS Storage Manager

client (SMclient).

Although both ESM units (A and B) are identical, they are seated in the EXP810

chassis in opposite orientations. See Figure 2 on page 6. If the ESM cannot fully be

inserted in the ESM bay, flip it 180 degrees and reinsert it.

Connectors, switch, and enclosure ID

The ESMs support fibre optic interfaces for both the host channels and drive

channels. The two interface ports located near the enclosure ID are reserved for

future use. Do not plug any SFPs into these ports.

The enclosure ID, comprised of a pair of seven-segment numbers, is located on the

back of each ESM next to the ESM indicator lights. The two digits that comprise the

enclosure ID are referred to as x10 and x1 digits. The enclosure ID provides a

unique identifier for each enclosure in the storage subsystem. The storage

management software automatically sets the enclosure ID number. You can only

Chapter 1. Introduction 5

Page 34

change the enclosure ID setting through the DS4000 storage management

software. There are no switches on the EXP810 chassis to manually set the

enclosure ID. Both ESM enclosure ID numbers will be identical under normal

operating conditions.

In addition to having unique enclosure IDs for each storage expansion enclosure

(including the DS4000 storage subsystems with drives installed) in the DS4000

storage subsystem configuration, ensure that the single digit (x1) of the enclosure

ID for every storage expansion enclosure in a redundant drive channel/loop pair is

unique.

If you do not set the single digit value of the enclosure IDs to be unique among

storage expansion enclosures (including the DS4000 storage subsystem with drives

installed) in a redundant drive channel/loop pair, then drive loop errors might be

randomly posted in the DS4000 subsystem Major Event Log (MEL) when you

intermix different types of storage expansion enclosures in a redundant drive loop

pair (such as an EXP100 with an EXP810). For example, with four enclosures

attached to a DS4500 in a redundant drive loop pair, the correct enclosure ID

settings should be x1, x2, x3, and x4 (where x can be any digits that can be set).

Examples of incorrect settings would be 11, 21, 31, 41; or 12, 22, 32 62. These

examples are incorrect because the x1 digits are the same in all enclosure IDs

(either 1 or 2).

If the enclosure IDs in your DS4000 subsystem configuration are not currently set to

have unique single digit (x1) values for the enclosures in the same redundant drive

channel/loop pair, make the changes to the enclosure IDs in the next maintenance

schedule if you have storage expansion enclosures or DS4000 storage subsystems

with mechanical switches such as EXP100s, EXP710s or DS4300 storage

subsystems in the DS4000 configuration. This will prevent unnecessary downtime

when you add enclosures of different types to the existing enclosures in the

redundant drive channel/loop pair. Storage expansion enclosures and DS4000

storage subsystems with mechanical enclosure ID switches require that you power

cycle the configurations to activate the new enclosure ID settings. The EXP810

storage expansion enclosures do not require you to power cycle the DS4000

configuration to activate new enclosure ID settings.

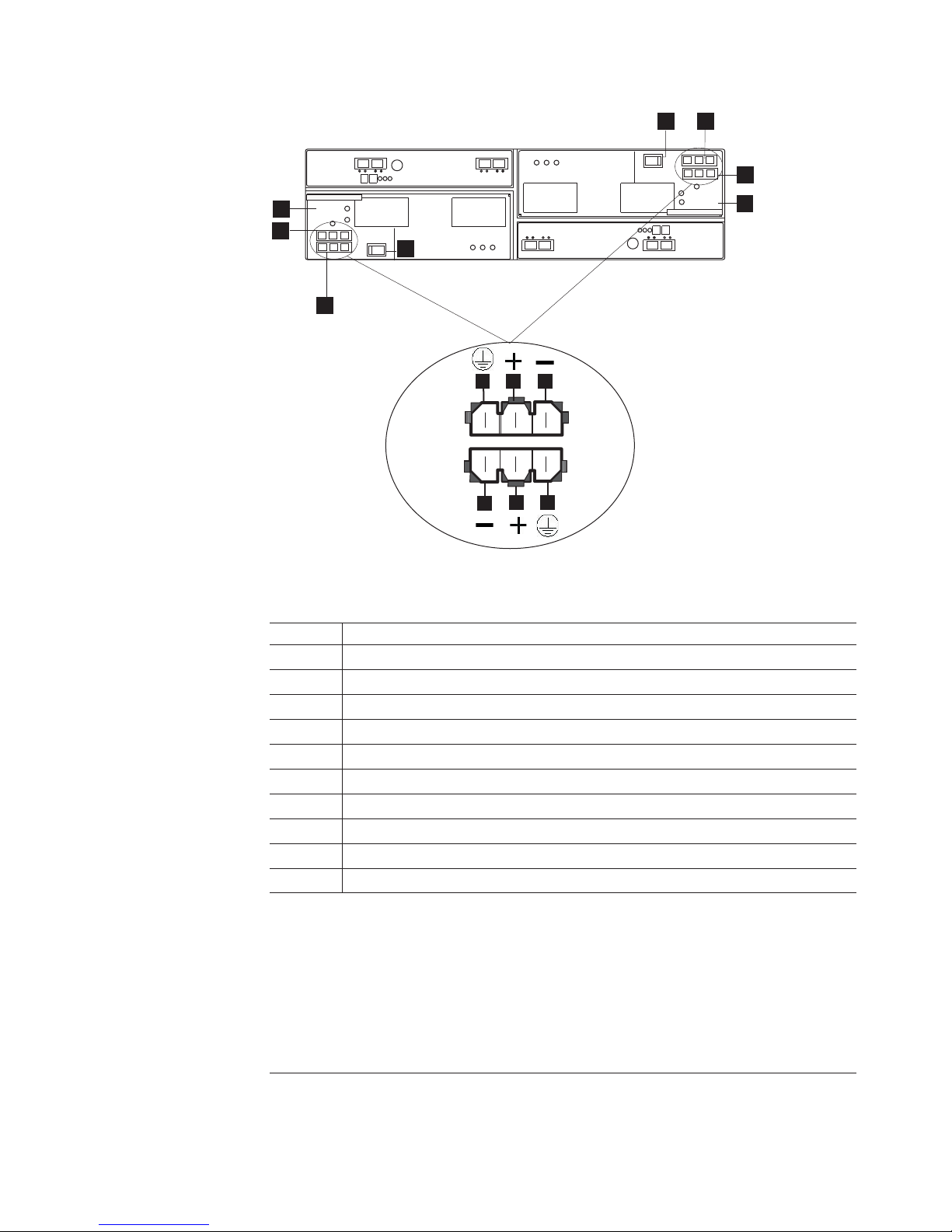

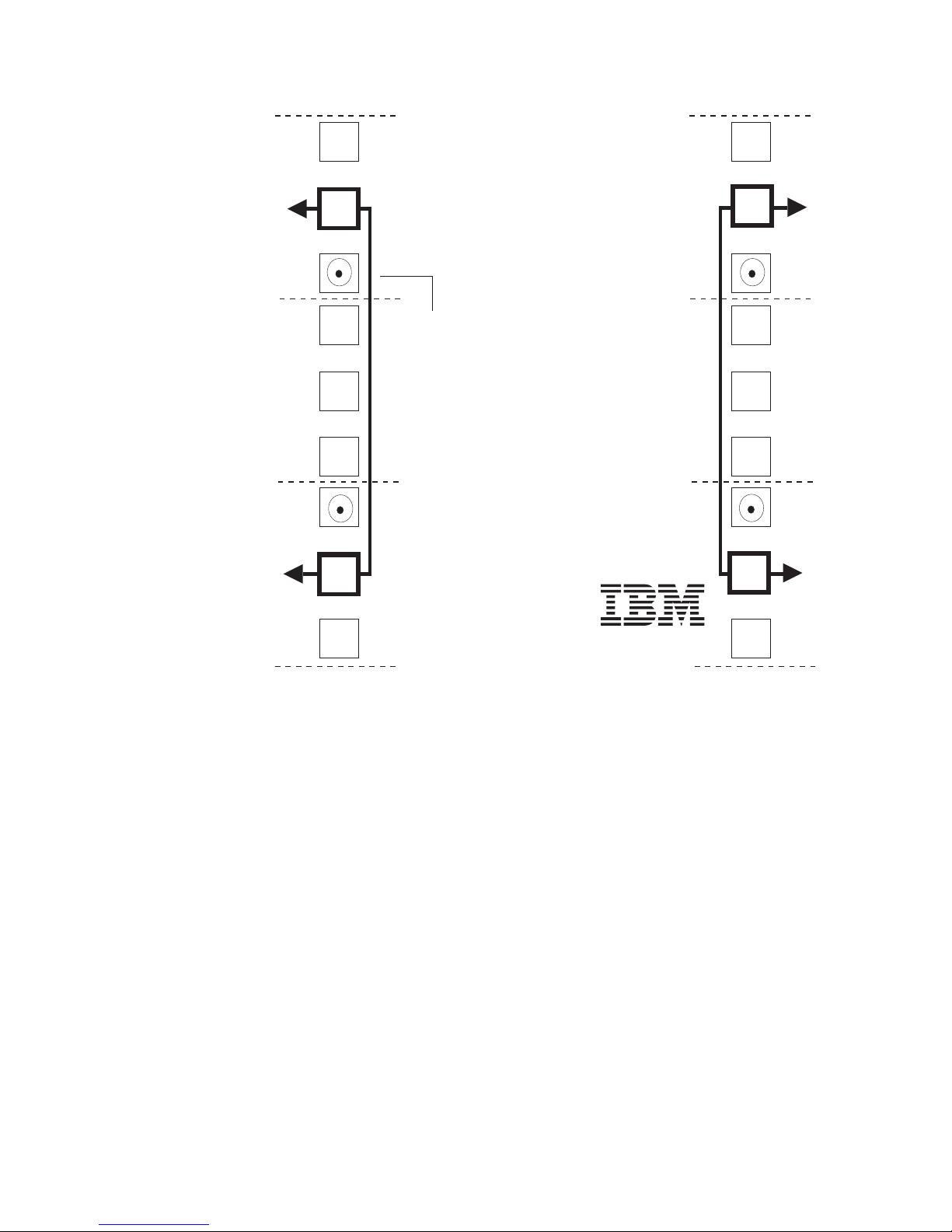

Figure 2 shows the rear view of the ESMs and power supply fan units for models

81A and 81H. Figure 3 on page 7 shows the rear view of the ESMs and dc power

supply fan units for model 81S and 81T.

4 6

7

2 3

1

Figure 2. Back view; power switch, enclosure ID, and connectors

6 IBM System Storage DS4000 EXP810 Storage Expansion Enclosure: Installation, User’s and Maintenance Guide

5

6

3 2 1

exp81023

5

4

7

Page 35

Table 2. Description of Figure 2 on page 6

Number Description

1 Power connector

2 Power switch

3 ESM indicator lights

4 Reserved for future use

5 Serial port

6 SFP interface connectors

7 Enclosure ID

4 6

5

7

3 2 1

7

exp81026

2

1

Figure 3. Back view; power switch, enclosure ID, and connectors

Table 3. Description of Figure 3

Number Description

1 Power connector

2 Power switch

3 ESM indicator lights

4 Reserved for future use

5 Serial port

6 SFP interface connectors

7 Enclosure ID

3

6

5

4

Rear drive channel ports

Figure 4 on page 8 shows the drive channel ports on the storage expansion

enclosure.

Chapter 1. Introduction 7

Page 36

Figure 4. Rear view of drive channel ports

Table 4. Description of Figure 4

Number Description

1 ESM A

2 ESM B

3 Port 1A

4 Port 1B

5 Port 2A (Reserved for future use)

6 Port 2B (Reserved for future use)

The ac power supply and fan units

The storage expansion enclosure has two removable power supply and fan units.

Each power supply and fan unit contains one power supply and two fans. The four

fans pull air through the drive from front to back across the drives.

The fans provide redundant cooling, which means that if one of the fans in either

fan housing fails, the remaining fans continue to provide sufficient cooling to

operate the storage expansion enclosure. The power supplies provide power to the

internal components by converting incoming ac voltage to dc voltage. If one power

supply is turned off or malfunctions, the other power supply maintains electrical

power to the storage expansion enclosure. To preserve the optimal airflow, do not

remove a failed power supply and fan unit CRU from the EXP810 chassis until you

are ready to replace it with a new CRU.

Figure 5 on page 9 shows power supply and fan unit components.

Note: Although both power supply and fan units (left and right) are identical, they

are seated in the EXP810 chassis in opposite orientations. If the power

supply and fan unit cannot fully be inserted in the power supply and fan unit

bay, flip it 180 degree and reinsert it.

8 IBM System Storage DS4000 EXP810 Storage Expansion Enclosure: Installation, User’s and Maintenance Guide

Page 37

4

3

2

1

exp81024

3

4

Figure 5. Power supply and fan unit components

Table 5. Description of Figure 5

Number Description

1 Power supply and fan unit A

2 Power supply and fan unit B

3 Power connector

4 Power switch

Figure 6 on page 10 shows a power supply and fan unit and the airflow through the

storage expansion enclosure.

Chapter 1. Introduction 9

Page 38

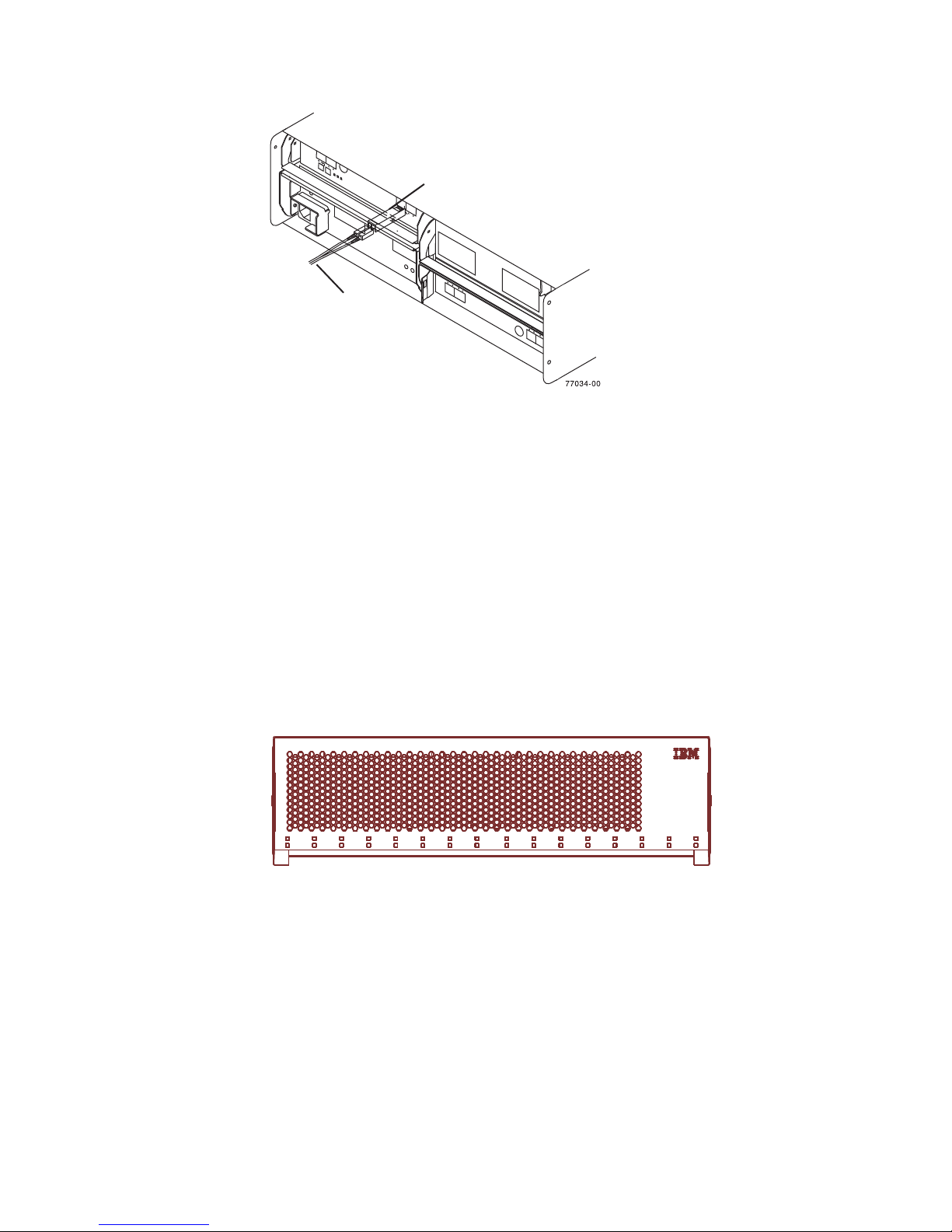

Latch

Lever

Figure 6. Power supply and fan unit and airflow

The dc power supply and fan units

EXP810 storage expansion enclosure (models 81S and 81T) has two removable dc

power supply and fan units. Each dc power supply and fan unit contains one dc

power supply and two fans. The four fans pull air through the drive from front to

back across the drives.

The fans provide redundant cooling, which means that if one of the fans in either

fan housing fails, the remaining fans continue to provide sufficient cooling to

operate the storage expansion enclosure.

The power supplies provide power to the internal components. If one dc power

supply is turned off or malfunctions, the other dc power supply maintains power to

the storage expansion enclosure. To preserve the optimal airflow, do not remove a

failed dc power supply and fan unit CRU from the EXP810 chassis until you are

ready to replace it with a new CRU.

Figure 7 on page 11 shows dc power supply and fan unit components.

Note: Although both power supply and fan units (left and right) are identical, they

are seated in the EXP810 chassis in opposite orientations. If the power

supply and fan unit cannot fully be inserted in the power supply and fan unit

bay, flip it 180 degrees and reinsert it.

10 IBM System Storage DS4000 EXP810 Storage Expansion Enclosure: Installation, User’s and Maintenance Guide

Page 39

4

7

6

1

2

4

3

10

8

8

9

109

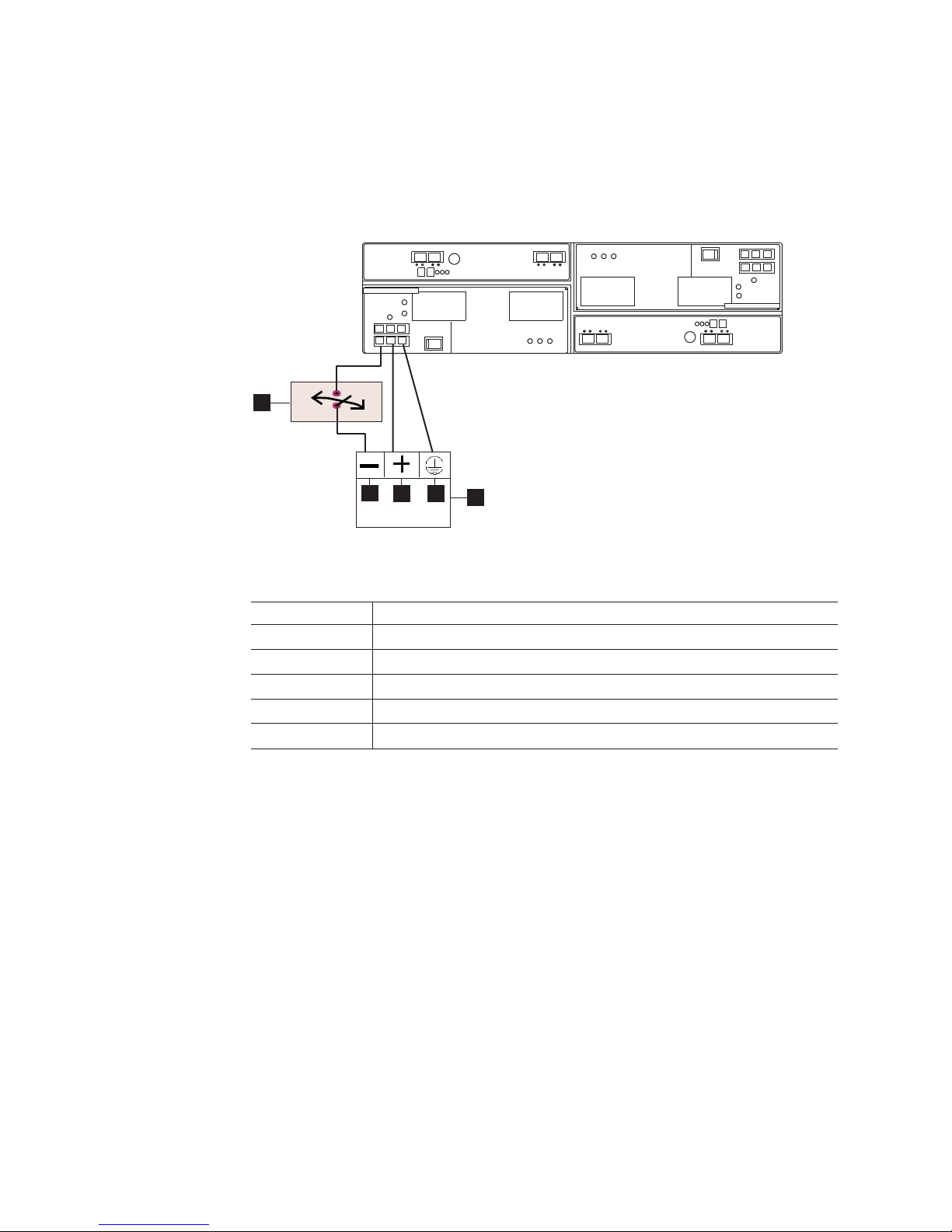

Figure 7. The dc power supply and fan unit components

Table 6. Description of Figure 7

Number Description

1 dc power supply and fan unit A

2 dc power connector A1

3 dc power connector A2

1

1

4 dc power switch

5 dc power supply and fan unit B

6 dc power connector B1

7 dc power connector B2

2

2

8 Pin 1: -48 V dc

9 Pin 2: POS RTN

10 Pin 3: GND

5

exp81028

Notes:

1. The A1 and A2 dc connectors are keyed so that the dc cables are connected to the A1

and A2 connectors in only one way and in opposite orientation from each other. If the dc

cable does not fit the dc connector, flip it 180 degrees and try again. Do not force fit

because you might damage the connectors and short out the power supply.

2. The B1 and B2 dc connectors are keyed so that the dc cables are connected to the B1

and B2 connectors in only one way and in opposite orientation from each other. If the dc

cable does not fit the dc connector, flip it 180 degrees and try again. Do not force fit

because you might damage the connectors and short out the power supply.

Figure 8 on page 12 shows a dc power supply and fan unit and the airflow through

the storage expansion enclosure.

Chapter 1. Introduction 11

Page 40

Latch

Lever

Figure 8. The dc power supply and fan unit and airflow

Small Form-Factor Pluggable (SFP) modules

The storage expansion enclosure supports fibre optic host interface cables. You

must install a Small Form-factor Pluggable (SFP) module in each interface

connector on the controller where a fibre optic cable is to be installed.

Attention: The maximum operating speed of the fibre channel port is determined

by two factors: the speed of the SFP module that is installed and the speed of the

fibre channel connection. For example, a 2-Gbps SFP that is plugged into a

4-Gbps-capable port will limit the speed of that port to a maximum of 2 Gbps.

Conversely, a 4-Gbps SFP that is plugged into a 2-Gbps-capable port will limit the

speed of the port to a maximum of 2 Gbps. Carefully check the SFP’s IBM part

number, option number, and FRU part number to identify its speed. There are no

physical features that distinguish a 4 Gbps from a 2 Gbps SFP.

Figure 9 on page 13 shows an SFP module with fibre optic cable.

Note: The SFP module shown might look different from those shipped with your

storage expansion enclosure. The differences does not affect transceiver

performance.

12 IBM System Storage DS4000 EXP810 Storage Expansion Enclosure: Installation, User’s and Maintenance Guide

Page 41

Telco bezel

SFP

Module

Fiber-optic

cable

Figure 9. SFP module and fibre optic cable

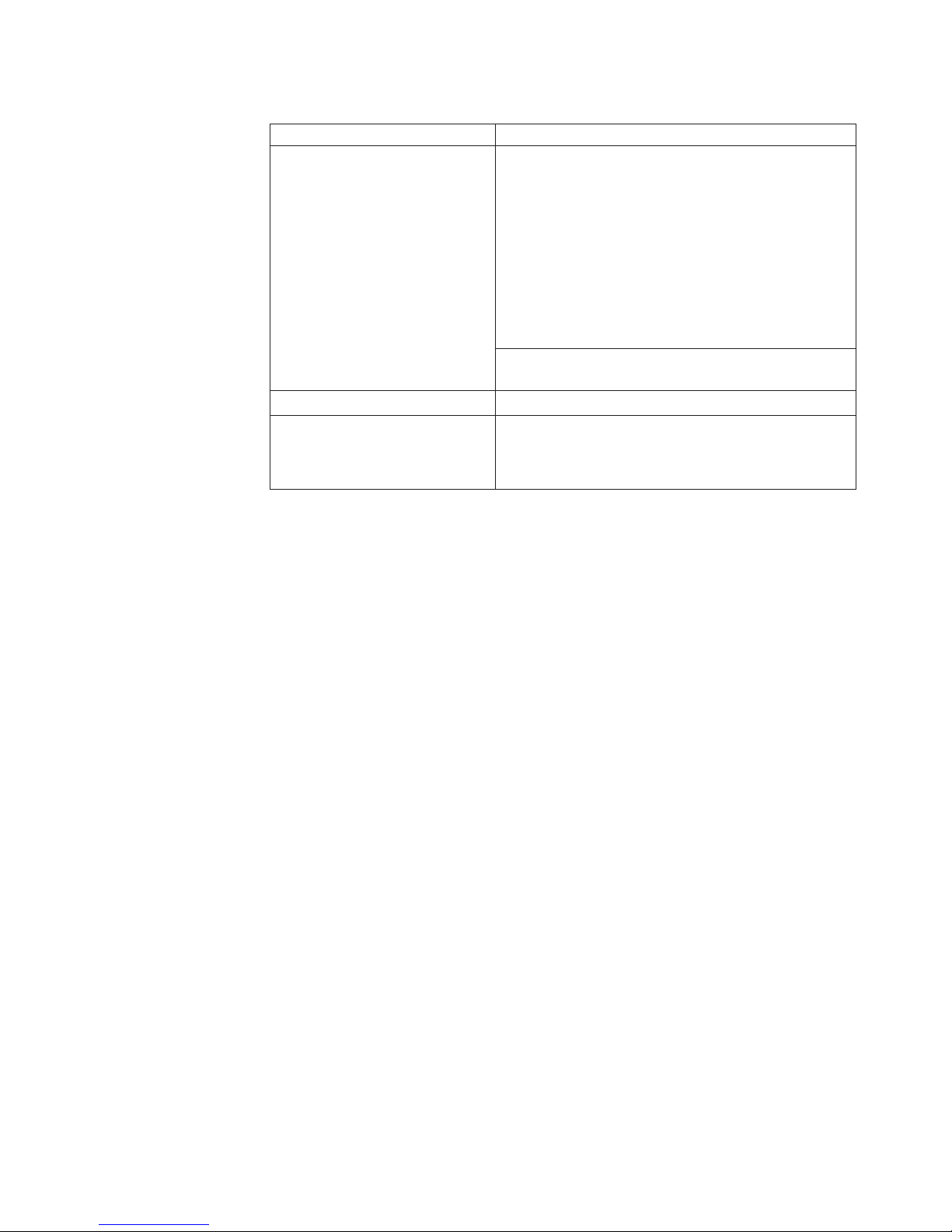

The EXP810 storage expansion enclosure can be ordered with a Telco bezel. The

Telco bezel also contains a filter and filter retainer. The replaceable filter is fitted

inside the Telco bezel and limits impurities, dust, air particles and other external

contaminants from adversely impacting the chassis, electronic CRUs, and hard

drive operational effectiveness. IBM recommends that you replace the filter every

three months or sooner, depending on your environment. Inspect the filter

periodically and replace it as required.

Figure 10 shows a front view of the bezel. Figure 11 on page 14 shows a side view

of the bezel, filter, and filter retainer.

ds470065

Figure 10. Bezel

Chapter 1. Introduction 13

Page 42

1

Figure 11. Filter and filter retainer

Table 7. Filter and filter retainer description

Number Description

1 Bezel

2 Filter

3 Filter retainer

2

3

ds470066

Software and hardware compatibility and upgrades

The latest DS4000 controller firmware and NVSRAM, drive enclosure ESM

firmware, and the fibre channel and SATA drive CRUs firmware must be installed to

ensure optimal functionality, manageability, and reliability.

Unless stated otherwise, you can find the latest DS4000 publications, firmware, and

host software at the IBM DS4000 System Storage Support Web site:

www.ibm.com/servers/storage/support/disk/

Software and firmware support code upgrades

To enable support for the EXP810, you must ensure that your system's software

and firmware are at the levels shown in Table 8:

Table 8. Software and firmware levels for the EXP810

Software/firmware Level

DS Storage Manager software 10.30

14 IBM System Storage DS4000 EXP810 Storage Expansion Enclosure: Installation, User’s and Maintenance Guide

Page 43

Table 8. Software and firmware levels for the EXP810 (continued)

Software/firmware Level

DS4000 controller firmware and

NVSRAM

ESM firmware 98Bx or higher in a DS4000 environment.

Drive firmware You can find the latest software and firmware at the

06.16.88.xx or 06.16.9x.xx for support with DS4700 and

DS4800. (EXP100 not supported.)

06.19.xx.xx for support with DS4300 and DS4500 only

with support for intermix of EXP100s.

06.23.05.xx or 06.60.02.xx supports DS4300, DS4500,

DS4700, and DS4800 with support of intermix with

EXP100s.