Page 1

IBM System Storage EXN1000 Storage Expansion Unit

Hardw are an d Service Guide

GC26-7802-02

Page 2

Page 3

IBM System Storage EXN1000 Storage Expansion Unit

Hardw are an d Service Guide

GC26-7802-02

Page 4

Note:

Before using this information and the product it supports, be sure to read the general information in “Notices”

on page 51.

The following paragraph does not apply to any country (or region) where such provisions are inconsistent with local

law.

INTERNATIONAL BUSINESS MACHINES CORPORATION PROVIDES THIS PUBLICATION “AS IS” WITHOUT

WARRANTY OF ANY KIND, EITHER EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. Some states (or regions) do

not allow disclaimer of express or implied warranties in certain transactions; therefore, this statement may not apply

to you.

Order publications through your IBM representative or the IBM branch office serving your locality.

© Copyright International Business Machines Corporation 2005, 2007. All rights reserved.

US Government Users Restricted Rights – Use, duplication or disclosure restricted by GSA ADP Schedule Contract

with IBM Corp.

Page 5

Safety and environmental notices

This section contains information about:

v “Safety notices and labels”

v “Laser safety” on page vii

v “Rack safety” on page viii

v “Product recycling and disposal” on page xi

v “Battery return program” on page xii

v “Fire suppression systems” on page xiii

Safety notices and labels

When using this product, observe the danger, caution, and attention notices

contained in this guide. The notices are accompanied by symbols that

represent the severity of the safety condition.

The following sections define each type of safety notice and provide

examples.

The following notices and statements are used in IBM® documents. They are

listed below in order of increasing severity of potential hazards. Follow the

links for more detailed descriptions and examples of the danger, caution, and

attention notices in the sections that follow.

v Note: These notices provide important tips, guidance, or advice.

v “Attention notices” on page vii: These notices indicate potential damage to

programs, devices, or data.

v “Caution notices” on page vi: These statements indicate situations that can

be potentially hazardous to you.

v “Danger notices”: These statements indicate situations that can be

potentially lethal or extremely hazardous to you. Safety labels are also

attached directly to products to warn of these situations.

v In addition to these notices, “Labels” on page vi may be attached to the

product to warn of potential hazards.

Danger notices

A danger notice calls attention to a situation that is potentially lethal or

extremely hazardous to people. A lightning bolt symbol accompanies a danger

notice to represent a dangerous electrical condition. A sample danger notice

follows.

© Copyright IBM Corp. 2005, 2007 iii

Page 6

DANGER

An

electrical outlet that is not correctly wired could place

hazardous voltage on metal parts of the system or the devices

that attach to the system. It is the responsibility of the

customer to ensure that the outlet is correctly wired and

grounded to prevent an electrical shock. (D004)

A comprehensive danger notice provides instructions on how to avoid shock

hazards when servicing equipment. Unless instructed otherwise, follow the

procedures in the following danger notice.

iv

Page 7

DANGER

When

working on or around the system, observe the following

precautions:

Electrical voltage and current from power, telephone, and

communication cables are hazardous. To avoid a shock hazard:

v Connect power to this unit only with the IBM provided

power cord. Do not use the IBM provided power cord for

any other product.

v Do not open or service any power supply assembly.

v Do not connect or disconnect any cables or perform

installation, maintenance, or reconfiguration of this product

during an electrical storm.

v The product might be equipped with multiple power cords.

To remove all hazardous voltages, disconnect all power

cords.

v Connect all power cords to a properly wired and grounded

electrical outlet. Ensure outlet supplies proper voltage and

phase rotation according to the system rating plate.

v Connect any equipment that will be attached to this product

to properly wired outlets.

v When possible, use one hand only to connect or disconnect

signal cables.

v Never turn on any equipment when there is evidence of fire,

water, or structural damage.

v Disconnect the attached power cords, telecommunications

systems, networks, and modems before you open the device

covers, unless instructed otherwise in the installation and

configuration procedures.

v Connect and disconnect cables as described below when

installing, moving, or opening covers on this product or

attached devices.

Disconnect:

To

1. Turn off everything (unless instructed otherwise).

2. Remove power cords from the outlet.

3. Remove signal cables from connectors.

4. Remove all cables from devices.

Connect:

To

1. Turn off everything (unless instructed otherwise).

2. Attach all cables to devices.

3. Attach signal cables to the connectors.

4. Attach power cords to the outlets.

5. Turn on the devices.

(D005)

Safety and environmental notices v

Page 8

Labels

As an added precaution, safety labels are often installed directly on products

or product components to warn of potential hazards.

The actual product safety labels may differ from these sample safety labels:

(L001)

(L003)

DANGER

Hazardous

voltage, current, or energy levels are

present inside any component that has this label

attached. Do not open any cover or barrier that

contains this label.

DANGER

Multiple

power cords. The product might be equipped

with multiple power cords. To remove all hazardous

voltages, disconnect all power cords.

Caution notices

A caution notice calls attention to a situation that is potentially hazardous to

people because of some existing condition. A caution notice can be

accompanied by different symbols, as in the examples below:

If the symbol is... It means...

A hazardous electrical condition with less severity than

electrical danger.

A generally hazardous condition not represented by

other safety symbols.

A hazardous condition due to the use of a laser in the

product. Laser symbols are always accompanied by the

classification of the laser as defined by the U. S.

Department of Health and Human Services (for

example, Class I, Class II, and so forth).

vi

Page 9

Attention notices

Laser safety

An attention notice indicates the possibility of damage to a program, device,

or system, or to data. An exclamation point symbol may accompany an

attention notice, but is not required. A sample attention notice follows:

Attention: Do not bend a fibre cable to a radius less than 5 cm (2

in.); you can damage the cable. Tie wraps are not recommended for

optical cables because they can be easily overtightened, causing

damage to the cable.

When using an NVRAM5 or NVRAM6 cluster media converter, the storage

system must be installed in a restricted access location.

CAUTION:

This product contains a Class 1M laser. Do not view directly with

optical instruments. (C028)

This equipment contains Class 1 laser products, and complies with FDA

radiation Performance Standards, 21 CFR Subchapter J and the international

laser safety standard IEC 825-2.

CAUTION:

Data processing environments can contain equipment transmitting on

system links with laser modules that operate at greater than Class 1

power levels. For this reason, never look into the end of an optical

fiber cable or open receptacle. (C027)

Attention: In the United States, use only SFP or GBIC optical transceivers

that comply with the FDA radiation performance standards, 21 CFR

Subchapter J. Internationally, use only SFP or GBIC optical transceivers that

comply with IEC standard 825–1. Optical products that do not comply with

these standards may produce light that is hazardous to the eyes.

Usage restrictions

The optical ports of the modules must be terminated with an optical

connector or with a dust plug.

Safety and environmental notices vii

Page 10

Rack safety

Rack installation

DANGER

Observe

the following precautions when working on or

around your IT rack system:

v Heavy equipment - personal injury or equipment damage

might result if mishandled.

v Always lower the leveling pads on the rack cabinet.

v Always install stabilizer brackets on the rack cabinet.

v To avoid hazardous conditions due to uneven mechanical

loading, always install the heaviest devices in the bottom of

the rack cabinet. Always install servers and optional devices

starting from the bottom of the rack cabinet.

v Rack-mounted devices are not to be used as shelves or work

spaces. Do not place objects on top of rack-mounted

devices.

viii

v Each rack cabinet might have more than one power cord. Be

sure to disconnect all power cords in the rack cabinet when

directed to disconnect power during servicing.

v Connect all devices installed in a rack cabinet to power

devices installed in the same rack cabinet. Do not plug a

power cord from a device installed in one rack cabinet into

a power device installed in a different rack cabinet.

v An electrical outlet that is not correctly wired could place

hazardous voltage on the metal parts of the system or the

devices that attach to the system. It is the responsibility of

the customer to ensure that the outlet is correctly wired and

grounded to prevent an electrical shock.

(R001 part 1 of 2

Page 11

CAUTION:

v Do not install a unit in a rack where the internal rack ambient

temperatures will exceed the manufacturer’s recommended ambient

temperature for all your rack-mounted devices.

v Do not install a unit in a rack where the air flow is compromised. Ensure

that air flow is not blocked or reduced on any side, front, or back of a

unit used for air flow through the unit.

v Consideration should be given to the connection of the equipment to the

supply circuit so that overloading of the circuits does not compromise the

supply wiring or overcurrent protection. To provide the correct power

connection to a rack, refer to the rating labels located on the equipment

in the rack to determine the total power requirement of the supply

circuit.

v (For sliding drawers.) Do not pull out or install any drawer or feature if the

rack stabilizer brackets are not attached to the rack. Do not pull out more

than one drawer at a time. The rack might become unstable if you pull

out more than one drawer at a time.

v (For fixed drawers) This drawer is a fixed drawer and should not be moved

for servicing unless specified by manufacturer. Attempting to move the

drawer partially or completely out of the rack may cause the rack to

become unstable or cause the drawer to fall out of the rack.

(R001

part 2 of 2)

Safety and environmental notices ix

Page 12

Rack relocation (19″ rack)

CAUTION:

Removing components from the upper positions in the rack cabinet

improves rack stability during relocation. Follow these general guidelines

whenever you relocate a populated rack cabinet within a room or building:

v Reduce the weight of the rack cabinet by removing equipment starting at

the top of the rack cabinet. When possible, restore the rack cabinet to the

configuration of the rack cabinet as you received it. If this configuration

is not known, you must do the following:

– Remove all devices in the 32U position and above.

– Ensure that the heaviest devices are installed in the bottom of the rack

cabinet.

– Ensure that there are no empty U-levels between devices installed in

the rack cabinet below the 32U level.

– If the rack cabinet you are relocating is part of a suite of rack cabinets,

detach the rack cabinet from the suite.

– Inspect the route that you plan to take when moving the rack to

eliminate potential hazards.

– Verify that the route that you choose can support the weight of the

loaded rack cabinet. Refer to the documentation that came with your

rack cabinet for the weight of a loaded rack cabinet.

– Verify that all door openings are at least 760 x 2030 mm (30 x 80 in.).

– Ensure that all devices, shelves, drawers, doors, and cables are secure.

– Ensure that the four leveling pads are raised to their highest position.

– Ensure that there is no stabilizer bracket installed on the rack cabinet

during movement.

– Do not use a ramp inclined at more than ten degrees.

– Once the rack cabinet is in the new location, do the following:

- Lower the four leveling pads.

- Install stabilizer brackets on the rack cabinet.

- If you removed any devices from the rack cabinet, repopulate the

rack cabinet from the lowest position to the highest position.

If a long distance relocation is required, restore the rack cabinet to the

–

configuration of the rack cabinet as you received it. Pack the rack

cabinet in the original packaging material, or equivalent. Also, lower

the leveling pads to raise the casters off of the pallet and bolt the rack

cabinet to the pallet.

(R002)

x

Page 13

Product recycling and disposal

This unit must be recycled or discarded according to applicable local and

national regulations. IBM encourages owners of information technology (IT)

equipment to responsibly recycle their equipment when it is no longer

needed. IBM offers a variety of product return programs and services in

several countries to assist equipment owners in recycling their IT products.

Information on IBM product recycling offerings can be found on IBM’s

Internet site at:

www.ibm.com/ibm/environment/products/prp.shtml

Esta unidad debe reciclarse o desecharse de acuerdo con lo establecido en la

normativa nacional o local aplicable. IBM recomienda a los propietarios de

equipos de tecnología de la informacion (TI) que reciclen responsablemente

sus equipos cuando éstos ya no les sean utiles. IBM dispone de una serie de

programas y servicios de devolucion de productos en varios países, a fin de

ayudar a los propietarios de equipos a reciclar sus productos de TI. Se puede

encontrar informacion sobre las ofertas de reciclado de productos de IBM en

el sitio web de IBM www.ibm.com/ibm/environment/products/prp.shtml.

Notice: This mark applies only to countries within the European Union (EU)

and Norway.

This appliance is labelled in accordance with European Directive 2002/96/EC

concerning waste electrical and electronic equipment (WEEE). The Directive

determines the framework for the return and recycling of used appliances as

applicable throughout the European Union. This label is applied to various

products to indicate that the product is not to be thrown away, but rather

reclaimed upon end of life per this Directive.

Safety and environmental notices xi

Page 14

In accordance with the European WEEE Directive, electrical and electronic

equipment (EEE) is to be collected separately and to be reused, recycled, or

recovered at end of life. Users of EEE with the WEEE marking per Annex IV

of the WEEE Directive, as shown above, must not dispose of end of life EEE

as unsorted municipal waste, but use the collection framework available to

customers for the return, recycling and recovery of WEEE. Customer

participation is important to minimize any potential effects of EEE on the

environment and human health due to the potential presence of hazardous

substances in EEE. For proper collection and treatment, contact your local IBM

representative.

Battery return program

This product may contain sealed lead acid, nickel cadmium, nickel metal

hydride, lithium, or lithium ion battery. Consult your user manual or service

manual for specific battery information. The battery must be recycled or

disposed of properly. Recycling facilities may not be available in your area.

For information on disposal of batteries outside the United States, contact

your local waste disposal facility or go to the following Web site:

xii

www.ibm.com/ibm/environment/products/batteryrecycle.shtml

In the United States, IBM has established a return process for reuse, recycling,

or proper disposal of used IBM sealed lead acid, nickel cadmium, nickel metal

hydride, and other battery packs from IBM Equipment. For information on

proper disposal of these batteries, contact IBM at 1-800-426-4333. Please have

the IBM part number listed on the battery available prior to your call.

For Taiwan:

Page 15

For the European Union:

Note: This mark applies only to countries within the European Union (EU).

Batteries or packaging for batteries are labeled in accordance with European

Directive 2006/66/EC concerning batteries and accumulators and waste

batteries and accumulators. The Directive determines the framework for the

return and recycling of used batteries and accumulators as applicable

throughout the European Union. This label is applied to various batteries to

indicate that the battery is not to be thrown away, but rather reclaimed upon

end of life per this Directive.

In accordance with the European Directive 2006/66/EC, batteries and

accumulators are labeled to indicate that they are to be collected separately

and recycled at end of life. The label on the battery may also include a

chemical symbol for the metal concerned in the battery (Pb for lead, Hg for

mercury and Cd for cadmium). Users of batteries and accumulators must not

dispose of batteries and accumulators as unsorted municipal waste, but use

the collection framework available to customers for the return, recycling and

treatment of batteries and accumulators. Customer participation is important

to minimize any potential effects of batteries and accumulators on the

environment and human health due to the potential presence of hazardous

substances. For proper collection and treatment, contact your local IBM

representative.

Fire suppression systems

A fire suppression system is the responsibility of the customer. The customer’s

own insurance underwriter, local fire marshal, or a local building inspector, or

both, should be consulted in selecting a fire suppression system that provides

the correct level of coverage and protection. IBM designs and manufactures

equipment to internal and external standards that require certain

environments for reliable operation. Because IBM does not test any equipment

Safety and environmental notices xiii

Page 16

for compatibility with fire suppression systems, IBM does not make

compatibility claims of any kind nor does IBM provide recommendations on

fire suppression systems.

xiv

Page 17

Contents

Safety and environmental notices . . . . . . . . . . . . . . . . . . . . . . . iii

Safety notices and labels . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Danger notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .vi

Caution notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . .vi

Attention notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Laser safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Usage restrictions . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Rack safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . viii

Rack installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . viii

Rack relocation (19″ rack) . . . . . . . . . . . . . . . . . . . . . . . . . .x

Product recycling and disposal . . . . . . . . . . . . . . . . . . . . . . . . .xi

Battery return program . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

For the European Union: . . . . . . . . . . . . . . . . . . . . . . . . . xiii

Fire suppression systems . . . . . . . . . . . . . . . . . . . . . . . . . xiii

Figures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xix

Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxi

About this document . . . . . . . . . . . . . . . . . . . . . . . . . . . xxiii

Who should read this document . . . . . . . . . . . . . . . . . . . . . . . xxiii

Supported features . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxiii

How this document is organized . . . . . . . . . . . . . . . . . . . . . . . xxiii

Getting information, help, and service . . . . . . . . . . . . . . . . . . . . . xxiv

Before you call . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxiv

Using the documentation . . . . . . . . . . . . . . . . . . . . . . . . . xxiv

Web sites . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxv

Hardware service and support . . . . . . . . . . . . . . . . . . . . . . . xxv

Supported servers and operating systems . . . . . . . . . . . . . . . . . . . xxv

Firmware updates . . . . . . . . . . . . . . . . . . . . . . . . . . . xxv

Conventions and terminology used in this document . . . . . . . . . . . . . . . . . xxv

Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxvi

Command conventions . . . . . . . . . . . . . . . . . . . . . . . . . xxvi

Formatting conventions . . . . . . . . . . . . . . . . . . . . . . . . . xxvi

Keyboard conventions . . . . . . . . . . . . . . . . . . . . . . . . . xxvii

How to send your comments . . . . . . . . . . . . . . . . . . . . . . . . xxviii

Chapter 1. Preparing for the installation . . . . . . . . . . . . . . . . . . . . .1

Required manuals, tools and equipment . . . . . . . . . . . . . . . . . . . . . .1

Required tools and equipment for installation . . . . . . . . . . . . . . . . . . .1

Handling static-sensitive devices . . . . . . . . . . . . . . . . . . . . . . . .1

Planning and organizing the installation . . . . . . . . . . . . . . . . . . . . . .2

Hardware specifications . . . . . . . . . . . . . . . . . . . . . . . . . .3

Checking shipment package contents . . . . . . . . . . . . . . . . . . . . . .4

© Copyright IBM Corp. 2005, 2007 xv

Page 18

Rules for installing EXN1000 expansion units in a rack . . . . . . . . . . . . . . . .4

Guide to the installation process . . . . . . . . . . . . . . . . . . . . . . .5

Before you begin your installation . . . . . . . . . . . . . . . . . . . . . . . .7

EXN1000 expansion unit numbering . . . . . . . . . . . . . . . . . . . . . .8

Drive addressing . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Speed setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Supported disk drives . . . . . . . . . . . . . . . . . . . . . . . . . .11

Drive bay requirements . . . . . . . . . . . . . . . . . . . . . . . . . .11

Chapter 2. Connecting an EXN1000 expansion unit . . . . . . . . . . . . . . . . .13

Handling fiber-optic cables . . . . . . . . . . . . . . . . . . . . . . . . . .13

Connecting EXN1000 expansion units . . . . . . . . . . . . . . . . . . . . . .14

EXN1000 expansion unit cabling requirements . . . . . . . . . . . . . . . . . .14

Connecting the expansion unit directly to the N series storage system . . . . . . . . .14

Connecting the expansion unit to other expansion units . . . . . . . . . . . . . .15

Grounding EXN1000 expansion units . . . . . . . . . . . . . . . . . . . . . .15

Connecting the EXN1000 expansion unit to a power source . . . . . . . . . . . . . . .15

Hot-adding an EXN1000 expansion unit to an existing loop . . . . . . . . . . . . . . .15

Error messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Chapter 3. Monitoring the EXN1000 expansion unit . . . . . . . . . . . . . . . . .19

Monitoring the front operation panel . . . . . . . . . . . . . . . . . . . . . .19

Location of LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Monitoring the disk shelf ID . . . . . . . . . . . . . . . . . . . . . . . .20

LED status on the front operation panel . . . . . . . . . . . . . . . . . . . .20

Front operation panel console error messages . . . . . . . . . . . . . . . . . . .21

Monitoring the AT-FCX modules . . . . . . . . . . . . . . . . . . . . . . . .22

Location of the module LEDs . . . . . . . . . . . . . . . . . . . . . . . .22

LED status on the AT-FCX . . . . . . . . . . . . . . . . . . . . . . . . .23

AT-FCX console error messages . . . . . . . . . . . . . . . . . . . . . . .23

Monitoring the power supply . . . . . . . . . . . . . . . . . . . . . . . . .24

Location of LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Power supply console error messages . . . . . . . . . . . . . . . . . . . . .26

Monitoring the ATA disk . . . . . . . . . . . . . . . . . . . . . . . . . .27

Location of LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Chapter 4. Replacing EXN1000 expansion unit devices . . . . . . . . . . . . . . .29

Removing an EXN1000 expansion unit . . . . . . . . . . . . . . . . . . . . . .29

Removing an EXN1000 expansion unit from a single EXN1000 expansion unit configuration . . .30

Removing an EXN1000 expansion unit from a loop . . . . . . . . . . . . . . . . .31

Replacing a disk in an EXN1000 expansion unit . . . . . . . . . . . . . . . . . . .32

Preparing to replace a disk . . . . . . . . . . . . . . . . . . . . . . . . .32

Removing a disk . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Installing a disk . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Replacing a power supply in an EXN1000 expansion unit . . . . . . . . . . . . . . .33

Rules for replacing power supplies . . . . . . . . . . . . . . . . . . . . . .34

Removing a power supply . . . . . . . . . . . . . . . . . . . . . . . . .34

Installing a power supply . . . . . . . . . . . . . . . . . . . . . . . . .35

Replacing an AT-FCX module . . . . . . . . . . . . . . . . . . . . . . . . .35

Connectors in an AT-FCX . . . . . . . . . . . . . . . . . . . . . . . . .36

xvi

Page 19

For detailed information . . . . . . . . . . . . . . . . . . . . . . . . . .36

Removing a module . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Installing a module . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Hot-swapping a module . . . . . . . . . . . . . . . . . . . . . . . . . .37

Appendix A. Recommended power line sizes . . . . . . . . . . . . . . . . . . .39

Recommended AC power line sizes . . . . . . . . . . . . . . . . . . . . . . .39

Appendix B. FRU/CRU and power cord list for N series products . . . . . . . . . . . .41

FRU/CRU list for N series products . . . . . . . . . . . . . . . . . . . . . . .41

Power cord list for N series products . . . . . . . . . . . . . . . . . . . . . .41

Appendix C. IBM System Storage N series documentation . . . . . . . . . . . . . .45

N7000 series systems library . . . . . . . . . . . . . . . . . . . . . . . . .45

N5000 series systems library . . . . . . . . . . . . . . . . . . . . . . . . .45

N3300 and N3600 storage systems library . . . . . . . . . . . . . . . . . . . . .45

N3700 storage system library . . . . . . . . . . . . . . . . . . . . . . . . .45

EXN1000, EXN2000 and EXN4000 expansion units library . . . . . . . . . . . . . . .46

Data ONTAP 7.2 filer library . . . . . . . . . . . . . . . . . . . . . . . . .46

Data ONTAP 7.1 filer library . . . . . . . . . . . . . . . . . . . . . . . . .47

Data ONTAP 7.2 gateway systems library . . . . . . . . . . . . . . . . . . . . .47

Data ONTAP 7.1 gateway systems library . . . . . . . . . . . . . . . . . . . . .48

Other N series and N series-related documents . . . . . . . . . . . . . . . . . . .48

Notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Trademarks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

Important notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

Electronic emission notices . . . . . . . . . . . . . . . . . . . . . . . . . .54

Federal Communications Commission (FCC) Class A Statement . . . . . . . . . . . .54

Industry Canada Class A Emission Compliance Statement . . . . . . . . . . . . . .55

Avis de conformité à la réglementation d’Industrie Canada . . . . . . . . . . . . . .55

European Union (EU) Electromagnetic Compatibility Directive . . . . . . . . . . . . .55

Australia and New Zealand Class A statement . . . . . . . . . . . . . . . . . .55

Germany Electromagnetic Compatibility Directive . . . . . . . . . . . . . . . . .56

People’s Republic of China Class A Electronic Emission Statement . . . . . . . . . . . .56

Taiwan Class A warning statement . . . . . . . . . . . . . . . . . . . . . .57

Japan VCCI Class A ITE Electronic Emission Statement . . . . . . . . . . . . . . .57

Korean Class A Electronic Emission Statement . . . . . . . . . . . . . . . . . .57

Power cords . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

Contents xvii

Page 20

xviii

Page 21

Figures

1. Shelf ID label . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

2. EXN1000 shelf ID . . . . . . . . . . . . . . . . . . . . . . . . . . .9

3. EXN1000 disk shelf IDs and drive addressing . . . . . . . . . . . . . . . . . .10

4. EXN1000 speed setting switch . . . . . . . . . . . . . . . . . . . . . . .11

5. Front panel LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . .20

6. LED indications of normal and fault conditions . . . . . . . . . . . . . . . . .21

7. Location of the LEDs for an AT-FCX . . . . . . . . . . . . . . . . . . . . .22

8. EXN1000 rear panel quick reference card . . . . . . . . . . . . . . . . . . .23

9. Third sheet of the quick reference cards . . . . . . . . . . . . . . . . . . . .25

10. Location of power supply LEDs . . . . . . . . . . . . . . . . . . . . . .26

11. ATA disk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

12. Cam mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . .35

© Copyright IBM Corp. 2005, 2007 xix

Page 22

xx

Page 23

Tables

1. EXN1000 physical characteristics and environmental requirements . . . . . . . . . . .3

2. EXN1000 electrical requirements . . . . . . . . . . . . . . . . . . . . . .4

3. EXN1000 expansion unit installation process . . . . . . . . . . . . . . . . . .6

4. Stages of enclosure services monitoring . . . . . . . . . . . . . . . . . . . .12

5. N series storage system console error messages . . . . . . . . . . . . . . . . .17

6. N series storage system error messages . . . . . . . . . . . . . . . . . . . .21

7. AT-FCX console error messages . . . . . . . . . . . . . . . . . . . . . .24

8. Power supply console error messages . . . . . . . . . . . . . . . . . . . .26

9. Recommended conductor size for 2% voltage drop . . . . . . . . . . . . . . . .39

10. American Wire Gauge (AWG) to Harmonized Cordage . . . . . . . . . . . . . .39

© Copyright IBM Corp. 2005, 2007 xxi

Page 24

xxii

Page 25

About this document

This guide provides general information about the IBM System Storage

EXN1000 Storage Expansion Unit (model number 2861-001), a roadmap on the

installation, and information on managing the expansion unit, which connects

to N series storage systems.

Compliance ID 2861–NAS covers the model 2861–001.

Who should read this document

This document is for customer use. It addresses setup, operation, and

servicing of the 2861–001. This document is intended to provide information

to customers, operators, administrators, installers, and service personnel.

Supported features

IBM N series products are driven by NetApp® Data ONTAP® software. Some

features described in the product software documentation are neither offered

nor supported by IBM. Please contact your local IBM representative or reseller

for further details.

Information about supported features can also be found at the following Web

site:

www.ibm.com/storage/support/nas/

™

A listing of currently available N series products and features can be found at

the following Web site:

www.ibm.com/storage/nas/

How this document is organized

This document contains the following chapters:

v Chapter 1, “Preparing for the installation,” on page 1 describes the

preparation requirements for first-time installation of the IBM EXN1000

Storage Expansion Unit (model number 2861-001).

v Chapter 2, “Connecting an EXN1000 expansion unit,” on page 13 describes

how to connect a single EXN1000 expansion unit or a loop of EXN1000

expansion units to a supported N series storage system, how to ground

your system, and how to connect your system to power.

© Copyright IBM Corp. 2005, 2007 xxiii

Page 26

v Chapter 3, “Monitoring the EXN1000 expansion unit,” on page 19 describes

how to monitor the EXN1000 expansion unit from the error messages

displayed on the console that is connected to the N series storage system

and identifies the location of the various LEDs on the EXN1000 expansion

unit.

v Chapter 4, “Replacing EXN1000 expansion unit devices,” on page 29

describes how to replace EXN1000 expansion units in a rack, disks in an

EXN1000 expansion unit, and other devices.

v Appendix A, “Recommended power line sizes,” on page 39 describes the

recommended AC power line lengths.

v Appendix B, “FRU/CRU and power cord list for N series products,” on

page 41 lists the feature codes for the power cords and FRU/CRUs for the

EXN1000 expansion unit.

v Appendix C, “IBM System Storage N series documentation,” on page 45

lists the documents in the IBM System Storage N series hardware and Data

ONTAP product libraries, as well as other related documents.

Getting information, help, and service

If you need help, service, or technical assistance or just want more

information about IBM products, you will find a wide variety of sources

available from IBM to assist you. This section contains information about

where to go for additional information about IBM and IBM products, what to

do if you experience a problem with your IBM N series product, and whom

to call for service, if it is necessary.

xxiv

Before you call

Before you call, make sure that you have taken these steps to try to solve the

problem yourself:

v Check all cables to make sure that they are connected.

v Check the power switches to make sure that the system is turned on.

v Use the troubleshooting information in your system documentation and use

the diagnostic tools that come with your system.

v Refer to the IBM Support Web site for information on known problems and

limitations.

Using the documentation

Information about the N series product and Data ONTAP software is available

in printed documents and a documentation CD that comes with your system.

The same documentation is available as PDF files on the IBM NAS support

Web site:

www.ibm.com/storage/support/nas/

Page 27

Web sites

IBM maintains pages on the World Wide We b where you can get the latest

technical information as well as download device drivers and updates.

v For N series product information, go to the following We b site:

www.ibm.com/storage/nas/

v For N series support information, go to the following Web site:

www.ibm.com/storage/support/nas/

v For AutoSupport information, go to the following We b site:

www.ibm.com/storage/support/nas/

v Yo u can order publications through the IBM Publications Ordering System

at the following We b site:

www.elink.ibmlink.ibm.com/public/applications/publications/

cgibin/pbi.cgi/

Hardware service and support

You can receive hardware service through IBM Integrated Technology

Services. Visit the following Web site for support telephone numbers:

www.ibm.com/planetwide/

Supported servers and operating systems

IBM N series products attach to many servers and many operating systems.

To determine the latest supported attachments, visit the following Web site

and access the IBM System Storage N series interoperability matrix:

www.ibm.com/storage/support/nas/

Firmware updates

As with all devices, it is recommended that you run the latest level of

firmware, which is embedded in DataONTAP. If there are changes, they will

be posted to the following Web site:

www.ibm.com/storage/support/nas/

Note: If you do not see new changes on the Web site, you are running the

latest level of firmware.

Verify that the latest level of firmware is installed on your machine before

contacting IBM for technical support.

Conventions and terminology used in this document

This guide uses the following terminology, command conventions, format

conventions and keyboard conventions:

About this document xxv

Page 28

Terminology

In this and other IBM N series documents, the term filer or storage system

describes IBM N series models that either contain internal disk storage or

attach to the disk storage expansion units specifically designed for the IBM N

series storage systems. There are three disk storage expansion units

specifically designed for the IBM N series:

v IBM EXN4000 fibre-channel disk storage expansion unit

v IBM EXN2000 fibre-channel disk storage expansion unit

v IBM EXN1000 serial advanced technology attachment (SATA) storage

expansion unit

Note:

This guide uses the following terms:

v Active-Active configuration (sometimes referred to as clustered configuration)

refers to a High Availability system with at least two nodes that share

resources to provide redundancy.

v AT-FCX refers to the EXN1000 module.

v Device carrier refers to the container that encases a fan/power supply unit

or a disk.

v Disk applies to any SATA disk encased in its device carrier.

v Disk shelf or expansion unit refers to any shelf or expansion unit containing

hard disk drives.

v Loop refers to one or more daisy-chained EXN1000 expansion units

connected to an N series storage system.

v Module refers to the AT-FCX module.

v System and N series storage system refer to the filer, either by itself or with

additional expansion units.

v SES refers to SCSI Enclosure Services.

None of these expansion units are intended to attach to a gateway

system.

xxvi

Command conventions

You can enter filer commands on the system console or from any client that

can obtain access to a filer using a Telnet session. In examples that illustrate

commands executed on a UNIX® workstation, the command syntax and

output might differ, depending on your version of UNIX.

Formatting conventions

The following table lists different character formats used in this guide to set

off special information.

Page 29

Formatting convention Type of information

Italic type

v Word s or characters that require special

attention.

v Placeholders for information you must

supply. For example, if the guide

requires you to enter the fctest

adaptername command, you enter the

characters “fctest” followed by the

actual name of the adapter.

v Book titles in cross-references.

Monospaced font

v Command and daemon names.

v Information displayed on the system

console or other computer monitors.

v The contents of files.

Bold monospaced font Word s or characters you type. What you

type is always shown in lowercase letters,

unless your program is case-sensitive and

uppercase letters are necessary for it to

work properly.

Keyboard conventions

This guide uses capitalization and some abbreviations to refer to the keys on

the keyboard. The keys on your keyboard might not be labeled exactly as they

are in this guide.

What is in this guide... What it means...

hyphen (-) Used to separate individual keys. For

example, Ctrl-D means holding down the

Ctrl key while pressing the D key.

Enter Used to refer to the key that generates a

carriage return, although the key is

named Return on some keyboards.

type Used to mean pressing one or more keys

on the keyboard.

enter Used to mean pressing one or more keys

and then pressing the Enter key.

About this document xxvii

Page 30

How to send your comments

Your feedback is important in helping us provide the most accurate and

high-quality information. If you have comments or suggestions for improving

this document, send us your comments by e-mail to starpubs@us.ibm.com or

use the Readers’ Comments form at the back of this publication. Be sure to

include the following:

v Exact publication title

v Form number (for example, GC26-1234-02)

v Page numbers to which you are referring

the Reader Comment Form in the back of this manual is missing, you can

If

direct your mail to:

International Business Machines Corporation

Information Development

Department GZW

9000 South Rita Road

Tucson, Arizona 85744-0001 U.S.A.

When you send information to IBM, you grant IBM a nonexclusive right to

use or distribute the information in any way it believes appropriate without

incurring any obligation to you.

xxviii

Page 31

Chapter 1. Preparing for the installation

This chapter describes the preparation requirements for first-time installation

of the IBM EXN1000 Storage Expansion Unit (model number 2861-001).

This chapter discusses the following topics:

v “Required manuals, tools and equipment”

v “Handling static-sensitive devices”

v “Planning and organizing the installation” on page 2

v “Before you begin your installation” on page 7

Required manuals, tools and equipment

In addition to this document, you need the following manuals:

v Installation and Setup Instructions for your storage system

v EXN1000 Installation and Setup Instructions

v Hardware and Service Guide for your storage system

Required tools and equipment for installation

You must supply the following tools and equipment:

v Ethernet LAN cables

v Fibre Channel cables

v Console (for example, a PC or laptop)

v #2 Phillips screwdriver and slotted screwdriver

v Pointed tool for setting switches

v 7-mm nut driver

v Antistatic ESD strap and grounding leash

Handling static-sensitive devices

Attention: The EXN1000 expansion unit uses electronic components that are

sensitive to static electricity. Static discharge from your clothing or other

fixtures around you can damage these components. Put on an antistatic ESD

strap and grounding leash to free yourself of static electricity before touching

any electronic components.

Attention: Static electricity can damage electronic devices and your system.

To avoid damage, keep static-sensitive devices in their static-protective

packages until you are ready to install them.

© Copyright IBM Corp. 2005, 2007 1

Page 32

To reduce the possibility of electrostatic discharge (ESD), observe the

following precautions:

v Limit your movement. Movement can cause static electricity to build up

around you.

v Handle the device carefully, holding it by its edges or its frame.

v Do not touch solder joints, pins, or exposed printed circuitry.

v Do not leave the device where others can handle and possibly damage the

device.

v While the device is still in its static-protective package, touch it to an

unpainted metal part of the system unit for at least two seconds. This

drains static electricity from the package and from your body.

v Remove the device from its package and install it directly into your system

unit without setting it down. If it is necessary to set the device down, place

it in its static-protective package. Do not place the device on your system

unit cover or on a metal table. Take additional care when handling devices

during cold weather because heating reduces indoor humidity and

increases static electricity.

Planning and organizing the installation

This section identifies the shipment contents and the rules and regulations

you need to observe for the proper installation of your EXN1000 expansion

unit. It also provides an overview of the entire system installation process and

the appropriate documentation references for the procedures.

For detailed information, see the following topics:

v “Hardware specifications” on page 3

v “Checking shipment package contents” on page 4

v “Rules for installing EXN1000 expansion units in a rack” on page 4

v “Guide to the installation process” on page 5

2

Page 33

Hardware specifications

The following table lists the characteristics and requirements for your

hardware.

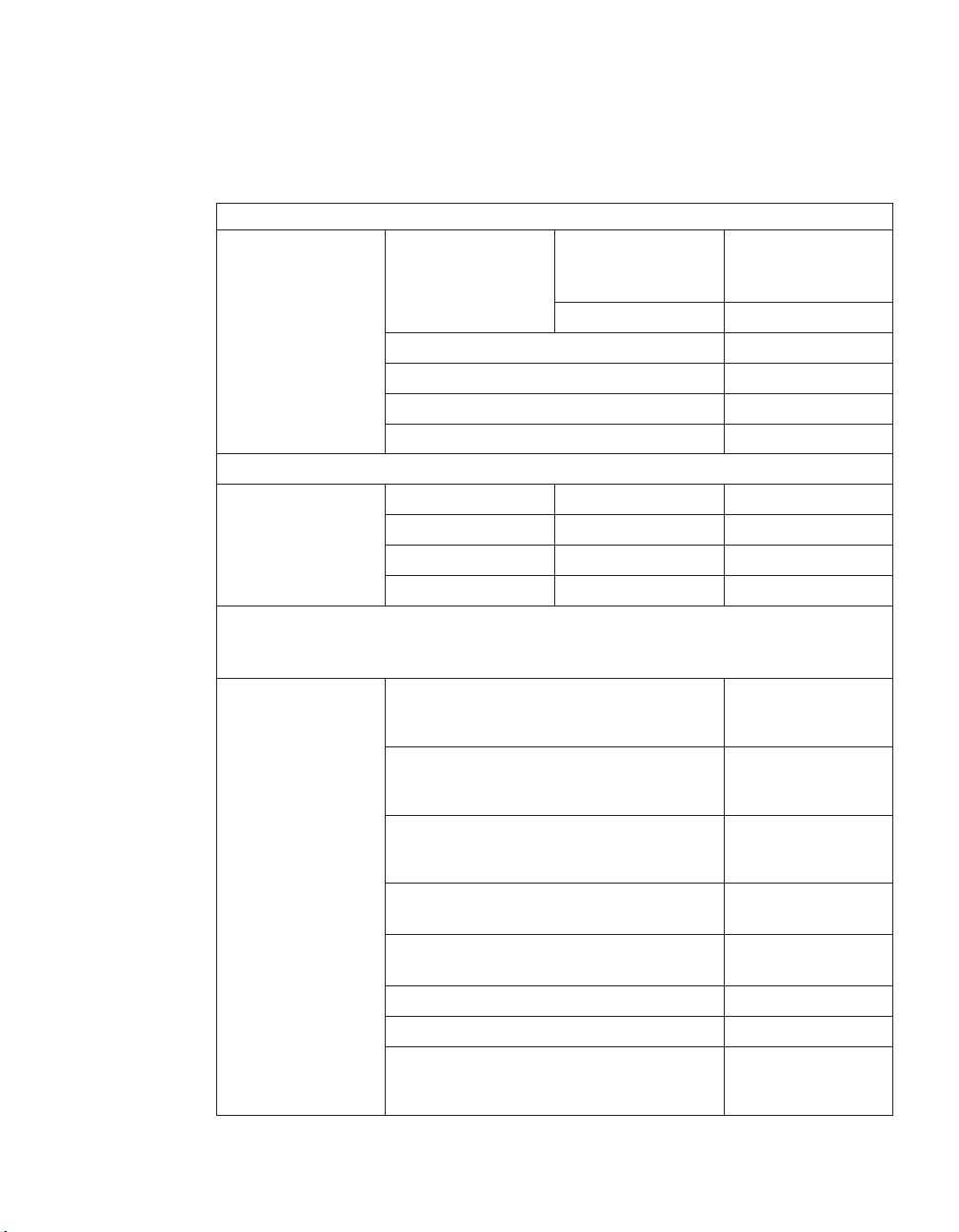

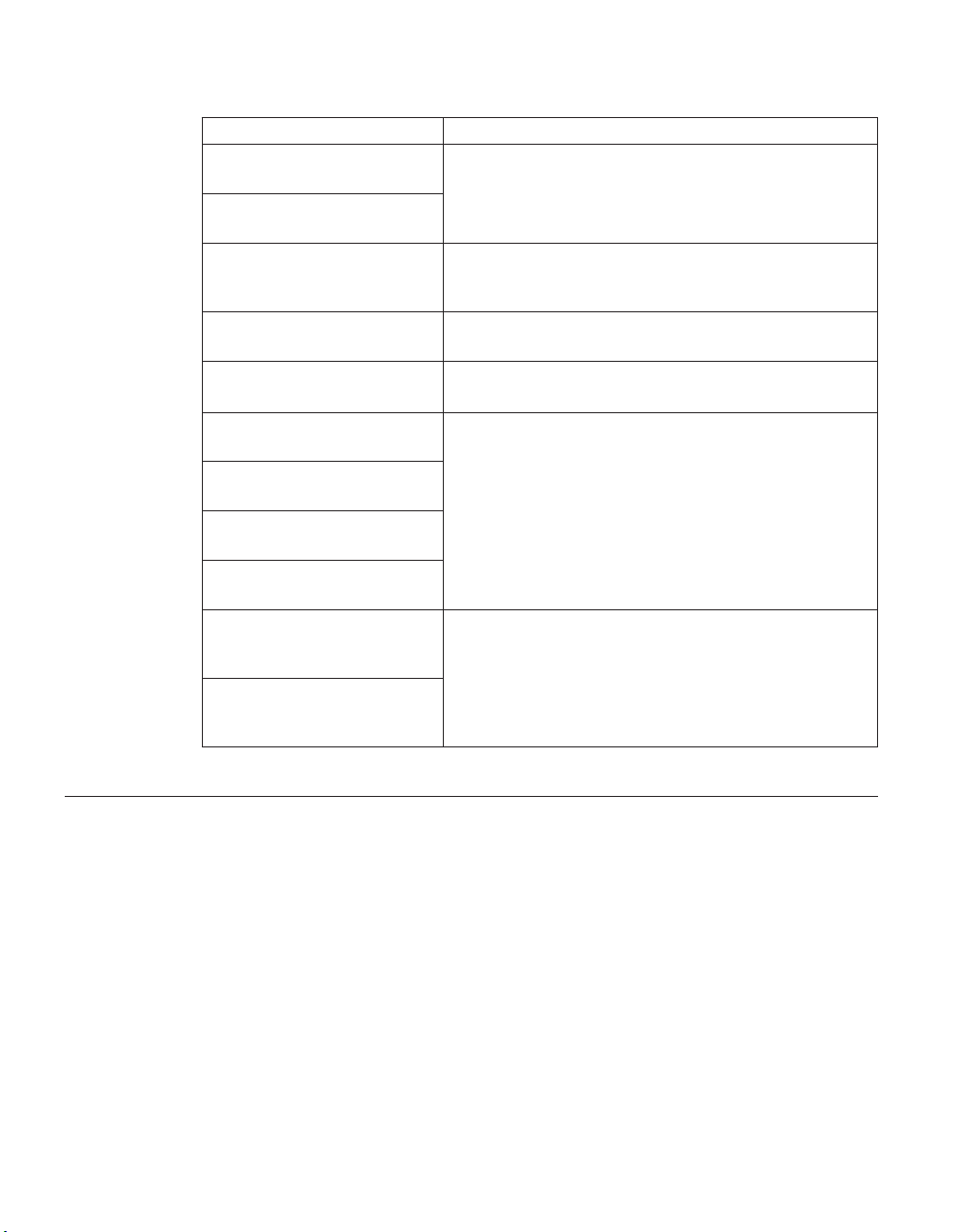

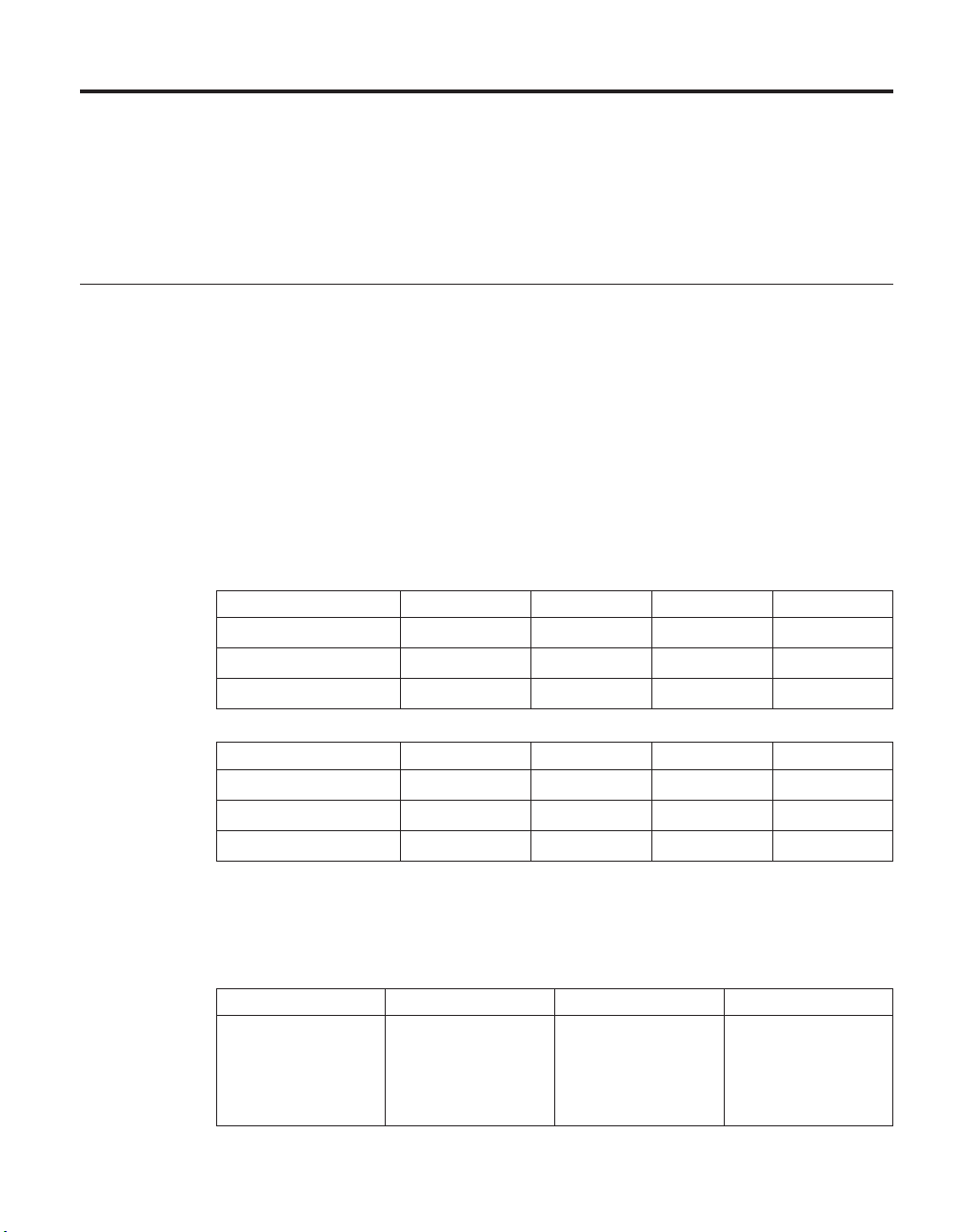

Table 1. EXN1000 physical characteristics and environmental requirements

Physical characteristics

Weight With maximum

77 lbs (35 kg)

number of disk

drives

Empty 50.6 lbs (23 kg)

Rack units 3U

Height 5.25 in. (13.3 cm)

Width 17.6 in. (44.8 cm)

Depth 20 in. (50.9 cm)

Clearance dimensions

Front-cooling All versions 6 in. (15.3 cm)

Front-maintenance All versions 25 in. (63.5)

Rear-cooling All versions 12 in. (30.5 cm)

Rear-maintenance All versions 12 in. (30.5 cm)

Environmental requirements

Note: Operating at the extremes of the following environmental requirements might

increase the risk of device failure.

Operating temperature maximum range 50° F to 104° F

(10° C to 40° C)

Operating temperature recommended

68° F to 77° F

range

(20° C to 25° C)

Nonoperating temperature range -40° F to 149° F

(-40° C to 65° C)

Relative humidity 10 to 90%

noncondensing

Recommended operating temperature

40 to 55%

relative humidity range

Maximum wet bulb temperature 28° C (82° F)

Maximum altitude 3050 m (10,000 ft.)

Acoustic level 56.4 dBA @ 23° C

5.64 bels @ 23° C

Chapter 1. Preparing for the installation 3

Page 34

Table 2. EXN1000 electrical requirements

Input voltage 100 to 120V 200 to 240V

Input current

Worst-case Typical

single

PSU/

system

7.2K drives 2.85 1.56/3.12 1.43 0.78/1.56

Worst-case Typical

single

PSU/

system

measured, A

Input power

7.2K drives 284 155/310 283 152/304

measured, W

Thermal

7.2K drives 968 529/1058 964 517.5/1035

dissipation,

BTU/hr

Inrush peak, A 7.2K drives 21 20 12.5 12.0

Input power frequency, Hz 50 to 60

Maximum electrical power 7 A 3.5 A

Note: Worst-case indicates a system running with one PSU and high fan

speed. Typical indicates a system running two PSUs on two circuits.

Checking shipment package contents

Make sure that your shipment package includes the following items, in

addition to the IBM System Storage EXN1000 Storage Expansion Unit Hardware

and Service Guide:

v EXN1000 Installation and Setup Instructions.

v An EXN1000 expansion unit containing the power supplies and SATA disks

you ordered.

v FC-AL cables and power cords, as ordered.

v A rail kit for mounting the EXN1000 in a standard 19–inch rack may also be

included.

Rules for installing EXN1000 expansion units in a rack

You need to observe the following rules and restrictions when installing an

EXN1000 expansion unit in a standard 19-inch (48.26 cm) equipment rack

with mounting rails:

4

Page 35

32-55 kg (70.5-121.2 lbs)

svc00168

DANGER

DANGER

The weight of this part or unit is between 32 and 55 kg (70.5

and 121.2 lb). It takes three persons to safely lift this part or unit. (C010)

Attention: Remove the power supplies and fan units from the chassis before

attempting to lift the system.

v Yo u must work with two other people.

DANGER

EXN1000 expansion unit is extremely heavy. To avoid injuring

The

yourself or damaging the EXN1000 expansion unit, you must work

with at least two other people when you install the EXN1000

expansion unit in the rack.

v Install the expansion unit at the bottom of the rack first.

DANGER

avoid hazardous conditions due to uneven mechanical loading,

To

always install the heaviest devices in the bottom of the rack cabinet.

Always install servers and optional devices starting from the bottom of

the rack cabinet. (R001 part 1 of 2)

For additional rack safety notices, refer to “Rack safety” on page viii.

v When installing EXN1000 expansion units in a rack, do not exceed the

maximum storage limit for your N series storage system.

v Always install the EXN1000 expansion units fully loaded. Do not remove

the disk drives or drive blank covers to reduce the weight.

Guide to the installation process

The following table provides a guide to the EXN1000 expansion unit

installation process.

Refer to the Installation and Setup Instructions for your storage system for

complete installation details.

Chapter 1. Preparing for the installation 5

Page 36

DANGER

people are required to lift the EXN1000 during installation. Do not

Three

remove the disk drives or drive blank covers to reduce the weight.

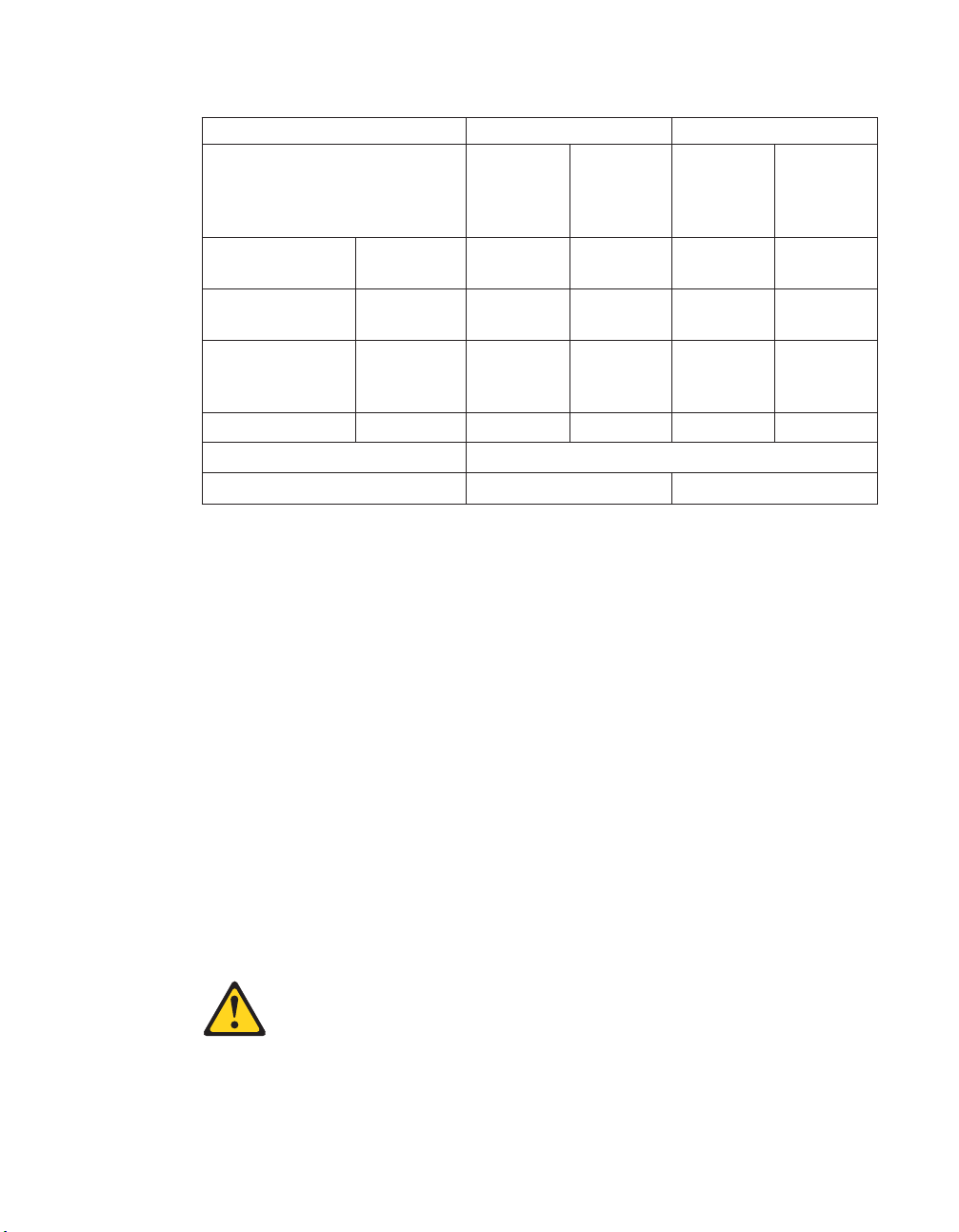

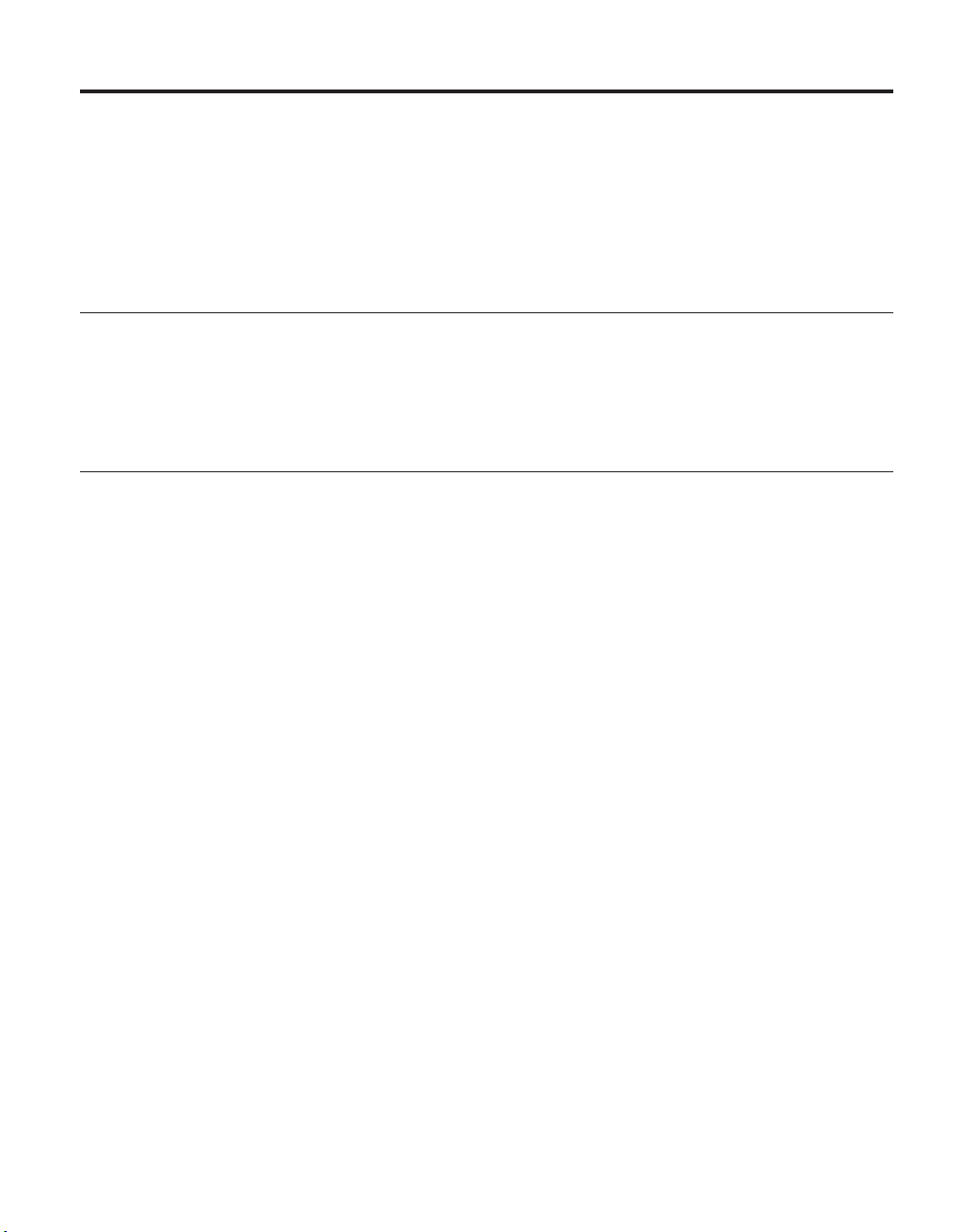

Table 3. EXN1000 expansion unit installation process

Is the procedure

Stage Procedure

1 Install the N series

storage system in a

freestanding rack.

required?

Only if the EXN1000

expansion unit

installation is part of a

new system

installation.

For instructions, go

to...

Hardware guide for

your N series storage

system, or the

Installation and Setup

Instructions that came

with your N series

storage system.

2 Install the EXN1000

expansion units in the

rack.

Yes, if the EXN1000

expansion unit is an

addition to your

See the EXN1000

Installation and Setup

Instructions.

existing system or if

Attention:

When

installing multiple

your new system was

not shipped in a rack.

storage expansion units

that share a drive loop,

always install them

sequentially as they

will appear in the loop.

3 Connect the EXN1000

expansion unit to the N

series storage system.

Only in the following

scenarios:

v If the EXN1000

expansion unit

installation is part of

a new system

Chapter 2, “Connecting

an EXN1000 expansion

unit,” on page 13, or

the EXN1000

Installation and Setup

Instructions.

installation.

v If the EXN1000

expansion unit is the

first in an additional

loop to your existing

system.

6

Page 37

Table 3. EXN1000 expansion unit installation process (continued)

Stage Procedure

4 Connect the EXN1000

expansion units.

Is the procedure

required?

Only in the following

scenarios:

v If the new system

For instructions, go

to...

See the EXN1000

Installation and Setup

Instructions.

installation has

multiple EXN1000

expansion units.

v If the EXN1000

expansion unit is an

addition to your

existing system.

5 Ground the EXN1000

expansion units and N

series storage system.

Yes. “Grounding EXN1000

expansion units” on

page 15, or the

EXN1000 Installation

and Setup Instructions.

6 Connect the EXN1000

expansion units to a

power source.

Yes. “Connecting the

EXN1000 expansion

unit to a power source”

on page 15

If the system was

shipped in a rack, you

must connect the rack

See the documentation

that shipped with your

cabinet.

to a power source.

7 Configure the system. Yes, if the EXN1000

expansion unit

installation is part of a

new system

See the Data ONTAP

Software Setup Guide for

your version of Data

ONTAP.

installation.

Before you begin your installation

Before you install one or more EXN1000 expansion units in a rack, you need

to understand the following information:

v EXN1000 expansion unit numbering

v Drive addressing

v Speed setting

v Supported disk drives

v Drive bay requirements

Chapter 1. Preparing for the installation 7

Page 38

Attention: Verify that all shelf IDs are correct and sequential in the

individual loop(s). If this system was configured by manufacturing, there are

labels on the outside of the packaging carton and on the side of the expansion

unit chassis to indicate which loop on which node (Filer 1 or 2) that shelf

should be located. Make certain the expansion units are placed and cabled

according to these labels. The filer nodes may also have a label on the

packaging carton and chassis side to clearly distinguish the nodes (Filer 1 and

Filer 2).

EXN1000 expansion unit numbering

Each EXN1000 expansion unit in a loop must have a unique ID. A valid shelf

ID is from 1 through 7. ID 1 is used for the first EXN1000 in a new loop, or if

the filer also contains disks, then ID 2 is used for the EXN1000 closest to the

N series storage system controller (which uses ID 1). Shelf IDs for additional

expansion units are incremented sequentially from the number of the first

expansion unit (either 1 or 2).

Each EXN1000 expansion unit shipped with an N series storage system has its

assigned ID already set on its back panel and has a shelf ID label already

placed on its front bezel.

You must ensure that the EXN1000 expansion unit has the correct shelf ID

number on the label. If you change the shelf ID of the expansion unit by

changing the ID switch at the rear of the unit, replace the shelf ID label to

match the new shelf ID for the unit.

Note: Additional shelf ID labels are supplied with your unit.

The shelf ID label is on the right side of the unit, as shown in the following

illustration.

Shelf 1

Drive Bays

013

Loop ID

29 - 16

Figure 1. Shelf ID label

7

8910111213 3 2 1 0

5

4

6

8

Page 39

IBM sets the disk shelf IDs at the factory on configured systems, using an ID

switch on the back panel. If you order additional EXN1000 expansion units,

you must set the disk shelf ID and apply the correct labels provided with the

EXN1000.

Note: If you enter a shelf ID that is not from 1 through 7, the drive addresses

default to those of a shelf with the ID switch set to 7 even though the

Shelf ID indicator in the front operation panel displays a dash (-).

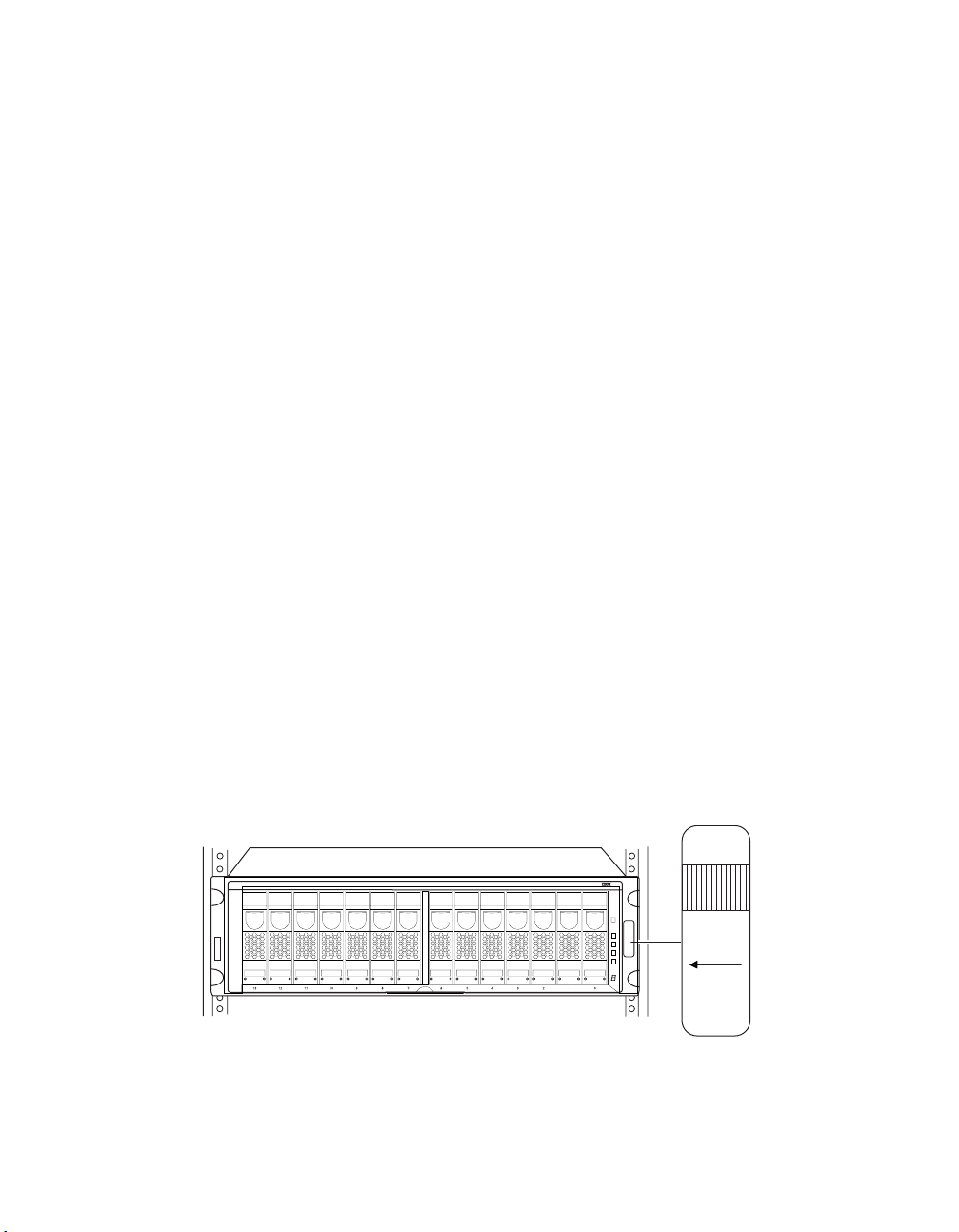

The example in the following illustration shows an EXN1000 expansion unit

with the disk shelf ID set to 2.

Shelf ID - close-up view

Mute button

2

Out port activity LED

Figure 2. EXN1000 shelf ID

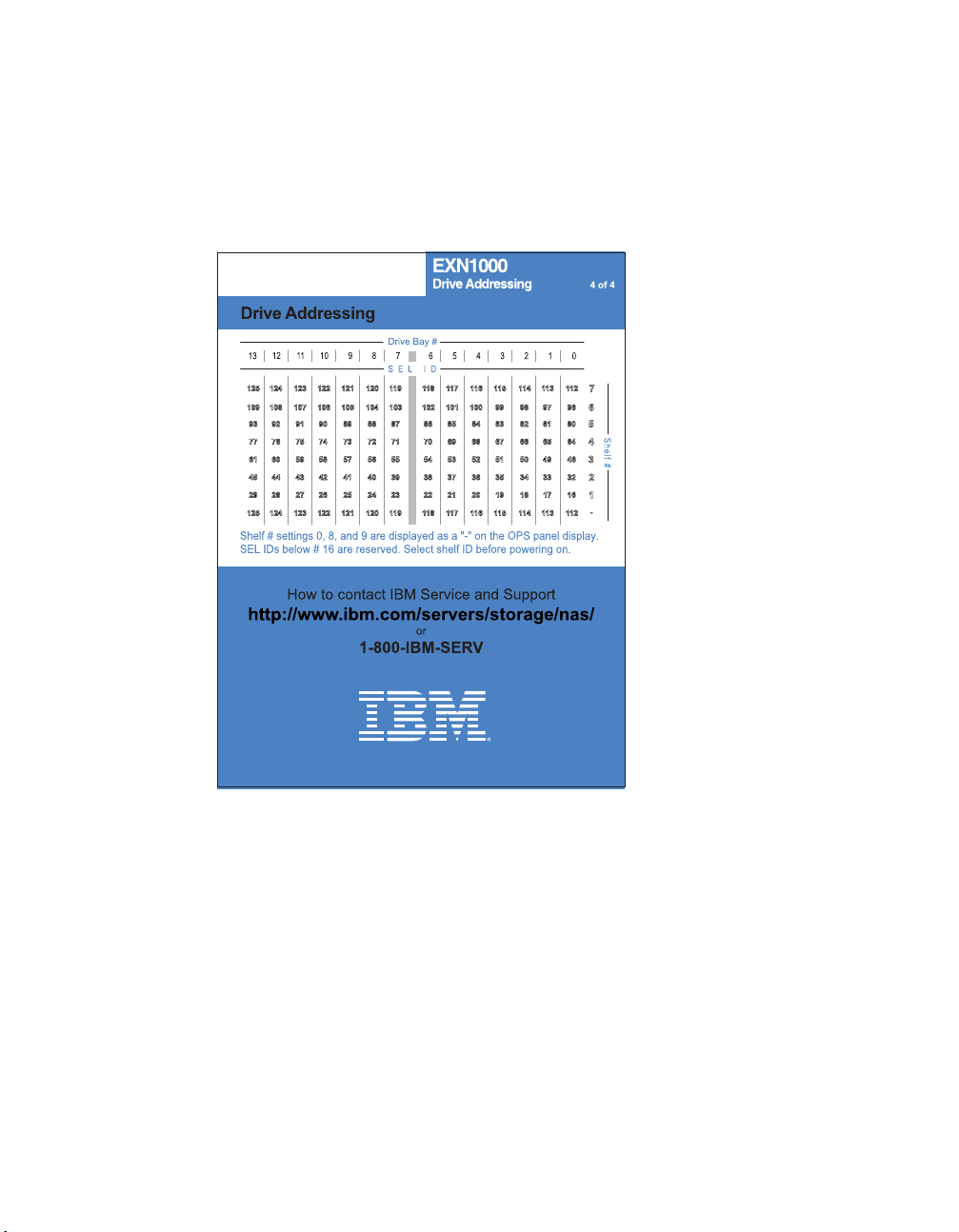

Drive addressing

In addition to identifying the disk shelf ID and the direction of the drive bays,

the ID label on the right side of the EXN1000 expansion unit includes the

drive address. The drive address identifies the disks in the EXN1000

expansion unit. The last sheet of the quick reference cards that come with

your EXN1000 expansion unit shows the seven disk shelf IDs and their

corresponding drive addresses.

Shelf ID

Out port

In port activity LED

2

In port

Ready LED

Fault LED

Chapter 1. Preparing for the installation 9

Page 40

Note: For AT-FCX module A, drive addressing is in descending order, and for

AT-FCX module B, drive addressing is ascending order. AT-FCX A is

the top controller module in the EXN1000. AT-FCX B is the bottom

controller module.

10

Figure 3. EXN1000 disk shelf IDs and drive addressing

Speed setting

Make sure that all expansion unit speed switches are set to the correct

position for your application.

v If connecting to an N3700 storage system, the speed switch must be set to

the 1Gb position.

v If connecting to any other N series storage system, the speed switch must

be set to the 2Gb position.

The speed setting switch is located on the circuit board inside the

Note:

AT-FCX module. In order to set or adjust the speed setting, you must

remove the AT-FCX module. See “Replacing an AT-FCX module” on

page 35.

Page 41

The speed setting must be set before you power on the expansion unit.

Figure 4. EXN1000 speed setting switch

Supported disk drives

For the types of disks the EXN1000 expansion unit supports, visit the

following Web site:

www.ibm.com/storage/nas/

Note: You should not mix different drive types in the same expansion unit.

Drive bay requirements

For enclosure services monitoring to work, drive bays 0 and 1 must contain a

disk. In addition, the EXN1000 expansion unit must be populated with at least

5 hard disk drives to ensure proper operation.

Attention: All drive bays in the expansion must contain either a hard disk

drive or a drive blank cover to maintain proper air flow and cooling.

The 14 drive bays in the EXN1000 expansion unit are numbered 0 through 13

from right to left, as shown in Figure 1 on page 8. Hard disk drives should be

populated in adjacent drive bays in the expansion unit in this sequence,

beginning with drive bay 0.

The N series storage system uses the enclosure services monitoring method to

monitor environmental conditions of the EXN1000 expansion unit. Enclosure

services conditions are communicated to the N series storage system through

the AT-FCX module.

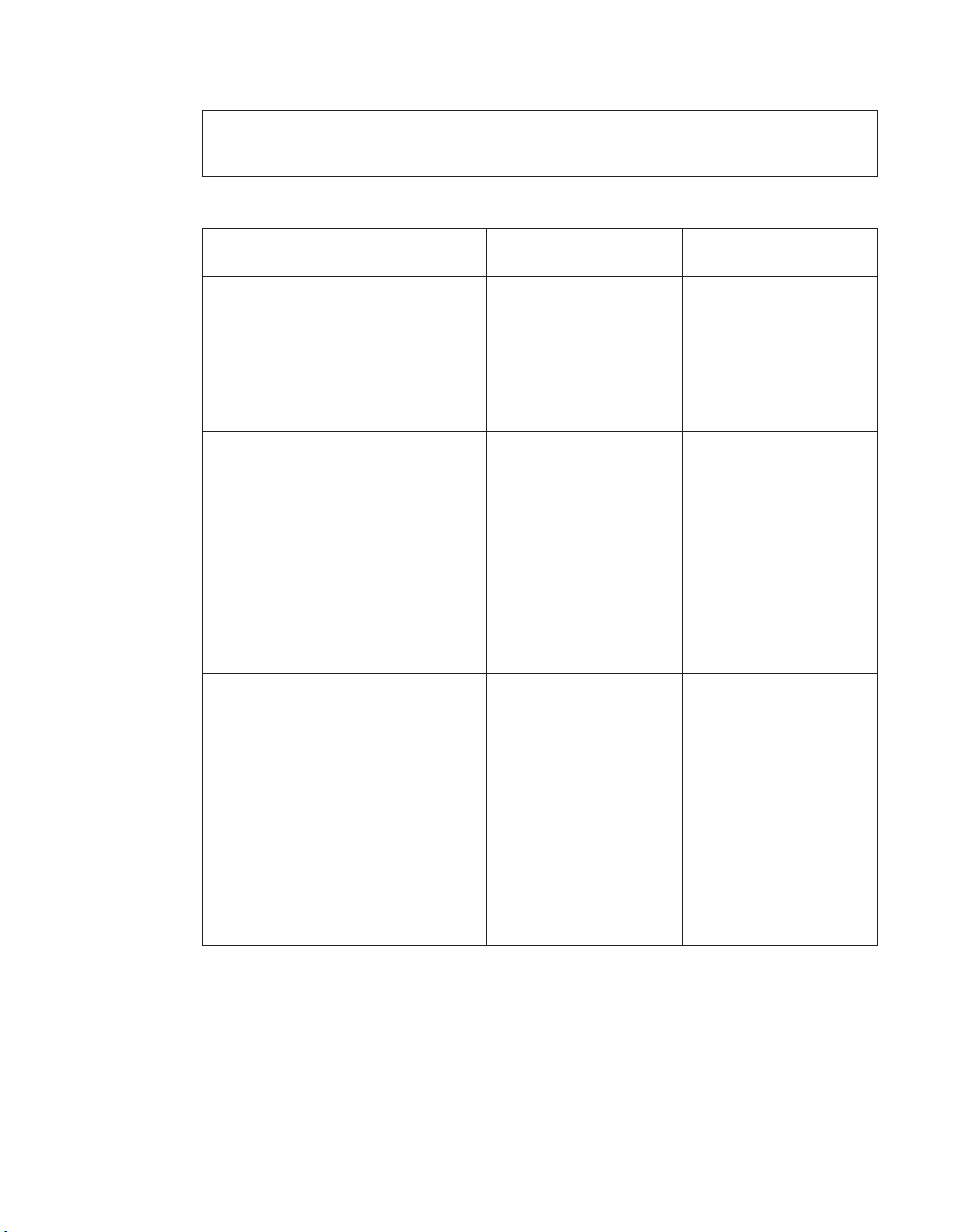

The following table describes the three stages of enclosure services

monitoring.

Chapter 1. Preparing for the installation 11

Page 42

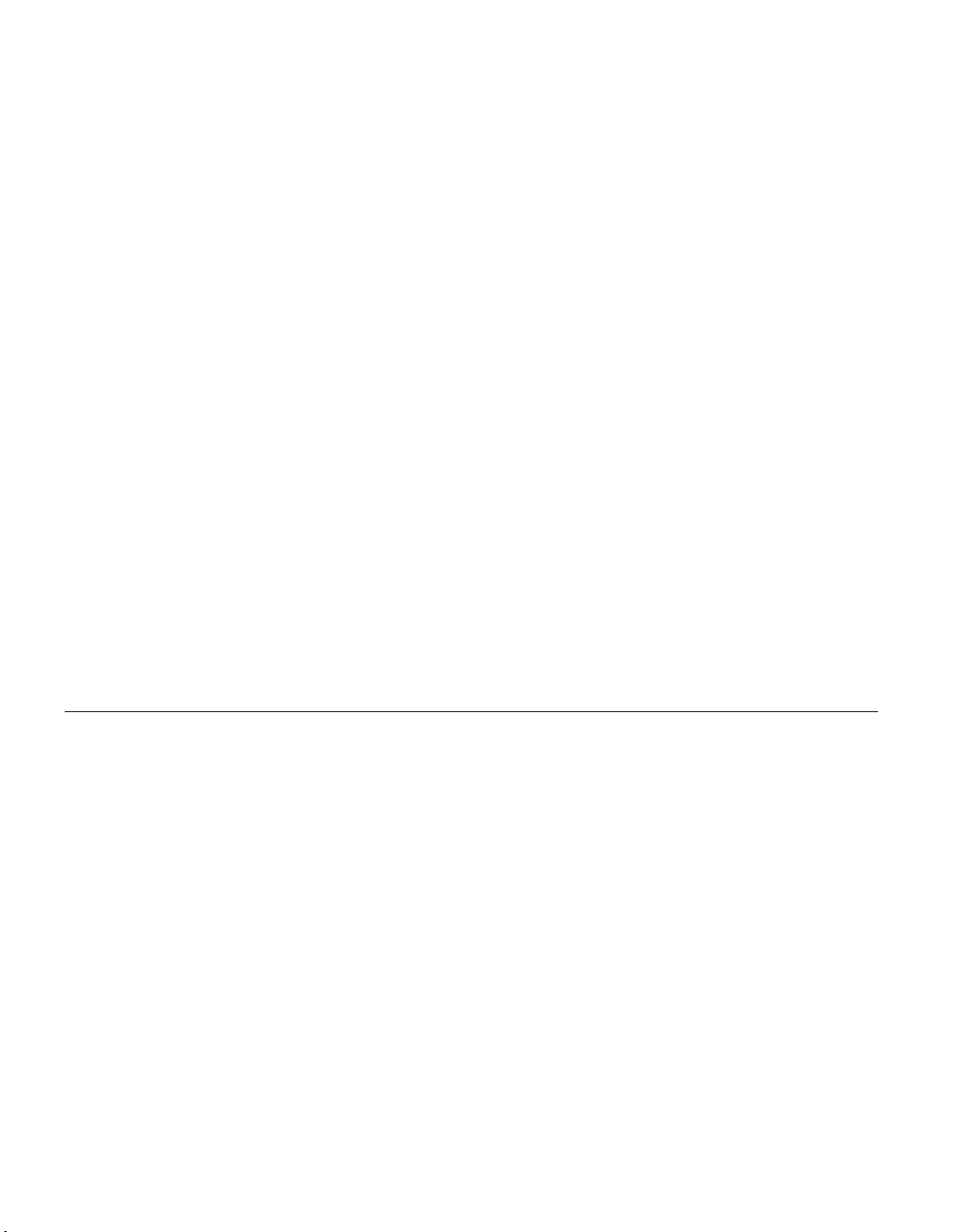

Table 4. Stages of enclosure services monitoring

Stage Device What it does...

1 N series storage system Uses a subset of SCSI-3

commands to monitor the

EXN1000 expansion unit

for data related to disk

presence, temperature,

power supply units, and

fan status.

2 N series storage system Sends the commands

through its Fibre Channel

interface to the AT-FCX

I/O module on the

EXN1000 expansion unit.

3 AT-FCX module Collects the requested data

and sends it to the storage

appliance.

12

Page 43

Chapter 2. Connecting an EXN1000 expansion unit

This chapter describes how to connect a single EXN1000 expansion unit or a

loop of EXN1000 expansion units to a supported N series storage system or to

other expansion units. This chapter also describes how to ground your system

and how to connect your system to power.

This chapter discusses the following topics:

v “Handling fiber-optic cables”

v “Connecting EXN1000 expansion units” on page 14

v “Grounding EXN1000 expansion units” on page 15

v “Connecting the EXN1000 expansion unit to a power source” on page 15

v “Hot-adding an EXN1000 expansion unit to an existing loop” on page 15

Handling fiber-optic cables

Before you use fiber-optic cables, read the following precautions.

Attention: To avoid damage to the fiber-optic cables, follow these guidelines:

v Do not route the cable along a folding cable-management arm.

v When attaching to a device on slide rails, leave enough slack in the cable so

that it does not bend to a radius of less than 38 mm (1.5 in.) when extended

or become pinched when retracted.

v Route the cable away from places where it can be snagged by other devices

in the rack cabinet.

v Do not overtighten the cable straps or bend the cables to a radius of less

than 38 mm (1.5 in.).

v Do not put excess weight on the cable at the connection point. Be sure that

the cable is well supported.

CAUTION:

Data processing environments can contain equipment transmitting on

system links with laser modules that operate at greater than Class 1

power levels. For this reason, never look into the end of an optical

fiber cable or open receptacle. (C027)

© Copyright IBM Corp. 2005, 2007 13

Page 44

Connecting EXN1000 expansion units

This section describes the requirements for connecting the EXN1000 expansion

unit to N series storage systems and other expansion units. For detailed

instructions about how to install and connect one or more EXN1000 expansion

units in a rack, refer to the Installation and Setup Instructions.

v IBM strongly recommends using optical (fibre channel) cabling whenever

possible.

v Refer to the IBM System Storage N series Introduction and Planning Guide for

details about the maximum number of drive loops, maximum number of

expansion units or hard disk drives per loop, maximum total storage

capacity, and maximum total number of hard disk drives for configurations

using your N series storage system. (For example, you can connect a

maximum of one loop of three fully populated expansion units to an

N3700.)

v Multipath looping is recommended for all configurations to provide

additional redundancy. This includes single or dual controller and single or

multiple EXN1000 expansion units.

v Do not mix Fibre Channel EXN2000 or EXN4000 and SATA EXN1000

expansion units in the same loop.

EXN1000 expansion unit cabling requirements

You must meet the cabling requirements discussed in the following sections

when connecting the EXN1000 AT-FCX module to an N series storage system

or to other expansion units.

14

For the latest information on cabling requirements, see the Installation and

Setup Instructions and the Hardware and Service Guide for your storage system.

Connecting the expansion unit directly to the N series storage system

When connecting the EXN1000 to an N series storage system, you must use

appropriate cables and connectors according to the following guidelines:

v For direct connections to N3700 storage systems with system serial

numbers between 13-00032 and 13-01000 (in general, these are N3700

systems shipped prior to January 31, 2006): Use a NAS-to-EXP fibre

channel copper cable (#2020 or 2022). For attachment to an N3700 Model

A10, one NAS-to-EXP fibre channel copper cable is required. For attachment

to an N3700 Model A20, two NAS-to-EXP fibre channel copper cables are

required.

v For direct connections to N3700 storage systems with system serial

numbers 13-01001 or higher (in general, these are N3700 systems shipped

after January 31, 2006): Use an LC-to-LC fibre channel optical cable and 2

SFPs for attachment to an N3700 Model A10. Use 2 LC-to-LC fibre channel

optical cables and 4 SFPs for attachment to an N3700 Model A20.

Page 45

v For direct connections to all other N series storage systems: Use an

LC-to-LC fibre channel optical cable and one SFP.

Connecting

the expansion unit to other expansion units

When connecting the EXN1000 to other expansion units, IBM strongly

recommends using LC-to-LC fibre channel optical cables. You must use 2 SFPs

per LC-to-LC fibre channel optical cable.

Note: SFP-to-SFP fibre channel copper cables may also be used for

connections (to a maximum of three meters) between expansion units.

Grounding EXN1000 expansion units

For proper grounding, you must daisy-chain the EXN1000 expansion units

together with the provided braided copper cables and screws. If possible, you

should ground the N series storage system to the EXN1000.

Each EXN1000 expansion unit is shipped with a 0.25m (~6 inch) braided

copper cable and an M5 x 0.5 inch Phillips head screw. The copper cable has a

hole on each end for grounding shelf-to-shelf.

For detailed instructions about how to ground connected EXN1000 expansion

units in a rack, refer to the Installation and Setup Instructions for your storage

system.

Connecting the EXN1000 expansion unit to a power source

The EXN1000 expansion unit is shipped with two power supplies, installed in

bay PSU1 and bay PSU2, respectively, and an AC power cord for each power

supply. You must have separate circuit breakers for each power supply.

For detailed instructions about how to connect EXN1000 expansion units to a

power source, refer to the EXN1000 Installation and Setup Instructions.

Hot-adding an EXN1000 expansion unit to an existing loop

This section provides information about how to hot-add an EXN1000

expansion unit to an existing loop. It also tabulates the error messages that

appear on your N series storage system console if the attempt at hot-adding

was unsuccessful.

Note: The hot-added EXN1000 expansion unit must have new drives that will

be used as spares only.

Chapter 2. Connecting an EXN1000 expansion unit 15

Page 46

Attention: It is recommended that you stop all I/O processes before

hot-adding an EXN1000 to an existing loop. Perform a hot-add only during

off-peak times.

To hot-add an EXN1000 expansion unit to an existing loop, complete the

following steps:

1. Put on the antistatic ESD strap and grounding leash.

2. Verify that you received the disk shelf ID labels.

3. Install the new EXN1000 expansion unit in the rack, cable and ground the

EXN1000, and connect the power cables to the EXN1000, as described in

the Installation and Setup Instructions you received with your N series

product.

CAUTION:

Do not turn on the power to the EXN1000 expansion unit yet.

After you have completed the installation steps described in the Installation

and Setup Instructions, continue with Step 4.

4. Verify that all the cables are securely fastened.

CAUTION:

Poorly secured cables cause the N series storage system to panic over an

open loop.

5. If you have not done so, give the EXN1000 expansion unit a unique disk

shelf ID. It is recommended that you choose a number which is one higher

than the previous shelf (or ID 1 if this is the first EXN1000 in the loop).

a. Press the small buttons on the switch on the rear of the EXN1000

expansion unit, using the + button to raise the number and the button to lower the number to a valid ID from 1 through 7. Refer to

Figure 2 on page 9 for an illustration.

16

Only use disk shelf ID 7 if it is the last ID available. If you

Note:

change a disk shelf ID, you must power-cycle the EXN1000

expansion unit for the new ID to take effect. The disk shelf ID

display on the front of the EXN1000 expansion unit blinks until

you power-cycle the EXN1000 expansion unit.

b. Verify that the disk shelf ID is not being used in the loop by entering

the following command at the console:

fcstat device_map adaptername

c. Select the correct matching shelf ID label, reference Figure 1 on page 8,

and attach it to the right flange of the new EXN1000 expansion unit.

CAUTION:

An invalid disk shelf ID causes the N series storage system to panic.

6. Turn on the power to the EXN1000 expansion unit. Yo u must wait 30

seconds for the shelf electronics to finish initializing.

Page 47

7. In 60 seconds, the N series storage system recognizes the hot-added

EXN1000 expansion unit.

Error messages

The following error messages appear on your N series storage system console

if your attempt at hot-adding the EXN1000 expansion unit is unsuccessful.

Table 5. N series storage system console error messages

Error message Explanation

Open loop panic One of two reasons cause this error message to appear:

v The shelf-to-shelf cable between the now second-to-last unit

and the newly added EXN1000 expansion unit is defective or

is not securely fastened.

v The speed of the newly added EXN1000 expansion unit is

incorrectly set.

Soft address

panic

One of two reasons cause this error message to appear:

v There is an invalid disk shelf ID.

v The power was turned on before the disk shelf ID was

changed and the EXN1000 expansion unit was not

power-cycled after the disk shelf ID was changed.

Chapter 2. Connecting an EXN1000 expansion unit 17

Page 48

18

Page 49

Chapter 3. Monitoring the EXN1000 expansion unit

This chapter describes how to monitor the EXN1000 expansion unit from the

error messages displayed on the console that is connected to the N series

storage system and identifies the location of the various LEDs on the

EXN1000 expansion unit.

Note: The quick reference cards in the slide-out tray at the base of the

EXN1000 expansion unit describe the functions of each LED on the

EXN1000 expansion unit and the suggested course of action.

This chapter discusses the following topics:

v “Monitoring the front operation panel”

v “Monitoring the AT-FCX modules” on page 22

v “Monitoring the power supply” on page 24

v “Monitoring the ATA disk” on page 27

Monitoring the front operation panel

The front operation panel has five LEDs and a disk shelf ID display. The

LEDs indicate whether your EXN1000 expansion unit is functioning normally

or there are problems with the hardware. Hardware failure associated with

the front operation panel of the EXN1000 expansion unit can be identified

from the error messages displayed on your N series storage system console.

© Copyright IBM Corp. 2005, 2007 19

Page 50

Location of LEDs

The following illustration shows the location of the disk shelf ID display and

the front panel LEDs.

Power

Fault

Loop A

Loop B

System

Disk shelf ID display

Figure 5. Front panel LEDs

Note: The Fault and System LEDs are amber. The other three LEDs are green.

See Figure 6 on page 21 for an illustrated explanation of how the LEDs

function.

Monitoring the disk shelf ID

When you use the switch on the back of the EXN1000 expansion unit to

change the disk shelf ID, the disk shelf ID display on the front panel blinks

until you power-cycle the EXN1000 expansion unit to make the change take

effect.

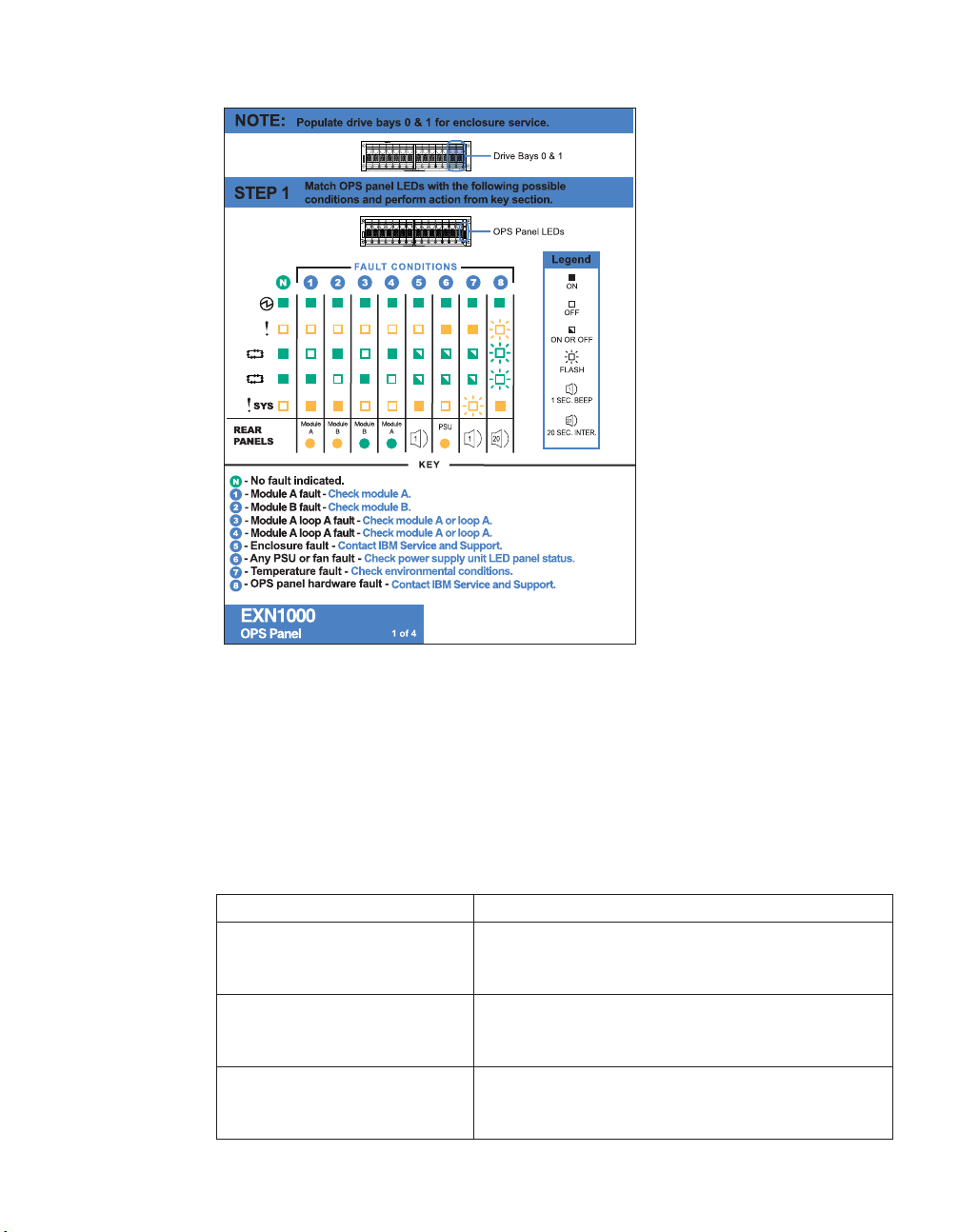

LED status on the front operation panel

The following illustration is of the first sheet of the quick reference cards that

come with your EXN1000 expansion unit. It shows the normal and fault

conditions that the LEDs indicate and recommends a corrective action.

20

Page 51

A

B

Figure 6. LED indications of normal and fault conditions

Front operation panel console error messages

The following error messages appear on your N series storage system console

if an SES element on the front operation panel fails. For information about

replacing an EXN1000 expansion unit, see “Removing an EXN1000 expansion

unit” on page 29.

Table 6. N series storage system error messages

Error message Action required

Temperature sensor

Element 1: failed

The temperature sensor on the front operation panel

failed. Contact IBM customer service to replace the

EXN1000 expansion unit.

Alarm

Element 1: failed

The alarm on the front operation panel failed.

Contact IBM customer service to replace the

EXN1000 expansion unit.

Display

Element 1: failed

The display on the front operation panel failed.

Contact IBM customer service to replace the

EXN1000 expansion unit.

Chapter 3. Monitoring the EXN1000 expansion unit 21

Page 52

Monitoring the AT-FCX modules

The AT-FCX module has four LEDs. The LEDs indicate whether the module is

functioning normally, or whether there are any problems with the hardware.

You can also identify any hardware failure associated with the module from

the error messages displayed on your N series storage system console.

This section also describes the different types of messages that appear on the

N series storage system console in response to a command monitoring the

AT-FCX.

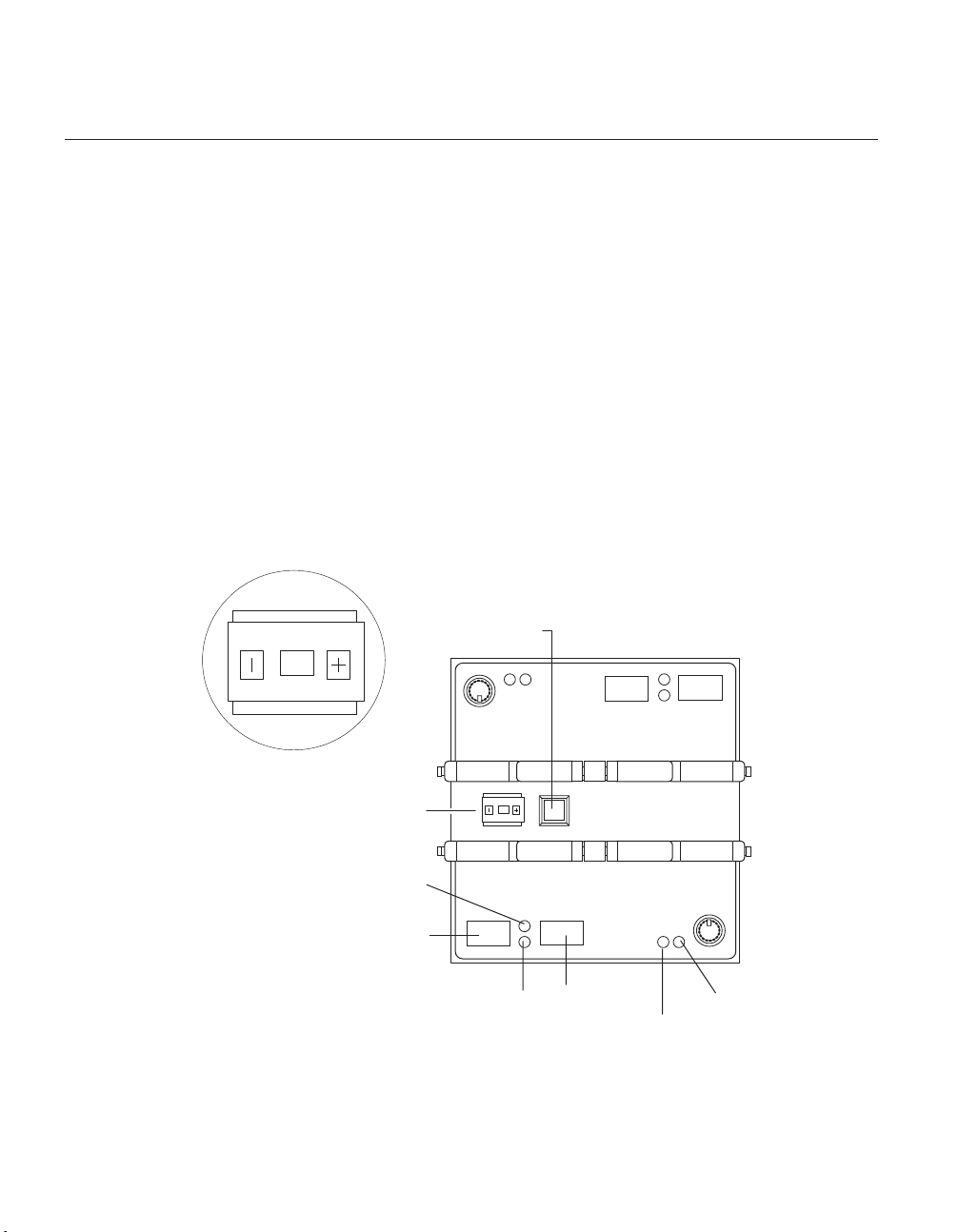

Location of the module LEDs

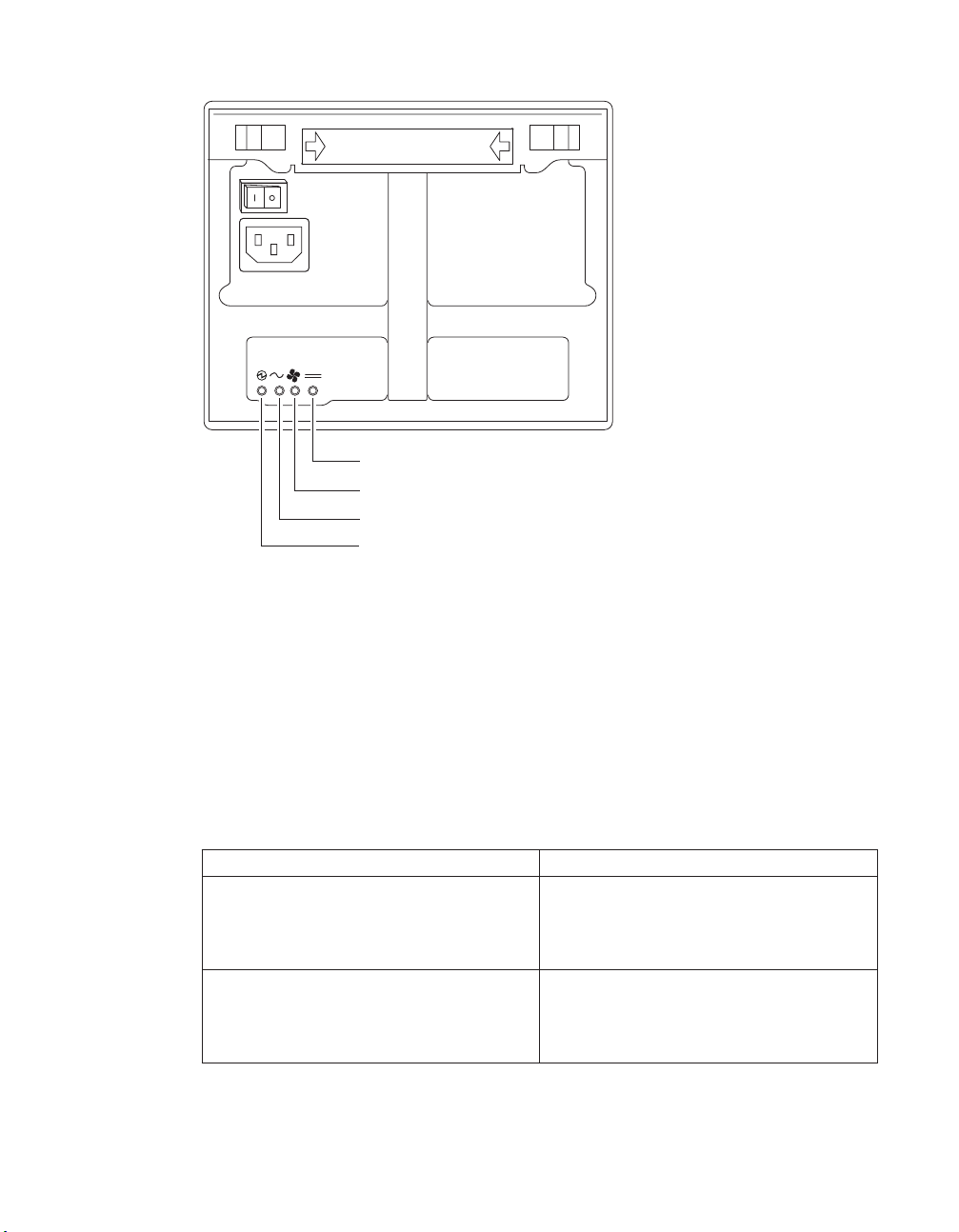

The modules are in the middle of the back of the EXN1000 expansion unit.

The following illustration shows the location of the LEDs for an AT-FCX. See

“LED status on the AT-FCX” on page 23 for an illustrated explanation of the

LED functions.

Shelf ID - close-up view

22

Mute button

2

Shelf ID

Out port activity LED

Out port

In port activity LED

Figure 7. Location of the LEDs for an AT-FCX

2

In port

Ready LED

Fault LED

Page 53

Note: Because module A on the EXN1000 expansion unit is inverted, the

location of the module A LEDs is the inverse of what is shown in the

preceding illustrations.

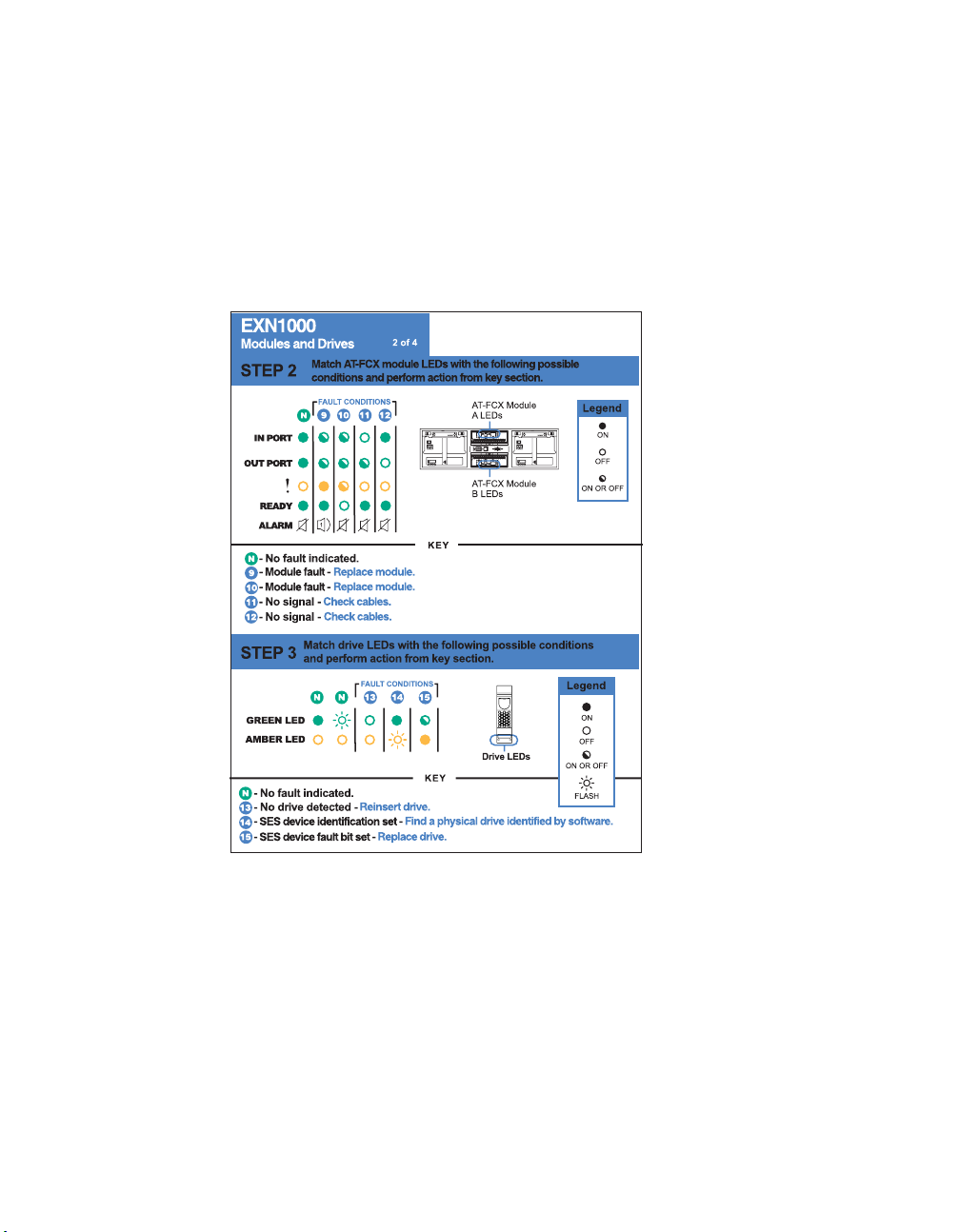

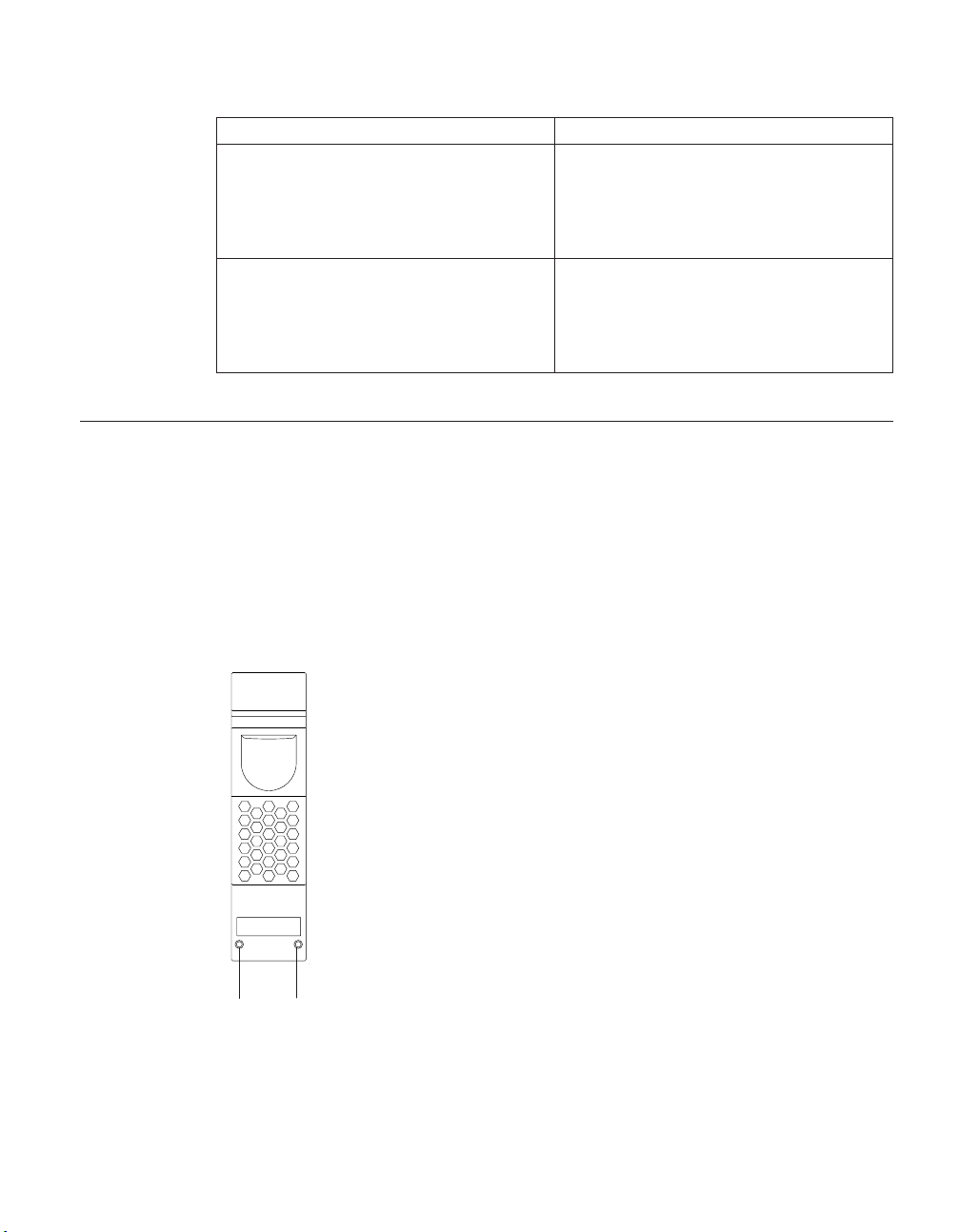

LED status on the AT-FCX

The following illustration is of the second sheet of the quick reference cards

that come with your EXN1000 expansion unit.

Figure 8. EXN1000 rear panel quick reference card

Note: The rest of the second sheet of the quick reference card identifies the

LED status conditions for the ATA disks.

AT-FCX console error messages

The following error messages appear on your N series storage system console

if an SES element on the AT-FCX fails. For information about replacing the

AT-FCX, see “Replacing an AT-FCX module” on page 35.

Chapter 3. Monitoring the EXN1000 expansion unit 23

Page 54

Table 7. AT-FCX console error messages

Error message Action required

Temperature sensor 2:

Contact IBM customer service to replace the module.

failed

Temperature sensor 3:

failed

SES electronics Element 1:

component is from a

This configuration is unsupported. Contact IBM

customer service to replace the module.

different product family

SES electronics

Contact IBM customer service.

Element 1: failed

SES electronics

Element 2: failed

Temperature sensor 2: not

The AT-FCX module on the expansion unit failed.

Contact IBM customer service to replace the module.

Contact IBM customer service.

installed or failed

Environmental sensor 3: not

installed or failed

SES electronics Element 1:

not installed or failed

Vendor-specific Element 1:

not installed or failed

SES electronics

Element 2: not

installed or failed

Communication with the temperature sensor on the

AT-FCX module failed. Replace the AT-FCX module as

described in “Hot-swapping a module” on page 37.

Vendor-specific

Element 2: not

installed or failed