Page 1

ERserver

Hardware Maintenance Manual

xSeries 360 Type 8686

Page 2

Page 3

ER s e r v e r

Hardware Maintenance Manual

xSeries 360 Type 8686

Page 4

©

US

Note:

Before using this information and the product it supports, be sure to read the general information under “Notices” on

page 178.

Eighth Edition August 2004

The following paragraph does not apply to the United Kingdom or any country where such provisions are

inconsistent with local law:

INTERNATIONAL BUSINESS MACHINES CORPORATION PROVIDES THIS PUBLICATION “AS IS” WITHOUT

WARRANTY OF ANY KIND, EITHER EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. Some states do not allow

disclaimer of express or implied warranties in certain transactions, therefore, this statement may not apply to you.

This publication could include technical inaccuracies or typographical errors. Changes are periodically made to the

information herein; these changes will be incorporated in new editions of the publication. IBM may make

improvements and/or changes in the product(s) and/or the program(s) described in this publication at any time.

This publication was developed for products and services offered in the United States of America. IBM may not offer

the products, services, or features discussed in this document in other countries, and the information is subject to

change without notice. Consult your local IBM representative for information on the products, services, and features

available in your area.

Requests for technical information about IBM products should be made to your IBM reseller or IBM marketing

representative.

Copyright International Business Machines Corporation 2003. All rights reserved.

Government Users Restricted Rights – Use, duplication or disclosure restricted by GSA ADP Schedule Contract

with IBM Corp.

Page 5

Be

©

About this manual

This manual contains diagnostic information, a Symptom-to-FRU index, service

information, error codes, error messages, and configuration information for the IBM

Eserver xSeries

®

Important: This manual is intended for trained servicers who are familiar with IBM

xSeries products.

Important safety information

sure to read all caution and danger statements in this book before performing

any of the instructions.

Leia todas as instruções de cuidado e perigo antes de executar qualquer operação.

Prenez connaissance de toutes les consignes de type Attention et

Danger avant de procéder aux opérations décrites par les instructions.

Lesen Sie alle Sicherheitshinweise, bevor Sie eine Anweisung ausführen.

®

360, Type 8686.

Online support

Accertarsi di leggere tutti gli avvisi di attenzione e di pericolo prima di effettuare

qualsiasi operazione.

Lea atentamente todas las declaraciones de precaución y peligro ante de llevar a

cabo cualquier operación.

WARNING: Handling the cord on this product or cords associated with accessories

sold with this product, will expose you to lead, a chemical known to the State of

California to cause cancer, and birth defects or other reproductive harm. Wash

hands after handling.

ADVERTENCIA: El contacto con el cable de este producto o con cables de

accesorios que se venden junto con este producto, pueden exponerle al plomo, un

elemento químico que en el estado de California de los Estados Unidos está

considerado como un causante de cancer y de defectos congénitos, además de

otros riesgos reproductivos. Lávese las manos después de usar el producto.

You can download the most current diagnostic, BIOS flash, and device driver files

from http://www.ibm.com/pc/support on the World Wide Web.

Copyright IBM Corp. 2003

iii

Page 6

iv

Hardware Maintenance Manual: xSeries 360 Type 8686

Page 7

©

Contents

About this manual . . . . . . . . . . . . . . . . . . . . . . . iii

Important safety information . . . . . . . . . . . . . . . . . . . . iii

Online support . . . . . . . . . . . . . . . . . . . . . . . . . iii

General checkout . . . . . . . . . . . . . . . . . . . . . . . .1

Features overview . . . . . . . . . . . . . . . . . . . . . . . .3

Features and specifications . . . . . . . . . . . . . . . . . . . . .4

Notices and statements used in this book . . . . . . . . . . . . . . .4

What the xSeries 360 offers . . . . . . . . . . . . . . . . . . . .5

Reliability, availability, and serviceability . . . . . . . . . . . . . . . .7

Controls and indicators . . . . . . . . . . . . . . . . . . . . . .8

Operator information panel . . . . . . . . . . . . . . . . . . . . .9

Turning on the server . . . . . . . . . . . . . . . . . . . . .10

Turning off the server . . . . . . . . . . . . . . . . . . . . .11

Standby mode . . . . . . . . . . . . . . . . . . . . . . . .12

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . .13

Diagnostic tools overview . . . . . . . . . . . . . . . . . . . . .13

POST . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Error logs . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Small computer systems interface (SCSI) messages . . . . . . . . . . .14

Diagnostic programs and error messages . . . . . . . . . . . . . . .15

Starting the diagnostic programs . . . . . . . . . . . . . . . . .15

Error code format . . . . . . . . . . . . . . . . . . . . . . .16

Text message format . . . . . . . . . . . . . . . . . . . . . .16

Viewing the test log . . . . . . . . . . . . . . . . . . . . . .17

Viewing the System Event/Error log . . . . . . . . . . . . . . . .17

Diagnostic error messages . . . . . . . . . . . . . . . . . . .17

Recovering the BIOS code . . . . . . . . . . . . . . . . . . . .18

Power supply LEDs . . . . . . . . . . . . . . . . . . . . . . .19

Level 2 Light Path Diagnostics . . . . . . . . . . . . . . . . . . .19

Level 2 diagnostic panel LEDs . . . . . . . . . . . . . . . . . .20

Level 2 Light Path troubleshooting . . . . . . . . . . . . . . . . .21

Power checkout . . . . . . . . . . . . . . . . . . . . . . . .22

Error symptoms . . . . . . . . . . . . . . . . . . . . . . . .22

Ethernet controller troubleshooting . . . . . . . . . . . . . . . . . .22

Battery replacement . . . . . . . . . . . . . . . . . . . . . . .23

Configuration . . . . . . . . . . . . . . . . . . . . . . . . .27

Using the Configuration/Setup Utility . . . . . . . . . . . . . . . . .28

Starting the Configuration/Setup Utility . . . . . . . . . . . . . . .28

Configuration/Setup Utility main menu . . . . . . . . . . . . . . .28

Using passwords . . . . . . . . . . . . . . . . . . . . . . . .32

Power-on password . . . . . . . . . . . . . . . . . . . . . .32

Administrator password . . . . . . . . . . . . . . . . . . . . .33

Remote-control security settings . . . . . . . . . . . . . . . . .34

Using the SCSISelect utility program . . . . . . . . . . . . . . . . .34

Starting the SCSISelect utility program . . . . . . . . . . . . . . .34

SCSISelect menu . . . . . . . . . . . . . . . . . . . . . . .35

PXE Boot Agent Utility program . . . . . . . . . . . . . . . . . . .36

Starting the PXE Boot Agent Utility program . . . . . . . . . . . . .36

PXE Boot Agent Utility menu . . . . . . . . . . . . . . . . . . .36

Copyright IBM Corp. 2003

v

Page 8

vi

ServeRAID configuration program . . . . . . . . . . . . . . . . . .37

Configuring the Ethernet controller . . . . . . . . . . . . . . . . . .37

Remote Supervisor Adapter . . . . . . . . . . . . . . . . . . . .38

Remote Supervisor Adapter features . . . . . . . . . . . . . . . .38

Setup requirements . . . . . . . . . . . . . . . . . . . . . .38

Using the documentation . . . . . . . . . . . . . . . . . . . .39

Cabling and configuring the Remote Supervisor Adapter . . . . . . . . .39

Configuring the adapter . . . . . . . . . . . . . . . . . . . . .41

Using the ASM interconnect network . . . . . . . . . . . . . . . .50

Using the ServerGuide CDs . . . . . . . . . . . . . . . . . . .57

Features at a glance . . . . . . . . . . . . . . . . . . . . . . .58

Setup and configuration overview . . . . . . . . . . . . . . . . . .58

System partition . . . . . . . . . . . . . . . . . . . . . . . .60

Typical NOS Installation . . . . . . . . . . . . . . . . . . . . .60

Setting up or updating multiple servers . . . . . . . . . . . . . . . .60

Installing the NOS without ServerGuide . . . . . . . . . . . . . . . .61

Additional programs included with ServerGuide . . . . . . . . . . . . .61

Installing components . . . . . . . . . . . . . . . . . . . . .63

Major components of the xSeries 360 server . . . . . . . . . . . . . .64

Internal connector and LED locations . . . . . . . . . . . . . . . . .65

System board locations . . . . . . . . . . . . . . . . . . . . .65

Level 2 diagnostic and system board LEDs . . . . . . . . . . . . .68

Memory board locations . . . . . . . . . . . . . . . . . . . .70

Remote Supervisor Adapter locations . . . . . . . . . . . . . . .71

Before you begin . . . . . . . . . . . . . . . . . . . . . . . .71

System reliability considerations . . . . . . . . . . . . . . . . .71

Working inside the server with the power on . . . . . . . . . . . . .72

Internal component locations . . . . . . . . . . . . . . . . . . . .72

Removing the server top cover and bezel . . . . . . . . . . . . . .72

Working with adapters . . . . . . . . . . . . . . . . . . . . .73

Internal drive installation . . . . . . . . . . . . . . . . . . . .79

Memory modules . . . . . . . . . . . . . . . . . . . . . . .84

Microprocessor installation . . . . . . . . . . . . . . . . . . .86

VRM replacement . . . . . . . . . . . . . . . . . . . . . . .89

Hot-swap power supply installation . . . . . . . . . . . . . . . .90

Hot-swap fan replacement . . . . . . . . . . . . . . . . . . . .92

Installing the serial cable . . . . . . . . . . . . . . . . . . . .93

Locking PCI slot 6 . . . . . . . . . . . . . . . . . . . . . . .94

Enabling the serial port . . . . . . . . . . . . . . . . . . . . .95

Completing the installation . . . . . . . . . . . . . . . . . . . .95

Connecting external options . . . . . . . . . . . . . . . . . . . .97

Input/output ports . . . . . . . . . . . . . . . . . . . . . . .97

Cabling the server . . . . . . . . . . . . . . . . . . . . . . 103

FRU information (service only) . . . . . . . . . . . . . . . . . . 105

Hot-swap drive backplane . . . . . . . . . . . . . . . . . . . . 105

Light path diagnostic card . . . . . . . . . . . . . . . . . . . . 106

Operator panel card . . . . . . . . . . . . . . . . . . . . . . 108

PCI adapter switch card . . . . . . . . . . . . . . . . . . . . . 109

Power supply backplane . . . . . . . . . . . . . . . . . . . . .110

System board/shuttle . . . . . . . . . . . . . . . . . . . . . .110

Replacing the serial port cable . . . . . . . . . . . . . . . . . . .113

Symptom-to-FRU index . . . . . . . . . . . . . . . . . . . . .115

Hardware Maintenance Manual: xSeries 360 Type 8686

Page 9

No

Beep symptoms . . . . . . . . . . . . . . . . . . . . . . . .115

beep symptoms . . . . . . . . . . . . . . . . . . . . . . .117

Level 2 light path LED errors . . . . . . . . . . . . . . . . . . .118

Diagnostic error codes . . . . . . . . . . . . . . . . . . . . . 120

Error symptoms . . . . . . . . . . . . . . . . . . . . . . . . 127

ServerGuide error symptoms . . . . . . . . . . . . . . . . . . . 131

SMI Handler messages . . . . . . . . . . . . . . . . . . . . . 132

Power supply LED errors . . . . . . . . . . . . . . . . . . . . . 133

POST error codes . . . . . . . . . . . . . . . . . . . . . . . 134

ServeRAID . . . . . . . . . . . . . . . . . . . . . . . . . . 139

SCSI error codes . . . . . . . . . . . . . . . . . . . . . . . 139

Temperature error messages . . . . . . . . . . . . . . . . . . . 139

Fan error messages . . . . . . . . . . . . . . . . . . . . . . 140

Power error messages . . . . . . . . . . . . . . . . . . . . . 140

System shutdown . . . . . . . . . . . . . . . . . . . . . . . 141

Voltage related system shutdown . . . . . . . . . . . . . . . . . 141

Temperature related system shutdown . . . . . . . . . . . . . . . 141

DASD checkout . . . . . . . . . . . . . . . . . . . . . . . . 141

Processor checkout . . . . . . . . . . . . . . . . . . . . . . . 142

I2C bus fault messages . . . . . . . . . . . . . . . . . . . . . 142

Undetermined problems . . . . . . . . . . . . . . . . . . . . . 143

Related service information . . . . . . . . . . . . . . . . . . . 145

Safety information . . . . . . . . . . . . . . . . . . . . . . . 145

General safety . . . . . . . . . . . . . . . . . . . . . . . 145

Electrical safety . . . . . . . . . . . . . . . . . . . . . . . 146

Safety inspection guide . . . . . . . . . . . . . . . . . . . . 147

Handling static-sensitive devices . . . . . . . . . . . . . . . . . 148

Grounding requirements . . . . . . . . . . . . . . . . . . . . 148

Safety notices (multilingual translations) . . . . . . . . . . . . . . 149

Problem determination tips . . . . . . . . . . . . . . . . . . . . 178

Notices . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

Trademarks . . . . . . . . . . . . . . . . . . . . . . . . . . 179

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

System . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

Keyboards . . . . . . . . . . . . . . . . . . . . . . . . . . 184

Contents

vii

Page 10

viii

Hardware Maintenance Manual: xSeries 360 Type 8686

Page 11

on

If

A

A

v

v

v

If

in

1.

2. If

3. If

on

4. If

5.

on

6.

7.

©

General checkout

The server diagnostic programs are stored in upgradable read-only memory (ROM)

the system board. These programs are the primary method of testing the major

components of a server. Major components that can be tested include the system

board, Ethernet controller, video controller, RAM, keyboard, mouse (pointing

device), diskette drive, serial ports, hard drives, and parallel port. Not all servers

include all of these items; your hardware might differ. You can also use the

diagnostic programs to test some external devices. See “Diagnostic programs and

error messages” on page 15.

you cannot determine whether a problem is caused by the hardware or by the

software, you can run the diagnostic programs to confirm that the hardware is

working properly.

When you run the diagnostic programs, a single problem might cause several error

messages. When this occurs, work to correct the cause of the first error message.

After the cause of the first error message is corrected, the other error messages

might not occur the next time you run the test.

failed server might be part of a shared DASD cluster (two or more servers

sharing the same external storage device(s)). Prior to running diagnostics, verify

that the failing server is not part of a shared DASD cluster.

server might be part of a cluster if:

The customer identifies the server as part of a cluster.

One or more external storage units are attached to the server and at least one of

the attached storage units is additionally attached to another server or

unidentifiable source.

One or more servers are located near the failing server.

the failing server is suspected to be part of a shared DASD cluster, all diagnostic

tests can be run except diagnostic tests which test the storage unit (DASD residing

the storage unit) or the storage adapter attached to the storage unit.

Notes:

For servers that are part of a shared DASD cluster, run one test at a time in

looped mode. Do not run all tests in looped mode, as this could enable the

DASD diagnostic tests.

multiple error codes are displayed, diagnose the first error code displayed.

the server stops working with a POST error, go to “Symptom-to-FRU index”

page 115.

the server stops working and no error is displayed, go to “Undetermined

problems” on page 143.

For information about power supply problems, see “Power supply LED errors”

page 133.

For safety information, see “Safety information” on page 145.

For intermittent problems, check the error log; see “Error logs” on page 14.

Copyright IBM Corp. 2003

1

Page 12

v

v

v

v

v

v

v

v

v

v

1.

2.

If

If

2

001 IS THE SERVER PART OF A CLUSTER?

YES. Schedule maintenance with the customer. Shut down all servers

related to the cluster. Run storage test.

NO. Go to step 002.

002 IF THE SERVER IS NOT PART OF A CLUSTER:

Turn off the server and all external devices.

Check all cables and power cords.

Set all display controls to the middle position.

Turn on all external devices.

Turn on the server.

Record any POST error messages displayed on the screen. If an error is

displayed, look up the first error in the “POST error codes” on page 134.

Check the diagnostic LED panel system error LED; if on, see “Level 2

Light Path Diagnostics” on page 19.

Check the System Error Log. If the server recorded an error, see

“Symptom-to-FRU index” on page 115.

Start the diagnostic programs. See “Diagnostic programs and error

messages” on page 15.

Check for the following responses:

One beep.

Readable instructions or the Main Menu.

003

DID YOU RECEIVE BOTH OF THE CORRECT RESPONSES?

NO. Find the failure symptom in “Symptom-to-FRU index” on page 115.

YES. Run the diagnostic programs. If necessary, see “Diagnostic programs

and error messages” on page 15.

you receive an error, go to “Symptom-to-FRU index” on page 115.

the diagnostics completed successfully and you still suspect a problem,

see “Undetermined problems” on page 143.

Hardware Maintenance Manual: xSeries 360 Type 8686

Page 13

If

©

Features overview

The IBM Eserver xSeries 360 server, which features IBM X-Architecture

technology, is a high-performance rack model server that can be upgraded to a

symmetric multiprocessing (SMP) server. It is ideally suited for networking

environments that require superior microprocessor performance, efficient memory

management, flexibility, and large amounts of reliable data storage.

Performance, ease of use, reliability, and expansion capabilities are key features of

the server. These design features make it possible for you to customize the

hardware to meet your needs today, while providing flexible expansion capabilities

for the future.

you have access to the World Wide Web, you can obtain up-to-date information

about the server model and other IBM server products at

http://www.ibm.com/eserver/xseries/.

The machine type, model number, and serial number are on the ID labels, one

located on the bezel to the left of the CD-ROM drive and the other at the rear of the

right side, as shown in the following illustration.

Note: The illustrations in this document might differ slightly from your hardware.

ID labels

Copyright IBM Corp. 2003

3

Page 14

v

–

–

v

v

–

–

v

v

v

v

v

v

v

v

v S3

v

v 8 MB

(3 U) v

v

v

v

v

v

v

v

–

–

–

–

–

v

v

v

v

v

v

v

v

–

–

–

–

–

v

v

v

v

–

–

–

–

–

–

–

in

v

v

4

Features and specifications

The following table provides a summary of the features and specifications for the

xSeries 360 server.

Table 1. Features and Specifications

Microprocessor:

®

Intel

™

Xeon

Processor MP (frequency

varies with server model; each MP

processor functions as two logical

processors)

Minimum: two

Maximum: four

v

Level-3 cache size varies with model

100 MHz front-side bus (FSB)

Chipset:

IBM XA-32

™

Chipset with integrated

memory, I/O controller, and remote I/O

controller. Memory:

DDR registered SDRAM DIMMs with

ECC and Chipkill

™™

memory

Minimum: 512 MB

Maximum: 8 GB

Slots: Interleaved, 8 slots

v

standard:

Drives

Slim diskette: 1.44 MB

Slim CD-ROM: 24X-10X IDE

disk drives:

Hard

Slim-high hot-swap drives. (number of

drives and drive capacity vary with

model)

Maximum: Three

™

PCI

Active

expansion slots:

Two 100 MHz/64-bit PCI-X

Four 66 MHz/64-bit PCI-X

Hot-swap

power supplies:

370 W (115-230 V ac)

Minimum: One or two power supplies

are shipped with server, depending on

model

Maximum: Three

Hot-swap cooling:

Six hot-swap fans Video:

Compatible with SVGA 4

Size

Height: 134 mm (5.28 in.)

Depth: 720 mm (28.35 in.)

Width: 440 mm (17.32 in.)

Weight: 25 kg (55 lb) to 31.7 kg (70 lb)

depending upon configuration

Integrated

Light Path Diagnostics

Ultra160 SCSI controller

One 10BASE-T/100BASE-TX Intel

Ethernet controller

Remote Supervisor Adapter (service

processor)

Three universal serial bus ports

v

Keyboard port

Mouse port

Video port

Serial port (uses the serial cable that

comes with the server to provide a serial

connector on the rear of the server in

the position usually occupied by an

adapter in PCI slot 6)

Acoustical

Sound power, idling: 6.3 bel maximum

Sound power, operating: 6.3 bel

maximum

Sound pressure, operating: 47 dBa

maximum

video controller

SDRAM video memory

functions:

™

ASM interconnect (peer-to-peer) port

RXE Expansion port

RXE management port

Ethernet port

Serial port

noise emissions:

Environment:

Air temperature:

Server on: 10° to 35°C (50° to 95°F).

Altitude: 0 to 914 m (3000 ft)

Server on: 10° to 32°C (50° to

89.6°F). Altitude: 914 m (3000 ft) to

2133 m (7000 ft)

Server off: 10° to 43°C (50° to

110°F). Maximum altitude: 2133 m

(7000 ft)

Humidity:

v

Server on: 8% to 80%

Server off: 8% to 80%

output:

Heat

Approximate heat output in British thermal

units (Btu) per hour

Minimum configuration: 1232 Btu (0.36

kilowatts)

Maximum configuration: 3566 Btu (1.045

kilowatts)

Electrical

input:

Sine-wave input (50-60 Hz) required

Input voltage low range:

Minimum: 100 V ac

Maximum: 127 V ac

v

Input voltage high range:

Minimum: 200 V ac

Maximum: 240 V ac

Input kilovolt-amperes (kVA)

v

approximately:

Minimum: 0.08 kVA (ac power

connected, server off)

Minimum: 0.38 kVA (dc power on,

server idle)

Maximum: 1.1 kVA

Notices and statements used in this book

The caution and danger statements used in this book also appear in the multilingual

Safety Information book, provided on the Documentation CD. Each caution and

danger statement is numbered for easy reference to the corresponding statements

the safety book.

The following types of notices and statements are used in this book:

Note: These notices provide important tips, guidance, or advice.

Important: These notices provide information or advice that might help you avoid

inconvenient or problem situations.

Hardware Maintenance Manual: xSeries 360 Type 8686

Page 15

v

to

v

v

v

v

v

v

v

v

Attention: These notices indicate possible damage to programs, devices, or

data. An attention notice is placed just before the instruction or situation in which

damage could occur.

Caution: These statements indicate situations that can be potentially hazardous

you. A caution statement is placed just before the description of a potentially

hazardous procedure step or situation.

Danger: These statements indicate situations that can be potentially lethal or

extremely hazardous to you. A danger statement is placed just before the

description of a potentially lethal or extremely hazardous procedure step or

situation.

What the xSeries 360 offers

The design of the server takes advantage of advancements in symmetric

multiprocessing (SMP), data storage, disk-array technologies, and memory

management. The server combines:

X-Architecture technology

X-Architecture technology is an IBM design blueprint that takes full advantage of

existing IBM technologies to build powerful, scalable, and reliable Intel

processor-based servers.

For more information about X-Architecture technology, go to the Web at

http://www.pc.ibm.com/us/eserver/xseries/xarchitecture/index.html.

Impressive performance using an innovative approach to SMP

The server supports up to four Intel Xeon Processor MP

server comes with at least one microprocessor installed; you can install additional

processors to enhance performance and provide SMP capability.

Large data-storage and hot-swap capabilities

The xSeries 360 server supports up to three 26 mm (1-inch) slim-high 3.5-inch

hot-swap hard disk drives in the hot-swap bays. This hot-swap feature enables

you to remove and replace hard disk drives without turning off the server.

Active PCI-X (hot-plug) adapter capabilities

The server has six hot-plug PCI-X slots for PCI or PCI-X adapters. With

operating-system support, you can replace failing hot-plug PCI/PCI-X adapters

without turning off the server. If the hot-add feature is supported by both the

operating system and a PCI/PCI-X adapter, you can also add such PCI/PCI-X

adapters in these slots without turning off the server.

Redundant hot-swap cooling and redundant hot-swap power capabilities

The fans in the server can operate at variable speeds so that if one fan fails, the

remaining fans increase in speed to enable continued operation until the failing

fan is replaced. You can replace a failing fan without turning off the server.

The server supports up to three 370-watt power supplies. Multiple hot-swap

370-watt power supplies ensure redundancy and hot-swap capability for a typical

configuration.

Large system memory

The memory bus in the server supports up to 8 GB of system memory. The

memory controller provides error correcting code (ECC) support for up to eight

industry-standard, 2.5 V, 168-pin, 16-byte, PC1600 registered DDR SDRAM dual

inline memory modules (DIMMs). The memory controller also provides Chipkill

Memory protection. Chipkill Memory protection is a technology that protects the

server from a single chip failure on a DIMM.

™

microprocessors. The

Features overview

5

Page 16

a

v

v

v

up to

v

v

on

6

v

Light Path Diagnostics

Light Path Diagnostics provide LEDs to assist in isolating problems with the

server. An LED on the operator information panel is lit if an unusual condition or

problem occurs. If this happens, you can look at the LEDs visible through a

special cutout in the cover and isolate the cause. Under some circumstances,

you might need to remove the cover and view LEDs on the system board to

pinpoint the source of a problem.

Systems-management capabilities

The server comes with a Remote Supervisor Adapter installed. This adapter, in

conjunction with the systems-management software provided with the server,

enables you to manage the functions of the server both locally and remotely. The

Remote Supervisor Adapter also provides system monitoring, event recording,

and dial-out alert capability.

Integrated network environment support

The server comes with an Ethernet controller integrated into the system board.

This Ethernet controller has an interface for connecting to 10-Mbps or 100-Mbps

networks. The server automatically selects between 10BASE-T and

100BASE-TX. The controller provides full-duplex (FDX) capability, which enables

simultaneous transmission and reception of data on the Ethernet local area

network (LAN).

Remote expansion enclosure

The addition of an optional, IBM RXE-100 Remote Expansion Enclosure provides

twelve additional hot-plug PCI/PCI-X slots for PCI or PCI-X adapters. The

enclosure can be managed through the Remote Supervisor Adapter, enabling

remote operation over a network or a modem.

Redundant network adapter

The addition of an optional, redundant network adapter provides a failover

capability to a secondary Ethernet connection. If a problem occurs with the

primary Ethernet connection, all Ethernet traffic associated with this primary

connection is automatically switched to the redundant network adapter. If the

appropriate device drivers are installed, this switching occurs without data loss

and without user intervention.

IBM ServerGuide

The ServerGuide

™

CDs

™

CDs that are included with the server provide programs to

help you set up the server and install the network operating system (NOS). The

ServerGuide program detects the installed hardware options and provides the

correct configuration programs and device drivers. In addition, the ServerGuide

CDs include a variety of application programs for the server.

Note: The latest level of basic input/output system (BIOS) code for the server is

available through the World Wide Web. See “Recovering the BIOS code”

For more information about the ServerGuide CDs, see “Using the ServerGuide

CDs” on page 57.

server is designed to be cost-effective, powerful, and flexible. It uses peripheral

The

component interconnect-extended (PCI-X) bus architecture to provide compatibility

with a wide range of existing hardware devices and software applications.

The server meets stringent worldwide certifications for power, electromagnetic

compatibility (EMC), and safety.

Hardware Maintenance Manual: xSeries 360 Type 8686

page 18 for more information.

Page 17

v

v

v

v

v

v

v

v

v

v

v

v

v

v

v

v

v

v

v

v

v

v

v

v

v

v

v

v

v

Reliability, availability, and serviceability

Three of the most important features in server design are reliability, availability, and

serviceability (RAS). These factors help to ensure that the integrity of the data

stored on the server is preserved, that the server is available when you want to use

it, and that should a failure occur, you can easily diagnose and repair the failure

with minimal inconvenience.

The following is an abbreviated list of the RAS features that the server supports:

ECC memory, L3 cache, and front side buses (FSBs)

Parity checking on the small computer system interface (SCSI) bus

Advanced Configuration and Power Interface (ACPI) power management

Power-on self-test (POST)

Systems-management monitoring through Intra-Integrated Circuit (I2C) bus

Light Path Diagnostics

Automatic error retry and recovery

Automatic restart after a power failure

Built-in temperature, fan, and voltage monitoring

Chipkill Memory protection

Hot-swap cooling with fan speed-sensing capability

Hot-swap and redundant power supplies

Hot-swap hard disk drives

Hot-plug (Active) PCI-X adapter slots

Menu-driven setup, system configuration, SCSISelect configuration, and

diagnostic programs

Memory scrubbing and Predictive Failure Analysis

time)

Microcode and diagnostic program levels available

System-management software and LANDesk

Network adapter failover support

Remote Supervisor Adapter to enable remote server management

Remote Connect

Remote system problem-determination support

Upgradable POST/BIOS, diagnostics, and Remote Supervisor Adapter microcode

Wake on LAN

Backup BIOS switching by means of a flash ROM page swap jumper

Error codes and messages

Microprocessor serial number access

Cable presence detection for standard internal cables

Vital product data (VPD) for microprocessors, system and memory boards,

memory DIMMs, power supplies, hot-swap-drive backplane, and power supply

backplane

™

®

and Alert on LAN

™

capability

®

enabled

™®

(PFA) (background and real

Features overview

7

Page 18

AC

DC

to

on

is

is

8

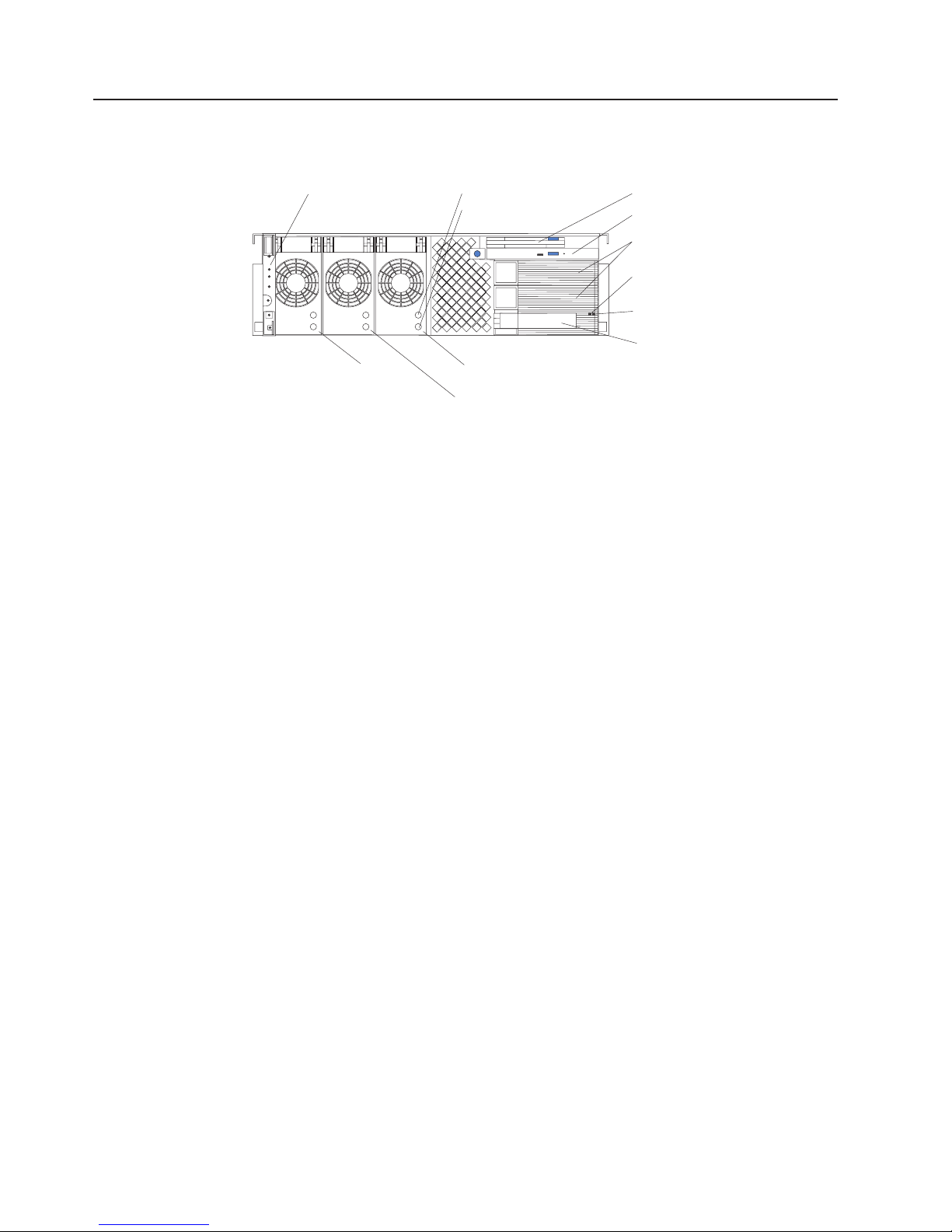

Controls and indicators

The following illustration shows the controls and indicators on the front of the

server.

Operator information

panel

AC LED

DC LED

Diskette drive

CD-ROM drive

Hard disk drive

filler panels

Activity

LED

(green)

Status

LED

(amber)

Hard disk drive

Power

supply 1

Power

supply 3

Power

supply 2

Operator information panel: This panel, also known as the front LED panel,

contains controls, indicators, and one of the three USB ports. See “Operator

information panel” on page 9 for details.

LED: Each hot-swap power supply has an ac power LED to indicate that ac

power is available to the power supply.

LED: Each hot-swap power supply has a dc power LED to indicate that the

power supply is active.

Diskette drive: The server contains one standard 3.5 diskette drive with an LED to

indicate when it is active.

CD-ROM drive: The server contains one standard IDE CD-ROM drive with an LED

indicate when it is active.

Hard disk drive filler panels: A filler panel is used to cover empty hard disk drive

bays. A filler panel must be installed in each empty bay to ensure proper system

cooling.

Activity LED: Each hot-swap hard disk drive has an activity LED, which flashes if

the drive is being accessed.

Status LED: Each hot-swap hard-disk drive has a status LED. If this amber LED is

continuously, the drive has failed. If an optional IBM ServeRAID

™

adapter is

installed in the server and the LED flashes slowly (one flash per second), the drive

being rebuilt. If the LED flashes rapidly (three flashes per second), the controller

identifying the drive.

Hard disk drive: The server supports a maximum of three hot-swap hard disk

drives.

Power supplies 1, 2, and 3: The server comes with a minimum of one hot-swap

power supply and supports a maximum of three hot-swap power supplies.

Hardware Maintenance Manual: xSeries 360 Type 8686

Page 19

The following illustration shows the indicators on the rear of the server.

Remote Supervisor

Adapter Ethernet port

Ethernet TX/RX LEDs

Ethernet link LEDs

Remote Supervisor

Adapter fault

LED

(amber)

Remote Supervisor

Adapter power LED

(green)

Ethernet port

Ethernet Link LEDs: These LEDs (one for the Remote Supervisor Adapter, one for

the network) indicate that the related Ethernet link is operational.

Ethernet TX/RX LEDs: These LEDs (one for the Remote Supervisor Adapter, one

for the network) indicate that activity is taking place on the related network.

Remote Supervisor Adapter Ethernet port: This port enables you to manage the

server from a remote location.

Remote Supervisor Adapter fault LED: This LED indicates that the Remote

Supervisor Adapter has failed.

Remote Supervisor Adapter power LED: This LED indicates that power is being

supplied to the Remote Supervisor Adapter.

Ethernet port: This port enables you to connect the server to a network.

Operator information panel

The following illustration shows the controls, indicators, and USB port on the

operator information panel (also known as the front LED panel).

USB port

SCSI bus activity LED

Information LED

Fault LED

USB port: This port enables you to attach a USB device to the front of the server.

Reset button

Power-control button

Power LED

Features overview

9

Page 20

it

to

or

1.

2.

to

3.

10

SCSI bus activity LED: This green LED is on when there is activity on the SCSI

bus.

Information LED: This amber light is on if the server power supplies are

nonredundant or some other noncritical event has occurred. See the LEDs on the

Level 2 diagnostic LED panel or on the system board for specific error information.

For details, see “Level 2 diagnostic and system board LEDs” on page 68.

Fault LED: This amber LED is on if a system error has occurred. See the LEDs on

the Level 2 diagnostic LED panel or on the system board for specific error

information. For details, see “Level 2 diagnostic and system board LEDs” on page

68.

Reset button: Press this button to reset the server and run the power-on self-test

(POST).

Power-control button: If the server is in operational mode, press this button to put

into standby mode. If the server is in standby mode, press this button to restore it

operational mode. See “Turning on the server” and “Turning off the server” on

page 11 for more information about applying and removing external power to the

server.

Power LED: This green LED is on if ac and dc power are present in the server. If

this LED is flashing, the server is in standby mode (ac power is present, but the

power supplies are turned off). If this LED is off, either ac power, all power supplies,

the light has failed.

Note: If this LED is off, it does not mean that there is no electrical power present in

the server. The LED might be burned out. To remove all electrical current

from the server, you must unplug the server power cords from the electrical

outlets.

Turning on the server

Turning on the server refers to the act of plugging the server power cords into the

power source and pressing the power-control button. After you install the network

operating system in the server, this typically causes the operating system to start.

Complete the following steps to turn on the server.

Turn on all external devices, such as the monitor.

Note: After you plug the power cords into the power source, wait 30 seconds

Plug the server power cords into the power source.

before pressing the power-control button on the operator information

panel. During this time, the Remote Supervisor Adapter is initializing and

the power-control button does not respond. The power LED on the

information panel blinks, indicating that ac power is present in the server.

Note: Plugging the power cords into the power source might cause the server

Wait 30 seconds; then, press the power-control button on the operator

information panel. The power LED comes on and the power-on self-test (POST)

begins.

Hardware Maintenance Manual: xSeries 360 Type 8686

start automatically. This is an acceptable action.

Page 21

on

If

a

1.

If the server is turned on and a power failure occurs, it restarts automatically when

power is restored. You can turn on the server remotely by means of the Remote

Supervisor Adapter.

When you start the server for the first time after you add or remove an internal

option or an external SCSI device, you might see a message telling you that the

configuration has changed. The Configuration/Setup Utility program automatically

starts so that you can save the new configuration information. See “Configuration”

page 27 for details.

Some options have device drivers that you need to install. See the documentation

that comes with the option for information about installing any required device

drivers.

The server comes with at least one microprocessor installed on the system board. If

you have installed one or more additional microprocessors, the server can now

operate as an SMP server. Therefore, you might need to upgrade the operating

system to support SMP. See “Using the ServerGuide CDs” on page 57 and the

operating system documentation for additional information.

the server has a ServeRAID adapter installed and you have installed or removed

hard disk drive, see the documentation that comes with the ServeRAID adapter

for information about reconfiguring the disk arrays.

Turning off the server

Turning off the server refers to the act of stopping the operating system, pressing

the power-control button, and disconnecting the server power cords from the power

source.

Statement 5:

CAUTION:

The power control button on the device and the power switch on the power

supply do not turn off the electrical current supplied to the device. The device

also might have more than one power cord. To remove all electrical current

from the device, ensure that all power cords are disconnected from the power

source.

2

1

See the operating system documentation for the proper procedure to shut down the

operating system before turning off the server. Each operating system is different.

Some allow an immediate shutdown; others require an orderly shutdown procedure.

Complete the following steps to turn off the server:

Press the power-control button on the operator information panel. This places

the server in standby mode. The power LED on the operator information panel

blinks. This does not remove all power from the server.

Features overview

11

Page 22

2.

1.

2.

12

Standby mode

Note: After doing this, wait at least 30 seconds before pressing the

power-control button to turn on the server again.

Disconnect the server power cords from the power source.

Note: Wait approximately 15 seconds after disconnecting the power cords for

the server to stop running. The power LED on the operator information

panel will stop blinking.

Standby mode refers to the condition in which the server operating system is not

running and all core logic is shut down except for the Remote Supervisor Adapter.

Complete the following steps to put the server into standby mode:

See the operating system documentation for the proper procedure to shut down

the operating system.

Note: Each operating system is different. Read all the documentation about

shutting down the operating system before continuing.

Press the power-control button on the front of the server.

can put the server into standby mode remotely by means of the Remote

You

Supervisor Adapter.

Hardware Maintenance Manual: xSeries 360 Type 8686

Page 23

If

v

14

v

v

of

©

Diagnostics

This chapter provides basic troubleshooting information to help you resolve some

common problems that might occur while setting up the server.

you cannot locate and correct the problem using the information in this chapter,

see “Symptom-to-FRU index” on page 115 for more information.

Diagnostic tools overview

The following tools are available to help you identify and resolve hardware-related

problems:

POST beep codes, error messages, and error logs

The power-on self-test (POST) generates beep codes and messages to indicate

successful test completion or the detection of a problem. See “POST” on page

for more information.

Diagnostic programs and error messages

The server diagnostic programs are stored in upgradable read-only memory

(ROM) on the system board. These programs are the primary method of testing

the major components of the server. See “Diagnostic programs and error

messages” on page 15 for more information.

Level 2 Light Path Diagnostics

The server has light-emitting diodes (LEDs) to help you identify problems with

server components. By following the light path, you can quickly identify the type

problem that occurred. The light path begins with the LEDs on the operator

information panel. See “Level 2 Light Path Diagnostics” on page 19 for more

information.

Copyright IBM Corp. 2003

13

Page 24

If

If

on

1. If

2. A

to

v

v

If

v A

v An

v

v An

v A

v An

v A

14

POST

When you turn on the server, it performs a series of tests to check the operation of

server components and some of the options that are installed in the server. This

series of tests is called the power-on self-test, or POST.

POST finishes without detecting any problems, a single beep sounds, and the first

screen of the operating system or application program appears.

POST detects a problem, more than one beep sounds, and an error message

appears on the screen. See “Beep symptoms” on page 115 and “POST error codes”

page 134 for more information.

Notes:

you have a power-on password or administrator password set, you must type

the password and press Enter, when prompted, before POST will continue.

single problem might cause several error messages. When this occurs, work

correct the cause of the first error message. After you correct the cause of

the first error message, the other error messages usually will not occur the next

time you run the test.

Error logs

The POST error log contains the three most recent error codes and messages that

the system generated during POST. The System Error log contains error messages

that were issued during POST and all system status messages from the Remote

Supervisor Adapter.

You can view the contents of the System Error log from either the

Configuration/Setup Utility program or from the diagnostic programs:

Start the Configuration/Setup Utility program; then, select Error Logs from the

main menu; then, select either Post Error Log or System Event/Error Log. See

“Starting the Configuration/Setup Utility” on page 28 for details.

Start the diagnostic programs; select Hardware Info from the top of the

diagnostic programs screen; select System Error Log from the list that appears;

then, follow the instructions on the screen. See “Starting the diagnostic

programs” on page 15 for details.

Small computer systems interface (SCSI) messages

you receive a SCSI error message while running the SCSISelect Utility program,

one or more of the following might be causing the problem:

failing SCSI device (adapter, drive, controller)

improper SCSI configuration

Duplicate SCSI IDs in the same SCSI chain

improperly installed SCSI terminator

defective SCSI terminator

improperly installed cable

defective cable

Hardware Maintenance Manual: xSeries 360 Type 8686

Page 25

v

v

v

v

on

be

To

1.

2.

If a

3.

4.

a. If

b.

c. If

d.

To solve the problem, verify that:

The external SCSI devices are turned on. You must turn on all external SCSI

devices before turning on the server.

The cables for all external SCSI devices are connected correctly.

The last device in each SCSI chain is terminated properly.

The SCSI devices are configured correctly.

you have verified these items and the problem remains, run the diagnostic

If

programs to obtain additional information about the failing device.

Diagnostic programs and error messages

The server diagnostic programs are stored in upgradable read-only memory (ROM)

the system board. These programs are the primary method of testing the major

components of the server.

Diagnostic error messages indicate that a problem exists; they are not intended to

used to identify a failing part. Troubleshooting and servicing of complex

problems that are indicated by error messages should be performed by trained

service personnel.

Sometimes the first error to occur causes additional errors. In this case, the server

displays more than one error message. Always follow the suggested action

instructions for the first error message that appears.

Starting the diagnostic programs

start the diagnostic programs:

Turn on the server and watch the screen.

When the message F2 for Diagnostics appears, press F2.

power-on password is set, the server prompts you for it. Type the power-on

password, and press enter.

When the Diagnostic Programs screen appears, select either Extended or

Basic from the top of the screen.

Select the test that you want to run from the list that appears; then, follow the

instructions on the screen.

Notes:

the server stops during testing and you cannot continue, restart the server

and try running the diagnostic programs again. If the problem remains, flash

the server with the latest diagnostics code and BIOS, and then run the test

again. If the problem remains, see “Undetermined problems” on page 143.

The keyboard and mouse (pointing device) tests assume that a keyboard

and mouse are attached to the server.

you run the diagnostic programs with no mouse attached to the server,

you will not be able to navigate between test categories using the Next Cat

and Prev Cat buttons. All other functions that are provided by

mouse-selectable buttons are also available using the function keys.

You can test the USB keyboard by using the regular keyboard test. The

regular mouse test can test a USB mouse. Also, you can run the USB

interface test only if there are no USB devices attached.

Diagnostics

15

Page 26

f.

is

is

is

cc is

is

16

the diagnostic programs do not detect any hardware errors but the problem

If

remains during typical server operations, a software error might be the cause. If you

suspect a software problem, refer to the information that comes with the software

package.

Error code format

This section shows the format of the error codes that might appear in the detailed

test log and summary log when running the diagnostic programs.

e.

You can view server configuration information (such as system configuration,

memory contents, interrupt request (IRQ) use, direct memory access (DMA)

use, device drivers, and so on) by selecting Hardware Info from the top of

the screen.

You can press F1 while running the diagnostic programs to obtain Help

information. You also can press F1 from within a help screen to obtain online

documentation from which you can select different categories. To exit from

the help information and return to where you left off, press Esc.

The error code format is as follows:

fff-ttt-iii-date-cc-text message

where:

fff

ttt

iii

date is the date that the diagnostic test was run and the error recorded.

text message

Text message format

This section shows the format of the diagnostic text messages that might appear in

the detailed test log and summary log when running the diagnostic programs.

The diagnostic text message format is as follows:

Function Name: Result (test specific string)

the three-digit function code that indicates the function being tested when

the error occurred. For example, function code 089 is for the

microprocessor.

the three-digit failure code that indicates the exact test failure that was

encountered.

the three-digit device ID.

the check value that is used to verify the validity of the information.

the diagnostic message that indicates the reason for the problem.

where:

Function Name

Result

Hardware Maintenance Manual: xSeries 360 Type 8686

The name of the function being tested when the error occurred.

This corresponds to the function code (fff) shown in the previous

list.

This can be one of the following:

Passed

This result occurs when the diagnostic test is completed

without any errors.

Page 27

it is

be

1.

2. To

1.

2. If

on

Failed This result occurs when the diagnostic test discovers an

error.

User Aborted

This result occurs when you stop the diagnostic test before

complete.

Not Applicable

This result occurs when you specify a diagnostic test for a

device that is not present.

Aborted

This result occurs when the test could not proceed, for

example, because of the system configuration.

Warning

This result occurs when a possible problem is reported

during the diagnostic test, such as when a device that is to

tested is not installed.

specific string

test

Additional information that you can use to analyze the problem.

Viewing the test log

When the tests have been completed, you can view the test log by selecting Utility

from the top of the screen and then selecting View Test Log.

Notes:

You can view the test log only while you are in the diagnostic programs. When

you exit the diagnostic programs, the test log is cleared (saved test logs are not

affected). To save the test log so that you can view it later, click Save Log on

the diagnostic programs screen and specify a location and name for the saved

log file.

save the test log to a diskette, you must use a diskette that you have

formatted yourself; this function does not work with preformatted diskettes. If the

diskette has sufficient space for the test log, the diskette may contain other

data.

For information about the system error log, see “Error logs” on page 14 and

“Configuration/Setup Utility main menu” on page 28.

Viewing the System Event/Error log

You can also view the System Event/Error log from the diagnostic programs. See

the instructions at “Error logs” on page 14.

Diagnostic error messages

Error messages may appear when you run the diagnostic programs.

Notes:

Depending on the server configuration, some of these error messages might not

appear when you run the diagnostic programs.

diagnostic error messages appear that are not listed, make sure that the

server has the latest levels of BIOS, Remote Supervisor Adapter, ServeRAID,

and diagnostics microcode installed.

For information about specific diagnostic error codes, see “Diagnostic error codes”

page 120.

Diagnostics

17

Page 28

If

v

v

1.

2.

3.

4.

5.

6.

7.

If

8.

9.

Do

18

Recovering the BIOS code

the BIOS has become damaged, such as from a power failure during a flash

update, you can recover the BIOS code using the flash ROM page swap jumper

(J56) and a BIOS flash diskette.

Note: Use one of the following methods to obtain a BIOS flash diskette:

Use the ServerGuide program to make a BIOS flash diskette.

Download a BIOS flash diskette from the World Wide Web at

http://www.ibm.com/pc/support.

flash memory of the server consists of a primary page and a backup page. The

The

J56 jumper controls which page is used to start the server. If the BIOS code in the

primary page is damaged, you can use the backup page to start the server; then,

start the BIOS flash diskette to restore the BIOS code to the primary page.

Complete the following steps to recover the BIOS:

Turn off the server and peripheral devices and disconnect all power cords and

external cables; then, remove the cover.

Locate jumper J56 (flash ROM page swap) on the system board. See “System

board locations” on page 65 for an illustration of the system board jumper

locations.

Move the jumper to pins 2 and 3 to enable BIOS recovery mode.

Reconnect all external cables and power cords and turn on the peripheral

devices.

Insert the BIOS flash diskette into the diskette drive and restart the server. The

system begins the power-on self-test (POST).

The Flash Update Utility program displays the Flash Update Menu. Select 1 -

Update POST/BIOS.

When prompted as to whether you want to move the current POST/BIOS

image to the backup ROM location, press N.

Attention:

secondary page.

When prompted as to whether you want to save the current code to a diskette,

press N.

When prompted to choose a language, select a language (from 0 to 7) and

press Enter to accept your choice.

10.

When prompted as to whether you want to change the serial number, ensure

that the correct serial number appears.

11.

When prompted as to whether you want to change the machine type, ensure

that the correct machine type appears.

12.

Attention:

Remove the flash diskette from the diskette drive.

13.

Turn off the server.

14.

Move the jumper on J56 to pins 1 and 2 to return to normal startup mode.

15.

Replace the cover and start the server.

you press Y, the damaged BIOS will be copied into the

not restart the server at this time.

Hardware Maintenance Manual: xSeries 360 Type 8686

Page 29

AC DC v 1

1

v 1

v 1

v 1

v

To

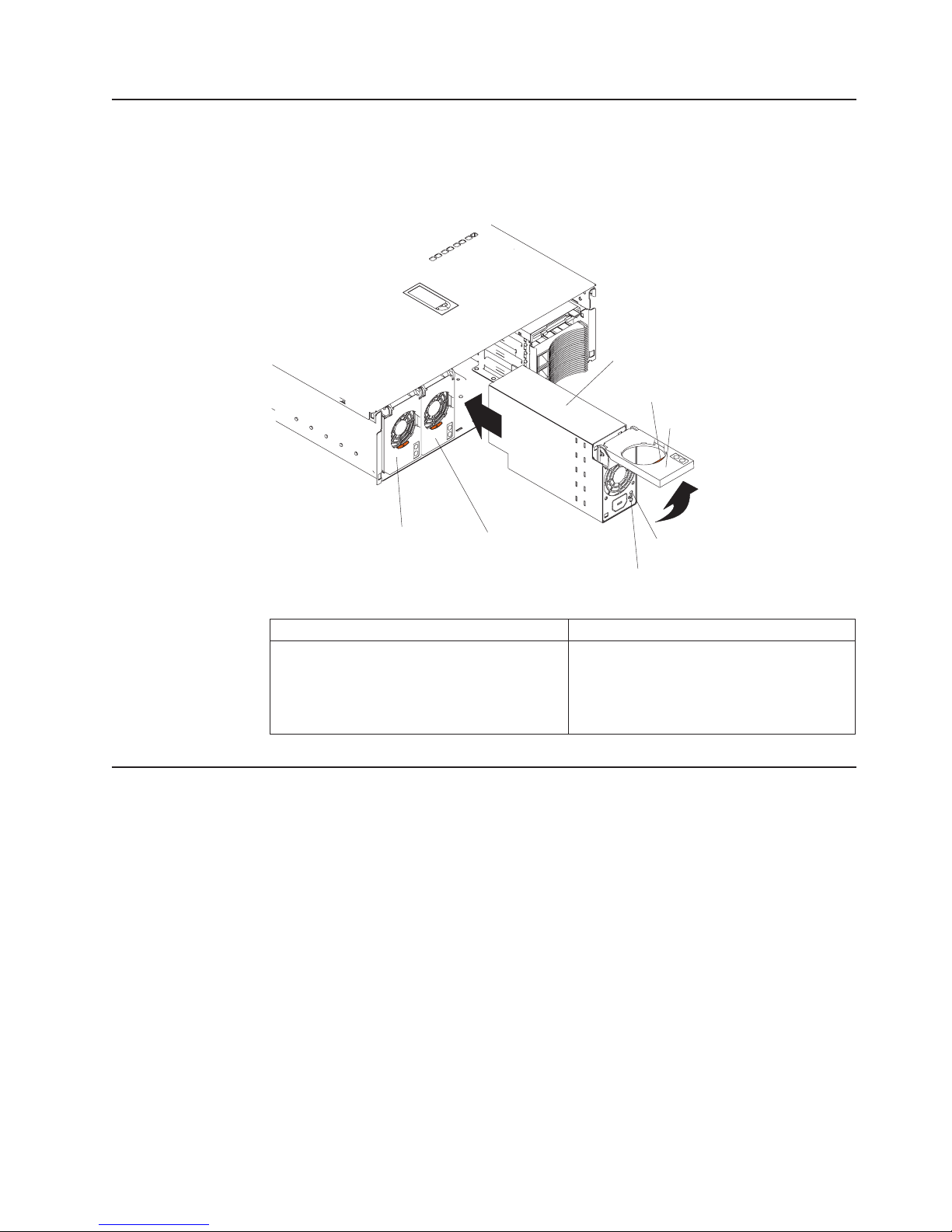

Power supply LEDs

The ac and dc power LEDs on a power supply provide status information about the

power supply. The following illustration shows the location of the ac and dc power

LEDs. For more information about interpreting the LEDs, see “Power supply LED

errors” on page 133.

Power supply 3

Locking latch

Locking handle

Power supply 1

Table 2. Power supply minimum configurations

power supply

Level 2 Light Path Diagnostics

The Light Path Diagnostics LEDs help you to identify problems with server

components. By following the light path, you can quickly identify and fix the type of

problem that occurred. The light path begins with the LEDs on the operator

information panel (also known as the front LED panel). If the server encounters a

problem, it lights either the Information LED or the Fault LED.

isolate the source of the trouble, examine the Level 2 Light Path Diagnostics

LEDs through the special cutout on the server top cover (shown at “Level 2

diagnostic panel LEDs” on page 20). These LEDs can indicate a problem with a

single component, or a problem with one of several similar components. In the latter

case, to isolate the specific failing component, remove the server top cover and

look for a lit LED on the system board, memory board, or failing component.

Power supply 2

AC power LED

DC power LED

v

power supply

power backplane

system board

processor in slot 1

Operator panel card

For example, if the FAN LED is lit, the specific failing fan is indicated by an LED

viewable with the top cover removed. If the MEM LED is lit, the specific failing

DIMM is indicated by an LED on the memory board.

Diagnostics

19

Page 30

on

SP

1.

2.

20

Level 2 diagnostic panel LEDs

The illustration at “Removing the server top cover and bezel” on page 72 shows the

location of the Level 2 diagnostic panel LEDs, visible through a special cutout area

the top cover. See “Level 2 Light Path troubleshooting” on page 21 for

information about using them to identify problems. The following illustration

identifies the diagnostic panel LEDs.

Over

See log

(CR17)

EXP

(CR8)

SP bus

(CR4)

NMI

(CR7)

Temp

(CR9)

Fan

(CR6)

Mem

(CR3)

PCI

(CR19)

CPU

(CR18)

VRM

(CR13)

DASD

(CR15)

Non

Redund

(CR16)

The meanings of these LEDs are as follows:

EXP

NMI

Over Temp

PCI

VRM

Attached expansion I/O failure

Nonmaskable interrupt

System over temperature condition

PCI failure

VRM failure

Out of

Spec

(CR14)

PS3

(CR10)

PS2

(CR11)

PS1

(CR12)

Remind

button

(SW1)

DASD

Out of Spec

PS2

Remind button

PS1

PS3

Non Redund

CPU

MEM

FAN

Bus

See Log

Hard disk drive failure

Power supplies being overdriven

Power supply number 2 failure

Remind to invoke remind mode

Power supply number 1 failure

Power supply number 3 failure

Nonredundant power mode

Microprocessor failure

Memory failure

Fan failure

Remote Supervisor Adapter failure

See event log or Remote Supervisor Adapter log for

non-optimal condition information

Notes:

The server supports replaceable voltage regulator modules (VRMs).

The server supports a maximum of three power supplies.

Hardware Maintenance Manual: xSeries 360 Type 8686

Page 31

v

v

v A

If

Remind button

You can use the Remind button to place the Fault light on the front panel into the

remind mode (blinks every 2 seconds). By pressing the button, you acknowledge

the failure but indicate that you will not take immediate action. If a new failure

occurs, the Fault light turns on again.

The Fault light stays in Remind mode until one of the following conditions occurs:

All known problems are resolved

The system is restarted

new problem occurs

can use the Remind button to delay server maintenance until a later time. In

You

this way, the light will indicate any subsequent error. If the light is still lit from the

first error, it is unable to indicate subsequent errors.

The Light Path Diagnostics feature might direct you to look for an LED on the

system board that identifies the specific failing component. The following illustration

identifies the LEDs on the system board.

Power backplane

LED (CR34)

PCI attention LED

PCI power LED

XA-32 chipset

VRM LED (CR29)

PCI switch card LED (CR 27)

Remote Supervisor Adapter

cable LED (CR28)

Microprocessor 4

VRM LED (CR20)

Microprocessor 4

LED (CR15)

Microprocessor 1

LED (CR4)

Microprocessor 1

VRM LED (CR2)

Microprocessor 3

LED (CR6)

Microprocessor 3

VRM LED (CR1)

Microprocessor 2

LED (CR8)

Microprocessor 2

VRM LED (CR21)

Level 2 Light Path troubleshooting

The Level 2 LEDs remain lit if the server shuts down, provided that the power

supplies are operating properly. This feature helps you to isolate the problem if an

error causes the server to shut down. For detailed information about the action to

take when the Level 2 Light Path Diagnostics indicate a problem, see “Level 2 light

path LED errors” on page 118.

the Level 2 Light Path Diagnostics indicate a problem that does not require

immediate action, you can press the Remind button on the diagnostic LED panel.

Diagnostics

21

Page 32

A

1.

2.

3.

4.

of

To

To

If

If

do

v

v

v

If

v

If

5

22

Power checkout

This causes the LED on the operator information panel to blink, reminding you that

you need to take action. The remind function enables normal operations to

continue, possibly using redundant components, until reduced server activity allows

you to correct the problem. The LED for the component causing the problem stays

lit until you make repairs.

Power problems can be difficult to troubleshoot. For instance, a short circuit can

exist anywhere on any of the power distribution busses. Usually a short circuit will

cause the power subsystem to shut down because of an overcurrent condition.

general procedure for troubleshooting power problems is as follows:

Power off the system and disconnect the AC cord(s).

Check for loose cables in the power subsystem. Also check for short circuits, for

instance if there is a loose screw causing a short circuit on a circuit board.

Remove adapters and disconnect the cables and power connectors to all

internal and external devices until system is at minimum configuration required

for power on (see “Undetermined problems” on page 143 for a description of the

minimum operating requirements).

Reconnect the AC cord and power on the system. If the system powers up

successfully, replace adapters and devices one at a time until the problem is

isolated. If system does not power up from minimal configuration, replace FRUs

minimal configuration one at a time until the problem is isolated.

use this method it is important to know the minimum configuration required for a

system to power up (see “Undetermined problems” on page 143 for a description of

the minimum operating requirements). For specific problems, see “Power error

messages” on page 140.

Error symptoms

find solutions to problems that have definite symptoms, see “Error symptoms” on

page 127.

you cannot find the problem in the table of error symptoms, go to “Starting the

diagnostic programs” on page 15 to test the server.

you have just added new software or a new option and the server is not working,

the following before using the error symptom charts:

Remove the software or device that you just added.

Run the diagnostic tests to determine if the server is running correctly.

Reinstall the new software or new device.

Ethernet controller troubleshooting

the Ethernet controller cannot connect to the network, check the following:

Make sure that the cable is installed correctly.

The network cable must be securely attached at all connections. If the cable is

attached but the problem remains, try a different cable.

you set the Ethernet controller to operate at 100 Mbps, you must use Category

cabling.

Hardware Maintenance Manual: xSeries 360 Type 8686

Page 33

v

v

–

–

v

v

v

v

If

To

If you directly connect two workstations (without a hub), or if you are not using a

hub with X ports, use a crossover cable.

Note: To determine whether a hub has an X port, check the port label. If the

label contains an X, the hub has an X port.

Determine if the hub supports auto-negotiation. If not, try configuring the

integrated Ethernet controller manually to match the speed and duplex mode of

the hub.

Check the Ethernet controller lights on the server rear panel.

These lights indicate whether a problem exists with the connector, cable, or hub.

The Ethernet Link Status light illuminates when the Ethernet controller

receives a LINK pulse from the hub. If the light is off, there might be a

defective connector or cable, or a problem with the hub.

The Ethernet Transmit/Receive Activity light illuminates when the Ethernet

controller sends or receives data over the Ethernet Network. If the Ethernet

Transmit/Receive Activity light is off, make sure that the hub and network are

operating and that the correct device drivers are loaded.

Check the LAN activity light (if available) on the rear of the server. The LAN

v

activity light is illuminated when data is active on the Ethernet network. If the

LAN activity light is off, make sure that the hub and network are operating and

that the correct device drivers are loaded.

Make sure that you are using the correct device drivers, which are supplied with

the server.

Check for operating-system-specific causes for the problem.

Make sure that the device drivers on the client and server are using the same

protocol.

Test the Ethernet controller.

The way you test the Ethernet controller depends on which operating system you

are using (see the Ethernet controller device driver README file).

The Ethernet wrap test can be used to determine if a hardware problem is

causing the Ethernet connection to fail. To perform the Ethernet wrap test, use

the wrap plug (FRU # 60G3981) in conjunction with the diagnostic tests.

the testing methods above indicate that the hardware is functioning normally

but the problem still exists, inform the network administrator.

Battery replacement

When replacing the battery, you must replace it with a lithium battery of the same

type from the same manufacturer. To avoid possible danger, read and follow the

safety statement below.

order replacement batteries, call 1-800-772-2227 within the United States, and

1-800-465-7999 or 1-800-465-6666 within Canada. Outside the U.S. and Canada,

call your IBM reseller or IBM marketing representative.

Note: After you replace the battery, you must reconfigure the system and reset the

system date and time.

Diagnostics

23

Page 34

a

Do

v

v

v

of

To

1.

2.

3.

4.

5.

a.

b.

c. To

24

Statement 2:

CAUTION:

When replacing the lithium battery, use only IBM Part Number 33F8354 or an

equivalent type battery recommended by the manufacturer. If your system has

module containing a lithium battery, replace it only with the same module

type made by the same manufacturer. The battery contains lithium and can

explode if not properly used, handled, or disposed of.

not:

Throw or immerse into water.

Heat to more than 100°C (212°F)

Repair or disassemble

Dispose

the battery as required by local ordinances or regulations.

replace the battery:

Read the information in “Before you begin” on page 71 and follow any special

handling and installation instructions supplied with the replacement battery.

Turn off the server and all attached devices, and disconnect all power cords and

external cables (see “Safety information” on page 145).

Remove the top cover as described at “Removing the server top cover and

bezel” on page 72.

Using the illustration at “System board locations” on page 65 as a reference,

locate the battery on the system board.

Remove the battery, as shown in the following illustration:

Use one finger to press down slightly on one side of the battery. The other

side of the battery will tilt up out of the socket.

Use your thumb and index finger to pull the battery out from under the

battery clip.

ensure that the battery clip will hold the replacement battery securely,

press gently on the clip so that it touches the base of the battery socket

momentarily.

Hardware Maintenance Manual: xSeries 360 Type 8686

Page 35

a.

b. As

7.

8.

of

9.

v

v

v

to

6.

Insert the new battery, as shown in the following illustration:

Tilt the battery so that you can insert it into the front of the socket, under the

battery clip.

you slide it under the battery clip, press the battery down into the socket.

Reinstall the top cover as described at “Installing the server top cover and

bezel” on page 95.

Reconnect the external cables and power cords; then, turn on the peripheral

devices and the server.

Note: You must wait approximately 30 seconds after you plug the power cord

the server into an electrical outlet before the power-control button

becomes active.

Start the Configuration/Setup Utility program and set configuration parameters.

Set the system date and time.

Set the power-on password.

Reconfigure the server.

Refer

“Using the Configuration/Setup Utility” on page 28.

Diagnostics

25

Page 36

26

Hardware Maintenance Manual: xSeries 360 Type 8686

Page 37

v

v

v

v

v

to

v

©

Configuration

You can use the following configuration programs to customize the settings for the

server hardware:

Configuration/Setup Utility program

This program is part of the basic input/output system (BIOS) code that comes

with the server. You can use this program to change interrupt request (IRQ)

settings, change the drive startup sequence, set the date and time, and set

passwords. For information about using this utility, see “Using the

Configuration/Setup Utility” on page 28.

SCSISelect utility program

This program is part of the basic input/output system (BIOS) code that comes

with the server. You can use this program to configure the devices that are

attached to the integrated SCSI controller. Use this program to change default

values, and to resolve configuration conflicts. For information about using this

utility, see “Using the SCSISelect utility program” on page 34.

PXE Boot Agent Utility program

The Preboot eXecution Environment (PXE) Boot Agent Utility program is part of

the BIOS code that comes with the server. You can use this program to select

the boot protocol and other boot options, to display the PXE setup prompt or to

disable it, to set the prompt display duration, and to select a power management

option. For information about using this utility, see “PXE Boot Agent Utility

program” on page 36

Note: The RPL selection for the Boot Protocol option is not supported for this

server.

ServerGuide CDs

The ServerGuide CDs provide software setup and installation tools that are

specifically designed for the server. Use these CDs during the initial installation of

the server to configure basic hardware features and to simplify network operating

system (NOS) installation. See “Using the ServerGuide CDs” on page 57 for

more information. The ServerGuide CDs also contain a collection of application

programs, which you can install after the server is up and running.

ServeRAID configuration program

This program comes with the optional ServeRAID adapters and with server

models that have a ServeRAID adapter preinstalled. If the server has a

ServeRAID adapter installed, you must use the ServeRAID configuration program

define and configure the disk-array subsystem before you install the operating

system. For more information about using the ServeRAID configuration program,

see “ServeRAID configuration program” on page 37 and also the ServeRAID

documentation that comes on the Documentation CD.

Remote Supervisor Adapter configuration process

Configuration activities are also required for the Remote Supervisor Adapter. See

“Remote Supervisor Adapter” on page 38 for information about setting up and

cabling the Remote Supervisor Adapter for use with an Advanced System

Management (ASM) network. For complete information about cabling,

configuring, and using the Remote Supervisor Adapter to manage the server

remotely, see the Remote Supervisor Adapter User’s Guide on the

Documentation CD.

Note: These configuration programs are not designed to help you configure the

Copyright IBM Corp. 2003