Page 1

BladeCenter H Type 8852, 7989, and 1886

P roblem Dete rminatio n an d Se rvice Gui de

Page 2

Page 3

BladeCenter H Type 8852, 7989, and 1886

P roblem Dete rminatio n an d Se rvice Gui de

Page 4

Note:

Before using this information and the product it supports, read: the general information in Appendix B, “Notices,” on page 63; the

IBM Warranty Information document; and the IBM Safety Information and IBM Systems and Environmental Notices and User Guide

documents on the IBM Documentation CD.

Seventh Edition (September 2010)

© Copyright IBM Corporation 2010.

US Government Users Restricted Rights – Use, duplication or disclosure restricted by GSA ADP Schedule Contract

with IBM Corp.

Page 5

Contents

Safety ...............v

Guidelines for trained service technicians ....vi

Inspecting for unsafe conditions ......vi

Guidelines for servicing electrical equipment . . vi

Safety statements ............vii

Chapter 1. Introduction ........1

Related documentation ...........1

Notices and statements in this document .....3

Features and specifications..........4

Controls, LEDs, and connectors ........5

Front view ..............5

Rear view ..............7

Supplying power to the BladeCenter unit.....9

Disconnecting power from the BladeCenter unit . . 9

Chapter 2. Diagnostics ........11

Diagnostic tools .............11

Troubleshooting tables...........12

Blade server problems ..........12

Blower module problems .........12

Fan pack problems ...........13

I/O module problems ..........13

Keyboard, mouse, or pointing-device problems 14

Management module problems .......14

Media tray problems ..........15

Monitor or video problems ........16

Power problems ............16

Light path diagnostic LEDs .........17

BladeCenter system LED panel .......17

Module LEDs.............18

Event log messages............19

Solving undetermined problems .......20

Calling IBM for service ..........21

Chapter 3. Parts listing ........23

Front view...............24

Rear view ...............26

Power cords ..............28

Chapter 4. Removing and replacing

BladeCenter components .......29

Installation guidelines ...........29

System reliability guidelines ........30

Handling static-sensitive devices ......30

Returning a device or component ......30

Removing and replacing Tier 1 CRUs......31

Removing a bezel ...........31

Installing a bezel ...........32

Removing and replacing the media tray and

optical drive or optical drive filler ......33

Removing and replacing a power module . . . 35

Removing and replacing a fan pack .....39

Removing a blade server .........41

Installing a blade server .........42

Removing an I/O module ........44

Installing an I/O module .........45

Removing a management module ......46

Installing a management module ......47

Removing and replacing a blower module . . . 48

Removing and replacing FRUs ........50

Removing the shuttle ..........50

Installing the shuttle ..........52

Removing the rear LED/serial connector

assembly ..............54

Installing the rear LED/serial connector assembly 55

Removing and replacing the midplane ....55

Chapter 5. Configuration information

and guidelines ...........59

Updating the firmware ..........59

Configuring the BladeCenter unit .......59

Configuring the management module ....59

Configuring I/O modules ........59

Configuring blade servers ........60

BladeCenter networking guidelines ......60

Appendix A. Getting help and technical

assistance .............61

Before you call .............61

Using the documentation ..........61

Getting help and information from the World Wide

Web.................62

Software service and support ........62

Hardware service and support ........62

IBM Taiwan product service .........62

Appendix B. Notices .........63

Trademarks ..............63

Important notes .............64

Particulate contamination..........65

Documentation format...........65

Electronic emission notices .........66

Federal Communications Commission (FCC)

statement ..............66

Industry Canada Class A emission compliance

statement ..............66

Avis de conformité à la réglementation

d'Industrie Canada ...........66

Australia and New Zealand Class A statement . 66

European Union EMC Directive conformance

statement ..............66

Germany Class A statement ........67

Japan VCCI Class A statement .......68

Japan Electronics and Information Technology

Industries Association (JEITA) statement....68

Korea Communications Commission (KCC)

statement ..............68

© Copyright IBM Corp. 2010 iii

Page 6

Russia Electromagnetic Interference (EMI) Class

A statement .............69

People's Republic of China Class A electronic

emission statement ...........69

Taiwan Class A compliance statement ....69

Index ...............71

iv

BladeCenter H Type 8852, 7989, and 1886: Problem Determination and Service Guide

Page 7

Safety

Before installing this product, read the Safety Information.

Antes de instalar este produto, leia as Informações de Segurança.

Pred instalací tohoto produktu si prectete prírucku bezpecnostních instrukcí.

Læs sikkerhedsforskrifterne, før du installerer dette produkt.

Lees voordat u dit product installeert eerst de veiligheidsvoorschriften.

Ennen kuin asennat tämän tuotteen, lue turvaohjeet kohdasta Safety Information.

Avant d'installer ce produit, lisez les consignes de sécurité.

Vor der Installation dieses Produkts die Sicherheitshinweise lesen.

Prima di installare questo prodotto, leggere le Informazioni sulla Sicurezza.

Les sikkerhetsinformasjonen (Safety Information) før du installerer dette produktet.

Antes de instalar este produto, leia as Informações sobre Segurança.

Antes de instalar este producto, lea la información de seguridad.

Läs säkerhetsinformationen innan du installerar den här produkten.

© Copyright IBM Corp. 2010 v

Page 8

Guidelines for trained service technicians

This section contains information for trained service technicians.

Inspecting for unsafe conditions

Use the information in this section to help you identify potential unsafe conditions

in an IBM product that you are working on. Each IBM product, as it was designed

and manufactured, has required safety items to protect users and service

technicians from injury. The information in this section addresses only those items.

Use good judgment to identify potential unsafe conditions that might be caused by

non-IBM alterations or attachment of non-IBM features or options that are not

addressed in this section. If you identify an unsafe condition, you must determine

how serious the hazard is and whether you must correct the problem before you

work on the product.

Consider the following conditions and the safety hazards that they present:

v Electrical hazards, especially primary power. Primary voltage on the frame can

cause serious or fatal electrical shock.

v Explosive hazards, such as a damaged CRT face or a bulging capacitor.

v Mechanical hazards, such as loose or missing hardware.

To inspect the product for potential unsafe conditions, complete the following

steps:

1. Make sure that the power is off and the power cords are disconnected.

2. Make sure that the exterior cover is not damaged, loose, or broken, and observe

any sharp edges.

3. Check the power cords:

v Make sure that the third-wire ground connector is in good condition. Use a

meter to measure third-wire ground continuity for 0.1 ohm or less between

the external ground pin and the frame ground.

v Make sure that the power cords are the correct type.

v Make sure that the insulation is not frayed or worn.

4. Remove the cover.

5. Check for any obvious non-IBM alterations. Use good judgment as to the safety

of any non-IBM alterations.

6. Check inside the computer for any obvious unsafe conditions, such as metal

filings, contamination, water or other liquid, or signs of fire or smoke damage.

7. Check for worn, frayed, or pinched cables.

8. Make sure that the power-supply cover fasteners (screws or rivets) have not

been removed or tampered with.

Guidelines for servicing electrical equipment

Observe the following guidelines when servicing electrical equipment:

v Check the area for electrical hazards such as moist floors, nongrounded power

extension cords, and missing safety grounds.

v Use only approved tools and test equipment. Some hand tools have handles that

are covered with a soft material that does not provide insulation from live

electrical current.

v Regularly inspect and maintain your electrical hand tools for safe operational

condition. Do not use worn or broken tools or testers.

vi BladeCenter H Type 8852, 7989, and 1886: Problem Determination and Service Guide

Page 9

v Do not touch the reflective surface of a dental mirror to a live electrical circuit.

The surface is conductive and can cause personal injury or equipment damage if

it touches a live electrical circuit.

v Some rubber floor mats contain small conductive fibers to decrease electrostatic

discharge. Do not use this type of mat to protect yourself from electrical shock.

v Do not work alone under hazardous conditions or near equipment that has

hazardous voltages.

v Locate the emergency power-off (EPO) switch, disconnecting switch, or electrical

outlet so that you can turn off the power quickly in the event of an electrical

accident.

v Disconnect all power before you perform a mechanical inspection, work near

power supplies, or remove or install main units.

v Before you work on the equipment, disconnect the power cord. If you cannot

disconnect the power cord, have the customer power-off the wall box that

supplies power to the equipment and lock the wall box in the off position.

v Never assume that power has been disconnected from a circuit. Check it to

make sure that it has been disconnected.

v If you have to work on equipment that has exposed electrical circuits, observe

the following precautions:

– Make sure that another person who is familiar with the power-off controls is

near you and is available to turn off the power if necessary.

– When you are working with powered-on electrical equipment, use only one

hand. Keep the other hand in your pocket or behind your back to avoid

creating a complete circuit that could cause an electrical shock.

– When using a tester, set the controls correctly and use the approved probe

leads and accessories for that tester.

– Stand on a suitable rubber mat to insulate you from grounds such as metal

floor strips and equipment frames.

v Use extreme care when measuring high voltages.

v To ensure proper grounding of components such as power supplies, pumps,

blowers, fans, and motor generators, do not service these components outside of

their normal operating locations.

v If an electrical accident occurs, use caution, turn off the power, and send another

person to get medical aid.

Safety statements

Important:

Each caution and danger statement in this document is labeled with a number.

This number is used to cross reference an English-language caution or danger

statement with translated versions of the caution or danger statement in the Safety

Information document.

For example, if a caution statement is labeled "Statement 1", translations for that

caution are in the Safety Information document under "Statement 1".

Be sure to read all caution and danger statements in this document before you

perform the procedures. Read any additional safety information that comes with

the server or optional device before you install the device.

Statement 1:

Safety vii

Page 10

DANGER

Electrical current from power, telephone, and communication cables is

hazardous.

To avoid a shock hazard:

v Do not connect or disconnect any cables or perform installation,

maintenance, or reconfiguration of this product during an electrical storm.

v Connect all power cords to a properly wired and grounded electrical outlet.

v Connect to properly wired outlets any equipment that will be attached to

this product.

v When possible, use one hand only to connect or disconnect signal cables.

v Never turn on any equipment when there is evidence of fire, water, or

structural damage.

v Disconnect the attached power cords, telecommunications systems,

networks, and modems before you open the device covers, unless

instructed otherwise in the installation and configuration procedures.

v Connect and disconnect cables as described in the following table when

installing, moving, or opening covers on this product or attached devices.

To Connect: To Disconnect:

1. Turn everything OFF.

2. First, attach all cables to devices.

3. Attach signal cables to connectors.

4. Attach power cords to outlet.

5. Turn device ON.

1. Turn everything OFF.

2. First, remove power cords from outlet.

3. Remove signal cables from connectors.

4. Remove all cables from devices.

viii BladeCenter H Type 8852, 7989, and 1886: Problem Determination and Service Guide

Page 11

Statement 2:

CAUTION:

When replacing the lithium battery, use only IBM Part Number 33F8354 or an

equivalent type battery recommended by the manufacturer. If your system has a

module containing a lithium battery, replace it only with the same module type

made by the same manufacturer. The battery contains lithium and can explode if

not properly used, handled, or disposed of.

Do not:

v Throw or immerse into water

v Heat to more than 100°C (212°F)

v Repair or disassemble

Dispose of the battery as required by local ordinances or regulations.

Statement 3:

CAUTION:

When laser products (such as CD-ROMs, DVD drives, fiber optic devices, or

transmitters) are installed, note the following:

v Do not remove the covers. Removing the covers of the laser product could

result in exposure to hazardous laser radiation. There are no serviceable parts

inside the device.

v Use of controls or adjustments or performance of procedures other than those

specified herein might result in hazardous radiation exposure.

DANGER

Some laser products contain an embedded Class 3A or Class 3B laser diode.

Note the following.

Laser radiation when open. Do not stare into the beam, do not view directly

with optical instruments, and avoid direct exposure to the beam.

Class 1 Laser Product

Laser Klasse 1

Laser Klass 1

Luokan 1 Laserlaite

Appareil A Laser de Classe 1

`

Safety ix

Page 12

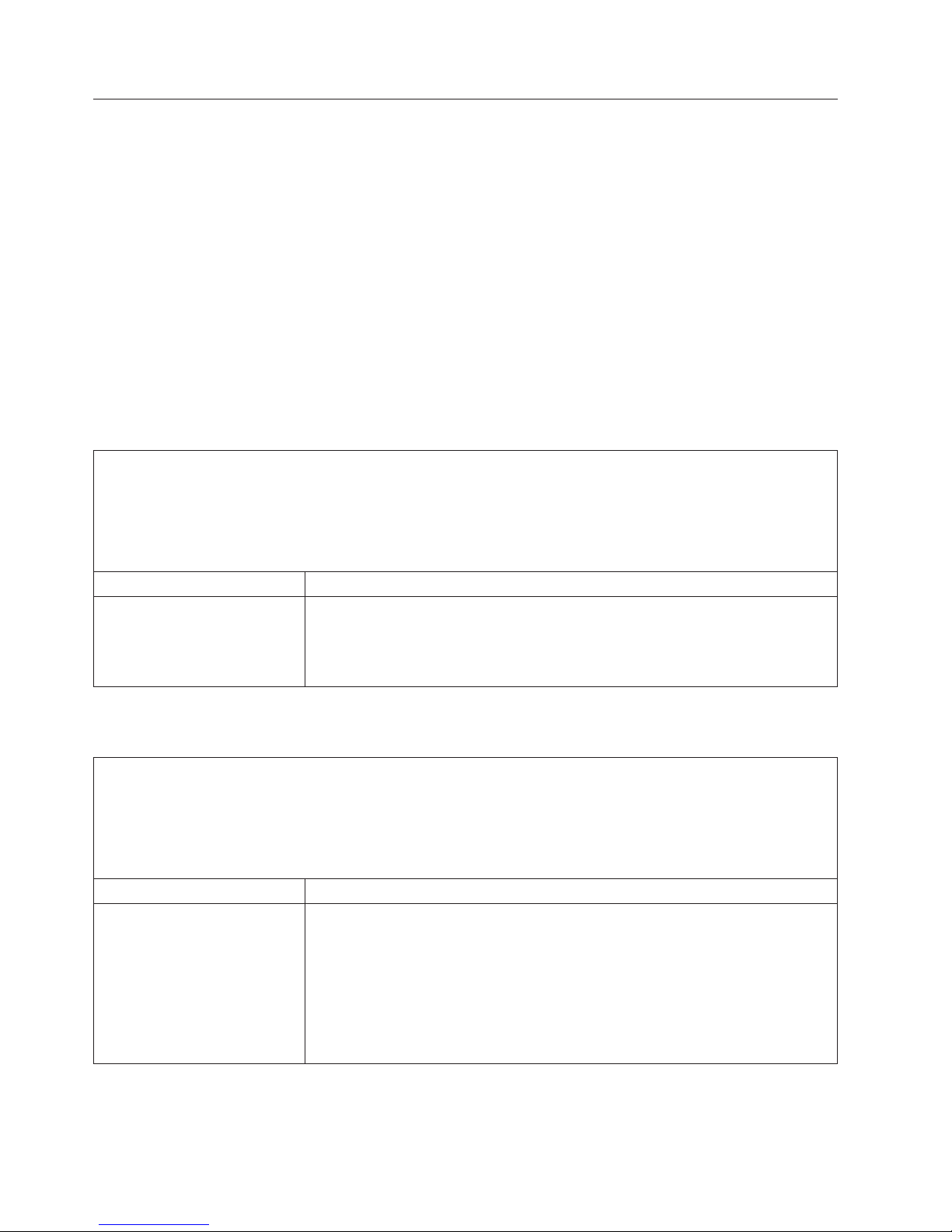

Statement 4:

≥ 18 kg (39.7 lb) ≥ 32 kg (70.5 lb) ≥ 55 kg (121.2 lb)

CAUTION:

Use safe practices when lifting.

Statement 5:

CAUTION:

The power control button on the device and the power switch on the power

supply do not turn off the electrical current supplied to the device. The device

also might have more than one power cord. To remove all electrical current from

the device, ensure that all power cords are disconnected from the power source.

2 / 3 1 / 4

x BladeCenter H Type 8852, 7989, and 1886: Problem Determination and Service Guide

Page 13

Statement 8:

CAUTION:

Never remove the cover on a power supply or any part that has the following

label attached.

Hazardous voltage, current, and energy levels are present inside any component

that has this label attached. There are no serviceable parts inside these

components. If you suspect a problem with one of these parts, contact a service

technician.

Statement 12:

CAUTION:

The following label indicates a hot surface nearby.

Statement 13:

DANGER

Overloading a branch circuit is potentially a fire hazard and a shock hazard

under certain conditions. To avoid these hazards, ensure that your system

electrical requirements do not exceed branch circuit protection requirements.

Refer to the information that is provided with your device for electrical

specifications.

Safety xi

Page 14

Statement 20:

CAUTION:

To avoid personal injury, before lifting the unit, remove all the blades to reduce

the weight.

(14X)

164 kg

(360 lbs)

(4X)

(2X)

44 kg

(96 lbs)

Statement 21:

CAUTION:

Hazardous energy is present when the blade is connected to the power source.

Always replace the blade cover before installing the blade.

United Kingdom - Notice to Customers:

This apparatus is approved under approval number NS/G/1234/J/100003 for

indirect connection to public telecommunication systems in the United Kingdom.

xii BladeCenter H Type 8852, 7989, and 1886: Problem Determination and Service Guide

Page 15

Chapter 1. Introduction

This Problem Determination and Service Guide contains information to help you solve

problems that might occur in your IBM®BladeCenter®Type 8852, 7989, and 1886

unit. It describes the diagnostic tools that come with the BladeCenter unit, error

codes and suggested actions, and instructions for replacing failing components.

Replaceable components are of three types:

v Tier 1 customer replaceable unit (CRU): Replacement of Tier 1 CRUs is your

responsibility. If IBM installs a Tier 1 CRU at your request, you will be charged

for the installation.

v Tier 2 customer replaceable unit: You can install a Tier 2 CRU yourself or

request IBM to install it, at no additional charge, under the type of warranty

service that is designated for your computer.

v Field replacement unit (FRU): FRUs must be installed only by trained service

technicians.

For information about the terms of the warranty and getting service and assistance,

see the Warranty and Support Information document on the IBM Documentation CD.

Related documentation

In addition to this document, the following related documentation is provided in

Portable Document Format (PDF) on the BladeCenter Documentation CD that comes

with your BladeCenter unit:

v BladeCenter H Installation and User’s Guide

This printed document contains instructions for setting up the BladeCenter unit

and general information about the BladeCenter unit, including information

about features, and how to configure the BladeCenter unit. It also contains

detailed instructions for installing, removing, and connecting optional devices

that the BladeCenter unit supports.

v BladeCenter H Rack Installation Instructions

This printed document contains instructions for installing the BladeCenter unit

in a rack.

v BladeCenter Advanced Management Module Installation Guide

This document contains instructions for installing the management module in

the BladeCenter unit and creating the initial configuration.

v BladeCenter Advanced Management Module User’s Guide

This document provides general information about the management module for

your BladeCenter unit type, including information about features, how to

configure the management module, and how to get help.

v BladeCenter Advanced Management Module Command-Line Interface Reference Guide

This document explains how to use the management-module command-line

interface to directly access BladeCenter management functions as an alternative

to using the Web-based user interface. The command-line interface also provides

access to the text-console command prompt on each blade server through a

Serial over LAN (SOL) connection.

© Copyright IBM Corp. 2010 1

Page 16

v BladeCenter Advanced Management Module Messages Guide

This document contains a complete list of all non-device specific events and

recommended actions, sorted by event ID. Device specific event information is in

the documentation for the device.

v Safety Information

This document contains translated caution and danger statements. Each caution

and danger statement that appears in the documentation has a number that you

can use to locate the corresponding statement in your language in the Safety

Information document.

v Warranty

This document contains information about the terms of the warranty.

v Serial over LAN Setup Guide

This document explains how to update and configure BladeCenter components

for Serial over LAN (SOL) operation. The SOL connection provides access to the

text-console command prompt on each blade server and enables the blade

servers to be managed from a remote location.

Additional documentation might be included on the IBM BladeCenter Documentation

CD.

The BladeCenter unit might have features that are not described in the

documentation that comes with the BladeCenter unit. The documentation might be

updated occasionally to include information about those features, or technical

updates might be available to provide additional information that is not included

in the BladeCenter unit documentation. These updates are available from the IBM

Web site. To check for updated documentation and technical updates, go to

http://www.ibm.com/support/.

2 BladeCenter H Type 8852, 7989, and 1886: Problem Determination and Service Guide

Page 17

Notices and statements in this document

The caution and danger statements that appear in this document are also in the

multilingual Safety Information document, which is on the IBM Documentation CD.

Each statement is numbered for reference to the corresponding statement in the

Safety Information document.

The following notices and statements are used in this document:

v Note: These notices provide important tips, guidance, or advice.

v Important: These notices provide information or advice that might help you

avoid inconvenient or problem situations.

v Attention: These notices indicate potential damage to programs, devices, or data.

An attention notice is placed just before the instruction or situation in which

damage could occur.

v Caution: These statements indicate situations that can be potentially hazardous

to you. A caution statement is placed just before the description of a potentially

hazardous procedure step or situation.

v Danger: These statements indicate situations that can be potentially lethal or

extremely hazardous to you. A danger statement is placed just before the

description of a potentially lethal or extremely hazardous procedure step or

situation.

Chapter 1. Introduction 3

Page 18

Features and specifications

The following table provides a summary of the features and specifications of the

BladeCenter unit. Depending on the model, some features might not be available,

or some specifications might not apply.

Media tray (on front):

v Optical drive (optional)

v Two USB v2.0 ports

v Front system LED panel

Blade bays (on front): 14 hot-swap

blade-server bays

Module bays (on front): Four hot-swap

power-module bays

Module bays (on rear):

v Two hot-swap management-module

bays

v Ten hot-swap I/O-module bays

v Two hot-swap blower bays

Power modules:

v Minimum: Two hot-swap power

modules that are configured for

redundant operation

v Maximum: Four hot-swap power

modules that provide redundancy to

all BladeCenter components

Redundant cooling: Two

variable-speed hot-swap blowers

Management module:

v Minimum: One hot-swap advanced

management module.

v Maximum: Two hot-swap advanced

management modules: one active,

one hot stand-by.

Upgradeable microcode:

v Management-module firmware

v I/O-module firmware (not all I/O

module types)

v Blade-server firmware

Security features:

v Login password for remote connection

v Secure Sockets Layer (SSL) security for

remote management access

Predictive Failure Analysis (PFA) alerts:

v Blowers

v Blade-dependent features

Size (9 U):

v Height: 400.1 mm (15.75 in. or 9 U)

v Depth: 711.2 mm (28 in.)

v Width: 482.6 mm (19 in.)

v Weight:

– Full configured weight with blade

servers: Approximately 158.8 kg (350

lbs)

– Empty chassis without modules or

blade servers: Approximately 40.82

kg (90 lbs)

Environment:

v Air temperature:

– BladeCenter unit on:

- Altitude: 0 to 914 m (3000 ft)

10° to 35°C (50° to 95°F)

- Altitude: 914 m to 2134 m (3000 ft to

7000 ft) 10° to 32°C (50° to 90°F)

– BladeCenter unit off: -40° to 60°C

(-40° to 140°F).

v Humidity: 8% to 80%

v Acoustics: declared sound power level: 7.5

1

bels

Electrical input:

v Sine-wave input (50-60 Hz single-phase)

required

v Input voltage:

– Minimum: 200 V ac

– Maximum: 240 V ac

Heat output: Approximate heat output in

British thermal units (Btu) per hour:

v Minimum configuration: 1024 Btu/hour

(300 watts)

v Maximum configuration: 32757 Btu/hour

(9600 watts)

Airflow: Approximate airflow in cubic feet

per minute (cfm):

v Minimum airflow: 450 cfm

v Maximum airflow: 975 cfm

Notes:

1. Government regulations (such as those prescribed by Occupational Safety and Health Administration or European Community

Directives) might govern noise level exposure in the workplace and might apply to you and your server installation. The actual

sound pressure levels in your installation depend on a variety of factors, including the number of racks in the installation; the

size, materials, and configuration of the room where you designate the racks to be installed; the noise levels from other

equipment; the room ambient temperature; and employees' location in relation to the equipment. Compliance with such

government regulations also depends on a variety of additional factors, including the duration of employees' exposure and

whether employees wear hearing protection. It is recommended that you consult qualified experts in this field to determine

whether you are in compliance with the applicable regulations.

4 BladeCenter H Type 8852, 7989, and 1886: Problem Determination and Service Guide

Page 19

Controls, LEDs, and connectors

This section identifies the components, controls, and LEDs on the front and rear of

the BladeCenter unit.

Note: The illustrations in this document might differ from your hardware.

Front view

This section identifies the components, controls, and LEDs on the front of the

BladeCenter unit.

Power module 1 Power module

bay 3

Blade

server

control

panel

System

service

cards

Power module 2 Power module

Media tray

Front system

LED panel

Optical drive

activity LED

Optical drive

eject button

USB connectors

bay 4

Power modules

The following illustration shows the LEDs on each power module.

AC power LED

Power module error LED

DC power LED

The LEDs on each power module indicate the condition of the power module and

fan pack. For additional information, see “Light path diagnostic LEDs” on page 17.

Note: The orientation of the power module shown in the illustration is for a

module that is installed in one of the top power-module bays. The orientation for a

module that is installed in one of the bottom power-module bays is rotated 180°.

v DC power LED: When this green LED is lit, the dc output from the power

module to the other components and blade servers is present and within

specifications. During typical operation, both the ac power and dc power LEDs

are lit.

Fan error LED

Chapter 1. Introduction 5

Page 20

v AC power LED: When this green LED is lit, ac input to the power module is

present and within specifications. During typical operation, both the ac power

and dc power LEDs are lit.

v Power module error LED: When this amber LED is lit, a power module has

failed and is not operating within specifications.

v Fan error LED: When this amber LED is lit, a fan pack has failed and is not

operating within specifications.

Media tray

The media tray contains the following:

v Front system LED panel

The LEDs on this panel provide status information for your BladeCenter unit.

Power-on

Location

Over-temperature

Information

System error

Note: You can turn off the location LED and the information LED through the

Web interface.

– Power-on: When this green LED is lit, power is present in the BladeCenter

unit. When this LED is off, the power subsystem, the ac power, or the LED

has failed, or the management module is not present or not functioning.

Attention: If the power-on LED is off, it does not mean there is no electrical

current present in the BladeCenter unit. The LED might be burned out. To

remove all electrical current from the BladeCenter unit, you must disconnect

all power cords from all power modules.

– Location: When this blue LED is lit or flashing, it has been turned on by the

system administrator, to aid in visually locating the BladeCenter unit. If a

blade server requires attention, the location LED on the blade server usually

will also be lit. After the BladeCenter unit has been located, you can have the

system administrator turn off the location LED.

– Over-temperature: When this amber LED is lit, the temperature in the

BladeCenter unit exceeds the temperature limits, or a blade server reports an

over-temperature condition. The BladeCenter unit might have already taken

corrective action, such as increasing the blower speed. This LED turns off

automatically when there is no longer an over-temperature condition.

– Information: When this amber LED is lit, a noncritical event has occurred

that requires attention, such as the wrong I/O module inserted in a bay or

power demands that exceed the capacity of power modules that are currently

installed. The event is recorded in the event log. Check the LEDs on the

BladeCenter unit and the blade servers to isolate the component (see

Chapter 2, “Diagnostics,” on page 11 for more information about event log

messages and checking the LEDs). After the situation is corrected, have the

system administrator turn off the information LED.

6 BladeCenter H Type 8852, 7989, and 1886: Problem Determination and Service Guide

Page 21

– System-error: When this amber LED is lit, it indicates that a system error has

v Optical-drive activity LED: When this LED is lit, it indicates that the optical

drive is in use.

v Optical-drive eject button: Press this button to release a disc from the optical

drive.

v USB connectors: Use these connectors to attach external USB devices.

System service cards

These cards contain system service instructions and a writable area. They slide in

and out of the storage location on the left side of the BladeCenter unit.

Blade server control panel

This panel contains indicators and controls for the blade server. See the

documentation that comes with your blade server for information about the blade

server control panel.

Rear view

This section identifies the components, connectors, and indicators on the rear of the

BladeCenter unit.

Power connector 2

occurred, such as a failed module or a system error in a blade server. An LED

on one of the components or on a blade server is also lit to further isolate the

error. (See Chapter 2, “Diagnostics,” on page 11 for more information.)

I/O module bay 7

I/O module bay 8

Power connector 1

Management

I/O module bay 1

I/O module bay 5

I/O module bay 2

I/O module bay 6

Blower module 2

error LED

Rear system

LED panel

Serial connector

I/O module bay 9

I/O module bay 10

module 1

I/O module bay 3

Blower module 1

error LED

Blower module 1

Management

module bay 2

I/O module bay 4

Blower module 2

Power connectors

Connect a power cord from each power connector to a 220-volt power distribution

unit (PDU) or an appropriate electrical outlet.

I/O modules

See the documentation that comes with each I/O module for a description of the

LEDs and connectors on the I/O module.

Chapter 1. Introduction 7

Page 22

Management modules

See the documentation that comes with each management module for a description

of the LEDs and connectors on the module.

Blower modules

When the amber LED on a blower module is lit, an error has been detected in the

blower or ac power to the blower is not present. The system-error LEDs on the

BladeCenter system LED panels are also lit.

Serial connector

This connector provides direct access to the serial ports on each of the 14 blade

server bays. Use this connector to attach the optional serial port breakout cable and

connect up to 14 local consoles. See the documentation that comes with your blade

server to see if it supports this cable.

Rear system LED panel

The LEDs on this panel provide status information. These LEDs duplicate the

LEDs in the front system LED panel (see “Front system LED panel” on page 6 for

more information).

8 BladeCenter H Type 8852, 7989, and 1886: Problem Determination and Service Guide

Page 23

Supplying power to the BladeCenter unit

To supply power to the BladeCenter unit, connect one end of each power cord to a

power connector on the rear of the BladeCenter unit and the other end of each

power cord to a 220-volt PDU that is connected to an appropriate electrical outlet.

The BladeCenter unit does not have a power switch.

After the BladeCenter unit has power, the blade servers in the BladeCenter unit are

connected to power but are not turned on. Depending on the configuration

settings, the blade servers might have to be individually turned on.

Disconnecting power from the BladeCenter unit

You can shut down the BladeCenter unit by turning off the blade servers and

disconnecting the BladeCenter unit from the power source.

To disconnect power from the BladeCenter unit, complete the following steps:

1. Shut down the operating systems and turn off any blade servers. See the

documentation that comes with the blade server for detailed instructions.

Statement 5:

CAUTION:

The power control button on the device and the power switch on the power

supply do not turn off the electrical current supplied to the device. The

device also might have more than one power cord. To remove all electrical

current from the device, ensure that all power cords are disconnected from

the power source.

2 / 3 1 / 4

2. Disconnect both power cords from the BladeCenter unit.

Attention: The power cords on the rear of the BladeCenter chassis are not

approved to be connected or disconnected under power. You must first

disconnect the power cords from the ac power source; then, you can remove

the power cords from the chassis connectors.

Note: After you disconnect the BladeCenter unit from power, wait at least 5

seconds before you connect the BladeCenter unit to power again.

Chapter 1. Introduction 9

Page 24

10 BladeCenter H Type 8852, 7989, and 1886: Problem Determination and Service Guide

Page 25

Chapter 2. Diagnostics

This chapter describes the diagnostic tools that are available to help you solve

problems that might occur in the BladeCenter unit.

If you cannot locate and correct the problem using the information in this chapter,

see Appendix A, “Getting help and technical assistance,” on page 61 for more

information.

Diagnostic tools

The following tools are available to help you diagnose and solve hardware-related

problems:

v Troubleshooting tables

These tables list problem symptoms and actions to correct the problems. See

“Troubleshooting tables” on page 12 for more information.

v Light path diagnostic LEDs

Use the light path diagnostic LEDs on the BladeCenter unit and the BladeCenter

components to identify system errors quickly. See “Light path diagnostic LEDs”

on page 17 for more information.

v Diagnostic program and error messages

The management module built-in self-test (BIST) program checks the

BladeCenter unit during startup; then while the BladeCenter unit is running, the

management module constantly monitors the status of all of the installed

components. If problems or changes in status are found, the management

module generates messages and displays them in the event log (see “Event log

messages” on page 19).

© Copyright IBM Corp. 2010 11

Page 26

Troubleshooting tables

Use the troubleshooting tables to find solutions to problems that have identifiable

symptoms. If one or more LEDs on the BladeCenter unit or the components is lit,

see “Light path diagnostic LEDs” on page 17.

If you cannot find the problem in these tables, see “Solving undetermined

problems” on page 20.

If you have just added a new optional device and the BladeCenter unit is not

working, complete the following steps before using the troubleshooting tables:

1. Remove the device that you just added.

2. Restart the BladeCenter unit to determine whether the BladeCenter unit is

working correctly.

3. Reinstall the new device.

Blade server problems

v Follow the suggested actions in the order in which they are listed in the Action column until the problem is

solved.

v See Chapter 3, “Parts listing,” on page 23 to determine which components are CRUs and which components

are FRUs.

v If an action step is preceded by “(Trained service technician only),” that step must be performed only by a

trained service technician.

Symptom Action

A blade server power-on LED

flashes rapidly for an extended

amount of time.

v Make sure that at least one management module is installed, and it is active

and working.

v Reseat the blade server.

v Replace the blade server.

Blower module problems

v Follow the suggested actions in the order in which they are listed in the Action column until the problem is

solved.

v See Chapter 3, “Parts listing,” on page 23 to determine which components are CRUs and which components

are FRUs.

v If an action step is preceded by “(Trained service technician only),” that step must be performed only by a

trained service technician.

Symptom Action

A blower module is running at

full speed.

12 BladeCenter H Type 8852, 7989, and 1886: Problem Determination and Service Guide

1. Make sure that:

v The other blower is installed and working.

v At least one management module is installed, and it is active and working.

2. Reseat the following components:

a. Media tray

b. Blower module

3. Replace the blower module.

Page 27

v Follow the suggested actions in the order in which they are listed in the Action column until the problem is

solved.

v See Chapter 3, “Parts listing,” on page 23 to determine which components are CRUs and which components

are FRUs.

v If an action step is preceded by “(Trained service technician only),” that step must be performed only by a

trained service technician.

Symptom Action

A blower module is not

working.

1. Make sure all power cords are plugged into 220-Volt power sources and that

the power sources are working.

2. Reseat the blower module.

3. Replace the blower module.

Fan pack problems

v Follow the suggested actions in the order in which they are listed in the Action column until the problem is

solved.

v See Chapter 3, “Parts listing,” on page 23 to determine which components are CRUs and which components

are FRUs.

v If an action step is preceded by “(Trained service technician only),” that step must be performed only by a

trained service technician.

Symptom Action

A fan pack is running at full

speed.

1. Make sure that at least one management module is installed, and it is active

and working.

2. Reseat the following components:

a. Power module.

b. Fan pack

3. Replace the fan pack

1

1

1

2900W power modules with removable fan pack only. If the unit is equipped

with 2980W power modules, reseat or replace the power module.

I/O module problems

v Follow the suggested actions in the order in which they are listed in the Action column until the problem is

solved.

v See Chapter 3, “Parts listing,” on page 23 to determine which components are CRUs and which components

are FRUs.

v If an action step is preceded by “(Trained service technician only),” that step must be performed only by a

trained service technician.

Symptom Action

An I/O module will not turn

on.

Cannot communicate with the

external ports on an I/O

module.

1. Make sure that at least one management module is installed, and it is active

and working.

2. Reseat the I/O module.

3. Replace the I/O module.

1. Make sure that external ports option is enabled in the management module

Web interface.

2. Reseat the I/O module.

3. Replace the I/O module.

Chapter 2. Diagnostics 13

Page 28

Keyboard, mouse, or pointing-device problems

Note: These symptoms apply only to the devices that are connected to the

management module; they do not apply to the remote console.

v Follow the suggested actions in the order in which they are listed in the Action column until the problem is

solved.

v See Chapter 3, “Parts listing,” on page 23 to determine which components are CRUs and which components

are FRUs.

v If an action step is preceded by “(Trained service technician only),” that step must be performed only by a

trained service technician.

Symptom Action

The keyboard, mouse, or

pointing device is not working.

The keyboard, mouse or

pointing device does not work

after switching ownership of

the KVM to a different blade

server.

1. Make sure that:

v The device is connected to the active management module.

v The KVM is owned by a blade server that supports KVM.

v The blade server that owns the KVM is turned on.

2. Reseat the device cable.

3. Replace the device.

Make sure that:

v The device cables are connected to the active management module, not the USB

ports on the media tray.

v The KVM is owned by a blade server that supports KVM.

Management module problems

v Follow the suggested actions in the order in which they are listed in the Action column until the problem is

solved.

v See Chapter 3, “Parts listing,” on page 23 to determine which components are CRUs and which components

are FRUs.

v If an action step is preceded by “(Trained service technician only),” that step must be performed only by a

trained service technician.

Symptom Action

Cannot connect to the

BladeCenter unit using the Web

interface or telnet.

1. Make sure that:

v The network cable is connected to the Ethernet port on the active

management module.

v The network cable is not connected to the serial port on the management

module.

v The IP address or host name is correct.

2. Reseat the management module.

3. Reset and reconfigure the management module (see the BladeCenter Advanced

Management Module Installation Guide for more information).

4. Replace the management module.

14 BladeCenter H Type 8852, 7989, and 1886: Problem Determination and Service Guide

Page 29

v Follow the suggested actions in the order in which they are listed in the Action column until the problem is

solved.

v See Chapter 3, “Parts listing,” on page 23 to determine which components are CRUs and which components

are FRUs.

v If an action step is preceded by “(Trained service technician only),” that step must be performed only by a

trained service technician.

Symptom Action

Cannot connect to the

BladeCenter unit after a

switchover to the redundant

management module

1. Make sure that:

v The redundant management module has been installed for at least 45

minutes to receive the transfer of data from the primary management

module.

v The network cable is connected to the Ethernet port on the active

(redundant) management module.

v The network cable is not connected to the serial port on the active

(redundant) management module.

v The IP address or host name is correct.

2. Reseat the management module.

3. Reset and reconfigure the management module (see the BladeCenter Advanced

Management Module Installation Guide for more information).

4. Replace the management module.

Media tray problems

v Follow the suggested actions in the order in which they are listed in the Action column until the problem is

solved.

v See Chapter 3, “Parts listing,” on page 23 to determine which components are CRUs and which components

are FRUs.

v If an action step is preceded by “(Trained service technician only),” that step must be performed only by a

trained service technician.

Symptom Action

The optical drive is not

recognized by any blade server.

1. Reseat the following components:

a. Media tray

b. Optical drive

2. Replace the optical drive.

Chapter 2. Diagnostics 15

Page 30

Monitor or video problems

Note: These symptoms apply only to the monitor that is connected to the

management module; they do not apply to the remote console.

Some IBM monitors have their own self-tests. If you suspect a problem with your

monitor, see the documentation that comes with the monitor for instructions for

testing and adjusting the monitor.

v Follow the suggested actions in the order in which they are listed in the Action column until the problem is

solved.

v See Chapter 3, “Parts listing,” on page 23 to determine which components are CRUs and which components

are FRUs.

v If an action step is preceded by “(Trained service technician only),” that step must be performed only by a

trained service technician.

Symptom Action

The monitor is not working

1. Make sure that:

v The monitor is turned on and the brightness and contrast controls are

adjusted correctly.

v The monitor is connected to the active management module.

v The blade server that owns the KVM is turned on.

v The KVM is owned by a blade server that supports KVM.

2. Reseat the monitor cable.

3. Replace the monitor.

Power problems

v Follow the suggested actions in the order in which they are listed in the Action column until the problem is

solved.

v See Chapter 3, “Parts listing,” on page 23 to determine which components are CRUs and which components

are FRUs.

v If an action step is preceded by “(Trained service technician only),” that step must be performed only by a

trained service technician.

Symptom Action

The BladeCenter unit does not

power on.

1. Make sure that:

a. All power cords are plugged into 220-Volt power sources and that the

power sources are working.

b. The ac power and dc power LEDs on the power modules are lit.

2. If you just installed an option, remove it, and restart the BladeCenter unit. If

the BladeCenter unit now powers on, you might have installed more options

than the power modules support. You might have to install power modules in

power-module bays 3 and 4.

3. If the problem remains, go to “Solving undetermined problems” on page 20.

16 BladeCenter H Type 8852, 7989, and 1886: Problem Determination and Service Guide

Page 31

Light path diagnostic LEDs

Light path diagnostic LEDs are a system of LEDs on the BladeCenter unit and the

BladeCenter components that can be used to identify system errors. If the front or

rear system-error LED of the BladeCenter unit is lit, one or more error LEDs on the

BladeCenter components also might be lit. These LEDs help identify the cause of

the problem.

BladeCenter system LED panel

Use the following table to find solutions to problems that are identified by LEDs

on the front and rear BladeCenter system LED panels.

v Follow the suggested actions in the order in which they are listed in the Action column until the problem is

solved.

v See Chapter 3, “Parts listing,” on page 23 to determine which components are CRUs and which components

are FRUs.

v If an action step is preceded by “(Trained service technician only),” that step must be performed only by a

trained service technician.

Lit LED Description Action

Location A condition has occurred in the

BladeCenter unit that has caused

the remote system management to

identify the BladeCenter unit as

needing attention.

Over-temperature The system temperature has

exceeded a threshold level.

Information A noncritical event has occurred

that should be looked at, such as

the wrong I/O module inserted in a

bay, or power requirements that

exceed the capacity of the power

modules currently installed.

System error A critical system error has occurred,

such as nonredundancy on the

power modules or a system error in

a blade server.

Look for any information or error LEDs on the

system-LED panels, the modules, and the blade

servers in the BladeCenter unit, and follow the

instructions for those LEDs in this section.

1. Determine whether a blower module has failed. If

it has, replace the blower module as soon as

possible, to regain redundancy.

2. Make sure that the room temperature is not too

high. (See “Features and specifications” on page 4

for temperature information.)

3. Determine whether a blade server has a lit error

LED. If it does, see the documentation that comes

with the blade server.

4. Make sure that there is a blade server, module, or

filler installed in each bay

1. Check the management module event log for

messages.

2. Check the LEDs on the BladeCenter unit and the

blade servers to isolate the component.

1. Check the management module event log for

messages.

2. Check the LEDs on the BladeCenter unit and the

blade servers to isolate the component.

v If the error LED is on a module, follow the

instructions for that LED in “Module LEDs” on

page 18.

v If the error LED is on a blade server, see the

documentation that comes with the blade server.

Chapter 2. Diagnostics 17

Page 32

Module LEDs

Use the following table to find solutions to problems that are identified by LEDs

on the modules installed in BladeCenter unit.

Note: To find descriptions and actions for LEDs on I/O modules or blade servers,

see the documentation that comes with the device.

v Follow the suggested actions in the order in which they are listed in the Action column until the problem is

solved.

v See Chapter 3, “Parts listing,” on page 23 to determine which components are CRUs and which components

are FRUs.

v If an action step is preceded by “(Trained service technician only),” that step must be performed only by a

trained service technician.

LED status Description Action

Management module:

Error LED lit

Power module:

AC power LED is lit,

DC power LED not lit

Power module:

AC power LED not lit,

DC power LED not lit

Power module:

Fan error LED lit

Power module:

Error LED lit

Blower module:

Error LED lit

A critical error has occurred in the

management module.

A system fault has shut down the

power module or the power

module has failed.

There is no ac power being

supplied to the power module or

the power module has failed.

The fan pack has failed. Replace the fan pack

The power module has failed. Replace the power module.

The blower module has failed. Replace the blower module.

1. Reseat the management module.

2. Reset and reconfigure the management module

(see the BladeCenter Advanced Management Module

Installation Guide for more information).

3. Replace the management module.

1. Determine whether a failed component caused the

shut down. If a component failed:

a. Replace the failed component.

b. Pull the power module out of the BladeCenter

unit approximately two inches; then reinstall it.

2. Replace the power module.

1. Make sure that all power cords are plugged into

220-Volt power sources and that the power sources

are working.

2. Replace the power module.

18 BladeCenter H Type 8852, 7989, and 1886: Problem Determination and Service Guide

Page 33

Event log messages

Messages that are generated while the management module is monitoring the

BladeCenter unit or by the BIST program during startup are displayed in the

management module event log. Each message includes a severity level (error [E],

warning [W], or information [I]), a source (such as, management module

[SERVPROC] or blade server number [BLADE_xx]), a timestamp, and a text

description.

When you are viewing the event log, consider the following information:

v If the source of a message is a blade server, see the documentation that comes

with the blade server for more information.

v If the source of a message is not a blade server or the management module, see

the documentation that comes with the device for more information.

v By default, the entries are sorted by timestamp, with the most recent entry first.

You can sort the entries by severity, source, or timestamp by clicking on the

appropriate column heading.

v You can filter the entries to show only the entries that match the severity, source,

or date you select.

v When a message identifies a specific component, use the following general

procedure to resolve the problem:

1. Check for lit LEDs on the component (see “Light path diagnostic LEDs” on

2. Reseat the component.

3. Replace the component.

v Review messages with earlier timestamps before taking action on a more recent

message. For example, an error message about a failing component with a recent

timestamp may be related to an error message about the prior failure of another

component.

v For some messages, when an problem has been resolved, the log will display a

message beginning with the word “Recovery” and followed by the same text as

the original message.

page 17 for more information).

Chapter 2. Diagnostics 19

Page 34

Solving undetermined problems

If the diagnostic aids did not diagnose the failure or if the BladeCenter unit is

inoperative, use the information in this section.

Note: When you are diagnosing a problem in the BladeCenter unit, you must

determine if the problem is in the BladeCenter unit, one of the BladeCenter

modules, or in a blade server.

v If the BladeCenter unit contains more than one blade server and only one of the

blade servers has the problem, troubleshoot the blade server that has the

problem.

v If all of the blade servers have the same symptom, it is probably a BladeCenter

unit or module problem.

Check the LEDs on all the power modules. If the LEDs indicate that the power

modules are working correctly, and reseating the BladeCenter components does not

correct the problem, complete the following steps to remove or disconnect the

BladeCenter components one at a time until you reach a minimal configuration or

you locate the problem.

Note: You do not have to remove power from the BladeCenter unit.

1. Shut down the operating system on all blade servers.

2. Make sure that each blade server is turned off; then, pull the release handles to

the open position and slide it out of the bay approximately 1 inch.

3. Disengage power modules 2, 3, and 4, one at a time. To do this, pull the release

handle to the open position and slide the power module out of its bay

approximately 1 inch.

4. Disengage the I/O modules, one at a time. To do this, pull the release handle to

the open position and slide the I/O module out of the bay approximately 1

inch.

Note: The following minimum configuration is required for troubleshooting the

BladeCenter unit. See “Features and specifications” on page 4 for the minimum

operational configuration.

v BladeCenter unit (media tray may be connected)

v One power module in any power module bay

v One management module in either management module bay

v One blower module in either blower module bay

The BladeCenter unit can be checked with the management module Web interface

at each stage as components are removed, and will work in the minimal

configuration. If the minimal configuration does not work, do the following.

1. Recheck the management-module network settings.

2. Disengage the media tray, and slide it out of the bay approximately 1 inch.

Note: The front and rear panel LEDs will not function with the media tray

removed.

3. Move the power module to power module bay 2.

4. Remove the power cords from the power connectors and reconnect them.

5. Replace the management module.

6. Replace the power module.

7. Replace the midplane.

20 BladeCenter H Type 8852, 7989, and 1886: Problem Determination and Service Guide

Page 35

Calling IBM for service

See Appendix A, “Getting help and technical assistance,” on page 61 for

information about calling IBM for service.

When you call for service, have as much of the following information available as

possible:

v Machine type and model

v Microprocessor or hard disk upgrades

v Failure symptoms

– Does the system fail the diagnostic programs? If so, what are the error codes?

– What occurred? When? Where? Did it occur on a single or multiple systems?

– Is the failure repeatable?

– Has the current system configuration ever worked?

– What changes, if any, were made before it failed?

– Is this the original reported failure, or has this failure been reported before?

v Diagnostic program type and version level

v Hardware configuration (print the screen with the system summary information)

v BIOS code level

v Operating-system type and version level

You can solve some problems by comparing the configuration and software setups

between working and nonworking systems. When you compare systems to each

other for diagnostic purposes, consider them identical only if all the following

factors are exactly the same in all the systems:

v Machine type and model

v BIOS code level

v Adapters and attachments, in the same locations

v Address jumpers, terminators, and cabling

v Software versions and release levels

v Diagnostic programs type and version level

v Configuration option settings

v Operating-system control-file setup

Chapter 2. Diagnostics 21

Page 36

22 BladeCenter H Type 8852, 7989, and 1886: Problem Determination and Service Guide

Page 37

Chapter 3. Parts listing

The illustrations and tables in this section identify the replaceable components that

are available for the BladeCenter H Type 8852, 7989, and 1886 unit.

Replaceable components are of three types:

v Tier 1 customer replaceable unit (CRU): Replacement of Tier 1 CRUs is your

responsibility. If IBM installs a Tier 1 CRU at your request, you will be charged

for the installation.

v Tier 2 customer replaceable unit: You may install a Tier 2 CRU yourself or

request IBM to install it, at no additional charge, under the type of warranty

service that is designated for your server.

v Field replaceable unit (FRU): FRUs must be installed only by trained service

technicians.

For information about the terms of the warranty and getting service and assistance,

see the Warranty and Support Information document.

© Copyright IBM Corp. 2010 23

Page 38

Front view

Index Description

1 Chassis shell, without shuttle (all models) 31R3308

2 Bezels, top and bottom (all models) 31R3300

3 Power Module, 2900W, without fan pack 39Y7364

4 Power Module, 2980W high efficiency, with fan pack 39Y7415

5 Filler, power module (all models) 31R3304

6 Fan pack (models equipped with 2900W power module only) 43V7099

7 CD-RW drive, primary (model 4Xx) 39M3545

7 CD-RW drive, alternate (model 4Xx) 39M3501

7 DVD-ROM drive 43W4619

7 DVD drive, multi-burner, primary (model 4Yx) 43W4607

7 DVD drive, multi-burner, alternate (model 4Yx) 43W4609

7 Ultrabay Slim CD-RW/DVD-ROM combo drive 42C0967

24 BladeCenter H Type 8852, 7989, and 1886: Problem Determination and Service Guide

CRU part

number

(Tier 1)

CRU part

number

(Tier 2)

FRU part

number

Page 39

CRU part

number

Index Description

(Tier 1)

7 Ultrabay Slim CD-RW/DVD-ROM combo drive 42C0969

7 DVD drive, SATA, multi-burner (model 4Sx) (option) 44W3254

7 UltraSlim enhanced SATA multi-burner 44W3256

Media tray (supports 9.5 mm optical drives, use with midplane

8

FRU 25R5780)

Media tray (supports 12.7 mm optical drives, use with midplane

8

FRU 25R5780)

8 Media tray (use with midplane FRU 44X2302)

1

1

1

31R3305

43X0299

44X2290

9 System service cards (model 4Sx) 44X2267

9 System service cards (model 4Yx) 43X0457

9 System service cards (model 4Xx) 25R5676

10 Filler, blade server (all models except 4Sx) 39M3317

Filler, optical drive 49Y4868

Filler, optical drive (model 4Sx) 46C5496

1

Your BladeCenter is equipped with one of two different midplane FRUs,

depending on the media tray connector design. The media tray you install must

match the connector on the midplane. Before you replace a media tray, identify the

part number of the midplane FRU by logging on to the Advanced Management

Module and checking the chassis hardware data. See the Advanced Management

Module User's Guide or the Advanced Management Module Command-Line Interface

Reference Guide for more information about viewing BladeCenter hardware data.

CRU part

number

(Tier 2)

FRU part

number

Chapter 3. Parts listing 25

Page 40

Rear view

8

7

1

2

3

4

5

6

Index Description

CRU part

number

(Tier 1)

CRU part

number

(Tier 2)

FRU part

1 Chassis shell (without shuttle) 31R3308

2 Midplane (older models, chassis hardware version v6 or earlier)

2 Midplane (newer models, chassis hardware version v8 or later)

1

1

3 Shuttle, with card and cable assembly (all models) 31R3331

4 Management module (all models) 60Y0621

5 Filler, I/O module bays 1-6 and management module (all models) 25R9934

Blower module (older models, chassis hardware version v6 or

6

earlier)

Enhanced blower module (newer models, chassis hardware

6

version v8 or later)

2

2

44E5083

68Y8205

7 Card and cable assembly, rear LED/serial connector (all models) 31R3307

8 Filler, I/O module bays 7-10, double high (all models) 31R3311

Cable, serial port breakout 40K9608

Cable, serial USB (option) 43X0510

Cable, switch stack, 1 meter (option) 44R8302

Card, 4x Expansion 49Y9976

Cisco Nexus 4001i switch module 46M6072

number

25R5780

44X2302

26 BladeCenter H Type 8852, 7989, and 1886: Problem Determination and Service Guide

Page 41

Index Description

Filler, I/O module bays 7-10, single high (option) 31R3303

Filler, optical drive (option)

Kit, miscellaneous (all models) 31R3306

Kit, rack (all models) 39M3256

Label, system service 44X2289

Module, Infiniband pass-thru (option) 43W4424

Module, 10 GB high speed switch (option) 39Y9265

Module, slim high speed switch (option) 39Y9312

Module, catalyst switch 3110X (option) 41Y8518

Module, catalyst switch 3110G (option) 41Y8519

Module, Inferion 1GB with out stacking (option) 43W4404

Module, Intelligent Copper pass-thru (option) 44W4486

Module, Nortel 1/10 Gb uplink Ethernet switch (option) 44W4407

Module, Nortel 1/10 Gb uplink Ethernet switch (option) 44W4411

Module, Qlogic 4 GB fibre channel 10 port full fabric switch

(option)

Module, Qlogic 4 GB fibre channel 20 port full fabric switch

(option)

Module, Qlogic 4 GB 850 nm fibre channel 20 port pass-thru

switch (option)

Voltaire 40 GB Infiniband switch module 46M6006

CRU part

number

(Tier 1)

CRU part

number

(Tier 2)

46C7009

46C7010

46C7011

FRU part

number

1

Before you replace a midplane FRU, identify the part number of the midplane

you are replacing either by reading the FRU label on the midplane or by logging

on to the Advanced Management Module and checking the chassis hardware data.

See the Advanced Management Module User's Guide or the Advanced Management

Module Command-Line Interface Reference Guide for more information about viewing

BladeCenter hardware data.

2

For a list of supported options for the BladeCenter, see the ServerProven®list at

http://www.ibm.com/servers/eserver/serverproven/compat/us/.

Chapter 3. Parts listing 27

Page 42

Power cords

FRU part

number Description Used in these countries

26R0001 Cable, IEC 320 C20 Worldwide

26R0003 Cable, NEMA L6-30P Canada, Japan, Mexico, United

States of America

26R0009 Cable, 30A 1-phase Korea

39M5436 Cable, IEC 309 32A/IEC 320 C20 Worldwide except: Australia,

Canada, Japan, Korea, Mexico, New

Zealand, United States of America

39M5438 Cable, 30A/IEC 250 C20 Australia, New Zealand

28 BladeCenter H Type 8852, 7989, and 1886: Problem Determination and Service Guide

Page 43

Chapter 4. Removing and replacing BladeCenter components

Replaceable components are of three types:

v Tier 1 customer replaceable unit (CRU): Replacement of Tier 1 CRUs is your

responsibility. If IBM installs a Tier 1 CRU at your request, you will be charged

for the installation.

v Tier 2 customer replaceable unit: You can install a Tier 2 CRU yourself or

request IBM to install it, at no additional charge, under the type of warranty

service that is designed for your computer.

v Field replaceable unit (FRU): FRUs must be installed only by trained service

technicians.

See Chapter 3, “Parts listing,” on page 23 to determine whether a component is a

Tier 1 CRU, Tier 2 CRU, or FRU.

For information about the terms of the warranty and getting service and assistance,

see the Warranty and Support Information document.

Installation guidelines

Before you remove or replace a component, read the following information:

v Read the safety information that begins on page v and “Handling static-sensitive

devices” on page 30. This information will help you work safely.

v Observe good housekeeping in the area where you are working. Place removed

covers and other parts in a safe place.

v You do not have to disconnect the BladeCenter unit from power to install or

replace any of the hot-swap modules in the BladeCenter unit. You must to shut

down the operating system and turn off a hot-swap blade server before you

remove the blade server, but you do not have to remove power from the

BladeCenter unit itself.

v Do not attempt to lift an object that you think is too heavy for you. If you have

to lift a heavy object, observe the following precautions:

– Make sure that you stand safely without slipping.

– Distribute the weight of the object equally between your feet.

– Use a slow lifting force. Never move suddenly or twist when you lift a heavy

object.

– To avoid straining the muscles in your back, lift by standing or by pushing

up with your leg muscles.

v Make sure that you have an adequate number of properly grounded electrical

outlets for the BladeCenter unit.

v Back up all important data before you make changes to disk drives.

v Have a small flat-blade screwdriver available.

v Orange on a component or an orange label on or near a component indicates

that the component can be hot-swapped, which means that you can remove or

install the component while the BladeCenter unit is running. (Orange can also

indicate touch points on hot-swap components.) See the instructions for

removing or installing a specific hot-swap component for any additional

procedures that you might have to perform before you remove or install the

component.

© Copyright IBM Corp. 2010 29

Page 44

v Blue on a component indicates touch points, where you can grip the component

to remove it from or install it in the BladeCenter unit, open or close a latch, and

so on.

v For a list of supported options for the BladeCenter unit, see

http://www.ibm.com/servers/eserver/serverproven/compat/us/.

System reliability guidelines

To help ensure proper system cooling and system reliability, make sure that the

following requirements are met:

v Each of the module bays on the front and rear of the BladeCenter unit has either

a module or a module filler installed.

v Each of the blade bays on the front of the BladeCenter unit has either a blade

server or a blade filler installed.

v Each of the drive bays in a blade server storage expansion option has either a

hot-swap drive or a filler panel installed.

v You have followed the cabling instructions that come with optional adapters.

v A removed hot-swap module, blade server, or drive is replaced within 1 minute

of removal.

v Cables for the optional modules are routed according to the illustrations and

instructions in this document.

v A failed blower is replaced as soon as possible, to restore cooling redundancy.

Handling static-sensitive devices

Attention: Static electricity can damage the BladeCenter unit and other electronic

devices. To avoid damage, keep static-sensitive devices in their static-protective

packages until you are ready to install them.

To reduce the possibility of electrostatic discharge, observe the following

precautions:

v Limit your movement. Movement can cause static electricity to build up around

you.

v The use of a grounding system is recommended. For example, wear an

electrostatic-discharge wrist strap, if one is available.

v Handle the device carefully, holding it by its edges or its frame.

v Do not touch solder joints, pins, or exposed circuitry.

v Do not leave the device where others can handle and damage it.

v While the device is still in its static-protective package, touch it to an unpainted

metal part of the BladeCenter unit or rack for at least 2 seconds. This drains

static electricity from the package and from your body.

v Remove the device from its package and install it immediately without setting

down the device. If it is necessary to set down the device, put it back into its

static-protective package.

v Take additional care when handling devices during cold weather. Heating

reduces indoor humidity and increases static electricity.

Returning a device or component

If you are instructed to return a device or component, follow all packaging

instructions, and use any packaging materials for shipping that are supplied to

you.

30 BladeCenter H Type 8852, 7989, and 1886: Problem Determination and Service Guide

Page 45

Removing and replacing Tier 1 CRUs

Replacement of Tier 1 CRUs is your responsibility. If IBM installs a Tier 1 CRU at

your request, you will be charged for the installation.

The illustrations in this document might differ from your hardware.

Removing a bezel

When working with some devices, such as the media tray and power modules,

you must first remove the top or bottom bezels to access the devices.

To remove either bezel, complete the following steps.

Release buttons

Release buttons

1. Press the blue release button on each end of the bezel.

2. Pull the bezel away from the BladeCenter unit.

Chapter 4. Removing and replacing BladeCenter components 31

Page 46

Installing a bezel

To install either the top or bottom bezel, complete the following steps.

Release buttons

Release buttons

1. Align the blue tabs on the ends of the bezel with the corresponding holes in the

front of the BladeCenter unit.

2. Firmly press the bezel into the BladeCenter unit until the tabs lock it into place.

32 BladeCenter H Type 8852, 7989, and 1886: Problem Determination and Service Guide

Page 47

Removing and replacing the media tray and optical drive or

optical drive filler

Your BladeCenter is equipped with one of two different media tray FRUs,

depending on the midplane connector design. Before you replace a media tray

FRU, identify the part number of the media tray you are replacing either by

reading the FRU label on the media tray or by logging on to the Advanced

Management Module and checking Hardware VPD information for the Media

Module. See the Advanced Management Module User's Guide or the Advanced

Management Module Command-Line Interface Reference Guide for more information

about viewing BladeCenter hardware data.

Notes:

1. If your BladeCenter Media Module information is version v4 or later, it is

compatible only with chassis hardware midplane version v8 (FRU PN 44X2302)

or later.

2. The following Media Module FRU PNs are compatible only with chassis

hardware version v6 midplane (FRU 25R5780) or earlier:

v Media module FRU PN 31R3305

v Media module FRU PN 43X0299

v Media module FRU PN 44X2268

Removing the media tray and optical drive or optical drive filler

To remove the media tray and optical drive or optical drive filler, complete the

following steps.

Retainer clip

Optical drive

retainer tab

Note: These instructions assume that the BladeCenter unit is connected to power.

1. Read the safety information that begins on page v and “Installation guidelines”

on page 29.

2. Remove the top and bottom bezels (see “Removing a bezel” on page 31).

3. Press the release tabs on the top and bottom of the media tray; then, pull the

tray out of the BladeCenter unit.

4. Place the media tray on a clean, static-free surface with the circuit board and

optical drive facing up.

Attention: To prevent damage to the circuit board, do not touch or apply

pressure to the circuit board or any of its components.

Media tray

release tabs