Page 1

I

E T

CUSTOMER

ENGINEERING

B-1

ADJUSTMENT

MANUAL

Page 2

®

ETD

CUSTOMER

ENGINEERING

8-1

ADJUSTMENT

MANUAL

all nOgk

ts

to

reproduce t

Ms

matenOal are reserved

by

IBM

Page 3

TABLE

OF

CONTENTS

BACKSPACE

CARRIAGE.

CARRIAGE RETURN

ESCAPEMENT

KEYLEVERS

AND

CAMS 7

MARGIN RELEASE

MARGIN SET

MOTOR

AND

DRIVE

OPERATIONAL CAMS

PAPER

FEED.

RAILS

· 19

9

•

32

4

•

13

•

12

1

•

1'8

·

14

· 11

RIBBON

•

40

RIBBON LIFT o 43

SHIFT

SPACEBAR.

TABULATION.

• 23

• 39

.26

Page 4

MOTOR AND

DRIVE

MODEL

B1

ADJUSTMENTS

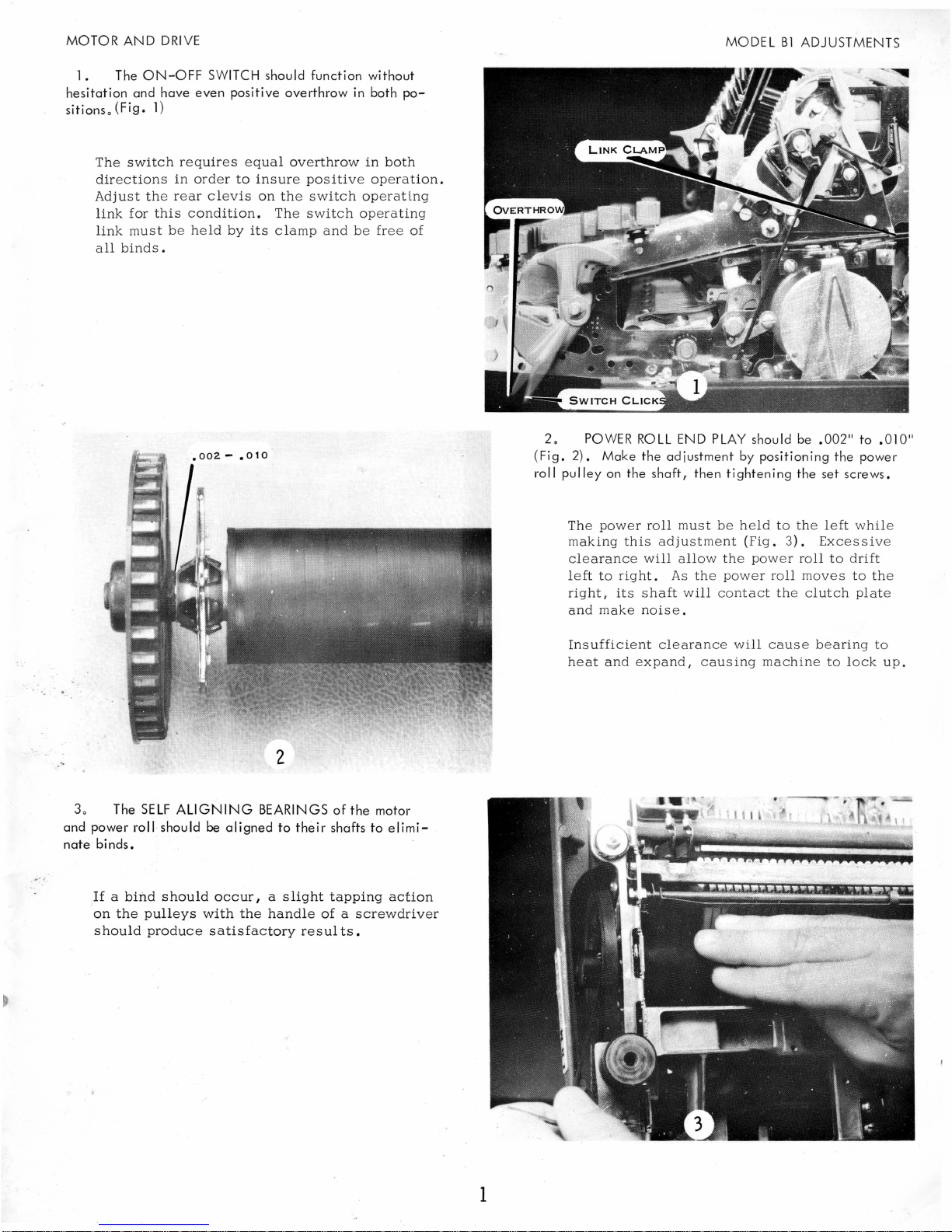

1. The

ON-OFF

hesitation and have

sitions.

(Fig.

The

switch

directions

Adjust

link

link

all

the rear

for

must be

binds.

1)

requires

in

this

SWITCH

even

positive overthrow

equal

order

to

clevis

condition.

held

by

its

should function without

in

both

overthrow

insure

on

the

The switch

clamp

positive

switch opera

and

in

both

operation.

operating

be

free

po-

ting

of

2.

(Fig.

roll

POWER

2).

Make

pulley

on the

The power

making

clearance

left

to

right,

and

its

make

ROLL

the

adjustment by positioning the power

shaft,

roll

this

adjustment (Fi

will

right.

shaft

noise"

END

then

must be

allow

As

the

will

PLAY

should be

tightening

held

to

g"

the

pow

power roll

contact the

.002"

the set screws.

the

left while

3)"

Excessiv

e r

roll

to

moves

clutch

to

drift

to the

plate

.010"

e

" 0

3. The

SELF

ALIGNING

and power roll should

nate

binds.

If

a

bind

should

on

the

pulleys

should

produce

BEARINGS

be

aligned

occur

I a

with

the

satisfactory

to

their

slight

handle

of

the

motor

shafts to

tapping

of a screwdriver

resul

ts.

elimi-

action

Insufficient

heat

and

expa

clearanc

nd I ca

e w

us

ill

ing

cause

machine

bearing

to lock

to

up"

1

Page 5

MODEL

B1

ADJUSTMENTS

5.

POWER

ROLL

SPEED

is

adjusted

by a two-step

motor

pu

Iley o The motor

pulley

shou

Id

be positioned on

the motor shaft to

align

the belts

~nd

the

pulleys (Fig.

5).

A

14-tooth

pulley

is

generally

used

for

the

Elite

or

12

pitch

type

styles, while

the

15-

tooth

pulley is

us

ed

for

the

larg

er

Pica

type

styles

or

bold

face type sty

les.

'

2

MOTOR AND

DRIVE

40

Adjust the

DRIVEN

BELT

by positioning the

inter

-

mediate

pulley

shaft.

The shaft incorporates a

left-hand

thread

so

that

pulley

rotation tends

to

ti ghten the

shaft.

The

deflection

of

the belt should

be

approximately 3/

8"

(Fig.

4).

60 Adjust

the

DRIVE

BELT

for approximately 3/ 16"

deflection

by positioning the motor adiusting screw for-

ward or back

in

its

elongated

mounting hole

(Fig.

4).

To

adjust

the

drive

belt

tension

on

ring

mount-

ed

motors,

loosen

the

motor

adjusting

screw

and

the

ring

mount

bracket

screw

(Fig

~

6).

The

motor

may

then

be

moved

front

to

rear

for

pro-

per

belt

tension.

After

tightening

these

screws,

check

the

motor

housing

to

be

sure

it

is

paral-

lel

to

the

frame

and

that

the

ring

mount

screws

are

tight.

To

adjust

the

drive

belt

tension

on

the

shaft

mounted

motor I it

is

necessary

only

to

loosen

the

motor

adjusting

screws.

Page 6

MOTOR

AND

DRIVE

The

following

are

the

effects

of

loose

or

tight

belts:

LOOSE BELTS

1.

Belt

noise

2.

Belt

climbing

on

pulley

3.

Uneven

impression

(due

to

momentary

slowing

of

the

power

roll

after

shift

or

backspace

operation).

4.

Be

lt

falling

off

when

machine

is

moved

TIGHT BELTS

1.

Belt

noise

2.

Motor

vibration

transmitted

to

machine

3.

Failure

of

motor

to

start

(extremely

tight

belts)

.

Properly

adjusted

belts

should

run

quietly,

bounce

only

slightly

during a shift

operation,

and

allow

the

drive-mechanism

to

coast

to a smooth

stop

as

the

switch

is

turned

off.

MODEL

Bl

ADJUSTMENTS

3

Page 7

MODEL

B1

ADJUSTMENTS

ESCAPEMENT

1.

. The MAIN SPRING tension

the

loop

of

the-

carriage

the

spring drum

(Fig.

7).

tension

is

tape

adjusted by

on

various lugs

placing

of

k

Carr.

CAUTION:

tens

injury

ning s pring

Length

12"

16"

20'

24"

20"

ion

can

.'

.

tape

Use

loop

result

drum.

Extreme

extreme

from

Left

2

1/2

2

1/2

2

3/4

2

3/4

3 4

care

from s pring

fingers

Extreme

3

3

3

3

when

drum.

caught

Right

3/8

Ib

1/2

Ib

5/8

Ib

7/8

Ib

1/8

Ib

removing

Serious

by

spin-

Carriage

full

left

riage

(excluding

is

measured

should

tension

to

the

with

measure

full

air

as

should

right

cylinder

the

push

follows

be

checked

position

range).

pull

(Fig.

of

scale

8).

from

the

Tension

and

the

car-

4

2.

Adjust UNIVERSAL

the escapement pawl

g.

9)

(Fi

~

at

the same

BAR

so

that

di

stElnce

all

from

typebars

the

trip

PLATE

N

Page 8

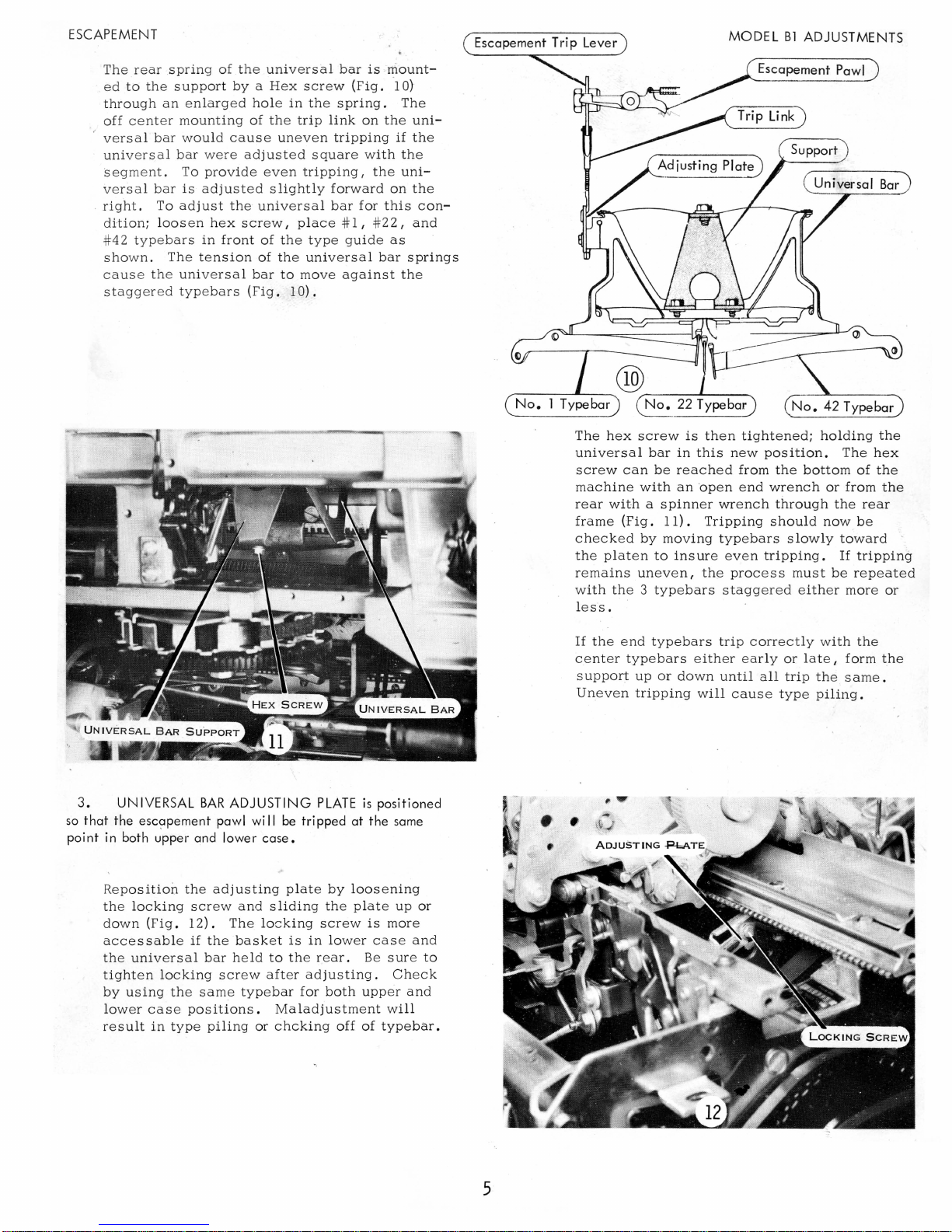

ESCAPEMENT

The

rear ,spring

ed

to

the

through

off

center

versal

universal

segment.

versal

,

right.

dition;

#42

typ

shown.

cause the

staggered

of

the

support by a Hex

an

enlarged

mounting

bar

would

bar

To

bar

is

To

adj

loosen

eba

rs

The

universal

typebars

cause uneven

were

provide

adjusted s lightly

ust

the

hex

scr

in

front

tension

universal

screw

hole

in

the

of

the

trip

adjusted

even

universal

ew I place # I,

of the

of

bar

(Fig.

square

tripping I the

type

the

universal

to

move

10).

bar

is ,mount-

(Fig.

spring.

link

on

tripping

with

forward

bar

for

guide

against

the

on

this

#22,

as

bar

'10)

The

uni-

if

the

the

uni-

the

and

springs

the

con-

Escapement Trip Lever

No.1

Typebar

The

hex

universal

screw

machine

rear

frame

checked

the

platen

remains

with the 3

l

ess

No.

22 Typebar

screw

can

with a spinner

(Fig.

uneven,

.

bar

be

with

11).

by

moving

to

typebars

is

in

reached

an 'open

insure

MODEL

then

tightened;

this

new

from

end

wrench

Tripping

typebars

even

the

proces s must

staggered

Bl

ADJUSTMENTS

, Escapement Pawl

holding

position.

the

wrench

through

should

slowly

tripping.

bottom

now

either

The

or

from

the

toward

If

be

more

repeated

Bar

the

hex

of

the

the

rear

be

tripping

or

3.

so

that

point

UNIVERSAL

BAR

the escapement pawl

in

both u'pper and lower

Reposition

the

locking

down

accessable

the

universal

tighten

by

using

lower

result

(Fig.

locking

case

in

the

screw

12).

if

bar

the

same

positions.

type

the

piling

ADJUSTING

wi

II

case.

adjusting

and

sliding

The

locking

basket

held

to

screw

after

type

or

PLATE

is

positioned

be

tripped at the same

plate

by

loosening

the

plate

up

screw

is

more

is

in

low

er

case

the

rear.

adjusting.

bar

for

Maladjustment will

chcking

both

off

Be

upp

of

typebar.

sure

Check

er

or

and

and

to

If

the

center

support

Uneven

end

typebars

typebars eith

up

or

down

tripping

trip

will

correctly

er early

until

all

cause

or

late I form

trip

type

with

the

same.

piling.

the

the

5

Page 9

MODEL

Bl

ADJUSTMENTS

ESCAPEMENT

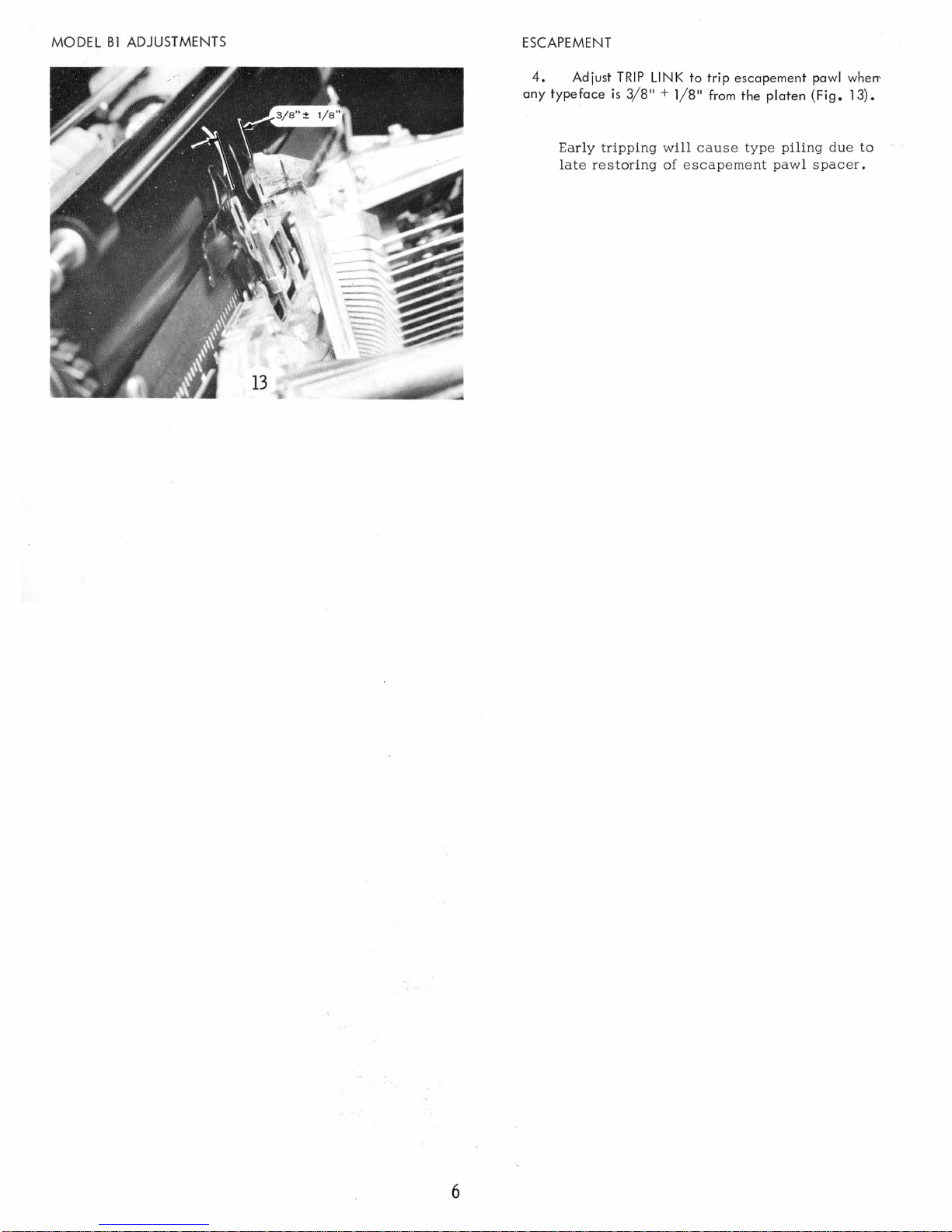

4.

Adjust

any

typeface

Early

tripping will

late

restoring

TRIP

is 3/8"

LINK

+ 1/

of

to

trip

escapement

8"

from

the

cause type

escapement

platen

piling

pawl

pawl wherl'

(Fig.

13).

due

to

spacer.

6

Page 10

KEYLEVERS

AND

CAMS

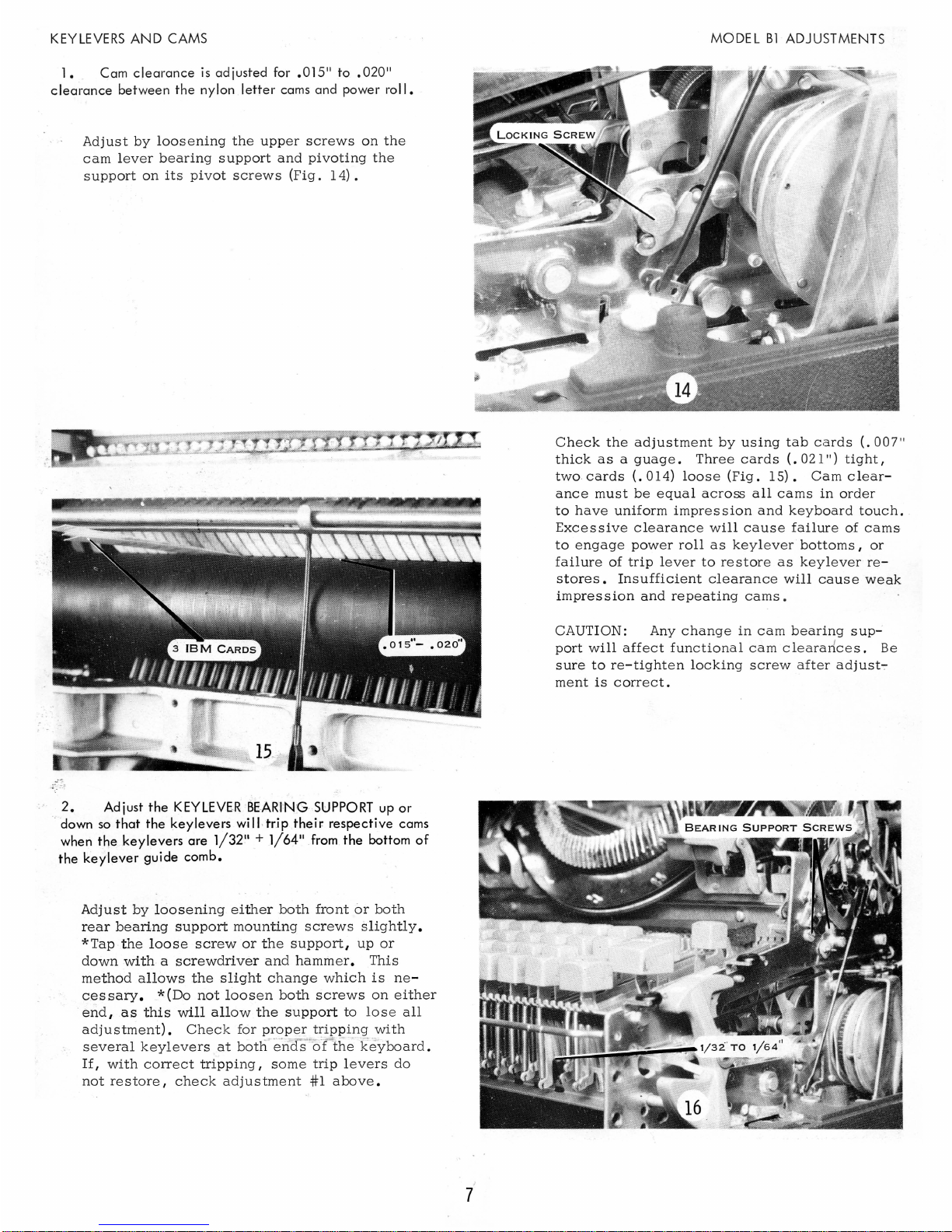

1.

Cam

clearance

is

adjusted

for

.015"

to

.020"

clearance

between

the

nylon

letter

cams

and

power

roll.

Adjust

by

loosening

the

upper

screws

on

the

cam

lever

bearing

support

and

pivoting

the

support

on

its

pivot

screws

(Fig.

14).

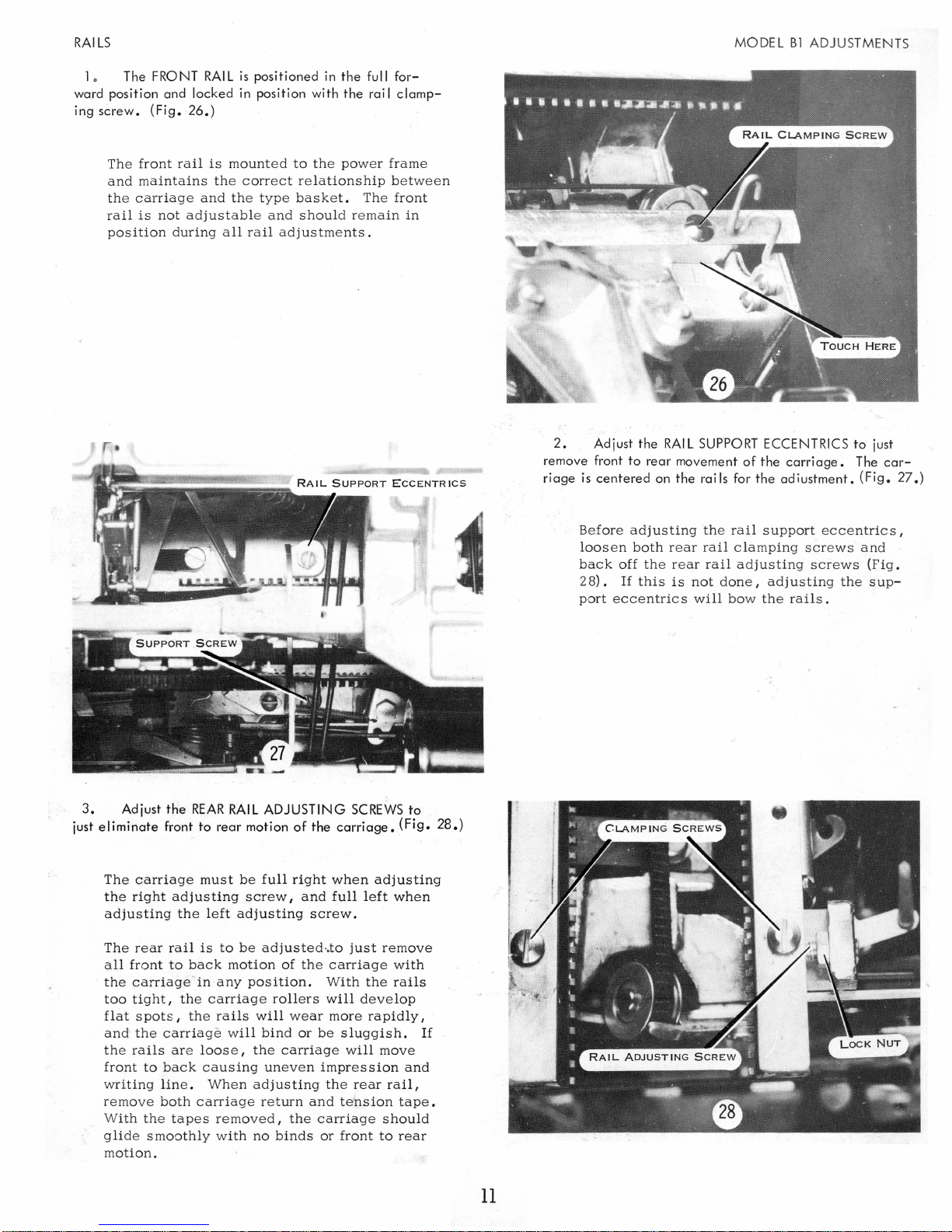

2.

Adjust

the

KEYLEVE,R BE-

ARINGSUPPORT

up

or

.

down

so

that

the

keylevers

will, trip

their

respective

cams

when

the

keylevers

are

1/32

11

+

1/64"

from

the

bottom

of

the

keylever

guide

comb.

Adjust

by

loosening

either

both

front

or

both

rear

bearing

support

mounting

screws

slightly.

*Tap

the

loose

screw

or

the

support,

up

or

down

with a screwdriver

and

hammer.

This

method

allows

the

slight

change

which

is

ne-

ces

sary.

* (Do

not

loosen

both

screws

on

either

end,

as

this

will

allow

the

support

to

lose

all

adjustment).

Check

for

proper

tripping

with

several

keylevers

at

both

end s

""-of;"";

the keyboard.

If,

with

correct

tripping,

some

trip

levers

do

not

restore,

check

adjustment

#1

above.

7

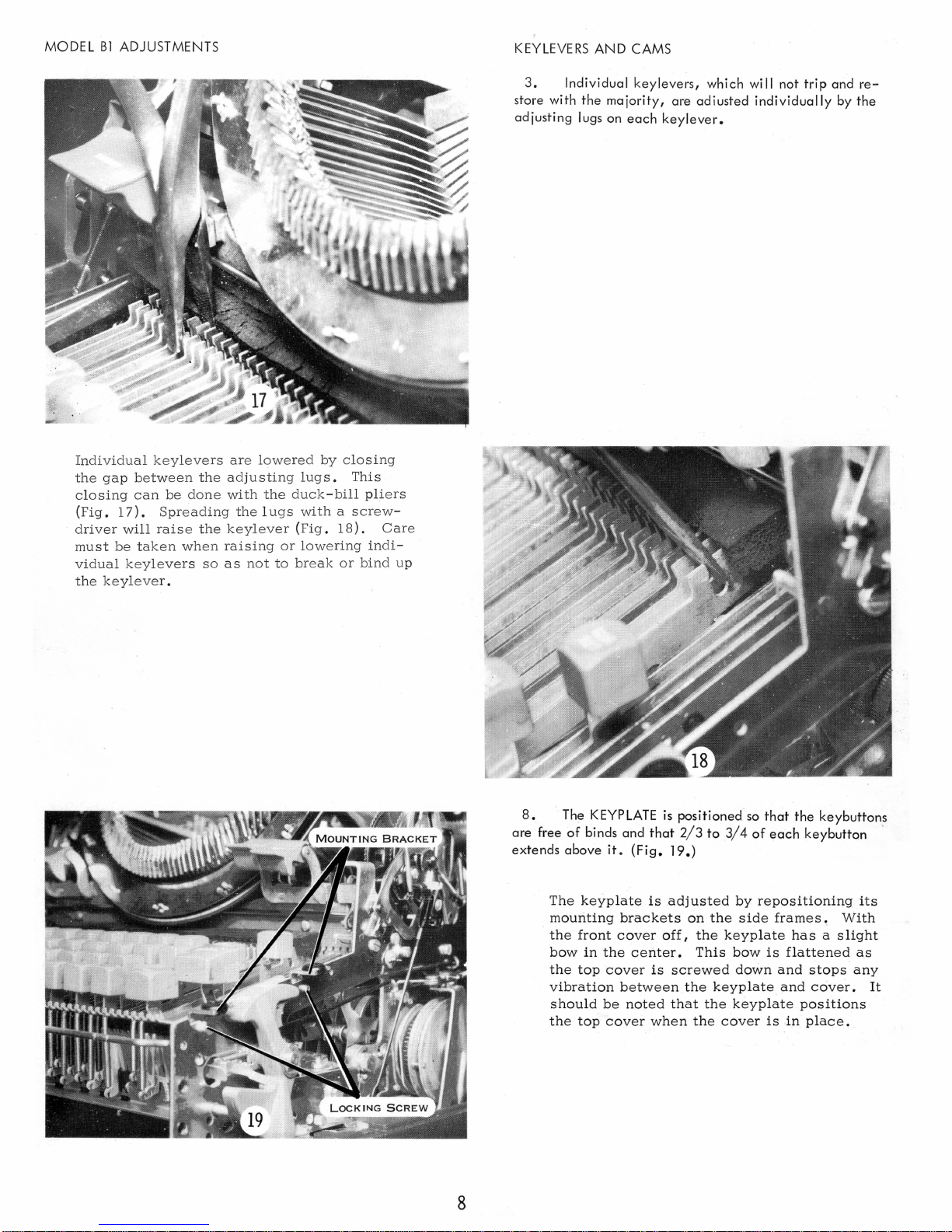

MODEL

B1

ADJUSTMENTS

Check

the

adjustment

by

using

tab

cards

(.007"

thick

as a guage.

Three

cards

(.

021")

tight,

two

cards

(.014)

loose

(Fig.

IS).

Cam

clear-

ance

must

be

equal

across

all

cams

in

order

to

have

uniform

impression

and

keyboard

touch.

Excessive

clearance

will

cause

failure

of

cams

to

engage

power

roll

as

keylever

bottoms,

or

failure

of

trip

lever

to

restore

as

key

lever

re-

stores.

Insufficient

clearance

will

cause

weak

impression

and

repeating

cams.

CAUTION: Any

change

in

cam

bearing

sup-

port

will

affect

functional

cam c leara11ces.

Be

sure

to

re-tighten

locking

screw

after

adjust-:-

ment

is

correct.

Page 11

MODE L

Bl

ADJUSTMENTS

KEYLEVERS

3.

AND CAMS

Ind

ividual

keylevers,

which will not

store with the majority, are adiusted

adjusting lugs on

each

keylever.

trip

individually

and re-

by the

Individual keylevers

t

he gap

closing

(Fi

driver will

mu

vidual

the

g.

17).

st

be taken

keylevers

keyleve

between

can

be

Spreading

raise the

r .

the adjustin

done

when rai

so

are

lowered

with

the

the 1 ugs with a screw

keylever

sing

as

not

by

closing

g l

ugs. This

duck-bill pliers

(Fig . 18) .

or

lowering indi-

to

break

or bin

-

Care

d up

8.

The

KEYPLATE

of

are free

binds and

extends above it .

The

keyplate

mounting

the

front

bow

in

the

the

top

cover

vibration

should

the

top

be

cover

that

(Fig.

is

brackets

cover

center.

is

between

noted

when

is

positioned

2/ 3

to

19.)

adjusted

on

off I the

This

screwed

the

that

the

the

so

3/4

of

by

the

side

keyplate

bow

down

keyplate

keyplate

cover

that

the

keybuttons

each

keybutton .

repositioning

frames ~ With

has a slight

is

flattened

and

stops

and

cover.

positions

is

in

place.

its

as

any

It

8

Page 12

CARRIAGE

1.

Adjust the

eliminate

verticle

PLATEN

movement

lATCH ECCENTRICS to just

of

the

platen.

(Fig.

20.)

MODEL

B1

ADJUSTMENTS

Loosen

attempting

w

writing

too

locking

ill

allow the platen

line.

tight.

nut

to

adjust· it.

Latches

on the

ecce

ntric before

Excessive clearance

to

mov e I

will

giving

work

hard

unev

if

adjusted

en

2.

Adjust

PLATEN

front to back movement

Some

machines will have locking scr

and

eccentrics;

With

both

types I lo

and

snug

adjust.

but eas

Correct

ily

CONTROL YOKES to remove

of

Platen.

others

osen the locking scr

re mov

(Fig.

21.)

only loc

adjustment ins

able platen.

kin

g s

ures

ews

crews.

ews

a

3.

Position

the

platen

adjusting

The

ward.

the

guide shaft

plates.

multiple

(Fig.

PLATEN

eccentrics

22.)

copy

control

RETAINING

tightly

lever

PLATES

to hold

against the platen

must

be

for-

9

Page 13

MODEL

Bl

ADJUSTMENTS

CARRIAGE

4.

Adjust RING AND

carriage

ing

and

eccentrics

CYLINDER

by

moving inner

platen front to rear with the ,platen adiu!;t-

(Fig. 23).

There

paper

the

proper

Check

plat

en

change

Be

fore

loosen

(Fig.

25)

screws.

should

as

be a slight

it

is

removed

position

this

adjustment

to

insure

across

the

adjusting

the

feed roll center

and

both

ring

the

rear

when

(Fig.

at

and

platen.

platen

platen

drag

on

the

24).

both

cylinder

adjusting

support

retaining

the

platen

ends

strip

of

will

eccentrics

screws

is

the

not

plate

of

in

I

Check

sheet

ribbon

in

a

the

I

RING AND CYLINDER

of

bond

paper

in

operating

lower

case

position

strip

of

bond

paper

ribbon

and

the

in

the

position.

against

used

sheet

with a single

machine I and

Hold a typebar

the

as a guage

of

bond

paper.

ring

the

with

between

10

5.

the

Adjust

eccentric

The

center

any

change

justment.

be

necessary

support

support.

Correct

relation

multiple

FEED

ROLL

CENTER

collar

on the platen guide shaft. (Fig.

supports

in

carriage

On

long

carriage

to

loosen

before

support

between

copy

adjusting

adjustment

platen

control

must

ring

is

SUPPORT

be

and

machines I it

the

margin

the

insures

and

feed

adjusted.

to just touch

readjusted

cylinder

rack

feed

roll

the

rolls

25.)

after

ad-

will

center

center

proper

as

the

Page 14

RAILS

10

The FRONT

RAI L is

ward position and locked

ing

screw.

The

front

and

maintains

the

carriage

rail

is

position

(Fig.

not

during

26.)

rail

is

the

and

adjustable

all

positioned

in

position with

mounted

correct

the

type

and

rail

in

the

the

to

the

power

relationship

basket.

should

adjustments.

full

rai I

The

remain

for-

clamp-

frame

between

front

in

2.

Adjust the

remove front to

riage

is

centered

RAI L SUPPORT

rear

movement

on

the

rails for the

MODEL

Bl

ADJUSTMENTS

ECCENTRICS to just

of

the

carriage.

adjustment.

The

(Fig.

car-

27.)

3.

just

Adjust

eliminate

The

carriage

the

right

adjusting

The

rear

all

front

the

carriage

too

tight,

flat

spots,

and

the

the

rails

front

to

writing

remove

With

the

glide

smoothly

motion.

the

REAR

RAIL

ADJUSTING

front to rear motion

must

be

full

adjusting

the

rail

to

back

in

the

the

carriage

are

back

line.

both

carriage

tapes

left

adjusting

is

to

motion

any

carriage

rails

will

loose,

causing

When

removed,

with

screw I and

be

adjusted·.to

position.

will

bind

the

uneven

adjusting

return

no

of

right

of

the

rollers

wear

or

carriage

the

binds

SCREWS

the

carriage.

when

full

screw.

just

carriage

With

will

more

be

sluggish.

will

impression

the

rear

and

tension

carriage

or

front

(Fig.

adjusting

left

when

remove

with

the

rails

develop

rapidly,

move

rail,

tape.

should

to

rear

to

and

If

28.)

Before

loosen

back

28).

port

adjusting

both

off

the

If

this

eccentrics

rear

rear

is

the

rail

rail

not

will

rail

clamping

adjusting

done,

bow

support

screws

adjusting

the

rails.

eccentrics,

and

screws

the

(Fig.

sup-

11

Page 15

MODEL

The

by

necessary

contact

erated.

compensates

and

form

adjustment.

the

set

adjusted

set

hairpin

lever

Bl

ADJUSTMENTS

margin

the

stop

margin

to

the

right

This s light

the

margin

the

margin

mounting

lever

mounting s'crew

to

remove

lever

without

spring

(Fig.

29).

is

control

adjust

side

for

the

will

set

Move

screws

binding

must

spring

lever.

the

of

off

center

tension

set

accurately.

lever

the

bracket

(Ficj.

all

side

reliably

loaded

margin

the

notch

of

when

30).

and

movement

the

restore

to

the

Therefore,

set

lever

as

adjustment

the

margin

Do

making

after

loosening

The

margin

lock

nut

set

lever.

the

left

it

this

must

of

set

it

to

is

not

the

The

is

op-

stop

be

MARGIN

1.

lever

enters

resting

at

SET

Adjust

the

the

the

MARGIN

notch

in

left margin

SET

BRACKET

so

the margin stop with

(Fig.

29).

that

the

the

set

carriage

12

2.

Adjust

the

MARGIN

set lever just

clears

the

margin rack with

keybutton fully depressed •

.

If

the

margin

not

reliably

m~rgin

too

low,

as

the

set

tween

the

rack.

it

set

release

If

the

will

not

lever

margins.

SET

lever

the

margin

cam

is

incorrectly

LINK

is

set

margin

set

over'the

so

thatthe

the

too

high

stop

lever

margin

operated

margin

margin set

I

it

will

from

the

is

set

stop

be-

Page 16

MARGIN

1.

the margin control lever will

.010"

RELEASE

Adjust MARGIN

to 0015".

(Fig.

RELEASE

32.)

ECCENTRIC

clear

the margin rack

so

that

by

LINE

1.

crank

the arm

(Fi

g.

LOCK

The

is

adjusted

of

33.)

VERTICAL

so

that

the

lower bellcrank

LINK

the

MODEL

from

angle

81

the upper line lock

between

is

approximately

ADJUSTME.NTS

bell-

the

link and

90°.

2.

Adjust the

. ing manner:

a.

b.

c.

do

e.

f.

LINE

LOCK

PUSH

ROD

in the follow-

Unhook

Position

Push

rear

lock

Push

Push

Match

the hole in the lower line lock

the

push

rod.

the

carriage

the switch lever far enough to the

to

allow

the

the

key

lever.

down and hold a

forward on the push rod until it stops.

the

pin in the push rod clevis with

at

the right margin.

linelock

bracket

letter

keylever.

to

un-

bellcrank.

This

adjustment

transmitted

to

insures

line

lock

maximum

push

rod.

motion

This

adjustment

action

without

insures

choking

maximum

off.

locking

13

Page 17

MODEL

Bl

ADJUSTMENTS

PAPER

FEED

Too

much

decrease

to

the

Check

flector

clearance

their

rear

feed

adjusting

out.

tension

rolls.

plate

at

the

and

adjustment

front

add

feed

greater

with

rolls

tension

the

will

de-

1. Position the ADJUSTING

pressu

re

leve

are

inserted

the front feed rolls have a

platen.

rolls should be free to turn

rs (F ig. 35)

between

If

five

IBM

the r

cards

so

ear

are

PLATES

that

when two I

feed rolls and the

sl

ight

amount

inserted,

(Fig.

34).

on

the

rear

BM

cards

of

the front feed

platen,

drag on the

14

2.

Support LUGS.

levels

(Fig.

35)

so

• 030" (one to four I

and

the

platen.

Card

strips

deflector

check

flector

must

the

and

not

and

clearance

bind

Form

that

there

BM

cards) between

can

be

between

platen

the

(Fig. 3 6).

platen

the lugs on

is a clearance

inserted

feed

rolls

between

or

feed

at

the

the

the

The

the

rear

of

paper

ends

to

paper

deflector

rolls.

pressure

.oor to .

deflector

of

the

accurately

de-

Page 18

PAPER

FEED

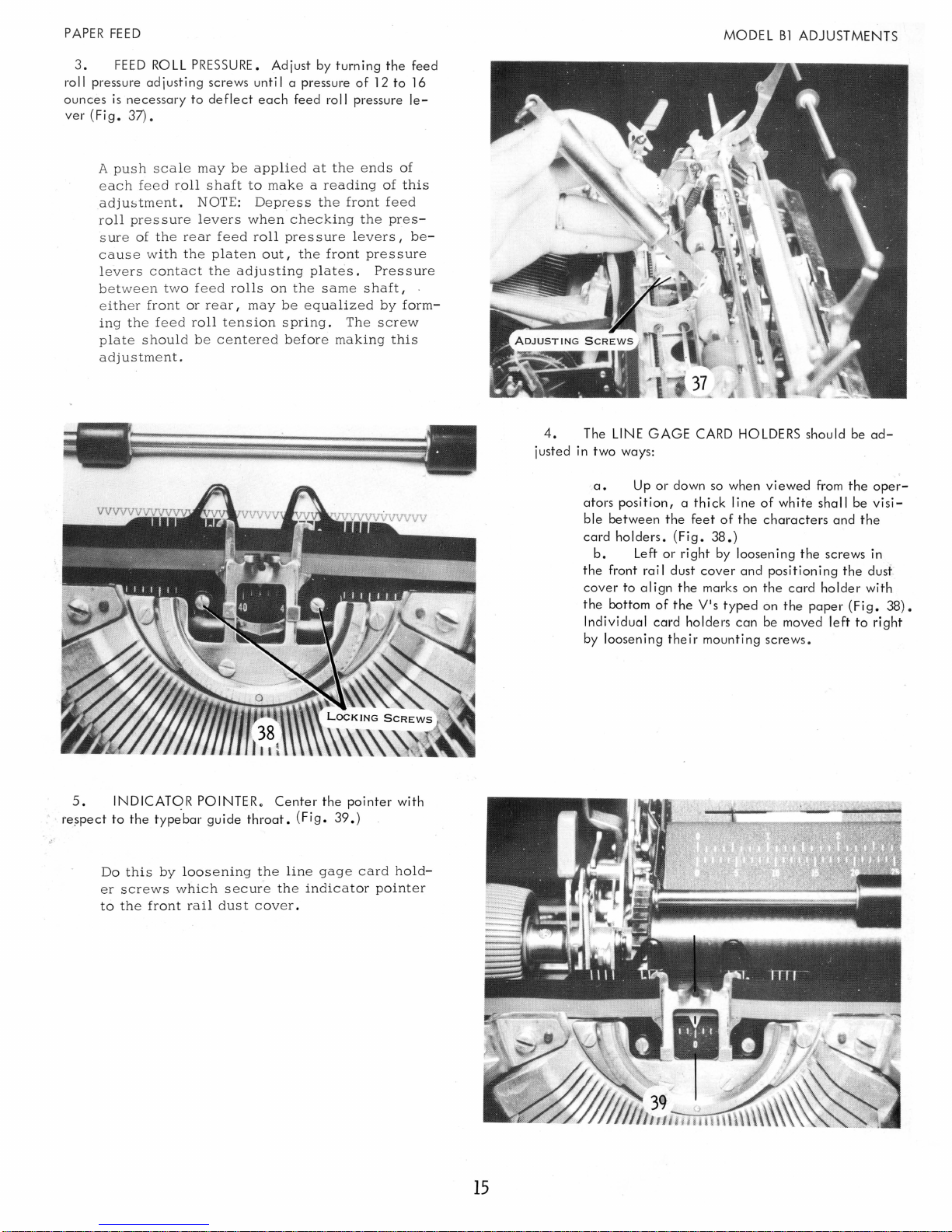

3.

FEED

r

oll

pressure

ounces

ver(Fig.37).

A

is

push

necessary

each

adjustmen

roll

s u

re

cause with

levers

bet

ween tw

e

ith

er fr

ing the f

pl

ate

adjustme

ROLL PRESSURE.

adjusting

to

sca

le

may

feed roll

pres

of the

shaft

t.

NO

sure levers

re

ar

the

c o

ntact

o f

eed rolls

ont

or rear I

eed

roll

should

be cent

nt.

Adjust

screws

until a pressure

deflect

plat

each

feed

be

applied

to

make

TE:

Depress the

whe n

checking

feed

roll

pre s sure lever

e n

out I the front pressure

the adjusting

on

the same

may

be equaliz

tension spring.

ered before making

by

turning

roll

at the

a r

eadi

front

plates.

The screw

the

of

12

pressure

ends

ng

of

feed

the

press I b

Pre

shaft

ed

by

thi

to

of

this

ssur

I

form-

feed

16

le-

e-

s

MODEL

B1

ADJUSTMENTS

e

4.

The

LINE

justed

in

two

GAGE

ways:

CARD HOLDERS

should

be

ad-

re?pect

~.

5.

INDICATOR

to

the

type'bar

Do

this by

er

screws which

to the

front

POINTER.

guide

throat.

loosening the

s e

cure the indicator

rail

dust

cover.

Center

(Fig.

line gage

the

pointer

39.)

card

pointer

with

hold-

a.

Up

ators

position, a thick

ble

between

card

holders.

b.

Left

the

front

cover

to

align

the

bottom

Individual

by

loosening

rail

card

or

of

down

the

(Fig.

or

dust

the

their

feet

right

cover

the

marks

ViS

holders

mounting

so

of

38.)

by

typed

when

line

viewed

of

white

the

characters

loosening

and

positioning

on

the

on

can

be

screws.

the

card

the

paper

moved

from

shall

and

screws

holder

left

the

be

the

(Fig.

the

to

oper-

visi-

in

dust

with

38).

right

15

Page 19

MODEL

7.

lationship

allow

the

catching

Bl

ADJUSTMENTS

REAR

PAPER TABLE.

between

paper

to

(Fig.

41).

the

pass

Adjust

deflector

freely

in

this

and

either

so

the

paper

direction

that

the

table

without

re-

wi

PAPER

FEED

6.

FRONT

manner:

Front

platen.

rear

II

a.

b.

c.

d.

as

shaft

(Fig. 40) .

zero

en

scal

paper

PAPER SCALE.

Loosen

the

collar

which

positions

Position

left

Move

Position

It

position.

the

with

the

e s

must rest

must

is

the

left

carriage

the

front

the

collar

also

inserted.

Adjust

in

the

on

the

platen

the

front

margin

indicator

screw (Fig. 39) .

evenly

be

to

the

paper

free to

stop

left

scale

pointer

across the

move

following

guide

paper

to

its

margin.

to

align

and

front

scale

extreme

the

tight-

to

This

clamp

bracket

Check

not

touching

is

adjusted

the

(Fig.

to

adjusting

42).

be

sure

the

by

the

locking

plates

that

the

deflector.

to

rear

screws

the

paper

paper

table

that

table

is

16

Page 20

PAPER

FEED

8.

FRONT

graduations

on

the

front

on

the

paper

PAPER

front

scale.

TABLE.

paper table

(Fig.

Adjust

43.)

are

this

in

so

that

line with

the

those

MODEL

Bl

ADJUSTMENTS

Adjust

on the

paper

table

its

by

carriage

table

to rest even

entire length.

forming the

riage

tie rod.

loosening

tie

(Fig.

44). Also adjust the

ly

stop

lugs which

the

rod

on

This

positioning

and

moving

the

platen

is

acc

omplish

contact

collars

the

rear

paper

throughout

ed

by

the

car-

17

Page 21

MODEL

Bl

ADJUSTMENTS

OPERATIONAL

CAMS

Operational

l

easing the

ing

the

position

respect

correct

rear h

th

lug

cams

e re l

by the

to

when

alf

ease lever

must

cam

cam with

the

the

of the

thickness

be

checked

®

clearance

of

the

cam

lug.

release

cam ,lug.

should. fall

is

checked

the

power

cam

release lever with

The adjustment

lever

On

the

behind

of the

on

lug.

both

ADJUSTABLE

off I and

rests

shift

~he

Double

lobes.

on

STOP

by

the

cam

SCRE

re-

not-

is

cam

lob

1. Adiust OPERATIONAL CAM

.010" to 0015"

Adjustable

operational

lock

45 I 46, and

The

of a stop

NOTE: All

a

W

I

ed

similar

ance.

will

CAM

from

stop

nut

before

ribbon

be

RELEASE

cam

screw.

operational

manner

Therefore I the

given

LEVER

the power roll 0

screws

cam

clearanc

adjusting

47) .

has

an

for

only

in

are

eccen

cams

the.

theory

this

CLEARANCE

used

e .

Be

sure

stop

screws.

tric

stop

are

adj

010"

to

of

adjustment

section.

to

change

usted

.015"

for

to

loo

(Fig.

instead

clear-

sen

in

\

~

CAM

LATCHED

~

CAM

~

®

Insufficient

cam

to

buzzing

duces

ride

sound.

the

cam

on

effective

RELEASE

clearance

the

power

Excessive

rise

SINGLE

LOBE

will

roll

clearance

of

the

CAM

and

ASSEMBLY

cause

make

cam.

the

re-

a

-'.

18

Page 22

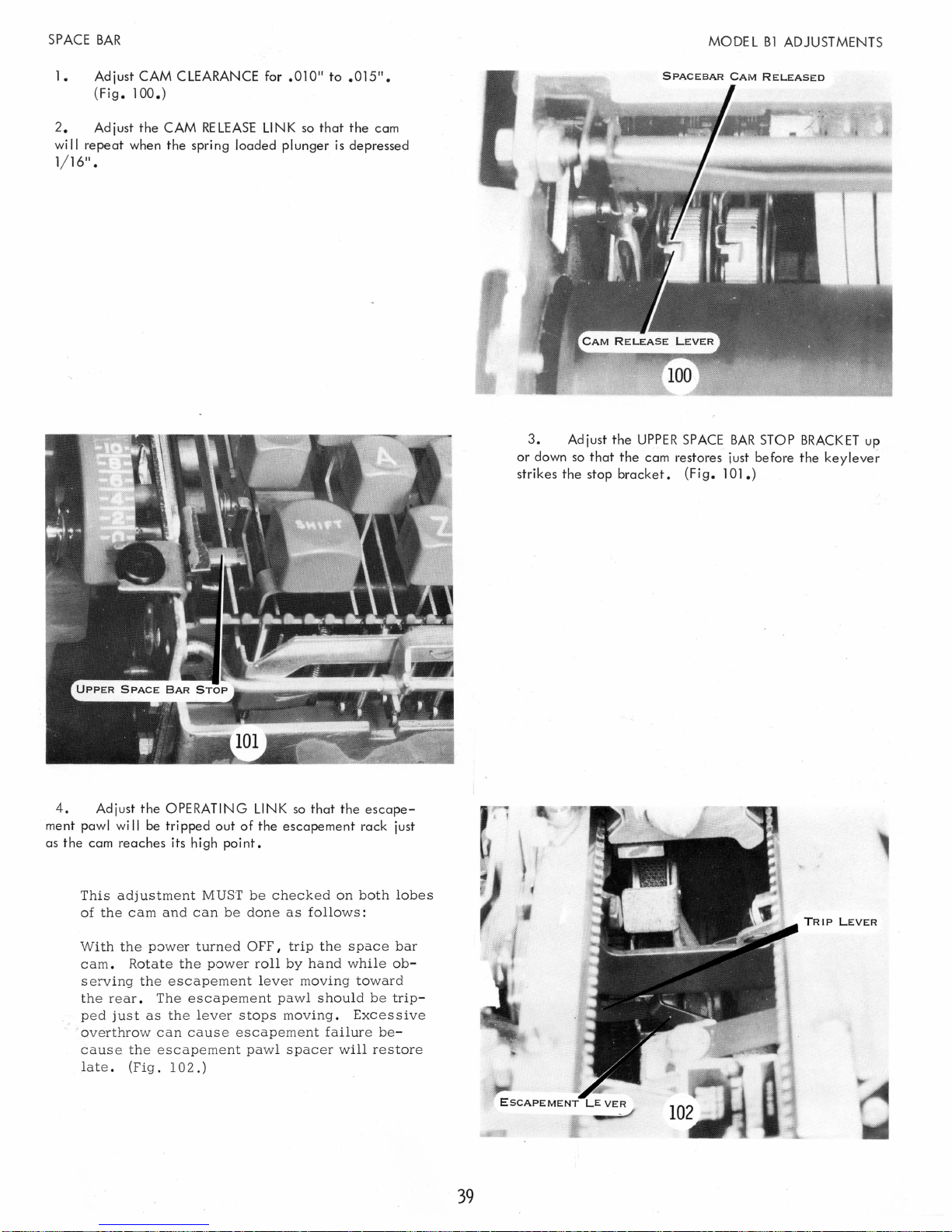

BACKSPACE

1.

Adjust CAM

CLEARANCE

for 0010" to

.015"

0

(Fig.

48.)

Adjust CAM

RE

LEASE

LINK

so

the cam repeats when the

plugger

is

depressed

1/16".

(Repeat cam). (Fig.

50.)

19

MODEL

B1

ADJUSTMENTS

2.

Adjust the CAM

RELEASE

LINK

so

that

the cam

is

released when the

keylever

is

depressed 1/ 2 to

~/3

of

its

travel.

(Non-~epeat

cam). (Fig.

49.)

Page 23

MODEL

B1

ADJUSTMENTS

BACKSPACE

3.

Adjust the

the

interlock mounting bracket left to

BACKSPACE

INTERLOCK

right.

by forming

(Fig.

51.)

4.

Form

the

PAWL

the

interlock

at

rest, the backspace pawl will just

the interlock as the pawl

This

adjustment

RE

LEASE

is

operated.

insures

LEVE R LUG

(Fig.

positive

so

that

with

clear

52.)

interlocking.

Adjust

clears

clearance.

so

the

that

as

backspace

the

interlock

pawl

by a minimum

is

rotated

I

it

20

5.

Form

the

BACKSPACE

right

so

that

it

wi

II

guide the backspace pawl into the

rack with

the

1/64"

clearance

between the right surface of

pawl tooth and an escapement rack

Place

the

blade

of a screwdriver

forward

dri

ver

portion

with the

of

the

hammer.

PAWL

lug

GUIDE

and

tooth.

against

tap the

LUG

(Fig.

left or

53~)

the

screw-

Page 24

BACKSPACE

6.

Adjust

stop

the

pawl

for

the

escapement

the

escapement

the

BACKSPACE PAWL STOP so

just as

the

rack.

pawl

carriage

to

(Fig.

drop

54.)

has

into

moved

the

next

far

tooth

that

enough

it

on

will

The

the

stop.

pawl

stop

backspace

(F i

g.

is

pawl

55.)

also

adjusted

is

interlocked

MODEL

front

it

B1

ADJUSTMENTS

to

back

so

will

pass

that

behind

when

the

7.

be 1/4

is

stopped

Adjust

11

of

by

This

the

escapement

With

riage

an

extra

the

OPERATING

trave I left

its

stop.

1/4

travel

the

pawl

will

be

space.

on

the

(Fig.

holds

rack

so

locked

stopped

cam

56.)

the

and

and

LINK so

when

backspace

against

in

position,

will

that

the

not

there

backspace

pawl

its

stop.

the

coast

will

in

car-

back

pawl

Observe

of

the

power

be

stopped

into

the

this

machine.

roll

by

just

next

adjustme

Release

hand.

as

rack

tooth.

nt

The

the

escapement

through

the

cam

backspace

the

and

bottom

turn

pawl

pawl

the

must

clicks

21

Page 25

MODEL

Bl

ADJUSTMEN

TS

22

BACKSPACE

8.

Form

the

CARRIAGE

RETURN

TAB

INTERLOCK

EXTENSION

toward

the

front

of

the

machine

iust far

enough to

prevent

the

clutch

from

latching

during a

simul-

taneous backspace and

carriage

return

operation.

The clutch will

not

latch because the back-

sp

ac e

interlock will preve

nt the ca

rri

age

re-

turn

tab

interlock

from

rotating

as

sho

wn

(Fig.

57)

.

Page 26

SHIFT

Before

adjusting

the

shift

mechanism,

ring

and

cylinder

adjustments

must be

correct.

(See

Carriage

Adj.

#4)0

1.

Adjust

EVEN

TOP

AND

BOTTOM

of

the

lower

case

letters

by

screwing

the

shift

stop

screws

up

and

down.

(Fig.

58.)

Loosen

lock

nuts

and

adjust

both

stop

screws.

The

heads

of

the

stop

screws

must

rest

with

equal

pressure

against

the

stop

washers.

Equal

pres

sure

is

checked

by

placing a nar-

row

strip

of

paper

between

the

stop

washer

and

the

stop

bracket.

Slowly

pull

the

paper

out

and

note

the

amount

of

drag.

Check

both

sides

for

equal

drag.

Unequal

pres

sure

will

bend

or

break

the

stop

bracket

that

is

being

used.

Be

sure

to

retighten

the

lock

nuts.

3.

Adjust

CAM

CLEARANCE

FOR.

010"

to

.015"

(Fig.

60).

4.

Adjust

CAM

RELEASE

LINK so

that

cam

will

be

released

when

keylever

is

depressed

1/2

to

3/4

of

its

total

travel.

23

MOD

EL

Bl

ADJUSTMENTS

2.

Adjust

SHIFT

MOTION

by

moving

the

lock

nuts

on

each

stop

screw

so

that

the

upper

case

characters

print

on

the

same

line

as

the

lower

case

characters.

(Fig.

59.)

The

lock

nuts

must

also

rest

with

equal

pres-

sure

on

the

stop

bracket.

Be

careful

not·to

turn

the

stop

screws

when

adjusting

the

stop

nuts.

Page 27

MODEL

Equal

ing

B1

ADJUSTMENTS

pin

clearance

manner:

is

checked

in

the

follow-

SHIFT

5.

Adiust

toggle brackets

(Fig. 61).

EQUAL

PIN

CLEARANCE

up

or down with the toggle bracket screws

by

moving the

a.

b.

c.

d.

With

lower

Depress

the

pusher

62) .

Place

Release

to

lower

power

case.

shift

basket

key

pin

OFF I

keylever

to

upper

down

lever

clearance

place

pin

in

and

basket

and

clearance

upper

observe

(Fig.

up

observe

case.

pusher

63) .

in

(Fig.

The

for

both

ance

it

is

To

adjust

upper

lower

Use

ance.

to

vary

lo

wer

pusher

positions.

at

this

equal

toggle

screws

the

converse

Unequal

in

case

to

point

(Fig.

equal

bracket

speed

(Fig.

pin

clearance

The

is

not

62 &

63).

pin

clearance I loosen

screws

to

reduce

to

reduce

pin

clearance

and

action

61).

must

amount

important

and

lower

upper

between

be

of

tighten

pin

clearance.

will

the

pin

as

pin

cause

upper

clear-

long

both

c l

ear-

same

as

both

shift

and

24

Page 28

SHIFT

6.

Adjust

pusher wil l be

upper pin when

This

adj

Slowly

s

erv

ing

as

the

cam

the pusher

the

PUSHER

even

the

ustment

depress

the

rising

operates

as

cam

LINK

with or slightly above the

is

released

is

checked

the

shift

pusher.

and

it contacts

so

that

the

top

of

the

top

of

(Fig.

64A.)

with

the

power

keybutton while ob-

Continue

note

the

with the

to

position

pin.

observe

the

ON.

of

7.

Adjust the OPERATING

clears

the pin by 1/ 32" to 1/ 16" ,

MODEL

LINK

(Fig.

B1

ADJUSTMENTS

so

that

the pusher

64B.)

8

Adjust

0

is

released just as

Check

buttons.

when

the

SHIFT

the

lock

for

easy

unlocking

Loos

en

adjusting the

LOCK

engages.

locking

bracket.

BRACKET

(Fig.

with

stud

only

so

65.)

both

that

the

shift

slightly

cam

key-

The

shift

as

the

shift

operating

e

r.

Insuffici

the

pusher

on

shift

due

to

too

Excessive

due

to

too

due

to

pusher

e

nough.

buffer

ent

keybutton

is

mounted

pusher

link

pusher

to

much

c l

earance

little buffer action

and

will effect

to

bind

on

or

buffer

can

not

rot

ating

pin

pin, giving

hesitating

to

the

same

a ny adju

both

clearance

action.

cause a noisy shift

or

toggle

stment

buffer

heavy

shift

shift

plate

and

can

action

failur

stud

of

cause

touch

far

the

push

e

-

25

Page 29

MODEL

Bl

ADJUSTMENTS

TABULATION

3.

;0

.

01

40

0002

tab

TAB

that

011

LEVER

the margin control

to .

01

511• ( Fig.

Adjust the

11

stop

to

.015

and

~

11

HEIGHT. Adjust the margin

TAB

clearance

engaging

lever

67.)

RACK

between

face

will

clearthe

left or right

the

left face

of

the

tab

release

margin rack by

so

that

there

of

lever

(Fig.

any

68).

eccentric

is

set

-

1.

Adjust CAM CLEARANCE for

(Fig.

66.)

2.

released

trave

I.

Adjust CAM

when

the

RELEASE

keylever

11

.010

to

.01511•

LINK <so

is

depr~ssed

that

2/3

the

cam

of

is

its

8

____

_

26

Check

tab

lever

held

of

the

lever

(Fig.

This

be

in

by

the

every

can

cause

tab

stop.

Be

sure

same

and

this

adjustment

to

as

the

escapement

just

past

68)

observe

adjustment

the

proper

check

other

carriage

to

adjust

amount

plates.

the

rear.

escapement

rack.

the

front

t1:1e

insures

position

lever.

tab

stop.

to

both

to

prevent

by

slowly

The

pawl

With

edge

.002"

that

when

It

also

Excessive

stop

ends

bowing

carriage

will

the

of

the

to ~ 01

the

it

allows

one

space

of

the

the

moving

must

be

held

tab

check

tab

S" .

ca-rriage

is

stopped

tabbing

clearance

past

tab

rack

carriage

the

be

out

stop

will

to

the

the

Page 30

o TABULATION

5.

Ad

just the

TAB

RACK

PARALLE

L to

the

rear rai I

and the front

of

a set

tab

stop

parallel

with

the

tip

of

the

check

lever.

(Fig.

69.)

Adjust

by

moving

the

right

-

end

of

the

tab

rack

front

to

rear

in

its

elongated

mounting

hole.

Check

this

adjustment

by

noting

the

tab

check

lever

bite

on

extreme

left

and

right

tab

stops.

Maintain

the

set

tab

stops

parallel

with

the

check

lever

when

tightening

the

lock

nuts.

/

Insufficient

latch

overthrow

on

the

keeper

can

cause

the

carriage

to

stop

one

space

too

soon

or

be

stopped

by

the

escapement

pawl

due

to

early

tab

unlatching.

o

Excessive

overthrow

of

the

latch

CAN

cause

failure

of

tab

to

unlatch

or a bouncing

sound

as

the

check

lever

stops

the

carriage

.

...fA.

correctly

adjusted

and

operating

tab

will

have

a

single

solid

sound

as

the

carriage

comes

to

rest

at

the

tab

stop.

27

MODEL

B1

ADJUSTMENTS

6.

Adjust

the

TAB

LATCH

KEEPER

front to back

so

that

when lat,

ched,

the

check

lever overlaps 1/ 2

to

2/ 3

of

a set

tab

stop

(Fi

g.

71).

Ad

iust

the

keeper

left

to

ri

ght

so

that

there

is

.030"

to

.050"

overlap

of

the

tab

latch

on

the

keeper

(Fig.

70).

This

adjustment

is

checked

by

latching

the

tab

lever

by

hand

and

hoiding

the

carriage

so

that a set

tab

stop

just

contacts

the

check

lever.

In

this

position,

both

adjustments

can

be

checked.

Page 31

MODEL

Bl

ADJUSTMENTS

8.

Adjust

PAWL CLEARANCE

by

forming

the

rear

upri

ght

I ug

of

the

pawl re

lease

lever

unti I

the

escapement

pawl

clears

the

esc.apement

rack

by

1/64"

with

the

tab

lever

latched.

(Fig.

73)

CAUTION:

Do

not

form

the

hook

on

the

tab

lever.

Form

only

the

pawl

release

lever

lug.

Check

the

1/64

clearance

by

latching

out

the

tab

h~ver

and

while

holding

the

carriage I sight

down

the

escapement

rack.

Excessive

clearance

can

cause

late

restoring

of

the

escapement

pawl

and

incorrect

tabulation.

28

TABULATION

7.

Adjust

the

TAB

OPERATING

LINK so

that with

the

cam

on

its

high

point,

there

is

.010"

to

.015"

clear

-

ance

between

the

tab

latch

and

the

keeper.

(Fig.

72.)

Check

this

adjustment

with

the

power

OFF.

Release

the

tab

cam

and

turn

power

roll

by

hand

until

cam

reaches

its

high

point.

Ob-

serve • 010"

to . 015"

overthro

w . The

ope

r-

ating

link

must

not

prevent

tab

lever

from re-

storing

against

the

rear

rail.

Be

sure

the

over-

throw

stop

does

not

limit

the

travel

of

the t

ab

lever

under

hand

operation.

Excessi

ve over

-

throw

can

cause

the

tab

check lever

to

strike

the

tab

rack.

Insufficient

overthrow can

cause

failure

of

the

tab

lever

to

latch.

9.

The REBOUND CHECK

BRACKET

is

adiusted

two

ways:

Position

the

bracket

left

or

ri

ght

so

that

the

ri

ght

edge

of

the

V-slot

of

the

rebound

check

lever

clears

the

right

hand

of

any

set

tab

stop

by

.010"

to

.018"

when

the

left

hand

face

of

the

stop

has pushed

the

tab

check

lever

to

the

extreme

left.

At

the

same

time,

the

bracket

should

be

positioned

front

or

rear

so

that,

when

the

rebound

check

lever

in its

operated

position

against

the

pin in its

bracket,

the

leading

edge

of

the

rebound

check

lever

is

even

with

the

tip

of

the

tab

check

lever

or

is

.005"

farther

to

the

rear.

The .

bracket

;an

be

conven i ent

I y

ad

i usted

for both

conditio~s

simultaneouslyo

Page 32

TABULATION

MODEL

Bl

ADJUSTMENTS

This adjust

l

easi

until

the

carriage

the check leve

c a n now be

ad

just

Excessive clearance will

to rebound and

th

e t

ab

ve

nt

ca

rriage lock-

ment

is most

ng the

the

tab lever from res

tab

cam I rotating

cam

is

on

its

to res

t w

r.

The rebound

loosened

ment (Fig. 74).

c o

me

stop.

Insufficient

up.

ith a tab

and

to

toring

rapidly

high

point

position

all

ow the

rest one

clearanc

made

the

power

I a

llowing

stop

agai

check

ed

carriage

space before

e c a n pre-

and res

ulting

by

re-

roll

nst

bracket

in correct

in

10.

Adjust the

is.OO5"

clearance

lug on the rebound

point. (Fig.

75.

)

TAB

LEVER

EXTENSION

so

that

there

between the extension and the upri ght

check

bracket

with

the

cam

on

its high

11.

Form

the

TAB

LEVER

LEAF

SPRING

tacts

the upri

at

rest.

(Fig.

ghtstud

76.)

on

the

rebound

check

so

that

with a

it

II

con-

parts

29

Page 33

MODEL

B1

ADJUSTMENTS

130 Position

the

TAB

SET

AND

CLEAR BRACKET r

ight

or

left

unti I the

tab

set

lever

strikes

the

center

of

the

back

of

the

tab

stop

which

is

second

to

the

left

of

the

tip

of

the

tab

check

lever.

(Fig.

78.)

Form

the

TAB

SET

AND

CLEAR

STOPS

so

that

the

levers

wi

II

clear

set

and

cleared

stops

by 1/32" with

the

levers

at

rest.

Loos

en

thr

ee

mounting scre

ws before position-

ing.

TABULATION

12.

CENTRIFUGAL

TAB

GOVERNOR

a.

Position

the

governor

by

means

of

its

mounting

screws

for a

maximum

of

.005"

backlash

between

the

pinion

gear

and

the

main

spring

drum

gea

ro

Check

full

length

of

the

carriage

-.

(Fig.

77.)

b.

Adjust

the

collar

on

the

governor

shaft

for

.003"

to

.005"

end

play

in

the

shaft.

c.

Speed

of

the

carriage

on

tabulation

is

adjusted

by

moving

the

governor

arm

spring.

Move

the

spring

closer

to

the

governor

arm

pivots

for

more

governor

action.

Move

the

spring away

from

the

pivots

for

less

governor

action.

(This

spring

must

be

in a correspond-

ing

hole

in

each

governor

arm) .

14.

Adjust

the

TAB

SET

AND

CLEAR LINKS so

that

-\,

when

the

set

and c lear

buttons

are

at

rest,

the

slope

of

the

i r

surfaces

wi

II

be

para

lie I to

the s lope

of

the

keyboard.

(Fig.

79.)

Page 34

TABULATION

150

Adjust the FRICTION GOVERNOR

PRESSURE

by

means

of

the two lock nuts on the hub

of

the main spring

drum until the speed

of

tabulation

approximates

the

speed

of

carriage

return.

(Fig.

80.)

Check

the

speed

by

clearing

all

tab

stops

ex-

cept

the

last

one

on

the

right.

Operate

the

car-

riage

return

and

tab . several

times

to

determine

this

speed.

16.

Adjust the

TAB

GOVERNOR

PAWL

LINK

so

that

when the

tab

lever

is

latched,

the governor pawl

wi

II

en-

gage the

fri

ction

plate

by

the thi ckness

of

the

pawl.

(Fig.

80.)

MODEL

B1

ADJUSTMENTS

31

Page 35

MODEL

B1

ADJUSTMENTS

CARRIAGE

RETURN

3. Adjust

the cam

on

clutch latch

FRONT

its high point, the clutch lever will

by

.020

CLUTCH

11

to

.025

LEVER

11

• (Fig.

LINK

82.)

so

that

clear

with

the

1.

2.

Ad

just CAM

(Fig.

81.)

Adjust CAM

peat

when the plunger

Fig.

50).

The

release

the

keylever

lever.

CLEARANCE

RELEASE

link

and

LINK

should

lower

for

so

is

depressed

be

hole

.010"

to

the cam will

1/16

in

the

rear

in

the

release

.015

11

hole

11

re-

(See

•

in

This

latched

overthrow

position.

allows

the

latch

to

rotate

to

its

4.

Adjust the

slot

in

the clutch lever bellcrank

rail,

with all parts at

in

outer hole

the

5. Adjust the

in

the clutch latch

The

link should

crank.

(Fig.

be

83.)

REAR

CLUTCH

rest.

bellcrank.

CLUTCH

be

I !crank

placed

in

.,

LEVER

LINK

is

parallel to the rear

The link should

(Fig.

83.)

LATCH

LINK

is

para lie I to the rear rai I.

the

center

be

so

that the slot

hole

of

so

that the,

in

the

the

bell-

32

All

parts

against

must

the

be

clutch

at

rest with

lever.

the

latch

resting

Page 36

CARRIAGE

RETURN

6.

OVERBANK

is

the amount

of

play

between

the

margin control lever and its final stop when

the

carriage

is

resting

at

the left

margin.

Place

the

carriage

one

space

from

the

left

margin.

Slowly

move

the

carriage

to

the

right

and

listen

that

the

escapement

pawl

drops

into

an

escapement

rack tooth

just

as

the

margin

control lever

strik

es

its

final

stop

(Fig.

84).

Excessive

overbank

can

cause

carriage

to

re-

turn

one

space

to

far.

Insufficient

overbank

may

prevent

carriage

from

returning

to

margin.

Adjust

both

ends

of

margin

rack.

Do

not

bow

the

carriage end

plates.

8.

Adjust

the

PAWL

RELEASE

LEVER

ECCENTRIC

so

that

the right side

of

the

ear

on

the

pawl release

lever

lust

clears

the

intermediate

pawl release lever when

all

parts

are

at

rest.

(Fig.

86.)

Keep

the

high

point

of

the

eccentric

toward

the

front

of

the

machine.

33

MODEL

Bl

ADJUSTMENTS

7.

Form

the

INTERMEDIATE

PAWL

RELEASE

LEVER

IPRIGHT

LUG

to

allow

the

intermediate

pawl release

;ver

to touch both

the

margin control

be

Ilcrank and pawl

; lease be Ilcrank when

the

carriage

is

one

space

from

the

~ft

rna

rgin 0

(Fig.

85.)

This

adjustment

insures

the

escapement

pawl

will

not

be released

from the

rack

when the

carriage

is

within

one

space

of

the

margin

and

"lill

remain

in

the

rack

during

repeat

line space.

Page 37

MODEL Bl ADJUSTMENTS

10.

Form

PAWL

RELEASE

it

wi

II

clear

the

carriage

both parts

at

rest.

(Fig.

88.)

LEVER

universal

FRONT

bar

by

LUG

.005"

so

'with

that

the

CARRIAGE

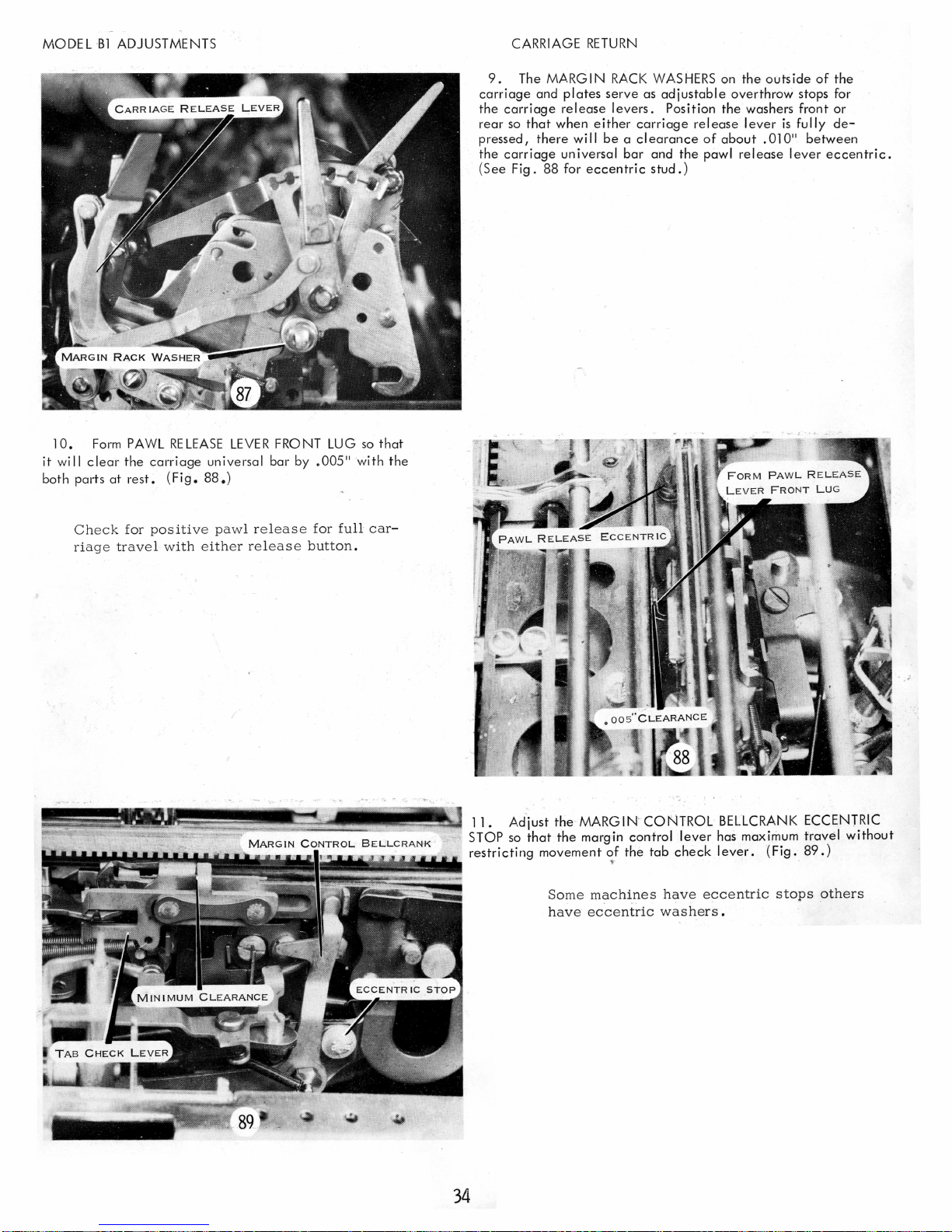

9.

The MARGIN

carriage

the

carriage

rear

so

pressed,

the

carriage

(

See

Fig.

and

that

there

plates

release

when

universal

88 for

RETURN

RACK

serve

levers.

either

will

be a clearance

bar

eccentric

WASHERS

as

adjustable

Position

carriage

and

stud.)

release

the

on

the

overthrow

the

washers front or

lever

of

about

pawl

release

outside

is

fully

.010"

lever

of

the

stops for

de-

between

eccentric.

Check

ri

age trave

for

positi

ve pawl re leas e

l w

ith eith

er release

for

full

car-

button.

--~

11. Ad-just the MARGIN '

so

that

STOP

restricting

the

movement

..

Some

have eccentric

of

the

CONTROL

tab

have

washers.

margin control

machines

BELlCRANK ECCENTRIC

lever

has maximum

check

lever.

eccentric

(Fig.

stops

travel

89.)

others

without

34

Page 38

CARRIAGE

12.

Adjust the CARRIAGE "

as follows:

RETURN

(Fig.

90.)

RETURN

TAB

INTERLOCK

MODEL

B1

ADJUSTMENTS

a.

b.

c.

This

be

unlatched

Unhook -the

clutch

Turn the high point

centri c stop to the rear

a pre

I iminary ad justment.

With the

carriage

the interlock

stud by about

lug on the

interlock

the margin control

adjustment

insures

when

the tab

so

1/16

un

latching

of

at

the

that

it clears the

11

when the

is

be

Ilcrank.

carriage

is

link.

the interlock

of

the

mach i ne as

left margin,

tab

left-hand

in

contact

with

return

operated.

ec-

will

form

latch

13.

Adjust the

the

clutch

unlatches when

margin control lever

(Fig.

91.)

Check

this

while depressing the

with

the

power

to

approach

gin

control lever

The

clutch

to

pull

until

1/

32"

to 1/64"

CLUTCH

-UNLATCHING

the

11

1/64

adjustment

ON.

the

left

as

should

the

r~main

margin

of

the

carriage

to

1/32

by

carriage

Slowly

margin.

it

nears

stop.

11

from

holding

allow

latched

control

LINK

has pushed the

its final

the

carriage

return

Observe

its

the

final

and

lever

button

carriage

the

stop.

continue

comes

so

that

stop.

mar-

to

'

14.

Adjust the

ECCENTRIC STOP

gates the

surface.

clutch

(See adjustment #12 for

stop.

15.

Adjust the

clutch

latched,

ment rack

the escapement pawl

by

1/64

lease link).

CARRI,AGE

(Fig. 90)

lever

by

PAWL

11

• (See Fig.

RETURN

so

that

1/3

to 1/ 2

RELEASE

83

TAB

the

clutch

of

the

pidure

LINK

so

wi

II

for picture

INTERLOCK

latch

clutch

of

eccentric

that

with the

clear

the

of

pawl

en-

latch

escape-

re-

Excessive

to

stop

clearance

one

space

can

.fro-m

cause

margin.

the

carriage

35

Page 39

MODEL

B1

ADJUSTMENTS

CARRIAGE

RETURN

With

the

clutch

lever

by

hand

erate

the

carriage

serve

that

the

not

strike the re

Form

the

top

of

to

provide a clearance

unlatched I operate

to

observe

return

rebound

bound

the

this

cam

check

check

interlo::::k

of

about.

the tab

adjustment.

by

hand

interlock

lever

at

lever

front

010"

and

does

rest.

to

: .

(Fig.

Op'-

ob-

rear

94.)

160 The REBOUND CHECK INTERLOCK LINK

justed

so

that

the

check

is

in its

lever by

operated

interlock

about.

position.

01

a"

lever

when

(Fig.

clears

the

93.)

the

tab

rebound

is

rebound

check

ad-

lever

This

the

riage

adj

us

rebound

return

tment

check

is

prevents

remains

operated.

carriage

to

the

!ock-

rear

up

and

if

car-

17.

Adjust the CLUTCH

the

clutch

earance

clutch

disc.

lever

plate

a

cI

the

friction

bracket

of . 01

with the

(Fig.

a"

95.)

to

PLATE

on

the

.015"

clutch

CLEARANCE by positioning

side

frame

(Fig.

97).

between

plate

the

operating

held tight

Obtain

arm and

against

the

Page 40

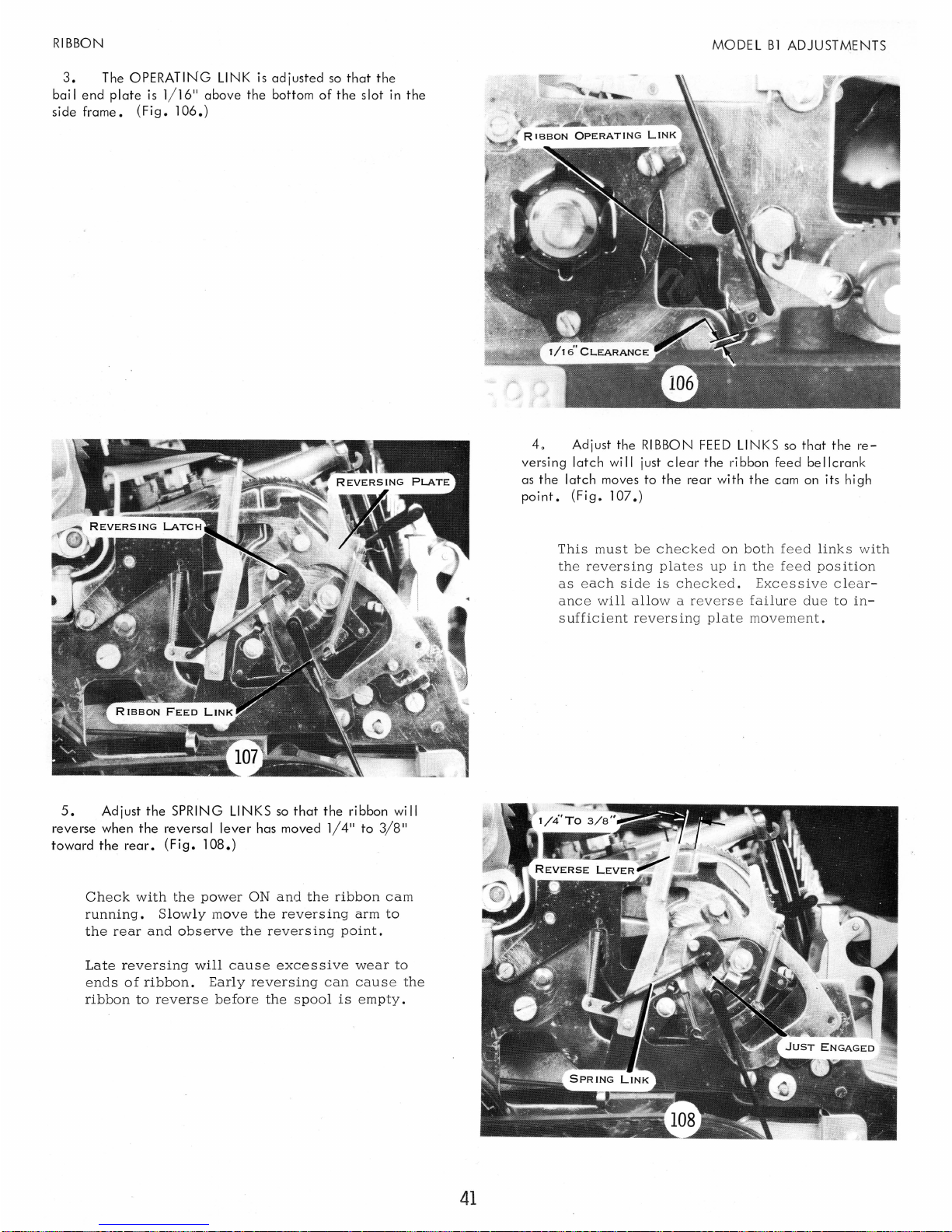

CARRIAGE

RETURN

18.

Position

AIR

CYLINDER front to rear on

the

side

frame to permit

the

plunger to move freely

(Fig.

96)0

190 AIR