Page 1

Power Systems

Site and hardware planning

IBM

Page 2

Note

Before using this information and the product it supports, read the information in “Safety notices” on

page v, “Notices” on page 139, the IBM Systems Safety Notices manual, G229-9054, and the IBM

Environmental Notices and User Guide, Z125–5823.

This edition applies to IBM® Power Systems servers that contain the POWER9™ processor and to all associated models.

©

Copyright International Business Machines Corporation 2018, 2019.

US Government Users Restricted Rights – Use, duplication or disclosure restricted by GSA ADP Schedule Contract with

IBM Corp.

Page 3

Contents

Safety notices........................................................................................................v

Site and hardware physical planning overview....................................................... 1

Planning activities................................................................................................. 3

Planning task checklist................................................................................................................................ 3

General considerations................................................................................................................................3

Site preparation and physical planning guidelines..................................................................................... 4

Site and hardware planning................................................................................... 7

Hardware specication sheets.................................................................................................................... 7

Server specications.............................................................................................................................. 7

Expansion unit and migration tower specications............................................................................ 18

Rack specications...............................................................................................................................22

Hardware Management Console specications..................................................................................64

Rack switch specications...................................................................................................................67

Rack installation specications for racks that are not purchased from IBM..................................... 70

Planning for power.....................................................................................................................................78

Determining your power requirements............................................................................................... 78

Plugs and receptacles.......................................................................................................................... 80

Modication of IBM-provided power cords.........................................................................................95

Uninterruptible power supply.............................................................................................................. 96

Power distribution unit and power cord options for 7014, 7953, and 7965 racks............................97

Calculating the power load for 7188 or 9188 power distribution units...........................................105

Planning for cables.................................................................................................................................. 107

Cable management............................................................................................................................ 107

Planning for serial-attached SCSI cables..........................................................................................111

Notices..............................................................................................................139

Accessibility features for IBM Power Systems servers..........................................................................140

Privacy policy considerations .................................................................................................................141

Trademarks..............................................................................................................................................141

Electronic emission notices.....................................................................................................................141

Class A Notices...................................................................................................................................142

Class B Notices...................................................................................................................................145

Terms and conditions.............................................................................................................................. 147

iii

Page 4

iv

Page 5

Safety notices

Safety notices may be printed throughout this guide:

• DANGER notices call attention to a situation that is potentially lethal or extremely hazardous to people.

• CAUTION notices call attention to a situation that is potentially hazardous to people because of some

existing condition.

• Attention notices call attention to the possibility of damage to a program, device, system, or data.

World Trade safety information

Several countries require the safety information contained in product publications to be presented in their

national languages. If this requirement applies to your country, safety information documentation is

included in the publications package (such as in printed documentation, on DVD, or as part of the product)

shipped with the product. The documentation contains the safety information in your national language

with references to the U.S. English source. Before using a U.S. English publication to install, operate, or

service this product, you must rst become familiar with the related safety information documentation.

You should also refer to the safety information documentation any time you do not clearly understand any

safety information in the U.S. English publications.

Replacement or additional copies of safety information documentation can be obtained by calling the IBM

Hotline at 1-800-300-8751.

German safety information

Das Produkt ist nicht für den Einsatz an Bildschirmarbeitsplätzen im Sinne § 2 der

Bildschirmarbeitsverordnung geeignet.

Laser safety information

IBM servers can use I/O cards or features that are ber-optic based and that utilize lasers or LEDs.

Laser compliance

IBM servers may be installed inside or outside of an IT equipment rack.

DANGER:

Electrical voltage and current from power, telephone, and communication cables are hazardous.

To avoid a shock hazard:

• If IBM supplied the power cord(s), connect power to this unit only with the IBM provided power

cord. Do not use the IBM provided power cord for any other product.

• Do not open or service any power supply assembly.

• Do not connect or disconnect any cables or perform installation, maintenance, or reconguration

of this product during an electrical storm.

• The product might be equipped with multiple power cords. To remove all hazardous voltages,

disconnect all power cords.

– For AC power, disconnect all power cords from their AC power source.

– For racks with a DC power distribution panel (PDP), disconnect the customer’s DC power

• When connecting power to the product ensure all power cables are properly connected.

When working on or around the system, observe the following precautions:

source to the PDP.

– For racks with AC power, connect all power cords to a properly wired and grounded electrical

outlet. Ensure that the outlet supplies proper voltage and phase rotation according to the

system rating plate.

©

Copyright IBM Corp. 2018, 2019 v

Page 6

– For racks with a DC power distribution panel (PDP), connect the customer’s DC power source

to the PDP. Ensure that the proper polarity is used when attaching the DC power and DC power

return wiring.

• Connect any equipment that will be attached to this product to properly wired outlets.

• When possible, use one hand only to connect or disconnect signal cables.

• Never turn on any equipment when there is evidence of re, water, or structural damage.

• Do not attempt to switch on power to the machine until all possible unsafe conditions are

corrected.

• Assume that an electrical safety hazard is present. Perform all continuity, grounding, and power

checks specied during the subsystem installation procedures to ensure that the machine meets

safety requirements.

• Do not continue with the inspection if any unsafe conditions are present.

• Before you open the device covers, unless instructed otherwise in the installation and

conguration procedures: Disconnect the attached AC power cords, turn off the applicable

circuit breakers located in the rack power distribution panel (PDP), and disconnect any

telecommunications systems, networks, and modems.

DANGER:

• Connect and disconnect cables as described in the following procedures when installing,

moving, or opening covers on this product or attached devices.

To Disconnect:

1. Turn off everything (unless instructed otherwise).

2. For AC power, remove the power cords from the outlets.

3. For racks with a DC power distribution panel (PDP), turn off the circuit breakers located in the

PDP and remove the power from the Customer's DC power source.

4. Remove the signal cables from the connectors.

5. Remove all cables from the devices.

To Connect:

1. Turn off everything (unless instructed otherwise).

2. Attach all cables to the devices.

3. Attach the signal cables to the connectors.

4. For AC power, attach the power cords to the outlets.

5. For racks with a DC power distribution panel (PDP), restore the power from the Customer's

DC power source and turn on the circuit breakers located in the PDP.

6. Turn on the devices.

Sharp edges, corners and joints may be present in and around the system. Use care when

handling equipment to avoid cuts, scrapes and pinching. (D005)

(R001 part 1 of 2):

DANGER:

• Heavy equipment–personal injury or equipment damage might result if mishandled.

• Always lower the leveling pads on the rack cabinet.

• Always install stabilizer brackets on the rack cabinet unless the earthquake option is to be

installed.

• To avoid hazardous conditions due to uneven mechanical loading, always install the heaviest

devices in the bottom of the rack cabinet. Always install servers and optional devices starting

from the bottom of the rack cabinet.

Observe the following precautions when working on or around your IT rack system:

vi Power Systems: Site and hardware planning

Page 7

• Rack-mounted devices are not to be used as shelves or work spaces. Do not place objects on top

of rack-mounted devices. In addition, do not lean on rack mounted devices and do not use them

to stabilize your body position (for example, when working from a ladder).

• Each rack cabinet might have more than one power cord.

– For AC powered racks, be sure to disconnect all power cords in the rack cabinet when directed

to disconnect power during servicing.

– For racks with a DC power distribution panel (PDP), turn off the circuit breaker that controls

the power to the system unit(s), or disconnect the customer’s DC power source, when

directed to disconnect power during servicing.

• Connect all devices installed in a rack cabinet to power devices installed in the same rack

cabinet. Do not plug a power cord from a device installed in one rack cabinet into a power device

installed in a different rack cabinet.

• An electrical outlet that is not correctly wired could place hazardous voltage on the metal parts

of the system or the devices that attach to the system. It is the responsibility of the customer to

ensure that the outlet is correctly wired and grounded to prevent an electrical shock. (R001 part

1 of 2)

(R001 part 2 of 2):

CAUTION:

• Do not install a unit in a rack where the internal rack ambient temperatures will exceed the

manufacturer's recommended ambient temperature for all your rack-mounted devices.

• Do not install a unit in a rack where the air flow is compromised. Ensure that air flow is not

blocked or reduced on any side, front, or back of a unit used for air flow through the unit.

• Consideration should be given to the connection of the equipment to the supply circuit so that

overloading of the circuits does not compromise the supply wiring or overcurrent protection. To

provide the correct power connection to a rack, refer to the rating labels located on the

equipment in the rack to determine the total power requirement of the supply circuit.

• (For sliding drawers.) Do not pull out or install any drawer or feature if the rack stabilizer

brackets are not attached to the rack or if the rack is not bolted to the floor. Do not pull out more

than one drawer at a time. The rack might become unstable if you pull out more than one drawer

at a time.

• (For xed drawers.) This drawer is a xed drawer and must not be moved for servicing unless

specied by the manufacturer. Attempting to move the drawer partially or completely out of the

rack might cause the rack to become unstable or cause the drawer to fall out of the rack. (R001

part 2 of 2)

CAUTION:

stability during relocation. Follow these general guidelines whenever you relocate a populated

rack cabinet within a room or building.

• Reduce the weight of the rack cabinet by removing equipment starting at the top of the rack

cabinet. When possible, restore the rack cabinet to the conguration of the rack cabinet as you

received it. If this conguration is not known, you must observe the following precautions:

Removing components from the upper positions in the rack cabinet improves rack

Safety notices vii

Page 8

– Remove all devices in the 32U position (compliance ID RACK-001 or 22U (compliance ID

RR001) and above.

– Ensure that the heaviest devices are installed in the bottom of the rack cabinet.

– Ensure that there are little-to-no empty U-levels between devices installed in the rack cabinet

below the 32U (compliance ID RACK-001 or 22U (compliance ID RR001) level, unless the

received conguration specically allowed it.

• If the rack cabinet you are relocating is part of a suite of rack cabinets, detach the rack cabinet

from the suite.

• If the rack cabinet you are relocating was supplied with removable outriggers they must be

reinstalled before the cabinet is relocated.

• Inspect the route that you plan to take to eliminate potential hazards.

• Verify that the route that you choose can support the weight of the loaded rack cabinet. Refer to

the documentation that comes with your rack cabinet for the weight of a loaded rack cabinet.

• Verify that all door openings are at least 760 x 230 mm (30 x 80 in.).

• Ensure that all devices, shelves, drawers, doors, and cables are secure.

• Ensure that the four leveling pads are raised to their highest position.

• Ensure that there is no stabilizer bracket installed on the rack cabinet during movement.

• Do not use a ramp inclined at more than 10 degrees.

• When the rack cabinet is in the new location, complete the following steps:

– Lower the four leveling pads.

– Install stabilizer brackets on the rack cabinet or in an earthquake environment bolt the rack to

the floor.

– If you removed any devices from the rack cabinet, repopulate the rack cabinet from the

lowest position to the highest position.

• If a long-distance relocation is required, restore the rack cabinet to the conguration of the rack

cabinet as you received it. Pack the rack cabinet in the original packaging material, or equivalent.

Also lower the leveling pads to raise the casters off of the pallet and bolt the rack cabinet to the

pallet.

(L001)

(L002)

(R002)

DANGER:

this label attached. Do not open any cover or barrier that contains this label. (L001)

Hazardous voltage, current, or energy levels are present inside any component that has

viii

Power Systems: Site and hardware planning

Page 9

(L003)

or

or

DANGER: Rack-mounted devices are not to be used as shelves or work spaces. Do not place

objects on top of rack-mounted devices. In addition, do not lean on rack-mounted devices and do

not use them to stabilize your body position (for example, when working from a ladder). (L002)

or

or

Safety notices

ix

Page 10

(L007)

DANGER: Multiple power cords. The product might be equipped with multiple AC power cords or

multiple DC power cables. To remove all hazardous voltages, disconnect all power cords and

power cables. (L003)

CAUTION:

(L008)

CAUTION:

All lasers are certied in the U.S. to conform to the requirements of DHHS 21 CFR Subchapter J for class 1

laser products. Outside the U.S., they are certied to be in compliance with IEC 60825 as a class 1 laser

product. Consult the label on each part for laser certication numbers and approval information.

CAUTION:

ROM drive, DVD-RAM drive, or laser module, which are Class 1 laser products. Note the following

information:

• Do not remove the covers. Removing the covers of the laser product could result in exposure to

hazardous laser radiation. There are no serviceable parts inside the device.

• Use of the controls or adjustments or performance of procedures other than those specied

herein might result in hazardous radiation exposure.

A hot surface nearby. (L007)

Hazardous moving parts nearby. (L008)

This product might contain one or more of the following devices: CD-ROM drive, DVD-

(C026)

x Power Systems: Site and hardware planning

Page 11

CAUTION: Data processing environments can contain equipment transmitting on system links

with laser modules that operate at greater than Class 1 power levels. For this reason, never look

into the end of an optical ber cable or open receptacle. Although shining light into one end and

looking into the other end of a disconnected optical ber to verify the continuity of optic bers may

not injure the eye, this procedure is potentially dangerous. Therefore, verifying the continuity of

optical bers by shining light into one end and looking at the other end is not recommended. To

verify continuity of a ber optic cable, use an optical light source and power meter. (C027)

CAUTION: This product contains a Class 1M laser. Do not view directly with optical instruments.

(C028)

CAUTION: Some laser products contain an embedded Class 3A or Class 3B laser diode. Note the

following information:

• Laser radiation when open.

• Do not stare into the beam, do not view directly with optical instruments, and avoid direct

exposure to the beam. (C030)

(C030)

CAUTION: The battery contains lithium. To avoid possible explosion, do not burn or charge the

battery.

Do Not:

• Throw or immerse into water

• Heat to more than 100 degrees C (212 degrees F)

• Repair or disassemble

Exchange only with the IBM-approved part. Recycle or discard the battery as instructed by local

regulations. In the United States, IBM has a process for the collection of this battery. For

information, call 1-800-426-4333. Have the IBM part number for the battery unit available when

you call. (C003)

CAUTION: Regarding IBM provided VENDOR LIFT TOOL:

• Operation of LIFT TOOL by authorized personnel only.

• LIFT TOOL intended for use to assist, lift, install, remove units (load) up into rack elevations. It is

not to be used loaded transporting over major ramps nor as a replacement for such designated

tools like pallet jacks, walkies, fork trucks and such related relocation practices. When this is not

practicable, specially trained persons or services must be used (for instance, riggers or movers).

• Read and completely understand the contents of LIFT TOOL operator's manual before using.

Failure to read, understand, obey safety rules, and follow instructions may result in property

damage and/or personal injury. If there are questions, contact the vendor's service and support.

Local paper manual must remain with machine in provided storage sleeve area. Latest revision

manual available on vendor's web site.

• Test verify stabilizer brake function before each use. Do not over-force moving or rolling the LIFT

TOOL with stabilizer brake engaged.

• Do not raise, lower or slide platform load shelf unless stabilizer (brake pedal jack) is fully

engaged. Keep stabilizer brake engaged when not in use or motion.

• Do not move LIFT TOOL while platform is raised, except for minor positioning.

• Do not exceed rated load capacity. See LOAD CAPACITY CHART regarding maximum loads at

center versus edge of extended platform.

• Only raise load if properly centered on platform. Do not place more than 200 lb (91 kg) on edge

of sliding platform shelf also considering the load's center of mass/gravity (CoG).

• Do not corner load the platforms, tilt riser, angled unit install wedge or other such accessory

options. Secure such platforms -- riser tilt, wedge, etc options to main lift shelf or forks in all four

(4x or all other provisioned mounting) locations with provided hardware only, prior to use. Load

objects are designed to slide on/off smooth platforms without appreciable force, so take care

Safety notices

xi

Page 12

not to push or lean. Keep riser tilt [adjustable angling platform] option flat at all times except for

nal minor angle adjustment when needed.

• Do not stand under overhanging load.

• Do not use on uneven surface, incline or decline (major ramps).

• Do not stack loads.

• Do not operate while under the influence of drugs or alcohol.

• Do not support ladder against LIFT TOOL (unless the specic allowance is provided for one

following qualied procedures for working at elevations with this TOOL).

• Tipping hazard. Do not push or lean against load with raised platform.

• Do not use as a personnel lifting platform or step. No riders.

• Do not stand on any part of lift. Not a step.

• Do not climb on mast.

• Do not operate a damaged or malfunctioning LIFT TOOL machine.

• Crush and pinch point hazard below platform. Only lower load in areas clear of personnel and

obstructions. Keep hands and feet clear during operation.

• No Forks. Never lift or move bare LIFT TOOL MACHINE with pallet truck, jack or fork lift.

• Mast extends higher than platform. Be aware of ceiling height, cable trays, sprinklers, lights, and

other overhead objects.

• Do not leave LIFT TOOL machine unattended with an elevated load.

• Watch and keep hands, ngers, and clothing clear when equipment is in motion.

• Turn Winch with hand power only. If winch handle cannot be cranked easily with one hand, it is

probably over-loaded. Do not continue to turn winch past top or bottom of platform travel.

Excessive unwinding will detach handle and damage cable. Always hold handle when lowering,

unwinding. Always assure self that winch is holding load before releasing winch handle.

• A winch accident could cause serious injury. Not for moving humans. Make certain clicking sound

is heard as the equipment is being raised. Be sure winch is locked in position before releasing

handle. Read instruction page before operating this winch. Never allow winch to unwind freely.

Freewheeling will cause uneven cable wrapping around winch drum, damage cable, and may

cause serious injury.

• This TOOL must be maintained correctly for IBM Service personnel to use it. IBM shall inspect

condition and verify maintenance history before operation. Personnel reserve the right not to use

TOOL if inadequate. (C048)

Power and cabling information for NEBS (Network Equipment-Building System) GR-1089-CORE

The following comments apply to the IBM servers that have been designated as conforming to NEBS

(Network Equipment-Building System) GR-1089-CORE:

The equipment is suitable for installation in the following:

• Network telecommunications facilities

• Locations where the NEC (National Electrical Code) applies

The intrabuilding ports of this equipment are suitable for connection to intrabuilding or unexposed wiring

or cabling only. The intrabuilding ports of this equipment must not be metallically connected to the

interfaces that connect to the OSP (outside plant) or its wiring. These interfaces are designed for use as

intrabuilding interfaces only (Type 2 or Type 4 ports as described in GR-1089-CORE) and require isolation

from the exposed OSP cabling. The addition of primary protectors is not sufcient protection to connect

these interfaces metallically to OSP wiring.

Note: All Ethernet cables must be shielded and grounded at both ends.

The ac-powered system does not require the use of an external surge protection device (SPD).

xii

Power Systems: Site and hardware planning

Page 13

The dc-powered system employs an isolated DC return (DC-I) design. The DC battery return terminal shall

not be connected to the chassis or frame ground.

The dc-powered system is intended to be installed in a common bonding network (CBN) as described in

GR-1089-CORE.

Safety notices xiii

Page 14

xiv Power Systems: Site and hardware planning

Page 15

Site and hardware physical planning overview

Successful installation requires effective planning of your physical and operational environment. You are

the most valuable resource in site planning because you know where and how your system, and the

devices that are attached to it, are used.

Site preparation for the complete system is the responsibility of the customer. The primary task of your

site planner is to ensure that each system is installed so that it can operate and be serviced efciently.

This topic collection provides the basic information that you need to plan for your system installation. It

provides an overview of each planning task and valuable reference information useful throughout the

performance of these tasks. Depending on the complexity of the system that you ordered and your

existing computing resource, you might not need to complete all the steps noted here.

First, with the help of your systems engineer, sales representative, or with the help of those coordinating

your installation, list the hardware for which you need to plan. Use the summary of your order to help you

when you make your list. This list is now your “To Do” list. You can use the Planning task checklist to

assist you.

While you are responsible for planning, vendors, contractors, and your sales representative are also

available to help with any aspect of the planning. For some system units, a customer service

representative installs your system unit and veries correct operation. Some system units are considered

customer-installed. If you are not sure, check with your sales representative.

The physical planning section of this topic collection provides the physical characteristics of many system

units, and associated products. For information on products not included in this topic collection, contact

your sales representative or your IBM reseller.

Before you proceed with planning, ensure that the hardware and software you chose meets your needs.

Your sales representative is available to answer questions.

While this information is for hardware planning, the system memory and disk storage needed are a

function of the software to be used, therefore some things to consider are listed below. Information on

software products is generally in or with the software licensed program itself.

In assessing the adequacy of hardware and software, consider the following guidelines:

• Available disk space and system memory for accommodating software, online documentation, and data

(including future growth needs resulting from extra users, more data, and new applications).

• Compatibility of all devices.

• Compatibility of software packages with each other and with the hardware conguration.

• Adequate redundancy or backup capabilities in hardware and software.

• Software portability to the new system, if necessary.

• Prerequisites and corequisites of chosen software are satised.

• Data to be transferred to the new system.

©

Copyright IBM Corp. 2018, 2019 1

Page 16

2 Power Systems: Site and hardware planning

Page 17

Planning activities

You can use this information to help you plan the physical installation for your server.

Proper planning for your system facilitates a smooth installation and fast system start-up. Sales and

installation planning representatives are also available to help you with installation planning.

As part of your planning activity, you make decisions about where to locate your server and who operates

the system.

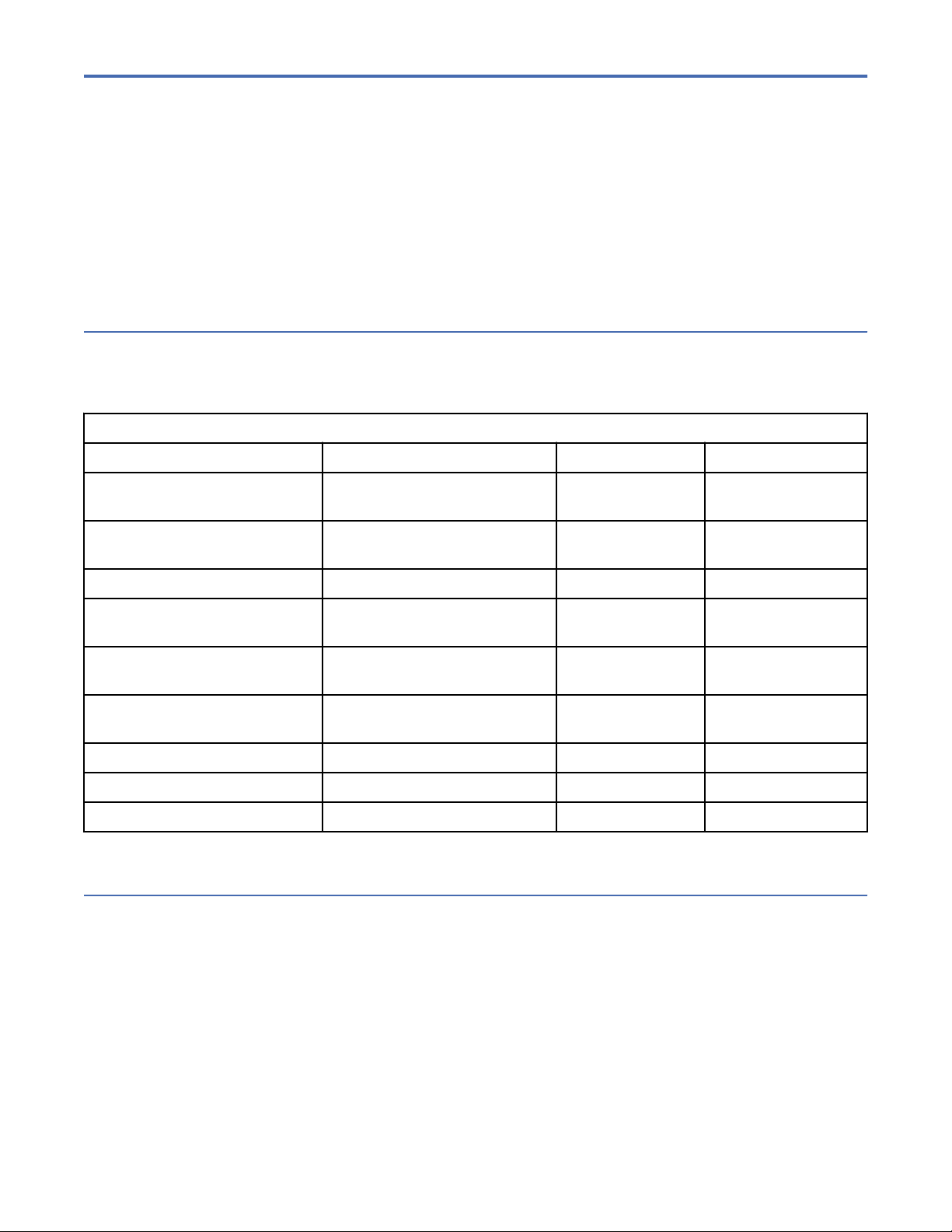

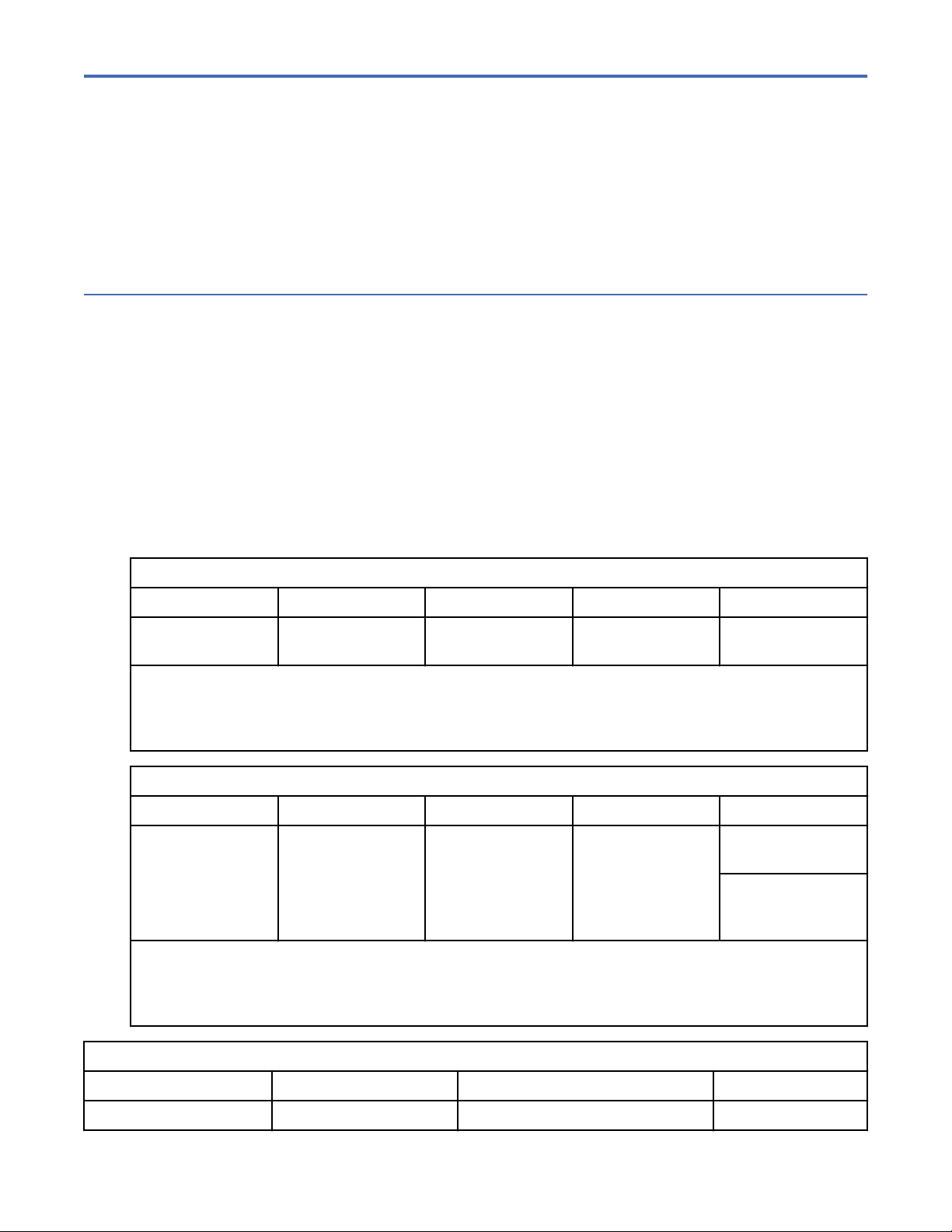

Planning task checklist

Use this checklist to document your planning progress.

Working with your sales representative, establish completion dates for each of the tasks. You might want

to review your planning schedule periodically with your sales representative.

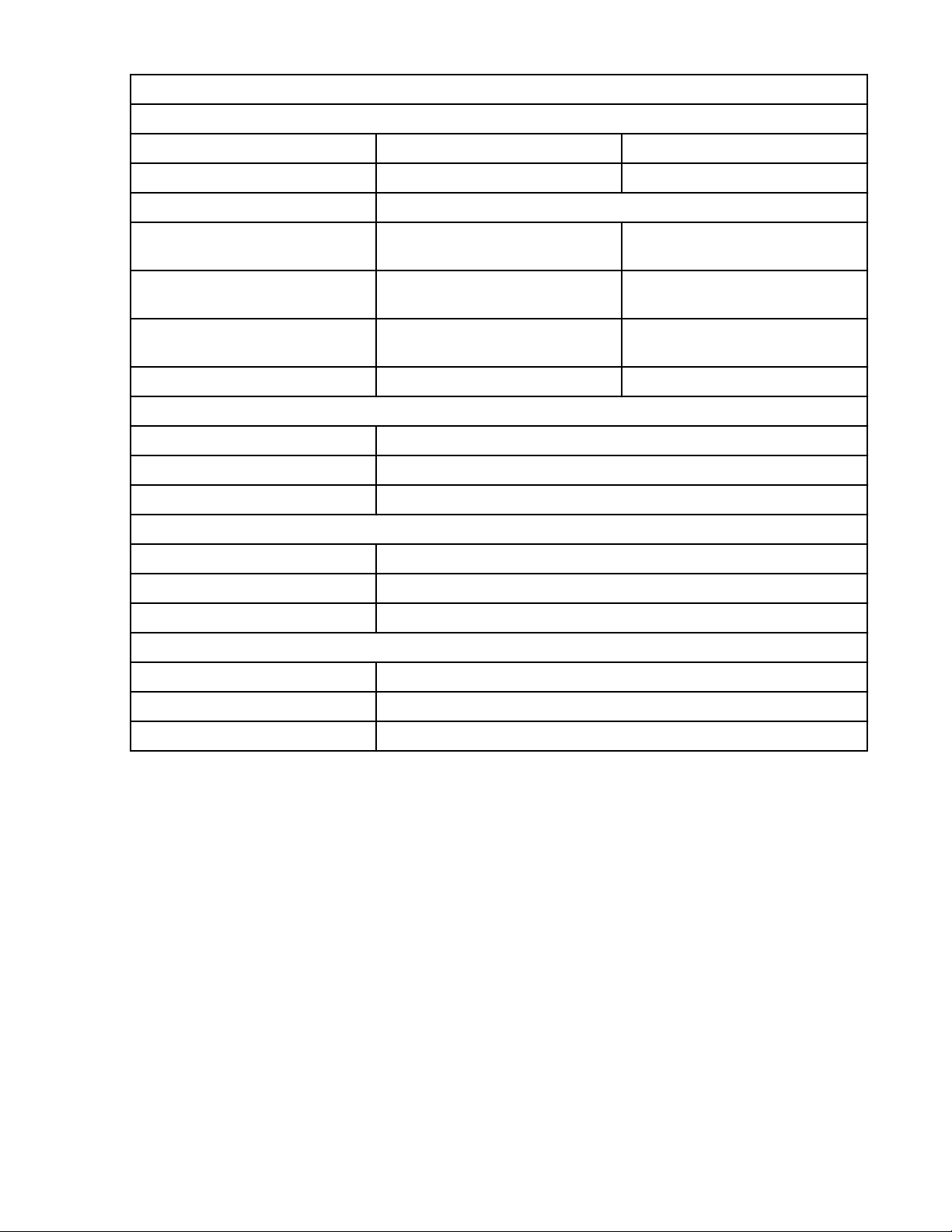

Table 1. Planning task checklist

Planning step Person responsible Target date Completion date

Plan your ofce or computer

room layout (physical planning)

Prepare for power cords and

electrical needs

Prepare for cables and cabling

Create or modify

communications networks

Perform building altercations, as

needed

Prepare maintenance, recovery,

and security plans

Develop an education plan

Order supplies

Prepare for system delivery

General considerations

Planning your system requires attention to the numerous details.

When you are determining the placement of your system, look the following considerations:

• Adequate space for the devices.

• Working environment of personnel who are using the devices (their comfort, ability to access the

devices, supplies, and reference materials).

• Adequate space for maintaining and servicing the devices.

• Physical security requirements necessary for the devices.

• Weight of the devices.

• Heat output of the devices.

• Operating temperature requirements of the devices.

©

Copyright IBM Corp. 2018, 2019 3

Page 18

• Humidity requirements of the devices.

• Air flow requirements of the devices.

• Air quality of the location where the devices are used. For example, excess dust can damage your

system.

Note: The system and devices are designed to operate in normal ofce environments. Dirty or other

poor environments might damage the system or the devices. You are responsible for providing the

proper operating environment.

• Altitude limitations of the devices.

• Noise emission levels of the devices.

• Any vibration of equipment near where the devices are placed.

• Paths of power cords.

The following pages contain the information that you need to evaluate these considerations.

Site preparation and physical planning guidelines

These guidelines help you prepare your site for the delivery and installation of your server.

The Site preparation and physical planning topic covers the following information:

Site selection, building and space considerations

• Site selection

• Access

• Static electricity and floor resistance

• Space requirements

• Floor construction and floor loading

• Raised floors

• Conductive contamination

• Computer room layout

Site environment, safety, and security

• Vibration and shock

• Lighting

• Acoustics

• Electromagnetic compatibility

• Computer room location

• Material and data storage protection

• Emergency planning for continuous operations

Electrical power and grounding

• General power information

• Power quality

• Voltage and frequency limits

• Power load

• Power source

• Dual power installations

Air conditioning

• Air conditioning determination

4

Power Systems: Site and hardware planning

Page 19

• General guidelines for data centers

• Temperature and humidity design criteria

• Temperature and humidity recording instruments

• Relocation and temporary storage

• Acclimation

• System air distribution

Planning for the installation of rear door heat exchangers

• Planning for the installation of rear door heat exchangers

• Heat exchanger specications

• Water specications for the secondary cooling loop

• Water delivery specications for secondary loops

• Layout and mechanical installation

• Suggested sources for secondary loop components

Communications

• Planning for communications

Planning activities 5

Page 20

6 Power Systems: Site and hardware planning

Page 21

Site and hardware planning

Learn about the specications that site planners can use to assess the physical site and operational

requirements necessary to prepare your site for a new server. This information includes specications for

servers and expansion units, plugs and receptacles, and cables, and information about power-distribution

units and uninterruptible power supplies.

Hardware specication sheets

Hardware specication sheets provide detailed information for your hardware, including dimensions,

electrical, power, temperature, environment, and service clearances.

Server specications

Server specications provide detailed information for your server, including dimensions, electrical, power,

temperature, environment, and service clearances.

Select the appropriate models to view the specications for your server.

Model 9008-22L, 9009-22A, 9009-41A, 9009-42A, 9223-22H, and 9223-42H server specications

Server specications provide detailed information for your server, including dimensions, electrical, power,

temperature, environment, and service clearances.

Use the following specications to plan for your server.

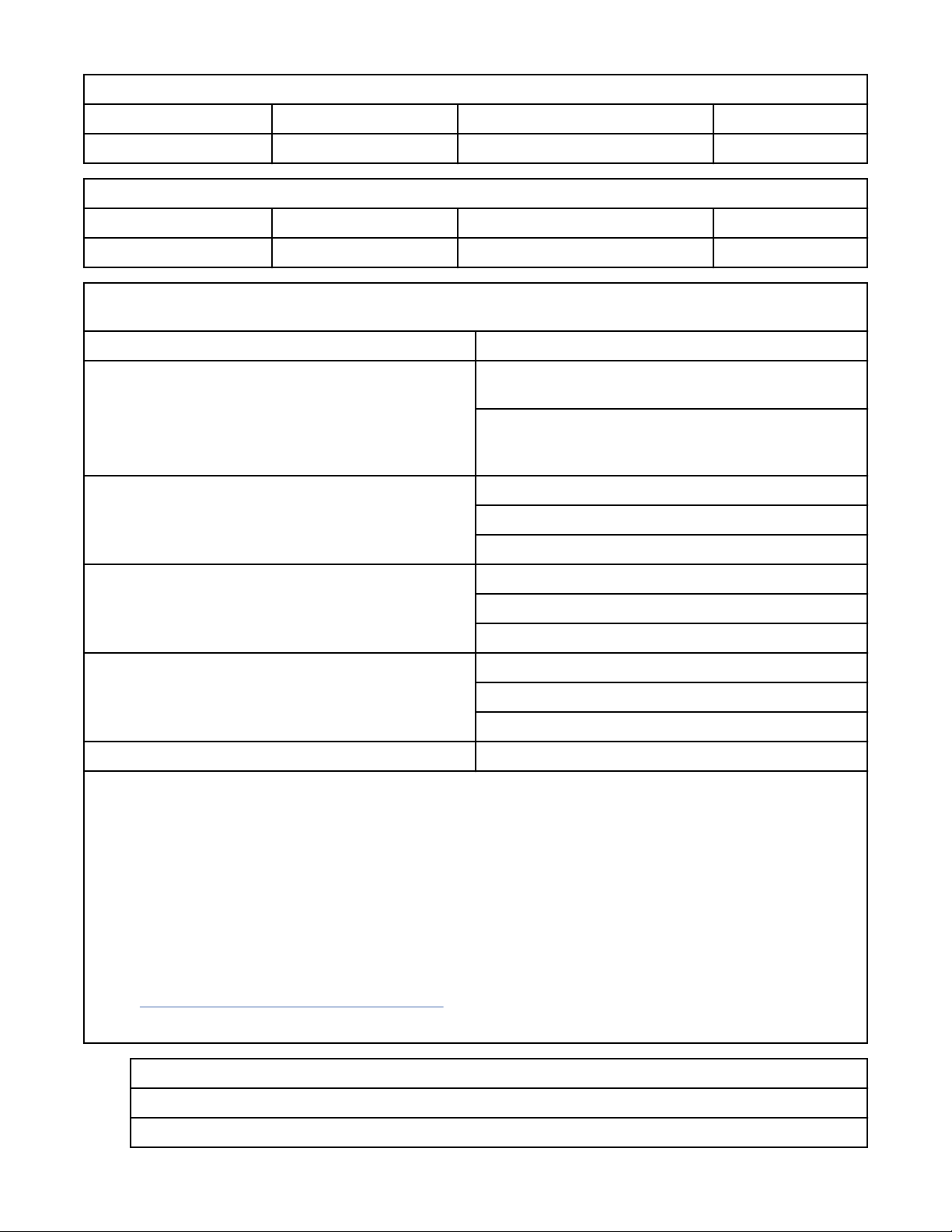

Table 2. Dimensions for the 9008-22L, 9009-22A, and 9223-22H

Width Depth Height EIA units Weight

482 mm (18.97 in.) 766.5 mm (30.2

in.)

Note:

1. The depth is measured from the front bezel to the back of the top cover. The depth from the front

rack EIA mounting post to the back of the server where the PCI cables exit is 713 mm (28 inches).

Table 3. Dimensions for the 9009-41A, 9009-42A, and 9223-42H

Width Depth Height EIA units Weight

482 mm (18.97 in.) 769.6 mm (30.3

in.)

Note:

1. The depth is measured from the front bezel to the back of the top cover. The depth from the front

rack EIA mounting post to the back of the server where the PCI cables exit is 713 mm (28 inches).

86.7 mm (3.4 in.) 2 30.4 kg (67 lb)

173.3 mm (6.8 in.) 4 36.3 kg (80 lb)

1

1

(9009-41A)

39.9 kg (88 lb)

(9009-42A and

9223-42H)

Table 4. Shipping dimensions for the 9008-22L, 9009-22A, and 9223-22H (without pallet)

Width Depth Height Weight

991 mm (39 in.) 597 mm (24 in.) 261 mm (10.3 in.) 45 kg (99 lb)

©

Copyright IBM Corp. 2018, 2019 7

Page 22

Table 5. Shipping dimensions for the 9009-41A, 9009-42A, and 9223-42H (without pallet)

Width Depth Height Weight

610 mm (24.0 in.) 1016 mm (40.0 in.) 345 mm (13.6 in.) 53.7 kg (118.5 lb)

Table 6. Pallet dimensions for the 9008-22L, 9009-22A, 9009-41A, 9009-42A, 9223-22H, and 9223-42H

Width Depth Height Weight

610 mm (24 in.) 1016 mm (40 in.) 125 mm (5 in.) 10 kg (22 lb)

Table 7. Electrical characteristics for the 9008-22L, 9009-22A, 9009-41A, 9009-42A, 9223-22H, and

9223-42H

Electrical characteristics Properties

AC rated voltage and frequency

2

900 W PSU: 100 - 127 V ac or 200 - 240 V ac at 50 or

60 Hz plus or minus 3 Hz (9009-41A)

1400 W PSU: 200 - 240 V ac at 50 or 60 Hz plus or

minus 3 Hz (9008-22L, 9009-22A, 9223-22H,

9009-42A, and 9223-42H)

Thermal output (maximum)

3

6416 BTU/hr (9008-22L, 9009-22A, and 9223-22H)

5461 BTU/hr (9009-41A)

9386 BTU/hr (9009-42A and 9223-42H)

Maximum power consumption

3

1880 W (9008-22L, 9009-22A, and 9223-22H)

1600 W (9009-41A)

2750 W (9009-42A and 9223-42H)

Maximum kVA

4

1.94 kVA (9008-22L, 9009-22A, and 9223-22H)

1.65 kVA (9009-41A)

2.835 kVA (9009-42A and 9223-42H)

Phase Single

Notes:

1. Redundancy is supported. The 9008-22L, 9009-22A, and 9223-22H have a maximum of two power

supplies, but can operate on one power supply. The 9009-41A, 9009-42A, and 9223-42H have a maximum

of four power supplies, but can operate on two power supplies.

2. The power supplies automatically accept any voltage with the published, rated-voltage range. If multiple

power supplies are installed and operating, the power supplies draw approximately equal current from the

utility (electrical supply) and provide approximately equal current to the load.

3. Power draw and heat load vary greatly by conguration. When you plan for an electrical system, it is

important to use the maximum values. However, when you plan for heat load, you can use the IBM Systems

Energy Estimator to obtain a heat output estimate based on a specic conguration. For more information,

see The IBM Systems Energy Estimator website.

4. To calculate the amperage, multiply the kVA by 1000 and divide that number by the operating voltage.

Table 8. Environment requirements

8 Power Systems: Site and hardware planning

Environment requirements

Environment (operating)

1

Page 23

Table 8. Environment requirements (continued)

Environment requirements

Properties Recommended Allowable

ASHRAE class A2 (Fourth edition)

Airflow direction Front-to-back

2,3,4

Temperature 18.0°C – 27.0°C (64.4°F –

80.6°F)

10.0°C – 35.0°C (50.0°F –

95.0°F)

Low end moisture -9.0°C (15.8°F) dew point -12.0°C (10.4°F) dew point and

8% relative humidity

High end moisture 60% relative humidity and 15°C

(59°F) dew point

85% relative humidity and

21.0°C (69.8°F) dew point

Maximum altitude 3050 m (10,000 ft)

Allowable environment (nonoperating)

5

Temperature 5°C - 45°C (41°F - 113°F)

Relative humidity 8% to 85%

Maximum dew point 27°C (80.6°F)

Environment (shipping)

Temperature -40.0°C to 60.0°C (-40°F to 140°F)

Relative humidity 5% - 100% (no condensation)

Maximum wet bulb temperature 29.0°C (84.2°F)

Environment (storage)

Temperature 1°C - 60°C (33.8°F - 140°F)

Relative humidity 5% - 80% (no condensation)

Maximum wet bulb temperature 29°C (84.2°F)

Site and hardware planning 9

Page 24

Table 8. Environment requirements (continued)

Environment requirements

Notes:

1. IBM provides the recommended operating environment as the long-term operating environment that

can result in the greatest reliability, energy efciency, and reliability. The allowable operating

environment represents where the equipment is tested to verify functionality. Due to the stresses

that operating in the allowable envelope can place on the equipment, these envelopes must be used

for short-term operation, not continuous operation.

2. Must derate the maximum allowable temperature 1°C (1.8°F) per 175 m (574 ft) above 900 m (2953

ft) up to a maximum allowable elevation of 3050 m (10000 ft).

3. The minimum humidity level is the larger absolute humidity of the -12°C (10.4°F) dew point and the

8% relative humidity. These levels intersect at approximately 25°C (77°F). Below this intersection,

the dew point (-12°C) represents the minimum moisture level, while above it, the relative humidity

(8%) is the minimum. For the upper moisture limit, the limit is the minimum absolute humidity of the

dew point and relative humidity that is stated.

4. The following minimum requirements apply to data centers that are operated at low relative

humidity:

• Data centers that have do not have ESD floors and where people are allowed to wear non-ESD

shoes might want to consider increasing humidity given that the risk of generating 8 kV increases

slightly at 8% relative humidity, when compared to 25% relative humidity.

• All mobile furnishings and equipment must be made of conductive or static dissipative materials

and be bonded to ground.

• During maintenance on any hardware, a properly functioning and grounded wrist strap must be

used by any personnel who comes in contact with information technology (IT) equipment.

5. Equipment that is removed from the original shipping container and is installed, but is powered

down. The allowable non-operating environment is provided to dene the environmental range that

an unpowered system can experience short term without being damaged.

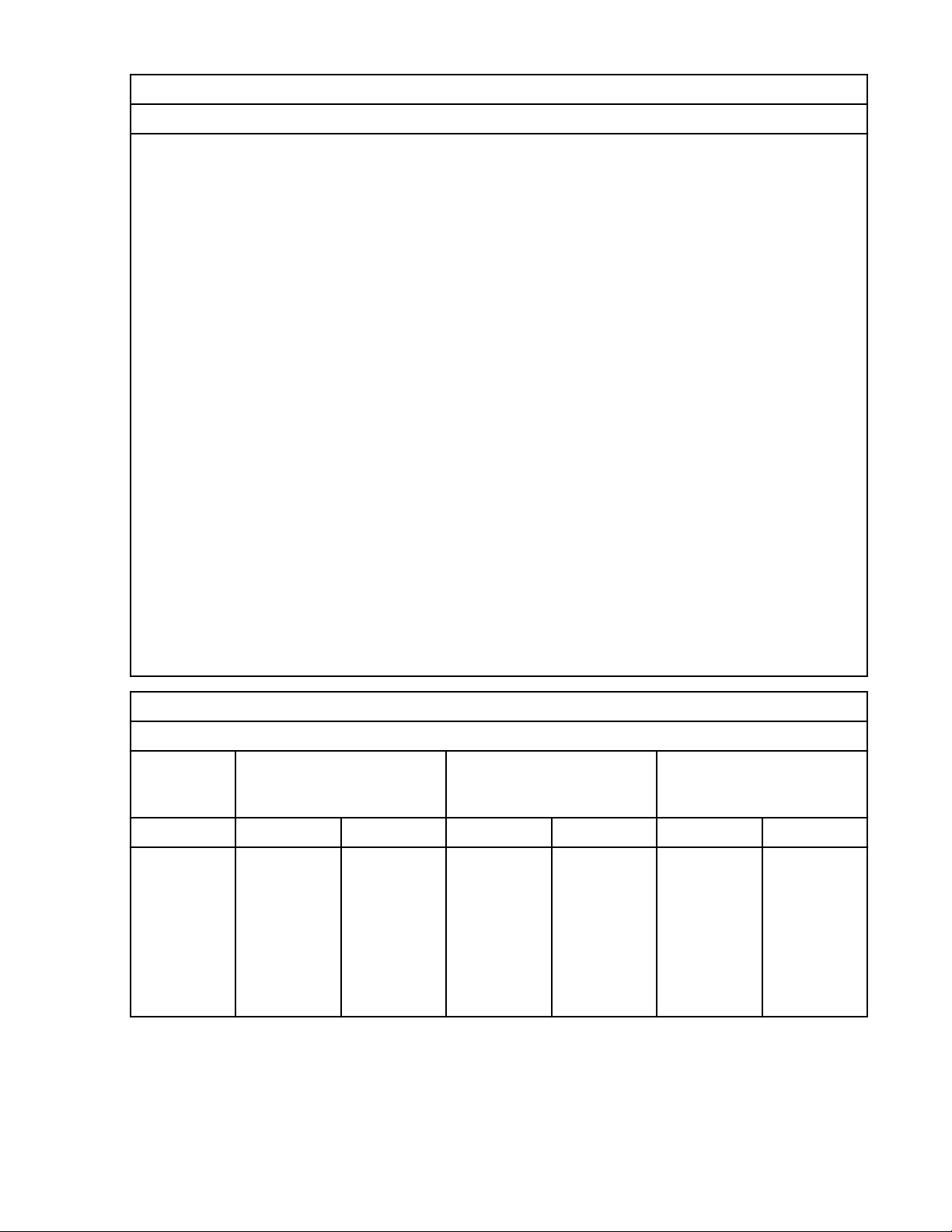

Table 9. Noise emissions for the 9008-22L, 9009-22A, and 9223-22H

Declared noise emission values in accordance with ISO 9296

Production

description

Declared A-weighted

sound power level, L

WA,m

Declared A-weighted

sound pressure level, L

(B)

1, 2, 3, 4, 5

(dB)

Operating Idling Operating Idling Operating Idling

9008-22L,

9009-22A,

and

9223-22H at

23°C

6.5 6.4 52 52 0.3 0.3

(73.4°F)

ambient

temperature

pA,m

Statistical adder for

verication, Kv (B)

10 Power Systems: Site and hardware planning

Page 25

Table 9. Noise emissions for the 9008-22L, 9009-22A, and 9223-22H (continued)

Declared noise emission values in accordance with ISO 9296

1, 2, 3, 4, 5

Production

description

9008-22L,

9009-22A,

and

9223-22H

with PCIe

adapters that

require extra

cooling or at

a

temperature

between

23°C - 27°C

(73.4°F -

80.6°F).

9008-22L,

9009-22A,

and

9223-22H

with

acoustical

doors

installed

Declared A-weighted

sound power level, L

(B)

6

7.4

7.4

WA,m

6

Declared A-weighted

sound pressure level, L

pA,m

Statistical adder for

verication, Kv (B)

(dB)

61 61 0.3 0.3

• 7042-T42

rack: FCs

EC07 and

EC08

• 7965-S42

rack: FCs

ECRA and

ECRB

and with

PCIe

adapters that

require extra

cooling or at

a

temperature

between

23°C - 27°C

(73.4°F -

80.6°F).

6.8 6.8 56 56 0.3 0.3

Site and hardware planning 11

Page 26

Table 9. Noise emissions for the 9008-22L, 9009-22A, and 9223-22H (continued)

Declared noise emission values in accordance with ISO 9296

1, 2, 3, 4, 5

Production

description

Declared A-weighted

sound power level, L

(B)

WA,m

Declared A-weighted

sound pressure level, L

(dB)

pA,m

Statistical adder for

verication, Kv (B)

9008-22L,

9009-22A,

and

9223-22H at

maximum

8.3

6

8.3

6

70 70 0.3 0.3

allowable

ambient

operating

temperature.

Notes:

1. Declared level L

is the upper-limit A-weighted sound power level. Declared level L

WA,m

PA,m

is the

mean A-weighted emission sound pressure level that is measured at the 1-meter bystander

positions.

2. The statistical adder for verication, Kv, is a quantity to be added to the declared mean A-weighted

sound power level, L

, such that there is a 95% probability of acceptance, when using the

WA,m

verication procedures of ISO 9296, if no more than 6.5% of the batch of new equipment has Aweighted sound power levels greater than (L

3. The quantity L

(formerly called L

WA,c

WAd

), can be computed from the sum of L

WA,m

+ Kv).

WA,m

and Kv.

4. All measurements made in conformance with ISO 7779 and declared in conformance with ISO 9296.

5. 10 dB (decibel) equals 1 B (bel).

6. Notice: Government regulations (such as those prescribed by OSHA or European Community

Directives) might govern noise level exposure in the workplace and might apply to you and your

server installation. This IBM system is available in racks with optional acoustical door features that

can help reduce the noise that is emitted from this system. The actual sound pressure levels in your

installation depend upon various factors, including the number of racks in the installation; the size,

materials, and conguration of the room where you designate the racks to be installed; the noise

levels from other equipment; the room ambient temperature, and employees' location in relation to

the equipment. Further, compliance with such government regulations also depends upon various

extra factors, including the duration of employees' exposure and whether employees wear hearing

protection. IBM recommends that you consult with qualied experts in this eld to determine

whether you are in compliance with the applicable regulations.

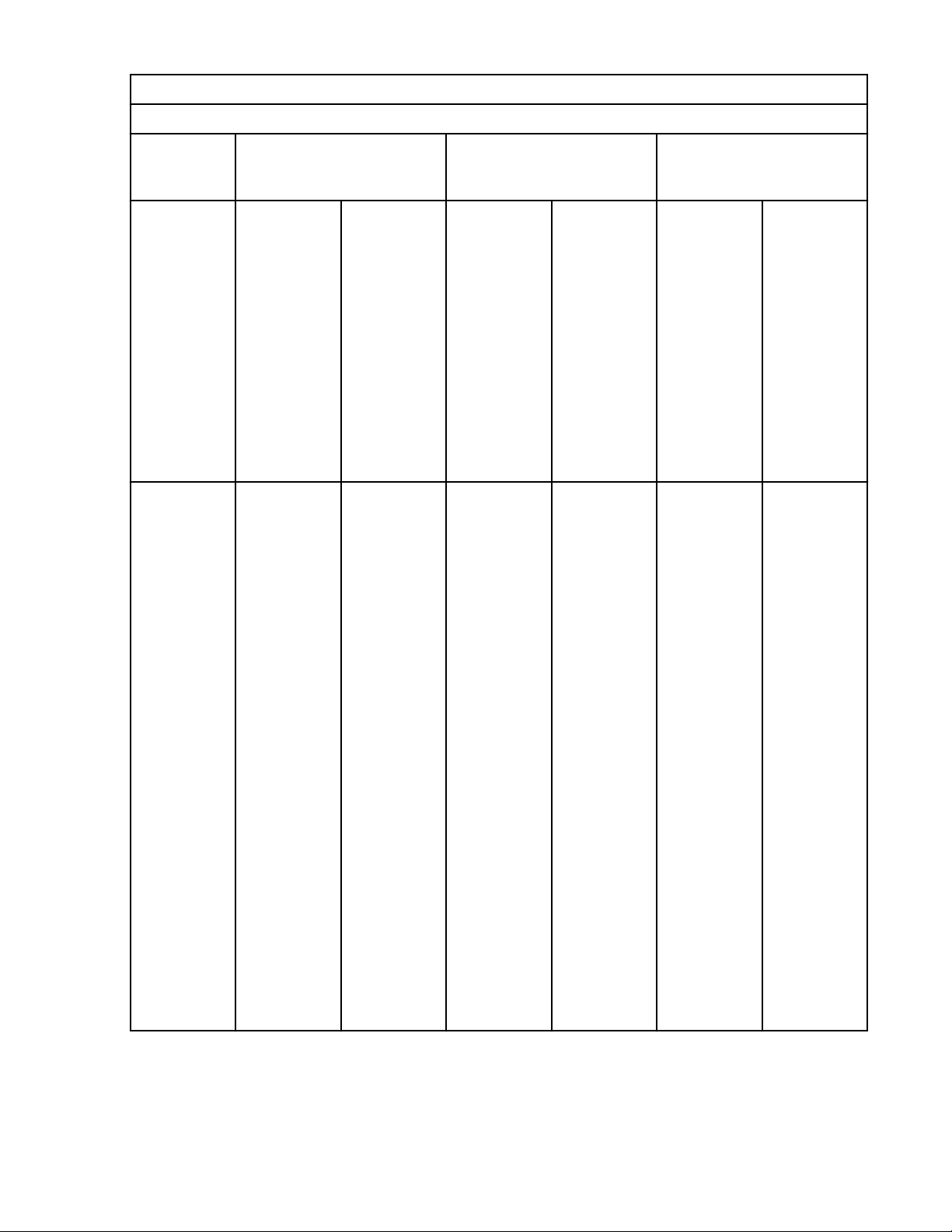

Table 10. Noise emissions for the 9009-41A

Declared noise emission values in accordance with ISO 9296

Production

description

Declared A-weighted

sound power level, L

WA,m

(B)

Operating Idling Operating Idling Operating Idling

9009-41A

(tower

version (FC

5.8 5.5 43 39 0.3 0.3

EJUB))

12 Power Systems: Site and hardware planning

1, 2, 3, 4, 5

Declared A-weighted

sound pressure level, L

(dB)

pA,m

Statistical adder for

verication, Kv (B)

Page 27

Table 10. Noise emissions for the 9009-41A (continued)

Declared noise emission values in accordance with ISO 9296

1, 2, 3, 4, 5

Production

description

9009-41A

(rack

version)

9009-41A

(rack

version) with

high-power

PCIe

adapters.

9009-41A

(rack

version) with

high-power

PCIe

adapters and

acoustical

doors

installed

• 7042-T42

rack: FCs

EC07 and

EC08

• 7965-S42

rack: FCs

ECRA and

ECRB

Declared A-weighted

sound power level, L

(B)

WA,m

Declared A-weighted

sound pressure level, L

(dB)

pA,m

Statistical adder for

verication, Kv (B)

5.8 5.5 43 39 0.3 0.3

7.3 7.3 60 60 0.3 0.3

6.6 6.6 54 54 0.3 0.3

9009-41A

(rack and

tower

version) at

maximum

allowable

ambient

operating

temperature.

8.0

6

8.0

6

67 67 0.3 0.3

Site and hardware planning 13

Page 28

Table 10. Noise emissions for the 9009-41A (continued)

Declared noise emission values in accordance with ISO 9296

1, 2, 3, 4, 5

Production

description

Declared A-weighted

sound power level, L

(B)

WA,m

Declared A-weighted

sound pressure level, L

(dB)

pA,m

Statistical adder for

verication, Kv (B)

Notes:

1. Declared level L

is the upper-limit A-weighted sound power level. Declared level L

WA,m

PA,m

is the

mean A-weighted emission sound pressure level that is measured at the 1-meter bystander

positions.

2. The statistical adder for verication, Kv, is a quantity to be added to the declared mean A-weighted

sound power level, L

, such that there is a 95% probability of acceptance, when using the

WA,m

verication procedures of ISO 9296, if no more than 6.5% of the batch of new equipment has Aweighted sound power levels greater than (L

3. The quantity L

(formerly called L

WA,c

WAd

), can be computed from the sum of L

WA,m

+ Kv).

WA,m

and Kv.

4. All measurements made in conformance with ISO 7779 and declared in conformance with ISO 9296.

5. 10 dB (decibel) equals 1 B (bel).

6. Notice: Government regulations (such as those prescribed by OSHA or European Community

Directives) might govern noise level exposure in the workplace and might apply to you and your

server installation. This IBM system is available in racks with optional acoustical door features that

can help reduce the noise that is emitted from this system. The actual sound pressure levels in your

installation depend upon various factors, including the number of racks in the installation; the size,

materials, and conguration of the room where you designate the racks to be installed; the noise

levels from other equipment; the room ambient temperature, and employees' location in relation to

the equipment. Further, compliance with such government regulations also depends upon various

extra factors, including the duration of employees' exposure and whether employees wear hearing

protection. IBM recommends that you consult with qualied experts in this eld to determine

whether you are in compliance with the applicable regulations.

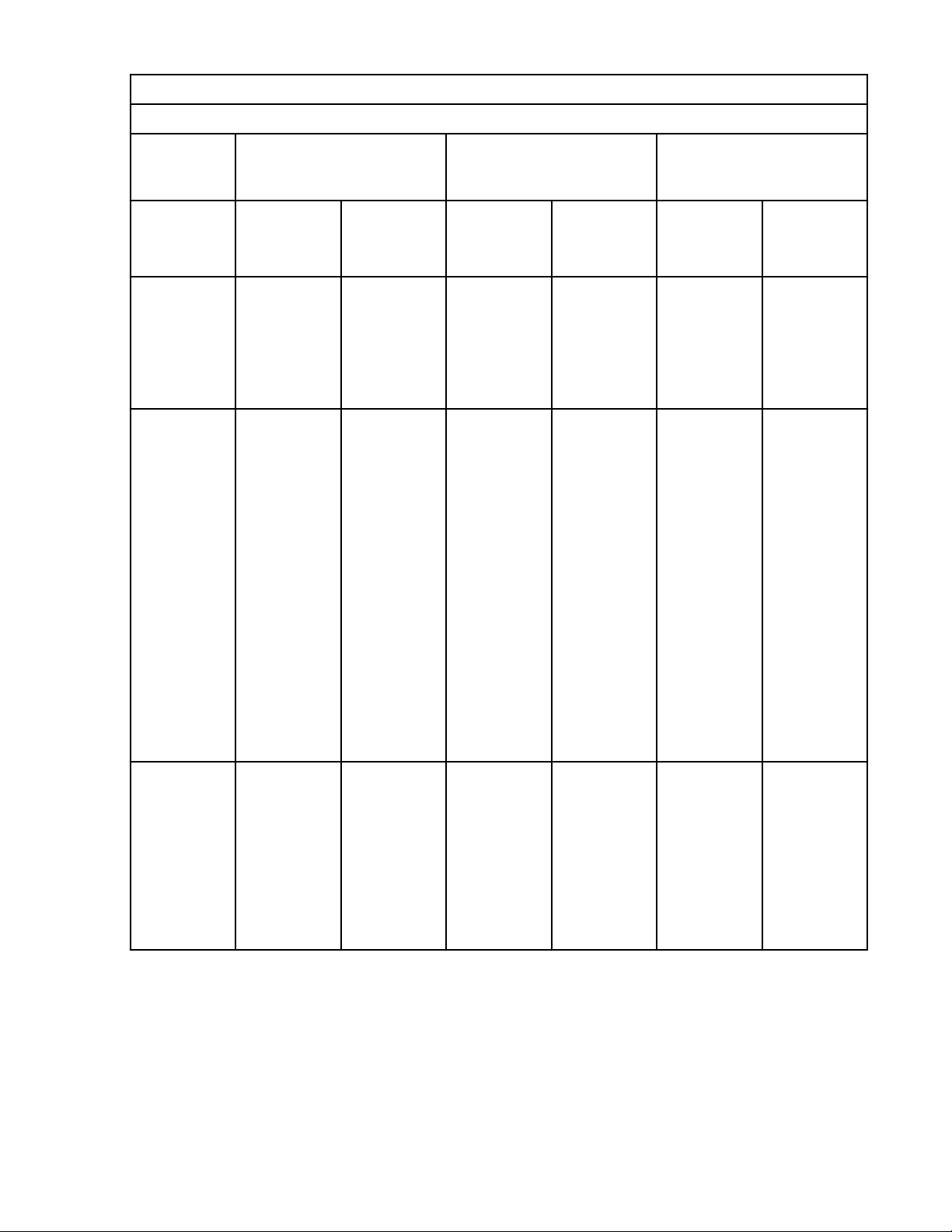

Table 11. Noise emissions for the 9009-42A and 9223-42H

Declared noise emission values in accordance with ISO 9296

Production

description

Declared A-weighted

sound power level, L

(B)

WA,m

Declared A-weighted

sound pressure level, L

(dB)

Operating Idling Operating Idling Operating Idling

9009-42A

and

6.6 6.5 53 53 0.3 0.3

9223-42H

9009-42A

and

9223-42H

with high-

7.4

6

7.4

6

61 61 0.3 0.3

power PCIe

adapters.

1, 2, 3, 4, 5

pA,m

Statistical adder for

verication, Kv (B)

14 Power Systems: Site and hardware planning

Page 29

Table 11. Noise emissions for the 9009-42A and 9223-42H (continued)

Declared noise emission values in accordance with ISO 9296

1, 2, 3, 4, 5

Production

description

9009-42A

and

9223-42H

with highpower PCIe

adapters and

acoustical

doors

installed

• 7042-T42

rack: FCs

EC07 and

EC08

• 7965-S42

rack: FCs

ECRA and

ECRB

9009-42A

and

9223-42H at

maximum

allowable

ambient

operating

temperature.

Declared A-weighted

sound power level, L

(B)

WA,m

Declared A-weighted

sound pressure level, L

(dB)

pA,m

Statistical adder for

verication, Kv (B)

6.9 6.9 55 55 0.3 0.3

8.1

6

8.1

6

68 68 0.3 0.3

Site and hardware planning 15

Page 30

Table 11. Noise emissions for the 9009-42A and 9223-42H (continued)

Declared noise emission values in accordance with ISO 9296

1, 2, 3, 4, 5

Production

description

Declared A-weighted

sound power level, L

(B)

WA,m

Declared A-weighted

sound pressure level, L

(dB)

pA,m

Statistical adder for

verication, Kv (B)

Notes:

1. Declared level L

is the upper-limit A-weighted sound power level. Declared level L

WA,m

PA,m

is the

mean A-weighted emission sound pressure level that is measured at the 1-meter bystander

positions.

2. The statistical adder for verication, Kv, is a quantity to be added to the declared mean A-weighted

sound power level, L

, such that there is a 95% probability of acceptance, when using the

WA,m

verication procedures of ISO 9296, if no more than 6.5% of the batch of new equipment has Aweighted sound power levels greater than (L

3. The quantity L

(formerly called L

WA,c

WAd

), can be computed from the sum of L

WA,m

+ Kv).

WA,m

and Kv.

4. All measurements made in conformance with ISO 7779 and declared in conformance with ISO 9296.

5. 10 dB (decibel) equals 1 B (bel).

6. Notice: Government regulations (such as those prescribed by OSHA or European Community

Directives) might govern noise level exposure in the workplace and might apply to you and your

server installation. This IBM system is available in racks with optional acoustical door features that

can help reduce the noise that is emitted from this system. The actual sound pressure levels in your

installation depend upon various factors, including the number of racks in the installation; the size,

materials, and conguration of the room where you designate the racks to be installed; the noise

levels from other equipment; the room ambient temperature, and employees' location in relation to

the equipment. Further, compliance with such government regulations also depends upon various

extra factors, including the duration of employees' exposure and whether employees wear hearing

protection. IBM recommends that you consult with qualied experts in this eld to determine

whether you are in compliance with the applicable regulations.

Table 12. Service clearances

Clearances Front Rear Side

1

Top

1

Operating 762 mm (30 in.) 762 mm (30 in.)

Nonoperating 762 mm (30 in.) 762 mm (30 in.) 762 mm (30 in.) 762 mm (30 in.)

1

Side and top clearances are optional during operation.

Electromagnetic compatibility compliance: CISPR 22; CISPR 32; CISPR 24; FCC, CFR 47, Part 15 (US);

VCCI (Japan); Directive 2014/30/EU (EEA); ICES-003, Issue 6 (Canada); ACMA (Australia, New Zealand);

CNS 13438 (Taiwan); Radio Waves Act (Korea); Commodity Inspection Law (China); TCVN 7189

(Vietnam); MoCI (Saudi Arabia); SI 961 (Israel); EAC (EAEU)

Safety compliance: UL 60950-1:2007 Underwriters Laboratory; CAN/CSA22.2 No. 60950-1-07;

EN60950-1:2006 + Am1 + Am2 European Norm; IEC 60950-1 2nd Edition + Am1 + Am2 and all National

Differences

Special Hardware Management Console considerations

When the server is managed by an HMC, the console must be provided within the same room and within 8

m (26 ft) of the server. For more considerations, see Installing and conguring the HMC.

Note: As an alternative to the local HMC requirement, you can provide a supported device, such as a PC,

with connectivity and authority to operate through a remotely attached HMC. This local device must be in

the same room and within 8 m (26 ft) of your server. This local device must provide functional capabilities

16

Power Systems: Site and hardware planning

Page 31

that are equivalent to the HMC that it replaces. This local device is needed by the service representative

to service the system.

Model 9008-22L, 9009-22A, and 9223-22H Technical Documentation for EU Regulation 617/2013

International Business Machines Corporation

New Orchard Road

Armonk, New York 10504

http://www.ibm.com/customersupport/

IBM Power Systems

Table 13. System characteristics

System characteristics Properties

Product type Computer server

Year rst manufactured 2018

Noise levels (declared A-weighted sound

power level of the computer)

Table 14. Power characteristics

1

8.3 bels (B)

Power characteristics Properties

Internal/external power supply efciency

80 PLUS Verication and Testing Report 1025 W

80 PLUS Verication and Testing Report 1400 W

Maximum power (watts) 1400 W and 1025 W

Idle state power (watts) Unavailable

Sleep mode power (watts) N/A for servers

1. Preliminary data is based on development systems and is subject to change.

Table 15. Test parameters for measurements

Test parameters Properties

Test voltage and frequency 230 V ac at 50 or 60 Hz

Total harmonic distortion of the electricity

supply system

The maximum harmonic content of the input voltage waveform

is equal to or less than 2%. The qualication is compliant with

EN 61000-3-2.

Information and documentation on the

instrumentation setup and circuits that are

used for electrical testing

Measurement methodology that is used to

determine information in this document

ENERGY STAR Test Method for Computer Servers; ECOVA

Generalized Test Protocol for Calculating the Energy Efciency

of Internal Ac-Dc and Dc-Dc Power Supplies

ENERGY STAR Servers Version 2.0 Program Requirements;

ECOVA Generalized Test Protocol for Calculating the Energy

Efciency of Internal Ac-Dc and Dc-Dc Power Supplies

Model 9009-41A, 9009-42A, and 9223-42H Technical Documentation for EU Regulation 617/2013

International Business Machines Corporation

New Orchard Road

Armonk, New York 10504

http://www.ibm.com/customersupport/

IBM Power Systems

Site and hardware planning

17

Page 32

Table 16. System characteristics

System characteristics Properties

Product type Computer server

Year rst manufactured 2018

Noise levels (declared A-weighted sound

power level of the computer)

Table 17. Power characteristics

1

8.3 bels (B)

Power characteristics Properties

Internal/external power supply efciency

80 PLUS Verication and Testing Report 1025 W

80 PLUS Verication and Testing Report 1400 W

Maximum power (watts) 1400 W and 1025 W

Idle state power (watts) Unavailable

Sleep mode power (watts) N/A for servers

1. Preliminary data is based on development systems and is subject to change.

Table 18. Test parameters for measurements

Test parameters Properties

Test voltage and frequency 230 V ac at 50 or 60 Hz

Total harmonic distortion of the electricity

supply system

The maximum harmonic content of the input voltage waveform

is equal to or less than 2%. The qualication is compliant with

EN 61000-3-2.

Information and documentation on the

instrumentation setup and circuits that are

used for electrical testing

Measurement methodology that is used to

determine information in this document

ENERGY STAR Test Method for Computer Servers; ECOVA

Generalized Test Protocol for Calculating the Energy Efciency

of Internal Ac-Dc and Dc-Dc Power Supplies

ENERGY STAR Servers Version 2.0 Program Requirements;

ECOVA Generalized Test Protocol for Calculating the Energy

Efciency of Internal Ac-Dc and Dc-Dc Power Supplies

Expansion unit and migration tower specications

Expansion unit and migration tower specications provide detailed information for your hardware,

including dimensions, electrical, power, temperature, environment, and service clearances.

Select a model to view its specications.

5887 expansion unit

Hardware specications provide detailed information for your expansion unit, including dimensions,

electrical, power, temperature, environment, and service clearances.

Table 19. Dimensions for rack-mounted expansion unit

Weight (with drives

installed) Width

25.4 kg (56.0 lb) 448.6 mm (17.7 in.) 530 mm (20.9 in.) 87.4 mm (3.4 in.)

Depth (including front

bezel)

Height (with support

rails)

18 Power Systems: Site and hardware planning

Page 33

Table 20. Electrical

Electrical characteristics Properties

kVA (maximum)

1

0.32

Rated voltage and frequency 100 - 127 V ac or 200 - 240 V ac at 50 - 60 Hz

Thermal output (maximum)

1

1024 Btu/hr

Power requirements (maximum) 300 W

Power factor 0.94

Leakage current (maximum) 1.2 mA

Phase 1

1

All measurements made in conformance with ISO 7779 and declared in conformance with ISO 9296.

Table 21. Temperature requirements

Operating Nonoperating

10°C - 38°C (50°F - 100.4°F)

1

The maximum 38°C (100.4°F) temperature must be derated 1°C (1.8 °F) per 137 m (450 ft) above 1295 m

1

-40°C - 60°C (-40°F - 140°F)

(4250 ft).

Table 22. Environmental requirements

Environment Operating Nonoperating Maximum altitude

Noncondensing humidity 20% - 80% (allowable)

40% - 55%

(recommended)

8% - 80% (including

condensing)

2134 m (7000 ft) above

sea level

Wet bulb temperature 21°C (69.8°F) 27°C (80.6°F)

Table 23. Noise emissions

1

Properties Operating Idle

L

WAd

L

(1-meter bystander) 43 dB 43 dB

pAm

1

Single drawer in standard 19-inch rack with 24 hard disk drives, nominal environmental conditions, and no

6.0 bels 6.0 bels

front or rear doors on rack.

For a description of noise emission values, see Acoustics.

All measurements made in conformance with ISO 7779 and declared in conformance with ISO 9296.

Table 24. Service clearances for rack-mounted expansion unit

Front Back Sides

914 mm (36 in.) 914 mm (36 in.) 914 mm (36 in.)

Side and top clearances are optional during operation.

Safety compliance: This hardware is designed and certied to meet the following safety standards: UL

60950; CAN/CSA C22.2 No. 60950–00; EN 60950; IEC 60950 including all National Differences

Site and hardware planning

19

Page 34

EMX0 PCIe Gen3 I/O expansion drawer (feature code EMX0)

Hardware specications provide detailed information for your expansion unit, including dimensions,

electrical, power, temperature, environment, and service clearances.

Table 25. Dimensions for rack-mounted expansion unit

Width Depth Height Weight (maximum)

482 mm (19 in.) 802 mm (31.6 in.)

Table 26. Electrical

1,2,3

173 mm (6.8 in.), 4 EIA

units

54.4 kg (120 lb)

Electrical characteristics Properties

AC rated voltage and frequency 100 - 127 V ac or 200 - 240 V ac at 50 or 60 Hz plus or

minus 3 Hz (FC EMXA)

DC rated voltage 192 - 400 V dc (FC EMXB)

Thermal output (maximum) 1740 BTU/hr

Maximum power consumption 510 W

Maximum kVA 0.520

Phase Single

Notes:

1. The power supplies for AC or DC voltage do not change. Only the power chunnel is different. The power

chunnel uses internal cables to carry power from the rear of the system node to the power supplies that are

in the front of the system node.

2. All measurements made in conformance with ISO 7779 and declared in conformance with ISO 9296.

3. AC and HVDC power supplies cannot be mixed in the same server or I/O drawer. IBM recommends that AC

products and HVDC products with HVDC PDUs are installed in separate racks. However, AC and HVDC

products can be supported in the same rack if all grounding (earthing) is done in accordance with the

applicable electrical code or codes. IBM provides documentation for different AC and HVDC products about

the disconnecting means for service. If a different disconnecting means is to be used for service of the

equipment in a rack with AC-powered and DC-powered products, the disconnecting means must be made

clear to service.

Table 27. Environment requirements

Environment Recommended operating Allowable operating Nonoperating

ASHRAE class A3

Airflow direction Front-to-back

Temperature

Humidity range 5.5°C (42°F) dew point

1

18°C - 27°C (64°F - 80°F) 5°C - 40°C (41°F - 104°F) 1°C - 60°C (34°F - 140°F)

(DP) to 60% relative

-12.0°C (10.4°F) DP and

8% - 80% RH

5% - 80% RH

humidity (RH) and 15°C

(59°F) dew point

Maximum dew point 24°C (75°F) 27°C (80°F)

Maximum operating

3050 m (10000 ft)

altitude

20 Power Systems: Site and hardware planning

Page 35

Table 27. Environment requirements (continued)

Environment Recommended operating Allowable operating Nonoperating

Shipping temperature -40°C to 60°C (-40°F to

140°F)

Shipping relative humidity 5% - 100%

1. Derate maximum allowable dry-bulb temperature 1°C per 175 m above 950 m.

Table 28. Service clearances for rack-mounted expansion unit

Front Back Sides

914 mm (36 in.) 914 mm (36 in.) 914 mm (36 in.)

Side and top clearances are optional during operation.

Safety compliance: This hardware is designed and certied to meet the following safety standards: UL

60950; CAN/CSA C22.2 No. 60950–00; EN 60950; IEC 60950 including all National Differences.

ESLL and ESLS storage enclosures

Hardware specications for ESLL and ESLS storage enclosures provide detailed information for your

storage enclosures, including dimensions, electrical, power, temperature, environment, and service

clearances.

Table 29. Dimensions for storage enclosures

Weight (maximum

Width Depth Height

conguration)

37.1 kg (81.8 lb) (ESLL)

448.6 mm (17.7 in.) 744.22 mm (29.3 in.) 87.4 mm (3.4 in.)

31.1 kg (68.6 lb) (ESLS)

Table 30. Electrical

Electrical characteristics Properties

AC rated voltage and frequency 100 - 127 V ac or 200 - 240 V ac at 50 or 60 Hz plus or

minus 3 Hz

Thermal output (maximum) 939 BTU/hr

Maximum power consumption 275 W

Maximum kVA 0.28

Phase Single

Table 31. Environment requirements

Environment Recommended operating Allowable operating Nonoperating

ASHRAE class A3

Airflow direction Front-to-back

Temperature

1

18°C - 27°C (64°F - 80°F) 5°C - 40°C (41°F - 104°F) 1°C - 60°C (34°F - 140°F)

Site and hardware planning 21

Page 36

Table 31. Environment requirements (continued)

Environment Recommended operating Allowable operating Nonoperating

Humidity range 5.5°C (42°F) dew point

(DP) to 60% relative

humidity (RH) and 15°C

(59°F) dew point

Maximum dew point 24°C (75°F) 27°C (80°F)

Maximum operating

altitude

Shipping temperature -40°C to 60°C (-40°F to

Shipping relative humidity 5% - 100%

1. Derate maximum allowable dry-bulb temperature 1°C per 175 m above 950 m.

Table 32. Service clearances for rack-mounted expansion unit

Front Back Sides

914 mm (36 in.) 914 mm (36 in.) 914 mm (36 in.)

Side and top clearances are optional during operation.

Safety compliance: This hardware is designed and certied to meet the following safety standards: UL

60950; CAN/CSA C22.2 No. 60950–00; EN 60950; IEC 60950 including all National Differences.

-12.0°C (10.4°F) DP and

8% - 80% RH

3050 m (10000 ft)

5% - 80% RH

140°F)

Rack specications

Rack specications provide detailed information for your rack, including dimensions, electrical, power,

temperature, environment, and service clearances.

For non-IBM rack specications, see “Rack installation specications for racks that are not purchased

from IBM” on page 70.

Select your rack model to view its specications.

Related reference

Rack installation specications for racks that are not purchased from IBM

Learn about the requirements and specications for installing IBM systems into racks that were not

purchased from IBM.

Planning for the 7014-T00 and 7014-T42 racks

Rack specications provide detailed information for your rack, including dimensions, electrical, power,

temperature, environment, and service clearances.

Some products can have rack installation limitations. Refer to the specic server or product specications

for any restrictions.

The following provide specications for the 7014-T00 and 7014-T42 racks.

22

Power Systems: Site and hardware planning

Page 37

Model 7014-T00 rack

Hardware specications provide detailed information for your rack, including dimensions, electrical,

power, temperature, environment, and service clearances.

Table 33. Dimensions for rack

Rack

conguratio

n

Rack Only

with side

covers

Rack with

standard rear

door only

Rack with

standard

front and

rear doors

Rack with FC

6101 OEM

front door

and standard

rear door

Width Depth Height Weight

(empty)

644 mm

(25.4 in.)

644 mm

(25.4 in.)

644 mm

(25.4 in.)

644 mm

(25.4 in.)

1016 mm

(40.0 in.)

1042 mm

(41.0 in.)

1100 mm

(43.3 in.)

1100 mm

(43.3 in.)

1804 mm

(71.0 in.)

1804 mm

(71.0 in.)

1804 mm

(71.0 in.)

1804 mm

(71.0 in.)

244 kg (535

lb)

254 kg (559

lb)

268 kg (590

lb)

268 kg (590

lb)

Weight

(maximum

EIA unit

capacity

conguratio

n)

816 kg (1795

1

lb)

36 EIA units

N/A N/A

N/A N/A

N/A N/A

Rack with FC

6068 high

644 mm

(25.4 in.)

1100 mm

(43.3 in.)

1804 mm

(71.0 in.)

268 kg (590

lb)

N/A N/A

perforation

front door

and standard

rear door

Rack with FC

6248

644 mm

(25.4 in.)

1413 mm

(55.6 in.)

1804 mm

(71.0 in.)

268 kg (589

lb)

N/A N/A

acoustic

front and

rear doors

1

For more information about rack weight distribution and floor loading, see 7014-T00, 7014-T42, and

0553 rack weight distribution and floor loading.

Table 34. Dimensions for doors

Door model Width Height Depth Weight

Standard front

639 mm (25.2 in.) 1740 mm (68.5 in.) 56 mm (2.3 in.) 14 kg (31 lb)

door

Standard rear door 639 mm (25.2 in.) 1740 mm (76.6 in.) 26 mm (1.0 in.) 11 kg (24 lb)

With acoustic

foam: 14 kg (31 lb)

Site and hardware planning 23

Page 38

Table 34. Dimensions for doors (continued)

Door model Width Height Depth Weight

Standard side

covers

FC 6101 front door

10 mm (0.4 in.)

each

1740 mm (68.5 in.)

each

1042 mm (41.0 in.)

each

18 lbs 8.25 kg (18

lb) each

639 mm (25.2 in.) 1740 mm (68.5 in.) 56 mm (2.3 in.) 14 kg (31 lb)

(OEM)

FC 6068 front door,

639 mm (25.2 in.) 1740 mm (68.5 in.) 56 mm (2.3 in.) 14 kg (31 lb)

high perforation

FC 6248 acoustic

doors, front and

639 mm (25.2 in.)

each

1740 mm (76.6 in.)

each

198 mm (7.8 in.)

each

12.3 kg (27 lb)

each

rear

Table 35. Electrical

1

Electrical characteristics Properties

Power source loading maximum in kVA

2

8.4 (FC 61173)

8.4 (FC EPB8

3,4

)

Notes:

1. The total rack power can be derived from the sum of the power that is used by the drawers in the

rack.

2. For FC EPB8, each side can support a maximum of 600 amps (A) and 10 circuit breakers. The PDP

can hold up to twenty (ten per power source) circuit breakers with ratings between 5 A and 90 A.

Each power source supports up to 8.4 kVA.

3. For more information about FC 6117 and FC EPB8, see “Model 7014-T00 rack with optional DC

power distribution panel” on page 25.

4. Preliminary data is subject to change.

See your individual server or hardware specications for temperature and humidity requirements.

Rack noise levels depend on the number and type of drawers installed. See your server or hardware

specications for specic requirements.

Note: All rack installations require careful site and facilities planning that are designed to both address

the cumulative drawer heat output and provide the airflow volume rates necessary to comply with drawer

temperature requirements. All rack installations require careful site and facilities planning that are

designed to address both the cumulative drawer heat output and provide the airflow volume rates

necessary to comply with drawer temperature requirements. Rack airflow requirements depend on the

number and type of drawers installed.

Note: Acoustic doors are available for IBM racks. Feature code 6248 is available for the 0551 and 7014T00 racks. Feature code 6249 is available for 7014-T42 racks. The overall sound reduction is

approximately 6 dB. The doors add approximately 381 mm (15 in.) to the depth of the racks.

Related reference

7014-T00 and 7014-T42 rack weight distribution and floor loading

24

Power Systems: Site and hardware planning

Page 39

Racks can be heavy when populated with several drawers. Use the Weight distribution distances for racks

when loaded and Floor loading for racks when loaded tables to ensure proper floor loading and weight

distribution.

Model 7014-T00 rack with optional DC power distribution panel

Hardware specications provide detailed information for your rack, including dimensions, electrical,

power, temperature, environment, and service clearances.

Feature code (FC) 6117 (-48 V dc power distribution panel (PDP))

This feature provides a top-mounted, dual DC power distribution panel for a rack that can contain varying

quantities of central processing unit (CPU) drawers, storage subsystems, or both. Up to two DC H80

systems or two DC M80 systems are supported, in addition to up to four DC storage subsystems. This

feature is built without attached power cables. It comes with a series of power connectors that are built

into its rear bulkhead. The appropriate DC power cables are included with supported drawer systems and

plug into the power connectors at the rear of the 6117 PDP.

FC EPB8 (-48 V dc power distribution panel (PDP))

This feature provides a top-mounted -48 V dc PDP for model 7014-T00 racks that can contain varying

quantities of drawers, storage subsystems, and OEM equipment. This feature is preinstalled on the 7014T00 rack. The PDP sits on top of the rack and does not take up any EIA space. The PDP supports

redundant power with a split A and B side. Each side can support up to 10 circuit breakers that are rated 5

- 90 amperes with a maximum load of 600 amperes. FC EPB8 does not include circuit breakers or DC

power cables. The circuit breakers and associated DC power cables are typically supplied with IBM

products. For OEM products, you must provide the applicable circuit breakers and DC power cables.

Note: Front doors are optional on the 7014-T00 rack.

Site and hardware planning

25

Page 40

Figure 1. FC EPB8 - power distribution panel

26

Power Systems: Site and hardware planning

Page 41

Figure 2. FC EPB8 - power distribution panel (top-down view)

Table 36. Dimensions for 7014-T00 rack with FC 6117 or FC EPB8 installed

Dimensions Properties

Width (rack with side panels) 644 mm (25.4 in.)

Depth 1148 mm (45.2 in.)

Height with -48 v DC power only 1926 mm (75.8 in.)

Height with -48 v DC power and overhead cable tray

(normally included with FC EPB8)

Table 37. Environment requirements for FC 6117 and FC EPB8

Environment Recommended operating Allowable operating Nonoperating

Temperature -5°C to 55°C (23°F -

Humidity range 0% - 90% relative

1941 mm (76.4 in.)

131°F)

humidity (RH) (noncondensing)

Site and hardware planning 27

Page 42

Table 37. Environment requirements for FC 6117 and FC EPB8 (continued)

Environment Recommended operating Allowable operating Nonoperating

Shipping temperature -40°C to 70°C (-40°F to

158°F)

Shipping relative humidity 0% - 93%

Model 7014-T42 and 7014-B42 rack

Hardware specications provide detailed information for your rack, including dimensions, electrical,