Page 1

Power Systems

Power supplies for the 9117-MMB,

9117-MMC, 9179-MHB, or 9179-MHC

Page 2

Page 3

Power Systems

Power supplies for the 9117-MMB,

9117-MMC, 9179-MHB, or 9179-MHC

Page 4

Note

Before using this information and the product it supports, read the information in “Safety notices” on page v, “Notices” on

page 91, the IBM Systems Safety Notices manual, G229-9054, and the IBM Environmental Notices and User Guide, Z125–5823.

This edition applies to IBM Power Systems servers that contain the POWER7 processor and to all associated

models.

© Copyright IBM Corporation 2010, 2011.

US Government Users Restricted Rights – Use, duplication or disclosure restricted by GSA ADP Schedule Contract

with IBM Corp.

Page 5

Contents

Safety notices .................................v

Power supplies for the 9117-MMB, 9117-MMC, 9179-MHB, or 9179-MHC ........1

Removing the 9117-MMB, 9117-MMC, 9179-MHB, or 9179-MHC power supply with the power turned off ....1

Removing the 9117-MMB, 9117-MMC, 9179-MHB, or 9179-MHC power supply with the power turned on ....3

Replacing the 9117-MMB, 9117-MMC, 9179-MHB, or 9179-MHC power supply with the power turned off ....4

Replacing the 9117-MMB, 9117-MMC, 9179-MHB, or 9179-MHC power supply with the power turned on ....6

Power supply LEDs .................................8

Power supplies, fans, and input power distribution assemblies in a 5802 or 5877 expansion unit .......9

Removing a power supply or fan from a 5802 or 5877 expansion unit with the power turned on ......9

Removing a power supply or fan from a 5802 or 5877 expansion unit with the power turned off ......13

Replacing a power supply or fan in a 5802 or 5877 expansion unit with the power turned on .......16

Replacing a power supply or fan in a 5802 or 5877 expansion unit with the power turned off .......21

Removing an input power distribution assembly from a 5802 or 5877 expansion unit with the power turned off 25

Replacing an input power distribution assembly in a 5802 or 5877 expansion unit with the power turned off. . 28

Replacing an input power distribution assembly in a 5802 or 5877 expansion unit with the power turned off. . 30

Common procedures for installable features ........................33

Before you begin ................................33

Identifying a part ................................35

Control panel LEDs...............................35

Identifying a failing part in an AIX system or logical partition ................37

Locating a failing part in an AIX system or logical partition ................37

Activating the indicator light for the failing part ....................37

Deactivating the failing-part indicator light ......................37

Identifying a failing part in an IBM i system or logical partition ................38

Identifying a failing part in a Linux system or logical partition ................38

Locating a failing part in a Linux system or logical partition ................38

Finding the location code of a failing part in a Linux system or logical partition .........38

Activating the indicator light for the failing part ....................38

Deactivating the failing-part indicator light ......................38

Locating a failing part in a Virtual I/O Server system or logical partition.............39

Identifying a part by using the Virtual I/O Server ...................39

Starting the system or logical partition .........................39

Starting a system that is not managed by an HMC or an SDMC................39

Starting a system or logical partition by using the Hardware Management Console .........41

Starting a system or virtual server with the Systems Director Management Console .........41

Stopping a system or logical partition .........................41

Stopping a system that is not managed by an HMC or an SDMC ...............42

Stopping a system by using the Hardware Management Console ...............43

Stopping a system with the Systems Director Management Console ..............43

Placing the 8202-E4B, 8202-E4C, 8205-E6B, or 8205-E6C system into the service or operating position ....44

Placing a rack-mounted 8202-E4B, 8202-E4C, 8205-E6B, or 8205-E6C system into the service position . . . 44

Placing the rack-mounted 8202-E4B, 8202-E4C, 8205-E6B, or 8205-E6C system into the operating position . . 45

Removing and replacing covers for the 8202-E4B, 8202-E4C, 8205-E6B, or 8205-E6C ..........47

Removing the front cover on a rack-mounted 8202-E4B, 8202-E4C, 8205-E6B, or 8205-E6C system ....47

Removing the front cover on a stand-alone 8202-E4B, 8202-E4C, 8205-E6B, or 8205-E6C system .....48

Installing the front cover on a rack-mounted 8202-E4B, 8202-E4C, 8205-E6B, or 8205-E6C system .....49

Installing the front cover and front door on a stand-alone 8202-E4B, 8202-E4C, 8205-E6B, or 8205-E6C system 50

Removing the service access cover on a rack-mounted 8202-E4B, 8202-E4C, 8205-E6B, or 8205-E6C system. . 51

Removing the service access cover on a stand-alone 8202-E4B, 8202-E4C, 8205-E6B, or 8205-E6C system . . 52

Installing the service access cover on a rack-mounted 8202-E4B, 8202-E4C, 8205-E6B, or 8205-E6C system . . 54

Installing the service access cover on a stand-alone 8202-E4B, 8202-E4C, 8205-E6B, or 8205-E6C system . . . 54

Disconnecting the power cords from the 8202-E4B, 8202-E4C, 8205-E6B, or 8205-E6C system .......56

Connecting the power cords to the 8202-E4B, 8202-E4C, 8205-E6B, or 8205-E6C system .........58

Installing a feature by using the Hardware Management Console ................58

© Copyright IBM Corp. 2010, 2011 iii

Page 6

Installing a part by using the Systems Director Management Console ...............59

Verifying the installed part .............................59

Verifying an installed part by using stand-alone diagnostics .................59

Verifying the installed part by using Hardware Management Console ..............60

Activating and deactivating LEDs by using the HMC ..................61

Viewing serviceable events by using the HMC.....................62

Verifying the installed part by using Systems Director Management Console ...........63

Activating and deactivating LEDs by using the SDMC ..................63

Viewing serviceable events by using the IBM Systems Director Management Console .......64

Verifying an installed feature or replaced part on a system or logical partition by using Virtual I/O Server

tools....................................65

Verifying a repair ................................67

Verifying the repair in AIX ............................68

Verifying a repair using an IBM i system or logical partition .................71

Verifying the repair in Linux ...........................73

Verifying the repair from the management console ....................73

Closing a service call ...............................75

Closing a service call using AIX or Linux .......................79

Closing a service call using Integrated Virtualization Manager ................83

Activating and deactivating LEDs ...........................87

Deactivating a system attention LED or partition LED using the management console ........88

Activating or deactivating an identify LED using the management console ............88

Deactivating a system attention LED or logical partition LED using the Advanced System Management

Interface ..................................89

Activating or deactivating an identify LED using the Advanced System Management Interface .....90

Notices ...................................91

Trademarks ...................................92

Electronic emission notices ..............................92

Class A Notices .................................92

Class B Notices .................................96

Terms and conditions ................................99

iv Power Systems: Power supplies for the 9117-MMB, 9117-MMC, 9179-MHB, or 9179-MHC

Page 7

Safety notices

Safety notices may be printed throughout this guide:

v DANGER notices call attention to a situation that is potentially lethal or extremely hazardous to

people.

v CAUTION notices call attention to a situation that is potentially hazardous to people because of some

existing condition.

v Attention notices call attention to the possibility of damage to a program, device, system, or data.

World Trade safety information

Several countries require the safety information contained in product publications to be presented in their

national languages. If this requirement applies to your country, a safety information booklet is included

in the publications package shipped with the product. The booklet contains the safety information in

your national language with references to the U.S. English source. Before using a U.S. English publication

to install, operate, or service this product, you must first become familiar with the related safety

information in the booklet. You should also refer to the booklet any time you do not clearly understand

any safety information in the U.S. English publications.

German safety information

Das Produkt ist nicht für den Einsatz an Bildschirmarbeitsplätzen im Sinne§2der

Bildschirmarbeitsverordnung geeignet.

Laser safety information

IBM®servers can use I/O cards or features that are fiber-optic based and that utilize lasers or LEDs.

Laser compliance

IBM servers may be installed inside or outside of an IT equipment rack.

© Copyright IBM Corp. 2010, 2011 v

Page 8

DANGER

When working on or around the system, observe the following precautions:

Electrical voltage and current from power, telephone, and communication cables are hazardous. To

avoid a shock hazard:

v Connect power to this unit only with the IBM provided power cord. Do not use the IBM

provided power cord for any other product.

v Do not open or service any power supply assembly.

v Do not connect or disconnect any cables or perform installation, maintenance, or reconfiguration

of this product during an electrical storm.

v The product might be equipped with multiple power cords. To remove all hazardous voltages,

disconnect all power cords.

v Connect all power cords to a properly wired and grounded electrical outlet. Ensure that the outlet

supplies proper voltage and phase rotation according to the system rating plate.

v Connect any equipment that will be attached to this product to properly wired outlets.

v When possible, use one hand only to connect or disconnect signal cables.

v Never turn on any equipment when there is evidence of fire, water, or structural damage.

v Disconnect the attached power cords, telecommunications systems, networks, and modems before

you open the device covers, unless instructed otherwise in the installation and configuration

procedures.

v Connect and disconnect cables as described in the following procedures when installing, moving,

or opening covers on this product or attached devices.

To Disconnect:

1. Turn off everything (unless instructed otherwise).

2. Remove the power cords from the outlets.

3. Remove the signal cables from the connectors.

4. Remove all cables from the devices

To Connect:

1. Turn off everything (unless instructed otherwise).

2. Attach all cables to the devices.

3. Attach the signal cables to the connectors.

4. Attach the power cords to the outlets.

5. Turn on the devices.

(D005)

DANGER

vi Power Systems: Power supplies for the 9117-MMB, 9117-MMC, 9179-MHB, or 9179-MHC

Page 9

Observe the following precautions when working on or around your IT rack system:

v Heavy equipment–personal injury or equipment damage might result if mishandled.

v Always lower the leveling pads on the rack cabinet.

v Always install stabilizer brackets on the rack cabinet.

v To avoid hazardous conditions due to uneven mechanical loading, always install the heaviest

devices in the bottom of the rack cabinet. Always install servers and optional devices starting

from the bottom of the rack cabinet.

v Rack-mounted devices are not to be used as shelves or work spaces. Do not place objects on top

of rack-mounted devices.

v Each rack cabinet might have more than one power cord. Be sure to disconnect all power cords in

the rack cabinet when directed to disconnect power during servicing.

v Connect all devices installed in a rack cabinet to power devices installed in the same rack

cabinet. Do not plug a power cord from a device installed in one rack cabinet into a power

device installed in a different rack cabinet.

v An electrical outlet that is not correctly wired could place hazardous voltage on the metal parts of

the system or the devices that attach to the system. It is the responsibility of the customer to

ensure that the outlet is correctly wired and grounded to prevent an electrical shock.

CAUTION

v Do not install a unit in a rack where the internal rack ambient temperatures will exceed the

manufacturer's recommended ambient temperature for all your rack-mounted devices.

v Do not install a unit in a rack where the air flow is compromised. Ensure that air flow is not

blocked or reduced on any side, front, or back of a unit used for air flow through the unit.

v Consideration should be given to the connection of the equipment to the supply circuit so that

overloading of the circuits does not compromise the supply wiring or overcurrent protection. To

provide the correct power connection to a rack, refer to the rating labels located on the

equipment in the rack to determine the total power requirement of the supply circuit.

v (For sliding drawers.) Do not pull out or install any drawer or feature if the rack stabilizer brackets

are not attached to the rack. Do not pull out more than one drawer at a time. The rack might

become unstable if you pull out more than one drawer at a time.

v (For fixed drawers.) This drawer is a fixed drawer and must not be moved for servicing unless

specified by the manufacturer. Attempting to move the drawer partially or completely out of the

rack might cause the rack to become unstable or cause the drawer to fall out of the rack.

(R001)

Safety notices vii

Page 10

CAUTION:

Removing components from the upper positions in the rack cabinet improves rack stability during

relocation. Follow these general guidelines whenever you relocate a populated rack cabinet within a

room or building:

v Reduce the weight of the rack cabinet by removing equipment starting at the top of the rack

cabinet. When possible, restore the rack cabinet to the configuration of the rack cabinet as you

received it. If this configuration is not known, you must observe the following precautions:

– Remove all devices in the 32U position and above.

– Ensure that the heaviest devices are installed in the bottom of the rack cabinet.

– Ensure that there are no empty U-levels between devices installed in the rack cabinet below the

32U level.

v If the rack cabinet you are relocating is part of a suite of rack cabinets, detach the rack cabinet from

the suite.

v Inspect the route that you plan to take to eliminate potential hazards.

v Verify that the route that you choose can support the weight of the loaded rack cabinet. Refer to the

documentation that comes with your rack cabinet for the weight of a loaded rack cabinet.

v Verify that all door openings are at least 760 x 230 mm (30 x 80 in.).

v Ensure that all devices, shelves, drawers, doors, and cables are secure.

v Ensure that the four leveling pads are raised to their highest position.

v Ensure that there is no stabilizer bracket installed on the rack cabinet during movement.

v Do not use a ramp inclined at more than 10 degrees.

v When the rack cabinet is in the new location, complete the following steps:

– Lower the four leveling pads.

– Install stabilizer brackets on the rack cabinet.

– If you removed any devices from the rack cabinet, repopulate the rack cabinet from the lowest

position to the highest position.

v If a long-distance relocation is required, restore the rack cabinet to the configuration of the rack

cabinet as you received it. Pack the rack cabinet in the original packaging material, or equivalent.

Also lower the leveling pads to raise the casters off of the pallet and bolt the rack cabinet to the

pallet.

(R002)

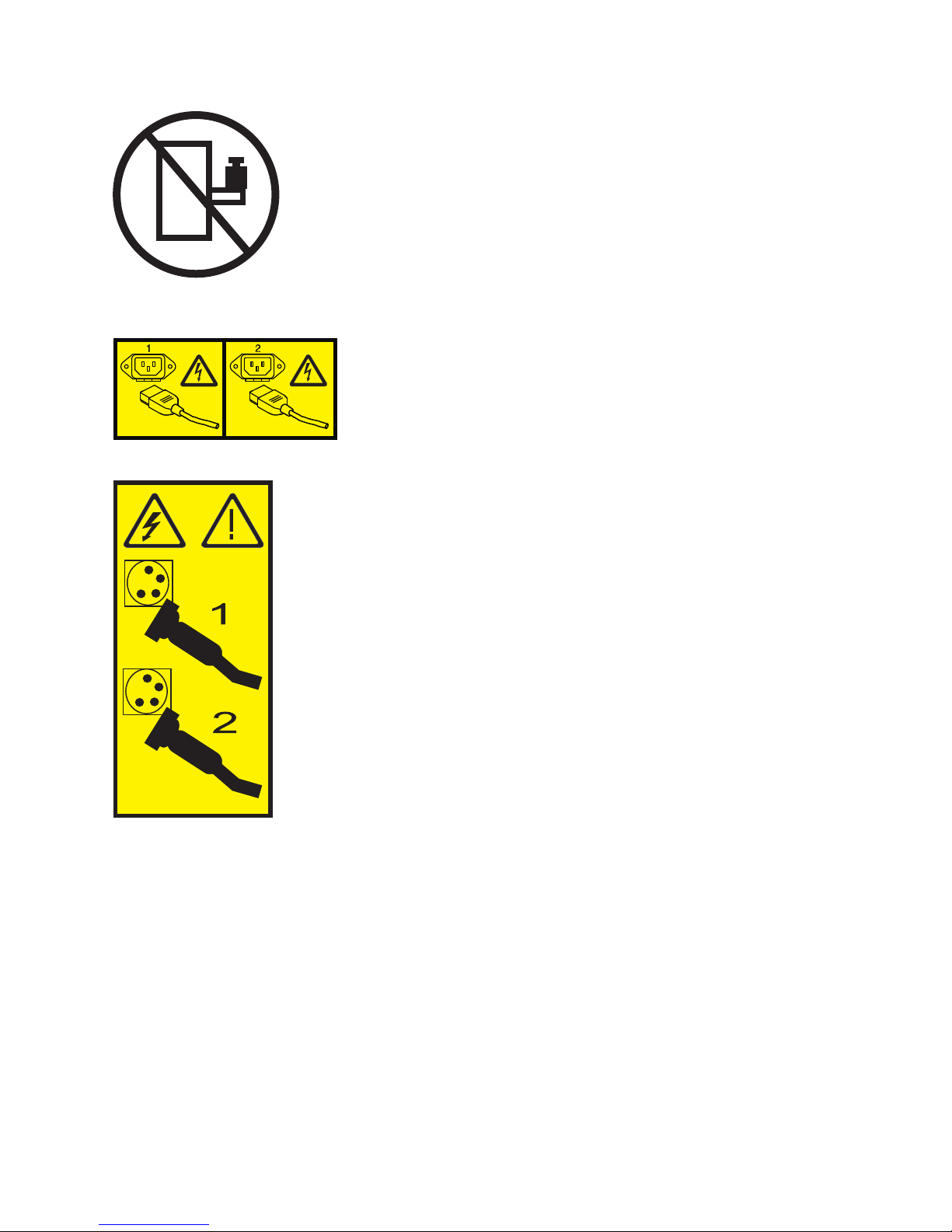

(L001)

(L002)

viii Power Systems: Power supplies for the 9117-MMB, 9117-MMC, 9179-MHB, or 9179-MHC

Page 11

(L003)

or

All lasers are certified in the U.S. to conform to the requirements of DHHS 21 CFR Subchapter J for class

1 laser products. Outside the U.S., they are certified to be in compliance with IEC 60825 as a class 1 laser

product. Consult the label on each part for laser certification numbers and approval information.

CAUTION:

This product might contain one or more of the following devices: CD-ROM drive, DVD-ROM drive,

DVD-RAM drive, or laser module, which are Class 1 laser products. Note the following information:

v Do not remove the covers. Removing the covers of the laser product could result in exposure to

hazardous laser radiation. There are no serviceable parts inside the device.

v Use of the controls or adjustments or performance of procedures other than those specified herein

might result in hazardous radiation exposure.

(C026)

Safety notices ix

Page 12

CAUTION:

Data processing environments can contain equipment transmitting on system links with laser modules

that operate at greater than Class 1 power levels. For this reason, never look into the end of an optical

fiber cable or open receptacle. (C027)

CAUTION:

This product contains a Class 1M laser. Do not view directly with optical instruments. (C028)

CAUTION:

Some laser products contain an embedded Class 3A or Class 3B laser diode. Note the following

information: laser radiation when open. Do not stare into the beam, do not view directly with optical

instruments, and avoid direct exposure to the beam. (C030)

Power and cabling information for NEBS (Network Equipment-Building System)

GR-1089-CORE

The following comments apply to the IBM servers that have been designated as conforming to NEBS

(Network Equipment-Building System) GR-1089-CORE:

The equipment is suitable for installation in the following:

v Network telecommunications facilities

v Locations where the NEC (National Electrical Code) applies

The intrabuilding ports of this equipment are suitable for connection to intrabuilding or unexposed

wiring or cabling only. The intrabuilding ports of this equipment must not be metallically connected to the

interfaces that connect to the OSP (outside plant) or its wiring. These interfaces are designed for use as

intrabuilding interfaces only (Type 2 or Type 4 ports as described in GR-1089-CORE) and require isolation

from the exposed OSP cabling. The addition of primary protectors is not sufficient protection to connect

these interfaces metallically to OSP wiring.

Note: All Ethernet cables must be shielded and grounded at both ends.

The ac-powered system does not require the use of an external surge protection device (SPD).

The dc-powered system employs an isolated DC return (DC-I) design. The DC battery return terminal

shall not be connected to the chassis or frame ground.

x Power Systems: Power supplies for the 9117-MMB, 9117-MMC, 9179-MHB, or 9179-MHC

Page 13

Power supplies for the 9117-MMB, 9117-MMC, 9179-MHB, or

9179-MHC

Learn about removing and replacing a power supply in a server. Learn about removing and replacing a

power supply, fan, or input power distribution assembly in a 5802 or a 5877 expansion unit.

Removing the 9117-MMB, 9117-MMC, 9179-MHB, or 9179-MHC power

supply with the power turned off

If your system power is already turned off, or if you want to perform another service task with power

turned off, learn how to remove a power supply with the system power turned off.

If your system is managed by the Hardware Management Console (HMC), use the HMC to remove a

power supply. For instructions, see Removing a part by using the Hardware Management Console.

If your system is managed by the IBM Systems Director Management Console (SDMC), use the SDMC to

remove a power supply in the server. For instructions, see Removing a part by using the Systems

Director Management Console.

If your system is not managed by an HMC or SDMC, complete the following steps to remove the power

supply from a system while the system power is turned off:

1. Perform the prerequisite tasks, as described in Before you begin.

2. Identify the failing part, as described in Identifying a failing part.

3. If the system is running, stop the system as described in Stopping the system or logical partition.

4. Open the rack door at the rear of the system.

5. Disconnect the power source from the system by unplugging the system, as described in

Disconnecting the power cords.

Note: This system is equipped with a second power supply. Before continuing with this procedure,

disconnect all power sources to the system.

(L003)

or

© Copyright IBM Corp. 2010, 2011 1

Page 14

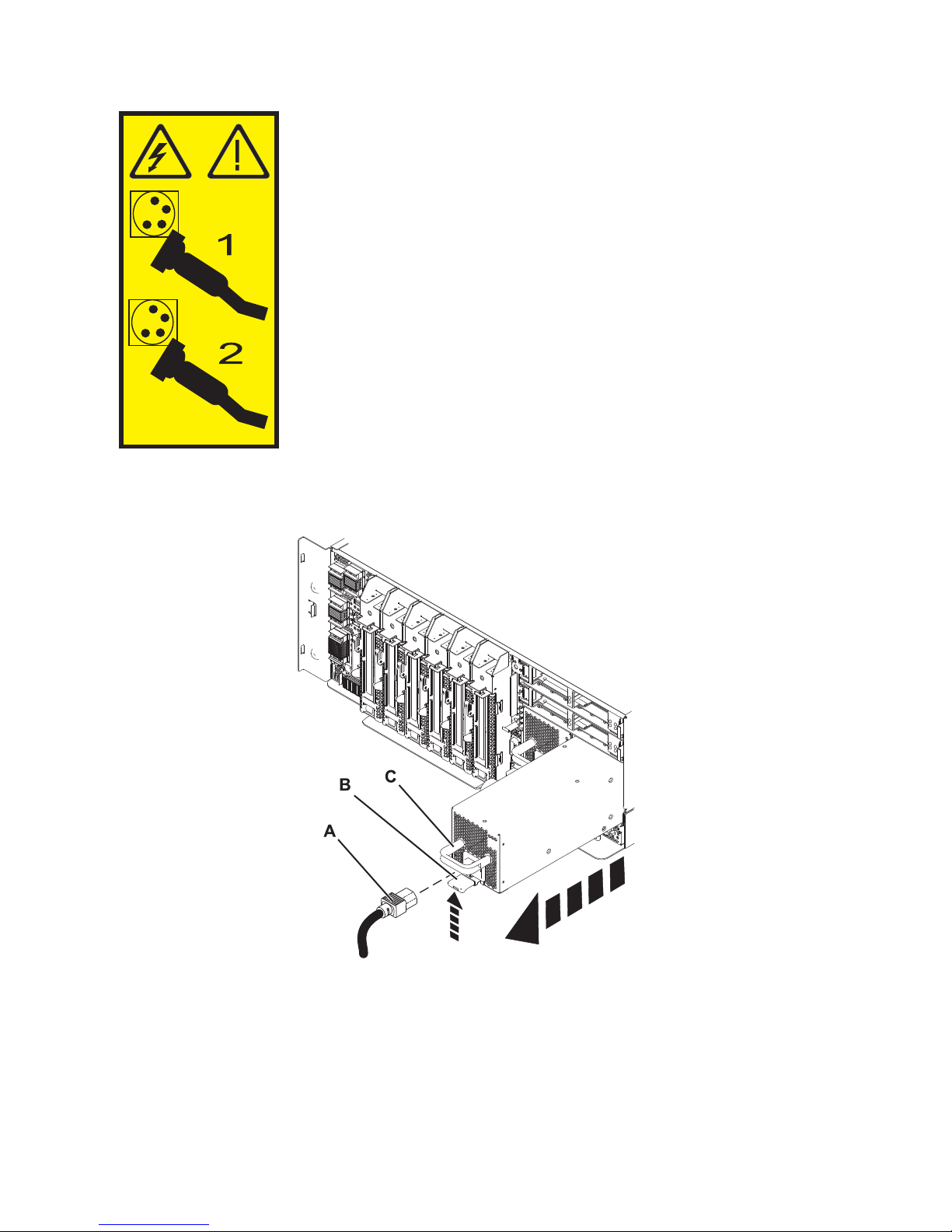

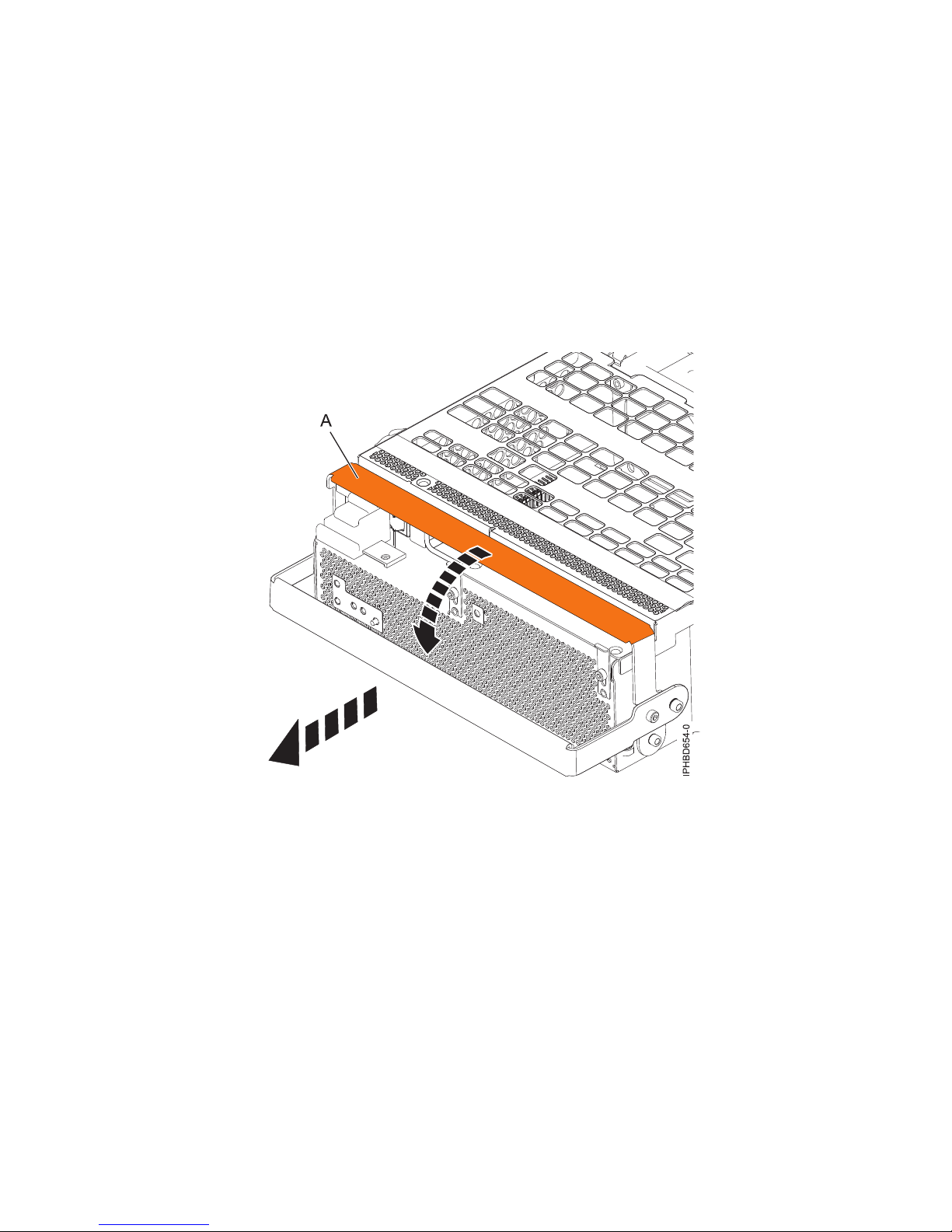

6. Lift the tab (B) toward the power cord retainer (C) to release the power supply. Pull the power supply

away from the system, as shown in Figure 1.

Figure 1. Removing the power supply

If you want to replace the power supply you removed, see “Replacing the 9117-MMB, 9117-MMC,

9179-MHB, or 9179-MHC power supply with the power turned off” on page 4.

2 Power Systems: Power supplies for the 9117-MMB, 9117-MMC, 9179-MHB, or 9179-MHC

Page 15

Removing the 9117-MMB, 9117-MMC, 9179-MHB, or 9179-MHC power

supply with the power turned on

Learn how to remove a power supply with the system power turned on if you want to replace a failing

power supply, or as a part of another service action.

Attention: Two power supplies must be present in the system to power on the system unit. If one power

supply fails, or you have a system failure that does not stop the fans, the system continues to operate.

You can remove and replace the power supply with the system power turned on if it is done in less than

5 minutes. After 5 minutes, the system turns off the power to prevent the system from overheating. If the

system power is turned off, go to “Removing the 9117-MMB, 9117-MMC, 9179-MHB, or 9179-MHC power

supply with the power turned off” on page 1.

If your system is managed by the Hardware Management Console (HMC), use the HMC to remove a

power supply. For instructions, see Removing a part by using the Hardware Management Console.

If your system is managed by the IBM Systems Director Management Console (SDMC), use the SDMC to

remove a power supply in the server. For instructions, see Removing a part by using the Systems

Director Management Console.

If your system is not managed by an HMC or SDMC, complete the following steps to remove a power

supply from a system while the system power is turned on:

1. Perform the prerequisite tasks, as described in Before you begin.

2. On a rack-mounted system unit, open the rear rack door.

3. Identify the failing part, as described in Identifying a failing part.

4. Disconnect the power source from the system by unplugging the system, as described in

Disconnecting the power cords.

5. Attach the wrist strap.

Attention:

v Attach a wrist strap to an unpainted metal surface of your hardware to prevent electrostatic

discharge (ESD) from damaging your hardware.

v When using a wrist strap, follow all electrical safety procedures. A wrist strap is for static control. It

does not increase or decrease your risk of receiving electric shock when using or working on

electrical equipment.

v If you do not have a wrist strap, just prior to removing the product from ESD packaging and

installing or replacing hardware, touch an unpainted metal surface of the system for a minimum of

5 seconds.

6. Lift the tab (B) toward the power cord retainer (C) to release the power supply. Pull the power supply

away from the system, as shown in Figure 2 on page 4.

Power supplies 3

Page 16

Figure 2. Removing the power supply

Note: When you remove a power supply with the system power turned on, an error is logged. No

action is required for this error.

If you want to replace the power supply you removed, see “Replacing the 9117-MMB, 9117-MMC,

9179-MHB, or 9179-MHC power supply with the power turned on” on page 6.

Replacing the 9117-MMB, 9117-MMC, 9179-MHB, or 9179-MHC power

supply with the power turned off

Learn how to replace a power supply with the system power turned off.

If your system is managed by the Hardware Management Console (HMC), use the HMC to replace a

power supply. For instructions, see Exchanging a part by using the Hardware Management Console.

If your system is managed by the IBM Systems Director Management Console (SDMC), use the SDMC to

replace a power supply in the server. For instructions, see Replacing a part by using the Systems Director

Management Console.

If your system is not managed by an HMC or SDMC, complete the following steps to replace a power

supply in a system while the system power is turned off:

1. To remove the power supply, see “Removing the 9117-MMB, 9117-MMC, 9179-MHB, or 9179-MHC

power supply with the power turned off” on page 1.

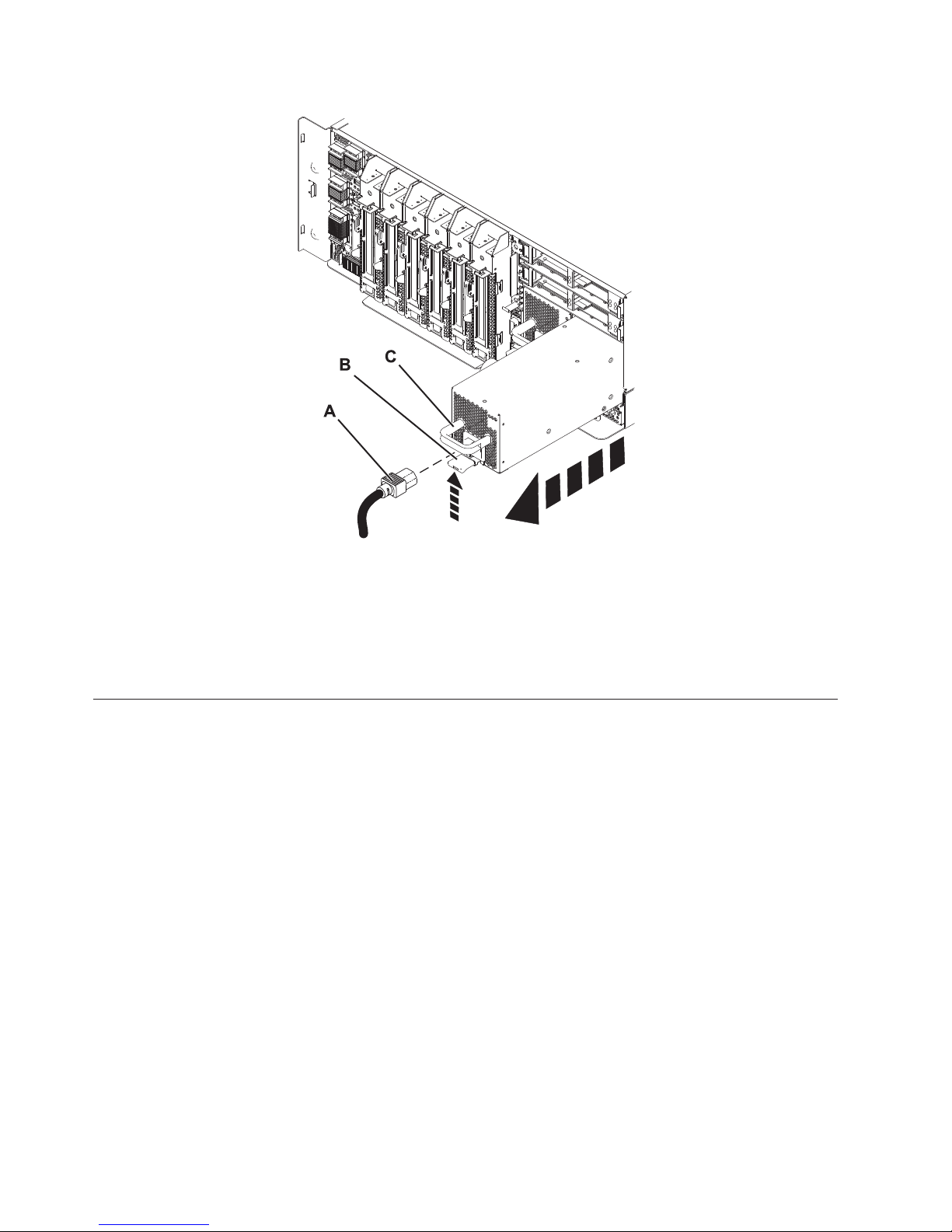

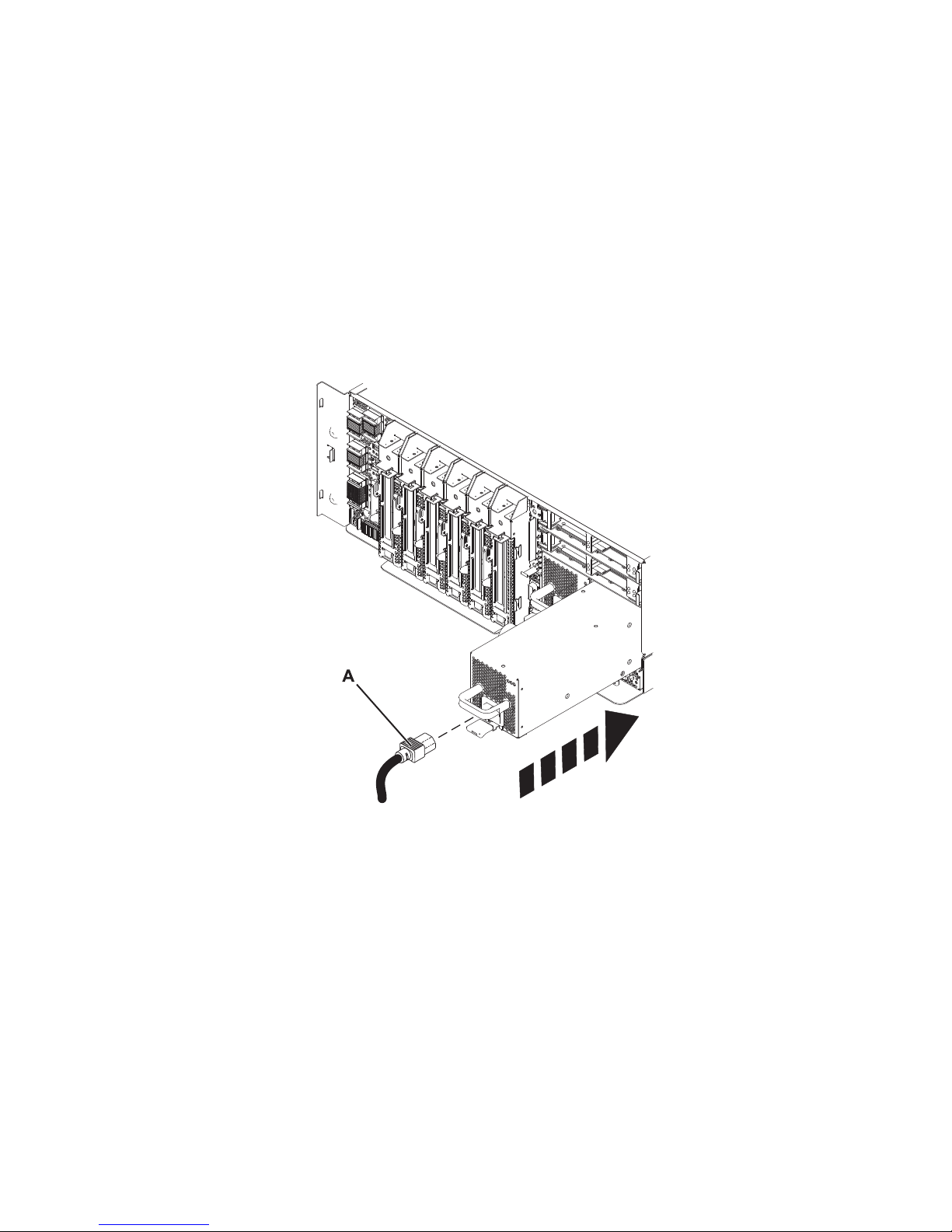

2. Align the power supply with the bay and slide the new power supply into the system until it locks in

place.

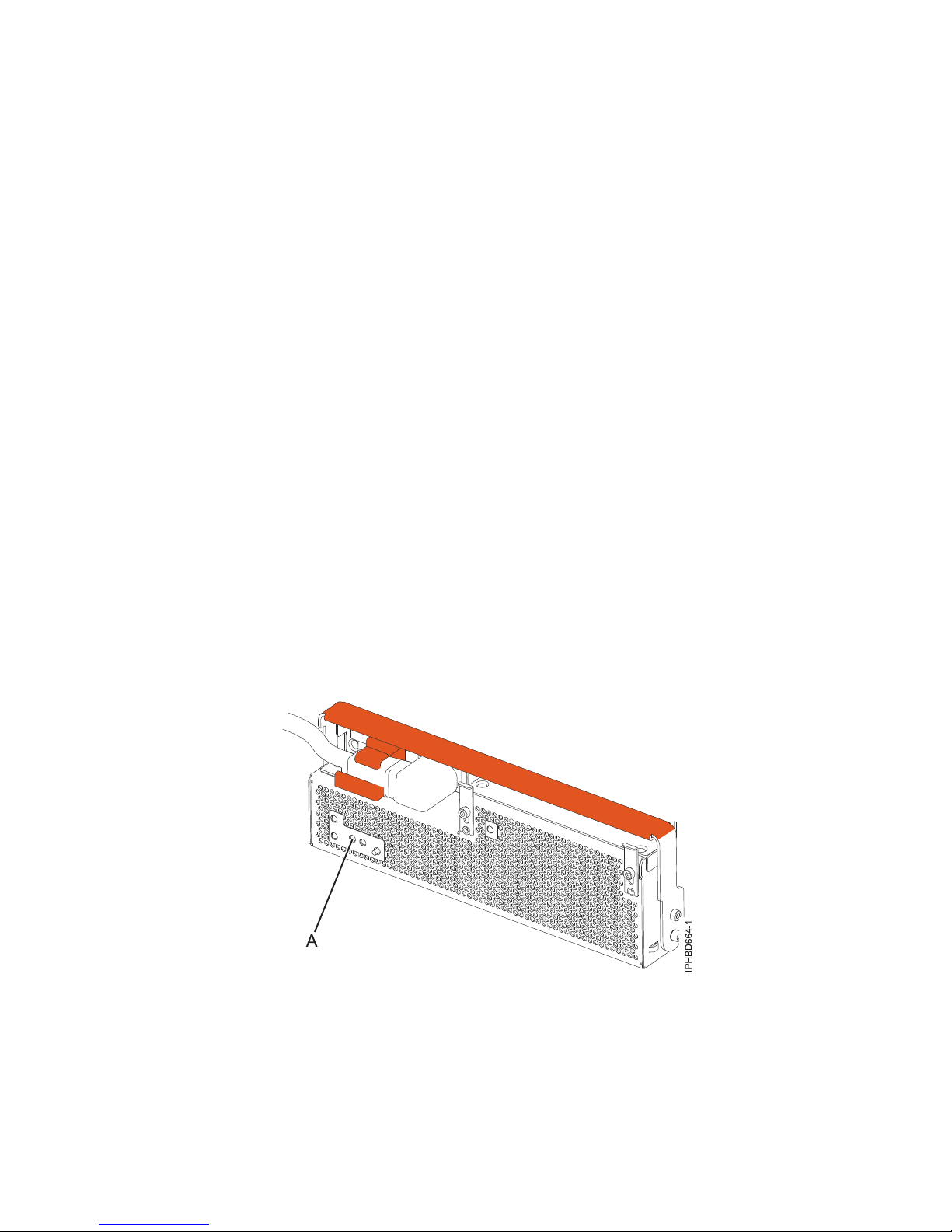

3. Connect the power cable A to the power supply.

4 Power Systems: Power supplies for the 9117-MMB, 9117-MMC, 9179-MHB, or 9179-MHC

Page 17

Note: This system is equipped with a second power supply. Before continuing with this procedure,

connect all power sources to the system.

Figure 3. Replacing a power supply

4. Start the system, as described in Starting the system or logical partition.

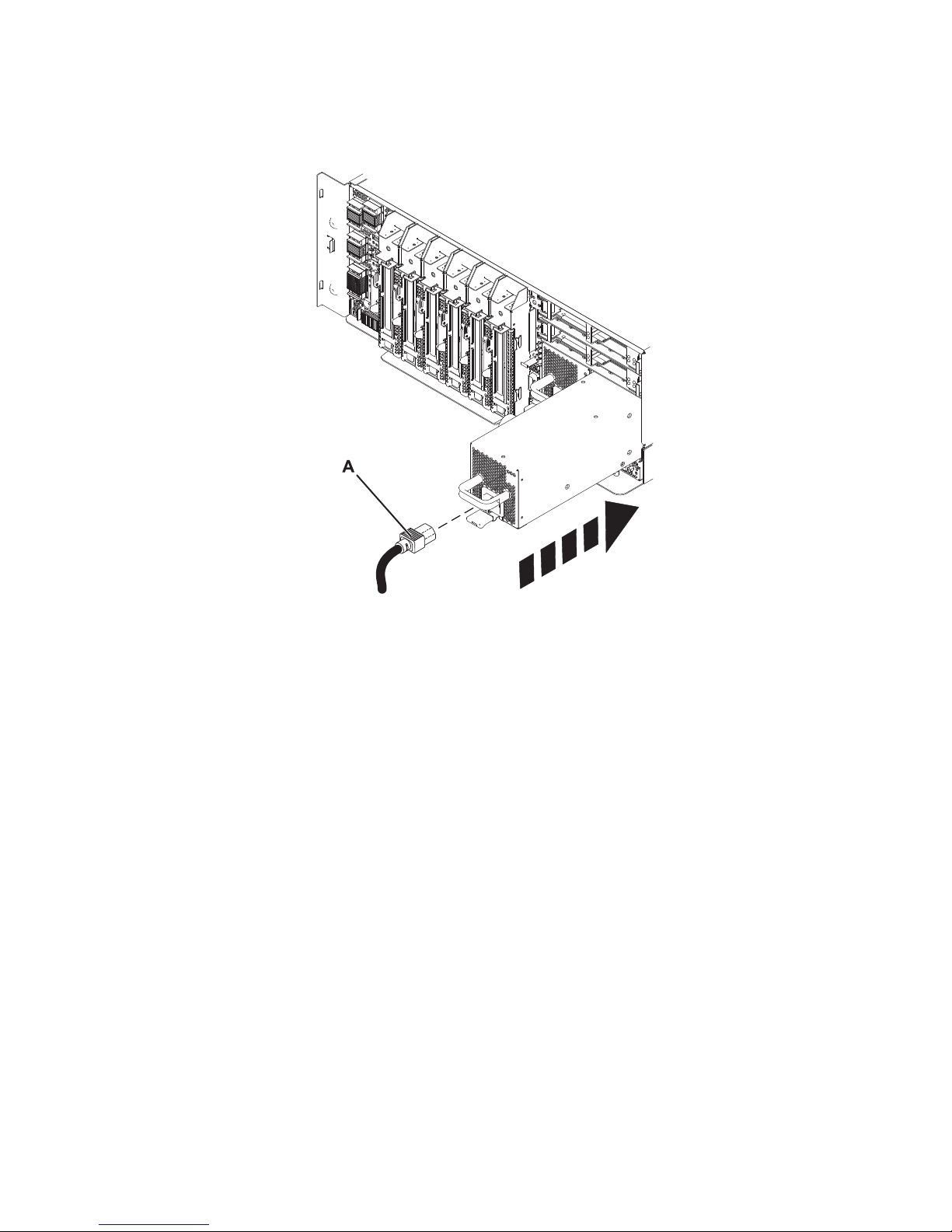

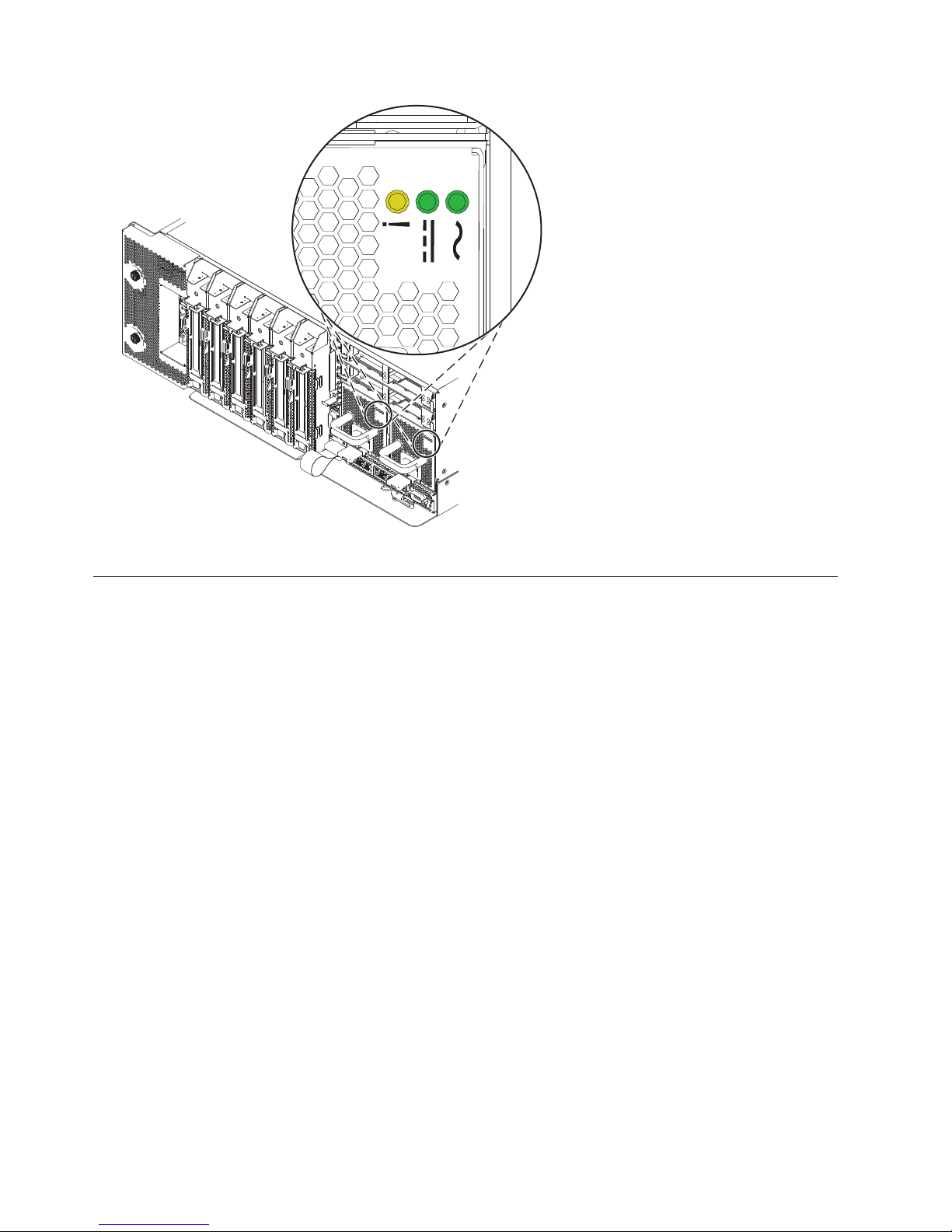

5. Note the state of the light-emitting diodes (LEDs) on the power supply. For more information, see

“Power supply LEDs” on page 8. If the LEDs indicate that the power supply is operating normally,

that is, the AC input LED and the DC output LED are on solid (not flashing) and the fault/identify

LED is flashing or off, continue to the next step. If not, remove the power supply from the system and

repeat the procedure starting with step 2 on page 4. If, after repeating the procedure, the power

supply is not operating normally, contact your service provider.

Figure 4. Power supply LEDs

Power supplies 5

Page 18

6. Close the rack door at the rear of the system.

Replacing the 9117-MMB, 9117-MMC, 9179-MHB, or 9179-MHC power

supply with the power turned on

Learn how to replace a power supply with the system power turned on.

Attention: Two power supplies must be present in the system to power on the system unit. If one power

supply fails, or you have a system failure that does not stop the fans, the system continues to operate.

You can remove and replace the power supply with the system power turned on if it is done in less than

5 minutes. After 5 minutes, the system turns off the power to prevent the system from overheating. If the

system power is turned off, go to “Replacing the 9117-MMB, 9117-MMC, 9179-MHB, or 9179-MHC power

supply with the power turned off” on page 4.

If your system is managed by the Hardware Management Console (HMC), use the HMC to replace a

power supply. For instructions, see Exchanging a part by using the Hardware Management Console.

If your system is managed by the IBM Systems Director Management Console (SDMC), use the SDMC to

replace a power supply in the server. For instructions, see Replacing a part by using the Systems Director

Management Console.

If your system is not managed by an HMC or SDMC, complete the following steps to replace a power

supply in a system while the system power is turned on:

1. To remove the power supply, see “Removing the 9117-MMB, 9117-MMC, 9179-MHB, or 9179-MHC

power supply with the power turned on” on page 3.

2. Perform the prerequisite tasks, as described in Before you begin.

3. Attach the wrist strap.

6 Power Systems: Power supplies for the 9117-MMB, 9117-MMC, 9179-MHB, or 9179-MHC

Page 19

Attention:

v Attach a wrist strap to an unpainted metal surface of your hardware to prevent electrostatic

discharge (ESD) from damaging your hardware.

v When using a wrist strap, follow all electrical safety procedures. A wrist strap is for static control. It

does not increase or decrease your risk of receiving electric shock when using or working on

electrical equipment.

v If you do not have a wrist strap, just prior to removing the product from ESD packaging and

installing or replacing hardware, touch an unpainted metal surface of the system for a minimum of

5 seconds.

4. Align the power supply with the power supply bay and slide the power supply into the system until

it locks into place.

5. Attach the power cable (A), as shown in Figure 5.

Figure 5. Replacing the power supply

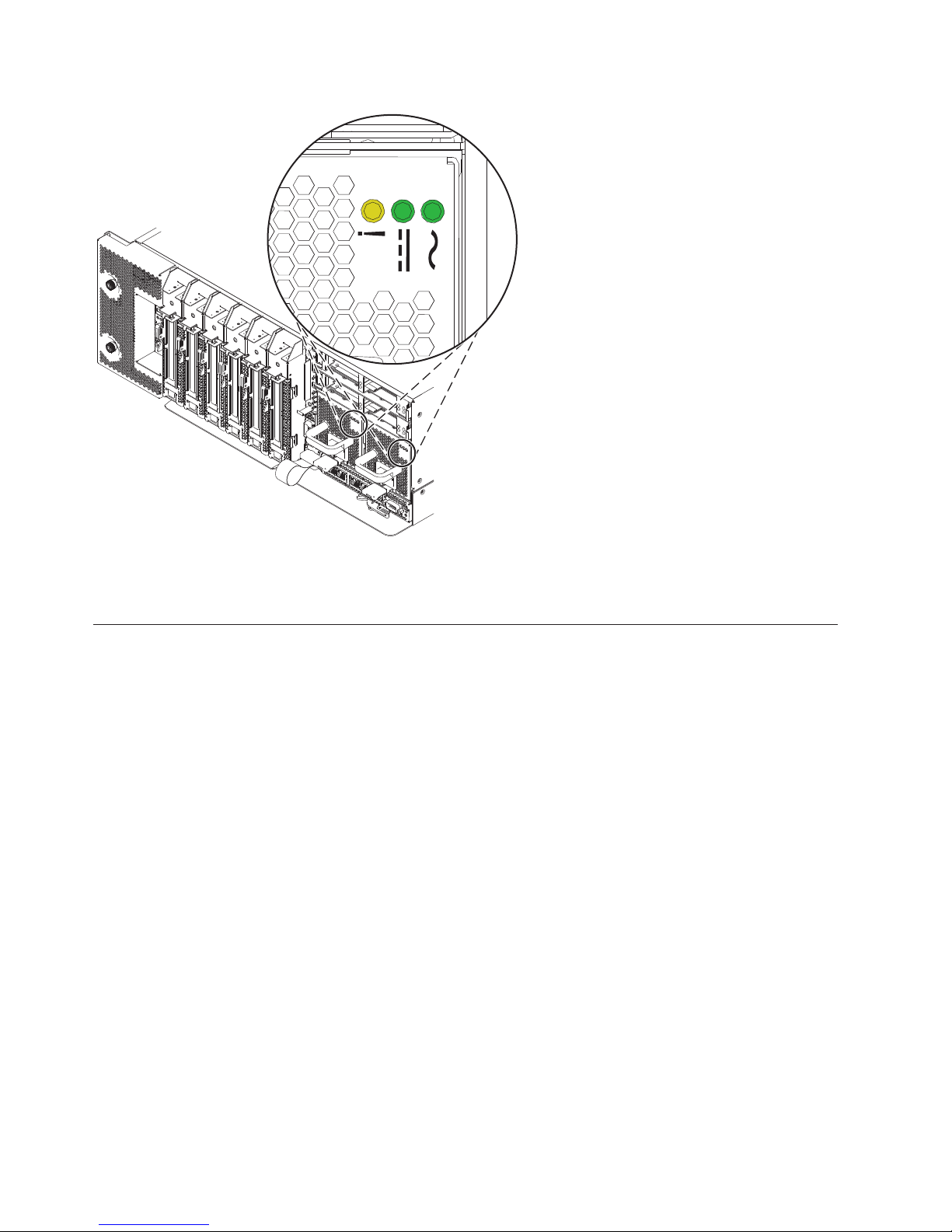

6. Note the state of the light-emitting diodes (LEDs) on the power supply. For more information, see

“Power supply LEDs” on page 8. If the LEDs indicate that the power supply is operating normally,

that is, the AC input LED and the DC output LED are on solid (not flashing) and the fault/identify

LED is flashing or off, continue to the next step. If not, remove the power supply from the system and

repeat the procedure starting with step 4. If, after repeating the procedure, the power supply is not

operating normally, contact your service provider.

Power supplies 7

Page 20

Figure 6. Power supply LEDs

7. Close the rack door at the rear of the system.

Power supply LEDs

The various states of the power supply light-emitting diodes (LEDs) can be used to identify or verify a

power supply that you are servicing.

The power supply has three LEDs that indicate the power supply status:

v an ac power LED (green, at the right of the 3 LEDs)

v a dc power LED (green, in the middle of the 3 LEDs)

v an error and identify function LED (amber, at the left of the 3 LEDs)

To locate the power supply LEDs, look on the top or at the back of an exposed power supply. You must

remove covers or panels to expose the power supply. Follow the instructions to remove covers or panels

for the power supply you are working with, and then return here.

To activate the identify function, see Identifying a failing part.

Descriptions for the states of the power supply LEDs follow:

v If both the ac power and dc power (green) LEDs are on solid (not flashing) and the error and identify

function (amber) LED is off, the power supply is operating correctly.

v If the ac power LED is on, the dc power LED is flashing, and the error and identify function (amber)

LED is off, then the system is turned off, but the power supply is still connected to the power source.

v If the error and identify function (amber) LED is flashing, the power supply identify function has been

selected.

v If the error and identify function (amber) LED is flashing, the ac power LED is on solid and the dc

power LED is off, the power supply is not operating correctly and has been identified for replacement.

8 Power Systems: Power supplies for the 9117-MMB, 9117-MMC, 9179-MHB, or 9179-MHC

Page 21

Power supplies, fans, and input power distribution assemblies in a

5802 or 5877 expansion unit

Learn about removing and replacing a power supply, fan, or input power distribution assembly to replace

a failing part or as part of another service action in a 5802 or 5877 expansion unit.

The power supply is located in an Offline Converter Assembly (OCA) in the 5802 expansion unit. The

expansion unit has two OCAs, with each OCA consisting of a power supply and two fans. To remove or

replace a failing fan, you must remove the affected power supply.

Removing a power supply or fan from a 5802 or 5877 expansion unit

with the power turned on

Learn how to remove a power supply or power-supply fan from a 5802 or 5877 expansion unit if you

need to replace a failing part with the power turned on.

If your system is managed by the Hardware Management Console (HMC), use the HMC to remove a

power supply. For instructions, see Removing a part by using the Hardware Management Console.

If your system is managed by the IBM Systems Director Management Console (SDMC), use the SDMC to

remove a power supply in the server. For instructions, see Removing a part by using the Systems

Director Management Console.

Determine if you are able to perform this procedure concurrently

Attention

Note: Two power supplies must be present in the expansion unit. If one power supply fails, the

expansion unit continues to operate. If you are performing this procedure concurrently (with the power

turned on), there is a time limit. From the moment the power supply is removed, the exchange of the

power supply must be completed in less than 5 minutes. If you cannot replace the power supply in less than

5 minutes, the I/O drawer automatically shuts down.

Read the following steps, but do not perform them yet. Then decide if you are ready (and able) to

complete this repair within 5 minutes.

1. Have the replacement power supply or fan ready.

2. Remove the power supply from the expansion unit.

3. Install the fan or fans into the power supply as required for the service procedure being performed.

4. Install the power supply into the enclosure.

Note: If you are replacing a midplane or a power supply, ensure that you only replace one of these parts

at a time. If a midplane and both power supplies are replaced at the same time, the enclosure vital

product data (VPD), which is present only in these entities, is lost. The enclosure VPD is the identity of

the 5802 or 5877 enclosure.

If your system is not managed by an HMC or an SDMC, complete the following steps to remove a power

supply or fan from an expansion unit or system while the system power is turned on:

1. Perform the prerequisite tasks, as described in Before you begin.

2. Open the front rack door.

3. Identify the failing part, as described in Identifying a failing part.

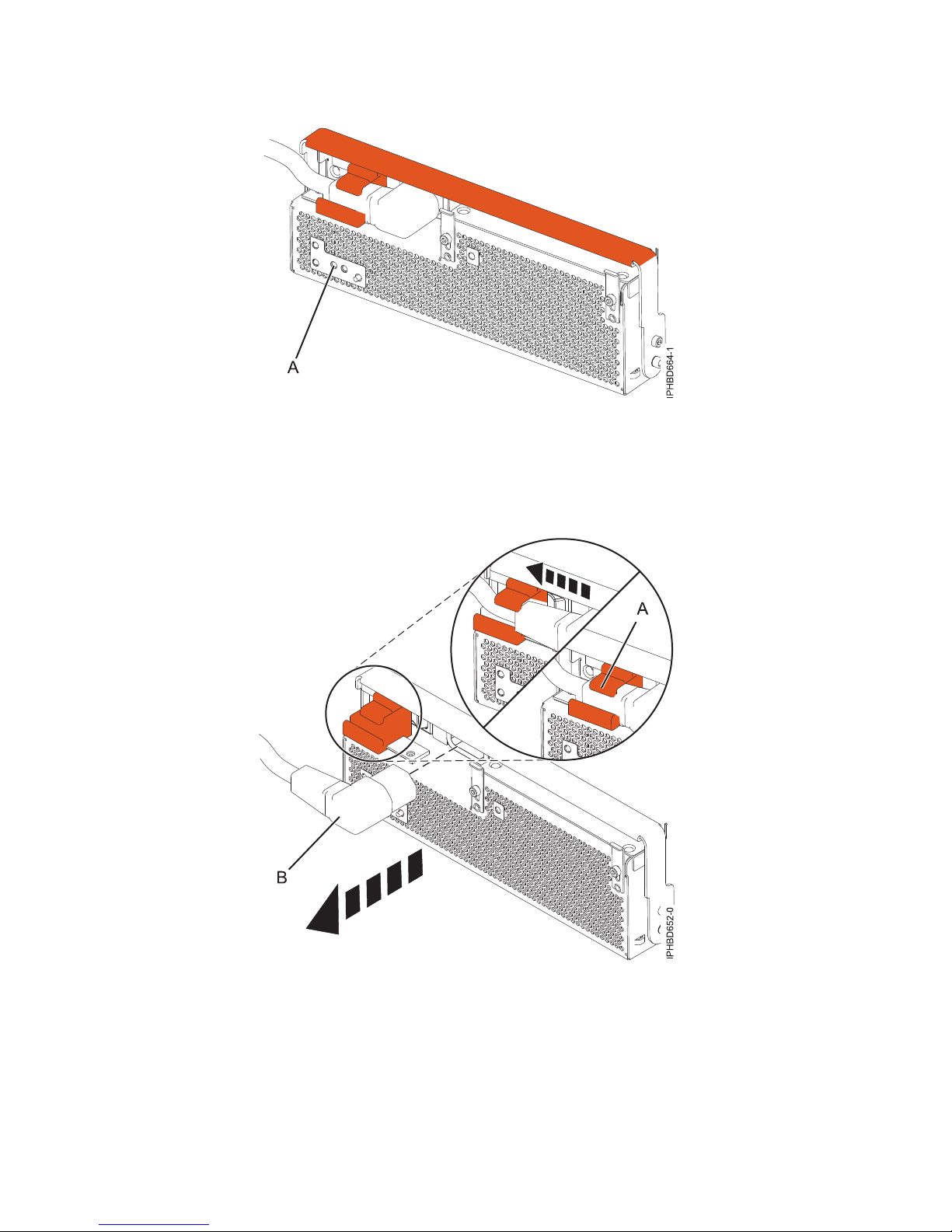

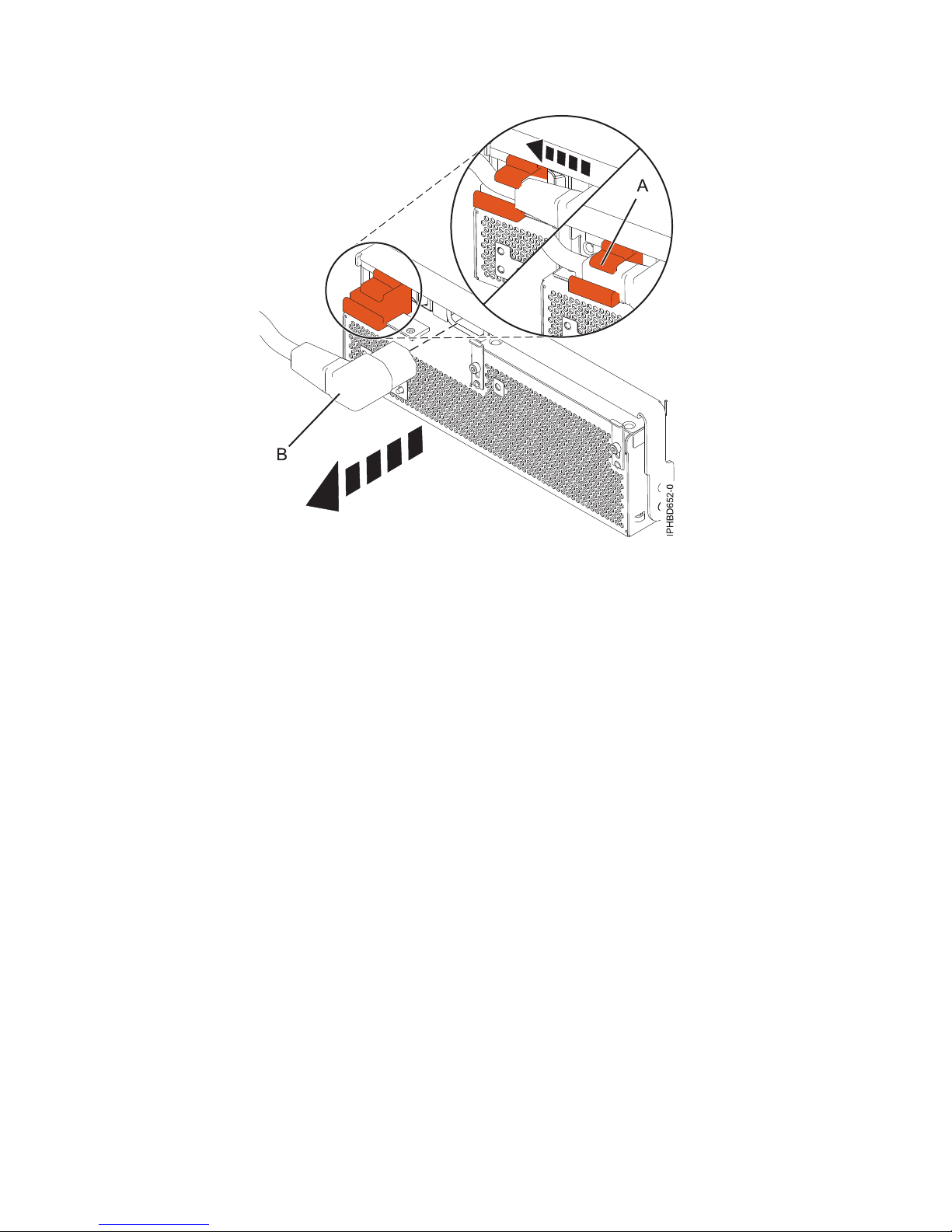

4. At the front of the expansion unit, identify the power supply that must be replaced. To identify the

power supply, observe the state of the amber field-replaceable unit (FRU) fault and identify

light-emitting diode (LED) (A) as shown in Figure 7 on page 10. A lit (flashing or on solid) LED

indicates the failing power supply.

Power supplies 9

Page 22

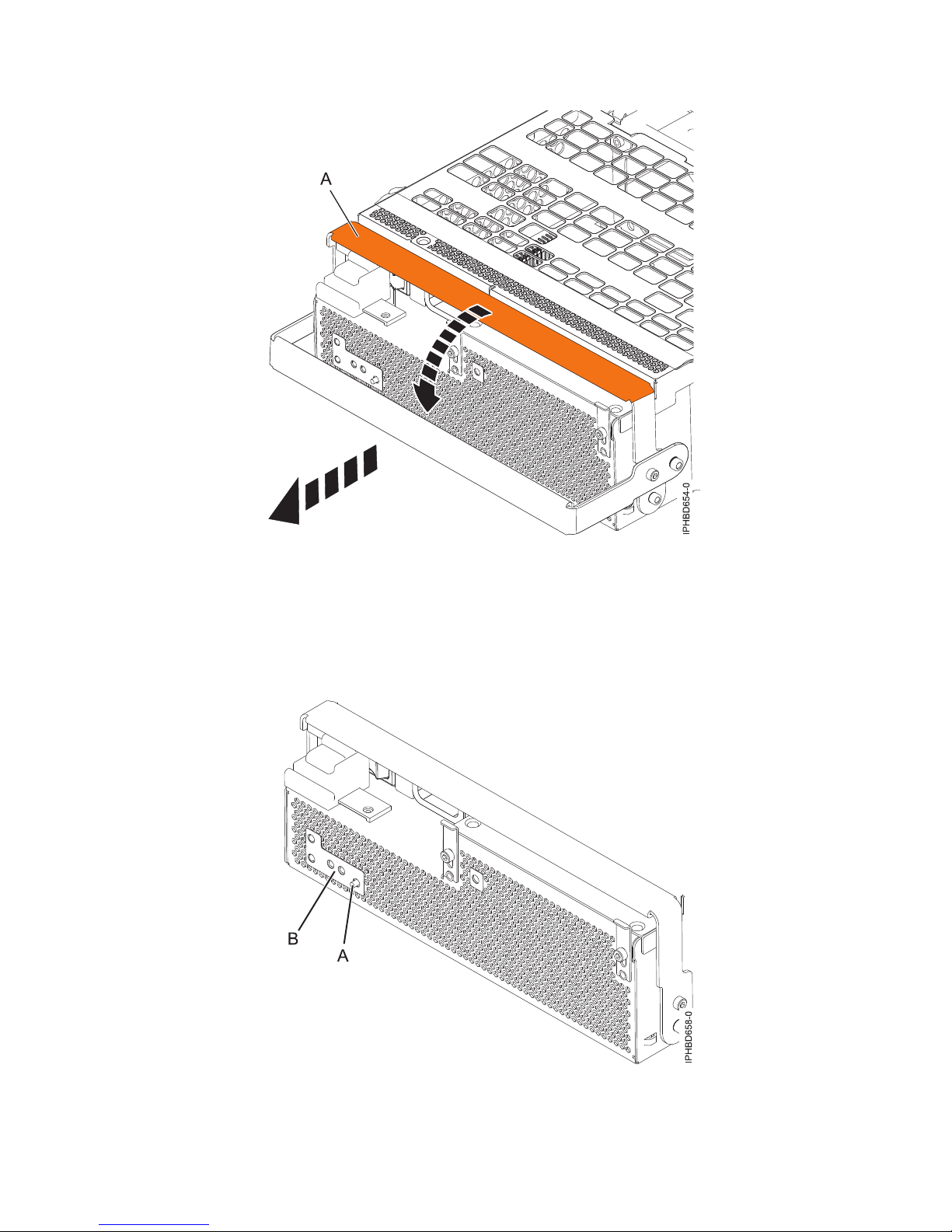

Figure 7. FRU fault and identify LED

5. For the power supply that you want to remove, slide the cable retention bracket to the open position

(A), and then disconnect the power cable (B) as shown in Figure 8. By moving the bracket to the

open position, you turn the power supply off.

Figure 8. Disconnecting the power cable from the front of an expansion unit

6. Attach the wrist strap.

10 Power Systems: Power supplies for the 9117-MMB, 9117-MMC, 9179-MHB, or 9179-MHC

Page 23

Attention:

v Attach a wrist strap to an unpainted metal surface of your hardware to prevent electrostatic

discharge (ESD) from damaging your hardware.

v When using a wrist strap, follow all electrical safety procedures. A wrist strap is for static control. It

does not increase or decrease your risk of receiving electric shock when using or working on

electrical equipment.

v If you do not have a wrist strap, just prior to removing the product from ESD packaging and

installing or replacing hardware, touch an unpainted metal surface of the system for a minimum of

5 seconds.

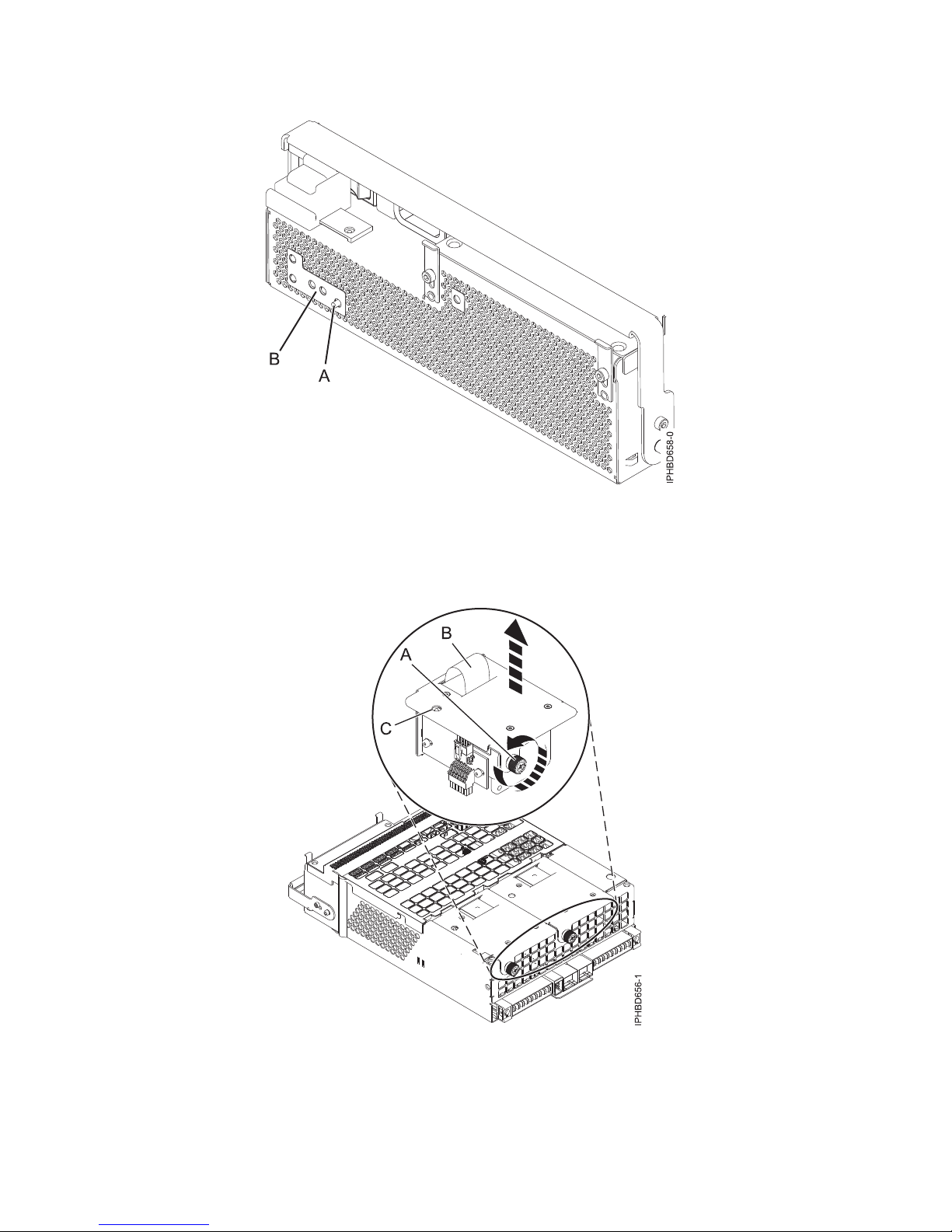

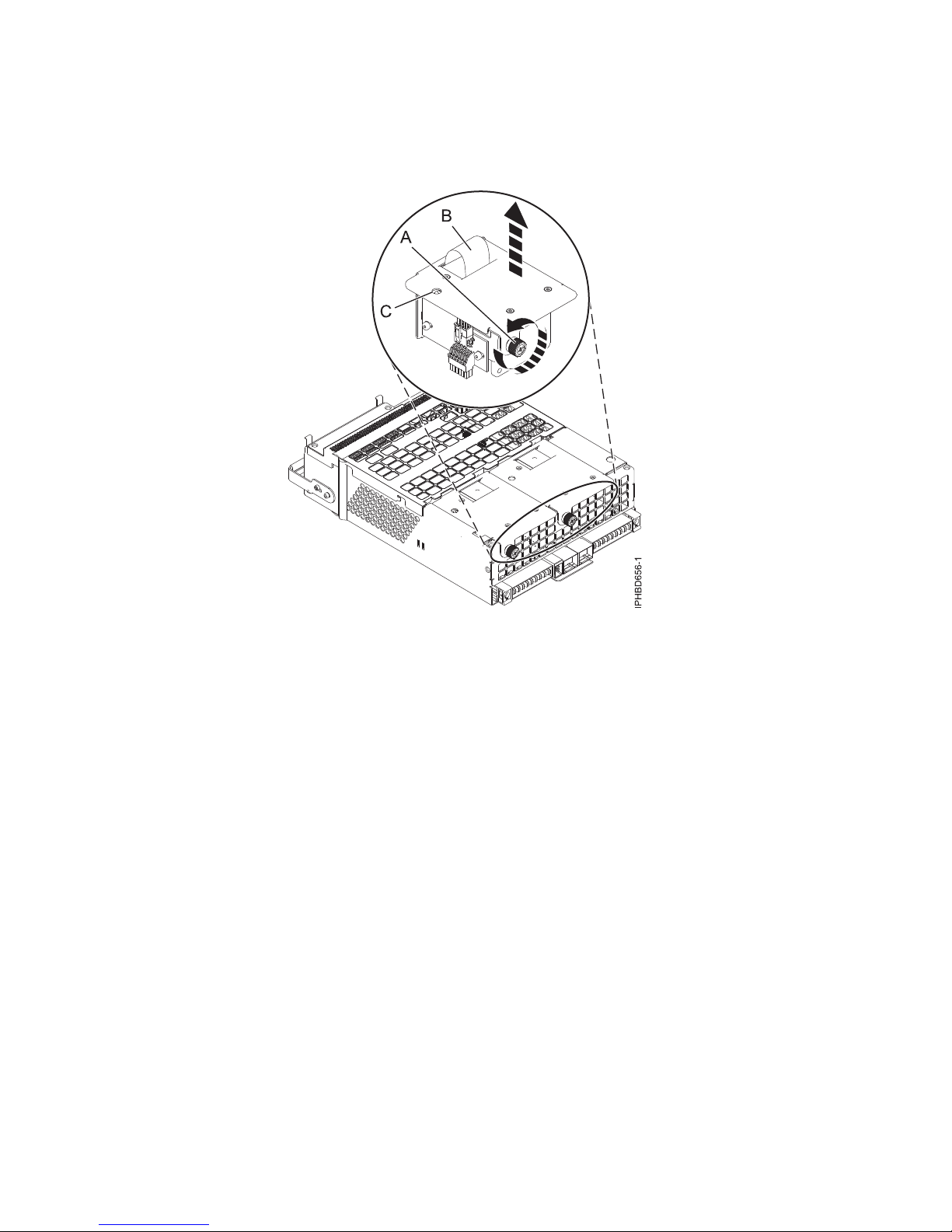

7. Rotate the power-supply locking handle (A) to the open position as shown in Figure 9. Pull the

power supply out of the expansion unit.

Figure 9. Removing a power supply

8. Optional: If you want to remove a failing power-supply fan, complete the following steps:

Note: If a fan fails, the amber fan fault LED (B) on the front of the Offline Converter Assembly

(OCA), as shown in Figure 10 on page 12, is on solid.

Power supplies 11

Page 24

Figure 10. Fan fault LED and fan identify button

a. To identify the failing fan. Press the fan identify button (A), as shown in Figure 10. An amber

left or right fan-fault LED (C) on solid, as shown in Figure 11, indicates the faulty fan.

Figure 11. Removing a fan

b. Loosen the thumbscrew (A) that holds the fan in the power-supply assembly, as shown in

Figure 11.

12 Power Systems: Power supplies for the 9117-MMB, 9117-MMC, 9179-MHB, or 9179-MHC

Page 25

c. Use the recessed fan handle (B) to lift the fan from the power-supply assembly, as shown in

Figure 11 on page 12.

If you removed the power supply or fan as part of another service action, or if you want to replace the

power supply or fan that you removed from an expansion unit, see Replacing a power supply or fan in a

5802 or 5877 expansion unit with the power turned on.

Removing a power supply or fan from a 5802 or 5877 expansion unit

with the power turned off

Learn how to remove a power supply or power-supply fan from a 5802 or 5877 expansion unit if you

want to replace a failing part with the power turned off.

If your system is managed by the Hardware Management Console (HMC), use the HMC to remove a

power supply. For instructions, see Removing a part by using the Hardware Management Console.

If your system is managed by the IBM Systems Director Management Console (SDMC), use the SDMC to

remove a power supply in the server. For instructions, see Removing a part by using the Systems

Director Management Console.

If your system is not managed by an HMC or an SDMC, complete the following steps to remove a power

supply or fan from an expansion unit or system while the system power is turned off:

1. Perform the prerequisite tasks, as described in Before you begin.

2. Open the front rack door.

3. Identify the failing part, as described in Identifying a failing part.

4. At the front of the expansion unit, identify the power supply that needs to be replaced. To identify

the power supply, observe the state of the amber field-replaceable unit (FRU) fault and identify

light-emitting diode (LED) (A) as shown in Figure 12. A lit (on solid or flashing) LED indicates the

failing power supply.

Figure 12. FRU fault and identify LED

5. If the system is running, stop the system as described in Stopping the system or logical partition.

6. At the front of the expansion unit, slide the cable retention bracket for the power supply that you

want to remove, to the open position (A). Disconnect the cable (B) as shown in Figure 13 on page

14.

Power supplies 13

Page 26

Figure 13. Disconnecting the power cable from the front of an expansion unit

7. Attach the wrist strap.

Attention:

v Attach a wrist strap to an unpainted metal surface of your hardware to prevent electrostatic

discharge (ESD) from damaging your hardware.

v When using a wrist strap, follow all electrical safety procedures. A wrist strap is for static control. It

does not increase or decrease your risk of receiving electric shock when using or working on

electrical equipment.

v If you do not have a wrist strap, just prior to removing the product from ESD packaging and

installing or replacing hardware, touch an unpainted metal surface of the system for a minimum of

5 seconds.

8. Rotate the power supply locking handle (A) to the open position, as shown in Figure 14 on page 15.

Pull out the power supply from the expansion unit.

14 Power Systems: Power supplies for the 9117-MMB, 9117-MMC, 9179-MHB, or 9179-MHC

Page 27

Figure 14. Removing a power supply

9. Optional: If you want to remove a failing power-supply fan, complete the following steps:

Note: If a fan fails, the amber fan fault LED on the front of the Offline Converter Assembly (OCA)

(B), shown in Figure 15, is on solid.

Figure 15. Fan fault LED and fan identify button

Power supplies 15

Page 28

a. Identify the failing fan by pressing the fan identify button (A) shown in Figure 15 on page 15.

An amber left or right fan-fault LED (C) on solid, as shown in Figure 16, indicates the faulty

fan.

Figure 16. Removing a power supply fan

b. Loosen the thumbscrew (A) that holds the fan in the power-supply assembly, as shown in

Figure 16.

c. Use the recessed fan handle (B) to pull the fan out of the power-supply assembly, as shown in

Figure 16.

If you removed the power supply or fan as part of another service action, or if you want to replace the

power supply or fan that you removed from the expansion unit, see “Replacing a power supply or fan in

a 5802 or 5877 expansion unit with the power turned off” on page 21.

Replacing a power supply or fan in a 5802 or 5877 expansion unit with

the power turned on

Learn how to replace a power supply or power-supply fan in a 5802 or 5877 expansion unit if you

removed a failing part and want to replace the power-supply assembly with the power turned on.

If your system is managed by the Hardware Management Console (HMC), use the HMC to replace a

power supply. For instructions, see Exchanging a part by using the Hardware Management Console.

If your system is managed by the IBM Systems Director Management Console (SDMC), use the SDMC to

replace a power supply in the server. For instructions, see Replacing a part by using the Systems Director

Management Console.

Determine if you are able to perform this procedure concurrently

16 Power Systems: Power supplies for the 9117-MMB, 9117-MMC, 9179-MHB, or 9179-MHC

Page 29

Attention: Two power supplies must be present in the expansion unit. If one power supply fails, the

expansion unit continues to operate. If you are performing this procedure concurrently (with the power

turned on), there is a time limit. From the moment the power supply is removed, the exchange of the

power supply must be completed in less than 5 minutes. If you cannot replace the power supply in less than

5 minutes, the I/O drawer automatically shuts down.

Before installing or reinstalling a power supply, inspect the signal connector pins to ensure that the pins

are not bent or damaged.

Attention: Bent pins damage the midplane receptacle. Be careful not to touch or damage the signal

connector pins.

Read the following steps, but do not perform them yet. Then decide if you are ready (and able) to

complete this repair within 5 minutes.

1. Have the replacement power supply or fan ready.

2. Remove the power supply from the expansion unit.

3. Install the fan or fans into the power supply as required for the service procedure being performed.

4. Install the power supply into the enclosure.

If your system is not managed by an HMC or an SDMC, complete the following steps to replace the

power supply in an expansion unit or system while the system power is turned on:

1. If you are replacing a power supply or power-supply fan because of a failure, remove the failing

part as described in Removing a power supply or fan from a 5802 or 5877 expansion unit with the

power turned on.

2. Perform the prerequisite tasks, as described in Before you begin.

3. Open the front rack door.

4. Attach the wrist strap.

Attention:

v Attach a wrist strap to an unpainted metal surface of your hardware to prevent electrostatic

discharge (ESD) from damaging your hardware.

v When using a wrist strap, follow all electrical safety procedures. A wrist strap is for static control.

It does not increase or decrease your risk of receiving electric shock when using or working on

electrical equipment.

v If you do not have a wrist strap, just prior to removing the product from ESD packaging and

installing or replacing hardware, touch an unpainted metal surface of the system for a minimum

of 5 seconds.

5. Optional: If you must replace a failing power-supply fan, complete the following steps:

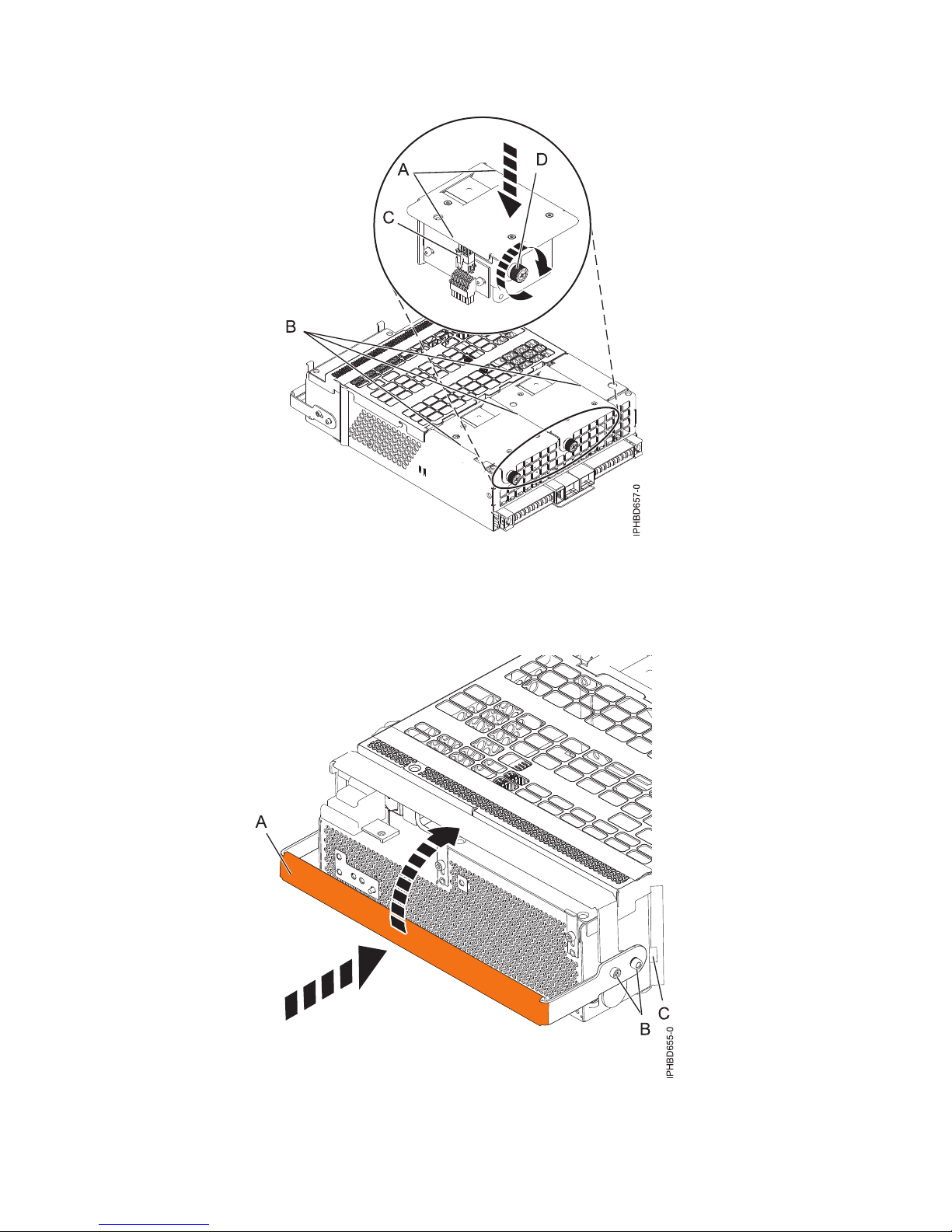

a. Align the new fan with the opening in the power-supply assembly.

b. Press the fan (A) into its connector in the assembly as shown in Figure 17 on page 18.

c. Tighten the thumbscrew (D) as shown in Figure 17 on page 18.

Power supplies 17

Page 30

Figure 17. Replacing a fan

6. To replace the power supply, with the locking handle (A) in the open position, push the power

supply into the expansion unit as shown in Figure 18.

Figure 18. Replacing a power supply

7. Close the locking handle (A) until the power supply locks into position.

18 Power Systems: Power supplies for the 9117-MMB, 9117-MMC, 9179-MHB, or 9179-MHC

Page 31

8. Reconnect the power cable (A) to the front of the power supply, and then slide the cable retention

bracket (B) to the closed position to secure the cable as shown in Figure 19. By moving the bracket

to the closed position, you turn on the power supply.

Figure 19. Connecting the power cable to the front of an expansion unit

9. Note the state of the green ac power in (A) and Offline Converter Assembly (OCA) power (B)

light-emitting diodes (LEDs) shown in Figure 20 on page 20, and do one of the following actions, as

applicable:

v If the LEDs indicate that the power supply is operating normally, that is, that the ac power in LED

(A) is on solid and the OCA power (B) LED is on solid or flashing, continue to the next step.

v If not, remove the power supply from the expansion unit and repeat the procedure starting with

step 6 on page 18. If, after repeating the procedure, the power supply is not operating normally,

contact your service provider.

Power supplies 19

Page 32

Figure 20. Expansion unit ac power and OCA power LEDs

Note: If you replaced a power-supply fan as part of this procedure, note the state of the fan fault

LED (B) shown in Figure 21. If the LED is off, indicating that both fans are operating normally,

continue to the next step. If not, remove the power-supply assembly from the expansion unit and

repeat the procedure starting with step 5 on page 17. If, after repeating the procedure, the

power-supply fan is not operating normally, contact your service provider.

Figure 21. Fan fault LED

10. Verify the installed part, as described in Verifying the installed part.

11. Close the front rack door.

Continue with any other service actions you want to perform.

20 Power Systems: Power supplies for the 9117-MMB, 9117-MMC, 9179-MHB, or 9179-MHC

Page 33

Replacing a power supply or fan in a 5802 or 5877 expansion unit with

the power turned off

Learn how to replace a power supply or power-supply fan in a 5802 or 5877 expansion unit if you

removed a failing part and want to replace the power supply assembly with the power turned off.

If your system is managed by the Hardware Management Console (HMC), use the HMC to replace a

power supply. For instructions, see Exchanging a part by using the Hardware Management Console.

If your system is managed by the IBM Systems Director Management Console (SDMC), use the SDMC to

replace a power supply in the server. For instructions, see Replacing a part by using the Systems Director

Management Console.

If your system is not managed by an HMC or an SDMC, complete the following steps to replace the

power supply in an expansion unit or system while the system power is turned off:

1. If you are replacing a power supply or power-supply fan because of a failure, remove the failing

part as described in “Removing a power supply or fan from a 5802 or 5877 expansion unit with the

power turned off” on page 13.

2. Perform the prerequisite tasks, as described in Before you begin.

3. Open the front rack door if it is not already open.

4. Attach the wrist strap.

Attention:

v Attach a wrist strap to an unpainted metal surface of your hardware to prevent electrostatic

discharge (ESD) from damaging your hardware.

v When using a wrist strap, follow all electrical safety procedures. A wrist strap is for static control.

It does not increase or decrease your risk of receiving electric shock when using or working on

electrical equipment.

v If you do not have a wrist strap, just prior to removing the product from ESD packaging and

installing or replacing hardware, touch an unpainted metal surface of the system for a minimum

of 5 seconds.

5. Optional: If you want to replace a failing power-supply fan, complete the following steps:

a. Align the new fan with the opening in the power-supply assembly.

b. Press the fan (A) into its connector in the assembly, as shown in Figure 22 on page 22.

Power supplies 21

Page 34

Figure 22. Replacing a fan

c. Tighten the thumbscrew (D) as shown in Figure 22.

6. To replace the power supply, with the locking handle (A) in the open position, push the power

supply into the expansion unit as shown in Figure 23 on page 23.

7. Close the locking handle (A) until the power supply locks into position.

22 Power Systems: Power supplies for the 9117-MMB, 9117-MMC, 9179-MHB, or 9179-MHC

Page 35

Figure 23. Replacing a power supply

8. Connect the power cable (A) to the front of the power supply, and then slide the cable retention

bracket (B) to the closed position to secure the cable as shown in Figure 24.

Figure 24. Connecting the power cable to the front of an expansion unit

9. Start the system, as described in Starting the system or logical partition.

Power supplies 23

Page 36

10. Note the state of the green ac power in (A) and Offline Converter Assembly (OCA) power (B)

light-emitting diodes (LEDs) shown in Figure 25, and do one of the following actions, as applicable:

v If the LEDs indicate that the power supply is operating normally, that is, that the ac power in LED

(A) is on solid and the OCA power (B) LED is on solid or flashing, continue to the next step.

v If not, remove the power supply from the expansion unit and repeat the procedure starting with

step 6 on page 22. If, after repeating the procedure, the power supply is not operating normally,

contact your service provider.

Figure 25. Expansion unit ac power and OCA power LEDs

Note: If you replaced a power supply fan as part of this procedure, note the state of the fan fault

LED (B) shown in Figure 26 on page 25. If the LED is off, indicating that both fans are operating

normally, continue to the next step. If not, remove the power supply assembly from the expansion

unit and repeat the procedure starting with step 5 on page 21. If, after repeating the procedure, the

power supply fan is not operating normally, contact your service provider.

24 Power Systems: Power supplies for the 9117-MMB, 9117-MMC, 9179-MHB, or 9179-MHC

Page 37

Figure 26. Fan fault LED

11. Verify the installed part, as described in Verifying the installed part.

12. Close the front rack door.

Continue with any other service actions you need to perform.

Removing an input power distribution assembly from a 5802 or 5877

expansion unit with the power turned off

Learn how to remove an input power distribution assembly from a 5802 or 5877 expansion unit if you

must replace a failing assembly.

If your system is managed by the Hardware Management Console (HMC), use the HMC to remove an

input power distribution assembly. For instructions, see Removing a part by using the Hardware

Management Console.

If your system is managed by the IBM Systems Director Management Console (SDMC), use the SDMC to

complete the steps for removing a power supply in the server. For instructions, see Removing a part by

using the Systems Director Management Console.

To remove an input power distribution assembly from an expansion unit for a system that is not

managed by an HMC or an SDMC, complete the following steps:

1. Perform the prerequisite tasks, as described in Before you begin.

2. Identify the failing part, as described in Identifying a failing part.

3. If the system is running, stop the system as described in Stopping the system or logical partition.

4. Open the rear rack door.

5. At the rear of the expansion unit, disconnect both of the power cables, as shown in Figure 27 on page

26.

Power supplies 25

Page 38

Figure 27. Disconnecting the power cables from the rear of an expansion unit

6. Attach the wrist strap.

Attention:

v Attach a wrist strap to an unpainted metal surface of your hardware to prevent electrostatic

discharge (ESD) from damaging your hardware.

v When using a wrist strap, follow all electrical safety procedures. A wrist strap is for static control. It

does not increase or decrease your risk of receiving electric shock when using or working on

electrical equipment.

v If you do not have a wrist strap, just prior to removing the product from ESD packaging and

installing or replacing hardware, touch an unpainted metal surface of the system for a minimum of

5 seconds.

7. On the input power distribution assembly cover, loosen the thumbscrew (A), and then remove the

cover as shown in Figure 28 on page 27.

26 Power Systems: Power supplies for the 9117-MMB, 9117-MMC, 9179-MHB, or 9179-MHC

Page 39

Figure 28. Removing an input power distribution assembly cover

8. Loosen the thumbscrew (B) on the input power distribution assembly. Pull out the assembly from

the expansion unit, as shown in Figure 29.

Figure 29. Removing an input power distribution assembly

Power supplies 27

Page 40

To replace an input power distribution assembly, see “Replacing an input power distribution assembly in

a 5802 or 5877 expansion unit with the power turned off.”

Replacing an input power distribution assembly in a 5802 or 5877

expansion unit with the power turned off

Learn how to replace an input power distribution assembly in a 5802 or 5877 expansion unit if you

removed a failing assembly and must replace it.

If your system is managed by the Hardware Management Console (HMC), use the HMC to replace an

input power distribution assembly. For instructions, see Exchanging a part by using the Hardware

Management Console.

If your system is managed by the IBM Systems Director Management Console (SDMC), use the SDMC to

complete the steps for replacing a power supply in the server. For instructions, see Replacing a part by

using the Systems Director Management Console.

To replace an input power distribution assembly in an expansion unit for a system that is not managed

by an HMC or an SDMC, complete the following steps:

1. If you are replacing an input power distribution assembly because of a failure, remove the failing

part, as described in “Removing an input power distribution assembly from a 5802 or 5877

expansion unit with the power turned off” on page 25.

2. Perform the prerequisite tasks, as described in Before you begin.

3. Open the rear rack door.

4. Attach the wrist strap.

Attention:

v Attach a wrist strap to an unpainted metal surface of your hardware to prevent electrostatic

discharge (ESD) from damaging your hardware.

v When using a wrist strap, follow all electrical safety procedures. A wrist strap is for static control.

It does not increase or decrease your risk of receiving electric shock when using or working on

electrical equipment.

v If you do not have a wrist strap, just prior to removing the product from ESD packaging and

installing or replacing hardware, touch an unpainted metal surface of the system for a minimum

of 5 seconds.

5. Push the input power distribution assembly into the expansion unit until it latches into place, and

then tighten the thumbscrew (A) to secure the assembly in place as shown in Figure 30 on page

29.

28 Power Systems: Power supplies for the 9117-MMB, 9117-MMC, 9179-MHB, or 9179-MHC

Page 41

Figure 30. Replacing an input power distribution assembly

6. Replace the input power distribution assembly cover, and then tighten the thumbscrew (A) as

shown in Figure 31.

Figure 31. Replacing an input power distribution assembly cover

Power supplies 29

Page 42

7. At the rear of the expansion unit, connect both of the power cables, as shown in Figure 32.

Figure 32. Connecting the power cables at the rear of an expansion unit

8. Close the rear rack door.

9. Start the system, as described in Starting the system or logical partition.

10. Verify the installed part, as described in Verifying the installed part.

Continue with any other service actions you want to perform.

Replacing an input power distribution assembly in a 5802 or 5877

expansion unit with the power turned off

Learn how to replace an input power distribution assembly in a 5802 or 5877 expansion unit if you

removed a failing assembly and must replace it.

If your system is managed by the Hardware Management Console (HMC), use the HMC to replace an

input power distribution assembly. For instructions, see Exchanging a part by using the Hardware

Management Console.

If your system is managed by the IBM Systems Director Management Console (SDMC), use the SDMC to

complete the steps for replacing a power supply in the server. For instructions, see Replacing a part by

using the Systems Director Management Console.

To replace an input power distribution assembly in an expansion unit for a system that is not managed

by an HMC or an SDMC, complete the following steps:

1. If you are replacing an input power distribution assembly because of a failure, remove the failing

part, as described in “Removing an input power distribution assembly from a 5802 or 5877

expansion unit with the power turned off” on page 25.

2. Perform the prerequisite tasks, as described in Before you begin.

30 Power Systems: Power supplies for the 9117-MMB, 9117-MMC, 9179-MHB, or 9179-MHC

Page 43

3. Open the rear rack door.

4. Attach the wrist strap.

Attention:

v Attach a wrist strap to an unpainted metal surface of your hardware to prevent electrostatic

discharge (ESD) from damaging your hardware.

v When using a wrist strap, follow all electrical safety procedures. A wrist strap is for static control.

It does not increase or decrease your risk of receiving electric shock when using or working on

electrical equipment.

v If you do not have a wrist strap, just prior to removing the product from ESD packaging and

installing or replacing hardware, touch an unpainted metal surface of the system for a minimum

of 5 seconds.

5. Push the input power distribution assembly into the expansion unit until it latches into place, and

then tighten the thumbscrew (A) to secure the assembly in place as shown in Figure 30 on page

29.

Figure 33. Replacing an input power distribution assembly

6. Replace the input power distribution assembly cover, and then tighten the thumbscrew (A) as

shown in Figure 31 on page 29.

Power supplies 31

Page 44

Figure 34. Replacing an input power distribution assembly cover

7. At the rear of the expansion unit, connect both of the power cables, as shown in Figure 32 on page

30.

Figure 35. Connecting the power cables at the rear of an expansion unit

32 Power Systems: Power supplies for the 9117-MMB, 9117-MMC, 9179-MHB, or 9179-MHC

Page 45

8. Close the rear rack door.

9. Start the system, as described in Starting the system or logical partition.

10. Verify the installed part, as described in Verifying the installed part.

Continue with any other service actions you want to perform.

Common procedures for installable features

This section contains all the common procedures related to installing, removing and replacing features.

Before you begin

Observe these precautions when you are installing, removing, or replacing features and parts.

These precautions are intended to create a safe environment to service your system and do not provide

steps for servicing your system. The installation, removal and replacement procedures provide the

step-by-step processes required to service your system.

DANGER

When working on or around the system, observe the following precautions:

Electrical voltage and current from power, telephone, and communication cables are hazardous. To

avoid a shock hazard:

v Connect power to this unit only with the IBM provided power cord. Do not use the IBM

provided power cord for any other product.

v Do not open or service any power supply assembly.

v Do not connect or disconnect any cables or perform installation, maintenance, or reconfiguration

of this product during an electrical storm.

v The product might be equipped with multiple power cords. To remove all hazardous voltages,

disconnect all power cords.

v Connect all power cords to a properly wired and grounded electrical outlet. Ensure that the outlet

supplies proper voltage and phase rotation according to the system rating plate.

v Connect any equipment that will be attached to this product to properly wired outlets.

v When possible, use one hand only to connect or disconnect signal cables.

v Never turn on any equipment when there is evidence of fire, water, or structural damage.

v Disconnect the attached power cords, telecommunications systems, networks, and modems before

you open the device covers, unless instructed otherwise in the installation and configuration

procedures.

v Connect and disconnect cables as described in the following procedures when installing, moving,

or opening covers on this product or attached devices.

To Disconnect:

1. Turn off everything (unless instructed otherwise).

2. Remove the power cords from the outlets.

3. Remove the signal cables from the connectors.

4. Remove all cables from the devices

To Connect:

1. Turn off everything (unless instructed otherwise).

2. Attach all cables to the devices.

3. Attach the signal cables to the connectors.

4. Attach the power cords to the outlets.

5. Turn on the devices.

(D005)

Power supplies 33

Page 46

DANGER

Observe the following precautions when working on or around your IT rack system:

v Heavy equipment–personal injury or equipment damage might result if mishandled.

v Always lower the leveling pads on the rack cabinet.

v Always install stabilizer brackets on the rack cabinet.

v To avoid hazardous conditions due to uneven mechanical loading, always install the heaviest

devices in the bottom of the rack cabinet. Always install servers and optional devices starting

from the bottom of the rack cabinet.

v Rack-mounted devices are not to be used as shelves or work spaces. Do not place objects on top

of rack-mounted devices.

v Each rack cabinet might have more than one power cord. Be sure to disconnect all power cords in

the rack cabinet when directed to disconnect power during servicing.

v Connect all devices installed in a rack cabinet to power devices installed in the same rack

cabinet. Do not plug a power cord from a device installed in one rack cabinet into a power

device installed in a different rack cabinet.

v An electrical outlet that is not correctly wired could place hazardous voltage on the metal parts of

the system or the devices that attach to the system. It is the responsibility of the customer to

ensure that the outlet is correctly wired and grounded to prevent an electrical shock.

CAUTION

v Do not install a unit in a rack where the internal rack ambient temperatures will exceed the

manufacturer's recommended ambient temperature for all your rack-mounted devices.

v Do not install a unit in a rack where the air flow is compromised. Ensure that air flow is not

blocked or reduced on any side, front, or back of a unit used for air flow through the unit.

v Consideration should be given to the connection of the equipment to the supply circuit so that

overloading of the circuits does not compromise the supply wiring or overcurrent protection. To

provide the correct power connection to a rack, refer to the rating labels located on the

equipment in the rack to determine the total power requirement of the supply circuit.

v (For sliding drawers.) Do not pull out or install any drawer or feature if the rack stabilizer brackets

are not attached to the rack. Do not pull out more than one drawer at a time. The rack might

become unstable if you pull out more than one drawer at a time.

v (For fixed drawers.) This drawer is a fixed drawer and must not be moved for servicing unless

specified by the manufacturer. Attempting to move the drawer partially or completely out of the

rack might cause the rack to become unstable or cause the drawer to fall out of the rack.

(R001)

Before you begin a replacement or installation procedure, perform these tasks:

1. If you are installing a new feature, ensure that you have the software required to support the new

feature.

To do this, go to the following Web site: IBM Prerequisite

2. If you are performing an installation or replacement procedure that might put your data at risk,

ensure, wherever possible, that you have a current backup of your system or logical partition

(including operating systems, licensed programs, and data).

3. Review the installation or replacement procedure for the feature or part.

4. Note the significance of color on your system.

34 Power Systems: Power supplies for the 9117-MMB, 9117-MMC, 9179-MHB, or 9179-MHC

Page 47

Blue or terra-cotta on a part of the hardware indicates a touch point where you can grip the hardware

to remove it from or install it in the system, open or close a latch, and so on. Terra-cotta might also

indicate that the part can be removed and replaced with the system or logical partition power on.

5. Ensure that you have access to a medium flat-blade screwdriver, a Phillips screwdriver, and a pair of

scissors.

6. If parts are incorrect, missing, or visibly damaged, do the following:

v If you are replacing a part, contact the provider of your parts or next level of support.

v If you are installing a feature, contact one of the following service organizations:

– The provider of your parts or next level of support.

– In the United States, the IBM Rochester Manufacturing Automated Information Line (R–MAIL)

at 1–800–300–8751.

In countries and regions outside of the United States, use the following Web site to locate your service

and support telephone numbers:

http://www.ibm.com/planetwide

7. If you encounter difficulties during the installation, contact your service provider, your IBM reseller,

or your next level of support.

8. If you are installing new hardware in a logical partition, you need to understand and plan for the

implications of partitioning your system. For information, see Logical Partitioning.

Identifying a part

Use these instructions to learn how to identify the location of a failed part, the location of a part to be

removed, or the location to install a new part on your system or expansion unit using the appropriate

method for your system.

™

For IBM Power Systems

servers that contain the POWER7®processor, the light-emitting diodes (LEDs)

can be used to identify or verify the location of a part that you are removing, servicing, or installing.

The fault (amber) LED indicates an error and corresponds to the location code in the system reference

code (SRC). The LED is activated and deactivated automatically.

If you need to use the identify function, use the following procedures.

Control panel LEDs

Use this information as a guide to the control panel LEDs and buttons.

The control panel has LEDs that indicate various system status.

Power supplies 35

Page 48

Figure 36. Control panel

v A: Power-on button

v B: Power LED

– A constant light indicates full system power to the unit.

– A blinking light indicates standby power to the unit.

Note: There is approximately a 30-second transition period from the time the power-on button is

pressed to when the power LED goes from blinking to solid. During the transition period, the LED

might blink faster.

v C: Enclosure identify light

– A constant light indicates the identify state, which is used to identify a part.

– No light indicates that the system is operating normally.

v D: System information light

– No light indicates that the system is operating normally.

– Light on indicates that the system requires attention.

v E: USB port

v F: Enclosure fault roll-up light

– A constant light indicates a fault in the system unit.

– No light indicates that the system is operating normally.

v G: Function/Data display

v H: Decrement button

v I: Enter button

v J: Increment button

v K: Pinhole reset button

36 Power Systems: Power supplies for the 9117-MMB, 9117-MMC, 9179-MHB, or 9179-MHC

Page 49

Related concepts

Identifying a failing part

Use these instructions to learn how to locate and identify a failing part on your system or expansion unit

using the appropriate method for your system.

Identifying a failing part in an AIX system or logical partition

Use these instructions to learn how to locate a failing part, and then activate the indicator light for that

part on a system or logical partition running the AIX

Locating a failing part in an AIX system or logical partition:

You might need to use AIX tools, before activating the indicator light, to locate a part that is failing.

1. Log in as root user or celogin-.

2. At the command line, type diag and press Enter.

3. From the Function Selection menu, select Task Selection and press Enter.

4. Select Display Previous Diagnostic Results and press Enter.

5. From the Display Previous Diagnostic Results display, select Display Diagnostic Log Summary. The

Display Diagnostic Log display shows a chronological list of events.

6. Look in the T column for the most recent S entry. Select this row in the table and press Enter.

7. Select Commit. The details of this log entry are shown.

8. Record the location information and the SRN value shown near the end of the entry.

9. Exit to the command line.

®

operating system.

Use the location information for the failing part to activate the indicator light that identifies the failing

part. “Activating the indicator light for the failing part.”

Activating the indicator light for the failing part:

Use these instructions to help physically identify the location of a part you are servicing.

1. Log in as root user.

2. At the command line, type diag and press Enter.

3. From the Function Selection menu, select Task Selection and press Enter.

4. From the Task Selection menu, select Identify and Attention Indicators and press Enter.

5. From the list of lights, select the location code for the failing part and press Enter.

6. Select Commit. This turns on the system attention and indicator light for the failing part.

7. Exit to the command line.

Deactivating the failing-part indicator light:

Use this procedure to turn off any indicator light that you turned on as a part of a service action.

To deactivate the indicator light, follow these steps:

1. Log in as root user.

2. At the command line, type diag and press Enter.

3. From the Function Selection menu, select Task Selection and press Enter.

4. From the Task Selection menu, select Identify and Attention Indicators and press Enter.

5. From the list of lights, select the location code for the failing part and press Enter. When a light is

activated for a failing part, an I character precedes the location code.

6. Select Commit. This turns off the system attention and indicator light for the failing part.

7. Exit to the command line.

Power supplies 37

Page 50

Identifying a failing part in an IBM i system or logical partition

You can activate or deactivate the indicator light by using IBM i to assist in locating a failing part.

Identifying a failing part in a Linux system or logical partition

If the service aids have been installed on a system or logical partition, you can activate or deactivate the

indicator lights to locate a part or compete a service action.

Locating a failing part in a Linux system or logical partition:

If the service aids have been installed on a system or logical partition, you need to activate the indicator

lights to locate a part.

To activate the indicator light, follow these steps:

1. Log in as root user.

2. At the command line, type /usr/sbin/usysident -s identify -l<location code> and press Enter.

3. Look for the system attention light to identify the enclosure that contains the failing part.

Related information

Service and productivity tools for Linux on POWER systems

IBM provides hardware diagnostic aids and productivity tools, as well as installation aids for Linux

operating systems on IBM Power systems.

Finding the location code of a failing part in a Linux system or logical partition:

To retrieve the location code of the failing part, if you do not know the location code, use the procedure

in this topic.

To locate the failing part in a system or logical partition follow these steps:

1. Log in as root user.

2. At the command line, type grep diagela /var/log/platform and press Enter.

3. Look for the most recent entry that contains a system reference code (SRC).

4. Record the location information.

Note: IBM provides hardware diagnostic aids and productivity tools, as well as installation aids for

Linux operating systems on IBM Power systems. See Service and productivity tools for Linux on

Power Systems servers

Activating the indicator light for the failing part:

If you know the location code of the failing part, activate the indicator light to help you locate which part

to replace.

To activate the indicator light, follow these steps:

1. Log in as root user.

2. At the command line, type /usr/sbin/usysident -s identify -l<location code> and press Enter.

3. Look for the system attention light to identify the enclosure that contains the failing part.

Note: IBM provides hardware diagnostic aids and productivity tools, as well as installation aids for

Linux operating systems on IBM Power systems. See Service and productivity tools for Linux on Power

Systems servers

Deactivating the failing-part indicator light:

38 Power Systems: Power supplies for the 9117-MMB, 9117-MMC, 9179-MHB, or 9179-MHC

Page 51

After you complete a removal and replacement procedure, you must deactivate the failing-part indicator

light.

To deactivate the indicator light, follow these steps:

1. Log in as root user.

2. At the command line, type /usr/sbin/usysident -s normal -l<location code> and press Enter.

Note: IBM provides hardware diagnostic aids and productivity tools, as well as installation aids for

Linux operating systems on IBM Power systems. See Service and productivity tools for Linux on Power

Systems servers

Locating a failing part in a Virtual I/O Server system or logical partition

You can use Virtual I/O Server (VIOS) tools, before activating the indicator light, to locate a part that is

failing.

1. Log in as root user or celogin-.