Page 1

IBM Storage Networking SAN128B-6

MTM Service information: 8960-F96, 8960-N96

Installation, Service, and User Guide

IBM

SC27-9251-00

Page 2

Read Before Using

This product contains software that is licensed under written license agreements. Your use of such software is subject to the

license agreements under which they are provided.

Before you use the information in this publication, be sure to read the general information under “Notices” on page 89.

Copyright

Portions Copyright © 2018 Broadcom Limited and/or its subsidiaries. All Rights Reserved.

© Copyright IBM Corporation 2018.

US Government Users Restricted Rights – Use, duplication or disclosure restricted by GSA ADP Schedule Contract

with IBM Corp.

Page 3

Contents

Figures ............... v

Tables ............... vii

Read this first ............ ix

Getting help .............. ix

Accessibility features for the SAN128B-6 ..... ix

How to send your comments ......... x

Safety and environmental notices ... xi

Safety notices and labels .......... xi

Cautions ............... xi

Danger Notices ............. xii

Safety labels .............. xiv

Attention notices ............ xv

ESD precautions ............ xvi

Rack safety .............. xvi

Rack installation ........... xvi

Rack relocation (19" rack) ........ xviii

Product recycling and disposal ....... xviii

Preface .............. xix

Product documents ........... xix

Brocade documents ........... xix

IBM and Brocade product matrix ....... xix

Device Overview ........... 1

License options ............. 2

Port-side view .............. 2

Nonport-side view ............ 3

Device management options ......... 4

Preparing for the Installation ...... 5

Safety precautions ............ 5

General precautions ........... 5

ESD precautions ............ 6

Power precautions ........... 7

Lifting and weight-related precautions..... 8

Laser precautions ............ 9

Facility requirements ........... 9

Quick installation checklist ......... 10

Shipping carton contents .......... 12

Mounting the switch ......... 13

Precautions specific to mounting ....... 13

Standalone installation........... 14

Installing the Universal Four-Post Rack Kit .... 14

Time and items required ......... 15

Parts list .............. 15

Flush-front mounting .......... 17

Attaching the front brackets ....... 17

Attaching the bracket extensions to the device 18

Installing the device in the rack...... 18

Attaching the rear brackets to the extensions 19

Attaching the rear brackets to the rack posts 20

Flush-rear (recessed) mounting ....... 21

Attaching the front brackets to the rear of the

device .............. 21

Attaching the bracket extensions to the front

of the device ............ 22

Installing the device in the rack...... 23

Attaching the rear brackets to the extensions

at the front of the device ........ 24

Attaching the rear brackets to the front rack

posts .............. 26

Installing the Universal Two-Post Rack Kit .... 26

Time and items required ......... 27

Parts list .............. 27

Flush-front mounting .......... 28

Attaching the front brackets to the device .. 28

Attaching the front brackets to the rack ... 29

Attaching the rear brackets to the rack ... 30

Attaching the rear brackets to the device .. 31

Mid-mounting ............ 32

Attaching the front brackets to the device .. 32

Attaching the front brackets to the rack ... 33

Attaching the rear brackets to the rack ... 34

Attaching the rear brackets to the device .. 35

Initial Setup and Verification ..... 37

Items required ............. 37

Providing power to the device ........ 37

Establishing a first-time serial connection .... 37

Configuring the IP address ......... 38

Using DHCP to set the IP address ...... 39

Setting a static IP address......... 39

Setting the date and time .......... 39

Setting the time zone .......... 40

Synchronizing local time with an external source 40

Customizing the chassis name and switch name .. 41

Establishing an Ethernet connection ...... 41

Setting the domain ID ........... 41

Verifying correct operation ......... 42

Backing up the configuration ........ 43

Powering down the device ......... 43

Installing Transceivers and Cables... 45

Time and items required .......... 45

Precautions specific to transceivers and cables ... 45

Cleaning the fiber-optic connectors ...... 46

Managing cables............. 46

Installing an SFP+ transceiver ........ 46

Replacing an SFP+ transceiver ........ 47

Installing a QSFP transceiver ........ 48

Replacing a QSFP transceiver ........ 49

Verifying the operation of new transceivers.... 50

Monitoring the device ........ 51

Port-side LED locations .......... 51

© Copyright IBM Corp. 2018 iii

Page 4

System power LED ........... 52

System status LED ........... 52

FC port status LED........... 53

QSFP port status LED .......... 53

Nonport-side LED locations ......... 54

Power supply OK and FAIL status LEDs ... 55

Fan assembly status LED ......... 55

Interpreting the POST results ........ 55

Interpreting the BOOT results ........ 56

Running diagnostic tests .......... 56

Power Supply Assemblies ...... 57

Precautions specific to the power supply assemblies 58

Identifying the airflow direction ....... 58

Power supply OK and FAIL status LEDs .... 59

Power supply assembly unit fault indicators ... 59

Power supply assembly task guide ...... 59

Time and items required .......... 60

Recording power supply assembly critical

information .............. 60

Removing a power supply and fan assembly ... 61

Inserting a new power supply assembly ..... 62

Verifying the operation of the power supply and fan

assemblies ............... 63

Fan Assemblies ........... 65

Precautions specific to the fan assemblies .... 66

Identifying the airflow direction ....... 66

Fan assembly status LED .......... 67

Fan assembly unit fault indicators ....... 67

Fan assembly task guide .......... 67

Time and items required .......... 68

Recording power supply and fan assembly critical

information .............. 68

Removing a fan assembly ......... 68

Inserting a new fan assembly ........ 69

Verifying the operation of the power supply and fan

assemblies ............... 70

Chassis replacement ........ 71

Customer replacement responsibilities ..... 71

Determining the need to replace the chassis .. 71

Chassis replacement overview ....... 71

Preparing for replacement ....... 72

Recording critical device and SAN information 72

Powering down the switch ....... 75

Reconnecting system to the network and fabric 75

Downloading the configuration....... 76

Verifying correct operation of system ..... 77

Verifying correct configuration of the fabric... 78

IBM service replacement responsibilities ..... 79

Disconnecting the cables ......... 79

Remove the old switch chassis and install the

new switch chassis ........... 79

Appendix A. Product specifications .. 81

Appendix B. Cable routing table .... 87

Notices .............. 89

Trademarks .............. 90

Homologation statement .......... 90

Electronic emission notices ......... 90

BSMI statement (Taiwan) ......... 90

Canadian requirements ......... 90

CE statement ............. 91

China CCC statement .......... 91

China ROHS ............. 92

FCC warning (US only) ......... 92

Germany statement........... 92

KCC statement (Republic of Korea) ..... 92

VCCI statement ............ 92

Index ............... 93

iv SAN128B-6 Installation, Service, and User Guide

Page 5

Figures

1. Port-side view ............ 2

2. Nonport-side view with AC power supply and

fan assembly units .......... 3

3. Rack kit parts ............ 16

4. Attaching the front brackets ....... 17

5. Attaching the bracket extensions to the device 18

6. Positioning the device in the rack ..... 19

7. Attaching the rear brackets to the extensions 20

8. Attaching the rear brackets to the rack posts 21

9. Attaching the front brackets to the rear of the

device .............. 22

10. Attaching the bracket extensions to the device 23

11. Positioning the device in the rack ..... 24

12. Attaching the rear brackets to the extensions at

the front of the device ......... 25

13. Attaching the short or long rear brackets to the

extensions ............. 25

14. Attaching the rear brackets to the front rack

posts ............... 26

15. Rack kit parts ............ 27

16. Attaching the front brackets ....... 29

17. Attaching front brackets to a rack ..... 30

18. Attaching the rear brackets to a rack .... 31

19. Attaching the rear brackets to the device 32

20. Attaching the front brackets ....... 33

21. Attaching front brackets to a rack ..... 34

22. Attaching the rear brackets to a rack .... 35

23. Attaching the rear brackets to the device 36

24. Optical transceiver extraction tool ..... 45

25. Installing a 32-Gbps SFP+ transceiver into an

upper port ............. 47

26. Replacing a 32-Gbps SFP+ optical transceiver

in an upper port ........... 48

27. Installing a 32-Gbps QSFP transceiver in an

upper port ............. 49

28. Replacing a QSFP optical transceiver .... 50

29. SAN128B-6 port-side LEDs ....... 51

30. Nonport-side LEDs with AC power supplies 54

31. AC power supply assembly ....... 57

32. Removing an AC power supply and fan

assembly ............. 61

33. Inserting an AC power supply and fan

assembly ............. 62

34. Fan assembly ............ 65

35. Removing a fan assembly ........ 69

36. Inserting a fan assembly ........ 70

© Copyright IBM Corp. 2018 v

Page 6

vi SAN128B-6 Installation, Service, and User Guide

Page 7

Tables

1. Brocade and IBM product and model number

matrix .............. xx

2. SFP+ ports numbering ......... 3

3. QSFP ports numbering ......... 3

4. Management options for the device ..... 4

5. Facility requirements .......... 9

6. Installation prerequisites ........ 10

7. Installation and basic system configuration 11

8. Space requirements .......... 14

9. tsTimeZone command parameter selection for

the US time zones .......... 40

10. System power LED patterns during normal

operation ............. 52

11. System status LED patterns during normal

operation ............. 52

12. SFP+ FC port status LED patterns during

normal operation........... 53

13. QSFP port status LED patterns during normal

operation ............. 53

14. Power supply status LEDs during normal

operation ............. 55

15. Fan assembly status LED patterns during

normal operation........... 55

16. Power supply status LEDs during normal

operation ............. 59

17. Fan assembly status LED patterns during

normal operation........... 67

18. Critical information checklist....... 73

19. Cable routing table for SAN128B-6..... 87

© Copyright IBM Corp. 2018 vii

Page 8

viii SAN128B-6 Installation, Service, and User Guide

Page 9

Read this first

Summary of changes

This is the first edition of the IBM®System Networking SAN128B-6 Installation, Service, and User Guide.

Getting help

For the latest version of your product documentation, visit the IBM Publications Center at

www.ibm.com/shop/publications/order. Search by form number or title.

For more information about IBM Storage Networking products, go to www.ibm.com/systems/

networking.

IBM Redbooks®often provide in depth information about product best practices, configurations, and

more technical information. For redbooks associated with this product, enter search terms on the

following Web site: www.redbook.ibm.com.

For support information for this and other IBM products, see the IBM Support Portal

www.ibm.com/supportportal. Search for the product Machine type or product name.

For Fabric OS Release Notes and access to Fabric OS firmware downloads, go to the IBM Support Portal

www.ibm.com/supportportal. Search for the product Machine type or product name, and then follow

links for Downloads. More detailed instructions are available through the Accessing firmware updates

and OS documentation updates link on the product documentation CD that is shipped with this

product.

You can also contact IBM within the United States at 1-800-IBMSERV (1-800-426-7378). For support

outside the United States, you can find the service number through the IBM contacts directory website at

www.ibm.com/planetwide/.

Visit the IBM contact website www.ibm.com/contact for contact information for your country or region.

For information about storage and networking industry standards, see the Storage Networking Industry

Association (SNIA) website at www.snia.org/.

Accessibility features for the SAN128B-6

Accessibility features help users who have a disability, such as restricted mobility or limited vision, to use

information technology products successfully.

Accessibility features

The following list includes the major accessibility features in this product:

v Light emitting diodes (LEDs) that flash at different rates, to represent the same information as the

colors of the LEDs

v Industry-standard devices for ports and connectors

v Management of the product through management applications is available through Web and Graphical

User Interface (GUI) options

© Copyright IBM Corp. 2018 ix

Page 10

Keyboard navigation

This product does not have an attached or integrated keyboard. Any keyboard navigation is provided

through the management software and GUI.

Vendor software

This product includes certain vendor software that is not covered under the IBM license agreement. IBM

makes no representation about the accessibility features of these products. Contact the vendor for the

accessibility information about its products.

Related accessibility information

You can view the publications for this product in Adobe Portable Document Format (PDF) using the

Adobe Acrobat Reader. The PDFs are provided on a product documentation CD-ROM that is packaged

with the product. The CD-ROM also includes an accessible HTML version of this document.

IBM and accessibility

See the IBM Human Ability and Accessibility Center website at www.ibm.com/able/ for more

information about the commitment that IBM has to accessibility.

How to send your comments

Your feedback is important in helping us provide the most accurate and high-quality information. If you

have comments or suggestions for improving this document, send us your comments by email to

starpubs@us.ibm.com. Be sure to include the following information:

v Exact publication title

v Form number (for example, GC27-2270-00)

v Page numbers to which you are referring

You can also mail your comments to:

International Business Machines Corporation

Information Development

Department GZW

9000 South Rita Road

Tucson, Arizona 85744-0001 U.S.A.

When you send information to IBM, you grant IBM a nonexclusive right to use or distribute the

information in any way it believes appropriate without incurring any obligation to you.

x SAN128B-6 Installation, Service, and User Guide

Page 11

Safety and environmental notices

This section contains information about:

v “Safety notices and labels”

v “Rack safety” on page xvi

v “Product recycling and disposal” on page xviii

Safety notices and labels

When using this product, observe the danger, caution, and attention notices contained in this guide. The

notices are accompanied by symbols that represent the severity of the safety condition. The danger and

caution notices are listed in numerical order based on their IDs, which are displayed in parentheses, for

example (D004), at the end of each notice. Use this ID to locate the translation of these danger and

caution notices in the Safety Notices publication that is shipped with this product.

The following notices and statements are used in IBM documents. They are listed below in order of

increasing severity of potential hazards. Follow the links for more detailed descriptions and examples of

the danger, caution, and attention notices in the sections that follow.

v Note: These notices provide important tips, guidance, or advice.

v “Attention notices” on page xv: These notices indicate potential damage to programs, devices, or data.

v “Cautions”: These statements indicate situations that can be potentially hazardous to you.

v “Danger Notices” on page xii: These statements indicate situations that can be potentially lethal or

extremely hazardous to you. Safety labels are also attached directly to products to warn of these

situations.

v In addition to these notices, “Safety labels” on page xiv may be attached to the product to warn of

potential hazards.

Cautions

A Caution statement alerts you to situations that can be potentially hazardous to you or cause damage to

hardware, firmware, software, or data.

General cautions

CAUTION:

Changes or modifications made to this device that are not expressly approved by the

party responsible for compliance could void the user's authority to operate the equipment.

CAUTION:

Do not install the device in an environment where the operating ambient temperature

might exceed 40°C (104°F).

CAUTION:

Make sure the airflow around the front, and back of the device is not restricted.

© Copyright IBM Corp. 2018 xi

Page 12

Electrical cautions

CAUTION:

Before plugging a cable into any port, be sure to discharge the voltage stored on the cable

by touching the electrical contacts to ground surface.

CAUTION:

Static electricity can damage the chassis and other electronic devices. To avoid damage,

keep static-sensitive devices in their static-protective packages until you are ready to

install them.

CAUTION:

If you do not install a module or a power supply in a slot, you must keep the slot filler

panel in place. If you run the chassis with an uncovered slot, the system will overheat.

CAUTION:

Carefully follow the mechanical guides on each side of the power supply slot and make

sure the power supply is properly inserted in the guides. Never insert the power supply

upside down.

CAUTION:

The power supply switch must be in the off position when you insert the power supply

into the chassis. Damage to the switch can result if a live power supply is installed.

Danger Notices

CAUTION:

All devices with DC power supplies are intended for installation in restricted access areas

only. A restricted access area is a location where access can be gained only by trained

service personnel through the use of a special tool, lock and key, or other means of

security, and is controlled by the authority responsible for the location.

CAUTION:

For the DC input circuit to the system, make sure there is a 10 Amp circuit breaker,

maximum 60 VDC, double pole, on the input terminal block to the power supply. The

input wiring for connection to the product should be copper wire, 16 AWG, marked

VW-1, and rated minimum 90°C.

CAUTION:

For a DC system, use grounding wire of at least 16 American Wire Gauge (AWG). The

grounding wire should be attached to the DC input connector; the other end connects to

the building ground.

CAUTION:

DC return shall be isolated from the chassis ground (DC-I) when connections to the

power supply are made.

A Danger statement indicates conditions or situations that can be potentially lethal or extremely

hazardous to you. Safety labels are also attached directly to products to warn of these conditions or

situations.

xii SAN128B-6 Installation, Service, and User Guide

Page 13

General dangers

Electrical dangers

DANGER

The procedures in this manual are for qualified service personnel.

DANGER

Be careful not to accidently insert your fingers into the fan tray while removing it

from the chassis. The fan may still be spinning at a high speed.

DANGER

For safety reasons, the ESD wrist strap should contain a series 1 megaohm resistor.

DANGER

Make sure that the power source circuits are properly grounded, then use the power

cord supplied with the device to connect it to the power source.

DANGER

Remove both power cords before servicing.

DANGER

Disconnect the power cord from all power sources to completely remove power from

the device.

DANGER

To avoid high voltage shock, do not open the device while the power is on.

Safety and environmental notices xiii

Page 14

DANGER

18-32kg(39.7-70.5lbs)

svc00167

Batteries used for RTC/NVRAM backup are not located in operator-access areas. There

is a risk of explosion if a battery is replaced by an incorrect type. Dispose of used

components with batteries according to local ordinance and regulations.

Dangers related to equipment weight

DANGER

Make sure the rack housing the device is adequately secured to prevent it from

becoming unstable or falling over.

Laser dangers

DANGER

All fiber-optic interfaces use Class 1 lasers.

Safety labels

As an added precaution, safety labels are often installed directly on products or product components to

warn of potential hazards. These can be either danger or caution notices, depending upon the level of the

hazard.

The actual product safety labels may differ from these sample safety labels:

DANGER

Hazardous voltage, current, or energy levels are present inside any component that

has this label attached. Do not open any cover or barrier that contains this label.

(L001)

DANGER

Rack-mounted devices are not to be used as a shelf or work space. (L002)

DANGER

Multiple power cords. The product might be equipped with multiple power cords. To

remove all hazardous voltages, disconnect all power cords. (L003)

xiv SAN128B-6 Installation, Service, and User Guide

Page 15

DANGER

Hazardous voltage present. Voltages present constitute a shock hazard, which can

cause severe injury or death. (L004)

CAUTION:

Hazardous moving parts nearby. (L008)

Attention notices

An attention notice indicates the possibility of damage to a program, device, or system, or to data. An

exclamation point symbol may accompany an attention notice, but is not required. A sample attention

notice follows:

Attention: Do not bend a fibre cable to a radius less than 5 cm (2 in.); you can damage the cable. Tie

wraps are not recommended for optical cables because they can be easily overtightened, causing damage

to the cable.

Safety and environmental notices xv

Page 16

ESD precautions

Attention: Many of the field replaceable units (FRUs) are sensitive to electrostatic discharge (ESD), and

can potentially be damaged by improper handling. When working with any FRU, use correct ESD

precautions:

v Attach ground to the indicated area on the chassis

v Wear a wrist grounding strap connected to chassis ground (if the switch is plugged in) or a bench

ground.

Note: For safety reasons, the ESD wrist strap should contain a series 1 megaohm resistor.

v Store ESD-sensitive components in antistatic packaging

Rack safety

Rack installation

DANGER

Observe the following precautions when working on or around your IT rack system:

v Heavy equipment—personal injury or equipment damage might result if mishandled.

v Always lower the leveling pads on the rack cabinet.

v Always install stabilizer brackets on the rack cabinet.

v To avoid hazardous conditions due to uneven mechanical loading, always install the heaviest devices in the

bottom of the rack cabinet. Always install servers and optional devices starting from the bottom of the rack

cabinet.

v Rack-mounted devices are not to be used as shelves or work spaces. Do not place objects on top of

rack-mounted devices.

v Each rack cabinet might have more than one power cord. Be sure to disconnect all power cords in the rack

cabinet when directed to disconnect power during servicing.

v Connect all devices installed in a rack cabinet to power devices installed in the same rack cabinet. Do not

plug a power cord from a device installed in one rack cabinet into a power device installed in a different

rack cabinet.

v An electrical outlet that is not correctly wired could place hazardous voltage on the metal parts of the system

or the devices that attach to the system. It is the responsibility of the customer to ensure that the outlet is

correctly wired and grounded to prevent an electrical shock.

(R001 part 1 of 2)

xvi SAN128B-6 Installation, Service, and User Guide

Page 17

CAUTION:

v Do not install a unit in a rack where the internal rack ambient temperatures will exceed the manufacturer’s

recommended ambient temperature for all your rack-mounted devices.

v Do not install a unit in a rack where the air flow is compromised. Ensure that air flow is not blocked or

reduced on any side, front, or back of a unit used for air flow through the unit.

v Consideration should be given to the connection of the equipment to the supply circuit so that overloading of

the circuits does not compromise the supply wiring or overcurrent protection. To provide the correct power

connection to a rack, refer to the rating labels located on the equipment in the rack to determine the total

power requirement of the supply circuit.

v (For sliding drawers) Do not pull out or install any drawer or feature if the rack stabilizer brackets are not

attached to the rack. Do not pull out more than one drawer at a time. The rack might become unstable if you

pull out more than one drawer at a time.

v (For fixed drawers) This drawer is a fixed drawer and must not be moved for servicing unless specified by the

manufacturer. Attempting to move the drawer partially or completely out of the rack might cause the rack to

become unstable or cause the drawer to fall out of the rack.

(R001 part 2 of 2)

Safety and environmental notices xvii

Page 18

Rack relocation (19" rack)

CAUTION:

Removing components from the upper positions in the rack cabinet improves rack stability during

relocation. Follow these general guidelines whenever you relocate a populated rack cabinet within a

room or building:

v Reduce the weight of the rack cabinet by removing equipment starting at the top of the rack

cabinet. When possible, restore the rack cabinet to the configuration of the rack cabinet as you

received it. If this configuration is not known, you must complete these steps:

– Remove all devices in the 32U position and above.

– Ensure that the heaviest devices are installed in the bottom of the rack cabinet.

– Ensure that there are no empty U-levels between devices installed in the rack cabinet below the

32U level.

– If the rack cabinet you are relocating is part of a suite of rack cabinets, detach the rack cabinet

from the suite.

– Inspect the route that you plan to take when moving the rack to eliminate potential hazards.

– Verify that the route that you choose can support the weight of the loaded rack cabinet. Refer to

the documentation that came with your rack cabinet for the weight of a loaded rack cabinet.

– Verify that all door openings are at least 760 x 2030 mm (30 x 80 in.).

– Ensure that all devices, shelves, drawers, doors, and cables are secure.

– Ensure that the four leveling pads are raised to their highest position.

– Ensure that there is no stabilizer bracket installed on the rack cabinet during movement.

– Do not use a ramp inclined at more than 10 degrees.

– Once the rack cabinet is in the new location, do the following:

- Lower the four leveling pads.

- Install stabilizer brackets on the rack cabinet.

- If you removed any devices from the rack cabinet, repopulate the rack cabinet from the lowest

position to the highest position.

– If a long distance relocation is required, restore the rack cabinet to the configuration of the rack

cabinet as you received it. Pack the rack cabinet in the original packaging material, or equivalent.

Also, lower the leveling pads to raise the casters off of the pallet and bolt the rack cabinet to the

pallet.

(R002)

Product recycling and disposal

Refer to the IBM Systems Environmental Notices and User Guide (Z125-5823) for translated environmental

statements and information regarding product recycling and disposal. This document may be provided

either in printed version or on the product documentation CD. A more current version may be available

through this link ftp://public.dhe.ibm.com/systems/support/warranty/envnotices/

environmental_notices_and_user_guide.pdf

xviii SAN128B-6 Installation, Service, and User Guide

Page 19

Preface

This document is intended for use by systems administrators and technicians experienced with

networking, Fibre Channel, and storage area network (SAN) technologies. It describes how to install,

service, and use the IBM Storage Networking SAN128B-6 (machine type-models 8960-F96 and 8960-N96

Switch). Throughout this document, the product is referred to as the SAN128B-6, or simply the switch.

This document has been created to include information specific to SAN128B-6 switches running on Fabric

OS version 7.1.1 or later. This document does not support all Fabric OS versions. It is specific to Fabric

OS v7.1.1 or later. Refer to the Fabric OS Release Notes for more information.

Product documents

The following documents contain information related to this product. The documentation may be printed

material or may be on the documentation CD that is shipped with the product.

v IBM Storage Networking SAN128B-6 Installation, Service, and User Guide, TBD (this document)

v IBM Storeage Networking SAN128B-6 Quick Start Guide, TBD

v Safety Notices

v IBM Systems Environmental Notices and User Guide, Z125-5823

v Warranty Information, 45W6626

Newer versions of product documentation may be available through the IBM Publications Center website

www.ibm.com/shop/publications/order. Search by publication title or publication number.

Newer versions may also be available through the IBM Support Portal www.ibm.com/supportportal.

Enter your product machine type (8960) or product name in the search field, and then select

Documentation from the displayed page.

Brocade documents

IBM b-type switches use software licensed from Brocade Communications Systems, Inc. You can find

information related to the software that supports the switch in the following documents on the CD-ROM

supplied with this product:

Brocade Fabric OS

v EZSwitchSetup Administrator's Guide

v Fabric OS Administrator's Guide

v Fabric OS Command Reference Manual

v Fabric OS MIB Reference Manual

v Fabric OS Message Reference Manual

v Fabric OS Troubleshooting and Diagnostics Guide

Brocade Fabric OS optional features

v Fabric Watch Administrator's Guide

v Web Tools Administrator's Guide

IBM and Brocade product matrix

The product matrix provides a cross-reference between the comparable IBM and Brocade product models.

© Copyright IBM Corp. 2018 xix

Page 20

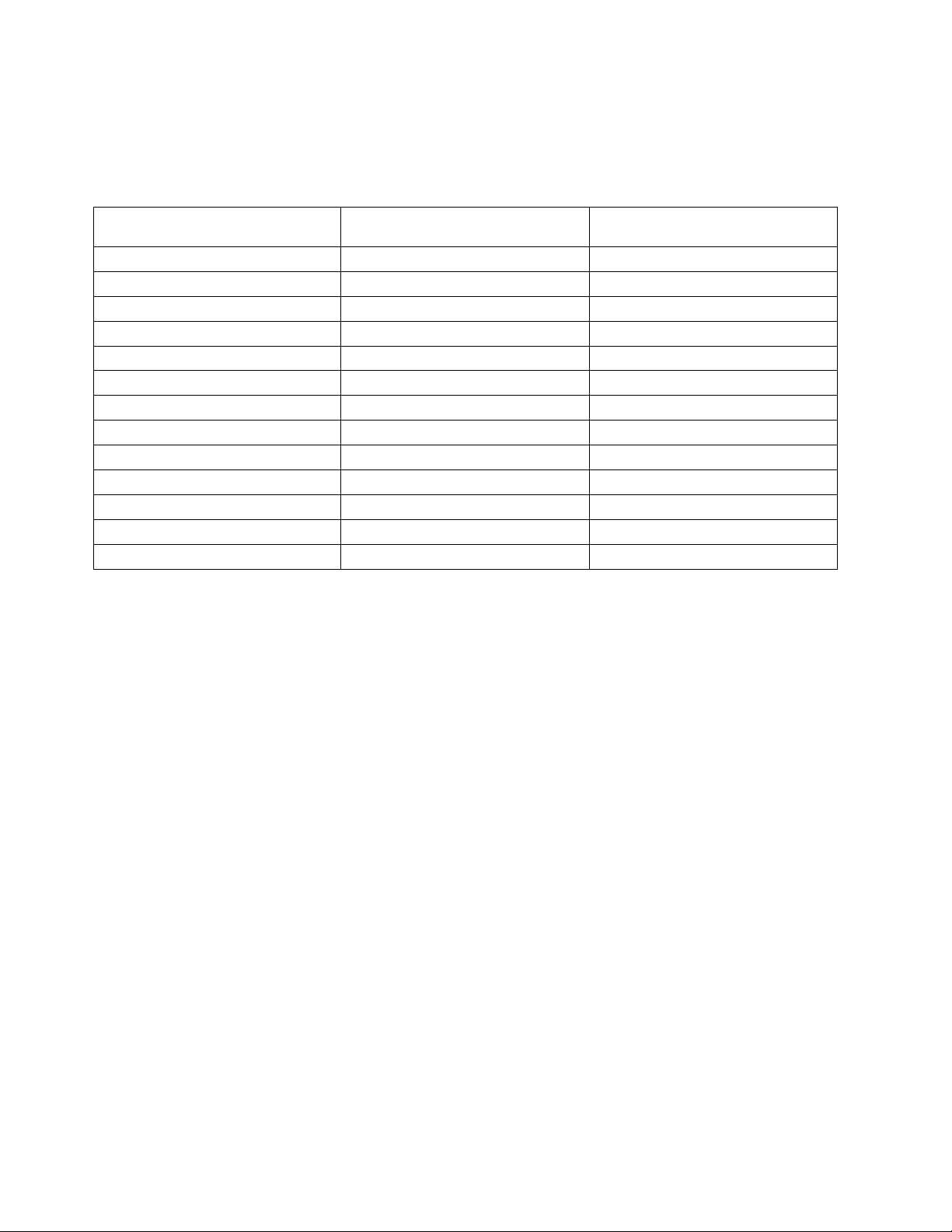

When you use any of the Brocade documents, such as Fabric Operating System (FOS) publications, you

will notice that the model numbers reflect the corresponding Brocade products. Table 1 provides a

product matrix to correlate the Brocade products and models to the IBM product names and machine

types and model numbers. Products withdrawn from marketing are not listed.

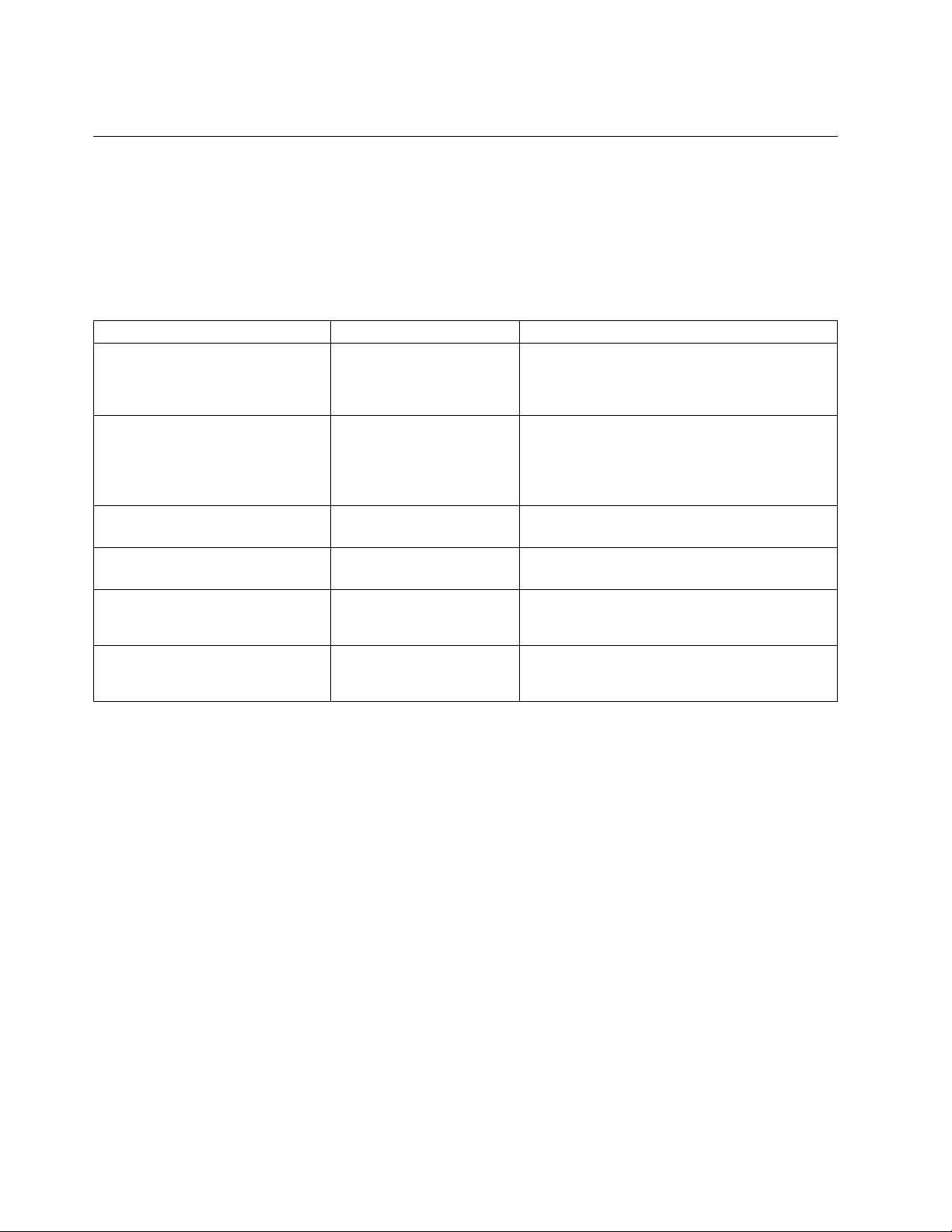

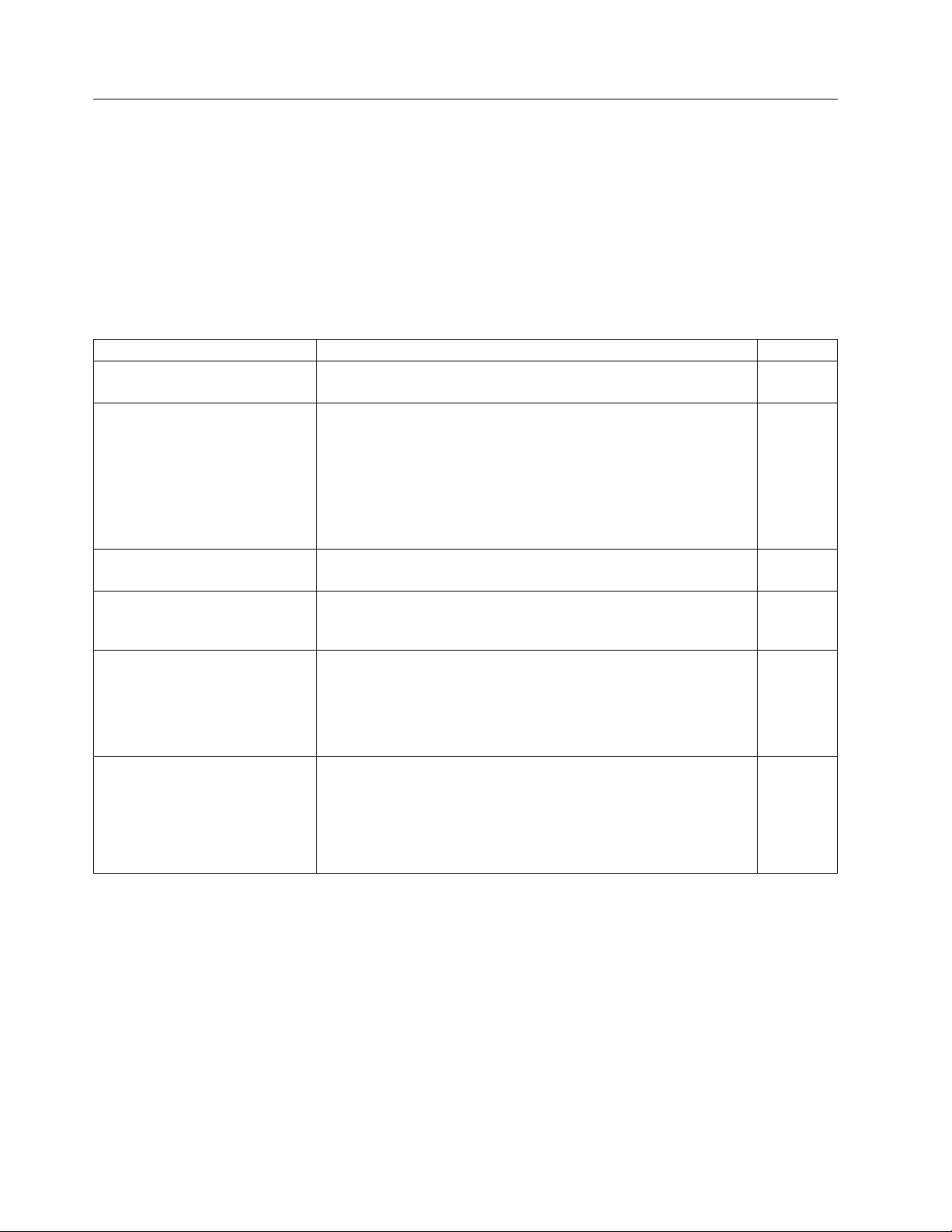

Table 1. Brocade and IBM product and model number matrix

IBM machine type and model

Brocade product name IBM product name

Brocade G630 SAN128B-6 8960 Models F96 and N96

Brocade G620 SAN64B-6 8960 Models F64 and N64

Brocade G610 SAN24B-6 8960 Models F24

Brocade X6-4 Director SAN256B-6 8961 Model F04

Brocade X6-8 Director SAN512B-6 8961 Model F08

Brocade 6520 SAN96B-5 2498 Models F96 and N96

Brocade 6505 SAN24B-5 2498 Model F24, 249824G

Brocade 6510 SAN48B-5 2498 Model F48

Brocade DCX 8510-4 SAN384B-2 2499 Model 416

Brocade DCX 8510-8 SAN768B-2 2499 Model 816

Brocade 7800 SAN06B-R 2498 Model R06

Brocade 7840 SAN42B-R 2498 Model R42

Brocade 300 SAN24B-4 2498 Models B24 and 24E

number

xx SAN128B-6 Installation, Service, and User Guide

Page 21

Device Overview

The IBM SAN128B-6 offers the following features and capabilities:

v Up to 96 auto-sensing ports supporting high-performance 32-Gbps SFP+ ports technology in a single

domain with NVMe support on egress-only.

v Up to eight auto-sensing 128-Gbps (4 x 32-Gbps) QSFP ports to connect to the QSFP ports of other

devices or F_Ports.

v Dynamic Ports on Demand (Dynamic-POD) scaling from a base configuration of 48 ports to 128 ports

(two 24-port SFP+ PODs and one 32-port QSFP POD).

v 4-, 8-, 16-, and 32-Gbps auto-sensing Fibre Channel switch and router ports.

– A 32-Gbps optical transceiver can auto-negotiate to 32 Gbps, 16 Gbps, or 8 Gbps.

– A 16-Gbps optical transceiver can auto-negotiate to 16 Gbps, 8 Gbps, or 4 Gbps.

– A 10-Gbps FC optical transceiver can support 10 Gbps speed.

Note: The port speed is determined by the maximum speed supported by the optical transceiver at the

other end of the link.

v Universal ports self-configure as a E_Ports, F_Ports, or D_Ports. EX_Ports can be activated on a

per-port basis with the optional Integrated Routing license.

– Diagnostic D_Port mode provides diagnostics, troubleshooting, and verification services for the

physical media.

v Up to 384 Gbps of combined in-flight data encryption/decryption and 192 Gbps of combined in-flight

compression/decompression capabilities per switch.

v Dynamic buffer sharing

v Support for nonport-side intake or nonport-side exhaust airflow for cooling.

v Hardware-enabled input and output (I/O) latency statistics collection.

v Hardware-enabled VM support.

v Brocade small form-factor pluggable plus (SFP+) optical transceivers support any combination of Short

Wavelength (SWL), Long Wavelength (LWL) or Extended Long Wavelength (ELWL) optical media

among the switch ports.

v Extended distance Fibre Channel to support long distance native FC connectivity.

v Port-to-port latency is minimized to 900 nanoseconds (including FEC) by using cut-through frame

switching at 32 Gbps.

v High performance T1042E processor with four cores operating at 1.5 GHz delivers high performance,

scalability, and advanced Fabric Vision functionality.

v One 10/100/1000 Mbps RJ45 connector Ethernet port for management connection. In conjunction with

EZSwitchSetup, this port supports switch IP address discovery and configuration, eliminating the need

to attach a serial cable to configure the switch IP address.

v One RS-232 3-wire (Tx, Rx, and Gnd) universal asynchronous receiver/transmitter (UART) serial port

to BMC with RJ-45 connector for debugging initial switch setup (if not using EZSwitchSetup) and

factory default restoration. Integral LEDs remain unlit at all times.

v One internal e-USB module provides 2 GB of persistent storage, increased serviceability, and error

logging functionality by facilitating easier firmware upgrades and downloads of the system log files.

v One external USB Type A connector.

v Two hot-swappable redundant power supply field-replaceable units.

v Three hot-swappable redundant fan assembly field-replaceable units.

v 128 bicolor (green/amber) LEDs to indicate the status for each port.

© Copyright IBM Corp. 2018 1

Page 22

v One green LED to indicate valid system power.

v One bicolor (green/amber) LED to indicate the system status.

v Two Ethernet LEDs: one bicolor (green/amber) LED to indicate link at 1000/100/10 Mbps and one

green LED to indicate activity.

v SEEPROM for switch identification.

v Real-time power monitoring.

v Real-time voltage monitoring.

v Real-time fan monitoring including airflow direction.

v Real-time digital thermometers for temperature monitoring.

v Real-time clock (RTC) with battery.

License options

The SAN128B-6 uses a capacity-based Ports on Demand (POD) license method. An Integrated Routing

(IR) license is required to enable EX_Port functionality on this device. Refer to the Fabric OS Software

Licensing Guide for more details.

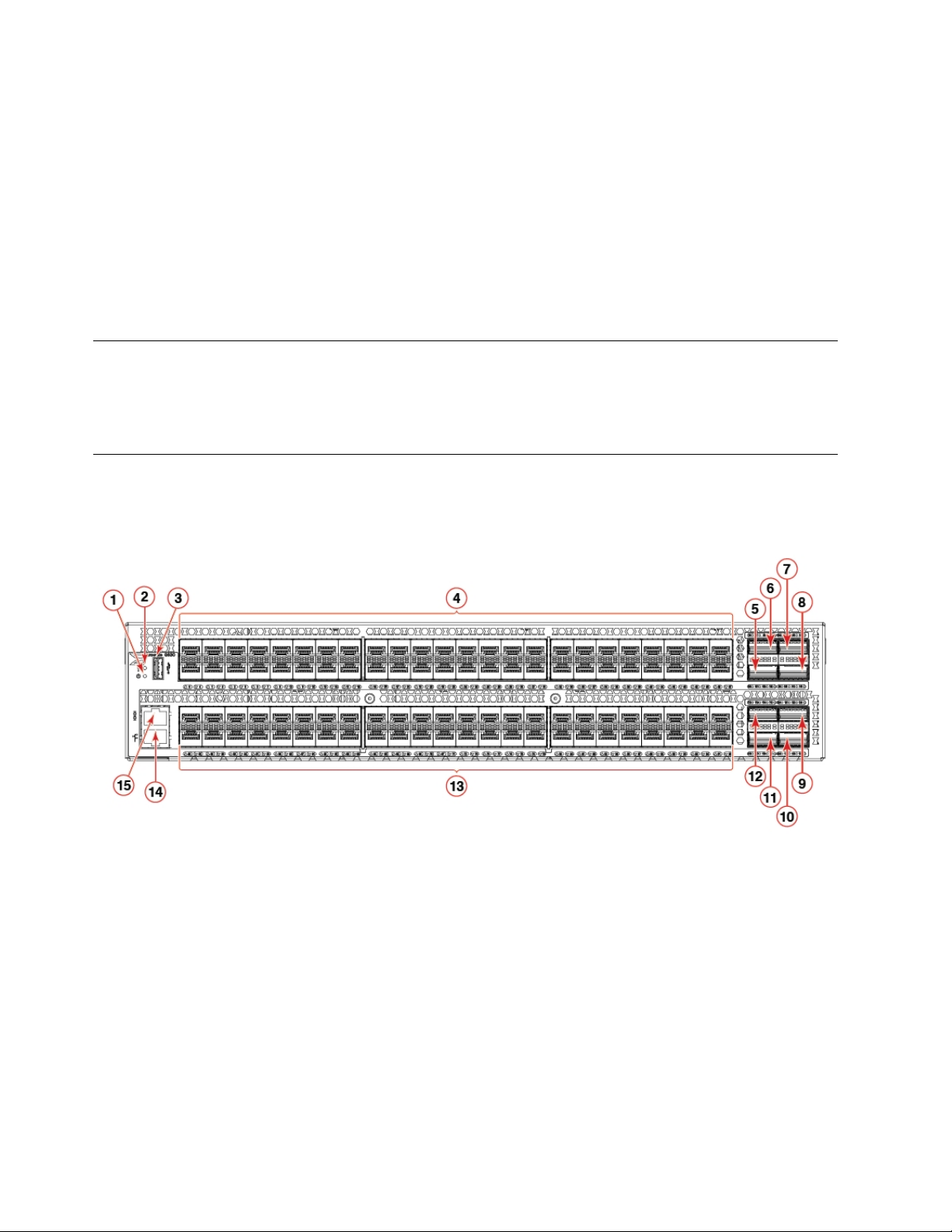

Port-side view

The following illustration shows the port-side view of the SAN128B-6 Fibre Channel switch.

Figure 1. Port-side view

1. System power LED

2. System status LED

3. USB port

4. 48 SFP+ 32-Gbps FC ports

5. QSFP port 1 ( FC ports 100 - 101 - 102 - 103 )

6. QSFP port 0 ( FC ports 96 - 97 - 98 - 99 )

7. QSFP port 2 ( FC ports 104 - 105 - 106 - 107 )

8. QSFP port 3 ( FC ports 108 - 109 - 110 - 111 )

9. QSFP port 6 ( FC ports 120 - 121 - 122 - 123 )

10. QSFP port 7 ( FC ports 124 - 125 - 126 - 127 )

11. QSFP port 5 ( FC ports 116 - 117 - 118 - 119 )

2 SAN128B-6 Installation, Service, and User Guide

Page 23

12. QSFP port 4 ( FC ports 112 - 113 - 114 - 115 )

13. 48 SFP+ 32-Gbps FC ports

14. 10/100/1000 Mbps RJ-45 Ethernet management port

15. UART RJ-45 serial console port

Table 2. SFP+ ports numbering

0 1 2 3 8 9 10 11 16 17 18 19 24 25 26 27 32 33 34 35 40 41 42 43

4 5 6 7 12 13 14 15 20 21 22 23 28 29 30 31 36 37 38 39 44 45 46 47

48 49 50 51 56 57 58 59 64 65 66 67 72 73 74 75 80 81 82 83 88 89 90 91

52 53 54 55 60 61 62 63 68 69 70 71 76 77 78 79 84 85 86 87 92 93 94 95

Table 3. QSFP ports numbering

QSFP port 0 ( FC ports 96 - 97 - 98 - 99 ) QSFP port 2 ( FC ports 104 - 105 - 106 - 107 )

QSFP port 1 ( FC ports 100 - 101 - 102 - 103 ) QSFP port 3 ( FC ports 108 - 109 - 110 - 111 )

QSFP port 4 ( FC ports 112 - 113 - 114 - 115 ) QSFP port 6 ( FC ports 120 - 121 - 122 - 123 )

QSFP port 5 ( FC ports 116 - 117 - 118 - 119 ) QSFP port 7 ( FC ports 124 - 125 - 126 - 127 )

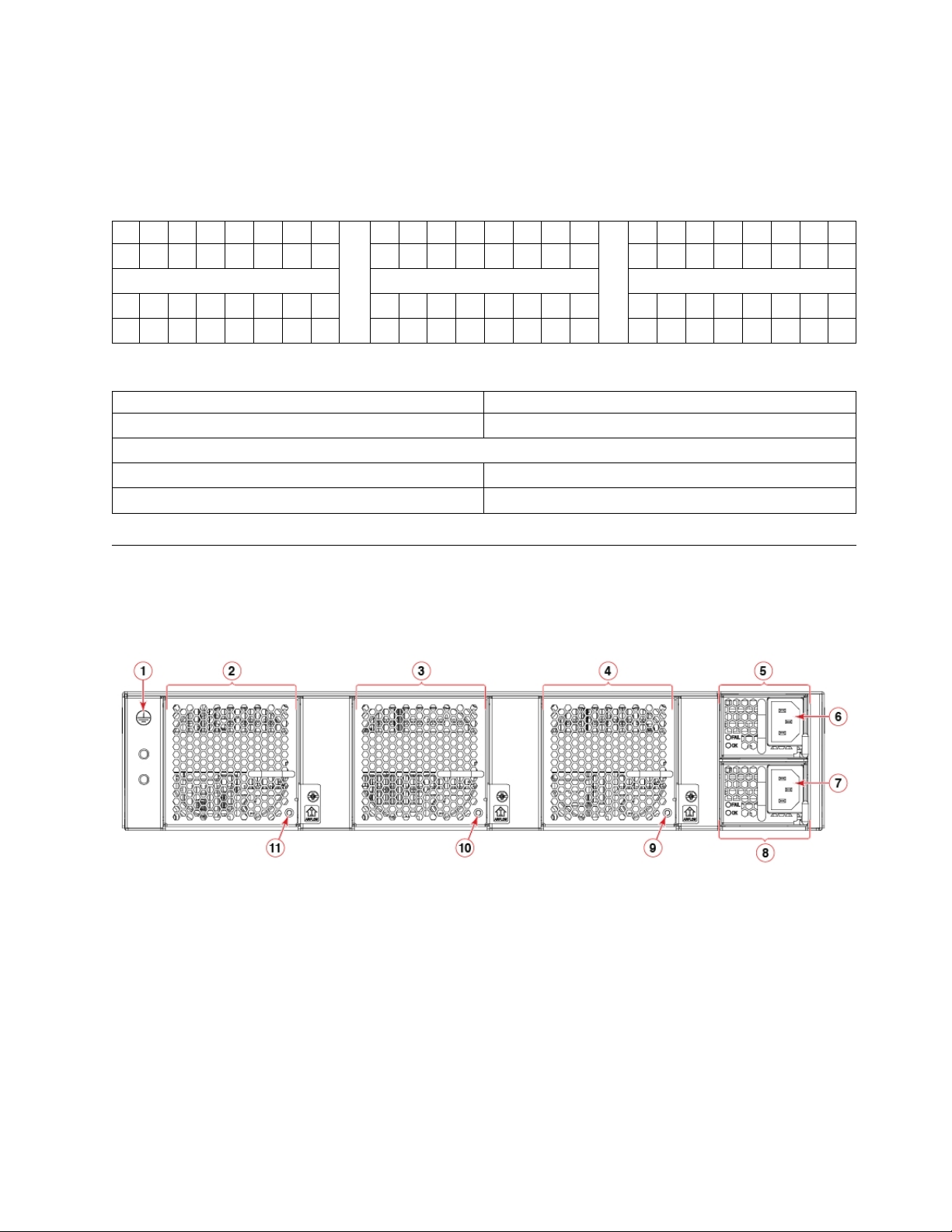

Nonport-side view

The following illustration shows the nonport-side view of the SAN128B-6 FC switch.

Figure 2. Nonport-side view with AC power supply and fan assembly units

1. Ground cable connector

2. Fan assembly unit 1

3. Fan assembly unit 2

4. Fan assembly unit 3

5. Power supply unit 1

6. Power supply receptacle 1

7. Power supply receptacle 2

8. Power supply unit 2

9. Fan assembly unit 3 status LED

10. Fan assembly unit 2 status LED

Device Overview 3

Page 24

11. Fan assembly unit 1 status LED

Device management options

You can use the management functions built into the device to monitor the fabric topology, port status,

physical status, and other information to help you analyze switch performance and to accelerate system

debugging. The device automatically performs a power-on self-test (POST) each time it is turned on. A

RASlog message is generated for any detected startup errors.

You can manage the device using any of the management options listed in the following table.

Table 4. Management options for the device

Management tool Out-of-band support Reference documents

Command line interface (CLI)

Up to two admin sessions and four

user sessions simultaneously.

EZSwitchSetup

EZSwitchSetup helps to complete

the basic configuration for

single-switch setup.

Web Tools Ethernet or serial

Standard SNMP applications Ethernet or serial

Management Server Ethernet or serial

IBM Network Advisor (NA)

NA must be purchased separately.

Ethernet or serial

connection

Ethernet or serial

connection

connection

connection

connection

Ethernet or serial

connection

Fabric OS Administration Guide

Fabric OS Command Reference

EZSwitchSetup Software Installation Guide

EZSwitchSetup Administrator's Guide

Web Tools Administration Guide

Fabric OS MIB Reference

Fabric OS Administration Guide

Fabric OS Command Reference

IBM Network Advisor documentation set

4 SAN128B-6 Installation, Service, and User Guide

Page 25

Preparing for the Installation

Use the following precautions and requirements for successful installation and operation of the switch.

Safety precautions

When using this product, observe all danger, caution, and attention notices in this manual. The safety

notices are accompanied by symbols that represent the severity of the safety condition

General precautions

DANGER

The procedures in this manual are for qualified service personnel.

DANGER

Before beginning the installation, see the precautions in “Power precautions.”

DANGER

Be careful not to accidently insert your fingers into the fan tray while removing it

from the chassis. The fan may still be spinning at a high speed.

CAUTION:

Changes or modifications made to this device that are not expressly approved by the

party responsible for compliance could void the user's authority to operate the equipment.

CAUTION:

Disassembling any part of the power supply and fan assembly voids the warranty and

regulatory certifications. There are no user-serviceable parts inside the power supply and

fan assembly.

CAUTION:

Make sure the airflow around the front, and back of the device is not restricted.

CAUTION:

Ensure that the airflow direction of the power supply unit matches that of the installed

fan tray. The power supplies and fan trays are clearly labeled with either a green arrow

with an "E", or an orange arrow with an "I."

© Copyright IBM Corp. 2018 5

Page 26

CAUTION:

Never leave tools inside the chassis.

CAUTION:

To protect the serial port from damage, keep the cover on the port when not in use.

CAUTION:

If you do not install a module or a power supply in a slot, you must keep the slot filler

panel in place. If you run the chassis with an uncovered slot, the system will overheat.

CAUTION:

Do not install the device in an environment where the operating ambient temperature

might exceed 40°C (104°F).

ESD precautions

Attention: Many of the field replaceable units (FRUs) are sensitive to electrostatic discharge (ESD), and

can potentially be damaged by improper handling. When working with any FRU, use correct ESD

precautions:

v Attach ground to the indicated area on the chassis

v Wear a wrist grounding strap connected to chassis ground (if the switch is plugged in) or a bench

ground.

Note: For safety reasons, the ESD wrist strap should contain a series 1 megaohm resistor.

v Store ESD-sensitive components in antistatic packaging

DANGER

For safety reasons, the ESD wrist strap should contain a series 1 megaohm resistor.

CAUTION:

Before plugging a cable into any port, be sure to discharge the voltage stored on the cable

by touching the electrical contacts to ground surface.

CAUTION:

Static electricity can damage the chassis and other electronic devices. To avoid damage,

keep static-sensitive devices in their static-protective packages until you are ready to

install them.

Note: Wear a wrist grounding strap connected to the chassis ground (if the device is plugged in) or to a

bench ground.

6 SAN128B-6 Installation, Service, and User Guide

Page 27

Power precautions

DANGER

Make sure that the power source circuits are properly grounded, then use the power

cord supplied with the device to connect it to the power source.

DANGER

If the installation requires a different power cord than the one supplied with the

device, make sure you use a power cord displaying the mark of the safety agency that

defines the regulations for power cords in your country. The mark is your assurance

that the power cord can be used safely with the device.

DANGER

This device might have more than one power cord. To reduce the risk of electric shock,

disconnect all power cords before servicing.

DANGER

Remove both power cords before servicing.

DANGER

Disconnect the power cord from all power sources to completely remove power from

the device.

DANGER

To avoid high voltage shock, do not open the device while the power is on.

DANGER

Batteries used for RTC/NVRAM backup are not located in operator-access areas. There

is a risk of explosion if a battery is replace by an incorrect type. Dispose of used

components with batteries according to local ordinance and regulations.

Preparing for the Installation 7

Page 28

CAUTION:

18-32kg(39.7-70.5lbs)

svc00167

18-32kg(39.7-70.5lbs)

svc00167

18-32kg(39.7-70.5lbs)

svc00167

18-32kg(39.7-70.5lbs)

svc00167

Use a separate branch circuit for each power cord, which provides redundancy in case one

of the circuits fails.

CAUTION:

Ensure that the device does not overload the power circuits, wiring, and over-current

protection. To determine the possibility of overloading the supply circuits, add the

ampere (amp) ratings of all devices installed on the same circuit as the device. Compare

this total with the rating limit for the circuit. The maximum ampere ratings are usually

printed on the devices near the input power connectors.

CAUTION:

The power supply switch must be in the off position when you insert the power supply

into the chassis. Damage to the switch can result if a live power supply is installed.

CAUTION:

Carefully follow the mechanical guides on each side of the power supply slot and make

sure the power supply is properly inserted in the guides. Never insert the power supply

upside down.

Note: Device control processors and management modules may contain batteries for RTC or NVRAM

backup. Dispose of components containing batteries as required by local ordinances and regulations.

Lifting and weight-related precautions

DANGER

Use safe lifting practices when moving the product.

DANGER

Mount the devices you install in a rack as low as possible. Place the heaviest device at

the bottom and progressively place lighter devices above.

DANGER

Make sure the rack housing the device is adequately secured to prevent it from

becoming unstable or falling over.

CAUTION:

Do not use the port cover tabs to lift the module. They are not designed to support the

weight of the module, which can fall and be damaged.

8 SAN128B-6 Installation, Service, and User Guide

Page 29

18-32kg(39.7-70.5lbs)

svc00167

CAUTION:

To prevent damage to the chassis and components, never attempt to lift the chassis using

the fan or power supply handles. These handles were not designed to support the weight

of the chassis.

Laser precautions

DANGER

All fiber-optic interfaces use Class 1 lasers.

DANGER

Use only optical transceivers that are qualified by IBM and comply with the FDA

Class 1 radiation performance requirements defined in 21 CFR Subchapter I, and with

IEC 60825 and EN60825. Optical products that do not comply with these standards

might emit light that is hazardous to the eyes.

Facility requirements

Before installing the device, be sure the following facilities requirements are met.

Table 5. Facility requirements

Type Requirements

Electrical

Thermal

Rack (when

rack-mounted)

v Adequate supply circuit, line fusing, and wire size, as specified by the electrical rating on

the switch nameplate

v Circuit protected by a circuit breaker and grounded in accordance with local electrical

codes

Refer to the Technical Specifications at the end of this guide for complete power supply

specifications.

v A minimum airflow of 79.8 cubic meters/hour (47 cubic ft/min.) available in the

immediate vicinity of the switch

Note: Although this airflow may exceed the airflow maximum listed in the device

Technical Specifications, the additional airflow is recommended to pressurize the inlet

(cool isle) side of rack installations relative to the exhaust side to minimize recirculation

of hot air back to the inlet side.

v Ambient air temperature not exceeding 40°C (104°F) while the switch is operating

v Two rack unit (2U) in a 48.3 cm (19-inch) rack

v All equipment in the rack grounded through a reliable branch circuit connection

v Additional weight of switch not to exceed the rack’s weight limits

v Rack secured to ensure stability in case of unexpected movement

Preparing for the Installation 9

Page 30

Quick installation checklist

This checklist provides a high-level overview of the basic installation process from the planning stage to

the point where the device comes online and is ready to be deployed. Completing all the tasks in the

suggested order ensures successful installation. Brocade recommends that you print this checklist and

take it to the installation site.

Pre-installation tasks

Review all installation requirements ahead of time as part of your site preparation. Careful planning and

site preparation ensures seamless installation, especially when installing multiple devices.

Table 6. Installation prerequisites

Task Task details or additional information Completed

Unpack the device. Take an inventory of the hardware components included in your

shipment. Refer to “Shipping carton contents” on page 12.

Gather necessary components and

required tools.

Review the safety precautions. Refer to “Safety precautions” on page 5. For translations, refer to

Plan the installation. Decide whether you want to install the unit on a flat surface or in a

Review and verify installation

requirements.

Gather network configuration

parameters.

Review the time and items required information at the beginning of

each chapter to ensure you have gathered all necessary components

required for the following installation tasks:

v “Mounting the switch” on page 13

v “Power Supply Assemblies” on page 57

v “Fan Assemblies” on page 65

v “Installing Transceivers and Cables” on page 45

“Cautions” on page xi at the end of this guide.

rack. For rack installation, obtain the appropriate rack mount kit.

Refer to “Mounting the switch” on page 13.

Verify that the following requirements are met. Refer to “Facility

requirements” on page 9.

v Power requirements

v Environmental requirements

v Clearance for standalone or rack installation

v IP address:

v Subnet mask:

v Default gateway:

v Domain ID:

v Time zone:

Installation and initial configuration

The initial setup includes mounting the device on a flat surface or in a rack and completing the

configuration tasks necessary to bring the device online and verify the operation.

10 SAN128B-6 Installation, Service, and User Guide

Page 31

Table 7. Installation and basic system configuration

Task Task details or additional information Completed

Mount the device. Choose one of the following mounting options:

v Mount the device as a standalone unit. Refer to“Standalone

installation” on page 14.

v Mount the device in a four-post rack. Refer to“Installing the

Universal Four-Post Rack Kit” on page 14.

v Mount the device in a two-post rack. Refer to“Installing the

Universal Two-Post Rack Kit” on page 26.

Check the airflow of the power

supply and fan assembly

The airflow direction of the power supply and fan should match.

The power supplies and fan trays are clearly labeled with either a

green arrow with an "E", or an orange arrow with an "I." For more

details, refer to “Identifying the airflow direction” on page 58.

Gather all components required

Refer to “Items required” on page 37.

for the initial setup.

Provide power to the device. Refer to “Providing power to the device” on page 37.

Attach a management station,

establish a serial connection, and

change the default passwords

Refer to “Establishing a first-time serial connection” on page 37.

After completing this task, log in to the serial port to configure the

device.

(optional).

Set the IP address, subnet mask,

and the default gateway IP

address.

Use the ipaddrset command to configure a static device IP address,

subnet mask, and gateway IP address, or you can use a DHCP

server to obtain the information dynamically. Refer to “Configuring

the IP address” on page 38.

Set the date and time.

v Use the date command to display and set the date and time.

v Use the tstimezone command to display and set the time zone.

v Use the tsclockserver command to synchronize the time with an

external NTP server.

Refer to “Setting the date and time” on page 39 for more

information.

Customize the switch name and

chassis name.

v Use the swicthname command to change the default switch name.

v Use the chassisname command to change the default chassis

name.

Refer to “Customizing the chassis name and switch name” on page

41 for more information.

Establish an Ethernet connection. By establishing an Ethernet connection, you can complete the

device configuration using a serial session, Telnet, or management

application, such as Brocade Network Advisor. Refer to

“Establishing an Ethernet connection” on page 41.

Optional: Configure the DNS

service.

Optional: Customize the domain

ID.

Use the dnsconfig command to create DNS server entries. Refer to

the Brocade Fabric OS Administration Guide.

Use the configure command to change the domain ID (default ID

is 1). Refer to “Setting the domain ID” on page 41 for more

information.

Preparing for the Installation 11

Page 32

Table 7. Installation and basic system configuration (continued)

Task Task details or additional information Completed

Verify that the device operates

correctly.

Back up the configuration. Use the interactive configupload command to back up the

Optional: Power off the devices. Enter the shutdown command and wait for the device to power

v Check the LEDs to verify operation of functional parts. Refer

to“Port-side LED locations” on page 51 and“Nonport-side LED

locations” on page 54.

v The following commands can be useful to establish an

operational baseline for the device. Refer to theFabric OS

Command Reference for more information on these commands.

– psshow

– fanshow

– tempshow

– historyshow

– errdump

configuration. Refer to “Verifying correct operation” on page 42 for

more information.

down, and then unplug the power cords. Refer to “Powering down

the device” on page 43 for more information.

Shipping carton contents

When unpacking the switch, verify that the contents of the shipping carton is complete. Save the

shipping carton and packaging in the event you need to return the shipment.

v The SAN128B-6 switch

v An accessory kit containing the following items:

– A serial cable

– Two 6-ft. power cords

– Power cord retainer clips

– Rubber feet

– China-RoHS Hazardous/Toxic Substance statement

– Network Advisor web pointer card.

– EZSwitch web pointer card

– Documentation web pointer card

v Inner foam

12 SAN128B-6 Installation, Service, and User Guide

Page 33

Mounting the switch

18-32kg(39.7-70.5lbs)

svc00167

18-32kg(39.7-70.5lbs)

svc00167

18-32kg(39.7-70.5lbs)

svc00167

18-32kg(39.7-70.5lbs)

svc00167

You can install the SAN128B-6 switch in several ways:

v As a standalone unit on a flat surface, for example, a table top. Use the rubber feet included with the

shipment to secure the device on the surface. No other equipment is required for desktop installation.

v In a four-post EIA rack: You will need a Universal Four-Post Rack Kit to install devices in EIA racks

that are between L-13.7 to 81.28 cm deep (L-5.0 to 32.0 in.), where L is the chassis depth.

v In a two-post Telco rack: You will need a Universal Two-Post Rack Kit to install 2U devices in a

two-post telecommunications (Telco) rack.

Note: Review the “Precautions specific to mounting” before mounting the switch.

Precautions specific to mounting

The following precautions specifically apply to mounting the device.

DANGER

Use safe lifting practices when moving the product.

DANGER

Mount the devices you install in a rack as low as possible. Place the heaviest device at

the bottom and progressively place lighter devices above.

CAUTION:

Make sure the airflow around the front, and back of the device is not restricted.

CAUTION:

Never leave tools inside the chassis.

CAUTION:

Do not use the port cover tabs to lift the module. They are not designed to support the

weight of the module, which can fall and be damaged.

CAUTION:

To prevent damage to the chassis and components, never attempt to lift the chassis using

the fan or power supply handles. These handles were not designed to support the weight

of the chassis.

© Copyright IBM Corp. 2018 13

Page 34

Standalone installation

About this task

Complete the following steps to install the device as a standalone unit on a table.

Procedure

1. Unpack the device and verify the items listed under “Shipping carton contents” on page 12 are

present and undamaged.

2. Apply the adhesive rubber feet to the underside of the device. The rubber feet help prevent the device

from sliding off the supporting surface.

a. Clean the indentations at each corner of the bottom of the device to ensure that they are free of

dust or other debris that might lessen the adhesion of the feet.

b. With the adhesive side against the chassis, place one rubber foot in each indentation and press

into place.

3. Place the device on a sturdy flat surface.

4. Provide power to the device as described in “Providing power to the device” on page 37.

Note: Do not connect the device to the network until the IP address is set correctly. For instructions

on how to set the IP address, refer to “Configuring the IP address” on page 38.

Installing the Universal Four-Post Rack Kit

Use the following instructions to install 1U and 2U devices in EIA racks that are between L-12.7 to 81.28

cm deep (L-5.0 to 32.0 in.), where L is the chassis depth, using the Universal Four-Post Rack Kit.

There are two ways you can mount the device in a four-post rack:

v With the port side flush with the front posts.

v With the nonport side flush with the rear posts in a recessed position. A recessed position allows a

more gradual bend in the fiber-optic cables connected to the switch and less interference in the aisle at

the front of the rack.

Table 8. Space requirements

Chassis with

port-side side

vents Notes Chassis depth

No Applicable to port-side and

nonport-side flush mounts.

Yes Applicable to port-side flush

mounts.

Yes Applicable to nonport-side flush

mounts.

L L-12.7 cm (L-5 in.) 81.28 cm (32 in.)

L L-12.7 cm (L-5 in.) 81.28 cm (32 in.)

L L 81.28 cm (32 in.)

Minimum rack

depth

Maximum rack

depth

Note that if chassis depth (L) is less than 40.64 cm (16 in.), the chassis will not fit into a rack with a

maximum depth of 81.28 cm (32 in.) using the universal four-post rack kit. The maximum rack depth for

a chassis less than 40.64 cm (16 in.) is 81.28 cm (32 in.) minus the difference between the chassis depth

and 40.64 cm (16 in.). For example, a chassis with a depth (L) of 35.56 cm (14 in.) is 5.08 cm (2 in.)

smaller than 40.64 cm (16 in.), so it will install into a rack with a maximum depth of 81.28 cm (32 in.) -

5.08 cm (2 in.) = 76.2 cm (30 in.).

Observe the following when mounting this device:

14 SAN128B-6 Installation, Service, and User Guide

Page 35

v Two people are required to install the device in a rack. One person holds the device, while the other

screws in the front and rear brackets.

v Before mounting your device, review any specific installation and facility requirements in this

Hardware Installation Guide.

v Hardware devices illustrated in these procedures are only for reference and may not depict the device

you are installing into the rack.

Time and items required

Allow 15 to 30 minutes to complete the installation.

The following items are required to install the device using the Universal Four-Post Rack Kit:

v #2 Phillips torque screwdriver

v 1/4-inch slotted-blade torque screwdriver

Parts list

The following parts are provided wit the 1U, 1.5U, and 2U Universal Kit for Four Post Racks Installation.

Mounting the switch 15

Page 36

Figure 3. Rack kit parts

1. Front brackets (2)

2. Extension brackets, medium (2)

3. Rear brackets, short (2)

4. Rear brackets, long (2)

5. Extension brackets, long (2)

6. Screw, 8-32 x 5/16-in., panhead Phillips (8)

7. Screw, 8-32 x 5/16-in., flathead Phillips (16)

8. Screw, 6-32 x 1/4-in., panhead Phillips (8)

9. Screw, 10-32 x 5/8-in., panhead Phillips (8)

10. Retainer nut, 10-32 (8)

Ensure that the items listed and illustrated are included in the kit. Note that not all parts may be used

with certain installations depending on the device type.

CAUTION:

CAUTION: Use the screws specified in the procedure. Using longer screws can damage the device.

16 SAN128B-6 Installation, Service, and User Guide

Page 37

Flush-front mounting

CAUTION:

The device must be turned off and disconnected from the fabric during this procedure.

Note: The illustrations in the rack installation procedures are for reference only and may not show the

device that you are installing.

Complete the following tasks to install the device in a four-post rack.

1. Attaching the front brackets

2. Attaching the bracket extensions to the device

3. Installing the device in the rack

4. Attaching the rear brackets to the extensions

5. Attaching the rear brackets to the rack posts

Attaching the front brackets

About this task

Complete the following steps to attach the front brackets to the device.

Procedure

1. Position the right front bracket with the flat side against the right side of the device at the front of the

device, as shown in Figure 4.

2. Insert four 8-32 x 5/16-in. flathead screws through the vertically aligned holes in the bracket and then

into the holes on the side of the device. Use the upper and lower screw holes, leaving the center holes

empty.

3. Repeat step 1 and step 2 to attach the left front bracket to the left side of the device.

4. Tighten all the 8-32 x 5/16-in. screws to a torque of 15 in-lb (17 cm-kg).

Figure 4. Attaching the front brackets

1. The SAN128B-6 device

2. Front brackets

Mounting the switch 17

Page 38

3. Screws, 8-32 x 5/16-in., flathead Phillips

Attaching the bracket extensions to the device

About this task

Complete the following steps to attach the extension brackets to the device. There are medium and long

extension brackets that you can use for this step.

Procedure

1. Select the proper length bracket extension for your rack depth.

2. Position the right bracket extension along the side of the device as shown in Figure 5.

3. Insert four 8-32 x 5/16-in. flathead screws through the vertically aligned holes in the bracket extension

and then into the holes on the side of the device. Use the upper and lower screw holes, leaving the

center holes empty.

4. Repeat step 2 and step 3 to attach the left bracket extension to the left side of the device.

5. Tighten all the 8-32 x 5/16-in. screws to a torque of 15 in-lb (17 cm-kg).

Figure 5. Attaching the bracket extensions to the device

Bracket extension

Screws, 8-32 x 5/16-in., flathead Phillips

Installing the device in the rack

About this task

Complete the following steps to install the device in the rack.

Procedure

1. Position the device in the rack, as shown in Figure 6 on page 19, providing temporary support under

the device until the rail kit is secured to the rack.

2. Attach the right front bracket to the right front rack post using two 10-32 x 5/8-in. panhead screws

and two retainer nuts. Use the upper and lower holes in the bracket.

18 SAN128B-6 Installation, Service, and User Guide

Page 39

3. Attach the left front bracket to the left front rack post using two 10-32 x 5/8-in. panhead screws and

two retainer nuts. Use the upper and lower holes in the bracket.

4. Tighten all the 10-32 x 5/8-in. screws to a torque of 25 in-lb (29 cm-kg).

Figure 6. Positioning the device in the rack

1. Screws, 10-32 x 5/8-in., panhead Phillips

2. Retainer nuts, 10-32

Attaching the rear brackets to the extensions

About this task

Complete the following steps to attach the rear brackets to the extensions. There are short and long rear

brackets that you can use for this step. Choose the correct bracket for the depth of your rack.

Procedure

1. Select the proper length rear bracket for your rack depth.

2. Slide the right rear bracket onto the right bracket extension, as shown in the following figure.

3. Attach the brackets using four 6-32 x 1/4-in. panhead screws. If possible, leave at least one empty

vertical pair of holes between the screws for better support.

4. Repeat step 2 and 3 to attach the left rear bracket to the left bracket extension.

5. Adjust the brackets to the rack depth and tighten all the 6-32 x 1/4-in. screws to a torque of 9 in-lb

(10 cm-kg).

Mounting the switch 19

Page 40

Figure 7. Attaching the rear brackets to the extensions

1. Rear brackets

2. Screws, 6-32 x 1/4-in., panhead Phillips

Attaching the rear brackets to the rack posts

About this task

Complete the following steps to attach the rear brackets to the rack posts.

Procedure

1. Attach the right rear bracket to the right rear rack post using two 10-32 x 5/8-in. panhead screws and

two retainer nuts, as shown in Figure 8 on page 21. Use the upper and lower holes in the bracket.

2. Attach the left rear bracket to the left rear rack post using two 10-32 x 5/8-in. panhead screws and

two retainer nuts. Use the upper and lower holes in the bracket.

3. Tighten all the 10-32 x 5/8-in. screws to a torque of 25 in-lb (29 cm-kg).

20 SAN128B-6 Installation, Service, and User Guide

Page 41

Figure 8. Attaching the rear brackets to the rack posts

1. Screws, 10-32 x 5/8-in., panhead Phillips

2. Retainer nuts, 10-32

Flush-rear (recessed) mounting

The flush-rear (recessed) mounting is similar to the flush-front mounting except that the brackets are

reversed on the device.

CAUTION:

The device must be turned off and disconnected from the fabric during this procedure.

Note: The illustrations in the rack installation procedures show a 1U device, but the instructions are the

same for a 2U device. The illustrations in the rack installation procedures are for reference only and may

not show the actual device.

Complete the following tasks to install the device in a four-post rack:

1. Attaching the front brackets to the rear of the device

2. Attaching the extensions to the front of the device

3. Installing the device in the rack

4. Attaching the rear brackets to the extensions at the front of the device

5. Attaching the rear brackets to the front rack posts

Attaching the front brackets to the rear of the device

About this task

Note: In this installation, the brackets are named as listed in the parts list even though the installation of

the brackets is reversed from the flush-front installation.

Complete the following steps to attach the front brackets to the rear of the device.

Mounting the switch 21

Page 42

Procedure

1. Position the right front bracket with the flat side against the right rear side of the device, as shown in

Figure 9.

2. Insert four 8-32 x 5/16-in. flathead screws through the vertically aligned holes in the bracket and then

into the holes on the side of the device. Use the upper and lower screw holes, leaving the center holes

empty.

3. Repeat step 1 and step 2 to attach the left front bracket to the left side of the device.

4. Tighten all the 8-32 x 5/16-in. screws to a torque of 15 in-lb (17 cm-kg).

Figure 9. Attaching the front brackets to the rear of the device

1. The SAN128B-6 device

2. Front brackets

3. Screws, 8-32 x 5/16-in., flathead Phillips

Attaching the bracket extensions to the front of the device

About this task

Complete the following steps to attach the bracket extensions to the front of the device. There are

medium and long extension brackets that you can use for this step.

Procedure

1. Select the proper length extension bracket for your rack depth.

2. Position the right bracket extension along the side of the device as shown in Figure 10 on page 23.

3. Insert four 8-32 x 5/16-in. flathead screws through the vertically aligned holes in the bracket extension

and then into the holes on the side of the device. Use the upper and lower screw holes, leaving the

center holes empty.

4. Repeat step 2 and step 3 to attach the left front bracket extension to the left side of the device.

5. Tighten all the 8-32 x 5/16-in. screws to a torque of 15 in-lb (17 cm-kg).

22 SAN128B-6 Installation, Service, and User Guide

Page 43

Figure 10. Attaching the bracket extensions to the device

1. Extension brackets

2. Screws, 8-32 x 5/16-in., flathead Phillips

Installing the device in the rack

About this task

Complete the following steps to install the device in the rack.

Procedure

1. Position the device in the rack, as shown in Figure 11 on page 24, providing temporary support under

the device until the rail kit is secured to the rack.

2. Attach the right front bracket to the right rear rack post using two 10-32 x 5/8-in. panhead screws

and two retainer nuts. Use the upper and lower holes in the bracket.

3. Attach the left front bracket to the left rear rack post using two 10-32 x 5/8-in. panhead screws and

two retainer nuts. Use the upper and lower holes in the bracket.

4. Tighten all the 10-32 x 5/8-in. screws to a torque of 25 in-lb (29 cm-kg).

Mounting the switch 23

Page 44

Figure 11. Positioning the device in the rack

Screws, 10-32 x 5/8-in., panhead Phillips

Retainer nuts, 10-32

Attaching the rear brackets to the extensions at the front of the device

About this task

Complete the following steps to attach the rear brackets to the extensions. There are short and long front

brackets that you can use for this step.

Procedure

1. Select the proper length rear bracket for your rack depth.

2. Slide the right rear bracket onto the right extension.

The short rear brackets are shown in Figure 12 on page 25. Use the first and third vertical pairs of

holes for the screws.

Refer to Figure 13 on page 25 for the positioning of the short or long brackets and screws.

3. Attach the brackets using four 6-32 x 1/4-in. panhead screws.

4. Repeat step 2 and step 3 to attach the left rear bracket to the left extension.

5. Adjust the brackets to the rack depth and tighten all the 6-32 x 1/4-in. screws to a torque of 9 in-lb

(10 cm-kg).

24 SAN128B-6 Installation, Service, and User Guide

Page 45

Figure 12. Attaching the rear brackets to the extensions at the front of the device

1. Rear brackets, short

2. Screws, 6-32 x 1/4-in., panhead Phillips

Figure 13. Attaching the short or long rear brackets to the extensions

1. Rear bracket, short or long

2. Screws, 6-32 x 1/4-in., panhead Phillips

Mounting the switch 25

Page 46

Attaching the rear brackets to the front rack posts

About this task

Complete the following steps to attach the rear brackets to the front rack posts.

Procedure

1. Attach the right rear bracket to the right front rack post using two 10-32 x 5/8-in. screws and two

retainer nuts, as shown in Figure 14. Use the upper and lower holes in the bracket.

2. Attach the left rear bracket to the left front rack post using two 10-32 x 5/8-in. screws and two

retainer nuts. Use the upper and lower holes in the bracket.

3. Tighten all the 10-32 x 5/8-in. screws to a torque of 25 in-lb (29 cm-kg).

Figure 14. Attaching the rear brackets to the front rack posts

1. Screws, 10-32 x 5/8-in., panhead Phillips

2. Retainer nuts, 10-32

Installing the Universal Two-Post Rack Kit

Use the following instructions to install a Brocade 1U or 2U device in a two-post telecommunications

(Telco) rack using the Universal Two-Post Rack Kit.

There are two ways you can mount the device in a two-post rack:

v With the port side flush with the front posts

v With the posts mounted to the mid-section of the device

Observe the following when mounting this device:

v Two people are required to install the device in a rack. One person should hold the device, while the

other while the other screws in the front and rear brackets.

v Before mounting your device, review any specific installation and facility requirements in this

Hardware Installation Guide.

26 SAN128B-6 Installation, Service, and User Guide

Page 47

v Hardware devices illustrated in these procedures are only for reference and may not depict the device

you are installing into the rack.

Time and items required

Allow 15 to 30 minutes to complete the installation.

The following items are required to install the device using the Universal Two-Post Rack Kit:

v #2 Phillips torque screwdriver

v 1/4-inch slotted-blade torque screwdriver

Parts list

The following parts are provided with the Universal Two-Post Rack Kit Installation.

Figure 15. Rack kit parts

1. Front brackets (2)

2. Rear brackets, 3-5 inch post (2)

3. Rear brackets, 5-6 inch post (2)

4. Screw, 8-32 x 5/16-in., panhead Phillips (8)

5. Screw, 8-32 x 5/16-in., flathead Phillips (16)

6. Screw, 6-32 x 1/4-in., panhead Phillips (8)

7. Screw, 10-32 x 5/8-in., panhead Phillips (8)

8. Retainer nut, 10-32 (8)

Ensure that the items listed and illustrated above are included in the kit. Note that not all parts may be

used with certain installations depending on the device type.

Mounting the switch 27

Page 48

Flush-front mounting

Observe the following notes when using this procedure: