Page 1

6400i Line Matrix Printers

Setup Guide

Cabinet and Pedestal Models

S544-5640-04

Page 2

Page 3

6400i Line Matrix Printers

Setup Guide

Cabinet and Pedestal Models

S544-5640-04

Page 4

Note!

Before using this information and the product it supports, read the information in “Notices” on

page 329.

Fifth Edition (May 2003)

This edition replaces S544-5640-03.

Requests for IBM

to the IBM branch office serving your locality. If you request publications from

the address given below, your order will be delayed because publications are

not stocked here. Many of the IBM Printing Systems Division publications are

available from the web page listed below.

®

publications should be made to your IBM representative or

Internet

Visit our home page at: http://www.ibm.com/printers

A Reader’s Comment form is provided at the back of this publication. If the

form has been removed, you can send comments by fax to 1-800-524-1519

(USA only) or 1-303-924-6873; by E-mail to printpub@us.ibm.com; or by mail

to:

IBM Printing Systems Division

Department H7FE Building 004M

Information Development

PO Box 1900

Boulder CO 80301-9191 USA

IBM may use or distribute whatever information you supply in any way it

believes appropriate without incurring any oblication to you.

© Copyright International Business Machines Corporation 2003. All

rights reserved.

US Government Users Restricted Rights – Use, duplication or disclosure

restricted by GSA ADP Schedule Contract with IBM Corp.

Page 5

Safety Noti ces

DANGER:

<1> Before powering on the printer ensure the printer is plugged

into an appropriate power source. Refer to Chapter 2 of the

Setup Guide for information on the proper source.

<2> Switch off the printer power and unplug the printer power

cord before cleaning the printer.

<4> Do not connect or disconnect any communication port,

teleport, attachment connector, or power cord during an

electrical storm.

<5> Power off the printer and disconnect the power cord before

connecting or disconnecting any communication port,

teleport, or attachment cable connector.

CAUTION:

This product is equipped with a 3-wire power cord and plug for the user’s safety. Use this power

cord in conjunction with a properly grounded electrical outlet to avoid electrical shock.

Page 6

Page 7

Table of Contents

1 Introduction........................................................... 13

About This Setup Guide..........................................................................13

Notes And Notices ....................................... ...... ....... ...... ....... ...... ....13

Conventions In This Setup Guide ....................................................14

Related Documents..........................................................................15

The IBM 6400 Printer Family..................................................................16

Standard Capabilities.......................................................................18

Optional Features.............................................................................21

Protocols And Emulations................................................................23

Graphics Enhancements..................................................................23

Taking Care Of Your Printer.............................................................23

2 Installation............................................................. 25

Installation, Attachment, And Configuration Overview............................25

Before You Begin....................................................................................27

Power Requirements ..............................................................................27

Select A Site ...........................................................................................28

Printer Dimensions .................................................................................29

Printer Component Locations.................................................................31

Remove Shipping Restraints (Cabinet Model)........................................33

Remove The Cardboard Packing And Envelope..............................34

Remove The Hammer Bank Protective Foam..................................35

Remove The Platen Protective Foam ..............................................37

Remove Wood Blocks......................................................................38

Adjust The Paper Supports..............................................................39

Release The Paper Chains (Cabinet Model)....................................40

Remove Tags (Cabinet Model) ........................................................41

Remove The S hipping Restraints From

The Power Paper Stacker ................................................................42

Removing Shipping Restraints (Pedestal Model)...................................44

Remove The Hammer Bank And Protective Foam..........................45

Remove The Platen Protective Foam ..............................................46

Attach The Input Paper Shelf and Output Basket ............................47

Remove Tags - Pedestal Model.......................................................48

Page 8

Table of Contents

Changing the Paper Exit Location

(Pedestal Models Only) ..........................................................................49

Setting Top Paper Exit .....................................................................49

Setting Rear Paper Exit....................................................................51

Connect The Interface And Power Cables (Cabinet Models).................52

Connect The Interface And Power Cables (Pedestal Models) ...............58

Attach The Operator Panel Overlay Label..............................................62

Install The Ribbon............................ ...... ...... ....... ....................................63

Load The Paper......................................................................................66

Power Paper Stacker Option..................................................................72

Power Paper Stacker Component Locations ...................................72

Setting Up The Power Paper Stacker ..............................................73

Loading And Starting The Power Paper Stacker .............................74

Checking The Paper Feed......................................................................75

Set The Top-of-Form ..............................................................................77

Test The Printer......................................................................................78

3 Configuring the Printer..........................................79

Overview.................................................................................................79

The Configurations...........................................................................79

Active Versus Saved Configurations................................................80

The Configuration Main Menu ................................................................80

Using The Operator Panel......................................................................83

Program Mode........................................................................................84

Unlocking The Program Mode .........................................................84

Locking The Program Mode.............................................................84

Entering Program Mode ...................................................................85

Printing The Current Configuration.........................................................85

Factory Default Configuration Values.....................................................87

Changing Parameters.............................................................................92

Saving Your Configuration In A Custom Set...........................................94

Loading Custom Sets Or Factory Default Values...................................97

Changing The Power On Configuration..................................................99

4 The Configuration Menus............................... .....103

Configuration Overview ........................................................................103

Main Menu............................................................................................104

Printer Control Menu.............................................................................106

Configuration Management Menu ........................................................113

Twinax Interface Menu .........................................................................117

Coax Interface Menu ............................................................................126

Compatibility Options Menu .................. ....... ...... ....... ...... ....... ...... ..135

Page 9

Table of Contents

5250 Interface Menu.............................................................................139

3270 Interface Menu.............................................................................145

Compatibility Options Menu ...........................................................151

Network Setup Menu ............................................................................155

Adapter Address Submenu............................................................155

Adapter Parameters Submenu.......................................................157

Ethernet Address Submenu...........................................................161

Ethernet Parameters Submenu......................................................162

Wireless Address Menu .................................................................165

Wireless Parameters Menu............................................................166

Parallel Interface Menu.........................................................................170

PC Parallel Menu ...........................................................................172

Dataproducts Menu........................................................................175

IEEE 1284......................................................................................178

Serial Interface Menu............................................................................180

Emulation Configuration Menu .............................................................186

IPDS Feature........................................................................................187

IPDS Configuration Menu ..............................................................188

ANSI...............................................................................................195

IGP Feature (PGL)................................................................................203

IGP Emulation Menu ......................................................................204

Code V Feature (VGL)..........................................................................209

Code V Emulation Menu ................................................................210

Printer Emulation Configuration Menu..................................................219

Proprinter III XL Emulation Menu...................................................220

Epson Emulation Menu ..................................................................222

P-Series Emulation Menu...............................................................224

P-Series XQ Emulation Menu ........................................................228

Serial Matrix Emulation Menu ........................................................231

Print Format Menu .........................................................................234

Operator Print Tests Menu ...................................................................242

Printer Information Menu......................................................................244

RibbonMinder Menu .............................................................................245

Page 10

Table of Contents

5 Printer Inter fa ces............... .. ............................. .. .24 9

Overview...............................................................................................249

RS-232 And RS-422 Serial Interfaces..................................................250

RS-232...........................................................................................250

RS-422...........................................................................................251

RS-232 Serial Interface Protocols..................................................252

RS-232 and RS-422 Serial Interface Protocols..............................252

RS-232 and RS-422 Serial Interface Error Handling .....................253

RS-232 and RS-422 Serial Interface Configuration .......................253

PC Parallel Interface.............................................................................254

PC Parallel Interface Signals .........................................................255

PC Parallel Interface Configuration................................................256

Dataproducts Parallel Interface ............................................................257

Dataproducts Parallel Interface Signals.........................................258

Dataproducts Parallel Interface Configuration ...............................258

IEEE 1284 Parallel Interface.................................................................259

Operating Modes............................................................................259

The Negotiation Phase...................................................................260

Signals ...........................................................................................260

Terminating Resistor Configurations..............................................263

6 Routine Service and Diagnostics........................265

Overview...............................................................................................265

Cleaning Requirements ...................................... ...... ............................265

Cleaning The Outside Of The Cabinet...........................................265

Cleaning Inside The Cabinet..........................................................266

Printer Self –Tests ................................................................................269

Running The Printer Self–Tests............................................................270

Hex Code Printout ................................................................................271

Fault Messages ....................................................................................275

Fault Correction Procedure ............................................................275

A Printer Specif ica tion s ............... .. ... ................ ......289

Ribbon Specifications...........................................................................289

6400i Models Except 6400-i20 and -i24.........................................289

6400-i20 and i24 Models................................................................289

Ordering Ribbons..................................................................................290

6400-ixx Models.............................................................................290

Paper Specifications.............................................................................291

Paper..............................................................................................291

Labels.............................................................................................292

Page 11

Table of Contents

Printer Dimensions and Weight ............................................................292

Cabinet Models ..............................................................................292

Pedestal Models.............................................................................292

Environmental Characteristics..............................................................293

Temperature...................................................................................293

Relative Humidity ...........................................................................293

Acoustic Noise Level......................................................................293

Electrical Characteristics ......................................................................294

Input Voltage..................................................................................294

Power Consumption.......................................................................294

Interfaces..............................................................................................297

Cables...................................................................................................297

Printing Rates .......................................................................................298

B A Quick Look at Line Matrix Printing................... 301

Character Formation................. ...... ....... ...... ....................................... ..301

Printing Speed ......................................................................................303

C Host Attachment ................................................. 305

Host Attachment ...................................................................................305

Compatibility and Limitations................. ...... ....... ...... ....... ...... ....... ........306

Compatibility...................................................................................306

Limitations......................................................................................308

D Attaching Host Syst ems to a

Coax/Twinax Printer............................................ 311

Attaching Printer to an iSeries or zSeries Host System........................311

Attaching Printer to an iSeries Host System.........................................311

Attaching Printer to an iSeries with Twinax Interface.....................311

Changing Your iSeries Printer Configuration .................................312

Attaching Printer to Remote Control Unit with Twinax Interface ....314

Attaching Printer to an IBM System/36 with Twinax Interface........315

Attaching Printer to zSeries Systems ...................................................316

Types of Installation covered for MVS/JES2..................................316

6400-LU1-SCS-Local SNA 3174 Control Unit................................316

6400-LU1-SCS-Remote SNA 3174 Control Unit............................318

6400-LU3-DSE-Local SNA 3174 Control Unit................................320

6400-LU3-DSE-Remote SNA 3174 Control Unit............................321

6400-LU0-DSC-Local Non-SNA 3174 Control Unit........................323

Attaching Printer to VM Host System ...................................................324

SNA Attachment.............................................................................324

Non-SNA Attachment.....................................................................325

Page 12

Table of Contents

Physical and Logical Unit Types...........................................................325

Physical Unit (PU) types and examples.........................................325

Summary of LU Types and Representative IBM Products.............326

Notices ................................................................329

Energy Star...........................................................................................329

Notices..................................................................................................329

Trademarks...........................................................................................331

Product Recycling and Disposal...........................................................332

Communication Statements................................ ...... ....... ...... ....... ...... ..333

Glossary..............................................................337

Page 13

1 Introduction

About This Setup Guide

This Setup Guide is designed so that you can quickly install and configure

your IBM 6400 printer.

Notes And Notices

For your safety and to protect valuable equipment, it is very important that you

read and comply with all information noted in the following section:

DANGER

<#> The word Danger next to the lightni ng slash ind icates the presence of a

hazard that could cause death or serious personal injury. Danger and

Caution notices are numbered to help you find the translated versions

in the IBM 6400 Safety Notices booklet.

CAUTION

<#> The word Caution next to the exclamation point (!) indicates the

presence of a hazard that could cause moderate or minor personal

injury.

CAUTION

<#> The word Caution next to this symbol indicates a part or assembly that

is hot enough to burn you.

13

Page 14

Chapter 1 About This Setup Guide

CAUTION

<#> The word Caution next to this symbol indicates a part or assembly that

is sharp enough to cut you.

The word Attention indicates the possibility of damage to a program,

device, system, or data.

The word Important indicates information vital to proper operation of

the printer.

NOTE: A note gives you helpful information and tips about printer operation

and maintenance.

ATTENTION

IMPORTANT

Conventions In This Setup Guide

Key names, indicator names, and messages that appear on the operator

panel display are capitalized as they actually appear on the printer. Key

names are shown in bold.

Example: Press the CLEAR key, then press the ON LINE key.

Quotation marks (“ ”) indicate messages on the Liquid Crystal Display (LCD).

For example:

Example: Press the ON LINE key. “OFFLINE” appears on the LCD.

14

Page 15

Related Documents

Related Documents

• Maintenance Information Manual — Explains how to maintain and repair

the line matrix printer at the field service level of maintenance.

• Coax/Twi nax Prog ramme r's Ref erenc e Manua l — Covers the host control

codes and character sets for the Coax and Twinax emulations.

• LinePrinter Plus Programmer's Reference Manual — Covers the host

control codes for the LinePrinter Plus emulation.

• IGP Programmer's Reference Manual — Provides information used with

the optional IGP emulation enhancement feature.

• Code V Programmer's Reference Manual — Provides information used

with the optional Code V

TM

emulation enhancement feature.

• ANSI Programmer's Reference Manual — Provides host control codes

and character sets for the ANSI emulation.

• IPDS Twinax Emulation Programmer's Reference Manual — Provides an

overview of Intelligent Printer Data Stream

and diagnostics.

TM

(IPDS) features, commands,

• Character Sets Reference Manual — Information about and examples of

the character sets available in line matrix printers.

• Ethernet Interface User's Manual — Informati on ab out netw ork pr ot oco ls,

configuration, and operation.

15

Page 16

Chapter 1 The IBM 6400 Printer Family

The IBM 6400 Printer Family

The IBM 6400 series consist of 500, 1000, 1500, 2000, and 2400 lines per

minute (lpm) models and are packaged in various configurations. All of the

models offer software versatility and the latest refinements in line matrix

printing technology. The print mechanisms are housed in sound-insulated

cabinets which make the printer family among the quietest printers in the

world. Additionally, your printer has a flexible architecture that allows you to

add new features and emulations as they become available.

®

LinePrinter Plus

®

Epson

Proprinter

PGL

FX-1050, Printronix® P-Series, P-Series XQ, Serial Mat rix and

®

®

and IGP/VGL graphics enhancement emulations are available as

optional upgrades. No matter what emulation is installed, your printer is easy

to use. The message display and lights on the control panel communicate

with you directly and clearly. You can select every function on your printer at

the control panel, or you can send commands from the host computer.

is the standard emulation. LinePrinter Plus includes the

III XL emulations. Coax/Twinax, IPDSTM, ANSI® and the IGP®/

The printer combines the use of Flash, RAM, and nonvolatile RAM for

program execution. The Flash is used for all program, font, and emulation

storage. New fonts, emulations, or program updates can be downloaded to

®

Flash memory via the parallel or serial interface, or through the PrintNet

interface. The RAM is used for buffers, print image storage, and execution

variables. The non-volatile RAM stores configuration, statistics, and internal

parameters.

16

Page 17

The IBM 6400 Printer Family

The printer model numbers indicate printing speed and physical configuration.

Related Documents

• All printer models start with the 6400 series prefix, followed by a three

digit or alphanumeric suffix. Models containing only numbers indicate

cabinet models. Model numbers containing the letter “P” indicate pedestal

models.

• For cabinet models, the alphanumeric suffix refers to the printer’s

maximum speed in lines per minute (lpm): i05 for 500 lpm, i10 for 1000

lpm, i15 for 1500 lpm, i20 for 2000 lpm, and -i24 for 2400 lpm.

• For pedestal models, the first two alphanumeric values in the suffix refer

to the printer’s maximum speed in lines per minute (lpm): i5P for 500 lpm

and i1P for 1000 lpm.

• The 6400-i5P and i1P models are pedestal models with the QuickAccess

Cover installe d.

• The 6400 i20, i2s, and i24 models are available with the power stacker

option installed.

Refer to the following table for a complete listing of model numbers and

options.

T a ble 1: 6400-i05, -i5P, -i10, -i1P, -i15, -i20, -i2s, i24 Printers

Model

Number

6400-i05 500 lpm X 28 Hammers

6400-i5P 500 lpm X 28 Hammers X

6400-i10 1000 lpm X 60 Hammers Available as option

6400-i1P 1000 lpm X 60 Hammers X

6400-i15 1500 lpm X 102 Hammers Available as option

6400-i20 2000 lpm X 156 Hammers Available as option

6400-i2s 2000 lpm X 126 Hammers Available as option

6400-i24 2400 lpm X 156 Hammers Available as option

Print

Speed

Cabinet Pedestal

Hammer

Bank

Quick

Access

Power Stacker

17

Page 18

Chapter 1 The IBM 6400 Printer Family

St andard Capab ilities

The 6400 printer family has the following general characteristics:

• A broad range of print speeds in both cabinet and pedestal models

• Support of similar features across the entire product line to allow

maximum flexibility in matching the printer to the requirements

• Energy Star compliant

The following sections summarize the standard capabilities of the IBM 6400

printers.

Host Computer Interfaces

• RS 232 Serial

• RS 422 Serial

• PC Parallel

• Dataproducts Parallel

• Ethernet Interface

• IEEE 1284

Coax/Twinax features are available with this printer:

• IBM Coax/Twinax

Printer Emulations

Each emulation provides a different set of configuration menus, control codes,

and character sets. The following printer emulations (or protocols) are

standard, and selectable at the operator panel:

• Proprinter III XL Emulation

• Epson FX Emulation

• P-Series Printer Emulation

• P-Series XQ Variant Printer Emulation

• Serial Matrix Printer Emulation

Proprinter III XL and Epson FX Emulations

The Proprinter III XL and Epson FX emulations are industry standard printer

emulations.

18

Page 19

Standard Capabilities

P-Series Printer Emulation

This code system was developed especially for line matrix printers. As line

matrix printers became more sophisticated, this code system kept pace by

adding codes that fully utilized line matrix printer capabilities.

IMPORTANT

This emulation appears as “P-Series” on the operator panel.

P-Series XQ Variant Printer Emulation

This code system was devised for a series of printers manufactured between

1974 and 1991, that are no longer available.

IMPORTANT

This emulation appears as “P-Series XQ” on the operator panel.

Serial Matrix Printer Emulation

This printer emulation is very similar to the code systems used by an IBM

Graphics Printer, but incorporates several systems into one emulation. This

emulation enables a line matrix printer to print files coded for a serial matrix

printer, and is sometimes referred to as the Serial Matrix collection.

IMPORTANT

This emulation appears as “Serial Matrix” on the operator panel.

NOTE: Serial matrix refers to the way printer characters are formed. A

moving printhead uses pins to form whole characters one at a time

and one after the other. The pins print dots according to programmed

matrix patterns. Data is sent to the printer through either a serial or

parallel interface, but the printhead must receive the data serially to

form each character.

An IBM line matrix printer also forms characters with dots in matrix

patterns, but it feeds print data in parallel to many hammers mounted

on a rapidly oscillating shuttle. The hammers fire simultaneously to

print entire lines at a time.

19

Page 20

Chapter 1 The IBM 6400 Printer Family

Output Control

The printers have the following output control features:

• Six modes for printing text:

• Near-Letter Quality (NLQ)

• Near-Letter Quality San Serif

• Data Processing (DP)

• Draft

• Optical Character Recognition Font A (OCR A)

• Optical Character Recognition Font B (OCR B)

OCR A and OCR B support 120 and 180 PEL, with 120 PEL the default value.

• Selectable forms length and width

• Character attribute specification:

• Selectable pitch: normal, expanded, and compressed

• Emphasized (shadow) printing

• Automatic underlining and overscoring

• Superscript and subscript printing

• Double high and wide printing

• Resident multinational cha ra cte r sets

Graphics And V ertical Form atting

Several graphics and vertical formatting features are available:

• Three built-in graphics generators:

• IBM Proprinter III XL bit-image graphics

• Epson FX dot graphics mode

• P-Series Plot

• Programmable electronic vertical formatting provides rapid vertical paper

movement to specified lines for printing repetitive and continuous forms.

You can use the following methods:

• Vertical tabbing in Serial Matrix, Proprinter III XL, and Epson FX

emulation modes

20

• Electronic Vertical Format Unit (EVFU) in P-Series emulation mode

Page 21

Optional Features

Built-in Diagnostic Tools

The following diagnostic tools are provided with the printer:

• Comprehensive diagnostic self-tests permanently stored in the printer

• Configuration printout

• Data stream hex code printout

Optional Features

The following features can be ordered and installed on this printer. If you

ordered a feature at the time of purchase, the feature may already be installed

on your printer. Refer to the documentation shipped with the feature for more

details.

For detailed information about these features or for information on ordering a

feature, contact your IBM sales representative.

• IBM Coax/Twinax Attachment:

Enables you to attach this printer to IBM host systems, such as an iSeries

or zSeries Host System. This feature also helps you to replace IBM coax/

twinax printers such as the IBM 3262 Models 3 and 13, IBM 4234 Models

1, 2, and 9, and IBM 5224 Models 1 and 2. This feature can be used with

the Intelligent Printer Data Stream (IPDS) feature which is described

below.

• IBM Intelligent Printer Data Stream Coax/Twinax:

Provides the ability to create forms, overlays, and graphics. IPDS also

provides compatibility when replacing printers such as the IBM 4234

Models 12 and 11. This feature also supports many versions of the Print

Services Facility* (PSF*). This feature requires the IBM Coax/Twinax or

Ethernet card attachment.

• Code V:

This is an implementation of the Intelligent Graphics Processor

architecture and is used commonly to create graphics for optical

character recognition and bar codes. This feature is also designed for

those applications which use the Quality Micro Systems, Inc. graphics

language, which is often referred to as the QMS Code V Magnum

emulation and those applications that use the Code V Graphics

Language. The Code V Graphics Language is often referred to as VGL.

21

Page 22

Chapter 1 The IBM 6400 Printer Family

• IGP:

This is an implementation of Intelligent Graphics Processor architecture

and is used commonly to create graphics for optical character recognition

and bar codes. This feature is also designed for those applications which

use the Graphics Language, which is often referred to as PGL.

This feature can co-exist with the IBM Intelligent Printer Data Stream

feature, and/or with either coax/twinax feature or can be used on the

ASCII models.

• Network Print Server:

Enables you to attach your printer to Local Area Networks using tokenring or Ethernet protocols. The Network Print Server functions as a

workstation server on your network, enabling your users to submit print

jobs to your printer.

The Network Print Server provides multiple network protocol support that

allows you to submit print jobs from Novell** Netware**, IBM LAN Server,

IBM AIX*, and other TCP/IP networks.

• Dataproducts Adapter:

Supplies a 50 pin AMP Amplimite HDH-20 data cable connector. This

feature is necessary if you are using the Dataproducts parallel protocol.

• Ethernet Interface:

Enables you to attach your printer to Local Area Networks using Ethernet

protocols. The Ethernet Interface functions as a workstation server on

your network, enabling your users to submit print jobs to your printer.

• Power Paper Stacker:

Mechanically directs the paper from the printer to the paper stacking area.

This feature provides consistent paper handling with fewer paper jam

errors.

• Input Paper Shelf:

Pedestal model only. Provides a shelf to hold a box of paper or forms.

This is a convenient feature if you need to move the printer often.

• TN5250/TN3270 Emula tio ns :

The TN5250/TN3270 feature enables your printer to communicate with

an IBM host through a Network Interface Card (NIC) using the 5250/3270

datastream. This feature allows you to use an application generated for

the Twinax/Coax emulation to be printed through the NIC.

22

Users who are converting from Twinax to TN5250 may see some

differences. Please refer to the “Compatibility and Limitations” on page

306 for details.

• ANSI Emulation:

The ANSI option allows you to print files coded for the ANSI (American

National Standards Institute) printer control language.

Page 23

Protocols And Emulations

Protocols And Emulations

A protocol is a set of rules governing the exchange of information between the

printer and its host computer. These rules consist of codes that manipulate

and print data and allow for machine-to-machine communication. A printer

and its host computer must use the same protocol. As used in this manual,

protocol and emulation mean the same thing.

Most impact printers are single ASCII character codes to print text, numbers,

and punctuation marks. Some characters, both singularly and in groups are

defined as control codes. Control codes instruct the printer to perform specific

functions, such as underlining text, print subscripts, setting page margins, etc.

The main difference between most printer protocols is in the characters used

to create control codes and the ways in which these characters are formatted.

When the printer executes the character and control codes of a particular

printer protocol, it is “emulating” that printer. If the printer uses the Proprinter

III XL protocol, for example, it is emulating an IBM

the printer is using the Epson FX printer protocol, for example, we can also

say it is in Epson FX emulation mode.

®

Proprinter III XL printer. If

There are additional emulations that are provided as optional features, such

the Code V and IGP emulations. For additional information, refer to “Code V

Feature (VGL)” on page 209 and “IGP Feature (PGL)” on page 203.

Graphics Enhanc ements

The PGL and Code V emulations allow you to create and store forms,

generate logos, bar codes, expanded characters, and create other graphics.

Alphanumeric and bar code data are added as the form is printed.

These emulations are available as factory-installed or field-installed options.

For more information, contact your authorized service representative.

Taking Care Of Y our Printer

Your printer will produce high print quality jobs if it is well taken care of.

Periodic cleaning, handling the printer properly, and using the correct printer

supplies such as paper and ribbons ensures optimum performance. Chapter

6 explains how to clean the printer, and printer supplies are listed in Appendix

A.

Whenever it is necessary to service the printer, remember these important

maintenance concepts:

• Use only the ribbons specified in Appendix A. Use of incorrect ribbons

can lead to ink migration problems, degraded print quality, and expensive

damage to the printer.

• Incorrect closure of the forms thickness lever can lead to smearing,

degraded print quality, paper jams, and damage to the platen and shuttle

assembly. Never close the forms thickness lever too tightly.

23

Page 24

Chapter 1 The IBM 6400 Printer Family

24

Page 25

2 Installation

Installa tion, Att achment, And Configuration Over view

Note!

Before using this information and the product it supports, read the

information in “Notices” on page 329.

DANGER

<4> Do not connect or disconnect any communication port, teleport,

attachment connector, or power cord during an electrical storm.

<5> Power off the printer and disconnect the power cord before

connecting or disconnecting communication port, teleport, or

attachment cable connector.

The following is an overview of the steps you need to complete to successfully

install, attach, and configure your printer:

1. Unpack the printer from the shipping package. Follow the instructions

provided on the shipping package.

2. Set up the printer, which includes; removing shipping materials, installing

a ribbon, and loading paper. Follow the instructions in this chapter.

3. Perform an initial print test by printing the current configuration page as

described on page 85.

4. Review the information contained in the README.1ST file on the

Configuration Utility diskette.

NOTE: The Configuration Utility diskette contains a README.1ST file that

describes the contents of the diskette, AIX print drivers, and

configuration information for replacing existing IBM printers. In

addition, there might be another file, called README.TXT that

contains information that was added after the printer documentation

was printed.

25

Page 26

Chapter 2 Installation, Attachment, And Configuration Overview

5. Attach the printer to the host system and configure the host system to

work with the printer.

a. For ASCII attachments, follow the instructions in the 6400 ASCII

Programmer’s Reference Manual.

b. For Coax/Twinax attachments, follow the instructions in the 6400

Coax/Twinax Programmer’s Reference Manual.

c. If you have ordered the Network Print Server feature, follow the

instructions in either the Network Print Server Ethernet

Administrator’s Guide, or the Network Print Server Token-Ring

Administrator’s Guide.

d. If you have ordered the Ethernet Interface, follow the instructions in

the Ethernet Interface User’s Manual.

NOTE: If you are attaching this printer to an AIX host system, use the AIX

Version 3.2.5 and 4.1 print drivers provided on the Configuration

Utility diskette.

6. If you have not already ordered a communications cable, see page 297.

7. Configure the printer to work with host systems and to match your

emulation, such as IBM Proprinter III XL. Follow the instructions provided

in Chapter 3, “Configuring the Printer” and review the information

provided in Appendix C, “Host Attachment.”

NOTE: If you are replacing an printer with this printer, make sure you review

the information on the Configuration Utility diskette. The

Configuration Utility diskette contains information that will help you

configure this printer to match the configuration of the printer you are

replacing.

8. Install and/or configure optional features by following instructions

provided in the appropriate feature manual. For a brief description of the

following optional features, refer to: “IPDS Feature” on page 187, “Code V

Feature (VGL)” on page 209, and “IGP Feature (PGL)” on page 203.

NOTE: For more detailed information about any optional feature, refer to the

manual that was shipped with the feature. If you want to order a

manual to learn more about these features, see “Related Documents”

on page 15.

26

Page 27

Before You Begin

Read this chapter carefully before installing and operating the printer. The

printer is easy to install. However, for your safety and to protect valuable

equipment, perform all the procedures in this chapter in the order presented.

Make sure you have a way to move the printer and shipping pallet. You

will need a jack.

Make sure you have adequate room to maneuver the shipping pallet and

printer to the location where you plan to install the printer.

<1> Two people are required to unload the printer from the shipping

Before You Begin

IMPORTANT

CAUTION

pallet. The shipping weight of the cabinet model is 129.3

kilograms (285 pounds) or 139 kilograms (306 pounds) if the

Power Paper Stacker is installed. The shipping weight of the

pedestal model printer is 72.6 kilograms (160 pounds.)

Power Requirements

The printer must be connected to a power outlet that supplies 88 to 135 Volts

AC or 178 to 271 Volts AC at 50 to 60 Hz. The printer automatically senses

and adjusts itself to conform to the correct voltage range.

Primary circuit protection is provided by the power switch, which is also a

circuit breaker. Consult an electrician if printer operation affects local

electrical lines. See “Electrical Characteristics” on page 294 for additional

power specifications.

Printer power should be supplied from a separate AC circuit protected

at 10 amperes for 100 - 120 volts or 5 amperes for 200 - 240 volts at 50 or

60 Hertz.

IMPORTANT

27

Page 28

Chapter 2 Select A Site

Select A Site

Select a printer site that meets all of the following requirements:

• Cabinet models: Permits complete opening of the printer cover and both

doors of the floor cabinet. Allows at least three feet of clearance behind

the printer. (This permits air to circulate freely around the printer and

provides access to the paper stacking area.)

• Pedestal models: Permits complete opening of the printer cover and

good access to the paper areas at the front and rear of the printer.

• Has a standard power outlet that supplies 88-135 Volts AC or

178-270 Volts AC power, at 47 to 63 Hz. The printer automatically senses

and adjusts itself to conform to the correct voltage range.

• Is relatively dust-free.

• Has a temperature range of 10° C to 40° C (50° F to 104° F) and a

relative humidity from 15% to 90% non-condensing.

• Is located within the maximum allowable cable length to the host

computer. This distance depends on the type of interface you plan to use,

as shown in Table 2.

Table 2. Maximum Interface Connection Cable Length

Interface Type Maximum Cable Length

PC Parallel 5 meters (15 feet)

IEEE 1284 Parallel 10 meters (32 feet)

Dataproducts Parallel 12 meters (40 feet)

Serial RS 232 15 meters (50 feet)

Serial RS 422 1220 meters (4000 feet)

Twinax (shielded cable) 1500 meters (4920 feet)

Twisted Pair / T ype 3 300 meters (985 feet)

Dataproducts Long Line 150 meters (492 feet)

Coax 1500 meters (4920 feet)

Twisted Pair / T ype 3 300 meters (985 feet)

Ethernet 10/100Base-T 100 meters (328 feet)

Ethernet 10Base-2 185 meters (607 feet)

28

Page 29

Printer Dimensions

Printer Dimensions

41.0 in

27.0 in

(68.84 cm)

83.0 in

(210.8 cm)

29.0 in

(73.7 cm)

(68.6 cm)

27.0 in

(68.6 cm)

(104 cm)

27.0 in

Figure 1. Exploded View Of Cabinet Model Printer Dimensions

57.5 in

(146.1 cm)

59.0 in

(149.9 cm)

27.0 in

(68.6 cm)

83.0 in

(210.8 cm)

32.5 in

(82.6 cm)

27.0 in

(68.6 cm)

42.5 in

(107.8 cm)

27.0 in

(68.6 cm)

32.0 in

(81.3 cm)

Figure 2. Exploded View Of Cabinet Model With Power Paper Stacker Printer Dimensions

29

Page 30

Chapter 2 Printer Dimensions

10.5 in.

(26.67 cm.)

25 in.

(63.5 cm)

48.0 in.

(122 cm)

24.6 in.

(62.48 cm)

30 in.

(76.2 cm.)

Figure 3. Exploded View Of Pedestal Model Printer Dimensions

30

Page 31

Printer Component Locations

Familiarize yourself with the names and locations of the printer components,

shown in Figure 4, and Figure 5 before continuing with the rest of the

installation procedures.

Ribbon Spool

Paper

Scale

Printer Component Locations

Paper

Support

Base

Casting

Hub Latch

Tractor Lock

Ribbon Path

Loading Diagram

Splined Shaft

Tractor

Ribbon

Guide

Forms

Thickness

Lever

Hammer Bank

Cover and

Ribbon Mask

Vertical

Position Knob

Figure 4. 6400 Series Models Printer Component Locations with Ribbon Spools Exploded

Above

31

Page 32

Chapter 2 Printer Component Locations

Ribbon Spool

Tractor Lock

Printer Cover

Shuttle

Cover

Assembly

Tractor

Door

Tractor

Adjustable

Paper Guide

Adjustable

Hinge

Hammerbank Cover

& Ribbon Mask

Operator

Panel

Splined Shaft

Ribbon Hub

Hub Latch

Forms

Thickness Lever

Ribbon

Guide

Figure 5. Pedestal Model Printer Component Locations with Open Access Cover and

Ribbon Spools Exploded Above

32

Page 33

Remove Shipping Restraints (Cabinet Model)

Remove Shipping Restrain t s (Cabinet Model)

Follow the instructions on the shipp ing pack age to perform thes e ste ps :

1. Remove shipping restraints from front of shipping pallet.

2. Move printer from shipping pallet.

3. Remove remaining shipping restraints from pallet.

4. Remove remaining packing material .

Cardboard packing, protective foam, and tie wraps protect printer

mechanisms from possible damage during shipment. You must remove these

shipping restraints before you operate the printer.

Save the cardboard packing and protective foam with the other packing

materials.

To avoid shipping damage, reinstall the shipping restraints whenever the

printer is moved or shipped. To reinstall the shipping restraints, simply

reverse the steps in this section.

33

Page 34

Chapter 2 Remove Shipping Restraints (Cabinet Model)

Remove The Cardboard Packing And Envelope

Cardboard

Packing (2)

Envelope

Forms Thickness

Lever

Figure 6. Removing the Cardboard Packing and Sample Configuration Printout

1. Raise the printer cover.

2. Remove the cardboard packing.

3. Open the tractor doors.

4. Push the tractor locks down.

5. Slide the tractors outward as far as they will go. The forms thickness lever

should be in the fully open (raised) position.

6. Remove the envelope that contains the sample configuration printout.

7. Store this in the pouch that is attached to the left interior side of the

cabinet.

34

Page 35

Remove The Hammer Bank Protective Foam

Remove The Hammer Bank Protective Foam

Hammer Bank

Protective Foam

Paper Supports (2)

Forms Thickness

Lever

Figure 7. Exploded View of the Removal of the Hammer Bank Protective Foam, 64 00 Series

Models

1. Slide the paper supports outward as far as they will go.

2. Lift the hammer bank protective foam and remove it from between the

ribbon mask and the platen.

3. Rotate the forms thickness lever downward to position “A.”

35

Page 36

Chapter 2 Remove Shipping Restraints (Cabinet Model)

Hammer Bank

Protective Foam

Figure 8. Exploded View of Removal of the Hammer Bank Protective Foam, -i20, -i2s, and

-i24 Models

-i20, -i2s, -i24 Models:

4. Cut the tie wrap and remove it from the side plate.

5. Lift the hammer bank protective foam and remove it from between the

ribbon mask and the platen.

36

Page 37

Remove The Platen Protective Foam

Remove The Platen Protective Foam

Platen

Protective Foam

Forms Thickness

Lever

Figure 9. Exploded View of Removal of the Platen Prote cti ve Foam , 6400 Series Mo dels

1. Rotate the forms thickness lever downward to position “A.”

2. Rotate the platen protective foam toward the front of the printer and out

from under the support shaft.

3. Remove the platen protective foam.

NOTE: The 6400-i20, -i2s, and -i24 models do not have a platen protective

foam.

37

Page 38

Chapter 2 Remove Shipping Restraints (Cabinet Model)

Remove Wood Blocks

Wood Blocks ( 6)

Figure 10. Cover, Front, and Back Door Cabinet Open, Showing the Removal of Six Wood

Blocks

1. Remove the six wood blocks.

NOTE: Make sure the tape securing the wood blocks is removed entirely.

38

Page 39

Adjust The Paper Supports

Paper Supports (2)

Adjust The Paper Supports

Tractor Doors (2)

Figure 11. Paper Supports With Directional Arrows Showing the Adjustment Capabilities,

6400 Series Models

Slide the paper supports inward until they are approximately four inches from

the tractor doors.

39

Page 40

Chapter 2 Remove Shipping Restraints (Cabinet Model)

Release The Paper Chains (Cabinet Model)

Tie Wraps (2)

Bags (2)

Figure 12. Back View of Printer Components, Cover Off, Showing the Release of Paper

Chains

NOTE: If you have the power paper stacker installed, skip this procedure and

go to “Remove The Shipping Restraints From The Power Paper

Stacker” on page 42.

1. Open the cabinet rear door.

2. Cut the tie wraps and release the paper chains from the bags at the top

rear of the printer frame. Remove the tie wraps and bags.

3. Make sure each chain hangs freely with no kinks or knots.

Paper Chains (8)

40

Page 41

Remove Tags (Cabinet Model)

Passive Stacker

Paper Fence

Remove Tags (Cabinet Model)

Tie Wrap

Red Tag

500 lpm model

Passive Stacker

Paper Fence

Tie Wrap

Red Tag

1000/1500/2000/2400 lpm model

Figure 13. Interior View Showing Removal Tag Removal from the Cabinet Models

NOTE: If you have the power paper stacker installed, skip this procedure and

go to “Remove The Shipping Restraints From The Power Paper

Stacker” on page 42.

1. Remove the tie wrap attached to the passive stacker paper fence. The tie

wrap is marked with a large, red tag.

2. Close the cabinet rear door.

41

Page 42

Chapter 2 Remove Shipping Restraints (Cabinet Model)

Remove The Shipping Restraints From The Power Paper Stacker

This section applies only to printers with the power stacker installed. The

power stacker can be factory or field installed.

The power stacker is a vertically movable paper guide which directs the paper

from the printer to the paper stack. This movement enhances the paper

stacking capabilities of the printer.

Special packaging protects the power stacker mechanisms from damage

during shipment. This section describes how to remove the shipping restraints

before you operate the printer.

Save the packaging materials. You will need to reinstall them if you decide to

move or ship the printer. To reinstall the packaging materials, reverse the

steps in this section.

IMPORTANT

To avoid shipping damage, install the shipping restraints whenever you

move or ship the printer.

Tie Wraps (8)

Paper Guide

Plastic Bags (3)

Figure 14. View of the Power Paper Stacker Showing Removal of the Shipping Restraints

such as Tie Wraps and Plastic Bags

42

Page 43

Remove The Shipping Restraints From The Power Paper Stacker

1. Open the rear door panel.

2. Remove the eight tie wraps.

3. Raise the paper guide to its highest position by hand.

4. Remove the plastic bags from the paper chains.

5. Verify that both fences are in the down position.

Paper Tent

Figure 15. View of the Pull-Out Drawer Illustrating Placement of the Paper Tent

6. Remove, unwrap, and replace the paper tent onto the pull-out drawer.

43

Page 44

Chapter 2 Removing Shipping Restraints (Pedestal Model)

Removing Shipping Restrain t s (Pedest al Model)

Protective films and foam blocks protect printer mechanisms from possible

damage during shipment. You must remove these shipping restraints before

you operate the printer.

Save the foam blocks with the other packing materials.

To avoid shipping damage, reinstall the shipping restraints whenever the

printer is moved or shipped. To reinstall the shipping restraints, simply

reverse the steps in this section.

Remove the Protective Film and Envelope

Envelope

Protective

Film

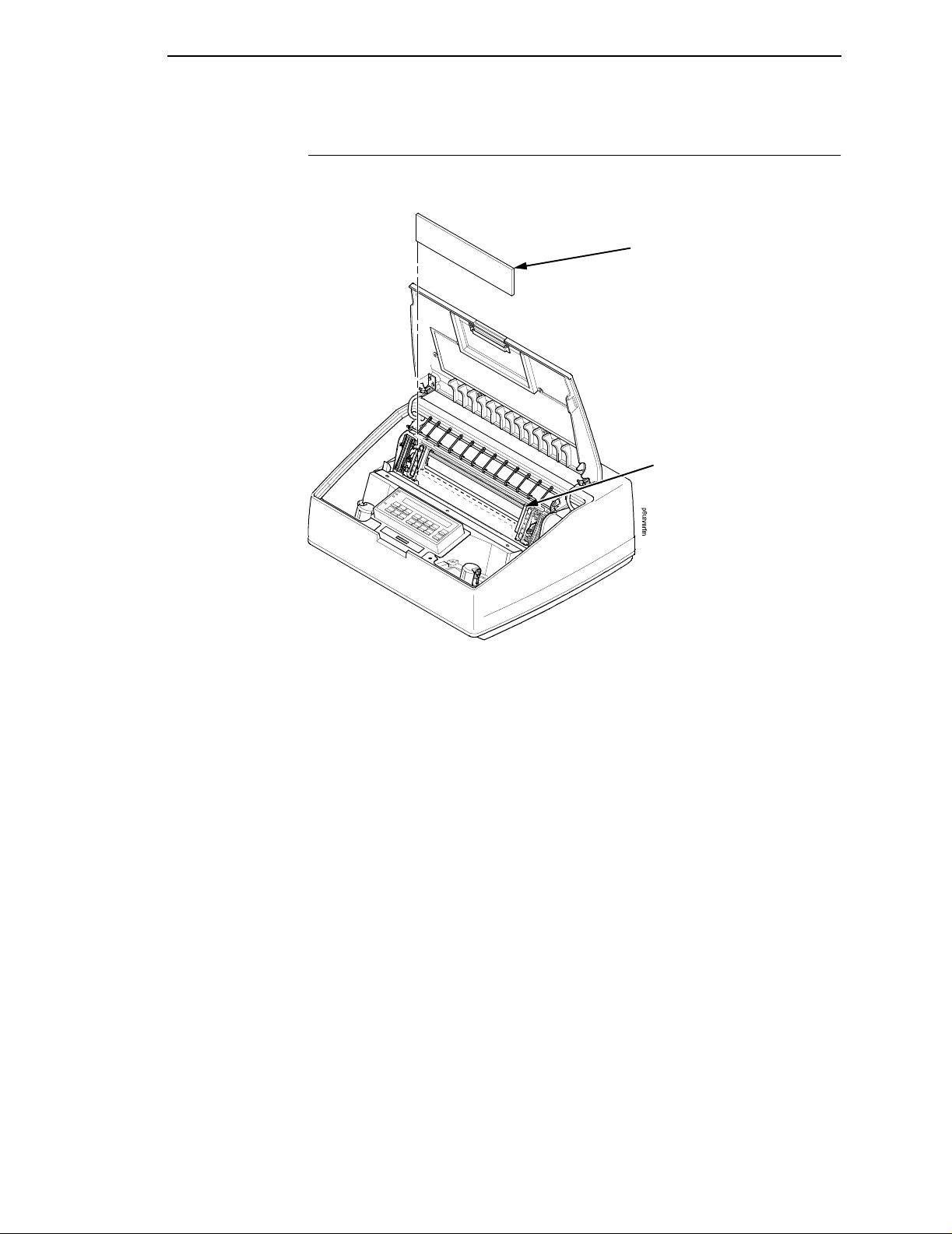

Figure 16. Pedestal Model with Cover Open Showing Removal of the Operator Panel

Message Display Protective Film and Sample Configuration Printout Envelope

1. Raise the printer cover.

2. Carefully peel off the tape and lift the protective film off the operator panel

message display.

3. Open the tractor doors.

4. Push the tractor locks down.

5. Slide the tractors outward as far as they will go. The forms thickness lever

should be raised (in the fully open position).

6. Remove the envelope that contains the sample configuration printout.

Store this envelope in a safe place so that you can refer to the

configuration printout.

44

Page 45

Remove The Hammer Bank And Protective Foam

Remove The Hammer Bank And Protective Foam

Hammer Bank

Protective Foam

Paper Supports

Figure 17. Pedestal Model with Cover Open Showing Removal of the Hammer Bank

Protective Foam

1. Slide the paper supports outward as far as they will go.

2. Lift the hammer bank protective foam and remove it from between the

ribbon mask and the platen.

45

Page 46

Chapter 2 Removing Shipping Restraints (Pedestal Model)

Remove The Platen Protective Foam

Platen

Protective Foam

Support Shaft

Forms

Thickness Lever

Figure 18. Pedestal Model with Cover Open Showing Removal of the Platen Protective

Foam

1. Rotate the forms thickness lever downward (to position “A”).

2. Rotate the platen protective foam toward the front of the printer and out

from under the support shaft.

3. Remove the platen protective foam.

46

Page 47

Attach The Input Paper Shelf and Output Basket

Attach The Input Paper Shelf and Output Bask et

Optional

Input Paper

Shelf

Screw

Ground Wire

A

Output

Basket

A

p5coutry

Figure 19. Exploded View of the Pedestal Model Showing Output Basket Attachment

1. Slide the two paper supports toward the center of the support shaft.

Position them so that they divide teh space between the tractors into

three approximately equal segments.

2. Place the output basket in the holes in the back of the printer.

3. Screw the ground wire attached to the output basket to the printer.

4. Place the input paper shelf (optional feaure) in the holes in the front of the

pedestal base.

47

Page 48

Chapter 2 Removing Shipping Restraints (Pedestal Model)

Remove Tags - Pedestal Model

Tie Wrap

Output

Basket

Red Tag

Figure 20. View of the Pedestal Model Showing Removal of the Tie Wrap

Remove the tie wrap attached to the output basket. It is marked with a large,

red tag.

48

Page 49

Changing the Paper E xit Locatio n (Pedesta l Models Only)

On pedestal model printers you can select whether the paper exits from the

rear or from the top of the printer. Normally, you should select the top exit only

when you will be tearing the forms from the printer and using them soon after

printing. Forms will not stack in top exit mode.

Setting Top Paper Exit

1. Press Stop to place the printer in NOT READY state.

If there is paper in the printer, unload the paper, then continue with step 2 of

this procedure.

Setting Top Paper Exit

Thumbscrew

Figure 21. Underview of the Right, Rear Pedestal Cover Showing Adjustment of the Hinge

Thumbscrews

2. Open the printer cover.

3. Loosen the two hinge adjustment thumbscrews.

4. Slide the cover toward the rear of the printer until it stops.

49

Page 50

Chapter 2 Changing the Paper Exit Location (Pedestal Models Only)

Figure 22. Inside View of the Pedestal Model Showing Paper Exit Options

5. Tighten t he two hinge adjustment thumbscrews.

6. Slide the paper guide slightly to the left and raise it to its upper position for

the top exit.

Paper

Top Paper Exit

Figure 23. Top Back View of the Pedestal Model with Paper Exiting through the Top Paper

Exit

7. Load the paper (see page 66), feeding it out the top paper exit.

50

Page 51

Setting Rear Paper Exit

Setting Rear Paper Exit

1. Press Stop to place the printer in NOT READY state.

NOTE: If there is paper in the printer, unload the paper, then continue with

step 2 of this procedure.

Thumbscrew

Figure 24. Loosening the Hinge Thumbscres, Open View of the Back Rear Pedestal Model

Cover

2. Open the printer cover.

3. Loosen the two hinge adjustment thumbscrews.

4. Slide the cover forward until it stops.

Figure 25. Internal View of the Pedestal Model Showing Paper Exit Options

5. Tighten t he two hinge adjustment thumbscrews.

6. Place the paper guide in its lower position.

51

Page 52

Chapter 2 Connect The Interface And Power Cables (Cabinet Models)

Figure 26. Top Back View of the Pedestal Model with Paper Exiting through the Rear

7. Load the paper (see page 66), feeding the paper out of the rear paper

exit.

Connect The Interface And Power Cables (Cabinet Models )

DANGER

<1> Before powering on the printer, ensure the printer is plugged into

an appropriate power source. Refer to page 27 for information on

the proper source.

<4> Do not connect or disconnect any communication port, teleport,

attachment connector, or power cord during an electrical storm.

<5> Power off the printer and disconnect the power cord before

connecting or disconnecting communication port, teleport, or

attachment cable connector.

1. Verify that the voltage source at the printer site conforms to the

requirements specified on page 28. Make sure that the printer power

switch is set to OFF. See Figure 29 on page 54.

2. Open the front cabinet door, remove and open the cardboard box

containing the power cord, printer ribbon, and operator panel overlay

label. Refer to “Printer Specifications” on page 289 for recommended

cables. Documentation is stored in a pouch container on the left interior

side of the cabinet.

52

Page 53

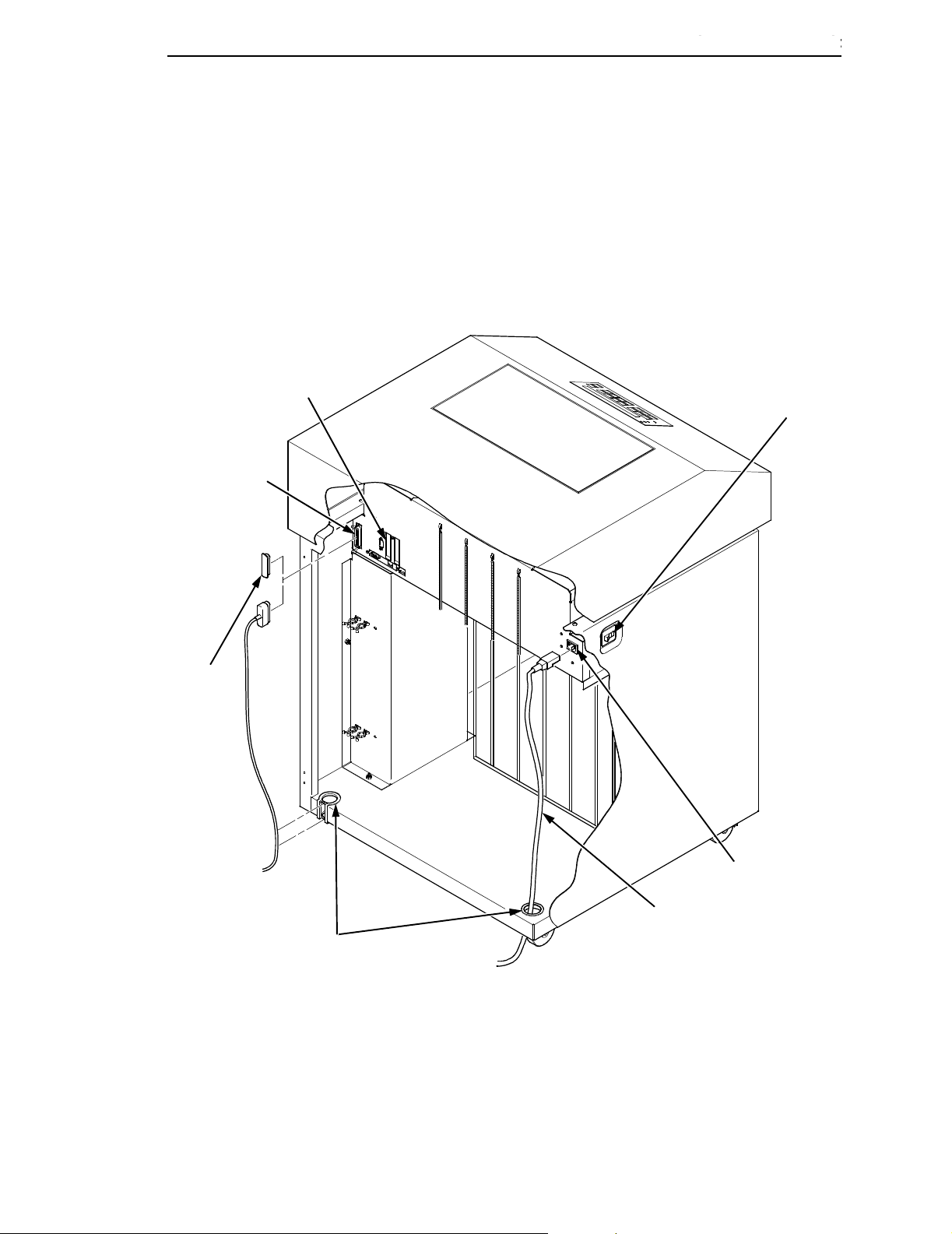

I/O Connector

Connect The Interface And Power Cables (Cabinet Models)

Setting Rear Paper Exit

3. Connect the customer supplied interface cable from the host computer to

the appropriate printer interface connector (refer to Figure 27 through

Figure 32).

4. Thread the power cable connector up through the notch in the lower-right

back corner of the cabinet (see Figure 31). Plug the power cord into the

printer AC power connector, then into the AC power outlet.

Host Interface

Connectors

Power

Switch

I/O Cover

AC Power

AC Power

Cable

Cable-Routing

Notches

Connector

NOTE:

(1)

The Dataproducts adapter feature attaches to the PC

Parallel interface connecto r.

(2)

Twinax, Coax, and Ethernet Interfaces appear only if these

features are installed.

Figure 27. Internal Back View of the Cabinet Model Showing Interface and Power Cable

Connections

53

Page 54

Chapter 2 Connect The Interface And Power Cables (Cabinet Models)

Figure 28. Interior Back View of the Cabinet Model Showing Product Description Label

Location

1. Check the product description label to verify that the voltage source at the

printer site conforms to the requirements specified on page 28.

Figure 29. Power Switch Turned OFF

54

2. Make sure the printer switch is set to OFF.

Page 55

Connect The Interface And Power Cables (Cabinet Models)

I/O Connector

Setting Rear Paper Exit

I/O Cover

Figure 30. Upper-Rear Inside View of the Cabinet Model Showing I/O Cover Removal

3. Open the cabinet rear door.

4. Remove the cover from the I/O connector you have selected.

I/O Cable

Grommet

6ciocabl

Figure 31. Bottom-Rear Inside View of the Cabinet Model Showing the Cable Routing Notch

5. Locate the notch in the lower-left corner of the back of the cabinet.

6. Hold the I/O cable below its connector, and gently push the cable through

the opening in the grommet seated in the notch.

55

Page 56

Chapter 2 Connect The Interface And Power Cables (Cabinet Models)

I/O Connector

I/O Plate

Cable

Connector

Figure 32. Upper Inside View of the Cabinet Model Showing Cable Connector Attachment

7. Pull the cable up through the notch until it reaches the I/O plate.

8. Attach the cable connector to the printer I/O connector.

9. Secure the cable to the printer using the two cable standoffs.

Strap

56

Figure 33. Open Cabinet Front Door Showing the Printer Accessories Package

10. Open the cabinet front door and cut the strap that secures the box, which

contains the power cord, printer ribbon, control panel overlay labels, and

documentation.

11. Open the box and remove the power cord, overlays, and documentation.

Page 57

Power Cord

Connect The Interface And Power Cables (Cabinet Models)

6

c

p

r

c

r

d

Setting Rear Paper Exit

Figure 34. Rear Inside View of the Cabinet Model Showing the Power Cord Route

12. Guide the power cord up through the hole in the lower right back corner of

the cabinet.

13. Thread the power cord inside the bracket where the gas spring is

attached.

Power

Cord

AC Power

Connector

6cprcrd2

Figure 35. Rear Inside View Cabinet Model Showing Power Cord Attachment

14. Plug the power cord into the printer AC power connector, then into the AC

power outlet.

57

Page 58

Chapter 2 Connect The Interface And Power Cables (Pedestal Models)

Connect The Interface And Power Cables (Pedest al Models )

DANGER

<1> Before powering on the printer, ensure the printer is plugged into

an appropriate power source. Refer to page 27 for information on

the proper source.

<4> Do not connect or disconnect any communication port, teleport,

attachment connector, or power cord during an electrical storm.

<5> Power off the printer and disconnect the power cord before

connecting or disconnecting communication port, teleport, or

attachment cable connector.

1. Verify that the voltage source at the printer site conforms to the

requirements specified on page 28.

2. Open the box containing the power cord, printer ribbon, and operator

panel overlay label. Refer to “Cables” on page 297 for recommended

cables.

58

Page 59

Connect The Interface And Power Cables (Pedestal Models)

Setting Rear Paper Exit

Parallel Connector

Auxiliary I/O

Serial Connector

NOTE:

(1)

The Dataproducts adapter feature attaches to the PC

Parallel interface connector.

(2)

Twinax, Coax, and Ethern et I nterfaces appear only if these

features are installed.

A

p6cprs wt

AC Power Connector

A

Power Switch

On Off

Figure 36. Views of Interface and the AC Power Connector

3. Make sure that the printer power switch is set to OFF. See Figure 29 on

I/O Connector

4. Remove the cover from the I/O connector you have selected.

page 54.

Figure 37. I/O Cover Removal from the Interface

59

Page 60

Chapter 2 Connect The Interface And Power Cables (Pedestal Models)

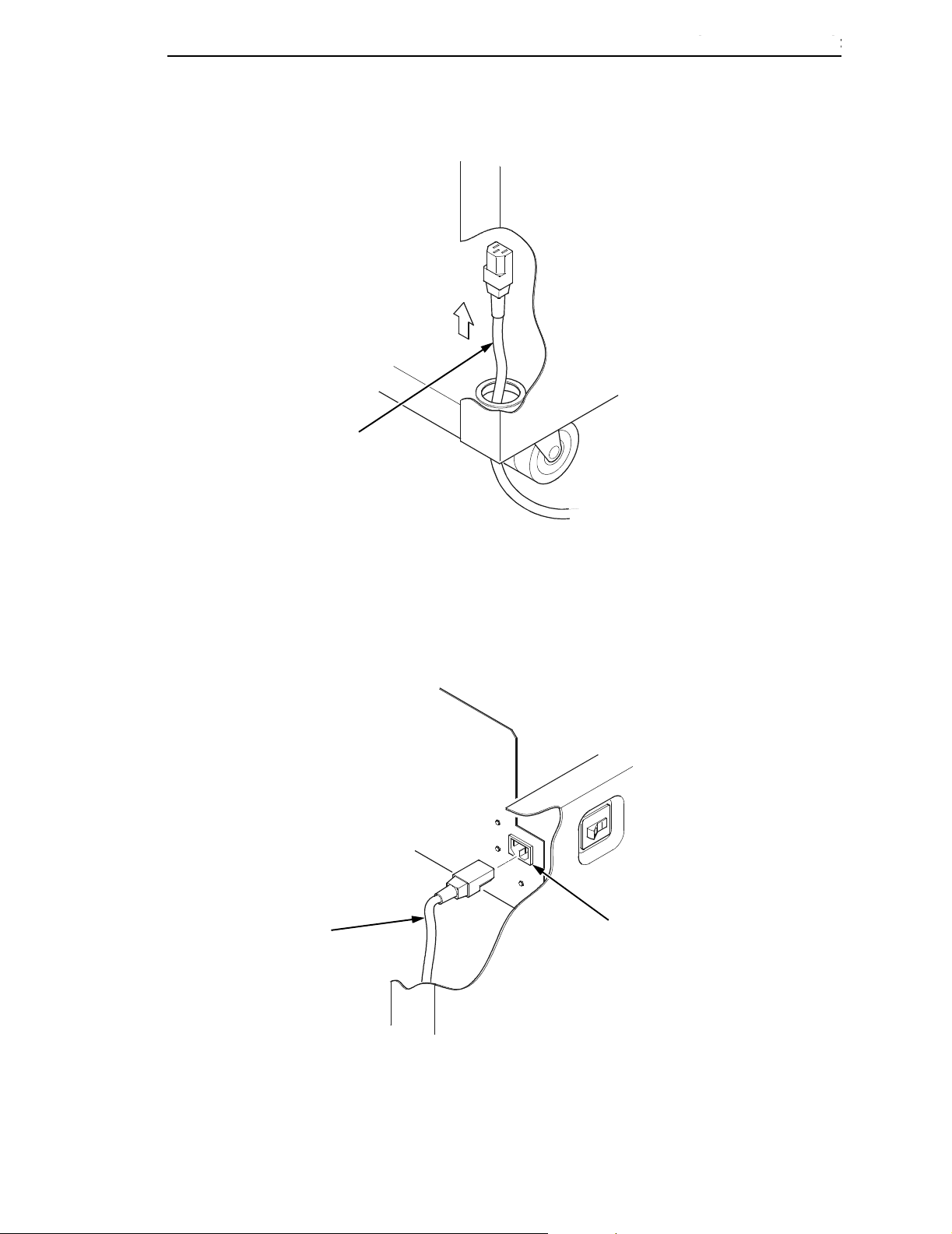

I/O Connector

Cable

Connector

Figure 38. View of the Printer Interface Showing Cable Connector Attachment

5. Attach the cable connector to the printer I/O connector.

PC Power Outlet

Power

Cord

Figure 39. View of the Power Cord Attachment

60

6. Plug the power cord into the printer AC power connector, then into the AC

power outlet.

Page 61

Connect The Interface And Power Cables (Pedestal Models)

Dataproduct s I/O Adap ter

Dataproducts

Standard Adapter

Setting Rear Paper Exit

Centronics, Ethernet

Auxiliary I/O

Diagnostic

Serial RS-232/RS-422

Pedestal Models

Ethernet

Auxiliary I/O

Centronics

Serial RS-23

Diagnostic

Cabinet Models

Figure 40. Pedestal and Cabinet Model Dataproducts I/O Adapter

NOTE: Centronics is not present on Network-based models.

61

Page 62

Chapter 2 Attach The Operator Panel Overlay Label

Coax/Twinax

Network

10/100Base-T

Figure 41. Optional Interface Types for Auxiliary I/O

Attach The Operator Panel Overlay La bel

Power

Ready

Processing

Attention

Menu

Printer

Configuration

Scroll

Scroll

Enter

Return

Micro

Micro

Line

Feed

View

Form

Feed

Set Top

of Form

Dataproducts

Long Line

Start

Stop

Cancel

Eject/

Restore

62

Figure 42. The Operator Panel Overlay Label

1. Choose the overlay labels in the appropriate language.

2. Attach the operator panel overlay label by adhering it to your operator

panel.

Page 63

Install Th e Ribbon

Refer to the ribbon path diagram molded onto the shuttle cover for the

following steps.

Install The Ribbon

Setting Rear Paper Exit

Cabinet Model Pedestal Model

Figure 43. Cabinet and Pedestal Models with the Printer Cover Open

1. Open the printer cover.

2. Pedestal models: pull the operator panel up and out of the way. The

operator panel can be pulled toward you to provide clearance.

63

Page 64

Chapter 2 Install The Ribbon

Tractor Door

Figure 44. View of the Forms Thickness Lever in the Raised Position

3. Raise the forms thickness lever as far as it will go.

Forms Thickness

Lever

4. Press STOP to silence the alarm.

5. Close the tractor doors.

6. Remove the ribbon spools from the package.

Spool

Right Hub

Latch

Figure 45. View of the Right Ribbon Hub with Ribbon Spool Above

7. With the ribbon supply to the outside, squeeze the right hub latch and

place the full spool on the right ribbon hub.

64

8. Press the spool down until the hub latch snaps into place.

NOTE: The ribbon must not be twisted. A twisted ribbon can lower print

quality, shorten ribbon life, and cause paper or ribbon jams.

If you are installing a “Clean Hands” ribbon (identified by a long

metalic leader), the leader will enable you to install the ribbon without

getting ink on your hands.

Page 65

Install The Ribbon

Setting Rear Paper Exit

Left Ribbon Spool

Cabinet Models

Forms Thickness

Lever

Left Ribbon

Spool

Pedestal Models

Forms Thicknes s

Lever

Figure 46. Cabinet and Pedestal Models, Interior View of Ribbon Installation

9. Starting from the right ribbon spool, thread the ribbon around the right

ribbon guide, under the right tractor door, between the hammer bank

cover and ribbon mask, and along the ribbon path to the left ribbon guide.

10. Place the empty spool on the left hub.

11. Press the spool down until the hub latch snaps into place.

12. Turn the left spool by hand and check to ensure that the ribbon tracks

correctly in the ribbon path and around the ribbon guides.

NOTE: Printers with the “Clean Hands” ribbon automatically load the ribbon

when the first print job is sent.

13. Close the forms thickness lever.

65

Page 66

Chapter 2 Load The Paper

Load The Paper

Figure 47. Cabinet and Pedestal Models with Printer Cover Open

1. Open the printer cover.

Tractor Door

Forms Thickn ess Lever

Figure 48. View of the Forms Thickness Lever in the Raised Position

66

2. Raise the forms thickness lever as far as it will go.

3. Open the tractor doors.

Page 67

Setting Rear Paper Exit

Label

Load The Paper

Figure 49. Interior Rear View of the Cabinet Model Paper Supply Label Location

4. Prepare the paper supply:

Cabinet models:

a. Open the front door of the printer cabinet.

b. Place the paper supply inside the printer, on the floor of the cabinet.

c. Align the paper supply with the front label on the floor of the printer.

d. Ensure that the paper pulls freely from the box.

Cabinet Model

Paper Slot

Paper Slot

Pedestal Model

Figure 50. Side View of the Cabinet and Pedestal Models Paper Feed

Pedestal models:

a. Place the paper supply on the floor in front of the printer, or on the

optional paper shelf, if attached.

b. Ensure that the paper pulls freely from the box.

67

Page 68

Chapter 2 Load The Paper

5. Feed the paper up through the paper slot.

NOTE: Be sure the paper feeds between the two wire guides.

Only the 6400-i20, -i2s, and -i24 printer models contain the paper

path guide as shown in Figure 50.

6. Hold the paper in place with one hand (to prevent it from slipping down

through the paper slot) while pulling it through from above with your other

hand.

7. Pull the paper above and behind the ribbon mask, which is a silver metal

strip with a clear plastic edge protector. Refer to the ribbon path diagram

on the shuttle cover.

Left Tractor Door

Paper

Left Tractor Lock

Figure 51. View of Paper Loaded Onto the Left Tractor with Door Closed and Tractor Lock

Lowered

8. Load the paper onto the left tractor sprockets.

9. Close the left tractor door.

68

Page 69

Setting Rear Paper Exit

Load The Paper

ATTENTION

T o avoid damage to the printer caused by printing on the platen, always

align the edge of the left tractor door with the number “1” on the paper

scale.

Tractor Splined Shaft

Tractor

Paper

Paper Scale

Figure 52. View of the Paper Scale Used as a Guide

10. If adjustment is necessary:

a. Unlock the left tractor.

b. Slide the tractor until it is directly to the left of the number “1” on the

paper scale and lock it. You can also use the paper scale to count

columns.

69

Page 70

Chapter 2 Load The Paper

Figure 53. Paper Loaded onto the Right Tractor Sprockets

Right Tractor Door

11. Unlock the right tractor.

12. Load the paper onto the right tractor sprockets.

13. Close the tractor door.

14. Make sure the leading edge of the first sheet of paper is parallel to the

tractor splined shaft. If the paper is misaligned, reload it onto the tractor

sprockets until its edge is parallel to the splined shaft.

15. Slide the right tractor to remove the paper slack or to adjust for various

paper widths.

16. Lock the tractor.

70

Page 71

Setting Rear Paper Exit

Load The Paper

Forms Thickness Lever

Figure 54. The Forms Thickness Lever in the Lowered Position

17. Turn the vertical position knob to feed the paper up into the paper guide

assembly.

18. Lower the forms thickness lever, and set it to match the paper thickness.

(The A-B-C scale corresponds approximately to 1-, 3-, and 6-part paper

thickness.)

NOTE: Do not set the forms thickness lever too tightly; excessive friction can

cause paper jams, ribbon jams (with potential for ribbon damage),

smeared ink, or wavy print.

19. Press STOP to remove the “LOAD PAPER” fault message from the

display.

20. Press FORM FEED several times to make sure the paper feeds properly

beyond the tractors and over the lower paper guide. Feed sufficient paper

to ensure the paper stacks correctly.

21. Close the printer cover.

22. Close the cabinet door.

23. Press START to place the printer in online mode and resume printing.

NOTE: For cabinet models with the power paper stacker installed, go to

“Power Paper Stacker Option” in the next section. For all other

cabinet models, go to “Set The Top-of-Form” on page 77.

71

Page 72

Chapter 2 Power Paper Stacker Opt io n

Power Paper St ack er Option

This section explains how to set up and use the optional power paper stacker.

The power stacker mechanically directs the paper from the printer to the

paper stacker.

Power Paper S tacker Component Locations

Familiarize yourself with the names and locations of the components shown in

the following illustration before operating the power paper stacker.

Elevator

Disable Switch

Elevator Lift

Handle

Paper Length

Indicator

Bearing Bracket

Pinch Rollers

Paper Throat

Rear