Page 1

S246-0149-03

6400

Line Matrix Printer

Coax/Twinax

Multi–Platform Interface Feature

Operation Guide

Page 2

Note!

Before using the information and the product it works with, ensure that you

read the general information under "Notices" on page vi.

February 1998

This manual may contain references to, or information about, IBM products

that are not announced in your country. Such references or information must

not be construed to mean that IBM intends to announce such IBM product,

programming or services in your country.

Information contained in this documentation is subject to change from time to

time. Changes will be reflected in the following revisions.

Reader comments may be sent by fax to 1-800-524-1519 or by e-mail to

print_pubs@vnet.ibm.com or by regular mail to:

Department H7FE Building 003G

The IBM Printing Systems Company

Information Development

P.O. Box 1900

Boulder, CO 80301-9191

U.S.A.

IBM may use or distribute any of the information you supply in any way it

believes suitable without incurring any obligation whatever. You may, of

course, continue to use the information you supply.

© Copyright International Business Machines Corporation 1995, 1996, 1997.

All rights reserved.

Note to U.S. Government Users – Documentation related to restricted rights –

Use, duplication or disclosure is subject to restrictions set forth in GSA ADP

Schedule Contract with IBM Corp.

Page 3

Table of Contents

About this setup guide

Related Publications .......................................... xii

CONFIGURATION

Preparing for Configuration ......................................2

Configuring MPI .............................................. 4

Configuring the Printer ..........................................9

Configuring for port switching ................................... 12

Using Coax with the MPI

Coax Connection ............................................. 14

Coax Buffer Size ............................................. 16

Coax Code Dump Mode ........................................17

Coax Command Interpreter ..................................... 19

Coax Code Maps ............................................. 22

Using Twinax with the MPI

Twinax Connection ........................................... 29

Twinax Code Maps ........................................... 34

Code Dump Mode ............................................ 37

Twinax Command Interpreter ....................................40

Using PC Parallel with MPI

Introduction ................................................. 44

Connection ................................................. 45

Setting time outs on the Parallel Host ............................. 46

TROUBLESHOOTING

Diagnostics ................................................. 48

Troubleshooting your Host Printer Operation ........................ 52

Compatibility Issues ........................................... 54

Appendix A: Defining a Printer in S/370-S/390

Environments

Overview ................................................... 58

6400-LU1-SCS-Local SNA 3174 Control Unit ........................59

6400-LU1-SCS-Remote SNA 3174 Control Unit ...................... 61

i

Page 4

6400-LU3-DSE-Local SNA 3174 Control Unit ........................63

6400-LU3-DSE-Remote SNA 3174 Control Unit ...................... 65

6400-LU0-DSC-Local Non-SNA 3174 Control Unit .................... 67

Appendix B: Describing Custom Set 8

Printer Configuration .......................................... 70

Appendix C: Illustrated Parts List

Hardware Assemblies ......................................... 75

Cable Assemblies ............................................ 76

Appendix D: Installing the MPI on the Printer

Introduction ................................................. 80

Accessing the card-cage ....................................... 81

Preparing the printer for MPI Installation ........................... 82

Installing the MPI Card in the Printer .............................. 83

Checking the MPI Installation .................................... 85

Appendix E: Host Character Sets

Twinax Character Sets .........................................87

Coax Character Sets .......................................... 91

ii

Page 5

List of Tables in this Manual

— Table 1 Sample Configuration Printout (Twinax) .................. 6

— Table 2 Sample Configuration Printout (Coax) .................... 7

— Table 3 Printer Configuration ................................ 10

— Table 4 Buffer Size Selections ............................... 16

— Table 5 Coax Command Interpreter commands .................. 20

— Table 6 Twinax Command Interpreter Commands ................ 41

— Table 7 Coax Diagnostic Tests ............................... 49

— Table 8 Twinax Diagnostic Tests ............................. 50

— Table 9 Twinax Error Messages .............................. 55

— Table 9 Twinax Error Messages .............................. 55

— Table 10 Coax Error Messages ............................55

iii

Page 6

Notices

References in this publication to IBM products, programs, or services do not

imply that IBM intends to make these available in all countries in which IBM

operates. Any reference to an IBM product, program, or service is not

intended to state or imply that only IBM’s product, program, or service may be

used. Any functionally equivalent product, program, or service that does not

infringe any of the intellectual property rights of IBM may be used instead of

the IBM product, program, or service. The evaluation and verification of

operation in conjunction with other products, except those expressly

designated by IBM, are the responsibility of the user.

IBM may have patents or pending patent applications covering subject matter

in this document. The furnishing of this document does not give you any

license to use these patents. You can send license inquiries, in writing, to the

IBM Director of Commercial Relations, IBM Corporation, Purchase, NY

10577, U.S.A.

Electronics Emission Notices

Federal Communications Commission (FCC) Statement

Note: This equipment has been tested and found to comply with the limits for

a Class A digital device, pursuant to Part 15 of the FCC Rules. These limits

are designed to provide reasonable protection against harmful interference

when the equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency energy and, if

not installed and used in accordance with the instruction manual, may cause

harmful interference to radio communications. Operation of this equipment in

a residential area is likely to cause harmful interference, in which case the

user will be required to correct the interference at his own expense.

Properly shielded and grounded cables and connectors must be used in order

to meet FCC emission limits. IBM is not responsible for any radio or television

interference caused by using other than recommended cables and

connectors or by unauthorized changes or modifications to this equipment.

Unauthorized changes or modifications could void the user’s authority to

operate the equipment.

iv

Page 7

This device complies with Part 15 of the FCC Rules. Operation is subject to

the following two conditions (1) this device may not cause harmful

interference, and (2) this device must accept any interference received,

including interference that may cause undesired operation.

Canadian Department of Communications Compliance

Statement

This equipment does not exceed Class A limits per radio noise emission for

digital apparatus, set out in the Radio Interference Regulation of the Canadian

Department of Communications. Operating in a residential area may caused

unacceptable interference to radio and TV reception requiring the owner or

operator to take whatever steps are necessary to correct the interference.

Avis de confomité aux normes du ministère des

Communications du Canada.

Cet équipment ne dépasse pas les limites de Classe A d’émission de bruits

radioélectriques pour les appareils numériques, telles que prescites par le

Réglement sur brouillage radiélectrique étabil par le ministére de

Communications de Canada. Léxploitation faite en milieu résidential peut

entraîner le brouillage des réceptions radio et télé, ce qui obligerait le

propriétaire ou l’opérateur à prendre les dispositions nécessaires pour en

éliminer les causes.

New Zealand Compliance Statement

This is a Class A computing device and shall not be located at a distance

closer than 20 meters from the boundary of a residential property.

v

Page 8

Trademarks and Service Marks

The following terms, denoted by an asterisk (*) in this publication, are

trademarks of the IBM Corporation in the United State or other countries or

both.

IBM AS/400

SCS

The following terms, denoted by a double asterisk (**) in this publication, are

trademarks of other companies:

Creative Controllers, Inc. Printronix, Inc.

Centronics QMS

vi

Page 9

Safety Notices

Disconnect the AC power cord before cleaning the

printer.

Before powering on the printer, make sure it is plugged

into the appropriate power source.

Refer to the "Select a Site" section in Chapter 2 of the

Setup Guide for information on proper power sources.

Sikkerhedsinstrukioner

Tag stikket ud af kontakten inden De gør printeren ren.

Forvis Dem om, at printeren er tilsluttet den korrekte

type strøm, inden De tænder for den.

DANGER

WARNING

FARE

FORSIGTIG

Korrekt strømtype er specificeret i afsnittet

Anbringelse af printeren (Select a Site) i Kapitel 2 i

Klargøringsvejledning (Setup Guide).

vii

Page 10

Huomautuksia Turvallisuudesta

VAARA

Irrota vaihtovirtajohto ennen kirjoittimen puhdistusta.

VAROITUS

Ennen virran kytkemistä kirjoittimeen on

varmistettava, että kirjoitin on liitetty sopivaan

virtalähteeseen.

Asennusoppaan (Setup Guide) luvussa 2, kohdassa

Asennuspaikan valinta (Select Site), on tietoja

virtalähteen valinnasta.

Normas de Segurança

PERIGO

Desligue o fio de corrente alternada antes de limpar a

impressora.

ATENÇÃO

Antes de ligar a impressora, certifique–se que esta

está ligada ao tipo de corrente apropriado.

viii

Consulte a secção Escolha de local (Select a Site), do

capítulo 2 do Guia de Instalação (Setup Guide), para

mais informações sobre os tipos de corrente

apropriados para esta impressora.

Page 11

Säkerhetsföreskrifter

Koppla los nätkabeln innan du rengör skrivaren.

Innan du kopplar på strömmen till skrivaren ska du

kontrollera att den är ansluten till rätt

strömförsörjning.

I avsnittet Val av uppställningsplats (Select a Site) i

kapitel 2 av Installationsanvisningar (Setup Guide)

finns information om rätt strömförsörjning.

Sikkerhetsinformasjon

Trekk ut strømledningens støpsel fra stikkontakten før

skriveren rengjøres.

Kontroller at skriveren er tilknyttet riktig strømkilde før

du slår den på.

Du finner nærmere opplysninger om egnede

strømkilder under avsnittet Valg av egnet sted for

skriveren (Select a Site) i kapittel 2 i

Installasjonshåndboken (Setup Guide).

FARA

VARNING

ADVARSEL

OBS!

ix

Page 12

x

Page 13

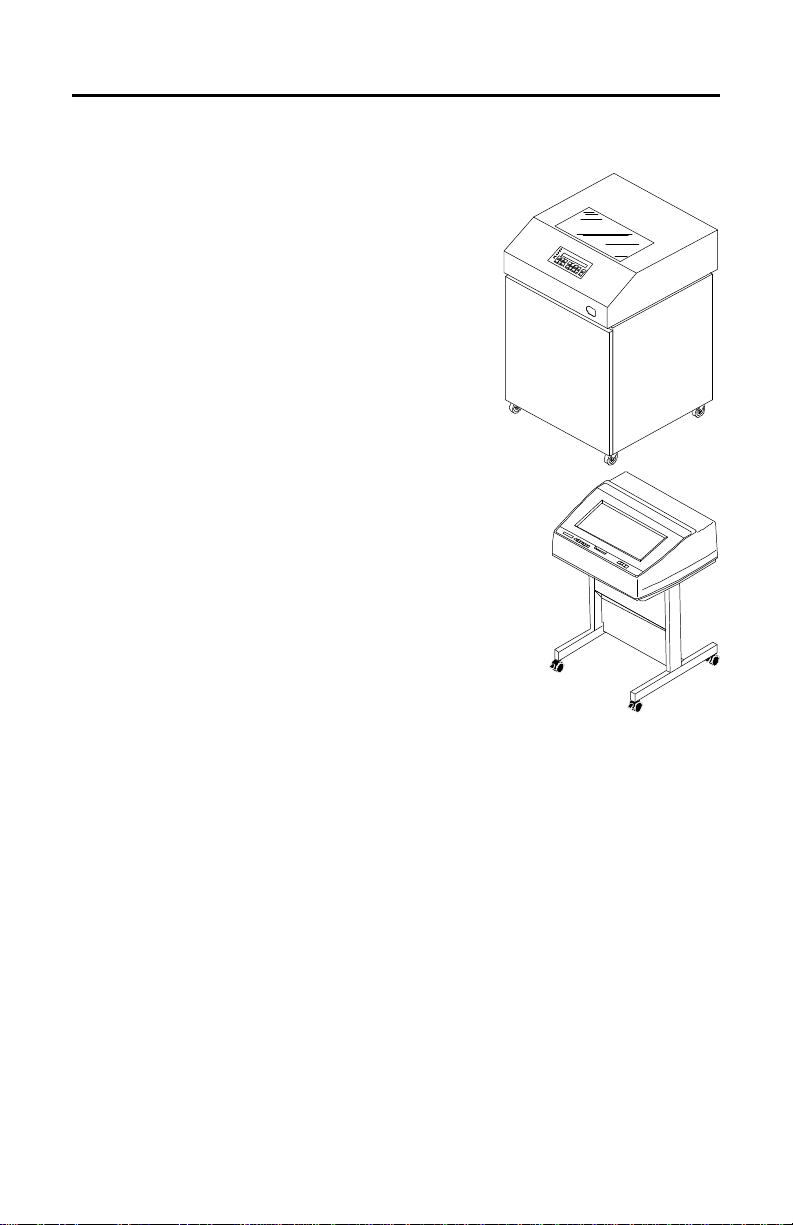

About this setup guide

This manual covers the configuration and

operation of the Coax/Twinax Multi-Platform

Interface (MPI) feature for the IBM 6400

Line Matrix Printers.

The MPI feature enables either coax

attachment of the 6400 printer to, for

example, a S/370 or S/390 host, or twinax

attachment of the printer in an AS/400 or

Systems 3X environment.

In addition, the parallel port of the printer is

available for attachment to a PC, Network

Print Server, or other device attaching

through the PC parallel port.

What does the MPI feature do? The MPI

acts as a protocol converter, taking coax or

twinax data streams and translating them

into an ASCII data stream that the 6400

printer parallel ASCII port is set up to

handle. As you install and configure the

MPI, you are defining the translation that is

performed.

The MPI feature will normally already be

installed in the printer. If it is not, then

follow the hardware installation instructions

found in Appendix D.

IBM 6400 Printer

Once the MPI feature is installed, begin its

configuration with the instructions on page

2.

Switching between Serial ASCII and Parallel ASCII

To switch between Serial ASCII and

Parallel ASCII, the operator must

reconfigure the printer interface selection

from the operator panel by selecting a

custom set that uses the correct ASCII

interfaces. This is because the MPI

interface communicates through the

Parallel ASCII port.

xi

Page 14

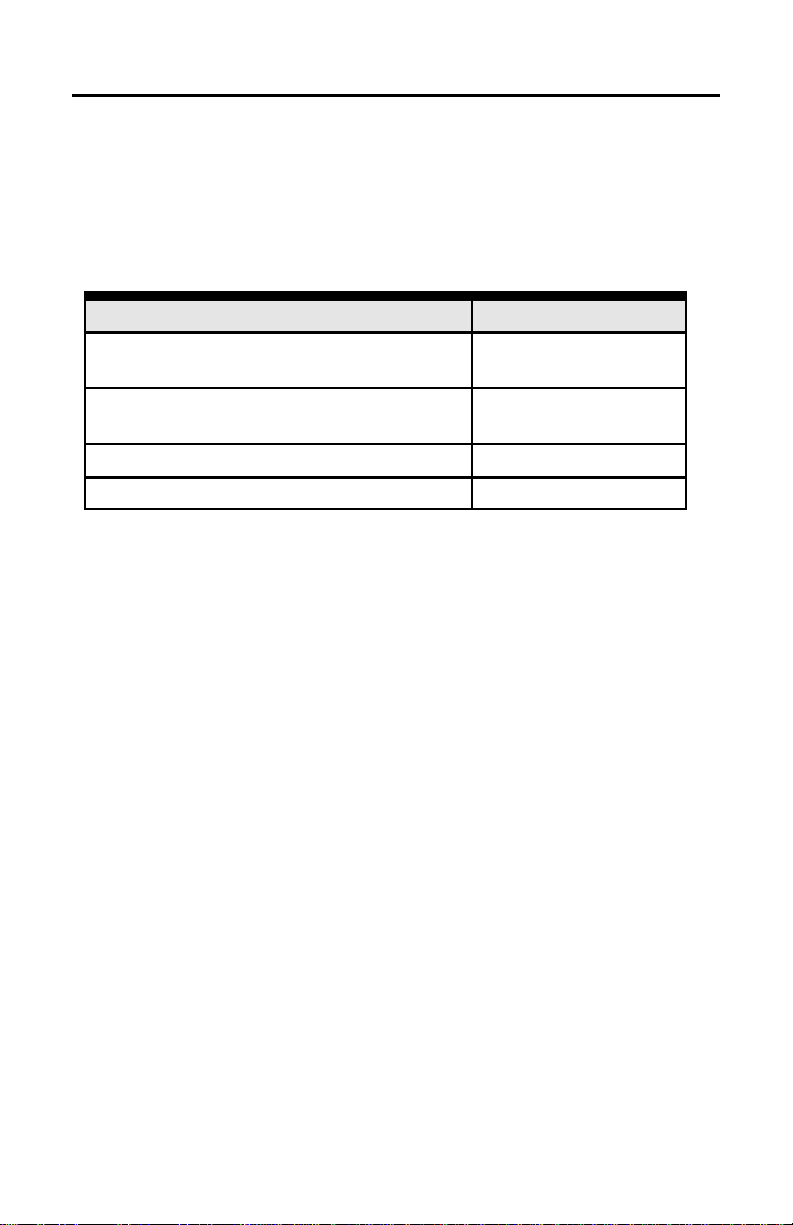

Related Publications

The following are publications referred to in

this manual.

Related Publications

Publication Title Document Number

6400 Line Matrix Printer

Setup Guide

6400 Line Matrix Printer

Operators Guide

6400 IGP User’s Guide S246-0151

6400 Code V User’s Guide S246-0150

S246-0116

S246-0115

xii

Page 15

CONFIGURATION

— Preparing for Configuration 2

— Configuring the Printer 9

— Configuring for port switching 12

Multi–Platform Interface Feature Operation Guide 1

Page 16

Preparing for Configuration

With the MPI feature installed, the following

steps must be performed before it will be

fully operational. The MPI feature must be

configured, the printer must be configured

for correct operation with the feature, and

the printer must be defined to the twinax or

coax host. In addition, if the parallel port

will be used to attach another host, then that

configuration must be performed.

Pre-Configuration Checklist

Before configuring the MPI and printer, you

should review the following checklist and

answer each question. Answering these

questions will help you to configure both the

MPI and the printer.

! Will you attach the printer to the host

with coax or twinax?

! What coax or twinax printer do you

want the MPI to emulate?

Your choices for coax are:

IBM 3287 and 3262

Your choices for twinax are:

IBM 4214, 5225, 5256, and 4234

! Will there be a host device attached

through the parallel port? If so, what

ASCII emulation will this host device

use?

Your choices are:

Epson, P-Series, and Serial Matrix

! Is either Code V or IGP graphics

feature installed in the printer?

Now that you understand the environment,

proceed with the MPI configuration.

2 Multi–Platform Interface Feature Operation Guide

Page 17

Quick Path

These are the basic steps you need to

complete to configure the MPI and the

printer:

! Set the MPI dip switches (Page 5)

! Set the printer configuration (Page 9)

! If configuring for coax, set the coax

buffer size using the rotary switch (see

Using Coax with the MPI)

! If configuring the MPI for twinax, set the

twinax address using the rotary switch

(see Using Twinax with the MPI)

Multi–Platform Interface Feature Operation Guide 3

Page 18

Configuring MPI

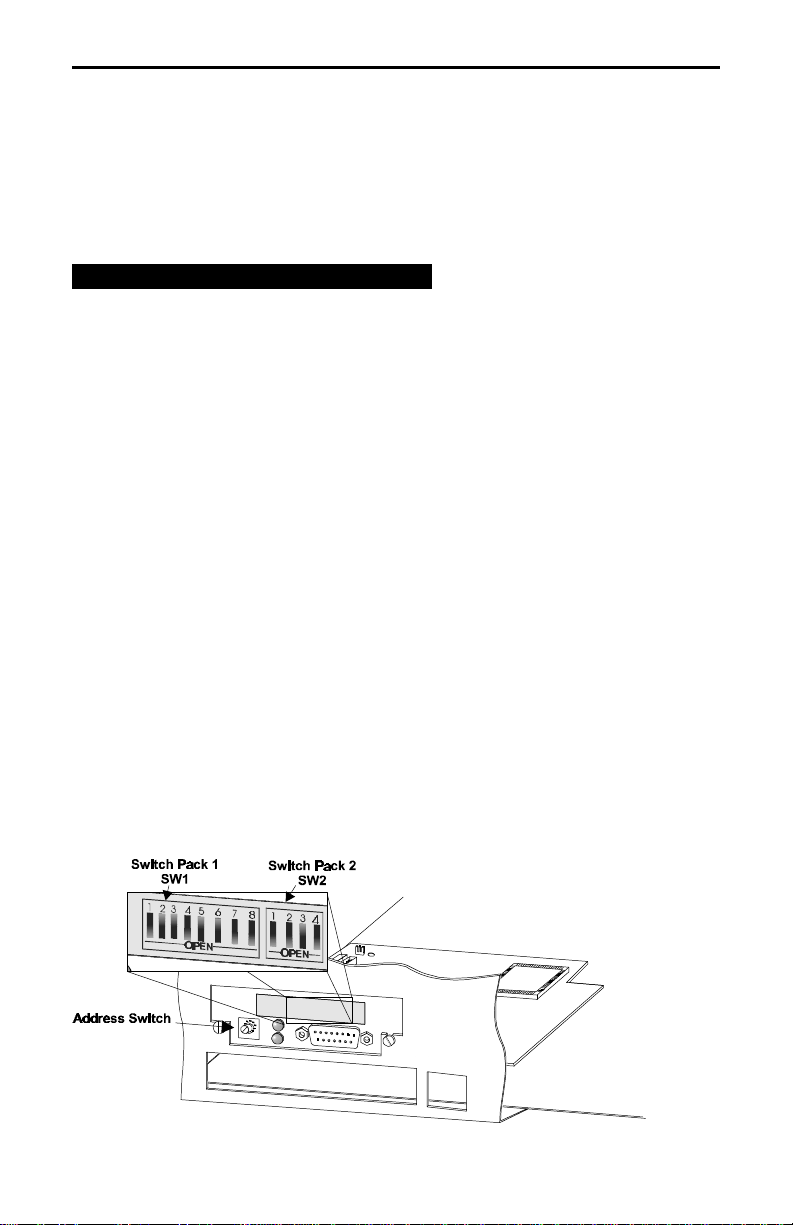

To configure the Multi–Platform Interface

Feature, you use the twelve (12) dip

switches and the rotary switch located on

the Interface I/O (See Figure 1 ).

The MPI is configured differently when

connected with twinax or coax cabling. You

must know whether you are attaching via

twinax or coax.

important

The MPI is set to coax or twinax

communications depending upon which

cable is attached to the MPI. The default

value is Twinax. If the coax BNC adapter

cable, part number 08H7968, is attached to

the MPI, then coax is the default. If the

twinax auto-termination cable, part number

14H5335, is attached to the MPI, twinax is

the default. Therefore, if you want to

configure the MPI for coax, the coax BNC

adapter cable must be attached to the MPI

The dip switches allow you to select the

emulation of the printer, character sets, IGP

options, etc. If you do not know the type of

printer to be emulated, consult your Data

Processing department.

The rotary address switch is used to select

the coax buffer size or twinax address. For

both coax and twinax it is used to select

diagnostics.

Table 1 and Table 2 show the different

configurations possible. The selected value

is indicated, as shown on the Diagnostic

Test 7 Printout, by '=>>'.

To get a printout of the current interface

configuration, run Diagnostic 7. See the

section starting on page 48 for complete

details.

4 Multi–Platform Interface Feature Operation Guide

Page 19

Configure the MPI by putting the dip

switches in the position that matches the

desired selection.

In the sample printout and the diagnostics,

the following convention is used.

0 = OFF or OPEN

1 = ON or CLOSED

note

After making MPI switch or cable changes,

the printer must be powered off, wait 15

seconds and then power on the printer in

order for those changes to take effect.

configuring MPI

Figure 1 Location of Configuration Switches.

Multi–Platform Interface Feature Operation Guide 5

Page 20

configuring MPI

Table 1 Sample Configuration Printout (Twinax)

SW1-2 SW1-1 EMULATION SELECTED

=>> 0 0 4214

0 1 5225

1 0 5256

1 1 4234

SW1-4 SW1-3 DEFAULT CHARACTER SET

=>> 0 0 MULTINATIONAL

0 1 USA

1 0 AUSTRIA/GERMANY

1 1 FRENCH CANADIAN

SW1-6 SW1-5 IGP OPTIONS

=>> 0 0 NO IGP INSTALLED

0 1 IGP-PGL INSTALLED*

1 0 IGP-VGL INSTALLED**

1 1 RESERVED

SW1-7 PRINTER TYPE

=>> 0 6400-PRINTRONIX

1 6400-EPSON

SW1-8 PRINTER EMULATION (6400-PRINTRONIX)

=>> 0 P-SERIES COMPATIBLE

1 SERIAL MATRIX

SW2-1 DEFAULT IGP SFCC

=>> 0 ^ CARET (5Eh, 94d)

1 ~ TILDE (7Eh, 126d)

SW2-3 SW2-2 PANEL AND SYSTEM CONTROL

=>> 0 0 SYSTEM CONTROLS CPI AND PRINT QUALITY

0 1 SYSTEM CONTROLS CPI, PANEL CONTROLS PRINT QUALITY

1 0 PANEL CONTROLS CPI, SYSTEM CONTROLS PRINT QUALITY

1 1 PANEL CONTROLS CPI, PRINT QUALITY, AND LPI

SW2-4 MULTIPLEXER TIMEOUT

=>> 0 SHORT (15 SEC)

1 LONG (45 SEC)

note

If you are replacing an existing Printronix PSeries printer, SW1-7 and SW1-8 should be

set to the Open (Off) state. This will provide

compatibility with existing jobs. Also, if you

will be port switching, you should set SW1-7

and SW1-8 to be compatible with the

alternate host. See page 12 for more

information. If you set SW1-7 to 6400

Printronix (Open), you must set SW1-8. If

you set SW1-7 to 6400-Epson (Closed), you

do not need to set SW1-8 and you can

leave SW1-8 to the factory default.

note

* indicates IGP Feature installed.

** indicates Code V Feature installed.

6 Multi–Platform Interface Feature Operation Guide

Page 21

Table 2 Sample Configuration Printout (Coax)

SW1-1 IBM EMULATION SELECTED

=>> 0 3287

1 3262

SW1-2 Character Set Selected

=>> 0 UNITED STATES

1 UNITED KINGDOM

SW1-3 DEFAULT MPP

=>> 0 132

1 NONE

SW1-4 DEFAULT MPL

=>> 0 NONE

1 66

SW1-6 SW1-5 IGP OPTIONS

=>> 0 0 NO IGP INSTALLED

0 1 IGP-PGL INSTALLED*

1 0 IGP-VGL INSTALLED**

1 1 RESERVED

SW1-7 PRINTER TYPE

=>> 0 6400-PRINTRONIX

1 6400-EPSON

SW1-8 PRINTER EMULATION (6400-PRINTRONIX)

=>> 0 P-SERIES COMPATIBLE

1 SERIAL MATRIX

SW2-1 DEFAULT IGP SFCC

=>> 0 ^ CARET (5Eh, 94d)

1 ~ TILDE (7Eh, 126d)

SW2-2 AUTO FORM FEED

=>> 0 ENABLE AFTER OPERATOR INITIATED LOCAL COPY

1 DISABLE AFTER OPERATOR INITIATED LOCAL COPY

SW2-3 PAPER ERROR REPORTING

=>> 0 NEVER REPORT PAPER ERRORS

1 REPORT PAPER ERRORS

SW2-4 MULTIPLEXER TIMEOUT

=>> 0 SHORT (15 SECONDS)

1 LONG (45 SECONDS)

configuring MPI

note

If you are replacing an existing Printronix PSeries printer, SW1-7 and SW 1-8 should be

set to the Open (Off) state. This will provide

compatibility with existing jobs.

Also, if you will be port switching, you should

set the SW1-7 and SW1-8 to be compatible

with the alternate host. See page 12 for

more information. If you set SW1-7 to 6400

Printronix (Open), you must set SW1-8. If

you set SW1-7 to 6400-Epson (Closed), you

do not need to set SW1-8 and you can

leave SW1-8 to the factory default.

Multi–Platform Interface Feature Operation Guide 7

Page 22

configuring MPI

* indicates IGP Feature installed.

** indicates Code V Feature installed.

MPP means Maximum Print Position

MPL means Maximum Page Length

note

note

8 Multi–Platform Interface Feature Operation Guide

Page 23

Configuring the Printer

In order for the Multi–Platform Interface

Feature to operate correctly with the 6400,

the printer must be properly configured.

The settings of Custom Set 8 provide

default values that work correctly with the

MPI feature to emulate a P-Series printer.

For other MPI ASCII printer emulations,

such as an Epson, you will need to change

the Custom Set 8 ASCII emulation.

Power-on the printer. If the power-on printer

configuration is not set to Custom Set 8, do

so now. Table 3 shows the most important

values: shuttle time out, latch data on, and

prime signal. If these printer configuration

values are set incorrectly, it may cause

erratic behavior. For a complete listing of

Custom Set 8, see Appendix B.

note

For proper printer operation, the ASCII

emulation in the 6400 must match the ASCII

emulation chosen for the MPI feature.

Check that these match and change as

needed.

See coax code map on page 22 and twinax

code map on page 34 to determine how the

coax or twinax host characters are

translated to ASCII characters.

note

Consult the printer's Setup Guide for a

complete description on how to setup your

printer.

Multi–Platform Interface Feature Operation Guide 9

Page 24

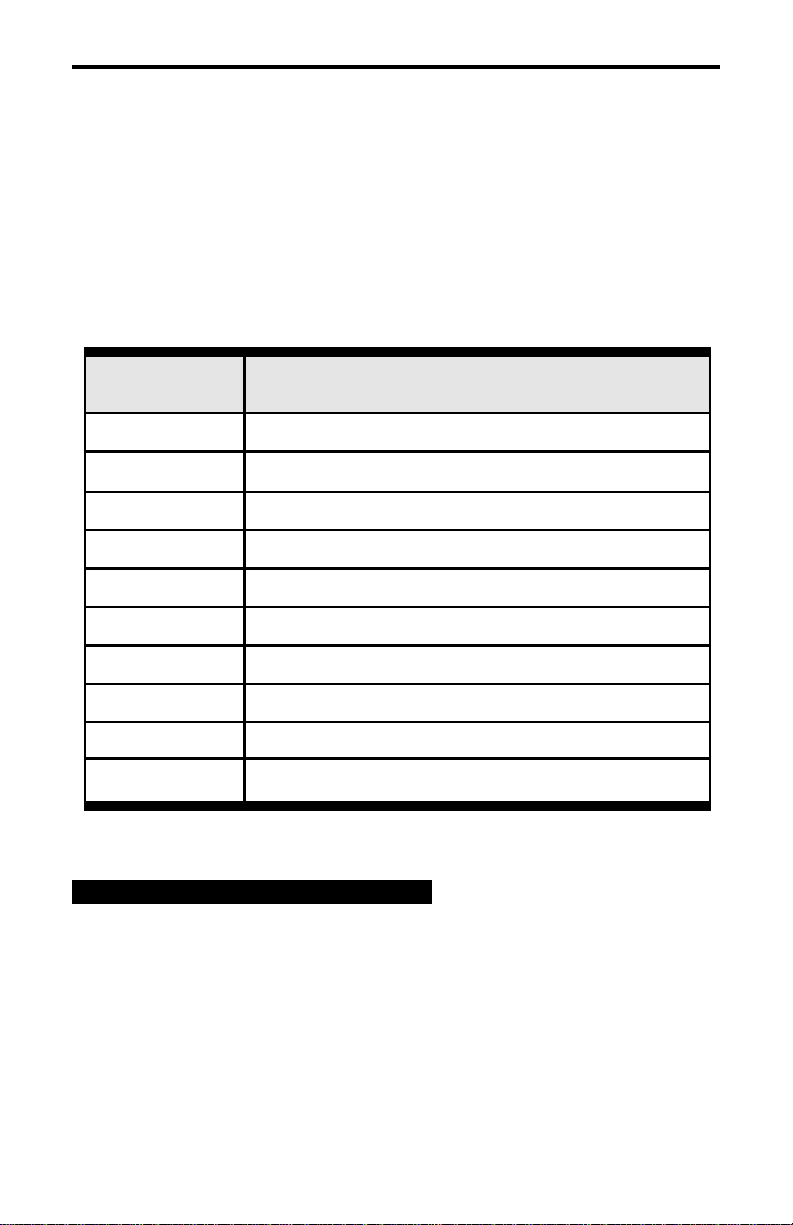

configuring the printer

Table 3 Printer Configuration

PRINTER CONTROL

SHUTTLE TIMEOUT ........ 20 SECONDS

PARALLEL INTERFACE

INTERFACE TYPE ........ PC PARALLEL

PC PARALLEL

DATA BIT 8 ......... ENABLE

DATA POLARITY ........ STANDARD

STROBE POLARITY ....... STANDARD

RESPONSE POLARITY ...... STANDARD

BUSY ON STROBE ....... ENABLE

LATCH DATA ON ........ TRAILING EDGE

PRIME SIGNAL ........ DISABLE

TOF ACTION AT PRIME SIGNAL . NO ACTION

note

In Table 3 , only the values for Shuttle

Timeout, Latch Data On, and Prime Signal

need to be changed. For all other

configuration items, the default values can

be used. If the values shown in bold in Table

3 are not set as shown, erratic operation of

the printer might occur.

10 Multi–Platform Interface Feature Operation Guide

Page 25

configuring the printer

Configuring MPI for Either IGP or Code V Graphic Feature

Those printers using an IGP or Code V

Graphics Feature must have the feature

installed and the printer properly configured.

Check the sample printouts of Table 2 and

Table 1 to see how to configure the MPI

when these two features are being used.

Further changes to Custom Set 8 values for

Code V or IGP emulation may have to be

made to support your host applications.

Refer to the Code V or IGP Programmer's

Reference manuals listed in Related

Publications on page xii.

Multi–Platform Interface Feature Operation Guide 11

Page 26

Configuring for port switching

If you will be port switching with the MPI,

you must set the printer emulation used by

the PC application to match the emulation

you have set in the printer.

For example, when you have set the printer

emulation to 6400-Epson, your host ASCII

application, should use a standard Epson

print driver.

When you have set the printer emulation to

the P-Series emulation, your application

should use a standard P-Series printer

driver.

12 Multi–Platform Interface Feature Operation Guide

Page 27

Using Coax with the MPI

— Coax Connection 14

— Coax Buffer Size 16

— Coax Code Dump Mode 17

— Coax Command Interpreter 19

— Coax Code Maps 22

Multi–Platform Interface Feature Operation Guide 13

Page 28

Coax Connection

To connect the coax line from the cluster

controller to the IBM 6400 printer, you must

use the supplied BNC Adapter (P/N#

08H7968).

Connect the BNC Adapter to the "HOST"

connector port on the Multi–Platform

Interface Feature I/O. (See Figure 2 )

Once you have securely connected the

adapter, connect the coax line to the coax

connector on the end of the adapter.

Before powering on the printer, it must be

defined to the host. For additional

information on defining the printer in the

S/370 and S/390 environments, refer to

Appendix A of this manual.

Power on the printer. At this point, the

SYNC LED indicating line activity will be on

if there is activity on the coax line. (See

page 75 for the location of the SYNC LED)

Send the printer a screen dump from a

terminal. If successful, send the printer a

print job from the host. In some systems,

the printer may not be configured for local

screen dumps. When the printer receives a

job from the host, the SYS LED will light

indicating a job in progress.

Figure 2 BNC adapter

attachment

important

The printer uses the 3270 data stream

format when connected via coax through the

MPI. The MPI supports LU0 (DSC), LU1

(SCS) and LU3 (DSE) types only.

14 Multi–Platform Interface Feature Operation Guide

Page 29

note

Remember! If you make any changes to

cables, switch settings or the configuration

you must power the printer off, wait 15

seconds and then power the printer on

again.

LED Indicators

The Multi-Platform Interface I/O has two

LEDs labeled SYNC and SYS (see page

75). These can be used to determine line

connection status and host

acknowledgment.

When the coax cable is first attached to the

BNC Adapter, the SYNC LED will light,

showing that active line connection has

been made. If the LED fails to light, the line

you are connected to may be faulty.

When the interface receives data from the

host system, the SYS LED will light

indicating a job is in progress.

Multi–Platform Interface Feature Operation Guide 15

Page 30

Coax Buffer Size

While connected to the coax line, the IBM

6400 Multi–Platform Interface Feature has a

built in buffer. The size of this buffer is user

configured by setting the Address switch

(see page 75 for location on I/O) on the MPI

I/O to a specified setting. Table 4 shows

the buffer size for each setting.

Table 4 Buffer Size Selections

ADDRESS

SETTING Display Screen Size, Print Buffer Size

0 1920 Screen, 2K Buffer

1 1920 Screen, 4K Buffer

2 2560 Screen, 2K Buffer

3 2560 Screen, 4K Buffer

4 3440 Screen, 4K Buffer

5 3564 Screen, 4K Buffer

6 960 Screen, 2K Buffer

7 Sets the interface to Code Dump mode

8 1920 Screen, 4K Buffer

9 1920 Screen, 4K Buffer

note

When using this printer with IBM compatible

controllers (e.g. 3174), use the maximum

buffer size (Address 5).

16 Multi–Platform Interface Feature Operation Guide

Page 31

Coax Code Dump Mode

The code dump mode allows you to print all

or S/390 system in a hexadecimal format.

This can be useful when debugging your

Entering Code Dump mode

To enter the Code Dump mode:

Power off the printer.

2

3 Power on the printer and place it on-

Once the Configuration Printout has printed,

the controller will be in Code Dump mode.

In order to use the "Code Dump Mode", the

MPI must be receiving data from the host

Multi–Platform Interface Feature Operation Guide

Page 32

coax code dump mode

Exiting Code Dump Mode

To exit Code Dump mode:

1 Power off the printer.

2 Reset the buffer size by setting the

ADDRESS switch to the desired

address 0-6, or 8-9.

3 Power on the printer and place it on-

line.

18 Multi–Platform Interface Feature Operation Guide

Page 33

Coax Command Interpreter

To gain access to some printer features not

available on the host system, a Command

Interpreter has been built into the

Multi–Platform Interface Feature.

By using special control codes, you can

pass the hexadecimal codes to the printer

that access the ASCII features of the printer.

These codes allow you to transparently pass

any character or sequence of characters to

the printer.

These codes are Hexadecimal ASCII

commands and must match ones supported

by the printer and MPI ASCII emulation

selected.

The commands are initiated by use of the

logical not (¬) character. You can access

this character by pressing the Shift and 6

keys on your terminal’s keyboard.

Multi–Platform Interface Feature Operation Guide 19

Page 34

coax command interpreter

Commands

The command interpreter is enabled after

the ¬ONN command is received.

The command interpreter is disabled by

sending a ¬OFF command. The default

power up state of the command interpreter

is disabled.

Table 5 gives an explanation of all the

commands available.

Table 5 Coax Command Interpreter commands

COMMAND ACTION

¬ONN Enable the command interpreter. Ignored if already on.

¬OFF Disable the command interpreter - Default, power up

state. Ignored if already off.

¬HEX Hexadecimal pass-thru mode. Data following this

command is packed into hexadecimal pairs and sent to

the printer. The command may be terminated by sending

the "@" character. Any non-hexadecimal characters

(except the "@") are ignored.

Terminate Hex mode by sending an at sign "@".

¬FLS Forms Length Switch. This command is accepted only in

LU3 (DSE) mode. It will set the forms length (in lines) to

the value of the three digit number immediately following

the command. Top of form will be set to the current

physical line. The value must be in the range 000 - 127.

There may NOT be any other characters embedded and

the forms length MUST be three digits long.

Sending the FLS command causes the MPI to load the

printers VFU and set the Top Of Form to the present

line.

¬L03 or

¬L04 or

¬L06 or

Lines Per Inch. This command is accepted in LU3 (DSE)

mode only. It will set the line spacing to 3, 4, 6 or 8 lines

per inch.

¬L08

20 Multi–Platform Interface Feature Operation Guide

Page 35

¬ONN - turns on command interpreter.

¬ONN¬HEX 0C 0C 0C @ - send three

¬ONN¬HEX 41 42 43 @ - send ABC in

ASCII to printer.

¬OFF¬HEX 0C 0C 0C @ ¬ONN¬HEX 0C

0C 0C @¬OFF printer then feed three sheets of paper.

¬ONN¬FLS058¬OFF

Multi–Platform Interface Feature Operation Guide 21

Page 36

Coax Code Maps

Data sent from the S/370 or S/390 host

computer to the Multi–Platform Interface

Feature is translated into the correct form

for the 6400 printer to understand. The

following sections show the maps used by

the interface to translate the various kinds of

host data into the ASCII printer language.

To translate the coax host character to

ASCII character, use the coax hex value as

the coordinates (grey column and row) on

the map. At that cell, is the ASCII translation

(ASCII hex value and character).

For example, a coax DSE hex value of 35

would be translated to ASCII hex 2B and is

the ASCII "+" character.

These maps illustrate the translation from

host code page United States to ASCII code

page PC850. Translation maps for other

code pages, such as United Kingdom, are

not shown. See Appendix E for Supported

Host Character sets.

Translating Host Code Page to ASCII Code Pages

Set the active printer ASCII printer

emulation as follows to correctly map host

code pages to ASCII code pages:

! Epson Emulation

Character Set=0850 PC MULTINATIONAL

! P-Series Emulation

Character set = IBM PC

Print Language/IBM PC/Select Subset Primary = ASCII (USA)

Print Language/IBM PC/Select Subset Extended = 0850 PC

Multilingual

Alternate Set 80-90F = Printable

! Serial Matrix Emulation

Character set = IBM PC

Print Language/IBM PC/Select Subset Primary = ASCII (USA)

Print Language/IBM PC/Select Subset Extended = 0850 PC

Multilingual

Alternate Set 80-90F = Printable

22 Multi–Platform Interface Feature Operation Guide

Page 37

Internal 3270 (DSE/DSC) to ASCII Character Map

0 1 2 3 4 5 6 7

NUL nc nc nc nc

0

EM nc nc nc nc

1

FF nc nc nc nc

2

NL nc nc nc nc

3

nc nc nc nc nc

4

CR nc nc nc nc

5

nc LN nc nc nc nc

6

nc nc nc nc nc nc

7

8

3E 3F 38

9

3C 21 39

A

5B 24 5E

B

5D 7E

C

29 23

D

28 40 60

E

7D 25 27

F { _

LSB

The following control codes are supported:

NUL = NULL EM = END

OF MESSAGE

FF = FORM FEED NL = NEW

LINE

CR = CARRIAGE RETURN ATT =

ATTRIBUTES

7B 5F

20 30 26

= 1 -

3D 31 2D

27 32 2E

" 3 ,

22 33 2C

/ 4 :

2F 34 3A

\ 5 +

5C 35 2B

7C 36

7C 37

> ? 8

< ! 9

[ $ ˆ

] ~

nc nc nc nc nc nc

) #

nc nc nc nc nc nc

( @ ´

nc nc nc nc nc

} % '

nc nc nc nc nc

nc nc nc nc nc nc

0 &

' 2 .

| 6

| 7

nc nc nc nc nc

nc nc nc nc nc

nc nc nc nc nc

coax code maps

Multi–Platform Interface Feature Operation Guide 23

Page 38

coax code maps

Internal 3270 (DSE/DSC) to ASCII Character Map

8 9 A B C D E F MSB

LSB

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

a q A Q

61 71 41 51

b r B R

62 72 42 52

c s C S

63 73 43 53

d t D T

64 74 44 54

e u E U

65 75 45 55

f v F V

66 76 46 56

g w G W

67 77 47 57

h x H X

68 78 48 58

i y I Y

69 79 49 59

j z J Z

6A 7A 4A 5A

k nc K nc

6B 4B

l nc L nc

6C 4C

m nc M nc

6D 4D

n nc N nc

6E 4E

o nc O ;

6A 4A 3A

p nc P *

70 50 2E

ATT ATT ATT ATT

ATT ATT ATT ATT

ATT ATT ATT ATT

ATT ATT ATT ATT

ATT ATT ATT ATT

ATT ATT ATT ATT

ATT ATT ATT ATT

ATT ATT ATT ATT

ATT ATT ATT ATT

ATT ATT ATT ATT

ATT ATT ATT ATT

ATT ATT ATT ATT

ATT ATT ATT ATT

ATT ATT ATT ATT

ATT ATT ATT ATT

ATT ATT ATT NUL

LN = LOGICAL NOT prints as an ASCII caret "^"

(5E)

nc = NO CODE AVAILABLE printed as an ASCII

space (20th)

24 Multi–Platform Interface Feature Operation Guide

Page 39

EBCDIC (SCS) to ASCII Character Map

0 1 2 3 4 5 6 7

NUL nf nf nf & - nc

0

1

2

nf nf nf nf nc nc / nc

nf nf nf nf nc nc nc nc

20 26 2D

coax code maps

2F

3

4

5

6

7

8

9

A

B

C

D

E

F

LSB

LN = LOGICAL NOT prints as "1" or "^" (ACH or 5EH)

EO = EO control code not supported, prints as a space

(20th)

nf = NO FUNCTION supported prints as a space (20th)

nc = NO CODE AVAILABLE printed as an ASCII hyphen

(2DH)

nf nf nf nf nc nc nc nc

VCS ENP INP nf nc nc nc nc

HT NL LF TRN nc nc nc nc

nf BS nf nf nc nc nc nc

nf nf nf nf nc nc nc nc

GE nf SA nf nc nc nc nc

nf nf nf nf nc nc nc `

nf nf nf nf nc ! | :

VT nf FMT nf . $ , #

FF nf nf nf < * % @

CR nf nf nf ( ) _ '

nf IRS nf nf + ; > =

nf nf BEL nf | LN ? "

07 7C 3F 22

60

21 7C 3A

2E 24 2C 23

3C 2e 25 40

28 29 5F 27

2B 3a 3E 3D

Multi–Platform Interface Feature Operation Guide 25

Page 40

coax code maps

EBCDIC (SCS) to ASCII Character Map

8 9 A B C D E F MSB

nc nc nc nc { } \ 0

0

1

2

3

4

5

6

7

8

9

A

a j ~ nc A J nc 1

61 6A 7E 41 4A 31

b k s nc B K S 2

62 6B 73 42 4B 53 32

c l t nc C L T 3

63 6C 74 43 4C 54 33

d m u nc D M U 4

64 6D 75 44 4D 55 34

e n v nc E N V 5

65 6E 76 45 4E 56 35

f o w nc F O W 6

66 6a 77 46 4a 57 36

g p x nc G P X 7

67 70 78 47 50 58 37

h q y nc H Q Y 8

68 71 79 48 51 59 38

i r z nc I R Z 9

69 72 7A 49 52 5A 39

nc nc nc nc nc nc nc nc

7B 7D 5C 30

nc nc nc nc nc nc nc nc

B

nc nc nc nc nc nc nc nc

C

nc nc nc nc nc nc nc nc

D

nc nc nc nc nc nc nc nc

E

F nc nc nc nc nc nc nc EO

LSB

The following control codes are supported.

NUL = Null VT = Vertical Tab TRN = Transparent

BS = Back space LF = Line Feed CR = Carriage Return

FF = Form Feed GE = Graphic Escape IRS = Interchange Record

ENP = Enable presentation HT = Horizontal Tab Separator

VCS = Vertical Channel Select

NL = New Line

26 Multi–Platform Interface Feature Operation Guide

Page 41

The following Format (FMT) control codes are supported

in LU1 (SCS):

SHF = "2BC1..." SET HORIZONTAL FORMAT. (any MPP

valid)

SVF = "2BC2..." SET VERTICAL FORMAT. (any Line

Density valid)

SLD = "2BC6..." SET LINE DENSITY. (00H, 09H, 12H,

18H AND 24H valid "6, 8, 6, 4, and 3

LPI"

coax code maps

Multi–Platform Interface Feature Operation Guide 27

Page 42

Using Twinax with the MPI

— Twinax Connection 29

— Twinax Code Maps 34

— Code Dump Mode 37

— Twinax Command Interpreter 40

28 Multi–Platform Interface Feature Operation Guide

Page 43

Twinax Connection

Before installing the printer into the twinax

environment, you should run the built-in

diagnostics. See page 48 for instructions

on running the diagnostics.

After the Multi–Platform Interface Feature

is running the built-in diagnostics you are

ready to connect the printer to the AS/400,

System 36 or other twinax host system.

Active jobs/devices

If there are any active devices on the

twinax line that the printer is going to be on:

1 Terminate the device immediately up

cable of the printer, on the twinax line.

2 Place on Hold any devices down cable

of the printer with active jobs.

3 SIGN OFF any active terminals and

terminal type devices down cable of

the printer.

twinax connection

note

"UP CABLE" describes any device that is

physically located closer to the Host System

on the twinax line. "DOWN CABLE"

describes a device physically located more

distant from the Host System on the twinax

line. For example, if this printer is the third

device on the line, the immediate "UP

CABLE" device would be the second device

on this line.

Multi–Platform Interface Feature Operation Guide 29

Page 44

twinax connection

Power off

The printer's POWER switch should be in

the "OFF" position.

"Smart T" attachment

Connect the supplied "Smart T" (twinax

auto-termination cable, part number

14H5335) to the 15-pin connector on the

printer’s MPI interface. (See Figure 3 )

Termination/cable thru is automatically

accomplished by the "Smart T". The

"Smart T" has no IN or OUT specific

connectors.

Figure 3 "Smart T"

Attachment

30 Multi–Platform Interface Feature Operation Guide

Page 45

Attach twinax cables

Attach the twinax cable from the host

computer to the "Smart T" connected to

the printer earlier.

1 If there is an up cable device

connected to the twinax cable (from

the host), the twinax cable must

originate from the "OUT" connector of

that device. The other end of this cable

attaches to either side of the "Smart T"

connected to the printer.

2 If this printer is the last or only device

on the twinax line, the twinax cable

attaches to either side of the "Smart T"

connected to the printer.

3 If there is a down cable device,

connect the other twinax cable to

either side of the "Smart T".

Address switch

Before testing, do the following:

twinax connection

1 Verify that the printer address matches

the one set up on your host system.

The I/O address should be unique on

the twinax line. BE CERTAIN THAT

NO ADDRESS ON THE LINE IS

DUPLICATED!!!

To set the printer address, rotate the

address switch, on the I/O, to the

number that corresponds to the

address setting for your environment.

This address should be some number

between 0 and 6.

2 Verify that the address matches the

one set up on your host system

configuration.

Multi–Platform Interface Feature Operation Guide 31

Page 46

twinax connection

Power On Printer

At this point, once the cable connection

and the address settings have been

verified, you should power on the printer.

LED Indicators

The Multi-Platform Interface I/O has two

LEDs labeled SYNC and SYS (see page

75). These can be used to determine line

connection status and host

acknowledgment.

When the twinax cable is first attached to

the Smart T, the SYNC LED will light,

showing that active line connection has

been made. If the LED fails to light, the line

you are connected to may be faulty.

When the interface receives data from the

host system, the SYS LED will light

indicating a job is in progress.

32 Multi–Platform Interface Feature Operation Guide

Page 47

Printer verification test

Power on the printer.

Access the terminal's SIGN ON SCREEN.

If this terminal is a 3180 or 3190, press the

"ALT, TEST" keys; otherwise, press the

"CMD, BACKSPACE" keys to access the

"Prime Option" menu.

From the "Prime Option" menu, run a

printer verification test by:

1 Select option "2" on the PRIME

OPTION MENU, "Work Station Printer

Verification", to run the IBM printer

verification test.

2 Select this printer's ID number to run

the test on this printer.

3 Select the number of times that you

wish to print the WORK STATION

VERIFICATION TEST. Possible

selections are:

a. PRINT TEST 1 TIME

b. PRINT TEST 2 TIMES

c. PRINT TEST 5 TIMES

d. PRINT TEST CONTINUOUSLY

4 Select option "C" on the WORK

STATION PRINTER VERIFICATION

menu, when you have finished printing

the test. You will be returned to the

"Prime Option Menu".

twinax connection

5 Select option "C" on the PRIME

OPTION MENU, "End", to EXIT the

"Prime Option Menu".

Should you have any problems while

running the Printer Verification test, see

Troubleshooting the Host Printer

Operation on page 52.

Multi–Platform Interface Feature Operation Guide 33

Page 48

twinax code maps

Twinax Code Maps

Data sent from the host computer to the

Multi–Platform Interface Feature is

translated into the correct form for the

6400 printer to understand.

This map illustrate the translation from

host code page USA to ASCII code page

PC850. Translation maps for other code

pages, such as Multinational, are not

shown. See Appendix E for supported host

character sets.

Translating Host Code Page to ASCII Code Pages

Set the active printer ASCII printer

emulation as follows to correctly map host

code pages to ASCII code pages:

! Epson Emulation

Character Set=0850 PC MULTINATIONAL

! P-Series Emulation

Character set = IBM PC

Print Language/IBM PC/Select Subset Primary = ASCII (USA)

Print Language/IBM PC/Select Subset Extended = 0850 PC

Multilingual

Alternate Set 80-90F = Printable

! Serial Matrix Emulation

Character set = IBM PC

Print Language/IBM PC/Select Subset Primary = ASCII (USA)

Print Language/IBM PC/Select Subset Extended = 0850 PC

Multilingual

Alternate Set 80-90F = Printable

34 Multi–Platform Interface Feature Operation Guide

Page 49

twinax code maps

EBCDIC (SCS) TO ASCII CHARACTER MAP

0 1 2 3 4 5 6 7

NULL nf nf nf & - ø

0

nf nf nf nf nc é / É

1

nf nf nf nf â ê Â Ê

2

ATR nf nf nf ä ë Ä Ë

3

4

5

6

7

8

9

A

B

C

D

E

F nf nf BEL nf ! ^ ? "

LSB 21 5E 3F 22

N 84 89 8E D3

nf nf nf PP ä è À È

nf NL LF ETR à í Á Í

nf BS nf nf ã î Ã Î

nf nf nf nf å ï Å Ï

nf nf nf nf ç ì Ç Ì

nf nf nf nf ñ ß Ñ `

nf nf nf nf [ ] | :

nf nf FMT nf . $ , #

FF nf nf nf < * % @

CR nf nf nf ( ) _ '

nf IRS nf nf + ; > =

20 26 2D 9B

82 2F 90

83 88 B6 D2

A0 8A B7 D4

N 85 A1 B5 D6

C6 8C C7 D7

86 8B 8F D8

87 8D 80 DE

A4 E1 A5 60

5B 5D 7C 3A

2E 24 2C 23

3C 2A 25 40

28 29 5F 27

2B 3B 3E 3D

Multi–Platform Interface Feature Operation Guide 35

Page 50

twinax code maps

EBCDIC (SCS) TO ASCII CHARACTER MAP

8 9 A B C D E F MSB

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F ± ¤ ® = õ ÿ Õ –

LSB F1 CF A9 3D E4 98 E5 FF

The following control codes are supported.

NULL = Null IRS = Interchange Record Separator

ATRN = ASCII Transparent LF = Line Feed

FF = Form Feed BEL=Bell Code (Not sent)

CR = Carriage Return PP = Print Position Commands

NL = New Line ETRN=EBCDIC Transparency

BS = Back space

Ø ° µ ¢ { } \ 0

9D F8 E6 BD 7B 7D 5C 30

a j ~ £ A J nc 1

61 6A 7E 9C 41 4A 31

b k s ¥ B K S 2

62 6B 73 BE 42 4B 53 32

c l t • C L T 3

63 6C 74 FA 43 4C 54 33

d m u ƒ D M U 4

64 6D 75 9F 44 4D 55 34

e n v § E N V 5

65 6E 76 F5 45 4E 56 35

f o w ¶ F O W 6

66 6F 77 F4 46 4F 57 36

g p x ¼ G P X 7

67 70 78 AC 47 50 58 37

h q y ½ H Q Y 8

68 71 79 AB 48 51 59 38

i r z ¾ I R Z 9

69 72 7A F3 49 52 5A 39

* ª ¡ ^ - ¹ ² ³

AE A6 AD 5E F0 FB FD FC

+ º ¿ | ô û Ô Û

AF A7 A8 B3 93 96 E2 EA

ð æ Ð ¯ ö ü Ö Ü

D0 91 D1 EE 94 81 99 9A

ý ¸ Ý ¨ ò ù Ò Ù

EC F7 ED F9 95 97 E3 EB

þ Æ Þ ´ ó ú Ó Û

E7 92 E8 EF A2 A3 E0 E9

36 Multi–Platform Interface Feature Operation Guide

Page 51

Code Dump Mode

The code dump mode allows you to print

all the data the controller receives from the

IBM system in a hexadecimal format.

Entering Code Dump mode

To access the Code Dump mode provided

by the controller:

1 Power off the printer.

2 Set the ADDRESS switch to address

7.

3 Power on the printer. After the MPI

configuration has printed, set the

ADDRESS switch on the interface I/O

to the device’s current address (0-6)

on the host system.

twinax code dump mode

note

In order to use the "Code Dump Mode", the

MPI must be receiving data from the host

computer.

Multi–Platform Interface Feature Operation Guide 37

Page 52

twinax code dump mode

Exiting Code Dump Mode

To exit Code Dump mode:

1 Power off the printer.

2 Set the ADDRESS switch on the MPI

to the device’s current address (0-6)

on the host system.

3 Power on the printer and place it on-

line.

38 Multi–Platform Interface Feature Operation Guide

Page 53

Code Dump Header

The "Code Dump" header is identical to

the "Diagnostic" self-test header, except

for the test identification in the first line.

Following the header, the received data is

printed in a structured field dump format

(See Figure 4 ). This shows the data as

received from the host system with each

SCS command on a separate line. Data is

presented in a standard Hex Dump format.

twinax code dump mode

Figure 4 An example of a

Structured Field

Dump

Multi–Platform Interface Feature Operation Guide 39

Page 54

Twinax Command Interpreter

To gain access to some features not

available on the AS/400, System 36 or

other twinax host system, a Command

Interpreter has been built into the

Multi–Platform Interface Feature.

By using special control codes, you can

pass the ASCII hexadecimal codes to the

printer that access the features of the

printer. These codes allow you to

transparently pass any character or

sequence of characters to the printer.

These codes are hexadecimal ASCII

commands and must match ones

supported by the printer and MPI ASCII

emulation selected.

The commands are initiated by use of the

logical not (¬) character. You can access

this character by pressing the Shift and 6

keys on your terminal’s keyboard.

40 Multi–Platform Interface Feature Operation Guide

Page 55

twinax command interpreter

Commands

Preface each of the commands in the

following list with a single logical-not

character as shown in this document by the

"¬" character.

Table 6 Gives an explanation of all the

available commands.

Table 6 Twinax Command Interpreter Commands

COMMAND ACTION

¬ONN Enable the command interpreter. Ignored if already

on.

¬OFF Disable the command interpreter - Default, power up

state. Ignored if already off.

¬HEX Pack valid Hexadecimal characters two to a byte and

send to the printer. Invalid Hexadecimal characters will

be skipped - all SNA commands will be passed out.

Terminate Hex mode by sending an at sign "@".

Multi–Platform Interface Feature Operation Guide 41

Page 56

twinax command interpreter

Example

To send a carriage return, line feed, ABC

followed by a form feed you would send

the following:

¬ONN¬HEX 0D 0A 41 42 43 0C @

or

¬ONN¬HEX 0D 0A @ABC ¬HEX 0C @

In either case, once the Command

Interpreter is enabled, you need not reenable it until the controller is powered down

or following a ¬OFF.

42 Multi–Platform Interface Feature Operation Guide

Page 57

Using PC Parallel with MPI

— Introduction 44

— Connection 45

— Setting time outs on the Parallel Host 46

Multi–Platform Interface Feature Operation Guide 43

Page 58

Introduction

The Multi–Platform Interface Feature has

the ability to connect to two different

operating systems at once. One of these

connections is the twinax or coax

connection already discussed.

In addition, the MPI supports the use of a

Centronics** "D" connector to connect to

systems that support devices attached via a

parallel port.

When connected to two host systems, the

interface will switch to the other port once

the port currently printing is idle for a preset

period of time.

When the MPI senses data at one of its

input ports, it switches to that input port until

the print job is complete. The time between

switching from one port to the other after a

print job has finished is a user configured

parameter. This is defined by the multiplexer

timeout (See pages 6 and 7) selections:

which are short (15 seconds) or long (45

seconds).

44 Multi–Platform Interface Feature Operation Guide

Page 59

Connection

Before powering on your parallel host

system, the printer cable from the system

must be plugged into the PC parallel

connector on the printer.

Select a time out configuration (either short

or long) to match your system's needs.

note

1) The printer will feed a blank page when

data host inputs are switched.

2) When switching host inputs, the printer

configuration is not preserved by the

printer's memory. Should any of your

PC or network jobs change the printer

configuration, it may be necessary for

you to reset the printer configuration.

Figure 5 PC parallel cable

attachment

Multi–Platform Interface Feature Operation Guide 45

Page 60

Setting time outs on the Parallel Host

DOS

If you are using the printer attached to a

host PC system using the DOS operating

system, use the following configuration for

the retry value. The command MODE LPTn:

RETRY=P (issued from the command

prompt, or in a batch file) will set the parallel

port timeout to "infinite retry". DOS will

continue to try to print a file until it is

completed, or removed from the print queue

with a PRINT /T command.

OS/2

If you are using the interface attached to a

host PC system using the OS/2 operating

system, the retry value for the parallel port

must be set high enough to allow a host

print job to complete, plus the multiplexer

timeout value. This value is set in the

Parallel Port Setting - LPTn: screen.

46 Multi–Platform Interface Feature Operation Guide

Page 61

TROUBLESHOOTING

— Diagnostics 48

— Troubleshooting your Host Printer Operation 52

— Compatibility Issues 54

Multi–Platform Interface Feature Operation Guide 47

Page 62

Diagnostics

The Multi–Platform Interface Feature has its

own built-in diagnostics programs to help

you verify that the printer and the MPI are

operating properly.

Diagnostic Header

Each diagnostic test prints a header that

displays the firmware part number, revision

level, and the controller board option switch

settings. For example:

IBM 6400 Multi-Platform Interface

ROM=CI-1717 CHECKSUM - 7108 PREDICTED, 7108 ACTUAL

COPYRIGHT 1995

note

Wait several seconds after powering on for

the selected diagnostic to start.

48 Multi–Platform Interface Feature Operation Guide

Page 63

Coax Operation

Dialing the diagnostic test number into the

“ADDRESS” (Address 7) switch selects the

diagnostic routine. Powering up the printer

executes them. (See Table 7 )

Table 7 Coax Diagnostic Tests

diagnostics

ADDRESS

SELECTION

DIAGNOSTIC TEST RESULTS

7 Selects Configuration printout and Code Dump Mode

All other address settings for the coax diagnostic mode are invalid.

note

The Coax adapter must be attached to the

MPI I/O for operating the Coax Diagnostics.

Multi–Platform Interface Feature Operation Guide 49

Page 64

diagnostics

Twinax Operation

Dialing the diagnostic test number into the

“ADDRESS” switch selects the diagnostic

routines. Powering up the printer executes

them. (See NOTE).

You may change the "ADDRESS" switch

while the diagnostic is running (printing) to

step to another diagnostic. (See Table 8 )

Table 8 Twinax Diagnostic Tests

ADDRESS

SELECTION

DIAGNOSTIC TEST RESULTS

0-6 Code Dump Mode (if selected after test 7)

7 Configuration Printout

8 Prints one full page in a floating pattern.

9 Continuously sends data to itself (loop back test)

and monitors the received data for any errors. Prints

"LOOP TEST PASSED" or "LOOP TEST FAILED"

at approximately ten second intervals. (SEE

CAUTION BEFORE RUNNING DIAGNOSTIC 9.)

caution

Make sure the host twinax cable is not

attached to the "Smart T" twinax autotermination cable, while running

diagnostic 9. This will result in system

errors and possibly cause a proc-check

on your system.

note

The "Smart T" supplied with the MPI feature

must be attached to the MPI for all twinax

diagnostics. Remember, it must not be

attached to the host System when running

diagnostic 9.

50 Multi–Platform Interface Feature Operation Guide

Page 65

Checklist

If the controller's built-in diagnostic tests do

not perform according to Table 7 (coax) on

page 49 and Table 8 (twinax) on page 50.

1 Run each diagnostic and save the

diagnostic printout.

2 Check all of the installation

connections.

3 Verify that the printer’s configuration is

set according to Table 3 on page 10.

When diagnostics are complete:

1 Power off the printer and wait 15

seconds

2 Set the address switch back to the

original position

diagnostics

3 Power on the printer and resume

normal operation

Multi–Platform Interface Feature Operation Guide 51

Page 66

Troubleshooting your Host Printer Operation

If any problems occur while running the

Printer Verification Test in either twinax or

coax host system check the following:

1 Verify that you have assigned the

correct address setting to the printer.

(Twinax Only)

2 Verify that the address in the system

configuration matches the address

setting on the printer. (Twinax Only)

3 Verify that the device type in the system

configuration is correct for the type of

printer that is being emulated. This

emulation is set using the interface

configuration switches SW1-1 and

SW1-2. Your emulation options for

twinax mode are 4214, 4234, 5225 or

5256. In the coax operating mode, 3287

or 3262 are available.

4 Verify that the cable to the device

immediately "up cable" on the twinax

line is correctly connected. That is, if

there is an "up cable" device, does the

cable from that device originate at the

"OUT" connection. (Twinax Only)

5 Verify that the device immediately "up

cable" is functioning properly. (Twinax

only)

6 Verify that the device immediately

"down cable" is functioning properly.

(Twinax Only)

7 Verify that the I/O switch settings on the

last device on this line has been set to

the "TERM" position. (Twinax Only)

8 Verify that the printer is properly

configured (see page 10).

52 Multi–Platform Interface Feature Operation Guide

Page 67

9 Verify that the Multi–Platform

Interface’s configuration switch settings

are correct (See Table 1 on page 6

(twinax) or See Table 2 on page 7

(coax)).

10Put the MPI in coax or twinax code

dump mode and print the job in

hexadecimal format. Use this printout to

verify data from the host.

11With the MPI not in code dump mode,

set the printer configuration to Hex Print

Mode and print the job. Use the printout

to verify the hexadecimal output of the

MPI going to the printer.

12With no host cable attached, the LEDs

will light briefly (about 1 second) when

the MPI has completed initialization. If

the LEDs do not do this, the MPI's

power connection may be faulty.

Multi–Platform Interface Feature Operation Guide 53

Page 68

Compatibility Issues

The following are issues that may arise

when implementing the printer in the host

environment.

Cancel Key

When the user presses the printer's

CANCEL key, nothing is reported to the

host application. The MPI does not send a

message to the host application to cancel

the print job.

Coax PA Keys

The MPI does not have coax PA1 or PA2

device response capability.

54 Multi–Platform Interface Feature Operation Guide

Page 69

compatibility issues

Error Messages

The following tables show error messages

as reported to the host system and the

causes of those messages. These are the

only error messages the MPI reports to the

Twinax or Coax host.

Table 9 Twinax Error Messages

Error Reported Cause

Unit Not Available Printer Offline

Unit Not Available, End of Forms Paper Error

Exception Status Codes

Invalid Activate

Invalid Command

Overrun

Power On Transition

Invalid SCS Control Code Invalid Control Code

Invalid SCS Parameter Invalid Parameter

Graphic Check Unprintable character detected

Twinax Protocol Error

Twinax Protocol Error

Twinax Protocol Error

Power On Transition

after receipt of a “set graphic

exception action”

Table 10 Coax Error Messages

Error Reported Cause

Intervention Required Paper Out (if enabled, after

timeout)

Order Reject Invalid Order Detected

Invalid Parameter Invalid Parameter in SCS data

stream

Multi–Platform Interface Feature Operation Guide 55

Page 70

compatibility issues

Switching between Serial ASCII and Parallel ASCII

To switch between Serial ASCII and

Parallel ASCII, the operator must

reconfigure the printer interface selection

from the operator panel by selecting a

custom set that used the correct ASCII

interfaces. This is because the MPI

interface communicates through the

Parallel ASCII port.

56 Multi–Platform Interface Feature Operation Guide

Page 71

Appendix A: Defining a Printer in S/370-S/390

Environments

— Overview ................................. 58

— 6400-LU1-SCS-Local SNA 3174 Control Unit ...... 59

— 6400-LU1-SCS-Remote SNA 3174 Control Unit .... 61

— 6400-LU3-DSE-Local SNA 3174 Control Unit ...... 63

— 6400-LU3-DSE-Remote SNA 3174 Control Unit .... 65

— 6400-LU0-DSC-Local Non-SNA 3174 Control Unit .. 67

Multi–Platform Interface Feature Operation Guide 57

Page 72

Overview

It is necessary to define a printer in the

S/370-S/390 environment to VTAM, JES2,

POWER, PSF, VPS, JES328X Print Facility,

NCP, VM, VSE, MVS, and/or other software

depending upon your operating environment

and printing requirements. The following are

examples of the type of setups that are

required.

58 Multi–Platform Interface Feature Operation Guide

Page 73

6400-LU1-SCS-Local SNA 3174 Control Unit

LU1-SCS mode is utilized when neither PSF

support nor IPDS is required to accomplish

the print function desired. An existing local

3174 SNA-connected control unit is

assumed. The steps required to install a

local LU1-SCS printer for host definitions

are as follows:

1. Define to VTAM by adding logmode

entry to VTAM Logmode Table

2. Define to JES2 (not required but

recommended. See details below)

3. Define to CICS or another Application

Program such as VPS or JES328X

products.

4. Select the options on the printer that

are appropriate for the environment.

Step 1 – VTAM Definition

The following should be added to the Local

Major Node VTAM definition. The printer will

be attached as an LU1-SCS capable printer.

LOC3174 VBUILD TYPE=LOCAL

LOCPU74 PU CUADDR=nnn...

LOC64XX LU LOCADDR=n,MODETAB=MYMODETB,DLOGMODE=64XXSCSL,

ISTATUS=ACTIVE

The following entry should be placed in the

VTAM MODE TABLE specified above or

another of your choice.

64XXSCSL MODEENT LOGMODE=64XXSCSL,

FMPROF=X'03',TSPROF=X'03',PRIPROT=X'B1'

SECPROT=X'90',COMPROT=X'3080',RUSIZES=X'8787',

PSERVIC=X'01000000E100000000000000',

PSNDPAC=X'02',SRCVPAC=X'02',SSNDPAC=X'00'

Multi–Platform Interface Feature Operation Guide 59

Page 74

Step2 – JES2 Definition (SYS1.PARMLIB)

RMT1 LUTYPE1,BUFSIZE=3840,LINE=1,NUMRD=0,NUMPR=1,NOCOMP,

R1.PR1 CLASS=A,NOSEP,PRWIDTH=132,NOFCBLOD,WS=(W,R,Q,PMD,LIM,

DESTID NAME=LOC64XX,DEST=R1

NOCMPCT,SETUPHDR,CONSOLE

F,T/C,P),CKTPAGE=30

Step 3 – Define to CICS or another

application program

An application program must provide the

SCS commands to control the printer. CICS,

VPS, and other applications support SCS as

well as numerous application programs,

both customer written and vendor supplied.

Refer to the vendor documentation for

defining an SCS printer to the program for

its use. If there is no specific information on

the 64XX you may use the IBM 4234 for

reference.

60 Multi–Platform Interface Feature Operation Guide

Page 75

6400-LU1-SCS-Remote SNA 3174 Control Unit

LU1-SCS mode is utilized when neither

IPDS nor PSF is needed to accomplish the

print function desired. An existing remote

3174 SNA-connected control unit is

assumed. The steps required to install a

remote LU1-SCS printer for host definitions

are as follows:

1. Define to NCP, point to LU1 Logmode

entry defined below

2. Define to VTAM by adding logmode

entry to VTAM Logmode Table

3. Define to JES2 (May not be required if

VPS. See details below)

4. Define to JES328X Print Facility, VPS,

or equivalent product.

5. Select the options on the printer that

are appropriate for the environment.

Step 1 – NCP Definition

XYZ GROUP TYPE=NCP,...

LINK ADDRESS=(032),...

REMPU74 PU ADDR=C1,...

REM64XX LU LOCADDR=#, (# replaced by port on control

DLOGMOD=64XXSCSR,(Default LOGMODE ENTRY NAME)

MODETAB=MYTABLE (Table name containing MODEENT)

unit)

*

Step 2 – VTAM Definition

* The following entry should be placed in

the VTAM MODE TABLE specified above

or another of your choice.

64XXSCSR MODEENT LOGMODE=64XXSCSR,

FMPROF=X'03',TSPROF=X'03',PRIPROT=X'B1'

SECPROT=X'90',COMPROT=X'3080',RUSIZES=X'87C6',

PSERVIC=X'01000000E100000000000000',

PSNDPAC=X'01',SRCVPAC=X'01'

Multi–Platform Interface Feature Operation Guide 61

Page 76

Step 3 – JES2 Definition

This definition is not required if you are

using VPS and using U1-U9999 as the

printer ID.

RMT1 LUTYPE1,BUFSIZE=3840,LINE=1,NUMRD=0,NUMPR=1,NOCOMP,

R1.PR1 CLASS=A,NOSEP,PRWIDTH=132,NOFCBLOD,WS=(W,R,Q,PMD,LIM,

DESTID NAME=P64XX,DEST=R1

NOCMPCT,SETUPHDR,CONSOLE (SETUPHDR=PDIR JES2 V3)

F,T/C,P),CKPTPAGE=30

Step 4 – Define to CICS or another

application program

An application program must provide the

SCS commands to control the printer. CICS,

VPS, and other applications support SCS as

well as numerous application programs,

both customer written and vendor supplied.

Refer to the vendor documentation for

defining an SCS printer to the program for

its use. If there is no specific information on

the 64XX you may use the IBM 4234 for

reference.

62 Multi–Platform Interface Feature Operation Guide

Page 77

6400-LU3-DSE-Local SNA 3174 Control Unit

LU3-DSE mode is utilized when no host

printing controls are required to accomplish

the print function desired. The printer

settings will be used and cannot be

overridden by the host system. An existing

local 3174 SNA-connected control unit is

assumed. The steps required to install an

LU3-DSE printer for host definitions are as

follows:

1. Define to VTAM by adding logmode

entry to VTAM Logmode Table

2. Define to JES2 (Not required but

recommended. See details below)

3. Define to CICS or another Application

Program such as VPS or JES328X

products.

4. Select the options on the printer that

are appropriate for the environment.

Step 1 – VTAM Definition

The following should be added to the Local

Major Node VTAM definition.

LOC3174 VBUILD TYPE=LOCAL

LOCPU74 PU CUADDR=nnn...

LOC64XX LU LOCADDR=n,MODETAB=MYMODETB,

DLOGMODE=64XXDSEL,ISTATUS=ACTIVE

The following entry should be placed in the

VTAM MODE TABLE specified above or

another of your choice.

64XXDSEL MODEENT LOGMODE=64XXDSEL,

FMPROF=X'03',TSPROF=X'03',PRIPROT=X'B1'

SECPROT=X'20',COMPROT=X'3080',RUSIZES=X'C7C7,

PSERVIC=X'038000000000185018507F00',

PSNDPAC=X'00',SRCVPAC=X'00',SSNDPAC=X'00'

Multi–Platform Interface Feature Operation Guide 63

Page 78

Step2 – JES2 Definition (SYS1.PARMLIB)

RMT1 LUTYPE3,BUFSIZE=3840,LINE=1,NUMRD=0,NUMPR=1,NOCOMP,

R1.PR1 CLASS=A,NOSEP,PRWIDTH=132,NOFCBLOD,WS=(W,R,Q,PMD,LIM,

DESTID NAME=LOC64XX,DEST=R1

NOCMPCT,SETUPHDR,CONSOLE

F,T/C,P),CKTPAGE=30

Step 3 – Define to CICS or another

application program

Refer to the vendor documentation for

defining a DSE printer to the program for its

use. Host system commands to change

printer setting are not supported in DSE

mode.

Step 4 – Printer Settings

In LU3 mode the printer settings control the

CPI, LPI and all other aspects of the printed

output. Therefore, you must set the printer

settings to match the characteristics of the

job you are printing. Host controls are not

supported in this mode, except for the coax

Command Interpreter commands on page

19.

64 Multi–Platform Interface Feature Operation Guide

Page 79

6400-LU3-DSE-Remote SNA 3174 Control Unit

LU3-DSE mode is utilized when host

controls are not needed to accomplish the

print function desired. An existing remote

3174 SNA-connected control unit is

assumed. The steps required to install a

local LU3-DSE printer for host definitions

are as follows:

1. Define to NCP point to LU3 default

logmode entry defined below

2. Define to VTAM by adding logmode

entry to VTAM Logmode Table

3. Define to JES2 (May not be required if

VPS. See details below)

4. Define to JES328X Print Facility, VPS,

or equivalent product.

5. Select the options on the printer that

are appropriate for the environment.

Step 1 – NCP Definition

XYZ GROUP TYPE=NCP,...

LINK ADDRESS=(032),...

PU ADDR=C1,...

&luname LU LOCADDR=#, (# replaced by port on control

DLOGMOD=64XXDSER,(Default LOGMODE ENTRY NAME)

MODETAB=MYTABLE (Table name containing MODEENT)

unit)

*

Step 2 – VTAM Definition

* The following entry should be placed in

the VTAM MODE TABLE specified above

or another of your choice.

64XXDSER MODEENT LOGMODE=64XXDSER,

FMPROF=X'03',TSPROF=X'03',PRIPROT=X'B1'

SECPROT=X'90',COMPROT=X'3080',RUSIZES=X'87C6',

PSERVIC=X'038000000000185018507F00',

PSNDPAC=X'01',SRCVPAC=X'01'

Step 3 – JES2 Definition

This definition is not required if you are

using VPS and using U1-U9999 as the

Multi–Platform Interface Feature Operation Guide 65

Page 80

printer ID.

RMT1 LUTYPE3,BUFSIZE=3840,LINE=1,NUMRD=0,NUMPR=1,NOCOMP,

R1.PR1 CLASS=A,NOSEP,PRWIDTH=132,NOFCBLOD,WS=(W,R,Q,PMD,LIM,

DESTID NAME=P64XX,DEST=R1

NOCMPCT,SETUPHDR,CONSOLE (SETUPHDR=PDIR JES2 V3)

F,T/C,P),CKPTPAGE=30

Step 4 – Define to CICS or another

application program

Refer to the vendor documentation for

defining a DSE printer to the program for its

use. Host system commands to change

printer settings are not supported in DSE

mode.

Step 5 – Printer Settings

Since the host controls are not supported,

the printer settings for CPI, LPI, and others

should be set at the printer. (See User’s

Guide beginning on page 8-14)

66 Multi–Platform Interface Feature Operation Guide

Page 81

6400-LU0-DSC-Local Non-SNA 3174 Control Unit

LU0-DSC mode is utilized when host

controls are not needed to accomplish the

print function desired and the control unit is

attached by a VTAM-Controlled NON-SNA

Control Unit. An existing local 3174 NONSNA-connected control unit is assumed.

The steps required to install a local LU0DSC printer for host definitions are as

follows:

1. Define to VTAM by adding logmode

entry to VTAM Logmode Table

2. Define to JES2 (NOT required but

recommended. See details below)

3. Define to CICS or another Application

Program such as VPS or JES328X

products.

4. Select the options on the printer that

are appropriate for the environment.

Step 1 – VTAM Definition

The following should be added to the Local

Major Node VTAM definition.

LOC3174 VBUILD TYPE=LOCAL

LOCPU74 PU CUADDR=nnn...

LOC64XX LU LOCADDR=n,MODETAB=MYMODTB,DLOGMODE=64XXDSCL,

ISTATUS=ACTIVE

The following entry should be placed in the

VTAM MODE TABLE specified above or

another of your choice.

64XXDSCL MODEENT LOGMODE=64XXDSCL,

FMPROF=X'02',TSPROF=X'02',PRIPROT=X'60'

SECPROT=X'40',COMPROT=X'0000',RUSIZES=X'C7C7',

PSERVIC=X'000000000000185018507F00',

PSNDPAC=X'80',SRCVPAC=X'00',SSNDPAC=X'00'

Multi–Platform Interface Feature Operation Guide 67

Page 82

Step2 – JES2 Definition (SYS1.PARMLIB)

RMT1 LUTYPE0,BUFSIZE=3840,LINE=1,NUMRD=0,NUMPR=1,NOCOMP,

R1.PR1 CLASS=A,NOSEP,PRWIDTH=132,NOFCBLOD,WS=(W,R,Q,PMD,LIM,

DESTID NAME=LOC64XX,DEST=R1

NOCMPCT,SETUPHDR,CONSOLE

F,T/C,P),CKPTAGE=30

Step 3 – Define to CICS or another

application program

Host commands for changing printer

settings are not supported in this mode.

Refer to the vendor documentation for

defining an DSC printer to the program for

its use.

Step 4 – Printer Settings

In LU0 mode the printer settings control the

CPI, LPI and all other aspects of the printed

output. Therefore, you must set the printer

settings to match the characteristics of the

job you are printing. Host controls are not

supported in this mode, except for the coax

Command Interpreter commands on page

19.

68 Multi–Platform Interface Feature Operation Guide

Page 83

Appendix B: Describing Custom Set 8

— Printer Configuration ......................... 70

Multi–Platform Interface Feature Operation Guide 69

Page 84

printer configuration

Printer Configuration

The following is a listing of the values stored