Page 1

6400 Line Matrix Printers

Cabinet and Pedestal Models

Form Number S246–0117–06

©Copyright IBM Corp., 1995, 1998

Page 2

Page 3

S246–0117–06

Page 4

Note!

Before using the information and the product it works with, make sure you read the general

information under “Notices,” located right after the Table of Contents.

Seventh Edition (October 1998)

This edition applies to the 6400 Line Matrix Printer.

The following paragraph does not apply to any other country where such provisions are

inconsistent with local law:

INTERNA

IS” WITHOUT W

NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE. Some states do not allow disclaimer of express or implied warranties

in certain transactions; therefore, this statement may not apply to you.

Requests for IBM publications should be made to your IBM representative or to the IBM branch

office serving your locality. Publications are not stocked at the address given below.

IBM welcomes your comments about this publication. You may send your comments by facsimile

to 1–800–524–1519, by E-mail to

IBM Printing Systems Company

Information Development

Department H7FE, Building 003G

P.O. Box 1900

Boulder, CO 80301–9191, U.S.A.

When you send information to IBM or IBM Printing Systems Company, you grant a nonexclusive

right to use or distribute the information in any way IBM or IBM Printing Systems Company

believes appropriate without incurring any obligation to you.

E Copyright International Business Machines Corporation 1995, 1998.

All rights reserved.

TIONAL BUSINESS MACHINES CORPORA

ARRANTY OF ANY KIND, EITHER EXPRESS OR IMPLIED, INCLUDING, BUT

print_pubs@vnet.ibm.com

TION PROVIDES THIS PUBLICA

, or by mail to:

TION “AS

Note to U.S. Government Users—Documentation related to restricted rights—Use, duplication or

disclosure is subject to restrictions set forth in GSA ADP Schedule Contract with IBM Corp.

Page 5

Table of Contents

1

2

Maintenance Overview

About the Printer 13.

The IBM 6400 Series Printer Family 13.

Printer Evolution 15.

How to Identify the Printer 15.

Important Maintenance Notes 16.

About This Manual 16.

How to Use This Manual 16.

Notes and Notices 16.

Printing Conventions in This Manual 18.

Related Documents 18.

Controls and Indicators 20.

Electrical Controls and Indicators 20.

Mechanical Controls and Indicators 24.

Tools, Test Equipment, and Supplies 26.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3

Installation 27

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preventive Maintenance

Cleaning the Printer 29.

Cleaning the Exterior 30.

Cleaning the Interior 30.

Cleaning the Shuttle Frame Assembly 31.

Cleaning the Card Cage Fan Assembly 33.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 6

4

Principles of Operation

5

Line Matrix Printing 35.

Printing Mechanism 38.

Shuttle Frame Assembly 38.

Paper Transport System 41.

Ribbon Transport System 42.

Logical Control of the Printer 43.

Operator Panel 44.

CMX Controller Board 45.

Data Controller 47.

Engine Controller 50.

Power Supply Board 51.

Printer Interface 52.

Graphics 53

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting

Introduction 55

Troubleshooting

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Aids

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

55.

Start of Call 56.

Troubleshooting Display Messages 57.

Message List 58.

Troubleshooting Other Symptoms 66.

General Symptom List 67.

Troubleshooting Procedures 70.

Operator Print Tests 135.

Selecting and Running Operator Print Tests 137.

Customer Engineer (CE) Tests 138.

Selecting and Running Customer Engineer Tests 140.

Boot Diagnostics Menu 142.

Hex Code Printout 145.

Printer Information Menu 148.

Displaying Printer Information 149.

Soft vs. Hard Reset 150.

The Power On Sequence 151.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

Page 7

6

Adjustment Procedures

Introduction 157.

Preparing the Printer for Maintenance 158.

Returning the Printer to Normal Operation 159.

Belt, Paper Feed Timing, Adjustment 160.

Belt, Platen Open, Adjustment 162.

Paper Drive Motor Pulley Alignment 164.

Paper Scale Alignment 166.

Platen Gap Adjustment 168.

Platen Open Motor Pulley Alignment 170.

Ribbon Guide Alignment 172.

Splined Shaft Skew Adjustment 174.

Adjusting the End of Forms Distance 175.

Hammer Phasing 179.

Loading Flash Memory 181.

Coil Temperature Adjustment 188.

Set Shuttle Speed 189.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7

Replacement Procedures and Illustrated Parts List

Organization of This Chapter 191.

Section I: Replacement Procedures

Preparing the Printer for Maintenance 194.

Belt, Paper Feed Timing 195.

Belt, Platen Open 197.

Cable Connectors and Connector Shells 198.

Circuit Board: Controller 200.

Circuit Board: Power Supply 203.

Circuit Breaker 204.

Coax/Twinax Multi-Platform Interface 205.

Cover Assembly, Hammer Bank / Ribbon Mask 206.

Cover Assembly, Shuttle 209.

Cover Assembly, Top, Pedestal Model 210.

Doors, Cabinet, Reversal 211.

Ethernet Interface Assemblies 212.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 8

Fan Assembly, Cabinet Exhaust 215.

Fan Assembly, Card Cage 216.

Fan Assembly, Hammer Bank 217.

Hammer Spring Assembly 218.

IBM Coax/Twinax Expansion Board 222.

Magnetic Pick-up (MPU) Assembly 223.

Memory Modules and Security PAL 224.

Motor Assembly, Paper Feed 227.

Motor Assembly, Platen Open 229.

Motor Assembly, Ribbon Drive 231.

Network Print Server 232.

Operator Panel Assembly, Cabinet Model 233.

Operator Panel Assembly, Pedestal Model 234.

Paper Guide Assembly 235.

Paper Ironer 236.

Platen 237

Resistors, Terminating 242.

Ribbon Guide Assembly (L/R) 244.

Ribbon Hub 245.

Security Module 224.

Shaft, Splined 246.

Shaft, Support 248.

Shuttle Frame Assembly 249.

Spring Assembly, Gas 251.

Spring, Extension 252.

Switch Assembly, Cover Open 253.

Switch Assembly, Paper Detector 254.

Switch Assembly, Platen Interlock 256.

Tractor (L/R) 258.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section II: Illustrated Parts List

Figure 39. Top Cover, Doors, and Casters, Cabinet Model 261.

Figure 40. Paper Stacker and Chains 263.

Figure 41. Control Panel and Cabinet Details 265.

Figure 42. Pedestal Details 267.

Figure 43. Inside Covers, Cabinet Model 269.

Figure 44. Inside Covers and Card Cage, Pedestal Models 271.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

. . . . . . . . . . . . . .

Page 9

Figure 44a. Card Cage Detail, Pedestal Models 273.

Figure 45. Print Mechanism and Circuit Boards: Early Models 275.

Figure 46. Print Mechanism and Circuit Boards: Later Models 277.

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . .

. . . . . . . . . . . .

Figure 47. Magnetic Pickup Unit (MPU) and Extension Spring 279.

Figure 48. Tractor Shafts 281.

Figure 49. Platen 283.

Figure 50. Motors, Card Cage Fan, and Paper Detector Switch 285.

Figure 51. Circuit Breaker 287.

Figure 52. IBM Coax/Twinax Expansion Board 289.

Figure 53. PrintNet Ethernet Interface Assemblies 291.

Appendices

A Wire Data

B Printer Specifications 333.

C Metric Conversion Tables 345.

D Torque Table 347.

E Safety Inspection Guide 349.

F Abbreviations and Signal Mnemonics 357.

. . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

293.

G Cords and Adapters 365.

H Part Numbers 367.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I Noise Suppression Devices 375.

J SureStak Power Stacker 377.

Index 413

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 10

ENERGY STAR

The

EP

A ENERGY

processing equipment to promote the introduction of energy-efficient personal computers,

monitors, and printers, and to reduce air pollution caused by power generation.

IBM participates in this program by introducing printers that reduce power consumption when

they are not being used. This feature can cut energy use by up to 50 percent.

E

Note: The

service.

NERGY

Notices

References in this publication to IBM products, programs, or services do not imply that IBM

intends to make these available in all countries in which IBM operates. Any reference to an IBM

licensed product, program, or service is not intended to state or imply that only IBM’s product,

program, or service may be used. Any functionally equivalent product, program, or service that

does not infringe any of IBM’s intellectual property rights may be used instead of the IBM product.

Evaluation and verification of operation in conjunction with other products, except those expressly

designated by IBM, is the user’s responsibility.

STAR** Computers program is a partnership effort with manufacturers of data

STAR emblem does not represent EPA endorsement of any product or

Any performance data contained in this document was obtained in a controlled environment

based on the use of specific data. The results that may be obtained in other operating

environments may vary significantly. Users of this document should verify the applicable data in

their specific environment. Therefore, such data does not constitute a performance guarantee or

warranty.

IBM may have patents or pending patent applications covering subject matter in this document.

The furnishing of this document does not give you any license to these patents. You can send

license inquiries, in writing, to the IBM Corporation, IBM Director of Licensing, 208 Harbor Drive,

Stamford, Connecticut, United States, 06904.

Electrical Safety

This printer is inspected and listed by recognized national testing laboratories, such as

Underwriters Laboratories, Inc. (UL) in the U.S.A. and Canadian Standards Association (CSA) in

Canada. Listing of a product by a national testing laboratory indicates that the product is designed

and manufactured in accordance with national requirements intended to minimize safety hazards.

IBM equipment meets a very high standard of safety in design and manufacture. Remember,

Page 11

however, that this product operates under conditions of high electrical potentials and heat

generation, both of which are functionally necessary.

Trademarks and Service Marks

The following terms, denoted by an asterisk (*) in this publication, are trademarks of the IBM

Corporation in the United States or other countries or both.

IBM

PC-DOS

SCS

Token-Ring

The following terms, denoted by a double asterisk (**) in this publication, are trademarks of other

companies:

Acrobat Adobe Systems Incorporated

Adobe Adobe Systems Incorporated

Code V Quality Micro Systems

ECOS ECOS Electronics Corp., Inc., Oak Park, Ill.

E

NERGY

Epson Epson Seiko Corporation

Ethernet Xerox Corporation

Fluke John Fluke Manufacturing Co., Inc.

FX Epson Seiko Corporation

IGP Printronix, Inc.

MS-DOS Microsoft Corporation

PrintNet Printronix, Inc.

Printronix Printronix, Inc.

SureStack Printronix, Inc.

Torx Camcar/Textron Inc.

STAR United States Environmental Protection Agency

Page 12

Safety Notices

Danger and Caution notices are numbered to help you find the translated

versions in the

DANGER:

<2> Switch off printer power and unplug the printer power cord before

cleaning the printer.

<3> Hazardous voltages are present in the printer with the power cord

connected to the power source. Switch off printer power and unplug the

printer power cord before proceeding.

<4> Do not connect or disconnect any communication port, teleport,

attachment connector, or power cord during an electrical storm.

<5> Power off the printer and disconnect the power cord before connecting

or disconnecting communication port, teleport, or attachment cable

connector.

IBM 6400 Line Matrix Printer Safety Notices

booklet.

CAUTION:

<2> Over time the upper edge of the paper ironer can become sharp. To

avoid cutting yourself handle the paper ironer on the sides.

<4> To prevent injury from electric shock, wait at least one minute after

powering off before removing the power supply circuit board.

<5> The constant force spring is a high tension spring. To avoid

pinching your fingers, coil the spring slowly and carefully. Do not let

the spring twist or crimp.

Page 13

1

Maintenance Overview

About the Printer

The entire system architecture of an IBM* 6400 line matrix printer is

contained on one circuit board. The use of DRAM and flash memory on this

board permits rapid access to stored printer emulations and fast processing

of print data. A variable-speed shuttle and half-step paper control enables the

printer to print a wide variety of high-volume jobs with minimum maintenance

and maximum reliability.

Although technologically advanced, the printer is easy to use. The operator

can select every printer function at the control panel or by sending printer

control codes in the data stream from the host computer.

This is also an excellent graphics printer, with optional features that simplify

the creation of dot images. The IGP** and Code V** Printronix** emulations

are simple but versatile graphics programming languages that load into flash

memory.

The IBM 6400 Series Printer Family

The IBM 6400 Line Matrix Printer family consists of pedestal mount and floor

cabinet models that print at different speeds, as shown in Table 1. The print

speeds listed in Table 1 are the maximum speeds attainable under certain

conditions. Actual print speed is determined by the interaction of many

variables. For more information, refer to the discussion of Printing Rates in

Appendix B, page 342.

Maintenance Overview

13

Page 14

Models that print 475, 500, 800, 900, and 1000 lpm are available in floor

cabinet and pedestal housings. Models that print 1200, 1400, and 1500 lpm

are available only in floor cabinets.

Table 1. The IBM 6400 Series Printer Family

Model

Number

Print

Speed

Enclosure Hammer

Bank

Data Controller

Clock

6400–004 475 lpm Cabinet 28 Hammers 25 MHz

6400–04P 475 lpm Pedestal 28 Hammers 25 MHz

6400–005 500 lpm Cabinet 28 Hammers 25 MHz

6400–05P 500 lpm Pedestal 28 Hammers 25 MHz

6400–050 500 lpm Cabinet 28 Hammers 40 MHz

6400–P50 500 lpm Pedestal 28 Hammers 40 MHz

6400–008 800 lpm Cabinet 49 Hammers 25 MHz

6400–08P 800 lpm Pedestal 49 Hammers 25 MHz

6400–009 900 lpm Cabinet 49 Hammers 25 MHz

6400–09P 900 lpm Pedestal 49 Hammers 25 MHz

6400–010 1000 lpm Cabinet 60 Hammers 40 MHz

6400–P10 1000 lpm Pedestal 60 Hammers 40 MHz

1

14

6400–012 1200 lpm Cabinet 91 Hammers 25 MHz

6400–014 1400 lpm Cabinet 91 Hammers 40 MHz

6400–015 1500 lpm Cabinet 102 Hammers 40 MHz

1

The microprocessor of the Data Controller unit on the CMX controller board

runs at 25 MHz or 40 MHz, depending on printer model. This means there

are two kinds of CMX controller board for IBM 6400 printers, used as shown

in Table 1. The 40 MHz controller board, however, is backwards compatible

in all models that use the 25 MHz board.

Maintenance Overview

Page 15

Printer Evolution

IBM 6400–050, –P50, –010, –P10, and –015 printers use a redesigned

shuttle frame assembly, hammer bank, and ribbon guides which are not

compatible with earlier models. These models use the CMX 040 controller

board, which has a 40 MHz clock speed on the Data Controller unit.

How to Identify the Printer

The model number of the printer indicates printer family, speed, and type of

enclosure. (See Figure 1.)

IBM 6400 Printer Family

6400–04P

Enclosure Code*:

P = Pedestal Model

* No Code = Cabinet Model

Figure 1. Interpreting the Printer Model Number

Speed Rating:

004 = 475 lpm

005 = 500 lpm (25 MHz controller)

050 = 500 lpm (40 MHz controller)

008 = 800 lpm

009 = 900 lpm

010 = 1000 lpm

012 = 1200 lpm

014 = 1400 lpm

015 = 1500 lpm

Maintenance Overview

15

Page 16

Important Maintenance Notes

Failure to observe the following guidelines can result in damage to the

equipment.

To ensure the best performance of the printer, remember these important

maintenance concepts when you service the printer:

♦ Do not adjust the platen gap unless the original shuttle frame assembly

or platen has been replaced with a new or rebuilt unit, or unless

instructed to do so in the troubleshooting chapter.

♦ Never bend or “tweak” hammer springs. Always handle hammer springs

by the thick mounting base. The hammer springs and hammer tips are

delicate and precisely aligned.

♦ Use only the ribbons specified in Appendix B. Use of incorrect ribbons

can lead to ink migration problems, degraded print quality, and expensive

damage to the printer.

♦ Do not close the forms thickness lever too tightly. Closing the forms

thickness lever too tightly can lead to smearing, degraded print quality,

paper jams, and damage to the platen and shuttle assembly.

ATTENTION

About This Manual

This is a field service maintenance manual. It is designed so that you can

quickly locate maintenance information.

How to Use This Manual

1. Find the procedure or information you need in the Table of Contents or

the Index.

2. Read the entire procedure before you do it.

3. Gather the parts and tools you will need.

4. Make sure you understand all safety notices before you start a task.

Notes and notices are defined below.

16

Maintenance Overview

Page 17

Notes and Notices

For your safety and to protect valuable equipment, it is very important that

you read and comply with all information highlighted under notes and notices:

DANGER:

The word Danger indicates the presence of a hazard that has the

potential of causing death or serious personal injury. Danger and

Caution notices are numbered to help you find the translated versions in

the IBM 6400 Line Matrix Printer Safety Notices booklet.

CAUTION:

The word Caution indicates the presence of a hazard that has the

potential of causing moderate or minor personal injury.

CAUTION:

This symbol indicates an assembly that requires two or more persons

to lift or hold.

ATTENTION

Indicates the possibility of damage to a program, device, system, or

data.

IMPORTANT

Information vital to proper operation of the printer.

NOTE: A note gives you helpful tips about printer operation and

maintenance.

Maintenance Overview

17

Page 18

Printing Conventions in This Manual

♦ Operator panel keys and indicators are printed bold.

Example: Press the Cancel key, then press the Start key.

♦ Liquid Crystal Display (LCD) messages are printed in capital letters

inside quotation marks ( “ ” ).

Example: Press the Stop key. “NOT READY” appears on the LCD.

♦ Key combinations are denoted by the + (plus) symbol.

Example: Press Scroll + Scroll

means

Press the

Scroll

key and the

Related Documents

To ensure complete understanding of important safety notices for technicians

whose native language is not English, the notices have been translated into

many languages in the

No. G544–5389.

IBM 6400 Line Matrix Printer Safety Notices

Scroll

key at the same time.

: Form

This maintenance manual does not explain how to operate or configure the

printer. For that information, refer to the

♦

IBM 6400 Line Matrix Printer Operator’s Guide,

Illustrated instructions on daily printer operation.

♦

IBM 6400 Line Matrix Printer Setup Guide,

Explains how to install and configure the printer.

Coax/Twinax Multi-Platform Interface Option Installation and Operation

♦

Guide

, Form Number S544–5642

Information pertaining to printer control languages, emulations, and control

codes is in the applicable

♦

IBM 6400 ASCII Programmer’s Reference

IBM 6400 CTA Programmer’s Reference

♦

IBM 6400 IPDS Programmer’s Reference

♦

Information pertaining to graphics programming is in the applicable

Manual

:

Programmer’s Reference

Operator’s Guide

Form No. S544–5641

Form No. S544–5640

manual:

: Form No. S544–5635

: Form No. S544–5636

: Form No. S544–5637

and

Setup Guide

User’s

:

18

Maintenance Overview

Page 19

♦

IBM 6400 Code V User’s Manual:

Provides information used with the optional Code V Printronix emulation

enhancement feature. The Code V Printronix emulation allows the user

to create and store forms, generate logos, bar codes, and expanded

characters, create other graphics, and merge graphics with alphanumeric

data as a document is printed.

Form No. S544–5638

IBM 6400 IGP User’s Manual:

♦

Provides information used with the optional IGP Printronix emulation

enhancement feature. The IGP Printronix emulation allows the user to

create and store forms, generate logos, bar codes, and expanded

characters, create other graphics, and merge graphics with alphanumeric

data as a document is printed.

Installation, configuration, and troubleshooting of the Network Print Server

are covered in the following documents:

♦

Print Server User’s Guide

Part No. 30H4056

♦

Ethernet** Interface User’s Manual

Form No. S246–0153

Form No. S544–5639

,

Maintenance Overview

19

Page 20

Controls and Indicators

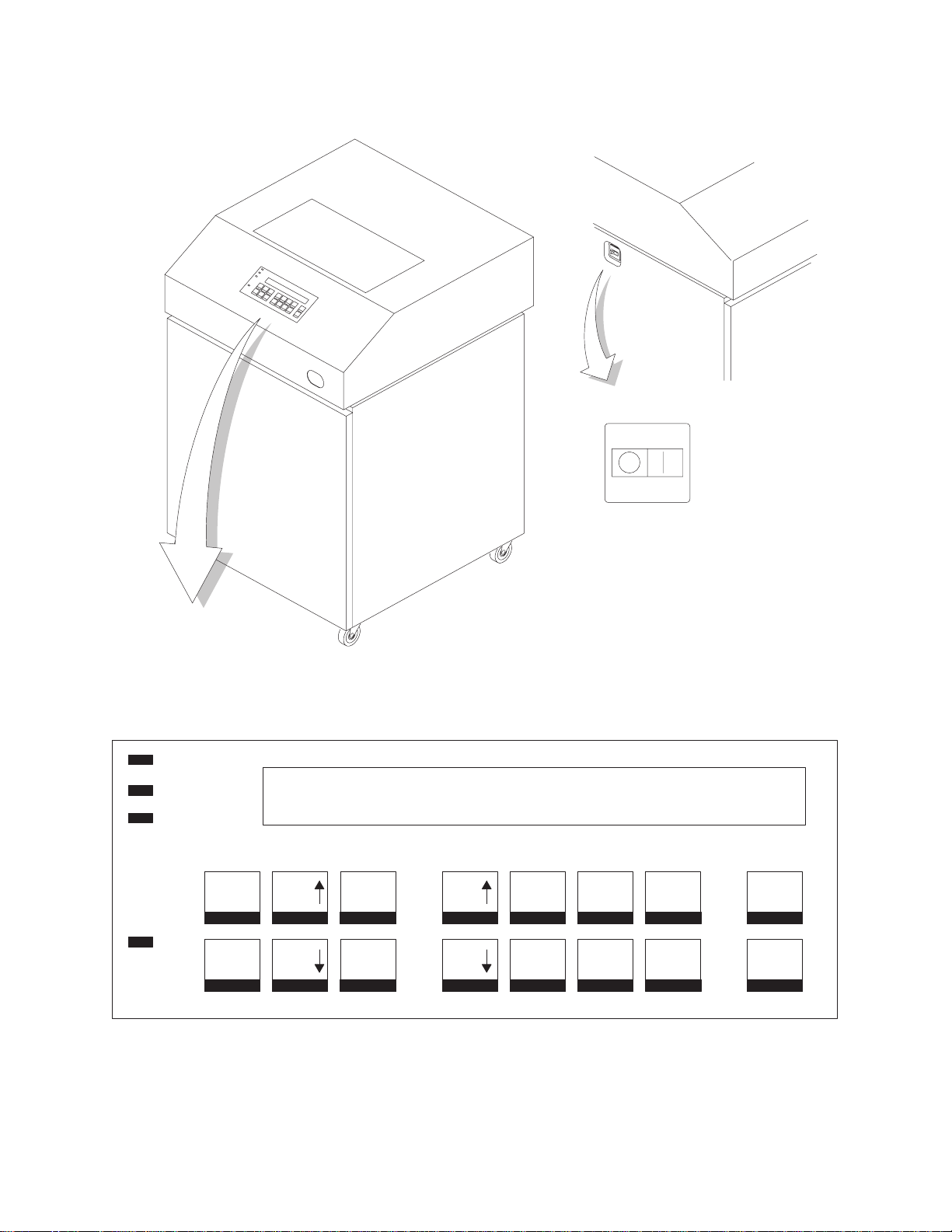

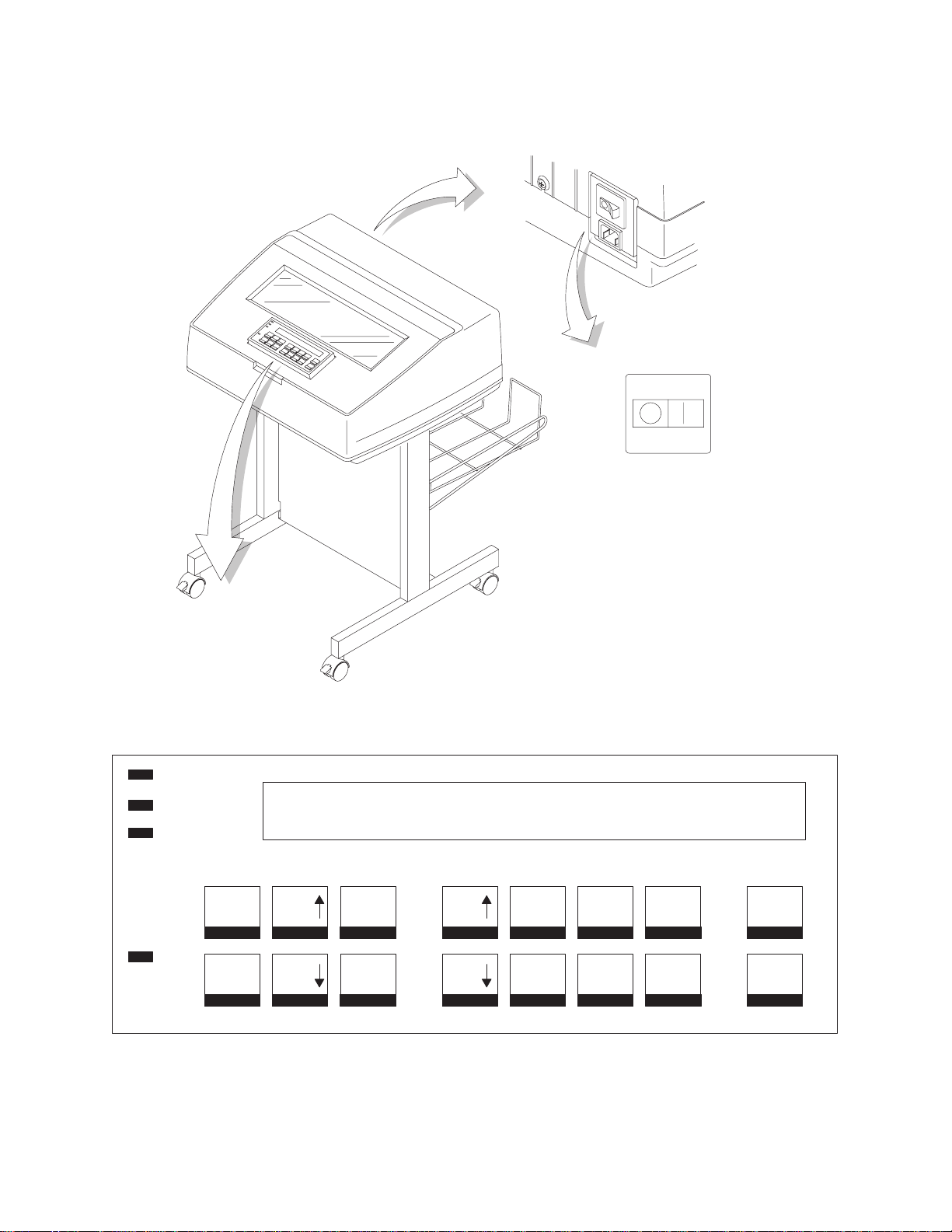

Electrical Controls and Indicators, Cabinet Models (Figure 2)

Key or

Indicator

Power Indicator Lit when the printer is on.

Function

Ready Indicator Lit when the printer is in READY mode (on-line), no errors are pending, and the printer is

Processing Indicator Flashes when the printer is receiving data from the host.

Attention Indicator Flashes when an error occurs. After correcting the error, press Stop to turn off this LED.

Power Switch Applies power to the printer: (1 = on, 0 = off.) This switch is also a circuit breaker.

LCD The LCD (Liquid Crystal Display) displays printer status messages.

Start Puts the printer in the READY (on-line) mode. This key also clears fault conditions, exits

Stop Puts the printer in the NOT READY (off-line) mode. This key also silences the audible

Form Feed Advances paper to next Top-Of-Form, as defined by the current page length.

Set Top Of Form Sets TOF and moves paper downward from the tractor alignment notches to the print

Line Feed

View Press to move the current print position up to the tractor area for viewing. Press again to

Cancel Cancels a print job.

Eject / Restore Moves paper for viewing or tear-off. This key is configurable: refer to the

Menu If in the NOT READY mode, this key puts the printer in the PROGRAM mode. If the

Enter Selects the option displayed on the LCD. This action either sets a value, moves to the next

ready to process data. Off when the printer is in NOT READY mode (off-line).

program mode menus, moves paper back to print position after View is pressed, and

restores after an eject.

alarm, stops a Printer Test, and restores after an eject. Stop + Enter resets the printer.

position.

Moves paper up one line, as determined by current line spacing.

return paper to original print position.

Operator’s Guide

configuration menus are locked, the LCD indicates the operator panel is locked.

lower level of configuration, or starts a self-test. Stop + Enter resets the printer.

.

Return Returns to the next higher level of a configuration menu.

Micro

Micro ± In the NOT READY mode, moves the paper downward 1/72 inch (“micro-step” function).

Scroll

Scroll ± In the PROGRAM mode, this key moves to the previous menu (“Scroll” function).

Printer

Configuration

Stop + Enter Soft reset: load power on configuration in memory. Printer must be in NOT READY mode.

Scroll + Scroll ±

20

In the NOT READY mode, moves the paper upward 1/72 inch (“micro-step” function).

In the PROGRAM mode, this key moves to the next menu (“Scroll” function).

Prints the current configuration.

Toggles the lock on the configuration menus.

Maintenance Overview

Page 21

Power

Ready

Processing

(Off) (On)

Power Switch

LCD

Menu

Attention

Printer Configuration

Figure 2. Electrical Controls and Indicators, Cabinet Models

Maintenance Overview

Scroll

Scroll

Enter

Return

Micro

Micro

Line

Feed

View

Form

Feed

Set Top

Of Form

Start

Stop

Cancel

Eject/

Restore

21

Page 22

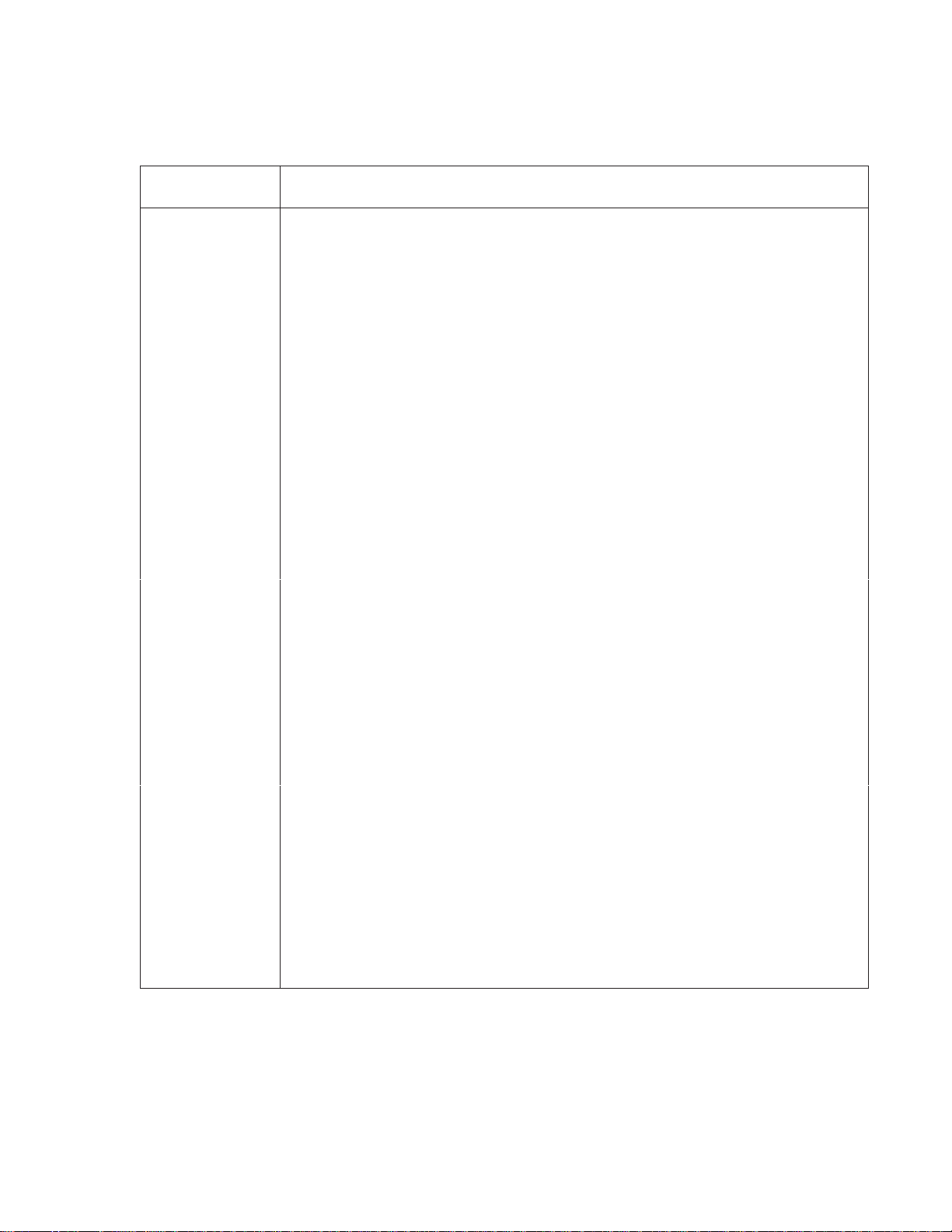

Electrical Controls and Indicators, Pedestal Models (Figure 3)

Key or

Indicator

Power Indicator Lit when the printer is on.

Function

Ready Indicator Lit when the printer is in READY mode (on-line), no errors are pending, and the printer is

Processing Indicator Flashes when the printer is receiving data from the host.

Attention Indicator Flashes when an error occurs. After correcting the error, press Stop to turn off this LED.

Power Switch Applies power to the printer: (1 = on, 0 = off.) This switch is also a circuit breaker.

LCD The LCD (Liquid Crystal Display) displays printer status messages.

Start Puts the printer in the READY (on-line) mode. This key also clears fault conditions, exits

Stop Puts the printer in the NOT READY (off-line) mode. This key also silences the audible

Form Feed Advances paper to next Top-Of-Form, as defined by the current page length.

Set Top Of Form Sets TOF and moves paper downward from the tractor alignment notches to the print

Line Feed

View Press to move the current print position up to the tractor area for viewing. Press again to

Cancel Cancels a print job.

Eject / Restore Moves paper for viewing or tear-off. This key is configurable: refer to the

Menu If in the NOT READY mode, this key puts the printer in the PROGRAM mode. If the

Enter Selects the option displayed on the LCD. This action either sets a value, moves to the next

ready to process data. Off when the printer is in NOT READY mode (off-line).

program mode menus, moves paper back to print position after View is pressed, and

restores after an eject.

alarm, stops a Printer Test, and restores after an eject. Stop + Enter resets the printer.

position.

Moves paper up one line, as determined by current line spacing.

return paper to original print position.

Operator’s Guide

configuration menus are locked, the LCD indicates the operator panel is locked.

lower level of configuration, or starts a self-test. Stop + Enter resets the printer.

.

Return Returns to the next higher level of a configuration menu.

Micro

Micro ± In the NOT READY mode, moves the paper downward 1/72 inch (“micro-step” function).

Scroll

Scroll ± In the PROGRAM mode, this key moves to the previous menu (“Scroll” function).

Printer

Configuration

Stop + Enter Soft reset: load power on configuration in memory. Printer must be in NOT READY mode.

Scroll + Scroll ±

22

In the NOT READY mode, moves the paper upward 1/72 inch (“micro-step” function).

In the PROGRAM mode, this key moves to the next menu (“Scroll” function).

Prints the current configuration.

Toggles the lock on the configuration menus.

Maintenance Overview

Page 23

Power

Ready

Processing

(Off) (On)

Power Switch

LCD

Menu

Attention

Printer Configuration

Figure 3. Electrical Controls and Indicators, Pedestal Model

Maintenance Overview

Scroll

Scroll

Enter

Return

Micro

Micro

Line

Feed

View

Form

Feed

Set Top

Of Form

Start

Stop

Cancel

Eject/

Restore

23

Page 24

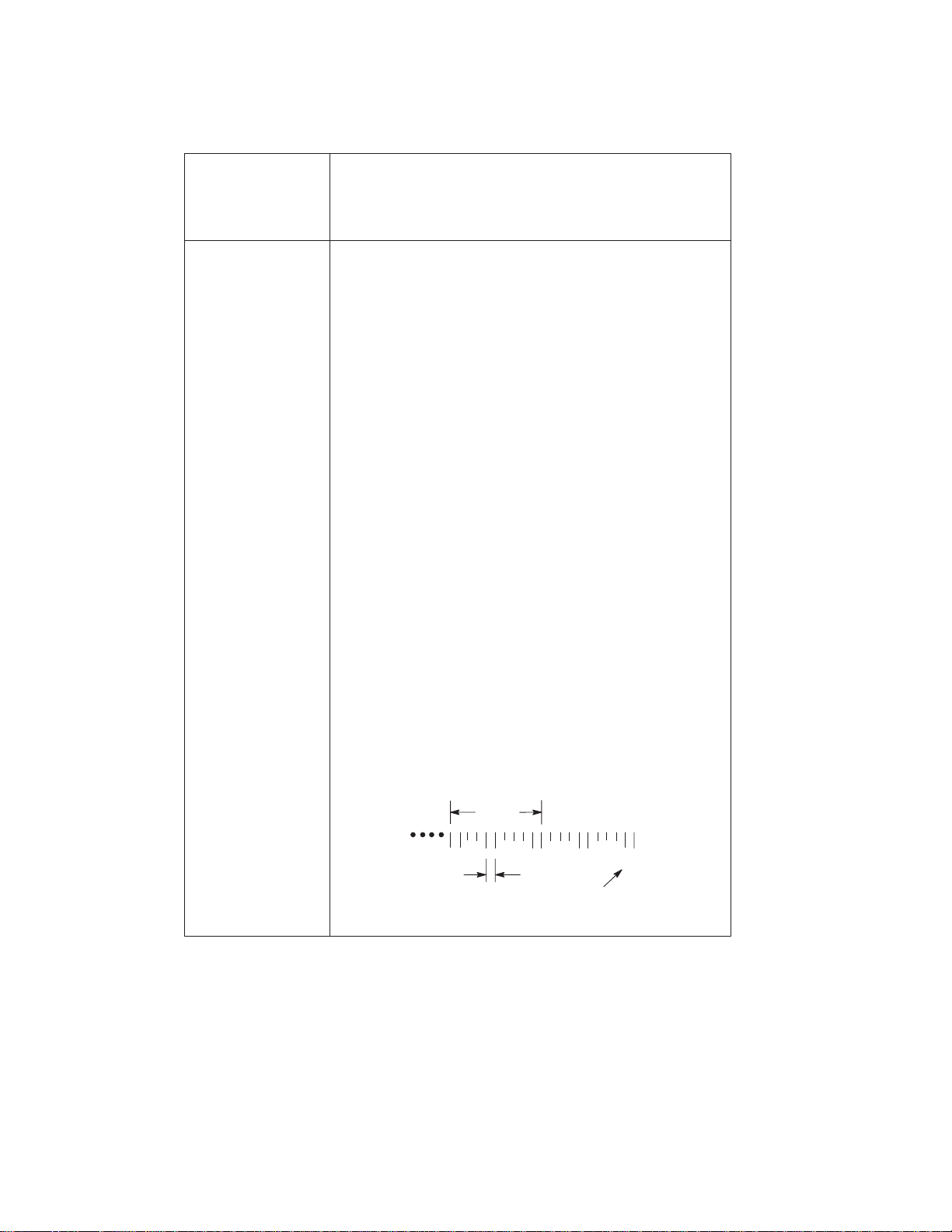

Mechanical Controls and Indicators, All Models (Figure 4)

Control or

Indicator

Forms Thickness

Lever

Paper Supports

Forms Thickness

Pointer and Scale

Tractors (2)

Tractor locks (2)

Horizontal

Adjustment Knob

Vertical Position

Knob

Ribbon Loading

Path Diagrams

Function

Sets the platen for paper and forms of different

thicknesses. Lever must be fully opened (raised) to load

or unload paper

Help prevent paper jams by supporting inner sections of

paper. Positioned manually by sliding them along shafts.

Indicates

at A for thin (single-part) forms, B for thicker forms, and

so on.

Hold and feed paper. Used to set side margin and

position paper horizontally.

Lock tractors in position.

Allows fine positioning of left print margin. Moves paper

and tractors left or right.

Used to set top of form or first line to be printed. Rotate

to move paper vertically. Works when Forms Thickness

Lever is open.

Instructions showing how to load the ribbon correctly.

One diagram is cast in relief on the shuttle cover

another is printed on the paper scale.

.

relative

thickness of forms/paper. Set this lever

, and

24

Paper Scale

A horizontal scale graduated in tenths of an inch, useful

for setting paper margins and counting text columns.

(See below.)

1 inch

110 20

0.1 inch

Column

Number

Maintenance Overview

Page 25

Left Tractor

Paper Scale

Paper

Supports

Horizontal

Adjustment

Knob

Tractor Lock

Ribbon Loading Path

Diagrams

Right Tractor

Tractor

Lock

Vertical

Position

Knob

Forms Thickness

Lever and Scale

Maintenance Overview

Forms

Thickness

Pointer

Figure 4. Mechanical Controls and Indicators

25

Page 26

Tools, Test Equipment, and Supplies

The tools and equipment required for field level maintenance of the printer

are listed below.

Item Part No.

6400 Line Matrix Printer Configuration

Utility Disk 63H7379

1–30 Inch-pound Torque Screwdriver 16F1661

ESD W

Feeler Gauge, .010 inch

Feeler Gauge, .011 inch

Feeler Gauge, .040 inch

Force Gauge, 20 lb 25F9687

Grip Ring Pliers 9900317

Lubricant, Bearing, IBM #20 117397

DIP Module Extracting Tool 9900764

Nut Driver, 1/4 inch

Nut Driver, 5/16 inch

Open End Wrench, 7/32 inch 1650843

Open End Wrench, 5/16 inch 9900005

PLCC Module Pick Extraction Tool 73G5523

PLCC Module Plier Extraction Tool 10G3902

Screwdriver, Philips, #1 73G5362

Screwdriver, Philips, #2 73G5363

Spring Hook, Heavy Duty

Tie Wraps 75X5972

Torque Screwdriver Adapter 39F8449

Torque Screwdriver Hex Adapter 3/32 inch 39F8451

Torque Screwdriver Hex Adapter 5/32 inch 39F8450

Torque Screwdriver Hex Adapter 3/16 inch 39F8455

Torque Screwdriver Hex Adapter 5/64 inch 16F1663

Torx** T-10 Bit 83F2834

rist Strap 6405959

26

Maintenance Overview

Page 27

2

Installation

Installation and configuration of the printer are covered in the

6400 Line Matrix Printer Set-Up Guide

Installation, operation, and replacement parts for the optional coax/twinax

interface are covered in the

Installation and Operation Guide

Installation, configuration, and troubleshooting of the Network Print Server

are covered in the following documents:

♦

IBM Network Print Server Ethernet Administrator’s Guide

Form No. S246–0111

Coax/Twinax Multi–Platform Interface Option

, Form No. S544–5640

, Form No. S246–0149.

,

♦

IBM Network Print Server Token-Ring Administrator’s Guide

Form No. S246–0112

♦ The

Network Print Server Technical Reference Manual

diskette that comes with the Network Print Server. This “softcopy”

document is in Adobe Acrobat Reader format.

is included on a

,

27Installation

Page 28

28 Installation

Page 29

3

Preventive Maintenance

Cleaning the Printer

Aside from normal replenishment of paper and ribbons, the only preventive

maintenance required for the printer is periodic cleaning.

Because operating conditions vary widely, the user must determine how often

to clean the printer.

There is no guarantee that the user will clean the printer regularly, however,

so you should clean the printer whenever you are called to service it.

DANGER:

<2> Switch off printer power and unplug the printer power cord before

cleaning the printer.

ATTENTION

Do not use abrasive cleaners, particularly on the window.

Do not drip water into the printer. Damage to the equipment will result.

Do not spray directly onto the printer when using spray solutions

(spray the cloth, then apply the dampened cloth to the printer).

Do not vacuum circuit boards.

Preventive Maintenance

29

Page 30

Cleaning the Exterior

1. Power off the printer.

2. Disconnect the AC power cord from the power source.

3. Wipe the outside of the enclosure with a clean, lint-free cloth dampened

(not wet) with water and a mild detergent or window cleaning solution.

4. Dry the enclosure with a clean, lint-free cloth.

5. Clean the inside of the printer, as described below.

Cleaning the Interior

1. Power off the printer.

2. Disconnect the AC power cord from the power source.

3. Open the printer cover.

4. Remove paper from the printer.

5. Remove the ribbon.

6. Using a soft-bristled, non-metallic brush, wipe paper dust and ribbon lint

off the tractors, shuttle cover assembly, base casting, and ribbon guides.

Vacuum up the residue.

7. Wipe the splined shaft and the ribbon guides with a soft cloth.

8. Vacuum up dust or residue that has accumulated inside the lower

cabinet.

9. Wipe the interior of the lower cabinet with a clean, lint-free cloth

dampened with water and a mild detergent or window cleaning solution.

10. Dry the cabinet interior with a clean, lint-free cloth.

11. Clean the shuttle frame assembly, as described below.

30

Preventive Maintenance

Page 31

Shuttle

Cover

Assembly

Base

Casting

Splined

Shaft

Tractor

NOTE: Cabinet model shown.

Procedure is the same for

pedestal model.

Forms

Thickness

Ribbon

Guide (2)

Lever

Figure 5. Cleaning Inside the Cabinet or Top Cover

Cleaning the Shuttle Frame Assembly

1. Remove the shuttle cover assembly (page 209).

2. Remove the shuttle frame assembly (page 249).

3. Remove the paper ironer (page 236).

CAUTION:

<2> Over time the upper edge of the paper ironer can become sharp. To

avoid cutting yourself handle the paper ironer on the sides.

4. Wipe the paper ironer with a soft cloth to remove lint, ink, and paper

residue.

5. Install the paper ironer (page 236).

6. Remove the hammer bank / ribbon mask cover assembly (page 206).

Preventive Maintenance

31

Page 32

ATTENTION

The thin plate (ribbon mask) of the hammer bank cover assembly is

fragile. Be careful not to over-bend or kink the ribbon mask when

handling and cleaning the hammer bank cover assembly.

7. Using a clean soft cloth, wipe the hammer bank cover and ribbon mask

to remove lint, ink, and paper residue. Clean the holes in the cover strips.

Carefully wipe between the hammer bank cover and the ribbon mask

(early models).

ATTENTION

Do not use any solvents or liquids to clean the hammer tips. Clean the

hammer tips gently—too much pressure can chip hammer tips.

8. Using a stiff, non-metallic brush (such as a toothbrush), gently brush the

hammer tips to remove lint and ink accumulations. (See Figure 6.)

Vacuum up any residue.

6400–004/04P

NOTE:

hammer bank shown.

Procedure is the same for

Hammer

Tip

all hammer banks.

32

Figure 6. Cleaning the Hammer Tips

ATTENTION

The hammer bank contains a strong magnet. To prevent damage to the

hammer tips, do not let the hammer bank cover assembly snap into

place as the hammer bank magnet attracts it. Any impact of the cover

against the hammer bank can break hammer tips.

9. Install the hammer bank / ribbon mask cover assembly (page 206).

10. Install the shuttle frame assembly (page 249).

11. Install the shuttle cover assembly (page 209).

12. Clean the card cage fan assembly, as described below.

Preventive Maintenance

Page 33

Cleaning the Card Cage Fan Assembly

1. Cabinet Models: Remove the paper guide assembly (page 235).

Pedestal Model: Remove the top cover assembly (page 210).

2. Vacuum the card cage fan assembly and surrounding areas to remove

paper particles, dust, and lint.

3. Cabinet Models: Install the paper guide assembly (page 235).

Pedestal Model: Install the top cover assembly (page 210).

4. Close the printer cover.

5. Connect the AC power cord to the power source.

NOTE: Cabinet model shown.

Procedure is the same for

pedestal model.

Card Cage

Fan Assembly

Preventive Maintenance

Figure 7. Cleaning the Card Cage Fan Assembly

33

Page 34

34

Preventive Maintenance

Page 35

4

Principles of Operation

Line Matrix Printing

The printer creates characters and graphics by printing patterns of ink dots

on paper, an entire line at a time. This technique is called line matrix printing.

Every text character is stored in printer memory as a pattern of dots on a

logical grid called the dot matrix. (See Figure 8.) The ink dots are made by a

row of small hammers mounted on a shuttle that sweeps rapidly back and

forth. Printer logic circuits divide every line of incoming data into horizontal

dot rows. The hammers put dots at the required positions for the entire

by striking an inked ribbon and the paper.

line

0.00835 inch

0.01389 inch

First row and column of next

character line (at 6 LPI)

0.02 inch

112Column No.

0.10 inch

First row and column

of next character column

(at 10 cpi)

Lowest descender dot line

Figure 8. A Dot Matrix

Principles of Operation

35

Page 36

When the shuttle reaches the end of a sweep, it reverses direction, the paper

is advanced one dot row, and the hammers print the next row of dots as the

shuttle sweeps in the opposite direction. After a line of characters is printed,

hammer action stops and the paper advances to the first dot row of the next

print line. The number of dot rows allowed for line separation depends on the

vertical line spacing the user selects.

The dot matrix patterns of text characters vary according to the font the user

selects. For example, in the data processing (DP) font at a line spacing of six

lines per inch (lpi), a dot matrix contains 12 dot rows from the top of one

character line to the top of the next. (See Figure 8 and Figure 9.) At eight lpi

there are nine dot rows per character line, at nine lpi eight dot rows per

character line, and so on.

Each individual hammer spring forms more than one character as the shuttle

moves horizontally. This principle is illustrated in Figure 10.

One

Text

Line

Direction of Shuttle Movement

Dot

Row

Start

1

2

3

4

5

6

7

8

*

9

**

10

11

Number of rows determined by line spacing

n

1

2

* This row is used only for lowercase descenders

** This row is used for underlining and lowercase descenders

Paper

Feed

Direction

36

Figure 9. Standard Character Formation

Principles of Operation

Page 37

Succesive Hammer Strokes Per Scan

Shuttle

Scan

1

2

3

4

5

6

Dot

Row

1

1

2

1

2

3

1

2

3

4

1

2

3

4

5

1

2

3

4

5

6

1 13 135 1 357 13579

******

1

2

3

4

5

6

7

7

*

Figure 10. Action of One Hammer Spring in Text Printing

Principles of Operation

Even column dot centers within the printed character

area and character space hammer positions are not

illustrated in this diagram.

NOTE:

= Hammer Released and Dot Printed

= Hammer Not Released; No Dot Printed

37

Page 38

Printing Mechanism

While the principles of line matrix printing are easy to state, the act of printing

dots accurately from a rapidly oscillating shuttle onto a vertically moving

piece of paper requires complex timing and coordination between printer

logic and the printing mechanism. The printing mechanism consists of the

shuttle frame assembly, the ribbon transport system, and the paper transport

system.

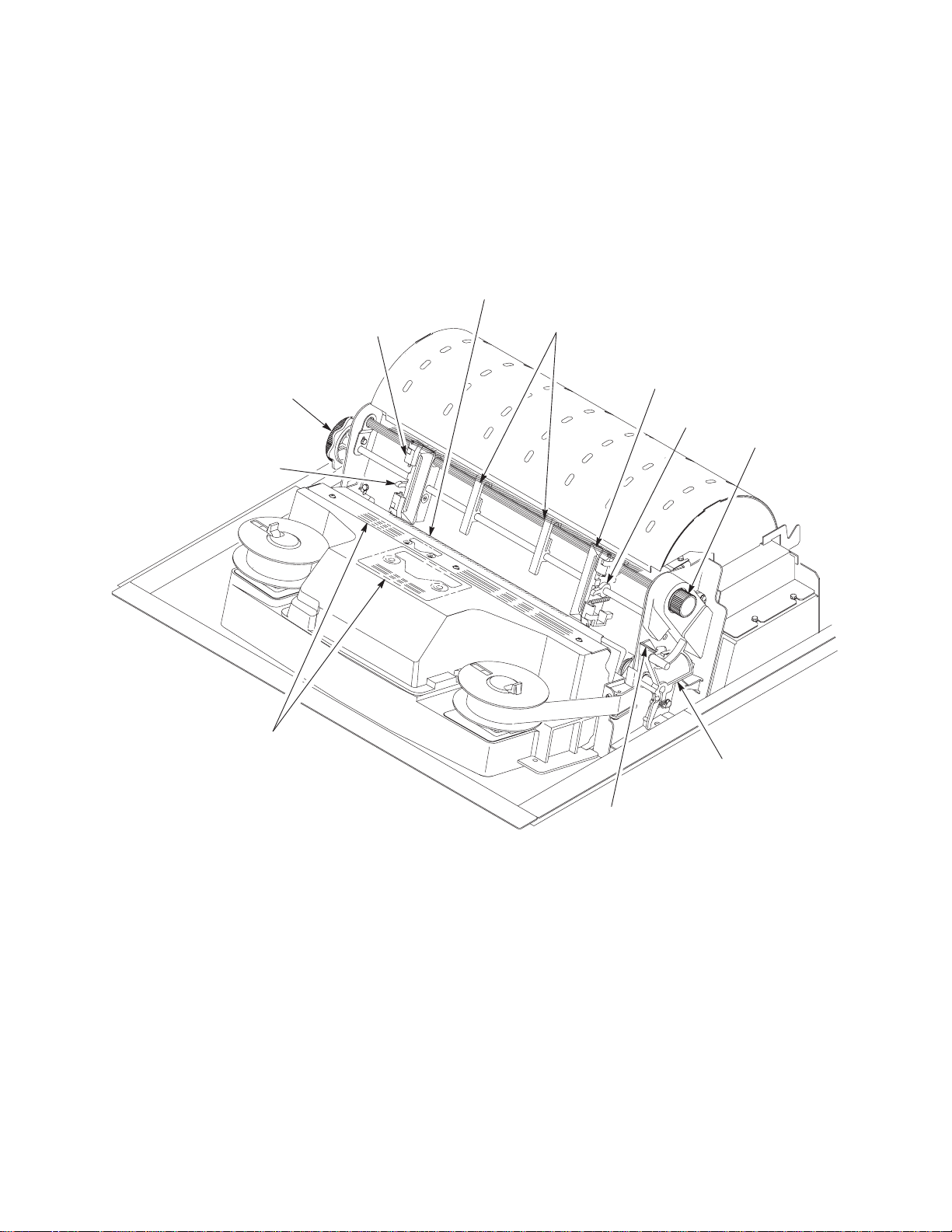

Shuttle Frame Assembly

The central element of the printing mechanism is the shuttle frame assembly,

which houses the hammer bank assembly and the shuttle drive motor. (See

Figure 11.)

Shuttle Frame

Assembly

Hammer Bank Assembly

Counterweight Assembly

Connecting Rod

Guide Shaft

Shuttle Drive Motor

38

Figure 11. Shuttle Frame Assembly

Principles of Operation

Page 39

Hammer Bank Assembly

The hammer springs are grouped in comb-like assemblies mounted on a

solid hammer bank. Both the number of hammer springs per hammer spring

assembly and the number of hammer spring assemblies on the hammer

bank vary according to printer model:

♦ 6400–004/–04P/–005/–05P/–050/–P50: seven 4-hammer assemblies, for

a total of 28 hammer springs

♦ 6400–008/–08P/009/–09P: seven 7-hammer assemblies, for a total of 49

hammer springs

♦ 6400–010, –10P: six 10-hammer assemblies, for a total of 60 hammer

springs

♦ 6400–012/–014: seven 13-hammer assemblies, for a total of 91 hammer

springs

♦ 6400–015: six 17-hammer assemblies, for a total of 102 hammer springs

Shuttle Drive Motor

The shuttle drive motor is built into the shuttle assembly casting and drives

two connecting rods on a crankshaft. (See Figure 11.) The small end of one

connecting rod attaches to the hammer bank; the small end of the other

connecting rod attaches to a counterweight frame surrounding the hammer

bank. (The hammer bank and the counterweight constitute the shuttle

assembly.) The rotary motion of the shuttle drive motor converts to linear and

opposing motion of the hammer bank assembly and the counterweight, in an

arrangement similar to that of a horizontally-opposed gasoline engine.

Mechanically, this design achieves the same benefits as this type of engine:

perfect primary balance, low vibration, and durability.

Each hammer spring is a stiff leaf spring with a cylindrical tungsten carbide

tip on the free end. (See Figure 12.) A permanent magnet is imbedded along

the length of the hammer bank and acts on the hammer springs through

individual pole pieces. The pole pieces magnetically attract and hold the free

end of the hammer spring under tension. This is called the retracted state.

Principles of Operation

39

Page 40

Tungsten

Carbide

Hammer Tip

Hammer Spring Assembly

NOTE:

6400–004/04P

hammer bank shown.

Alignment Pin

Hammer Bank Assembly:

Coils, Magnet, Pole Pieces,

Hammer Spring Assemblies

40

Figure 12. Hammer Springs and Hammer Bank (Detail)

Two electromagnetic coils are mounted behind each hammer and wound

around each pole piece. The coils are normally de-energized. When hammer

driver logic determines that the hammer must print a dot, a current pulse

energizes the coils. The polarity of the resulting magnetic field opposes the

field of the permanent magnet, canceling its effect and releasing the hammer.

The hammer springs forward, strikes the ribbon and paper, and leaves a dot

impression of the hammer tip on the paper.

While the hammer is in flight the coil is de-energized and its field collapses.

After striking the ribbon and paper, the hammer rebounds and the permanent

magnet recaptures it. When the shuttle reaches the end of a sweep, it

reverses direction, the paper is moved up one dot row, and the hammer

springs print the next row of dots as the shuttle sweeps in the opposite

direction.

Principles of Operation

Page 41

Paper Transport System

Tractor

Support

Shaft

Horizontal

Adjustment

Knob

Shuttle Cover

Assembly

Paper

Supports

Tractors

Paper Path

Splined

Shaft

Paper Feed Timing

Belt (Under the cover)

Vertical Adjustment

Knob and Splined

Shaft Pulley

A two-phase DC stepper motor, directed by the EC on the controller board,

drives two tractor sprockets by means of a toothed belt and splined shaft

pulley arrangement. The stepper motor permits extremely accurate

incremental vertical paper movement. This drive configuration is designed for

continuous, fan-folded paper three to 17 inches wide and one to six sheets

thick. For reverse paper feeding, the platen open motor opens and closes the

platen via a toothed belt. Opening the platen prevents paper jams when

paper direction is reversed—that is, paper is moved downwards—in order to

view the print area, set top of form, or allow applications to overprint forms.

Paper is positioned horizontally using the tractors and the horizontal

adjustment knob. Each tractor engages paper perforations with six sprocket

pins and locks in place with a friction lock. The horizontal adjustment knob

allows vernier positioning of the left print margin.

Paper can be positioned vertically by hand with the vertical adjustment knob.

Principles of Operation

Figure 13. Paper Transport System

41

Page 42

Ribbon Transport System

Left Ribbon Guide

(Not Shown)

Hub Locking

Latch

Ribbon

Spool

Ribbon Hub

Ribbon

Motors

Right Ribbon Guide

Ribbon

Figure 14. Ribbon Transport System

An inked ribbon winds and unwinds continuously on a pair of spools latched

to hubs that are driven by the ribbon motors. The hubs and spools are offset

vertically to equalize ribbon wear and prolong ribbon life. The ribbon motors

operate only when the shuttle assembly is moving. Ribbon motion reverses

when a metal strip at either end of the ribbon crosses the left or right ribbon

guide, completing a circuit that causes both motors to reverse direction.

Constant ribbon tension is maintained by controlling each motor with a drive

or drag circuit. While the shuttle assembly is in motion, one motor acts as a

drive motor, pulling the ribbon against the resistance exerted by the other

motor—the drag motor. This system maintains a constant motor speed and

ribbon tension.

42

Principles of Operation

Page 43

Logical Control of the Printer

The printer is divided into four functional elements: the operator panel, the

CMX controller board, the power supply, and the print mechanism. See

Figure 15.

AC

Input

Circuit

Breaker

Card Cage

Fan

ON/OFF

SWITCH

Line 1

CHASSIS

GND

Line 2 / Neutral

CMX Controller Board

AC

POWER

Power Supply

Board

EIA–232–E

Serial I/O

+5 V Remote

Power

Operator

Panel

Parallel

I/O

Shield

GND

Cabinet

Exhaust

Fan

(Cabinet

models

only)

Platen

Motor

Paper Motion

Detector

Paper Out

Detector

Left Ribbon

Guide

Left Ribbon

Motor

Print Mechanism

Principles of Operation

Flex Circuits:

Shuttle

Assy

Terminator Board

Shuttle Motor

Hammer Bank Board

MPU

Shuttle Assembly

Hammer Bank

Fan

Figure 15. Functional Elements of the Printer

Paper Feed

Motor

Platen Open

Switch

Right Ribbon

Guide

Right Ribbon

Motor

43

Page 44

Operator Panel

The user communicates with the printer by pressing keys on the operator

panel. The keys are momentary contact switches. The operator panel

processes and sends key closure information to the controller board and

displays information from the controller on the LCD. A status indicator next to

the LCD also conveys printer status information to the user.

The LCD, status indicator, and keys are mounted on a printed circuit board

assembly enclosed in a protective housing.

Operator Panel

CMX Controller Board

♦ Data

♦ Control

♦ Key

(Switch)

Closures

J110

44

Figure 16. Operator Panel Functional Overview

Principles of Operation

Page 45

CMX Controller Board

The heart of the printer is the CMX controller board, which monitors and

directs all printer functions. The controller board receives and processes all

data from the host computer, builds the printable images, controls all motors,

and drives the hammer springs. Except for the power supply and final

hammer drive circuits, all logic and drive circuitry for the printer are contained

on the controller board.

The CMX controller board consists of two functional units: the Data Controller

(DC) and the Engine Controller (EC).

The DC is responsible for:

♦ Host I/O

♦ Operator I/O

♦ Security Interface

♦ Print Image Generation

♦ Overall High Level (Logical) Control

The EC is responsible for:

♦ Print Mechanism Operation

♦ Print Mechanism Fault Monitoring

♦ Power Shutdown/Power Saving Modes

The EC and DC communicate through semaphore registers. The DC

receives host and operator input and returns dot images and LCD messages

to buffers in memory. Image data are passed to the EC upon request, are

processed, then sent to the hammer bank. The EC synchronizes paper,

ribbon, platen, and shuttle motion as it feeds dot data to the hammer drivers.

Figure 17 summarizes this architecture.

Principles of Operation

45

Page 46

25 or 40 MHz

Expansion

Port

RS–232

Diagnostic

Port

Control

Panel

RS–232/422

IEEE–1284

(Parallel)

Fault

Sensors

Paper

Feed

Ribbon

TTL

Diagnostic

Port

46

Shuttle

Platen

Hammer

Drive

Figure 17. CMX Controller Board Block Diagram

Principles of Operation

Page 47

Data Controller

The data controller (DC) consists of the following elements:

♦ 68EC030 microprocessor

♦ Two flash SIMM sockets, used for up to 30MB of program memory

(Base configuration: 1MB flash in bank 0)

♦ Two DRAM SIMM sockets, used for up to 32MB of data memory

(Base configuration: 1MB DRAM in bank 0)

♦ 8K x 8 Non-Volatile Battery-Backed static RAM (NVRAM) for storage of

configuration and system statistical data

♦ VX ASIC (Application-Specific Integrated Circuit)

♦ Host I/O Drivers/Termination

68EC030 Microprocessor

A Motorola 68EC030 microprocessor serves as the processor of the DC unit.

This processor runs at 25 MHz on all models except the 6400–050, –P50,

–010, –P10, and –015.

On 6400–050, –P50, –010, –P10, and –015 printers the 68EC030 processor

runs at 40 MHz and the controller board on these models is called the “CMX

040.” The CMX 040 controller is backward compatible with any 6400 Series

printer, but must be used in 6400–050, –P50, –010, –P10, and –015 printers.

Although this chapter refers to the DC microprocessor as simply the “030,”

remember that two different clock speeds are available.

Flash Memory

The DC stores program and emulation code in flash memory. Flash memory

is erasable, non-volatile, and significantly faster than a disk drive.

The DC uses AMD 5.0V-only flash memory, which does not require higher

programming and erasing voltages on the board (it has an internal charge

pump to make these voltages itself). This memory supports at least 100,000

write/erase cycles. The flash memory is 32 bits wide. It is byte, word, and

double word readable, but is always written as double words.

Two 80-pin SIMM sockets are provided for flash memory. Up to 30MB of

flash (total), organized as up to four banks, may be installed in the two

sockets on the controller board. The boot code for the 68EC030 processor

must reside in bank 0.

Programs stored in flash memory are changed through the parallel or serial

port.

Principles of Operation

47

Page 48

DRAM

System DRAM is used for program variables, image buffers, and input

buffers. All DRAM supports page mode operation and is addressable by

individual byte.

Two standard 72-pin DRAM SIMMs are used for expansion memory. The DC,

through the VX ASIC, may address up to 32MB of DRAM in four banks.

NVRAM

A 8K x 8 bit Non-Volatile battery-backed static RAM (NVRAM) device

provides for the storage of configuration and system statistical data.

VX ASIC

The VX is a multifunction custom gate array ASIC containing all the logic for

the DC that is not contained in the 68EC030 processor. The VX provides the

following services:

♦ Memory Access Controller

♦ DRAM Controller

♦ Flash Controller

♦ Two DMA Channels

♦ Operator Panel Interface

♦ “Dot Plucking” and Adjacent Dot Checking

♦ “Cajun” Bus Interface

♦ Host I/O and Diagnostic Port

Memory Access Controller All 030 addresses go through the VX ASIC. The VX handles all address decoding, chip selects, DTACKs, and so on.

DRAM Controller The VX supports up to four banks of page mode DRAM. FLASH Controller The VX supports up to four banks of flash memory. DMA Channels The VX provides two channels for direct memory access.

These channels move data from the host interface or expansion bus to the

DRAM and vice versa. One address is an I/O address, the other is a memory

address with auto-increment.

Operator Panel Interface The VX operator panel interface consists of five lines: serial clock, serial data, and three select lines. It is the VX that handles all parallel-to-serial (and vice versa) conversion to and from the panel, as well as any special timing needed when toggling select lines, etc.

48

Principles of Operation

Page 49

“Dot Plucking” and Adjacent Dot Checking “Dot Plucking” is a specialized

DMA function that removes dot data from a dot image buffer in DRAM in a

programmable manner, serializes it, and sends it to the hammer bank. This

function is actually controlled by the EC (see page 50), which has access to

the VX through the “Cajun” Bus Interface.

“Cajun” Bus Interface The “Cajun” bus interfaces the DC, the EC, and the

expansion port. The EC uses this bus to access DC resources, including the

semaphore registers. (The semaphore registers are the primary

communications path between the EC and DC.)

Ports The VX ASIC controls the following I/O functions:

♦ Interface to an IEEE 1284 Level 2 host

♦ Interface to RS–232E serial host

♦ Interface to RS–422 serial host

All the circuitry required for these host types is provided on the CMX board,

except for the drivers themselves, ESD protection, and terminations.

Host I/O Drivers and Termination

Beyond the 030 processor and VX ASIC, additional support circuitry

completes the serial and parallel interfaces. These circuits include:

♦ RS–232 drivers and receivers. These circuits use internal charge pumps

to eliminate the need for 12V power.

♦ RS–422 differential drivers and receivers

♦ Parallel port pull up and pull down terminating resistors are DIP-socketed

for easy removal and installation.

All interface ICs and terminations have the following characteristics:

♦ Provide ESD protection to 15KV for all inputs.

♦ Less than 0.05V common mode ripple, measured at the power and

ground of the interface ICs.

♦ Less than 0.02V common mode ripple, measured between chassis

ground and the ground pins of the interface ICs.

♦ Greater than 200V/ms slew rate for all outputs.

Principles of Operation

49

Page 50

Engine Controller

The engine controller (EC) consists of four main elements:

♦ 80C166 Microcontroller

♦ 128KB 5.0V-only FLASH program memory, organized as 64K x 16 bits.

This memory is not expandable.

♦ MECA (Mechanism Engine Control ASIC)

♦ Analog drive circuitry

80C166 Microprocessor

The Siemens SAB 80C166 is a high-integration microcontroller. It has many

features that suit it extremely well to real-time control applications. This

controller and the MECA ASIC provide the functionality of three separate

processors used in earlier controller board architectures. In this manual, the

80C166 is referred to as either the EC or the 166.

The 166 used on the CMX board runs at 20MHz and is housed in a 100-pin

metric rectangular flat pack.

Bus Configuration The 166 bus is configured for 18-bit address, 16-bit data,

non-multiplexed and segmented operation. The flash memory runs with zero

wait states. An external PAL is used for address decoding.

Power Reduction The 166 chip has two power reduction modes: idle and Energy Star. Idle mode is not used. In Energy Star mode, +48V and all motors are de-energized, but the 166 operates as normal.

EC Flash Memory The EC stores all boot code, program code, and tables in its own local flash memory. This flash is organized as 64K x16 bits and uses the same technology as the DC flash: it is + 5.0V-only and is rated for a minimum of 100,000 write/erase cycles. EC memory is fixed; it is soldered to the controller board. Its contents can be updated through the DC (through the serial or parallel ports). At run time, the EC also stores tables in shared DRAM, which is accessed through the Cajun bus.

MECA ASIC

in the MECA to control many printer motor functions. The MECA is a custom

gate array, specifically designed to drive this system.

Analog Drive Circuitry

The analog drive functions convert 48 and 8.5 volts into the power used to

drive the motors and hammers in the printer. Sensors are used to monitor the

operation and status of critical components within the printer.

The 166 uses numerous counters, PWM generators, and FIFOs

50

Principles of Operation

Page 51

The printer uses five motors: two ribbon drive, one paper feed, one platen

open, and one shuttle motor. The shuttle motor is a brushless DC motor

driven by current control. The MPU encoder is used as feedback for motor

commutations, hammer fire timing, and motor stall detection. The paper feed

motor is a DC stepping motor driven by current control. The paper feed motor

may be driven in full, half, or microsteps, depending on print requirements.

The ribbon system uses two DC stepping motors that alternate drive and

drag roles when the ribbon reaches turnaround. The drive ribbon motor is

microstepped in voltage mode, while the drag motor is loaded and monitored

to maintain correct linear speed and tension. The platen motor is driven in

current mode and can be full or half stepped. The overall current level may

be reduced for standby modes.

The paper feed, ribbon drive, and shuttle motors are driven in control loops

containing power MOSFETs, voltage and current sensors, the MECA ASIC,

and the EC processor. The platen open motor is driven by a stepping motor

controller IC and the EC processor.

Control of the hammer drive is split between the controller board and the

hammer bank. Common circuits are located on the controller board, while

hammer specific circuitry is contained on the hammer bank. The EC uses the

MECA ASIC on the controller board to set timing and upper drive profiles for

hammer fire events. The controller also contains diagnostic circuitry for the

hammer system. The hammer bank contains HBA ASICs that interpret fire

commands and data from the MECA and VX ASICs. The HBAs control lower

drive MOSFETs on the hammer bank. These determine which hammers will

participate in a fire event generated by the controller’s upper drive.

Power Supply Board

The printer power supply is contained on a printed circuit board mounted in

the card cage. The power supply automatically senses and adjusts to any

commercial electrical system that provides AC mains potential in 50 or 60

Hertz systems. In other words, the printer is fully operational from available

commercial power anywhere in the world.

The power supply converts alternating current (AC) to direct current (DC) at

three voltage levels and sends the DC voltages to the controller board. The

controller board distributes all DC power to the logic and electromechanical

circuits.

AC Power

The power supply operates on AC voltages ranging from 88 to 270 V. It can

tolerate variations in frequency of 47 to 63 Hz. The power supply is designed

Principles of Operation

51

Page 52

to withstand an AC input overvoltage of 300 VAC for one second with no

degradation of DC output voltage or damage to printer circuits.

DC Power

The power supply board contains two DC power supply systems for the

printer. The first is a + 5 V bus for logic. The second consists of + 48 V and

+ 8.5 V buses for the hammer bank and all motors.

The + 5 V supply has an isolated return line that connects to the + 48 V

return at the printer load. Both returns are tied together in a single-point

ground. The + 5 V power supply has its own inverter, separate from the + 48

V and + 8.5 V outputs.

There is an opto-isolated input on the power supply that will shut down and

latch off the + 48 V and + 8.5 V supplies unless it is pulled up to 5V with a 1K

Ω resistor. This resistor is mounted on the controller board and may be pulled

down or disconnected by software or internal cable interlocks. The + 5 V

output will remain stable for reporting and latching the fault condition. The

return for this signal is the + 5 V return. In addition, this shutdown circuit

discharges and latches the + 48 V down to a level lower than 15 V in less

than 200 milliseconds and requires recycling of the circuit breaker (On/Off

switch) to reset the latch.

Loss of + 48 V is seen by the EC and reported as a fault.

Printer Interface

The printer interface is the point where the data line from the host computer

plugs into the printer. The printer interface processes all signals and data to

and from the host computer.

The printer supports supports a number of standard and optional interfaces

to the host:

♦ Centronics parallel (standard)

♦ IEEE 1284 parallel (standard)

♦ EIA-232-E serial (standard)

♦ EIA-422-B serial (standard)

♦ Coaxial/twinaxial “Expansion-CT” (optional)

♦ Ethernet10Base-2 or 10Base-T adapter (optional)

52

Principles of Operation

Page 53

Graphics

Selection of the input/output interface is controlled by configuration menus

accessed at the operator panel. It is possible to physically connect more than

one interface, but only one interface at a time can be used electrically.

The Code V programming language (a QMS graphics emulation) and the

IGP programming language (a Printronix IGP emulation) are options that

install in flash memory on the CMX controller board.

These programming languages simplify the job of creating forms, bar codes,

logos, expanded characters, and other graphics. These languages enable

the printer to print sideways, upside down, and to make forms combining