Page 1

IBM 3592 TS1140, TS1150, TS1155, and

TS1160 Tape Drives

Maintenance Information

Rack Mount Models EH7, EH8, 55F, and

60F

IBM

SC27-9295-00

Page 2

Read this rst

This Maintenance Information (MI) is intended for use only by trained, IBM® service personnel. Use the MI

as a guide when you make a service call to diagnose or maintain an IBM 3592 tape drive.

How to use this information

• Go to “Maintenance starting point” on page 1 to begin all service activity.

• The glossary, beginning on page “Glossary” on page 297, provides terms and abbreviations that are

used throughout this Maintenance Information (MI) document.

• Do not use this MI to complete service procedures on an IBM TS3500 Tape Library 3584, but refer to

the MI for that product. If the drive is installed in a 3584 and you need operator information, use the

TS3500 (3584) Operator Guide.

• Do not use this MI to complete service procedures on a 3592 EH7, EH8, 55F, or 60F drive installed in

an IBM TS4500, but refer to the Knowledge Center for that product. If the drive is installed in a 3584

and you need operator information, use the TS4500 (3584) Operator Guide.

• In this MI, any reference to the Operator panel, or Service panel, or Virtual Service panel, refers to the

Virtual Operator panel.

• Many gures in this MI depict typical representations of all 3592 drives, and might not exactly depict

your drive.

• Review Table 1 on page ii

in this MI.

to learn about some directional terms and other conventions that are used

Attention:

environment that contains corrosive gases (for example, high sulfur) or metallic shavings (for

example, zinc whiskers). Dusty environments can impact the air-cooling of assemblies and

corrosive gasses can degrade components, causing a change to their characteristics, leading to a

breakdown of the equipment.

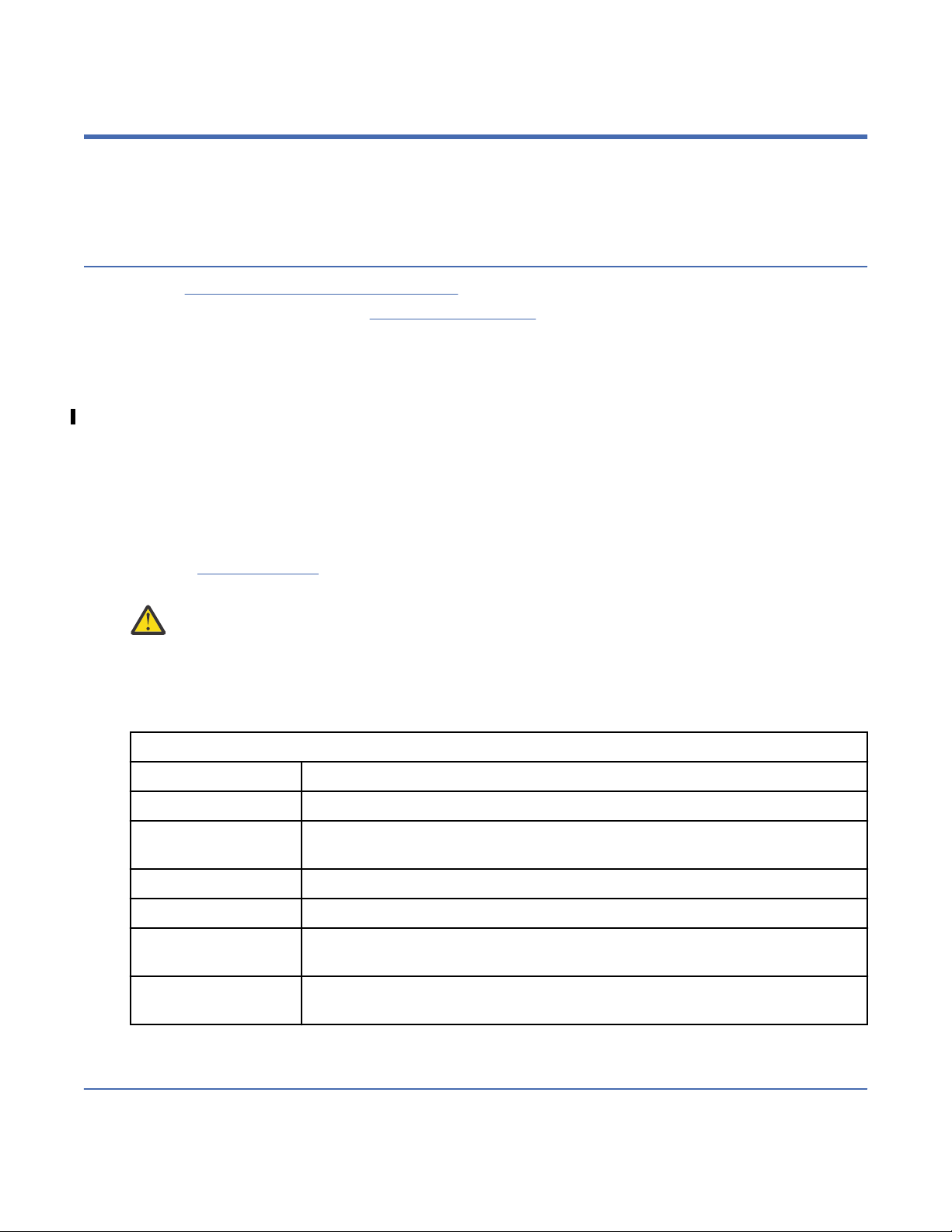

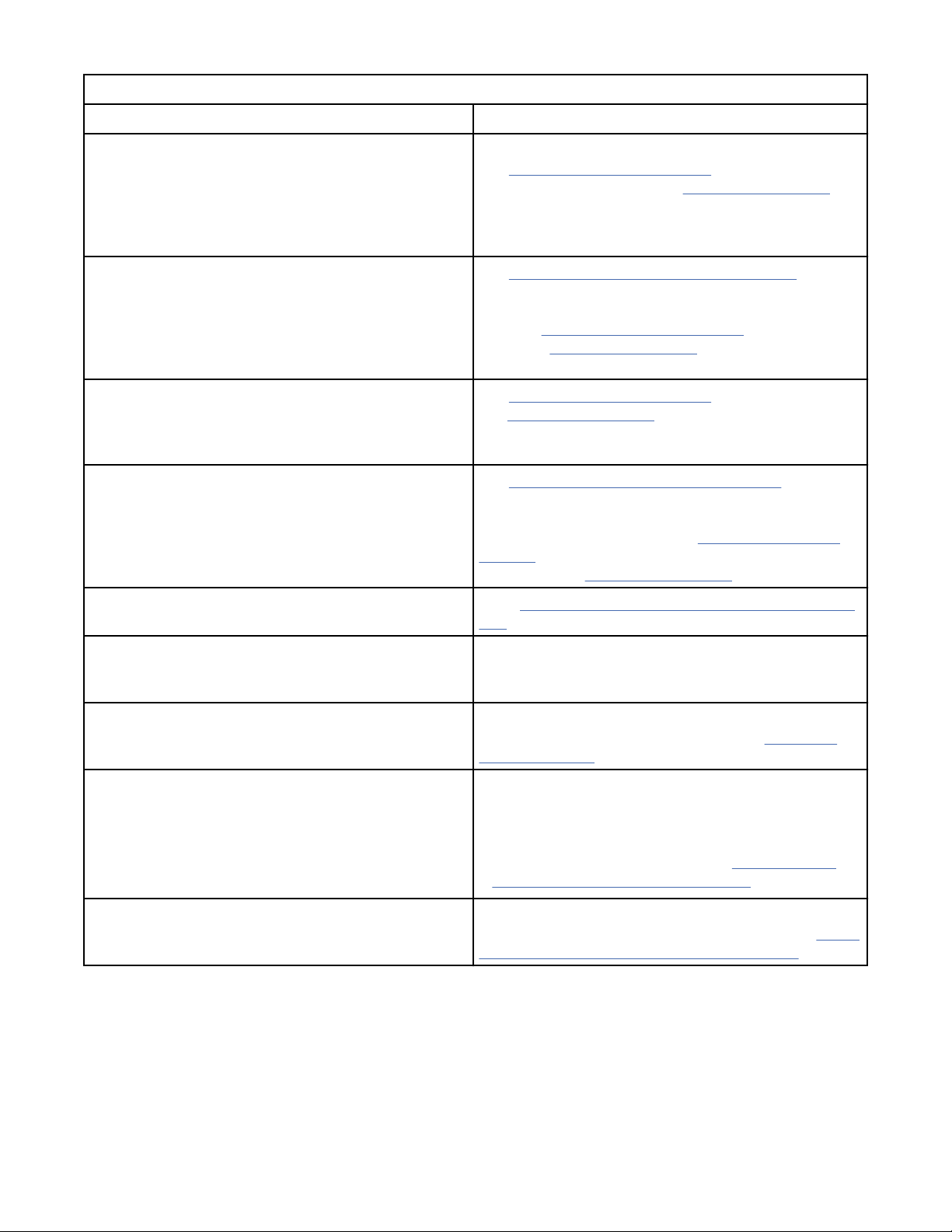

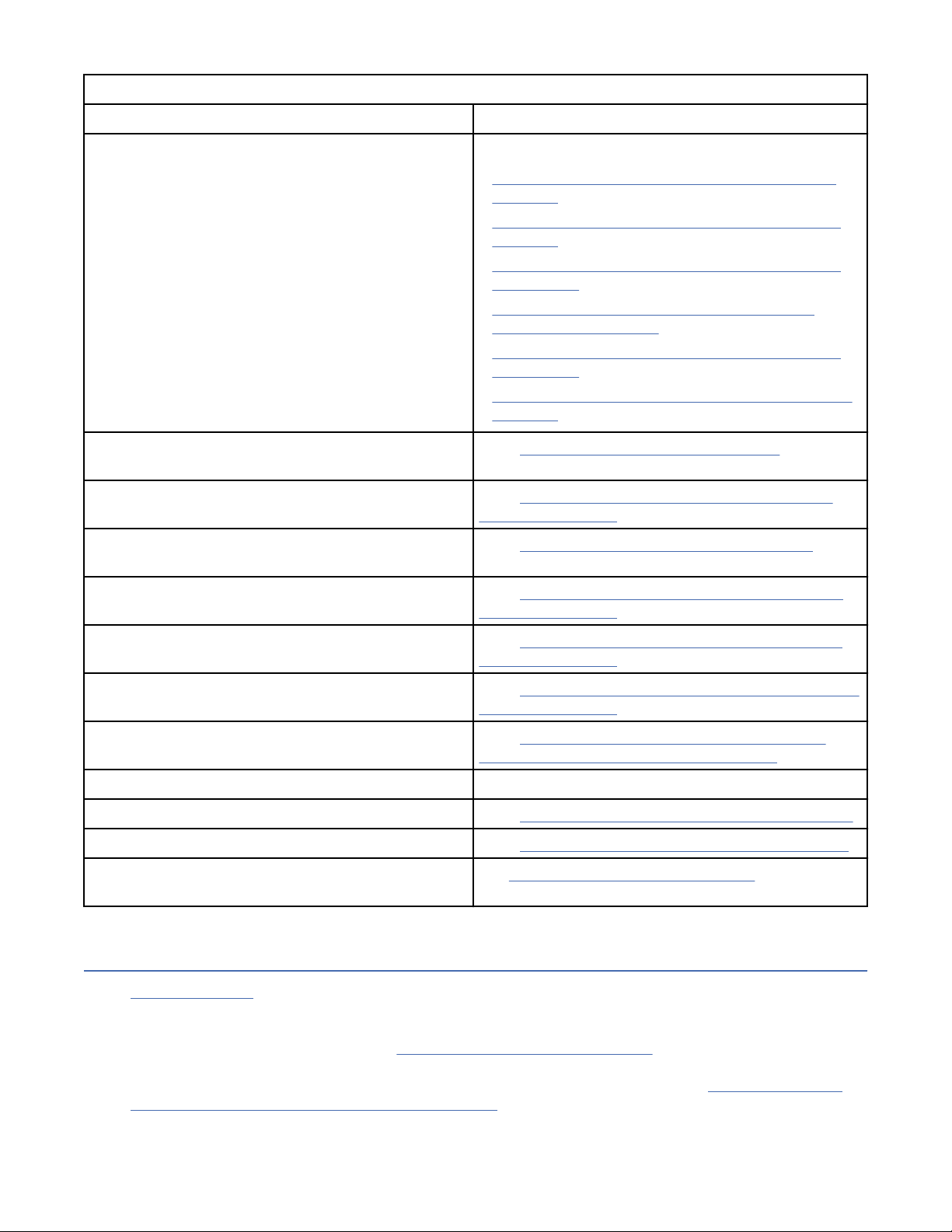

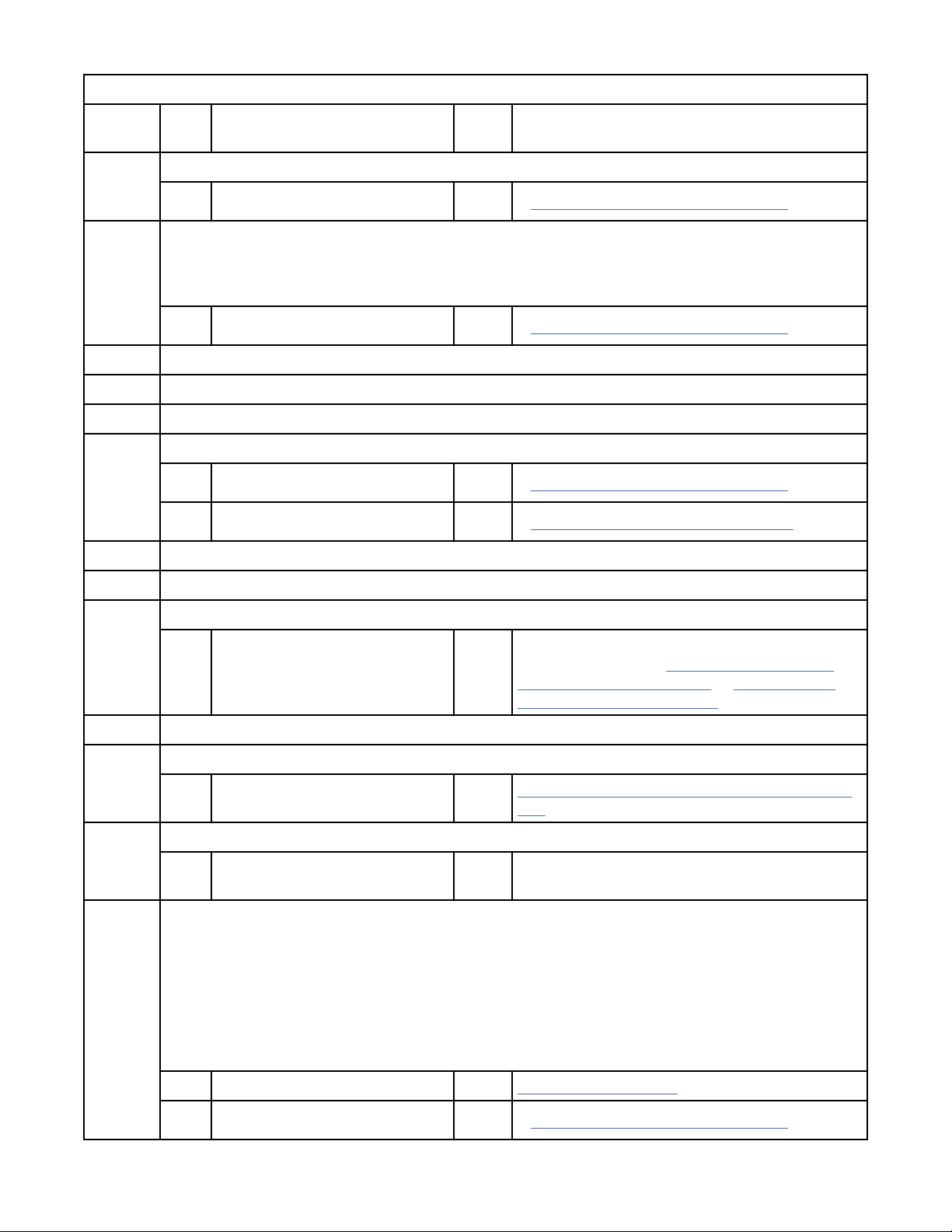

Table 1: MI terms and descriptions

This term . . . . . . imparts this knowledge.

Front Refers to the end of the drive where the tape cartridge enters the drive.

Left or left-hand drive Refers to the drive on the left as you face the rear of a frame (the cable-

See Directs you to page to another area in this MI for information

Refer to Directs you to consult another publication or source for information.

3592 or drive For this MI, the terms 3592 and drive imply any 3592 drive, such as the 3592

4804 Refers to the rack mount chassis or enclosure where the 3592 drives are

The customer must be instructed to not put the system into a dusty or contaminated

connection end of a drive).

EH7 drive.

installed

Sending comments

Your feedback is important in helping to provide the most accurate and highest quality information.

To submit any comments about this publication or any other IBM storage product documentation:

ii

IBM 3592 TS1140, TS1150, TS1155, and TS1160 Tape Drives: Maintenance Information

Page 3

• Send your comments by email to ibmkc@us.ibm.com. Be sure to include the following information:

– Exact publication title and version

– Page, table, or illustration numbers that you are commenting on

– A detailed description of any information that should be changed

Read this rst iii

Page 4

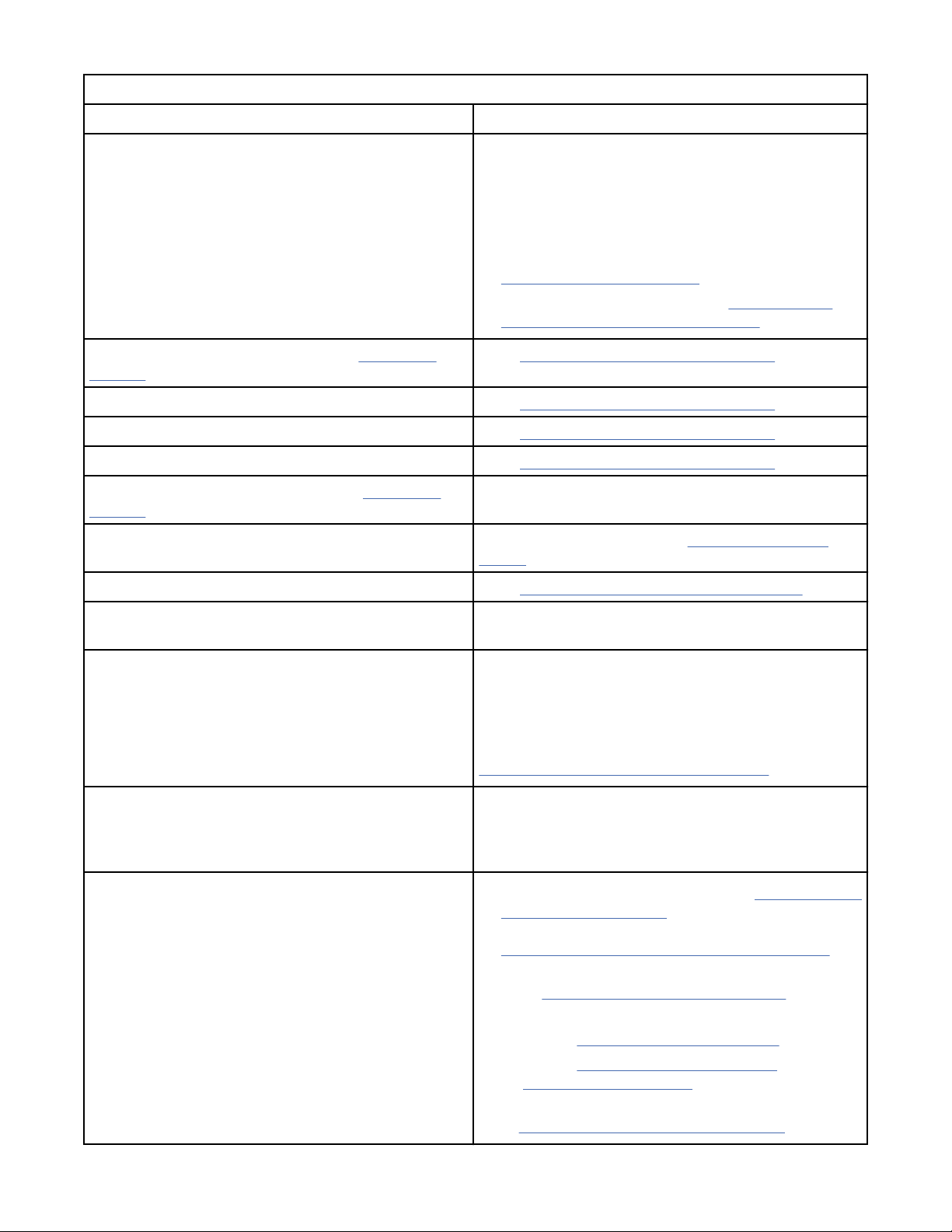

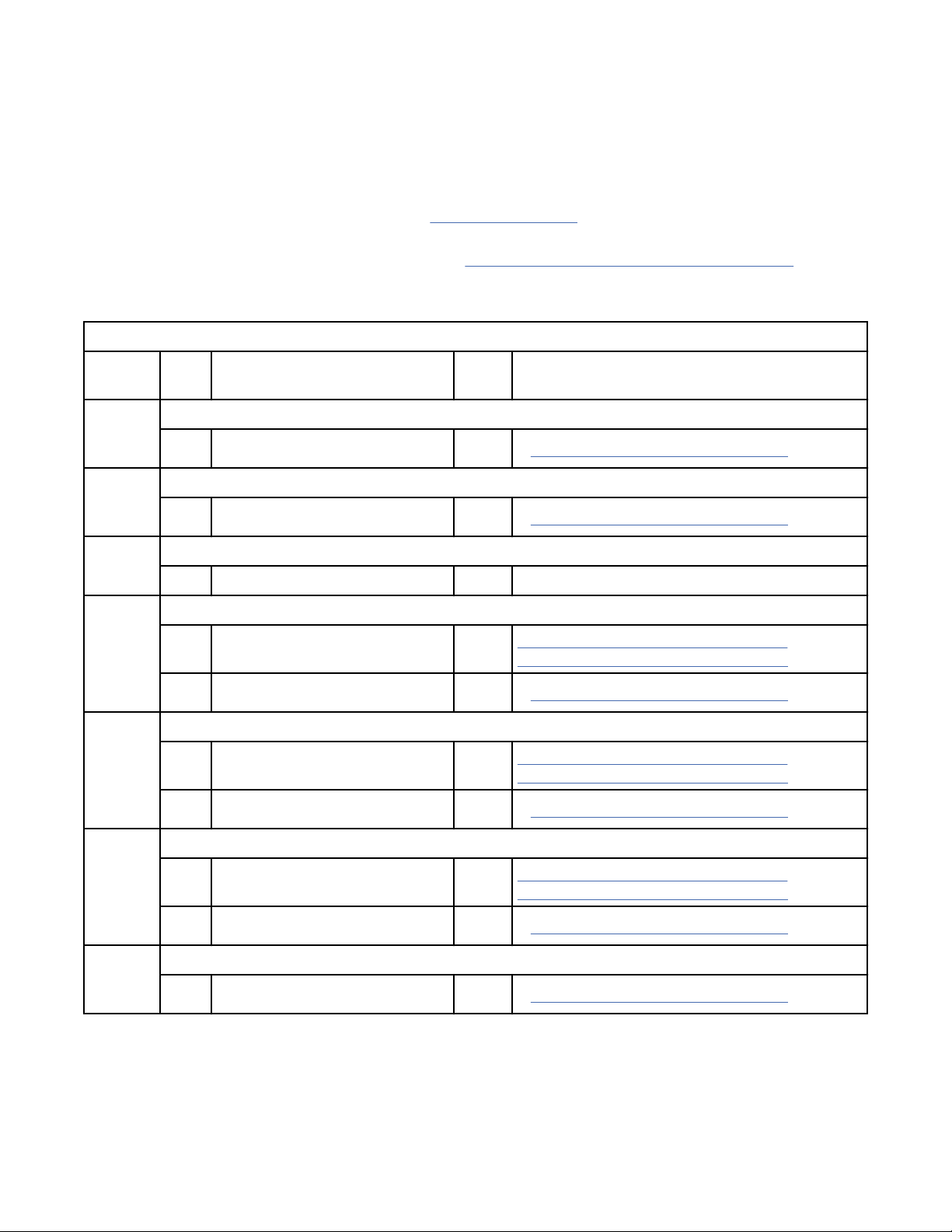

Contents

Read this rst........................................................................................................ii

How to use this information.........................................................................................................................ii

Feedback...................................................................................................................................................... ii

List of Figures........................................................................................................x

List of Tables.......................................................................................................xiii

Preface.............................................................................................................xviii

Related information................................................................................................................................. xviii

3584 information............................................................................................................................... xviii

Fibre Channel attachment information .............................................................................................xviii

Website information...........................................................................................................................xviii

Chapter 1. Start.....................................................................................................1

Maintenance starting point..........................................................................................................................1

FID entry point............................................................................................................................................. 6

Attention Drive (ATTN DRV) messages......................................................................................................11

TapeAlert reporting.................................................................................................................................... 12

Chapter 2. Introduction....................................................................................... 19

3592 introduction...................................................................................................................................... 19

RAS characteristics....................................................................................................................................20

Reliability..............................................................................................................................................21

Availability............................................................................................................................................ 21

Serviceability........................................................................................................................................ 21

Maintenance strategy................................................................................................................................ 22

FID strategy................................................................................................................................................22

Host messages...........................................................................................................................................22

Federal Information Processing Standards (FIPS)...................................................................................23

Device characteristics................................................................................................................................24

Fibre Channel connectivity ..................................................................................................................24

Tape cartridge............................................................................................................................................ 25

Cartridge type indicator........................................................................................................................25

3592 data tape cartridge..................................................................................................................... 25

Cartridge capacity scaling....................................................................................................................27

Cartridge memory (CM)........................................................................................................................27

Write-once read-many (WORM)................................................................................................................ 27

Tape drive...................................................................................................................................................28

Drive layout................................................................................................................................................ 28

Operator bezel......................................................................................................................................28

Drive rear layout................................................................................................................................... 30

Power supplies...........................................................................................................................................32

Power switch and power sequence..................................................................................................... 34

Power cords..........................................................................................................................................34

Power specications............................................................................................................................ 34

Redundant power.................................................................................................................................35

Subsystem initialization.............................................................................................................................35

Initial microprogram load (IML)...........................................................................................................35

Power sequencing................................................................................................................................ 35

Subsystem diagnostic tests................................................................................................................. 35

Field microcode update.............................................................................................................................35

iv

Page 5

Special tools and customer supplies........................................................................................................ 35

Cleaning cartridge................................................................................................................................ 36

Leader pin replacement kit.................................................................................................................. 37

ESD kit...................................................................................................................................................38

Tape unit cleaner.................................................................................................................................. 38

Hook-and-loop fastener.......................................................................................................................38

Fibre wrap tool..................................................................................................................................... 38

Chapter 3. Messages............................................................................................39

Service and Media Information messages (SIMs and MIMs)...................................................................39

SIMs......................................................................................................................................................39

SIM error information...........................................................................................................................39

MIMs..................................................................................................................................................... 41

MIM error information..........................................................................................................................41

Statistical Analysis and Reporting System (SARS)................................................................................... 43

Obtaining drive error information at host..................................................................................................44

Error log on host display.......................................................................................................................44

Message codes...........................................................................................................................................45

MIM exception messages..........................................................................................................................46

SIM exception messages...........................................................................................................................46

SIM/MIM service messages...................................................................................................................... 46

SIM/MIM severity.......................................................................................................................................47

Sense Keys, ASC, and ASCQ information..................................................................................................47

Sense Key 0 (No Sense)....................................................................................................................... 47

Sense Key 1 (Recovered Error)............................................................................................................ 48

Sense Key 2 (Not Ready)......................................................................................................................48

Sense Key 3 (Medium Error)................................................................................................................ 48

Sense Key 4 (Hardware Error)..............................................................................................................50

Sense Key 5 (Illegal Request)..............................................................................................................50

Sense Key 6 (Unit Attention)................................................................................................................52

Sense Key 7 (Data Protect).................................................................................................................. 52

Sense Key 8 (Blank Check).................................................................................................................. 53

Sense Key B (Aborted Command)........................................................................................................53

Sense Key D (Volume Overflow).......................................................................................................... 53

Error Log Analysis - AIX.............................................................................................................................53

Tapeutil command................................................................................................................................54

Diag command......................................................................................................................................54

Analyzing Tapeutil and Diag command Error Log................................................................................ 54

Tapeutil errors...................................................................................................................................... 56

SMIT command.................................................................................................................................... 58

ERRPT command..................................................................................................................................58

SMIT/ERRPT errors...............................................................................................................................58

Error Log Analysis - System i.....................................................................................................................63

System i with RISC processor..............................................................................................................64

Obtaining drive error information from Linux system...............................................................................68

Forcing a drive dump............................................................................................................................69

Reading a dump....................................................................................................................................69

Automatically retrieved SIM/MIM data............................................................................................... 69

Error Log Analysis - Linux system ....................................................................................................... 69

Obtaining drive error information from Solaris system............................................................................ 70

Obtaining drive error information from HP-UX system.............................................................................71

Obtaining drive error information from Windows system.........................................................................71

Running NTUTIL................................................................................................................................... 71

NTUTIL symbolic error and error number........................................................................................... 71

SCSI sense data......................................................................................................................................... 73

Chapter 4. Virtual Operator panel.........................................................................77

v

Page 6

Virtual Operator panel............................................................................................................................... 77

Virtual Operator panel indicators, icons, and message areas..................................................................77

Virtual Operator panel controls........................................................................................................... 77

Virtual Operator panel display............................................................................................................. 78

Drive type and capability indicator...................................................................................................... 82

Media data indicator.............................................................................................................................82

Horizontal bar indicators......................................................................................................................83

Clean icon............................................................................................................................................. 83

Dump icons...........................................................................................................................................83

Write-protected icons.......................................................................................................................... 84

Intervention messages........................................................................................................................ 84

Virtual Operator panel menus................................................................................................................... 87

Virtual Operator panel menu trees...................................................................................................... 88

Conrm Mode Change menu................................................................................................................96

Operator Mode menus......................................................................................................................... 97

CE Offline Mode menus......................................................................................................................107

CE Online Mode menus......................................................................................................................151

Chapter 5. Safety and Inspection....................................................................... 156

General instructions................................................................................................................................ 156

Materials needed................................................................................................................................156

Education............................................................................................................................................156

Safety....................................................................................................................................................... 156

Safety inspection procedure..............................................................................................................157

Labels.......................................................................................................................................................158

Completion report....................................................................................................................................161

Completion report (additional copy).......................................................................................................162

Completion report (additional copy).......................................................................................................163

Completion report (additional copy).......................................................................................................164

Completion report (additional copy).......................................................................................................165

Sécurité....................................................................................................................................................166

Inspection de sécurité....................................................................................................................... 166

Seguridad.................................................................................................................................................166

Procedimiento de inspección de seguridad...................................................................................... 167

Segurança................................................................................................................................................ 167

Procedimentos Para Inspeção de Segurança................................................................................... 167

vi

Chapter 6. Installation.......................................................................................168

Before installation................................................................................................................................... 168

Tools.........................................................................................................................................................169

Installing the Rack Mount Kit.................................................................................................................. 169

Installation checkout...............................................................................................................................174

Setting customer options...................................................................................................................175

Setting drive options.......................................................................................................................... 176

Running tests......................................................................................................................................177

Fibre Channel attachments..................................................................................................................... 177

Supported host attachments.............................................................................................................177

Fibre Channel cabling examples........................................................................................................178

Fibre Channel cable at host............................................................................................................... 179

Online testing...........................................................................................................................................179

Post-installation reporting and activities................................................................................................180

Removing the drive from service.............................................................................................................180

Relocating or storing the drive................................................................................................................ 180

Repacking instructions............................................................................................................................ 181

Chapter 7. Procedures....................................................................................... 182

Problem determination........................................................................................................................... 182

Page 7

Excessive Clean messages................................................................................................................ 183

Preparing the tape drive for service........................................................................................................183

Powering the device ON and OFF............................................................................................................183

Removing drive canister power......................................................................................................... 183

Restoring drive canister power..........................................................................................................184

End of call.................................................................................................................................................185

Verifying the x...................................................................................................................................185

Setting the device online....................................................................................................................185

Final checks........................................................................................................................................185

Connecting and disconnecting the laptop from the drive...................................................................... 186

Ethernet (laptop) Drive Dump procedures..............................................................................................187

Determining current dump status..................................................................................................... 187

Offloading microcode dumps with the front Ethernet port...............................................................188

Ethernet (laptop) Microcode procedures................................................................................................189

Determining current drive microcode level.......................................................................................189

Updating microcode with the Ethernet port......................................................................................189

Obtaining microcode image with the Ethernet port..........................................................................189

Drive FRU VPD procedures......................................................................................................................190

Displaying the Drive Status page.............................................................................................................191

Electrostatic discharge (ESD) sensitive parts.........................................................................................192

Cleaning the operator bezel.................................................................................................................... 193

Power problems MAP.............................................................................................................................. 193

Step power 01....................................................................................................................................194

Step power 02....................................................................................................................................194

Step power 03....................................................................................................................................194

Step power 04....................................................................................................................................194

Step power 05....................................................................................................................................194

Step power 06....................................................................................................................................195

Manual cartridge removal........................................................................................................................195

Tape spooled off supply reel..............................................................................................................198

Tape pulled from leader pin or broken near leader pin.....................................................................199

Tape broken in midtape..................................................................................................................... 201

Tape tangled along tape path............................................................................................................ 202

No apparent failure or damage to tape............................................................................................. 203

FMR tape maintenance............................................................................................................................204

Making FMR tape from CE scratch tape.............................................................................................204

Updating FMR tape from the drive.....................................................................................................204

Updating microcode from the FMR tape cartridge............................................................................204

Converting FMR tape to a CE scratch tape........................................................................................ 205

History log examples............................................................................................................................... 205

Microcode EC level history log...........................................................................................................205

Fibre Channel worldwide names history log..................................................................................... 206

Setting Root names............................................................................................................................210

Dump maintenance utilities.................................................................................................................... 210

Offloading the dump to flash memory...............................................................................................211

Offloading Dumps to System i (OS/400)........................................................................................... 212

Offloading dumps to AIX with TAPEUTIL.......................................................................................... 212

Offloading dumps to Linux system with TAPEUTIL...........................................................................213

Offloading dumps to Solaris system with TAPEUTIL.........................................................................214

Offloading dumps to HP-UX system with TAPEUTIL.........................................................................215

Offloading dumps to Windows system with NTUTIL.........................................................................216

Offloading dumps to tape cartridge...................................................................................................216

Microcode maintenance.......................................................................................................................... 217

Updating microcode from System i (OS/400)................................................................................... 217

Updating microcode from AIX with TAPEUTIL.................................................................................. 218

Updating microcode from Linux with TAPEUTIL............................................................................... 219

Updating microcode from Solaris with TAPEUTIL.............................................................................220

Updating microcode from HP-UX system with TAPEUTIL................................................................ 221

vii

Page 8

Updating microcode from Windows with NTUTIL.............................................................................222

Updating microcode with an FMR cartridge......................................................................................222

Starting NT UTILITY (ntutil) from Windows............................................................................................222

Exercising drive attached to Windows with NTUTIL......................................................................... 224

Host attachment checkout......................................................................................................................225

Checking channel attachment - System i (OS/400)..........................................................................225

Checking channel attachment - AIX..................................................................................................225

Checking channel attachment - Linux............................................................................................... 229

Checking channel attachment - Solaris.............................................................................................230

Checking channel attachment - HP-UX.............................................................................................232

Checking channel attachment - Windows ........................................................................................234

Checking channel attachment with NTUTIL under Windows .......................................................... 236

Fibre Channel testing...............................................................................................................................236

Fibre wrap test................................................................................................................................... 236

Fibre Channel problem determination.............................................................................................. 237

FID 83 or E5 - Microcode problem..........................................................................................................239

FID 84 or E6 - Isolating fault between microcode and hardware..........................................................240

FID 84 or E6 - Normal FID display procedure...................................................................................241

FID 84 or E6 - Smaller font (abnormal display condition)................................................................242

FID 87 or F2 - Isolating fault between media and hardware.................................................................243

FID FF - Operator action or host program error......................................................................................245

FID FF displayed on service panel and message display................................................................. 245

FID FF displayed at host only - not on service panel or message display........................................245

Suspected microcode problem............................................................................................................... 246

Setting the error match trap (to get dump).............................................................................................246

Removing the error match trap............................................................................................................... 247

Removing a NORMAL trap..................................................................................................................248

Removing a SAVED trap..................................................................................................................... 248

Setting default density.............................................................................................................................249

Setting drive encryption.......................................................................................................................... 250

Chapter 8. Locations, checks, adjustments, removals, and replacements............ 251

Rack FRU locations, removals, and replacements................................................................................. 251

FID 82: Power supply.........................................................................................................................252

FID 85: Drive canister........................................................................................................................ 252

FID EA: Cables FRU kit.......................................................................................................................255

Removing the enclosure from a rack.................................................................................................258

Chapter 9. Parts catalog information.................................................................. 259

3592 EH7/EH8/55E/55F/60F Rack FRU list.......................................................................................... 259

Appendix A. ITDT support..................................................................................261

TAPEUTIL in Sun (Solaris) system environment...................................................263

TAPEUTIL in HP-UX system environment............................................................269

Introduction.............................................................................................................................................269

Interactive menu-driven interface..........................................................................................................269

Command-line mode...............................................................................................................................270

Command-line commands and syntax..............................................................................................270

Flag descriptions................................................................................................................................272

Examples............................................................................................................................................273

TAPEUTIL in Windows system environment (NTUTIL) .........................................275

NT utility program....................................................................................................................................275

Starting NTUTIL..................................................................................................................................275

Interactive mode................................................................................................................................275

Base mode..........................................................................................................................................276

Library mode...................................................................................................................................... 276

TAPEUTIL in Linux system environment..............................................................278

viii

Page 9

IBMtapeutil run procedure......................................................................................................................278

Interactive mode................................................................................................................................278

Command-line mode......................................................................................................................... 280

TAPEUTIL in AIX environment............................................................................281

Appendix C. Metric conversion and similar comparisons..................................... 282

Appendix D. Minimum microcode requirements.................................................. 288

Minimum requirements for Rack Mount tape drives.............................................................................. 288

Appendix E. Notices...........................................................................................289

Trademarks .............................................................................................................................................290

Symbols ...................................................................................................................................................291

Compliance statements...........................................................................................................................291

Canada Notice.................................................................................................................................... 291

Avis de conformité à la réglementation d'Industrie Canada............................................................ 291

European Community and Morocco Notice.......................................................................................292

Germany Notice..................................................................................................................................292

Japan VCCI Council Class A statement............................................................................................. 293

Japan Electronics and Information Technology Industries Association (JEITA) statement...........293

Korea Notice.......................................................................................................................................293

Taiwan Notice..................................................................................................................................... 294

Russia Notice......................................................................................................................................294

United States Federal Communications Commission (FCC) Notice................................................. 294

Flat panel display............................................................................................................................... 295

Monitors and workstations................................................................................................................ 295

IBM cryptographic coprocessor card return program.......................................................................295

Système Internationale d'unités (SI)................................................................................................ 295

Laser information.....................................................................................................................................295

Notes................................................................................................................ 296

Glossary............................................................................................................297

Index................................................................................................................ 320

ix

Page 10

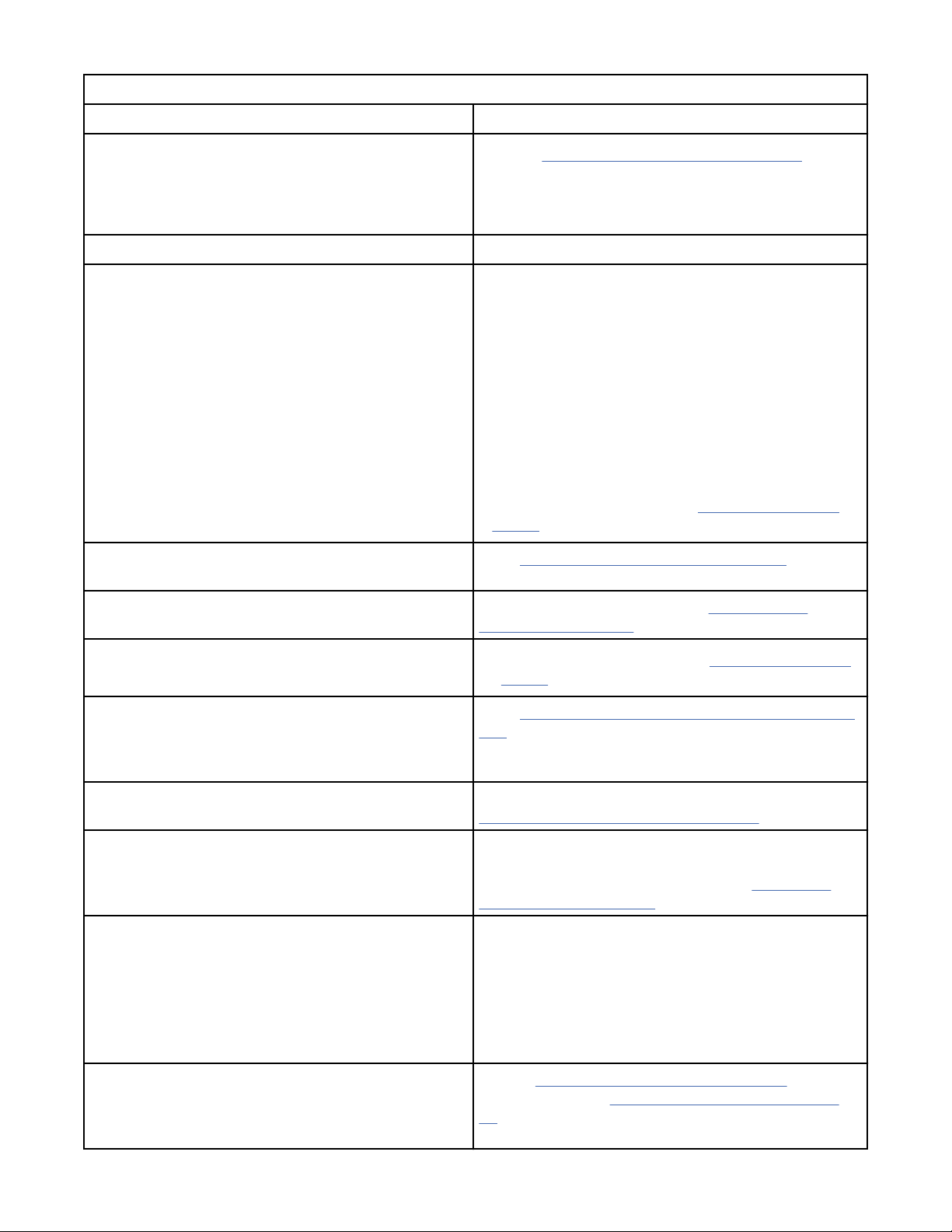

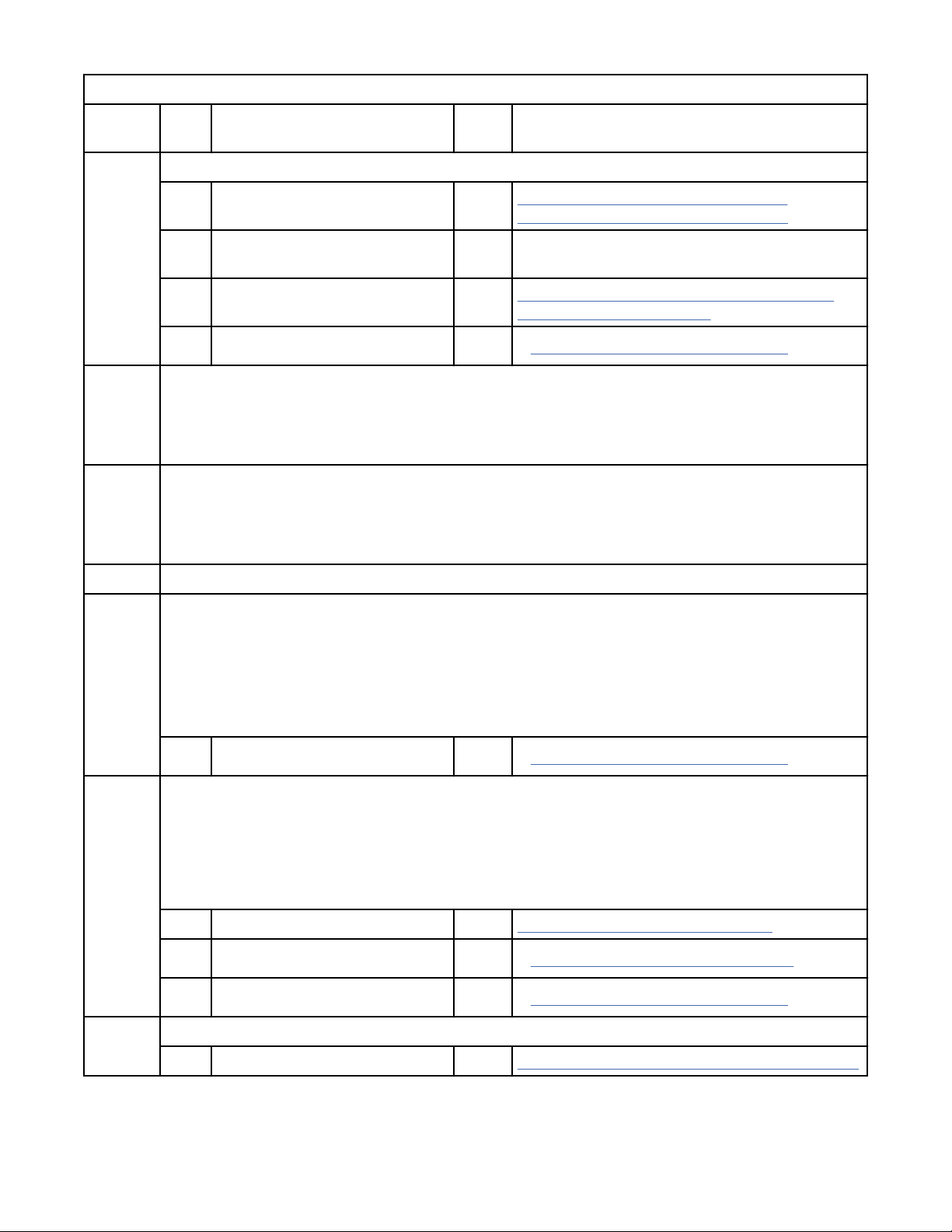

List of Figures

1. 3592 tape cartridge.....................................................................................................................................26

2. Operator bezel - drive canister front view..................................................................................................29

3. Drive rear layout - Models EH7/EH8/55F/60F (Fibre Channel) ................................................................ 30

4. LED locations for EH7/EH8/55F/60F..........................................................................................................31

5. Power distribution diagram.........................................................................................................................33

6. Cleaning cartridge ...................................................................................................................................... 37

7. Leader pin replacement kit......................................................................................................................... 37

8. ESD grounding strap....................................................................................................................................38

9. Hook-and-loop fastener..............................................................................................................................38

10. LC bre wrap tool and plugs..................................................................................................................... 38

11. SIM format - sample................................................................................................................................. 40

12. MIM format - sample................................................................................................................................ 42

13. Drive error log example.............................................................................................................................44

14. AIX TAPEUTIL and DIAG commands Error Log example......................................................................... 55

15. AIX TAPEUTIL and DIAG commands SIM Error Log example..................................................................55

16. AIX TAPEUTIL and DIAG commands MIM Error Log example.................................................................56

17. AIX TAPEUTIL and DIAG commands Error Log example......................................................................... 56

18. Tapeutil error example - AIX.....................................................................................................................56

19. AIX SMIT and ERRPT command Error Log example................................................................................ 59

20. Error Log example of SIM message - AIX.................................................................................................60

21. Error Log example of MIM message - AIX................................................................................................61

22. AIX SMIT and ERRPT command Error Log example................................................................................ 62

23. AIX SMIT and ERRPT commands Error Log example - descriptions.......................................................63

24. System i example Error Log of SIM message...........................................................................................64

25. System i example Error Log of SIM message...........................................................................................65

26. System i hexadecimal Error Log (display)................................................................................................ 66

27. System i (AS/400) Product Activity Log (display).....................................................................................67

28. System i Hexadecimal Error Log (printout).............................................................................................. 68

29. Linux Error Log record example................................................................................................................70

30. NTUTIL error sample.................................................................................................................................71

31. SCSI sense data........................................................................................................................................ 73

32. Virtual Operator panel...............................................................................................................................77

33. Virtual Operator panel display - Menu, status, and message areas........................................................79

34. Intervention screen, Mount screen, and Abend screen on service panel...............................................85

35. Error message example............................................................................................................................ 87

36. Selection options example....................................................................................................................... 88

37. Conrm mode change and CE Online Mode menus.................................................................................89

38. Operator Options menus - Operator Mode...............................................................................................90

39. CE Options menu - CE Offline Mode (Part 1 of 6).....................................................................................91

x

Page 11

40. CE Options menu - CE Offline Mode (Part 2 of 6).....................................................................................92

41. CE Options menu - CE Offline Mode (Part 3 of 6).....................................................................................93

42. CE Options menu - CE Offline Mode (Part 4 of 6).....................................................................................94

43. CE Options menu - CE Offline Mode (Part 5 of 6).....................................................................................95

44. CE Options menu - CE Offline Mode (Part 6 of 6).....................................................................................96

45. Microcode Level menu.............................................................................................................................. 98

46. Conrmation menu................................................................................................................................... 99

47. Status menu............................................................................................................................................ 110

48. Loop Status menu - from CE Loop Fix menu..........................................................................................110

49. Final Status display.................................................................................................................................110

50. CE Action Successful display..................................................................................................................111

51. CE Action Failed display..........................................................................................................................111

52. Grounding inspection..............................................................................................................................158

53. Label locations........................................................................................................................................ 159

54. Enclosure label locations (top of enclosure shown)..............................................................................160

55. Exploded Rack Mount view.....................................................................................................................170

56. Installing the rail - front..........................................................................................................................171

57. Installing the rail - rear........................................................................................................................... 171

58. Lock/unlock positions.............................................................................................................................172

59. Connecting the power supply.................................................................................................................172

60. Securing the drive cable with the retention strap..................................................................................173

61. Installing the drive ller panel................................................................................................................173

62. Drive canister LEDs (EH8 Fibre Channel)............................................................................................... 175

63. Typical bre-to-host cabling.................................................................................................................. 179

64. Rack service position - rear view............................................................................................................184

65. Enclosure - front view, showing the bezel removed and the Ethernet ports (circled)..........................186

66. Drive Status page....................................................................................................................................191

67. Static-sensitive device attention symbol and grounding wrist strap.................................................... 192

68. Drive canister - canister screws............................................................................................................. 197

69. Drive canister - bezel screws..................................................................................................................197

70. Hex wrench rewinds tape into cartridge................................................................................................ 199

71. Drive canister with cover removed to reveal gear train......................................................................... 200

72. Leader block assembly (LBA)................................................................................................................. 201

73. Microcode level menu.............................................................................................................................206

74. Base Mode...............................................................................................................................................224

75. Host attachment example...................................................................................................................... 226

76. Device bre addresses - available..........................................................................................................226

77. Device bre addresses - dened............................................................................................................226

78. Flow diagram for FID 84 or E6 in a smaller font.................................................................................... 243

79. Drive enclosure FRU locations in a rack.................................................................................................251

80. Removing the lower power supply.........................................................................................................252

81. Drive canister connectors.......................................................................................................................253

82. Front of the drive canister, showing the spring plunger.........................................................................254

xi

Page 12

83. Removing the top cover, showing the cable assembly.......................................................................... 255

84. Ferrite beads on the cable assembly..................................................................................................... 256

85. Unscrewing the power supply bracket...................................................................................................257

86. Removing the power supply bracket......................................................................................................257

87. Exploded Rack Mount view.....................................................................................................................259

88. TAPEUTIL Program menu – Sun Solaris system.................................................................................... 264

89. TAPEUTIL Program menu – HP-UX system............................................................................................270

90. Base mode: Windows environment........................................................................................................276

91. Library mode: Windows environment.................................................................................................... 277

92. TAPEUTIL Program Commands menu - Linux environment (Interactive mode command).................279

93. Laser safety label - Class I......................................................................................................................295

xii

Page 13

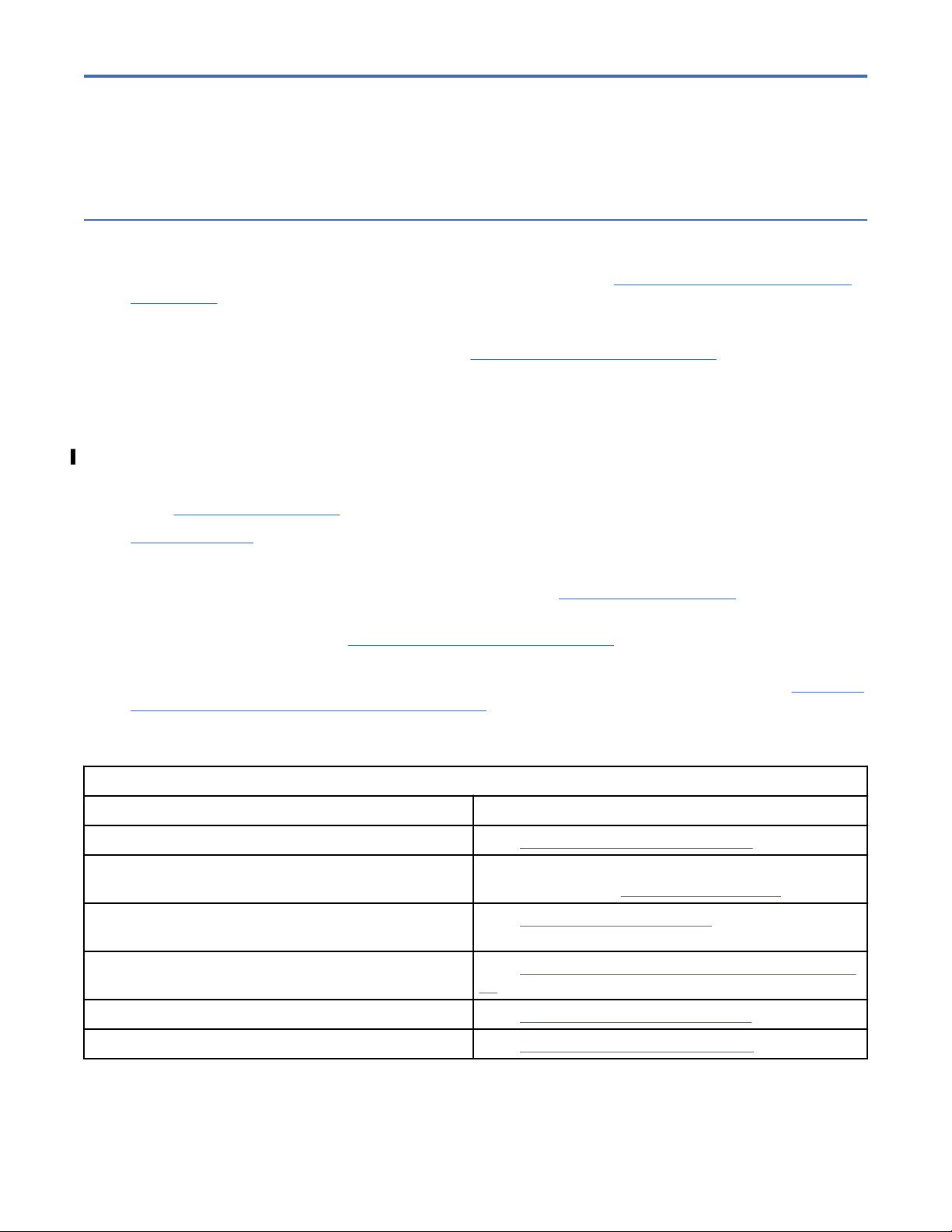

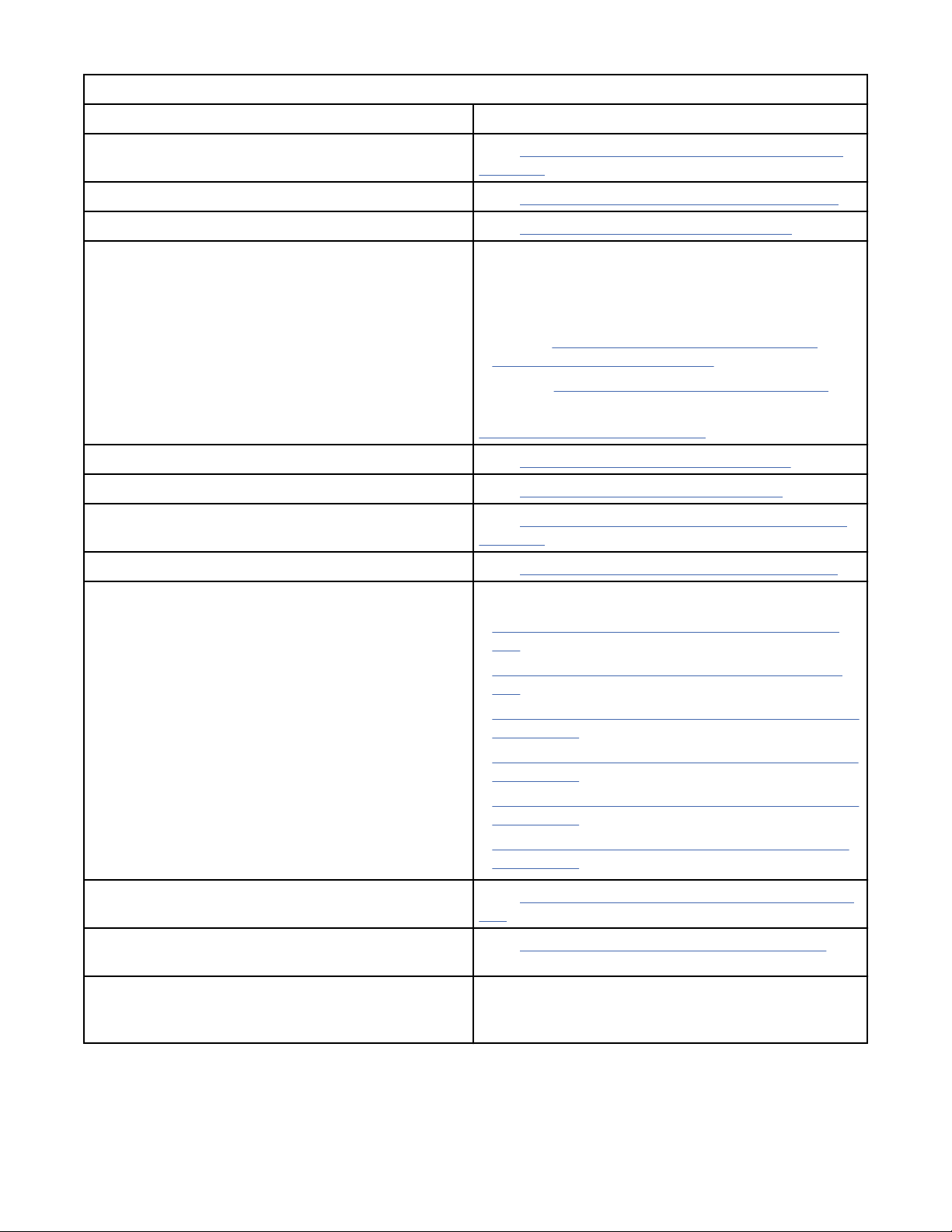

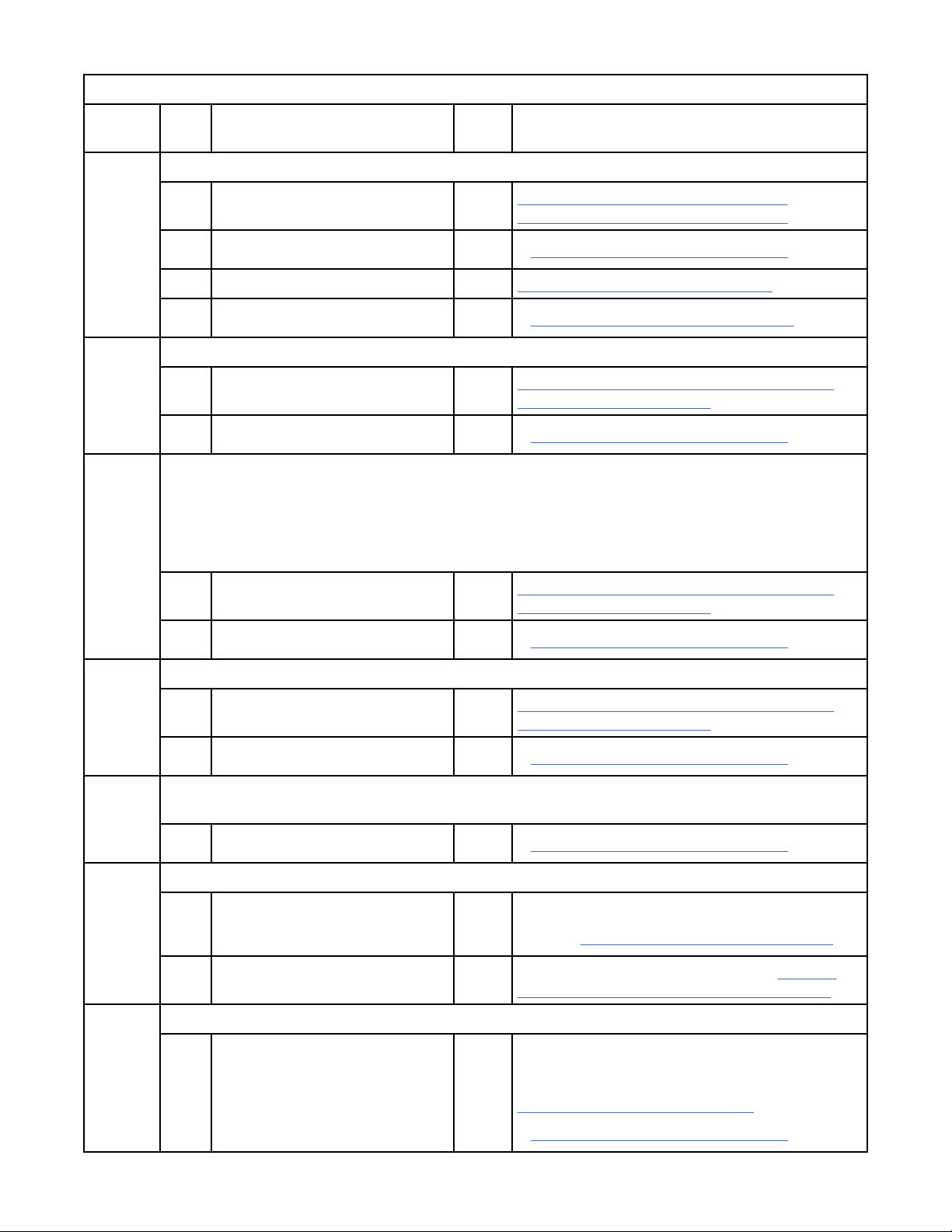

List of Tables

1. MI terms and descriptions.............................................................................................................................ii

2. Information website URLs........................................................................................................................ xviii

3. Start here....................................................................................................................................................... 1

4. FIDs and FRUs............................................................................................................................................... 7

5. ATTN DRV messages................................................................................................................................... 11

6. Supported TapeAlert flags.......................................................................................................................... 12

7. 3592 Drive functions and capabilities........................................................................................................19

8. Model 60F enhancements to Model EH8................................................................................................... 19

9. Model EH8/55F enhancements to Model EH7...........................................................................................19

10. 3592 drive attachment capabilities..........................................................................................................20

11. Minimum installation conguration..........................................................................................................20

12. FIPS availability.........................................................................................................................................23

13. Types of data tape cartridges................................................................................................................... 26

14. Operator bezel functional areas............................................................................................................... 29

15. Drive rear layout........................................................................................................................................30

16. LED indicators for EH7/EH8/55F/60F......................................................................................................31

17. Power supplies and related components.................................................................................................33

18. Special tools and customer supplies........................................................................................................36

19. Leader pin replacement kit.......................................................................................................................37

20. Meaning of SIM severity codes.................................................................................................................39

21. SIM elds descriptions............................................................................................................................. 40

22. Meaning of MIM severity codes................................................................................................................ 41

23. MIM elds descriptions.............................................................................................................................42

24. Hexadecimal-to-ASCII conversion...........................................................................................................43

25. Drive error log data................................................................................................................................... 44

26. Message codes and descriptions..............................................................................................................45

27. MIM exception messages and descriptions.............................................................................................46

28. SIM exception messages and descriptions..............................................................................................46

29. SIM/MIM service messages and descriptions......................................................................................... 47

30. SIM/MIM severity descriptions.................................................................................................................47

31. ASC, and ASCQ summary for Sense Key 0 (No Sense)............................................................................ 47

32. ASC, and ASCQ summary for Sense Key 1 (Recovered Error)................................................................. 48

33. ASC, and ASCQ summary for Sense Key 2 (Not Ready)...........................................................................48

34. ASC, and ASCQ summary for Sense Key 3 (Medium Error)......................................................................48

35. ASC, and ASCQ summary for Sense Key 4 (Hardware Error)...................................................................50

36. ASC, and ASCQ summary for Sense Key 5 (Illegal Request)................................................................... 50

37. ASC, and ASCQ summary for Sense Key 6 (Unit Attention).....................................................................52

38. ASC, and ASCQ summary for Sense Key 7 (Data Protect)....................................................................... 52

39. ASC, and ASCQ summary for Sense Key 8 (Blank Check)........................................................................53

xiii

Page 14

40. ASC, and ASCQ summary for Sense Key B (Aborted Command).............................................................53

41. ASC, and ASCQ summary for Sense Key D (Volume Overflow)............................................................... 53

42. Device driver to AIX ERRNO translation...................................................................................................57

43. Virtual Operator panel controls................................................................................................................ 78

44. Virtual Operator panel display - Menu, status, and message areas........................................................79

45. Drive activity indicators - service panel....................................................................................................83

46. Dump icon images.....................................................................................................................................83

47. Intervention messages............................................................................................................................. 85

48. Menu terms and display icons.................................................................................................................. 88

49. Virtual Operator panel menu trees guide.................................................................................................89

50. Conrm Mode Change menu.................................................................................................................... 96

51. Options menu (operator mode)................................................................................................................ 97

52. Services menu...........................................................................................................................................98

53. Set Online menu........................................................................................................................................99

54. Set Offline menu....................................................................................................................................... 99

55. Conrm Offline menu..............................................................................................................................100

56. Fibre Options menu (Services menu).....................................................................................................100

57. Port/Node Names menu (Services menu)..............................................................................................101

58. Set Port 0 {or 1} Menu (Services menu)................................................................................................. 102

59. Set Port 0 {or 1} (Speed) menu...............................................................................................................102

60. Set Topology menu - Speed and Topology.............................................................................................103

61. CE Save Data menu (Speed and Topology)............................................................................................ 104

62. Set Hard Address menu..........................................................................................................................104

63. Use Soft Address menu.......................................................................................................................... 105

64. Statistics menu (Operator Mode)........................................................................................................... 106

65. Drive Statistics menu (Operator Mode)..................................................................................................106

66. Tape Statistics menu (Operator Mode).................................................................................................. 107

67. CE Options menu (CE Offline mode).......................................................................................................108

68. CE Verify Fix/Diag menu......................................................................................................................... 108

69. CE Loop Diag menu................................................................................................................................. 111

70. Test Fibre Wrap menu.............................................................................................................................113

71. CE Dump menu....................................................................................................................................... 113

72. CE Copy Dump to Tape menu................................................................................................................. 114

73. CE FMR Tape menu................................................................................................................................. 115

74. Load FMR Tape menu..............................................................................................................................115

75. CE Select Level menu..............................................................................................................................116

76. Load Scratch Tape menu........................................................................................................................ 117

77. Unload Tape menu.................................................................................................................................. 118

78. CE Cong/Install menu...........................................................................................................................118

79. CE DRV (Drive) Options menu.................................................................................................................119

80. CE DRV Serial No menu (CE Offline Mode).............................................................................................121

81. DRV Encryption menu.............................................................................................................................121

82. Method Cong menu (Encryption)..........................................................................................................122

xiv

Page 15

83. Advanced Cong menu (Encryption)......................................................................................................123

84. Crypto Ofcer menu (Encryption)...........................................................................................................124

85. Key Path Cong menu (Encryption)........................................................................................................124

86. BOP Encryption menu.............................................................................................................................125

87. Restore Defaults menu (Encryption)......................................................................................................126

88. CE Save Data menu (Encryption)............................................................................................................126

89. CE Default Density menu........................................................................................................................126

90. CE Wrap Tools menu............................................................................................................................... 127

91. CE VPD Data menu..................................................................................................................................128

92. CE Save Data menu (Ser No)...................................................................................................................128

93. Fibre Options menu (CE Offline Mode)...................................................................................................129

94. Port/Node Names menu (CE Offline Mode)........................................................................................... 130

95. Set Root Name menu (CE Offline Mode)................................................................................................ 130

96. Set Port 0 {or 1} Name menu..................................................................................................................131

97. Set Node 0 {or 1} Name menu................................................................................................................131

98. Show Orig Names menu (CE Offline Mode)............................................................................................132

99. Restor Orig Names menu (CE Offline Mode)..........................................................................................132

100. CE Save Data menu (Root, Port, and Node names)............................................................................. 133

101. CE Logs menu (CE Offline mode)..........................................................................................................133

102. CE Error Log menu................................................................................................................................ 134

103. Time stamp for CE Error Log.................................................................................................................135

104. CE FID FE Log menu............................................................................................................................. 136

105. CE FID FF Log menu............................................................................................................................. 137

106. CE Temp Error Log menu...................................................................................................................... 137

107. CE Utilities menu.................................................................................................................................. 138

108. CE Disp/Alt VPD menu..........................................................................................................................139

109. CE Microcode Traps menu....................................................................................................................140

110. CE Saved Traps menu...........................................................................................................................141

111. CE FSC Trap List menu..........................................................................................................................141

112. CE Read Tape menu.............................................................................................................................. 142

113. CE Process Tape menu......................................................................................................................... 142

114. Space menu.......................................................................................................................................... 143

115. Read Block menu..................................................................................................................................143

116. Next Block ID menu..............................................................................................................................144

117. Enter Password menu...........................................................................................................................144

118. CE Engr Use Only menu........................................................................................................................145

119. HSARS Cong menu............................................................................................................................. 146

120. VSARS Cong menu..............................................................................................................................147

121. Special Modes menu.............................................................................................................................147

122. OEM Use Only menu............................................................................................................................. 148

123. Show Statistics menu (CE Offline Mode)..............................................................................................148