Page 1

IBM 4019

IBM 4028

IBM 4029

BDT Ergoprint 510, 610II

Unisys AP 9025, 9210

HIgh Yield

Part Number: 1380200

Gram Load: 300 grams

Yield @ 5%: 7,000

Pages per min.:5/10 ppm

Resolution: 300dpi

HIgh Yield Plus

Part Number: 1380520

Gram Load: 450 grams

Yield @ 5%: 9500

Pages per min.:5/10 ppm

Resolution: 300dpi

#1 Phillips Head Screwdriver

Small Flat Blade Screwdriver

Needle Nose Pliers

Anhydrous Isopropyl Alcohol

Damp Cloth

Soft Lint-Free Cloth

Cotton Swabs

Drill

3/32” Drill Bit

Razor Knife

Nipper PLiers

Rubber Cement

Teflon Shims for Electrostatic Roller

Waste Hopper Strip

Plastic Toner Hopper Cover

Tap e(p vc )

Toner Hopper Replacement Mylars (A&B)

Technical Instructions Printers OEM Info Tools 1

Te chnical Resource Center: Toll Free: 800 394.9900 Website: www.futuregraphicsllc.com

Brand names and trademarks are the

properties of their respective holders

and are for descriptive use only.

CORPORATE

LOS ANGELES

T 800 394.9900

818 316.0656

F 800 394.9910

818 313.9568

DALLAS

T 877 499.4989

972 840.4989

F 877 774.1750

972 840.1750

ATLANTA

T 877 676.4223

770 516.9488

F 877 337.7976

770 516.7794

MIAMI

T 800 595.4297

305 594.3396

F 800 522.8640

305 594.3309

TORONTO

T 877 848.0818

905 712.9501

F 877 772.6773

905 712.9502

NEW YORK

T 800 431.7884

631 345.0121

F 800 431.8812

631 345.0690

SYDNEY

T 02 9648.2630

F 02 9648.2635

4019 TECH

Step 1

Place the cartridge top down on the table

with the drum alignment side plate facing you. For the plastic side plates, drill

three 3/32" holes. These holes are for

screws used in final assembly. For the

metal side plate, drill out the middle of

each plastic rivet head.

(See Photo 1b)

Photo 1a

The 4019 has a standard cartridge holding 300 grams of toner and yielding 7,000

pages, and a plus cartridge that holds 450 grams of toner and yields 9500 pages at

5% coverage.

The 4019 uses a corona wire to charge the drum while the 4039 and 4049 use the

newer PCR technology.

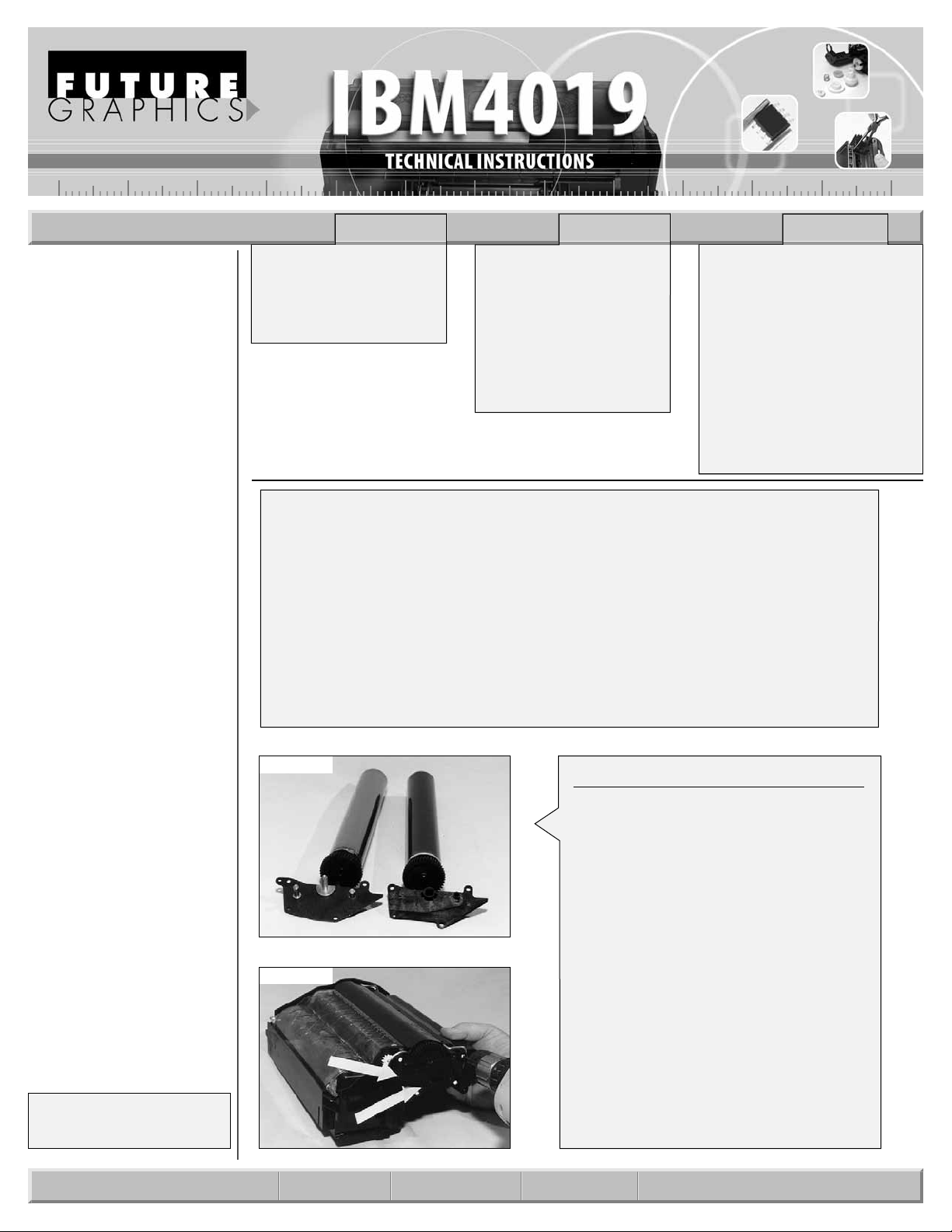

There are two different side plates on the 4019 cartridge and two different drum

gear types. The older side plate (bottom left) is metal, compared with the newer

plastic part (bottom right). In the older unit, the metal spindle fits inside the drum

gear,while the newer drum gear has a plastic spindle that fits inside the plastic side

plate.

(See Photo 1a)

Photo 1b

Page 2

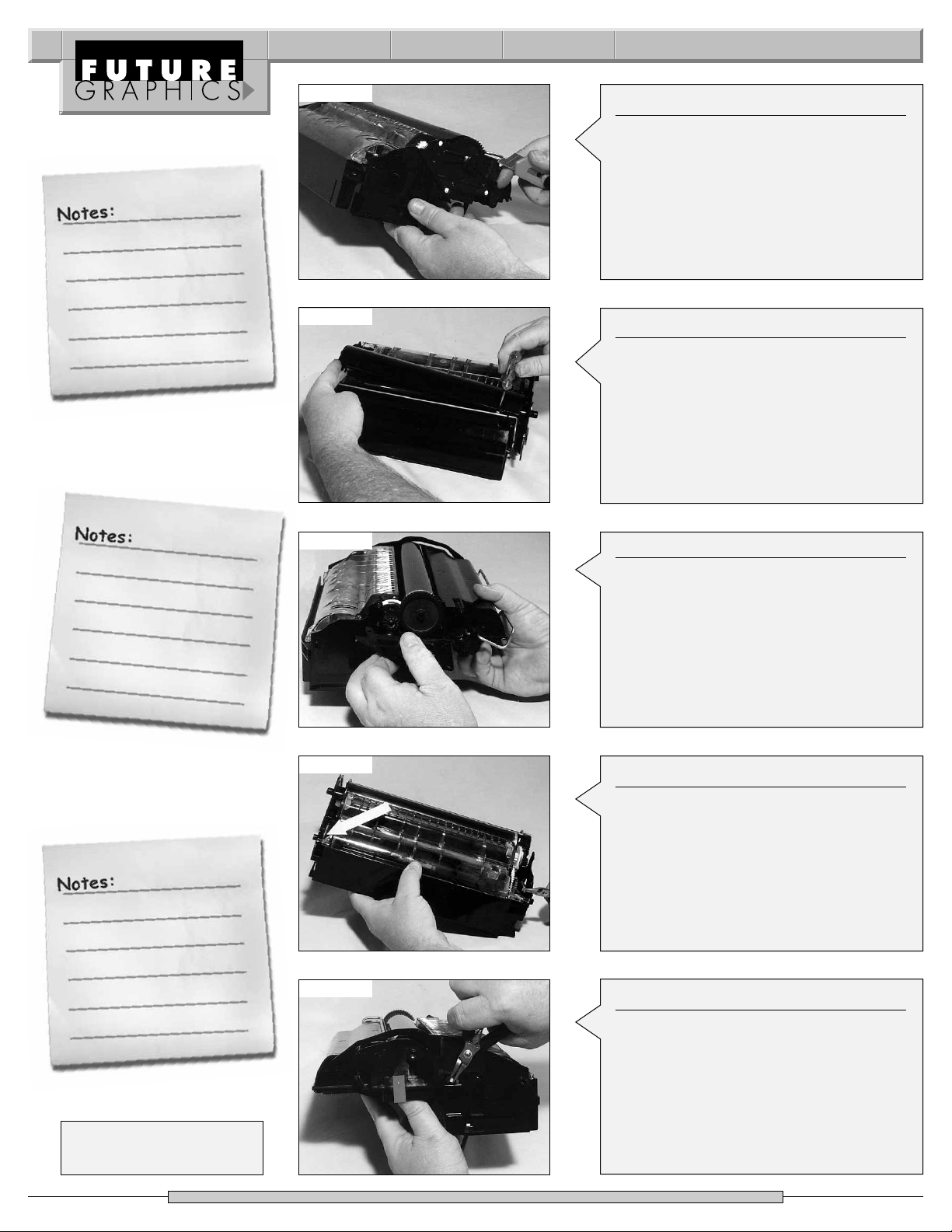

Step 2

Cut off the four heads of the black plastic

rivets (shown in white in Photo #2) with a

razor knife or flush cut nipper pliers.

(See Photo 2)

Photo 2

Step 4

Move the drum shutter rod aside and

remove the drum alignment plate by

pulling it straight out.

(See Photo 4)

Photo 3

Photo 4

Step 5

Using Needle Nose pliers, disconnect the

toner hopper tension springs.

(See Photo 5)

Photo 5

Photo 6

2IBM 4019 Technical Instructions

Need trust-worthy, detailed Technical

Instructions for another engine?

V isit: www.futuregraphicsllc.com

Step 6

Turn the cartridge 180° and remove the

toner hopper guide pin from the rectangular hole.

(See Photo 6)

Step 3

Remove the OPC drum cover from the

shutter rod using a small flat blade screwdriver.

(See Photo 3)

Page 3

Step 9

Lift the alignment plate side of the cartridge enough to expose the lock tab on

the top of the waste hopper and gently

pry the tab with a small flat blade screwdriver, to release the toner hopper.

(See Photo 9a)

Now lift the toner hopper and separate it

from the waste hopper.

(See Photo 9b)

NOTE:An arrow points to the tab being

pulled down by the screwdriver.

Photo 9a

Photo 9b

Need help with a particular remanufacturing problem?

Call the Technical Resource Center from

8am - 5pm PST: 800 394.9900

IBM 4019 Technical Instructions 3

Photo 7

Step 7

Rotate the cartridge 180° again, pull back

the toner hopper with one hand, and

remove the OPC drum with the other.

Wrap the drum in protective cloth or

paper and put it aside until later. You can

usually use the OEM drum one more

cycle after the original OEM cycle.

(See Photo 7)

Photo 8

Photo 10

Step 10

Now,set the toner hopper aside and

remove the waste hopper mylar strip

(recovery blade) opposite the wiper blade.

Dump out the waste toner and clean the

waste hopper with either compressed air

or vacuum.

(See Photo 10)

Step 8

Remove the drum clutch gear assembly

and set it aside.

(See Photo 8)

Page 4

Step11

Wipe down the entire waste hopper with a damp cloth.

Step 13

Use a cotton swab and alcohol to clean all contact points on the side of the waste

hopper.

Photo 12

Step 14

Remove the adhesive backing cover from

a new mylar waste hopper strip and

install it. Be sure that the strip is straight

before pressing it into place.

(See Photo 14)

If the toner hopper tension springs on

each side of the waste hopper are

stretched or weak replace them with new

springs. This will pull the toner hopper

tighter to the OPC drum and allow a better transfer of toner from the electrostatic

roller to the OPC. Now, set aside the completed waste hopper until you are ready

to assemble the cartridge.

Photo 15

4IBM 4019 Technical Instructions

Need trust-worthy, detailed Technical

Instructions for another engine?

V isit: www.futuregraphicsllc.com

Step 15

Holding the toner hopper upright,

remove the paper cover and tape, and

dump out the old toner. Vacuum completely. Then wipe clean with a slightly

damp cloth. Be careful not to damage

mylar strips inside the toner hopper.

(See Photo 15)

Step12

Clean the place where the waste hopper

mylar strip was with a cotton swab and

alcohol.This area must be free of all adhesive and toner. Clean the wiper blade with

a soft cloth. Clean any grease residue

from around the axle with a cotton swab

and alcohol.

(See Photo 12)

Photo 14

Page 5

Step 17

Remove the metering blade tension

spring.

(See Photo 17)

Photo 18a

Photo 18b

Need help with a particular remanufacturing problem?

Call the Technical Resource Center from

8am - 5pm PST: 800 394.9900

IBM 4019 Technical Instructions 5

Photo 16

Step 16

Remove the toner hopper mylar retaining

blade by peeling it away from the toner

hopper.

(See Photo 16)

Photo 17

Photo 19

Step 19

Vacuum out any toner from

within the electrostatic roller cavity.

Remove the black mylar blade from the

inside of the electrostatic roller cavity.

Once the toner hopper is completely

clean, use a swab and isopropyl alcohol

and clean the area where the old mylar

blades were removed. Install new interior

mylar blade “A”.

(See Photo19)

NOTE: If not cleaned completely the new

blades will not adhere to the toner hopper properly, resulting in a leaky toner

hopper.

Step 18

Using a small screwdriver, remove the

electrostatic roller retaining piece. Clean

it with a cotton swab and alcohol and set

aside.Be careful not to lose the little metal

contact clip (not shown).

(See Photo18a)

Remove the electrostatic roller by grasping the shaft and pulling it out and to the

left.

(See Photo18b)

Page 6

Step 20

Replace OEM .010" shims with new .020" Teflon shims on the electrostatic roller and

re-install the roller into the toner hopper.

NOTE: Two old .010" shims may be used on each end if new .020” shims aren’t available.

Re-install the electrostatic roller end piece.

Step 22

Fill the toner hopper with the proper

amount of toner.

(See Photo 22)

Photo 21

Photo 22

Step 23

Place a new toner hopper cover over the

top of the toner hopper. Using tape, seal

the toner hopper cover to the toner hopper.

(See Photo 23)

Photo 23

Photo 24

6IBM 4019 Technical Instructions

Need trust-worthy, detailed Technical

Instructions for another engine?

V isit: www.futuregraphicsllc.com

Step 24

Using a “ScotchBrite”pad,clean a 1-inch

long area on the front of the metering

blade, corresponding to where the

grounding contact strap will touch.

(See Photo 24)

This will help avoid the 1/4" gray horizontal line that appears on the “trailing edge”

of some prints due to a poor ground contact. Clean the bottom edge of metering

blade with a swab and alcohol.

Step 21

Clean the foam roller end shaft and contact strap with a cotton swab and alcohol.

(See Photo 21)

Page 7

Photo 29

Need help with a particular remanufacturing problem?

Call the Technical Resource Center from

8am - 5pm PST: 800 394.9900

IBM 4019 Technical Instructions 7

Photo 25

Step 25

Place a thin film of rubber cement, or a

similar flexible sealant, at each end of the

metal metering blade to keep toner from

leaking at these points.

(See Photo 25)

Photo 26

Photo 31

Step 29

Slide the toner hopper,top down and tilted at an angle, into the waste hopper.

(See Photo 29)

NOTE: Use your right index finger to hold

back the grounding contact strap.

Step 26

Install the new mylar blade “B”,making

sure it is flat and square, with no waves or

wrinkles, and that the bottom edge is

approximately 1/32" above the bottom

edge of the hopper. If it extends too low,

it will cause paper jams. Re-install the

metering blade tension spring.

(See Photo 26)

Step 27

Dust the wiper/recovery blade area with

padding powder.

Step 29

Place a small amount of conductive

grease on the waste hopper drum axle.

Step 30

Hold the toner hopper back with your left

hand while installing the drum with your

right.

(See Photo 30)

Step 31

Using Needle Nose pliers, reinstall the

toner hopper tension springs.

(See Photo 31)

CAUTION: Do not overstretch the

springs.

Photo 30

Page 8

Step 32

Turn the cartridge around and install the

toner hopper guide pin. A small amount

of rubber cement may be used to keep it

in place.

(See Photo 32)

Step 33

Make sure that the toner hopper moves

back and forth against the spring tension

smoothly. Realign the hopper if necessary, then install the cloth gear assembly.

Photo 32

Step 34

Install the drum alignment plate. While

holding the drum shutter rod back, position the four holes in the plate onto the

four black plastic rivet posts.

(See Photo 34)

Photo 34

Photo 35

Step 35

Install screws into holes previously drilled

in Step 1.

(See Photo 35)

Make sure the plate is correctly aligned

and held firmly in place. Turn the drum

against the wiper blade while listening for

noise and testing for undue torque or

stiffness. Proper alignment and free rotation of the drum is essential to good cartridge performance.

Photo 36

Photo 37

8IBM 4019 Technical Instructions

Need trust-worthy, detailed Technical

Instructions for another engine?

V isit: www.futuregraphicsllc.com

Step 37

Clean the corona wire with the cartridge

corona wire cleaner provided by sliding it

in and out several times.

(See Photo 37)

The cartridge is now ready for post

testing.

Step 36

Carefully reinstall the OPC shutter.

(See Photo 36)

Te chnical Resource Center: Toll Free: 800 394.9900 Website: www.futuregraphicsllc.com

Page 9

TAR GET MARKET ENGINE SOLD TO

This engine/printer is sold to

CARTRIDGE MARKET OVERVIEW

OEMCARTRIDGE # OEM STATED PAGE YIELD OEM CARTRIDGE LIST PRICE COMPATIBLE CARTRIDGE RETAIL PRICE

1380200 7,000 Pgs @ 5%

1380520 9,500 Pgs @ 5%

CARTIDGE CROSS COMPATIBILITY

IBM 4019 IBM 4028 IBM 4029

IBM WinWriter 600 Lexmark Laser Printer 5/6/10 BDT Ergoprint510, 61011

Unisys AP 9025, 9210

FUTURE GRAPHICS PRODUCT LISTING

PRODUCT DESCRIPTION ITEM # PACK QTY.

Cartridge Bag 14x18, 2.5 mil Heat-Sealable Black/Silver Anti-Static Foil BAG14X18 100

Cartridge Box 14 1/2x6 5/8x11 1/4, Tape-Top White Box/Blue Print BLUEBAR15X11 25

Cartridge Box Insert Use Box # BLUEBAR15X11, Die Cut Corrugated IBMINSERT 50

Cartridge Tech Guide Remanufacturing Instructions IBM4019TECH 1

Cartridge Warp 15X26 Gray Open cell Foam, Grabs Toner Leaked in Transit FOAMWRAP15X26 10

Developer Roller LMKDVRROL 5

Dev. Roller Washer/Shim Teflon HP1200DRBALDEK 10/150

Doctor Bar Two-Cycle,Double Edge, Flip Over for Second Cycle LMKDRBAR 10

Doctor Bar Tape Prevents Dr.Bar Spring From Falling Out While Shipping Like OEM LMKDRBARTAPE

Drum AEG, Green IBM4019AEG 5/60

Drum Protector Felt Shutter Felt, Adhesive, 5 Inch SHUTTERFELT5 100

Drum Shutter Actuator Tab Triangular Black Plastic IBM4019TAB 50

Hooper Cover/Seal Clear Plastic, Flexible Lid, Use Tape to Seal IBMCOVER 50

Retaining Blade Toner, Inner/Outer Black Mylar, Set of Two IBMRBLADE10SET 10

Retaining Blade Toner, Inner/Wide, Angle cut 9 1/4 x 5/8 IBM4019RBLADEIA 100

Retaining Blade Toner, Inner/Wide, Black 9 1/4 x 5/8 IBM4019RBLADEI 100

Retaining Blade Toner, Outer/Long, Black 9 3/4 x 1/2 IBM4019RBLADEO 100

Recover Blade Waste,Hopper Clear Mylar IBM4019BLADEW 100

Sealing Tips Solutions to Leaking Problems Common to IBM Cartridge IBMSEALTECH 1

Page 10

TECHNICAL TIP

PROBLEM:

SOLUTION:

PROBLEM:

SOLUTION:

Toner 300 gm Bottle Standard Hopper IBM4039TNR300 10

Toner 480 gm Bottle High Yield Hopper IBM4039TNR480 10

Toner With Nomex Felt, Unflocked, Universal IBM 4019-49 IBMWAND 10

Wiper Blade Kuroki IBM4019WBLADEK 10/240

Loading...

Loading...