Page 1

IBM x-series of Ethernet Switches

Installation and User Guide

Service information: 4002-X2A, 4002AX2

GC27-2267-00

Page 2

Page 3

IBM x-series of Ethernet Switches

Installation and User Guide

Service information: 4002-X2A, 4002AX2

GC27-2267-00

Page 4

Note:

Before using this information and the product it supports, be sure to read the general information in Appendix B, “Notices,” on

page 51.

The following paragraph does not apply to any country (or region) where such provisions are inconsistent with local

law.

INTERNATIONAL BUSINESS MACHINES CORPORATION PROVIDES THIS PUBLICATION ″AS IS″ WITHOUT

WARRANTY OF ANY KIND, EITHER EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. Some states (or regions) do

not allow disclaimer of express or implied warranties in certain transactions; therefore, this statement may not apply

to you.

Order publications through your IBM representative or the IBM branch office serving your locality.

© Copyright International Business Machines Corporation 2009.

US Government Users Restricted Rights – Use, duplication or disclosure restricted by GSA ADP Schedule Contract

with IBM Corp.

Page 5

Contents

Figures ...........................vii

Tables ............................ix

Preface ............................xi

Safety notices .........................xi

Safety notices and labels ....................xi

Notes ..........................xii

Attention notices ......................xii

Caution notices .......................xii

Danger notices .......................xiii

Safety labels .......................xvi

Rack safety.........................xviii

Rack installation ......................xviii

Rack relocation (19″ rack)...................xix

Product recycling and disposal ...................xix

Product documents .......................xx

Software documents .......................xx

Accessibility features for the IBM x-series of Ethernet Switches .......xxii

Accessibility features .....................xxii

Keyboard navigation .....................xxii

Vendor software .......................xxii

Related accessibility information .................xxii

IBM and accessibility .....................xxiii

Getting help .........................xxiii

Taiwan Contact Information ...................xxiii

How to send your comments ...................xxiii

About This Document ......................xxiii

Audience .........................xxiv

Supported hardware and software ................xxiv

Document conventions ....................xxiv

Text formatting ......................xxiv

Command syntax conventions .................xxiv

Chapter 1. Product Overview ...................1

Software features........................1

Hardware features ........................1

Control features .........................2

Serial management interface (Console port)..............2

Management port.......................2

Network interfaces ........................2

Viewing the media types installed in the ports .............3

10 Gbps ports.........................3

Four 10/100/1000 Mbps ports

10GbE SFP+ transceiver.....................4

LEDs for network interfaces and power supplies .............4

Power supplies .........................6

Chapter 2. Installing the B24X ...................9

Unpacking a system .......................9

Package contents .......................9

General requirements ......................9

Summary of installation tasks ....................9

© Copyright IBM Corp. 2009 iii

...................4

Page 6

Installation precautions ......................10

General precautions ......................11

Power precautions ......................11

Preparing the installation site....................12

Cabling infrastructure .....................12

Installation location ......................12

Installing the device .......................12

Desktop installation ......................12

Rack mount installation .....................12

Powering on the system .....................14

Powering off the system ....................14

Verifying proper operation .....................14

Observing the power status LEDs .................15

Attaching a PC or terminal ....................15

Chapter 3. Connecting Network Devices and Checking Connectivity ...19

Assigning permanent passwords ..................19

Recovering from a lost password .................20

Configuring IP addresses .....................20

Devices running Layer 2 software .................21

Connecting network devices ....................21

Connectors and cable specifications ................21

Connecting to Ethernet or fast Ethernet hubs .............21

Connecting to workstations, servers, or routers ............23

Automatic MDI or MDIX detection ................23

Connecting a network device to a fiber port ............23

Testing connectivity .......................24

Pinging an IP address .....................24

Observing LEDs .......................24

Tracing a route ........................25

Troubleshooting network connections.................26

Support for digital optical monitoring ................26

Chapter 4. Managing the B24X ..................27

Managing temperature settings ...................27

Using the temperature sensor ..................27

Displaying the temperature ...................27

Displaying temperature messages .................27

Changing the temperature warning level ..............28

Changing the device temperature polling interval ...........28

Removing MAC address entries ..................28

Chapter 5. Maintaining the B24X Hardware .............31

Hardware maintenance schedule ..................31

Replacing a fiber optic module ...................31

Removing a fiber optic module ..................31

Installing a new fiber optic module .................32

Cabling a fiber optic module ...................32

Cleaning the fiber-optic connectors ................33

Replacing a power supply .....................33

Installation precautions and warnings................33

Determining which power supply failed ...............33

Replacing AC power supplies ..................34

Removing an AC power supply

Installing an AC power supply .................35

Removing the battery ......................38

iv IBM x-series of Ethernet Switches Installation and User Guide

.................34

Page 7

Replacing the fan tray ......................39

Installation precautions and warnings................39

Removing the fan tray .....................40

Appendix A. Hardware Specifications................43

Device specifications.......................43

Physical dimensions and weight .................43

Environmental considerations ..................43

Operating environment ....................43

Storage environment .....................44

Cooling...........................44

Power source interruptions ...................44

Pinouts and signalling .....................45

Serial (Console) port pinouts ..................45

10/100/1000 Gigabit port pinouts ................46

Cable specifications ......................46

Power cords .........................48

Power supply specifications ....................48

Overview ..........................48

Key features .........................48

Physical dimensions and weight .................48

Environmental considerations ..................48

Operating environment ....................49

Storage environment .....................49

Power supply consumption ...................49

Input connector and plug ....................49

Electrical specifications .....................50

Appendix B. Notices ......................51

Trademarks ..........................52

Electronic emission notices ....................52

Federal Communications Commission (FCC) Class A Statement .....52

Industry Canada Class A Emission Compliance Statement ........53

Avis de conformité à la réglementation d’Industrie Canada ........53

European Union (EU) Electromagnetic Compatibility Directive.......53

Germany Electromagnetic Compatibility Directive ...........53

People’s Republic of China Class A Electronic Emission Statement ....54

Japan VCCI Class A ITE Electronic Emission Statement.........54

Korea Class A Electronic Emission Statement ............54

Contents v

Page 8

vi IBM x-series of Ethernet Switches Installation and User Guide

Page 9

Figures

1. IBM Ethernet Switch B24X............................1

2. Console and Management ports..........................2

3. 24 10-GbE ports ...............................4

4. AC power supply front panel ...........................6

5. Attaching the short mounting brackets .......................13

6. Installing the device in a rack ..........................13

7. Attaching the AC power cord ..........................14

8. Serial port pin and signalling details ........................17

9. Serial port pin assignments showing cable connection options to a terminal or PC .......17

10. 10 UTP crossover cable ............................22

11. Cat-5 crossover cable for 1000Base-T .......................22

12. Disconnecting a fiber optic module latch ......................32

13. Removing a fiber optic module ..........................32

14. AC power supply ...............................34

15. Releasing the power supply ...........................35

16. Removing the power supply ...........................35

17. Releasing the cover plate............................36

18. Removing the cover plate ...........................36

19. Installing the power supply ...........................37

20. Securing the power supply in the device ......................37

21. Connecting the power cord ...........................38

22. Removing the battery .............................39

23. B24X Fan Tray ...............................40

24. B24X fan tray location .............................40

25. Removing the fan tray .............................40

26. Inserting a replacement fan tray .........................41

27. Device air flow................................44

28. Serial port pin and signalling details ........................45

29. Serial port pin assignments showing cable connection options to a terminal or PC .......46

30. Pin assignment and signalling for 10/100/1000 ports ..................46

31. AC power cord plug and input connector ......................50

© Copyright IBM Corp. 2009 vii

Page 10

viii IBM x-series of Ethernet Switches Installation and User Guide

Page 11

Tables

1. Comparable IBM and Brocade products. ......................xx

2. Formatting conventions ............................xxiv

3. Command syntax conventions .........................xxiv

4. Network interfaces...............................2

5. LEDs ...................................4

6. Summary of installation tasks...........................9

7. Power LEDs ................................15

8. Network connection-related LED states ......................25

9. Physical dimensions and weight of the B24X and modules ...............43

10. Operating environmental conditions for the device ..................43

11. Storage environmental conditions for the device ...................44

12. Device power surge and drop protection ......................44

13. Cable length summary .............................47

14. Physical dimensions and weight of power supplies ..................48

15. Operating environmental conditions for power supplies .................49

16. Storage environmental conditions for power supplies .................49

17. Input connector for power supplies ........................49

18. Power supply electrical specifications .......................50

© Copyright IBM Corp. 2009 ix

Page 12

x IBM x-series of Ethernet Switches Installation and User Guide

Page 13

Preface

Safety notices

This publication is provided for use with your particular IBM®Ethernet switch or

router product or product family. It provides information on installing, configuring,

maintaining, and using your product. Please retain this publication and the

accompanying documentation CD in a convenient location for easy reference and

future use.

The following sections provide information on safety and environmental

considerations, related publications and resources, as well as how to get

assistance, and how to send IBM feedback on this publication.

v “Safety notices”

v “Product recycling and disposal” on page xix

v “Product documents” on page xx

v “Getting help” on page xxiii

v “How to send your comments” on page xxiii

This section contains important safety information that should be read before

starting any installation or service procedure.

v “Safety notices and labels,” including:

– “Notes” on page xii

– “Attention notices” on page xii

– “Caution notices” on page xii

– “Danger notices” on page xiii

– “Safety labels” on page xvi

v “Rack safety” on page xviii

Safety notices and labels

When using this product, observe the danger, caution, and attention notices

contained in this guide. The notices are accompanied by symbols that represent the

severity of the safety condition. The danger and caution notices are listed in

numerical order based on their IDs, which are displayed in parentheses, for

example (D004), at the end of each notice. Use this ID to locate the translation of

these danger and caution notices in the IBM Systems Safety Notices (G229–9054)

publication, which is on the product documentation CD that accompanies this

product.

The following notices and statements are used in IBM documents. They are listed

below in order of increasing severity of potential hazards. Follow the links for more

detailed descriptions and examples of the notes, attention notices, caution, and

danger notices in the sections that follow.

v “Notes” on page xii: These notices provide important tips, guidance, or advice.

v “Attention notices” on page xii: These notices indicate potential damage to

programs, devices, or data.

v “Caution notices” on page xii: These statements indicate situations that can be

potentially hazardous to you.

© Copyright IBM Corp. 2009 xi

Page 14

v “Danger notices” on page xiii: These statements indicate situations that can be

potentially lethal or extremely hazardous to you. Safety labels are also attached

directly to products to warn of these situations.

v In addition to these notices, “Safety labels” on page xvi may be attached to the

product to warn of potential hazards.

Notes

Notes can provide tips, guidance, suggestions, or advice for simplifying procedures,

clarifying information, or avoiding potential problems. A sample note follows.

Note: The POE LEDs work only when POE is enabled on your device.

Attention notices

An attention notice indicates the possibility of damage to a program, device, or

system, or to data. An exclamation point symbol may accompany an attention

notice, but is not required. A sample attention notice follows:

Attention: Do not bend a fibre cable to a radius less than 5 cm (2 in.); you can

damage the cable. Tie wraps are not recommended for optical cables because they

can be easily overtightened, causing damage to the cable.

ESD precautions: Attention: Many of the field replaceable units (FRUs) are

sensitive to electrostatic discharge (ESD), and can potentially be damaged by

improper handling. Wear a wrist grounding strap connected to chassis ground (if the

device is plugged in) or a bench ground. Store all ESD-sensitive components in

antistatic packaging.

Caution notices

A caution notice calls attention to a situation that is potentially hazardous to people

because of some existing condition. A caution notice can be accompanied by

different symbols, as in the examples below:

If the symbol

is... It means....

A hazardous electrical condition with less severity than electrical danger.

A generally hazardous condition not represented by other safety symbols.

A specification of product weight that requires safe lifting practices. The

weight range of the product is listed below the graphic, and the wording

of the caution varies, depending on the weight of the device.

55 kg ( 121.2 lbs)

>55kg (121.2 lb)

P/N 18P5850-B

svc00169

A potential hazard of pinching the hand or other body parts between

parts.

SJ000752

A hazardous condition due to moving parts nearby.

xii IBM x-series of Ethernet Switches Installation and User Guide

Page 15

If the symbol

is... It means....

A hazardous condition due to the use of a laser in the product. Laser

symbols are always accompanied by the classification of the laser as

defined by the U.S. Department of Health and Human Services (for

example, Class I, Class II, and so forth).

Read and comply with the following caution notices before installing or servicing this

device.

CAUTION:

Energy hazard present. Shorting may result in system outage and

possible physical injury. Remove all metallic jewelry before

servicing. (C001)

CAUTION:

This product is equipped with a 3-wire (two conductors and ground)

power cable and plug. Use this power cable with a properly

grounded electrical outlet to avoid electrical shock. (C018)

CAUTION:

Servicing of this product or unit is to be performed by trained

service personnel only. (C032)

Danger notices

A danger notice calls attention to a situation that is potentially lethal or extremely

hazardous to people. A lightning bolt symbol accompanies a danger notice to

represent a dangerous electrical condition. Read and comply with the following

danger notices before installing or servicing this device.

DANGER

To prevent a possible shock from touching two surfaces with

different protective ground (earth), use one hand, when possible,

to connect or disconnect signal cables. (D001)

DANGER

Overloading a branch circuit is potentially a fire hazard and a

shock hazard under certain conditions. To avoid these hazards,

ensure that your system electrical requirements do not exceed

branch circuit protection requirements. Refer to the information

that is provided with your device or the power rating label for

electrical specifications. (D002)

Preface xiii

Page 16

DANGER

If the receptacle has a metal shell, do not touch the shell until

you have completed the voltage and grounding checks. Improper

wiring or grounding could place dangerous voltage on the metal

shell. If any of the conditions are not as described, STOP. Ensure

the improper voltage or impedance conditions are corrected

before proceeding. (D003)

DANGER

An electrical outlet that is not correctly wired could place

hazardous voltage on metal parts of the system or the devices

that attach to the system. It is the responsibility of the customer

to ensure that the outlet is correctly wired and grounded to

prevent an electrical shock. (D004)

The following general electrical danger notice provides instructions on how to avoid

shock hazards when servicing equipment. Unless instructed otherwise, follow the

procedures in this danger notice.

xiv IBM x-series of Ethernet Switches Installation and User Guide

Page 17

DANGER

When working on or around the system, observe the following

precautions:

Electrical voltage and current from power, telephone, and

communication cables are hazardous. To avoid a shock hazard:

v Connect power to this unit only with the IBM provided power

cord. Do not use the IBM provided power cord for any other

product.

v Do not open or service any power supply assembly.

v Do not connect or disconnect any cables or perform

installation, maintenance, or reconfiguration of this product

during an electrical storm.

v The product might be equipped with multiple power cords. To

remove all hazardous voltages, disconnect all power cords.

v Connect all power cords to a properly wired and grounded

electrical outlet. Ensure that the outlet supplies proper voltage

and phase rotation according to the system rating plate.

v Connect any equipment that will be attached to this product to

properly wired outlets.

v When possible, use one hand only to connect or disconnect

signal cables.

v Never turn on any equipment when there is evidence of fire,

water, or structural damage.

v Disconnect the attached power cords, telecommunications

systems, networks, and modems before you open the device

covers, unless instructed otherwise in the installation and

configuration procedures.

v Connect and disconnect cables as described below when

installing, moving, or opening covers on this product or

attached devices.

To Disconnect:

1. Turn off everything (unless instructed otherwise).

2. Remove the power cords from the outlets.

3. Remove the signal cables from the connectors.

4. Remove all cables from the devices.

To Connect:

1. Turn off everything (unless instructed otherwise).

2. Attach all cables to the devices.

3. Attach the signal cables to the connectors.

4. Attach the power cords to the outlets.

5. Turn on the devices.

(D005)

If the weight of the product is greater than 227 kg (500 lb), the following statement

and notice apply. This could apply if multiple products are installed in a single

cabinet, and that cabinet and products needs to be moved.

Preface xv

Page 18

Delivery and subsequent transportation of the equipment: The customer

should prepare his environment to accept the new product based on the installation

planning information provided, with assistance from an IBM Installation Planning

Representative (IPR) or IBM authorized service provider. In anticipation of the

equipment delivery, the final installation site should be prepared in advance such

that professional movers/riggers can transport the equipment to the final installation

site within the computer room. If for some reason, this is not possible at the time of

delivery, the customer will need to make arrangements to have professional

movers/riggers return to finish the transportation at a later date. Only professional

movers/riggers should transport the equipment. The IBM authorized service provider

will only perform minimal frame repositioning within the computer room, as needed,

to perform required service actions. The customer is also responsible for using

professional movers/riggers in the case of equipment relocation or disposal.

DANGER

Heavy equipment—personal injury or equipment damage might

>(>)500 lbs. 227 kg.

result if mishandled. (D006)

a69i0333

Safety labels

As an added precaution, safety labels are often installed directly on products or

product components to warn of potential hazards. These can be either danger or

caution notices, depending upon the level of the hazard.

The actual product safety labels may differ from these sample safety labels:

DANGER

Hazardous voltage, current, or energy levels are present inside

any component that has this label attached. Do not open any

cover or barrier that contains this label. (L001)

DANGER

Rack-mounted devices are not to be used as a shelf or work

space. (L002)

DANGER

Multiple power cords. The product might be equipped with

multiple power cords. To remove all hazardous voltages,

disconnect all power cords. (L003)

xvi IBM x-series of Ethernet Switches Installation and User Guide

Page 19

DANGER

Hazardous voltage present. Voltages present constitute a shock

hazard, which can cause severe injury or death. (L004)

CAUTION:

Hazardous energy present. Voltages with hazardous energy might

cause heating when shorted with metal, which might result in

splattered metal, burns, or both. (L005)

CAUTION:

Hazardous moving parts nearby (L008)

P/N 18P5850-B

CAUTION:

Pinch hazard. (L012)

SJ000752

Preface xvii

Page 20

Rack safety

Rack installation

DANGER

Observe the following precautions when working on or around your IT rack system:

v Heavy equipment—personal injury or equipment damage might result if

mishandled.

v Always lower the leveling pads on the rack cabinet.

v Always install stabilizer brackets on the rack cabinet.

v To avoid hazardous conditions due to uneven mechanical loading, always install

the heaviest devices in the bottom of the rack cabinet. Always install servers and

optional devices starting from the bottom of the rack cabinet.

v Rack-mounted devices are not to be used as shelves or work spaces. Do not

place objects on top of rack-mounted devices.

v Each rack cabinet might have more than one power cord. Be sure to disconnect

all power cords in the rack cabinet when directed to disconnect power during

servicing.

v Connect all devices installed in a rack cabinet to power devices installed in the

same rack cabinet. Do not plug a power cord from a device installed in one rack

cabinet into a power device installed in a different rack cabinet.

v An electrical outlet that is not correctly wired could place hazardous voltage on

the metal parts of the system or the devices that attach to the system. It is the

responsibility of the customer to ensure that the outlet is correctly wired and

grounded to prevent an electrical shock.

(R001 part 1 of 2)

CAUTION:

v Do not install a unit in a rack where the internal rack ambient temperatures will

exceed the manufacturer’s recommended ambient temperature for all your

rack-mounted devices.

v Do not install a unit in a rack where the air flow is compromised. Ensure that air

flow is not blocked or reduced on any side, front, or back of a unit used for air flow

through the unit.

v Consideration should be given to the connection of the equipment to the supply

circuit so that overloading of the circuits does not compromise the supply wiring or

overcurrent protection. To provide the correct power connection to a rack, refer to

the rating labels located on the equipment in the rack to determine the total power

requirement of the supply circuit.

v (For sliding drawers) Do not pull out or install any drawer or feature if the rack

stabilizer brackets are not attached to the rack. Do not pull out more than one

drawer at a time. The rack might become unstable if you pull out more than one

drawer at a time.

v (For fixed drawers) This drawer is a fixed drawer and must not be moved for

servicing unless specified by the manufacturer. Attempting to move the drawer

partially or completely out of the rack might cause the rack to become unstable or

cause the drawer to fall out of the rack.

(R001 part 2 of 2)

xviii IBM x-series of Ethernet Switches Installation and User Guide

Page 21

Rack relocation (19″ rack)

CAUTION:

Removing components from the upper positions in the rack cabinet improves

rack stability during relocation. Follow these general guidelines whenever you

relocate a populated rack cabinet within a room or building:

v Reduce the weight of the rack cabinet by removing equipment starting at

the top of the rack cabinet. When possible, restore the rack cabinet to the

configuration of the rack cabinet as you received it. If this configuration is

not known, you must do the following:

– Remove all devices in the 32U position and above.

– Ensure that the heaviest devices are installed in the bottom of the rack

cabinet.

– Ensure that there are no empty U-levels between devices installed in the

rack cabinet below the 32U level.

– If the rack cabinet you are relocating is part of a suite of rack cabinets,

detach the rack cabinet from the suite.

– Inspect the route that you plan to take when moving the rack to

eliminate potential hazards.

– Verify that the route that you choose can support the weight of the

loaded rack cabinet. Refer to the documentation that came with your

rack cabinet for the weight of a loaded rack cabinet.

– Verify that all door openings are at least 760 x 2030 mm (30 x 80 in.).

– Ensure that all devices, shelves, drawers, doors, and cables are secure.

– Ensure that the four leveling pads are raised to their highest position.

– Ensure that there is no stabilizer bracket installed on the rack cabinet

during movement.

– Do not use a ramp inclined at more than 10 degrees.

– Once the rack cabinet is in the new location, do the following:

- Lower the four leveling pads.

- Install stabilizer brackets on the rack cabinet.

- If you removed any devices from the rack cabinet, repopulate the rack

cabinet from the lowest position to the highest position.

– If a long distance relocation is required, restore the rack cabinet to the

configuration of the rack cabinet as you received it. Pack the rack

cabinet in the original packaging material, or equivalent. Also, lower the

leveling pads to raise the casters off of the pallet and bolt the rack

cabinet to the pallet.

(R002)

Product recycling and disposal

Refer to the IBM Systems Environmental Notices and User Guide (Z125-5823) for

translated environmental statements and information regarding product recycling

and disposal. This document may be provided either in printed version or on the

product documentation CD.

See “Removing the battery” on page 38 for battery removal instructions, if needed

to meet environmental regulations.

Preface xix

Page 22

Product documents

The following documents contain information related to this product. The

documentation may be printed material or may be on the documentation CD that is

shipped with the product. Newer versions of product documentation may be

available through the IBM Publications Center web site www.ibm.com/shop/

publications/order or through the IBM Systems Networking Support web site

www.ibm.com/systems/support/networking. Search by product, publication title, or

publication number.

v IBM x-series of Ethernet Switches Installation and User Guide, GC27-2267 (this

document)

v IBM Systems Safety Notices, G229–9054

v IBM Systems Environmental Notices and User Guide, Z125-5823

v IBM Warranty

Software documents

IBM Ethernet switch and router products use software licensed from Brocade

Communications Systems, Inc. You can find software publications that support your

product on the CD-ROM supplied with this product.

The software publications associated with this product are:

v FastIron and TurboIron 24X Configuration Guide

v IronWare MIB Reference

These software publications reflect only the original Brocade products names. Use

the cross-reference of products in Table 1 to assist you when determining which

information in those publications applies to your product. Brocade products with no

IBM equivalents are not listed in the table. Note that the IBM products can be

ordered with additional features, while Brocade products with those additional

features may be offered as separate models.

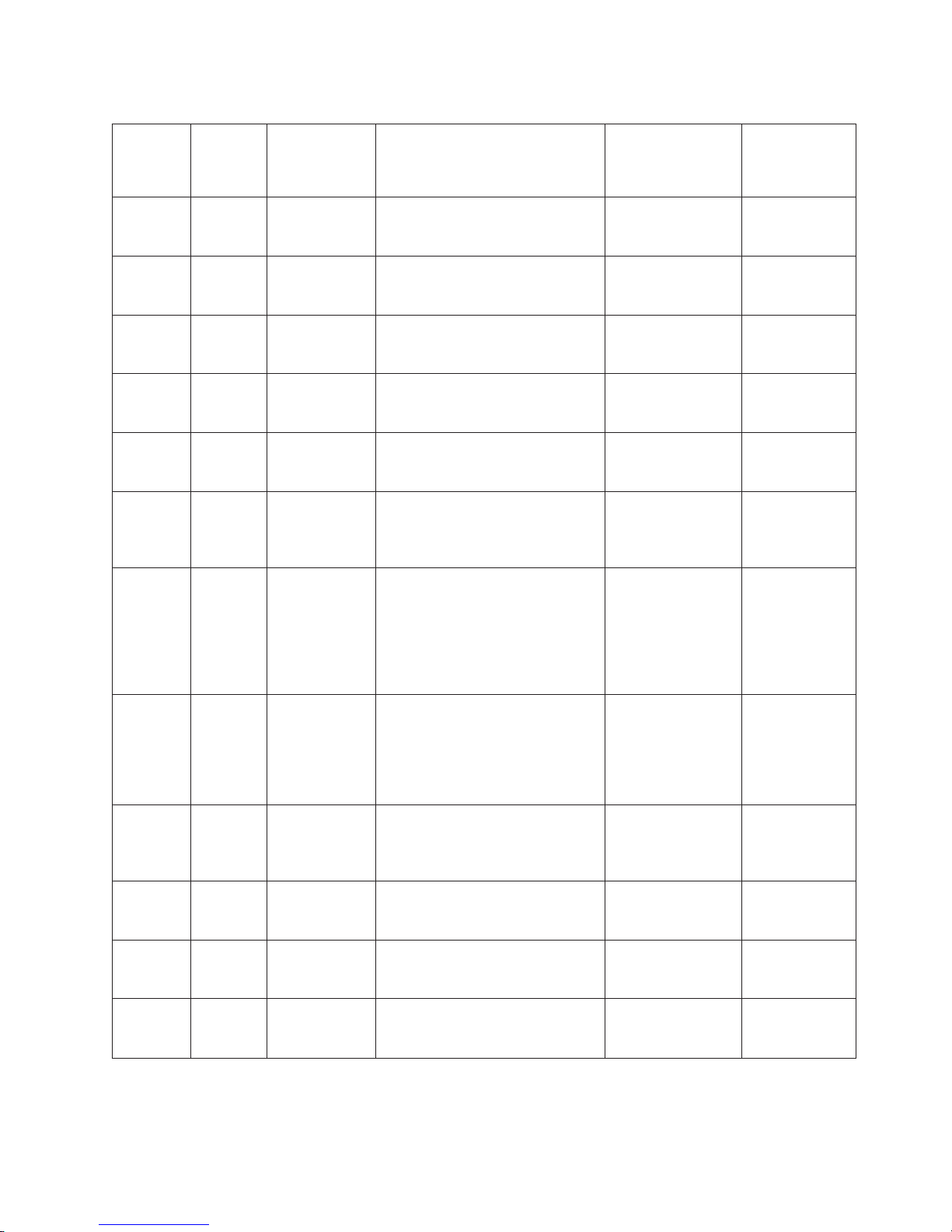

Table 1. Comparable IBM and Brocade products.

IBM model

IBM

product

name

Ethernet

Router

B04M

Ethernet

Router

B08M

Ethernet

Router

B16M

Ethernet

Router

B32M

Ethernet

Switch

B04R

IBM

machine

type

4003 M04 4U modular Ethernet router with 4

4003 M08 7U modular Ethernet router with 8

4003 M16 14U modular Ethernet router with

4003 M32 33U modular Ethernet and IP

4003 R04 4U modular Ethernet switch with 4

(HVEC/XCC

model in

parentheses) Brief product description

interface slots

interface slots

16 interface slots

router with 32 interface slots

interface slots

Brocade

Brocade product

name

NetIron MLX-4 NI-MLX-4-AC

NetIron MLX-8 NI-MLX-8-AC

NetIron MLX-16 NI-MLX-16-AC

NetIron MLX-32 NI-MLX-32-AC-A

BigIron RX-4 BI-RX-4-AC

product part

number

xx IBM x-series of Ethernet Switches Installation and User Guide

Page 23

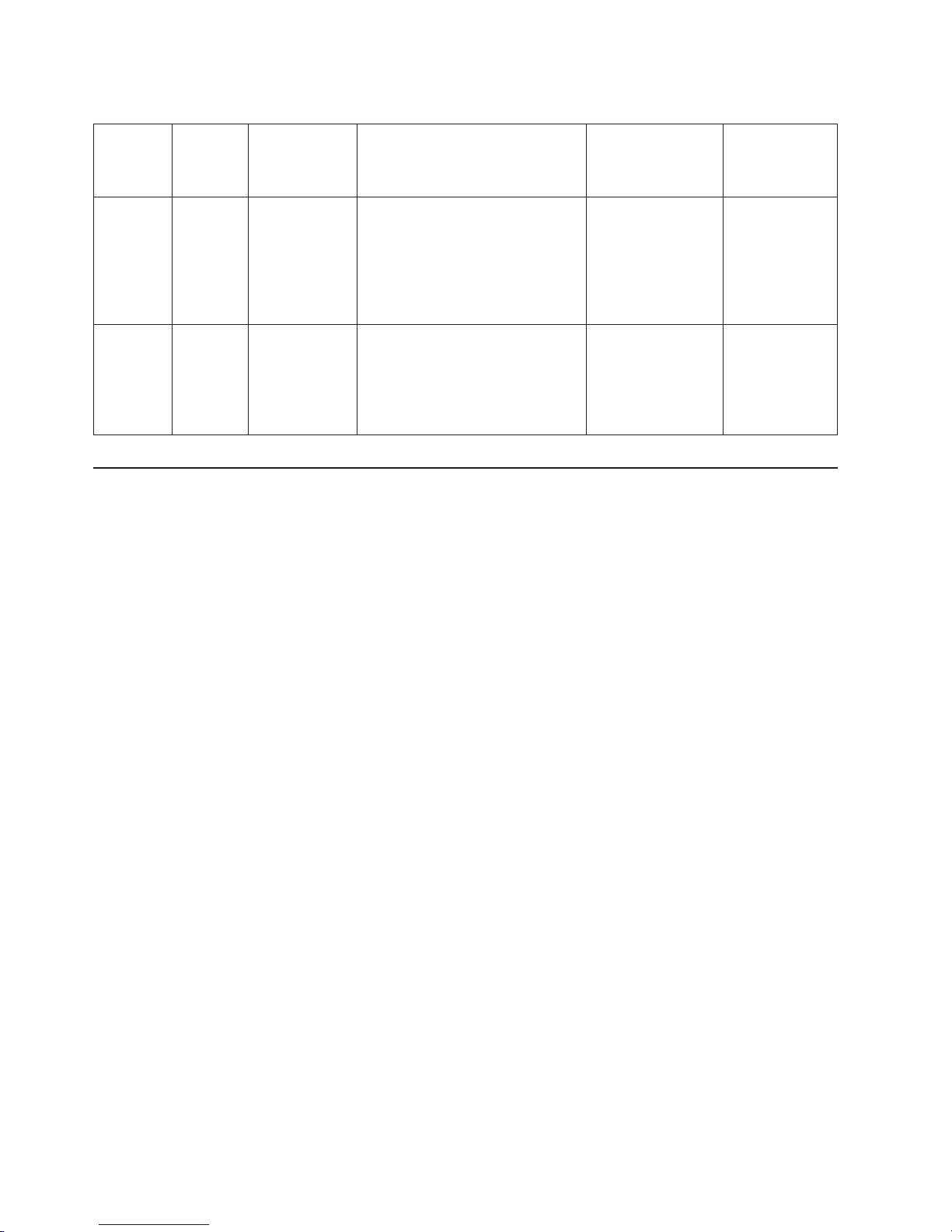

Table 1. Comparable IBM and Brocade products. (continued)

IBM model

IBM

product

name

Ethernet

Switch

IBM

machine

type

(HVEC/XCC

model in

parentheses) Brief product description

4003 R08 7U modular Ethernet switch with 8

interface slots

B08R

Ethernet

Switch

4003 R16 14U modular Ethernet switch with

16 interface slots

B16R

Ethernet

Switch

4003 R32 33U modular Ethernet switch with

32 interface slots

B32R

Ethernet

Switch

4003 S08 6U modular Ethernet switch with 8

interface slots

B08S

Ethernet

Switch

4003 S16 14U modular Ethernet switch with

16 interface slots

B16S

Ethernet

Switch

B24X

4002 X2A (4002AX2) 1U Ethernet switch with

twenty-four 10/1 GbE SFP+/SFP

ports plus four 10/100/1000 MbE

RJ45 ports

Ethernet

Switch

B24C (C)

4002 C2A (4002AC2) 1U Ethernet switch with

twenty-four 10/100/1000 MbE

RJ45 ports including four

combination 100/1000 MbE SFP

ports and one module slot for

optional 2-port 10 GbE XFP

module

Ethernet

Switch

B24C (F)

4002 C2B (4002BC2) 1U Ethernet switch with

twenty-four 100/1000 MbE SFP

ports including four combination

10/100/1000 MbE RJ45 ports and

one module slot for optional 2-port

10 GbE XFP module

Ethernet

Switch

B48C (C)

4002 C4A (4002AC4) 1U Ethernet switch with forty-eight

10/100/1000 MbE RJ45 ports

including four combination

100/1000 SFP ports

Ethernet

Switch

4002 C4B,

(4002BC4)

1U Ethernet switch with forty-eight

100/1000 MbE SFP ports

B48C (F)

Ethernet

Switch

B50C (C)

Ethernet

Switch

B50C (F)

4002 C5A,

(4002AC5)

4002 C5B,

(4002BC5)

1U Ethernet switch with forty-eight

10/100/1000 MbE RJ45 ports plus

two 10 GbE XFP ports

1U Ethernet switch with forty-eight

100/1000 MbE SFP ports plus two

10 GbE XFP ports

Brocade

Brocade product

name

product part

number

BigIron RX-8 BI-RX-8-AC

BigIron RX-16 BI-RX-16-AC-A

BigIron RX-32 I-RX-32-AC-A

FastIron SX 800 FI-SX800-AC

FastIron SX 1600 FI-SX1600-AC

Ethernet Switch

TI-24X-AC

B24X

NetIron CES 2024C NI-CES-

2024C-AC

NetIron CES 2024F NI-CES-

2024F-AC

NetIron CES 2048C NI-CES-

2048C-AC

NetIron CES 2048F NI-CES-

2048F-AC

NetIron CES

2048CX

NetIron CES

2048FX

NI-CES-

2048CX-AC

NI-CES-

2048FX-AC

Preface xxi

Page 24

Table 1. Comparable IBM and Brocade products. (continued)

IBM model

IBM

product

name

Ethernet

Switch

B48G

Ethernet

Switch

B50G

IBM

machine

type

4002 G4A,

4002 G5A,

(HVEC/XCC

model in

parentheses) Brief product description

(4002AG4)

(4002AG5)

1.5U Ethernet switch with

forty-eight 10/100/1000 MbE RJ45

(PoE capable) ports including four

combination 100/1000 MbE SFP

ports and one module slot for

optional 2-port 10 GbE (XFP or

CX4) module

1.5U Ethernet switch with

forty-eight 10/100/1000 MbE RJ45

(PoE capable) ports including four

combination 100/1000 MbE SFP

ports plus 2-port 10 GbE CX4

module supporting stacking

Brocade

Brocade product

name

FastIron GS FGS648P

FastIron GS-STK FGS648P-STK

product part

number

Accessibility features for the IBM x-series of Ethernet Switches

Accessibility features help users who have a disability, such as restricted mobility or

limited vision, to use information technology products successfully.

Accessibility features

Use and operation of this device is accomplished primarily through external devices

which may provide different accessibility features.

The following list includes the major accessibility features in the product either

directly or through external devices or interfaces:

v Keyboard-only operation

v Interfaces that are commonly used by screen readers

v Keys that are discernible by touch but do not activate just by touching them

v Industry-standard devices for ports and connectors

v The attachment of alternative input and output devices

Keyboard navigation

This product uses standard Microsoft®Windows®navigation keys.

Vendor software

These products include certain vendor software that is not covered under the IBM

license agreement. IBM makes no representation about the accessibility features of

these products. Contact the vendor for the accessibility information about its

products.

Related accessibility information

You can view the publications for these products in Adobe Portable Document

Format (PDF) using the Adobe Acrobat Reader. The PDFs are provided on a CD

that is packaged with the product. An accessible HTML version of this document is

also included on the documentation CD for this product.

xxii IBM x-series of Ethernet Switches Installation and User Guide

Page 25

IBM and accessibility

See the IBM Human Ability and Accessibility Center for more information about the

commitment that IBM has to accessibility: www.ibm.com/able.

Getting help

For the latest version of your product documentation, visit the web at

www.ibm.com/shop/publications/order. Search by form number or title.

For more information about this and other IBM products, visit the IBM web site:

www.ibm.com/

For support information for this product and other IBM products, see the following

web site: www.ibm.com/systems/support/. Select your product family, and follow the

web navigation to your specific product.

You can also contact IBM within the United States at 1-800-IBMSERV

(1-800-426-7378). For support outside the United States, you can find the service

number at: www.ibm.com/planetwide/.

Visit www.ibm.com/contact for the contact information for your country or region.

Taiwan Contact Information

IBM Taiwan Product Service Contact Info:

IBM Taiwan Corporation

3F, No 7, Song Ren Rd., Taipei Taiwan

Tel: 0800-016-888

How to send your comments

Your feedback is important in helping us provide the most accurate and high-quality

information. If you have comments or suggestions for improving this document,

send us your comments by e-mail to starpubs@us.ibm.com.

Be sure to include the following:

v Exact publication title

v Publication form number (for example, GC26-1234-02)

v Page, table, or illustration numbers

v A detailed description of any information that should be changed

About This Document

This guide describes the IBM x-series of Ethernet Switch products from IBM. It

provides procedures for installing the IBM Ethernet Switch B24X switch, cabling,

and performing a basic configuration of the switch. This guide also provides

information on managing and maintaining the switch. When reference to a specific

model is not required, the general terms switch, product,ordevice will be used to

Preface xxiii

Page 26

refer to all models. The term x-series may also be used when needed to

differentiate between different IBM Ethernet switch product lines.

Audience

This manual is designed for system administrators with a working knowledge of

Layer 2 and Layer 3 switching and routing.

You should be familiar with the following protocols if applicable to your network: IP,

RIP, OSPF, IS-IS, BGP4, MBGP, IGMP, PIM, DVMRP, IPX, AppleTalk, FSRP, VRRP,

and VRRPE.

Supported hardware and software

The following hardware platform is supported by this release of this guide:

v x-series of Ethernet switches Series

Document conventions

This section describes text formatting conventions and important notice formats

used in this document.

Text formatting

The narrative-text formatting conventions that are used are as follows:

Table 2. Formatting conventions

bold text Identifies command names

Identifies the names of user-manipulated GUI

elements

Identifies keywords

Identifies text to enter at the GUI or CLI

italic text Provides emphasis

Identifies variables

Identifies document titles

code text Identifies CLI output

For readability, command names in the narrative portions of this guide are

presented in bold: for example, show version.

Command syntax conventions

Command syntax in this manual follows these conventions:

Table 3. Command syntax conventions

command and

parameters

[ ] Optional parameter.

variable Variables are printed in italics enclosed in angled brackets < >.

... Repeat the previous element, for example “member[;member...]”

| Choose from one of the parameters.

Commands and parameters are printed in bold.

xxiv IBM x-series of Ethernet Switches Installation and User Guide

Page 27

Chapter 1. Product Overview

The IBM Ethernet Switch B24X provides high port density and 512 MB of DDR

RAM when shipped from the factory. The B24X delivers a full complement of

standards-based, feature-rich Layer 2 switching capability. The extensive feature set

supports network requirements ranging from basic connectivity to multicast- enabled

full streaming audio and video applications for converged services.

The B24X supports the following:

v Twenty-four SFP+ ports at either 1 GbE or 10 GbE using the standard E1MG

optics, as well as the new SFP+ 10GbE optics

v Four 10/100/1000 RJ-45 ports

Software features

Software features differ depending on the software version that is loaded on the

device. When first shipped, the devices support full Layer 2 Switching.

For a complete list of software features supported, refer to the release notes or the

FastIron and TurboIron 24X Configuration Guide.

Hardware features

This section describes the physical characteristics of the models. For details about

physical dimensions, power supply specifications, and pin-outs, refer to Appendix A,

“Hardware Specifications,” on page 43.

Figure 1 shows the B24X.

Figure 1. IBM Ethernet Switch B24X

The B24X contains the following ports:

v Twenty-four (24) SFP+ 10 Gigabit and Gigabit Ethernet fiber ports

v Four (4) 10/100/1000 Mbps copper ports, supporting 100Base-TX and

1000Base-T RJ-45 connectors

Mgmt

Console

netx001

© Copyright IBM Corp. 2009 1

Page 28

Control features

The B24X front panel has the following control features:

v Serial management interface-DB-9 connector interface (Console Port)

v 10/100/1000 RJ-45 Management Port

1 shows the Management port and 2 shows the Console port.

Mgmt

Console

A

netx002

1

Figure 2. Console and Management ports

Serial management interface (Console port)

The serial management interface (port labeled Console) enables you to configure

and manage the device using a third-party terminal emulation application on a

directly connected PC, straight-through EIA or TIA DB-9 serial cable (M/F) is

included. The console port is located in the upper right of the front panel.

Management port

The Management port provides connectivity to your existing management network

through 10/100/1000 copper ports that uses auto-sensing and auto-negotiating to

determine the speed (10 Mbps, 100 Mbps, or 1000 Mbps) and mode (full-duplex or

half-duplex) of the port at the other end of the link, and adjusts port speed

accordingly. The Management port on the B24X supports RJ-45 copper connectors,

auto MDI or MDIX detection, and has an RJ-45 unshielded twisted pair (UTP)

connector.

Note: This port interfaces with the CPU only and not the data plane.

Network interfaces

Table 4 describes the network interfaces supported on B24X devices. For network

interface specifications, refer to Table 13 on page 47.

2

Table 4. Network interfaces

Interface Show Media Description

1000Base-BX-D M-GBXD

1000Base-BX-U M-GBXU

1000Base-LHA M-LHA

1000Base-LHB M-LHB

1000Base-LX M-LX

1000Base-SX M-SX

1000Base-SX2 M-SX2

1000Base-T C

100Base-TX

10GBase-LR XG-LR

2 IBM x-series of Ethernet Switches Installation and User Guide

Page 29

Table 4. Network interfaces (continued)

Interface Show Media Description

10GBase-SR XG-SR

Viewing the media types installed in the ports

The show media command displays the types of media (copper or fiber) installed in

the ports. The following example is show media output.

FastIron# show media

Port 1: Type : 10G XG-SR(SFP+)

Vendor: Brocade Version: 1

Part# : PLRXPLSCS4371 Serial#: C833UQ06H

Port 2: Type : EMPTY

Port 3: Type : EMPTY

Port 4: Type : EMPTY

Port 5: Type : EMPTY

Port 6: Type : 10G XG-SR(SFP+)

Vendor: Brocade Version: 1

Part# : PLRXPLSCS4371 Serial#: C847UQ04C

Port 7: Type : 10G XG-SR(SFP+)

Vendor: Brocade Version: 1

Part# : PLRXPLSCS4371 Serial#: C847UQ04H

Port 8: Type : EMPTY

Port 9: Type : EMPTY

Port 10: Type : EMPTY

Port 11: Type : EMPTY

Port 12: Type : EMPTY

Port 13: Type : 10G XG-SR(SFP+)

Vendor: Brocade Version: 1

Part# : PLRXPLSCS4371 Serial#: C847UQ04T

Port 14: Type : 10G XG-SR(SFP+)

Vendor: Brocade Version: 1

Part# : PLRXPLSCS4371 Serial#: C847UQ04R

Port 15: Type : 10G XG-SR(SFP+)

Vendor: Brocade Version: 1

Part# : PLRXPLSCS4371 Serial#: C847UQ050

Port 16: Type : 10G XG-SR(SFP+)

Vendor: Brocade Version: 1

Part# : PLRXPLSCS4371 Serial#: C847UQ059

Port 17: Type : EMPTY

Port 18: Type : EMPTY

Port 19: Type : 10G XG-SR(SFP+)

Vendor: Brocade Version: 1

Part# : PLRXPLSCS4371 Serial#: C847UQ04K

Port 20: Type : 10G XG-SR(SFP+)

Vendor: Brocade Version: 1

Part# : PLRXPLSCS4371 Serial#: C833UQ068

Port 21: Type : EMPTY

Port 22: Type : EMPTY

Port 23: Type : EMPTY

Port 24: Type : EMPTY

Port 25: Type : 1G M-C (Gig-Copper)

Port 26: Type : 1G M-C (Gig-Copper)

Port 27: Type : 1G M-C (Gig-Copper)

Port 28: Type : 1G M-C (Gig-Copper)

10 Gbps ports

Ports1-24support 1-GbE SFP transceivers and 10-GbE SFP and SFP+

transceivers listed in Table 4 on page 2. 1 in Figure 3 on page 4 shows GbE ports

1-24, numbered from left to right.

Chapter 1. Product Overview 3

Page 30

Figure 3. 24 10-GbE ports

Four 10/100/1000 Mbps ports

The ports 25~28 are 10/100/1000 copper ports that use auto-sensing and

auto-negotiating to determine the speed (10 Mbps, 100 Mbps, or 1000 Mbps) and

mode (full-duplex or half-duplex) of the port at the other end of the link, and adjust

port speed accordingly.

10/100/1000 ports on the B24X support RJ-45 copper connectors. The output of the

show media command displays C next to the ports that have copper connectors

installed.

Gigabit copper ports on the B24X support auto MDI or MDIX detection. For more

information about this feature, refer to “Configuring MDI/MDIX” in the FastIron and

TurboIron 24X Configuration Guide.

Mgmt

Console

A

netx003

1

10GbE SFP+ transceiver

The B24X supports a 10GbE SFP+ transceiver specifically for ports 1-24. LEDs on

the module faceplates indicate operational status:

v If the LED is on, the port is connected. If the LED is off, no connection exists, or

the link is down.

v If the LED is on or blinking, traffic is being transmitted and received on the port.

LEDs for network interfaces and power supplies

The fiber and copper ports on the B24X provide status information through the

LEDs listed in Table 5. The following are the LEDs for network interfaces and power

supplies:

v 24 10-Gbps fiber ports (1~24 port) have LEDs located under each of them.

v Four 10/100/1000 copper ports (25~28) have Link and Activity LEDs to indicate

port status.

v The Management port has a Link LED and Activity LED to indicate port status.

The Link LED is on the left of the copper connector and the Activity LED is on

the right.

v The System power on LED is on the left side of the front panel.

v The dual power supply 1 and 2 LEDs are on the front panel of the power supply

(when you are facing the rear of the device).

Table 5. LEDs

LEDs Position State Meaning

10Gbps Port LEDs

4 IBM x-series of Ethernet Switches Installation and User Guide

Page 31

Table 5. LEDs (continued)

LEDs Position State Meaning

LNK or ACT Located under the

10-GbE ports

On The port is

connected.

Off No fiber port

connection exists or

the link is down.

Blinking Traffic is begin

transmitted or

received on the fiber

port.

10/100/1000 Copper Port LEDs

Lnk This is the left LED

on RJ45

On The port is

connected.

Off No copper port

connection exists or

the link is down.

Act This is the right LED

on RJ45

On or Blinking Traffic is being

transmitted or

received on the

copper port.

Off No traffic is being

transmitted or

received on the fiber

port.

Management Port LEDs

Lnk This is the left LED

on RJ45

On The port is

connected.

Off No copper port

connection exists or

the link is down.

Act This is the right LED

on RJ45

On or Blinking Traffic is being

transmitted or

received on the

copper port.

Off No traffic is being

transmitted or

received on the fiber

port.

System Power and Power Supply LEDs

Power On the upper left side

of the front panel

(when facing the front

of the device)

On The device is

powered on and has

enough power to

operate.

Off The device is not

powered on, or has

been powered on but

does not have

sufficient power to

operate.

Chapter 1. Product Overview 5

Page 32

Power supplies

Table 5. LEDs (continued)

LEDs Position State Meaning

AC OK Upper center of

power supply’s front

panel (when facing

the rear of the

device)

On Indicated power

supply is installed

and is functioning

normally.

Note: Power supply

1 is located in the

right-hand bay and

power supply 2 in the

left-hand bay (when

facing the rear of the

device).

Off Power supply is not

installed or is not

providing power.

Each B24X comes with one AC power supply installed, and a optional second

power supply for redundancy. See “Replacing AC power supplies” on page 34 for

instructions on installing a power supply.

Figure 4 shows the front panel of the AC power supplies used in the B24X. 1 is

the AC LED.

1

netx004

Figure 4. AC power supply front panel

The power supplies are auto-sensing and auto-switching, and provide up to 300

watts of total output power, having a universal input (90 VAC to 264 VAC) and 12

VDC regulated output.

Power supplies can be swapped in or out of the device while the device is running,

and without opening the device. You can remove one of the supplies without

interrupting operation because the remaining power supply provides enough power

for all of the ports.

For power supply hardware specifications, refer to “Power supply specifications” on

page 48.

6 IBM x-series of Ethernet Switches Installation and User Guide

Page 33

CAUTION:

Disconnect the power supply cable from the power source (outlet) before you

install it in or remove it from the device. Failure to do this can result in

damage to the power supply or the device, or both (the device can be running

while a power supply is being installed or removed, but the power supply

itself should not be connected to a power source).

Attention: The B24X power supply is designed exclusively for use with the B24X.

Installing the power supply in a device other than a B24X will cause extensive

damage to your equipment.

Chapter 1. Product Overview 7

Page 34

8 IBM x-series of Ethernet Switches Installation and User Guide

Page 35

Chapter 2. Installing the B24X

This chapter contains information on how to install the B24X switch.

Attention: Before starting any installation procedure, refer to “Safety notices” on

page xi.

Unpacking a system

Attention: The procedures in this manual are intended for qualified service

personnel.

Information about configuring IP addresses and connecting network devices is in

Chapter 3, “Connecting Network Devices and Checking Connectivity,” on page 19.

Systems ship with all of the items listed below. Please review the list and verify the

contents. If any items are missing, please contact the place of purchase.

Package contents

Verify the package contents listed below:

v IBM Ethernet Switch B24X device with dual AC power supplies installed

v AC power cord

v Rack mount brackets and mounting screws (already secured on the device)

v CD-ROM containing software images and user documentation (including this

guide)

v Warranty card

General requirements

To manage the system, you will need the following items for serial connection to a

Layer 2 or Layer 3 switch:

v A management station, such as a PC running a terminal emulation application.

v A serial cable (provided).

v Use the serial connection to perform basic configuration tasks, such as assigning

an IP address and network mask. This information is required to manage the

system using IronView Network Manager or using the CLI through Telnet.

Summary of installation tasks

Follow the steps listed in Table 6 to install your B24X device. Details for each of

these steps are provided in this chapter and in the following chapter.

Table 6. Summary of installation tasks

Task No. Task

1 Ensure that the physical

environment where the

device will be installed has

the proper cabling and

ventilation.

Where to Find More

Information

“Preparing the installation

site” on page 12

© Copyright IBM Corp. 2009 9

Page 36

Table 6. Summary of installation tasks (continued)

Where to Find More

Task No. Task

2 Install the device on a

desktop or in an equipment

rack. Devices may also be

wall-mounted.

3 When the device is installed,

plug the power cord into a

nearby power source that

adheres to the regulatory

requirements outlined in this

manual.

4 Verify that power LED is on

after the system is

powered-on.

5 Attach a terminal or PC to

the device. This enables you

to configure the device

through the Command Line

Interface (CLI).

6 No default password is

assigned to the CLI. For

additional access security,

assign a password.

7 Before attaching equipment

to the device, you must

configure an interface IP

address to the subnet on

which it will be located. Initial

IP address configuration is

performed using the CLI with

a direct serial connection.

8 Once you power-on the

device and assign IP

addresses, the system is

ready to accept network

equipment.

9 Test IP connectivity by

pinging other devices and

tracing routes.

10 Continue configuration using

the CLI. You also can use

IronView Network Manager to

manage the device.

11 Secure access to the device. FastIron and TurboIron 24X

Information

“Installing the device” on

page 12

“Powering on the system” on

page 14

“Verifying proper operation”

on page 14

“Attaching a PC or terminal”

on page 15

“Assigning permanent

passwords” on page 19

“Configuring IP addresses”

on page 20

“Connecting network devices”

on page 21

“Testing connectivity” on

page 24

FastIron and TurboIron 24X

Configuration Guide

Configuration Guide

Installation precautions

Attention: Before starting any installation procedure, refer to “Safety notices” on

page xi.

10 IBM x-series of Ethernet Switches Installation and User Guide

Page 37

General precautions

Attention: Do not install the device in an environment where the operating

ambient temperature might exceed 40°C (104°F).

Make sure that air flow around the front, sides, and back of the device is not

restricted.

Never leave tools inside the device.

Attention: Use the erase startup-config command only for new systems. If you

enter this command on a system you have already configured, the command

erases the configuration. If you accidentally do erase the configuration on a

configured system, enter the write memory command to save the running

configuration to the startupconfig file.

Power precautions

The following precautions apply to B24X devices:

Attention: Make sure you insert the power supply right-side up. It is possible to

insert the supply upside down, although the supply will not engage with the power

backplane cotter pin when plugged upside down. The label of the power supply is

on the top when you plug in the power supply right-side up when the power

connector is on the left and the fan vent is on the right.

Attention: Remove the power cord from a power supply before you install it in or

remove it from the device. Otherwise, the power supply or the device could be

damaged. (The device can be running while a power supply is being installed or

removed, but the power supply itself should not be connected to a power source.)

Attention: The B24X power supply is designed exclusively for use with B24X

devices. Installing the power supply in a device other than the B24X will cause

extensive damage to your equipment.

CAUTION:

The battery contains lithium. To avoid possible explosion, do not burn or

charge the battery.

Do not:

v Throw or immerse into water

v Heat to more than 100°C (212°F)

v Repair or disassemble

Exchange only with the IBM-approved part. Recycle or discard the battery

as instructed by local regulations. In the United States, IBM has a process

for the collection of this battery. For information, call 1-800-426-4333. Have

the IBM part number for the battery unit available when you call. (C003)

CAUTION:

Power supplies are hot swappable. However, IBM recommends that you

disconnect the power supply from AC power before installing or removing the

supply. The device can be running while a power supply is being installed or

removed, but the power supply itself should not be connected to a power

source. Otherwise, you could be injured or the power supply or other parts of

the device could be damaged.

Chapter 2. Installing the B24X 11

Page 38

CAUTION:

For safety reasons, the ESD wrist strap should contain a series 1 MB ohm

resistor.

Preparing the installation site

Ensure that any required facility electrical work has been completed before starting

the installation, and that there is adequate clear work space to accomplish the

installation.

Cabling infrastructure

Ensure that the proper cabling is installed in the site. Refer to “Device

specifications” on page 43 or visit www.ibm.com/systems/support/networking.

Installation location

Before installing the device, plan its location and orientation relative to other devices

and equipment. Allow at least 3 in. of space at the front of the device for the

twisted-pair, fiber-optic, and power cabling. Also, allow a minimum of 3 in. of space

between the sides and the back of the device and walls or other obstructions.

Installing the device

You can install switch devices on a desktop or in an equipment rack. See “Rack

safety” on page xviii before installing this device in a rack or cabinet.

Desktop installation

Complete the following steps for desktop installation:

1. Set the device on a flat desktop, table, or shelf. Make sure that adequate

ventilation is provided for the system. A 3 in. clearance is recommended on

each side.

2. Proceed to “Powering on the system” on page 14.

Rack mount installation

For rack mount installation, it is recommended that you use a Telco equipment rack.

The B24X device is compatible with two rack mount kits; a kit with short mounting

brackets that ships with the device, and long mounting brackets (not supplied) to

prevent the device from sagging when installed in a non-compliant (non-Telco)

equipment rack.

In addition to the rack mount kit, you will need the following tools for installation:

v #2 Phillips-head screwdriver

v Four 12-24 screws to mount the device in the rack.

Attention: Reduced Air Flow - Installation of the equipment in a rack should be

such that the amount of air flow required for safe operation of the equipment is not

compromised.

Complete the following steps to install the rack mount brackets and mount the

device in a rack:

1. Remove the rack mount kit from the shipping carton. The kit contains two

mounting brackets.

12 IBM x-series of Ethernet Switches Installation and User Guide

Page 39

2. Place the Network switch on a hard flat surface with the front panel facing you.

3. Attach a rack-mount bracket to one side of the Network switch with the supplied

screws. Then attach the other bracket to the other side.

Attention: Make sure you use the screws supplied with the mounting

brackets. Using the wrong screws could damage the B24X and would invalidate

your warranty.

Figure 5 shows how to attach the short mounting brackets.

Figure 5. Attaching the short mounting brackets

netx005

4. Mount the device in the rack as illustrated in Figure 6.

Note: Although Figure 6 shows a device with short mounting brackets, the

procedure for securing a device with long mounting brackets is the same.

Figure 6. Installing the device in a rack

5. Proceed to “Powering on the system” on page 14.

netx006

Chapter 2. Installing the B24X 13

Page 40

Powering on the system

Note that the outlet should be installed near the equipment and should be easily

accessible. Install the outlet using the following steps:

1. Ensure that all power supplies are fully and properly inserted.

2. Remove the power cord from the shipping package.

3. Attach the AC power cord to the AC connector on the rear panel as shown in

Figure 7.

Note: Align the locating notch on the underside of the AC power cord before

inserting.

4. Insert the power cord plug into a properly grounded 115V or 120V electrical

outlet.

Figure 7. Attaching the AC power cord

5. Repeat this procedure for the second power supply.

6. Verify the device is working properly (refer to “Verifying proper operation”).

Powering off the system

To turn an AC system off, unplug all power cords from the power source. There is

no power switch for the device.

Verifying proper operation

After you have installed any additional power supplies and powered on the system,

verify that the device is working properly.

1. Verify that the LEDs on the power supply and system power LED are solid

green.

2. Verify proper operation by observing the LEDs on the front panel.

14 IBM x-series of Ethernet Switches Installation and User Guide

netx007

Page 41

10 Gbps port LEDs should be lit while the device performs diagnostics. After the

diagnostics are complete, the LEDs will be dark except for those that are attached

by cables to other devices.

If the links on these cables are good and the connected device is powered on, the

link LEDs will light. Table 7 provides more details on specific LED conditions after

system start-up.

Observing the power status LEDs

Table 7 lists the device LEDs that show power status.

Table 7. Power LEDs

LEDs Position State Meaning

Pwr (Power) Left-most LED on the

front panel

AC OK On power supply 1

front panel

AC OK On power supply 2

front panel

On The device is

powered on and has

enough power to

operate.

Off The device is not

powered on, or has

been powered on but

does not have

sufficient power to

operate.

On Power supply 1 is

installed and is

functioning normally.

Power supply 1 is

located in the

right-hand bay (when

you are facing the

rear of the device).

Off Power supply 1 is not

installed or is not

providing power.

On Power supply 2 is

installed and is

functioning normally.

Power supply 2 is

located in the lefthand bay (when you

are facing the rear of

the device).

Off Power supply 2 is not

providing power.

The software regularly polls the hardware for power status information. You can

display the status information from any management session using the show

chassis CLI command. In addition, the software automatically generates a Syslog

message and SNMP trap if a status change occurs.

Attaching a PC or terminal

To assign an IP address, you must have access to the Command Line Interface

(CLI). The CLI is a text-based interface that can be accessed through a direct serial

connection to the device or through Telnet connections.

Chapter 2. Installing the B24X 15

Page 42

You will need to assign an IP address using the CLI. You can access the CLI by

attaching management station through a serial cable to the Console port. After you

assign an IP address, you can access the system through Telnet or IronView

Network Manager.

Complete the following steps to attach a management station using the serial port:

1. Use a straight-through cable to connect a PC or terminal to the male DB-9

serial port connector.

Note: You need to run a terminal emulation program on the PC.

2. Open the terminal emulation program and set the session parameters as

follows:

v Baud: 9600 bps

v Data bits: 8

v Parity: None

v Stop bits: 1

v Flow control: None

When you establish the serial connection to the system, press Enter to display the

CLI prompt in the terminal emulation window. For example:

TurboIron>

When you see one of these prompts, you are connected to the system and can

proceed to “Assigning permanent passwords” on page 19.

You can customize the prompt by changing the system name. Refer to the FastIron

and TurboIron 24X Configuration Guide.

If you do not see a prompt:

v Make sure the cable is securely connected to your PC and to the device.

v Check the settings in your terminal emulation program. In addition to the session

settings listed above, make sure the terminal emulation session is running on the

same serial port you attached to the device.

The EIA or TIA 232 serial communication port serves as a connection point for

management by a PC or SNMP workstation. The switches come with a standard

male DB-9 connector, shown in Figure 8 on page 17.

16 IBM x-series of Ethernet Switches Installation and User Guide

Page 43

Pin assignment

Pin number Switch signal

1

DB-9 male

5

96

Figure 8. Serial port pin and signalling details

Most PC serial ports also require a cable with a female DB-9 connector.

Terminal connections will vary, requiring either a DB-9 or DB-25 connector, male or

female.

Serial cable options between a switch or router and a PC or terminal are shown in

Figure 9.

DB-9 to DB-9

Female switch

Terminal or PC

1

2

3

4

5

6

7

8

9

DB-9 to DB-25

Female switch

Reserved

TXD (output)

RXD (input)

Reserved

GND

Reserved

CTS (input)

RTS (output)

Reserved

net_com004

Terminal or PC

1

Reserved

2

3

4

Reserved

5

6

Reserved

7

8

9

Figure 9. Serial port pin assignments showing cable connection options to a terminal or PC

Reserved

1

2

3

4

5

6

7

8

9

1

Reserved

2

3

4

Reserved

5

6

Reserved

7

8

9

Reserved

8

3

2

20

7

6

4

5

22

net_com005

Note: As indicated in Figure 8 and Figure 9, some of the wires should not be

connected. If you do connect the wires that are labeled "Reserve”, you might

get unexpected results with some terminals.

Chapter 2. Installing the B24X 17

Page 44

18 IBM x-series of Ethernet Switches Installation and User Guide

Page 45

Chapter 3. Connecting Network Devices and Checking

Connectivity

This chapter provides the details for connecting network devices and checking

network connectivity.

Attention: The procedures in this manual are intended for qualified service

personnel.

Assigning permanent passwords

By default, the CLI is not protected by passwords. To secure CLI access, IBM

strongly recommends assigning passwords.

Note: You can assign passwords using IronView Network Manager if an enable

password for a Super User has been configured on the device.

The CLI contains the following access levels:

v User EXEC-The level you enter when you first start a CLI session. At this level,

you can view some system information but you cannot configure system or port

parameters.

v Privileged EXEC-Also called the Enable level, and can be secured by a

password. At this level, you can perform tasks such as manage files on the flash

module, save the system configuration to flash, and clear caches.

v CONFIG-This level lets you configure the system IP address, and switching and

routing features. To access the CONFIG mode, you must already be logged into

the Privileged level of the EXEC mode (the Enable level).

You can set the following levels of Enable passwords:

v Super User - Allows complete read-and-write access to the system. This is

generally for system administrators and is the only password level that allows

you to configure passwords.

Note: You must set a super user password before you can set other types of

passwords.

v Port Configuration - Allows read-and-write access for specific ports but not for

global (system-wide) parameters.

v Read Only - Allows access to the Privileged EXEC mode and CONFIG mode but

only with read access.

Complete the following steps to set passwords:

1. At the opening CLI prompt, enter the following command to change to the

Privileged level of the EXEC mode.

TurboIron> enable

2. Access the CONFIG level of the CLI by entering the following command.

TurboIron# configure terminal

TurboIron(config)#

3. Enter the following command to set the super-user password.

TurboIron(config)# enable super-user-password <text>

Note: You must set the super user password before you can set other types of

passwords.

© Copyright IBM Corp. 2009 19

Page 46

4. Enter the following commands to set the port configuration and read-only

passwords.

TurboIron(config)# enable port-config-password <text>

TurboIron(config)# enable read-only-password <text>

Note: If you forget your super user password, refer to “Recovering from a lost

password.”

Syntax: enable super-user-password | read-only-password |

port-config-password <text>

Passwords can be up to 32 characters long.

Recovering from a lost password

By default, the CLI does not require passwords. However, if someone has

configured a password for the device but the password has been lost, you can

regain super-user access to the device using the following procedure.

Note: Recovery from a lost password requires direct access to the serial port and a

system reset.

Complete the following steps to recover from a lost password:

1. Start a CLI session over the serial interface to the device.

2. Reboot the device.

3. While the system is booting, before the initial system prompt appears, enter b to

enter the boot monitor mode.

4. Enter no password at the prompt. (You cannot abbreviate this command.)

5. Enter boot system flash primary at the prompt. This command causes the

device to bypass the system password check.

6. After the console prompt reappears, assign a new password.

Configuring IP addresses

You must configure at least one IP address using the serial connection to the CLI

before you can manage the system using the other management interfaces. In

addition, routers require an IP subnet address for the subnet in which you plan to

place them in your network.

The x-series devices support both classical IP network masks (Class A, B, and C

subnet masks, and so on) and Classless Interdomain Routing (CIDR) and network

prefix masks as follows:

v To enter a classical network mask, enter the mask in IP address format. For

example, for an IP address with a Class-C subnet mask enter the following:

209.157.22.99 255.255.255.0

v To enter a prefix number for a network mask, enter a forward slash(/)andthe

number of bits in the mask immediately after the IP address. For example, enter

the following for an IP address that has a network mask with 24 significant

(“mask”) bits:

209.157.22.99/24

By default, the CLI displays network masks in classical IP address format (example:

255.255.255.0). You can change the display to the prefix format. Refer to the

FastIron and TurboIron 24X Configuration Guide.

20 IBM x-series of Ethernet Switches Installation and User Guide

Page 47

Devices running Layer 2 software

Complete the following steps to configure an IP address on a device running Layer