Page 1

IBM 400/800GB LTO3 Tape Drive User’ s

Guid e

Page 2

Page 3

IBM 400/800GB LTO3 Tape Drive User’ s

Guid e

Page 4

Note

Before using this guide and the product it supports, read the information in Appendix C, “Service and Support,” on page 71

and Appendix D, “IBM Statement of Limited Warranty Z125-4753-08 04/2004,” on page 73.

Note

Please carefully review the information in “Cleaning the Drive Head” on page 14, “Updating Firmware” on page 26 and

“Using Ultrium Media” on page 31 sections as periodic maintenance is not covered by the IBM warranty. Repairs or

exchanges resulting from improper maintenance may result in billable service charges.

First Edition (May 2005)

© Copyright International Business Machines Corporation 2005. All rights reserved.

US Government Users Restricted Rights – Use, duplication or disclosure restricted by GSA ADP Schedule Contract

with IBM Corp.

Page 5

Contents

Safety information . . . . . . . . . .v

General safety guidelines . . . . . . . vii

Service . . . . . . . . . . . . . . . . vii

Power cords and power adapters . . . . . . . vii

Extension cords and related devices . . . . . . viii

Plugs and outlets . . . . . . . . . . . . viii

Batteries . . . . . . . . . . . . . . . viii

Heat and product ventilation . . . . . . . .ix

CD and DVD drive safety . . . . . . . . . .ix

Safety and Environmental Notices . . .xi

Danger Notices . . . . . . . . . . . . .xi

Caution Notices . . . . . . . . . . . . .xi

End of Life (EOL) Plan . . . . . . . . . . xii

About This Guide . . . . . . . . . . xiii

Related Publications . . . . . . . . . . . xiii

Product Description . . . . . . . . .1

Front Panel of the Drive . . . . . . . . . .2

Rear Panel of the SCSI Drive . . . . . . . . .3

Speed Matching and Channel Calibration . . . . .3

Sleep Mode . . . . . . . . . . . . . . .4

SCSI Attachment . . . . . . . . . . . . .4

Physical Characteristics of the SCSI Interface . .4

Speed . . . . . . . . . . . . . . . .4

Installing the Drive . . . . . . . . . .5

Installation Overview . . . . . . . . . . .5

Unpack the Drive . . . . . . . . . . . . .5

Power Off the Server/Enclosure . . . . . . . .6

Set the SCSI ID . . . . . . . . . . . . .7

Setting the SCSI ID with Jumpers . . . . . .7

Setting the SCSI ID with a SCSI ID Switch . . .7

Supplying TERMPOWER (SCSI Drive Only) . . .7

Mount the Drive into the Server/Enclosure . . . .8

Connect and Test Power to the Drive . . . . . .9

Connect the Internal SCSI Cable . . . . . . . .9

Run Drive Diagnostics . . . . . . . . . . .9

Install Device Drivers . . . . . . . . . . .10

Connect the Enclosure’s External SCSI Interface to

the Server . . . . . . . . . . . . . . .10

Operating the Drive . . . . . . . . .11

Single-character Display (SCD) . . . . . . . .11

SCD Dot . . . . . . . . . . . . . .11

Status Light . . . . . . . . . . . . . .11

Unload Button . . . . . . . . . . . . .12

Inserting a Tape Cartridge . . . . . . . . .13

Removing a Tape Cartridge . . . . . . . . .14

Mid-tape Recovery . . . . . . . . . . . .14

Cleaning the Drive Head . . . . . . . . . .14

Diagnostic and Maintenance Functions . . . . .15

Entering Maintenance Mode . . . . . . . .15

Function Code 0: Exit Maintenance Mode . . .16

Function Code 1: Run Drive Diagnostics . . . .16

Function Code 2: Update Drive Firmware from

FMR Tape . . . . . . . . . . . . . .17

Function Code 3: Create FMR Tape . . . . .18

Function Code 4: Force a Drive Dump . . . .18

Function Code 5: Copy Drive Dump . . . . .19

Function Code 6: Run SCSI Wrap Test . . . .20

Function Code 7: Run RS-422 Wrap Test . . . .20

Function Code 8: Unmake FMR Tape . . . . .21

Function Code 9: Display Error Code Log . . .22

Function Code A: Clear Error Code Log . . . .22

Function Code C: Insert Cartridge into Tape

Drive . . . . . . . . . . . . . . .22

Function Code E: Test Cartridge & Media . . .22

Function Code F: Fast Read/Write Test . . . .23

Function Code H: Test Head . . . . . . . .24

Function Code L: Load/Unload Test . . . . .25

Function Code P: Enable Post Error Reporting . .26

Function Code U: Disable Post Error Reporting 26

Updating Firmware . . . . . . . . . . . .26

Updating Firmware using Tapetool . . . . .26

Updating Firmware through the SCSI Interface 26

Updating Firmware through the Library/Drive

Interface . . . . . . . . . . . . . .27

ITDT SCSI Firmware Update, Dump Retrieval

and Library/Drive Test Tool . . . . . . . .27

LTO-TDX: LTO SCSI and Fibre Drive Firmware

Download & LTO Drive Dump Upload Tool . .28

Updating the Firmware with an FMR Tape

Cartridge . . . . . . . . . . . . . .29

Using Ultrium Media . . . . . . . . .31

Cartridge Compatibility . . . . . . . . . .31

Data Cartridge . . . . . . . . . . . . .32

Cleaning Cartridge . . . . . . . . . . .32

Bar Code Label . . . . . . . . . . . .33

Write-Protect Switch . . . . . . . . . .34

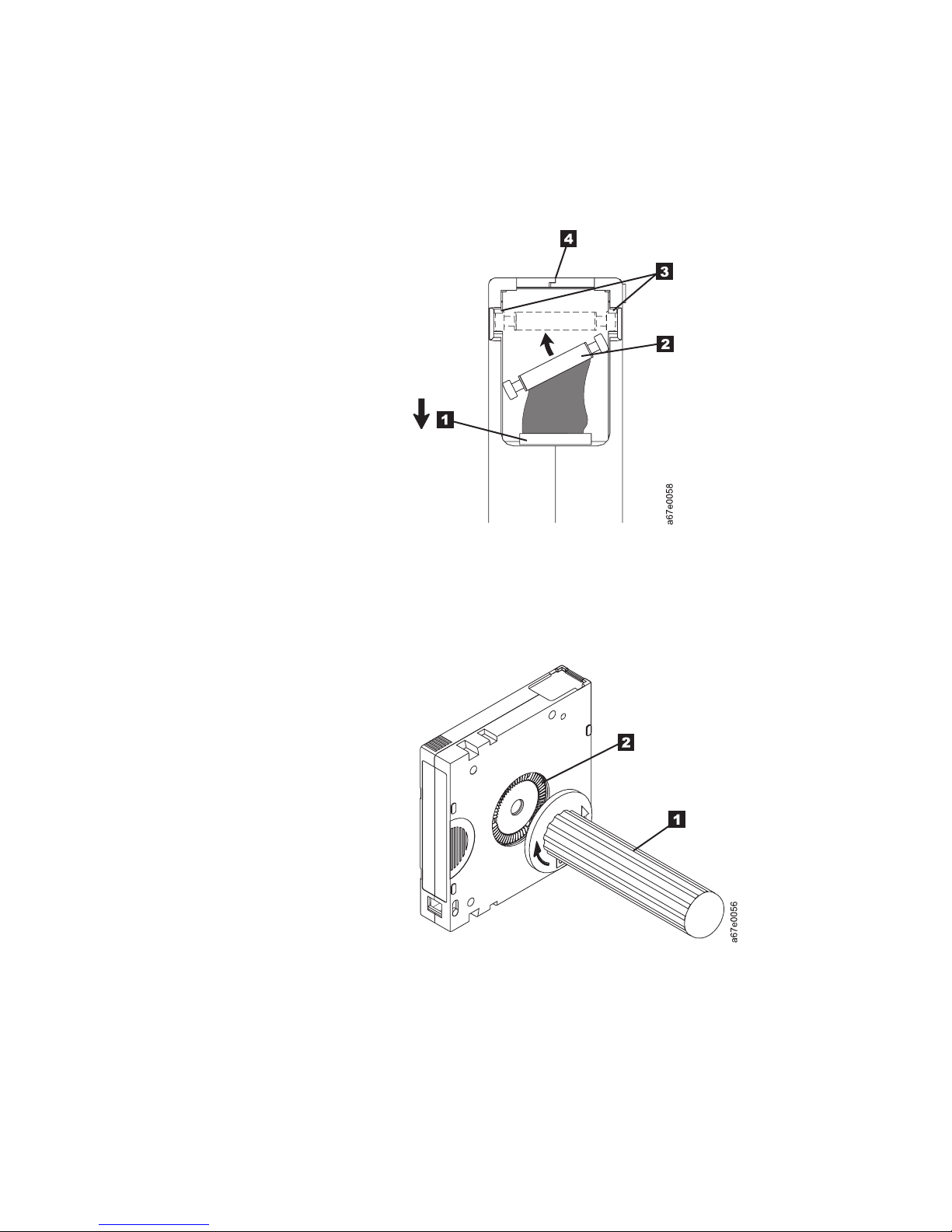

Repositioning or Reattaching a Leader Pin . . .35

Disposing of Tape Cartridges . . . . . . .41

Ordering Media Supplies . . . . . . . . .41

Resolving Problems . . . . . . . . . . . .43

Methods of Receiving Errors and Messages . . .44

Obtaining a Drive Dump . . . . . . . . .49

Viewing the Drive Error Log . . . . . . .49

Resolving Problems Reported by the Server . .50

Resolving Media-Related Problems . . . . .52

Servicing the Drive . . . . . . . . . . . .52

Manually Removing a Tape Cartridge . . . .52

Appendix A. TapeAlert Flags . . . . .65

Appendix B. Specifications . . . . . .69

Physical Specifications . . . . . . . . . . .69

© Copyright IBM Corp. 2005 iii

Page 6

Power Specifications . . . . . . . . . . .69

Environmental Specifications . . . . . . . .69

Other Specifications . . . . . . . . . . .70

Appendix C. Service and Support . . .71

Online technical support . . . . . . . . . .71

Telephone technical support . . . . . . . . .71

Appendix D. IBM Statement of Limited

Warranty Z125-4753-08 04/2004 . . . .73

Part 1 - General Terms . . . . . . . . . . .73

Part 2 - Country-unique Terms . . . . . . . .76

Part 3 - Warranty Information . . . . . . . .87

Warranty Period . . . . . . . . . . . .87

Types of Warranty Service . . . . . . . .87

Worldwide telephone list . . . . . . . . .88

Appendix E. Guarantee supplement for

Mexico . . . . . . . . . . . . . . .95

Notices . . . . . . . . . . . . . .97

Trademarks . . . . . . . . . . . . . .98

Electronic emission notices . . . . . . . . .98

Federal Communications Commission (FCC)

statement . . . . . . . . . . . . . .98

iv IBM 400/800GB LTO3 Tape Drive User’s Guide

Page 7

Safety information

Before installing this product, read the Safety Information.

Antes de instalar este produto, leia as Informações de Segurança.

Pred instalací tohoto produktu si prectete prírucku bezpecnostních instrukcí.

Læs sikkerhedsforskrifterne, før du installerer dette produkt.

Ennen kuin asennat tämän tuotteen, lue turvaohjeet kohdasta Safety Information.

Avant d’installer ce produit, lisez les consignes de sécurité.

Vo r der Installation dieses Produkts die Sicherheitshinweise lesen.

Prima di installare questo prodotto, leggere le Informazioni sulla Sicurezza.

Lees voordat u dit product installeert eerst de veiligheidsvoorschriften.

Les sikkerhetsinformasjonen (Safety Information) før du installerer dette produktet.

Antes de instalar este produto, leia as Informações sobre Segurança.

Antes de instalar este producto lea la información de seguridad.

© Copyright IBM Corp. 2005 v

Page 8

Läs säkerhetsinformationen innan du installerar den här produkten.

Page 9

General safety guidelines

Always observe the following precautions to reduce the risk of injury and property

damage.

Service

Do not attempt to service a product yourself unless instructed to do so by the IBM

Support Center. Use only an IBM authorized service provider who is approved to

repair your particular product.

Note: Some parts can be upgraded or replaced by the customer. These parts are

referred to as Customer Replaceable Units, or CRUs. IBM expressly identifies CRUs

as such, and provides documentation with instructions when it is appropriate for

customers to replace those parts. Yo u must closely follow all instructions when

performing such replacements. Always make sure that the power is turned off and

that the product is unplugged from any power source before you attempt the

replacement. If you have any questions or concerns, contact the IBM Support

Center.

Power cords and power adapters

Use only the power cords and power adapters supplied by the product

manufacturer.

Never wrap a power cord around the power adapter or other object. Doing so can

stress the cord in ways that can cause the cord to fray, crack or crimp. This can

present a safety hazard.

Always route power cords so that they will not be walked on, tripped over, or

pinched by objects.

Protect the cord and power adapters from liquids. For instance, do not leave your

cord or power adapter near sinks, tubs, toilets, or on floors that are cleaned with

liquid cleansers. Liquids can cause a short circuit, particularly if the cord or power

adapter has been stressed by misuse. Liquids can also cause gradual corrosion of

the power cord terminals and/or the connector terminals on the adapter which can

eventually result in overheating.

Always connect power cords and signal cables in the correct order and ensure that

all power cord connectors are securely and completely plugged into receptacles.

Do not use any power adapter that shows corrosion at the ac input pins and/or

shows signs of overheating (such as deformed plastic) at the ac input or anywhere

on the power adapter.

Do not use any power cords where the electrical contacts on either end show signs

of corrosion or overheating or where the power cord appears to have been

damaged in any way.

© Copyright IBM Corp. 2005 vii

Page 10

Extension cords and related devices

Ensure that extension cords, surge protectors, uninterruptible power supplies, and

power strips that you use are rated to handle the electrical requirements of the

product. Never overload these devices. If power strips are used, the load should

not exceed the power strip input rating. Consult an electrician for more

information if you have questions about power loads, power requirements, and

input ratings.

Plugs and outlets

If a receptacle (power outlet) that you intend to use with your computer

equipment appears to be damaged or corroded, do not use the outlet until it is

replaced by a qualified electrician.

Do not bend or modify the plug. If the plug is damaged, contact the manufacturer

to obtain a replacement.

Some products are equipped with a three-pronged plug. This plug fits only into a

grounded electrical outlet. This is a safety feature. Do not defeat this safety feature

by trying to insert it into a non-grounded outlet. If you cannot insert the plug into

the outlet, contact an electrician for an approved outlet adapter or to replace the

outlet with one that enables this safety feature. Never overload an electrical outlet.

The overall system load should not exceed 80 percent of the branch circuit rating.

Consult an electrician for more information if you have questions about power

loads and branch circuit ratings.

Batteries

Be sure that the power outlet you are using is properly wired, easily accessible,

and located close to the equipment. Do not fully extend power cords in a way that

will stress the cords.

Connect and disconnect the equipment from the electrical outlet carefully

All IBM personal computers contain a non-rechargeable coin cell battery to provide

power to the system clock. In addition many mobile products such as Thinkpad

notebook PCs utilize a rechargeable battery pack to provide system power when in

portable mode. Batteries supplied by IBM for use with your product have been

tested for compatibility and should only be replaced with IBM approved parts.

Never attempt to open or service any battery. Do not crush, puncture, or incinerate

batteries or short circuit the metal contacts. Do not expose the battery to water or

other liquids. Only recharge the battery pack strictly according to instructions

included in the product documentation.

Battery abuse or mishandling can cause the battery to overheat, which can cause

gasses or flame to “vent” from the battery pack or coin cell. If your battery is

damaged, or if you notice any discharge from your battery or the buildup of

foreign materials on the battery leads, stop using the battery and obtain a

replacement from the battery manufacturer.

Batteries can degrade when they are left unused for long periods of time. For some

rechargeable batteries (particularly Lithium Ion batteries), leaving a battery unused

in a discharged state could increase the risk of a battery short circuit, which could

viii IBM 400/800GB LTO3 Tape Drive User’s Guide

Page 11

shorten the life of the battery and can also pose a safety hazard. Do not let

rechargeable Lithium-Ion batteries completely discharge or store these batteries in a

discharged state.

Heat and product ventilation

Computers generate heat when turned on and when batteries are charging.

Notebook PCs can generate a significant amount of heat due to their compact size.

Always follow these basic precautions:

v Do not leave the base of your computer in contact with your lap or any part of

your body for an extended period when the computer is functioning or when

the battery is charging. Your computer produces some heat during normal

operation. Extended contact with the body could cause discomfort or, potentially,

a skin burn.

v Do not operate your computer or charge the battery near flammable materials or

in explosive environments.

v Ventilation slots, fans and/or heat sinks are provided with the product for safety,

comfort, and reliable operation. These features might inadvertently become

blocked by placing the product on a bed, sofa, carpet, or other flexible surface.

Never block, cover or disable these features.

CD and DVD drive safety

CD and DVD drives spin discs at a high speed. If a CD or DVD is cracked or

otherwise physically damaged, it is possible for the disc to break apart or even

shatter when the CD drive is in use. To protect against possible injury due to this

situation, and to reduce the risk of damage to your machine, do the following:

v Always store CD/DVD discs in their original packaging

v Always store CD/DVD discs out of direct sunlight and away from direct heat

sources

v Remove CD/DVD discs from the computer when not in use

v Do not bend or flex CD/DVD discs, or force them into the computer or their

packaging

v Check CD/DVD discs for cracks before each use. Do not use cracked or

damaged discs

General safety guidelines ix

Page 12

x IBM 400/800GB LTO3 Tape Drive User’s Guide

Page 13

Safety and Environmental Notices

When using this product, observe the danger and caution notices contained in this

guide. The notices are accompanied by symbols that represent the severity of the

safety condition.

The sections that follow define each type of safety notice.

Danger Notices

A danger notice calls attention to a situation that is potentially lethal or extremely

hazardous to people.

Caution Notices

A lightning bolt symbol always accompanies a danger notice to

represent a dangerous electrical condition.

A caution notice calls attention to a situation that is potentially hazardous to

people because of some existing condition. A caution notice can be accompanied

by one of several symbols:

If the symbol is... It means....

A hazardous electrical condition with less severity than

electrical danger.

A generally hazardous condition not represented by other

safety symbols.

A hazardous condition due to the use of a laser in the

product. Laser symbols are always accompanied by the

classification of the laser as defined by the U. S. Department

of Health and Human Services (for example, Class I, Class

II, and so forth).

A hazardous condition due to mechanical movement in or

around the product.

© Copyright IBM Corp. 2005 xi

A hazardous condition due to the weight of the unit.

Weight symbols are accompanied by an approximation of

the product’s weight.

Page 14

End of Life (EOL) Plan

This product is a purchased unit. Therefore, it is the sole responsibility of the

purchaser to dispose of it in accordance with local laws and regulations at the time

of disposal. This unit contains recyclable materials. The materials should be

recycled where facilities are available and according to local regulations. Some

areas may provide a product take-back program that ensures proper handling of

the product. Contact your IBM representative for more information.

xii IBM 400/800GB LTO3 Tape Drive User’s Guide

Page 15

About This Guide

This guide includes the following information:

v “Product Description” on page 1 describes the drive, discusses supported

servers, operating systems, and device drivers.

v “Installing the Drive” on page 5 tells how to unpack and set up the drive.

v “Operating the Drive” on page 11 describes the unload button, and status light

on the drive. It explains the function of the message display and the

single-character display. It tells how to insert and remove a tape cartridge,

describes methods of updating drive firmware, and explains how to clean the

drive. It also lists the diagnostic and maintenance functions that the drive can

perform.

v “Using Ultrium Media” on page 31 describes the types of tape cartridges to use

in the drive and defines the conditions for storing and shipping them. It also

tells how to handle the cartridges, how to set a cartridge’s write-protect switch,

and how to order additional cartridges.

v “Resolving Problems” on page 43 gives tips for solving problems with the drive

and includes a flowchart that analyzes when the drive requires maintenance.

v “Servicing the Drive” on page 52 gives instructions on servicing the drive.

v Appendix A, “TapeAlert Flags,” on page 65 lists TapeAlert messages that are

supported by the drive and that may aid during problem determination.

v Appendix B, “Specifications,” on page 69 lists product specifications.

Related Publications

v IBM®TotalStorage

information about the supported SCSI commands and protocol that govern the

behavior of the SCSI interface for the IBM 3580 LTO Ultrium Tape Drive Model

L33/L3H and the IBM TotalStorage Ultrium Tape Drive Model T800.

v IBM Ultrium Device Drivers Programming Reference, GC35-0483 supplies information

to application developers who want to integrate their open-systems applications with

IBM-supported Ultrium hardware. The reference contains information about the

application programming interfaces (APIs) for each of the various supported

operating-system environments. Yo u can obtain this reference via File Transfer Protocol

(FTP) at ftp://ftp.software.ibm.com/storage/devdrv.

v IBM Translated Safety Notices, 96P0851, provides translation of danger and caution

notices.

®

LTO Ultrium Tape Drive SCSI Reference, GA32-0450, gives

© Copyright IBM Corp. 2005 xiii

Page 16

xiv IBM 400/800GB LTO3 Tape Drive User’s Guide

Page 17

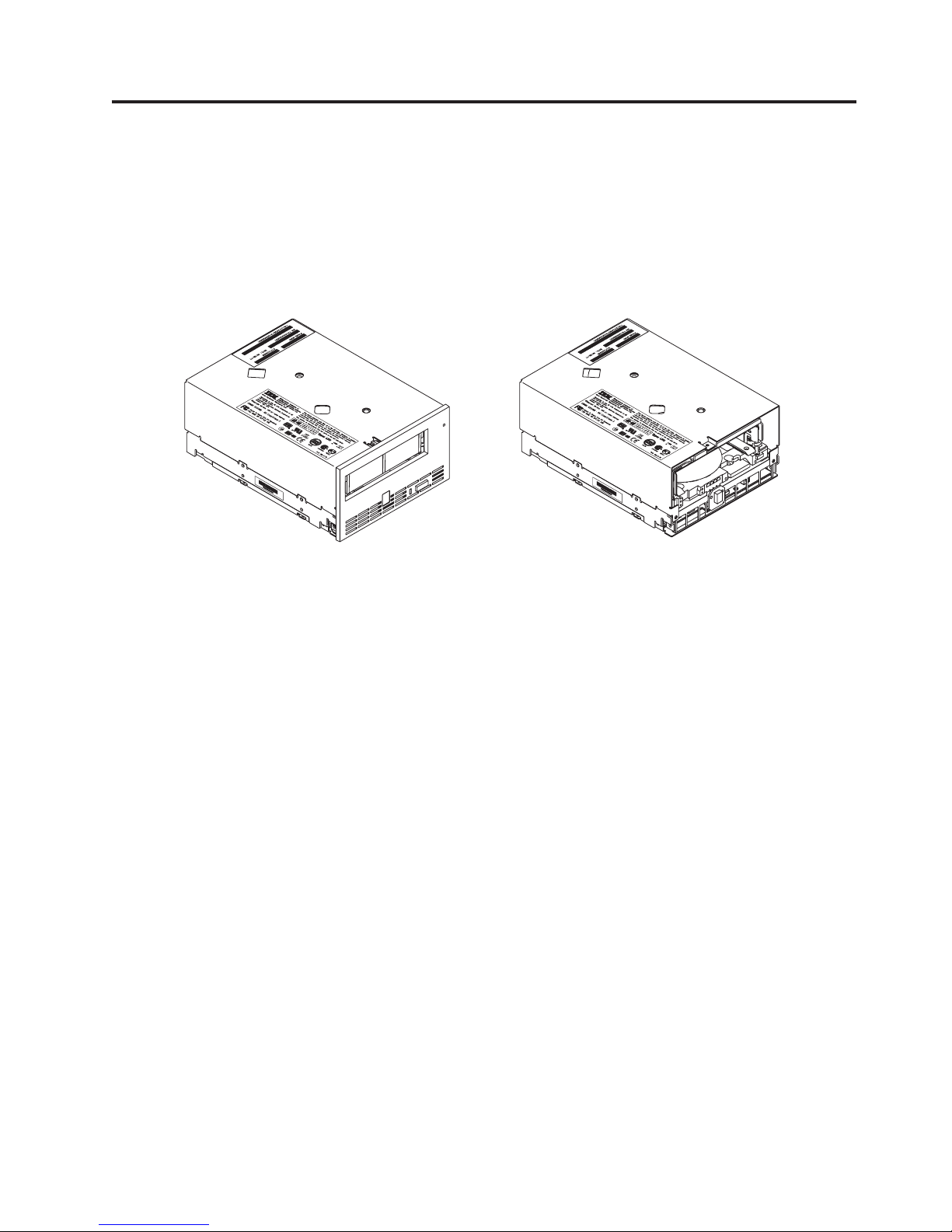

Product Description

The IBM 400/800GB LTO 3 Tape Drive is a high-performance, high-capacity

data-storage device that is designed to backup and restore open systems

applications. The drive is the third-generation in the Ultrium series of products. It

is available as Model with a Small Computer Systems Interface (SCSI).

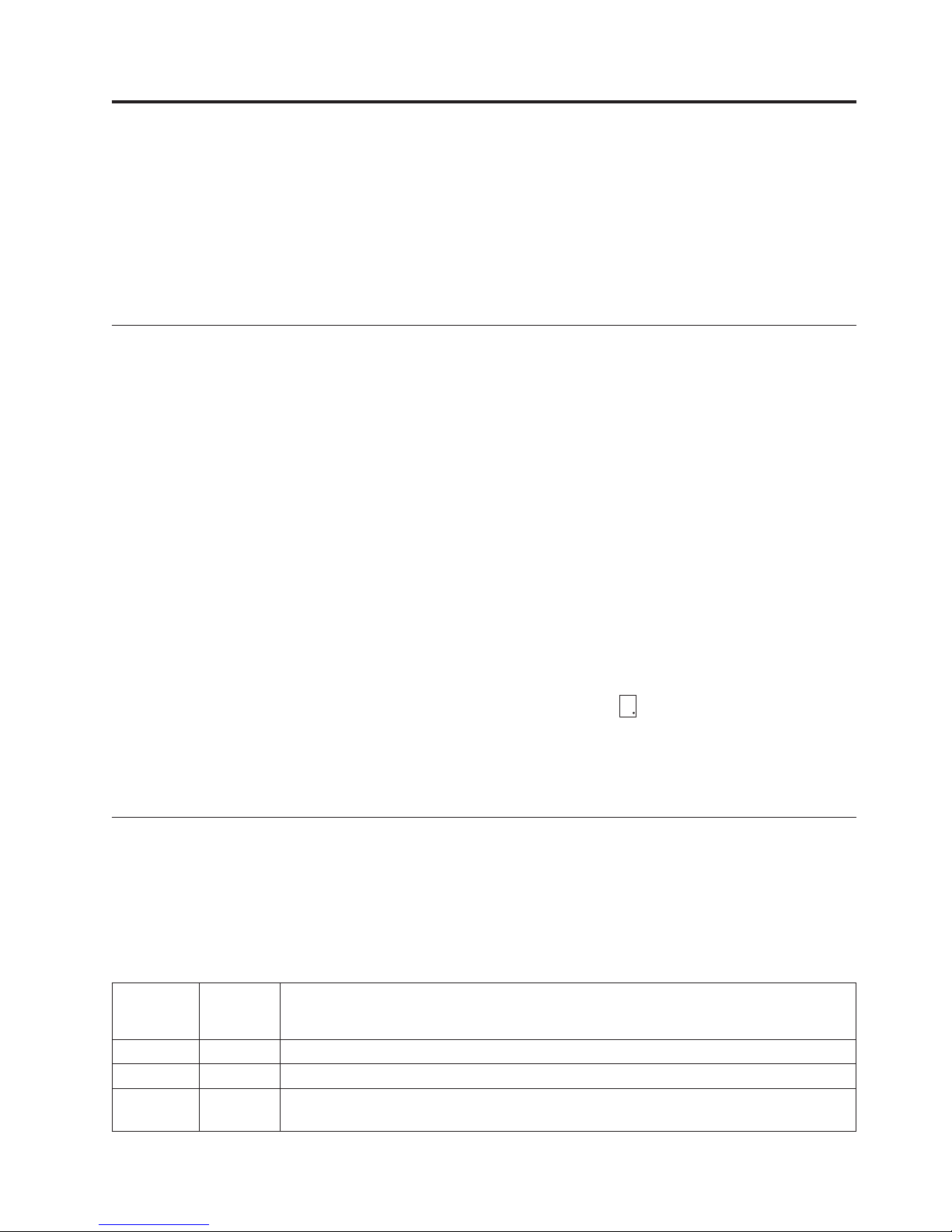

Figure 1. View of the drive with and without the bezel

The drive offers the following features:

v Ultra160 Low Voltage Differential (LVD) Small Computer Systems Interface

v 68-pin, D-shell connector (for SCSI signals, SCSI ID selection, and power

connection)

v Native storage capacity of 400 GB per cartridge (800 GB at 2:1 compression)

v Native data transfer rate of up to 80 MB per second

v Burst data transfer rate of 160 MB per second

v New dual stage 16 channel head activator for precision head alignment to help

support higher track density with improved data integrity and backwards

compatibility with previous LTO generations

v Graceful dynamic braking designed to maintain tension until the tape comes to

a complete stop, to help prevent stretching or breaking the tape, and loose tape

wraps

v Larger internal buffer (the size has been doubled over the Ultrium 2 to 128 MB)

v New independent tape loader and threader motors designed to help with

cartridge insertion in the tape drive.

v Highly integrated electronics designed to reduced the total number of

components in the drive, lower chip temperatures, and reduce power

requirements, helping to provide for a more reliable drive. The Generation 3

drive electronics also incorporate on-the-fly error correction of soft errors in the

memory arrays in data and control paths.

a82ru002

© Copyright IBM Corp. 2005 1

Page 18

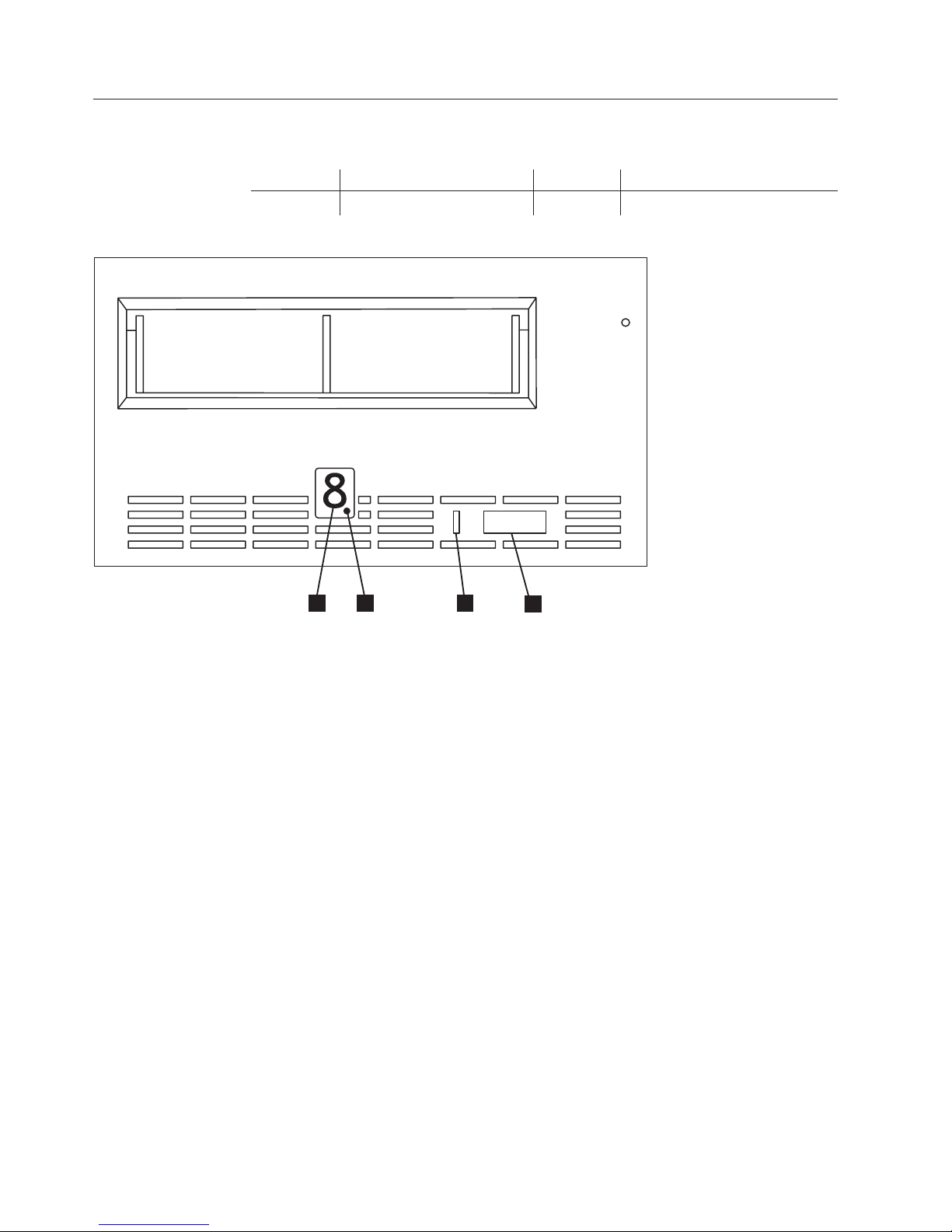

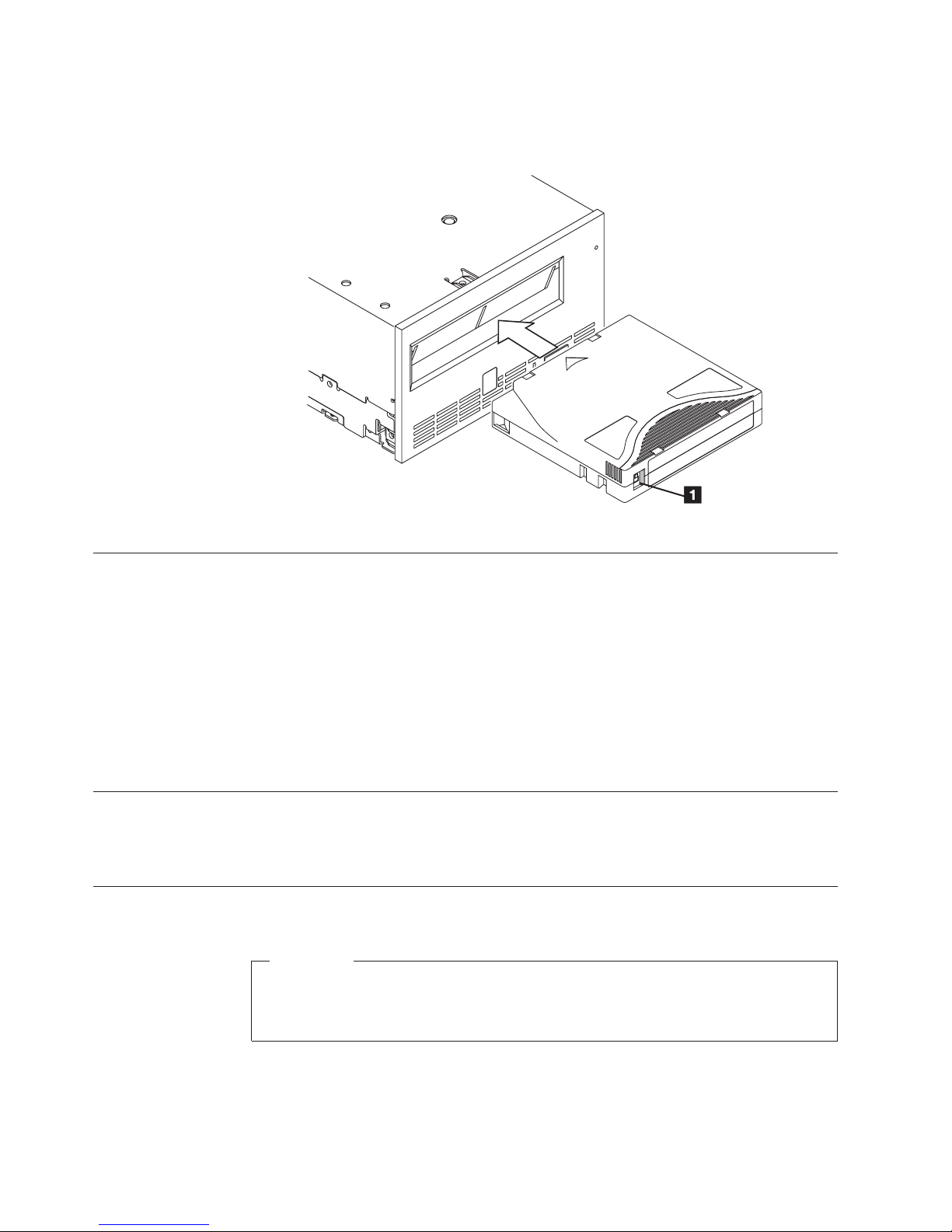

Front Panel of the Drive

Figure 2 shows the front panel of the drive.

1 Status Light 3 Single-character Display (SCD)

2 Unload Button 4 SCD Dot

3

4

1

2

a82ru001

Figure 2. Front panel of the drive

2 IBM 400/800GB LTO3 Tape Drive User’s Guide

Page 19

Rear Panel of the SCSI Drive

1 SCSI connector 4 Library/Drive Interface (LDI or

RS-422 interface) connector

2 SCSI ID connector 5 Serial port

3 Power connector

4

1

2

Figure 3. Rear panel of the drive

Speed Matching and Channel Calibration

To improve system performance, the drive uses a technique called speed matching to

dynamically adjust its native (uncompressed) data rate to the slower data rate of a

server. With speed matching, the drive operates at one of five speeds when reading

or writing the Generation 3 cartridge format to achieve a native data rate of 40, 50,

60, 70, or 80 MB per second (MB/s). If the server’s net (compressed) data rate is

between two of the preceding native data rates, the drive calculates the

appropriate data rate at which to operate. Speed matching dramatically reduces

backhitch, the condition that occurs when a tape stops, reverses, and restarts

motion. A backhitch is usually the result of a mismatch between the data rates of

the server and the drive.

System performance is further optimized by a feature called channel calibration, in

which the drive automatically customizes each read/write data channel to

compensate for variations in such things as the recording channel’s transfer

function, the media, and characteristics of the drive head.

3

5

a82ru011

Product Description 3

Page 20

Sleep Mode

To conserve energy when circuit functions are not needed for drive operation, the

drive features a power-management function that causes the drive’s electronics to

enter a low-power mode known as sleep mode. To enter sleep mode, the drive must

be inactive for a minimum of 30 seconds (default value; this is programmable via

the mode pages); to exit, the drive must receive a command across the SCSI

interface, a command across the Library/Drive Interface (LDI or RS-422 interface),

or a load or unload request. When in sleep mode, the drive’s response time to

commands that do not require media motion increases by up to ten microseconds.

Commands that require media motion may be delayed an additional 100

milliseconds because the tape must be retensioned.

SCSI Attachment

To communicate with a server, the drive uses the Ultra160 LVD SCSI interface.

Physical Characteristics of the SCSI Interface

The drive contains a high-density, 68-pin, D-shell receptacle connector (HD68) for

attachment to the server. The HD68 connector includes the connectors for the SCSI

signal, the SCSI ID, and the drive’s power. The drive supports LVD SCSI cables

with HD68 connectors.

Speed

The Ultra160 LV D SCSI interface is compatible with older SCSI technology and is

capable of data transmission at 160 MB/s. Ultra160 SCSI uses the three

management features of the Ultra3 SCSI standard that specifically affect data

transfer rate:

v Double transition clocking - a data-transfer technique that enables data rates to

double without increasing clock speed

v Domain validation - a procedure that detects and adjusts SCSI configuration

issues that might prevent interoperation between SCSI devices

v Cyclic redundancy check (CRC) - an error-checking technique

Because the cables, connectors, and terminators are the same for the Ultra160 and

Ultra2 SCSI interfaces, devices with those interfaces can be mixed on the same bus

and each device can operate at its fully rated speed.

4 IBM 400/800GB LTO3 Tape Drive User’s Guide

Page 21

Installing the Drive

Attention:

To avoid static electricity damage when handling the drive, use the following

precautions:

v Limit your movement. Movement can cause static electricity to build

around you.

v Always handle the drive carefully. Never touch exposed circuitry.

v Prevent others from touching the drive.

v Before unpacking and installing the drive into an enclosure, touch its

static-protective packaging to an unpainted metal surface on the enclosure

for at least two seconds. This reduces static electricity in the packaging and

your body.

v When possible, remove the drive from its static-protective packaging and

install it directly into an enclosure without setting it down. When this is

not possible, place the drive’s packaging on a smooth, level surface and

place the drive on the packaging.

v Do not place the drive on the cover of the enclosure or on any other metal

surface.

The steps that follow describe how to install the drive into an enclosure.

Note: Depending on the type of enclosure, installation procedures may vary.

Before starting this installation, read these instructions and compare them to

the drive installation instructions for your enclosure.

Installation Overview

__ 1. “Unpack the Drive”

__ 2. “Power Off the Server/Enclosure” on page 6

__ 3. “Set the SCSI ID” on page 7

__ 4. “Mount the Drive into the Server/Enclosure” on page 8

__ 5. “Connect and Test Power to the Drive” on page 9

__ 6. “Connect the Internal SCSI Cable” on page 9

__ 7. “Run Drive Diagnostics” on page 9

__ 8. “Install Device Drivers” on page 10

__ 9. “Connect the Enclosure’s External SCSI Interface to the Server” on page 10

Unpack the Drive

Unpack the drive and store the packaging for future moves or shipping.

© Copyright IBM Corp. 2005 5

Page 22

Attention:

Acclimation time is required if the temperature of the drive when unpacked

is different than the temperature of its operating environment (measured at

the front of the bezel near the air intake area as shown in Figure 4). The

recommended acclimation time is four hours after the drive has been

unpacked or one hour after any condensation that you can see has

evaporated, whichever is greater. When acclimating the drive, apply the

following measures:

v If the drive is colder than its operating environment and the air contains

sufficient humidity, condensation may occur in the drive and damage it.

When the drive has warmed to the operating temperature range (greater

than 10°C or 50°F) and no danger of condensation is present (the air is

dry), warm the drive more quickly by powering it on for 30 minutes. Use a

diagnostic tape to test the drive before inserting a tape that contains data.

v If the drive is hotter than its operating environment, the tape can stick to

the drive head. When the drive has cooled to the operating temperature

range (less than 40°C or 104°F), cool the drive more quickly by applying

airflow for 30 minutes. Power-on the drive and use a diagnostic tape to test

it before inserting a tape that contains data.

If you are uncertain about whether the temperature of the drive is within the

recommended operating range or the humidity is sufficient to cause

condensation, acclimate the drive for the full four hours.

Air Intake

Area

Figure 4. Temperature of the drive is taken near the air intake area

a82ru003

Power Off the Server/Enclosure

__ 1. Power-off the enclosure (or the server that provides power to the drive)

__ 2. Disconnect the power cord from both the electrical outlet and the host.

6 IBM 400/800GB LTO3 Tape Drive User’s Guide

Page 23

Set the SCSI ID

Setting the SCSI ID with Jumpers

The SCSI ID can be set in one of two ways:

v By placing jumpers on the SCSI ID connector

v By using a SCSI ID switch that is connected to the SCSI ID connector

The SCSI ID can be set on the drive by installing 2 mm jumpers on the drive’s

SCSI ID connector (see 2 in Figure 3). Your drive may come set to a default SCSI

configuration, with jumpers already installed. Yo u can change the SCSI ID by

rearranging, adding, or removing jumpers.

To set the SCSI ID:

__ 1. Locate the SCSI ID connector (2in Figure 3).

__ 2. Before attaching the SCSI bus cable to the server, determine the SCSI ID.

Make sure that the ID is not being used by another device.

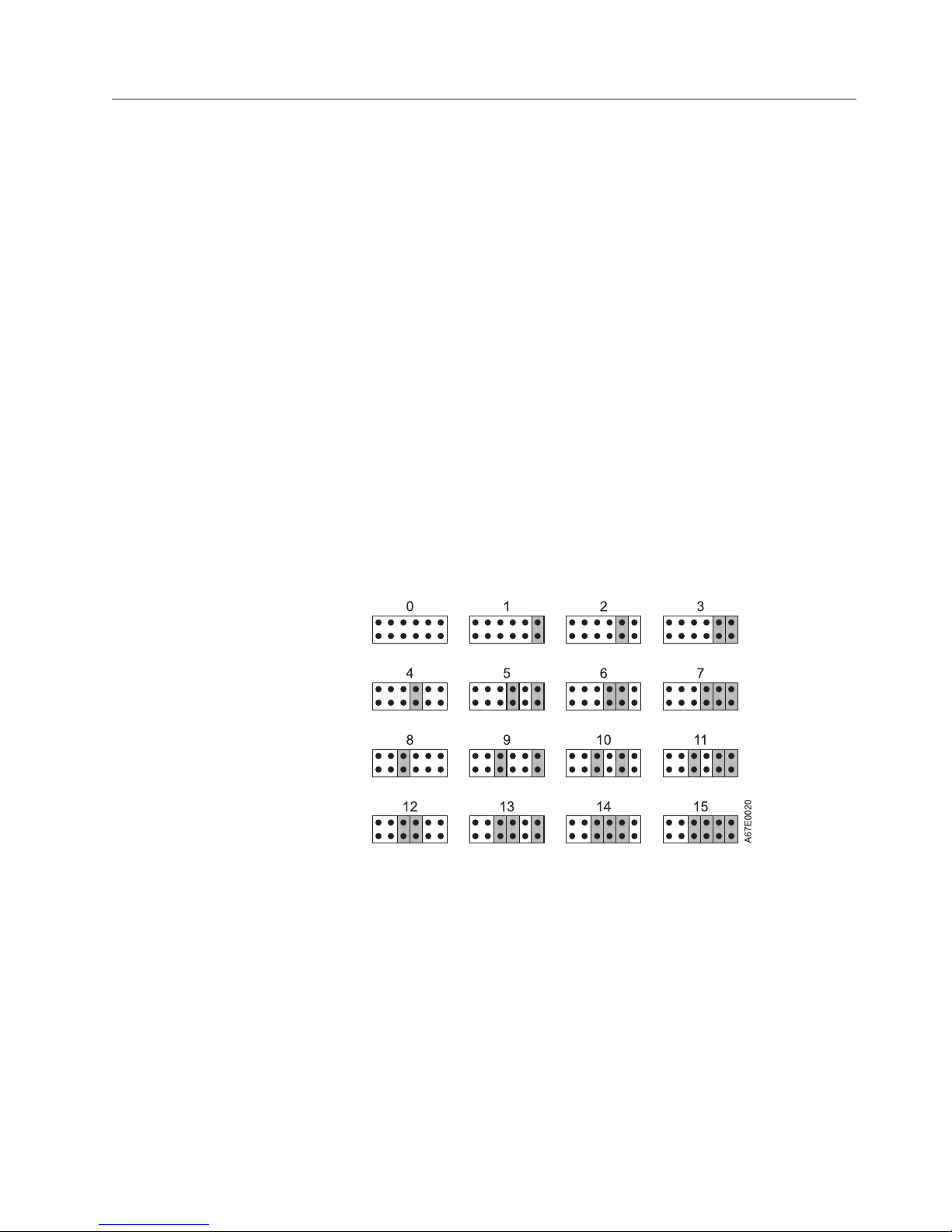

__ 3. Referring to Figure 2, find the ID number that you chose, then place

jumpers on the connector pins as shown (use a pair of needle-nose pliers to

connect the jumpers to the pins that are shaded).

Note: If you set the SCSI ID to 15, the drive will not necessarily be set to

that ID; instead, the drive will expect to receive the SCSI ID through a

command over its LDI interface.

Figure 5. SCSI ID settings on the SCSI ID connector

Setting the SCSI ID with a SCSI ID Switch

If your enclosure uses a SCSI ID switch (rather than jumpers), connect the switch

to the drive’s SCSI ID connector 2in Figure 3 . If any jumpers are preinstalled, be

sure to remove them before connecting the switch. The SCSI ID switch must be

compatible with the drive’s SCSI ID connector and must make an electrical

connection between the same pins as the jumpers to achieve the same

corresponding SCSI ID.

Supplying TERMPOWER (SCSI Drive Only)

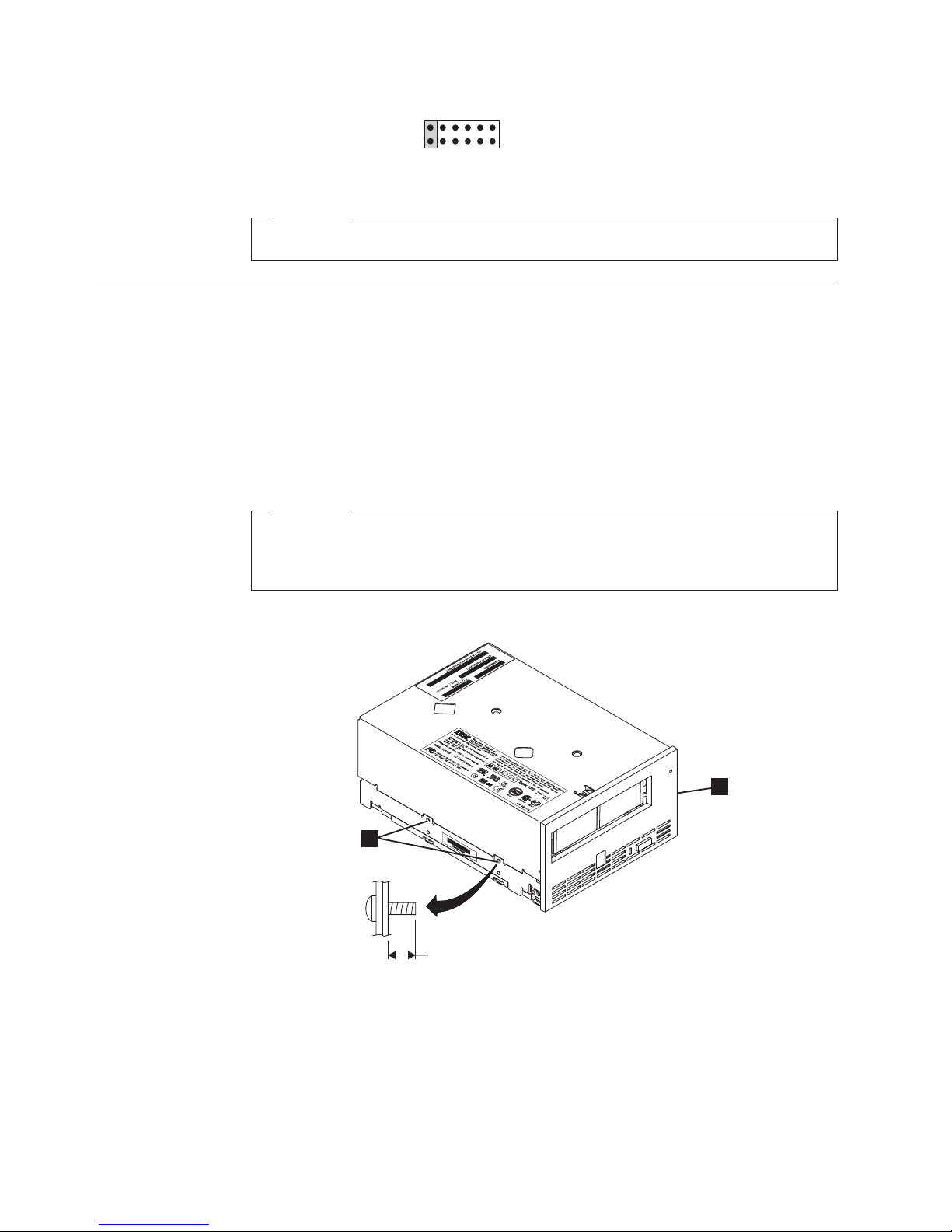

To supply TERMPOWER to the bus, locate one of the five jumpers shipped with

the drive and place it on the SCSI ID connector as shown in the following figure.

Place the jumper on the pins that are shaded.

Installing the Drive 7

Page 24

A67E0049

Attention

SCSI termination must be provided externally to the drive.

Mount the Drive into the Server/Enclosure

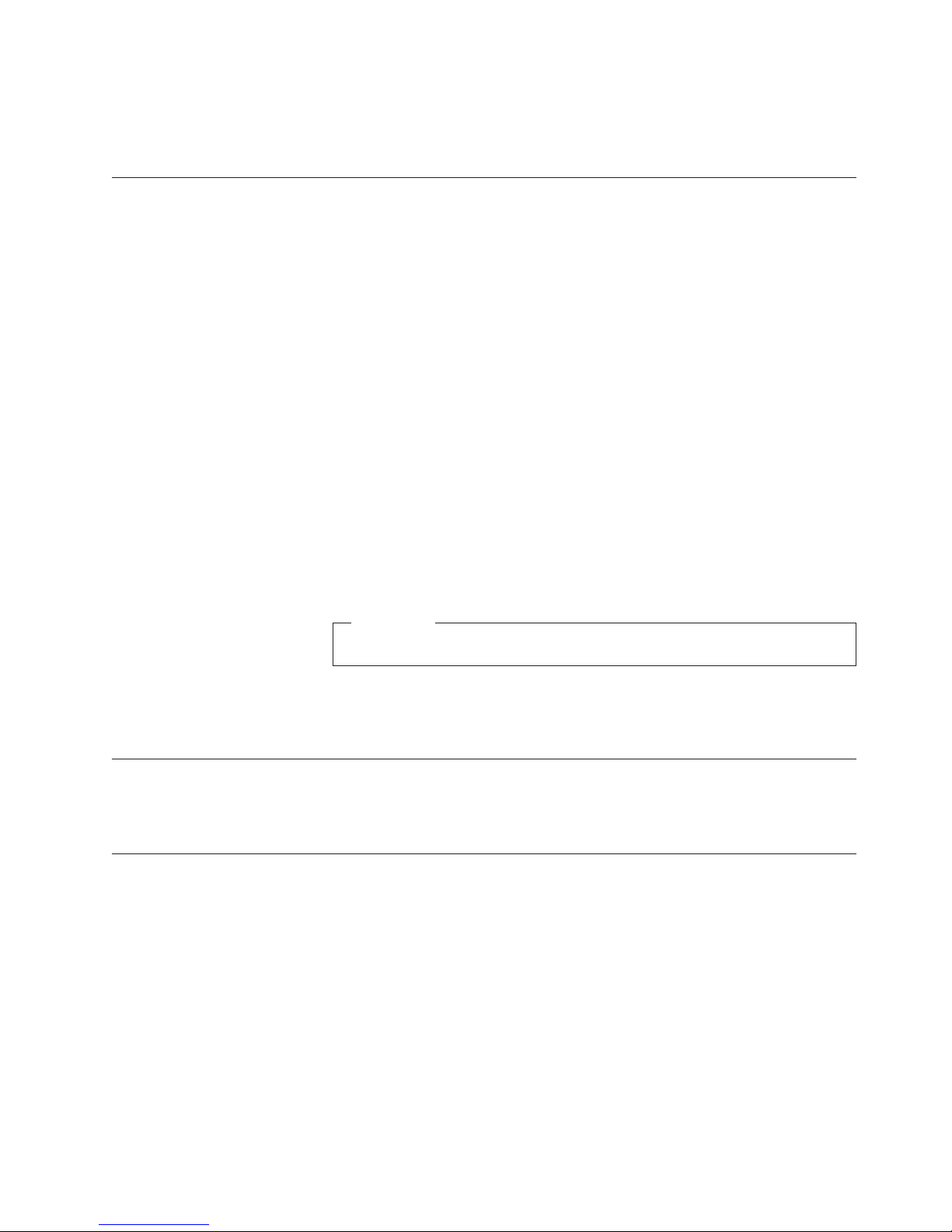

To mount the drive into a enclosure:

__ 1. Remove the cover of your enclosure (refer to the instructions in the

documentation provided with your enclosure).

__ 2. Place the drive into the enclosure so that the tape load compartment of the

drive faces the tape load compartment of the enclosure.

__ 3. Insert two M3 screws into the mounting holes 2 of the two side brackets

located on the left and right sides of the chassis.

Attention

When inserted into the drive, the length of the mounting screws must not

exceed 3.5 mm (0.14 in.) inside the chassis. If the length exceeds this

measurement, the drive may become damaged.

1

2

< 3.5 mm (0.14 in.)

a82ru004

Figure 6. Mounting holes on drive. The holes are located on both sides of the drive. The

drive is shown with a front bezel.

8 IBM 400/800GB LTO3 Tape Drive User’s Guide

Page 25

To mount the drive into a server:

1. Refer to the option (or drive) installation instructions in your server Installation

Guide.

Connect and Test Power to the Drive

The drive does not contain its own power source; it must be powered externally.

To connect and test power to the drive:

__ 1. Ensure that the host (or unit that supplies power to the drive) is powered

off.

__ 2. Ensure that the power cord is disconnected from both the host and the

power outlet.

__ 3. Connect the host’s internal power cable to the power connector on the drive

(see 3 in Figure 3 on page 3).

__ 4. Connect the power cord to the host and to the electrical outlet.

__ 5. Review the location of the Single-character Display (SCD) and the Status

Light in “Single-character Display (SCD)” on page 11 and “Status Light” on

page 11 (if your drive does not have a bezel, note that the bulb of the Status

Light is recessed and the light is not visible until lit). To ensure that the

drive is receiving power, watch for the following while turning on the

power to the host:

v The SCD presents a series of random characters, then becomes blank (not

lit).

Attention

If the SCD does not come on, the drive may not be getting power.

v The Status Light briefly becomes solid amber, then becomes solid green.

__ 6. Power-off the host.

__ 7. Disconnect the power cord from both the host and the electrical outlet.

Connect the Internal SCSI Cable

Connect the enclosure’s internal SCSI cable to the SCSI connector on the drive (see

1 in Figure 3).

Run Drive Diagnostics

__ 1. Replace the cover on the host.

__ 2. Connect the power cord to both the host and the electrical outlet.

__ 3. Power-on the host.

__ 4. Run one or more of the following drive diagnostics:

v “Function Code 1: Run Drive Diagnostics” on page 16

v “Function Code 6: Run SCSI Wrap Test” on page 20

v “Function Code 7: Run RS-422 Wrap Test” on page 20

an error code appears on the single-character display (SCD), go to “Error

If

Codes and Messages” on page 45. If no error appears, continue to the next

step.

__ 5. Power-off the host.

Installing the Drive 9

Page 26

__ 6. Disconnect the power cord from both the host and the electrical outlet.

Install Device Drivers

For information about installing device drivers, refer to the documentation for your

server and/or Operating System.

Connect the Enclosure’s External SCSI Interface to the Server

__ 1. Connect an external SCSI bus cable to both the enclosure and the server (for

the location of the connectors, refer to the documentation for your enclosure

and server).

__ 2. Run the appropriate SCSI attachment verification procedure from your

server (for instructions, refer to the IBM Ultrium Device Drivers Installation

and User’s Guide).

If you want to power a device on or off while it is connected to the same SCSI bus

as the drive, you can do so if, during the power-on cycle, you quiesce all devices

(including the drive) on the bus.

10 IBM 400/800GB LTO3 Tape Drive User’s Guide

Page 27

Operating the Drive

Operating the drive involves using the following front panel items:

v Single-character Display (SCD)

v SCD Dot

v Status Light

v Unload Button

Single-character Display (SCD)

The SCD (see3 in Figure 2) presents a single-character code for:

v Error conditions and informational messages:

“Error Codes and Messages” on page 45 lists the codes for error conditions and

informational messages. If multiple errors occur, the code with the highest

priority (represented by the lowest number) displays first. When the error is

corrected, the code with the next highest priority displays, and so on until no

errors remain.

v Diagnostic or maintenance functions (while in maintenance mode only):

“Diagnostic and Maintenance Functions” on page 15 lists the single-character

codes that represent diagnostic or maintenance functions. To initiate a function

the unit must be in maintenance mode.

SCD is blank during normal operation.

The

SCD Dot

If a drive dump is present while the drive is in maintenance mode, a single red dot

illuminates in the lower right corner of the SCD (

“Function Code 5: Copy Drive Dump” on page 19.

The SCD Dot turns off when you obtain the dump (by using an FMR tape, a SCSI

command, or a library command).

Status Light

The Status Light (1 in Figure 2) is a light-emitting diode (LED) that provides

information about the state of the drive. The light can be green or amber, and

(when lit) solid or flashing. The table below lists the conditions of the Status Light

and Single-character Display (SCD) and provides an explanation of what each

condition means.

Table 1. Meaning of Status Light and Single-character Display (SCD)

If the

Status Light

is...

Off Off The drive has no power or is powered off.

Green Off The drive is powered on and in an idle state.

Flashing

Green

and the

SCD is...

Off The drive is reading from the tape, writing to the tape, rewinding the tape, locating data

on the tape, loading the tape, or unloading the tape.

Meaning

8

). To copy the dump, see

© Copyright IBM Corp. 2005 11

Page 28

Table 1. Meaning of Status Light and Single-character Display (SCD) (continued)

If the

Status Light

is...

Flashing

Green

and the

SCD is...

Meaning

Off The drive contains a cartridge during the power-on cycle. In this case, the drive

completes POST and slowly rewinds the tape (the process may take up to ten minutes).

The light stops blinking and becomes solid when the drive completes the recovery and is

ready for a read or write operation. To eject the cartridge, press the unload button.

Amber Displaying

Error Code

The drive is displaying error code(s) from the error code log on the SCD. For more

information, see “Function Code A: Clear Error Code Log” on page 22“ and “Error Codes

and Messages” on page 45.

Amber Red

The drive is powering on, resetting, or in maintenance mode.

numbers,

letters, or

segments

Amber Flashing

0

Amber Flashing

The drive is exiting from maintenance mode. For more information, see “Function Code

0: Exit Maintenance Mode” on page 16“.

The drive is executing the selected function while in maintenance mode.

selected

function

Flashing

Amber once

Displaying

error code

An error occurred and the drive or media may require service, or it may require cleaning.

Note the code on the SCD, then go to Table 9 to determine the action that is required.

per second

Flashing

Amber once

per second

Flashing

Amber

twice per

second

Displaying

C

Displaying

Function

Code

8

The drive needs cleaning.

1

The drive is updating firmware.

8

The SCD will display a

if using an FMR cartridge. The SCD will be off if using the SCSI interface. For more

information, see ““Updating Firmware” on page 26.

or Off

Flashing

Amber

Off The drive detected an error and is performing a firmware recovery. It will reset

automatically.

twice per

second

Flashing

Amber

twice per

Flashing

C

The drive is requesting a cartridge to be loaded.

second

Flashing

Off There is a drive dump in flash memory.

Amber

twice per

second

1

Power should not be removed from the drive until the microcode update is complete. The drive indicates that the

update is complete by resetting and performing POST.

Unload Button

The Unload Button (2in Figure 2 in “Front Panel of the Drive” on page 2)

performs the following functions:

12 IBM 400/800GB LTO3 Tape Drive User’s Guide

Page 29

Table 2. Functions that the Unload Button performs

Unload Button Function How to Initiate the Function

Rewind the tape into the

cartridge and eject the

cartridge from the drive

Press the Unload Button once. The Status Light flashes green while the drive is

rewinding and unloading.

Note: During a rewind and eject operation, the drive does not accept SCSI commands

from the server.

Place the drive in

maintenance mode

Ensure that the drive is unloaded. Then, within two seconds, press the Unload Button

three times. The drive is in maintenance mode when the Status Light becomes solid

amber and

0

appears in the SCD.

Note: While in maintenance mode, the drive does not accept SCSI interface

commands.

Scroll through the

maintenance functions

While in maintenance mode, press the Unload Button once per second to increment

the display characters by one. When you reach the character of the diagnostic or

maintenance function that you want (see “Diagnostic and Maintenance Functions” on

page 15), press and hold the Unload Button for three seconds.

Exit maintenance mode Press the Unload Button once per second until

0

displays. Then press and hold the Unload Button for three seconds. Maintenance

mode is exited when the Status Light becomes solid green and the SCD becomes

blank.

Force a drive dump (part of

the maintenance mode)

Attention: If the drive detects a permanent error and displays an error code, it

automatically forces a drive dump (also known as a save of the firmware trace). If

you force a drive dump, the existing dump will be overwritten and data will be lost.

After you force a drive dump, do not turn off the power to the drive or you may lose

the dump data.

Choose one of the following procedures:

v If the drive is in maintenance mode (Status Light is solid amber), refer to “Function

Code 4: Force a Drive Dump” on page 18.

v If the drive is in operating mode (Status Light is solid or flashing green), press and

hold the Unload Button for ten seconds.

captured dump data exists, the drive places it into a dump area.

If

Reset the drive Press and hold the Unload Button on the drive for ten seconds. The drive saves a

dump of the current drive state, then reboots to allow communication. Do not cycle

power as this will erase the contents of the dump.

Inserting a Tape Cartridge

To insert a tape cartridge:

1. Ensure that the drive is powered-on.

2. Ensure that the write-protect switch is properly set (see “Write-Protect Switch”

on page 34).

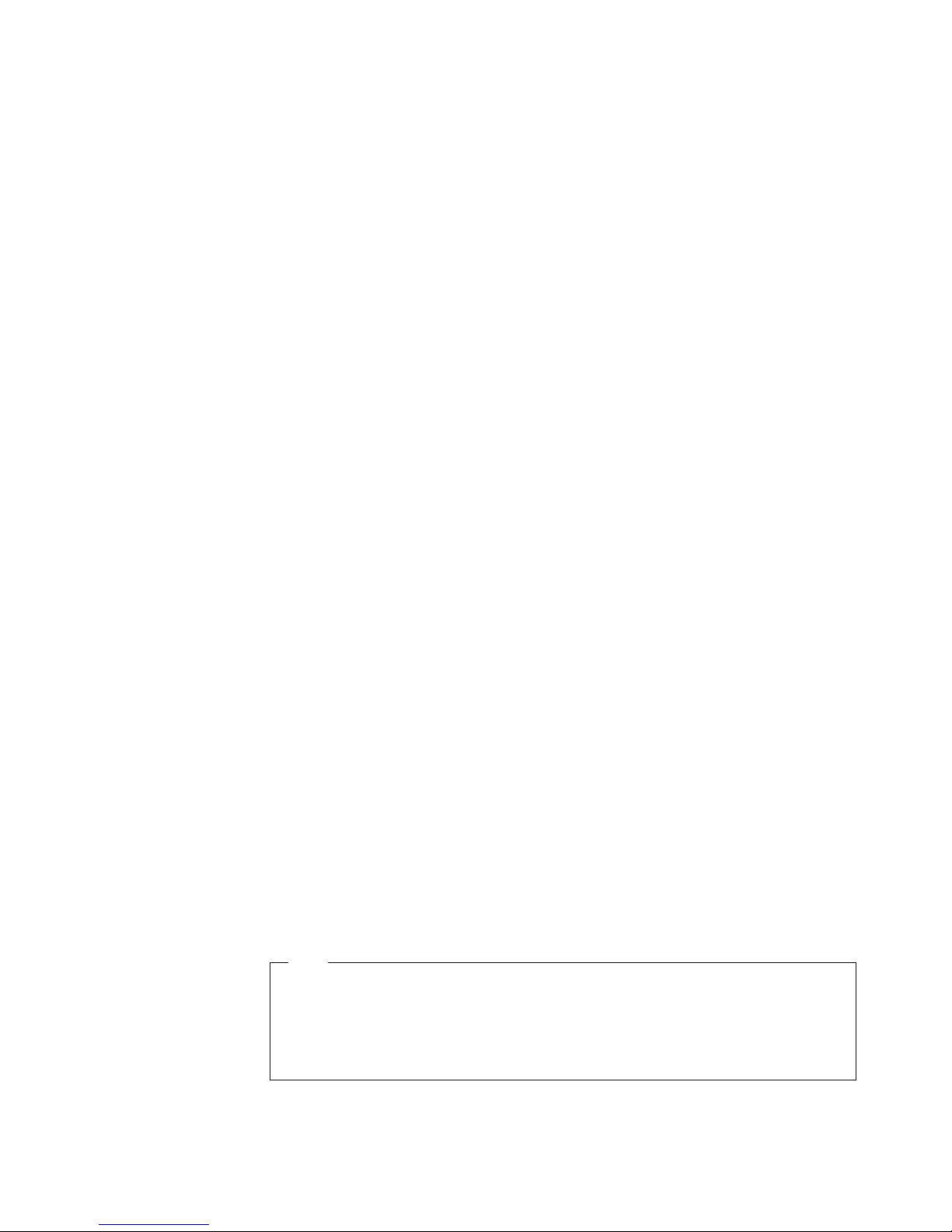

3. Grasp the cartridge so that the write-protect switch faces you (1 in Figure 7

on page 14).

4. Slide the cartridge into the tape load compartment.

Notes:

a. If the cartridge is already in an ejected position and you want to reinsert it,

remove the cartridge then insert it again.

Operating the Drive 13

Page 30

b. If the cartridge is already loaded and you cycle the power (turn it off, then

on), the tape will reload.

Figure 7. Inserting a cartridge into the drive

Removing a Tape Cartridge

To remove a tape cartridge:

1. Ensure that the drive is powered-on.

2. Press the Unload Button. The drive rewinds the tape and partially ejects the

cartridge. The Status Light flashes green while the tape rewinds, then goes out

before the cartridge partially ejects.

3. After the cartridge partially ejects, grasp the cartridge and remove it.

Whenever you unload a tape cartridge, the drive writes any pertinent information

to the cartridge memory.

Mid-tape Recovery

If a power cycle or reset occurs while a cartridge is loaded, the drive will slowly

rewind the tape and eject the cartridge.

Cleaning the Drive Head

a82ru005

Attention

When cleaning the drive head, use the LTO Ultrium Cleaning Cartridge. For

more information, please see: http://www-

307.ibm.com/pc/support/sit.wss/document.do?Indocid=MIGR-39931

14 IBM 400/800GB LTO3 Tape Drive User’s Guide

Page 31

Clean the drive head whenever

C

the Status Light is flashing amber once per second. It is not recommended that you

clean the drive head on a periodic basis; only when the drive requests to be

cleaned.

To clean the head, insert the cleaning cartridge into the tape load compartment (see

“Front Panel of the Drive” on page 2). The drive performs the cleaning

automatically in less than two minutes then ejects the cartridge.

Note: If a cleaning cartridge is inserted when the drive does not need to be

cleaned or a cleaning cartridge is inserted that has expired, the drive will

automatically eject the cartridge.

The LTO Ultrium Cleaning Cartridge is valid for 50 uses.

Diagnostic and Maintenance Functions

The drive can:

v Run diagnostics

v Test write and read functions

v Test a suspect tape cartridge

v Update its own firmware

v Perform other diagnostic and maintenance functions

displays on the Single-character Display and

drive must be in maintenance mode to perform these functions.

The

Attention

Maintenance functions cannot be performed concurrently with read or write

operations. While in maintenance mode, the tape drive does not accept SCSI

commands from the server. The tape drive does accept LDI or RS-422

commands.

Entering Maintenance Mode

The drive must be in maintenance mode to run drive diagnostics or maintenance

functions. To place the unit in maintenance mode:

1. Make sure that no cartridge is in the drive.

2. Press the Unload Button three times within two seconds.

Single-character Display (SCD), and the Status Light turns amber.

Note: If a cartridge is in the tape drive, it will eject the first time that you press

the Unload Button and the drive will not be placed in maintenance

mode. To continue placing the drive in maintenance mode, perform the

preceding step.

Maintenance

operations. While in maintenance mode, the drive does not receive SCSI

commands from the server.

functions cannot be performed concurrently with read or write

0

appears in the

Operating the Drive 15

Page 32

Function Code 0: Exit Maintenance Mode

Function Code

0

makes the drive available for reading and writing data.

1. Place the drive in maintenance mode. For instructions, see “Entering

Maintenance Mode” on page 15.

2. Press and hold the Unload Button for 3 or more seconds to take the drive out

of maintenance mode. The Status Light turns off.

v If no error is detected,

0

temporarily appears in the SCD, then goes blank.

The drive then exits maintenance mode.

v If an error is detected, the SCD shows an error code but still exits

maintenance mode. To determine the error, locate the code in Table 9 on page

45. To clear the error, turn the power off, then on again.

The drive also exits maintenance mode automatically after it completes a

maintenance function or after 10 minutes if no action has occurred.

Function Code 1: Run Drive Diagnostics

Approximate Run Time = 20 minutes per loop

Total Number of Loops = 10

Function Code

and unload cartridges, and read and write data.

1

runs tests that determine whether the drive can properly load

The diagnostic loops ten times. To stop the diagnostic and exit maintenance mode,

press the Unload Button once to abort the test.

Attention

For this test, insert only a scratch (blank) data cartridge or a cartridge that

may be overwritten. During the test, the drive overwrites the data on the

cartridge.

1. Place the drive in maintenance mode. For instructions, see “Entering

Maintenance Mode” on page 15.

2. Press the Unload Button once per second until

1

appears in the SCD. (If you

cycle past the desired code, press the Unload Button once per second until the

code reappears.)

3. Press and hold the Unload Button for three or more seconds, then release it to

select function

4. Insert a scratch (blank) data cartridge that is not write-protected (or the tape

drive exits maintenance mode). The SCD changes to a flashing

1

. The SCD changes to a flashing

C

.

1

and the test

begins.

Note: If you inserted an invalid or write-protected tape cartridge, error code

7

appears in the SCD. The tape drive unloads the cartridge and exits

maintenance mode.

16 IBM 400/800GB LTO3 Tape Drive User’s Guide

Page 33

v If no error is detected, the diagnostic will loop and begin again. To stop the

loop, press the Unload Button for one second and release. When the loop

0

ends,

temporarily appears in the SCD. The drive rewinds and unloads

the cartridge, and then exits maintenance mode. The solid amber Status Light

turns off.

v If an error is detected, the Status Light flashes amber and the drive posts an

error code to the SCD. To determine the error, locate the code in Table 9 on

page 45. The tape drive unloads the tape cartridge and exits maintenance

mode. To clear the error, turn the power off, then on again.

Function Code 2: Update Drive Firmware from FMR Tape

Attention

When updating drive firmware, do not power-off the drive until the update

is complete or the firmware may be lost.

Function Code

(FMR) tape.

8

loads drive firmware from a field microcode replacement

Attention: While the drive supports firmware update with a FUP tape, IBM

recommends you update the drive firmware using the easier to use Tapetool found

at http://www-307.ibm.com/pc/support/site.wss/document.do?lndocid=TAPEFILES.

Attention: Customers should only attempt this step when requested by IBM

service.

1. Place the drive in maintenance mode. For instructions, see “Entering

Maintenance Mode” on page 15.

2. Press the Unload Button once per second until

8

appears in the SCD. (If you

cycle past the desired code, press the Unload Button once per second until the

code reappears.)

3. Press and hold the Unload Button for three or more seconds, then release it to

select the function. The SCD changes to a flashing

4. Insert the FMR tape cartridge (or the tape drive exits maintenance mode). The

SCD changes to a flashing

8

. The tape drive loads the updated firmware

C

.

from the FMR tape into its erasable programmable read-only memory (EPROM)

area.

v If the update completes successfully, the tape drive rewinds and unloads the

FMR tape, resets itself, and is ready to use the new firmware. The drive

automatically reboots.

v If the update fails, the tape drive posts an error code to the SCD. To

determine the error, locate the code in Table 9 on page 45. The drive then

unloads the FMR tape and exits maintenance mode. Contact Technical

Support for problem determination or machine replacement.

Operating the Drive 17

Page 34

Function Code 3: Create FMR Tape

Function Code

scratch data cartridge.

Attention

For this function, insert only a scratch (blank) data cartridge or a cartridge

that may be overwritten. During the test, the drive overwrites the data on the

cartridge.

Attention: Customers should only attempt this step when requested by IBM

service.

1. Place the drive in maintenance mode. For instructions, see “Entering

Maintenance Mode” on page 15.

2. Press the Unload Button once per second until

cycle past the desired code, press the Unload Button once per second until the

code reappears.)

3. Press and hold the Unload Button for three or more seconds, then release it to

select the function. The SCD changes to a flashing

4. Insert a scratch (blank) data cartridge that is not write protected (or the tape

drive exits maintenance mode). The SCD changes to a flashing

drive copies the FMR data to the scratch data cartridge.

3

copies the drive’s field microcode replacement (FMR) data to a

3

appears in the SCD. (If you

C

.

3

. The tape

Note: If you inserted an invalid or write-protected tape cartridge, error code

7

appears in the SCD. The tape drive unloads the cartridge and exits

maintenance mode.

v If the tape drive creates the FMR tape successfully, it rewinds and unloads

the new tape, exits maintenance mode, and the tape is ready to use.

v If the tape drive fails to create the FMR tape, it displays an error code. To

determine the error, see Table 9 on page 45. The tape drive then unloads the

FMR tape, exits maintenance mode.

Function Code 4: Force a Drive Dump

8

Function Code

also known as saving a microcode trace).

Attention: Customers should only attempt this step when requested by IBM

service.

1. Place the drive in maintenance mode. For instructions, see “Entering

Maintenance Mode” on page 15.

2. Press the Unload Button once per second until

cycle past the desired code, press the Unload Button once per second until the

code reappears.)

performs a dump of data collected by the drive (this process is

8

appears in the SCD. (If you

18 IBM 400/800GB LTO3 Tape Drive User’s Guide

Page 35

3. Press and hold the Unload Button for three or more seconds, then release it to

select the function. The drive performs the dump. The SCD shows

goes blank. To access the contents of the dump, see “Function Code 5: Copy

Drive Dump.”

Note: Yo u can also force a drive dump when the tape drive is in normal

operating mode. Simply press and hold the Unload Button for ten

seconds.

Function Code 5: Copy Drive Dump

Function Code

to the beginning of a scratch (blank) data cartridge.

Attention

For the

cartridge that may be overwritten. During the test, the drive overwrites the

data on the cartridge.

Attention: Customers should only attempt this step when requested by IBM

service.

1. Place the drive in maintenance mode. For instructions, see “Entering

Maintenance Mode” on page 15.

2. Press the Unload Button once per second to cycle through the following

functions:

5

v

5

v

5

v

5

v

5

copies data from a drive dump (captured in Function Code 4)

1

5

-

function, insert only a scratch (blank) data cartridge or a

0

-

: no function

1

-

: copy dump to tape

8

-

: copy dump to flash memory

3

-

: erase flash memory

0

, then

you cycle past the desired code, press the Unload Button once per second

If

until the code reappears.

3. Press and hold the Unload Button for three or more seconds, then release it to

select one of the above functions. The SCD changes to a flashing

4. Insert a scratch (blank) data cartridge that is not write protected (or the tape

drive exits maintenance mode). The SCD flashes the selection number while

performing the function.

Note: If you inserted an invalid or write-protected tape cartridge, error code

v If the copy operation completes successfully, the tape drive rewinds and

unloads the tape, and exits maintenance mode.

C

7

appears in the SCD. The tape drive unloads the cartridge and exits

maintenance mode.

Operating the Drive 19

.

Page 36

v If the copy operation fails, an error code appears in the SCD. To determine

the error, locate the code inTable 9 on page 45. The tape drive unloads the

tape cartridge and exits maintenance mode.

Function Code 6: Run SCSI Wrap Test

Approximate Run Time = 10 seconds per loop

Number of Loops = This test runs until stopped by pressing the Unload Button.

Function Code

connector.

Note: This test requires that the drive be terminated by either the terminator on

the connector or at the end of the bus. Before you select this function,

disconnect the SCSI cable of the drive that is closest to the server. Then,

attach the SCSI wrap plug to that SCSI connector.

Attention: Customers should only attempt this step when requested by IBM

service.

1. Place the drive in maintenance mode. For instructions, see “Entering

Maintenance Mode” on page 15.

2. Press the Unload Button once per second until

cycle past the desired code, press the Unload Button once per second until the

code reappears.)

3. Make sure that the SCSI wrap plug is connected to one of the SCSI connectors

at the rear of the drive.

4. Make sure that the drive is terminated at one of its SCSI connectors or at the

SCSI bus.

5. Press and hold the Unload Button for three or more seconds, then release it to

select the function. The drive automatically starts the test (one loop of which

lasts for less than one second).

v If no error is detected, the test will loop and begin again. To stop the loop,

press the Unload Button for one second and release. When the loop ends,

function code

drive then exits maintenance mode. Disconnect the SCSI wrap plug.

v If an error is detected, the test stops, error code

determine the error, locate

the power off, then on again.

6

performs a check of the SCSI circuitry from and to the SCSI

0

temporarily appears in the Single-character Display. The

8

in Table 9 on page 45. To clear the error, turn

6

appears in the SCD. (If you

8

appears in the SCD. To

Function Code 7: Run RS-422 Wrap Test

This test causes the drive to perform a check of the circuitry from and to the LDI

or RS-422 connector.

Before selecting this function, attach an LDI or RS-422 wrap plug to the drive’s LDI

or RS-422 connector (in place of the LDI or RS-422 cable).

Attention: Customers should only attempt this step when requested by IBM

service.

1. Make sure that no cartridge is in the drive.

20 IBM 400/800GB LTO3 Tape Drive User’s Guide

Page 37

2. Within a 1.5-second interval, press the Unload Button three times. The Status

Light becomes solid amber, which means that the drive is in maintenance

mode.

3. Press the Unload Button once per 1.5 seconds until

Single-character Display (SCD). If you cycle past

7

appears in the

7

, continue to press the

Unload Button until it displays again.

4. To select the function, press and hold the Unload Button for three seconds.

After you select the function,

7

flashes and the drive automatically starts the

test.

v If the test is successful, it loops and begins again. To half the test, press the

Unload Button. The test continues to the end of its loop and then stops. The

drive then displays

v If the test fails,

mode. To resolve the error, locate

0

9

and exits maintenance mode.

displays, the test stops, and the drive exits maintenance

9

in Table 9 on page 45

Function Code 8: Unmake FMR Tape

Function Code

rewrites the cartridge memory on the tape. This converts the cartridge into a valid

scratch (blank) data cartridge.

Attention: Customers should only attempt this step when requested by IBM

service.

1. Place the drive in maintenance mode. For instructions, see “Entering

Maintenance Mode” on page 15.

2. Press the Unload Button once per second until

cycle past the desired code, press the Unload Button once per second until the

code reappears.)

3. Press and hold the Unload Button for three or more seconds, then release it to

select function

4. Insert the FMR data cartridge (or the tape drive exits maintenance mode). The

SCD changes to a flashing

and rewrites the header in the cartridge memory to change the cartridge to a

valid scratch (blank) data cartridge:

v If the operation is successful, the tape drive displays function code

rewinds and unloads the newly converted scratch data cartridge, and exits

maintenance mode.

v If the operation is not successful, an error code displays. To determine the

error, locate the code in Table 9 on page 45. To clear the error, turn the power

off, then on again.

8

erases the field microcode replacement (FMR) data and

8

. The SCD changes to a flashing

8

. The tape drive erases the firmware on the tape

8

appears in the SCD. (If you

C

.

0

,

Operating the Drive 21

Page 38

Function Code 9: Display Error Code Log

Function Code

ordered; the most recent is presented first and the oldest is presented last). If there

are no errors in the log, function code

9

displays the last ten error codes, one at a time (the codes are

0

displays in the Single-character Display

(SCD).

1. Place the drive in maintenance mode. For instructions, see “Entering

Maintenance Mode” on page 15.

2. Press the Unload Button once per second until

cycle past the desired code, press the Unload Button once per second until the

code reappears.)

3. Press and hold the Unload Button for three or more seconds, then release it to

view the most recent error codes.

4. Press the Unload Button again to view successive error codes. Let two to three

seconds pass between each depression.

5. After viewing all error codes, exit this function and maintenance mode by

pressing the Unload Button again.

Function Code A: Clear Error Code Log

Function Code

1. Place the drive in maintenance mode. For instructions, see “Entering

Maintenance Mode” on page 15.

2. Press the Unload Button once per second until

cycle past the desired code, press the Unload Button once per second until the

code reappears.)

3. Press and hold the Unload Button for three or more seconds, then release it to

select the function.

erases all errors from the error code log. The tape drive exits maintenance

mode.

A

erases the contents of the error code log.

A

flashes in the SCD, followed by

9

appears in the SCD. (If you

A

appears in the SCD. (If you

0

. The tape drive

Function Code C: Insert Cartridge into Tape Drive

This function cannot be selected by itself, but is part of other maintenance

functions (such as Run Tape Drive Diagnostics and Create FMR Tape) that require

a tape cartridge to be inserted.

Function Code E: Test Cartridge & Media

Approximate Run Time = 15 minutes per loop

Total Number of Loops = 10

Function Code

its magnetic tape are acceptable.

The diagnostic loops ten times. To stop the diagnostic and exit maintenance mode,

press the Unload Button once to abort the test.

22 IBM 400/800GB LTO3 Tape Drive User’s Guide

E

performs tests that determine whether a suspect cartridge and

Page 39

Attention

When you perform this test, data on the suspect tape will be overwritten.

1. Place the drive in maintenance mode. For instructions, see “Entering

Maintenance Mode” on page 15.

2. Press the Unload Button once per second until

E

appears in the SCD. (If you

cycle past the desired code, press the Unload Button once per second until the

code reappears.)

3. Press and hold the Unload Button for three or more seconds, then release it to

select the function. The SCD changes to a flashing

C

.

4. Ensure that the write-protect switch on the suspect cartridge is off, then insert

the cartridge (or the tape drive exits maintenance mode). The SCD changes to

E

. The tape drive runs the tests.

v If no error is detected, the test will loop and begin again. To stop the loop,

press the Unload Button for one second and release. When the loop ends,

0

temporarily appears in the SCD. The drive rewinds the tape, unloads the

cartridge, and exits maintenance mode.

v If an error is detected the test stops,

code could appear). To determine the error, locate

6

or

7

appears in the SCD (another

6

or

7

in Table 9 on

page 45. The drive unloads the tape cartridge, exits maintenance mode. To

clear the error, turn the power off, then on again.

Function Code F: Fast Read/Write Test

Approximate Run Time = 5 minutes

Total Number of Loops = 10

Function Code

to tape.

The diagnostic loops ten times. To stop the diagnostic and exit maintenance mode,

press the Unload Button once to abort the test.

Attention

For this test, insert only a scratch (blank) data cartridge or a cartridge that

may be overwritten. During the test, the drive overwrites the data on the

cartridge.

1. Place the drive in maintenance mode. For instructions, see “Entering

Maintenance Mode” on page 15.

2. Press the Unload Button once per second until

cycle past the desired code, press the Unload Button once per second until the

code reappears.)

F

performs tests to ensure that the drive can read from and write

F

appears in the SCD. (If you

Operating the Drive 23

Page 40

3. Press and hold the Unload Button for three or more seconds, then release it to

select the function. The SCD changes to a flashing

4. Insert a scratch (blank) data cartridge that is not write-protected (or the tape

drive exits maintenance mode). The SCD changes to a flashing

drive runs the tests.

Note: If you inserted an invalid or write-protected tape cartridge,

in the SCD. The tape drive unloads the cartridge and exits maintenance

mode.

v If no error is detected, the test will loop and begin again. To stop the loop,

press the Unload Button for one second and release. When the loop ends,

temporarily appears in the SCD. The drive rewinds and unloads the tape,

partially ejects the cartridge, then exits maintenance mode. The solid amber

Status Light turns off.

v If an error is detected, the Status Light flashes amber, the tape drive posts an

error code to the SCD. To determine the error, locate the code in Table 9 on

page 45. The tape drive unloads the cartridge and exits maintenance mode.

To clear the error, turn the power off, then on again.

Function Code H: Test Head

Approximate Run Time = 10 minutes

C

.

F

. The tape

7

appears

0

Total Number of Loops = 10

Function Code

H

performs tests to ensure that the tape drive’s head and

tape-carriage mechanics work correctly.

The diagnostic loops ten times. To stop the diagnostic and exit maintenance mode,

press the Unload Button once to abort the test.

Attention

For this test, insert only a scratch (blank) data cartridge or a cartridge that

may be overwritten. During the test, the drive overwrites the data on the

cartridge.

1. Place the drive in maintenance mode. For instructions, see “Entering

Maintenance Mode” on page 15.

2. Press the Unload Button once per second until

H

appears in the SCD. (If you

cycle past the desired code, press the Unload Button once per second until the

code reappears.)

3. Press and hold the Unload Button for three or more seconds, then release it to

select the function. The SCD changes to a flashing

4. Insert a scratch (blank) data cartridge that is not write-protected (or the tape

drive exits maintenance mode). The SCD changes to a flashing

C

.

H

. The tape

drive runs the tests.

24 IBM 400/800GB LTO3 Tape Drive User’s Guide

Page 41

v If no error is detected, the test will loop and begin again. To stop the loop,

press the Unload Button for one second and release. When the loop ends,

temporarily appears in the SCD. The drive rewinds the tape and unloads the

cartridge. The drive then exits maintenance mode.

v If an error is detected the test stops, error code

determine the error, locate

5

in Table 9 on page 45. The drive unloads the

tape cartridge and exits maintenance mode. To clear the error, turn the power

off, then on again.

Function Code L: Load/Unload Test

Approximate Run Time = 3 seconds per loop

Total Number of Loops = 10

Function Code

The diagnostic loops ten times. To stop the diagnostic and exit maintenance mode,

press the Unload Button once to abort the test.

Attention

Even though no data is written during this test, it is recommended that you

use a blank (scratch) cartridge for this test.

L

tests the drive’s ability to load and unload a tape cartridge.

5

appears in the SCD. To

0

1. Place the drive in maintenance mode. For instructions, see “Entering

Maintenance Mode” on page 15.

2. Press the Unload Button once per second until

L

appears in the SCD. (If you

cycle past the desired code, press the Unload Button once per second until the

code reappears.)

3. Press and hold the Unload Button for three or more seconds, then release it to

select the function. The SCD changes to a flashing

4. Insert a scratch (blank) data cartridge that is not write-protected (or the tape

drive exits maintenance mode). The SCD changes to a flashing

C

.

L

. The tape

drive runs the tests.

v If no error is detected, the test will loop and begin again. To stop the loop,

press the Unload Button for one second and release. When the loop ends,

temporarily appears in the SCD. The drive rewinds the tape and unloads the

cartridge. The drive then exits maintenance mode.

v If an error is detected the test stops,

the error, locate

6

in Table 9 on page 45. The drive unloads the tape

6

appears in the SCD. To determine

cartridge and exits maintenance mode. To clear the error, turn the power off,

then on again.

0

Operating the Drive 25

Page 42

Function Code P: Enable Post Error Reporting

When selected, deferred-check conditions are reported to the host. Therefore,

temporary errors are reported in the sense data. This selection is normally used as

a request from support personnel. Default is

U

(disabled).

1. Place the drive in maintenance mode. For instructions, see “Entering

Maintenance Mode” on page 15.

2. Press and hold the Unload Button for three seconds while

SCD. The SCD changes to

P

then exits maintenance mode.

U

appears in the

Function Code U: Disable Post Error Reporting

When selected, turns Post Error reporting off. Deferred-check conditions

(temporary errors) are NOT reported to Host (normal mode of drive operation).

Default is

1. Place the drive in maintenance mode. For instructions, see “Entering

Maintenance Mode” on page 15.

2. Press and hold the Unload Button for three seconds while

SCD. The SCD changes to

U

(disabled).

U

then exits maintenance mode.

P

appears in the

Updating Firmware

Attention:

When updating firmware, do not power-off the drive until the update is

complete, or the firmware may be lost.

Update drive firmware using:

v Using Tapetool (recommended)

v The SCSI interface

v The LDI or RS-422 interface

v A field microcode replacement (FMR) tape cartridge

update the firmware, refer to the following sections.

To

Updating Firmware using Tapetool

Periodically check for updated levels of drive firmware by visiting the web at

http://www-307.ibm.com/pc/support/site.wss/document.do?Indocid=TAPEFILES.

The Tapetool file and instructions for use are included in this URL.

Updating Firmware through the SCSI Interface

When updating drive firmware by using the SCSI interface, the procedure varies,

depending on whether your server uses an IBM tape device driver or a non-IBM

tape device driver (such as a driver from Sun, Hewlett-Packard, or Microsoft®).

26 IBM 400/800GB LTO3 Tape Drive User’s Guide

Page 43

For instructions about updating firmware from a server that uses an IBM tape

device driver, refer to the IBM Ultrium Device Drivers Installation and User’s Guide.

To update firmware from a server that uses a non-IBM tape device driver, refer to

the documentation for that device.

Updating Firmware through the Library/Drive Interface

The drive includes a firmware update feature that allows a tape library to

download firmware to the drive by using the Library/Drive Interface (LDI) while

the drive performs normal host operations on logical unit number (LUN) 0 of the

SCSI Protocol Interface. The update typically takes 63 seconds and a maximum of

140 seconds. The command may be received by the SCSI interface or the LDI

(RS-422) interface.

Note: If a Power-on Reset command is received while a cartridge is loaded in the

drive, the drive will respond with a Check Condition. It will not activate the

new code level until you cycle power, or until a Power-on Reset command is

received and the drive does not contain a cartridge.

ITDT SCSI Firmware Update, Dump Retrieval and Library/Drive

Test Tool

A newly designed tool, ITDT, is a tool with multiple functional capability and is a

very quick, convenient and efficient method for both drive and library firmware

updates. As a note, both drive and library dump retrievals can be performed by

the tool as well. Currently, the tool is very similar to the LTO-TDX drive only

firmware update and drive dump retrieval tool (explained in detail later on in the

Tape Drive Update firmware paragraph in this section).

Below are some of the capabilities of this tool:

1. Firmware update capability via SCSI to all IBM LTO Tape Drive and Tape

Library products.

2. The tool does not require any special device drivers.

3. The tool is available for most major platforms (Windows®, AIX®, SUN,

NetWare).

4. Linux

5. The tool is capable of uploading drive and library dump files.

6. The tool’s primary function is thoroughly testing a drive. However, if the

library is online to the server/host where the tool resides, ITDT will

communicate with the drive through the library to load and unload a test

cartridge thereby exercising some library functions.

7. The tool scans the SCSI bus and will find and display for selection all IBM

LTO devices. The tool will not display and allow for selection any non-IBM

device.

8. Each function has ″Help″ selection which explains the required syntax as well

as a brief explanation of the particular function.

9. A Readme text file will be posted with the .exe file for a thorough explanation

of initial tool download information from the web as well as explanation of

tool capabilities.

10. The tool is currently a ″command line″ tool with a simple entry by keying in

the executable name, itdt, from the directory where the tool is located.

Operating the Drive 27

Page 44