Page 1

3745 Communication Controller Models A

3746 Expansion Unit Model 900

3746 Nways Multiprotocol Controller Model 950

Service Processor

Installation and Maintenance

(Based on 6578)

GY27-0406-01

Page 2

Page 3

3745 Communication Controller Models A

3746 Expansion Unit Model 900

3746 Nways Multiprotocol Controller Model 950

Service Processor

Installation and Maintenance

(Based on 6578)

GY27-0406-01

Page 4

Note

Before using this information and the product it supports, be sure to read the general information under “Notices”

on page xi.

First Edition (October 2001)

This edition applies to the Service Processor based on 6578 Model RAU.

Order publications through your IBM representative or the IBM branch office serving your locality. Publications are not stocked at the

address given below.

A form for readers’ comments appears at the back of this publication. If the form has been removed, address your comments to:

Department CGFA

Design & Information Development

IBM Corporation

PO Box 12195

Research Triangle Park NC 27709

U.S.A.

When you send information to IBM, you grant IBM a nonexclusive right to use or distribute the information in any way it believes

appropriate without incurring any obligation to you.

Copyright International Business Machines Corporation 2001. All rights reserved.

US Government Users Restricted Rights – Use, duplication or disclosure restricted by GSA ADP Schedule Contract with IBM Corp.

Page 5

Contents

Figures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

European Union (EU) Statement ........................... xii

Year 2000 Statement

Electronic Emission Notices .............................. xii

Korean Communications Statement ....................... xiii

New Zealand Radiocommunications (Radio) Regulations

Trademarks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

Service Inspection Procedures ............................ xiv

About This Guide ................................... xv

Who Should Use This Guide

How to Use This Guide ................................ xv

How This Guide Is Organized

Where to Find More Information ........................... xvi

Additional Information on the Web ........................ xvii

Online Documentation from CD-ROM ...................... xvii

Service Personnel Definitions ............................. xvii

................................. xii

........... xiii

............................. xv

............................ xv

Chapter 1. Installing and Setting Up Your Service Processor ....... 1-1

Prerequisite Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Installation Scenarios . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

| Installing Your Service Processor (Based on 6578 Model RAU) ......... 1-7

Service Processor Overview ............................ 1-7

Service Processor Installation Tasks ....................... 1-8

Step 1: Preparing Your Installation ........................ 1-8

Step 2: Installing the System Unit, Display, and Keyboard .......... 1-9

Step 3: Installing the Service Processor Access Unit (8228) ........ 1-18

Step 4: Installing and Connecting the RSF Modem to the Service Processor 1-21

Step 5: Installing and Connecting the 7858 to the Service Processor ... 1-22

7858 Modem Installation ............................. 1-22

Installing the Modem .............................. 1-23

Setting the 7858 Connected to the COM1 Connector (ASYN) ...... 1-25

Saving the Configuration of the 7858 .................... 1-25

Connecting the 7858 .............................. 1-26

Step 6: Installing and Connecting the 7857 to the Service Processor ... 1-27

Telecommunication Cables Part Numbers ................... 1-27

Setting the 7857 Connected to the COM1 Connector (ASYN) ...... 1-31

Saving the Configuration of the 7857 .................... 1-31

Connecting the 7857 to COM1 ........................ 1-31

Step 7: Customizing Your Service Processor ................. 1-33

Completing Your Installation ............................ 1-49

Chapter 2. Service Processor Problem Determination ............ 2-1

MAP: Entry Point for Problem Isolation ..................... 2-1

MAP: Service Processor / Display / Keyboard Problem Isolation ...... 2-7

Chapter 3. Service Processor Troubleshooting ................ 3-1

MAP: Service Processor Troubleshooting .................... 3-1

Copyright IBM Corp. 2001 iii

Page 6

Note about POST error code .......................... 3-1

How to proceed

Beep Symptoms

No Beep Symptoms .............................. 3-17

Display

Keyboard

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

Power Supply

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

20-Pin Main Power Supply Connection ..................... 3-20

Undetermined Problems

Before Replacing a System Board

Devices List

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23

Hard Disk Drive Boot Error ............................. 3-24

When to Use the Low-Level Format Program ................. 3-24

Preparing the Hard Disk Drive for Use ..................... 3-24

Token-Ring Adapter Card LED Status

Token-Ring Table Terms and Definitions ................... 3-26

Additional Service Information

Security Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-27

Passwords . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-27

Vital Product Data ............................... 3-28

Management Information Format (MIF) ................... 3-28

Alert on LAN .................................. 3-29

Hard-Disk Drive Jumper Settings ........................ 3-30

CD-ROM, PD/CD-ROM Drive Jumper Settings ................ 3-31

BIOS Levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-32

Flash (BIOS/VPD) Update Procedure ..................... 3-33

Flash Recovery Boot Block ........................... 3-33

Power Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-34

Automatic Configuration and Power Interface (ACPI) BIOS ....... 3-34

Advanced Power Management ........................ 3-34

Automatic Hardware Power Management features ............ 3-34

Setting Automatic Hardware Power Management Features ....... 3-35

Automatic Power-On Features ........................ 3-35

Network Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-35

Flash Over LAN (Update POST/BIOS Over Network) ............ 3-36

Wake on LAN ................................... 3-36

System Board Memory .............................. 3-37

................................. 3-1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22

....................... 3-22

....................... 3-25

........................... 3-27

Chapter 4. Service Processor Diagnostics and Test Information ..... 4-1

Power-On Self-Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

POST Beep Codes ................................... 4-1

Error Code Format ................................... 4-2

Diagnostics Test Programs .............................. 4-3

IBM PC Enhanced Diagnostics .......................... 4-3

Starting the IBM PC Enhanced Diagnostics Program ............ 4-4

Navigating through the Diagnostic Programs ................. 4-4

Running Diagnostic Tests ............................ 4-4

Test Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

IBM PC Enhanced Memory Diagnostics ....................... 4-5

Alert on LAN Test ................................... 4-5

Asset ID Test ...................................... 4-5

Test Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Hard File Smart Test .................................. 4-6

iv 3745-XXA iv 3746-9X0: 6578 SPIM

Page 7

IBM Fixed Disk Optimized Test ............................ 4-6

Quick and Full Erase - Hard Drive

Asset EEPROM Backup

................................ 4-7

Viewing the Test Log ................................. 4-8

SIMM/DIMM Memory Errors

IBM PC Enhanced Diagnostic Error Codes

.......................... 4-7

............................ 4-8

..................... 4-9

Chapter 5. Service Processor FRUs / Display Exchange

.......... 5-1

Display Removal/Display Install ........................... 5-1

Removing and Installing Service Processor FRU

Battery Exchange

Board Exchange

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

................. 5-2

Processor Exchange . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Hard Disk Drive Exchange ............................. 5-6

CD-ROM Drive Exchange ............................. 5-7

Diskette Drive Exchange

.............................. 5-7

Token-Ring Adapter Card Exchange ....................... 5-8

Other FRUs Exchange

............................... 5-9

After FRU Exchange .................................. 5-9

After Battery or Board Exchange ........................ 5-10

After Token-Ring Adapter Card Exchange ................... 5-10

After Hard Disk Drive Exchange ........................ 5-12

After Other FRU Exchanges ........................... 5-15

Chapter 6. CE Leaving Procedure ........................ 6-1

Appendix A. Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . A-1

General Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Electrical Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Safety Inspection Guide ............................. A-3

Handling Electrostatic Discharge-Sensitive Devices ............. A-4

Grounding Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

Safety Notices (Multilingual Translations) ..................... A-5

| Appendix B. Specifications 6578 . . . . . . . . . . . . . . . . . . . . . . . . B-1

Appendix C. Parameter Worksheets . . . . . . . . . . . . . . . . . . . . . . C-1

Controller Integration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

Controller Names . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

Set Power ON Schedule ............................. C-1

MOSS-E Database Optimization ........................ C-1

NCP Dump Transfer ................................. C-1

Service Processor Integration ............................ C-2

Definition of Service Processor LAN Address ................. C-2

Service Processor LAN Management Definition ................ C-2

Definition of the Service Processor in an SNA/Subarea Network ...... C-2

Definition of Service Processor in an APPN/HPR Network ......... C-2

3746-900 Integration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-2

Definition of 3746-900 LAN Address ...................... C-2

Definition of Service LAN IP Addresses .................... C-2

Network Routing Protocol for Each Processor Type ............... C-3

Password . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-3

DCAF Remote Logon Password ........................ C-3

Disable Incoming Calls (to Service Processor) ................ C-3

Contents v

Page 8

Parameter Definitions for Reporting Alerts to NetView ............. C-3

Network Node Processor Alerts

MOSS-E Alerts: Mainstream Path Definition

APPN/HPR Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-3

SNA/Subarea Network

MOSS-E Alerts: Alternate Path Definition

Generate MOSS-E Alerts ............................ C-4

Performance Management CM/2 Parameters (NPM)

Service Processor Parameters for DCAF using CM/2 .............. C-4

For LAN-Attached Consoles

For SNA-Attached Consoles

For APPN/HPR-Attached Consoles

For IP-Attached Consoles ............................ C-4

For Modem-Attached Consoles ......................... C-4

Parameter Definitions for Point-to-Point Link Definition ............. C-5

Parameter Definitions for RSF

Customer Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-5

Remote Support Facility Authorization

Set Automatic Microcode Download Option .................. C-5

......................... C-3

.................. C-3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . C-4

................... C-4

.............. C-4

........................... C-4

........................... C-4

....................... C-4

........................... C-5

..................... C-5

Appendix D. Supported Connections between the Service Processor and

a Remote Workstation .............................. D-1

Appendix E. Use of the 7855 Buttons: ←, ↑, →, and ↓ ........... E-1

Appendix F. Controller Expansion Component Locations .......... F-1

Appendix G. Service Processor External Cable References ....... G-1

Service Processor and Network Node Processor Cables for the 3746-900 . G-1

Service Processor and Network Node Processor Cables for the 3746-950 . G-2

Service Processor Cables for the 3745 Models 21A, 31A, 41A, 61A, and 17A G-3

Cable from the Service Processor Processor to the 8228 ........... G-4

Interchange Circuit for Standard LAN Cable ................... G-4

Cable from the Service Processor to the External Modem for RSF ...... G-5

Modem Cable (PN 0782985) ........................ G-5

Interchange Circuits for the Cables between the Service Processor and

the Modem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-5

Modem Cable (PN 0782984) ........................ G-6

Interchange Circuits for the Modem Adapter Cable ............ G-6

Cable between the Service Processor and the Display ............. G-7

Interchange Circuits for the Extender Cable between the Service

Processor and the Display ......................... G-7

Cables between the Keyboard, the Mouse and the Service Processor .... G-8

Keyboard Extender Cable .............................. G-8

Mouse Extender Cable ............................... G-8

Appendix H. Service Processor Aids ..................... H-1

Computer Exploded View .............................. H-1

Input/Output Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . H-2

Cover Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . H-2

| Cover Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . H-2

Front Bezel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . H-3

EMC Shield . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . H-3

| Diskette / Hard Drive Removal ......................... H-3

vi 3745-XXA vi 3746-9X0: 6578 SPIM

Page 9

CD-ROM Drive Removal ............................. H-4

Power Supply Removal

System Board Layout

System Board Locations ............................. H-5

System Board Switch Settings

Diskette Write Access Switch (SW1-1)

Clear CMOS Switch (SW1-2) ......................... H-7

Service Processor Configuration / Setup Utility

| Service Processor Configuration Reference Based on 6578-RAU ..... H-8

Appendix I. Service Processor Part Numbers ................. I-1

| Parts Listing

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-2

Appendix J. Bibliography . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . J-1

Customer Documentation for the 3746 Model 950 ................. J-1

Service Documentation for the IBM 3746 Model 950

Customer Documentation for the 3745 (All Models) and 3746 (Model 900) . J-10

| Additional Customer Documentation for the 3745 Models 130, 150, 160, and

| 170

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . J-16

Service Documentation for the IBM 3745 (Models 210, 21A, 310, 31A, 410,

41A, 610, and 61A) and 3746 (Model 900) ................... J-17

Additional Service Documentation for the IBM 3745 Models 130, 150, 160,

170, and 17A .................................... J-22

.............................. H-4

............................... H-5

.......................... H-7

................... H-7

.................. H-8

............... J-6

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . X-1

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . X-3

Contents vii

Page 10

viii 3745-XXA viii 3746-9X0: 6578 SPIM

Page 11

Figures

1-1. Service Processor Environment ...................... 1-7

1-2. Installing Label on the Front Side of the Service Processor ..... 1-10

1-3. Installing Brackets PN 58G5752 ..................... 1-10

1-4. Installing Plate PN 58G5755 ....................... 1-11

1-5. Installing Captive Nuts for the Service Drawer

1-6. Installing the Service Drawer ....................... 1-12

1-7. Installing the Service Processor Unit in the Controller Expansion

(Front Side)

1-8. Installing the Display in the Controller Expansion (Front Side) ... 1-13

1-9. Installing the Keyboard .......................... 1-14

1-10. Cable Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

1-11. Installing the Display and Keyboard on a Table ............ 1-15

1-12. Power Cords Connection

1-13. Power Cord for Power Strip ....................... 1-17

1-14. Use of the 8228 Setup Aid

1-15. Installing the 8228 (Controller Expansion Rear Side) ......... 1-19

1-16. Connecting the 8228 to the Service Processor ............ 1-20

1-17. Connecting the 8228 to the Service Processor Installed in the

Controller Expansion . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20

1-18. 7858 Front Side .............................. 1-22

1-19. 7858 Rear Panel .............................. 1-22

1-20. 7858 Operator Panel Display ....................... 1-23

1-21. 7858 Operator Panel Display ....................... 1-24

| 1-22. Connecting the Service Processor (6578) from COM1 to the 7858 . 1-26

1-23. Installing the 7858 in the Controller Expansion ............ 1-26

1-24. 7857 Front Panel ............................. 1-27

1-25. 7857 Rear Panel .............................. 1-28

1-26. 7857 Operator Panel Display ....................... 1-30

| 1-27. Connecting the Service Processor (6578) from COM1 to the 7857 . 1-31

1-28. Installing the 7857 in the Controller Expansion ............ 1-32

1-29. MOSS-E View Primary Panel ...................... 1-34

1-30. Service Processor Customization .................... 1-35

1-31. Customer Information Customization .................. 1-36

1-32. SP Time and Date Customization .................... 1-36

1-33. Service LAN Addresses .......................... 1-37

1-34. NetView Links . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-38

1-35. NetView Link/Reporting Customization ................. 1-39

1-36. Example of Switched Major Node Definition .............. 1-40

1-37. Example of NCP Generation for an SDLC Link to NetView ..... 1-41

1-38. Example of NCP Generation for a LAN Link to NetView ....... 1-41

1-39. Token-Ring 3270 Session Customization ................ 1-42

1-40. CCM Remote Configuration Panel .................... 1-42

1-41. Example of a Switched Major Node Definition ............. 1-43

1-42. Retain Customization . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-44

1-43. DCAF Links . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-45

1-44. DCAF Customization . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-46

1-45. Point-to-Point Protocol Configuration .................. 1-47

1-46. Java Console Configuration ....................... 1-48

1-47. SP Customization Message ....................... 1-48

1-48. SP Customization In Progress ...................... 1-49

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

......................... 1-16

........................ 1-18

............. 1-11

Copyright IBM Corp. 2001 ix

Page 12

1-49. SP Customization Completed ...................... 1-49

1-50. SP Reboot

2-1. AC Outlet Distribution Box Connections in Controller Rack

2-2. LAN attached to the Service Processor .................. 2-7

3-1. Keyboard Connector Voltages

3-2. Drive Connector Labels

5-1. Screw Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

5-2. Customization Panel

E-1. 7855 Front Panel ............................. E-1

F-1. Controller Expansion Inventory Chart (Front View)

F-2. Controller Expansion Inventory Chart (Rear View)

F-3. Installing Captive Nuts and Brackets for the Display, Drawer, SP and

NNP Based on PC Type 6578

F-4. Installing Captive Nuts for LCBs ...................... F-5

F-5. Installing Captive Nuts for 8229s ..................... F-6

F-6. Installing Captive Nuts and Brackets for MAE

F-7. Installing Brackets (PN 58G5752) for Processor Type 6578 ...... F-8

F-8. Units Installation in the Controller Expansion (SP and NNP Type

6578)

F-9. Units Installation in the Controller Expansion (SP and NNP Type 6578

+ MAE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-9

F-10. Connecting the Units to the ac Outlet Distribution Box ........ F-10

G-1. Service Processor and Network Node Processor Cables for 3746-900 G-1

G-2. Service Processor and Network Node Processor Cables for 3746-950 G-2

G-3. Service Processor Cables for 3745 Models xxA ............ G-3

G-4. LAN Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-4

G-5. Cable between the Service Processor and the Modem (PN 0782985) G-5

G-6. Modem Cables Pin Assignments (PN 0782985) ............ G-5

G-7. Modem Cable Adapter (PN 0782984) .................. G-6

G-8. Modem Cables Pin Assignments (PN 0782984) ............ G-6

G-9. Cables between the Service Processor and the Display ....... G-7

G-10. Extender Cable for Service Processor and Display connection ... G-7

G-11. Cables between the Service Processor and the Display ....... G-8

G-12. Keyboard Extender Cable ........................ G-8

G-13. Mouse Extender Cable .......................... G-8

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-49

...... 2-2

...................... 3-19

.......................... 3-31

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

........... F-2

........... F-3

....................... F-4

.............. F-7

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-9

x 3745-XXA x 3746-9X0: 6578 SPIM

Page 13

Notices

This information was developed for products and services offered in the U.S.A.

IBM may not offer the products, services, or features discussed in this document in

other countries. Consult your local IBM representative for information on the

products and services currently available in your area.

References in this publication to IBM products, programs, or services do not imply

that IBM intends to make these available in all countries in which IBM operates.

Any reference to an IBM product, program, or service is not intended to state or

imply that only IBM’s product, program, or service may be used. Any functionally

equivalent product, program, or service that does not infringe any of IBM’s

intellectual property rights may be used instead of the IBM product, program, or

service. Evaluation and verification of operation in conjunction with other products,

except those expressly designated by IBM, are the user’s responsibility.

IBM may have patents or pending patent applications covering subject matter in

this document. The furnishing of this document does not give you any license to

these patents. You can send license inquiries, in writing, to:

IBM Director of Licensing

IBM Corporation

North Castle Drive

Armonk, NY 10504-1785

U.S.A.

For license inquiries regarding double-byte (DBCS) information, contact the IBM

Intellectual Property Department in your country or send inquiries, in writing, to:

IBM World Trade Asia Corporation

Licensing

2-31 Roppongi 3-chome, Minato-ku

Tokyo 106, Japan

The following paragraph does not apply to the United Kingdom or any other country

where such provisions are inconsistent with local law:

INTERNATIONAL BUSINESS MACHINES CORPORATION PROVIDES THIS

PUBLICATION "AS IS" WITHOUT WARRANTY OF ANY KIND, EITHER EXPRESS

OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES

OF NON-INFRINGEMENT, MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE. Some states do not allow disclaimer of express or

implied warranties in certain transactions, therefore, this statement may not apply to

you.

This information could include technical inaccuracies or typographical errors.

Changes are periodically made to the information herein; these changes will be

incorporated in new editions of the publication. IBM may make improvements

and/or changes in the product(s) and/or the program(s) described in this publication

at any time without notice.

This information is for planning purposes only. The information herein is subject to

change before the products described become available.

Copyright IBM Corp. 2001 xi

Page 14

European Union (EU) Statement

This product is in conformity with the protection requirements of EU Council

Directive 89/336/EEC on the approximation of the laws of the Member States

relating to electromagnetic compatibility. IBM can not accept responsibility for any

failure to satisfy the protection requirements resulting from a non-recommended

modification of the product, including the fitting of non-IBM option cards.

Year 2000 Statement

This product is Year 2000 ready. When used in accordance with its associated

documentation, it is capable of correctly processing, providing, and/or receiving

date data within and between the 20th and 21st centuries, provided all other

products (for example, software, hardware, and firmware) used with the product

properly exchange accurate date data with it.

Electronic Emission Notices

Federal Communications Commission (FCC) Statement

Note: This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to Part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This equipment generates,

uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely to cause

harmful interference, in which case the user will be required to correct the

interference at his own expense.

Properly shielded and grounded cables and connectors must be used in order to

meet FCC emission limits. IBM is not responsible for any radio or television

interference caused by using other than recommended cables and connectors or by

unauthorized changes or modifications to this equipment. Unauthorized changes or

modifications could void the user's authority to operate the equipment.

This device complies with Part 15 of the FCC Rules. Operation is subject to the

following two conditions: (1) this device may not cause harmful interference, and

(2) this device must accept any interference received, including interference that

may cause undesired operation.

Industry Canada Compliance Statement

This Class A digital apparatus complies with Canadian ICES-003.

Avis de conformité aux normes d'Industrie Canada

Cet appareil numérique de la classe A est conform à la norme NMB-003 du

Canada.

Japanese Voluntary Control Council For Interference (VCCI) Statement

This equipment is in the 1st Class category (information equipment to be used in

commercial and/or industrial areas) and conforms to the standards set by the

xii 3745-XXA xii 3746-9X0: 6578 SPIM

Page 15

Voluntary Control Council for Interference by Information Technology Equipment

aimed at preventing radio interference in commercial and industrial areas.

Consequently, when used in a residential area or in an adjacent area thereto, radio

interference may be caused to radios and TV receivers, and so on.

Read the instructions for correct handling.

Power Line Harmonics (JEIDA) Statement

The guidelines of power line harmonics required by JEIDA are satisfied.

Korean Communications Statement

Please note that this device has been certified for business purpose with regard to

electromagnetic interference. If you find this is not suitable for your use, you may

exchange it for one of residential use.

New Zealand Radiocommunications (Radio) Regulations

Attention: This is a Class A product. In a domestic environment this product may

cause radio interference in which case the user may be required to take adequate

measures.

Taiwanese Class A Warning Statement

This is a Class A product. In a domestic environment this product may cause radio

interference in which case the user will be required to take adequate measures.

Notices xiii

Page 16

Trademarks

The following terms are trademarks of International Business Machines Corporation

in the United States, or other countries, or both:

ACF/VTAM

AIX

Alert on LAN

APPN

AS/400

AssetID

AT

DATABASE 2

DB2

Enterprise Systems Connection Architecture

ES/3090

ES/9000

ESCON

Fax Concentrator

HelpCenter

IBM

LPDA

Micro Channel

MVS/ESA

Nways

OS/2

Parallel Sysplex

PowerPC (logo)

RETAIN

S/370

S/390

System/36

VM/ESA

VTAM

Wake on LAN

NetView and Tivoli are trademarks of Tivoli Systems, Inc. in the United States, or

other countries, or both.

Java and all Java-based trademarks and logos are trademarks or registered

trademarks of Sun Microsystems, Inc. in the United States and/or other countries.

Microsoft, Windows, Windows NT, and the Windows logo are trademarks or

registered trademarks of Microsoft Corporation.

Pentium is a registered trademark of Intel Corporation in the U.S. and other

countries.

UNIX is a registered trademark of the Open Group in the United States and other

countries.

Other company, product, and service names may be trademarks or service marks

of others.

Service Inspection Procedures

The Service Inspection Procedures help service personnel check whether the

3745/3746 conforms to IBM safety criteria. They have to be used each time the

3745/3746 safety is suspected. The Service Inspection Procedures section is

located at the beginning of the:

3745 Communication Controller Models 210 to 61A Maintenance Information

Procedures, SY33-2054

3745 Communication Controller Models 130 to 17A Maintenance Information

Procedures, SY33-2070

3746-950 Service Guide, SY33-2108.

3746-900 Service Guide, SY33-2116.

For the Service Processor, see the Service Inspection Procedures in “Safety

Inspection Guide” on page A-3.

xiv 3745-XXA xiv 3746-9X0: 6578 SPIM

Page 17

About This Guide

This guide provides installation and maintenance information for the Service

Processor.

Who Should Use This Guide

The IBM personnel using this guide should be:

Trained to service the Service Processor, IBM 3745 Communication Controller,

3746-900, and 3746-950.

Familiar with the configuration of the 3745 Communication Controller,

3746-900, and 3746-950.

Familiar with the Service Processor service documentation.

How to Use This Guide

This guide provides procedures for installing and maintaining a Service Processor.

To ensure the most efficient installation:

Read the instructions carefully before attempting to do them.

Complete each step before going to the next one.

Go through the chapters sequentially.

How This Guide Is Organized

Chapter 1 Presents the procedures for installing and connecting the Service

Processor, the 8228, and the RSF modem. It also gives

procedures to customize the MOSS-E parameters.

Chapter 2 Introduces to the Service Processor problem determination.

Chapter 3 Provides maintenance analysis procedures (MAPs) and

troubleshooting information for the Service Processor.

Chapter 4 Describes the diagnostics and tests available on the Service

Processor and how to invoke them.

Chapter 5 Describes the procedures for Service Processor FRU exchange.

Chapter 6 Describes the service representative leaving procedure.

| Appendix A Provides safety notices for the Service Processor.

| Appendix B Provides 6578 machine model specifications.

| Appendix C Provides parameter worksheets for the Service Processor.

| Appendix D Provides the supported connections between the Service Processor

| and a remote workstation.

| Appendix E Explains how to use the 7855 modem buttons.

| Appendix F Gives the component locations in the controller expansion

| Appendix G Gives the external cable references.

Copyright IBM Corp. 2001 xv

Page 18

| Appendix H Provides Service Processor aids for FRU location and removal, and

| for configuration and setup.

| Appendix I Provides Service Processor part numbers.

| Appendix J Gives the customer and service documentation bibliography.

Glossary X Gives a list of abbreviations.

Where to Find More Information

For a complete list of the Service Processor, 3745, 3746-900, and 3746-950

customer and service information manuals, see at the end of this manual. In this

SPIM, references are made to the following publications:

3746-950 Installation Guide, SY33-2107

3746-900 Installation Guide, SY33-2114

| 3746-950 IG: 3746-950 Installation Guide, SY33-2107

| 3745/130-17A Installation Guide, SY33-2067

3745 Communication Controller Models 210 to 61A Maintenance Information

Procedures, SY33-2054

3745 Communication Controller Models 130 to 17A Maintenance Information

Procedures, SY33-2070

3746-950 Service Guide, SY33-2108

3746-900 Service Guide, SY33-2116

| Service Processor and Network Node Processor Service User, SY33-2127

3745 Communication Controller Models A and 3746 Models 900 and 950:

Overview, Installation, and Integration, GA27-4234

3745 Communication Controller Models A and 3746 Models 900 and 950:

Serial Line Adapters, GA27-4235

3745 Communication Controller Models A and 3746 Models 900 and 950:

Token Ring and Ethernet, GA27-4236

3745 Communication Controller Models A and 3746 Models 900 and 950:

ESCON Channels, GA27-4237

3745 Communication Controller Models A and 3746 Models 900 and 950:

Physical Planning, GA27-4238

3745 Communication Controller Models A and 3746 Models 900 and 950:

Management Planning, GA27-4239

3745 Communication Controller Models A and 3746 Models 900 and 950:

Multiaccess Enclosure Planning, GA27-4240

3745 Communication Controller Models A and 3746 Models 900 and 950:

Protocol Introductions, GA27-4241

xvi 3745-XXA xvi 3746-9X0: 6578 SPIM

Page 19

Additional Information on the Web

You can access the latest news and information about IBM network products,

customer service and support, and microcode upgrades at:

www.ibm.com/networking

Online Documentation from CD-ROM

| Starting at EC H10000A and EC H10010A (and above), the Service Processor is

| shipped with a CD-ROM that contains the licensed internal code and a copy of the

| 3746 Web site. You will find marketing, product engineering, and other information

about CCP products on this Web page.

To access this page:

1. Insert the CD-ROM into the CD-ROM disk drive of the Service Processor.

2. From the MOSS-E primary menu, click Information

3. Double-click CD-ROM documentation

4. If you want to display the CCP documentation, click Go to Documentation

Note: To see the latest version of the Web site, go to:

w3.lagaude.ibm.com/ccp/3746.htm

Service Personnel Definitions

See one of the following manuals:

3745 Communication Controller Models 210 to 61A Maintenance Information

Procedures, SY33-2054

3745 Communication Controller Models 130 to 17A Maintenance Information

Procedures, SY33-2070

3746-950 Service Guide, SY33-2108

3746-900 Service Guide, SY33-2116

About This Guide xvii

Page 20

xviii 3745-XXA xviii 3746-9X0: 6578 SPIM

Page 21

Chapter 1. Installing and Setting Up Your Service Processor

This chapter describes a number of installation scenarios and the tasks involved in

each scenario, and provides detailed installation steps.

Prerequisite Documentation

Note: The following list gives the references to all the documents that can be used

during the installation, but depending on your installation scenario not all of the

documents will be needed.

Documents used during the installation:

1. 3746-900 IG: 3746-900 Installation Guide, SY33-2114 (see note 1)

2. 3745 IG: 3745/210-61A Installation Guide, SY33-2057 (see note 2)

3. 3746-950 IG: 3746-950 Installation Guide, SY33-2107 (see note 4)

4. 3745/130-17A Installation Guide, SY33-2067 (see note 3)

5. Output from the standalone Controller Configuration and Management.

6. SPIM:

Service Processor Installation and Maintenance (Based on 7585, 3172, and

9585), SY33-2120

Service Processor Installation and Maintenance (Based on 6275),

SY33-2125

Service Processor Installation and Maintenance (Based on 6563),

SY27-0393

| Service Processor Installation and Maintenance (Based on 6578),

| GY27-0406

7. NNPIM:

Network Node Processor Installation and Maintenance (Based on 7585 or

3172), SY33-2112

Network Node Processor Installation and Maintenance (Based on 6275),

SY33-2126

Network Node Processor Installation and Maintenance (Based on 6563),

SY27-0394

| Network Node Processor Installation and Maintenance (Based on 6578),

| GY27-0407

8. Service Processor and Network Node Processor Service User, SY33-2127

9. MES: 3745 MES and Field BMs for model conversion

10. 3745 Bypass Card Plugging Guide, SY33-2097 (on line document see note 1)

11. 7855 Modem Model 10 Guide to Operation, GA33-0160 or 7857 Guide to

Operation, GA13-1839

12. Parameter sheets from the 3745 Communication Controller Models A and 3746

Models 900 and 950: Overview, Installation, and Integration, GA27-4234.

Copyright IBM Corp. 2001 1-1

Page 22

Notes:

This document is used when:

1. Installing a 3746-900.

2. Installing a 3745 Model X1A.

3. Installing a 3745 Model 17A.

4. Installing a 3746-950.

5. Installing the MES 3745 models conversion to models A

6. Installing the MES 3746-900 model conversion to 3746-950

1-2 3745-XXA 1-2 3746-9X0: 6578 SPIM

Page 23

Installation Scenarios

Depending on the machine and the MES received, determine which installation

scenario you are going to perform (from Scenario 1 to Scenario 16). See

Table 1-1 on page 1-4 and Table 1-1 on page 1-4 to see how the installation

tasks can be distributed between two service representatives and define which

document must be used to start the installation and have an overview of the

installation sequence.

Note: See Table 1-2 on page 1-4 for more details about each scenario. If you

are installing a 3745 Model 17A, the statements concerning the installation of an

expansion frame and the procedures "CDF verify" and "locate bypass cards

positions" are not applicable.

Note: You can install the 3746-900 first and then connect the Service Processor

and run all diagnostics. Afterward the 3745 can be modified to model A (if

necessary) and connected to the 3746-900

Chapter 1. Installing and Setting Up Your Service Processor 1-3

Page 24

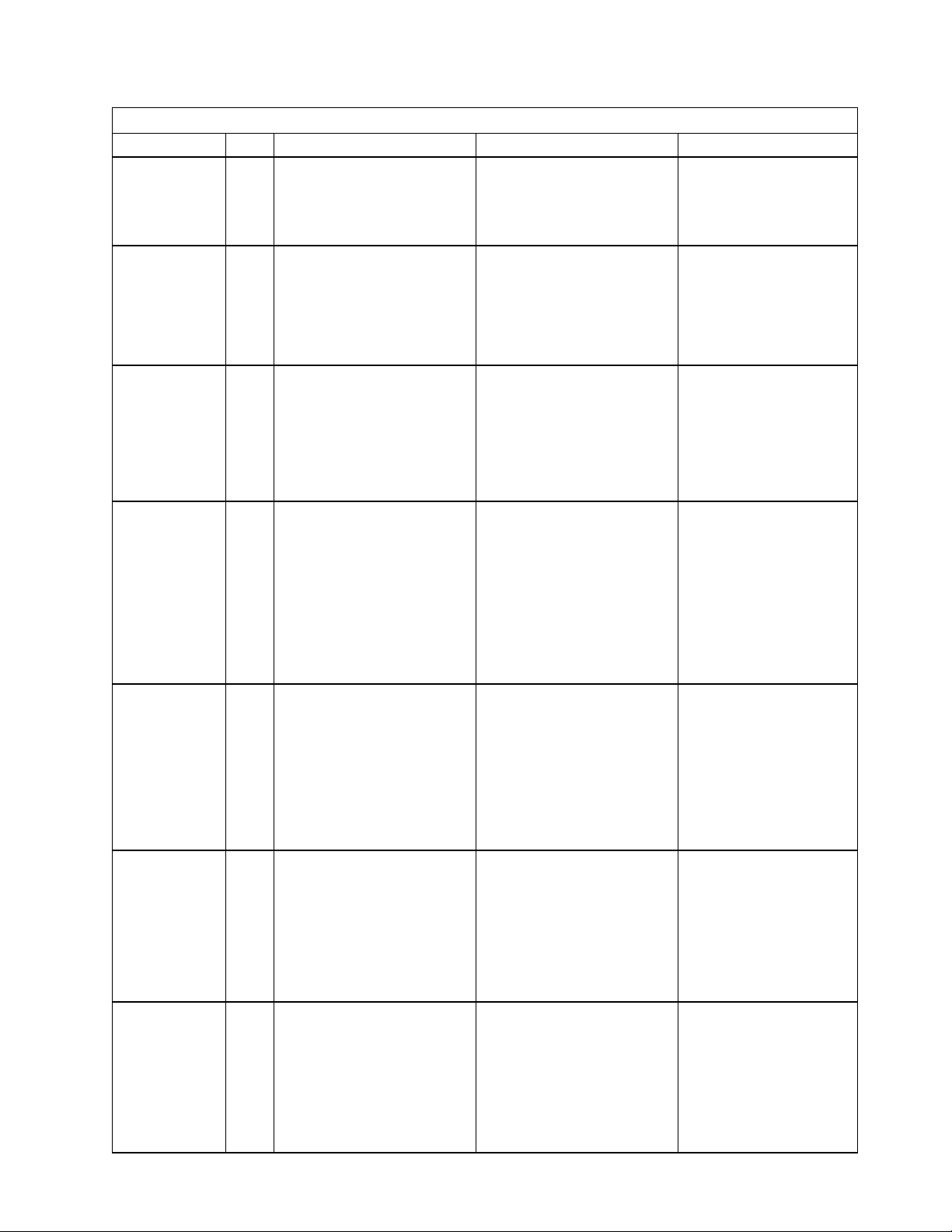

Table 1-1. Installation Scenarios

Machine and/or MES Received Scenario

3745 Model 170 or Model 210 to 610 1

Service Processor 2

3745 MES model conversion and 3746-900 3

3745 MES model conversion and 3746-900 and Service Processor 4

3745 Model 17A or Model 21A to 61A 5

3745 Model 17A or Model 21A to 61A and Service Processor 6

3746-900 7

3746-900 and 3745 MES model conversion 8

3746-900 and 3745 MES and Service Processor 9

3746-900 and 3745 Model 17A or 21A to 61A 10

3746-900 and 3745 Model 17A or 21A to 61A and Service Processor 11

3746-950 and network node processor 12

3746-950, Service Processor, and Network Node Processor 13

3746-900 MES conversion to Model 3746-950 and network node processor 14

3746-900 MES conversion to Model 3746-950, Service Processor and Network Node

15

Processor

3746-900 MES installation of APPN and network node processor 16

Note: The installation sequence given in Table 1-2 can be modified as you are

able to install the 3746-900 first and then connect to the 3745 model A. It is no

more mandatory to start with the 3745 MES (to migrate to model A) or with the

3745 Installation Guide.

Table 1-2 (Page 1 of 3). Installation Scenario Tasks and Documentation

Scenario CE Tasks Documentation Installation Sequence

Scenario 1 1st Install the 3745-XX0 base

frame.

2nd Install expansion frame (if any). 3745 Installation Guide

Scenario 2 1st Install the Service Processor. Service Processor Installation

Scenario 3 1st Install the MES model

conversion.

Scenario 4 1st Install the MES model

conversion.

2nd Install the Service Processor. Service Processor Installation

Scenario 5 1st Install the 3745-XXA base

frame.

2nd Install expansion frame (if any). 3745 Installation Guide

3745 Installation Guide Start with the 3745 IG and

install the 3745-XX0.

Start with the SPIM and

and Maintenance

MES model conversion XX0 to

XXA

MES model conversion XX0 to

XXA

and Maintenance

3745 Installation Guide Start with the 3745 IG and

install the SP..

Start with the MES and

connect the 3745 XXA to

the existing SP.

Start with the MES and

using the SPIM install the

SP.

connect the 3745-XXA to

the existing SP.

1-4 3745-XXA 1-4 3746-9X0: 6578 SPIM

Page 25

Table 1-2 (Page 2 of 3). Installation Scenario Tasks and Documentation

Scenario CE Tasks Documentation Installation Sequence

Scenario 6 1st Install the 3745-XXA base

frame.

2nd Install the Service Processor. Service Processor Installation

Scenario 7 1st Install the 3746-900 (off line). 3746-900 Installation Guide Start with the 3746 IG and

2nd Prepare the 3745-XXA: CDF

verify, Bypass Cards

2

CEs

Connect the 3746-900 to the

3745.

3745 Installation Guide Start with the 3745 IG and

using the SPIM install and

connect the SP..

and Maintenance

install and connect the

3746-900 to the 3745-XXA.

3746-900 Installation Guide

3746-900 Installation Guide

Scenario 8 1st Install the MES model

conversion and prepare the

3745-XXA.

CDF verify - Bypass Cards

2nd Install the 3746-900 (offline. 3746-900 Installation Guide

2

CEs

Scenario 9 1st Install the MES model

2nd Install the Service Processor. Service Processor Installation

Install the 3746-900 (offline). 3746-900 Installation Guide

2

CEs

Scenario 10 1st Install the 3745-XXA base

2nd Install expansion frame (if any)

2

CEs

Connect the 3746-900 to the

3745.

conversion and prepare the

3745-XXA.

CDF verify - Bypass Cards

Connect the 3746-900 to the

3745.

frame.

and the 3746-900.

Connect the 3746-900 to the

3745.

MES model conversion XX0 to

XXA 3746-900 Installation

Guide

3746-900 Installation Guide

MES model conversion XX0 to

XXA 3746-900 Installation

Guide

and Maintenance

3746-900 Installation Guide

3745 Installation Guide Start with the 3745 IG and

3745 Installation Guide

3746-900 Installation Guide

3746-900 Installation Guide

Start with the MES to

convert the 3745 to model

XXA, then using the 3746

IG install and connect the

3746-900.

Start with the 3745 MES

convert the 3745 to XXA

using the SPIM install the

SP, then using the 3746 IG

install and connect the

3746-900.

install the 3745 XXA.

Then, using the 3746 IG,

install the 3746-900. The

machines are connected to

an existing SP.

Scenario 11 1st Install the 3745-XXA base

frame and the Service

Processor.

2nd Install expansion frame (if any)

and the 3746-900.

2

CEs

Scenario 12 1st Install the 3746-950.. 3746-950 Installation Guide Start with the 3746 IG and

2nd Install the Network Node

Chapter 1. Installing and Setting Up Your Service Processor 1-5

Connect the 3746-900 to the

3745.

Processor.

3745 Installation Guide

Service Processor Installation

3745 Installation Guide

3746-900 Installation Guide

3746-900 Installation Guide

Network Node Processor

Installation and Maintenance

Start with the 3745 IG and

install the 3745 XXA. Then,

using the SPIM, install the

SP. Using the 3746 IG,

install the 3746-900.

connect the 3746 950 to

the existing SP. Then

using the network node

processor installation and

maintenance, install the

NNP.

Page 26

Table 1-2 (Page 3 of 3). Installation Scenario Tasks and Documentation

Scenario CE Tasks Documentation Installation Sequence

Scenario 13 1st Install the 3746-950. 3746-950 Installation Guide Start with the 3746 IG to

install the 3746-950, the

SPIM to install the SP, and

the network node

processor installation and

maintenance to install the

NNP.

2nd Install Service Processor. Service processor Installation

and Maintenance

2nd Install the Network Node

Processor.

Scenario 14 1st Install the MES model

conversion from 3746-900 to

3746-950.

Scenario 15 1st Install the MES model

conversion from 3746-900 to

3746-950

2nd Install the Service Processor. Service Processor Installation

2nd Install the Network Node

Processor.

Network Node Processor

Installation and Maintenance

3746-900 to 3746-950 MES

model conversion and the

3746-950 Installation Guide

3746-900 to 3746-950 MES

model conversion, 3746-950 IG

and the

and Maintenance

Network Node Processor

Installation and Maintenance

Start with the MES, then

use the 3746 IG to connect

the 3746-950 to an existing

SP, and the network node

processor installation and

maintenance to install the

NNP.

Start with the MES and the

3746-950 IG then use the

SPIM to install the SP and

the network node

processor installation and

maintenance to install the

NNP.

Scenario 16 1st Install APPN on the 374-900

MES.

2nd Install the Network Node

Processor.

MES APPN on 3746-900 Start with the MES to

install APPN on the

3746-900, then use the

NNPIM to install the

network node processor.

Network Node Processor

Installation and Maintenance

1-6 3745-XXA 1-6 3746-9X0: 6578 SPIM

Page 27

Installing Your Service Processor (Based on 6578 Model RAU)

|

Service Processor Overview

| The Service Processor is based on an IBM 6578 Model RAU, see “Service

| Processor Configuration / Setup Utility” on page H-8 for details of the features

| installed.

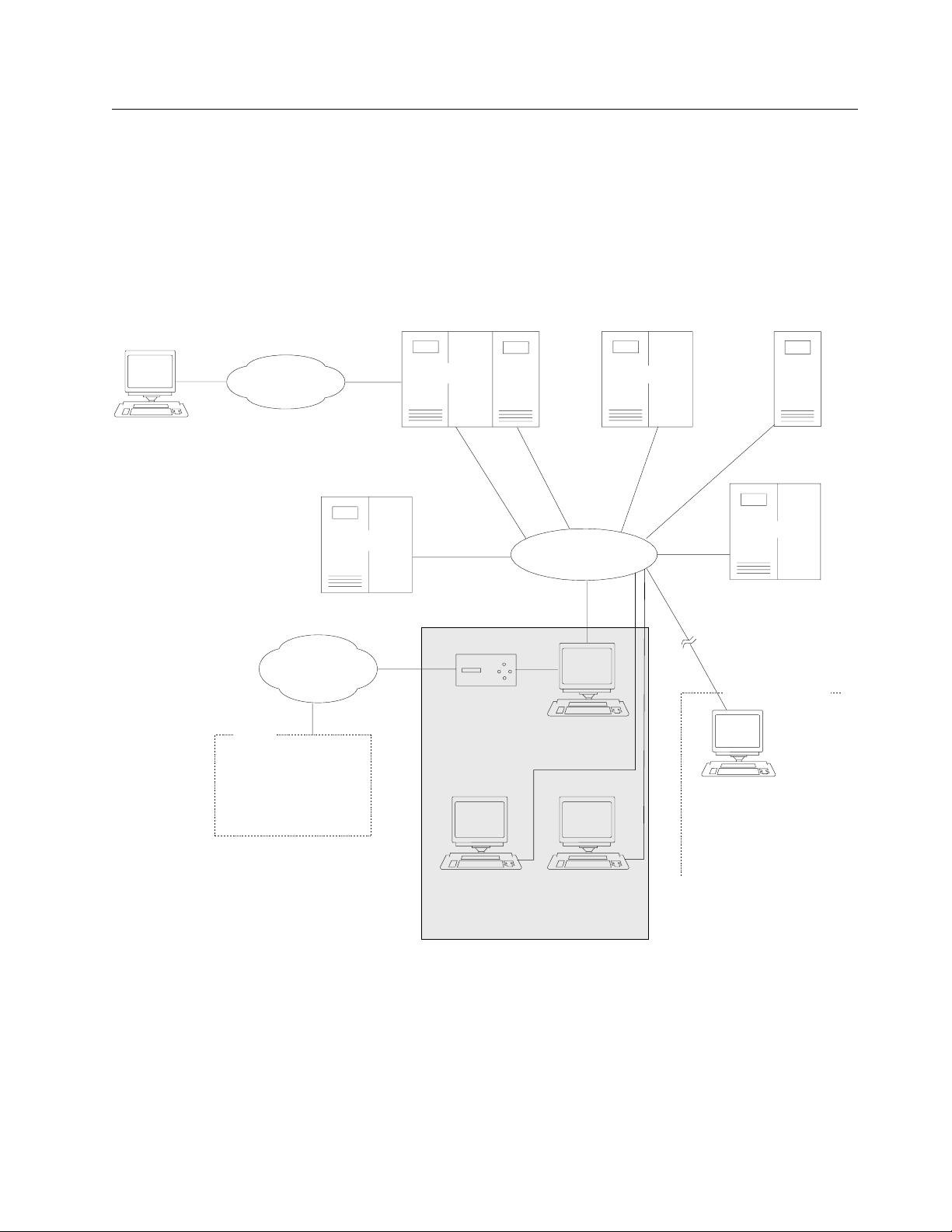

DCAF

Remote

Console

SNA

Network

Public

Switched

Network

IBM

RETAIN HOST

REMOTE SUPPORT

3745

3745 3745

900

Token-Ring

LAN

Modem

3746

MOSS-E

Service

Processor

CPCP

3746

950

3745

Control Room

DCAF

LAN-Attached

Console

Network Node

Processor-B

Network Node

Processor-A

Controller Rack

Figure 1-1. Service Processor Environment

Chapter 1. Installing and Setting Up Your Service Processor 1-7

Page 28

Service Processor Installation Tasks

Note: If you are not familiar with the Service Processor operations, refer to Service Processor and

Network Node Processor Service User, SY33-2127, and then return here.

TASK DESCRIPTION GO TO

1 Installation preparation “Step 1: Preparing Your Installation”.

2 Install the System Unit, Display, and Keyboard “Step 2: Installing the System Unit, Display,

and Keyboard” on page 1-9.

3 Install the 8228 and connect to the Service

Processor

4 Install and connect the RSF modem to the Service

Processor

5 Customize your &SO. according to the customer’s

options

“Step 3: Installing the Service Processor

Access Unit (8228)” on page 1-18.

“Step 4: Installing and Connecting the RSF

Modem to the Service Processor” on

page 1-21 .

“Step 7: Customizing Your Service Processor”

on page 1-33.

Step 1: Preparing Your Installation

Obtain from the customer the following parameter worksheets:

1. "Parameter definitions for RSF"

2. "NetView path parameters"

3. "Service Processor integration"

4. "Service Processor parameters for DCAF"

5. "NCP dump transfer" (not applicable for 3746-950)

These parameter worksheets are part of the 3745 Communication Controller

Models A and 3746 Models 900 and 950: Planning Guide, GA33-0457 Appendix A

and must be filled in by the customer. A copy of these parameter worksheets is

given at the end of this manual see Appendix C, “Parameter Worksheets.”

1-8 3745-XXA 1-8 3746-9X0: 6578 SPIM

Page 29

Step 2: Installing the System Unit, Display, and Keyboard

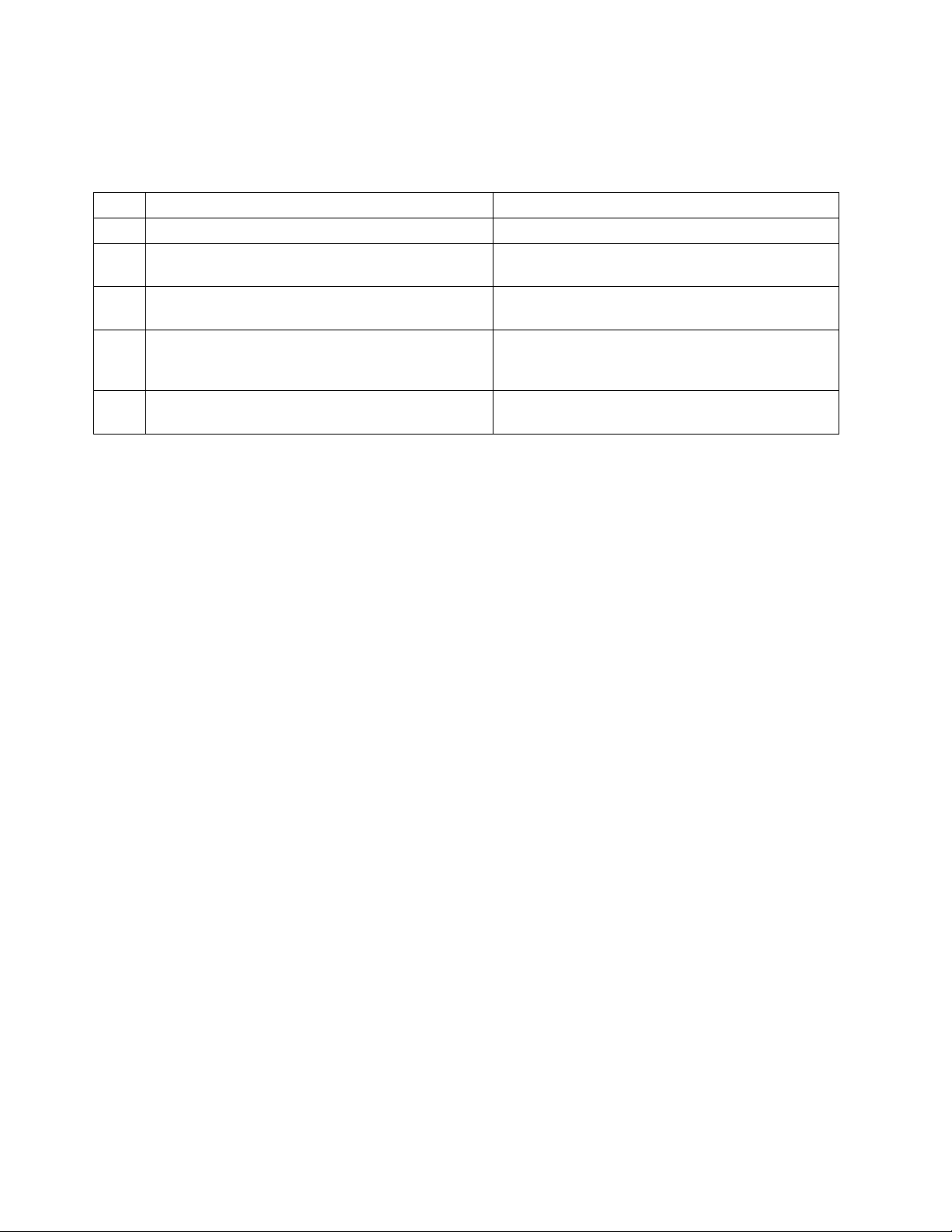

1. Unpack Your Service Processor

You need the following items to complete this installation:

Service Processor and

Power Cord

Keyboard, Mouse,

and Keyboard Cable

Display and

Display Power Cord

Publications and diskettes

2. Check that you have received the following parts:

a. Four brackets (PN 58G5752)

b. Two plates (PN 58G5755)

c. One service drawer assembly (PN 58G5763)

d. One label (PN 0782966)

e. Ten nuts (PN 58G5766)

f. Twelve screws (PN 1621230), eight screws (PN 2665527) and two screws

(PN 1621232)

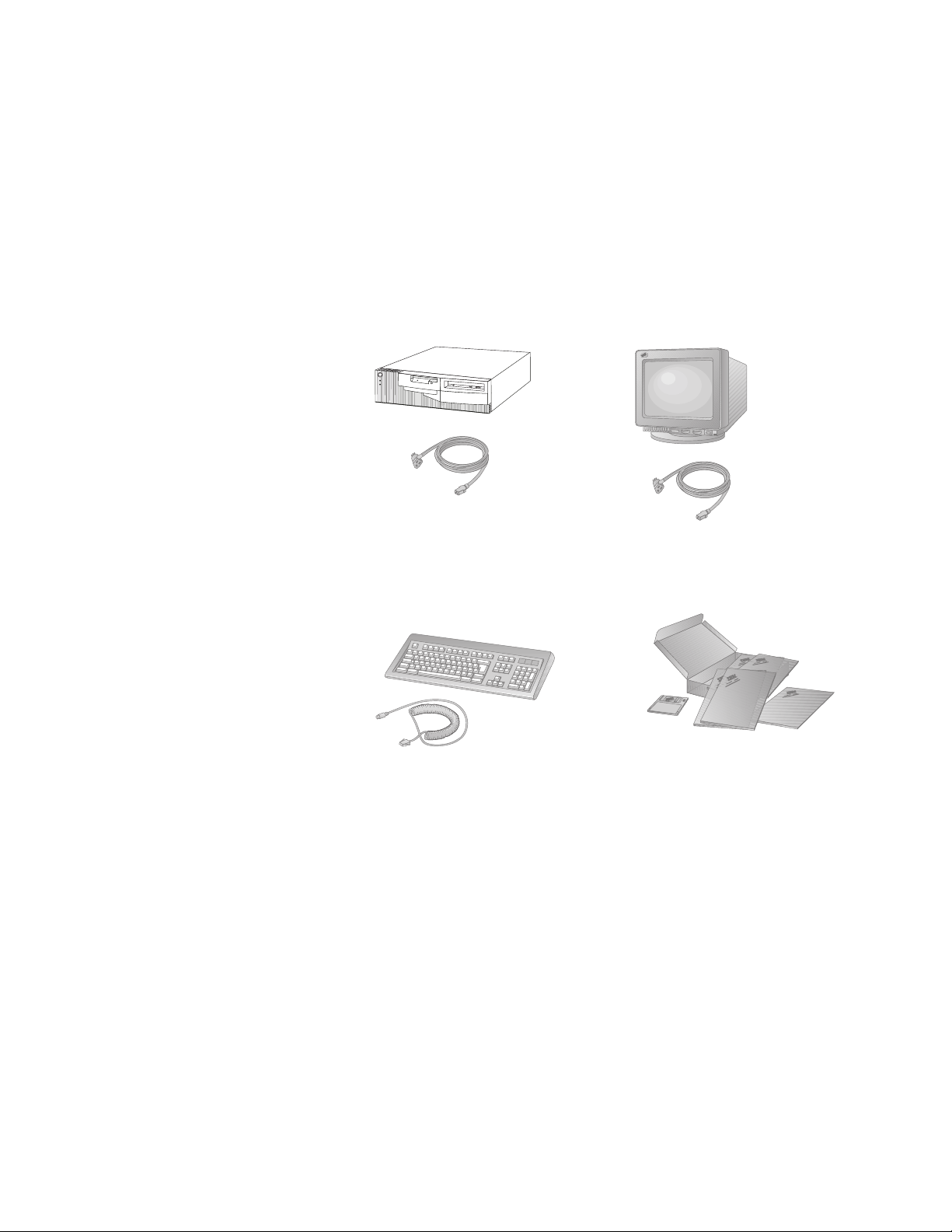

3. Using label (PN 0782966), identify your Service Processor-A or Service

Processor-B by sticking the appropriate label A on the front side of the unit

(see Figure 1-2 on page 1-10).

Chapter 1. Installing and Setting Up Your Service Processor 1-9

Page 30

A

Figure 1-2. Installing Label on the Front Side of the Service Processor

4. If you have a controller expansion, install the Service Processor kit PN

58G5698 (service drawer, brackets, and plates), and go to step 5. Otherwise,

go to step 16 on page 1-14.

5. Open the front and rear doors of the controller expansion. See Figure F-3 on

page F-4 and locate the positions to install the brackets for the display and the

Service Processor. Also, locate the position to install the service drawer.

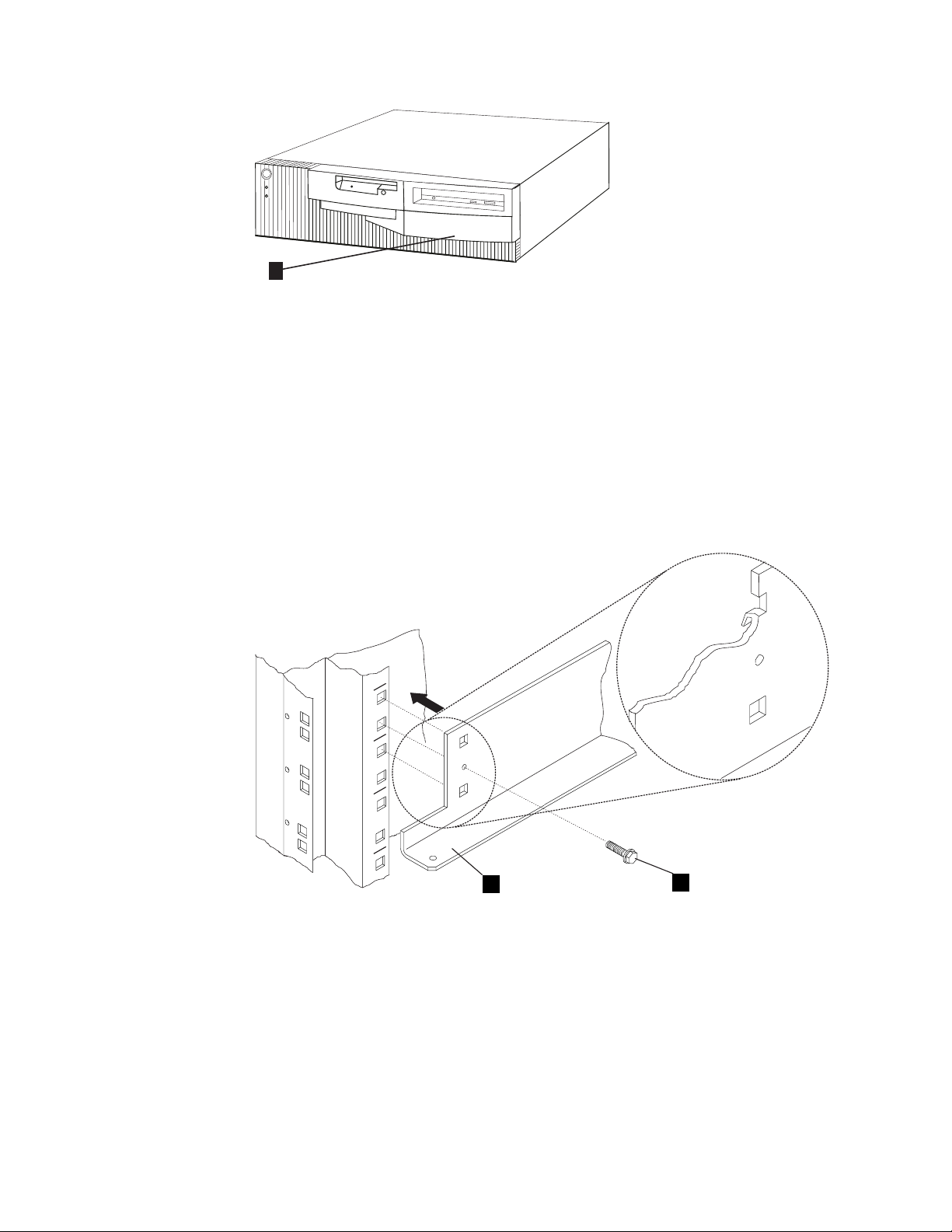

6. For the display and the Service Processor, install four brackets 1 (PN

58G5752) and secure using eight screws 2 (PN 2665527).

X

X

X

X

X

X

1

Figure 1-3. Installing Brackets PN 58G5752

2

7. On the brackets installed for the display and the service processor, install plate

4 (PN 58G5755) using four screws 3 (PN 1621230).

1-10 3745-XXA 1-10 3746-9X0: 6578 SPIM

Page 31

3

4

Figure 1-4. Installing Plate PN 58G5755

8. See Figure 1-5, and if needed, install four captive nuts A (PN 58G5766) on

the front and on the rear side of the controller expansion, to install the service

drawer.

.

Front View

Rear View

23 23

A

22 22

21 21

Drawer

Drawer

20 20

19 19

18 18

Left Side Left SideRight Side Right Side

Figure 1-5. Installing Captive Nuts for the Service Drawer

Chapter 1. Installing and Setting Up Your Service Processor 1-11

Page 32

9. See Figure 1-6, on the rear side of the controller expansion, install bracket A

using two screws C (PN 1621230).

10. On the front side of the controller expansion, slide the drawer B on the

bracket A and secure using two screws C (PN 1621230).

A

B

CC

Rear View Front View

Figure 1-6. Installing the Service Drawer

11. If the Service Processor is installed in the controller expansion, go to step 12.

Otherwise, go to step 16 on page 1-14.

12. Slide the &SO. unit on the brackets as shown in Figure 1-7 on page 1-13.

1-12 3745-XXA 1-12 3746-9X0: 6578 SPIM

Page 33

Figure 1-7. Installing the Service Processor Unit in the Controller Expansion (Front Side)

13. Now you have the choice to install the display and keyboard either in the rack

or on a table. If the display is installed in the rack, go to step 14. Otherwise,

go to step 16 on page 1-14.

14. Slide the display panel on the top of the controller expansion (see Figure 1-8).

Figure 1-8. Installing the Display in the Controller Expansion (Front Side)

| 15. Open the drawer and install the keyboard as shown in Figure 1-9 on

| page 1-14. Then go to step 17 on page 1-14.

Chapter 1. Installing and Setting Up Your Service Processor 1-13

Page 34

Figure 1-9. Installing the Keyboard

16. Obtain a table or a desk large enough to receive the Service Processor, the

display, the keyboard, and the modem, and go to step 17.

| 17. Connect the cables to the 6578 as follows (see Figure 1-10 on page 1-15):

a. Connect the keyboard cable A to the connector at the rear of the Service

Processor.

b. Connect the mouse cable B to the connector at the rear of the Service

Processor.

Note: If you are installing the keyboard and the mouse outside of the

controller expansion, use the keyboard extender cable PN 10K8632 G

and the mouse extender cable PN 10K8633 H (see Figure 1-11 on

page 1-15).

c. Connect the Service Processor power cord C.

d. Connect the token-ring cable D (PN 6339098) to the Service Processor

connector.

e. Connect the display signal cable F to the Service Processor connector.

Note: If you are installing the display outside of the controller expansion,

use the extender cable PN 59G1270 (see Figure 1-11 on page 1-15,

reference J).

f. After you secure all these connections, plug the power cords into

properly grounded electrical outlets.

1-14 3745-XXA 1-14 3746-9X0: 6578 SPIM

Page 35

Figure 1-10. Cable Locations

Note: Cable E is the cable coming from the modem and it will be connected

later, see “Step 4: Installing and Connecting the RSF Modem to the Service

Processor” on page 1-21.

Figure 1-11. Installing the Display and Keyboard on a Table

Chapter 1. Installing and Setting Up Your Service Processor 1-15

Page 36

Go To

If you have installed:

All the units in the controller expansion, go to step 18 on page 1-16

The keyboard and display are installed on a table, go to step 19 on

page 1-16.

All the units on a table, go to step 21 on page 1-17 .

Attention

The ac outlet distribution box is connected to a 220-V power source;

therefore, all the units must be set to support this voltage.

18. Route and connect the power cords (PN 58G5783) from the display and

Service Processor unit to the ac outlet distribution box as shown in

Figure 1-12. Secure these cables using tie clamps along the frame, then go to

step 20.

Figure 1-12. Power Cords Connection

19. Connect the display power cable M to the ac outlet distribution box (see

Figure 1-11 on page 1-15). Secure all the cables using tie clamps along the

frame.

20. If it is not already plugged, connect the main power cord P coming from the

ac outlet distribution box to the customer receptacle (see Figure 1-13 on

page 1-17).

1-16 3745-XXA 1-16 3746-9X0: 6578 SPIM

Page 37

P

Figure 1-13. Power Cord for Power Strip

21. If the customer ordered a backup Service Processor, resume step 1 on

page 1-9 to step 16 on page 1-14 to install this machine near the active

Service Processor. Install the system unit, display, and keyboard, but never

connect this machine to the LAN. This Service Processor is used to replace

the active Service Processor if it fails.

Chapter 1. Installing and Setting Up Your Service Processor 1-17

Page 38

Step 3: Installing the Service Processor Access Unit (8228)

1. Unpack the 8228, and then reset the 8228 ports as explained in the following

steps:

Note: Use the IBM 8228 Setup Aid after you have installed the 8228 and

before you connect any cables to it. Save one Setup Aid to be used later if

you relocate an 8228.

2. Before you begin, make sure no cables are connected to the 8228. If a cable

bracket has been installed on the 8228, remove it.

3. Insert the aid into receptacle 1 of the 8228. The yellow stripe should be

aligned with the edge of the receptacle to ensure that the aid is firmly seated.

Yellow

Indicator

Lamp

4

1 2

3

Figure 1-14. Use of the 8228 Setup Aid

The light will glow brightly when the aid is initially inserted and will gradually

dim when the aid is firmly seated in the receptacle.

If the light does not glow brightly when you insert the Setup Aid, remove the

screw from the aid and replace the battery. If the light still does not glow

brightly after you have replaced the battery, try another Setup Aid.

4. Leave the aid in the receptacle for 4 seconds after the light has gone out.

Remove the aid from the receptacle and insert it into the next receptacle. The

yellow stripe should be aligned with the edge of the receptacle to ensure that

the aid is firmly seated.

Go to the next receptacle and repeat this step until you have set each

receptacle, 1 through 8.

5. When you have set receptacle 8, insert the aid into the RI receptacle for 4

seconds.

The light should glow brightly while the aid is in the receptacle. If the light does

not come on or goes out while the aid is connected to the receptacle, the 8228

must be replaced. Notify your network planner or supervisor.

Note: The 8228 Setup Aid is to be used only in setting up the 8228 either

initially or after relocating the 8228. It should never be used when the network

is operating.

1-18 3745-XXA 1-18 3746-9X0: 6578 SPIM

Page 39

6. Install the 8228 in a safe place near the Service Processor. If you received a

controller expansion, the 8228 is installed on the rear side of the controller

expansion using two screws (PN 1621232) and two captive nuts (PN 58G5766)

see Figure 1-15 on page 1-19. Using label A (PN 0782966), identify the

8228 as Service Processor Access Unit.

A

Figure 1-15. Installing the 8228 (Controller Expansion Rear Side)

7. Connect the 8228 to the Service Processor as follows:

Note: If you have a controller expansion, see Figure 1-17 on page 1-20, if

not, see Figure 1-16 on page 1-20.

a. Plug connector 1 of cable A to the Service Processor.

b. Using a sticker, identify the connector 2 as the "Service Processor cable."

c. Plug connector 2 to any plug of the 8228 from 1 to 8.

Chapter 1. Installing and Setting Up Your Service Processor 1-19

Page 40

Figure 1-16. Connecting the 8228 to the Service Processor

Figure 1-17. Connecting the 8228 to the Service Processor Installed in the Controller Expansion

Go to “Step 4: Installing and Connecting the RSF Modem to the Service

Processor” on page 1-21

1-20 3745-XXA 1-20 3746-9X0: 6578 SPIM

Page 41

Step 4: Installing and Connecting the RSF Modem to the Service

Processor

See Appendix D, “Supported Connections between the Service Processor and a

Remote Workstation” to see if the connection between your Service Processor

modem and remote workstation modem is supported.

Go To

If you are installing:

A 7858, go to “Step 5: Installing and Connecting the 7858 to the Service

Processor” on page 1-22.

A 7857, go to “Step 6: Installing and Connecting the 7857 to the Service

Processor” on page 1-27.

Note: For the other types of RSF Modems, use the installation instructions

shipped with the modem (set the modem speed to 9600 bps).

Chapter 1. Installing and Setting Up Your Service Processor 1-21

Page 42

Step 5: Installing and Connecting the 7858 to the Service Processor

Notes:

1. If you are not familiar with the 7858, refer to the 7858 Professional Modem

Guide to Operation, GA13-1981.

2. Power requirements:

Low-voltage range: 90 to 137 V ac.

High-voltage range: 180 to 265 V ac.

3. The document Power Supply and Telecommunication Connections for IBM

Modems GA33-0054, contains useful information about the different

telecommunication connectors and power supply plugs.

4. Read the IBM Telecommunication Products Safety Handbook, SD21-0030.

Figure 1-18. 7858 Front Side

Figure 1-19. 7858 Rear Panel

7858 Modem Installation

This chapter describes how the modem can be easily installed and how to

configure it in order to have it immediately operational.

Besides the modem and this manual, the carton should contain:

The power attachment cord.

Two telecommunication cables:

– Black cable for the switched line, with label SW, which fits into the PSTN

socket in the modem rear panel.

– Gray cable for the leased line, with label LL, which fits into the LL socket in

the modem rear panel.

The IBM Telecommunication Products Safety Handbook.

1-22 3745-XXA 1-22 3746-9X0: 6578 SPIM

Page 43

If any of these items is missing or damaged, contact the place of purchase for

instructions on how to exchange your modem or obtain the missing items.

Installing the Modem

Attention

In order to avoid damages to the unit, before starting the installation, verify the

modem input ac voltage setting against the power voltage source available at

your wall socket.

If needed, the selector switch can easily be moved to the correct position, using

a screwdriver or a pen:

Switch set to 115 V for low-voltage range: 90 - 137 V ac.

Switch set to 230 V for high-voltage range: 180 - 265 V ac.

Step 1. Be sure that the power switch located on the modem rear panel is off

(switch in position "O")

Step 2. If you are going to use a switched line telecommunication cable, plug it

into the PSTN socket located on the modem rear panel. If this modem is

not being installed in the United Kingdom, connect the other end of the

cable to the telecommunication line.

Step 3. If you plan to use a leased line telecommunication cable, plug it into the

LL socket located on the modem rear panel. If this modem is not being

installed in the United Kingdom, connect the other end of the cable to the

telecommunication line.

Step 4. Connect the power attachment cord to the ac power socket located on

the modem rear panel and the power plug to a standard 3-pin grounded

ac outlet. If this modem is being install the United Kingdom, connect the

telecommunication cables you have attached to the modem, to the

telecommunication lines.

Step 5. Observe the modem power-on sequence.

This is the normal power-on sequence:

PWR light is turned on.

SELFTEST RUNNING message is displayed for about 15 seconds.

Set the modem power switch to ON (switch in position "I").

If the PWR light is not on and the voltage selector switch is correctly set

and you are sure the power voltage is present at the wall socket, the

modem is defective and should be replaced.

If the message SELFTEST RUNNING is not appearing on the operator panel

within 10 seconds, the modem is defective and should be replaced. This

message remains on the display for about 15 seconds, then it is changed

by the power-on sequence.

If the modem is set to the factory defaults, the operator panel shows:

AT CMD ec aa

td_ rd_ dsr_ II_

Figure 1-20. 7858 Operator Panel Display

Chapter 1. Installing and Setting Up Your Service Processor 1-23

Page 44

This operational message shows that the modem is set in AT command

mode for switched-line operation with error control enabled and will

auto-answer an incoming call.

In the next steps, you are instructed to manipulate the front panel buttons

of the modem. Unless the step suggests otherwise, do not press them in

for longer than 1 second.

The next step reset the modem options to the factory default

configuration 0. Jump ahead to step 7 if the modem has never been

used.

Step 6. Set the modem power switch to OFF, then hold the ↑ key pressed and

set the power switch to ON. When the message SELFTEST RUNNING is

shown, release the ↑ key.

After about 15 seconds the message is changed to:

AT CMD ec aa

td_ rd_ dsr_ II_

Figure 1-21. 7858 Operator Panel Display

If this sequence does not occur, the modem is defective and should be

replaced.

Step 7. The next steps can only be done if you have attached the modem to the

public switched network. Go to step 11 if you do not want to test the

modem’s public switched network interface.

Step 8. On the modem operator panel:

a. Press the ↑ until the DTR (C108) message is displayed on the top

row.

b. Press the → key until the Forced On message is displayed on the

bottom row.

c. Press Enter twice to select the option and to return to the modem

operational mode message.

Step 9. Dial the modem phone number from another telephone. You should hear

the ringing tones and then the 2100-Hz answer tone from the called

modem in the handset of the dialing telephone. If you hear the answer

tone, go to step 11. Otherwise, continue with step 10.

Step 10. If you do not hear the modem answer tone, verify that the telephone line

is operating properly. In most countries, you can do this by replacing the

modem with a handset and then attempting a second time to dial the

modem phone number from another telephone to verify that the handset

rings properly.

Connect again the modem to the public switched network and try dialing

the modem phone number again. Observe the front panel OH light. This

light turns off when the modem answers. If this attempt to call the modem

fails, the modem is defective and should be replaced.

Step 11. Set the modem power switch to OFF.

Note: The following steps assume that your DTE is already installed

and operational.

1-24 3745-XXA 1-24 3746-9X0: 6578 SPIM

Page 45

Step 12. Connect the 25-pin V.24 cable from the DTE to the 25-pin connector on

the modem rear panel. Fasten the connector retaining screws.

Step 13. Set the modem power switch to ON. Wait until the modem operational

message is displayed on the operator panel (about 15 seconds).

If the modem is connected to an asynchronous DTE that can send AT

commands to the modem, you can use the DTE to configure the modem

to match your communication system requirements. Otherwise, the

modem can be configured through the operator panel, see “Setting the

7858 Connected to the COM1 Connector (ASYN)”

Note: Ten factory-redefined modem configurations are available. You

could retrieve the factory configuration that better matches your system

requirements, make any further configuration adjustment you should

require, and save your modem configuration in one of the ten user

configuration slots.

Step 14. Now the modem is ready for operation. You can try it with your system. If

you observe a basic system problem, such as the DTE not being able to

send commands to the modem successfully, verify again that your

individual modem configuration parameters are matching your system

requirements.

If you have a problem because the dialing tone is not provided by

your PBX or exchange set the modem as follow:

Power OFF the modem.

Power ON the modem while you are pushing Enter at the same time.

Release Enter key when the message DATAPUMP TEST is displayed.

After this, the modem performs the dial through the switchboard without

looking for dial tone (Blind dial ATX1). This setting is maintained even if

the modem is powered OFF and ON again.

Step 15. If you have a problem while using the modem, refer to the "Problem

Determination" chapter in the 7858 Professional Modem Guide to

Operation, GA13-1981.

Setting the 7858 Connected to the COM1 Connector (ASYN)

1. Power OFF the modem.

2. Press and hold the ↑ key while you power ON the modem.

3. The modem is set to Factory 0 in AT command mode.

Saving the Configuration of the 7858

If you want to save the configuration just defined, in order to have it loaded again at

the next modem reset, perform the following steps:

1. Press the ↓ key until the CONFIGURATIONS message

displayed the top row.

2. Press the → key until the Store User Conf.

message is displayed in the bottom row.

3. Press Enter to select the option.

Chapter 1. Installing and Setting Up Your Service Processor 1-25

Page 46

4. Pressing the ↑ key, select the User Configuration Location where the current

modem configuration must be saved (0 to 9).

5. Press Enter to save the current modem configuration.

6. The defined configuration is now active and saved.

Every time the modem is reset (powered on), the last user configuration that was

saved is loaded as the current modem configuration.

Connecting the 7858

1. Plug the cable (PN 782984) into slot 1 of the Service Processor.

2. On the modem’s rear panel, plug the other cable lead into the 25-pin connector

2.

| Figure 1-22. Connecting the Service Processor (6578) from COM1 to the 7858

If you received a controller expansion, go to step 3 , otherwise, go to “Step 7:

Customizing Your Service Processor” on page 1-33.

3. Slide the 7858 in the controller expansion as shown in Figure 1-23.

Figure 1-23. Installing the 7858 in the Controller Expansion

Go to “Step 7: Customizing Your Service Processor” on page 1-33 .

1-26 3745-XXA 1-26 3746-9X0: 6578 SPIM

Page 47

Step 6: Installing and Connecting the 7857 to the Service Processor

Notes:

1. If you are not familiar with the 7857, refer to the 7857 Guide to Operation,

GA13-1839.

2. Power and frequency requirements: 90 to 259 V ac, and 49.5 to 60.5 Hz (no

adjustment).

3. The document Power Supply and Telecommunication Connections for IBM

Modems GA33-0054, contains useful information about the different

telecommunication connectors and power supply plugs.

4. Read the IBM Telecommunication Products Safety Handbook, SD21-0030

Figure 1-24. 7857 Front Panel

Besides the modem and this manual, the carton should contain:

Telecommunication cables as needed for your country:

– Black cable:

- Switched line cable, with label SW, which fits into the PSTN socket in

the modem rear panel.

– Gray cables:

- 2-wire leased line cable, with label LL 2W, which fits into the LL socket

in the modem rear panel.

- 4-wire leased line cable, with label LL 4W, which fits into the LL socket

in the modem rear panel.

DTE interface / 4-wire leased line wrap plugs.

Telecommunication Products Safety Handbook.

If any of these items is missing or damaged, contact the place of purchase for

instructions on how to exchange your modem or obtain the missing items.

The user is recommended to use the telecommunication cables supplied with the

modem (see “Telecommunication Cables Part Numbers”).

Telecommunication Cables Part Numbers

Table 1-3. Telecom. cables Table 1-3. Telecom. cables Table 1-3. Telecom. cables

Country PN Country PN Country PN

Albania 89G2554 Argentina 89G2554 Australia 89G2564

Chapter 1. Installing and Setting Up Your Service Processor 1-27

Page 48

Table 1-3. Telecom. cables Table 1-3. Telecom. cables Table 1-3. Telecom. cables

Country PN Country PN Country PN

Austria 89G2544 Germany 89G2549 Paraguay 89G2554

Belgium 89G2545 Greece 89G2554 Peru 89G2554

Bolivia 89G2554 Guatemala 89G2554 Poland 89G2554

Brazil 89G2554 Honduras 89G2554 Portugal 89G2554

Bulgaria 89G2554 Hong Kong 89G2565 Romania 89G2554

Canada 89G2562 Hungary 89G2554 Russia 89G2554

China 89G2554 Iceland 89G3145 Saudi Arabia 89G2554

Colombia 89G2554 Ireland 89G2554 Slovakia 89G2554

Costa Rica 89G2554 Israel 89G3131 Slovenia 89G2554

Croatia 89G2554 Italy 89G2551 South Africa 89G3135

Cyprus 89G2577 Japan 89G2562 Spain 89G2554

Czech Republic 89G2554 Korea 89G2554 Sweden 89G2555

Denmark 89G2546 Kuwait 89G2554 Switzerland 89G2556

Egypt 89G2554 Luxembourg 89G3134 Taiwan 89G2554

El Salvador 89G2554 Macedonia 89G2554 Thailand 89G2554

Ecuador 89G2554 Mexico 89G2554 Turkey 89G2554

Finland 89G2547 Netherlands 89G2552 U.K. 89G2577

France 89G2548 New Zealand 89G2577 Ukraine 89G2554

Norway 89G2553 Uruguay 89G2554

Pakistan 89G2554 U.S. 89G2562

Panama 89G2554 Venezuela 89G2554

Installation procedure: Figure 1-25 shows the modem rear panel with the

connectors where the DTE and line cables must be connected:

Figure 1-25. 7857 Rear Panel

Step 1. Be sure that the power switch located on the modem rear panel is off.

Step 2. If you are going to use a switched line telecommunication cable, plug it

into the PSTN socket located on the modem rear panel, with the ferrite

cylinder at the modem side. If this modem is not being installed in the

United Kingdom, connect the other end of the cable to the