Page 1

IBM TotalStorage 358 1 Tape Autoloader

Models L28/L38/L3H and F28/F38/F3H

Setup, Operato r, and Service Guid e

GA32-0470-01

Page 2

Page 3

IBM TotalStorage 358 1 Tape Autoloader

Models L28/L38/L3H and F28/F38/F3H

Setup, Operato r, and Service Guid e

GA32-0470-01

Page 4

Note!

Before using this information and the product it supports, read the information in “Safety and Environmental Notices” on

page xv and “Notices” on page 293.

To ensure that you have the latest publications, visit the web at http://www.ibm.com/storage/support/lto, select your

product, and click ″Documentation″.

Second Edition (March 2005)

This edition applies to the IBM TotalStorage Ultrium Tape Autoloader 3581 Models L28/L38/L3H and F28/F38/F3H Setup,

|

Operator, and Service Guide and to all subsequent releases and modifications until otherwise indicated in new

|

editions.

|

The IBM« TotalStorage Ultrium Tape Autoloader 3581 Models L28/L38/L3H and F28/F38/F3H offer a 3-year

|

parts-only warranty and are supported by the Customer Replaceable Unit (CRU) process. For details about the CRU

|

process and customer responsibilities, see the warranty that is included in the back of this document.

|

© Copyright International Business Machines Corporation 2004, 2005. All rights reserved.

US Government Users Restricted Rights – Use, duplication or disclosure restricted by GSA ADP Schedule Contract

with IBM Corp.

Page 5

Read This First

Accessing Online Technical Support

For online Technical Support for your Autoloader, visit:

http://www.ibm.com/storage/support/lto

Summary of Changes

|

|

|

|

Second Edition (March 2005)

|

|

|

|

|

|

|

|

This section summarizes changes to this publication. A vertical line in the left

margin indicates each change.

v Clarified the steps for determining the proper rack holes to use when installing

the autoloader in a rack.

v Modified the Operator Guide section by updating procedures, menus, and

artwork, as necessary, to reflect changes in the microcode.

v Changed the sequence of steps in the Configuration section in an effort to

streamline the configuration procedure.

v Expanded and restructured the Troubleshooting section.

v Added new service procedures to the Appendices.

Registering for My Support

|

|

|

My Support registration provides email notification when new firmware levels

have been updated and are available for download and installation. To register for

My Support, visit the web at http://www.ibm.com/support/mySupport.

Sending IBM Your Feedback

Your feedback is important in helping IBM

information. If you have comments or suggestions for improving this publication,

send your comments by:

v E-mailing IBM:

– Internet or IBMLink

– IBMLink from Canada: STARPUBS at TORIBM

®

provide accurate and useful

™

from US: starpubs@us.ibm.com

Include

the following information in your e-mail:

– Exact publication title

– Form number (for example, GA32–1234–02) or part number (located on the

back cover of the publication)

– Page numbers to which you are referring

Using the Readers’ Comments form at the back of this publication

v

v Mailing your comments to:

International

Business Machines Corporation

Information Development

Department GZW

9000 South Rita Road

Tucson, AZ 85744-0001 USA

© Copyright IBM Corp. 2004, 2005 iii

Page 6

iv IBM 3581 Autoloader Models L28/L38/L3H and F28/F38/F3H Setup, Operator, and Service Guide

Page 7

Contents

Read This First . . . . . . . . . . . iii

Accessing Online Technical Support . . . . . . iii

Summary of Changes . . . . . . . . . . . iii

||

Second Edition (March 2005) . . . . . . . . iii

||

Registering for My Support . . . . . . . . . iii

Sending IBM Your Feedback . . . . . . . . . iii

Figures . . . . . . . . . . . . . . .ix

Tables . . . . . . . . . . . . . . . xiii

Safety and Environmental Notices . . .xv

Danger Notice . . . . . . . . . . . . .xv

Caution Notice . . . . . . . . . . . . .xv

Laser Safety and Compliance . . . . . . . . xvi

Class I Laser Product . . . . . . . . . . xvi

Intended Use . . . . . . . . . . . . . xvi

Safeguards . . . . . . . . . . . . . . xvi

Precautions . . . . . . . . . . . . . . xvii

Safety Inspection Procedure . . . . . . . . xvii

3581 Library ac Grounding Inspection . . . . . xvii

||

End of Life (EOL) Plan . . . . . . . . . . xviii

About This Guide . . . . . . . . . . xix

| |

Related Publications . . . . . . . . . . . xix

3581 Autoloader Publications . . . . . . . xix

||

Redbooks . . . . . . . . . . . . . . xix

||

Device Driver Publications . . . . . . . .xx

||

Safety Publications . . . . . . . . . . .xx

||

SCSI Publications . . . . . . . . . . .xx

||

|

Online Support . . . . . . . . . . . . .xx

||

| |

Autoloader Firmware . . . . . . . . . .xx

||

IBM Online Support . . . . . . . . . .xx

||

IBM Publications Center . . . . . . . . .xx

||

| |

IBM Redbooks . . . . . . . . . . . .xx

||

| |

Device Drivers . . . . . . . . . . . .xx

||

| |

Media and Supplies . . . . . . . . . . xxi

||

Part 1. Setup Guide . . . . . . . . .1

Product Description . . . . . . . . .3

Product Features . . . . . . . . . . . . .4

Standard Features . . . . . . . . . . .4

| |

Optional Features . . . . . . . . . . . .6

| |

Component Descriptions . . . . . . . . . .7

Front Panel Components . . . . . . . . .7

Interior Components . . . . . . . . . . .8

Rear Panel Components . . . . . . . . .10

Media . . . . . . . . . . . . . . . .11

Tape Drive Performance . . . . . . . . . .12

Interfaces . . . . . . . . . . . . . . .12

||

SCSI Differential (HVD) . . . . . . . . .12

||

SCSI Differential (LVD) . . . . . . . . .13

||

Fibre Channel Supported Topologies . . . . .13

||

Server (Host) Attachment . . . . . . . . . .14

Supported Servers (Hosts) and Operating

Systems . . . . . . . . . . . . . .14

Supported Device Drivers . . . . . . . .15

TapeAlert Support . . . . . . . . . . . .15

Specifications . . . . . . . . . . . . . .15

Installation . . . . . . . . . . . . .17

Step 1. Unpack the Autoloader . . . . . . . .18

Step 2. Verify the Shipment Inventory . . . . .19

Step 3. Inspect the Power Cord and Outlet . . . .21

Step 4. Install the Optional Remote Management

Unit (RMU) . . . . . . . . . . . . . .22

Tools Required . . . . . . . . . . . .22

Installing the RMU . . . . . . . . . . .22

Step 5. Install the Optional HVD Converter (L28

Models Only) . . . . . . . . . . . . . .23

Tools Required . . . . . . . . . . . .23

Installing the HVD Converter . . . . . . .23

Step 6. Install the Optional Bar Code Reader (BCR) 25

Tools Required . . . . . . . . . . . .25

Installing the BCR . . . . . . . . . . .25

Step 7. Install the Autoloader as a Desktop Unit . .26

Step 8. Install the Autoloader in a Rack . . . . .27

Rack Safety . . . . . . . . . . . . .27

Tools Required . . . . . . . . . . . .28

Verify the Rack Mount Kit . . . . . . . .28

Check the Installation Environment . . . . .30

Prepare the Autoloader for Installation . . . .31

Install the Support Rails in the Rack . . . . .31

Install the Rack Front-Mount Brackets on the

Autoloader . . . . . . . . . . . . .33

Secure the Autoloader to the Rack . . . . . .34

Step 9. Connect Power . . . . . . . . . . .36

Desktop Installation . . . . . . . . . .36

Rack Installation . . . . . . . . . . . .36

Running a Drive Recalibration Test . . . . .37

LIBRARY VERIFY Test . . . . . . . . . .37

Step 10. Connect the Autoloader to Your Server

(Host) . . . . . . . . . . . . . . . .38

RMU Cabling . . . . . . . . . . . . .38

SCSI Interface . . . . . . . . . . . .38

Fibre Channel Interface . . . . . . . . .39

Step 11. Power on the Autoloader . . . . . . .41

Configuring Your Autoloader . . . . . . . .41

Saving / Restoring VPD on the RMU . . . . .41

Part 2. Operator Guide . . . . . . .43

Menus . . . . . . . . . . . . . . .45

Access Protocol . . . . . . . . . . . . .45

Operator Control Panel (OCP) . . . . . . . .46

Power On Display . . . . . . . . . . .47

Home Screen . . . . . . . . . . . . .47

Online Menu . . . . . . . . . . . . . .49

© Copyright IBM Corp. 2004, 2005 v

Page 8

Information Menu . . . . . . . . . . .49

Go Offline . . . . . . . . . . . . . .53

Model L28/L38/L3H (SCSI Drive) Offline Menu . .55

Information Menu . . . . . . . . . . .55

|

| |

Commands Menu . . . . . . . . . . .55

|

Configuration Menu . . . . . . . . . .60

| |

Diagnostic Menu . . . . . . . . . . .67

Go Online . . . . . . . . . . . . . .74

|

Model F28/F38/F3H (Fibre Channel Drive) Offline

|

| |

Menu . . . . . . . . . . . . . . . .75

||

|

Information Menu . . . . . . . . . . .76

| |

Commands Menu . . . . . . . . . . .76

Configuration Menu . . . . . . . . . .76

| |

Diagnostic Menu . . . . . . . . . . .84

| |

Go Online . . . . . . . . . . . . . .84

|

| |

Configuration . . . . . . . . . . . .85

| |

Passwords . . . . . . . . . . . . . . .85

OCP Password . . . . . . . . . . . .85

| |

RMU Passwords . . . . . . . . . . . .86

|

Serial Communication Password . . . . . .86

| |

Configuring a Model L28/L38/L3H Autoloader . .91

||

| |

Step 1. Go Offline Using the OCP . . . . . .91

||

Step 2. Change SCSI ID . . . . . . . . .91

|

Step 3. Change SCSI Speed . . . . . . . .92

| |

Step 4. Change the Operating Mode . . . . .92

|

Step 5. Configure the RMU . . . . . . . .95

| |

Step 6. Configure the BCR . . . . . . . .96

Step 7. Cycle Autoloader Power . . . . . .96

||

Step 8. Set Protection Mode ON or OFF . . . .97

||

Step 9. Save Vital Product Data (Autoloader with

RMU Only) . . . . . . . . . . . . .97

| |

Step 10. Update Autoloader Configuration Form 98

||

Configuring a Model F28/F38/F3H Autoloader . .99

|

Step 1. Go Offline Using the OCP . . . . . .99

||

| |

Step 2. Change Loop ID . . . . . . . . .99

||

|

Step 3. Select Fibre Channel Port . . . . . . 100

| |

Step 4. Enter WW Node Name . . . . . . 100

Step 5. Change Fibre Channel Speed . . . . 100

Step 6. Change the Operating Mode . . . . . 101

Step 7. Configure the RMU . . . . . . . . 103

Step 8. Configure the BCR . . . . . . . . 104

Step 9. Cycle Autoloader Power . . . . . . 104

Step 10. Set Protection Mode ON or OFF . . . 105

Step 11. Save Vital Product Data (Autoloader

with RMU Only) . . . . . . . . . . . 105

Step 12. Update Autoloader Configuration Form 106

||

Completing Configuration of Autoloader . . . . 107

Step 1. Import Cartridges . . . . . . . . 107

Step 2. Configure RMU User Accounts . . . . 108

Step 3. Install Device Drivers . . . . . . .110

Step 4. Configure the Autoloader to the Server

(Host) . . . . . . . . . . . . . . .110

Step 5. Update Firmware . . . . . . . . 111

Step 6. Register for My Support . . . . . . 121

Remote Management Unit (RMU) . . . 123

Access Protocol . . . . . . . . . . . . . 123

Login . . . . . . . . . . . . . . . . 124

Help . . . . . . . . . . . . . . . . 125

Quick Status . . . . . . . . . . . . . . 125

Status Icons . . . . . . . . . . . . . 125

Information Menu . . . . . . . . . . . . 126

Autoloader (Models L28/L38/L3H and

F28/F38/F3H) . . . . . . . . . . . . 126

Drive (Models L28/L38/L3H and

F28/F38/F3H) . . . . . . . . . . . . 127

Status Menu . . . . . . . . . . . . . . 128

Autoloader (Models L28/L38/L3H and

F28/F38/F3H) . . . . . . . . . . . . 128

Media (Models L28/L38/L3H and

F28/F38/F3H) . . . . . . . . . . . . 129

Configuration Menu . . . . . . . . . . . 130

Device (Model L28/L38/L3H) . . . . . . . 130

Device (Model F28/F38/F3H) . . . . . . . 131

Network (Models L28/L38/L3H and

F28/F38/F3H) . . . . . . . . . . . . 132

User (Models L28/L38/L3H and F28/F38/F3H) 133

RTC (Models L28/L38/L3H and F28/F38/F3H) 134

Log (Models L28/L38/L3H and F28/F38/F3H) 134

Event Notification (Models L28/L38/L3H and

F28/F38/F3H) . . . . . . . . . . . . 135

Reset (Models L28/L38/L3H and F28/F38/F3H) 136

Maintenance Menu . . . . . . . . . . . 137

Operations (Models L28/L38/L3H and

F28/F38/F3H) . . . . . . . . . . . . 137

General Diagnostic (Models L28/L38/L3H and

F28/F38/F3H) . . . . . . . . . . . . 138

Advanced Diagnostic (Models L28/L38/L3H

and F28/F38/F3H) . . . . . . . . . . 138

Firmware (Models L28/L38/L3H and

F28/F38/F3H) . . . . . . . . . . . . 139

Reset (Models L28/L38/L3H and F28/F38/F3H) 139

Logs Menu . . . . . . . . . . . . . . 140

Loader (Models L28/L38/L3H and

F28/F38/F3H) . . . . . . . . . . . . 140

Drive (Models L28/L38/L3H and

F28/F38/F3H) . . . . . . . . . . . . 141

Logout . . . . . . . . . . . . . . . 142

Media . . . . . . . . . . . . . . . 143

Data Cartridge . . . . . . . . . . . . . 144

Cleaning Cartridge . . . . . . . . . . . 145

Bar Code Label . . . . . . . . . . . . . 145

Guidelines for Using Bar Code Labels . . . . 146

Setting the Write-Protect Switch . . . . . . . 147

Handling Cartridges . . . . . . . . . . . 147

Provide Training . . . . . . . . . . . 148

Ensure Proper Packaging . . . . . . . . 148

Provide Proper Acclimation and Environmental

Conditions . . . . . . . . . . . . . 149

Perform a Thorough Inspection . . . . . . 149

Handle the Cartridge Carefully . . . . . . 150

Examples of Cartridge Problems . . . . . . 150

Environmental and Shipping Specifications for

Tape Cartridges . . . . . . . . . . . . 151

Repositioning or Reattaching a Leader Pin . . . 152

Repositioning a Leader Pin . . . . . . . . 152

Reattaching a Leader Pin . . . . . . . . 154

Disposing of Tape Cartridges . . . . . . . . 158

Ordering Media Supplies . . . . . . . . . 159

vi IBM 3581 Autoloader Models L28/L38/L3H and F28/F38/F3H Setup, Operator, and Service Guide

Page 9

Ordering Bar Code Labels . . . . . . . . 160

| |

| |

Part 3. Service Guide . . . . . . . 161

Troubleshooting . . . . . . . . . . 163

Maintenance/Service Starting Point . . . . . . 163

||

Resolving Error Messages/Codes . . . . . . . 166

Resolving Autoloader and Drive Error Codes or

Messages . . . . . . . . . . . . . . 166

Autoloader Error Codes . . . . . . . . . . 168

Not Ready Errors 01h - 0Fh . . . . . . . 169

Unit Attention 10h - 1Fh . . . . . . . . . 169

Recovered Errors 20h - 2Fh . . . . . . . . 169

Hardware Errors 30h - 4Fh . . . . . . . . 170

Illegal Request Errors 50h - 6Fh . . . . . . 170

Aborted Command Errors 70h - 73h . . . . . 171

Additional Errors 7Ah - 7Fh . . . . . . . 171

Error 80h . . . . . . . . . . . . . . 172

Robotic Control Errors 81h - 8Fh . . . . . . 172

Function Errors 90h - 9Fh . . . . . . . . 173

Low Level Axis Errors A0h - AFh . . . . . 174

Electronic Hardware Errors B0h - B9h . . . . 174

Drive Errors BAh - BFh . . . . . . . . . 175

Drive Errors C0h - CFh . . . . . . . . . 175

||

Drive Errors D0h - D5h . . . . . . . . . 176

||

Network Error F0h - F3h . . . . . . . . 176

Subcode Descriptions . . . . . . . . . . 176

Drive Error Codes . . . . . . . . . . . . 179

Access Protocol . . . . . . . . . . . . . 184

Copying a Drive Dump Log to Server (Host) . . . 185

ITDT SCSI Firmware Update, Dump Retrieval,

|

and Library/Drive Test Tool . . . . . . . 185

||

LTO-TDX: LTO SCSI and Fibre Drive Firmware

Download & LTO Drive Dump Upload Tool . . 185

Via Serial Communication . . . . . . . . 187

Via RMU . . . . . . . . . . . . . . 192

Copying Autoloader Error Log and Trace Log Files

to the Server (Host) . . . . . . . . . . . 193

Via Serial Communication . . . . . . . . 193

Via RMU . . . . . . . . . . . . . . 197

Obtaining Autoloader and Drive Error Information

from Different Servers (Hosts) . . . . . . . . 197

TapeAlert Flags . . . . . . . . . . . . . 197

Sense Data . . . . . . . . . . . . . . 197

Verifying SCSI/Loop IDs . . . . . . . . . 197

Power/External Fan Analysis Procedure . . . . 197

RMU Analysis Procedure . . . . . . . . . 198

BCR Analysis Procedure . . . . . . . . . . 198

HVD Converter Analysis Procedure . . . . . . 199

Tape Unload/Export Problems Procedure . . . . 199

||

Unload Problems . . . . . . . . . . . 199

||

Export Problems . . . . . . . . . . . 199

||

Pre-call Checklist . . . . . . . . . . . . 200

Contacting IBM Technical Support . . . . . . 200

Removal and Replacement

Procedures . . . . . . . . . . . . 203

Safety Inspection . . . . . . . . . . . . 203

Removing/Replacing the Autoloader . . . . . 204

Tools Required . . . . . . . . . . . . 204

Before Powering OFF the Autoloader . . . . 204

Removing the Autoloader . . . . . . . . 204

Replacing the Autoloader . . . . . . . . 205

Removing/Replacing the External Fan . . . . . 208

Tools Required . . . . . . . . . . . . 208

Removing the External Fan . . . . . . . . 208

Replacing the External Fan . . . . . . . . 208

Removing/Replacing the Bar Code Reader (BCR) 210

Tools Required . . . . . . . . . . . . 210

Removing the BCR . . . . . . . . . . 210

Replacing the BCR . . . . . . . . . . .211

Removing/Replacing the RMU . . . . . . . 212

Tools Required . . . . . . . . . . . . 212

Removing the RMU . . . . . . . . . . 212

Replacing the RMU . . . . . . . . . . 213

Removing/Replacing the HVD Converter . . . . 214

Tools Required . . . . . . . . . . . . 214

Removing the HVD Converter . . . . . . 214

Replacing the HVD Converter . . . . . . . 215

Parts Lists . . . . . . . . . . . . 217

Parts for Autoloader . . . . . . . . . . . 217

Power Cords . . . . . . . . . . . . . 218

Power Cord Information . . . . . . . . 218

Part 4. Appendixes . . . . . . . . 223

Element Addresses . . . . . . . . . 225

TapeAlert Flags . . . . . . . . . . 227

Supported by the Autoloader . . . . . . . . 227

Supported by the Drive . . . . . . . . . . 229

Messages . . . . . . . . . . . . . 233

Obtaining Tape Drive or Library Error Information

at the Host . . . . . . . . . . . . . . 233

Obtaining Error Information from an RS/6000 or

pSeries . . . . . . . . . . . . . . . 233

Obtaining Service Information Message from an

iSeries or AS/400 . . . . . . . . . . . . 237

iSeries or AS/400 System with RISC Processor 237

Obtaining Error Information from a Sun System 238

Obtaining Error Information from an HP-UX

System . . . . . . . . . . . . . . . 238

Obtaining Error Information from a Linux System 239

Fixing Drive SCSI Bus Errors . . . . . . . . 239

Fixing a Consistent Error with a Single Drive on

a SCSI Bus . . . . . . . . . . . . . 239

Fixing an Intermittent Error with a Single Drive

on a SCSI Bus . . . . . . . . . . . . 240

Sense Data . . . . . . . . . . . . 241

Autoloader Sense Data . . . . . . . . . . 241

Drive Sense Data . . . . . . . . . . . . 245

Using Host Sense Data . . . . . . . . . . 249

Autoloader Configuration Form . . . 251

Rack Mount Template . . . . . . . . 253

Contents vii

Page 10

| |

Information for IBM Service Personnel 255

| |

Gripper Calibration . . . . . . . . . . . 255

| |

Service Menus . . . . . . . . . . . . . 255

| |

LIBRARY SERVICE via the OCP . . . . . . 256

| |

Advanced Diagnostics via the RMU . . . . . 258

| |

Using Serial Port Communications . . . . . 259

| |

Upgrading Code via FMR Tape . . . . . . . 264

Removing a Cartridge Manually . . . . . . . 266

Removing a Cartridge Slot and Cartridge . . . 266

Replacing a Cartridge Slot . . . . . . . . 268

Manually Removing a Tape Cartridge from an

Ultrium 1 or 2 Drive . . . . . . . . . . . 270

Required Tools . . . . . . . . . . . . 270

Removing a SCSI Drive from the Autoloader 270

||

Removing a Fibre Channel Drive from the

|

Autoloader . . . . . . . . . . . . . 273

||

Removing the Cover of the Internal Drive . . . 275

Fixing the Problem . . . . . . . . . . 276

Removing the Cartridge from the Drive . . . 277

Manually Removing a Tape Cartridge from an

|

Ultrium 3 Tape Drive . . . . . . . . . . . 279

||

Before You Begin . . . . . . . . . . . 279

||

Recommended Tools . . . . . . . . . . 279

Beginning Procedure . . . . . . . . . . 280

Tape Spooled off Supply Reel . . . . . . . 281

Tape Pulled from or Broken near Leader Pin 283

Tape Broken in Mid-tape . . . . . . . . 285

Tape Tangled Along Tape Path . . . . . . 286

No Apparent Failure or Damage to Tape . . . 289

Notices . . . . . . . . . . . . . . 293

Getting Help . . . . . . . . . . . . . 294

Trademarks . . . . . . . . . . . . . . 295

Electronic Emission Notices . . . . . . . . 296

IBM 3581 Ultrium Tape Autoloader . . . . . 296

Statement of Limited Warranty . . . . . . . 298

Part 1 - General Terms . . . . . . . . . 298

Part 2 - Country-unique Terms . . . . . . 301

Part 3 - Warranty Information . . . . . . .311

Glossary . . . . . . . . . . . . . 317

Index . . . . . . . . . . . . . . . 325

viii IBM 3581 Autoloader Models L28/L38/L3H and F28/F38/F3H Setup, Operator, and Service Guide

Page 11

Figures

1. AC Grounding Diagram (50 Hz and 60 Hz) xviii

||

2. IBM TotalStorage Ultrium Tape Autoloader 3581

Models L28/L38/L3H and F28/F38/F3H . . .3

3. Front panel components . . . . . . . . .7

4. Interior components with one cartridge slot 8

5. Rear panel label showing power ratings and

|

|

||

|

|

||

warning customers not to remove the

Autoloader cover . . . . . . . . . .10

6. Rear panel with standard elements and SCSI

connectors with an LVD SCSI (Model

L28lL38/L3H) drive . . . . . . . . . .10

7. Rear panel components with an LVD SCSI

drive (Model L28/L38/L3H) and HVD

Converter . . . . . . . . . . . . .11

8. Rear panel with a Fibre Channel (Model

|

||

F28/F38/F3H) drive connection . . . . . .11

9. Installing the RMU . . . . . . . . . .22

10. Aligning the HVD Converter to the

Autoloader . . . . . . . . . . . . .23

11. Installing the HVD Converter . . . . . .24

12. SCSI HVD Differential terminator . . . . .24

13. Installing the Bar Code Reader . . . . . .25

||

14. Illustration of parts contained in the Rack

|

||

||

Mount Kit . . . . . . . . . . . . .29

15. PCC cable . . . . . . . . . . . . .30

16. EIA identification . . . . . . . . . .31

17. Attaching cage clip-nuts to a rack with square

holes . . . . . . . . . . . . . . .32

18. Attaching expanding rails to the rack . . . .33

||

19. Installing rack-mount brackets . . . . . .34

||

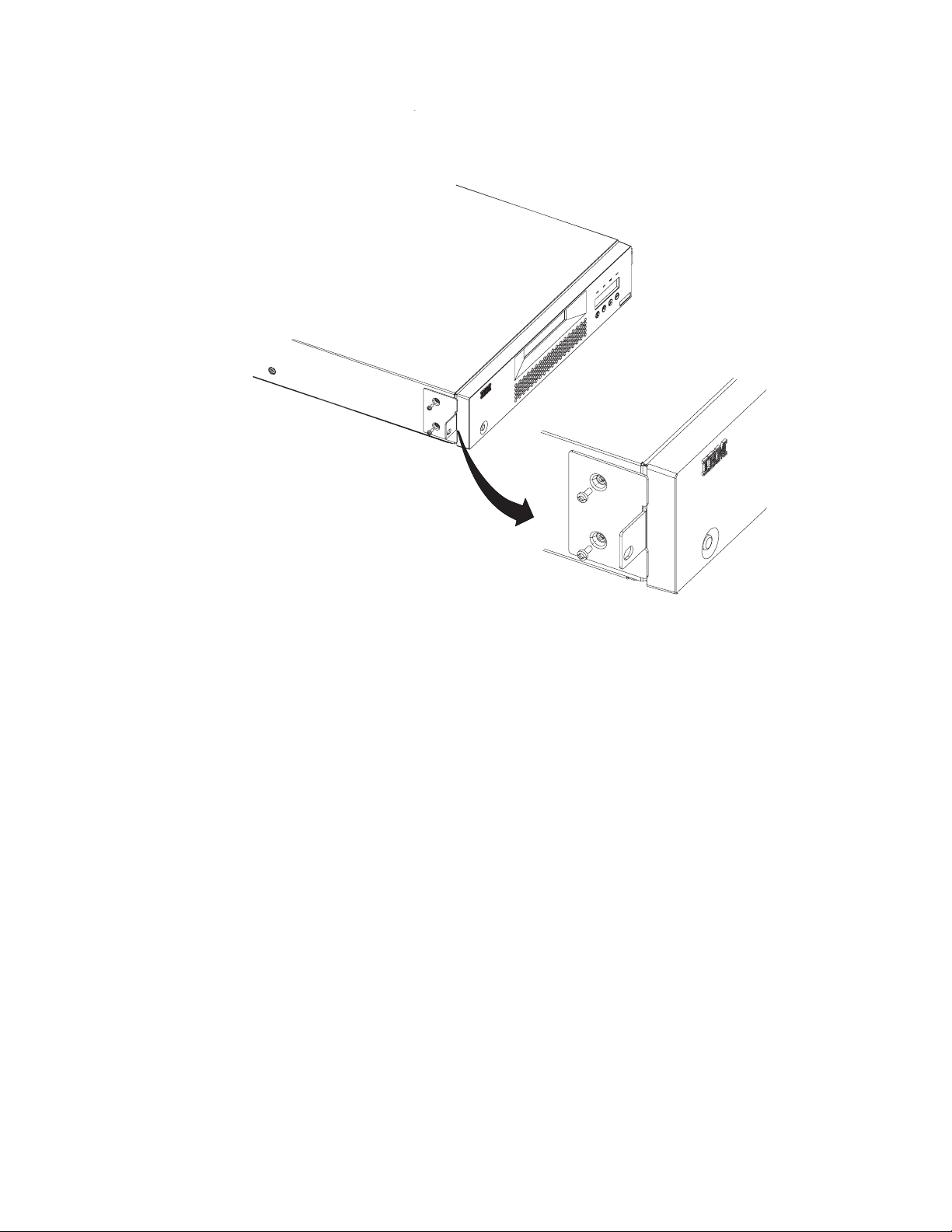

20. Installing the Autoloader in a rack . . . . .35

21. PCC cable . . . . . . . . . . . . .36

||

22. SCSI receptacles on rear of Autoloader . . .39

23. SCSI receptacles on HVD Converter . . . .39

24. Fibre Channel receptacle . . . . . . . .40

25. Operator Control Panel (OCP) . . . . . .46

26. Operator Control Panel (OCP) Home Screen 47

27. Online menu tree . . . . . . . . . .49

||

28. Information Menu LOADER INFO item 50

29. Information Menu Error Log for the

Autoloader command . . . . . . . . .51

30. Information Menu DRIVE INFO item . . . .52

31. Information Menu SCSI Event Log for the

drive command . . . . . . . . . . .52

32. Information Menu Error Log for the drive

command . . . . . . . . . . . . .53

33. Autoloader Model L28/L38/L3H Offline Menu 55

||

34. Commands Menu BULK EXCHANGE

command . . . . . . . . . . . . .56

35. Commands Menu IMPORT command . . . .56

36. Commands Menu EXPORT command . . . .57

37. Commands Menu LOAD CARTRIDGE and

UNLOAD CARTRIDGE commands . . . .58

38. Commands Menu CLEAN DRIVE command 59

39. Commands Menu RE-INVENTORY command 60

40. Configuration Menu’s RESET command 60

41. Configuration Menu’s CHANGE SCSI ID

command . . . . . . . . . . . . .61

42. Configuration Menu’s SCSI SPEED command 61

43. Configuration Menu’s CHANGE LDR MODE

command . . . . . . . . . . . . .62

44. Configuration Menu’s LOOP MODE command 63

45. Configuration Menu’s AUTOLOAD MODE

command . . . . . . . . . . . . .63

46. Configuration Menu’s NET PARAMETER

command . . . . . . . . . . . . .64

47. Configuration Menu’s BARCODE READER

command . . . . . . . . . . . . .65

48. Configuration Menu’s PROTECTION MODE

command . . . . . . . . . . . . .66

49. Configuration Menu’s SERIAL NUMBER

command . . . . . . . . . . . . .67

50. Diagnostic Menu’s LOADER DIAG Library

Verify command . . . . . . . . . . .68

51. Diagnostic Menu’s LOADER DIAG System

Test command . . . . . . . . . . .69

52. Diagnostic Menu’s DRIVE DIAG menu 70

53. Autoloader Model F28/F38/F3H Offline Menu 75

54. Configuration Menu’s RESET command 76

55. Configuration Menu’s CHANGE LOOP ID

command . . . . . . . . . . . . .76

56. Configuration Menu’s FIBRE CHANNEL

command . . . . . . . . . . . . .77

57. Configuration Menu’s WW NODE NAME

command . . . . . . . . . . . . .77

58. Configuration Menu’s FC SPEED command 78

59. Configuration Menu’s CHANGE LDR MODE

command . . . . . . . . . . . . .79

60. Configuration Menu’s LOOP MODE command 80

61. Configuration Menu’s AUTOLOAD MODE

command . . . . . . . . . . . . .80

62. Configuration Menu’s NET PARAMETER

command . . . . . . . . . . . . .81

63. Configuration Menu’s BARCODE READER

command . . . . . . . . . . . . .82

64. Configuration Menu’s PROTECTION MODE

command . . . . . . . . . . . . .82

65. Configuration Menu’s SERIAL NUMBER

command . . . . . . . . . . . . .83

66. HyperTerminal Connection Description

window . . . . . . . . . . . . . .87

67. HyperTerminal Connect To window . . . .88

68. HyperTerminal COMx Properties window 89

69. Configuration Menu’s CHANGE SCSI ID

command . . . . . . . . . . . . .91

70. Configuration Menu’s SCSI SPEED command 92

71. Configuration Menu’s CHANGE LDR MODE

command . . . . . . . . . . . . .92

72. Configuration Menu’s LOOP MODE command 93

73. Configuration Menu’s AUTOLOAD MODE

command . . . . . . . . . . . . .94

© Copyright IBM Corp. 2004, 2005 ix

Page 12

74. Configuration Menu’s NET PARAMETER

command . . . . . . . . . . . . .95

75. Configuration Menu’s BARCODE READER

command . . . . . . . . . . . . .96

76. Configuration Menu’s PROTECTION MODE

|

||

command . . . . . . . . . . . . .97

77. Configuration Menu’s CHANGE LOOP ID

command . . . . . . . . . . . . .99

78. Configuration Menu’s FIBRE CHANNEL

command . . . . . . . . . . . . . 100

79. Configuration Menu’s WW NODE NAME

command . . . . . . . . . . . . . 100

80. Configuration Menu’s FIBRE SPEED

command . . . . . . . . . . . . . 101

81. Configuration Menu’s CHANGE LDR MODE

command . . . . . . . . . . . . . 101

82. Configuration Menu’s LOOP MODE

command . . . . . . . . . . . . . 102

83. Configuration Menu’s AUTOLOAD MODE

command . . . . . . . . . . . . . 102

84. Configuration Menu’s NET PARAMETER

command . . . . . . . . . . . . . 103

85. Configuration Menu’s BARCODE READER

command . . . . . . . . . . . . . 104

86. Configuration Menu’s PROTECTION MODE

|

||

command . . . . . . . . . . . . . 105

87. Commands Menu BULK EXCHANGE

command . . . . . . . . . . . . . 107

88. Commands Menu IMPORT command 108

89. RMU displaying the Configuration Menu’s

| |

User screen . . . . . . . . . . . . 109

90. HyperTerminal Connection Description

window . . . . . . . . . . . . .113

91. HyperTerminal Connect To window . . . .114

92. HyperTerminal COMx Properties window 115

93. Send File window . . . . . . . . . .117

94. Verification screen . . . . . . . . . .117

95. RMU login page . . . . . . . . . . 124

|

96. RMU Information Menu’s Autoloader page 126

| |

97. RMU Information Menu’s Drive page 127

98. RMU Status Menu’s Autoloader page 128

99. RMU Status Menu’s Media page . . . . . 129

100. RMU Configuration Menu’s Device page for

Model L28/L38/L3H . . . . . . . . . 130

101. RMU Configuration Menu’s Device page for

Model F28/F38/F3H . . . . . . . . . 131

102. RMU Configuration Menu’s Network page 132

103. RMU displaying the Configuration Menu’s

User screen . . . . . . . . . . . . 133

104. RMU Configuration Menu’s RTC page 134

105. RMU Configuration Menu’s Log page 134

106. RMU Configuration Menu’s Event

Notification page . . . . . . . . . . 135

107. RMU Configuration Menu’s Reset page 136

108. RMU Maintenance Menu’s Operations page 137

109. RMU Maintenance Menu’s General

Diagnostic page . . . . . . . . . . . 138

110. RMU Maintenance Menu’s Firmware page 139

111. RMU Maintenance Menu’s Reset page 139

|

112. RMU Logs Menu’s Loader page . . . . . 140

| |

113. RMU Logs Menu’s Drive page . . . . . . 141

114. The IBM TotalStorage LTO Ultrium 200 GB

Data Cartridge . . . . . . . . . . . 144

115. Sample bar code label on the LTO Ultrium

Tape Cartridge . . . . . . . . . . . 146

116. Setting the write-protect switch . . . . . 147

117. Tape cartridges in a Turtlecase . . . . . . 148

118. Double-boxing tape cartridges for shipping 149

119. Checking for gaps in the seams of a cartridge 150

120. Leader pin in the incorrect and correct

positions . . . . . . . . . . . . . 152

121. Placing the dislodged leader pin into the

correct position . . . . . . . . . . . 153

122. Rewinding the tape into the cartridge 153

123. Leader Pin Reattachment Kit . . . . . . 154

124. Attaching the leader pin attach tool to the

cartridge . . . . . . . . . . . . . 155

125. Winding the tape out of the cartridge 156

126. Removing the C-clip from the leader pin 156

127. Attaching the leader pin to the tape . . . . 157

128. HyperTerminal Connection Description

window . . . . . . . . . . . . . 188

129. HyperTerminal Connect To window . . . . 189

130. HyperTerminal COMx Properties window 190

131. Receive File window . . . . . . . . . 192

132. HyperTerminal Connection Description

window . . . . . . . . . . . . . 193

133. HyperTerminal Connect To window . . . . 194

134. HyperTerminal COMx Properties window 195

135. HyperTerminal Capture Text window 196

136. Removing Autoloader from a rack . . . . 205

137. Repair Identification Tag . . . . . . . . 206

138. Autoloader rear panel with the External Fan

removed . . . . . . . . . . . . . 208

139. Removing/replacing the BCR . . . . . . 210

140. Removing/replacing the RMU . . . . . . 212

141. Removing/replacing the HVD Converter 214

142. Types of receptacles . . . . . . . . . 221

143. Default Element Addresses and Element

Indexes . . . . . . . . . . . . . 226

144. AIX ERRPT Library Error Log Example 234

145. AIX ERRPT Drive Error Log Example 235

146. AIX ERRPT Commands Error Log Example 236

147. Rack mount template . . . . . . . . . 253

148. Service menu . . . . . . . . . . . 255

149. RMU Maintenance Menu’s Advanced

Diagnostic page . . . . . . . . . . . 258

150. Serial port pin-out . . . . . . . . . . 259

151. HyperTerminal Connection Description

window . . . . . . . . . . . . . 260

152. HyperTerminal Connect To window . . . . 261

153. HyperTerminal COMx Properties window 262

154. Configuration Menu’s DRIVE FW UPGRADE

FROM FMR TAPE command . . . . . . 264

155. Bottom view of cartridge slot . . . . . . 267

156. Top view of Autoloader with top cover

removed showing cartridge slot being

removed . . . . . . . . . . . . . 268

157. Belt loop for cartridge slot pin . . . . . . 269

158. Location of screws on rear panel for drive

removal . . . . . . . . . . . . . 271

x IBM 3581 Autoloader Models L28/L38/L3H and F28/F38/F3H Setup, Operator, and Service Guide

Page 13

159. Location of screws on bottom cover for drive

|

| |

|

||

| |

||

|

||

| |

|

| |

| |

|

||

| |

|

|

||

| |

|

| |

||

removal . . . . . . . . . . . . . 272

160. Internal view of drive in Autoloader 273

161. Internal view of drive in Autoloader 275

162. Removing the cover of the tape drive 276

163. Rewinding the leader pin into the tape

cartridge . . . . . . . . . . . . . 277

164. Guiding the leader pin into the tape cartridge 278

165. Removing the cover from the internal drive 280

166. Using hex wrench to rewind tape into

cartridge . . . . . . . . . . . . . 282

167. Drive with cover removed to reveal gear

train. . . . . . . . . . . . . . . 283

168. Leader Block Assembly (LBA) . . . . . . 284

169. Using hex wrench to rewind tape into

cartridge . . . . . . . . . . . . . 285

170. Using hex wrench to rewind tape into

cartridge . . . . . . . . . . . . . 286

171. Drive with cover removed to reveal gear

train. . . . . . . . . . . . . . . 287

172. Leader Block Assembly (LBA) . . . . . . 288

173. Using hex wrench to rewind tape into

cartridge . . . . . . . . . . . . . 289

174. Drive with cover removed to reveal gear

train. . . . . . . . . . . . . . . 290

175. Leader Block Assembly (LBA) . . . . . . 291

Figures xi

Page 14

xii IBM 3581 Autoloader Models L28/L38/L3H and F28/F38/F3H Setup, Operator, and Service Guide

Page 15

Tables

1. Data access, rewind, and load times . . . . .4

||

2. Performance characteristics of the Ultrium 2

|

||

||

| |

| |

||

||

and Ultrium 3 Tape Drive . . . . . . . .12

3. SCSI terms and characteristics . . . . . .13

4. Physical Specifications for the Autoloader 15

5. Power Specifications for the Autoloader 15

6. Acoustic Specifications for the Autoloader 15

7. Environmental Specifications for the

Autoloader . . . . . . . . . . . . .16

8. Shipment inventory checklist . . . . . . .19

9. Default SCSI IDs for the Autoloader’s drive 91

10. Default Loop IDs for the Autoloader’s drive 99

11. Firmware upload times via different methods 111

12. Ultrium data and cleaning cartridge

|

||

compatibility with Ultrium tape drives . . . 143

13. Environment for operating, storing, and

shipping the IBM LTO Ultrium Tape

Cartridge . . . . . . . . . . . . . 151

14. Ordering media supplies for the Autoloader 159

15. Authorized suppliers of custom bar code

labels . . . . . . . . . . . . . . 160

16. Ordering media supplies for the Autoloader 160

17. Start Here . . . . . . . . . . . . . 163

||

18. Not Ready Errors 01h - 0Fh . . . . . . . 169

19. Unit Attention 10h - 1Fh . . . . . . . . 169

20. Recovered Errors 20h - 2Fh . . . . . . . 169

21. Hardware Errors 30h - 4Fh . . . . . . . 170

22. Illegal Request Errors 50h - 6Fh . . . . . 170

23. Aborted Command Errors 70h - 73h . . . . 171

24. Additional Errors 7Ah - 7Fh . . . . . . 171

25. Error 80h . . . . . . . . . . . . . 172

26. Robotic Control Errors 81h - 8Fh . . . . . 172

27. Function Errors 90h - 9Fh . . . . . . . 173

28. Low Level Axis Errors A0h - AFh . . . . . 174

29. Electronic Hardware Errors B0h - B9h 174

30. Drive Errors BAh - BFh . . . . . . . . 175

31. Drive Errors C0h - CFh . . . . . . . . 175

32. Drive Errors D0h - D5h . . . . . . . . 176

33. Network Error F0h - F3h . . . . . . . . 176

34. Subcode Descriptions . . . . . . . . . 176

35. Drive error codes . . . . . . . . . . 179

36. Parts list for the 3581 Tape Autoloader 217

37. Power cord information . . . . . . . . 218

38. TapeAlert Flags supported by the Autoloader 227

39. TapeAlert flags supported by the drive 229

40. AIX ERRPT Library Sense Data . . . . . 234

41. AIX ERRPT Drive Sense Data . . . . . . 235

42. Autoloader Sense Data . . . . . . . . 241

43. Autoloader possible Additional Sense Codes

(ASC) and Additional Sense Code Qualifiers

(ASCQ) . . . . . . . . . . . . . 241

44. LTO Tape Drive Sense Data . . . . . . . 245

45. Host Method of Recording Tape Drive Errors 249

46. Telephone numbers and e-mail addresses for

IBM Customer Assistance Centers . . . . . 294

© Copyright IBM Corp. 2004, 2005 xiii

Page 16

xiv IBM 3581 Autoloader Models L28/L38/L3H and F28/F38/F3H Setup, Operator, and Service Guide

Page 17

Safety and Environmental Notices

|

|

|

|

|

Danger Notice

Caution Notice

Read all safety and operating instructions before operating this product. Keep this

guide for future reference. This unit is engineered and manufactured for your

personal safety. Improper use can result in potential electrical shock or fire hazards.

Note: In addition to the safety instructions in this guide, local and professional

safety rules apply.

When using this product, observe the danger, caution, and attention notices

contained in this guide. Danger and caution notices are accompanied by symbols

that represent the severity of the safety condition.

á

A danger notice calls attention to a situation that is potentially lethal or

extremely hazardous to people. A lightning bolt symbol always

accompanies a danger notice to represent a dangerous electrical

condition.

A caution notice calls attention to a situation that is potentially hazardous to

people because of some existing condition. A caution notice can be accompanied

by one of several symbols:

If the symbol is... It means....

A hazardous electrical condition with less severity than

electrical danger.

A generally hazardous condition not represented by other

safety symbols.

A hazardous condition due to the use of a laser in the

product. Laser symbols are always accompanied by the

classification of the laser as defined by the U. S.

Department of Health and Human Services (for example,

Class I, Class II, and so forth).

A hazardous condition due to mechanical movement in or

around the product.

© Copyright IBM Corp. 2004, 2005 xv

Page 18

If the symbol is... It means....

Laser Safety and Compliance

Before using the Autoloader, review the following laser safety information.

Class I Laser Product

The Autoloader may contain a laser assembly that complies with the performance

standards set by the U.S. Food and Drug Administration for a Class I laser

product. Class I laser products do not emit hazardous laser radiation. The

Autoloader has the necessary protective housing and scanning safeguards to

ensure that laser radiation is inaccessible during operation or is within Class I

limits. External safety agencies have reviewed the Autoloader and have obtained

approvals to the latest standards as they apply.

A hazardous condition due to the weight of the unit.

Weight symbols are accompanied by an approximation of

the product’s weight.

Indicates access by IBM Authorized Service Personnel only.

Intended Use

Safeguards

This equipment is designed for processing magnetic tape cartridges. Any other

application is not considered the intended use. IBM shall not be held liable for

damage arising from unauthorized use of the Autoloader. The user assumes all risk

in this aspect.

To maintain safeguards, observe the following basic rules for installation, use, and

servicing of the Autoloader.

v Follow Warnings - Adhere to all warnings on the product and in the operating

instructions.

v Read Instructions - Read and follow all installation and operating instructions.

v Ventilation - Situate the Autoloader so that its location or position provides

adequate front and rear ventilation (at least two inches).

v Heat - Situate the product away from heat sources such as radiators, heat

registers, furnaces, or other heat-producing appliances.

v Power Sources - Connect the Autoloader to a power source only of the type

directed in these operating instructions or as marked on the product label.

v Power Cord Protection - Route the AC line cord so that it is not likely to be

walked on or pinched by items placed upon or against it, paying particular

attention to the cord at the wall receptacle, and the point where the cords exits

from the product.

xvi IBM 3581 Autoloader Models L28/L38/L3H and F28/F38/F3H Setup, Operator, and Service Guide

Page 19

Precautions

v Object and Liquid Entry - Take care to ensure that objects do not fall and

liquids are not spilled into the product’s enclosure through openings.

v Servicing - Do not attempt to service the product beyond that described in the

operating and installation instructions. All other servicing should be referred to

qualified service personnel.

Use these precautions when using or choosing an environment for the unit:

v Do not use oil, solvents, gasoline, paint thinners, or insecticides on the unit or

near the unit. Vapors from these types of chemicals can damage the tape media

components.

v Do not expose the unit to moisture or store the unit in temperatures higher than

60°C (140°F), or to extreme low temperatures. See “Specifications” on page 15 for

operating temperatures.

v Keep the unit away from direct strong magnetic fields, excessive dust, and

electronic or electrical equipment that generates electrical noise.

v Hold the AC power plug by the head when removing it from the AC source

outlet; pulling the cord can damage the internal wires.

v Use the unit on a firm, level surface free from vibration. Do not place any

objects on top of the unit..

Safety Inspection Procedure

Before you service the Autoloader, perform the following safety inspection

procedure:

1. Stop all activity on the SCSI bus.

2. Power off the Autoloader.

3. Unplug the Autoloader’s power cord from the electrical outlet and then from

the rear of the unit.

|

3581 Library ac Grounding Inspection

|

|

|

|

|

|

|

4. Disconnect all cables and terminators and inspect for damage.

5. Check the Autoloader’s power cord for damage, such as a pinched, cut, or

frayed cord.

6. Check the cover of the Autoloader for sharp edges, damage, or alterations that

expose its internal parts.

7. Check the cover of the Autoloader for a proper fit. It should be in place and

secure.

8. Check the product label on the bottom of the Autoloader to make sure it

matches the voltage at your outlet.

1. Power off the Autoloader.

2. Disconnect all cables.

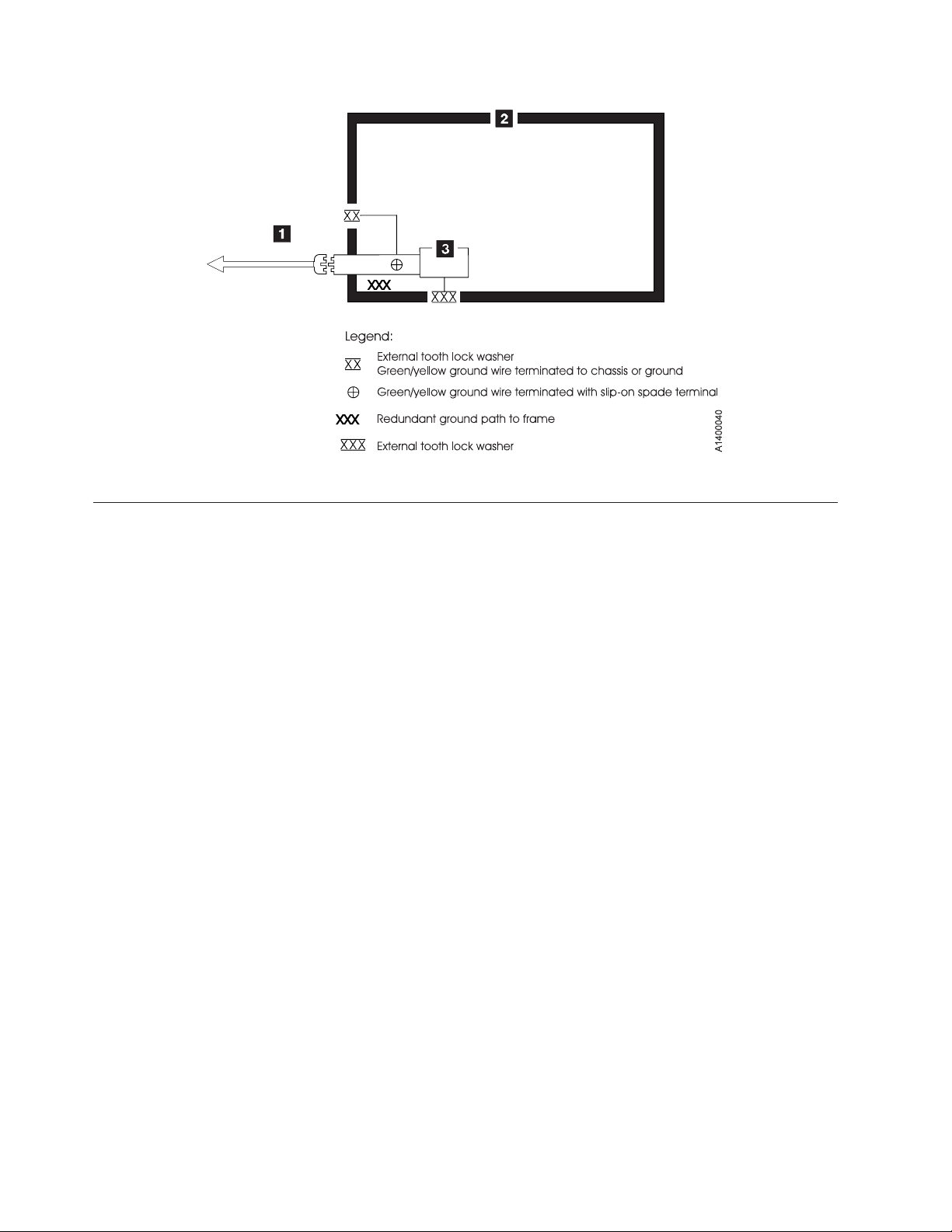

3. See Figure 1 on page xviii which is provided for reference only. Disconnect the

power cord from its source.

4. Inspect the power cable for visible cracks, wear, or damage.

Safety and Environmental Notices xvii

Page 20

Figure 1. AC Grounding Diagram (50 Hz and 60 Hz)

|

End of Life (EOL) Plan

This box is a purchased unit. Therefore, it is the sole responsibility of the purchaser

to dispose of it in accordance with local laws and regulations at the time of

disposal.

This unit contains recyclable materials. The materials should be recycled where

facilities are available and according to local regulations. In some areas IBM may

provide a product take-back program that ensures proper handling of the product.

For more information, contact your IBM representative.

xviii IBM 3581 Autoloader Models L28/L38/L3H and F28/F38/F3H Setup, Operator, and Service Guide

Page 21

About This Guide

This Setup, Operator, and Service Guide is intended to provide information for

operators, system administrators, installer, and service personnel. The publication

is divided into the following parts:

v Part 1, “Setup Guide,” on page 1 contains product description, installation, and

configuration information.

v Part 2, “Operator Guide,” on page 43 contains menu, operation, and media

information.

v Part 3, “Service Guide,” on page 161 contains troubleshooting,

diagnostic/maintenance, serial port connection, removal/replacement, and parts

information.

v Part 4, ″The Appendix, ″ contains:

– “Element Addresses” on page 225

– “TapeAlert Flags” on page 227

– “Messages” on page 233

– “Sense Data” on page 241

– “Autoloader Configuration Form” on page 251

– “Rack Mount Template” on page 253

– “Information for IBM Service Personnel” on page 255

Store

information, refer to the section that follows.

Related Publications

Refer to the following publications for additional information about the

Autoloader. To ensure that you have the latest versions of the publications, visit

the web at http://www.ibm.com/storage/support/lto.

|

3581 Autoloader Publications

The following publications can be accessed at

http://ehone.ibm.com/public/applications/publications/cgibin/pbi.cgi.

v IBM TotalStorage Ultrium Tape Autoloader 3581 Models L28/L38/L3H and

this guide with your server’s (host’s) manuals. For additional reference

F28/F38/F3H Quick Reference, GX35-5071, provides quick start information for the

Autoloader.

IBM TotalStorage Ultrium Tape Autoloader 3581 Models L28/L38/L3H and

F28/F38/F3H SCSI Reference, GA32–0471, provides the supported SCSI commands

and protocol that govern the behavior of the SCSI interface for the 3581 Tape

Autoloader.

IBM TotalStorage LTO Ultrium Tape Drive SCSI Reference, GA32–0450, provides

information on the use and programming of all models of the LTO Ultrium Tape

Drive.

|

|

|

© Copyright IBM Corp. 2004, 2005 xix

Redbooks

v The IBM LTO Ultrium Tape Libraries Guide provides information on all LTO tape

drive products.

Page 22

|

|

|

|

|

|

Device Driver Publications

Safety Publications

v Using IBM LTO Ultrium with Open Systems, SG-6502, provides information on all

LTO tape drive products.

v Implementing IBM LTO in Linux and Windows, SG-6268, provides information on

all LTO tape drive products.

v IBM Ultrium Device Drivers Installation and User’s Guide, GA32-0430, provides

instructions for attaching IBM-supported hardware to open-systems operating

systems. It indicates what devices and levels of operating systems are supported,

gives the requirements for adapter cards, and tells how to configure servers to

use the device driver with the Ultrium family of devices. To order by using File

Transfer Protocol (FTP), visit ftp://ftp.software.ibm.com/storage/devdrvr.

v IBM TotalStorage Ultrium Device Drivers Programming Reference, GC35-0483,

supplies information to application owners who want to integrate their

open-systems applications with IBM-supported Ultrium hardware. The reference

contains information about the application programming interfaces (APIs) for

each of the various supported operating-system environments. To order by using

File Transfer Protocol (FTP), visit ftp://ftp.software.ibm.com/storage/devdrvr.

v IBM Externally Attached Devices Safety Information, SA26-2004, provides

translations of safety notices.

|

Online Support

|

|

|

|

|

|

|

|

|

|

|

|

SCSI Publications

Autoloader Firmware

IBM Online Support

IBM Publications Center

IBM Redbooks

v SCSI-3 Stream Commands (SSC), published by the American National Standards

Institute and available on the web at http://www.t10.org.

v SCSI Primary Commands-2 (SPC-2), published by the American National

Standards Institute and available on the web at http://www.t10.org.

v http://www.ibm.com/storage/support/lto/

v ftp://index.storsys.ibm.com/358x

v http://www.ibm.com/storage/support/lto/

v http://www.ibm.com/support/mySupport

v http://ehone.ibm.com/public/applications/publications/cgibin/pbi.cgi

v http://www.ibm.com/storage/support/lto/

v http://w3.itso.ibm.com/

|

|

|

Device Drivers

v ftp://ftp.software.ibm.com/storage/devdrvr

v ftp://index.storsys.ibm.com/358x

xx IBM 3581 Autoloader Models L28/L38/L3H and F28/F38/F3H Setup, Operator, and Service Guide

Page 23

|

|

Media and Supplies

http://www.ibm.com/storage/media/

About This Guide xxi

Page 24

xxii IBM 3581 Autoloader Models L28/L38/L3H and F28/F38/F3H Setup, Operator, and Service Guide

Page 25

Part 1. Setup Guide

Product Description . . . . . . . . . . .3

Product Features . . . . . . . . . . . . .4

Standard Features . . . . . . . . . . .4

| |

Optional Features . . . . . . . . . . . .6

| |

Component Descriptions . . . . . . . . . .7

Front Panel Components . . . . . . . . .7

Interior Components . . . . . . . . . . .8

| |

Rear Panel Components . . . . . . . . .10

| |

Media . . . . . . . . . . . . . . . .11

Tape Drive Performance . . . . . . . . . .12

Interfaces . . . . . . . . . . . . . . .12

||

SCSI Differential (HVD) . . . . . . . . .12

||

SCSI Differential (LVD) . . . . . . . . .13

||

Fibre Channel Supported Topologies . . . . .13

||

Server (Host) Attachment . . . . . . . . . .14

Supported Servers (Hosts) and Operating

Systems . . . . . . . . . . . . . .14

Supported Device Drivers . . . . . . . .15

TapeAlert Support . . . . . . . . . . . .15

Specifications . . . . . . . . . . . . . .15

Installation . . . . . . . . . . . . . .17

Step 1. Unpack the Autoloader . . . . . . . .18

Step 2. Verify the Shipment Inventory . . . . .19

Step 3. Inspect the Power Cord and Outlet . . . .21

Step 4. Install the Optional Remote Management

Unit (RMU) . . . . . . . . . . . . . .22

Tools Required . . . . . . . . . . . .22

Installing the RMU . . . . . . . . . . .22

Step 5. Install the Optional HVD Converter (L28

Models Only) . . . . . . . . . . . . . .23

Tools Required . . . . . . . . . . . .23

Installing the HVD Converter . . . . . . .23

Step 6. Install the Optional Bar Code Reader (BCR) 25

Tools Required . . . . . . . . . . . .25

Installing the BCR . . . . . . . . . . .25

Step 7. Install the Autoloader as a Desktop Unit . .26

Step 8. Install the Autoloader in a Rack . . . . .27

Rack Safety . . . . . . . . . . . . .27

||

||

||

Rack Installation . . . . . . . . . . .27

Rack Relocation (19″ Rack) . . . . . . .28

Tools Required . . . . . . . . . . . .28

Verify the Rack Mount Kit . . . . . . . .28

Check the Installation Environment . . . . .30

Prepare the Autoloader for Installation . . . .31

Install the Support Rails in the Rack . . . . .31

Install the Rack Front-Mount Brackets on the

|

Autoloader . . . . . . . . . . . . .33

||

Secure the Autoloader to the Rack . . . . . .34

Step 9. Connect Power . . . . . . . . . . .36

Desktop Installation . . . . . . . . . .36

||

Rack Installation . . . . . . . . . . . .36

||

Running a Drive Recalibration Test . . . . .37

||

LIBRARY VERIFY Test . . . . . . . . . .37

Step 10. Connect the Autoloader to Your Server

(Host) . . . . . . . . . . . . . . . .38

RMU Cabling . . . . . . . . . . . . .38

SCSI Interface . . . . . . . . . . . .38

Attaching to a SCSI-LVD System . . . . .38

Attaching to a SCSI-HVD System . . . . .39

Fibre Channel Interface . . . . . . . . .39

Step 11. Power on the Autoloader . . . . . . .41

Configuring Your Autoloader . . . . . . . .41

Saving / Restoring VPD on the RMU . . . . .41

© Copyright IBM Corp. 2004, 2005 1

Page 26

2 IBM 3581 Autoloader Models L28/L38/L3H and F28/F38/F3H Setup, Operator, and Service Guide

Page 27

Product Description

|

|

|

|

|

|

|

|

|

|

The IBM TotalStorage

F28/F38/F3H offer high capacity, performance, and technology designed for the

mid-range open systems environment. These models incorporate a single Linear

Tape Open (LTO) IBM TotalStorage Ultrium 2 (Models L28/F28) or Ultrium 3

(Models L38/F38/L3H/F3H) Tape Drive. The IBM TotalStorage Ultrium 3 Tape

Drive more than doubles tape drive performance over the previous generation

Ultrium 2 Tape Drive, with up to 80 MB per second native data transfer rate. In

addition, with the use of the new IBM TotalStorage Ultrium 400 GB Data

Cartridge, the Ultrium 3 Tape Drive has the capability of writing twice as much

data, up to 400 GB native capacity (800 GB with 2:1 compression).

®

Ultrium Tape Autoloader 3581 Models L28/L38/L3H and

|

|

|

|

|

|

|

|

|

|

|

|

The Model L28/L38/L3H comes with an LVD Ultra160 SCSI attachment, while the

Model F28/F38/F3H comes with a Native Switched Fabric Fibre Channel

attachment, for connection to a wide spectrum of open systems servers. Both

models connect to a wide spectrum of open systems servers. Note that the Ultrium

3 Tape Drive does not support HVD technology.

The 3581 Tape Autoloader is a desktop or rack-mountable unit (requiring two rack

units) that operates in automatic, sequential, or random mode and comes equipped

with a robotic interface that moves tape cartridges to and from the drive and

cartridge carousel. With an eight tape cartridge capacity, it provides a media

capacity of up to 3.2 TB (6.4 TB with 2:1 compression) data storage per unit.

Optional features include an HVD Converter, a Remote Management Unit (RMU),

and a Bar Code Reader (BCR).

Figure 2. IBM TotalStorage Ultrium Tape Autoloader 3581 Models L28/L38/L3H and

F28/F38/F3H

|

The Autoloader’s Ultrium 2 and Ultrium 3 Tape Drive offer:

v Digital speed matching

|

The Ultrium 2 and Ultrium 3 Tape Drive will perform dynamic speed

matching to adjust the drive’s native data rate as closely as possible to the

net host data rate (after data compressibility has been factored out). This

offers the dual benefit of reducing the number of backhitch repositions and

improving throughput performance.

Power management

v

© Copyright IBM Corp. 2004, 2005 3

a67s0243

Page 28

The power management function controls the drive’s electronics to be either

completely turned off or to be in a low-power mode. These power modes

occur only when the circuit functions are not needed for drive operation.

v Channel calibration

The channel calibration feature allows for customization of each read/write

data channel for optimum performance. The customization enables

compensation for variations in the recording channel transfer function, media

characteristics, and read/write head characteristics.

v Separate writing of multiple filemarks

Separate writing of multiple filemarks causes any write command of two or

more filemarks to cause a separate data set to be written containing all

filemarks after the first. This feature has two advantages:

- First, it can improve performance if a subsequent append overwrites

somewhere after the first filemark.

- Second, write of multiple filemarks typically indicates a point where an

append operation might occur after the first of these filemarks.

change prevents having to rewrite datasets containing customer data

This

and the first filemark in cases when (where) such an append occurs.

Large internal buffer

v

|

|

|

The Ultrium 2 Tape Drive and has a 64 MB internal data buffer. The Ultrium

3 Tape Drive has a 128 MB internal buffer .

Fast cartridge fill times (for Ultrium 3, Ultrium 2 and Ultrium 1 data cartridges)

v

v Fast data access, rewind, and load times

|

Table 1. Data access, rewind, and load times

|

Action Autoloader Ultrium 2 Tape Drive Ultrium 3 Tape Drive

||||

Cartridge Load Time 32 seconds 15 seconds 10 seconds

||||

Maximum Rewind Time N/A 80 seconds 88 seconds

||||

Average File Access Time N/A 49 seconds 49 seconds

||||

|

Product Features

This section describes the standard and optional features of the Autoloader.

Standard Features

The Autoloader includes the following standard features:

v Operator Control Panel (OCP)

The OCP provides an easy-to-read display and a four button keypad

allowing the user to monitor and control the operations of the Autoloader.

The OCP’s display provides access to library status, commands, setup, and

tools. See “Front Panel Components” on page 7 and “Operator Control Panel

(OCP)” on page 46 for additional information.

v Robotic system

The Autoloader’s robotic system includes an I/O Door, a cartridge carousel

with cartridge slots, and a cartridge loader. The I/O Door allows importing

or exporting a single cartridge to or from the Autoloader. The cartridge

|

carousel encircles the Ultrium 2 and Ultrium 3 Tape Drive and positions the

specified cartridge slot in front of the tape drive. A robotic cartridge loader

moves the cartridges between the cartridge slots and the tape drive.

4 IBM 3581 Autoloader Models L28/L38/L3H and F28/F38/F3H Setup, Operator, and Service Guide

Page 29

v Eight-cartridge capacity

|

Up to eight Ultrium 3, Ultrium 2 or Ultrium 1 tape cartridges can be stored

in cartridge slots mounted on the carousel.

Cartridge inventory

v

Each time the Autoloader is powered on, an inventory of all cartridge slots is

performed.

Setup Guide: Product Description 5

Page 30

v Built-in diagnostics

The Autoloader includes firmware that performs diagnostic tests and reports

drive operating status. An error and event log is available through the OCP

or optional RMU.

|

|

|

Ultrium 2 or Ultrium 3 Tape Drive

v

The Autoloader is available with an LVD SCSI (Model L28/L38/L3H) or a

Fibre Channel (Model F28/F38/F3H) Ultrium 2 or Ultrium 3 Tape Drive.

Optional Features

The Autoloader has the following optional features:

v Bar Code Reader (BCR)

The BCR reads bar code labels and sends the label IDs to the server (host)

and to the Remote Management Unit (RMU), if installed.

Remote Management Unit (RMU)

v

The RMU provides remote access to the Autoloader over a network via a

web browser and makes functions accessible without the need for a

dedicated server or separate software.

HVD Converter

v

The HVD Converter is a SCSI HVD to LVD converter/expander. It converts

the Autoloader’s low voltage differential (LVD) to wide high voltage

differential (HVD). This allows LVD-peripherals to be used on an HVD bus.

The converter can also be used to reshape poor quality LVD signals, and

allow additional cable length.

Rack Mount Kit

v

The Rack Mount Kit supplies the necessary mounting hardware to install the

Autoloader in a 19-inch rack.

6 IBM 3581 Autoloader Models L28/L38/L3H and F28/F38/F3H Setup, Operator, and Service Guide

Page 31

Component Descriptions

This section contains descriptions of the following:

v “Front Panel Components”

v “Interior Components” on page 8

v “Rear Panel Components” on page 10

Front Panel Components

Figure 3 shows the Autoloader’s front panel components.

Figure 3. Front panel components

™

1POWER

For powering the Autoloader on and off.

2I/O Door

Allows the user to insert or remove cartridges from the Autoloader.

3Operator Control Panel (OCP)

Allows the operator to control the Autoloader without a Remote

button

Management Unit (RMU) and contains the following:

- Status LEDs (4)

- Liquid crystal display (OCP display)

- Keypad with four buttons (Cancel, Previous, Next, Enter)

4 Serial Number

A label with machine type, model, and serial number.

Setup Guide: Product Description 7

Page 32

Interior Components

Figure 4 shows the Autoloader’s interior components and one cartridge slot.

|

|

|

|

|

á

Attention: Only IBM Authorized Service Personnel should remove the

Autoloader’s cover.

||

|

4

3

2

1

a67s0179

Figure 4. Interior components with one cartridge slot

1Cartridge slot

Each cartridge is installed in a cartridge slot to ensure the cartridge is

properly aligned for insertion into the tape drive.

2Cartridge loader

The cartridge loader moves cartridges between the cartridge slots and the

tape drive. When a cartridge slot is positioned in front of the drive, the

loader grips the sides of the cartridge and slides it forward or backward

between the slot and drive. The loader then releases the cartridge and

pushes it firmly into the drive or slot.

3Ultrium 2 or Ultrium 3 Tape Drive (LVD or Fibre Channel)

|

|

|

|

|

|

|

|

|

|

Generation 2 models of the Autoloader contain one LVD (Model L28) or

Fibre Channel (Model F28) Ultrium 2 Tape Drive. The drive can sustain a

maximum data transfer rate of 107 MB per second (compressed) and can

store up to 400

®

GB of compressed information on a single data cartridge

(assuming an average compression ratio of 2:1.)

Generation 3 models of the Autoloader contain one LVD (Model L38/L3H)

or Fibre Channel (Model F38/F3H) Ultrium 3 Tape Drive. The drive can

sustain a maximum data transfer rate of 160 MB per second and can store

up to 800 GB of compressed information on a single data cartridge

(assuming an average compression ratio of 2:1).

8 IBM 3581 Autoloader Models L28/L38/L3H and F28/F38/F3H Setup, Operator, and Service Guide

Page 33

4Carousel

The carousel stores up to eight Ultrium 3, Ultrium 2 or Ultrium 1 data

cartridges. The carousel consists of a drive chain, guides, and gears that

move the cartridges into position in front of the drive.

Setup Guide: Product Description 9

Page 34

Rear Panel Components

All rear panels regardless of configuration contain the following standard elements:

v 1Power cord receptacle

Provides AC power and chassis grounding to the Autoloader.

|

|

|

2 Power Ratings / Warning Label

v

A label showing power ratings and warning the customer not to remove the

cover of the Autoloader.

|

|

Power Ratings: 100 - 240V~

1.3 - 07A 50 -60Hz

!

a67s0271

|

|

|

|

|

|

|

|

|

|

Figure 5. Rear panel label showing power ratings and warning customers not to remove the

Autoloader cover

v 3Fan

Provides cooling for the Autoloader.

4Serial Port

v

Allows serial communication between the Autoloader and a server (host).

6 shows the rear panel components of the Autoloader with an LVD SCSI

Figure

(Model L28/L38/L3H) drive.

v 5SCSI Receptacles

The Autoloader has two HD68 SCSI receptacles for connecting the

Autoloader to a single LVD SCSI bus to accommodate one of the following:

- A SCSI cable connecting the Autoloader to a server (host).

- A wide external terminator or a cable to another SCSI device.

|

|

|

|

|

5

4

3

2

Figure 6. Rear panel with standard elements and SCSI connectors with an LVD SCSI (Model

L28lL38/L3H) drive

Figure 7 on page 11 shows the rear panel components of the Autoloader with an

LVD SCSI drive (Model L28/L38/L3H) and HVD Converter.

v 1Optional HVD Converter

10 IBM 3581 Autoloader Models L28/L38/L3H and F28/F38/F3H Setup, Operator, and Service Guide

1

a67s0202

Page 35

Used to convert an Autoloader with an LVD SCSI drive to communicate with

an HVD system.

Figure 7. Rear panel components with an LVD SCSI drive (Model L28/L38/L3H) and HVD

Converter

1

a67s0197

|

|

|

|

|

|

Media

|

|

|

Figure 8 shows the rear panel components of the Autoloader with a Fibre Channel

(Model F28/F38/F3H) drive.

v 1Fibre Channel Receptacle

The receptacle for the Fibre Channel interface cable that connects the

Autoloader with the server (host).

1

Figure 8. Rear panel with a Fibre Channel (Model F28/F38/F3H) drive connection

The Autoloader uses the following cartridge types:

v

v IBM TotalStorage LTO Ultrium 400 GB Data Cartridge (Ultrium 3)

v IBM TotalStorage LTO Ultrium 200 GB Data Cartridge (Ultrium 2)

v IBM LTO Ultrium Data Cartridge (Ultrium 1 with 100 GB capacity)

v IBM TotalStorage LTO Ultrium Cleaning Cartridge

v LTO Ultrium Cleaning Cartridge (universal cleaning cartridge compatible with

Ultrium 3, Ultrium 2 and Ultrium 1 drives)

a67s0204

additional information, refer to “Media” on page 143.

For

Setup Guide: Product Description 11

Page 36

Tape Drive Performance

|

Table 2. Performance characteristics of the Ultrium 2 and Ultrium 3 Tape Drive

|

|

|

||

||||

|

|||

|

|||

|

|||||

|||

|||

|

|

|

|

||

|

|

|

|

|||

|||

||||

|

|

|

|

|

|

|

|

Performance Characteristic

Native sustained data rate N/A

Compressed data rate (at 2:1

compression)

Maximum sustained data rate (at

maximum compression)

Burst data rate 160 MB/s (LVD)

Nominal load-to-ready time 15 seconds 15 seconds

Nominal unload time 15 seconds 15 seconds

Average search time to first byte of

data

Note: Although the Autoloader provides the capability for high tape performance, the actual throughput is a

function of many components, such as system processor, disk data rate, data block size, data compressibility, I/O

attachments, and the system or application software used. For example, the HVD Ultra SCSI converter interface has

a maximum data transfer rate of 40 MB/second, so Ultrium Tape Drives on that SCSI interface will have a lower

data transfer rate. The compression technology used in the tape drive can typically double the amount of data that

can be stored on the media; however, the actual degree of compression achieved is highly sensitive to the

characteristics of the data being compressed.

Ultrium 2 Tape Drive Ultrium 3 Tape Drive

(with Ultrium 3 media)

35 MB/s

(with Ultrium 2 media)

20 MB/s

(with

Ultrium 1 media)

70 MB/s

(with Ultrium 2 media)

40 MB/s

(with Ultrium 1 media)

107 MB/s (LVD)

37 MB/s (HVD)

110 MB/s (Fibre Channel)

40 MB/s (HVD)

200 MB/s (Fibre Channel)

49 seconds 47 seconds

Tape Drive

(with

200 MB/s (Fibre Channel-2Gbits)

80 MB/s

(with Ultrium 3 media)

35 MB/s

(with Ultrium 2 media)

20 MBs

Ultrium 1 media - read only)

135 MB/sec (SCSI)

150 MB/sec (FC)

135 MB/s (LVD)

150 MB/s (Fibre Channel)

160 MB/s (LVD)

|

Interfaces

|

|

|

SCSI Differential (HVD)

|

|

|

|

|

|

|

|

|

|

|

The Autoloader is available with a choice of interfaces, either SCSI HVD (with the

optional HVD Converter or) LVD, or Fibre Channel.

The SCSI differential HVD converter is only available on Ultrium 2 tape drives.

HVD (often referred to as just ″differential″) uses differential signaling. The idea

behind differential signals is that each bus signal is carried on a pair of wires. The

first wire of the pair carries the same type of signal as single-ended SCSI.

However, the second wire of the pair carries its logical inversion. The receiver of

the signals takes the difference of the pair (hence the name), which makes it less

susceptible to noise and capable of supporting greater cable lengths. HVD and

single-ended SCSI are completely incompatible with each other.

In general, IBM HVD tape devices support an overall bus length of 25 meters,

using point-to-point or multi-drop interconnection (daisy-chaining). For each

daisy-chained device, the maximum cable length must be reduced by 0.5 meters.

12 IBM 3581 Autoloader Models L28/L38/L3H and F28/F38/F3H Setup, Operator, and Service Guide

Page 37

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|||||

|||||

|||||

||||||

||||||

||||||

|

|

|

|

|

|

SCSI Differential (LVD)

LVD uses less power than the HVD differential interface, and allows the higher

speeds of Ultra-2 SCSI. LVD requires 3.3 V dc instead of 5 V dc for HVD.

IBM LVD tape devices support a bus length of 25 meters point-to-point, and 12

meters using multi-drop interconnection (daisy-chaining). For each daisy-chained

device, the maximum cable length must be reduced by 0.5 meters.

The terms fast, wide, and ultra indicate characteristics that are separate from those

implied by differential, single-ended, and high or low voltage. Table 3 shows the

SCSI terms used to describe different host and device adapters and what they

imply in terms of bus width and speed.

Table 3. SCSI terms and characteristics

SCSI Term Bus Width (bits) Speed (MB/s) Max. Length Max. Devices

SCSI 8 5 6 m 7

Fast SCSI 8 10 3 m 7

Fast Wide SCSI 16 20 3 m 15

Ultra (Wide)

SCSI HVD

Ultra (Wide)

SCSI 2 LVD

Ultra 160 SCSI

LVD

Note: A faster bus does not imply that an attached device will support that data rate, but

that multiple devices can operate on the bus at that maximum speed. For a detailed table

of SCSI terms and related specifications, refer to the SCSI Trade Association Web site at

http://www.scsita.org/terms/scsiterms.html. To ensure best performance, if possible, avoid

daisy-chaining.

16 40 25 m 15

16 80 25 m / 12 m 15

16 160 25 m / 12 m 15

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Fibre Channel Supported Topologies

Fibre Channel allows for an active intelligent interconnection scheme, called a

Fabric, to connect devices. Everything between the ports on Fibre Channel is called

the Fabric. The Fabric is most often a switch or series of switches that takes the

responsibility for routing. Fibre channel supports three basic topologies:

v Arbitrated loop (supported by the Autoloader)

v Switched Fabric (supported by the Autoloader)

v Point-to-point (unsupported by the Autoloader)

actual topology is transparent to each individual attached device. All

The

point-to-point and arbitrated loop topologies require that all nodes use the same

data rate at all times. In the switched topology, different speed devices can be

supported.

The Switched Fabric topology is similar to the star network layout commonly

implemented on networks that use twisted pair cabling. A central device, in this

case a fibre channel switch, provides a central connectivity point for all of the

devices in the fabric. This allows each node to access all other nodes that are

connected to the fabric.

Setup Guide: Product Description 13

Page 38

|

|

|

|

|

|

|

The Autoloader allows the selection of the following Fibre channel port behaviors:

v LN Port: (default setting) an automatic configuration that tries arbitrated loop

first, then switched fabric.

v NL Port: an automatic configuration that tries switched fabric first, then

arbitrated loop.

v L Port: arbitrated loop.

v N Port: point to point protocol in a switched fabric topology.

Server (Host) Attachment

|

The Autoloader supports LVD Ultra160, HVD Ultra SCSI (with the optional HVD

Converter) or Fibre Channel interfaces. The Autoloader features two HD68

receptacles or one LC Fibre Channel receptacle. For instructions on attaching your

Autoloader to a server (host), see “Step 4. Configure the Autoloader to the Server

(Host)” on page 110.

Supported Servers (Hosts) and Operating Systems

The Autoloader is supported by a wide variety of servers (hosts) and operating

systems, as well as adapters. The following operating systems are supported by the

Autoloader:

v AS/400

v HP-UX

|

|

|

|

v IBM Eserver i5 and iSeries

v IBM Eserver p5 and pSeries

v IBM Eserver xSeries

v Linux

v Microsoft

v Microsoft Windows 2003

v Microsoft Windows NT

v Netfinity

v RS/6000

v RS/6000 SP

v Sun

v zSeries

®

™

®

®

®

Windows

®

®

™

®

Linux (Model F28/F38/F3H only)

®

2000

®

(Ultrium 2 only)

determine the latest supported attachments and host software versions and

To

releases, visit the web at http://www.ibm.com/storage/support/lto. Select ″LTO

Support″, then the ″Interoperability Matrix and Software ISVs″, and view the

″Supported Servers and Operating Systems″.

Note:

1. IBM does not provide backup application software with the Autoloader.

To order software, contact your IBM marketing representative, IBM

Business Partner, or an independent software provider.

2. If you attach your library to a non-IBM platform with non-IBM software,

IBM recommends that you contact your software vendor to obtain a