Page 1

S84H-7202-00

IBM PC Servers

PC Server Rack

Storage Enclosure - Type 3519

Hardware Maintenance

Manual Supplement

April 1997

Use this supplement with the

PC Servers Hardware

Maintenance Manual

We Want Your Comments!

(Please see page 37)

IBM

Page 2

Note

Before using this information and the product it

supports, be sure to read the general information

under “Notices” on page 41.

First Edition (May 1997)

The following paragraph does not apply to the United

Kingdom or any country where such provisions are

inconsistent with local law: INTERNATIONAL

BUSINESS MACHINES CORPORATION PROVIDES THIS

PUBLICATION “AS IS” WITHOUT WARRANTY OF ANY

KIND, EITHER EXPRESS OR IMPLIED, INCLUDING, BUT

NOT LIMITED TO, THE IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE. Some states do not allow disclaimer of

express or implied warranties in certain transactions,

therefore, this statement may not apply to you.

This publication could include technical inaccuracies or

typographical errors. Changes are periodically made to

the information herein; these changes will be incorporated

in new editions of the publication. IBM may make

improvements and/or changes in the product(s) and/or the

program(s) described in this publication at any time.

This publication was developed for products and services

offered in the United States of America. IBM may not offer

the products, services, or features discussed in this

document in other countries, and the information is subject

to change without notice. Consult your local IBM

representative for information on the products, services,

and features available in your area.

Requests for technical information about IBM products

should be made to your IBM reseller or IBM marketing

representative.

Copyright International Business Machines

Corporation 1996, 1997. All rights reserved.

Note to U.S. Government users–Documentation related to

Restricted rights–Use, duplication, or disclosure is subject

to restrictions set forth in GSA ADP Schedule Contract

with IBM Corp.

ii PC Server HMM

Page 3

About This Supplement

This supplement contains the following service information

for the PC Server Rack Storage Enclosure - Type 3519.

Diagnostic information

Parts Listing

This supplement should be used with the advanced

diagnostic tests and the information in the IBM PC Servers

Hardware Maintenance Manual Supplement (part number

70H0751, form number S30H-2501) to troubleshoot

problems effectively.

Important

This manual is intended for trained servicers who are

familiar with IBM PC Server products.

Before servicing an IBM product, be sure to review

“Safety Information” on page 30.

iii

Page 4

Related Publications

The following publications are available for IBM products.

For more information, contact IBM or your IBM Authorized

Dealer.

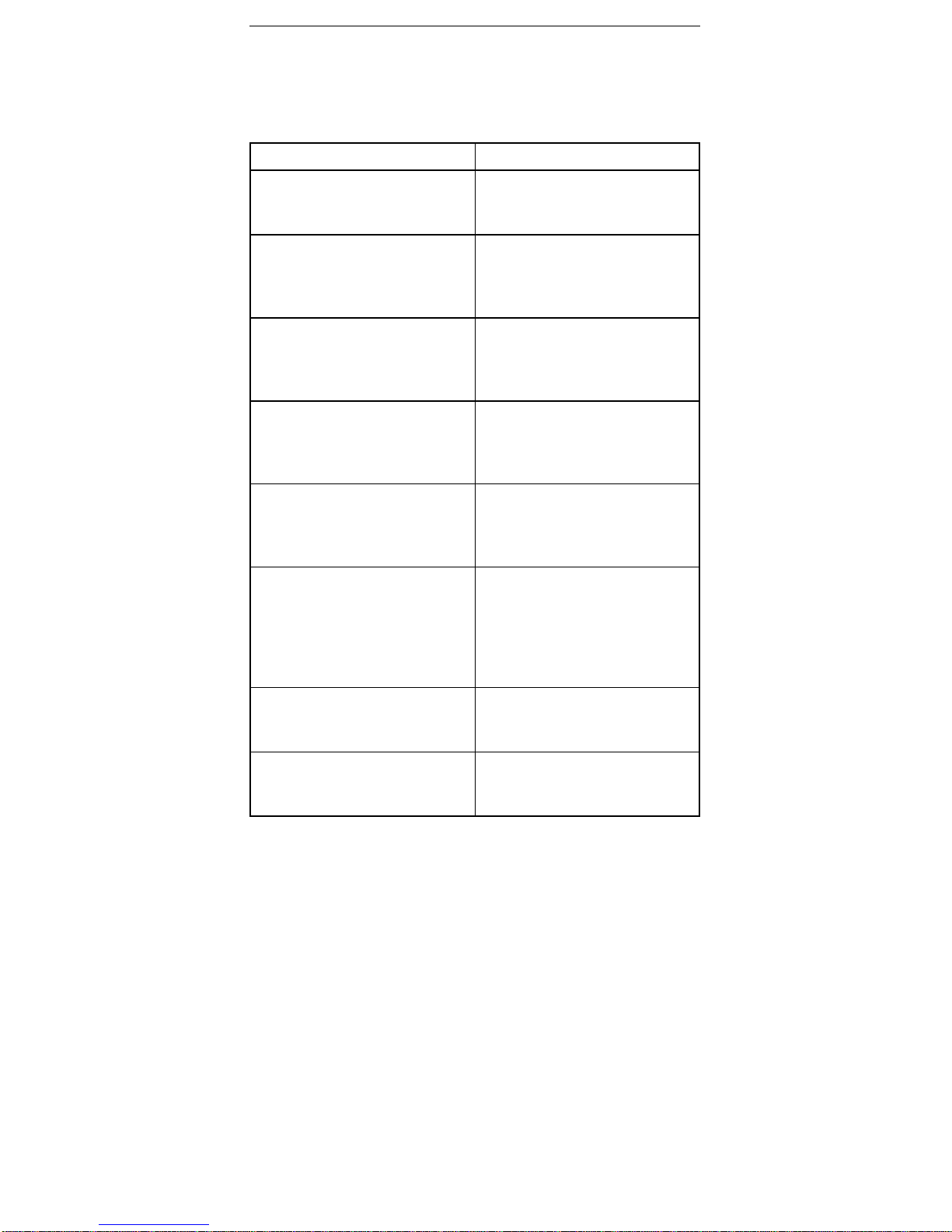

For Information About See Publication

PS/2 Computers IBM Personal System/2

Hardware Maintenance

Manual (S52G-9971)

PS/ValuePoint Computers IBM PS/ValuePoint

Hardware Maintenance

Service and Reference

(S61G-1423)

Laptop, Notebook, and

Portable Computers

IBM Mobile Systems

Hardware Maintenance

Manual Volume 1

(S82G-1501)

ThinkPad computers IBM Mobile Systems

Hardware Maintenance

Manual Volume 2

(S82G-1502)

ThinkPad computers IBM Mobile Systems

Hardware Maintenance

Manual Volume 3

(S82G-1503)

Monitors (Displays) IBM Display Hardware

Maintenance Manual

(SA38-0053)

IBM Monitor Hardware

Maintenance Manual

(S71G-4197)

Disk Array technology

overview and using the IBM

RAID Configuration Program

Configuring Your Disk Array

booklet (S82G-1506)

Installation Planning for

Personal System/2

computers

Personal System/2

Installation Planning and

Beyond (S41G-2927)

iv PC Server HMM

Page 5

Contents

About This Supplement .............. iii

Related Publications . . . . . . . . . . . . . . . iv

PC Server Rack Storage Enclosure - Type 3519 . 1

Features . . . . . . . . . . . . . . . . . . . . . 2

Diagnostics and Test Information ......... 3

Locations . . . . . . . . . . . . . . . . . . . . . 12

Symptom-to-FRU Index . . . . . . . . . . . . . . 24

Parts Listings (PC Server Rack Storage Enclosure -

Type 3519) . . . . . . . . . . . . . . . . . . . 25

Related Service Information ........... 29

Safety Information . . . . . . . . . . . . . . . . 30

Laser Compliance Statement ........... 35

Send Us Your Comments! ............. 37

Problem Determination Tips ............ 38

Phone Numbers, U.S. and Canada ......... 39

Notices . . . . . . . . . . . . . . . . . . . . . . 41

Trademarks . . . . . . . . . . . . . . . . . . . 41

Copyright IBM Corp. 1996, 1997 v

Page 6

PC Server Rack Storage Enclosure Type 3519

Features . . . . . . . . . . . . . . . . . . . . . 2

Diagnostics and Test Information ......... 3

Power-on Self-Test . . . . . . . . . . . . . . 3

Power-on Sequence . . . . . . . . . . . . . . 4

Power Supply (FRU Number 60H8301) ..... 4

Power Supply Shutdowns .......... 5

SCSI IDs . . . . . . . . . . . . . . . . . . 6

SCSI Repeater Cards ............. 7

Connecting Two Servers and One Storage

Enclosure . . . . . . . . . . . . . . . . 8

Connecting One Server and Two Storage

Enclosures . . . . . . . . . . . . . . . . 9

SCSI Termination . . . . . . . . . . . . . . . 10

Specifications . . . . . . . . . . . . . . . . . 11

Locations . . . . . . . . . . . . . . . . . . . . . 12

Access Cover . . . . . . . . . . . . . . . . . 13

Cable Management Arm Bracket ........ 13

Chassis Draw Bracket ............. 13

Controls and Indicators ............. 14

Expansion Bays . . . . . . . . . . . . . . . . 15

Drive Bays 1 to 3 .............. 16

Hot-Swap Drives Bays 4 through 9 ..... 17

External Connectors . . . . . . . . . . . . . . 18

Front Door . . . . . . . . . . . . . . . . . . 18

Hot-Swap Drive Tray III ............ 19

Keylock Assembly Exploded View ....... 20

Rack Slides . . . . . . . . . . . . . . . . . . 20

SCSI Repeater Card .............. 21

Slide Management Bracket ........... 21

Voltage Setting . . . . . . . . . . . . . . . . 23

Symptom-to-FRU Index . . . . . . . . . . . . . . 24

Parts Listings (PC Server Rack Storage Enclosure -

Type 3519) . . . . . . . . . . . . . . . . . . . 25

System (Model R01) .............. 26

Power Cords . . . . . . . . . . . . . . . . . 27

Copyright IBM Corp. 1996, 1997 1

Page 7

Features

The features in the storage enclosure vary according to the

model. The following is a summary of the features that are

available with the PC Server Rack Storage Enclosure Type 3519.

Expansion Bays

Nine:

– Six hot-swap

– Up to three slim-high or two half-high non-hot-swap

devices

Options Supported

Up to six slim-high or three half-high hot-swap hard disk drives

Tape autoloader

4/10 GB 3.5-inch DAT tape drive

CD-ROM drive

Security Features

Door lock

Fan failure detection

Integrated Functions

LED usability support

SCSI Repeater Card:

– One card standard

– Supports maximum of two

Power Supply

200-watt with manual voltage selection (100–240 Vac)

Built-in overload and surge protection

Hard Disk Drives

Supports up to six hot-swap and three non-hot-swap

2 PC Server HMM

Page 8

Diagnostics and Test Information

Important

The service procedures are designed to help you

isolate problems. They are written with the

assumption that you have model-specific training on

all computers, or that you are familiar with the

computers, functions, terminology, and service-related

information provided in this supplement and the PC

Servers Hardware Maintenance Manual (part number

70H0751, form number S30H-2501-01).

The following is a list of problems and references for

diagnosing the PC Server Rack Storage Enclosure - Type

3519.

Problem Reference

Error Codes/Error Messages Refer to the

Symptom-to-FRU Index for

the server that the Storage

Enclosure you are servicing

is connected to.

Fan Light indications See “Controls and

Indicators” on page 14 and

“Symptom-to-FRU Index” on

page 24.

Hot Swap Tray LED

indications

See “Hot-Swap Drive Tray

III” on page 19.

Power Supply Voltages See “Power Supply (FRU

Number 60H8301)” on

page 4.

Setting SCSI IDs See “SCSI IDs” on page 6.

Terminating a SCSI chain See “SCSI Termination” on

page 10.

Power-on Self-Test

When you power-on the server, it performs a series of

tests to check the operation of the system, including the

drives and other components of the storage enclosure.

This series of tests is called the

power-on self-test

, or

POST

. If the tests indicate a problem, a message appears

on the server's information panel or display.

Rack Storage Enclosure - Type 3519 3

Page 9

Power-on Sequence

Note

For normal operation, power on the server; then,

power on the expansion enclosure.

The expansion enclosure can be powered on without

connecting it to a server. However, the expansion

enclosure must be connected to a server before the drives

installed in the enclosure can be used.

Power Supply (FRU Number 60H8301)

Note

Verify that the voltage-select switch is set for the

correct voltage. If the voltage switch is set to the

wrong position, permanent damage might occur to the

rack when you power it on.

If the power-on indicator is not on, and the power-supply

fan is not running, check the power cord for proper

installation and continuity.

If the power cord is OK, either the power supply is

defective or a defective device is causing the power supply

to shut off. Check the power supply voltages.

The power supply is rated at 200 watts. Too many

devices (adapters or hard disk drives) can cause power

consumption to exceed 200 watts and cause the power

supply to shut down. See “Power Supply Shutdowns” on

page 5. Remove adapters or devices to determine if this

is the cause.

If the voltages are incorrect, replace the power supply.

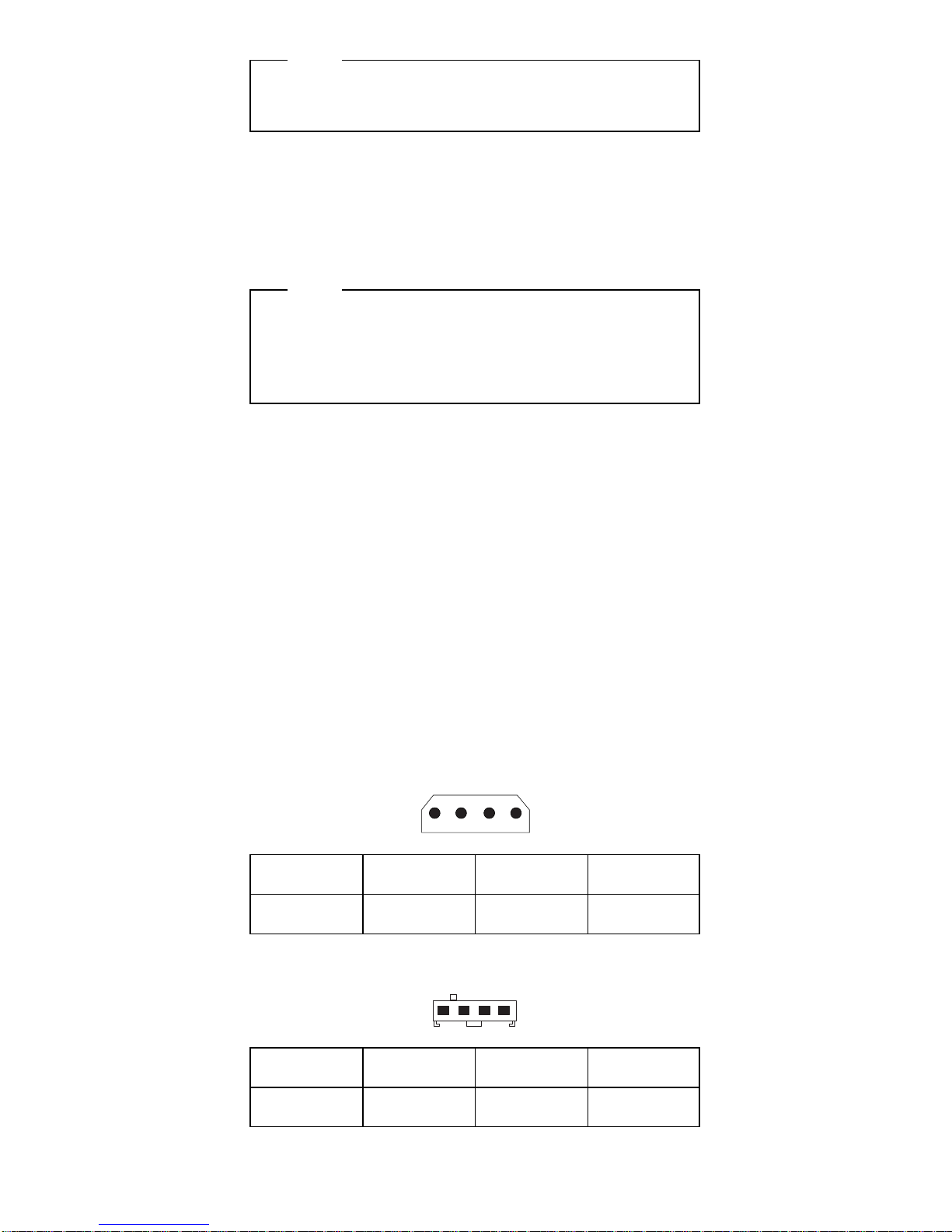

DASD Connectors P1, P2, P3, P4, P5, P6, P7, P8

14

Aux SCSI Board Power Connectors P9, P10

41

−Lead

Pin

+Lead

Pin

V dc

Minimum

V dc

Maximum

2

3

1

4

+11.52V

+4.8V

+12.6V

+5.25V

−Lead

Pin

+Lead

Pin

V dc

Minimum

V dc

Maximum

2

3

1

4

+11.52V

+4.8V

+12.6V

+5.25V

4 PC Server HMM

Page 10

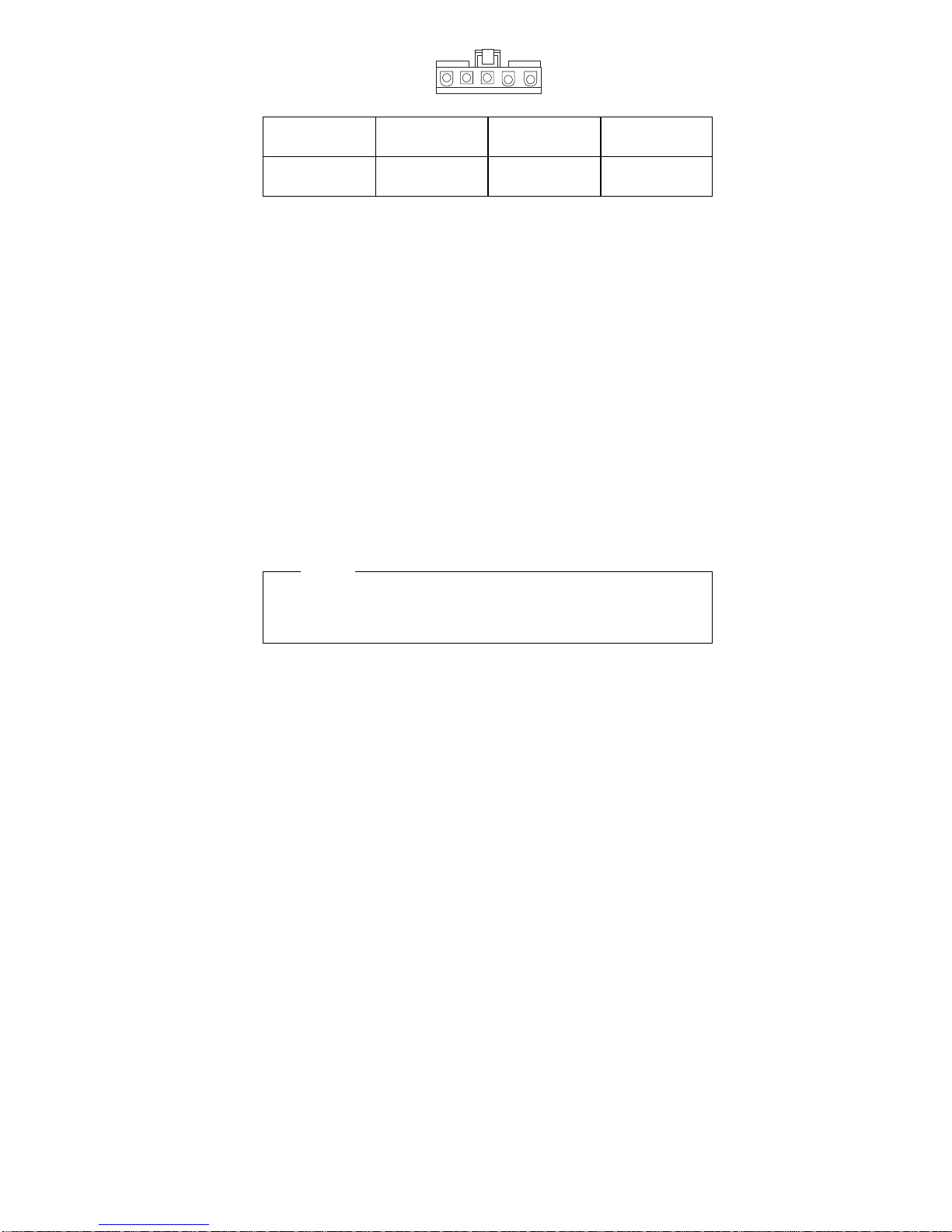

Switch Board Connector P11

5

1

Power Supply Shutdowns:

If the power supply shuts down, or

appears

to fail at

power-on, you might have one of the following problems:

Too many devices are set to start instantly. See

“Setting the Motor-Start Jumper” on page 414 in the

PS/2 Hardware Maintenance Manual.

There are too many large-capacity devices installed

(such as hard disk drives). The nominal operating

current of the devices installed collectively exceeds

the available current of the power supply. See the

“Personal System/2 Installation Planning” guide (form

number S41G-2927) for more information.

Also ensure that the fans operate when the machine is

powered on.

Note

Verify that the voltage-select switch (if applicable) is

set for the correct voltage.

−Lead

Pin

+Lead

Pin

V dc

Minimum

V dc

Maximum

5

5

4

3

+11.52V

+4.8V

+12.6V

+5.25V

Rack Storage Enclosure - Type 3519 5

Page 11

SCSI IDs: Each SCSI device installed in the storage

enclosure must have a unique SCSI identifier (ID). This

unique ID enables the SCSI controller to recognize the

device. This SCSI ID also prevents two devices from

attempting to send or receive data on the SCSI bus at the

same time. IBM PC Server SCSI controllers use ID 7.

Therefore, you must not assign ID 7 to any device that you

install in the storage enclosure. SCSI devices support the

following IDs:

Narrow devices support SCSI IDs 0 to 6.

Wide devices support 0 to 6 or 8 to 15.

When you install a hot-swap drive, the backplane behind

bays 4 through 9 automatically assigns the drive its SCSI

ID. However, when you install a drive in bays 1 through 3,

you must set a unique SCSI ID for the drive that does not

conflict with any of the IDs that the backplane assigns to

drives in bays 4 through 9.

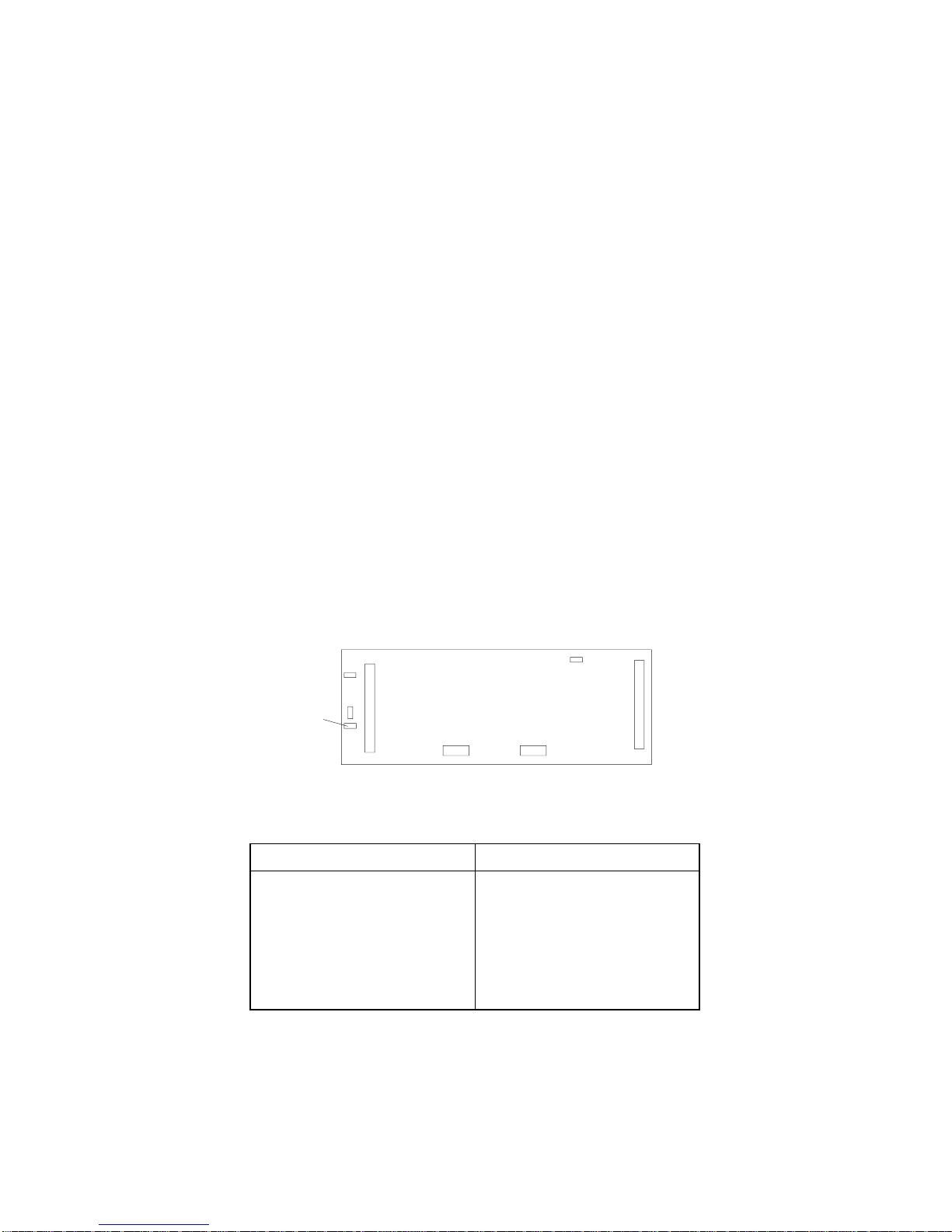

Depending on the setting of the SCSI ID address jumper

(J12) on the rear of the backplane, the backplane sets the

SCSI IDs for bays 4 through 9. SCSI IDs 8 to 13 are the

default IDs for the hot-swap drives. SCSI IDs 0 to 5 are

also available for the hot-swap drives.

The SCSI ID address jumper, a pin block with four pairs of

pins (J12), is located on the rear of the backplane. The

default, cover installed on the HI ID N pins, sets the

addresses to HI.

J12

The backplane sets the SCSI IDs for bays 4 through 9 as

follows:

LO Settings HI Settings (default)

Bay SCSI ID

4 0

5 1

6 2

7 3

8 4

9 5

Bay SCSI ID

4 8

5 9

6 10

7 11

8 12

9 13

6 PC Server HMM

Page 12

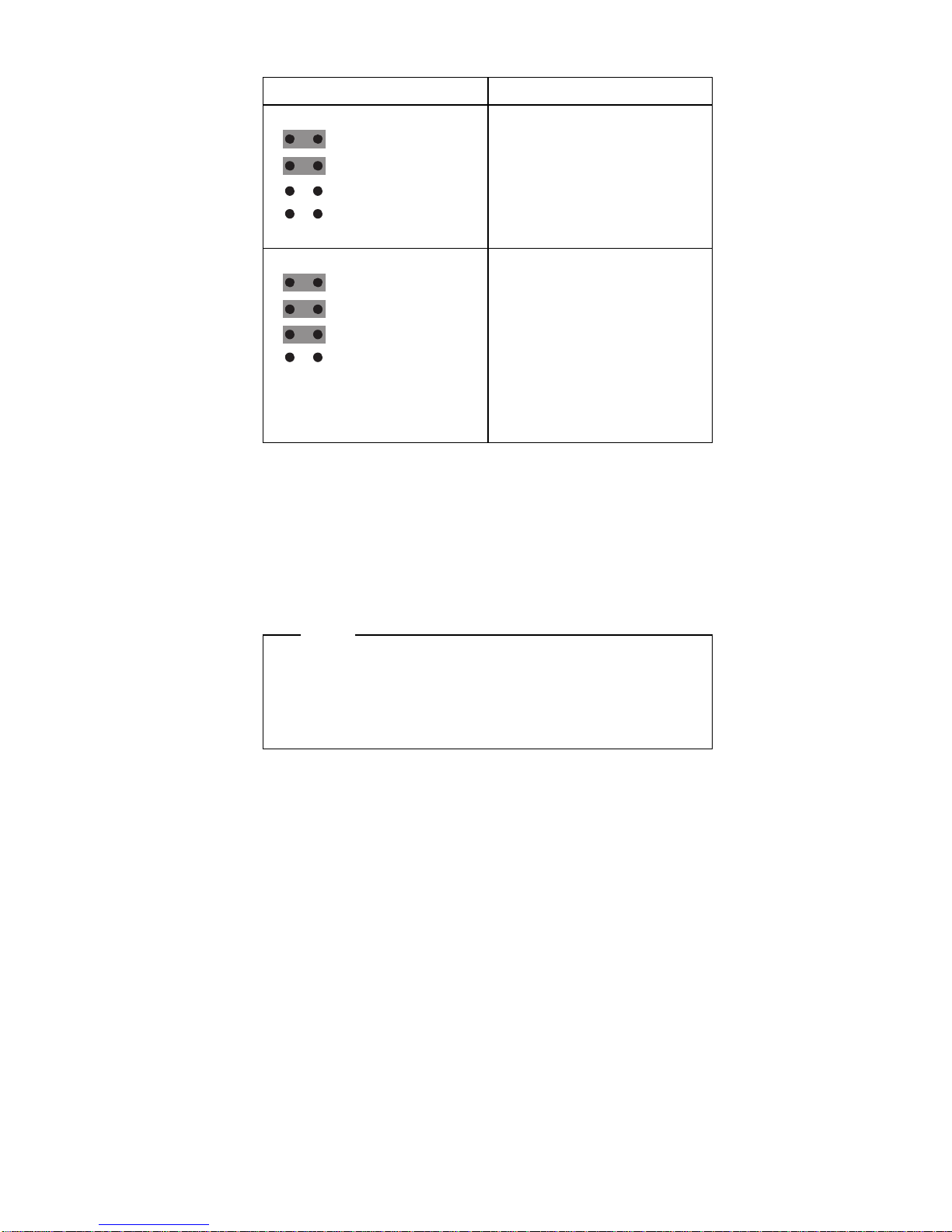

The following table summarizes the jumper settings for the

SCSI ID address jumper (J12).

Refer to the documentation that came with the drive for

information about setting its SCSI ID.

If the storage enclosure is attached to a RAID adapter,

refer to the information that came with the adapter for

SCSI ID requirements.

Jumper Position Description

LO

J12

SYS RST

ID REV

HI ID N

HP PULSE N

No cover installed on the HI

ID N pins, sets SCSI IDs to

LO.

HI

J12

SYS RST

ID REV

HI ID N

HP PULSE N

Sets SCSI IDs to HI. Use

this setting, cover installed

on the HI ID N pins, when

you install narrow

non-hot-swap devices and

the configuration requires

you to define some

non-hot-swap devices with

high IDs. This is the default

setting.

SCSI Repeater Cards

Note

If you connect the storage enclosure to a

non-disk-array server, the SCSI bus must be

dedicated to the storage enclosure. That is, you

cannot connect other devices to the SCSI bus.

The storage enclosure comes equipped to connect to one

server. To connect:

Two servers and one storage enclosure, see

“Connecting Two Servers and One Storage

Enclosure” on page 8.

One server and two storage enclosures, see

“Connecting One Server and Two Storage

Enclosures” on page 9.

Rack Storage Enclosure - Type 3519

7

Page 13

Connecting Two Servers and One Storage

Enclosure: To install a second SCSI Repeater Card

to connect two servers and the storage enclosure, do the

following.

1. Set the SCSI ID address jumper on the backplane of

the storage enclosure to HI. See “SCSI IDs” on

page 6 for information on the SCSI ID address

jumper.

2. Assign a unique SCSI ID to the SCSI controller of

each server. For example, if the SCSI controller in

both servers is set to 7, set the SCSI ID of one SCSI

controller to 6.

3. Install the SCSI Repeater Card in the expansion

enclosure.

4. Connect the power cable to the SCSI Repeater Card.

5. Connect one end of the SCSI option cable to the

internal SCSI connector on the SCSI Repeater Card;

then, connect the other end of the cable to the

backplane on the storage enclosure.

External SCSI

Connector

Power Connector

Internal SCSI

Connector

SCSI Knockout

Panel

8 PC Server HMM

Page 14

Connecting One Server and Two Storage

Enclosures

Note

You must have a Y-cable available for connecting the

server and storage enclosures. The Y-cable can be

ordered from an IBM marketing representative or an

IBM reseller.

To connect the storage enclosure to one server and

another storage enclosure, do the following.

1. Set jumpers (J3 and J6) on the SCSI Repeater Card.

J3

J6

The default settings for both jumpers is ON (covers

on each jumper). The following table summarizes the

jumper settings for the SCSI Repeater Card jumpers.

Jumper Description

J3 Leave the jumper in the ON

position.

J6 Use the OFF position (cover

removed) to connect the

storage enclosure to the

double connector of a

Y-cable.

Use the ON position (cover in

place) in all other cases.

Rack Storage Enclosure - Type 3519 9

Page 15

2. Set the SCSI ID address jumpers on the backplanes

of the storage enclosures. See “SCSI IDs” on page 6

for information on the SCSI ID address jumpers. The

following illustrates cabling and jumper setting

requirements.

J3 ON

J6 ON

HI

J3 ON

J6 OFF

LO

Backplane

Jumpers

SCSI Address

Jumpers

Expansion

Enclosure 2

Expansion

Enclosure 2

Expansion

Enclosure 1

Expansion

Enclosure 1

Server

Double

Cable

Connector

Y-Cable

The storage enclosures can contain a maximum of

twelve slim-high, or six half-high hot-swap drives.

SCSI Termination

Termination ensures that the quality of the signal is

maintained throughout the SCSI chain. If you chain SCSI

devices in bays 1 through 3, the backplane automatically

sets termination for all devices. The backplane also

automatically sets termination for hot-swap drives.

Before you install a SCSI device, set the termination to

DISABLED. On some devices, you will need to remove

jumpers. Refer to the information that came with the

device for instructions.

10 PC Server HMM

Page 16

Specifications

Size

Depth: 465 mm (18.3 in.)

Height: 216 mm (8.5 in.)

Width: 482 mm (19.0 in.)

Weight

Typical storage enclosure as shipped: 17 kg (37.5 lb)

Environment

Air temperature:

– Storage Enclosure on:

10° to 35° C

(50° to 95° F)

Altitude: 0 to 914 m (3000 ft.)

– Storage Enclosure on:

10° to 32° C

(50° to 90° F)

Altitude: 914 m (3000 ft.) to 2133 m (7000 ft.)

– Storage Enclosure off:

10° to 43° C

(50° to 110° F)

Maximum Altitude: 2133 m (7000 ft.)

Humidity:

– Storage Enclosure on:

8% to 80%

– Storage Enclosure off:

8% to 80%

Maximum altitude: 2133 m (7000 ft)

Electrical Input

Sine-wave input (50 to 60 Hz) is required

Input voltage:

– Low range:

- Minimum: 90 V ac

- Maximum: 137 V ac

– High range:

- Minimum: 180 V ac

- Maximum: 265 V ac

– Input kilovolt-amperes (kVA) approximately:

- Minimum configuration as shipped: 0.08 kVA

- Maximum configuration: 0.52 kVA

Total Power Available for Drives

Nominal Operating Current allowed:

– +5 V dc line: 5.3 A

– +12 V dc line: 5.0 A

Heat Output

Approximate heat output in British Thermal Units (Btu) per

hour:

– Minimum configuration:

350 Btu (102 watts)

– Maximum configuration:

860 Btu (251 watts)

Rack Storage Enclosure - Type 3519 11

Page 17

Locations

“Access Cover” on page 13.

“Cable Management Arm Bracket” on page 13.

“Chassis Draw Bracket” on page 13.

“Controls and Indicators” on page 14.

“Expansion Bays” on page 15.

“External Connectors” on page 18.

“Front Door” on page 18.

“Hot-Swap Drive Tray III” on page 19.

“Keylock Assembly Exploded View” on page 20.

“Rack Slides” on page 20.

“SCSI Repeater Card” on page 21.

“Slide Management Bracket” on page 21.

“Voltage Setting” on page 23.

12 PC Server HMM

Page 18

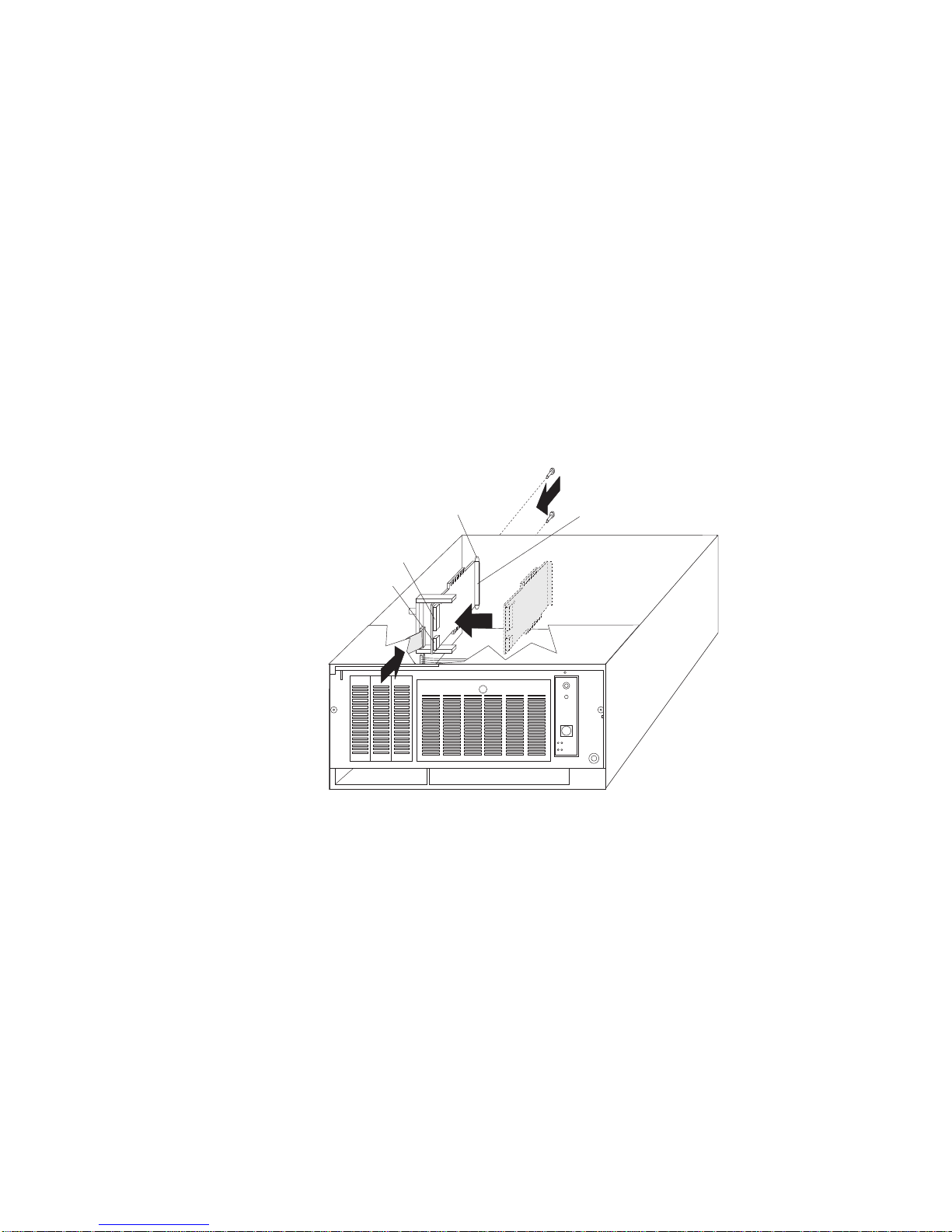

Access Cover

Captive Screws

Cable Management Arm Bracket

Chassis Draw Bracket

Rack Storage Enclosure - Type 3519 13

Page 19

Controls and Indicators

Reset Switch

Power Switch

Power-On Light

Fan Failure Light

Attention

The storage enclosure produces heat. Fans in the

storage enclosure pull in fresh air and force out hot

air. Operating the storage enclosure with an idle fan

can cause overheating, which might result in a

malfunction or damage.

Reset

Switch:

Use to cancel the fan failure warning buzzer.

Power

Switch:

Use to power the storage enclosure on and off.

To power-on the storage enclosure, press the

Power switch momentarily, and the Power On

indicator will illuminate in approximately one

second.

Power-On

Light:

This green LED lights when the storage

enclosure is powered on by pressing the Power

switch.

Fan

Failure

Light:

This amber LED lights if one or more of the

internal fans fail.

Note

If one or more fans remain idle, a warning

buzzer sounds. Press the Reset switch to

silence the warning buzzer.

14 PC Server HMM

Page 20

Expansion Bays

1 23456789

Table 1. Maximum Allowable Drive Sizes

Bay Drive Width Drive Type Drive Height

1 – 3 3.5-inch

5.25-inch

Removable

media drive1,

hard disk

drive

2

41.3 mm (1.6

in.)

4 – 9 3.5-inch Hot-Swap

3

25.4 mm (1.0

in.)

41.3 mm (1.6

in.)

Notes:

1. Removable media includes CD-ROMs, optical discs, and

tape.

2. You can install a maximum of two 41.3 mm drives.

3. A 41.3 mm drive installed in bays 4 through 9 occupies

two bays.

Rack Storage Enclosure - Type 3519 15

Page 21

Drive Bays 1 to 3

16 PC Server HMM

Page 22

Hot-Swap Drives Bays 4 through 9

Unlocked

Position

Locked

Position

Rack Storage Enclosure - Type 3519 17

Page 23

External Connectors

Power Connector

External SCSI Connector

( 68 Pin )

Note

See “SCSI Repeater Cards” on page 7 for information on

external connector requirements.

Power

Connector:

The storage enclosure power cable connects

here.

External

SCSI

Connector:

A SCSI cable attaches here, and connects

to the external SCSI connector on the

server. For disk-array servers, the cable

connects to the external SCSI connector on

a RAID adapter.

Front Door

Flange

18 PC Server HMM

Page 24

Hot-Swap Drive Tray III

Locked

Position

Green

Light

Amber

Light

Notes

1. Each hot-swap drive that you plan to install must

have a hot-swap drive tray III attached.

2. Trays are available for two drive types: narrow

and wide. The narrow tray supports 8-bit drives;

the wide tray supports 16-bit drives.

Green Amber Description

On Off Drive tray is powered on; the hard

disk drive is inactive; and the drive

should

not

be removed.

Blinking Off The hard disk drive is inactive.

The hot-swap drive can be

removed safely.

Note

This indication will only

appear if the expansion

enclosure is attached to a

RAID adapter.

On On or

Blinking

The hard disk drive is in use, and

should

not

be removed.

Off Off The drive is defective, or no power

is being supplied to the drive. The

hot-swap drive can be removed

safely.

Attention

Press the small switch on the

drive before you remove the

drive.

Rack Storage Enclosure - Type 3519 19

Page 25

Keylock Assembly Exploded View

Rack Slides

20 PC Server HMM

Page 26

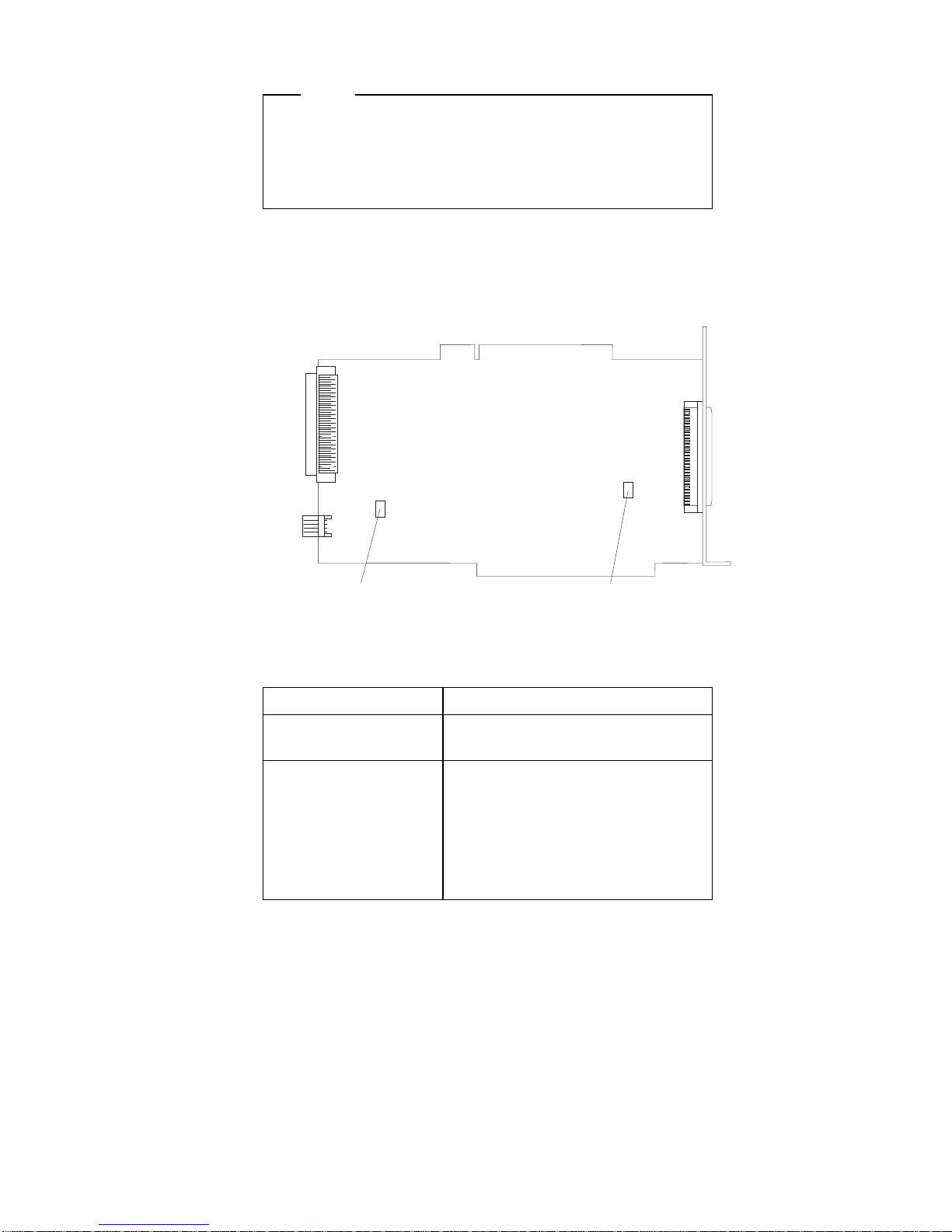

SCSI Repeater Card

Power Connector

Internal SCSI

Connector

SCSI Knockout

Panel

External SCSI

Connector

Slide Management Bracket

Rack Storage Enclosure - Type 3519 21

Page 27

22 PC Server HMM

Page 28

Voltage Setting

Attention: If you set the voltage switch to the wrong

position, you might permanently damage your storage

enclosure when you turn it on.

If the voltage range in your country is between 100

and 127 volts, check to see that 115 is visible. (Use

the 115-volt setting in the U.S. and Canada.)

If the voltage range in your country is between 200

and 240 volts, check to see that 230 is visible.

To adjust the voltage setting, slide the switch to the correct

position.

115V

Rack Storage Enclosure - Type 3519 23

Page 29

Symptom-to-FRU Index

This index supports the PC Server Rack Storage

Enclosure - Type 3519.

The Symptom-to-FRU Index lists symptoms and the

possible causes. The most likely cause is listed first. Use

this Symptom-to-FRU Index to help you decide which

FRUs to have available when servicing the rack enclosure.

Symptom FRU/Action

Expansion Enclosure will

not power-on.

1. Check voltage

switch, power cord,

power source and

cables.

2. Check the Power

Supply , see “Power

Supply (FRU Number

60H8301)” on page 4.

Fan Failure buzzer sounds,

Fan Failure LED lights, or

one or more of the internal

fans is not operating.

Attention

Do not operate the

expansion enclosure

unless all fans are

working properly.

1. Fan

2. Power Supply

SCSI Repeater Card that

was just installed does not

work.

1. Check termination

(See “SCSI

Termination” on

page 10.)

2. Repeater Card

3. SCSI Adapter that the

repeater card is

connected to.

SCSI Repeater Card that

used to work does not work

now.

1. Check termination

(See “SCSI

Termination” on

page 10.)

2. Repeater Card

3. SCSI Adapter that the

repeater card is

connected to.

SCSI device that used to

work does not work now.

1. Check SCSI ID

settings (See “SCSI

IDs” on page 6.)

2. Check termination

(See “SCSI

Termination” on

page 10.)

3. SCSI Device

4. Repeater Card

5. SCSI Adapter that the

repeater card is

connected to.

24 PC Server HMM

Page 30

Parts Listings (PC Server Rack Storage

Enclosure - Type 3519)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

Rack Storage Enclosure - Type 3519 25

Page 31

System (Model R01)

Index System (PC Server Rack Storage

Enclosure - Type 3519)

Model R01

FRU No.

1 Access Cover with Rear Bezel 72H2643

2 Fan Assembly 120 mm with Connector 60H9308

3 200W UV PFC Power Supply Assembly 60H8301

4 Base Frame Assembly 60H9283

5 Access Cover with Rear Bezel 72H2643

6 Hot-Plug Backplane 06H8576

7 Front Bezel Rack 60H8300

8 Cable Management Arm Bracket 72H2674

9 Chassis Draw Bracket 72H2676

10 Slide Management Bracket 72H2655

11 Rack Slides 72H2653

12 Slide Management Bracket 72H2655

13 Cable Management Arm 72H2657

14 Keylock with Keys 33F8433

15 Front Door Assembly Rack 60H8308

16 5.25-Inch Blank Bezel 76H3451

17 LED/On/Off Switch Cable Assembly 60H8302

18 Hot-Swap Door Assembly 60H9284

19 DASD Tray 06H2652

20 4.3 m 68/68 Cable 76H0501

21 SCSI Repeater Card 93H6409

22 Internal SCSI Cable 5X 60H8304

Miscellaneous Parts Kit 55H8179

PC Server Label 60H8306

Power Cords (See, “Power Cords” on

page 27.)

Push Catch and Bracket 60H9285

26 PC Server HMM

Page 32

Power Cords

PC Server Rack Storage Enclosure - Type 3519

FRU

No.

Arabic 14F0033

Belgium 1339520

Bulgaria 1339520

Czech Republic 1339520

Denmark 13F9997

Finland 1339520

France 1339520

Germany 1339520

Hungary 1339520

Israel 14F0087

Italy 14F0069

Latvia 1339520

Netherlands 1339520

Norway 1339520

Poland 1339520

Portugal 1339520

Serbia 1339520

Slovakia 1339520

South Africa 14F0015

Spain 1339520

Switzerland 1339520

Switzerland (French/German) 14F0051

U.S. English 62X1045

U.K./Ireland 14F0033

Yugoslavia 1339520

Rack Storage Enclosure - Type 3519 27

Page 33

Related Service Information

Safety Information . . . . . . . . . . . . . . . . 30

General Safety . . . . . . . . . . . . . . . . 30

Electrical Safety . . . . . . . . . . . . . . . . 31

Safety Inspection Guide ............ 32

Handling Electrostatic Discharge-Sensitive Devices 34

Grounding Requirements . . . . . . . . . . . . 34

Laser Compliance Statement ........... 35

Send Us Your Comments! ............. 37

Problem Determination Tips ............ 38

Phone Numbers, U.S. and Canada ......... 39

Notices . . . . . . . . . . . . . . . . . . . . . . 41

Trademarks . . . . . . . . . . . . . . . . . . . 41

Copyright IBM Corp. 1996, 1997 29

Page 34

Safety Information

The following section contains the safety information that

you need to be familiar with before servicing an IBM

computer.

General Safety

Follow these rules to ensure general safety:

Observe good housekeeping in the area of the

machines during and after maintenance.

When lifting any heavy object:

1. Ensure you can stand safely without slipping.

2. Distribute the weight of the object equally

between your feet.

3. Use a slow lifting force. Never move suddenly

or twist when you attempt to lift.

4. Lift by standing or by pushing up with your leg

muscles; this action removes the strain from the

muscles in your back.

Do not attempt to lift any

objects that weigh more than 16 kg (35 lb) or

objects that you think are too heavy for you.

Do not perform any action that causes hazards to the

customer, or that makes the equipment unsafe.

Before you start the machine, ensure that other

service representatives and the customer's personnel

are not in a hazardous position.

Place removed covers and other parts in a safe

place, away from all personnel, while you are

servicing the machine.

Keep your tool case away from walk areas so that

other people will not trip over it.

Do not wear loose clothing that can be trapped in the

moving parts of a machine. Ensure that your sleeves

are fastened or rolled up above your elbows. If your

hair is long, fasten it.

Insert the ends of your necktie or scarf inside clothing

or fasten it with a nonconductive clip, approximately 8

centimeters (3 inches) from the end.

Do not wear jewelry, chains, metal-frame eyeglasses,

or metal fasteners for your clothing.

Remember: Metal objects are good electrical

conductors.

Wear safety glasses when you are: hammering,

drilling soldering, cutting wire, attaching springs, using

solvents, or working in any other conditions that might

be hazardous to your eyes.

After service, reinstall all safety shields, guards,

labels, and ground wires. Replace any safety device

that is worn or defective.

Reinstall all covers correctly before returning the

machine to the customer.

30 PC Server HMM

Page 35

Electrical Safety

Observe the following rules when working on electrical

equipment.

Important

Use only approved tools and test equipment. Some

hand tools have handles covered with a soft material

that does not insulate you when working with live

electrical currents.

Many customers have, near their equipment, rubber

floor mats that contain small conductive fibers to

decrease electrostatic discharges. Do not use this

type of mat to protect yourself from electrical shock.

Find the room emergency power-off (EPO) switch,

disconnecting switch, or electrical outlet. If an

electrical accident occurs, you can then operate the

switch or unplug the power cord quickly.

Do not work alone under hazardous conditions or

near equipment that has hazardous voltages.

Disconnect all power before:

– Performing a mechanical inspection

– Working near power supplies

– Removing or installing main units

Before you start to work on the machine, unplug the

power cord. If you cannot unplug it, ask the customer

to power-off the wall box that supplies power to the

machine and to lock the wall box in the off position.

If you need to work on a machine that has

exposed

electrical circuits, observe the following precautions:

– Ensure that another person, familiar with the

power-off controls, is near you.

Remember: Another person must be there to

switch off the power, if necessary.

– Use only one hand when working with

powered-on electrical equipment; keep the other

hand in your pocket or behind your back.

Remember: There must be a complete circuit to

cause electrical shock. By observing the above

rule, you may prevent a current from passing

through your body.

– When using testers, set the controls correctly

and use the approved probe leads and

accessories for that tester.

– Stand on suitable rubber mats (obtained locally,

if necessary) to insulate you from grounds such

as metal floor strips and machine frames.

Observe the special safety precautions when you

work with very high voltages; these instructions are in

Related Service Information

31

Page 36

the safety sections of maintenance information. Use

extreme care when measuring high voltages.

Regularly inspect and maintain your electrical hand

tools for safe operational condition.

Do not use worn or broken tools and testers.

Never assume

that power has been disconnected

from a circuit. First,

check

that it has been

powered-off.

Always look carefully for possible hazards in your

work area. Examples of these hazards are moist

floors, nongrounded power extension cables, power

surges, and missing safety grounds.

Do not touch live electrical circuits with the reflective

surface of a plastic dental mirror. The surface is

conductive; such touching can cause personal injury

and machine damage.

Do not service the following parts

with the power on

when they are removed from their normal operating

places in a machine:

– Power supply units

– Pumps

– Blowers and fans

– Motor generators

and similar units. (This practice ensures correct

grounding of the units.)

If an electrical accident occurs:

– Use caution; do not become a victim

yourself.

– Switch off power.

– Send another person to get medical aid.

Safety Inspection Guide

The intent of this inspection guide is to assist you in

identifying potentially unsafe conditions on these products.

Each machine, as it was designed and built, had required

safety items installed to protect users and service

personnel from injury. This guide addresses only those

items. However, good judgment should be used to identify

potential safety hazards due to attachment of non-IBM

features or options not covered by this inspection guide.

If any unsafe conditions are present, you must determine

how serious the apparent hazard could be and whether

you can continue without first correcting the problem.

Consider these conditions and the safety hazards they

present:

Electrical hazards, especially primary power (primary

voltage on the frame can cause serious or fatal

electrical shock).

Explosive hazards, such as a damaged CRT face or

bulging capacitor

32 PC Server HMM

Page 37

Mechanical hazards, such as loose or missing

hardware

The guide consists of a series of steps presented in a

checklist. Begin the checks with the power off, and the

power cord disconnected.

Checklist:

1. Check exterior covers for damage (loose, broken, or

sharp edges).

2. Power-off the computer. Disconnect the power cord.

3. Check the power cord for:

a. A third-wire ground connector in good condition.

Use a meter to measure third-wire ground

continuity for 0.1 ohm or less between the

external ground pin and frame ground.

b. The power cord should be the appropriate type

as specified in the parts listings.

c. Insulation must not be frayed or worn.

4. Remove the cover.

5. Check for any obvious non-IBM alterations. Use

good judgment as to the safety of any non-IBM

alterations.

6. Check inside the unit for any obvious unsafe

conditions, such as metal filings, contamination, water

or other liquids, or signs of fire or smoke damage.

7. Check for worn, frayed, or pinched cables.

8. Check that the power-supply cover fasteners (screws

or rivets) have not been removed or tampered with.

Related Service Information

33

Page 38

Handling Electrostatic

Discharge-Sensitive Devices

Any computer part containing transistors or integrated

circuits (ICs) should be considered sensitive to electrostatic

discharge (ESD). ESD damage can occur when there is a

difference in charge between objects. Protect against ESD

damage by equalizing the charge so that the machine, the

part, the work mat, and the person handling the part are all

at the same charge.

Notes:

1. Use product-specific ESD procedures when they

exceed the requirements noted here.

2. Make sure that the ESD protective devices you use

have been certified (ISO 9000) as fully effective.

When handling ESD-sensitive parts:

Keep the parts in protective packages until they are

inserted into the product.

Avoid contact with other people.

Wear a grounded wrist strap against your skin to

eliminate static on your body.

Prevent the part from touching your clothing. Most

clothing is insulative and retains a charge even when

you are wearing a wrist strap.

Use the black side of a grounded work mat to provide

a static-free work surface. The mat is especially

useful when handling ESD-sensitive devices.

Select a grounding system, such as those listed

below, to provide protection that meets the specific

service requirement.

Note: The use of a grounding system is desirable

but not required to protect against ESD

damage.

– Attach the ESD ground clip to any frame ground,

ground braid, or green-wire ground.

– Use an ESD common ground or reference point

when working on a double-insulated or

battery-operated system. You can use coax or

connector-outside shells on these systems.

– Use the round ground-prong of the AC plug on

AC-operated computers.

Grounding Requirements

Electrical grounding of the computer is required for

operator safety and correct system function. Proper

grounding of the electrical outlet can be verified by a

certified electrician.

34 PC Server HMM

Page 39

Laser Compliance Statement

Some IBM Personal Computer models are equipped from

the factory with a CD-ROM drive. CD-ROM drives are

also sold separately as options. The CD-ROM drive is a

laser product. The CD-ROM drive is certified in the U.S. to

conform to the requirements of the Department of Health

and Human Services 21 Code of Federal Regulations

(DHHS 21 CFR) Subchapter J for Class 1 laser products.

Elsewhere, the drive is certified to conform to the

requirements of the International Electrotechnical

Commission (IEC) 825 and CENELEC EN 60 825 for

Class 1 laser products.

When a CD-ROM drive is installed, note the following.

CAUTION:

Use of controls or adjustments or performance of

procedures other than those specified herein might

result in hazardous radiation exposure.

O uso de controles, ajustes ou desempenho de

procedimentos diferentes daqueles aqui especificados

pode resultar em perigosa exposição à radiação.

Pour éviter tout risque d'exposition au rayon laser,

respectez les consignes de réglage et d'utilisation des

commandes, ainsi que les procédures décrites.

Werden Steuer- und Einstellelemente anders als hier

festgesetzt verwendet, kann gefährliche

Laserstrahlung auftreten.

L'utilizzo di controlli, regolazioni o l'esecuzione di

procedure diverse da quelle specificate possono

provocare l'esposizione a

El uso de controles o ajustes o la ejecución de

procedimientos distintos de los aquí especificados

Related Service Information

35

Page 40

puede provocar la exposición a radiaciones

peligrosas.

Opening the CD-ROM drive could result in exposure to

hazardous laser radiation. There are no serviceable parts

inside the CD-ROM drive. Do not open.

Some CD-ROM drives contain an embedded Class 3A or

Class 3B laser diode. Note the following.

DANGER:

Laser radiation when open. Do not stare into the

beam, do not view directly with optical instruments,

and avoid direct exposure to the beam.

Radiação por raio laser ao abrir. Não olhe fixo no feixe

de luz, não olhe diretamente por meio de instrumentos

óticos e evite exposição direta com o feixe de luz.

Rayonnement laser si carter ouvert. Évitez de fixer le

faisceau, de le regarder directement avec des

instruments optiques, ou de vous exposer au rayon.

Laserstrahlung bei geöffnetem Gerät. Nicht direkt oder

über optische Instrumente in den Laserstrahl sehen

und den Strahlungsbereich meiden.

Kinyitáskor lézersugár ! Ne nézzen bele se szabad

szemmel, se optikai eszközökkel. Kerülje a

sugárnyalábbal való érintkezést !

Aprendo l'unità vengono emesse radiazioni laser. Non

fissare il fascio, non guardarlo direttamente con

strumenti ottici e evitare l'esposizione diretta al fascio.

Radiación láser al abrir. No mire fijamente ni examine

con instrumental óptico el haz de luz. Evite la

exposición directa al haz.

36 PC Server HMM

Page 41

Send Us Your Comments!

We want to know your opinion about this manual (part

number 84H7202). Your input will help us to improve our

publications.

Please photocopy this survey, complete it, and then fax it

to IBM HMM Survey at 919-543-8167 (USA).

Name

Phone Number

1. Do you like this manual?

Ø Yes Ø No

2. What would you like to see added, changed, or

deleted in this manual?

3. What is your service experience level?

Ø Less than five years

Ø More than five years

4. Which Servers do you service most?

Thanks in advance for your response!

Related Service Information

37

Page 42

Problem Determination Tips

Due to the variety of hardware and software combinations

that can be encountered, use the following information to

assist you in problem determination. If possible, have this

information available when requesting assistance from

Service Support and Engineering functions.

Machine type and model

Processor or hard disk upgrades

Failure symptom

– Do diagnostics fail?

– What, when, where, single, or multiple systems?

– Is the failure repeatable?

– Has this configuration ever worked?

– If it has been working, what changes were made

prior to it failing?

– Is this the original reported failure?

Reference/Diagnostics Diskette Version

– Type and version level

Hardware configuration

– Print (print screen) configuration currently in use

– BIOS level

Operating system software

– Type and version level

Important

To eliminate confusion, identical systems are

considered

identical

only if they:

1. Are the exact machine type and models

2. Have the same BIOS level

3. Have the same adapters/attachments in the

same locations

4. Have the same address

jumpers/terminators/cabling

5. Have the same software versions and levels

6. Have the same Reference/Diagnostics Diskette

(version)

7. Have the same configuration options set in the

system

8. Have the same setup for the operation system

control files

Comparing the configuration and software set-up

between “working and non-working” systems will often

lead to problem resolution.

38 PC Server HMM

Page 43

Phone Numbers, U.S. and Canada

Note

EMEA customers should contact their Dealer or IBM

Service organization.

Before you place a call to the Support Center, refer to

“Problem Determination Tips” on page 38.

Authorized Dealers or Servicers

U.S. Customers and Helpware Subscribers

Number Information

919-517-0001 Bulletin Board Service - PC Company

800-528-7705 Bulletin Board Service - TSS Only

800-937-3737 IBM Business Partner Education

800-426-2472 IBM Customer Engineer Technical

Support

800-IBM-DEAL IBM Dealer Support Center

800-342-6672 IBM Direct Desktop Software Sales

303-924-4015 IBM Part Number ID and Look Up

800-426-7763 IBM PC HelpCenter

800-237-5511 IBM Software Defect Support (CSDs)

800-327-5711 IBM Software Ordering (Publications)

800-426-1484 IBM Supplies Technical Hotline

800-388-7080 IBM Warranty Parts Claims Center

Number Information

919-517-0001 Bulletin Board Service - PC Company

800-426-8322 Customer Education Business Unit

800-999-0052 Customized Operational Services

800-237-4824 EduQuest (Educational Computers)

800-964-8523 End User HelpDesk Support

800-742-2493 IBM Anti-Virus Services

800-447-4700 IBM Authorized Dealer Referrals

800-426-2468 IBM Dealer Referral

800-426-3333 IBM Information Referral Service

800-IBM-SERV IBM Service

800-772-2227 IBM PC HelpCenter and HelpDesk

800-426-7282 IBM Technical Manuals

800-426-9402

(Ext. 150)

Multimedia Information Center

800-241-1620 Multimedia HelpCenter

800-342-6672 OS/2 Information Line

800-237-5511 OS/2 Support Services

800-284-5933 Prodigy

914-962-0310 Prodigy User Questions

800-547-1283 Technical Coordinator Program

SystemXtra for Personal Systems

LAN Automated Distribution/2

OS/2 Bulletin Board

OS/2 Application Assistance Center

800-551-2832 Technical Solutions Magazine

Related Service Information 39

Page 44

IBM Canada Customer and Servicer Support

Number Information

800-661-PSMT Business Partner Marketing Support

905-316-5556 Business Partner Marketing Support -

Toronto

514-938-6048 Business Partner Marketing Support -

French

800-465-6600 Customer Relations

905-316-6666 Customer Relations - Toronto

800-465-6666 Customer Service Dispatch

800-263-2769 Customer Service Parts

800-465-2222 Customer Support Center (ISC)

416-443-5701 Customer Service Repair Center

800-465-7999 HelpClub Registration

800-465-7999 IBM Direct

905-513-3367 IBM Certification Administrator

905-316-2683 IBM Certification Coordinator

Mail to: 50 Acadia Drive

Markham, Ontario L3R 0B3

800-465-3299 IBM HelpFax

905-316-3299 IBM HelpFax - Toronto

800-565-3344 IBM HelpPC

800-268-3100 IBM Information Network Support

800-268-3100 IBM Information Network Support -

Toronto

800-387-8343 IBM PC Service Partners

800-663-7662 Lexmark Product Information

800-263-2769 Parts Orders, Exchange or Emergency

416-443-5808

(Fax)

Parts Regular Orders, Exchange

416-443-5755 Parts Orders, Inquiries

514-938-3022 PC Co Bulletin Board - Montreal

905-316-4255 PC Co Bulletin Board - Toronto

604-664-6464 PC Co Bulletin Board - Vancouver

204-934-2735 PC Co Bulletin Board - Winnepeg

800-661-7768 PS Marketing Support (PSMT)

800-465-1234 Publications Ordering

905-316-4148 Service Management Support

905-316-4100

(Fax)

Service Management Support

905-316-4150 Service Manager

905-316-4100

(Fax)

Service Manager

905-316-4872 Service Quality Programs

905-316-4100

(Fax)

Service Quality Programs

800-661-2131 Skill Dynamics (Education)

800-565-3344 PS/1 Warranty Customer Helpline

800-387-8483 PS/1 Warranty Service (DOAs)

416-443-5835

(Fax)

Warranty Claim Fulfillment

905-316-2445 Warranty Claim Reimbursement

905-316-3515

(Fax)

Warranty Claim Reimbursement

416-443-5778 Warranty Claim Parts Inquiry

800-505-1855 Warranty Provider Support Hotline

800-267-7472 Warranty Service, ThinkPad

40 PC Server HMM

Page 45

Notices

References in this publication to IBM products, programs,

or services do not imply that IBM intends to make these

available in all countries in which IBM operates. Any

reference to an IBM product, program, or service is not

intended to state or imply that only that IBM product,

program, or service may be used. Subject to IBM’s valid

intellectual property or other legally protectable rights, any

functionally equivalent product, program, or service may be

used instead of the IBM product, program, or service. The

evaluation and verification of operation in conjunction with

other products, except those expressly designated by IBM,

are the responsibility of the user.

Trademarks

The following terms are trademarks of the IBM Corporation

in the United States or other countries or both:

The following terms are trademarks of other companies:

Business Partner EduQuest

HelpCenter HelpClub

HelpFax IBM

OS/2 Personal System/2

PS/1 PS/2

PS/ValuePoint Skill Dynamics

ThinkPad SystemXtra

Frame Frame Technology, Inc.

Lexmark Lexmark International, Inc.

Related Service Information 41

Page 46

IBM

Part Number: 84H7202

Printed in U.S.A.

S84H-72ð2-ðð

Loading...

Loading...