Page 1

-----.J

..

~

~------1

------1

------1

------1

------1

-----.J

-.:......J

~

~

'

------1

------1

----.J

------1

------1

-----.J

----

"---./

-----!l:

.

~

------1

------1

,

.........:..-:;

--...!..:.J

'

~

------1

~

,

I

~

------1

----'-....J

• -----"--..J

------1

~

------1

------1

------1

•

__

-..I

------1

~

------1

------1

------1

------1

,.

I

------1

~

------1

-----------

"----

----1

-----./

-----.J

----1

-----./

-----.J

---

~

----.J

-----J

.---l

----1

----1

......:........

---~

---------

----.J

~

----.J

----.J

~

---./

~

~

----.J

~

-' -'

~

---./

----.J

----.J

---.--

~

-----0.

----./

----.J

-'

----./

-'

-'

~

-' -'

----./

-'

----.J

----.J

~ ~

----.J

----./

----.J ----.J

----.J

~

~ ~

---------

---------

'--------'.

.'

========:=~~

~

--J

----.J

----.J

--'

---.J

---'

---.J

---'

~

---'

---.J

---'

---'

---'

---'

---'

---.J

--'

--'

---'

---'

---

---'

---'

---"

----,

---'

---'

-----l

---'

---'

---'

---'

---' ---' ---'

---'

---'

--'

---'

---'

~

---'

---' ---'

---'

---'

----'

---'

---'

----'

........:....,

---'

----'

---'

---'

----'

---'

---'

----'

---'

---'

----'

---'

---'

-----

-----

-----

-----

,

----

------

,

~~

/

-----'

'

-----'

-----'

-----'

,

,

~

---J

-----'

-----'

-'

---J

.---'

-----' -----'

-----'

--

~

.

-----'

~

-

~

-----'

---=

-----'

-----' -----'

-----'

-----'

-----'

-----'

-----'

-----' -----'

-----'

-----'

-----'

-----'

IBM

3420/3803

Magnetic Tape Subsystem

Reference Guide

Page 2

'PREFACE

, . This

reference~guide

and associated video presentation were created by FE Service Plan-

'.

'ning and Support to assist you in maintaining the 3420/3803 Magnetic Tape Subsystem.

Two approaches were taken:

L',

New information

is

included as a result

of

IR

data indicating the areas where more

in-depth knowledge

is

needed.

2.

Current information, which

is

frequently used, has been condensed from the

MLM/

:

Pathfinder and included here.

The guide

is

divided'into four major sections. Each

of

these sections contains informa-

tion which logically

fits into that section. Take the time to glance through the guide and

get an idea

of

what

is

included.

Pay particular attention

to

the "NTF Service Checks" portion

of

each area.

It

is

intended

..

to

give

you a list

of

actions

to

be performed which may help eliminate many call-back

situations.

When

you write a no trouble found

IR

(major unit 960) try to

use

unit/cause

codes which best describe the reported failure symptom

so

that FE SP/S may have a

better understanding

of

areas

of

the machines with intermittent problems.

THIRD

EDITION (January 1980)

This

is

a major revision of,

but

does not make S229-6019-1

obsolete.

Address any comments concerning the contents

of

thls publication to:

IBM

Field

Engineering Service

Planning, Department 96C,

BUilding

005, Tucson, Arizona 85744.

© Copyright International Business Machines Corporation 1978,

1980

Page 3

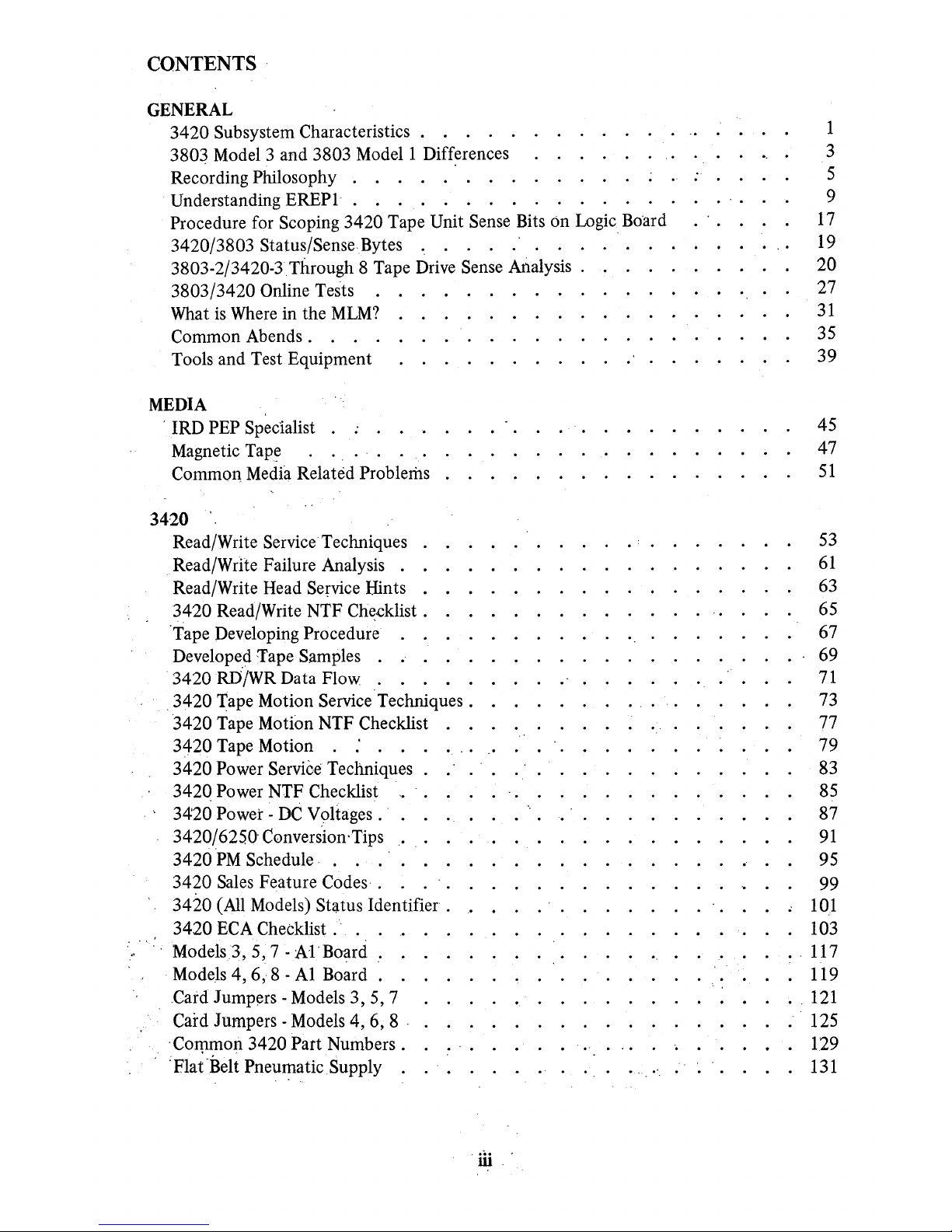

CONTENTS

GENERAL

3420 Subsystem Characteristics. . . . .

3803 Model 3 and 3803

Modell

Differences

Recording Philosophy . . . . . . . .

Understanding

EREP1.

. . . . . . .

Procedure for

Scoping 3420 Tape Unit Sense Bits on Logic Board

3420/3803 Status/Sense Bytes

~

. . . .' . . .

3803-2/3420-3Tiuough 8 Tape Drive

Sense Atialysis. .

3803/3420 Online Tests

What

is

Where in the

MLM?

Common

Abends.

. . .

Tools and Test Equipment

MEDIA

, IRD PEP Specialist

Magnetic

Tap~

CommOl1

Media Related Problems

3420 "

Read/Write Service Techniques

Read/Write Failure Analysis .

Read/Write Head

Service Hints .

3420 Read/Write NTF

Ch~ck1ist

.

Tape Developing Procedure

Developed Tape Samples . . .

3420 RD/WR Data Flow . . .

,3420

Tape Motion Service Techniques. .

3420 Tape Motion NTF Checklist .

3420

Tape Motion . : . . .

3420 Power Service Techniques

342Q Power NTP Checklist

,

34:20

Power -

DC

Voltages .

3420/625,0- Conversion-Tips .

34

20

PM

Schedule, . .

.'

3420 Sales Feature Codes, .

3420 (All Models) Status

Identifier.

3420 ECA Checklist

."

.

Models3, 5, 7 -

AI'

BO'ard

,.

.

Models 4, 6, 8 -

Al

Board.

.

.Card

Jump~rs

- Models 3, 5, 7

Card Jumpers - Models

4,6,8

'

'Co1l1mon

3420 Part Numbers.

'FlafBelt

Pneuf!1atic

Supply

.,

3

5

9

17

19

20

27

31

35

39

45

47

51

53

61

63

65

67

69

71

73

77

79

83

85

87

91

95

99

~

101

103

117

119

, 121

125

129

131

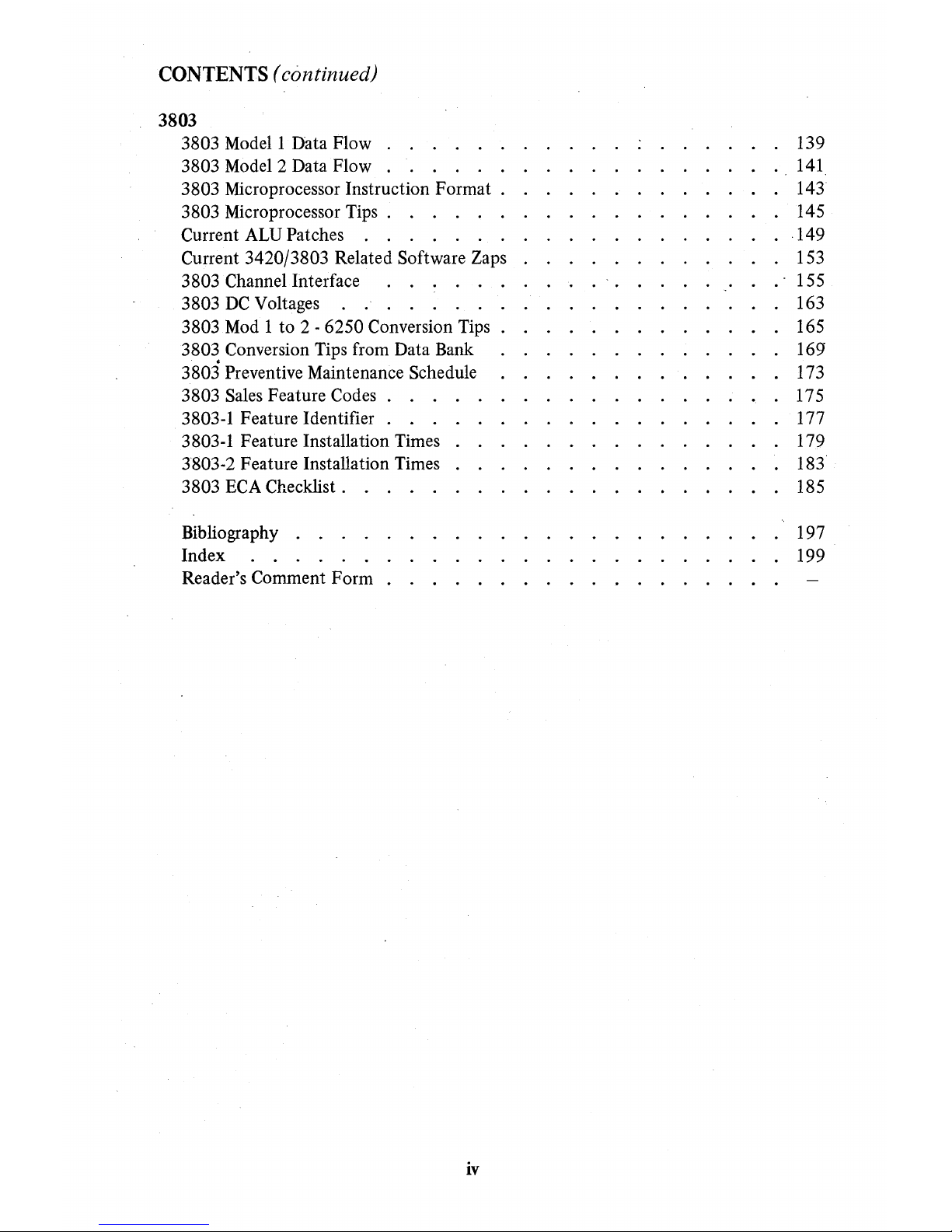

Page 4

CONTENTS

(continued)

3803

3803

Modell

Data Flow

3803 Model 2 Data Flow

3803 Microprocessor Instruction

Format.

3803 Microprocessor

Tips.

. . . . .

Current ALU Patches . . . . . . .

Current

3420/3803 Related Software Zaps

3803

Channel Interface . . . . .

3803

DC

Voltages . . . . . . .

3803

Mod

1 to 2 - 6250 Conversion Tips

3803 Conversion Tips from Data Bank

3803 Preventive Maintenance Schedule

3803 Sales Feature

Codes.

. .

3803-1 Feature Identifier . . .

3803-1 Feature Installation Times .

3803-2 Feature Installation Times

3803

ECA

Checklist. .

Bibliography . . . .

Index . . . . .

Reader's Comment Form

iv

139

141

143

145

149

153

155

163

165

169

173

175

177

179

. 183

185

197

199

Page 5

" GENERAL

Page 6

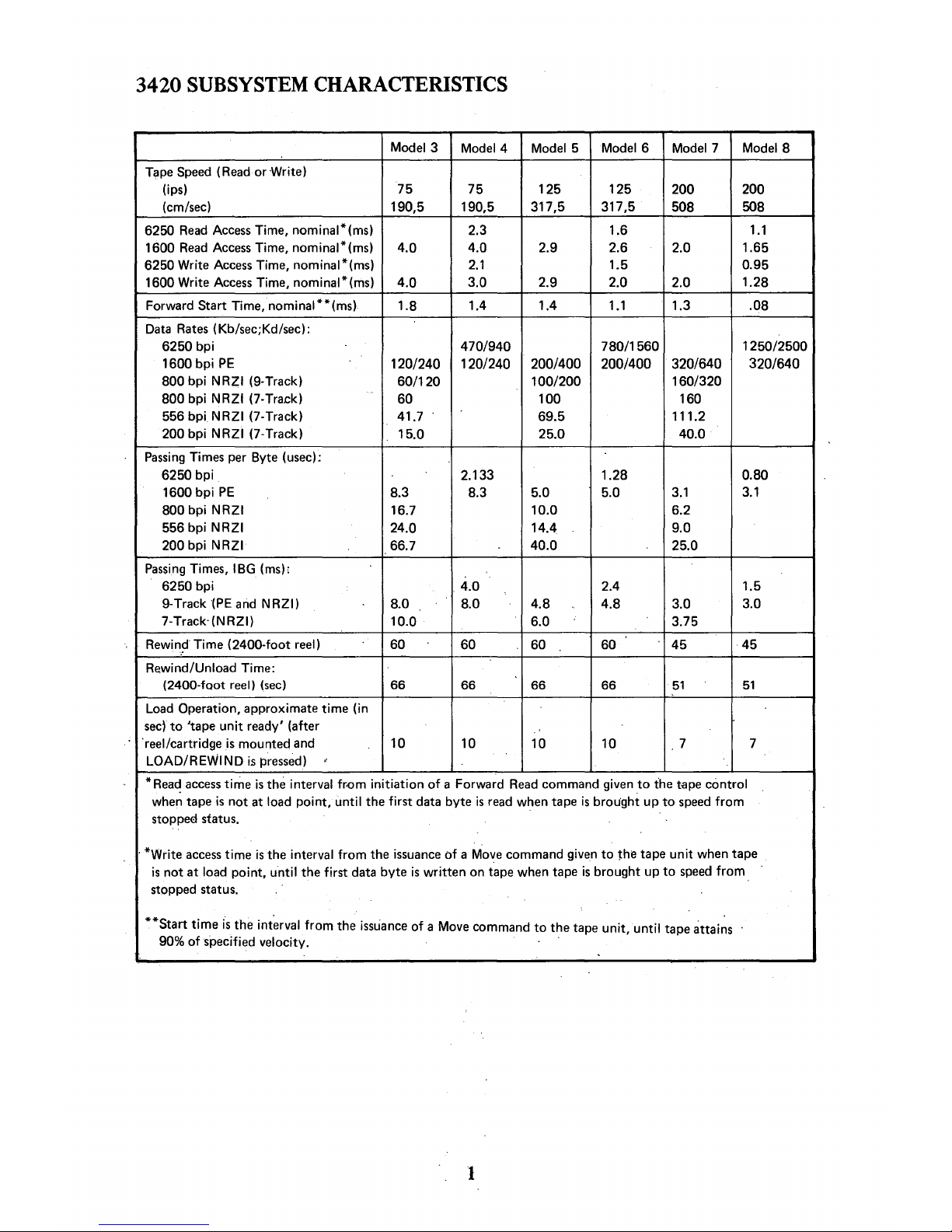

3420

SUBSYSTEM

CHARACTERISTICS

Model 3

Model 4 Model 5

Model 6

Model 7 Model 8

Tape

Speed

(Read

or Write)

(ips) 75

75

125 125

200 200

(cm/sec)

190,5

190,5

317,5 317,5

508

508

6250

Read

Access

Time, nominal*(ms)

2.3 1.6

1.1

1600

Read

Access

Time, nominal*(ms)

4.0

4.0

2.9 2.6 2.0

1.65

6250 Write

Access

Time, nominal*(ms)

2.1

1.5 0.95

1600

Write

Access

Time, nominal*(ms)

4.0

3.0

2.9 2.0

2.0

1.28

Forward

Start Time, nominal**(ms)

1.8 1.4 1.4

1.1

1.3 .08

Data

Rates

(Kb/sec;Kd/sec):

6250 bpi

470/940 780/1560

1250/2500

1600

bpi

PE

120/240

1201240

200/400 200/400

320/640 320/640

800

bpi NRZI (9-Track)

60/120

100/200 160/320

800

bpi NRZI (7-Tra.ck)

60

100 160

556 bpi NRZI (7-Track)

41.7 69.5

111.2

200 bpi NRZI (7-Track)

15.0

25.0 40.0

Passing

Times per Byte (usec):

6250 bpi

2.133 1.28

0.80

1600

bpi

PE

8.3

8.3

5.0

5.0

3.1

3.1

800 bpi NRZI

16.7 10.0 6.2

556 bpi

NRZI

24.0

14.4 9.0

200

bpi NRZI

66.7

40.0

25.0

Passing

Times, IBG (ms):

6250 bpi

4.0 2.4

1.5

9-Track(PE

and

NRZI)

8.0 8.0

4.8 4.8

3.0

3.0

7-Track'(NRZI)

10.0

6.0

3.75

Rewin.~·

Time (2400-foot reel) 60

60 60 60

45

45

Rewind/Unload Time:

(2400-fQot reel)

(sec)

66

66 66 66

51

51

Load

Operation, approximate time (in

sec)

to

'tape

unit

ready' (after

'reel/cartridge

is

mounted and

10

10 10 10

7

7

LOAD/REWIND

is

pressed)

*

Read

access

time

is

the interval fr.om initiation

of

a Forward

Read

command given

to

the

t-ape

control

whe~

tape

is

not

at load point, until the first data byte

is

read

when tape

is

brought up

to

speed

from

stoppe€!

status.

, *Write

access

time

is

the interval

from

the

issuance

of a Move

command given

to

~he

tape

unit

when tape

is

not

at load point,

until

the first data byte

is

written on tape when tape

is

brought up

to

speed

from

stopped status.

**Start

time

is

the

int~rval

from

the

issuance

of

a Move command

to

the tape unit, until tape

attai~s

90%

of

specified velocity. .

1

Page 7

Page 8

3803

MODEL 3 AND

3803

MODEL 1 DIFFERENCES

The Model 3

was

designed

to

attach

to

370/ 115s and 125s.

It

is

basically a

Modell

with

three major differences. These differences are required because the 115 and 125

don't

use

a standard 370 channel.

- ALUI

is

modified

to

interface with the channel on the 115 and 125 and translate the

activity to

370 channel sequences which the rest

of

the 3803 understands.

- Hardware logic called

AUTO DATA TRANSFER

is

provided

to

handle the data trans-

fer.

It

includes the byte counter.

- A 32-BYTE DATA BUFFER

is

provided for reading and writing. This large a buffet

is

required in the event

that

data crosses a page boundary. When this happens, time

is

required for ALUI to set the address

of

the new page back into the data address con-

trol in the 115 or 125.

The 3803 Model 3 tape subsystem connects to the Magnetic Tape Adaptor (MT

A)

inter-

face

of

system 3115 or system 3125. The term

MT

A interface refers

to

a set

of

lines over

which control and data signals are exchanged between the control unit and the

MT

A

portion

of

the system.

The basic

3803-3 Control Unit consists

of a MT

A interface attachment section, a data

buffer section, a microprogram section, a read section, a write section, a tape unit

inter-

face and a

CE

section.

I/O commands received from

CPU

through

MTA

are executed with microprograms resident in two independent read-only storage (ROS) units within the 3803-3 Control Unit.

One ROS controls the MTA interface lines while the other ROS controls the tape unit

interface.

The

3803-3 Control Unit operates in burst mode for all data transfers and executes com-

mands received across the interface, performing one command

on

a single tape unit at a

time.

When

a 3803 Mode13

is

taken offline, all functions from the control

to

the tape unit

become the same

as a Modell

3803.

3

Page 9

Page 10

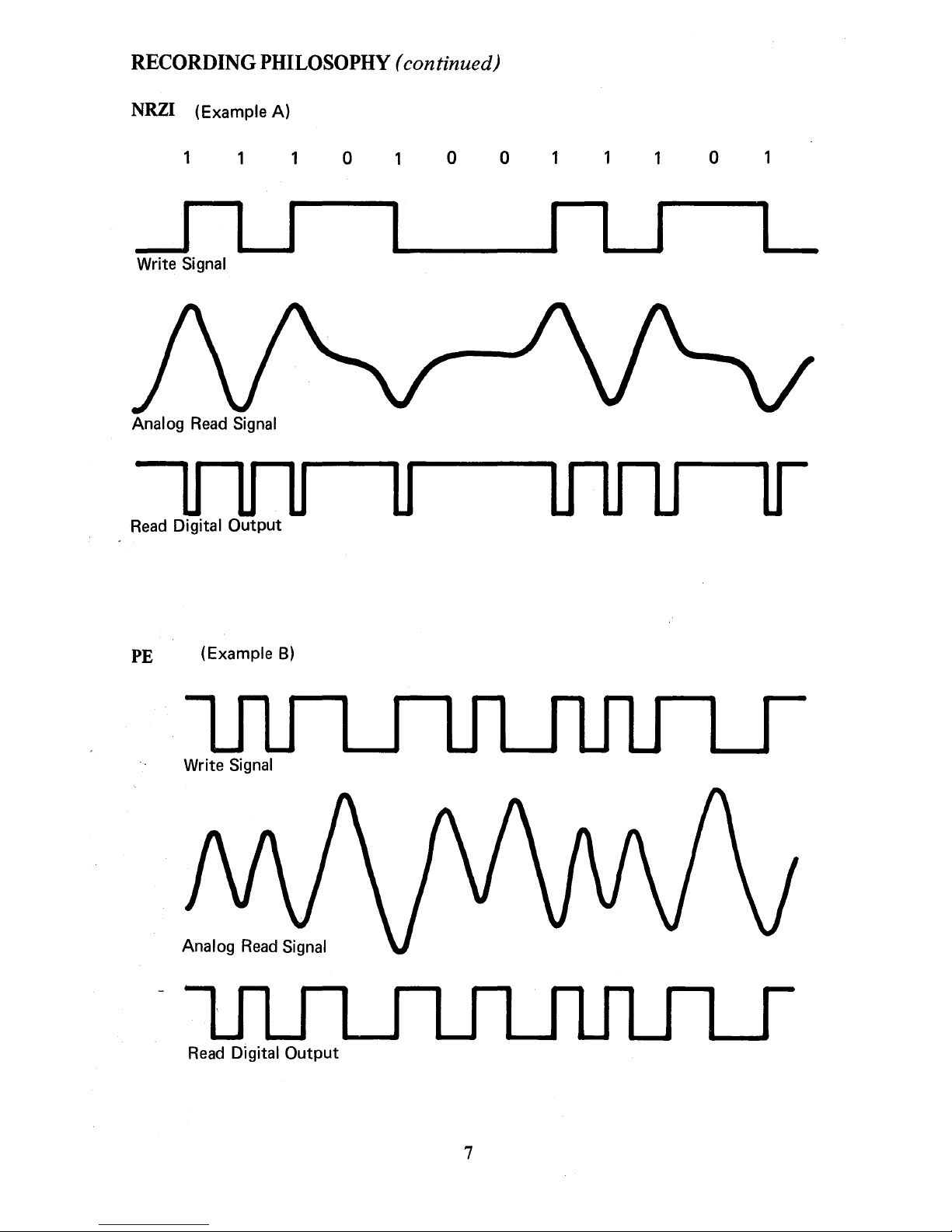

RECORDING

PHILOSOPHY

Types

of

Codes:

NRZI

PE

GCR

Non-Return

to

Zero Indicating

Phase Encoding

Group Coded Recording

The progression

of

IBM

digital recording from NRZI

to

PE to GRC

is

the result

of

IBM's

effort to provide the customer with

the lowest cost and highest reliability tape storage

devices.

NRZI coding utilizes a chnage in flux

to

indicate a one and no change

to

represent a zero.

NRZI tapes can be written in densities

of

200, 556 bpi in 7 -track format, and 800 bpi in

9-trace format. (See example A.)

PE coding utilizes a change

of

magnetic flux in the positive direction

to

indicate a one

and a change in the negative direction

to

indicate a zero. PE tapes are written

in

1600

bpi 9-track density only. (See example B.)

GCR coding utilizes a combination

of

NRZI and PE

to

achieve the highest density avail-

able on

IBM

drives. Density for GCR

is

effectively 6250 bpi. (See Example C.)

Group

Coded Recording -

6250

bpi

Group Coded Recording (GCR) offers many advantages over previously used recording

methods. This recording offers higher reliability even with existing tape libraries.

Greatly expanded error correction capability has been engineered into GCR. Higher

data rates and lower access times

give

higher throughput and reduced channel time,

re-

sulting in higher system performance. Data

is

compacted on tape, reducing rewind

times, shortening the length

of

tape required for a data set, reducing the number

of

reels, reducing mounts and dismounts, and improving overall tape handling. Other

advantages exist,

but

here

we

wish

to

discuss only the recording technique.

The data

is

still recorded in blocks, or groups

of

characters. A block

of

data may be

a single character or byte, or a number

of

bytes

as

determined by the programming

system used. The significant improvements in the GCR mode are:

1. The information data

is

recorded at an effective density

of

6250 bytes per inch.

2. The separation between blocks (IBG)

is

0.3 inch, and,

3. That simultaneous errors in any two

of

the nine tracks are corrected automatically.

A GCR block consists

of

a preamble, data and a postamble. The preamble and post-

amble are each

80 bytes long and serve to synchronize the read detection circuits in a

manner similar

to

previous 1600 bpi subsystems. The data portion

of

the block consists

of

the following:

5

Page 11

RECORDING

PHILOSOPHY

(continued)

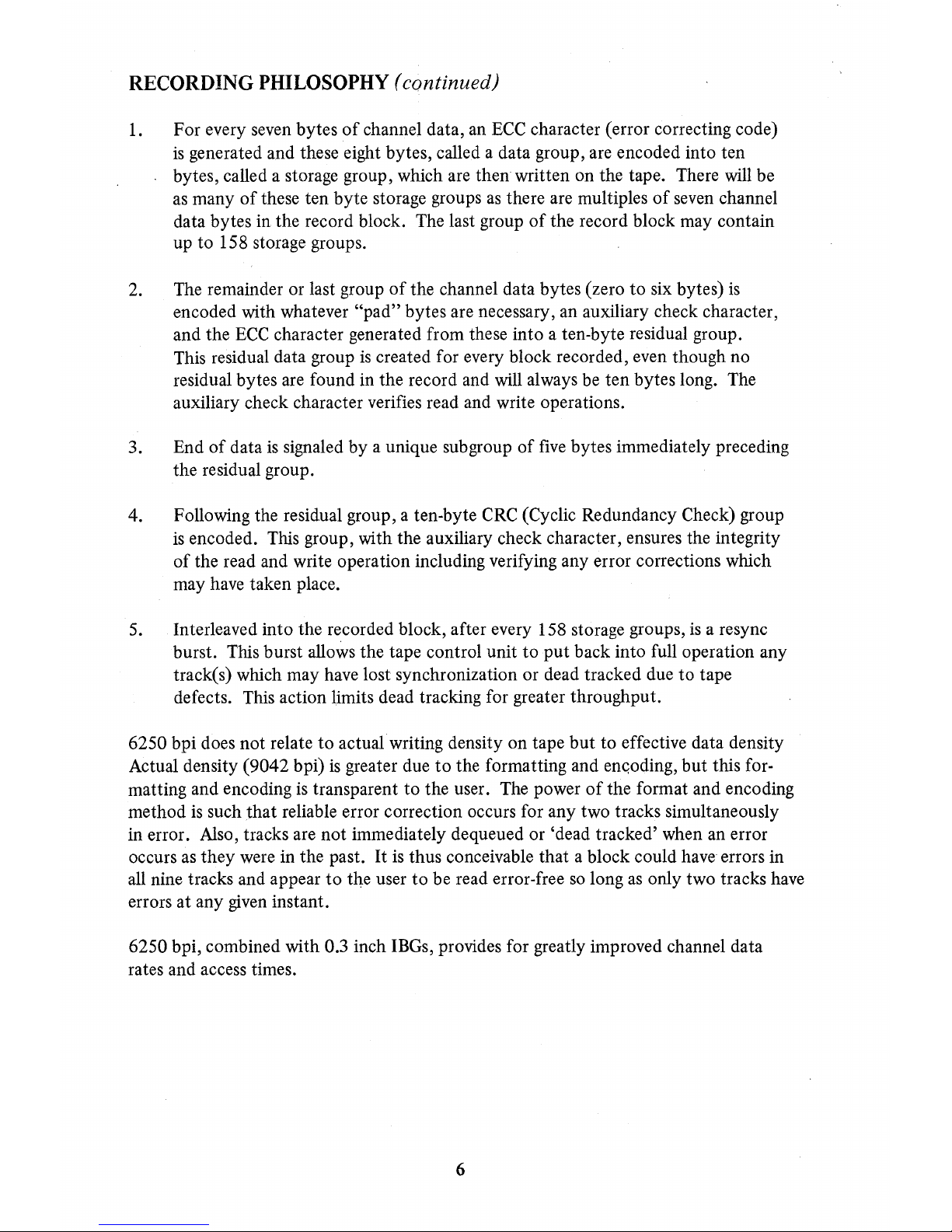

1.

For every seven bytes

of

channel data, an

ECC

character (error correcting code)

is

generated and these eight bytes, called a data group, are encoded into ten

bytes, called a storage group, which are then written on the tape. There will be

as

many

of

these ten byte storage groups

as

there are multiples

of

seven channel

data bytes in the record block. The last group

of

the record block may contain

up to 158 storage groups.

2.

The remainder or last group

of

the channel data bytes (zero

to

six bytes)

is

encoded with whatever

"pad"

bytes are necessary, an auxiliary check character,

and the

ECC

character generated from these into a ten-byte residual group.

This residual data group

is

created for every block recorded, even though no

residual bytes are found in the record and will always be ten bytes long. The

auxiliary check character verifies read and write operations.

3. End

of

data

is

signaled by a unique subgroup

of

five

bytes immediately preceding

the residual group.

4. Following the residual group, a ten-byte

CRC

(Cyclic Redundancy Check) group

is

encoded. This group, with the auxiliary check character, ensures the integrity

of

the read and write operation including verifying any error corrections which

may have taken place.

5.

Interleaved into the recorded block, after every 158 storage groups,

is

a resync

burst. This burst allows the tape control unit

to

put

back into full operation any

track(s) which may have lost synchronization or dead tracked due to tape

defects. This action limits dead tracking for greater throughput.

6250 bpi does not relate

to

actual writing density on tape

but

to effective data density

Actual density (9042 bpi)

is

greater due

to

the formatting and enGoding,

but

this for-

matting and encoding

is

transparent

to

the user. The power

of

the format and encoding

method

is

such

that

reliable error correction occurs for any two tracks Simultaneously

in error. Also, tracks are not immediately dequeued or 'dead tracked' when an error

occurs

as

they were in the past.

It

is

thus conceivable that a block could have errors in

all nine tracks and appear

to

the user

to

be read error-free

so

long

as

only two tracks have

errors at any

given

instant.

6250 bpi, combined with 0.3 inch IBGs, provides for greatly improved channel data

rates and access times.

6

Page 12

RECORDING

PHILOSOPHY

( continued)

NRZI

(Example

A)

o

o o

o

--1

u

L

Write Signal

Analog

Read Signal

Read

Digital Output

PE

(Example

B)

Write

Signal

Read Digital Output

7

Page 13

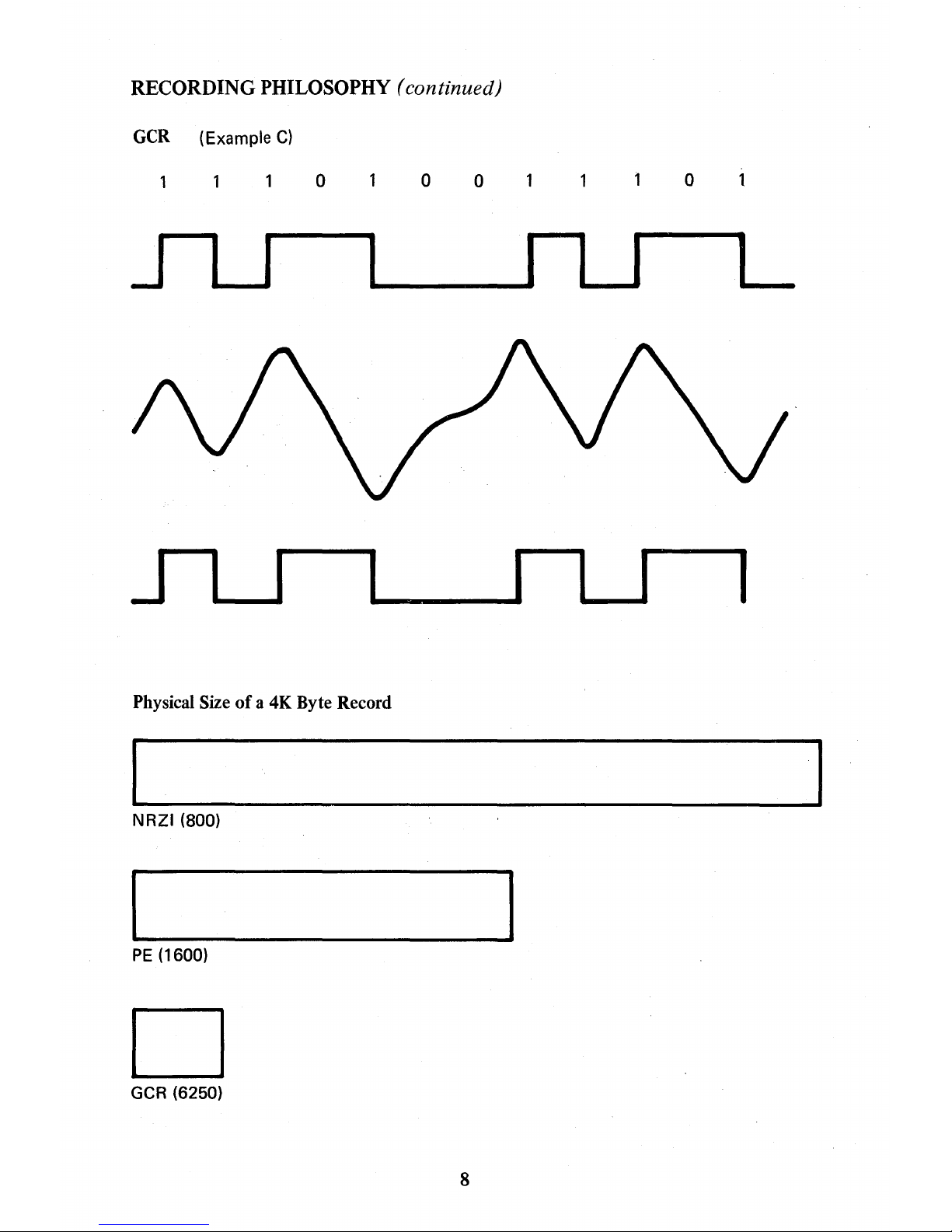

RECORDING PHILOSOPHY

(continued)

GCR

(Example

C)

o

o

o

o

J

I

I

I ..-.-..

________

n

_______

1

L

J I

I

I

I

I

I

I

Physical Size

of

a 4K Byte Record

NRZI (800)

PE

(1600)

D

GCR

(6250)

8

Page 14

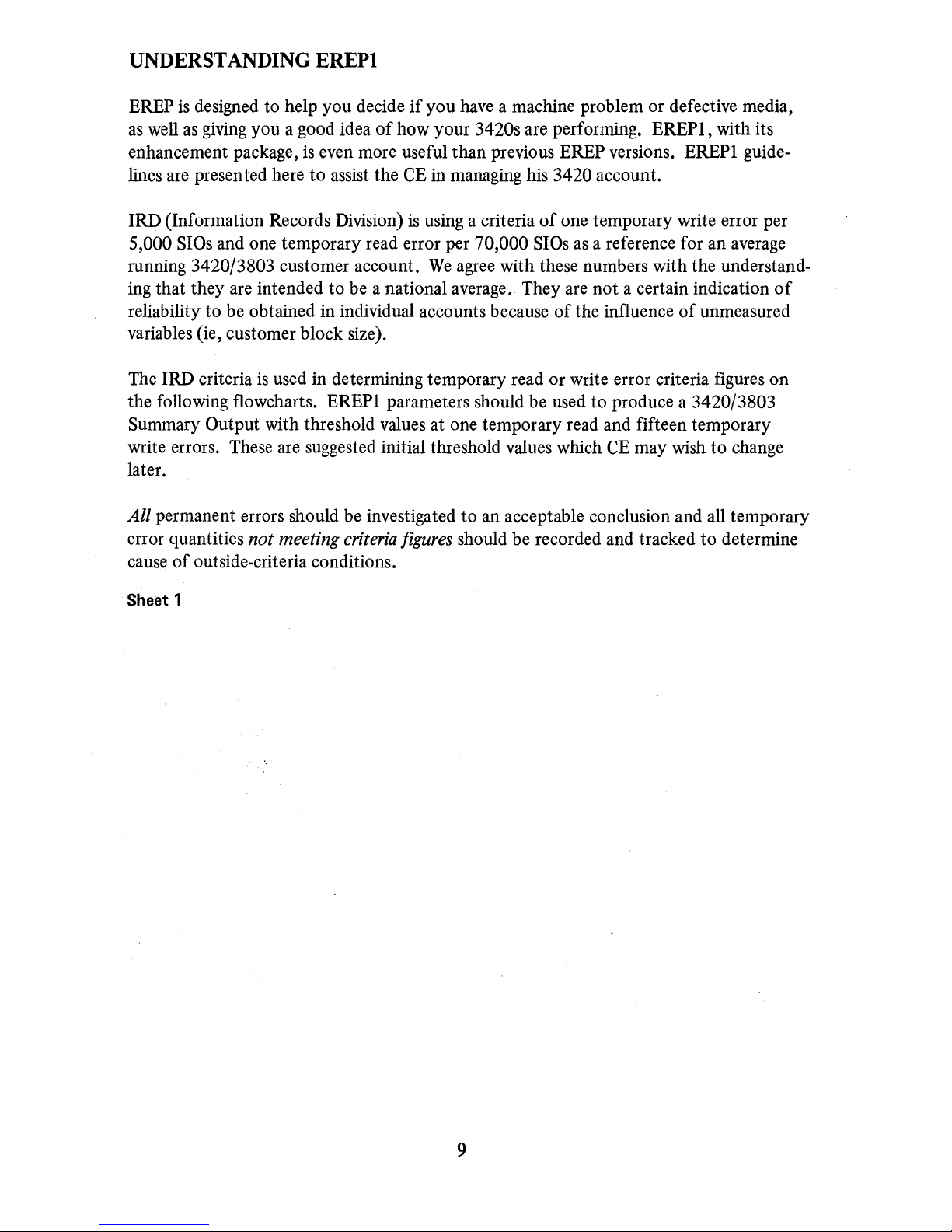

UNDERSTANDING

EREPI

EREP

is

designed to help you decide

if

you have a machine problem or defective media,

as

well

as

giving you a good idea

of

how your 3420s are performing. EREPI, with its

enhancement package,

is

even more useful than previous EREP versions. EREPI guide-

lines are presented here

to

assist the

CE

in managing his 3420 account.

IRD (Information Records Division)

is

using a criteria

of

one temporary write error per

5,000 SIOs and one temporary read error per 70,000 SIOs

as

a reference for an average

running

3420/3803 customer account.

We

agree with these numbers with the understand-

ing that they are intended

to

be a national average. They are not a certain indication

of

reliability

to

be obtained in individual accounts because

of

the influence

of

unmeasured

variables (ie, customer block size).

The IRD criteria

is

used in determining temporary read or write error criteria figures

on

the following flowcharts. EREPI parameters should be used

to

produce a 3420/3803

Summary Output with threshold values at one temporary read and fifteen temporary

write errors. These are suggested initial threshold values which

CE

may wish

to

change

later.

All

permanent errors should be investigated

to

an acceptable conclusion and all temporary

error quantities

not meeting

criteria

figures

should be recorded and tracked

to

determine

cause

of

outside-criteria conditions.

Sheet 1

9

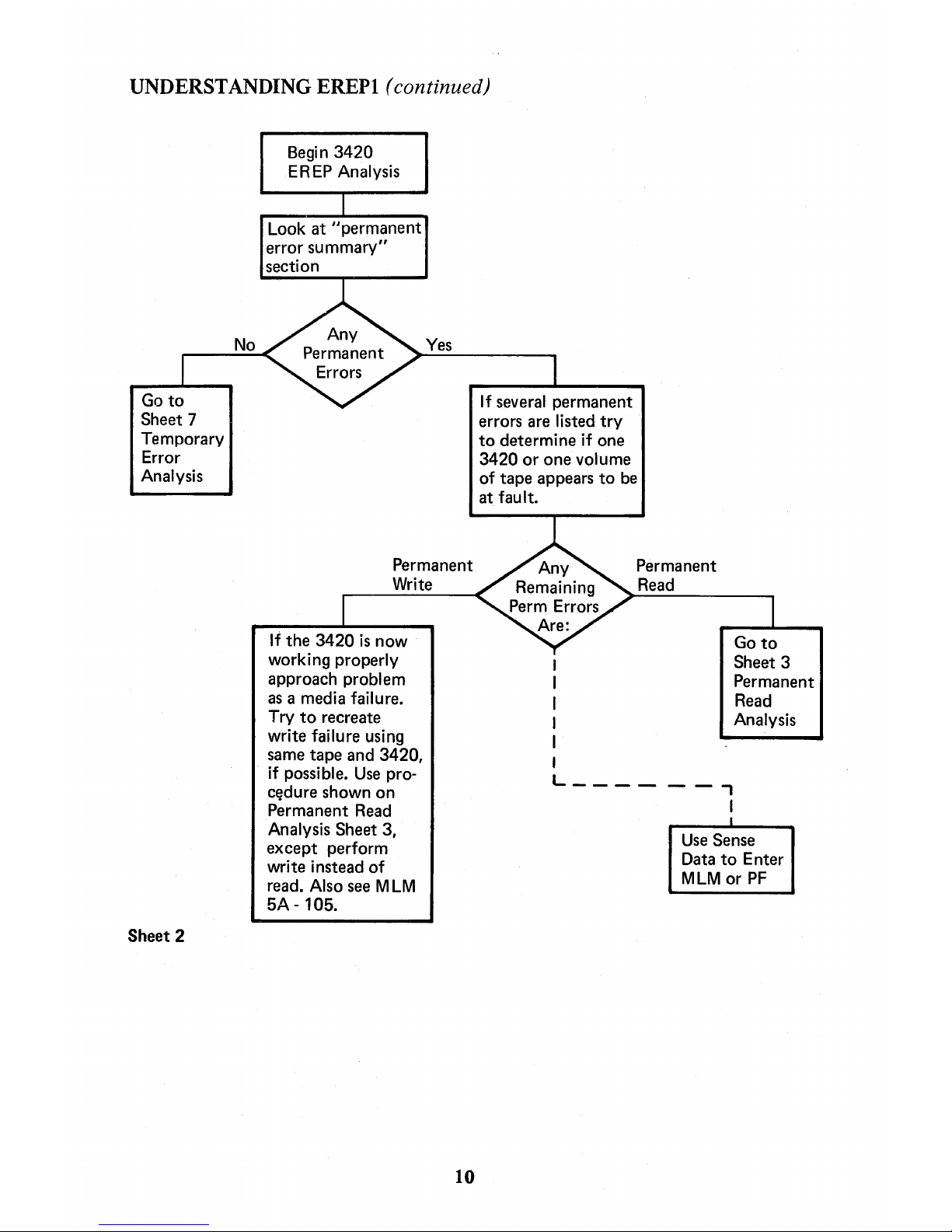

Page 15

UNDERSTANDING EREPI

(continued)

Go

to

Sheet 7

Temporary

Error

Analysis

Sheet 2

Begin

3420

E R

EP

Analysis

Look

at

"permanent

error

summary"

section

Yes

Permanent

Write

If

the

3420

is

now

working properly

approach problem

as

a media failure.

Try

to

recreate

write failure using

same

tape

and

3420,

if possible.

Use

pro-

c~dure

shown

on

Permanent

Read

Analysis Sheet 3,

except

perform

wri

te

instead

of

read. Also see M

LM

5A - 105.

10

If

several

permanent

errors are listed

try

to

determine

if one

3420

or

one

volume

of

tape

appears

to

be

at

fault.

I

Permanent

Read

Go

to

Sheet

3

Permanent

Read

Analysis

L

______

,

I

I

Use

Sense

Data

to

Enter

MLM

or

PF

Page 16

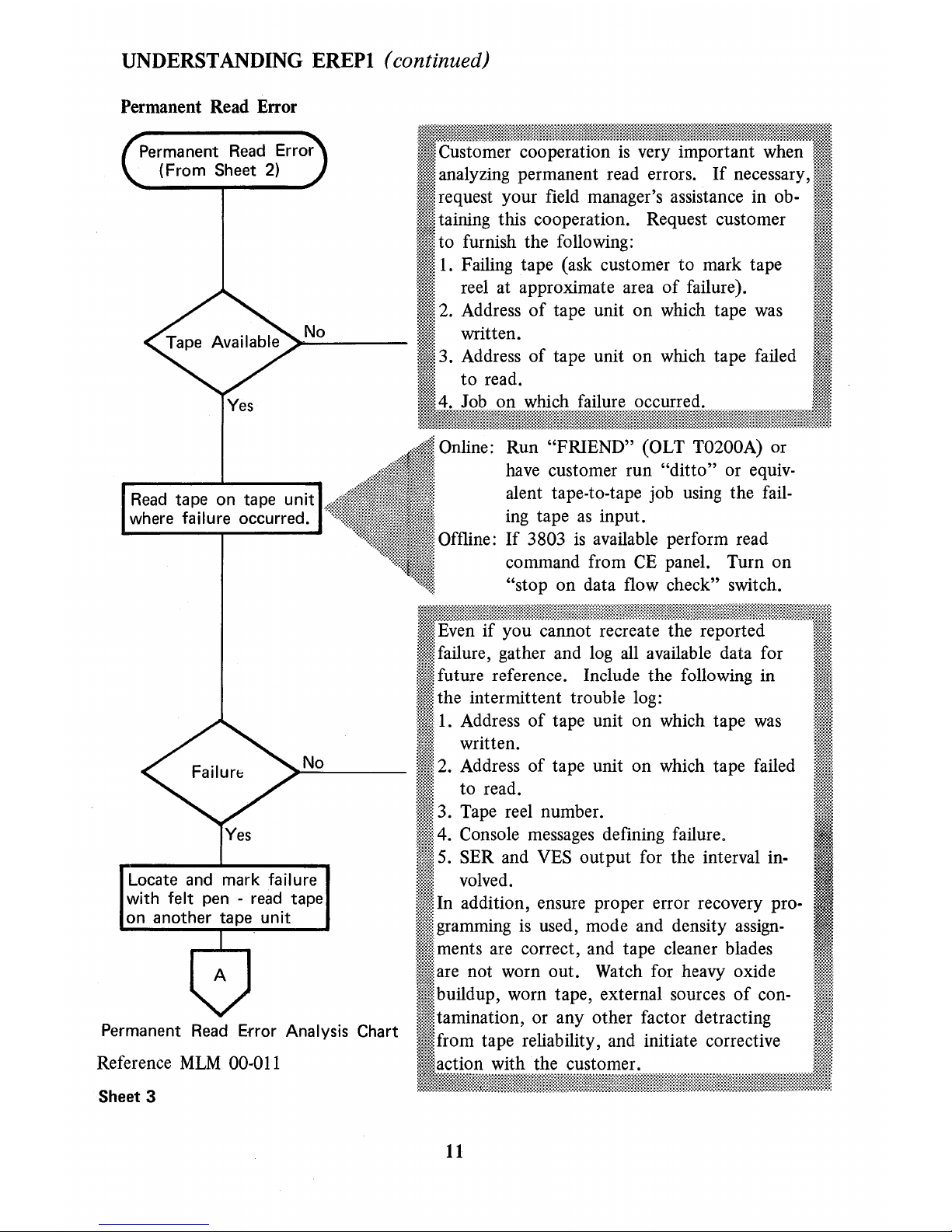

UNDERSTANDING EREPI (continued)

Permanent Read Error

Permanent

Read Error

(From

Sheet

2)

No

Yes

Read

tape

on

tape

unit

where failure

occurred.

No

Locate

and

mark failure

with felt pen - read

tape

on

another

tape

unit

Permanent

Read Error Analysis Chart

Reference

MLM

00-011

Sheet

3

Online: Run "FRIEND" (OLT T0200A) or

have customer run

"ditto"

or equivalent tape-to-tape job using the failing tape

as

input.

Offline:

If

3803

is

available perform read

command from

CE

panel. Turn on

"stop on data flow check" switch.

11

Page 17

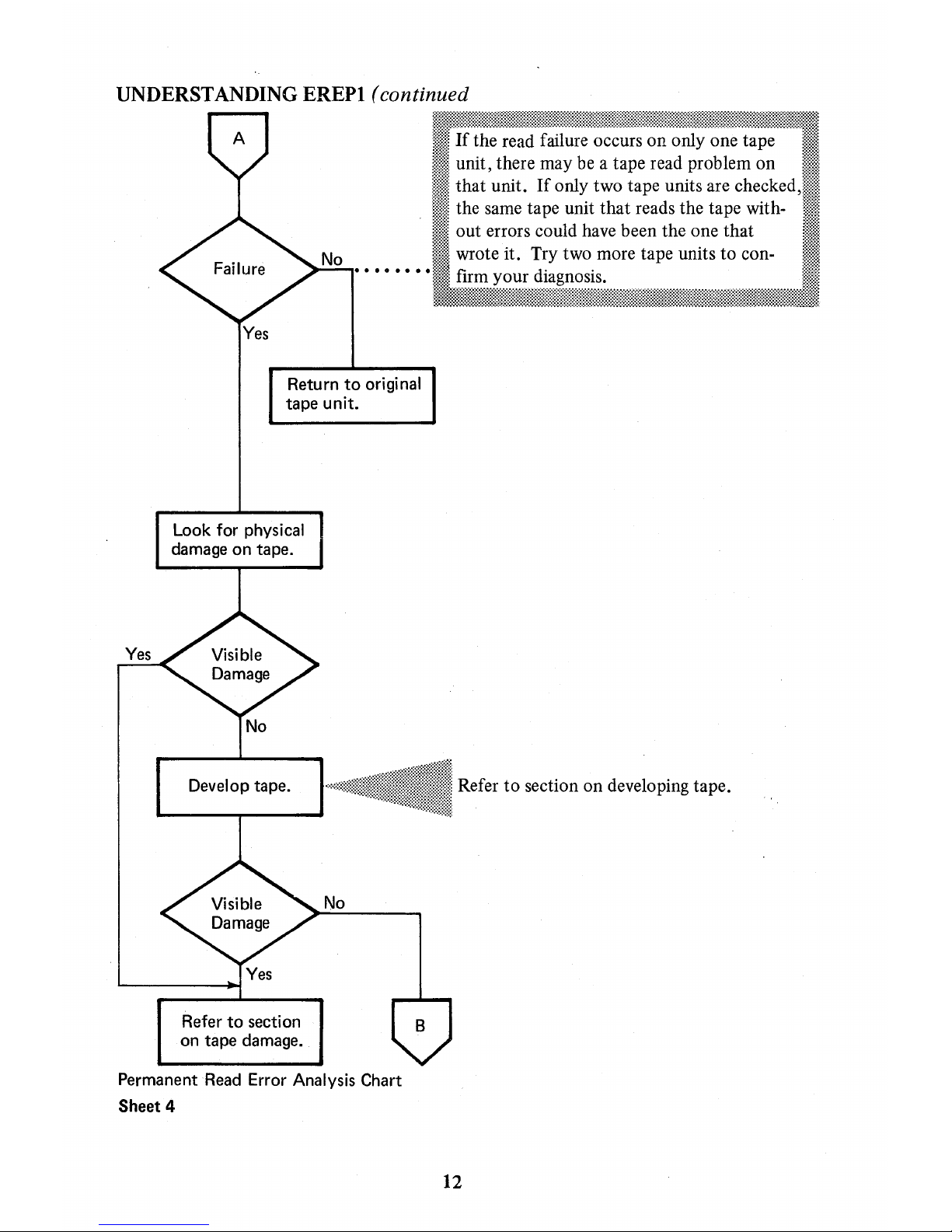

UNDERSTANDING EREPI

(continued

Yes

Return

to

original

tape

unit.

Look for physical

damage

on

tape.

Develop

tape.

Refer

to

section

on

tape

damage.

No

Permanent Read Error Analysis Chart

Sheet

4

Refer

to

section on developing tape.

12

Page 18

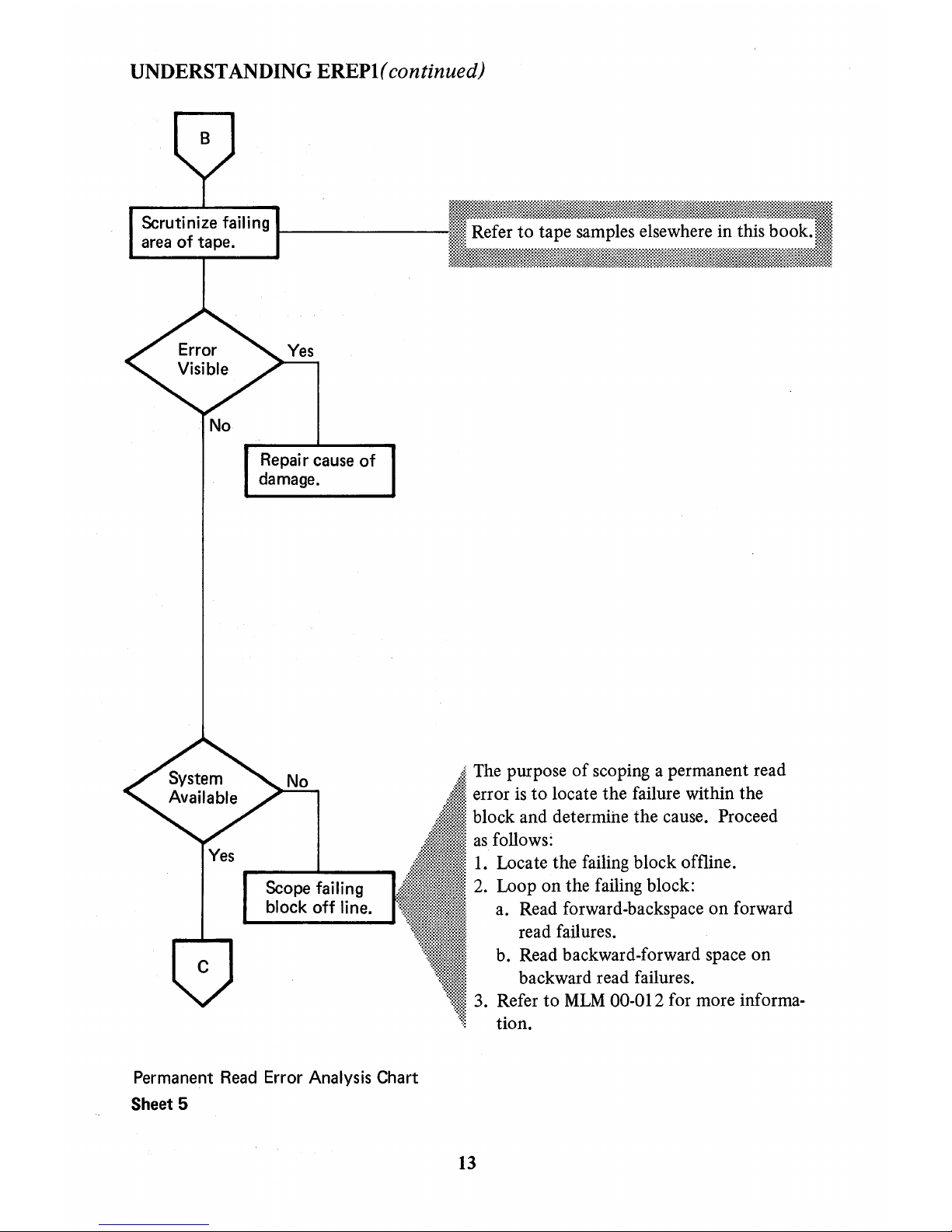

UNDERSTANDING

EREPl(

continued)

No

Yes

Repai

r cause of

damage.

Scope failing

block off line.

Permanent

Read

Error Analysis Chart

Sheet 5

: Refer

to

tape samples elsewhere in this book.

.

The

purpose

of

scoping a permanent read

error

is

to locate the failure within the

block and determine the cause.

Proceed

as

follows:

1.

Locate the failing block offline.

2. Loop on the failing block:

a. Read forward-backspace on forward

read failures.

b. Read backward-forward space on

backward read failures.

3.

Refer

to

MLM

00-012 for more informa-

tion.

13

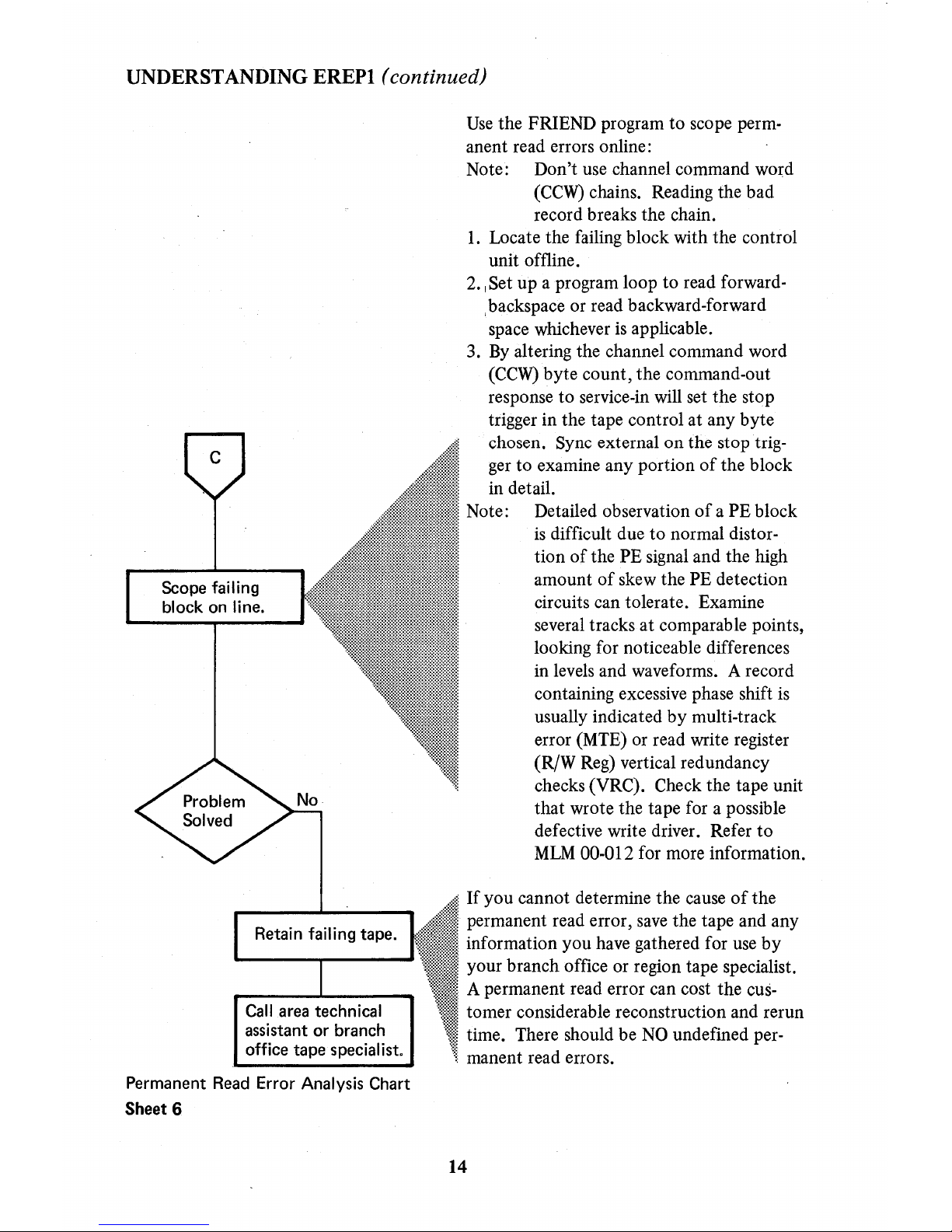

Page 19

UNDERSTANDING

EREPI

(continued)

Scope failing

block

on

line.

Call

area technical

assistant

or

branch

office

tape

specialist.

Permanent

Read Error Analysis Chart

Sheet 6

Use

the FRIEND program to scope permanent read errors online:

Note: Don't use channel command word

(CCW)

chains. Reading the bad

record breaks the chain.

1.

Locate the failing block with the control

unit offline.

2.

I Set up a program loop to read forward-

I backspace or read backward-forward

space whichever

is

applicable.

3.

By

altering the channel command word

(CCW)

byte count, the command-out

response to service-in will set the stop

trigger in the tape control at any byte

chosen. Sync external on the stop

trig-

ger

to examine any portion

of

the block

in detail.

Note:

Detailed observation

of

a PE block

is

difficult due

to

normal distor-

tion

of

the PE signal and the high

amount

of

skew the PE detection

circuits can tolerate. Examine

several tracks

at

comparable points,

looking for noticeable differences

in levels and waveforms. A record

containing excessive phase shift

is

usually indicated by multi-track

error (MTE) or read write register

(R/W Reg) vertical redundancy

checks

(YRC). Check the tape unit

that wrote the tape for a possible

defective write driver. Refer

to

MLM

00-012 for more information.

·

If

you cannot determine the cause

of

the

permanent read error,

save

the tape and any

: information you have gathered for

use

by

· your branch office or region tape specialist.

· A permanent read error can cost the cus: tomer considerable reconstruction and rerun

time. There should be

NO

undefined per-

manent read errors.

14

Page 20

UNDERSTANDING EREPI

(continued)

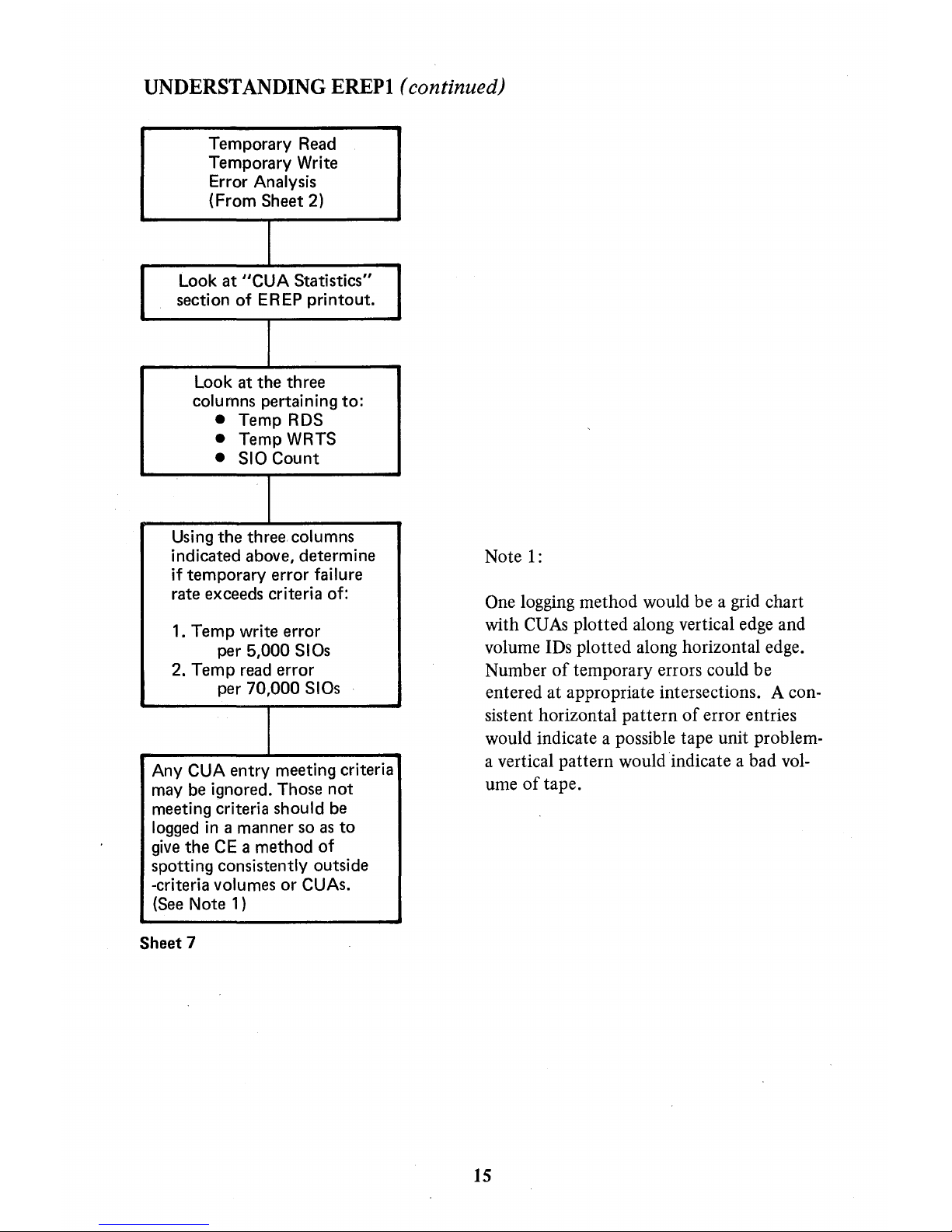

Temporary Read

Temporary Write

Error

Analysis

(From Sheet 2)

I

Look

at

"CUA

Statistics"

section

of

EREP

printout.

I

Look

at

the

three

columns pertaining

to:

• Temp RDS

•

Temp WRTS

•

SIO

Count

I

Using

the

three

columns

indicated above, determine

if

temporary

error

failure

rate exceeds criteria of:

1.

Temp

write error

per

5,000

SIOs

2.

Temp

read error

per

70,000

SIOs

I

Any CUA

entry

meeting criteria

may be ignored. Those

not

meeting criteria should be

logged

in

a manner so

as

to

give

the

CE a

method

of

spotting consistently outside

-criteria

volumes

or

CUAs.

(See Note 1)

Sheet 7

Note

1:

One logging

method

would

be

a grid chart

with

CUAs

plotted

along vertical edge

and

volume IDs

plotted

along horizontal edge.

Number

of

temporary

errors could

be

entered

at

appropriate intersections. A con-

sistent

horizontal

pattern

of

error entries

would indicate a possible

tape

unit

problem-

a vertical

pattern

would

indicate a bad

vol-

ume

of

tape.

15

Page 21

Page 22

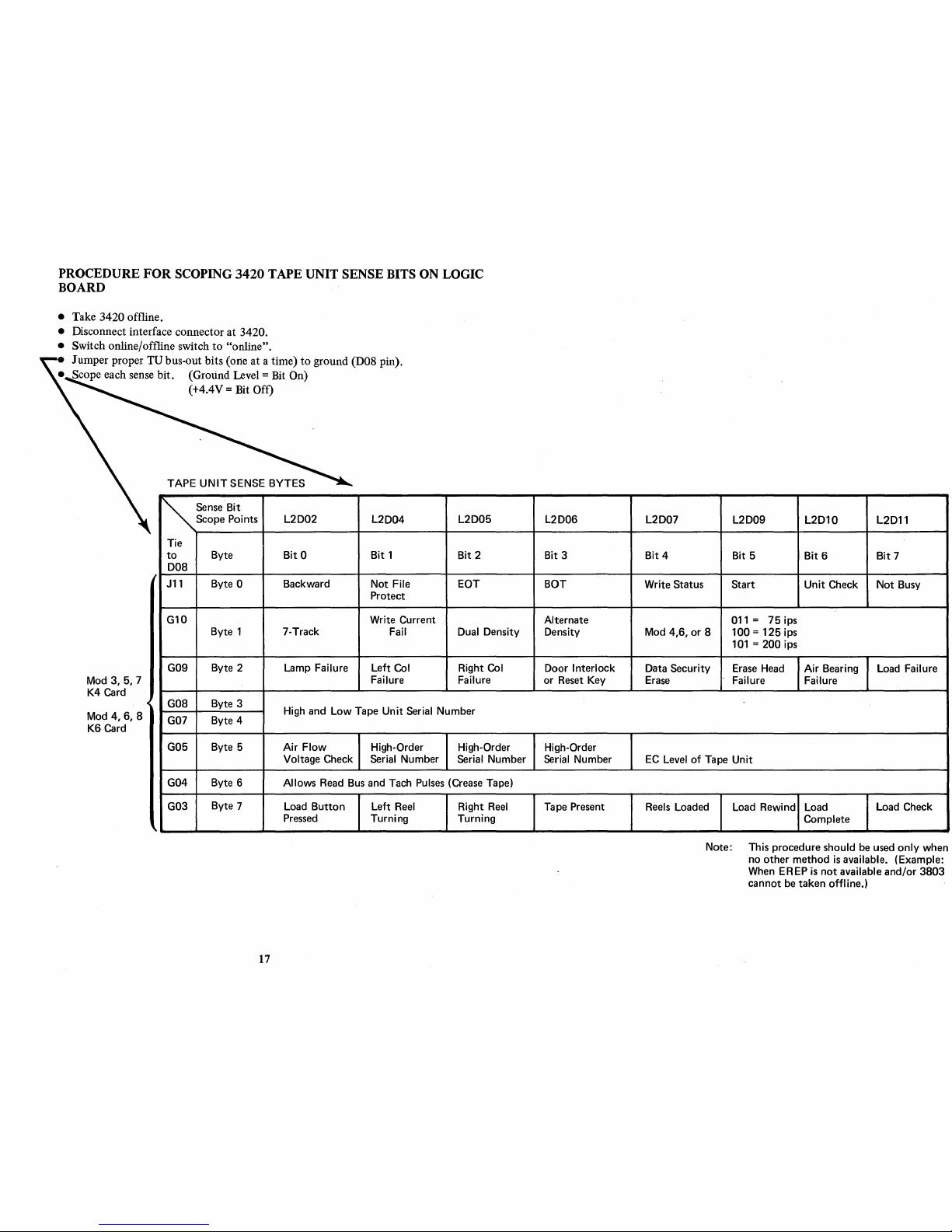

PROCEDURE

FOR

SCOPING

3420

TAPE UNIT SENSE BITS ON LOGIC

BOARD

• Take

3420

offline.

• Disconnect interface connector at 3420.

•

Switch online/offline switch

to

"online".

• Jumper proper

TV

bus-out bits (oIle at a time)

to

ground (D08 pin).

• Scope each sense bit. (Ground Level = Bit On)

Mod 3, 5, 7

K4

Card

<C

~

(+4.4V = Bit Off)

TAPE

UNIT

SENSE BYTES

~

SensoBit

Scope

Points

L2D02

Tie

to

Byte

Bit

0

D08

J11

Byte 0 Backward

G10

Byte 1 7-Track

G09

Byte 2

Lamp Failure

L2D04

Bit

1

Not File

Protect

Write

Current

Fail

Left Col

Failure

L2D05

Bit

2

EOT

Dual Density

Right

Col

Failure

Mod

4,6,8

K6

Card

G08

G07

Byte 3

Byte 4

High and

Low

Tape

Unit

Serial Number

G05

Byte 5

Air

Flow

High-Order High-Order

Voltage Check Serial Number

Serial Number

G04 Byte 6

Allows

Read

Bus

and

Tach

Pulses

(Crease

Tape)

G03

Byte 7

Load

Button

Left

Reel

Right

Reel

Pressed

Turning Turning

,

17

L2D06

Bit 3

BOT

Alternate

Density

Door

Interlock

or

Reset

Key

High-Order

Serial

Number

Tape

Present

L2D07

L2D09

L2D10

L2D11

Bit

4

Bit 5

Bit

6

Bit

7

Write Status Start

Unit

Check

Not

Busy

011

= 75

ips

Mod 4,6, or 8 100 = 125 ips

101

= 200 ips

Data Security

Erase

Head

Air

Bearing

Load Failure

Erase

Failure Failure

EC

Level

of

Tape

Unit

Reels

Loaded

Load Rewind

Load

Load

Check

Complete

Note: This procedure should

be

used

only

when

no other method

is

available. (Example:

When

EREP

is

not

available and/or 3803

cannot

be

taken offline.)

Page 23

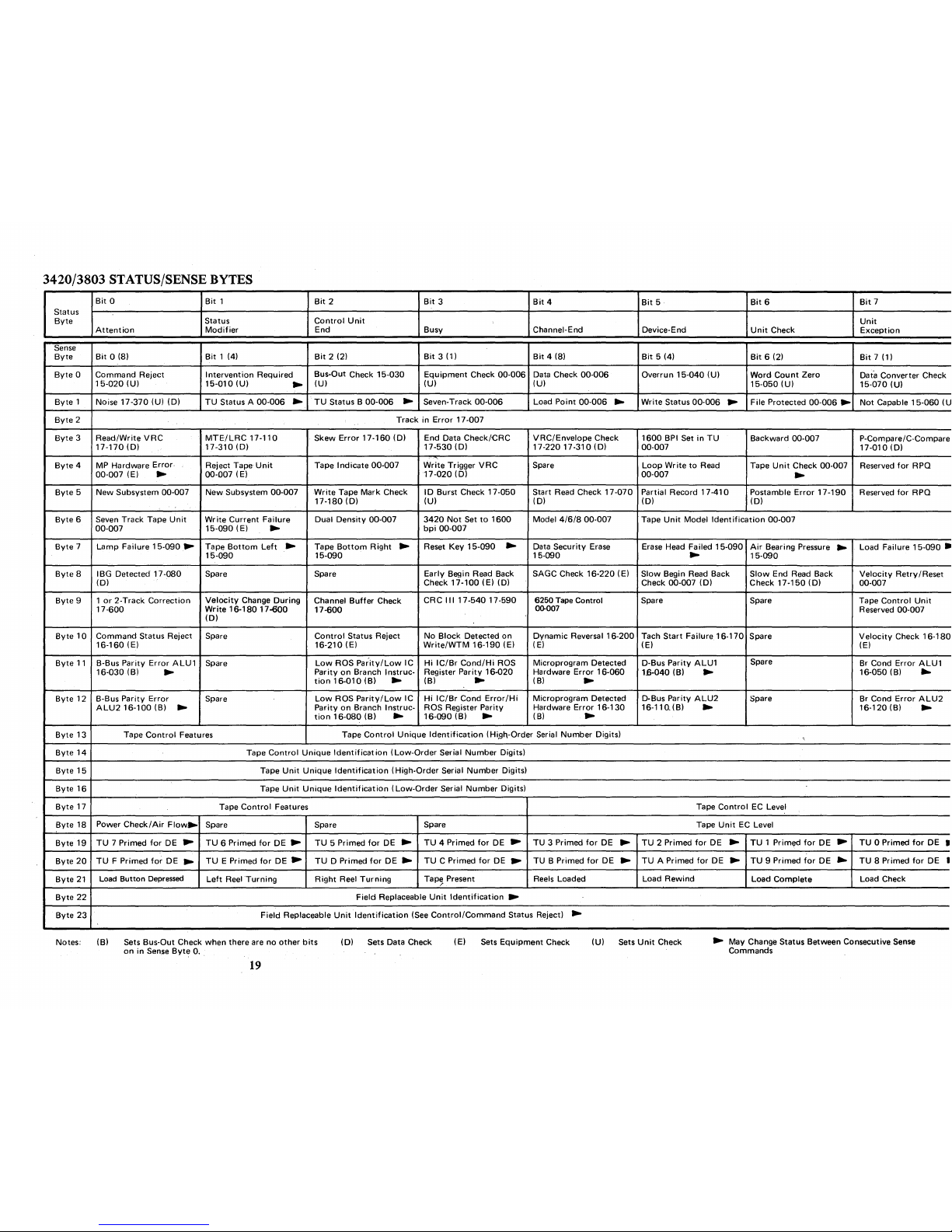

3420/3803

STATUS/SENSE BYTES

Bit

0

Bit

1

Bit

2

Bit

3

Bit

4

Bit

5·

Bit

6

Bit

7

Status

Byte

Status

Control

Unit

Unit

Attention

Modifier

End Busy Channel-End

Device-End

Unit

Check

Exception

Sense

Byte

Bit

0 (8)

Bit

1 (4)

Bit

2 (2)

Bit

3 (1)

Bit

4 (8)

Bit

5 (4)

Bit

6 (2)

Bit

7 (1)

Byte 0 Command

Reject

Intervention

Required

Bus-Out Check

15-030

Equipment

Check

00-006

Data Check

00-006

Overrun

15-040

(U)

Word

Count

Zero

Data Converter Check

15-020

(U)

15-010

(U)

~

(U)

(U)

(U)

15-050

(U)

15-070

(U)

Byte

1

Noise

17-370

(U)

(D)

TU

Status A

00-006

~

.'.

TU

Status B

00-006

~

Seven-Track

00-006

Load

Point

00-006

~

Write

Status

00-006

~

File Protected

00-006 ~ Not

Capable

15-060

(U:

Byte

2

Track

in

Error

17-007

Byte 3 Read/Write

VRC

MTEILRC

17-110

Skew

Error

17-160

(D)

End Data

Check/CRC

VRC/Envelope

Check

1600

BPI Set

in

TU

Backward 00-007

P-Compare/C-Compare

17-170

(D)

17-310

(D)

17-530

(D)

17-22017-310

(D)

00-007

17-010

(D)

Byte

4

MP Hardware Error,

Reject Tape

Unit

Tape

Indicate

00-007

Write

Trigger

VRC

Spare

Loop

Write

to

Read

Tape

Unit

Check

00-007

Reserved

for

RPQ

00-007 (E)

~

00-007 (E)

17-020

(D)

00-007

~

Byte 5 New

Subsystem 00-007

New

Subsystem 00-007

Write

Tape

Mark

Check

ID

Burst Check

17-050

Start Read Check

17-070

Partial Record

17-410

Postamble

Error

17-190

Reserved

for

RPQ

17-180

(D)

(U) (D) (D) (D)

Byte

6 Seven

Track

Tape

Unit

Write

Current

Failure

Dual

Density

00-007

3420

Not

Set

to

1600

Model

4/6/8

00-007

Tape

Unit

Model

Identification

00-007

00-007

15-090

(E)

~

bpi

00-007

Byte 7 Lamp

Failure

15-090

~

Tape

Bottom

Left

~

Tape

Bottom

Right ~ Reset

Key

15-090

~

Data

Security

Erase Erase Head Failed

15-090

Air

Bearing Pressure

~

Load Failure

15-090

•

15-090

15-090

15-090

~

15-090

Byte

8 I

BG

Detected 17

-080

Spare

Spare

Early

Begin Read Back SAGC Check

16-220

(E)

Slow

Begin Read Back

Slow

End Read Back

Velocity

Retry/Reset

(D)

Check

17-100

(E) (D) Check 00-007 (D)

Check

17-150

(D)

00-007

Byte

9 1

or

2-Track

Correction

Velocity

Change

During

Channel

Buffer

Check

CRC

III

17-54017-590

6250

Tape

Control Spare Spare

Tape

Control

Unit

17-600

Write

16-180

17-600

17-600

00-007

Reserved 00-007

(D)

Byte

10

Command

Status Reject Spare

Control

Status Reject

No

Block

Detected

on

Dynamic

Reversal

16-200

Tach

Start

Failure

16-170

Spare

Velocity

Check

16-180

16-160

(E)

16-210

(E)

Write/WTM

16-190

(E)

(E)

(E) (E)

Byte

11

B-Bus

Parity

Error

ALU1

Spare

Low

HOS

Parity/Low

IC Hi

IC/Br

Cond/Hi

ROS

Microprogram

Detected

D-Bus

Parity

ALU1

Spare

Br Cond

Error

ALU1

16-030

(B)

~

Parity

on

Branch Instruc-

Register

Parity

16-020

Hardware

Error

16-060

1.6-040 (B)

~

16-050

(B)

~

tion

16-010

(B)

~

(B)

~

(B)

~

Byte

12

B-Bus

Parity

Error

Spare

Low

ROS

Parity/Low

IC

Hi

IC/Br

Cond

Error/Hi

Microprogram

Detected

D-Bus Parity

ALU2

Spare

Br Cond

Error

ALU2

ALU2

16-100

(B)

~

Parity

on

Branch Instruc- ROS Register

Parity

Hardware

Error

16-130

16-11Q(B)

~

16-120

(B)

~

tion

16-080

(B)

~

16-090

(B)

~

(B)

~

Byte

13

Tape

Control

Features

Tape

Control

Unique

Identification

(Hi,gh-Order Serial

Number

Digits)

Byte

14

Tape

Control

Unique

Identificat

ion

(Low-Order

Serial

Number

Digits)

Byte

15

Tape

Unit

Unique

Identification

(High-Order

Serial

Number

Digits)

Byte

16

Tape

Unit

Unique

Identification

(Low-Order

Serial

Number

Digits)

Byte

17

Tape

Control

Features

Tape

Control

EC Level

Byte

18 Power

Check/Air

Flow.

Spare Spare

Spare

Tape

Unit

EC

Level

Byte

19

TU

7 Primed

for

DE

~

TU

6 Primed

for

DE

~

TU

5 Primed

for

DE

~

TU

4 Primed

for

DE ~ TU

3 Primed

for

DE ~ TU

2 Primed

for

DE ~ TU

1 Priml;ld

for

DE ~ TU

0 Primed

for

DE

•

Byte

20

TU

F Primed

for

DE

~

TU

E Primed

for

DE

~

TU

0 Primed

for

DE

~

TU

C Primed

for

DE ~ TU

B Primed

for

DE ~ TU

A Primed

for

DE ~ TU

9 Primed

for

DE

~

TU

8 Primed

for

DE

I

Byte

21

Load Button

Depressed

Left

Reel

Turning

Right

Reel

Turning

Tap~

Present

Reels Loaded

Load

Rewind

Load

Complete

Load Check

Byte

22

Field

Replaceable

Unit

Identification

•

Byte

23

Field

Replaceable

Unit

Identification

(See

Control/Command

Status Reject)

~

Notes: (B) Sets Bus-Out Check

when

there

are

no

other

bits

on

in Sense

Byte

O.

(D) Sets Data Check (E) Sets

Equipment

Check (U) Sets

Unit

Check

~

May Change Status Between Consecutive Sense

Commands

19

Page 24

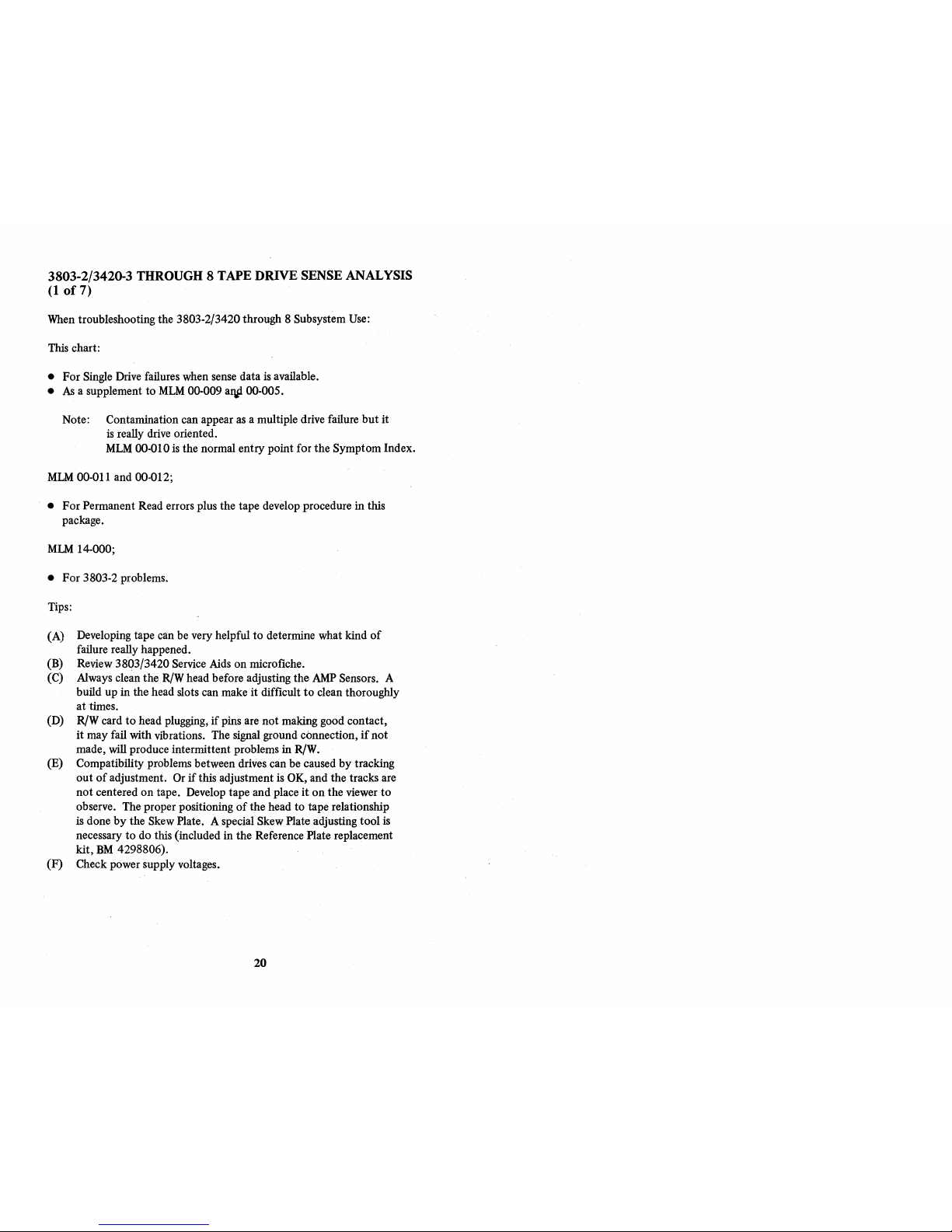

3803-2/3420-3 THROUGH 8 TAPE DRIVE SENSE ANALYSIS

(1

of

7)

When troubleshooting the 3803-2/3420 through 8 Subsystem Use:

This chart:

• For Single Drive failures when sense data

is

available.

•

As

a supplement

to

MLM

00-009 aqp 00-005.

Note: Contamination can appear

as

a multiple drive failure

but

it

is

really drive oriented.

MLM

00-010

is

the normal entry point for the Symptom Index.

MLM

00-011 and 00-012;

•

For

Permanent Read errors plus the tape develop procedure in this

package.

MLM

14-000;

•

For

3803-2 problems.

Tips:

(A) Developing tape can be very helpful

to

determine what kind

of

failure really happened.

(B) Review

3803/3420 Service Aids on microfiche.

(C) Always clean the

R/W

head before adjusting the

AMP

Sensors. A

build up in the head slots can make

it

difficult

to

clean thoroughly

at

times.

(D)

R!W

card

to

head plugging,

if

pins are

not

making good contact,

it

may fail with vibrations. The signal ground connection,

if

not

made, will produce intermittent problems in

R/W.

(E) Compatibility problems between drives can be caused

by

tracking

out

of

adjustment. Or

if

this adjustment is OK, and the tracks are

not

centered

on

tape. Develop tape and place

it

on

the viewer

to

observe. The proper positioning

of

the head to tape relationship

is

done

by

the Skew Plate. A special Skew Plate adjusting tool

is

necessary

to

do this (included in the Reference Plate replacement

kit,

BM

4298806).

(F) Check power supply voltages.

20

Page 25

3803-2/3420-3 THROUGH 8 TAPE DRIVE SENSE ANALYSIS

(2

of

7)

(continued)

Note: Sense byte bits are in the order

of

their importance except bits in byte 10.

No

No

Recheck

Symptoms

No

Yes

(A)

If

Ready

is

Off,

Go

to

Sense

Byte

7, Under

Entry

Point

"Au.

(B)

If

Ready

is

On, Go

to

MLM

15·010.

(C)

If

Not

Ready, Go

to

15-090.

(A)

Auto

Cleaner Binding.

(B)

Not

Able

to

Read

Track 1 (6250)

or

Track P 1600.

Dirty

or

Defective

Head.

(C)

Damaged

Tape in Inverse TM Area,

But

After

SAGC Area.

(D)

Read

Card

or

Cable

Loose

(E)

A1

L2

(F) ECA 073

(G) 15-060

(A) Write -

Auto

Cleaner Binding

and

Sticking Over Head.

Note:

SAGC

Not

On.

(B) Write -

10 Burst and SAGC,

Dirty

or Defective

Head

and

Could

be

Edge

Damage

on Tape

at

or

Near

LP.

(C)

Read

or

Write Card.

(D)

Read

Cable Loose.

(E)

5B-000

(F) 17-050

21

[FE127601)

Page 26

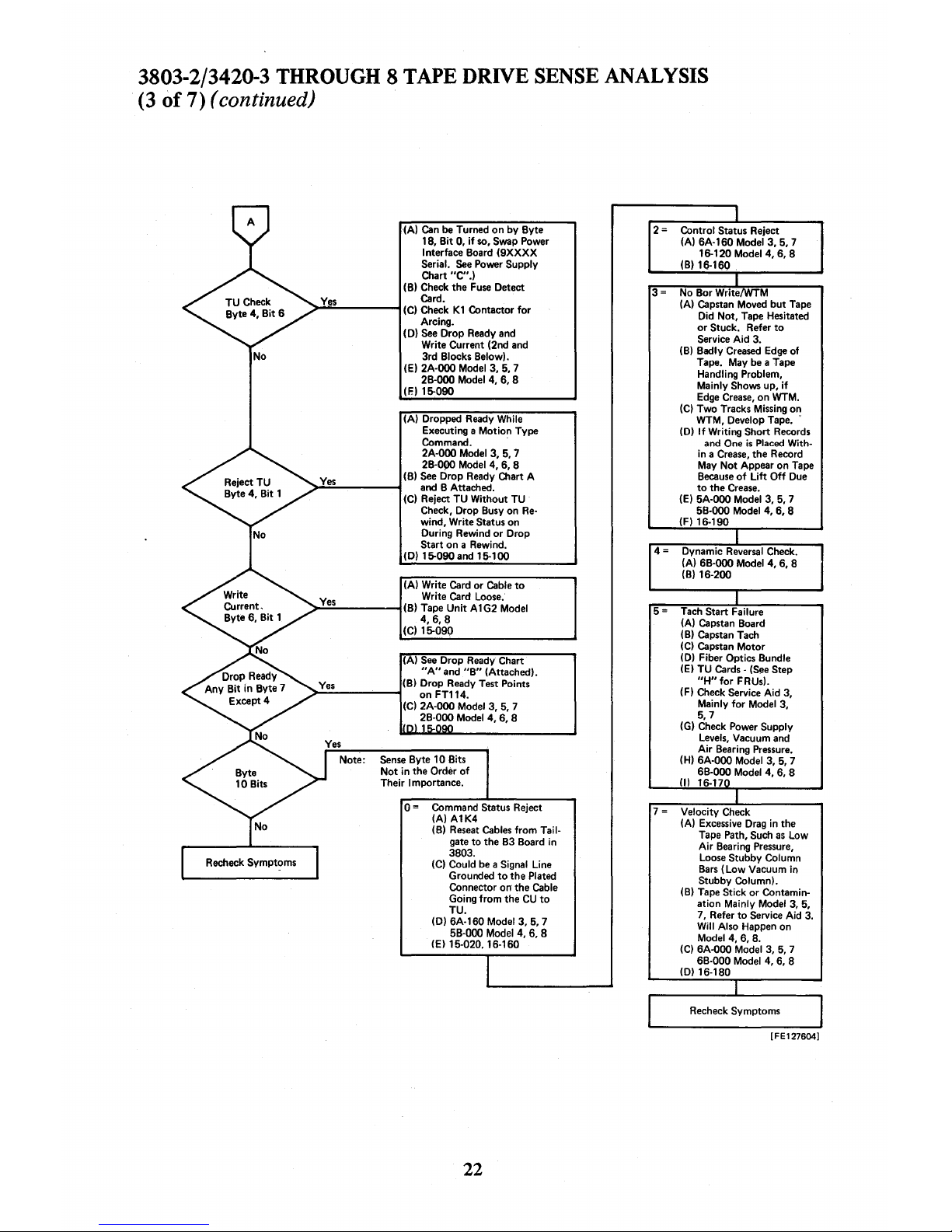

3803-2/3420-3 THROUGH 8 TAPE

DRNE

SENSE ANALYSIS

(3

of

7)

(continued)

No

(A)

Can

be

Turned

on

by

Byte

18,

Bit

0,

if

so,

Swap Power

Interface Board

(9XXXX

Serial.

See

Power Supply

Chart

"C".)

(B) Check the

Fuse

Detect

Ye~

Card.

>~-----1

(C) Check

Kl

Contactor

for

Arcing.

(D)

See

Drop Ready and

Write Current (2nd

and

3rd Blocks Below).

(E) 2A·000 Model 3, 5, 7

2B·000 Model 4, 6, 8

(E) 15-090

(A) Dropped Ready While

Executing a Motion Type

Command. .

2A·000 Model 3, 5, 7

2B·000 Model 4, 6, 8

(B)

See

Drop Ready Chart A

>;.::.-----1

and

B Attached.

(C) Reject

TU

Without TU

Check, Drop Busy on

Re·

wind, Write Status on

During Rewind

or

Drop

Start on a Rewind.

(D)

15-090

and

15-100

(A) Write Card or Cable

to

Write Card

Loose."

>:..::::..-----1 (B) Tape

Unit

A 1 G2 Model

4,6,8

(C) 15-090

(A)

See

Drop

Ready

Chart

"A"

and

"B"

(Attached).

(B) Drop Ready Test Points

>..;;.;;..-----1 on

FTl14.

(C)

2A·000 Model 3, 5, 7

2B·000 Model 4, 6, 8

Sense

Byte 10 Bits

Not

in the Order

of

Their Importance.

0=

Command Status Reject

(A)A1K4

(B)

Reseat

Cables

from

Tail·

gate

to

the B3 Board in

3803.

(C) Could

be

a Signal Line

Grounded

to

the Plated

Connector

on

the Cable

Going

from

the

CU

to

TU.

(D) 6A·160

Modell,

5, 7

5B·000 Model 4, 6, 8

(E)

15-020.16·160

22

No Bor WritelWTM

(A) Capstan Moved

but

Tape

Did

Not,

Tape Hesitated

or

Stuck. Refer

to

Service

Aid

3.

(B)

Badly

Creased

Edge

of

Tape. May

be

a Tape

Handling Problem,

Mainly

Shows up,

if

Edge

Crease,

on WTM.

(C)

Two Tracks Missing on

WTM, Develop Tape. .

(D)

If

Writing Short Records

and

One

is

Placed

With·

in a

Crease,

the Record

May

Not

Appear on Tape

Because

of

Lift

Off

Due

to

the

Crease.

(E) 5A·000 Model

3,5,7

5B·000 Model 4, 6, 8

(F)

16·190

5 = Tach Start Failure

(A) Capstan Board

(B) Capstan Tach

(C)

Capstan

Motor

(D) Fiber Optics Bundle

(E) TU Cards·

(See

Step

"H"

for

FRUs).

(F) Check Service

Aid

3,

Mainly

for

Model 3,

5,7

(G) Check Power Supply

Levels,

Vacuum and

Air

Bearing

Pressure.

(H)

6A·000

Model 3, 5, 7

6B·000 Model 4, 6, 8

(I) 16-17

7 = Velocity Check

(A)

Excessive

Drag

in the

Tape

Path, Such

as

Low

Air

Bearing

Pressure,

Loose Stubby Column

Bars

(Low

Vacuum in

Stubby

Column).

(B) Tape Stick

or

Contamin·

ation Mainly Model 3, 5,

7,

Refer

to

Service Aid 3.

Will

Also Happen on

Model 4, 6, 8.

(C)

6A·000 Model 3,

5,

7

6B·000 Model 4, 6, 8

(0)

16·180

[FE127604]

Page 27

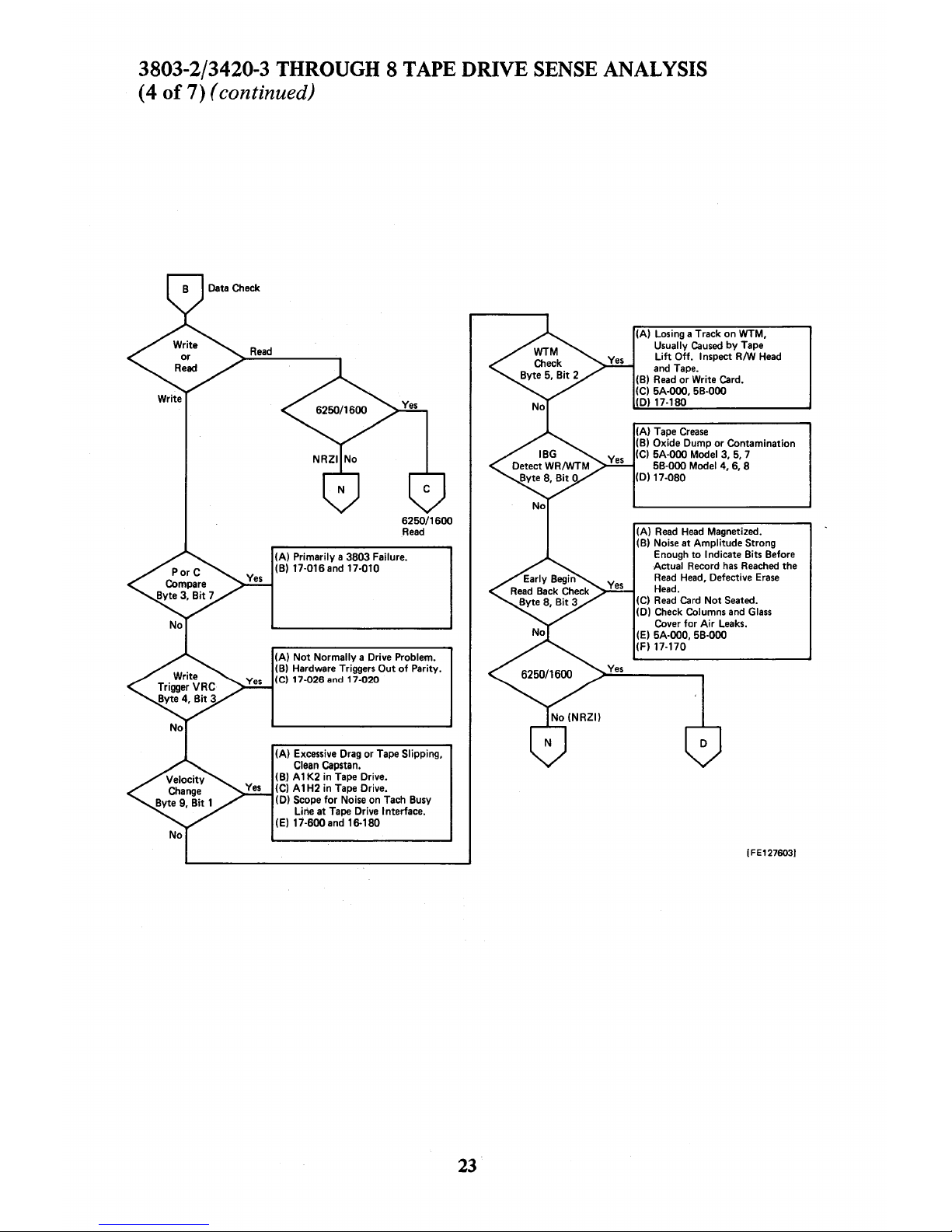

3803-2/3420-3

THROUGH 8 TAPE

DRIVE

SENSE

ANALYSIS

(4

of

7) (continued)

6250/1600

Read

(A)

Primarily a 3803 Failure.

(B)

17-016 and 17-010

(A)

Not

Normally

a Drive Problem_

(B) Hardware Triggers

Out

of

Parity.

Ie)

17-026

and

17-020

(A)

Excessive Drag or Tape Slipping,

Clean Capstan.

(B) A 1

K2

in Tape Drive.

(C)

A1H2

in Tape Drive.

(D) Scope

for

Noise on Tach Busy

line

at

Tape Drive Interface.

(E) 17-600 and 16-180

23

(A) Losing a Track

on

WTM,

Usually

Caused

by

Tape

Lift

Off.

Inspect R/W

Head

and

Tape_

(B)

Read

or

Write Card.

(C)

5A-ooo,5B-000

(D) 17-180

(A) Tape

Crease

(B) Oxide Dump

or

Contamination

(C)

5A-000 Model 3,

5,

7

5B-000 Model 4, 6, 8

(D)

17-080

(A)

Read

Head

Magnetized.

(B) Noise

at

Amplitude

Strong

Enough

to

Indicate Bits Before

Actual Record

has

Reached the

Read

Head, Defective

Erase

Head.

(C)

Read

Card

Not

Seated.

(D)

Check Columns and

Glass

Cover

for

Air

Leaks.

(E)

5A-000, 5B-000

(F) 17-170

[FE127603]

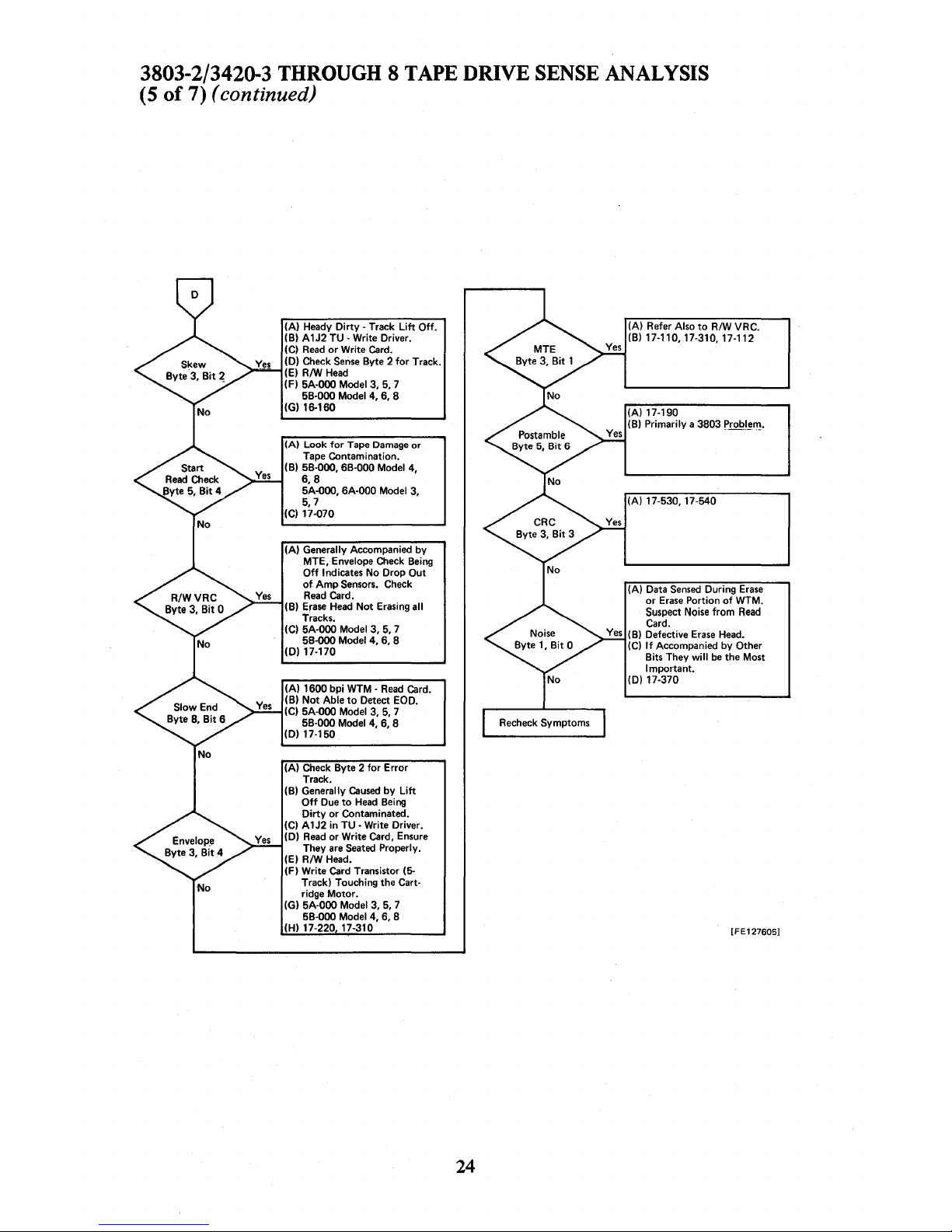

Page 28

3803-2/3420-3

THROUGH 8 TAPE

DRIVE

SENSE

ANALYSIS

(S

of

7) (continued)

No

(A) Heady

Dirty

- Track

Lift

Off.

(B) A1J2 TU - Write Driver.

(C)

Read

or

Write

Card.

(D) Check

Sense

Byte 2

for

Track.

(E)

RIW

Head

(F) 5A-000 Model 3,

5,7

5B-000 Model 4, 6, 8

(G) 16-160

(A)

Look

for

Tape

Damage

or

Tape Contamination.

(B)

5B-000, 6B-000 Model 4,

6,8

5A-000,

6A-OOO

Model 3,

5,7

(C) 17-070

(A) Generally Accompanied

by

MTE, Envelope Check

Being

Off

Indicates No Drop Out

of

Amp

Sensors.

Check

Read

Card.

(B)

Erase

Head

Not

Erasing all

Tracks.

(C)

5A-000 Model 3, 5, 7

5B-000 Model 4, 6, 8

(D)

17-170

(A) 1600 bpi WTM -

Read

Card.

(B)

Not

Able

to

Detect EOO.

(C) 5A-000 Model 3,

5,

7

5B-000 Model 4, 6, 8

(D)

17-150

(A) Check Byte 2

for

Error

Track.

(B)

Generally

Caused

by

Lift

Off

Due

to

Head

Being

Dirty

or

Contaminated.

(C) A1J2 in TU

- Write Driver.

(D)

Read

or Write Card, Ensure

They

are

Seated

Properly.

(E) RIW Head.

(F) Write Card Transistor

(5-

Track) Touching the Cartridge Motor.

(G)

5A-000 Model 3,

5,

7

5B-000 Model 4, 6, 8

(H)

17-220 17-310

24

(A) Refer Also

to

R/W VRC.

(B)

17-110,17-310,17-112

Yes

(A) 17-190

Yes

(B) Primarily a 3803

Probl~l!'.

(A) 17-530,17-540

(A) Data

Sensed

During

Erase

or

Erase

Portion

of

WTM.

Suspect Noise from

Read

Card.

Yes

(B) Defective

Erase

Head.

(C)

If

Accompanied

by

Other

Bits They

will

be

the Most

Important.

(D)

17-370

[FE127605]

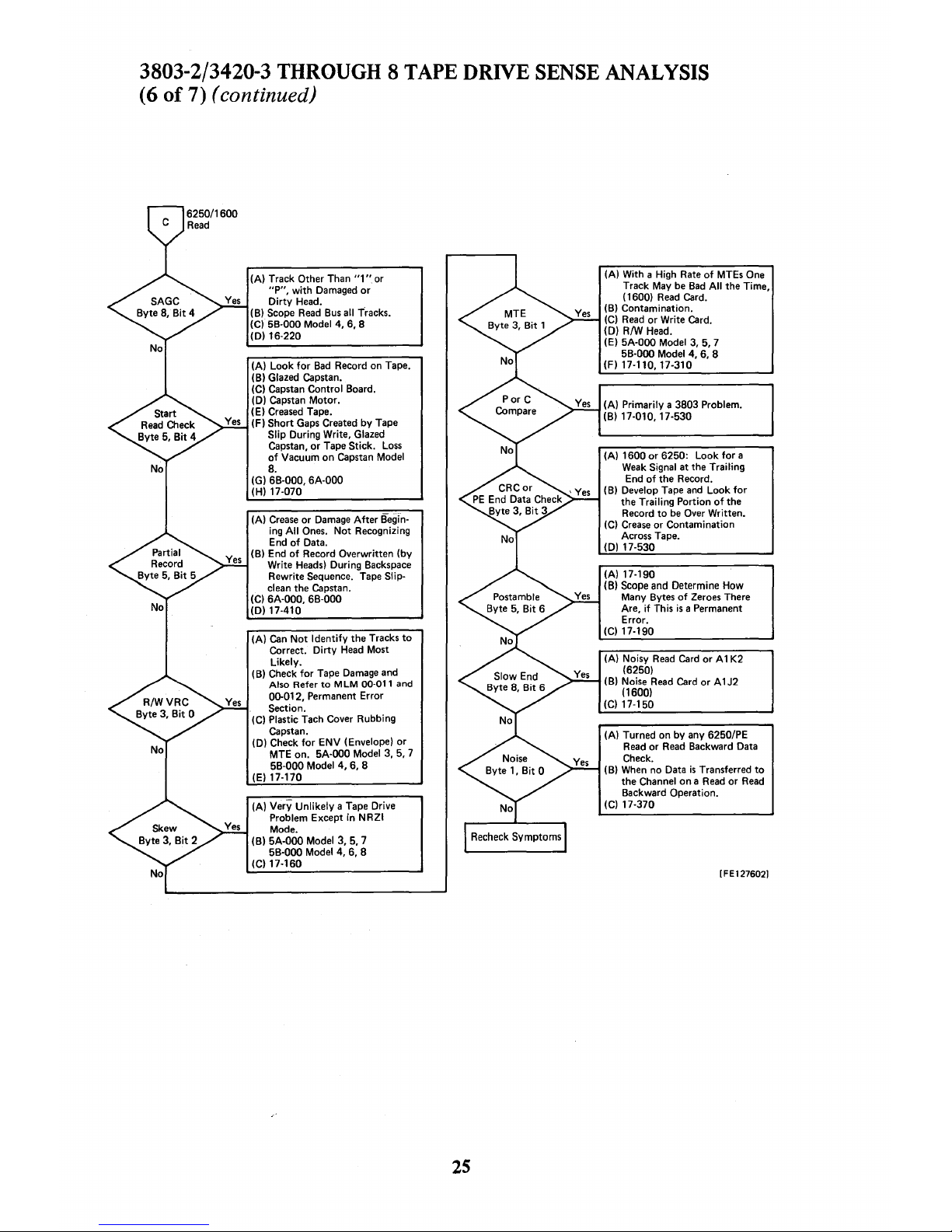

Page 29

3803-2/3420-3

THROUGH 8 TAPE

DRNE

SENSE

ANALYSIS

(6

of

7)

(continued)

(A) Track Other Than

"1"

or

"P",

with

Damaged

or

Dirty

Head.

(B)

Scope

Read

Bus

all Tracks.

(C)

58·000

Model

4,6,8

(D) 16·220

(A)

Look

for

Bad

Record on Tape.

(B)

Glazed Capstan.

(C) Capstan Control Board.

(D) Capstan

Motor.

(E)

Creased

Tape.

(F)

Short

Gaps Created

by

Tape

Slip During Write, Glazed

Capstan,

or

Tape Stick.

Loss

of

Vacuum

on

Capstan Model

8.

(G) 6B·000,

6A·000

(H) 17·070

(A)

Crease

or

Damage

After

Begin·

ing

All

Ones.

Not

Recognizing

End

of

Data.

(B) End

of

Record Overwritten (by

Write Heads) During Backspace

Rewrite

Sequence. Tape Slip·

clean the Capstan.

(C) 6A·000, 6B·000

(D) 17·410

(A)

Can

Not

Identify

the

Tracks

to

Correct.

Dirty

Head

Most

Likely.

(8) Check

for

Tape

Damage

and

Also Refer

to

MLM

00·011

and

00-012, Permanent Error

Section.

(C)

Plastic Tach Cover Rubbing

Capstan.

(D)

Check

for

ENV

(Envelope)

or

MTE on.

5A·QOO

Model 3, 5, 7

5B·000 Model

4,

6, 8

(E)

17·170

(A)

Very

Unlikely

a Tape Drive

Problem Except in

NRZI

Mode.

(B)

5A·000

Model

3,5,7

5B·000 Model 4, 6, 8

(C) 17·160

2S

(A) With a High Rate

of

MTEs One

Track May

be

Bad

All

the Time,

(1600)

Read

Card.

(B) Contamination.

(C)

Read

or

Write Card.

(D) R/W Head.

(E)

5A·000

Model 3,

5,7

5B·000 Model 4, 6, 8

(F)

17·110,17·310

(A)

Primarily a 3803 Problem.

(B)

17·010, 17·530

(A)

1600

or

6250: Look

for

a

Weak

Signal at the Trailing

End

of

the

Record.

(B)

Develop Tape

and

Look

for

the Trailing Portion

of

the

Record

to

be

Over Written.

(C)

Crease

or

Contamination

Across Tape.

(D)

17·530

(A) 17·190

(B) Scope and Determine How

Many Bytes

of

Zeroes There

Are,

if

This

is

a Permanent

Error.

(C)

17·190

(A) Noisy

Read

Card

or

A 1 K2

(6250)

(B) Noise

Read

Card

or

A 1 J2

(1600)

(C)

17·150

(A) Turned on by any 6250/PE

Read

or

Read

Backward Data

Check.

(B)

When

no Data

is

Transferred

to

the Channel

on a Read

or

Read

Backward Operation.

(C)

17·370

[FE127602]

Page 30

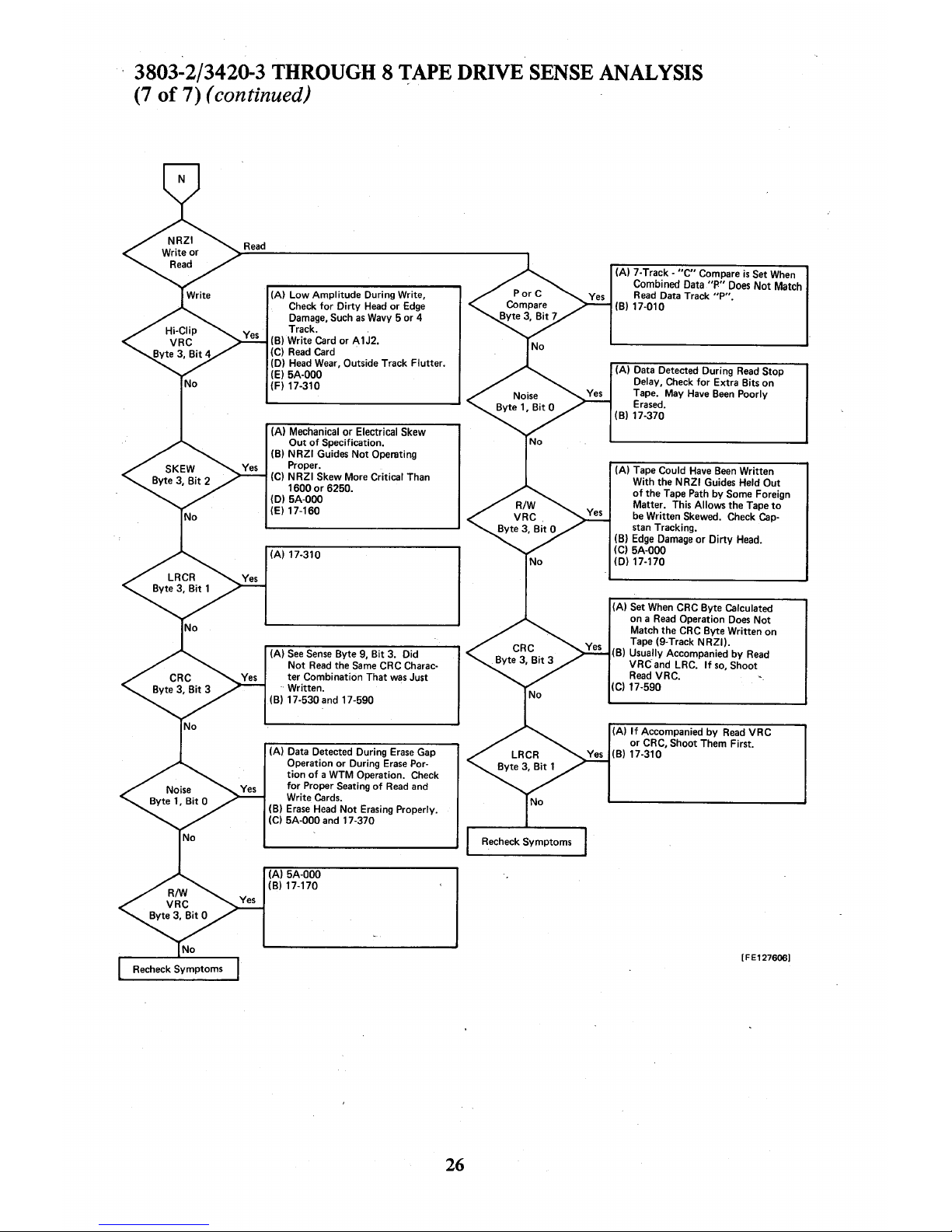

3803-2/3420-3

THROUGH 8 TAPE

DRIVE

SENSE

ANALYSIS

(7

of

7) (continued) ,

(A)

Low

Amplitude

During Write,

Check

for

Dirty

Head

or

Edge

Damage, Such

as

Wavy 5

or

4

Track.

(B) Write Card

or

A1J2.

(C)

Read

Card

(D)

Head

Wear, Outside Track Flutter.

(E)

5A-000

(F) 17-310

(A)

Mechanical

or

Electrical Skew

Out

of

Specification.

(B)

NRZI

Guides

Not

Operating

Proper.

(C)

NRZI

Skew More Critical Than

1600

or

6250.

(D)

5A-OOD

(E) 17-160

(A) 17-310

(A)

See

Sense

Byte 9,

Bit

3. Did

Not

Read

the

Same

CRC Charac-

ter Combination That

was

Just

Written.

(B)

17-530 and 17-590

(A) Data Detected During

Erase

Gap

Operation

or

During

Erase

Por-

tion

of

a WTM Operation. Check

for

Proper Seating

of

Read

and

Write Cards.

(B)

Erase

Head

Not

Erasing Properly.

(C)

5A-000 and 17-370

(A) 5A-000

(B) 17-170

26

(A) 7-Track -

"C"

Compare

is

Set

When

Combined Data

"P"

Does

Not

Match

Read

Data Track

"P".

(B) 17-010

(A) Data Detected During

Read

Stop

Delay, Check

for

Extra Bits

on

Tape. May

Have

Been

Poorly

Erased.

(B)

17-370

(A) Tape Could

Have

Been

Written

With the

NRZI

Guides Held

Out

of

the Tape Path by Some Foreign

Matter. This Allows the Tape

to

be

Written Skewed. Check

Cap-

stan Tracking.

(B)

Edge

Damage

or

Dirty

Head.

(C)

5A-OOD

(D) 17-170

(A) Set

When

CRC Byte Calculated

on a

Read

Operation

Does

Not

Match

the

CRC Byte Written

on

Tape (9·Track

NRZI).

(B) Usually Accompanied

by

Read

VRC

and LRC.

If

so,

Shoot

Read

VRC.

(C)

17-590

(A)

If

Accompanied

by

Read

VRC

or

CRC, Shoot Them First.

(B)

17-310

[FE127606]

Page 31

3420/3803 ONLINE TESTS

IBM

3420/3803 Online Tests, Listed

by

Section

Section

Test Focus

Test Mode

Test

TYEe

A:

CMD

Sequence Analysis

Control Unit

PE/6250/NRZI

Diagnostic

B:

Control Unit

Control Unit

PE/6250/NRZI

Functional

C:

Control Unit

Control Unit

PE and 6250

Functional

D:

Channel Buffer R/W & Mode Set Control Unit

6250/1600/NRZI

Functional

E:

Basic

Read and Write

Subsystem

PE/6250/NRZI

Functional

F:

6250 Data Path Verify

Control Unit 6250 Only

Functional

G:

6250 Error Detect/Correct

Control Unit 6250 Only

Functional

H:

PE Diagnostic Mode (Part 1)

Control Unit

PE Only Functional

I: PE Diagnostic Mode (Part 2)

Control Unit PE Only

Functional

J:

PE Diagnostic Mode (Part 3)

Control Unit PE Only Functional

K:

PE Diagno,stic Mode (part 4)

Control Unit PE Only Functional

L: Mod 4, 6, 8 Clip Level Check

Tape Unit PE Only Functional

M:

NRZI Control Unit

Control Unit

NRZIOnly

Functional

N:

NRZI Diagnostic Mode (Part

1)

Control Unit NRZIOnly Functional

0:

NRZIDiagnostic Mode (Part 2)

Control Unit

NRZIOnly Functional

P:

7 -Track Functional Tests

Tape

Unit NRZIOnly Functional

Q;

Long Record Write/RDB/Read Subsystem

PE/6250/NRZI

Functional

R:

Write Reliability

Subsystem

PE/6250/NRZI

Reliability

RO:

MAPs

Analysis

Control Unit 3803-2 Analysis

S:

Read Reliability

Subsystem

PE/6250/NRZI

Reliability

T:

Tach Parameters

Tape

Unit

PE/6250/NRZI

Diagnostic

U:

Tach Asymmetry

Tape

Unit

Pp/6250/NRZI

Diagnostic

V:

Start/Stop

Tape

Unit

PE/6250/NRZI

Functional

W:

IBG and Creep

Tape Unit

PE/6250/NRZI

Functional

WR:

MAPs

Analysis Control Unit

3803-2

Analysis

X:

Reel Response

Tape

Unit

PE/6250/NRZI

Functional

Y:

Data Access Measure 1

Tape

Unit

PE/NRZI

Functional

Z:

Data Access Measure 2

Tape

Unit

PE/6250

Functional

AB:

Device Switching

Control Unit

PE/6250/NRZI

Functional

AC:

Control Unit Status

Control Unit

PE/6250/NRZI

Functional

AD:

2-Channel Switch (Part 1)

Control Unit

PE/6250/NRZI

Functional

AE:

2-Channel Switch (part 2)

Control Unit

PE/6250/NRZI

Functional

AF:

2-Channel Switch (Part 3)

Control Unit

PE/6250/NRZI

Functional

AG:

2-Channel Switch (part 4)

Control Unit

PE/6250/NRZI

Functional

BA:

Stress Tape 1

Control Unit 6250 Only Diagnostic

BB:

Stress Tape 2

Control Unit 6250 Only Diagnostic

27

Page 32

3420/3803 ONLINE TESTS (continued)

Section RO-WR: Error Analysis

These two

OLTs apply

to

the 3803-2 only. The MAPs and the OLTs are designed as

an

integrated package. You should start with

the

MAPs

and

run

the OLTs

as

indicated when

analyzing an error.

All

of

the

3803-3420 OLTs diagnostics can

save

the

error sense data for later analysis

by

OLT 3420RO and OLT 3420WR. The error sense data "save" field

is:

a common area for

all

of

the 3803-3420 OLTs. Therefore,

if

more

than

one OLT is

run

and has errors, the

sense data from the last error in the last

OLT

run

is

available for analysis.

Although the sense data

is

saved for an error in all

of

the OLTs, only OLTs A-G, P, Q, R,

and

S are recommended for

FRU

analysis. The sense data from the other OLTs can be

analyzed,

but

the results may be misleading. This

is

due

to

errors

that

are forced

by

the

OLTs.

OLT

WR

has an EXT= option whereby sense data

to

be analyzed can be entered from

the keyboard.

Example:

DEV j3420WRjEXT= ,SNS=804400

8000002C000008000000C7j

At least the first fourteen bytes (0-13) should be entered. The extent field (EXT=) however, will

not

permit entry

of

all

24

bytes.

How

to

Generate a 'Prewritten' or 'Read Only' Tape

In MAPs,

you

will note references to a 'Read Only' tape. (In several sections

of

the User's

Guide,

you

will note references

to

a 'prewritten tape'. The terms 'prewritten' and 'read

only' are synonymous.) This tape

is

a diagnostic

tool

which should be generated when

the system

is

operating correctly. You should have a 'Read Only' tape generated in 6250

bpi available for analyzing failures. Sense switch Z which

is

in OLTs routines

A-G

gener-

ates 'Read

Only' data in

6250

bpi.

Note: When changing the EXT= parameter, the program must always be called:

Example: DEVj3420A-GjEXT=Zj

Example: j3420A-ZjEXT=WZj

not

j jEXT=Zj.

28

Page 33

3420/3803

ONLINE

TESTS

(continued)

To

generate a 'Read Only' tape (6250 bpi), the OLTs

A-G

are run with first error option

and sense switch

Z on.

Example: DEVj3420A-GjFE,EXT=Zj.

When

the 'Read Only' tape has been generated without any errors, the tape should be

file

protected.

False

Crease Tape Error -

OLT-

OLT

T3420I

T3420L

T3420K

T3420M

Messages

AIOI08

AI0137

AKOI06

AMOI08

If

byte

17

(EC)

is

not plugged correctly

on

logic AA004.

Prior

to EC733843 bit 6 and 7 should be

01

After EC733843 bit 6 and 7 should be 10

After EC734866 bit 6 and 7 should be

11

R060 OLTs reversed test I and

M.

If

byte

17

is

plugged incorrectly the wrong routine will be run.

o This

is

for a 3803

ModOOl

only. A 3803 Mod002 will be plugged for bit 6 and 7 = 01.

Stress Tape PjN1848621

A prewritten tape used for diagnosing the operating parameters

of

the 3803

Mod

2 has been

been generated by a unique machine for this purpose and cannot be created or duplicated

by any other known method. This tape

is

used in conjunction with OLT diagnostic

T3420BA and T3420BB (stress tape 1 and stress tape 2) and should be ordered from the

nearest

EPC

just prior

to

converting a 3803

Modell

to

a Model 2. Reference OLT User's

Guide dated March 1974 or later for explanation

of

tests etc. After the tape has been

used

to

check out the converted units the tape

is

to

be returned

to

its original stocking

location for use

by

other conversion sites. The tape

is

not intended

to

be kept

at

the

branch office or customer location. The reason for this

is

that there are only a limited

number

of

these tapes available.

As

recertification

of

the stressed data

is

not possible,

care must be exercised

so

as

not

to

damage the tape. A damaged tape will have

to

be re-

placed with a new one.

The recommended stocking level

is

three tapes

at

each emergency parts center (EPC).

29

Page 34

Page 35

WHAT IS WHERE

IN

THE

MLM?

MLMVolume 1

Section

PLAN

00

IA-6A

IB-6B

Contents

Safety information; table

of

contents (organization

of

publication), a list

of

abbreviations and symbols and the address for ordering the OLTs

User's

Guide.

Notes on how

to

use the

MAPs

effectively; training requirements for using

the

MAPs

effectively, method

of

identifying

ECs

which affect the MAPs,

standard plus and minus voltage levels encountered

;in

the machines,

sense byte chart with references to descriptions, a symptom index (page

0-010) for normal entry into the MAPs, a quick index (page 0-009) for

entry into the

MAPs

when you have one

of

the symptoms listed there

and you know whether the problem is in the

TU or TCU.

MAPs

for 3420 Models 3, 5, and 7 attached to 3803-2. (Same

as

Path-

finder for these models attached

to

3803-1.)

MAPs

for 3420 Models 4, 6, and 8. Note that Section I B follows Section

6A,not

IA.

Sections 1 through 6

(both

A and

B)

contain

MAPs

for TU power supply,

thread/load, basic motion, unload, read/write and capstan motion control

problems, in that order.

31

Page 36

WHAT IS WHERE

IN

THE

MLM?

(continued)

:MLM

Volume 2

Section

7

8

11

12

13

14

15

Contents

TV interface theory

Checks, adjustments, removals and replacements

Tev

power supply

MAPs

Procedures for duplicating failures offline and procedures for performing

various CE panel functions (extracting sense data, restart

on

ALV

error,

etc.)

MAP

procedures for

ALV

hangs or loops, channel busy, timeout, or other

indications where

the

microprogram does not appear

to

be looping nor-

mally (possibly also causing channel hang).

Manual analysis

of

sense data using a prioritized scheme.

MAP

procedures for miscellaneous errors.

32

Page 37

WHAT IS WHERE IN

THE

MLM?

(continued)

MLMVolume 3

Section

16

17

18

19

20

21

Contents

MAP

procedures for equipment checks

MAP

procedures for data checks, including timing charts

of

various data

operations plus second levels

of

the conditions required

to

produce

the

error.

Device switch theory and

MAPs

for problems isolated

to

the device switch.

Board layouts for the

TCU and TU boards showing

the

functions perform-

ed for each card to assist in card swapping.

Logic net cross-reference list. The MAP scoping procedures allow

you

to

identify a failing line and the

FRU

from which this line originates.

If

replacing

that

FRU

does

not

correct

the

problem,

you

may suspect a load-

ing problem

at

the

other

end

of

the

line (net). This cross-reference list

provides the references

to

logic for all line (net) names encountered in

the

MAPs

so

that

you

may more easily pursue problems

of

this nature.

OLTEP error message analysis. Used as directed

by

sense analysis sections

3420RO and

WR

after certain errors encountered

by

sections 3420 F and

G.

33

Page 38

WHAT IS WHERE

IN

THE

MLM?

(continued)

MLM

Volume 4

Section

40

50

52

53

54

55

57

58

75

80

85

90

Index

Contents

Subsystem characteristics, features, etc.

TCV data flow, MPI/MP2 schematic, ROSI trap conditions 6250 read/

write service requirements.

Microprocessor theory

TCV oscillators, clocks, counters and controls, second levels and theory

TV

selection and priority

Loop write

to

read (LWR) purpose, operation and data flow

NRZI data flow and theory

Two-channel switch and device switch theory

CE

panel-

description

of

switches and indicators

Tools and test equipment

Subsystem preventive maintenance

Subsystem installation procedures

34

Page 39

COMMON

ABENDS

Reference

MLM

00-035

Abends-

Theory

Abend

137,237,413,613,

and 637 may be caused

by

missing tape marks.

Missing

tape marks are caused by:

• Incorrect forward-backward ratio.

•

Loss

of

signal amplitude causing a failure

to

recognize the tape mark.

• Excessive crosstalk, indicating

that

data

is

fed into a dead zone. Data recorded on any

track in a dead zone. will prevent reading a tape mark correctly.

To

check for loss

of

amplitude and crosstalk

use

the failing drive and tape. Find the tape-

mark on the tape that

was

not read correctly. Cycle back and forth across the failing tape

mark with the

CE

panel. Sync on Go Forward (T-AIF2J10) and scope all tracks (read

card test points) and ensure that the signal

is

good on all tracks in zones 1 and 2 (tracks

P,

0, 5, and

2,6,

7).

Measure the amplitude on tracks 1, 3, and 4 (zone 3) and ensure that there

is

less than

140

mv

of

signal (Models 4, 6, and 8 only).

Crosstalk

is

caused by:

• Defective write

card.

• Defective read card.

• Defective R/W head.

• Poor tracking.

If

tracking

is

out

of

specifications

go

to

Capstan Dynamic Alignment

(see

08-150). The drive that wrote or read the tape, or both, could cause crosstalk.

If

the failing tape

is

not available, write a tape on a working tape drive offline, and use

that tape

to

check for crosstalk on the suspected failing drive.

137/637 Abend

Machine

Possible

Causes

Type

3803

Defective

01

A-A2N2

card

,

3803

Defective

01

A-B2F2

35

Page 40

COMMON

ABENDS

(continued)

237 Abend

Machine

Possible Causes

Type

3420

Large tape creases detected

as

gaps (check

stubby

bar clearance).

3420

Short

records (80 characters) falling within a

tape

crease.

3420

Tape edge damage.

3420

E/C

443935

(6250) - Fix for

short

gap verification

during backspace after a write error caused by

erratic

tape

motion,

not

installed.

3420

R/W

head forward-to-backward ratio

is

out

of

specifications.

3420

Tape sticking.

3420

Dirty capstan.

3803

Missing Suppress

Out,

intermittently breaking

channel/command word

(CCW)

chain, updating

the

count

but

not

losing a record.

3803

Defective

01

A-B3F2 inbound tag card XC700.

3803

ECA079 - Unexpected interrupt with status

=

'00'

from a non-two channel switch

in

multiple

CPU

2X, 3X, 4X, installation.

36

Page 41

COMMON

ABENDS

(continued)

413 Abend

Machine

Type

Possible

Causes

3420 Defective

T-A 1 C2

MST card.

3420

Reading 6250 tape in

1600 mode.

E/C 443890 -

Autocleaner sluggish,

not

installed.

3420 Defective

A1

H2

3420

. Defective

T-A

1 L2

3420 E/C 735817 -

Delay Ready after rewind,

Models

to

allow autocleaner

to

return,

is

not

installed.

4,6,8

3420

Damaged

tape

at

load point.

3420

Contamination on the Read/Write head, or the

capstan

is

glazed.

3803 Defective

01

A-A2D2 MST card or defective

01A-A2E2

MST card.

3803

Broken

CCW

chain

without

Unit

Check. Run

an

I/O software trace

for

more problem definition.

3803 ECA079 - Prevent busy in

middle

of

CCW

chain,

not

installed.

3803

ROS

patch

to

ALU1

for

allocated busy

is

not installed.

37

Page 42

COMMON

ABENDS

(continued)

613 Abend

Machine

Possible Causes

Type

3420

E/C

443935 -Short

gap engineering change

not

,.

installed.

3420

ECA073 - Delay Ready after rewind

to

allow

Models

autocleaner

to

return,

is

not

installed.

4,6,8

3420

Contaminated Read/Write head.

3420

Damaged

tape

at

or

near load

point

3420

Read/Write head forward-to-backward ratio

not

in

specifications.

3803

Defective

01

A-A2N2 card, extra

tape

mark.

Defective

3168/2880

card, high-speed buffer

~

data compare.

OS/VS2

PTF 70751

not

installed.

R017

3803-1

Tape Tracking, leaves a faint

TM

(where

existing files are updated) because

of

the

overwriting

of

the

old EOF TM.

In

this

case

the

writeheads actually

do

the

erasing

of

the

old TM.

3803-1 Defective

01

A-B2F2

3803

Incorrect

UCW

Plugging