Page 1

----

----

-----

- -

---

- -

---

-

--

--

----

---

---

---

- -

-

- - -

- - -~ -

-

-

--

Maintenance

Library

=-=-=-=-

=~

ffff:

- s 3 G

~

Color

Models 2A, 28, 3A,

Maintenance

Display

Station

and

Infonnation

38

SY33-0069-3

(Part

1)

Page 2

Maintenance

Library

=~ff-;:

~

Color Display

Models

Maintenance

2A,

Station

28,

3A, and

Information

38

SY33-0069-3

(Part

1)

Page 3

3279

MIM

Preface

Part

This publication contains the information needed

service

and

Station Models 2A, 2B, 3A,

Part 1 comprises the Maintenance Information

Parts Catalog.

maintain the IBM

and

3279

Color Display

3B.

to

and

Fourth Edition, November 1981

This is a major revision of,

and

specifications contained herein shall

part without written permission.

IBM has prepared this maintenance manual for the use of IBM customer

engineers in the installation. maintenance, or repair

machines indicated.

any

other

purpose.

Information contained in this manual

time.

Any

Technical Newsletters.

It

abollt, IBM products (machines or programs), programming,

that

must

products, programming,

Publications are not stocked

IBM publications should be made

IBM

A form for reader's comments

if the form has been removed, comments may be addressed

• International Business Machines Corporation, Department

or

IBM

believes appropriate without incurring

e Copyright International Business Machines Corporation 1979, 1980,

1981

sllch change will be reported in subsequent revisions

is possible

that

are

not

announced in your country. Such references

not

be construed

branch

office serving your locality.

1133 Westchester Avenue, White Plains,

IBM United Kingdom Laboratories Limited,

Point 95, Hursley Park, Winchester, Hampshire

may use or distribute whatever information you supply

and

obsoletes, SY33-0069-2.

not

he reproduced

to

to

at

the back

New

York 10604.

Product

obligation

of

that

change from time

announce such IBM

S021

to

IBM makes no representations

is

subject

this material may contain references to,

to

mean

that

or

IBM intends

services in your country.

at

the addresses given below; requests for

to

your IBM representative

is

provided

any

2 comprises the Maintenance Analysis

Procedures.

If

this machine

extra

RPQ

under

the keyboard.

The

drawings

in

whole

or

the specific

it is suitable for

to

or

or

information

or

services

or

information

or

to

the

of

this publication;

to

either:

812H,

Publications, Mail

2JN, England.

in

any

you.

way

is

fitted with

documentation

in

it

can

any

he

RPQ

found

features,

in a tray

ii

any

Page 4

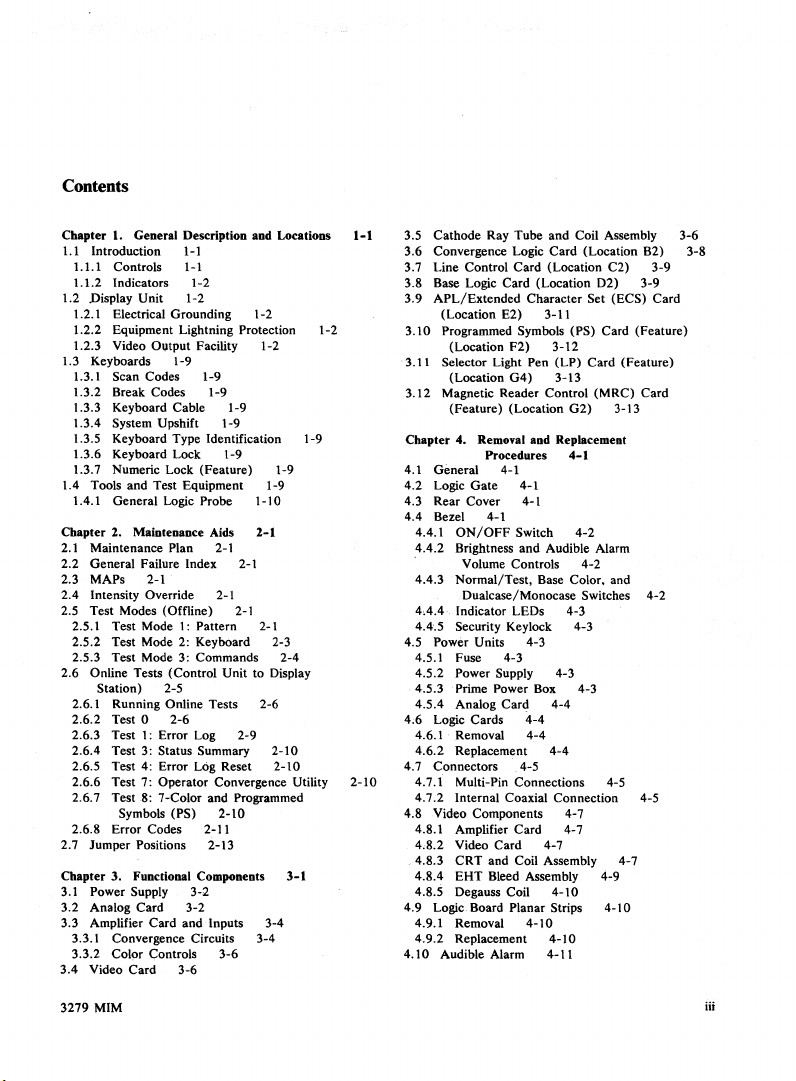

Contents

Chapter

1.

1.1 Introduction

1.2 Display Unit 1-2

1.3 Keyboards 1-9

1.4 Tools and Test Equipment 1-9

Chapter 2. Maintenance Aids 2-1

2.1 Maintenance

2.2 General Failure Index 2-1

2.3

2.4 Intensity Override 2-1

2.S Test Modes (Offline) 2-1

2.S.\

2.S.2 Test Mode 2: Keyboard 2-3

2.S.3 Test Mode 3: Commands 2-4

2.6 Online Tests (Control

2.6.1 Running Online Tests 2-6

2.6.2 Test

2.6.3 Test

2.6.4 Test 3:

2.6.S Test 4: Error Log Reset

2.6.6 Test 7: Operator Convergence Utility

2.6.7 Test 8: 7-Color and

2.6.8 Error Codes

2.7 Jumper Positions 2-13

Chapter 3. Functional Components

3.1 Power Supply 3-2

3.2 Analog Card 3-2

3.3 Amplifier Card

3.3.1 Convergence Circuits 3-4

3.3.2 Color Controls

3.4

General Description and Locations

1.1. 1 Controls 1-1

1. 1.

2 Indicators 1-2

1.2.1 Electrical Grounding 1-2

1.2.2 Equipment Lightning

1.2.3 Video

Scan Codes 1-9

1.3.1

1.3.2 Break Codes 1-9

1.3.3 Keyboard Cable 1-9

System Upshift 1-9

1.3.4

1.3.5 Keyboard Type Identification 1-9

1.3.6 Keyboard Lock 1-9

1.3.7 Numeric Lock (Feature) 1-9

1.4.1 General Logic Probe

MAPs 2-1

Test Mode

Station)

Symbols (PS) 2-10

Video Card 3-6

1-1

1:

and

Pattern

2-\\

Inputs

Protection 1-2

Unit to Display

Programmed

3-6

01)tput Facility 1-2

Plan 2-1

2-S

0

2-6

1:

Error Log 2-9

Status Summary

1-10

2-\

3-4

2-\0

2-\0

3-1

3.S

Cathode

1-1

3.6 Convergence Logic

3.7 Line Control Card (Location

3.8 Base Logic Card (Location

3.9

3.10

3.11 Selector Light

3.12

Chapter 4. Removal and Replacement

4.1 General 4-1

4.2 Logic

4.3 Rear Cover 4-1

4.4 Bezel 4-1

4.4.1

4.4.2 Brightness and Audible Alarm

4.4.3

4A.4

4A.S Security Keylock 4-3

4.S Power Units 4-3

4.S.1 Fuse 4-3

4.S.2 Power Supply 4-3

4.S.3 Prime Power Box 4-3

4.S.4 Analog Card 4-4

4.6 Logic Cards

4.6. I Removal

4.6.2 Replacement 4-4

4.7 Connectors 4-5

2-10

4.7.\

4.7.2 Internal Coaxial Connection 4-S

4.8 Video Components 4-7

4.8.\

4.8.2 Video Card 4-7

4.8.3

4.8.4

4.8.S Degauss Coil 4-10

4.9 Logic. Board

4.9.1 Removal

4.9.2 Replacement

4.10

Ray Tube and Coil Assembly

APL/Extended

(Location E2) 3-11

Programmed Symbols (PS) Card (Feature)

(Location

(Location

Magnetic Reader Control (MRC) Card

(Feature) (Location

Procedures 4-1

Gate

ON/OFF

Volume Controls 4-2

Normal/Test,

Oualcase/Monocase Switches 4-2

Indicator LEOs 4-3

Multi-Pin Connections 4-S

Amplifier Card 4-7

CRT

and Coil Assembly 4-7

EHT

Bleed Assembly 4-9

Audible Alarm 4-1 \

Card

(Location B2)

C2)

Character Set (ECS) Card

F2)

Pen (LP) Card (Feature)

G4)

4-\

Switch 4-2

4-4

4-4

Planar Strips 4-10

4-10

02)

3-12

3-13

G2)

3-13

Base Color. and

4-\0

3-9

3-9

3-6

3-8

3279 MIM

iii

Page 5

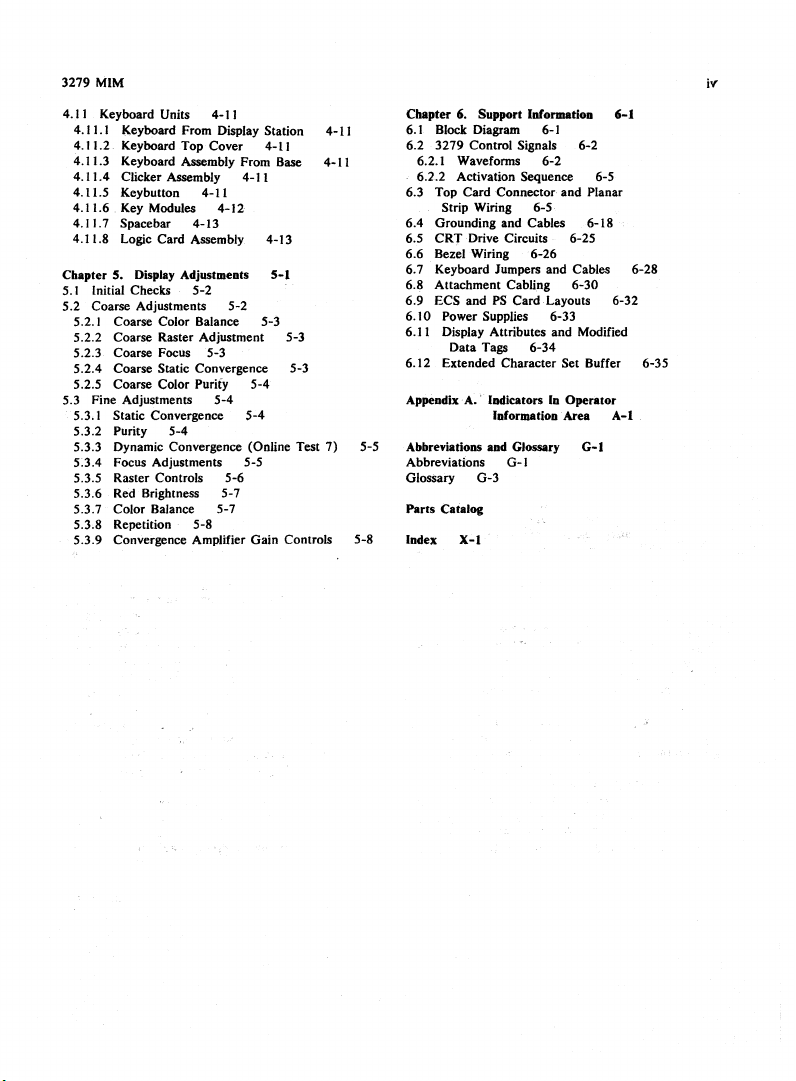

3279 MIM

6.

4.1 I Keyboard Units 4-11

4.11.1 Keyboard From Display

4.11.2 Keyboard Top Cover 4-11

4.11.3 Keyboard Assembly From Base 4-11

4.11.4 Clicker Assembly 4-11

4.11.5 Keybutton 4-11

4.11.6 Key Modules 4-12

4.11.7

Spacebar 4-13

4.11.8 Logic Card Assembly 4-13

Chapter 5. Display Adjustments 5-1

5.1

Initial Checks 5-2

5.2 Coarse Adjustments 5-2

5.2.1 Coarse Color Balance 5-3

5.2.2 Coarse Raster Adjustment 5-3

5.2.3 Coarse Focus 5-3

5.2.4 Coarse

5.2.5 Coarse Color

5.3 Fine Adjustments 5-4

5.3.1

5.3.2 Purity 5-4

5.3.3 Dynamic Convergence (Online Test

5.3.4 Focus Adjustments 5-5 Abbreviations G-I

5.3.5 Raster Controls 5-6

5.3.6 Red Brightness 5-7

5.3.7 Color Balance 5-7

5.3.8 Repetition 5-8

5.3.9 Convergence Amplifier Gain Controls 5-8

Static Convergence 5-3

Purity 5-4

Static Convergence 5-4 Information Area

Station 4-11

7)

Chapter

6.

1 Block Diagram 6-1

6.2 3279 Control

6.2.1 Waveforms 6-2

6.2.2 Activation

6.3 Top Card Connector and Planar

6.4 Grounding and Cables 6-18

6.5

6.6 Bezel Wiring 6-26

6.7 Keyboard Jumpers and Cables 6-28

6.8 Attachment Cabling

6.9 ECS and

6.10 Power Supplies 6-33

6.11 Display Attributes and Modified

6.12 Extended Character

Appendix

5-5

Abbreviations and Glossary

Glossary G-3

Parts Catalog

Index

Support Information 6-1

Strip Wiring 6-5

CRT

Drive Circuits 6-25

Data Tags 6-34

A.

Indicators In Operator

X-I

Signals 6-2

Sequence 6-5

PS

6-30

Card Layouts 6-32

Set Buffer 6-35

G-I

iY'

A-I

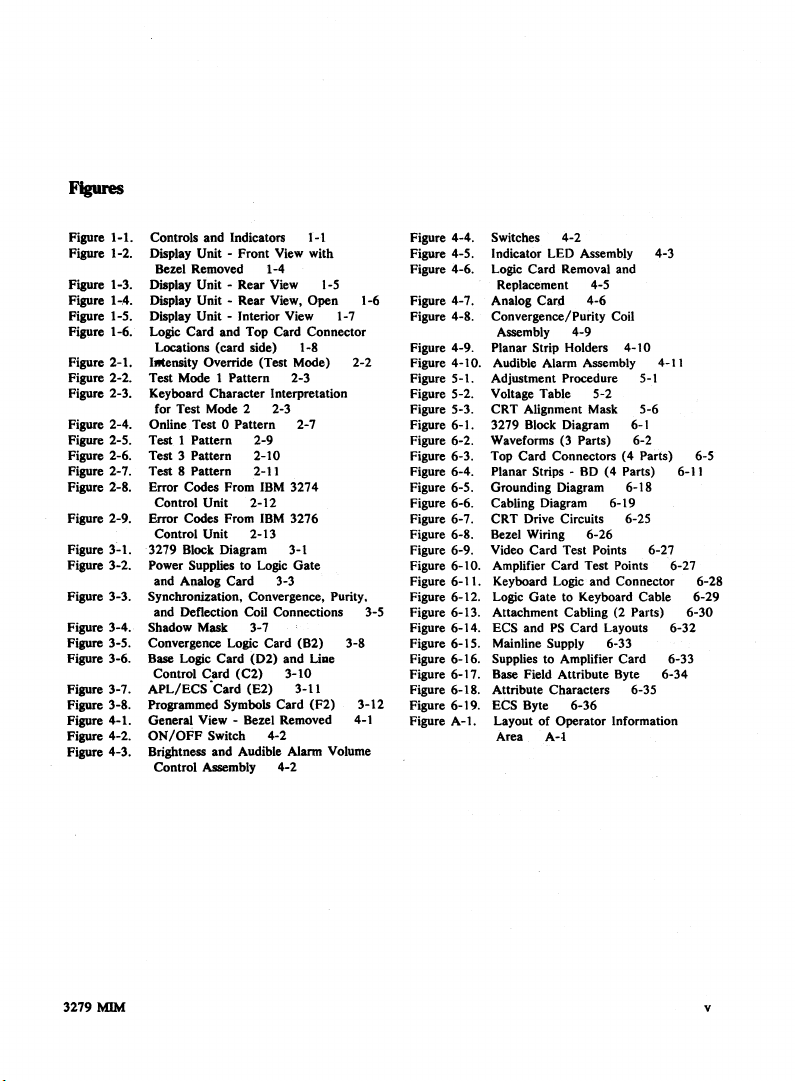

Page 6

Figure

1-l.

Figure 1-2.

Figure 1-3.

1-4.

Figure

Figure 1-5.

Figure 1-6.

Figure

2-l.

Figure 2-2.

Figure 2-3.

Figure 2-4.

Figure 2-5.

Figure 2-6.

Figure 2-7.

Figure 2-8.

Figure 2-9.

Figure 3-1.

Figure 3-2.

Figure 3-3.

Figure 3-4.

Figure 3-5.

Figure 3-6.

Figure 3-7.

Figure 3-8.

Figure 4-1.

Figure 4-2.

Figure 4-3.

2-10

IBM

IBM

(02)

3274

3276

and

3-10

I-I

Uoe

(F2)

1-5

3-12

Controls and Indicators

Display Unit - Front View with

Bezel Removed 1-4

Display Unit - Rear View

Display Unit - Rear View, Open 1-6

Display Unit - Interior View 1-7

Logic Card and Top Card Connector

Locations (card side) 1-8

Illtensity Override (Test Mode) 2-2

Test Mode 1 Pattern 2-3

Keyboard Character Interpretation

for Test Mode 2 2-3

Online Test

Test 1 Pattern 2-9

Test 3 Pattern

Test 8 Pattern 2-11

Error Codes From

Control Unit 2-12

Error Codes From

Control Unit 2-13

3279 Block Diagram 3-1

Power Supplies to Logic Gate

and Analog Card 3-3

Synchronization, Convergence, Purity.

and Deflection Coil Connections 3-5

Shadow Mask 3-7

Convergence Logic Card (B2) 3-8

Base Logic Card

Control Card

APL/ECS

Programmed

General View - Bezel Removed 4-1

ON/OFF

Brightness and Audible Alarm Volume

Control Assembly 4-2

0 Pattern 2-7

(C2)

'Card (E2) 3-11

Symbols Card

Switch 4-2

Figure 4-4.

Figure 4-5.

Figure 4-6.

Figure 4-7.

Figure 4-8.

Figure 4-9.

4-10.

Figure

Figure 5-1.

Figure 5-2.

Figure 5-3.

Figure 6-1.

Figure 6-2.

Figure 6-3.

Figure 6-4.

Figure 6-5.

Figure 6-6.

Figure 6-7.

Figure 6-8.

Figure 6-9.

Figure

6-10.

Figure 6-I

Figure 6-12.

Figure 6-13.

Figure 6-14.

Figure 6-15.

Figure 6-16.

Figure 6-17.

Figure 6-18.

Figure 6-19.

A-I.

Figure

Switches 4-2

Indicator LED Assembly 4-3

Logic Card Removal and

Replacement 4-5

Analog Card 4-6

Convergence/Purity Coil

Assembly 4-9

Strip Holders 4-10

Planar

Audible Alarm Assembly 4-11

Adjustment Procedure

Voltage Table 5-2

CRT Alignment Mask 5-6

3279 Block Diagram 6-1

Waveforms (3 Parts) 6-2

Top Card Connectors (4 Parts) 6-5

Planar

Strips Grounding Diagram 6-18

Cabling Diagram 6-19

CRT Drive Circuits 6-25

Bezel Wiring 6-26

Video Card Test Points 6-27

Amplifier Card Test Points 6-27

1.

Keyboard Logic and Connector 6-28

Logic Gate to Keyboard Cable 6-29

Attachment Cabling (2 Parts)

and

PS

ECS

Mainline

Supplies to Amplifier Card 6-33

Base Field Attribute Byte 6-34

Attribute Characters 6-35

ECS Byte 6-36

Layout of Operator Information

Area

Card Layouts 6-32

Supply 6-33

A-I

BD

5-1

(4

Parts) 6-11

6-30

3279 MIM

v

Page 7

3279 MIM

Safety

If

with

practice these

with

You

respect

You should take every

possible

pactices

1.

2. Remove all

3.

4. Unplug the

5.

Guidelines

you are aware

electrical and mechanical equipment and

this

need.

You should

conditions or around equipment with

dangerous voltage.

manager

assembling

the immediate area

performing

supplies,

Circuitry.

Power

generators, and other units

Which exceed 30 V ac

be serviced

removed

within the machine, unless maintenance

documentation clearly states otherwise.

(This

grounding is maintained.)

possible

The

be locked in the

a DO NOT OPERATE tag

Be

aware

IBM machine may be

source and be controlled

disconnect

When

equipment having exposed live electrical

circuitry, observe the

a.

Another

controls

(Someone

power

of

the guidelines

guidelines, you can

equipment.

not

fear

it.

and observe the

while

is

wall

it

electricity,

safety

'maintaining IBM equipment:

not

if

this is a potential problem.

power

major

mechanical inspection

or

installing changes

supplies, pumps, blowers,

with

from

done

power

before

box

that a non-IBM

or

is

absolutely necessary

person familiar

must

if it

following

work

alone under hazardous

Always

before removing

components,

of

power

or

power

on when the

its

normal installed position

to

ensure

that

supply

working

switch

circuit breaker.

must

should become necessary.)

on the machine.

when

off

position

(form

powered

by a different

following

be in immediate vicinity.

be there

but

precaution

advise

supplies,

with

42.4 V

proper

cord

turned

or

attachment

with

to

for

working

work

safely

you

must

safety

your

or

working

of

power

in

machine

motor

voltages

dc

must

unit

whenever

off

should

tagged

with

Z229-0237).

to

from

another

to

work

precautions:

power

off

turn

off

vi

b. Do

not

wear

any

jewelry,

frame

eyeglasses,

of

the event

current

contact

c. Use

and appropriate probe

(Remember,

unsafe.)

d. Use only one hand

energized equipment. Keep the

hand in

(Remember there

circuit

procedure helps eliminate a path

in

not

is

an

on

could complete a circuit through you!)

e.

When

that

insulated

used.

f.

Avoid

floor

suitable

necessary.

6.

Follow

working

These instructions are outlined in CEMs and

the

safety

documentation. Use extreme care

checking high voltage.

7.

Avoid

have

not

tools

hand

should be inspected periodically.)

8. Replace

equipment.

-After maintenance, restore all

9.

such as guards, shields, signs, and

leads. Replace

worn

or

are

there

Don't

defeat

them

at

contact, there

flowing

because

area

afforded

only

insulated pliers, screwdrivers,

worn

your

pocket

for

electrical shock. This

using

test

controls are

probes

contacting

strips, machine frames, etc.). use

rubber

mats

special

safety

with

extremely high voltages.

portion

of

use

of

tools

[wire

wrap

or

broken

any

protect

their

purpose

completion

and

been apPllf)ved

worn

.defective. (These

to

the

chains, metallic

or

metal

cuff

links. (In

will

be

of

by

tips/

or

cracked insulation

when

or

behind

must

be a complete

equipment, be certain

set

correctly and

of

proper

ground

purchased locally

instructions

maintenance

test

equipment

by

IBM. (Electrical

guns, drills, etc.]

tools

safety

device

safety

you

from

by

of

the

more

the greater

the metaL)

extenders.

working

on

other

your

that

that

capacity are

potential (metal

when

when

and

test

safety

devices,

ground

that

is

devices

a hazard.

not

replacing

service call.)

is

back.

if

that

Page 8

10.

Safety

glasses

must

be

worn

Using

a hammer

Power

hand drilling.

•

Using spring hooks, attaching springs.

Soldering,

bands.

Parts

cleaning, using solvents, chemicals,

to

wire

cutting, removing steel

when:

drive pins, etc.

and cleaners.

All

other

conditions

hazardous

11.

Never

assume

(Check

it

first.)

Always

12.

your

nongrounded extension cords,

missing safety

13. Do

surface

surface

and can

personal injury.

14. Four

event

a.

be alert

working

not

touch live electrical circuits

of

the plastic dental mirrors. The

of

the dental

result in machine damage and

steps

that

of

an

electrical accident:

USE CAUTION - DON'T

YOURSELF.

b. TURN POWER

c. HAVE SOMEONE

HELP.

d.

ADMINISTER RESCUE BREATHING

VICTIM

IS

15. Do

not

use solvents, cleaners,

have

not

been approved

16.

Lift

by

standing

stronger

leg muscles. This takes strain

back muscles. Do

parts

which

you

17. Each

18. Place removed machine covers in a safe

customer

be certain

renders the

hazards

out-of-the-way

machine. These covers

the machine

to

that

product

to

customer

the customer.

before

which

to

your

eyes.

that

a circuit is deenergized.

to

potential hazards in

environment (i.e.,

grounds,

etc.).

mirror

is conductive

should be taken in the

BE

OFF.

ELSE

GET

NOT BREATHING.

by

IBM.

or

pushing up

not

lift

engineer

action on

unsafe

personnel.

while

the machine

any

is

responsible

his/her

or

must

feel uncomfortable

no

location

might be

damp

floors,

power

surges,

with

A VICTIM

MEDICAL

IF

or

oils

that

with

off

equipment

with.

part

exposes

servicing the

be in place on

is

returned

3279 MIM

to

the

or

19.

Always

place

CE

tool

kit

away

areas

where

no

under

desk

20.

Avoid

caught in machinery.

left

buttoned

Long hair and scarves

21. Ties

clasp (preferably non-conductive)

approximately three inches

when

servicing a machine.

22. Before starting equipment, make sure

fellow

in a hazardous position.

23. Maintain

the machines

completing maintenance.

24.

Avoid

when

lubricating, checking

Prevention

should

always

and practice

Making certain

receptacle meets IBM equipment

requirements.

Inspect line

loose, damaged

Before removing a

retain a charge from the machine, review the

procedure in the maintenance documentation.

CAREFULLY discharge the necessary

components

service procedure.

not

Do

trouble

Never

assume

circuit.

No

time. The exact condition

unknown.

The

power

wired.

Safety

or

defective.

The maintenance and /

may

be uncertain

one can

or

table).

wearing

loose

clothing

Shirt sleeves

or

rolled

up

must

must

be tucked in

CEs

and

customer

good

housekeeping in the area

while

performing and

touching

moving

is the key

good

to

be conscious

cords

electrical safety. You

habits

such as:

that

the customer's

and plugs. Check

or

worn

component

exactly as directed

use

an

ordinary

light.

anything

machine

Here are some

receptacle could be incorrectly

devices

about

is

completely safe a/l

or

features could be missing

or

or

unclear.

from

trip

ovor

it

(i.e.,

that

may be

must

above the

be

secured.

shirt

or

have a

from

the end

personnel are

after

mechanical parts

for

play, etc.

of

electrical safety

power

Pl,lrts.

for

which

by

the

lamp as

an

extension

a machine

of

a machine may be

of

the reasons

modification

elbow.

can

walk

be

tie

that

not

or

of

the

why:

history

of

vii

Page 9

3279 MIM

A

possible

The

machine

transportation

The machine

or

attachment.

An

EC

improperly

The machine

age

or

design

may

damage.

might

or

sales change

installed.

may

environmental

deficiency

have

suffered

have an

may

have

deteriorated

extr8mes.

could

exist.

unsafe

alteration

have been

due

viii

A

component

hazard.

Some

been

Relating

the

condition

to

Before

exercise

caution.

component

incorrectly

to

safety,

of

the

you

begin a service

good

jud!!ment

could

be

of

assembled.

these

machine can

defective,

the

machine

are

and

some

call

proceed

creating

may

of

the

be

affected.

or

procedure,

a

have

ways

with

Electrical

Administering

In

implementing

electrical accident

Use

with

necessary

Power

the

disconnect

dry

pull

with

Act

hel she

possibly

heart

Call

Emergency,

someone

Determine

Make

1.

and

mouth

airway

the

and place one hand beneath the

neck

Then

head

forehead

Figure 1.

Accidents

First

rescue

Caution

the electrical

electrical current.

stick

or

the

Quickly

is

Fire

that

tongue.

and the

lift

backward

one

If

the

so~rce,

to

use the

Off)

or

disconnect

switch

cannot

or

another

push

the

victim

electrical

equipment.

If

the

may

need rescue breathing and

external

cardiac

not

beating.

Rescue

(Rescue Squad,

Ambulance,

summon

medical aid.

if

the

victim

certain

that

the

it

is

not

objects

the

from

obstructed.

that

gum,

Position

other

neck

with

with

the

other

for

such as

Aid

procedures

must

victim

room

If

nonconducting

away

victim

needs rescue breathing.

victim's

food,

the

hand

pressure

is

still in

it

may

EPO

switch

the

EPO

be located,

from

is

unconscious,

compression

Hospital

airway

Check

may

be

blocking

dentures

victim

on

his

one

hand and

on

hand as

in an

contact

be

(Emergency

to

remove

or

use

object

contact

if

the

etc.) Have

is

open

the

the

or

even

on

his

back

victim's

forehead.

tilt

the

shown

in

a

the

2.

Now

you

must

look,

listen,

and

feel

determine

Place

and

of

to

Figure

At

the

upper

If

the

should:

a.

With

shown

pressure

your

so

nostrils

index

CAUTION

Use

reSCue

have

NOT

THE

your

nose

air,

1

same

abdomen

victim

the

in Figure

hand

that

you

together

finger

extreme

breathin!!

breathed

INHALE

VICTIM,

if

the

cheek

to

listen

time,

to

is

not

head

in a backward

on

the

while

can

(Figure 2),

care

AIR

victim

close

and feel

look

at

see

if

breathing

1,

continue

victim's

rotating

pinch

with

when

to a victim

in

toxic

EXHAUSTED

is

breathing

to

the

for

the

chest

they

rise and fall,

properly,

forehead

this

the

victim's

the

thumb

administering

fumes,

freely,

victim's

the

exhaling

and

you

tilt

as

to

exert

with

same hand

and

that

may

DO

BY

to

mouth

Page 10

Figure

b. Open

your

breath. Make a

mouth

blow

into the

2

mouth

around the

victim's

wide

tight

victim's

seal

mouth

and take a deep

with

your

mouth

and

(Figure 3).

Figure

4

Figure

3

c.

Remove

your

to

exhale

chest

while

to

fall (Figure

mouth

watching

4).

Cathode Ray Tube

The primary hazard

result·

of

an implosion. The

deal

with

phases are equally

any area could result in

employee

Any

information

unit's

Storage

1.

different

or

additional

CEM/Service

Cathode Ray

received,

from

area

carton,

one

of

sealed

to

of

CRTs

phases

important

customer.

will

of

Cathode Ray Tubes

transported,

to

they

equivalent strength, and securely

prevent accidental opening.

possible

information

be included under

Aids.

Tubes

must

area.

If

must

be in the original carton

and

allow

the

for

the

Safety

is

flying

following

of

CRT SAFETY,

and negligence in

injury

or

variation

that

be enclosed

or

otherwise

they

are shipped in a

victim

victim's

glass

sections

to

an

from

specific

when

moved

Also,

as a

All

this

d. Repeat this cycle once every five

seconds until the victim breathes

himself

or

medical help arrives.

Reporting Accidents

It is

aCE's

accidents, potential electrical hazards, and

miss"

Remember, a linear miss!! accident might be the

result

reporting

resolved quickly.

It's

since the conditions

be varied

2. CRTs should be stacked as per directions on

3.

or

responsibility

accidents

of

a design deficiency and

will

ensure

important

original

and/

carton

protection.

or

be able

should

manufacturer's carton.

with

Cartons should

two

CRT storage areas

flow

pedestrian

be

moisture

to

slightly

or

equivalent packing materials

or

forms

to

give the

piece

of

equipment, the equipment

to

contain the glass fragments

an

implosion occur.

faceplate (viewing surface)

high.

of

material handling equipment and

traffic.

dry

to

insure

and collapse.

to

to

your

field

that

the situation

report

even a

which

to

If

caused

cause serious injury.

must

be placed inside the

tube

proper

tubes

are transported in a unit

When

not

be stacked more than

will

be away

Also, storage areas

that

cartons

for

report all electrical

manager.

minor

prompt

shock

it

need

support

in

doubt,

down.

from

will

not

will

"near

be

only

and

must

stack

normal

must

absorb

3279 MIM

ix

Page 11

3279

MIM

Maintenance and Installation

1.

No one shall be permitted

maintain, replace, or handle high-vacuum

tubes

until

he

has reviewed this CEM.

2. Cathode Ray Tubes

transported,

to

area should be

their original shipping carton and sealed.

3.

When

safety

safety

a.

b. Long-Sleeved Garment.

4.

Tubes

remain

under

5.

Avoid

tube

possibly

6. Prior

discharge all stored potential which

exist

socket

high-voltage

Ray Tubes

both

capacitor.

capacitive

original

discharge

immediately

7. Do

neck alone. The neck is the

the

handle

shipped

be used

placement

container.

or

otherwise

handling CRTs, personnel

equipment at all times. The required

equipment is:

Safety

Glasses - IBM Part 5715010

und<;>r

vacuum

out

of

their

test

or

inspection.

scratching

because

this

cause

it

to

removal

of

on the

tube's

pins and the capacitor

supply. (NOTE: Some Cathode

contain a conductive

the

inside

and

Within

charge

discharge.

each

tube a second

before

not

handle Cathode Ray Tubes

tube

and

is

easily broken.

tubes

with

with a lifting

for

the removal

of a tube

to

install, adjust,

when

received,

moved

completely

carton unless

or

bumping any

may

to

any high-vacuum tube,

anode button

outside

some

builds

It

removal.)

two

enclosed in

will

not

be permitted

weaken

implode.

surfaces

tubes, a

up

following

is

therefore

time

weakest

hands.

strap, this strap should

of a tube

into,

the shipping

from

area

will

wear

they

are

part

of

the glass and

may

or

base

in

the

coating

on

to

form

second

the

important

by

the

part

Always

If

the CRT is

from,

the

and

x

8.

When

inserting

or

equipment,

large end

or

out

of

present, can be used in this process.

9.

Avoid

placing the

when

there

rolling.

If

anywhere except in its special carton, a

of

felt

piece

placed under

glass. Place larger tubes vertically on

faces, and

to

a

to

of

possibility

10.

When

removing a

should be enclosed in

as soon as

of

breaking. Cathode Ray Tubes should be

placed in the carton

up

and the neck

weight

of

neck. The container should be sealed

with

securely

tipping,

turned

positioned

Disanning Cathode Ray Tubes

Field personnel should

Tubes. Tubes

in

accordance with existing Environmental

Protection

return.

Disposal

An

Inventory/Distribution

to

the Branch

disposal

of

July

14, 1980

removing tubes

they

must

while

position. The

is

it

is necessary

not

of

possible

the

face

Agency

of

CRTs.

be supported

carefully guiding

lifting

tubes

any

or

it

rolling.

tube

strong

will

on a table

possibility

to

other

soft

to

prevent scratching the

on their sides,

tube

its

to

reduce the chances

with

down.

Be

is

not

tape

over

so the tube is

down.

not

be disarmed and

requirements at the plant

Cathode Ray Tubes

Office

with

from

by

the

the

neck in

strap,

if

or

bench

of

the

tube

place a

tube

material should be

their

to

prevent the

from

equipment,

shipping container

the large face end

sure

that

resting on the

and,

disarm Cathode Ray

letter

instructions on the

the

to

prevent

disposed

has been issued

it

of

of

Page 12

hand

Chapter

1.

General

Description

and

Locations

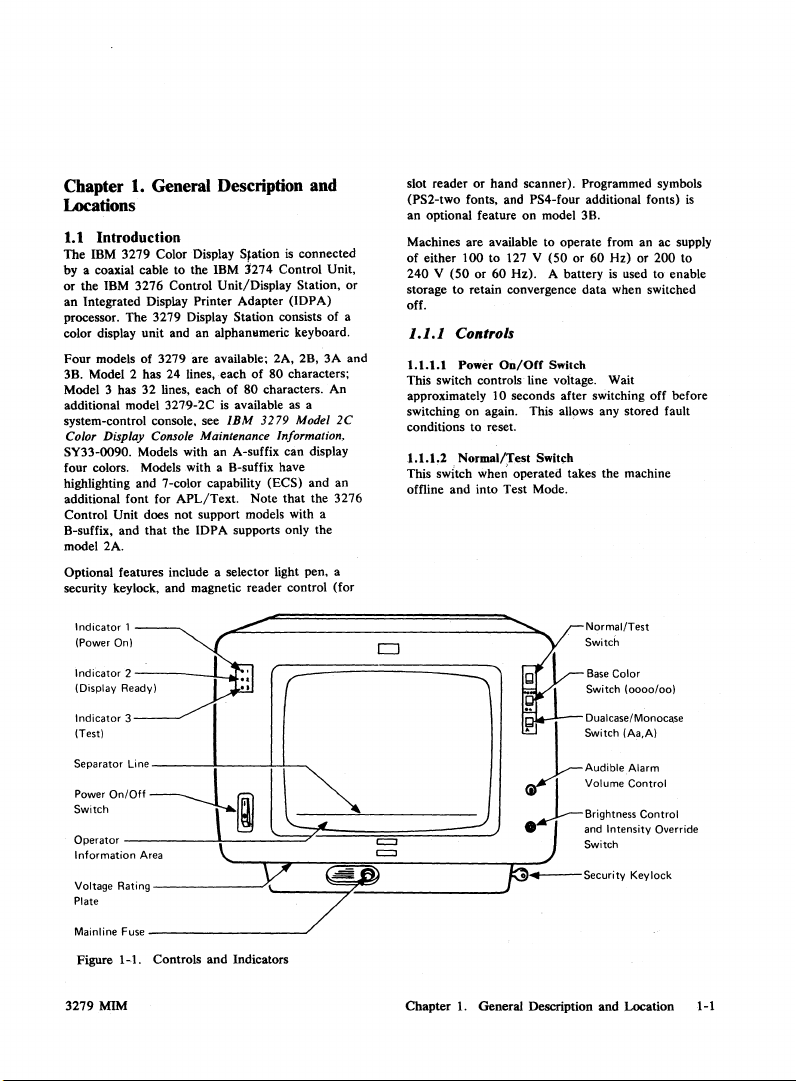

1.1 Introduction

The

IBM

3279

by

a coaxial cable

or the IBM

an

Integrated Display Printer

processor.

color display

Four

3B. Model 2 has

Model 3 has

additional model

system-control console. see

Color Display Console Maintenance Information

SY33-0090. Models with an A-suffix

four colors. Models with a B-suffix have

highlighting and 7-color capability

additional font for

Control

B-suffix,

model2A.

Optional features include a selector light pen, a

security keylock, and magnetic reader control (for

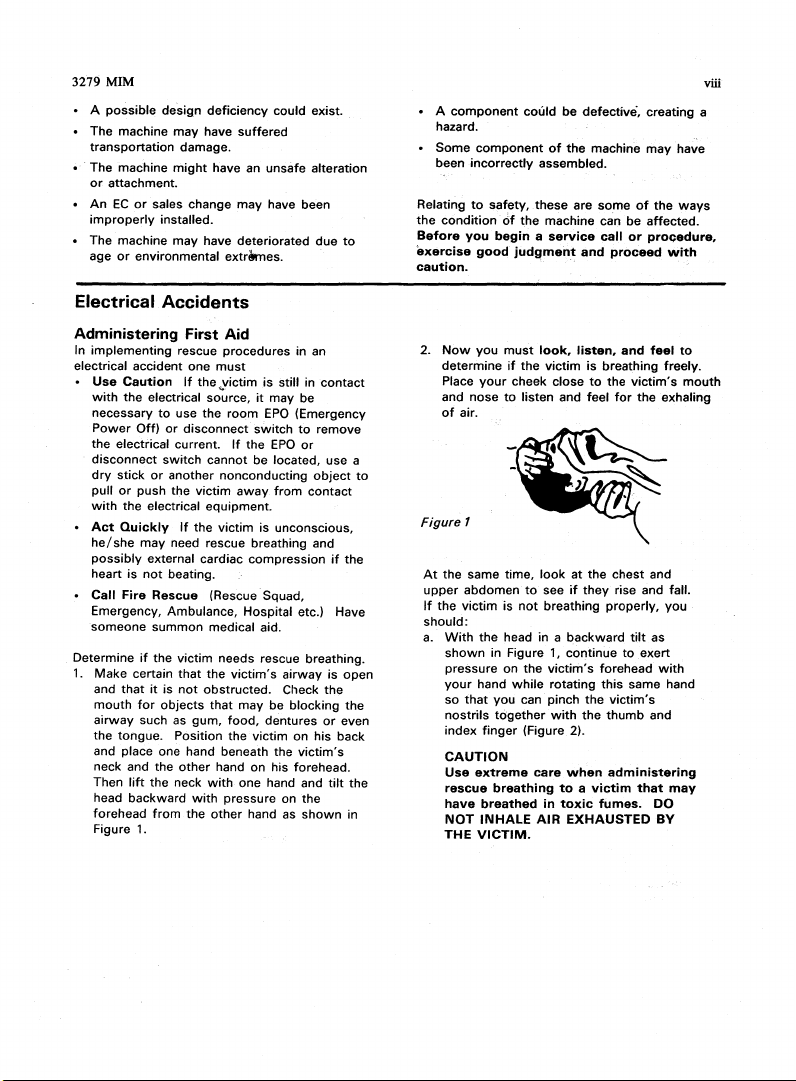

Indicator

(Power Onl 0 Switch

Indicator

(Display Ready)

Indicator 3 I

ITestl

Color Display Sfation

to

the IBM :1274 Control Unit,

3276

Control

Unit/Display

The

3279

Display Station consists of a

unit

and an alphanumeric keyboard.

models of 3279 are available; 2A, 2B,

24

lines,

32

lines, each of 80 characters.

3279-2C

and

APL/Text.

not

support models with a

that

the

IDPA

Unit does

each

is available as a

'~i

2.~

is

connected

Station, or

Adapter

(IDPA)

3A

characters;

An

Model

display

and

an

the

3276

2C

and

..

of

80

IBM

3279

can

(ECS)

Note

that

supports only the

r-"(-=============-::,

••

slot reader or

(PS2-two fonts, and PS4-four additional fonts)

an

optional feature

Machines are available

of

either

100

240 V (50

storage to retain convergence data when switched

off.

1.1.1

COli

1.1.1.1 Power

This switch controls line voltage. Wait

approximately

switching on again. This allows any stored fault

conditions

1.1.1.2

NormallTest

This switch when' operated takes the machine

and

offline

scanner). Programmed symbols

on

model 3B.

to

127 V

Hz).

operate

(SO

or

A battery

to

or

60

trois

On/Off

Switch

10 seconds after switching off before

to

reset.

Switch

into Test Mode.

iNormal/Test

Q

ea

~

I Switch IAaAI

from an ac supply

60

Hz)

or

200

is

used

to

Base

Color

Switch (oooo/col

Dualcase/Monocase

is

to

enable

:::~:::/~~:----~

Switch

Operator ,

Information

Voltage Rating

Plate

Mainline Fuse

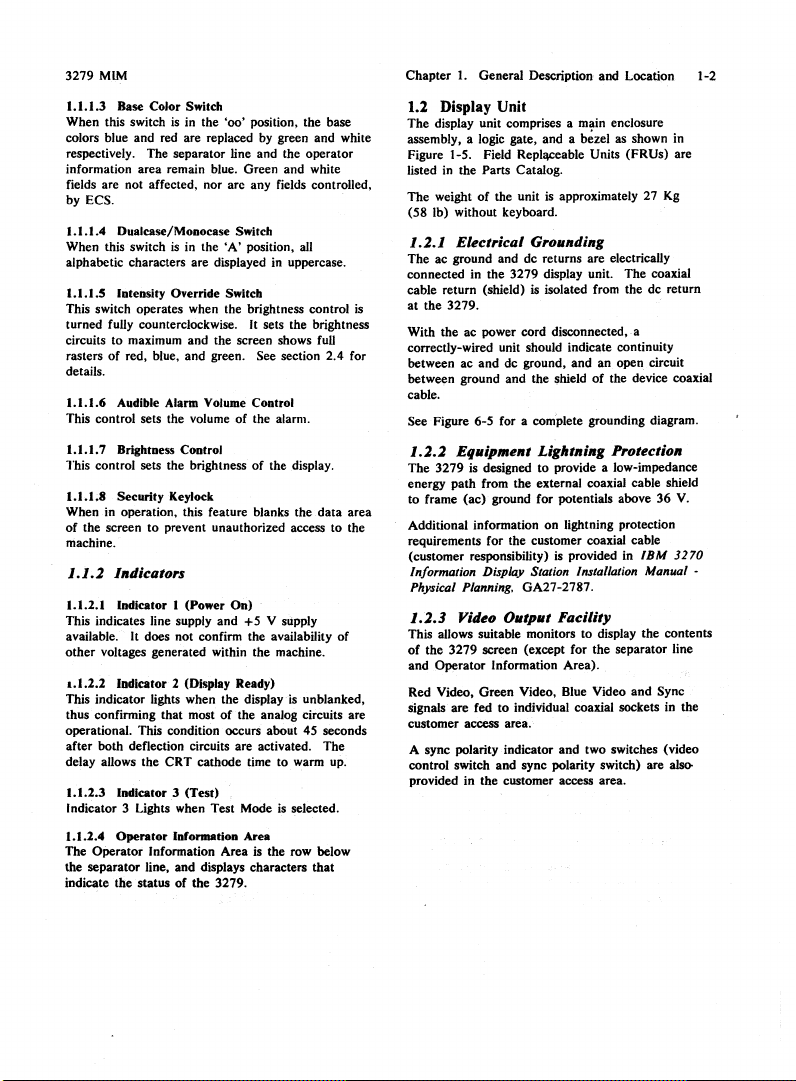

Figure 1-1. Controls

3279

-------!-....

Area

-------

-----------

MIM

I--~-,

-++-----'"

___

\

~~L._______

'--

."

~

.-/

'-"----r-7---::=====;:-=---------r:::--

V,

-r@A)h_securitYKeYIOCk

1...

____

~_:;;.?-:..---------..JJ-

and

Indicators

Chapter

I.

~~~~~~:

.J.---arightness

• ) and Intensity Override

General Description

~~~:Ol

Control

Switch

and

Location

1-1

Page 13

3279

MLM

1.1.1.3

Base Color Switch

is

in the

'00'

When this switch

colors blue and red are replaced by green and white

respectively. The separator line and the operator

information area remain blue. Green and white

fields are not affected, nor arc any fields controlled,

ECS.

by

1.1.1.4

Dualcase/Monocase Switch

When this switch

alphabetic characters are displayed

1.1.1.5 Intensity Override Switch

This switch operates when the brightness control

turned fully counterclockwise. It sets the brightness

circuits to maximum and the screen shows

rasters

of

details.

1.1.1.6

This control sets the volume of the alarm.

1.1.1. 7 Brightness Control

This control sets the brightness of the display.

1.1.1.8

When in operation, this feature blanks the data area

of

the screen

machine.

1.1.2

1.1.2.1 Indicator I (Power On)

This indicates line supply and

available.

other voltages generated within the machine.

1.1.2.2 Indicator 2 (Display Ready)

This indicator lights when the display

thus confirming that most

operational. This condition occurs about 45 seconds

after both deflection circuits are activated. The

delay allows the CRT cathode time to warm up.

1.1.2.3 Indicator 3 (Test)

Indicator 3 Lights when Test Mode

1.1.2.4 Operator Information Area

The Operator Information Area is the row below

the separator line, and displays characters that

indicate the status of the 3279.

is

in the

red, blue, and green. See section 2.4 for

Audible Alarm Volume Control

Security Keylock

to

prevent unauthorized access to the

Indicators

It

does not confirm the availability of

position, the base

'A'

position, all

in

uppercase.

+5

V supply

is

is

selected.

unblanked,

of

the analog circuits are

is

fuU

Chapter

1.

General Description and Location

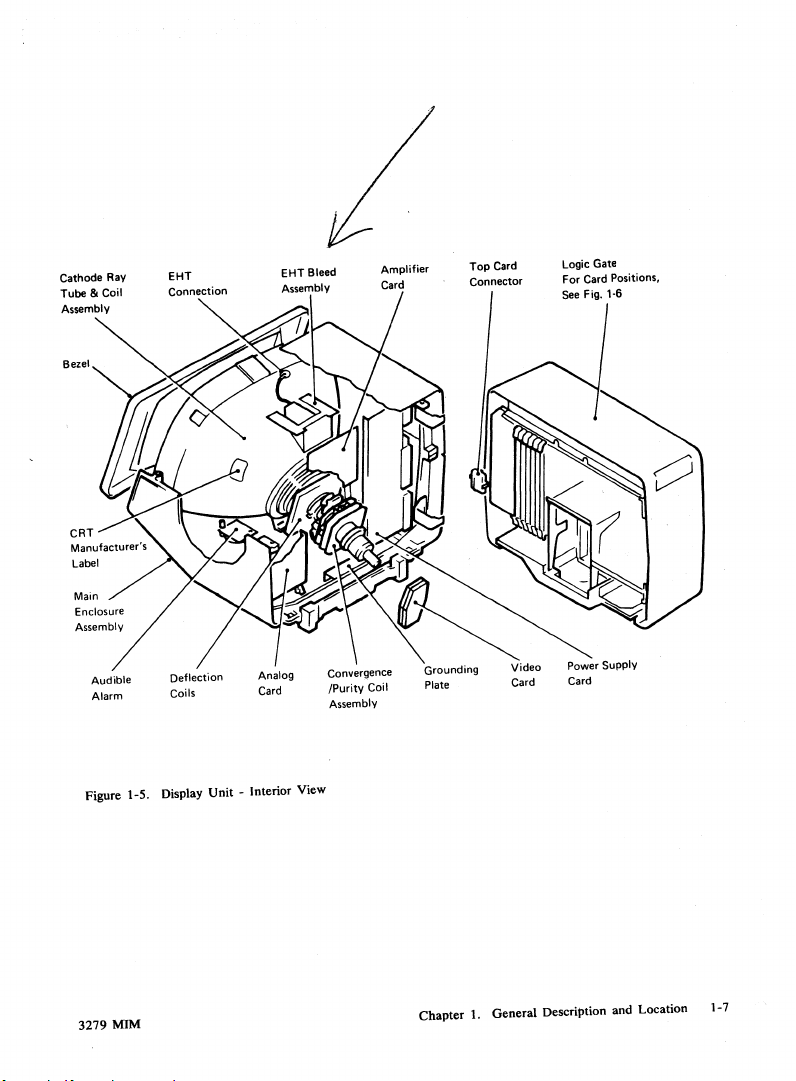

1.2 Display Unit

The display unit comprises a main enclosure

assembly, a logic gate, and a

Figure 1-5. Field Repl""eable Units (FRUs) are

in

the Parts Catalog.

listed

The weight of the unit

(58 lb) without keyboard.

1.2.1

Electrical Grounding

The ac ground and de returns are electrically

connected in the 3279 display unit. The coaxial

cable return (shield)

at

the 3279.

With the ac power cord disconnected, a

correctly-wired unit should indicate continuity

between ac and de ground, and an open circuit

between ground and the shield of the device coaxial

b~zel

as shown

is

approximately 27

is

isolated from the dc return

in

Kg

cable.

See Figure 6-5 for a complete grounding diagram.

1.2.2

Equipment Lightning Protection

The 3279

energy path from the external coaxial cable shield

to frame (ac) ground for potentials above 36

Additional information on lightning protection

requirements for the customer coaxial cable

This allows suitable monitors to display the contents

of

and Operator Information Area).

Red Video, Green Video. Blue Video and

signals are fed to individual coaxial sockets

customer access area.

is

designed to provide a low-impedance

V.

is

(customer responsibility)

Information Display Station Installation Manual Physical Planning. GA27-2787.

1.2.3

Video Output Facility

provided in

IBM

3270

the 3279 screen (except for the separator line

Sync

in

the

A sync polarity indicator and two switches (video

control switch and sync polarity switch) are

provided in the customer access area.

also-

1-2

Page 14

1.2.3.1 Video Control Stritch

This switch has three positions:

1.

Central position: The monitor receives the same

balance of color signals

2. ENHANCE position: The blue color of the

monitor

is brightened by the addition of a

fifty-percent-green signal.

3.

TEST position: The color signals to the monitor

are internally connected to the 3279 CRT, thus

allowing direct comparison of the two displays

(except for the separator line and Operator

Information Area).

1.2.3.2

Sync Polarity Stritcb

This switch is used to select either positive or

negative sync pulses at the sync output socket.

devices attached at the same time will receive the

same polarity.

1.2.3.3

SIgDaI

This indicator lights when either

Test Indicator

as

the 3279 CRT.

• The synchronizing signal is faulty,

or

• The Video Control Switch is set to TEST.

All

3279MfM

Chapter

1.

General

De8o;riptil>n

and

Location

Page 15

3279 MlM

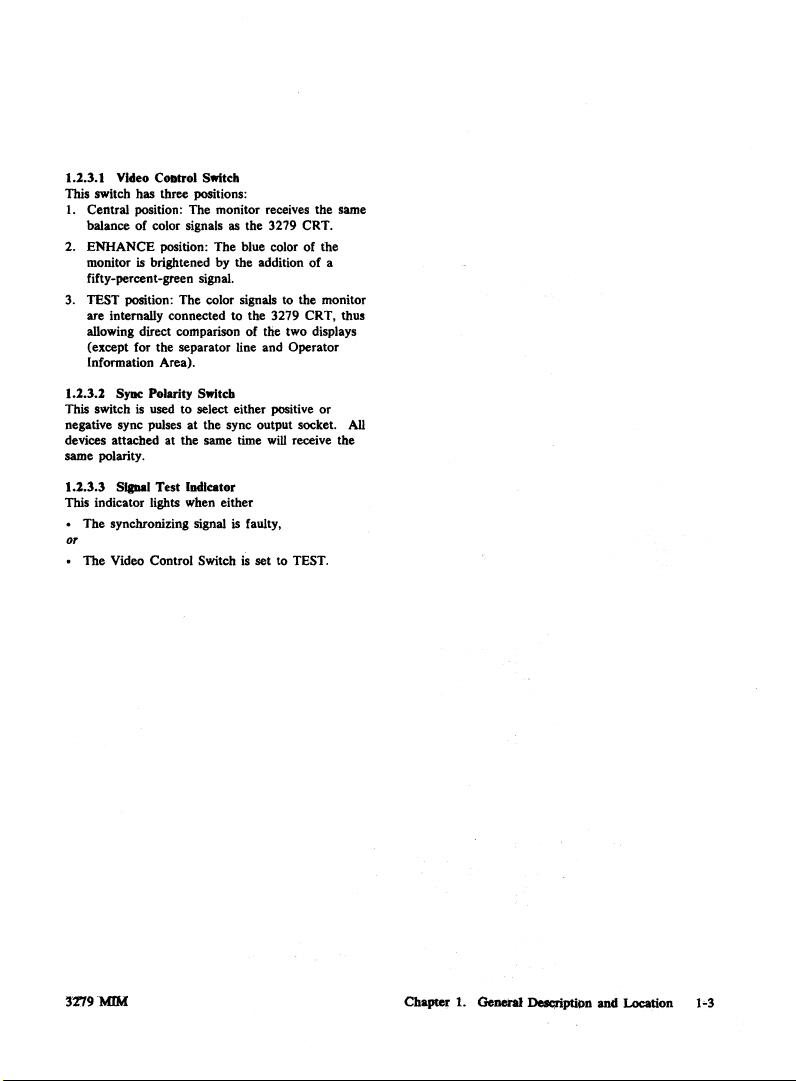

*

DANGER

Pins

Use

*1

P3

Power

Edge

Connector

Pin Assignments

~~~

Securing,

Degauss

may be-up

to

probe,

IBM

Part 1749249/1749250.

+12 V

±12 V Retum

3

-12

V

103 V Return

4

103 V

5

Ground

6

Ground

7

8

LOPT

.lOPT

9

10

Line

Input

Line

11

•

Degauss

12

Degauss Return

13

• - Neutral

14

Neutral

15

Ground

16

Test Points are shown

as

bullets ( • )

Supply

-------,

___

COil

250 V above ground potential

Return

Test

Point

Test

Po-int

Input

---..

Brightness 2 To

Chapter 1. General Description and

Skip

Skip.

Vertical

Sync

-5V

Gnd from

A3

+12 V LOPT

Display Ready

-

- Display Ready

I ntensity Override Sw 4

Intensity Override Sw 1

+6.3 V Return •

+5V

+8.5 V

+8.5 V •

+5 V •

Gnd •

+103 V •

Brightness

Color Balance

-135

V •

+70

V •

+6.3 V •

Pot

26 Horizontal

27

28

29 4

30 5

31

32

33 8

34

35

36

37

38

39 14

40

41

42 17

43

44

45 20

46

47 22

48 23

49

50

Analog Card

Hariz

•

Vert

3

•

o V

form

-5

•

o V

to

6

7

o V

to

9 o V

to

l)

o V

to

11

"Power

12

Input

13

+103 V Return

+103 V

15

Brightness 3

16

Brightness 1

18

Intensity Override

Brightness 2

19

Balance Pots Ret

21

Heater (6.3

+70 V to

+70 V Return

24

Heater (+6.3

25

P4

Edge

Connector

Pin Assignments

V

security key

Color

A,af

LED Card

Prohibited

Sync

Sync

Sync

A3

A

Good"

V)

Video

Sw

Switch

(+5 VI

Return

VI

Loclltion

lock

Sw

2

(-150

V/39

1-4

kUI

P12-----~~~

Figure 1-2. Display Unit -

Front

View with Bezel Removed

Page 16

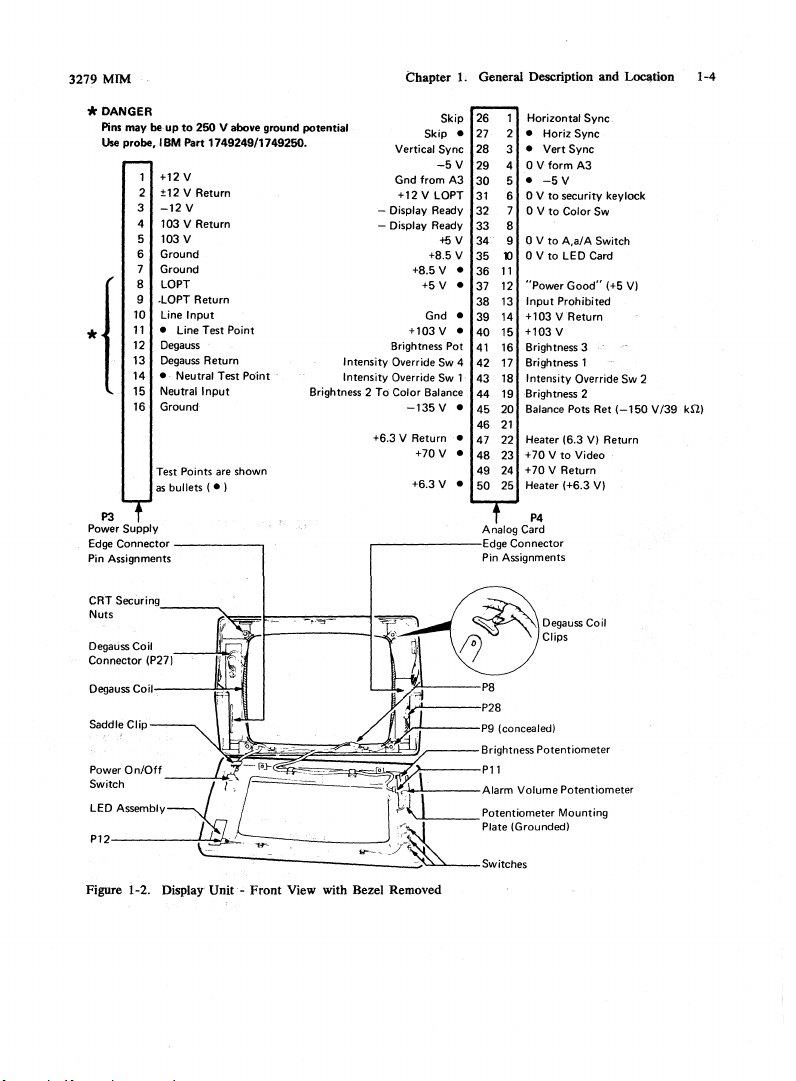

Top

Card Connector

Identification

Card Socket

Identification

For logic card locations,

see Figure 1-6

Internal

Cabling

A2

to

power supply card

A3

to

the

enclosure

to

amplifier and video cards

to

keyboard connector

to

G4f

crossovers for M

to

G5

RC

G2

G3

A5

05

Figure 1-3. Display Unit - Rear View

3279 MIM

Sync

Polarity

Switch

Signal Test

Lamp Control

Chapter

1.

Video

Switch

I

Video

Output

Facility

General

Description and Location 1-5

Sync

,

Red Green

Output

Sockets

Blue

,

Page 17

3279 MIM Chapter

1.

General Description and Location

\-6

Analog Card

,

View

hole

CRT

filament

Jumper

*

**

*

**

**

o HCENT

for

***

Two

Factory

preset (some presets are

Four

Static Convergence Controls

DANGER

Ensure the insulated covers are

transistor

in

these

(1

kV pkl

two

potentials

Amplifier

(J)Q:.~:PURITyA

BLAT0B~}

G0R~

MIN ~ 0

MAX

~

PI?

All

ground

wires

only

on

positions

as

the

Card

o STATIC

4BLAT

GAIN*

Q}COLOR

~

S BALANCE

1011

I

(

In'

\"

~p'4

I'

•

\

1'1'2

L."'.l_

Video Card

(for

Test Points,

see

Figure 6·10)

early

level cards)

in

place on

cases are

Test Points

alpl?S

any

at

dangerous

(see

Figure 6-11) Power Supply Card ***

N

Convergence and Purity

Coil Assembly

Figure

\-4.

Display Unit - Rear View, Open

Page 18

Cathode

Tube

& Coil

Assembly

Bezel

Ray

EHT

Connection

CRT

Label

Main

Enclosure

Assembly

Audible

Alarm

Deflection

Coils

Analog

Card

Figure 1-5. Display Unit - Interior View

EHT Bleed

Assembly

Convergence

IPurity Coil

Assembly

Amplifier

Card

Grounding

Plate

Top

Card

Connector

Video

Card

Logic

Power

Card

Gate

Supply

3279

MIM

Chapter

1.

General Description

and

Location

1-7

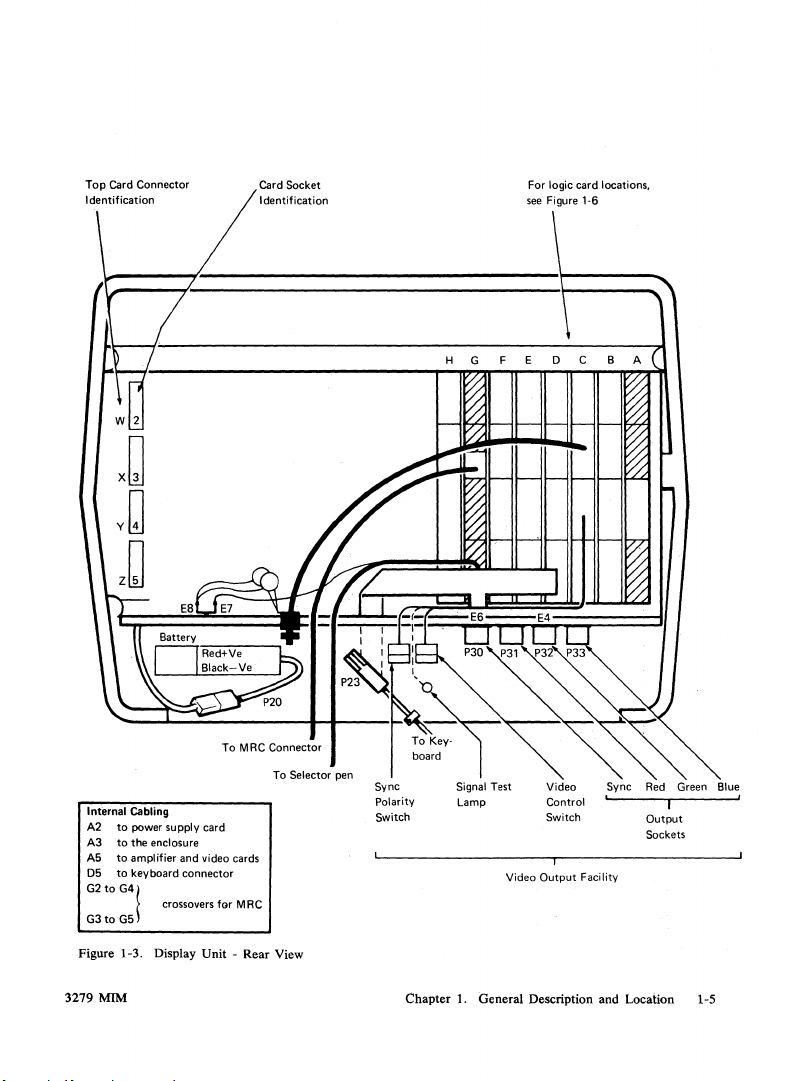

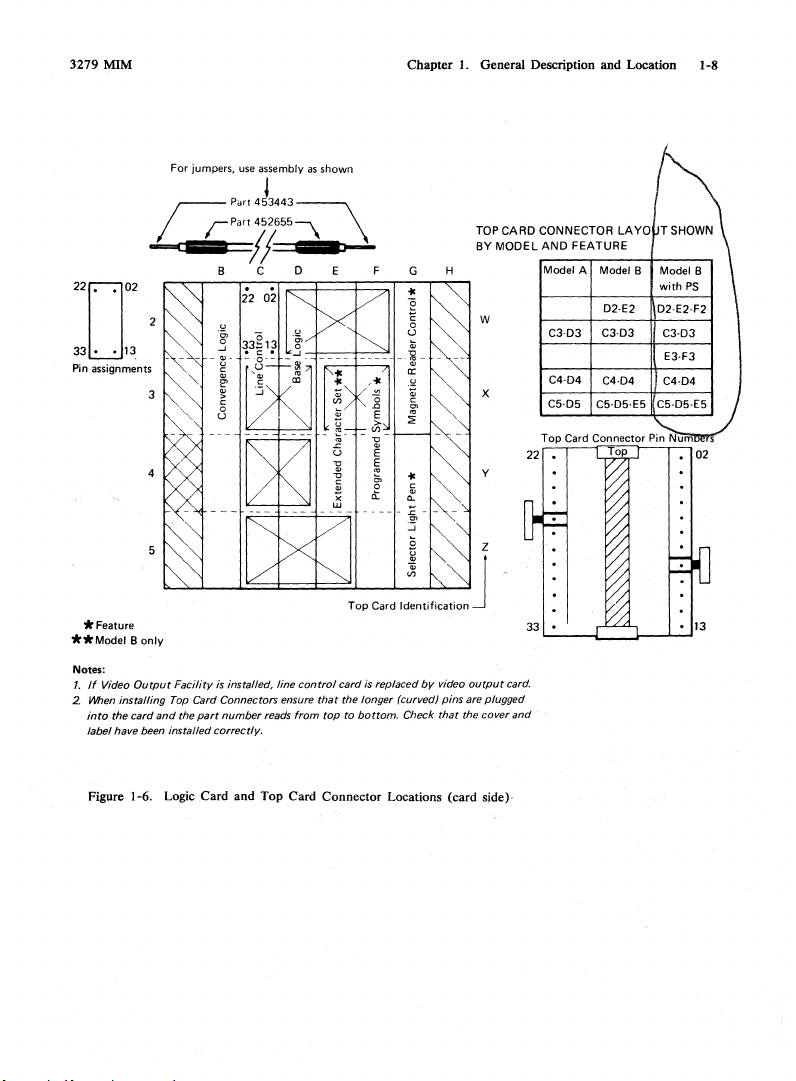

Page 19

3279

MIM

Chapter

I.

General Description and Location

1-8

220'

02

33,

,13

Pin

assignments

For jumpers, use assembly

~

Pon

/ Lpan

..bcSIa:=!

BCD

3

4

as

shown

j

453443:-\

452655~

!==CIIIIa~

.~

.::

~

'"

E F

-+--+---

it

i<

\

~i<

•

"'-

--

"0

.c

~

til

"0

~

~

0

0:

G

i<

~

o

u

~-

a:

u

~

§,

~

i<

c

~

a.

.c

0>

.J

TOP

BY

H

w

x

Y

§ Z

Top

Card

Id:ntlflcatlon

* Feature

** Model B

Notes:

1.

2.

only

If

Video

Output

Facility

is

Mlhen

installing Top Card Connectors ensure

into the card and the part number reads from top to bottom. Check that the cover and

label have been installed correctly.

installed, line

control

card

is

replaced

that

the longer (curved) pins are plugged

J

by

video

output

CARD

MODEL

card.

22

33

CONNECTOR

AND

Model A Model B

C3·D3 C3·D3

C4·D4

C5·D5

~-----L

LA

FEATURE

D2·E2

C4·D4 C4·D4

____

YO

with

D2·E2·F2

C3·D3

E3·F3

i---~-"

PS

Figure 1-6. Logic Card

and

Top Card

Connector

Locations (card side)·

Page 20

1.3 Keyboards

1.3.1

Scan Codes

Pressing a key generates a seven-bit scan code that

is presented serially

code for a specific key position

The control unit translates each scan code into the

appropriate character

1.3.2

Break Codes

Several keys, including the reset key, produce a

second scan code (called a

is released. The break code for the reset key

ignored by

1.3.3

Keyboard Cable

This cable carries the control and data signals

between

the

provides the

Figure 6-12 for details).

1.3.4

System Upshift

System upshift cannot be selected from the

keyboard; it is controlled by the application program

and

applies

is

in upshift mode,

or

IDPA,

Characters

entered by an operator using the override capability.

1.3.5

Keyboard Type Identification

The keyboard logic card contains four pairs

that

must

keyboard (see Figure

1.3.6

Keyboard Lock

The

keyboard can

characters are ignored by the control unit).

data, for example a 'reset'

accepted.

The

operator

change in

clicker normally clicks

but

stops clicking

operator

has chosen

normal operation, then- keyboard lock will cause

to

click at each key depression.

An

)(

is displayed

Area

when

to

the control unit. The scan

is

a1ways

the same.

or

function.

'break

code') as the key

the

control unit.

keyboard

and

+5

V supply for the keyboard (see

to

all keyboard types. When the system

processes only specified characters.

other

be

jumpered

is

made

the

action

the

keyboard

the display unit.

the

control unit

than

those specified may be

to

6-11).

be

'locked'

aware of keyboard lock by a

of

the

once

after

keyboard lock.

to

turn

in

the

is

(3274

indicate the type of

(that

is, keyed

scan

code, may still be

keyboard clicker.

for each key depression,

off

the clicker for

Operator Information

locked.

If

It

or

of

Specific

the

is

also

3276),

pins

The

it

1.3.7

Numeric Lock (Feature)

The numeric lock feature

keyboard jumper in position 1

jumper block. This feature limits the characters

that

can be

entered

o through 9

period

(.)

or comma (,)

(-)

minus

The DUP key remains active. Depression

other key while the cursor

causes

the

keyboard

)(

* NUM in the operator infonnation area.

RESET

Press

1.4 Tools

The following tools and test equipment are required

for maintenance of the 3279.

Item

Insulated probes·

General

Miniprobe**

GLP

Key top puller

Keylock retaining nut wrench

MR

C test card

SLT jumper (3)

SLT

Adjusting tool

Metric tools

Alignment mask

Isopropyl Alcohol

Lint-free

to clear the locked condition.

and

logic probe

extension cable

pins···

cloth

For use with standard

This probe

(up

to

15 volts)

For use with jumpers on some top

card connectors

is

selected by installing a

of

into a numeric field to:

is

in

to

a numeric field

lock with the symbol

Test Equipment

CE

is

for use on low voltage

meter

the keyboard

of

IBM

Part

Number

1749249

and

1749250

453212

453718

453605

9900373

4418787

1742659

452655

453443

1864853

1749235

4423472

2200200

2108930

1D

any

3279

MIM

Chapter

1.

General

Description

and

Location

1-9

Page 21

3279

MIM

1.4.1

Ge"eral Logic Probe

To use the General Logic Probe (GLP),

453212, set the switches as follows:

Technology

Latch

Gate

Ref.

Power the probe from any D03 pin (red wire

+5

V) and any D08 pin (black wire, ground). The

ground lead

connected to a nearby ground.

Test

GLP

D08.

MULTI

NONE

GND

on

the probe tip must also be

operation by probing on D03 and then

IBM

Chapter 1. General Description

Part

and

Location

1-10

Page 22

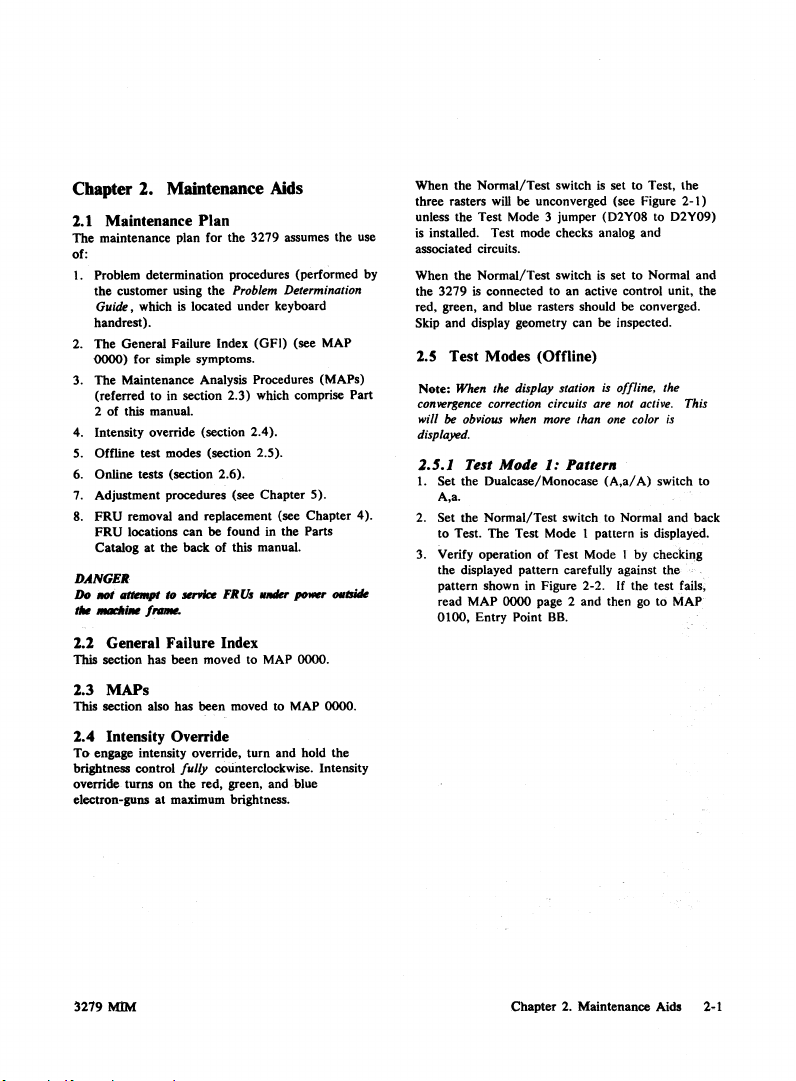

Chapter 2. Maintenance

1.1 Maintenance Plan

The maintenance plan for

of:

1.

Problem determination procedures (performed by

the customer using

Guide,

which is located under keyboard

handrest).

2.

The

General Failure Index

QOOO)

for simple symptoms.

3. The Maintenance Analysis Procedures (MAPs)

(referred

2

of

this manual.

4. Intensity override (section 2.4).

5. Offline test modes (section 2.5).

6. Online tests (section 2.6).

7. Adjustment procedures (see Chapter 5).

FRU

removal and replacement (see Chapter 4).

8.

FRU

locations

Catalog

at

DANGER

Do

.."

Iltmltpt

It.

lfItIdti,..

f-

1.1 General Failure Index

This section has been moved to MAP 0000.

1.3

MAPs

This section also has

1.4

Intensity Override

To

engage intensity override, turn and hold

brightness control

override turns

electron-guns

the

to

in section 2.3) which comprise Part

can

be

the back of this manual.

to

...-.It% FR

been

fully

on

the

red, green, and blue

at

maximum brightness.

Aids

the

3279

assumes the use

Problem Determination

(GFI)

(see MAP

found in the Parts

Us

"".,

ptJW#"

OIImM

moved to MAP 0000.

counterclockwise. Intensity

the

When the

three rasters

unless the Test Mode 3 jumper (D2Y08 to D2Y09)

is installed. Test mode checks analog and

associated circuits.

When the

the 3279 is connected to an active control unit, the

red. green, and blue rasters should be converged.

Skip and display geometry can be inspected.

Normal/Test

will

Normal/Test

switch is set to Test, Ihe

be unconverged (see Figure

switch

is

set to Normal

2-1)

and

1.S Test Modes (Offline)

Note: When the display station is offline. the

convergence correction circuits are no/ active. This

will

be obvious when more than one color

displayed.

2.5.1

Test Mode

1. Set the Dualcase/Monocase

A,a.

2. Set the

3. Verify operation of Test Mode 1 by checking

Normal/Test

to Test. The Test Mode 1 pattern

the displayed pattern carefully against the

pattern shown in Figure 2-2.

MAP 0000 page 2 and then go to MAP

read

0100,

Entry Point

1:

Patterll

(A,a/

switch to Normal and back

BB.

is

A) switch to

is

displayed.

If the test fails,

3279

M1M

Chapter

2. Maintenance Aids 2-1

Page 23

3279 MIM

Chapter

2.

Maintenance Aids 2-2

*At

regular intervals across

double

skipline

as a dark

line when converged.

the

appears on Maqel 3. Each

screen on Model 2. Only the

skipline

Figure 2-1. Intensity Override (Test Mode)

appears

Page 24

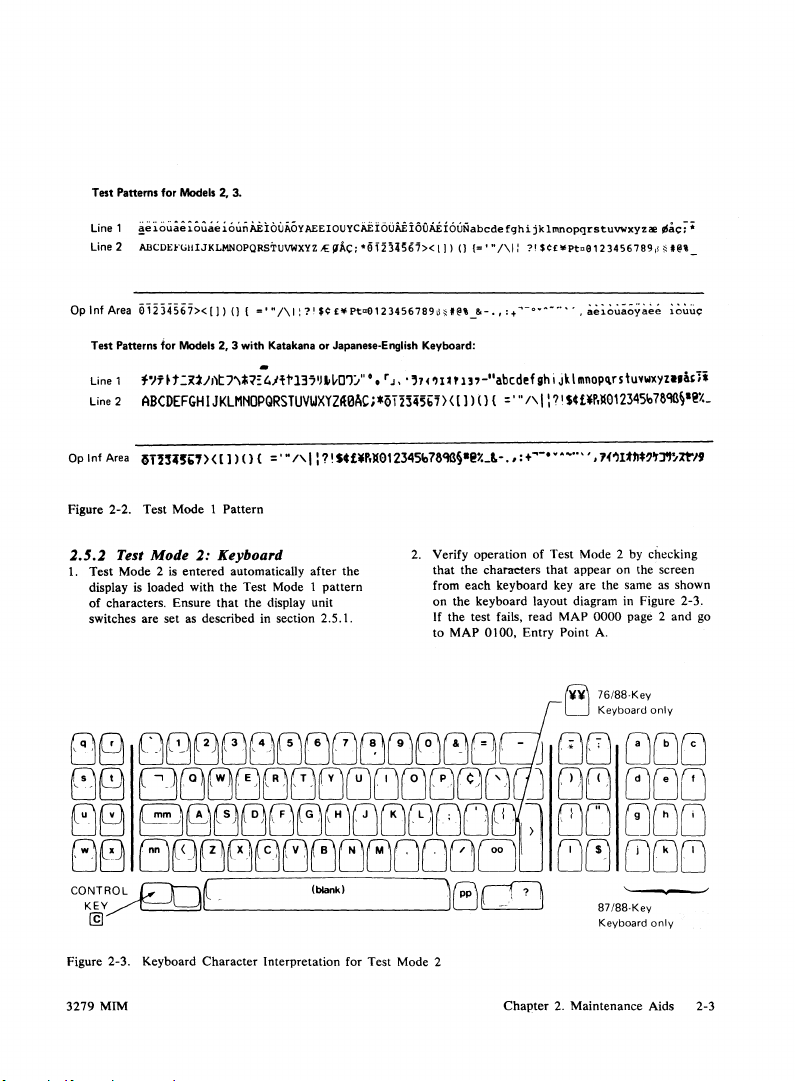

Test Pattems for Models 2, 3.

Line

1

~e

laUa';

i.ouae

Line 2

iounAEiOUAOY

ABCDEt'~UlJKLMNOPQRSTUVWXYZ

AEEIOUYCA.EIotiAi:i60fi-Ei6uNabcde

A':

~Ac;'e

ii'ig67><l1 ) ()

(='"

/'1:

fghi

jk

7'

lmnopqrstuvwxyz22

$¢£"PtoB

12

3456

~ac;-;;

789"

H@%

OplnfArea

Figure 2-2. Test Mode 1 Pattern

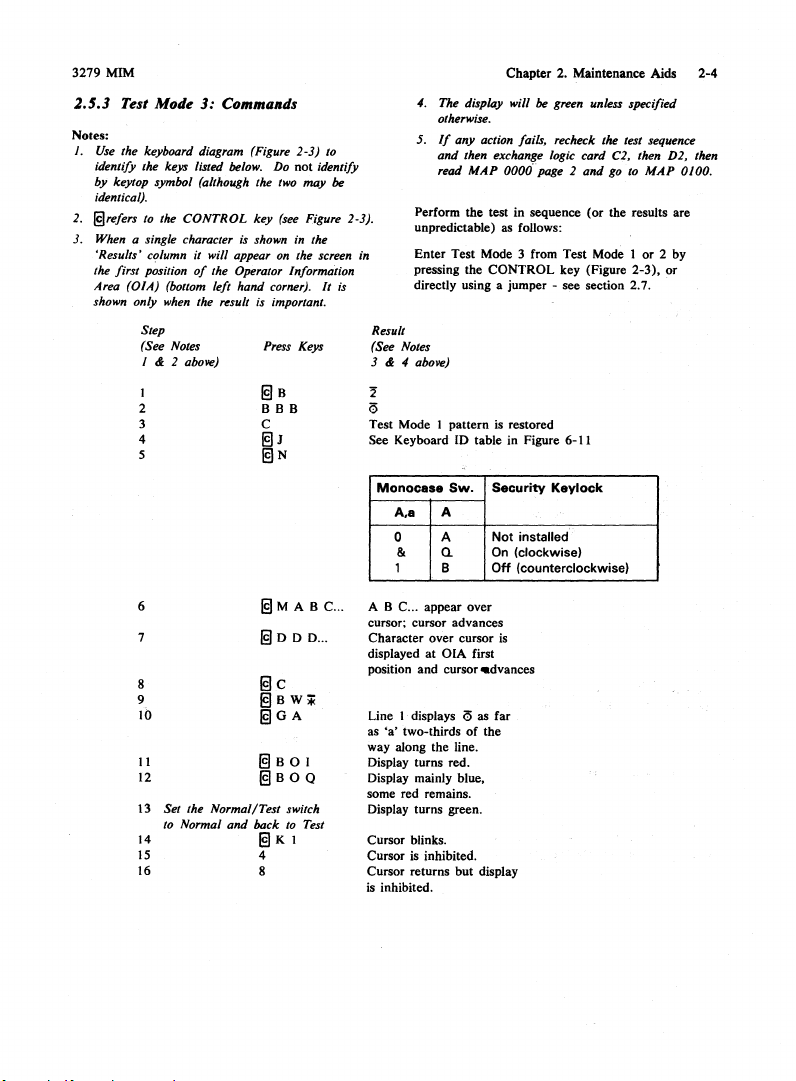

2.5.2

1.

61234567><{})

Test Patterns for Models

Line 1

f·)fft::<~JJ)tJ"I*~:"/H137')I>~O'J:'''·.

Line 2

ABCDEFGHI

Test Mode

Test

Mode 2 is

display is loaded with the Test Mode 1

of characters. Ensure

switches are set as described in section 2.5.1.

(}

(='"/\I:?I$¢£¥Pt<le123456789~~t@,_&-.,q-'-o,,"'-··",

2,

3 with Katakana or Japanese-English Keyboard:

-

JKLMNOPQRSTUVWXYZli0flCi

2:

Keyboard

entered

automatically

that

the display unit

after

pattern

the

~elou~oy~e~

r

J,

"7<

?IH

13,-"abcdefgh I

*012345b7)

( (1) () ( =

2. Verify operation of Test Mode 2 by

that

the characters

from each keyboard key are the same as shown

on the keyboard layout diagram in Figure 2-3.

If the test fails, read MAP

to

MAP 0100, Entry Point A.

Jklmnop~rs\uvwxyza.kii

".

/\1:

?ISU¥P.1I01Z3451078'11l§'@%-

that

appear

!i¥\

U

on

0000

page 2

76/BB·Key

Keyboard

lOUUC

checking

the screen

and

only

go

Figure 2-3. Keyboard

3279

MIM

Character

Interpretation for Test Mode 2

Chapter

2. Maintenance Aids 2-3

Page 25

3279

MIM

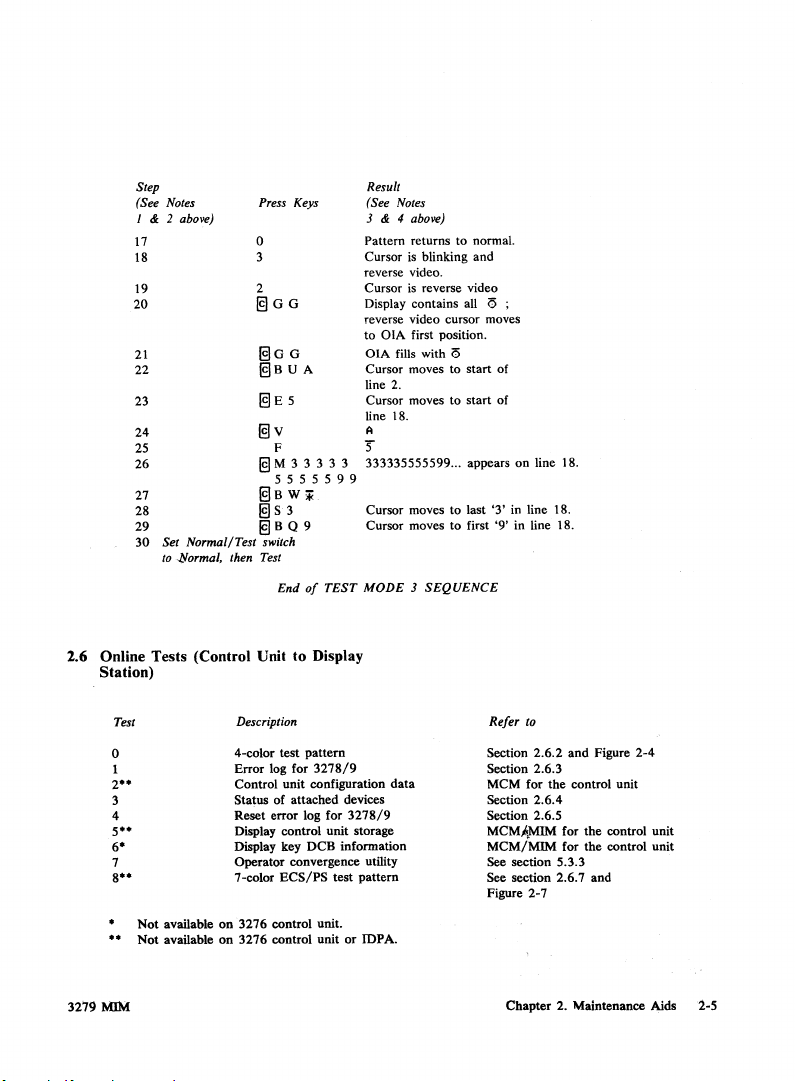

2.5.3

Test Mode

Notes:

1.

Use

the keyboard diagram (Figure 2-3) to

identify the keys listed below.

by

key

top symbol (although the

identical).

2.

I9refers to the

3. When a single character

'Results' cl!/umn it will appear

the first

(OIA) (bol/om left hand corner). It

Area

shown only

4

6

8

9

10

11

12

13 Set the Normal/Test switch

14

15

16

J:

Commands

CONTROL

pOSition

of

the Operator Information

when

the

r~sult

Step

(See Notes

1

& 2 above)

I

2

3

to Normal and bock to

Do

two

key

(see

is

shown

on

is important.

Press Keys

I9B

BBB

C

@lJ

@IN

19

M

19

DO

I9c

@lBW;

@lGA

@I

B 0 I

@lBOQ

@I

K I

4

8

not identify

may be

Figure 2-3).

in

the

the screen in

is

ABC

...

D ...

Test

Chapter 2. Maintenance Aids

4.

The display will

otherwise.

5.

If

any action fails, recheck the test sequence

and the

MAP

read

Perform the test in sequence (or the results are

unpredictable)

Enter

Test Mode 3 from Test Mode I

pressing the

directly using a jumper - see section 2.7.

Result

(See Notes

3 & 4 above)

2

6

Test Mode 1

See Keyboard

Monocasa

ABC

cursor; cursor advances

Character over cursor is

displayed

position and cursor

Line I displays

as

'a'

way along the line.

Display turns red.

Display mainly blue,

some red remains.

Display turns green.

Cursor blinks.

Cursor

Cursor returns but display

is

inhibited.

pattern

ID

Sw_

A,a A

0 A

a.

&

1 B

... appear over

at

OIA first

two-thirds

is inhibited.

table in Figure 6-11

<5

of

be

green unless specified

.. exchange logic card C2, then D2, then

0000' page 2 and go to MA.P 0100.

as

follows:

CONTROL key (Figure 2-3),

is restored

Sacurity

Kaylock

Not

installed

On

(clockwise)

Off

(counterclockwise)

.dvances

as far

the

or

2 by

or

2-4

Page 26

Step

(See Notes

I & 2 above)

17

18

19

20

21

22

23

24

25 F

26

27

28

29

30

Set Normal/Test switch

to

-1!Iormal,

then

Press Keys

o

2

@lGG

@lGG

@lBVA

@lE5

@lv

@lM

@lB

@l

19

Test

3 3 3 3 3

5555599

W

iii

S 3

B Q 9

End

of

Result

Notes

(See

3 & 4 above)

Pattern returns to normal.

Cursor

is

blinking

reverse video.

is

reverse video

Cursor

Display contains all

reverse video cursor moves

to

OIA

first position.

OIA

fills with

Cursor moves to start of

line 2.

CUTsor

moves to start

line 18.

A

5

333335555599

CUTsor

moves to last '3'

Cursor moves

TEST

MODE 3

SEQUENCE

and

(5

<5

of

... appears

to

on

in

first '9' in line 18.

line 18.

line 18.

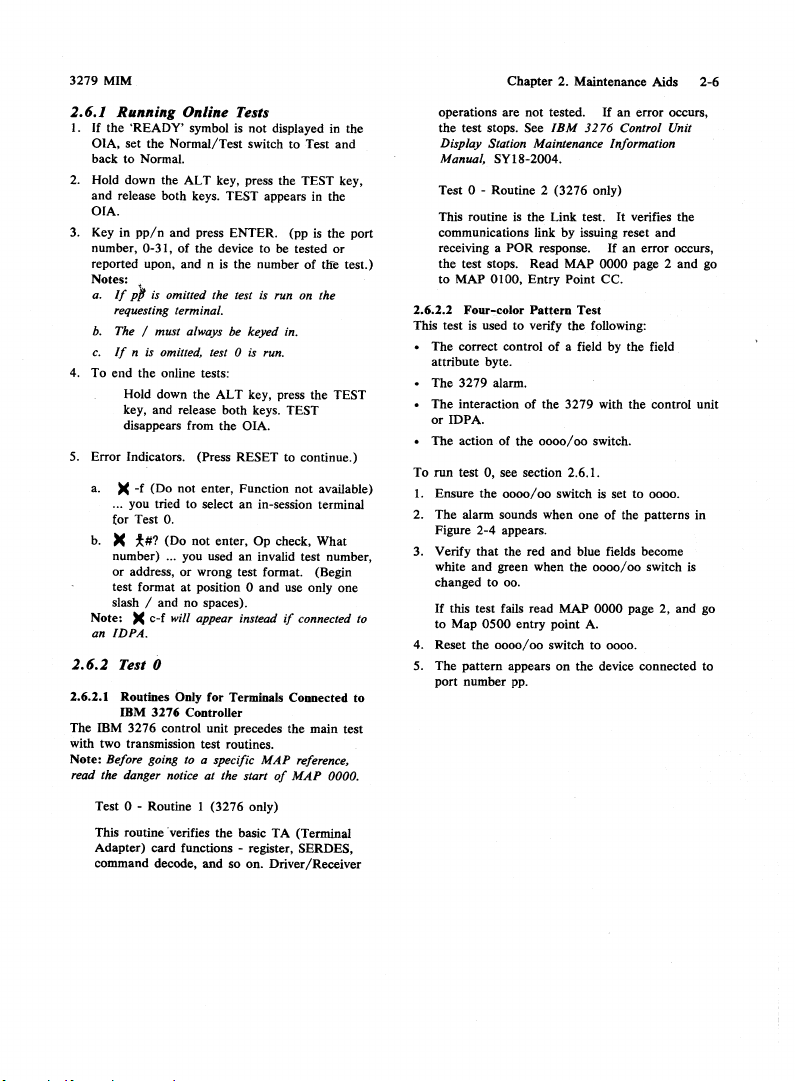

2.6 Online Tests (Control Unit

Station)

Description

4-color

Error

log for

Control

Status of

Reset error log for

Display control unit storage

Display key

Operator

7-color

on

3276

control unit.

on

3276

control unit or IDPA.

3219

Test

o

2"

3

4

5··

6·

7

8··

MIM

Not

Not

available

available

to

Display

test

pattern

3278/9

unit configuration

attached

devices

3278/9

DCB

information

convergence utility

ECS/PS

test

pattern

data

Refer

10

Section 2.6.2

Section 2.6.3

MCM

Section 2.6.4

Section 2.6.5

MCMfoMIM for

MCMiMIM

See section 5.3.3

See section 2.6.7

Figure

Chapter

and

for the control unit

for the control unit

2-7

2.

Figure

2-4

the

control unit

and

Maintenance Aids 2-5

Page 27

3279

MIM

2.6.1

Running Online Tests

I.

If the

'READY'

symbol

is

OIA, set the

back to Normal.

2.

Hold down the ALT key, press the TEST key,

and release both keys.

OIA.

3. Key in

number,

reported upon, and n

Notes:

a.

b.

c.

Normal/Test

pp/

n and press ENTER. (pp

0-31,

of

~

If

pfJ

is omitted the test

requesting terminal.

The / must always be keyed in.

If

n

is

omitted, test 0

not displayed in the

switch to Test and

TEST appears

the device to be tested

is

the number

is

is

run on the

run.

in

is

of

the

the

port

or

tile test.)

4. To end the online tests:

ALT

Hold down the

key, and release both keys. TEST

disappears from the OIA.

key, press the TEST

5. Error Indicators. (Press RESET to continue.)

)C

-f

(Do

a.

... you tried to select an in-session terminal

for

b.

)C

number) ...

or

test format

slash / and no spaces).

Note:

an IDPA.

2.6.2

2.6.2.1 Routines Only

The IBM 3276 control unit precedes the main test

with two transmission test routines.

Note: Before going

read the danger notice at the start

not enter, Function not available)

Test

O.

*.#? (Do not enter,

yOll

address,

)C

used an invalid test number,

or

wrong test format. (Begin

at

position 0

c-f will appear instead

Test 0

for

IBM

3276

Terminals Connected to

Controller

to

a specific

Op

check, What

and

use only

if

MAP

of

MAP

connected

reference,

0000.

one

Test 0 - Routine 1 (3276 only)

This routine 'verifies the basic

Adapter) card functions

command decode, and so on. Driver/Receiver

TA

(Terminal

- register, SERDES,

operations are not tested.

the test stops.

Display Station Maintenance Information

Manual,

Test 0 - Routine 2 (3276 only)

This routine

communications link

receiving a

the

test stops.

to MAP

2.6.2.2 Four-color

This test is used to verify

The correct control

attribute byte.

3279

The

The interaction

or

IDPA.

The action of the

To

run

test 0, see section 2.6.1.

J. Ensure the

2. The alarm sounds when one

Figare 2-4 appears.

3. Verify

white

and

changed to

If

to

this test fails read MAP

to Map

the

4. Reset

5. The

pattern

port number pp.

Chapter 2. Maintenance Aids

See

If

IBM

3276 Control Unit

SYlS-2oo4.

is

the

Link

test.

by

POR

0100,

issuing reset

response.

Read

MAP

Entry

Point CC.

Pattern

Test

the

of

a field by the field

0000

following:

alarm.

of

the 3279 with the control unit

0000/00

switch.

0000/00

switch is set to

that

the red

and

green when the

00.

0500

entry point A.

0000/00

appears

blue fields become

0000/00

0000

switch to

on

the device connected to

an

eITor occurs,

It

verifies the

and

If

an error occurs,

page 2

0000

of

the patterns

switch is

page 2, and go

0000.

and

•

2-6

go

in

Page 28

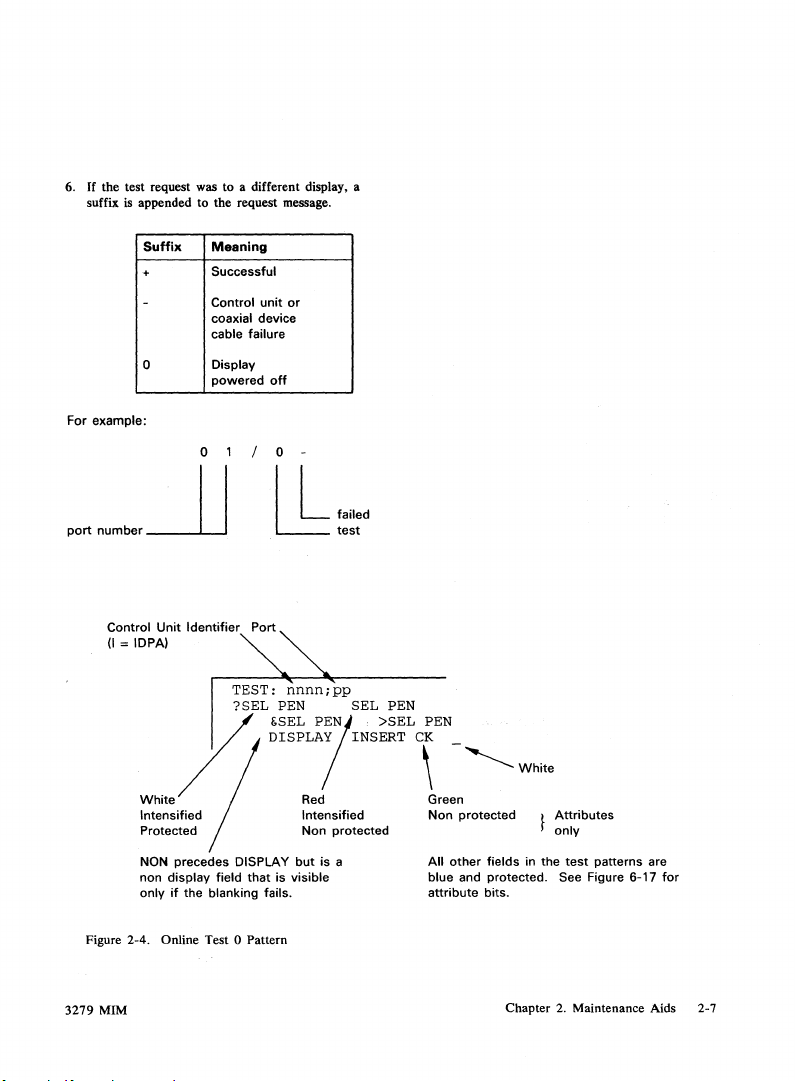

6.

If

the

test request was to a different display, a

suffix

is

For example:

Control

(I

= IDPA)

appended to

Suffix Meaning

+

-

0

Unit

the

Successful

Control

coaxial device

cable failure

Display

powered

Identifier

I/,

/

/

White

IntensIfIed

Protected

NON precedes DISPLAY

non

display

only

field

if

the blanking fails.

request message.

unit

or

off

o

I L failed

~test

Port

TEST:

nnnn;pp

?SEL

that

PEN

&SEL

DISPLAj

is visible

SEL

P'~I

Red Green

Intensified

Non

but

INSERT

protected

is

a

>SEL

PEN

PEN

C\

-~

Non

protected t Attributes

All

other

fields

blue and

protected.

attribute

bits.

White

f

only

in

the

See Figure 6-17

test

patterns are

for

Figure 2-4. Online Test 0 Pattern

3279

MIM

Chapter 2. Maintenance Aids 2-7

Page 29

3279 MIM Chapter 2. Maintenance Aids 2-8

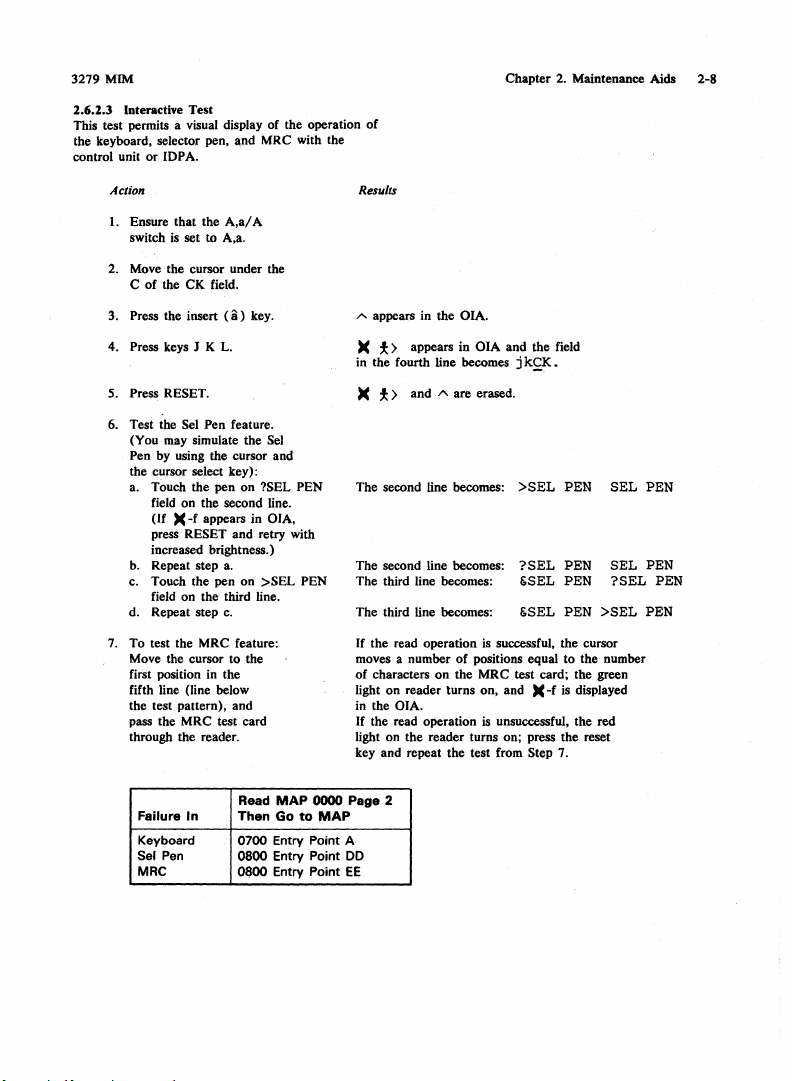

Interactive Test

2.6.2.3

This test permits a visual display of the operation of

the keyboard, selector pen. and

control unit or

IDPA.

Action

1. Ensure that the

2. Move the cursor under the

3.

4.

5.

6.

7.

is

set to A.a.

switch

C of the CK field.

Press the insert

Press keys J K

Press RESET.

Test the Sel Pen feature.

(You may simulate the Sel

Pen by using the cursor and

the cursor select key):

a. Touch the pen

field on the second line.

(If

)(

-f

press RESET and retry with

increased brightness.)

b. Repeat step

c. Touch the pen

field on the third line.

d. Repeat step

To test the MRC feature:

Move the cursor to the

first position in the

fifth line (line below

the test pattern), and

pass the MRC test card

through the reader.

MR

C with the

A,a/

A

(II)

key.

L.

on

?SEL PEN

appears in OIA,

a.

on

>SEL

c.

Results

A appears in the OIA.

)(

* > appears in OIA

in the fourth line becomes

)(

* > and A are erased.

The second line becomes:

The second line becomes:

PEN

The third line becomes: &SEL

The third line becomes: &SEL

If the read operation

moves a number of positions equal to the number

of characters

light on reader turns on, and

in

the OIA.

If

the read operation

light on the reader turns on; press the reset

key and repeat the test from Step 7.

on

and

j

>SEL

?SEL

is

successfUl, the cursor

the MRC test card; the green

is

unsuccessful, the red

the field

k£K

)(

-f

•

is

PEN

PEN

PEN

PEN

SEL

SEL

?SEL

>SEL

displayed

PEN

PEN

PEN

PEN

Failure In

Keyboard

Sel

Pen

MRC

Read

MAP

0000 Page 2

Then Go to

0700 Entry Point A

0800

0800

MAP

Entry Point

Entry Point

DO

EE

Page 30

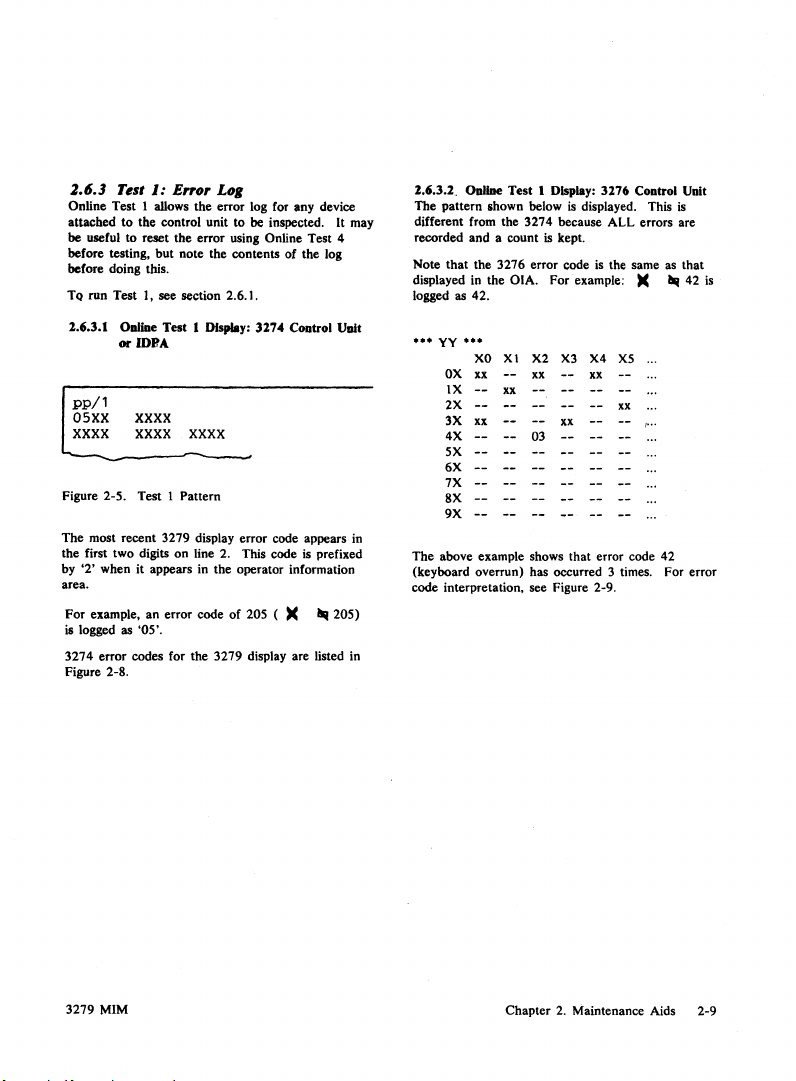

2.6.3 Test 1: Error Log

Online Test 1 allows the error log for any device

attached

to

be useful to reset the error using Online Test 4

before testing, but note the contents of the log

before doing this.

TQ

2.6.3.1 Oaline Test 1 DIsplay:

pp/1

05XX

XXXX

Figure 2-5. Test 1 Pattern

The most recent 32 79 display error code appears in

the first two digits

by

area.

For

is logged as '05'.

3274 error codes for the 3279 display are listed in

Figure 2-8.

the control unit to be inspected. It may

run Test I, see section 2.6.1.

3274

205

Control

()(

or

mBA

XXXX

XXXX

XXXX

on

'2'

when it appears in the operator information

example, an error code

line 2. This code is prefixed

of

~

UDit

205)

2.6.3.2. OnIIoe Test 1 Display: 3276 Control Unit

The pattern shown below is displayed. This

different from the 3274 because

recorded and a count is kept.

Note that the 3276 error code is the same as that