Page 1

====-

- -

-

-

- -

-

- - -

- - -

-

-

-

---

----

---

_.-

---

--

---

---

---

.=

Maintenance Library

Display Station Models 1

Troubleshooting Guide

and

2

SY27-2314-5

Page 2

Preface

The

IBM

3270

Information Display System consists of

control units, display stations, printers, and optional

feature devices. This manual contains

required

to

maintain

IBM

3277 Display Stations and

all

the

information

features such as keyboards, selector-light pen, magnetic

card reader, security keylock, and audible alarm. The

purpose of this

manual

is

to

present maintenance and repair

information rather than theory of operation information.

This

manual

is

organized

in

eight sections. Sections 1

and 2 contain introductory and maintenance background

material. Sections 3, 4, and 5 contain the Symptom Index,

Troubleshooting Diagrams, and repair data. These three

all

sections contain

mation necessary

Miscellaneous reference data

Section 7 contains location diagrams

and locating

other

sections

display station are presented

To successfully use this

display stations, maintenance personnel

of training equivalent

Because the

units,

3277

an

understanding of

display station

diagnostic procedures and repair infor-

to

correct a display station malfunction.

is

included

the

display station components referenced

of

this manual. Instructions for installing the

in

Section 8.

manual and repair

to

aid

in

Section 6.

in

identifying

IBM

should have a

to

the

3270

attaches

is

attached

system basic

to

both local and remote control

the

control unit

is

also helpful.

FE

to

which the

in

3277

level

course.

The titles and form numbers

Trou

bleshooting

"Companion

tain a glossary

Manuals". Both Troubleshooting Guides con-

Guides are listed below under

of

terms

that

of

the

are applicable

two

and display stations.

Companion Manuals:

3271

•

Guide,

3272

•

Guide,

3275/3277

•

Catalog,

•

IDR-M

Catalog,

Control

SY27-2311

Control

SY27-2312

ID

Unit

Unit

Display

Models 1

Models 1

Station

and

and

Models

2

Troubleshooting

2

Troubleshooting

1 and

S 126-0006

Reader-Motorized Theory-Maintenance-Parts

SY26-4188

The following pUblications may also prove useful:

•

An

Introduction

System,

•

IBM

GA27-2739

3270

Description, GA27-2749

to

Information

the

3270

Information

Display System Component

control unit

to

control units

2 Parts

Display

Sixth

Edition

(July,

This

is a major

SN31-0146.

mation

Troubleshooting

This

periodically

subsequent revisions

Text

been removed,

Product

©Copyright

is

throughout

made

illustrations

edition

for

this

A

form

is

Publications,

ii

revision

The

TN L incorporated

included

Diagram in

are

indicated

applies

made

manual

provided

comments

International

1975)

of,

and obsoletes,

in

Chapters

the

manual.

by a vertical

to

display

to

the

or

Technical Newsletters.

has

been prepared

at

the

back

may

Dept.

4,

Chapter

Significant

stations

information

of

this

be addressed

52L,

Neighborhood

Business Machines

SY27-2314-4

maintenance

5, and 7. Several

4.

Other

line

at

Board EC level

herein;

with

publication

technical and

changes

to

the

left

any

the

IBM

for

to:

IBM

Road,

Corporation,

information

of

such changes

SELECTRIC

reader's

System

with

corrections

or

additions

the

change.

717946

comments.

Communications

Kingston,

1972, 1973,

Technical

about

editorial

and earlier. Changes are

will

®Composer.

N.Y.,

Newsletter

fuses.

This

are made

corrections

to

the

be

reported

If

the

Division,

12401

1974,

1975'

infor-

to

text

form

the

are

and

in

has

Page 3

Contents

Section

1.1

1.1.1

1.1.2

1.1.3

1.2

1.2.1

1.2.2

1.2.3

1.2.4

1.2.5

Section

2.1

2.1.1

2.1.2

2.1.3

2.1.3.1

2.1.3.2

2.1.3.3

2.1.3.4

2.1.4

2.1.5

2.2

Maintenance

1.

Introduction

Online/Offline

Field

Replaceable

Troubleshooting

Trouble

Obvious

Analysis

Symptoms

Isolation

Offline

Symptoms

Formatted

Customer-Reported

2.

Tools

and

Maintenance

Customer

Osci 1I0scope

Logic

Probes

Description

Probe

Usage

Probe

Checkout

Probe

Repair

Alignment

lOR

FE Test Card

Diagnostic Programs

to a Display

Diagnostic

Engineer

2.2.1 Test Patterns

2.2.2

2.2.2.1

2.2.2.2

2.2.3

Section

3.1

3.2

Section

Section

5.1

5.1.1

Requesting

Local Display

Remote

Online

Symptom

3.

Symptom I ndex

Developing

4.

Trouble!'hooting

5.

Checks,

Checks

Display

Display

Tests

Index

Adjustments,

Station

Pattern 1

5.1.2

Display

Station

(without

5.1.3

5.1.3.1

5.1.3.2

5.1.3.3

5.1.3.4

5.1.3.5

5.1.4

5.1.4.1

5.1.4.2

Voltage

Checks

low-Voltage

High·Voltage

Arc-Suppression Check

6.3V

AC

Check

High-Voltage

Keyboard

Voltages

Key

Module

Keyboards

5.1.4.3

5.1.4.4

5.1.4.5

5.2

5.2.1

5.2.1.1

5.2.1.2

5.2.1.3

5.2.1.4

5.2.1.5

5.2.1.6

Output

Codes

Shift

Key

Modules Spacebar Assembly Mechanical Checks

Adjustm

Display

ents

I mage

Brightness

Contrast

Focus

Yoke

Magnetic Centering Rings

Modell

Analog

Approach

1-1

1-1

Maintenance

Units

(FRU)

Aids

1-1

1-1

1-1

1-1

1-1

Station

1-1

1-2

Buffer

Tools

Symptoms

Failures

Programs

Tool

Kit

1-2

1-2

2-1

2-1

2-1

2·1

2-1

:2

~

2-1

2-1

2-3

Mask

2-3

2-3

2-3

2-3

RFT

Patterns

Stations

Stations

(Ol

Ts)

2-4

2-8

2-8

2-9

3-1

Usage

Symptoms

Diagrams

and Removals

3-1

3-1

4-1

5-1

5-1

Test Using Test 5.3.5.9

5-1

Test

Operational

Pattern

1)

Test

5-2

5-3

DC

Checks

Check

5-3

5-4

5-4

5-4

Power

Supply

Checks

Check

5·5

5-5

5-5

and

Encoding -Type

Only

Type A Keyboards

A

"

Only

5-5

5-6

5-6

5-6

5-6

Adjustments

5-6

5·7

5·7

5·7

5-7

5-7

Card

Adjustments

5-7

5.2.1.7

5.2.2

5.2.3

5.3

5.3.1

5.3.2

5.3.2.1

5.3.2.2

5.3.2.3

5.3.2.4

5.3.2.5

5.3.2.6

5.3.2.7

5.3.2.8

5.3.2.9

5.3.2.

Model 2 Analog

-12V

OFF-PUSH

Removals

Covers 5-9

Power

Low-Voltage

-12V

AC

Model 1 Prime

Model 2 Prime

Modell

Modell

Model 2 Ferro

Model 2 Ferro

High·

to

5.3.2.11 Fuses

~.3.3

5.3.3.1

5.3.3.2

5.3.3.3

5.3.3.4

5.3.3.5

5.3.3.6

5.3.3.7

5.3.4

5.3.4.1

5.3.4.2

5.3.5

5.3.5.1

5.3.5.2

5.3.5.3

5.3.5.4

5.3.5.5

5.3.5.6

5.3.5.7

5.3.5.8

Anaiog

CRT

Yoke

Modell

Model 2 Analog

Modell

Model

Power

Logic

Logic

logic

Keyboard

Keyboard

Keyboard

Keyboard

Audible

Keybutton

Type A Switch

Type

Keybutton

Keyboards

Type B Module

5.3.5.10

5.3.5.11

Type

Circuit

Type B Keyboards

5.3.6

5.3.7

5.3.8

5.3.9

Audible

Security

Selector

Operator

(Optional

5.4

5.4.1

5.4.2

5.4.3

5.4.4

5.4.5

5.4.6

5.4.7

5.4.8

Section

6.1

6,1.1

6.1.2

6.2

6.2.1

Type B Keyboard

Cleaning

Liquid

Key

Contamination

Protective

G rou nd Check

Ground

Crooked

6.

Reference

Controls

External

I

ntern:ll

I ndicatC' "

External I nd

Card

Regulator

Switch

Adjustments

Card 5-8

(Model 2 Only)

Components

Power

Regulator

Supply

Card

Capacitor

Power

Box

Power

Ferro

Ferro

Box

Transformer

Transformer

Transformer

Transformer

Vo lrage

Power

Supply

Components

and

Shields

Analog

Card

Card

Brightness and

2 Brightness and

Control

Switch

Components

Card

Board

Components

from

Display

Top

Cover

A~mbly

Feedback Assembly

A Spacebar Assemblies

Support

B Spacebar

Board

Alarm

Keylock

Light-Pen

Identification

Feature)

Spills

Modules

Membrane/Shield

Loop

or

Data

Controls

Cf'fltrols

Module

Only

and

(Optional

Shields

Isolation

loose

Icalo.

Electronics

(Optional

Maintenance

;,

from

Modules -Type

Only

(Optional

Key

A~mbly

(50-Hz)

(50-Hz)

(50-Hz)

(50-Hz)

Contrast

Contrast

Station

Bottom

Assembly

Feature)

Feature)

Feature)

Card Reader

Aids

tops

Controls

Controls

Pan

A

5-8

5-8

5-9

5-10

5-10

5-10

5-10

5-10

5-10

5-10

5-10

5-11

5-11

5-11

5-11

5-11

5-11

5-13

5-13

5-13

5-13

5-13

5-14

5-14

5-14

5-14

5-14

5-14

5-14

5-14

5-14

5-15

5-15

5-17'

5-17

5-18

5-20

5·20

5-20

5-20

5-21

5-21

5-21

5-21

5-21

5-21

5-21

5-22

5-22

5-22

5-22

6-1

6-1

6-1

6-2

6-2

6-2

Contents

iii

Page 4

6.2.2

6.2.3

6.3

6.3.1

6.3.2

6.4

6.4.1

6.4.2

6.5

Internal

Indicator

Arc-Suppression Neon

Keyboards

Types

of

EBCDIC

ASCII

ASCII

ASCII

Reference Diagrams

Keyboards

Keyboard

Options

Character Generators (Optional

Features)

Keyboards

(SWEEP

(Optional

(Optional

Feature)

Codes

INDIC)

Features) 6-4

6-3

6-3

6-3

6-3

6-3

6-3

6-3

64

Section

Section

8.1

8.2

8.2.1

8.2.2

8.2.3

8.2.4

8.2.5

Component

7.

I nstallation

8.

General

Installation

Line

Feature

Prepowe~-On

Power-On Checks 8-2

Hexadecimal Address Label 8-2

Locations

Instructions

Voltage Check 8·1

Installation

Checks

7-1

8-1

8·1

8·1

8·1

8·2

Diagrams

3277

1·1

2-1

2·2

2-3

24

2-5

2-6 Test Pattern 3

2·7

2-8

2·9

3-1

3·2

3·3

3-4 Test Pattern 3

3-5

3-6

3-7

3-8

3-9

3·10

3-11

3-12

3-13

3-14

3·15

3-16

3·17

3-18

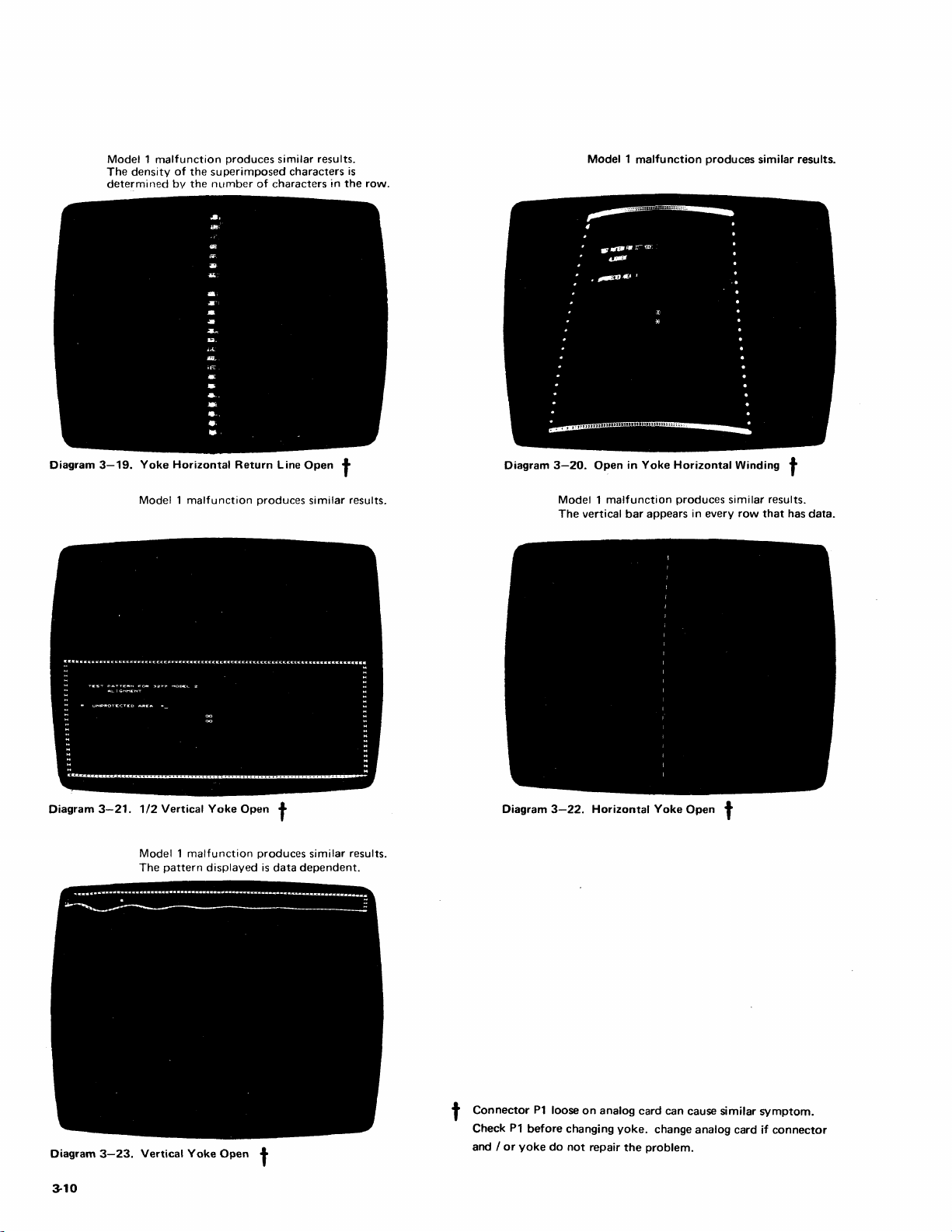

3·19

3-20

3·21

3·22

3-23

4·1

5-1

5·2

5-3

54

5-5

5-6

5-7

5-8

5-9

5-10

Maintenance

Logic Probes

Alignment

Alignment

Test Pattern 1

T est Pattern 2

Test Pattern 5

Character Differences

WTC Languages

Test Pattern 10

Test Pattern 1, Model 1

Test Pattern 1,

Test Pattern 2 3·7

Yoke

Yoke

Centering Rings

Character

Glow

Single

Model 1 Raster

Model

Cursor

Box

No

No I nterrow

Correct 0 isplay

Out

Yoke

Open

1/2

Horizontal

Vertical

Display

(29

OFF-PUSH

Switch

Unsoldering Lead Frame

Lead Frame Removal

Switch

(Type

Switch

Torsion

Spacebar

Screw

Keyboard Assembly

Mask,

Mask,

Back

Too

Tilted

Height

Only

on

Horizontal

2 Raster

in

Every

in

Every Character Position

Horizontal

of

Focus I mage 3-9

Horizontal

in

Yoke

Vertical

Yoke

Yoke

Station

Sheets)

Module

Plunger

A)

Module

Bar Removal

Guide

Loosening

Approach

Model

1

Model

(USA

(USA

Model

CRT

Sync

Spacing 3-9

Horizontal

Yoke

Open 3-10

Switch

Removal

Return

Orientation

2

EBCDIC)

EBCDIC)

for

ASCII

Numbers

2

Far

on

CRT

Neck

Not

Adj

usted Properly 3-8

Too

Small

Line

on

CRT

Row

after

PO

R 3-9

Return

Line

Open

Winding

Open

Open

Troubleshooting

Adjustment

(Type

Terminals

(Type

A)

Spring

Positioning

(Type

(Type

A)

Module

Removal

(Type

B)

Separatio~

and

Di&grams

A)

(Type

A)

(Tyoe

(Typ".

A)

A)

HI

1·2

2·2

2·3

24

2-5

2-6

2-6

2·7

2-8

2-8

3-7

3-7

3-7

3-7

3-7

3-8

3-8

3-8

3-8

3-8

3-9

3-9

3-9

3-10

3·10

3·10

3·10

4-3

5-9

5·15

5-15

5-15

5-16

5·16

5-17

&17

E-l?

5~R

Index

Module

5·11

5·12

5-13

5·14

6·1

6-2

6-3

6-4

6·5

6-7

6=8

'6•

6·9

6-10

6-11

6·12

6-13

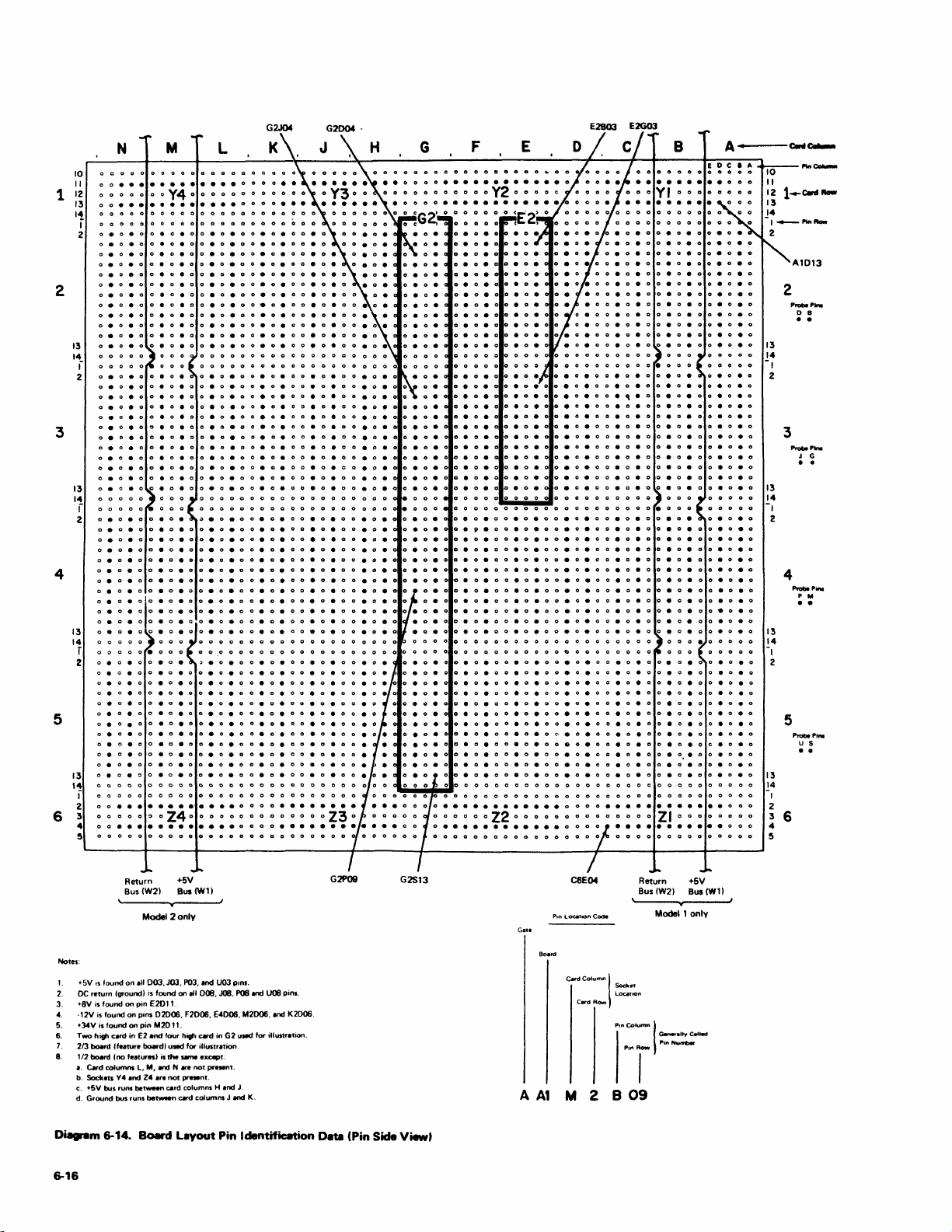

6-14

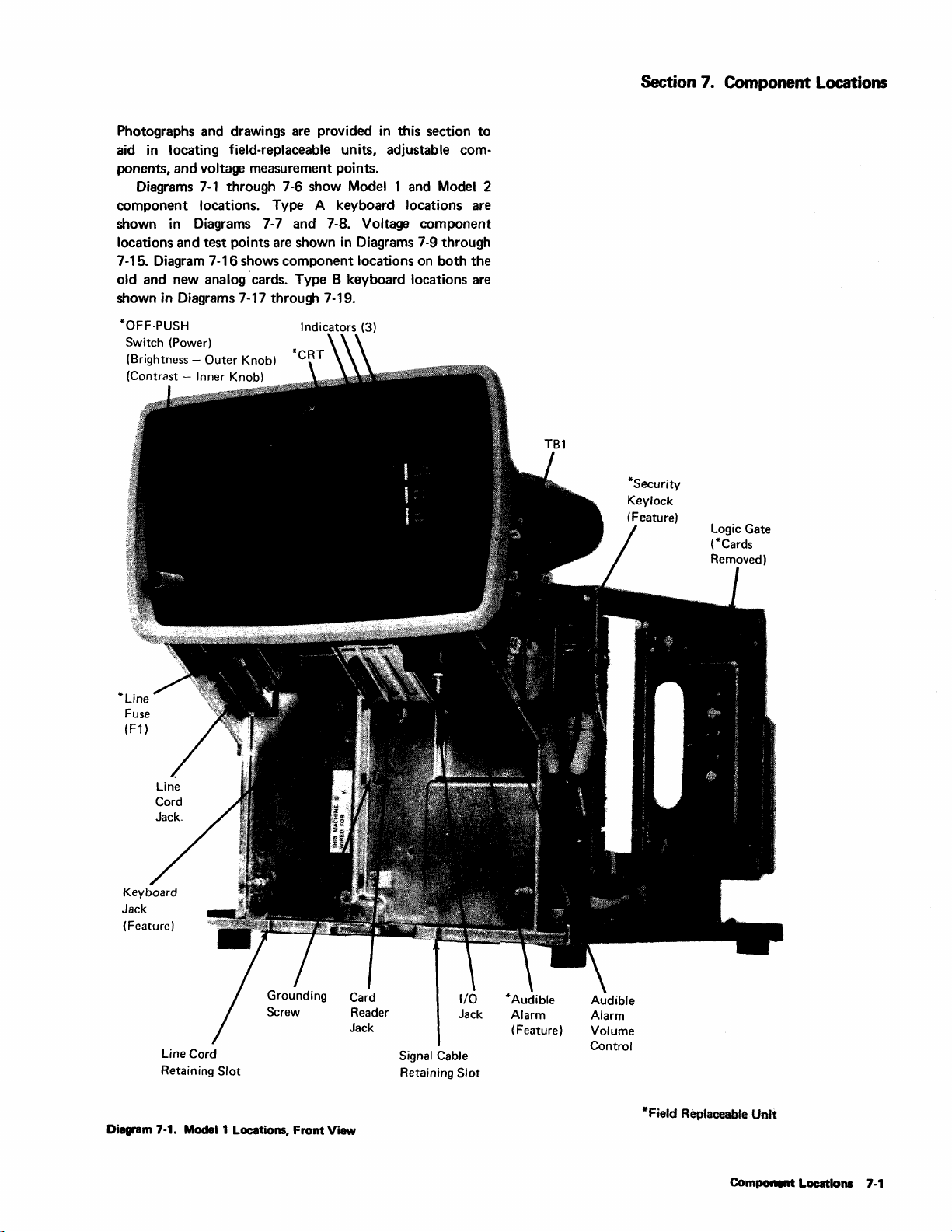

7-1

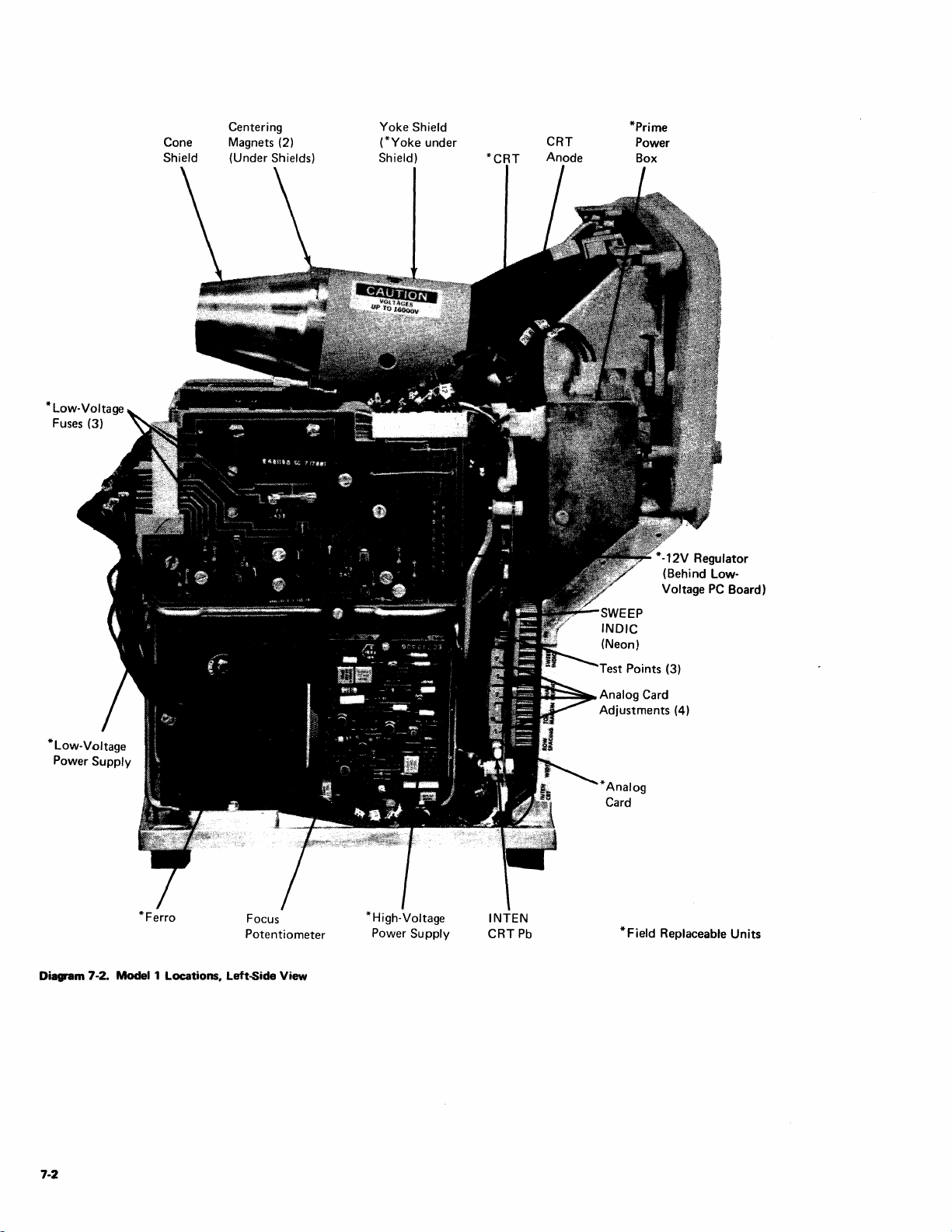

7-2

7-3

17-3.1

74

7·5

I 7·5.1

7-6 Model 2 Locations, Left-Side

7-7

7-8

7·9

7-10

7·11

7-12

7-13

7-14

7-15

7-16

7-17

7-18

7-19

8-1

f

;,)-1

Spacebar

External

Typewriter

Operator

Data

USA

WTC Language Keyboard Codes

6

ASCII

Logic

Probe Pin Data 6-12

Keyboard Feature Jumpers

Type

Board

Board

Board

Model 1 Locations,

Model

Model

Location

Model

Model

Location

Type

Type

Low-Voltage

Low-Voltage

Model 2 Voltage

Model

Brightness and Contrast

High-Voltage Power

Model

Analog Card (2

Type

Type

Type

50-Hz Ferro TB·1

Data

Removal

Circuit

Board and Electronics Assembly

(Type

B)

Base

Plate

Controls

Entry

EBCDIC

and WTC Language Keyboard Codes

Card Data (2 Sheets)

A Keyboard Encoding 6-13

Layout

Features (Card Side View)

Layout

Features (Card Side View)

Layout

(Pin Side

1 Locations, Left·Side

1 Locations, Rear

2 Locations,

2 Locations, Right-5ide

A Keyboard Locations

A Keyboard Pin Assembly and

Location

1 Prime Power

1 Arc-Suppression Board 7-14

B Keyboard Locations

B Keyboard Assembly

B Keyboard Assembly Pin and Terminal

Locations 7-19

F!ow

(Type

Ground

Pivot

Console Keyboard 6-5

of

of

Studs

Removal

and

Keyboard

Keyboards

Keyboard Codes (2 Sheets) 6-7

by

Card

by

Card

Pin

Identification

View)

Front

+5V

and

+34V

Front

+5V

and

+34V

Printed

Circuit

Printed

Circuit

Distribution

Box

Supply

Sheets)

(Foldout;

at

B)

(Type

B)

(Type

B)

Indicators

Function -Without

Function -With

Data

View

View

View

Fuses (Model 1) 7-4

View

View

Fuses (Model

View

Board

Board Shield 7-12

Board

Control

Terminals 7-13

back

of

manual)

2)

Terminal

. X-1

5-19

5·19

5·19

5-20

6-1

6-5

6-6

6-9

6-9

6-10

6-13

6-14

6·15

6-16

7-1

7-2

7-3

7·5

7-6

7·7

7-8

7·9

7·10

7·11

7-12

7·13

7·14

7-15

7-17

7·18

8-1

FO-1

iv

Page 5

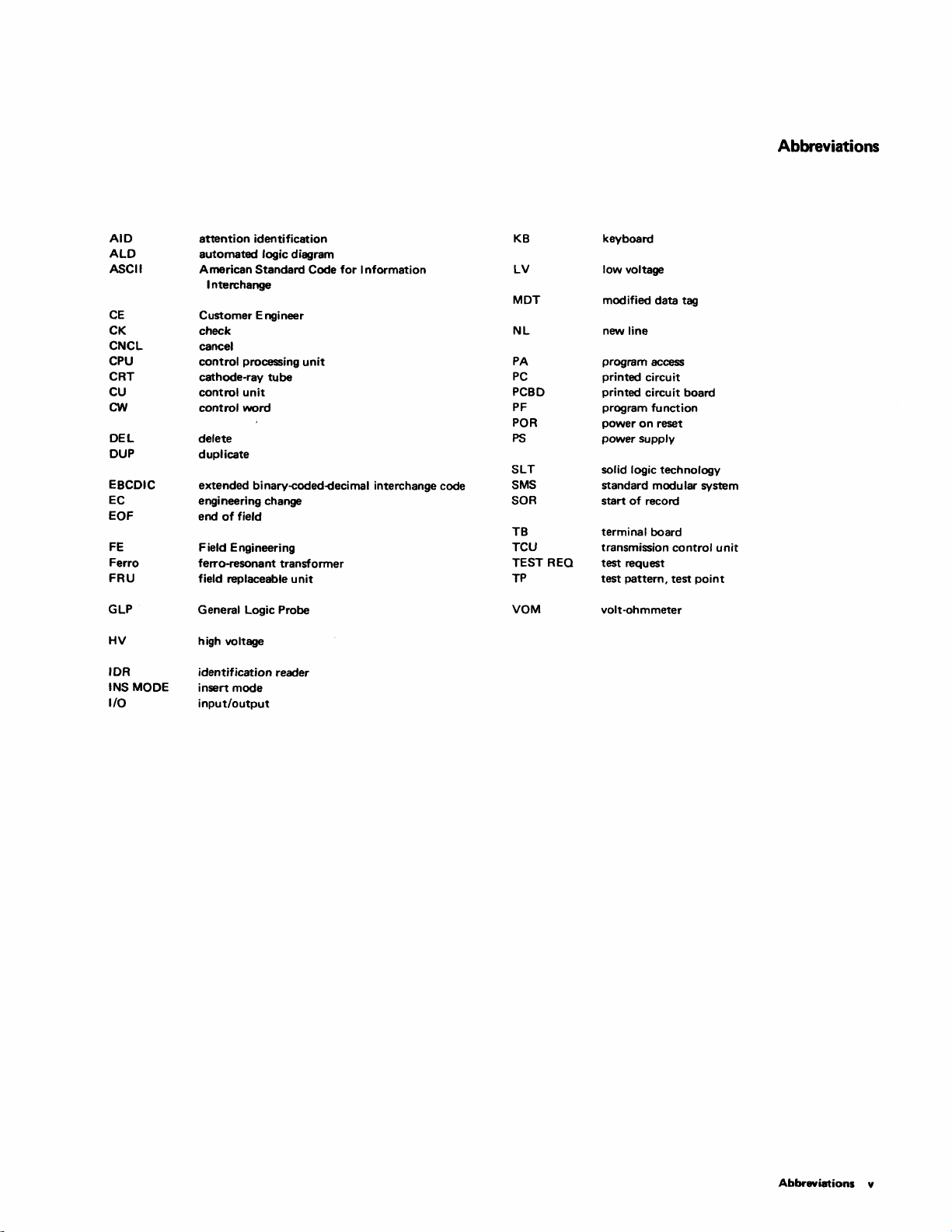

Abbreviations

AID

ALD

ASCII

CE

CK

CNCL

CPU

CRT

CU

CW

DEL

DUP duplicate

EBCDIC

EC

EOF

FE

Ferro

FRU

GLP

HV

lOR

INS MODE

I/O

attention

automated

American

Interchange

Customer Engineer

check

cancel

control

cathode-ray

control

control

delete

extended

engineering change

end

of

field

Field Engineering

ferro-resonant transformer

field replaceable

General Logic Probe

high voltage

identification reader

insert

mode

input/output

identification

logic diagram

Standard

processing

unit

word

binary-coded-decimal interchange code

tube

unit

unit

Code

for

Information

KB

LV

MDT

NL

PA

PC

PCBD

PF

POR

PS

SLT

SMS

SOR

TB

TCU

TEST REO

TP

VOM

keyboard

low voltage

mod ified data tag

new line

program access

printed circuit

printed circuit board

program function

power

on

power supply

solid logic technology

standard modu lar system

start

terminal board

transmission

test request

test

volt-ohmmeter

reset

of

record

pattern,

control

test

point

unit

Abbreviations

y

Page 6

LEGEND

,

)

I:

<>

o

v

Terminal

Indicates beginning

Action

Indicates a major action. When

to

left of each action.

Annotation

Gives descriptive

Decision

Indicates a

is

pOSSible,

Probe

Indicates a

the

determilled

Car

d Chanqe

IndlCd(~

()+t

~f)dH,dtes

point

point

loqlc

probe. Pin

by

rhat card

Paqe Connector

connection

point

of

a Troubleshooting Diagram.

comment

in

a Troubleshooting Diagram

in a Troubleshooting Diagram

probe

or

or

is

specified in

result.

cards specified in symbol should

point

between

more

than

explanatory

the

symbol. Path

different

one

note.

sheets

action

is

described,

where

a branch

where

a logic pin should

to

be

be

of

the

bullet

symbols

to

alternate

followed

changed

Troubleshooting Diagrams.

and

data

paths

be

probed

after

probing is

new ones installed.

appear

with

o

7P

Uri

/)aqe Connector

Indicates

S',

t\.1

Millor

Data

Nlimber

Data Transfer

Identifies

Screwdriver

Switch

'!1t)C)1

I"

II

Bus

connection

points

Data

Path

Data Path

of

lines

data

between

to

correspondingly-numbered symbol (line-of·sight).

or

Control

on

bus

bits transferred

Adjustment

two

parts

Line

is

identified in circle.

to

or

from

of

the

same

sheet

a logic element.

or

diagram. Arrow leaving

vi

Page 7

Section 1. Maintenance Approach

1.1 INTRODUCTION

Maintenance

repair and adjustment

attached features

can

be

of

attached

IBM

3277 Display Stations (including

of

Model 1 and Model 2 units) and

is

described

to

a 3277 include keyboards, a selector

in

this manual. Features

of

that

light-pen, and an operator identification card reader.

The objective

the failing

unit

of

display station maintenance

to

customer service as quickly as possible.

is

to

return

This manual guides the Customer Engineer through

procedures

enable him

to

adjust

or

replace a

that

malfunctioning component.

1.1.1

Online/Offline Maintenance

Display Station maintenance and testing can be performed

online

and/or

unit

offline when possible because

possibility

system. Unnecessary delays

offline. It

of

interaction with

is

better, however,

other

in

normal customer infor-

it

units

to

service

eliminates

of

the display

the

the

mation processing are thereby avoided. The maintenance

approach described

offline analysis first

this manual

to

resolve reported troubles.

is

structured

to

perform

in

1.1.2 Field Replaceable Units (FRU)

Component replacement

replaceable units (FRU). When

the

FRU

unit should be replaced immediately rather

is

limited

the

trouble

to

certain field-

is

isolated

to

than

an

repaired. The FRU parts replacement philosophy

practical because functionally packaged logic and densely

the

packed components are used throughout

display

station.

1.1.3 Troubleshooting Aids

Several tools are available

the Customer Engineer

to

to

simplify trouble analysis. The following paragraphs describe

these aids.

1.1.3.1 Symptom Index

The Symptom Index (Section

malfunctions

that

may be encountered on display stations.

3)

lists (by category)

The categories include such areas as display malfunctions,

power malfunctions, keyboard malfunctions, etc.

In

each

category, subcategories specify unique trouble areas. The

subcategories direct the Customer Engineer

to

an entry

the Troubleshooting Diagrams (Section 4), which contain

step-by-step isolation procedures.

Symptom

I ndex points directly

In some cases, the

to

a replaceable unit

causing the problem.

1.1.3.2 Troubleshooting Diagrams

The Customer Engineer

Diagrams from

procedures

adjustment.

observations

procedure.

the

to

isolate a failing F

The

diagrams call

that

shou

The

logic probe test device

is

directed

Symptom Index.

RU

out

Id

be made during

to

Troubleshooting

The

diagrams detail

or

an out-of-tolerance

specific checks

the

is

used

the diagrammed procedures.

1.

1.3.3 Diagnostic Programs

Two types

of

diagnostic programs may be available

Customer Engineer. Diagnostic program aids are described

in

Section 2

1.1.3.4 Customer Engineer Tool

Special tools are

Stations. The basic Customer Engineer

volt-ohmmeter, and

of

this

manual.

Kit

not

required

to

maintain

3277

tool

the

logic probe can successfully isolate

most display station problems. An oscilloscope may

required

in

some instances when

the

basic tools fail

resolve a problem.

1.2 TROUBLE ANAL

The sequence

performed

is

Diagram

used

1-1

to

isolate display station failures.

in

is

important

shows

VSIS

which display station trouble analysis

in

minimizing machine down-time.

the

five-step procedure

that

The

main points

the display station maintenance approach are summarized

below.

1.2.1 Obvious Symptoms

that

Obvious symptoms are those

operator or Customer Engineer action

that

Failures

could cause obvious symptoms

do not require any

to

bep>me evident.

include display image quality and positioning, mechanical

problems, and component breakage. These failures should

be

remedied by going directly

to

the Symptom Index

the appropriate adjustment or removal procedure

5.

Use

the

in

first entry

1.2.2

Isolation

If

an obvious symptom does

the cause

of

that

matches the failure.

to

a Display Station

not

the failure must

exist on a display station,

be

isolated between the

control unit and the display station. Sheet 1

Troubleshooting Diagrams describes

of

isolating the cause

connecting coaxial cable,

a failure

or

display station.

to

the

either

procedure for

the

and

diagnostic

in

many

of

to

the

Display

kit,

the

IBM

be

to

should be

of

to

occur

or

in

Section

of

the

control unit,

is

to

Maintenance

Approach

1-1

Page 8

1.2.3 Offline Symptoms

Once it

is

determined

that

the

display station

is

the

cause

of

a failure, an offline symptom should be developed. A quick

offline

test

of

the

r---

.......

---or--------...---------..,

I.

~_.Ylie.s

.J'

____

,Obvious

focus,

physi col

'

Find

(Use

that

failure

first

matches

.. ~ Symptom

symptoms

tilt,

damage,

Index.

entry

include:

centering,

etc.

in

failure.)

That

3.2.

the

test

as soon as a symptom becomes evident, and match

the

symptom

the

first

Index tells

test should expose a repairable symptom.

entry

what

display station

with one listed in

that

matches

corrective action should be taken .

is

described

the

the

failure. The

Symptom

in

paragraph

Index.

Symptom

Stop

Use

2,

3.

4.

,-'

f

I

L

,':,>01-

persis

•

_____

...

_____

po

Yes

..

_____

,.. (Paragraph 5. 1 •

Yes

•

-----.~

...

.. ~ Use Troubleshooting

.. ~ Use keyboard

..

~Use

Sheet

Diagram,

(Paragraph

3.2).

failure

Find

Symptom

Index.

(Use

first

entry

that

matches foil

Test Pattern 1

Find

failure

Symptom

Index.

(Use first

entry

that

matches

Find

failure

Symptom Index .

(Use first

entry

that

matches

1.

check

in

ure.)

1).

in

failure.)

in

failure.)

1.2.4 Formatted Buffer Symptoms

If

an offline

symptom

does

not

become evident,

the

display station, including features, must be tested with

buffer formatted. The procedure described

5.1.1 should be used with Test Pattern 1

symptom.

evident, and match it

entry

what

Stop

the

test

as

soon as a

in

the

Symptom

that

matches

the

failure. The

corrective action should be taken.

Symptom

in

to

symptom

Index.

Use

paragraph

develop a

becomes

the

I ndex tells

1.2.5 Customer-Reported Failures

It may be necessary

failure if a

symptom

Test Pattern 1 using the procedures described

preceding paragraphs. Try

existed when

the

duplicated symptom

the

corrective action indicated.

matches the failure.

be duplicated, it must be assumed

error or an interm ittent failure

to

work with a customer-reported

cannot

be developed offline or with

in

to

duplicate the conditions

customer failure occurred. Match

in

the

Symptom

If

the

originally reported failure

that

Index and perform

Use

the

first

that

it was an

has failed

entry

operator

to

reappear.

cannot

entire

the

first

the

that

the

that

a>.·.:

'·2

·n

1·1.

3277

Malfltenance

Approach

Page 9

This

section describes

aids used

hensive description

proper

station maintenance.

2.1

to

maintain

use

of

MAINTENANCE TOO LS

this

of

tool

the

the

tools

and programmed diagnostic

3277

Display Stations. A compre-

logic probe

is essential

is

included because

to

successful display

2.1.1 Customer Engineer Tool Kit

The

Customer Engineer

necessary

standard

voltage measurements. The meter's

20,000 ohms per

checking

when a check

using

referenced

return and frame ground are

display station

the

to

maintain

IBM

volt-ohmmeter

the

400V

of

VOM,

to

dc return rather than

is

not

tool

kit

contains all basic tools

IBM

3277

Display Stations. The

(VOM)

volt

causes

an erroneous reading when

dc power supply. This effect

that

power

supply

all

dc

voltage measurements should

at

connected

to a control

is

adequate

input

is

called

to

frame ground. DC

different

levels when the

unit.

for

impedance

is

noted

out.

When

all

be

2.1.2 Oscilloscope

I n some

an

equivalent, should

However, the

whenever possible, rather than

cases

of

trouble

oscilloscope. The

be

logic probe

analysis,

Tektronix

used

when

it

may be necessary

* model

is

an

453

an

oscilloscope

recommended

oscilloscope.

to

oscilloscope,

is

required.

for

use

use,

2.1.3 Logic Probes

Either

of

two

styles

of

logic probes

levels

while

signal

FE ALDs. The older-style probe (PN453652)

completely in

Diagram

shown in Diagram 2-18.

includes the G LP, standard accessories, and the General

Logic Probe Manual,

features

feature,

duplicated here,

Customer

ordering procedures should

*Trademark

2·1

of

the

and

A probe should

Engineers

of

using the Troubleshooting Diagrams

the

following

A.

The newer General Logic Probe

An

available GLP

SY27-0113. The manual describes the

GLP,

the

functions and

a checkout procedure.

so

the

user

is

referred

be

obtained

who

service

be

used

Tektronix,

Inc.

can

be

used

to

probe

is

described

paragraphs and shown in

(G

LP)

Kit

(PN 453212)

limitations

(That

information

to

SY27-0113.)

from

Mechanicsburg by all

3270

units. Normal tool-

to

obtain the probe.

of

each

is

not

Section 2. Tools and Diagnostic Programs

2.

1.3.

1 Description

2-1

A)

is

The logic probe (Diagram

of

an

consisting

green indicator incorporated near the probe end. A cable

containing

from

the

sealed

threaded stud

green indicators tell the state

three signal states

plus level, (2) a solid minus level, and (3) a pulse

presence

push-on connectors are attached

logic board being probed. They carry the operating voltage

(+5V dc

tip

of

carries the

2.1.3.2 Probe

To

threaded stud.

equivalent) should

probe are attached

probed. The

Connect the

+6V

to

or

lead

connected, the red

in the Troubleshooting Diagrams

The

probe:

1.

or

2.

is

3.

2.1.3.3 Probe Checkout

Note: This checkout procedure applies

logic probe

General Logic

panies the GLP.

and

screws

use

the logic probe, a probe

lead

to

the board

onto

Connect the oscilloscope probe

following

Red

indication

a.

Probe

b.

Plus signal on

Green indication - Ground (negative) signal on the

being probed.

Red

and

plus

and

condition

This

indicator pulsing on

seemingly on at the

frequency

seen.

anodized aluminum

two

wires and

top

is

at

that

of

pulses. The

ground)

on

the threaded stud

input

signals

Usage

An

leads

GND

any

D03

by

pushing

the designated pin. When the last wire

conditions can

not

attached

green

indication

ground)

can

of

the pulsing signal). Single pulses

(PN

453652). G

Probe Manual, SY27-0113, which accom-

SL

T-type

end

of

the

the

probe end

can

be

two

for

the

to

the indicators.

SL

T probe

be

used. The

to

the back

are

clearly labeled:

lead

to

any D08 pin, and connect the

pin

(+5V dc). The leads are connected

the

indicator

the

should light.

to

a pin

net being probed.

- A pulsing signal (alternately

is

present on

appear

and

same

a self-contained device

tube

with

push-on terminals leads

probe. A plastic

of

the device.

of

the

net

being probed. The

distinguished are: (1) a solid

wires

with

to

pins on the back

probe.

An

oscilloscope probe

at

the

tip

of

the probe. This

tip

must

be

attached

tip

(PN 453163,

two

wires at

of

the

logic board being

GND

connector

be

either

off,

LP

at

the end

tip

to

the pin designated

or

as

determined in logic.

observed

(floating

time

checkout

condition),

the

net being probed.

as

the red and the green

or

as

both

(depending on the

to

the Older-style

is

a red and

head

with

Red

or

the SL

T-type

of

to

the

top

of

and

of

by

the logic

indicators

can

also

described in

a

and

the

the

the

or

the

+6V.

each

is

or

net

be

Tools

and

Diagnostic Programs 2-1

Page 10

Threaded

Tip

Cable

Red Green

A.

Tip

Older

Style

Probe

61

0

...J

0

Z

J:

U

W

.....

Q.

:>

~

0)

I11I1

~

t=

N

..J

:>

~

en

~

~

I

.-

~

~

Z

~

8

~

0)

J:

U

.....

«

...J

I 1II1 I

Q.

w

Z

:>

z

~

0

0

Z

0

I IIII I

~I

w

.....

«

<:J

>

~

+

Connect

003

0

>

Z

~

(!)

.,

pin

to

any

~@

.....

«

<:J

Push-Qn

Connectors

@

+

w

III

0

II:

Q.

u

e,:)

0

..J

..J

ct

II:

w

Z

W

e,:)

Z

.xl

.....

B.

IBM

General

Diagram 2·1.

2-2

Logic

Logic

Cable

Probe

Probes

Page 11

Power must be applied

1.

Attach

453163

2.

Connect probe

3. Connect probe +6V lead wire

red indicator should light as soon as this wire

4. Touch probe

should remain lighted.

5.

Touch probe tip

should

008

6. Remove probe tip from

should light again.

2.1.3.4

The logic probe

experienced during probe checkout, check for

conditions:

1.

Power

2.

Probe leads are on

3. Proper pins are being probed.

If

operate correctly, obtain a new probe before troubleshooting

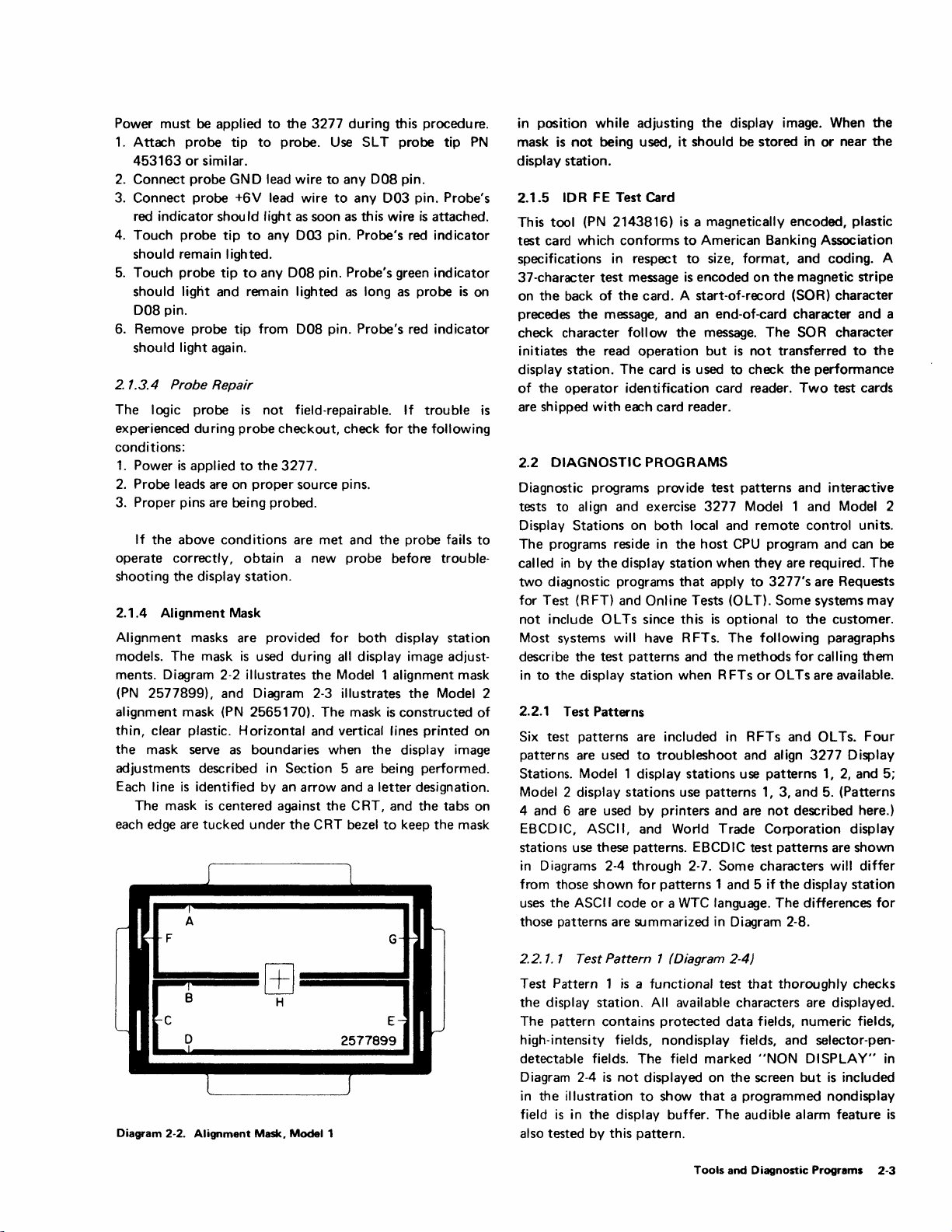

2.1.4 Alignment Mask

Alignment masks are provided for both

models. The mask

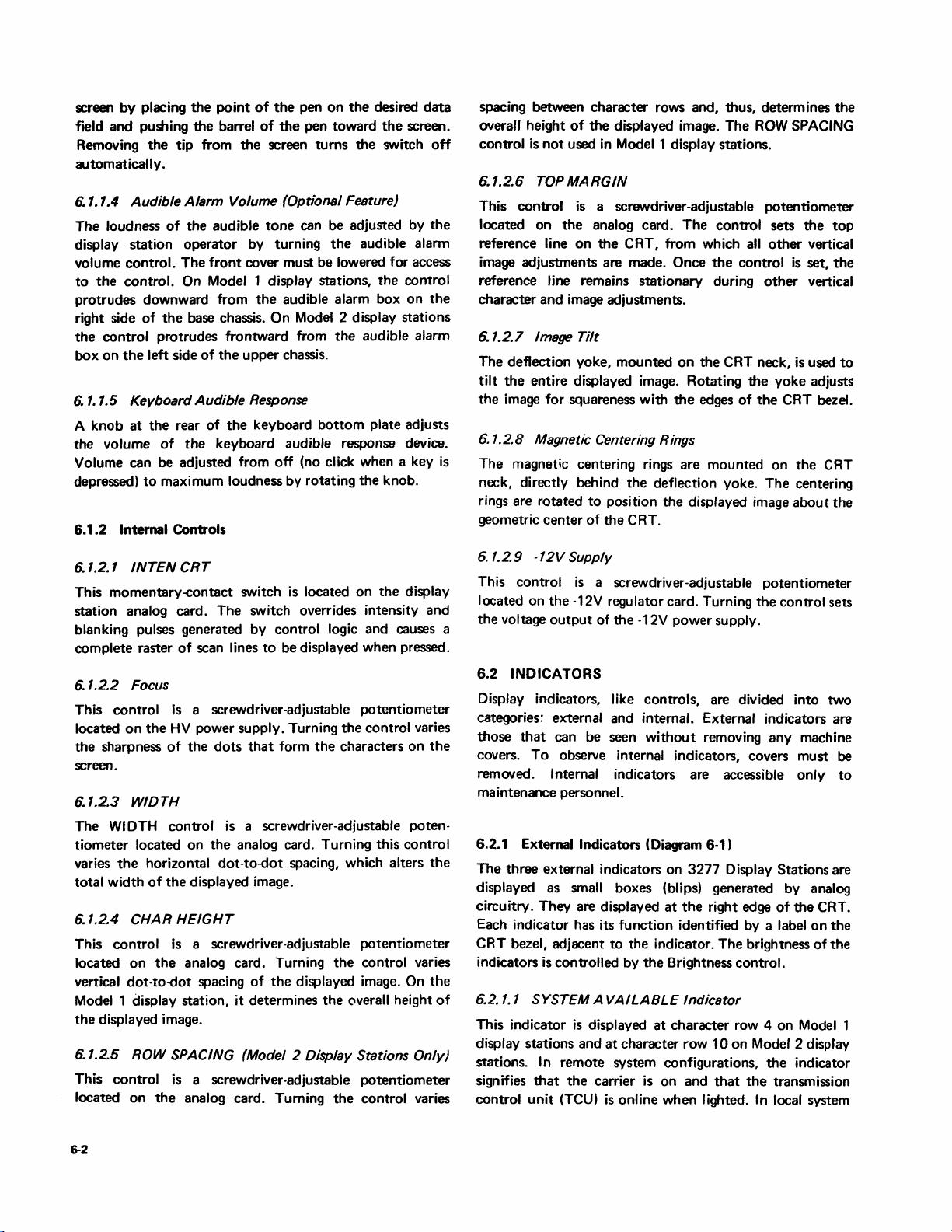

ments. Diagram 2-2 illustrates

(PN

alignment mask

thin, clear plastic. Horizontal and vertical lines printed on

the

adjustments described

Each line

The mask

each edge are tucked under

probe

or

similar.

light and remain lighted

pin.

Probe Repair

is

applied

the

above conditions are met and

the

display station.

2577899), and Diagram 2-3 illustrates

mask serve

is

identified by an arrow and a letter designation.

is

centered against

to

the

3277

tip

to

probe. Use SL T probe tip

GN

0 lead wire

tip

to

any

003

to

any

008

008

is

not

field-repairable.

to

the

3277.

proper

source pins.

is

used during

the

(PN

2565170). The mask

as

boundaries when

in

Section 5 are being performed.

the

CRT bezel

during this procedure.

PN

to

any

008

pin.

to

any

003

pin. Probe's

is

attached.

pin. Probe's red indicator

pin. Probe's green indicator

as

long as probe

pin. Probe's red indicator

If

the

the

probe fails

display station

all

display image adjust-

Model 1 alignment mask

the

is

constructed

the

display image

the

CRT, and

to

keep

trouble

following

Model 2

the

tabs on

the

is

on

mask

in

position while adjusting

mask

is

not

being used, it should be

display station.

lOR FE Test Card

2.1.5

tool

(PN

This

test

card which

specifications

37-character

the

back of

on

precedes

check character

initiates

display station.

of

the

operator

are shipped with each card reader.

is

2.2

DIAGNOSTIC PROGRAMS

Diagnostic programs provide

tests to

Display

to

The programs reside

called

in

two

diagnostic programs

for Test (RFT) and

not

include OL Ts since this

Most

systems will have RFTs.

describe

in

to

the

2.2.1 Test Patterns

of

Six test patterns are included

patterns are used

Stations. Model 1 display

Model 2

4 and 6 are used by printers and are

EBCDIC, ASCII, and World Trade Corporation display

stations use these patterns. EBCDIC test

in

Diagrams 2-4 through 2-7. Some characters will differ

from those shown for

uses the ASCII code or a

those patterns are summarized

2143816)

conforms

in

respect

test

message

the

card. A start-of-record (SOR) character

the

message, and an end-of-card character

follow

the

read operation

The

card

identification card reader.

al

ign

and exercise

Stations

by

the

display station when R FTs

display

on both local and

the

display station when

Online Tests (OLT).

test

patterns and

to

stations

the

display image. When

stored

is

a magnetically encoded, plastic

to

American Banking Association

to

size, format,

is

encoded

the

message.

but

is

used

to

test

3277

in

the

host

CPU

that

apply

is

optional

The

the

in

troubleshoot

stations

use patterns 1, 3,

patterns

1 and 5 if

WTC

language. The differences

in

Diagram 2-8.

is

not

check

patterns and interactive

Model 1

to

methods

RFTs and OL Ts.

and align

use

and

on

the

magnetic stripe

The

SOR character

transferred

the

Two

remote

program and can

they

are required.

3277's

Some

to

following paragraphs

for

or

OL

Ts

patterns

and

not

described here.)

patterns

the

the

in

or

near

the

coding. A

and

a

to

the

performanct~

test cards

and

Model 2

control units.

be

The

are Requests

systems

the

calling them

are

3277

display

may

customer.

available.

Four

Display

1,

2,

and 5;

5. (patterns

are shown

station

for

~===

Diagram 2-2.

Alignment

[±]

=====

H

Mask. Model 1

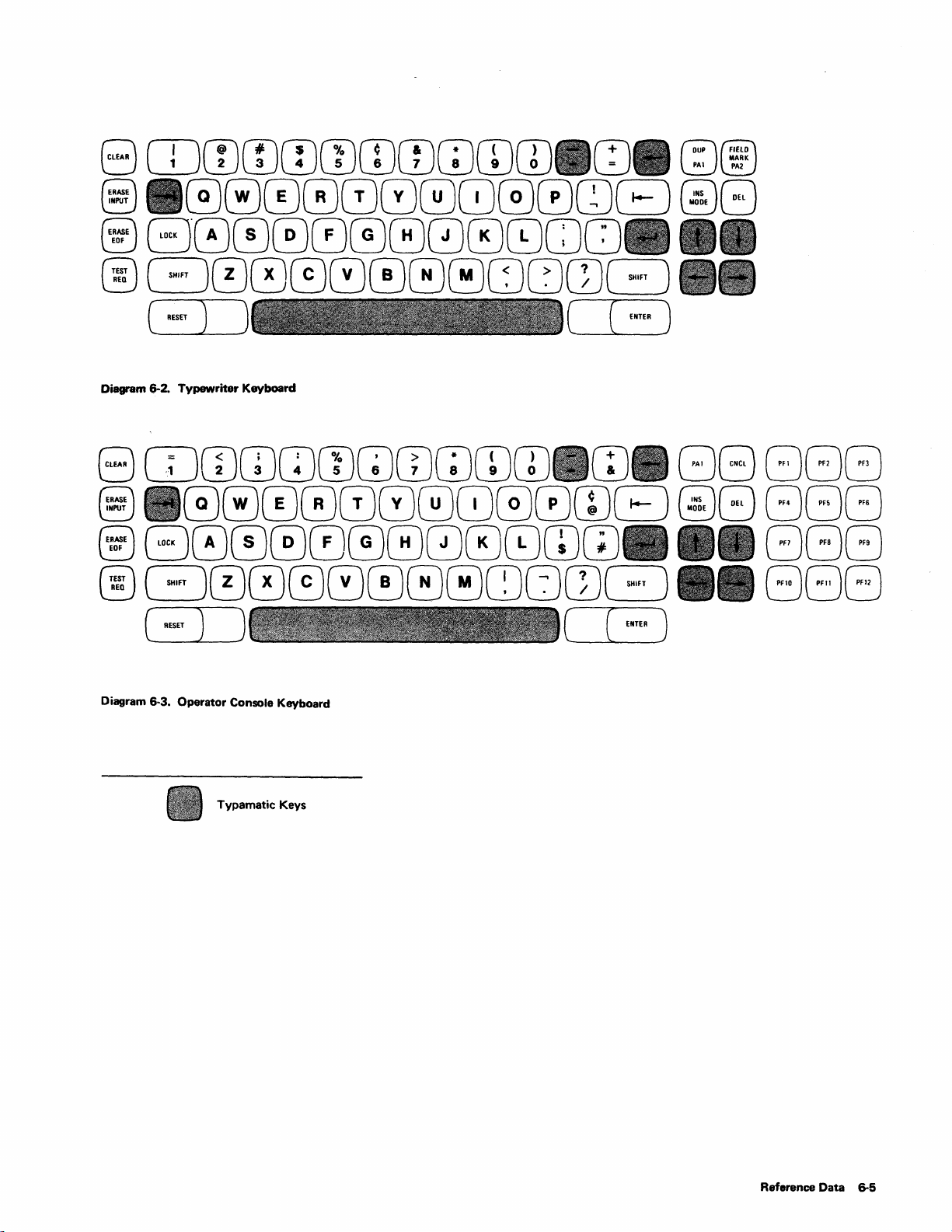

2.2.1. 1

Test Pattern 1

the

The pattern contains

high-intensity

detectable fields.

Diagram 2-4

in

field

also tested by this pattern.

Test Pattern 1 (Diagram 2-4)

is

a functional test

display station.

is

the

illustration

is

in

the

All

protected

fields, nondisplay fields, and selector-pen-

The

not

displayed on

to

show

display buffer.

field marked "NON DISPLAY"

that

thoroughly checks

available characters are displayed.

data

fields, numeric fields,

in

the

screen

but

is

included

that

a programmed nondisplay

The

audible alarm feature

Tools

and

Diagnostic

Programs

2-3

is

Page 12

t'

r-

0

'-

E

'-

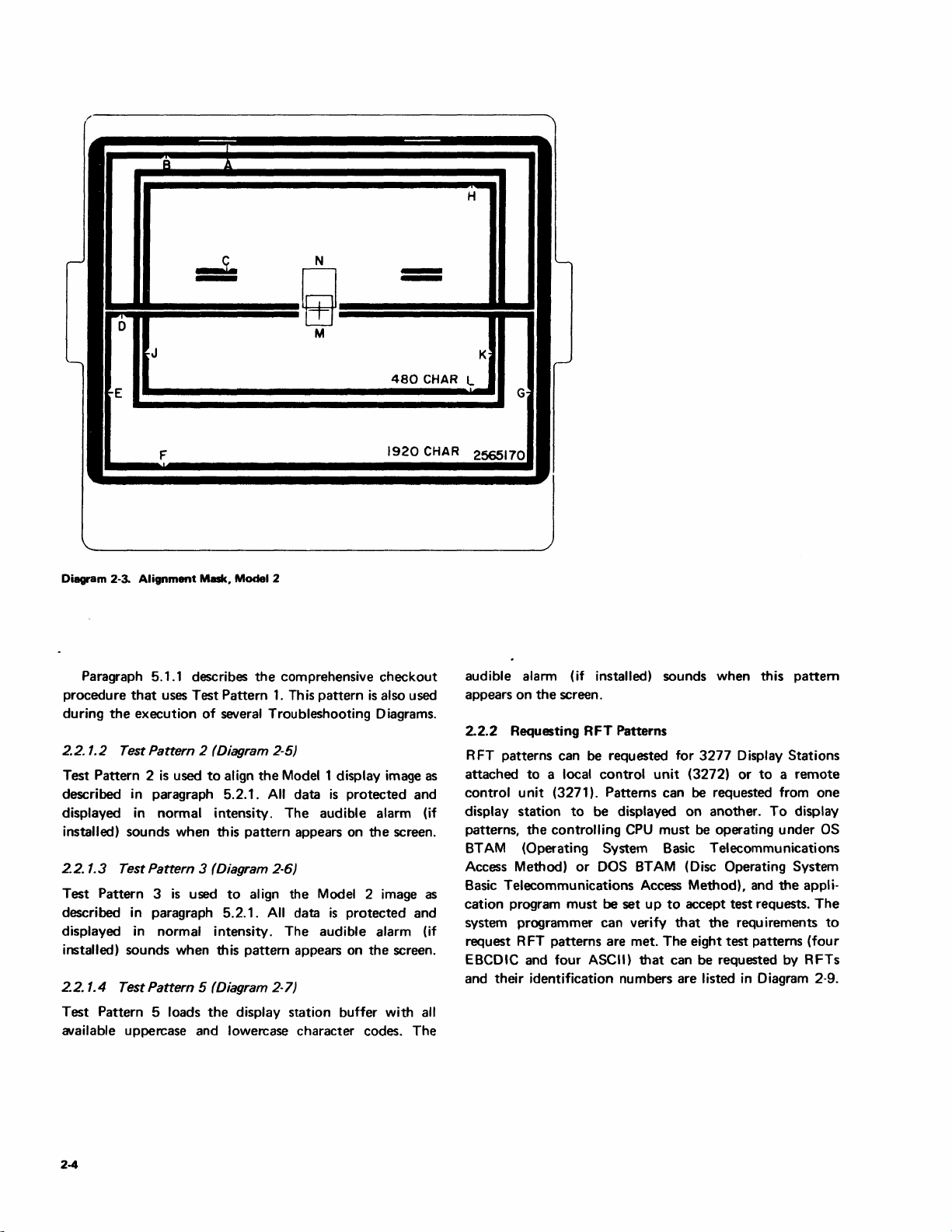

Diagram 2-3.

B

J

F

Alignment

11

-1.

-

Mask, Model 2

N

9

M

-

-

480

1920

CHAR

CHAR

H

.........

K

L

G

2565170

-----.

--

./

Paragraph 5.1.1 describes

procedure

during

2.2.1.2 Test Pattern 2 (Diagram 2-5)

Test Pattern 2

described in paragraph 5.2.1.

displayed in normal intensity. The audible alarm (if

installed) sounds when this pattern appears on

22.1.3

Test Pattern 3

described in paragraph 5.2.1.

displayed in normal intensity. The audible alarm (if

installed) sounds when this pattern appears on

22.1.4

Test Pattern 5 loads

available uppercase and lowercase character codes. The

that

uses Test Pattern

the

execution of several Troubleshooting Diagrams.

is

used

to

Test Pattern 3 (Diagram 2-6)

is

used

Test Pattern 5 (Diagram 2-7)

the

the

comprehensive checkout

1.

This

pattern

align

the

Modell

All

data

to

align the Model 2 image

All

data

display station buffer with

is

also used

display image

is

protected and

the

is

protected and

the

as

screen.

as

screen.

all

audible alarm (if installed) sounds when this pattern

on

the

appears

2.2.2 Requesting RFT Patterns

RFT patterns can be requested for

attached

control unit (3271). Patterns can be requested from

display station

patterns,

BTAM

Access Method)

Basic Telecommunications Access Method), and

cation program must

system programmer can verify

request RFT patterns are met. The eight test patterns (four

EBCDIC and four ASCII)

and their identification numbers are listed

screen.

3277

Display Stations

to

a local control

to

be displayed

the

controlling

(Operating System Basic Telecommunications

or

DOS

be

unit

(3272)

on

another.

CPU

must be operating under

BTAM

set

(Disc Operating System

up

to

accept test requests.

that

the

that

can be requested by RFTs

or

to a remote

To

display

the

appli-

requirements

in

Diagram 2-9.

one

as

The

to

2-4

Page 13

ABCDEFGHIJKLMNOPQRSTUVWXYZ

NON

DISPLAY

COpy

I Q # $ % ¢ &

COpy

?SEL

(Model 1 Patternl

ABOVE

~:

ABOVE

PEN

IN

( ) _ + ! ; f t < >? - =

IN

TEST

THIS LINE INSERT

I;

I /

01

2 3 4 5 6 7 8 9 ~ • - A

THIS LINE

> SEL

PEN

TEST

ADR-6G48

CK

(Model 2 Pattern)

Notes:

Diagram 2-4. Test Pattern 1

1.

AOR

NON

Use

- ctppears

OISPLA

Olawam

2.

3.

Y

2-8

only

Ie;

to

(USA

when

not

displayed

determlnP

EBCDIC)

patter')

unique

Ie;

called

chilrilctp.r

"'

Irr"n

()L

fEP

rr>p!.I(.;elr.~nts

wiWIl

A~";CII

vr

lllTe

1.1!)(ludges

.lrE'

u~ed

ToOls and Diagnostic Programs 2·5

Page 14

EEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEE

H H

H H

H H

H H

,H

H

H

H

TEST

H *

0

00

DO

PATTERN

FOR

ALIGNMENT

UNPROTECTED

3275-1/3277-1

AREA

* H

H 0 ADR-6040 H

EEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEEE

appears

only

when

pattern

IS

called

In

from

OL

Note'

AOR

TEP

c

H

H

H

H

Diagram

2·5.

Test Pattern 2

Not£!

Diagram

2·6

AOR

2·6.

dpf..H.'ars

(HliV

Test Pattern 3

when

pattern

IS c<Jlled

111

from

OL

TEP

Page 15

ABCD~FGHI~«+I&JKLMNOPQR!);~

STU

V W x Y Z

~u

_ > ? :

~

~

, = ' , . $ * - / , G 1 2 34 5 6 7 8 9

ABCDEFGHIJKLMNOPQRSTUVWXYZG123456789

ABCDEFGHIJKLMNOPQRSTUVWXYZ8123456789

(Model

&-/

<;:.«+1

<;:.«+1

I"J/L

EOfVl

1

Pattern)

&-/

!$*);-,

!$*)j-'

,%

,~t=>?:#Qt="

CHECK55555

CHECK99

>?:n0'="

Note:

Diagram

I

Jse

27.

DlagrnJn

fest

28

to

deterrninf'

Pattern 5 (USA

unique

EBCDIC)

Lhdrdcter

repldU'n1t'nts

,,,,,'twn

A:,\::

I

l'

\",

T

~

1,!fHjlJd<WS

drt'

lJSPU,

Tools

dnd

Diagnostic

Programs

2-7

Page 16

Hex Code/Graphic

Language 4A 5A 5B 78

-USA

EBCDIC

USA ASCII-A

USA ASCII-B

Austrian/German

Danish/Norwegian

Finnish/Swedish

Portuguese

Spanish

United Kingdom

t

[

r

0 U U

{lS

0

A

~

$

! $

)

)

l

1

C

!

!

$

$

1

1

~

p+

t.

#

#

#

A

4-

A

cr

N

#

7C

@

@

fit

ii

0

0

A

-

•

@

7F

"

..

"

A

4-

A

0'

N

"

4F

I

I

I

I

I

I

I

t

I

SF

-.,

--,

~

-.,

--,

-.,

.....,

-.,

-.,

-Belgian,

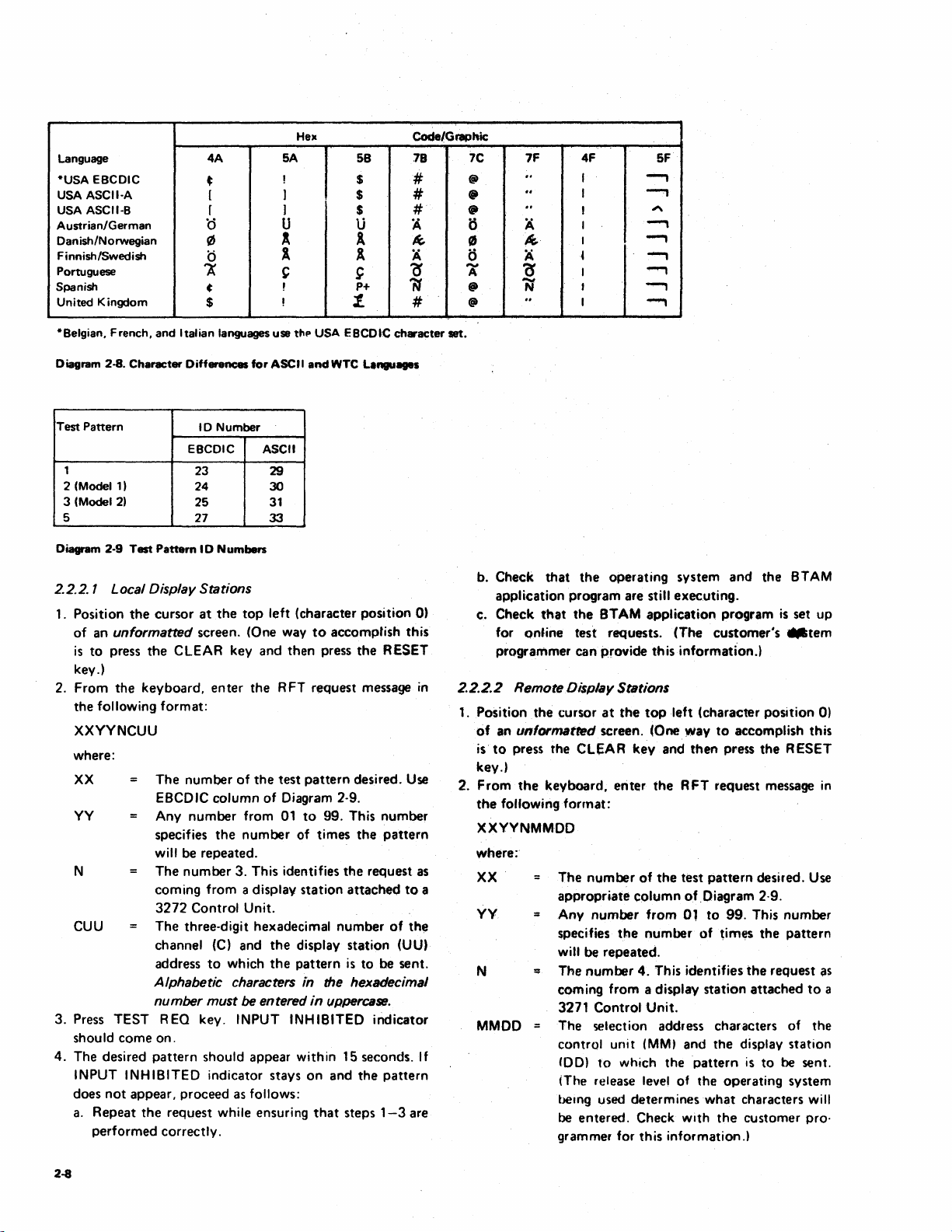

Diagram 2-8.

Test

1

2 (Model

3 (MocIe121

5

Diagram 2-9

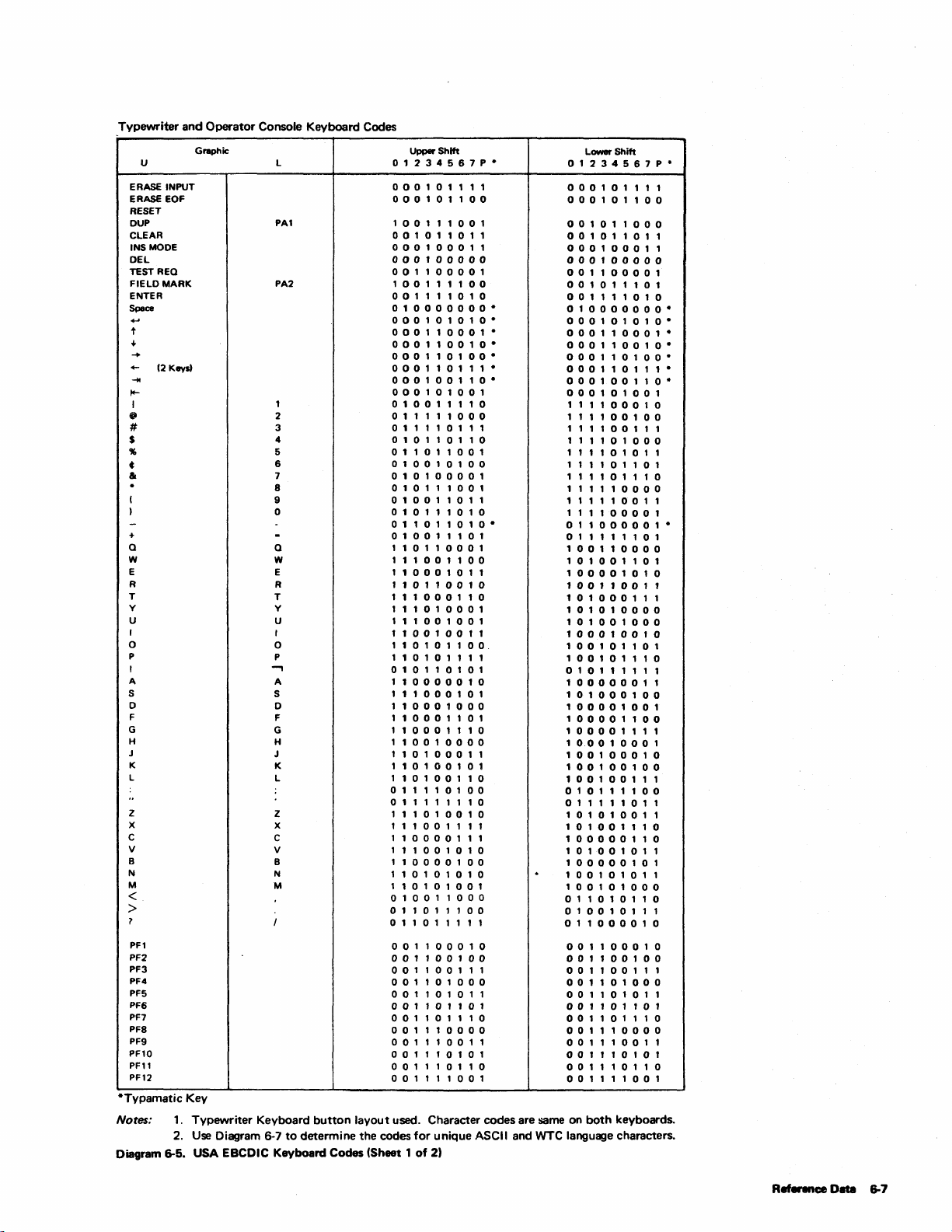

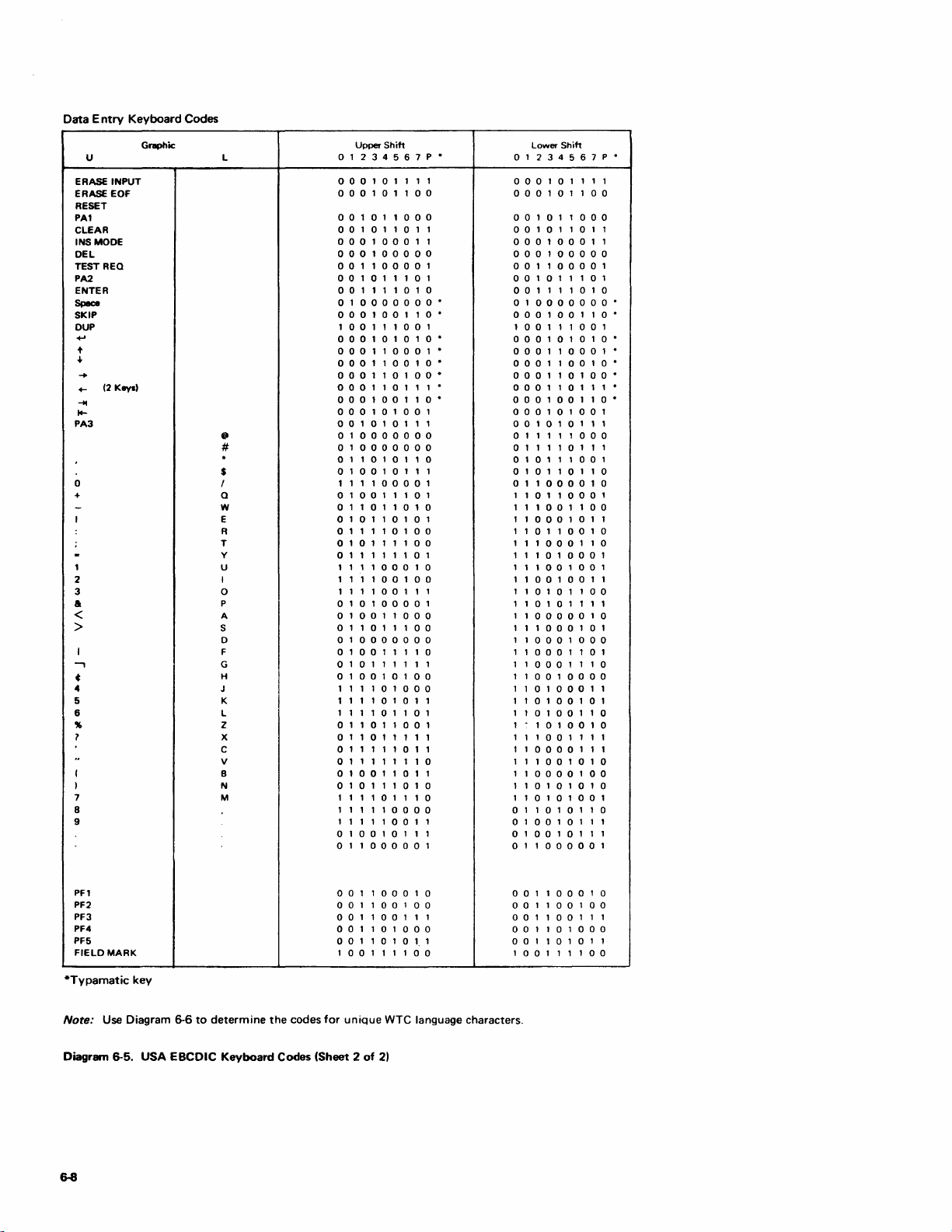

2.2.2. 1 Local Display Stations

1. Position

2.

3. Press

4.

French,

and

Italian languages

Character

Pattern

1)

Test

the

of

an

unformatted

is

to

press

key.)

From

the

the

following

XXYYNCUU

where:

XX

YY

N

CUU

TEST

should

come

The

desired

INPUT INHIBITED

does

not

appear,

a.

Repeat

performed

Differences

EBCDIC

Pattern

cursor

the

CLEAR

keyboard,

format:

The

number

EBCDIC

Any

number

specifies

will be

The

number

com

ing

3272

The

three-digit hexadecimal

channel (C)

address

A/phabetic characters in the hexadecimal

number must

R EQ key. INPUT INHIBITED

on.

pattern

proceed

the

request

correctly.

10

Number

23

24

25

27

10

Numbers

at

the

top

screen. (One way

key

enter

of

column

from

the

number

repeated.

3. This identifies

from

a display

Control

Unit.

and

to

which

be entered

should

indicator

as follows:

while ensuring

use

for

ASCII

ASCII

29

30

31

33

left

and

the

RFT

the

test

of

Diagram 2-9.

01

the

the

appear

stays

t"p

USA

and

WTC L.nguages

(character

to

accomplish

then

press

request

pattern

to

99. This

of

times

station

display

pattern

in

uppercase.

within

on

and

that

eecotC

position

the

RESET

message

desired. Use

number

the

pattern

the

request

attached

number

15 seconds.

station

is

to

indicator

the

steps

of

be

pattern

1-3

character

0)

this

in

as

to

a

the

(UU)

sent.

If

are

set.

b.

Check

application

c.

Check

for

programmer

2.2.2.2 Remote Display Stations

1. Position

of

an

is

to

key.)

2.

From

the

that

that

online

the

cursor

unformatted

press

the

the

keyboard,

following

the

program

the

STAM

test

can

CLEAR

format:

operating

are still

requests.

provide

at

the

screen. (One

key

enter

XXYYNMMDD

where:

XX

YY

N

MMOD

The

number

appropriate

Any

number

specifies

witt be

:;

The

coming

3271

The

control

tOO)

(The release level of

bemg used

be

grammer

the

repeated.

number

from

Control

selection address

unit

to

which

entered.

for

of

column

4. This

determines

Check

this

system

executing.

application

(The

this

information.)

top

left

(character

way

and

then

the

RFT

the

test

of

.Diagram 2·9.

from

Ol

number

a display

Unit.

(MM)

of

identifies

and

the

pattern

the

with

information.!

and

the

program

customer's

to

accomplish this

press

the

request

pattern

to

station

what

desired. Use

99. This

times

the

the

attached

characters

the

display

is

to

operating

characters

the

customer

BTAM

is

set

_tern

position

RESET

message

number

pattern

request

of

station

be sent.

system

up

0)

in

~s

to

the

will

pro·

a

2-8

Page 17

3.

Press TEST REQ key. INPUT INHIBITED indicator

should

come

on.

4.

The

desired

iNPUT INHIBITED indicator slays

does

not

a. Repeat

pattern

shoUld appear within

appear, proceed

the

request while ensuring

as

follows:

on

that

15

and

steps

seconds. If

the

1-3

performed correctiy.

b. Check

application program are

c. Check

for

that

the

operating system and

stili executing.

that

the

BTAM application program

online test reQuests. (The

the

is

customer's

programmer can provide this information.)

pattern

are

BTAM

set up

system

2.2.3 Online Tests (OL

Online tests may

aid

in

maintaining 3277 Display Stations. Detailed descrip-

tions and instructions

diagnostic program binder

unit. Control unit

Most

OL T routines apply

three routines

apply

1. KEY - This routine handles

rupts from

the

function keyboard. The

presented on

CE

of

the

success

Th

is

routine also reads back

keyboard

2.

MAG

to

check lowercase character codes.

- This routine tests

Ts)

be

available,

for

ML

TGs also

to

display stations:

at

the

customer's

using OL Ts are

that

is

shipped with each

contain

to

control units. The following

contained

this information.

manually generated inter-

keyboard, selector light-pen, and program

results

the

display station screen, informing

or

failure

the

of

of

the

data

operator

the

interrupt

entered

identification card

reader and identification cards.

3. PAT - This routine

paragraph 2.2.1.

the

CRT after

message containing instructions

pattern

sequence precedes Test

displays

The

they

are initially called in. An explanatory

'test

the

test patterns described

patterns

appear in sequence on

for

running

Pattern

1.

option,

in

to

the

control

interrupts are

the

operation.

from

the

in

the

test

Tools

and

Diagnostic

Programs

2-9

Page 18

3.1

SYMPTOM INDEX USAGE

The

Symptom

encountered on

trations

images are

Index and illustrations as

method

Index lists

3277

that

show

also

contained

of

resolving display station problems.

trouble

Display

both

in

symptoms

Stations

correct and incorrect display

this section.

the

first step

that

could be

and features. Illus-

Use

the

Symptom

in

a systematic

The

index

divided into six major categories:

1. Display malfunctions.

2. Keyboard malfunctions.

Selector light-pen malfunctions.

3.

4. Power malfunctions.

CPU error indications.

5.

6. Operator identification card reader malfunctions.

Some categories are divided into subcategories, making it

easier

to

relate

the

trouble

in

the

index. Beginning

closely describes the display station trouble should

experienced

with

1A

1,

the

to

first

the

item

correct

that

be

item

most

used.

Categories and specific items are identified by a one-, two-,

or three-letter/number code (e.g., 1 A 1, 2G, or

of

the

column

into

the

Troubleshooting Diagrams

The right column of the

to take

index. The code specifies the

Symptom

to

remedy

the

display station problem.

in

Section 4.

I ndex specifies action

column directs the Customer Engineer

shooting diagram sheet

change. When more than

or

specifies a logic card (or cards)

one

card

is

4)

in

the

entry

to

a section trouble-

listed, isolate the

left

point

That

failing card by card swapping from among those specified.

the

others

to

Change the failing card and return

stock. The

right column may also specify an adjustment procedure

Section 5.

Diagrams 3-1 through 3-24 show both

incorrect display images.

illustrations

As an aid

to

aid in identifying display station symptoms.

to

rapid repair, diagrams

display images also specify

The

symptom

the

repair action.

correct

I ist refers

that

show incorrect

and some

to

these

Section 3. SYmptom Index

3.2 DEVELOPING SYMPTOMS

Display station malfunctions should be isolated offline

unless

the

trouble

through

type

the

control

are listed in Category 5 (CPU Error Indications).

Display station operations

is

for failure

1.

Selector light-pen operations.

symptoms

2. Display intensity

display).

3. Protected and numeric field operations.

4. Tab operations.

5. Erase input and erase field operations.

Test Pattern 1 contains fields

test

The

or

pattern may be loaded from

OL T.

Symptoms

marked with an asterisk

Offline

the

symptoms

following

removed.

1. Turn power on. (Always begin from a power-on reset

condition.)

2. Test cursor move keys

3. Test CLEAR key.

4. Enter four

to

5. Press Tab

6. Press Backspace

7.

Enter

four

8. Press Backspace

Enter

INS

four

in

9. Press

10.

11. Test DEL key.

Stop

the

when

the

first failure occurs.

occurs only when operating online

unit

to

the

host CPU. Failures

that

require a formatted buffer

to

become evident are:

control

that

(*)

(high intensity and non-

that

test

these operations.

the

system as an RFT

require a

in

the

formatted

Symptom

should be developed by performing

tl..'5t

sequence after

or

five characters.

(~)

key.

(+-) four times.

--+,

t,

..t.,

+-, ~ ,

the

I/O signal cable

~,

characters.

(+-) four times.

MODE.

or

five characters.

test sequence and go to

the

Symptom

Index.

+-'

of

buffer are

•

Index

this

is

Symptom

Index

3-1

Page 19

SYMPTOM

INDEX

Symptom

Note: Bad

failures ranging

checker

1.

DISPLAY

A.

B.

or

mIssing green

from

PN

9900453.

MALFUNCTIONS

No

Display:

1.

No

visible

characters,

Glow

2.

Intensity and Focus:

One

1.

2.

3. Block displayed

horizontal

Modell

Model 2 ten

scan

a.

INPUT

INPUT

b.

I 4. Display

effect

5. Characters

*6. Dual-intensity problems

7.

Display erratic (e.g., display flashes, characters move, more than one cursor)

I

8. Screen

9. Retrace unblanked

10. Random data on screen. INPUT

11. Cursor on

One

12.

dot

wire

grounds on display stations

intermittent

light

or

indicators displayed.)

only

on CRT (Diag 3-9)

line on

- Full raster on screen (Diag 3-11)

24

rows

lines) (Diag 3-12)

INHIBITED

INHIBITED

too

dim

usi

ng

display focus

out

of

full

of

lines

left

side

at character location zero cursor

to

catastrophic.

or

glow on CRT. (Device Check

CRT

(Diag 3-10)

of

nine

scan

lines

..................

in

every character

lighted

not

or

too

bright (No

control).

focus (Diag 3-18)

or

characters displayed

.............

.............

in all rows . . . . . . . . .

position;

................

lighted

control

INHIBITED

or

Verify

proper grounding

not

................

OR

with

space

between

cursor normal (Diag 3-14).

..............

of

intensity),

that

should

.

.

lighted

position

control

indicated;

each

or

dim

not

units can

by

row

and blurred (no

cause

using ground

no

cursor,

(one

row

.

.

.

Diagram Sheet

Direct

Action

Sheet 2

Sheet 4

Sheet 4

.

of

Sheet 5

Change card J2.

Change card

Sheet 5

Sheet 5

Sheet 6

Sheet 6

Sheet 6

Change cards H2, J2, K2.

Change card H

Change card H2.

Change card J2.

K2.

or

Repair

2.

C.

Display Position and Size:

Horizontal

1.

Vertical size

2.

Both

No

space

3.

•

Requ

ires a

formatted

3-2

size

too

horizontal

between rows

buffer.

too

large

or

too

large

or

too

and vertical size

of

characters (Model 2

small (vertical normal) OR

small (horizontal normal, Diag 3-8)

too

large

or

too

small

only)

(Diag 3-16) . . . . .

..

Adjust

analog card.

of

range

of

change analog card and

card J2.

If

less

than

direction, adjust analog

If

card.

if

change

supply.

Sheet 7

more than

display size erratic,

HV

If

adjustment,

1"

in either

1",

power

out

or

Page 20

Symptom

1.

DISPLAY MALFUNCTIONS (Cont)

C.

Display Position and Size: (Cont)

4. Rows

5. Display

of

characters

not

centered (Diag 3-7)

not

6. Display tilted (Diag 3-6) . . .

D.

Dlaracters:

1. No characters displayed,

problem only.) . . . . . . . . . . . . . . . . . . . . . . . . . .

0 isplay

2.

than one cursor

3. Character(s)

4.

Screen full

a. Quote mark

out

of sync. (Characters may be recognizable

is

seen. INPUT INHIBITED

not

formed correctly wherever displayed

of

quote

in

location 0 and cursor in location 1 after

5. Wrong character displayed from program, keyboard,

a. Without Device Check

b. With Device Check . . . . . . . . . . . . . . . . .

6.

Data displayed

Screen full

7.

8.

Screen slowly fills with character

INHIBITED

that

should

of

one character with

not

lighted

9. Attribute characters displayed

SYMPTOM

INDEX

(Cont)

Diagram Sheet or

Direct Action Repair

evenly spaced

Change analog card

See centering procedure

(5.2.1.5).

See

yoke

adjustment

procedure (5.2.1.4)

but

cursor displayed. (See Symptom 2B4 if keyboard

..

Sheet 7

but

are moving, and more

not

lighted.) (Diag 3-15) Sheet 6

on

screen Change card K2.

marks (no Device Check) . . . . . . . . Change cards A2, K2.

POR

Replug connector inside

keyboard.

or

POR:

Change card K2.

Sheet 7

not

............

or

without

of

INPUT INHIBITED lighted

last keyboard key pressed. INPUT

.

Sheet 8

Sheet 8

Change card A2.

Sheet 8

E.

Cursor:

1.

No cursor on screen,

No

cursor with INPUT INHIBITED lighted. Cursor cannot

2.

by

Power

Cursor appears normally. INPUT INHIBITED lighted

3.

4. Cursor under

INHIBITED

5.

Cursor under all character positions,

6. Cursor

7.

Cursor

No

8.

cursor, and INPUT INHIBITED

character enters until

character.

9.

Screen slowly fills with cursors . . . . . . . . . . . . . . . . . . . . .

10. Cursor appears

PORe

may blink

No

11.

cursor on screen after

each row displays

but

rest

of

On

Reset

or

CLEAR key

display normal (no Device Check)

be

..................

.....

returned

...........

all

or

most character positions, and Device Check indicated (INPUT

lighted) (Diag 3-13)

not

positioned correctly under a character; may be in character area

too

long

or

too

short

80

characters

...................

but

Device Check

not

indicated (Diag 3-13) .

. . . . . . . . . . . . . . . . . . . .

not

on. Partial cursor appears as each

in

row appear with partial cursor under each

Occurs on one row at a time . . . . . . . . . . . . . . . . . .

in

Characters

three or four rows equally spaced

mayor

may

not

enter and appear at cursor location. Display

on

left side

of

display after

.............................

PORe

Characters may enter,

as

character enters. (INPUT INHIBITED

but

only first scan

not

lighted)

to

screen

1ine

of

.

Change card

.

Sheet 9

.

Sheet 9

.

Sheet

K2.

10

Change card K2.

Change card

Change card

K2.

K2.

Change card J2.

Change cards A2, C2, H2.

.

Sheet 10

Change

card

Symtom

J2.

Index

3-3

Page 21

SYNIPTOM

INDEX

(Cont)

Symptom

1.

DISPLAY MALFUNCTIONS (Cont)

F. Indicators:

1.

No indicators light. (Characters and cursor normal.)

*2. One indicator fails to light . . . . .

One indicator lit when it should

*3.

2.

KEYBOARD MALFUNCTIONS

Note:

If

card reader feature

at

feature logic card

If

keyboard operates correctly with card removed and cable swapped, change card N2,

location N2, and move keyboard cable from socket Z4

and return keyboard cable

cable swapped, select symptom

A.

All

Keys

is

installed on failing display station, remove card reader

to

socket Z4.

that

not

be

.....

If

keyboard still fails with card removed and

best describes failure.

.

to

1. Keyboard inoperative . . . . . . . . . . . . . . . . . . . . . . .

2. Keyboard operation erratic (INPUT

3. Diagonal row of

INPUT INHIBITED not lighted

enter.

dots

appears starting

INHIBITED

at

..

on

after certain keys.) Sheet 12

lower left corner of screen as characters

. . . . . . . . . . . . . .

socket Z1.

..

..

Diagram Sheet

or

Direct Action Repair

11

Sheet

Sheet

11

Sheet 9

Sheet 12

Change card J2.

B.

Character Keys:

one

1. Wrong character for

key

2. Wrong character for more than one key

No

characters

3.

*3a. Correct character enters,

No

character enters for all keys; cursor advances with each key depression. Dots

4.

may appear

Alpha characters enter into "numeric

*5.

numeric lock feature

on

enter

for all keys .

but

one

line. (INPUT INHIBITED indicator does

is

installed. See

*6. Numeric characters cannot enter

7. Typamatic failures

...............

8. Cursor disappears when character enters

Cl)aracters entered

9.

INHIBITED