Page 1

4232 Printer

Model 302

User’s Guide

SA24-4386-01

Page 2

Page 3

4232 Printer

Model 302

User’s Guide

SA24-4386-01

IBM

Page 4

Note!

Before using this information and the product it supports, be sure to read the

general information under “Notices” on page ix.

| Second Edition (September 1994)

| This major revision obsoletes and replaces SA24-4386-00 and Technical Newsletter

| SN24-2028-00. Changes or additions to the text and illustrations are indicated by a

| vertical line to the left of the change.

Changes are made occasionally to the information herein; any such changes will be

reported in subsequent revisions or Technical Newsletters.

Publications are

publications by calling the IBM Software Manufacturing Company at 1–800–879–2755.

Outside the U.S., customers should contact the IBM branch office serving their locality.

A form for reader's comments is provided at the back of this publication. If the form

has been removed, comments may be addressed to IBM Corporation, Information

Development, Dept. G60, 1701 North Street, Endicott, NY, 13760-5553 USA. IBM

may use or distribute whatever information you supply in any way it believes

appropriate without incurring any obligation to you.

Copyright International Business Machines Corporation 1993, 1994. All rights

reserved.

Note to U.S. Government Users — Documentation related to restricted rights — Use,

duplication or disclosure is subject to restrictions set forth in GSA ADP Schedule

Contract with IBM Corp.

not

stocked at the address given below. U.S. customers can order

Page 5

Contents

Notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Electronic Emission Notices ...................... ix

Trademarks and Service Marks ................... xii

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . xiii

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

How to Use This Guide ........................ xv

Publications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xix

Chapter 1. Setting Up the 4232 Printer Model 302 ...... 1-1

Beginning Printer Installation .................... 1-2

Installing the Ribbon Cartridge and Guide ............ 1-6

Preparing for Forms Device Installation ............. 1-10

Selecting the Forms Device Installation Procedure ...... 1-17

Installing and Using the Continuous Forms Device (F1) ... 1-18

Installing the Continuous Forms Device (F1) ........ 1-18

Preparing to Load Forms .................... 1-21

Loading Forms in the F1 Forms Device ........... 1-23

Using the Printer Verification Test for the F1 Forms Device 1-30

Adjusting the Print Quality ................... 1-35

Adjusting the Tractor Tension ............... 1-37

Adjusting the Forms Thickness Setting .......... 1-38

Adjusting the Forms Tension ................ 1-40

Adjusting the Left Margin .................. 1-42

Adjusting the Top of Form Position ............ 1-44

Adjusting the Print Alignment ................ 1-46

Unloading Forms . . . . . . . . . . . . . . . . . . . . . . . . 1-49

Removing the Continuous Forms Device (F1) ........ 1-51

Installing and Using the Dual Purpose Forms Device (F2) .. 1-53

Installing the Dual Purpose Forms Device (F2) ....... 1-53

Preparing to Load Forms .................... 1-56

Loading Forms in the F2 Forms Device ........... 1-57

Using the Printer Verification Test for the F2 Forms Device 1-62

Adjusting the Print Quality ................... 1-67

Adjusting the Tractor Tension ............... 1-68

Copyright IBM Corp. 1993, 1994 iii

Page 6

Adjusting the Forms Thickness Setting .......... 1-70

Adjusting the Left Margin .................. 1-72

Adjusting the Top of Form Position ............ 1-74

Adjusting the Tear-off Position ............... 1-76

Adjusting the Load Position ................. 1-78

Adjusting the Print Alignment ................ 1-78

Unloading Forms . . . . . . . . . . . . . . . . . . . . . . . . 1-81

Removing the Dual Purpose Forms Device (F2) ...... 1-83

Installing and Using the Document Insertion Device (F3) ... 1-85

Installing the Document Insertion Device (F3) ........ 1-85

Changing the Paper Door ................... 1-88

Preparing to Load Forms .................... 1-90

Loading Forms in the F3 Forms Device ........... 1-91

Using the Printer Verification Test for the F3 Forms Device 1-93

Adjusting the Print Quality ................... 1-98

Adjusting the Forms Thickness Setting .......... 1-99

Adjusting the Left Margin .................. 1-101

Adjusting the Top of Form Position ............ 1-104

Adjusting the Print Alignment ................ 1-106

Unloading Forms . . . . . . . . . . . . . . . . . . . . . . . . 1-110

Removing the Document Insertion Device (F3) ....... 1-111

Using the Acoustic Cover ..................... 1-114

Removing the Acoustic Cover ................. 1-114

Reinstalling the Acoustic Cover ................ 1-114

Attaching the 4232 Printer Model 302 to Your Computer ... 1-116

Connecting to the Parallel or Serial Interface ........ 1-116

Attaching a Parallel Cable ................... 1-116

Attaching a Serial Cable .................... 1-119

Chapter 2. Getting to Know Your Printer ........... 2-1

Parts of the Printer .......................... 2-2

Model Identification . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Power Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Power-On Test . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Acoustic Cover . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Access Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Front Paper Door ......................... 2-5

Forms Guide/Forms Sensor ................... 2-6

Automatic Forms Thickness Adjustment (AFTA) ....... 2-8

Platen Rod . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

iv User’s Guide Model 302

Page 7

Operator Panel . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Power Indicator . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Ready Indicator . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Processing Indicator . . . . . . . . . . . . . . . . . . . . . 2-11

Online Indicator . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Attention Indicator . . . . . . . . . . . . . . . . . . . . . . 2-11

Unit Check Indicator ..................... 2-12

Operator Panel Keys .................... 2-12

Configuration Parameter Values ................. 2-13

Operating States . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Ready and Not Ready ....................... 2-14

Forms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

Forms Handling Devices ..................... 2-16

Continuous Forms Device (F1) ................ 2-16

Dual Purpose Forms Device (F2) ............... 2-17

Document Insertion Device (F3) ................ 2-18

Auto Sheet Feeder Device (F4) ................ 2-19

Ribbons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

Print Head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

Problem Determination . . . . . . . . . . . . . . . . . . . . . . 2-20

Relocation Instructions . . . . . . . . . . . . . . . . . . . . . . . 2-20

Caring for Your Printer ....................... 2-21

Starting a Print Job ......................... 2-22

Stopping or Canceling a Print Job ................ 2-23

Chapter 3. Replacing Your Ribbon ............... 3-1

Removing the Ribbon Cartridge .................. 3-2

Installing the Ribbon Cartridge ................... 3-4

Chapter 4. Using the Operator Print Tests .......... 4-1

General Test Instructions ...................... 4-1

Printer Demonstration . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Top of Form Alignment ....................... 4-4

Left Margin Alignment ........................ 4-6

Printer Configuration . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Printer Verification . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Bidirectional Adjustment . . . . . . . . . . . . . . . . . . . . . . 4-15

Contents v

Page 8

Appendix A. Training Guideline . . . . . . . . . . . . . . . . . A-1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Guideline for Training ........................ A-3

Customer Responsibility . . . . . . . . . . . . . . . . . . . . . . . A-7

Appendix B. Problem Solving . . . . . . . . . . . . . . . . . . B-1

Using the Status Code and Problem Listings ........... B-2

Status Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

Problem List Index ......................... B-23

Forms Device Inspection .................... B-24

Problem List . . . . . . . . . . . . . . . . . . . . . . . . . . . B-27

Print Quality and Ribbon Problems .............. B-33

Miscellaneous Problems . . . . . . . . . . . . . . . . . . . . B-36

Appendix C. Forms Information . . . . . . . . . . . . . . . . . C-1

Forms Specifications . . . . . . . . . . . . . . . . . . . . . . . C-1

Continuous Forms — F1 or F2 ................ C-2

Cut Sheet Forms — F3 .................... C-3

Cut Sheet Forms — F4 .................... C-4

Additional Forms Restrictions .................. C-6

Positioning Forms . . . . . . . . . . . . . . . . . . . . . . . . . C-8

Appendix D. Declaration of IBM Product Noise Emission

Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-1

| Appendix E. Cabling Information . . . . . . . . . . . . . . . . E-1

| Serial Attachment . . . . . . . . . . . . . . . . . . . . . . . . . E-1

| RS-232C Connector Pin Assignments ............ E-1

| RS-422A Connector Pin Assignments ............ E-1

| Recommended Attachment Cables for PCs and

| Compatible Serial Ports ................... E-2

| Recommended Attachment Cables for AS/400 Workstation

| Controllers . . . . . . . . . . . . . . . . . . . . . . . . . . . E-2

| Cable Configurations . . . . . . . . . . . . . . . . . . . . . . . E-3

| RS-232C . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-3

| RS-422A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-5

| Parallel Attachment . . . . . . . . . . . . . . . . . . . . . . . . E-6

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . X-1

vi User’s Guide Model 302

Page 9

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . X-7

Contents vii

Page 10

viii User’s Guide Model 302

Page 11

Notices

References in this publication to IBM products, programs, or services

do not imply that IBM intends to make these available in all countries

in which IBM operates. Any reference to an IBM product, program,

or service is not intended to state or imply that only IBM's product,

program, or service may be used. Any functionally equivalent

product, program, or service that does not infringe any of the

intellectual property rights of IBM may be used instead of the IBM

product, program, or service. The evaluation and verification of

operation in conjunction with other products, except those expressly

designated by IBM, are the responsibility of the user.

IBM may have patents or pending patent applications covering

subject matter in this document. The furnishing of this document

does not give you any license to these patents. You can send

| license inquiries, in writing, to the IBM Director of Licensing, IBM

| Corporation, 500 Columbus Avenue, Thornwood, NY 10594 USA.

Electronic Emission Notices

Federal Communication Commission (FCC) Statement

Note: This equipment has been tested and found to comply with the

limits for a Class A digital device, pursuant to Part 15 of the FCC

Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in

a residential area is likely to cause harmful interference, in which

case the user will be required to correct the interference at his own

expense.

| Properly shielded and grounded cables and connectors (IBM part

| number 04H5053 or its equivalent) must be used in order to meet

| FCC emission limits. IBM is not responsible for any radio or

television interference caused by using other than recommended

Copyright IBM Corp. 1993, 1994 ix

Page 12

cables and connectors or by unauthorized changes or modifications

to this equipment. Unauthorized changes or modifications could void

the user's authority to operate the equipment.

This device complies with Part 15 of the FCC Rules. Operation is

subject to the following two conditions: (1) this device may not cause

harmful interference, and (2) this device must accept any

interference received, including interference that may cause

undesired operation.

Canadian Department of Communications Compliance

Statement

This equipment does not exceed Class A limits per radio noise

emissions for digital apparatus, set out in the Radio Interference

Regulation of the Canadian Department of Communications.

Operation in a residential area may cause unacceptable interference

to radio and TV reception requiring the owner or operator to take

whatever steps are necessary to correct the interference.

Avis de conformité aux normes du ministère des

Communications du Canada

Cet équipement ne dépasse pas les limites de Classe A d’émission

de bruits radioélectriques pour les appareils numériques, telles que

prescrites par le Réglement sur le brouillage radioélectrique établi

par le ministére de Communications du Canada. Léxploitation faite

en milieu résidentiel peut entraîner le broulliage des réceptions radio

et télé, ce qui obligerait le propriétaire ou l’opérateur à prendre les

dispositions nécessaires pour en éliminer les causes.

United Kingdom Telecommunications Compliance Act

This equipment is approved under approval number

NS/G/23/J/100003 for indirect connections to the public

telecommunications systems in the United Kingdom.

x User’s Guide Model 302

Page 13

New Zealand Compliance Statement

This is a Class A computing device and shall not be located at a

distance closer than 20 meters from the boundary of a residential

property.

Japanese VCCI

Korean EMI

Notices xi

Page 14

Trademarks and Service Marks

The following terms, denoted by an asterisk (*) in this publication, are

trademarks of the IBM Corporation in the United States or other

countries or both.

AS/400

| IBM and the IBM logo

Personal System/2

| Proprinter

RISC System/6000

The following terms, denoted by a double asterisk (**) in this

publication, are trademarks of other companies as follows:

Lexmark Lexmark International, Inc.

| Centronics Centronics Data Computer Corporation

xii User’s Guide Model 302

Page 15

Safety Information

The construction of this machine provides extra protection against

the risk of electric shock by grounding appropriate metal parts. The

extra protection may not function unless the power cord is connected

to a properly grounded outlet. This machine has a grounding-type

(3-wire) power cord because grounding is necessary. It is the

responsibility of the customer or the person installing the machine to

connect it to a properly grounded outlet. Seek professional

assistance before using an adapter or extension cord; such a device

could interrupt the grounding circuit.

If this machine is connected to an outlet that has been

incorrectly connected to the building wiring, serious electric

shock could result.

For continued protection against the risk of electric shock and

personal injury:

Connect the machine only to a properly grounded outlet of the

correct voltage. The voltage your machine will accept is

indicated on the machine.

Make sure the machine is turned Off (O) before you connect or

disconnect the power cord or other cables.

If the machine has cables other than the power cord, you must

connect them before you plug the power cord into an outlet. You

must first unplug the power cord from the outlet when you

remove the other cables.

Do not use the machine in an area where it can become wet.

Keep hair and personal articles away from moving parts in the

machine to avoid the possibility of getting them caught.

Refer service or repairs to qualified personnel.

There may be some increased risks of electric shock and

personal injury during disassembly and servicing of this machine.

Professional service personnel should understand this and take

necessary precautions.

Copyright IBM Corp. 1993, 1994 xiii

Page 16

The safety features of some parts may not always be obvious.

Therefore, replacement parts must have the identical or

equivalent characteristics as the original parts.

The maintenance information for this machine has been written

for the professional service person and is not intended to be

used by others.

xiv User’s Guide Model 302

Page 17

Preface

This guide describes the basic operating procedures for the IBM*

4232 Printer Model 302 and should be read and used by those who

install or operate the printer, or supervise printer operations.

You need only basic operating experience to use the printer. This

experience includes an understanding of how a printer works, how to

connect cables, and how to select items from an operator panel

menu.

You can use the printer for many different types of applications. This

guide includes the procedures necessary for you to put together

step-by-step instructions tailored to your operation.

A training outline in the Appendix gives the experienced IBM 4232

Printer Model 302 operator a guideline for teaching others how to

use the printer.

How to Use This Guide

The following list describes the contents of each chapter and the

appendixes in more detail:

Chapter 1, “Setting Up the 4232 Printer Model 302,” provides

information on setting up the printer and connecting it to the host

computer.

Chapter 2, “Getting to Know Your Printer,” gives locations,

descriptions of parts, a checklist of things you need to do to start

a print job, and general information about the care and use of

your printer.

Chapter 3, “Replacing Your Ribbon,” describes the removal and

replacement of damaged or worn ribbons.

Chapter 4, “Using the Operator Print Tests,” describes

procedures for testing and adjusting the printer.

Appendix A, “Training Guideline” describes the tasks an operator

needs to learn to operate the printer.

Copyright IBM Corp. 1993, 1994 xv

Page 18

Appendix B, “Problem Solving,” describes how to diagnose and

solve printer problems.

Appendix C, “Forms Information,” describes the types of forms

needed for each forms device.

Appendix D, “Declaration of IBM Product Noise Emission

Values,” provides the noise emission values for the printer.

| Appendix E, “Cabling Information,” contains parallel and serial

| cable information.

You will use the

IBM 4232 Printer Model 302 Operator Panel Instructions

the

IBM 4232 Printer Model 302 Operator Panel Instructions

IBM 4232 Printer Model 302 User’s Guide

. Topics in

with the

include:

The operator panel

Configuration options.

See “Publications” on page xvii for a complete list of publications.

Note: If you plan to install the Auto Sheet Feeder feature, see

4232 Printer Model 302 Auto Sheet Feeder General Information

IBM

for

additional setup and operation procedures.

This guide uses color to help you identify parts of the printer. The

blue color in this guide shows parts of the printer that are actually

blue in the printer.

xvi User’s Guide Model 302

Page 19

Publications

The following publications provide information on the 4232 Printer

Model 302.

For planning, setup, and operating information, see:

IBM 4232 Printer Model 302 User’s Guide

guide describes the operating procedures for the printer (with

special emphasis on using the forms devices).

IBM 4232 Printer Model 302 Operator Panel Instructions

SA24-4387. This manual describes how to operate the printer

control panel.

IBM 4232 Printer Model 302 Quick Reference Guide

SA24-4388. This card shows the key functions and the available

configuration values and the process for setting them.

IBM 4232 Printer Model 302 Planning and Site Preparation

Guide

, GA24-4390. This guide contains detailed information to

help you plan for and prepare the site for installation.

IBM 4232 Printer Model 302 Product and Programming

Description

programming functions specific to the 4232 Printer Model 302

that attaches to the IBM Personal Computer, IBM Personal

System/2, IBM RISC System/6000, IBM AS/400 with ASCII

controller, and the IBM 4033 LAN Adapter.

, GA24-4385. This manual describes the printer and

, SA24-4386. This

,

,

IBM 4232 Printer Model 302 Auto Sheet Feeder General

Information

use of the Auto Sheet Feeder with the printer.

IBM 4230 and 4232 Printers Safety Information

Preface xvii

, SA24-4391. This manual describes the setup and

, SA40-0575.

Page 20

For service information, see:

IBM 4230 and 4232 Printers Maintenance Analysis Procedures

SA40-0571. This manual is a guide for servicing the IBM 4230

and 4232 Printers. It is the primary maintenance tool for trouble

analysis and repair of the 4230 and 4232 Printers.

IBM 4230 and 4232 Printers Maintenance Information Manual

SA40-0572. This manual provides detailed maintenance

procedures for the 4230 and 4232 Printers.

IBM 4230 and 4232 Printers Illustrated Parts Catalog

,

SA40-0573. This parts catalog contains listings and illustrations

of all replacement assemblies and detail parts for the 4230 and

4232 Printers.

IBM 4230 and 4232 Printers Safety Information

, SA40-0575.

,

,

xviii User’s Guide Model 302

Page 21

Introduction

Your IBM 4232 Printer Model 302 is a wire-matrix printer with many

features to help you perform your work efficiently. Your printer

combines excellent print quality along with the ability to print in

several print styles and graphics.

Your printer receives some instructions from you and some

instructions from the

processing

; the printer prints the result. It is important that you

computer system

. The computer does the

communicate with the people who operate and program the

computer so that you know when any changes are made that could

affect your printer.

The printer can use one of four different

forms devices

to move

paper through the printer. Each device does a different type of print

job, depending on the type of forms you use: continuous forms for

large printouts, tear-off forms such as retail invoices, or cut sheet

forms. See “Forms Handling Devices” on page 2-16 for more

information.

The printer has four different

print quality

settings:

DP (Data Processing) Quality

Fast Draft Quality

DP Text Quality

Near Letter Quality.

You can set the

character spacing

on the printer to the following

characters per inch (CPI):

| 20 (Fast Draft and DP Quality only).

| 17.1 (Fast Draft and DP Quality only).

16.7 (Fast Draft and DP Quality only).

15

12

10

Preface xix

Page 22

You can set

line spacing

to the following lines per inch (LPI) from the

operator panel. LPI represents the number of lines to be printed per

vertical inch.

6

8.

For more information, see “Using Print Format and Quality

Parameters” in

Instructions

Printer Model 302 Product and Programming Description

IBM 4232 Printer Model 302 Operator Panel

or “Introducing the 4232 Printer Model 302” in

.

IBM 4232

xx User’s Guide Model 302

Page 23

Chapter 1. Setting Up the 4232 Printer Model

302

The following sections describe how to install the IBM* 4232 Printer

Model 302. The installation procedure includes:

Installing the ribbon

Installing the forms device

Attaching the printer to your computer.

Included with the printer are several manuals that can help you get

started:

IBM 4232 Printer Model 302 User’s Guide

Use this guide to setup and test the printer (as well as to perform

simple maintenance and error checking). This guide also

contains error codes and a symptoms list.

IBM 4232 Printer Model 302 Operator Panel Instructions

Use this manual to learn how to have the printer perform each

function available through the operator panel.

IBM 4232 Printer Model 302 Quick Reference Guide

Use the guide as a reference when operating the printer. The

guide should be posted near the printer.

If you are installing an Auto Sheet Feeder (ASF), see “Setting Up

Your 4232 Printer Model 302 with ASF” in

302 Auto Sheet Feeder General Information

Do Each Step in Order

Complete each step before you start the next one. If you

cannot successfully complete all of the following steps, call

your place of purchase.

Copyright IBM Corp. 1993, 1994 1-1

IBM 4232 Printer Model

for the setup procedure.

Page 24

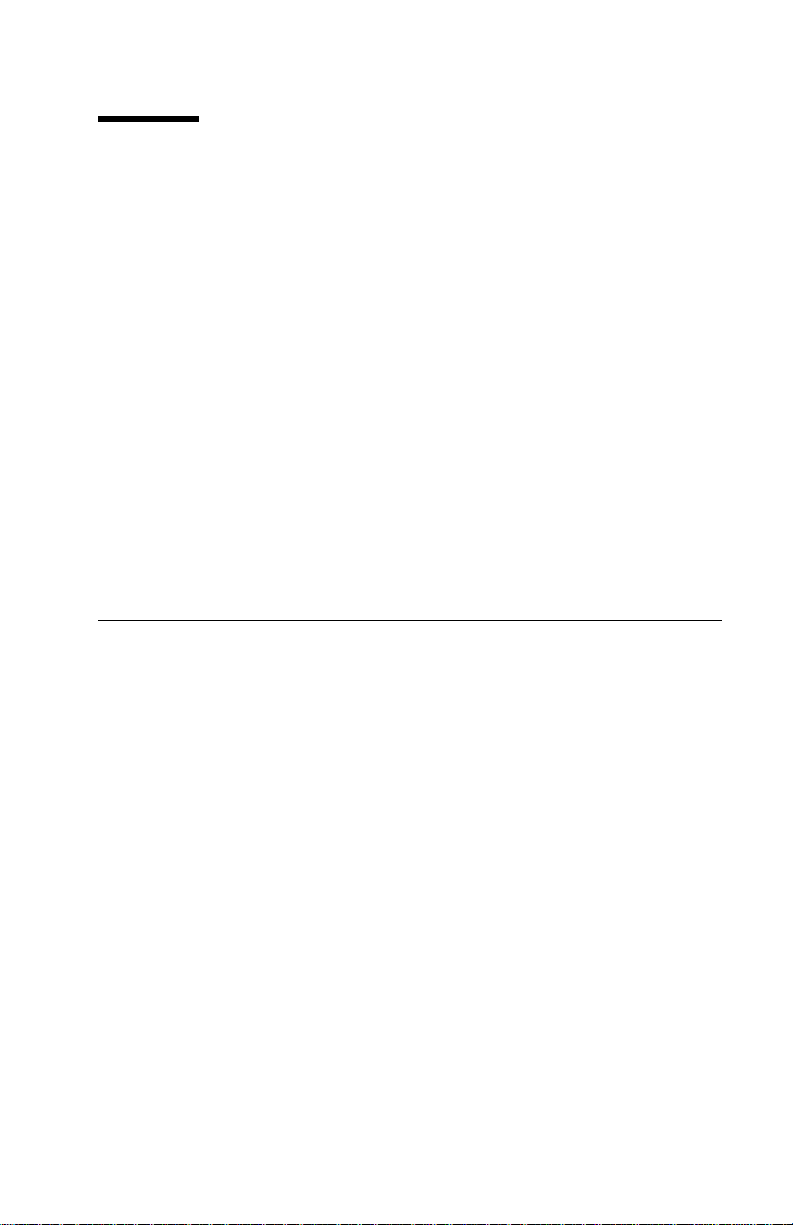

Beginning Printer Installation

To install the printer, follow these steps:

1. Be sure that you have the following items:

Printer

Acoustic Cover

Lower Forms G uides

(F3DeviceOnly)

User's Guide

Operator Panel Instructions

Forms Device

Paper Door

(F3DeviceOnly)

Maintenance Manuals

Power Cord

Ribbon Cartridge

Quick Reference Guide

Notes:

a. Contact your place of purchase if any of the items shown

above are missing.

b. The Document Insertion Device (F3) is shipped with a long

and short lower forms guide and a paper door. If you

ordered the F3 forms device, be sure that you find the

guides and paper door and set them aside.

Note: The printer weighs approximately 20.4 kg (45 lb). Do not

lift it by yourself.

1-2 User’s Guide Model 302

Page 25

2. Place the printer at the workstation (printer stand or table of your

choice). Be sure that you have access to both the front and the

rear of the printer.

3. Remove the protective film from the access cover window and

discard it.

4. Remove the packaging material, if present, from under the

acoustic door.

5. Open the

access cover

. Then open the front paper door as

follows:

a. Pull the door up until it will not go any higher.

b. Push the door back slightly to lock it in the open position.

Access C over

Paper Door

Chapter 1. Setting Up the 4232 Printer Model 302 1-3

Page 26

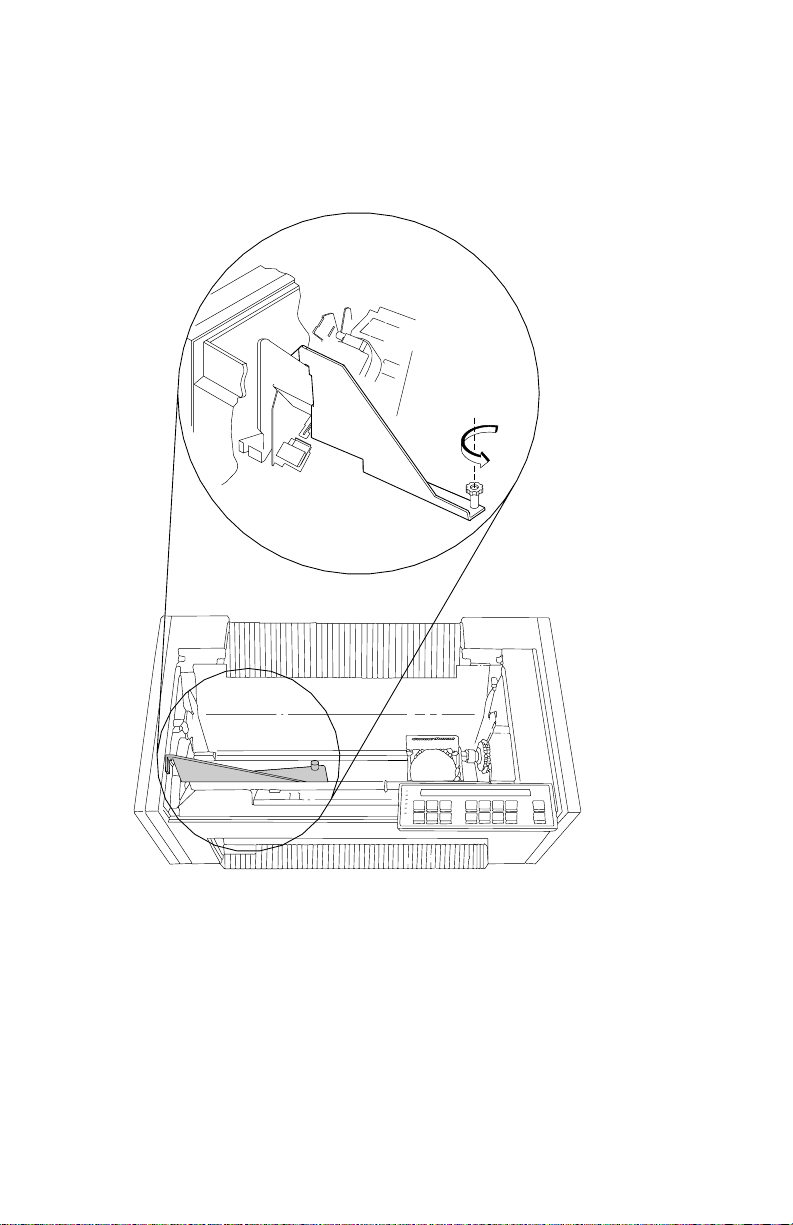

6. Find the

the

print head

the printer.

orange tie

on the right side of the printer to the left of

. Carefully cut the

Orange Tie

orange tie

and remove it from

1-4 User’s Guide Model 302

Page 27

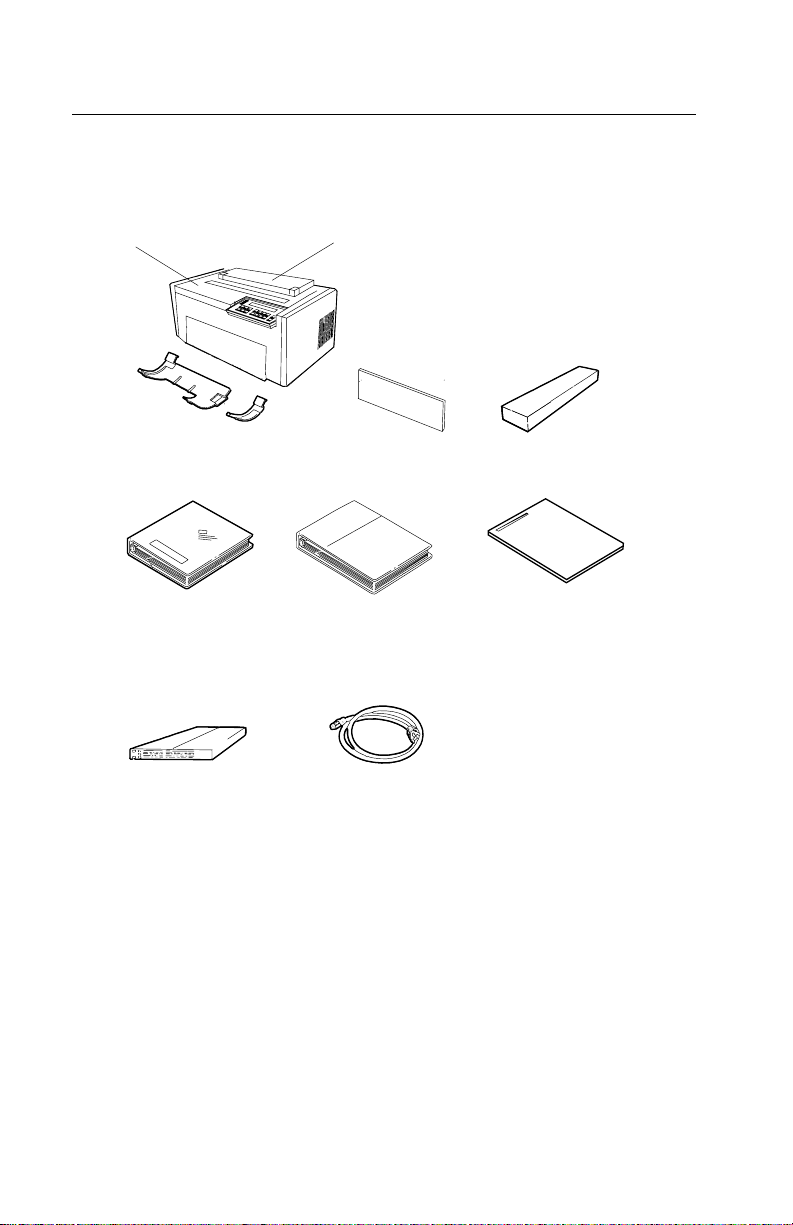

7. Consult the following figure and then find the large

and

orange shipping brace

in the center of the printer. Unscrew

orange knob

the knob and remove the knob and shipping brace from the

printer.

Shipping

Brace

Note: Save the shipping brace in case you relocate the printer.

Chapter 1. Setting Up the 4232 Printer Model 302 1-5

Page 28

Installing the Ribbon Cartridge and Guide

The following sections describe preparation, installation, and

verification of the ribbon cartridge.

To install a new ribbon cartridge, follow these steps:

1. Slide the print head to the center of the printer.

2. Remove the ribbon cartridge from the package.

3. Remove the yellow clip from the ribbon.

4. Turn the blue ribbon advance knob clockwise to take up slack

in the ribbon. If the ribbon does not move, contact your place of

purchase and replace the ribbon cartridge.

Remove Yellow Clip

Blue Ribbon Advance Knob

1-6 User’s Guide Model 302

Page 29

5. Align the blue slotted opening on the bottom of the ribbon

cartridge with the

metal post

. You may need to turn the blue

ribbon advance knob to align the slots. Lower the ribbon

cartridge onto the

metal post

. Be sure that the

plastic tab

bottom of the ribbon cartridge aligns with the hole in the printer

casting.

Tab

Blue S lotted Opening

MetalPost

on the

6. Press the cartridge down firmly to snap it into place.

Chapter 1. Setting Up the 4232 Printer Model 302 1-7

Page 30

7. Align the holes in the ribbon guide with the

the

print head carrier

. Press the guide all the way down on

ribbon guide posts

the posts until the tops of the posts are even with the top of

the ribbon guide.

Ribbon Guide

Ribbon

Guide Posts

on

1-8 User’s Guide Model 302

Page 31

8. To be sure you have installed the ribbon cartridge correctly,

check that:

a. The left side of the ribbon cartridge is securely snapped onto

the printer. The right side fits over the ribbon drive post but

does not latch down.

b. There are no twists or folds in the ribbon.

c. The ribbon is not catching on the print head.

d. The ribbon moves when you turn the blue ribbon advance

knob clockwise. If the ribbon does not move, replace the

ribbon cartridge.

Blue Ribbon Advance Knob

Chapter 1. Setting Up the 4232 Printer Model 302 1-9

Page 32

Preparing for Forms Device Installation

To prepare for installing the forms device, follow these steps:

CAUTION:

The construction of this machine provides extra protection

against the risk of electric shock by grounding appropriate

metal parts. The extra protection may not function unless

the power cord is connected to a properly grounded outlet.

This machine has a grounding-type (3-wire) power cord

because grounding is necessary. It is the responsibility of

the customer or the person installing the machine to

connect it to a properly grounded outlet. Seek professional

assistance before using an adapter or extension cord; such

a device could interrupt the grounding circuit.

If this machine is connected to an outlet that has been

incorrectly connected to the building wiring, serious electric

shock could result.

1. Make sure the

power switch

is Off (O). Connect the

power cord

to the rear of the printer. Press firmly to be sure that the plug is

securely seated.

Power Switch

Plug the power cord into the electrical outlet.

1-10 User’s Guide Model 302

Page 33

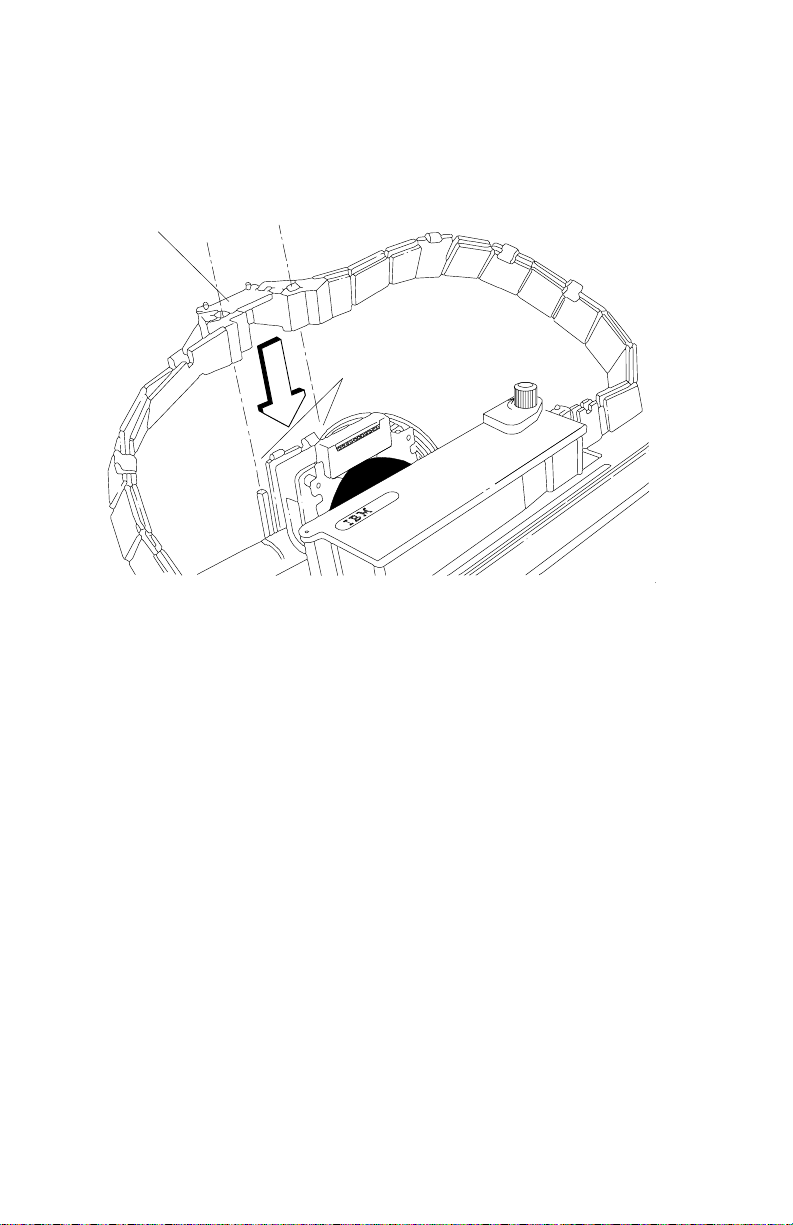

2. If you received your printer without an operator panel template

installed, you must install the template shipped with the printer.

To install the template, do the following:

a. Remove the paper from the back of the template.

b. Press the template into place on the operator panel, as

shown in the following figure.

xxxxx

xxxxx

xxxxxxxxx

xxxxx

xxxxxxxx

xxxx xxxx

xxxx

xxxxx

xxxxxx

xxxx

xxxxx

xxxx

xxxxx

xxxxx

xxxx

xxxxxx

xxxxx

xx x

xx x

xxxx

xxxx

xxxxx

xxxxx

To change the language shown on the operator panel

display, see “Using Printer Setup Parameters” in

Printer Model 302 Operator Panel Instructions

IBM 4232

.

3. Use the following figure to learn the location of keys and

indicators on the operator panel.

Power

Ready

Processing

Micro

Online

Attention

UnitCheck

Menu

Quick

Scroll

Micro

Scroll

Darker

Enter

Lighter

Return

Figure 1-1. 4232 Printer Model 302 Operator Panel

Chapter 1. Setting Up the 4232 Printer Model 302 1-11

Hex

Print

Display

In terfa ce

Line

Feed

Load/

Eject

Form

Feed

Set Top

of Form

Start

Stop

Cancel

Print

Test

Page 34

4. Turn the power On (|).

Note: Do not turn the printer power Off (O) during setup unless

instructed to do so.

The printer does the following:

a. All indicators and blocks on the display light, and the alarm

beeps. Then the printer displays

The printer then displays

DIAGNOSTICS IN PROGRESS <A>

b. The print head and ribbon move.

c. The printer displays

Calibrating Printer <A>

Please Wait

and then

DIAGNOSTICS COMPLETE <A>

followed by

ðð1 END OF FORMS

LOAD FORMS

The Attention indicator also blinks and the alarm beeps.

This status code appears because forms have not been

loaded.

1-12 User’s Guide Model 302

Page 35

d. Press Stop.

The printer may display

ð9ð COVER/DOOR OPEN

PRINT SPEED REDUCED

and then

| ð29 LINK ERROR

Ignore these messages until you have attached the printer to

your computer. (Press Stop to turn off the alarm, if

necessary.)

5. If the printer operated correctly, go to Step 6 on page 1-14,

otherwise, check the following:

Operator Note

If you turned the power Off (O) and back On (|) in

10 seconds

, the display may be blank or a message may

less than

appear.

If the power-on messages do not appear in your language,

see “Using Printer Setup Parameters” in

Model 302 Operator Panel Instructions

IBM 4232 Printer

to change the Display

Language.

a. Did the printer come on after you turned the power On (|) in

Step 4 on page 1-12?

If

Yes

, go to Step 5b on page 1-14.

If No, perform Steps 5a1 through 5a6 on page 1-14.

1) Turn the power Off (O).

2) Unplug the printer power cord from the electrical outlet.

3) Be sure that the power cord is firmly connected to the

rear of the printer.

Chapter 1. Setting Up the 4232 Printer Model 302 1-13

Page 36

4) Try another electrical device (such as a lamp) in the

outlet.

5) If the outlet is working, connect the printer to the outlet

again. Return to Step 4 on page 1-12 and try again.

6) If the printer still fails to come on, call your service

representative.

b. Did the printer display a code or message and did the same

code or message remain on the display after approximately

30 seconds?

If

Yes

, go to Appendix B, “Problem Solving,” find the

status code or message the printer displayed, and follow

the instructions.

If No, go to Step 5c.

c. Did the indicators or display not respond, or did you have an

alarm problem?

If

Yes

, then call for service.

If No, go to Step 6.

6. The shipping box for the forms device has printing on the side to

help you identify what type of forms device you have. Note

which forms device is checked off, then remove the forms device

from the shipping box.

Note: If you have forms device F3, the shipping box also

contains the lower forms guides and F3 paper door.

7. Press Menu.

The printer displays

CONFIGURATION MENU

Print Format and Quality

8. Press Scroll ↑ or Scroll ↓ until the printer displays

CONFIGURATION MENU

Printer Setup

1-14 User’s Guide Model 302

Page 37

9. Press Enter to select this category.

10. Press Scroll ↑ or Scroll ↓ until the printer displays

Printer Setup

Forms Device

11. Press Enter to select this parameter.

12. Press Scroll ↑ or Scroll ↓ until the printer displays the desired

forms device.

13. Press Enter to set the device.

An asterisk (*) appears beside your choice of device.

14. You now need to save this change to the power-on custom set

(Custom Set A), so the printer will have the correct device setting

the next time it is turned on.

a. Press Return twice to get back to the category level of the

Configuration Menu.

CONFIGURATION MENU

Printer Setup

b. Press Scroll ↑ or Scroll ↓ until the printer displays

CONFIGURATION MENU

Configuration Storage

c. Press Enter.

The printer displays

Configuration Storage

Save Current Values

Chapter 1. Setting Up the 4232 Printer Model 302 1-15

Page 38

d. Press Enter.

The printer displays

Save Current Values

Custom Set A

e. Press Enter to save the configuration changes.

The printer displays

Save Current Values

Custom Set A Saved

15. Turn the power Off (O).

16. Slide the print head to the center of the printer.

17. You are now ready to install the forms device. Go to “Selecting

the Forms Device Installation Procedure” on page 1-17.

1-16 User’s Guide Model 302

Page 39

Selecting the Forms Device Installation Procedure

Select the forms device installation procedure you will use:

Go to “Installing and Using the Continuous Forms Device (F1)”

on page 1-18 to install the F1 forms device.

Go to “Installing and Using the Dual Purpose Forms Device (F2)”

on page 1-53 to install the F2 forms device.

Go to “Installing and Using the Document Insertion Device (F3)”

on page 1-85 to install the F3 forms device.

See “Setting Up Your 4232 Printer Model 302 with ASF” in

4232 Printer Model 302 Auto Sheet Feeder General Information

to install the F4 forms device.

IBM

Chapter 1. Setting Up the 4232 Printer Model 302 1-17

Page 40

Installing and Using the Continuous Forms Device

(F1)

The following sections describe how to install and use the

Continuous Forms Device (F1).

Note: Make sure that the proper forms device is configured. See

“Preparing for Forms Device Installation” on page 1-10 for the exact

steps.

Installing the Continuous Forms Device (F1)

To install the F1 forms device, follow these steps:

1. Hold the forms device so that the

upper left corner facing you. Note the

clips

; they will be important later.

device number

bottom metal bar

F1 is in the

2. Remove the orange shipping clip, if installed.

Important

The F1 forms device for the 4232 Printer Model 302 has a

circle around the F1 emblem. Use only these forms devices

in the printer.

Top of Form s Device

F1

Tensioner Plates

Bottom Metal Bar

Clips

and the

1-18 User’s Guide Model 302

Page 41

3. Lower the forms device into the printer behind the

that the

bottom metal bar

enters the printer first. Align the ends

platen rod

so

of the forms device with the slots in the frame. Continue to lower

the forms device until the device rests in the slots of the frame.

Top of

Form s

D evice

End of

D evice

Platen R od

End of

D evice

Slot in

Frame

Slot in

Frame

4. Look through the front bottom opening in the printer and find the

metal bar

at the bottom of the forms device.

5. Grasp the

metal bar

with BOTH hands and pull firmly toward you

and then upward until both ends LOCK into place.

MetalBar

Bottom of Form s Device

Chapter 1. Setting Up the 4232 Printer Model 302 1-19

Page 42

6. To be sure that you have installed the forms device correctly,

look at the following figure and compare it to your printer. Check

both the left and right sides. Are the

clips

around the

platen rod

as shown? If so, you installed the forms device correctly. If not,

repeat Steps 3 through 5.

Platen Rod

Platen Rod

Clip

Clip

1-20 User’s Guide Model 302

Page 43

Preparing to Load Forms

To prepare to load forms in the F1 forms device, follow these steps:

1. Slide the print head to the far left side of the printer.

2. Loosen the blue forms tension knob by turning it

counterclockwise, and then move the blue forms tension knob

towards the bottom of the printer until you see the* below the

number 1.

Blue Forms

Tension Knob

Note: Moving the blue forms tension knob to the* position

lets you load forms.

3. Unlock the blue locking lever on the

right tractor

. Slide the

tractor to the extreme right.

Blue Locking Lever

Chapter 1. Setting Up the 4232 Printer Model 302 1-21

Page 44

4. Open both of the blue tractor doors.

Blue Tractor Doors

5. Get continuous forms paper that is at least 203.2 mm (8 in.)

wide.

1-22 User’s Guide Model 302

Page 45

Loading Forms in the F1 Forms Device

To load forms in the F1 forms device, follow these steps:

1. Feed the form into the bottom front of the printer. Be sure that

the form goes under the blue forms guide/forms sensor and

between the tensioning plates. See the figure on page 1-18 for

help in locating the tensioning plates.

Blue Form s G uide/

Form s Sensor

Chapter 1. Setting Up the 4232 Printer Model 302 1-23

Page 46

2. Align and put the left paper holes of the form over the

tractor pins

. Close the left blue tractor door.

Blue Tractor Door

left

1-24 User’s Guide Model 302

Page 47

3. Move the

on the

right tractor

right tractor pins

Tractor Pins

until the right paper holes of the form fit

. Be sure that the forms are straight.

4. Close the right blue tractor door. Hold the tractor in place and

lock the blue locking lever.

Note: If necessary, unlock the tractor and adjust it so that the

forms are not buckled or stretched too tightly.

Blue Tractor

Door

Blue Locking Lever

Chapter 1. Setting Up the 4232 Printer Model 302 1-25

Page 48

5. Close the access cover. Then close the paper door by pulling it

out and pushing it down until it latches.

6. To align the top of form position, follow these steps:

a. Turn the power On (|) and wait for the power-on sequence to

complete (see “Power-On Test” on page 2-3).

b. Press Stop.

The printer displays

NOT READY <A>

and then may display

| ð29 LINK ERROR

Ignore this message until you have attached the printer to

your computer. (Press Stop to turn off the alarm, if

necessary.)

1-26 User’s Guide Model 302

Page 49

c. Press Micro ↑, Micro ↓, or Line Feed to move the form so

that the position of the first line you want to print is in the

center of the flat platen rod surface.

Platen R od

abcdef

Platen R od

First Print Line

Platen R od Surface

d. If you pressed Micro ↓, you might have slack in the forms.

Pull lightly downward on the forms at the bottom of the

printer to remove the slack.

e. Press Set Top of Form to establish the first print line.

Note: The Set Top of Form key establishes the first line at

which printing is to start on each form. The alarm beeps

each time you press the Set Top of Form key, and the

printer displays

TOP OF FORM SET

Chapter 1. Setting Up the 4232 Printer Model 302 1-27

Page 50

7. To adjust the forms tension:

a. Open the front paper door as follows:

1) Pull the door up until it will not go any higher.

2) Push the door back slightly to lock it in the open position.

Paper Door

b. Move the blue forms tension knob upward to the number

of form copies you are using. Make sure you do not unlatch

the forms device. For example, if you are using single-part

forms, set the lever to 1. If you are using two-part forms, set

the lever to 2.

Tighten the blue forms tension knob by turning it

clockwise. Close the paper door by pulling it out and

pushing it down until it latches.

Blue Forms

Tension Knob

1-28 User’s Guide Model 302

Page 51

c. Press Start.

The printer displays

READY <A>

and then may display

| ð29 LINK ERROR

Ignore this message until you have attached the printer to

your computer. (Press Stop to turn off the alarm, if

necessary.)

Chapter 1. Setting Up the 4232 Printer Model 302 1-29

Page 52

Using the Printer Verification Test for the F1 Forms

Device

To run the printer verification test, follow these steps:

1. Turn the power On (|) if not already on.

2. Wait until the printer displays

READY <A>

3. Press Stop.

The printer displays

NOT READY <A>

and then may display

| ð29 LINK ERROR

Ignore this message until you have attached the printer to your

computer. (Press Stop to turn off the alarm, if necessary.)

4. Press Test.

The printer displays

OPERATOR PRINT TESTS

Printer Demonstration

1-30 User’s Guide Model 302

Page 53

5. Press Scroll ↑ or Scroll ↓ until the printer displays

OPERATOR PRINT TESTS

Printer Verification

6. Press Enter or Start to print this test. The Ready indicator

comes on and printing begins.

7. Wait for the printer to stop printing and the Ready indicator to go

off.

8. Press Form Feed until you can remove the printout.

The lines numbered 1 through 9 should print as shown on the

sample printout on page 1-31, and the remainder of the printout

should be clear and readable.

Chapter 1. Setting Up the 4232 Printer Model 302 1-31

Page 54

1-32 User’s Guide Model 302

Page 55

9. Compare your printout with the sample printout.

Did the lines print and is the remainder of the printout clear and

readable?

If

YES

, go to Step 10.

If NO, do the following:

a. If any of the following items are not installed correctly, the

printer can experience forms jamming, ribbon jamming, or an

incorrect printer verification printout:

Forms device

Ribbon cartridge

Forms.

Repeat the Setup Instructions from page 1-6 if you suspect a

ribbon, forms, or forms device installation problem.

b. Be sure that enough forms are loaded and press Enter or

Start to get another printout.

c. If the second printout is not similar to the sample printout, go

to Appendix B, “Problem Solving.”

d. Once you get a good printout, go to Step 10.

10. Turn the power Off (O).

Power Switch

Chapter 1. Setting Up the 4232 Printer Model 302 1-33

Page 56

Setup and Checkout Complete

You have completed a simple setup and checkout of the printer.

IBM recommends that you print your power-on custom set

(Custom Set A) factory defaults and save this printout for future

reference. You are ready to attach the printer to your computer.

Go to “Attaching the 4232 Printer Model 302 to Your Computer”

on page 1-116.

Note: See pages 1-35 through 1-51 for making adjustments,

unloading forms, and removing the forms device.

1-34 User’s Guide Model 302

Page 57

Adjusting the Print Quality

After the printer prints a few lines, press Stop and verify that the

print quality is satisfactory. Good print quality includes:

Clear, legible print

Satisfactory darkness or lightness of output.

It is up to you to decide if the print quality is satisfactory.

Adjustments you can make that affect print quality include:

Tractor Tension

Incorrect tension on the right tractor can cause the paper holes

on the forms to tear, wrinkle, or jam in the printer. To adjust the

tractor tension, see “Adjusting the Tractor Tension” on

page 1-37.

Forms Thickness Setting

This setting can affect the darkness or lightness of output.

The printer will normally sense the forms thickness and adjust

itself automatically. However, if this setting is not correct, it can

be adjusted. To adjust the forms thickness, see “Adjusting the

Forms Thickness Setting” on page 1-38.

Note: The Automatic Forms Thickness Adjustment (AFTA)

mechanism automatically measures the forms thickness and

adjusts the gap from the print head to the platen rod based on

the measured value. See “Automatic Forms Thickness

Adjustment (AFTA)” on page 2-8 for information on how the

printer sets the forms thickness.

Forms Tension

Incorrect tension on the forms can cause forms to tear, wrinkle,

or buckle and can affect the appearance of the output. To adjust

the forms tension, see “Adjusting the Forms Tension” on

page 1-40.

Chapter 1. Setting Up the 4232 Printer Model 302 1-35

Page 58

Left Margin and Top of Form Position

The adjustment of the first print position can affect the

appearance of the output, especially if you are using preprinted

forms. To adjust the position of the first print character, see

“Adjusting the Left Margin” on page 1-42. To adjust the position

of the first print line, see “Adjusting the Top of Form Position” on

page 1-44.

Print Alignment

This adjustment can affect the character formation and dot

mixing on those characters that are printed with two passes of

the print mechanism. To adjust the print alignment, see

“Adjusting the Print Alignment” on page 1-46.

1-36 User’s Guide Model 302

Page 59

Adjusting the Tractor Tension

The tractor tension adjustment controls the amount of buckle the

forms have after they are loaded in the printer. Since the left tractor

does not move, you make this adjustment by moving the right tractor.

The ideal adjustment is to center the right and left paper holes of the

forms on the tractor pins without stretching or tearing the holes.

To adjust the tractor tension on the F1 forms device, follow these

steps:

1. Feed several forms through the printer.

2. Observe the left and right paper holes of the forms:

If the paper holes are stretched or torn on the outside edges,

the tractor tension is too tight (not enough buckle in the

forms).

If the forms twist or wrinkle as they move through the printer,

the tractor tension is too loose (too much buckle in the

forms).

3. Adjust the right tractor as necessary:

Unlock and move the tractor toward the left side of the

printer to loosen the tension on the forms.

Unlock and move the tractor toward the right side of the

printer to tighten the tension on the forms.

Left Margin

Right M argin

C orre ct

Left Margin

Right M argin

Incorrect

4. Lock the tractor.

Chapter 1. Setting Up the 4232 Printer Model 302 1-37

Page 60

Adjusting the Forms Thickness Setting

To adjust the lightness or darkness of the print, you must increase or

decrease the gap between the print head and the platen rod. This

distance is automatically set for you by the Automatic Forms

Thickness Adjustment (AFTA), but you can make corrections to the

distance if the print output is not as you desire. It is up to you to

decide if the print is dark (or light) enough to meet your

requirements.

To adjust the forms thickness setting with the F1 forms device, follow

these steps:

1. The forms thickness setting must be adjusted when the printer is

printing or has printed and is

ready

. Press Start, if needed, to

have the printer display

READY <A>

2. To make the print darker, press Darker.

The printer displays

LIGHT |wwwwwwwwwwww-------| DARK

The print head moves closer to the paper, and the print becomes

darker.

Note: The print may not get darker if the ribbon is worn or if

there is a problem with the print head.

3. To make the print lighter, press Lighter.

The printer displays

LIGHT |wwwwwwww-----------| DARK

The print head moves farther away from the paper, and the print

becomes lighter.

1-38 User’s Guide Model 302

Page 61

4. When you release the key, the printer automatically saves the

current value.

Note: The J’s indicate the position of the print head relative to the

limits.

As long as you press Darker or Lighter, the printer displays an

increasing amount of darkness or lightness until one of the limits of

the gap is reached. The printer displays either

LIGHT |wwwwwwwwwwwwwwwwwww| DARK

DARKNESS LIMIT REACHED

or

LIGHT |w------------------| DARK

LIGHTNESS LIMIT REACHED

As you adjust the gap, you may also see the printer display

LIGHT |wwwwwwwwww---------| DARK

DEFAULT DARKNESS

This message tells you that the forms thickness setting is at the

automatically set value.

See “Understanding the Operator Panel” in

302 Operator Panel Instructions

Chapter 1. Setting Up the 4232 Printer Model 302 1-39

for more information on this setting.

IBM 4232 Printer Model

Page 62

Adjusting the Forms Tension

The forms tension lever controls the tension on the forms. The blue

forms tension knob lets you adjust the setting of the forms tension

lever. The forms tensioner is a metal plate with a row of metal

fingers that applies tension to the form according to the setting of the

forms tension lever.

Settings range from* to 6. The * setting puts no tension on the

form and allows forms to pass freely while loading. The 1 setting

puts the least amount of tension on the form. Settings 2 through 6

vary the amount of tension on the form and approximately relate to

the number of sheets in the form you use. Set the tension lever to

the number of sheets in the form being used.

Note: Higher numbers are toward the top and lower numbers are

toward the bottom of the printer.

When you adjust the forms tension, be sure that the forms are not

held too tightly or too loosely. If too much tension is on the forms,

the forms can tear, the paper holes of the form can stretch, and

forms can jam. If too little tension is on the forms, the forms can

wrinkle or buckle, causing the forms to jam.

Blue Forms

Tension Knob

1-40 User’s Guide Model 302

Page 63

Decreasing Forms Tension:

To decrease tension on the forms,

follow these steps:

1. Loosen the blue forms tension knob by rotating the knob

counterclockwise.

2. Move the knob to a lower number setting.

For example, if the knob was set at 3, move the knob to 2.

3. Tighten the blue forms tension knob by rotating the knob

clockwise. Be sure to avoid unlatching the F1 forms device

when adjusting the forms tension.

4. Press Start to print.

5. Observe the forms.

If the form paper holes are still tearing or stretching, press Stop

and repeat Steps 1 through 5 of this procedure.

If the forms are buckling, there is too little tension on the forms.

If the tension is satisfactory, continue to print.

Increasing Forms Tension:

To increase tension on the forms,

follow these steps:

1. Loosen the blue forms tension knob by rotating the knob

counterclockwise.

2. Move the knob to a higher number setting.

For example, if the knob was set at 2, move the knob to 3.

3. Tighten the blue forms tension knob by rotating the knob

clockwise. Be sure to avoid unlatching the F1 forms device

when adjusting the forms tension.

4. Press Start to print.

5. Observe the forms.

If the forms are still buckling, press Stop and repeat Steps 1

through 5 of this procedure.

If the forms are tearing or jamming, there is too much tension on

the forms.

If the tension is satisfactory, continue to print.

Chapter 1. Setting Up the 4232 Printer Model 302 1-41

Page 64

Adjusting the Left Margin

You can print a single line of text to help in setting the left margin

position using the Left Margin Alignment Test. You can also change

the current left margin position using this test.

You can set the left margin position from 1 to 66 units (where each

| unit is 0.686 mm [0.027 in.]). The factory default setting is 10. The

| margin is measured starting at 1.27 mm (0.05 in.) from the center of

the tractor pins for continuous forms and from the left edge of a cut

form.

To align the left margin position, follow these steps:

1. If the printer is

ready

, press Stop.

The printer displays

NOT READY <A>

2. Enter the Operator Print Tests by pressing Test.

The printer displays

OPERATOR PRINT TESTS

Printer Demonstration

3. Press Scroll ↑ or Scroll ↓ until the printer displays

OPERATOR PRINT TESTS

Left Margin Alignment

4. Press Enter or Start to begin the test.

The printer displays

Left Margin Position

\ xxx

where

xxx

is the current value of the left margin position.

1-42 User’s Guide Model 302

Page 65

The printer also prints a single line of H’s.

5. If the H’s do not start where you want your left margin, press

Scroll ↑ or Scroll ↓ until the printer displays the desired value

for the left margin position.

6. Press Enter.

An asterisk (*) appears in front of the selected value. The

forms advance one line and the row of H’s prints again. This

value is now the current left margin position.

7. Repeat Steps 5 and 6 until the left margin is correctly positioned.

(You can press Line Feed or Form Feed to move the forms

between printing the rows of H’s.)

8. Press Stop or Cancel Print to exit the test.

Note: If you want the new left margin position saved when you

turn off the printer, you must save it in a Custom Set.

See “Storing Configuration Parameters” in

Printer Model 302 Operator Panel Instructions

IBM 4232

for

information on saving configurations.

You may also adjust the left margin position without

printing the row of H’s by changing the Left Margin

Position in the Configuration Menu. (See “Using Print

Format and Quality Parameters” in

Model 302 Operator Panel Instructions

Chapter 1. Setting Up the 4232 Printer Model 302 1-43

IBM 4232 Printer

.)

Page 66

Adjusting the Top of Form Position

The Micro ↑ and Micro ↓ keys control fine vertical movement. Each

time you press these keys, the printer moves the form in 0.355 mm

(0.014 in.) increments.

Open the access cover. Then open the front paper door as follows:

1. Pull the door up until it will not go any higher.

2. Push the door back slightly to lock it in the open position.

Access Cover

Paper Door

Next load forms, if necessary (see “Loading Forms in the F1 Forms

Device” on page 1-23 for more information). Complete the following

steps to make fine vertical adjustments to the top of form position.

To set the top of form position, follow these steps:

1. Press Stop.

The printer displays

NOT READY <A>

1-44 User’s Guide Model 302

Page 67

2. If the first print line is not where you want it to be, press Micro ↑,

Micro ↓, or Line Feed until it reaches the desired line.

Note: If you need to adjust the paper downward, adjust at least

five steps beyond where you want the top of form position; then

make your final adjustment in the up direction. You can also use

the Top of Form Alignment Test (see “Top of Form Alignment” on

page 4-4) to print a line of characters to determine more

accurately where you have set the top of form position.

3. When the form is in the correct position, press Set Top of Form.

The alarm beeps and the printer displays

TOP OF FORM SET

4. Advance the form by pressing Form Feed, and decide if the form

is on the desired line. If necessary, repeat Steps 1 through 4 of

this procedure until the first print line is correctly aligned.

Chapter 1. Setting Up the 4232 Printer Model 302 1-45

Page 68

Adjusting the Print Alignment

You can adjust dot registration and print quality for characters

created using bidirectional printing. The bidirectional alignment may

need periodic adjustment to maintain print quality.

To change the bidirectional alignment, follow these steps:

1. If the printer is

ready

, press Stop.

The printer displays

NOT READY <A>

2. Press Test.

The printer displays

OPERATOR PRINT TESTS

Printer Demonstration

3. Press Scroll ↓ or Scroll ↑ until the printer displays

OPERATOR PRINT TESTS

Bidirectional Adjustment

4. Press Enter or Start to print this test.

The Ready indicator goes on and printing begins. The test

prints samples using alignment values higher and lower than the

default value. The print sample using the default value is

indicated with an asterisk (*). The alignment printout is

complete when the Ready indicator goes off.

1-46 User’s Guide Model 302

Page 69

The printer displays

Bidirectional Adjustment

\

Chapter 1. Setting Up the 4232 Printer Model 302 1-47

Page 70

5. If the default value does not give the best print sample, press

Scroll ↓ or Scroll ↑ until the printer displays the same number of

arrows that were printed beside the

best

print sample line. Press

Enter to set this as the new default value. The printer then

prints another line to demonstrate the new default value, and the

test is complete.

or

Press Stop to end the test without changing anything and return

to the Operator Print Tests menu.

or

Press Cancel Print to end the test, exit test mode, perform a

partial reset, and have the printer display

READY <A>

Note: See Chapter 4, “Using the Operator Print Tests” for more

information.

1-48 User’s Guide Model 302

Page 71

Unloading Forms

To unload forms from the F1 forms device, follow these steps:

1. Press Stop.

The printer displays

NOT READY <A>

2. Open the acoustic cover.

3. Grasp the form below the printer and tear along the perforation.

4. Press Form Feed as many times as needed to advance and

remove the remaining form or forms.

Chapter 1. Setting Up the 4232 Printer Model 302 1-49

Page 72

5. Remove the form or forms from the top of the printer.

Warning: Do not remove forms by pulling them out from the

bottom. Damage to the forms device can result.

1-50 User’s Guide Model 302

Page 73

Removing the Continuous Forms Device (F1)

Note: If you are removing this forms device to install a different

forms device, make sure you change the selected forms device in

the Configuration Menu.

To remove the F1 forms device, follow these steps:

1. If forms are in the printer, unload them (see “Unloading Forms”

on page 1-49); then continue with Step 2 of this procedure.

2. Turn the power Off (O).

3. Open the access cover. Then open the front paper door as

follows:

a. Pull the door up until it will not go any higher.

b. Push the door back slightly to lock it in the open position.

Access C over

Paper Door

Chapter 1. Setting Up the 4232 Printer Model 302 1-51

Page 74

4. Push the metal bar at the bottom of the device toward the rear of

the printer until the forms device unlocks.

Metal Bar

Bottom of Forms Device

5. Grasp the top of the forms device and lift it out.

Top of

Forms

Device

Platen Rod

1-52 User’s Guide Model 302

Page 75

Installing and Using the Dual Purpose Forms Device

(F2)

The following sections describe how to install and use the Dual

Purpose Forms Device (F2).

Note: Make sure that the proper forms device is configured. See

“Preparing for Forms Device Installation” on page 1-10 for the exact

steps.

Installing the Dual Purpose Forms Device (F2)

To install the F2 forms device, follow these steps:

1. Hold the forms device so that the

upper left corner facing you. Note the bottom

clips

; they will be important later.

device number

metal bar

F2 is in the

Important

The F2 forms device for the 4232 Printer Model 302 has a

box around the F2 emblem. Use only these forms devices in

the printer.

Tear Bar

Top of F o rm s D e vice

B o tto m M e tal B a r

C lip s

and the

Chapter 1. Setting Up the 4232 Printer Model 302 1-53

Page 76

2. Unlock the right blue locking lever and move the right tractor

assembly to the extreme right.

Tear Bar

Blue S liding

Guides

Top of Forms Device

Bottom Metal Bar

Blue Locking Lever

Right Tractor Assembly

3. Lower the forms device into the printer behind the

platen rod

Be sure that F2 is in the upper left corner facing you and the

blue tractor doors at the bottom of the device enter the printer

first. Align the ends of the device with the slots in the frame.

Continue to lower the device until the ends of the device rest in

the slots of the frame.

Top of

Forms

Device

End of

Device

Platen Rod

End of

Device

Slot in

Frame

Slot in

Frame

.

1-54 User’s Guide Model 302

Page 77

4. Look through the front bottom opening in the printer and find the

metal bar

at the bottom of the forms device.

5. Grasp the

metal bar

with BOTH hands and pull firmly toward you

and then upward until both ends LOCK into place.

MetalBar

Bottom of Form s Device

6. To be sure that you have installed the forms device correctly,

look at the following figure and compare it to your printer. Check

both the left and right sides. Are the

clips

around the

platen rod

as shown? If so, you installed the forms device correctly. If not,

repeat Steps 3 on page 1-54 through 5.

Platen R od

Clip

Chapter 1. Setting Up the 4232 Printer Model 302 1-55

Platen R od

Clip

Page 78

Preparing to Load Forms

To prepare to load forms in the F2 forms device, follow these steps:

1. Slide the print head to the far left side of the printer.

2. Open both of the blue tractor doors.

Blue Tractor Doors

3. Get continuous forms paper that is at least 203.2 mm (8 in.)

wide.

1-56 User’s Guide Model 302

Page 79

Loading Forms in the F2 Forms Device

To load forms in the F2 forms device, follow these steps:

1. Turn the power On (|) (see “Power-On Test” on page 2-3).

2. Wait until the printer displays

ðð1 END OF FORMS

LOAD FORMS

3. Press Stop.

The printer displays

NOT READY <A>

and then may display

| ð29 LINK ERROR

Ignore this message until you have attached the printer to your

computer. (Press Stop to turn off the alarm, if necessary.)

Chapter 1. Setting Up the 4232 Printer Model 302 1-57

Page 80

4. Feed the form into the printer until the paper is on at least two

tractor pins on each side. Be sure that the form goes under the

blue forms guide/forms sensor.

Blue Fo rms Guide/

Forms Sensor

5. Put the

left paper holes

blue tractor door.

over the

Blue Tractor Door

left tractor pins

. Close the left

1-58 User’s Guide Model 302

Page 81

6. Move the right tractor assembly and blue sliding guides until

the right paper holes of the form fit on the

right tractor pins

sure that the forms are straight. Close the right blue tractor

door.

Right Tractor Assem bly

.Be

7. Hold the

right tractor

Blue Locking

Lever

in place and lock the blue locking lever.

Blue Locking Lever

Right Tractor

Note: If necessary, unlock the tractor and adjust it so that the

forms are not buckled or stretched too tightly. Be sure that you

lock the locking lever when you are finished adjusting.

Chapter 1. Setting Up the 4232 Printer Model 302 1-59

Page 82

8. Evenly space the blue sliding guides between the tractors.

Sliding Guides

9. Perform an autoload by pressing Load/Eject, and the form will

automatically move to the load position. For more information,

see “Adjusting the Load Position” on page 1-78.

Note: You can adjust the load position by using the

Micro ↑, Micro ↓, or Line Feed keys. If you plan to use the

Document on Demand feature, see “Adjusting the Tear-off

Position” on page 1-76 for more information.

Platen Rod

Platen Rod

abcdef

First Print Line

Platen Rod Surface

1-60 User’s Guide Model 302

Page 83

10. If you adjusted the load position, press Set Top of Form to keep

the load position consistent with the top of form position.

Pressing Set Top of Form establishes the first print line at which

printing is to start on each form. The alarm beeps each time you

press the Set Top of Form key and the printer displays

TOP OF FORM SET

11. Close the access cover. Then close the paper door by pulling it

out and pushing it down until it latches.

Note: If you load forms on the tractors before turning on the

power, the printer will automatically load forms to the load

position.

Chapter 1. Setting Up the 4232 Printer Model 302 1-61

Page 84

Using the Printer Verification Test for the F2 Forms

Device

To run the printer verification test, follow these steps:

1. Turn the power On (|) if not already on.

2. Wait until the printer displays

READY <A>

3. Press Stop.

The printer displays

NOT READY <A>

and then may display

| ð29 LINK ERROR

Ignore this message until you have attached the printer to your

computer. (Press Stop to turn off the alarm, if necessary.)

4. Press Test.

The printer displays

OPERATOR PRINT TESTS

Printer Demonstration

1-62 User’s Guide Model 302

Page 85

5. Press Scroll ↑ or Scroll ↓ until the printer displays

OPERATOR PRINT TESTS

Printer Verification

6. Press Enter or Start to print this test. The Ready indicator

comes on and printing begins.

7. Wait for the printer to stop printing and the Ready indicator to go

off.

8. Press Form Feed until you can remove the printout.

The lines numbered 1 through 9 should print as shown on the

sample printout on page 1-64, and the remainder of the printout

should be clear and readable.

Chapter 1. Setting Up the 4232 Printer Model 302 1-63

Page 86

1-64 User’s Guide Model 302

Page 87

9. Compare your printout with the sample printout.

Did the lines print and is the remainder of the printout clear and

readable?

If

YES

, go to Step 10.

If NO, do the following:

a. If any of the following items are not installed correctly, the

printer can experience forms jamming, ribbon jamming, or an

incorrect printer verification printout:

Forms device

Ribbon cartridge

Forms.

Repeat the Setup Instructions on page 1-6 if you suspect a

ribbon, forms, or forms device installation problem.

b. Be sure that enough forms are loaded and press Enter or

Start to get another printout.

c. If the second printout still is not similar to the sample

printout, go to Appendix B, “Problem Solving.”

d. Once you get a good printout, go to Step 10.

10. Turn the power Off (O).

Power Switch

Chapter 1. Setting Up the 4232 Printer Model 302 1-65

Page 88

Setup and Checkout Complete

You have completed a simple setup and checkout of the printer.

IBM recommends that you print your power-on custom set

(Custom Set A) factory defaults and save this printout for future

reference. You are ready to attach the printer to your computer.

Go to “Attaching the 4232 Printer Model 302 to Your Computer”

on page 1-116.

Note: See pages 1-67 through 1-83 for making adjustments,

unloading forms, and removing the forms device.

1-66 User’s Guide Model 302

Page 89

Adjusting the Print Quality

After the printer prints a few lines, press Stop and verify that the

print quality is satisfactory. Good print quality includes:

Clear, legible print

Satisfactory darkness or lightness of output.

It is up to you to decide if the print quality is satisfactory.

Adjustments you can make that affect print quality include:

Tractor Tension

Incorrect tension on the right tractor can cause the paper holes

on the forms to tear, wrinkle, or jam in the printer. To adjust the

tractor tension, see “Adjusting the Tractor Tension” on

page 1-68.

Forms Thickness Setting

This setting can affect the darkness or lightness of output.

The printer will normally sense the forms thickness and adjust

itself automatically. However, if this setting is not correct, it can

be adjusted. To adjust the forms thickness, see “Adjusting the

Forms Thickness Setting” on page 1-70.

Note: The Automatic Forms Thickness Adjustment (AFTA)

mechanism automatically measures the forms thickness and

adjusts the gap from the print head to the platen rod based on

the measured value. See “Automatic Forms Thickness

Adjustment (AFTA)” on page 2-8 for information on how the

printer sets the forms thickness.

Left Margin and Top of Form Position

The adjustment of the first print position can affect the

appearance of the output, especially if you are using preprinted

forms. To adjust the position of the first print character, see

“Adjusting the Left Margin” on page 1-72. To adjust the position

of the first print line, see “Adjusting the Top of Form Position” on

page 1-74.

Chapter 1. Setting Up the 4232 Printer Model 302 1-67

Page 90

Tear-off Position

By moving the perforations in continuous forms close to the tear

bar, you can separate the forms more easily. To adjust the tear

position, see “Adjusting the Tear-off Position” on page 1-76.

Load Position

By using the operator panel, you can adjust the load position.

To adjust the load position, see “Adjusting the Load Position” on

page 1-78.

Print Alignment

This adjustment can affect the character formation and dot

mixing on those characters that are printed with two passes of