Page 1

RS/6000 44P Series Model 270

Service Guide

IBM

SA38-0572-02

Page 2

Third Edition (September 2001)

Before using this information and the product it supports, read the information in “Safety Notices” on page xi,

“Appendix A. Environmental Notices” on page 289, and “Appendix B. Notices” on page 291.

A reader’s comment form is provided at the back of this publication. If the form has been removed, address comments

to Publications Department, Internal Zip 905-6C006, 11400 Burnet Road,Austin, Texas 78758-3493. To send

comments electronically, use this commercial internet address: aix6kpub@austin.ibm.com.Any information that you

supply may be used without incurring any obligation to you.

International Business Machines Corporation, 2000, 2001. All rights reserved.

Note to U.S. Government Users Restricted Rights--Use, duplication or disclosure restrictions by GSA ADP Schedule

Contract with IBM Corp.

Page 3

Contents

Safety Notices ........................xi

Electrical Safety .......................xii

Laser Safety Information.....................xii

Data Integrity and Verification ..................xv

About This Book ......................xvii

ISO 9000 .........................xvii

Online Publications ......................xvii

Related Publications......................xvii

Trademarks ........................xviii

Chapter 1. Reference Information .................1

System Unit Locations......................1

Front View with Media Door Removed ...............1

Rear View.........................2

I/O Board Component Locations .................4

SCSI IDs and Bay Locations ..................6

System Board Locations ....................7

Memory Card Locations ....................7

Operator Panel .......................8

System Cables ........................9

Location Codes ........................9

Physical Location Codes ....................9

Location Code Format .....................9

AIX Location Codes .....................10

AIX and Physical Location Code Reference Table ...........13

Specifications ........................17

Dimensions ........................17

Weight .........................18

Operating Environment - Class B.................18

Power Source Loading ....................18

Power Requirements .....................18

Power Factor .......................18

Operating Voltage......................18

Heat Output (Maximum) ....................18

Acoustics ........................18

Power Cables ........................19

Service Inspection Guide ....................20

Chapter 2. Diagnostics Overview .................21

Maintenance Analysis Procedures (MAPs)...............21

Checkpoints.........................22

FRU Isolation ........................23

Electronic Service Agent for the RS/6000 ...............23

Using the Service Processor and Electronic Service Agent Features ......24

Service Processor......................24

iii

Page 4

Electronic Service Agent ...................25

Chapter 3. Maintenance Analysis Procedures (MAPs) ..........27

Quick Entry MAP .......................27

Quick Entry MAP Table of Contents ................28

MAP 1020: Problem Determination .................34

Purpose of This MAP.....................34

Step 1020-1........................35

Step 1020-2........................37

Step 1020-3........................38

Step 1020-4........................38

MAP 1240: Memory Problem Resolution ...............39

Purpose of This MAP.....................39

General Memory Information ..................39

Step 1240-1........................40

Step 1240-2........................40

Step 1240-3........................41

Step 1240-4........................41

Step 1240-5........................41

Step 1240-6........................42

Step 1240-7........................42

Step 1240-8........................43

Step 1240-9........................43

Step 1240-10 .......................44

Step 1240-11 .......................44

MAP 1520: Power.......................45

Step 1520-1........................46

Step 1520-2........................46

Step 1520-3........................46

Step 1520-4........................47

Step 1520-5........................47

Step 1520-6........................47

Step 1520-7........................48

Step 1520-8........................49

MAP 1540: Minimum Configuration .................50

Purpose of this MAP .....................51

Step 1540-1........................51

Step 1540-2........................52

Step 1540-3........................53

Step 1540-4........................54

Step 1540-5........................54

Step 1540-6........................55

Step 1540-7........................55

Step 1540-8........................56

Step 1540-9........................57

Step 1540-10 .......................58

Step 1540-11 .......................59

Step 1540-12 .......................60

Step 1540-13 .......................61

Step 1540-14 .......................62

iv Service Guide

Page 5

Step 1540-15 .......................63

Step 1540-16 .......................64

Step 1540-17 .......................65

Step 1540-18 .......................66

Step 1540-19 .......................66

Step 1540-20 .......................67

Step 1540-21 .......................67

Step 1540-22 .......................67

Step 1540-23 .......................68

Step 1540-24 .......................68

Step 1540-25 .......................69

Step 1540-26 .......................69

Step 1540-27 .......................70

Chapter 4. Checkpoints ....................71

Service Processor Checkpoints ..................71

Firmware Checkpoints .....................75

Boot Problems/Concerns ...................90

Chapter 5. Error Code to FRU Index ................93

Considerations for Using this Chapter ................93

Performing Slow Boot ....................93

General Considerations ....................93

Firmware/POST Error Codes ...................94

Memory Problem Determination Bits ................142

Bus SRN to FRU Reference Table .................143

Typical Boot Sequence.....................144

Chapter 6. Loading the System Diagnostics .............147

Performing Slow Boot .....................147

Standalone Diagnostics ....................147

Online Diagnostics ......................147

Default Boot List and Service Mode Boot List .............148

Chapter 7. Using the Service Processor ..............149

Service Processor Menus ....................151

Service Processor Menu Inactivity ................151

Accessing Service Processor Menus Locally ............151

Accessing Service Processor Menus Remotely............151

General User Menu ......................152

Privileged User Menus .....................153

Main Menu........................153

Service Processor Setup Menu .................154

Passwords........................155

Serial Port Snoop Setup Menu .................158

System Power Control Menu..................159

System Information Menu ...................164

Language Selection Menu ..................167167

Call-In/Call-Out Setup Menu ..................167

Modem Configuration Menu ..................168

Contents v

Page 6

Serial Port Selection Menu ..................168

Serial Port Speed Setup Menu .................169

Telephone Number Setup Menu.................169

Call-Out Policy Setup Menu ..................171

Customer Account Setup Menu .................172

Call-Out Test .......................172

Service Processor Functions ...................173

System Power-On Methods ...................175

Service Processor Call-In Security .................176

Service Processor Reboot/Restart Recovery .............176

Boot (IPL) Speed .....................176

Failure During Boot Process ..................176

Failure During Normal System Operation..............176

Service Processor Reboot/Restart Policy Controls...........177

Processor Boot-Time Deconfiguration (CPU Repeat Gard) ........177

Processor Run-Time Deconfiguration (CPU-Gard) ...........177

Memory Boot-Time Deconfiguration (Memory Repeat Gard) .......178

Service Processor System Monitoring - Surveillance ...........179

System Firmware Surveillance .................179

Operating System Surveillance .................179

Call Out.........................180

Console Mirroring ......................181

System Configuration for Console Mirroring .............181

Service Processor Firmware Updates ................181

Service Processor Error Log ...................182

System POST Errors .....................182

Service Processor Operational Phases ...............183

Pre-Standby Phase .....................183

Standby Phase ......................183

Bring-Up Phase ......................184

Run-time Phase ......................184

Service Processor Procedures in Service Mode ............185

vi Service Guide

Chapter 8. System Management Services..............187

Graphical System Management Services...............187

Config ..........................190

Multiboot .........................191

Utilities ..........................193

Password ........................195

Spin Delay........................199

Error Log .........................200

RIPL...........................201

Set Address .......................202

Ping ..........................203

Config .........................205

SCSI ID..........................206

Firmware Update.......................207

Firmware Recovery .....................207

Text-Based System Management Services ..............209

Display Configuration .....................210

Page 7

Multiboot Menu .......................210

Select Boot Device .....................211

Configure Nth Boot Device ..................213

Utilities ..........................214

Set Password and Unattended Start Mode .............215

SCSI Spin Up.......................216

Display Error Log .....................216

Remote Initial Program Load Setup ...............216

Change SCSI ID ......................220

Update System or Service Processor Firmware ...........220

Firmware Recovery .....................221

Select Console ......................221

Select Language.......................221

Open Firmware .......................222

Chapter 9. Removal and Replacement Procedures ..........223

Handling Static-Sensitive Devices .................224

Stopping the System Unit ....................224

Procedure List .......................224

Covers ..........................226

Removal of Covers .....................226

Replacement of Covers ...................231

Processor and Memory Card Cover ................232

Removal of Processor and Memory Card Cover ...........232

Replacement of Processor and Memory Card Cover ..........233

Memory Cards .......................234

Removal of Memory Cards ..................234

Replacement of Memory Cards .................236

Memory Modules.......................239

Removal of Memory Modules .................239

Replacement of Memory Modules ................241

Processor Card .......................242

Removal of Processor Card ..................242

Replacement of Processor Card.................244

Adapters .........................246

Removal of Adapters ....................246

Replacement of Adapters ...................247

Internal Drives .......................248

Checklist For Handling Drives .................248

Disk Drives ........................249

Removal of Disk Drives ...................249

Replacement of Disk Drives ..................250

Configuration or Unconfiguration of Disk Drives ............251

Configuration of Disk Drives ..................251

Unconfiguration of Disk Drives .................251

Battery Replacement .....................252

System Board........................256

Removal of System Board ..................256

Replacement of System Board .................257

I/O Board .........................258

Contents vii

Page 8

Removal of I/O Board ....................258

Replacement of I/O Board ..................261

Power Supply........................262

Removal of Power Supply...................262

Replacement of Power Supply .................264

Operator Panel .......................265

Removal of Operator Panel ..................265

Replacement of Operator Panel.................266

Operator Panel Vital Product Data (VPD) Update Procedure ........267

CECFan.........................269

Removal of CEC Fan ....................269

Replacement of CEC Fan...................269

I/OFan..........................270

Removal of I/O Fan .....................270

Replacement of I/O Fan ...................270

Disk Drive Cage .......................271

Removal of Disk Drive Cage ..................271

Replacement of Disk Drive Cage ................273

CD-ROM Drive, Tape Drive, Diskette Drive ..............274

Removal of Media Drives ...................274

Replacement of Media Drives .................274

Chapter 10. Parts Information ..................277

Keyboards and Mouse .....................282

Keyboards and Mouse (Black) ..................284

Power Cables........................286

viii Service Guide

Appendix A. Environmental Notices................289

Product Recycling and Disposal..................289

Environmental Design .....................289

Unit Emissions.......................289

Appendix B. Notices .....................291

Appendix C. Firmware Updates .................293

Checking the Current Firmware Levels ...............293

Updating System Firmware ...................293

Appendix D. Service Processor Setup and Test ...........295

Service Processor Setup Checklist .................295

Testing the Setup ......................295

Testing Call-In ......................296

Testing Call-Out ......................296

Serial Port Configuration ...................297

Appendix E. Modem Configurations................299

Sample Modem Configuration Files ................299

Configuration File Selection ...................299

Examples for Using the Generic Sample Modem Configuration Files ....301

Customizing the Modem Configuration Files.............301

Page 9

IBM 7852-400 DIP Switch Settings................302

Xon/Xoff Modems .....................302

Ring Detection ......................303

Terminal Emulators .....................303

Recovery Procedures ....................303

Transfer of a Modem Session ..................303

Recovery Strategy .....................304

Prevention Strategy .....................305

Modem Configuration Samples .................306

Appendix F. Interpreting Firmware Error Codes ...........321

Index ..........................327

Contents ix

Page 10

x Service Guide

Page 11

Safety Notices

A

danger

death or serious personal injury. Danger notices appear on the following pages:

v xii

v 45

v 45

v 223

v 262

A

caution

moderate or minor personal injury. Caution notices appear on the following pages:

v xii

v xiii

v 45

v 223

v 252

v 274

notice indicates the presence of a hazard that has the potential of causing

notice indicates the presence of a hazard that has the potential of causing

Note: For a translation of these notices, see the

manual, order number SA23-2652.

System Unit Safety Information

xi

Page 12

Electrical Safety

Observe the following safety instructions any time you are connecting or disconnecting

devices attached to the workstation.

DANGER

An electrical outlet that is not correctly wired could place hazardous voltage

on metal parts of the system or the devices that attach to the system. It is the

responsibility of the customer to ensure that the outlet is correctly wired and

grounded to prevent an electrical shock.

Before installing or removing signal cables, ensure that the power cables for

the system unit and all attached devices are unplugged.

When adding or removing any additional devices to or from the system,

ensure that the power cables for those devices are unplugged before the

signal cables are connected. If possible, disconnect all power cables from the

existing system before you add a device.

Use one hand, when possible, to connect or disconnect signal cables to

prevent a possible shock from touching two surfaces with different electrical

potentials.

During an electrical storm, do not connect cables for display stations, printers,

telephones, or station protectors for communications lines.

CAUTION:

This product is equipped with a four-wire power cable and plug for the user’s

safety. Use this power cable in conjunction with a properly grounded electrical

outlet to avoid electrical shock.

DANGER

To prevent electrical shock hazard, disconnect all power cables from the

electrical outlet before relocating the system.

Laser Safety Information

The optical drive in this system unit is a laser product. The optical drive has a label that

identifies its classification. The label, located on the drive, is shown below.

xii Service Guide

Page 13

CLASS 1 LASER PRODUCT

LASER KLASSE 1

LUOKAN 1 LASERLAITE

APPAREIL A LASER DE CLASSE 1

IEC 825:1984 CENELEC EN 60 825:1991

The optical drive in this system unit is certified in the U.S. to conform to the

requirements of the Department of Health and Human Services 21 Code of Federal

Regulations (DHHS 21 CFR) Subchapter J for Class 1 laser products. Elsewhere, the

drive is certified to conform to the requirements of the International Electrotechnical

Commission (IEC) 825 (1st edition 1984) and CENELEC EN 60 825:1991 for Class 1

laser products.

CAUTION:

A class 3 laser is contained in the device. Do not attempt to operate the drive

while it is disassembled. Do not attempt to open the covers of the drive as it is

not serviceable and is to be replaced as a unit.

Class 1 laser products are not considered to be hazardous. The optical drive contains

internally a Class 3B gallium-arsenide laser that is nominally 30 milliwatts at 830

nanometers. The design incorporates a combination of enclosures, electronics, and

redundant interlocks such that there is no exposure to laser radiation above a Class 1

level during normal operation, user maintenance, or servicing conditions.

Preface xiii

Page 14

xiv Service Guide

Page 15

Data Integrity and Verification

IBM computer systems contain mechanisms designed to reduce the possibility of

undetected data corruption or loss. This risk, however, cannot be eliminated. Users who

experience unplanned outages, system failures, power fluctuations or outages, or

component failures must verify the accuracy of operations performed and data saved or

transmitted by the system at or near the time of the outage or failure. In addition, users

must establish procedures to ensure that there is independent data verification before

relying on such data in sensitive or critical operations. Users should periodically check

the IBM support websites for updated information and fixes applicable to the system and

related software.

xv

Page 16

xvi Service Guide

Page 17

About This Book

This book provides maintenance information that is specific to the RS/6000 44P Series

Model 270, as well as to adapters and attached devices that do not have their own

service information. In this book, the RS/6000 44P Series Model 270 is hereafter

referred to as the ″system″ or the ″server.″

This book also contains maintenance analysis procedures (MAPs) that are not common

to other systems. MAPs that are common to all systems are contained in the

and

Eserver

This book is used by the service technician to repair system failures. This book

assumes that the service technician has had training on the system unit.

ISO 9000

ISO 9000 registered quality systems were used in the development and manufacturing

of this product.

Online Publications

RS/6000 publications are available online. To access the online books, visit our Web

site at: http://www.rs6000.ibm.com/resource/hardware_docs/

Related Publications

The following publications provide additional information about your system unit:

v The

translations of safety information used throughout this book.

v The

information on how to use the system, use diagnostics, use service aids, and verify

system operations..

v The

Systems

codes, service request numbers, and failing function codes. This manual is intended

for trained service technicians.

v The

Multiple Bus Systems

adapters, devices, and cables for your system. This manual is intended to

supplement the service information found in the

Diagnostics Information for Multiple Bus Systems

v The

information to help you plan your installation.

pSeries Diagnostics Information for Multiple Bus Systems

System Unit Safety Information Guide,

44P Series Model 270 User’s Guide

RS/6000 and

, order number SA38-0509, contains common diagnostic procedures, error

RS/6000 and

Site and Hardware Planning Information

Eserver

Eserver

pSeries Diagnostics Information for Multiple Bus

pSeries Adapters, Devices, and Cable Information for

, order number SA38-0516, contains information about

order number SA23-2652, contains

, order number SA38-0573-02, contains

RS/6000 and

.

order number SA38-0508, contains

.

Eserver

pSeries

RS/6000

xvii

Page 18

Trademarks

The following terms are trademarks of International Business Machines Corporation in

the United States, other countries, or both:

v AIX

v IBM

v e (logo)

v PowerPC

v PowerPC Reference Platform

v pSeries

v RS/6000

Other company, product, and service names may be trademarks or service marks of

others.

xviii Service Guide

Page 19

Chapter 1. Reference Information

This chapter provides an overview of the system, including system unit locations,

location codes, and environmental specifications.

System Unit Locations

Front View with Media Door Removed

CD-ROM Drive

Disk Drives

Diskette Drive

Operator Panel

1

Page 20

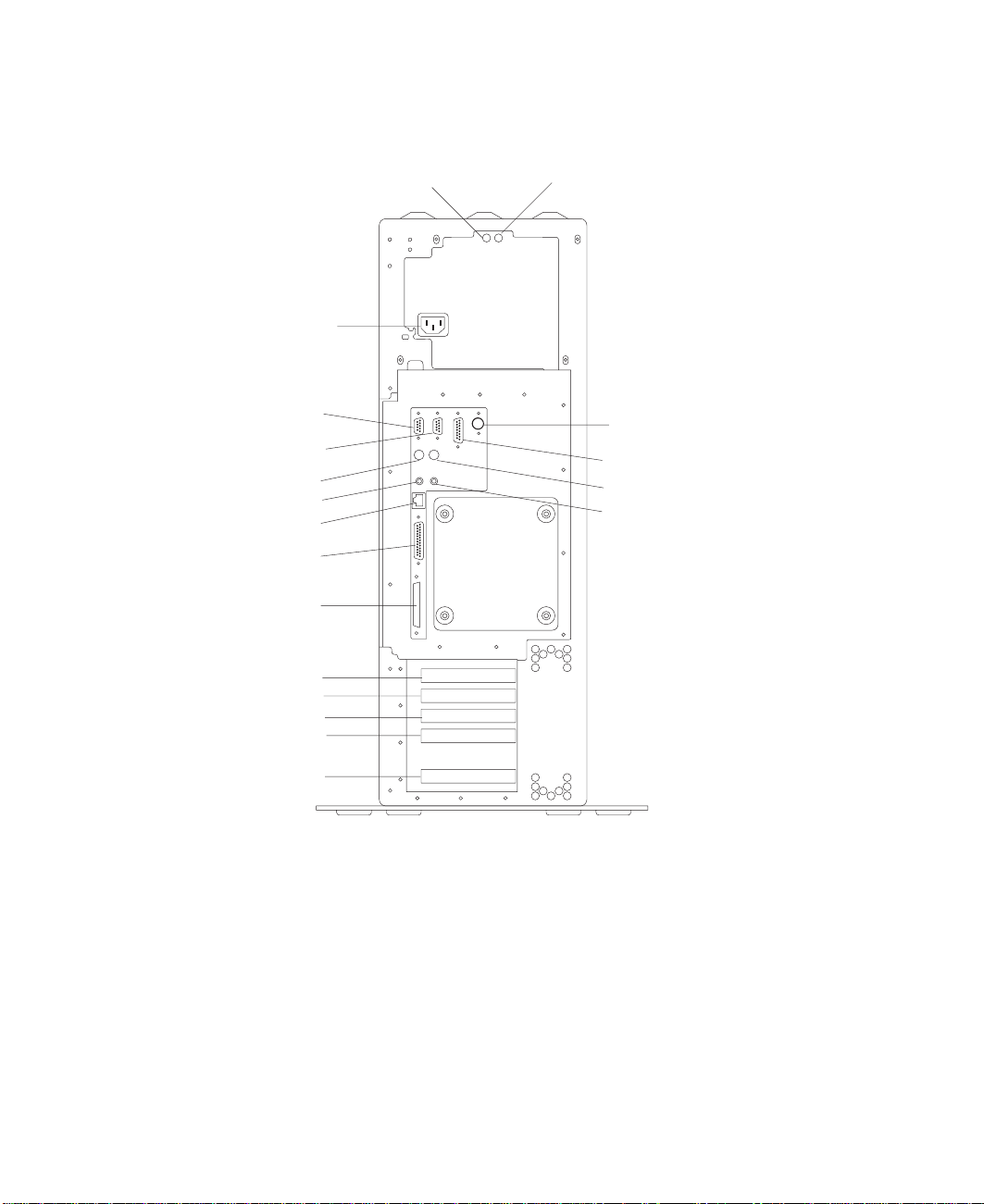

Rear View

14

13

15

10

12

16

4

5

8

17

18

1

3

2

7

6

9

11

2 Service Guide

19

Page 21

1 Power Supply LED

2 Power Supply Test Switch

3 Power Connector

4 Serial Connector S1

5 Serial Connector S2

6 AUI Ethernet Connector

7 Tablet Connector

8 Keyboard Connector

9 Mouse Connector

10 Audio Line Out

11 Audio Line In

12 RJ45 Ethernet Connector

13 Parallel Connector

14 External SCSI Connector

15 PCI Slot 5 (32-bit)

16 PCI Slot 4 (32-bit)

17 PCI Slot 3 (32-bit)

18 PCI Slot 2 (64-bit)

19 PCI Slot 1 (64-bit)

Chapter 1. Reference Information

3

Page 22

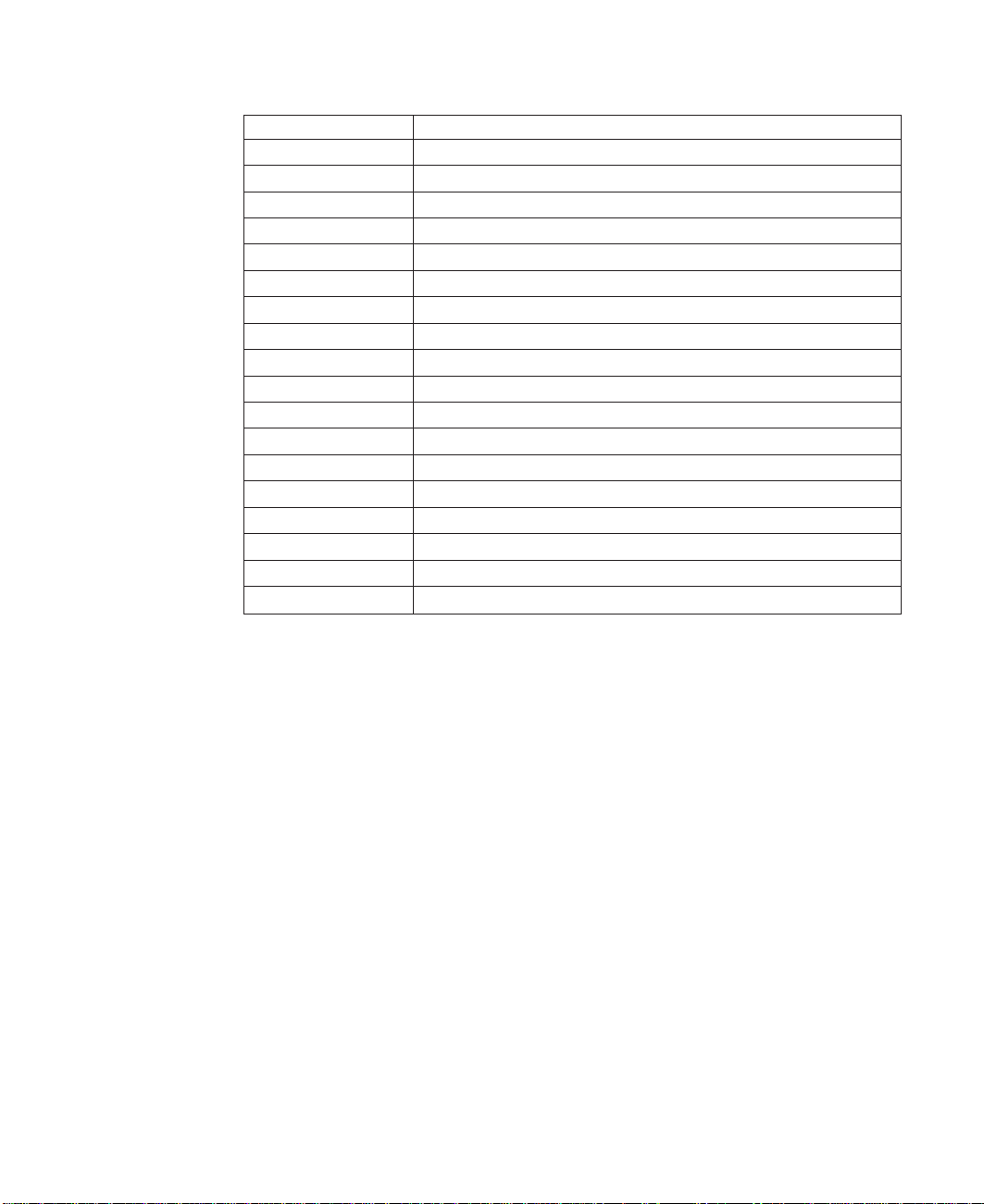

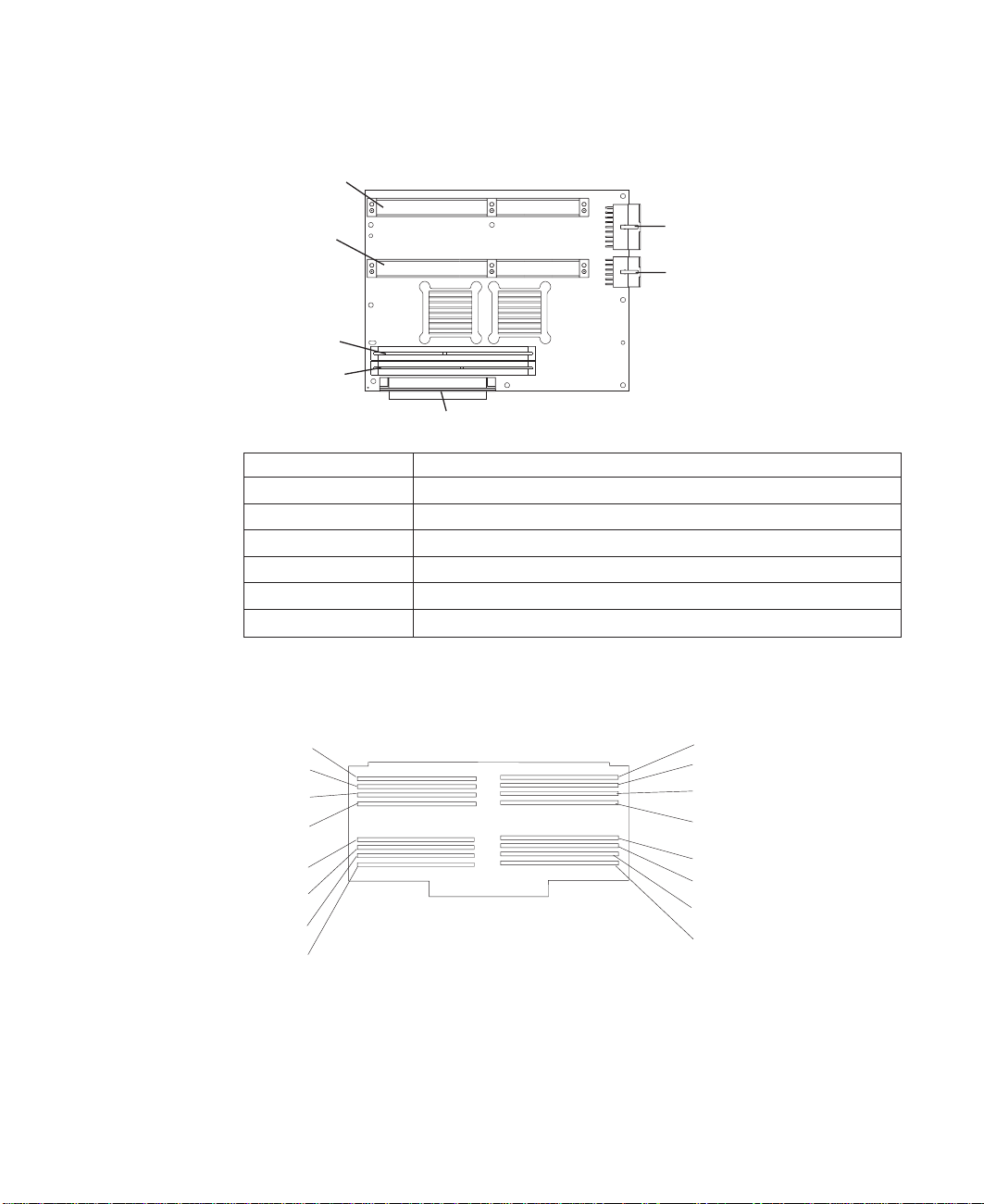

I/O Board Component Locations

J23

J24

J26

J25

J27

J21

J28

J12

J13

J14

J8

J15

J9

J20

J19

J18

J17

J16

J10

J7

J11

J4

J1

J2

J3

4 Service Guide

J6

J5

Page 23

J1 Operator panel power connector

J2 Operator panel audio connector

J3 I/O fan connector

J4 I/O board connector to system board

J5 VPD module connector

J6 ESP external connector

J7 Internal SCSI connector

J8, J9 64-bit PCI connectors

J10 CD-ROM audio connector

J11 Battery Socket

J12, J13, J14 32-bit PCI connectors

J15 Service processor external connector

J16 Power connector

J17 Diskette drive connector

J18 Tablet connector

J19 Power connector

J20 AUI Ethernet connector

J21 CEC fan connector

J23 Serial port connectors

J24 Keyboard/Mouse connector

J25 RJ45 Ethernet connector

J26 Audio in/out

J27 Parallel port connector

J28 External SCSI connector

Chapter 1. Reference Information

5

Page 24

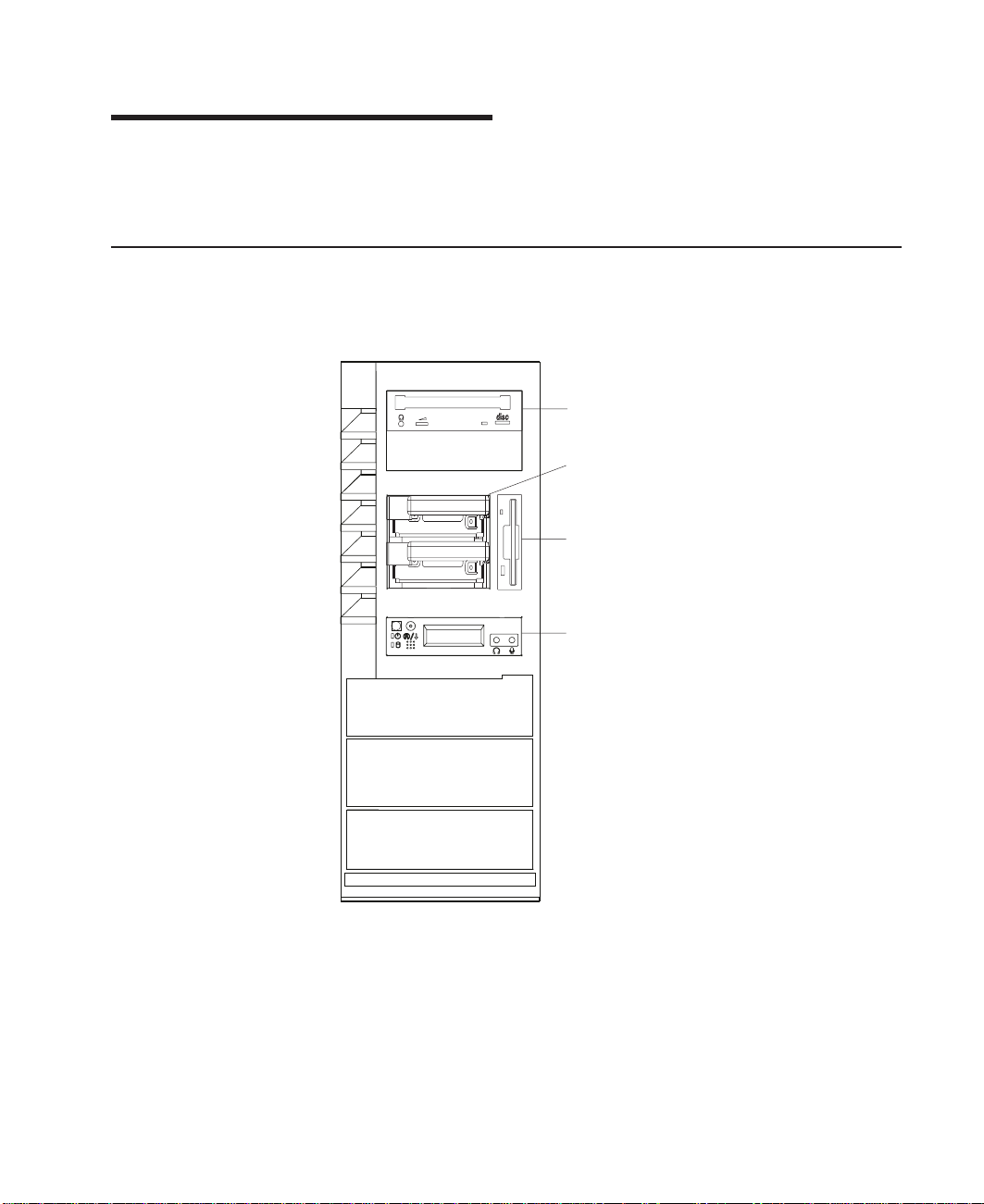

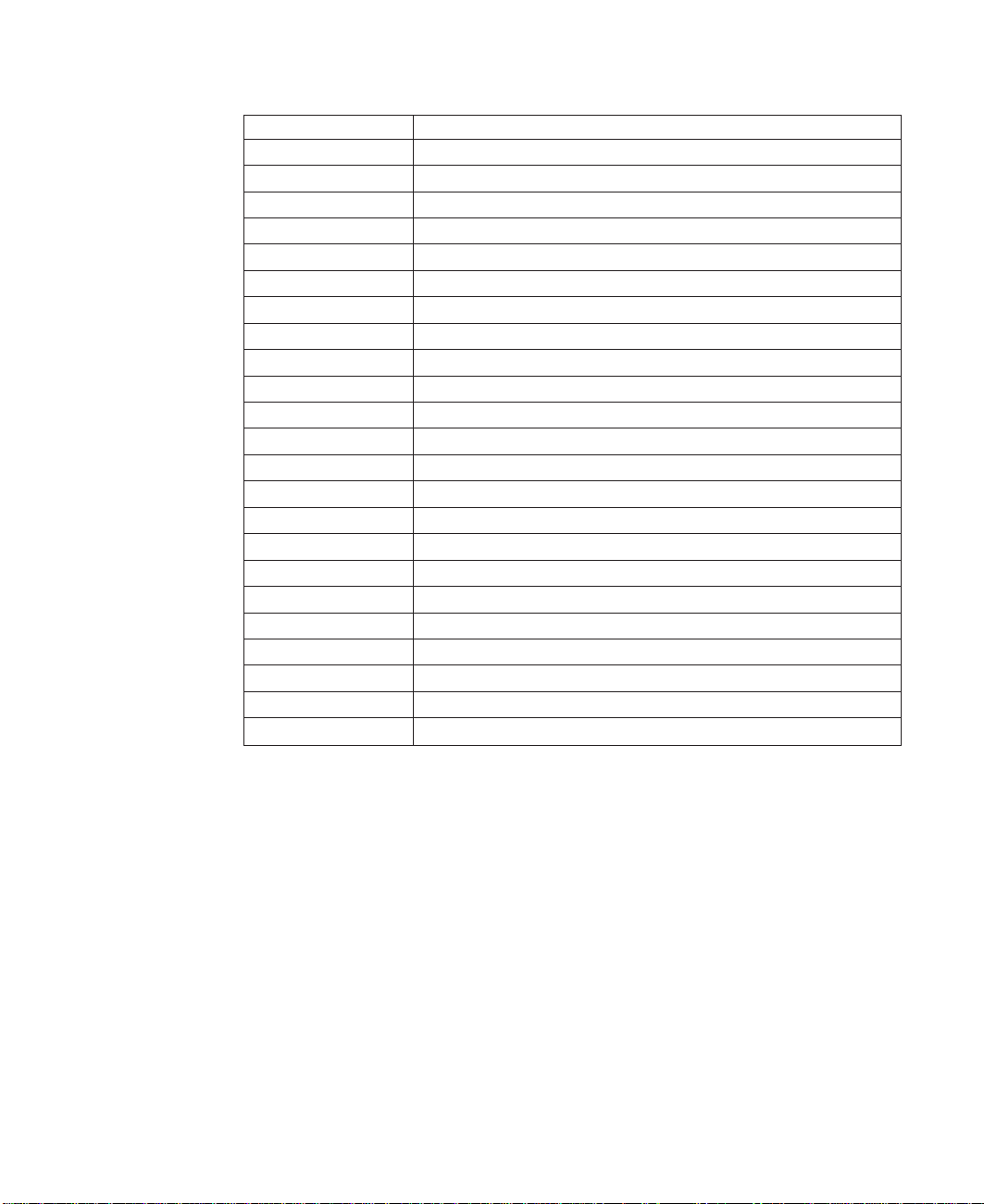

SCSI IDs and Bay Locations

4

5

1

2

3

6 Service Guide

Index Bay Location Drive Name SCSI ID

1 Bay D2 CD-ROM SCSI ID 1

2 Bay D3 Media device SCSI ID 0

3 Bay D1 Diskette drive Non-SCSI

4 Bay D4 Disk drive SCSI ID 9

5 Bay D5 Disk drive SCSI ID 8

Note: The SCSI bus IDs listed are the recommended values. The SCSI IDs shown for

media devices indicate how the devics are set when shipped from the factory.

Field installations might not comply with these recommendations.

Page 25

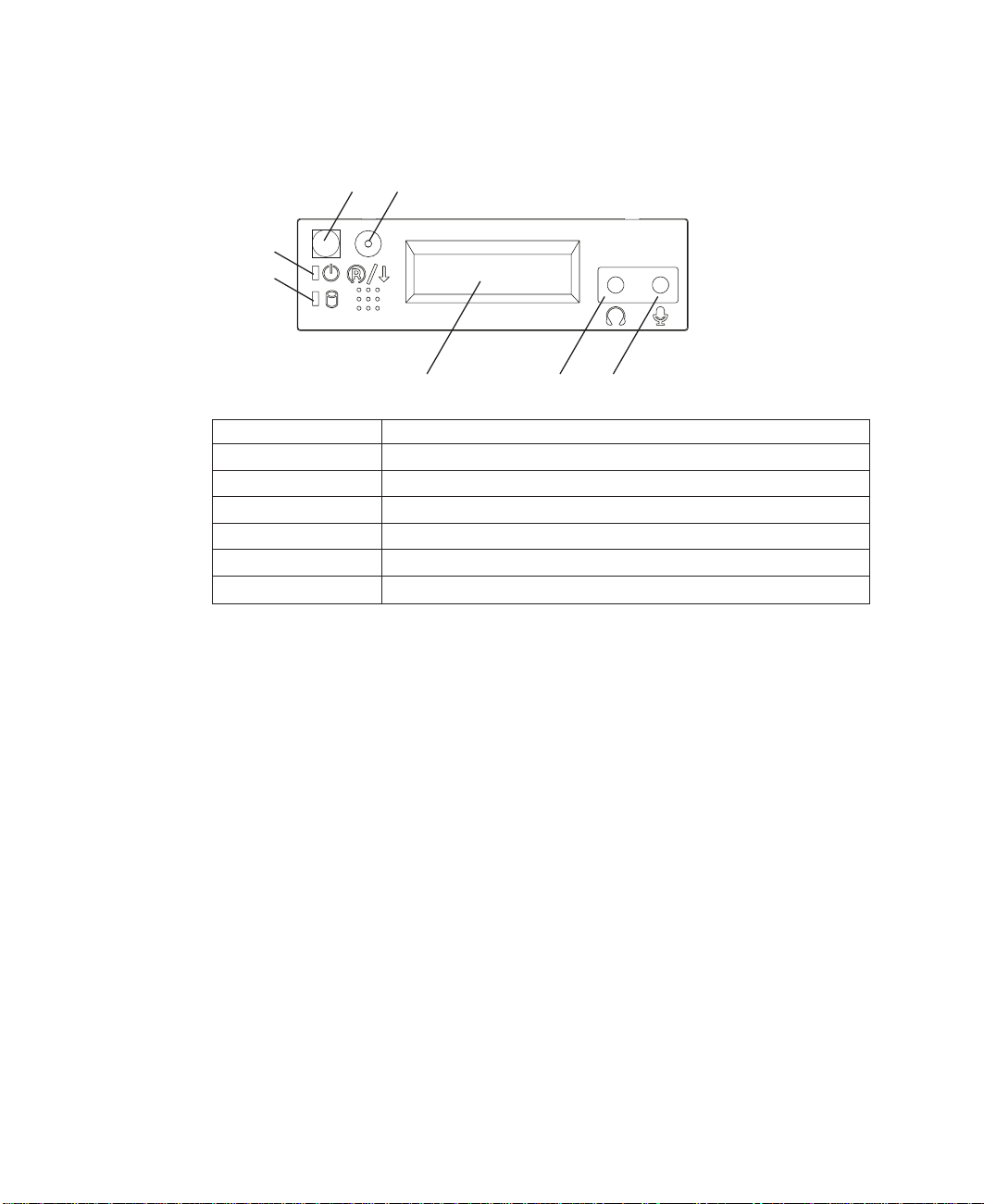

System Board Locations

J8

J6

J3

J2

J1 System board connector to I/O board

J2 Memory card 2 connector

J3 Memory card 1 connector

J5 Power supply connector

J6 Processor card connector #1 (Primary)

J7 Power supply connector

J8 Processor card connector #2

Memory Card Locations

Slot J15

Slot J13

Slot J11

Slot J9

Slot J7

Slot J5

Slot J3

Slot J1

J7

J5

J1

Slot J16

Slot J14

Slot J12

Slot J10

Slot J8

Slot J6

Slot J4

Slot J2

Note: Memory modules must be installed in pairs and in the correct slot configuration.

(Slots J1 and J2, J3 and J4, J5 and J6, and so on.)

Chapter 1. Reference Information 7

Page 26

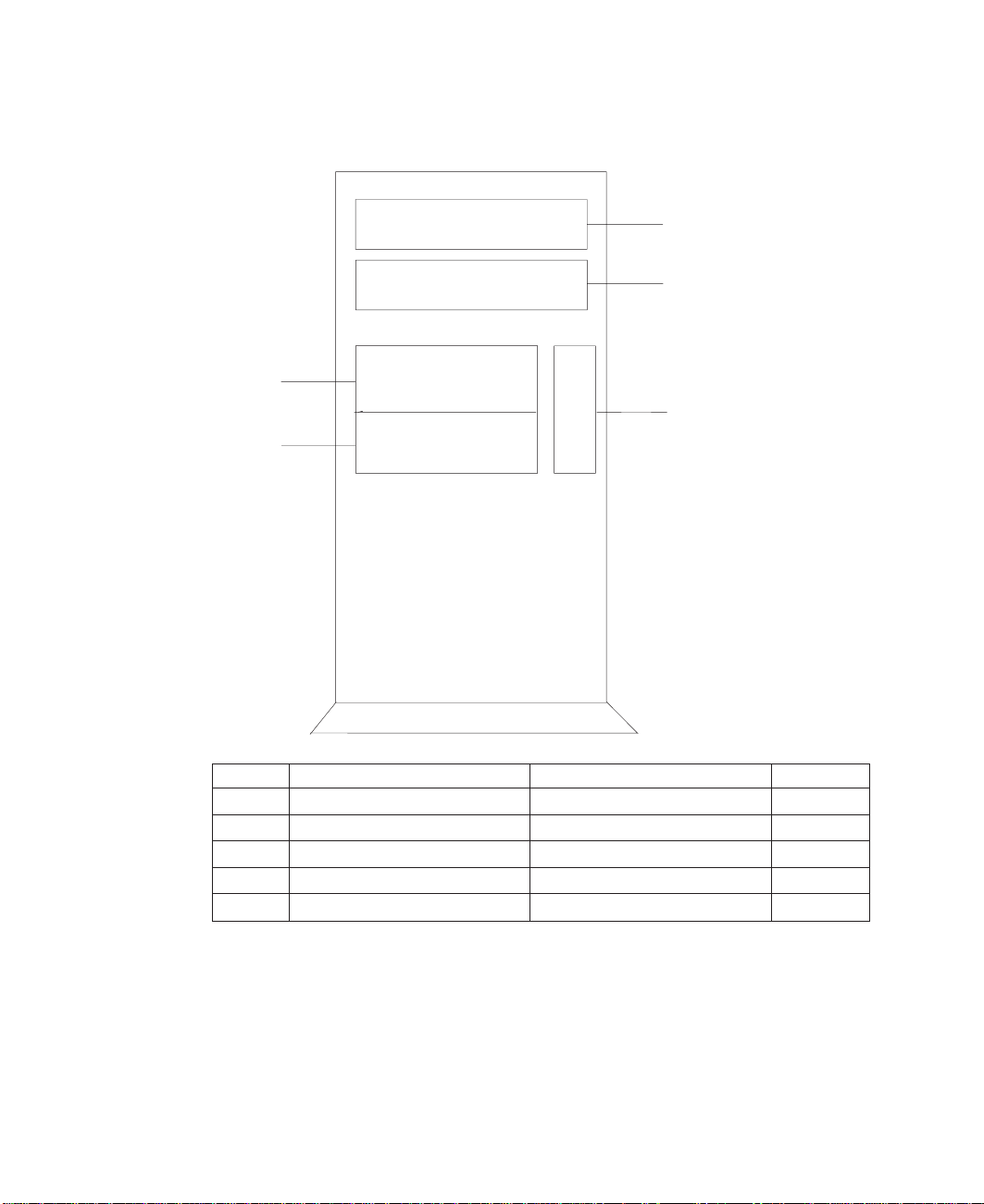

Operator Panel

1

2

3

4

5

1 Power-On Switch

2 Reset Switch

3 Power-On LED

4 Disk Drive Activity LED

5 Display

6 Headset Receptacle

7 Microphone Receptacle

6

7

8 Service Guide

Page 27

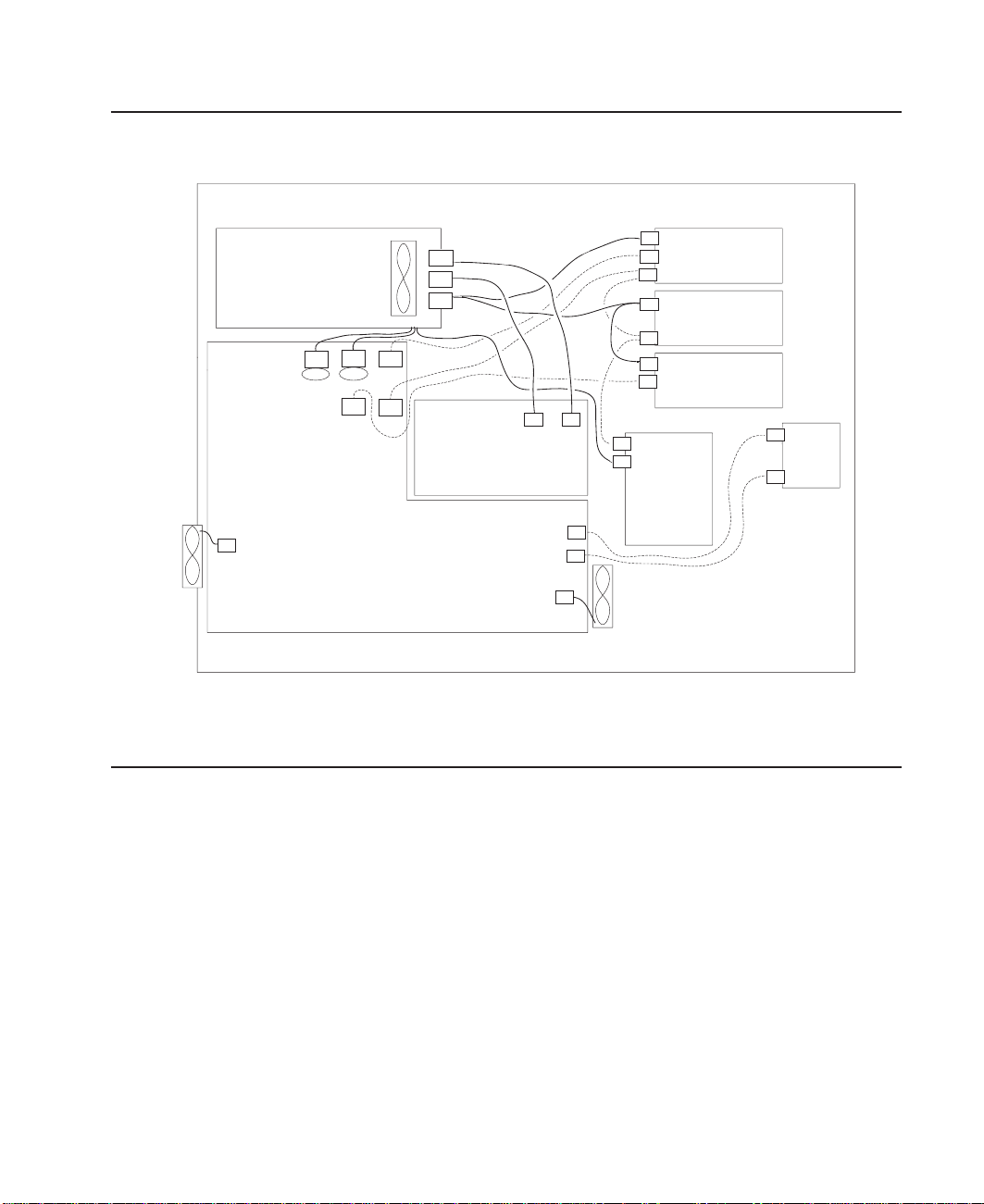

System Cables

Fan

SCSI

P6

Disk

Disk

Drives

Drives

Backplane

Fan

Power

Audio

SCSI

Power

SCSI

Power

Data

ROM

CD ROMCD

Media

Media

Device

Device

Diskette

Power

Operator

Operator

Panel

Panel

Audio

Power SupplyPower

J21

Supply

P3

J19

P4

J16

J17

Fan

J10

J7

P1

P2

P5

System BoardSystem Board

J7

J5

J1

J2

J3

I/O BoardI/O Board

Note: P3 cable goes into designated socket J19. P4 cable goes into designated socket

J16.

Location Codes

This system unit uses physical location codes in conjunction with AIX location codes to

provide mapping of the failing field replaceable units. The location codes are produced

by the system unit’s firmware and AIX.

Physical Location Codes

Physical location codes provide a mapping of logical functions in a platform (or

expansion sites for logical functions, such as connectors or ports) to their specific

locations within the physical structure of the platform.

Location Code Format

The location code is an alphanumeric string of variable length, consisting of a series of

location identifiers, separated by a dash (-), slash (/), or a pound sign (#) character. The

series is hierarchical; that is, each location identifier in the string is a physical or logical

child of the one preceding it.

Chapter 1. Reference Information 9

Page 28

v The - (dash) separator character represents a normal structural relationship where

the child is a separate physical package and it plugs into (or is connected to) the

parent. For example, P1-C1 is a processor card (C1) plugged into a planar (P1), or

P1-M1 is a memory card (M1) plugged into a planar (P1).

v The / (slash) separator character separates the base location code of a function from

any extended location information. A group of logical devices can have the same

base location code because they are all on the same physical package, but may

require extended location information to describe the connectors they support. For

example, P2/S1 describes the location of the serial port 1 controller and its connector

(S1), which is located on planar P2 (its base location code), but the / indicates that

further devices can be connected to it at the external S1 serial connector. The

keyboard controller and its connector likewise have location code P2/K1, which

means they have the same base location code (P2) as serial port 1, but a different

external connector. In contrast, the location code P2-K1 actually points to the device

connected to connector K1; that is, the keyboard. The location code P2/Z1 indicates

an integrated SCSI controller which drives connector Z1, while location codes of

P2-Z1-... point to the actual SCSI bus and devices.

v The # (pound sign) separator character indicates a cable connection between a

connector and parent.

The following are examples:

v P1-C1 identifies processor card C1 plugged into planar P1.

v P1-M1 identifies memory card M1 plugged into planar P1.

v P2/S1 identifies serial port 1 controller on I/O board P2, or the connector for serial

port 1.

v P1-K1 identifies a keyboard attached to connector K1 on planar P1.

v P2/Z1 identifies an integrated SCSI controller on planar P2 which drives connector

Z1.

v P2-Z1-... points to the actual SCSI bus and devices attached to Z1.

The . (period) identifies sub locations (DIMMs on a memory card, or SCSI addresses).

The following are examples:

v P1-M1.4 identifies memory DIMM 4 on memory card 1 plugged into planar P1.

v P1-C1.1 identifies processor 1 on processor card 1 plugged into planar P1.

v P2-Z1-A3.1 identifies a SCSI device with SCSI address of LUN 1 at SCSI ID 3

attached to SCSI bus 1, which is integrated on planar P2.

v P2.1 identifies a riser card plugged into planar P2.

AIX Location Codes

The basic formats of the AIX location codes are as follows:

v For non-SCSI devices/drives:

– AB-CD-EF-GH

v For SCSI devices/drives:

– AB-CD-EF-G,H

10 Service Guide

Page 29

For planars, cards, and non-SCSI devices, the location code is defined as follows:

AB-CD-EF-GH

||||

| | | Device/FRU/Port ID

| | Connector ID

| devfunc Number, Adapter Number or Physical Location

Bus Type or PCI Parent Bus

v The AB value identifies a bus type or PCI parent bus as assigned by the firmware.

v The CD value identifies adapter number, the adapter’s devfunc number, or physical

location. The devfunc number is defined as the PCI device number times 8, plus the

function number.

v The EF value identifies a connector.

v The GH value identifies a port, address, device, or FRU.

Adapters and cards are identified only with AB-CD.

The possible values for AB are:

00 Processor bus

01 ISA bus

02 EISA bus

03 MCA bus

04 PCI bus used in the case where the PCI bus cannot be identified

05 PCMCIA buses

xy For PCI adapters where x is equal to or greater than 1. The x and y are characters in the

range of 0-9, A-H, J-N, P-Z (O, I, and lower case are omitted) and are equal to the parent

bus’s ″ibm, aix-location″ open firmware property.

The possible values for CD depend on the adapter/card:

v For pluggable PCI adapters/cards, CD is the device’s devfunc number (PCI device

number times 8, plus the function number). The C and D are characters in the range

of 0-9, and A-F (hex numbers). Location codes therefore uniquely identify multiple

adapters on individual PCI cards.

v For pluggable ISA adapters, CD is equal to the order of the ISA cards

defined/configured either by SMIT or the ISAAdapter Configuration Service Aid.

v For integrated ISA adapters, CD is equal to a unique code identifying the ISA

adapter. In most cases, this code is equal to the adapter’s physical location code. In

cases where a physical location code is not available, CD will be FF.

EF is the connector ID, used to identify the adapter’s connector to which a resource is

attached.

GH is used to identify a port, device, or FRU. For example:

v For async devices, GH defines the port on the fanout box. The values are 00 to 15.

v For a diskette drive, H identifies either diskette drive 1 or 2. G is always 0.

v For all other devices, GH is equal to 00.

Chapter 1. Reference Information 11

Page 30

For integrated adapters, EF-GH is the same as the definition for a pluggable adapter.

For example, the location code for a diskette drive is 01-D1-00-00. A second diskette

drive is 01-D1-00-01.

For SCSI devices, the location code is defined as follows:

AB-CD-EF-G,H

| | |||

| | | | Logical Unit address of the SCSI Device

| | | Control Unit Address of the SCSI Device

| | Connector ID

| devfunc Number, Adapter Number or Physical Location

Bus Type or PCI Parent Bus

Where

AB-CD-EF are the same as non-SCSI devices.

G defines the control unit address of the device. Values of 0 to 15 are valid.

H defines the logical unit address of the device. Values of 0 to 255 are valid.

A bus location code that is also generated as ’00-XXXXXXXX’ where XXXXXXXX is

equivalent to the node’s unit address.

Examples of physical location codes displayed by AIX are as follows:

v First processor card plugged into planar 1:

P1-C1

v Second memory card in planar P1:

P1-M2

v Memory DIMM 12 on second memory card plugged into planar P1:

P1-M2.12

12 Service Guide

Examples of AIX location codes displayed are as follows:

v Integrated PCI adapter as follows:

10-80 Ethernet

10-60 Integrated SCSI Port 1 (internal)

10-88 Integrated SCSI Port 2 (external)

v Pluggable PCI adapters as follows:

20-58 to 20-5F Any PCI card in slot 1

20-60 to 20-67 Any PCI card in slot 2

10-68 to 10-6F Any PCI card in slot 3

10-70 to 10-77 Any PCI card in slot 4

10-78 to 10-7F Any PCI card in slot 5

v Integrated ISA adapters as follows:

01-D1 Diskette adapter

01-R1 Parallel port adapter

01-S1 Serial port 1 adapter

Page 31

01-S2 Serial port 2 adapter

01-S3 Serial port 3 adapter

01-K1 Keyboard adapter

v Device attached to SCSI controller

10-60-00-4,0 Device attached to integrated SCSI controller 1:

AIX and Physical Location Code Reference Table

AIX

Location

Codes

10-80

01-S1

01-S2

01-K1-01

01-K1-00

01-Q1-00

01-Q2-00

10-80

01-R1

10-88

10-78 to 10-7F

or

1F-XX

10-70 to 10-77

or

1E-XX

10-68 to 10-6F

or

1D-XX

20-60 to 20-67

or

2C-XX

20-58 to 20-5F

or

2B-XX

Physical

Location

Codes

P2/E1

P2/S1

P2/S2

P2/O1

P2/K1

P2/Q1

P2/Q2

P2/E1

P2/R1

P2/F1

P2/Z2

P2-I5

P2-I4

P2-I3

P2-I2

P2-I1

AUI Ethernet

Serial

Mouse

Keyboard

Tablet

Integrated Audio

RJ45 Ethernet

Parallel

CEC Fan

Ext SCSI

PCI 32-Bit

PCI 32-Bit

PCI 32-Bit

PCI 64-Bit

PCI 64-Bit

Chapter 1. Reference Information 13

Page 32

Physical

Location

Codes

AIX

Location

Codes

Internal SCSI

Diskette Drive

Processor Card

Processor Card

(primary)

Memory Card

Memory Card

Operator Panel

I/O Fan

P2/Z1

P2/D1

P1-C2

P1-C1

P1-M1

P1-M2

P2/L1

P2/F2

10-60

01-D1

14 Service Guide

Page 33

FRU Name AIX Location

System board 00-00 P1

Processor card 1 00-00 and 00–01

Processor card 2 00-02 and 00–03

Memory card 1 00-00 P1-M1 Memory card

Memory card 1

modules 1 thru 16

Memory card 2 00-00 P1-M2 Memory card

Memory card 2

modules 1 thru 16

I/O board 00-00 P2

Diskette Drive 01-D1-00-00 P2-D1 I/O board

Keyboard 01-K1-00-00 P2-K1 I/O board

Mouse 01-K1-01-00 P2-O1 I/O board

Diskette Port 01-D1 P2/D1 I/O board

Keyboard Port 01-K1-00 P2/K1 I/O board

Mouse Port 01-K1-01 P2/O1 I/O board

Tablet Port 01-Q1-01-00 P2/Q1 I/O board

Audio 01-Q2-00 P2/Q2 I/O board

Serial Port 1 01-S1 P2/S1 I/O board

Code

Central Electronics Complex (CEC)

(2–way card)

(2–way card)

00-00 P1-M1.1 through

00-00 P1-M2.1 through

Physical

Location Code

P1-C1 Processor

P1-C2 Processor

P1-M1.16

P1-M2.16

Integrated Devices

Physical

Connection

connector J6

connector J8

connector J3

Memory card

sockets J1, J2,

J3, J4, J5, J6, J7,

J8 J9, J10, J11,

J12, J13, J14,

J15, J16

connector J2

Memory card

sockets J1, J2,

J3, J4, J5, J6, J7,

J8 J9, J10, J11,

J12, J13, J14,

J15, J16

Connector J13

connector J24

connector J24

connector J17

connector J24

connector J24

connector J18

connector J26

connector J23

Logical

Identification

CPU ID proc0

and proc1 (2-way

card)

CPU ID proc2

and proc3 (2-way

card)

Extents: 8L, 8H,

10L, 10H, 12L,

12H, 14L, 14H,

9L, 9H, 11L, 11H,

13L, 13H, 15L,

15H

Extents: 8L, 8H,

10L, 10H, 12L,

12H, 14L, 14H,

9L, 9H, 11L, 11H,

13L, 13H, 15L,

5H

Base Address

0x0310

Base Address

0x0060

0x0060

0x03f0

0x0060

0x0060

0x0060

0x0060

0x0318

Chapter 1. Reference Information

15

Page 34

FRU Name AIX Location

Serial Port 2 01-S2 P2/S2 I/O board

Parallel Port 01-R1 P2/R1 I/O board

AUI Ethernet Port 10-80 P2/E1 I/O board

RJ45 Ethernet

Port

Internal SCSI Port 10-60 P2/Z1 I/O board

External SCSI

Port

Card in PCI Slot1P20-58 to 20-5F or

Card in PCI Slot2P20-60 to 20-67 or

Card in PCI Slot3P10-68 to 10-6F or

Card in PCI Slot4P10-70 to 10-77 or

Card in PCI Slot5P10-78 to 10-7F or

Base CD-ROM

(Bay D1)

Media Device in

Bay D2

DASD in Bay D4 10-60-00-9,0 P2-Z1-A9 Primary SCSI bus

DASD in Bay D5 10-60-00-8,0 P2-Z1-A8 Secondary SCSI

I/O fan F2 Fan connector J3

CEC fan F1 Fan connector

Code

10-80 P2/E1 I/O board

10-88 P2/Z2 I/O board

2B-xx

2C-xx

1D-xx

1E-xx

1F-xx

10-60-00-1, 0 P2-Z1-A1 Primary SCSI bus

10-60-00-0,0 P2-Z1-A0 Primary SCSI bus

Physical

Location Code

Pluggable Adapters

P2-I1 I/O board

P2-I2 I/O board

P2-I3 I/O board

P2-I4 I/O board

P2-I5 I/O board

SCSI Devices

Fans

Physical

Connection

connector J23

connector J27

connector J20

connector J25

connector J7

connector J28

connector J9

connector J8

connector J14

connector J13

connector J12

at system board

J21 at system

board

Logical

Identification

0x0218

0x0378

Host Bridge ID00,

Device 06

Host Bridge ID00,

Device 06

Host Bridge ID00,

Device 02

Host Bridge ID00,

Device 07

Host Bridge ID01,

Device 01

Host Bridge ID01,

Device 02

Host Bridge ID00,

Device 03

Host Bridge ID00,

Device 04

Host Bridge ID00,

Device 05

ID 1 (refer to the

note at the end of

this table)

ID 0 (refer to the

note at the end of

this table)

ID 9

bus ID 8

16 Service Guide

Page 35

FRU Name AIX Location

Code

I/O fan connector P2/F2 Fan connector J3

CEC fan

connector

Operator panel L1 I/O board

Operator panel

Connector

Power supply V1

Battery V2 I/O board

Notes:

1. The physical location code for the PCI slots, when empty, uses the P1/Ix notation, where the

’/’ identifies an integrated device (in this case the empty slot). A PCI device plugged into the

slot uses the P1-Ix notation, where the ’-’ identifies a plugged device.

2. The SCSI bus IDs are the recommended values. The SCSI IDs shown for media devices

indicate how the devices are set when they are shipped from the factory. Field installations

may not comply with these recommendations.

Physical

Location Code

P2/F1 Fan connector

Operator Panel

P2/L1 I/O board

Power Supply

Battery

Physical

Connection

at system board

J21 at system

board

connector J1

connector J1

connector J11

Logical

Identification

Specifications

Dimensions

The mechanical packaging, cooling, power supply, and environmental requirements for

the server are as follows:

v With pedestal:

– Height - 615 mm (24.2 inches)

– Depth - 681 mm (26.8 inches)

– Width - 340 mm (13.4 inches)

v Without pedestal:

– Height - 610 mm (24.0 inches)

– Depth - 681 mm (26.8 inches)

– Width - 221 mm (8.7 inches)

Chapter 1. Reference Information 17

Page 36

Weight

Configuration-dependent

Operating Environment - Class B

v Temperature - 16° to 32°C (60° to 90°F)

v Humidity - 8% to 80% noncondensing

v Maximum Altitude - 2135 m (7000 feet)

Power Source Loading

v Typical EMC Configuration - 0.3 kVA

v Maximum - 0.5 kVA

Power Requirements

v Typical - 275 watts

v Maximum - 640 watts

Power Factor

0.89 - 0.98

Operating Voltage

v 100 to 127V ac; 50 to 60 Hz

v 200 to 240V ac; 50 to 60 Hz

Heat Output (Maximum)

v Typical - 400 Btu/hr

v Maximum - 794 Btu/hr

Acoustics

v 6.0 Bels operating

v 5.5 Bels idle

18 Service Guide

Page 37

Power Cables

To avoid electrical shock, a power cable with a grounded attachment plug is provided.

Use only properly grounded outlets.

Power cables used in the United States and Canada are listed by Underwriter’s

Laboratories (UL) and certified by the Canadian Standards Association (CSA). These

power cords consist of the following:

v Electrical cables, Type SVT or SJT.

v Attachment plugs complying with National Electrical Manufacturers Association

(NEMA) 5-15P, that is:

″For 115 V operation, use a UL listed cable set consisting of a minimum 18 AWG,

Type SVT or SJT three-conductor cord a maximum of 15 feet in length and a parallel

blade, grounding type attachment plug rated at 15 A, 125 V.″

″For 230 V operation in the United States use a UL listed cable set consisting of a

minimum 18 AWG, Type SVT or SJT three-conductor cable a maximum of 15 feet in

length, and a tandem blade, grounding type attachment plug rated at 15 A, 250 V.″

v Appliance couplers complying with International Electrotechnical Commission (IEC)

Standard 320, Sheet C13.

Power cables used in other countries consist of the following:

v Electrical cables, Type HD21.

v Attachment plugs approved by the appropriate testing organization for the specific

countries where they are used.

″For units set at 230 V (outside of U.S.): use a cable set consisting of a minimum 18

AWG cable and grounding type attachment plug rated 15 A, 250 V. The cable set

should have the appropriate safety approvals for the country in which the equipment

will be installed and should be marked ′HAR’.″

Refer to “Chapter 10. Parts Information” on page 277 to find the power cables that are

available.

Chapter 1. Reference Information 19

Page 38

Service Inspection Guide

Perform a service inspection on the system when:

v The system is inspected for a maintenance agreement.

v Service is requested and service has not recently been performed.

v An alterations and attachments review is performed.

v Changes have been made to the equipment that may affect the safe operation of the

equipment.

v External devices with their own power cables have those cables attached.

If the inspection indicates an unacceptable safety condition, the condition must be

corrected before anyone can service the machine.

Note: The correction of any unsafe condition is the responsibility of the owner of the

system.

Perform the following checks:

1. Check the covers for sharp edges and for damage or alterations that expose the

internal parts of the system unit.

2. Check the covers for proper fit to the system unit. They should be in place and

secure.

3. Gently rock the system unit from side to side to determine if it is steady.

4. Set the power switch of the system unit to Off.

5. Remove the covers.

6. Check for alterations or attachments. If there are any, check for obvious safety

hazards such as broken wires, sharp edges, or broken insulation.

7. Check the internal cables for damage.

8. Check for dirt, water, and any other contamination within the system unit.

9. Check the voltage label on the back of the system unit to ensure that it matches

the voltage at the outlet.

10. Check the external power cable for damage.

11. With the external power cable connected to the system unit, check for 0.1 ohm or

less resistance between the ground lug on the external power cable plug and the

metal frame.

12. Perform the following checks on each device that has its own power cables:

a. Check for damage to the power cord.

b. Check for the correct grounded power cable.

c. With the external power cable connected to the device, check for 0.1 ohm or

less resistance between the ground lug on the external power cable the metal

frame of the device.

13. Install the covers.

20 Service Guide

Page 39

Chapter 2. Diagnostics Overview

Model 270 systems use an integrated set of software diagnostic procedures to facilitate

isolation of failing components and system maintenance. This book, along with the

RS/6000 and

the basis of the diagnostic procedures for the system. In particular, the following

sections in this book are important for the trained service representative to understand

and use when isolating a failure on the system:

v “Chapter 4. Checkpoints” on page 71

v “Chapter 5. Error Code to FRU Index” on page 93

v “Chapter 6. Loading the System Diagnostics” on page 147

v “Chapter 10. Parts Information” on page 277

The manufacturer recommends that systems configured with 4 GB of memory or

greater have access toa4mmor8mmtape drive for submission of system dump

information if required. This function can be accomplished through locally-attached or

network-attached devices, as appropriate.

Maintenance Analysis Procedures (MAPs)

Maintenance analysis procedures (MAPs) guide the trained service person through the

system. These MAPs are the entry point for all isolation and error-recovery procedures.

The MAPs are consistent with existing procedures and methods. The system uses a set

of integrated procedures, mentioned earlier, to which the MAPS are the primary entry

point.

Eserver

pSeries Diagnostics Information for Multiple Bus Systems

, are

The MAPS are as follows:

v Entry MAP

v Quick Entry MAP

v Problem Determination MAP

v Power MAP

v Minimum Configuration MAP

The Entry Map is the starting point for problem determination. The purpose of this MAP

is to quickly point to the appropriate MAP or service reference information either in this

book, or in the common book set, which includes the

Diagnostics Information for Multiple Bus Systems

Reference

The Quick Entry MAP is a subset of the Entry MAP and helps to save time for some

types of problems.

The Problem Determination MAP provides a structured analysis method to get an error

code if one is not provided by the customer, or if diagnostics cannot be loaded.

.

RS/6000 and

and the

Eserver

pSeries

PCI Adapter Placement

21

Page 40

Checkpoints

The Power MAP deals with isolation of components to diagnose a power problem. The

nature of power problems can be related to powering up and down the system, or

power failures that occur after power is turned on.

The Minimum Configuration MAP is used to locate defective components not found by

normal diagnostics or error-isolation methods. This MAP provides a systematic method

of isolation to the failing item or items.

Model 270 servers use various types of checkpoints, error codes, and SRNs, which are

referred to throughout this book (primarily in “Chapter 4. Checkpoints” on page 71,

“Chapter 5. Error Code to FRU Index” on page 93, “Chapter 6. Loading the System

Diagnostics” on page 147, and “Chapter 10. Parts Information” on page 277). These

codes may appear in the service processor boot progress log, the AIX error log, and the

operator panel display. Understanding the definition and relationships of these codes is

important to the service personnel who are installing or maintaining Model 270 servers.

Codes that can appear on the operator panel or in error logs are as follows:

Checkpoints

Checkpoints display in the operator panel from the time ac power is connected

to the system until the AIX login prompt is displayed after a successful

operating system boot. These checkpoints have the following forms:

E000 - E075

These checkpoints display from the time ac power is connected to the

system until the OK prompt displays on the operator panel display.

During this time, the service processor performs self-test and NVRAM

initialization.

E0A0 - E0E1

When power up is initiated, the service processor starts built-in

self-test (BIST) on the central electronics complex (CEC). VPD data

are read.

E0E2 - E2xx

This range indicates that the system processor is in control and is

initializing system resources.

E3xx These codes indicate that the system processor is running memory

tests.

E1xx The system firmware attempts to boot from devices in the boot list.

Control is passed to AIX when E105 (normal mode boot) or E15B

(service mode boot) displays on the operator panel display.

0xxx 0xxx codes are AIX checkpoints and configuration codes. Location

codes may also be shown on the operator panel display during this

time.

22 Service Guide

Page 41

FRU Isolation

Error Codes

If a fault is detected, an 8-digit error code is displayed in the operator panel

display.A location may be displayed at the same time on the second line of

the display.

Checkpoints can become error codes if the system fails to advance past the

point at which the code was presented.

For a list of checkpoints, see “Chapter 4. Checkpoints” on page 71. Each entry

provides a description of the event and the recommended action if the system

fails to advance.

SRNs Service request numbers, in the form xxx-xxx, may also be displayed on the

operator panel display and be noted in the AIX error log.

SRNs are listed in the

for Multiple Bus Systems

For a list of error codes and recommended actions for each code, see “Chapter 5. Error

Code to FRU Index” on page 93. These actions can refer to “Chapter 10. Parts

Information” on page 277, “Chapter 3. Maintenance Analysis Procedures (MAPs)” on

page 27, or provide informational message and directions. If a replacement part is

indicated, the part name is included. The respective AIX and physical location codes

are listed for each occurrence as required. For a list of location codes, see “AIX and

Physical Location Code Reference Table” on page 13.

RS/6000 and

.

Eserver

pSeries Diagnostics Information

To look up part numbers and view component diagrams, see “Chapter 10. Parts

Information” on page 277. The beginning of the chapter provides a parts index with the

predominant field replaceable units (FRUs) listed by name. The remainder of the

chapter provides illustrations of the various assemblies and components that make up

RS/6000 44P Series Model 270 systems.

Electronic Service Agent for the RS/6000

Service support for the system can be enhanced through the use of the application

program, Electronic Service Agent. This application provides a number of advantages

for the RS/6000 44P Series Model 270 customer, including automatic error reporting

and analysis without customer intervention. The Electronic Service Agent kit is provided

with the RS/6000 44P Series Model 270 server and includes the following:

v Electronic Service Agent for the RS/6000 program on CD-ROM

v The

CE Information Guide

For more details on Electronic Service Agent for the RS/6000, see the

,

Guide

for Electronic Service Agent

CE Information

Chapter 2. Diagnostics Overview 23

Page 42

Using the Service Processor and Electronic Service Agent Features

The service processor and Electronic Service Agent features protect users against

unnecessary system downtime by advising support personnel (both internal and

external) of any unexpected changes in the system environment. In combination, the

two features provide a flexible solution to automated system maintenance.

Service Processor

The service processor runs on its own power boundary and continually monitors

hardware attributes, the AIX operating system, and the environmental conditions within

the system. Any system failure which prevents the system from returning to an

operational state (a fully functional AIX operating system) is reported by the service

processor. The service processor is controlled by firmware and does not require the AIX

operating system to be operational to perform its tasks. If any system failures are

detected, the service processor has the ability to take predetermined corrective actions.

The methods of corrective actions are as follows:

v Surveillance

v Call home

v AIX operating system monitoring

Surveillance is a function in which the service processor monitors the system through

heartbeat

that the firmware can monitor. During system startup, the firmware surveillance monitor

is automatically enabled to check for heartbeats from the firmware. If a heartbeat is not

detected within a default period, the service processor cycles the system power and

attempts to restart until the system either restarts successfully, or a predetermined retry

threshold is reached. In the event the service processor is unsuccessful in bringing the

system online (or in the event that the user asked to be alerted to any service

processor-assisted restarts), the system can call home to report the error.

communication with the system firmware. The heartbeat is a periodic signal

24 Service Guide

The call home function can be initialized to call either a service center telephone

number, a customer administration center, or a digital pager telephone number. The

service processor can be configured to stop at the first successful call to any of the

numbers listed, or can be configured to call every number provided. If connected to the

service center, the service processor transmits the relevant system information (the

system’s serial number and model type) and service request number (SRN). If

connected to a digital pager service, the service processor inputs a customer voice

telephone number defined by the customer. An established sequence of digits or the

telephone number to a phone near the failed system could be used to signal a system

administrator to a potential system failure.

During normal operations, the service processor can also be configured to monitor the

AIX operating system. If AIX does not respond to the service processor heartbeat, the

service processor assumes the operating system is hung. The service processor can

automatically initiate a restart and, if enabled, initiate the call home function to alert the

appropriate people to the system hang. Enabling operating system surveillance also

enables AIX detect any service processor failures and report those failures to the

Electronic Service Agent application.

Page 43

Unlike the Electronic Service Agent, the service processor cannot be configured in a

client/server environment where one system can be used to manage all dial-out

functions for a set of systems.

Prior to installing the Electronic Service Agent feature, ensure that you have the latest

level of system firmware. You also need a properly configured modem. For more

information on configuring a modem, see “Appendix E. Modem Configurations” on

page 299.

Electronic Service Agent

The Electronic Service Agent is a software extension to the AIX operating system that

monitors the system while the AIX operating system is running. The Electronic Service

Agent monitors and analyzes all recoverable system failures, and, if needed, can

automatically place a service call to a service center (without user intervention).

The service center receives the machine type/serial number, host name, SRN, and a

problem description. The service center analyzes the problem report and, if warranted,

dispatches a service person to the customer site. The service center also determines if

any hardware components need to be ordered prior to the service person’s arrival.

The Electronic Service Agent code also gives the user the option to establish a single

system as the problem reporting server. A single system, accessible over the user

network, can be used as the central server for all the other systems on the local area

network (LAN) that are running the Electronic Service Agent application. If the

Electronic Service Agent application on a remote client decides a service request needs

to be placed, the client forwards the information to the Electronic Service Agent server

that dials the service center telephone number from its locally attached modem. In this

scenario, the user only needs to maintain a single analog line for providing call-out

capabilities for a large set of servers.

When used in a scalable parallel (SP) environment, a client/server type implementation

is configured. The Electronic Service Agent client code runs on each of the SP nodes.

The server component runs on the control workstation. In the event of any system

failures, the relevant information is transmitted to the control workstation through the

integrated Ethernet. After it has been alerted to the system failure, the control

workstation initiates actions to prepare and send the service request.

A modem is required for enabling automated problem reporting to the service center.

Configuration files for several types of modems are included as part of the Electronic

Service Agent package. Refer to “Appendix E. Modem Configurations” on page 299 for

more information on configuring your modem.

Chapter 2. Diagnostics Overview 25

Page 44

26 Service Guide

Page 45

Chapter 3. Maintenance Analysis Procedures (MAPs)

This chapter contains maintenance analysis procedures (MAPs).

Notes:

1. When possible, run online diagnostics in service mode. Online diagnostics perform

additional functions, compared to standalone diagnostics. This ensures that the

error state of the system is captured in NVRAM (non-volatile random access

memory) for your use in fixing the problem. The AIX error log and SMIT are only

available when diagnostics are run from the hard drive.

2. If more than eight digits are displayed in the operator panel, use only the first eight

digits to find the error in the tables. The digits that display beyond the first eight

digits are location codes that can assist you in diagnosing the problem. See

“Location Codes” on page 9.

3. Licensed programs frequently rely on network configuration and system information

stored on the VPD (vital product data) module on the operator panel control

assembly. If the MAPs indicate that the operator panel control assembly should be

replaced, swap the VPD module from the old operator panel to the new one. If the

existing VPD module must be replaced, call technical support for recovery

instructions. If recovery is not possible, notify the system owner that new keys for

licensed programs may be required.

4. If a network adapter or the I/O board is replaced, the network administrator must be

notified so that the client IP addresses used by the server can be changed. In

addition, the operating system configuration of the network controller might need to

be changed in order to enable system startup. Also check to ensure that any client

or server that addresses this system is updated.

Quick Entry MAP

Use the following table to determine your starting point.

If you replace FRUs or perform an action and the problem is still not corrected, go to

“MAP 1540: Minimum Configuration” on page 50 unless otherwise indicated in the

tables.

If you replace FRUs or perform an action and the problem is corrected, go to "MAP

410: Repair Checkout" in the

for Multiple Bus Systems

RS/6000 and

.

Eserver

pSeries Diagnostics Information

27

Page 46

Quick Entry MAP Table of Contents

Problem Description Page No.

Service Actions 28

System Stops With an 8-Digit Number Displayed 28

System Stops With a 4-Digit Number Displayed 28

System Stops With a 3-Digit Number Displayed 29

System Stops or Hangs With Alternating Numbers Displayed in the

Operator Display Panel.

Display Problem (Distortion, Blurring, Etc.) 29

Power and Cooling Problems 30

Flashing 888 in Operator Panel Display 30

Other Symptoms or Problems 30

You Cannot Find the Symptom in this Table 33

Symptom Action

You have parts to exchange or a corrective

action to perform.

You need to verify that a part exchange or

corrective action corrected the problem.

You need to verify correct system operation. Go to "MAP 410: Repair Checkout" in the

System Stops With A 8-Digit Number Displayed

The system stops with an 8-digit error code

displayed in the operator panel display or on

the console.

System Stops With A 4-Digit Number Displayed

Service Actions

1. Go to “Chapter 9. Removal and Replacement

Procedures” on page 223.

2. Go to "MAP 410: Repair Checkout" in the

RS/6000 and

Eserver

pSeries Diagnostics

Information for Multiple Bus Systems

Go to "MAP 410: Repair Checkout" in the

RS/6000 and

Eserver

pSeries Diagnostics

Information for Multiple Bus Systems

RS/6000 and

Eserver

pSeries Diagnostics

Information for Multiple Bus Systems

Record the error code. Go to “Chapter 5. Error

Code to FRU Index” on page 93.

29

.

.

.

28 Service Guide

Page 47

Symptom Action

The system stops and a 4-digit number is

displayed in the operator panel display or on

the console.

If the number displayed has the format ″E0xx″

then go to “Service Processor Checkpoints” on

page 71.

If the number displayed is in the range

″E1xx-EFFF″, make note of any location code

that is displayed on the second line of the

operator panel. If the location code indicates a

card slot (for example P2-I3), replace the card in

the indicated slot. If this does not correct the

problem, then go to “Firmware Checkpoints” on

page 75.

For all other numbers, record SRN 101-xxx,

where xxx is the last three digits of the four-digit

number displayed in the operator panel, then go

to the Fast Path MAP in the

Eserver

Multiple Bus Systems

Note: If the operator panel displays two sets of

numbers, use the bottom set of numbers as the

error code.

System Stops With A 3-Digit Number Displayed

The system stops and a 3-digit number

displayed in the operator panel display or on

the console.

Record SRN 101-xxx, where xxx is three-digit

number displayed in the operator panel, then go

to the Fast Path MAP in the

Eserver

Multiple Bus Systems

pSeries Diagnostics Information for

RS/6000 and

.

RS/6000 and

pSeries Diagnostics Information for

.

System Stops or Hangs With Alternating Numbers Displayed in the Operator Display Panel

The operator panel display alternates

between the code ″E1FD″ and another

″Exxx″ code.

The operator panel display alternates

between the codes ″E1DE″ and ″E1AD″.

Display Problem (Blank, Distortion, Blurring, Etc.).

Record both codes. Go to ″E1FD″ in “Firmware

Checkpoints” on page 75.

Record both codes. Go to ″E1DE″ in “Firmware

Checkpoints” on page 75.

Chapter 3. Maintenance Analysis Procedures

29

Page 48

Symptom Action

All display problems.

v If using a graphics display:

1. Go to the

procedures

2. If you do not find a problem, replace the

display adapter.

3. If you do not find a problem, suspect the

I/O board. Go to “MAP 1540: Minimum

Configuration” on page 50.

v Using an ASCII terminal:

1. Make sure that the ASCII terminal is

connected to S1.

2. If problems persist, go to the

problem determination

for the display.

determination procedures

3. If you do not find a problem, suspect the

I/O board. Go to “MAP 1540: Minimum

Configuration” on page 50.

Power and Cooling Problems

The power LEDs on the operator panel and

the power supply do not start flashing within

30 seconds of ac power application.

The power LEDs on the operator panel and

the power supply do not come on or stay on.

The power LEDs on the operator panel and

the power supply come on and stay on but

the system does not power on.

The cooling fan(s) do not come on or come

on but do not stay on.

Flashing 888 in Operator Panel Display

888 is displayed in the operator panel. Go to the Fast Path MAP in the

Go to “MAP 1520: Power” on page 45.

Go to “MAP 1520: Power” on page 45.

Go to “MAP 1520: Power” on page 45.

Go to “MAP 1520: Power” on page 45.

Eserver

Multiple Bus Systems

pSeries Diagnostics Information for

.

problem

for the terminal.

RS/6000 and

30 Service Guide

Other Symptoms or Problems

You have OK displayed. The service processor is ready. Go to ″MAP

You have STBY displayed. The service processor is ready. The system was

0020: Problem Determination Procedure″ in the

RS/6000 and

Information for Multiple Bus Systems

shut down by the operating system and is still

powered on. This condition can be requested by

a privileged system user with no faults. See

service processor error log for possible operating

system fault indications.

Eserver

pSeries Diagnostics

.

Page 49

Symptom Action

The system POST indicators are displayed on

the system console; the system pauses and

then restarts. The term ″POST indicators″

refers to the icons (graphic display) or device

mnemonics (ASCII terminal) that appear

during the power-on self-test (POST).

The system stops and POST indicators are

displayed on the system console. The term

″POST indicators″ refers to the icons (graphic

display) or device mnemonics (ASCII

terminal) that appear during the power-on

self-test (POST).

The system stops and the message

″STARTING SOFTWARE PLEASE WAIT...″ is

displayed on the ASCII terminal, or the boot

indicator

is displayed on a graphics terminal.

The system does not respond to the

password being entered, or the system login

prompt is displayed when booting in service

mode.

Go to “Boot Problems/Concerns” on page 90.

Go to “MAP 1540: Minimum Configuration” on

page 50 to isolate the problem.

Go to “Chapter 4. Checkpoints” on page 71.

Verify that the password is being entered from

the ASCII terminal or keyboard defined as the

system console. If so, then the keyboard or its

controller may be faulty.

v If entering the password from the keyboard

which is attached to the system, replace the

keyboard. If replacing the keyboard does not

fix the problem, replace the I/O board. (See

note 4 on page 27.)

v If entering the password from a keyboard

which is attached to an ASCII terminal, use the

problem determination procedures for the

ASCII terminal. Make sure the ASCII terminal

is connected to S1. Replace the I/O board if

these procedures do not reveal a problem.

v If the problem is fixed, go to "MAP 410: Repair

Checkout" in the

pSeries Diagnostics Information for Multiple

Bus Systems

“MAP 1540: Minimum Configuration” on

page 50 to isolate the problem.

RS/6000 and

. If the problem persists, go to

Eserver

Chapter 3. Maintenance Analysis Procedures

31

Page 50

Symptom Action

No codes are displayed on the operator panel

within a few seconds of turning on the

system. The operator panel is blank before

the system is powered on.

Reseat the operator panel cable. If the problem is

not resolved, replace these parts in the following

order:

1. Operator panel assembly. Update the VPD

information in the new operator panel.

2. I/O board (See notes 4 on page 27.)

If the problem is fixed, go to "MAP 410:

Repair Checkout" in the

Eserver

Multiple Bus Systems

go to “MAP 1540: Minimum Configuration” on

page 50 to isolate the problem.

The SMS configuration list or boot sequence

selection menu shows more SCSI devices

attached to a controller/adapter than are

actually attached.

A device may be set to use the same SCSI bus

ID as the control adapter. Note the ID being used

by the controller/adapter (this can be checked

and/or changed via an SMS utility), and verify

that no device attached to the controller is set to

use that ID.

If settings do not appear to be in conflict:

1. Replace the SCSI cable.

2. Replace the device.

3. Replace the SCSI adapter (or I/O board if

connected to one of the two integrated SCSI

controllers on the I/O board). (See note 4 on

page 27.

pSeries Diagnostics Information for

RS/6000 and

. If the problem persists,

32 Service Guide

Note: In a ″twin-tailed″ configuration where there

is more than one initiator device (normally

another system) attached to the SCSI bus, it may

be necessary to change the ID of the SCSI

controller or adapter with the System

Management Services.

Page 51

Symptom Action

The System Management Services menu is

displayed.

You have a problem that does not prevent the

system from booting.

You have an SRN. Go to the Fast Path MAP in the

You suspect a cable problem. See the

The device or media you are attempting to boot

from may be faulty.

1. Check the SMS error log for any errors. To

check the error log:

a. Choose error log from the utilities menu.

b. If an error is logged, check the time

stamp.

c. If the error was logged during the current

boot attempt, record it.

d. Look up the error in “Chapter 4.

Checkpoints” on page 71 and perform the

listed action.

e. If no recent error is logged in the error

log, continue to the next step below.

2. Try to boot from an alternate boot device

connected to the same controller as the

original boot device. If the boot succeeds,

replace the original boot device. (For

removable media devices try the media first.)

3. Go to “MAP 1540: Minimum Configuration” on

page 50.

Go to the Fast Path MAP in the

Eserver

Multiple Bus Systems

pSeries Diagnostics Information for

.

RS/6000 and

RS/6000 and

Eserver

Multiple Bus Systems

pSeries Diagnostics Information for

.

RS/6000 and

Eserver

pSeries

Adapters, Devices, and Cable Information for

Multiple Bus Systems

You do not have a symptom. Go to MAP 0020 in the

.

RS/6000 and

Eserver

pSeries Diagnostics Information for Multiple Bus

Systems

You have not determined a symptom. Go to “MAP 1020: Problem Determination” on

page 34.

You Cannot Find the Symptom in this Table

All other problems. Go to “MAP 1020: Problem Determination” on

page 34.

.

Chapter 3. Maintenance Analysis Procedures

33

Page 52

MAP 1020: Problem Determination

Purpose of This MAP

Use this MAP to get an error code if you were not provided one by the customer or you

are unable to load diagnostics. If you are able to load the diagnostics, go to MAP 0020

in the

RS/6000 and

The service processor may have recorded one or more symptoms in its error log. It is a

good idea to examine that error log before proceeding (see Service Processor System

Information Menu).

Be prepared to record code numbers and use those numbers in the course of analyzing

a problem. Go to “Step 1020-1” on page 35.

The service processor may have been set by the user to monitor server operations and

to attempt recoveries. You can disable these actions while you diagnose and service

the system. You can use that same service aid to restore the settings at the end of your

service action.

In case the service processor settings were not saved by the user, if you disable them,

make notes of their current settings so that you can restore them before you leave.

In addition to the parameters in the table below, you might want to disconnect the

modem to prevent incoming signals that could cause the system to power on.

Following are the service processor settings. The service processor menus are

described in “Service Processor Menus” on page 151.

Eserver

pSeries Diagnostics Information for Multiple Bus Systems

.

34 Service Guide

Surveillance From the Service Processor Setup Menu, go to

the Surveillance Setup Menu and disable